Comtech EF Data KPA-040, KPA-080, KPA-020IN, KPA series, KPA-100 Installation And Operation Manual

Page 1

Ku-Band Indoor Solid-State Power Amplifier Series

IMPORTANT NOTE: The information contained in this document supersedes all previously

published information regarding this product. Product specifications are subject to change

without prior notice.

KPA

Installation and Operation Manual

Part Number MN/KPA.IOM

Revision 1

October 29, 2010

Part Number MN/KPA.IOM Revision 1

Page 2

Comtech EF Data, 2114 West 7th Street, Tempe, Arizona 85281 USA, 480.333.2200, FAX: 480.333.2161

Copyright © Comtech EF Data, 2010. All rights reserved. Printed in the USA.

Page 3

Errata A

Comtech EF Data Documentation Update

Subject: AddTPEandTPSCommands/QueriestoAppendixC.REMOTECONTROL

Sect.C.6.1RemoteCommandsandQueries(FWVersion2.X.XandHigher)

OriginalManualPart

Number/Rev: MN/KPA.IOMRev1

ErrataNumber/

PLMDocumentID: ER‐KPA‐EA1

PLMCONumber: C‐0027379

Comments: Theupdatedinformationwillbeincorpor

ofthemanual:

AddTPEandTPSCommands/QueriestoAppendC.REMOTECONTROL

Sect.C.6.1RemoteCommandsandQueries(FWVersion2.X.Xand

Higher),pageC‐16:

atedintothenextformalrevision

ER-KPA-EA1 THIS DOCUMENT IS NOT SUBJECT TO REVISION/UPDATE! PLM CO C-0027379 Page 1 of 2

Page 4

ErrataAforMN/KPA.IOMRev1 AddTPEandTPSCommands/QueriestoAppendixC

Thispag

eisintentionallyblank.

ER-KPA-EA1 THIS DOCUMENT IS NOT SUBJECT TO REVISION/UPDATE! PLM CO C-0027379 Page 2 of 2

Page 5

Table of Contents

TABLE OF CONTENTS .............................................................................................................. III

TABLES ..................................................................................................................................... VII

FIGURES ................................................................................................................................... VII

PREFACE ................................................................................................................................... IX

About this Manual

..................................................................................................................................... ix

Disclaimer ................................................................................................................................................ ix

Reporting Comments or Suggestions Concerning this Manual ............................................................... ix

Military Standards ..................................................................................................................................... ix

Conventions and References ...................................................................................................................... x

Metric Conversion .................................................................................................................................... x

Recommended Standard Designations ..................................................................................................... x

Trademarks ............................................................................................................................................... x

Cautions and Warnings .............................................................................................................................. x

Electrical Safety and Compliance ............................................................................................................. xi

Electromagnetic Compatibility (EMC) Compliance ............................................................................... xi

European Low Voltage Directive (LVD) ................................................................................................. xi

Warranty Policy ........................................................................................................................................ xii

Limitations of Warranty ......................................................................................................................... xii

Exclusive Remedies ............................................................................................................................... xiii

Customer Support .................................................................................................................................... xiv

Online Customer Support ...................................................................................................................... xiv

CHAPTER 1. INTRODUCTION ........................................................................................... 1–1

1.1 Overview ..................................................................................................................................... 1–1

1.2 Functional Description .............................................................................................................. 1–2

1.3 KPA Specifications..................................................................................................................... 1–5

1.3.1 KPA-020IN Specifications ...................................................................................................... 1–5

1.3.2 KPA-040 Specifications .......................................................................................................... 1–6

1.3.3 KPA-080 Specifications ................................................................................................ 1–7

iii

Page 6

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Table of Contents MN/KPA.IOM

1.3.4 KPA-100 Specifications ................................................................................................ 1–8

1.3.5 Dimensional Envelopes ................................................................................................ 1–9

CHAPTER 2. INSTALLATION ............................................................................................ 2–1

2.1 Unpacking and Inspection ......................................................................................................... 2–1

2.2 Rack Mounting the KPA ........................................................................................................... 2–2

2.2.1 Installation of the Optional Rack Slides ................................................................... 2–2

CHAPTER 3. CONNECTORS AND PINOUTS ................................................................... 3–1

3.1 Connector Overview .................................................................................................................. 3–1

3.2 RF Connections .......................................................................................................................... 3–3

3.2.1 J1 RF IN / Tx IN Connectors ................................................................................................... 3–3

3.2.2 J2 RF OUT Connector ............................................................................................................. 3–3

3.3 Utility Connections .................................................................................................................... 3–4

3.3.1 Sample Port Connectors (Front Panel) .................................................................................... 3–4

3.3.2 J4 REDUNDANT LOOP Connector ....................................................................................... 3–4

3.3.3 J5 DISCRETE CONTROL Connector .................................................................................... 3–5

3.3.4 J8 10/100 ETHERNET Connector .......................................................................................... 3–6

3.3.5 J9A EXT REF IN / J9B EXT REF OUT Connectors .............................................................. 3–6

3.3.6 J7 RF SWITCH Connector ...................................................................................................... 3–7

3.3.7 J6 COM 1 Connector ............................................................................................................... 3–7

3.4 Power / Ground Connections .................................................................................................... 3–8

3.4.1 Alternating Current Prime Power Switch and Connector ........................................................ 3–8

3.4.2 Chassis Ground Connector ...................................................................................................... 3–8

CHAPT

ER 4. FLASH UPGRADING .................................................................................... 4–1

4.1 Flash Upgrading via Internet .................................................................................................... 4–1

4.2 Ethernet FTP Upload Procedure .............................................................................................. 4–2

CHAPTER 5. FRONT PANEL OPERATION ....................................................................... 5–1

5.1 Introduction ................................................................................................................................ 5–1

5.1.1 Startup Checklist ..................................................................................................................... 5–2

5.1.2 LED Indicators ........................................................................................................................ 5–2

5.1.3 Keypad ..................................................................................................................................... 5–3

5.1.4 Front Panel Display ................................................................................................................. 5–4

5.2 Opening Screen .......................................................................................................................... 5–4

5.3 SELECT: (Main) Menu ............................................................................................................. 5–5

5.3.1 SELECT: Config (Configuration) ........................................................................................... 5–6

iv

Page 7

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Table of Contents MN/KPA.IOM

5.3.1.1 CONFIG: Remote (Remote Control) .............................................................................. 5–6

5.3.1.2 CONFIG: Amp ............................................................................................................. 5–10

5.3.1.3 CONFIG: FltRec (Fault Recovery) Menu Branches ..................................................... 5–11

5.3.1.4 CONFIG: Redundancy Menu Branches ....................................................................... 5–11

5.3.1.5 CONFIG: ExtRef (External Reference) ........................................................................ 5–13

5.3.2 SELECT: Monitor ................................................................................................................. 5–13

5.3.2.1 MONITOR: Faults ........................................................................................................ 5–14

5.3.2.2 MONITOR: Stored ....................................................................................................... 5–14

5.3.2.3 MONITOR: Power ....................................................................................................... 5–15

5.3.2.4 MONITOR: Vltgs ......................................................................................................... 5–15

5.3.2.5 MONITOR: PS (Power Supply) ................................................................................... 5–15

5.3.2.6 MONITOR: Temp ........................................................................................................ 5–15

5.3.2.7 MONITOR: FETs ......................................................................................................... 5–15

5.3.3 SELECT: Utility .................................................................................................................... 5–15

5.3.3.1 UTILITY: Date/Time ................................................................................................... 5–16

5.3.3.2 UTILITY: CID (Circuit ID) .......................................................................................... 5–16

5.3.3.3 UTILITY: PowerMon ................................................................................................... 5–16

5.3.3.4 UTILITY: Firmware ..................................................................................................... 5–17

5.3.3.5 UTILITY: RefOsc ......................................................................................................... 5–17

5.3.4 SELECT: Front Panel ............................................................................................................ 5–18

5.3.4.1 Front Panel: Brightness ................................................................................................. 5–18

5.3.4.2 Front Panel: Lamp Test ................................................................................................. 5–18

CHAPTER 6. KPA ETHERNET MANAGEMENT ............................................................... 6–1

6.1 Overview ..................................................................................................................................... 6–1

6.2 Ethernet Ma

nagement Interface Protocols .............................................................................. 6–1

6.3 SNMP Interface .......................................................................................................................... 6–1

6.3.1 Management Information Base (MIB) Files ............................................................................ 6–2

6.3.2 SNMP Community Strings ...................................................................................................... 6–2

6.4 Telnet Interface .......................................................................................................................... 6–3

6.5 Web Server (HTTP) Interface .................................................................................................. 6–4

6.5.1 Web Server page Introduction ................................................................................................. 6–4

6.5.2 Web Server Interface Access ................................................................................................... 6–4

6.5.3 Web Server Menu Tree ............................................................................................................ 6–5

6.5.4 Web Server page Descriptions ................................................................................................ 6–5

6.5.4.1 Home pages ..................................................................................................................... 6–6

6.5.4.1.1 Home (Splash) page .................................................................................................. 6–6

6.5.4.1.2 Home | Support page................................................................................................. 6–7

6.5.4.2 Admin pages ................................................................................................................... 6–8

6.5.4.2.1 Admin | Access page................................................................................................. 6–8

6.5.4.2.2 Admin | SNMP page ............................................................................................... 6–10

6.5.4.3 Config (Configuration) pages ....................................................................................... 6–11

6.5.4.3.1 Config | Amplifier page .......................................................................................... 6–11

6.5.4.3.2 Config | Utility page ............................................................................................... 6–13

6.5.4.3.3 Config | Redundancy page ...................................................................................... 6–14

v

Page 8

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Table of Contents MN/KPA.IOM

6.5.4.4 Status pages ................................................................................................................... 6–16

6.5.4.4.1 Status | Events page ................................................................................................ 6–16

6.5.4.4.2 Status | Status page ................................................................................................. 6–17

6.5.4.4.3 Status | FETs page .................................................................................................. 6–18

APPENDIX A. MAINTENANCE AND TROUBLESHOOTING ........................................... A–1

A.1 Introduction ............................................................................................................................... A–1

A.2 Maintenance Testing ................................................................................................................. A–2

A.2.1 Test Point Samples ............................................................................................................. A–2

A.3 Troubleshooting ........................................................................................................................ A–2

A.3.1 Troubleshooting Guide ....................................................................................................... A–3

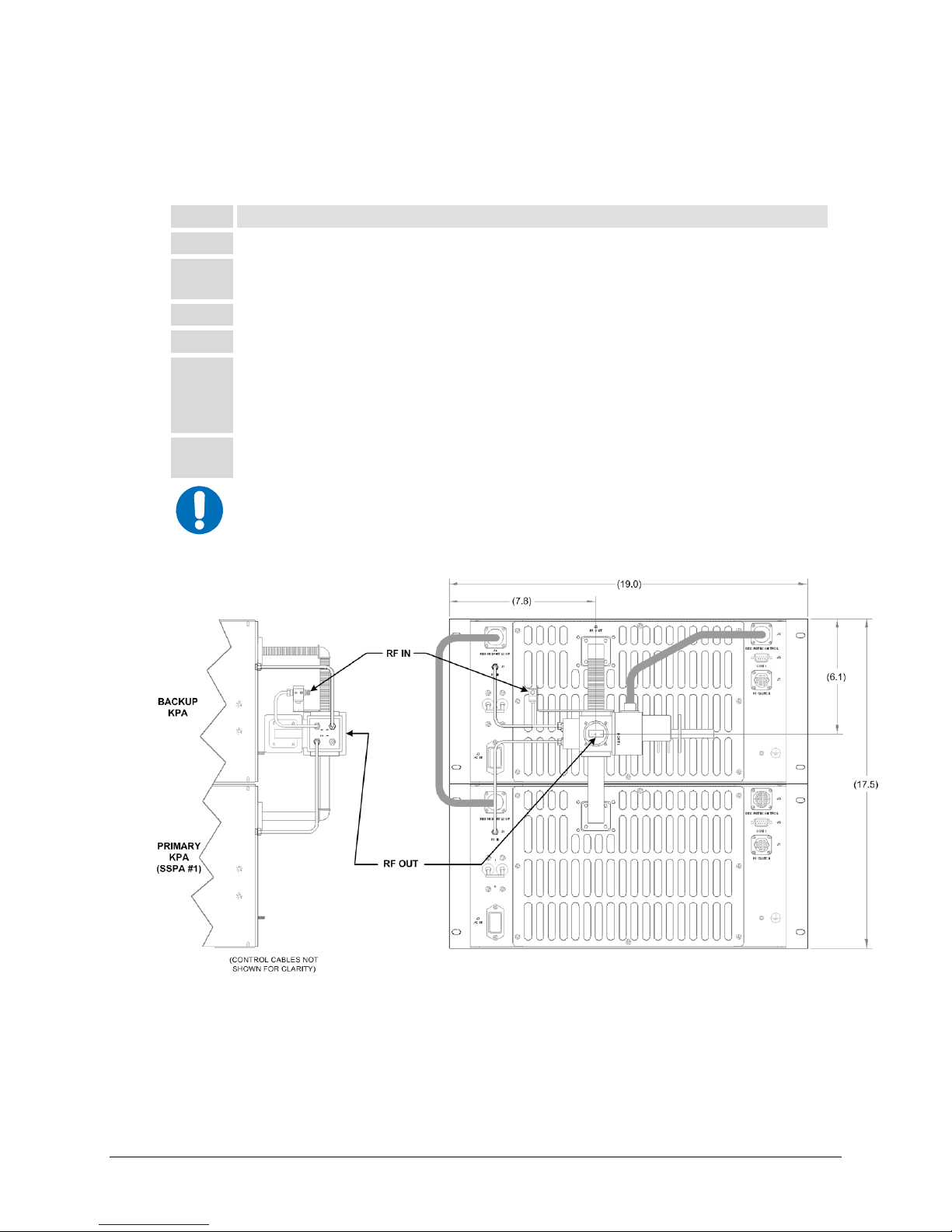

APPENDIX B. KPA REDUNDANT OPERATIONS ............................................................ B–1

B.1 Introduction ............................................................................................................................... B–1

B.2 Redundancy Operation ............................................................................................................ B–2

B.3 Redundancy Kit Installation .................................................................................................... B–2

B.3.1 Redundancy Kit Control Cabling ....................................................................................... B–4

B.4 Gain Equalization of Redundant Units ................................................................................... B–8

B.4.1 Case Examples ................................................................................................................... B–9

APPENDIX C. REMOTE CONTROL .................................................................................. C–1

C.1 Overview .................................................................................................................................... C–1

C.2 EIA-485 ...................................................................................................................................... C–1

C.3 EIA-232 ...................................................................................................................................... C–2

C.4 Basic Protocol ............................................................................................................................ C–2

C.5 Packet Structure

....................................................................................................................... C–3

C.5.1 Start of Packet .................................................................................................................... C–3

C.5.2 Target Address ................................................................................................................... C–4

C.5.3 Address Deli miter .............................................................................................................. C–4

C.5.4 Instruction Code ................................................................................................................. C–4

C.5.5 Instruction Code Qualifier .................................................................................................. C–4

C.5.5.1 Backward Compatibility Code Qualifier ....................................................................... C–5

C.5.6 Optional Message Argu ments ............................................................................................ C–5

C.5.7 End of Packet ..................................................................................................................... C–6

C.6 Remote Control Using FW Version 2.X.X and Higher (CURRENT) .................................. C–7

C.6.1 Remote Commands and Queries (FW Version 2.X.X and Higher) ................................... C–8

vi

Page 9

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Table of Contents MN/KPA.IOM

C.7 Remote Control Using Firmware Version 1.X.X (OLD) ..................................................... C–17

C.7.1 Old Utility Commands ..................................................................................................... C–18

C.7.2 Old Configuration Commands ......................................................................................... C–20

C.7.3 Old Operating Mode Commands ..................................................................................... C–21

C.7.4 Old Status Commands ...................................................................................................... C–22

C.7.5 Old Stored Alarms ............................................................................................................ C–28

C.7.6 Error Processing ............................................................................................................... C–29

C.7.7 Configuration Errors ........................................................................................................ C–29

C.7.8 Time-Outs ........................................................................................................................ C–29

Tables

Table 3-1. KPA Interface Connectors Summary ...................................................................................... 3–2

Table 3-2. J4 Redundancy Loop Connector Pinout ................................................................................. 3–4

Table 3-3. J5 DISCRETE CONTROL Connector Pinout (Standalone or 1:1 Redundant Systems) ....... 3–5

Table 3-4. J5 DISCRETE CONTROL Connector Pinout (1:2 Redundant Systems) .............................. 3–6

Table 3-5. J7 RF SWITCH Connector Pinout ......................................................................................... 3–7

Table 3-6. J6 COM 1 Connector Pinout (EIA-232/EIA-485 Interface) ................................................... 3–7

Table B-1. KPA Redundancy Kits – Parts List ........................................................................................ B–6

Figures

Figu r e 1-1. C o m tech EF D a t a KPA Fam ily of Ku - B and Soli d - State Amplifier s .......................................... 1–1

Figure 1-2. KPA-020IN/-040 Block Diagram .......................................................................................... 1–3

Figure 1-3. KPA-080/-100 Block Diagram ............................................................................................... 1–4

Figure 1-4. KPA-020IN Dimensional Envelope (Shown with Optional Slide Railings Installed) ........... 1–9

Figure 1-5. KPA-040/-080/-100 Dimensional Envelope (Shown with Optional Slide Railings Installed) 1–10

Figure 2-1. Installation of Optional Heavy-Duty Rack Slides (CEFD P/N FP/SL00004) ........................ 2–3

Figure 3-1. KPA Rear Panel Views .......................................................................................................... 3–1

Figure 4-1. Flash Upgrade via Internet ..................................................................................................... 4–1

Figure 5-1. KPA-XXX Front Panel View ................................................................................................. 5–1

Figure 5-2. KPA Front Panel Keypad ....................................................................................................... 5–3

Figure 5-3. KPA Front Panel Keypad ....................................................................................................... 5–4

Figure 5-4. KPA Principle Menu Tree ...................................................................................................... 5–5

Figure 6-1. KPA Home (Splash) page ...................................................................................................... 6–6

Figure 6-2. KPA Home | Support page ..................................................................................................... 6–7

Figure 6-3. Admin | Access page .............................................................................................................. 6–8

Figure 6-4. Admin | SNMP page ............................................................................................................ 6–10

Figure 6-5. Config | Amplifier page ........................................................................................................ 6–11

Figure 6-6. Config | Utility page ............................................................................................................. 6–13

Figure 6-7. Config | Redundancy page ................................................................................................... 6–14

Figure 6-8. Status | Events page .............................................................................................................. 6–16

Figure 6-9. Status | Status page ............................................................................................................... 6–17

Figure 6-10. Status | FETs page .............................................................................................................. 6–18

Figure B-1. 1:1 Redundancy Block Diagram ........................................................................................... B–2

Figure B-2. 1:1 Redundancy Installation – Complete .............................................................................. B–3

Figure B-3. KPA Redundancy System – Control Cabling Schematics ................................................... B–4

Figure B-4. 1:1 Redundancy Kit Assembly ............................................................................................. B–7

vii

Page 10

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Table of Contents MN/KPA.IOM

This page is deliberately blank.

viii

Page 11

About this Manual

This manual provides installation and operation information for the Comtech EF Data family of

Ku-Band Indoor Solid-State Power Amplifiers (ISSPAs) – the KPA-020IN, KPA-040, KPA-080, and

KPA-100. This is a technical document intended for earth station engineers, technicians, an d ope ra tors

responsible for the operation and maintenance of the KP As.

PREFACE

Revision 1 of this manual represents a complete rewrite in which all content has been updated in its

entirety and re-ordered to conform to current Comtech EF Data Technical Publication s standards

and practices.

Disclaimer

Comtech EF Data has reviewed this manual thoroughly in order that it will be an easy-to-use

guide to your equipment. All statements, technical information, and recommendations in this

manual and in any guides or related documents are believed reliable, but the accuracy and

completeness thereof are not guaranteed or warranted, and they are not intended to be, nor should

they be understood to be, representations or warranties concerning the products described.

Further, Comtech EF Data reserves the right to make changes in the specifications of the products

described in this manual at any time without notice and without obligation to notify any person of

such changes.

If you have any questions regarding your equipment or the information in this manual, please

contact Comtech EF Data’s Customer Support Department during normal business hours.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual are appreciated. To

submit comments, please contact the Comtech EF Data Technical Publications department:

Military Standards

References to “MIL-STD-188” apply to the 114A series (i.e., MIL-STD-188-114A), which

provides electrical and functional characteristics of the unbalanced and balanced voltage digital

interface circuits applicable to both long haul and tactical communications. Specifically, these

TechnicalPublications@comtechefdata.com

ix

Page 12

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Preface MN/KPA.IOM

references apply to the MIL-STD-188-114A electrical characteristics for a balanced voltage

digital interface circuit, Type 1 generator, for the full range of data rates. For more information,

refer to the Department of Defense (DOD) MIL-STD-188-114A, “Electrical Characteristics of

Digital Interface Circuits.”

Conventions and References

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This information

is provided to assist the operator in cross-referencing non-Metric to Metric conversions.

Recommended Standard Designations

The Recommended Standard (RS) designation has been superseded by the new designation of the

Electronic Industries Association (EIA). References to the old designation may be shown only

when depicting actual text displayed on the screen of the unit (RS-232, RS-485, etc.). All other

references in the manual will be shown with the EIA designation.

Trademarks

Windows is a trademark of the Microsoft Corporation. Other product names mentioned in this

manual may be trademarks or registered trademarks of their respective companies and are hereby

acknowledged.

The User should carefully review the information that follows.

IMPORTANT

Cautions and Warnings

IMPORTANT or NOTE indicates a statement that is associated with the task being

IMPORTANT

performed or information critical for proper equipment function.

CAUTION indicates a hazardous situation that, if not avoided, may result in minor or

moderate injury. CAUTION may also be used to indicate other unsafe practices or

risks of property damage.

WARNING indicates a potentially hazardous situation that, if not avoided, could

result in death or serious injury.

x

Page 13

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Preface MN/KPA.IOM

Electrical Safety and Compliance

This product contains a Lithium Battery. DANGER OF EXPLOSION EXISTS if the

battery is incorrectly replaced. Replace only with the same or equivalent type

WARNING

CAUTION

recommended by the manufacturer. Dispose of used batteries in accordance with

local and national regulations

This equipment has been designed to minimize exposure of personnel to hazards. The

operators and technicians must:

• Know how to work around, with, and on high voltage and high RF power level

equipment.

• Exercise every precaution to ensure personnel safety.

• Exercise extreme care when working near high voltages/high RF power level

equipment.

• Be familiar with the warnings presented in this manual.

• Disconnect the power supply cord before servicing the ISSPA.

Electromagnetic Compatibility (EMC) Compliance

Properly shielded cables for DATA I/O are required in order to meet the European

Electromagnetic Compatibility (EMC) Directive (EN55022, EN50082-1). More specifically,

IMPORTANT

these cables must be shielded from end-to-end, ensuring a continuous ground shield.

In accordance with European Directive 2004/108/EEC, the KPA family of products has been

shown, by independent testing, to comply with the following standards:

Emissions: EN 55022 Class B – Limits and Methods of Measurement of Radio

Interference Characteristics of Information Technology Equipment.

(Also tested to FCC Part 15 Class B.)

Immunity: EN 55024 – Information Technology Equipment: Immunity Characteristics,

Limits, and Methods of Meas urement.

European Low Voltage Directive (LVD)

The following information is applicable for the European Low Voltage Directive (2006/95/EC):

Symbol Description

<HAR>

Type of power cord required for use in the European Community.

CAUTION: Double-pole/Neutral Fusing

!

ACHTUNG: Zweipolige bzw. Neutralleiter-Sicherung

xi

Page 14

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Preface MN/KPA.IOM

International Symbols

Symbol Definition Symbol Definition

For additional symbols, refer to Cautions and Warnings listed earlier in this

IMPORTANT

Preface.

Warrant y Policy

Comtech EF Data products are warranted against defects in material and workmanship for a specific

period from the date of shipment, and this period varies by product. In most cases, the warranty

period is two years. During the warranty period, Comtech EF Data will, at its option, repair or

replace products that prove to be defective. Repairs are warranted for the remainder of the origin al

warranty or a 90 day extended warranty, whichever is longer. Contact Comtech EF Data fo r the

warranty period specific to the product purchased.

For equipment under warranty, the owner is responsible for freight to Comtech EF Data and all

related customs, taxes, tariffs, insurance, etc. Comtech EF Data is responsible for the freight charges

only for return of the equipment from the factory to the owner. Co mtech EF Data will return the

equipment by the same method (i.e., Air, Express, Surface) as the equipment was sent to Comtech

EF Data.

Alternating Current

Fuse

Protective Earth

Chassis Ground

All equipment returned for warranty repair must have a valid RMA number issued prior to return

and be marked clearly on the return packaging. Comtech EF Data strongly recommends all

equipment be returned in its original packaging.

Comtech EF Data Corporation’s obligations under this warranty are limited to repair or replacement

of failed parts, and the return shipment to the buyer of the repaired or replaced parts.

Limitations of Warranty

The warranty does not apply to any part of a product that has been installed , altered, repaired, or

misused in any way that, in the opinion of Comtech EF Data Corporation, would affect the

reliability or detracts from the performance o f any part of the produ ct, or is damaged as the result of

use in a way or with equipment that had not been previously approved by Comtech EF Data

Corporation.

The warranty does not apply to any product or parts thereof where the serial numb er or the serial

number of any of it s pa r ts ha s been altered, defaced, or removed.

The warranty does not cover damage or loss incurred in transportation of the product.

xii

Page 15

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Preface MN/KPA.IOM

The warranty does not cover replacement or repair necessitated by loss or damage from any cause

beyond the control of Comtech EF Data Corporation, such as lightning or other natural and weather

related events or wartime environme nts .

The warranty does not cover any labor involved in the removal and or reinstallation of warranted

equipment or parts on site, or any labor required to diagnose the necessity for repair or replacement.

The warranty excludes any responsibility by Comtech EF Data Corporation for incidental or

consequential damages arising from the use of the equip ment or p ro duct s, or for any inability to use

them either separate from or in combination with any other equipment or products.

A fixed charge established for each product will be imposed for all equipment returned for warranty

repair where Comtech EF Data Corporation cannot identify the cause of the reported failure.

Exclusive Remedies

Comtech EF Data Corporation’s warranty, as stated is in lieu of all other warranties, expressed,

implied, or statutory, including those of merchantability and fitness for a particular purpose. The

buyer shall pass on to any purchaser, lessee, or other user of Comtech EF Data Corporation’s

products, the aforementioned warranty, and shall indemnify and hold harmless Co mtech EF Data

Corporation from any claims or liability of such purchaser, lessee, or user based upon allegations

that the buyer, its agents, or employees have made additional warrant ies or representations as to

product preference or use.

The remedies provided herein are the buyer’s sole and exclusive remedi es. Comtech EF Data sha ll

not be liable for any direct, indirect, special, incidental, or consequential damages, whether based on

contract, tort, or any other legal theory.

xiii

Page 16

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Preface MN/KPA.IOM

Customer Support

Refer to p. xii in this Preface for information regarding this product’s Warranty Policy.

Contact the Comtech EF Data Customer Support Department for:

• Product support or training

• Reporting comments or suggestions concerning manuals

• Information on upgrading or returning a product

A Customer Support representative may be reached during normal business hours at:

Comtech EF Data

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

480.333.2200 (Main Comtech EF Data number)

480.333.4357 (Customer Support Desk)

480.333.2161 FAX

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or

replacement:

• Contact the Comtech EF Data Customer Support Department during normal business

hours. Be prepared to supply the Customer Support representative with the model number,

serial number, and a description of the problem.

• Request a Return Material Authorization (RMA) number from the Comtech EF Data

Customer Support representative.

• Pack the product in its original shipping carton/packaging to ensure that the product is

not damaged during shipping.

• Ship the product back to Comtech EF Data. (Shipping charges should be prepaid.)

Online Customer Support

An RMA number can be requested electronically by accessing Comtech EF Data’s online

Support page (

• Click the Service hyperlink, then read the Return Material Authorization section for

detailed instructions on Comtech EF Data’s return procedures.

• Click [Send RMA Request] on the Support page or the RMA Request hyperlink provided

in the Service | Return Material Authorization section; fill out the Billing Information,

Return Information, and Unit to be Returned sections completely, then click [Send em ail]

www.comtechefdata.com/support.asp). From this page:

– or –

• Send an e-mail providing this same detailed information to the Customer Support

Department at service@comtechefdata.com.

xiv

Page 17

1.1 Overview

The Comtech EF Data Ku-Band Solid-State Power Amplifier (KPA) family of products, shown

in Figure 1-1, is a line of Indoor

communication systems or satellite uplink data systems. The KPA operates over the RF input

frequency range of 14.0 to 14.5 GHz and provides a cost effective and more reliable replacement

for Traveling Wave Tube (TWT) amplifiers in Ku-Band terminals.

Due to its small form factor, it is also ideal for the construction of small “flyaway” terminals,

medium size (equivalent to Intelsat F) earth stations, hub earth stations for small to medium size

private networks, or point-to-point links.

Chapter 1. INTRODUCTION

Solid-State Power Amplifiers (ISSPAs) designed for use in

Figure 1-1. Comtech EF Data KPA Family of Ku-Band So lid-State A mplif iers

1–1

Page 18

Ku-Band Solid-State Power Amplifier Revision 1

Introduction MN/KPA.IOM

1.2 Functional Description

Each KPA ISSPA is constructed with highly reliable Gallium Arsenide Field Effect Transistors

(GaAs FETs). With Third-Order Intermodulation products from 4 to 6 dB better than TWT

ratings, the Comtech EF Data unit replaces TWTs with saturated power levels of up to twice the

KPA’s rated output. These KPAs also provide a Mean Time Between Failure (MTBF) that is 4 to

5 times greater than the typical TWT MTBFs.

The KPA is designed to be rack-mounted in a standard 19-inch (48 cm) rack or cabinet by hardmounting the unit to the rack’s front mounting rails using the front panel mounting holes;

optionally, rack slides may be installed onto the chassis that allow servicing of the unit without its

removal from the rack. Handles at the front of the unit facilitate easy installation into and removal

from the rack.

All user controls, indicators, and displays for local and remote operation – as well as the RF Input

and Output sample test ports – are located on the front panel of the unit. User external interface

connectors are located on the chassis rear panel.

Two internally mounted exhaust fans provide cooling – cool air is taken in through the front panel

and exhausted out the rear panel.

An AC power connector and On/Off switch are located on the chassis rear panel. A six-foot AC

power cord is supplied with the unit.

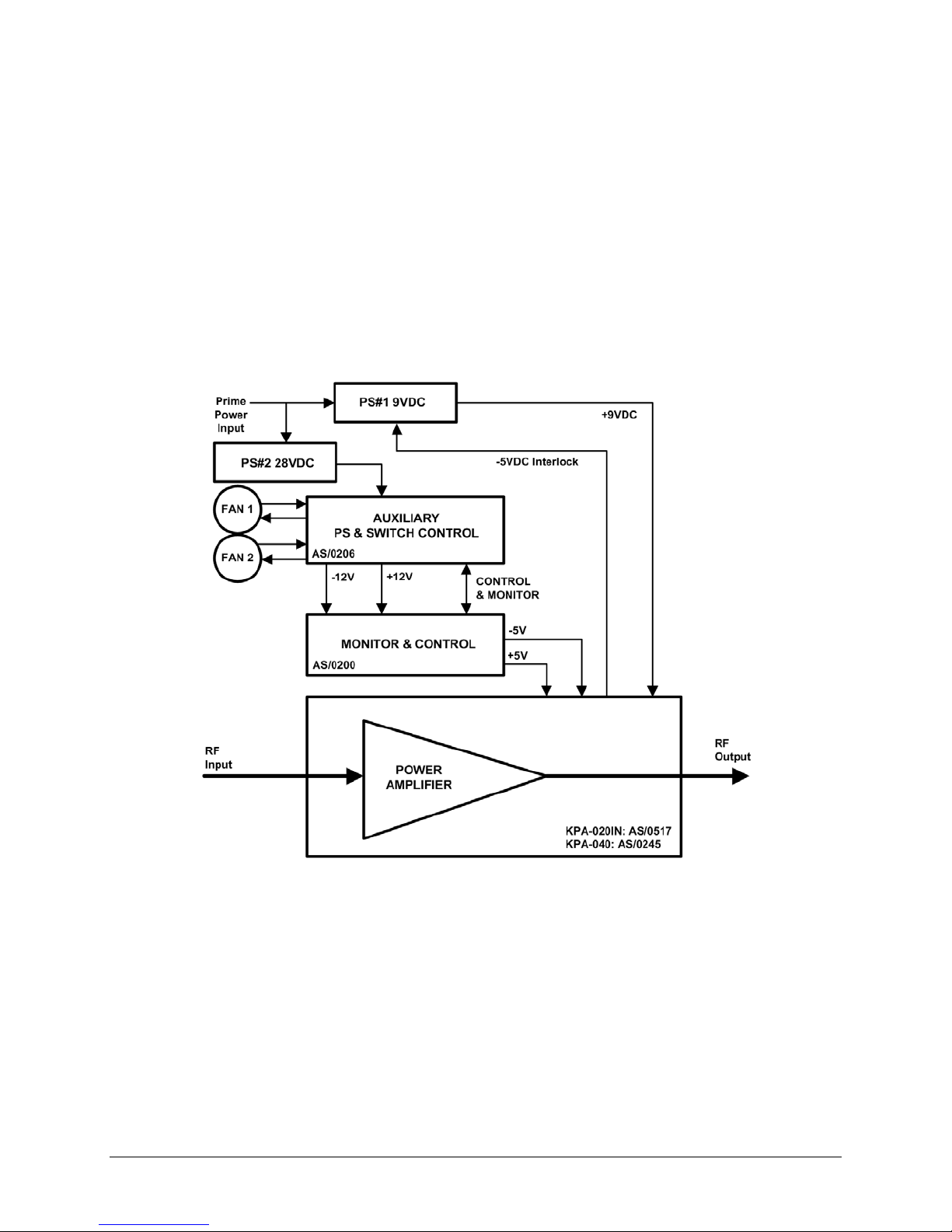

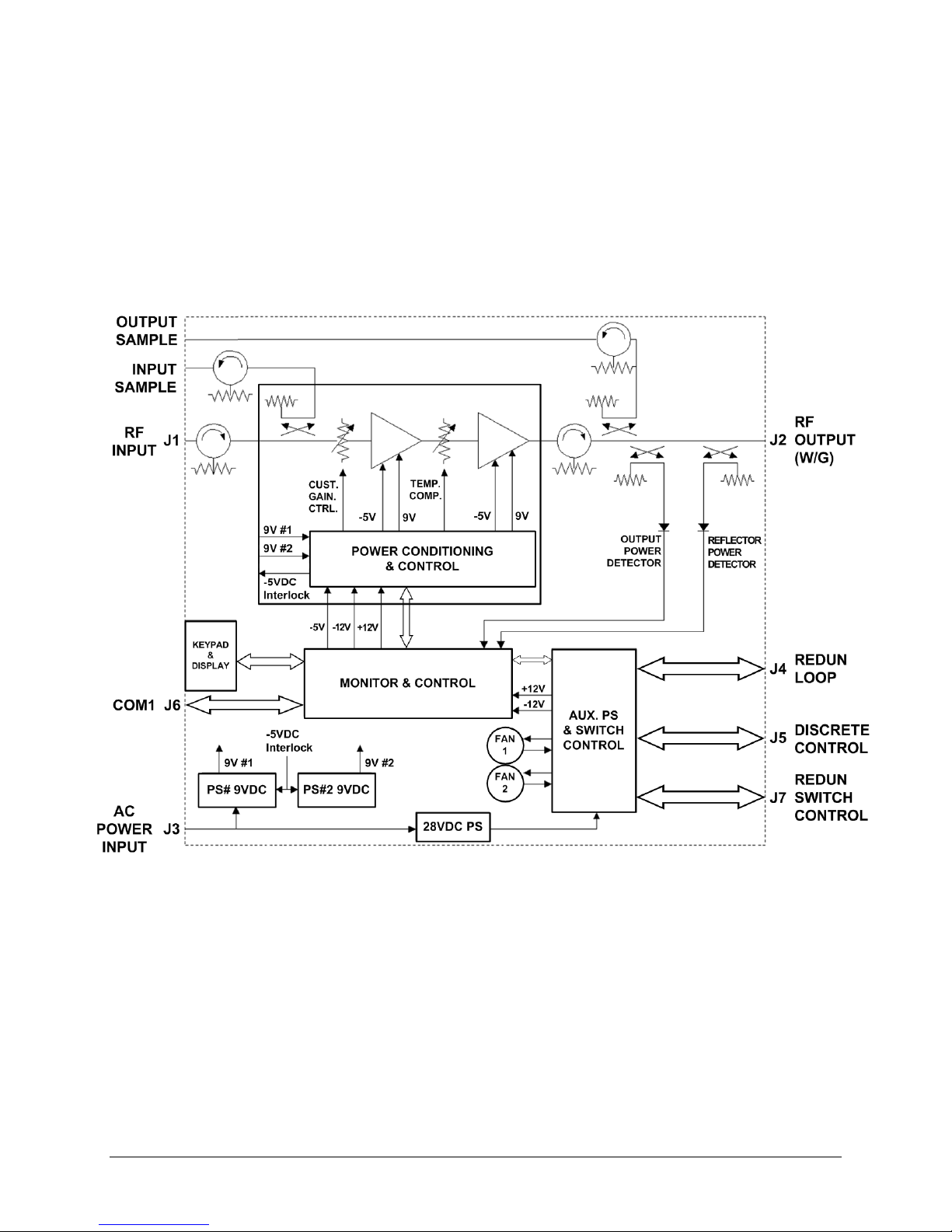

On the pages that follow, Figure 1-2 and Figure 1-3 depict the b

lock diagrams for the available

KPAs. Each KPA chassis consists of a power supply, fan assembly, front panel assembly,

monitor/control processor (MCP), and a Comtech EF Data SSPA module. The KPA is designed

using a Comtech EF Data low loss combining technique and an MCP based temperature versus

gain compensation.

The front panel features:

• A Vacuum Fluorescent Display for user-friendly visual status update (Liquid Crystal

Diode display for KPA-020IN and older KPA-040/-080/-100 units)

• The six-button cursor array is used to set or change operating parameters

• Six Light-Emitting Diodes (LEDs) provide quick reference to binary status points

• Input and output sample ports at –20 dBc and–40 dBc provide easy test point access

Each unit has the ability to function as a 1:1 or 1:2 redundancy controller in the backup mode.

The optional redundancy configuration is implemented by attaching a ganged waveguide/coax

transfer switch(es) to input and output connectors of the amplifiers with a combination coaxial

cable and waveguide kit. When the backup KPA is commanded into the controller mode, it

monitors the online KPAs for faults. A faulted online unit may be disconnected and replaced

without affecting the online power amplifier. For detailed information about using the KPA in 1:1

or 1:2 redundancy, see Appendix B. KPA REDUNDANT OPERATIONS.

1–2

Page 19

Ku-Band Solid-State Power Amplifier Revision 1

Introduction MN/KPA.IOM

Figure 1-2. KPA-020IN/-040 Block Diagram

1–3

Page 20

Ku-Band Solid-State Power Amplifier Revision 1

Introduction MN/KPA.IOM

Figure 1-3. KPA-080/-100 Block Diagram

1–4

Page 21

Ku-Band Solid-State Power Amplifier Revision 1

Ω

Ω

Introduction MN/KPA.IOM

1.3 KPA Specifications

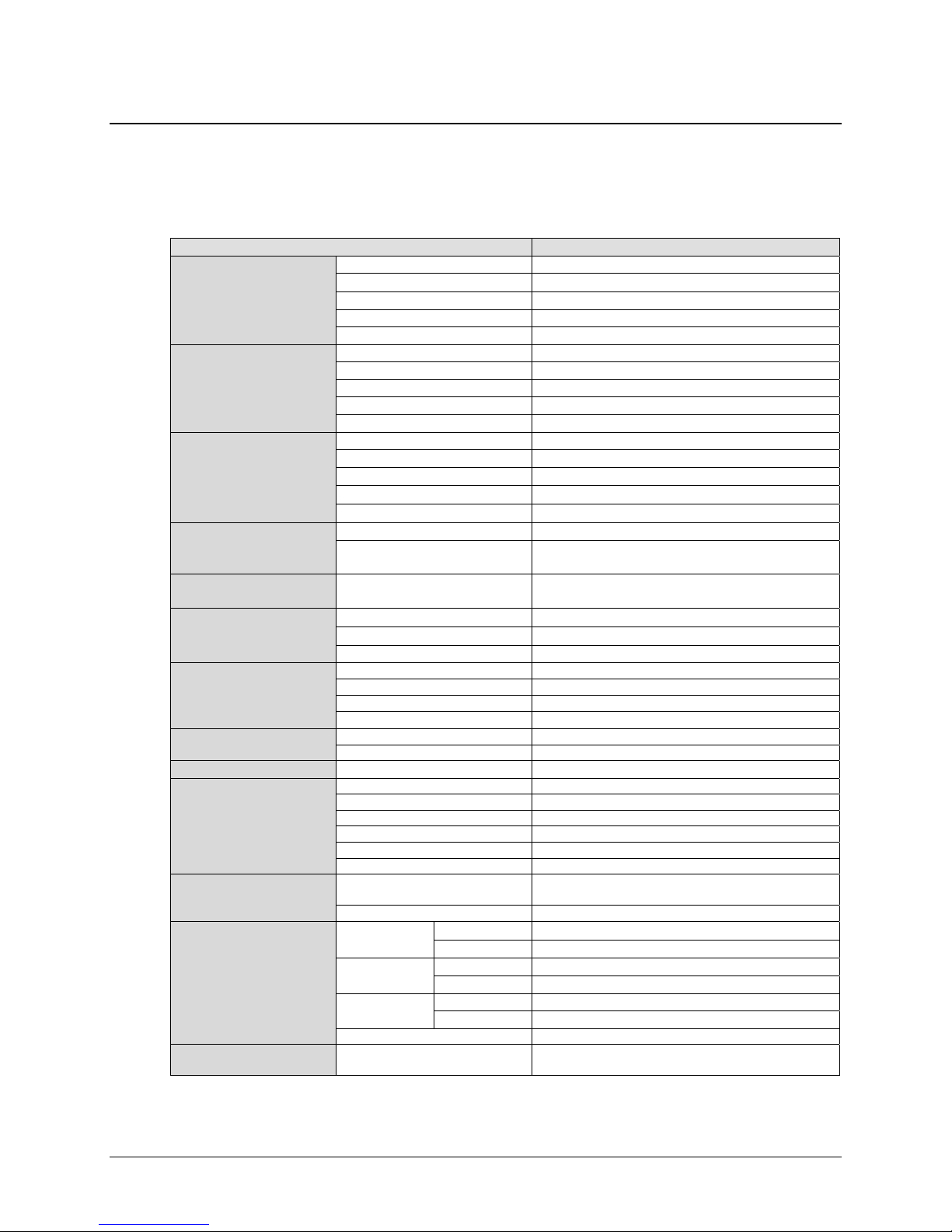

1.3.1 KPA-020IN Specifications

Parameters Specifications

Input

Output

Gain

Third Order Modulation

AM to PM Conversion

Group Delay (per 40

MHz)

Front Panel

Remote Control

Alarms

LEDs

Mechanical

Environmental

Power Requirements

Level -10dBm Typical

Impedance

Noise Figure 10 dB Typical, 15 dB max @ max gain

VSWR 1.25: 1 maximum

Connector SMA Female

Frequency 14.0 to 14.5 GHz

Power 42.5 dBm minimum @ 1 dB Compression

Mute 60 dB

VSWR 1.25:1 maximum

Connector WR75G Waveguide

Linear 50 dB minimum, 53 dB Typical

Adjust 20 dB in 0.25 dB steps

Fill Band

Per 40 MHz

0 to +50°C (32 to 122°F) ± 0.75dB

Intercept +56.5 dBm minimum, 59.0 Typical

Products -25 dBc max, -30 dBc typical @ 3 dB total

Output 2.0 degrees typical

Linear

Parabolic

Ripple 1.0 ns Peak-to-Peak

Display 24 x 2 LCD

Data Entry Cursor Control Keypad (6 keys)

Output Sample

Input Sample

COM Port EIA-232 or EIA-485

Protocol ASCII

Summary Fault Form C

Power On Green

Fault Red

Stored Fault Red

TX On Yellow

Online Yellow

Remote Yellow

Envelope 3.5H x 19W x 24D inches

Weight TBD

Temperature Operating

Storage

Humidity Operating

Storage 0 to 100% Noncondensing

Altitude Operating

Storage 50, 000 ft

Shock Normal Commercial Shipping and Handling

VAC 90 to 135 or 180 to 270 VAC, 47 to 63 Hz

50Ω

± 0.75 dB

± -0.25 dB

backoff from rated P1dB (two tones, Δf+MHz)

3.0 max @ 42.5 dBm

± 0.03 ns/MHz

± 0.0025 ns/MHz

Type N female, 50

Type N female, 50

(8.89H x 48.26W x 60.96D cm)

0 to 50°C (32 to 122°F)

–40 to 70°C (–40 to 158°F)

10 to 95% Noncondensing

15, 000 ft MSL

400W (Auto Select)

2

, –40 dBc

, –20 dBc

1–5

Page 22

Ku-Band Solid-State Power Amplifier Revision 1

Ω

Ω

Introduction MN/KPA.IOM

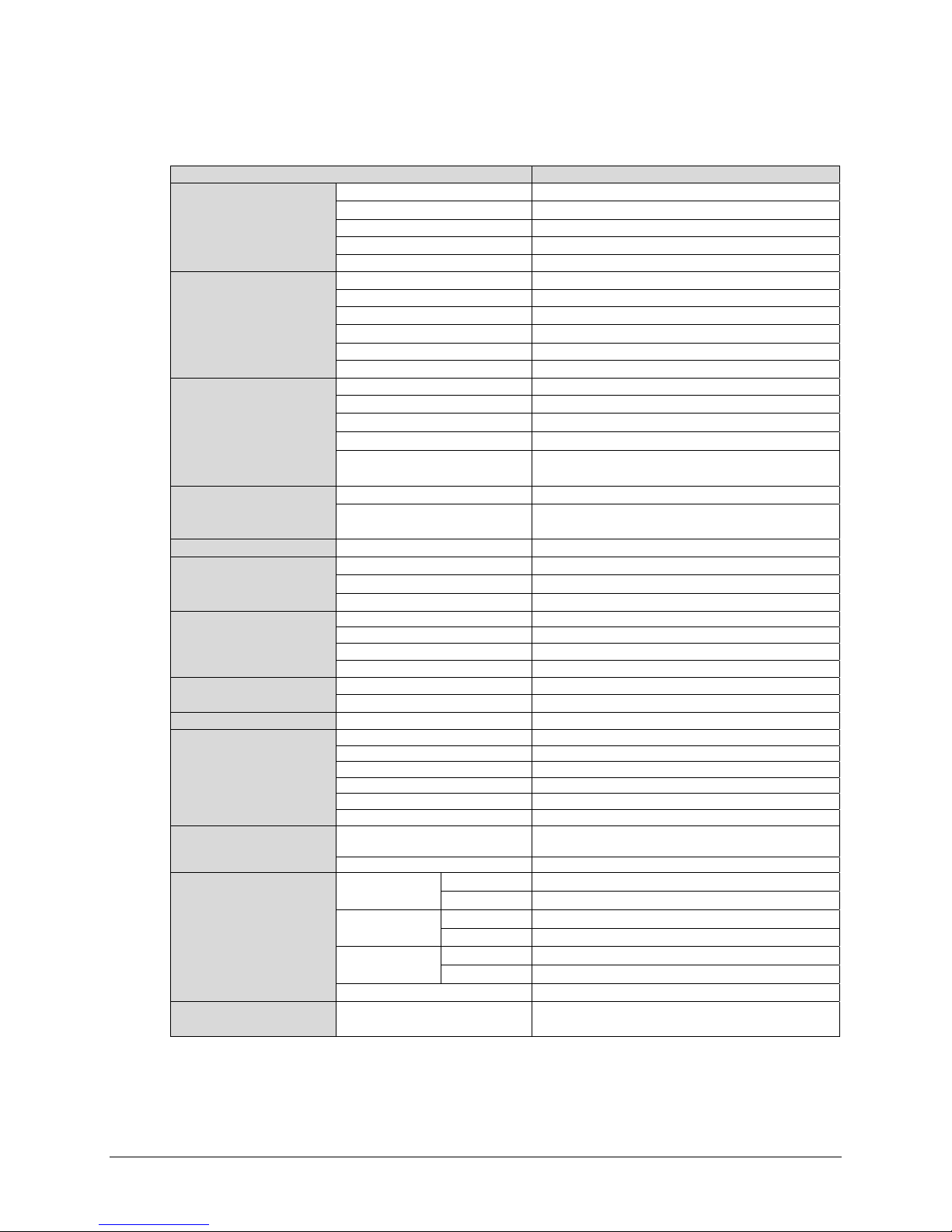

1.3.2 KPA-040 Specifications

Parameters Specifications

Input

Output

Gain

Third Order Modulation

AM to PM Conversion

Group Delay (per 40

MHz)

Front Panel

Remote Control

Alarms

LEDs

Mechanical

Environmental

Power Requirements

Level 10 dBm Typical

Impedance

Noise Figure 10 dB typical, 15 dB maximum @ max gain

VSWR 1.25:1 Maximum

Connector SMA Female

Frequency 14.0 to 14.5 GHz

Power 45.5 dBm min @ 1 dB Compression

Mute -60 dB

Impedance

VSWR 1.25:1 Maximum

Connector WR75G Waveguide

Linear 60.0 dB minimum, 63 dB typical

Adjust 20 dB in 0.25 dB steps

Fill Band

Per 40 MHz

0 to +50°C (32 to 122°F) ± 0.50 dB @ center frequency

Intercept +53.5 dBm minimum, 56.0 dBm typical

Products -30 dBc typical @ –25 dBc maximum

Output 2.0 degrees typical, 3.0 maximum @ rated output

Linear

Parabolic

Ripple 1.0 ns Peak-to-Peak

Display 24 x 2 LCD

Data Entry Cursor Control Keypad (6 keys)

Output Sample

Input Sample

COM Port

Protocol

Summary Fault Form C

Power On Green

Fault Red

Stored Fault Red

TX On Yellow

Online Yellow

Remote Yellow

Envelope 7H x 19W x 24D inches

Weight TBD

Temperature Operating

Storage

Humidity Operating

50Ω

50 Ω

± 0.75 dB

± 0.25 dB

± 1.00 dB full band

3 dB total backoff (2 tones, Δf = 1 MHz)

± 0.03 ns/MHz

± 0.03 ns/MHz

Type N, 50

Type N, 50

EIA-232 or EIA-485

ASCII

(18H x 48.26W x 60.96D cm)

0 to 50°C (32 to 122°F)

–40 to 70°C (–40 to 158°F)

2

, –40 dBc

, –20 dBc

10 to 95% Noncondensing

Storage 0 to 100% Noncondensing

Altitude Operating

15, 000 ft MSL

Storage 50, 000 ft

Shock Normal Commercial Shipping and Handling

VAC 90 to 135 VAC, or 180 to 270 VAC, 47 to 63

Hz, 600W (Auto-Select)

1–6

Page 23

Ku-Band Solid-State Power Amplifier Revision 1

Ω

Ω

Introduction MN/KPA.IOM

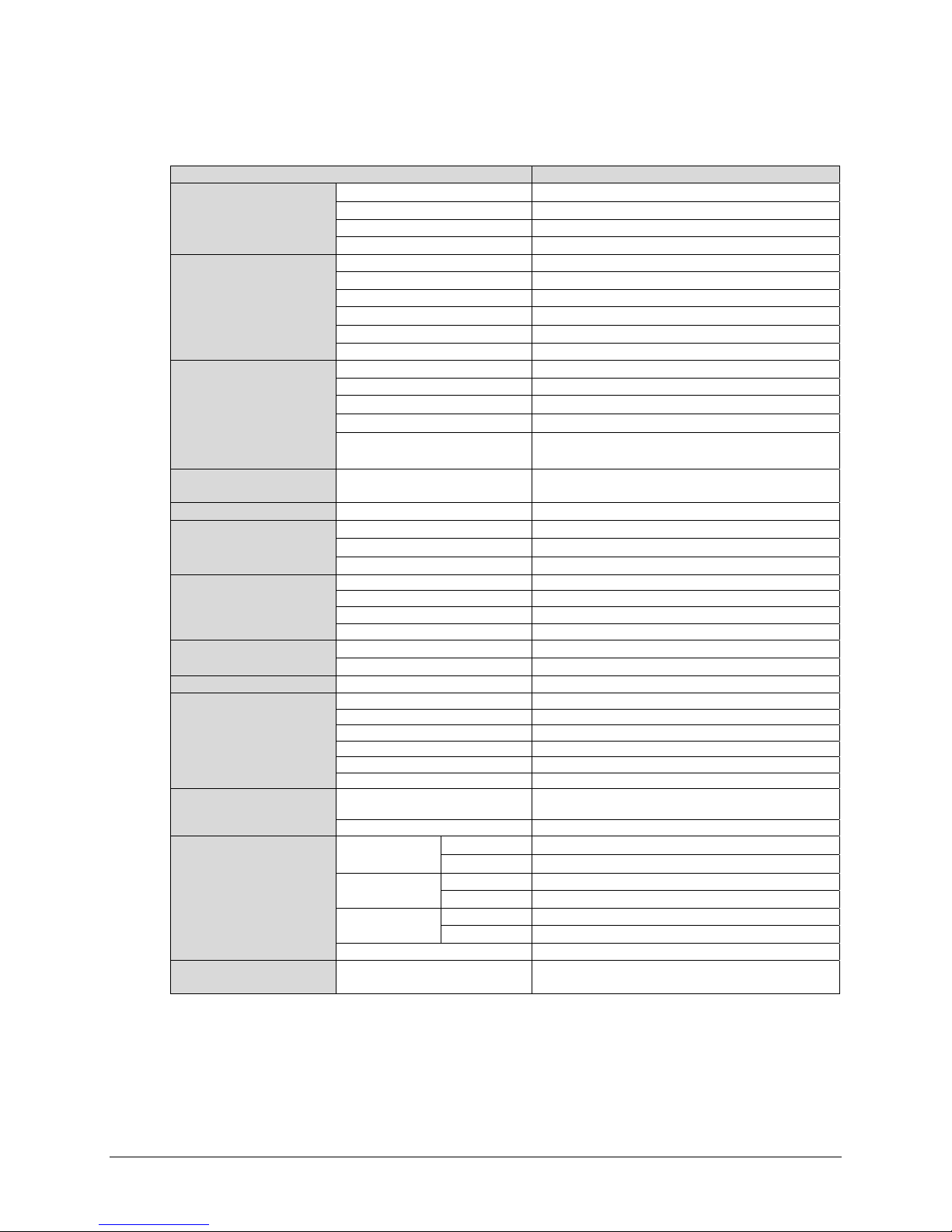

1.3.3 KPA-080 Specifications

Parameters Specifications

Input

Output

Gain

Third Order Modulation

AM to PM Conversion

Group Delay (per 40

MHz)

Front Panel

Remote Control

Alarms

LEDs

Mechanical

Environmental

Power Requirements

Impedance

Noise Figure 10 dB typical, 15 dB maximum @ max gain

VSWR 1.25:1 Maximum

Connector SMA Female

Frequency 14.0 to 14.5 GHz

Power 48.5 dBm min @ 1 dB Compression

Mute 60 dB

Impedance

VSWR 1.25:1 Maximum

Connector WR75G Waveguide

Linear 61 dB minimum, 64 dB typical

Adjust 20 dB in 0.25 dB steps

Fill Band

Per 40 MHz

0 to +50°C (32 to 122°F) ± 0.50 dB @ center frequency

Products -30 dBc typical @ –25 dBc maximum @ 3 dB

Output 2.0 degrees typical, 3.0 maximum @ rated output

Linear

Parabolic

Ripple 1.0 ns Peak-to-Peak

Display 24 x 2 LCD

Data Entry Cursor Control Keypad (6 keys)

Output Sample

Input Sample

COM Port

Protocol

Summary Fault Form C

Power On Green

Fault Red

Stored Fault Red

TX On Yellow

Online Yellow

Remote Yellow

Envelope 8.75H x 19W x 24D inches

Weight 75 lbs (34 kg)

Temperature Operating

Storage

Humidity Operating

Storage 0 to 100% Noncondensing

Altitude Operating

Storage 50, 000 ft

Shock Normal Commercial Shipping and Handling

VAC

50Ω

50 Ω

± 0.75 dB

± -0.25 dB

± 1.00 dB full band

total backoff (2 tones, Δf = 1 MHz)

± 0.03 ns/MHz

± 0.003 ns/MHz

Type N female, 50

Type N female, 50

EIA-232 or EIA-485

ASCII

(22.22H x 48.26W x 60.96D cm)

0 to 50°C (32 to 122°F)

–40 to 70°C (–40 to 158°F)

10 to 95% Noncondensing

15, 000 ft MSL

180 to 270 VAC, 47 to 63 Hz

1100W nominal

2

, –40 dBc

, –20 dBc

1–7

Page 24

Ku-Band Solid-State Power Amplifier Revision 1

Ω

Ω

Introduction MN/KPA.IOM

1.3.4 KPA-100 Specifications

Parameters Specifications

Input

Output

Gain

Third Order Modulation

AM to PM Conversion

Group Delay (per 40

MHz)

Front Panel

Remote Control

Alarms

LEDs

Mechanical

Environmental

Power Requirements

Level -10 dBm Typical

Impedance

Noise Figure 10 dB typical, 15 dB maximum @ max gain

VSWR 1.25:1 Maximum

Connector SMA Female

Frequency 14.0 to 14.5 GHz

Power 49.5 dBm min @ 1 dB Compression

Mute -60 dB

Impedance

VSWR 1.25:1 Maximum

Connector WR75G Waveguide

Linear 65 dB minimum, 70 dB typical

Adjust 20 dB in 0.25 dB steps

Fill Band

Per 40 MHz

0 to +50°C (32 to 122°F) ± 0.50 dB @ center frequency

Products -30 dBc typical @ –25 dBc maximum @ 3 dB

Output 2.0 degrees typical, 3.0 maximum @ rated output

Linear

Parabolic

Ripple 1.0 ns Peak-to-Peak

Display 24 x 2 LCD

Data Entry Cursor Control Keypad (6 keys)

Output Sample

Input Sample

COM Port

Protocol

Summary Fault Form C

Power On Green

Fault Red

Stored Fault Red

TX On Yellow

Online Yellow

Remote Yellow

Envelope 8.75H x 19W x 24D inches

Weight 75 lbs (34 kg)

Temperature Operating

Storage

Humidity Operating

Storage 0 to 100% Noncondensing

Altitude Operating

Storage 50, 000 ft

Shock Normal Commercial Shipping and Handling

VAC

50Ω

50 Ω

± 0.75 dB

± 0.25 dB

± 1.00 dB full band

total backoff (2 tones, Δf = 1 MHz)

± 0.03 ns/MHz

± 0.003 ns/MHz

Type N female, 50

Type N female, 50

EIA-232 or EIA-485

ASCII

(22.22H x 48.26W x 60.96D cm)

0 to 50°C (32 to 122°F)

–40 to 70°C (–40 to 158°F)

10 to 95% Noncondensing

15, 000 ft MSL

180 to 270 VAC, 47 to 63 Hz

1100W nominal

2

, –40 dBc

, –20 dBc

1–8

Page 25

Ku-Band Solid-State Power Amplifier Revision 1

Introduction MN/KPA.IOM

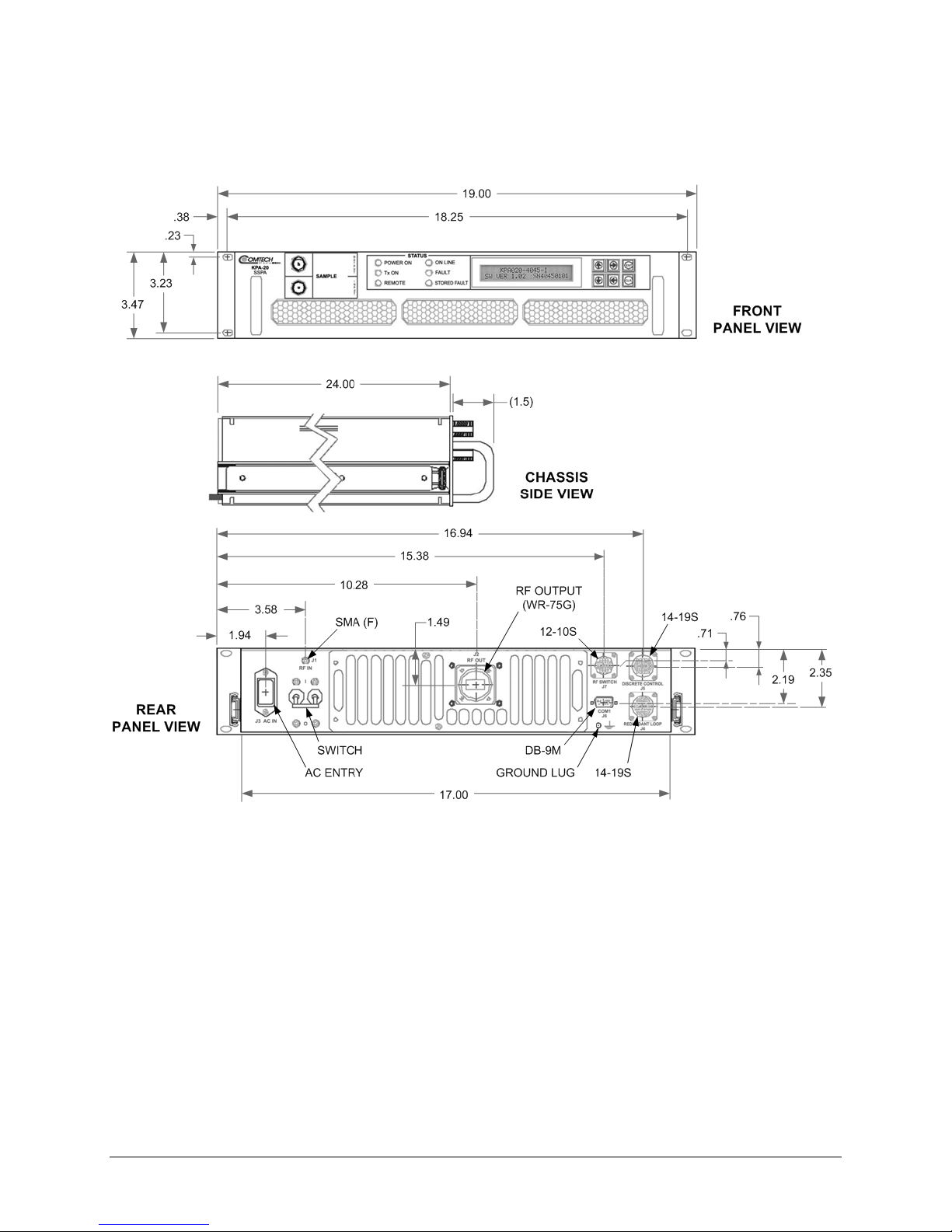

1.3.5 Dimensional Envelopes

Figure 1-4. KPA-020IN Dimensional Envelope

(Shown with Optional Slide Railings Installed)

1–9

Page 26

Ku-Band Solid-State Power Amplifier Revision 1

Introduction MN/KPA.IOM

Figure 1-5. KPA-040/-080/-100 Dimensional Envelope

(Shown with Optional Slide Railings Installed)

1–10

Page 27

Chapter 2. INSTALLATION

2.1 Unpacking and Inspection

The KPA ISSPA and its Installation and Operation Manual are packaged and shipped in a preformed, reusable cardboard carton containing foam spacing for maximum shipping protection.

Do not use any cutting tool that will extend more than 1 inch into the container.

CAUTION

Unpack and inspect the unit as follows:

Step Procedure

This can cause damage to the unit.

1

2

3

4

5

6

7

8

Inspect shipping containers for damage.

If shipping containers are damaged, keep them until the contents of the shipment have

been carefully inspected and checked for normal operation.

Remove the packing list from th e outsid e of the shi pping ca rton.

Open the carton and remove the contents.

Check the contents against the packing list to verify completeness of the shipment.

If physical damage is evident, contact the carrier and Comtech EF Data immediately

and submit a damage report.

Test the unit for proper operation.

If the unit needs to be returned to Comtech EF Data, use the original shipping container.

Be sure to keep all shipping materials for the carrier's inspection.

2–1

Page 28

KPA Ku-Band Indoor Solid State Power Amplifier Revision 1

Installation MN/KPA.IOM

2.2 Rack Mounting the KPA

The KPA is designed to be rack-mounted in a standard 19-inch (48 cm) rack or cabinet by hardmounting the unit to the rack’s front mounting rails using the front panel mounting holes/

Handles at the front of the units facilitate easy installation into and removal from the rack.

Optionally, rack slides may be installed onto the chassis that allow servicing of the unit without

its removal from the rack.

The KPA-020IN chassis is a 3RU unit requiring 4 inches (10 cm) of panel height space. The

KPA-040/-080/-100 units are 5RU units requiring 8.75 inches (22 cm) of panel height space.

Two internally mounted exhaust fans provide cooling – cool air is taken in through the front panel

and exhausted out the rear panel. Locate the KPA so that the input and output airflow paths

are not obstructed or restricted. This will minimize the amplifier operating temperature.

It is important to ensure that there is adequate clearance for ventilation in the rack. In rack

systems where there is high heat dissipation, provide forced-air cooling by installing top- or

bottom-mounted fans or blowers.

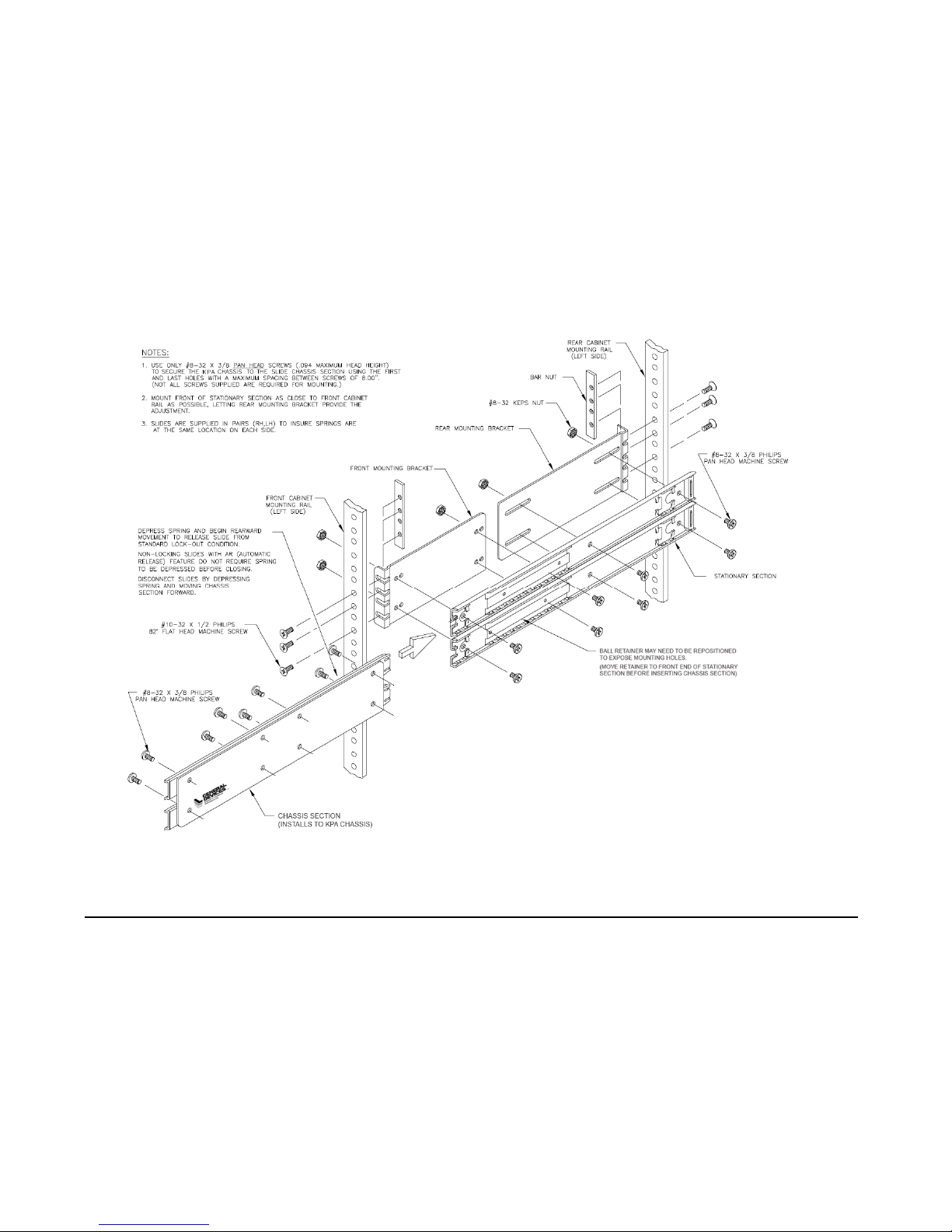

2.2.1 Installation of the Optional Rack Slides

The following table identifies the rack slides options that may be purchased for use with the KPA

unit (take note that the 5RU units require a heavy duty, dual rail rack slide).

KPA Unit Rack Slide (CEFD P/N) Description

FP/SL0007 22” Rack Slide Se t (single rail )

KPA-020IN

KPA-040

KPA-080

KPA-100

FP/SL0008 24 ” Rack Slide Se t (single rail )

FP/SL0006 26 ” Rack Slide Se t (single rail )

FP/SL0004 24” Heavy Duty Rack Slide Set (dual rail)

Install the rack slides as follows:

Step Procedure

Typical for either side of the KPA ch assi s, instal l the “ch assi s secti on ” of the rack sli de to

1

2

the KPA chassis side, using the pan head machine scr ews provided with the rack slide

installation kit.

Typical for either side of the rack cabinet: using the mounting hardware provided

with the rack slide installation kit, install the “stationary section” of the rack slide,

either to the interior wall of the cabinet (for single rail rack slides) or, for the heavyduty rack slides, to the front and rear mounting rails of the cabinet as shown in

Figure 2-1.

Install the KPA unit into position by ma ting the chassis-mounted rails into the cabinetmounted stationary portion of the rack slide. Be sure that the ball retainer for either slide

3

has first been positioned forward befo re inst alling t he chas sis secti on.

The user may leave the unit free in place (to slide on the rails freely) or, alternately, bolt

the unit into place via the slotted front panel mounting holes.

2–2

Page 29

KPA Ku-Band Indoor Solid State Power Amplifier Revision 1

Installation MN/KPA.IOM

2–3

Figure 2-1. Installation of Optional Heavy-Duty Rack Slides (CEFD P/N FP/SL00004)

Page 30

KPA Ku-Band Indoor Solid State Power Amplifier Revision 1

Installation MN/KPA.IOM

2–4

Notes:

Page 31

Chapter 3. CONNECTORS AND

3.1 Connector Overview

The KPA ISSPA rear panel connectors, shown in Figure 3-1, provide all necessary external

connections between the unit and other equipment. Table 3-1 on

connectors provided on the rear panel interface (as well as the front panel sample ports), grouped

according to service function.

PINOUTS

the next page summarizes the

KPA-020IN Unit

KPA-040/-080/-100 Units

Figure 3-1. KPA Rear Panel Views

3–1

Page 32

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Connectors and Pinouts MN/KPA.IOM

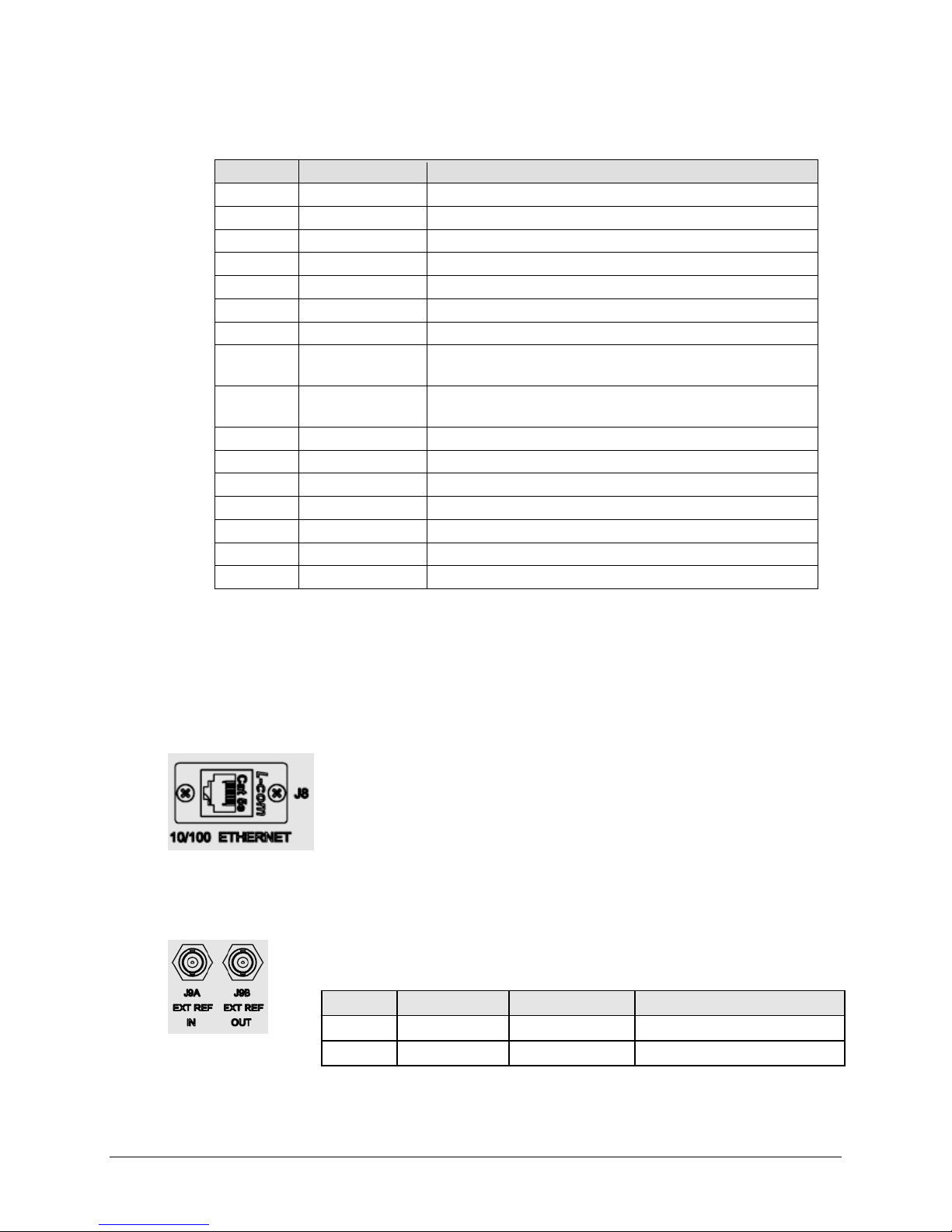

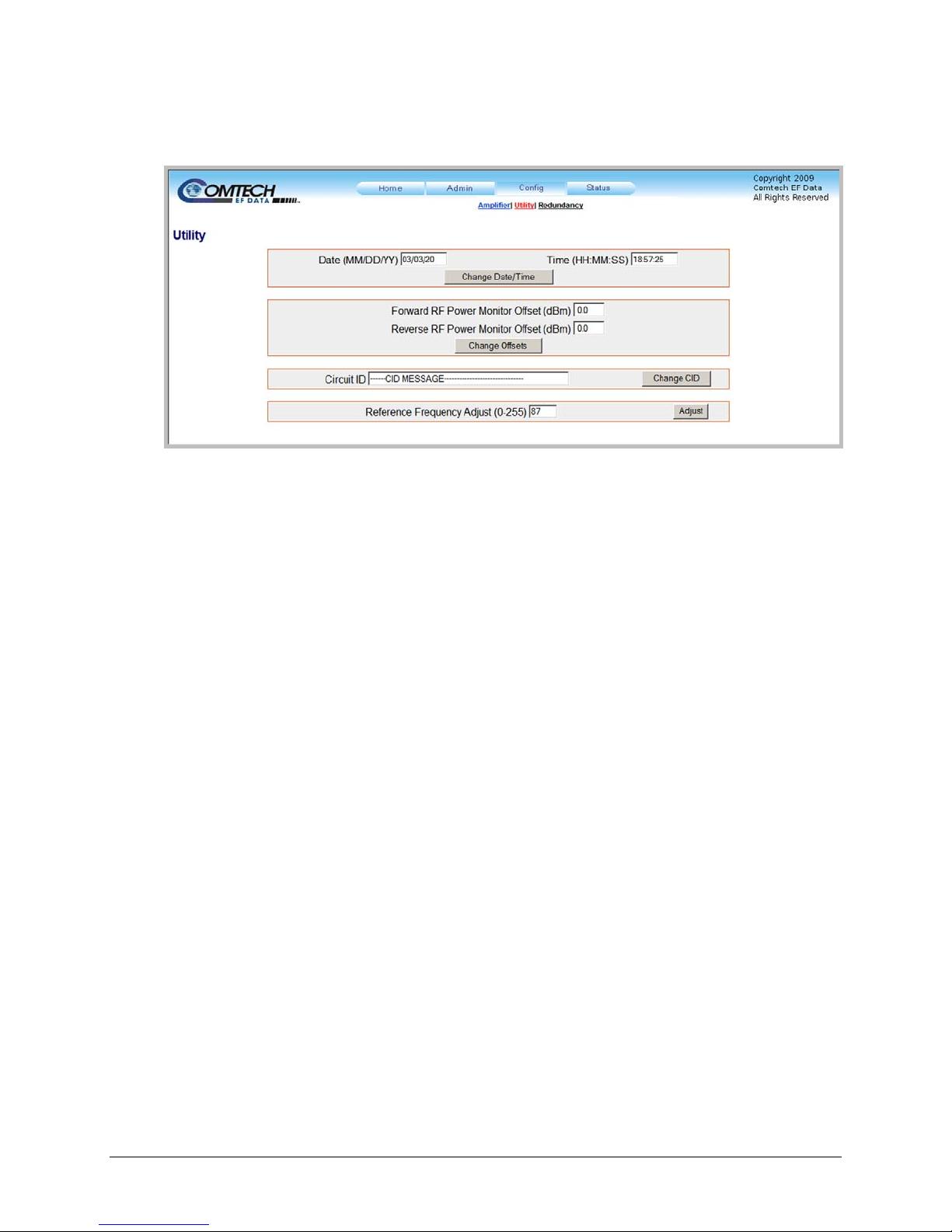

Table 3-1. KPA Interface Connectors Summary

Connector Group

RF

Sect. 3.2

Utility

Sect. 3.3

Power/Ground

Sect 3.5

Ref

Des

J1 KPA-020IN: RF IN

J2 RF OUT WR75G Waveguide

N/A SAMPLE | INPUT Type ‘N’ Female Front Panel –20 dBc and –40 dBc test

N/A SAMPLE | OUTPUT

J4** REDUNDANT LOOP 19-pin Circular Conn Unit-to-Unit Redundant Connection

J5 DISCRETE

J8* 10/100 ETHERNET RJ-45 female CAT5 10/100 BaseT Management and

J9A* EXT REF IN BNC Female External Reference Input

J9B* EXT REF OUT BNC Female External Reference Output

J7** RF SWITCH 10-pin Circular Conn Waveguide Switch Interface

J6 COM1 9-pin Type ‘D’ male Serial Remote Comms Interface

J3 AC IN See Sect. 3.5.1 Chassis prime power input

N/A (Ground) #10-32 stud Common chassis ground

Name Connector Type Function

Type ‘SMA’ Female RF Input

KPA-040: Tx IN

KPA-080

KPA-100

RF Output

Flange

sample ports

19-pin Circular Conn User ISSPA M&C

CONTROL

Data

(EIA-232 or EIA-485)

Notes:

1. * KPA-040/-080/-100 units only (not provided on the KPA-020IN).

2. ** Used in redundant operations only. See Appendix B. KPA REDUNDANT OPERATIONS

for further information about use of the KPA in 1:1 or 1:2 redundant systems.

3–2

Page 33

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Connectors and Pinouts MN/KPA.IOM

3.2 RF Connections

3.2.1 J1 RF IN / Tx IN Connectors

KPA-020IN Unit KPA-040/-080/-100 Units

Connector Type Description Direction

SMA RF Signal In

3.2.2 J2 RF OUT Connector

Connector Type Description Direction

WR75G Waveguide Flange RF Signal Out

3–3

Page 34

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Connectors and Pinouts MN/KPA.IOM

3.3 Utility Connections

3.3.1 Sample Port Connectors (Front Panel)

The SAMPLE INPUT / OUTPUT ports are Type ‘N’ female connectors,

providing easy user access –20 dBc and –40 dBc test points on the KPA

front panel.

Name Connector Type Description Direction

SAMPLE | OUTPUT

Type ‘N’ Female

SAMPLE | INPUT Output

–20 dBc / –40 dBc

Sample Test Port

Input

3.3.2 J4 REDUNDANT LOOP Connector

The J4 Redundant Loop connector is a 19-pin circular connector, type

MS3112E14-19S. The pin-out specification is contained in Table 3-2.

This connector is used only

B. KPA REDUNDANT OPERATIONS for further information about

use of the KPA in 1:1 or 1:2 redundancy.

Mating connector: ITT KPT06J14-19P or MS3116J14-19P

in redundant configurations – see Appendix

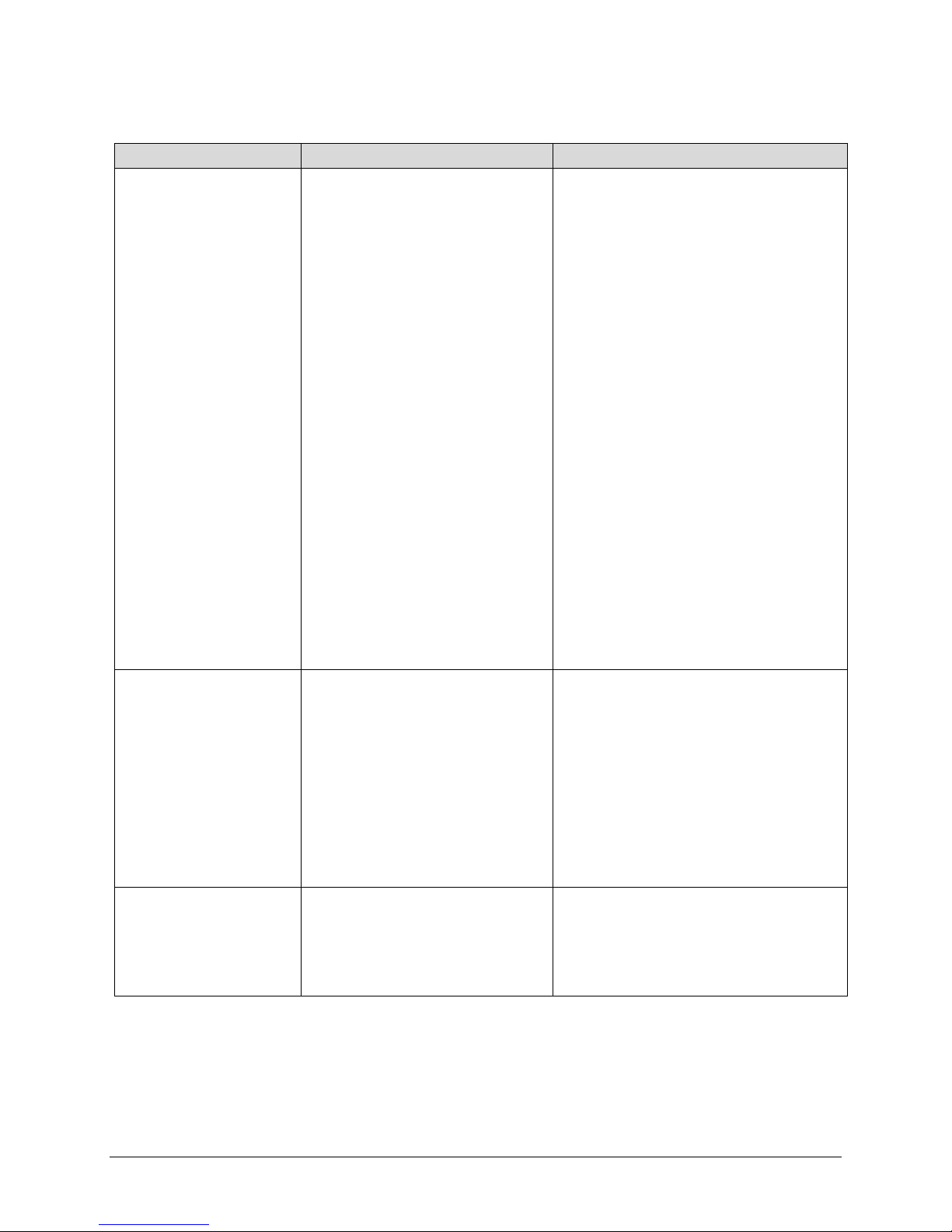

Table 3-2. J4 Redundancy Loop Connector Pinout

Pin # Description Pin # Description

A Loop In 1 L SumFlt 2 NO

B ADDR 2 M SumFlt 2 Common

C Loop In 2 N Local Loop Out

D Loop Out 2 P SumFlt 1 NO

E ADDR Common R SumFlt 1 Common

F ADDR 1 S Local SumFlt Common

G Loop Out 1 T Local SumFlt NO

H HSB +RX/TX U No Connect

J HSB – RX/TX V No Connect

K Local Loop In

3–4

Page 35

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Connectors and Pinouts MN/KPA.IOM

3.3.3 J5 DISCRETE CONTROL Connector

The J5 DISCRETE CONTROL connector is the primary input for

monitoring and controlling the ISSPA. It is a 19-pin circular connector, type

MS3112E14-19S. The pinout specification for Standalone or 1:1 Redundant

Systems is provided in Table 3-3; fo

Table 3-4.

See Appendix B. KPA REDUNDANT OPERATIONS for

further information about use of the KPA in 1:1 or 1:2 redundant systems.

Mating connector: ITT: KPT06J14-19P or MS3116J14-19P.

Table 3-3. J5 DISCRETE CONTROL Connector Pinout (Standalone or 1:1 Redundant Systems)

Pin # Signal Name Description

A Auto Select Momentary short to pin F to force entire subsystem to Auto

Mode.

B BU-1 Command Momentary short to pin F to force backup of KPA #1.

C Priority 2 Sel Not applicable for 1:1 system

D BU-2 Command Not applicable for 1:1 system

E 2 Online NO Not applicable for 1:1 system

F Remote Common Control – Remote Common.

G Online Common Online Status Common.

H BU Online NO Open when Online, all other conditions tied to Pin G.

J Manual Select Momentary short to pin F to force entire subsystem to Manual

Mode.

K 1 Online NO Open when Online, all other conditions tied to Pin G.

L 2 Fault NO Not applicable for 1:1 system

M Priority 1 SEL Momentary short to pin F to set KPA #1 as High priority.

N Fault Common Fault Status Common.

P BU Fault NO Open when faulted, else tied to Pin N.

R BU Offline CMD Momentary short to pin F to force backup KPA Offline.

S 1 Fault NO Open when faulted, else tied to Pin N.

r 1:2 Redundant Systems, refer to

3–5

Page 36

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Connectors and Pinouts MN/KPA.IOM

Table 3-4. J5 DISCRETE CONTROL Connector Pinout (1:2 Redundant Systems)

Pin # Signal Name Description

A Auto Select Momentary short to pin F to force entire subsystem to Auto Mode.

B BU-1 Command Momentary short to pin F to force backup of KPA #1.

C Priority 2 Sel Momentary short to pin F to set KPA #2 as HIGH priority.

D BU-2 Command Momentary short to pin F to force backup of KPA #2.

E 2 Online NO Open when Online, all other conditions tied to pin G. see Note 1.

F Remote Common Control – Remote Common.

G Online Common Online Status Common.

H BU Online NO Tied to pin G when Redundancy functioning correctly, all other

conditions OPEN. See Note 2.

J Manual Select Momentary short to pin F to force entire subsystem to Manual

Mode.

K 1 Online NO Open when Online, all other conditions tied to Pin G. see Note 1.

L 2 Fault NO Open when faulted, else tied to Pin N.

M Priority 1 SEL Momentary short to pin F to set KPA #1 as HIGH priority.

N Fault Common Fault Status Common.

P BU Fault NO Open when faulted, else tied to Pin N.

R BU Offline CMD Momentary short to pin F to force backup KPA Offline.

S 1 Fault NO Open when faulted, else tied to Pin N.

Notes:

1. Online status subject to state of Pin H.

2. When Open, can indicate loss of power or cabling problem. Online State of unit not

determinable when open.

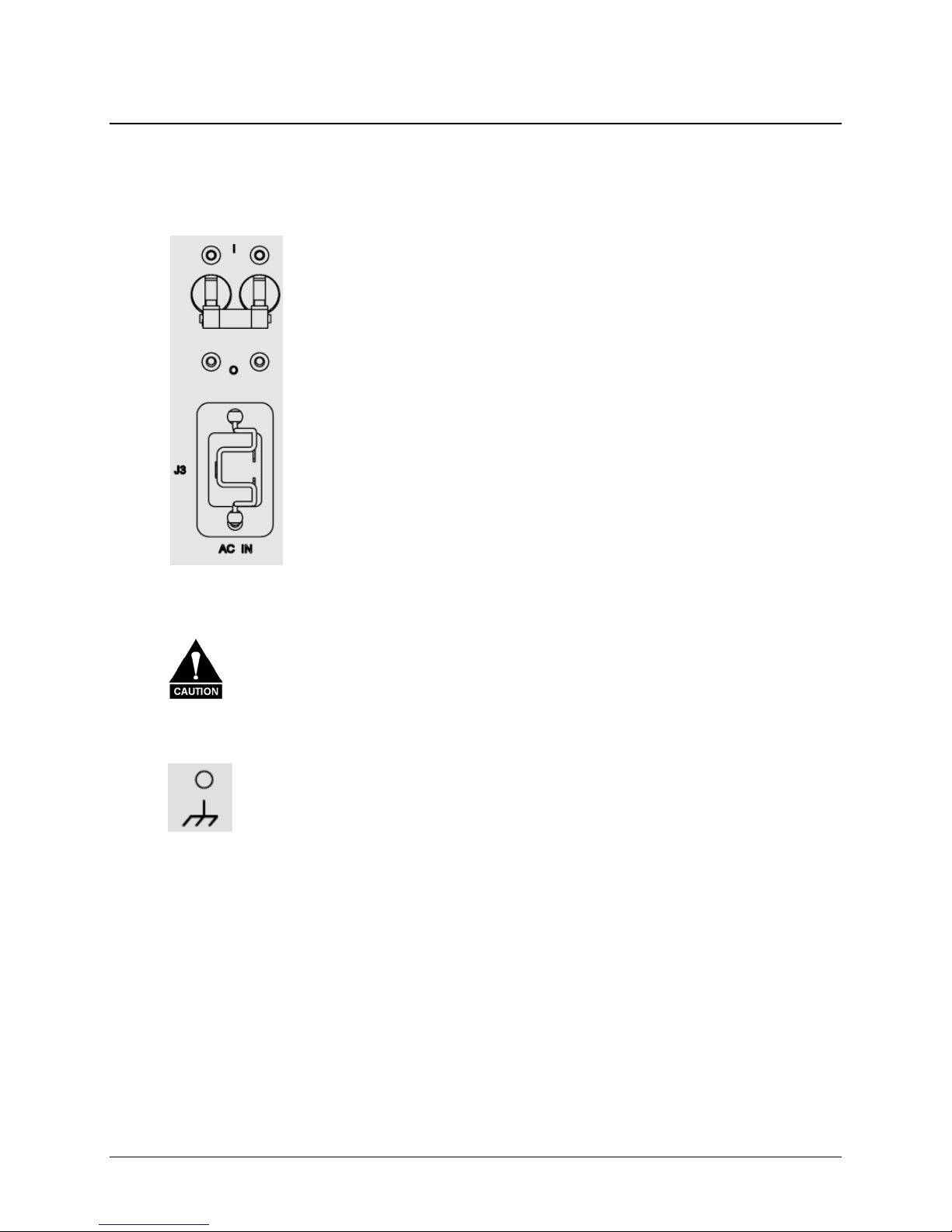

3.3.4 J8 10/100 ETHERNET Connector

The J8 10/100 ETHERNET connector is not provided on the

KPA-020IN unit. This RJ-45 connector provides the CAT5 10/100 BaseT

interface for management and data exchange between the unit and the user.

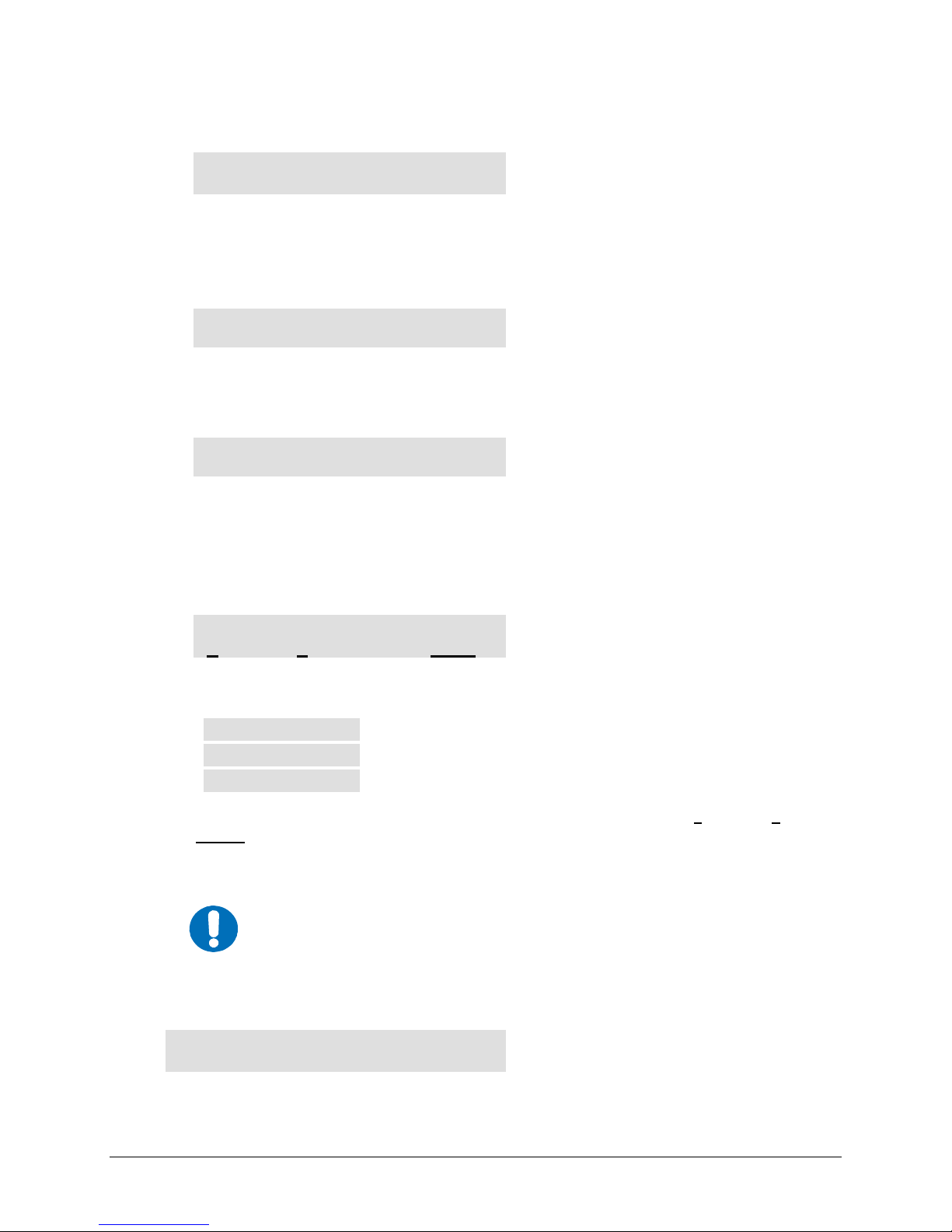

3.3.5 J9A EXT REF IN / J9B EXT REF OUT Connectors

The J9A EXT REF IN and J9BN EXT REF OUT connectors are not

provided on the KPA-020IN unit.

REF DES Name Connector Type Description

J9A EXT REF IN BNC External Reference Input

J9B EXT REF OUT BNC External Reference Output

3–6

Page 37

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Connectors and Pinouts MN/KPA.IOM

3.3.6 J7 RF SWITCH Connector

The J7 RF SWITCH connector is a 10-pin circular connector, type

MS3112E12-10S. Used only in redundant configurations, it functions as

the waveguide switch interface connector. The pinout specification is

contained in Table 3-5. See Appendix B. K

PA REDUNDANT

OPERATIONS for further information about use of the KPA in 1:1 or

1:2 redundant systems.

Table 3-5. J7 RF SWITCH Connector Pinout

Pin Description

A Command BU-1

B Command Common

C Command 1 Online

D IND 1 Online

E IND Common

F IND BU Online

G Command BU-2

H Command BU-2

J IND 2 Online

K No Connect

3.3.7 J6 COM 1 Connector

The J6 COM 1 connector is a 9-pin Type ‘D’ female (DB-9F) connector

that provides the EIA-232/EIA-485 Interface. The pinout specifications

are provided in Table 3-6.

Mating Connector: 9-pin T

Table 3-6. J6 COM 1 Connector Pinout (EIA-232/EIA-485 Interface)

Pin # EIA-232 EIA-485 4-Wire EIA-485 2-Wire

1 No Connect Ground (GND) Ground (GND)

2 Transmit Data (TD) No Connect No Connect

3 Receive Data (RD) No Connect No Connect

4 No Connect +TX Signal +RX/TX Signal Loop In

5 Ground (GND) -TX Signal Compliment -RX/TX Signal Complement Loop In

Unit Ready – always

6

high (DSR)

Request to Send.

7

Looped to CTS (RTS)

8 Clear to Send (CTS) +RX Signal +RX/TX Signal Loop Out

9 No Connect -RX Signal Complement -RX/TX Signal Complement Loop Out

No Connect No Connect

No Connect No Connect

ype ‘D’ male connector (DB-9M).

3–7

Page 38

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Connectors and Pinouts MN/KPA.IOM

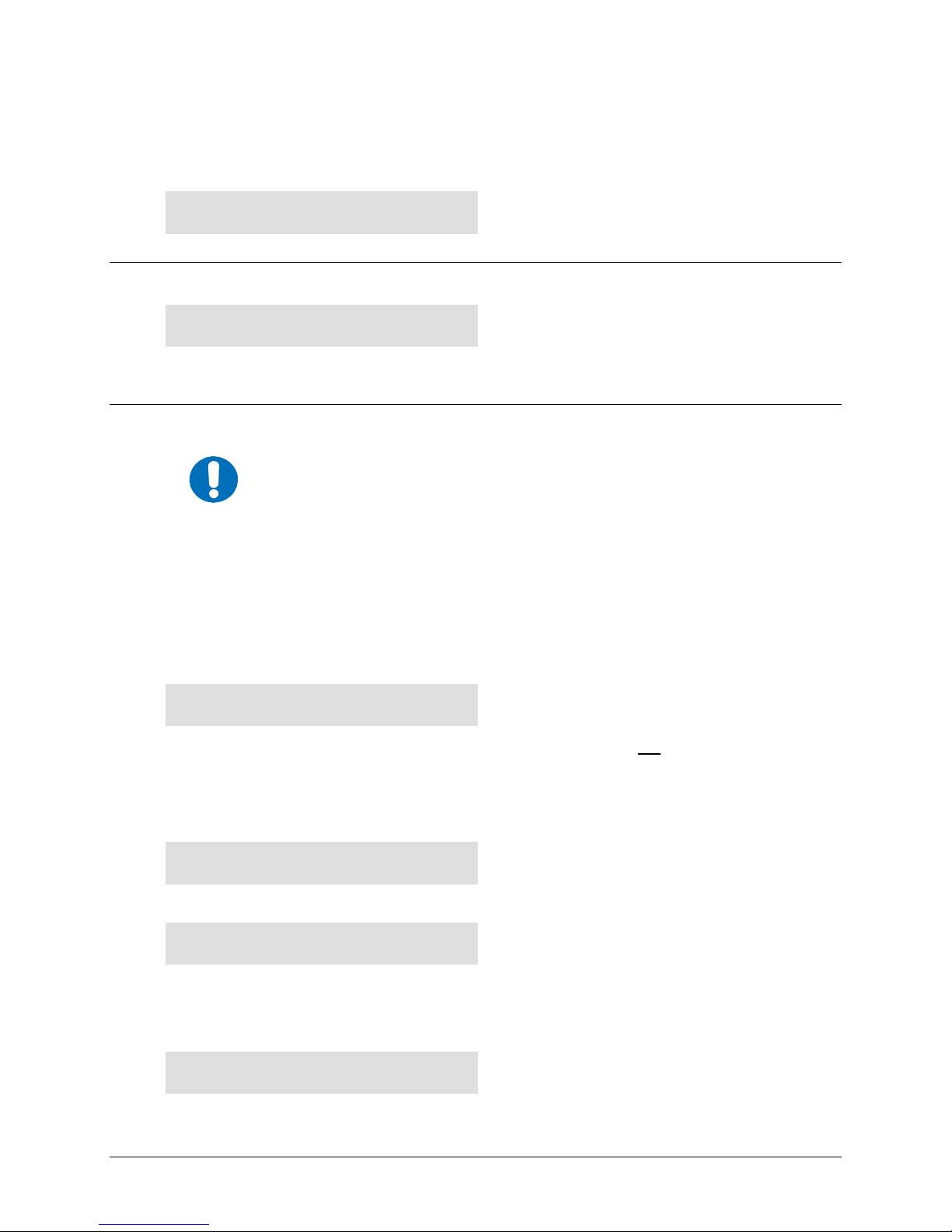

3.4 Power / Ground Connections

3.4.1 Alternating Current Prime Power Switch and Connector

The On/Off prime power switch is located on the rear of the chassis adjacent to

the prime power input connector. The circuit breaker is rated for 30 Amps.

A standard, detachable, non-locking, 3-prong power cord (IEC plug) supplies

the Alternating Current (AC) power to the unit via the prime power input

connector. Note that the specification for the power source is specific to the

unit as follows:

• For KPA-020IN only – 90 to 135 VAC, 47 to 63 Hz

• For KPA-040 only – 90 to 270 VAC, 47 to 63 Hz

• For KPA-080/-100 only – 180 to 270 VAC, 47 to 63 Hz

3.4.2 Chassis Ground Connector

PROPER GROUNDING PROTECTION IS REQUIRED: The installation instructions

require that the integrity of the protective earth must be ensured and that the

equipment shall be connected to the protective earth connection at all times.

Therefore, it is imperative during inst allation, configuration, and operation that the

user ensures that the unit has been properly grounded using the ground stud

provided on the rear panel of the unit.

A #10-32 stud is provided for connecting a common chassis ground among

equipment.

Note: The AC power connector provides the safety ground.

3–8

Page 39

Chapter 4. FLASH UPGRADING

4.1 Flash Upgrading via Internet

The KPA ISSPAs use ‘Flash memory’ technology internally, which makes upgrading the

firmware very simple. For current KPA-040/-080/-100 production models, updates can now be

sent via the Internet (Figure 4-1), via E

This chapter outlines the complete upgrading process as follows:

• New firmware can be downloaded via the Internet to an external M&C PC.

• The upgrade can be performed without opening the KPA by simply connecting the unit to

the serial port or Ethernet port of the M&C PC.

• The firmware update is transferred, via File Transfer Protocol (FTP), to the KPA.

-mail, or on CD.

Figure 4-1. Flash Upgrade via Internet

4–1

Page 40

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Flash Upgrading MN/KPA.IOM

4.2 Ethernet FTP Upload Procedure

Follow the steps provided in this section. Once the upload is complete, the KPA’s top-level

display screen will appear (for more information, see Chapter 5. FRONT PANEL

OPERATION) as shown in Step 10 of this procedure.

Note: This procedure is applicable to KPA-040/-080/-100 production units featuring the J8 10/100

ETHERNET connector on the rear panel. For the KPA- 020IN, FTP Upload is accomplished via

Telnet / HyperTerminal configured as Telnet Client using the KPA-020IN’s J6 COM1 serial port.

See Chapter 6. KPA ETHERNET MANAGEMENT for further information.

Step Procedure

1

Identify the reflashable product, firmware number, and version for download:

The current base unit M&C version can be viewed at the top level display on the KPA front

panel (press the CLEAR key several times to view). The firmware information can also be

found within the Utility: Firmware Æ Boot menu tree. For more information, refer to

Chapter 5. KPA FRONT PANEL OPERATION.

Alternately, when using the Web Server Interface, the Bootrom, Bulk, App, and FPGA

firmware loads may be viewed in the Firmware Information section of the Status | Status

page. For more information, refer to Chapter 6.5 Web Server (HTTP ) Interface.

2

3

Create a temporary folder (directory) on an external M&C PC:

• For Windows Explorer: Select File > New > Folder to create a new folder, then

rename it from “New Folder” to "temp" or another convenient, unused name.

Assuming "temp" works, a "c:\temp" folder should now be created.

Note: The drive letter c: is used in this example. Any valid writable drive letter

can be used.

• For Windows Command-line: Click [Start] on the Windows taskbar, then click

the “Run...” icon (or, depending on Windows OS versions prior to Windows 95,

click the “MS-DOS Prompt” icon from the Main Menu). Then, to open a

Command-line window…

o For Windows 95 or Windows 98 – Type “command”.

o For any Windows OS versions later

“command”.

Alternately, from [Start], select All Programs > Accessorie s > Command

Prompt.

At the Command-line prompt (c:\>), type “mkdir temp” or “md temp” (without

quotes – mkdir and md stand for make directory). This is the same as creating a

new folder from Windows Explorer. There should now be a "c:\temp" subdirectory

created (where c: is the drive letter used in this example).

Download the correct firmware file to this temporary folder. As shown in Figure 4-1:

a)

Go online to: www.comtechefdata.com

b) From the Home page menu bar, click the Support tab;

c) Click the Software Downloads drop-down or hyperlink from the Support page;

d) Click the Download Flash and Software Update Files icon;

e) Click the (Select a Product Line:) Amplifiers hyperlink provided on the Flash

and Software Update Files page;

f) Click the KPA product hyperlink;

g) Select the appropriate firmware hyperlink.

than Windows 98 – Type “cmd” or

;

4–2

Page 41

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Flash Upgrading MN/KPA.IOM

3

(cont)

4

5

6

About Firmware Numbers, File Versions, and Formats: Comtech EF Data’s Web site

catalogues its flashable firmware upgrade files by product type (e.g., KPA, converter, etc.)

and specific model/optional configuration. The hyperlinks appear as per the example to the

right. For the KPA, the firmware download hyperlink appears as F0000086X_V###, where

‘X’ denotes the revision letter, and ### represents the firmware version.

The current version firmware release is provided. If applicable, one version prio r to the

current release is also available. Be sure to identify and download the desired version.

The downloadable files are stored in two formats: *.exe (self-extracting) and *.zip

(compressed). Some firewalls will not allow the downloading of *.exe files. In this case,

download the *.zip file instead.

For additional help with "zipped" file types, refer to PKZIP for Windows, WinZip, or

ZipCentral help files. PKZIP for DOS is not supported due to file naming conventions.

Extract the files into the temporary folder on the M&C PC. At least three files should be

extracted:

• FW-0000086x.bin (where ‘x’ denotes the bulk image revision letter);

ReleaseNotes_ISSPA_v###.pdf (where ‘###’ denotes the firmware version);

•

Confirm that the files have been extracted to the specified temporary folder on the

M&C PC. Using Command-line, type “cd c:\temp” to change to the temporary directory

created in Step 2, then use the “dir” command to list the files extracted from the

downloaded archive file.

Connect the external M&C PC from either the KPA’s J6 COM1 serial port (for the

KPA-020IN only), or the J8 10/100 Ethernet port (for all other KPA models) via a hub or

a switch or directly to the PC with a crossover cable.

7

8

9

Send a “ping” command to the KPA to verify the connection and communication.

First, determine the IP address of the unit by using the front panel:

SELECT: Configuration Æ Remote Æ Ethernet ÆAddress

Then, using Command-line to PING: At the Command-line prompt, type “ping

xxx.xxx.xxx.xxx” (where ‘xxx.xxx.xxx.xxx’ is the IP address of the KPA).

The results should confirm whether or not the KPA is connected and communicating.

Initiate an FTP session with the KPA (this example uses Command-line):

a) From the M&C PC, at the prompt type “ftp xxx.xxx.xxx.xxx” where ‘xxx.xxx.xxx.xxx’

is the IP address of the KPA.

b) Verify the FTP transfer is binary by typing "bin".

c) Type "prompt" then type "hash" to facilitate the file transfers.

Transfer the files:

Type "put FW-00000086x.bin bulk:" (where ‘x’ denotes the revision letter) to begin the file

transfer.

Note: The destination “bulk:” must be all lower case.

Allow a few seconds for the file to transfer.

4–3

Page 42

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Flash Upgrading MN/KPA.IOM

10

Verify the file transfer.

a) The M&C PC should report that the file transfer has occurred, and the display on the

KPA will report:

Programming APP flash…

Please wait…

b) The process sequences through several blocks – this will take several minutes. When

it has finished, the KPA front panel will display:

KPA-080-4045-I

Ver. X.X.X SNXXXXXXXXX

c) Terminate the FTP session by typing "bye" and closing the Command-line window.

d) Recycle the power and wait for the unit to reboot.

e) Verify that the new file loaded using the procedure in Step 1.

The Ethernet FTP Upload Procedure is now complete.

4–4

Page 43

5.1 Introduction

The user can fully control and monitor the operation of the KPA ISSPA from the front panel

using the keypad and display. Nested menus are used, which display all available options and

prompt the user to carry out a required action.

Figure 5-1 identifies the key operational features of the front panel – both the original (obsolete)

and current panel layouts. The function of each feature is explained in greater detail in this

chapter.

LED Indicators

Chapter 5. FRONT PANEL

OPERATION

Original (Obsolete) Front Panel Layout

Liquid Crystal Diode

Vacuum Fluorescent Display

Current Front Panel Layout

(LCD) Display

(VFD)

Keypad

Figure 5-1. KPA-XXX Front Panel View

5–1

Page 44

KPA Ku-Band Indoor Solid-State Power Amplifier Revision 1

Front Panel Operation MN/KPA.IOM

5.1.1 Startup Checklist

The user should always perform the following checklist before operating the KPA:

Step Procedure

1

2

3

4

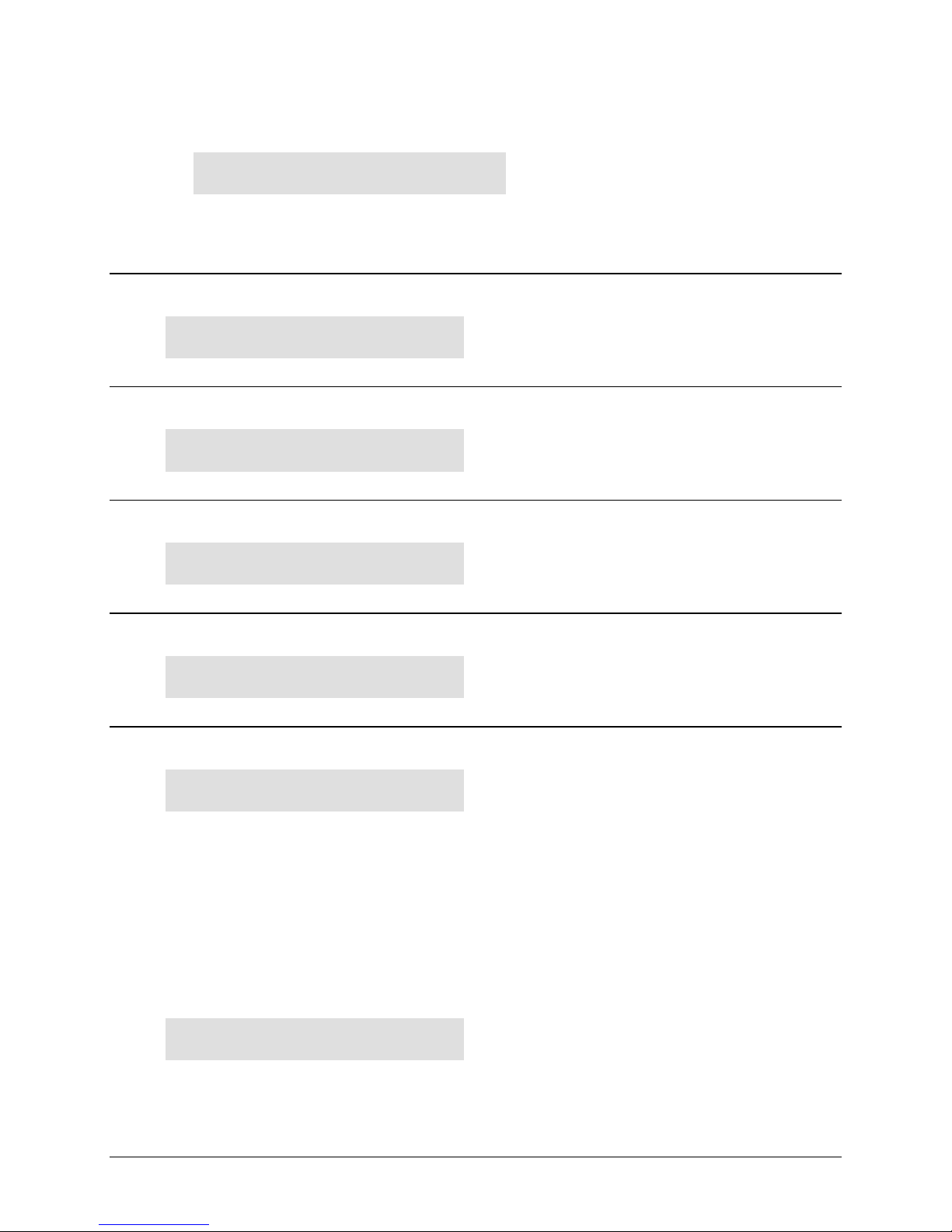

Check to ensure that the installation is complete.