Daewoo DWF-315W, DWF-415S Service Manual

Service Manual

Auto Washer

Model: DWF-315W

DWF-415S

✔ Caution

: In this Manual, some parts can be changed for improving,

their performance without notice in the parts list. So, if you

need the latest parts information, please refer to PPL(Parts

Price List) in Service Information Center (http://svc.dwe.co.kr).

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO

WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO

WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO

WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO

WASHER AUTO

WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

WASHING MACHINE

C o n t e n t s

1. SPECIFICATIONS

................................................................................................................

.....................................................................

..................................................................

...................................................................

.................................................

............................................................................................................

..........................................................................................

............................................................................

2

3

4

2. STRUCTURE OF THE WASHING MACHINE

3. DIRECTIONS FOR INSTALLATION AND USE

INSTALLATION OF THE NOISE INULATION PLATE

................................................................

............................................................................

.....................................................................................

....................................................................................................

...................................................................................

.....................................................

.....................................................................................

............................................................................

.................................................................................

.................................................................

................................................................................................................................

..........................................................................................................

...........................................................................................................................

........................................................................................................

............................................................................

............................................................

..............................................................................

...............................................................

..........................................................................................

................................................................................................

........................................................................................

...............................................................................................

.........................................................................................................

.........................................................................................................

...........................................................................................................

.....................................................................................................

..........................................................................................

....................................................................................................................

......................................................................................................................

................................................................................................................................

4

HOW TO INSTALL ON AN INCLINED PLACE 4

HOW TO CONNECT THE INLET HOSE 5

6

HOW TO CLEAN THE FILTER

4. FEATURE AND TECHNICAL EXPLANATION

7

12

15

22

27

FEATURE OF THE WASHING MACHINE

7

7

WATER CURRENT TO ADJUST THE UNBALANCED LOAD

AUTOM

ATIC WATER SUPPLY SYSTEM 7

8

AUTOMATIC DRAINING TIME ADJUSTMENT

AUTOMATIC UNBALANCE ADJUSTMENT

9

CIRCULATING-WATER COURSE AND LINT FILTER 9

LINT FILTER 10

10

10

1

12

14

15

16

17

19

21

22

23

24

25

26

28

29

33

1

RESIDUAL TIME DISPLAY

DRAIN MOTOR

GEAR MECHANISM ASS’Y

5. DIRECTIONS FOR DISASSEMBLY AND ADJUSTMENT

GEAR MECHANISM ASS’Y REPLACEMENT

MOTOR SYNCRONOUS AND VALVE REPLACEMENT

6. THE REPAIR METHOD OF GEAR MECHANISM FOR CLUTCH

SPRING PROBLEM

THE STRUCTURE OF GEAR MECHANISM

HOW TO CHECK THE CLUTCH SPRING PROBLEM

THE PROCESS OF DISASSEMBLE

THE PROCESS OF ASSEMBLE

REPLACE THE CASE FILTER ASS’Y

7. TROUBLE SHOOTING GUIDE

CONCERNING WATER SUPPLY

CONCERNING WASHING

CONCERNING DRAINING

CONCERNING SPINING

CONCERNING OPERATION

27

CONCERNING ERROR MESSAGE

8. PRESENTATION OF THE P.C.B ASS’Y

APPENDIX

WIRING DIAGRAM

PARTS DIAGRAM

PARTS LIST

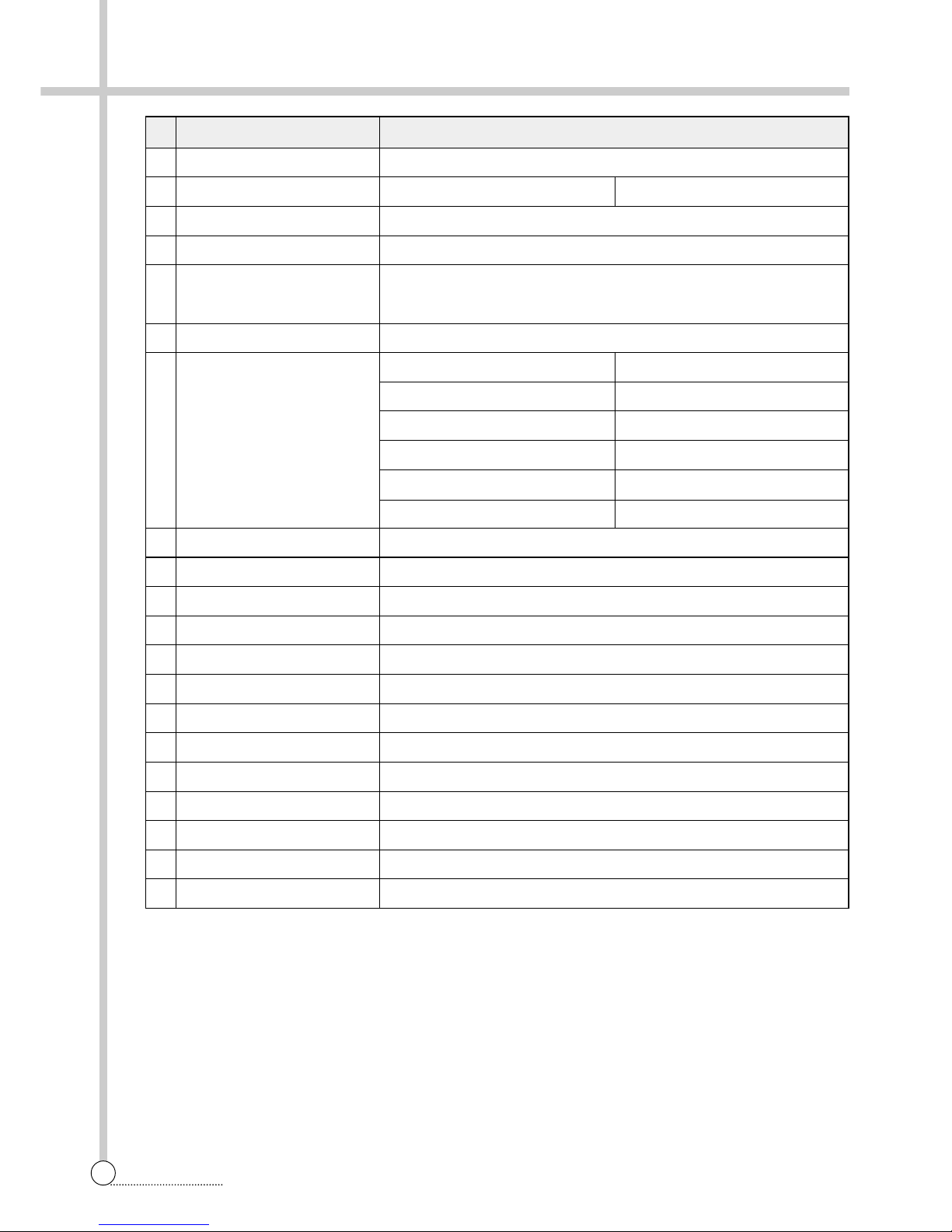

1. SPECIFICATIONS

2

SPECIFICATIONS

DWF-315W / DWF-415SMETI.ON

ELCYC DNA EGATLOV CA LACOL LLA NI ELBALIAVAECRUOS REWOP1

2 POWER CONSUMPTION

3 MACHINE WEIGHT

630 × 1030 × 670W × H × D)( NOISNEMID4

5 WASHING COURSE

FULL AUTOMATIC 6 COURSE

(FUZZY, SEDA, LANA, BLANCOS, CHILE WASH, SUAVE)

6 WATER CONSUMPTION

7 WATER LEVEL SELECTOR

9 REVOLUTION PER MINUTE

mc/fgk3.0ERUSSERP RETAW GNITAREPO8

2

~8kgf/cm

2

(2.94 N/cm2~78.4N/cm2)

MPR 047 - 017 : NIPS ,MPR 051 - 031 : HSAW

)mm604Ø( TBMROTASLUP01

ROSNES LACINORTCELELORTNOC LEVEL RETAW11

RAEG LACILEHY’SSA MSINAHCEM RAEG21

ORETLIF TNIL31

OHSAW KAOS ROF NOITCNUF41

OLANGIS MRALA51

OYALPSID EMIT LAUDISER61

OYLPPUS RETAW .OTUA71

18

FUNCTION FOR BUBBLE AND RADICAL

O

O

RETAW DEEF-ER OTUA91

OFFO REWOP OTUA02

50Hz

550W

48Kg

270 L

HIGH 104L

*

93L

MEDIUM 83L

*

72L

LOW 61L

E. LOW 50L

* : POUR DIRECTLY INTO TUB AFTER FINAL RINSE.

DRYTEN [OPTION] COVER UNDER (OPTION) WATER TAP ADAPTER INLET HOSE

HOSE DRAIN [FOR PUMP] HOSE DRAIN[FOR NONPUMP] CONNECTOR INLET [OPTION]

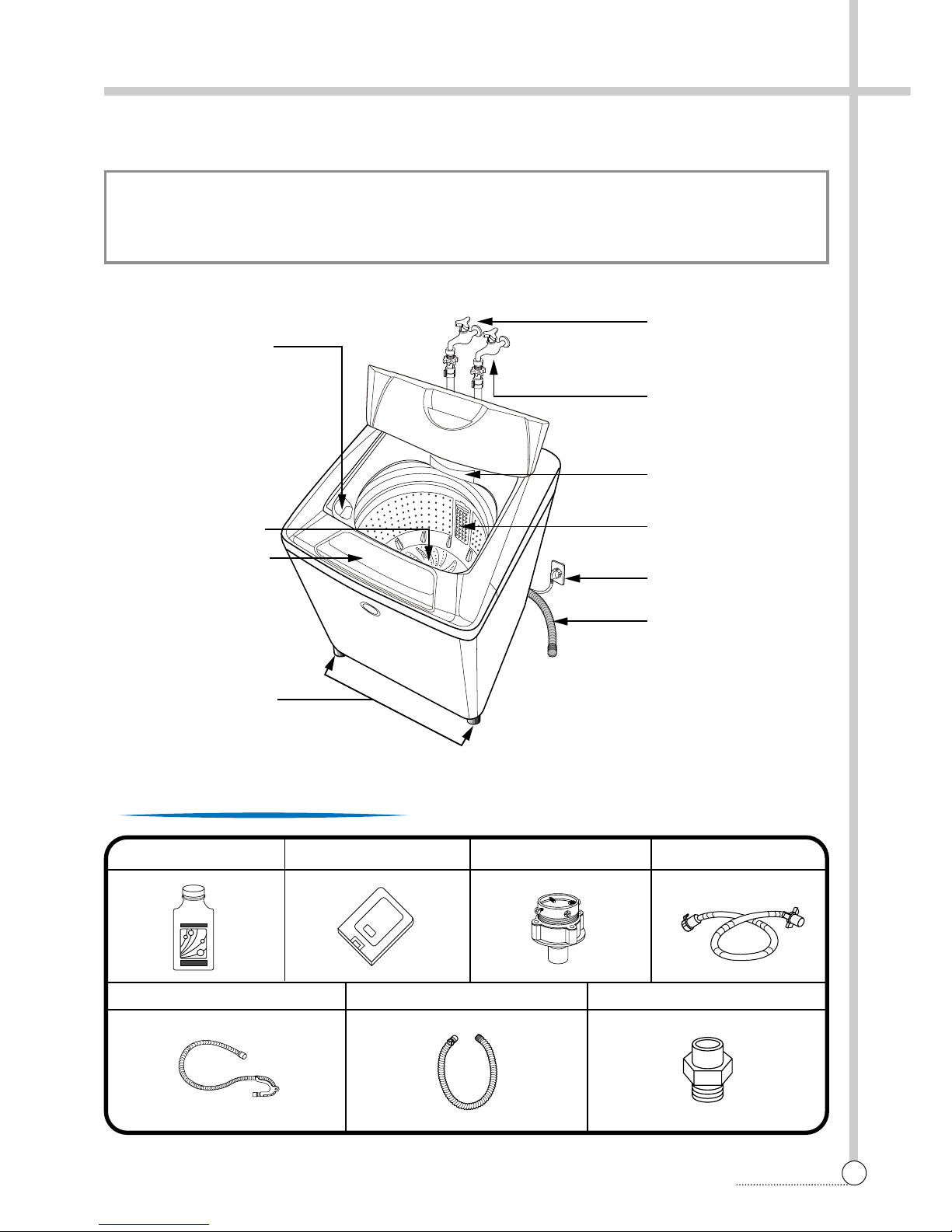

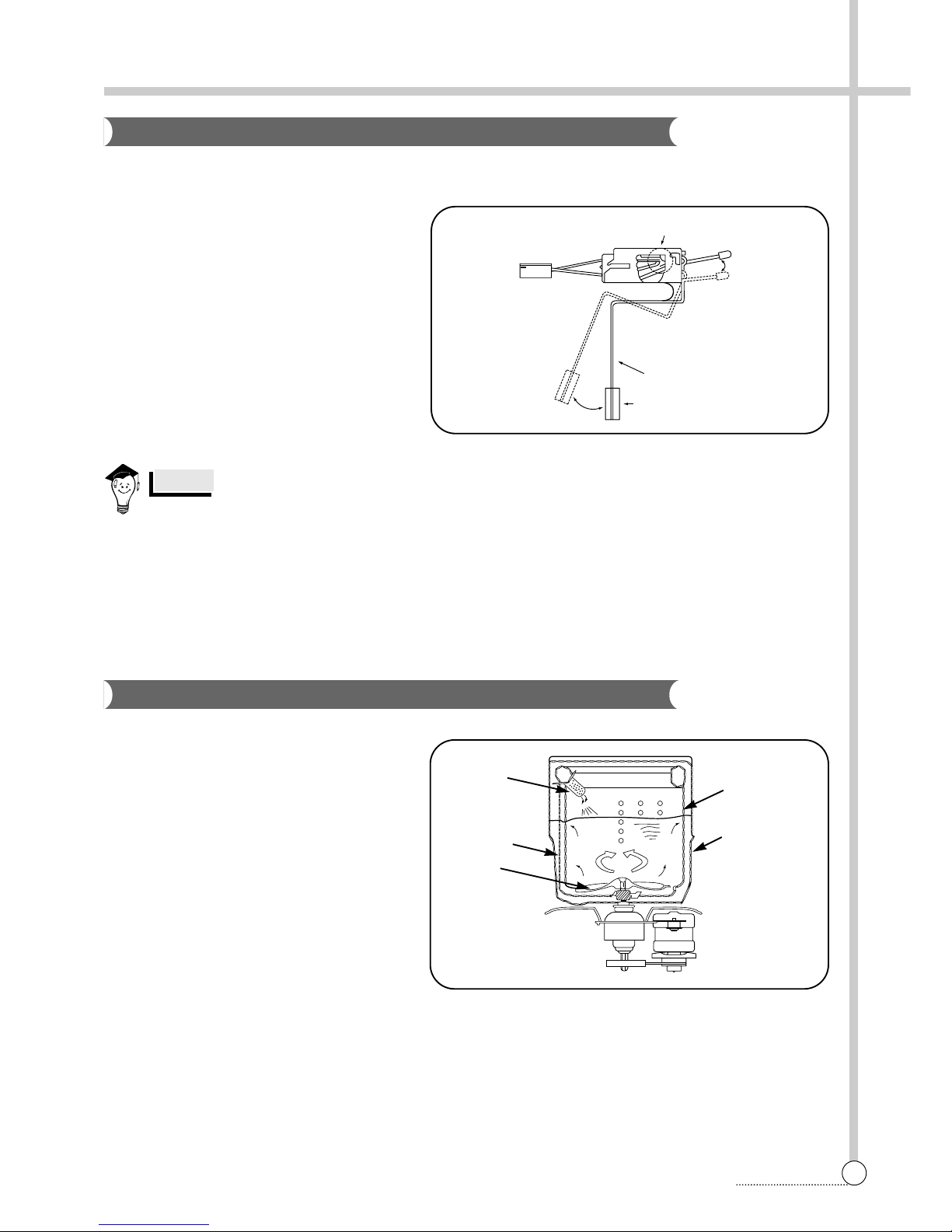

2. STRUCTURE OF THE WASHING MACHINE

3

STRUCTURE

• HOSE DRAIN

• POWER CORD

• LINT FILTER

•

HOT WATER TAP

•

COLD WATER TAP

After using the washer,

close the water tap, In case

of the single valve model,

there is no hot water valve.

After using the washer,

close the water tap

•

CASE DETERGENT

AND SOFTENER

•

BLEACH INLET

• ADJUSTABLE LEG

•

PULSATOR

•

CONTROL PANEL

Accessories (Full Option)

The parts and features of your washer are illustrated on this page.

Become familiar with all parts and features before using your washer.

NOTE

• The drawings in this book may vary from your washer model.

They are designed to show the different features of all models covered by this book,

Your model may not include all features.

DRYTEN

UP

3. DIRECTIONS FOR INSTALLATION AND USE

4

DIRECTIONS

The openings must not

be obstructed by carpeting when the washing

machine is installed on a

carpeted floor.

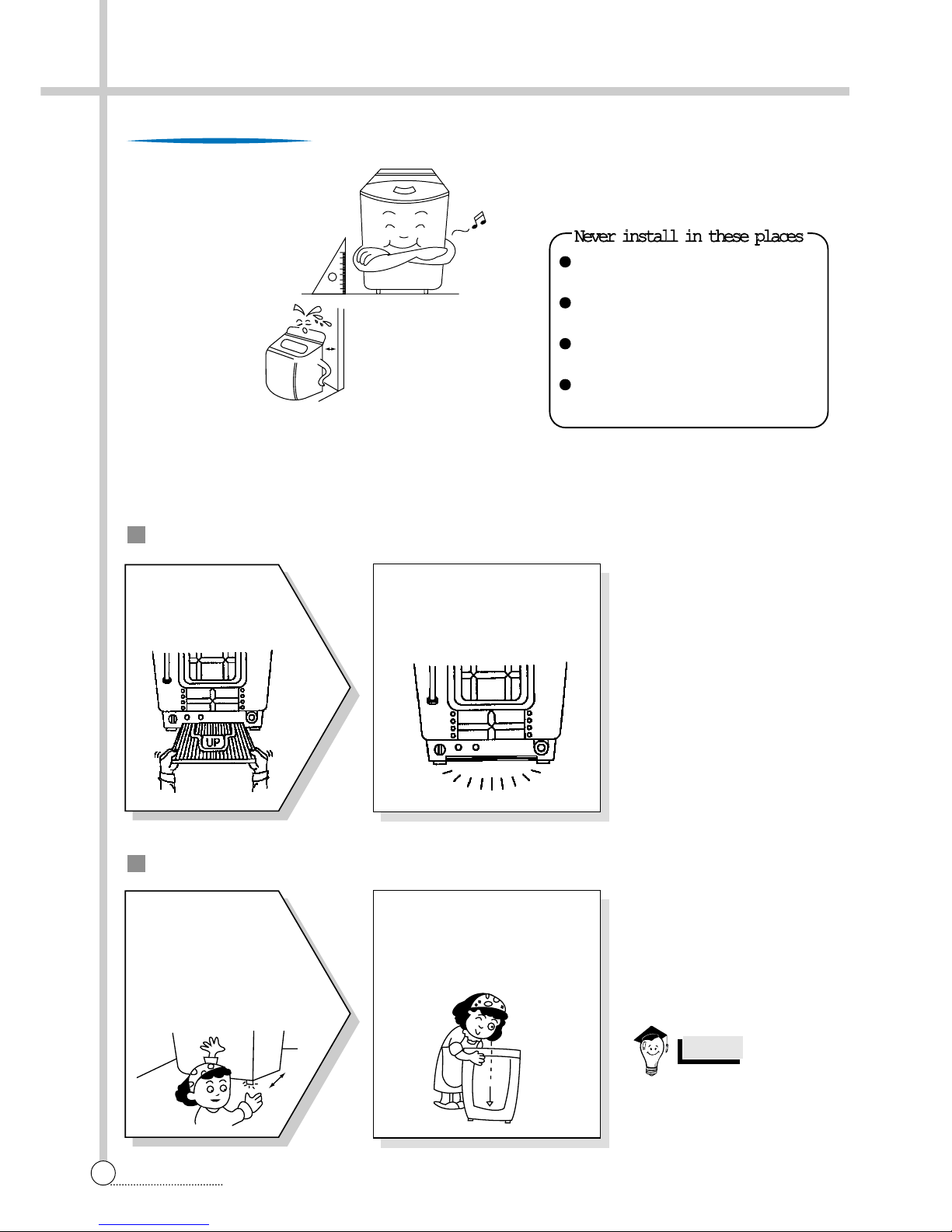

Installation Of The Noise Inulation Plate (OPTION)

How To Install On An Inclined Place

The place where it would be exposed to

direct sunlight.

The place nearby a heater or heat appli-

ance.

The place where it would be supposed

to be frozen in winter.

The kitchen with coal gas and a damp

place like a bathroom.

NOTES

10Cm

Install the washer on a horizontal

solid floor. If the washer is installed

on an unsuitable floor, it could make

considerable noise and vibration.

Installing Place

Never install in these places

2

Push the noise insulation plate

into the end, which decrease

the noise made by this washer.

1

The packing box

opened, there is a

noise insulation plate

at the bottom of the back.

2

Check the Horizon

Status

Check the position of tub above

the center of the washer.

1

Horizon

Setting

After controlling the height

by turning the adjustable

le g, let th e w as her put

down to the ground.

Keep the machine body

more than 25cm apart from

the wall surface. It will

make easy cleaning the

drain filter which is equipped

at the back side of it. And if

it comes into contract vibration may occur.

5

CONNECTION

FOR ORDINARY TAP

6

Connect the inlet hose adapter

of the hose to the water inlet of

the washer by turning it clockwise to be fixed tightly.

• Please check the rubber packing

inside the inlet hose adapter of

the hose.

1

Pull down the collar

of the inlet hose to

separate it from the

water tap adapter.

2

Loosen the four

screws at the water

tap adapter, but don’t

loosen the screws until

they are separated from

the water tap adapter.

4

Remove the tape,

and screw connector

B into connect A tightly.

5

Connect the inlet

hose to the water tap

adapter by puling down

the collar of the hose end.

3

Connect the water tap

adapter to the water tap tighten the four screws evenly

while pushing up the adapter

so that the rubber packing

can stick to the water tap

tightly.

How to Connect the Inlet Hose

Be careful not to mistake in supplying between the hot (maximum : 50 C) and cold water.

In using only one water tap or in case of attached one water inlet valve, connect the inlet hose to the cold water inlet

valve.

Do not over tighten : this could cause damage to couplings.

FOR SCREW-SHAPED TAP

3

Insert the inlet hose adapter

into the water inlet of a washer

and turn it to be fixed.

• Check the packing in the inlet

1

Connect the inlet

hose to the water tap

by screwing the connector D tightly.

2

Connect the connector-inlet supplied if

necessary.

Inlet Hose

Connector D

Rubber

Packing

Connector C

Connector

Inlet

Rubber

Packing

Connector D

Connector C

Hose

TAPE

Connector B

Connector A

6

CONVENIENCE

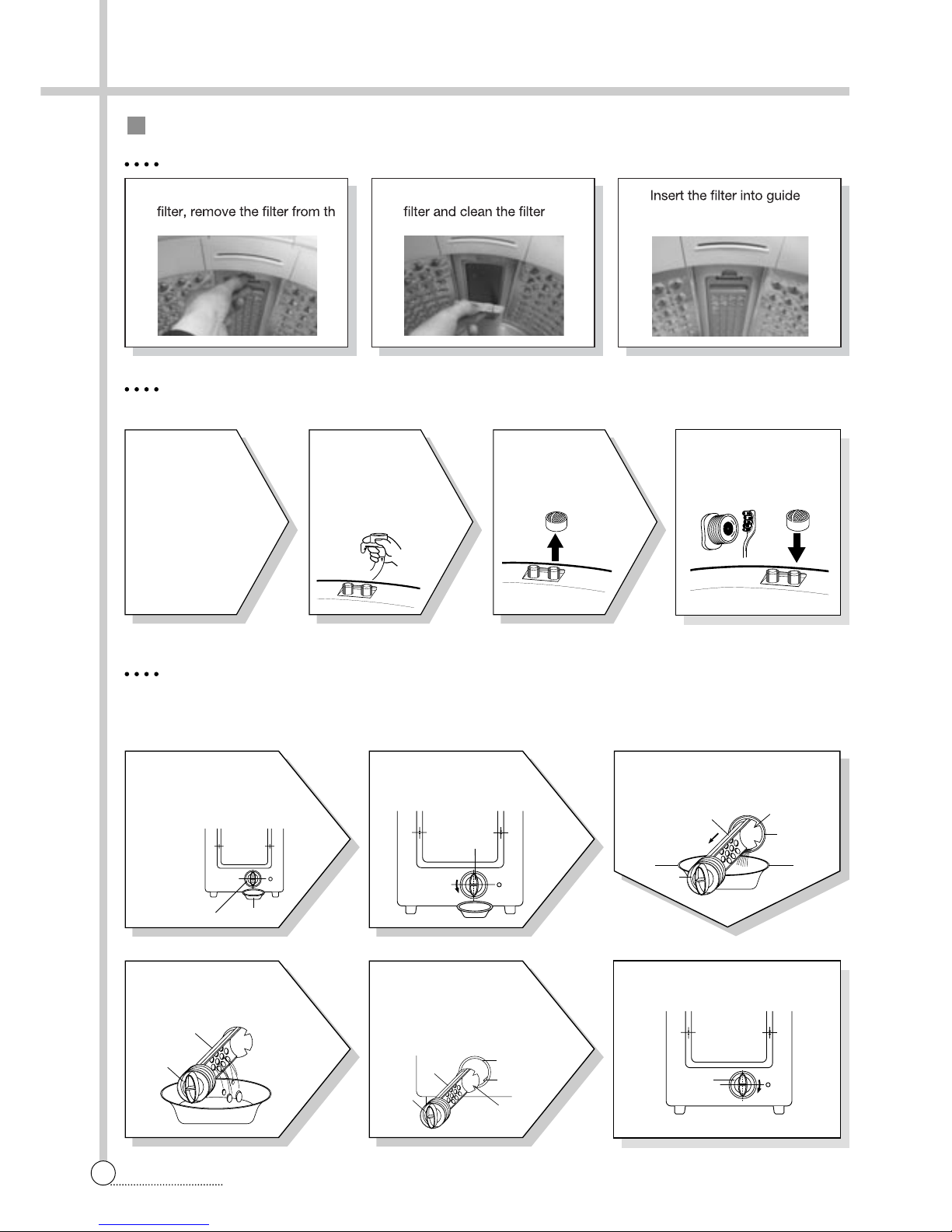

How To Clean The Filter

4

Remove the dirt

from the inlet filter

with a brush.

1

Pull the

power plug

out before

cleaning it.

2

Turn off the

water supply

to the washer

and sperate the

inlet hose.

3

Pull the

inlet filter out.

CLEANING THE LINT FILTER

CLEANING THE WATER INLET FILTER

• Clean the filter when water leaks from, the water inlet.

CLEANING THE DRAIN FILTER

• In case “U” shape drain hose, this filter’s equipped at the back side of washer.

• This drain filter is to screen the foreign stuffs such as threads, coins, pins, buttons etc ...

• If the drain filter is not cleaned at proper time (every 10 times of use), Drain problem could be caused.

1

Put down the

remained water in the

hose. And put a container

under the filter to collect

water.

2

Turn the cap counter

clockwise.

3

Pull out the filter assembly off

the case of the main body.

6

Turn the cap clockwise tightly.

4

Clean the drain filter

removing the foreign

stuffs.

5

Put in the filter along the

guiding prominence of the

case. Please note the left

position of the filter adjusting

the groove to the guide rib.

FILTER

CONTAINER

CAP

SLIT

CASE

FILTER

CAP

CAP

FILTER

CAP

FILTER

CASE

GUIDE

RIB

SLIT

CAP

1

While pressing the handle of

e

guide.

2

Remove the dirt inside the

.

3

.

4. FEATURE AND TECHNICAL EXPLANATION

7

FEATURE

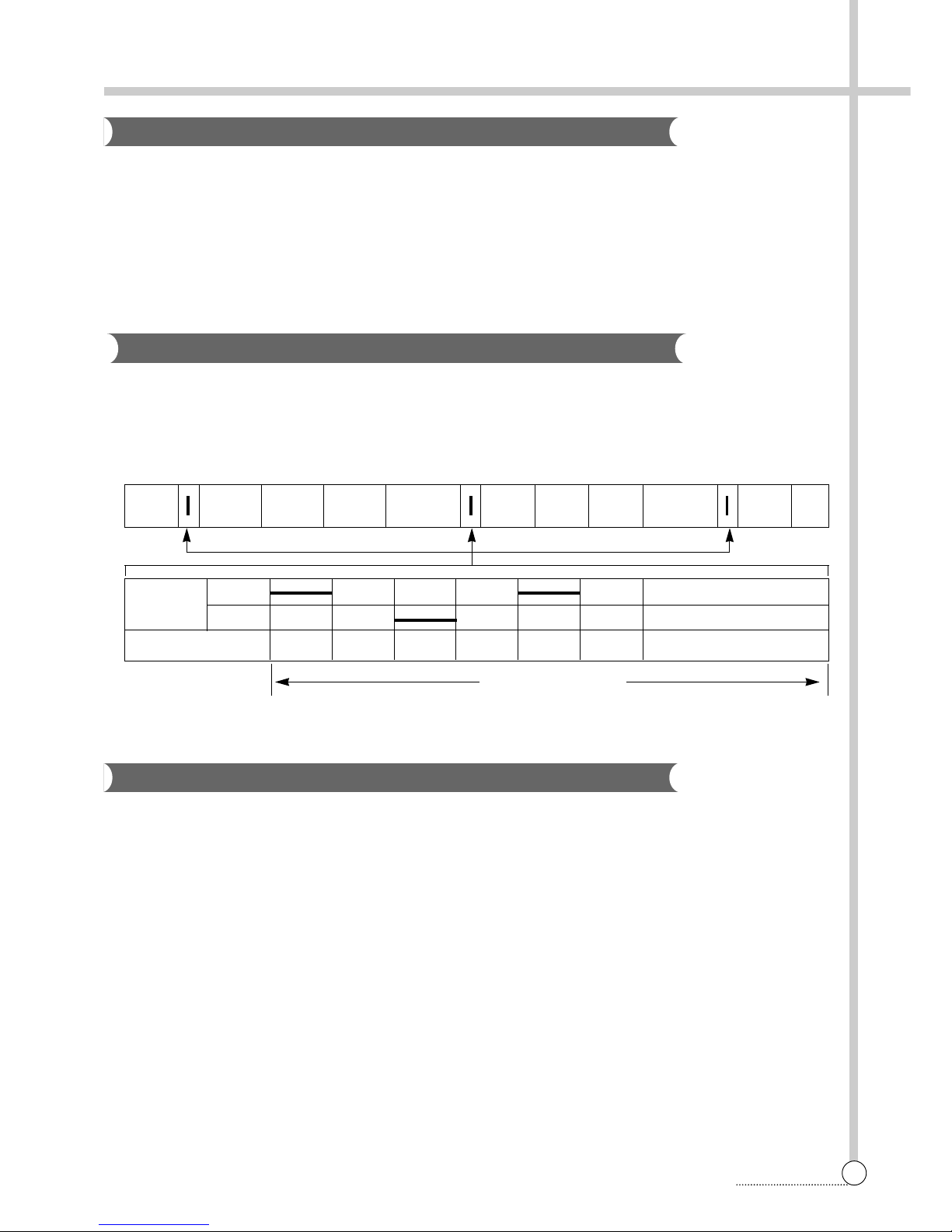

WASH DRAIN SPIN FILL RINSE 1 DRAIN SPIN FILL RINSE 2 DRAIN •••

MOTOR C.W

SINGAL C.C.W

TIME(SEC.) 0.3 0.3 0.3 0.3 0.3 0.3 • • • • • • •

35 SEC.

Feature of the Washing Machine

① First applying the Radical Technology in the world, go beyond washing, sterilize your colthes and deodorize a

bad smell.

② The first air bubble washing system in the world.

③ Quiet washing through the innovational low-noise design.

④ The laundry detergent dissolves well in water because of the air bubble washing system.

⑤ The adoption of the water currents to adjust the unbalanced load.

⑥ One-touch operation system.

Water Current to Adjust the Unbalanced Load

It is a function to prevent eccentricity of the clothes after wash by rotating pulsator C.W and C.C.W for 35

seconds.(But, the WOOL course have no operation of the water currents to adjust the unbalnced load.)

EFFECT

It reduces vibration and noise effectively while spinning.

WATER FLOW

Automatic Water Supply System

The water level would be lowered because the clothes absorbs water at the beginning of washing. Therefore, after 2

minutes, the operation is interrupted to check the water level, and then the water is supplied again until the selected

water level is reached.

8

FEATURE

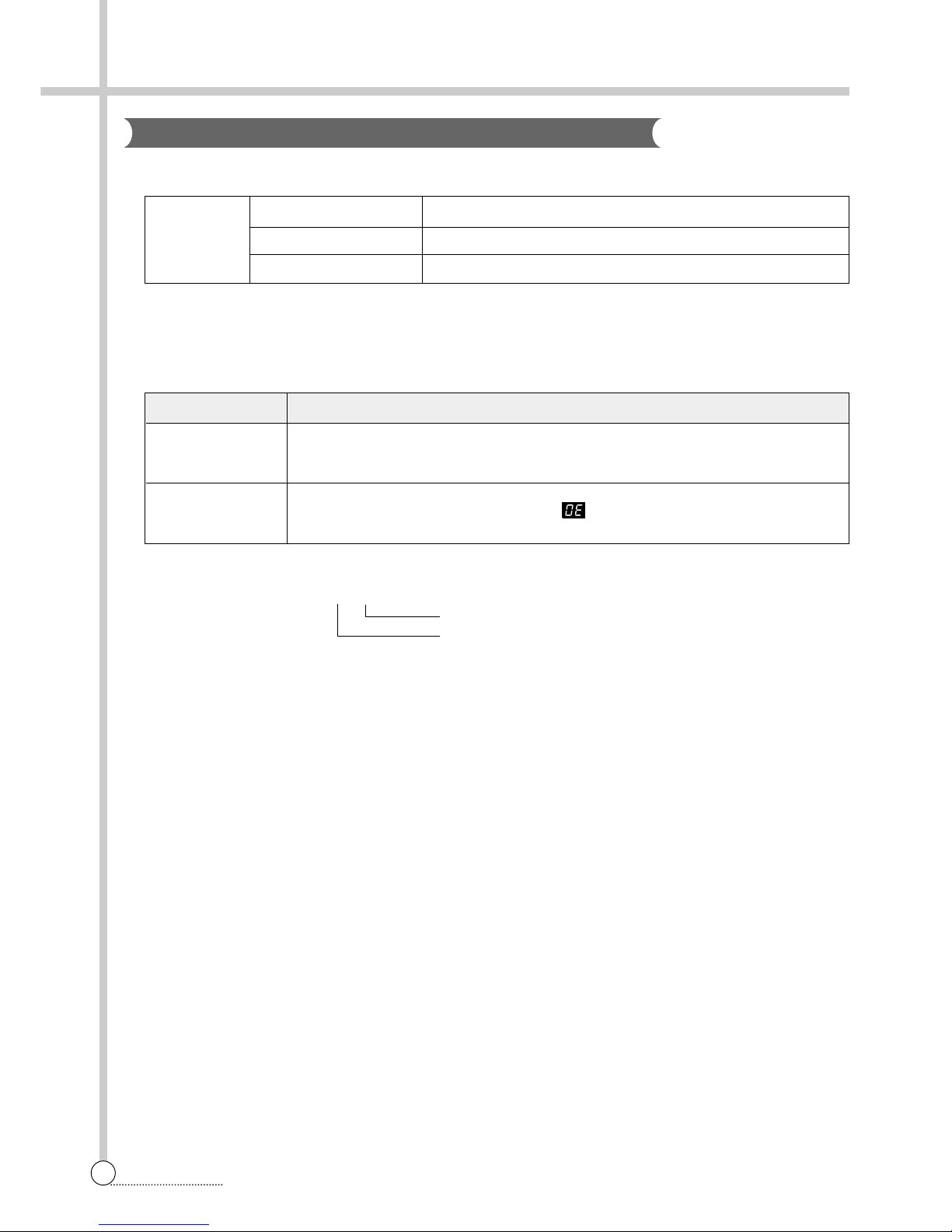

FUNCTIONAL PRINCIPLE

① The micom can remember the time from the begining of drain to reset point when the pressure switch reaches to

“OFF” point

② In case of continuous draining, residual drain time is determined by micom.

Draining time as a whole = D + 90

Residual drain time.

The time remembered by micom.

Draining

Good draining The washer begins spin process after drainage.

condition

Bad draining Draininig time is prolonged.

No draining Program is stopped and gives the alarm.

margorP eht fo tnemevoMemiT niarD

Less than

Continue draining

15 minutes

More than

Program stops and gives the alarm with blinked on display lamp.

15 minutes

Automatic Draining time Adjustment

This system adjusts the draining time automatically according to the draining condition.

9

FEATURE

Contact of safety switch Lid closing

Lid opening

Contact lever A

Normal (ON)

Position of

unbalanced load (OFF)

Automatic Unbalance Adjustment

Circulating-Water Course and Lint Filter

The alarm finished when you close the lid after opening

it. Check the unbalance of the wash load and the installation condition.

NOTES

Filter

Tub

Outer tub

Water

channel

Pulsator

This system is to prevent abnormal vibration during intermittent spin and spin process.

FUNCTIONAL PRINCIPLE

① When the lid is closed, the safety switch

contact is “ON” position.

② In case that wash loads get uneven during

spin, the outer tub hits the safety switch

due to the serious vibration, and the spin

process is interrupted.

③ In case that P.C.B. ASS’Y gets “OFF” signal

from the safety switch, spin process are

stopped and rinse process is started automatically by P.C.B. ASS’Y.

④ If the safety switch is operated due to the

un balance of the tu b, th e program is

stopped and the alarm is given.

CIRCULATING-WATER

The washing and rinsing effects have been

improved by adopting the water system in

wh ich water in the tub i s c ir culated in a

designed pattern.

When the pulsator rotates during the washing

or rinsing process, the water below the pulsator fans creates a water currents as shown in

figure.

The water is then discharged from the upper

par t of the tub through the water channel.

About 40 L/min. water is circulated at the ‘high’

water

level, standard wash load and standard

water currents.

10

FEATURE

Much lint may be obtained according to the kind of

clothes to be washed and some of the lint may also

sticks to the clothes.

To minimize this possibility a lint filter is provided on

the upper part of the tub to filter the wash water as it

is discharged from the water channel. It is good to

use the lint filter during washing.

HOW TO REPLACE LINT FILTER

① Pull the filter frame upward.

② Turn the lint filter inside out, and wash the lint off with water.

③ Return the filter as it was, and fix the filter frame to the slot.

When the START/HOLD button is pressed, the residual time (min.) i

s displayed on the time indicator, and it will be

counted down according to process.

When operation is finished, the TIME INDICATOR will light up .

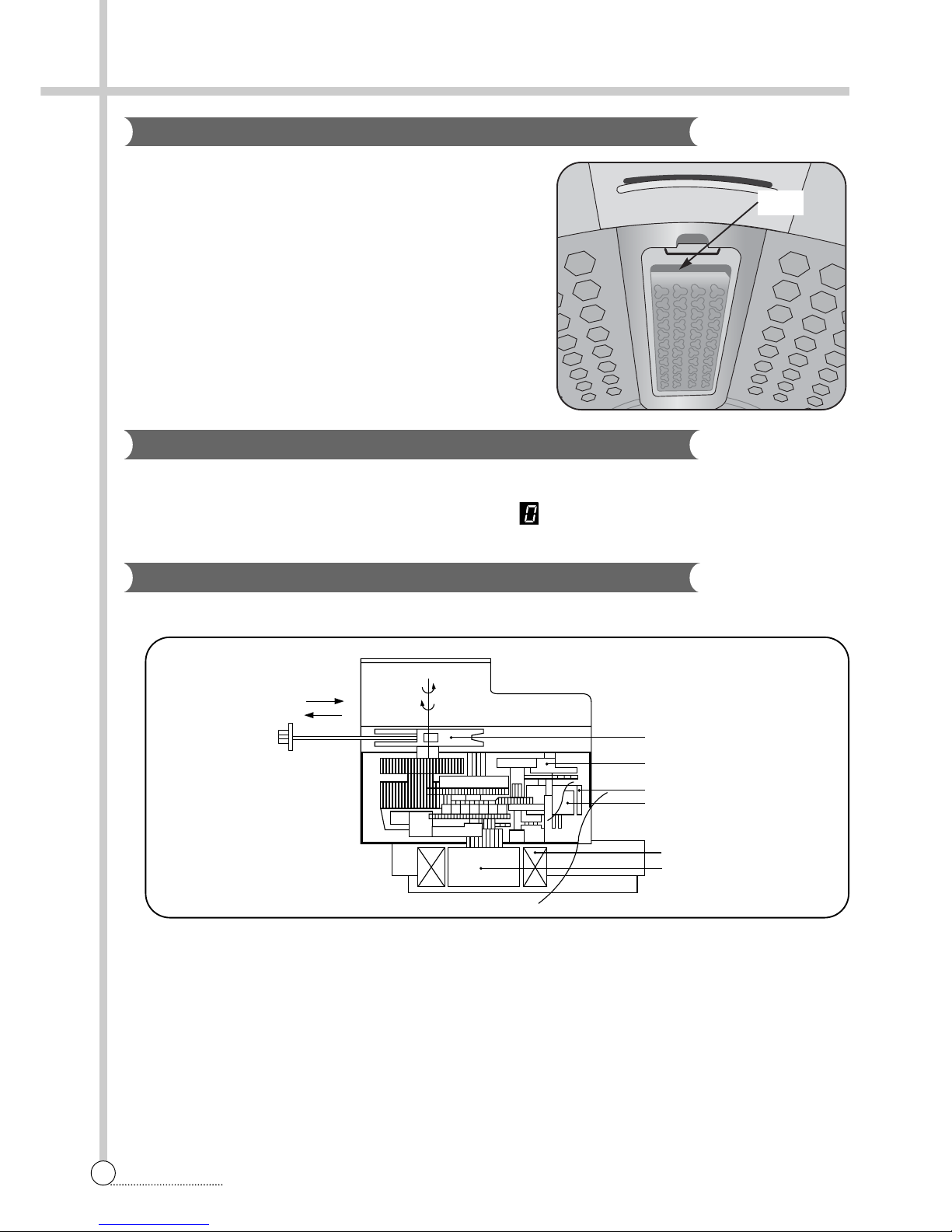

STRUCTURE

FUNCTIONAL PRINCIPLE

① When the DRAIN MOTOR connected to the power source, the DRAIN MOTOR rotates with 900 r.p.m and

revolves the pulley by gear assembly for reducing.

② When the pulley is rotated, the pulley winds the wire to open the drain valve.

③ Therefore, rotation of pulley changed to the linear moving of wire.

④ The wire pulls the brake lever of Gear Mechanism Ass’y within 5 seconds.

⑤ After the wire pulled, gear assembly is separated from motor and c

ondition of pulling is held by operation of the

lever.

⑥ When the power is turned off, the drain valve is closed because the wire returns to original position.

Pull

Loosen

Pulley

Lever

Inductive ring

Magnet

Coil of motor

Magnet of motor

Lint Filter

Residual Time Display

Drain Motor

Filter

Filter

Loading...

Loading...