Page 1

KST-12000

Ku-Band Satellite Terminal

Installation and Operation Manual

IMPORTANT NOTE: The information contained in this document supercedes all previously published

information regarding this product. Product specifications are subject to change without prior notice.

Part Number MN/KST12000.IOM Revision 4

Page 2

Page 3

KST-12000

Comtech EF Data is an ISO 9001

Registered Company.

Ku-Band Satellite Terminal

Installation and Operation Manual

Part Number MN/KST12000.IOM

Revision 4

June 30, 2003

Copyright © Comtech EF Data, 2003. All rights reserved. Printed in the USA.

Comtech EF Data, 2114 West 7th Street, Tempe, Arizona 85281 USA, 480.333.2200, FAX: 480.333.2161

Page 4

KST-12000 Ku-Band Satellite Terminal Revision 4

Preface MN/KST12000.IOM

Customer Service

Contact the Comtech EF Data Customer Support Department for:

• Product support or training

• Information on upgrading or returning a product

• Reporting comments or suggestions concerning manuals

A Customer Support representative may be reached at:

Comtech EF Data

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

480.333.2200 (Main Comtech EF Data Number)

480.333.4357 (Customer Support Desk)

480.333.2161 FAX

or, E-Mail can be sent to the Customer Support Department at:

service@comtechefdata.com

Contact us via the web at www.comtechefdata.com

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or

replacement:

• Request a Return Material Authorization (RMA) number from the Comtech EF Data

Customer Support Department.

• Be prepared to supply the Customer Support representative with the model number,

serial number, and a description of the problem.

• To ensure that the product is not damaged during shipping, pack the product in its

original shipping carton/packaging.

• Ship the product back to Comtech EF Data. (Shipping charges should be prepaid.)

For more information regarding the warranty policies, see Warranty Policy, p. xi.

.

ii

Page 5

Table of Contents

CHAPTER 1.

1.1 DESCRIPTION............................................................................................................... 1–2

1.1.1 Application ..............................................................................................................1–5

1.1.2 Monitor and Control ................................................................................................1–5

1.1.3 Low Noise Amplifier (LAN)...................................................................................... 1–6

1.1.4

1.2 OPTIONS .......................................................................................................................1–7

1.2.1 Configuration...........................................................................................................1–7

1.2.2 Equipment...............................................................................................................1–7

1.3 SPECIFICATIONS .........................................................................................................1–8

1.5 NEW IN THIS RELEASE AND RECENT RELEASES ...................................................1–6

CHAPTER 2. SINGLE-THREAD SYSTEM INSTALLATION ................................................2–1

2.1 UNPACKING..................................................................................................................2–1

2.2 INSPECTING THE EQUIPMENT................................................................................... 2–1

2.3 RFT INSTALLATION...................................................................................................... 2–6

2.3.1 Tools Required........................................................................................................ 2–7

2.3.2 Vertical Pole Installation..........................................................................................2–8

2.3.3 Spar Installation ....................................................................................................2–16

2.4 LNA AND FLXIBLE WAVEGUIDE INSTALLATION.....................................................2–18

2.5 EXTERNAL CONNECTIONS....................................................................................... 2–19

2.5.1 TX/IF Input (J1) .....................................................................................................2–20

2.5.2 TX/RF Output (J2)................................................................................................. 2–20

2.5.3 RX/IF Output (J3)..................................................................................................2–20

2.5.4 RX/RF Input (J4) ...................................................................................................2–20

2.5.5 Prime Power (J5) ..................................................................................................2–21

2.5.6 Serial Remote Control (J6) ...................................................................................2–21

2.5.7 GND ......................................................................................................................2–23

INTRODUCTION .............................................................................................1–1

Outdoor Enclosure ..................................................................................................1–6

CHAPTER 3. REDUNDANT SYSTEM INSTALLATION.......................................................3–1

UNPACKING..................................................................................................................3–2

3.1

3.2 INSPECTING THE EQUIPMENT................................................................................... 3–2

3.3

RFT INSTALLATION...................................................................................................... 3–7

3.3.1 Tools Required........................................................................................................ 3–8

3.3.2 Vertical Pole Installation..........................................................................................3–9

3.3.3 Spar Installation ....................................................................................................3–16

3.3.4 1:1 Redundant Plate Installation ...........................................................................3–19

3.3.5 Waveguide Switch Installation ..............................................................................3–20

3.4 RSU-503L INSTALLATION.......................................................................................... 3–22

3.5

EXTERNAL CONNECTIONS....................................................................................... 3–22

iii

Page 6

KST-12000 Ku-Band Satellite Terminal Revision 4

Preface MN/KST12000.IOM

CHAPTER 4. OPERATION ...................................................................................................4–1

4.1 SYSTEM OPERATION .................................................................................................. 4–1

4.2 REMOTE CONTROL .....................................................................................................4–2

4.3 FRONT PANEL DISPLAY/KEYPAD .............................................................................. 4–2

4.3.1 Front Panel Controls ...............................................................................................4–3

4.3.2 Menu Explanations .................................................................................................4–7

CHAPTER 5. THEORY OF OPERATION .............................................................................5–1

5.1 MONITOR AND CONTROL ...........................................................................................5–1

5.1.1 EEPROM Memory ..................................................................................................5–3

5.1.2 Remote Interface ....................................................................................................5–3

5.1.3 Terminal Default Conditions.................................................................................... 5–4

5.1.4 Theory of Operation ................................................................................................5–4

5.1.5 M&C Board Connector Pinouts...............................................................................5–6

5.1.6 Test Points and LEDs ...........................................................................................5–10

5.2 HIGH STABILITY OSCILLATOR .................................................................................5–10

5.3 IF LOCAL OSCILLATOR .............................................................................................5–12

5.4 SYNTHESIZER ............................................................................................................5–13

5.4.1 Specifications........................................................................................................5–13

5.4.2 Theory of Operation ..............................................................................................5–13

5.5 DOWN CONVERTER .................................................................................................. 5–15

5.5.1 Specifications........................................................................................................5–15

5.5.2 Theory of Operation ..............................................................................................5–17

5.6 UP CONVERTER......................................................................................................... 5–18

5.6.1 Specifications........................................................................................................5–13

5.6.2 Theory of Operation ..............................................................................................5–13

CHAPTER 6. MAINTENANCE ..............................................................................................6–1

6.1 TEST POINTS AND LEDS............................................................................................. 6–1

6.2 FAULT ISOLATION........................................................................................................ 6–2

APPENDIX A. REMOTE CONTROL OPERATION ............................................................... A–1

iv

Page 7

KST-12000 Ku-Band Satellite Terminal Revision 4

Preface MN/KST12000.IOM

Figures

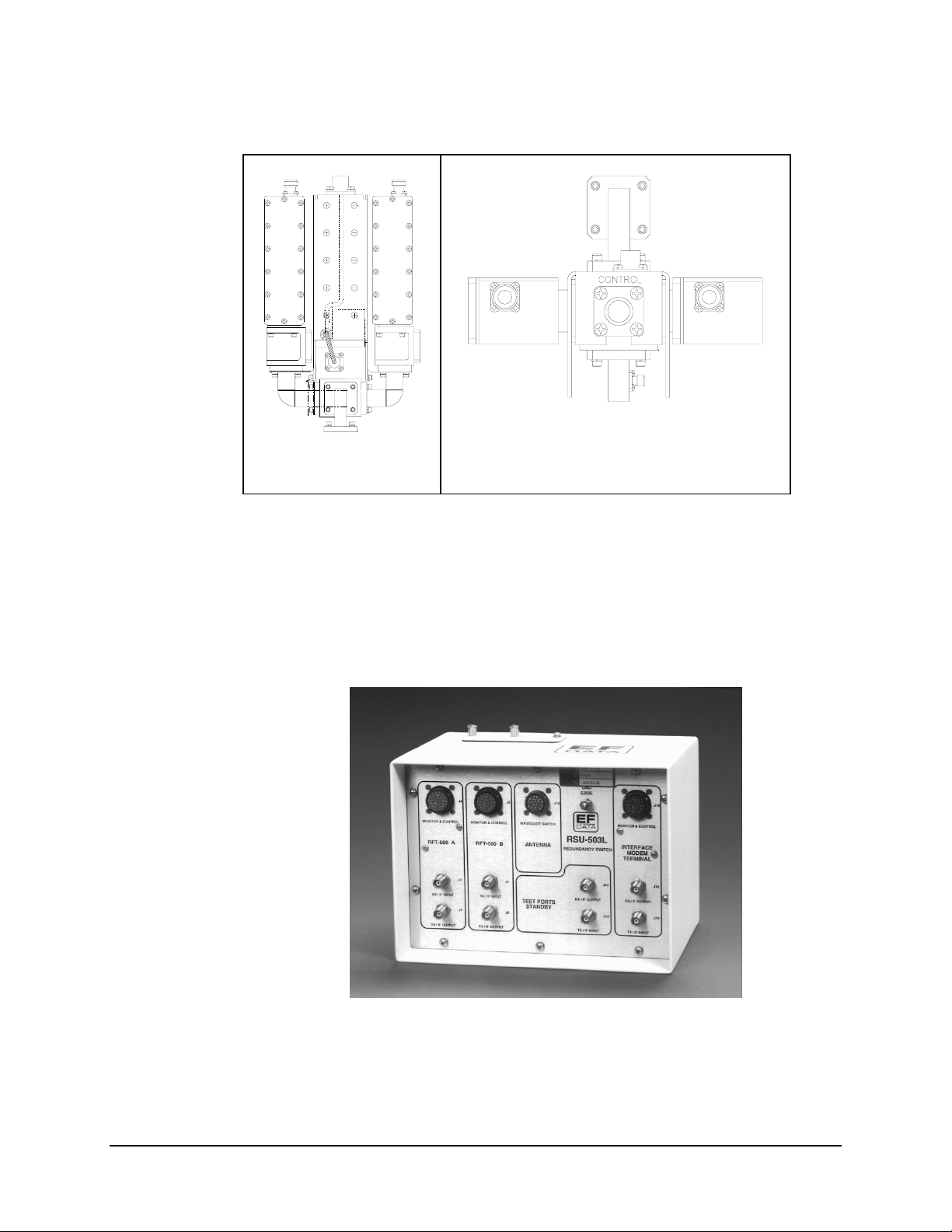

Figure 1-1. KST-12000 Single-Thread System........................................................................................ 1–2

Figure 1-2. Redundant LNA Plate............................................................................................................ 1–3

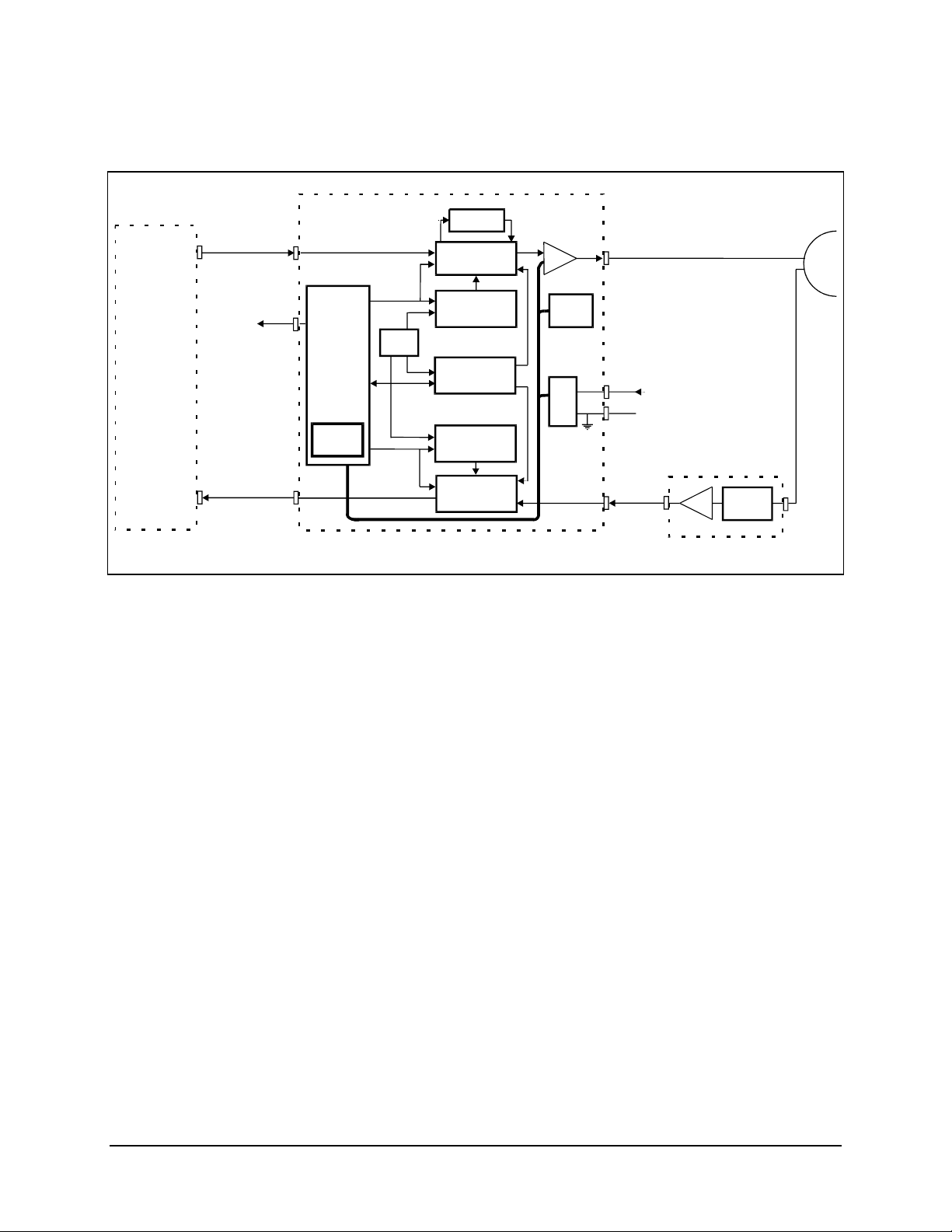

Figure 1-3. RSU-503L .............................................................................................................................. 1–3

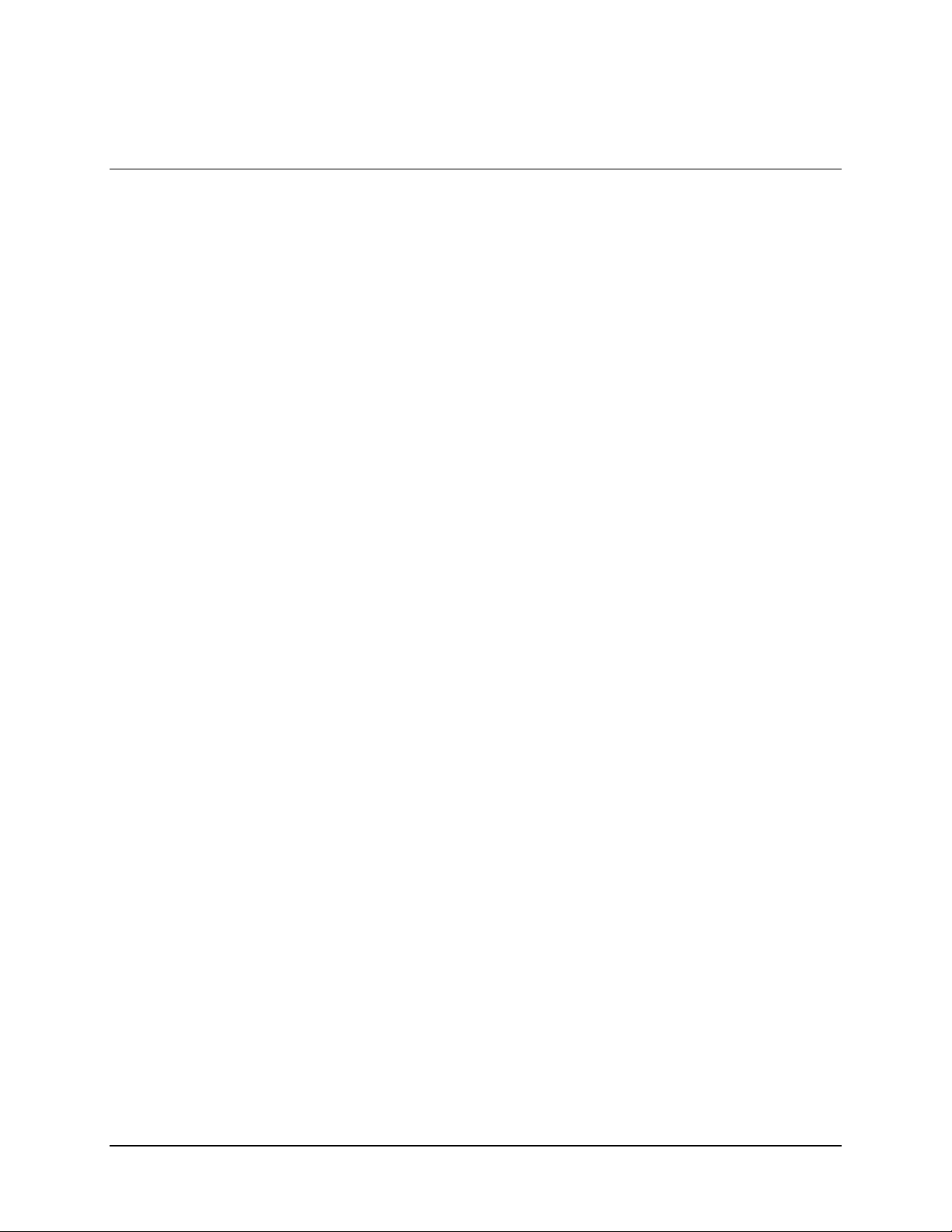

Figure 1-4. KST-12000 Block Diagram .................................................................................................... 1–4

Figure 1-5. Dimensions for Single-Thread LNA ..................................................................................... 1–13

Figure 1-6. Dimensions for 1:1 Redundant LNA Plate........................................................................... 1–14

Figure 2-1. RFT External Connections ..................................................................................................2–19

Figure 2-2. Serial Adapter Cables.......................................................................................................... 2–23

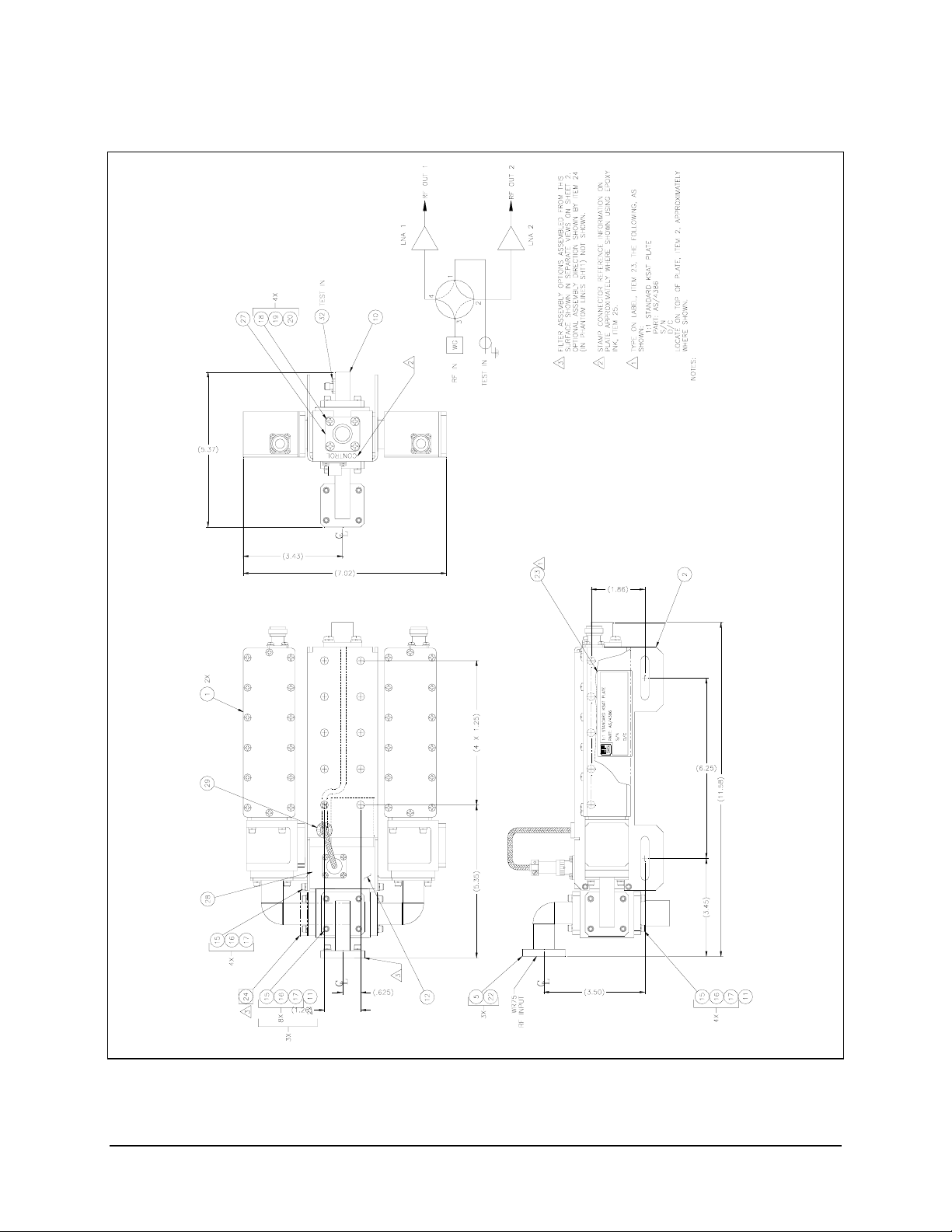

Figure 3-1. 1:1 Redundant LNA Plate....................................................................................................3–19

Figure 3-2. Installed Waveguide Switch.................................................................................................3–20

Figure 4-1. RFT-1200 Terminal Keypad ..................................................................................................4–2

Figure 5-1. M&C Card .............................................................................................................................. 5–2

Figure 5-2. M&C Jumper Placement at JP3 ............................................................................................5–3

Figure 5-3. M&C Functional Block Diagram............................................................................................. 5–5

Figure 5-4. High Stability Oscillator Block Diagram ...............................................................................5–11

Figure 5-5. IF LO Block Diagram ...........................................................................................................5–12

Figure 5-6. Down Converter Synthesizer Diagram ................................................................................5–14

Figure 5-7. Up Converter Synthesizer Diagram..................................................................................... 5–14

Figure 5-8. Down Converter Block Diagram ..........................................................................................5–16

Figure 5-9. Up Converter Block Diagram...............................................................................................5–19

Figure 6-1. RFT-1200 Inside Front View..................................................................................................6–3

Figure 6-2. RFT-1200 Inside Rear View ..................................................................................................6–4

Tables

Table 1-1. KST-12000 System Specifications .........................................................................................1–8

Table 1-2. RFT-1200 Specifications ........................................................................................................1–9

Table 1-3. LNA Specifications................................................................................................................ 1–11

Table 1-4. Evironmental and Physical Specifications ............................................................................1–12

Table 2-1. Rear Panel Connectors ........................................................................................................2–19

Table 2-2. RFT-1200 Remote Control Connector, J6............................................................................ 2–22

Table 4-1. Main Menu ..............................................................................................................................4–4

Table 4-2. Configuration Menu ................................................................................................................4–5

Table 4-3. Monitor Menu.......................................................................................................................... 4–5

Table 4-4. Fault Menu .............................................................................................................................. 4–6

Table 6-1. M&C LEDs ..............................................................................................................................6–1

Table 6-2. Test Points .............................................................................................................................. 6–2

v

Page 8

KST-12000 Ku-Band Satellite Terminal Revision 4

Preface MN/KST12000.IOM

This page is intentionally left blank.

vi

Page 9

About this Manual

This manual provides installation and operation information for the Comtech EF Data

KST-12000 Ku-Band Satellite Terminal. This is a technical document intended for earth

station engineers, technicians, and operators responsible for the operation and

maintenance of the KST-12000.

Conventions and References

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assist the operator in cross-referencing English to Metric

conversions.

Preface

Cautions and Warnings

Indicates information critical for proper equipment

IMPORTANT

WARN ING

function.

WARNING indicates a potentially hazardous situation that,

if not avoided, could result in death or serious injury.

vii

Page 10

KST-12000 Ku-Band Satellite Terminal Revision 4

Preface MN/KST12000.IOM

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EF Data Technical

Publications Department: techpub@comtechefdata.com

Electrical Safety

The KST-12000 Ku-Band Satellite Terminal has been shown to comply with the

following safety standard:

• EN 60950: Safety of Information Technology Equipment, including

electrical business machines

The equipment is rated for operation over the range 100 - 240 volts AC. It has a

maximum power consumption of 40 watts, and draws a maximum of 400 mA.

The user should observe the following instructions:

IMPORTANT

Fuses

The KST-12000 is fitted with two fuses - one each for line and neutral connections.

These are contained within the body of the IEC power inlet connector, behind a small

plastic flap.

• For 230 volt AC operation, use T0.75A, 20mm fuses.

• For 115 volt AC operation, use T1.25A fuses, 20mm fuses.

FOR CONTINUED OPERATOR SAFETY, ALWAYS REPLACE THE FUSES

WITH THE CORRECT TYPE AND RATING.

Environmental

The KST-12000 must not be operated in an environment where the unit is exposed to

extremes of temperature outside the ambient range 0 to 50°C, precipitation, condensation,

or humid atmospheres above 95% RH, altitudes (un-pressurized) greater than 2000

meters, excessive dust or vibration, flammable gases, corrosive or explosive atmospheres.

Operation in vehicles or other transportable installations that are equipped to provide a

stable environment is permitted. If such vehicles do not provide a stable environment,

safety of the equipment to EN60950 may not be guaranteed.

viii

Page 11

KST-12000 Ku-Band Satellite Terminal Revision 4

Preface MN/KST12000.IOM

Installation

The installation and connection to the line supply must be made in compliance to local or

national wiring codes and regulations.

The KST-12000 is designed for connection to a power system that has separate ground,

line and neutral conductors. The equipment is not designed for connection to power

system that has no direct connection to ground.

The KST-12000 is shipped with a line inlet cable suitable for use in the country of

operation. If it is necessary to replace this cable, ensure the replacement has an equivalent

specification. Examples of acceptable ratings for the cable include HAR, BASEC and

HOXXX-X. Examples of acceptable connector ratings include VDE, NF-USE, UL, CSA,

OVE, CEBEC, NEMKO, DEMKO, BS1636A, BSI, SETI, IMQ, KEMA-KEUR and

SEV.

International Symbols:

Symbol Definition Symbol Definition

~

Alternating Current

Fuse

Telecommunications Terminal Equipment Directive

In accordance with the Telecommunications Terminal Equipment Directive 91/263/EEC,

this equipment should not be directly connected to the Public Telecommunications

Network.

Protective Earth

Chassis Ground

ix

Page 12

KST-12000 Ku-Band Satellite Terminal Revision 4

Preface MN/KST12000.IOM

EMC (Electromagnetic Compatibility)

In accordance with European Directive 89/336/EEC, the CDM-600 Modem has been

shown, by independent testing, to comply with the following standards:

Emissions: EN 55022 Class B - Limits and methods of measurement of radio

interference characteristics of Information Technology Equipment.

(Also tested to FCC Part 15 Class B)

Immunity: EN 50082 Part 1 - Generic immunity standard, Part 1: Domestic,

commercial and light industrial environment.

Additionally, the CDM-600 has been shown to comply with the following standards:

EN 61000-3-2 Harmonic Currents Emission

EN 61000-3-3 Voltage Fluctuations and Flicker

EN 61000-4-2 ESD Immunity

EN 61000-4-4 EFT Burst Immunity

EN 61000-4-5 Surge Immunity

EN 61000-4-6 RF Conducted Immunity

EN 61000-4-8 Power frequency Magnetic Field Immunity

EN 61000-4-9 Pulse Magnetic Field Immunity

EN 61000-4-11 Voltage Dips, Interruptions, and Variations Immunity

EN 61000-4-13 Immunity to Harmonics

In order that the Modem continues to comply with these standards,

observe the following instructions:

IMPORTANT

• Connections to the transmit and receive IF ports (BNC female connectors) should

be made using a good quality coaxial cable - for example RG58/U (50Ω or

RG59/U (75Ω).

• All 'D' type connectors attached to the rear panel must have back-shells that

provide continuous metallic shielding. Cable with a continuous outer shield

(either foil or braid, or both) must be used, and the shield must be bonded to the

back-shell.

• The equipment must be operated with its cover on at all times. If it becomes

necessary to remove the cover, the user should ensure that the cover is correctly

re-fitted before normal operation commences.

x

Page 13

KST-12000 Ku-Band Satellite Terminal Revision 4

Preface MN/KST12000.IOM

Warranty Policy

This Comtech EF Data product is warranted against defects in material and workmanship

for a period of 1 year from the date of shipment. During the warranty period, Comtech EF

Data will, at its option, repair or replace products that prove to be defective.

For equipment under warranty, the customer is responsible for freight to Comtech EF

Data and all related custom, taxes, tariffs, insurance, etc. Comtech EF Data is responsible

for the freight charges only for return of the equipment from the factory to the customer.

Comtech EF Data will return the equipment by the same method (i.e., Air, Express,

Surface) as the equipment was sent to Comtech EF Data.

Limitations of Warranty

The foregoing warranty shall not apply to defects resulting from improper installation or

maintenance, abuse, unauthorized modification, or operation outside of environmental

specifications for the product, or, for damages that occur due to improper repackaging of

equipment for return to Comtech EF Data.

No other warranty is expressed or implied. Comtech EF Data specifically disclaims the

implied warranties of merchantability and fitness for particular purpose.

Exclusive Remedies

The remedies provided herein are the buyer's sole and exclusive remedies. Comtech EF

Data shall not be liable for any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any other legal theory.

Disclaimer

Comtech EF Data has reviewed this manual thoroughly in order that it will be an easy-touse guide to your equipment. All statements, technical information, and

recommendations in this manual and in any guides or related documents are believed

reliable, but the accuracy and completeness thereof are not guaranteed or warranted, and

they are not intended to be, nor should they be understood to be, representations or

warranties concerning the products described. Further, Comtech EF Data reserves the

right to make changes in the specifications of the products described in this manual at any

time without notice and without obligation to notify any person of such changes.

If you have any questions regarding your equipment or the information in this manual,

please contact the Comtech EF Data Customer Support Department.

xi

Page 14

KST-12000 Ku-Band Satellite Terminal Revision 4

Preface MN/KST12000.IOM

This page is intentionally left blank.

xii

Page 15

This chapter describes the KST-12000 Ku-band satellite terminal, referred to in this

manual as “the KST-12000.”

1.1 Description

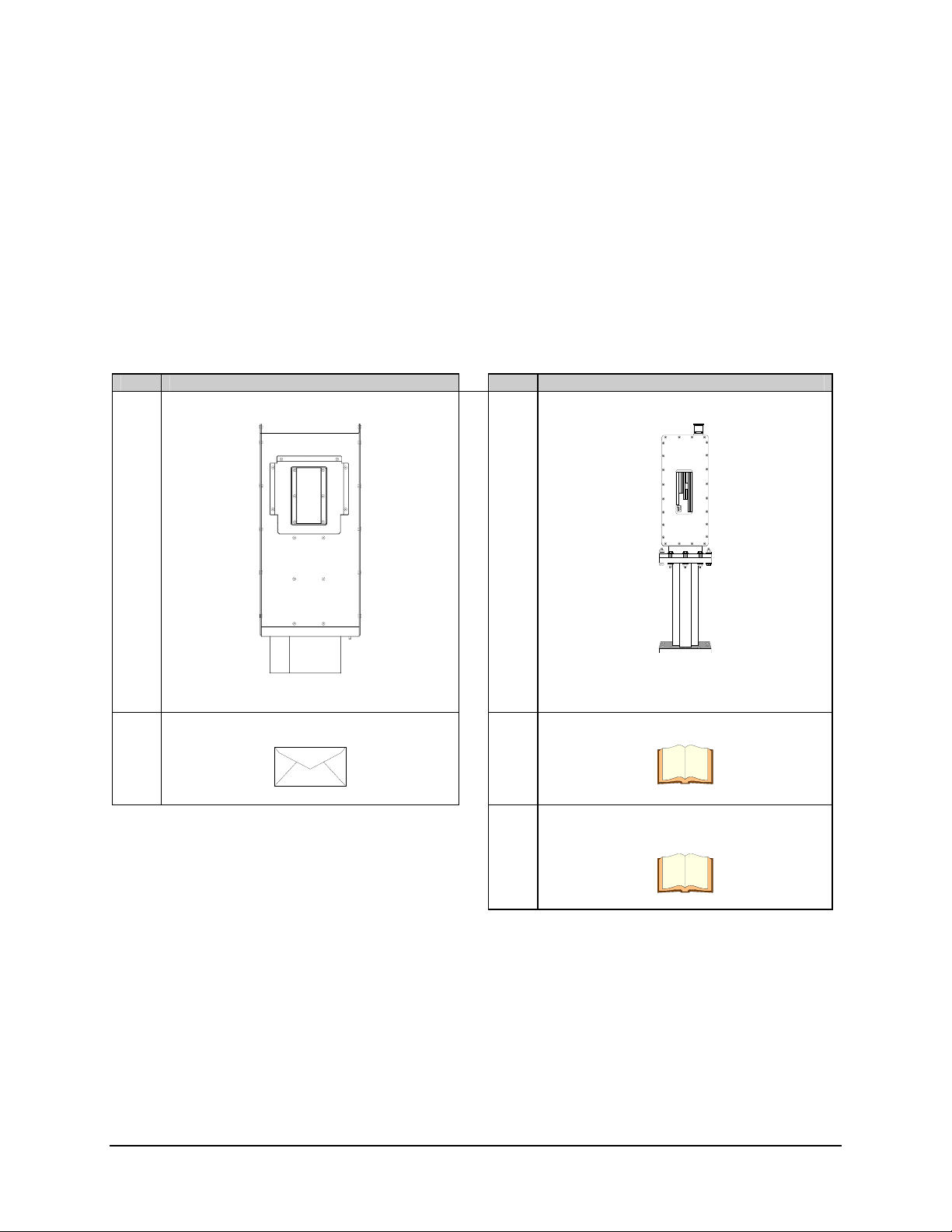

As a single-thread system, the KST-12000 is comprised of the following assemblies

(Figure 1-1):

• The outdoor enclosure assembly (the RFT-1200)

• Low Noise Amplifier (LNA)

As a redundant system, the KST-12000 is comprised of the following assemblies:

• Two outdoor enclosure assemblies (RFT-1200s)

• 1:1 redundant LNA plate (Figure 1-2)

• RSU-503L (Figure 1-3)

For information on the RSU-503L, refer to the RSU-503 Redundancy Switch Unit

Installation and Operation Manual.

Refer to Figure 1-4 for a block diagram of the KST-12000.

The KST-12000 meets all requirements for operation on both private and regional

domestic Ku-band satellite networks.

Chapter 1. INTRODUCTION

1–1

Page 16

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

Figure 1-1. KST-12000 Single-Thread System

Note: The LNAs shown in Figures 1-1 and 1-2 are typical LNAs. Other LNAs are

available, and can be ordered from an Comtech EF Data marketing representative.

1–2

Page 17

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

Top View

Figure 1-2. 1:1 Redundant LNA Plate

Side View

Figure 1-3. RSU-503L

1–3

Page 18

KST-12000 Ku-Band Satellite Terminal Revision 4

/

Introduction MN/KST12000.IOM

70 M Hz

SYSTEM

MODEM

TX / I F

+/-18MHz

70 MHz

-30 dBm

RS-485/ 232

SERI AL

REMOTE PORT

26 PIN CI RCULAR

CONNECTOR

RX/IF

70 MHz+ /-18 MHz

RFT-1200

J1

TNC

J

6

TNC

J3

M&C

OPTIONAL

DISPLAY/

KEYPAD

10 MHz

REF

BANDPASS

FILTER

UP

CONVERTER

UP

CONVERTER

LO SYNTHESI ZER

IF LO &

REF PLO

DOWN

CONVERTER

LO SYNTHESIZER

DOWN

CONVERTER

HPA

PS

FAN

TYPE N

TX / R F O U TPUT

J2

14.0 to 14.5 GHz

WR-75

J5

PRIME POWER

GND

AC INPUT -3 P IN CIRCUL AR

DC INPUT -4 PI N CIRCUL AR

10.95 to 12.15 GHz

10.95to11.7GHz

11.7 to 12.2 GHz

12.25 to 12.75 GHz

(DC OPTIONAL)

J4

Ca/3722

17 FT. CABLE

RF IN PUT

RX

LNA

TX REJECT

FILTER

ANTENNA

Figure 1-4. KST-12000 Block Diagram

1–4

Page 19

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

1.1.1 Applications

When used in conjunction with Comtech EF Data modems, the KST-12000 is ideal for:

• Single digit carriers

• Multiple carrier operation over a 36 MHz bandwidth

Because the KST-12000 has a 70 MHz IF, it can also be used for other analog and digital

applications.

Small-to-medium size earth stations are easily constructed and commissioned with the

KST-12000.

When used with a high-gain antenna, the KST-12000 can also be used as the Radio

Frequency (RF) electronics of a central hub in point-to-multipoint applications, as well as

serve as the terminal for the end points of the network.

1.1.2 Monitor and Control

An on-board microcomputer monitors and controls all operational parameters and system

status of the KST-12000. This powerful M&C system enables the user to locally or

remotely control functions such as:

• Output power

• Transmit/receive channel frequencies

The system also reports terminal configuration status, as well as fault status of all

KST-12000 components.

The KST-12000 can be initially configured using the:

• Keyboard/LCD controller within the enclosure.

• Connection of a common ASCII/RS-232 terminal connected to the serial port. A

simple command set allows total configuration control and retrieval of status

information.

If the indoor unit is a more sophisticated station M&C computer, the serial port can be set

to RS-485 for bus operation.

For more information on the M&C board, refer to Section 5.1.

1–5

Page 20

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

1.1.3 Low Noise Amplifier (LNA)

The feed assembly consists of an LNA and a wave guide Transmit Reject Filter (TRF).

The TRF provides receive system protection from transmit energy fed back through the

antenna feed system.

The LNA standard noise temperature is 120°K, with optional upgrades down to 80°K,

depending upon Gain over Temperature (G/T) requirements.

1.1.4 Outdoor Enclosure

The RFT-1200 is a weatherproof enclosure housing the following:

• Solid-State Power Amplifier (SSPA)

• Up and down converters

• M&C microprocessor

• Power supply and cables which interface with an antenna subsystem

In the transmit (uplink) direction, the RFT-1200 accepts a 70 MHz IF signal, and

transmits it in the 14.0 to 14.5 GHz frequency band.

In the receive (downlink) direction, depending upon the frequency band options, the

terminal accepts an RF signal in either the full 10.95 to 12.75 GHz band, or within an

individual sub-band (10.95 to 11.7 GHz, 11.7 to 12.2 GHz, 12.25 to 12.75 GHz), and

converts the signal to 70 MHz IF output.

Power levels range from +8 dBm (for driving an external TWT) to 16W, depending upon

Equivalent Isotropically Radiated Power (EIRP) requirements. The SSPAs are

temperature compensated for maximum stability.

The up and down converters are dual conversion with individual synthesizers for

independent transmit and receive transponder selection.

The microprocessor provides:

• Online loop monitoring

• Dynamic control functions

• Configuration control

• Fault/status monitoring

• Serial computer/terminal interface

1–6

Page 21

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

1.2 Options

1.2.1 Configurations

The KST-12000 can be ordered with various configurations, including:

• Step sizes

• Output power levels

• Input power (AC/DC)

• Synthesizers

• LNA gain

• Redundant LNA mounting plates

• Custom logos

Contact an Comtech EF Data marketing representative for more information.

1.2.2 Equipment

The following item is available:

• KP-10 hand-held keypad. The KP-10 provides portable, external access for

• Front panel display/keypad. The optional front panel provides the local user

• High-power amplifiers:

controlling the RFT. For more information, refer to the Comtech EF Data KP-10

External Keypad Installation and Operation Manual.

interface, which can be used to configure and monitor the status of the terminal.

For more information, refer to Chapter 4.

Traveling Wave Tube Amplifier (TWTA). For more information, refer to the

Comtech EF Data High-Power TWTA Satellite Terminals Installation and

Operation Manual.

Solid-State Power Amplifier (SSPA). For more information, refer to the

Comtech EF Data High-Power SSPA Satellite Terminals Installation and

Operation Manual.

1–7

Page 22

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

1.3 Specifications

Table 1-1 lists the specifications for the KST-12000 system, Table 1-2 lists the

specifications for the RFT-1200, and Table 1-3 lists the specifications for the LNA.

Notes:

1. For specifications on the RSU-503L, refer to Appendix A of the Comtech EF

Data RSU-503 Redundancy Switch Unit Installation and Operation Manual.

2. For more information pertaining to KST-12000 specifications, refer to Comtech

EF Data Specification SP/3044.

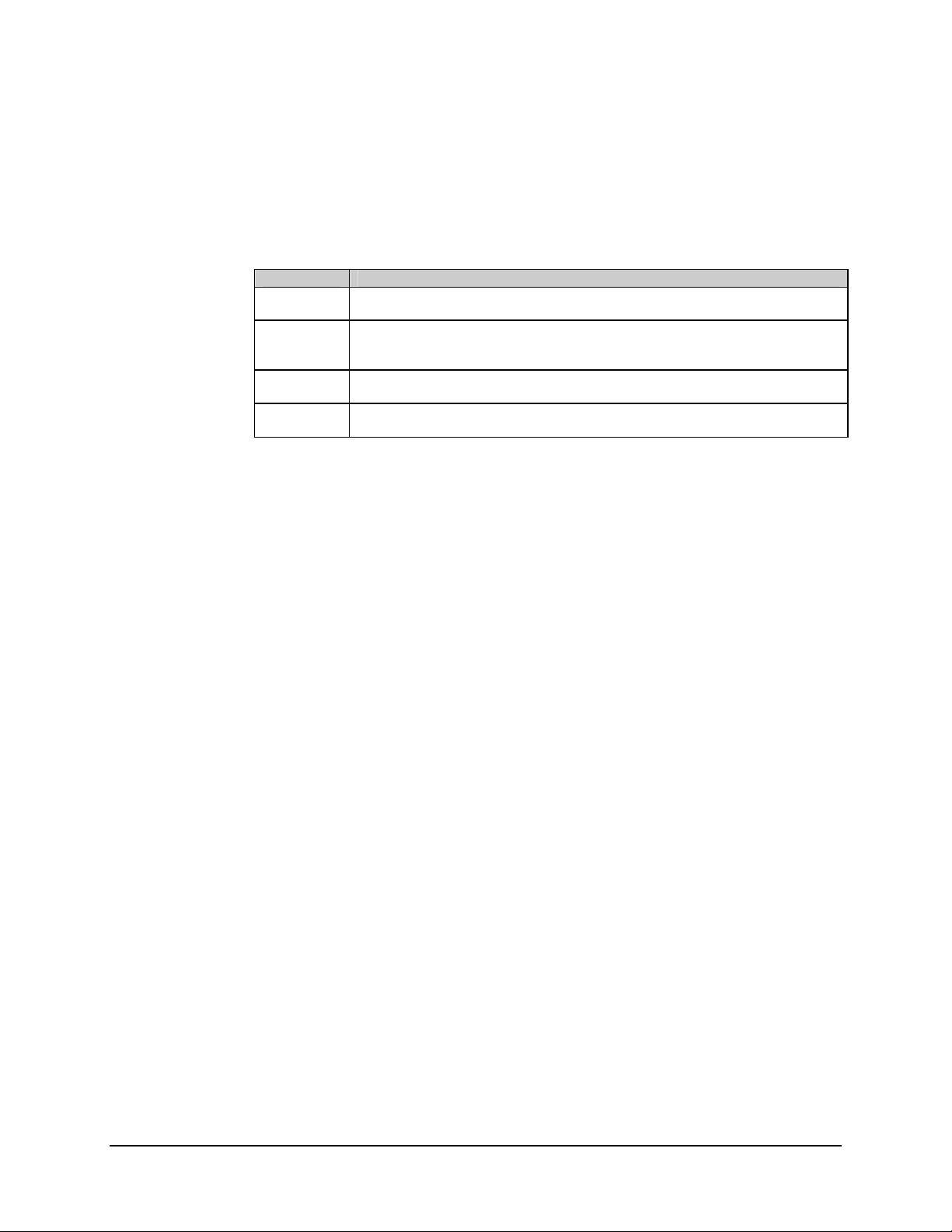

Table 1-1. KST-12000 System Specifications

Parameter Specification

RF Input Connector Type N Female

RF Output Connector WR-75G

TX Band 14.0 to 14.5 GHz

RX Band 10.95 to 12.75 GHz

10.95 to 11.7 GHz

11.7 to 12.2 GHz

12.25 to 12.75 GHz

IF Interface Two 70 MHz ports

IF Out Connector Type TNC female

IF In Connector Type TNC female

IF Out Impedance

IF Out Return Loss > 19 dB at 70 MHz, ± 18 MHz

IF In Impedance

IF In Return Loss > 19 dB at 70 MHz, ± 18 MHz

50Ω

50Ω

1–8

Page 23

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

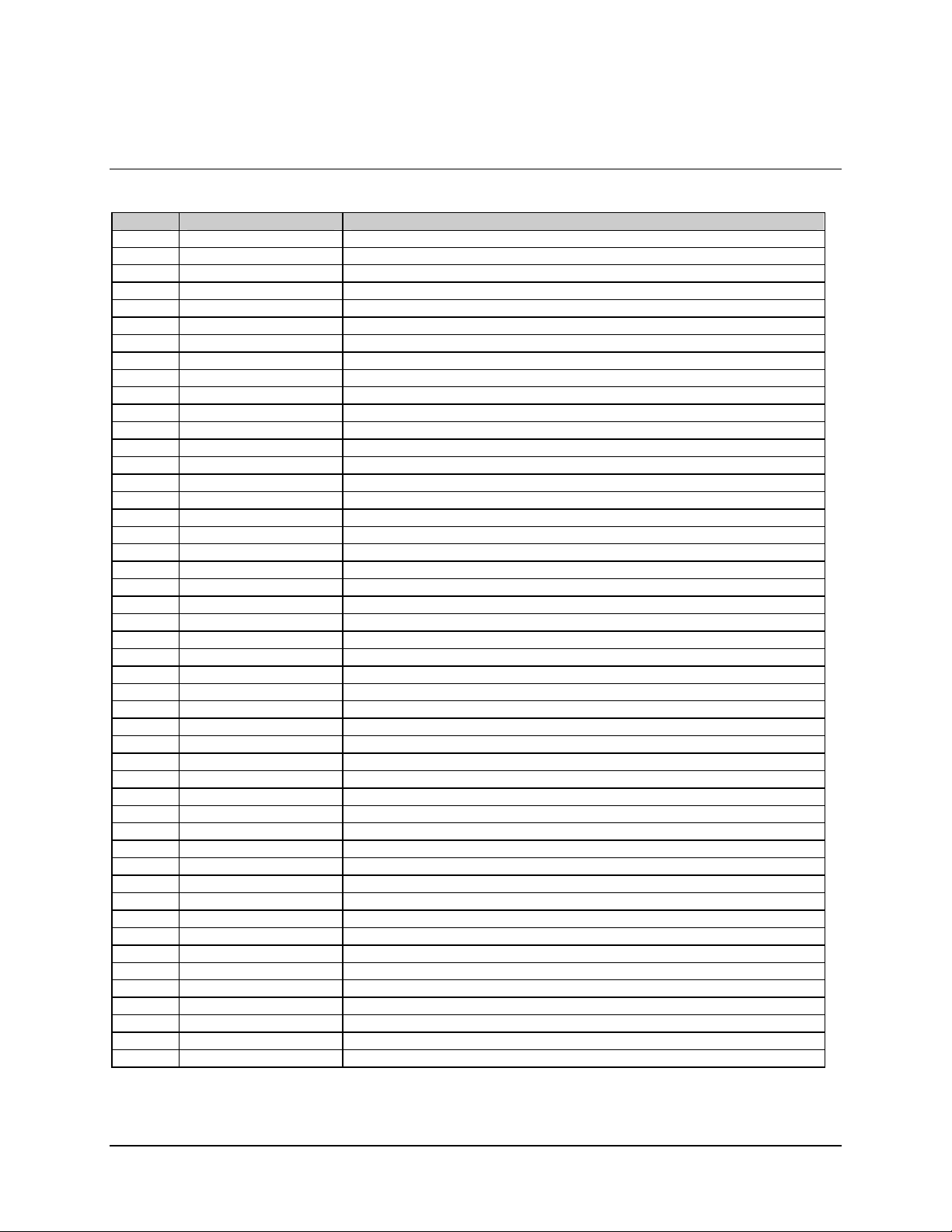

Table 1-2. RFT-1200 Specifications

Receive

Frequency Range 10.95 to 12.75 GHz, in 2.5 MHz steps

10.95 to 11.7 GHz, in 2.5 MHz steps

11.7 to 12.2 GHz, in 2.5 MHz steps

12.25 to 12.75 GHz, in 2.5 MHz steps

Frequency Range (Optional) 10.95 to 12.75 GHz, in 1.0 MHz steps

10.95 to 11.7 GHz, in 1.0 MHz steps

11.7 to 12.2 GHz, in 1.0 MHz steps

12.25 to 12.75 GHz, in 1.0 MHz steps

Frequency Sense No inversion

Receiver Gain Variable 70 to 95 dB with LNA

Frequency Stability

Daily RX Freq Stability

Annual RX Freq Stability

Life RX Freq Drift

RX Drift/Temp

± 1 x 10

± 1 x 10

± 1 x 10

± 1 x 10

± 1 x 10

Gain Flatness ± 1.0 dB/36 MHz

Bandwidth 70 MHz with 1 dB BW of ± 18 MHz

Noise Figure 120°K (options to 90°K)

Receive Image Rejection -45 dBc

Linearity T.O.I. -35 dBc for 2 tones at -86 dBm Pin (with LNA)

Group Delay < 20 ns/36 MHz

Synth Lock Time < 1 second

RX (2.5 MHz steps)

Phase Noise

-60 dBc/Hz at 100 Hz

-70 dBc/Hz at 1 kHz

-75 dBc/Hz at 10 kHz

-80 dBc/Hz at 100 kHz

Optional RX (1.0 MHz steps)

Phase Noise

-60 dBc/Hz at 100 Hz

-66 dBc/Hz at 1 kHz

-75 dBc/Hz at 10 kHz

-80 dBc/Hz at 100 kHz

Inband Overdrive No damage to 0 dBm

Third Order Intercept +24 dBm minimum

1 dB Output Compression +17 dBm minimum

-8

at 23°C (73°F)

-8

at 23°C (73°F)

-7

at 23°C (73°F)

-7

at 23°C (73°F)

-8

from -40 to +55°C (-40 to 131°F)

1–9

Page 24

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

Table 1-2. RFT-1200 Specifications (Continued)

Transmit

Frequency Range 14.0 to 14.5 GHz, in 2.5 MHz steps

Frequency Range (Optional) 14.0 to 14.5 GHz, in 1.0 MHz steps

Transmitter Power Options at 1 dB Compression

Point:

+8 dBm

2W

5W

8W

16W

Transmitter Power Option:

+8 dBm

2W

5W

8W

Gain at 1 dB compression point with customer

attenuator at 10 dB:

26 dB gain

63 dB gain

67 dB gain

69 dB gain

72 dB gain

Linear Gain with customer attenuator at 10 dB:

27 dB

64 dB

68 dB

70 dB

73 dB

16W

Transmitter Linear Gain vs. Customer Controlled

0 to 25 dB, factory setting = 10 dB

Attenuator Setting

TX Bandwidth 70 MHz with 1 dB BW of ± 18 MHz

Gain Flatness ± 1 dB/36 MHz

Gain Variation ± 2 dB max for flatness, temp, aging

TX Freq Stability

Daily TX Freq Stability

Annual TX Freq Stability

TX Freq Drift/Temp

± 1 x 10

± 1 x 10

± 1 x 10

± 1 x 10

-8

at 23°C (73°F)

-8

at 23°C (73°F)

-7

at 23°C (73°F)

-8

from -40 to +55°C (-40 to 131°F)

TX Synthesizer Lock-Up time < 1 second

TX Phase Noise (2.5 MHz steps) -60 dBc/Hz at 100 Hz

-70 dBc/Hz at 1 kHz

-75 dBc/Hz at 10 kHz

-80 dBc/Hz at 100 kHz

Optional TX (1.0 MHz steps)

Phase Noise

-60 dBc/Hz at 100 Hz

-66 dBc/Hz at 1 kHz

-75 dBc/Hz at 10 kHz

-80 dBc/Hz at 100 kHz

M&C (optional):

Signals Monitored/Controlled

RS-232/RS-485

Transmit Frequency

Receive Frequency

Transmit Gain

Receive Gain

RF On/Off

LNA Fault

SSPA Fault

Up Converter Fault

Down Converter Fault

TX Synthesizer Fault

RX Synthesizer Fault

1–10

Page 25

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

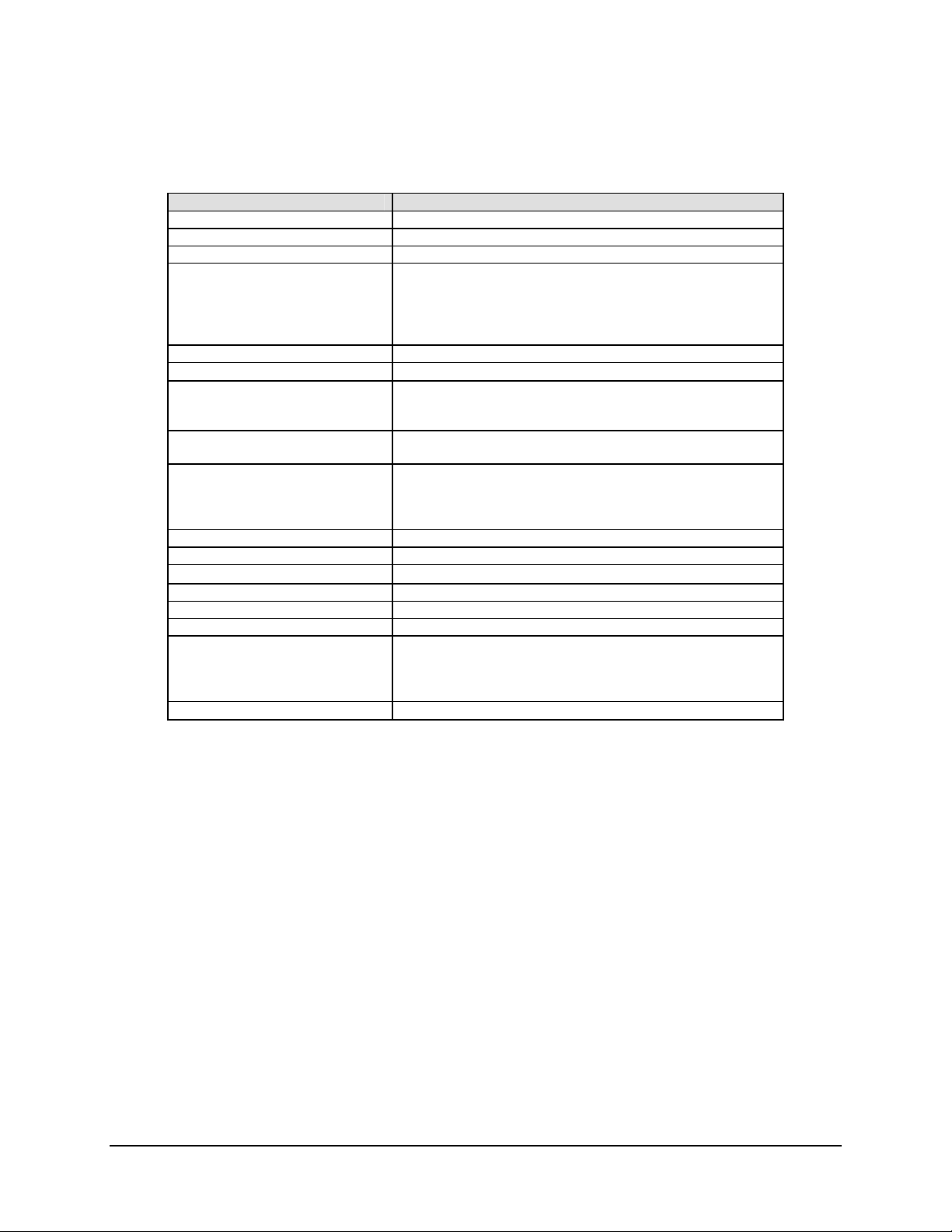

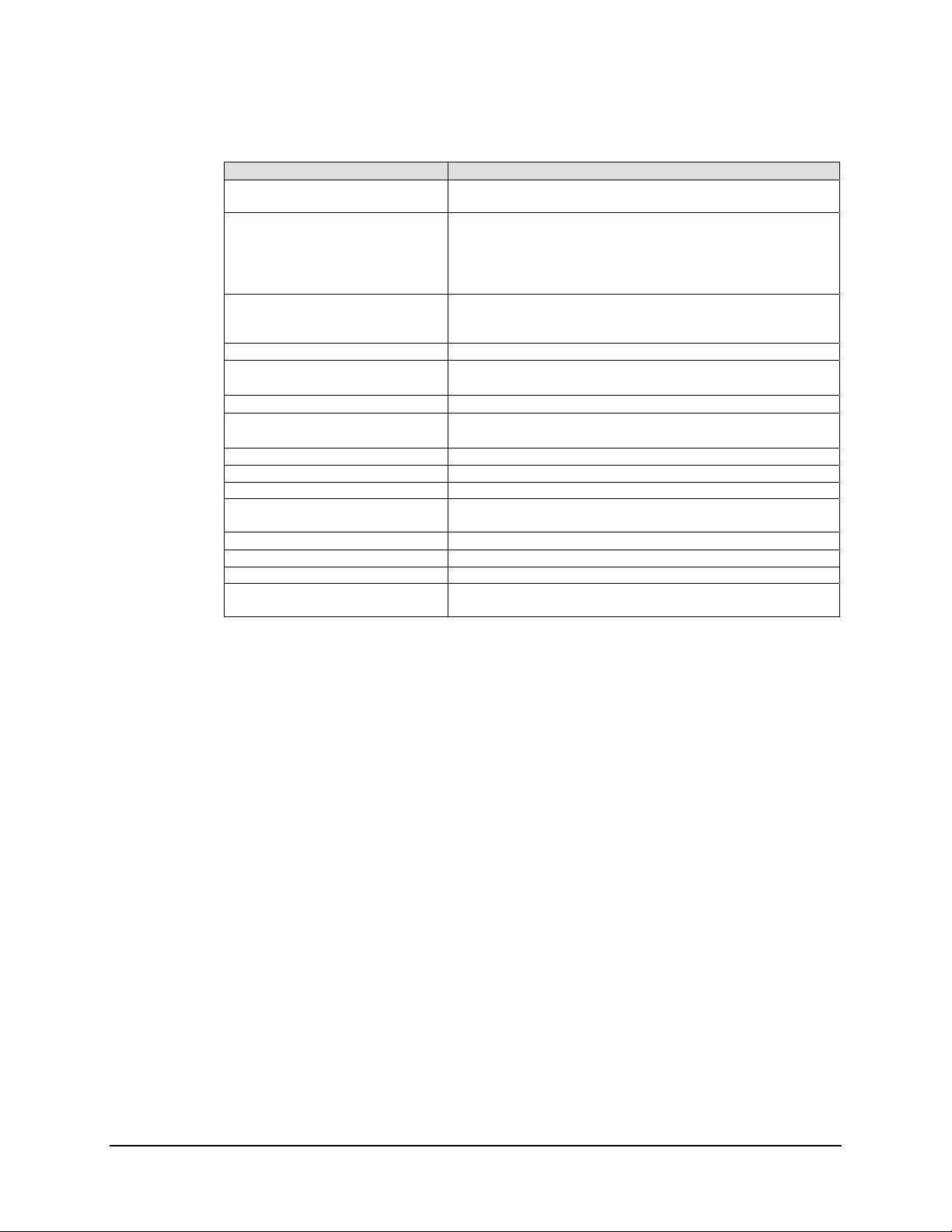

Table 1-3. LNA Specifications

Parameters Specifications

Dimensions Refer to Figures 1-5 or 1-6

Input VSWR 1.25:1 max.

Output VSWR 1.25:1

Gain Flatness:

10.95 to 12.75 GHz

10.95 to 11.7 GHz

11.7 to 12.2 GHz

12.25 to 12.75 GHz

Gain vs. Temperature ± 1.5 dB Max.

Operating Temperature

1 dB Gain Comp. Pt.

(optional)

Third Order Intercept Point

(optional)

Group Delay:

Linear

Parabolic

Ripple

Power Connector Powered in KST-12000 through the coax

Linear Group Delay 0.01 ns/MHz

Parabolic Group Delay

Ripple Group Delay 0.1 ns/P-P

RF Input W/G WR-75 Cover

Input Power +12 to +24 VDC at 100 mA Nominal

Frequency 10.95 to 12.75 GHz

AM-PM Conversion

± 2.0 dB/full band ± 0.50 dB/40 MHz

± 1.5 dB/full band ± 0.25 dB/40 MHz

± 1.5 dB/full band ± 0.25 dB/40 MHz

± 1.5 dB/full band± 0.25 dB/40 MHz

-40°C to +60°C (-40°C to + 140°F)

+10 dBm

+20 dBm Optional

+8 dBm

+20 dBm

+18 dBm

0.01 ns/MHz

0.001 ns/MHz

0.1 ns/P-P

0.001 ns/MHz

10.95 to 11.7 GHz

11.7 to 12.2 GHz

12.25 to 12.75 GHz

0.5°/dB at -5 dBm

2

2

1–11

Page 26

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

Table 1-3. Environmental and Physical Specifications

Parameters Specifications

Prime Power Options 90 to 230 VAC, 47 to 63 Hz, using a 6-foot cable North

American 3-prong plug or 48 VDC (40V to 60V)

2W

5W

8W

16W

100W

150W

200W

250W

450W

Power Consumption: +80 dBm

Physical:

RFT-12000 size

Weight

Enviromental:

Temperature:

Thermal Gradient

Humidity

Precipitation MIL-STD-810/ Method 506.2

Salt Fog MIL-STD-810/ Method 509.2

Sand and Dust MIL-STD-810/ Method 510.1

Altitude Operating: 0 to 15,000 ft

Solar Radiation

Safety Capable of UL, CSA, VDE, IEC

Emissions FCC Part 15, J, Class A

ES Discharge Operating: 10 kV

23H x 10.3W x 9.3D inches (58.4H x 26.16W x 23.6D cm)

38lbs (17.24kg) maximum

Operating: -40° to +55°C (-40° to 131°F)

Survival: -50° to +75°C (-58° to 167°F)

40°C/hour

0% to 100% Relative at -40° to +55°C (-40° to 131°F)

95% at 65°C/72hours

Survival: 0 to 50,000 ft

360 BTU/hr/ft2 at 50°C

Survival: 15 kV

1–12

Page 27

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

Figure 1-5. Dimensions for Single-Thread LNA

1–13

Page 28

KST-12000 Ku-Band Satellite Terminal Revision 4

Introduction MN/KST12000.IOM

Figure 1-6. Dimensions for 1:1 Redundant LNA Plate

1–14

Page 29

This chapter provides installation information for single-thread systems.

2.1 Unpacking

The KST-12000 terminal system is packaged in preformed, reusable foam inside a

cardboard carton.

Before unpacking the carton components, ensure that there is plenty of room around the

carton for workspace. A large table is recommended.

To remove the parts:

Note: Save the packing material for reshipment.

Chapter 2. SINGLE-THREAD

SYSTEM INSTALLATION

1. Cut the tape at the top of the carton where it is indicated OPEN THIS END.

2. Lift out the cardboard/foam spacer covering the unit.

3. Remove each part from the carton. Refer to Section 2.2.1 for a parts breakdown.

Because the RFT is heavy, assistance may be necessary to remove

the unit from the box.

CAUTION

2.2 Inspecting the Equipment

1. Carefully check the equipment for damage incurred during shipment.

2. Carefully check the equipment against the packing list shipped with the

equipment to ensure that the shipment is complete. Refer to the following

paragraphs.

2–1

Page 30

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

2.2.1 Included Parts

A typical single-thread KST-12000 configuration contains the following components.

Notes:

1. Parts are not drawn to scale. Because each system can be custom ordered, it is

beyond the scope of this manual to provide the unlimited configuration

possibilities.

2. This chapter does not describe the installation procedures for amplifiers, high

performance LNAs, phase-locked LNBs, LNBs, and phase-locked block

converters. Comtech EF Data is herein abbreviated to CEFD.

Qty. Description Qty. Description

1 RFT outdoor unit.

1 Feed assembly.

RF OUT

SERIALNO.

MODELNO.

FREQUENCY

NOISETEMP GAIN

RF IN

Note: Pictured is a typical LNA. Other LNAs

are available, and can be ordered from an

CEFD marketing representative.

1 Envelope containing the test data sheet.

1 KST-12000 installation and operation manual.

1 Monitor and Control Software for CEFD

Satellite Terminals User’s Guide.

2–2

Page 31

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

1 Kit KT/3954-x (where x = 1 for AC power, and 2 for DC power), which includes:

Qty. Description Qty. Description

1 Connector kit.

1

Note: Either the AC or DC cable is provided,

depending upon the product ordering code.

Assembly, 15-ft AC prime power cable.

CEFD Part # PL/2754.

Assembly, 15-ft DC prime power cable.

CEFD Part # PL/4157.

CEFD Part # CN/STPG26M01.

Used to connect customer’s cable to the RFT

26-pin J6 (REMOTE). For remote control and

status monitoring (by using M&C system

monitor software).

1 17’ Heliax cable.

CEFD Part # CA/3722.

Used for LNA to down converter.

1 O-Ring, -024, buna, black.

CEFD Part # 32P1037.

10 6-32 x 7/8” socket head cap screw.

1 Flexible Waveguide.

CEFD Part # RF/WGFLXWR75-5.

Used to connect LNA to antenna.

2 O-Ring, black neoprene.

CEFD Part # 32P1039.

20 #6 flat washer.

CEFD Part # HW/6-32X7/8SHCS.

10 6-32 nut.

CEFD Part # HW/6-32HEXNUT.

CEFD Part # HW/6-FLT.

10 #6 split lockwasher.

CEFD Part # HW/6-SPLIT.

2–3

Page 32

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

Note: If an RFT for a spar mount is ordered, Comtech EF Data will provide a spar mount

kit (KT/4061). Otherwise, the universal installation kit (KT/3576) will be provided.

1 Kit KT/4061, which includes:

Qty. Description Qty. Description

2 Spar support bracket.

4 5/16-18 x 1” bolt.

CEFD Part # FP/3175.

Used for spar mount only.

8 1/4-20 x 5/8” bolt.

CEFD Part # HW/1/4-20X5/8BT.

Used to attach 8” or 14” unistruts to RFT.

8 1/4” flat washer.

CEFD Part # HW/1/4-FLT.

Used to attach 8” unistruts to RFT.

8 1/4” split lockwasher.

CEFD Part # HW/1/4-SPLIT.

Used to attach 8” unistruts to RFT.

2 Unistrut — 8” long.

CEFD Part # HW/5/16-18X1BLT.

Used to attach spar support bracket to 8”

unistrut.

4 5/16” split lockwasher.

CEFD Part # HW/5/16-SPLIT.

Used to attach spar support bracket to 8”

unistrut.

4 5/16” flat washer.

CEFD Part # HW/5/16-FLT.

Used to attach spar support bracket to 8”

unistrut.

4 5/16-18 spring nut.

CEFD Part # HW/5/16-18SPNUT.

Used to attach spar support bracket to 8”

unistrut.

CEFD Part # FP/3481.

Attaches directly to RFT.

2–4

Page 33

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

1 Kit KT/3576, which includes:

Qty. Description Qty. Description

2 Spar support bracket.

12 5/16-18 x 1” bolt.

CEFD Part # FP/3175.

Used for spar mount only.

4 Unistrut — 14” long.

CEFD Part # FP/3595.

Used for round and square pole mount only.

2 Unistrut — 8” long.

CEFD Part # FP/3481.

Attaches directly to RFT.

8 1/4-20 x 5/8” bolt.

CEFDa Part # HW/1/4-20X5/8BT.

Used to attach 8” unistruts to RFT.

8 1/4” flat washer.

CEFD Part # HW/5/16-18X1BLT.

24 5/16” split lockwasher.

24 5/16” flat washer.

12 5/16-18 hex nut.

16 5/16-18 spring nut.

CEFD Part # HW/5/16-SPLIT.

CEFD Part # HW/5/16-FLT.

CEFD Part # HW/5/16-18HEXNT.

CEFD Part # HW/1/4-FLT.

Used to attach 8” unistruts to RFT.

8 1/4” split lockwasher.

CEFD Part # HW/1/4-SPLIT.

Used to attach 8” unistruts to RFT.

8 Pipe block.

CEFD Part # HW/BLK-PIPE2-8.

Used for round pole mount only.

CEFD Part # HW/5/16-18SPNUT.

8 Flat fitting plate, 5/16”.

CEFD Part # HW/FIT-PLT-5/16.

4 Threaded rod, 5/16-18 x 14”.

CEFD Part # HW/RD5/16-18X14.

Used for round and square pole mount only.

2–5

Page 34

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

2.3 RFT Installation

At the customer’s discretion, the RFT can be installed anywhere on or near the antenna.

The supplied hardware allows the installer a wide range of installation alternatives,

including:

• Vertical pole (e.g., mast) (either square or round). This is the most typical

installation.

• Within the hub of a large antenna.

• Spar (i.e., square bar) on the antenna structure.

Comtech EF Data recommends that the RFT be mounted vertically, with the air inlet

facing the ground.

2–6

Page 35

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

2.3.1 Tools Required

Qty. Description

3/8” drive ratchet.

1

3” x 3/8” drive extension.

1

7/16” x 3/8” drive socket. (Metric equivalent: 12mm, 6 pt.)

1

1/2” x 3/8” drive socket. (Metric equivalent: 13mm, 6 pt.)

1

1 1/2” combination wrench. (Metric equivalent: 13mm combination

wrench with a 6 pt. box end.)

1 7/64” hex key (allen wrench). (No metric equivalent.)

1 5/16” combination wrench. (Metric equivalent: 8mm combination

wrench with a 6 pt. box end.)

2–7

Page 36

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

2.3.2 Vertical Pole Installation

2.3.2.1 Round Pole

Note: The following process is for a typical installation. Custom systems may be ordered,

and are beyond the scope of this manual.

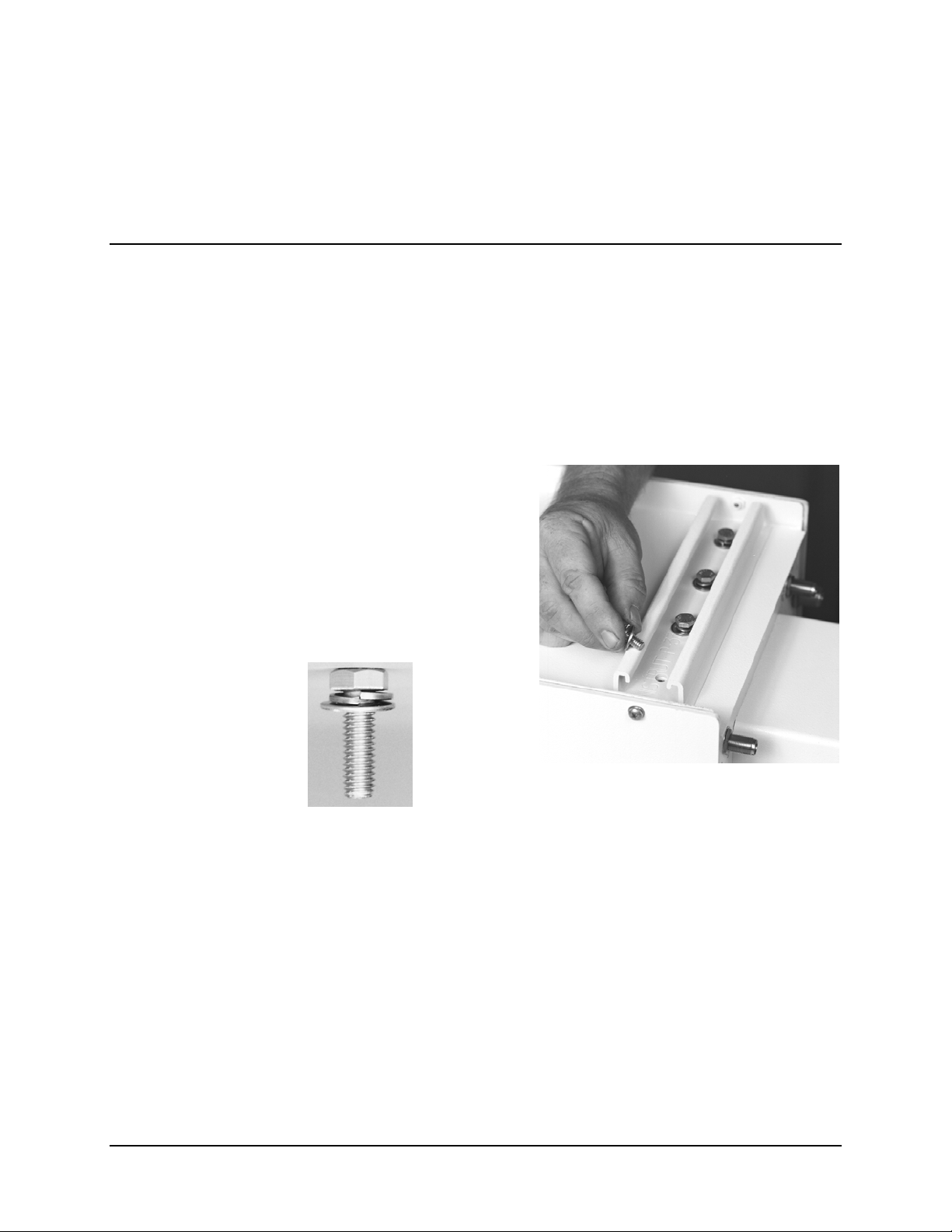

To install the RFT to a round vertical pole:

1. Set the unit on its side, with the mounting holes facing up.

2. Install the 8” unistruts as follows:

a. Position an 8” unistrut (with

the open side facing up)

over one set of the mounting

holes on the RFT.

b. Using four 1/4-20 bolts,

1/4” split lockwashers, and

1/4” flat washers, attach an

8” unistrut to the RFT.

Tighten the bolts firmly.

c. Repeat Steps 2.a. and 2.b.

for the second 8” unistrut.

2–8

Page 37

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

3. Install the 14” unistruts as follows:

a. Position a spring nut

between the inner and outer

bolts on both sides of each

8” unistrut.

b. Install each spring nut as

follows:

(1) Place the spring nut in

the unistrut channel,

spring side down, with

its wide side parallel

with the unistrut

channel.

(2) Press down on the

spring nut to compress

the spring, and rotate

the nut 90° (i.e.,

perpendicular to the

unistrut).

(3) Release pressure on the

spring nut.

(4) Repeat Steps 3.b.(1)

through 3.b.(3) for

each spring nut.

2–9

Page 38

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

c. Position a 14” unistrut

(open side facing up) over

one of the 8” unistruts.

Ensure the 14” unistrut is

centered over the RFT.

d. Using two 5/16-18 bolts,

5/16” split lockwashers, and

5/16” flat washers, attach

the 14” unistrut to the 8”

unistrut.

Note: The bolts should be installed in the fifth hole from each end, as

illustrated.

Tighten the bolts firmly.

e. Attach the second 14” unistrut to the second 8” unistrut by repeating

Steps 3.a. through 3.d.

2–10

Page 39

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

4. Install the pipe blocks as follows:

a. Install two spring nuts in each of four 14” unistruts (the two just mounted on

the RFT, and two additional).

Be sure to position the spring nuts in the unistruts wide enough apart so that

when the pipe blocks are installed, they will clear the pole when the unit is

lifted into place for installation.

b. Install each spring nut as follows:

(1) Place the spring nut in the unistrut channel, spring side down, with its

wide side parallel with the unistrut channel.

(2) Press down on the spring nut to compress the spring, and rotate the nut

90° (i.e., perpendicular to the unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 4.b.(1) through 4.b.(3) for each spring nut.

c. Using four 5/16-18 bolts, 5/16” split

lockwashers, and 5/16” flat washers,

loosely secure the pipe blocks to the

spring nuts.

Ensure the pipe blocks are installed

with the long angle facing inward,

toward the pipe, as illustrated.

DO NOT tighten the pipe block bolts

until after mounting the RFT on the

vertical pole. (See Step 6.e.)

2–11

Page 40

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

5. Install the threaded rods as follows:

a. Install two spring nuts in both 14”

unistruts mounted on the RFT.

Note: Ensure the spring nuts are

positioned over the outer holes in the

14” unistruts, as illustrated.

b. To install each spring nut:

(1) Place the spring nut in the

unistrut channel, spring side

down, with its wide side parallel

with the unistrut channel.

(2) Press down on the spring nut to

compress the spring, and rotate

the nut 90° (i.e., perpendicular to

the unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 5.b.(1) through 5.b.(3) for each spring nut.

c. Thread a 5/16-20 nut approximately 1-1/2” onto each threaded rod. (This will

ensure that the threaded rods will extend beyond the spring nuts when

installed.)

d. Place a 5/16” split lockwasher, 5/16” flat washer, and flat fitting plate over

each threaded rod.

2–12

Page 41

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

e. One threaded rod at a time, hold the

washers and plate in place on the rod,

and screw the rod into a spring nut, as

illustrated.

Notes:

1. Be sure to position the flanges

of the flat fitting plates in the

grooves of the unistruts.

2. Before tightening the nuts on

the threaded rods, ensure that

the end of each rod is screwed

in until it is flush with the

backside of the unistruts. This

ensures the rods are threaded

completely through the spring

nuts.

Tighten each nut firmly.

f. Thread a 5/16-18 nut about 2” onto the

end of each threaded rod.

g. Slip a 5/16” split lockwasher, 5/16” flat

washer, and flat fitting plate (in that

order) onto each threaded rod.

2–13

Page 42

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

6. Mount the RFT as follows:

a. Lift the RFT into position on the vertical pole.

b. Slip a 14” unistrut over each of pair of threaded rods (upper and lower).

Note: Install the 14” unistruts with the open face toward the pole as

illustrated below.

2–14

Page 43

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

c. Install a 5/16” flat washer, 5/16” split lockwasher, and 5/16-18 nut on each

threaded rod.

d. Position the RFT as desired, and tighten the 5/16-18 nuts installed in

Step 6.c.

e. Slide the pipe blocks inward until they contact the vertical pole, then firmly

tighten the 5/16-18 bolts.

2.3.2.2 Square Pole

For square vertical pole installation, follow the steps in Section 2.3.2.1, with the

following exceptions:

• Do not perform Step 4.

• Do not perform Step 6.e.

2–15

Page 44

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

2.3.3 Spar Installation

Note: The following process is for a typical installation. Custom systems may be ordered,

and are beyond the scope of this manual.

To install the RFT to a spar:

1. Set the unit on its side, with the mounting holes facing up.

2. Install the 8” unistruts as follows:

a. Position an 8” unistrut (with the open

side facing up) over one set of the

mounting holes on the RFT.

b. Using four 1/4-20 bolts, 1/4” split

lockwashers, and 1/4” flat washers,

attach an 8” unistrut to the RFT.

Tighten the bolts firmly.

c. Repeat Steps 2.a. and 2.b. for the

second 8” unistrut.

2–16

Page 45

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

3. Mount the RFT as follows:

a. Position a spring nut between the

inner and outer bolts on both sides

of each 8” unistrut, as illustrated.

b. Install each spring nut as follows:

(1) Place the spring nut in the

unistrut channel, spring side

down, with its wide side

parallel with the unistrut

channel.

(2) Press down on the spring nut

to compress the spring, and

rotate the nut 90° (i.e.,

perpendicular to the unistrut).

(3) Release pressure on the spring

nut.

(4) Repeat Steps 3.b.(1) through

3.b.(3) for each spring nut.

c. Lift the RFT into position.

d. Using four 5/16-18 bolts, 5/16”

split lockwashers, and 5/16” flat

washers, bolt the two spar support

brackets in place.

Tighten the bolts firmly.

2–17

Page 46

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

2.4 LNA and Flexible Waveguide Installation

Refer to Section 2.2.1 for included parts.

To install a single LNA to an antenna:

1. Remove the protective cover from the antenna mount location (if installed).

2. Remove the plastic cover from the antenna end (RF IN) of the LNA.

3. Remove the plastic cover from the RF OUT end of the LNA.

After removing the protective cover(s), ensure that no foreign

material or moisture enters the antenna waveguide or LNA.

CAUTION

4. Install the appropriate O-ring on the antenna end of the LNA:

a. If both components have O-ring grooves, use EFData Part # 32P1039.

b. If only one component has an O-ring groove, use EFData Part # 32P1037.

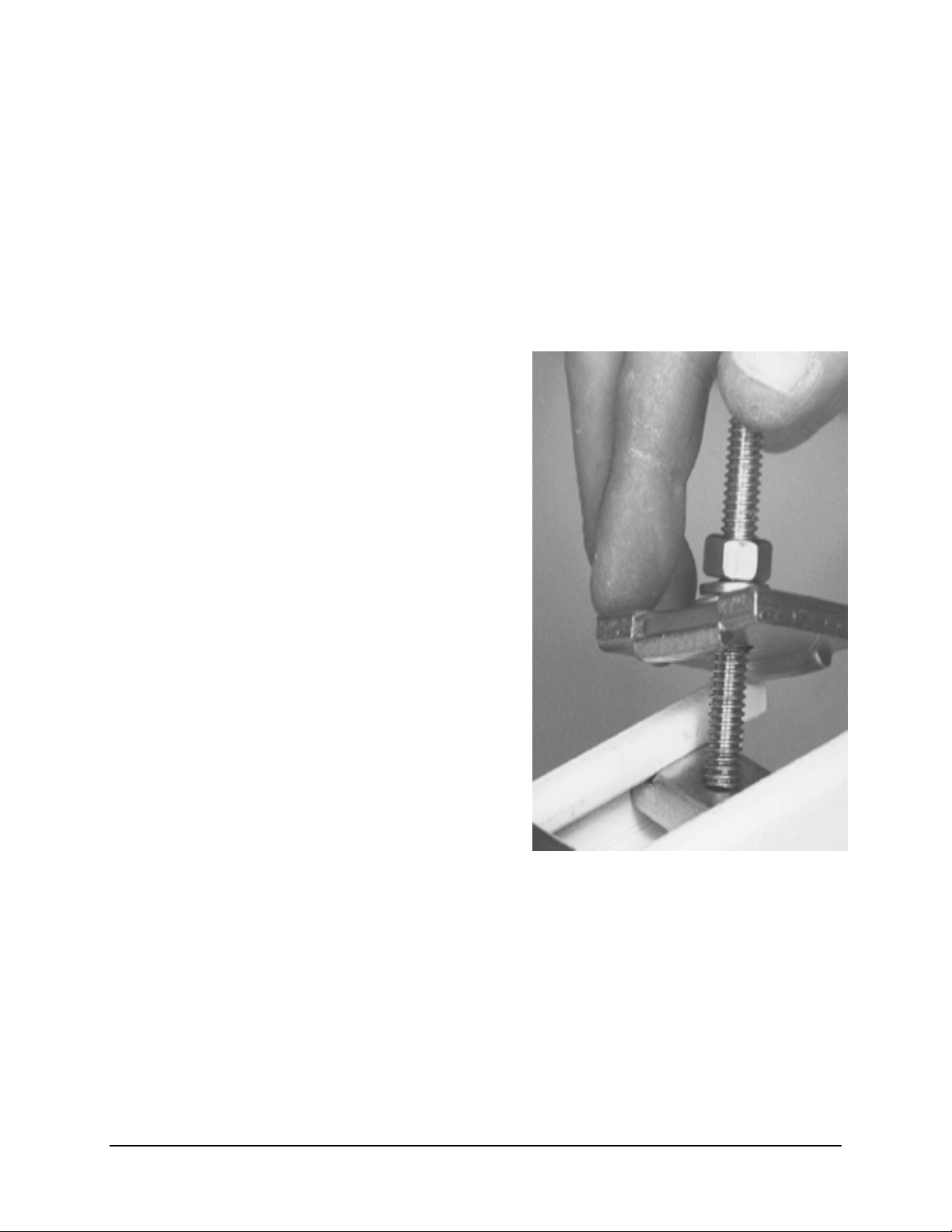

5. Using four 6-32 x 7/8” socket head cap screws, eight #6 flat washers, four #6

split lockwashers, and four 6-32 nuts, attach the LNA to the antenna. Tighten the

cap screws firmly.

To install the flexible waveguide:

1. Install the appropriate O-ring between the flexible waveguide and the antenna.

2. Using four 6-32 x 7/8” socket head cap screws, four #6 split lockwashers, eight

#6 flat washers, and four 6-32 nuts, attach the flexible waveguide to the antenna.

Tighten the cap screws firmly.

3. Install the appropriate O-ring between the flexible waveguide and the waveguide

flange on the RFT.

4. Using four 6-32 x 7/8” socket head cap screws, four #6 split lockwashers, eight

#6 flat washers, and four 6-32 nuts, attach the flexible waveguide to the

waveguide flange on the RFT. Tighten the cap screws firmly.

2–18

Page 47

KST-12000 Ku-Band Satellite Terminal Revision 4

E

Single-Thread System Installation MN/KST12000.IOM

2.5 External Connections

Connections between the RFT and other equipment are made through six connectors.

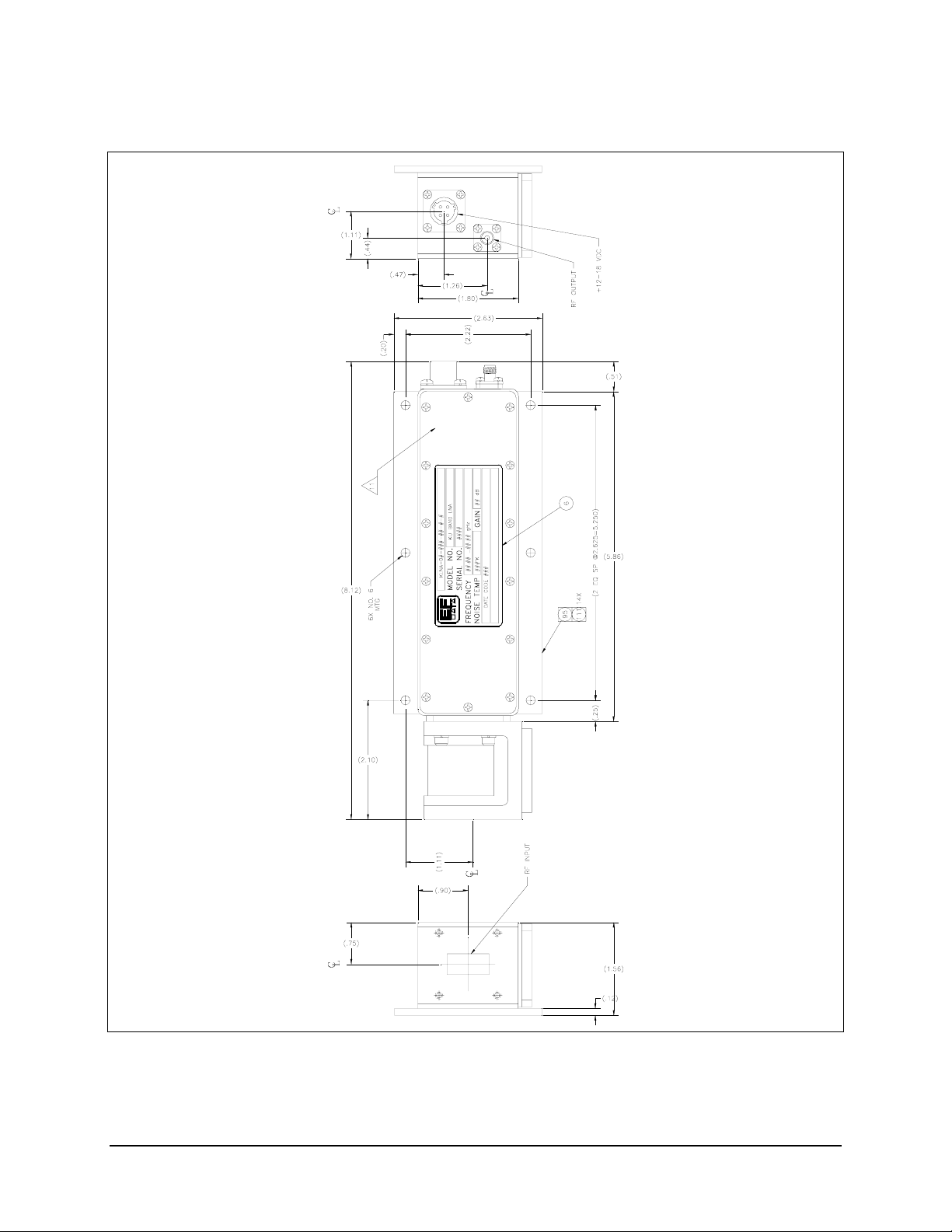

These connectors are listed in Table 2-1, and their locations are shown in Figure 2-1.

The use of each connector is described in the following paragraphs.

Table 2-1. Rear Panel Connectors

Name

TX/IF IN J1 TNC TX IF INPUT (70 MHz)

TX/RF OUT J2 WR-75 G 14.0 to 14.5 GHz OUT

RX/IF OUT J3 TNC RX IF OUT (70 MHz)

RX/RF IN J4 Type N 10.95 to 12.75 GHz Input

PRIME PWR J5 Standard Prime Power Input

REMOTE J6 26-pin CIR Remote Interface

GND None #10-32 Stud Chassis Ground

Ref Des

Connector

Type

Function

J6

J1

REMOTE

TX/IF IN

WAVEGUID

OUTPUT

J2

RX/IF

OUT

J4

RX/RF

IN

ERDE

J5

PRIME

POWER

GND

FUSE

FUSE

Figure 2-1. RFT External Connections

2–19

Page 48

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

2.5.1 TX/IF Input (J1)

The TX/IF input is a TNC type connector that comes from the indoor unit. The input

impedance is 50

Ω, and the frequency is 70 MHz, ± 18 MHz. The typical power level is

from -43 to -19 dBm, depending on the customer’s configuration and application.

2.5.2 TX/RF Output (J2)

The TX/RF output is a WR-75 G interface with an output impedance of 50Ω. The output

frequency range is 14.0 to 14.5 GHz. The output power level is dependent on the power

amplifier ordered in the system.

2.5.3 RX/IF Output (J3)

The RX/IF output is a TNC type connector that sends the received signal to the indoor

unit. The output impedance is 50

The 1 dB output compression point is +17 dBm.

The level of the signal at the RX/IF output is a factor of input signal level and total

system gain.

The system gain is adjustable by the user over a 25 dB range.

The typical system gain includes a 50 dB LNA, making the total typical system gain 70

to 95 dB.

Note: A 60 dB LNA is only used when there are extremely long cables from the LNA to

the down converter.

Ω, and the frequency is 70 MHz, ± 18 MHz.

2.5.4 RX/RF Input (J4)

The RX/RF input is a type N connector that comes from the LNA. The input impedance

Ω. The connector also has the LNA DC power on the center conductor.

is 50

The input frequency range depends upon receive band options, either:

• Full 10.95 to 12.75 GHz band

• Individual sub-band:

10.95 to 11.7 GHz

11.7 to 12.2 GHz

12.25 to 12.75 GHz

2–20

Page 49

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

2.5.5 Prime Power (J5)

The AC power is supplied to the RFT by a 3-pin power connector. Normal input voltage

is 90 to 232 VAC, 47 to 63 Hz. The AC pinout is as follows:

Pin # Name Function Wire Color

A HI Line Brown

B LO Neutral Blue

C GND Ground Green/yellow

Maximum power consumption depends on the power amplifier used in the RFT. The

following is a list of the maximum power consumption at each configuration:

SSPA Maximum Power

+8 dBm 100W

2W 150W

5W 200W

8W 250W

16W 450W

A circular 4-pin power connector is used for the DC (48 VDC) option. The pinout is as

follows:

Pin # Name

A + INPUT

B GROUND

C - INPUT

D NC

2.5.6 Serial Remote Control (J6)

The remote connector on the RFT is used to interface the M&C functions to a remote

location. This interface can be either RS-232 or RS-485.

When using an RS-485 interface, the transmit and receive signals are able to

accommodate either type of remote equipment pinouts. As long as the polarities of the

remote equipment TX and RX signals are correct, this remote interface will be

completely compatible.

Refer to Table 2-2 for a list of pinouts for the J6 connector.

For standard RS-232 or RS-485 applications, an adapter cable must be used to connect

the 26-pin connector (J6) to a standard 9-pin D.

Refer to Figure 2-2 for an illustration of the adapter cable with its pinouts.

2–21

Page 50

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

Table 2-2. RFT-1200 Remote Control Connector, J6

Pin Name Description

RS-232 RS-485

A GND -RX/TX RX/TX Data

B -RX/TX RX/TX Data

C +RX/TX RX/TX Data

D CTS +RX/TX Clear to Send (see Note 1 below)

E RD/RX Receive Data

F RTS Ready to Send (see Note 1 below)

G TD/TX Transmit Data

H DSR Data Set Ready

J GND Ground

K LNA Power Output, 10V for powering LNA (see Note 2 below)

L EXT_PWR Output voltage, 11V, to power RSU-503L and KP-10

M EXT TWT FLT Input, logic 0 or 5V, 5V = FLT, 0V = normal

N EXT IN_2 Input, logic 0 or 5V, spare (see Note 3 below)

P SPARE N/C

R GRD Ground

S SPARE N/C

T ALOG TST Analog test voltage output

U UL_NC Uplink fault relay, connects to uplink COM with fault

V UL_COM Uplink fault relay, COMMON

W UL_NO Uplink fault relay, opens with fault

X DL_NC Downlink fault relay, connects to downlink COM with

Y DL_COM Downlink fault relay, COMMON

Z DL_NO Downlink fault relay, opens with fault

a LNA PWR RTN Return for LNA Power (see Note 2 below)

b SPARE

c SPARE

(see Note 3 below)

fault

Notes:

1. In RS-232 mode, CTS is tied to RTS (and vice versa).

2. LNA can be powered from these pinouts instead of up through the RF cable.

3. 5V is a floating level.

2–22

Page 51

KST-12000 Ku-Band Satellite Terminal Revision 4

A

A

ATA

ADA

A

A

Single-Thread System Installation MN/KST12000.IOM

EFDATA: CN/STPG26M01

PT06E16-26P(SR)

D

E

F

G

H

26 PIN

EFD

: CN/STPG26M01

PT06E16-26P(SR)

B

C

D

J

GND

CTS

RD/R

RTS

TD/T

D

SR

RS-232 ADAPTER CABLE

-RX/TX

-RX/TX

+RX/TX

+RX/TX

GND

P1

5

9

4

8

3

7

2

6

1

M

LE

P1

5

9

4

8

3

7

2

6

1

2.5.7 GND

M

26 PIN

RS-485

PTER CABLE

LE

Figure 2-2. Serial Adapter Cables

A #10-32 stud is available on the rear for the purpose of connecting a common chassis

ground between all of the equipment.

2–23

Page 52

KST-12000 Ku-Band Satellite Terminal Revision 4

Single-Thread System Installation MN/KST12000.IOM

This page is intentionally left blank.

2–24

Page 53

Chapter 3. REDUNDANT SYSTEM

INSTALLATION

This chapter provides installation information for redundant systems, including:

• Unpacking and inspecting the parts

• Installing the RFTs

• Installing the 1:1 redundant plate

• Installing the waveguide switch

• External connections

For RSU-503L installation information, refer to the Comtech EF Data RSU-503

Redundancy Switch Unit Installation and Operation Manual.

For single-thread systems, refer to Chapter 2.

If the RFTs are to be mounted individually, refer to Chapter 2 for installation

information.

3–1

Page 54

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

3.1 Unpacking

The KST-12000 redundant system is shipped in two cartons (one RFT each) and one

crate.

To remove the parts:

1. Cut the tape at the top of each carton where it is indicated OPEN THIS END.

2. Lift out the cardboard/foam spacer covering the units.

3. Remove the parts from the cartons. Refer to Section 3.2.1 for a parts breakdown.

Because the RFTs are heavy, assistance may be necessary to remove

the units from the boxes.

CAUTION

4. Remove the screws from the lid of the wooden crate, and remove the lid.

5. Unbolt the redundant LNA plate and remove it from the crate.

6. Remove the remainder of the parts from the crate. Refer to Section 3.2.1 for a

parts breakdown.

Note: Save the packing material for reshipment.

3.2 Inspecting the Equipment

1. Carefully check the equipment for damage incurred during shipment.

2. Carefully check the equipment against the packing list shipped with the

equipment to ensure that the shipment is complete. Refer to the following

paragraphs.

3–2

Page 55

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

3.2.1 Included Parts

A typical redundant KST-12000 configuration contains the following components.

Notes:

1. Parts are not drawn to scale.Because each system can be custom ordered, it is

beyond the scope of this manual to provide the unlimited configuration

possibilities.

2. This chapter does not describe the installation procedures for amplifiers, high

performance LNAs, phase-locked LNBs, LNBs, and phase-locked block

converters.

3. Comtech EF Data is referenced throughout this section as CEFD.

Qty. Description Qty. Description

2 RFT outdoor unit.

1 Redundant LNA plate.

Note: Pictured is a typical LNA. Other LNAs

are available, and can be ordered from an

CEFD marketing representative.

1 RSU-503L.

1 KST-12000 installation and operation manual.

1 Envelope containing the test data sheet.

1 RSU-503 installation and operation manual.

1 Monitor and Control Software for Comtech EF

Data Satellite Terminals User’s Guide.

3–3

Page 56

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

1 Kit KT/3950-x (where x = 1 for AC power, and 2 for DC power), which includes:

Qty. Description Qty. Description

1 Connector kit.

CEFD Part # CN/STPG26M01.

Used to connect customer’s cable to the RFT

26-pin J6 (REMOTE). For remote control and

status monitoring (by using M&C system

monitor software).

1 Cable assembly.

2

2 Cable assembly.

Note: Either the AC or DC cable is provided,

depending upon the product ordering code.

Assembly, AC prime power cable.

CEFD Part # PL/2754.

Assembly, DC prime power cable.

CEFD Part # PL/4157.

CEFD Part # PL/3951.

“Y” to waveguide switches.

4 Cable assembly.

CEFD Part # CA/3005-1.

TNC to TNC, 50

1 Weldment.

CEFD Part # FP/4427.

Used to attach switch to antenna feed.

Ω

.

CEFD Part # PL/3003.

Used for communications from RFTs A and B

to RSU.

2 Cable.

CEFD Part # CA/3722.

LNA to down converter.

1 Termination.

CEFD Part # RF/TERM-11923-2.

Used on port 3 of the switch.

3–4

Page 57

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

Kit KT/3950-x (Continued):

Qty. Description Qty. Description

4 O-Ring, -024, BUNA, black.

4 O-Ring, black neoprene.

CEFD Part # 32P1037.

2 Flexible waveguide.

CEFD Part # RF/WGFLXWR75-5.

Used to attach RFTs to switch.

10 6-32 x 1/2” socket head cap screw.

CEFD Part # HW/6-32X1/2SHCS.

20 6-32 x 7/8” socket head cap screw.

CEFD Part # 32P1039.

1 Switch.

CEFD Part # SW/WGS+28V-75SB.

Used to switch between RFT outputs.

50 #6 flat washer.

CEFD Part # HW/6-FLT.

20 6-32 hex nut.

CEFD Part # HW/6-32X7/8SHCS.

30 #6 split lockwasher.

CEFD Part # HW/6-SPLIT.

CEFD Part # HW/6-32HEXNUT.

3–5

Page 58

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

2 Kit KT/3577, which includes:

Qty. Description Qty. Description

3 Spar support bracket.

CEFD Part # FP/3175.

Used for spar mount only.

4 Unistrut — 14” long.

42 5/16” flat washer.

CEFD Part # HW/5/16-FLT.

42 5/16” split lockwasher.

CEFD Part # FP/3595.

Used for round and square pole mount only.

18 5/16-18 hex nut.

CEFD Part # HW/5/16-18HEXNT.

30 5/16-18 spring nut.

CEFD Part # HW/5/16-18SPNUT.

28 5/16-18 x 1” bolt.

CEFD Part # HW/5/16-18X1BLT.

2 Unistrut, modified, 20” long.

CEFD Part #FP/3482.

Used for round and square pole mount only.

19 1/4-20 x 5/8” bolt.

`

CEFD Part # HW/5/16-SPLIT.

12 Pipe block.

CEFD Part # HW/BLK-PIPE2-8.

Used for round pole mount only.

12 Flat fitting plate, 5/16”.

CEFD Part # HW/FIT-PLT-5/16.

6 Threaded rod, 5/16-18 x 14”.

CEFD Part # HW/RD5/16-18X14.

Used for round and square pole mount only.

4 Unistrut — 8” long.

19 1/4” flat washer.

CEFD Part # FP/3481.

Attaches directly to RFTs.

CEFD Part # HW/1/4-20X5/8BT.

Used to attach short unistruts to RFTs.

19 1/4” split lockwasher.

CEFD Part # HW/1/4-SPLIT.

Used to attach short unistruts to RFT.

CEFD Part # HW/1/4-FLT.

Used to attach short unistruts to RFT.

3–6

Page 59

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

3.3 RFT Installation

At the customer’s discretion, the RFTs can be installed anywhere on or near the antenna.

The supplied hardware allows the installer a wide range of installation alternatives,

including:

• Vertical pole (e.g., mast) (either square or round). This is the most typical

installation.

• Within the hub of a large antenna.

• Spar (i.e., rectangular bar) on the antenna structure.

Comtech EF Data recommends that the RFTs be mounted vertically, with the air inlets

facing the ground.

3–7

Page 60

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

3.3.1 Tools Required

Qty. Description

3/8” drive ratchet.

1

3” x 3/8” drive extension.

1

7/16” x 3/8” drive socket. (Metric equivalent: 12mm, 6 pt.)

1

1/2” x 3/8” drive socket. (Metric equivalent: 13mm, 6 pt.)

1

1 1/2” combination wrench. (Metric equivalent: 13mm combination

wrench with a 6 pt. box end.)

1 7/64” hex key (allen wrench). (No metric equivalent.)

1 5/16” combination wrench. (Metric equivalent: 8mm combination

wrench with a 6 pt. box end.)

3–8

Page 61

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

3.3.2 Vertical Pole Installation

3.3.2.1 Round Pole

The following process is for a typical installation. Custom systems may be ordered, and

are beyond the scope of this manual.

To install the RFTs to a round vertical pole:

1. Set the units on their sides, with the mounting holes facing up.

2. Install the 8” unistruts as follows:

a. Position an 8” unistrut (with

the open side facing up) over

one set of the mounting holes

on the RFT.

b. Using four 1/4-20 bolts, 1/4”

split lockwashers, and 1/4” flat

washers, attach an 8” unistrut

to the RFT.

Tighten the bolts firmly.

c. Repeat Steps 2.a. and 2.b. for

each of the remaining 8”

unistruts (for a total of four).

3–9

Page 62

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

3. Install the 20” unistruts as follows:

Note: The placement of the pipe blocks may interfere with the inner or center

unistrut attaching bolts. Be sure to determine the pipe block placement locations

before bolting the 20” unistruts in place. It may be necessary to eliminate the

center or inner 20” unistrut mounting spring nuts and bolts.

a. Insert a spring nut between

the unistrut mounting bolts

on both RFTs, as illustrated.

b. To install each spring nut:

(1) Place the spring nut in

the unistrut channel,

spring side down, with

its wide side parallel

with the unistrut

channel.

(2) Press down on the

spring nut to compress

the spring, and rotate

the nut 90° (i.e.,

perpendicular to the

unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 3.b.(1) through 3.b.(3) for each spring nut.

3–10

Page 63

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

c. With the RFTs side by side,

position a 20” unistrut (open

side facing up) in place over

one pair of 8” unistruts.

Ensure the long unistrut is

centered over the RFT.

d. Using two or three 5/16-18

bolts, 5/16” split

lockwashers, and 5/16” flat

washers, attach the 20”

unistrut to the 8” unistruts.

Tighten the bolts firmly.

e. Attach the second 20” unistrut to the second set of 8” unistruts by repeating

Steps 3.a. through 3.d.

4. Install the pipe blocks as follows:

a. Install two spring nuts in each of the two 20” long unistruts and two 14” long

unistruts (centered in the unistruts, and wide enough apart so the pipe blocks

will clear the pole when the unit is installed).

b. Install each spring nut as follows:

(1) Place the spring nut in the unistrut channel, spring side down, with its

wide side parallel with the unistrut channel.

(2) Press down on the spring nut to compress the spring, and rotate the nut

90° (i.e., perpendicular to the unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 4.b.(1) through 4.b.(3) for each spring nut.

3–11

Page 64

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

c. Using eight 5/16-18 bolts, 5/16” split lockwashers, and 5/16” flat washers,

loosely secure the pipe blocks to the spring nuts.

Ensure the pipe blocks are installed with the long angle face inward, toward

the pipe, as illustrated.

DO NOT tighten the pipe block bolts until after mounting the RFTs on the

vertical pole. (See Step 6.e.)

5. Install the threaded rods as follows:

3–12

Page 65

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

a. Install two spring nuts in both

20” unistruts mounted on the

RFT.

b. Install each spring nut as

follows:

(1) Place the spring nut in

the unistrut channel,

spring side down, with

its wide side parallel

with the unistrut

channel.

(2) Press down on the spring

nut to compress the

spring, and rotate the nut

90° (i.e., perpendicular

to the unistrut).

3–13

Page 66

KST-12000 Ku-Band Satellite Terminal Revision 4

Redundant System Installation MN/KST12000.IOM

(3) Release pressure on the spring nut.

(4) Repeat Steps 5.b.(1) through 5.b.(3) for each spring nut.

c. Thread a 5/16-20 nut approximately 1-1/2” onto each threaded rod. (This will

ensure that the threaded rods will extend beyond the spring nuts when

installed.)

d. Place a 5/16” split lockwasher, 5/16” flat washer, and flat fitting plate over

each threaded rod.

e. One threaded rod at a time,