Page 1

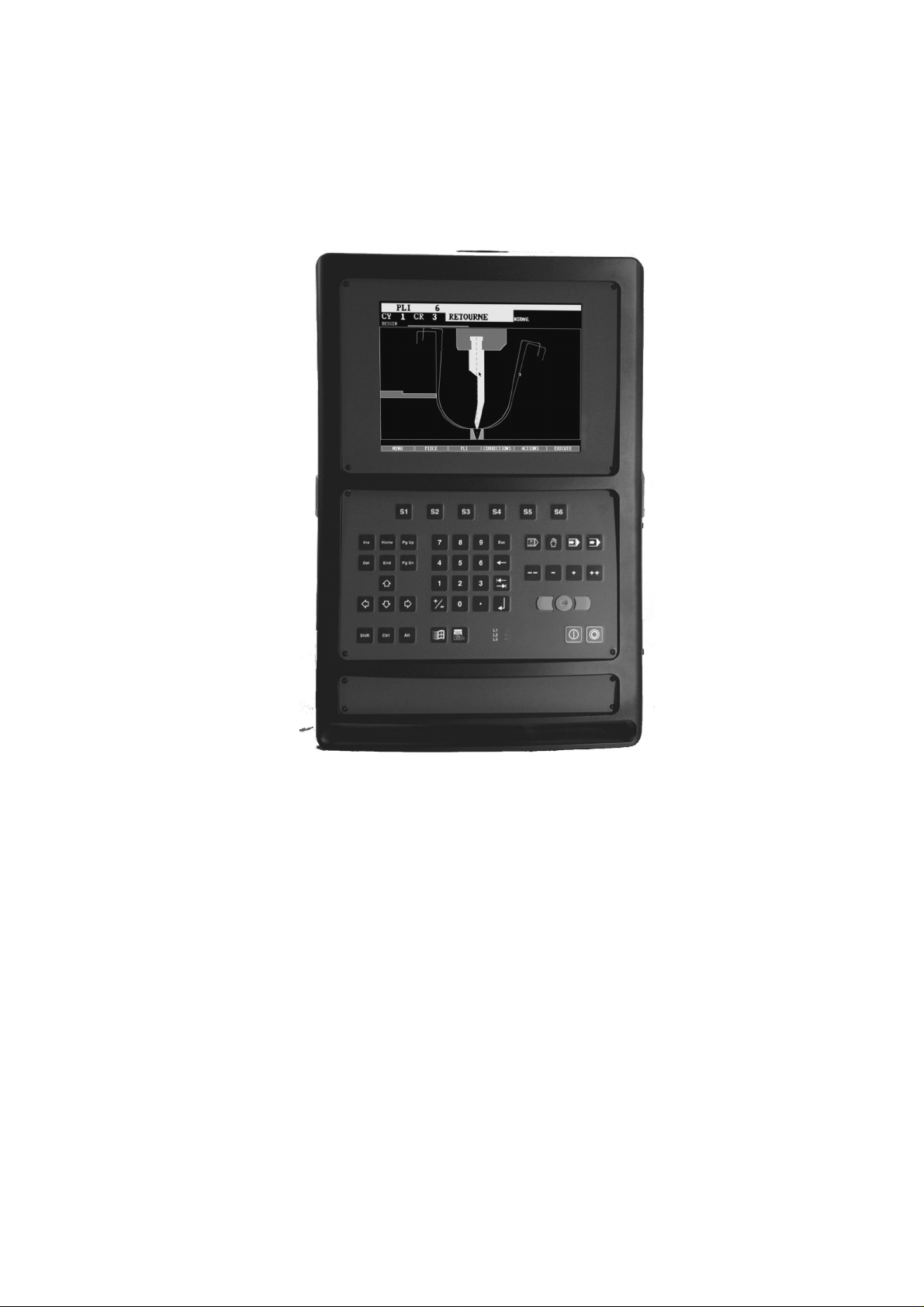

PC 1200

2D Reference Manual

Page 2

Page 3

25 September 2000 V. 2.1

TABLE OF CONTENTS

INTRODUCTION..............................................................................................................................5

About this Manual 5

Licence Agreement and Copyright 5

CONVENTIONS...............................................................................................................................7

DEFINITIONS...................................................................................................................................11

ABS......................................................................................................................................11

REL 11

Active Peripherals................................................................................................................12

Active Peripherals Machine 12

Active Peripheral Products 13

Active Peripheral Punches / Dies 13

Admissible Force applied to the Dies ..................................................................................13

Alphanumeric Fields............................................................................................................15

Angle Corrections................................................................................................................16

General Remarks 16

Direct Corrections 16

Angular Corrections 17

Corrections by Thickness Measurement 17

Measuring at the TDC 18

Measuring at the PP 19

Independent Thickness Correction Y1-Y2 21

Corrections: Sensitivity BDC 22

Auxiliary Functions...............................................................................................................22

Backgauge Retraction .........................................................................................................23

Bend ....................................................................................................................................23

At the bottom of the Die 23

Final 23

Intermediate 23

Sequence without Bend 23

Bend Counter.......................................................................................................................24

Bending Force .....................................................................................................................24

Bending Order .....................................................................................................................24

Automatic Bending Order 24

Modifying the Bending Order 25

Unbend Mode 27

Bending Speed....................................................................................................................29

BG (Backgauge) or STOP...................................................................................................29

Bottoming ............................................................................................................................30

Corrections (Table)..............................................................................................................31

Crowning..............................................................................................................................32

Data Backup........................................................................................................................32

INTRODUCTION PAGE 1

Page 4

Data Transfer......................................................................................................................33

Date and Hour.....................................................................................................................35

Decentered Punches & Backgauge Correction.................................................................. 36

Depth Collision authorized.................................................................................................. 36

Drawing...............................................................................................................................37

Dwell Time..........................................................................................................................38

Erase / Delete.....................................................................................................................38

Erasing Memories...............................................................................................................39

Free Memory.......................................................................................................................39

Gauge Clearance................................................................................................................40

Ideal Curve (CR)................................................................................................................. 41

PRODUCT NUM Page 41

Indexing Axes ..................................................................................................................... 45

Inserting a Sequence.......................................................................................................... 46

Internal Radius....................................................................................................................47

Keyboard.............................................................................................................................48

L. Bending...........................................................................................................................48

Language............................................................................................................................49

Leaving the Software..........................................................................................................49

Leg......................................................................................................................................50

Length.................................................................................................................................51

Low Speed Distance !.......................................................................................................51

Machine Parameters...........................................................................................................51

Maintenance ....................................................................................................................... 52

Manual Adjustment of the Backgauge................................................................................52

Modifying the Origin of the Axes......................................................................................... 53

Product Groups...................................................................................................................55

Definitions 55

Working example in the PRODUCTS GROUP page 56

Product information.............................................................................................................57

See an Informtion 58

Creating an Information (text only) 58

Creating an Information (text and images) 58

Product Management ......................................................................................................... 61

Programming a Profile........................................................................................................62

Programming on Bend Num ............................................................................................... 62

Q.Needed. ___ Done.___................................................................................................... 63

Reference YR cor. ..............................................................................................................64

Screen Capture...................................................................................................................65

Black and white, colour 65

Screen printing 66

Searching for Products according to Criteria......................................................................68

Memorization date 69

Section................................................................................................................................ 70

Sigma..................................................................................................................................70

Simulation criteria ............................................................................................................... 71

SP (Switch Point)................................................................................................................ 74

Special bends ..................................................................................................................... 75

Preliminary / Final bend 75

Start Axes/AF......................................................................................................................80

TDC (Top Dead Centre) .....................................................................................................81

Test.....................................................................................................................................82

Tolerance............................................................................................................................85

Too short segment authorized............................................................................................86

Tools...................................................................................................................................86

Programming punches 87

PAGE 2 2D REFERENCE MANUAL

Page 5

Programming dies 89

Modifying a tool 91

Tool positions 91

Punch list / Die list 91

Unfolded Length ..................................................................................................................92

DIN 93

REAL 93

Correction coefficient of calculation DIN 6935 93

INDEX...............................................................................................................................................95

ANNEXES ........................................................................................................................................99

Corrections by thickness measurement..............................................................................99

TABLE OF CONTENTS PAGE 3

Page 6

This page has been left blank intentionally.

PAGE 4 2D REFERENCE MANUAL

Page 7

NTRODUCTION

I

A

BOUT THIS MANUAL

This document has been conceived to try and answer particular questions

after having acquired the basis for using the PC/DNC 1200 software.

It is complementary to the User guide which informs you about the basic

procedures to be followed for using this software.

A supplement called 3D Reference manual is supplied with the

PC/DNC 1200 software in 3D version.

This manual is organized like a dictionary, that its elements are classed in

alphabetical order.

If a subject is dealt with in another chapter than the one in which you are

looking for information, you will find a reference to the new subject..

An index situated at the end of the manual completes and facilitates the

search for information. Do not hesitate to use it.

L

ICENCE AGREEMENT AND COPYRIGHT

This manual is subject to the licence and copyright agreement to be found at

the beginning of this manua l .

INTRODUCTION PAGE 5

Page 8

This page has been left blank intentionally.

PAGE 6 2D REFERENCE MANUAL

Page 9

ONVENTIONS

C

As a general rule, in this manual, we will not repeat how to validate a field,

select a tool, call a page or any other basic manipulations.

These are described by means of examples in the User guide of the numerical

control or the relevant software.

In order to ensure a better readability of the reproduced screens, these ones

have been converted in black and white.

Possibly, certain screens illustrated in this manual may not correspond exactly

to your software, this can result from the configuration of your software

(number of options, axes, etc.) or from the used software version (DOS or

Windows).

Typographical conventions

Arial bold Quotations of text as seen on the screen.

Arial bold italic Used to indicate the name of a DNC input or

output.

Italic Reference to a written element , a paragraph or a

manual.

For example: See Typographical conventions.

Indicates a double pressure on the key.

General conventions for this manual

It is accepted that:

Mouse means a mouse for a PC

or trackball / tracksensor for a DNC.

Click press the left mouse button.

Click right press the right mouse button.

Click left/right press simultaneously the left and right mouse

buttons.

Round robin lists or multiple choice fields:

They are violet coloured and signify that several

options are available.

The choice of the contents is made by pressing

the

A window appears displaying the list of the

available choices for this field.

To validate the choice:

- type the number indicated next to the choice,

or

- place the cursor on the choice and press the

key.

key.

CONVENTIONS PAGE 7

Page 10

It is possible, without displaying the choice

window, to make appear one after the other the

Reach the BEND 2D

page

Function keys

choices by pressing the

To validate, leave the field.

Each time you are asked to press a function key

to , the appropriated menu appears.

Generally, the name of the function key will be

used. For example: press PRODUCT

designates the

key.

key.

Example when you want to reach the BEND 2D

page, press t he function key BEND

sélect BEND 2D or simply type 02 (or the

number indicated next to the choice).

Rapid validation To facilitate the operator's work, the DNC

memorizes the last choice made in a menu.

To validate faster an option of a menu, just

double press on a function key (e.g.:

directly validate the last selected page.

, then

), to

PAGE 8 2D REFERENCE MANUAL

Page 11

Software conventions, DOS version

The software uses colours to facilitate the reading of information, that is:

Light blue Used for titles and headnotes.

Green Designates fixed i nformation, designates fields

etc.

White Variable information. Not accessible by the

cursor.

Yellow Fields accessible by the cursor which can be

modified by the user.

Violet Scrolling fields. Accessible by the user for

choosing between several predefined options (see

Scrolling lists above).

Red Important message.

Monochrome In the case of a monochrome screen the user will

quickly determine the different types of fields.

The User guide of the numerical control or the

software illustrates with examples the majority of

cases.

Software conventions, Windows version

In basic configuration, the Windows version uses the following colours:

Black Designates fixed i nformation, designates fields

etc.

or

fields accessible by the cursor which can be

modified by the user.

Blue Used for titles and headnotes.

Bluish-grey Variable information. Not accessible by the

cursor.

Green Scrolling fields. Accessible by the user for

choosing between several predefined options (see

Scrolling lists above).

CONVENTIONS PAGE 9

Page 12

This page has been left blank intentionally.

PAGE 10 2D REFERENCE MANUAL

Page 13

EFINITIONS

D

ABS

Page: BEND NUMERICAL

This round robin list is placed next to the name of the axis of the X stop.

Two choices: ABS and REL.

ABS indicates that the X axis functions in absolute mode.

This means that the destination of the axis is an absolute distance measured

from the die V.

Absolute mode is selected by default.

See REL below.

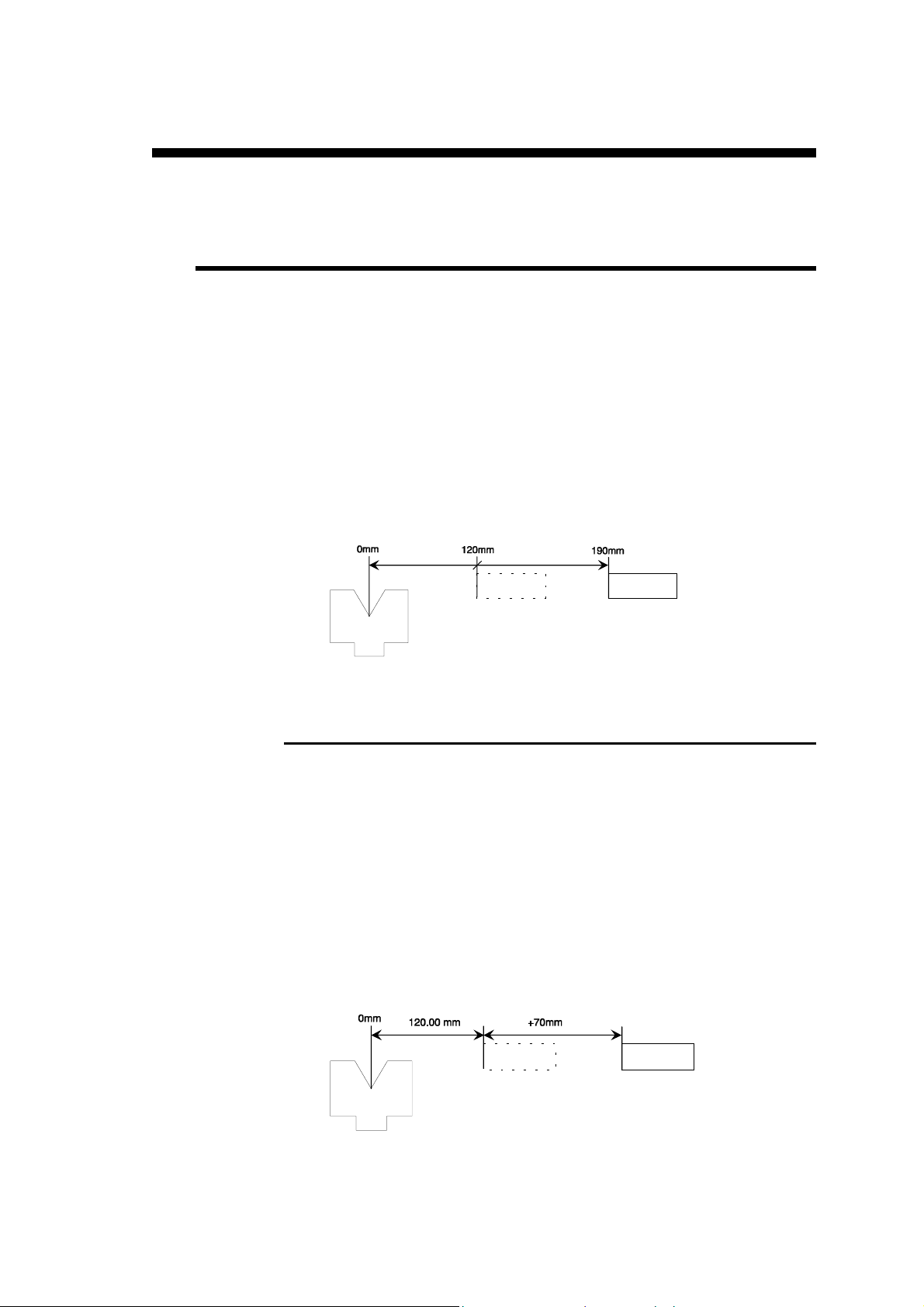

Example: MEM POS

X ABS 190.00 120.00

REL

REL indicates that the X axis functions in relative mode.

This means that the displacement programmed is made departing from the

actual stop position.

Generally a negative value is programmed.

The relative mode is often used with the cycle repetition (CY 2 at 99).

For example with a punching t ool, you wish to make 5 holes equidistant of

30.00mm. The first sequence must be in absolute mode (location of the first

hole. The second sequence will be programmed in relative mode

(X REL 30.00) with a cycle repetition equal to 4 (CY 4).

Example: MEM POS

X REL 70.00 120.00

DEFINITIONS PAGE 11

Page 14

Remark: It is not possible to use the relative mode on the first sequence.

CTIVE PERIPHERALS

A

Page: WELCOME

Aim:

This function allows to choose the peripheral containing the required

information and this separately for the machine parameters, the products, the

tools the CAD files and the complementary files on the product information

page.

It offers a multitude of combinations especially appreciated on a PC work

station. Effectively using these choices, the operator could easily manage

several machines.

The comprehension of this notion is important, as its flexibility allows a large

diversity of choice.

If such is the case, an error is generated when changing mode

(AUTO, SEMI-AUTO) and the message DEPL. X REL.

IMPOSSIBLE is displayed in the interactive field.

Definition:

The active peripheral is the peripheral in which the software is going to read,

search, save or delete data. The active peripherals are designated on the

WELCOME page.

On certain pages, another peripheral can be temporarily selected for an

operation (for ex. PRODUCT LIST, PROGRAMMING PUNCHES /

DIES, TRANSFER).

Active Peripherals Machine

When you change the peripheral in the MACHINE field, automatically

PRODUCTS, PUNCHES and DIES are redirected on to the same

peripheral.

To change them independently one from the other, you must simply modify

them afterwards.

The CAD FILES and COMPLIMENT peripherals are not modified

automatically, as they are generally situated on a network and are often the

object of a “specific classification” in one or several directories.

By modifying in this way the MACHINE peripheral, the environment of the

software “ becomes” that of another machine. It is thus easy to simulate

products for different configurations of pressbrakes.

Also, more and more you will find diskettes containing examples of special

products (supplied by CYBELEC or by the machine manufacturer) for which

the realization needs a special (Tools for example). With this possibility you

can thus easily visualize these demonstrations with all the machine context in

which they were created.

On a numerical control, it is evidently only possible to work with a machine

when the MACHINE field is switched to INTERNAL.

If another peripheral is used to visualize a demonstration product for

example, it will however still be possible to switch the DNC to semi-auto or

auto mode.

However the massage ENC NOT CONNECTED will appear and it will not

PAGE 12 2D REFERENCE MANUAL

Page 15

be possible to work with the machine.

To reactivate the INTERNAL machine peripheral, you must:

" Select MACHINE INTERNAL.

" Initialize the ENC by pressing INIT ENC, Action menu.

Active Peripheral Products

Selects the default peripheral in which the operations of searching, saving and

deleting of products is effectuated.

Active Peripheral Punches / Dies

Selects the default peripheral in which the operations of searching, saving and

deleting punches and dies is effectuate d.

Evidently the tools specified in the current product must be available in the

addressed peripheral, without which the software will give an error message.

DMISSIBLE FORCE APPLIED TO THE DIES

A

Page: PROGRAMMING OF DIES

The maximum admissible force is defined when programming the tools. In

reality however, the admissible maximum force varies depending on the

bending angle (and, of course, on the other customary parameters).

The die programming page contains two pairs of fields which make it

possible to adapt the safety parameters.

The fifth field enables the user to test the result.

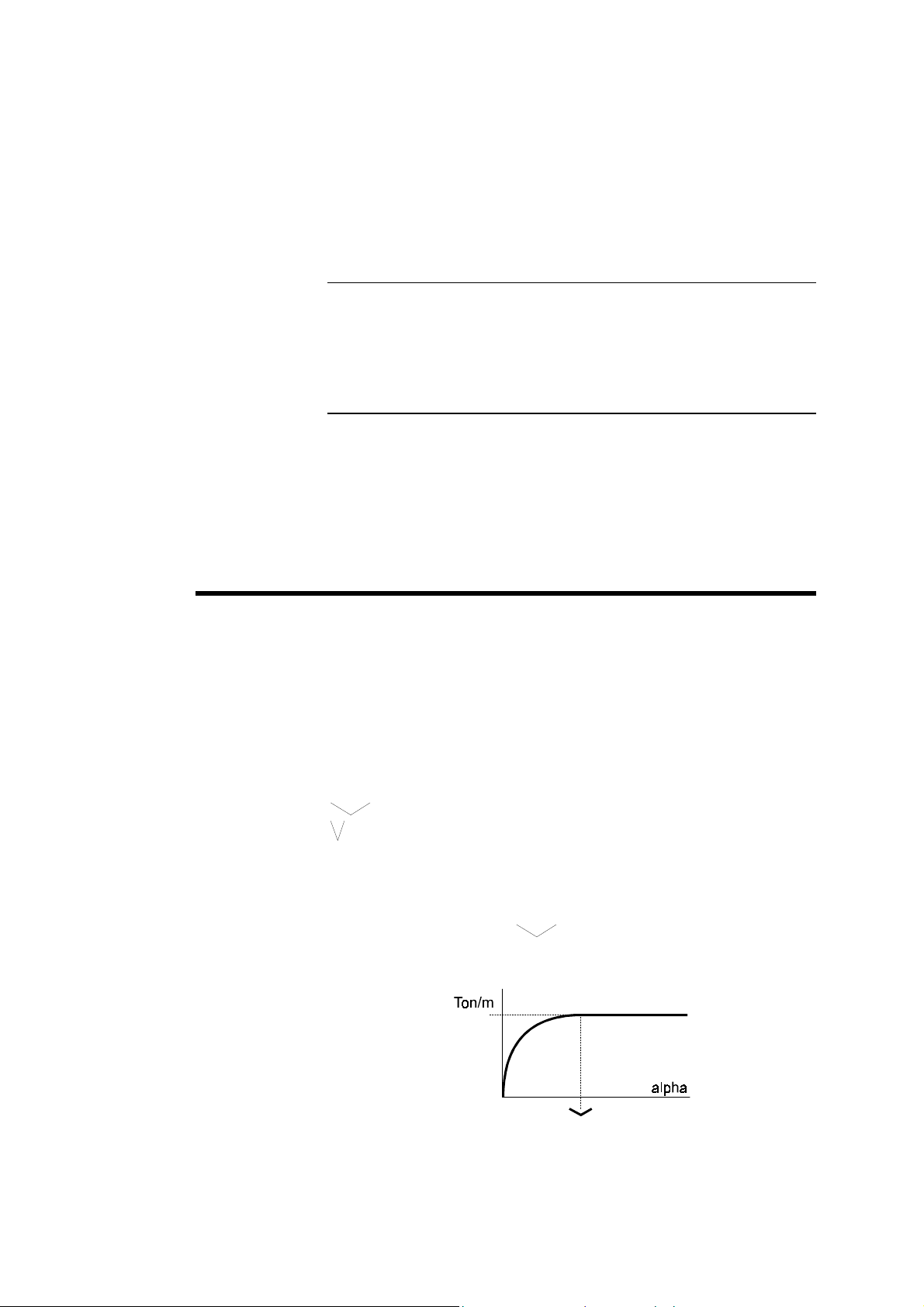

When only the first Ton/m field is programmed, this means that the pressure

limit is constant and not depending on the angle.

__._° -> max 200.0 Ton/m

__._° -> max ___._ Ton/m

Test 90.0° = 200.0 Ton/m

The Test field indicates the maximum admissible force for the programmed

angle.

When the fields "open angle"

programmed, the calculation of the admissible force is limited according to

the diagram shown below.

and Ton/m on the same line have been

If there is no specific indication given by the manufacturer, you enter the

maximum admissible force already known, and an "open angle" of 90°

(as below).

DEFINITIONS PAGE 13

Page 16

90.0° -> max 200.0 Ton/m

__._° -> max ___._ Ton/m

Test 60.0° = 115.5 Ton/m

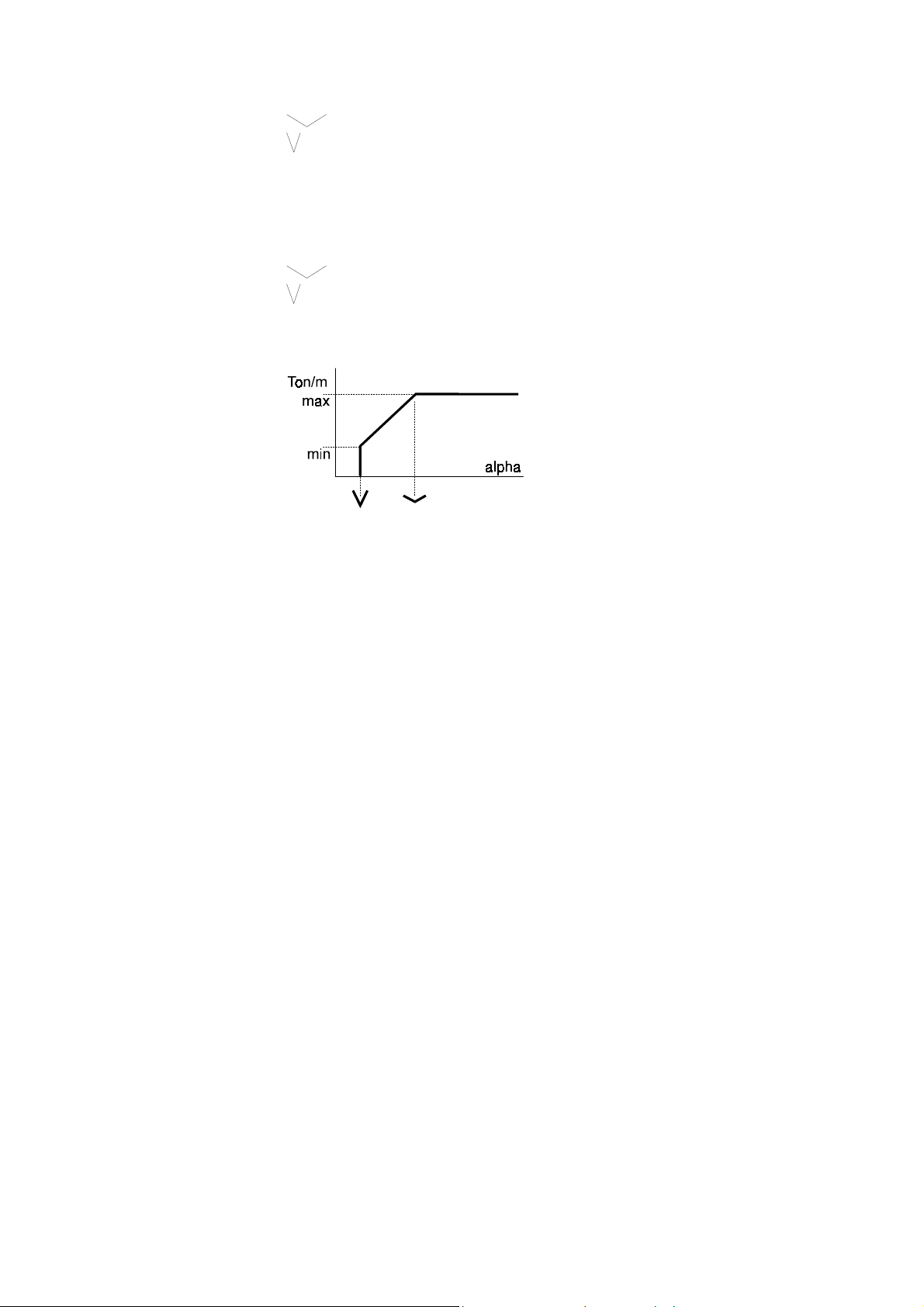

When the 4 fields have been programmed, the calculation of the admissible

force is limited according to the diagram below. The choice between the

above method and the method explained in this paragraph depends on the

known data and the decision of the person who enters the die data.

90.0° -> max 200.0 Ton/m

30.0° -> max 45.0 Ton/m

Test 60.0° = 122.5 Ton/m

PAGE 14 2D REFERENCE MANUAL

Page 17

LPHANUMERIC FIELDS

A

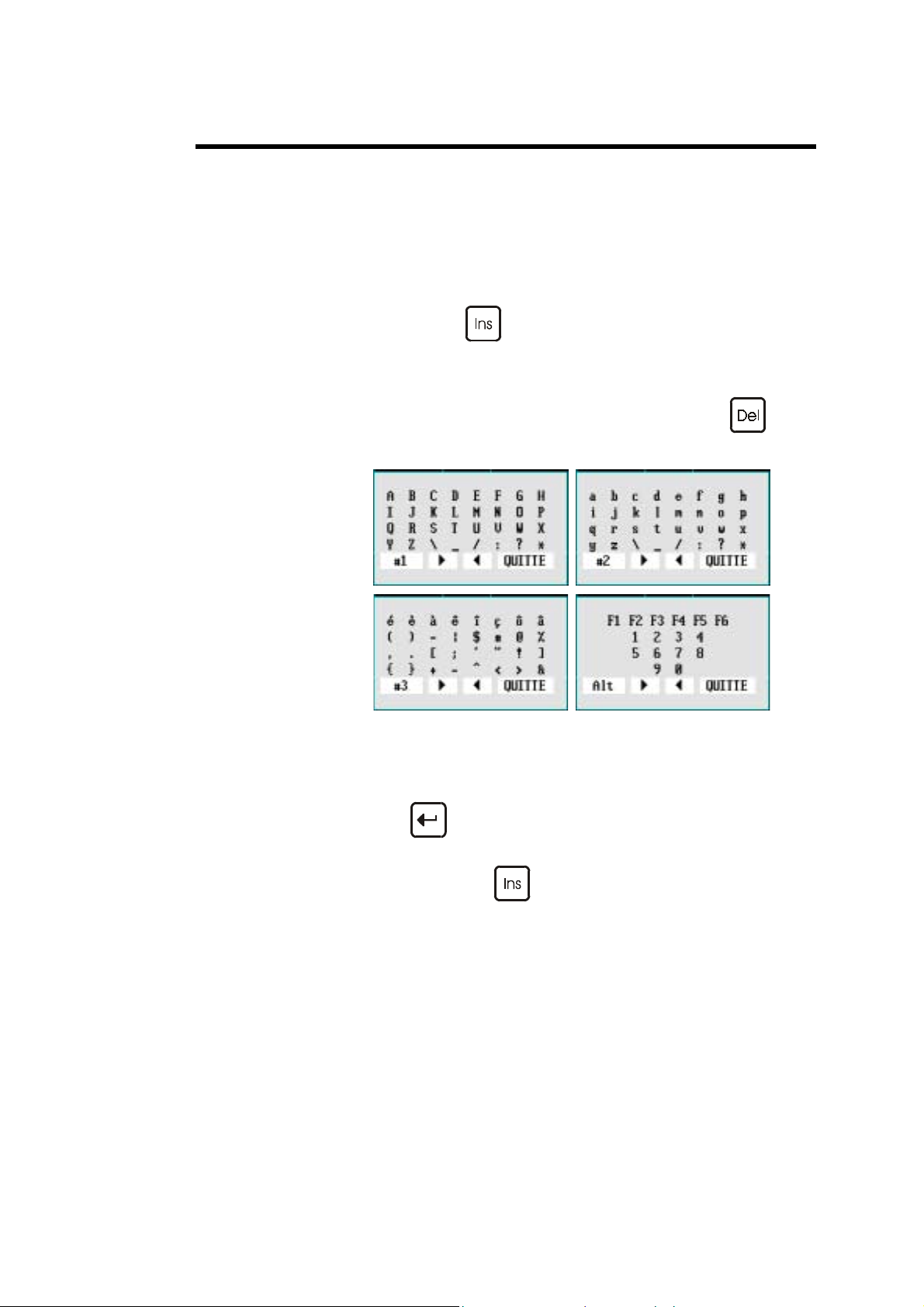

Certain fields (DRAWING, PUNCH, DIE etc.) can contain alphanumeric

characters.

To program the alphanumeric fields on the numerical controls, you must use

the "soft" alphanumeric keyboard.

To call the "soft” alphanumeric keyboard in the software , position the cursor

on the alphanumeric field (if the field is only numeric the keyboard will not

appear) and press the

4 tables of characters are available (#1, #2, #3 and Alt).

To change the "table":

" Point to the field bottom left #1, #2, #3 or Alt and press

or click left in this field.

To enter the characters in to the alphanumeric field:

key.

" Select the character.

" Press

Repeat the operation for the other characters.

" To leave, press the

DEFINITIONS PAGE 15

or click left.

key again.

Page 18

NGLE CORRECTIONS

A

Pages: CORRECTIONS

G

ENERAL REMARKS

The sheet metals used in the workshops have hardly ever their nominal

thickness. The real thickness commonly varies ±10 % from the nominal value.

Also the variation is not constant across the whole length of the sheet. The

thickness on the left side can be different to the thickness on the right side

(sheets with a trapezoidal section). The software allows to correct this type of

error by dissociating the correction of one extremity from that of the other

extremity of the bend.

The bending depth calculations (as well as those for elongation, pressure and

crowning) are ba sed on the nominal thickness (that which is programmed in

the THICKNESS field).

In this Angle corrections chapter we will deal with 3 types of correction:

" Direct corrections " Angular corrections " Corrections by measuring the sheet thickness.

Depending on the field in which it is entered, a correction can act on:

" The releva nt bend (uniquely)

" All the bends (with the same angle) situated on the same section (same

profile)

" All the bends (with the same angle) of the product (also on distinct

sections)

D

IRECT CORRECTIONS

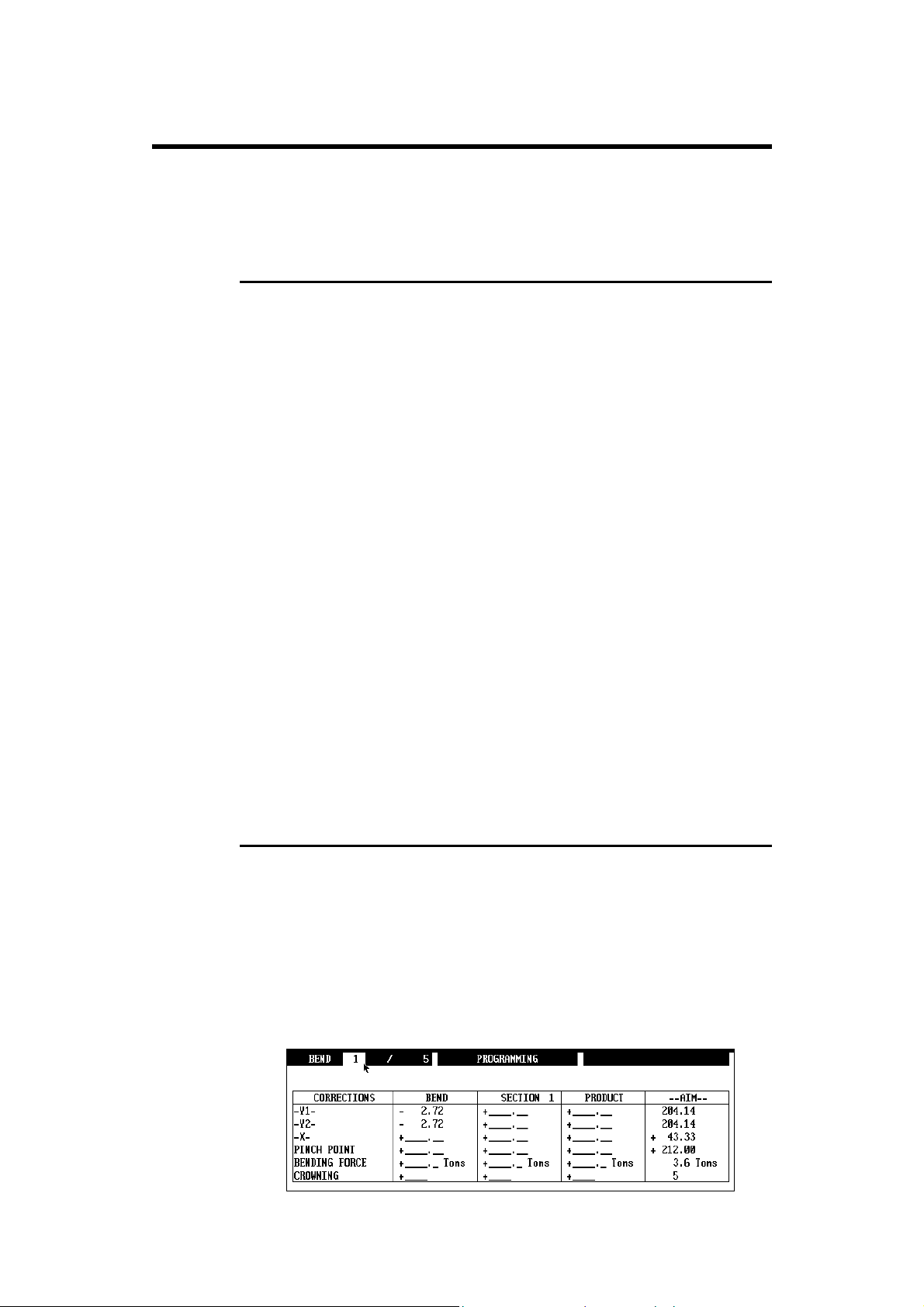

To use direct corrections, the DNC must be in programming or semiautomatic mode and you simply enter a value in to the required field on the

first table of the page. The number of the current bend is located at the top of

the screen.

If the correction concerns the two sides of the beam, the same value for Y1

and Y2 must be entered.

It is also possible to correct the other axes, the PP, the bending force and the

crowning according to the same principles.

PAGE 16 2D REFERENCE MANUAL

Page 19

Direct corrections are additioned. This means that if there is a global

correction for the product and a correction for a given bend is programmed,

the final correction for this bend will be the sum of the two corrections.

A

NGULAR CORRECTIONS

After having made a bend, the operator measures the angle obtained. The

measured angular value is entered in to the ANGLE field. The DNC

automatically calculates the correction to obtain the angle originally

programmed. If after making the corrected bend, the angle is still not correct,

simply enter the new measured angle value. In certain cases this operation

may have to be repeated 2 or 3 times.

Attention, you must not intervene in the direct corrections table

simultaneously with the angular cor rections.

As for the direct corrections the corrections can be attributed to:

BEND Corrects only the current bend.

SECTION _ Corrects all the angles of the specified section

PRODUCT Corrects all the angles of the product which

which have the same programmed value and the

same tools.

have the same programmed value and the same

tools.

The DNC must be in programming or semi-automatic mode.

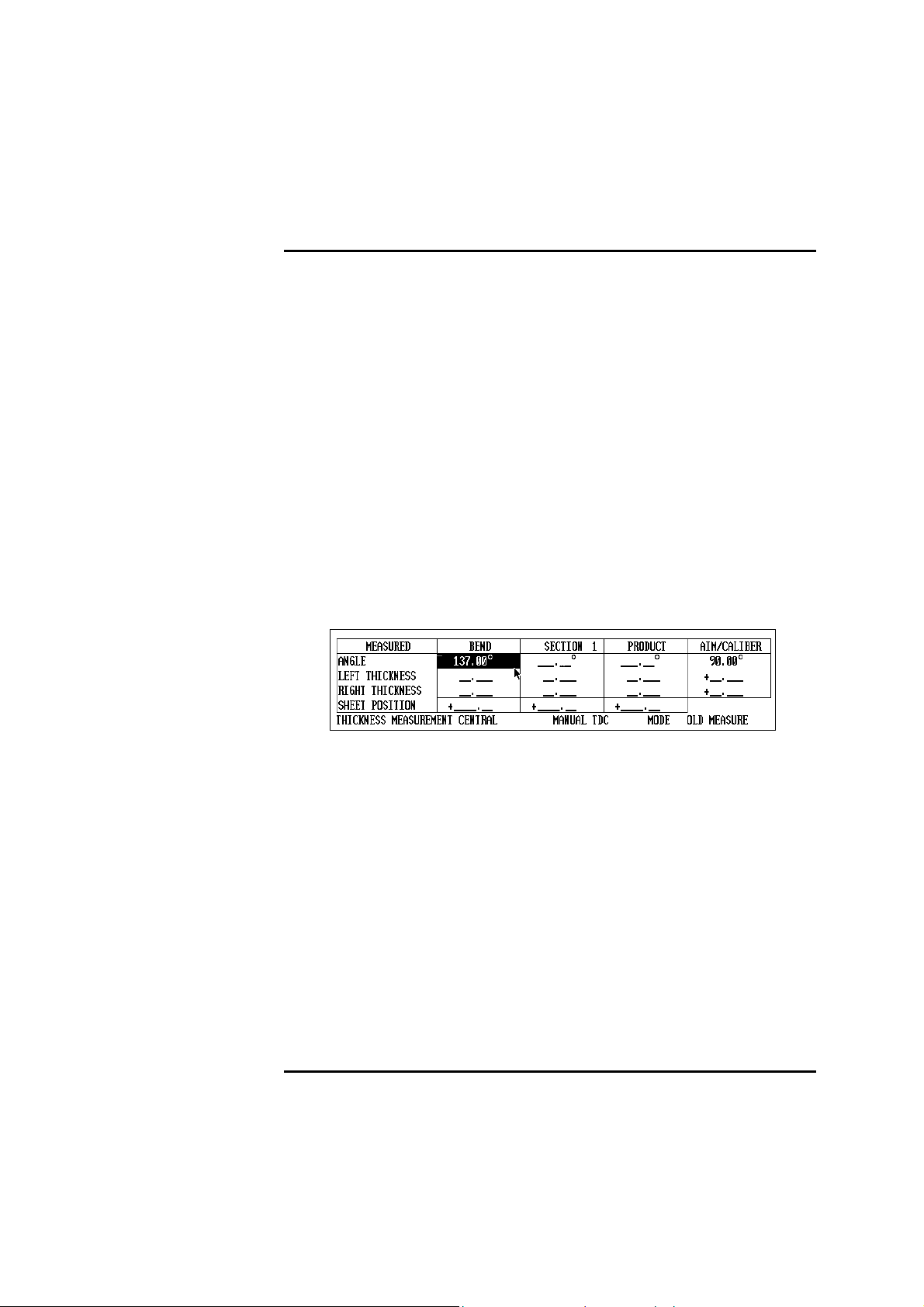

" Program the THICKNESS MEASUREMENT field in the following

manner:

THICKNESS MEASUREMENT CENTRAL NONE MODE OLD MEASURE

" Measure the angle obtained.

" Introduce the measured value in to the ANGLE field under one of the

columns BEND, SECTION or PRODUCT.

" Test the result and redo if necessary.

See also the machine parameter COMPENSATION ELASTIC RETURN

on the MATERIAL page. This parameter allows to correct in permanence an

angle in a given plane.

C

ORRECTIONS BY THICKNESS MEASUREMENT

Correction by thickness measurement can be realized in several ways, but the

principle remains identical. A system (or the operator) furnishes the DNC

with the real measurement of the material. With these parameters, the DNC

calculates the necessary correction.

DEFINITIONS PAGE 17

Page 20

The two main methods are:

Measuring at the TDC (Top dead center)

Measuring at the PP (Pinch point).

Measuring at the TDC The principle is that the measurement is made

and entered in to the DNC while the machine is

at the TDC.

The measurement is entered either conventionally using the keyboard, or by a RS232 link

using an adequate i nstrument of measure, or

otherwise by a system integrated at the stop. See

the Annexes for more information on this subject.

Measuring at the PP In this case the measurement is made at the PP.

Three possibilities are offered.

- Measurement by the beam.

- Measurement by the beam with die

displacement. See the Annexes.

- Measurement of the real PP by an external

system.

As for the direct and angular corre ctions, it is possible t o affect the correc t ion

to the current bend, to the section or to the whole product.

Also, with the correction in function of the measurement of the thickness, it is

possible to differentiate the correction for each extremity of the bend. The

choice is made using the round robin list CENTRAL or EXTREMITIES.

(See further on in this chapter for the use of this possibility).

Remarks: For technical reasons, you can only pass to programming

mode during working (DNC in automatic mode and programming) if NO

THICKNESS MEASUREMENT has been selected.

For technical reasons, the fields POS. SHEET and THICKNESS

MEASUREMENT can no longer be modified in semi-automatic mode.

Measuring at the TDC

As described in the introduction to this chapter, the measurement is made

when the beam is at the TDC.

Only the introduction of the measurement by the operator , such as the

"standard" DNC software will allow, will be described in this paragraph.

The DNC must be in programming or semi-automatic mode.

Proceed in the following way:

" Program the THICKNESS MEASUREMENT field in the following

way:

THICKNESS MEASUREMENT CENTRAL TDC MANUAL MODE BY BEND

" Measure the thickness very precisely (using a micrometer).

" Enter the measured value in to the LEFT THICKNESS field of the

PRODUCT, SECTION or BEND column dep ending on your needs.

By only programming the LEFT THICKNESS field, the software

assumes that the measurement is central.

PAGE 18 2D REFERENCE MANUAL

Page 21

" Leave the field.

" Bend.

If the introduction is made in the

PRODUCT column:

- The measurement made by the operator on whatever bend will remain

valid until the next measurement.

- The real thickness obtained is saved in association with the product.

- It is considered that the real thickness is the same for all the bends.

- At each new measurement, all the bends are re-corrected.

- If no measurement is made, the correction is made according to the

last measurement saved.

SECTION

- The measurement made by the operator on whatever bend of the

section will remain valid until the next measurement..

- The real thickness obtained is saved in association with the section to

which belongs the bend on which it was made. It is valid for all the

successive bends belonging to the same section.

- If a new measurement is made, all the bends of the relevant section are

re-corrected.

- If no measurement is made, the correction is made according to a

possible former measurement saved in association with that section.

Remark: This means that if any values are present in the SECTION

column, they will be taken in to account and the values in the

PRODUCT column will be ignored. If there are no values in

the SECTION column, the values in the PRODUCT column,

if they exist will be taken in to account.

BEND

- The measurement made by the operator on whatever bend is only valid

for that bend. It will also be memorized.

- If no measurement is made, the correction is made according to a

possible old measure memorized in association with that bend.

Remark: If any values are present in the BEND column, they will be

taken in to account and the values in the SECTION and

PRODUCT columns will be ignored. If there are no values in

the BEND column, the values in the SECTION column, if they

exist will be taken in to account. If only PRODUCT column

contains any values, then it is these that will be taken into

account.

Measuring at the PP

Only the measurement at the PP with the beam will be described in this

chapter.

Principle:

The beam makes its usual approach (in semi-auto or automatic). When it

reaches just before the theoretical PP, the DNC reduces the system pressure

and "lands" freely on the sheet. The DNC detects the stopping of the beam

and in this way allows the measurement of the sheet thickness.

It is evident that in this phase the sheet must not flex under the influence of

the beam, otherwise the measurement will be falsified. The way in which this

DEFINITIONS PAGE 19

Page 22

option functions will depend directly on the machine hydraulics, the speed

when arriving on the sheet and the minimum force of the beam in this

measurement phase.

It is obviously unthinkable that in this phase the beam be out of true, the

measurement would then be totally false.

Ideally the product should be in the centre of the machine, have a bending

length greater than 2/3 of the total length of the machine and be able to

support the weight of the beam without flexing.

As for the other corrections the measurement can be made by product, section

or bend, central or at the extremities depending on the choice made.

Before each use, a calibration must be done in order to gauge the whole.

Calibration

A calibration cycle is very similar to a measurement cycle.

Simple, the real thickness obtained is subtracted from the nominal thickness.

This difference is memorized to be used later as a correction for the real

thickness calculations.

Procedure:

" Measure the sheet with a micrometer.

" Select CALIBRATION MODE.

" Enter the values in the appropriate fields RIGHT THICKNESS and

LEFT THICKNESS of the CORRECTIONS page.

" Put the DNC into semi-auto mode.

" Place the sheet at the centre of the machine and make a bend.

" If the calibration cycle has been done correctly the differences

between the real thicknesses measured and the reference values will be

displayed in the lines LEFT THICKNESS and RIGHT

THICKNESS, under the --AIM-- column. They will remain there until

the next calibration.

" Select the required measurement mode MODE BY PRODUCT,

BY SECTION or BY BEND. From that moment on, during working,

the measurement will be made according to the option chosen. See

also the description of OLD MEASUREMENT mode which follows.

Remark: If the POS. SHEET field is not defined, it is supposed that the

sheet is centred between the two rulers.

If the length of the sheet is not defined, it is supposed that it is

equal to the distance between the two rulers Y1 and Y2

(machine parameters).

Working with the correction MEASUREMENT AT THE PP

After having done the calibration, MODE BY PRODUCT, BY SECTION

or BY BEND must be selected depending on whether you wish to effectuate

a measurement by product, section or bend respectively.

OLD MEASUREMENT In this mode no new measurements are made.

PAGE 20 2D REFERENCE MANUAL

The old measurements memorized in association

with the product, section or bend are conserved

and used.

This mode is especially useful when working

with a batch of sheets sufficiently homogenous.

In such a case it is sufficient to proceed with a

Page 23

single thickness measurement during the first

bend of the first product and to correct on the

same basis thereafter. This allows to avoid the

inevitable time loss associated with measuring.

This work mode also applies in the case of

working with groups of products, because the old

measurements associated with the last product

executed are recopied on to the following

product.

PP TOLERANCE IN % OF THICKNESS

Page: MACHINE PARAMETERS /

MATERIALS.

This field allows to define a maximum limit to

the "dispersion" of the material when the

thickness correction at the PP is being used.

In cases where the thickness of the measured

sheet is superior or inferior to nn%, the bend will

not be carried out and the system will issue a

message to the operator.

See Corrections (Table).

THICKNESS CORRECTION FACTOR

Page: MACHINE PARAMETERS /

MATERIALS.

This table allows to define a set of corrections

according to the thickness variation when the

thickness correction at PP is being used. The

default value for this factor is 1.00.

If the user notes that for a given material, the

software has a tendency of overcompensating

(i.e. the beam goes too far down when the real

thickness is less than the nominal thickness, or

the beam does not go down far enough when the

real thickness exceeds the nominal thickness) he

enters a value between 0.99 and 0.0 in the

respective angle range.

However, if the software does not compensate

enough, the operator enters a val ue between 1.01

and 99.99.

See Corrections (Table).

I

NDEPENDENT THICKNESS CORRECTION

The principle consists of furnishing or (using one of the methods described

above) the thickness at each extremity of the bend. By means of this data and

knowing the position of the sheet, the DNC will calculate a different

correction for Y1 and Y2. This type of correction is particularly appreciated

for bending sheets with a great bending length and an important variation in

thickness.

For this to function, the machine parameters describing the position of the

rulers, the machine width ,etc. must be programmed, otherwise an error

message will appear.

The independent thickness correction Y1 Y2 can be used in conjunction with

either the thickness measurement at the PP or the thickness measurement at

DEFINITIONS PAGE 21

Y1-Y2

Page 24

the TDC. It will also function with the choice of correction by product,

section or bend..

Thickness measurement at the TDC

Functioning is identical to that described in the Measurement at the TDC

paragraph above, except that the position of the sheet and the thickness at

each extremity must be programmed.

" Select THICKNESS MEASUREMENT AT EXTREMITIES

" Program the position of the sheet in the POSITION SHEET field and

in the chosen column.

" Introduce in the same column the sheet thickness measured at each

extremity of the future bend.

" Leave the field.

" Bend.

Thickness measurement at the PP

Functioning is identical to that described in the Measurement at the PP

paragraph above, except that the position of the sheet must be programmed.

" Select THICKNESS MEASUREMENT AT EXTREMITIES.

" Program the position of the sheet in the POSITION SHEET field and

in the chosen column.

" Proceed as described in the Measuring at the PP paragraph above.

" Continue bending.

C

ORRECTIONS

Page: CORRECTIONS, field: SENSITIVITY BDC.

This field indicates which depth variation is necessary to obtain an angle

variation of 1 (one) degree in the current sequence.

If this value is too small (e.g. < or = 0.05 mm), it is recommended to use a die

with a wider V opening.

UXILIARY FUNCTIONS

A

: S

ENSITIVITY

BDC

The auxiliary functions can be programmed and used for various means by

the manufacturers.

It is thus inappropriate to discuss them here, please ask the manufacturer of

the machine for details of their functions.

PAGE 22 2D REFERENCE MANUAL

Page 25

ACKGAUGE RETRACTION

B

Page: BEND NUMERICAL

In certain situations it is necessary to disengage the back gauge during

bending.

This field is automatically programmed when an automatic search for the

bending range is made. This value can be modified after the simulation by the

operator.

The retraction value is a relative value usually positive. If a negative value is

programmed, this allows to execute a negative “retraction”, that is a

displacement towards the die.

A minimum default retraction can be imposed in the machine parameters.

END

B

A

T THE BOTTOM OF THE DIE

See Bottoming.

F

I

NTERMEDIATE

S

INAL

See Special bends.

See Special bends.

EQUENCE WITHOUT BEND

Page: BEND NUM

It can be useful for the operator to create a sequence which does not realize a

bend, but executes the displacement of an axis or an auxiliary function.

" Insert a supplementary sequence for this operation (see Inserting a

Sequence).

" On BEND NUM page, in the desired sequence, delete the angle and

program a value Y1/Y2 greater than that of the pinch point.

DEFINITIONS PAGE 23

Page 26

END COUNTER

B

When executing the product, the axes and auxiliary functions position

themselves as normally, but when the operator gives a descent command, the

beam will not descend. If the DNC is in automatic mode, the next sequence

will be displayed, the axes position themselves on the new values and the

beam will be waiting for a descent command, as usual.

In the case that the beam should not descend and the operator has directly

programmed the Y1/Y2 values, it is to verify that these values are not greater

than those of the pinch point.

The WELCOME page displays the number of bends c arried out since a given

date. The counter is set to zero in our plant. When the first bend in automatic

or semi-automatic mod e is done, the counter starts running and the date is

automatically written. This data can not be modified on-site.

ENDING FORCE

B

Page: BEND NUM

If the data concerning the length, the thickness, the sigma and the tools are

known, this field is automatically calculated. It indicates the bending force

(tonnage) needed for the bend .

This field can be reprogrammed as you require. However if the value entered

is greater than the tool safety, an error message is generated in the interactive

field. These safety controls are executed when changing the DNC mode (see

Tools).

ENDING ORDER

B

A

UTOMATIC BENDING ORDER

The software can effectuate on demand an automatic search for the bending

order. The result is conditioned by the "simulation criteria" that the operator

can enter depending on his requirements according to the product to be

produced (see Simulation criteria).

Enter the product data (see the manual User guide).

BEND 2D page, BEND 3D page.

" Choose the simulation criteria.

" Position the cursor on the SIMULE field and select WITHOUT

IMPOSED BEND.

PAGE 24 2D REFERENCE MANUAL

Page 27

" Choose SEARCH BENDING ORDER in the action menu.

Depending on the complexity of the product, the software will furnish a

complete solution, a partial solution, or no solution. See hereinafter Unbend

Mode.

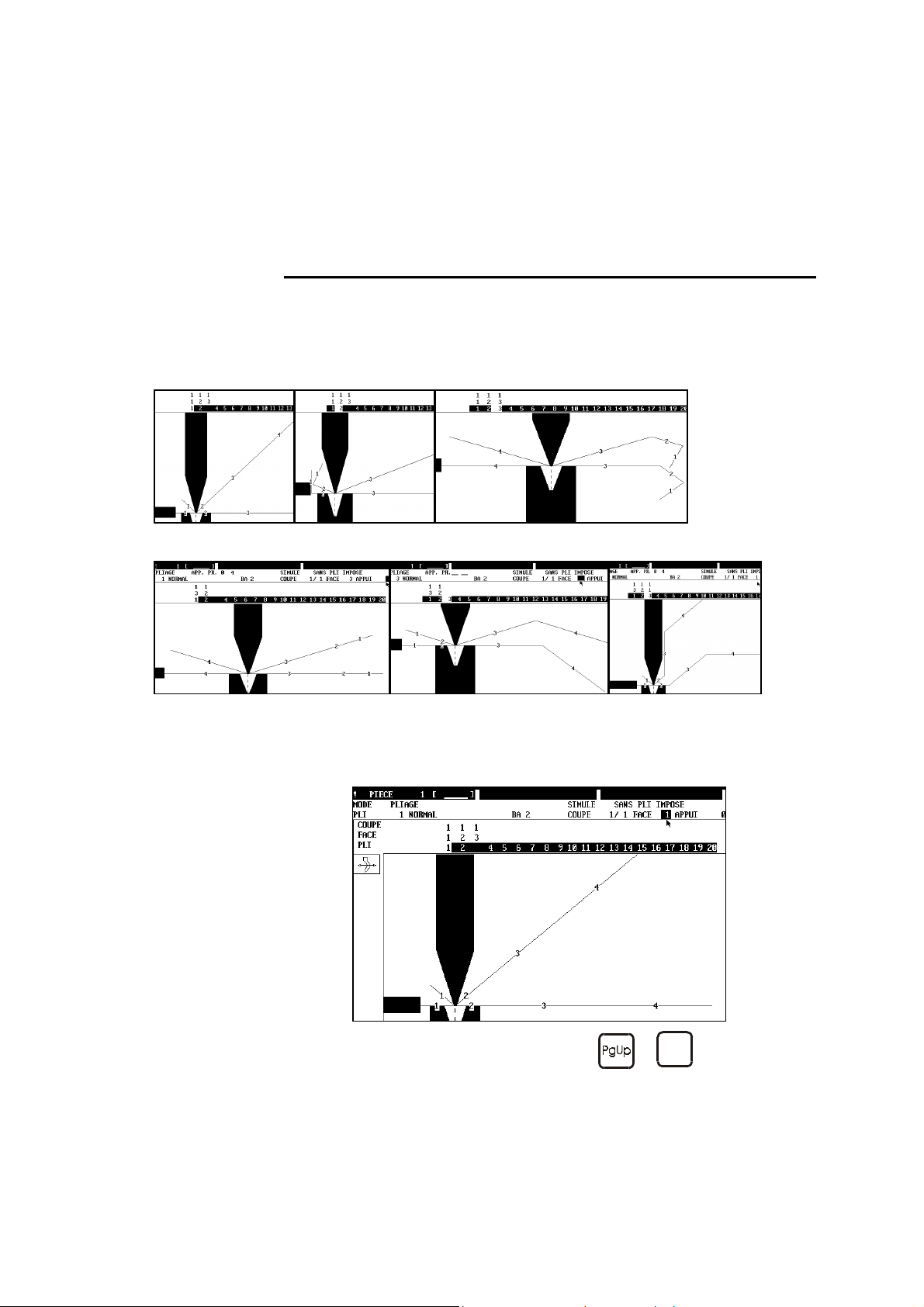

M

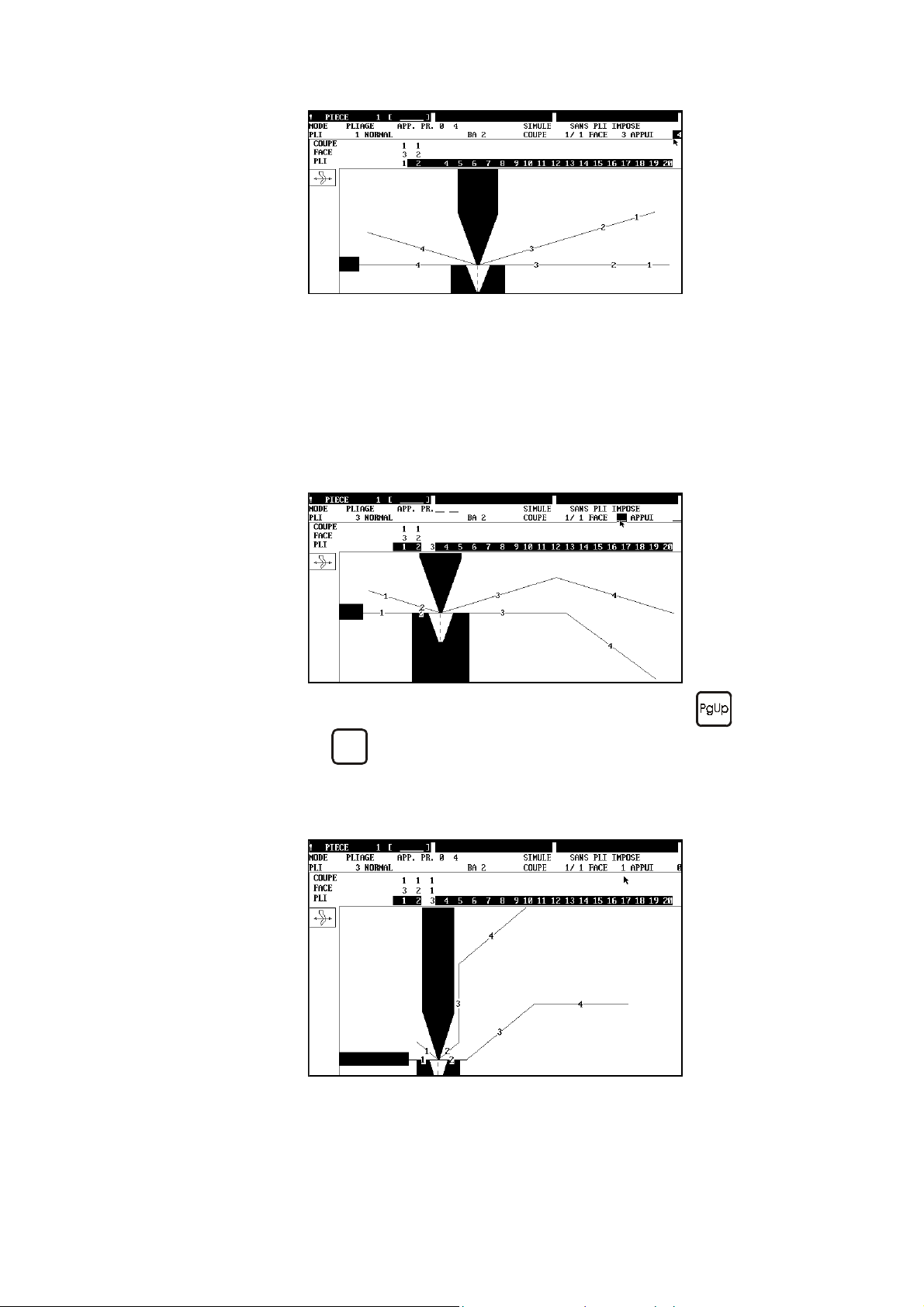

Above: Initial situation.

Requested situation.

ODIFYING THE BENDING ORDER

This operation is preferable done on the BEND 2D page (with a 3D version,

it is possible to realize this operation on the BEND 3D page. See also the

3D Reference manual).

Pg Dn

" Select the sequence to be modified (

or

keys).

DEFINITIONS PAGE 25

Page 28

" Place the cursor on the FACE field and enter the number of the face to

be bent (3).

" Place the cursor on the STOP field and enter the number of the stop

(4). The software proposes the possible stops in the STOP PR field .

" Select SIMULE BEND in the Action menu.

The sequence which bends the chosen face has been deleted.

The next sequence bends the same face (BEND 2).

Change the stop if necessary.

" "Move" to the sequence to be modified (BEND 3 with the

Pg Dn

keys).

or

" Place successively the cursor on the FACE field and enter the number

of the face, then on STOP and enter the stop for this sequence (in this

example FACE 1 and STOP 0).

" Select SIMULE BEND in the Action menu.

Proceed in the same way for other bends or to totally impose a simulation.

If you have mastered the numbering of the faces and stops, it is not necessary

to simulate each bend. After having finished the introduction for sequence

PAGE 26 2D REFERENCE MANUAL

Page 29

simply position the cursor on the SIMULE field, select WITH IMPOSED

BEND and SEARCH BENDING ORDER in the Action menu.

U

NBEND MODE

The unbend mode is useful when the software cannot find a solution for the

bending order.

The unbend mode presents the finished product, the operator determines the

bending order manually in the same way as described above, but by

commencing with the last bend and going towards the first.

Below a simple example in which the product touches the table frame before

the bend, however the sheet is put. The solution for this product is to create

an intermediate bend. This solution is described in Special bends.

This section only shows how to use the unbend function.

st

In the 1

already touches at the 2

figure, the product touches at the last bend, in the 2nd figure it

nd

bend.

DEFINITIONS PAGE 27

Page 30

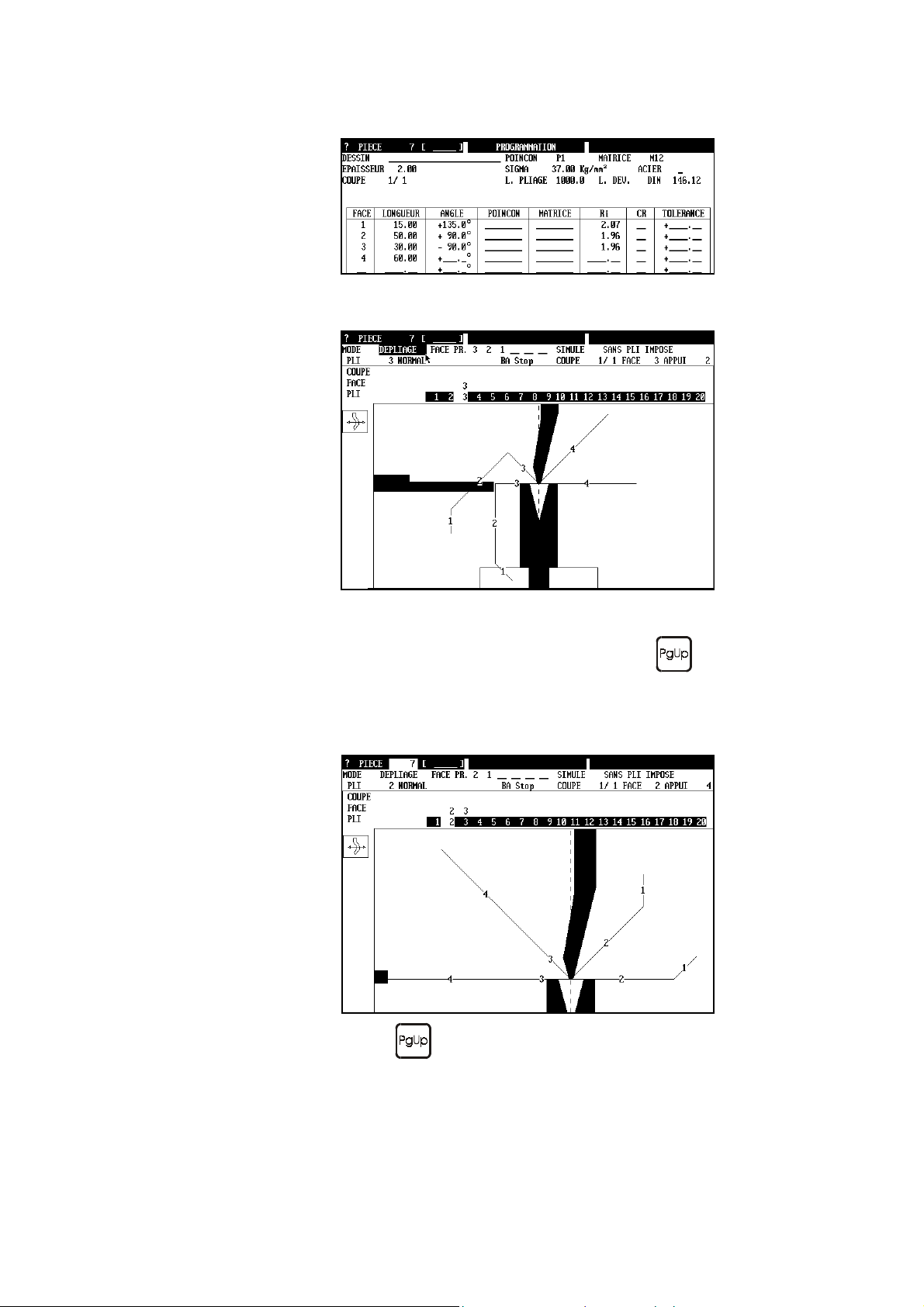

Below are the data of the product (the die height is 50 mm).

In BEND 2D page, when asking to search a bending order, the message

Solution not found is displayed.

" Select UNBEND mode.

The last bend is displayed, you immediately can remark the collision.

If a solution without collision is displayed, press the

if the software furnishes a solution. If no solution is proposed, that

means that there is collision.

Program or change in the FACE field the different faces and see

which possibilities exist.

key and see

" Press the

If the software finds a solution, this will be displayed immediately as

well as the other possible faces (field PR FACE = proposed face).

In unbend mode the proposed faces are displayed in the PR FACE field. So

the operator can introduce one by one the proposed faces in the FACE field,

in order to see the result.

PAGE 28 2D REFERENCE MANUAL

key to move in the previous sequence.

Page 31

ENDING SPEED

B

Page: BEND NUM

This field allows to reduce the bending speed. It is programmable in % of the

maximum bending speed.

BG (B

ACKGAUGE) OR

Pages: BEND NUM, BEND 2D

Displays or allows to select the stop for the current sequence.

The DNC recalculates the target value of the X and R axes as a function of

the choice.

Display the round robin list and choose a stop appropriate for the sequence.

This field will not appear if only one stop is defined in the machine

parameters.

Changing the stop on the BEND 2D page

See also Bending Order.

" Introduce the designation of the required stop or select it in the round

robin list.

STOP

Leg

Support

DEFINITIONS PAGE 29

Page 32

OTTOMING

B

Page: BEND NUM.

The bend by bottoming is a bending mode in which the DNC does not aim for

a predefined or calculated position to be reached, but descends until it reaches

a position which mechanically prohibits the beam from going any further. The

DNC detects this stop; and this determines the end of the descent cycle.

The bend by bottoming allows to obtain special be nds which it is not possible

to obtain in any other manner, such as the flattened bend in a special die, but

this technique involves certain risks.

In bottoming mode the beam furnishes the tonnage

programmed in the sequence or

pressures of the machine parameters are higher than those

of the current sequence.

The DNC stops the beam descent cycle when it realizes that it

is immobilized mechanically on the object to be worked. Which

means that the totality of the programmed force will be exerted

on this object and in consequence on the tools.

You must be aware that the sheet and the tools solicited in this

operation must be capable of supporting such a force without

damage.

Also, i f t he work d o es no t ne ed the whole b end ing l ength o f the

machine, it is absolutely necessary to position everything in the

middle of the machine.

higher

, if the minimum

To execute a bend in bottoming mode:

" erase the programmed angle (empty field),

" then erase the MEM values of Y1 and Y2 (empty fields).

The cycle is effectuated normally but after passing the pinch point, the DNC

monitors the beam displacement.

As soon as the beam has stopped and no longer sends any displacement

information to the DNC, the DNC considers that the operation has ended, the

dwell time is executed and the ascent cycle is activated according to the

chosen mode.

PAGE 30 2D REFERENCE MANUAL

Page 33

ORRECTIONS (TABLE

C

)

During practical work it can sometimes be found that certain angles and/or

flap lengths often or always need to be adjusted by the same value.

In order for the operator to avoid never-ending corrections, a correction table

is available to him. The table is called MATERIAL and can be reached via

the machine parameters.

5 types of material are pre-programmed:

STEEL

ALUMINIUM

SS

SPECIAL 1

SPECIAL 2

For each of these materials, the tables of the MATERIAL are different.

The main items within this page are 3 tables:

UNFOLDED LENGTH By means of 10 columns (0 to 9), it is possible

to apply 10 different corrections to the

DIN 6935 calculation of the unbended length. In

the example shown above, if the chosen material

is STEEL 3, the correction will be:

DIN * 0.850.

The choice of the correction can be entered in

pages such as PROD NUM, BEND NUM, etc.,

in the field immediately following the material

designation.

DEFINITIONS PAGE 31

Page 34

SPRINGBACK COMPENSATION

Allows to define an angle correction for each

type of material, according to the programmed

angle. In the example shown above, the angles

comprised between 76° and 90° and which use

the material named STEEL will be corrected

automatically by -2.5°.

PRESSURE These two factors replace the calculation of the

bending force normally carried out by the DNC.

If they are not programmed, these two values

will be:

AIR BENDING = 1.75

BOTTOMING = 42.0

If necessary, these values can be changed by the

operator. These two values are specific to each

of the 5 material types.

PP TOLERANCE IN % OF THICKNESS

This field represents a safety factor for the tools.

See the section Corrections by Thickness

Measurement / Measuring at the PP.

THICKNESS CORRECTION FACTOR

This table is used by the "thickness correction at

PP" function. See the section Corrections by

Thickness Measurement / Measuring at the PP.

ROWNING

C

ATA BACKUP

D

Page: BEND NUM.

Only valid if your machine is equipped with a crowning option.

The crowning is calculated automatically during simulation. The result is a

function of the applied force and the calibration curve programmed in the

machine parameters.

The operator can modify these values sequence by sequence, however they

will be recalculated during the next simulation.

The working units can vary depending on the const ructor, to know the use of

this function, please consult the manufacturer of your machine.

However, the "per cent" is currently used as unit, that means that 50

programmed in this field will give 50% of the maximum crowning.

See Data Transfer.

PAGE 32 2D REFERENCE MANUAL

Page 35

ATA TRANSFER

D

Page: TRANSFER

From this page data can be saved or loaded in the different peripherals.

(Diskette, Network, etc.)

Source

This field selects the peripheral which will supply the data to the destination

peripheral at the time of the transfer.

Destination

This field selects the peripheral which will receive the data at the time of the

transfer.

Global transfer

The choices are:

PUNCHES

DIES

SELECTED TOOLS

LIST OF

PERIPHERALS

MACHINE

PARA METERS

PRODUCTION

ALL THE PRODUCTS

AND THE GROUPS

Partial transfer

Select the transfer of the products mentioned in the table below.

Transfer of all the punches.

Transfer of all the dies.

Transfer of the tools defined in multisimulation.

Transfer of the list of peripherals.

Transfer of the machine parameters.

Transfer of the production pages.

Global transfer of all the products and groups of

products.

In this table it can be specified for each product the source and the destination

in the respective columns. If these fields are not specified, it is the choice of

SOURCE and DESTINATION at the top of the page which is used by

default.

To simplify the selection of the products to be transferred, simply “mark”

them on the PRODUCT LIST page. They will automatically appear in this

table (see Marking products).

The STATUS column gives the state of the transfer.

DEFINITIONS PAGE 33

Page 36

$

?

!

*

Making a transfer:

Recommendations:

Make a backup of the tools, the machine parameters and the list of peripherals

(if your DNC is on a network) just after the first installation and before the

intervention of a technician. Keep this information in a safe place.

The product is being transferred.

The product has not been transferred.

(Double definition in the list or another error).

An error has been detected during the transfer phase,

it has not been transferred.

The product has been transferred correctly.

" Select the SOURCE and the DESTINATION.

" Position the cursor on the type of transfer chosen.

" Start the transfer using the TRANSFER function in the Action menu,

then confirm.

Save the products periodically on a floppy disk if your DNC is not connected

to a network. Its simple, fast and less expensive than having to reintroduce

everything if any problems arise.

PAGE 34 2D REFERENCE MANUAL

Page 37

ATE AND HOUR

D

Change Date and Hour

Page: WELCOME

" Call the WELCOME page.

" Position the cursor in the upper part of the screen on the Date or Hour

field and enter the new value, thereby respecting the format.

On the DNC, the locking key must be set on position 2. Use the

key as separator.

Year 2000 When the year format uses two digits only, the software assumes that:

00 to 68 = 2000 to 2068

and

82 to 99 = 1982 to 1999.

Change Date and Hour Display Format

Sub-page of the WELCOME page.

To modify the date and the hour of the numerical control:

" Call the WELCOME page and select DATE/TIME in the ACTION

menu.

A new screen appears on which the context of the DNC can be parametered.

(International parametering).

It is possible to load the default parameters by actioning the DEFAULT

function in the ACTION menu.

Classification,

search

DEFINITIONS PAGE 35

To facilitate the classification or the search for programmed products (by

date / hour), it is strongly recommended to put the DNC or the PC to the

correct time regularly (about every 3 months or after an intervention).

Page 38

ECENTERED PUNCHES

D

ORRECTION

C

Page: PUNCH PROGRAMMING

The field, named X CORRECTION allows the user to carry out a correction

if a punch is decentered.

This correction applies to the backgauge a "modification of origin" according

to the decentering of the punch. It also takes into account the mounting

direction of the tool.

The correction becomes effective when the control switches to semi-auto or

automatic mode.

& B

ACKGAUGE

EPTH COLLISION AUTHORIZED

D

Pages: TOOL BEND, PROGRAMMING PUNCH / DIE

The software generates an error message if it detects a collision of the

material at the bottom of the die and / or between the lateral faces of the

punch and the die. This message is displayed in the interactive field. The

software switches to the TOOL BEND page with the cursor pointing to this

field.

By default if nothing is specified, the collision test is made on each bend. On the TOOL BEND page the DEPTH COLLISION AUTHORIZED field is equal to ON THIS BEND NO.

However it is possible to inhibit this safety measure on the TOOL BEND

page for the current product (see below) or by default on the

PROGRAMMING PUNCH or DIE page.

PAGE 36 2D REFERENCE MANUAL

Page 39

TOOL BEND Page

Two choices are available:

ON THIS BEND / YES /

NO

GLOBALLY

Side collision Bottom of the die collision

The collision test is made (or not depending on

the choice YES / NO) only on the current

sequence (bend).

The collision test is ignored for all of the

sequences constituting the product.

RAWING

D

PROGRAMMING PUNCH / DIE Page

If the collision test is generally not desirable, it is possible to arrange for it to

be ignored by default when a product is created.

To create this situation when creating the tool you must program DEPTH

COLLISION AUTHORIZED YES.

For this authorization to be valid (on the TOOL BEND page), the punch and

the die must both have this authorization.

If one or the other of the tools does not give this authorization, then it is NO

which is again valid.

Pages: On most pages.

This field allows to enter an alphanumerical reference 24 characters (see

Alphanumeric Fields).

It is recommended to use this possibility to define a product in a unique

manner when a large number of products are dealt with. This facilitates

searching using product search criteria.

DEFINITIONS PAGE 37

Page 40

WELL TIME

D

Page: BEND NUM

Defines the dwell time.

If not programmed, the default value is 0.5 seconds.

Other values between 0.0 and 9.9 seconds can be entered.

RASE

E

ELETE

/ D

These operations are available in the ACTION menu, they vary according to

the context. Below you will find the definitions of these actions.

ERASE BEND Erases the contents of all the fields, but the

ERASE SECTION Erases the data (bending order) of the selected

ERASE PRODUCT Erases the contents of the work memory.

DELETE BEND Deletes the selected sequence (with automatic

DELE TE SECTION Deletes the selected section.

DELETE PRODUCT Deletes the selected product.

DELETE Depending on which field the cursor is located,

sequence remains.

section.

recompacting of the remaining sequences).

On the PRODUCT LIST page, it is possible to

delete a product by placing the cursor directly

on the required number in the list.

deletes the selected punch, die or product.

PAGE 38 2D REFERENCE MANUAL

Page 41

RASING MEMORIES

E

Page: MACHINE INITIALIZATION - DNC/ENC

General remarks:

This page allows to empty (erase) different memories. Depending on the type

of erasure, it is necessary to have the key in position 1, 2 or 3.

REE MEMORY

F

To delete the contents of one or all the memories:

" Select the peripheral in which the operation is to be made.

" Place the cursor on the relevant field.

" Click right or

" Confirm.

key or Action menu DELETE.

Pages: PRODUCT LIST, WELCOME

Indicates to the operator the quantity of available free memory, given as a %

for the selected peripheral.

DEFINITIONS PAGE 39

Page 42

AUGE CLEARANCE

G

Page: BEND TOOLS

Reminder: the following movements are considered to be dangerous and thus

to require die clearance: displacement of Z, M1 and M2 axes, as well as the

auxiliary function of the DIE type.

In order to offer functionalities adapted to particular needs, the operator now

has the possibility of specifying the type of gauge clearance.

The operator can make his choice for each sequence within the BEND

TOOLS page, on the X CLEARANCE field.

Attention:

The clearance distances (parameter 233) are programmed in the machine

parameters, they must not be changed.

Three types of clearance are available:

MAXIMUM

OUTSIDE CLEARANCE

ZONE

NONE

PM 50

Default value.

In this case, the die clearance is made according

to the higher value of the two parameters

X Position for Safety Speed and

X Position for die clearance.

Normally, the X Posi tion for Safety Speed

is the higher of both values.

Afterwards, the axes move at maximum speed.

Clearance until X Position for die

clearance.

Then the axes move at the speed authorized

within the X Position for die clearance

zone.

This type of clearance should be used when

there are only small distances to be covered.

There is no clearance at all. The axes will move

at safety speed when they are located within the

X Position for Safety Speed zone.

PM 50

PM 50

PM 233

The clearance distance is dependent on the die width. If several posts are mounted,

the distance takes into account the largest of the tools.

PM 50 and PM 233 are the numbers of the concerned machine parameters.

PAGE 40 2D REFERENCE MANUAL

PM 233

PM 233

Page 43

DEAL CURVE

I

Tips If 99 is programmed in the CR field, the software automatically determines

(CR)

Pages: PRODUCT NUMERIC and BEND NUM.

The ideal curve allows to make a bend with a large internal radius.

An ideal curve can be programmed on one or the other of these pages.

An ideal curve is defined by programming from 4 to 98 (programming 0, 2 or

3 will give an error).

Remark: For the result to be coherent, the number of bends to realize the

angle must be such that the length of each segment is greater

than half the length o f t he V opening of the die.

If this is not the case a message informs the operator and the

result will be an angle too open.

the maximum of bends for the ideal curve. Of course the operator can reduce

the number of bends.

In ideal curve mode, the software calculates different bends for the first,

second, next but last and last bend according to the drawing which follows.

Procedure for realizing an ideal curve

PRODUCT NUM Page

" Call the PRODUCT NUM page.

" Introduce the value of the required segment in the L column.

" Introduce the final angle required.

" Introduce the final internal radius in the Ri field.

" Introduce the number of bends for the ideal curve in the CR field.

See also Tolerance.

DEFINITIONS PAGE 41

Page 44

Programming example

" Call the PRODUCT NUM page.

" Introduce the tools and the material in the usual way.

" Introduce the product dimensions with the internal radius of the ideal

curve in the Ri column.

" Introduce 99 in the CR field, the software will calculate the maximum

number of bends for this ideal curve (see fig. above).

" Start the calculation (via Action menu) to obtain the unfolded length,

the tolerance (see Tolerance) and the number of bends for the ideal

curve.

" Call the BEND 2D page.

" Make sure that the SIMULE field is on WITHOUT IMPOSED

BEND.

" Choose SEARCH BENDING ORDER (via the Action menu).

" Then pass in semi-automatic

programming mode).

(on PC key F8 and F10 to return to

" Simulate the bending with the

PAGE 42 2D REFERENCE MANUAL

key.

Page 45

Programming example for a gutter

To realize the above type of product:

" Call the PRODUCT NUM page.

" Introduce the tools and the material in the usual way.

" Introduce the product dimensions with the internal radius of the ideal

curve.

" Introduce 99 in the CR field, the software will calculate the maximum

number of bends for this ideal curve (see fig. above).

" Start the calculation to obtain the unfolded length, the tolerance and

the number of bends for the ideal curve.

" Call the BEND 2D page.

In the actual state of the software, the automatic simulation of this example

product will not give a result.

The UNBEND mode must be used to impose semi-automatically the order of

bends. In the example below, the bending order has not been modified. The

operator is free to do so during this procedure.

DEFINITIONS PAGE 43

Page 46

" Select UNBEND mode

The product is displayed in the tools with the last programmed bend.

" Introduce the face which must be bent last (3 in this example)

When leaving the FACE field, the software displays the chosen bend.

" Place the cursor on the STOP field and modify the stop if necessary.

For this product the stop 4 proposed automatically has been

conserved.

In spite of the "collision" visible in this situation, there will not be any

collision due to the ideal curve (see further on under simulation in

semi-automatic mode).

" Press the

The software displays the previous bend (another bend can be selected

by programming in the face field the one required). The proposed stop

(5) is conserved but can also be modified.

PAGE 44 2D REFERENCE MANUAL

key.

Page 47

" Repeat the operation above until you have reached bend No 1.

" Change to semi-automatic mode

" Visualize the result step by step by pressing the

bend made. (On PC, to return to programming mode press F10).

Remark: In this example, the stop is equipped with an R axis. The

software thus calculates its position automatically as a function

of the ideal curve. If your DNC is not equipped with an R axis,

a vertical stop can be fixed perpendicular to the original stop.

(on PC press F8).

Pg Dn

key for each

NDEXING AXES

I

Page: MACHINE INITIALIZATION DNC / ENC, Action menu.

The INDEX AXES function allows to index or index the axes once again (if

already done).

If the DNC has not been indexed, this function will have the same effect as if

the Start button

If the DNC is already indexed, this function allows to re-index the axes

without switching the power off. In this case the DNC will ask the operator to

confirm this operation. Make sure that the beam is located underneath the

indexes !

DEFINITIONS PAGE 45

had been pressed in order to index the DNC.

Page 48

NSERTING A SEQUENCE

I

BEND NUM page

To insert a sequence:

" Position the cursor in the BEND field, then take position on the

sequence you wish to insert (for example 2) using the

key.

" Select INSERT BEND (Action menu).

The inserted sequence will take place 2 in our example and displace the

sequence 2 to position 3. An inserted sequence is empty.

If you wish to insert a sequence and copy its contents, you must proceed in

the same way, but you must choose COPY A BEND (Action menu).

BEND 2D page

This possibility is used, for example, for effectuating special work (Punching,

modelling, etc.) which cannot be represented graphically.

On the BEND 2D page, if a sequence is inserted, the graphic of the previous

sequence is always displayed.

This sequence will NOT be represented graphically.

A sequence inserted in this way is empty. You must go to the BEND NUM

page to modify the inserted sequence.

or

To insert a sequence:

" Position the cursor in the BEND field, then take position on the

sequence you wish to insert (for example 2) using the

key.

" Select INSERT BEND (Action menu).

The inserted sequence will take place 2 in our example and displace the

sequence 2 to position 3. An inserted sequence is empty.

PAGE 46 2D REFERENCE MANUAL

or

Page 49

NTERNAL RADIUS

I

Pages: PRODUCT NUM, BEND NUM

The internal radius is calculated automatically as a function of the sheet metal

thickness and the tools. This calculated radius is only valid for air bends.

If the radius of the punch is greater than the natural internal radius of the

sheet, it is that of the punch which takes precedence.

It is possible to impose the radius in order to adapt the calculation of the

unfolded length and the calculation of the stop positions at best for a

particular material. To do this:

Ri

" Program the radius in the relevant field.

" Program the CR field at 1.

DEFINITIONS PAGE 47

Page 50

EYBOARD

K

External keyboard for the DNC

In case of necessity, it is possible to connect a 100% PC AT compatible

external keyboard to the rear of the numerical control..

Attention: The DNC must be disconnected from the power supply to

connect the keyboard, otherwise correct functioning may be

impeded.

When an external keyboard is connected to the DNC, the front panel of the

numerical control remains permanently active.

L. B

ENDING

Pages: PRODUCT NUM, BEND NUM

Bending length, sometimes called "bending width", means the distance

between the two extremities of a bend.

If the product is programmed on the PRODUCT NUM or BEND NUM

page, the bending length must be entered by the operator.

This value is indispensable for the software to be able to automatically

calculate the pressure, the crowning and or the axis separation (Z1 and Z2) of

the machine.

With the 3D software version and if the programming is realized in 3D, this

value is treated automatically by the software.

PAGE 48 2D REFERENCE MANUAL

Page 51

ANGUAGE

L

Pages: WELCOME or MACHINE PARAMETERS

The software gener ally possesses a choice of sever al languages.

The composition o f the s e languages varies depending on the manufacturers

request.

To switch languages:

" Call the WELCOME page.

" Key on position 2.

" Place the cursor on the LANGUAGE field.

" Press the

the available languages.

" Place the cursor on the language required.

" Validate the selection using the

EAVING THE SOFTWARE

L

To switch off he machine proceed as follows:

" For safety reasons:

Lower the machine beam in to the tools or on to the blocks of wood or

metal.

" Stop the main motor.

" Press the MENU

" Validate with the

" In the new window select TERMINATE.

key or click right to display the round robin list with

key.

key and select QUIT.

key.

" Validate with the

" Wait until the screen of the DNC becomes black and gives the

message EXECUTION TERMINATED. Under Windows, the DNC

will automatically leave Windows and give a message when the system

is ready to switch off the supply.

" Switch off the mains supply to the DNC or the machine.

DEFINITIONS PAGE 49

key.

Page 52

On a PC proceed in the same way or:

L

EG

" Press simultaneously the

" Click on TERMINATE.

and keys.

Page: BEND 2D

Allows to select a different leg than the one displayed for the current

sequence. See also Bending Order and BG (Backgauge) or STOP.

" Select the required bend using the

and key.

Leg on the 0 face

" Place the cursor in the LEG field.

" Introduce the N° of the face which must be resting on the back gauge

(3 in this example).

" Press the

key to validate the modification.

Modified leg

PAGE 50 2D REFERENCE MANUAL

Page 53

ENGTH

L

Page: PRODUCT NUMERICAL

This field expresses the length of a segment (see examples in the User

Manual) and indicates that you are in L-alpha mode. That is a length is

entered, then the corresponding angle, the following length, the angle, etc.

Sometimes the drawing which is used as a basis for the realization of the product does not allow to program easily in the L-alpha method. You can switch to the LU / LW cotation method using the LENGTH round robin list and thus program in coordinates.

LW

LU

LW

This is a facility which unfortunately is not standardized. The results can thus

vary slightly dependi ng on the case.

OW SPEED DISTANCE

L

Page: BEND NUM

Allows to define that only a portion (expressed in %) of the upward

movement between the lower dead center and the clamping point will be

carried out in low speed, the remainder of the upward movement being done

in high speed.

If BENDING SPEED ! has been programmed and LOW SPEED

DISTANCE ! is not programmed, the upward movement up to the clamping

point is carried out in low speed. (= 100%).

LU

!

!

!!

ACHINE PARAMETERS

M

Pages: MACHINE PARAMETER

These pages contain the parameters necessary for the functioning of your

machine. It is very important to have a backup copy on diskette (see Data

Transfer). If any problems occur, you will save a lot of time if you have to reintroduce them.

Under no circumstanc es should the machine param eters be modified

without the consent and the support of the machine manufacturer.

Erroneous programming can cause important damage to the material

or render the machine dangerous.

DEFINITIONS PAGE 51

Page 54

AINTENANCE

M

Maintenance of the numerical control is restricted to the changing of the

filters and the cleaning of their housing at regular intervals.

Change of filters

It is important to regularly (once per month) change the filters of the fans of

the numerical control. If this maintenance is neglected, the numerical control

might build up exaggerated heat and cause damage which can sometimes be

irreversible.

" Interrupt the main power supply.

" Remove the 4 screws of the protection grid.

" Change the filter.

" Install the protection grid again.

Cleaning of the DNC

Interrupt the main power supply.

Clean the keyboard, the casing and the rear panel with a humid cloth and

some liquid soap.

Dry with a clean and dry cloth.

Never use alcohol-based products nor solvents (trichlorethylene,

thinner, acetone or the like).

ANUAL ADJUSTMENT OF THE BACKGAUGE

M

In many cases, the backgauges are not equipped with Z axes enabling lateral

displacement of the gauge fingers. In other cases, the operator must change

the gauge configuration by hand or add some accessories. To do this, he had

to either intervene from behind the machine, or else stretch his arms across

the machine below the beam.

In order to facilitate this task and to provide increased safety, it is now

possible to program specific positions for the X and R axes and/or auxiliary

functions in GAUGE manage ment mode.

The purpose of this is to place the backgauge forwards above the die

(provided that the machine allows for this possibility), so as to enable the

operator to carry out his task easily and without danger staying in front of the

machine.

PAGE 52 2D REFERENCE MANUAL

Page 55

Ideally, the machine manufacturer would conceive a mechanical or

electric/pneumatic system that unlocks the gauge fingers within this

adjustment position, and locks them again once the gauge is leaving this

location.

The gauge positions for this operation can be programmed in the machine

parameters page called SPECIAL CYCLES.

" The beam must be located in its max. TDC.

When the numerical control is in semi-automatic or automatic mode,

the operator activates this special cycle from the BEND NUM page by

means of the ADJ.GAUGE function (ACTION menu) .

" The operator will then have to confirm each step of this cycle by

clicking inside the appropriate dialogue window.

" At the end of the cycle, the gauge returns to its original location.

ODIFYING THE ORIGIN OF THE AXES

M

Page: MACHINE INITIALIZATION DNC/ENC

General remarks:

This page allows to modify the origin of the axes of the machine, to consult

the position of the axes (POSITION field), the index (INDEX field) and the

limit switches (LIMIT+ and LIMIT- fields).

The second part dealing with erasing the memories is dealt with in the

Erasing Memories section.

It is understood by "modification of the origin" (also called "setting an axis")

to impose a value (at the moment of the operation) in the electronic position