EHVH04CB3VF

EHVH08CB3VF

We advise to first carefully read this addendum and only then to consult delivered manuals and proceed with installation of the unit.

For this floor standing low temperature heat pump EHVH04CB3VF or EHVH08CB3VF, instructions in the manuals delivered with the unit are these

of the EHVH04CB3V or EHVH08CB3V.

All delivered manuals as well as the Installer reference guide and User reference guide referred to in delivered manuals apply, but there are some

exceptions and attention points for the “F”-version units.

These exceptions and attention points are described in this addendum.

Differences mainly relate to

1) water piping and refrigerant piping connections (see pictures in this addendum);

2) the built-in 12 l flow-through vessel under the domestic hot water tank (which impacts on the minimum water volume of the installation);

3) lay-out of the internal piping;

4) impact of these differences on technical specification drawings. The correct versions are therefore added to this addendum.

There is no difference for everything related to the user interface, the software or the operation of the unit. All information in the delivered manual

related hereto is therefore correct.

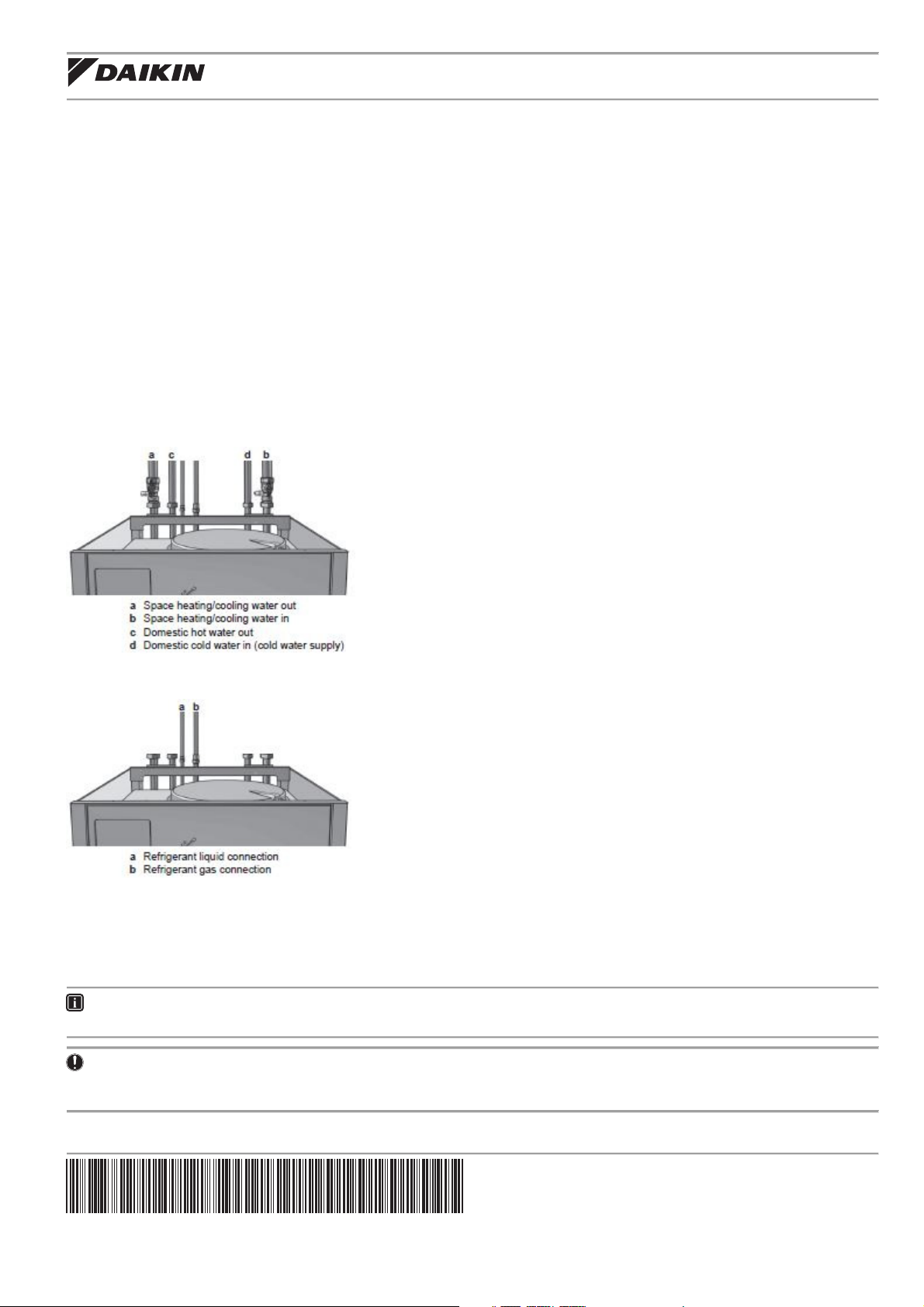

1. Water piping connections and refrigerant piping connections

The following picture illustrates the water piping connections of your unit (chapter “To connect the water piping”). Analogous pictures in the

EHVH04/08CB3V manual are to be neglected.

Addendum to the documentation set

The following picture illustrates the refrigerant piping connections of your unit (chapter “To connect the refrigerant piping to the indoor unit”).

Analogous pictures in the EHVH04/08CB3V manual are to be neglected as well.

2. Minimum water volume (chapter “To check the water volume and flow rate)

ONLY applicable for EHVH04+08S18CB3VF

The system does not require a minimum water volume. Since an extra flow-through vessel is built into the unit, the total water volume in the

installation can be 0 l. It is however required that when all heat emitters are closed, the user interface displays a minimum water flow of 15 l/min.

INFORMATION

Critical processes or rooms with a high heat load may require extra water.

NOTICE

When circulation in each space heating loop is controlled by remote controlled valves, it is important that a minimum water flow of 15 l/min is

guaranteed, even if all valves are closed.

*4P412945-1 0000000N*

Addendum to the documentation set

1

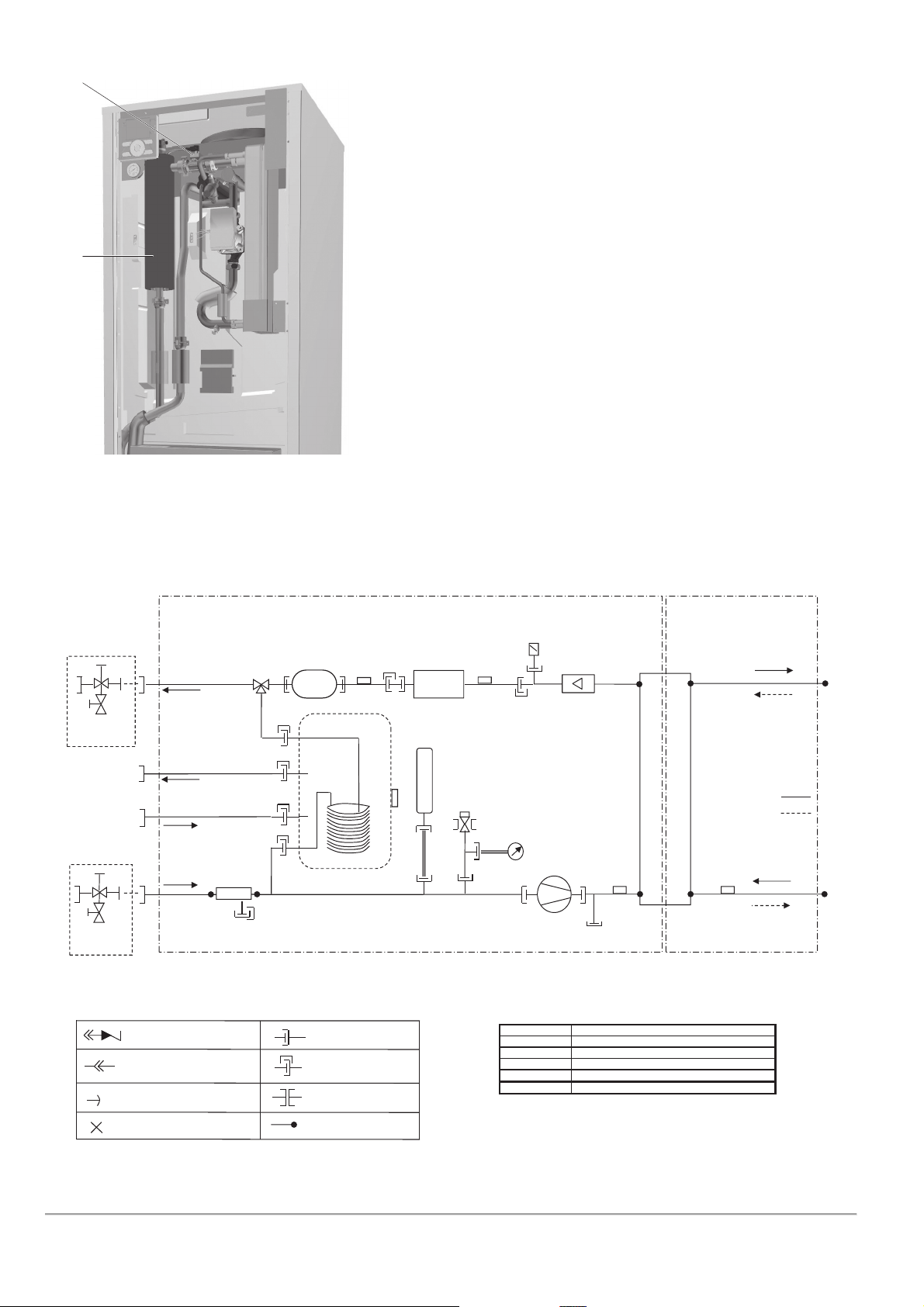

3. Lay-out of internal piping

a

b

a Flow sensor

b Backup heater

4. Impact of these differences on technical specification drawings (chapter “Technical data” of the Installer reference guide referred to in

delivered manuals)

Piping diagram: Indoor unit

Space heating

water out

FIELD INSTALLED

shut off valve

with drain/fill

valve

Domestic hot water:

hot water out

Domestic hot water:

cold water in

FIELD INSTALLED

Filter

Flow-through

vessel

R2T

Domestic Hot Water Tank

Heat exchanger

R5T

BUH

Expansion

vessel

Safety

valve

R1T

Air purge

Flow sensor

Manometer

Pump

R4T

REFRIGERANT SIDE WATER SIDE

Plate heat

exchanger

REFR. OUT

REFR. IN

EVAPORATOR

CONDENSOR

REFR. IN

R3T

shut-off valve

with drain/fill

valve

Drain cap

REFR. OUT

Space heating water in

LEGEND:

CHECK VALVE

FLARE CONNECTION

SPINNED PIPE

PINCHED PIPE

SCREW CONNECTION

QUICK COUPLING

FLANGE CONNECTION

BRAZED CONNECTION

R5T

R4T

R3T

R2T

R1T

THERMISTOR DESCRIPTION

Tank thermistor

Inlet water thermistor

Refrigerant liquid side thermistor

Outlet water backup heater thermistor

Outlet water heat exchanger thermistor

3D077572-1A page 2

Addendum to the documentation set 4P412945-1 – 2015.06

2

Components: Indoor unit

b

g

c d e f

a

b

h

y

x

n

v

cc

j

i

k

y

l

m

x

cc

w

u

n

r

n

o

p

bb

o

z

s

q

t

a Space heating cooling out

b Shut-off valves (accessory)

aa

s Backup heater thermal protector

Allows isolation of the indoor unit water circuit side from the

residential water circuit side.

c Domestic hot water out

d Refrigerant liquid connection R410A

e Refrigerant gas connection R410A

f Domestic hot water in

g Fill valve (accessory)

h Space heating cooling in

i Expansion vessel (10 l)

j Pressure relief valve

u Backup heater

v Manometer

w Flow sensor

Prevents excessive water pressure in the water circuit by

opening at 3 bar.

k Water filter

Removes dirt from the water to prevent damage to the pump

x Air purge valve

or blockage of the heat exchanger.

l Heat exchanger

m Water pump

y 3-way valve

Circulates the water in the water circuit.

n Thermistors

Determines the water and refrigerant temperature at various

points in the circuit.

o Drain caps

p Tank thermistors

q Domestic hot water tank drain valve

z User interface (accessory)

aa Flow-through vessel

bb Drain flexible pressure relief valve

cc Air valve

Empties the full tank.

r Switch box

Contains the main electronic and electrical parts of the

indoor unit.

The protector activates when the temperature of the backup

heater becomes too high.

Provides additional heating in case of cold outdoor

temperatures. Also serves as backup in case of

malfunctioning of the outdoor unit.

Allows readout of the water pressure in the water circuit.

Gives feedback to the interface about the actual flow. Based

on this information (and other), the interface adjusts the

pump speed.

Remaining air in the water circuit will be automatically

removed via the air purge valve.

Controls whether the water is used for space heating, or the

domestic hot water tank.

4P412945-1 – 2015.06 Addendum to the documentation set

3

Dimensions and service space: Indoor unit

Dimensions

Pay special attention towards position of water piping connections and of refrigerant piping connections.

194 52

150 301

141 223 45

60

45075

s

110

115

199

m

761

728

r

300

600

l

ba

k

n

hi

g

dj

g

p

f

c

R210

t

1762

1744

1732

e

q

u

ooo

3D087616-1

a Gas pipe connection Ø15.9 mm

b Liquid pipe connection Ø6.35 mm

c Pressure gauge

d Safety valve

e Drain valve water circuit

f Air purge

g Stop valve with fill valve (included accessory)

h Water filter

i Water IN connection 1-1/4" female British standard pipe thread

j Water OUT connection 1-1/4" female British standard pipe thread

k Tank IN connection 1" female British standard pipe thread

l Tank OUT connection 1" female British standard pipe thread

m Control wiring intake (Ø24 mm)

n Power supply wiring intake (Ø24 mm)

o Levelling feet

p User interface (included accessory)

q Drain valve tank circuit

r Recirculation connection G 1/2" female

s Hole for recirculation piping or option wiring (Ø62 mm)

t Drain outlet (unit+safety valve)

u Flow-through vessel (12 l)

Note 1: Typical field installation is according to local and

national regulations.

Service space

Service space of EHVH04CB3VF or EHVH08CB3VF units is same as service space of EHVH04CB3V and EHVH08CB3V units, and therefore not

considered in this addendum.

Addendum to the documentation set 4P412945-1 – 2015.06

4

Loading...

Loading...