Daihatsu Type A4Q, A4R Automatic Transmission (Electrically-Controlled) Service Manual (NO. 9738)

Page 1

SERVICE MANUAL

This service manual describes the disassembling, checks and assembling procedures

for the unit itself of the FR, four-speed, electronically-controlled automatic transmission.

As for the removal/installation procedures from and to the vehicle and the check procedure for the control system, refer to the Chassis Volume.

Furthermore, in respect to the illustrations, they are for Type A4R-D1, unless there are

problems in describing their operations.

A4Q-D1: J-Type AT

A4R-D1: S-Type AT

TYPE

Automatic Transmission

(Electrically-Controlled)

A4Q, A4R

FOREWORD

Series

Published in May, 2000

NO. 9738

©2000

All rights reserved. This material may not be reproduced or copied, in whole or in part, without the written permission of Daihatsu Motor Co., ltd.

Page 2

SECTION INDEX

TYPE A4Q,A4R

Series

Automatic Transmission

(Elecrically-Controlled)

SECTION NAME

GENERAL INFORMATION

AUTOMATIC TRANSMISSION

SECTION

GI

AT

NO. 9170-AE

Page 3

GENERAL INFORMATION

TO INDEX

IMPORTANT SAFETY NOTICE ...................... GI–2

WARNINGS, CAUTIONS AND NOTES ...... GI–2

HOW TO USE THIS MANUAL ........................ GI–4

CONTENTS OF EXPLANATION ................ GI–4

ABBREVIATION CODES ............................... GI–6

GENERAL SERVICE INSTRUCTION ............ GI–7

JGI00001-00000

GI

Page 4

GI–2

IMPORTANT SAFETY NOTICE

The vehicle is a machine comprising a great number of parts. Basically speaking, the vehicle is potentially hazard. However, one can handle it safely if he has the required knowledge.

Correct service methods and repair procedures are very vital for assuring not only the safety and reliability of a vehicle, but also the safety of service personnel concerned.

The methods and procedures contained in this manual describe in a general way the techniques

which the manufacturer has recommended. Thus, they will contribute to ensuring the reliability of

the products. The contents of the servicing operations come in a wide variety of ways. Moreover,

techniques, tools and parts necessary for each operation are different widely from each other.

This manual does not cover all details of techniques, procedures, parts, tools and handling instructions which are necessary for these operations, for such coverage is impossible. Hence, any one

who obtains this manual is expected first to make his responsible selection as to techniques, tools

and parts which are necessary for servicing the vehicle concerned properly. Furthermore, he must

assume responsibility for his actions in connection with his own safety.

Therefore, one should not perform any service if he is not capable of making responsible selection

and/or if he can not understand the contents herein described, for this manual has been prepared

for experienced service personnel.

WARNINGS, CAUTIONS AND NOTES

All these symbols have their specific purposes, respectively.

WARNING:

• This symbol means that there is the possibility of personal injury of the operator himself or the

nearby workers if the operator fails to follow the operating procedure prescribed in this manual.

CAUTION:

• This symbol means that there is the possibility of damage to the component being repaired if

the operator fails to follow the operating procedure prescribed in this manual.

NOTE:

• To accomplish the operation in an efficient manner, additional instructions concerning the operation are given in this section.

The following list describes general WARNINGS:

• Always wear safety glasses for eye protection.

• Use safety stands whenever a procedure requires you to be under the vehicle.

• Be sure that the ignition switch is always in the OFF position, unless otherwise required by

the procedure.

• Set the parking brake when working on the vehicle.

• Operate the engine only in a well-ventilated area to avoid the danger of carbon monoxide.

• Keep yourself and your clothing away from moving parts, when the engine is running, espe-

cially from the fan and belts.

• To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust

manifold, tail pipe, catalytic converter and muffler.

• Do not smoke while working on a vehicle.

• To avoid injury, always remove rings, watches, loose hanging jewelry, and loose clothing be-

fore beginning to work on a vehicle.

• Keep hands and other objects clear of the radiator fan blades! The electric cooling fan is

mounted on the radiator and can start to operate at anytime by a rise in coolant temperature

Page 5

or turning ON of the air conditioner switch in the case of vehicles equipped with an air conditioner. The electric cooling fan is also mounted on the condenser for air conditioner and starts

to operate anytime when the air conditioner switch is turned “ON”. For this reason care should

be taken to ensure that the electric cooling fan motor is completely disconnected when working under the hood.

The UNITS used in this manual are showed as the SI UNIT (International System of Unit).

“Example”

24.5 - 34.3 N·m

GI–3

JGI00002-00000

Page 6

GI–4

FRONT

B

B

6.9 - 9.8

14.7 - 17.6

!2

!1

!0

o

★

i

y

r

u

t

q

w

e

HOW TO USE THIS MANUAL

CONTENTS OF EXPLANATION

1. Schematic Diagram of Components

(1) The schematic diagram of components that appears at the beginning of each section describes the

nomenclature and installed conditions of each component. Furthermore the tightening torque is

posted in the figure.

(2) Those parts whose reuse is not permitted bear a “

to replace these parts with new ones during the assembly.

(3) During the assembly, be sure to apply grease to those parts indicated by the mark in the figure.

(Example)

★” mark for an identification purpose. Be certain

: Tightening torque

★ : Non-reusable parts

Unit : N⋅m

q Torsion spring

w Parking lock pawl shaft

e Parking lock pawl

r Manual valve lever

t Manual valve idler shaft

y Manual valve idler plug

u Parking lock rod

i Parking lock lever

o Manual lever shaft

!0 Slotted spring pin

!1 Paring lock cam support

!2 Manual detent spring

JGI00003-00001

Page 7

GI–5

SST

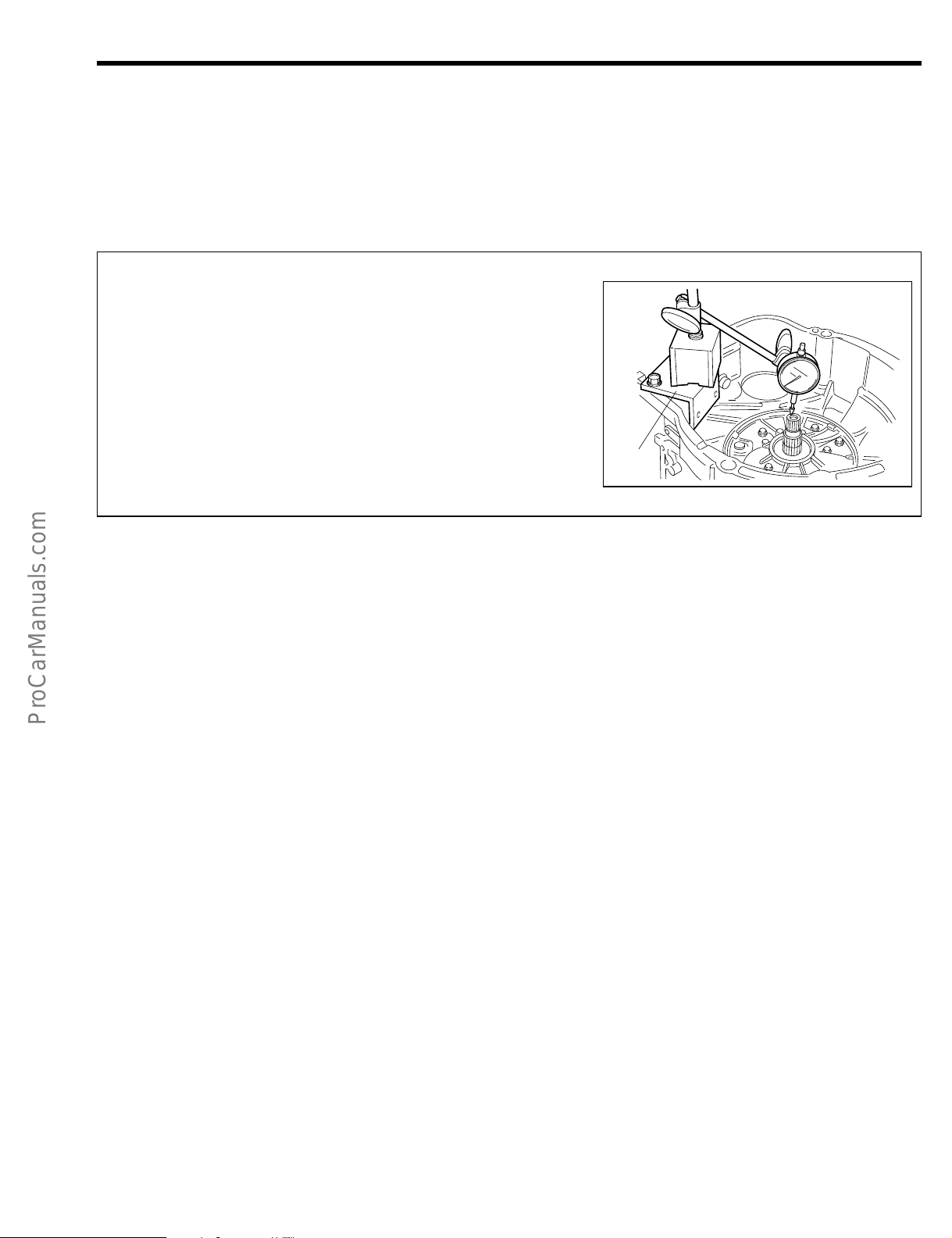

2. Servicing Procedure

(1) In principle, the servicing procedure is described in the following sequence given below: Removal

→ Inspection → Installation, and Disassembly → Inspection → Assembly.

(2) The explanation covers detailed servicing methods, specifications and notes.

(3) The main point of each item explains the servicing section and servicing procedure, using illustra-

tions.

(Example)

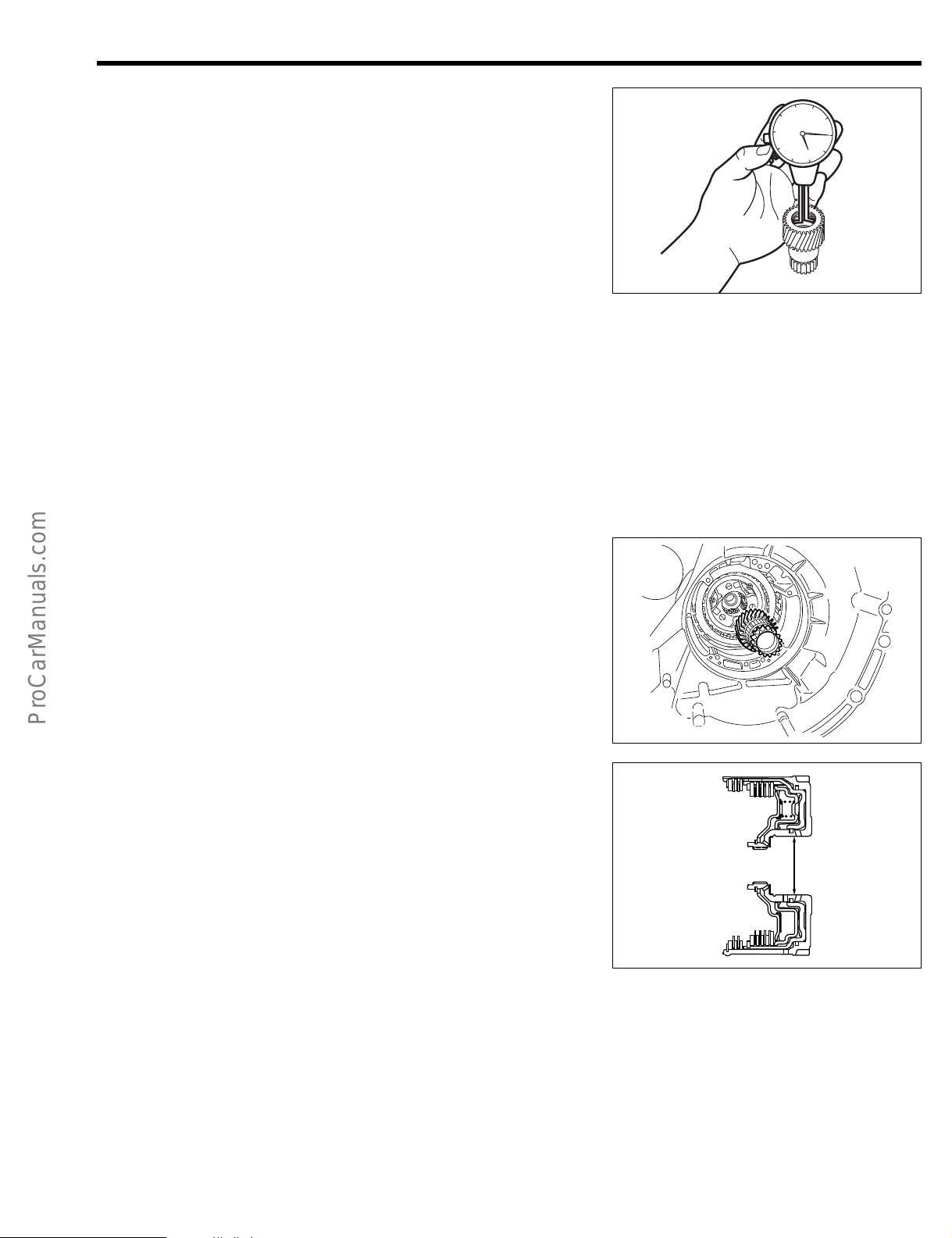

15. Remove the stator shaft & oil pump assembly.

(1) Measure the input shaft end play, using a dial

gauge and following SST.

SST: 09350-87202-000 (09351-87210-000)

Specified Value: 0.26 - 0.88 mm

NOTE:

• Be sure to record the measured value for a guide

during the assembly.

(4) The inspection in this manual describes only checking

operation. Therefore, if you find any malfunction, replace any defective parts with new ones.

3. SST

For those operations which require the use of any SST, the SST numbers concerned are given in bold

letters.

4. Service Specifications

Service specifications are indicated in bold letters or enclosed by heavy lines. Be certain to confirm the

specifications concerned.

5. Tightening Torque

For those operations which require the control of tightening torque, the relevant tightening torque is

given in bold letters. Be certain to confirm the tightening torque concerned.

6. Definitions of Terms

Specified Value.......... A value which represents the allowable range during the inspection and adjust-

Limit ........................... A maximum or a minimum limit which the value should not exceed or fall below.

JGI00004-00002

ment.

JGI00005-00000

Page 8

Bolt

Nut

Screw

Washer

B

N

S

W

GI–6

SAE

SST

Society of Automotive

Engineers

Special Service Tool

For example, automotive oils are designated as SAE so and so number.

These designation numbers have been set forth by the Society of Automotive

Engineers in the United States of America (SAE). The larger the SAE number, the

higher the oil viscosity. Conversely, the smaller the SAE number, the lower the oil

viscosity.

Refers to a tool designed for a specific purpose.

When referring to automotive parts, “standard” represents those parts which have been

installed originally by the manufacturer and which have standard dimensions.

STD Standard

T

Torque

Refers to tightening torque.

VSV

Vacuum Switching

Valve

Refers to vacuum switching valve.

W/

With

Denotes that the following part is attached.

Abbreviation code

API

Assy, A/Y or Ay

A/T, AT

EFI

EJ-BE

ISC

IGN

LH

LHD, L.H.D.

MP

RH

RHD, R.H.D.

S/A

Original word

American Petroleum

Institute

Assembly

Automatic Transmission

Electronic Fuel Injection

EJ-D EFI

Idle Speed Control

Ignition

Left Hand

Left-Hand Drive

Multipurpose

Right Hand

Right-Hand Drive

Sub-Assembly

Meaning

The standards set forth by the American Petroleum Institute (abbreviated as API

Classification) have been employed to evaluate and classify properties of various oils.

Engine oils for gasoline engines are classified as SD, SE, SF and so on, whereas

engine oils for diesel engines are classified as CC, CD and so on.

Refers to an assembled component comprising more than two single parts or subassembly parts.

Refers to automatic transmission

Refers to electronic fuel injection.

EJ engine equipped with EFI system

Refers to idle speed control

Refers to ignition

Refers to left side.

Left-hand drive vehicle.

Means that the following item has multi-purposes.

Refers to right side.

Right hand drive vehicle

Refers to a component comprising more than two single parts which are welded,

staked, or studded to each other to form a single component.

ABBREVIATION CODES

The abbreviation codes that appear in this service manual stand for the following, respectively.

The abbreviation codes that appear in the figure stand for the following, respectively.

JGI00006-00000

JGI00007-00000

Page 9

GI–7

TO INDEX TO NEXT SECTION

GENERAL SERVICE INSTRUCTION

1. Use fender covers, seat covers and floor sheets so that the vehicle may not get dirty or be scratched.

2. Jacking up

(1) When only the front section or rear section of the vehicle is jacked up, be sure to place chocks at

the wheels so as to insure safe operations.

(2) When the vehicle has been jacked up, be sure to support the vehicle at the specified section using

the safety stands. (Refer to the relevant Chassis section in the manual for the vehicle concerned.)

3. Handling instructions related to battery.

(1) Before you start performing the electrical works, make certain to disconnect the battery ground

cable terminal from the negative (–) terminal of the battery.

NOTE:

• Before disconnecting the battery ground cable terminal from the negative (–) terminal of the battery,

be sure to read out the diagnosis code of the EFI systems if it equipped.

• After reconnect the battery ground cable terminal to the negative terminal of the battery, be sure to

reset the watch or radio, if vehicle equipped with such equipments.

(2) When it becomes necessary to disconnect the battery power supply for the purpose of carrying out

checks or repairs, always disconnect the negative (–) terminal of the battery ground cable from negative terminal of the battery first.

(3) To avoid damaging battery plates, after the terminal nut has been loosened, pull out the battery

ground cable terminal straight upward, rather than turning or prying the terminal.

NOTE:

• Be sure to employ the battery terminal puller (commercially available) to remove battery ground cable

terminal from the negative terminal of the battery, if encountered any difficulty.

(4) Clean the battery terminal posts or battery ground terminals, using a cloth. Never use a file or other

adhesive agents.

(5) When connecting the battery ground cable terminal to the battery, first the battery ground cable ter-

4. For increased work efficiency and improved accuracy, be sure to utilize the SSTs (Special Service Tools)

minal should be fitted onto the battery post with the attaching nut in a loose state.

Then, tighten the nut. Never tap the terminal onto the battery post, using the hammer or spanner

wrench or the like.

(6) As for the cover at the positive (+) terminal side, be sure to install it at the correct position.

effectively.

JGI00008-00000

Page 10

TO INDEX

AT

AUTOMATIC TRANSMISSION

OUTLINE ......................................................AT–2

SECTIONAL VIEW OF AUTOMATIC

TRANSMISSION .................................AT–2

COMPONENTS ............................................AT–3

COMPONENTS (INNER PARTS) .............AT–5

REMOVAL ....................................................AT–7

INSPECTION ...............................................AT–17

FRONT AND REAR MULTIPLE

CLUTCH ASSEMBLY ..........................AT–17

ONE-WAY CLUTCH ................................AT–18

ASSEMBLY ..................................................AT–19

SST (Special Service Tools) ......................AT–36

TIGHTENING TORQUE ...............................AT–39

JAT00001-00000

Page 11

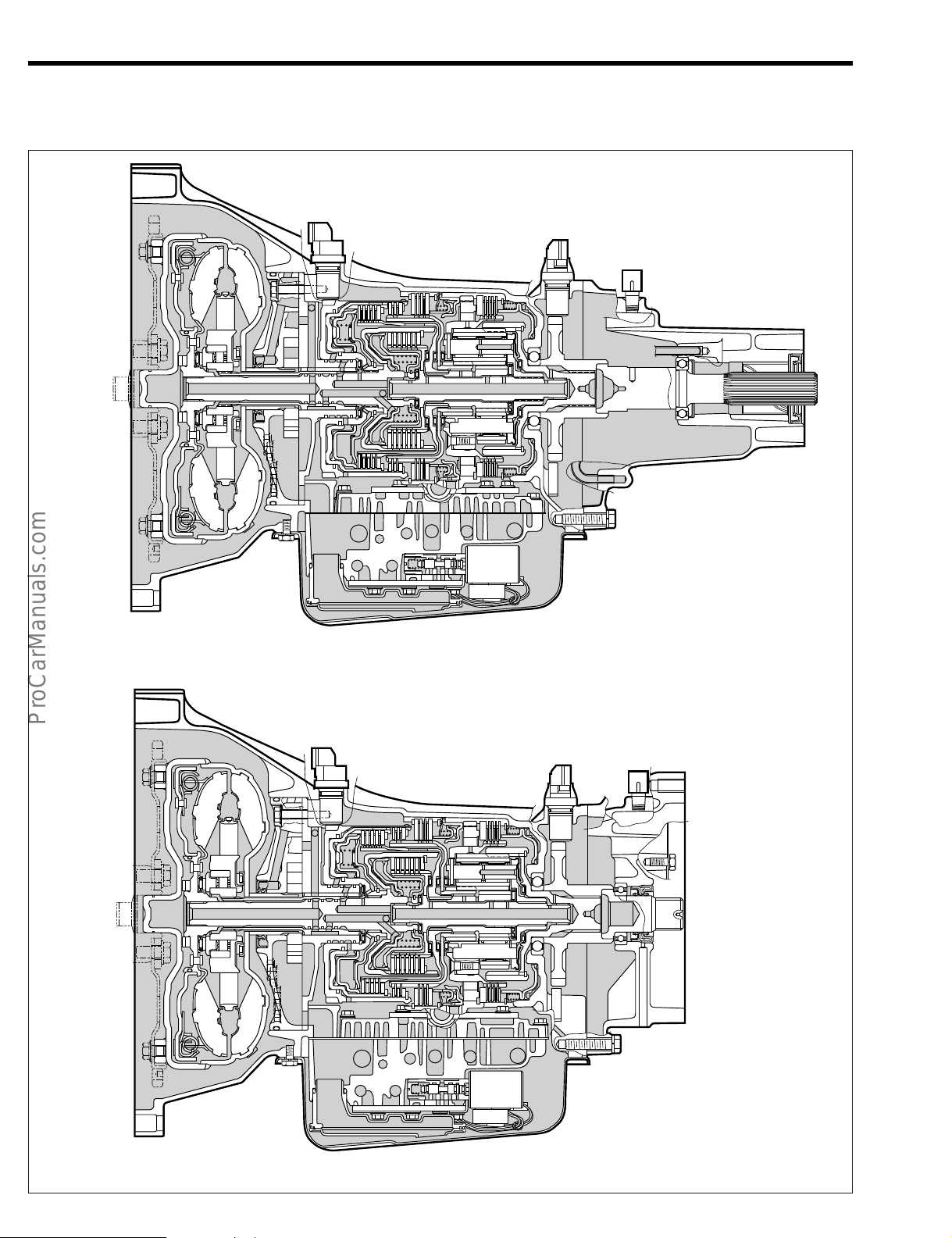

AT–2

<2WD>

<4WD>

OUTLINE

SECTIONAL VIEW OF AUTOMATIC TRANSMISSION [A4Q-D1]

JAT00002-00001

Page 12

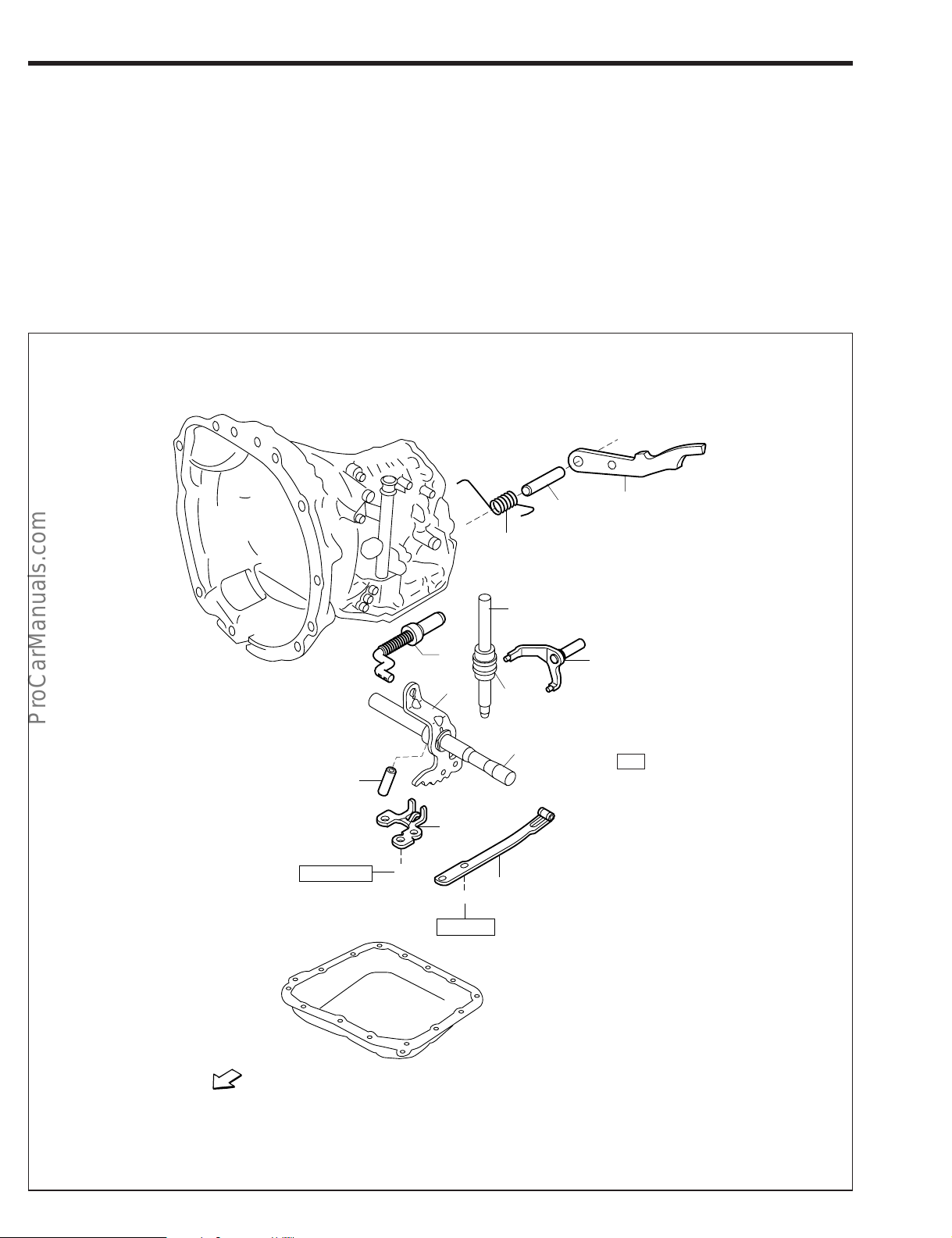

COMPONENTS

FRONT

B

B

B

B

B

B

B

B

B

B

N

B

B

B

B

14.7 - 21.6

19.6 - 29.4

6.9 - 9.8

6.9 - 9.8

6.9 - 9.8

6.9 - 9.8

6.9 - 9.8

2.9 - 9.8

6.9 - 9.8

6.9 - 9.8

14.7 - 21.6

9.8 -15.7

14.7 - 21.6

14.7 - 21.6

14.7 - 21.6

29.4 - 44.1

2WD

@6

@7

@9

@8

@5

#0

@4

@3

@2

★

★

★

@1

@0

★

!7

!5

!5

!4

!3

!2

i

★

!6

★

★

★

★

★

★

★

!6

!8

!9

!1

!0

#1

e

r

t

w

q

o

y

u

AT–3

: Tightening torque

★ : Non-reusable parts

Unit : N·m

q Transmission control shaft lever sub-

assembly

w Neutral start switch

e T-type oil seal

r Breather plug cap

t Breather plug union

y Control cable bracket

[A4Q-D1, A4R-D1 (4WD)]

u Neutral start switch bracket

i Transmission oil filler tube

o Oil guide plate

!0 Transmission solenoid connector

subassembly

!1 Transmission case side cover

!2 O-ring

!3 T-type oil seal

!4 Knock pin

!5 Transmission revolution sensor

!6 O-ring

!7 2nd & 4th brake cylinder tube

!8 Compression spring

!9 Plate

@0 O-ring

@1 Oil strainer

@2 Magnet

@3 Oil pan

@4 Gasket

@5 Drain plug

@6 Extension housing

@7 T-type oil seal

@8 Knock pin

@9 Oil pipe

#0 Engine mount bracket

[A4R-D1 (2WD)]

JAT00003-00002

Page 13

AT–4

FRONT

B

B

6.9 - 9.8

14.7 - 17.6

!2

!1

!0

o

★

i

y

r

u

t

q

w

e

q Torsion spring

w Parking lock pawl shaft

e Parking lock pawl

r Manual valve lever

t Manual valve idler shaft

y Manual valve idler plug

u Parking lock rod

i Parking lock lever

o Manual lever shaft

!0 Slotted spring pin

!1 Paring lock cam support

!2 Manual detent spring

JAT00128-00124

Page 14

COMPONENTS (INNER PARTS)

2WD

#0

@9

@9

#0

q

w★

w★

w★

A

e

B

C

C

C

r

t

y

u

i

o

!1

!0

!0

!0

!1

!1

!2

!3

!4

!5

!6

!7

★

!8

!9

@0

@0

@0

@0

@1

@1

@1

@1

★

@2

D

@3

@4

@5

@6

@7

@8

Outer diameter

Inner diameter

Thickness

44.5

29.7

44.5

29.7

A B C D

3.81

3.41

4.21

30

14

3.62

57

41.4

3.91 3.81

Thrust bearing specification

AT–5

★ : Non-reusable parts

★★ : Selection parts

q Front multiple clutch assembly

w Oil seal ring

e Rear multiple clutch assembly

r Intermediate shaft

t Forward clutch hub

y Planetary sun gear

u Rear planetary sun gear

i Hole snap ring

o Flange

!0 Brake disc

!1 Brake plate

!2 Hole snap ring

!3 Retainer

!4 Wave spring

!5 2nd & 4th brake piston

!6 2nd & 4th brake cylinder

!7 One-way clutch

!8 Hole snap ring

!9 Brake flange

@0 Brake disc

@1 Brake plate

@2 Planetary gear ay.

@3 Planetary output shaft

@4 Hole snap ring

@5 Retainer

@6 Wave spring

@7 1st & reverse brake piston

@8 Radial ball bearing

@9 Reduction drive gear

#0 Radial ball bearing

JAT00004-00003

Page 15

AT–6

FRONT

B

B

B

B

B

B

B

B

q

!4

!5

w

u★

i★

o★

!0★

6.9 - 9.8

4.9 - 6.9

e

r

!1

!2

!3

y

t

4.9 - 6.9

4.9 - 6.9

4.9 - 6.9

4.9 - 6.9

4.9 - 6.9

4.9 - 6.9

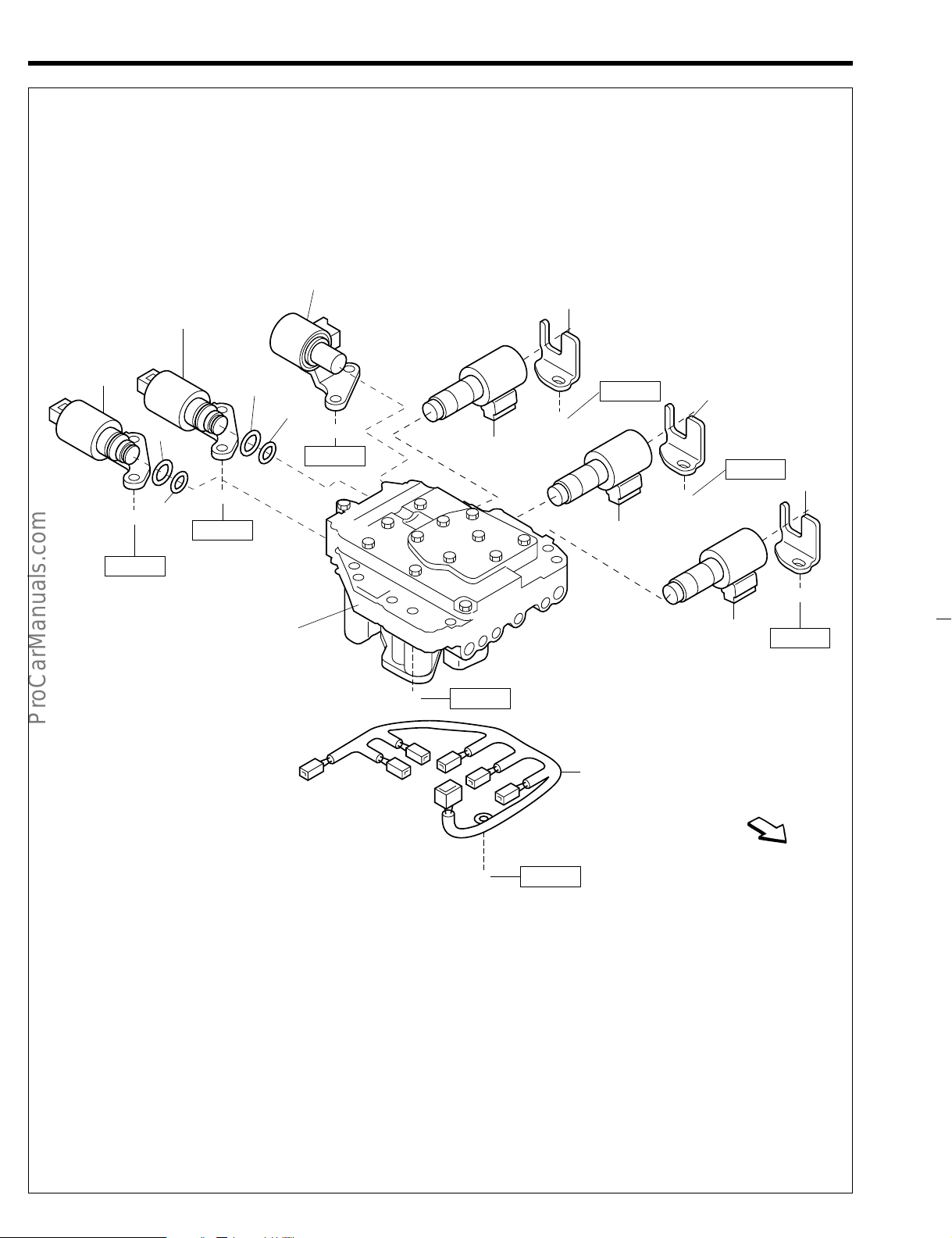

q Lockup clutch control solenoid Ay

w Transmission 3-way solenoid Ay

e Transmission 3-way solenoid Ay

r Clutch control solenoid Ay No. 1

t Clutch control solenoid Ay No. 2

y Clutch control solenoid Ay No. 3

u O-ring

i O-ring

o O-ring

!0 O-ring

!1 Bracket

!2 Bracket

!3 Bracket

!4 Valve body assembly

!5 Wire harness

JAT00129-00125

Page 16

REMOVAL

O-ring

1. Remove the bolt of the transmission oil filler tube subassembly.

2. Pull out the tube subassembly upwards.

3. Remove the O-ring from the tube subassembly.

NOTE:

• Never reuse the removed O-ring.

4. Removal of breather plug.

(1) Remove the breather plug cover and the breather plug

union.

NOTE:

• Never reuse the removed unions, and cover.

• Number of breather plugs.

2WD: 1

4WD: 2

AT–7

JAT00005-00004

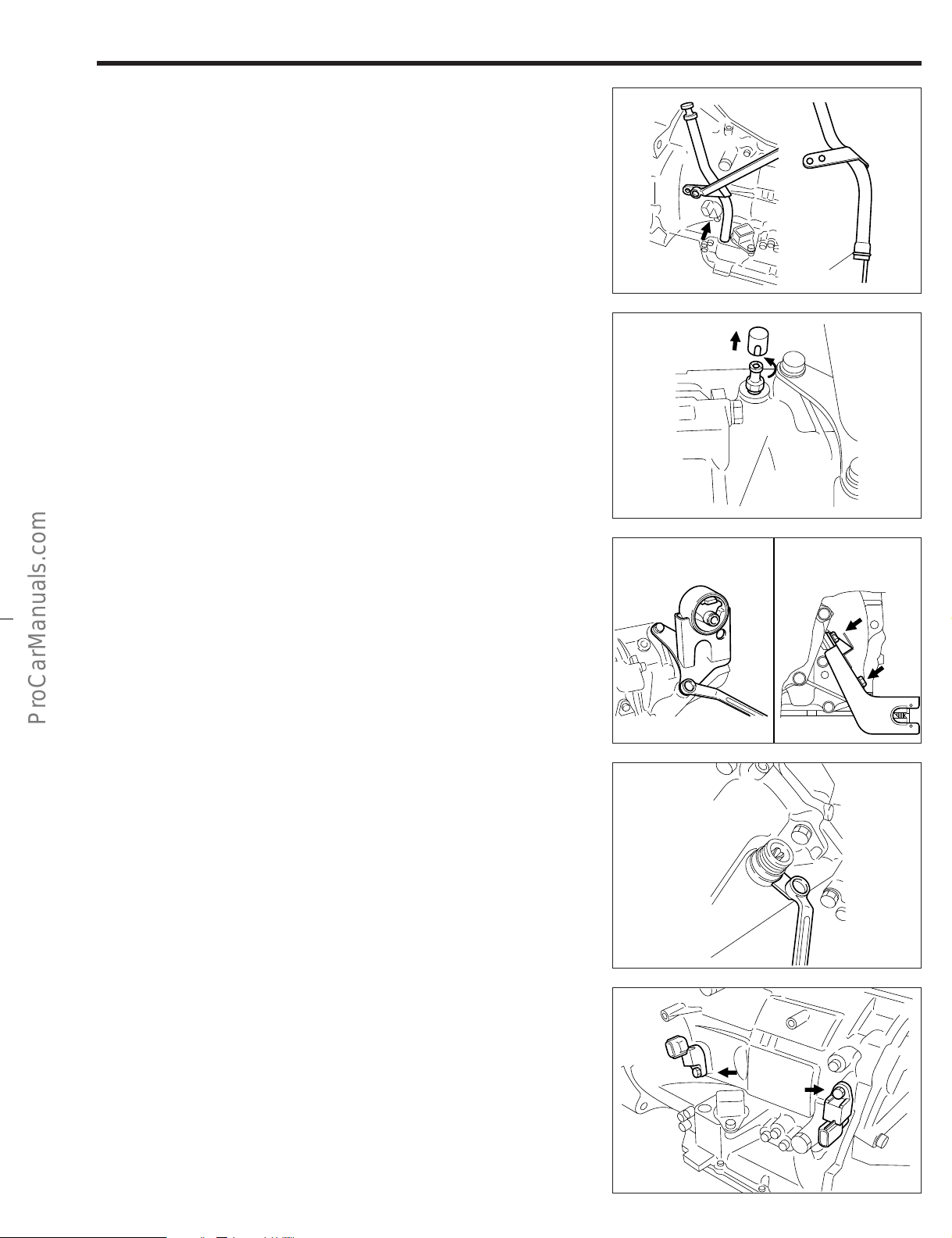

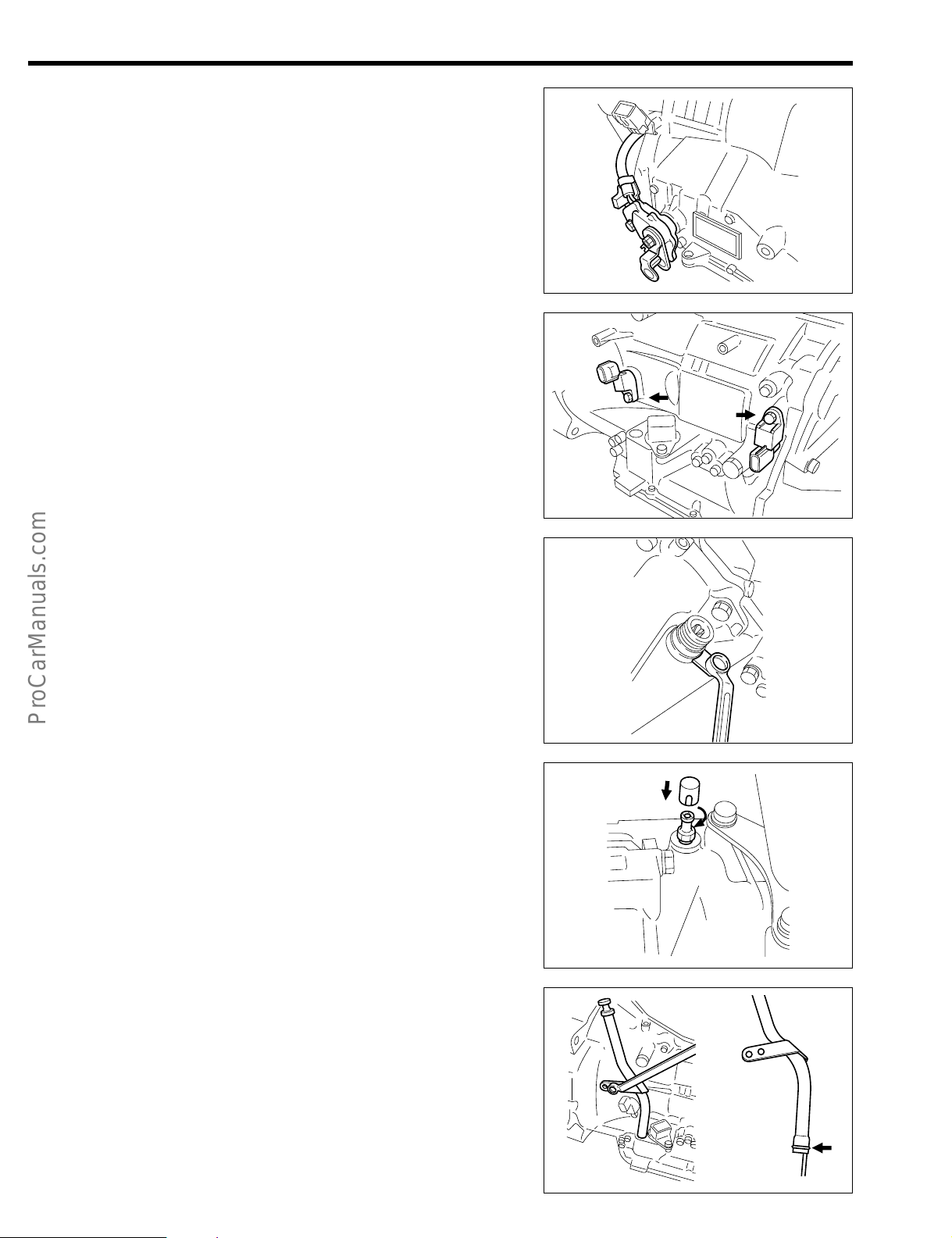

5. Removal of bracket.

(1) Remove the 3 bolts of the engine mount bracket.

[A4R-D1 (2WD)]

Remove the 2 bolts of the control cable bracket.

[A4Q-D1, A4R-D1 (4WD)]

6. Removal of speedometer shaft sleeve subassembly.

[A4R-D1]

(1) Remove the speedometer sleeve lock plate by remov-

ing a bolt.

(2) Remove the speedometer shaft sleeve subassembly,

using the flat screwdriver.

NOTE:

• Never reuse the removed O-ring of the speedometer

shaft sleeve subassembly.

7. Remove the two transmission revolution sensors by removing the bolts.

NOTE:

• Never reuse the removed O-rings of the transmission

revolution sensors.

Engine mount bracket

A4R-D1 (2WD)

A4R-D1

JAT00006-00005

Coutrol cable bracket

A4Q-D1, A4R-D1 (4WD)

JAT00007-00006

JAT00008-00007

JAT00009-00008

Page 17

AT–8

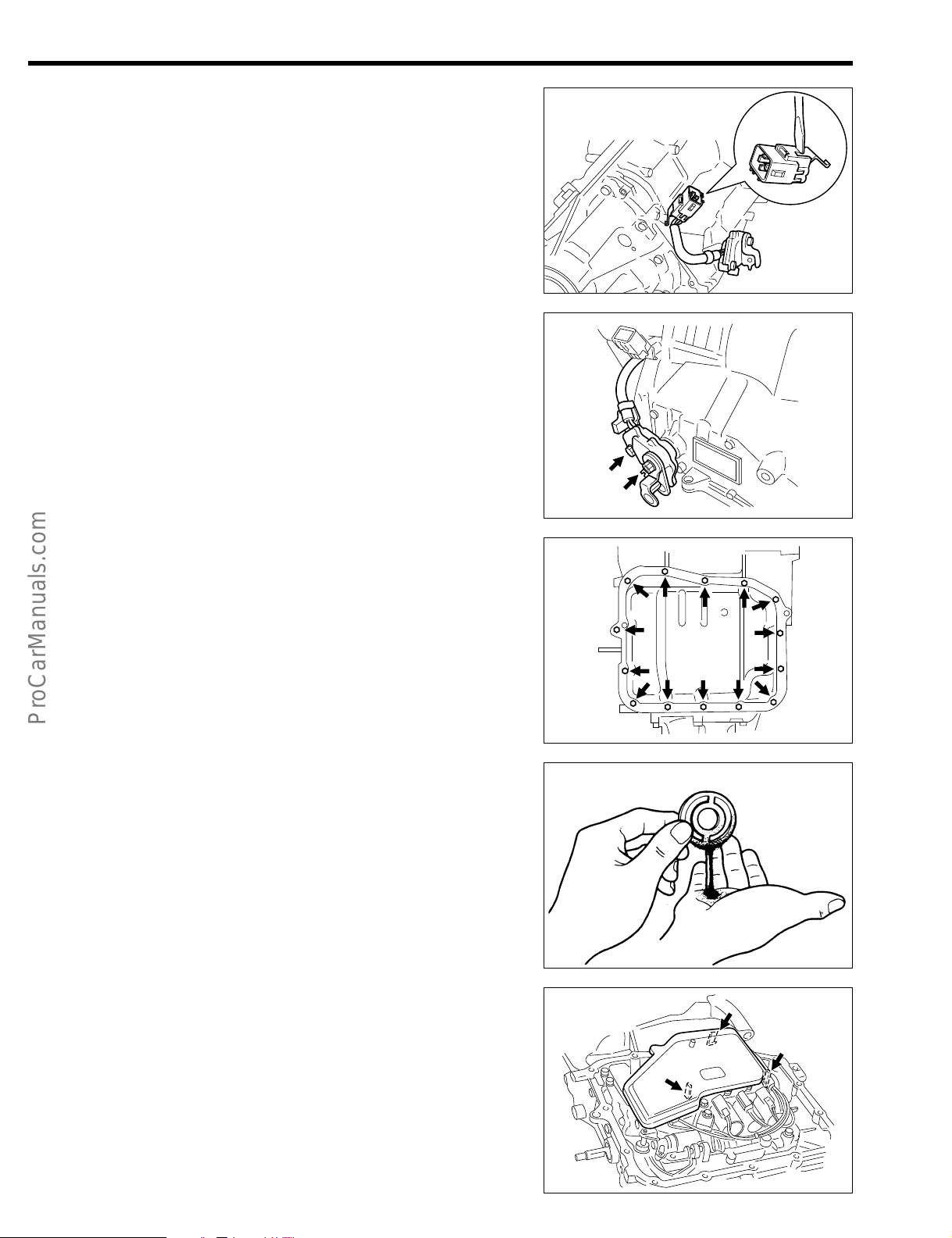

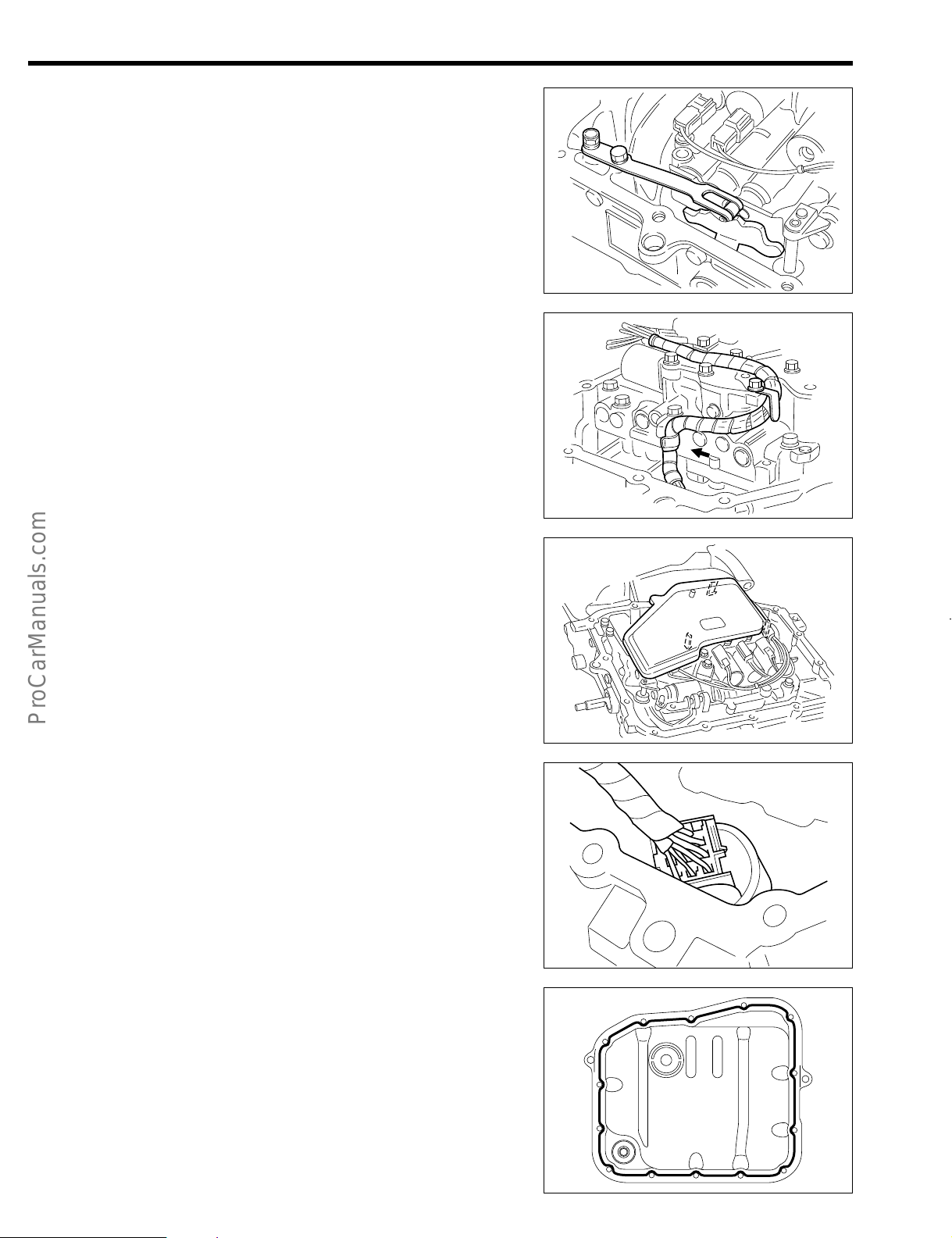

8. Removal of neutral start switch assembly

(1) Disassemble the coupler from the bracket using a flat

screwdriver.

NOTE:

• In the case of A4Q-D1, the direction of the coupler dif-

fers from that of A4R-D1.

(2) Remove the neutral start switch assembly by removing

the bolt and nut.

9. Remove the valve body assembly.

(1) Remove the 14 bolts of the transmission oil pan sub-

assembly.

(2) Remove the transmission oil pan subassembly by gen-

tly tapping on the rim, with a plastic hammer.

CAUTION:

• Do not turn over the transmission, for this will contami-

nate the valve body with foreign materials deposited at

the bottom of the oil pan.

JAT00010-00009

JAT00011-00010

NOTE:

• Never reuse the removed transmission oil pan sub-

assembly.

(3) Check of pan for particles.

Remove the magnet and use it to collect any steel

chips. Inspect the oil pan for any chips and particles

collected on the magnet to find out the type of wear of

the transmission.

Steel (magnetic) ... Wear of bearing, gear and plate

Brass (nonmagnetic) ... Wear of bush

(4) Turn over the transmission.

NOTE:

• This turning-over of the transmission is necessary, for

the control-related parts would drop when the valve

body is removed if the transmission was not turned

over.

(5) Remove the oil strainer subassembly by pushing out

the 3 pawls of the oil strainer using a flat screwdriver.

CAUTION:

• The strainer subassembly has 3 pawls. Be very careful

not to break or bend them during removal.

JAT00012-00011

JAT00013-00012

NOTE:

• Be sure to check whether the mesh of oil strainer is

clean.

JAT00014-00013

Page 18

(6) Remove the O-ring from the stem of the oil strainer.

NOTE:

• Never reuse the removed O-ring.

(7) Remove the manual detent spring by removing the 2

bolts.

NOTE:

• Be sure to remove the bolts evenly and uniformity.

AT–9

JAT00015-00014

(8) Detach the harness from the clamp of the valve body

assembly.

(9) Disconnect the connector, using a flat screwdriver.

NOTE:

• Never pull out the wire itself directly when you disconnect the connector.

10. Remove the valve body and the bracket by removing the 7

bolts.

NOTE:

• Be sure to remove the bolts evenly and diagonally.

• The numerals in the right illustration indicate the nomi-

nal length of the bolt.

#5

#5

^5

JAT00016-00015

JAT00017-00016

JAT00018-00017

#5

#5

#5

#5

JAT00019-00018

Page 19

AT–10

Manual valve

lever pin

11. Remove the manual valve sleeve by pulling up the manual

valve lever pin.

12. Remove the compression spring by removing the bolt and

plate.

13. Remove the 2nd & 4th brake cylinder seal.

NOTE:

• Never reuse the removed seal.

JAT00020-00019

2nd & 4th brake

cylinder seal

14. Remove the manual lever subassembly.

(1) Remove the slotted spring pin, using a pin punch and

a hammer.

NOTE:

• When removing the pin, be very careful not to drop it

into the transmission case.

• Never reuse the removed pin.

(2) Pull out the manual valve lever shaft toward the out-

side.

(3) Remove the manual lever subassembly and parking

lock rod subassembly.

15. Remove the stator shaft & oil pump assembly.

(1) Measure the input shaft end play, using a dial gauge

and following SST.

SST: 09350-87202-000 (09351-87210-000)

Specified Value: 0.26 - 0.88 mm

JAT00021-00020

JAT00022-00021

Manual lever

Parking lock rod

JAT00023-00022

NOTE:

• Be sure to record the measured value for a guide dur-

ing the assembly.

SST

JAT00024-00023

Page 20

(2) Remove the T-type oil seal, using the following SST.

SST

SST: 09308-10010-000

NOTE:

• Never reuse the removed oil seal.

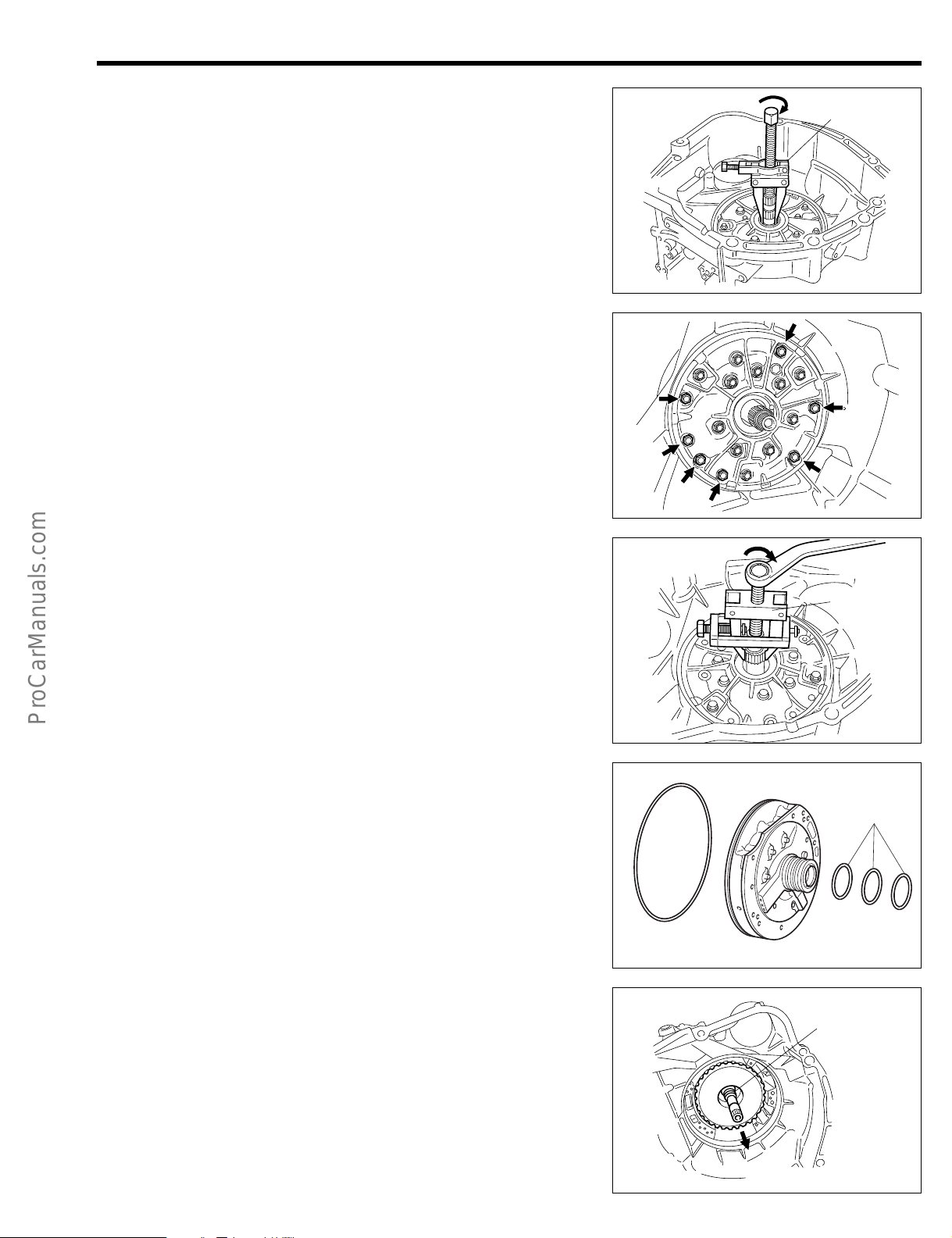

(3) Remove the 7 bolts of the stator shaft & oil pump as-

sembly.

NOTE:

• Be sure to remove the bolts evenly and diagonally.

• Never loosen any bolt other than the specified ones in

the right figure.

AT–11

JAT00025-00024

(4) Remove the stator shaft & oil pump assembly with the

O-ring, using the following SST.

SST: 09820-00021-000

(5) Remove the O-ring from the stator shaft & oil pump as-

sembly and the 3 clutch drum oil seal rings.

NOTE:

• Never reuse the removed O-ring.

• Never reuse the removed oil seal rings.

16. Remove the front and rear multiple clutch assembly.

(1) Pull out the front and rear multiple clutch assembly by

holding the stator shaft.

NOTE:

• Do not touch the seal rings.

JAT00026-00025

SST

JAT00027-00026

Seal rings

JAT00028-00027

Seal rings

JAT00029-00028

Page 21

AT–12

Bearing

Front multiple

clutch assembly

Rear multiple

clutch assembly

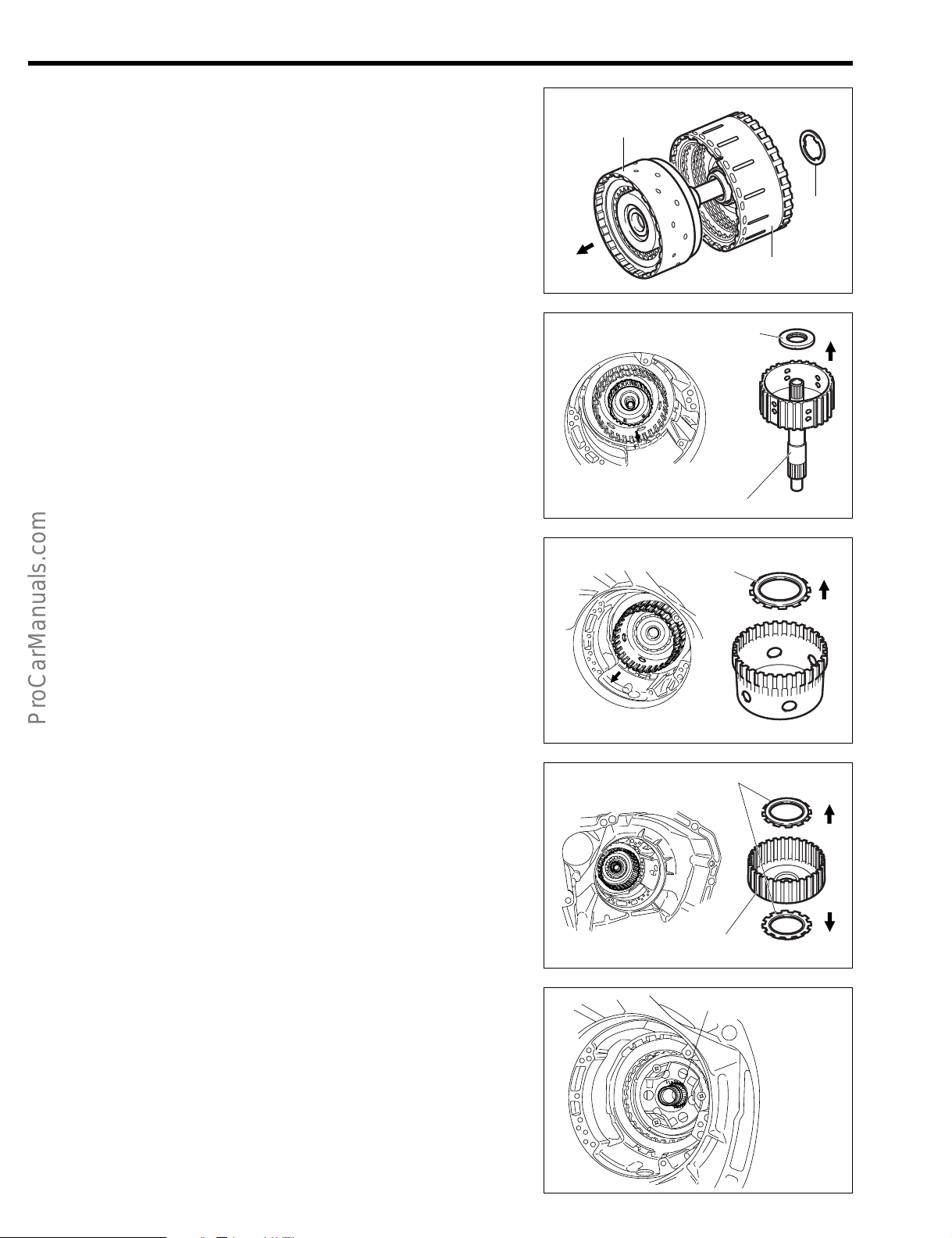

(2) Separate the front multiple clutch assembly with the

rear multiple clutch assembly.

(3) Remove the thrust needle bearing from the front multi-

ple clutch assembly.

(4) Remove the 3 oil seal rings from the rear multiple

clutch assembly.

NOTE:

• Never reuse the removed seal rings.

17. Removal of intermediate shaft subassembly.

(1) Remove the intermediate shaft subassembly.

(2) Remove the thrust needle bearing from the intermedi-

ate shaft subassembly.

JAT00030-00029

Bearing

18. Removal of forward clutch hub.

(1) Remove the forward clutch hub.

(2) Remove the thrust needle bearing from the forward

clutch hub.

19. Removal of planetary sun gear assembly.

(1) Remove the planetary sun gear assembly.

(2) Remove the two thrust needle bearings from the plane-

tary sun gear assembly.

20. Removal of the rear planetary sun gear subassembly.

(1) Remove the rear planetary sun gear subassembly.

Intermediate shaft subassembly

JAT00031-00030

Bearing

JAT00032-00031

Bearings

Planetary sun

gear assembly

JAT00033-00032

Rear planetary sun gear

JAT00034-00033

Page 22

21. Measurement of 2nd & 4th and 1st & reverse brake end

1st & Rev.

2nd & 4th

Thickness

gauge

play.

(1) Turn over the transmission case.

(2) Measure the 2nd & 4th brake end play from window

(A), using a thickness gauge.

Specified Value: 1.08 - 1.53 mm

(3) Measure the 1st & reverse brake end play from win-

dow (B), using a thickness gauge.

Specified Value: 0.69 - 1.18 mm

NOTE:

• As for the 1st & reverse brake end play, the measurement should be conducted between the snap ring and

the flange.

• Be sure to record the measured value for a guide during the assembly.

• The tightness which you encounter during this insertion/withdrawal of the thickness gauge should be virtually the same as the tightness which you would encounter during the thickness adjustment of the valve

rocker arm.

AT–13

JAT00035-00034

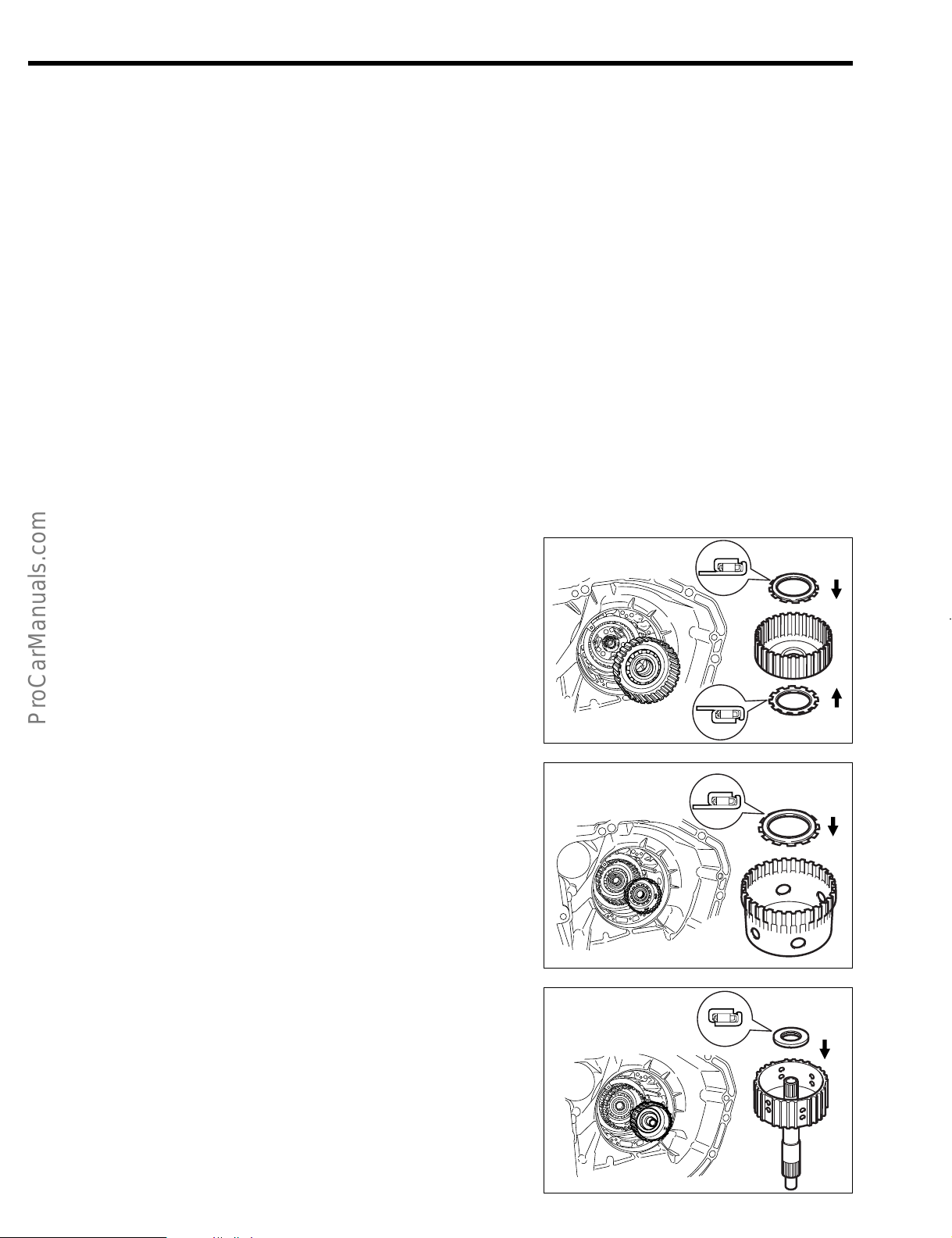

22. Removal of 2nd & 4th brake discs and plates.

(1) Remove the hole snap ring, using snap ring pliers.

(2) Move the brake flanges, brake discs and brake plates

in a set faces toward the front side and remove them in

the following order.

F = Brake flange, D = Brake disc, P = Brake plate

F → D → P → D → P → D → F

23. Removal of 2nd & 4th brake piston assembly.

(1) Remove the hole snap ring, using snap ring pliers.

(2) Remove the piston return spring seat, piston return

spring, and the 2nd and 4th piston.

(3) Divide the 2nd and 4th brake piston using pliers.

NOTE:

• Never reuse the divided piston.

2nd & 4th

piston

Piston return

spring seat

JAT00036-00035

Piston return spring

Hole snap

ring

JAT00037-00036

JAT00038-00037

Page 23

AT–14

Planetary gear Ay

One-way clutch

#5

#5

#5

#5

#5

170

#5

(A)

A4Q-D1

#5

4WD

170

24. Removal of the one-way clutch and the planetary gear assembly.

(1) Remove the planetary gear assembly with the one-way

clutch installed.

(2) Remove the one-way clutch from the planetary gear

assembly.

25. Removal of the 1st and reverse brake discs and plates.

(1) Remove the thrust needle roller bearing from the plan-

etary output shaft subassembly.

JAT00039-00038

Bearing

(2) Remove the hole snap ring, using snap ring pliers, and

move the brake flange, brake discs and brake plates

in a set faces toward the front side and remove them in

the following order.

F = Brake flange, D = Brake disc, P = Brake plate

F → D → P → D → P → D → P → D → P

26. Removal of the transfer assembly [4WD]

(1) Remove the 7 bolts of the transfer assembly.

NOTE:

• Be sure to loosen the bolts evenly and diagonally

• For A4Q-D1, remove the bolt marked (A), too. (Total 8

bolts)

• The numeral in the right figure indicates the nominal

length of the bolt.

(2) Remove the transfer assembly.

(3) Remove the oil guide plate, by removing the 2 bolts.

(B)

JAT00040-00039

Cut-out section

JAT00041-00040

JAT00130-00126

Removal of the extension housing [2WD], side cover

[4WD].

(1) Remove the oil seal, using the following SST given

below.

SST: 09950-20017-000

SST

JAT00042-00041

Page 24

(2) Remove the 8 bolts of the extension subassembly.

(A)

(A)

2WD

[2WD]

Remove the 10 bolts of the side cover. [4WD]

NOTE:

• Be sure to loosen the bolts evenly and diagonally.

• For A4Q-D1, remove the bolts marked (A), too. (Total

10 bolts)

AT–15

JAT00043-00042

4WD

(3) Remove the extension housing or side cover sub-

assembly by lightly and uniformly tapping the 2 rib

sections, using a plastic hammer.

27. Removal of the output shaft.

(1) Remove the output shaft.

(2) Remove the bearing by using SST.

SST: 09950-20017-000

NOTE:

• Never reuse the removed bearing.

(3) Remove the speedometer drive gear. [A4R-D1]

28. Remove the parking lock pawl.

(1) Remove the torsion spring, the parking lock pawl and

the parking lock pawl shaft.

JAT00000-00127

JAT00044-00043

A4R-D1

SST

Speedometer

drive gear

Bearing

JAT00052-00051

Parking lock pawl

Shaft

Torsion spring

JAT00046-00045

Page 25

AT–16

29. Removal of the planetary output shaft.

(1) Tap the planetary output shaft subassembly lightly,

using a plastic hammer, until it becomes free.

NOTE:

• Be sure to place a cloth or the like under the transmis-

sion case in case that the planetary output shaft subassembly drops.

(2) Remove the bearing.

NOTE:

• If any difficulty is encountered in removing the bearing,

remove it by applying a light impact from the inside of

the transmission case, using a brass bar and a plastic

hammer.

JAT00047-00046

30. Removal of control-related parts:

(1) Remove the parking lock pawl can support by remov-

ing 3 bolts.

(2) Remove the manual valve idler shaft.

31. Remove the 1st & reserve brake assembly.

(1) Remove the shaft snap ring q, using snap ring pliers.

(2) Remove the piston return spring seat w and, piston re-

turn spring e.

(3) Applying compressed air of 392 - 784 kPa from the oil

hole indicated in the right figure.

(4) Remove the 1st & reverse piston r.

WARNING:

• Care must be exercised as to oil splashing when com-

pressed air is used for blowing.

JAT00048-00047

Parking lock pawl cam support

Manual valve idle shaft

JAT00049-00048

q

w

e

r

JAT00050-00049

Apply air

NOTE:

• Never reuse the removed 1st & reverse piston.

JAT00051-00050

Page 26

INSPECTION

FORWARD CLUTCH

FRONT AND REAR MULTIPLE CLUTCH

ASSEMBLY

1. Check of forward clutch (C2) piston stroke and Rear

clutch (C3) piston stroke

(1) Measure the forward clutch (C2) end play, Rear clutch

end play using a thickness gauge.

Specified Value:

Forward Clutch (C2): 0.67 - 0.98 mm

Rear Clutch (C3): 1.24 - 1.55 mm

NOTE:

• The tightness which you encounter during this inser-

tion/withdrawal of the thickness gauge should be virtually the same as the tightness which you would encounter during the thickness adjustment of the engine

valves.

If the measured end play fails to conform to the specified value above, replace the multiple clutch assembly

with a new one.

AT–17

JAT00053-00052

REAR CLUTCH

JAT00054-00053

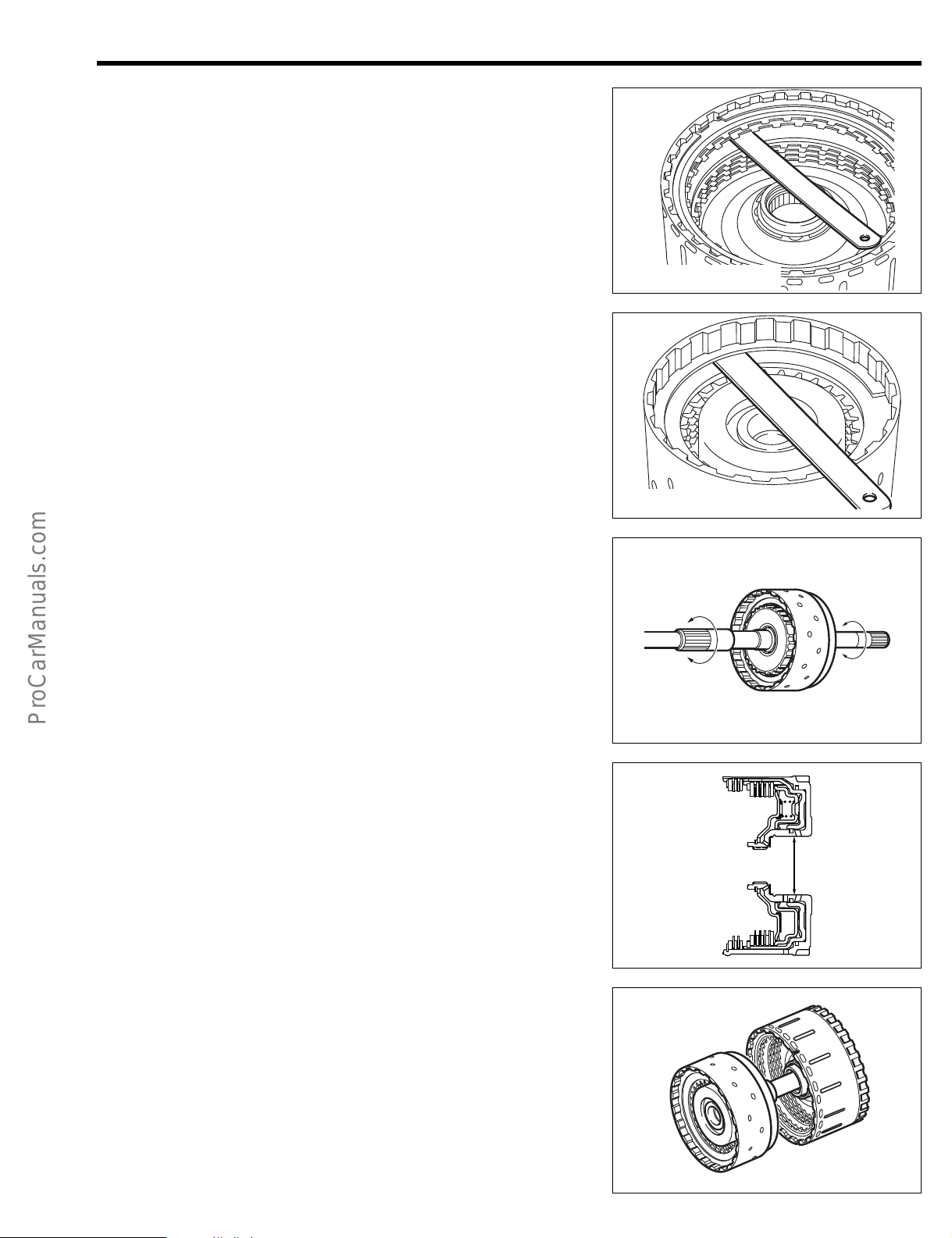

2. Confirmation of turning effort of rear clutch disc

(1) Install the thrust needle bearing to the rear multiple

clutch assembly, in the right direction.

(2) Assemble the intermediate shaft subassembly. Ensure

that the clutch discs rotate smoothly.

3. Measure the bush inner diameter of the front multiple

clutch assembly, using an inner caliper gauge.

Specified Value: 44.50 - 44.53 mm

Allowable Limit: 44.58 mm

NOTE:

• Ensure that the measurement should be performed at

several points.

• If the measured value exceeds the allowable limit, re-

place the front multiple clutch assembly with a new

one.

4. Confirmation of turning effort of front multiple clutch assembly

(1) Insert the rear multiple clutch assemble to the front

multiple clutch assembly, with the 3 new oil seal rings

assembled.

NOTE:

• Be careful not to damage the seal rings of the rear mul-

tiple clutch assembly, with the 3 new oil seal rings

JAT00055-00054

JAT00056-00055

JAT00057-00056

Page 27

AT–18

(2) Install the thrust needle bearing to the rear multiple

clutch assembly, in the right direction.

(3) Assemble the forward clutch hub. Ensure that it rotate

smoothly.

(4) Install the thrust needle bearing to the rear multiple

clutch assembly, in the right direction.

(5) Assemble the planetary sun gear assembly. Ensure

that it rotate smoothly.

JAT00058-00057

ONE-WAY CLUTCH

Hold the planetary gear assembly and turn the one-way

clutch.

NOTE:

• Ensure that it turns freely when turned counterclockwise and locked when turns clockwise.

JAT00059-00058

JAT00060-00059

Page 28

ASSEMBLY

Brake flange

Brake plates

(4 pieces)

Brake discs

(4 pieces)

A

X

1st & reverse brake piston

1. Selection of brake flanges, snap rings for 1st & reverse

brake piston and 2nd & 4th brake piston

Before assembling the unit, determine the thickness of the

snap rings brake flanges, as follows.

(1) Assemble the piston, brake discs and brake plates as

shown in the right figure. Push them from the direction

A with a load of 4.9 to 7.8 N. (Place a suitable weight).

(2) Measure the dimension X with a height gauge. Based

on this dimension, select a suitable brake flange (1st &

Rev), snap ring (2nd & 4th) according to the table

below.

NOTE:

• The dimension X is the distance measured between

the following points.

• The dimension X shall be the maximum value among

values measured at three points on the circumference.

• If the variation of the three measured values exceed

0.2 mm, redo the measurement of the dimension of

each part.

1st & Rev.: Brake disc end and brake piston end sur-

face

2nd & 4th: Brake flange end and brake piston end

surface

Brake plates

(2 pieces)

Brake

flanges

(2 pieces)

X

2nd & 4th brake piston

AT–19

JAT00131-00128

A

Brake discs

(3 pieces)

JAT00132-00129

Table Showing Availability of Brake Flanges for 1st &

Reverse Brake Piston

No.

1

2

3

4

5

6

Dimension X

39.45 - 39.661

39.25 - 39.45

39.05 - 39.25

38.85 - 39.05

38.65 - 38.85

38.439 - 38.65

Table Showing Availability of Snap Rings for 2nd & 4th Brake Piston

No.

1

2

3

4

Dimension X

35.854 - 36.11

36.11 - 36.36

36.36 - 36.61

36.61 - 36.866

Part number

35885-97201

35885-97202

35885-97203

35885-97204

35885-97205

35885-97206

Part number

90045-21179

90045-21178

90045-21177

90045-21176

Thickness

4.0

4.2

4.4

4.6

4.8

5.0

Thickness

2.25

2.00

1.75

1.50

Identification color

Black

Brown

Blue

Silver

JAT00133-00000

Page 29

AT–20

Speedometer

drive gear

A4R-D1

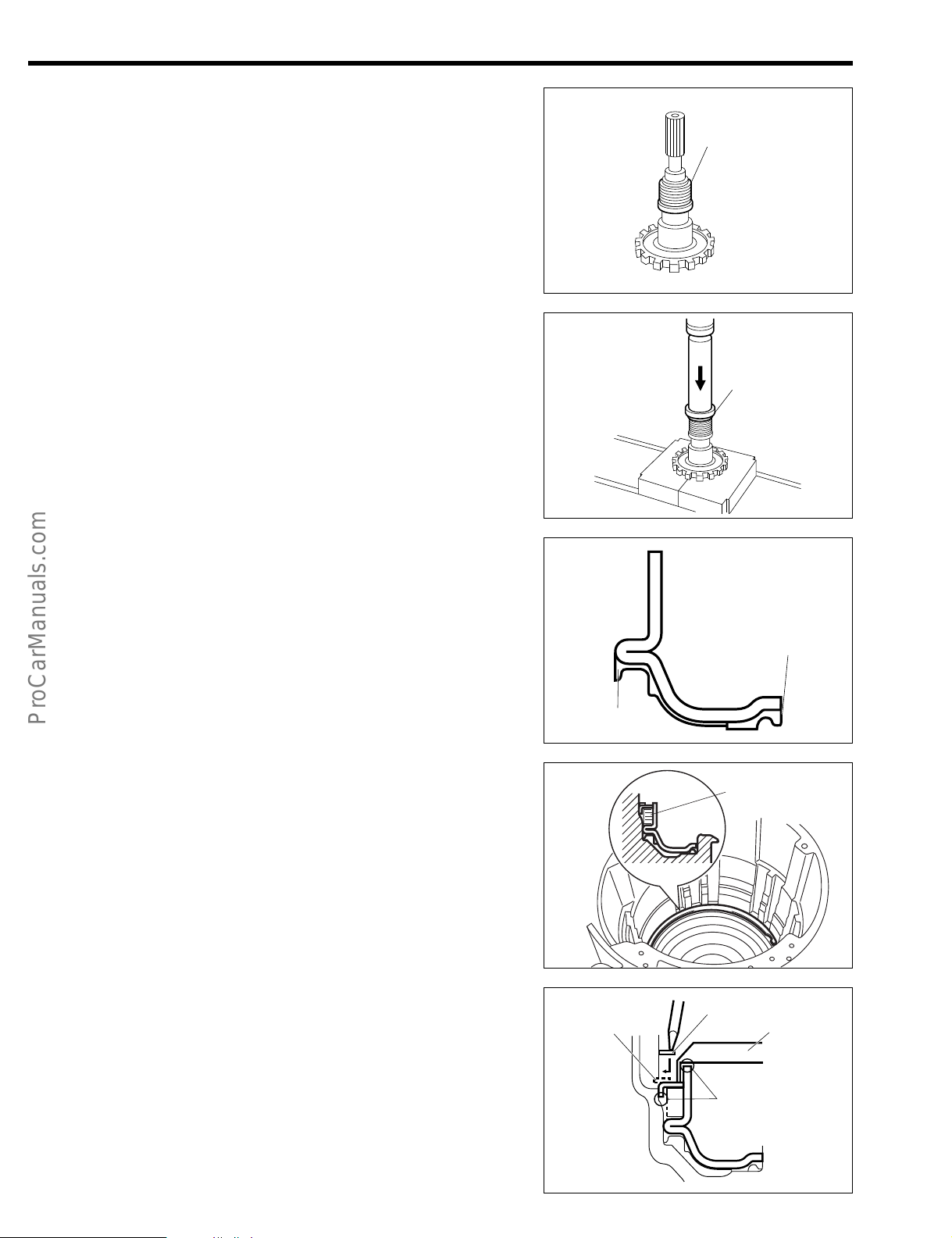

2. Assembly of output shaft

(1) Insert the speedometer drive gear to the output shaft.

[A4R-D1]

(2) Temporally insert a new radial ball bearing to the out-

put shaft. Press the bearing in place, using a press in

combination with the following SST given below.

SST: 09309-87201-000

JAT00061-00060

Bearing

3. Assembly of 1st & reverse brake piston.

(1) Apply ATF to the outer and inner periphery of the new

brake piston and to the inserted section of brake piston of the transmission case.

(2) Insert the new brake piston, piston return spring, and

piston return spring seat into the transmission case.

(3) Temporarily assemble the hole snap ring on the return

spring seat using snap ring pliers.

(4) Compress the piston return spring seat, using the fol-

lowing SST.

SST: 09351-97201-000, 09350-87202-000

Apply ATF

Groove

JAT00062-00061

Apply ATF

JAT00063-00062

Spring

JAT00064-00063

Snap ring

SST

NOTE:

• To prevent deformation, be sure to stop tightening the

SST when the spring has been lowered 1 to 2 mm from

the snap ring installation groove.

• Do not expand the ring excessively.

• The hole snap ring will become a center guide for the

SST.

Deformation

JAT00065-00064

Page 30

(5) Install the hole snap ring, using a flat screwdriver. And

Spring

remove the SST.

(6) Install the parking lock pawl shaft and the parking lock

pawl to the transmission case.

(7) Install the torsion spring, as indicated in the right fig-

ure.

NOTE:

• Push the parking lock pawl and release it. At this time,

make sure that the pawl returns to the original position.

AT–21

JAT00066-00065

Spring

4. Measure the inner diameter of the planetary output shaft

subassembly, using an inner caliper gauge.

Specified Value: 13.00 - 13.02 mm

Allowable Limit: 13.07 mm

NOTE:

• Perform the measurement at several points. Calculate

the mean value.

• If the measured value exceeds the allowable limit, re-

place the planetary output shaft subassembly with a

new one. Moreover, when replacing it, be sure to check

the bush contacting surface of the planetary output

shaft subassembly for scratch or discoloration. If the

surface is scratched or discolored, replace the planetary output shaft subassembly with a new part.

5. Installation of planetary output shaft subassembly.

(1) Install the radial ball bearing to the transmission case.

Parking lock pawl shaft Parking lock pawl

JAT00067-00066

Inner

diameter

JAT00068-00067

SST

Bearing

(2) Insert the planetary output shaft subassembly into the

radial ball bearing with your hand.

(3) Drive the reduction drive shaft subassembly, using the

following SSTs, and a press.

SSTs: 09309-87301-000 (A)

09636-20010-000 (B)

JAT00069-00068

SST (B)

Planetary

output shaft

SST (A)

JAT00070-00069

Page 31

AT–22

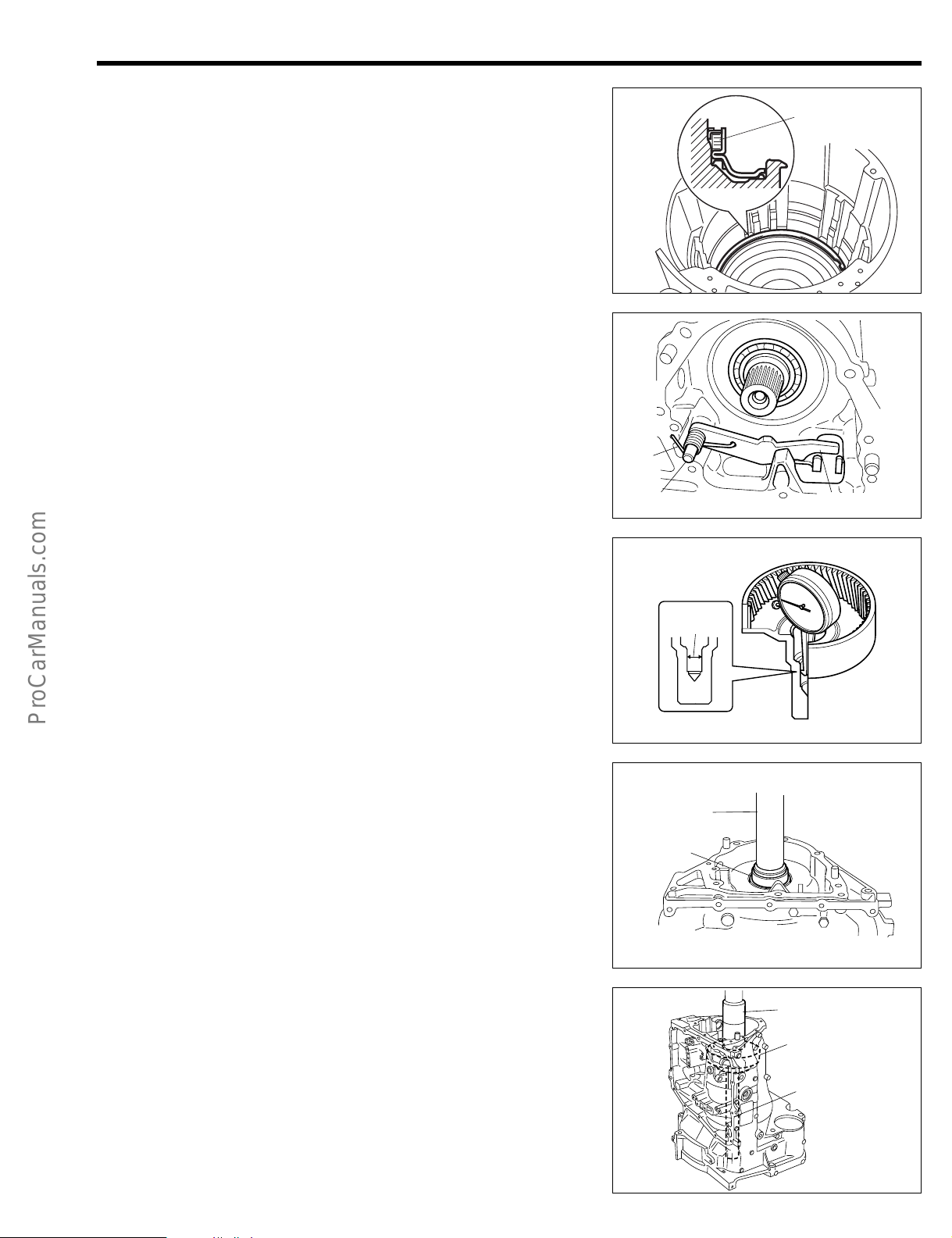

6. Installation of extension housing [2WD], side cover [4WD]

(1) Insert the extension housing bush apply tube to the

extension housing. [2WD]

(2) Thoroughly remove any foreign matters (seal bond,

grease, water, etc.) from both the mating surfaces.

(3) Apply Three Bond TB1281B to the surface of the trans-

mission case in such a way that a sealing may be

formed without any discontinued spot, in a size equivalent to a 0.5 mm to 1.5 mm diameter, following the

procedure given in the right figure.

NOTE:

• If the seal bond is applied in an excessive amount, the

sealing agent may mix with the ATF, resulting in a restricted strainer. Therefore, care must be exercised not

to apply the seal bond excessively.

JAT00071-00070

2WD

JAT00072-00071

4WD

(4) Tighten the 8 bolts of the extension subassembly.

[2WD]

Tighten the 10 bolts of the side cover. [4WD]

Tightening Torque: 14.7 - 21.6 N·m

NOTE:

• Be sure to tighten the bolts alternately and diagonally.

• In the case of A4Q-D1, be sure to tighten the bolts lo-

cated at the (A)-marked points.

7. Installation of the transfer assembly [4WD]

(1) Install the oil guide plate to the side cover by tighten-

ing the 2 bolts.

Tightening Torque: 6.9 - 9.8 N·m

(2) Install the transfer by tightening the 7 bolts.

Tightening Torque: 29.4 - 44.1 N·m

NOTE:

• Be sure to tighten the bolts alternately and diagonally

• In the case of A4Q-D1, be sure to tighten the bolts lo-

cated at the (A)-marked points.

• The numeral in the right figure indicates the nominal

length of the bolt.

JAT00000-00130

2WD

(A)

(A)

JAT00073-00072

4WD

(A)

(A)

JAT00000-00131

Page 32

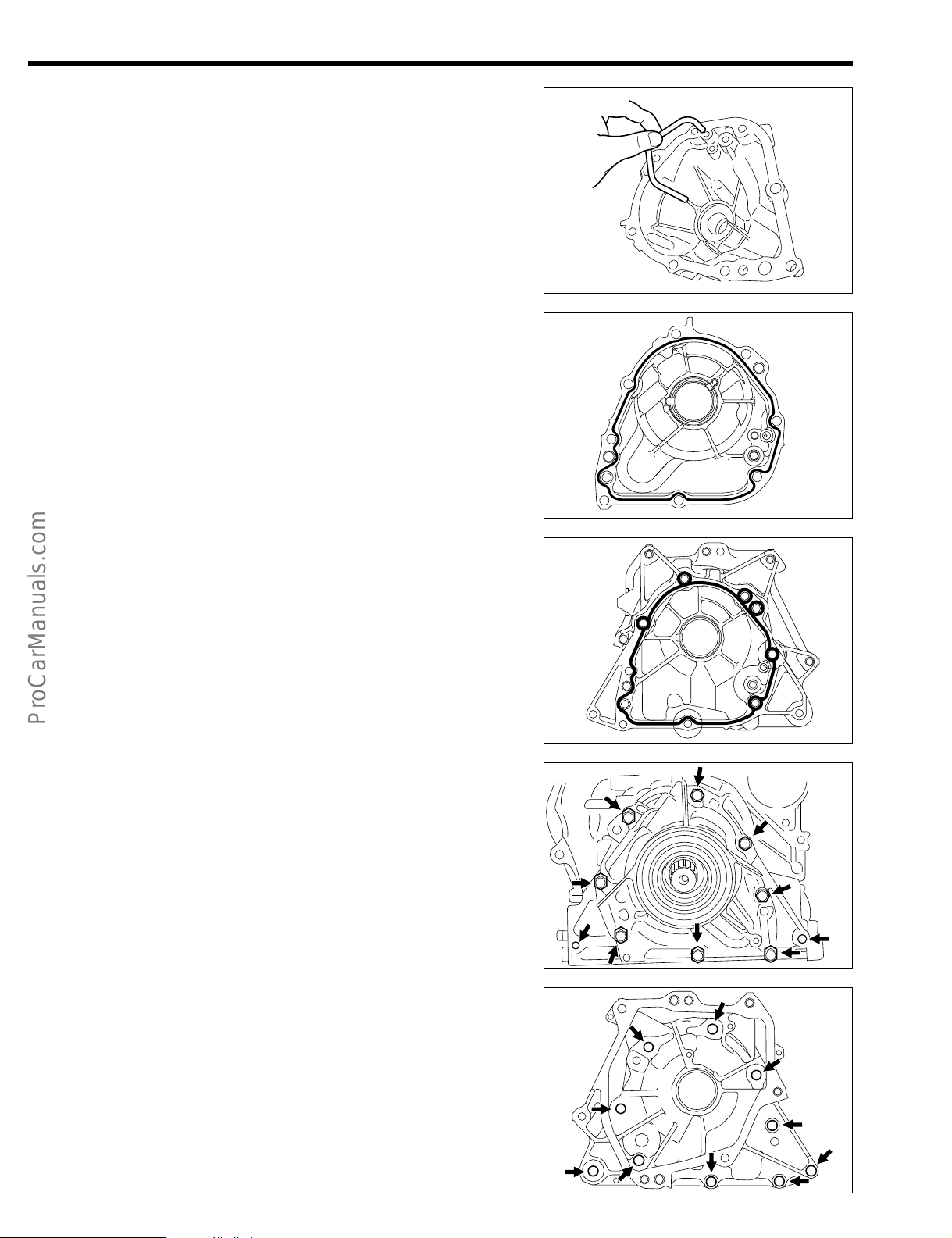

8. Installation of 1st & reverse brake

P P P P

F

D D D D

Piston side

(1) Install the brake flanges, plates and discs in the follow-

ing order.

F = Brake flange, P = Brake plate, D = Brake disc

P → D → P → D → P → D → P → D → F

NOTE:

• Before assembling new discs, soak them in the ATF for

at least two hours.

• Be sure to align the cut-out section of the brake plates

and flange stalling the brake plate.

• Install a new hole snap ring to the grooved section of

the transmission case.

AT–23

JAT00074-00073

Cut-out section

9. Install the planetary gear assembly.

(1) Install the thrust needle roller bearing to the planetary

output shaft subassembly.

Reference Value:

Thrust Needle Roller Bearing Dimension:

Refer to page AT–5

NOTE:

• Be sure to install the (B) section of the bearing faces

toward the output shaft side.

(2) Apply ATF to the surface of each gears and install the

planetary gear assembly.

NOTE:

• Ensure that the assembly rotates smoothly.

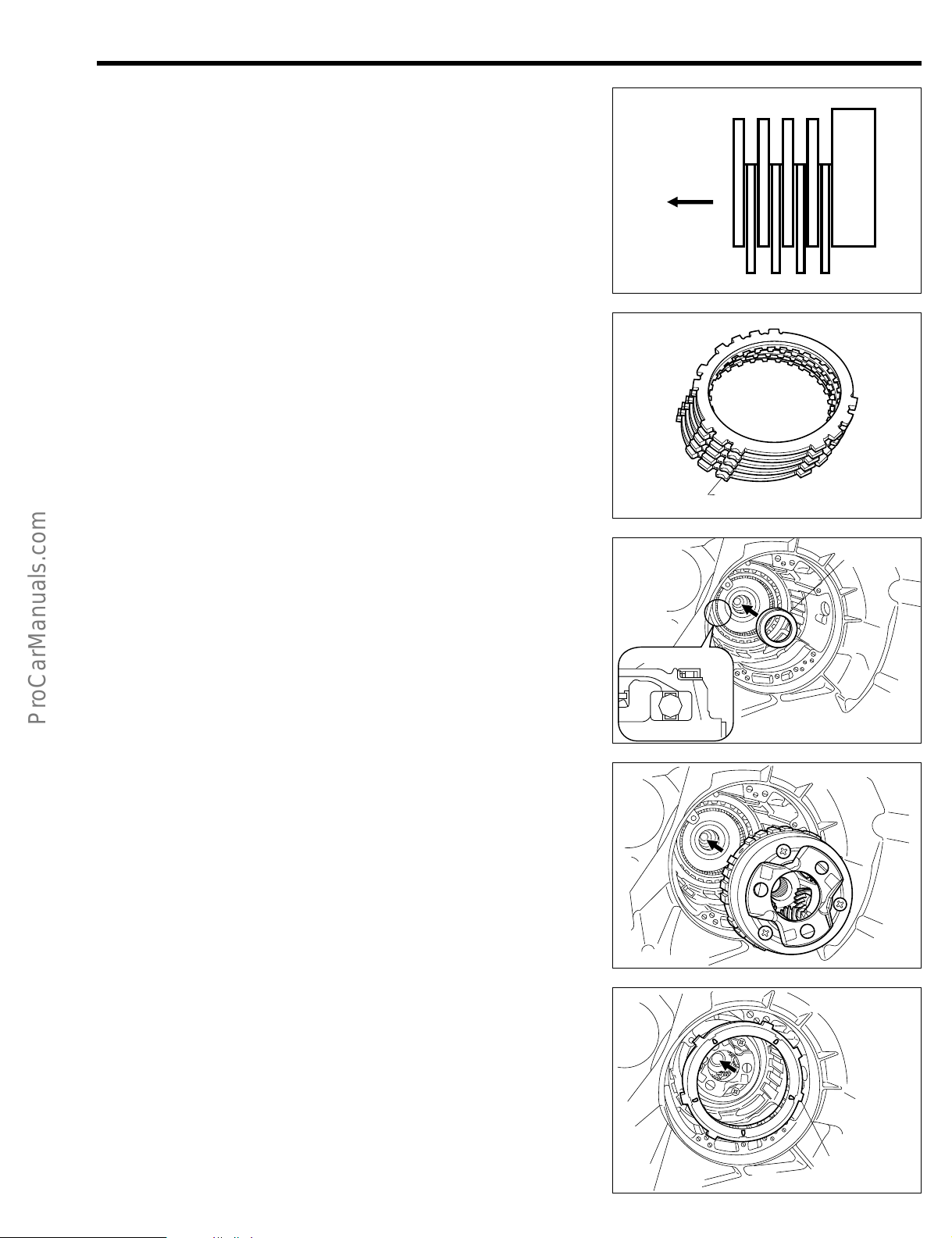

10. Installation of one-way clutch

(1) Coat the sliding section of the one-way clutch with the

ATF.

(2) Install the one-way clutch.

NOTE:

• Ensure that the one-way clutch with the snap ring faces

toward the upside.

• Align the cut-out section at the inside of the transmis-

sion case with the protruding section provided with the

match mark of the one-way clutch.

JAT00000-00074

Bearing

Output shaft

(B)

JAT00075-00075

JAT00076-00076

Cut-out section

JAT00077-00077

Page 33

AT–24

11. Installation of the 2nd & 4th piston

(1) Apply ATF to the outer periphery of the new brake pis-

ton and to the inserted section of brake piston of the

transmission case.

(2) Assemble the 2nd & 4th piston and cylinder.

NOTE:

• Be sure to insert the piston vertically.

(3) Insert the new brake piston subassembly, piston return

spring into the transmission case.

(4) Insert the piston return spring seat in the right direction.

(5) Assemble the hole snap ring using snap ring pliers

and 2 flat screwdrivers.

NOTE:

• Be sure to align the cut-out section of the brake plate

with the protruding section of the transmission when in-

stalling the brake plate.

• Make sure to assemble the snap ring in such a way

that its end gaps face upward of the unit.

12. Installation of 2nd & 4th brake

(1) Install the brake flanges, plates and discs in the follow-

ing order.

F = Brake flange, P = Brake plate, D = Brake disc

F → D → P → D → P → D → F

NOTE:

• Before assembling new discs, soak them in the ATF for

at least two hours.

• Be sure to align the cut-out section of the brake plate

with the protruding section of the transmission when installing the brake plate.

• Install a new hole snap ring to the grooved section of

the transmission case.

JAT00078-00078

JAT00079-00079

JAT00080-00080

1st & Rev.

13. Measurement of 1st & reverse brake and 2nd & 4th brake

end play

(1) Turn over the transmission case.

(2) Measure the 1st & reverse brake and 2nd & 4th brake

end play, using a flat thickness gauge.

Specified Value:

1st & Reverse Brake: 0.69 - 1.18 mm

2nd & 4th Brake: 1.08 - 1.53 mm

NOTE:

• The tightness which you encounter during this inser-

tion/withdrawal of the flat thickness gauge should be

virtually the same as the tightness which you would encounter during the thickness adjustment of the valve

rocker arm.

• If the measured end play fails to conform to the speci-

fied value above, select a snap ring from the table, of

the step 1.

2nd & 4th

Thickness

gauge

JAT00081-00081

Page 34

14. Installation of rear planetary sun gear subassembly

(1) Measure the bush bore diameter of the rear planetary

sun gear subassembly.

Specified Value: 18.00 - 18.02 mm

Allowable Limit: 18.07 mm

NOTE:

• The measurement should be performed at several

points. Determine the mean value.

• If the bore diameter exceeds the allowable limit, re-

place the rear planetary sun gear subassembly.

• When replacing the rear planetary sun gear subassem-

bly, be sure to check the bush contacting surface of the

intermediate shaft subassembly. If the contacting surface is scored or discolored, replace the intermediate

shaft subassembly, too, with a new one at the same

time.

AT–25

JAT00083-00083

(2) Install the rear planetary sun gear subassembly to the

planetary gear assembly.

NOTE:

• Apply ATF to the bush section.

15. Measure the bush inner diameter of the front multiple

clutch assembly, using an inner caliper gauge.

Specified Value: 44.50 - 44.53 mm

Allowable Limit: 44.58 mm

NOTE:

• Ensure that the measurement should be performed at

several points.

• If the measured value exceeds the allowable limit, re-

place the front multiple clutch assembly with a new

one.

JAT00084-00084

JAT00056-00055

Page 35

AT–26

16. Installation of the front planetary sun gear assembly, forward clutch hub and intermediate shaft subassembly

(1) Measure the bush bore diameter of the planetary sun

gear subassembly.

Specified Value: 27.00 - 27.02 mm

Allowable Limit: 27.07 mm

NOTE:

• The measurement should be performed at several

points. Determine the mean value.

• If the bore diameter exceeds the allowable limit, re-

place the planetary sun gear subassembly.

• When replacing the planetary sun gear subassembly,

be sure to check the bush contacting surface of the

rear planetary sun gear subassembly. If the contacting

surface is scored or discolored, replace the rear planetary sun gear subassembly with a new one, too, at the

same time.

(2) Assemble the front planetary sun gear assembly with

the two thrust needle roller bearings to the planetary

gear assembly.

NOTE:

• Apply ATF to the bush section.

• Make sure that the two thrust needle roller bearings are

assembled in the correct direction.

• Assemble by aligning the pawls of the clutch disc of the

2 & 4 brake with the groove of the planetary sun gear

assembly hub

JAT00085-00000

REFERENCE:

• Dimensions of thrust needle roller bearing: Refer to

page AT–5.

(3) Assemble the forward clutch hub with the thrust nee-

dle roller bearing to the planetary sun gear assembly.

NOTE:

• Apply ATF to the forward clutch hub.

• Make sure that the thrust needle roller bearing is as-

sembled in the correct direction.

REFERENCE:

• Dimensions of thrust needle roller bearing: Refer to

page AT–5.

(4) Assemble the Intermediate shaft subassembly with the

thrust needle roller bearing to the forward clutch hub.

NOTE:

• Apply ATF to the Intermediate shaft subassembly.

• Make sure that the thrust needle roller bearing is as-

sembled in the correct direction.

REFERENCE:

• Dimensions of thrust needle roller bearing: Refer to

page AT–5.

JAT00086-00085

JAT00087-00086

JAT00088-00087

Page 36

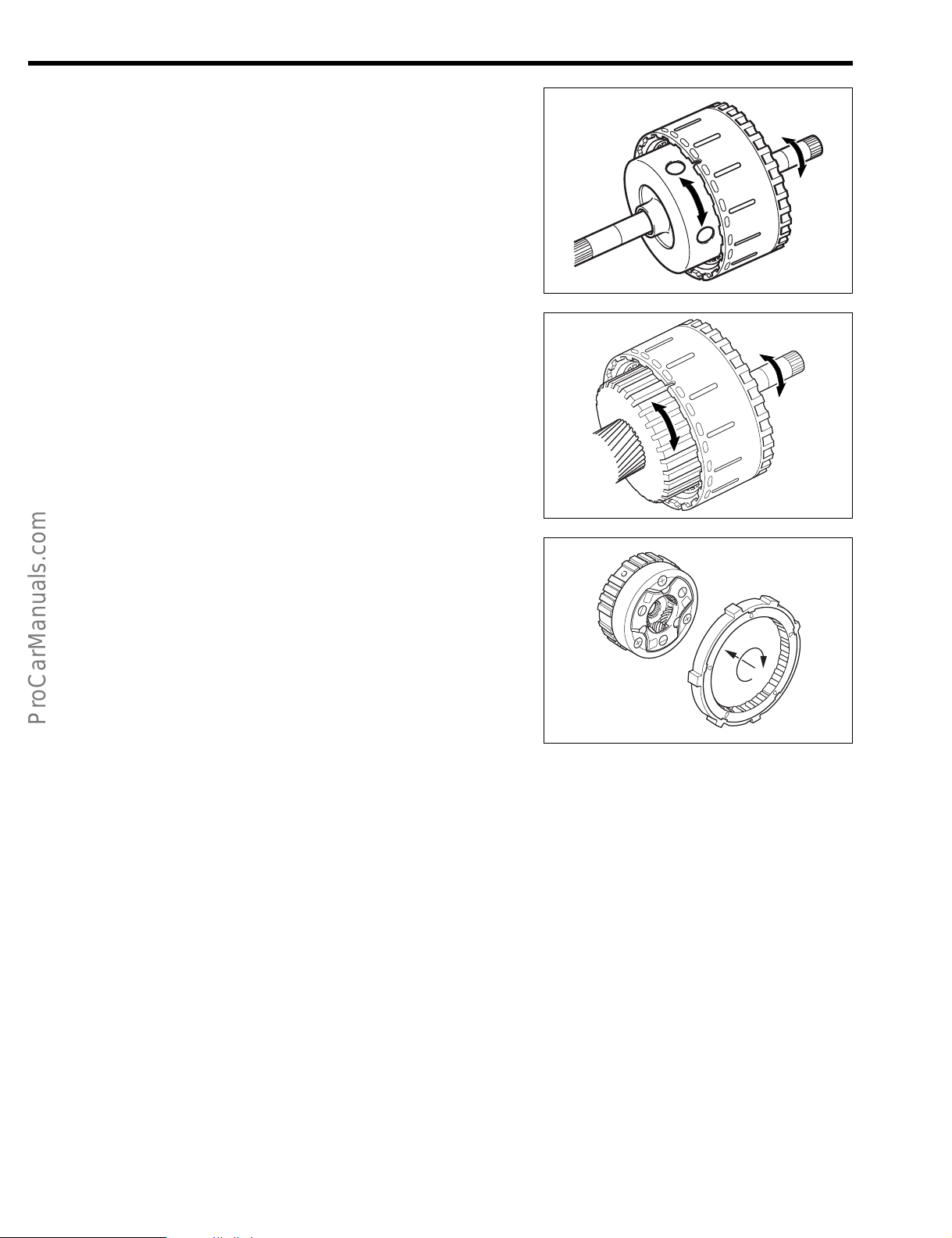

17. Installation of the rear multiple clutch assembly

Align the pawls of the clutch disc of the rear multiple

clutch assembly with each other.

Assemble the rear multiple clutch by aligning the pawls of

the clutch disc of the rear multiple clutch assembly with

the groove of the forward clutch hub and with the groove

of the intermediate shaft subassembly.

18. Measure the height of the rear multiple clutch assembly

between the installation section of the oil pump using the

following SST & vernier calipers.

SST: 09350-87202-000 (09351-87208-000)

Specified Value: Approx. 43 mm

Dimension X: Distance between oil pump contact

surface and rear multiple clutch assembly.

AT–27

JAT00089-00088

Vernier calipers

SST

Seal rings

X

NOTE:

• If the measured value is less than 43 mm, the pawl

section of the forward clutch disc is probably not fitted

in the groove of the forward clutch hub. Be sure to perform the operation of the step again.

• Do not touch the seal rings.

19. Turn the forward clutch clockwise and counterclockwise.

At this time, ensure that the forward clutch turns lightly

and the planetary sun gear assembly makes a relative

movement with the forward clutch.

JAT00090-00135

20. Installation of front multiple clutch assembly

(1) Measure and record the thickness of the thrust needle

roller bearing.

(2) Install the front multiple clutch assembly to the forward

clutch drum and the planetary sun gear assembly as

turning clockwise and counterclockwise.

NOTE:

• Be careful not to damage the seal rings of the rear mul-

tiple clutch assembly.

JAT00091-00089

JAT00092-00090

Page 37

AT–28

X

(3) Confirm the height of the oil pump attaching surface

from the front multiple clutch assembly upper surface,

using the following SST.

SST: 09350-87202-000 (09351-87208-000)

Specified Height: Approx. 43.5 mm

Dimension X: Distance between oil pump contact

surface and rear multiple clutch assembly.

NOTE:

• Perform the measurement at several points. Calculate

the mean value.

• If the measured value is less then 43.5 mm, the two

pawls of the clutch disc are probably not fitted into the

groove of the forward clutch drum or the planetary sun

gear assembly. Be sure to perform the operation of the

step (3) above again.

JAT00093-00091

(4) Install the thrust roller bearing into the front multiple

clutch assembly.

NOTE:

• Make sure that the thrust needle roller bearing is assembled in the correct direction.

21. Inspection of stator shaft & oil pump assembly

(1) Inspection of oil pump operation

Ensure that the oil pump drive gear rotates smoothly,

using the following SST.

SST: 09350-87202-000 (09351-87206-000)

NOTE:

• Be sure to insert the flat sections (2 points) of the SST

into the flat sections of the oil pump drive gear.

(2) Measure the inner diameter of the oil pump bush sec-

tion, using an inner caliper gauge.

Allowable Limit:

NOTE:

• Perform the measurement at several points. Calculate

the mean value.

• If the actually measured value exceeds the allowable

limit, replace the stator shaft & oil pump assembly with

a new one.

• When replacing it, be sure to check the bush contact-

ing surface of the input shaft subassembly. If the surface is scratched or discolored, replace the shaft with a

new one, too.

023.52 mm

Thrust bearing

Planetary gear side

JAT00094-00092

JAT00096-00000

Cut view

Inner diameter

JAT00097-00094

Page 38

22. Assembly of stator shaft & oil pump assembly

Thrust bearing thickness mm

3.41

3.81

4.21

90043-74044-000

90043-74043-000

90043-74045-000

Part No.

Brown

––

Black

Color

(1) Coat 3 new clutch drum oil seal rings with the ATF and

install it to the stator shaft & oil pump assembly.

NOTE:

• Do not spread the new oil seal rings excessively.

(2) Coat and install the new O-ring.

(3) Assembly the stator shaft & oil pump assembly, follow-

ing the procedure given in the steps 16–(1) through

16–(8).

23. Installation of stator shaft & oil pump assembly

(1) Install the following SST to the transmission case.

SST: 09350-87202-000 (09351-87207-000)

(2) Apply the ATF to the outer periphery of the stator shaft

& oil pump assembly and install it to the transmission

case.

NOTE:

• Be very careful not to damage or twist the O-ring dur-

ing the installation.

(3) Tighten the 7 bolts of the stator shaft & oil pump as-

sembly.

Tightening Torque: 6.9 - 9.8 N·m

AT–29

JAT00098-00095

SST

JAT00099-00096

NOTE:

• Be sure to tighten the bolts alternately and diagonally.

(4) Measure the input shaft end play with a dial gauge

and the following SST.

SST: 09350-87202-000 (09351-87210-000)

Specified Value: 0.26 - 0.88 mm

NOTE:

• If the measured end play exceeds the specified value,

remove the stator shaft & oil pump assembly and the

direct clutch from the transmission case. Then, select

the thickness of the thrust bearing race from the lower

table. Proceed to perform the operations of the steps

from 20–(4) to 23–(4).

Thrust bearing availability

JAT00101-00098

JAT00102-00099

JAT00135-00000

Page 39

AT–30

Parking lock pawl cam support.

Manual valve idle shaft

(A)

(B)

(C)

(5) Install a new T-type oil seal, using the following SST.

SST: 09310-87301-000

NOTE:

• Make sure that the T-type oil seal is in contact at right

angles with the assembly.

24. Installation of manual valve lever shaft assembly

(1) Install the parking lock pawl cam support and manual

valve idle shaft by first temporary tightening bolt (A).

Then tighten the bolts to the tightening torque in the

following order. Bolt (B) → (C) → (A)

Tightening Torque: 14.7 - 17.6 N·m

SST

JAT00103-00100

(2) Install the cut-out groove of the manual valve lever and

the protruding section of the parking lock rod to the

manual valve lever.

(3) Install the parking lock lever shaft subassembly from

the engine side.

(4) Install a new slotted spring pin, using a pin punch and

a hammer.

NOTE:

• Be sure to install the pin, until it reaches the edge sur-

face of the manual valve lever.

JAT00136-00133

JAT00104-00101

ATF

JAT00105-00102

JAT00138-00103

Page 40

(5) Install the the compression spring, bolt and plate.

ATF

Tightening Torque: 6.9 - 9.8 N·m

(6) Install the new 2nd & 4th brake cylinder seal.

25. Installation of the valve body assembly

(1) Assemble the manual valve idler plug (A) and manual

valve idler shaft.

NOTE:

• Ensure that the pin sections of the manual valve lever

subassembly (B) and the parking rod lever subassembly (C) are engaged with the groove section of the

manual valve idler plug.

• Ensure that each link moves smoothly.

(B)

AT–31

JAT00106-00104

(C)

ATF

(A)

ATF

(2) Install the valve body assembly to the transmission

case.

NOTE:

• Ensure that the protrusion of the manual valve lever (A)

and grooved section of the manual valve (B) are

matched securely.

• Align the forward end of the manual valve idler shaft

with the hole (C) of the valve body assembly.

(3) Tighten the 2 bolts with the (A) mark in the right figure,

and then tighten the other 5 bolts.

Tightening Torque: 6.9 - 9.8 N·m

NOTE:

• One bolt should be tightened together with the bracket.

• The numeral in the right figure indicates the nominal

length of the bolt.

(4) Ensure that the manual valve operates smoothly and

set it to the neutral position, using the following SST.

SST: 09350-87202-000 (09351-87211-000)

(C)

#5

#5

JAT00107-00105

(B)

(A)

ATF

JAT00108-00106

^5

#5

(A)

#5

#5

#5

JAT00109-00107

SST

JAT00110-00108

Page 41

AT–32

(5) Tighten the 2 bolts of the manual detent spring.

Tightening Torque: 6.9 - 9.8 N·m

NOTE:

• Be sure to tighten the bolts alternately.

(6) Attach the harness to the harness clamp.

JAT00111-00109

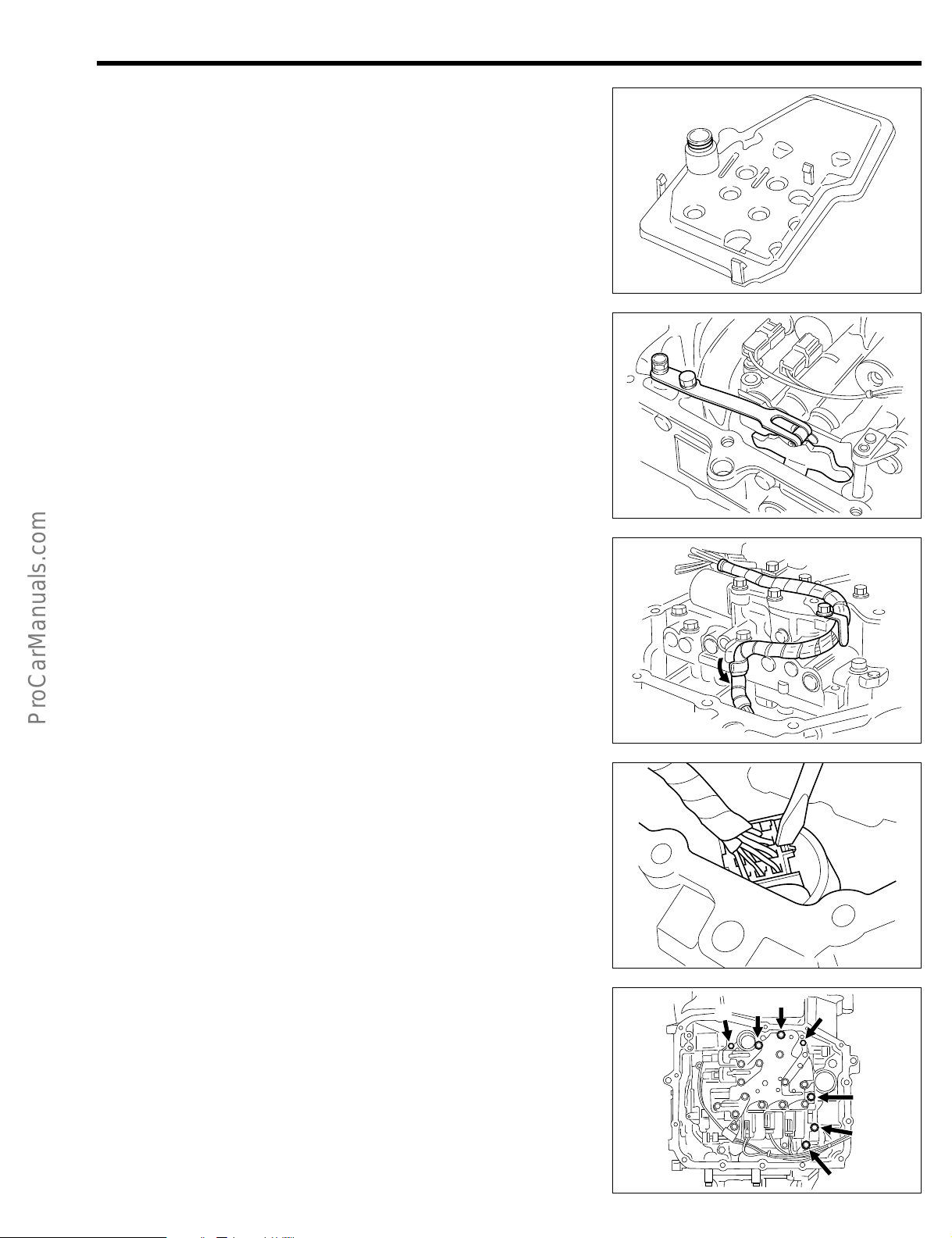

(7) Apply ATF to the new O-ring. Install the oil strainer with

the O-ring to the valve body assembly.

NOTE:

• Be sure that all 3 pawls are firmly set.

(8) Connect the transmission solenoid connector.

NOTE:

• Make sure that the pawls are firmly set.

26. Installation of transmission oil pan subassembly

(1) Place the oil cleaner magnet in the protrusion of the

transmission oil pan subassembly.

(2) Toughly remove any foreign matter (grease and water,

etc.) from both the transmission case and the transmission oil pan subassembly

(3) Apply Three Bond TB1281B or equivalent to the sur-

face of the transmission case in such a way that a

sealing may be formed without any discontinued spot,

in a size equivalent to a 1.5 mm to 2.5 mm diameter,

following the procedure given in the right figure.

JAT00112-00110

JAT00113-00111

JAT00137-00134

JAT00114-00112

Page 42

(4) Tighten the 14 bolts

Tightening Torque: 6.9 - 9.8 N·m

NOTE:

• Be sure to tighten the bolts alternately and diagonally.

27. Installation of the brackets.

Install the engine mount bracket by tightening the 3 bolts.

[A4R-D1 (2WD)]

Tightening Torque: 29.4 - 44.1 N·m

Install the control cable bracket by tighten the 2 bolts.

[A4Q-D1, A4R-D1 (4WD)]

Tightening Torque: 14.7 - 21.6 N·m

Engine mount bracket

A4R-D1 (2WD)

AT–33

JAT00115-00113

Coutrol cable bracket

A4Q-D1, A4R-D1 (4WD)

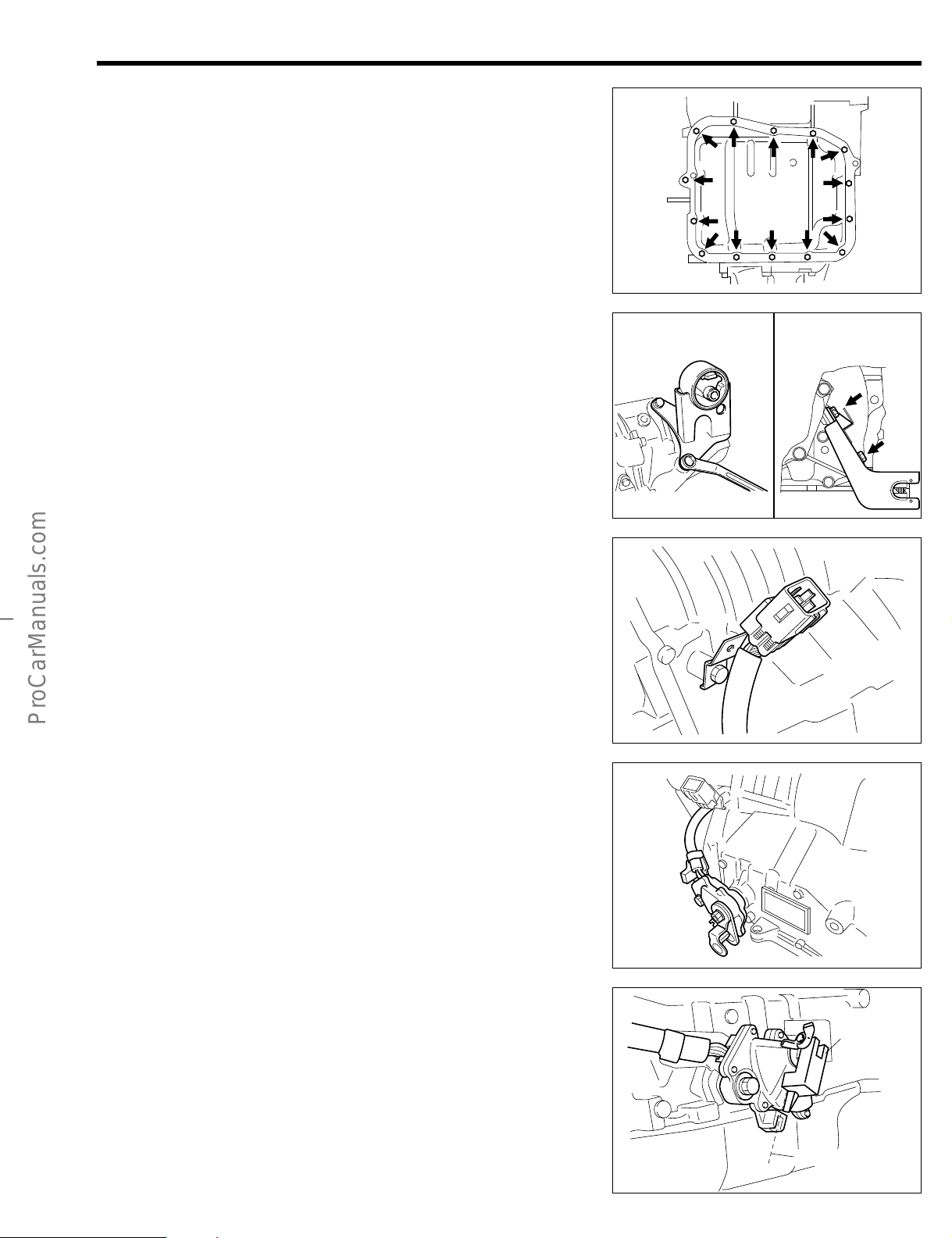

28. Tighten the bracket with the bolt and clamp the connector

of neutral start switch.

Tightening Torque: 6.9 - 9.8 N·m

NOTE:

• In the case of A4Q-D1, the direction of the coupler dif-

fers from that of A4R-D1.

29. Adjustment of neutral start switch

(1) Temporarily tighten the bolt of the neutral start switch

assembly.

(2) Place the transmission control shaft lever subassem-

bly.

(3) Push the lever toward the front side (ie: P range).

(4) Back off the lever two notches to the NEUTRAL posi-

tion.

(5) Remove the lever subassembly.

(6) Install the following SST.

SST: 09302-87201-000

(7) Adjust the neutral start switch assembly until the neu-

tral basic line on the SST should be aligned with SST

above.

(8) Tighten the bolt.

Tightening Torque: 14.7 - 21.6 N·m

JAT00124-00122

JAT00119-00117

JAT00116-00114

SST

Neutral basic line

JAT00117-00115

Page 43

AT–34

30. Tighten the lever subassembly with a nut.

Tightening Torque: 9.8 - 15.7 N·m

31. Installation of the 2 transmission revolution sensors.

(1) Coat the new O-ring section of the 2 transmission revo-

lution sensors with the ATF and insert the 2 transmission revolution sensors into the transmission case.

(2) Tighten the bolts

Tightening Torque: 6.9 - 9.8 N·m

JAT00118-00116

32. Install the speedometer shaft sleeve assembly. [A4R-D1]

(1) Coat the new O-ring section of the speedometer shaft

sleave assembly, and insert it to the transmission case.

(2) Tighten the bolt.

Tightening Torque: 6.9 - 9.8 N·m

33. Tighten the breather union and install the breather cap.

Tightening Torque: 2.9 - 9.8 N·m

34. Coat a new O-ring with the ATF and install it to the transmission oil filler tube subassembly.

NOTE:

• Be very careful not to twist or damage of the O-ring

during installation.

JAT00120-00118

JAT00121-00119

JAT00122-00120

35. Insert the transmission oil filler tube subassembly to the

transmission case and tighten it with the bolt.

Tightening Torque: 6.9 - 9.8 N·m

JAT00123-00121

Page 44

36. Install the transmission case assembly to the vehicle.

NOTE:

• Be sure to follow instructions in the AT section of the

Chassis Section of each model.

AT–35

JAT00125-00000

Page 45

AT–36

Shape Part No.

09302-87201-000

09301-87702-000

Gauge, neutral start switch adjust

Tool, clutch guide

Puller, oil seal

Replacer, counter shaft front bearing

Tool set, automatic transmission

Compressor, piston spring No. 1

Compressor, piston spring No. 2

Attachment, dial gauge

Compressor, spring

09308-10010-000

09310-87301-000

09350-87202-000

09351-87201-000

09351-87202-000

09351-87203-000

09351-87204-000

Part name

*It should be noted that 09350-87202 contains SSTs other than those posted in this section.

09351-87205-000

09351-87206-000

09351-87207-000

Holder, reduction drive gear holding

Driver, oil pump

Guide, oil pump

SST (Special Service Tools)

Page 46

AT–37

Shape Part No.

09351-87208-000

09351-87209-000

Measure, direct & forward clutch

Stopper, drive gear

Base, dial gauge stand

Tool, manual value setting

Holder, direct clutch

Gauge, centering side gear

Holder, ball bearing

Handle

09351-87210-000

09351-87211-000

09351-87212-000

09351-87213-000

09351-87214-000

09611-87506-000

Replacer, oil seal No. 809518-87709-000

Part name

*It should be noted that 09350-87202 contains SSTs other than those posted in this section.

09636-20010-000 Replacer, upper ball joint dust cover

Puller, alternator rear bearing

Puller, universal

09820-00021-000

09950-20017-000

Replacer, hole snap ring09351-97201-000

Page 47

AT–38

Shape Part No.

Bearing remover

Replacer, output shaft bearing

Replacer, oil seal No. 1

09950-87701-000

09309-87301-000

09517-87203-000

Replacer, oil seal No. 209517-87205-000

Remover & replacer, camshaft bearing09215-00101-000

Tool set, front hub & drive pinion bearing09608-30012-000

Part name

JAT00126-00123

Page 48

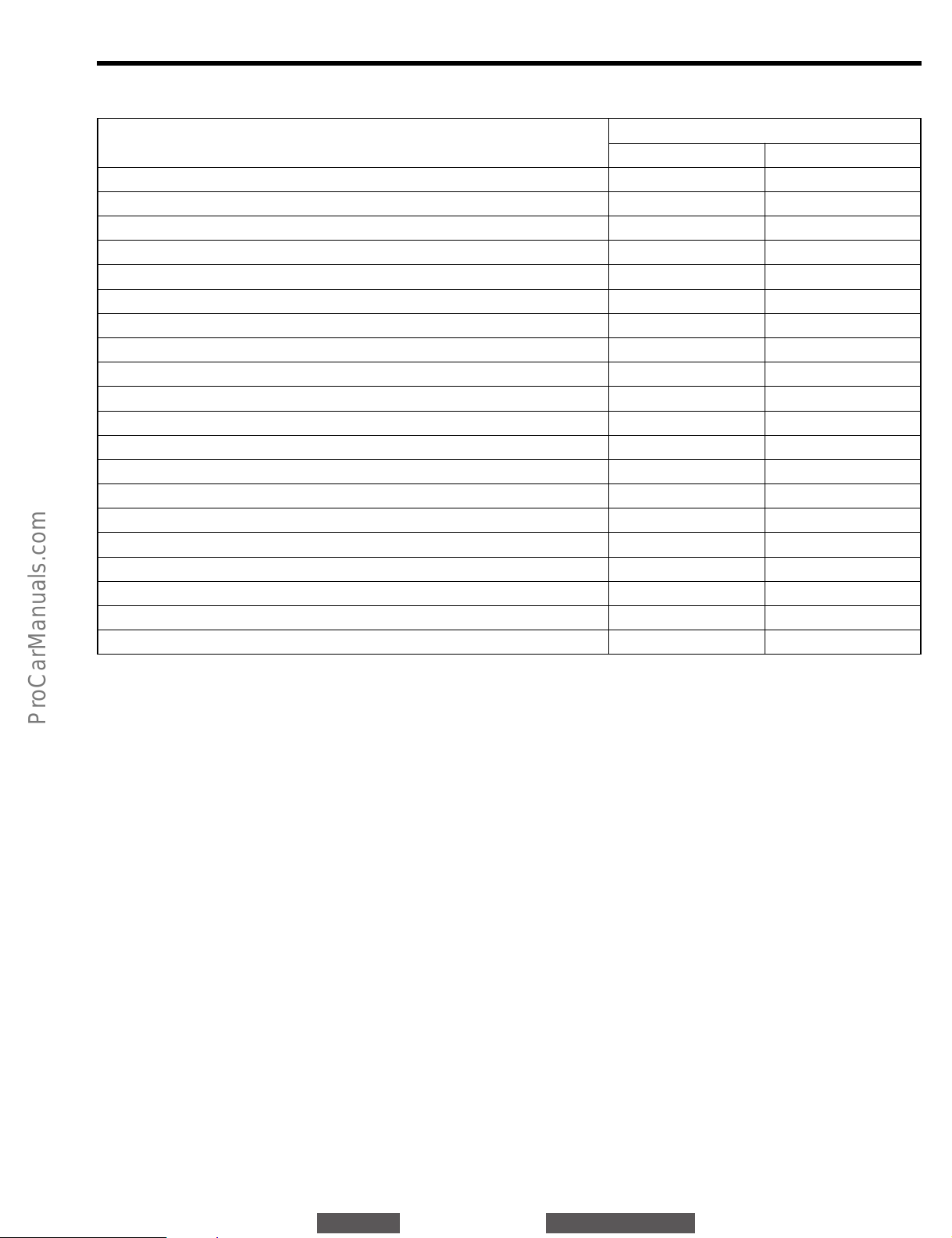

TIGHTENING TORQUE

Tightening torque

N·m kgf-m

Tightening components

Transfer × Side cover [4WD]

Side cover × Transmission case [4WD]

Oil guide plate × Side cover [4WD]

Extension × Transmission case [2WD]

Control cable bracket × Transmission case [A4Q-D1, A4R-D1 (4WD)]

Engine mount bracket × Extension [A4R-D1 (2WD)]

Speedometer sleeve lock plate × Transmission case [A4R-D1 (2WD)]

Stator shaft & oil pump × Transmission case

Oil pan × Transmission case

Drain plug × Oil pan

Valve body × Transmission case

Manual detent spring × Transmission case

Parking lock cam support × Transmission case

Neutral start switch × Transmission case

Transmission control shaft lever × NSS

Neutral start switch bracket × Transmission case

Transmission revolution sensor × Transmission case

Transmission solenoid connector × Transmission case

Oil filler tube × Transmission case

Breather plug union × Transmission case

29.4 - 44.1

14.7 - 21.6

6.9 - 9.8

14.7 - 21.6

14.7 - 21.6

29.4 - 44.1

6.9 - 9.8

6.9 - 9.8

6.9 - 9.8

19.6 - 29.6

6.9 - 9.8

6.9 - 9.8

14.7 - 17.6

14.7 - 21.6

9.8 - 15.7

6.9 - 9.8

6.9 - 9.8

6.9 - 9.8

6.9 - 9.8

2.9 - 9.8

3.0 - 4.5

1.5 - 2.2

0.7 - 1.0

1.5 - 2.2

1.5 - 2.2

3.0 - 4.5

0.7 - 1.0

0.7 - 1.0

0.7 - 1.0

2.0 - 3.0

0.7 - 1.0

0.7 - 1.0

1.5 - 1.8

1.5 - 2.2

1.0 - 1.6

0.7 - 1.0

0.7 - 1.0

0.7 - 1.0

0.7 - 1.0

0.3 - 1.0

TO INDEX TO NEXT SECTION

AT–39

JAT00127-00000

Loading...

Loading...