Daikin D-BACS Design Manual

ED 72 - 721

<Preliminary>

Daikin Buildings

Air-conditioning Control System

D-BACS

DESIGN GUIDE

i

Contents

1. Introduction ...................................................................viii

1-1 DAIKIN Building Air-conditioning Control System

(D-BACS) Overview ...... ................................................. . viii

1-2 Advantages of D-BACS over Automatic Control by

Central System................................................................viii

1-3 How to Use this Document.................................................x

1-4 Safety Precautions ........................ .....................................x

1-5 Open Network Glossary ....................................................xi

Part 1 Outline of D-BACS System .......................... 1

1. D-BACS (DAIKIN Building Air Conditioning Control

System) System Over View.............................................2

1-1 D-BACS System Integrated System Diagram................... 2

2. System Over View............................................................4

2-1 Targeted Project Scale and Map....................................... 4

2-2 Number of Group for Centralized-Control Devices

Connectable with Indoor-Units .......................................... 5

2-3 Control Function of the Devices ........................................ 5

3. List of D-BACS System Equipment................................6

3-1 List of Control System Equipment.....................................6

3-2 Main Specifications and Functions of the Equipment........8

4. List of Control System Equipment and Functions......14

5. Functions of Centralized Controllers...........................15

6. Central Control Equipment Combinations...................22

7. List of Applicable Models of DAIKIN............................23

Part 2 Fundamental of DIII-NET........................... 25

1. Design of DIII-NET..................................... .... ..... ..... .......26

1-1 Features of DIII-NET ....................................................... 26

2. DIII-NET Design Standard..............................................27

2-1 Terminal Number.............................................................27

2-2 Detail of Outdoor Unit Terminal No. ................................ 27

2-3 Connection Method......................................................... 28

3. Wiring Length.................................................................34

4. Unit and Group .......................................... .....................35

5. Number of Connectable Units.......................................36

5-1 Number of Connectable Units............... .......................... 36

5-2 Flow Chart to Determined the Number of Units to

Connected....................................................................... 37

5-3 Number of Units to be Connected [VRV]

(Supplementary Explanation)..........................................38

5-4 Connection of Devices other than VRV..................... ......39

ii

6. Group and Zone..............................................................40

6-1 Definition ......................................................................... 40

6-2 Patterns of Group and Zone............................................ 40

6-3 Group Address Number .................................................. 41

6-4 Setting Group No. for Centralized Control ....................... 4 2

6-5 Zone Address Number.................................................... 47

7. Wiring Specifications of DIII-NET .................................48

8. Combination of Multiple Central Remote Controllers

<DCS302CA61 • DCS301BA61 • DST301BA61>...........49

8-1 Check for Centralized Control Devices in

Simultaneous Use........... ................................................ 49

8-2 Combination of intelligent Touch Controller and

Central Remote Controller...............................................51

8-3 Combination of DCS302CA61·DCS301BA61·

DST301BA61 ..................................................................52

8-4 Sequential Start.................... ........................................... 54

8-5 Under Central Control ..................................................... 54

8-6 Error Code on Intial Setting and Wiring Troubles............ 54

Part 3 Remote Controllers ................................... 55

1. List of Indoor Units with Corresponding Individual

Operation Remote Controllers......................................56

2. Dimensions of Remote Controllers..............................58

2-1 Wired Remote Controller................................................. 58

2-2 Wireless Remote Controller / Receiver ........................... 59

2-3 Simplified Remote Controller........................................... 62

2-4 Remote Controller for Hotel Use ....... ..............................62

2-5 Wired Remote Controller with

Weekly Schedule Timer .................................................. 63

2-6 Wired Remote Controller for HRV................................... 63

3. Functions of Remote Controllers .................................64

3-1 Function List.................................................................... 64

3-2 Example of Control by Remote Controller.......................64

3-3 Remote Controller <BRC1C62>............ .......................... 65

3-4 Simplified Remote Controller

<BRC2C51 (BRC2A51)>................................................. 68

3-5 Remote Controller for Hotel Use <BRC3A61>................69

3-6 Wired Remote Controller with

Weekly Schedule Timer <BRC1D61>............................. 70

3-7 Wireless Remote Controller <BRC4C, 7C, 7E>..............72

3-8 Wired Remote Controller for HRV <BRC301B61>.......... 75

4. Various Control by Remote Controller Control...........76

4-1 Group Control.................................................................. 76

4-2 Forced OFF or ON/OFF Control...................................... 76

4-3 2 Remote Controllers ........... ........................................... 77

4-4 Remote Controller Thermostat........................................ 78

4-5 <KRCS01-1A> Remote Sensor..... ..................................80

iii

5. Field Setting by Remote Controller ..............................82

5-1 Wired Remote Controller <BRC1C62> ........................... 82

5-2 Wireless Remote Controller <BRC4C, 7C, 7E>..............85

5-3 Simplified Remote Controller

<BRC2C51 (BRC2A51)>................................................. 86

5-4 HRV <BRC301B61>........................................................ 88

Part 4 intelligent Touch Controller...................... 91

1. Part Names and Functions............................................92

1-1 Front and Side View.......... .............................................. 9 2

1-2 Part Names on the Monitoring Screen and

the Functions................................................................... 93

2. System Configuration....................................................99

2-1 System Outline................................................................ 99

2-2 Double intelligent Touch Controllers ............................... 99

3. Specification.................................................................100

3-1 Specification.................................................................. 100

3-2 Dimension .....................................................................100

4. Functions......................................................................101

4-1 Functions....................................................................... 101

5. Electric Wiring..............................................................104

5-1 Terminals on the Back of

intelligent Touch Controller... ......................................... 104

5-2 Points of Installation ...................................................... 105

5-3 Wiring for Force Stop Input and for

Electric Power Distribution ............................................ 106

5-4 Connection to Public Telephone Line............. ............... 107

5-5 Connection to LAN ........................................................ 107

5-6 DIII-NET Plus Adaptor Connection................................ 108

5-7 Connection for Unification Adaptor................................108

5-8 DII-NET Plus Adaptor.................... ................................109

5-9 Wiring Example for intelligent Touch Controller

(DCS601C51)................................................................ 111

6. Web function.................................................................117

Part 5 Control Devices ....................................... 123

1. <DCS302CA61> Central Remote Controller...............124

1-1 Function......................................................................... 124

1-2 System Configuration.................................................... 125

1-3 Specifications / Dimensions ....... ...................................128

1-4 Names and Functions of Operating Part.......................129

1-5 Description of Functions................................................131

1-6 Selection of Control Mode No. ................. ..................... 139

1-7 Initial Setting............................................. ..................... 142

1-8 Electric Wiring ...............................................................143

1-9 Special Function Settings.............................................. 144

1-10 Refreshed Operation..................................................... 145

1-11 Error Diagnosing Function............................................. 146

1-12 Installation ..................................................................... 149

iv

2. <DCS301BA61> Unified ON/OFF Controller ..............150

2-1 Function......................................................................... 150

2-2 System Configuration.................................................... 150

2-3 Specification and Dimension......................................... 151

2-4 Part names and Functions ............................................ 151

2-5 Initial Setting............................................. ..................... 153

2-6 Electric Wiring ...............................................................155

2-7 Confirming Operation ...... .............................................. 155

2-8 Installation ..................................................................... 156

3. <DST301BA61> Schedule Timer.................................157

3-1 Function......................................................................... 157

3-2 System Configuration.................................................... 157

3-3 Specification and Dimension......................................... 158

3-4 Part names and Functions (DST301BA61)................... 159

3-5 Initial Setting............................................. ..................... 161

3-6 Electric Wiring ...............................................................162

3-7 Installation ..................................................................... 163

3-8 Error Diagnosing Function............................................. 163

Part 6 intelligent Manager ................................. 165

1. intelligent Manager Overview......................................166

1-1 Features........................................................................ 166

1-2 Specification.................................................................. 176

1-3 Functions....................................................................... 177

2. System Design of intelligent Manager .......................178

2-1 System Configuration of intelligent Manager................. 178

2-2 List of Required Devices for

intelligent Manager System.. ......................................... 178

2-3 Creation of DIII-NET Wiring Diagram ............................ 179

2-4 Allocation of Centralized Address ......... ........................ 181

2-5 Points to Note for Design .............................................. 182

2-6 Use with Other Centralized Devices.............................. 183

3. Installation and Electric Wiring...................................184

3-1 Components..................................................................184

3-2 Part Name and Function ............... ................................184

3-3 Installation ..................................................................... 186

3-4 “DIII-NET master” setting ....... ....................................... 187

3-5 System Wiring ............................................................... 188

3-6 Electric Wiring Connection ............................................ 189

3-7 Setting group No. for centralized control.......................192

3-8 Wiring Example ............................................................. 193

Part 7 Interface for Use in BACnet®.................. 199

1. BACnet® Interface.............................................. ..... .....200

1-1 Outline and Features.....................................................200

1-2 System Outline.............................................................. 200

1-3 System Configuration.................................................... 201

1-4 Specifications ................................................................202

v

1-5 Components..................................................................202

1-6 Dimensions.................................................................... 202

1-7 BACnet Object List........................................................ 204

1-8 Names and Functions of each Part............................... 205

1-9 Electric Wiring ...............................................................207

1-10 Functions....................................................................... 212

1-11 Backup Systems for Troubles ....................................... 214

1-12 BMS (Building Management System) ........................... 216

1-13 Adopting “Super Wiring System”................................... 216

2. Daikin's Interface for

Use in BACnet® Agreement ........................................217

3. Wiring Example ............................................................219

3-1 Interface for Use in BACnet® (DMS502B51)................. 219

3-2 Interface for Use in BACnet

®

(DMS502B51)+

Optional Dlll Board (DAM411B51).................................220

3-3 Interface for Use in BACnet

®

(DMS502B51) with

P.P.D. Application Using Optional Di Board

(DAM412 B51)...............................................................221

Part 8 Interface for use in LONWORKS®........... 223

1. Introduction ..................................................................225

2. System Configuration..................................................226

3. Part Names and Functions..........................................227

4. Function........................................................................228

4-1 Overview of Functions................ ...................................228

4-2 Applicable Models ......................................................... 229

5. Specifications of Devices............................................230

6. Hardware.......................................................................231

6-1 Physical Appearance and Branch Connection..............231

6-2 Definition of LED and Switch......................................... 231

7. Object Details ...............................................................232

7-1 Node Objects...... ............................. .......................... ....232

7-2 DIII-NET Common Objects............................................ 232

7-3 Air Conditioner Objects .......... ....................................... 233

8. Precautions Regarding XIF Files................................234

8-1 File Name....... ............................................................... 234

8-2 Limitations with Version 3.............................................. 234

8-3 Unused Network Variables............................................ 234

9. Notes for when Commissioning .................................235

9-1 Suspension of Message Transmission when

Receiving Set Node Mode Online............ ..................... 235

10. Refere n ce Ma t eria l s

(Error Code Conversion Table)...................................236

11. Electric Wiring..............................................................237

11-1 Electric Wiring Connection ............................................ 237

11-2 Wiring Example .............................................................238

vi

12. Control-related Design Keypoints..............................239

12-1 Introduction.................................................................... 239

12-2 System Configuration....................................................239

12-3 Hardware....................................................................... 241

12-4 Outline of Functions ......................................................242

12-5 LON Communication Specifications.............................. 247

12-6 Monitoring and Control Restrictions..............................249

13. Workflow.......................................................................251

14. Check Sheet for Control and Monitoring Items.........252

Part 9 Power Proportional Distribution

(P.P.D.) ..................................................... 255

1. P.P.D. Design Guide.....................................................256

1-1 System Architecture ...................................................... 256

1-2 Design Preca u tions... .. .................................................. 25 7

1-3 Connection other than VRV........................................... 260

1-4 Conditions and Method to Exclude Calculation for

Specified Indoor Unit.....................................................261

1-5 Explanations of Power Proportional Distribution........... 262

1-6 Notes.............................................................................267

2. intelligent Touch Controller (DCS601C51) with

the Software for P.P.D. Application (DCS002C51)

Including PCMCIA........................................................269

3. intelligent Touch Controller (DCS601C51) with

the Software for P.P.D. Application (DCS002C51)

Including PCMCIA Card and with the Software for

WEB Usage (DCS004A51).................................. ..... .....270

4. intelligent Manager III (DAM602B51) with

P.P.D. Application ........................................................271

5. Interface for Use in BACnet® (DMS502B51) with

P.P.D. Application Using Optional Di Board

(DAM412 B51)...............................................................272

Part 10Adaptor .................................................... 273

1. Adaptor for System......................................................274

1-1 <DCS302A52> Unification Adaptor for

Computeriz ed C o n tr o l ...................................................274

1-2 <KRP2A61 / KRP2A62 / KRP2A53>

Wiring Adaptor for Electrical Appendices (1).................277

1-3 <DTA104A61 / DTA104A62 / DTA104A53>

External Control Adaptor for Outdoor Unit

(Must be Installed on Indoor Units) ...............................287

1-4 <DTA109A51> DIII-NET Expander Adaptor.................. 295

1-5 Dio Unit (DEC102A51)..................................................299

1-6 Di Unit (DEC101A51)...................................... ..............311

1-7 Ai Unit (DAM101A51).................................................... 320

vii

2. Adaptor for Indoor Unit and Other Equipment..........325

2-1 <KRP4A51 / KRP4A52 / KRP4A53 / KRP4A54>

Wiring Adaptor for Electrical Appendices (2)................. 325

2-2 <DTA102A52> Interface Adaptor for SkyAir Series.. ....334

2-3 <DTA112BA51> Interface Adaptor for

DIII-NET (SA) ................................................................ 337

2-4 <DTA107A55> Central Control Adaptor Kit........... ........338

2-5 <DTA103A51> Wiring Adaptor for

Other Air Conditioners................................................... 344

2-6 <KRP928B2S> Interface Adaptor for

DIII-NET (RA)................................................................ 348

2-7 <KRP1B61 / KRP1B56, 59 / KRP1C3>

Adaptor for Wiring ....... ................................................ .. 352

viii 1.1 DAIKIN Building Air-conditioning Control System (D-BACS) Overview

Introduction

1. Introduction

1.1 DAIKIN Building Air-conditioning Control System (D-BACS) Overview

D-BACS is a building air-conditioning control system built upon Daikin's unique high-speed multiplex ed-transmis sion

technology. D-BACS can integrate and centrally control various air-conditioners. With Daikin’s VR V system at the center

various Daikin air-conditioning units, such as total heat exchangers, SkyAir, room ai r-conditioners, package air-conditioners,

and screw chillers can be integrated into the system. D-BACS can be also combined with other third-party buildi ng facilities,

such as ventilation air blowers, pumps, and illuminations.

D-BACS can mainly control operations such as:

1. Starting/Stopping equipment operation

2. Setting temperatures

3. Setting air volume for indoor unit fans in VRV system and total heat exchanger

4. Switching of cooling and heating

5. Displaying abnormalities

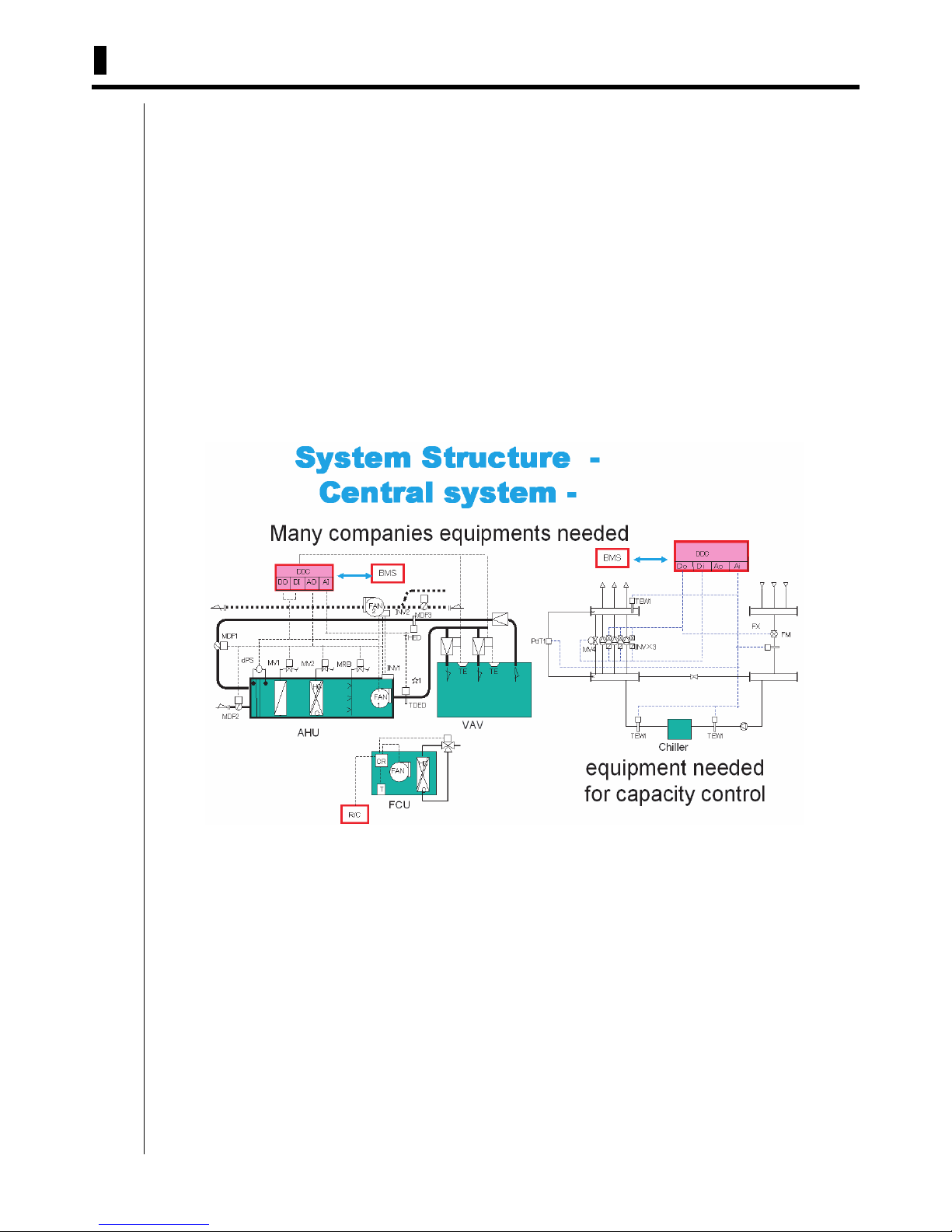

1.2 Advantages of D-BACS over Autom atic Control by Central System

To enable automatic control in a central system, a capacity control and remote control must be designed carefully for

each different third-party air-conditioner, thus requiring a special system engineer (SE).

1.2 Advantages of D-BACS over Automatic Control by Central System ix

Introduction

On the contrary, the D-BACS system built around VRV basically does not require such a design process for the capacity

control, because a detection unit (mainly sensors), an operation unit (mainly valves), and an adjustment unit etc. are

already incorporated in the product at the time of factory shipment.

Therefore, a general air-conditioner facility designer can design an air-conditioner facility around Daikin's VRV system

without special knowledge. In addition, D-BACS can fully satisfy control-related customer requirements.

Capacity Control Detection Units and Operating Units,

and Adjustment Units are incorporated into Indoor Units

and Outdoor Units.

x 1.3 How to Use this Document

Introduction

1.3 How to Use this Document

All the contents of this document are written for general air-conditioner facility designers. An air-conditioner facility

designer must provide the most economical and most efficient air-conditioner facility to end-users, comprehensively

taking all aspects of the air-conditioner into consideration, including air, water, refrigerant, environment, energy

consumption, and facility management. In particular, to allow efficient operation of the air-conditioner facility,

management or operation of the air-conditioning system must be examined thoroughly. All aspects of the management

and operation of the air-conditioning system must be designed based on user requirements.

Daikin's controlling equipment described in this document enables designers to fully satisfy user requirements.

Therefore, this document is an essential for source of information for air-conditioning system design.

This document covers almost all of the controlling equipment available from Daikin. This single document enables the

designers to explain the position or functions of equipment, required end-user operations, and prepare a proposal of the

air-conditioning system for a particular property. The designer of an air-conditioner facility can design a controlling

system for the property, and prepare the documents, such as below, for presentation to the end-user:

1. Equipment List: Types and quantities of equipment required

2. System Diagram: Diagram of connections between equipment items

3. Layout Plan for Controlling Equipment: Layout plan for each floor

4. Initial Settings: Minimum settings required for system operation, especially when there is a mixture of control

equipment types.

For the documentation required after satisfying the end user and obtaining the approval for the proposal, please refer to

installation guide an d operat ion guide f or the eq uipme nt for co nstructio n and te st -operati ons. Also, separa te En gineeri ng

Data are available for the following products. If more detailed information about anything from total planning to testoperation is required, or if you are an engineer specialized in control technology itself, our recommendation is to refer to

the Engineering Data:

1. intelligent Touch Controller ED72-423B

2. intelligent Manager ED72-746

3. BACnet

®

ED72-749

4. LONWORKS

®

ED72-333

1.4 Safety Precautions

Safety Precautions

For design, installation and maintenance, be sure to read the catalogue, this manual and the installation and operation

manual enclosed in the unit, and to follow their instructions.

Be sure to follow the “WARNING” (Failure to follow these instructions may cause a heavy injury or death.) and the

“CAUTIONS” (Failure to follow these instruction may cause the injury or damage on the property.) described in the

installation manual and etc.

<Cautions when designing the system>

1. Select the right products for your applications.

2. Be sure to consider the safety, electric shock and electric leakage when you design the system.

3. Be sure to follow the instructions in this manual for the operating range, characteristics of performance and limitation

for installation and etc.

<Cautions for the installation/operation>

1. Be sure to follow the safety pre-cautions described in the installation and operation manuals.

2. Be sure to install correctly according to the descriptions of the installation manual. Make sure to perform by the

authorized personnel the works such as a electrical work which requires the qualification.

3. Be sure to perform the commissioning of the system properly, and be sure that the power supply is correct and there

is no electric leakage and othe r abnorma lities , such as abnorma l sound , abnorm al smel l, smok e and etc. Also keep a

record of all the test operating data all the time.

4. Be sure to explain the contents of the ope ration m anual when you ha nd over th e job to the custo mer, and also as k the

customer to keep this manual wherever the operator can refer to all the time.

5. Hand over to the customer the warranty card duly filled.

1.5 Open Network Glossary xi

Introduction

<Cautions for maintenance>

1. Follow the instructions in the operation manual.

2. Be sure to perform the maintenance of the system properly, and be sure that the power supply is correct and there is

no electric leakage an d other a bnorma lities , suc h as abnorm al so und, ab normal smel l, sm oke an d etc. Al so rec ord all

the maintenance data and keep this record all the time.

1.5 Open Network Glossary

Term Explanation

Ai Unit Connecting adapter that communicates information from environmental sensors (temperature, pressure,

humidity and voltage/electric current) to measurement unit.

ANSI A

merican National Standa r d s I nstitute

Architecture Refers to the overall design concept of the computer from hardware to software.

It is a systematic layout detailing the connection between the communications network and the devices in an

open network.

ASHRAE A

merican Society of Heating, Refrigeration and Air-conditioning Engineers, Inc.

BACnet B

uilding Automation Control Network

BAS B

uilding Automation System

Users: Building management engineers

Main functions: Facility device status monitoring

Alarm monitoring

Operation management (scheduling)

Automatic cont ro l o f fa c ilities

Bind Refers to one of the activities included in a test run. Specifically, the logical address is appropriated and

allocated.

Binding Refers to the logical connecting between the network variables that the user wishes to communicate.

It is a setting that enables communication of nvo from one device/machine and nvi from another. This is a job

usually handled by an NI.

BMS B

uilding Management System

Refers to a system for building management (management of electricity charges, equipment and the like).

BASs are configured within BMSs.

Users: Building management engineers

Main functions: Facility equipment ledger management

Repair history management

Maintenance schedule management

Billing data

Well known BMS manufacturers in Japan include NEC, YBS, YJ, Fujitsu, Panasonic and Oki.

Broadcast Refers to the simultaneous transmission of a message to all the devices connected in a system.

Messages involved in the communication between devices connected within a network are simultaneously

sent to all the devices within the network.

Centralized remote

controllers

Devices for collectively programming and managing operation of multiple air conditioners, installed in facility

from one or many locations.

Closed Network Refers to a system configured by only one manufacturer that does not allow access by other manufacturers.

DIII-NET is one such example.

Commission The work conducted when the central monitoring panel is connected to a gateway.

Specifically, the data within the gateway is sent to the central monitoring panel for data confirmation.

Refers to installation of settings in the node after the communication content is set via binding.

Communication Traffic

Volume

Refers to the traffic volume determined according to the number of nodes and network variables and the

frequency of communication between these two.

Configuration Property Refers to parameters related to the behavior of the LON nodes. Configuration properties are set for the

respective nodes by an NI when the network is being installed. They are assigned to the nodes' nonvolatile

memory. Unlike network variables, configuration properties represent semi-fixed variable values.

CRC C

entral Remote Controller

A device that allows remote controllers of up to 64 indoor units, groups or zones (total of 128 indoor units).

The single device provides centralized control to each connected indoor units for functions such as individual/

zone/simultaneous operation start/stop, room temperature control, etc. The device offers the same control

as individual remote controllers.

xii 1.5 Open Network Glossary

Introduction

Term Explanation

D-BACS It stands for D

aikin Building Air-conditioning Control System.

Means centralized air-conditioning management and control system based on highly expandable DAIKIN

original network communication

technology, DIII-NET. It is DAIKIN products that can be mainly controlled

through DIII-NET on D-BACS. And with various expander adapters connected , functions and usage of

control system can be expanded for following 3 sections of devices : 1) Equipment (electricity, plumbing,

elevator, ventilation, fire alarm, lighting, car park and crime/disaster prevention panel), 2) meters (electricity,

gas and water supply) and 3) environmental monitoring sensors (temperature, pressure, humidity and

voltage/current).

Di Unit Device by which DAIKIN centralized controllers are able to monitor operation and malfunction of up to 8

individual building facility equipment through DIII-NET, and pass them to centralized controllers. 'I' in Di

stands for INPUT from building facility equipment, and Di unit is only able to receive INPUT signal from

equipment, while Dio unit can receive operation signals from centralized controllers, and dictribute OUTOUT

signals to individual building equipment.

Dio Unit Device that is able to control operation, and monitor operation and malfunction for building equipment. 'I' in

Dio stands for INOUT from building facilities, while 'o' stands for OUTOUT to building facilities. This means

Dio unit can control building facility equipment for both ON and OFF operation. Di unit can only monitor ON

and OFF operation from building facility equipment.

DIII-NET Refers to Daikin Industries original communication network for A/C communications. (closed network)

Echelon The U.S. company that developed the LON.

Ethernet Refers to the name of and standard pertaining to a LAN product developed by Xerox.

Jointly developed by Xerox, DEC and Intel in 1980, Ethernet is the LAN used within BASs.

Free Topology Refers to a branched free-type connection arrangement within a network.

Daikin's Interface for LONWORKS

®

only supports free topology.

Gateway Refers to a device that translates the different communication codes sent between central monitoring panels

and A/C units to enable mutual communication.

It is used when more than one network is connected.

Interface for LONWORKS

®

and the Master Station are two such examples.

General Refers to the term 'general' used when conducting general or batch control. When controlling an entire

system, control is not conducted on each particular A/C unit, but on a generalized basis (all of the A/C units

together).

Group System of up to 16 indoor units controlled simultaneously from single or double remote controllers.

Heartbeat Refers to a function that cyclically communicates values of specific network variables.

Even if a main monitoring node does not request the data (does not confirm the status of the A/C unit), the

machine itself will automatically send the values. It allows the user to conclude that the node is operating

normally while this value is being sent.

HIM H

uman Interface Module

A device that incorporates the concept of the standard BAS protocol supported by the Institute of Electrical

Installation Engineers of Japan (IEIEJ). It enables the setting of parameters for status display, control and

monitoring of building equipment. It refers to a human interface device that performs On/Off operations and

the like.

Icont I

ntelligent Controller

A device that incorporates the concept of the standard BAS protocol supported by the IEIEJ. It is a control

device that is connected to either the building equipment or devices targeted for control via an interface. It

refers to a device that can support functions of independent monitoring, control and the like.

IEIEJ I

nstitute of Electrical Installation Engineers of Japan

1.5 Open Network Glossary xiii

Introduction

Term Explanation

IEIEJ Specifications Refers to the specifications established by the institute that determines them for the Japanese version of the

BACnet. (The international specifications must be certified, however, by ASRAE.)

The IEIEJ Specifications feature functions added onto the BACnet according to demand in the Japanese

market. Related discussions are currently being held with ASHRAE. The points of discussion are as follows:

1. Measurement: The data type used to calculate electric energy, heat and the like. This is absolutely

necessary in energy management.

2. Power demand: The method of determining the contract demand with electric power companies differs

with respect to the country. Accordingly, it is necessary in Japan to interpret the average electric power used

over 30 minutes as the maximum electricity demand.

3. Common data dissemination methods: Due to the common adoption of comprehensive monitoring

systems in Japan, it is necessary to have a system by which large volumes of disaster-related data can be

efficiently transmitted. This point has not been considered in the BACnet.

4. Collective objects: Devices that support several forms of data should be managed on a per device basis.

This will be proposed by the Japanese side (IEIEJ).

intelligent Manager III A centralized control system for VRV that can be connected to up to 1,024 indoor units. It features various

functions such as targeted power control function, fire alarm linkup, database maintenance and error

prediction (Air Conditioning Network Service System). These functions effect iv ely make it BMS speciali zed

for air conditioning. Synonyms: i-Touch Controller, Air Conditioning Network Service System. i-Manager is

served as the specialized air-conditioning control system.

intelligent

Touch Controller

Multi-function system management controller that allows you to operate and monitor up to 128 VRV indoor

units or 64 groups on colour LCD touch screen. It comes with functions that are combined with CRC, Unified

ON/OFF cobtroler and Schedule Timer. And it also includes applied functions such as electric power

distribution, Change Over Setting, Temperature Limit Setteing, Heating Optimization Settinfs. Furthermore,

this devise can be connected with LAN or public telephone line.

Interoperability Refers to the coordinated interlinking between related devices. An example of this is the control of lighting,

A/C, TV and the like with one R/C. If each of the respective companies involved uses a different protocol,

then they have to disclose their protocols and carry out discussions on several occasions to coordinate

efforts, which leads to an increase in costs. However, an open network essentially obviates such a situation

and allows machines manufactured by different companies to operate together without any problems. For

example, if A company's sensor breaks down, then it is possible to buy and install a product manufactured

by B company that will readily operate (interconnectivity). Different devices are, thus, able to communicate

and link up with each other.

iPU i

ntelligent Processing Unit

Units for use of Intelligent Manager III

I/O I

NPUT/OUTPUT

Examples: Di (Digital input), Do (Digital output), Ai (Analog input), Ao (Analog output)

LON L

ocal Operating Network

Refers to an intelligent distributed control network developed by the U.S. company, Echelon.

LONMARK The logo for products manufactured according to the guidelines established by the LONMARK Association.

LONMARK Refers to the LONMARK Interoperability Association.

The LONMARK Association is a nonprofit organization established to promote the use of LONWORKS. It

consists of some 350 companies from all over the world, including 19 from Japan.

The LONMARK Association was formed in order to create standard specifications for connection to LONs

between different vendors (companies).

LONMAKER Refers to the Echelon-developed tool (software) that allows installation commissioning (addressing), variable

binding, variable browsing (monitoring) and the like.

LONTALK Refers to the protocol used in LONs.

LONWORKS The generic term used to refer to the hardware, software, protocol and the like used to design, configure and

manage/service LONs.

Multi-vendor Refers to various machine/device manufacturers. The term 'multi-vendor envi ronm ent' is also often used.

Network Variable The unit in which data are sent/received in communication between nodes. There are two types: network

variable input (nvi) and network variable output (nvo).

Neuron Chip Refers to a LON chip. It is the interface used to access the LON.

xiv 1.5 Open Network Glossary

Introduction

Term Explanation

NI The acronym for N

etwork Integrator.

In the narrow sense, NI is the term used to refer to companies that have signed an NI contract with

ECHELON. In the broad sense, NI is the generic term used to refer to companies and engineers that

configure LONWORKS system networks proposed by ECHELON. The work of an NI is included in that of an

SI (system integrator) or SE (system engineer) in the case of computer systems. In LONWORKS systems,

the work of an NI involves network topology and network.

NI companies in Japan Obayashi Corporation

Takasago Thermal Engineering Co., Ltd.

DAI-DAN Co., Ltd.

NTT DATA Corporation

Hitachi Plant Engineering & Construction Co., Ltd.

Shimizu Corporation

Yukoukeisou Co., Ltd.

Chiyoda Keiso Co., Ltd.

System instrumentation Co., Ltd.

Hibiya Engineering, Ltd.

Shinryo Corporation

Mita Engineering Co., Ltd.

Taikisha Ltd.

Creight Co., Ltd.

Kyowa Exeo Corporation

As of August 2001

Node Refers to the devices connected by cable to the LON.

In other words, it refers to the devices to be controlled by the LON or BACnet.

VRV, valves and sensors are some examples.

nvi N

etwork Variable Input

nvo N

etwork Variable Output

Object Monitoring items and data.

Refers to something that regulates the operation of the object to be controlled.

The equivalent of a LON's SNVT or BACnet's object.

Open Network Refers to a network in which machines with different specifications are able to communicate with each other.

Profile In terms of a LON, the following are examples of items that are determined for each function of the respective

nodes in the LON:

- Network variable type

- Meaning of the network variable (function)

- Range and meaning of the network variable value (function).

Standardizing these ensures interconnectivity.

However, a LON is not configured for VRVs or PAs, so profiles for such A/C systems must be created by

each manufacturer in accordance with the respective network variable regulations. (Due to the fact that the

profiles differ with respect to the manufacturer, profiles such as those for VRVs and PAs are not certified by

LONMARK. However, because they conform with regulations, they can be treated as open networks by

disclosing the network variables.

Polling When the control station does not have the necessary data (the central monitoring panel does not have any

commands), it sends requests at regular intervals to each tributary station asking whether it has any data

transmission requests (data that the tributary station would like to communicate to the control station). The

control station sequentially gives each of the tributary stations request transmission rights, allowing them to

send the respective data.

Property Refers to each of the elements comprising an object.

Protocol The agreed rules and regulations used in communication between different computer programs.

When the protocol differs, two computer programs are unable to comprehend each other (communicate).

P.P.D It stands for P

ower Proportional Distribution

Proportional calculation of electric comsumption of VRV indoor unit

Router Refers to a device used for connections between different networks.

A router forwards data packets between networks. In an internal (in-company) LAN, it is used to connect the

LANs installed on a per floor basis. Meanwhile, a dial-up router is used to connect the Internet with a LAN.

Routers are also used for connections between an Ethernet and LON, for example, in the field of open

protocols used for building control.

R/C R

emote Controller

A Controller that let you individually control the operation of indoor unit for Air-conditioners

1.5 Open Network Glossary xv

Introduction

Term Explanation

SE S

ystem Engineer

System Engineer (SE) is a generic term used in the computer industry to refer to engineers who install

computers and communications devices for end-users. System engineers also generally conf i rm proper

operation of OS (operating software) and AS (application software) after set up. These capabilities are, of

course, necessary in the case of a BAS, but unlike the so-called computer systems, the SE must also

determine necessary specifications in order for vendors to manufacture systems that can effectively realize

functions and achieve desired performance levels detailed on the provided drawings. In addition, appropriate

instruction to and/or coordination between related parties, such as departments that design and create

hardware and software, according to the pertinent process as well as the promotion of smooth system

configurations are also responsibilities of the SE.

Selecting When a control station (central monitoring panel) sends data to a tributary station (DMS II or Interface for

LONWORKS

®

), a message is first sent to the latter to check if the data can be received. The data is then

sent upon receipt of an affirmative response from the tributary station (indicating that the data can be

received).

SI S

ystem Integrator

System Integrator (SI) is a generic term used in the computer industry to refer not only to the work of selecting

hardware and software suited to configured computer systems, setting up networks and altering software to

accompany the systems to be installed but also to the companies/engineers who perform the work. BASs,

including building management systems, represent a type of computer system, so the responsibilities of an

SI are the same. In addition, the responsibilities of the SI also include: a thorough understanding of functions

and features of the targeted electric equipment, A/C system and the like; coordination between hardware,

software and network designs provided by a multiple number of vendors; and smooth configuring of systems

to meet the objectives within a predetermined cost in cooperation with design supervisors and BA orderers.

Single Vendor Refers to a situation involving only one vendor or manufacturer.

SNVT S

tandard Network Variable Types

Refers to the variables used to control A/C units within LONs. These variables have been established by the

The Japan Refrigeration and Air Conditioning Industry Association (JRAIA) and are the standard variables in

Japan.

They are the equivalent of codes for control and monitoring items that enable interoperability in LONs.

(Predefined objects)

TCP-IP T

ransmission Control Protocol/Internet Protocol

TCP-IP is a standard protocol supported in all OS such as UNIX, an OS used in mid- to large-sized

computers, Windows and Mac.

TCP-IP was designed by an organization associated with the U.S. Department of Defense to allow for

communications between computers through another route even if a part or parts of a network were

destroyed.

Topology Refers to the connection arrangement within a network. Equivalent to the wiring method in DIII-NET. Star and

bus are some examples of topologies.

Unicast Refers to the sending of messages only to specified devices.

Specifically, it is the sending of messages between devices connected in a network on a one-to-one basis.

Unit Minimum unit of indoor unit or outdoor unit: One indoor unit shall be assumed to be one unit, and one outdoor

unit with refrigerating cycle shall be assumed to be one unit.

UNVT U

ser-defined Network Variable Types

Refer to the variables used to control A/C units within LONs. They are determined according to specific

projects (buildings, etc.) and, thus, are usually not used.

Vendor The seller or manufacturer

XIF File Refers to a file comprised of data containing network variables for LON nodes. The company manufacturing

the node (in this case, Daikin) creates the file and submits it to the NI upon receipt of an order for a system.

Zone A specified air-conditioning area that requires the same control in a building.

xvi 1.5 Open Network Glossary

Introduction

1

Part 1

Outline of D-BACS System

1. D-BACS (DAIKIN Building Air Conditioning

Control System) System Over View ....................2

1-1 D-BACS System Integrated System Diagram...................2

2. System Over View ................................................. 4

2-1 Targeted Project Scale and Map....................................... 4

2-2 Number of Group for Centralized-Control Devices

Connectable with Indoor-Units..........................................5

2-3 Control Function of the Devices........................................5

3. List of D-BACS System Equipment .....................6

3-1 List of Control System Equipment.....................................6

3-2 Main Specifications and Functions of the Equipment ....... 8

4. List of Control System Equipment and

Functions .............................................................14

5. Functions of Centralized Controllers................15

6. Central Control Equipment Combinations........22

7. List of Applicable Models of DAIKIN .................23

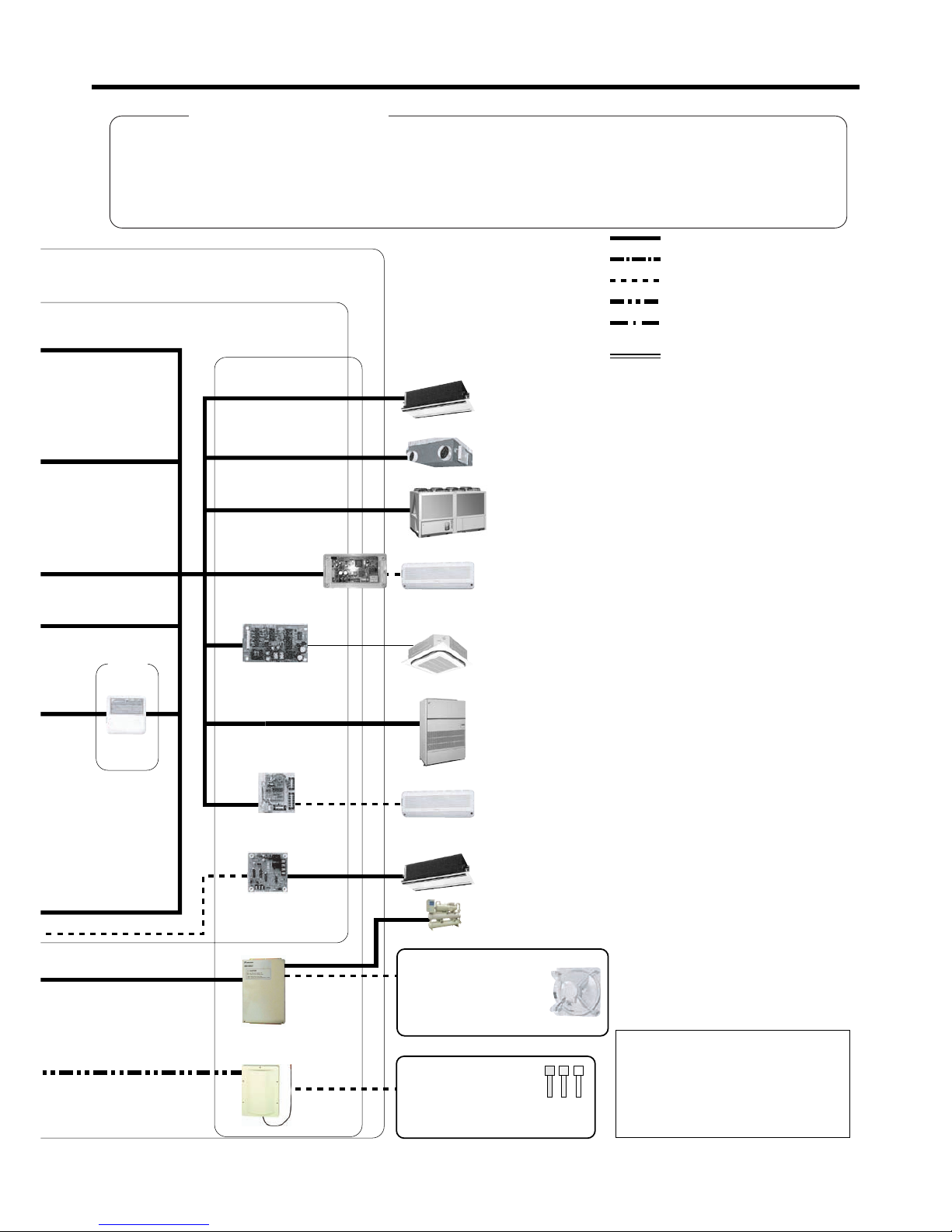

2 1.1 D-BACS System Integrated System Diagram

Outline of D-BACS System

1.

D-BACS (DAIKIN Building Air Conditioni ng Control System) System Over View

1.1 D-BACS System Integrated System Diagram

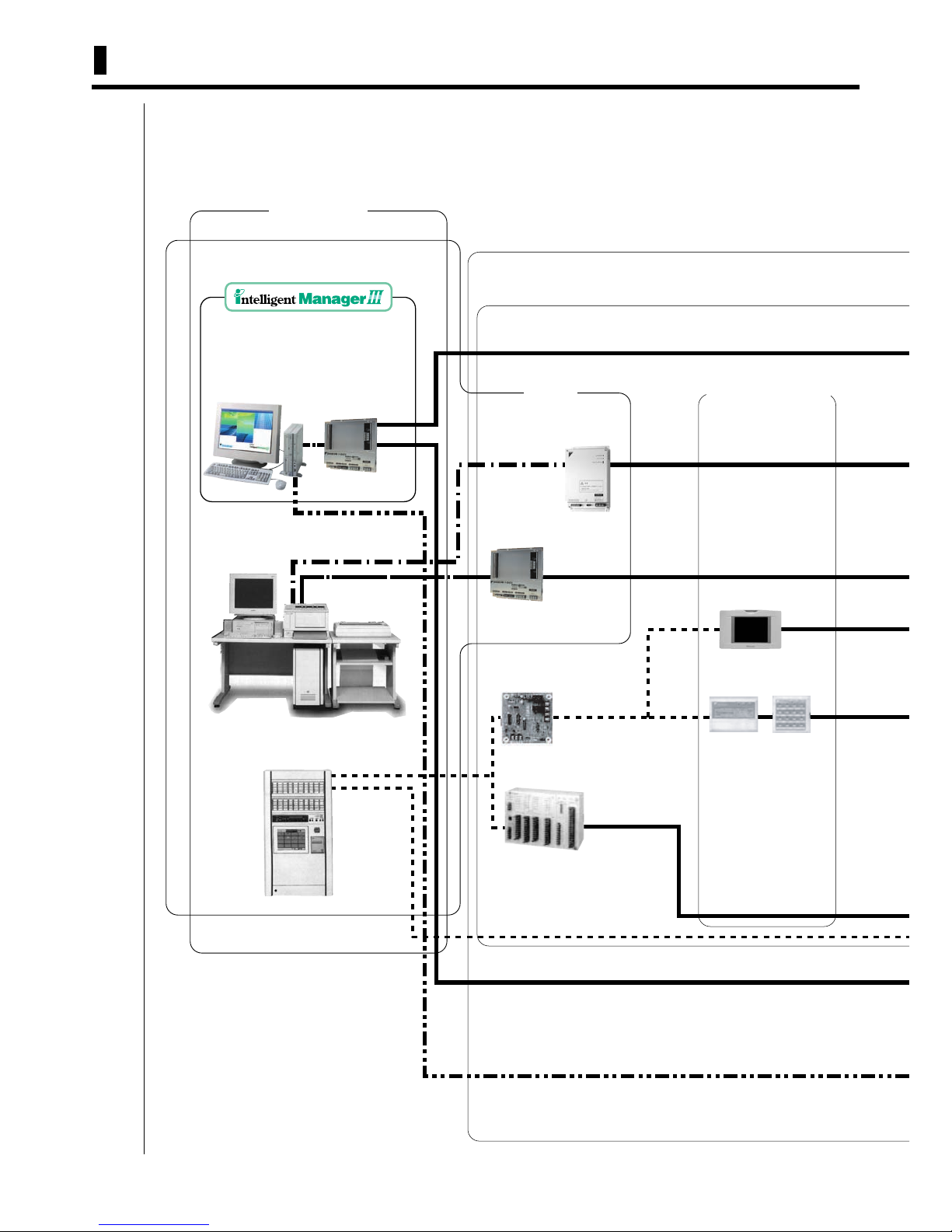

A variety of central control systems with high speed communication DIII-NET method are provided. By combining a

variety of controllers, the system implements not only advanced multiple operational controls for buildings but also

advanced building integrated monitoring systems that control a variety of building equipment.

D-BACS

System

Air Conditioning Control System

BMS / BAS

intelligent

Touch Controller

BAS

(field supplied)

BAS

(Field supplied)

Contact point

signal line

Interface for

Control /

connection

Central Remote

Control Equipment

for Air Conditioning

Unification

Adaptor for

computerized

control

Central

Remote

Controller

Unified ON/OFF

Controller

Parallel Interface

Upper

Upper middle/Middle

Interface for use

in BACnet

Interface for

use in

LONWORKS

Air-conditioner Data Management

System backed by the Building Multi

Communication Line DIII-NET. Airconditioner data can be directly

transferred without interface for

100% data management.

1.1 D-BACS System Integrated System Diagram 3

Outline of D-BACS System

TNP

Interfoce Adoptor for DIII -NET(RA)Interface Adaptor for DIII -NET(RA)

Extended Adaptor

VRV

Total Heat Exchanger

Unit HRV

Can be connected directly.

DAIKIN Air cooled

Water Chillers

SkyAir

(Round flow, wall mounted

type unnecessary)

Air Conditioner for Equipment

* Some models require adaptors

Room Air-conditioner

Room Air-conditioner

VRV

Interface Adaptor for

SkyAir series

Wiring Adaptor for

other air-conditioners

Wiring Adaptor for

Electrical Appendices

Dio Unit

Di Unit

Ai Unit

Building Equipment

CUWD Series DAIKIN

Water cooled (Chiller)

· Electric

equipment

· Elevator

· Plumbing

equipment

· Ventilating

equipment

· Automatic fire

alarm panel

· Illuminating lamps

· Parking facility

· Crime/disaster

prevention panel

Analog Input Equipment

Ai: · Temperature sensor

· Pressure sensor

· Humidity sensor

· Voltage/current monitoring

Note

Control function may vary according

to the model.

The expansion of the control system

requires discussions etc. beforehand.

Please enquire DAIKIN distributer

while you are studying.

DIII-NET line

RS232 communication line

Contact point signal line

Ai transmission line

LONWORKS

®

network

communication line

BACnet

®

/ Ethernet

Schedule

Timer

The features of DIII-NET

*

Integrates a variety of air-conditioning machines extending throughout a building while provides accurate control and monitoring.

* Reduces the wiring in a building by providing the nonpolar double wire system. The wiring work is easy to accomplish with

few faulty wiring.

* Later installation is also easy to accomplish. In total, up to two kilometers can be extended for wiring.

* A variety of controllers can be combined which also allows construction of a hierarchical risk diversification system.

* Our total heat exchangers and central air-conditioning machines can also be controlled totally.

Lower

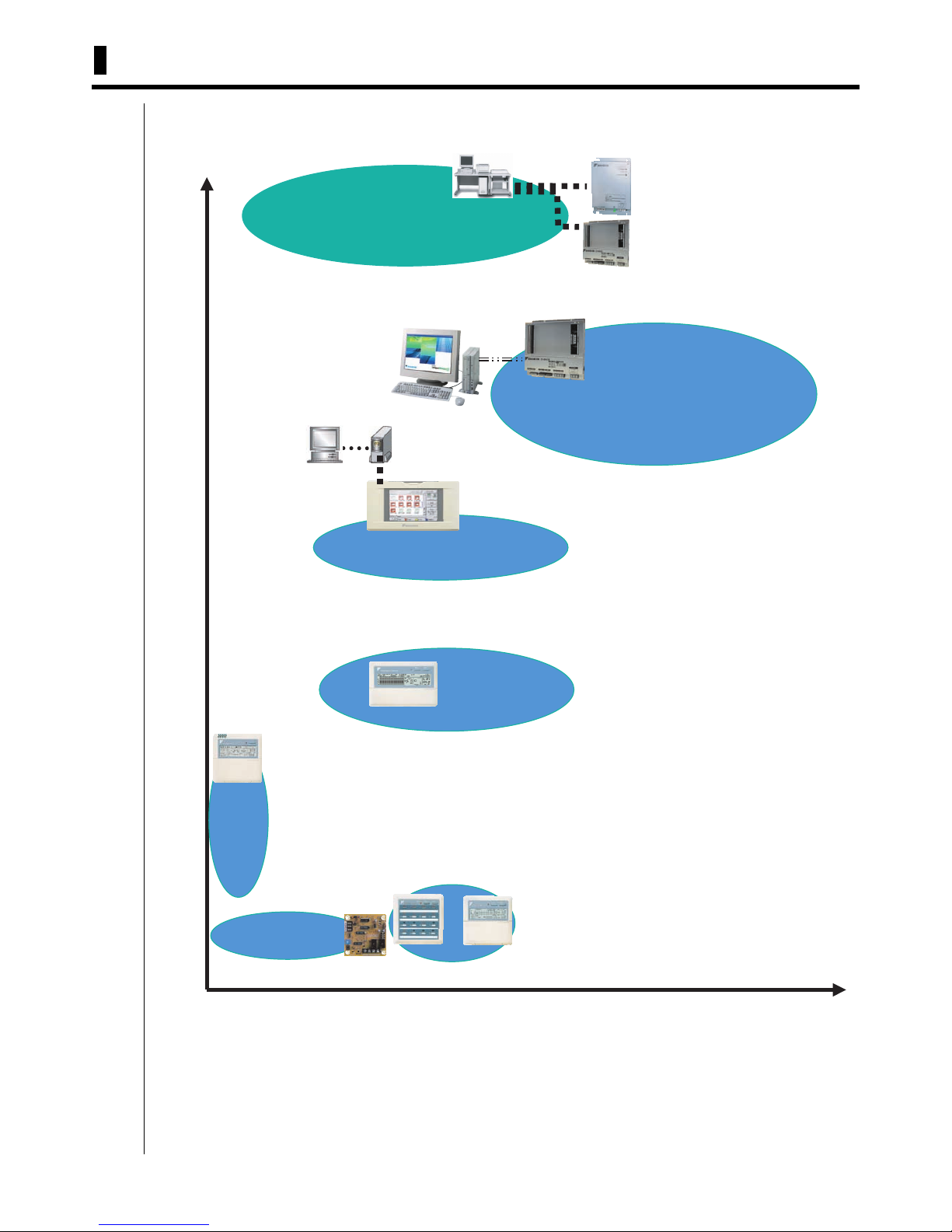

4 2.1 Targeted Project Scale and Map

Outline of D-BACS System

2. System Over View

2.1 Targeted Project Scale and Map

1

560

R/C

Adaptors

Central remote

controller

intelligent Touch Controller

Unified ON/OFF

Controller

Schedule

Timer

Project scale (m2)

•A/C Management system

•Report,

•

Management of equipment

including other facilities

intelligent Manager

Ethernet

BMS

(Field Supply)

Functionality

• Report to BMS

•

A/C control from BMS

•

Management of equipment

including other facilities

LONWORKS

BACNET GATEWAY

•

Sophisticated A/C control

• Data collecting

1

5360

1152

0

7

6803840

2

880

192

0960960600

24

0

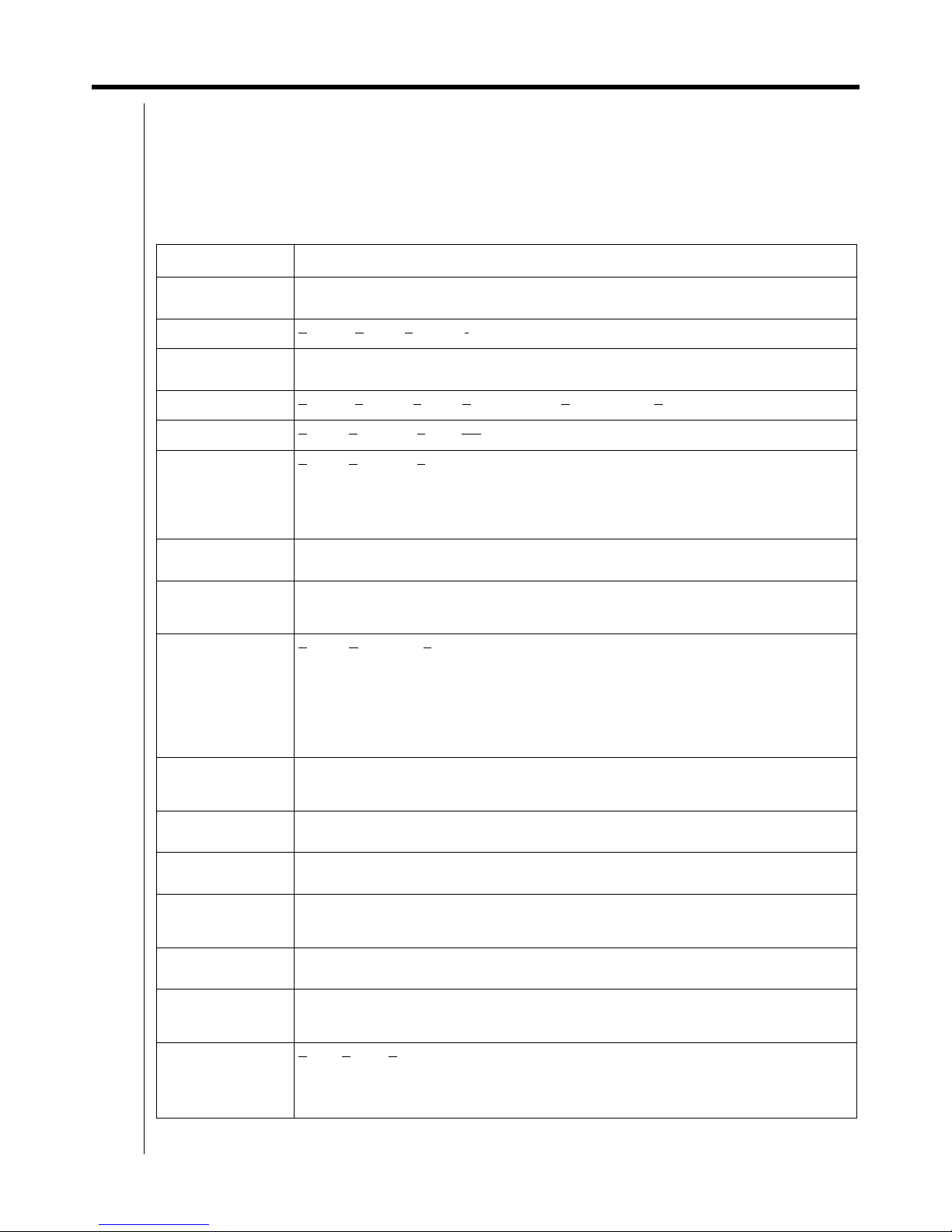

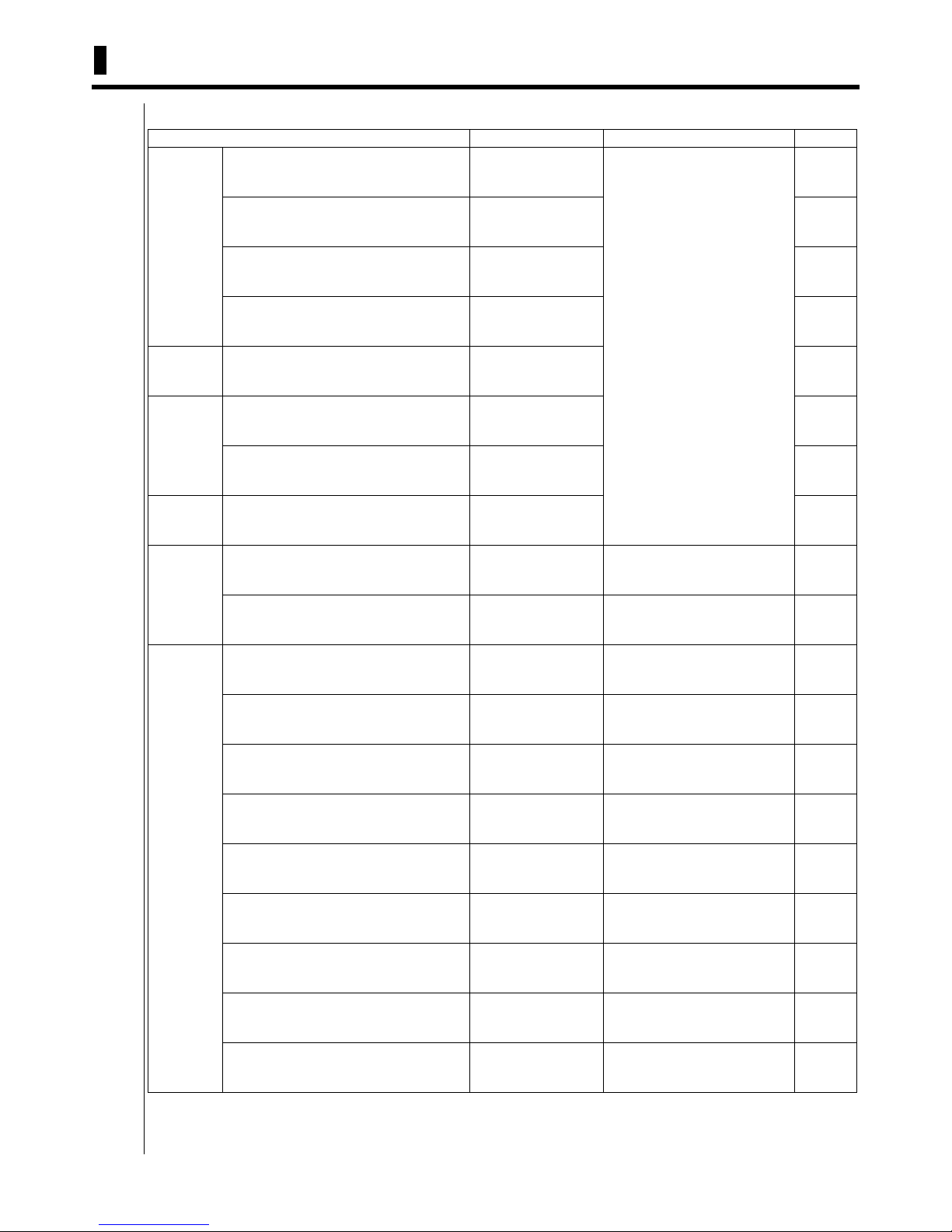

2.2 Number of Group for Centralized-Control Devices Connectable with Indoor-Units 5

Outline of D-BACS System

2.2 Number of Group for Centralized-Control Devices Connectable with Indoor-Units

2.3 Control Function of the Devices

Ex:On/Off, temperature, air flow and mode setting, operation and an malfunction display

DCS302CA61

[Central]

ModelName

[Dio]

[Schedule]

[ON/OFF]

[intelligent Touch Controller]

[intelligent Manager]

[Unification]

[BAC-net]

[Adaptor 2]

[Adaptor 1]

[KRP2A----]

[KRP4A----]

DCS302A52

DMS504B51

DAM502B51

(64Gp x

4 ports)

DAM602B51

+DCS601A52

DAM602B52

DCS601C51

DEC102A51

DST301BA61

DCS301BA61

Contact signal

Contact signal

Contact signal

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

Communication

Lon Talk

BACnet

1

1

1

1

1

4

3

2

1

1

1

1

1

1

1

2

1

102476851225619212864401641

Qt

15 60 240 600

Gp.

m

2

1920 2880 3840 7680 11520 15360960

Batch operation

Possible PC Control

Individual operation

Reference floor space (m

2

)

based on the assumption as

1Gp. 1Hp equal to

15m

2

(+DCS302CA61, or DCS601C51)

[LONWORKS]

[Wired R/C]

[Adaptor 2]

[Adaptor 1]

[Unification]

[LONWORKS]

[BAC-net]

[intelligent Manager]

[intelligent Touch Controller]

[Dio]

[Schedule]

[ON/OFF]

[Central]

Name

For VRV I/UBRC1C62

[KRP2A----]

+DCS601A52

[KRP4A----]

DCS302A52

DMS504B51

DAM502B51

DAM602B51

(64Gp x

4 ports)

DAM602B52

DCS601C51

DEC102A51

DST301BA61

DCS301BA61

DCS302CA61

CommunicationModel

C/H Display

Error

For 1Gp. DisplayH/LFor 1Gp.

OperationModeFanTemperatureON/OFF

Signal for all

Code for Each Gp.

Code for Each Gp.

Signal for allSimultaneous control

Signal for 1Gp.For 1Gp.

Simultaneous

control

Code for Each Gp. For each Gp.

Code for Each Gp. For each Gp.

For each Gp.

For each Gp.

Code for Each Gp.For each Gp.

Code for Each Gp.For each Gp.

Code for Each Gp.For each Gp.

Code for Each Gp.For each Gp.

Code for Each Gp.For each Gp.

Signal for each Gp.For each Gp.

one lamp for all

Lamp for each Gp.For each Gp.

For each Gp.

Contact signal

Contact signal

Contact signal

Lon Talk

BACnet

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

DIII-NET

Simultaneous

control

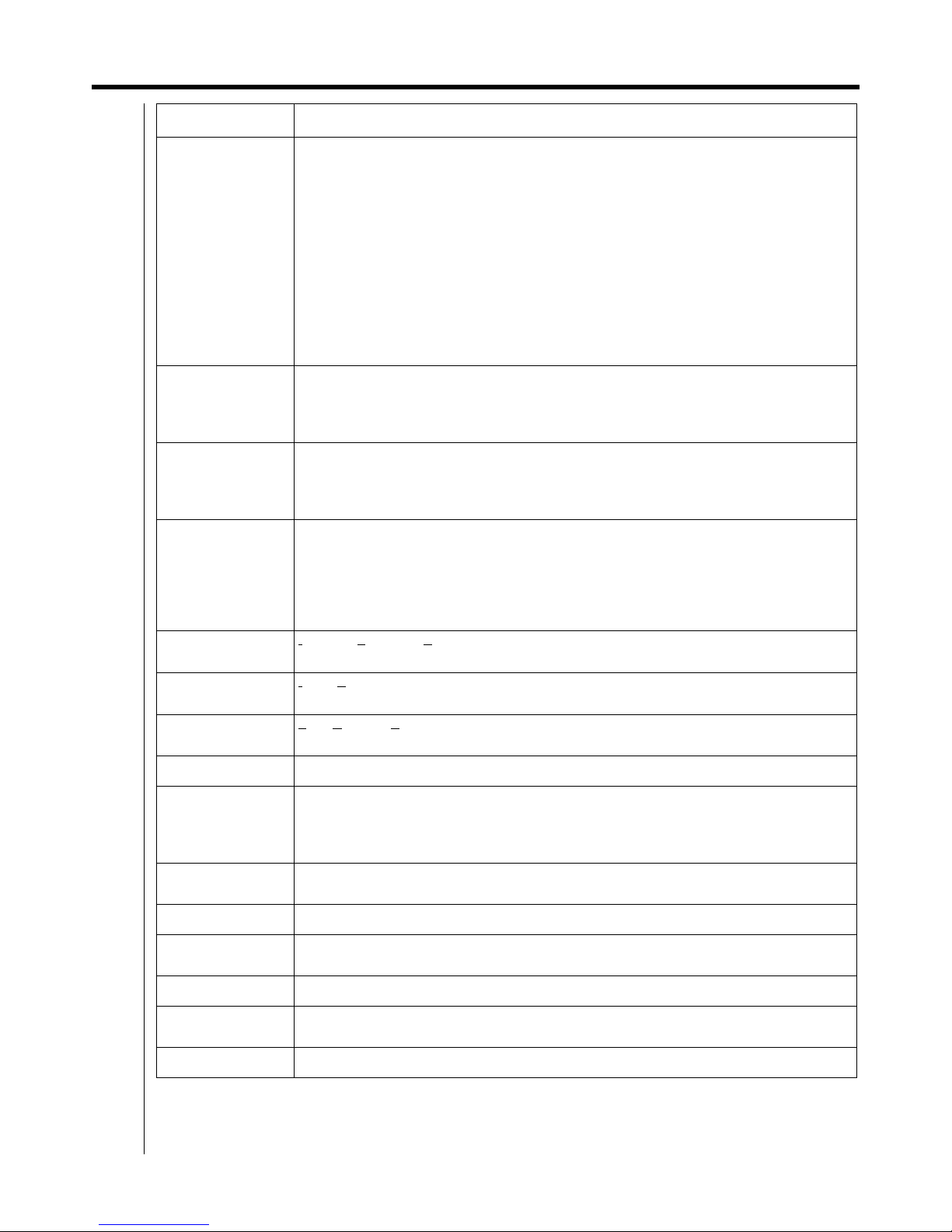

6 3.1 List of Control System Equipment

Outline of D-BACS System

3. List of D-BACS System Equipment

3.1 List of Control System Equipment

Equipment using DIII-NET Unit Name Applied Model Page

Upper

intelligent Manager III DAM602B51/52

VRV series, SkyAir series,

Room Air-conditioner, HRV unit,

Other Air-conditioner

BACnet Interface DAM502B51

DMS-IF DMS504B51

Parallel Interface DPF201A51/52/53

Upper

middle

intelligent Touch Controller DCS601C51

Middle

Central remote Controller DCS302CA61

Unified ON/OFF controller DCS301BA61

Lower Schedule Timer DST301BA61

DIII-NET

expansion

adaptor

DIII-NET Plus Adaptor DCS601A52 intelligent Touch Controller

DIII-NET Expander Adaptor DTA109A51 VRV indoor units 295

Interface for

DIII-NET

Unification Adaptor for Computerized Control DCS302A52

intelligent Touch Controller &

Central remote Controller

274

Di/Dio Unit

DEC101A51/

DEC102A51

other facilities than air conditioners 299/ 311

Interface Adaptor for SkyAir Series DTA102A52 DAIKIN SkyAir series 334

Interface Adaptor for DIII-NET(SA) DTA112BA51 DAIKIN SkyAir series 337

Interface Adaptor for DIII-NET(RA) KRP928B2S DAIKIN Room Air-conditioner 348

Wiring Adaptor for Other Air-conditioners DTA103A51 DAIKIN Other Air-conditioner 344

Central control Adaptor Kit DTA107A55

DAIKIN FD series &

UAT(Y) series

338

External Control Adaptor for Outdoor Unit * DTA104A61/62/53 VRV outdoor units 287

Wiring Adaptor for Electrical Appendices (1) * KRP2A61/62/53 VRV indoor units 277

3.1 List of Control System Equipment 7

Outline of D-BACS System

*Note: Wiring Adaptor with "*" mark cannot be used with Upper, Upper middle, Middle, Lower grade equipment.

Equipment not using DIII-NET Unit Name Applied Model Page

Adaptor

Wiring Adaptor for Electrical Appendices (2) * KRP4A51/52/53/54 VRV indoor units 325

Adaptor for Wiring

KRP1B56/59/61,

KRP1C3

VRV indoor units 352

Equipment using DIII-NET Unit Name Applied Model Page

Ai Unit DAM101A51 intelligent Manager III 320

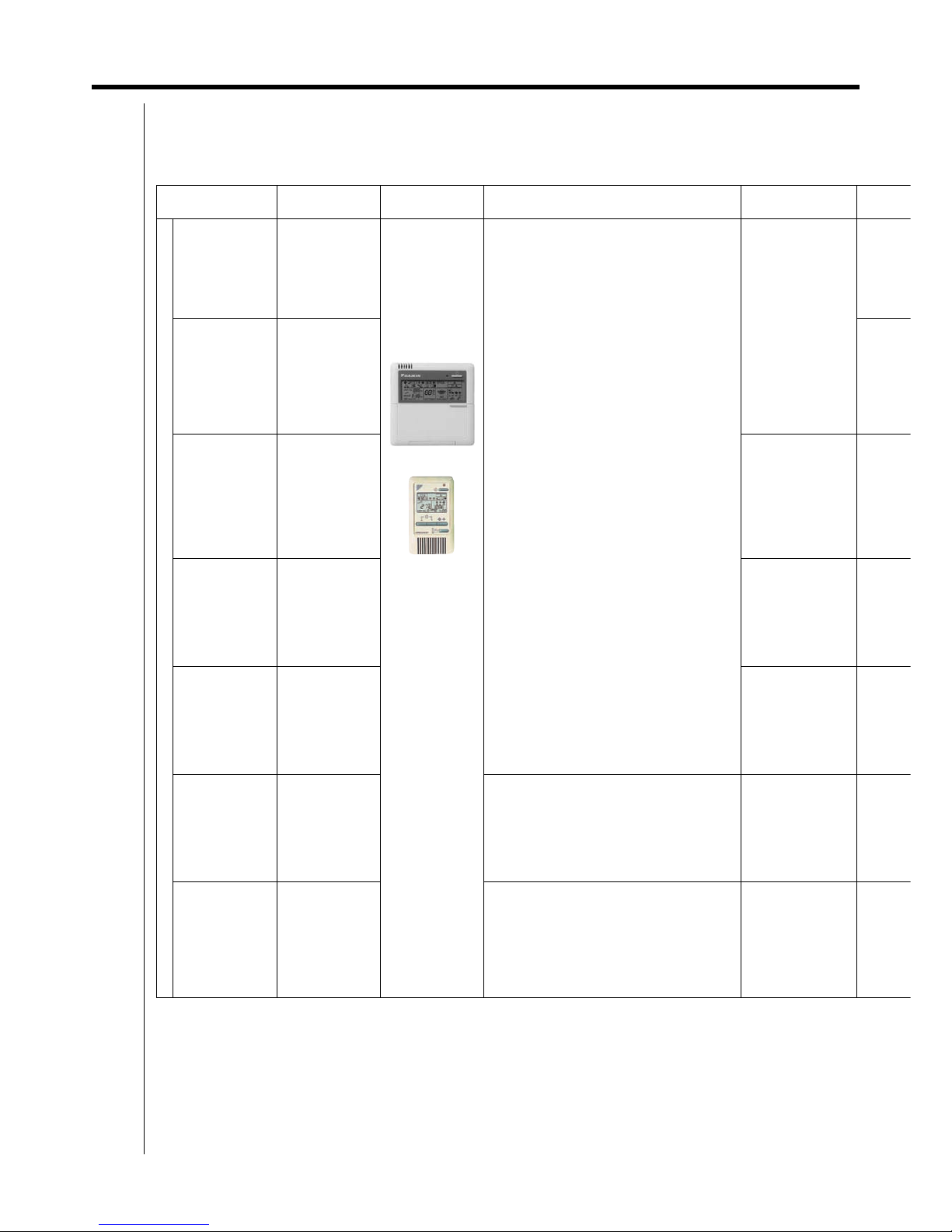

8 3.2 Main Specifications and Functions of the Equipment

Outline of D-BACS System

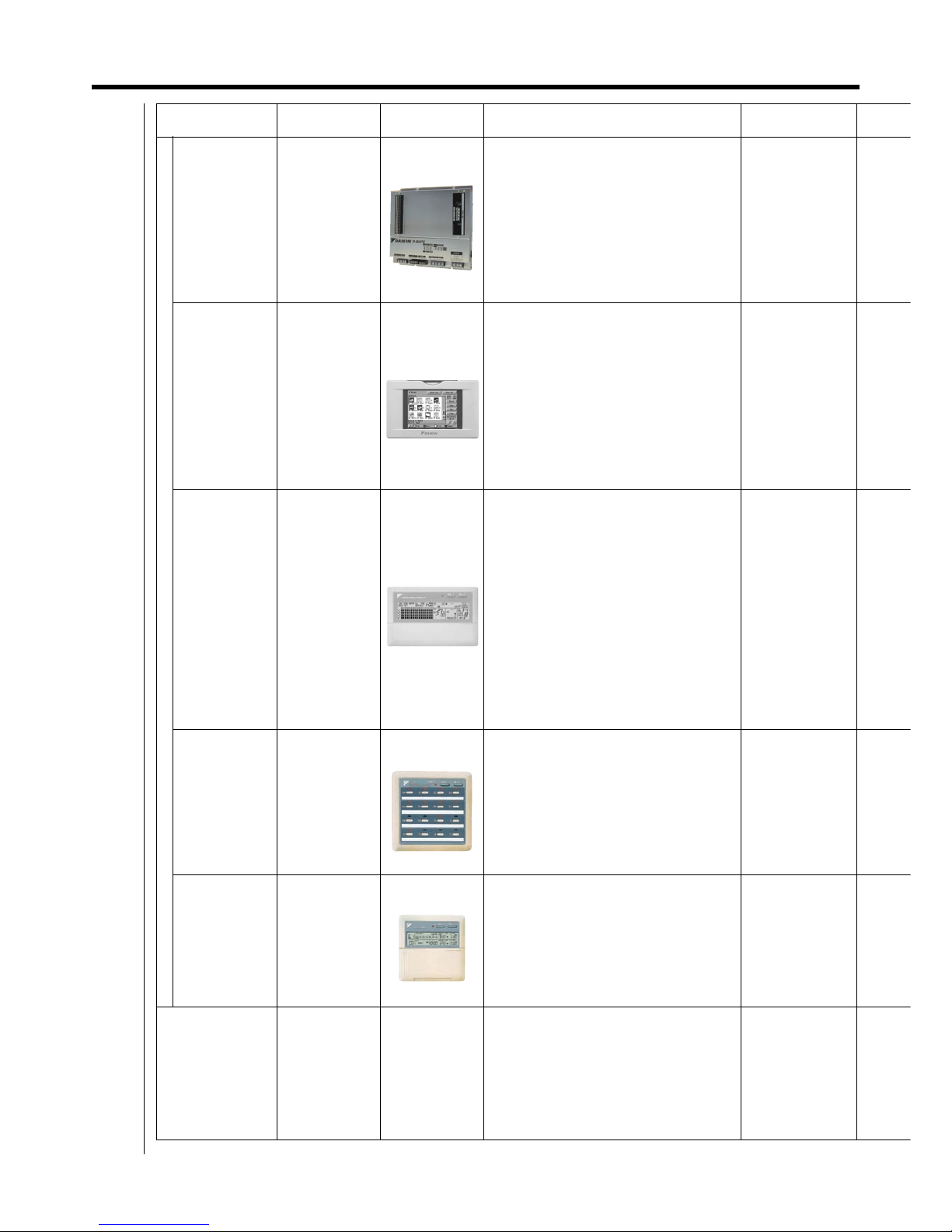

3.2 Main Specifications and Functions of the Equipment

For more effective localized envi ron me ntal control Daikin offers various cont rol sy stems such as single or double remo te

control or centralized control. This enables the construction of a variety of operational control systems which can be

adapted for various uses from remote control to building automation.

∗1 In case of group control, the remote controller used as master control must be selected with auto-swing function

(BRC1A61). When the group has cassette (FXC (Q)), FXF (Q)) or ceiling suspended (FXH (Q)) or cassette corner

(FXK (Q)) or wall mounted (FXA (Q)) models.

∗2 In case of using BRC2A51 (Simplified Remote Controller) to Heat Recovery Series, be sure not to use this

independently. Use with other remote controllers (BRC1A51 · 52, BRC1C62 or KRC19-26A or DCS302A51).

Control Method Objective / Use

Unit Name and

Model

Function

Standard Number of

Units

Control by Remote Controller

Local operation of

remote controller

Example of typical

use

BRC1C62

*2 BRC2C51

In the right

figure, a wired

remote

controller is

used for the

system

configuration.

However, the

same control is

available if the

controller is

replaced by a

wireless.

When using

two remote

controllers, it is

not possible to

set both of

them for

wireless

remote

controllers. Be

sure to set at

least one of

them for a

wired remote

controller.

Operational functions

Start/Stop (ON/OFF)

Operation Mode Selection

Temperature setting

Timer setting (Settings in units of 1 hour up to

a maximum of 72 hours)

Air flow settin g

Air flow direction adjustment (Swing flap)

Indication function

Operating display

Program dry function display

Defrost/Hot start display

Filter sign

Temperature setting display

Timer display

Air flow display

Abnormal operation display

∗

In case of group control all the indoor units in

the system are set to the same value and

each unit is controlled individually by its

internal thermostat. (Not by the thermostat

equipped in remote controller) In commond

case of double remote control the last

command priority. (Selection between main

and sub controller is essential)

Note)

Some functions cannot be set depending on the

shape of indoor unit.

1 remote controller

controls 1 indoor unit

Remote operation

of remote

controller

For control from

distant place

2 remote control

For control from 2

places (distant or

local)

2 remote controllers

control 1 indoor unit

Group control

∗

1

For the control of

plural indoor units

on a floor at the

same time

1 remote controller

controls up to 16

indoor units

simultaneously

∗

1

Group control by 2

remote controllers

For above control

from distant place.

2 remote controllers

control up to 16

indoor units from 2

different places

simultaneously

Forced OFF

command from

outside

Forced OFF for

forgetting to turn

equipment off, or

in times of an

emergency.

Forcibly stops indoor unit operation by

command from outside.

During remote controller group control, input a

command from outside to any one of the

indoor units.

Same as the number

of units controlled by

remote controller

Combining control

by remote

controller

Operation of other

equipment

combined with the

operation of

indoor unit

Operates HRV in accordance with indoor unit

operation.

Same as the number

of units controlled by

remote controller

3.2 Main Specifications and Functions of the Equipment 9

Outline of D-BACS System

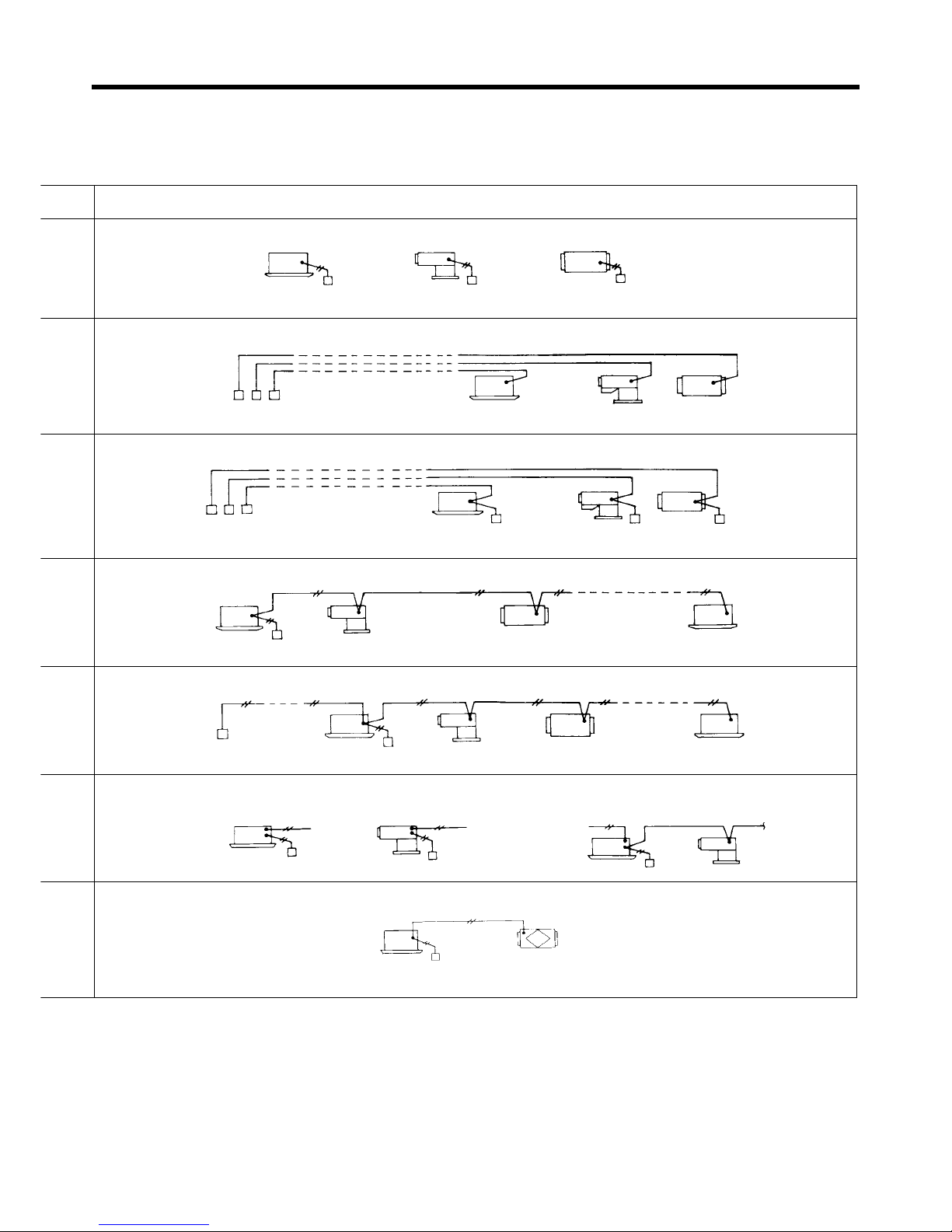

Outline of System

For local operation of remote controller

For HRV

Remote controller Remote controller

Remote controller

Remote

controller

Remote

controller

Remote

controller

Available up to 500m respectively

Remote

controller

Remote

controller

Remote

controller

Remote

controller

Remote controller Remote controller

Available up to 500m respectively

Remote

controller

Communication wire is

available up to 500m

Remote controller

Remote controller

Communication wire is

available for 500m in total

Remote controller Remote controller

Remote

control

(V0097)

Forced /

OFF input

Forced /

OFF input

Forced

ON / OFF

input

zFor group control

Remote controller

HRV

10 3.2 Main Specifications and Functions of the Equipment

Outline of D-BACS System

Control Method Objective / Use

Unit Name and

Model

Function

Standard Number of

Units

Central Control

intelligent

Manager III

For providing total

management of a

Daikin VRV

system as well as

equipment from

other

manufacturers,

such as air

conditioning,

lighting, and water

supply systems.

DAM602B51

Simple Operation and Management

Data Management

Total Building Management

Automated Operation Management

Web Access Function

Open Network Support

Air Conditioning Network Service System

Up to 1024 groups

(Max. 1024 indoor

units with P.P.D.)

intelligent Touch

Controller

For control all

indoor units just

like remote

controller

Provides three

remote control

fanctions, central

remote controller,

Unified ON/OFF

controller and

schedule timer.

DCS601C51

Adds various functions other than the

functions of existing central remote controller.

Scheduled operation and function to distribute

electricity proportionally.

Simple handling through a large sized liquid

crystal display.

Adopts a touch-panel

Twin centralized control function

Controls up to 64

groups (Max. 128

indoor units) with one

intelligent Touch

Controller.

Central remote

controller

For control all

indoor units just

like remote

controller

DCS302CA61

Double central control function

LCD remote control function is possible by

each indoor unit zone

Individual/unified operation

Up to 8 schedule patterns may be set with the

combined use of schedule timer.

Temperature setting by each zone

Individual room control operation at the time

of central control

Command to prohibit remote control

operation.

Sequential start function

Individual setting function of air blow direction

and volume

One central remote

controller may control

a maximum of 64

groups of indoor units

(However, up to 128

units)

Unified ON/OFF

controller

For ON/OFF

operate all indoor

units just like

remote controller

DCS301BA61

Double central control function

Indoor unit ON/OFF control

Individual/unified operation

Remote controller operation rejected

command (Central remote controller given

priority when used in combination with central

remote controller.)

Sequential start function

Controls up to 16

groups of indoor units

with one unified ON/

OFF controller.

Max. 128 units

Schedule timer

For carrying out

weekly schedule

operation by

1-minute units

DST301BA61

ON/OFF time can be set by units of day, hour

and minute; ON/OFF pattern can be set by

time zone of twice per day in accordance with

application.

Simultaneously

controls 64 groups

with one schedule

timer. Max. 128 units

Equipment control

system

Di/Dio Unit

Ai Unit

The use of this unit makes it possible to be

connected to facility equipment (for example,

pumps, illumination appliances, fans, etc.).

3.2 Main Specifications and Functions of the Equipment 11

Outline of D-BACS System

Outline of System

When using 1 unit of IPU

When using 1 unit of intelligent touch controller

When using one central remote controller

When using 1 unified ON/OFF controller

When using one unit of schedule timer

Note: For the schedule timer, take the electric power supply from the indoor unit.

intelligent

Manager III

Remote

controller

Remote

controller

Up to 1024 groups for group control

Up to 2048 units

for individual control

Power source

Single phase 100 - 240V

Maximum length of communication

wires for central control: 1 km

intelligent

touch controller

Remote

controller

Remote

controller

Up to 64 groups for group control

(however, up to 128 units can be controlled)

Up to 64 units

for individual control

Power source

Single phase 100 - 240V

Maximum length of communication

wires for central control: 1 km

Central

remote controller

Remote

controller

Remote

controller

Up to 64 groups for group control

(however, up to 128 units can be controlled)

Up to 64 units

for individual control

Power source

Single phase 100 - 240V

Maximum length of communication

wires for central control: 1 km

Unified

ON/OFF controller

Remote

controller

Remote

controller

Up to 16 groups for group control

(however, up to 128 units can be controlled)

Up to 16 units

for individual control

Power source

Single phase 100 - 240V

Maximum length of communication

wires for central control: 1 km

Schedule time

Electric power supply

for schedule timer

Maximum length of communication

wires for central control: 1 km

Up to 128 indoor units

can be controlled

12 3.2 Main Specifications and Functions of the Equipment

Outline of D-BACS System

Note) Central control units such as central remote controller cannot be used at the same time.

Control Method Objective / Use

Unit Name and

Model

Function

Standard Number of

Controllers

Building Control

System

Building control

computer,

air-conditioning

control computer

and control

system for

air-conditioning

are carried out by

communication

and contact

signal.

Interface for

use in BACnet®

DMS502B51

Optional DIII

board

DAM411A1

Optional Di

Board

DAM412A1

Parallel

interface

DPF201A51, 52, 53

Interface for

use in

LONWORKS

®

DMS504B51

Interface for use in BACnet

®

Interface unit to allow communications

between VRV and BMS.

Parallel interface

Carries out operation and monitoring function

of each indoor unit by contact and analog

signal.

Interface for use in LONWORKS

®

The LON Gateway functions as the interface for

a building monitoring system and cannot be winstalled on the DIII-NET along with following

equipment / devices that have similar functions.

Interface for use in

BACnet

®

:

Up to 256 indoor

units (256groups)

When the option DIII

board is used

Parallel Interface,

Interface for use in

LONWORKS

®

Up to 64 indoor units

(64 groups)

Power Proportional

Distribation (P.P.D)

Performs

monitoring of

accumulated

charges and

operation for each

indoor unit.

Intelligent Touch

Controller

i-Manager III

intelligent

Touch

Controller

(Proportional

division

software is

used)

Air conditioning charges are accumulated for

each indoor unit.

Registration can be made for each tenant.

Operation/stop/abnormality monitoring for an

indoor unit is available for each tenant.

A charge

management unit

can cover 64 indoor

units.

Adaptor

Wiring adaptor for

electrical

appendices (2)

For control by

operation

command from

BAS

With remote

temperature

setting

KRP4A51

KRP4A52

KRP4A53

KRP4A54

Built into indoor

unit

Normally open or momentary open type

contactor

12~24 VDC or no-voltage

Various control methods available by mode

select switch

Voltage, no-voltage selector switch

Alarm and operation display signal (novoltage)

Selector switch of zone/individual of alarm

display

Remote temperature setting (resistance input

of 0~135Ω)

Selector switch for remote controller

temperature setting enable/inhibit

∗

For group unified control, the setting becomes

the same for all connected indoor units, and

each indoor unit is controlled individually by

built-in thermostat.

∗

In case of using wiring adaptor for Electrical

Appendices (2), the control by 2 remote

controller is not available.

Function is the same as above.

Used only when 3 groups or more of HRV are

interlocked and operated.

∗

In case of integrated zone control, settings for

all indoor units connected to respective

groups become the same, and each indoor

unit is controlled by built-in thermostats.

1 PC board controls

1 indoor unit.

1 PC board

simultaneously

controls 1 group of

indoor units (max. 16

units).

Wiring adaptor for

electrical

appendices (1)

With remote

temperature

setting

KRP2A53

KRP2A61

KRP2A62

Built into indoor

unit

1 adaptor could

control a maximum

of 64 groups with 1

group consisting of a

maximum of 16 units

(up to 126 units in

total).

Adaptor for wiring

When controlling

operation with

optional

accessories added

inside indoor units,

the status is

displayed outside.

Built into indoor unit

KRP1B56, 57, 59, 61

KRP1C3

Necessary when electric heater and

humidifier are incorporated optionally

Operation indicating signal is made by taking

out compressor operation signal.

1 adaptor controls

electric heaters and

humidifiers.

Adaptor for

connection with

optional

controllers for

centralized control

For controlling all

indoor units from

one place

Unification

adaptor for

computerized

control

DCS302A52

Interface

adaptor for

SkyAir series

DTA102A52

Wiring adaptor

for other air

conditioners

DTA103A51

Unification adaptor for computerized control

allows you to simultaneously turn indoor units

connected to the central remote controller on

or off or display at the central monitor panel,

etc.

Interface adaptor for SkyAir series, wiring

adaptor for other air conditioners and wiring

adaptor for ‘H’ indoor unit are for connection of

optional controllers for centralized control.

Simultaneously controls

by one unification adaptor

for computerized control,

all indoor units connected

to a central remote

controller.

Controls one indoor unit by

one interface adaptor for

SkyAir series, wiring

adaptor for other air

conditioners, and wiring

adaptor for ‘G(J)’ indoor

unit.

3.2 Main Specifications and Functions of the Equipment 13

Outline of D-BACS System

Outline of System

Individual Control (Controls Indoor Units Individually.)

KRP1B56, 57, 59, 61, KRP1C3,

KRP2A61,62 and KRP4A51,52,53

can be built-in together into the

indoor units

Combined use of wiring adaptor for

Electrical Appendices (1) and (2) is not

available.

Group Unified Control (Controls group controlled indoor units all at once and simultaneously.)

Zone Unified Control (Unified, simultaneous control of up to 64 groups of group controlled indoor units