Page 1

p

KST-2000L

Satellite Terminal System

Installation and O

eration Manual

Part Number MN/KST2000L.IOM Revision 2

Page 2

Page 3

KST-2000L

Comtech EF Data is an ISO 9001

Registered Company.

Satellite Terminal System

Installation and Operation Manual

Part Number MN/KST2000L.IOM

Revision 2

February 7, 2002

Copyright © Comtech EF Data, 2002. All rights reserved. Printed in the USA.

Comtech EF Data, 2114 West 7th Street, Tempe, Arizona 85281 USA, (480) 333-2200, FAX: (480) 333-2161.

Page 4

Customer Support

Contact the Comtech EF Data Customer Support Department for:

• Product support or training

• Information on upgrading or returning a product

• Reporting comments or suggestions concerning manuals

A Customer Support representative may be reached at:

Comtech EF Data

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

(480) 333-2200 (Main Comtech EF Data Number)

(480) 333-4357 (Customer Support Desk)

(480) 333-2161 FAX

or, E-Mail can be sent to the Customer Support Department at:

service@comtechefdata.com

Contact us via the web at www.comtechefdata.com

1. To return a Comtech EF Data product (in-warranty and out-of-warranty) for

repair or replacement:

2. Request a Return Material Authorization (RMA) number from the Comtech EF

Data Customer Support Department.

3. Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

4. To ensure that the product is not damaged during shipping, pack the product in

its original shipping carton/packaging.

5. Ship the product back to Comtech EF Data. (Shipping charges should be

prepaid.)

For more information regarding the warranty policies, see Warranty Policy, p. xi.

.

ii Rev. 2

Page 5

Table of Contents

Customer Support ...................................................................................................................................................... ii

Overview of Changes to Previous Edition .............................................................................................................. vii

About this Manual.................................................................................................................................................... vii

EMC Compliance .......................................................................................................................................................ix

Warranty Policy..........................................................................................................................................................xi

CHAPTER 1

1.1 Description ..................................................................................................................................................1–2

1.1.1 Areas of Operation:..................................................................................................................................1–2

1.1.2 Transmit and Receive Band Coverage.....................................................................................................1–2

1.1.3 Features ....................................................................................................................................................1–3

1.1.4 KST-2000L System..................................................................................................................................1–4

. INTRODUCTION................................................................................... 1–1

CHAPTER 2. SUMMARY OF SPECIFICATIONS....................................................... 2–1

2.1 Summary of Specifications ........................................................................................................................2–1

2.1.1 Solid-State Power Amplifier (SSPA).......................................................................................................2–3

2.1.2 Interface Requirements ............................................................................................................................2–4

2.1.3 Internal Data Interface..............................................................................................................................2–6

2.2 Size and Weight Specifications..................................................................................................................2–6

2.3 Environment Specifications.......................................................................................................................2–7

2.4 CE Certification..........................................................................................................................................2–8

2.5 Terminal Assemblies ..................................................................................................................................2–8

CHAPTER 3. CONNECTOR PINOUTS ...................................................................... 3–1

Rev. 2 iii

Page 6

Preface KST-2000L Satellite Terminal System

3.1 System Equipment Information................................................................................................................3–1

3.1.1 System Components.................................................................................................................................3–1

3.1.2 Description of Options .............................................................................................................................3–2

3.1.3 Spare Parts................................................................................................................................................3–2

3.2 Electrical Connections................................................................................................................................3–3

3.2.1 Converter Unit..........................................................................................................................................3–3

CHAPTER 4. OPERATION......................................................................................... 4–1

4.1 Initial Setup.................................................................................................................................................4–1

4.1.1 Uplink Setup ............................................................................................................................................4–2

4.1.2 Downlink Setup........................................................................................................................................4–3

4.2 Monitor and Control (M&C).....................................................................................................................4–4

4.3 Up Converter Description..........................................................................................................................4–6

4.4 L-Band to IF Down Converter Description..............................................................................................4–7

4.5 Automatic Gain Control (AGC)................................................................................................................4–8

4.5.1 Operation..................................................................................................................................................4–8

4.5.2 Fault and Error Response.........................................................................................................................4–9

4.5.3 Manual Gain Operation..........................................................................................................................4–10

CHAPTER 5. FAULT INDICATION AND ISOLATION ............................................... 5–1

5.1 Fault Indication ..........................................................................................................................................5–1

5.2 Fault Isolation .............................................................................................................................................5–2

5.3 Stored Faults...............................................................................................................................................5–2

CHAPTER 6. EQUIPMENT MOUNTING .................................................................... 6–1

6.1 Tools Required............................................................................................................................................6–2

6.2 Converter Unit Installation........................................................................................................................6–2

6.2.1 Spar Arm Mount ......................................................................................................................................6–2

6.2.2 Pole Mount...............................................................................................................................................6–4

6.3 SSPA Installation........................................................................................................................................6–8

6.3.1 Feed Mount Offset Antenna.....................................................................................................................6–8

6.4 LNB Installation .......................................................................................................................................6–10

6.4.1 Feed Mount Offset Antenna...................................................................................................................6–10

6.5 Cable Installation......................................................................................................................................6–11

iv Rev. 2

Page 7

KST-2000L Satellite Terminal System Preface

CHAPTER 7. TERMINAL MODE COMMANDS ......................................................... 7–1

7.1 General ........................................................................................................................................................7–1

7.2 Message Structure ......................................................................................................................................7–1

7.2.1 Start Character..........................................................................................................................................7–2

7.2.2 Device Address ........................................................................................................................................7–2

7.2.3 Command/Response.................................................................................................................................7–3

7.2.4 End Character...........................................................................................................................................7–3

7.3 System Configuration Commands ............................................................................................................7–4

7.4 HPA Commands .........................................................................................................................................7–5

7.5 LNB Commands .........................................................................................................................................7–6

7.6 System Communications Commands .......................................................................................................7–6

7.7 Miscellaneous Commands..........................................................................................................................7–7

7.8 Fault Commands .......................................................................................................................................7–8

7.9 Burst Control Mode ................................................................................................................................7–10

APPENDIX A. EQUIPMENT OUTLINE DRAWINGS..................................................A–1

A.1 2 and 4 Watt SSPA Equipment Outline ..................................................................................................A–2

A.2 KST-2000L Converter Equipment Outline............................................................................................. A–4

A.3 Ku-Band LNB Equipment Outline ..........................................................................................................A–5

Rev. 2 v

Page 8

Preface KST-2000L Satellite Terminal System

Figures

Figure 1-1. KST-2000L......................................................................................................................................... 1–1

Figure 1-2. KST-2000L System ........................................................................................................................... 1–4

Figure 3-1. I/O View of KST-2000L Converter Unit............................................................................................3–3

Figure 3-2. Serial (EIA-232) Adapter Cable Wiring Diagram ............................................................................. 3–6

Figure 4-1. System Block Diagram......................................................................................................................4–1

Figure 4-2. Monitor and Control (M&C) Block Diagram....................................................................................4–4

Figure 4-3. IF to S-Band Converter Module Block Diagram...............................................................................4–6

Figure 4-4. S to Ku-Band Up Converter Module.................................................................................................4–7

Figure 4-5. Ku-Band to IF Down Converter Block Diagram............................................................................... 4–7

Figure 4-6. AGC Operating Region ...................................................................................................................4–10

Figure 6-1. KST-2000L System Installed on Spar Arm....................................................................................... 6–1

Figure 6-2. Typical Converter Unit Installation on Spar......................................................................................6–3

Figure 6-3. KST-2000L Converter with Mounting Brackets ...............................................................................6–5

Figure 6-4. Rear View of Converter Installed on Round Pole..............................................................................6–6

Figure 6-5. Front View of Converter Installed on Round Pole ...........................................................................6–7

Figure 6-6. Installing the SSPA............................................................................................................................6–9

Figure A-1. 2 Watt SSPA Equipment Outline..................................................................................................... A–2

Figure A-2. 4 Watt SSPA Equipment Outline..................................................................................................... A–3

Figure A-3. KST-2000L Converter Equipment Outline...................................................................................... A–4

Figure A-4. Ku-Band LNB Equipment Outline .................................................................................................. A–5

Tables

Table 1-1. Features................................................................................................................................................ 1–3

Table 2-1. Transmit Specifications.......................................................................................................................2–1

Table 2-2. Receive Specifications........................................................................................................................2–2

Table 2-3. SSPA M&C Specifications .................................................................................................................2–3

Table 2-4. M&C Interface Specification..............................................................................................................2–4

Table 2-5. M&C Functions/Parameters................................................................................................................2–5

Table 2-6. Internal Data Interface Specifications.................................................................................................2–6

Table 2-7. Size and Weight Specifications...........................................................................................................2–6

Table 2-8. Converter Unit and SSPA Environmental Requirements....................................................................2–7

Table 2-9. CE Certification ..................................................................................................................................2–8

Table 2-10. Part Numbers for Various Equipment...............................................................................................2–8

Table 3-1. Description of Options........................................................................................................................3–2

Table 3-2. Spare Parts ..........................................................................................................................................3–2

Table 3-3. Converter Unit External Connections..................................................................................................3–4

Table 3-4. Prime Power Input (J1) Pin Assignments ............................................................................................3–4

Table 3-5. Remote M&C Connector (J2) Pin Assignments ..................................................................................3–5

Table 3-6. HPA Connector (J8) Pin Assignments (2 and 4W SSPAs)..................................................................3–7

Table 4-1. AGC Fault and Error Response ..........................................................................................................4–9

Table 5-1. KST-2000L Fault Tree.........................................................................................................................5–3

Table 5-2. KST-2000L Fault Tree (Continued).....................................................................................................5–4

vi Rev. 2

Page 9

KST-2000L Satellite Terminal System Preface

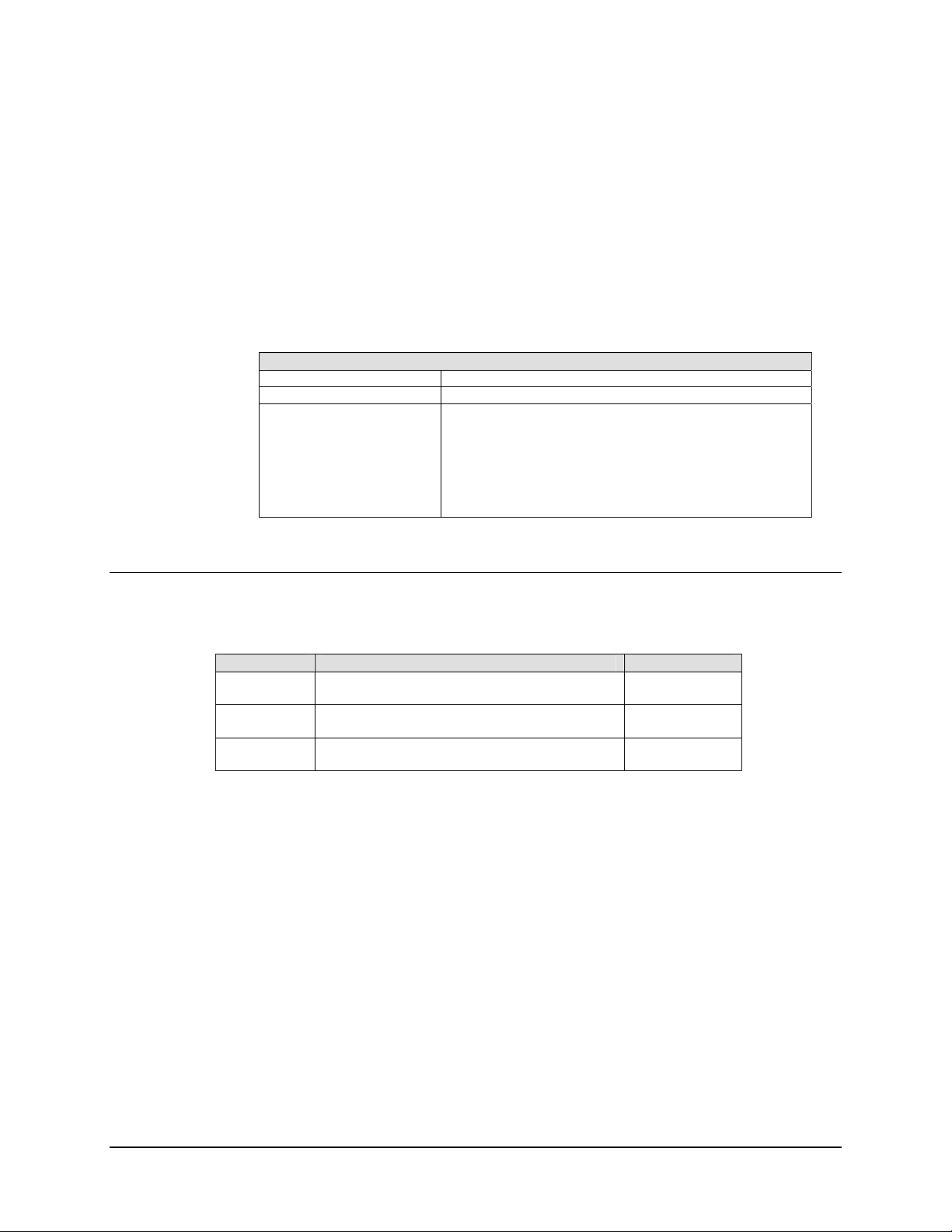

Overview of Changes to Previous Edition

A summary of the changes made for Rev. 2 includes:

Chapter 2 Updated specification data.

Chapter 4

Chapter 6

Chapter 7

Updated controls and commands.

Updated installation procedure.

Update remote commands.

About this Manual

This manual provides installation and operation information for the Comtech EF Data

KST-2000L Satellite Terminal System. This is a technical document intended for earth

station engineers, technicians, and operators responsible for the operation and

maintenance of the KST-2000L Satellite Terminal System.

Conventions and References

Cautions and Warnings

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other

CAUTION

WARN ING

unsafe practices or risks of property damage.

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

Rev. 2 vii

Page 10

Preface KST-2000L Satellite Terminal System

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assist the operator in cross-referencing English to Metric

conversions.

Recommended Standard Designations

Recommended Standard (RS) Designations have been superseded by the new designation

of the Electronic Industries Association (EIA). References to the old designations are

shown only when depicting actual text displayed on the screen of the unit (RS-232, RS485, etc.). All other references in the manual will be shown with the EIA designations

(EIA-232, EIA-485, etc.) only.

Trademarks

Other product names mentioned in this manual may be trademarks or registered

trademarks of their respective companies and are hereby acknowledged.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EF Data Customer

Support Department.

viii Rev. 2

Page 11

KST-2000L Satellite Terminal System Preface

EMC Compliance

This is a Class A product. In a domestic environment, it may cause radio interference that

requires the user to take adequate protection measures.

EN55022 Compliance

This equipment meets the radio disturbance characteristic specifications for information

technology equipment as defined in EN55022.

EN50082-1 Compliance

This equipment meets the electromagnetic compatibility/generic immunity standard as

defined in EN50082-1.

Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses, and can radiate radio frequency energy. If not installed

and used in accordance with the instruction manual, it may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference; in which case, users are required to correct the interference at their

own expense.

Note: To ensure compliance, properly shielded cables for DATA I/O shall be used.

More specifically, these cables shall be shielded from end to end, ensuring a

continuous shield.

Rev. 2 ix

Page 12

Preface KST-2000L Satellite Terminal System

Safety Compliance

EN 60950

This equipment meets the Safety of Information Technology Equipment specification as

defined in EN60950.

Low Voltage Directive (LVD)

The following information is applicable for the European Low Voltage Directive

(EN60950):

<HAR>

Type of power cord required for use in the European Community.

CAUTION: Double-pole/Neutral Fusing.

!

ACHTUNG: Zweipolige bzw. Neutralleiter-Sicherung.

International Symbols:

Symbol Definition Symbol Definition

Alternating Current.

Fuse.

Note: For additional symbols, refer to “Cautions” listed earlier in this preface.

Applicable testing is routinely performed as a condition of manufacturing on all units to

ensure compliance with safety requirements of EN60950.

Protective Earth.

Chassis Ground.

x Rev. 2

Page 13

KST-2000L Satellite Terminal System Preface

Warranty Policy

This Comtech EF Data product is warranted against defects in material and workmanship

for a period of two years from the date of shipment. During the warranty period, Comtech

EF Data will, at its option, repair or replace products that prove to be defective.

For equipment under warranty, the customer is responsible for freight to Comtech EF

Data and all related custom, taxes, tariffs, insurance, etc. Comtech EF Data is responsible

for the freight charges only for return of the equipment from the factory to the customer.

Comtech EF Data will return the equipment by the same method (i.e., Air, Express,

Surface) as the equipment was sent to Comtech EF Data.

Limitations of Warranty

The foregoing warranty shall not apply to defects resulting from improper installation or

maintenance, abuse, unauthorized modification, or operation outside of environmental

specifications for the product, or, for damages that occur due to improper repackaging of

equipment for return to Comtech EF Data.

No other warranty is expressed or implied. Comtech EF Data specifically disclaims the

implied warranties of merchantability and fitness for particular purpose.

Exclusive Remedies

The remedies provided herein are the buyer's sole and exclusive remedies. Comtech EF

Data shall not be liable for any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any other legal theory.

Disclaimer

Comtech EF Data has reviewed this manual thoroughly in order that it will be an easy-touse guide to your equipment. All statements, technical information, and

recommendations in this manual and in any guides or related documents are believed

reliable, but the accuracy and completeness thereof are not guaranteed or warranted, and

they are not intended to be, nor should they be understood to be, representations or

warranties concerning the products described. Further, Comtech EF Data reserves the

right to make changes in the specifications of the products described in this manual at any

time without notice and without obligation to notify any person of such changes.

If you have any questions regarding your equipment or the information in this manual,

please contact the Comtech EF Data Customer Support Department.

Rev. 2 xi

Page 14

Preface KST-2000L Satellite Terminal System

xii Rev. 2

Page 15

Chapter 1. INTRODUCTION

This chapter provides a description and the specifications for the KST-2000L satellite

terminal system. The terminal system is shown in Figure 1-1.

Figure 1-1.

KST-2000L

1–1

Page 16

Satellite Terminal System Revision 2

Introduction MN/KST2000L.IOM

1.1 Description

The KST-2000L satellite terminal system is a high-performance transceiver designed for

single-thread configuration outdoor operation. The unit transmits in Ku-Band and

receives in L-Band.

1. The converter unit controls external High Power Amplifiers (HPAs).

2. Automatic Gain Control (AGC) from the converter input to the HPA output

assures power output stability over varying conditions.

1.1.1 Areas of Operation:

The areas of operation are divided into three sections:

Converter

HPA

Low Noise Block Down Converter

(LNB) Assembly

Convection cooled up/down converter with an internal power

supply and microprocessor-based monitor and control (M&C).

Offered with 2 or 4 W power output capabilities.

LNBs with various frequency coverage are available.

1.1.2 Transmit and Receive Band Coverage

14.0 to 14.5 GHz

10.95 to 11.70 GHz

11.70 to 12.20 GHz

12.25 to 12.75 GHz

Transmit range in 1 MHz steps

LNB-Select: Receive range in 1 MHz steps

1–2

Page 17

Satellite Terminal System Revision 2

Introduction MN/KST2000L.IOM

1.1.3 Features

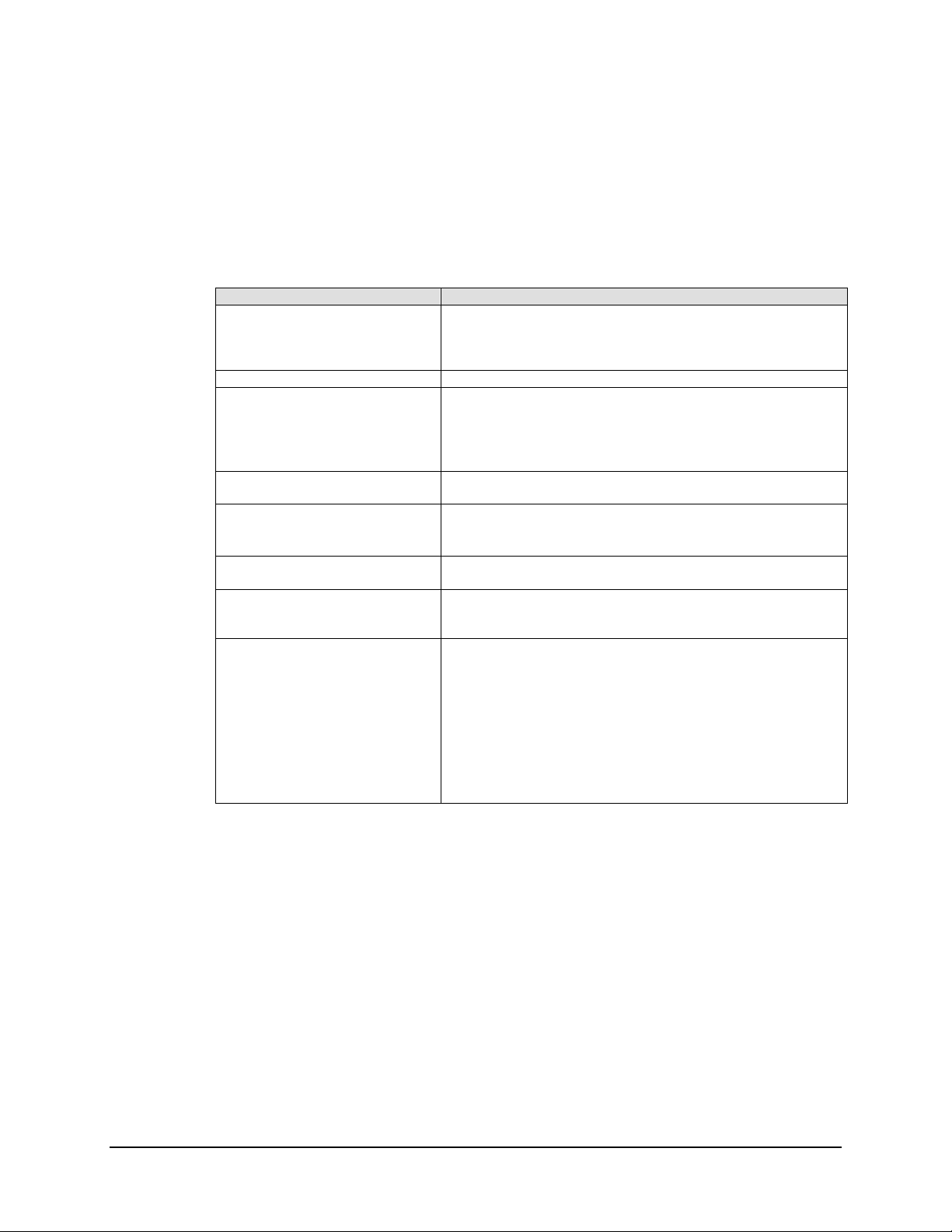

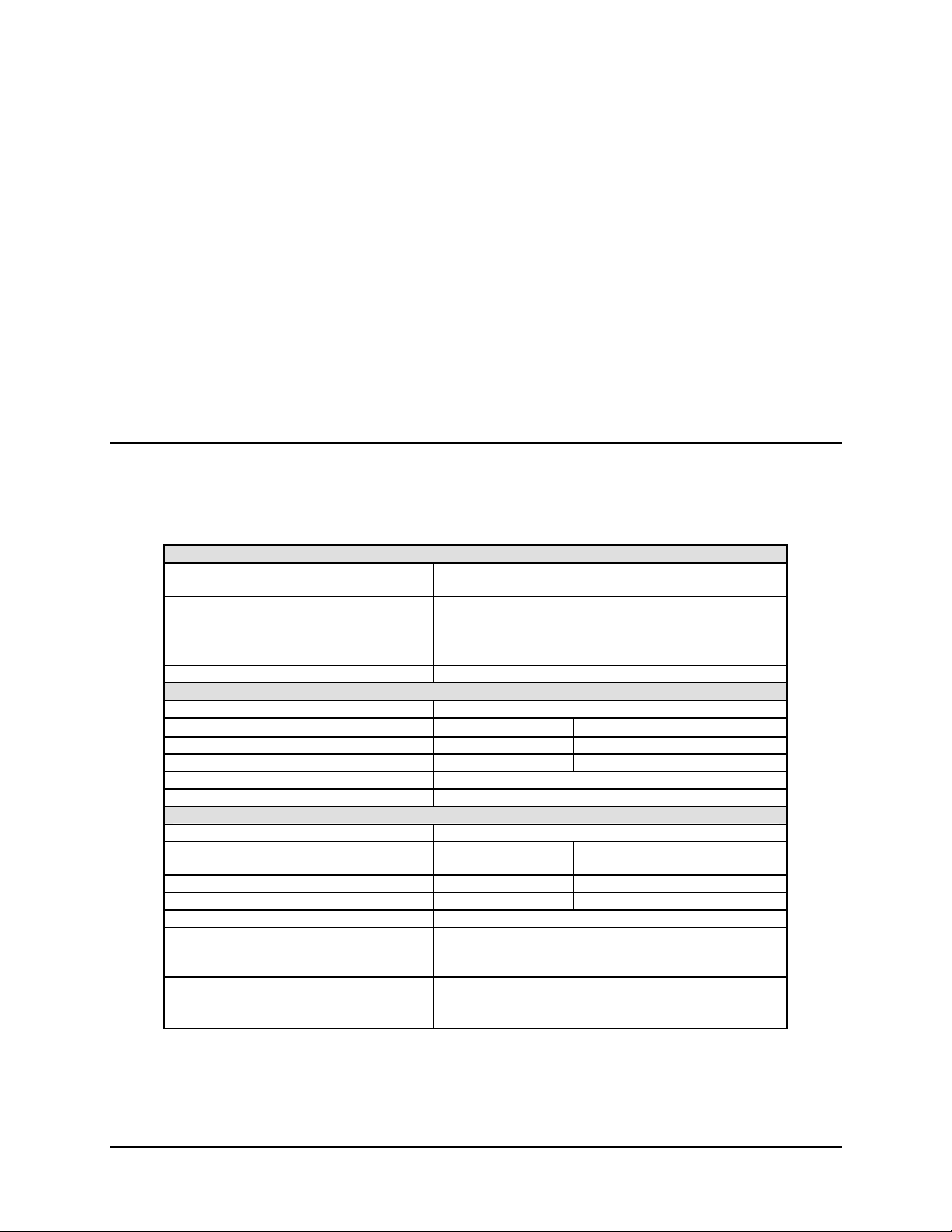

Refer to Table 1-1 for KST-2000L features.

Table 1-1. Features

Parameter Description

Automatic Gain Control The KST-2000L incorporates a closed loop control system that

maintains the system’s conversion gain (as measured from the

IF input to the Ku-Band SSPA output) at the user’s preset

value despite the effects of temperature, aging, and cable loss.

IF Input/Output of 70 /140 MHz Optional

Selectable Serial

Communication

L-Band RX Power Monitor Output An isolated output covers the 950 to 1700 MHz downlink

External LED Indicators for

Power On and Fault Indications

Power Factor Corrected Internal

Power Supply

HPA Options The converter has built-in monitor and control circuitry and

Industry Standards

There are several selectable serial communications protocols

and bandwidths:

• EIA-232, EIA-485, or EIA-422 half-duplex

• Baud Rate = 300 to 19200

bands.

• A blinking GREEN LED indicates prime power ON.

• A steady GREEN LED indicates TX RF Power ON.

• A RED LED indicates a summary fault.

All power supply is power factor corrected and meets all CE

Mark requirements.

functions that operate with the product line Solid-State Power

Amplifiers (SSPAs) with 2 or 4 W output power

• IESS 308 and IESS 309

• FCC radiated emissions requirements

• CE Mark

The system components are completely weatherproof units

designed for the harsh environments of antenna-mounted

systems. The system’s operating parameters can be monitored

and controlled using Windows™ based M&C software with a

personal computer or a hand held KP-10, as described in

Chapter 3.

1–3

Page 18

Satellite Terminal System Revision 2

Introduction MN/KST2000L.IOM

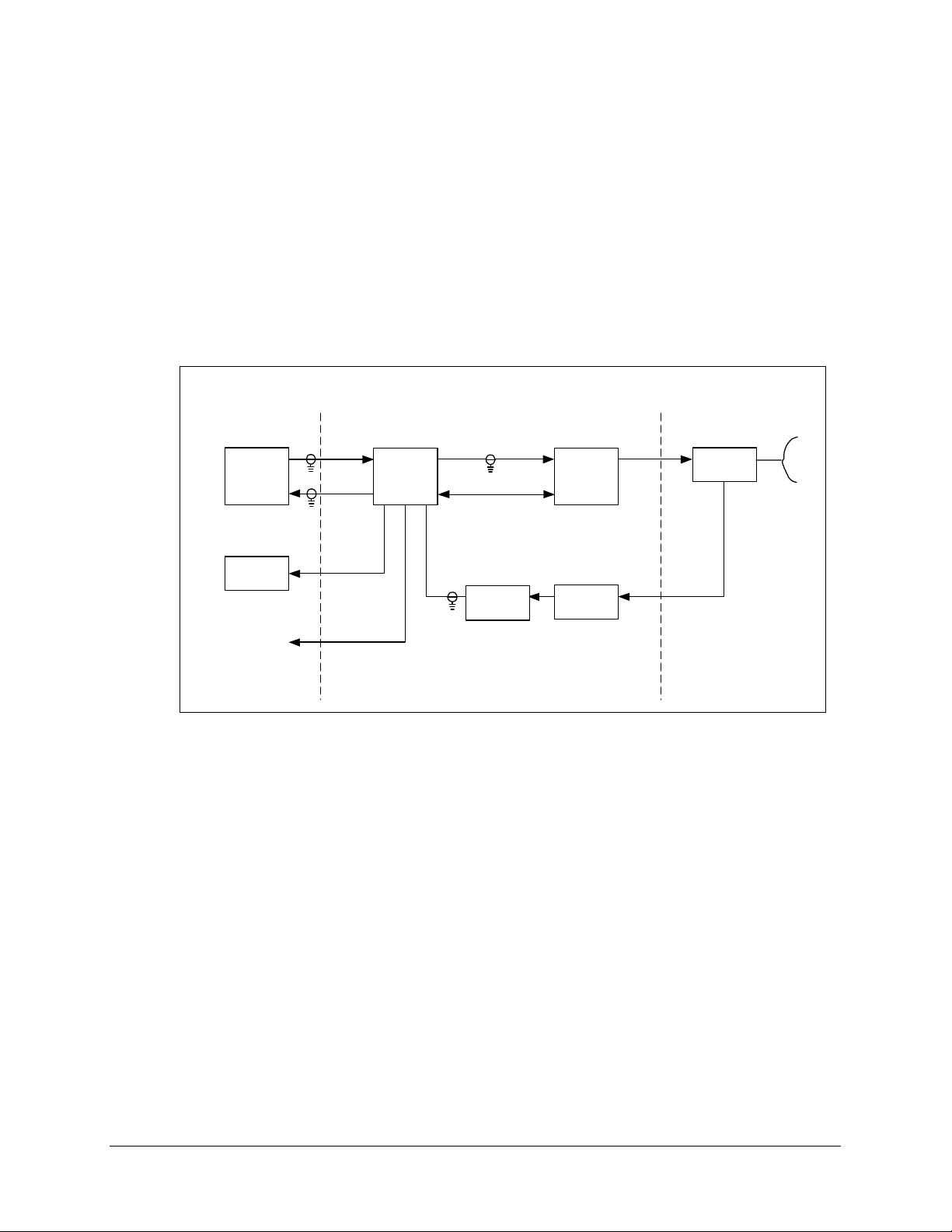

1.1.4 KST-2000L System

A block diagram of a single thread configuration, the system is shown in Figure 1-2.

Note: The modem, the remote M&C, OMT, and the antenna are not part of the system

and are shown for reference only.

Indoor Units

(Reference Only)

TX

Modem

RX

Remote

M&C

L-Band

RX Monitor

70 or 140 MHz

L-Band,

DC Power &

10 MHz Ref.

Ku-Band

M&C (Power)

LNB

HPA

TRF

Converter

Unit

TX

Figure 1-2. KST-2000L System

Ku-Band

Reference Only

Antenna

OMT

Ku-Band

1–4

Page 19

Satellite Terminal System Revision 2

Introduction MN/KST2000L.IOM

The M&C remote control, whose operation is described in Chapter 3, is used to set the

operating parameters of the system such as transmit and receive frequency, gain, etc.; and

to monitor the operation of the system. Connection to the remote M&C is only required

during set up and fault finding.

In the TX (uplink) direction, the converter unit receives a 70 MHz ± 20 MHz signal (140

MHz ± 40 MHz signal optional) at –25 to –45 dBm from a modem via a 50 or 75

Ω

coaxial cable. The converter’s input connector for this signal is a type N, female.

The converter unit performs a block conversion (non-inverted sense) first to S-Band, then

to Ku-Band. The exact frequency output and power level are set by the user via the

remote M&C. The converter output is coupled to an HPA via a coaxial cable with a 50

Ω,

female, type N connector at the converter output.

The HPA receives the Ku-Band input from the converter and amplifies it to the

user-selected level. The converter via the M&C cable supplies prime power for the HPA.

The user via the remote M&C sets the output power of the SSPA, and this output is

connected to the feed of the antenna via a WR-75 waveguide.

In the RX (downlink) direction, the received Ku-Band signal from the antenna is offset in

frequency from the transmitted signal allowing rejection of the transmitted signal by the

Transmit Reject Filter (TRF). The exact RX frequency is set by the user via the remote

M&C. The RX signal is down-converted to L-Band and is amplified in an LNB whose

output is coupled to the converter’s input via a coaxial cable with type N connectors. This

same cable is used to provide prime power (+15 VDC) and a 10 MHz reference to the

LNB.

An output is provided at L-Band (950 to 1700 MHz) to monitor the received signal. This

is particularly useful during set up and fault finding.

1–5

Page 20

Satellite Terminal System Revision 2

Introduction MN/KST2000L.IOM

This page is intentionally left blank.

1–6

Page 21

Chapter 2. Specifications

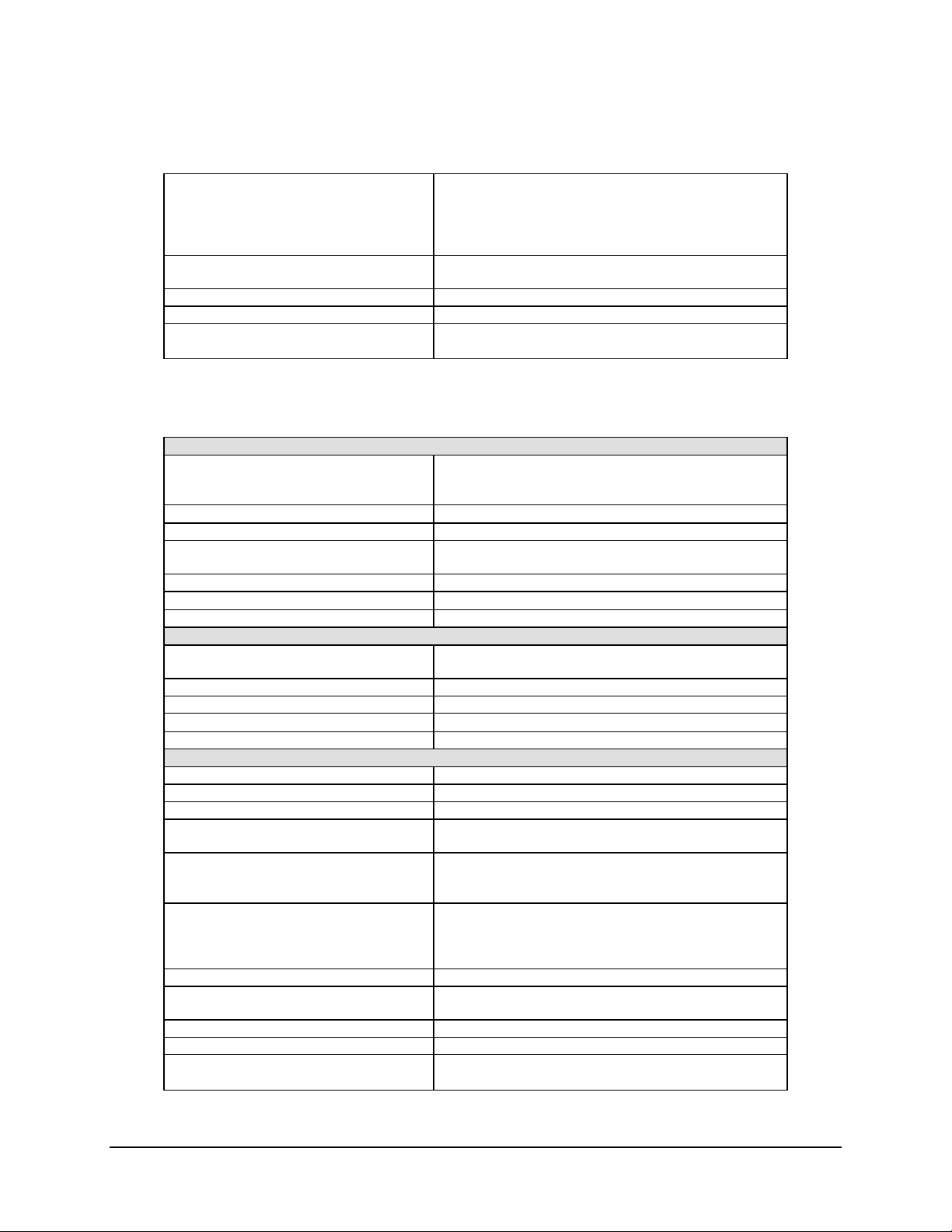

2.1 Summary of Specifications

Table 2-1. Transmit Specifications

Input Characteristics:

Frequency Range 50 to 90 MHz,

Optional: 100 to 180 MHz

Power Level Operational: -25 to –45 dBm

Survival: -10 dBm

Connector Type N, female

Impedance

VSWR 1.5:1

Output Characteristics:

Frequency Range 14.0 to 14.5 GHz, in 1 MHz steps

Output Power at Flange:

2 Watt 33 dBm 32 dBm

4 Watt 36 dBm 35 dBm

Connector WR-75

VSWR 1.5:1

Transfer Characteristics:

Frequency Sense Non-inverting

System Gain:

(SSG @ 10 dB backoff)

2 Watt 73 dB 63 dB

4 Watt 76 dB 66 dB

User Attenuator Range 0 to 20 dB, 1 dB steps

Gain Stability over temperature

AGC On, Fixed Frequency

AGC Off, Fixed Frequency

Gain variation with frequency:

70 ± 20 MHz

140 ± 40 MHz

50Ω, unbalanced

Typical Pso +25°C

Maximum

2.0 dB p-p

3.0 dB p-p

2.0 dB p-p

3.0 dB p-p

Guaranteed P1 dBm

Nominal

2–1

Page 22

Satellite Terminal System Revision 2

Summary of Specifications MN/KST2000L.IOM

Table 2-1. Transmit Specifications (Continued)

Spurious Signals:

Signal Related

Harmonics

<250 kHz

Non-signal Related

Third Order Intermods -30 dBc (for summed output of 2 signals @ 6 dB for

Group Delay < 10 ns over any 40 MHz

Phase Noise Exceed IESS 308/309 requirements, Limit 2

Frequency Stability

-50 dBc at 6 dB below P1dB

-50 dBc at 6 dB below P1dB

-35 dBc at 6 dB below P1dB

-20 dBm/4 kHz

maximum output power rating)

± 1E-7/Year max

± 1E-8/Temperature

Table 2-2. Receive Specifications

Input Characteristics:

Frequency Range 10.95 to 11.7 GHz (Option A)

11.7 to 12.2 GHz (Option B)

12.2 to 12.75 GHz (Option C)

LNB Noise Figure

LNB Gain 60 dB

Power Level Operational: -125 to –95 dBm

Connector WR-75

Impedance

VSWR 2.5:1

Output Characteristics:

Frequency Range 50 to 90 MHz, in 1 MHz steps

P1dB +10 dBm

Connector Type N, female

Impedance

VSWR 1.5:1

Transfer Characteristics:

Frequency Sense Non-inverting

System Gain: (SSG @ -10 dB backoff) Nominal: 90 dB

User Attenuator Range 0 to 20 dB, 1 dB steps

Gain Stability over temperature

Fixed Frequency

Gain variation with frequency:

± 20 MHz

Entire Band

Spurious Signals:

Signal Related

< 250 kHz

Non-signal Related

P1dBm +10 dBm

Third Order Intermods -30 dBc (for summed output of 2 signals @ 9 dB

Group Delay < 10 ns over any 40 MHz

Phase Noise Exceed IESS 308/309 requirements, Limit 2

Frequency Stability

1.1 dB (85°) Max

Survival: -10 dBm

50Ω, unbalanced

Optional: 100 to 180 MHz

50Ω, Unbalanced

8.0 dB p-p

2.0 dB p-p

6.0 dB p-p

-50 dBc (-5 dBm output)

-35 dBc

-126 dBm max referred to LNB input

below P1dB

± 1E-7/Year max

± 1E-8/Temperature

2–2

Page 23

Satellite Terminal System Revision 2

Summary of Specifications MN/KST2000L.IOM

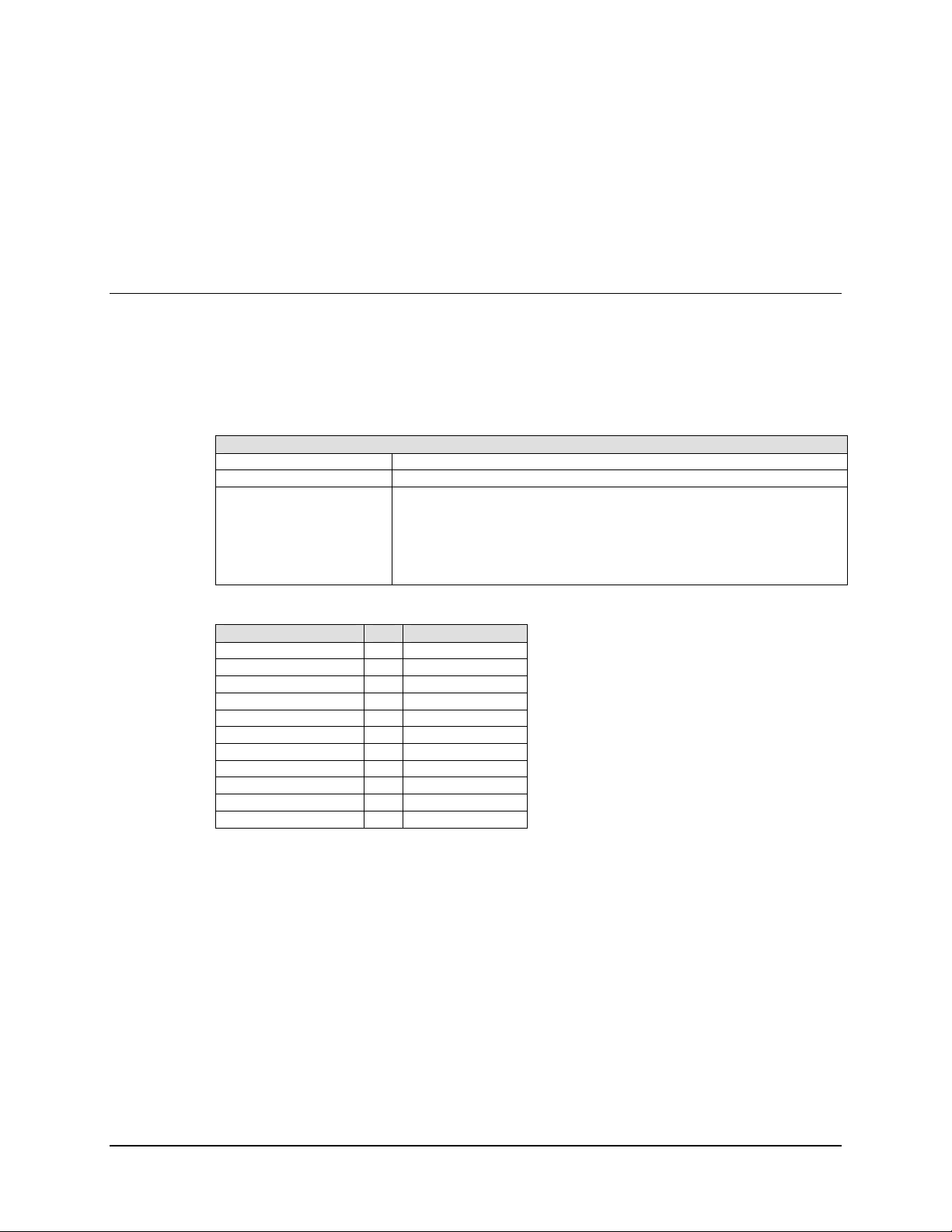

2.1.1 Solid-State Power Amplifier (SSPA)

2.1.1.1 SSPA Monitor and Control Interface

The M&C function for all SSPAs with output powers of ≤ 4W should conform to

requirements of Table 2-3.

Table 2-3. SSPA M&C Specifications

SSPA M&C Specification

Signaling Type EIA-485 (2-wire, half-duplex)

Baud Rate 83333 bps

Data Structure

11 Data Bits

1 Start Bit

1 Stop Bit

8 Data Bits

9 Data Bits

Type Pin Function

M&C Communication A EIA-485 + RX/TX

B EIA-485 – RX/TX

DC Power C +10.5 VDC

D +10.5 VDC

E +10.5 VDC

F +10.5 VDC

G GND

H GND

I GND

J GND

K GND

Note: Connector type is PT00E-12-10S.

= 1 when previous 8 bits represents a slave address; = 0 otherwise

2–3

Page 24

Satellite Terminal System Revision 2

Summary of Specifications MN/KST2000L.IOM

2.1.2 Interface Requirements

2.1.2.1 M&C Interface

The M&C of the system shall be via the M&C connector located on the Converter Unit.

Specifications for the M&C interface are listed in Table 2-4.

Table 2-4. M&C Interface Specification

M&C Interface Specifications

Serial Data Signal Interface (User selectable)

EIA-232

EIA-485 (2-wire, half duplex)

EIA-485 (4-wire, half duplex)

Serial Data Baud Rates (User selectable) 300, 600, 1200, 2400, 4800, 9600, 19200 kbps

Discrete Alarm Outputs

Uplink Summary Alarm

Downlink Summary Alarm

System Summary Alarm

The converter unit and the SSPA are capable of being monitored and controlled via the

data connector whose connections are listed in Table 1-6 using Comtech EF Data

supplied software on an IBM compatible PC running DOS version ≤ 5.0 with at least

192K of available RAM and running with a 386SX processor or greater.

Form ‘C’ Relay Contacts

Form ‘C’ Relay Contacts

Form ‘C’ Relay Contacts

2–4

Page 25

Satellite Terminal System Revision 2

Summary of Specifications MN/KST2000L.IOM

Table 2-5. M&C Functions/Parameters

Pin Signal Description

A -TX/-RX or –TX only (see Notes) -EIA-485 TX/RX or -EIA-422 TX

B -TX/-RX or –RX only (see Notes) -EIA-485 TX/RX or -EIA-422 TX

C +TX/+RX or +TX only (see Notes) +EIA-485 TX/RX or +EIA-422 TX

D +TX/+RX or +RX only (see Notes) +EIA-485 TX/RX or +EIA-422 TX

E RXD EIA-232 RX Data

F RTS EIA-232 Ready-to-Send (tied to CTS)

G TXD EIA-232 TX Data

H DSR EIA-232 Data Set Ready

J GND Ground

K LNA Power +15 VDC to LNA

L LNA Power Return +15 VDC Return from LNA

M RESET Reset (momentary low resets system)

N GND Ground

P CTS EIA-232 Clear-to-Send (tied to RTS)

R GND Ground

S +12V (KP10 Power) KP10 Power Supply Output

T 2/4 WIRE (SEE note) EIA-485/EIA-232 Operation Selection

U UL_FLT_NC Uplink Fault Relay, Closed = Fault

V UL_FLT_COM Uplink Fault Relay, Common

W UL_FLT_NO Uplink Fault Relay, Open = Fault

X DL_FLT_NC Downlink Fault Relay, Closed = Fault

Y DL_FLT_COM Downlink Fault Relay, Common

Z DL_FLT_NO Downlink Fault Relay, Open = Fault

a SUM_FLT_NO Summary Fault Relay, Open = Fault

b SUM_FLT_NC Summary Fault Relay, Closed = Fault

c SUM_FLT_COM Summary Fault Relay, Common

Notes:

1. These signals can be configured as EIA-485, 2-wire, half-duplex or EIA-422, 4-wire,

half-duplex.

2. In 2-wire mode, pins A and B are tied together as are pins C and D.

3. To select 2-wire operation, pin T is left open.

4. Tie pin T to ground for EIA-422 (4-wire) operation.

2–5

Page 26

Satellite Terminal System Revision 2

Summary of Specifications MN/KST2000L.IOM

2.1.3 Internal Data Interface

The individual RF uplink and downlink subassemblies, along with the separate SSPA,

contains a separate microprocessor that will individually monitor and control each

subassembly and communicate via a high-speed serial data bus with the central M&C

subassembly. The communications provides control parameters, status monitoring, and

fault reporting. Specification for the internal data bus are listed in Table 2-6.

Table 2-6. Internal Data Interface Specifications

Internal Data Interface Specification

Signaling Type Balanced Multipoint EIA-485, 2-wire

Baud Rate 83333 bps

Data Structure:

11 Data Bits:

1 Start Bit

1 Stop Bit

8 Data Bits

or 9 Data Bits

= 1 when previous 8 bits represents a slave address; = 0

otherwise

2.2 Size and Weight Specifications

Table 2-7. Size and Weight Specifications

Unit Size Weight

Converter 21.75L x 8.25W x 8.0H inches

(54.48L x 20.95W x 20.3H cm)

2W SSPA 12.95L x 6.0W x 3.9H inches

(32.89L x 15.24W x 9.9H cm)

4W SSPA 12.95L x 6.0W x 3.9H inches

(32.89L x 15.24W x 9.9H cm)

30 lbs (13.6 kg)

7 lbs (3.17 kg)

7 lbs (3.17 kg)

2–6

Page 27

Satellite Terminal System Revision 2

Summary of Specifications MN/KST2000L.IOM

2.3 Environment Specifications

Table 2-8. Converter Unit and SSPA Environmental Requirements

Parameter Requirements

Temperature

Thermal Gradient

Humidity

Precipitation MIL-STD-810, Method 506.2 Proc I, 5.2 inches/hour

Salt Fog MIL-STD-810, Method 506.2

Sand and Dust MIL-STD-810, Method 509.2

Altitude MIL-STD-810, Method 510.1

Solar Radiation

ES Discharge Operational: 10 KV

Shock Operation: 10 g for 10 mS (half-sine) on three axis

Vibration Survival – 5minute resonant dwell at four major resonances at 1 g

Frequency

Operational – 0.91 g

Frequency

Operation: -40 to 55°C (-40 to 131°F)

Survival: -50 to 75°C (-58 to 167°F)

40°C/hour

10°C/15 minute

0 to 100% relative at -40 to 55°C (-40 to 131°F)

95% at 65°C/72 hours

Operational: 0 to 15,000 ft

Survival: 0 to 50,000ft

360 BTU/ft

2

/hr at 50°C (122°F)

Survival: 15 KV

Survival: 40 g for 10 mS (half-sine) on three axis

peak.

Survival – 2.41g

of random vibration as listed below, 10

rms

minutes/axis

Slope

5 to 100 Hz

100 to 137 Hz

137 to 350 Hz

350 to 500 Hz

500 Hz

0

-6 dB/oct

0

-6 dB/oct

0

0.20 g

-

0.0107 g

-

0.0052 g

of random vibration as listed, 10

rms

minutes/axis

Slope

5 to 350 Hz

350 to 500 Hz

500 Hz

0

-6 dB/oct

0

0.0015 g

-

0.00074 g

2

/Hz

PSD

2

/Hz

2

/Hz

PSD

2

/Hz

2

/Hz

2–7

Page 28

Satellite Terminal System Revision 2

Summary of Specifications MN/KST2000L.IOM

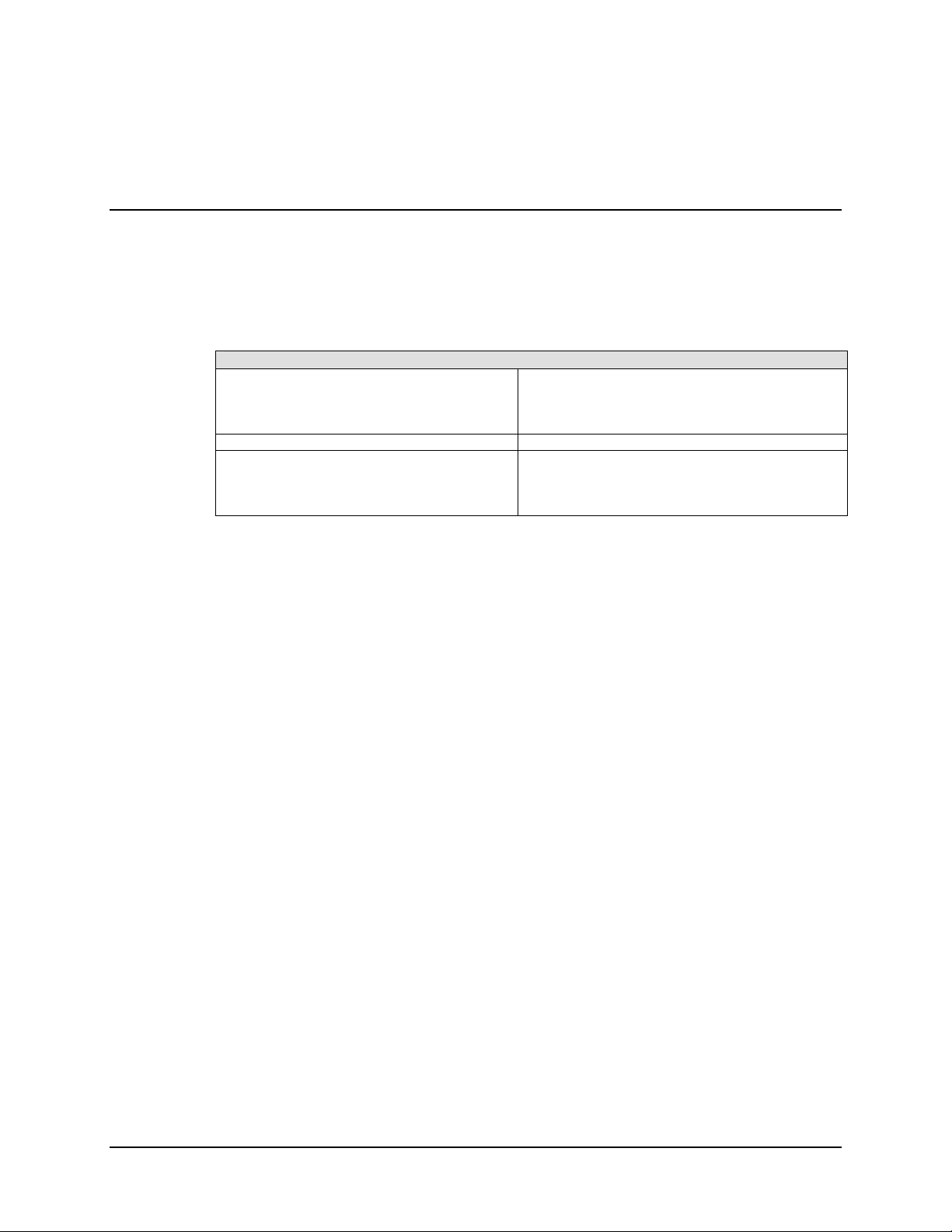

2.4 CE Certification

Table 2-9. CE Certification

Specification Description/Test

EN55022 Conducted and Radiated Emissions

EN50082-1 Immunity

• Fast Transmit Burst

• Static Discharge

• Radiated Immunity

EN60958 Safety

2.5 Terminal Assemblies

Table 2-10. Part Numbers for Various Equipment

Part Number Description Comments

System/FW Configuration:

FW/8439-1 TX/RX Duplex System/FW Configuration

Primary Input Power:

CA/84914-0223 90-264 VAC

TX Output Power:

KT/2819(2) 2 Watt CEFD SSPA 13.75 – 14.50 GHz

KT/2819 (2) 4 Watt CEFD SSPA 13.75 – 14.50 GHz

RX KLNB:

RF/LNB-10.9-11.7

RF/LNB-11.7 to 12.2

RF/LNB-12.2-12.7

RX Transmit Reject Filter:

RF/TRF-KU-WR75R2

RF/TRF-KU-WR75G

IF Frequency

KT/8766-2 70 MHz, IF

KT/8766-2 140 MHz, IF

TX Interlink Cables

CA/3722-2 5-Foot Cables

CA/3722-8 10-Foot Cables

CA/3722-9 15-Foot Cables

CA/3722-7 20-Foot Cables

RX Interlink Cables

CA/3722-2 5-Foot Cables

CA/3722-8 10-Foot Cables

CA/3722-9 15-Foot Cables

CA/3722-7 20-Foot Cables

10-95 to 11.70 GHz

11.70 to 12.20 GHz

12.25 to 12.75 GHz

Right-Angle, TRF

Straight, TRF

None (TX only) or No KLNB

KT/2819 for selected RX KLNB

None (TX only) or No KLNB

2–8

Page 29

Satellite Terminal System Revision 2

Summary of Specifications MN/KST2000L.IOM

Table 2-10. Part Numbers for Various Equipment (Contd)

Part Number Description Comments

Antenna Mounting Hardware:

KT/8324-1 Spar (1 x 2 in) Mount Base Unit Only

KT/8326-1 Spar (2.5 x 2.5 in) Mount Base Unit Only)

KT/7805-1 Spar (1 x 2in) Mount Prodelin Offset 5.25 in. Interface

SSPA/LNA Feed Mount

KT/7945-1 Spar (1 x 2in) Mount Prodelin Offset 3.74 in. Interface

SSPA/LNA Feed Mount

KT/7595 Spar (2.5 x 2.5) Mount Channel Master 5.29 in. Interface

SSPA/LNA Feed Mount

KT/8324-1/KT/8094-1 Spar (1 x 2) Mount for

Amplifier

KT/8326-1/KT/8094-1 Spar (2.5 x 2.5) Mount for

Amplifier

TX Flexible Waveguide:

KT/5860 5-Foot Flex Waveguide

KT-5860-1 3-Foot Flex Waveguide

KT/5860-2 2-Foot Flex Waveguide

RX Flexible Waveguide:

KT/5860 5-Foot Flex Waveguide

KT-5860-1 3-Foot Flex Waveguide

KT/5860-2 2-Foot Flex Waveguide

Handheld Keypad Controller:

KT/8078 KP10: RS-232

KT/8078-1 KP10: RS-485

KT/8078-2 KP10: RS-422

Mast Pipe Mount for Base Unit

Mast Pipe Mount for Base Unit

Notes:

1. Several items of equipment are customer-select.

2. All inquiries shall be directed to Comtech EF Data Customer Support

department.

2–9

Page 30

Satellite Terminal System Revision 2

Summary of Specifications MN/KST2000L.IOM

This page is intentionally left blank.

2–10

Page 31

Chapter 3. Connector Pinouts

This chapter provides system equipment and external connections information. Refer to

Chapter 6 for installation procedures specific to particular mounting applications.

3.1 System Equipment Information

3.1.1 System Components

The standard components delivered with a single thread system include:

QTY Description

1 Base converter unit

1 HPA

1 LNB

1 12ft (3.66m) Prime power cable for the converter unit

As Required 5ft (1.52m) Interlink cabling

As Required Mounting hardware for a spar mounted offset antenna. (see Note)

Note: Antenna type shall be indicated when ordering the KST-2000L.

3–1

Page 32

Satellite Terminal System Revision 2

Connector Pinous MN/KST2000L.IOM

3.1.2 Description of Options

Table 3-1 lists the various equipment options, and Table 3-2 lists the available spare

parts.

Table 3-1. Description of Options

LNB OPTIONS (discrete narrow bands at 1.1db max NF only):

10.95 to 11.70 GHz Europe

11.70 to 12.20 GHz North American

12.25 to 12.75 GHz Aussat

MOUNTING HARDWARE OPTIONS:

Standard Prodelin spar offset antenna

Standard Channel Master spar offset antenna

Non-standard single thread converter pole-mount Kit

No mounting hardware beyond the “pick off points” on the completed assembly

For mounting requirements outside those previously indicated, please consult the factory for

availability.

CABLING OPTIONS:

No RF or control cabling. Includes only the prime power cable(s) and applicable MS

connectors

For cabling requirements outside those previously indicated, please consult the factory for

availability.

3.1.3 Spare Parts

Description P/N

2 Watt SSPA (white) PL/8308-1

4 Watt SSPA (white) PL/8235-1

M&C PCB assembly PL/8314-1

10.95 to 11.7 GHz Europe and also Intelsat

(11.2 to 11.7 GHz) KLNB (white)

11.7 to 12.2 GHz North American KLNB

(white)

12.25 to 12.75 GHz Aussat KLNB (white) RF/LNB-KU-60-753

10ft RF heliax “N” cable CA/3722-8

12ft RF heliax “N” cable CA/3722

15ft RF heliax “N” cable CA/3722-9

Base A/C converter power supply PS/AC150W02P01

Transmit reject filter (right angle) RF/TRF-KU-WR75R1

Transmit reject filter (straight) RF/TRF-KU-WR75G

Table 3-2. Spare Parts

RF/LNB-KU-60-751

RF/LNB-KU-60-752

3–2

Page 33

Satellite Terminal System Revision 2

Connector Pinouts MN/KST2000L.IOM

3.2 Electrical Connections

3.2.1 Converter Unit

The external connections on the converter unit are shown in Figure 2-1 and listed in

Table 3-3. The connectors are described in the following paragraphs.

TRANSCEIVER

Figure 3-1. I/O View of KST-2000L Converter Unit

3–3

Page 34

Satellite Terminal System Revision 2

Connector Pinous MN/KST2000L.IOM

Table 3-3. Converter Unit External Connections

Ref. Des. Name Connector Type Function

J1 PRIME POWER 3 pin circular Male Prime AC Power Input

J2 REMOTE 26 pin circular, Female Remote M&C Interface

J3 IF IN Type N, Female TX IF Input 70 MHz (Optional: 140 MHz)

J4 IF OUT Type N, Female RX IF Output 70 MHz (Optional: 140 MHz)

J5 RX MON Type N, Female Ku-Band Receive Monitor (950 to 700MHz)

J6 RF OUT Type N, Female 14.00 to 14.50 GHz TX out to HPA

J7 RF IN Type N, Female 950 to 1700 MHz from LNB

J8 HPA 10 pin circular, Stet HPA M&C Interface

3.2.1.1 Prime Power Connector (J1)

Prime power is supplied to the converter unit through a 3–pin circular male connector

(J1). Prime power input requirements are 85 to 264 VAC, 47 to 63 Hz, 100 watts. The J1

connections are listed in Table 3-4 for pin assignments.

Note: Pin C is adjacent to the connector notch.

Table 3-4. Prime Power Input (J1) Pin Assignments

Pin Function

A Line

B Neutral

C Ground

3–4

Page 35

Satellite Terminal System Revision 2

Connector Pinouts MN/KST2000L.IOM

3.2.1.2 Remote Connector (J2)

The Remote Connector (J2) is a 26-pin, circular, female connector. It is used to allow

remote control and monitoring of KST-2000L operating parameters. Interface is via EIA232, EIA-485, or EIA-422 half-duplex. Refer to Table 3-5 for pin assignments.

Note: This cable must be assembled by the user. Figure 3-2 shows the connections for an

EIA-232 adapter for use with a PC COM port.

Table 3-5. Remote M&C Connector (J2) Pin Assignments

Pin Signal Description

A -TX/-RX or –TX only (see Note) – EIA-485 TX/RX or – EIA-422 TX

B -TX/-RX or –RX only (see Note) –EIA-485 TX/RX or – EIA-422 RX

C +TX/+RX or +TX only (see Note) + EIA-485 TX/RX or + EIA-422 TX

D +TX/+RX or +RX only (see Note) + EIA-485 TX/RX or + EIA-422 RX

E RXD EIA-232 receive data

F RTS EIA-232 ready to send (tied to CTS)

G TXD EIA-232 transmit data

H DSR EIA-232 data set ready

J GND Ground

K LNB Power +15 VDC to LNB

L LNB Power Return +15 VDC Return from LNB

M RESET Reset (momentary low resets system)

N GND Ground

P CTS EIA-232 clear to send (tied to RTS)

R GND Ground

S +12V (KP10 Power) KP10 power supply output

T 2/4 wire (see note) EIA-485/EIA-422 operation selection

U UL_FLT_NC Uplink fault relay, closed = fault

V UL_FLT_COM Uplink fault relay common

W UL_FLT_NO Uplink fault relay, open = fault

X DL_FLT_NC Downlink fault relay, closed = fault

Y DL_FLT_COM Downlink fault relay common

Z DL_FLT_NO Downlink fault relay, open = fault

a SUM_FLT_NO Summary fault relay, open = fault

b SUM_FLT_NC Summary fault relay, closed = fault

c SUM_FLT_COM Summary fault relay, common

Note: These signals can be configured as EIA-485, 2-wire, half-duplex or EIA-422,

4-wire, half-duplex. In 2-wire mode, pins A and B are tied together as are pins C and D.

To select 2 wire operation, pin T is left open. Tie pin T to ground for EIA-422 (4-wire)

operation.

3–5

Page 36

Satellite Terminal System Revision 2

Connector Pinous MN/KST2000L.IOM

Comtech EF Data: CN/STPG26M01

P1

PT06E16-26P(SR)

J

P

E

F

G

H

26 PIN

EIA-232 ADAPTER CABLE

Figure 3-2. Serial (EIA-232) Adapter Cable Wiring Diagram

3.2.1.3 IF IN Connector (J3)

The IF IN connector (J3) is a Type N, female connector used to connect the IF at 70 MHz

(140 MHz optional) at –25 to – 45 dBm from the modem to the converter unit. Either

50Ω or 75Ω cables may be used to connect to J3.

GND

CTS

RD/R

RTS

TD/T

DSR

5

9

4

8

3

7

2

6

1

MALE

3.2.1.4 IF OUT Connector (J4)

The IF OUT connector (J4) is a Type N, female connector used to connect the IF at

70 MHz (140 MHz optional) from the converter unit to the modem. Either 50Ω or 75Ω

cables may be used to connect to J4.

3.2.1.5 RX MON Connector (J5)

The RX Mon (J5) connector provides the received (downlink) signal at L-Band (950 to

1700 MHz) for monitoring. This signal has a gain of 20 dB relative to the carrier. J5 is a

Type N, female connector. Nominal output impedance is 50Ω.

3–6

Page 37

Satellite Terminal System Revision 2

Connector Pinouts MN/KST2000L.IOM

3.2.1.6 RF OUT Connector (J6)

The RF OUT connector (J6) is a type N, female, 50Ω connector used to connect the

converter unit’s output at Ku-Band (uplink) to an HPA. Power output at 1 dB

compression is +15 dBm minimum.

3.2.1.7 RF IN Connector (J7)

The RF IN connector (J7) is a type N, female, 50Ω connector used to connect the LNB’s

output at L-Band (downlink) to the converter unit.

3.2.1.8 HPA Connector (J8)

The HPA connector (J8) is a 10 pin circular, female (ITT #KPT02E-12-105) connector

used for HPA M&C and power functions. Refer to Table 3-6 for pin assignments for 2

and 4 watt SSPAs.

Table 3-6. HPA Connector (J8) Pin Assignments (2 and 4W SSPAs)

Pin Signal Description

A IPA Communications line A

B IPB Communications line B

C +10V +10V Power Supply Output

D +10V +10V Power Supply Output

E +10V +10V Power Supply Output

F +10V +10V Power Supply Output

G +10V_RTN +10V Power Supply Return

H +10V_RTN +10V Power Supply Return

J +10V_RTN +10V Power Supply Return

K +10V_RTN +10V Power Supply Return

3.2.1.9 2 and 4 Watt SSPA RF Connections

3–7

Page 38

Satellite Terminal System Revision 2

Connector Pinous MN/KST2000L.IOM

The 2 and 4 Watt SSPAs have a Type N, female (50Ω) connector (J1) at one end for the

Ku-Band input and a WR-75 waveguide isolator (J2) at the other end for the Ku-Band

output.

3.2.1.10 LNB Connections

Note: The power supply for the LNB can be supplied by the KST-2000L.

The RF input of the LNB is a WR-75 waveguide flange. The RF OUT/REF/PWR IN

connector of the LNB is a type N, 50Ω connector. It supplies the block-converted output

of 950 to 1700 MHz. It accepts +15 V at 400 mA, and a 10 MHz reference signal

supplied by the converter unit.

3–8

Page 39

Chapter 4. OPERATION

This chapter describes the procedures for initial testing of a KST-2000L system, and describes each major system function.

4.1 Initial Setup

This section details the procedures necessary to laboratory test a KST-2000L system for

the first time. Refer to Figure 4-1 for system setup.

PC

OR

KP10

TO DEMOD

FROM MOD

EARTH

GROUND

AC POWER

SOURCE

J2 REMOTE

J4 IF OUT

J3 IF IN

GND

(ERDE)

J1 PRIME

PO WER

RF OUT J6

HPA J8

RF IN J7

Figure 4-1. System Block Diagram

MON

J1

J2

HPA

J3

LNB

TERM

4–1

Page 40

Satellite Terminal System Revision 2

Operation MN/KST2000L.IOM

Note: Ensure that the termination selected for the HPA output is sized to handle the HPA output

power.

1. Apply power to the KST-2000L. After a few seconds ensure that the green TX

ON LED is flashing, and the fault LED is extinguished. Refer to Section 4 if this

is not the case.

2. Using a KP-10 or PC equipped with a terminal or Windows based M&C program, ensure that you can communicate to the system M&C, via J2, remote connector. (Refer to M&C software manual, part number MN/M&CWIN.IOM)

Default Communication Parameters Address 1

Baud Rate 9600

Parity even

Stop bits 2

Data length 7 bits

If the communication parameters for the system are not known, the Windows

based M&C system has a facility that will search all combinations of address,

baud rate, and parity until communication is established with the system.

Using the KP-10 or terminal program, send a miscellaneous command such as

EQUIPMENT TYPE (see appendix B.8) and confirm a response is displayed.

The Windows based status screen will turn from red to gray when communication with the KST-2000L is established.

4.1.1 Uplink Setup

1. Apply a 70 MHz (140 MHz) signal at a known level between –25 and

–45 dBm to the IF IN (J3) connector of the KST-2000L.

Note: This assumes that the AGC function is selected as ON. The AGC will

not function below a – 45 dBm input level. If the AGC function is selected

as OFF, lower input levels can be used limited only by noise. See section

3.12 for more information on the AGC function.

2. Set the up converter to the desired RF transmit frequency using the appropriate

commands from the KP10 terminal, or Windows M&C. See the up converter

frequency select command (Appendix B.3). If an error message is received, see

Appendix B.2.3 to determine the cause.

3. Before proceeding, ensure that the HPA is properly terminated. If a directional

coupler and termination is used or an attenuator is used, note the value.

4. Enable external faults, execute the appropriate HPA Power commands. See section B.4 HPA commands.

4–2

Page 41

Satellite Terminal System Revision 2

Operation MN/KST2000L.IOM

5. Turn the RF output of the up converter ON. See appendix B.3 system configuration commands. There should be no up converter faults at this time.

6. Using an appropriate frequency measuring device, ensure that the output of the

HPA (measured through the coupler or attenuator) is at the correct frequency.

Note: The internal, high-stability oscillators frequency can be fine tuned using the reference frequency adjust command. See Appendix B.3. Allow at

least 30 minutes warm-up before adjusting the oscillator.

7. Using an appropriate RF power measuring device, set the up converter attenuation until the power measured at the output of the coupler or attenuator is at the

correct value. See Appendix B.3.

8. Turn the RF output of the up converter off. See Appendix B.3.

4.1.2 Downlink Setup

1. Apply a signal in the appropriate receive frequency range according to the following table at a known level (approximately –95 dBm) to the LNB input.

10.95 to 11.70 GHz

11.70 to 12.20 GHz

12.25 to 12.75 GHz

a. If the LNB is using power supplied by the KST-2000L, enable the LNB

power – see section B.5.

b. After a 10-minute warm-up, perform an LNB calibration, and enable LNB

faults if desired. See Appendix B.5.

2. Set the down converter to the desired RX operating frequency. See Appendix

B.3. There should not be any existing receive system faults. See Appendix B.9.

3. Using an appropriate power measuring device attached to the IF OUT connector

(J4), set the down converter attenuator until the desired downlink gain is attained. See section B.3.

Note: At this point there should be no existing faults.

4. Execute a Clear Stored Faults command to clear the fault log (see Appendix

B.9), wait a few moments, and execute a System Fault Status command to verify.

5. Remove the AC power from the unit, remove the 70 MHz (140 MHz) test

source, remove the RX signal source, and remove the coupler/attenuator from

the HPA.

4–3

Page 42

Satellite Terminal System Revision 2

Operation MN/KST2000L.IOM

6. The system is ready for final installation to the antenna feed. Perform the rest of

the system alignment to applicable international, national, or local regulations.

4.2 Monitor and Control (M&C)

The Monitor and Control (M&C) monitors the KST-2000L and provides configuration

updates to the up converter, down converter, and HPA when necessary. Refer to

Figure 4-2.

EXT

OUTPUT

FAULT

RELAY

72 Mhz

Generator

10 Mhz

Output

485

Module

COMM

232 / 422

Analog

MON

M & C

2

IC

RAM

LNB

CTL

LEDROMRAM

EXT

INPUT

10 MHz

OCVCXO

Figure 4-2. Monitor and Control (M&C) Block Diagram

The KST-2000L configuration parameters are maintained on battery locked RAM, which

provides recovery after power down.

The M&C functions include extensive fault and status reporting. All KST-2000L functions are accessible through the remote communications interface.

The M&C is composed of the following sections:

• Microcontroller and UART • D to A and A to D converters

• ROM • RAM

• Fault relays • 10 MHz/72MHz Oscillators

• LNB power control

• Inter-module communication interface

The microcontroller is an Intel 80C32 operating at 16 MHz. The micro-controller contains 256 bytes of internal RAM. The external ROM is 29F020 (256 kbytes). The battery

backed RAM is 8 kbytes in size.

The non-volatile RAM allows the KST-2000L to retain configuration information without prime power for 1 year.

4–4

Page 43

Satellite Terminal System Revision 2

Operation MN/KST2000L.IOM

The UART supports serial asynchronous communication (remote port) with a maximum

data rate of 19,200 bit/s. The communications type can be EIA-232, EIA-485 (2-wire), or

EIA-422 (4-wire) half duplex.

The DAC supplies a voltage that fine tunes the reference oscillator operating frequency.

The ADC monitors the internal power supply voltages, as well as external temperature

and analog inputs from SSPAs.

The three fault relay outputs are failsafe. They will indicate a fault in the event of a power

outage. The three relays are uplink fault, downlink fault, and summary fault.

The M&C has a switching regulator that can generate +15VDC at 400 mA to power an

external LNB. This voltage can be enabled or disabled via the remote interface. The

M&C monitors the LNB current and generates a fault if the LNB current draw increases

or decreases excessively.

The M&C communicates status and control information to the up converter, down converter and SSPAs via a high speed RS-485 interface.

The 10 MHz OCVCXO is a high stability, low phase noise, crystal oscillator. It has a tuning voltage input which can be used to fine tune the oscillator frequency. The M&C generates a bias voltage which can be changed remotely to set the oscillator frequency.

The 72 MHz VCXO is phase locked to the 10 MHz reference. The 72 MHz output of the

VCXO is amplified and distributed throughout the KST-2000L to provide a reference frequency for the up converter and portions of the down converter.

4–5

Page 44

Satellite Terminal System Revision 2

-

Operation MN/KST2000L.IOM

4.3 Up Converter Description

The up converter accepts a 70 MHz (140 MHz) IF input signal and translates it to an output frequency in the range of 13.750 to 14.500 GHz. The up converter consists of two

modules: the IF to S-Band module and the S to Ku-Band module.

The IF to S-Band module translates the 70 MHz (140 MHz) IF input to an output frequency in the range of 2,330 to 3,080 MHz. Refer to Figure 4-3 for a block diagram of

the IF to S-Band module.

MX1 MX2

70/ 140

MHZ

GAIN

CONTROL

DETECT

72 MHZ

REF

L01

1035 (70)

960 (140)

Figure 4-3. IF to S-Band Converter Module Block Diagram

L02

3.435-4. 185 (70)

3.430-4. 180 (140)

2330

3080

MHZ

The 70 MHz (140 MHz) IF input is first amplified, and then applied to an electronically

variable attenuator. This attenuator is controlled via the local M&C to provide calibrated

1dB attenuation steps over a 20 dB attenuation range. The signal is then amplified and

heterodyned with a fixed frequency LO1. The desired sideband of this process is selected

via bandpass filtering and applied to the second up conversion stage MX2. LO2 is a low

noise synthesized source, whose output covers 750 MHz in 1 MHz steps. The output of

the second up conversion stage is a signal in the 2,330 to 3,080 MHz frequency range.

This signal is applied to the input of the S to Ku-Band module.

This module is slightly different for the 70 MHz and 140 MHz IF input options. As

shown in Figure 4-3, the LOs are tuned to different frequencies and filtering is different.

4–6

Page 45

Satellite Terminal System Revision 2

Z

F

Operation MN/KST2000L.IOM

23303080 MHZ

L03

16.830

GHZ

72 MHZ

REF

Figure 4-4. S to Ku-Band Up Converter Module

The S to Ku-Band up converter module (Figure 4-4) performs block up conversion of the

2,330 to 3,080 MHz signal input to an output in the range of 13.750 to 14.500 GHz. This

is done by mixing the IF input with a fixed frequency Dielectric Resonator Oscillator

(DRO), operating at 16.830 GHz. The correct sideband of this process is amplified and

filtered before being applied to the isolated output of the module.

4.4 L-Band to IF Down Converter Description

The L-Band to IF down converter (Figure 4-5) accepts an RF input in the frequency

range of 950 to 1,700 MHz and translates it to an output of 70 (140) MHz. The RF input

to this module is supplied from an externally mounted LNB.

13.750 t o

14.500 GH

950- 1700

MHZ

Fro m LN B

L-BAND

MONITOR

INTERFACE

72 MHZ

RE

1.6- 2. 35

GHZ

Figure 4-5. Ku-Band to IF Down Converter Block Diagram

The 950 to 1,700 MHz input is first pre-selected and then heterodyned with a local oscillator in the range of 1.6 to 2.35 GHz to generate the first IF signal of 650 MHz. The 650

MHz signal is then mixed with 790 or 720 MHz to generate the 70 or 140 MHz output.

The IF output frequency of the second down conversion stage is then amplified and applied to a 0 to 20 dB step attenuator with 1 dB steps. The overall Ku-Band down converter tunes in a frequency step-size of 1 MHz across the 950 to 1700 MHz band.

This module is slightly different for the 70 and 140 MHz options.

4–7

720 (70)

790 (140)

0-2 0 dB STEP

ATTENUATOR

70/ 1 40

MHZ

Page 46

Satellite Terminal System Revision 2

Operation MN/KST2000L.IOM

4.5 Automatic Gain Control (AGC)

The KST-2000L incorporates a closed-loop Automatic Gain Control (AGC) function that

maintains the system gain, as measured from the TX IF input to the Ku-Band output of

the SSPA, at the user’s preset value despite the effects of aging, operating temperature, or

cabling loss. This is not a Automatic Level Control (ALC) function, but a true AGC that

maintains the gain of the system constant independent of input and output absolute levels.

This is important to multicarrier operation, when individual carriers turn On/Off and the

level of the remaining carriers must remain unaffected. The transceiver can be set to operate in either the AGC, non-AGC, or MANUAL gain mode.

4.5.1 Operation

The AGC function is implemented by using two calibrated RF detectors.

• The first detector monitors the TX input (70 or 140 MHz; amplitude range of

–25 to –45 dBm). The DC voltage from the detector is converted to a digital

word in an A/D converter and read by the main processor.

• The second detector monitors the output signal of the SSPA. This detector is calibrated for five frequencies over the output frequency range. Additionally, the

second detector calibration covers output power from the saturation point of the

amplifier down to 30 dB (approximately) below saturation.

The calibration data is stored in a non-volatile memory within each SSPA making all

SSPAs interchangeable without loss of system gain accuracy. The estimate of output

power corresponds to the detector voltage linearly interpolated between nearby frequency

and power steps stored in memory. The main processor reads the estimated output power

from the SSPA and computes an error function as follows:

Gain Error = SSPA Output Power – Input Power – Gain_Max + UCA

Where Gain_Max is the maximum specified gain of the entire transceiver (converter unit

plus SSPA) and UCA is the value of the up converter attenuator and is set by:

<add/UCA_xx.x (Appendix B)

The main processor processes this data and generates an analog voltage that adjusts the

up converter attenuator to drive the error function to zero.

When the uplink AGC is enabled (<add/UAGC_ON) the display value of UCA will include a decimal point. Attenuation is adjustable over a range of 0 to 20 dB in 1 dB steps.

When the uplink AGC is disabled (<add/UAGC_OFF) the displayed value of UCA does

not include the decimal point.

4–8

Page 47

Satellite Terminal System Revision 2

Operation MN/KST2000L.IOM

4.5.2 Fault and Error Response

Table 4-1 shows how the AGC system reacts to power outages, system faults and operation outside the specified limits.

Table 4-1. AGC Fault and Error Response

Problem Response/Notes

If the transceiver prime power fails The UCA value is effect prior to the failure is restored on power up.

If the input signal (70 or 140 MHz) is removed

or is set to ≤ –45dBm.

If the user enters a value of UCA that is low for

a set input level.

If the input power is increased, such that the

SSPA is driven into saturation.

Loop fault occurs when the Gain Error is nonzero for >5 out 255 iterations of the processor

control loop.

INSUFFICIENT INPUT POWER fault is generated when the IF input power transitions from

normal power to low power (< – 45 dBm).

EXCESSIVE INPUT POWER fault is generated when the IF input power transitions from

normal power to high power (> –25 dBm).

The LOOP, INSUFFICIENT INPUT POWER, and EXCESSIVE INPUT POWER faults can be displayed

by issuing the AGC current faults command (<add/AGS_) . The allowed ranges of IF input power and

UCA settings are limited by the SSPA saturation and detector range to the shaded area defined in Figure 4-

6.

1. The internal Up Converter attenuator is set to its maximum value (minimum gap).

2. The value of UCA is not affected.

3. The output power will slowly increase for several seconds until the gain

error reaches zero, when the input signal is reapplied.

1. The SSPA will be driven into saturation and the value of UCA will

automatically increase (Gain decreased) in steps of 1 dB until the SSPA

output power is below saturation.

2. The new (increased) value of UCA is displayed at the user’s interface.

Even if the input power is reduced, the new value of UCA will remain

fixed.

1. The value of UCA is increased (Gain decreased) in steps of 1 dB until

the SSPA is below saturation.

2. The new value of UCA is displayed at the user’s interface. Even if the

input power is reduced, the new value of UCA will remain fixed.

1. A top level AGS_Fault is reported.

2. Excessive cable loss between the converter unit and the SSPA can cause

this condition.

3. If the AGC is enabled and the RF is commanded Off (<add/RF_OFF),

this fault is registered.

Under this condition, a top level AGS_fault is reported and the internal up

converter attenuator is set to its maximum value (minimum RF output). The

value of UCA is not affected. When the input signal increases above –45

dBm, the output power will slowly increase for several seconds until the gain

error reaches zero.

Under this condition, a top level AGS_Fault is reported. If the combination of

the input power and the up converter attenuator is such that the SSPA is

driven into saturation, the value of the UCA will automatically increase in

steps of 1 dB until the SSPA output power is below saturation. The new value

of UCA is displayed at the user’s interface. Even if the input power is reduced, the new values of UCA will remain fixed.

4–9

Page 48

Satellite Terminal System Revision 2

Operation MN/KST2000L.IOM

SSPA Power Saturation

Boundary

Allowed Up Converter

Attenuation, dB (UCA)

-50 -45

Figure 4-6. AGC Operating Region

4.5.3 Manual Gain Operation

With AGC disabled, the closed loop control of the uplink path is disabled. The SSPA

saturation, INSUFFICIENT INPUT POWER, EXCESSIVE INPUT POWER, and LOOP

faults are not monitored or reported as faults. The status of the AGS_fault is displayed as

OK. In this mode, the system gain is not accurately defined as in the AGC mode, because

the accuracy of the up converter’s programmable attenuator and the static gains of the uplink amplifiers determine the gain.

When this mode is selected, UCA will display as an integer (with no decimal point), and

the allowed range of the UCA is 0 to 55 dB in 1 dB steps. The accuracy of the attenuator

is not guaranteed and degrades at high values.

-40

Allowed IF Input Power Range,

-35 -30

dBm

-25

-20

4–10

Page 49

Chapter 5. FAULT INDICATION

AND ISOLATION

This section describes fault indication and isolation methods for the KST-2000L system.

Routine maintenance for the system consists only of assuring air flow for cooling of the

units. A system fault is indicated in three ways:

• An external LED

• Form C relay contacts

• The remote M&C control

5.1 Fault Indication

The KST-2000L converter unit has two external LED indicators as shown in Figure 2-1.

The TX ON indicator is green when illuminated, and the FAULT indicator is red.

When prime power is applied to the KST-2000L and the HPA is transmitting power, the

TX ON indicator is a steady green. The indicator flashes when prime power is applied but

the HPA is not transmitting. The FAULT indicator is a steady red when any fault is detected by the internal M&C processor.

The REMOTE connector (J2) has pins assigned (see Chapter 2, for pin assignments) for

the contacts on two form C relays, one for the uplink and one for the downlink. Normally

open contacts close and normally closed contacts open when there is a fault in any part of

the uplink or downlink. Fault isolation requires the use of the remote M&C as described

in section 4.2.

5–1

Page 50

Satellite Terminal System Revision 2

Fault Indication and Isolation MN/KST2000L.IOM

5.2 Fault Isolation

System faults are reported on the fault log screen in the Windows™ based remote M&C

software. (Alternatively, they may be viewed in the terminal mode as shown in

Chapter 7). Chapter 7 lists the KST-2000L faults and their indication in the LEDs and relays. In some cases, items listed in Chapter 7 give no LED or relay indication when they

occur because they are not equipment faults but are useful for troubleshooting problems.

5.3 Stored Faults

Each of the major modules within the KST-2000L (up converter, down converter, HPA,

LNB, and Reference), together with the AGC function and the Common Equipment, report their individual fault status to the main M&C. Each time there is a change in the fault

status, that status is stored in a non-volatile memory on the main M&C. Note that each

event corresponds to a change in status. Therefore, when a fault occurs, that constitutes

one status change, and when that fault clears, another event occurs. The M&C can store

up to ten fault status conditions.

After ten fault status changes are logged, no further logging can take place until the Clear

Stored Faults (<add/CLSF) command is issued. Refer to Appendix B, Table B-7 for the

fault commands to access the fault status of each function. When the fault status is queried, such as <add/HS_, the response returned will indicate how many stored faults are

actually stored. To retrieve the individual fault status, issue the appropriate stored fault

command with the corresponding stored fault number, such as <add/HSF_2. That particular fault condition will be returned. Note that the stored fault numbers (locations) are

0 through 9 inclusive.

It is good maintenance practice to query the stored faults and record them in a logbook or

other permanent record and then issue the clear stored fault command, <add/CLSF_.

There is no time stamp associated with these stored faults. Noting them in a logbook is

the only way to establish an approximate time reference,.

5–2

Page 51

Satellite Terminal System Revision 2

Fault Indication and Isolation MN/KST2000L.IOM

Table 5-1. KST-2000L Fault Tree

D

U

S

S

T

T

T

COMMON EQUIPMENT FAULTS

M&C MODULE X X

-7 VOLT POWER SUPPLY X X

+7 VOLT POWER SUPPLY X X