Daikin EWWD440AAYNNO, EWWD850AAYNNO, EWWD600AAYNNO Installation And Operation Manual

INSTALLATION AND OPERATION MANUAL

Packaged water-cooled water chillers

EWWD440AAYNNO

EWWD600AAYNNO

EWWD850AAYNNO

**

**

**

.

.

01

02

03

04

05

06

07

08

09

10

ATITIKTIES-DEKLARACIJA

ATBILSTĪBAS-DEKLARĀCIJA

VYHLÁSENIE-ZHODY

CE -

CE -

CE -

CE - UYUMLULUK-BİLDİRİSİ

ZJAVA O SKLADNOSTI

VASTAVUSDEKLARATSIOON

ДЕКЛАРАЦИЯ-ЗА-СЪОТВЕТСТВИЕ

CE - I

CE -

CE -

z vso odgovornostjo izjavlja, da so modeli klimatskih naprav, na katere se izjava nanaša:

kinnitab oma täielikul vastutusel, et käesoleva deklaratsiooni alla kuuluvad kliimaseadmete mudelid:

декларира на своя отговорност, че моделите климатична инсталация, за които се отнася тази декларация:

visiška savo atsakomybe skelbia, kad oro kondicionavimo prietaisų modeliai, kuriems yra taikoma ši deklaracija:

ar pilnu atbildību apliecina, ka tālāk uzskaitīto modeĮu gaisa kondicionētāji, uz kuriem attiecas šī deklarācija:

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

.

F>

.

.

.

.

.

.

.

Direktive z vsemi spremembami.

Direktiivid koos muudatustega.

Директиви, с техните изменения.

Direktyvose su papildymais.

Direktīvās un to papildinājumos.

Smernice, v platnom znení.

Değiştirilmiş halleriyle Yönetmelikler.

<A> DAIKIN.TCF.013

Direktiver, med senere ændringer.

Direktiv, med företagna ändringar.

Direktiver, med foretatte endringer.

Direktiivejä, sellaisina kuin ne ovat muutettuina.

v platném znění.

Smjernice, kako je izmijenjeno.

irányelv(ek) és módosításaik rendelkezéseit.

z późniejszymi poprawkami.

Directivelor, cu amendamentele respective.

vyhlasuje na vlastnú zodpovednosť, že tieto klimatizačné modely, na ktoré sa vzťahuje toto vyhlásenie:

megfelelnek az alábbi szabvány(ok)nak vagy egyéb irányadó dokumentum(ok)nak, ha azokat előírás szerint használják:

spełniają wymogi następujących norm i innych dokumentów normalizacyjnych, pod warunkiem że używane są zgodnie z naszymi

instrukcjami:

sunt în conformitate cu următorul (următoarele) standard(e) sau alt(e) document(e) normativ(e), cu condiţia ca acestea să fie utilizate în

conformitate cu instrucţiunile noastre

skladni z naslednjimi standardi in drugimi normativi, pod pogojem, da se uporabljajo v skladu z našimi navodili:

on vastavuses järgmis(t)e standardi(te)ga või teiste normatiivsete dokumentidega, kui neid kasutatakse vastavalt meie juhenditele:

съответстват на следните стандарти или други нормативни документи, при условие, че се използват съгласно нашите

инструкции:

atitinka žemiau nurodytus standartus ir (arba) kitus norminius dokumentus su sąlyga, kad yra naudojami pagal mūsų nurodymus:

tad, ja lietoti atbilstoši ražotāja norādījumiem, atbilst sekojošiem standartiem un citiem normatīviem dokumentiem:

sú v zhode s nasledovnou(ými) normou(ami) alebo iným(i) normatívnym(i) dokumentom(ami), za predpokladu, že sa používajú v súlade

s našim návodom:

tamamen kendi sorumluluğunda olmak üzere bu bildirinin ilgili olduğu klima modellerinin aşağıdaki gibi olduğunu beyan eder:

ürünün, talimatlarımıza göre kullanılması koşuluyla aşağıdaki standartlar ve norm belirten belgelerle uyumludur:

оценено положително от <B> съгласно Сертификат <C>.

оценено положително от <E> (Приложен модул <F>) съгласно

21 * както е заложено в Акта за техническа конструкция <A> и

** както е заложено в Акта за техническа конструкция <D> и

(taikomas modulis <F>) pagal pažymėjimą <G>.

Сертификат <G>.

pagal pažymėjimą <C>.

22 * kaip nurodyta Techninėje konstrukcijos byloje <A> ir patvirtinta <B>

** kaip nurodyta Techninėje konstrukcijos byloje <D> ir patvirtinta <E>

23 * kā noteikts tehniskajā dokumentācijā <A>, atbilstoši <B>

.

.

.

. 07 *

<B> KEMA

<C> 71801-KRQ/ECM97-4240

<D> Daikin.TCFP.004

<E> AIB Vinçotte (NB0026)

pozitīvajam lēmumam ko apliecina sertifikāts <C>.

pozitīvajam lēmumam (piekritīgā sadaĮa: <F>), ko apliecina

sertifikāts <G>.

24 * ako je to stanovené v Súbore technickej konštrukcie <A> a kladne

** kā noteikts tehniskajā dokumentācijā <D>, atbilstoši <E>

posúdené <B> podľa Certifikátu <C>.

** ako je to stanovené v Súbore technickej konštrukcie <D> a kladne

posúdené <E> (Aplikovaný modul <F>) podľa Certifikátu <G>.

<F> B+D

25 * <A> Teknik Yapı Dosyasında belirtildiği gibi ve <C> sertifikasına

.

<G> 52846/05/10/01, 52846/06/01/01

göre <E> tarafından olumlu olarak (Uygulanan modül <F>)

değerlendirilmişti.

göre <B> tarafından olumlu olarak değerlendirilmiştir.

** <D> Teknik Yapı Dosyasında belirtildiği gibi ve <G> sertifikasına

.

.

.

.

.

.

.

.

Zandvoordestraat 300, B-8400 Oostende, Belgium

IZJAVA-O-USKLAĐENOSTI

DEKLARACJA-ZGODNOŚCI

DECLARAŢIE-DE-CONFORMITATE

CE - MEGFELELŐSÉGI-NYILATKOZAT

CE -

CE -

CE -

PROHLÁŠENÍ-O-SHODĚ

CE - ERKLÆRING OM-SAMSVAR

CE - ILMOITUS-YHDENMUKAISUUDESTA

CE -

prohlašuje ve své plné odpovědnosti, že modely klimatizace, k nimž se toto prohlášení vztahuje:

izjavljuje pod isključivo vlastitom odgovornošću da su modeli klima uređaja na koje se ova izjava odnosi:

teljes felelőssége tudatában kijelenti, hogy a klímaberendezés modellek, melyekre e nyilatkozat vonatkozik:

deklaruje na własną i wyłączną odpowiedzialność, że modele klimatyzatorów, których dotyczy niniejsza deklaracja:

declară pe proprie răspundere că aparatele de aer condiţionat la care se referă această declaraţie:

erklærer under eneansvar, at klimaanlægmodellerne, som denne deklaration vedrører:

deklarerar i egenskap av huvudansvarig, att luftkonditioneringsmodellerna som berörs av denna deklaration innebär att:

erklærer et fullstendig ansvar for at de luftkondisjoneringsmodeller som berøres av denne deklarasjon innebærer at:

ilmoittaa yksinomaan omalla vastuullaan, että tämän ilmoituksen tarkoittamat ilmastointilaitteiden mallit:

CE - DECLARAÇÃO-DE-CONFORMIDADE СЕ - ЗАЯВЛЕНИЕ-О-СООТВЕТСТВИИ

CE - OPFYLDELSESERKLÆRING

CE - FÖRSÄKRAN-OM-ÖVERENSTÄMMELSE

CE - ¢H§ø™H ™YMMOPºø™H™

CE - DECLARACION-DE-CONFORMIDAD

CE - DICHIARAZIONE-DI-CONFORMITA

‰ЛПТУВИ МВ ·ФОПВИЫЩИО‹ ЩЛ˜ В˘ı‡УЛ fiЩИ Щ· МФУЩ¤П· ЩˆУ ОПИМ·ЩИЫЩИОТУ Ы˘ЫОВ˘ТУ ЫЩ· ФФ›· ·У·К¤ЪВЩ·И Л ·ЪФ‡Ы· ‰‹ПˆЫЛ:

заявляет, исключительно под свою ответственность, что модели кондиционеров воздуха, к которым относится настоящее заявление:

declares under its sole responsibility that the air conditioning models to which this declar ation relates:

erklärt auf seine alleinige Verantwortung daß die Modelle der Klimageräte für die diese Erklärung bestimmt ist:

déclare sous sa seule responsabilité que les appareils d'air conditionné visés par la présente déclar ation:

verklaart hierbij op eigen exclusieve verantwoordelijkheid dat de airconditioning units waarop deze verklaring betrekking heeft:

declara baja su única responsabilidad que los modelos de aire acondicionado a los cuales hace referencia la declaración:

dichiara sotto sua responsabilità che i condizionatori modello a cui è riferita questa dichiarazione:

declara sob sua exclusiva responsabilidade que os modelos de ar condicionado a que esta declaração se refere:

CE - DECLARATION-OF-CONFORMITY

CE - KONFORMITÄTSERKLÄRUNG

CE - DECLARATION-DE-CONFORMITE

CE - CONFORMITEITSVERKLARING

Daikin Europe N.V.

EWWD440AAYNNO**, EWWD600AAYNNO**, EWWD850AAYNNO**,

estão em conformidade com a(s) seguinte(s) norma(s) ou outro(s) documento(s) normativo(s), desde que estes sejam utilizados de

acordo com as nossas instruções:

соответствуют следующим стандартам или другим нормативным документам, при условии их использования согласно нашим

инструкциям:

overholder følgende standard(er) eller andet/andre retningsgivende dokument(er), forudsat at disse anvendes i henhold til vore

instrukser:

respektive utrustning är utförd i överensstämmelse med och följer följande standard(er) eller andra normgivande dokument, under

förutsättning att användning sker i överensstämmelse med våra instruktioner:

respektive utstyr er i overensstemmelse med følgende standard(er) eller andre normgivende dokument(er), under forutssetning av at

disse brukes i henhold til våre instrukser:

are in conformity with the following standard(s) or other normative document(s), provided that these are used in accordance with our

instructions:

der/den folgenden Norm(en) oder einem anderen Normdokument oder -dokumenten entspricht/entsprechen, unter der Voraussetzung,

daß sie gemäß unseren Anweisungen eingesetzt werden:

sont conformes à la/aux norme(s) ou autre(s) document(s) nor matif(s), pour autant qu'ils soient utilisés conformément à nos instructions:

conform de volgende norm(en) of één of meer andere bindende documenten zijn, op voorwaarde dat ze worden gebruikt overeenkomstig

onze instructies:

están en conformidad con la(s) siguiente(s) norma(s) u otro(s) documento(s) nor mativo(s), siempre que sean utilizados de acuerdo con

nuestras instrucciones:

* = , -, 0, 1, 2, 3, ..., 9

sono conformi al(i) seguente(i) standard(s) o altro(i) documento(i) a carattere normativo, a patto che vengano usati in conformità alle

Directives, as amended.

Direktiven, gemäß Änderung.

Directives, telles que modifiées.

Richtlijnen, zoals geamendeerd.

Directivas, según lo enmendado.

Direttive, come da modifica.

√‰ËÁÈÒv, fiˆ˜ ¤¯Ô˘Ó ÙÚÔÔÔÈËı›.

Directivas, conforme alteração em.

Директив со всеми поправками.

*

**

igazolta a megfelelést a(z) <C> tanúsítvány szerint.

igazolta a megfelelést (alkalmazott modul: <F>), a(z) <G>

tanúsítvány szerint.

opinią <B> i Świadectwem <C>.

opinią <E> (Zastosowany moduł <F>) zgodnie ze

Świadectwem <G>.

16 * a(z) <A> műszaki konstrukciós dokumentáció alapján, a(z) <B>

** a(z) <D> műszaki konstrukciós dokumentáció alapján, a(z) <E>

17 * zgodnie z archiwalną dokumentacją konstrukcyjną <A>, pozytywną

** zgodnie z archiwalną dokumentacją konstrukcyjną <D> i pozytywną

Low Voltage 73/23/EEC

Machinery Safety 98/37/EEC

Electromagnetic Compatibility 89/336/EEC

vastaavat seuraavien standardien ja muiden ohjeellisten dokumenttien vaatimuksia edellyttäen, että niitä käytetään ohjeidemme

mukaisesti:

za předpokladu, že jsou využívány v souladu s našimi pokyny, odpovídají následujícím normám nebo normativním dokumentům:

u skladu sa slijedećim standardom(ima) ili drugim normativnim dokumentom(ima), uz uvjet da se oni koriste u skladu s našim uputama:

ob upoštevanju določb:

vastavalt nõuetele:

следвайки клаузите на:

laikantis nuostatų, pateikiamų:

ievērojot prasības, kas noteiktas:

održiavajúc ustanovenia:

bunun koşullarına uygun olarak:

vilket också

<B>

Pressure Equipment 97/23/EEC

som positivt intygas av

<A>

utrustningen är utförd i enlighet med den Tekniska

Konstruktionsfilen

11 *

e giudicato

<C>

<A>

Certificato

secondo il

<B>

og

<A>

som positivt

<D>

Sertifikat <C>

ifølge

) vilket också framgår av

<B>

<F>

<C>

(Fastsatt modul

<E>

Certifikat

<G>

framgår av

i enlighet med den Tekniska Konstruktionsfilen

Certifikat

som det fremkommer i den Tekniske Konstruksjonsfilen

gjennom positiv bedømmelse av

intygats av

**

12 *

ηÈ

ηÈ

<A>

<D>

¶ИЫЩФФИЛЩИОfi <C>

e giudicato

<D>

applicato) secondo il

<F>

Û‡Ìʈӷ Ì ÙÔ

<B>

(Modulo

<E>

apreciate pozitiv de <B> în conformitate cu Certificatul <C>.

18 * conform celor stabilite în Dosarul tehnic de construcţie <A> şi

og

<D>

(Anvendt modul <F>) ifølge

<E>

Sertifikat <G>.

som det fremkommer i den Tekniske Konstruksjonsfilen

gjennom positiv bedømmelse av

**

13 * jotka on esitetty Teknisessä Asiakirjassa <A> ja jotka <B> on

)

e

<F>

<C>

<A>

Certificado

<G>

de acordo com o

(ГЪЛЫИМФФИФ‡МВУЛ ˘ФМФУ¿‰·

<B>

<E>

¶ИЫЩФФИЛЩИОfi

skladu s certifikatom <C>.

apreciate pozitiv de <E> (Modul aplicat <F>) în conformitate cu

Certificatul <G>.

** kot je določeno v tehnični mapi <D> in odobreno s strani <E>

19 * kot je določeno v tehnični mapi <A> in odobreno s strani <B> v

** conform celor stabilite în Dosarul tehnic de construcţie <D> şi

hyväksynyt Sertifikaatin <C> mukaisesti.

hyväksynyt (Sovellettu moduli <F>) Sertifikaatin <G> mukaisesti.

zjištěno <B> v souladu s osvědčením <C>.

14 * jak bylo uvedeno v souboru technické konstrukce <A> a pozitivně

** jotka on esitetty Teknisessä Asiakirjassa <D> ja jotka <E> on

** jak bylo uvedeno v souboru technické konstrukce <D> a pozitivně

e

<D>

и в

) de acordo

согласно

<A>

<F>

<B>

(Módulo aplicado

<E>

<G>

<C>

<G>

Certificado

positivamente da

delineato nel File Tecnico di Costruzione

delineato nel File Tecnico di Costruzione

Certificato

fiˆ˜ ÚÔÛ‰ÈÔÚ›˙ÂÙ·È ÛÙÔ ∞Ú¯Â›Ô ∆¯ÓÈ΋˜ ∫·Ù·Û΢‹˜

positivamente da

06 *

**

under iagttagelse af bestemmelserne i:

enligt villkoren i:

gitt i henhold til bestemmelsene i:

noudattaen määräyksiä:

za dodržení ustanovení předpisu:

prema odredbama:

követi a(z):

zgodnie z postanowieniami Dyrektyw:

în urma prevederilor:

and judged

and judged

<C>

<A>

<D>

Certificate

according to the

<B>

positively by

as set out in the Technical Construction File

following the provisions of:

gemäß den Vorschriften der:

conformément aux stipulations des:

overeenkomstig de bepalingen van:

siguiendo las disposiciones de:

secondo le prescrizioni per:

Ì ًÚËÛË Ùˆv ‰È·Ù¿Íˆv Ùˆv:

nostre istruzioni:

В›У·И Ы‡МКˆУ· МВ ЩФ(·) ·ОfiПФ˘ıФ(·) ЪfiЩ˘Ф(·) ‹ ¿ППФ ¤ББЪ·КФ(·) О·УФУИЫМТУ, ˘fi ЩЛУ ЪФ¸fiıВЫЛ fiЩИ ¯ЪЛЫИМФФИФ‡УЩ·И

Û‡Ìʈӷ Ì ÙȘ Ô‰ËÁ›Â˜ Ì·˜:

EN60335-2-40,

de acordo com o previsto em:

в соответствии с положениями:

01 *

as set out in the Technical Construction File

**

fiˆ˜ ÚÔÛ‰ÈÔÚ›˙ÂÙ·È ÛÙÔ ∞Ú¯Â›Ô ∆¯ÓÈ΋˜ ∫·Ù·Û΢‹˜

ÎÚ›ÓÂÙ·È ıÂÙÈο ·fi ÙÔ

ÎÚ›ÓÂÙ·È ıÂÙÈο ·fi ÙÔ

Û‡Ìʈӷ Ì ÙÔ

**

aufgeführt und von

aufgeführt und von

<C>

<A>

<D>

) according to the

Zertifikat

) positiv ausgezeichnet gemäß

<F>

(Applied module <

<E>

positively by

Certificate <G>

<G>

positiv ausgezeichnet gemäß

(Angewandtes Modul

wie in der Technischen Konstruktionsakte

<B>

wie in der Technischen Konstruktionsakte

<E>

Zertifikat

02 *

**

tal como estabelecido no Ficheiro Técnico de Construção

tal como estabelecido no Ficheiro Técnico de Construção

com o parecer positivo de

com o parecer positivo de

08 *

**

et

et jugé

<A>

<D>

<C>

Certificat

) conformément au

<F>

conformément au

<B>

(Module appliqué

<E>

positivement par

jugé positivement par

tel que stipulé dans le Fichier de Construction Technique

tel que stipulé dans le Fichier de Construction Technique

03 *

**

com o

как указано в Досье технического толкования

Свидетельству

соответствии с положительным решением

09 *

en in orde

en in orde

<A>

<D>

Certificaat <C>

overeenkomstig

<B>

<G>

bevonden door

Certificat

zoals vermeld in het Technisch Constructiedossier

zoals vermeld in het Technisch Constructiedossier

04 *

**

kiidetud <E> järgi (lisamoodul <F>) vastavalt sertifikaadile <G>.

(Uporabljen modul <F>) v skladu s certifikatom <G>.

kiidetud <B> järgi vastavalt sertifikaadile <C>.

** nagu on näidatud tehnilises dokumentatsioonis <D> ja heaks

20 * nagu on näidatud tehnilises dokumentatsioonis <A> ja heaks

Certifikatu <G>.

ocijenjeno od strane <E> (Primijenjen modul <F>) prema

zjištěno <E> (použitý modul <F>) v souladu s osvědčením <G>.

ocijenjeno od strane <B> prema Certifikatu <C>.

** kako je izloženo u Datoteci o tehničkoj konstrukciji <D> i pozitivno

15 * kako je izloženo u Datoteci o tehničkoj konstrukciji <A> i pozitivno

и в

(Прикладной

<D>

og positivt vurderet

og positivt vurderet

<E>

<A>

<D>

<G>

Certifikat <G>

) i henhold til

<F>

Свидетельству

Certifikat <C>

) согласно

<F>

i henhold til

(Anvendt modul

<B>

<E>

af

som anført i den Tekniske Konstruktionsfil

som anført i den Tekniske Konstruktionsfil

модуль

10 *

**

y

y

<A>

<D>

) según el

<F>

Certificado <C>

según el

(Modulo aplicado

<B>

<E>

juzgado positivamente por

tal como se expone en el Archivo de Construcción Técnica

tal como se expone en el Archivo de Construcción Técnica

juzgado positivamente por

05 *

**

af

<G>

Certificado

3PW24367-7C

как указано в Досье технического толкования

соответствии с положительным решением

**

) overeenkomstig

<F>

(Toegepaste module

<E>

bevonden door

Certificaat <G>

Jiro Tomita

Director Quality Assurance

Ostend, 3rd of October 2005

EWWD440AAYNNO**

EWWD600AAYNNO**

EWWD850AAYNNO**

Packaged water-cooled water chillers

Installation and

operation manual

CONTENTS Page

Safety considerations ........................................................................ 1

Precautions during installation................................................................... 1

Precautions when using............................................................................. 2

Precautions when relocating or repairing the unit...................................... 3

Moving and Rigging........................................................................... 3

Inspecting the unit...................................................................................... 3

Lifting the unit............................................................................................. 3

Pulling the unit horizontally ........................................................................4

Description.........................................................................................4

Function of the main components.............................................................. 5

Installation .........................................................................................6

Selection of installation site and foundation work ......................................6

Sound insulation and vibration isolation work............................................ 7

Water quality specifications........................................................................8

Piping work ................................................................................................8

Power supply work ...................................................................................10

Internal wiring - Parts table ......................................................................10

Power circuit and cable requirements ......................................................11

Connection of the watercooled water unit power supply.......................... 11

Interconnection cables............................................................................. 11

Operating the graphic panel display................................................12

Explanation common to respective screens ............................................13

How to change settings of “DATE” and “TIME”.........................................15

How to change settings in the touch panel ..............................................15

Before test run.................................................................................17

Checking the electric circuit (Check the following before power-up) ........ 17

Checking the bridge wiring....................................................................... 17

Check at first electrification...................................................................... 17

Checking the water system...................................................................... 18

Checking the unit body ............................................................................18

Checking the settings on the controller.................................................... 18

Instructions before operation...........................................................19

First operation (Very important) ...............................................................19

Local operation on the unit “LOCAL” ........................................................ 19

Remote operation “REMOTE”.................................................................. 20

Confirming the ON/OFF condition ........................................................... 20

Consulting operational data .....................................................................21

Functions of this model....................................................................21

Automatic water temperature control....................................................... 21

Low load stop (Thermo off)...................................................................... 21

ON-OFF limiting function .........................................................................22

Current limiting function ...........................................................................23

Current demand function .........................................................................23

Units control thermo................................................................................. 24

Compressor starting order rotation function ............................................ 24

2-temperature setting function (Optional) ................................................24

Operation between power failure and power recovery ............................. 25

Unit start flow ...........................................................................................26

Unit stop flow ...........................................................................................28

I/O timing of various contacts................................................................... 29

Maintenance and inspection............................................................ 30

Periodic inspection of safety devices....................................................... 30

Before inspecting .....................................................................................31

Periodical inspection................................................................................ 31

Refrigerant and lubrication oil ..................................................................31

Daily inspection........................................................................................ 32

Disposal requirements .............................................................................32

Cautions when stopping for a long time ..........................................32

Troubleshooting ...............................................................................33

Safety devices.......................................................................................... 34

Operating range...............................................................................35

Operating limit.......................................................................................... 35

Water flow rate......................................................................................... 35

Minimum holding water quantity within the system.................................. 36

Standards for use..................................................................................... 36

How to continue............................................................................... 36

Thank you for purchasing this Daikin air conditioner.

READ THIS MANUAL ATTENTIVELY BEFORE STARTING

UP THE UNIT. DO NOT THROW IT AWAY. KEEP IT IN

YOUR FILES FOR FUTURE REFERENCE.

IMPROPER INSTALLATION OR ATTACHMENT OF

EQUIPMENT OR ACCESSORIES COULD RESULT IN

ELECTRIC SHOCK, SHORT-CIRCUIT, LEAKS, FIRE OR

OTHER DAMAGE TO THE EQUIPMENT. BE SURE ONLY

TO USE ACCESSORIES MADE BY DAIKIN WHICH ARE

SPECIFICALLY DESIGNED FOR USE WITH THE

EQUIPMENT AND HAVE THEM INSTALLED BY A

PROFESSIONAL.

IF UNSURE OF INSTALLATION PROCEDURES OR USE,

ALWAYS CONTACT YOUR DAIKIN DEALER FOR

ADVICE AND INFORMATION.

SAFETY CONSIDERATIONS

For your safety and that of others, observe the precautions listed

here after at all time.

There are two types of precautions:

WARNING: When improper handling or operation could result

in death or serious injury.

CAUTION: When improper handling or operation could result

in injury or physical damage. Depending on the

circumstances, neglecting could lead to serious

consequences.

Both types are extremely important to ensure safety, and must be

payed attention to at all time.

Precautions during installation

WARNING

■ For installation work, be sure to contact your dealer.

Improper installation could result in leaks, electric

shock or fire.

■ Be sure to perform installation work in accordance with

the instructions.

Improper installation could result in leaks, electric

shock or fire.

■ Be sure to install the unit in a level place capable of

holding its weight and fix it with bolts completely.

Incomplete installation or installing in a place that

cannot support the weight of the unit could result in leaks or in

the unit overturning or falling.

■ Ta ke proper measures required for preventing

refrigerant leaks.

If the unit is installed in places such as engine rooms,

countermeasures must be taken against exceeding a certain

concentration of leaking refrigerant. If the concentration limit is

exceeded, it could result in a lack of oxygen.

■ For electrical work, be sure to use a dedicated circuit.

Electrical work should be performed by a qualified

electrician.

Perform the work in accordance with technical standards for

electrical equipment and indoor wiring regulations.

Insufficient circuit capacity of the power supply or improper

electrical work could result in electrical shock or fire.

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

Installation and operation manual

1

■ Use the prescribed cable for wiring, and make sure that

connections are secure.

Be sure to securely fasten cables to their terminals so

that external force on cables has no effect on terminal

connections. Incomplete connection or fixing can lead to heat

generation or fire.

CAUTION

■ Do not install the unit in a place which could be

exposed to leaking of flammable gas.

If gas were to leak and collect around the unit, the gas

could be ignited by the unit.

■ Be sure to install an electrical leakage breaker.

The electrical leakage breaker should conform to

technical standards for electrical equipment and indoor

wiring regulations. Failure to install an electrical leakage breaker

could result in electrical shock.

■ Be sure to provide proper drainage.

Failure to provide proper drainage could result in water

leaking inside and could wet other equipment,

furniture, etc.

■ Apply water-proof to the floor surface where the unit is

to be installed.

Poor water-proof could cause other facility/device to

get wet.

■ Use chilled (hot) water and condenser water that

conforms to the water quality specifications.

Poor quality water could result in water leaks.

■ Do not attempt to run the compressor by pushing the

magnetic contactor with your finger.

Doing so could result in electrical shock or fire.

■ Do not mistake the types of refrigerant and lubrication

oil.

Doing so could result in fire or explosion.

■ Provide proper grounding for the unit.

Do not connect the ground wire to gas piping, water

piping, lightning rods or telephone ground wire.

Improper grounding could result in electrical shock.

■ Be sure to provide each unit with a circuit breaker.

Using a single circuit breaker for more than one unit

could result in electrical shock or fire.

■ Do not run power supply wiring between units.

Doing so could result in fire.

■ Do not expose the unit to humid environments.

The unit should not be installed near hot water springs,

or near the seashore, nor in areas exposed to oil or

corrosive gas atmospheres such as ammonia.

Corrosion caused by such elements can result in electrical

shock or fire.

■ Be sure to dispose of cleansing solutions as stipulated

by law.

Illegal disposal is not only against the law, but can

harm health and the environment.

■ Do not apply any machining to the unit main body, or

do not fit by welding.

Doing so could result in the poor air-tightness and

could result in a lack of oxygen in the latter case.

■ Make sure there is enough service space.

If the space is not enough, maintenance work cannot

be carried out safely, and could result in any injuries.

Precautions when using

WARNING

■ If a malfunction occurs (burning smell, etc.), turn off the

power supply and contact your dealer.

Continuing to operate while the unit is malfunctioning

can result in equipment damage, electrical shock or fire.

■ Do not use any heating medium other than water for

chilled (hot) water and condenser water.

Doing so could result in fire or explosion.

■ Do not turn the unit ON or OFF with the power supply

switch or circuit breaker, etc.

Doing so could result in electrical shock or fire.

■ Ta ke countermeasures against refrigerant leaking.

Ta ke proper countermeasures to prevent refrigerant

leaks from exceeding the concentration limit.

If the concentration limit is exceeded, it could result in a lack of

oxygen.

CAUTION

■ Do not use the unit for any purpose other than for

which it is designed.

The unit should not be used for applications such as

preservation of food, plants or animals, high-tech equipment,

art, etc.

Using the unit for such applications could adversely affect the

quality of these goods.

■ Do not use fuses other than the ones specified.

Using wire, etc., instead of a fuse could result in

equipment damage or fire.

■ Do not attempt to run the compressor by pushing the

magnetic contactor with your finger.

Doing so could result in electrical shock or fire.

■ Do not operate the unit with the cabinet or switch box

cover open.

Doing so could result in electrical shock or fire.

■ Do not operate the unit with wet hands.

Doing so could result in electrical shock.

■ Do not place any inflammable spray nearby. Do not

spray it over the unit.

Doing so could result in fire.

■ Do not attempt to force-operate the unit by short

circuiting safety devices.

Doing so could result in fire.

■ Observe the specified power supply.

If you use a power supply other than specified on the

machine rating plate, it could result in fire or electrical

shock.

■ Do not change settings of safety devices.

Doing so could result in fire, etc.

■ Do not place liquid containers such as flower vases on

the unit.

If the liquid spills out, it could get inside the unit and

cause the electrical insulation to deteriorate, resulting in

electrical shock.

■ Be sure to stop the unit and turn the power supply off

before cleaning.

Failure to do so could result in injury.

■ Do not use chilled (hot) water or condenser water for

drinking or hot water supply.

Doing so could be harmful to health.

■ Do not mistake the types of refrigerant and lubrication

oil.

Doing so could result in fire or explosion.

Installation and operation manual

2

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

■ Do not allow water to remain in the water piping during

prolonged idle periods.

For prolonged idle periods you should fill the water

pipes with antifreeze or drain all the water from the pipes. Failure

to do so could result in leaking.

■ Do not climb or place objects on top of the unit.

Falling or overturning could result in injury.

■ Make sure the unit base is not damaged by prolonged

use.

If damage is not repaired, the unit could fall and result

in injury.

■ Do not wash the unit with water.

Doing so could result in electrical shock.

■ Use chilled (hot) water and condenser water that

conforms to water quality specifications.

Poor quality water could result in water leaks.

■ Never touch parts which tend to become hot such as

compressors and refrigerant piping.

Doing so could result in skin burning.

Precautions when relocating or repairing the unit

WARNING

■ For repairs, be sure to contact your dealer.

Improper repair could result in electrical shock or fire.

■ Do not modify the unit in any way.

Doing so could result in electrical shock or fire.

■ To relocate the unit, be sure to contact your dealer.

Improper installation could result in electrical shock or

fire.

CAUTION

■ Pay attention to ventilation when repairing indoors.

If refrigerant leaks and the room is not sufficiently

ventilated, it could result in accidents caused by lack of

oxygen.

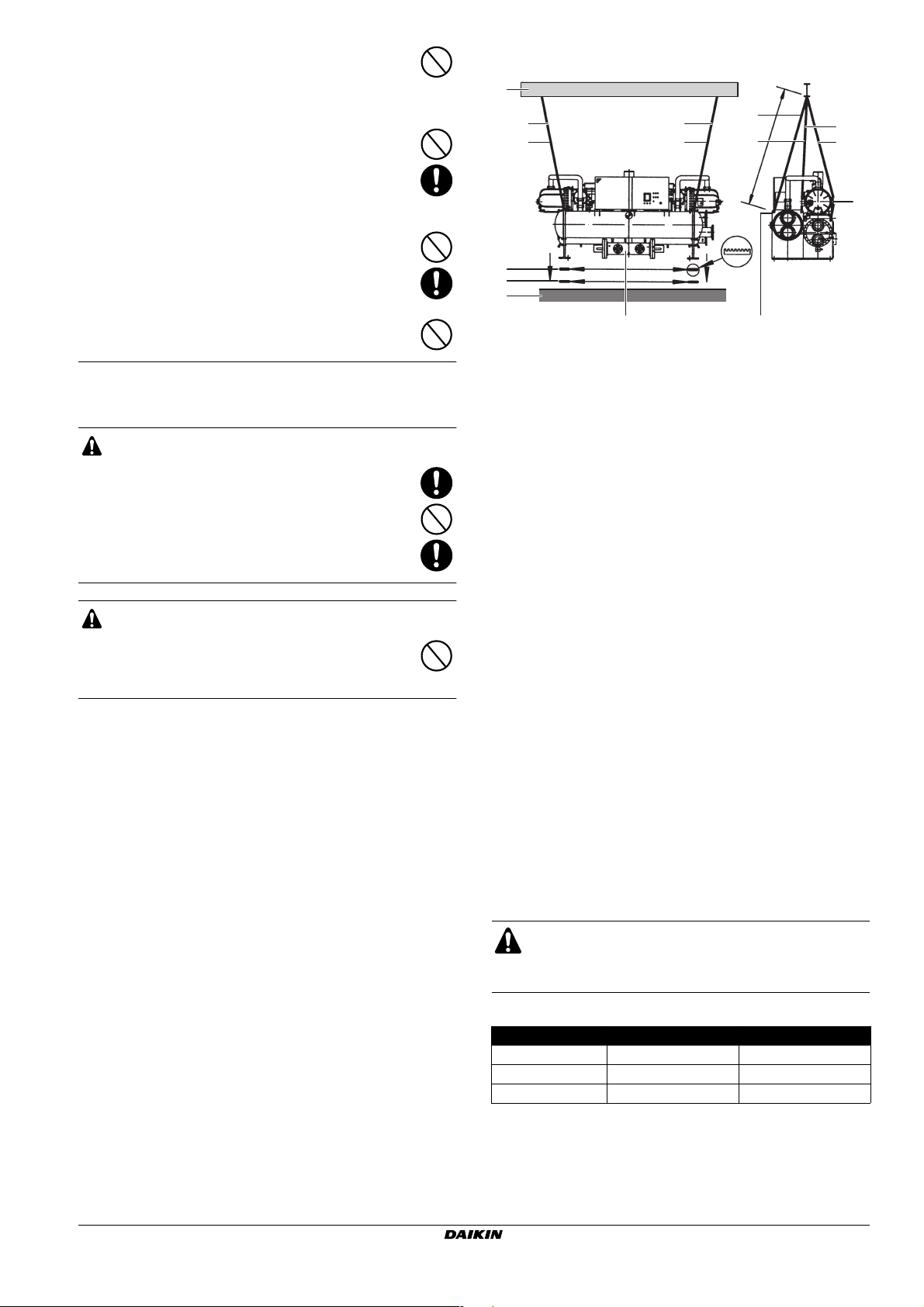

MOVING AND RIGGING

Inspecting the unit

At delivery, the unit should be checked and any damage should be

reported immediately to the carrier claims agent.

The unit comes with 6 rubber vibration isolator pads and 6 metal anti

vibration supports.

Lifting the unit

1

2 (1)

2 (2)

7

6

2 (3)

2 (4) 2 (4)

8

3

1 Lifting beam

2 Wire rope (L>5 m)

3 Collector under condenser

4 Lifting hole Ø50

5 Protection patches

6 Metal anti vibration support (6 pieces delivered with the unit)

7 Vibration isolation pad (6 pieces delivered with the unit)

8 Foundation

■ Refer to the diagram above. Have the lifting beam (1) and 4 wire

ropes prepared (2). Make sure that wire ropes are longer than

5 m. Be sure to lift the unit horizontally levelled.

■ The unit is shipped with transport stays under it. These have to

be removed before installation.

Pay special attention not to damage the lower collector (3) under

the condenser when removing the transport stays.

■ The condenser and evaporator have lifting holes (Ø50) at both

sides. Use these holes for lifting (4).

■ Perform lifting and transfer the unit slowly avoiding brusque

movements.

The unit is shipped from factory with refrigerant charged.

Brusque movement may result in unexpected behavior of the

product due to inertia force of the liquid refrigerant.

■ Select and use equipment for lifting, including the lifting

beam (1), with a sufficient safety factor. Take offset load into

account that can develop when the product inclines while lifting.

■ For preventing any external damage to the product, we request

you to protect the product by using protection patches (5) where

appropriate.

■ Make sure to first put the 6 metal anti vibration supports (6) and

6 rubber vibration isolation pads (7) in place on the

foundation (8) before putting the unit in its final position. Refer to

"Sound insulation and vibration isolation work" on page 7.

2 (1)

2 (2)

2 (3)

>5 m

4

5

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

■ Do not hang wire ropes on the piping.

Damage of piping and drop of unit may result.

Due to leakage of refrigerant, oxygen deficiency

accident or frostbite may result.

Tab le 1

Model Machine weight (kg) Operation weight (kg)

EWWD440 4200 4430

EWWD600 4650 4900

EWWD850 6100 6450

Before lifting, check the lifting weight stated in the delivery

specification again.

Installation and operation manual

3

Pulling the unit horizontally

■ Ta ke care not to bend the unit base of the chiller.

■ There are copper pipes at the bottom of the unit. Take care to

avoid scrubbing the bottom of the unit. Movement at the slope or

uneven surfaces require special attention.

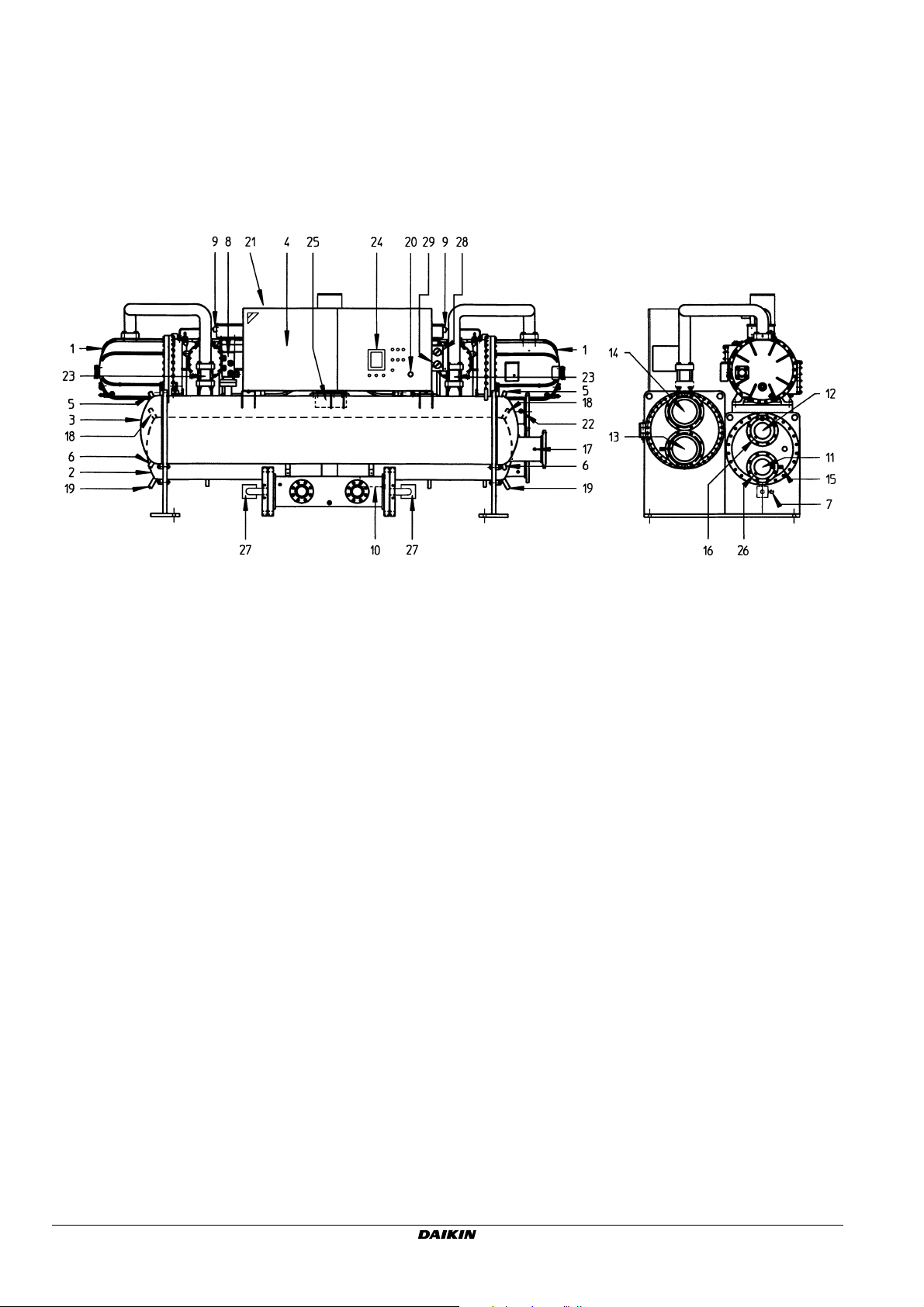

DESCRIPTION

EWWD850

Figure - Main components

1 Compressor 16 Evaporator leaving water temperature sensor

2 Evaporator 17 Condenser entering water temperature sensor

3 Condenser 18 Air purge evaporator

4 Switchbox 19 Water drain evaporator

5 Air purge condenser 20 Emergency stop

6 Water drain condenser 21 Power supply intake and field wiring intake

7 Charge valve 22 Condenser leaving water temperature sensor

8 Safety valve 23 Discharge non-return valve

9 High pressure switches 24 Digital display controller

10 Drier 25 Suction stop valve

11 Chilled water in 26 Evaporator entering water temperature sensor

12 Chilled water out 27 Liquid stop valve

13 Condenser water in 28 High pressure gauge

14 Condenser water out 29 Low pressure gauge

15 Flow switch

Installation and operation manual

4

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

Function of the main components

24

13

14

6

5

6

4

1

8

9

M1C M2C

10

3

2

5

4

1

8

3

2

9

9

12

21

14 14

23

A

13

S.HP

HPS

272

13

23

14

13

20

B

11

S.LP

2

2

17

4

22

25

6

9

13 13 13

16

18

19

9

16

16

Figure - Functional diagram

1 Compressor 15 Stop valve

2 Service valve 16 Service valve

3 Male connector 17 Suction stop valve

4 Stop valve 18 Stop valve

5 Solenoid valve 19 Filter/drier

6 Filter 20 Low pressure transmitter

7 High pressure switch 21 High pressure transmitter

8 Male connector 22 Male connector

9 Solenoid valve 23 One-way valve

10 Ejector 24 Condenser

11 Low pressure gauge 25 Evaporator

12 High pressure gauge

13 Retaining valve A Only for EWWD600+850

14 Safety valve B Only for EWWD850

13 13

1515

B

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

Installation and operation manual

5

As the refrigerant circulates through the unit, changes in its state or

condition occur. These changes are caused by the following main

components:

■ Compressor

The compressor (M*C) acts as a pump and circulates the

refrigerant in the refrigeration circuit. It compresses the refrigerant vapour coming from the evaporator at the pressure at

which it can easily be liquefied in the condenser.

■ Condenser

The function of the condenser is to change the state of the

refrigerant from gaseous to liquid. The heat gained by the gas in

the evaporator is discharged through the condenser to the

water, and the vapour condenses to liquid.

■ Filter/drier

The filter installed behind the condenser removes small particles

from the refrigerant to prevent blockage of the tubes.

The drier takes water out of the system.

■ Expansion valve

The liquid refrigerant coming from the condenser enters the

evaporator via an expansion valve. The expansion valve brings

the liquid refrigerant to a pressure at which it can easily be

evaporated in the evaporator.

■ Evaporator

The main function of the evaporator is to take heat from the

water that flows through it. This is done by turning the liquid

refrigerant, coming from the condenser, into gaseous

refrigerant.

■ Water in/outlet connection

The water inlet and outlet connection allow an easy connection

of the unit to the water circuit of the air handling unit or industrial

equipment.

INSTALLATION

Selection of installation site and foundation work

■ This is a class A product. In a domestic environment this product

may cause radio interference in which case the user may be

required to take adequate measures.

■ Indoor installation: This is an indoor-only model

Do not install this product at places subject to effect of weather

and places exposed to water splash.

Do not install this product at places exposed to direct sunlight.

WARNING

Install this product indoors

Do not install this product at places exposed to water

drop or subject to water splash.

Electric leak or electric shock may result.

■ Well-ventilated installation sites

Set up a ventilation facility so that the leakage of refrigerant

does not lead to oxygen deficiency.

Even in case the capacity of the machine room is big enough to

the extent that leakage of refrigerant does not lead to critical

concentration in terms of volumes, depending on the density

characteristics of the refrigerant gas, places with high

concentration may form locally and oxygen deficiency accidents

may result.

CAUTION

Take measures against refrigerant leakage

■ Ta ke measures so that the critical concentration

is not exceeded when a leakage of refrigerant

takes place.

■ Exceeding the critical concentration due to

leakage of refrigerant may lead to oxygen

deficiency accidents.

Installation and operation manual

6

■ An atmosphere with flammable gas is not allowed.

Because this product is not explosion-proof, do not install this

product at places in atmospheres with flammable gas or places

with risk of leakage of flammable gas.

CAUTION

Do not install this product at places with risk of

leakage of flammable gas.

Accumulation of flammable gas around the unit due to

leakage of flammable gas may lead to ignition.

■ Avoid installing this product at high temperature or low

temperature places and at places with high humidity.

Avoid installing this product where the temperature exceeds

35°C or temperature only reaches 0°C or less.

Avoid installing this product at places with relative humidity of

90% or more.

Mounting this product at places where the temperature variation

per hour exceeds 8°C or more is also inappropriate.

If you use this product in cold climates, consideration must be

given not only to the unit but also to freezing of chilled and

cooling water facilities.

■ Do not install this product near a flame

As a rule, install this product in a separate room away from

flame facilities including boilers, etc.

When you install this product in the same room where a boiler is

placed, restriction may arise on the installation conditions.

Therefore, please consult with the responsibles of competent

public agencies before doing so.

■ Special atmosphere is not allowed

Do not install the unit in atmospheres that attack metal, electric

parts, etc.

Be careful with the installation site of the cooling tower so that

the cooling water does not become highly corrosive.

If installed in the vicinity of contaminated rivers, seaside, plating

plant and chemical plant, or main roads, take care to protect the

cooling tower from inhaling harmful gases directly and increase

the frequency of water examination.

Do not install this product near ammonia facilities, exhaust ports

of toilets or exhaust ports of operating rooms of hospitals,

sewage treatment facilities, etc.

Gas leakage accident due to corrosion of heat exchanger tubes

of the condenser may result.

CAUTION

Do not install the unit in special atmospheres

Do not install this product in hot spring resorts,

seaside areas, oily places or atmosphere with

corrosive gases including ammonia. Electric shock or

fire due to corrosion may result.

■ Avoid installing this product in places where sound or vibration

can present problems.

Select a place where operating sound or vibration does not

present possible problems.

In response to such conditions, take proper measures for

vibration isolation and sound insulation.

Vibration may propagate from the installation and produce

sound from floor or wall.

In living areas, special attention is required when you install the

unit in upper stories of a building.

■ Fix the unit with bolts on a flat place that bears the weight of the

unit sufficiently.

Set the unit on a solid and level foundation (the levelness should

be ≤2 mm/1000 m).

WARNING

Fix the product correctly with anchor bolts on a

flat foundation that bears the weight of the unit.

Insufficient strength of the foundation and insufficient

fixing may result in water leakage or a roll-over

accident.

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

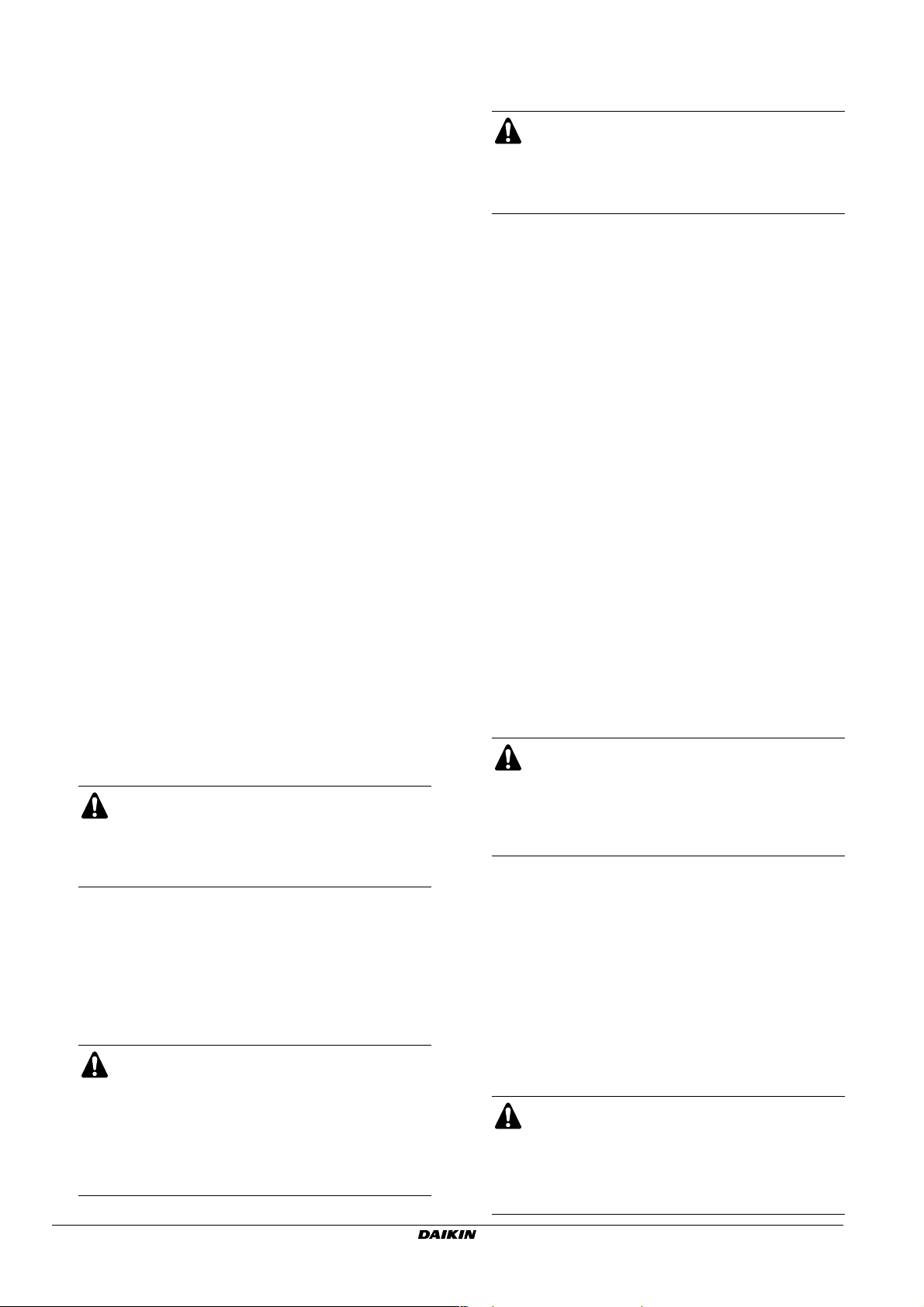

■ Provide for sufficient service space.

A

1

2

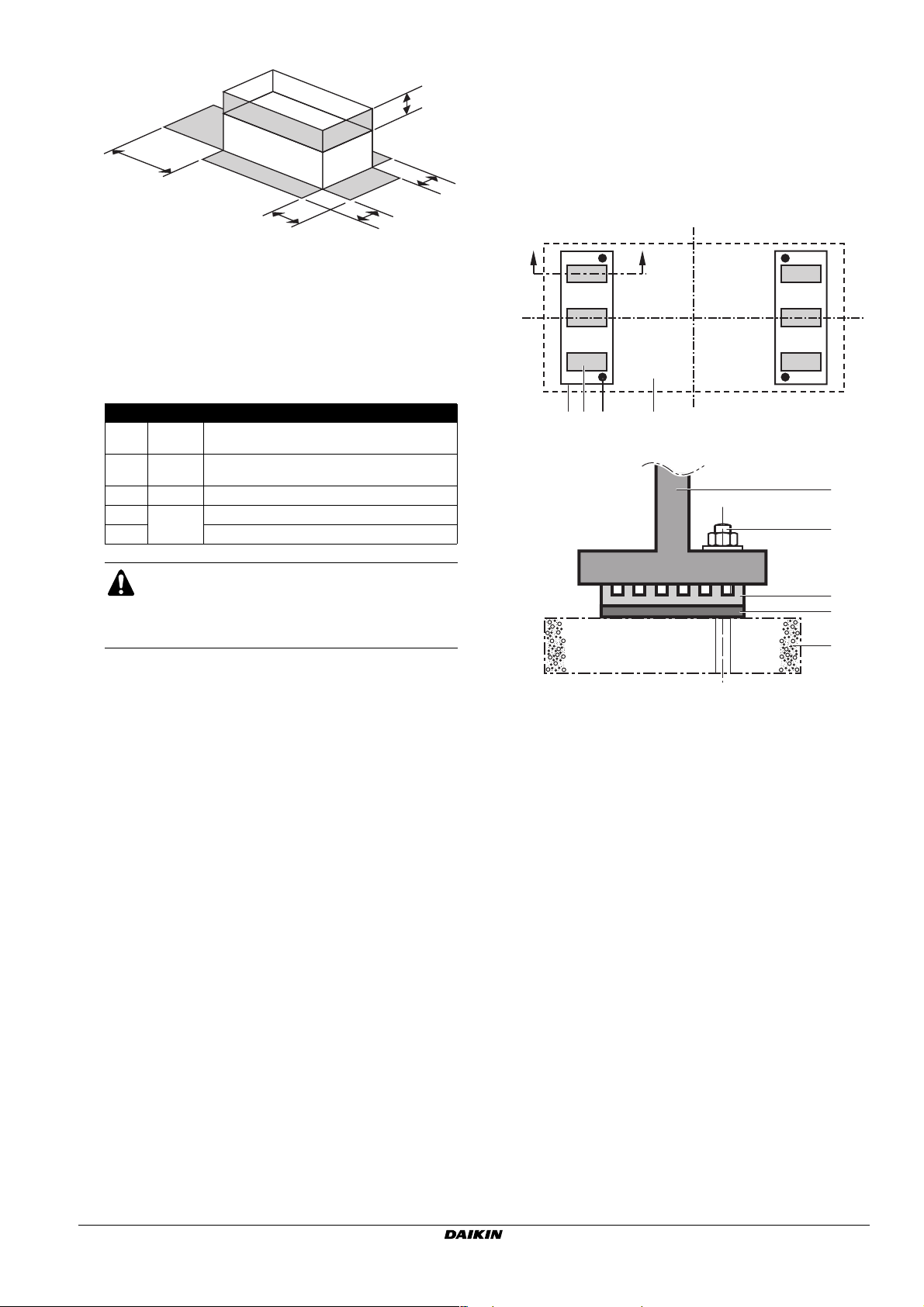

■ Perform the vibration isolation in function of the installation site.

This machine comes with vibration isolation pads and metal anti

vibration supports as a standard. Position of vibration isolation

E

pads and metal anti vibration supports as on the foundation

drawing results in a sufficient degree of vibration isolation.

However, when vibration is critical, like at middle stories of the

building, take proper vibration isolation measures with spring

vibration isolating devices.

This machine comes with 6 vibration isolating pads and 6 metal

D

B

C

anti vibration supports. Lay them down near foundation bolts

and near the center of the unit base. (See the following figure)

1 Unit

2 Front side – switch box side

A From the leftmost end of the equipment

B From the rightmost end of the equipment

C From the frontmost of the equipment

D From the backmost of the equipment

E From the top of the equipment

Service space dimensions

A ≥3000

B ≥500

C ≥1200 Required at front side

D

≥500

E Required for maintenance of compressor

Required in the direction of the length or side to

side (space for pulling out tubes)

Required both in the direction of the length and

side to side

Backside maintenance space

CAUTION

Provide for enough service space.

Insufficient space does not allow safe maintenance

and may lead to injury.

■ Pay attention to the drain

Make foundation of the unit higher than the surrounding.

For machine maintenance, the floor should be treated with

water-proofing. The drainage ditch should be provided around

the foundation. Equip the drain ditch with drain piping. Avoid

installing the unit in a place where overhead flooding or

submersion is expected during flood.

■ Pay attention to lighting

For the sake of performing daily maintenance provide for

efficient lighting around the unit.

Unit front (Switch box side): ≥100 lux.

Surrounding of the unit except for the above: ≥80 lux.

■ For further information about foundation dimensions, see the

foundation drawing to perform correct work.

AA

12+34 5

A-A

1

4

2

3

5

1 Unit base

2 Vibration isolating pad

3 Metal anti vibration support

4 Foundation anchor bolt

5 Foundation

Sound insulation and vibration isolation work

■ Be careful with the reflected sound

Sound in the machine room may get higher due to the effect of

reflected sound and interference with operating sound of other

equipment, etc. Take appropriate sound absorption and sound

insulation measures.

■ Preventing the vibration propagation through piping

Unit vibration may propagate through chilled water piping,

cooling water piping and relief valve discharge pipes. Sound/

vibration problems may result in unexpected places.

Perform the isolation of vibration by using expansion joints

immediately near the unit.

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

Installation and operation manual

7

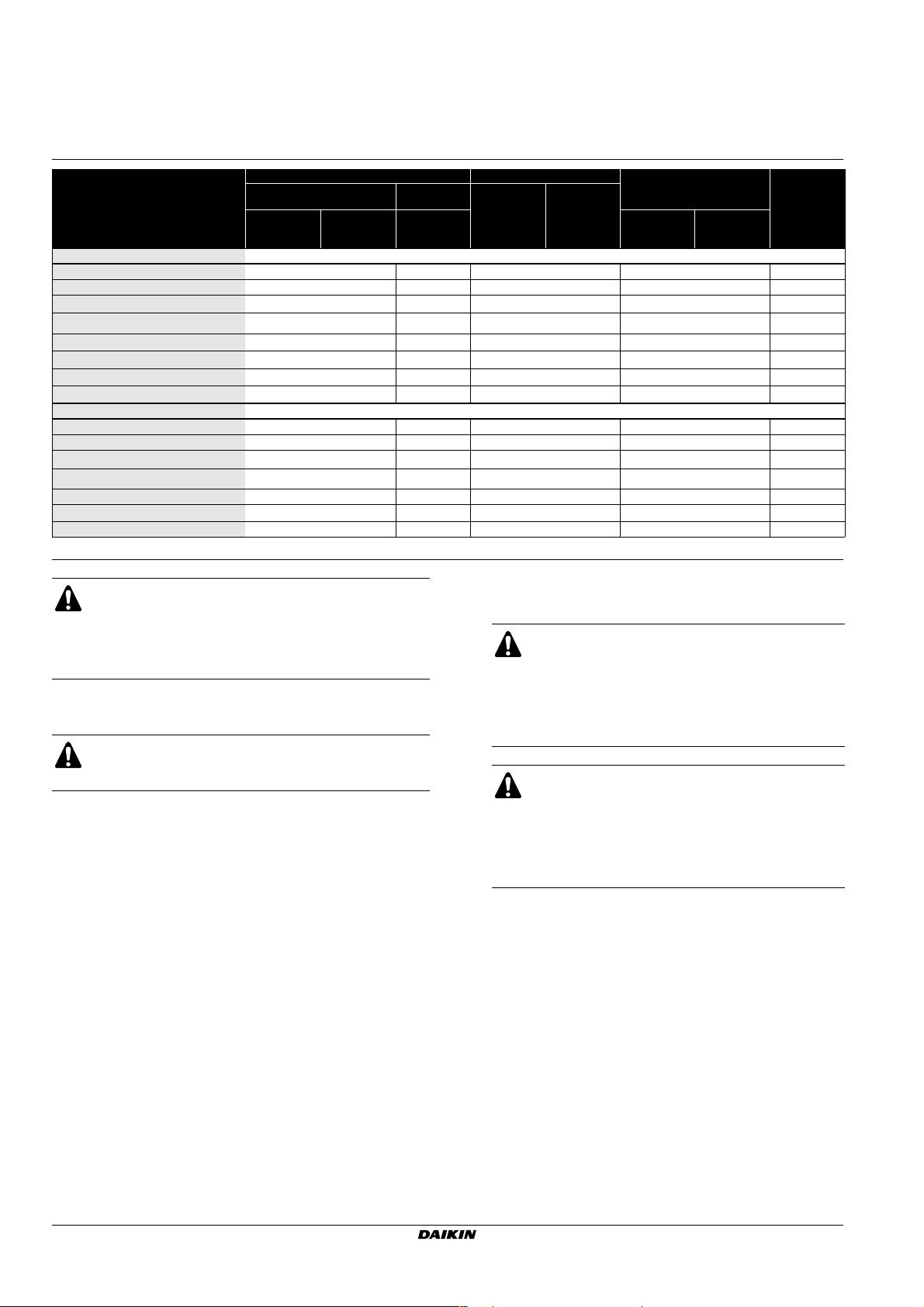

Water quality specifications

The quality of chilled (hot) water largely affects the performance and

life time of this unit. It is therefore very important to check the water

quality before using it, and to keep monitoring the quality of water

after installing the unit.

Water quality standard values for the water shall be as in the table.

condenser water evaporator water heated water

circulating system

circulating

Items to be controlled

pH at 25°C 6.5~8.2 6.0~8.0 6.8~8.0 6.8~8.0 6.8~8.0 7.0~8.0 7.0~8.0 (C)

Electrical conductivity [mS/m] at 25°C <80 <30 <40 <40 <30 <30 <30 (C)

Chloride ion [mg Cl–/l]

Sulfate ion [mg SO

M-alkalinity (pH 4.8) [mg CaCO3/l]

Total hardness [mg CaCO3/l]

Calcium hardness [mg CaCO3/l]

Silica ion [mg SiO2/l]

Items to be referred to

Iron [mg Fe/l] <1.0 <0.3 <1.0 <1.0 <0.3 <1.0 <0.3 (C)

Copper [mg Cu/l] <0.3 <0.1 <1.0 <1.0 <0.1 <1.0 <0.1 (A)

Sulfide ion [mg S2–/l]

Ammonium ion [mg N

Remaining chloride [mg Cl/l] <0.3 <0.3 <0.3 <0.3 <0.3 <0.25 <0.3 (A)

Free carbide [mg CO2/l]

Stability index 6.0~7.0 ——————(C)

(A) corrosion (B) scale (C) corrosion+scale

2

–/l

4

water

<200 <50 <50 <50 <50 <50 <50 (A)

<200 <50 <50 <50 <50 <50 <50 (A)

<100 <50 <50 <50 <50 <50 <50 (B)

<200 <70 <70 <70 <70 <70 <70 (B)

<150 <50 <50 <50 <50 <50 <50 (B)

<50 <30 <30 <30 <30 <30 <30 (B)

+

<1.0 <0.1 <1.0 <1.0 <0.1 <0.3 <0.1 (A)

/l]

4

<4.0 <4.0 <4.0 <4.0 <4.0 <0.4 <4.0 (A)

supply water

not detectable not detectable not detectable not detectable (A)

once through

system

once through

water

circulating

water

[<20°C]

supply water

low temperature

circulating

water

[20°C~60°C]

supply water

tendency if

out of criteria

2. Supplying a proper flow to the unit

CAUTION

Use chilled/hot water and condenser water that

complies with water quality specifications.

Deterioration of water quality may lead to water leakage,

etc.

A circulation pump must be provided in such a way that it

discharges the water directly into the evaporator.

■ Pump interlocks must be installed in the water

outlet pipe to prevent the unit from operating at a

water flow which is too low. 3 terminals are

provided in the switch box for the electrical

Piping work

connection of the pump interlock.

■ Improper installation of the pump interlock can

result in severe damage of the equipment.

All field piping must be installed by a licensed refrigeration

technician and must comply with relevant local and

national regulations.

■ A wire mesh strainer must be installed at the inlet

of the heat exchanger to protect the heat

■ The units are equipped with a water inlet and water outlet for

connection to a chilled water circuit. This circuit must be

provided by a licensed technician and must comply with all

relevant European and national regulations.

■ The evaporator and condenser are foreseen of flanges for the

exchanger from foreign matter. Distance between

the inlet of the heat exchanger and the wire mesh

strainer must be <0.5 m.

■ Improper installation of the wire mesh strainer will

result in severe damage of the equipment.

water inlet and outlet (refer to the outlook diagram). Evaporator

and condenser water connections are to be made in accordance

with the outlook diagram, respecting the water in- and outlet.

If air, moisture or dust gets in the water circuit, problems may

occur. Therefore, always take into account the following when

connecting the water circuit:

1. Use clean pipes only.

2. Hold the pipe end downwards when removing burrs.

3. Cover the pipe end when inserting it through a wall so that no

dust and dirt enter.

Before continuing the installaiton of the unit, check the following

points:

1. Measures against vibration

■ Mount the expansion joint near the unit so that operation

vibration of the unit does not propagate to the equipment

3. Removing foreign materials

■ Periodic cleaning of the scale adhered to the inside of the

unit is required.

For the sake of facilitating the cleaning, provide the water

piping system with stopvalves at both inlet and outlet sides.

In addition, for ease of opening the water chamber of the

condenser and evaporator, we recommend to use short

pipes with flanges at both the water piping side and the unit

side.

■ For periodic cleaning and maintenance, provide valves for

release to atmosphere, drain off valves and valves for

chemical cleaning between stopvalves provided in the water

piping system and the unit body.

For drain off valves, lay down the drain piping to the drain

ditch.

system.

■ Equip the piping with supports at appropriate points.

Installation and operation manual

8

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

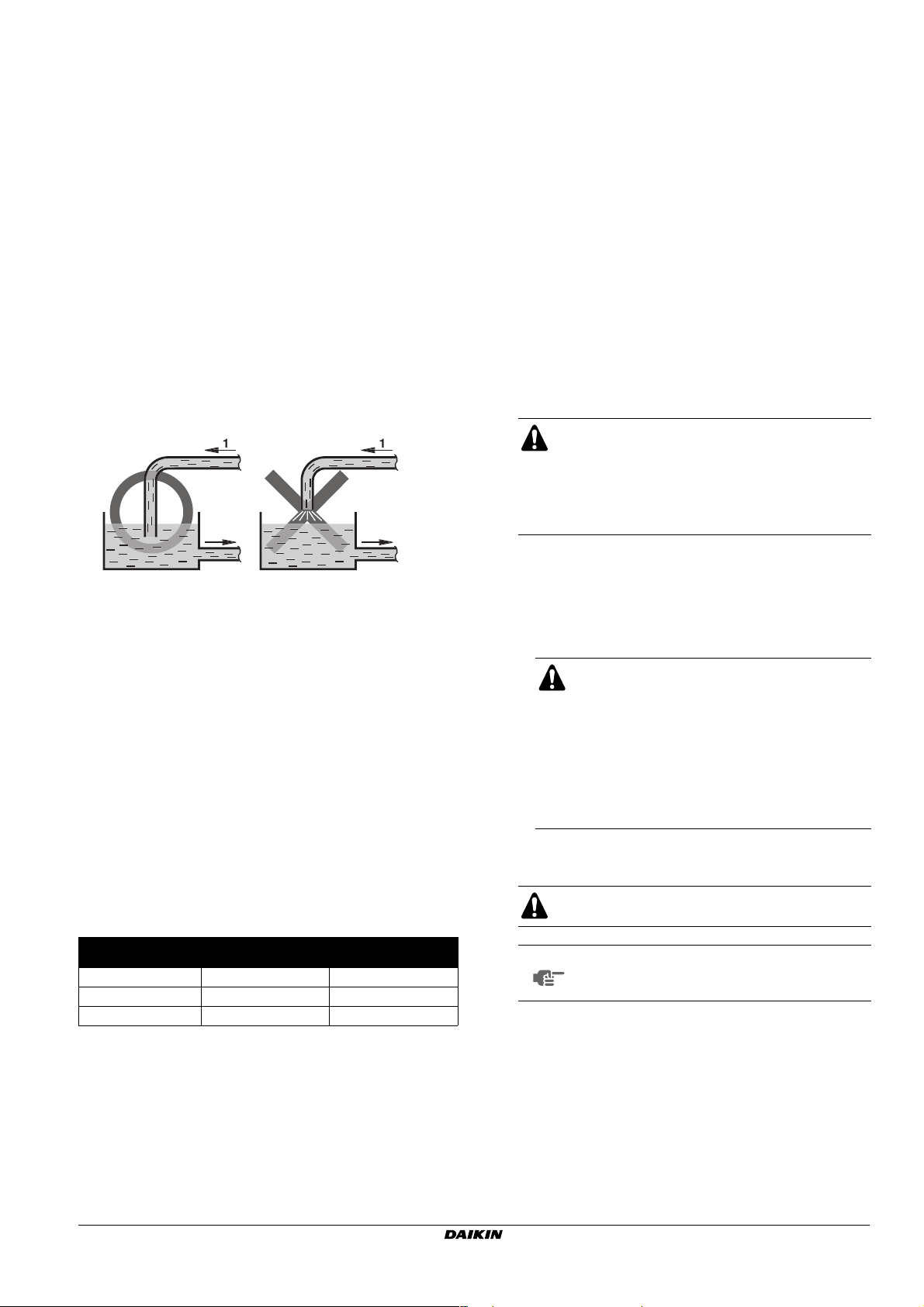

4. Prevent from getting mixed air into the system

1

1

■ Install the air purge valves at proper positions so that the air

purge of the entire equipment system is possible.

Operation of units with air mixed may lead to deterioration in

performance, actuation of protective devices, or damage of

heat exchanger tubes.

■ Pay attention to the flow velocity inside the water system,

position of the expansion tank, and to the position of air

purges along the piping, so that cavitations do not occur.

■ This machine is designed on the precondition that circulating

water is used. Use of once-through water may lead to

damage of the heat exchanger tubes due to dissolved

oxygen or free carbonate in chiller water (hot water) systems.

■ When using the unit in a heat recovery application, additional

care must be taken that water flow rate does not get

excessive. In the same application, a deaeration treatment

unit must be installed.

■ Do not allow aeration along the cooling water system as

shown in the following diagram.

Aerating water causes the dissolved oxygen to increase, and

pollutants in the atmosphere condensed in the water cause

the water to become corrosive.

■ Avoid execution of piping in such a way that a draft line is

formed inside the condenser or evaporator while the unit is

operating or stops.

■ In case of semi hermetic chilled water system with a thermal

storage tank, perform periodic replacement of water and

cleaning and inspection of the bottom of the thermal storage

tank (once every 1 or 2 years).

A new concrete heat storage tank will give off ions, and it is

not seldom that pH of the heat storage tank water rises

above 10. If pH rises above the standard, the rate at which

copper corrodes increases. The water must be changed

before the pH reaches that level.

If a heat storage tank is used for a prolonged period,

springing and leaking of water could occur due to cracks in

the heat storage tank. Water leaks pose no serious problem

for water quality, but if seawater or dirty underground water

springs, it could cause an outbreak of microorganisms in the

water of the heat storage tank, thus producing slime in the

system. It could also cause calcium carbonate to adhere.

■ Make sure to perform periodic water quality inspections,

especially as to water quality of the cooling water. Insufficient

water quality may result not only in performance deterioration

of the unit but also in damage to the heat exchanger tubes.

CAUTION

Use chilled (hot) water/cooling water that

complies with the water quality standard as in

chapter "Water quality specifications" on page 8.

Deterioration of water quality may lead to water

leakage and damage to the heat exchanger tubes.

1 Discharge pipe

2 Inlet pipe

5. Observing the operation range of the unit

■ Observe the maximum operating water pressure of the unit.

■ Pay attention so that the cooling water inlet temperature

reaches 25°C or more.

When you use the unit during intermediate season and

winter season, control the cooling water supply water

temperature by using a thermostat for the cooling water inlet

and a 3-way mixing valve.

■ Pull-down time of this machine (time required for cooling from

ordinary temperature to reach the recommended operating

range) is within 1 hour under no load condition.

Make sure to prevent the water flow from becoming to high.

■ To assure proper operation of the unit a minimum water

volume is required in the system and the water flow through

the evaporator must be within the operation range as

specified in Ta ble 2.

Tab le 2: Minimum water volume

Minimum water

Model

EWWD440 2660 105

EWWD600 3710 110

EWWD850 5020 157

volume (l)

Water quantity inside the

evaporator (l)

7. Freeze-up protection

■ The complete water circuit, inclusive all piping, must be

insulated to prevent condensation and reduction of the

cooling capacity.

■ Protect the water piping against water freezing during winter

period (e.g. by using glycol solution or heatertape).

CAUTION

Do not confuse the connection of outlet and

inlet of the water piping.

■ Do not confuse the inlet and outlet of the

chilled water and connection position of the

condenser water.

■ Normal operation may get impossible.

■ It may lead to breakdown including freezing

fracture of heat exchanger tubes.

8. Preventing excessive increase of chilled water and condenser

water temperature

The water pressure should not exceed the maximum

working pressure of 10 bar.

NOTE

Provide adequate safeguards in the water circuit

to make sure that the water pressure will never

exceed the maximum allowable working pressure.

■ When it is impossible to secure the minimum holding water

quantity, increase of thermo differential value is required. For

how to change the differential value, see "Settings screen" on

page 14 and "Target temperature and low load stop related

settings screen" on page 22.

6. Prevent corrosion of water piping and of the unit interior

■ Do not install the earth of the electric equipment to the water

piping. Corrosion due to electric corrosion may occur.

■ If piping is to be put underground, be extremely careful and

take dust preventive measures.

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

Installation and operation manual

9

Power supply work

All field wiring and components must be installed by a

licensed electrician and must comply with relevant

European and national regulations.

The field wiring must be carried out in accordance with the

wiring diagram supplied with the unit and the instructions

given below.

Be sure to use a dedicated power circuit. Never use a

power supply shared by another appliance.

Internal wiring - Parts table

Refer to the internal wiring diagram supplied with the unit. The

abbreviations used are listed below:

20R3, 20R4 ............Oil return solenoid valve circuit 1, circuit 2

20R8.......................Dryer line solenoid valve

20R1, 20R2 ............Forcely closed solenoid valve circuit 1, circuit 2

20R5, 20R6 ............Equalizing oil level solenoid valve circuit 1,

circuit 2

20R7.......................Float chamber gas purging solenoid valve

20R9.......................Ejecter solenoid valve

26WE .....................Chilled water overcooling sensor

2-88X......................Auxiliary relay run/stop monitor

42-1, 42-2...............Deltacontactor for circuit 1, circuit 2

49C1, 49C2 ............Thermal protector compressor motor circuit 1,

circuit 2

51C1, 51C2 ............Overcurrent relay for circuit 1, circuit 2

52-1, 52-2...............Linecontactor for circuit 1, circuit 2

52X-1, 52X-2 ..........Auxiliary relay for circuit 1, circuit 2

5X-1, 5X-2 ..............Compressor circuit error relay for circuit 1,

circuit 2

5X-3........................Common error relay

6-1, 6-2...................Starcontactor for circuit 1, circuit 2

63CH-1~4...............High discharge pressure sensor

63WEL ...................Chilled water interruption sensor

88CH ......................High discharge pressure relay

88CHX....................High discharge pressure auxiliary relay

88WCX...................condenser water pump run/stop relay

88WE .....................Chilled water overcooling relay

88WEX ...................Chilled water pump run/stop relay

AXP1, AXP2...#.....Pumpinterlock

BS ..........................PCB-controller

BS1 ........................Local stop push button

BS2 ........................Local run push button

CH1, CH2...............Oil heater for circuit 1, circuit 2

CT1, CT2................Current transfo

CT-T1, CT-T2..........Current transducer 5 A/5 V; 24 V DC

F11U~F13U....# .....Main fuses

F21U~F23U....# .....Main fuses

F10S, F11S ............Circuit breakers with fuses for circuit 1, circuit 2

GL1 ........................Indication lamp: unit stop

GP ..........................Display

H1P, H2P........*......Indication lamp: run/stop remote display

H3P ................*......Indication lamp: common error remote display

H4P, H5P........*......Indication lamp: compressor error 1, 2 remote

display

H6P.................* ..... Indication lamp: condenser water pump run/stop

H7P.................* ..... Indication lamp: chiller water pump run/stop

HF1-2..................... Fuse for primary of TR1

HF3.1, 3.2.............. Fuse for reverse phase protector

KP1, KP2............... Compressor slide valve position sensor for circuit

1, circuit 2

M1C, M2C ............. Compressor motors circuit 1, circuit 2

MCCB1.................. Automate fuse for secundary of TR1

NF1........................ EMC-filter for power supply PCB

NF2~NF4............... Ferrite

ÖL.......................... Indication lamp: error

PBS ....................... Common error reset push button

PE.......................... Main earth terminal

R2-1, R2-2............. Auxiliary relay: error compressor-motor overload-

phase sequence

RL1........................ Indication lamp: unit running

RL2, RL3 ............... Indication lamp: compressor running for circuit 1,

circuit 2

RL4........................ Indication lamp: remote operation

RPP.1, RPP.2 ......... Reverse phase protector for circuit 1, circuit 2

S5E........................ Emergency stop

S6S.................*..... Switch: remote start/stop

S10S...............*..... Switch: demand control ON/OFF

S12S, S14S....* ..... Push button: remote run, remote stop

S13S...............# .... Main isolator switch

Sen H..................... Discharge pressure sensor

Sen L ..................... Suction pressure sensor

T2 .......................... Time relay; time delay / 0.5 s

Th1, Th2 ................Compressor discharge gas temperature for

circuit 1, circuit 2

Th3 ........................ Discharge gas temperature sensor

Th4 ........................ Chilled water inlet temperature sensor

Th5 ........................ Chilled water outlet temperature sensor

Th6 ........................ Condenser water inlet temperature sensor

Th7 ........................ Condenser water outlet temperature sensor

TR1........................ Transfo control circuit

WL ......................... Indication lamp: power supply

Not included with standard unit

Not possible as option

Obligatory #

Not obligatory *

Installation and operation manual

10

EWWD440~850AAYNNO**

Packaged water-cooled water chillers

4PW25558-1B

Loading...

Loading...