Page 1

r

KPA080

Ku-Band Solid-State Power Amplifie

Installation and Operation Manual

Part Number MN/KPA80IN.IOM Revision 0

Page 2

Comtech EFData is an ISO 9001

Registered Company.

KPA080

Ku-Band Solid-State Power Amplifier

Installation and Operation Manual

Part Number MN/KPA80IN.IOM

Revision 0

December 15, 2000

Copyright © Comtech EFData, 2000. All rights reserved. Printed in the USA.

Comtech EFData, 2114 West 7th Street, Tempe, Arizona 85281 USA, (480) 333-2200, FAX: (480) 333-2161.

Page 3

Customer Support

Contact the Comtech EFData Customer Support Department for:

• Product support or training

• Information on upgrading or returning a product

• Reporting comments or suggestions concerning manuals

A Customer Support representative may be reached at:

Comtech EFData

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

480.333.2200 (Main Comtech EFData Number)

480.333.4357 (Customer Support Desk)

480.333.2161 FAX

or, E-Mail can be sent to the Customer Support Department at:

service@comtechefdata.com

Contact us via the web at www.comtechefdata.com

1. To return a Comtech EFData product (in-warranty and out-of-warranty) for

repair or replacement:

2. Request a Return Material Authorization (RMA) number from the Comtech

EFData Customer Support Department.

3. Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

4. To ensure that the product is not damaged during shipping, pack the product in

its original shipping carton/ packaging.

5. Ship the product back to Comtech EFData. (Shipping charges should be prepaid.)

For more information regarding the warranty policies, see Warranty Policy, p. x.

.

ii Rev. 0

Page 4

Table of Contents

Customer Support.......................................................................................................................................................ii

About this Manual ....................................................................................................................................................vii

Conventions and References....................................................................................................................................... vii

Safety Notices ............................................................................................................................................................vii

Reporting Comments or Suggestions Concerning this Manual .................................................................................viii

European EMC Directive.......................................................................................................................................... ix

Warranty Policy.......................................................................................................................................................... x

Limitations of Warranty................................................................................................................................................ x

Exclusive Remedies...................................................................................................................................................... x

CHAPTER 1. INTRODUCTION.......................................................................................................... 1-1

1.1

1.2

1.2.1 Front Panel...................................................................................................................................................1-3

1.2.2 Front Panel Indicators..................................................................................................................................1-4

1.2.3 Built-in Redundancy Controller................................................................................................................... 1-4

1.3

CHAPTER 2. INSTALLATION ........................................................................................................... 2-1

2.1

Overview.....................................................................................................................................................1-1

Functional Description..............................................................................................................................1-3

Specifications..............................................................................................................................................1-5

Unpacking...................................................................................................................................................2-1

2.2

2.2.1 Prime Power Connection.............................................................................................................................2-2

2.2.2 Cable Connections.......................................................................................................................................2-3

2.2.3 Optional: Redundancy Kit Installation ........................................................................................................2-3

2.3

2.3.1 Rear Panel Connections...............................................................................................................................2-6

Rev. 0 iii

Installation..................................................................................................................................................2-2

External Connections ................................................................................................................................2-6

Page 5

Preface KPA080 Ku-Band Solid-State Power Amplifier

2.4

CHAPTER 3. OPERATION ................................................................................................................ 3-1

3.1

3.1.1 Switching On...............................................................................................................................................3-1

3.2

3.2.1 SSPA Commands ........................................................................................................................................3-5

3.2.2 Configuration Menu.....................................................................................................................................3-9

3.2.3 Monitor Status Menu.................................................................................................................................3-11

3.2.4 Current Faults Menu..................................................................................................................................3-13

3.2.5 Stored Faults Menu....................................................................................................................................3-15

3.2.6 Utility Menu ..............................................................................................................................................3-17

CHAPTER 4. REDUNDANT CONFIGURATION ............................................................................... 4-1

4.1

4.2

4.2.1 Gain Equalization of Redundant Units........................................................................................................4-3

CHAPTER 5. REMOTE CONTROL SPECIFICATION ....................................................................... 5-1

Dimensional and Outline Diagrams.........................................................................................................2-8

General .......................................................................................................................................................3-1

Operation....................................................................................................................................................3-3

General .......................................................................................................................................................4-1

Redundancy Operation.............................................................................................................................4-1

5.1

5.2

5.3

5.4

5.5

5.5.1 Format..........................................................................................................................................................5-4

5.6

5.6.1 Direct Access...............................................................................................................................................5-5

5.6.2 Indirect Access ............................................................................................................................................5-5

5.7

5.7.1 Physical Address..........................................................................................................................................5-6

5.7.2 Virtual Address............................................................................................................................................5-6

5.7.3 Message Structure........................................................................................................................................5-6

5.7.4 Start Character.............................................................................................................................................5-6

5.7.5 Device Address............................................................................................................................................5-7

5.7.6 Command.....................................................................................................................................................5-7

5.8

5.8.1 Error Response ............................................................................................................................................5-7

5.8.2 End Of Message...........................................................................................................................................5-8

General .......................................................................................................................................................5-1

Electrical Interface....................................................................................................................................5-2

Interface Connector...................................................................................................................................5-2

Cables..........................................................................................................................................................5-3

Protocol.......................................................................................................................................................5-4

Access Methods..........................................................................................................................................5-5

Addressess ..................................................................................................................................................5-6

Confirmation Response.............................................................................................................................5-7

5.9

iv Rev. 0

Command/Response Pairs ........................................................................................................................5-9

Page 6

KPA080 Ku-Band Solid-State Power Amplifier Preface

5.9.1 Utility Commands........................................................................................................................................5-9

5.9.2 Configuration Commands..........................................................................................................................5-10

5.9.3 Mode Commands.......................................................................................................................................5-11

5.9.4 Status Commands......................................................................................................................................5-12

5.9.5 Stored Alarms............................................................................................................................................5-16

5.9.6 Error Processing ........................................................................................................................................5-17

5.9.7 Configuration Errors..................................................................................................................................5-17

5.9.8 Time-Outs..................................................................................................................................................5-17

5.10 Command Summaries.............................................................................................................................5-18

CHAPTER 6. MAINTENANCE AND TROUBLESHOOTING ............................................................. 6-1

6.1

6.2

6.2.1 Test Point Samples ......................................................................................................................................6-2

6.3

APPENDIX A. PARTS LIST/WIRING DIAGRAM...............................................................................A–1

A.1

General .......................................................................................................................................................6-1

Maintenance Testing .................................................................................................................................6-2

Troubleshooting.........................................................................................................................................6-2

Parts List .................................................................................................................................................. A–1

A.2

Wiring Diagram....................................................................................................................................... A–4

Rev. 0 v

Page 7

Preface KPA080 Ku-Band Solid-State Power Amplifier

Figures

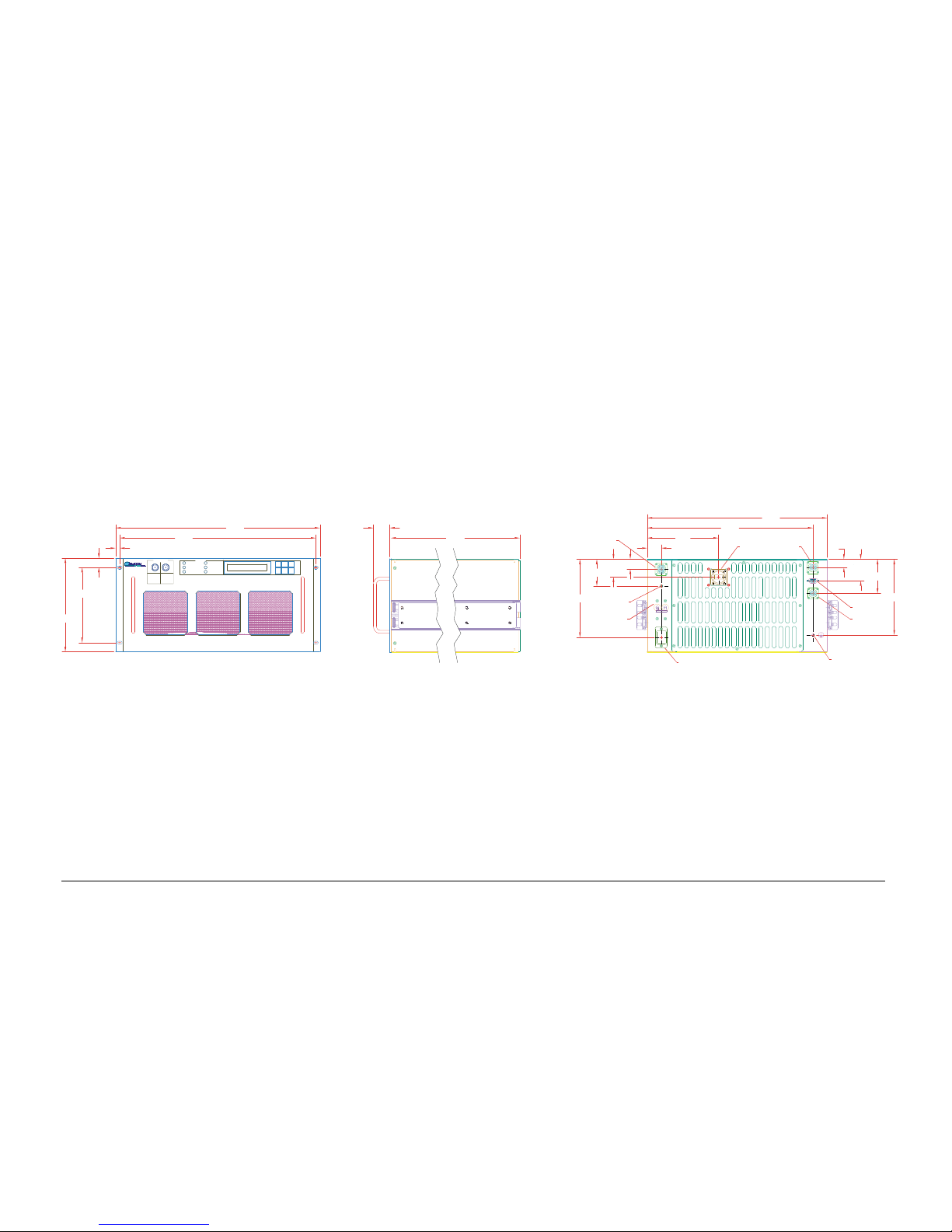

Figure 1-1. KPA080..................................................................................................................................................1-1

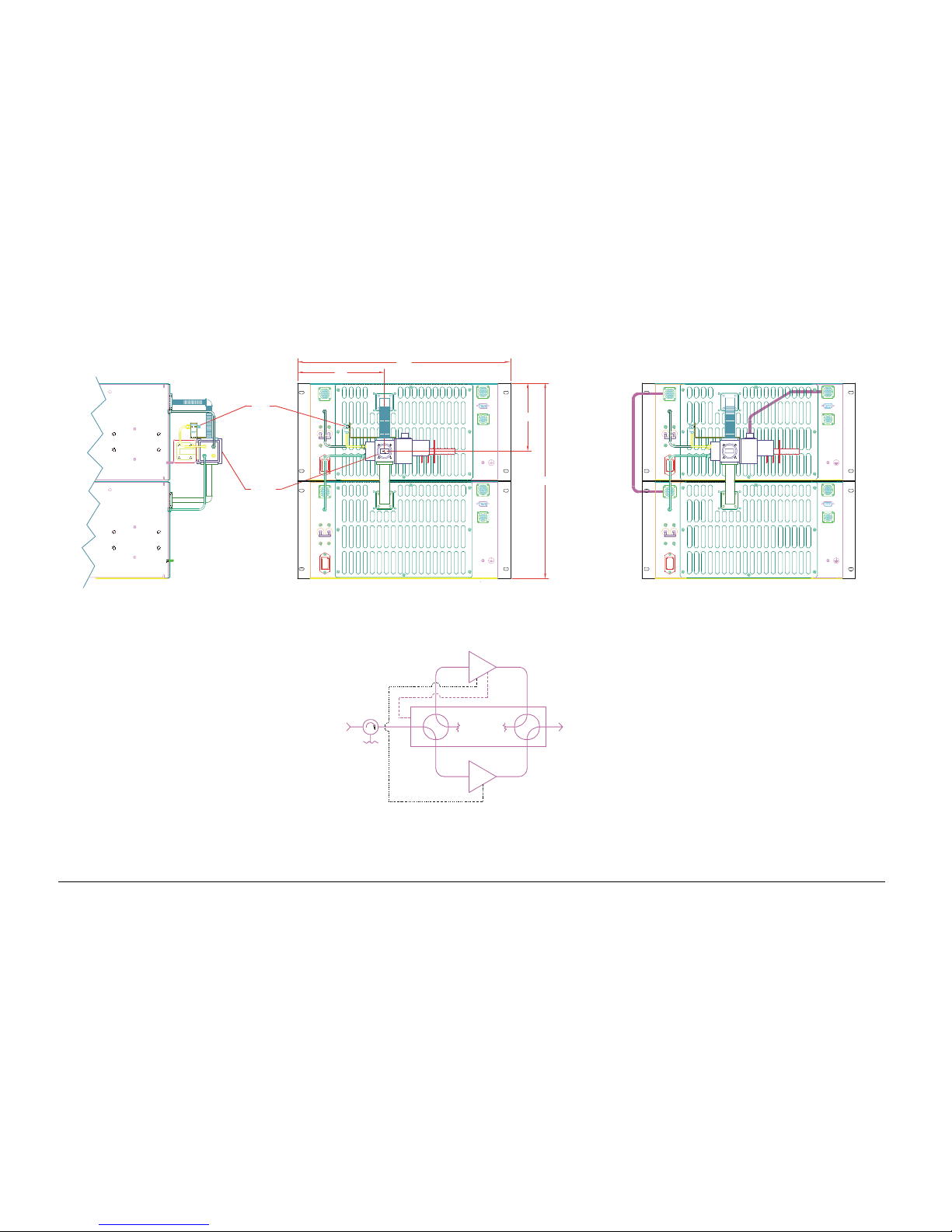

Figure 1-2. Functional Block Diagram .....................................................................................................................1-2

Figure 2-1. Redundancy Installation.........................................................................................................................2-4

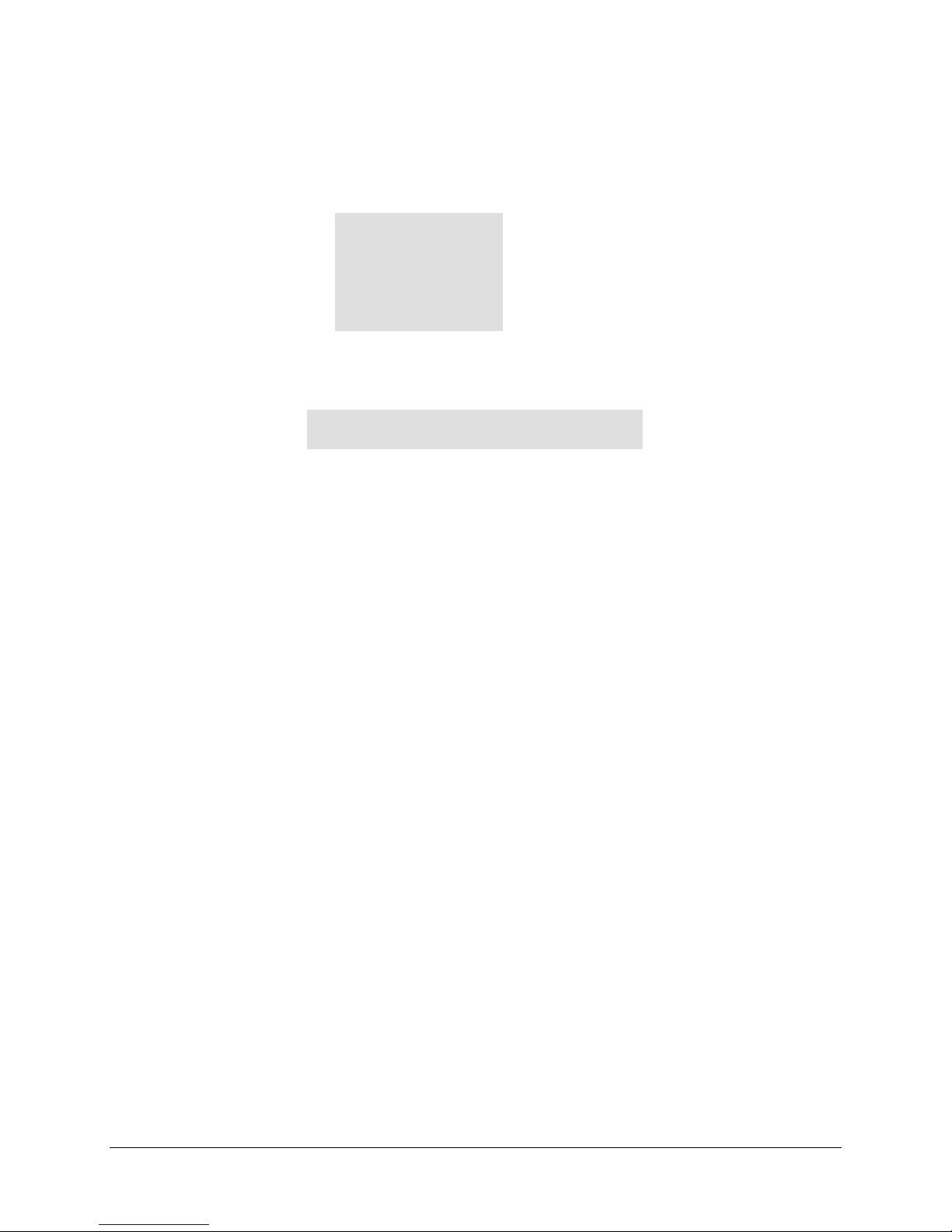

Figure 0-1. Dimensional Diagram (inches)...............................................................................................................2-9

Figure 0-3. Redundancy Outline Diagram .............................................................................................................2-10

Figure 3-1. SSPA Operating Command Functions...................................................................................................3-4

Figure 3-2A. Configuration Menu Commands (Single Configuration) ...................................................................3-7

Figure 3-3. Monitor Status Menu Commands.........................................................................................................3-10

Figure 3-4. Current Faults Menu Commands..........................................................................................................3-12

Figure 3-5. Stored Faults Menu Commands...........................................................................................................3-14

Figure 3-6. Utility Functions Menu Commands .....................................................................................................3-16

Figure 4-1. Control Cabling of a 1:1 System ............................................................................................................4-2

Figure 4-2. Control Cabling of a 1:2 System ............................................................................................................4-3

Tables

Table 1-1. Operating Functions.................................................................................................................................1-3

Table 1-2. Front Panel Indicators..............................................................................................................................1-4

Table 2-1. Cable Connections...................................................................................................................................2-3

Table 2-2. Redundancy Kit.......................................................................................................................................2-5

Table 2-3. Rear Panel Connectors.............................................................................................................................2-6

Table 2-4. Redundant Loop Interface, Connector J4 ................................................................................................2-7

Table 2-5. Customer Discrete Control, Connector J5...............................................................................................2-7

Table 2-6. EIA-232/EIA-485 Interface, Connector J6..............................................................................................2-8

Table 2-7. Waveguide Switch Interface, Connector J7.............................................................................................2-8

Table 5-1. Protocol Description...............................................................................................................................5-4

Table 5-2. Possible Time-Out Sources....................................................................................................................5-17

Table 5-3. Remote Control Summary.....................................................................................................................5-18

Table 5-4. Commands Supported by Virtual Addressing Mode.............................................................................5-19

Table 6-1. Troubleshooting.......................................................................................................................................6-3

vi Rev. 0

Page 8

KPA080 Ku-Band Solid-State Power Amplifier Preface

About this Manual

This manual provides installation and operation information for the Comtech EFData

KPA080 Ku-Band Solid-State Power Amplifier. This is a technical document intended

for earth station engineers, technicians, and operators responsible for the operation and

maintenance of the KPA080.

Conventions and References

Cautions and Warnings

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other

CAUTION

WARNING

unsafe practices or risks of property damage.

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

Safety Notices

This equipment has been designed to minimize exposure of personnel to hazards. The

operators and technicians must:

CAUTION

WARNING

• Know how to work around, with, and on high voltage and high RF power

level equipment.

• Exercise every precaution to ensure personnel safety.

• Exercise extreme care when working near high voltages/high RF power

level equipment.

• Be familiar with the warning presented in this manual.

• Disconnect the power supply cord before servicing the SSPA.

Lithium Battery Replacement: There is a damage that the Lithium battery

on the M&C assembly will explode if the battery is incorrectly replaced.

Replace only with the same or equivalent type battery recommended by the

manufacturer. Dispose of used batteries according to the Lithium battery

manufacturer’s ins truc tio n s.

Rev. 0 vii

Page 9

Preface KPA080 Ku-Band Solid-State Power Amplifier

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assi st the oper ato r in cross-referencing English to Met ric

conversions.

Recommended Standard Designations

Recommended Standard (RS) Designations have been superseded by the new designation

of the Electronic Industries Association (EIA). References to the old designations are

shown only when depicting actual text displayed on the screen of the unit (RS-232, RS485, etc.). All other references in the manual will be shown with the EIA designations

(EIA-232, EIA-485, etc.) only.

Military Standards

References to “MIL-STD-188” apply to the 114A series (i.e., MIL-STD-188-114A),

which provides electrical and functional characteristics of the unbalanced and balanced

voltage digital interface circuits applicable to both long haul and tactical

communications. Specifically, these references apply to the MIL-STD-188-114A

electrical characteristics for a balanced voltage digital interface circuit, Type 1 generator,

for the full range of data rates. For more information, refer to the Department of Defense

(DOD) MIL-STD-188-114A, “

Electrical Characteristics of Digital Interface Circuits

.”

Trademarks

Windows is a trademark of the Microsoft Corporation.

Other product names mentioned in this manual may be trademarks or registered

trademarks of their respective companies and are hereby acknowledged.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EFData Customer Support

Department.

viii Rev. 0

Page 10

KPA080 Ku-Band Solid-State Power Amplifier Preface

European EMC Directive

In order to meet the European Electro-Magnetic Compatibility (EMC) Directive

(EN55022, EN50082-1), properly shielded cables for DATA I/O are required. More

specifically, these cables must be shielded from end-to-end, ensuring a continuous

ground shield.

The following information is applicable for the European Low Voltage Directive

(EN60950):

<HAR> Type of power cord required for use in the European Community .

CAUTION: Double-pole/Neutral Fusing

!

International Symbols:

ACHTUNG: Zweipolige bzw. Neutralleiter-Sicherung

Alternating Current.

Fuse.

Safety Ground.

Chassis Ground.

Note:

For additional symbols, refer to “Cautions and Warn ing s” lis ted ea rl ier in t his

preface.

Rev. 0 ix

Page 11

Preface KPA080 Ku-Band Solid-State Power Amplifier

Warranty Policy

This Comtech EFData product is warranted against defects in material and workmanship

for a period of 2 years from the date of shipment. During the warranty period, Comtech

EFData will, at its option, repair or replace products that prove to be defective.

For equipment under warranty, the customer is responsible for freight to Comtech

EFData and all related custom, taxes, tariffs, insurance, etc. Comtech EFData is

responsible for the freight charges

only

for return of the equipment from the factory to

the customer. Comtech EFData will return the equipment by the same method (i.e., Air,

Express, Surface) as the equipment was sent to Comtech EFData.

Limitations of Warranty

The foregoing warranty shall not apply to defects resulting from improper installation or

maintenance, abuse, unauthorized modification, or operation outside of environmental

specifications for the product, or, for damages that occur due to improper repackaging of

equipment for return to Comtech EFData.

No other warranty is expressed or implied. Comtech EFData specifically disclaims the

implied warranties of merchantability and fitness for particular purpose.

Exclusive Remedies

The remedies provided herein are the buyer's sole and exclusive remedies. Comtech

EFData shall not be liable for any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any other legal theory.

Disclaimer

Comtech EFData has reviewed this manual thoroughly in order that it will be an easy-touse guide to your equipment. All statements, technical information, and

recommendations in this manual and in any guides or related documents are believed

reliable, but the accuracy and completeness thereof are not guaranteed or warranted, and

they are not intended to be, nor should they be understood to be, representations or

warranties concerning the products described. Further, Comtech EFData reserves the

right to make changes in the specifications of the products described in this manual at any

time without notice and without obligation to notify any person of such changes.

If you have any questions regarding your equipment or the information in this manual,

please contact the Comtech EFData Customer Support Department.

x Rev. 0

Page 12

This chapter describes the instructions on the installation, operation and maintenance of

the KPA080-4045-I Ku-Band Solid-State High Power Amplifier (SSPA).

1.1 Overview

The KPA080-4045-I Ku-Band Solid-State High Power Amplifier is designed for use in

communication systems, or in satellite up-link data systems. The SSPA (Figure 1-1)

operates over the RF input frequency range of 14.0 to 14.5 GHZ.

Chapter 1.

INTRODUCTION

1

Rev. 0 1-1

Figure 1-1. KPA080

Page 13

Introduction KPA080 Ku-Band Solid-State Power Amplifier

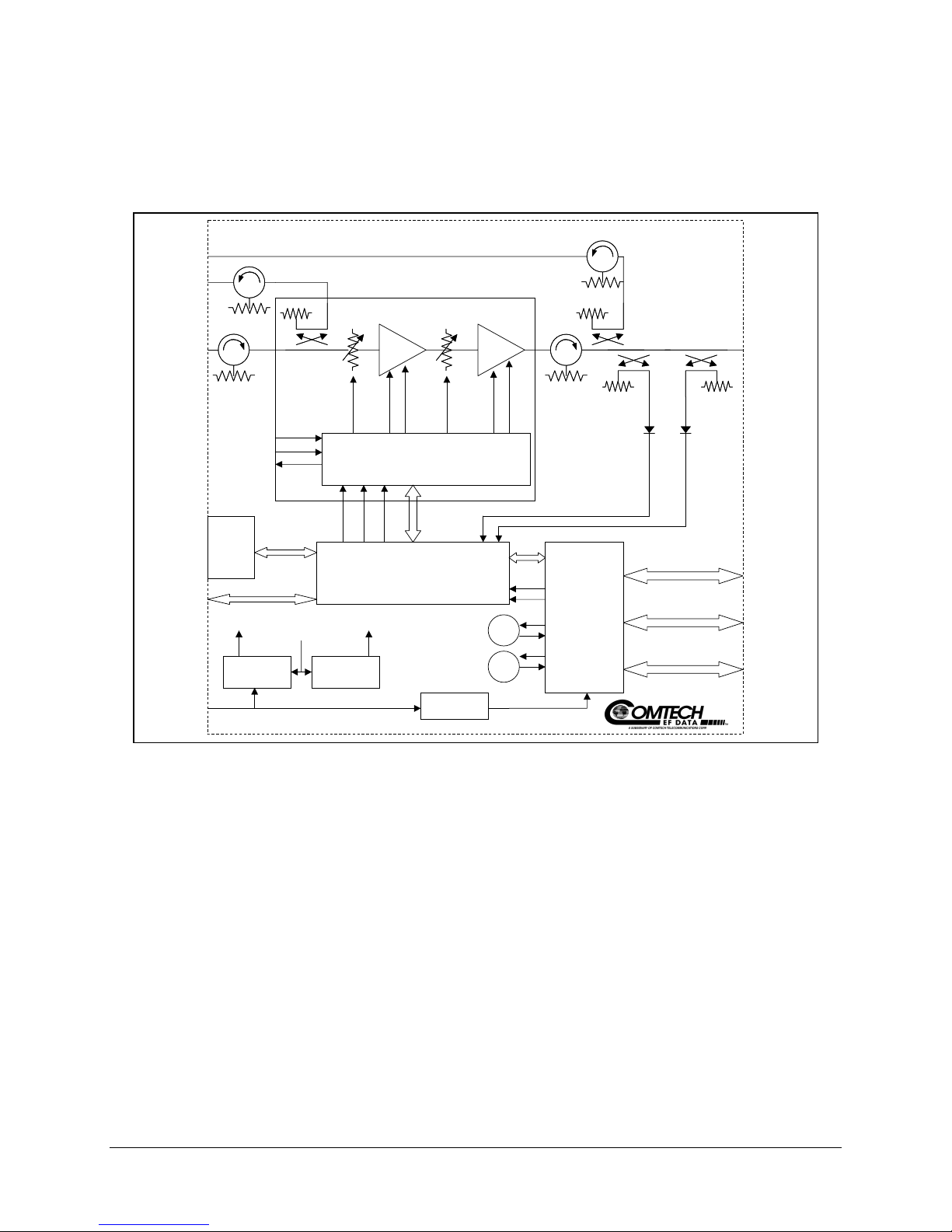

The RF output power is 48.5 dBm minimum at 1 dB compression. A functional block

diagram is shown in Figure 1-2.

KPA 80

OUTPUT

SAMPLE

INPUT

SAMPLE

J9

J8

BLOCK DIAGRAM

RF INPUT

AC

POWER

INPUT

J1

CUST.

GAIN

CTRL

9V #1

9V #2

-5Vdc

Interlock

-5Vdc

Interlock

-5V -12V 12V

PS #2 9Vdc

Keypad

&

Display

J6COM1

9V #1 9V #2

PS #1 9Vdc

J3

-5V -5V9V 9V

POWER CONDITIONING & CONTROL

MONITOR & CONTROL

TEMP.

COMP.

CONTROL

& MONITOR

28Vdc PS

FAN1

FAN2

+12V

-12V

AUX. PS

& SWITCH

CONTROL

OUTPUT

POWER

DETECTOR

REFLECTED

POWER

DETECTOR

RF

J2

OUTPUT

(W/G)

REDUND.

J4

LOOP

DISCRETE

J5

CONTROL

REDUND.

SWITCH

J7

CONTROL

Figure 1-2. Functional Block Diagram

The SSPA is designed to be hard mounted in a standard 19-inch (48 cm) rack or cabinet,

or to be rack mounted using Comtech EFData slide mechanisms provided with the SSPA

to allow it to be serviced without its removal from the rack. Two internally mounted

exhaust fans are mounted on the chassis for cooling. An AC power connector, with an

On/Off switch, is located on the rear on the chassis. A six-foot AC power cord is supplied

with the SSPA.

All operator controls, indicators, and displays for local and remote operation as well as

the RF Input and Output sample test ports are located on the front panel of the SSPA.

Connectors for the external interface connections are located on the rear of the SSPA

chassis.

1-2 Rev. 0

Page 14

KPA080 Ku-Band Solid-State Power Amplifier Introduction

1.2 Functional Description

The SSPA consists of a chassis, power supplies, fan assembly, front panel assembly,

monitor/control processor (MCP) and a Comtech EFData solid-state power amplifier

module. The amplifier is designed using a Comtech EFData low loss combining

technique and an MCP based temperature versus gain compensation.

1.2.1 Front Panel

The front panel contains a User Interface Key-Pad which is used by a local operator to

input commands to the SSPA. The keypad is used to select the configuration for

operating and monitoring the status of the SSPA.

In conjunction with the front panel two line, 24-character, LCD display, the keypad

allows the operator to select one of five configurations. The configuration functions are:

Configuration Menu

•

Monitor Status Menu

•

Currents Faults Menu

•

Stored Faults Menu

•

Utility Functions Menu

•

Refer to Table 1-1 for logical function of each keypad entry:

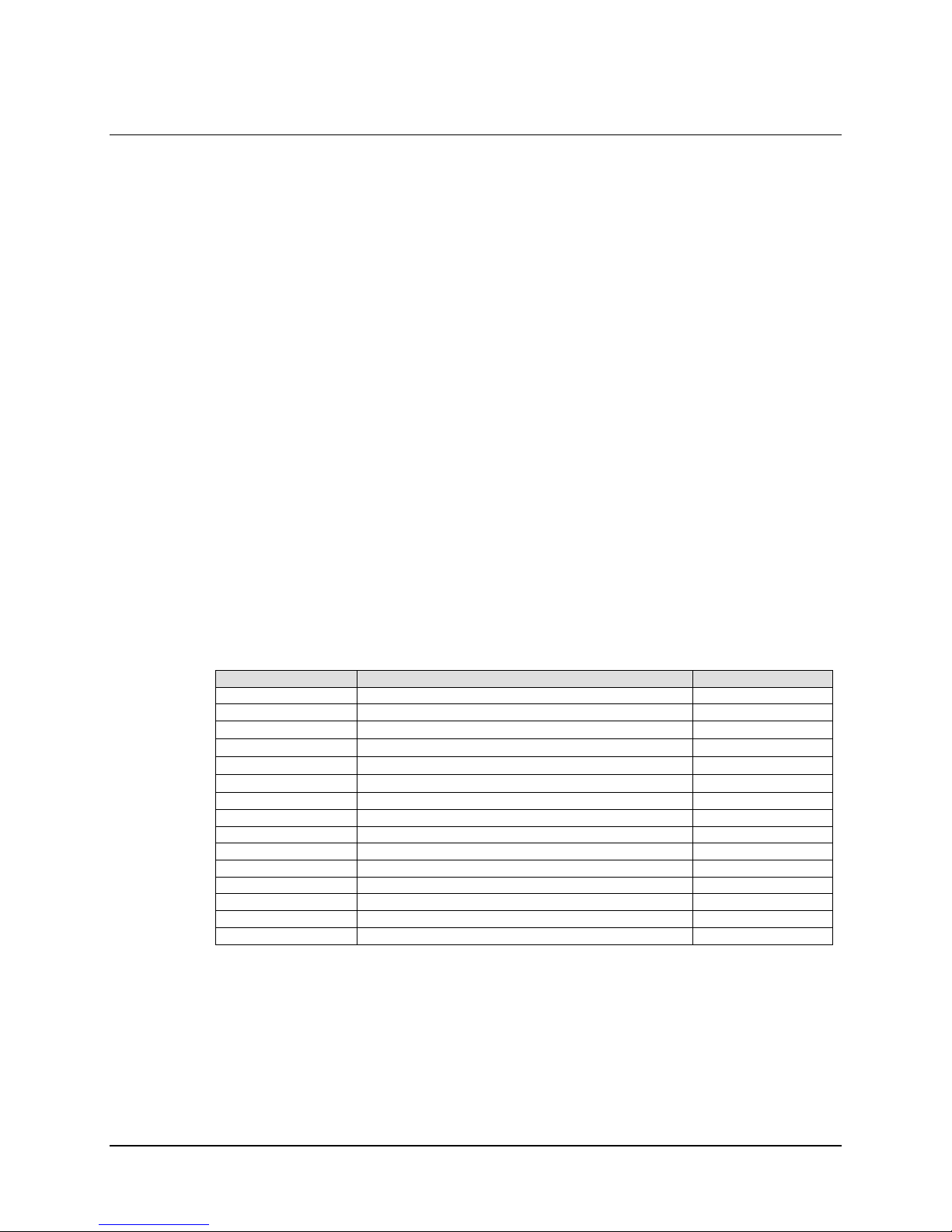

Table 1-1. Operating Functions

Item Function D escription Reference

[ENTER] Enters commands into the converter. ENT

CLR Clears commands and data selected and not entered. CLR

Arrow Key

→

Arrow key

←

Arrow Key

↑

Arrow Key

↓

LCD Display Displays commands and data entered into the keypad.

GREEN Indicator Prime Power is applied when the light is On. POWER ON

YELLOW Indicator Transmit function operating when the light is On. TRANSMIT ON

YELLOW Indicator In REMOTE CONTROL Mode, when the light is ON. REMOTE

YELLOW Indicator Operating On-Line to RX data when the light is On. ON-LINE

RED Indicator Fault condition exists when the light is On. FAULT

RED Indicator Faults stored and logged when the light is On. STORED FAULT

Input Sample Type N connector test point to sample RF input. SAMPLE INPUT

Output Sample Type N connector test point to sample RF output. SAMPLE OUTPUT

Selects functions and the menu operating data.

Selects functions and the menu operating data.

Selects functions and the menu operating data.

Selects functions and the menu operating data.

→

←

↑

↓

Rev. 0 1-3

Page 15

Introduction KPA080 Ku-Band Solid-State Power Amplifier

1.2.2 Front Panel Indicators

There are six LED indicator lights on the front panel which indicate the status of the

SSPA and provide summary fault information. Refer to Table 1-2 for description of the

LED lamps:

Table 1-2. Front Panel Indicators

LED Lamp Condition

Fault Red Indicates that a fault condition exists when the LED light is

On.

Stored Fault Red Indicates that the fault has been logged and stored When the

LED light is On. The fault may, or may not, be active.

Power Status Green Indicates that power is applied to the SSPA when the LED

light is On.

TX ON Yellow Indicates that the transmit function of the SSPA is on when

the LED light is On. The indicator light reflects the actual

condition of the tran smit function.

Online Yellow Indicates that the SSPA is operating on-line to transmit data.

Remote Yellow Indicates that the SSPA is being operated in the remote

control mode where commands and data are transferred via

an EIA-485 (EIA-232 is optional) serial

communications link.

1.2.3 Built-in Redundancy Controller

Each SSPA has the ability to function as a 1+1 or 1+2 redundancy controller in the

backup mode. The optional redundancy configuration is implemented by attaching a

ganged Waveguide/coax transfer switch(es) to input and output connectors of the

amplifiers with a combination coaxial cable and Waveguide kit. When the backup SSPA

is commanded into the controller mode, it monitors the online SSPA(s) for faults. A

faulted online unit may be disconnected and replaced without affecting the online power

amplifier.

1-4 Rev. 0

Page 16

KPA080 Ku-Band Solid-State Power Amplifier Introduction

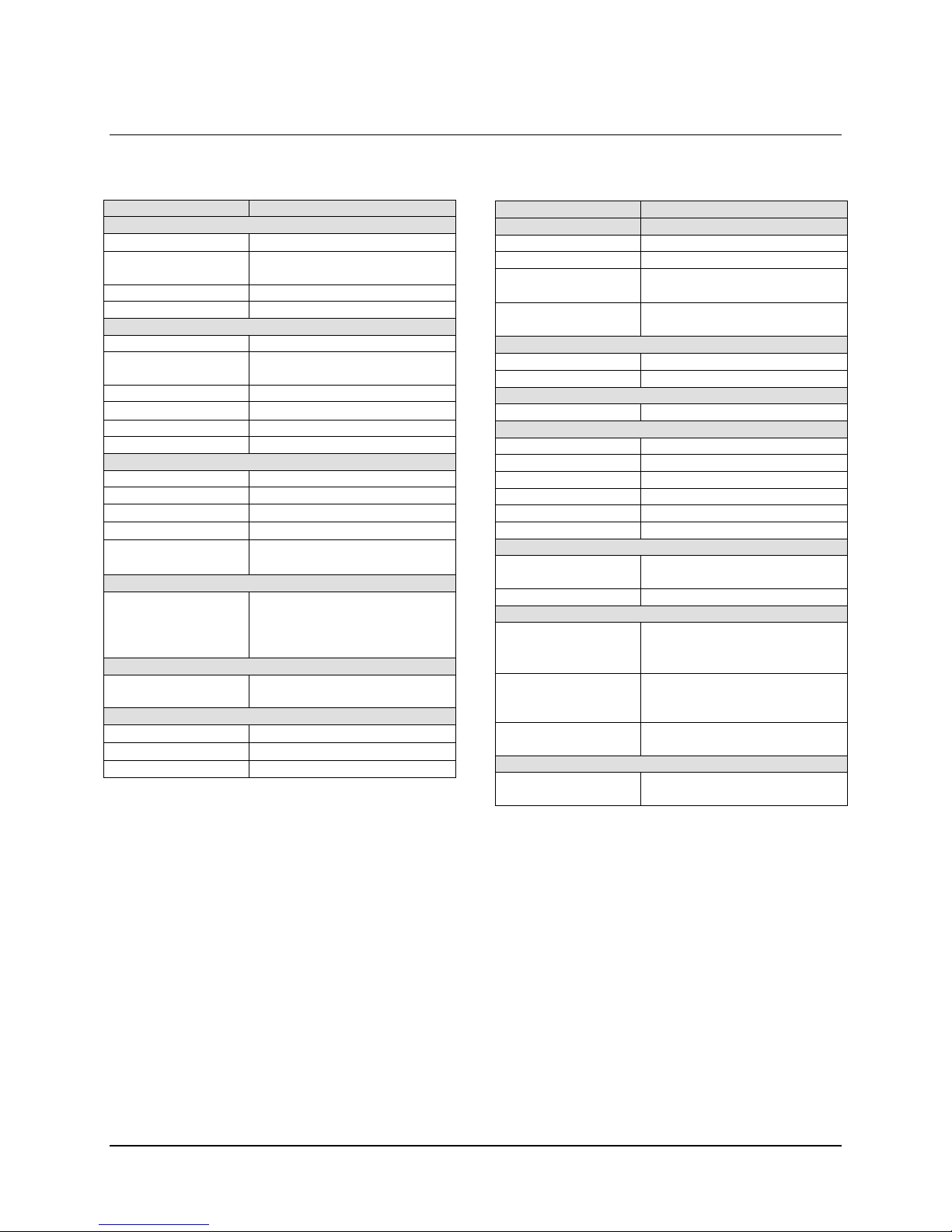

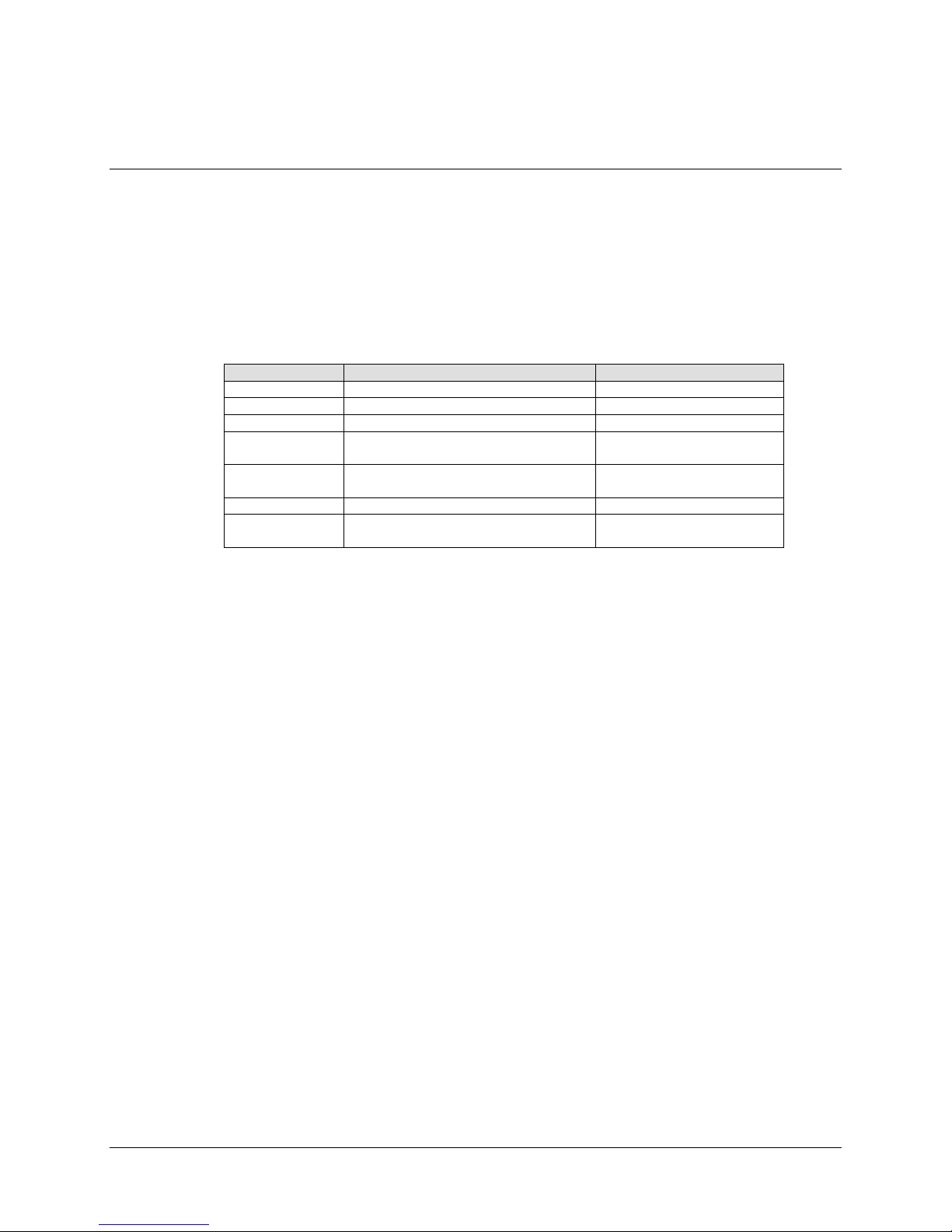

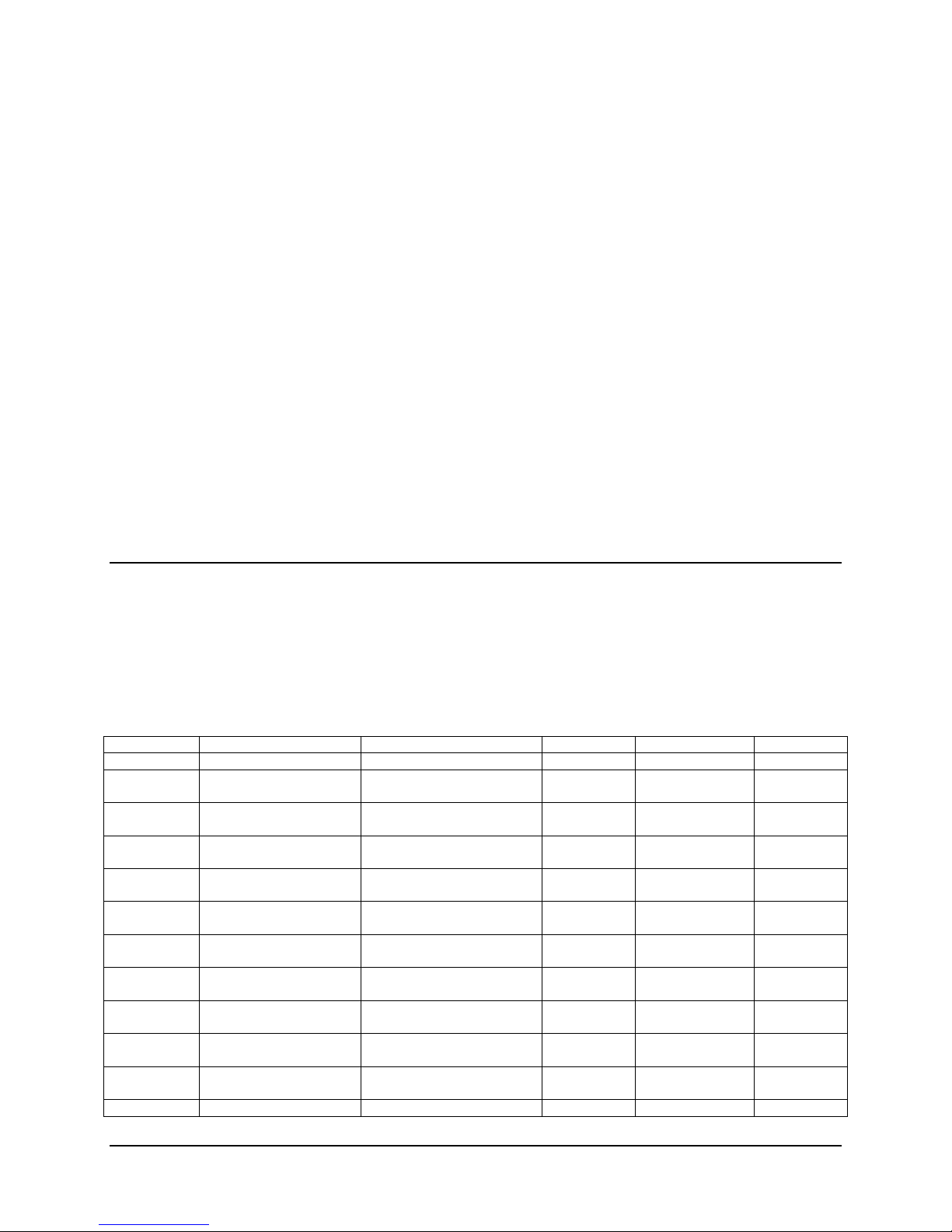

1.3 Specifications

Parameters Specifications

Input

Impedance

Noise Figure 10 dB Typical, 15 dB max at max

VSWR 1.25: 1 maximum

Connector SMA Female

Frequency 14.0 to 14.5 GHz

Power 48.5 dBm minimum at 1 dB

Mute 60 dB

Impedance

VSWR 1.25:1 maximum

Connector WR75G Waveguide

Linear 65 dB minimum, 68 dB Typical

Adjust 20 dB in 0.25 dB steps

Full Band

Per 40 MHz

0 to +50°C (32 to

122°F)

Third Order Intermodulat ion

Products -30 dBc Typical, -25 dBc

Output 2.0 degrees typical, 3.0 max at

Group Delay (per 40 MHz)

Linear

Parabolic

Ripple 1.0 ns Peak-t o-Peak

50Ω

gain

Output

Compression

50Ω

Gain

0.75 dB

±

-0.25 dB

±

0.50 dB at center frequency

±

1.00 dB full band

±

maximum

at 3 dB total backoff

(two tones, ∆F = 1 MHz)

AM to PM Conversion

rated output

0.03 ns/MHz

±

0.003 ns/MHz2

±

Parameters Specifications

Front Panel

Display 20 x 2 LCD

Data Entry Cursor Control Keypad

Output Sample

Input Sample

Remote Control

COM Port EIA-232 or EIA-485

Protocol ASCII

Summary Fault Form C

Power On Green

Fault Red

Stored Fault Red

TX On Yellow

Online Yellow

Remote Yellow

Envelop 8.75H x 19W x 24D inches

Weight 75 lbs (34 kg)

Temperature

Operating

Storage

Humidity

Operating

Storage

Shock Normal Commercial

Power Requirements

VAC 180 to 270 VAC, 47 to 63 Hz

Type N (f), 50Ω, –40 dBc

nominal

Type N (f), 50Ω, –20 dBc

nominal

Alarms

LED

Mechanical

(22.22H x 48.26W x 60.96D cm)

Environmental

0 to 50°C (32 to 122°F)

–40 to 70°C (–40 to 158°F)

10 to 95% Noncondensing

0 to 100% Noncondensing

Shipping and Handling

1100W nominal

Rev. 0 1-5

Page 17

This page is intentionally blank.

Rev. 0 1-6

Page 18

This chapter describes the instructions for unpacking and installing the KPA080-4045-I

Ku-Band Solid State High Power Amplifier

2.1 Unpacking

Perform a receiving inspection as follows:

Inspect the shipping container for damage. The shipping container and packing

•

materials should be retained for possible reshipment.

Check to determine that all parts, materials and documentation have been shipped

•

with the SSPA. The SSPA should be inspected for possible damage, and then tested

for proper operation.

If the shipment exhibits any of the following, contact Comtech EFData Customer

•

Support:

Incomplete

♦

Mechanical damage

♦

Inoperable

♦

If there is damage to the shipping container, notify the carrier. Retain all shipping

materials for inspection by the carrier.

Chapter 2.

INSTALLATION

2

Rev. 0 2-1

Page 19

Installation KPA080 Ku-Band Solid-State Power Amplifier

2.2 Installation

The SSPA is designed for installation to mount in a standard 19-inch (48 cm) rack

cabinet or enclosure. The SSPA chassis requires 8.75 inches (22 cm) of panel height

space.

Adequate air ventilation should be provided to the rack mounted equipment.

air is taken in through the front panel and exhausted out the rear panel.

Locate the SSPA so the input and output airflow paths are not obstructed or

restricted.

This will minimize the amplifier operating temperature.

If the SSPA is to be mounted on slides, the slides must be the Comtech

•

EFData rack slides provided with the SSPA. Proceed as follows:

!" Mount the slides on the sides of the SSPA chassis with the provided

mounting hardware.

!" Install the slide rails on the rack cabinet enclosure.

!" Secure the SSPA to the cabinet with four screws inserted through the

SSPA front panel slotted holes.

Cool

2.2.1 Prime Power Connection

The On/Off prime power switch is located on the rear of the chassis adjacent to the prime

power input connector. The circuit breaker is ra ted for 30 Amps.

The detachable power cord mates with the AC Prime power receptacle on the rear of the

SSPA chassis.

A power cord for connection to 180 to 270 VAC, 47 to 63 Hz, power sources is provided

with the SSPA.

2-2 Rev. 0

Page 20

KPA080 Ku-Band Solid-State Power Amplifier Installation

2.2.2 Cable Connections

The cable signal functions are shown in Table 2-1.

Table 2-1. Cable Connections

Connector Function

J1 SSPA RF Input (RF). Mating connector: Type SMA Female

J2 SSPA RF Output (RF). Mating connector: WR75G

J3 AC Prime Power (Cord provided with SSPA)

J4 Redundant Loop Int erface (for use in redundant configurations)

J5 Customer Discrete Control

J6 COM 1: Serial Communications Interface, EIA-232 or EIA-485

communications links

Mating connector: Type DB9M

J7 Waveguide Switch Interface (for use in redundant configurations)

2.2.3 Optional: Redundancy Kit Installation

Comtech EFData SSPAs are easily configured for redundant systems by using one of the

optional Redundant Cable Kits. These kits include all the necessary controls, semi-rigid,

and waveguide cabling, and appropriate waveguide/coax switches and terminations.

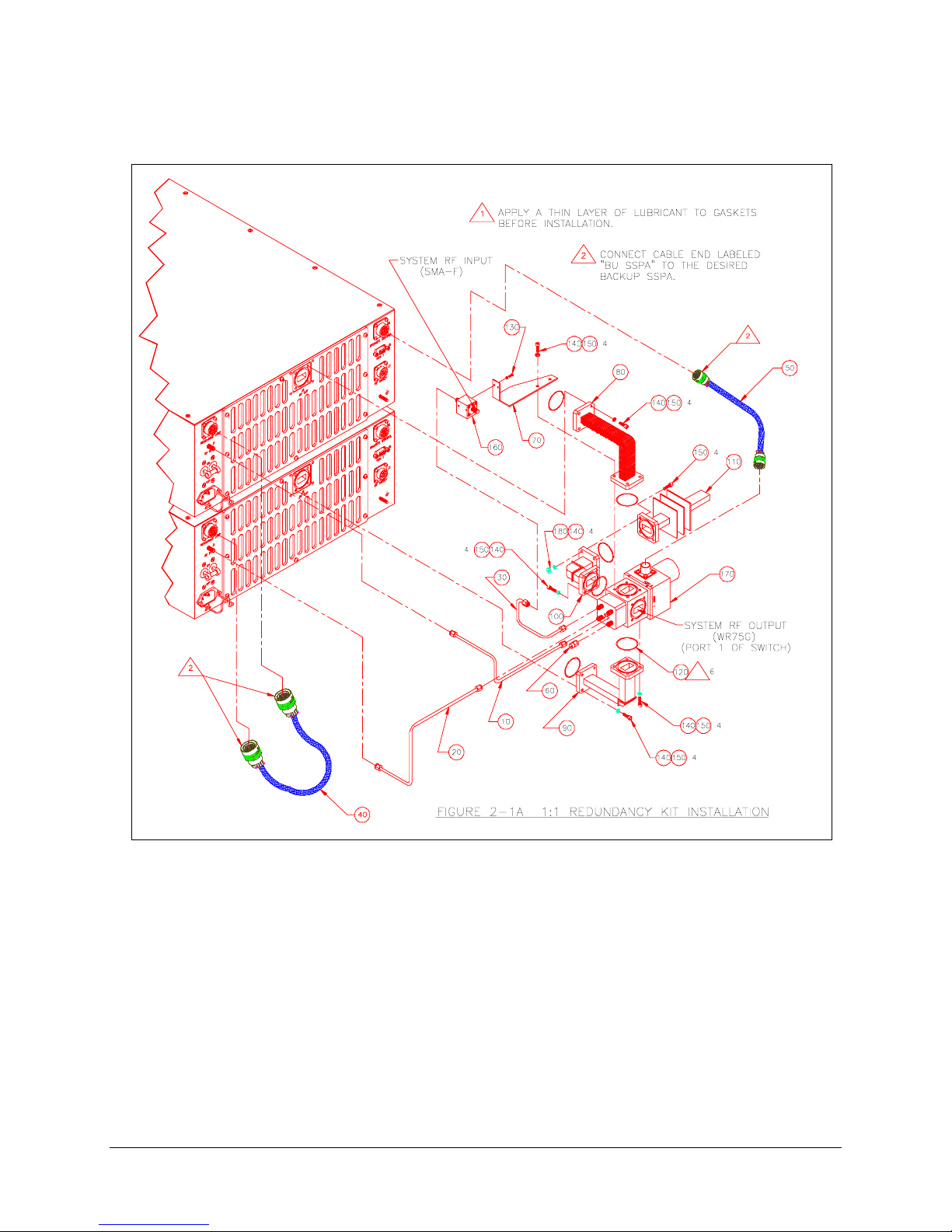

Figure 2-1 shows the typical 1:1 installation and Table 2-2 shows the associated parts list.

The primary and backup SSPAs shall be installed next to each other in a standard 19-inch

(48 cm) equipment rack. Because of the configuration of the dual WG-Coax Switch, the

upper SSPA will always act as the backup.

Rev. 0 2-3

Page 21

Installation KPA080 Ku-Band Solid-State Power Amplifier

Figure 2-1. Redundancy Installation

1

2-4 Rev. 0

Page 22

KPA080 Ku-Band Solid-State Power Amplifier Installation

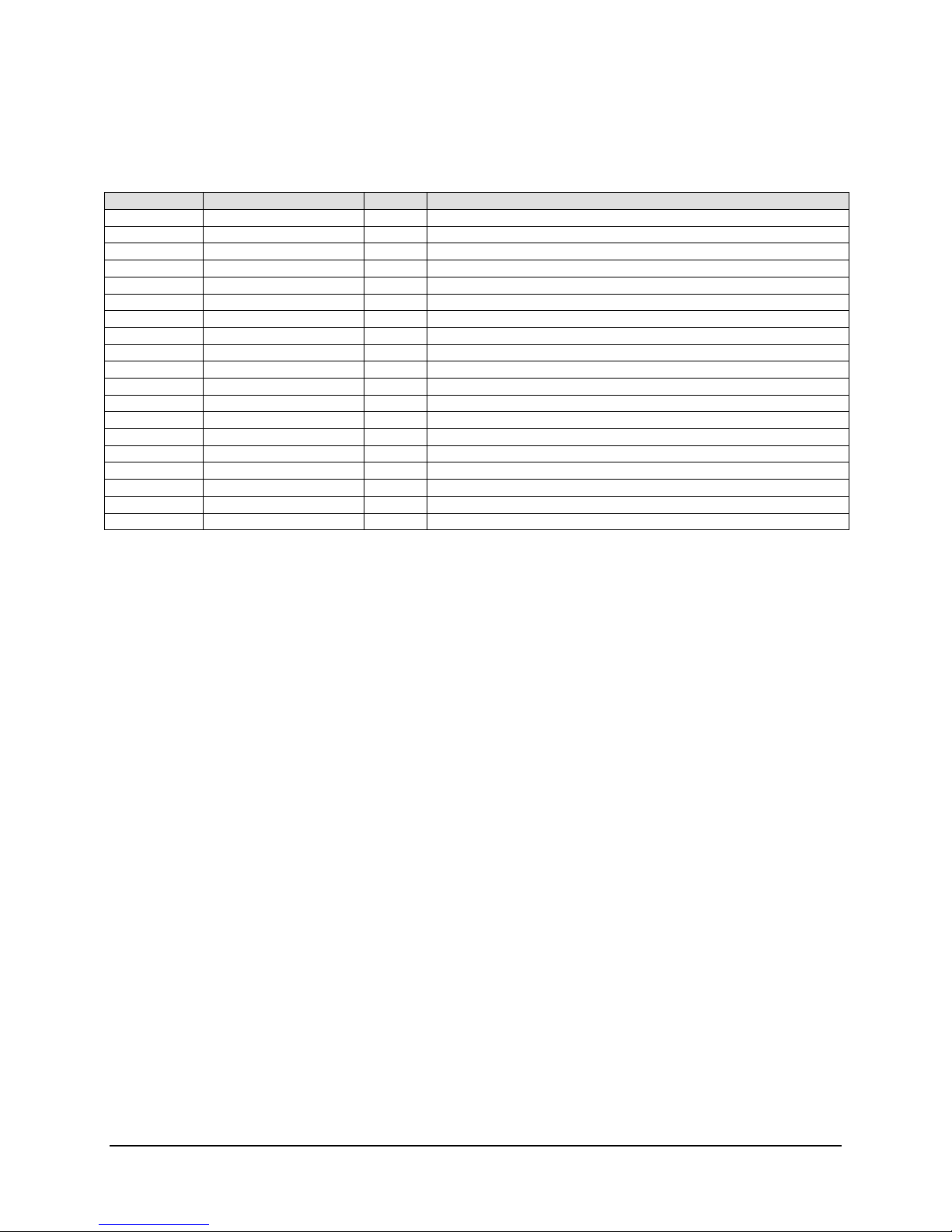

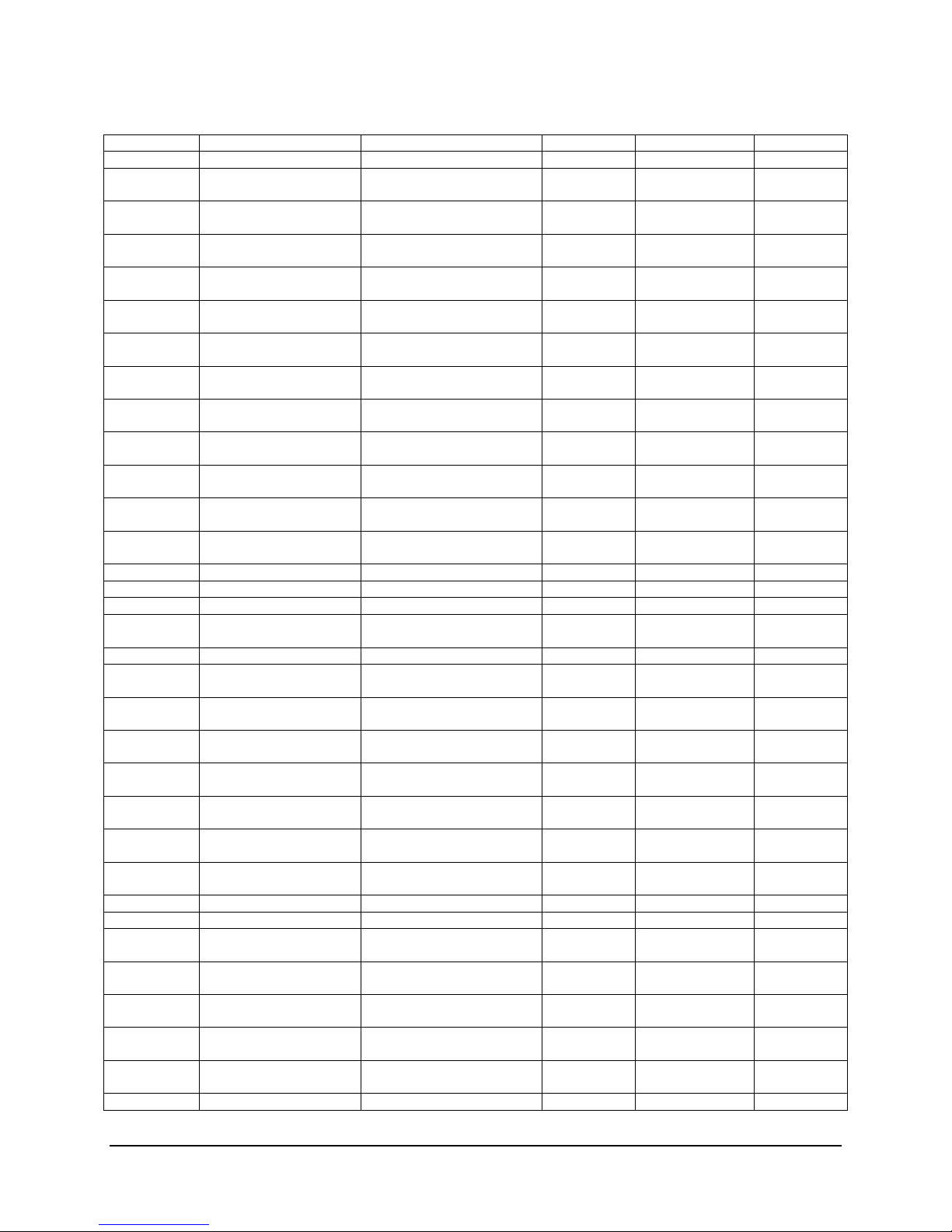

Table 2-2. Redundancy Kit

Item No. Part No. QTY Nomenclature

AS/0435 KPA080 SSPA

10 CA/RF0075 1 Cable, SW P3 to Upper J1, Red Kit, 1:1

20 CA/RF0076 1 Cable, SW P2 to Lower J1, Red Kit, 1:1

30 CA/RF0065 1 Cable, SW P4 to Isolator, Red Kit. 1:1

40 CA/WR0006 1 Cable, Redundant Loop

50 CA/WR0007 1 Cable, Waveguide Switch to B-UP J7

60 CN/CX2001-6501-00 1 Connector, OSM, SMS, Plug Termination

70 FP/BR0042 1 Bracket, Mounting, Isolator, Red Kit 1:1

80 FP/WG0045 1 Waveguide, WR75, Upper, 90, Red Kit 1:1

90 FP/WG0046 1 Waveguide, WR75, Lower, 90, Red Kit 1:1

100 FP/WG0024 1 Waveguide, WR75, Elbow, 90, Red Kit 1:1

110 FP/WG0025 1 Waveguide, WR75, Termination, 150W, Red Kit, 1:1

120 GA/GSKT,WR75,FULL 7 Gasket, WR75, Full THK

130 HW/080/3/16PHMS 2 0-80 x 3/16 PHM Screw, SS

140 HW/632X3/8SHCS-B 32 Screw, 6-32 x 3/8 SHCS, Black

150 HW/06LOCK 32 #6 Lock Washer, SS

160 RF/ISHF037306-001 1 RF-ISO, 13-16G, SMS-FF

170 SW/WG-754A0 1 SW-WR75, O-Ring, Dual WGSMA

180 XX/P-SUPER O-LUBE AR Parker Super, O-Lube, 2 oz

Perform the installation as follows:

1. Assemble the waveguide load and bend to the proper port of the switch.

Note:

Remember to install a gasket between each waveguide interface (refer to

Figure 2-1).

2. Attach the rigid lower waveguide arm, using the supplied screws. The switch

should be installed with “Port 1” facing outward.

3. The upper Waveguide (flexible arm) along with the isolator bracket should

be installed next.

4. Complete the installation by attaching the coaxial cables, coaxial load, and

control cables.

5. Note that the installation of the control cables determines which unit will

function as the backup SSPA. Due to the nature of the dual WG-coax switch,

this will always be the upper unit. Therefore, the end of the redundant loop

cable (40, Figure 2-1) labeled “BU SSPA,” should be connected to J4 of the

upper (back-up) unit.

6. The appropriate end of the control cable attaching to the Waveguide switch

(50) should also be attached to the backup unit (J7).

Redundancy kits with all the cabling and switches for a 1:2 configuration also are

available, and are usually designed to a particular customer’s specifications. Contact

Comtech EFData for 1:2 redundancy kits and installati on diagram s.

Rev. 0 2-5

Page 23

Installation KPA080 Ku-Band Solid-State Power Amplifier

2.3 External Connections

2.3.1 Rear Panel Connections

Refer to Table 2-3 for a list of the connectors on the rear panel.

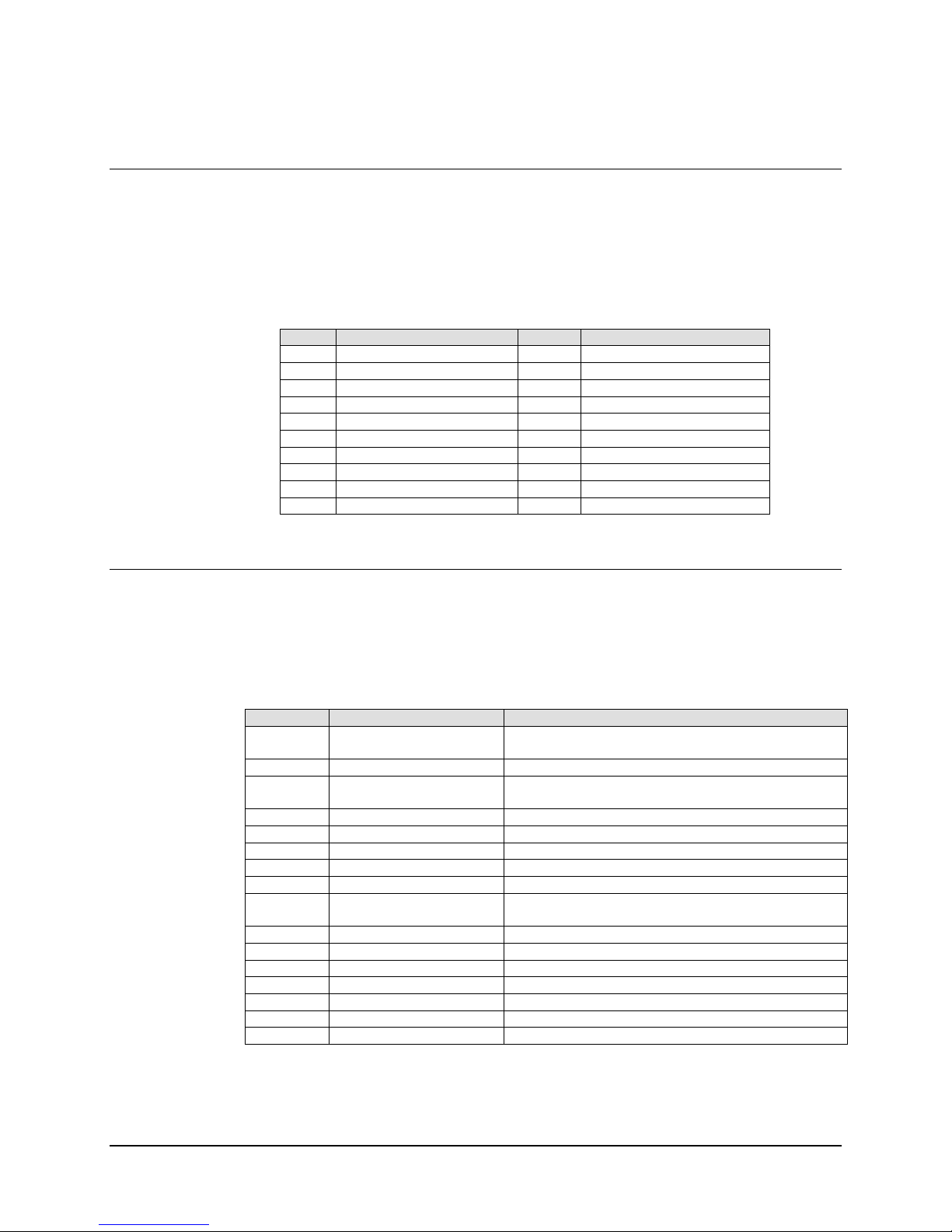

Table 2-3. Rear Panel Connectors

Connector Description Mating Co nnecting

J1 SSPA RF Input (RF IN) Type SMA (f)

J2 SSPA RF Output (RF OUTPUT) WR75G

J3 AC Prime Power Input (AC IN)

J4 Redundant Loop Interface

(REDUND LOOP)

J5 Customer Discrete Control

(DISCRETE CONTROL)

J6 COM1 Port (EIA-232/EIA-485) (COM1) DB9M

J7 Waveguide Switch Interface

(RF SWITCH)

MS3116F14-19P

MS 3116F14-19P

MS3116F12-10P

2-6 Rev. 0

Page 24

KPA080 Ku-Band Solid-State Power Amplifier Installation

2.3.1.1 Redundant Loop Interface, Connector J4

The Redundant Loop Interface connector J4 is a 19-pin circular connector, type

MS3112E14-19S. The pin-out specification is contained in Table 2-4. This connector is

used only in redundant configurations.

Table 2-4. Redundant Loop Interface, Connector J4

Pin # Description Pin # Description

A Loop In 1 L Sumflt 2 NO

B ADDR 2 M SumFlt 2 Common

C Loop In 2 N Local Loop Out

D Loop Out 2 P Sumflt 1 NO

E ADDR Common R Sumflt 1 Common

F ADDR 1 S Local Sumflt Common

G Loop Out 1 T Local Sumflt NO

H HSB +RX/TX U No Connect

J HSB – RX/TX V No Connect

K Local Loop In

2.3.1.2 Customer Discrete Control, Connector J5

The Customer Discrete Control connector J5 is a 19-pin circular connector, type

MS3112E14-19S. The pin-out specification is contained in Table 2-5.

Table 2-5. Customer Discrete Control, Connector J5

Pin # Signal Name Description

A Auto Select Momentary short to pin F to force entire subsystem to

Auto Mode.

B BU-1 Command Momentary short to pin F to force backup of SSPA #1.

C Priority 2 Sel Momentary short to pin F to set SSPA #2 as HIGH

priority.

D BU-2 Command Momentary short to pin F to force backup of SSPA #2.

E 2 Online NO Tied to pin G when Online, all other conditions OPEN.

F Remote Common Control – Remote Common.

G Online Common Online Status Common.

H BU Online NO Tied t o pin G when Online, all other condi tions OPEN.

J Manual Select Momentary short to pin F to force entire subsystem to

Manual Mode.

K 1 Online NO Tied to pin G when Online, all other conditions OPEN.

L 2 Fault NO Tied to pin N when Faulted, all other conditions OPEN.

M Priority 1 SEL Momentary short to pin F to set SSPA #1 as High priority.

N Fault Common Fault Status Common.

P BU Fault NO Open when faulted, else tied to Pin N.

R BU Offline CMD Momentary short to pin F to force backup SSPA Offline.

S 1 Fault NO Open when faulted, else tied to Pin N.

Rev. 0 2-7

Page 25

Installation KPA080 Ku-Band Solid-State Power Amplifier

2.3.1.3 EIA-232/EIA-485 Interface, Connector J6

The EIA-232/EIA-485 Interface connector J6 is a 9-pin D type DB9F connector socket.

The pin-out specifications are contained in Table 2-6. The mating connector is a DB9M.

Table 2-6. EIA-232/EIA-485 Interface, Connector J6

Pin # EIA-232 EIA-485 4-W i r e EIA-485 2-Wire

1 No Connect Ground (GND) Ground (GND)

2 Transmit Data (TD) No Connect No Connect

3 Receive Data (RD) No Connect No Connect

4 No Connect +TX Sign al +RX/TX Signal

5 Ground (GND) -TX Signal -RX/TX Signal

6 Unit Ready – always high

(DSR)

7 Request to Send. Looped to

CTS (RTS)

8 Clear to Send (CTS) +RX Signal +RX/TX Signal

9 No Connect -RX Signal -RX/TX Signal

No Connect No Connect

No Connect No Connect

2.3.1.4 Waveguide Switch Interface, Connector J7

The waveguide switch interface connector J7 is a 10-pin circular connector, type

MS3112E12-10S. The pin-out specification is contained in Table 2-7. This connector is

used only in redundant configurations.

Table 2-7. Waveguide Switch Interface, Connector J7

Pin # Description

A Command BU-1

B Command Common

C Command 1 Online

D IND 1 Online

E IND Common

F IND BU Online

G Command BU-2

H Command BU-2

J IND 2 Online

K No Connect

2.4 Dimensional and Outline Diagrams

Refer to Figure 2-2 for the Dimensional Diagram (all measurements shown in inches) and

to Figure 2-3 for the Redundancy Outline Diagram.

2-8 Rev. 0

Page 26

KPA080 Ku-Band Solid-State Power Amplifier Installation

Rev. 0 2-9

Figure 2-2. Dimensional Diagram (inches)

REMOTE

Tx ON

8.72

7.00

OUTPUT

KPA-080

SSPA

INPUT

STORED FAULT

FAULT

POWER ON

18.25

.86

.38

SAMPLE

ON LINE

19.00 1.50

24.00

14-19S

.92

RF OUTPUT

(WR-75G)

RF OUT

SMA (F)

SWITCH

1.66

7.28

2.50

AC ENTRY

AC IN

J3

O

I

RF IN

REDUNDANT LOOP

J4

J1

GROUND LUG

DE09 (S)

10-10S

RF SWITCH

J7

DISCRETE CONTROL

COM1

J6

J5

2.00

7.06

3.19

6.65

1.31

J2

15.44

.75

16.75

14-19S

Page 27

Installation KPA080 Ku-Band Solid-State Power Amplifier

2-10 Rev. 0

Figure 2-3. Redundancy Outline Diagram

BLOCK DIAGRAM

RF IN

4

COAX

RF OUT

SSPA

#1

3

2

1

SWITCH

2

4

31

WG

BU

SSPA

DISCRETE CON TROL

COM1

RF SWITCH

COM1

DISCRETE CON TROL

RF SWITCH

RF OUT

REDUNDANT LOOP

REDUNDANT LOOP

RF OUT

AC IN

J3

O

I

RF IN

J1

RF IN

1

2

3

4

AC IN

J3

RF IN

J4

J1

PORT 1

19.0

7.8

J2

RF OUT

J7

J6

J5

17.5

J7

J6

J5

6.1

AC IN

J3

O

REDUNDANT LOOP

I

RF IN

J1

AC IN

J3

REDUNDANT LOOP

RF IN

J4

J1

PORT 1

J2

RF SWITCH

J7

DISCRETE CON TROL

COM1

J6

J5

RF SWITCH

J7

DISCRETE CON TROL

COM1

J6

J5

(CONTROL CABLES NOT SHOWN IN THIS VIEW)

Page 28

This chapter describes the instructions for operating the KPA080-4045-I Ku-Band Solid

State High Power Amplifier.

3.1 General

The front panel of the SSPA has a keypad for the operator input commands, an LCD

Display, LED status indicators, and connector test sample ports to monitor the RF input

and output signals.

3.1.1 Switching On

Chapter 3.

OPERATION

3

Prior to positioning the Prime Power Switch to On, perform the following:

1. Check to ensure that the installation is complete.

2. Verify that the SSPA is connected to the proper prime power source, RF input,

and RF output.

3. Switch the On/Off Prime Power Switch on the rear panel to On.

4. Verify that the cooling fans are operating, and that the POWER ON LED

STATUS indicator light is On.

Rev. 0 3-1

Page 29

Operation KPA080 Ku-Band Solid-State Power Amplifier

5. After the PRIME POWER is switched on, the STATUS indicators should be as

follows:

POWER ON

TRANSMIT

REMOTE

ON LINE

FAULT

STORED FAULT

ON

OFF

ON

ON

OFF

OFF

After the AC power is switched on and prior to pressing the buttons on the keypad, the

LCD display message should read as follows:

KPA080-4045-I

SW VER X.XX SN4045 XXXX

3-2 Rev. 0

Page 30

KPA080 Ku-Band Solid-State Power Amplifier Operation

3.2 Operation

Local control of the SSPA is controlled by operator input commands initiated through the

six button keypad on the front panel. The keypad is the local operator’s interface to

control, configure and monitor the status of the SSPA. Operator inputs and commands

entered into the keypad are displayed by the front panel, 24-character, 2-line LCD

display.

There are five operating functions:

Configuration

•

Monitor Status

•

Current Faults

•

Stored Faults

•

Utility Functions

•

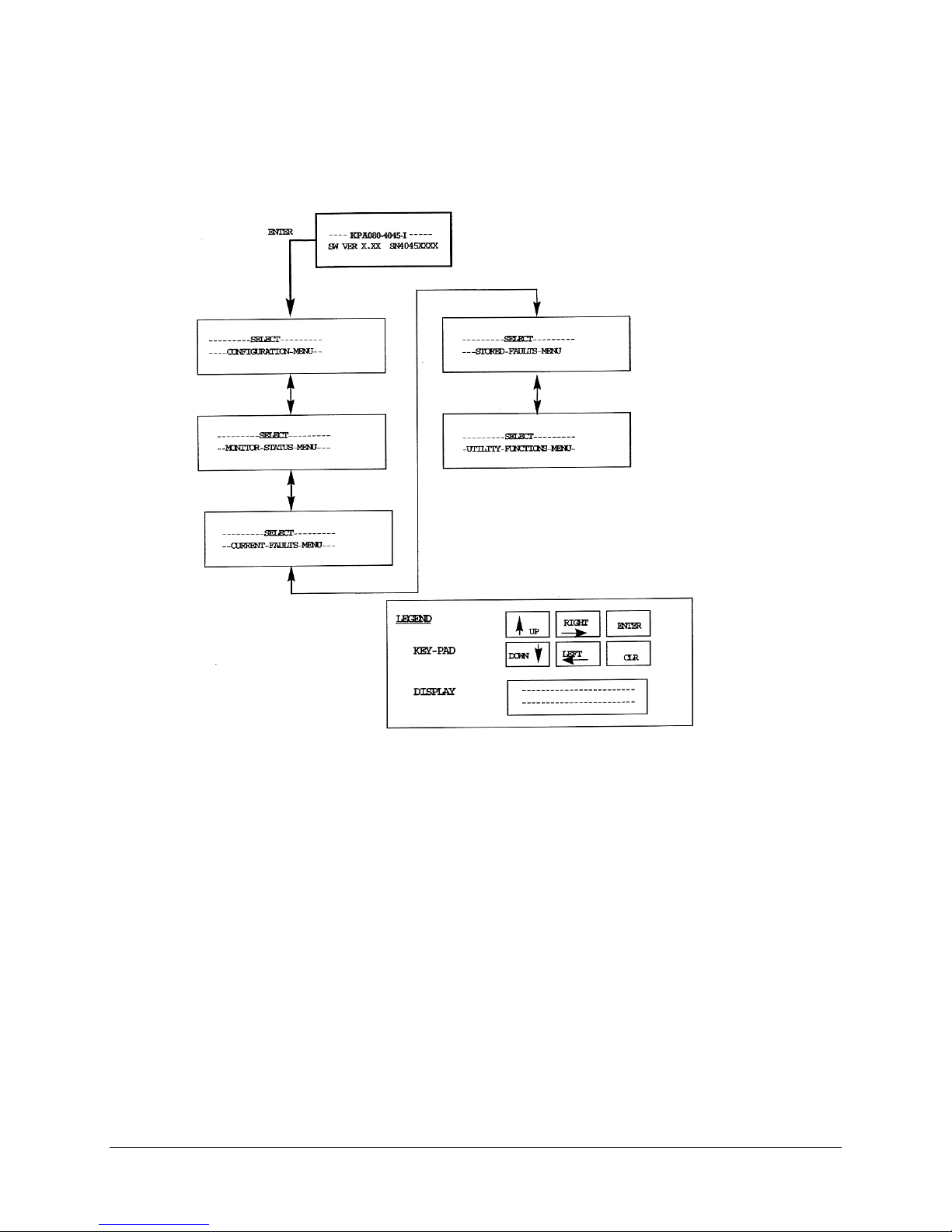

Flow charts for selecting the commands, operating menus, and data inputs are shown in

Figure 3-1 through Figure 3-6.

Rev. 0 3-3

Page 31

Operation KPA080 Ku-Band Solid-State Power Amplifier

Figure 3-1. SSPA Operating Command Functions

3-4 Rev. 0

Page 32

KPA080 Ku-Band Solid-State Power Amplifier Operation

3.2.1 SSPA Commands

The SSPA commands are presented in a tree structured menu format designed for access

and execution of all control functions and to prevent the execution of an invalid entry by

the operator. When the prime power is turned On, the LCD display will contain a

message indicating the SSPA model number and the version number of the firmware

installed in the SSPA.

To select a Command Function press the <ENT> button on the keypad. The LCD display

will indicate:

SELECT

CONFIGURATION MENU

This will provide the local operator access to the Command Function Menus, which is the

top level structure to start the selection of Command Function Menus to input into the

SSPA.

To sequence to the next Command Function Menu press a ↓ or ↑ arrow button on the

keypad. The SSPA will step to the next Command Function Menu each time a ↓ or ↑

arrow button is pressed. The current Command Function Menu will be displayed on the

LCD display. The Command Function Menus are shown in Figure 3-1.

To select a specific Command Function Menu press the <ENT> keypad button. If a

function is selected in error, press the clear <CLR> button which will return the SSPA to

the main command menus to allow the selection of another function. Any one of the five

Command Function Menus can be selected using this procedure.

Once a Command Function has been selected, use the → or ← arrow key-pad buttons to

sequence through the Operating Mode Commands. Each of the modes will be displayed

on the LCD display. A specific operating mode is selected by pressing the <ENT>

button. If a mode is selected in error, press the clear <CLR> button which will return the

SSPA to the operating menus to allow the selection of another mode.

When an operating mode is selected, a parameter or a digit within the parameter will be

flashing on the LCD display. Use the → and ← arrows buttons to sequence through the

parameters or digits to select the next parameter or digit. A specific parameter or value is

selected by pressing the <ENT> button. If a parameter or value is selected in error, press

the <CLR> button which will return the SSPA to the original parameter or value to allow

another selection.

After selecting a parameter or digit, use the ↓ or ↑ arrow buttons to select the next

parameter, or to increment or decrement the value of a digit. A specific new parameter or

new value is selected by pressing the <ENT> button. If a parameter or value is selected in

error, press the <CLR> button which will return the SSPA to the original parameter or

value to allow another selection.

Each time the clear ("CLR") button is pressed, the SSPA will return to the menu level

prior to the last "ENT" command.

Rev. 0 3-5

Page 33

Operation KPA080 Ku-Band Solid-State Power Amplifier

This page is intentionally left blank.

3-6 Rev. 0

Page 34

KPA080 Ku-Band Solid-State Power Amplifier Operation

Figure 3-2A. Configuration Menu Commands (Single Configuration)

Rev. 0 3-7

Page 35

Operation KPA080 Ku-Band Solid-State Power Amplifier

Figure 3-2B. Configuration Menu Commands (Redundancy Mode)

3-8 Rev. 0

Page 36

KPA080 Ku-Band Solid-State Power Amplifier Operation

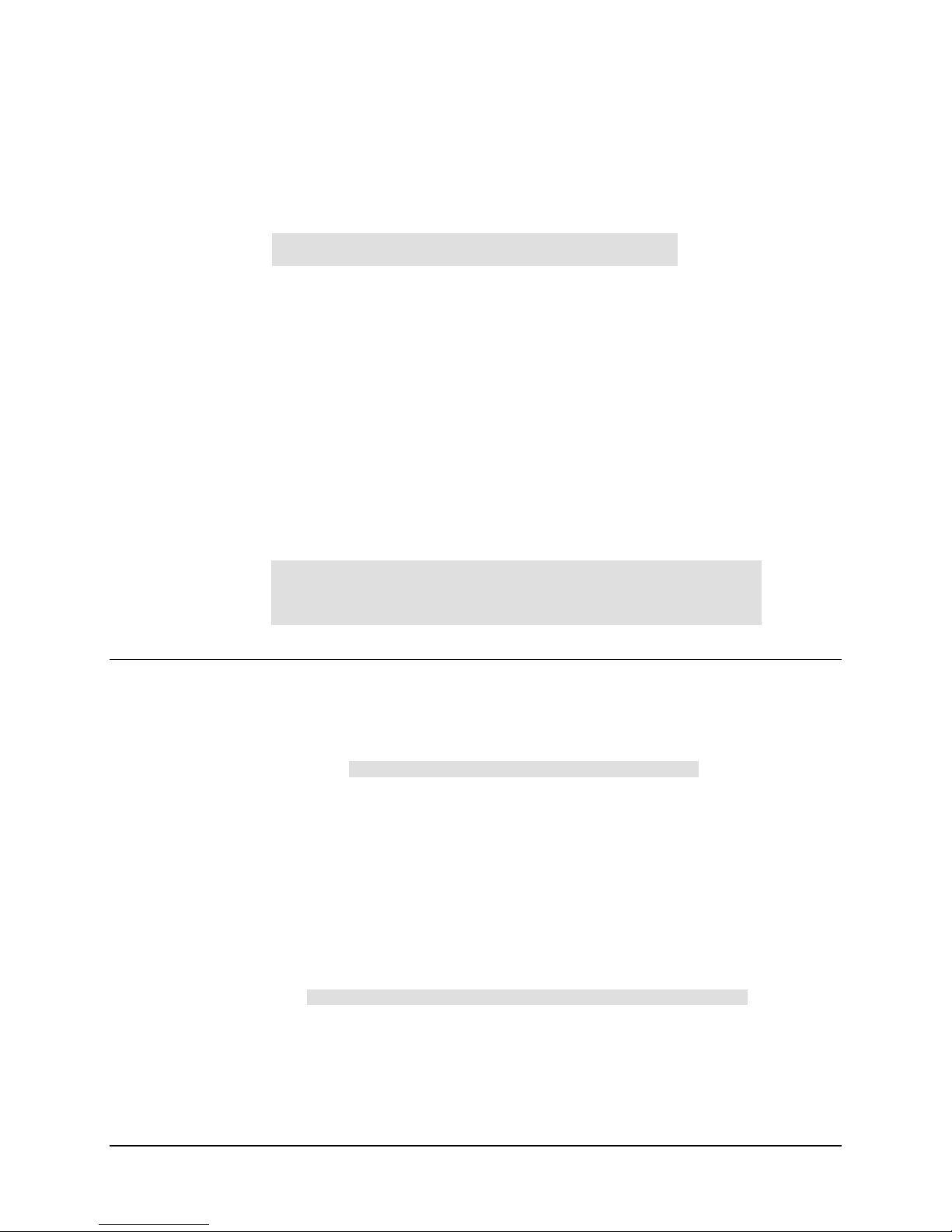

3.2.2 Configuration Menu

The Configuration Functions (Figure 3-2A or Figure 3-2B)are as follows:

Attenuation:

Amplifier

Mute

Entry Mode

Fault Recovery:

Redundancy Configuration

Priority SSPA

Operating Mode

Gain OFFSET/ Forced Backup

Activate Backup:

Attenuation (ATTN): Input and displays the SSPA attenuation setting

which is selected between 0.00 to 20.00 in 0.25 dB steps. The default

setting is 10.00 dB.

Amplifier: Control supply voltage to RF FETS. The default mode is

ON.

Mute: Provide SSPA mute control. The default is OFF.

Mode: The entry mode is Local or Remote. The default is Local.

Fault Recovery is Manual or Auto. The default is Auto.

This menu window provides indication of the operating

mode (i.e. stand alone or redundancy).

Provides selection of priority SSPA in 1:2 redundancy systems.

Always 1 in 1:1 redundancy systems.

Note:

Window not displayed when redundancy is Off.

Provides selection of either AUTO or MANUAL operating mode in

redundancy systems.

Note:

Window not displayed when redundancy is Off.

Gain offset: Provides for ± 7.0 dB offset to be entered for individual

SSPA’s in redundancy systems for Gain Equalization.

Note:

Window not displayed when redundancy is Off.

Provides ONLINE/OFFLINE control when manual mode is selected.

Note:

Window not displayed when redundancy is Off.

Rev. 0 3-9

Page 37

Operation KPA080 Ku-Band Solid-State Power Amplifier

UP

UPUP

SELECT

---------

---------

--

--

SELECT

---------

MONITOR-STATUS-MENU

MONITOR-STATUS-MENU

ENTER

ENTER

---------

---

---

DOWN

DOWNDOWN

-RF-

-RF-

FET

----Q3-=-

FET

----Q4-=-

X.X-AMPS

X.X-AMPS

+12V=+12.2

+12V=+12.2

VCC=4.9

VCC=4.9

--

--

28-VDC-PS-=-27.9--

28-VDC-PS-=-27.9--

----

----

9VPS1=9.1 9VPS2=9.0

9VPS1=9.1 9VPS2=9.0

AMPLIFIER-TEMP=+44C

AMPLIFIER-TEMP=+44C

--

--

------------------------

------------------------

FORWARD-RF-PWR:-53.0-DBM

FORWARD-RF-PWR:-53.0-DBM

REVERSE-RF-PWR:-<26.2-DBM

REVERSE-RF-PWR:-<26.2-DBM

FET

FET

--RF-

--RF-

FET

FET

--RF-

--RF-

-12V=-12.0

-12V=-12.0

----

----

-5V=-4.9

-5V=-4.9

-----

-----

----Q1-=-

----Q1-=-

----Q2-=-

----Q2-=-

XXXmA

XXXmA

XXXmA

XXXmA

---

---

--

--

--

--

--

--

--

--

-RF-

-RF-

-RF-

-RF-

-RF-

-RF-

-RF-

-RF-

-RF-

-RF-

-RF-

-RF-

-RF-

-RF-

FET

FET

----Q5-=-

----Q5-=-

FET

FET

----Q6-=-

----Q6-=-

FET

FET

----QX-=-

----QX-=-

FET

FET

----QX-=-

----QX-=-

FET

FET

FET

----

----

----

FET

FET

FET

----

----

----

LEGEND

LEGEND

KEY-PAD

KEY-PAD

DISPLAY

DISPLAY

X.X-AMPS

X.X-AMPS

X.X-AMPS

X.X-AMPS

X.X-AMPS

X.X-AMPS

X.X-AMPS

X.X-AMPS

Q26=-X.X-AMPS

Q26=-X.X-AMPS

Q26=-X.X-AMPS

Q27=-X.X-AMPS

Q27=-X.X-AMPS

Q27=-X.X-AMPS

DOWN

DOWN

DOWNDOWN

------------------------

------------------------

------------------------

------------------------

------------------------

------------------------

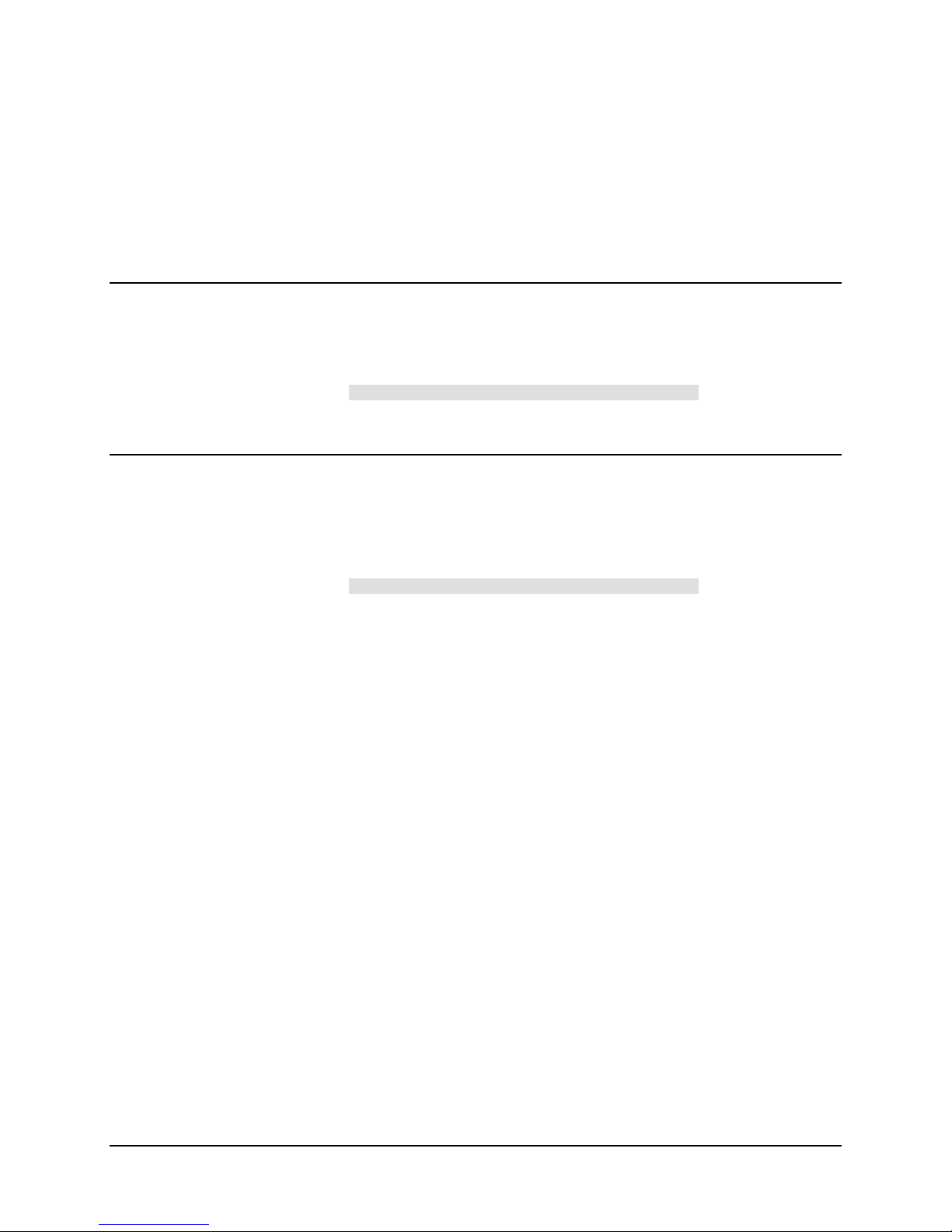

Figure 3-3. Monitor Status Menu Commands

ENTER

ENTER

ENTERENTER

RIGHT

RIGHT

RIGHTRIGHT

UP

UP

UPUP

LEFT

LEFT

LEFTLEFT

CLR

CLR

CLRCLR

3-10 Rev. 0

Page 38

KPA080 Ku-Band Solid-State Power Amplifier Operation

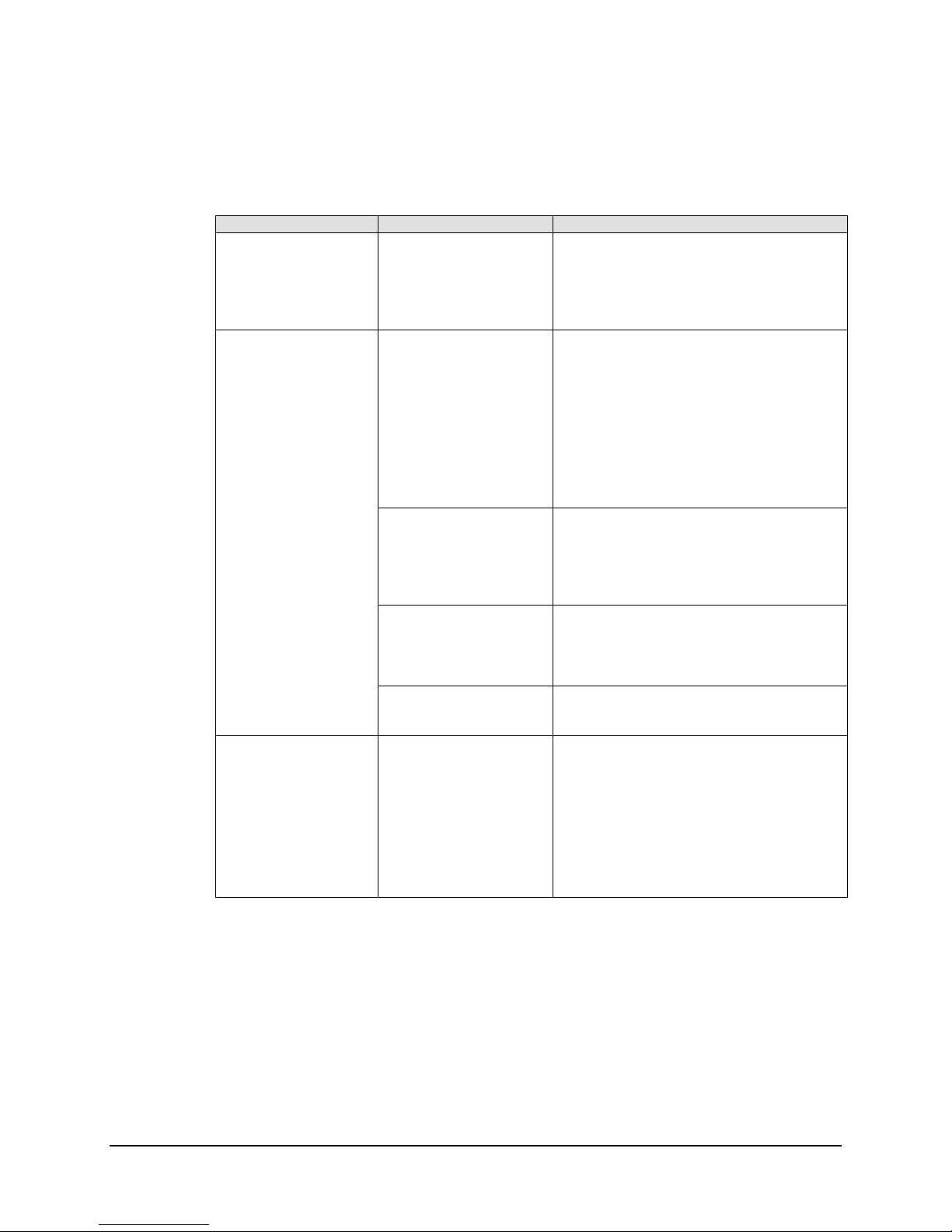

3.2.3 Monitor Status Menu

Monitors and displays the status (Figure 3-3) of:

All SSPA power supplies.

•

SSPA internal temperature.

•

RF output power level.

•

RF FET currents (Q1 through Q27).

•

Rev. 0 3-11

Page 39

Operation KPA080 Ku-Band Solid-State Power Amplifier

UP

UP

UPUP

SELECT

SELECT

ENTER

ENTER

ENTER

SELECT

---------

---------

---------

---

---

---

DOWN

DOWN

DOWNDOWN

---------

---------

---------

CURRENT-FAULTS-MENU

CURRENT-FAULTS-MENU

CURRENT-FAULTS-MENU

--

--

--

POWER-FAULTS:

POWER-FAULTS:

POWER-FAULTS:

12V=OK--VCC=OK---5V=OK

12V=OK--VCC=OK---5V=OK

12V=OK--VCC=OK---5V=OK

-

-

-

---28-VDC-PS-=-OK---

---28-VDC-PS-=-OK---

---28-VDC-PS-=-OK---

--

--

--

9VPS1=OK---9VPS2=OK--

9VPS1=OK---9VPS2=OK--

9VPS1=OK---9VPS2=OK--

---

---

---

AMPLIFIER-TEMP-=-OK

AMPLIFIER-TEMP-=-OK

AMPLIFIER-TEMP-=-OK

---

---

---

FAN-1-=-OK--FAN-2-=-OK

FAN-1-=-OK--FAN-2-=-OK

FAN-1-=-OK--FAN-2-=-OK

-

-

-

M&C-PROCESSORS-=-OK

M&C-PROCESSORS-=-OK

M&C-PROCESSORS-=-OK

M&C-PROCESSORS-=-OK

--

--

--

--

------------------------

------------------------

------------------------

------------------------

----

----

----

+12V=OK

+12V=OK

+12V=OK

--

--

--

--

--

--

---

---

---

---

Figure 3-4. Current Faults Menu Commands

-

-

-

LEGEND

LEGEND

-

-

-

LEGEND

KEY-PAD

KEY-PAD

KEY-PAD

DISPLAY

DISPLAY

DISPLAY

ENTER

ENTER

ENTER

RIGHT

RIGHT

RIGHT

RIGHTRIGHT

UP

UP

UP

UPUP

DOWN

DOWN

DOWN

DOWNDOWN

------------------------

------------------------

------------------------

------------------------

------------------------

------------------------

------------------------

------------------------

LEFT

LEFT

LEFT

LEFTLEFT

ENTERENTER

CLR

CLR

CLR

CLRCLR

3-12 Rev. 0

Page 40

KPA080 Ku-Band Solid-State Power Amplifier Operation

3.2.4 Current Faults Menu

Displays the status of the current fau lt cond it ions. T he LCD display will indic ate "F T"

when a fault condition exists. The display will indicate "OK" when a fault has not

occurred.

3.2.4.1 Power Faults

Displays the DC voltage power supply faults (Figure 3-4). The DC voltages displayed

are:

+12 VDC

•

-12 VDC

•

VCC

•

-5 VDC

•

• +28 VDC

• +9 VDC, PS1/PS2

3.2.4.2 SSPA Over Temperature Fault

Note:

A temperature fault is indicated if the unit is ≤ -20°C (≤ 4°F) or ≥ 85°C (≥ 185°F).

This creates a summary fault and will cause the unit to mute itself and switchover to the

backup unit. However, the 9V supply to the FET transistors will remain on until the unit

reaches the thermal shutdown temp erature of ≥ 90°C (194°F). For protection reasons, the

unit will shutdown the 9V supply to the power transistors at temperatures ≥ 90°C

(≥ 194°F).

Displays an SSPA temperature fault condition.

3.2.4.3 Fan Fault

Displays status of Fan #1 and Fan #2.

Rev. 0 3-13

Page 41

Operation KPA080 Ku-Band Solid-State Power Amplifier

Figure 3-5. Stored Faults Menu Commands

3-14 Rev. 0

Page 42

KPA080 Ku-Band Solid-State Power Amplifier Operation

3.2.5 Stored Faults Menu

The SSPA displays a total of 100 faults with a date and time stamped and stored in

memory as they occur. The stored faults (Figure 3-5) remain in memory until a clear

command is entered.

Total Stored Faults

Clear All Stored Faults

Display Stored Fault

Displayed the total number of faults stored. The most recent fault stored is

displayed on the LCD display.

Input command to clear all faults. The command is YES or NO which is

displayed on the LCD display.

The local operator can sequence through the stored faults st art ing with the most

recent fault. The Fault nu mber, time, description and date is di splayed on the

LCD disp lay.

Rev. 0 3-15

Page 43

Operation KPA080 Ku-Band Solid-State Power Amplifier

UP

UP

UPUP

SELECT

SELECT

ENTER

ENTER

ENTER

SELECT

---------

---------

---------

---

---

---

DOWN

DOWN

DOWNDOWN

FORWARD -RF-POWER-MONITOR

FORWARD -RF-POWER-MONITOR

FORWARD -RF-POWER-MONITOR

----OFFSET-=-+0.0dBm----

----OFFSET-=-+0.0dBm----

----OFFSET-=-+0.0dBm----

REVERSE-RF-POWER-MONITOR

REVERSE-RF-POWER-MONITOR

REVERSE-RF-POWER-MONITOR

----OFFSET-=-+0.0dBm----

----OFFSET-=-+0.0dBm----

----OFFSET-=-+0.0dBm----

--------LAMP-TEST-------

--------LAMP-TEST-------

--------LAMP-TEST-------

----------OFF-----------

----------OFF-----------

----------OFF-----------

---------

---------

---------

UTILITY-FUNCTIONS-MENU

UTILITY-FUNCTIONS-MENU

UTILITY-FUNCTIONS-MENU

--

--

--

----TIME:- 10:20:05AM----

----TIME:- 10:20:05AM----

----TIME:- 10:20:05AM----

-----DATE--09/15/94------

-----DATE--09/15/94------

-----DATE--09/15/94------

---SERIAL-MODE=RS232C---

---SERIAL-MODE=RS232C---

---SERIAL-MODE=RS232C--ADDR=XXX-BAUD=YYYY-P=ZZ-

ADDR=XXX-BAUD=YYYY-P=ZZ-

ADDR=XXX-BAUD=YYYY-P=ZZ-

SERIAL-PORT-DATA-FORMAT=

SERIAL-PORT-DATA-FORMAT=

SERIAL-PORT-DATA-FORMAT=

-7-DATA,-2-STOP,-PARITY-

-7-DATA,-2-STOP,-PARITY-

-7-DATA,-2-STOP,-PARITY-

DISPLAY-CONTRAST-=XX--

DISPLAY-CONTRAST-=XX--

DISPLAY-CONTRAST-=XX--

-

-

-

DISPLAY-BRIGHTNESS-=-XX-

DISPLAY-BRIGHTNESS-=-XX-

DISPLAY-BRIGHTNESS-=-XX-

Figure 3-6. Utility Functions Menu Commands

LEGEND

LEGEND

LEGEND

KEY-PAD

KEY-PAD

KEY-PAD

DISPLAY

DISPLAY

DISPLAY

ENTER

ENTER

ENTER

RIGHT

RIGHT

RIGHT

RIGHTRIGHT

UP

UP

UP

UPUP

DOWN

DOWN

DOWN

DOWNDOWN

------------------------

------------------------

------------------------

------------------------

------------------------

------------------------

------------------------

------------------------

LEFT

LEFT

LEFT

LEFTLEFT

ENTERENTER

CLR

CLR

CLR

CLRCLR

3-16 Rev. 0

Page 44

KPA080 Ku-Band Solid-State Power Amplifier Operation

3.2.6 Utility Menu

The local operator can input commands to the following Utility Functions (Figure 3-6)

which are displayed on the LCD display:

Time

Date

Serial MODE

Serial Interface

Physical Address

Baud (Rate)

Parity

Serial Port Data a Format

Display Contrast

Display Brightness

Forward RF Power

Monitor Offset

Reverse RF Power

Monitor Offset

Lamp Test

Military time is displayed in hours, minutes and seconds.

The date is displayed in month, day and year.

Communications link.

EIA-232, EIA-485 (2-Wire), EIA-485 (4-Wire).

The default address starts from 001.

The default baud rate is 9600.

Even (EV) is the default.

Odd (OD) can be selected.

NA appears when the 8,N,1 format is selected.

The default is 7 Data, 2 Stop Bits, with Parity.

An optional format is 8 Data, 1 Stop Bit, with No Parity.

Note:

This can only be changed via the front panel menu system.

The default is 15, with values from 0 to 30.

The default is 15, with values from 0 to 30.

This function allows the operator to calibrate (fine tune) the RF Power

Monitor for a specific carrier frequency. The RF Power Monitor is calibrated

in the factory at the SSPA center frequen cy. The operator can adjust (offset)

the display level using this function.

The range equal: -6.0 to +6.0 dBm in 0.1 dBm steps.

This function allows the operator to calibrate (fine tune) the RF Power

Monitor for a specific carrier frequency. The RF Power Monitor is calibrated

in the factory at the SSPA center frequency. The operator

the display level using this function.

The range equals: -6.0 to +6.0 dBm in 0.1 dBm steps.

The default is OFF

can adjust (offset)

Rev. 0 3-17

Page 45

Operation KPA080 Ku-Band Solid-State Power Amplifier

This page is intentionally left blank.

3-18 Rev. 0

Page 46

This chapter describes the instructions for SSPA redundancy configurations.

4.1 General

All Comtech EFData SSPAs are designed to operate in both stand-alone and redundant

configurations. Every SSPA contains the circuitry and logic necessary to perform all the

functions of a backup controller in both a 1:1 and 1:2 configuration. This includes the

ability to monitor and control up to two RF waveguide switch assemblies. In addition, the

SSPA has been designed to automatically detect whether it is in a stand-alone or

redundancy system. These features greatly simplify redundancy configurations from both

the cost and operational complexity standpoint.

CHAPTER 4.

REDUNDANT

CONFIGURATION

4

4.2 Redundancy Operation

Refer to Figure 2-1 for a full installation diagram of a typical redundant system.

In normal operation, incoming RF signals are routed through the primary online SSPA

(1:1 configuration), or SSPA(s) (1:2 configuration), to the system output(s) by the

combination waveguide/coax switch(es).

With the backup SSPA in the controller mode, it monitors the online unit(s) for faults.

When a fault occurs in an online unit, the backup SSPA automatically configures itself

with the settings of the faulted online unit. (These now-active settings also incorporate

any user defined offsets that may have been programmed into the backup unit.)

Rev. 0 4-1

Page 47

Redundant Configuration KPA080 Ku-Band Solid-State Power Amplifier

Figure 4-1. Control Cabling of a 1:1 System

The position of the waveguide/coax switch also is automatically changed to route the

signal through the backup unit, thereby minimizing the loss of traffic.

Control cable assemblies are required to set up either a 1:1 or a 1:2 system (other RF

coaxial cables and waveguides are required as shown in Figure 2-1).

Figure 4-1 shows the control cabling for a 1:1 system. The redundant loop cable

connecting the two SSPAs together provides a number of functions.

• This cable assembly is not a straight through cable.

The cable assembly is labeled “backup” on one end, and SSPA #1 on the

•

other end.

The cable assembly is wired so that when connected to two SSPAs, one

•

SSPA will automatically configure itself as the Backup Controller and the

other SSPA will automatically configure itself as the ‘Primary SSPA’.

The backup SSPA communicates to the primary SSPA via a serial interface also provided

by this redundant loop cable assembly. This interface is used by the Backup SSPA to

acquire configuration information from SSPA #1. In addition, this interface provides the

link for virtual addressing as described in Section 5 of this manual.

Summary fault relay contacts also are included in this cable assembly and are used by the

backup SSPA as an input to its switching logic. The second cable assembly is a

six-wire assembly between the backup SSPA and the Waveguide Switch Assembly.

Figure 4-2 shows the cabling for a 1:2 system. Note that the functionality describes for

the 1:1 cable assembly is directly applicable for the 1:2 cable assembly. The only

difference is that there is now a third connector daisy-chained onto the cable assembly.

This connector is labeled SSPA #2. When connected to a Comtech EFData SSPA, the

SSPA will automatically configure itself as Primary SSPA #2.

The second control cable attaches from the Backup Unit J7 to the Waveguide switch.

4-2 Rev. 0

Page 48

KPA080 Ku-Band Solid-State Power Amplifier Redundant Configuration

Figure 4-2. Control Cabling of a 1:2 System

4.2.1 Gain Equalization of Redundant Units

Typical procedures to equalize the gain between the Backup Unit and the Online Unit(s)

via the Gain Offset adjustment in the backup unit’s CONFIGURATION Menu are as

follows:

Note:

Make sure all connections are made as outlined previously in Sections 2 and 4.)

Determine the relative gain of the Backup Unit vs the Online unit(s).

Rev. 0 4-3

Page 49

Redundant Configuration KPA080 Ku-Band Solid-State Power Amplifier

Make sure the Online Unit is “online” and transmitting. This can be verified through the

Configuration Menu, and the front panel LEDs.

1. Apply an RF signal to the RF redundancy input isolator. Monitor the output

power level at the waveguide switch output. (Make sure not to apply too large of

an input signal which will saturate the amplifiers. Also be sure to have a properly

rated load to measure the output power.)

3. Adjust the input signal power level and attenuation of the Online Unit to arrive at

the desired output power level.

4. Record the output level of the Online Unit in dBm.

5. Force the backup unit to be the active path as outlined in the CONFIGURATION

Menu. Ensure the Offset Value at this point is 0.0 dBm. Record the output level

in dBm of the back-up unit.

6. If the output levels are equal, no more adjustment is necessary. Otherwise

proceed as follows.

4-4 Rev. 0

Page 50

KPA080 Ku-Band Solid-State Power Amplifier Redundant Configuration

Case 1. Backup < Online unit(s).

1. Ensure the online unit attenuation is set to a value in dB greater than or equal (

)

≥

to the difference in levels measured above.

2. With the backup unit forced to be the active unit, adjust the Offset Value in the

CONFIGURATION Menu to approximately the difference measured above. This

will be a (-) negative

number.

3. Toggle between the online and backup units as being the active path by forcing

and un-forcing a back-up through the back-up unit CONFIGURATION Menu

settings. Ensure the output levels measured are equal. If necessary, re-adjust the

Offset Value until equal levels are measured. (Note that the back-up unit total

attenuation level as now indicated in the CONFIGURATION Menu will be equal

to the setting of the online unit less

the Offset Value.)

For Example:

Online Unit Output Level

Backup Unit Output Level

Backup Unit Offset Value

Online Attenuation Setting

AFTER TOGGLING AND ADJUSTING:

Backup Offset Value

New Equaliz ed Output Level

Backup Attenuation Setting

47.0 dBm

45.25 dBm

0.00 dBm

3.00 dB (must be > 1.75 dB)

-1.75 dB

47.0 dBm

1.25 dB (3+(-1.75)=1.25)

Case 2. Backup > Online unit(s).

1. With the backup unit forced to be the active unit, adjust the Offset Value in the

CONFIGURATION Menu to roughly the difference measured above. This will

be a (+) positive

number.

2. Toggle between the online and backup units as being the active path by forcing

and un-forcing a back-up through the back-up unit CONFIGURATION Menu

settings. Make sure the output levels measured are equal. If necessary, re-adjust

the Offset Value until equal levels are measured. (Note that the back-up unit total

attenuation level as now indicated in the CONFIGURATION Menu will be equal

to the setting of the online unit plus

the Offset Value.)

For Example:

Online Unit Output Level

Backup Unit Output Level

Backup Unit Offset Value

Online attenuation setting

AFTER TOGGLING AND

ADJUSTING:

Backup Offset Value

New Equaliz ed Output Level

Backup Attenuation Setting

= 47.00 dBm

= 48.75 dBm

= 0.00 dBm

= 3.0 dBm

= +1.75 dB

= 47.00 dBm

= 4.75 dB (3+(+1.75)=4.75)

Rev. 0 4-5

Page 51

Redundant Configuration KPA080 Ku-Band Solid-State Power Amplifier

This page is intentionally left blank.

4-6 Rev. 0

Page 52

This chapter describes the instructions for SSPA remote control operation through a serial

port. Primary SSPAs in a redundancy subsystem also can be indirectly controlled through

the backup SSPA using virtual addressing. All SSPA configuration parameters as well as

all monitor and status information is available via the remote port.

5.1 General

Chapter 5.

REMOTE CONTROL

SPECIFICATION

5

The backup SSPA in the redundancy subsystem automatically monitors the configuration

and status for each of the primary (chained) SSPAs. This information is communicated

via the dedicated serial interface between the SSPAs.

If a primary SSPA fails, the backup detects this event and automatically

•

reconfigures itself to the proper attenuation setting and positions the

waveguide switch to provide minimal loss of traffic.

A result of this design is to greatly lessen the throughput requirements (i.e. polling rate)

of earth station monitor and control systems. The backup SSPA handles all of the time

critical tasks allowing the earth station monitor and control system to focus on less

intelligent subsystems.

Rev. 0 5-1

Page 53

Remote Control KPA080 Ku-Band Solid-State Power Amplifier

5.2 Electrical Interface

The remote control interface supports either EIA-485 (2-wire), EIA-485 (4-wire ) or

EIA-232. The default port is EIA-485 (2-wire). Selection of the interface type is made

via front panel menu selection. The three interface types are impletemented alternately

through the same 9-pin connector.

EIA-232

EIA-485

Levels, pulse shapes and impedances conform to EIA standards for asynchronous operation.

Levels, pulse shapes and impedances conform to EIA standards.

5.3 Interface Connector

All three interface types (2-wire EIA-485, 4-wire EIA-485 and EIA-232C) are

implemented alternately through the same 9-pin connector. The remote control port is a

female DB-9 connector located on the rear of the SSPA.

EIA-232

Pin Name Function

2 TD SSPA Transmit Data

3 RD SSPA Receive Data

5 GND Ground

6 DSR Unit Ready. Always high.

7 RTS Request to Send (Looped to CTS)

8 CTS Clear to Send

EIA-485 (2-Wire)

Pin Name Function

1 GND Ground

4 +RX/TX Signal Loop In

5 -RX/TX Signal Complement Loop In

8 +RX/TX Signal Loop Out

9 -RX/TX Signal Complement Loop Out

EIA-485 (4-Wire)

Pin Name Function

1 GND Ground

4 +TX Transmit Signal

5 -TX Transmit Signal Complement

8 +RX Receive Signal

9 -RX Receive Signal Complement

Rev. 0 5-2

Page 54

KPA080 Ku-Band Solid-State Power Amplifier Remote Control

5.4 Cables

EIA-232

The remote control port is configured with pin 2 as the TX data signal (TD) and pin 3 as