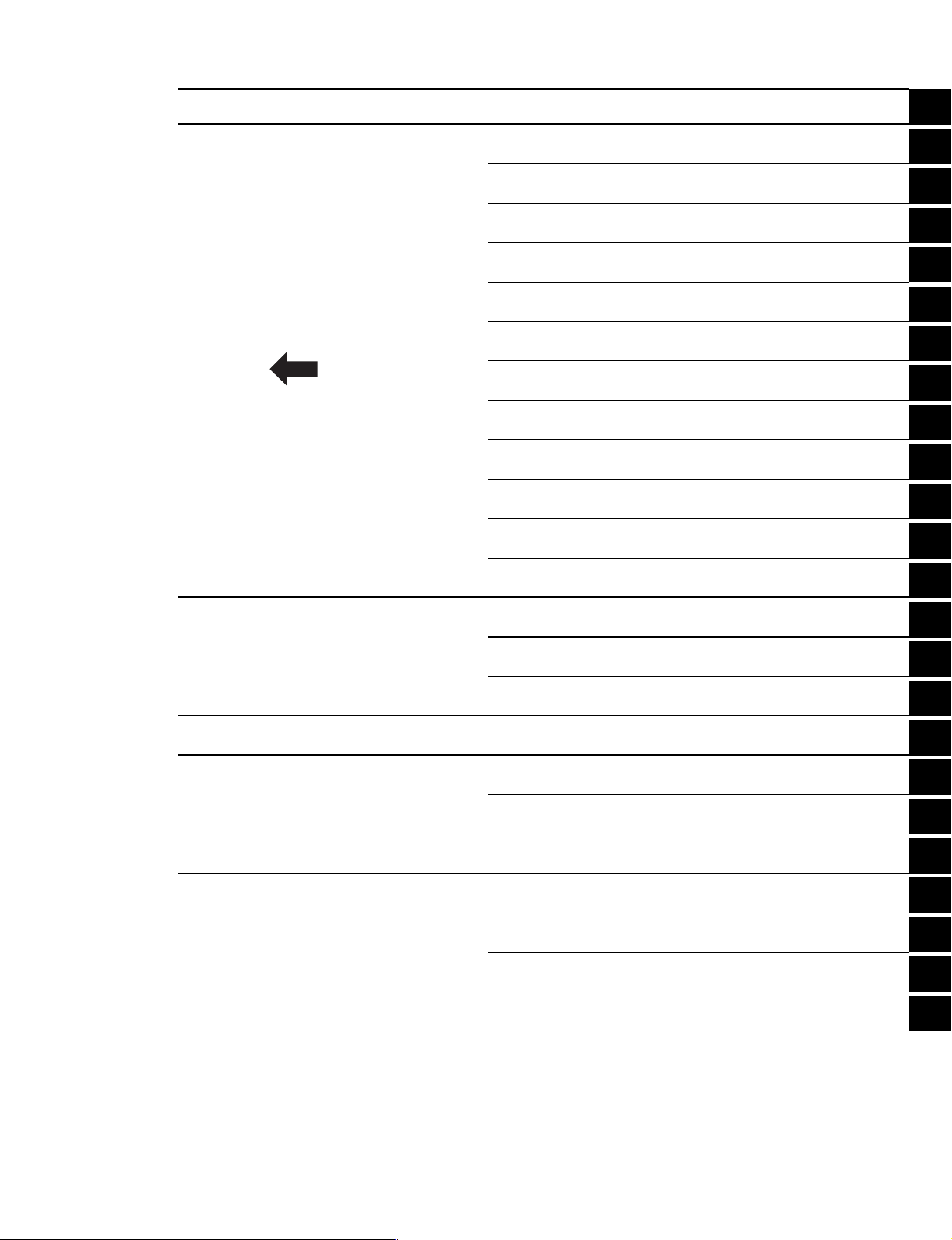

Page 1

A1

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

C1

C2

C3

D2

E1

E2

E3

F1

F2

F3

F5

A.

GENERAL INFORMATION

B.ENGINE

C.SUSPENSION

D.DRIVELINE/AXLE

E.BRAKE

F. TRANSMISSION/

TRANSAXLE

GENERAL INFORMATION

ENGINE DESCRIPTION

ENGINE MECHANICAL

INTAKE SYSTEM

EXHAUST SYSTEM

LUBRICATION SYSTEM

COOLING SYSTEM

FUEL SYSTEM

ENGINE CONTROL SYSTEM

EMISSION CONTROL SYSTEM

IGNITION SYSTEM

STARTING SYSTEM/CHARGING SYSTEM

ENGINE MOUNTING

FRONT SUSPENSION

REAR SUSPENSION

WHEEL & TIRE

PROPELLER SHAFT/AXLE

BRAKE

PARKING BRAKE

BRAKE CONTROL

CLUTCH

MANUAL TRANSMISSION/MANUAL TRANSAXLE

AUTOMATIC TRANSMISSION/AUTOMATIC TRANSAXLE

TRANSMISSION CONTROL

Page 2

G1

G2

H1

I1

I2

I3

I4

J1

J2

J3

J4

J5

J6

K1

L2

G.STEERING

H.SRS AIRBAG

I.BODY

J.

BODY ELECTRICAL SYSTEM

K.

HEATER AND AIR CONDITIONER

L.

VEHICLE COMMUNICATIONS

STEERING

POWER STEERING

SRS AIRBAG SYSTEM

BODY

EXTERIOR/INTERIOR

WINDSHIELD WINDOWGLASS/MIRROR

DOOR LOCK & THEFT DETERRENT

LIGHTING

WIPER & WASHER

METER

AUDIO & VISUAL SYSTEM

WIRING

OTHER ELECTRICAL PARTS

HEATER & AIR CONDITIONER

MULTIPLEX COMMUNICATION SYSTEM

Page 3

CAN COMMUNICATION SYSTEM ------------ L2 - 1

OUTLINE ----------------------------------------- L2 - 1

DESCRIPTION ------------------------------- L2 - 1

SYSTEM DRAWING ----------------------- L2 - 1

SYSTEM WIRING DIAGRAM ------------ L2 - 3

LOCATION OF COMPONENTS--------- L2 - 8

CONTROL---------------------------------------- L2 - 9

COMMUNICATION CONTROL ---------- L2 - 9

COMMUNICATION PROTOCOL ------ L2 - 10

COMMUNICATION DATA---------------- L2 - 10

DIAGNOSIS (SELF-DIAGNOSIS)

FUNCTION----------------------------------- L2 - 11

FAIL-SAFE CONTROL ------------------- L2 - 11

COMPONENTS ------------------------------- L2 - 12

DLC-------------------------------------------- L2 - 12

TERMINATING RESISTANCE --------- L2 - 12

LIN COMMUNICATION SYSTEM ------------ L2 - 13

OUTLINE---------------------------------------- L2 - 13

DESCRIPTION ----------------------------- L2 - 13

SYSTEM DRAWING --------------------- L2 - 13

SYSTEM WIRING DIAGRAM ---------- L2 - 14

LOCATION OF COMPONENTS ------- L2 - 16

CONTROL -------------------------------------- L2 - 17

COMMUNICATION CONTROL -------- L2 - 17

WAKE-UP/SLEEP FUNCTION --------- L2 - 17

LIN COMMUNICATION PROTOCOL

(COMMUNICATION REGULATION)-- L2 - 18

DIAGNOSIS (ONBOARD

DIAGNOSIS FUNCTION)---------------- L2 - 18

FAIL-SAFE FUNCTION ------------------ L2 - 18

L2 MULTIPLEX COMMUNICATION SYSTEM

L2

TO INDEX

Page 4

ÄÄ

CAN COMMUNICATION SYSTEM

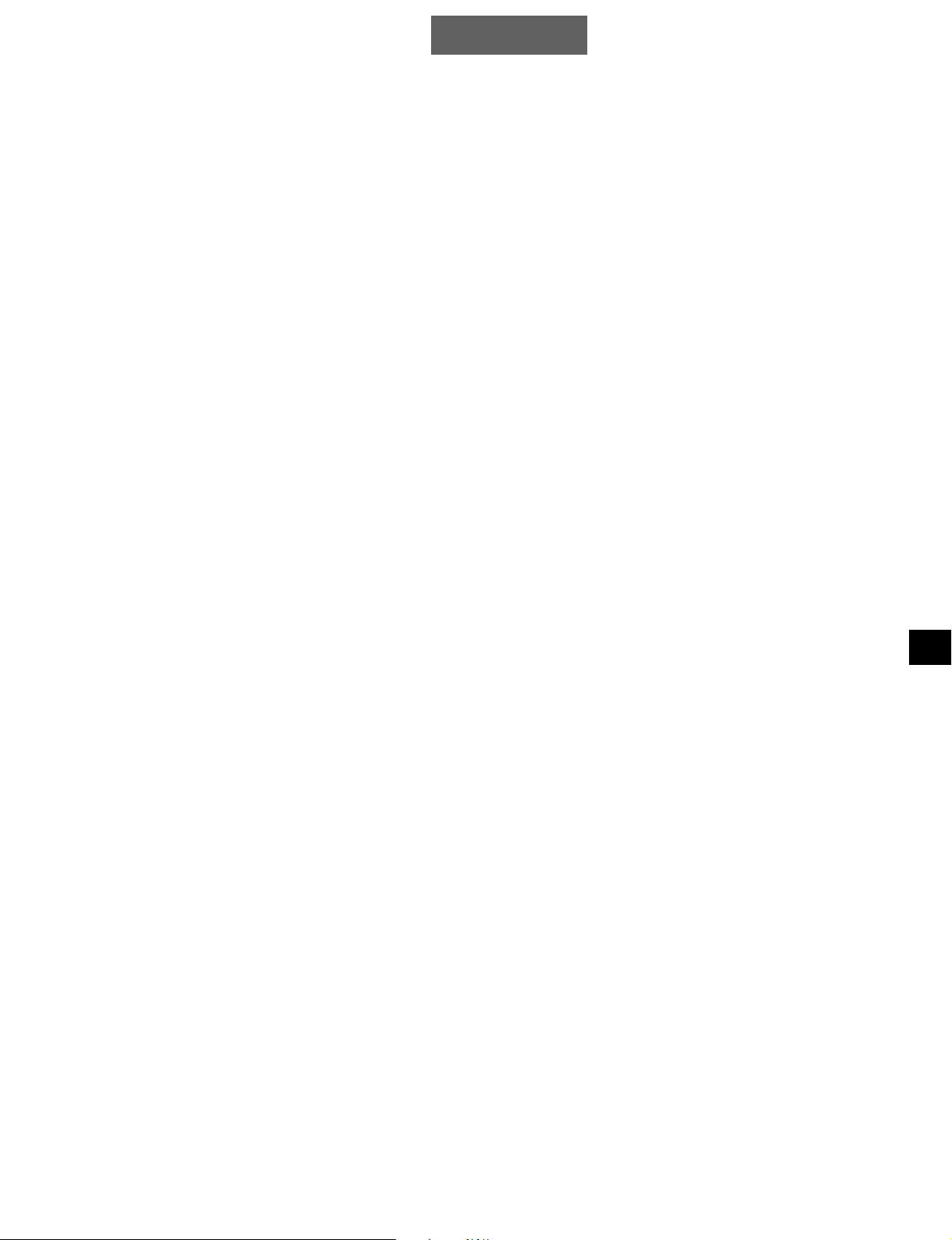

1OUTLINE

1-1 DESCRIPTION

1.A CAN

ŕg,DK_Mŧ

communication system which controls data relating to the power train at a higher speed

is used in all vehicles.

2.The CAN system sends over a single communications line (twisted pair cable) multiple items of information and data which have been converted into digital form by a communication circuit.

This system reduces the number of the wiring harnesses and the size of the electronic control system

for the systems that connect the input side (sensors, switches, etc.), the control units and the output

side (display lamps, etc.).

3.The CAN communication system in use is a daisy chain type network with several computers connected to a pair of communication lines.

NOTE

• ~1:CAN stands for Controller Area Network. It is the serial communication based on the ISO

standard (ISO011898).

1-2 SYSTEM DRAWING

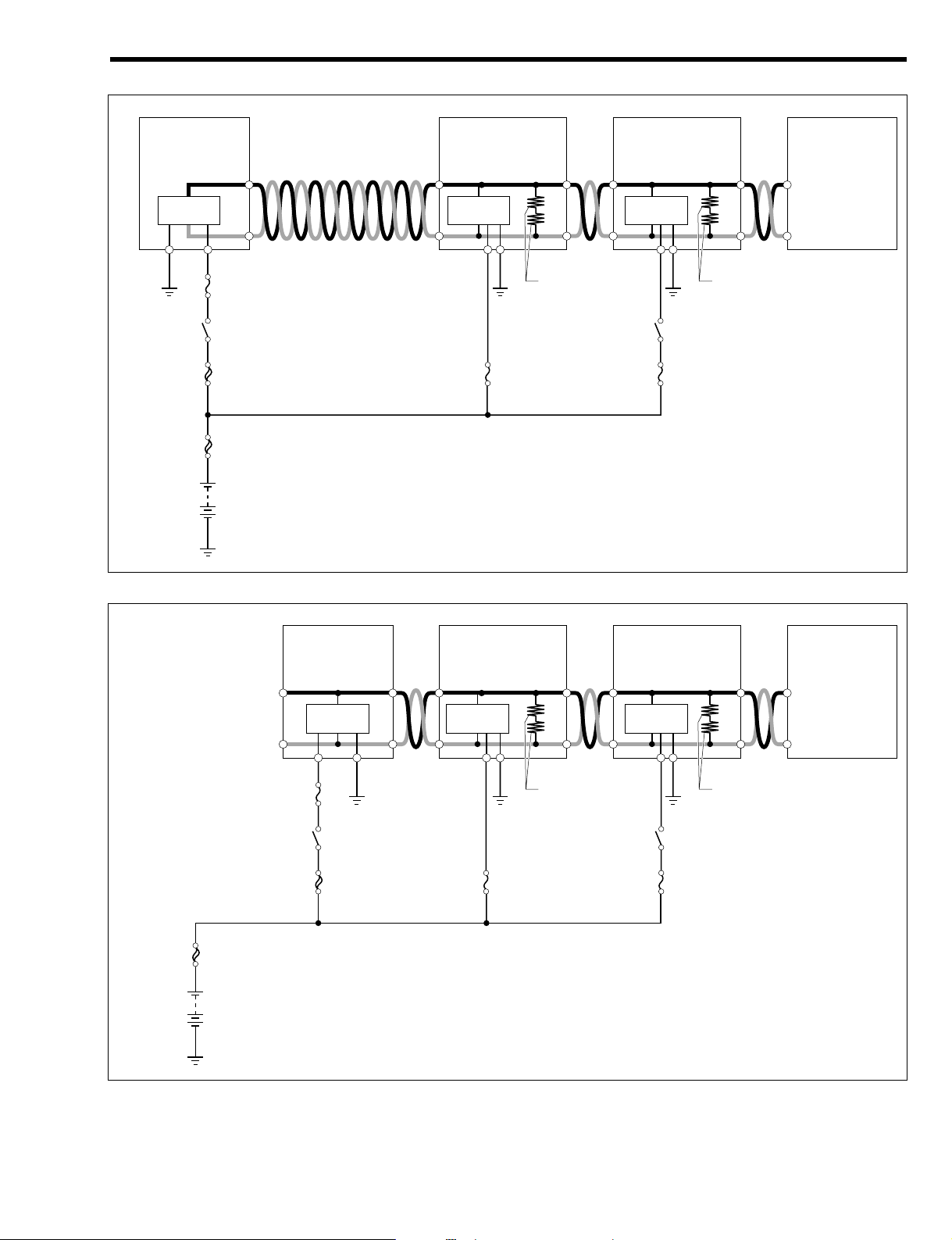

1-2-1 RHD VEHICLES

T11E1201ES24

DLC

Meter

(Meter ECU)

Transmission

control computer

(A/T ECU)

Engine control

computer

(EFI ECU)

ABS actuator

(ABS ECU)

L2–1

Page 5

CAN communication connection system (RHD vehicles)

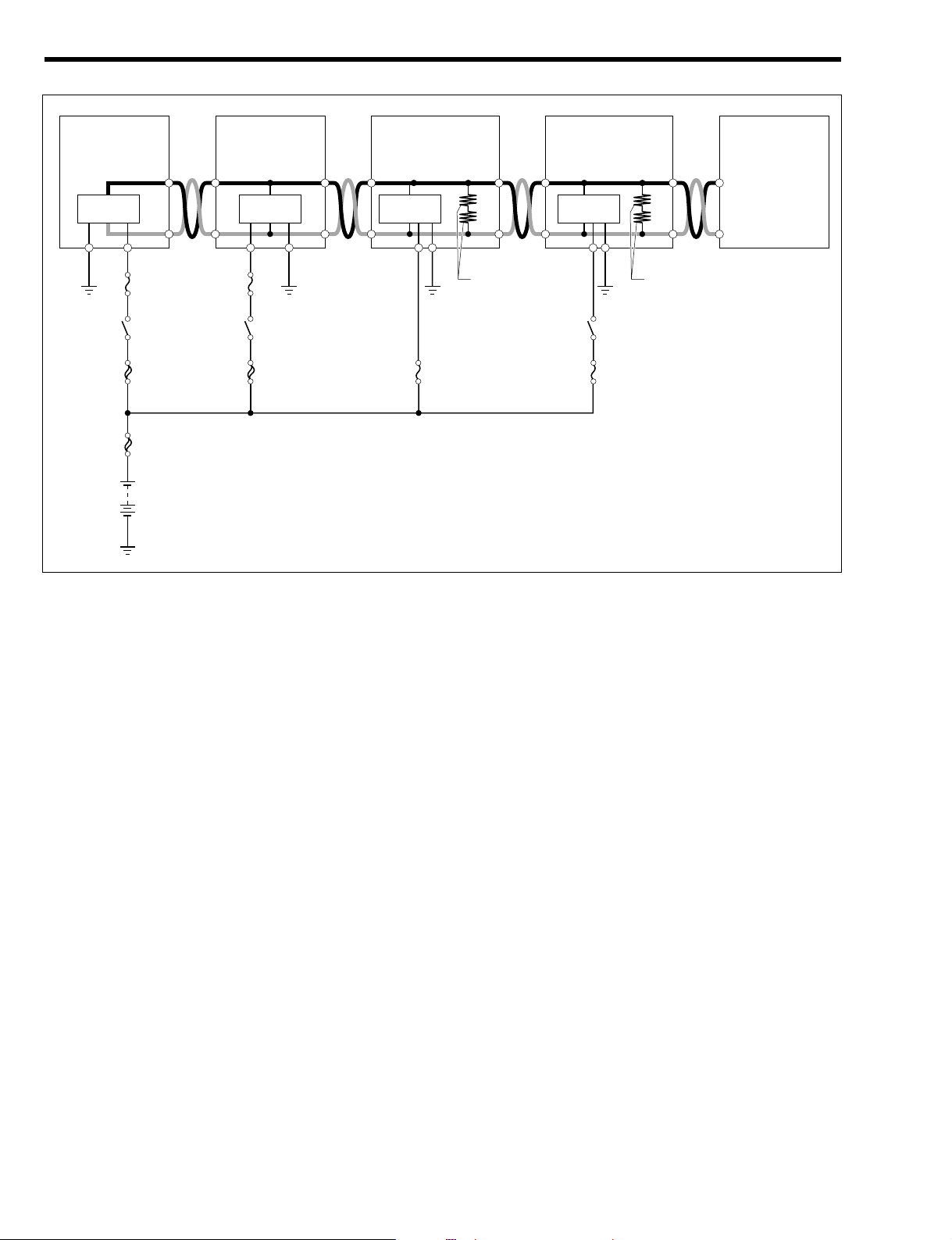

1-2-2 LHD VEHICLES

T11E1711ES24

DLC

Meter

(Meter ECU)

Transmission control

computer (A/T ECU)

Engine control

computer (EFI ECU)

ABS actuator

(ABS ECU)

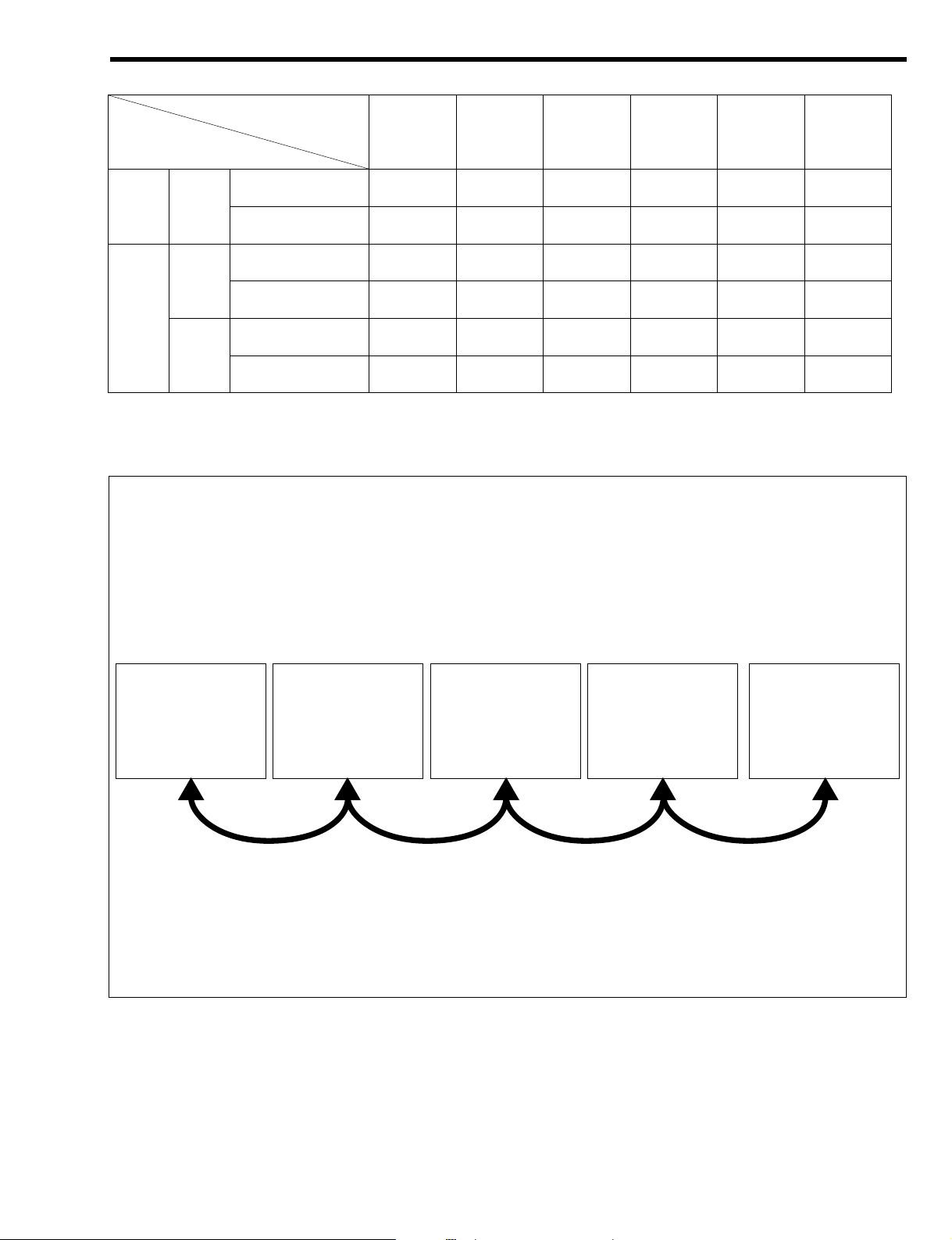

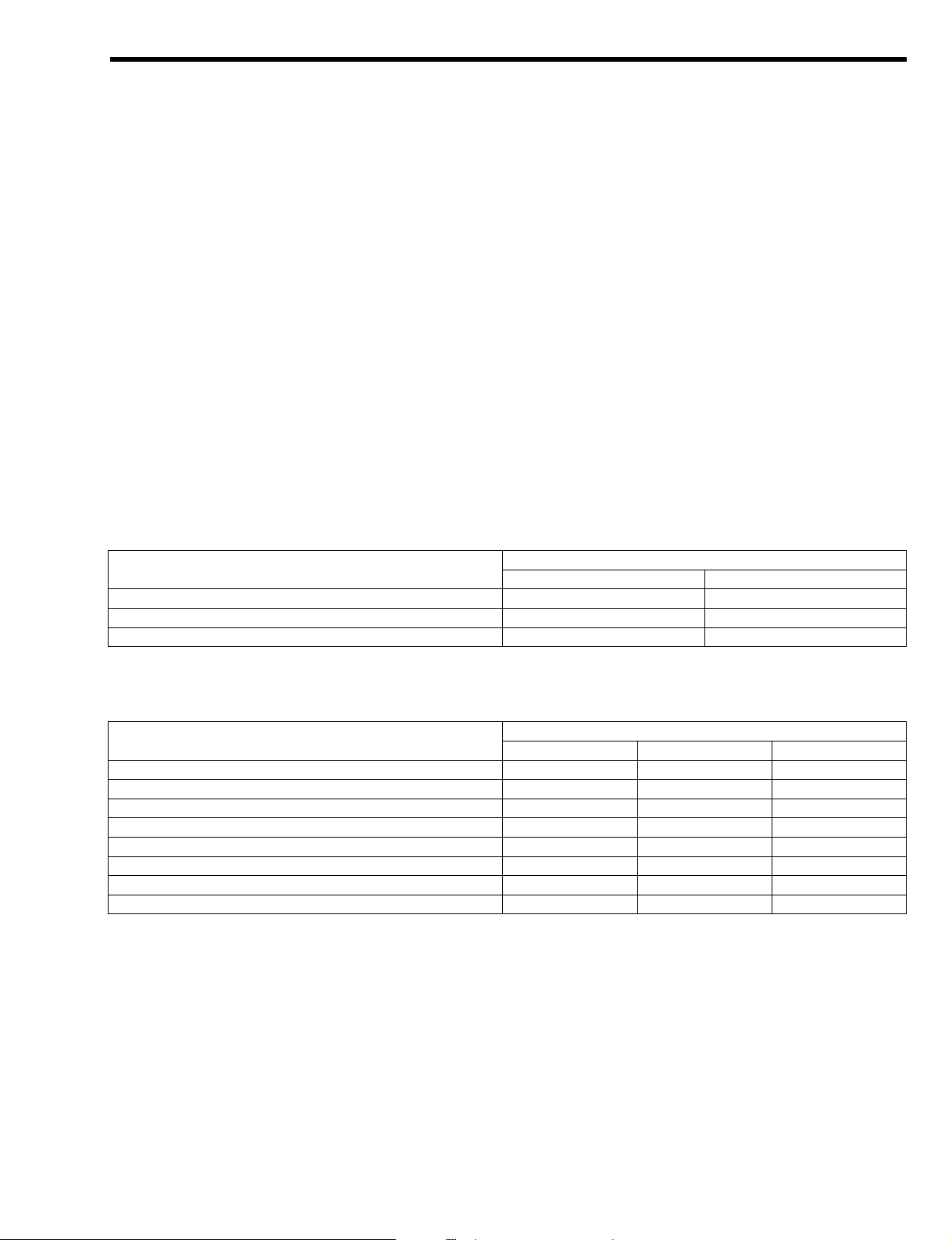

ABS ECU A/T ECU EFI ECU Meter ECU DLC Name of

CAN com-

munication

system type

Vehicles not

equipped with ABS

((<<<Type 1 1KR M/T

ABS-equipped vehi-

cles

<(<<<Type 2

Vehicles not

equipped with ABS

((<<<Type 1 M/T

ABS-equipped vehi-

cles

<(<<<Type 2

Vehicles not

equipped with ABS

(<<<<Type 3

K3

A/T

ABS-equipped vehi-

cles

<<<<<Type 4

L2–2

Page 6

CAN communication connection system (LHD vehicles)

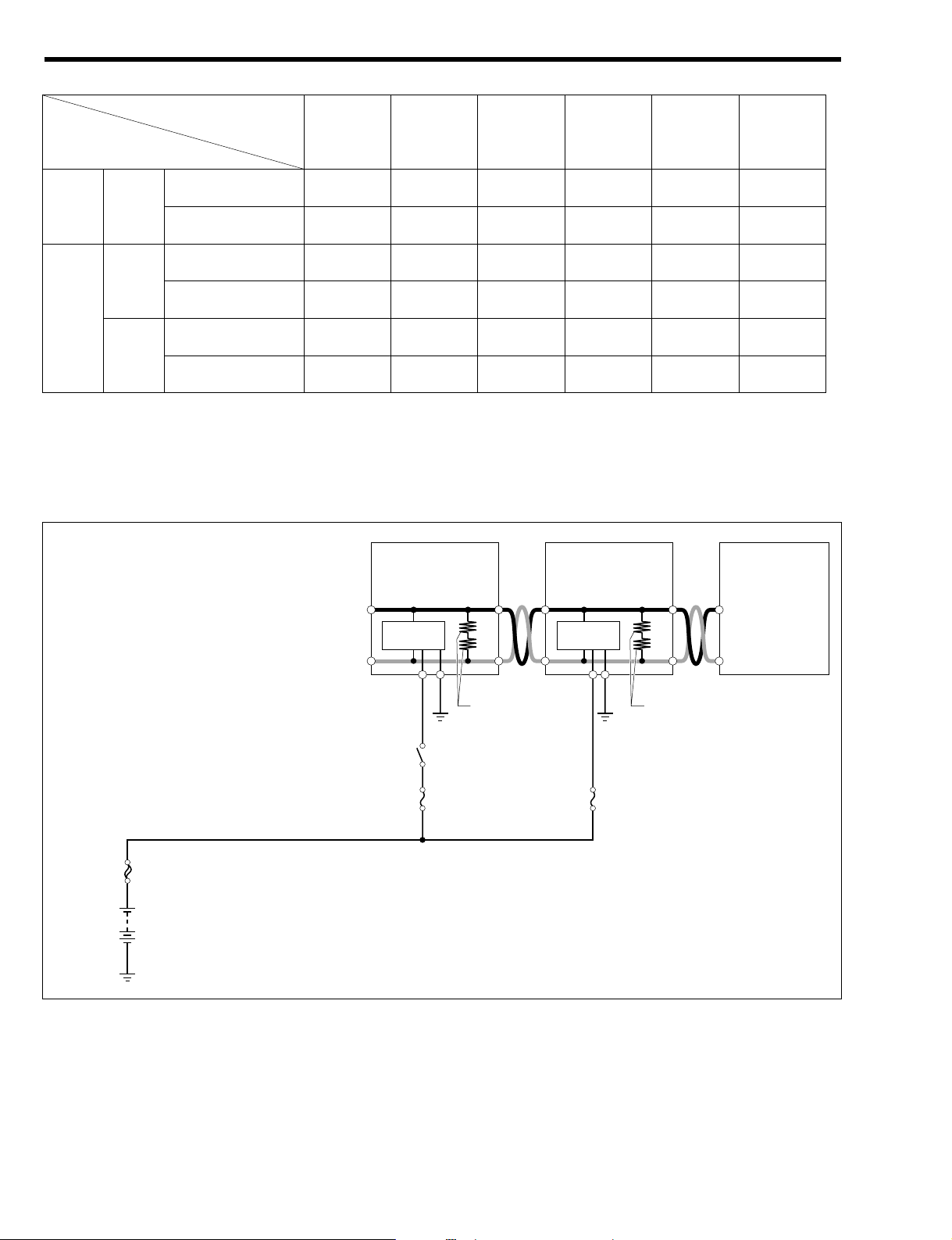

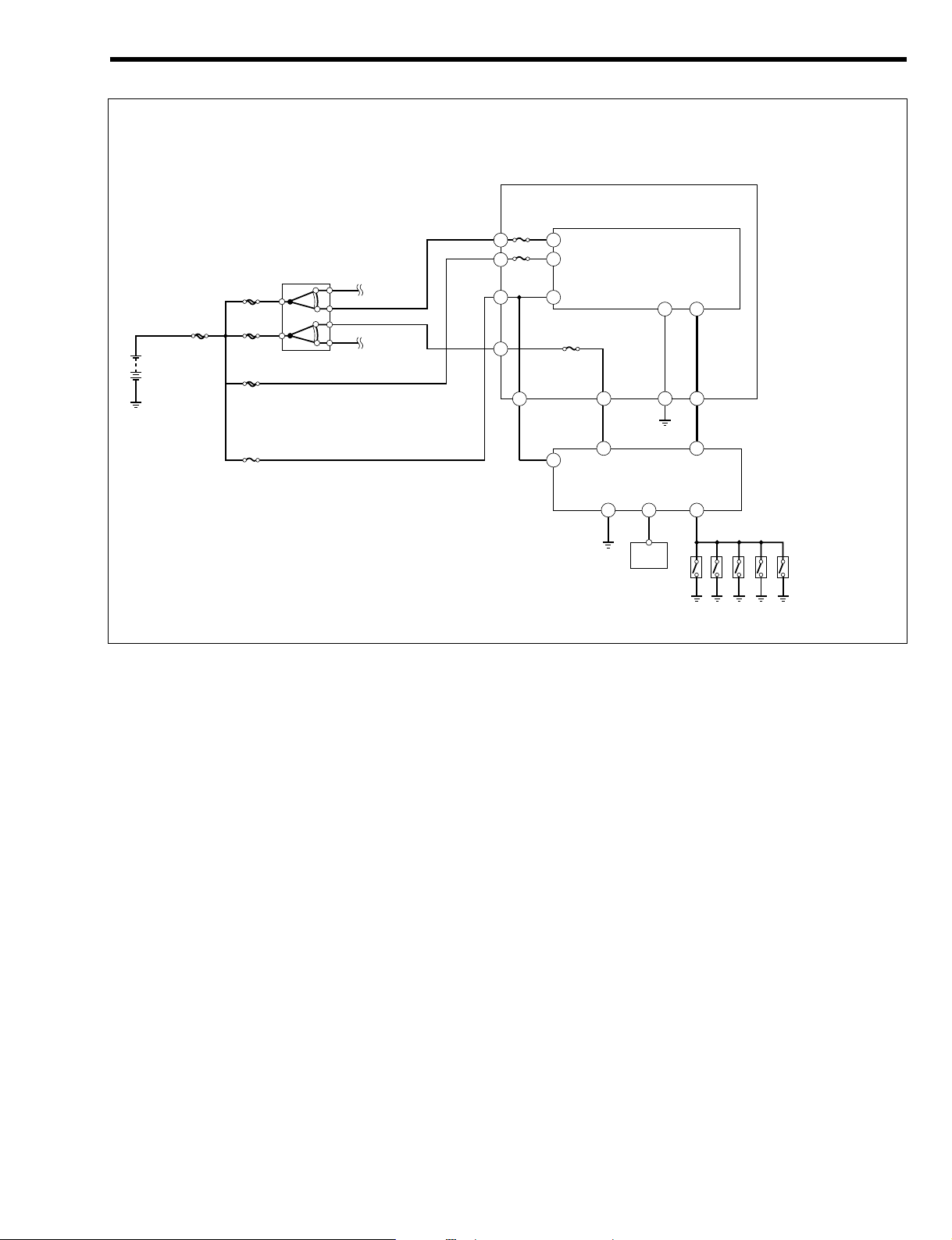

1-3 SYSTEM WIRING DIAGRAM

1-3-1 RHD VEHICLES

(1) Type 1

F/L

EFI BACK UP

Main relay

CAN

transceiver

CAN

transceiver

CANL

CANH

CANL 'B'BGND

CANH

LCAN

HCAN

CANL

CANH

Terminating resistance

(60+)

Terminating resistance

(60+)

LCANE1

HCAN

Battery

Engine control

computer (EFI ECU)

Meter (Meter ECU)

DLC

T11E1712ES22

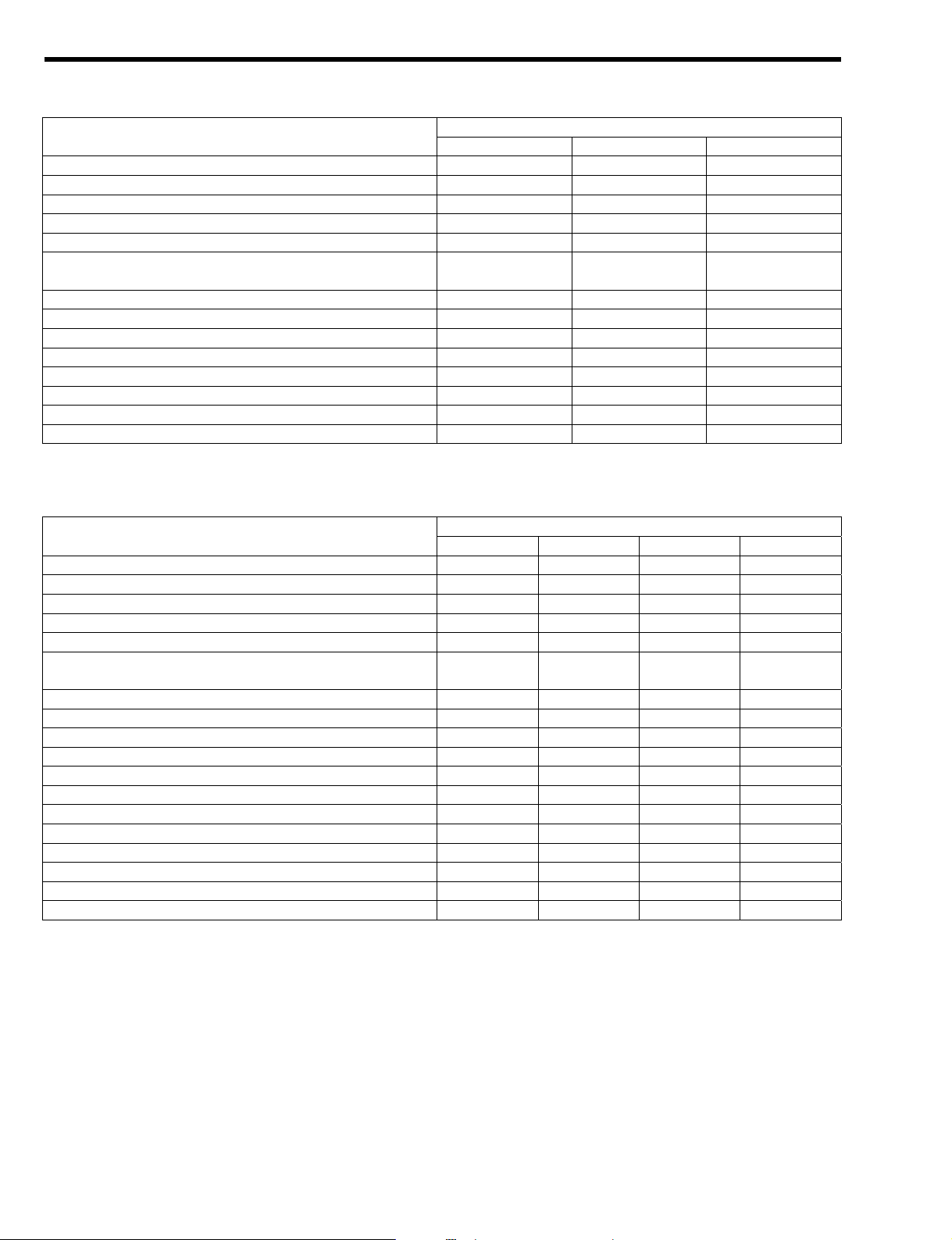

ABS ECU A/T ECU Meter ECU EFI ECU DLC Name of

CAN com-

munication

system type

Vehicles not

equipped with ABS

((<<<Type 5 1KR M/T

ABS-equipped vehi-

cles

<(<<<Type 6

Vehicles not

equipped with ABS

((<<<Type 5 M/T

ABS-equipped vehi-

cles

<(<<<Type 6

Vehicles not

equipped with ABS

(<<<<Type 7

K3

A/T

ABS-equipped vehi-

cles

<<<<<Type 8

L2–3

Page 7

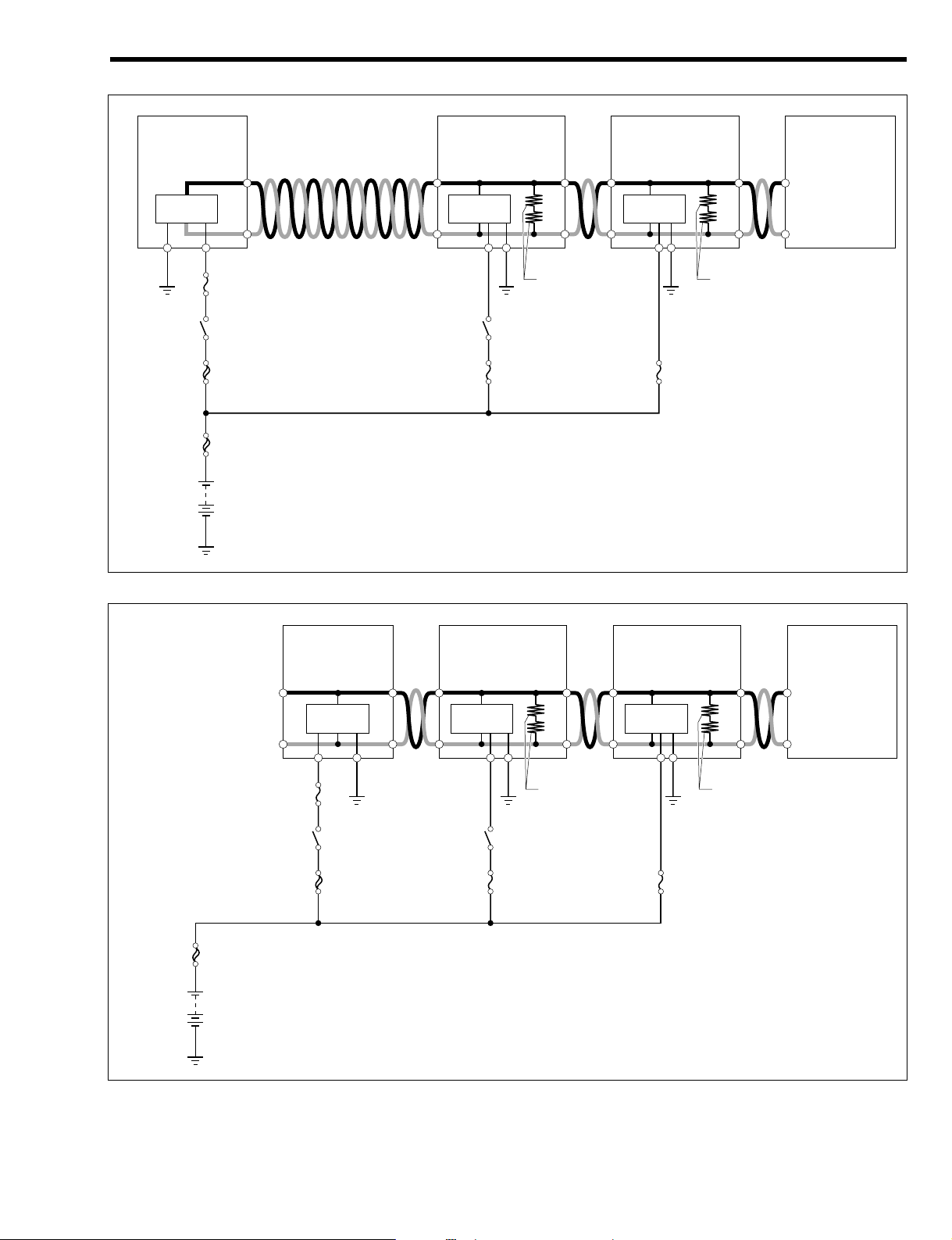

(2) Type 2

(3) Type 3

F/L

AM2 F/L EFI BACK UP

Main relay

CAN

transceiver

CAN

transceiver

CAN

transceiver

IG2 SW

ECU IG2

CANL

'B1 E1

CANH

LCN1

HCN1

CANL

CANH

CANL 'B'BGND

CANH

LCAN

HCAN

CANL

CANH

Terminating resistance

(60+)

Terminating resistance

(60+)

LCANE1

HCAN

Battery

Transmission control

computer (A/T ECU)

Engine control

computer (EFI ECU)

Meter

(Meter ECU)

DLC

T11E1714ES22

F/L

AM1 F/L

IG1 SW

ECU IG1

EFI BACK UP

Main relay

CAN

transceiver

CAN

transceiver

CAN

transceiver

GND 'IG LCAN

HCAN

CANL

CANH

CANL 'B'BGND

CANH

LCAN

HCAN

CANL

CANH

Terminating resistance

(60+)

Terminating resistance

(60+)

LCANE1

HCAN

Battery

ABS actuator

(ABS ECU)

Engine control

computer (EFI ECU)

Meter

(Meter ECU)

DLC

T11E1713ES22

L2–4

Page 8

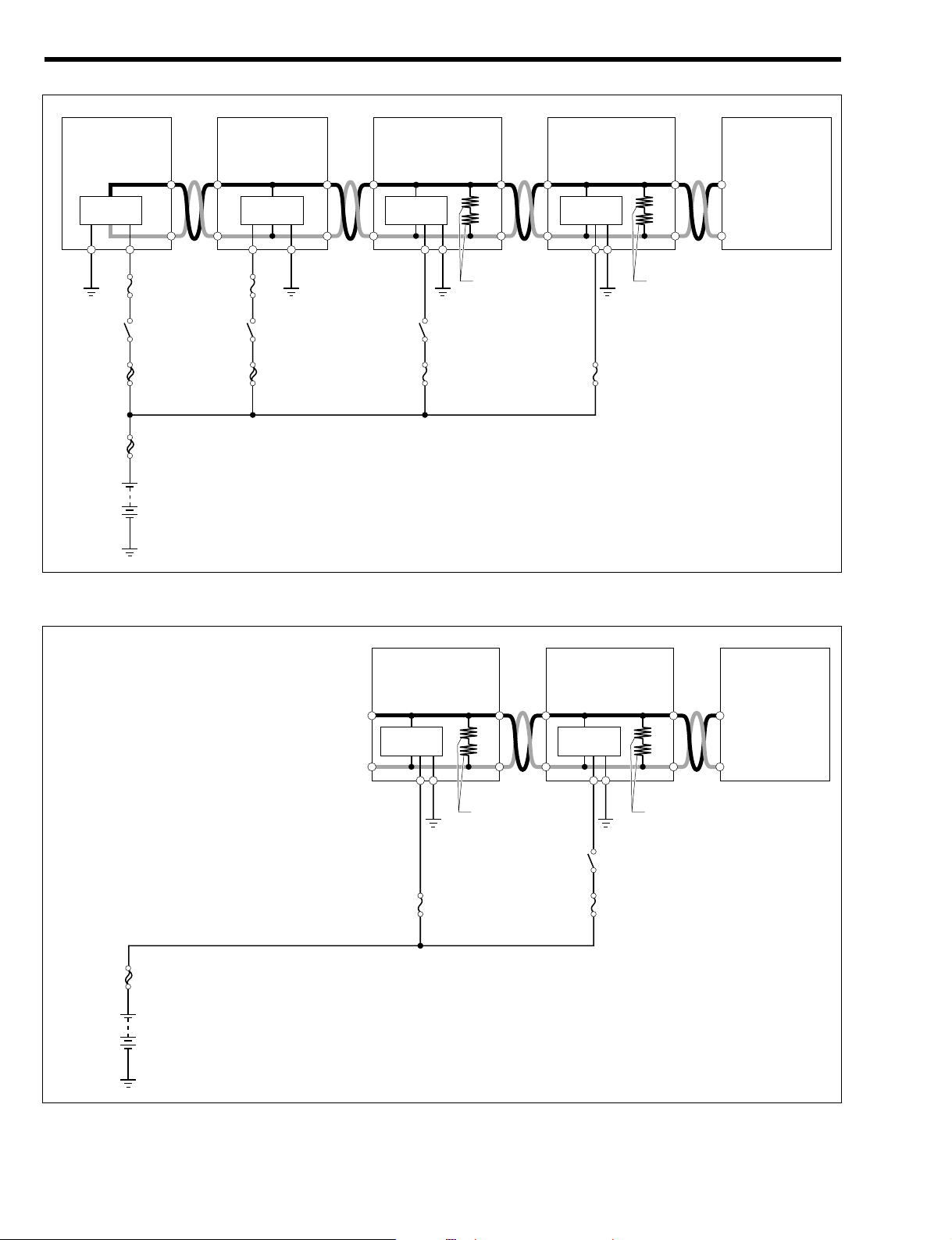

(4) Type 4

1-3-2 LHD VEHICLES

(1) Type 5

F/L

EFIBACK UP

Main relay

CAN

transceiver

CAN

transceiver

CANL

CANH

CANL 'B'BGND

CANH

LCAN

HCAN

CANL

CANH

Terminating resistance

(60+)

Terminating resistance

(60+)

LCAN E1

HCAN

Battery

Engine control

computer (EFI ECU)

Meter

(Meter ECU)

DLC

T11E1716ES22

F/L

AM1 F/L

IG1 SW

ECU IG1

AM2 F/L EFI BACK UP

Main relay

CAN

transceiver

CAN

transceiver

CAN

transceiver

CAN

transceiver

IG2 SW

ECU IG2

GND 'IG LCAN

HCAN

CANL

'B1 E1

CANH

LCN1

HCN1

CANL

CANH

CANL 'B'BGND

CANH

LCAN

HCAN

CANL

CANH

Terminating resistance

(60+)

Terminating resistance

(60+)

LCANE1

HCAN

Battery

ABS actuator

(ABS ECU)

Transmission control

computer (A/T ECU)

Engine control

computer (EFI ECU)

Meter

(Meter ECU)

DLC

T11E1715ES22

L2–5

Page 9

(2) Type 6

(3) Type 7

F/L

AM2 F/L EFIBACK UP

Main relay

CAN

transceiver

CAN

transceiver

CAN

transceiver

IG2 SW

ECU IG2

CANL

'B1 E1

CANH

LCN1

HCN1

CANL

CANH

CANL 'B'BGND

CANH

LCAN

HCAN

CANL

CANH

Terminating resistance

(60+)

Terminating resistance

(60+)

LCAN E1

HCAN

Battery

Transmission control

computer (A/T ECU)

Engine control

computer (EFI ECU)

Meter

(Meter ECU)

DLC

T11E1718ES22

F/L

AM1 F/L

IG1 SW

ECU IG1

EFIBACK UP

Main relay

CAN

transceiver

CAN

transceiver

CAN

transceiver

GND 'IG LCAN

HCAN

CANL

CANH

CANL 'B'BGND

CANH

LCAN

HCAN

CANL

CANH

Terminating resistance

(60+)

Terminating resistance

(60+)

LCAN E1

HCAN

Battery

ABS actuator

(ABS ECU)

Engine control

computer (EFI ECU)

Meter

(Meter ECU)

DLC

T11E1717ES22

L2–6

Page 10

(4) Type 8

F/L

AM1 F/L

IG1 SW

ECU IG1

AM2 F/L EFIBACK UP

Main relay

CAN

transceiver

CAN

transceiver

CAN

transceiver

CAN

transceiver

IG2 SW

ECU IG2

GND 'IG LCAN

HCAN

CANL

'B1 E1

CANH

LCN1

HCN1

CANL

CANH

CANL 'B'BGND

CANH

LCAN

HCAN

CANL

CANH

Terminating resistance

(60+)

Terminating resistance

(60+)

LCAN E1

HCAN

Battery

ABS actuator

(ABS ECU)

Transmission control

computer (A/T ECU)

Engine control

computer (EFI ECU)

Meter

(Meter ECU)

DLC

T11E1719ES22

L2–7

Page 11

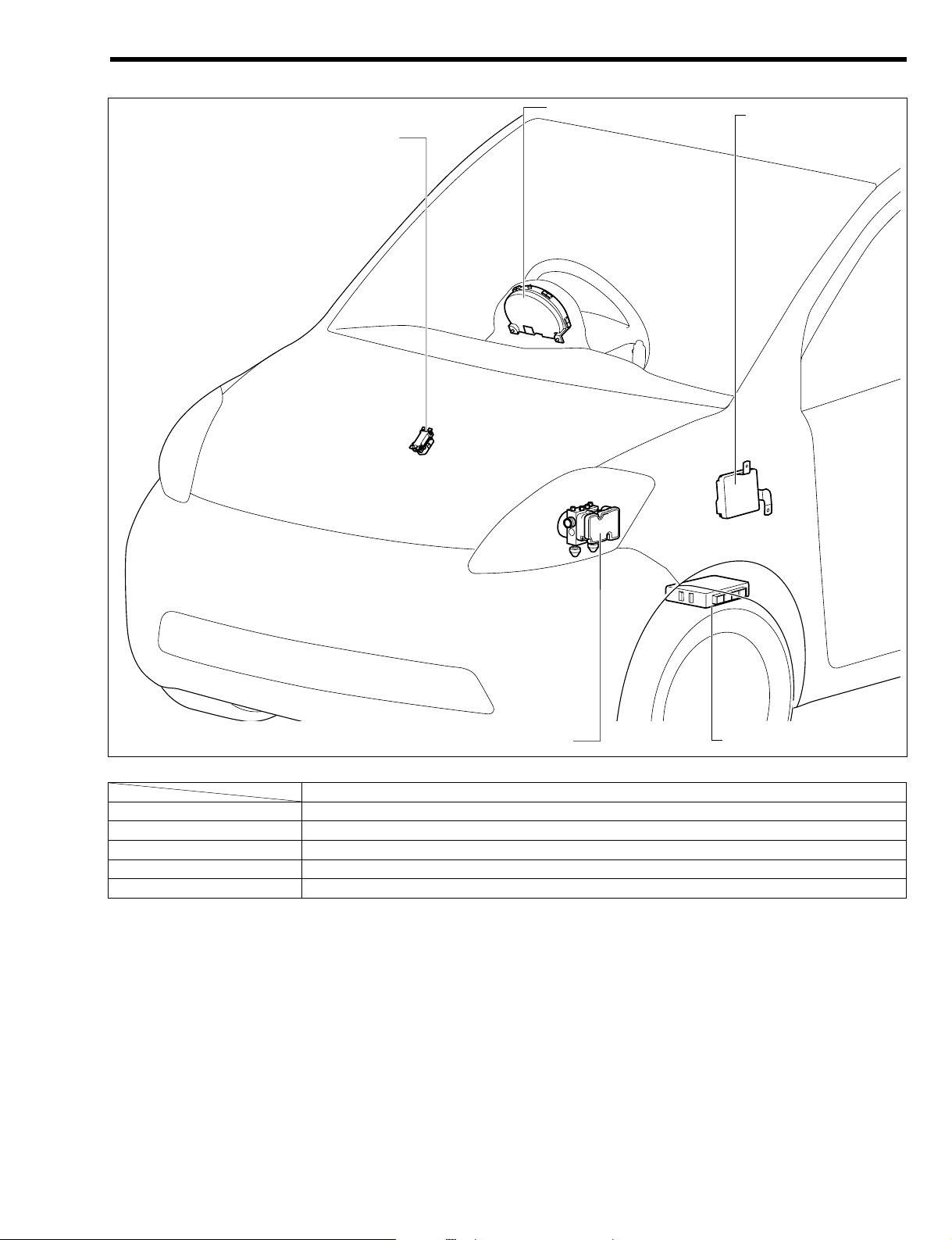

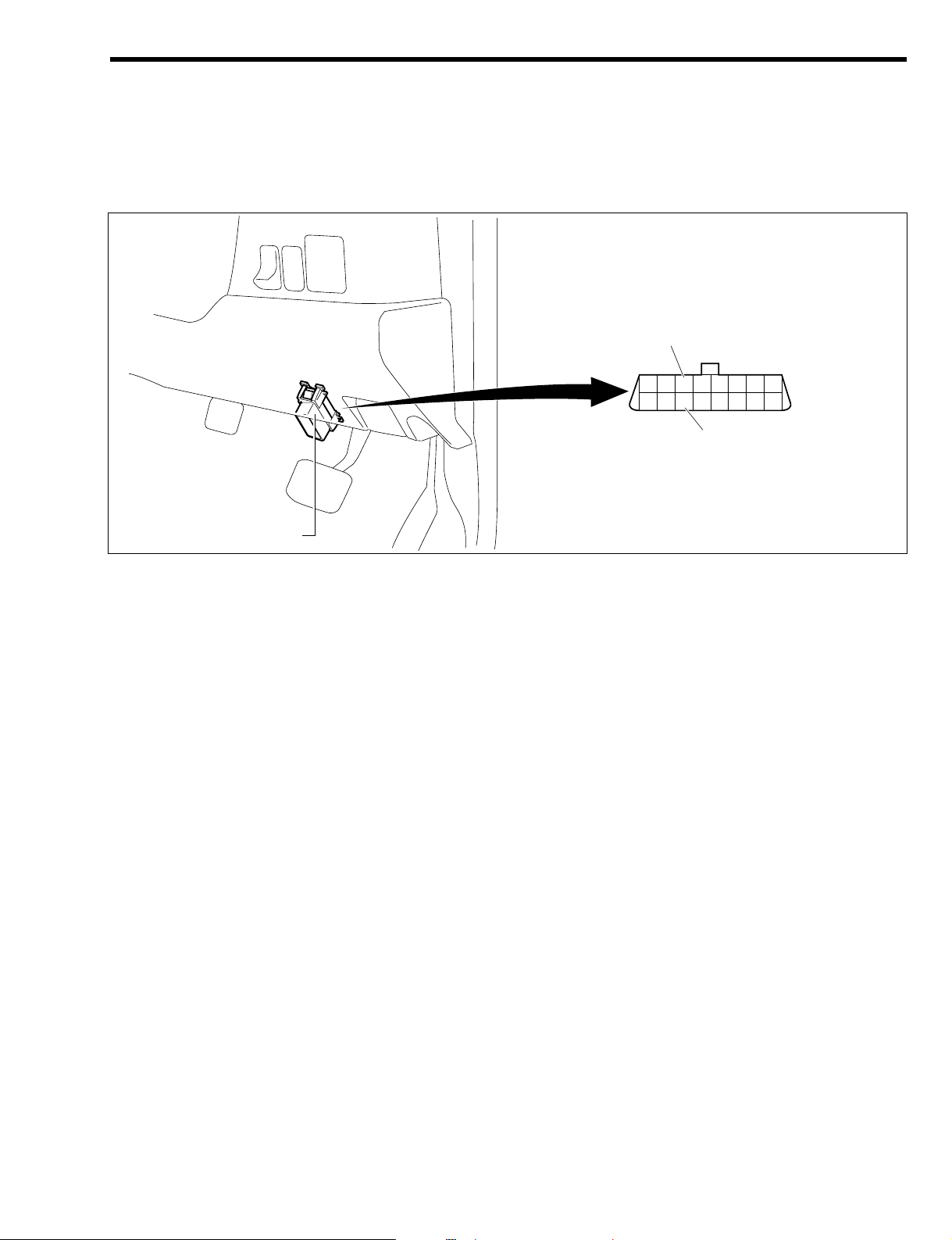

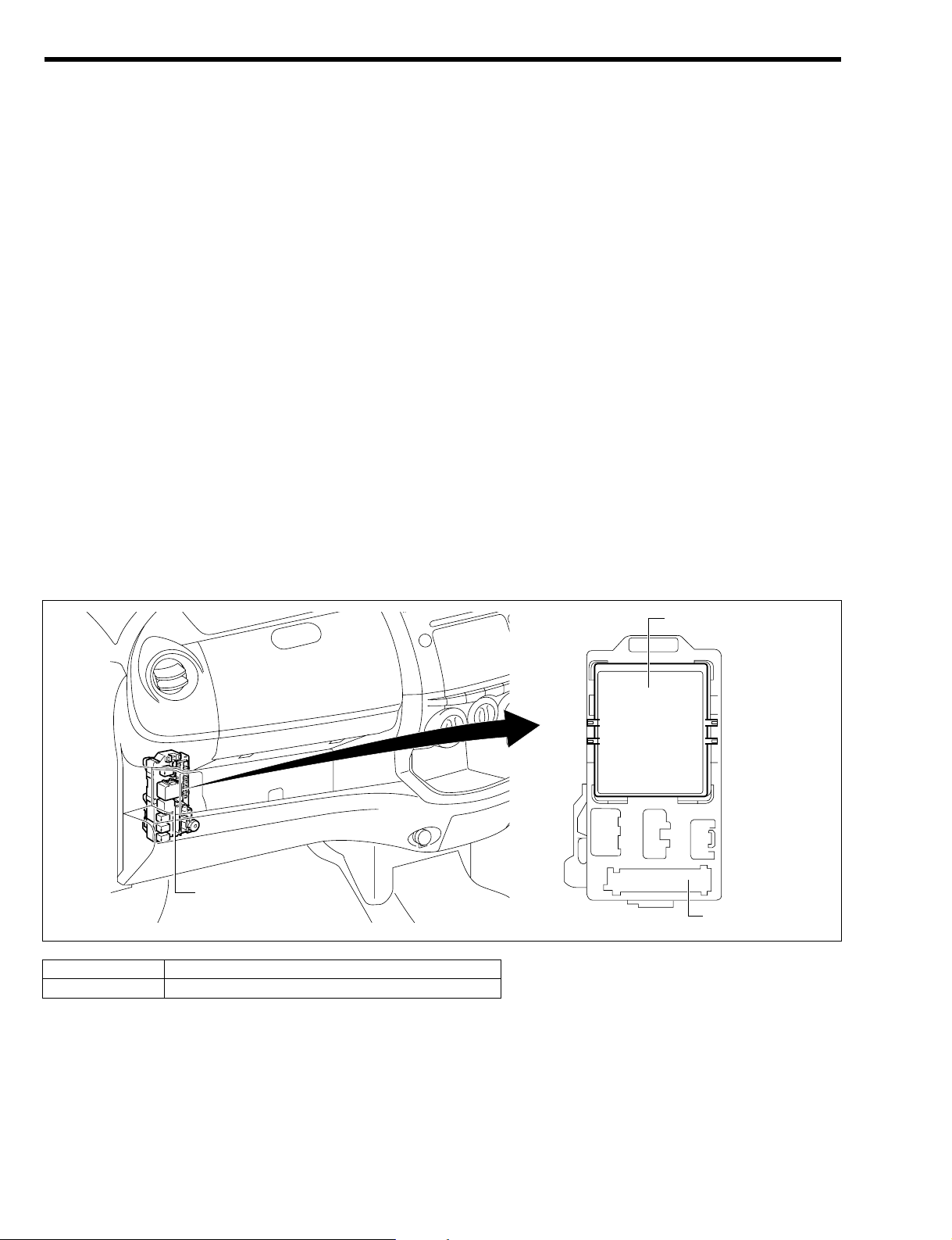

1-4 LOCATION OF COMPONENTS

The illustration show a right-hand drive vehicle.

Part name

a DLC

b Meter (meter ECU)

c Engine control computer (EFI ECU)

d Transmission control computer (A/T ECU)

e ABS actuator (ABS ECU)

T11E1203S30

a

b

d

e

c

L2–8

Page 12

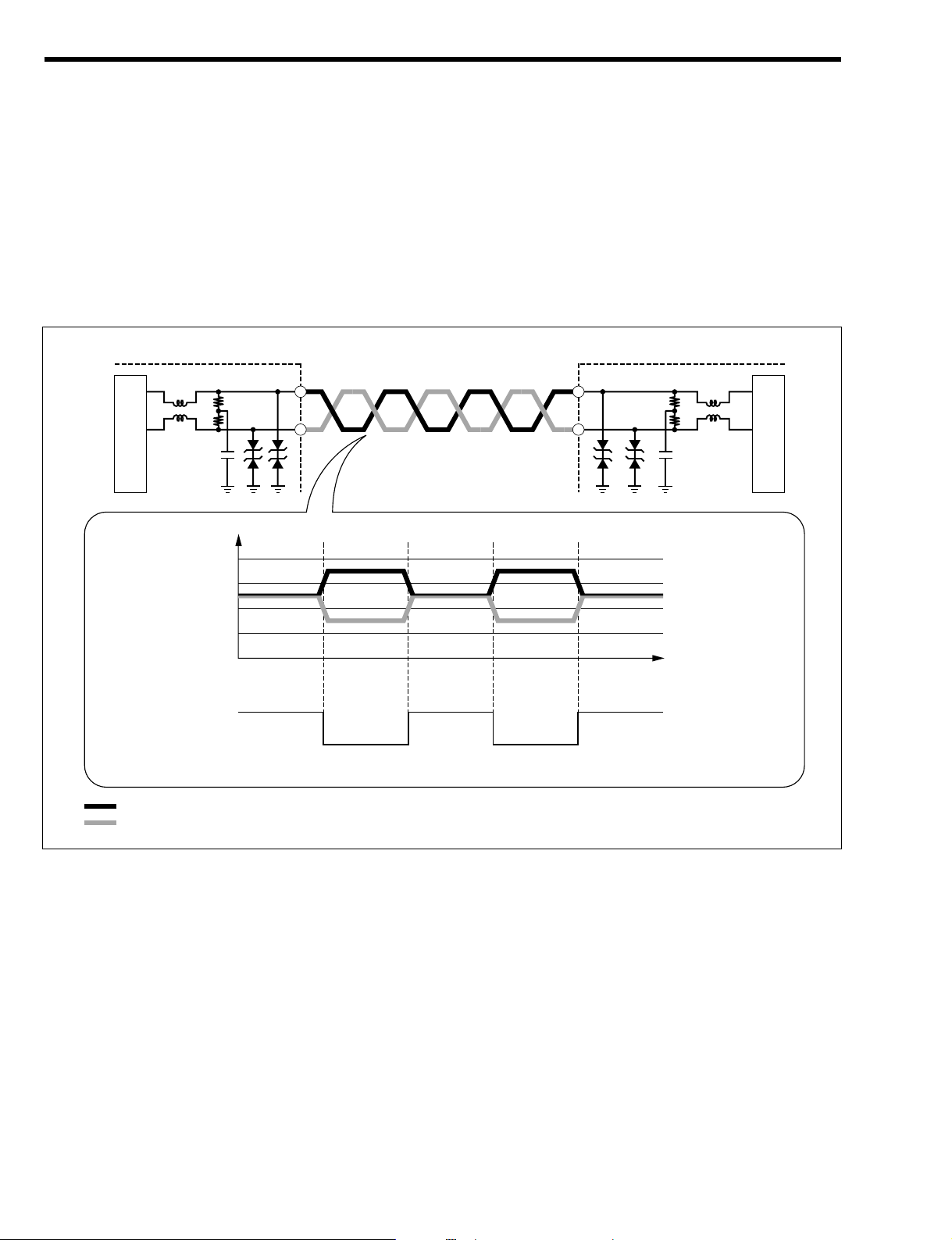

2CONTROL

2-1 COMMUNICATION CONTROL

1. A CAN communication system has two communication lines (bus) acting as a pair and the bus level

ŕg,DK_Mŧŕg,DK_Mŧ

is determined by the voltage differential between them. The two lines are called CAN

high (CANH) and CAN low (CANL) respectively. Data is transmitted at the rate of 500kbps

ŕg,DK_Mŧ

as

a digital signal according to the CAN dedicated communication protocol.

NOTE

• ~2: The bus level has a dominant level and a recessive level. CAN communication system logic

deems dominant to be 808 and recessive to be 818.

• ~3: The signal rate of data transmission is expressed in bits per second (bps). 8500kbps8

means that 500,000 bits of data are transmitted per second.

mB11E1204ES24

ECU

Voltage[V]

RecessiveBus level

: CAN High

: CAN Low

HI="1"

LO="0"

Passing of time

(Communication

speed 500kbps)

Recessive RecessiveDominant Dominant

4

3

2

1

0

ECU

CANH

CANL

CANL

CANH

CAN transceiver

CAN transceiver

"Outline of CAN

communication system wiring"

"Differential voltage and physical layer of CAN bus system"

L2–9

Page 13

2-2 COMMUNICATION PROTOCOL

1.The CAN communication system is a multiplex systems in which all the ECU's in the network use a pair

of communication lines (bus). Any of the ECU's can transmit data if the CAN bus is in an idol (open)

state. Therefore, each ECU performs the communication according to the common communication

protocol so that the communication can be done smoothly and securely.

2. Under CAN communication protocol all the ECU's share a common pair of communication lines and

have the right to start transmitting data. CSMA/CD (Carrier Sense Multiple Access / Collision

Detection)

ŕg,DK_Mŧ

is the protocol used for sending data to the communication line.

NOTE

• ~4: CSMA/CD stands for Carrier Sense Multiple Access with Collision Detection. It is a commu-

nication access protocol where ECU's check the status of the communication line (carrier) and only

if there is no other data flowing will they start to send data of their own. Further, in addition to this,

if a collision of data is detected (i.e. with data that has been transmitted by another ECU at the

same time), the offending ECU will wait for a fixed period of time and then resend the data.

3.ECU's start to transmit data when other data is not flowing in the CAN bus, but if two or more ECU's

start to transmit data simultaneously then the priority of the data is determined by the ID which the

transmitted data itself contains.

2-3 COMMUNICATION DATA

2-3-1 TYPE 1, TYPE 5

CAN communication signal

.: signal sending, <:signal receiving

2-3-2 TYPE 2, TYPE 6

CAN communication signal

.: signal sending, <:signal receiving

Applicable ECU

Nomenclature of signals

EFI ECU ABS ECU Meter ECU

Engine coolant temperature .(<

Stop lamp switch (.(

Vehicle speed <.<

Brake warning lamp request (.<

ABS warning lamp request (.<

Running distance (.<

ECU-T terminal (<.

Tail switch <(.

Applicable ECU

Nomenclature of signals

EFI ECU Meter ECU

Engine coolant temperature .<

Vehicle speed <.

Tail switch <.

L2–10

Page 14

2-3-3 TYPE 3, TYPE 7

CAN communication signal

.: signal sending, <:signal receiving

2-3-4 TYPE 4, TYPE 8

CAN communication signal

.: signal sending, <:signal receiving

2-4 DIAGNOSIS (SELF-DIAGNOSIS) FUNCTION

Diagnostics means failure diagnosis. This is a function by which if there are any abnormalities in the input

signal the ECU will inform a mechanic/technician of the abnormal item.

CAN communication failure diagnosis sets up a separate diagnosis code for each ECU which constitutes

the CAN.

Please refer to the repair/maintenance manual for details of the failure diagnosis function.

2-5 FAIL-SAFE CONTROL

If the CAN communication system continues operating in the event of abnormalities such as open wires

or short circuits in the CAN communication line and communication abnormality between ECU's, there

may be the possibility that the abnormalities may effect the control of each system. Under these circumstances each ECU will come under the control of a preset internal control system.

For details of the fail-safe controls please refer to the item of each system which makes up the CAN.

Applicable ECU

Nomenclature of signals

EFI ECU A/T ECU ABS ECU Meter ECU

Throttle opening degree .<((

Engine torque .<((

Water temperature state .<((

Engine coolant temperature .<(<

Request of deletion of MIL-related malfunction codes in A/T .<((

Completion of deletion of MIL-related malfunction codes in

A/T

<.((

Torque reduction request <.((

Shift range information <.(<

O/D OFF lamp request (.(<

A/T warning request (.(<

A/T learning value erasure completion (.(<

Stop lamp switch (<.(

Vehicle speed <<.<

Brake warning lamp request ((.<

ABS warning lamp request ((.<

Running distance ((.<

ECU-T terminal (<<.

Tail switch <((.

Applicable ECU

Nomenclature of signals

EFI ECU A/T ECU Meter ECU

Throttle opening degree .<(

Engine torque .<(

Water temperature state .<(

Engine coolant temperature .<<

Request of deletion of MIL-related malfunction codes in A/T .<(

Completion of deletion of MIL-related malfunction codes in

A/T

<.(

Torque reduction request <.(

Shift range information <.<

O/D OFF lamp request (.<

A/T warning request (.<

A/T learning value erasure completion (.<

Vehicle speed <.<

ECU-T terminal (<.

Tail switch <(.

L2–11

Page 15

3COMPONENTS

3-1 DLC

A DLC (Data Link Connector) is installed forward of the driver's seat (lower portion of the instrument panel,

driver's seat door side).

CANH and CANL terminals have been added to the DLC with the adoption of a CAN communication system.

3-2 TERMINATING RESISTANCE

The terminating resistance is located in the combination meter and in the engine control computer.

As the terminating resistance, there are two 60 + resistors in series. As a result, the differential voltage

can be judged from the loop connected network.

T11E1206S16

DLC

12345678

9 10 11 12 13 14 15 16

CANL

CANH

L2–12

Page 16

ÄÄ

LIN COMMUNICATION SYSTEM

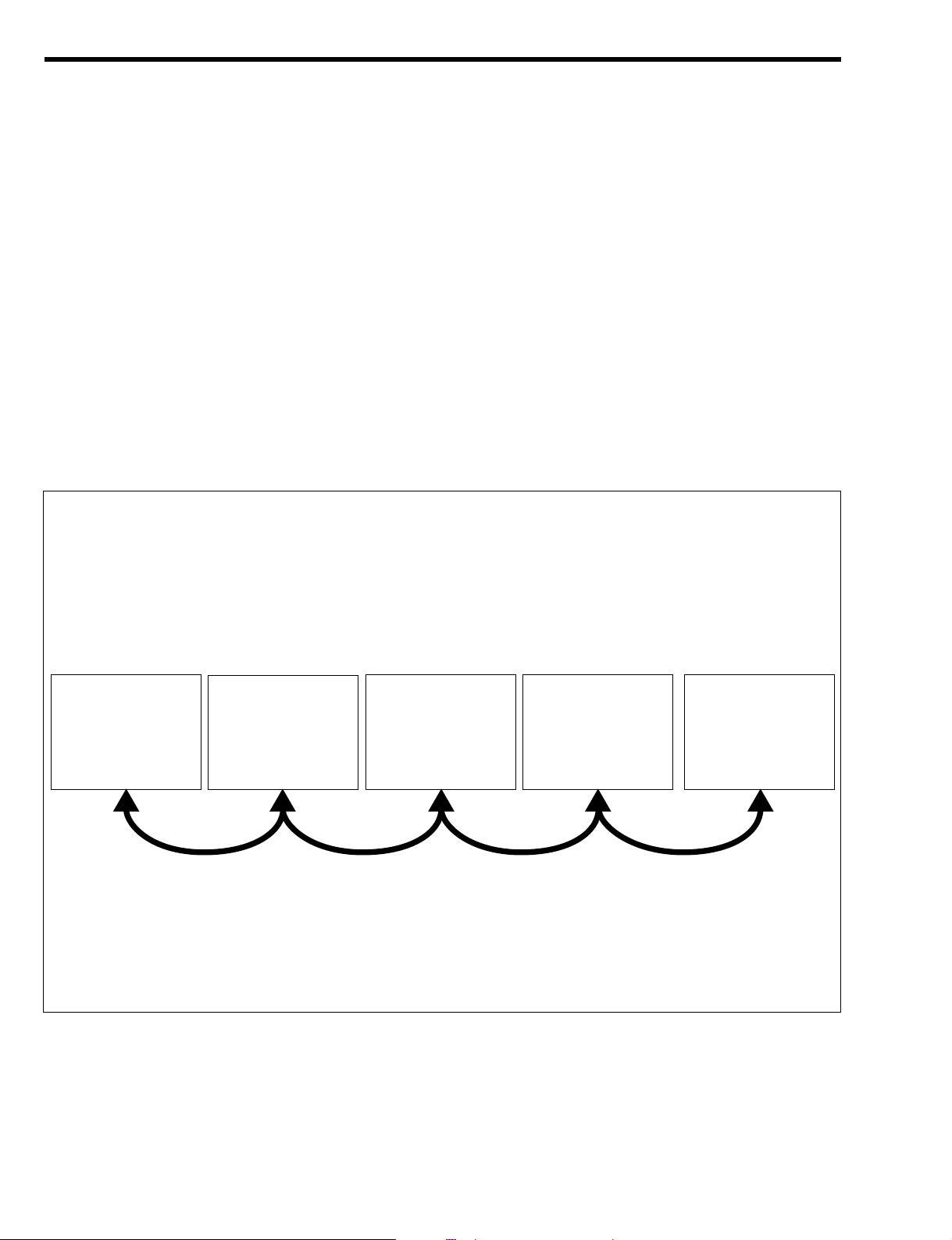

1OUTLINE

1-1 DESCRIPTION

1.All vehicles are equipped with LIN communication (LIN: Local Interconnect Network) *.

2.The LIN communication consists of the meter ECU and ITC.

3.Multiplex communication is a system in which plural ECU's are connected to a single communication

line to provide mutual data exchange. This has made it possible to integrate the system and prevent

the number of wires from increasing when a function is added.

4.Controls actually taking place in the multiplex communications are the wake-up/sleep controls, system

controls by applicable ECU and so forth.

5.A diagnosis function is provided that will inform the operator of any abnormality of the system. Also,

fail-safe functions are provided that will assure the minimum functions for each ECU and protect the

systems when abnormal communications occur between the ECUs.

6.The communication method employs a single master system in which the meter ECU controls the sleep

(low current mode), wake-up (standby mode), etc. of the communication applicable ECU.

NOTE

• *: The LIN communication is a multiplex communication network mainly intended for the data communications between the body-related control ECUs.

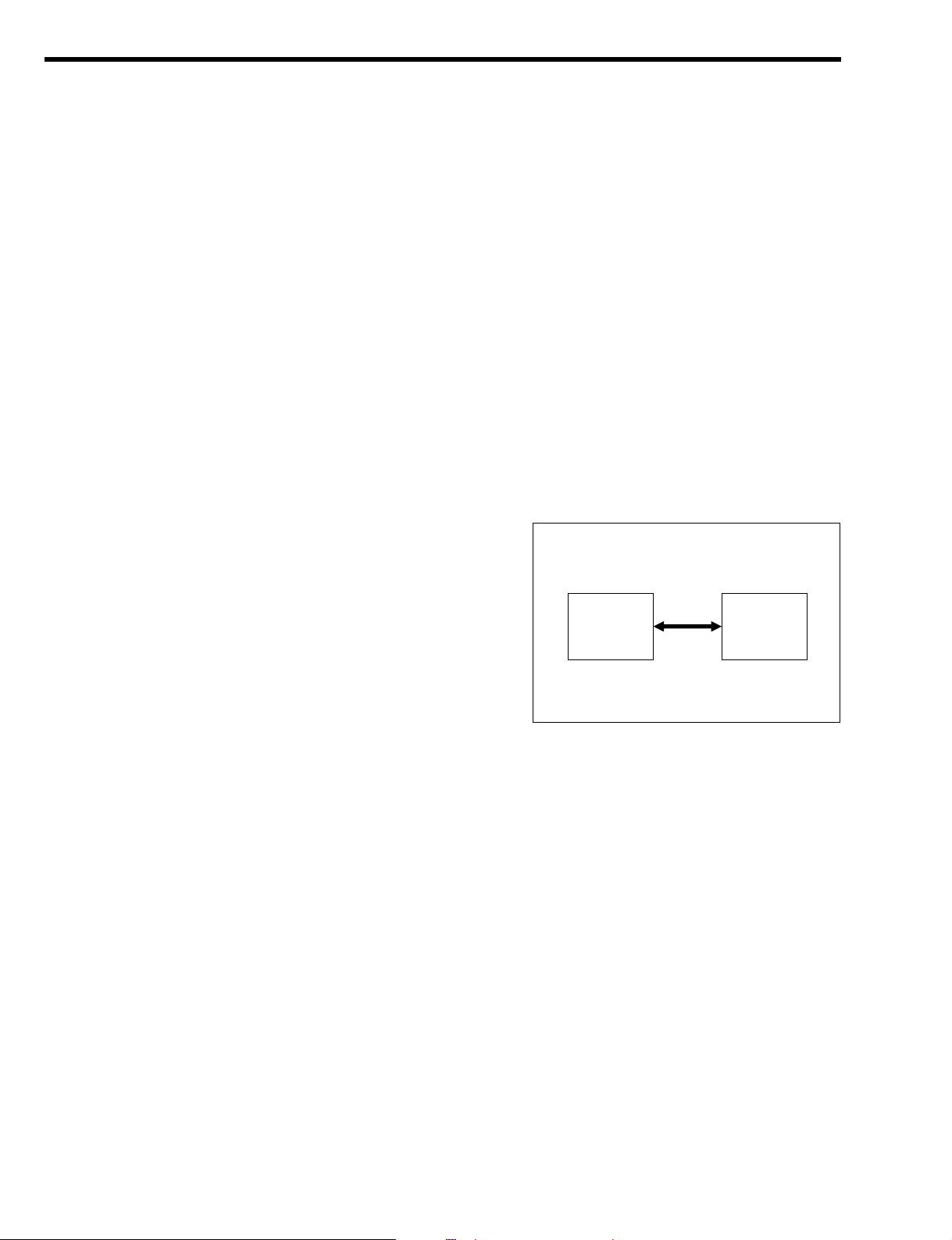

1-2 SYSTEM DRAWING

The LIN communication consists of the meter ECU and ITC.

L2–13

B11H1022ET10

Meter ECU ITC

Page 17

1-3 SYSTEM WIRING DIAGRAM

T11H1539ES25

DLC

9

ECUB

ECU IG2

17

BDR1

7

IG1

'B

ITC

MPX

6

GND

1

LIN communication

wire

AM1

AM2

IG1

IG1/BACK

D/LOCK

BACK UP

F/L

IG SW

ST

ACC

IG1

IG2

Fuse block

10

IG2

9

LIN

20

Combination meter

GND

18

ECU-T17DOOR

11

Courtesy switch

Front left

Front right

Rear right

Rear left

BACK

L2–14

Page 18

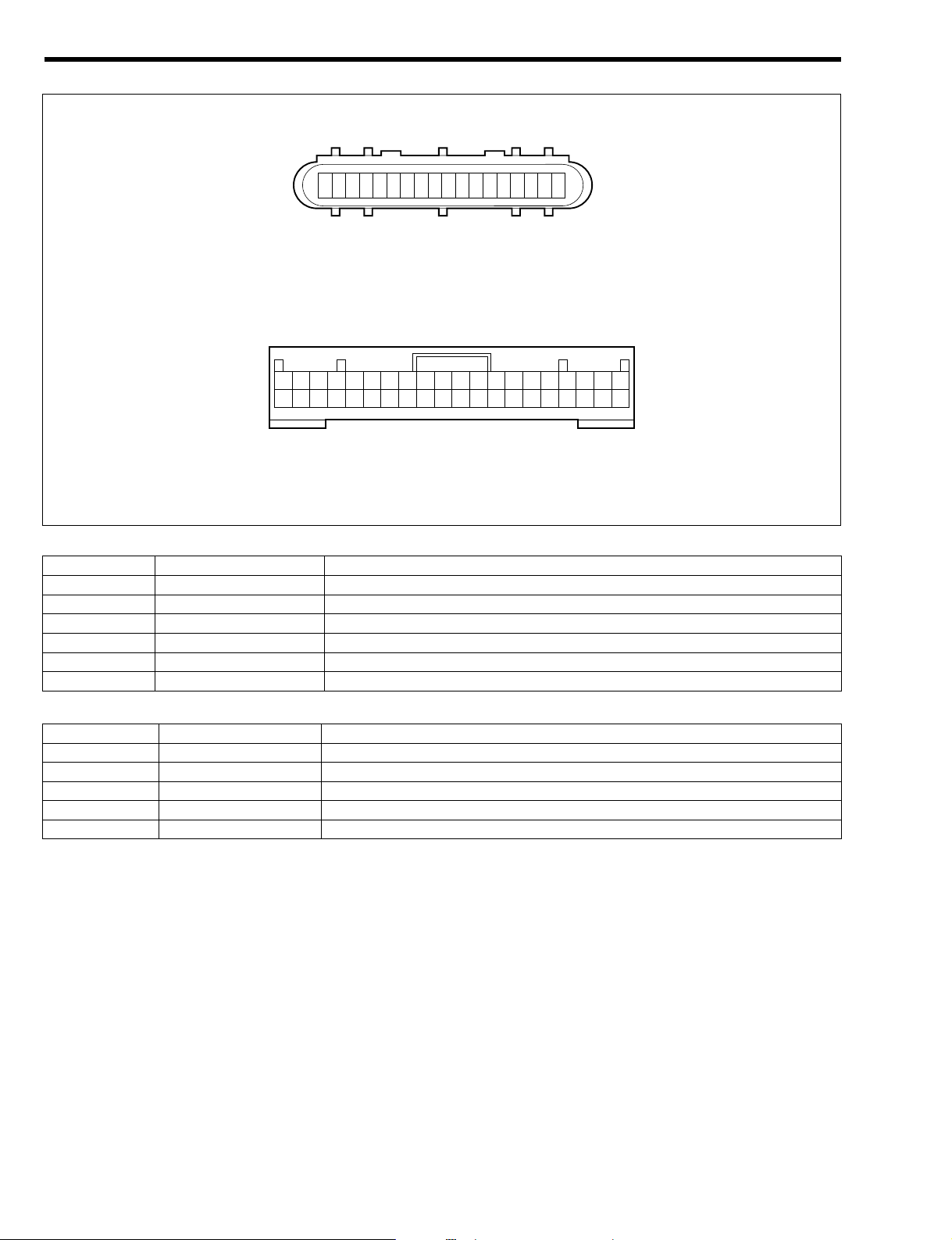

Arrangement of ECU terminal

Meter terminal name (Multiplex communication system)

ITC terminal name (Multiplex communication system)

Terminal No. Terminal code Terminal name

1 GND Earth

6 MPX Multiple communication input/output

7 IG1 ECU power supply

9 ECU B ECU power supply

17 BDR1 Power supply

Terminal No. Terminal code Terminal name

9 IG2 IG power supply

10 +B 'B power supply

11 DOOR Input of courtesy switch signal

17 ECU-T ECU-T terminal signal input

18 GND Earth

20 LIN LIN communication input/output

T11H9502ES20

ITC

Combination meter

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

30 29 28 27 26 25 24 23 22 21

10 9 8 7 6 5 4 3 2 1

40 39 38 37 36 35 34 33 32 31

20 19 18 17 16 15 14 13 12 11

L2–15

Page 19

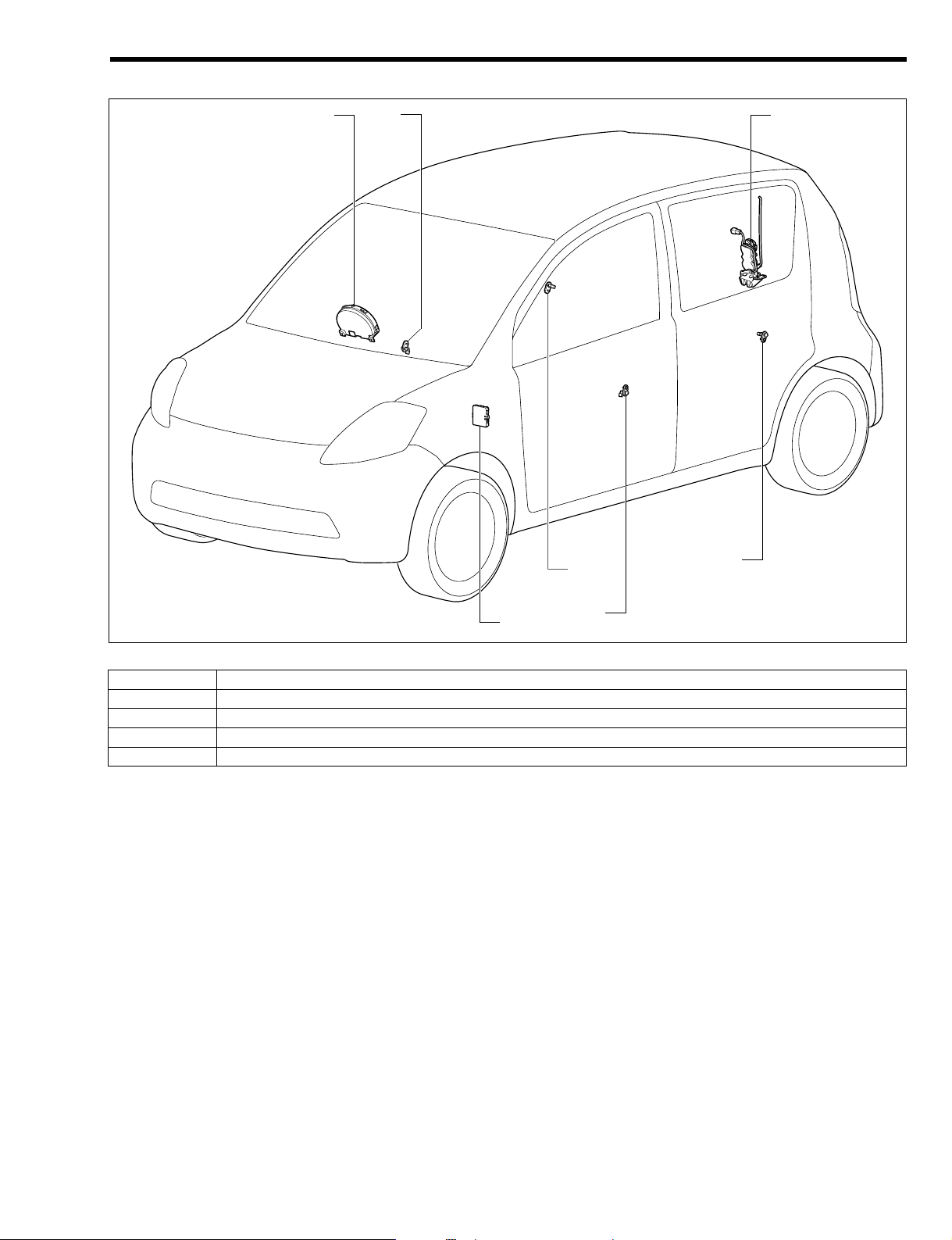

1-4 LOCATION OF COMPONENTS

The illustration represents the RHD vehicle. In the case of the LHD vehicle, the combination meter is located at the left side.

a Meter ECU (inside the combination meter)

b ITC

c Front door courtesy switch

d Rear door courtesy switch

e Back door courtesy switch (inside the back door lock Ay)

T11H1525S25

a

e

c

b

d

d

c

L2–16

Page 20

2CONTROL

2-1 COMMUNICATION CONTROL

2-1-1 DESCRIPTION

The meter ECU controls the following items.

1.Evaluation of presence/non-presence of ECU

2.Communication start informing control

3.Wake-up/sleep control

2-1-2 EVALUATION OF PRESENCE/NON-PRESENCE OF ECU

The meter ECU detects the presence of the ECU every time the battery power supply is turned on.

1.When the LIN communication applicable ECU is not connected to the meter ECU, or when it does not

respond to the meter ECU due to failure, etc. of the LIN communication applicable ECU, the meter

ECU transmits a command to other ECUs that have been judged to be present to perform such communication control that is to be carried out when the ECU that has made no response is not mounted

(Evaluation of ECU non-presence).

2.The meter ECU, after detecting the presence of the ECU, continues to monitor ECU connecting status

at constant intervals.

3.When the LIN communication applicable ECU responds properly to the meter ECU during the ECU

presence/non-presence evaluation, or when the ECU that has made no response returns to the normal condition and makes a proper response after the ECU has been judged not to be present, the

meter ECU transmits a command to other LIN communication applicable ECUs to perform such communication control that is to be carried out when the ECU that has made a response is mounted

(Evaluation of ECU presence).

2-1-3 COMMUNICATION START CONTROL

The communication start is always started from the meter ECU. The signal of communication start is transmitted to other ECU.

2-1-4 WAKE-UP/SLEEP CONTROL

When transferring to the sleep (the low current mode), or transferring from the sleep (the low current

mode) to the wake-up (the standby mode), the meter ECU transmits a transfer start command to the other

LIN communication applicable ECUs, thereby transferring to the wake-up/sleep control.

2-2 WAKE-UP/SLEEP FUNCTION

2-2-1 DESCRIPTION

The LIN communication system is equipped with a wake-up/sleep function to reduce the current used

when the IG switch is in the ACC and LOCK positions.

2-2-2 CONDITIONS FOR REALIZING SLEEP

When the following conditions 1 and 2, or the condition 3 is satisfied, the meter ECU sends a sleep command to each ECU, thus transferring to the sleep state (the low current mode).

1.The IG switch is set to the ACC position or the LOCK position.

2.The meter ECU received the information that the control of each ECU is complete, and the control of

the meter itself is complete.

3.Ten minutes have passed after the IG switch was set to the ACC position or the LOCK position, with

the door open (the battery discharging prevention function).

2-2-3 CONDITIONS FOR REALIZING WAKE-UP

When either of the following conditions is satisfied, the meter ECU sends a wake-up command to each

ECU, thus transferring to the wake-up state (the standby mode).

1.Cases where there is a change in the data to be communicated at each ECU, and the ECU transmits

a wake-up (the standby mode) signal to the meter ECU.

2.Cases where the IG switch is turned from the ACC or LOCK position to the ON position.

3.Immediately after connecting a battery.

L2–17

Page 21

2-3 LIN COMMUNICATION PROTOCOL (COMMUNICATION REGULATION)

1.The LIN communication system is a two-way interactive time-division multiplexing communication system, where all ECUs that make up the network can send and receive data by delaying the timing for

using a communication line in order to share a single communication line. Each ECU, therefore, communicates according to the common communication protocol (communication regulation) to ensure

smooth and reliable communication.

2.The data used by the LIN communication system consist of digital signals that include information such

as ID to identify each ECU (node ID) and contents of communication data.

3.In order for all ECUs to be able to communicate by sharing a single communication line, based on the

specified transmission time schedule, the single master system is employed as a communication regulation for the communication line, in which the meter ECU controls the communication timing, sleep

(the low current mode) and wake-up (the standby mode), etc. of the communication applicable ECU.

2-4 DIAGNOSIS (ONBOARD DIAGNOSIS FUNCTION)

This is a function whereby the ECU informs the inspection operator of the abnormal items when there has

been a failure in the system. When failure takes place, the ECU memorizes the abnormal item.

Please refer to the repair manual for details concerning the diagnosis.

2-5 FAIL-SAFE FUNCTION

When communication remains unestablished between the applicable ECU and the meter ECU for a certain length of time, the predetermined control is performed by transferring to the fail-safe mode.

Conditions of each system during the fail-safe mode

CAUTION

• When the meter ECU transfers to the fail-safe mode, the ITC, being unable to communicate with

the meter ECU, will transfer to the fail-safe mode.

Applicable ECU Condition

ITC

;The keyless operation will not take place.

;The room lamp control will not take place.

*: The power door locking operates normally.

L2–18

TO INDEX TO NEXT SECTION

Page 22

HEATER AND AIR CONDITIONER----------- K1 - 1

OUTLINE ----------------------------------------- K1 - 1

CONSTRUCTION AND OPERATION ---- K1 - 4

REFRIGERANT------------------------------ K1 - 4

DISCHARGE PORT ------------------------ K1 - 4

CONTROL PANEL-------------------------- K1 - 5

HEATER CORE------------------------------ K1 - 5

EVAPORATOR------------------------------- K1 - 6

COMPRESSOR ----------------------------- K1 - 6

CONDENSER -------------------------------- K1 - 6

MANUAL AIR CONDITIONER SYSTEM ---- K1 - 7

OUTLINE ----------------------------------------- K1 - 7

SYSTEM WIRING DIAGRAM ------------ K1 - 7

LOCATION OF COMPONENTS--------- K1 - 9

LOCATION OF COMPONENTS ------- K1 - 11

CONTROL-------------------------------------- K1 - 13

AIR CONDITIONER CONTROL BY

ENGINE CONTROL COMPUTER ---- K1 - 13

COMPONENTS------------------------------- K1 - 14

ENGINE CONTROL COMPUTER ---- K1 - 14

BLOWER RESISTOR -------------------- K1 - 14

PRESSURE SWITCH -------------------- K1 - 14

EVAPORATOR TEMPERATURE

SENSOR------------------------------------- K1 - 15

CONTROL PANEL ------------------------ K1 - 15

K1 HEATER & AIR CONDITIONER

K1

TO INDEX

Page 23

ÄÄ

HEATER AND AIR CONDITIONER

1OUTLINE

1.Some specifications have an air conditioner with manual controls.

2.A Three-dial control panel has been set.

3.The evaporator employs a small, lightweight type RS Evaporator (RS: Revolutionary Super Slim) which

improves the evaporator's heat exchange efficiency when the air conditioner is running.

4.The heater core employs a small, lightweight SFA heater core @ (SFA: straight flow aluminum) which

should give superior heat transmission performance when the system is heating.

5.The refrigerant HFC-134a (R-134a) that contains no chlorine has been adopted as the air conditioner

refrigerant, taking into consideration the need to prevent ozone layer depletion.

K1–1

Page 24

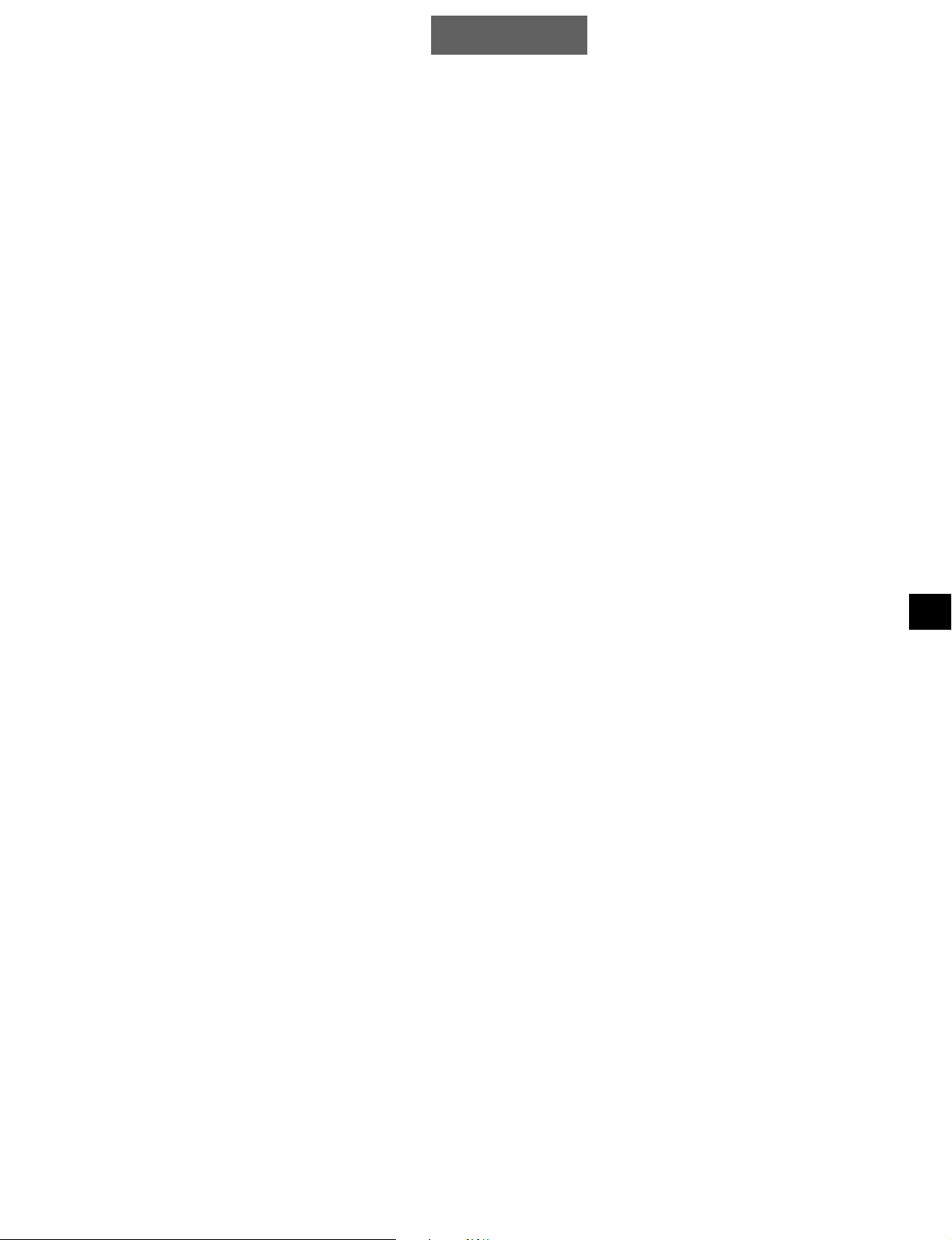

Front section (LHD vehicle)

The illustration shows a typical example.

Front section (RHD vehicle)

The illustration shows a typical example.

T11H1023ES20

Compressor

Air conditioner unit

Condenser

T11H1514ES20

Cooling unit

Compressor

Condenser

K1–2

Page 25

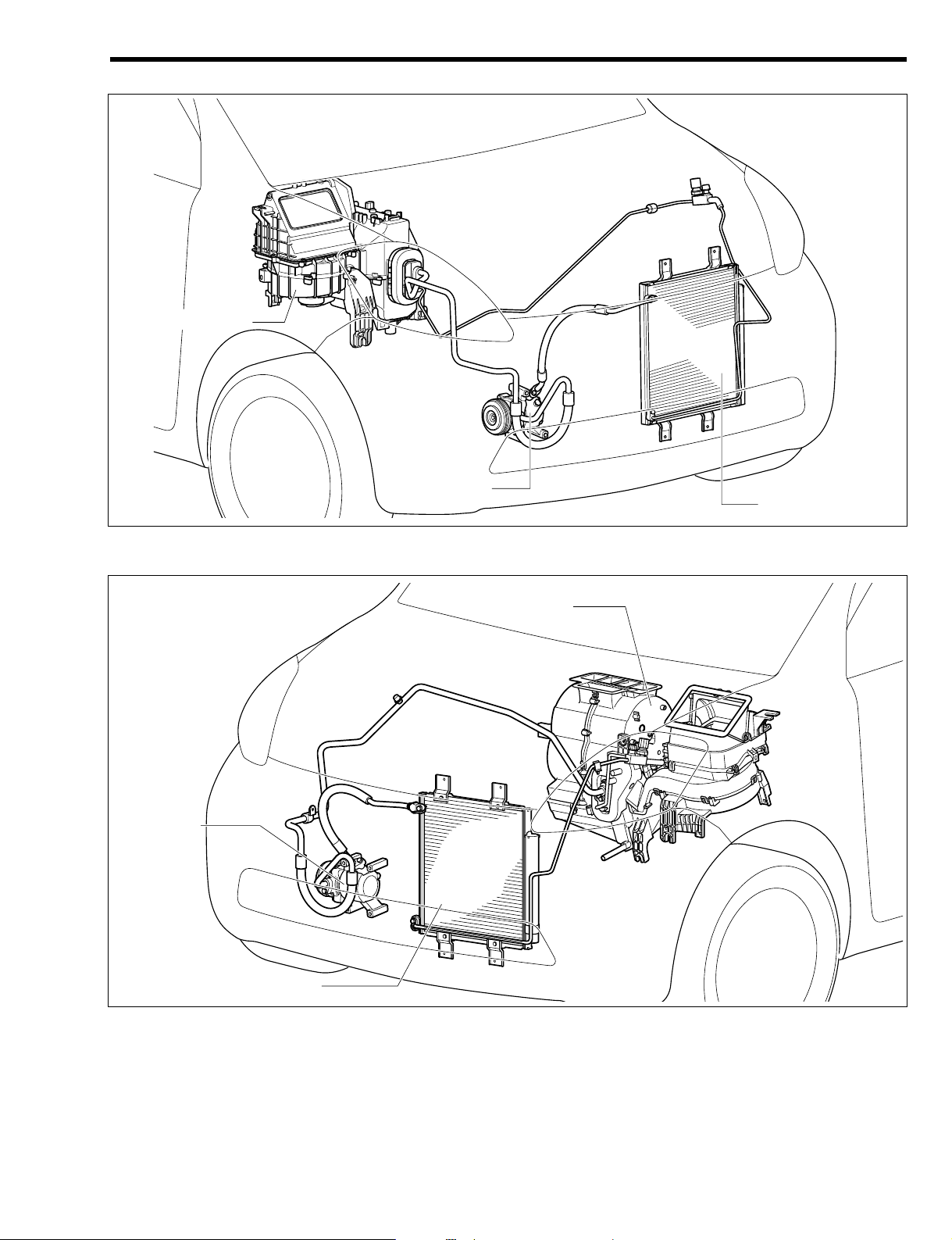

Instrument panel section (LHD vehicle)

The illustration shows a typical example.

Instrument panel section (RHD vehicle)

The illustration shows a typical example.

T11H1516ES20

Front defroster

Side register

Center register

Air conditioner unit

T11H1515ES20

Cooling unit

Heater unit

Side register

Center register

Side defroster

Front defroster

K1–3

Page 26

2CONSTRUCTION AND OPERATION

2-1 REFRIGERANT

The refrigerant HFC-134a (R-134a) that contains no chlorine has been adopted as the air conditioner

refrigerant, taking into consideration the prevention of deletion of ozone layer.

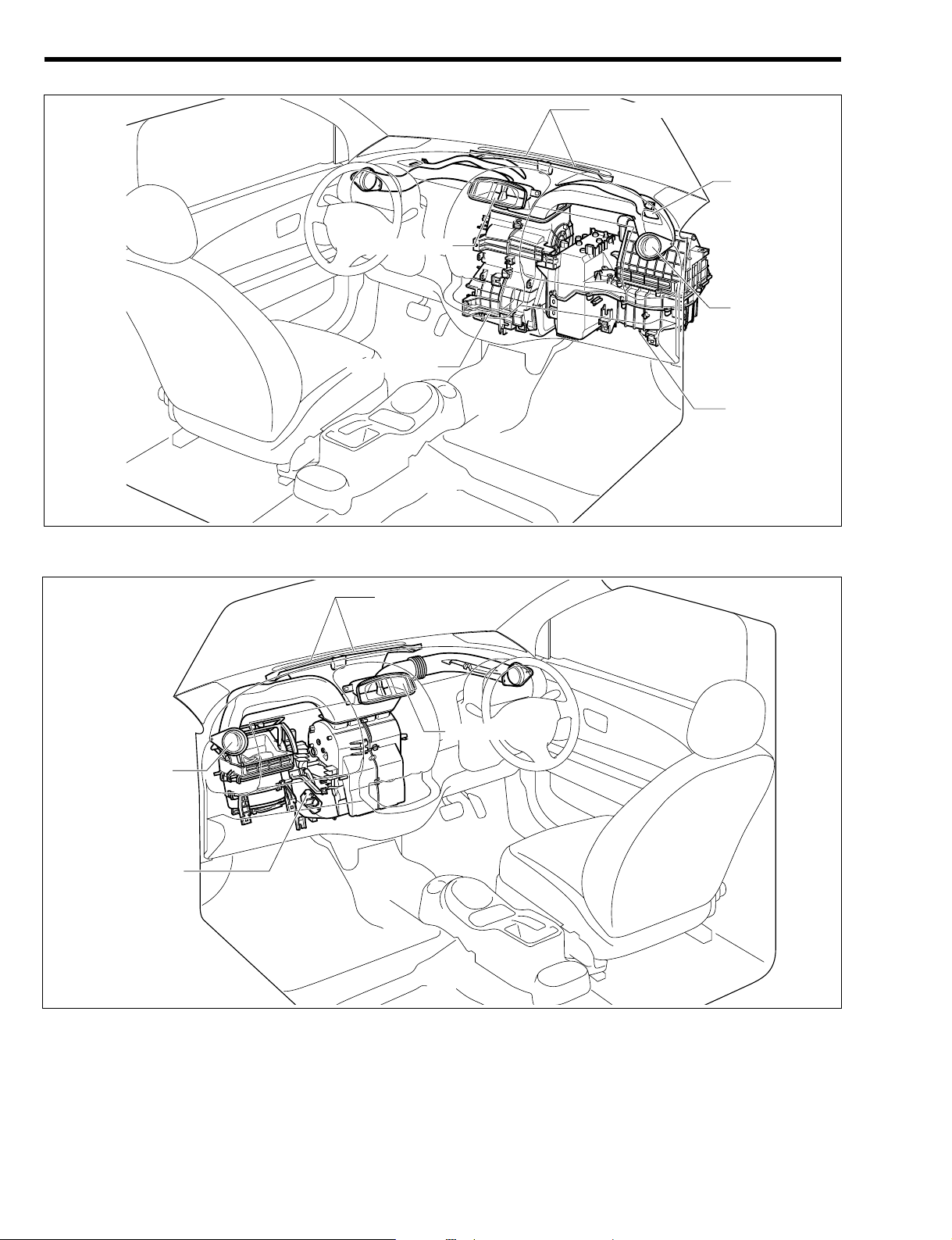

2-2 DISCHARGE PORT

The air outlets are located in the center of the instrument panel, on both side-sections, on the defroster

and on the leg sections of people sitting in front seats.

Air outlets according to mode

T11H1517ES20

LHD vehicle RHD vehicle

K1–4

Page 27

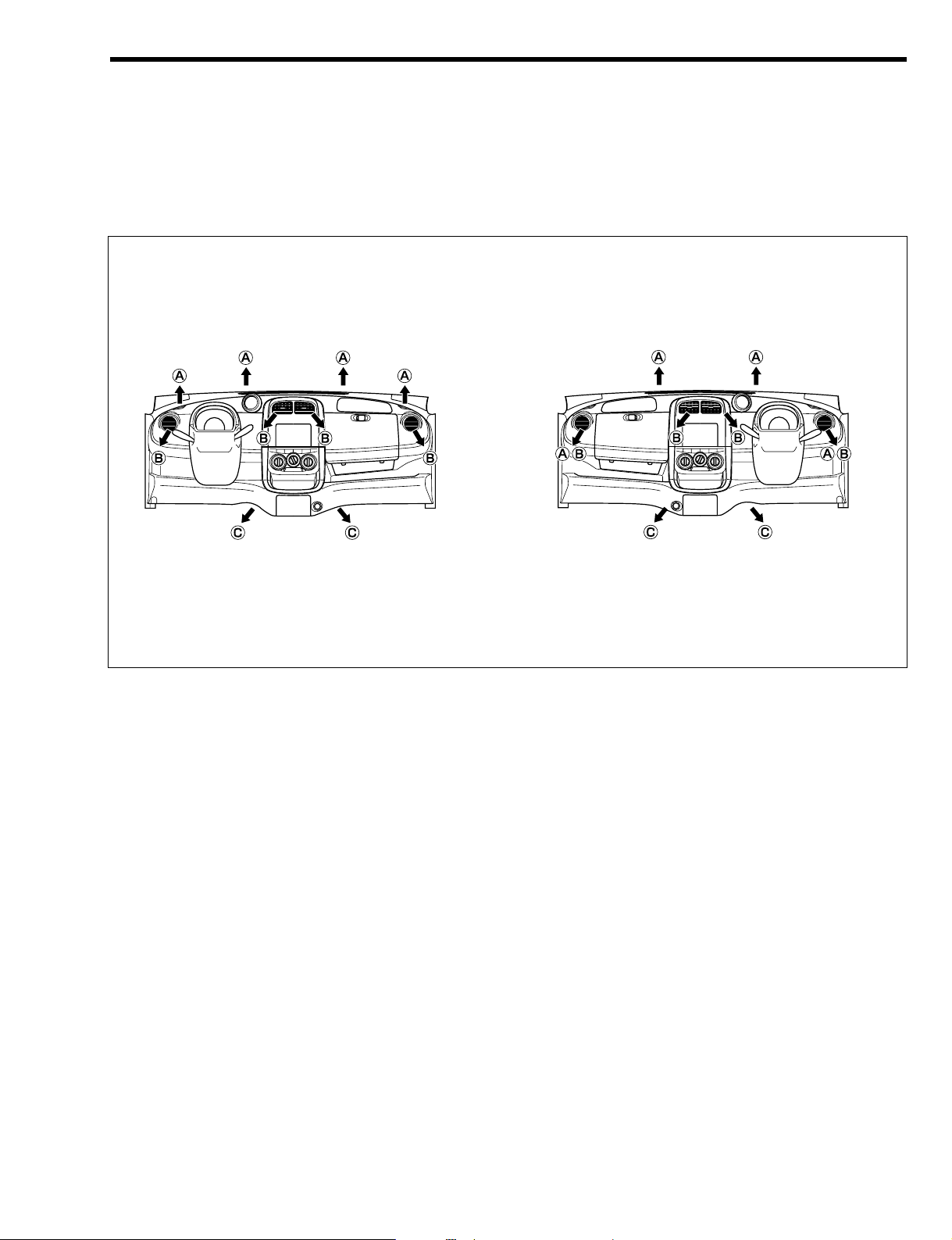

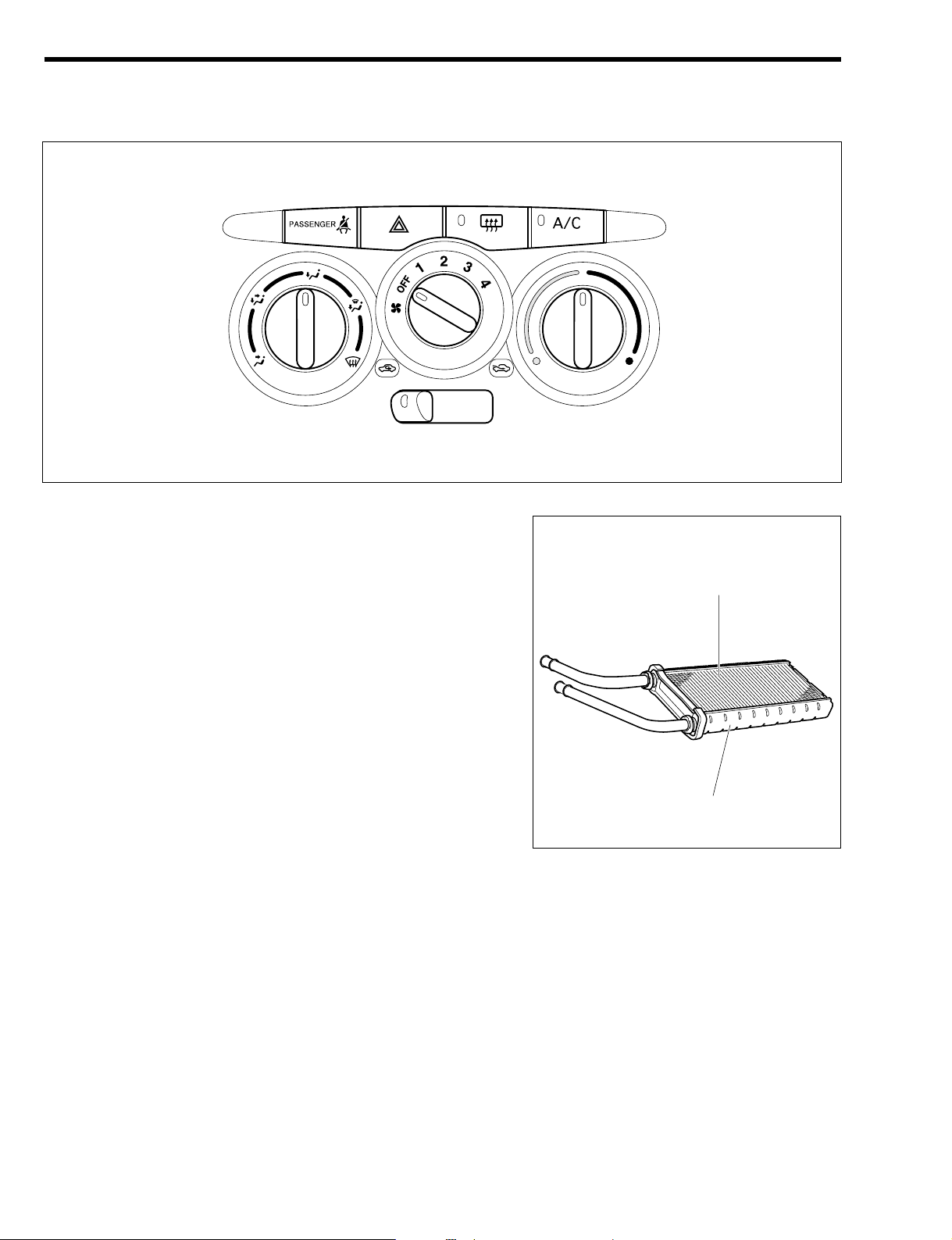

2-3 CONTROL PANEL

A three-dial type control panel is employed. The dial pointer adopts night illumination to assure easy operation and reading night time. The blower switch can be adjusted over four stages.

The illustration shows a typical example.

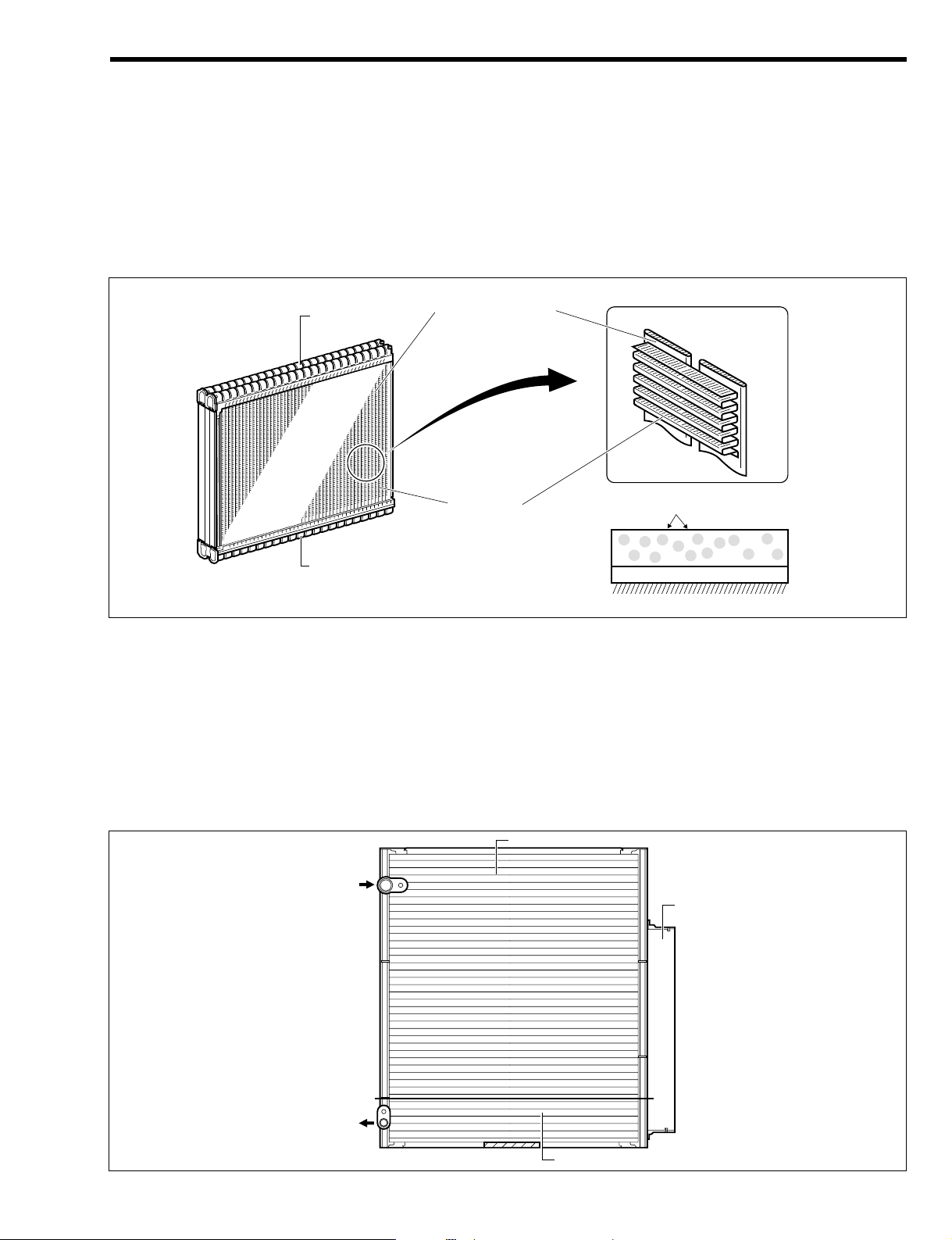

2-4 HEATER CORE

The heater core employs a small, lightweight SFA heater core

@ (SFA: straight flow aluminum).

The SFA heater core @ is more compact than conventional

SFA heater cores because of the reduction in tank width and

height/miniaturization of the core (core area expansion). This

has achieved increased air flow, noise reduction, and an

improvement in heating capacity. The SFA heater core @ is

constructed from tubes, fins and capsules and the result has

been that by flattening the tubes the heat transfer rate has

been improved as well as producing a lightweight, small size

heater. Further, the use of aluminum makes the heater more

environmentally friendly.

T11H1054S16

K1–5

T11H1055ET16

TubeQfin

Capsule

Page 28

2-5 EVAPORATOR

The evaporator employs a small, lightweight type RS Evaporator (RS: Revolutionary Super Slim).

The RS evaporator consists of a tank, tubes and cooling fins. Thanks to the press molding of the tube,

minute flow paths have been formed and this leads to improved heat transfer capability and very thin

dimensions. Further, the RS evaporator has improved heat transfer due to the reduced fin height, tube

thickness, and fin pitch, and the unit is much reduced in size and weight due to the reduced stock thickness of the core material. The evaporator is coated with a hydrophilic plastic film which contains anti-bacteria agent to control the breeding of germs and bacteria which can lead to unpleasant smells. In consideration of the environment the surface treatment is chrome-free.

2-6 COMPRESSOR

Vane type compressor is employed.

2-7 CONDENSER

A new type of sub cooling condenser is used which has improved performance with its miniaturized core

and an increased effective surface area, compared with the conventional ones. Inside the sub cooling

condenser are provided the condensing section, the modulator and the over cooling section (sub cooling

section). The refrigerant vapor goes through a 2-stage condensation process which lead to nearly 100%

liquidizing.

Further, the modulator separates the gas and liquid.

The illustration shows a typical example.

T11H1057ES16

Modulator

Condensing section

Super cooling section (sub-cooling section)

IN

Evaporated refrigerant

OUT

Liquid refrigerant

T11H1056ES16

Tank

Tank

Cooling fin

Fine multi-hole tube

Anti-bacteria agent is added to hydrophilic

resin coating

Hydrophilic resin coating

Chrome-free chemical conversion coating

Aluminum base metal

K1–6

Page 29

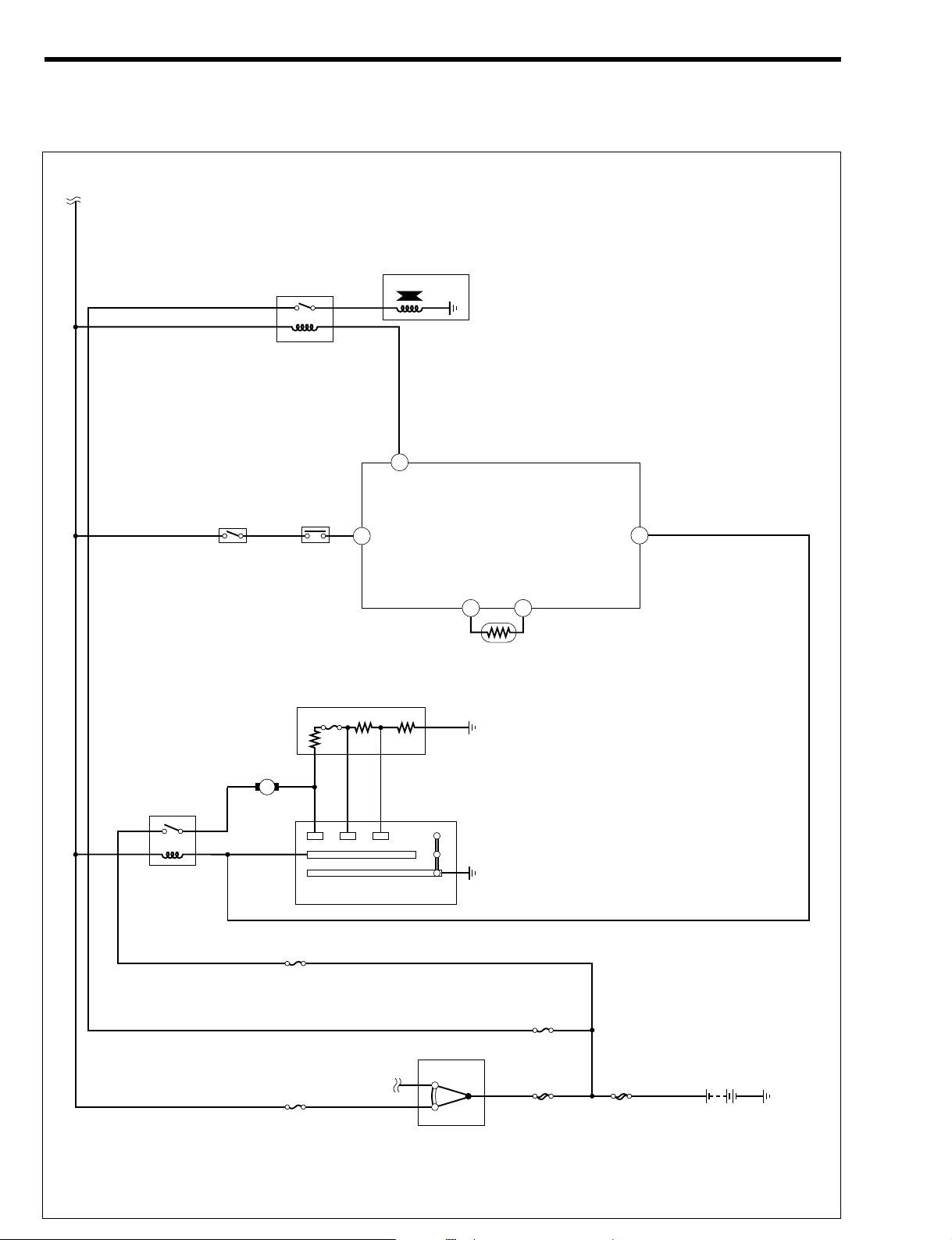

ÄÄ

MANUAL AIR CONDITIONER SYSTEM

1OUTLINE

1-1 SYSTEM WIRING DIAGRAM

T11H8501ES48

IG1

/BACK

AM1

HEATER

Heater

relay

Hi

M2

M1

Lo

F/L

MGC

IG

SW

IG1 ACC

A/C

SW

Pressure switch

Magnetic clutch relay

Compressor

magnet clutch

Blower switch

Blower resistor

M

Blower motor

ACSW

MGC

3

BLW

42

ACEV45E21

116

Evaporator

temperature

sensor

Engine control computer

36

K1–7

Page 30

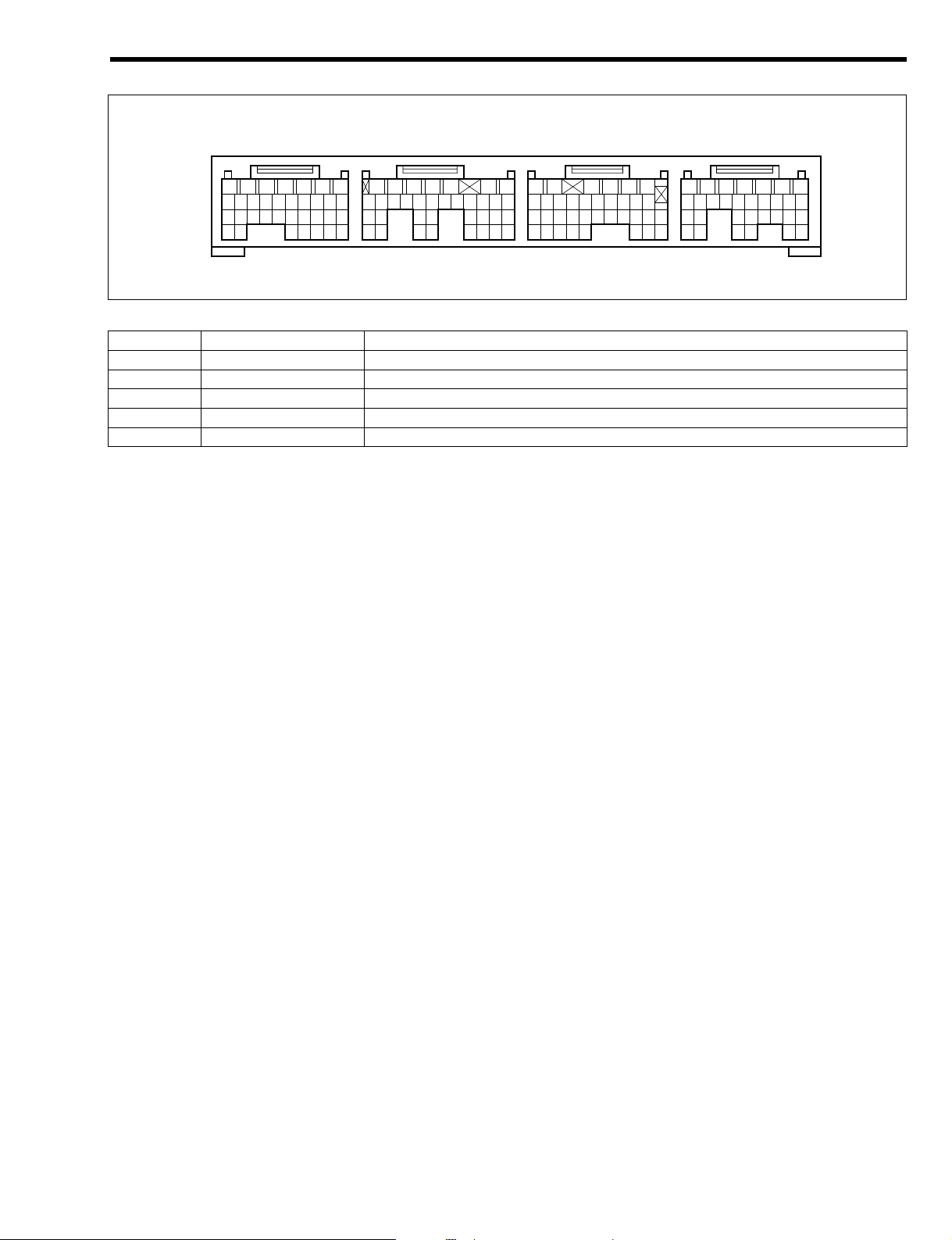

Arrangement of ECU terminal

Engine Control Computer terminal name

Terminal No. Terminal code Terminal name

3 ACSW A/C switch input

36 MGC Magnet clutch drive output

42 BLW Heater blower operation input

45 ACEV Evaporator temperature sensor input

116 E21 Sensor earth

H11E6091S10

1

28293031323334353637

7071727374757677

107108109110111112

23

4

56721

60616263646566676869

979899

100101102105106

129

130133134135

222324252627

103104

131

132

383940414243444546

7879808182838687

113114118119

8910111213

8485

115116117

47

88

120

495051525354555657

89909192

121122

141516171819

48

9394

123124125126

58

95

127

59

96

128

20

K1–8

Page 31

1-2 LOCATION OF COMPONENTS

a Pressure switch

b Compressor magnet clutch

c Blower switch

d A/C switch

e Engine control computer

T11H1519S33

b

c

d

e

a

K1–9

Page 32

K1–10

h

f Blower motor

g Blower resistor

h Evaporator temperature sensor

g

f

T11H1520S25

Page 33

1-3 LOCATION OF COMPONENTS

a Pressure switch

b Compressor magnet clutch

c Blower switch

d A/C switch

e Engine control computer

T11H1521S33

b

c

d

e

a

K1–11

Page 34

K1–12

f

f Blower motor

g Blower resistor

h Evaporator temperature sensor

h

g

T11H1522S25

Page 35

2CONTROL

2-1 AIR CONDITIONER CONTROL BY ENGINE CONTROL COMPUTER

2-1-1 AIR CONDITIONER CUT CONTROL

Type 1 KR-FE eng ine mo unt ed veh icl es

Refer to Page B8-16.

Type K 3-VE en gin e mo unt ed veh icl es

Refer to Page B8-44.

2-1-2 RADIATOR FAN MOTOR CONTROL

Type 1 KR-FE eng ine mo unt ed veh icl es

Refer to Page B8-17.

Type K 3-VE en gin e mo unt ed veh icl es

Refer to Page B8-45.

2-1-3 AIR CONDITIONER IDLE-UP CONTROL

Type 1 KR-FE eng ine mo unt ed veh icl es

Refer to Page B8-17.

Type K 3-VE en gin e mo unt ed veh icl es

Refer to Page B8-45.

2-1-4 MAGNETIC CLUTCH CONTROL

Type 1 KR-FE eng ine mo unt ed veh icl es

Refer to Page B8-17.

Type K 3-VE en gin e mo unt ed veh icl es

Refer to Page B8-45.

K1–13

Page 36

3COMPONENTS

3-1 ENGINE CONTROL COMPUTER

This is attached below the air conditioning unit. It controls the

compressor magnetic clutch ON/OFF function depending on

the state of the A/C switch, vehicle conditions and each sensor's input.

3-2 BLOWER RESISTOR

The blower resistor controls the speed of the blower motor. A

temperature fuse is fitted. The mounting location is on the air

conditioning unit.

3-3 PRESSURE SWITCH

A pressure switch, which corresponds to abnormal pressure variation inside the liquid tube, is provided

inside the liquid tube. When the pressure inside the liquid tube becomes excessively high or low, the wire

between the A/C switch and the engine control computer is interrupted, thus stopping the rotation of the

compressor.

L21H1504ES16

OFF

[kPa]

{kgf/cm }

ON

196

{2.0}

225

{2.3}

2550

{26}

3140

{32}

2

Pressure switch

K1–14

T11E1026T10

C11H1032ET10

Hi M2 M1 Lo

Temperature fuse

Page 37

3-4 EVAPORATOR TEMPERATURE SENSOR

This sensor detects the air temperature at a point immediately downstream of the evaporator as a change in resistance.

Thus, the outputted value is sent to the engine control computer.

3-5 CONTROL PANEL

Refer to Page K1-5.

K1–15

T11H1523ET16

Evaporator temperature

sensor

T11H1062ET16

Evaporator

temperature

sensor

TO INDEX TO NEXT SECTION

Page 38

CONSTRUCTION AND OPERATION----- J6 - 1

HORN------------------------------------------- J6 - 1

REAR WINDOW DEFOGGER ----------- J6 - 1

POWER OUTLET---------------------------- J6 - 1

CIGARETTE LIGHTER--------------------- J6 - 2

J6 OTHER ELECTRICAL PARTS

J6

TO INDEX

Page 39

1CONSTRUCTION AND OPERATION

1-1 HORN

The horn has employed the flat type high-pitch horn which

features a compact design and light weight.

Specification table

1-2 REAR WINDOW DEFOGGER

1.The rear window defogger is provided on all models.

2.The switch is provided inside the air conditioner control

panel.

3.When the switch is turned ON, the operation indicating

lamp provided at the switch illuminates.

Specification table

1-3 POWER OUTLET

1.The power outlet which can provide power to DC12V electric appliances is provided according to the specifications.

2.The installing location is at the central/lower section of the

instrument panel.

Specification table

Rated voltage (V) 12

Maximum power capacity (W) 120

Maximum current (A) 10

Number of wires 12

Rated voltage (V) 12

Consumption power (W) 93

Rated voltage (V) 12

Operating current (A) 3.0&1

Sound pressure level (dB) 113

Basic frequency (Hz) 420

J6–1

T11H1051T10

T11H1535T10

T11H1540T16

Page 40

1-4 CIGARETTE LIGHTER

1.The cigarette lighter is provided according to the specifications.

2.The cigarette lighter body is provided with a temperature

fuse. This fuse is melt down if current continues to flow to

the cigarette lighter due to abnormality.

Specifications table

Rated voltage (V) 12

Maximum current (A) less than 10

Temperature fuse melt time (sec) 90 - 145

J6–2

C11H1015ET16

Temperature fuse

TO INDEX TO NEXT SECTION

Page 41

CONSTRUCTION AND OPERATION----- J5 - 1

FUSIBLE LINK-------------------------------- J5 - 1

BATTERY -------------------------------------- J5 - 1

SIDE JUNCTION BLOCK ----------------- J5 - 1

FUSE BLOCK--------------------------------- J5 - 2

RELAY BLOCK------------------------------- J5 - 2

J5 WIRING

J5

TO INDEX

Page 42

1CONSTRUCTION AND OPERATION

1-1 FUSIBLE LINK

The wire type fusible link is provided at the side of the battery.

1-2 BATTERY

1.Two kinds of the batteries shown below have been provided.

2.The battery is provided at the left side of the engine compartment.

Specification table

1-3 SIDE JUNCTION BLOCK

1.The side junction block integrates junction connectors that

internally connect the wirings.

2.Use of the side junction block has made it possible to

reduce the number of the junction connectors, thus simplifying wirings.

3.The side junction block is located at the foot area of the

front left seat at the vehicle outer side.

Standard vehicle 40B19L

Cold region specification vehicle 44B20L

J5–1

T11H1048ET16

Fusible link

T11H1049T16

Page 43

1-4 FUSE BLOCK

The fuse block is located at the left side of the instrument panel.

1-5 RELAY BLOCK

The relay block is located at the rear of the battery.

T11H1533S20

IG

50A

7.5A

10A

10A

15A

7.5A

10A

10A

20A

BACK UP

TAIL

(DOME)

(ABS2)

(ECU-B)

10A

10A

10A

10A

(A/C)

(H-LP HI LH)

(H-LP HI RH)

(FOG LH)

(FOG RH)

H-LP LH

/H-LP LO LH

H-LP RH

/H-LP LO RH

(EPS)

50A

(ABS1)

40A

AM1

50A

AM2

30A

RAD

30A

(POWER)

30A

HEATER

40A

HEATER

RAD

HEAD

(MGC)

EFI

HORN

(MGC)

STOP

15A

15A

10A

10A

(FOG)

T11H1532ES25

7.5A

15A

ST

10A

D/LOCK

HAZ

7.5A

ENGINE

10A 20A

ECU IG2

7.5A

DEFOG

20A 7.5A

IG1/BACK

WIPER

POWER

7.5A

ECU IG1

15A

ACC

CIG

30A

Starter relay

Flasher relay

IG relay

EFI main relay

Horn relay

Fuel pump relay

RHD vehicle

LHD vehicle

J5–2

TO INDEX TO NEXT SECTION

Page 44

CONSTRUCTION AND OPERATION----- J4 - 1

AUDIO SYSTEM ----------------------------- J4 - 1

J4 AUDIO & VISUAL SYSTEM

J4

TO INDEX

Page 45

1CONSTRUCTION AND OPERATION

1-1 AUDIO SYSTEM

1-1-1 DESCRIPTION

1.As for the speakers, 10cm front speakers or 10cm front speakers & 16 cm rear speakers are available

according to the specifications.

2.As for the radio antenna, roof antennas have been employed for all models.

The illustration represents a typical example.

T11H1530ES33

Rear speaker

Rear speaker

Front speaker

Front speaker

Tuner

Roof antenna

J4–1

Page 46

1-1-2 TUNER

1.An AM/FM radio with compact disc player employing a surface design which has a single surface with

the center cluster is available in some specifications. The AM/FM radio with compact disc player has

only buttons that are needed indispensably. For improved operation and easy reading, large indicating letters are employed.

2.For improved operation and easy reading, the mounting position has been set to the upper part of the

instrument panel.

1-1-3 SPEAKER

1.As for the speakers, 10cm front speakers or 10cm front speakers & 16 cm rear speakers are available according to the specifications.

2.The front speakers have been set on either side at the upper side of the instrument panel.

3.The rear speakers have been set on the bottom section of the door panels on either side.

Specification table

Applicable place Front Rear

Size (cm) 10 16

Rated input (W) 12 15

Momentary maximum input (W) 35 35

Impedance (+) 6&0.9 4&0.6

Output sound pressure level 85&3 85.5&3

Minimum resonance frequency (Hz) 95&19 90&18

1 2 3

Power supply switch / volume and mode control knob

Mute button

Sound button

Mode button

AM button / AM auto store button

FM button / FM auto store button

Tuning button / track button

Preset station selection button1

Preset station selection button2

Preset station selection button3

Preset station selection button4 / scan button

Preset station selection button5 / repeat button

Preset station selection button6 / random button

AF (alternative frequency) button

PTY (Program type) button

TA (traffic announcement) button

Compact disc insertion slot

Play / pause button

Eject button

q

w

e

r

t

y

u

i

o

!0

!1

!2

!3

!4

!5

!6

!7

!8

!9

Preset station selection indicator

Radio mode indicator

Disc indicator

Compact disc mode indicator

Sound mode indicator

Display section

<Display section>

T11H1531S20

J4–2

Page 47

1-1-4 RADIO ANTENNA

A roof antenna has been employed. As for this antenna, it is

movable (in 180 degrees) in the backward and forward direction and its pole is detachable. Installation and removal may

be done by turning the pole of the antenna.

J4–3

A11H1015ET1

Installation

Removal

TO INDEX TO NEXT SECTION

Page 48

OUTLINE------------------------------------------ J3 - 1

DESCRIPTION ------------------------------- J3 - 1

SYSTEM WIRING DIAGRAM ------------ J3 - 3

CONSTRUCTION AND OPERATION----- J3 - 7

SPEEDOMETER----------------------------- J3 - 7

TACHOM ETE R ----- --- -------- -------- ------- J3 - 9

ODOMETER TRIP METER --------------- J3 - 9

FUEL GAUGE------------------------------- J3 - 10

WARNING / INDICATOR ----------------- J3 - 11

WARNING BUZZER----------------------- J3 - 16

CLOCK---------------------------------------- J3 - 16

WATER TEMPERATURE

INDICATION FUNCTION ---------------- J3 - 17

CAN COMMUNICATION----------------- J3 - 18

LIN COMMUNICATION------------------- J3 - 18

DIAGNOSIS (ONBOARD

DIAGNOSIS FUNCTION) ---------------- J3 - 19

FAIL-SAFE FUNCTION------------------- J3 - 19

J3 METER

J3

TO INDEX

Page 49

1OUTLINE

1-1 DESCRIPTION

1.The designing and legibility have been enhanced by positioning the meter on the upper part of the

steering column.

2.Legibility and visibility have been enhanced by employing the letter size which provides comprehensibility and easy reading.

3.As for the odometer ; trip meter, electric type odometer ; trip meter equipped with a twin trip meter

has been employed.

4.A tachometer is available on some Specifications. The tachometer is separate from the combination

meter and is positioned on the upper part of the instrument panel.

5.For some of the communications of the meter and other ECU, multiplex communication of CAN

(Controller Area Network) and LIN (Local Interconnect Network) has been employed.

6.A clock is set within the meter.

7.An excellent visibility is achieved by indicating fuel gauge, odometer ; trip meter, shift position indicator and clock in LCD (Liquid Crystal Display).

8.A multi-buzzer that makes a buzzer sound while various warnings are given such as when the key is

remaining in the key cylinder, or when reversing has been employed and is built in the meter.

9.Fuel level warning function has been employed for all models.

10.Power saving and long lasting features have been promoted by employing LED for all lightings such

as the dial plate and the indicator lamps.

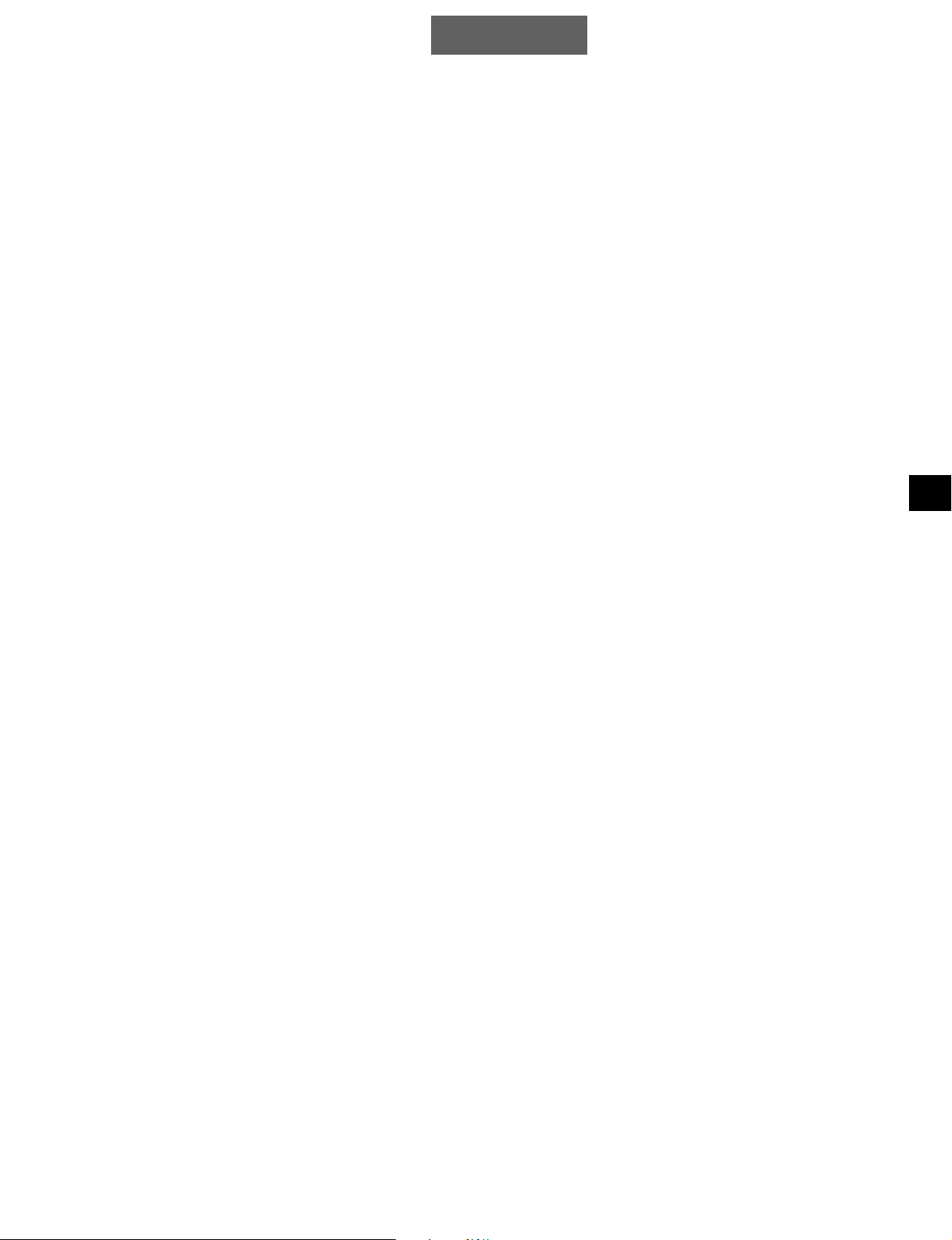

Combination meter

The illustration represents a major example.

T11H1526S16

J3–1

Page 50

Ta ch o me t er

T11H1031S16

J3–2

Page 51

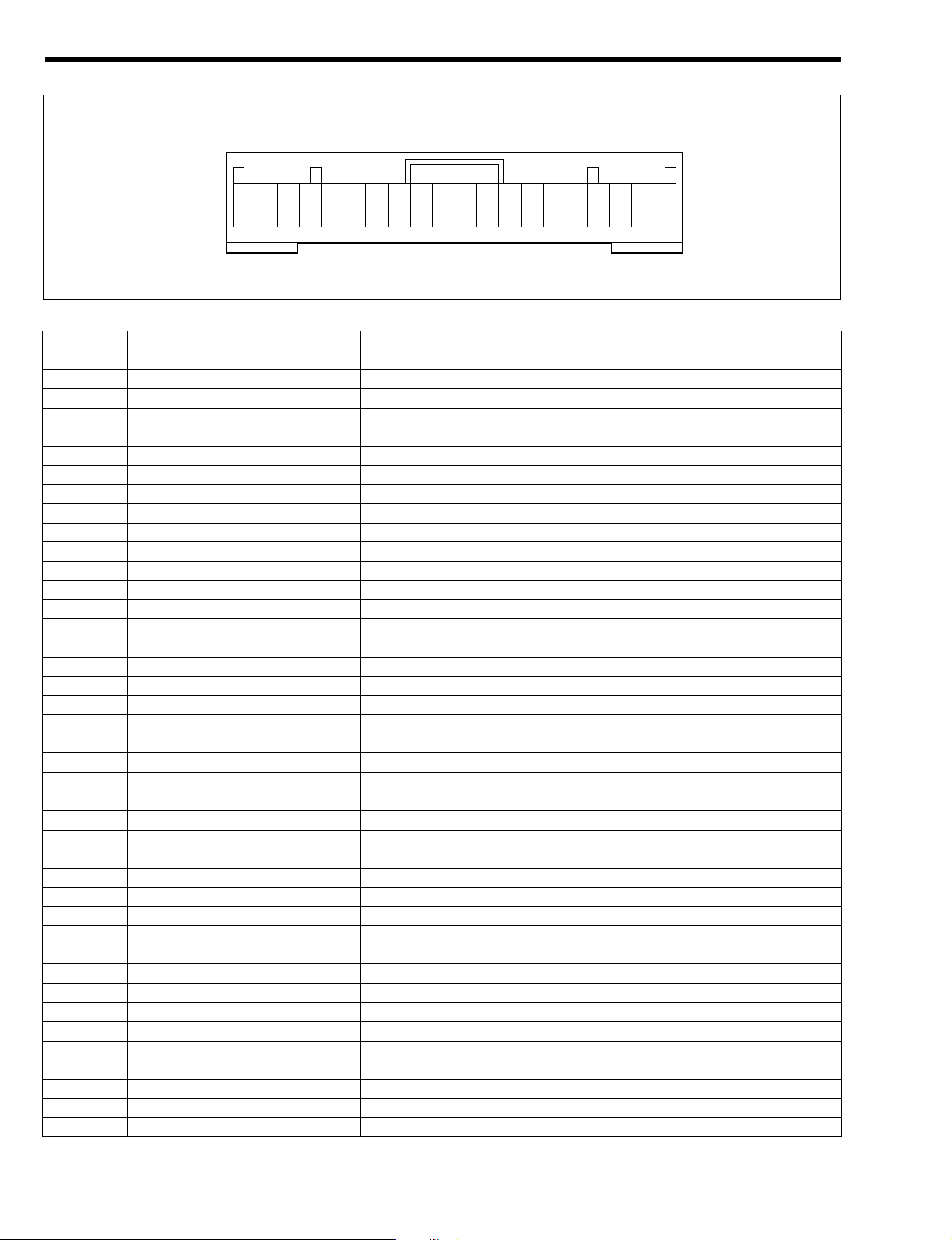

1-2 SYSTEM WIRING DIAGRAM

1-2-1 COMBINATION METER

T11H6501ES48

IG SW

AM2

TAIL

BACK UP

F/L

HORN

Key switch

Parking brake switch

ST

ACC

AM1

IG1

IG2

ECU IG2

Tail SW

SPEED

Immobilizar

ECU

LCD

ITC

Fuel sender gauge

Buzzer

High-water

temperature

Courtesy

switch

Door

10

32

26

2

KSW

DLC

bac

d

Low-water

temperature

ABS

O/D OFF

Brake

Driver's seat belt

9 14

1 3 4

ECU-T

17

MPX

20

Keyless

receiver

21

SIG

11

Brake fluid level switch

M/TandABS

non-equipped

vehicle

Vehicle

speed sensor

Driver's seat belt switch

Passenger's seat belt warning

lamp

Passenger's seat

belt switch

Occupant

detectiion

sensor

8 39

EPS ECU

To EFI ECU

A/T ECU

ABS ECU

(CAN

communication)

To DLC

(CAN

communication)

RHD vehicles

SPD

12

Meter ECU

Seat belt warning

lamp flashing

control circuit

22 1821 3 4

To A/T ECU

ABS ECU

(CAN

communication)

To EFI ECU

DLC

(CAN

communication)

LHD vehicles

7

23 31

J3–3

Page 52

J3–4

To headlamp circuit

To rear fog switch

IND

Immobilizer

ECU

To flasher relay

High beam

Dimmer passing switch

Meter illumination

Rear fog

Security

Turn R

28 29 27 16 13 5

Turn L

bac

MIL

Oil

Charge

EPS

Air bag

LA

A/B ECU

W

EFI ECU

Oil pressure switch

Alternator

15 24 25 30 33 6

d

EPSW

EPS ECU

T11H6502ES48

Page 53

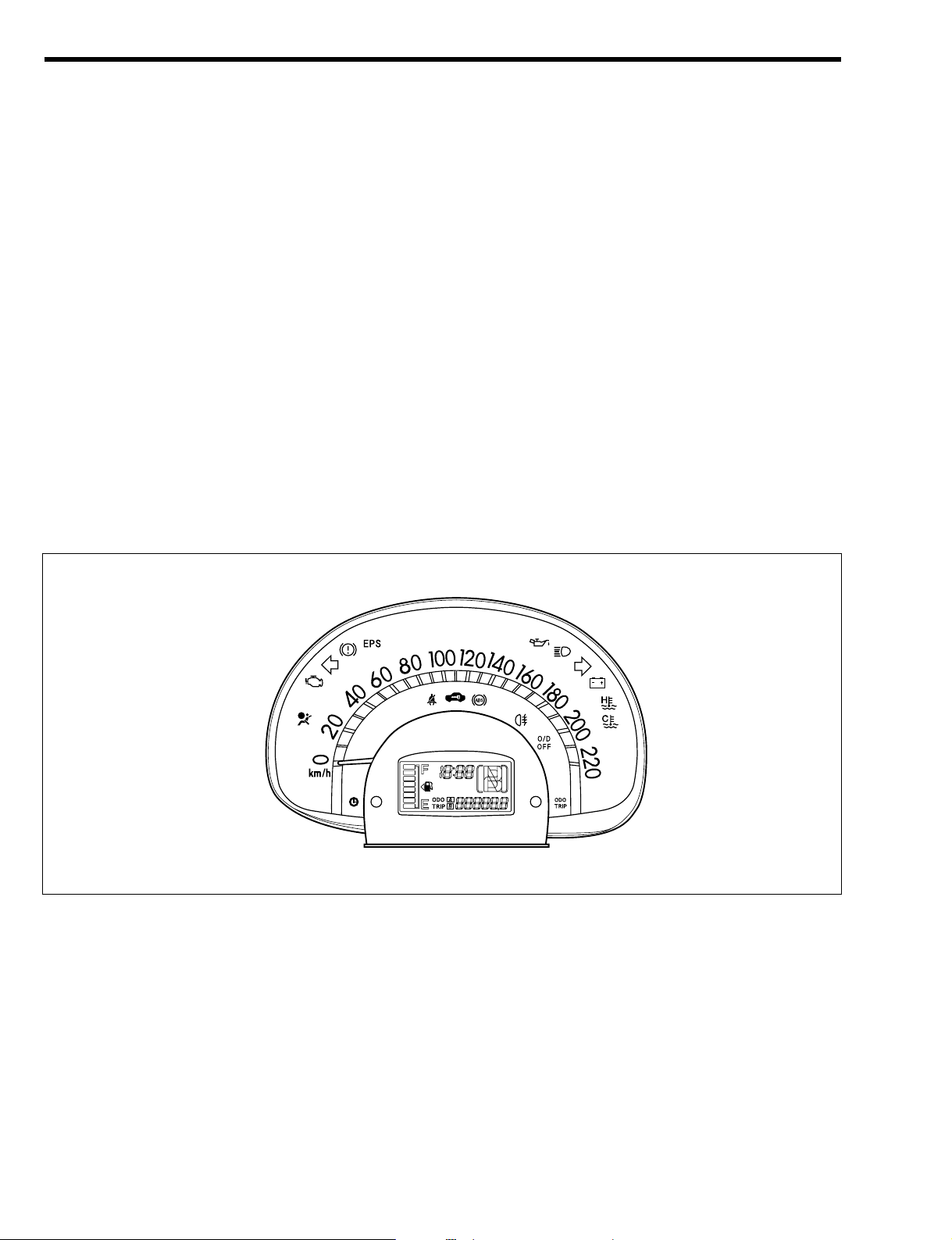

Arrangement of meter terminal

Meter terminal name

Terminal

No.

Terminal code Terminal name

1 CANH CAN communication HI (1)

2 CANL CAN communication LO (1)

3 HCAN CAN communication HI (2)

4 LCAN CAN communication LO (2)

5 BEAM+ High beam '

6 BEAM( High beam (

7 SPD Input of vehicle speed signal

8 BRK Input of brake fluid signal

9 IG2 IG power supply

10 +B 'B power supply

11 DOOR Input of courtesy switch signal

12 SPOUT Output of vehicle speed signal

13 TAIL Illumination +

14 PKBSW Parking brake

15 EPS EPS

16 RR-FOG Rear fog lamp

17 ECU-T ECU-T terminal signal input

18 GND Earth

19 ((

20 LIN LIN communication input/output

21 FUEL Input of fuel signal

22 D-BELT Seat belt at driver's seat side

23 P-BELT Front passenger seat side seat belt signal input

24 CHG Charge

25 OIL Oil

26 KEY2 Output of key switch signal

27 SEC Security

28 TURNL Turn LH

29 TURNR Turn RH

30 MIL MIL

31 P-BELOUT Front passenger seat side seat belt signal output

32 KEY Input of key switch signal

33 A/B Airbag

34 ((

35 ((

36 ((

37 ((

38 ((

39 KLS Keyless receiver signal input

40 ((

T11H6013S10

30 29 28 27 26 25 24 23 22 21

10 9 8 7 6 5 4 3 2 1

40 39 38 37 36 35 34 33 32 31

20 19 18 17 16 15 14 13 12 11

J3–5

Page 54

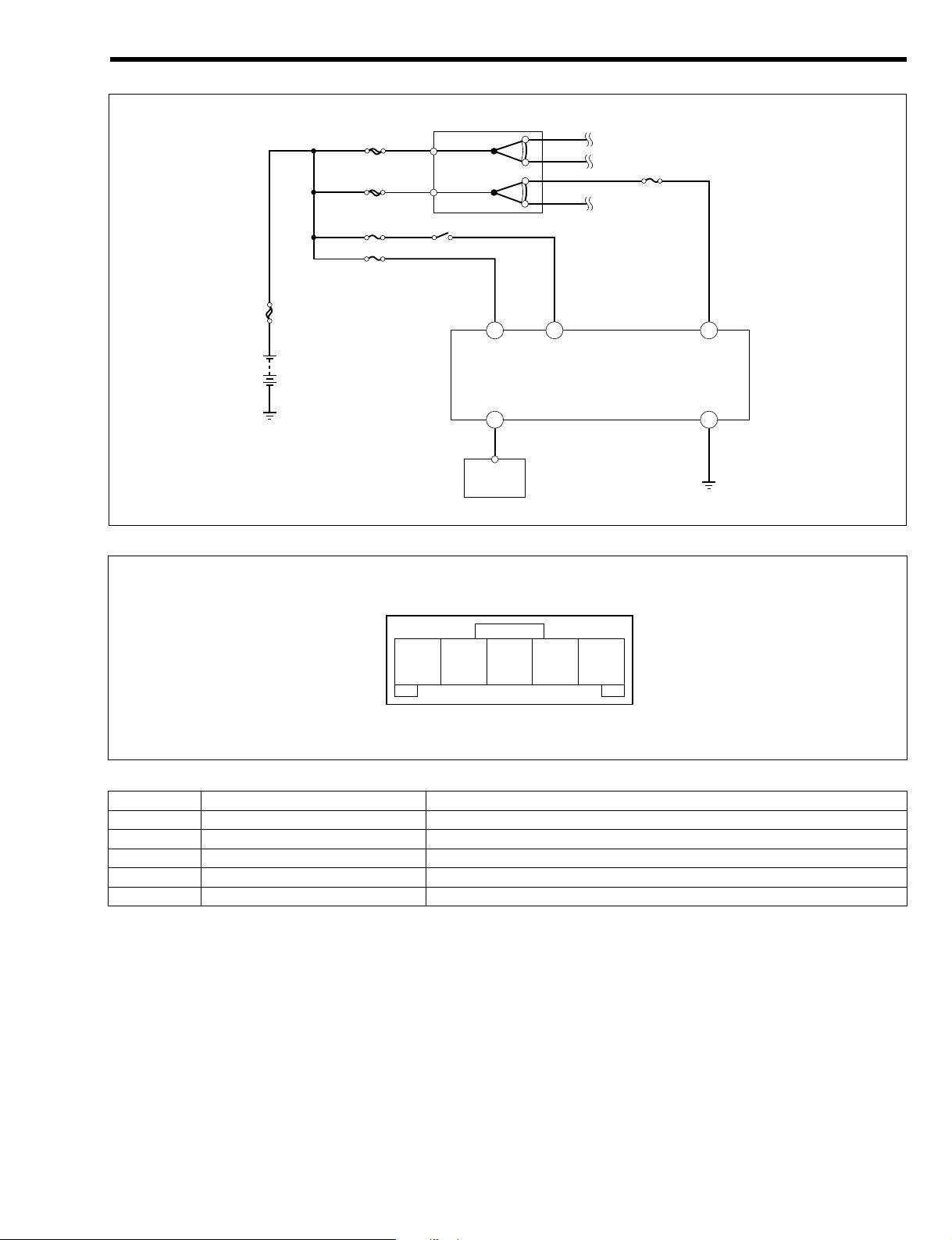

1-2-2 TACHOMETER

Arrangement of tachometer terminal

Ta ch o me t er termi n al name

Terminal No. Terminal code Terminal name

1 ILL Illumination

2 REV Input of engine revolution speed signal

3 IG IG power supply

4 'B 'B power supply

5 GND Earth

T11H6017S10

54321

T11H6016ES20

IG SW

AM2

TAIL

BACK UP

F/L

ST

ACC

AM1

IG1

IG2

ECU IG2

Tail SW

Tachometer

EFI ECU

REV

+B ILL

IG

REV GND

1

4

2

3

5

J3–6

Page 55

2CONSTRUCTION AND OPERATION

2-1 SPEEDOMETER

2-1-1 DESCRIPTION

1.For the speedometers, the electric type has been employed for all models.

2-1-2 SPECIFICATIONS

2-1-3 VEHICLE SPEED SENSOR (MRE TYPE)

(1) Description

1.A MRE type (MRE: Magnetic Resistance Element) vehicle

speed sensor has been set in the ABS non-installed M/T

vehicle as the vehicle speed signal detection sensor.

2.The vehicle speed sensor is installed to the transaxle.

3.The vehicle speed is detected by the rotating gear of the

vehicle speed sensor.

Indication Function

Indication range:

0 - 220 km/h

0 - 140 MPH

At increments of 10 km/h

At increments of 10 MPH

Electric type (pointer: stepper motor type)

Vehicle speed signal source:

ABS ECU [ABS-equipped vehicles]

A/T ECU [A/T vehicles without ABS]

Vehicle speed sensor (MRE type) [M/T vehicles without ABS]

Meter output vehicle speed pulse:

4 pulse/rev (42.47 Hz [at 60 km/h])

4 pulse/rev (68.33 Hz [at 60 MPH])

The vehicle speed is indicated by inputting the vehicle speed signal from the ABS ECU over the CAN communication and processing the signal at the meter ECU. (ABS-equipped vehicles)

The vehicle speed is indicated by inputting the vehicle speed signal from the A/T ECU over the CAN communication and processing the signal at the meter ECU. (A/T vehicles without ABS)

The vehicle speed is indicated by inputting the vehicle speed signal from the vehicle speed sensor (MRE type) and processing the

signal at the meter ECU. (M/T vehicles without ABS)

J3–7

W13H1006T16

Page 56

(2) Construction and operation

1.The resistance of the MRE becomes maximum when the direction of the electric current flowing in the

element becomes parallel to the direction of the line of magnetic force. Conversely, the resistance

becomes minimum when the electric current intersects with the direction of the line of magnetic force.

2.The direction of the line of magnetic force is determined by the rotation of the magnetized eight-pole

magnet in the magnet ring. The MRE output becomes an eight-cycle alternating waveform per rotation of the magnet ring. The comparator converts these waveforms into eight-pulse short waveforms

and the divider transforms them into four cycles. Finally, it will be outputted to the combination meter.

H11H2044ES25

NS

NS

Magnet ring

MRE resistance

1,3 2,4 1,3 2,4 1,3 2,4

MRE output

point A

Comparator

output

waveform

Speed sensor

output

waveform

MRE

Magnetic line

of force

2 4

MRE 1 3

Terminal

Terminal

2

1

12

A

Comparator

Output

B

34

MRE

Frequency

divider

NNS

NNS

Large resistance

Small resistance

Potential

'

Potential(

ON

OFF

ON

OFF

Small current

Element

Magnetic line of force

Large current

Element

Magnetic line of force

<Resistance minimum> <Resistance maximum>

M21H2058ES16

J3–8

Page 57

2-2 TACHOMETER

2-2-1 DESCRIPTION

1.A tachometer is available in some Specifications.

2.The revolution signal detected by the engine revolution speed sensor and converted by the EFI ECU

is inputted. Then the tachometer counts the pulse signals and performs calculation and finally indicates the engine revolution speed.

2-2-2 SPECIFICATIONS

2-3 ODOMETER TRIP METER

2-3-1 DESCRIPTION

1.An excellent visibility is achieved by employing an odometer ; trip meter with LCD (Liquid Crystal

Display) indication.

2.As for the odometer ; trip meter, an electric type odometer ; trip meter equipped with a twin trip meter

has been employed.

3.The changing of each mode is done by pressing the selection switch at the right of the speedometer.

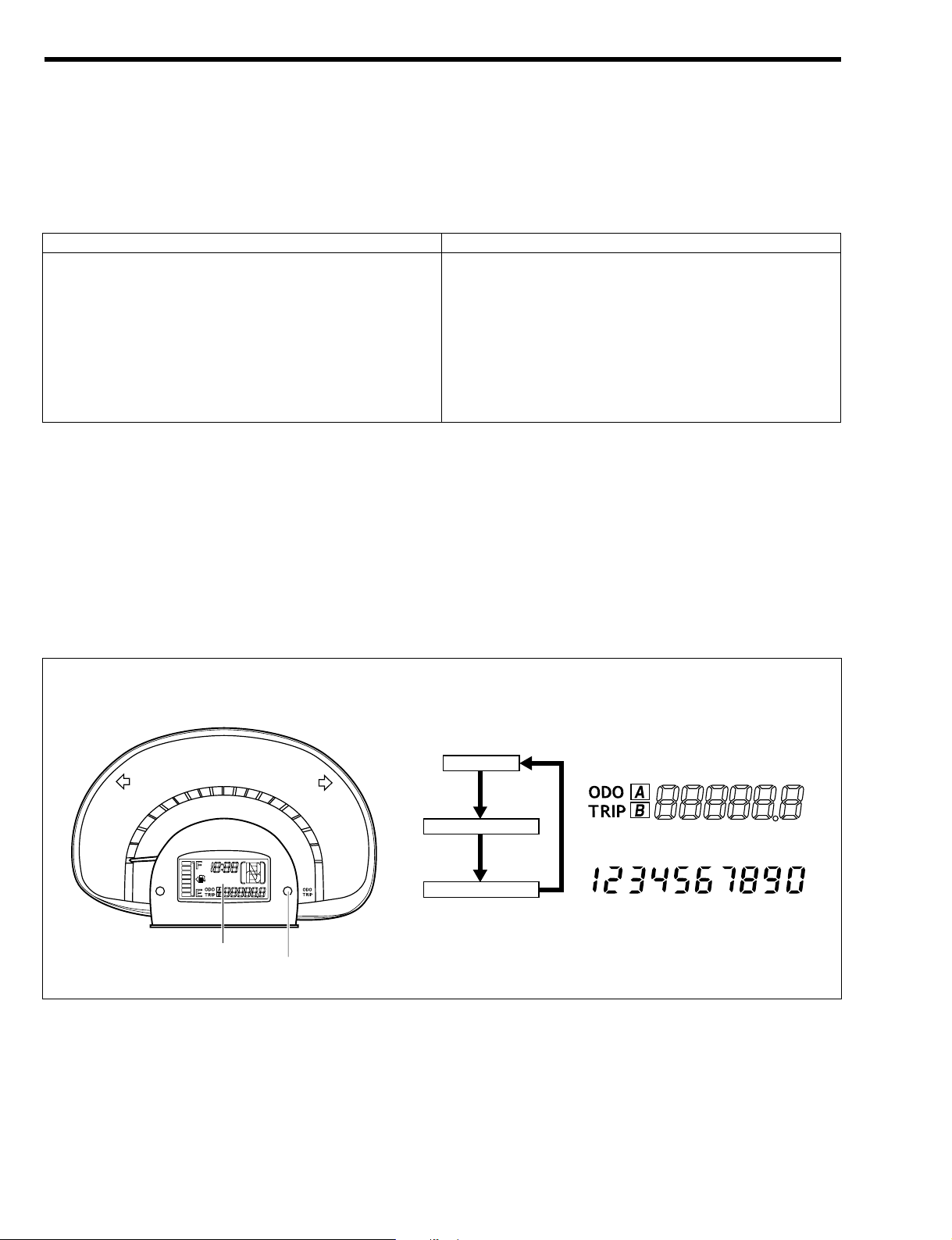

Indications are made in the order of odometer!trip meterA!trip meter B!odometer.

4.The figure of the trip meter is reset by pressing the selection switch for more than about one second.

Numeral pattern

Odometer

Trip meter A

Trip meter B

T11H1032ES16

Selection switch

LCD

Indication Function

Indication range: 0 - 8400 rpm (Red zone: 6800 - 8400 rpm) Electric type (pointer: stepper motor type)

Revolution signal source: EFI ECU

Number of input pulses: 2pulse/rev (100 Hz at 3000 rpm)

The pulse signal from the EFI ECU is inputted. Then, the tachometer counts the pulse signals and performs calculation

and finally indicates the engine revolution speed.

J3–9

Page 58

2-3-2 SPECIFICATIONS

2-4 FUEL GAUGE

2-4-1 DESCRIPTION

1.An excellent visibility is achieved by indicating fuel gauge

in LCD (Liquid Crystal Display).

2.The meter ECU calculates the accurate fuel level by calculating the average data of a certain period of time

based on the level signal from the fuel sender gauge.

3.The Fuel gauge indicates the fuel level by turning on/off of

the eight segments in the bar graph.

2-4-2 SPECIFICATIONS

2-4-3 FUEL LEVEL INDICATION FUNCTION

The meter ECU indicates the corresponding LCD segments by calculating the average data of a certain

period of time based on the level signal from the fuel sender gauge.

2-4-4 FUEL LEVEL WARNING FUNCTION

The driver is warned by the No.1 segment (bottom position) blinking when No.2 segment is turned off

(when the fuel level is about 6%).

Indication Function

Digital indication by LCD (Liquid Crystal Display)

Indicated by 8 segment bar graph.

Indication range: E - F

The fuel level is indicated by inputting the fuel sender gauge voltage and calculating at the meter ECU.

No.1 segment (bottom position) blinks when No.2 segment is

turned off (when fuel level is about 6%).

Indication Function

Digital indication by LCD

Indication range:

Odometer:

0 - 999999 km

0 - 999999 MILE

Trip meter A ; B:

0 - 9999.9 km

0 - 9999.9 MILE

LCD type

Mileage signal source:

ABS ECU [ABS-equipped vehicles]

A/T ECU [A/T vehicles without ABS]

Vehicle speed sensor (MRE type) [M/T vehicles without ABS]

The running distance is indicated by inputting the running distance signal from the ABS ECU over the CAN communication and

processing the signal at the meter ECU. (ABS-equipped vehicles)

The running distance is indicated by inputting the running distance signal from the A/T ECU over the CAN communication and

processing the signal at the meter ECU. (A/T vehicles without

ABS)

The running distance is indicated by inputting the running distance signal from the vehicle speed sensor (MRE type) and processing the signal at the meter ECU. (M/T vehicles without ABS)

The backward moving distance is also added.

By pressing the selection switch, indications are made in the order

of odometer!trip meter A !trip meter B.

By pressing the selection switch for more than about one second,

the figure of the trip meter is reset.

J3–10

T11H1033ET10

Fuel mark

No.8 segment

No.1 segment

Page 59

2-5 WARNING / INDICATOR

2-5-1 TURN

1.A turn indicator has been set in the meter.

2.It blinks when the turn signal switch and the hazard switch

are "ON".

2-5-2 HIGH-BEAM

1.A high-beam indicator is set in the meter.

2.It is lighted when the headlamp is set at high-beam or

passing.

2-5-3 CHARGE

1.A charge warning lamp is set in the meter.

2.If the charging system is normal, it is lighted when the IG

switch is turned "ON" and is turned off when the engine is

started.

3.It is constantly lighted when there is an abnormality in the

system.

2-5-4 OIL

1.An oil warning lamp has been set in the meter.

2.It is lighted when the oil pressure switch is "ON" and is

turned off when the engine is started.

3.It is constantly lighted when the oil pressure is low.

2-5-5 MIL

1.If the engine control system is normal, it is lighted when the

IG switch is turned "ON" and is turned off when the engine

is started.

2.It is constantly lighted when there is an abnormality in the

system.

3.The diagnosis code of the engine control system is outputted.

J3–11

H11H2052T10

H11H2053T10

H11H2054T10

H11H2055T10

H11H2056T10

Page 60

2-5-6 BRAKE

1.A brake warning lamp has been set in the meter.

2.If the system is normal, it is lighted when the IG switch is

turned "ON" and is turned off three seconds later under

the condition in which the parking brake is not operating.

3.It is lighted when the parking brake switch or the brake

fluid level switch is "ON".

4.It is constantly lighted when there is an abnormality in the

ABS.

2-5-7 ABS

1.An ABS warning lamp has been set in the meter.

2.If the system is normal, it is lighted when the IG switch is

turned "ON" and is turned off about three seconds later.

3.It is constantly lighted when there is an abnormality in the

system.

4.The diagnosis code of the ABS is outputted.

2-5-8 AIRBAG

1.An airbag warning lamp has been set in the meter.

2.If the system is normal, it is lighted when the IG switch is

turned "ON" and is turned off about six seconds later.

3.It is constantly lighted when there is an abnormality in the

system.

4.The diagnosis code of the airbag system is outputted.

2-5-9 EPS

1.An EPS warning lamp has been set in the meter.

2.If the system is normal, it is lighted when the IG switch is

turned "ON" and is turned off two seconds later.

3.It is constantly lighted when there is an abnormality in the

system.

4.The diagnosis code of the EPS system is outputted.

J3–12

W13C6012T10

S16C5061T10

L11A5009T10

L15C5002T10

Page 61

2-5-10 HIGH WATER TEMPERATURE/LOW WATER TEM-

PERATURE

1.A high water temperature warning lamp and low water

temperature indicator lamp have been set in the meter.

2.If the system is normal, the high temperature warning lamp

and low temperature indicator lamp are lighted when the

IG switch is turned "ON" and are turned off about three

seconds later under the condition in which the water temperature is neither high or low.

NOTE

•Even if the IG switch is turned "ON" when the engine

water temperature is low, the high water temperature

warning lamp is lighted for about three seconds for initial check. In that case, the low water temperature indicator lamp is also lighted and will continue to be lighted after three seconds until the engine water temperature becomes high.

3.The high water temperature warning lamp blinks when the

water temperature is about 117˚C or above and is turned

off when it is about 112˚C or below.

4.The low water temperature indicator lamp is lighted when

the water temperature is about 35˚C or below and is

turned off when it is about 40˚C or above.

J3–13

H11H2059T10

T11H1069ET10

COOL illuminated HOT illuminated

35$C40$C112$C117$C

Extinguished

ON

OFF

Page 62

2-5-11 SEAT BELT

(1) Description

1.A blinking type seat belt warning lamps have been set to the driver seat and the passenger seat

according to the specifications. As for the position of the warning lamp, the one of the driver seat is

set in the meter and the other for the passenger seat is set in the air conditioner control panel.

2.The driver seat belt warning lamp blinks if the seat belt is not fastened on the driver seat.

3.As for the front passenger seat belt warning lamp, it blinks if the seat belt is not fastened on the front

passenger seat when there is somebody seated on the passenger seat.

4.A passenger detection sensor which detects if the passenger is seated or not has been set below the

skin of the front passenger seat cushion.

T11H1034ES16

Driver's seat belt warning Front passenger seat belt warning

J3–14

Page 63

(2) Passenger detection sensor structure

When the IG switch is "ON" and a passenger seats on the front passenger seat, the electrodes of the sensor have contact and let the warning lamp blink. Then, when the passenger seat belt is fastened, the seat

belt switch is turned "OFF" and the warning lamp is turned off.

NOTE

• If a load above a certain level is applied to the seat cushion such as in the case of placing luggage

on the passenger seat cushion, the sensor may detect this.

2-5-12 O/D OFF

1.An O/D OFF indicator has been set in the meter.

2.It is lighted when the O/D is "OFF".

3.It blinks when there is an abnormality in the transmission

control system.

4.The diagnosis code of the transmission control system is

outputted.

2-5-13 SHIFT POSITION

1.A shift position indicator has been set in the LCD of the

meter.

2.The present shift position is indicated.

NOTE

• The frame indication blinks corresponding to the

buzzer interval during R range indication.

T04B1010ES20

A

A

Spacer

Electrode

Contact film

Section A(A

J3–15

T11H1036T10

H11H2058T10

Page 64

2-5-14 SECURITY

1.A security indicator has been set in the meter.

NOTE

• Please refer to the pages of the immobilizer system for

details concerning lighting conditions.

Refer to Page I4-13.

2.The diagnosis code of the immobilizer system is outputted.

2-5-15 REAR FOG LAMP

1.A rear fog lamp indicator has been set in the meter.

2.It is lighted when the rear fog lamp is lighted.

2-6 WARNING BUZZER

2-6-1 DESCRIPTION

1.A multi-buzzer is employed and incorporated in the meter. This multi-buzzer sounds while various

warnings are given such as when the key is remaining in the key cylinder, or when the reverse gear is

selected.

2-6-2 SPECIFICATIONS

2-7 CLOCK

1.A digital clock by LCD (Liquid Crystal Display) indication

has been employed.

2.An excellent usability has been achieved by setting the

installation position in the meter.

3.A clock adjusting switch to adjust the time has been set on

the left side of the clock.

Category Function

Key remaining in key cylinder

Light remaining to be illuminated

Reverse

Seat belt remaining (Europe specification)

Vehicle speed warning (Some specifications)

Warnings and abnormalities of each system are notified by sound.

J3–16

T11H1037T10

T11H1038T10

T11H1042ET10

Clock

Clock correction switch

Page 65

2-8 WATER TEMPERATURE INDICATION FUNC-

TION

2-8-1 DESCRIPTION

1.The water temperature may be indicated on LCD (Liquid

Crystal Display) by the following procedures.

(1) Turn "ON" the IG switch.

(2) Short the terminal ECU-T and terminal E of the DLC.

(3) Press on the selection switch for about a second.

CAUTION

• If the vehicle is driven with the terminal ECU-T ad terminal E of the DLC in the above (2) short-circuited, the

figures on the liquid crystal display will remain to indicate the water temperature until the vehicle speed is

above 8km/h and thus the odometer ; trip meter cannot be seen. Please remove the short circuit between

the terminal ECU-T and terminal E when the operation

is finished.

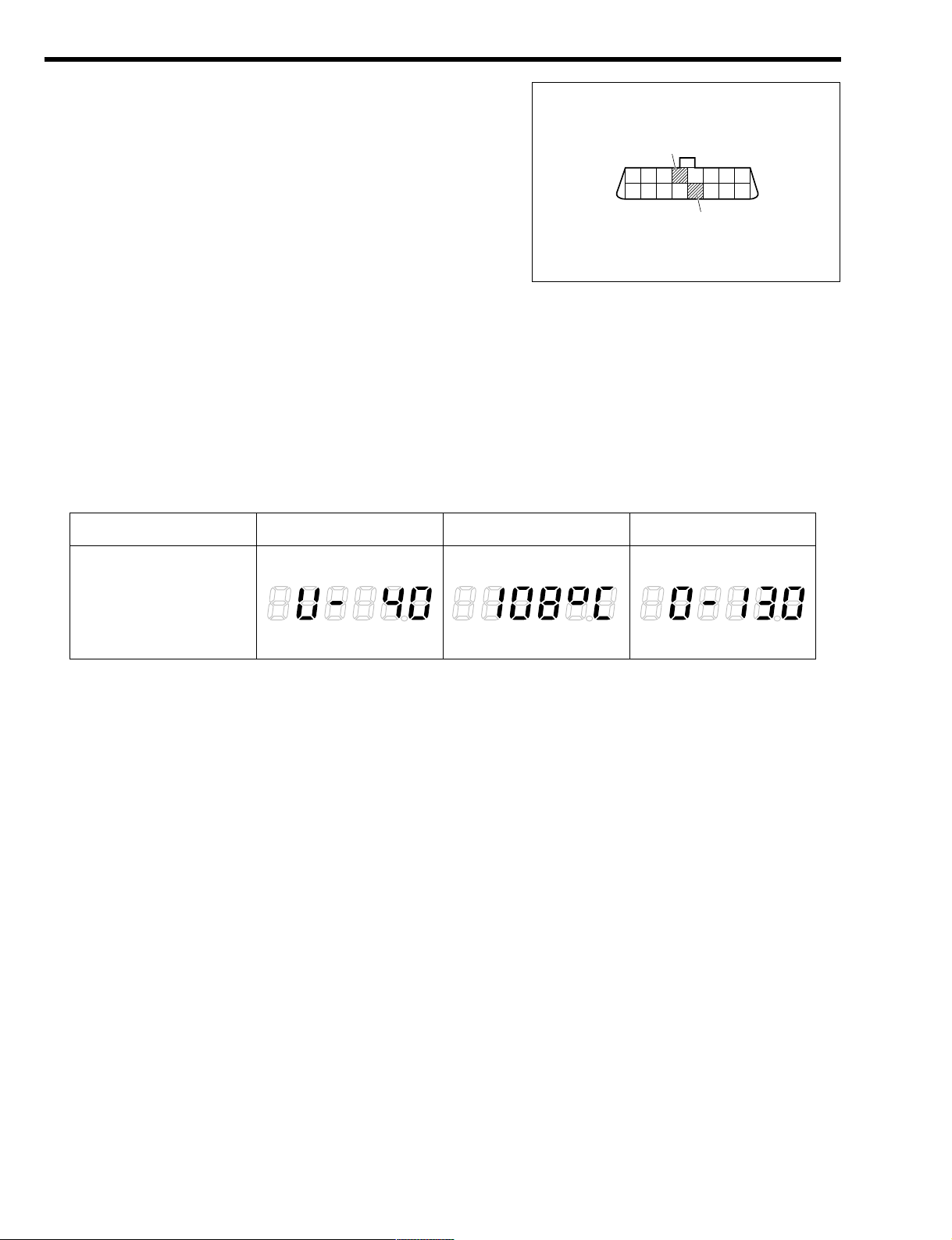

2.The temperature indicated on the LCD (Liquid Crystal Display) is from 40Ç to 130Ç with 1Ç intervals.

Water temperature

Indication example

40$C or less 130$C or more

108$C

T11H1040ES10

J3–17

H11A5014T10

E

ECU-T

Page 66

2-9 CAN COMMUNICATION

For the meter ECU in the meter, CAN communication is employed for some of the communications with

other ECU's.

Please refer to the pages of the CAN communication system for the CAN communication.

Refer to Page L2-1.

2-10 LIN COMMUNICATION

For the meter ECU in the meter, the LIN communication is

employed for some of the communications with other ECU's.

Please refer to the pages of the LIN communication system

for the LIN communication.

Refer to Page L2-13.

Contents of meter ECU communication (LIN communication)

Meter ECU

Nomenclature of signals

Receiving Sending

Applicable ECU

ITC sleep refusal <( ITC

Request of keyless door lock (< ITC

Request of keyless door unlock (< ITC

Key switch (< ITC

Terminal ECU-T (< ITC

Door courtesy switch (< ITC

T11H1527ES25

A/T ECU Meter ECU ABS ECU

EFI ECU

Shift range information

O/D OFF lamp demand

A/T warning demand

Completion of A/T

learning value erasure

Vehicle speed

Brake warning lamp demand

ABS warning lamp demand

Engine cooling water temperature

Tail switch

Vehicle speed (Meter)

Running distance

ECU-T terminal ECU-T terminal

J3–18

B11H1022ET10

Meter ECU ITC

Page 67

2-11 DIAGNOSIS (ONBOARD DIAGNOSIS FUNCTION)

This is a function whereby the ECU informs the inspection operator of the abnormal items when there has

been a failure in the system. When failure takes place, the ECU memorizes the abnormal item.

Please refer to the repair manual for details concerning the diagnosis.

2-12 FAIL-SAFE FUNCTION

When an abnormality takes place in each function, the meter shifts to the fail mode and carries out the

processes as in the following.

List of fail mode

Function Abnormality item Process when failure takes place

Vehicle speed signal (CAN) communication disabled

Indicates 0km/h

Speedometer

Abnormality in the meter Indicates 0km/h

Vehicle speed signal (CAN) communication disabled

Does not integrate mileage

Odometer

Abnormality in the meter

; Does not integrate mileage

; Indicates "ODO" on the LCD.

; Blinks indication of integrated mileage figure

;The running distance is measured in the unit of km.

Either of the above is done.

Vehicle mileage signal (CAN) communication disabled

Does not integrate mileage

Trip meter

Abnormality in the meter

; Blinks indication of integrated mileage figure

;The running distance is measured in the unit of km.

Either of the above is done.

Fuel gauge Signal analog / digital conversion error

Turns off of all segments until the IG switch is turned "ON"

again.

Multiple receiving of shift range information

signal (CAN)

Turns off of the shift position indication and blinking of the

frame indication only

Shift position

indicator

Shift range information signal (CAN) communication disabled

Turns off of the shift position indication and blinking of the

frame indication only

High water

temperature

warning lamp/

Low water

temperature

indicator lamp

Engine water temperature signal (CAN)

communication disabled

High water temperature warning lamp extinguished

Low water temperature indicator lamp blinking

O/D OFF lamp request signal (CAN) communication disabled

Indicator extinguished

O/D OFF indicator

A/T warning request signal (CAN) communication disabled

Indicator extinguished

Brake

warning lamp

Brake warning lamp request signal (CAN)

communication disabled

Lamp illuminated

ABS

warning lamp

ABS warning lamp request signal (CAN)

communication disabled

Lamp illuminated

Reverse

warning buzzer

Multiple receiving of shift range information

signal (CAN)

Buzzer sound stopped

J3–19

TO INDEX TO NEXT SECTION

Page 68

OUTLINE------------------------------------------ J2 - 1

DESCRIPTION ------------------------------- J2 - 1

SYSTEM WIRING DIAGRAM ------------ J2 - 3

CONSTRUCTION AND OPERATION----- J2 - 5

FRONT WIPER------------------------------- J2 - 5

REAR WIPER--------------------------------- J2 - 8

WASHER--------------------------------------- J2 - 9

J2 WIPER & WASHER

J2

TO INDEX

Page 69

1OUTLINE

1-1 DESCRIPTION

1.Improvements have been made in the downward field of view and the interior appearance of the arm

by positioning the front wiper system lower than the previous model.

2.The appearance and the workability when replacing the blade has been improved by employing the

U-hook type for the tightening of the front wiper arm and the front wiper blade.

3.The frame integrated module type has been employed for the installation structure of the front wiper

motor and the front wiper link. As a result, the system rigidity has been enhanced, thus reducing the

wiper operation sound as well as the variation of the wiper sweep angle.

4.Careful consideration has been made for the protection of pedestrians by employing a pivot section

breaking structure for the front passenger seat side wiper.

5.The rear wiper which has a plastic arm and blade has been provided on some specifications.

6.Two 1-hole type washer nozzles have been set in the front and one 1-hole type washer nozzle has been

set in the rear side.

T11H1020ES25

Front wiper motor & link

Washer tank

Front washer nozzle

Front wiper arm & blade

Windshield wiper switch

J2–1

Page 70

The illustration represents the RHD vehicle.

T11H1021ES25

Rear washer nozzle

Rear wiper arm & blade

Rear wiper motor

J2–2

Page 71

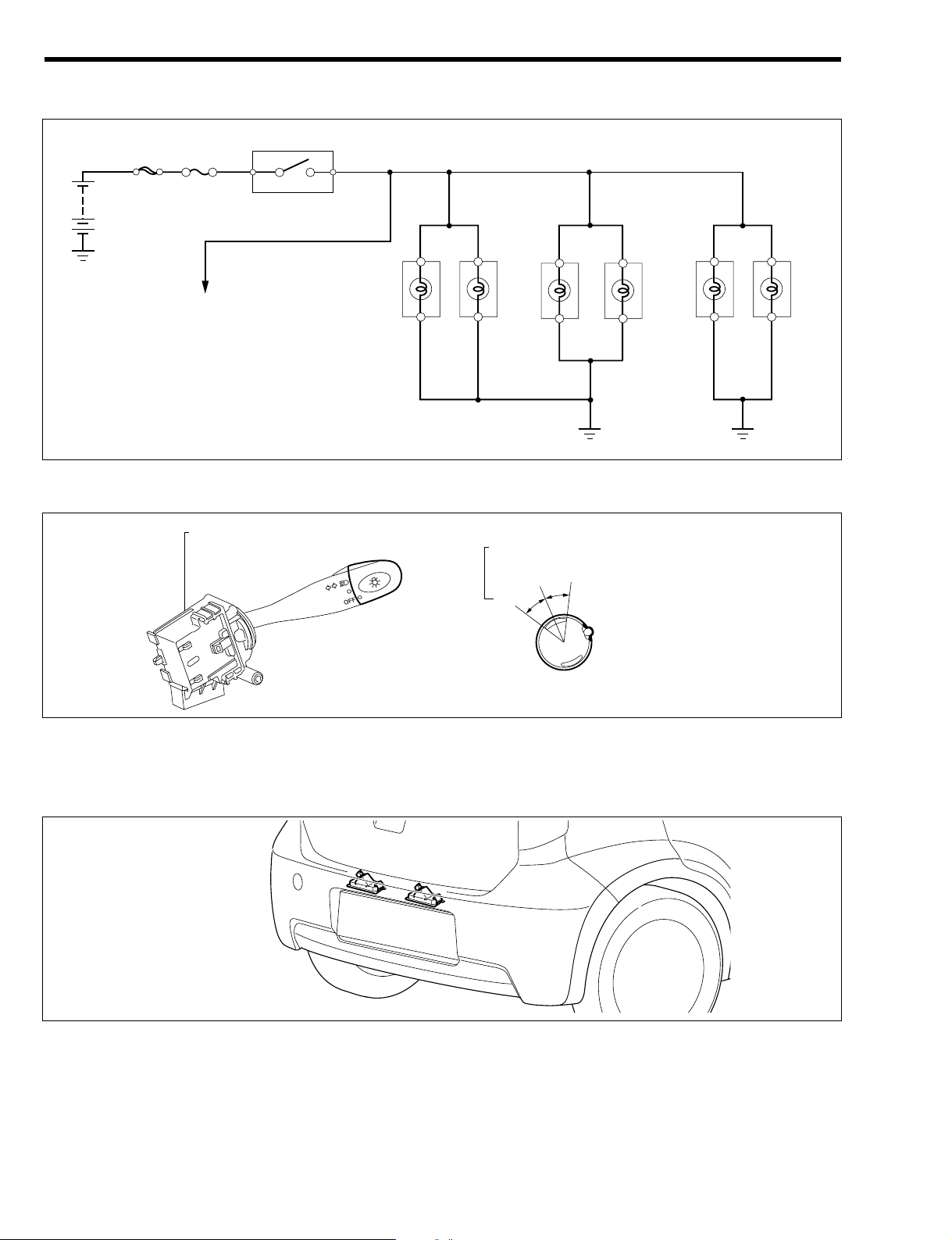

1-2 SYSTEM WIRING DIAGRAM

1-2-1 FRONT WIPER & WASHER

T11H1536ES25

M

M

HI

LO

INT

OFF

MIST

OFF

ON

P

WB '2 '1 'S INT1 INT2 B1

T

P

T

WEW

Wiper switch

Front wiper switch

Washer switch

Wiper relay

Washer motor

Wiper motor

R1

R6

R7

R8

R5

LO

HI

C1

C2

ZD

R3

R2

R4

D1

Tr1

Tr2

WIPER

IG relay

IG1

F/L

J2–3

Page 72

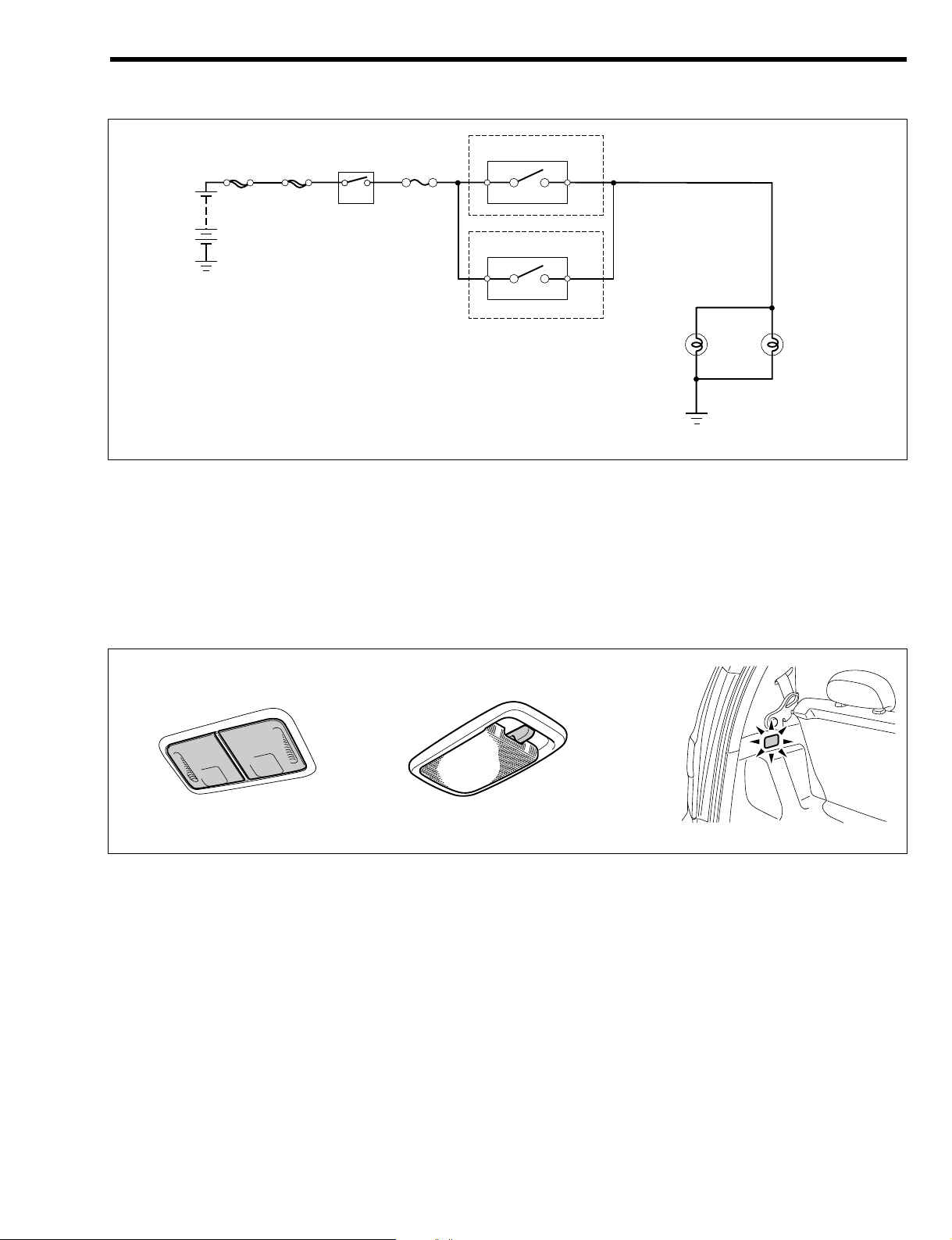

1-2-2 REAR WIPER & WASHER (VEHICLES WITHOUT INTERMITTENT FUNCTION)

1-2-3 REAR WIPER & WASHER (VEHICLES WITH INTERMITTENT FUNCTION)

T11H5605ES16

F/L

IG1

IG relay

WIPER

M

2

M

2

2

1

2 6 5 4 3

3 1 2

3

1

P

T

Washer motor

Rear wiper switch

Rear wiper motor

Rear wiper relay

WR CIR '1R EW

WASH

OFF

INT

ON

ON WASH

5

Intermittent

control circuit

T11H1537ES16

ON WASH

ON

OFF

WASH

P

WR '1R EW

T

Washer motor

Rear wiper switch

Rear wiper motor

M

IG relay

WIPER

IG1

F/L

M

J2–4

Page 73

2CONSTRUCTION AND OPERATION

2-1 FRONT WIPER

2-1-1 DESCRIPTION

1.The module type wiper motor & link has been employed for the front wiper.

2.Careful consideration has been made for the protection of pedestrians by employing a breaking structure for the front passenger seat side pivot section.

2-1-2 FRONT WIPER MOTOR AND LINK

The frame integrated module type has been employed for the installation structure of the front wiper motor

and the front wiper link. As a result, the system rigidity has been enhanced, thus reducing the wiper operation sound as well as the variation of the wiper sweep angle.

2-1-3 FRONT WIPER MOTOR

For the front wiper motor, a motor with rated voltage of 12V and rated torque of 18N;m has been employed

for all models.

Specification table

2-1-4 FRONT WIPER ARM & BLADE

Specification table

Driver seat side

front wiper blade length (mm)

500

Front passenger seat side

front wiper blade length (mm)

400

Rated voltage (V) 12

Rated torque (N;m) 18

T11H1027S16

J2–5

Page 74

2-1-5 FRONT WIPER LINK

1.Careful consideration has been made for the protection of pedestrians by employing the pivot section

breaking structure for the front passenger seat side wiper.

2.A structure in which it is difficult for the head of the pedestrian to hit the base of the wiper directly has

been employed by positioning the hood higher than the base of the wiper.

3.Even in the event that the vehicle and the pedestrian collide and the pedestrian hit the base of the

wiper, the pivot shaft falls off downward and reduces the impact by the breaking of the pivot section