Page 1

IMPORTANT NOTE: The information contained in this document supersedes all previously published

information regarding this product. Product specifications are subject to change without prior notice.

MBT-4000

Multi-Band Transceiver System

Installation and Operation Manual

Part Number MN/MBT4000.IOM Revision 4

Page 2

Page 3

MBT-4000

Multi-Band Transceiver System

Installation and Operation Manual

Part Number MN/MBT4000.IOM

Revision 4

July 2, 2009

Copyright © 2009 Comtech EF Data. All rights reserved. Printed in the USA.

Comtech EF Data, 2114 West 7th Street, Tempe, Arizona 85281 USA, 480.333.2200, FAX: 480.333.2161

Page 4

This page is intentionally blank.

ii

Page 5

Errata A for MN/MBT4000.IOM Rev 4

)

Comtech EF Data Documentation Update

Subject:

Chapter 4, p. 4-2, Update Table 4-2, C-band frequency

Errata Part Number: ER-MNMBT4000.EA4 (Errata docum ents are not subject to revision.

PL M CO Number:

Comments:

C-0024197

See attached page(s). The new information will be included in the next released

revision of the m anual.

ER-MNMBT4000.EA 4 PLM C-0024197

Page 6

MBT-4000 Multi-Band Transceiver System Revision 4

y

System Operating Parameters MN/MBT4000.IOM

4.4 Block Down Converter Module (BDC-4000) Operating Parameters

The BDC-4000 translates a band-specific input frequency block (C-, X-, or Ku- or Ka-Band)

from the LNA down to L-Band (950 to 2000 MHz).

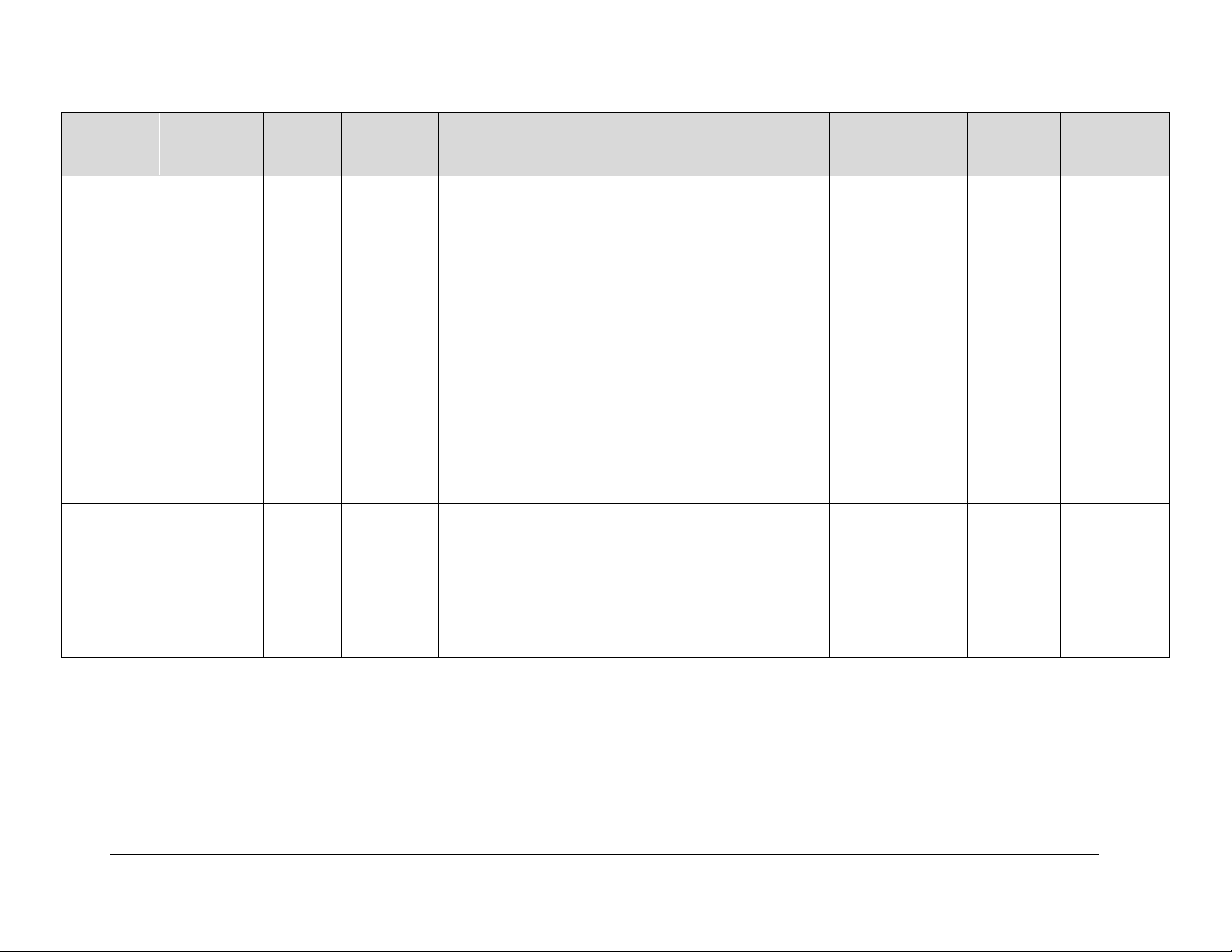

Table 4-2. BDC-4000 C-, X-, KU-, and Ka-Ba nd Ope rating Pa r ameters

Band Frequency LO Frequenc

C-Band 3625 – 4200 MHz 2300 MHz No

X-Band 7250 – 7750 MHz 6300 MHz No

Ku-Band-W

(Single module

containing three LOs)

Ka-Band 20.20 – 21.20 GHz

Notes:

1. No spectral inversion, selectable inversion for inverted Bl oc k Down Converter.

2. 10 dB gain adjustment.

10.95 – 11.70 GHz

11.7 – 12.20 GHz

12.250 – 12.75 GHz

10.00 GHz

10.75 GHz

11.30 GHz

4.5 Monitoring Operations via the LED Indicators

The MBT-4000 Multi-Band Transceiver System features two Light-Emitting Diode (LED)

indicators – one for each operational unit (module). Each LED provides the user with visual cues

to th e operati onal, onli n e, and of fline status of th e s ytem.

Figure 4-1 illustrates the location of the LED Indicators. Located on the top of the MBT-4000’s

Base Module under a pivoting protective plate, the LEDs may be viewed by loosening the

thumbscrew that keeps the plate in place; the user can then swing the plate away to reveal the

LED display window.

Inverting

No

Appendix B. FAUL T S/EVENT S provides complete details for interpreting the LED Indicators.

Figure 4-1. MBT-4000 Multi-Band RF Transceiver LED Indicators

4–2

Page 7

Table of Contents

TABLE OF CONTENTS .............................................................................................................. III

TABLES ...................................................................................................................................... VI

FIGURES .................................................................................................................................... VI

PREFACE .................................................................................................................................. VII

About this Manual

New in this Release ................................................................................................................................. vii

Reporting Comments or Suggestions Concerning this Manual .............................................................. vii

Conventions and References ................................................................................................................... viii

Cautions and Warnings .......................................................................................................................... viii

Recommended Standard Designations ................................................................................................... viii

Trademarks ............................................................................................................................................ viii

Metric Conversion ................................................................................................................................. viii

Electromagnetic Compatibility (EMC) Compliance ............................................................................... ix

EN 55022 –1998 Compliance .................................................................................................................. ix

EN 55082-1 – 1997 Compliance .............................................................................................................. ix

Federal Communications Commission (FCC) ......................................................................................... ix

Safety Compliance ...................................................................................................................................... x

EN 60950 – 1997 Compliance .................................................................................................................. x

Low Voltage Directive (LVD) .................................................................................................................. x

Warranty Policy ......................................................................................................................................... xi

Limitations of Warranty ........................................................................................................................... xi

Exclusive Remedies ................................................................................................................................ xii

Customer Support .................................................................................................................................... xiii

Online Customer Support ...................................................................................................................... xiii

.................................................................................................................................... vii

CHAPTER 1. INTRODUCTION ............................................................................................. 1–1

1.1 Overview ...................................................................................................................................... 1–1

1.2 Functional Description ............................................................................................................... 1–1

1.3 Common Features ....................................................................................................................... 1–2

1.4 Options ......................................................................................................................................... 1–2

iii

Page 8

MBT-4000 Multi-Band Transceiver System Revision 4

Table of Contents MN/MBT4000.IOM

1.5 System Overview ......................................................................................................................... 1–3

1.6 Summary of Specifications ......................................................................................................... 1–4

1.6.1 Environmental & Physical .................................................................................................... 1–4

1.6.2 BUC-4000 Block Up Converter ODU .................................................................................. 1–4

1.6.3 BDC-4000 Block Down Converter ODU ............................................................................. 1–5

1.7 Dimensional Envelope ................................................................................................................ 1–6

CHAPTER 2. INSTALLATION .............................................................................................. 2–1

2.1 Unpacking and Inspection .......................................................................................................... 2–1

2.2 Installation ................................................................................................................................... 2–2

2.3 Operation ..................................................................................................................................... 2–2

CHAPTER 3. EXTERNAL CONNECTORS ........................................................................... 3–1

3.1 External Connectors Overview .................................................................................................. 3–1

3.2 MBT-4000 External Connectors ................................................................................................ 3–2

3.2.1 IF Signal Side Connectors ..................................................................................................... 3–3

3.2.1.1 POWER (J1) ..................................................................................................................... 3–3

3.2.1.2 COMM (J2) ....................................................................................................................... 3–3

3.2.1.3 UNIT 1 COMM (J3) ......................................................................................................... 3–4

3.2.1.4 IF Switch (J4) .................................................................................................................... 3–5

3.2.1.5 Ext Ref (External Reference) (J5) .................................................................................... 3–5

3.2.1.6 UNIT 2 COMM (J6) ......................................................................................................... 3–6

3.2.1.7 Ground Connector ............................................................................................................. 3–7

3.2.1.8 IF IN (J4, BUC-4000 ONLY)

........................................................................................... 3–7

3.2.1.9 COMM (J6, BUC-/BDC-4000) ......................................................................................... 3–7

3.2.1.10 IF OUT (J4, BDC-4000 ONLY) ................................................................................... 3–8

3.2.2 RF Signal Side Connectors ................................................................................................... 3–8

3.2.2.1 REDUNDANT LOOP (J7) ............................................................................................... 3–8

3.2.2.2 AUX COMM 2 (J8) .......................................................................................................... 3–9

3.2.2.3 AUX COMM 1 (J9) .......................................................................................................... 3–9

3.2.2.4 RF SWITCH (J10) .......................................................................................................... 3–10

3.2.2.5 RF OUT (J5, BUC-4000 ONLY) .................................................................................... 3–10

3.2.2.6 RF IN (J5, BDC-4000 ONLY) ........................................................................................ 3–10

CHAPTER 4. SYSTEM OPERATING PARAMETERS .......................................................... 4–1

4.1 Overview ...................................................................................................................................... 4–1

4.2 Remote Configuration, Monitoring and Control ..................................................................... 4–1

4.3 Block Up Converter Module (BUC-4000) Operating Parameters .......................................... 4–1

iv

Page 9

MBT-4000 Multi-Band Transceiver System Revision 4

Table of Contents MN/MBT4000.IOM

4.4 Block Down Converter Module (BDC-4000) Operating Parameters ..................................... 4–2

4.5 Monitoring Operations via the LED Indicators ....................................................................... 4–2

CHAPTER 5. FLASH UPGRADING ...................................................................................... 5–1

5.1 Overview ...................................................................................................................................... 5–1

5.2 Flash Upgrading via Internet ..................................................................................................... 5–1

5.2.1 Firmware File Transfer Procedure ........................................................................................ 5–2

5.3 Flash Upgrade Procedure ........................................................................................................... 5–3

APPENDIX A. REMOTE CONTROL .................................................................................... A–1

A.1 Overview ..................................................................................................................................... A–1

A.2 RS-485 ......................................................................................................................................... A–1

A.3 RS-232 ......................................................................................................................................... A–2

A.4 Basic Protocol ............................................................................................................................. A–2

A.5 Packet Structure ......................................................................................................................... A–2

A.5.1 Start of Packet ...................................................................................................................... A–3

A.5.2 Target Address ..................................................................................................................... A–3

A.5.3 Address Delimiter ................................................................................................................ A–3

A.5.4 Instruction Code ................................................................................................................... A–3

A.5.5 Instruction Code Qualifier ................................................................................................... A–4

A.5.6 Optional Message Arguments .............................................................................................. A–5

A.5.7 End of Packet ....................................................................................................................... A–5

A.6 Remote Commands and Queries .............................................................................................. A–6

APPENDIX B. FAULTS/EVENTS .........................................................................................

B–1

B.1 LED Status Indicators ............................................................................................................... B–1

B.2 Faults/Events .............................................................................................................................. B–2

B.2.1 Summary Faults ................................................................................................................... B–2

B.2.2 Configurable Summary Faults ............................................................................................. B–3

B.2.3 Informational Events ............................................................................................................ B–4

APPENDIX C. REDUNDANCY CONFIGURATION / OPERATION ..................................... C–1

C.1 Overview ..................................................................................................................................... C–1

C.2 Single-Base Redundancy Operation ......................................................................................... C–1

v

Page 10

MBT-4000 Multi-Band Transceiver System Revision 4

Table of Contents MN/MBT4000.IOM

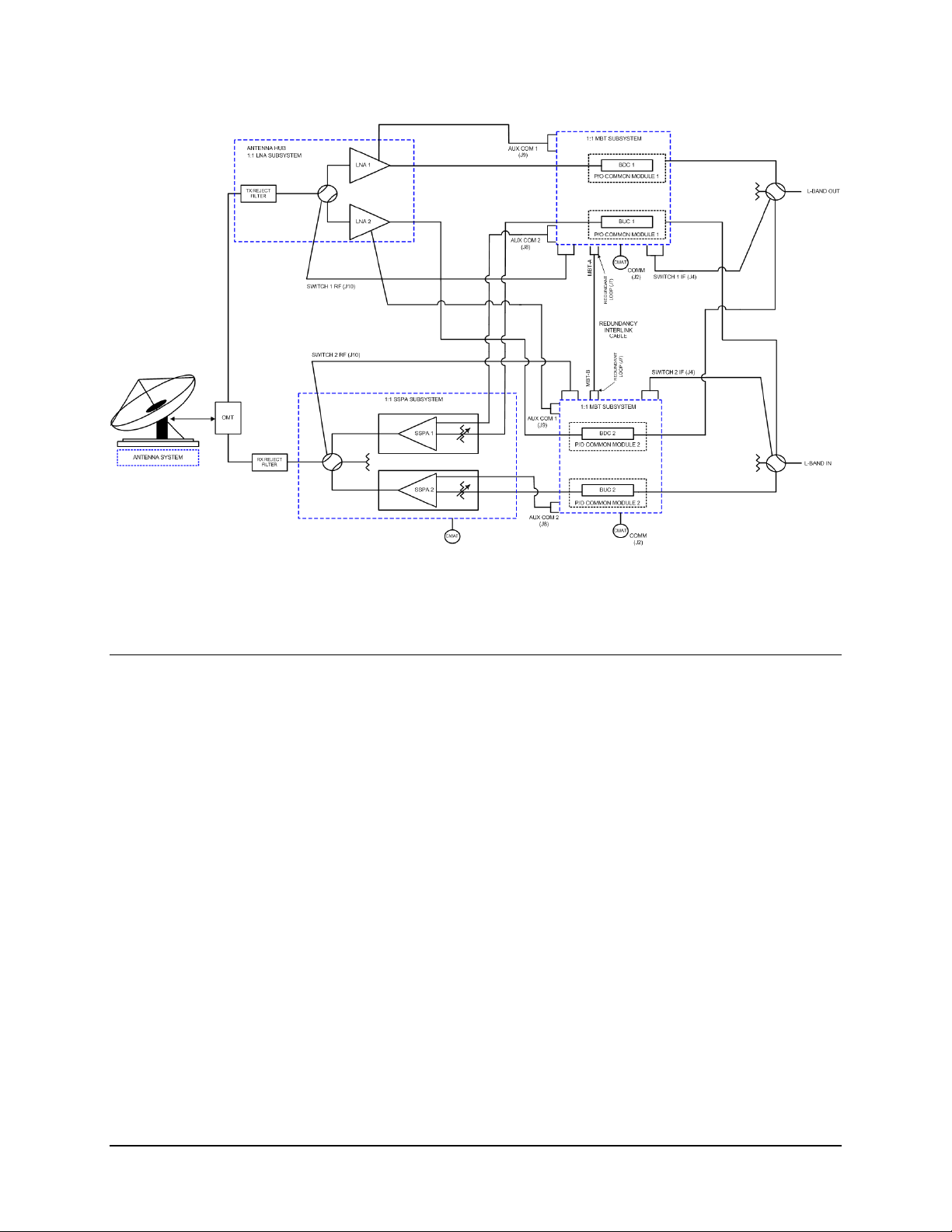

C.3 Dual-Base (Chain) Redundancy Operation ............................................................................. C–2

C.4 External Fault Monitoring ........................................................................................................ C–3

C.5 LNA Power Supply Current Monitoring ................................................................................. C–3

C.6 Gain Equalization of Redundant Units .................................................................................... C–4

C.7 Operational Configuration Commands ................................................................................... C–4

Tables

Table 3-1. MBT-4000 External Connectors ............................................................................................ 3–2

Table 3-2. POWER (J1) Pin Connections ................................................................................................. 3–3

Table 3-3. COMM (J2) Connector Pinouts ............................................................................................... 3–3

Table 3-4. UNIT 1 COMM (J3) Connector Pinouts ................................................................................. 3–4

Table 3-5. IF Switch (J4) Connector Pinouts ............................................................................................ 3–5

Table 3-6. UNIT 2 COMM (J6) Connector Pinouts ................................................................................. 3–6

Table 3-7. UNIT 2 COMM (J6) Connector Pinouts ................................................................................. 3–7

Table 3-8. REDUNDANT LOOP (J7) Connector Pinouts ....................................................................... 3–8

Table 3-9. AUX COMM 2 (J8) Connector Pinouts .................................................................................. 3–9

Table 3-10. AUX COMM 1 (J9) Connector Pinouts ................................................................................ 3–9

Table 3-11. RF Switch (J10) Connector Pinouts .................................................................................... 3–10

Table 4-1. BUC-4000 C-, X-, Ku-, and Ka-Band Operating Parameters ................................................. 4–1

Table 4-2. BDC-4000 C-, X-, KU-, and Ka-Band Operating Parameters ................................................. 4–2

Table B-1. MBT-4000 Summary Faults .................................................................................................. B–2

Table B-2. BDC-4000/BUC-4000 Summary Faults ................................................................................ B–2

Table B-3. MBT-4000 Configurable Summary Faults ............................................................................ B–3

Table B-4. BDC-4000 Configurable Summary Faults ............................................................................. B–4

Table B-5. MBT-4000 Informational Events ........................................................................................... B–4

Table B-6. BDC-4000/BUC-4000 Informational Events ......................................................................... B–4

Figures

Figure 1 -1. Comtech EF Da ta MBT-4000 Mult i- B a n d R F T r ansceiver ..................................................... 1–1

Figure 1-2. MBT-4000 Operational Schematic ........................................................................................ 1–2

Figure 1-3. Operational Diagram for Dual-Base (Chain) Redundancy Option ........................................ 1–3

Figure 1-4. MBT-4000 Dimensional Envelope ........................................................................................ 1–6

Figure 3-1. MBT-4000 External Connectors ............................................................................................ 3–1

Figure 3-2. Unit 1 Base Module to Converter Module Connection .......................................................... 3–4

Figure 3-3. Unit 2 Base Module to Converter Module Connection .......................................................... 3–6

Figure 4-1. MBT-4000 Multi-Band RF T ransceiver LED Indicators ......................................................... 4–2

Figure 5-1. Flash Update via Internet ....................................................................................................... 5–1

Figure B-1. MBT-4000 LED Indicators .................................................................................................. B–1

Figure B-2. Faulted System Example ...................................................................................................... B–2

Figure C-1. Dual-Base (Chain) Redundancy Operation .......................................................................... C–2

vi

Page 11

About this Manual

This manual provides installation and operation information for the Comtech EF Data MBT-4000

Multi-Band Transceiver System. Thi s is a technical document inten ded for earth station engineers,

technicians, and operators responsible for the operation and maintenance of the MBT-4000.

Comtech EF Data has reviewed this manual thoroughly in order to provide an easy-to-use guide to

your equipment. All statements, techn ical information, and recommendation s in this manual and in

any guides or related documents are believed reliable, but the accuracy and co mpleteness thereof

are not guaranteed or warranted, and they are not intended to be, nor should they be understood to

be, representations or warranties concerning the products described. Further, Comtech EF Data

reserves the right to make changes in th e specifications of the products describe d in this manual at

any time without notice and without obligation to notify any person of such changes.

If you have any questions regarding your equipment or the information in this manual, contact the

Comtech EF Data Customer Support Department.

PREFACE

New in this Release

• This manual (CEFD P/N MN/MBT4000.IOM) has been revised in its entirety to comply with

current Comtech EF Data Technical Publications standards and practices.

• All Errata and/or Addenda content generated since publication of the previous revision

(MN/MBT4000.IOM Rev 3, released June 3, 2005) has been incorporated into this revision.

• The Flash Upgrade procedure outlined in Chapter 5 serves to supersede CEFD Application

Note P/N AN/MBT4000 (released June 22, 2006) in its entirety.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual are appreciated. To

submit comments, please contact the Comtech EF Data Technical Publications Department:

TechnicalPublications@comtechefdata.com

vii

.

Page 12

MBT-4000 Multi-Band Transceiver System Revision 4

Preface MN/MBT4000.IOM

Conventions and References

Cautions and Warnings

IMPORTANT or NOTE indicates information cri tical for proper equipm ent functio n.

IMPORTANT

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other unsafe

CAUTION

practices or risks of property damage.

WARNING indicates a potentially hazardous situation that, if not avoided,

WARNING

could result in death or serious injury.

Recommended Standard Designations

Recommended Standard (RS) Designations have been superseded by the new designation of the

Electronic Industries Association (EIA). References to the old designations are shown only when

depicting actual text displayed on the screen of the unit (RS-232, RS-485, etc.). All other references

in the manual will be shown with the EIA designations.

Trademarks

Other product names mentioned in this manual may be trademarks or registered trademarks of

their respective companies and are hereby acknowledged.

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This information

is provided to assist the operator in cross-referencing non-metric to metric conversions.

viii

Page 13

MBT-4000 Multi-Band Transceiver System Revision 4

Preface MN/MBT4000.IOM

Electromagnetic Compatibility (EMC) Compliance

This is a Class A product. In a domestic environment, it may cause radio interference that

requires the user to take adequate protection measures.

EN 55022 –1998 Compliance

This equipment meets the radio disturbance characteristic specifications for information

technology equipment as defined per EN 55022 1998.

EN 55082-1 – 1997 Compliance

This equipment meets the EMC/generic immunity standard as defined per EN 55082-1 1997.

Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy. If not installed and used

in accordance with the instruction manual, it may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference; in which case, users are required to correct the interference at their own expense.

To ensure compliance, properly shielded cables for DATA I/O shall be used.

More specifically, these cables shall be shielded from end to end, ensuring a

continuous shield.

NOTE

ix

Page 14

MBT-4000 Multi-Band Transceiver System Revision 4

Preface MN/MBT4000.IOM

Safety Compliance

EN 60950 – 1997 Compliance

Applicable testing is routinely performed as a condition of manufacturing on all units to ensure

compliance with safety requirements of the European Union Low Voltage Directive (EN 60950).

This equipment meets the Safety of Information Technology Equipment specification as defined in

EN 60950.

Low Voltage Directive (LVD)

The following information is applicable for EN 60950:

International Symbols:

NOTE

<HAR>

!

Symbol Definition Symbol Definition

~

For additional symbols, refer to Cautions and Warnings listed earlier in this

Preface.

Type of power cord required for use in the European Union.

CAUTION: Double-pole/Neutral Fusing

ACHTUNG: Zweipolige bzw. Neutralleiter-Sicherung

Alternating Current

Fuse

Protective Earth /

Safety Ground

Chassis Ground

x

Page 15

MBT-4000 Multi-Band Transceiver System Revision 4

Preface MN/MBT4000.IOM

Warrant y Policy

Comtech EF Data products are warranted against defects in material and workmanship for a

specific period from the date of shipment, and this period varies by product. In most cases, the

warranty period is two years. During the warranty period, Comtech EF Data will, at its option,

repair or replace products that prove to be defective. Repairs are warranted for the remainder of

the original warranty or a 90 day extended warranty, whichever is longer. Contact Comtech EF

Data for the warranty period specific to the product purchased.

For equipment under warranty, the owner is responsible for freight to Comtech EF Data and all

related customs, taxes, tariffs, insurance, etc. Comtech EF Data is responsible for the freight charges

only for return of the equipment from the factory to the owner. Co mtech EF Data will return the

equipment by the same method (i.e., Air, Express, Surface) as the equipment was sent to Comtech

EF Data.

All equipment returned for warranty repair must have a valid RMA number issued prior to return

and be marked clearly on the return packaging. Comtech EF Data strongly recommends all

equipment be returned in its original packaging.

Comtech EF Data Corporation’s obligations under this warranty are limited to repair or

replacement of failed parts, and the return shipment to the buyer of the repaired or replaced parts.

Limitations of Warranty

The warranty does not apply to any part of a product that has been installed, altered, repaired, or

misused in any way that, in the opinion of Comtech EF Data Corporation, would affect the

reliability or detracts from the performance of any part of the product, or is damaged as the result

of use in a way or with equipment that had not been previously approved by Comtech EF Data

Corporation.

The warranty does not apply to any product or parts thereof where the serial number or the serial

number of any of its parts has been a ltered, defaced, or rem oved.

The warranty does not cover damage or loss incurred in transporta tion of the pr oduct.

The warranty does not cover replacement or repair necessitated by loss or damage from any cause

beyond the control of Comtech EF Data Corporation, such as lightning or other natural and

weather related events or wartime environments.

The warranty does not cover any labor involved in the removal and or reinstallation of warranted

equipment or parts on site, or any labor required to diagnose the necessity for repair or

replacement.

The warranty excludes any responsibility by Comtech EF Data Corporation for incidental or

consequential damages arising from the use of the equipment or products, or for any inability to use

them either separate from or in c ombina tion w ith a ny ot her eq uipm ent or pr oduc ts.

xi

Page 16

MBT-4000 Multi-Band Transceiver System Revision 4

Preface MN/MBT4000.IOM

A fixed charge established for each product will be imposed for all equipment returned for

warranty repair where Comtech EF Data Corporation cannot identify the cause of the reported

failure.

Exclusive Remedies

Comtech EF Data Corporation’s warranty, as stated is in lieu of all other warranties, expressed,

implied, or statutory, including those of merchantability and fitness for a partic ular purpose . The buyer

shall pass on to any purchaser, lessee, or other user of Comtech EF Data Corporation’s products, the

aforementioned warranty, and shall indemnify and hold harmless Comtech EF Data Corporation from

any claims or liability of such purchaser, lessee, or user based upon allegations that the buyer, its

agents, or employees have made additional warranties or representations as to product preference or

use.

The remedies provided herein are the buyer’s sole and exclusive remedies. Comtech EF Data

shall not be liable for any direct, indirect, special, incidental, or consequential damages, whether

based on contract, tort, or any other legal theory.

xii

Page 17

MBT-4000 Multi-Band Transceiver System Revision 4

Preface MN/MBT4000.IOM

Customer Support

Contact the Comtech EF Data Customer Support Department for:

• Product support or training

• Reporting comments or suggestions concerning manuals

• Information on upgrading or returning a product

A Customer Support representative may be reached at:

Comtech EF Data

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

480.333.2200 (Main Comtech EF Data number)

480.333.4357 (Customer Support Desk)

480.333.2161 FAX

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or

replacement:

• Contact the Comtech EF Data Custo mer Support Department. Be prepared to supply the

Customer Support representative with the model number, serial number, and a description

of the problem.

• Request a Return Material Authorization (RMA) number from the Comtech EF Data

Customer Support representative.

• Pack the pro duct in its original shipping carton/packaging to ensure that the product is not

damaged during shipping.

• Ship the product back to Comtech EF Data. (Shipping charges should be prepaid.)

Online Customer Support

An RMA number request can be requested electronically by contacting the Customer Support

Department through the online support page at

• Click on “Service” for detailed instructions on our return procedures.

• Click on the “RMA Request Form” hyperlink, then fill out the form completely before

sending.

• Send e-mail to the Customer Support Department at service@comtechefdata.com.

For information regarding this product’s warranty policy, refer to the Warranty Policy, p. xii.

www.comtechefdata.com/support.asp:

xiii

Page 18

MBT-4000 Multi-Band Transceiver System Revision 4

Preface MN/MBT4000.IOM

Notes:

xiv

Page 19

1.1 Overview

Comtech EF Data’s MBT-4000 Multi-Band RF Transceiver, shown in Figure 1-1, is designed to

perform C-, X-, or Ku-Band RF to L-Band down conversion and L-Band to C-, X-, or Ku- or KaBand RF up conversion.

Chapter 1. INTRODUCTION

Figure 1-1. Comtech EF Data MBT-4000 Multi-Band RF Transceiver

1.2 Functional Description

The MBT-4000 is designed to perform the following functions:

• C-, X-, or Ku-Band RF to L-Band down conversion

• L-Band to C-, X-, or Ku-Band RF up conversion

• RF Band switching in minimal time without requiring tools

• Easy expansion for providing a redundant system or other frequency bands

• Automatic band identification for the Block Up converter (BUC), Block Down Converter

(BDC), and antenna feed (if the feeds provide an identifying connector)

1–1

Page 20

MBT-4000 Multi-Band Transceiver System Revision 4

Introduction MN/MBT4000.IOM

• System status verification via LEDs located behind a removable cover

• Flexible configuration:

2 Ups

2 Downs

1Up / 1 Down

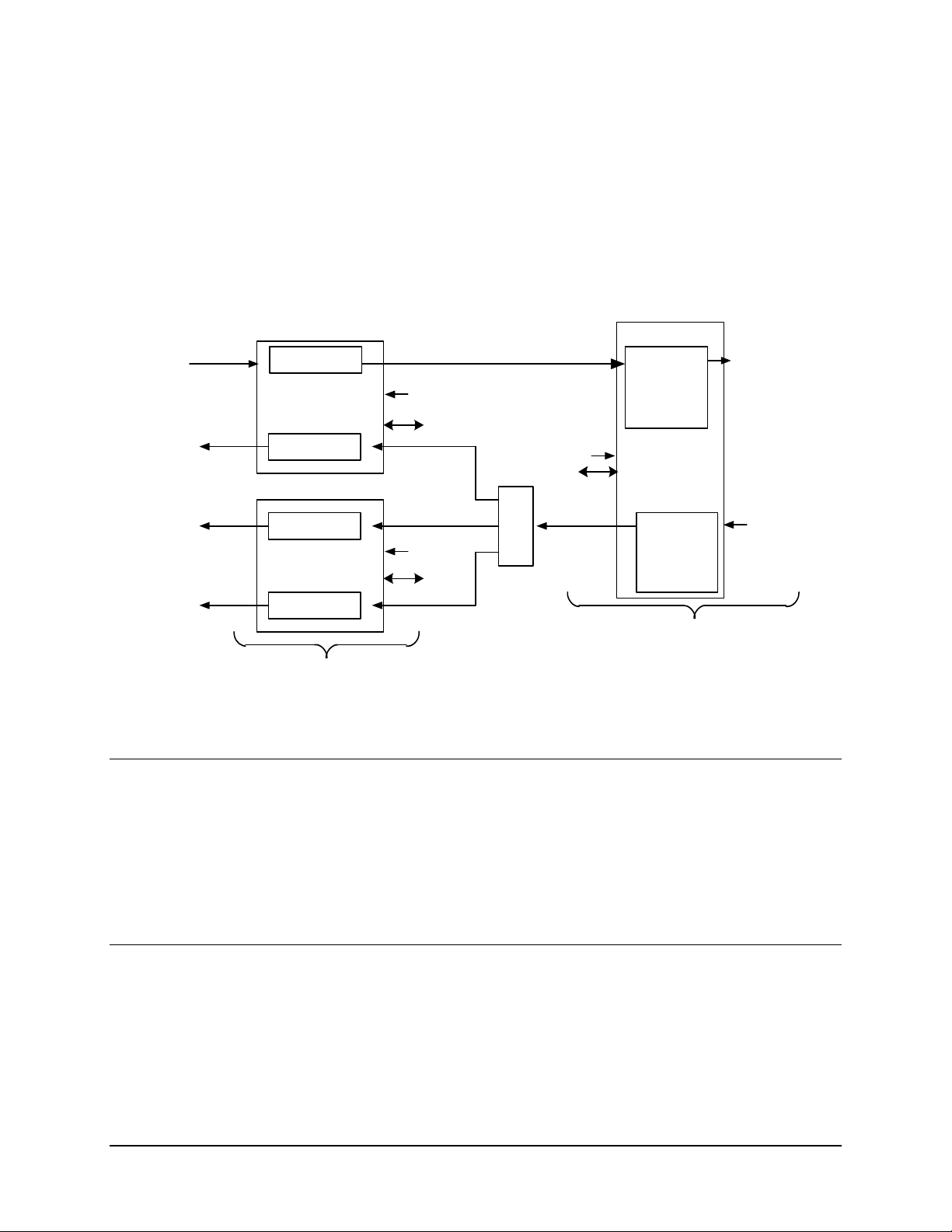

Figure 1-2 d

From

Modem

To

Modem

To

Modem

To

Modem

70 MHz

70 MH z

70 MH z

70 MH z

epicts the operation schematic for a typical MBT-4000 application.

LBC-4000

IF In

IF Out

LBC-4000

IF Out

IF Out

RF Out

RF In

RF In

RF In

IDU

Ref In

M&C

Ref In

M&C

L-Band

5 MHz

L-Band

L-Band

5 MHz

L-Band

RS-485

RS-485

5 MH z

RS-485

L-Band

Splitter

BUC-4000C

IF In

RF Out

Ref In

M&C

BDC-4000C

IF O u t

M ulti-Band Tra nsceiver

RF IN

Figure 1-2. MBT-4000 Operational Schematic

To C-Band HPA

From C-Ban d LNA

1.3 Common Features

• Meets or exceeds MIL-STD-188-164A

• Low phase noise

• Auto band sensing capability

• Functions in 1 MHz step sizes

1.4 Options

• Functions in 1 kHz step sizes

• Dual-Base (Chain) Redundancy Operation (see Figure 1-3)

1–2

Page 21

MBT-4000 Multi-Band Transceiver System Revision 4

Introduction MN/MBT4000.IOM

Figure 1-3. Operational Diagram for Dual-Base (Chain) Redundancy Option

1.5 System Overview

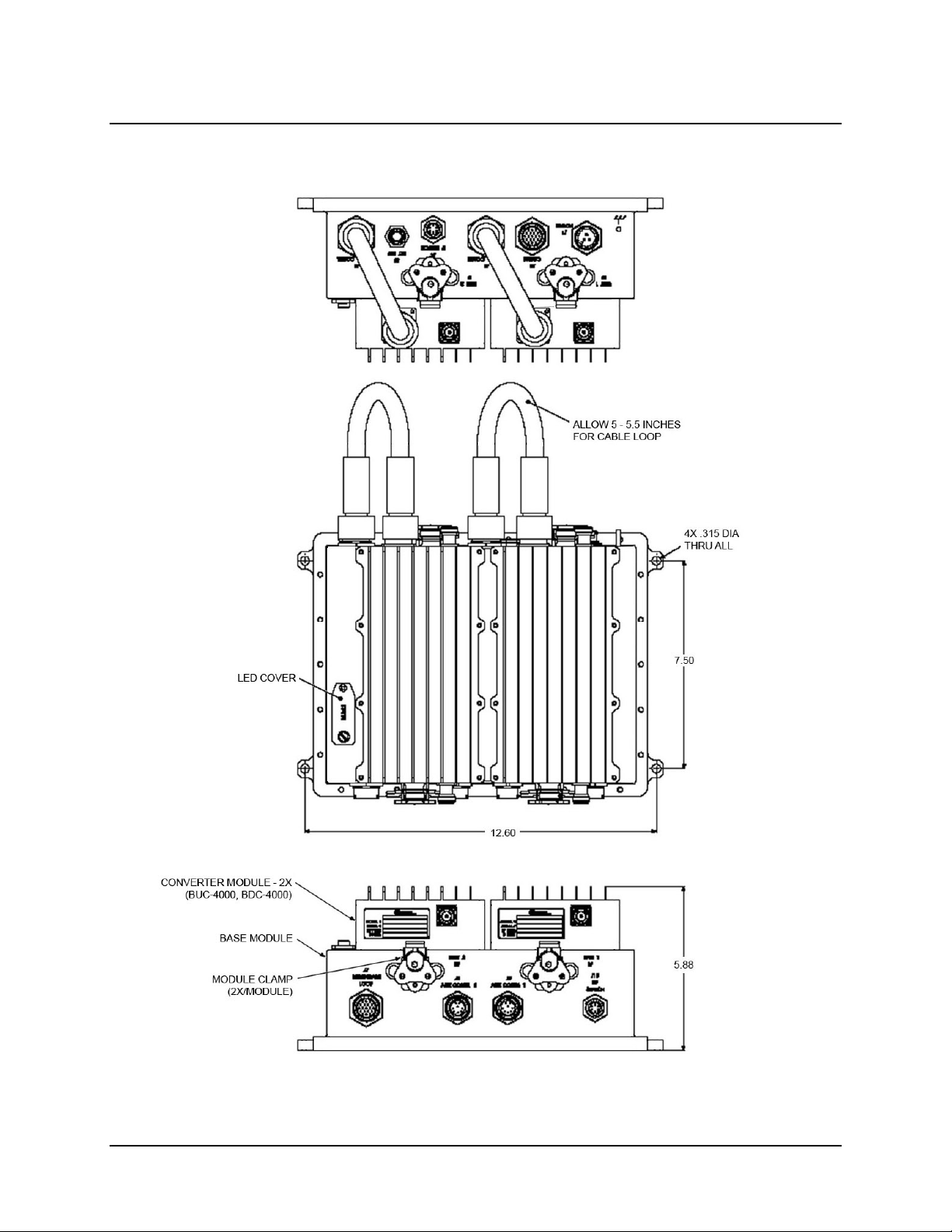

The MBT-4000 Multi-Band Tranceiver System is constructed in a modular configuration. Figure

1-4 illustrates the key components of this configuration.

Common to the configuration for any frequency band of operation is a base module, which

provides the Monitor and Control (M&C), Power Supply, and Reference function.

Band-specific BUC and BDC modules can be mounted to the base module with clip-type

fasteners. BUC and BDC modules for other bands and spares for all modules are stored in a

transit case until needed.

1–3

Page 22

MBT-4000 Multi-Band Transceiver System Revision 4

9

7

Introduction MN/MBT4000.IOM

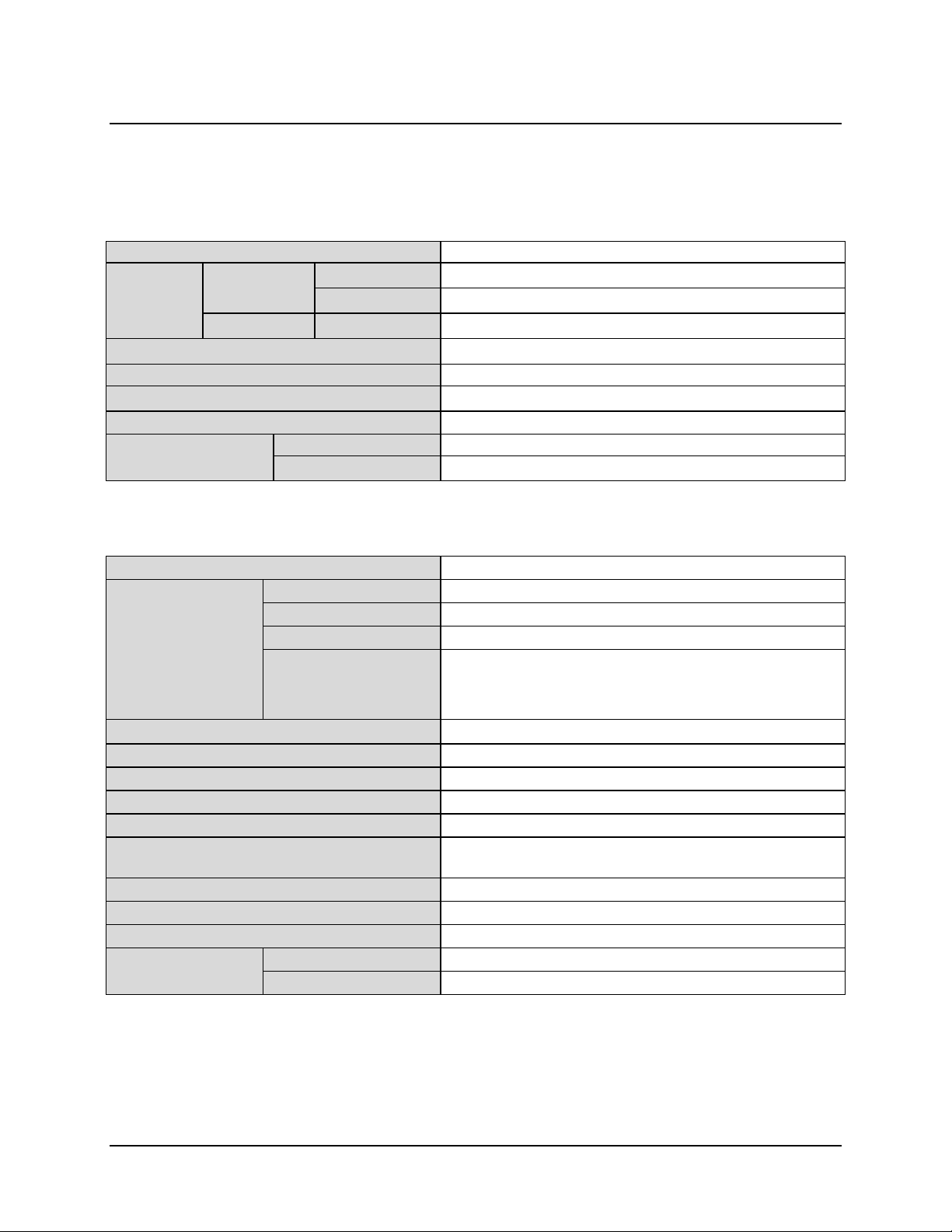

1.6 Summary of Specifications

1.6.1 Environmental & Physical

Dimensions (excluding connectors)

Temperature

Operating

Non-operating ODU: MBT-4000

Operational Humidity

Operational Altitude

Prime Power

External Reference Input

Frequency Stability

ODU: BUC-4000

IDU: LBC-4000

Over time

Over temperature

See Figure 1-4

-40º – 122ºF (-40º to 50ºC)

14º – 122ºF (-10º to 50ºC)

-58º

– 160ºF (-50º to 71ºC)

5 – 95 non-condensing

10,000 ft above sea level

90

– 260 VAC, 47-63 Hz

Either 5 MHz or 10 MHz ±5 dBm optional

-

/day, 1x10

1x10

40º – 55ºC, 1x10-8

1.6.2 BUC-4000 Block Up Converter ODU

Input Frequency Range

Output Frequency

(by model)

Input/Output Impedance

Input Return Loss

Output Return Loss

Input Connector

Output Connector

Gain

User Attenuation Range

Output Power, P1dB

Third Order Intercept

Spurious

BUC-4000C

BUC-4000X

BUC-4000Ku

BUC-4000Ka

Carrier Related

Non-Carrier Related

950 – 2000 MHz

5860 – 6650 MHz

7900 – 8400 MHz

13.75 – 14.50 GHz

30.00 – 31.00 GHz

27.50 – 28.50 GHz (optional)

28.50 – 29.50 GHz (optional)

29.50 – 30.10 GHz (optional)

50Ω

15 dB minimum

18 dB minimum

Type ‘N’ Female

Type ‘N’ Female (C-, X-, and Ku-Band)

15 dB nominal at minimum attenuation

(18 dB for Ku-Band BUC)

0 – 10 dB

+10 dBm minimum

+20 dBm minimum

-60 dBc

-60 dBm

-

/year

1–4

Page 23

MBT-4000 Multi-Band Transceiver System Revision 4

Introduction MN/MBT4000.IOM

1.6.3 BDC-4000 Block Down Converter ODU

Output Frequency Range

BUC-4000C

BUC-4000X

Input Frequency

(by model)

Input/Output Impedance

Input Return Loss

Output Return Loss

Input Connector

Output Connector

Gain

User Attenuation Range

Output Power, P1dB

Third Order Intercept

Spurious (Carrier Related)

Noise Figure

BUC-4000Ku

BUC-4000Ka

950 – 2000 MHz

3400 – 4200 MHz

7250 – 7750 MHz

10.95 – 12.75 GHz

20.20 – 21.20 GHz

17.70 – 18.70 GHz (optional band)

18.70 – 19.20 GHz (optional band)

19.20 – 20.20 GHz (optional band)

50Ω

18 dB minimum

15 dB minimum

Type ‘N’ Female (C-, X-, and Ku-Band)

Type ‘N’ Female

15 dB nominal at minimum attenuation

0 – 10 dB, in 0.25 dB steps (0.1 dB optional)

+12 dBm minimum

+22 dBm minimum

-60 dBc

15 dB maximum @ 0 dB attenuation

1–5

Page 24

MBT-4000 Multi-Band Transceiver System Revision 4

Introduction MN/MBT4000.IOM

1.7 Dimensional Envelope

Figure 1-4. MBT-4000 Dimensional Envelope

1–6

Page 25

Chapter 2. INSTALLATION

2.1 Unpacking and Inspection

Inspect shipping containers for damage. If shipping containers are damaged, keep them until the

contents of the shipment have been carefully inspected and checked for normal operation.

The MBT-5003 L-Band Up/Down Converter System and its Installation and Operation Manual

are packaged and shipped in a pre-formed, reusable cardboard carton containing foam spacing for

maximum shipping protection.

Do not use any cutting tool that will extend more than 1” into the container

CAUTION

Unpack and inspect the MBT-4000 as follows:

Step Procedure

and cause damage to the transceiver.

1

2 Remove the cardboard/foam space covering the MBT-4000.

3 Remove the MBT-4000 and manual from the carton.

4 Save the packing material for storage or reshipment purposes.

5 Inspect the equipment for any possible damage incurred during shipment.

6 Check the equipment against the packing list to ensure the shipment is correct.

7 Refer to the next section (Section 2.2) for installation instructions.

2–1

Cut the tape at the top of the carton indicated by OPEN THIS END.

Page 26

MBT-4000 Multi-Band Transceiver System Revision 4

Installation MN/MBT4000.IOM

2.2 Installation

The Base Module for the MBT-4000

system – which provides the M&C,

Power Supply, and Reference

interfaces – may be located near or

on the antenna. Guide pins and

mechanical clamps keep the bandspecific BUC and BDC modules in

place on top of the Base Module.

Cables to the antenna and IDU complete the installation. For complete information on the

MBT-4000’s connectors, including the pinout tables, refer to Chapter 3. EXTERNAL

CONNECTORS.

To change the band of operation, the cables to the BUC/BDC modules are disconnected and the

modules are unlatched from the Base unit, allowing removal and replacement of the existing

modules with appropriate band-specific modules.

2.3 Operation

Once all pertinent connections have been made between the MBT-4000 and other equipment,

refer to Chapter 4. SYSTEM OPERATING PARAMETERS for further information.

2–2

Page 27

Chapter 3. EXTERNAL

3.1 External Connectors Overview

As shown in Figure 3-1, connectors provided on the MBT4000 Multi-Band Transceiver System

provide all necessary external connections between the the transceiver and other equipment.

Note: This figure depicts an MBT-4000 configuration with (1) BUC-4000 Block Up Converter

Module and (1) BDC-4000 Block Down Converter Module installed.

RF Side

CONNECTORS

(Cable Loops removed for clarity)

IF Side

Figure 3-1. MBT-4000 External Connectors

3–1

Page 28

MBT-4000 Multi-Band Transceiver System Revision 4

External Connectors MN/MBT4000.IOM

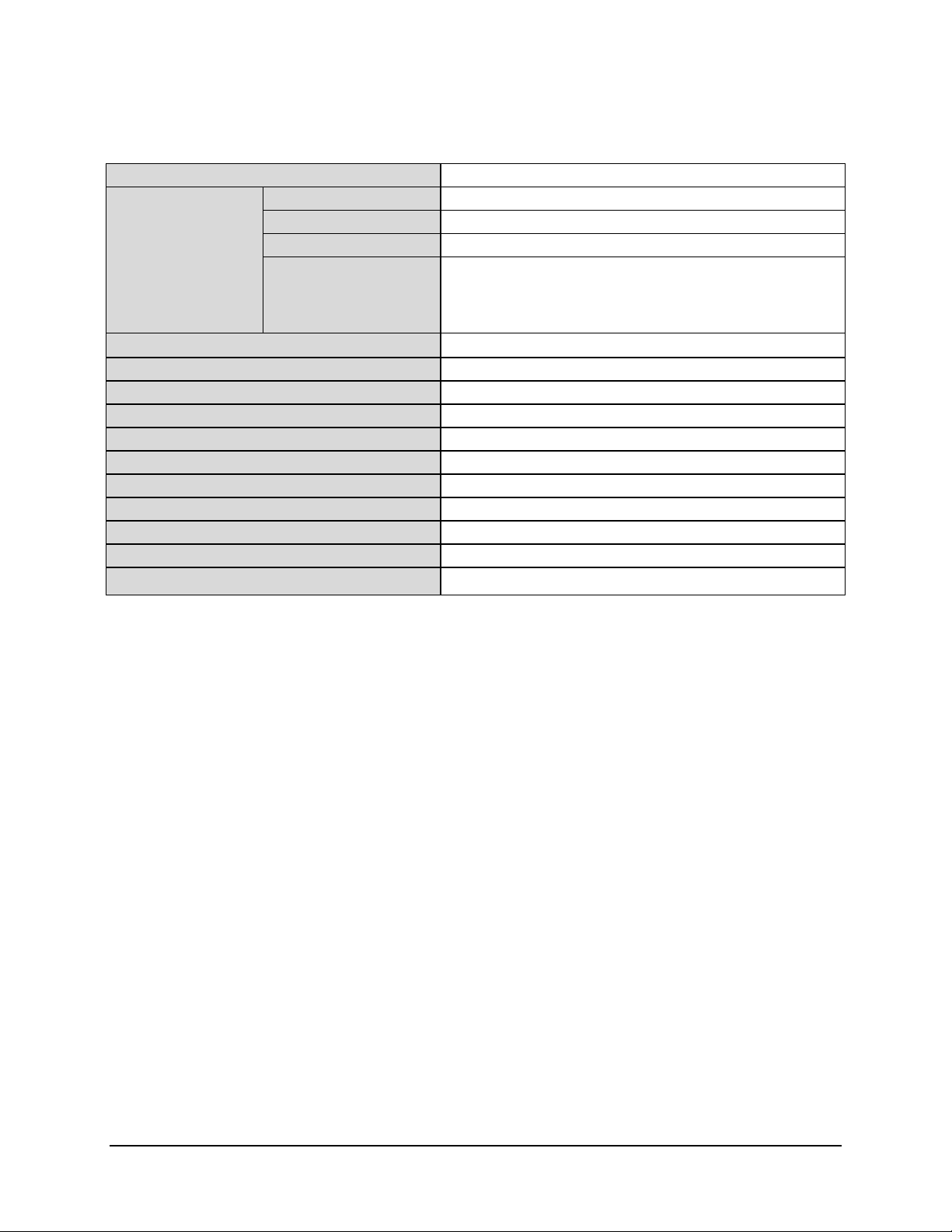

3.2 MBT -4000 External Connectors

Table 3-1 summarizes the external connections and identifies the chapter sections providing

connector pinout information.

Table 3-1. MBT-4000 External Connectors

Signal Side

(Sect.)

IF

(3.2.1)

RF

(3.2.2)

Module

MBT-4000 Base

BUC-4000

BDC-4000

MBT-4000 Base

BUC-4000

BDC-4000

Ref

Des

J1

J2

J3

J4

J5

J6

N/A

J4

J6

J4

J6

J7

J8

J9

J10

J5

J5

Name Sect. Function

POWER 3.2.1.1

COMM 3.2.1.2

UNIT 1 COMM 3.2.1.3

IF SWITCH 3.2.1.4

EXT REF 3.2.1.5

UNIT 2 COMM 3.2.1.6

N/A 3.2.1.7

IF IN 3.2.1.8

COMM 3.2.1.9

IF OUT 3.2.1.10

COMM 3.2.1.9

REDUNDANT

LOOP

AUX COMM 2 3.2.2.2

AUX COMM 1 3.2.2.3

RF SWITCH 3.2.2.4

RF OUT 3.2.2.5

RF IN 3.2.2.6

3.2.2.1

AC Power

Serial communication and Summary

Fault

Communicate to BxC Unit 1

Monitor & Control IF Switch

External 10 MHz Reference Input

Communicate to BxC Unit 2

#10-32 Ground stud

IF Input

Communicate to Base Unit

IF Input

Communicate to Base Unit

Connected for dual base redundant

operation

External Equipment Monitoring

Monitor and Control RF Switch

RF Output

RF Input

3–2

Page 29

MBT-4000 Multi-Band Transceiver System Revision 4

External Connectors MN/MBT4000.IOM

3.2.1 IF Signal Side Connectors

3.2.1.1 POWER (J1)

Table 3-2. POWER (J1) Pin Connections

Pin Signal

A

LINE

3.2.1.2 COMM (J2)

B NEUTRAL

C

GND

NOTE - Mating Connectors:

CEFD P/N CN/MS-STPG03F02

(ITT Cannon KPT06B-12-3S)

Table 3-3. COMM (J2) Connector Pinouts

Pin Signal

A RS 485 Rx+

B RS 485 RxC RS 485 Tx+

D RS 485 TxE RS 232 RD

F NC

G RS 232 TD

H NC

J NC

K SUM FLT COMM

L SUM FLT NO

M SUM FLT NC

N NC

P NC

R NC

S NC

T GND

U GND

V NC

NOTE - Mating Connectors:

CEFD P/N CN/MS3116J14-19P

(Cannon MS3116J14-19P)

3–3

Page 30

MBT-4000 Multi-Band Transceiver System Revision 4

External Connectors MN/MBT4000.IOM

3.2.1.3 UNIT 1 COMM (J3)

The J3 UNIT 1 COMM connector is used for connecting the MBT-4000

Base Module Unit 1 section to the J6 COMM connector featured on both the

BUC-4000 Block Up Converter and BDC-4000 Block Down Converter

Modules via the 15-15 Power & Signal Harness (CEFD P/N

CA/WR10963-1), as shown in Figure 3-2.

Table 3-4. UNIT 1 COMM (J3) Conn

Pin Signal

A SUM FLT

M RxD BXC

C Tx+ BXC

D GND

E +7.5V

F +7.5V

G +15V

H GND

J Rx+ BXC

K Rx- BXC

L Tx- BXC

B TxD BXC

N SPARE

P 10 MHz REF

R SPARE

ector Pinouts

NOTE – Mating Connector:

CEFD P/N CN/8LT5-15B15PN

Figure 3-2. Unit 1 Base Module to Converter Module Connection

3–4

Page 31

MBT-4000 Multi-Band Transceiver System Revision 4

External Connectors MN/MBT4000.IOM

3.2.1.4 IF Switch (J4)

Table 3-5. IF Switch (J4) Connector Pinouts

Pin Signal

A POS 1 IF

B GND

C POS 2 IF

D POS 1 IND IF

E GND

F POS 2 IND IF

NOTE - Mating Connectors:

CEFD P/N CN/MS3116J10-6P

(Cannon MS3116J10-6P)

3.2.1.5 Ext Ref (External Reference) (J5)

The J5 EXT REF connector is a Type ‘N’ female connector, used to provide an External

10MHz Reference Input.

3–5

Page 32

MBT-4000 Multi-Band Transceiver System Revision 4

External Connectors MN/MBT4000.IOM

3.2.1.6 UNIT 2 COMM (J6)

The J6 UNIT 2 COMM connector is used for connecting the MBT-4000

Base Module Unit 2 section to the J6 COMM connector featured on both

the BUC-4000 Block Up Converter and BDC-4000 Block Down Converter

Modules, via the 15-15 Power & Signal Harness (CEFD P/N

CA/WR10963-1), as shown in Figure 3-3.

Table 3-6. UNIT 2 COMM (J6) Connector Pinouts

Pin Signal

A SUM FLT

M RxD BXC

C Tx+ BXC

D GND

E +7.5V

F +7.5V

G +15V

H GND

J Rx+ BXC

K Rx- BXC

L Tx- BXC

B TxD BXC

N SPARE

P 10 MHz REF

R SPARE

NOTE – Mating Connector

CEFD P/N CN/8LT5-15B15PN

Figure 3-3. Unit 2 Base Module to Converter Module Connection

3–6

Page 33

MBT-4000 Multi-Band Transceiver System Revision 4

External Connectors MN/MBT4000.IOM

3.2.1.7 Ground Connector

A #10-32 stud is used for connecting a common chassis ground among equipment.

3.2.1.8 IF IN (J4, BUC-4000 ONLY)

The J4 IF IN connector, lo cated on the BUC-4000 Block Up Converter Module, is

a Type ‘N’ female connector, used to provide the IF Input signal for the

upconverter.

3.2.1.9 COMM (J6, BUC-/BDC-4000)

The J6 COMM connector, featured on both the BUC-4000 Block Up

Converter and BDC-4000 Block Down Converter Modules, is used for

connecting the module to the MBT-4000 Base Module J3 UNIT 1 COMM

or J6 UNIT 2 COMM connectors via the 15-15 Power & Signal Harness

(CEFD P/N CA/WR10963-1), as shown in Figure 3-2 and Figure 3-3.

Table 3-7. UNIT 2 COMM (J6) Connector Pinouts

Pin Signal

A SUM FLT

B TxD BXC

C Tx+ BXC

D GND

E +7.5V

F +7.5V

G +15V

H GND

J Rx+ BXC

K Rx- BXC

L Tx- BXC

M RxD BXC

N SPARE

P 10 MHz REF

R SPARE

NOTE – Mating Connector:

CEFD P/N CN/8LT5-15B15SN

3–7

Page 34

MBT-4000 Multi-Band Transceiver System Revision 4

External Connectors MN/MBT4000.IOM

3.2.1.10 IF OUT (J4, BDC-4000 ONLY)

The J4 IF OUT connector, located on the BDC-4000 Block Down Converter

Module, is a Type ‘N’ female connector, used to provide the downcoverted IF

Output signal.

3.2.2 RF Signal Side Connectors

3.2.2.1 REDUNDANT LOOP (J7)

The J7 REDUNDANT LOOP connector is used to connect the MBT-4000 Base

Module, via the Redundant Loop Bus Cable (CEFD P/N CA/WR11224), to

another base unit for a dual base (redundant) setup.

Table 3-8. REDUNDANT LOOP (J7) Connector Pinouts

Pin Signal

A SW POS 2 DRIVE OUT

B GND

C SW POS 2 DRIVE OUT

D RF SW IND OUT

E IF SW IND OUT

F SW POS 1 DRIVE IN

G SW POS 2 DRIVE IN

H RF SW IND IN

J IF SW IND IN

K MBT A IND

L MBT B IND

M NC

N BXC 1 FLT OUT

P BXC 2 FLT OUT

R BXC 1 FLT IN

S BXC 2 FLT IN

T NC

U TX

V RX

3–8

Page 35

MBT-4000 Multi-Band Transceiver System Revision 4

External Connectors MN/MBT4000.IOM

3.2.2.2 AUX COMM 2 (J8)

Table 3-9. AUX COMM 2 (J8) Connector Pinouts

Pin Signal

A AUX Rx + B

B AUX Rx – B

C AUX Tx + B

D AUX Tx – B

E +12.6V LNA B

F

I02 A/Fault

G

I02 B

H GND

NOTE - Mating Connectors:

CEFD P/N CN/MS3116J12-8P

(Cannon MS3116J12-8P)

3.2.2.3 AUX COMM 1 (J9)

Table 3-10. AUX COMM 1 (J9) Connector Pinouts

Pin Signal

A AUX Rx + A

B AUX Rx – A

C AUX Tx + A

D AUX Tx – A

E +12.6V LNA A

F

IO1 A/Fault

G

IO1 B

H GND

NOTE - Mating Connectors:

CEFD P/N CN/MS3116J12-8P

(Cannon MS3116J12-8P)

3–9

Page 36

MBT-4000 Multi-Band Transceiver System Revision 4

External Connectors MN/MBT4000.IOM

3.2.2.4 RF SWITCH (J10)

Table 3-11. RF Switch (J10) Connector Pinouts

Pin Signal

A POS 1 RF

B GND

C POS 2 RF

D POS 1 IND RF

E GND

F POS 2 IND RF

NOTE – Mating Connectors:

CEFD P/N CN/MS3116J10-6P

(Cannon MS3116J10-6P)

3.2.2.5 RF OUT (J5, BUC-4000 ONLY )

The J5 RF OUT conn ector, located on the BUC-4000 Block Up Converter Module,

is a Type ‘N’ female connector, used to provide the upconverted RF Output.

3.2.2.6 RF IN (J5, BDC-4000 ONLY)

The J5 RF IN connector, located on the BDC-4000 Block Down Converter Module,

is a Type ‘N’ female connector, used to provide RF Input for the downcoverter.

3–10

Page 37

Chapter 4. SYSTEM OPERATING

PARAMETERS

4.1 Overview

An introduction to the Monitoring and Control (M&C) features o f the MBT-4000 Multi-Band RF

Transceiver, as well as the operating parameters for the BUC-4000 Block Up Converter and

BDC-4000 Block Down Converter, are provided in this chapter.

4.2 Remote Configuration, Monitoring and Control

Remote monitoring and control (M&C) of the MBT-4000 is possible via use of a remotelyconnected PC or dumb terminal. From this location, the user may issue commands and queries to

configure, control, and monitor one or more MBT-4000 systems.

Complete information for these features is provided in Appendix A. REMOTE CONTROL.

4.3 Block Up Converter Module (BUC-4000) Operating Parameters

The BUC-4000 translates the MBT-4000 L-Band output carrier to the desired output frequency (C,

X-, or Ku- or Ka-Band) with an output level capable of driving a High-Power Amplifier (HPA).

Table 4-1. BUC-4000 C-, X-, Ku-, and Ka-Band Operating Parameters

Band Frequency LO Frequency Inverting

C-Band 5850 – 6650 MHz 4900 MHz No

X-Band 7900 – 8400 MHz 6950 MHz No

Ku-Band-W 13.75 – 14.50 GHz 12.800 GHz No

Ka-Band 30.00 – 31.00 GHz

Notes:

1. No spectral inversion.

2. 10dB gain adjustment.

4–1

Page 38

MBT-4000 Multi-Band Transceiver System Revision 4

System Operating Parameters MN/MBT4000.IOM

4.4 Block Down Converter Module (BDC-4000) Operating Parameters

The BDC-4000 translates a band-specific input frequency block (C-, X-, or Ku- or Ka-Band)

from the LNA down to L-Band (950 to 2000 MHz).

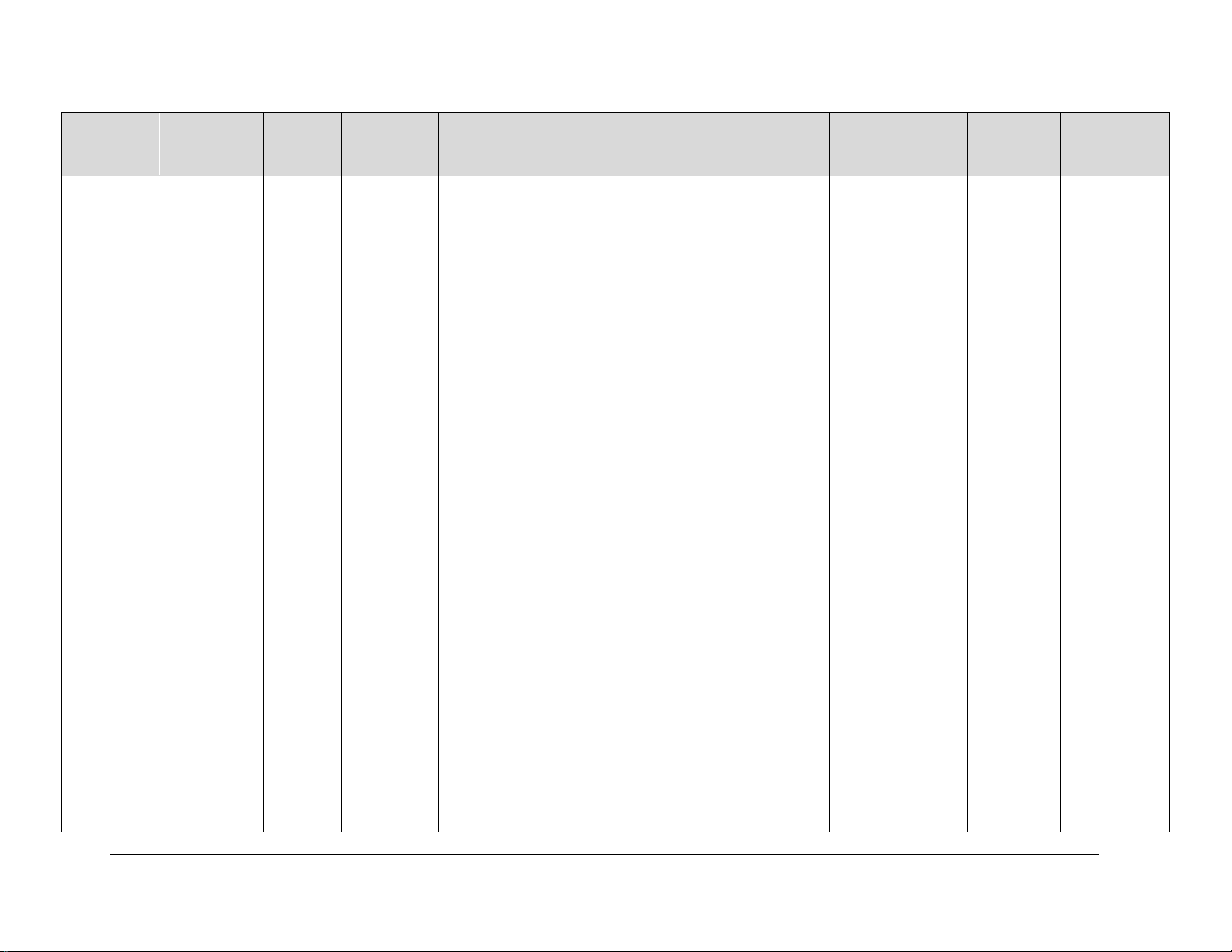

Table 4-2. BDC-4000 C-, X-, KU-, and Ka-Band Operating Parameters

Band Frequency LO Frequency Inverting

C-Band 3400 – 4200 MHz 5150 MHz Yes

X-Band 7250 – 7750 MHz 6300 MHz No

Ku-Band-W

(Single module

containing three LOs)

Ka-Band 20.20 – 21.20 GHz

Notes:

1. No spectral inversion, selectable inversion for inverted Block Down Conve rter.

2. 10 dB gain adjustment.

10.95 – 11.70 GHz

11.7 – 12.20 GHz

12.250 – 12.75 GHz

10.00 GHz

10.75 GHz

11.30 GHz

No

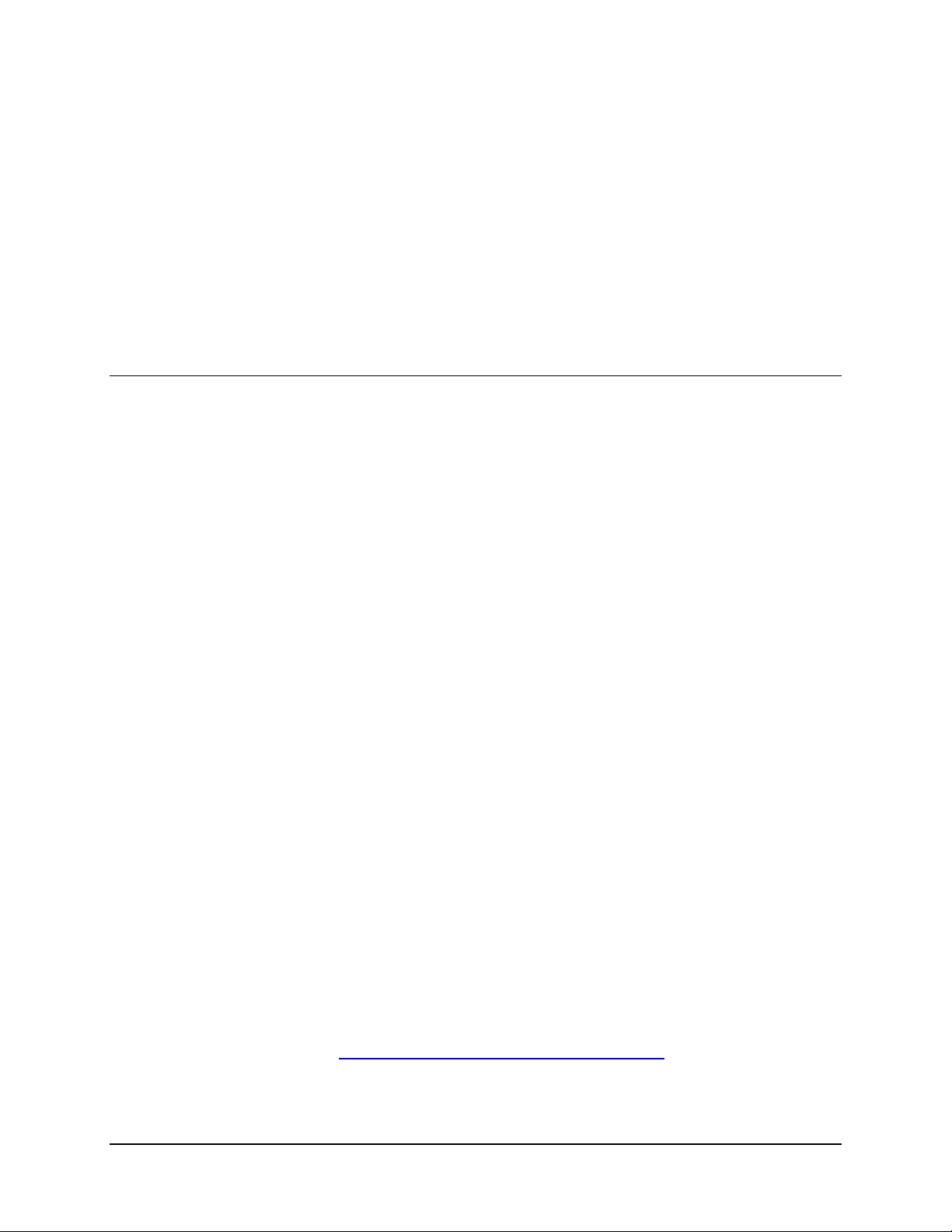

4.5 Monitoring Operations via the LED Indicators

The MBT-4000 Multi-Band Transceiver System features two Light-Emitting Diode (LED)

indicators – one for each operational unit (module). Each LED provides the user with visual cues

to the operational, online, and offline status of the sytem.

Figure 4-1 illustrates the location of the LED Indicators. Located on the top of the MBT-4000’s

Base Module under a pivoting protective plate, the LEDs may be viewed by loosening the

thumbscrew that keeps the plate in place; the user can then swing the plate away to reveal the

LED display window.

Appendix B. FAULTS/EVENTS provides complete details for interpreting the LED Indicators.

Figure 4-1. MBT-4000 Multi-Band RF Transceiver LED Indicators

4–2

Page 39

Chapter 5. FLASH UPGRADING

5.1 Overview

This chapter provides procedural information for upgrading the firmware for the Base Module of

the Comtech EF Data MBT-4000 Multi-Band Transceiver System. This is a technical document

intended for users – i.e., earth station engineers, technicians, and operators – responsible for the

operation and maintenance of the MBT-4000. This chapter also assumes that the user has

familiarity with Microsoft Windows-based operating systems.

5.2 Flash Upgrading via Internet

The MBT-4000 uses internal ‘Flash memory’ technology; this makes firmware upgrading very

simple, and updates can now be sent via the Inte rnet ( Figure 5-1)

This chapter outlines the complete upgrading process as follows:

• New firmware update for upgrading the MBT-4000 Base Unit is transferred to a user-

provided PC intended for Monitor and Control (M&C) of the MBT-4000 system.

, via E-mail, or on CD.

• By simply connecting the MBT-4000 to an available serial port on the user-provided PC, the

upgrade can then be performed without opening the MBT-4000 base unit. (Note: The block

up and down converter modules are factory-serviced items, and are not updated during this

procedure.)

• Once the firmware update is extracted from the transferred archive file, the upgrade

process is executed via use of a utility program, FLSHCSAT.exe.

Figure 5-1. Flash Update via Internet

5–1

Page 40

MBT-4000 Multi-Band Transceiver System Revision 4

Flash Upgrading MN/MBT4000.IOM

5.2.1 Firmware File Transfer Procedure

1. Identify the reflashable product, firmware number, and version for download.

Using serial remote control, the current MBT-4000 firmware revision can be determined with

the following query: <0/ FRW?

2. Create a temporary directory (folder) on the user-provided external PC.

Windows: Select File > New > Folder, then rename the New Folder to "temp" or another

convenient, unused name. Assuming "temp" works, a "c:\temp" folder should now be

created.

Note: The c: is the drive letter used in this example. Any valid writable drive letter can

be used.

CMD Prompt: At the command prompt (c:\>), type "mk dir t emp ” or “MD temp" without

quotes (mkdir and MD stand for make directory). This is the same as creating a new folder

from Windows. There should now be a "c:\temp" subdirectory created (where c: is the

drive letter used in the example).

3. Download the correct firmware file to this temporary folder as shown in Figure 5-1:

1. Go online to:

www.comtechefdata.com

2. Click on: Support tab

3. Click on: Software Downloads drop-down or hyperlink from Support page

4. Click on: Download Flash and Software Update Files icon

5. Click on: (Select a Product Line) Transceivers hyperlink

6. Select the appropriate firmware hyperlink from the roster of displayed MBT-4000

products/components.

The flashable files on the download server are organized by product p refix. Depending on the

product for which it is intended, the file name may designate the firmware number (v erify that

the correct firmware number is known – see Step 1); revision letter, if applicable; version; and

release date. The naming convention for MBT-4000 Base Unit firmware is FW11811*.CCC

(where the asterisk signifies the firmware revision letter).

The current version firmware release is provided. If applicable, one version prior to the

current release is also available. Be sure to identify and download the desired version.

The downloadable files are stored in two formats: *.exe (self-extracting) and *.zip

(compressed). Some firewalls will not allow the downloading of *.exe files. In this case,

download the *.zip file instead.

For additional help with "zipped" file types, refer to PKZIP for Windows, WinZip, or

ZipCentral help files. PKZIP for DOS is not supported due to file naming conventions.

5–2

Page 41

MBT-4000 Multi-Band Transceiver System Revision 4

Flash Upgrading MN/MBT4000.IOM

4. Extract the files to the temporary folder on the PC, then verify the success of the file extraction

and transfer via the dir command. At least four files should be extracted:

• ReleaseNotes_vX-X-X.pdf, where “X-X-X”

denotes the firmware version.

• FW11811x.CCC, where "x" denotes the firmware

revision letter.

• FLSHCSAT.EXE: CEFD Flash Upload Utility

Program.

• CCCflash.hlp: FLSHCSAT Help File.

If these four files as identified are displayed, proceed to the next section to perform the flash

upgrade.

5.3 Flash Upgrade Procedure

Step Procedure

Locate and Identify the

MBT-4000 Multi-Band

Transceiver System.

1

The illustration to the right

serves to identify key

features of a typical

system.

Ensure that the MBT-4000

system is connected to a

user-provided, Windowsbased PC.

2

Note: If needed, the

CA/WR12243-1 System

Programming Cable is

available from Comtech

EF Data. Contact CEFD

Customer Support for

ordering information.

5–3

Page 42

MBT-4000 Multi-Band Transceiver System Revision 4

Flash Upgrading MN/MBT4000.IOM

Double-click FLSHCSAT.EXE

(filename or icon) to execute

3

the flash upload utility.

From the FLSHCSAT

window, select the pertinent

serial port used for

communication between the

user-provided PC and the

4

MBT-4000.

(In this example, as noted at

‘A’, COM1 has been

selected.)

A

Do not select a Baud Rate

(noted at ‘B’) other than the

default selection of 38400,

5

unless otherwise instructed

by Comtech EF Data

Technical Support.

Click on ‘Software Upload’,

6

as noted at ‘C’.

The user is prompted to

select the firmware file to

upload. Click ‘Choose File’,

then select the file from the

temporary folder created

7

earlier by using the box to the

right to navigate to the

desired folder, then doubleclicking on the firmware file

using the box to the left.

Prior to continuing the upload

process, the MBT-4000

system must be powered off.

Disconnect the power cable

8

from the Base Unit, then click

on ‘Start Upload’ to resume

the upload process.

B

C

5–4

Page 43

MBT-4000 Multi-Band Transceiver System Revision 4

Flash Upgrading MN/MBT4000.IOM

When prompted, reconnect

the power cable to the Base

9

Unit.

Once communication has

been established between

the PC and MBT-4000, the

upload will take place – do

not interrupt this upload

process.

10

Note: If the upload is not

successful for any reason –

e.g., the communications

cable is not physically

connected, the wrong COM

port has been specified, the

user inadvertently interrupted

the upload, etc. – the user

may troubleshoot the setup

as needed, then click on

‘Repeat Upload’ or ‘Go

Back to Start’ to

resume/retry the upload

process.

5–5

Page 44

MBT-4000 Multi-Band Transceiver System Revision 4

Flash Upgrading MN/MBT4000.IOM

Upon successful completion

of the upload, the user may

click on ‘Go Back to Start’

(if, for example, more than

one MBT-4000 system

11

requires upgrade), or ‘Close’

(to exit the FLSHCSAT

program).

If needed, disconnect the

System Programming Cable

(CEFD P/N CA/WR12243-1)

12

and reconnect the original

System Communications

Connection Cable.

The LEDs on the MBT-4000

Base Unit will illuminate

GREEN (unmuted) or

YELLOW (muted) to indicate

the current status of the Unit

1 and Unit 2 modules.

13

(Note: If either LED

illuminates RED, refer to

Appendix B. FAULTS/EVENTS

for further information.)

The upgrade process has been successfully completed.

5–6

Page 45

Appendix A. REMOTE CONTROL

A.1 Overview

This appendix describes the protocol and message command set for remote monitor and control

of the MBT-4000 Multi-Band Transceiver System (more specifically, the BUC-4000 and

BDC-4000 modules).

The electrical interface is either an RS-485 multi-drop bus (for the control of many devices) or an

RS-232 connection (for the control of a single device), and data is transmitted in asynchronous

serial form using ASCII characters. Control and status information is transmitted in packets of

variable length, in accordance with the structure and protocol defined in later sections.

A.2 RS-485

For applications where multiple devices are to be monitored and controlled, a full-duplex (or 4wire plus ground) RS-485 is preferred. Half-duplex (2-wire plus ground) RS-485 is possible, but

is not preferred. In full-duplex RS-485 communications, there are two separate, isolated,

independent, differential-mode twisted pairs, each handling serial data in different directions.

It is assumed that a 'Controller' device (a PC or dumb terminal) transmits data in a broadcast

mode via one of the pairs. Many 'Target' devices are connected to this pair, and all simultaneously

receive data from the Controller. The Controller is the only device with a line-driver connected to

this pair – the Target devices have only line-receivers connected.

In the other direction, on the other pair each Target has a tri-stateable line driver connected, and

the Controller has a line-receiver connected. All the line drivers are held in high-impedance mode

until one (and only one) Target transmits back to the Controller. Each Target has a unique

address, and each time the Controller transmits, the address of the intended recipient Target is

included in a framed 'packet' of data. All of the Targets receive the packet, but only one (the

intended) will reply. The Target enables its output line driver and transmits its return data packet

back to the Controller in the other direction, on the physically separate pair.

RS-485 (full duplex) summary:

• Two differential pairs – one pair for Controller-to-Target, one pair for Targe t-to-Con troller.

• Controller-to-Target pair has one line driver (Controller) , and al l Targe ts have line-re ceivers.

• Target-to-Controller pair has one line receiver (Controller), and all Targets have tri-state

drivers.

A–1

Page 46

MBT-4000 Multi-Band Transceiver System Revision 4

Remote Control MN/MBT4000.IOM

A.3 RS-232

This is a much simpler configuration in which the Controller device is connected directly to the

Target via a two-wire-plus-ground connection. Controller-to-Target data is carried, via RS-232

electrical levels, on one conductor, and Target-to-Controller data is carried in the other direction

on the other conductor.

A.4 Basic Protocol

Whether in RS-232 or RS-485 mode, all data is transmitted as asynchronous serial characters,

suitable for transmission and reception by a UART. The asynchronous character is fixed at 8-N-1

(8 data bits, no parity, one stop bit). Only two baud rates are supported: 9600 baud and 19200 baud.

All data is transmitted in framed packets. The Controller is assumed a PC or ASCII dumb

terminal that is in charge of the process of monitor and control. The Controller is the only device

that is permitted to initiate, at will, the transmission of data. Targets are only permitted to transmit

when they have been specifically instructed to do so by the Controller.

All bytes within a packet are printable ASCII characters, less than ASCII code 127. In this

context, the Carriage Return and Line Feed characters are considered printable.

All messages from Controller-to-Target require a response – with one exception: This will be either to

return data that has been requested by the Controller, or to acknowledge reception of an instruction to

change the configuration of the Target. The exception to this is when the Controller broadcasts a

message (such as Set Time/Date) using Address 0, when the Target is set to RS-485 mode.

A.5 Packet Structure

Start of

Packet

<

ASCII code 60

(1 character)

Example: <0412/MUT=1{CR}

Start of

Packet

>

ASCII code 62

(1 character)

Target

Address

(4 or 6

characters)

Target

Address

(4 or 6

characters)

Controller-to-Target

Address

Delimiter

/

ASCII code 47

(1 character)

Address

Delimiter

/

ASCII code 47

(1 character) (3 characters)

Instruction

Code

(3 characters)

Target-to-Controller

Instruction

Code

Code

Qualifier

= or ?

ASCII codes

61 or 63

(1 character)

Code

Qualifier

=, ?, !, or *

ASCII codes

61,63,33 or 42

(1 character)

Optional

Arguments

(n characters)

Optional

Arguments

(From 0 to n

characters)

End of Packet

Carriage Return

ASCII code 13

(1 character)

End of Packet

Carriage Return,

Line Feed

ASCII codes

13,10

(2 characters)

Example: >0412/MUT={CR}{LF}

A–2

Page 47

MBT-4000 Multi-Band Transceiver System Revision 4

Remote Control MN/MBT4000.IOM

A.5.1 Start of Packet

Controller-to-Target: This is the character '<' (ASCII code 60)

Target-to-Controller: This is the character '>' (ASCII code 62)

Because this is used to provide a reliable indication of the start of packet, these two characters

may not appear anywhere else within the body of the message.

A.5.2 Target Address

Up to 9,999 devices can be uniquely addressed. In both RS-232 and RS-485 applications, the

permissible range of values is 1 to 9999. It is programmed into a target unit using the remote

control port.

The BDC and BUC subdevices may also be addressed by appending the corresponding subdevice

address. The subdevice address is ‘A1’ for the BUC and ‘A2’ for the BDC. For example, a mute

command addressed to a BUC attached to an MBT-4000 at address 0412 will be:

<0412A1/MUT=1{CR}

The format of the response will be:

>0412A1/MUT={CR}{LF}

Subdevice addresses cannot be changed.

The Controller sends a packet with the address of a Target - the destination of

the packet. When the Target responds, the address used is the same address, to

IMPORTANT

indicate to the Controller the source of the packet. The Controller does not have

its own address.

A.5.3 Address Delimiter

This is the ‘forward slash’ character '/' (ASCII code 47).

A.5.4 Instruction Code

This is a three-character alphabetic sequence that identifies the subject of the message. Wherever

possible, the instruction codes have been chosen to have some significance. This aids in the

readability of the message if seen in its raw ASCII form. Upper and lower case alphabetic

characters (i.e., A-Z – ASCII codes 65-90, and a-z – ASCII codes 97-122) may be used.

A–3

Page 48

MBT-4000 Multi-Band Transceiver System Revision 4

Remote Control MN/MBT4000.IOM

A.5.5 Instruction Code Qualifier

This single character further qualifies the preceding instruction code. Code Qualifiers obey the

following rules:

1. From Controller-to-Target, the only permitted values are:

=

(ASCII code 61)

?

(ASCII code 63)

The = code is used as the assignment operator, and is used to indicate that the

parameter defined by the preceding byte should be set to the value of the

argument(s) that follow it. For example: MUT=1 would mean 'enable the Mute

function.'

The ? (ASCII code 63) is used as the query operator, and is used to indicate

that the Target should return the current value of the parameter defined by the

preceding byte. For example: MUT? Would mean ‘retur n the curre nt state of the

Mute function.’

2. From Target-to-Controller, the only permitted values are:

=

(ASCII code 61)

?

(ASCII code 63)

!

(ASCII code 33)

*

(ASCII code 42)

#

(ASCII code 35)

The = code is used in two ways:

First, if the Controller has sent a query code to a Target (for example: MUT?

would mean ‘return the current state of the Mute function’), the Target would

then respond with MUT=x, where ‘x’ represents the state in question ( 1 being

‘enabled’, 2 being ‘disabled).

Second, if the Controller sends an instruction to set a parameter to a particular

value, then, providing the value sent in the argument is valid, the Target will

acknowledge the message by replying with MUT= (with no message arguments).

The ? code is only used as follows:

If the Controller sends an instruction to set a parameter to a particular value,

then, if the value sent in the argument is not valid, the Target will acknowledge

the message by replying (for example) with MUT? (with no message

arguments). This indicates that there was an error in the argument of the

message sent by the Controller.

The ! code is only used as follows:

If the Controller sends an instruction code that the T arget does not recognize,

the Target will acknowledge the message by echoing the invalid instruction,

followed by the ! character; for example, XYZ!

The * code is only used as follows:

If the Controller sends an instruction to set a parameter to a particular value,

then, if the value sent in the argument is valid, but the target is in the wrong

mode (e.g., Standby mode in Redundancy configuration) such that it will not

permit that particular parameter to be changed at that time, the Target will

acknowledge the message by replying (for example) with MUT* (with no

message arguments).

The # code is only used as follows:

If the controller sends an instruction code that the target cannot currently perform

because of hardware resource issues, then the target will acknowledge the

message by echoing the invalid instruction, followed by the # character; for

example, MUT# (with no message arguments).

A–4

Page 49

MBT-4000 Multi-Band Transceiver System Revision 4

Remote Control MN/MBT4000.IOM

A.5.6 Optional Message Arguments

Arguments are not required for all messages. Arguments are ASCII codes for the characters 0

to 9 (ASCII codes 48-57), period (ASCII code 46), and comma (ASCII code 44).

A.5.7 End of Packet

Controller-to-Target: This is the 'Carriage Return' character (ASCII code 13).

Target-to-Controller: This is the two-character sequence 'Carriage Return', 'Line Feed' (ASCII

codes 13 and 10).

Both indicate the valid termination of a packet.

A–5

Page 50

MBT-4000 Multi-Band Transceiver System Revision 4

Remote Control MN/MBT4000.IOM

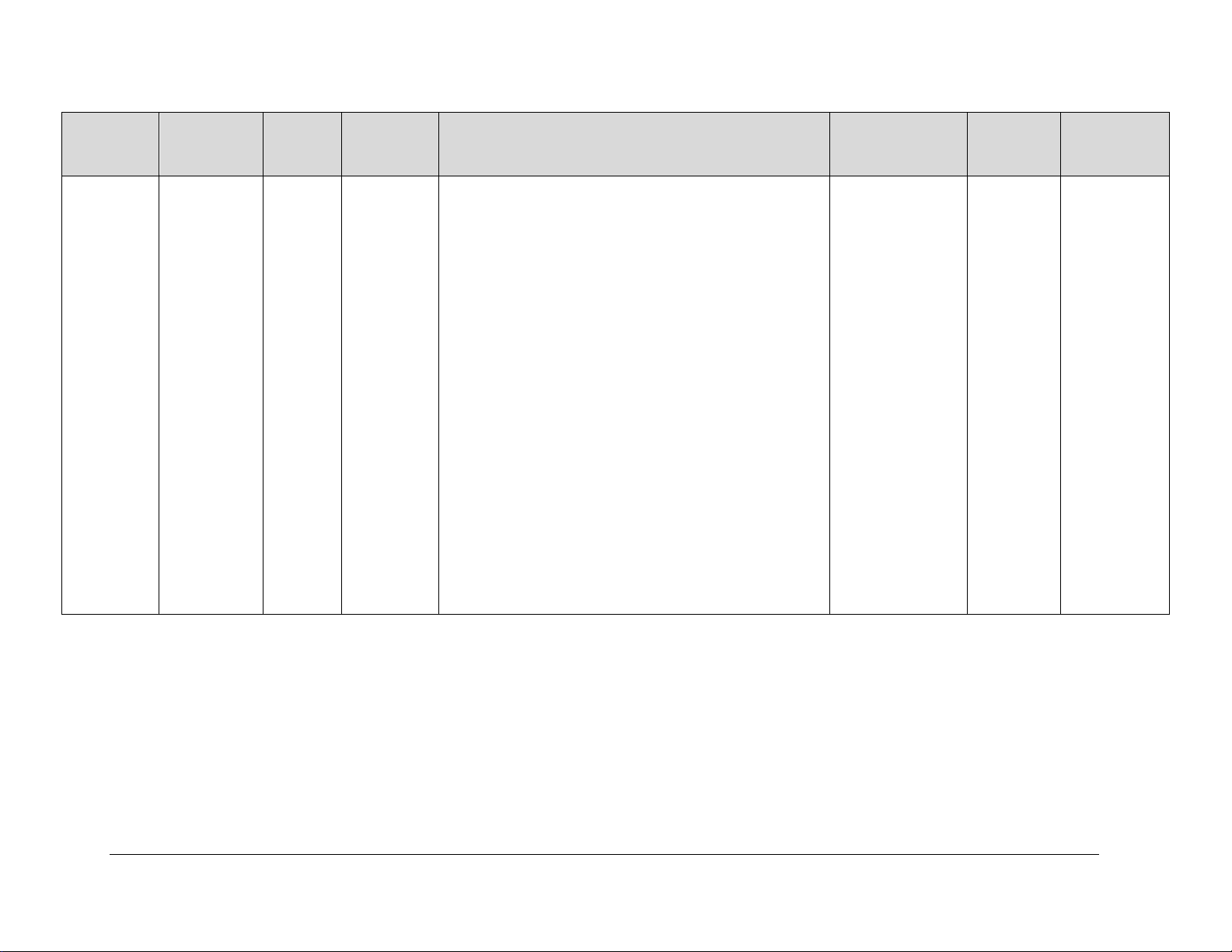

A.6 Remote Commands and Queries

Where Column ‘C’ = Command; Column ‘Q’ = Query: Columns marked (X) indicate Command

only, Query only, or Command/Query for Instruction Code.

Instr Code C Q Page

Instr Code C Q Page

AFR

ATT

CAA

CAI

CAS

CCS

CID

CLC

CMS

CUS

DAT

EAM

FRE

FRW

X X

X X

X

X

X

X

X X

X

X

X

X X

X X

X X

X

A-7 RED

A-7 REF

A-7 RET

A-7 RMS

A-8 RSN

A-9 RUS

A-9 SBR

A-10 SFS X A-21

A-11 SPA

A-12 SSA

A-12 SSW

A-12 TIM

A-12 TNA

A-12 TSC

X X

X X

X

X

X

X

X X

X X

X X

X

X X

X

X

A-18

A-19

A-19

A-20

A-21

A-21

A-21

A-21

A-22

A-22

A-22

A-22

A-23

LCM

LCS

LCW

LFL

LNA

MUT

OFM

ONL

RAI

RAM

RAS

RCS

X

X X

X X

X X

X

X X

X X

X

X

X X

X

X

A-13

A-13

A-13, A-14

A-14

A-15

A-15

A-24

A-15

A-16

A-16

A-17

A-18

A–6

XRF

X X

A-23

Page 51

MBT-4000 Multi-Band Transceiver System Revision 4

V

Remote Control MN/MBT4000.IOM

Parameter

Type

Automatic

Fault

Recovery

State

Attenuation ATT=xx.xx BDC

Clear All

Stored Alarms

Concise AUX

COMM I/O

Command

(Instruction

Code and

qualifier)

AFR=x All 1 byte, value

CAA= All None Command only.

N/A MBT n=Slot

alid on

MBT,

BDC, or

BUC

BUC

Arguments

for Command

or Response

to Query

of 0, 1

5 bytes,

numeric

1=AUX

COMM 1

2=AUX

COMM 2

(Note that all arguments are ASCII numeric codes – i.e.,

Description of Arguments

ASCII codes between 48 and 57)

Command or Query.

Enable Automatic Fault Recovery on a BXC, where:

0=Disabled

1=Enabled

Example: AFR=1

Command or Query.

Valid attenuation level, in dB, at 0.25dB step size as factory

default.

Example: ATT=08.25

Instructs the slave to clear all Stored Events.

This command takes no arguments.

Query only.

Used to Query the Concise AUX COMM I/O of the MBT-4000

base unit, where: n=1 (AUX COMM 1) or 2 (AUX COMM 2)

Example: <0001/CAI?n{cr}

>0001?CAI=nabcd{cr}{lf}

Where:

n=1 or 2 (AUX COMM)

a=12V (0=Off, 1=On)

b=IOA (O=logic low [voltage input < 0.5],

1=logic high [voltage input > 2.7 vdc)

c=IOB (O=logic low [voltage input < 0.5],

1=logic high [voltage input >2.7 vdc]

d=Reserved (Always zero)

Response to

Command

(Target to

Controller)

AFR=(message OK)

AFR? (received OK,

but invalid arguments

found)

AFR*(message OK,

but not permitted in

current mode)

ATT=(message OK)

ATT? (received OK,

but invalid arguments

found)

ATT*(message OK,

but not permitted in

current mode)

ATT! (Command not

accepted by MBT4000 base unit. It

must be addressed

to BUC or BDC subunits)

CAA=(message OK) N/A N/A

CAI=(message OK)

CAI? (received OK,

but invalid arguments

found)

CAI*(message OK,

but not permitted in

current mode)

Query

(Instruction

Code and

qualifier)

AFR? AFR=x

CAI?n CAI=nabcd

Response to

(same format as

(see description

for details of

arguments)

Query

(Target to

Controller)

command

arguments)

A–7

Page 52

MBT-4000 Multi-Band Transceiver System Revision 4

V