DAEWOO DWF-7560, DWF-7590, DWF-8060, DWF-8090 Service Manual

DAEWOO ELECTRONICS CO., LTD.

Service Manual

DWF-7560/7590 series

DWF-8060/8090 series

Full-Auto Electric Washing Machine

1

TABLE OF CONTENTS

1. SPECIFICATIONS.....................................................................................................................................................................2

2. FEATURE AND TECHNICAL EXPLANATION...................................................................................................................... 3

CONTROL SYSTEM FOR AUTO COURSE............................................................................................................................. 3

CONTROL SYSTEM FOR WOOL WASH ................................................................................................................................ 3

CONTROL SYSTEM FOR WOOL SPIN....................................................................................................................................4

WATER FLOW TO ADJUST THE UNBALANCED LOAD......................................................................................................... 4

FUNCTION FOR SOAK WASH..................................................................................................................................................4

AUTOMATIC WATER SUPPLY SYSTEM ON BLANKET WASH............................................................................................ 5

WATER FLOW ON STRONG WASH.........................................................................................................................................5

PULSATOR SYSTEM.................................................................................................................................................................5

AUTOMATIC DRAINING TIME ADJUSTMENT ........................................................................................................................6

SOFTENER DISPENSER............................................................................................................................................................ 7

AUTOMATIC UNBALANCE ADJUSTMENT............................................................................................................................. 8

CIRCULATING-WATER COURSE AND LINT FILTER..............................................................................................................8

AUTOMATIC POWER OFF ........................................................................................................................................................9

RESIDUAL TIME DISPLAY.........................................................................................................................................................9

DRAIN MOTOR........................................................................................................................................................................... 9

WATER LEVEL SWITCH.............................................................................................................................................................9

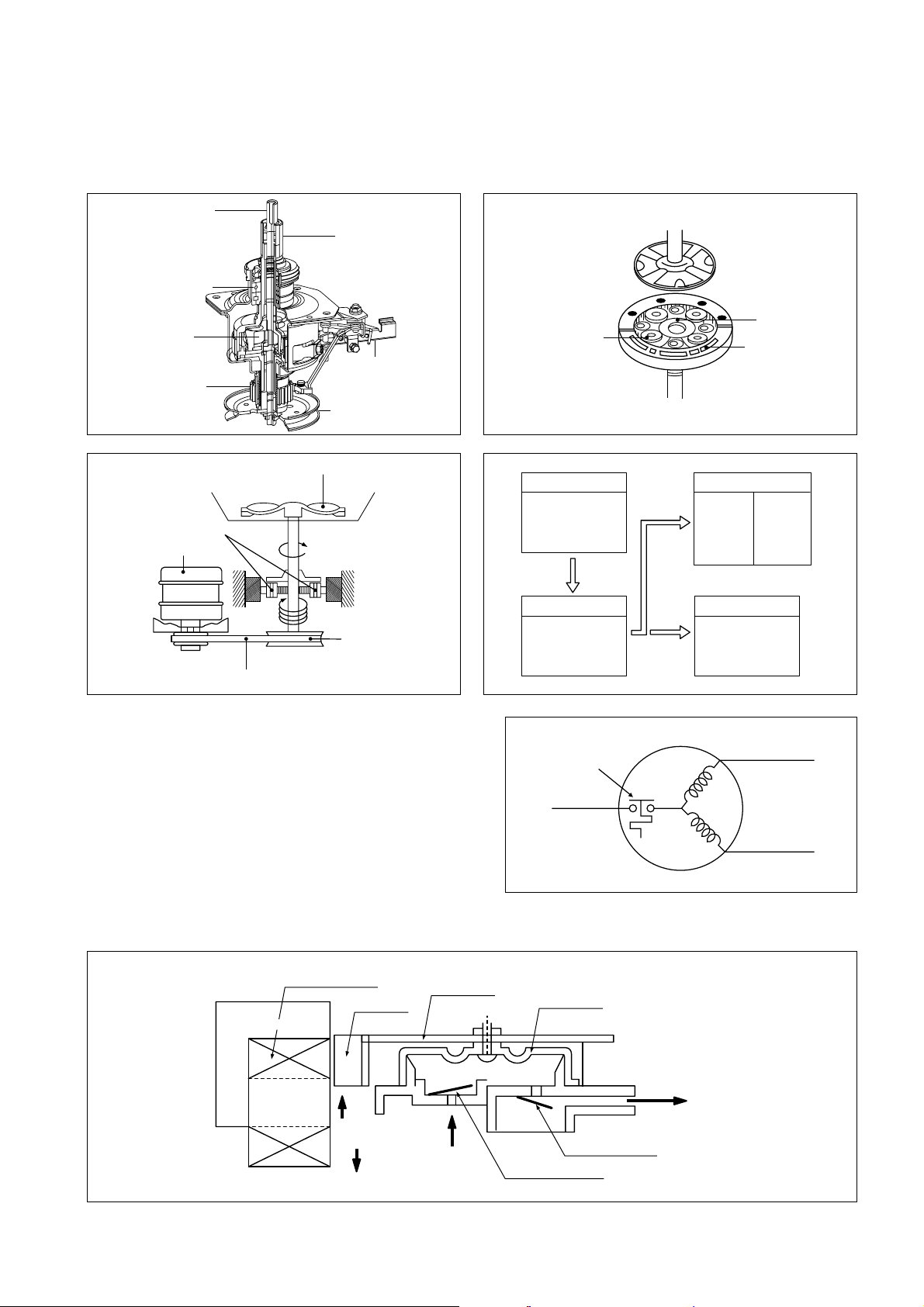

GEAR MECHANISM ASS'Y.....................................................................................................................................................10

SAFETY DEVICE FOR MOTOR...............................................................................................................................................10

PRINCIPLE OF BUBBLE GENERATOR..................................................................................................................................10

FUNCTIONAL PRINCIPLE OF BUBBLE WASHING MACHINE............................................................................................ 11

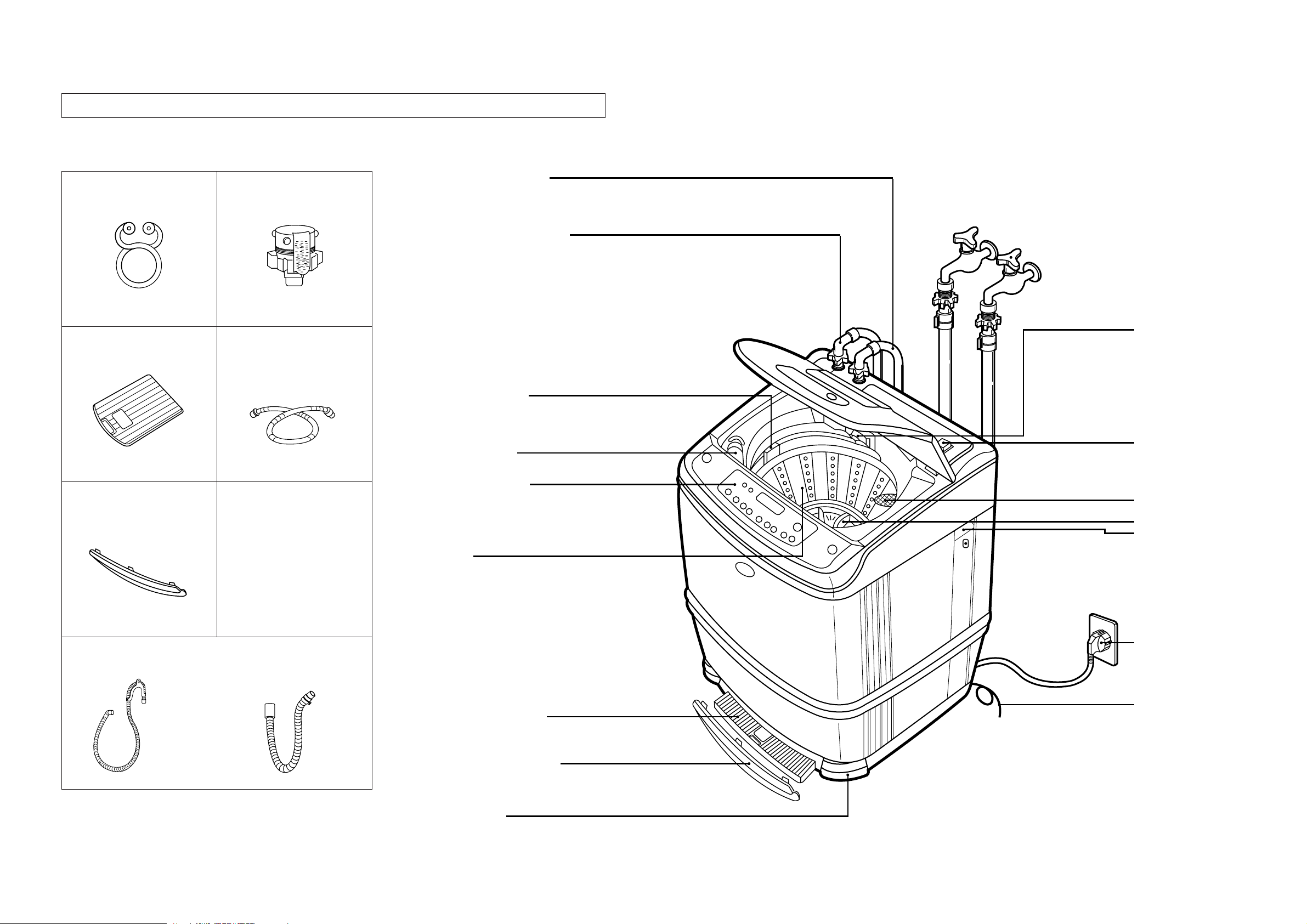

3. STRUCTURE OF WASHING MACHINE..............................................................................................................................12

STRUCTURE OF WASHING MACHINE.................................................................................................................................12

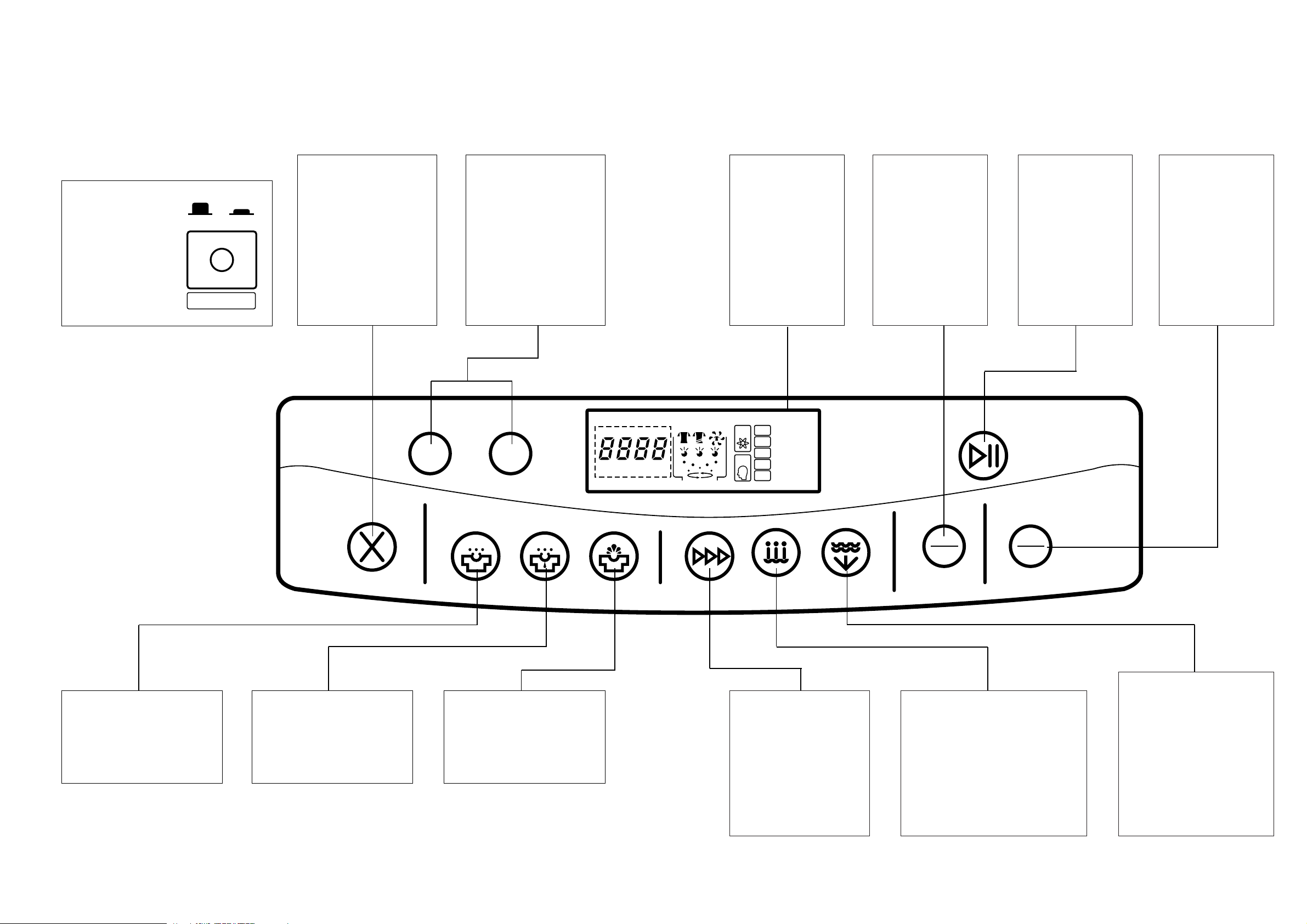

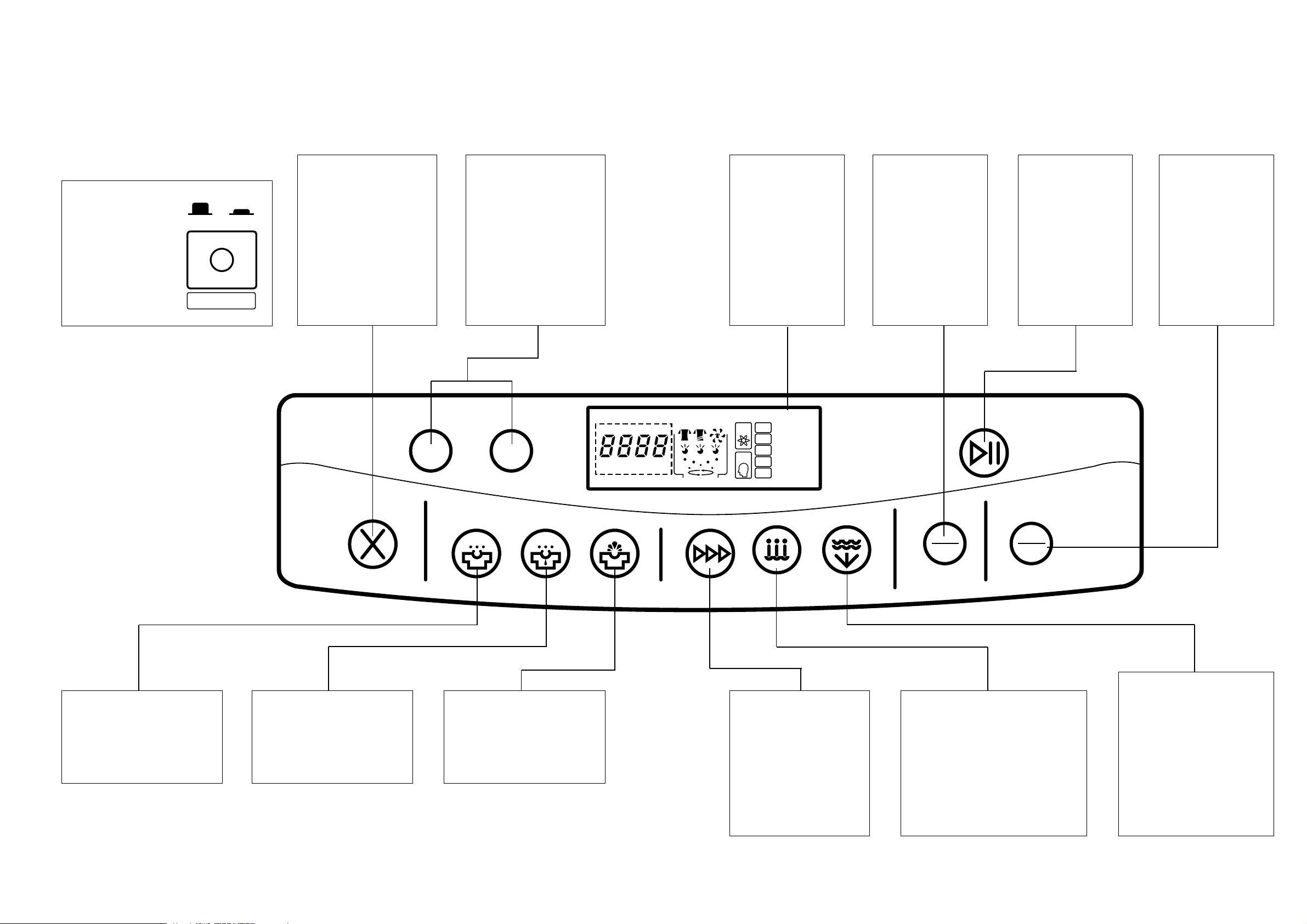

FUNCTION OF CONTROL PANEL.......................................................................................................................................... 13

4. INSTALLATION INSTRUCTIONS.........................................................................................................................................14

HOW TO INSTALL OF THE WASHING MACHINE................................................................................................................14

HOW TO CONNECT THE INLET HOSE..................................................................................................................................16

HOW TO REROUTE THE DRAIN HOSE.................................................................................................................................17

HOW TO INSTALL THE DRAIN HOSE....................................................................................................................................18

HOW TO CLEAN THE DRAIN FILTER.....................................................................................................................................19

5. OPERATING INSTRUCTIONS.............................................................................................................................................. 20

PROCEDURE OF FULL-AUTOMATIC WASHING.................................................................................................................20

PARTIAL SELECTIONS AMONG WASH, RINSE AND SPIN ................................................................................................22

6. PROGRESS CHART...............................................................................................................................................................24

7. HOW TO CHECK THE P.C.B. ASS'Y................................................................................................................................... 28

8. WIRING DIAGRAM................................................................................................................................................................. 29

9. DIRECTIONS FOR DISASSEMBLY AND ADJUSTMENT.................................................................................................32

GEAR MECHANISM ASS'Y REPLACEMENT........................................................................................................................32

DRAIN MOTOR VALVE REPLACEMENT................................................................................................................................ 33

BRAKE ADJUSTMENT............................................................................................................................................................. 33

10. EXPLODED VIEW AND PART LIST......................................................................................................................................34

EXPLODE VIEW........................................................................................................................................................................ 34

PARTS LIST...............................................................................................................................................................................37

11. TROUBLE SHOOTING GUIDE ..............................................................................................................................................41

CONCERNING WATER SUPPLY............................................................................................................................................41

CONCERNING WASHING.......................................................................................................................................................42

CONCERNING DRAINING.......................................................................................................................................................43

CONCERNING SPINNING.......................................................................................................................................................44

CONCERNING OPERATIONS.................................................................................................................................................45

CONCERNING ERROR MESSAGE........................................................................................................................................46

2

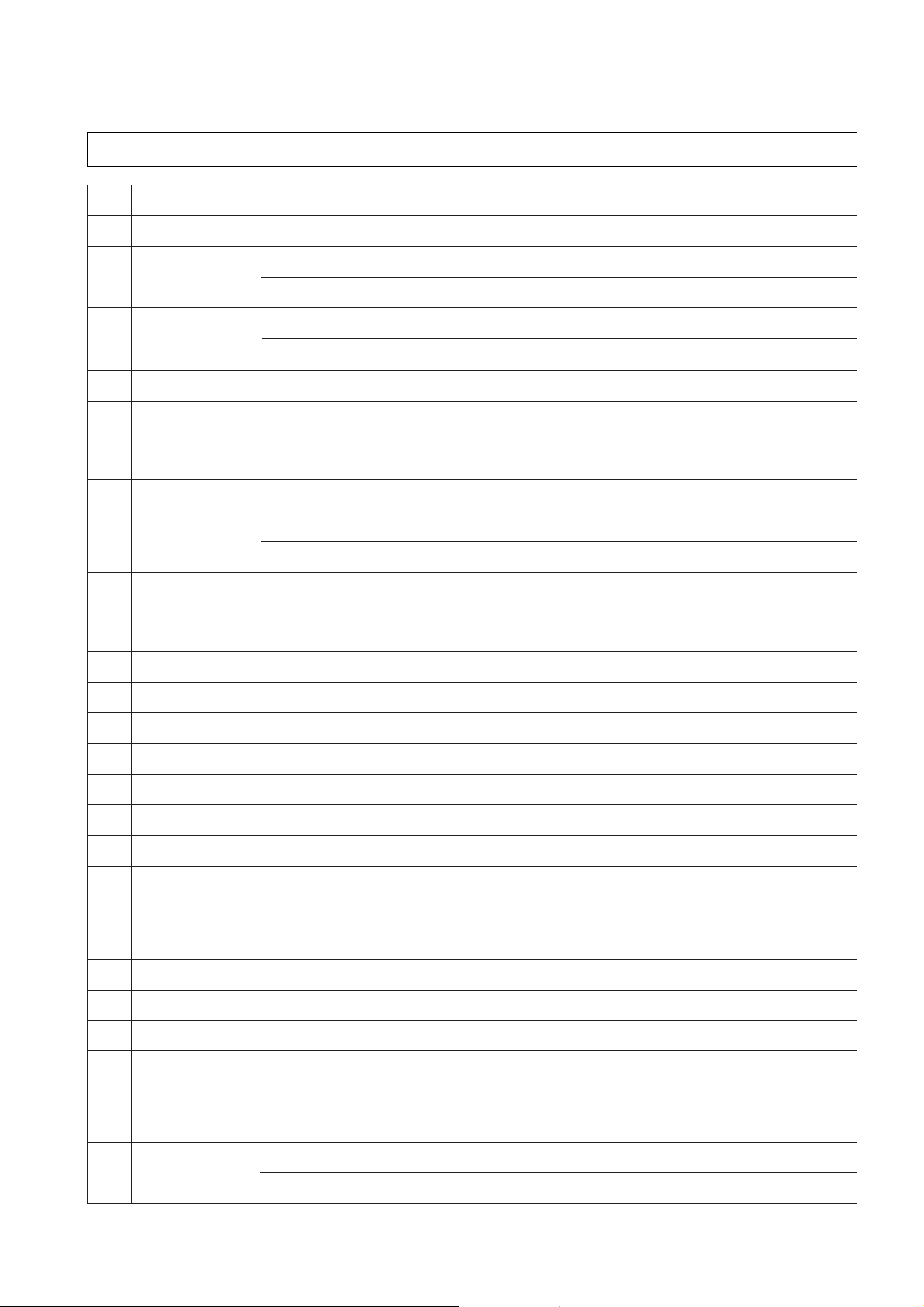

1. SPECIFICATIONS

NO ITEM SPECIFICATIONS

1 POWER SOURCE Available in All Local AC Voltage and Frequency

2 POWER DWF-7560/90 370W (50Hz), 460W (60Hz)

CONSUMPTION DWF-8060/90 400W (50Hz), 480W (60Hz)

3 MACHINE DWF-7560/90 NON PUMP: NET; 48kg, GROSS; 52kg PUMP: NET; 49kg, GROSS; 53kg

WEIGHT DWF-8060/90 NON PUMP: NET; 49kg, GROSS; 53kg PUMP: NET; 50kg, GROSS; 54kg

4 DIMENSION (WXHXD) 650X1005X650 mm

5 WASHING COURSE Full Automatic 6 Courses:

DRY; FUZZY, DRY, SILK, SPEED, STRONG, BLANKET

NON DRY; FUZZY, WOOL, SPEED, STRONG, BLANKET, NIGHT

and MEMORY Course

6 WATER CONSUMPTION 259 ` (7.5kg), 265 ` (8.0kg)

7 WATER LEVEL DWF-7570/90 HIGH (80 `), MIDDLE (68 `), LOW (55 `), SMALL (42 `), E.SMALL (32 `)

SELECTOR DWF-8060/90 HIGH (82 `), MIDDLE (70 `), LOW (57`), SMALL (43 `), E.SMALL (32 `)

8 OPERATING WATER PRESSURE 0.3~8kg/cm

2

(2.9~78.4N/cm2)

9 REVOLUTION PER MINUTE SPIN: 680rpm, WASH: 130rpm (50Hz)

WOOL WASH: 70rpm

SPIN: 780rpm, WASH: 150rpm (60 Hz)

10 PULSATOR 6 WINGS (ø 376mm)

11 WATER LEVEL CONTROL ELECTRONICAL SENSOR

12 OUTER CABINET PLASTIC

13 ANTI-NOISE PLATE O

14 GEAR MECHANISM ASSY HELICAL GEAR FOR LOW NOISE

15 LINT FILTER O

16 SOFTENER DISPENSOR O

17 AUTO. LOAD SENSING O

18 AUTO. POWER OFF O

19 FUNCTION FOR SOAK WASH O

20 ALARM SIGNAL O

21 RESIDUAL TIME DISPLAY O

22 AUTO. RE-FEED WATER O

23 NEW WATER FLOW WATER FLOW FOR ADJUSTING THE UNBALANCED LOAD

24 TRANSPARENT WINDOW O

25 FUNCTION FOR BUBBLE O

26

DWF-7560/90 7.5kg

DWF-8060/90 8.0kg

MAXIMUM

MASS of

TEXTILE

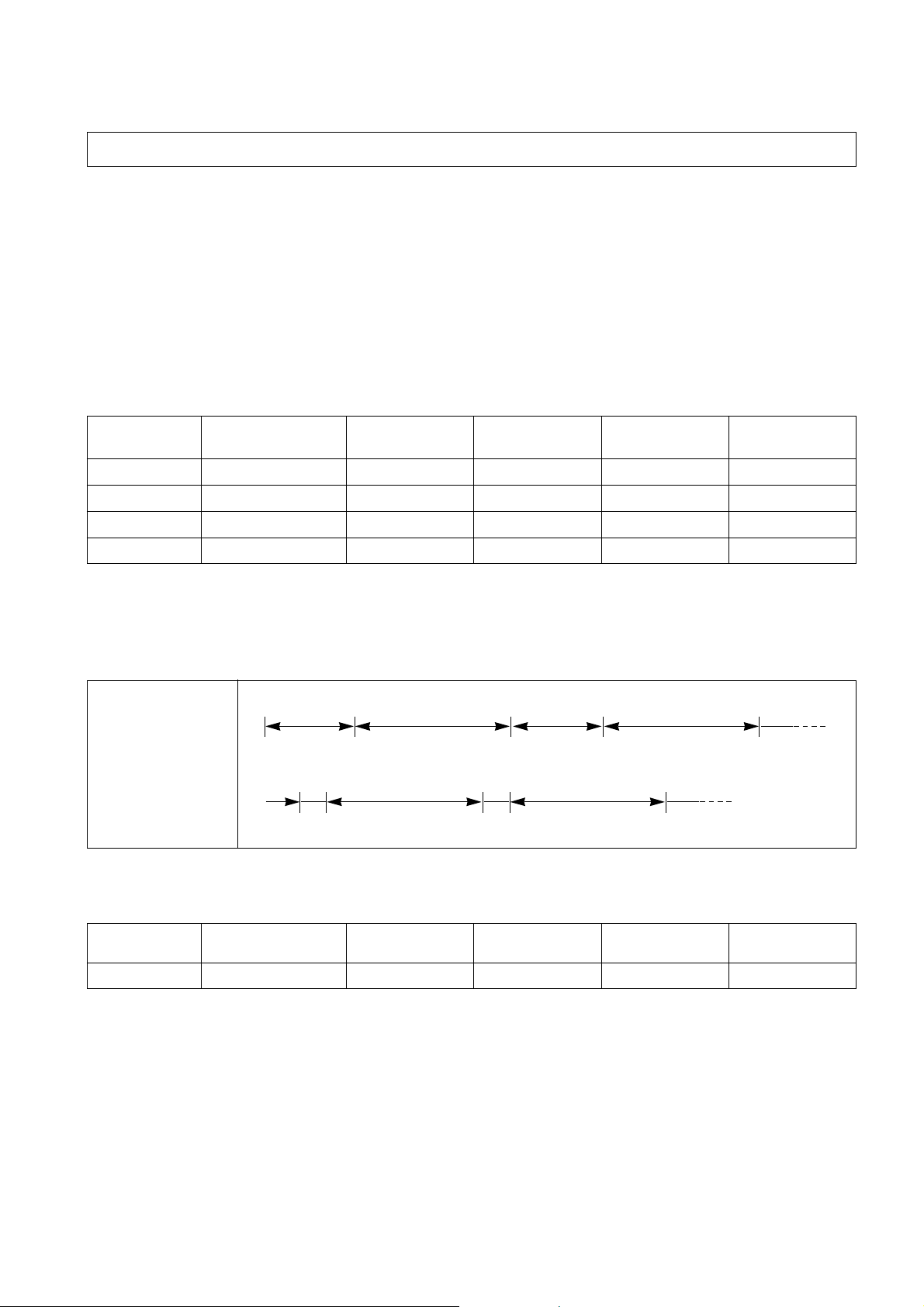

CONTROL SYSTEM FOR AUTO COURSE

FUNCTION PRINCIPLE OF SENSING

1) Sensing the wave width of two ports of capacitor.

2) Choosing the 'A~D' course according to the wave width.

3) Setting up the most suitable time to wash, rinse and spin by the judgement.

SENSING TIME

Sense the wave width for 28 seconds from start of washing.

OPERATING PROCESS ACCORDING TO THE WASHING CAPACITY

CONTROL SYSTEM FOR WOOL WASH

R.P.M of pulsator become half of normal wash by signal of P.C.B. Ass'y.

INPUT WAVE FORM OF MOTOR ON WOOL WASH

PROCESS OF WOOL WASH

When the DRY WOOL COURSE is selected, process shall be set up as below table automatically.

NOTE:

You can't change the water temperature because the P.C.B. ASS'Y set up the 'COLD TEMP' automatically at the

same time you select the 'WOOL COURSE'.

DRY/WOOL WASH

SILK WASH

[Only DRY series]

4sec ON 5sec OFF 4sec ON 5sec OFF

(C.W) (C.W)

3

2. FEATURE AND TECHNICAL EXPLANATION

3sec ON 5sec OFF 3sec ON 5sec OFF

(C.W) (C.W)

COURSE

WASHING WATER WASH TIMES OF SPIN

CAPACITY LEVEL TIME RINSE TIME

A 0~2.0 Kg E.Low 6 min 2 3 min

B 1.0~3.0 Kg Low 9 min 2 4 min

C 2.0~4.0 Kg MIDDLE 12 min 2 5 min

D Above 3.0 Kg High 15 min 2 5 min

(LOAD TO BE WATER WASH TIMES OF SPIN WASH

WASHED) LEVEL TIME RINSE TIME TEMP.

(Below 2 Kg) MIDDLE 6 min 2 30 sec COLD

CONTROL SYSTEM FOR WOOL SPIN

It is a function to prevent the deformation of WOOL.

PROGRESS CHART ON WOOL SPIN

WATER FLOW TO ADJUST THE UNBALANCED LOAD

It is a function to prevent eccentricity of the clothes after wash by rotating pulsator C.W and C.C.W for 20 seconds.

EFFECT

Reduce vibration and noise effectively while spinning.

WATER FLOW

FUNCTION FOR SOAK WASH

DISPLAY THE REMAINING TIME

When the SOAK WASH is selected, the total wash time will increase by 40 minutes.

PROGRESS

NOTE: "I" Mark shows the water flow to adjust the unbalanced laod.

4

R.P.M.

ON-OFF

TIME

OF

MOTOR

(sec)

WOOL

NORMAL

4

4

3

3

4

4

3

3

3

3

2

2

27474

BALANCE SPIN NORMAL SPIN

NORMAL

WOOL

WASH I DRAIN SPIN FILL RINSE 1 I DRAIN SPIN FILL RINSE 2 I DRAIN ...

SIGNAL

C.W

C.C.W

TIME (sec) 0.3 0.5 0.3 0.5 0.3 0.5 .........

20 sec (About 13 Cycles)

FILL WASH STOP WASH STOP WASH STOP

• 2min I 12min 1min I 12min 1min I 12min

SOAK PROCESS MAIN PROCESS

40 Minutes

AUTOMA TIC W ATER SUPPLY SYSTEM ON BLANKET WASH

The water level would be lowered because the blanket absorbs water at the beginning of washing.

Therefore, after 30 seconds, the operation is interrupted to check the water level, and then the water is supplied again until it

is reached at the selected level.

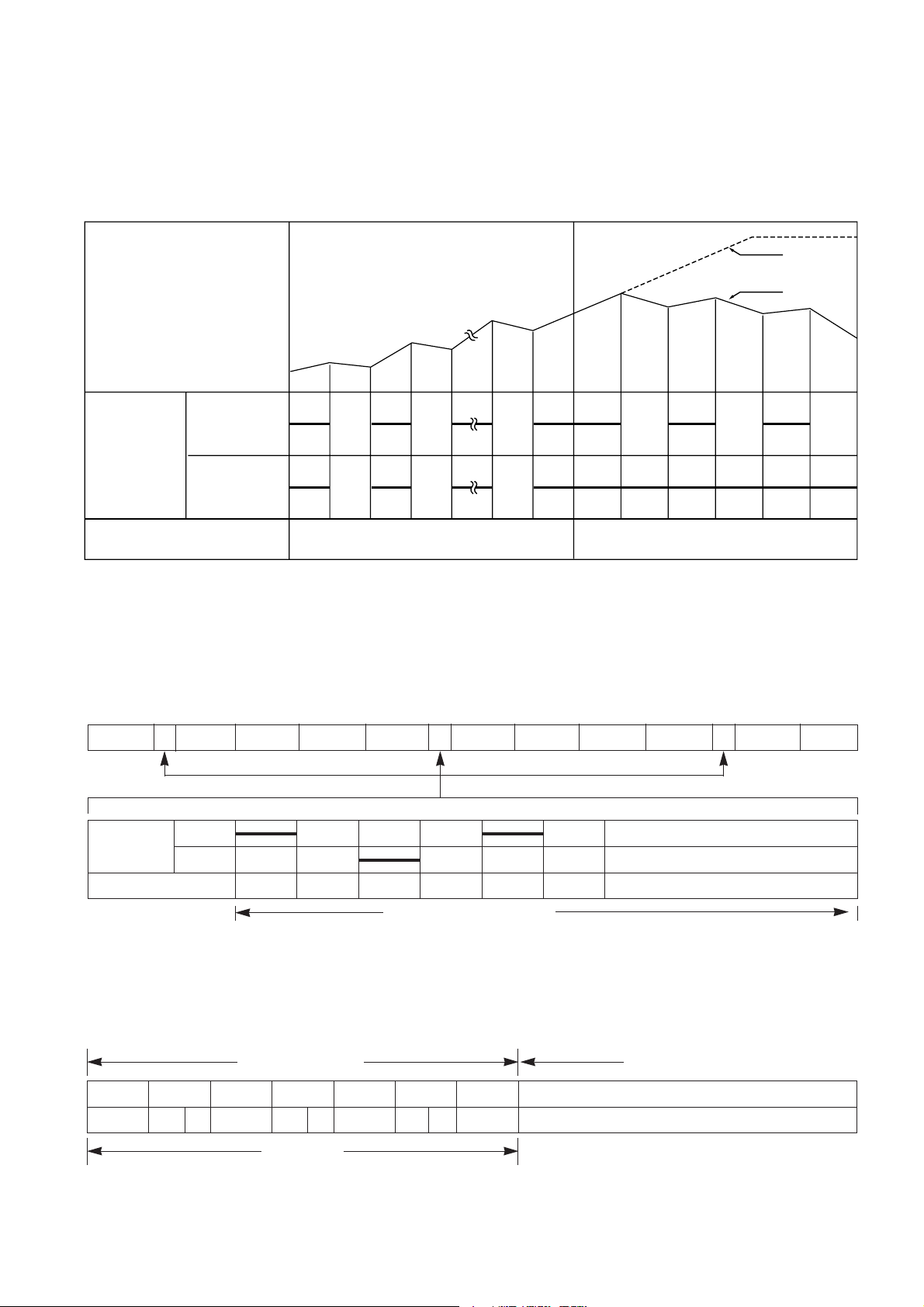

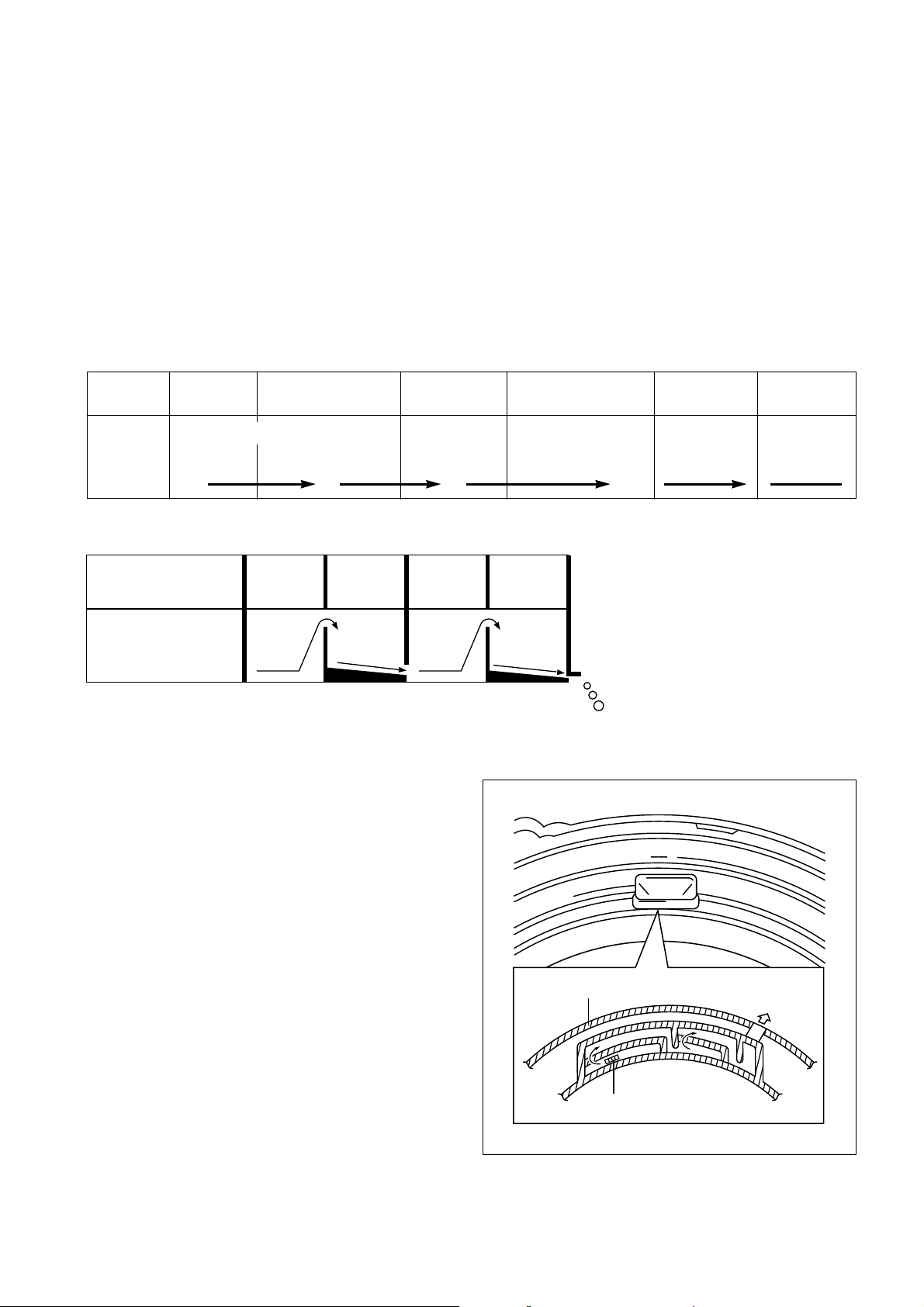

WATER FLOW ON STRONG WASH

It washes cleanly the heavily stained clothes such as working-clothes, climbing-clothes and blue-jean by using this strong

water currents as shown below.

WATER FLOW

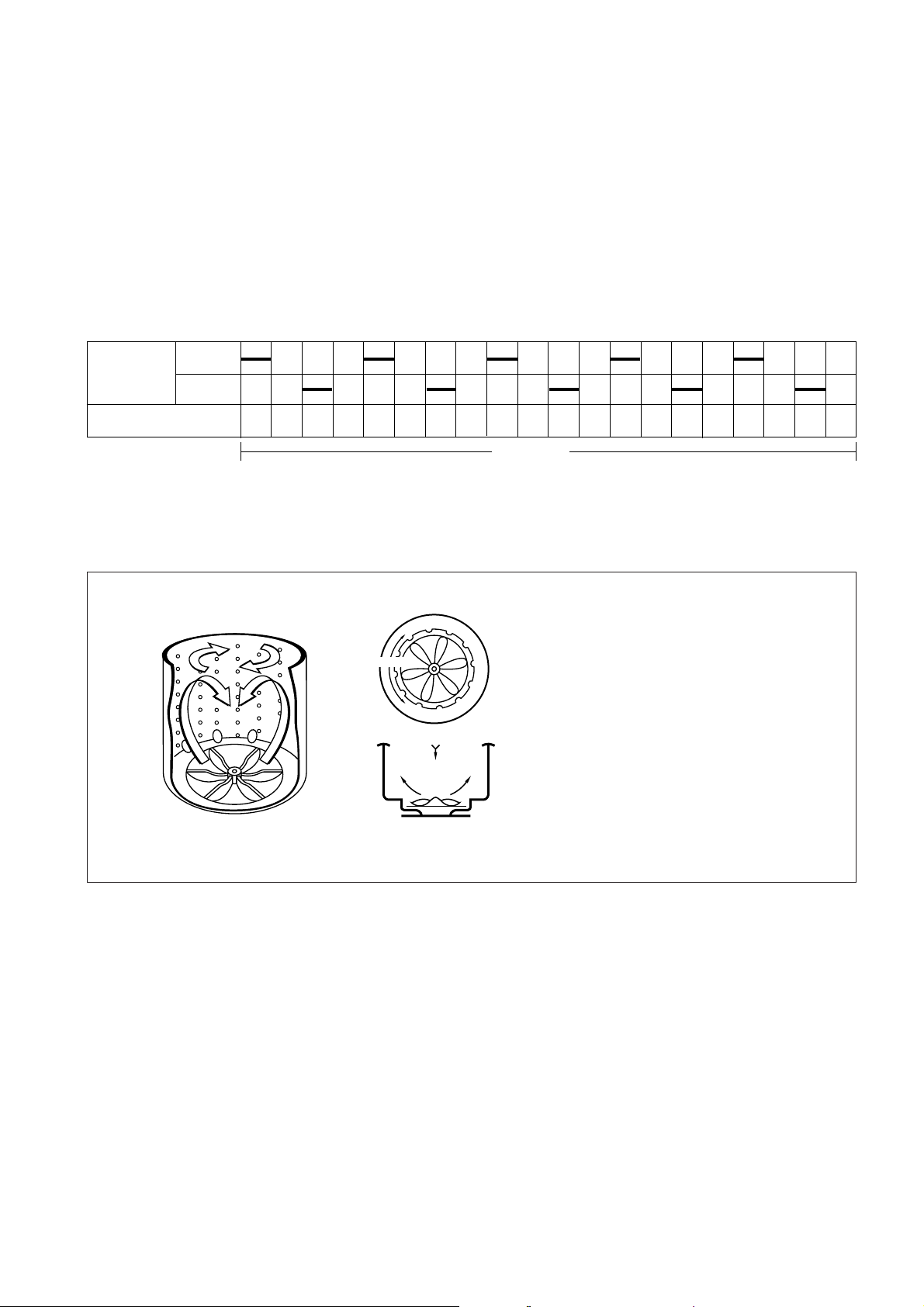

PULSA TOR SYSTEM

When the new shaped pulsator is rotated C.W or C.C.W at a high speed, it makes the 'heart-shaped' water currents as

shown below.

5

C.C.W

C.W

TIME (sec) 0.8 0.5 0.8 0.5 0.8 0.5 0.8 0.5 0.8 0.5 0.8 0.5 0.8 0.5 0.8 0.5 3.2 0.8 3.2 0.8

SIGNAL

OF

MOTOR

1 CYCLE

Rotate

B

AA

C

WATER FLOW

A Water is pushed out by rotation of

the pulsator.

B Water is pulled down by rotation

of the pulsator.

C Water flow is generated by

rotation of the pulsator.

6

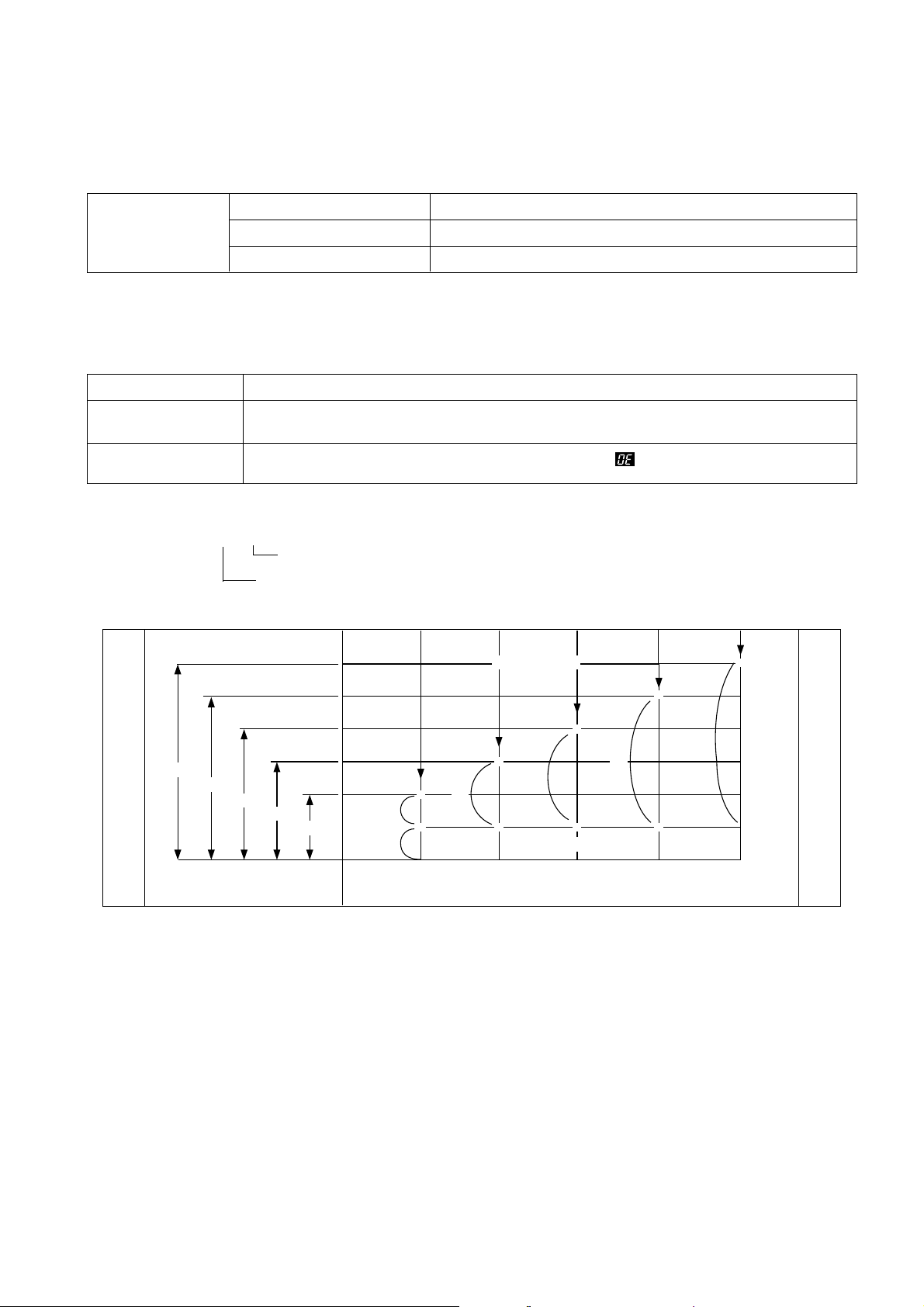

AUTOMA TIC DRAINING TIME ADJUSTMENT

This system set a drain time automatically depending on condition of draining.

FUNCTIONAL PRINCIPLE

1. The micom can remember the time from the beginning of drain to reset point when the pressure switch reaches to "OFF"

point.

2. In case of continuous draining, residual drain time is determined by micom.

Total drain time = D + 60

(T sec) Time of remaining drain process.

Count time of P.C.B. ASS'Y.

Good draining The washer begins spin process after drainage.

Bad draining Draining time is prolonged.

No draining Program is stopped and gives the alarm.

Draining

condition

Drain Time Movement of the program

Less than

Continue draining.

5 minutes

More than

Program are stopped and give an alarm with twinkle the " " on display lamp.

5 minutes

DRAINING TIME

T5

TRIP POINTS

*

T4

T3

T2

T1

D1

60

E. SMALL

D2

*

*

SMALL LOW MIDDLE

D3

*

RESET POINTS

(mm)

*

400

*

*

D4

*

D5

*

340

WATER LEVEL

280

220

170

60

0

HIGH

T1=D1+60 (sec) T2=D2+60 (sec) T3=D3+60 (sec)

T4=D4+60 (sec) T5=D5+60 (sec)

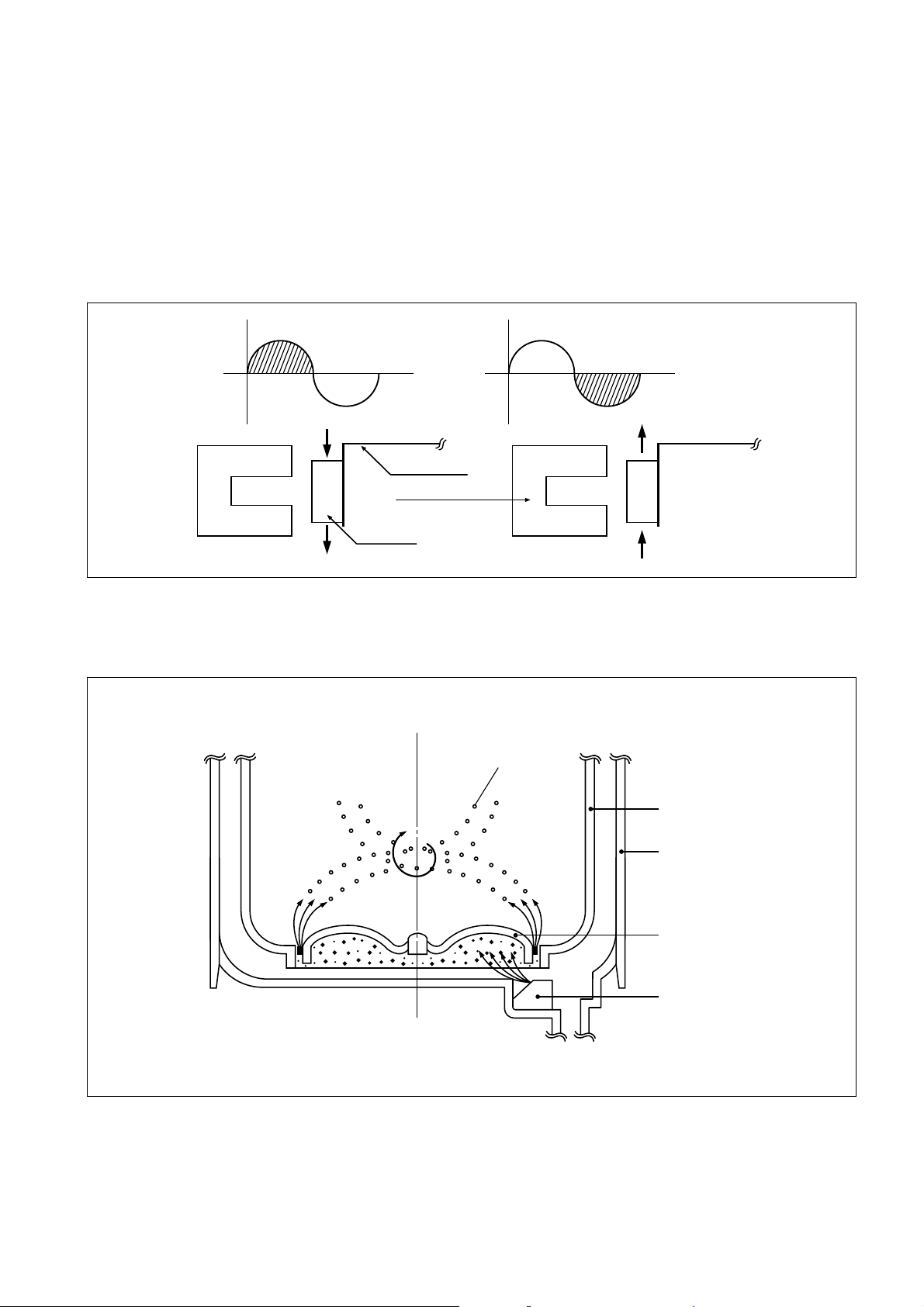

SOFTENER DISPENSER

This is the device to dispense the softener automatically by centrifugal force.

This is installed inside the auto-balancer.

FUNCTIONAL PRINCIPLE

1. Softener stays in room (A) when pour the softener to softener inlet.

2. Softener move (A) to (B) by centrifugal force during intermediate spin process.

3. Softener flow (B) to (C) during rinse process next of intermediate spin.

4. Softener move (C) to (D) by centrifugal force during second intermediate spin.

And after finish spin process, softener drop between tub and outer tub ass'y from softener outlet.

FLOW OF THE SOFTENER

FLOW OF THE SOFTENER INSIDE OF THE BALANCE

NOTE: Softener moves into next room when r.p.m of the tub is more than 100 r.p.m.

HOW TO CHECK MOVEMENT

Pour a reasonable amount of "MILK" into softener dispenser

and operate the washer with no load.

In final rinse cycle, make sure than the milk is added into the

tub through softener outlet.

7

Balancer

Softener inlet

Softener outlet

A

C

D

B

Wash intermediate Hold intermediate Rinse Spin

Spin Spin

Normal Centrifugal force Flow by Centrifugal force Flow by

weight weight

Course

(A) (B) (C) (D)

Room inside

ABCD

the balancer

Flow by

Centrifugal

force

8

AUTOMA TIC UNBALANCE ADJUSTMENT

This system is to prevent abnormal vibration during intermittent spin and spin process.

FUNCTIONAL PRINCIPLE

1. When the lid is closed, the safety switch contact is

"ON" position.

2. In case that wash loads get uneven during spin, the

outer tub hits the safety switch due to the serious

vibration, and the spin process is interrupted.

3. In case that P.C.B. ASS'Y gets "OFF" signal from the

safety switch, spin process are stopped and rinse

process is started automatically by P.C.B. ASS'Y.

4. If the safety switch is operated due to the unbalance

of the tub, the program is stopped and the alarm is

given.

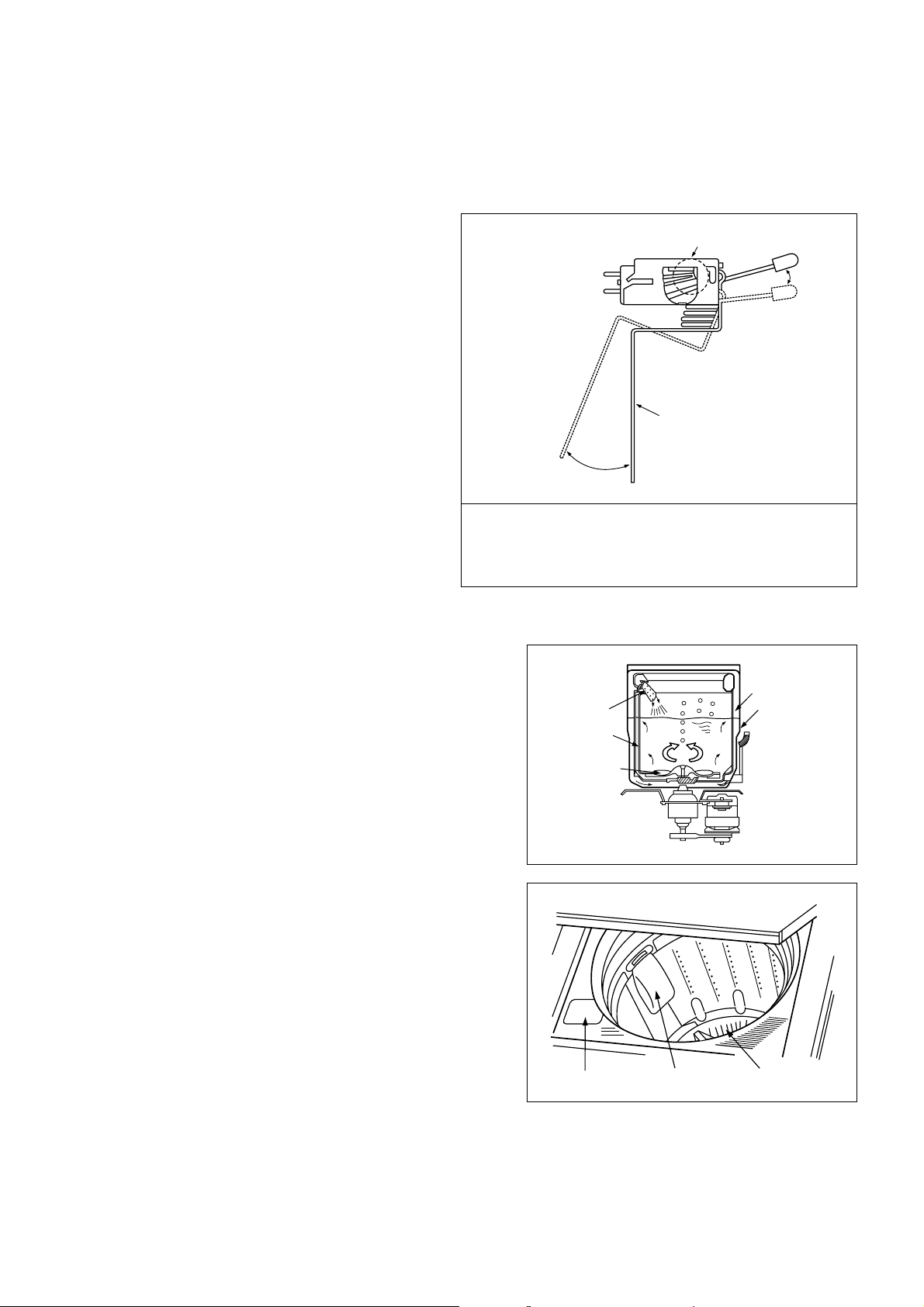

CIRCULA TING-W ATER COURSE AND LINT FILTER

CIRCULATING-WATER

The washing and rinsing effects have been improved by adopting

the water system in which water in the tub is circulated in a

designed pattern.

When the pulsator rotates during the washing or rinsing process,

the water below the pulsator vanes creates a water currents as

shown in figure.

The water is then discharged from the upper part of the tub

through the water channel.

About 40L/min. water is circulated at the 'high' water level,

standard wash load and standard water currents.

LINT FILTER

Much lint may be obtained according to the kind of clothes

to be washed and some of the lint may also sticks to the clothes.

To minimize this possibility, a lint filter is provided on the upper

part of the tub to filter the wash water as it is discharged from the

water channel. It is good to use the lint filter during washing.

HOW TO CLEAN THE LINT FILTER

1. Pull the filter frame upward.

2. Turn the lint filter inside out, and wash the lint off with water.

3. Return the filter as it was, and fix the filter frame to the slot.

Contact of safety switch Lid closing

Contact lever A

Normal(ON)

Position of

unbalanced

load(OFF)

Lid opening

NOTE:

The alarm finish when you close the lid after opening it.

Check the unbalance of the wash load and the

installation condition.

PulsatorFilterBleach inlet

Filter

Water

channel

Pulsator

Tub

Outer tub

9

AUTOMA TIC POWER OFF

P.C.B. ASS'Y sends a signal to the solenoid in the power switch 10 minutes later after complete washing.

Then the solenoid pull the locking lever which had lock the push button. Therefore the power is turned off automatically.

RESIDUAL TIME DISPLA Y

When the START/HOLD button is pressed, the residual time (min.) is displayed on the time indicator, and it will be counted

down according to the process.

When operation is finished, the TIME INDICATOR will light up .

DRAIN MOTOR

STRUCTURE

FUNCTIONAL PRINCIPLE

1. When the DRAIN MOTOR connected to the power source (AC 220V), the DRAIN MOTOR rotates with 900 r.p.m and

revolves the pulley by gear assembly for reducing.

2. When the pulley is rotated, the pulley winds the wire to open the drain valve.

3. Therefore, rotation of pulley is changed to the linear moving of wire.

4. The wire pulls the brake lever of Gear Mechanism Ass'y within 5 seconds.

5. After the wire pulled, gear assembly is separated from motor and condition of pulling is held by operation of the lever.

6. When the power is turned off, the drain valve is closed because the wire returns to original position.

WATER LEVEL SWITCH

Water pressure of air room which is at the side of outer-tub is transmitted to the air room in the water level switch through

air-tube. Diaphragm moves up and down by the transmitted pressure to move the core.

Movement of core transforms the inductance of coil by Henly's Law.

The generative frequency (Hertz) is obtained by this transformation of the coil inductance in the LC generative circuit.

‚

Pull

Loosen

Pulley

Lever

Inductive ring

Magnet

Coil of motor

Magnet of motor

Spring

Spring

Coil

Case

Core

Diaphragm

(rubber)

Coil

Core

Diaphragm

Case

Air-pressure

10

GEAR MECHANISM ASS'Y

The proper water currents is made by the rotation of pulsator at a low speed (about 145 r.p.m) to prevent the damage to

the small sized clothes.

SAFETY DEVICE FOR MOTOR

In case of occurring disorder of motor caused by extreme-high

voltage, over-heating, overload, safety devices (Thermal

Protector) of motor can be operated and cut off the power

sources automatically.

At this case, motor does not run.

However, motor can be operated normally again about 1 hour

later.

PRINCIPLE OF BUBBLE GENERA TOR

STRUCTURE

Pusator Shaft

Spinner Shaft

Roller Clutch

Bearing

Planetary

Gear

Clutch Boss

Brake Lever

Spinner Pulley

(Motor)

Sun gear

Planetary gear

Internal gear

Pulsator

Planetary

Motor

V-Belt

1 revolution

5 revolutions

Spinner

pulley

Motor

1700 r.p.m

(60Hz)

1400 r.p.m

(50Hz)

V.BELT

Spinner Pulley

650 r.p.m

(60Hz)

740 r.p.m

(50Hz)

Thermalprotector

White/Red

Planetary

gear

Directly

Pulsator

140 r.p.m

(60Hz)

150 r.p.m

(50Hz)

TUB

650 r.p.m

(60Hz)

740 r.p.m

(50Hz)

60 r.p.m

(60Hz)

70 r.p.m

(50Hz)

Dry/Silk

Violet

Blue

Bobbin & coil

Trans core

Magnet

Air

Air

Armature

Air in hole

Bellows

Air out hole

Protector A

Protector B

11

PRINCIPLE OF INTAKE & OUTLET OF THE AIR

INTAKE : ARMATURE moves to the upper side, and BELLOWS inhales the air. At same time, PROTECTOR B is open and A

is close.

OUTLET: ARMATURE moves to the down side, and BELLOWS exhaust the air. At same time, PROTECTOR B is close and

A is open.

FUNCTIONAL PRINCIPLE OF TRANS & MAGNET

• A.C electric power's phase changes to 60 cycle/sec.

• Trans core's magnetic pole is changed by changing of A.C electric power's phase.

• The core repeat push and pull (3600 times/min) the armature magnet.

FUNCTIONAL PRINCIPLE OF BUBBLE WASHING MACHINE

ACROSS SECTION

FUNCTIONAL PRINCIPLE

Bubble generator supplies the air from the bottom of outer tub to the inner space of pulsator, the air break up by pulsator's

agitating spin. Air-bubble was created by the centrifugal force, and rise up.

A.C A.C

N

S

NS

Magnet

Pan spring

Trans core

S

N

NS

Air bubble

Tub

Outer tub

Pulsator

Nozzle

12

3. STRUCTURE OF THE WASHING MACHINE

UP

• COLD WATER INLET

After using the machine,

close the water faucet

and turn off the power.

• DETERGENT CASE

• POWER SWITCH

• LINT FILTER

• PULSATOR

• HANDLE

• POWER CORD

• GROUNDING WIRE

In case of 3-pin power

cord grounding wire will

not be provided.

• HOT WATER INLET [Option]

• SOFTENER INLET

Pour softener into the softener

inlet and it will be added the

tub just before the final rinse.

• BLEACH INLET

• CONTROL PANEL

• TUB

(SUS: DWF-8060

DWF-8090)

• UNDER BASE COVER

• BOTTOM BOARD COVER

[Option]

• LEG COVER

[Option]

STRUCTURE OF WASHING MACHINE

ACCESSORIES

Hose Clamp Water Tap Adapter (COLD)

Water Tap Adapter (HOT)

[option]

In case of screw-shaped inlet hoses

water tap adapters will be provided.

Under Base Cover

Bottom Board Cover [Option]

Drain Hose

[PUMP] [NON-PUMP]

Inlet Hose (COLD)

Inlet Hose (HOT) [Option]

FUNCTION OF CONTROL P ANEL (DRY)

Control Panel

• It has micom sensor.

• As the button is pressed, course is

selected by your desired.

13

Use of Switch

• Power Switch

–Press to turn the

power On or Off

• After turning off

the power, wait

for over 3

seconds and then

turn it On again.

ON

OFF

AUTO OFF

WASH

RINSE

SPIN

COURSE

WASH TEMP.

WATER LEVEL

START/HOLD

CANCEL

RES HOUR

DAEWOO AUTOMATIC

WASHER

AERO FUZZY & AIR POWER

ONLY

SPIN

FUZ.

MEM.

DRY

SILK

SPEE

STRO

BLAN

WASH RINS SPIN

SOAK WASH RINS SPIN

HOUR MIN. TIME MIN.

RES. REM.

TIME

COURSE TEMP. LEVEL

HOT

WARM

COLD

H.

M.

L..

S.

E.S.

Dry cleaning

MEM

ORY

Time Display

•The lamps easily

indicate the option

selection of wash

program and

process by letters.

Button for Program

Cancel

• It can be used to cancel

the full-automatic course.

• When the button is

pressed time, display will

be light down.

If you want to wash, rinse

or spin, you can press

one of the other buttons.

Wash Time

Pre-engagement

• It can be used to preengage time for wash

Wash Time Selector

•It can be used to adjust

washing time.

Speed Time Selector

•It can be use to adjust

spin time.

Rinse Time Selector

•This button selects the

number of time you want

to rinse.

Course Selection

•It can be used to select

the full-automatic course.

•As the button is pressed,

it will be selected

following order;

DRY: Dry ¤ASilk ¤ASpeed ¤A

Strong ¤ABlanket ¤AFuzzy

Water Temperatur e

Selection [Option]

•It can be used to select the water

temperature according to the

clothes being washed.

•If you select 'Dry/Silk Washing',

selection for water temperature is

selected 'Cold' by automatically in

order to prevent the laundry from

damage.

Water Level Selector

•It can be used to adjust

amount of water according to

the size of the load to be

washed.

•If you select 'Dry/Silk

Washing', Selection for water

level is selected 'MID;

automatically in order to

prevent the laundry from

damage.

Memory Button

•It can be used by

remembering by

your desire.

Start/Hold Button

•Operation and

temporary stop are

repeated as it is

pressed.

•It will be repeated

(operation),

(temperary stop)

according to the one

time pressing or two

times pressing.

Exclusive Spin

Button

•It can be used to

spin exclusively.

FUNCTION OF CONTROL P ANEL (Non-Dry)

Control Panel

• It has micom sensor.

• As the button is pressed, course is

selected by your desired.

13-1

Use of Switch

• Power Switch

–Press to turn the

power On or Off

• After turning off

the power, wait

for over 3

seconds and then

turn it On again.

ON

OFF

AUTO OFF

WASH

RINSE

SPIN

COURSE

WASH TEMP.

WATER LEVEL

START/HOLD

CANCEL

RES HOUR

DAEWOO AUTOMATIC

WASHER

AERO FUZZY & AIR POWER

ONLY

SPIN

FUZ.

MEM.

SPEE

WOOL

STRO

NIGHT

BLAN

WASH RINS SPIN

SOAK WASH RINS SPIN

HOUR MIN. TIME MIN.

RES. REM.

TIME

COURSE TEMP. LEVEL

HOT

WARM

COLD

H.

M.

L..

S.

E.S.

Dry cleaning

MEM

ORY

Time Display

•The lamps easily

indicate the option

selection of wash

program and

process by letters.

Button for Program

Cancel

• It can be used to cancel

the full-automatic course.

• When the button is

pressed time, display will

be light down.

If you want to wash, rinse

or spin, you can press

one of the other buttons.

Wash Time

Pre-engagement

• It can be used to preengage time for wash

Wash Time Selector

•It can be used to adjust

washing time.

Speed Time Selector

•It can be use to adjust

spin time.

Rinse Time Selector

•This button selects the

number of time you want

to rinse.

Course Selection

•It can be used to select

the full-automatic course.

•As the button is pressed,

it will be selected

following order;

NON-DRY:

Speed ¤AWool¤A

Strong ¤ANigh t¤A Blanket

¤AFuzzy

Water Temperatur e

Selection [Option]

•It can be used to select the water

temperature according to the

clothes being washed.

•If you select 'Dry/Silk Washing',

selection for water temperature is

selected 'Cold' by automatically in

order to prevent the laundry from

damage.

Water Level Selector

•It can be used to adjust

amount of water according to

the size of the load to be

washed.

•If you select 'Dry/Silk

Washing', Selection for water

level is selected 'MID;

automatically in order to

prevent the laundry from

damage.

Memory Button

•It can be used by

remembering by

your desire.

Start/Hold Button

•Operation and

temporary stop are

repeated as it is

pressed.

•It will be repeated

(operation),

(temperary stop)

according to the one

time pressing or two

times pressing.

Exclusive Spin

Button

•It can be used to

spin exclusively.

Loading...

Loading...