Page 1

HPCST-5000/-7000

HPKST-12000

HIGH-POWER TWTA

HIGH-POWER TWTA

HIGH-POWER TWTAHIGH-POWER TWTA

SATELLITE TERMINALS

SATELLITE TERMINALS

SATELLITE TERMINALSSATELLITE TERMINALS

Installation and Operation Manual

Installation and Operation Manual

Installation and Operation ManualInstallation and Operation Manual

Part Number MN/TWTA.I0M

Revision 1

Page 2

Page 3

EFData Corporation is an ISO 9001 Registered Company

HPCST-5000/-7000

HPCST-5000/-7000

HPCST-5000/-7000HPCST-5000/-7000

HPKST-12000

HPKST-12000

HPKST-12000HPKST-12000

HIGH-POWER TWTA

HIGH-POWER TWTA

HIGH-POWER TWTAHIGH-POWER TWTA

SATELLITE TERMINALS

SATELLITE TERMINALS

SATELLITE TERMINALSSATELLITE TERMINALS

Installation and Operation Manual

Installation and Operation Manual

Installation and Operation ManualInstallation and Operation Manual

Part Number MN/TWTA.I0M

Revision 1

March 28, 1998

Special Instructions:

Change bars were not utilized. For an overview of changes made to Rev. 0, refer to the preface

(“Overview of Changes to previous Edition”).

The revision supersedes part number MN/TWTA, Rev. 0 dated May 31,1997.

Copyright © EFData Corporation, 1998

All rights reserved.

Printed in the USA.

EFData Corporation, 2105 West 5th Place, Tempe, Arizona 85281 USA, (602) 968-0447, FAX: (602) 921-9012.

Page 4

Warranty Policy

This EFData Corporation product is warranted against defects in material and

workmanship for a period of one year from the date of shipment. During the warranty

period, EFData will, at its option, repair or replace produc t s that prove to be defective.

For equipment under warranty, the customer is responsible for f rei ght to EFData and

all related custom, taxes, tariffs, insurance, etc. EFData is responsible for the freight

charges

return the equipment by the same method (i.e., A i r, Express, Surface) as the

equipment was sent to EFDat a.

for return of the equipment f rom the factory to the c ustomer. EFData will

only

Limitations of Warranty

The foregoing warranty shall not apply to defects resulting from i mproper installation

or maintenance, abuse, unaut horized modification, or operat i on outside of

environmental specifi cations for the product, or, for damages that occ ur due to

improper repackaging of equipment for return to EFData.

No other warranty is expressed or implied. EFData Corporation specifically

disclaims the implied warranties of merchantability and fitness for particular

purpose.

Exclusive Remedies

The remedies provided herein are the buyer's sole and exclusive remedies. EF Dat a

Corporation shall not be liable for any direct, indirect, special, incidental, or

consequential damages, whether bas ed on contract, tort, or any ot her l egal theory.

Disclaimer

EFData has reviewed this manual thoroughly in order that it will be an easy-to-use

guide to your equipment. All statements, t echnical information, and recommendations

in this manual and in any guides or rel ated documents are believed reliabl e, but the

accuracy and completeness thereof are not guaranteed or warranted, and they are

not intended to be, nor should they be unders t ood to be, representations or warranties

concerning the products described. Further, EFData reserves the right to make

changes in the specifications of the products described in this manual at any time

without notice and without obligation to not i fy any person of such changes.

If you have any questions regarding your equipment or the information in this manual,

please contact the EFData Customer Support Department. (For more inform at i on,

refer to the preface.)

Page 5

About this Manual

This manual provides installation and operation information for the EFData high-power

Traveling Wave Tube (TWT) amplifier (TWTA) systems for EFData satellite terminal

systems. This is a technical document intended for earth station engineers, technicians,

and operators responsible for the operation and maintenance of the high-power TWTA

systems.

Conventions and References Used in this Manual

Cautions and Warnings

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other

CAUTION

unsafe practices or risks of property damage.

Preface

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

WARNING

Trademarks

Product names mentioned in this manual may be trademarks or registered trademarks of

their respective companies and are hereby acknowledged.

Rev. 1 i

Page 6

Preface High-Power TWTA Satellite Terminals

Related Documents

The following documents are referenced in this manual:

• EFData CST-5000 C-Band Satellite Terminal Installation and Operation

Manual

• EFData CST-7000 C-Band Satellite Terminal (Insat) Installation and Operation

Manual

• EFData KST-12000 Ku-Band Satellite Terminal Installation and Operation

Manual

• EFData RSU-503 Redundancy Switch Unit Installation and Operation Manual

• IESS-309

Metric Conversions

Metric conversion information is located on the inside back cover of this manual. This

information will assist the operator in cross-referencing English to Metric conversions.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the EFData Customer Support

Department according to the following information.

Overview of Previous Editions

Changes made to Rev. 0 were:

Manual changed to reflect model number HPCST-5000/-7000 and HPKST -12000.

Incorporated new styles and profiles.

ii Rev. 1

Page 7

High-Power TWTA Satellite Terminals Preface

Customer Support

Contact the EFData Customer Support Department for:

• Product support

• Information on returning a product

• Information on upgrading a product

• Product training

• Reporting comments or suggestions concerning manuals

An EFData Customer Support representative may be reached at:

EFData Corporation

Attention: Customer Support Department

2105 West 5th Place

Tempe, Arizona 85281 USA

(602) 968-0447 (Main EFData Number)

(602) 370-7904 (24-Hour Customer Support Desk)

(602) 921-9012 FAX

or, E-Mail can be sent to the Customer Support Department at:

service@efdata.com

or, contact Customer Support Department at the web site

www.efdata.com

To return an EFData product (in-warranty and out-of-warranty) for repair or

replacement:

1. Request a Return Material Authorization (RMA) number from the EFData

Customer Support Department.

Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

2. To ensure that the product is not damaged during shipping, pack the product in

its original shipping carton/packaging.

3. Ship the product back to EFData. (Shipping charges should be prepaid.)

For more information regarding the warranty policies, refer to the disclaimer page

located behind the title page.

Rev. 1 iii

Page 8

Preface High-Power TWTA Satellite Terminals

This page is intentionally left blank.

iv Rev. 1

Page 9

Table of Contents

CHAPTER 1. INTRODUCTION..................................................................................1–1

1.1 Introduction...................................................................................................................................................... 1–2

1.2 Component Descriptions..................................................................................................................................1–7

1.2.1 Low-Noise Amplifier (LNA) Assembly ..................................................................................................... 1–7

1.2.2 Radio Frequency Terminal (RFT) .............................................................................................................. 1–7

1.2.3 TWTA Models............................................................................................................................................ 1–8

1.2.4 High-Power Controller (HPC) .................................................................................................................. 1–10

1.2.4.1 HPC-1200.......................................................................................................................................... 1–10

1.2.4.2 HPC-1110.......................................................................................................................................... 1–11

1.2.5 Redundant Switch Unit (RSU).................................................................................................................. 1–12

1.2 Equipment List ............................................................................................................................................... 1–13

1.3 Specifications.................................................................................................................................................. 1–17

1.3.1 System Interface ....................................................................................................................................... 1–17

1.3.2 Prime Power ............................................................................................................................................. 1–18

1.3.3 Performance.............................................................................................................................................. 1–19

1.3.3.1 Receive.............................................................................................................................................. 1–19

1.3.3.2 Transmit ............................................................................................................................................ 1–21

1.3.4 Environment............................................................................................................................................. 1–25

1.3.5 Monitor and Control................................................................................................................................. 1–26

1.3.6 Physical Size and Weight......................................................................................................................... 1–27

Rev. 1 v

Page 10

Table of Contents High-Power TWTA Satellite Terminals

CHAPTER 2. SINGLE THREAD SYSTEM INSTALLATION......................................2–1

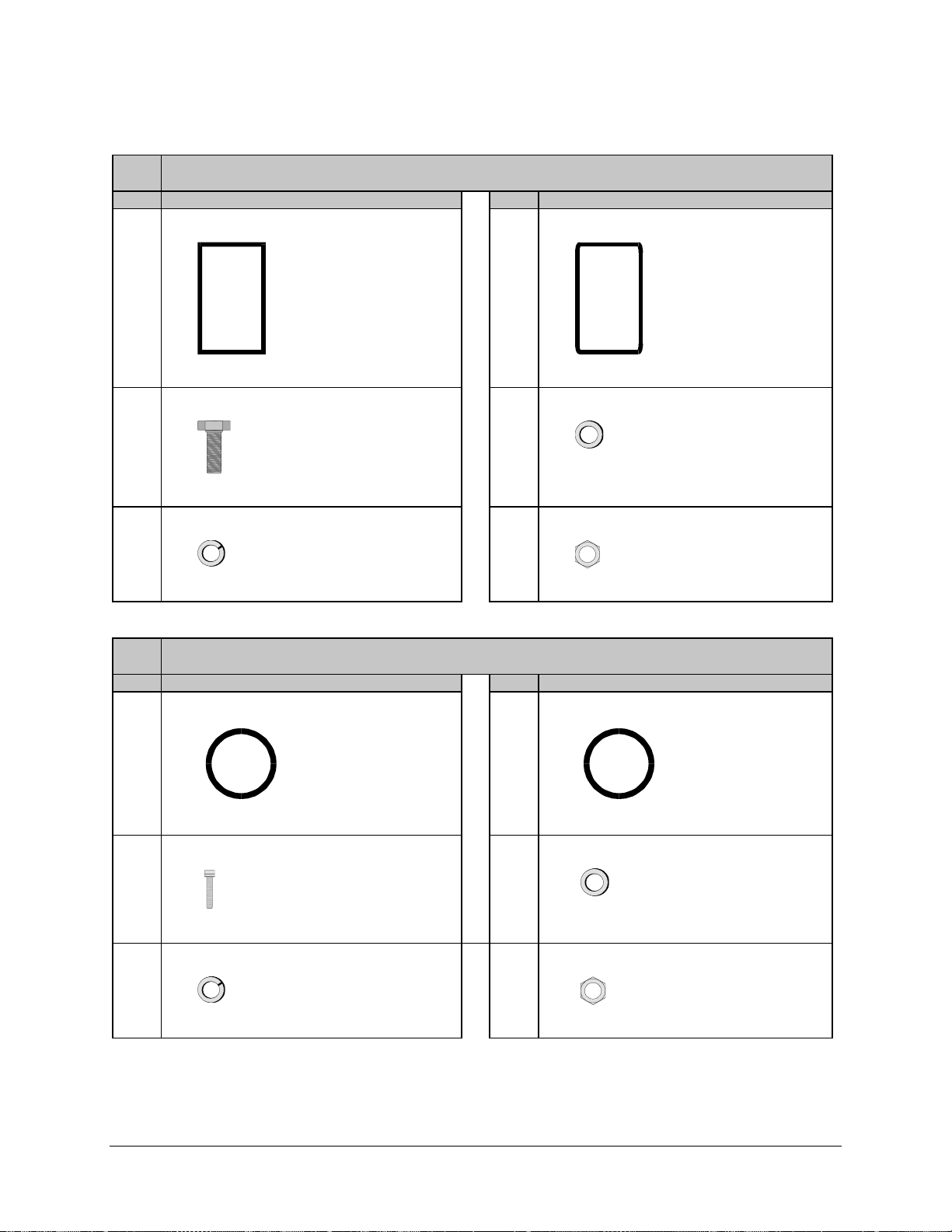

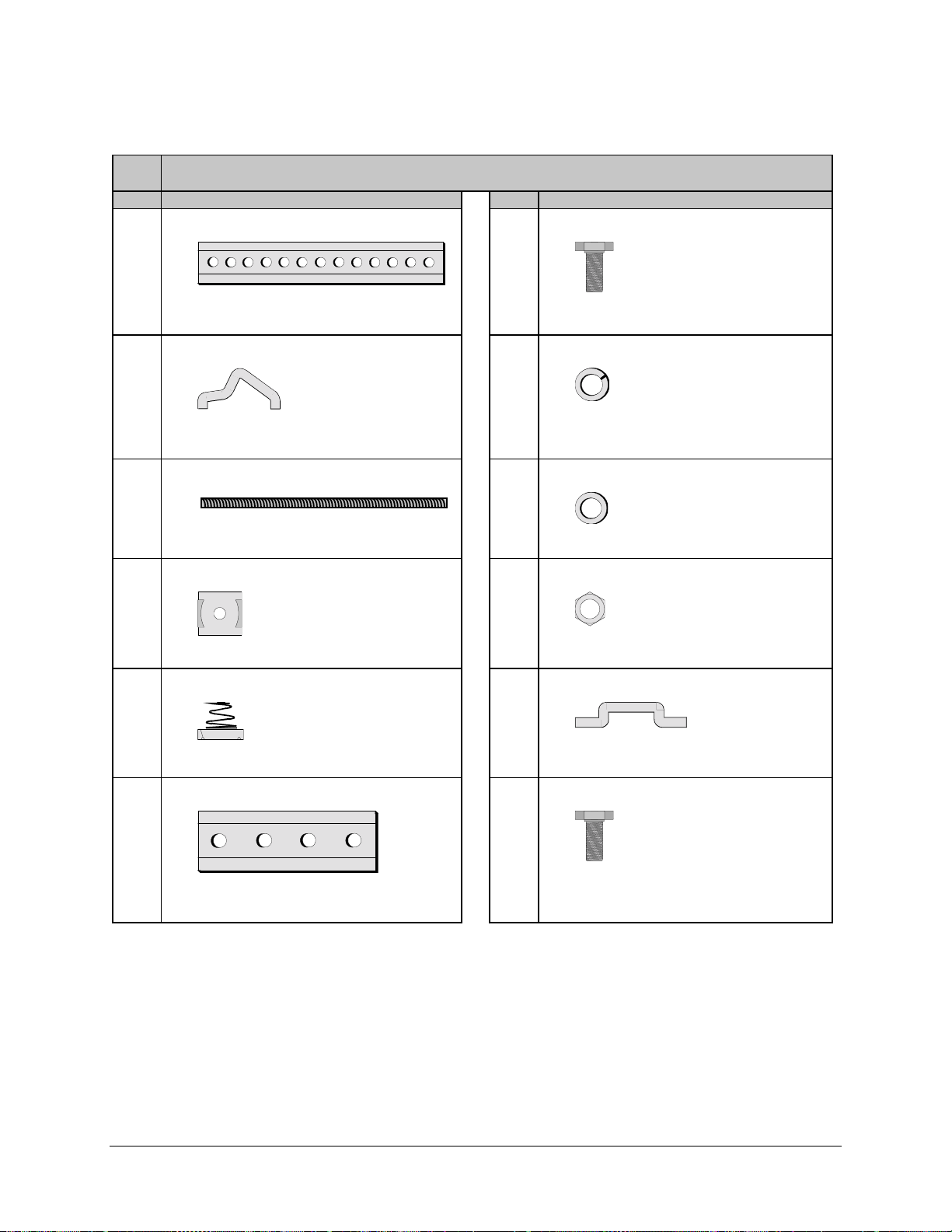

2.1 Unpacking......................................................................................................................................................... 2–2

2.2 Inspecting the Equipment................................................................................................................................ 2–3

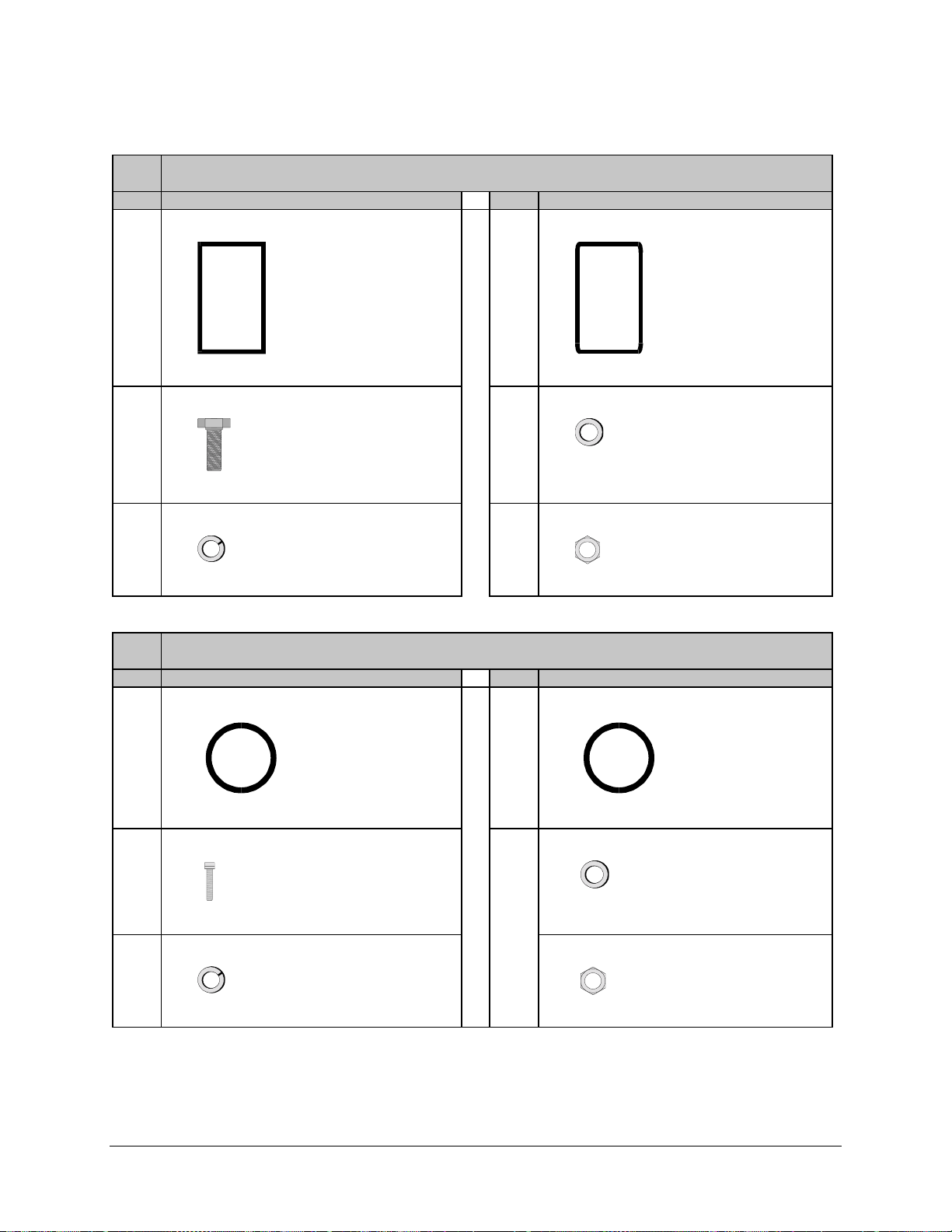

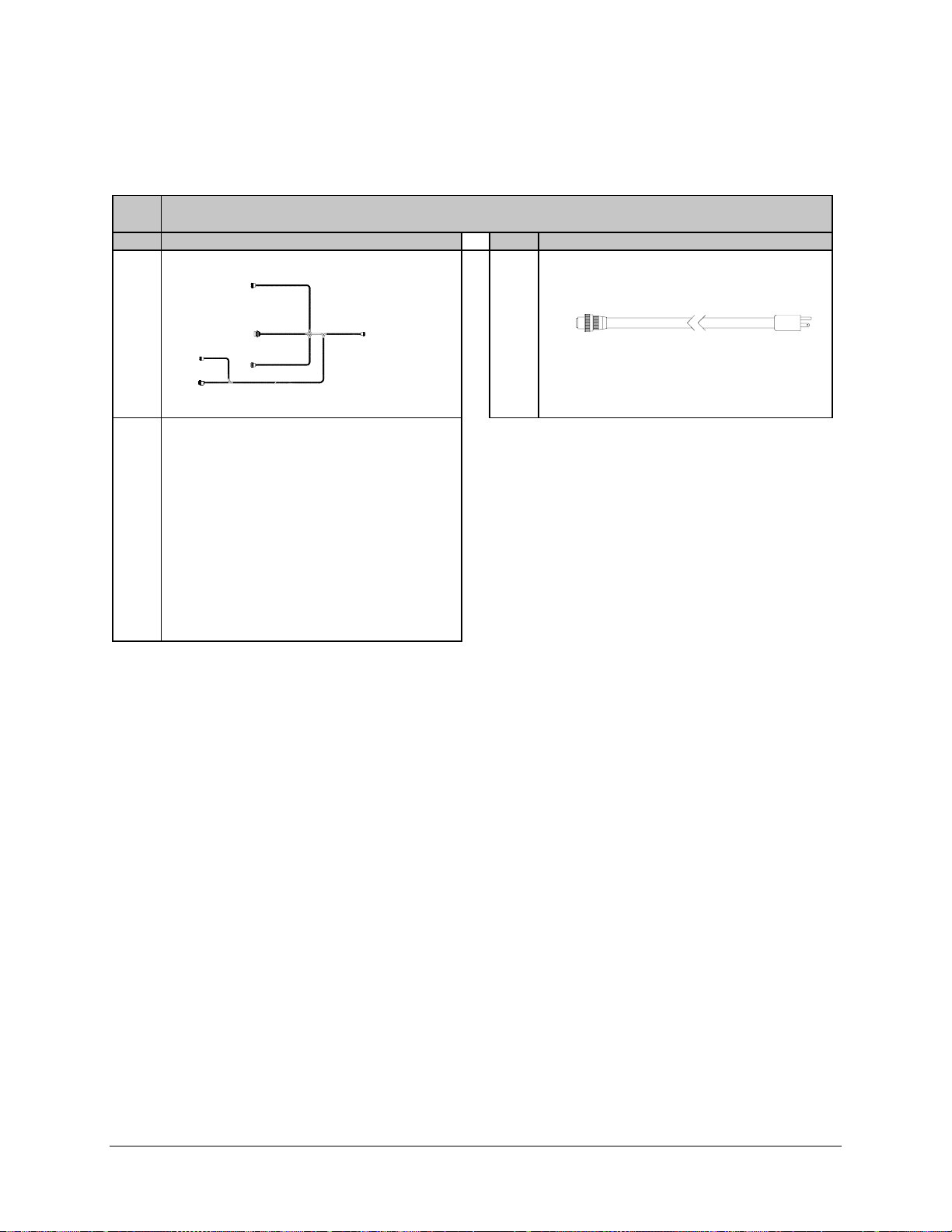

2.2.1 Included Parts............................................................................................................................................. 2–3

2.3 TWTA Installation........................................................................................................................................... 2–7

2.3.1 Tools Required ........................................................................................................................................... 2–8

2.3.2 Vertical Pole Installation ............................................................................................................................ 2–9

2.3.2.1 Round Pole.......................................................................................................................................... 2–9

2.3.2.2 Square Pole........................................................................................................................................ 2–13

2.3.3 Spar Installation ........................................................................................................................................ 2–14

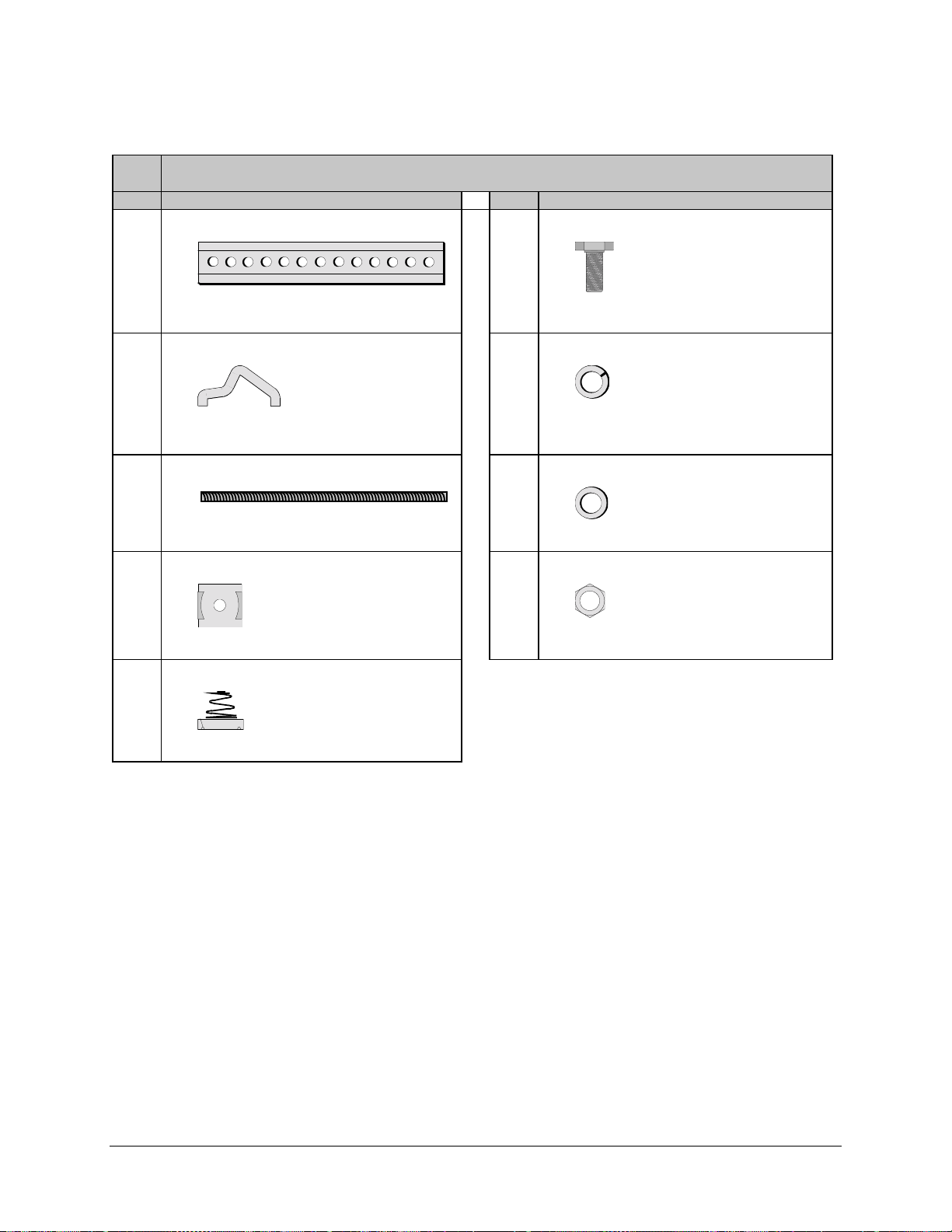

2.3.4 External Connections................................................................................................................................ 2–16

2.3.4.1 TWTA Monitor & Control (J1)......................................................................................................... 2–18

2.3.4.1.1 Control Interfaces....................................................................................................................... 2–20

2.3.4.1.2 Digital Status Circuits................................................................................................................ 2–21

2.3.4.1.3 Analog Status Circuits................................................................................................................ 2–23

2.3.4.1.4 Output Voltage Circuits............................................................................................................. 2–24

2.3.4.1.5 Control/Status Ground Isolation................................................................................................ 2–24

2.3.4.2 TWTA Prime Power (J2) .................................................................................................................. 2–25

2.3.4.2.1 Prime Power............................................................................................................................... 2–25

2.3.4.3 RF TX Input (J3)............................................................................................................................... 2–26

2.3.4.4 RF TX Sample (J4) ........................................................................................................................... 2–27

2.3.4.5 RF Output (J5)................................................................................................................................... 2–27

2.3.4.6 Waveguide......................................................................................................................................... 2–27

2.3.4.7 System Interface Wiring.................................................................................................................... 2–28

2.4 HPC-1200 Installation................................................................................................................................... 2–30

2.4.1 Mechanical................................................................................................................................................ 2–30

2.4.2 External Connections................................................................................................................................ 2–31

2.4.2.1 External Interfaces (J1) ..................................................................................................................... 2–31

2.4.2.1.1 Control Interfaces....................................................................................................................... 2–33

2.4.2.1.2 Digital Status Circuits................................................................................................................ 2–33

2.4.2.1.3 Analog Status Circuits................................................................................................................ 2–35

2.4.2.1.4 Output Voltage Circuits............................................................................................................. 2–35

2.4.2.2 ODU Monitor and Control (J2)......................................................................................................... 2–36

2.4.2.3 Prime Power...................................................................................................................................... 2–36

CHAPTER 3. REDUNDANT SYSTEM INSTALLATION............................................3–1

3.1 Unpacking......................................................................................................................................................... 3–2

3.2 Inspecting the Equipment................................................................................................................................ 3–3

3.2.1 Included Parts............................................................................................................................................. 3–3

3.3 TWTA Installation........................................................................................................................................... 3–9

3.3.1 Tools Required ......................................................................................................................................... 3–10

3.3.2 Vertical Pole Installation .......................................................................................................................... 3–11

3.3.2.1 Round Pole........................................................................................................................................ 3–11

3.3.2.2 Square Pole........................................................................................................................................ 3–14

3.3.3 Spar Mount............................................................................................................................................... 3–14

vi Rev. 1

Page 11

High-Power TWTA Satellite Terminals Table of Contents

3.3.4 External Connections................................................................................................................................ 3–15

3.3.4.1 System Interface Wiring.................................................................................................................... 3–15

3.4 HPC-1110 Installation................................................................................................................................... 3–23

3.4.1 Mechanical................................................................................................................................................ 3–23

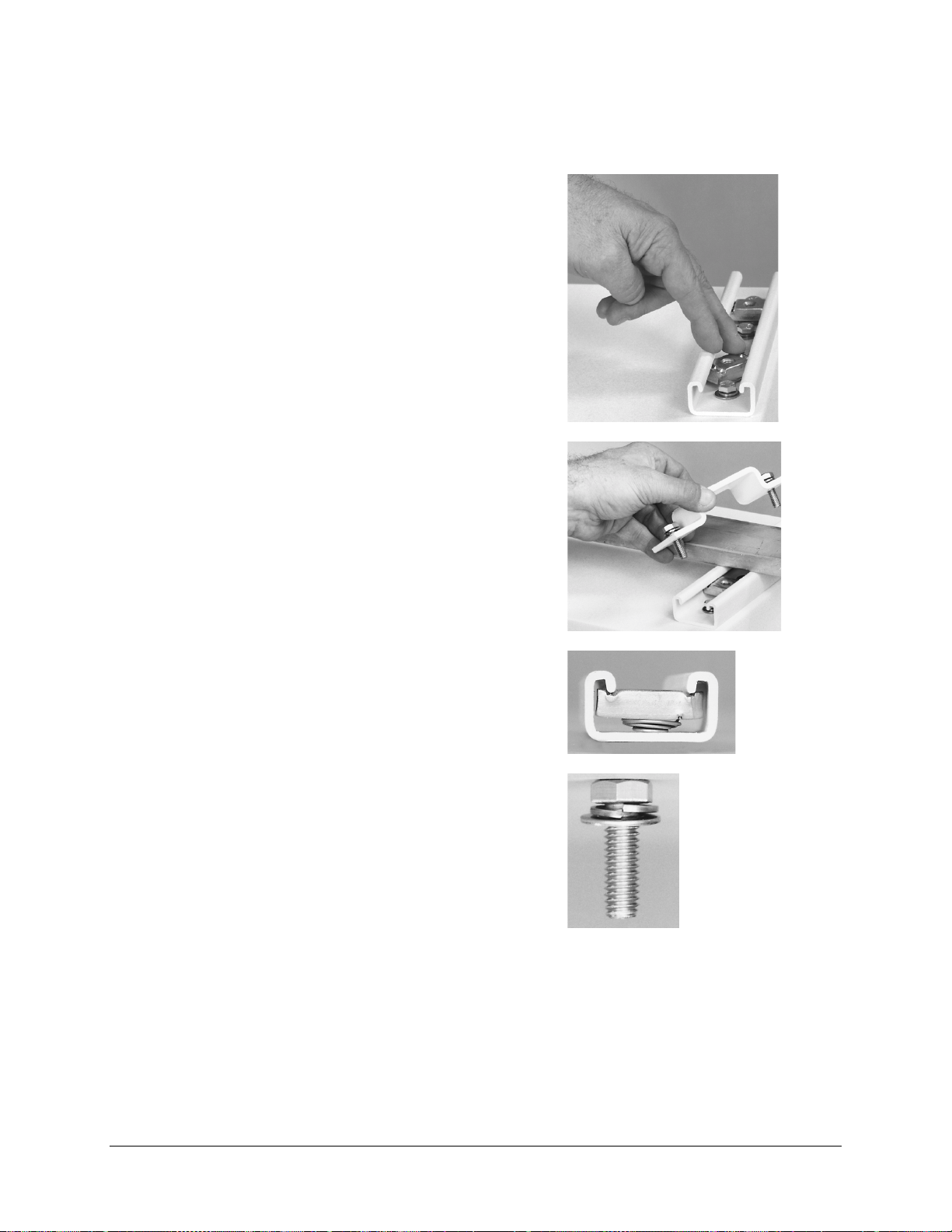

3.4.1.1 Cabinet Slide Assembly..................................................................................................................... 3–25

3.4.2 External Connections................................................................................................................................ 3–27

3.4.2.1 Standard Connections........................................................................................................................ 3–28

3.4.2.1.1 AC Prime Power........................................................................................................................ 3–28

3.4.2.1.2 TWTA Serial Interface ..............................................................................................................3–29

3.4.2.1.3 External Interlock/Remote Functions......................................................................................... 3–29

3.4.2.1.4 Waveguide Switch #1 ................................................................................................................ 3–29

3.4.2.1.5 Waveguide Switch #2 ................................................................................................................ 3–29

3.4.2.1.6 Remote Control Serial Interface................................................................................................. 3–30

3.4.2.2 “X” Insert Panel Connectors............................................................................................................. 3–32

3.4.2.2.1 Auxiliary Interface..................................................................................................................... 3–32

3.4.2.3 “X” Insert Panel Configurations........................................................................................................ 3–33

3.4.2.4 “Y” Insert Panel Connectors............................................................................................................. 3–34

CHAPTER 4. TWT AMPLIFIERS...............................................................................4–1

4.1 Operation and Control.................................................................................................................................... 4–2

4.1.1 Control and Status Interface....................................................................................................................... 4–2

4.1.2 Operating Modes........................................................................................................................................ 4–2

4.1.2.1 Heater Delay........................................................................................................................................ 4–2

4.1.2.2 Heater Standby.................................................................................................................................... 4–3

4.1.2.3 Standby................................................................................................................................................ 4–3

4.1.2.4 High Voltage ON................................................................................................................................. 4–3

4.1.2.5 Fault..................................................................................................................................................... 4–4

4.1.2.5.1 Clearing Faults............................................................................................................................. 4–5

4.1.3 Control and Status Signals.......................................................................................................................... 4–5

4.1.3.1 Control................................................................................................................................................. 4–5

4.1.3.2 Digital Status....................................................................................................................................... 4–6

4.1.3.3 Analog................................................................................................................................................. 4–7

4.1.4 Initial Power-Up......................................................................................................................................... 4–8

4.1.4.1 Pre-Power Check................................................................................................................................. 4–8

4.1.4.2 Power-On Sequence............................................................................................................................ 4–9

4.1.5 Shut Down.................................................................................................................................................. 4–9

4.2 Maintenance and Service............................................................................................................................... 4–10

4.2.1 Preventive Maintenance............................................................................................................................ 4–10

CHAPTER 5. CONTROLLER FOR SINGLE THREAD SYSTEMS............................5–1

5.1 Operation.......................................................................................................................................................... 5–2

5.1.1 LOCAL Control Configuration................................................................................................................... 5–3

5.1.2 REMOTE Control Configuration............................................................................................................... 5–3

5.1.3 Controls and Indicators............................................................................................................................... 5–3

Rev. 1 vii

Page 12

Table of Contents High-Power TWTA Satellite Terminals

5.2 Maintenance and Service................................................................................................................................. 5–9

5.2.1 Preventative Maintenance........................................................................................................................... 5–9

5.2.2 Operator Troubleshooting........................................................................................................................... 5–9

5.2.3 Clearing a Fault.........................................................................................................................................5–10

5.2.3.1 Clearing a Fault-LOCAL Control Configuration.......................................................................... ..... 5–10

5.2.3.2 Clearing a Fault-REMOTE Control Configuration ........................................................................... 5–10

CHAPTER 6. CONTROLLER FOR REDUNDANT SYSTEMS ..................................6–1

6.1 Overview........................................................................................................................................................... 6–2

6.1.1 “X” Insert and “Y” Insert Panels ................................................................................................................ 6–2

6.2 Operation.......................................................................................................................................................... 6–3

6.2.1 User Operational Choices........................................................................................................................... 6–3

6.2.1.1 Warm-Standby or Hot-Standby........................................................................................................... 6–3

6.2.1.2 Manual or Automatic Switching.......................................................................................................... 6–4

6.2.2 Local Controls and Indicators..................................................................................................................... 6–4

6.2.2.1 Basic Controls and Indicators.............................................................................................................. 6–4

6.2.2.1.1 Power Indicator............................................................................................................................ 6–5

6.2.2.1.2 Local/Remote Push Button Switch............................................................................................... 6–5

6.2.2.1.3 Manual/Automatic Push Button Switch....................................................................................... 6–6

6.2.2.1.4 HV ON Push Button Switch......................................................................................................... 6–7

6.2.2.1.7 Waveguide Switch Position Indicators......................................................................................... 6–8

6.2.2.1.8 Fault Reset Push Button Switch................................................................................................... 6–8

6.2.2.1.9 Lamp Test Push Button Switch.................................................................................................... 6–8

6.2.3 TWTA Setup for Redundant System Operation ......................................................................................... 6–9

6.2.3.1 Remote Controller Mode..................................................................................................................... 6–9

6.2.3.2 Local Controller Mode........................................................................................................................ 6–9

6.2.4 Initial Power-On......................................................................................................................................... 6–9

6.2.5 Normal Operation..................................................................................................................................... 6–10

APPENDIX A. PROGRAMMING GUIDE FOR REDUNDANT CONTROLLER......... A–1

A.1 Overview..........................................................................................................................................................A–1

A.1.1 Communication Protocols ..........................................................................................................................A–2

A.2 Communication Protocols..............................................................................................................................A–3

A.2.1 Command Message Format........................................................................................................................A–3

A.2.1.1 Header and Ending Byte.....................................................................................................................A–3

A.2.1.2 Primary Address Byte.........................................................................................................................A–4

A.2.1.3 Secondary Address Byte.....................................................................................................................A–4

A.2.1.4 Command Byte...................................................................................................................................A–4

A.2.1.5 Parameters..........................................................................................................................................A–4

A.2.1.6 Check Byte.........................................................................................................................................A–5

A.2.1.7 Parity .................................................................................................................................................. A–5

A.2.2 Response Message Format.........................................................................................................................A–6

A.2.2.1 Header and Ending Byte.....................................................................................................................A–6

A.2.2.2 Address Byte......................................................................................................................................A–6

A.2.2.3 Response Byte .................................................................................................................................... A–6

A.2.2.4 Parameters..........................................................................................................................................A–6

A.2.2.5 Check Byte.........................................................................................................................................A–6

A.2.2.6 Parity .................................................................................................................................................. A–7

viii Rev. 1

Page 13

High-Power TWTA Satellite Terminals Table of Contents

A.2.2.7 Command Reject Argument ...............................................................................................................A–7

A.2.3 ASCII Reference Information....................................................................................................................A–8

A.3 Redundant System Command Set................................................................................................................A–10

A.3.1 Controller Query Commands...................................................................................................................A–11

A.3.2 Controller Control Commands.................................................................................................................A–13

A.4 TWTA Command Set....................................................................................................................................A–15

A.4.1 TWTA Query Commands........................................................................................................................A–15

A.4.2 TWTA Control Commands......................................................................................................................A–17

GLOSSARY .................................................................................................................g-1

INDEX ...........................................................................................................................i-1

Rev. 1 ix

Page 14

Table of Contents High-Power TWTA Satellite Terminals

Figures

Figure 1-1. HPCST-5000/-7000 and HPKST-12000............................................................................................... 1–1

Figure 1-2. TWTA Redundant Assembly (Typical)................................................................................................. 1–3

Figure 1-3. HPCST-5000/-7000 Redundant Terminal Systems Block Diagram (Typical)...................................... 1–5

Figure 1-4. HPKST-12000 Redundant Terminal System Block Diagram (Typical)................................................ 1–6

Figure 1-5. 100W and 140W Unit Block Diagram.................................................................................................. 1–9

Figure 1-6. 300W and 350W Unit Block Diagram.................................................................................................. 1–9

Figure 1-7. HPC-1200 Single Thread Controller................................................................................................... 1–10

Figure 1-8. HPC-1110 1:1 Redundant Controller.................................................................................................. 1–11

Figure 1-9. RSU-503L........................................................................................................................................... 1–12

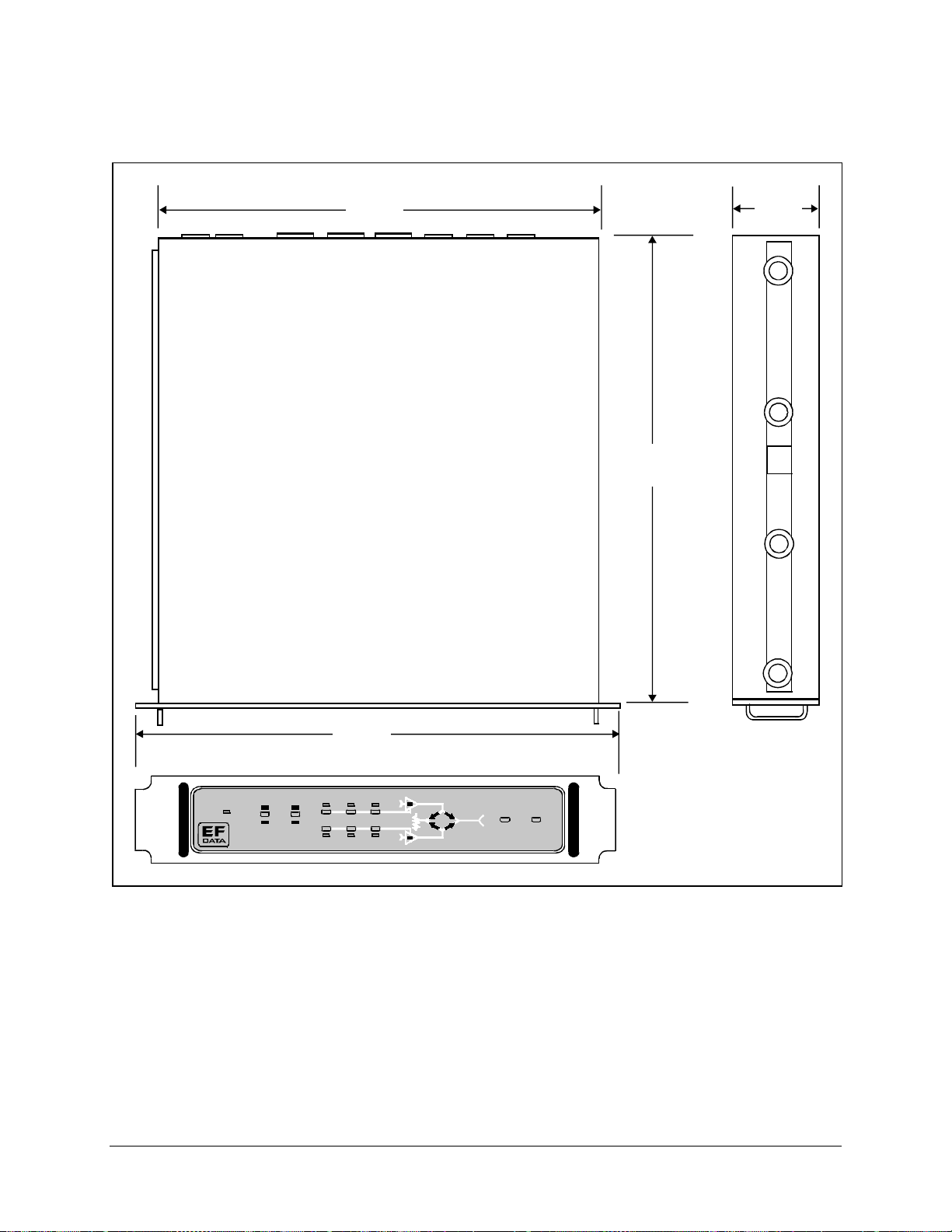

Figure 1-10. TWTA Outline Drawing (Typical).................................................................................................... 1–28

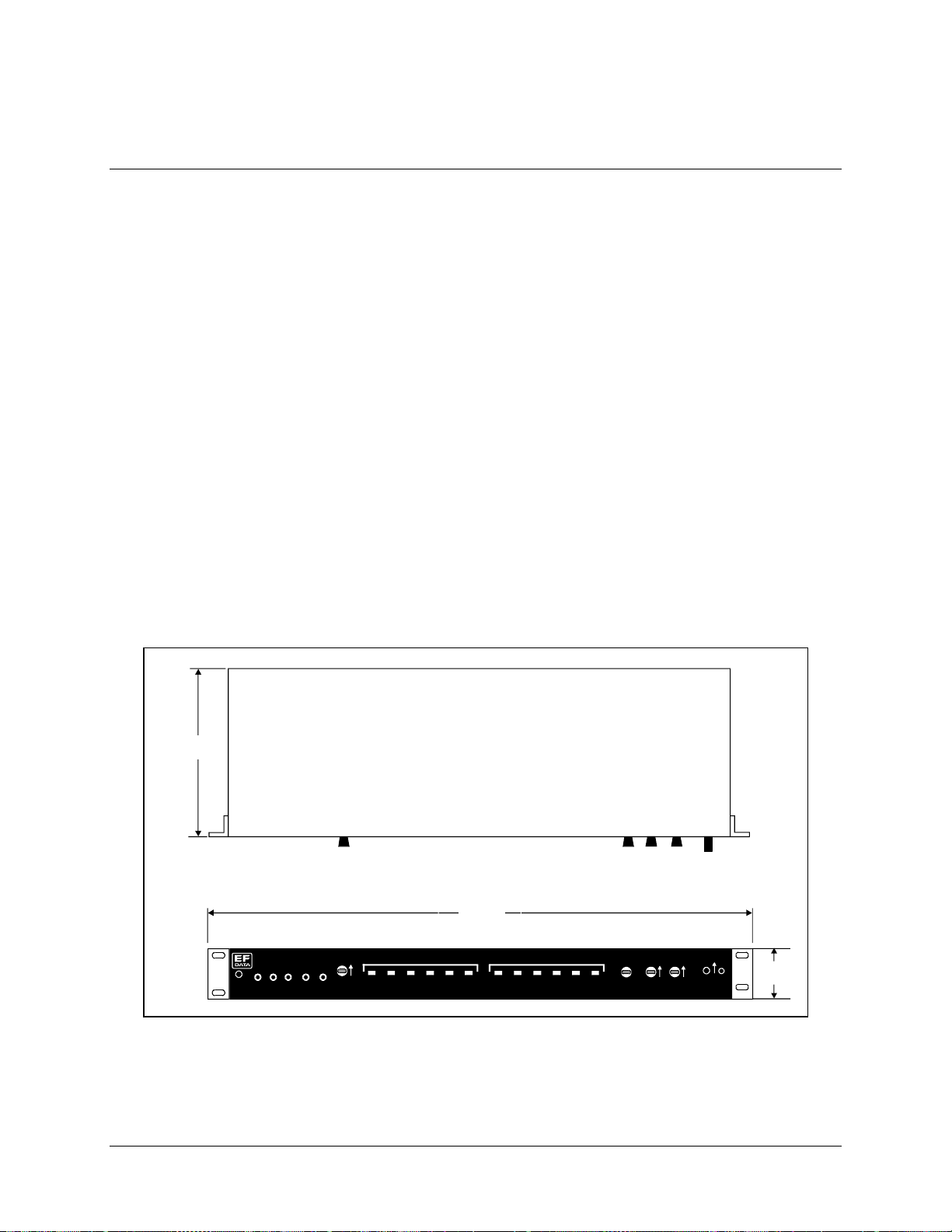

Figure 1-11. HPC-1200 Outline Drawing.............................................................................................................. 1–29

Figure 1-12. HPC-1110 Outline Drawing.............................................................................................................. 1–30

Figure 2-1. Typical TWTA Spar Installation......................................................................................................... 2–14

Figure 2-2. 100W and 140W TWTA External Connections.................................................................................. 2–16

Figure 2-3. 300W and 350W TWTA External Connections.................................................................................. 2–17

Figure 2-4. Interface Connector Pinouts ................................................................................................................ 2–19

Figure 2-5. TWT Temperature: Temperature vs. Voltage ..................................................................................... 2–23

Figure 2-6. Single Phase AC Power Connections................................................................................................. 2–26

Figure 2-7. Single Thread System M&C Cable Harness (CA/5124)...................................................................... 2–29

Figure 2-8. HPC-1200 Outline Drawing................................................................................................................ 2–30

Figure 2-9. HPC-1200 Rear Panel Connector Locations ....................................................................................... 2–31

Figure 2-10. Interface Connector Pinouts ...................................................................................... ........................ 2–32

Figure 2-11. Digital Status Circuit Isolation ..........................................................................................................2–33

Figure 3-1. HPCST/HPKST 1:1 Redundant System Cable Harness (CA/5122) .................................................... 3–16

Figure 3-2. HPCST/KST 1:1 Redundant M&C System Interface Cable (Optional) (CA/5279)............................ 3–18

Figure 3-3. HPCST/HPKST 1:1 Uplink-Only Redundant System Cable Harness (CA/5248)............................... 3–20

Figure 3-4. HPCST/HPKST HPCST/HPKST Single TWTA System Cable Harness (CA/5124)......................... 3–22

Figure 3-5. HPC-1110 Outline Drawing................................................................................................................ 3–24

Figure 3-6. Cabinet Slide Assemblies.................................................................................................................... 3–26

Figure 3-7. HPC-1110 rear Panel........................................................................................................................... 3–27

Figure 3-8. Prime Power Connector....................................................................................................................... 3–28

Figure 3-9. Waveguide Switch Connector Pinouts................................................................................................. 3–29

Figure 3-10. EIA-422, -485 Pinouts, COM2 Only................................................................................................. 3–31

Figure 3-11. EIA-232-C Pinouts............................................................................................................................ 3–32

Figure 3-12. Auxiliary interface Connector Pinouts............................................................................................... 3–33

Figure 3-13. “X” Insert Configuration ................................................................................................................... 3–34

Figure 3-14. Configuration 1, “X” Insert Panel...................................................................................................... 3–34

Figure 5-1. HPC-1200.............................................................................................................................................. 5–1

Figure 5-2. Typical Configuration............................................................................................................................ 5–2

Figure 5-3. Monitor Points and Lamp Test.............................................................................................................. 5–4

Figure 5-4. Fault Indicators...................................................................................................................................... 5–5

Figure 5-5. Status Indicators.................................................................................................................................... 5–6

Figure 5-6. HPC-1200 Local Controls..................................................................................................................... 5–7

Figure 5-7. TEMP ANALOG Output Calibration.................................................................................................... 5–8

Figure 6-1. HPC-1110.............................................................................................................................................. 6–1

Figure 6-2. Basic HPC-1110 Rear Panel.................................................................................................................. 6–2

x Rev. 1

Page 15

High-Power TWTA Satellite Terminals Table of Contents

Tables

Table 1-1. Major Assemblies of the HPCST-5000/-7000........................................................................................ 1–2

Table 1-2. Major Assemblies of the HPKST-12000................................................................................................ 1–3

Table 1-3. TWTA Models........................................................................................................................................ 1–8

Table 1-4. Description of the HPC-1200............................................................................................................... 1–10

Table 1-5. Description of the HPC-1110............................................................................................................... 1–11

Table 1-6. HPCST-5000/–7000 Single Thread Systems Equipment List (Typical)............................................... 1–13

Table 1-7. HPKST-12000 Single Thread System Equipment List (Typical)......................................................... 1–15

Table 1-8. HPKST-12000 Redundant System Equipment List (Typical) .............................................................. 1–16

Table 1-9. System Interfaces for System Components........................................................................................... 1–17

Table 1-10. Prime Power ....................................................................................................................................... 1–18

Table 1-11. HPCST-5000/–7000 Receive Characteristics..................................................................................... 1–19

Table 1-12. HPKST-12000 Receive Characteristics............................................................................................. 1–20

Table 1-13. HPCST-5000 and -7000 Transmit Characteristics.............................................................................. 1–21

Table 1-14. HPA-500, -700 Transmit Characteristics............................................................................................ 1–22

Table 1-15. HPKST-12000 Transmit Characteristics ............................................................................................ 1–23

Table 1-16. HPA-1200 Transmit Characteristics................................................................................................... 1–24

Table 1-17. ODU Environmental Specifications.................................................................................................... 1–25

Table 1-18. IDU Environmental Specifications..................................................................................................... 1–25

Table 1-19. Monitor and Control........................................................................................................................... 1–26

Table 1-20. Physical Size and Weight Characteristics........................................................................................... 1–27

Table 2-1. External Connections............................................................................................................................ 2–16

Table 2-2. TWTA Monitor & Control Pinouts ...................................................................................................... 2–18

Table 2-3. Prime Power ......................................................................................................................................... 2–25

Table 2-4. Mating Connector for AC Unit............................................................................................................. 2–26

Table 2-5. Rear Panel Connectors.......................................................................................................................... 2–31

Table 2-6. Remote Control Interface Connector Pinouts....................................................................................... 2–32

Table 2-7. M&C Connector Pinouts...................................................................................................................... 2–36

Table 5-1. Monitor Point and Lamp Test Descriptions............................................................................................ 5–3

Table 5-2. Fault Indicator Descriptions.................................................................................................................... 5–5

Table 5-3. Status Indicator Desvcriptions................................................................................................................ 5–6

Table 5-4. HPC-1200 Local Control Descriptions................................................................................................... 5–7

Table 6-1. HPC-1110 Local Functions..................................................................................................................... 6–4

Table 6-2. Local/Remote Modes.............................................................................................................................. 6–5

Table 6-3. Manual/Automatic Mode........................................................................................................................ 6–6

Table 6-4. HV ON Push Button Switch................................................................................................................... 6–7

Table A-1. Header Byte Codes................................................................................................................................A–1

Table A-2. Command Not Executed Codes............................................................................................................. A-7

Table A-3. ASCII Cross Reference..........................................................................................................................A–8

Table A-4. Meaning of Multi-Character ASCII Codes............................................................................................A–9

Table A-5. Redundant System Controller Query Commands.................................................................................A–11

Table A-6. Redundant Sytem Controller Control Commands................................................................................A–13

Table A-7. TWTA Query Commands....................................................................................................................A–15

Table A-8. TWTA Control Commands..................................................................................................................A–17

Rev. 1 xi

Page 16

Table of Contents High-Power TWTA Satellite Terminals

This page is intentionally left blank.

xii Rev. 1

Page 17

Chapter 1.

INTRODUCTION

1

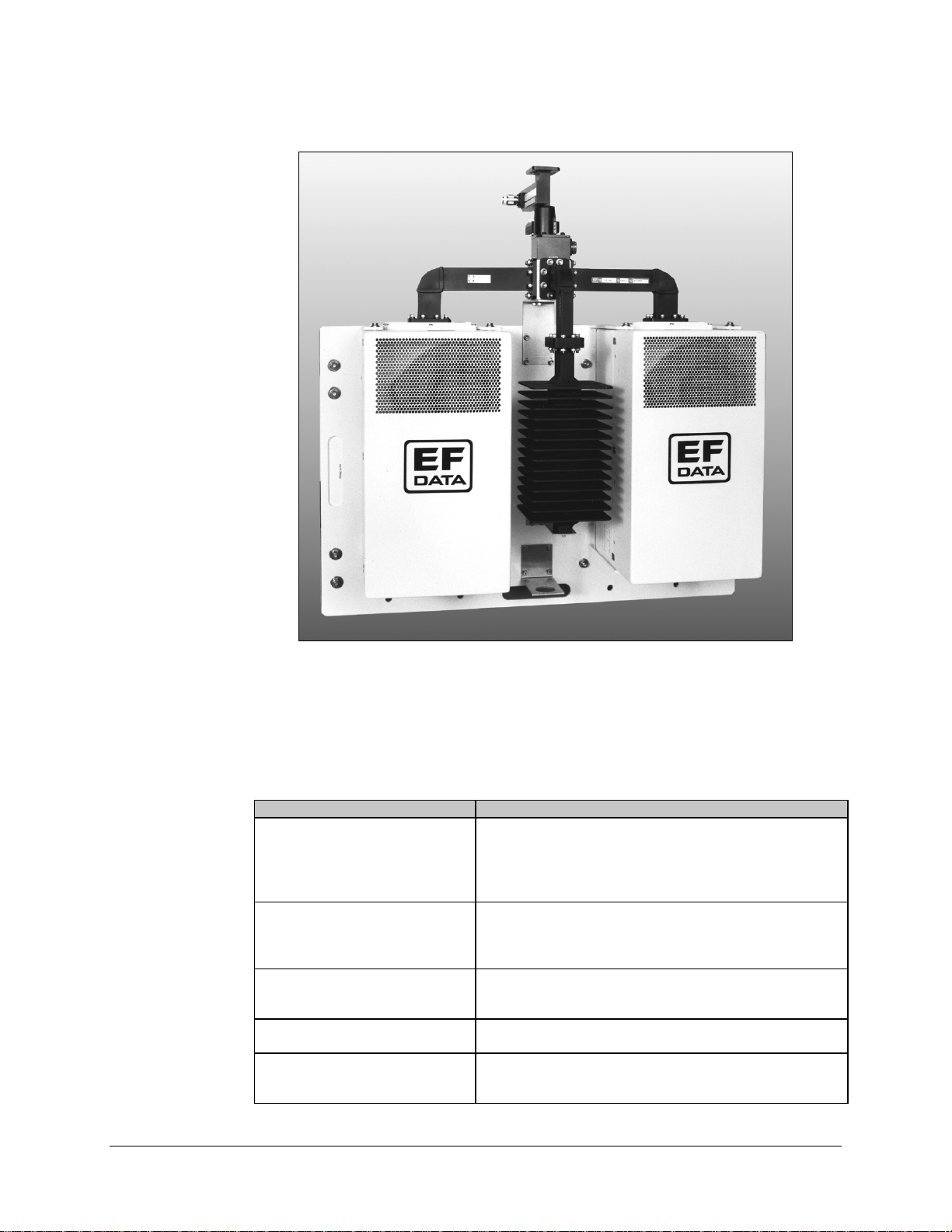

This chapter provides an overview of the Traveling Wave Tube Amplifier (TWTA)

coupled with various components:

• HPCST-5000 high-power C-band satellite terminal (Figure 1-1)

• HPCST-7000 high-power extended C-band satellite terminal (Figure 1-1)

• HPKST-12000 high-power Ku-band satellite terminal (Figure 1-1)

Figure Chapter 1-1. HPCST-5000/-7000, and HPKST-12000

Rev. 1 1–1

Page 18

Introduction High-Power TWTA Satellite Terminals

1.1 Introduction

The key component of these high-power systems is the external high-power TWTA.

When the TWTA is coupled with the CST-5000/-7000, and KST-12000 satellite terminal

systems, these components form an integrated high-power transceiver system. These

all-weatherized units are designed for the harsh, uncontrolled, outdoor environment

typical of antenna mounting. These completely integrated systems meet the requirements

for private, regional domestic, and international C-band or Ku-band satellite networks.

All three products may be configured for single thread or 1:1 redundant systems.

Refer to Table Chapter 1-1 for a typical HPCST-5000 and -7000 redundant system.

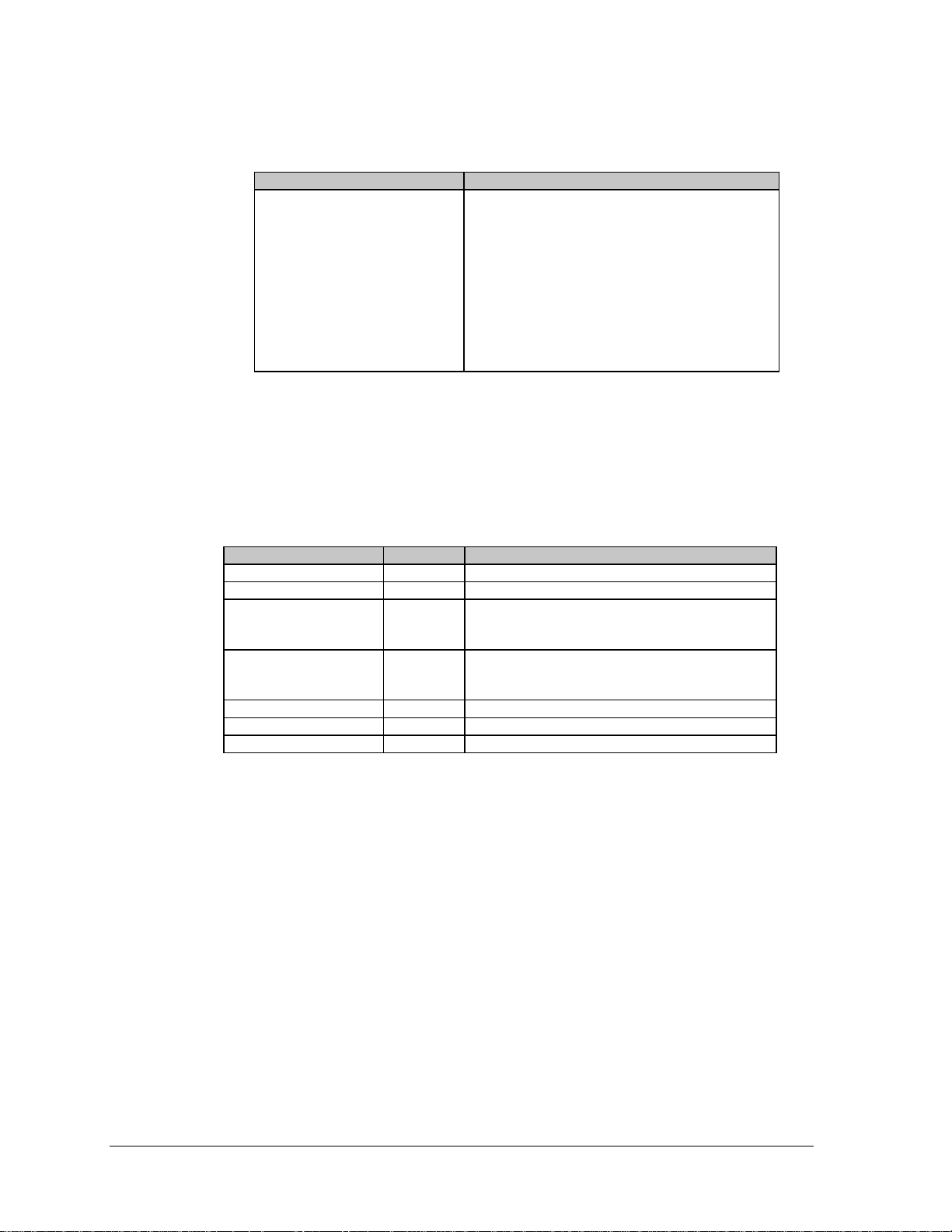

Table Chapter 1-1. Major Assemblies of the HPCST-5000/-7000

Nomenclature Description

Outdoor Low-Noise Amplifier (LNA) Ass y Consists of a transit reject filter, redundant LNAs

(65°K; 40°K Optional) and a C-Band waveguide

switch.

Outdoor HPCST-5000/HPCST-7000 R e dunda nt

Assy

Outdoor high-power T W TA Redundant Ass y

(Figure Chapter

HPS-1110 An optional indoor, rack- mounted, redundant

Redundancy Sw itch U nit (R SU ) Along with a redunda nc y cable/hardware k it,

1-2

)

Consists of two ra dio frequency term ina ls (R FT s )

assemblies. Each RFT includes an up converter

with a 70 MHz IF input, a dow n c onv e rte r with a

70 MHz IF output, a monitor and c ontrol (M& C )

microproces s or, a nd a power supply.

Consists of two hig h-power TWTAs , a waveguide

switch, an output coupler, and a s ystem cable

harness with a customer-interface connector for

system control.

TWTA controlle r. Allows the customer M&C of

TWTAA operations.

provides the system with a single M&C interface,

redundancy switchover, and cabling.

1–2 Rev. 1

Page 19

High-Power TWTA Satellite Terminals Introduction

Figure Chapter 1-2. TWTA Redundant Assembly (Typical)

Refer to Table Chapter 1-2 for a typical HPKST-12000 redundant system.

Table Chapter 1-2. Major Assemblies of the HPKST-12000

Nomenclature Description

Outdoor LNA A ss y

Outdoor KST-12000 Redunda nt

Assy

Outdoor TWTA R e dunda nt Assy

(Figure 1-2)

HPS-1110 An optional indoor, rack-mounted, redundant TWTA controller.

Redundancy Sw itc h Unit (R SU ) Along with a redunda nc y cable/hardware k it, provides the system

Consists of a transit reject f ilte r, re dundant LNAs (120°K; 90°K

Optional) and a

Ku-Band waveguide sw itc h. Optiona lly, a Ku-Band coaxial

switch, 1:4 power splitter, and frequency (block) conv e rte r a re

available.

Consists of two RFT-12000 redundant assemblie s. Eac h R FT

includes an up converte r with a 70 MHz IF input, a down

converter with a 70 MHz I F output, a n M&C microprocessor,

and a power supply.

Consists of two high- power TWTAs, a waveguide switch, a n

output coupler, and a sys te m cable harness with a c us tomerinterface connector for sys te m control.

Allows the cust omer M&C of TWTAA operations.

with a single M&C interface, redundancy switchove r , a nd

cabling.

Rev. 1 1–3

Page 20

Introduction High-Power TWTA Satellite Terminals

The system outdoor terminal components are weatherproof units for the uplink and

downlink requirements. The redundant assemblies have been designed for antenna or

pole mounting. The system has a single customer interface connector for remote monitor

and control.

The onboard microcomputer monitors and controls the operational parameters. This

M&C system enables the user to locally or remotely control functions such as:

• Output power level

• Output On/Off

• Transmit/Receive channel frequency

The system also reports terminal configuration status, as well as fault status of all

components. The RFT can be initially configured by a keyboard/LCD controller within

the enclosure, or by connection of a common ASCII/EIA-232 terminal connected to the

serial port at the system interface connector (P1). A simple command set allows

configuration control and retrieval of status information.

If the customer M&C control unit is a more sophisticated monitor and control station

computer, the serial port can be set to EIA-485 for bus operation. A separate,

rack-mounted, redundant controller for the TWTAs provides the user with control and

status of the TWTA operation, as well as an automatic high voltage enable for

switchover.

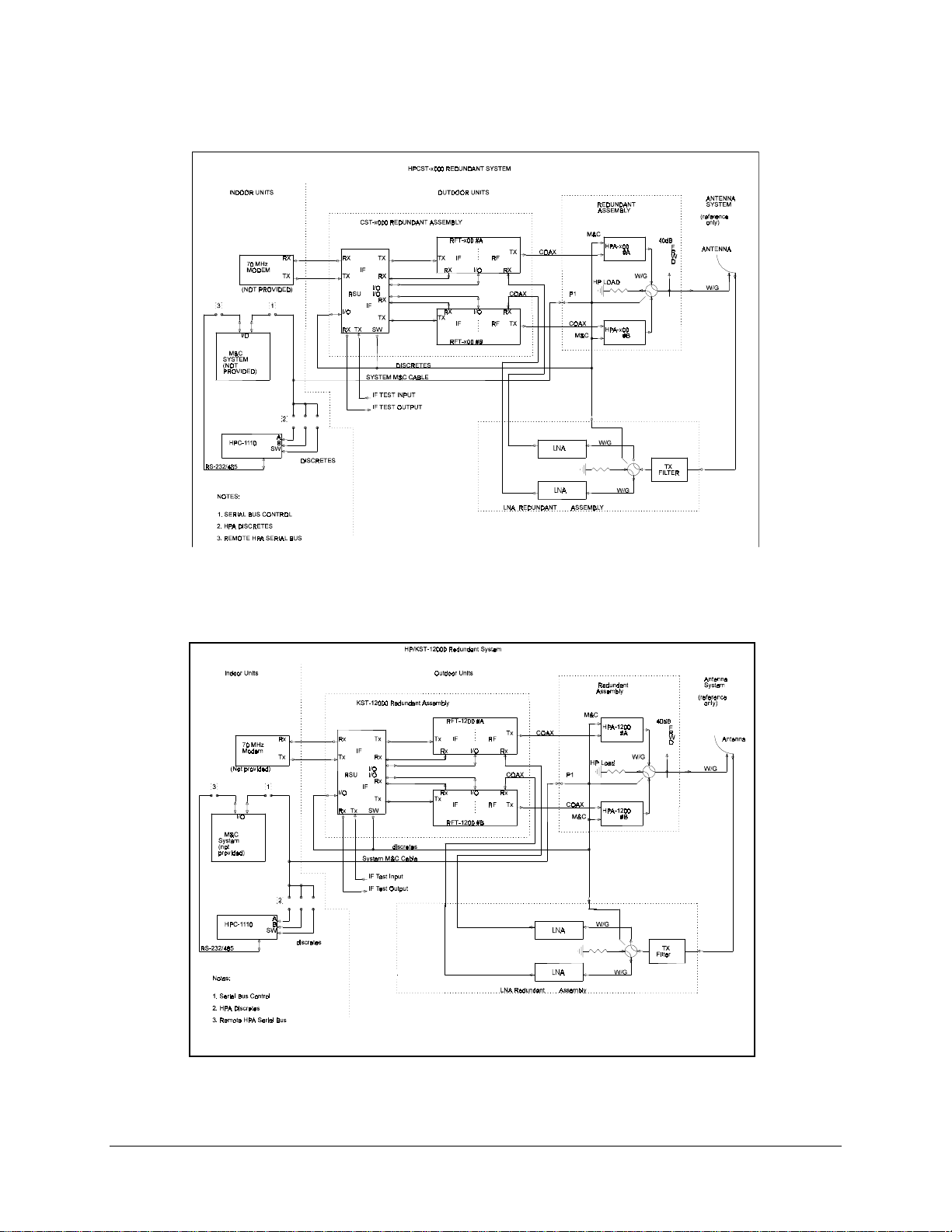

Refer to Figure Chapter 1-3 for a system block diagram of the HPCST-5000/-7000

redundant systems.

Refer to Figure 1-4 for a system block diagram of the HPKST-12000 redundant systems.

1–4 Rev. 1

Page 21

High-Power TWTA Satellite Terminals Introduction

Figure Chapter 1-3. HPCST-5000/7000 Redundant Terminal Systems Block

Diagram (Typical)

Figure Chapter 1-4. KST-12000 Redundant Terminal System Block Diagram (Typical)

Rev. 1 1–5

Page 22

Introduction High-Power TWTA Satellite Terminals

1.2 Component Descriptions

1.2.1 Low-Noise Amplifier (LNA) Assembly

A typical redundant LNA assembly consists of a transmit reject filter, waveguide switch,

and two LNAs. Optionally, a coaxial switch, 1:4 power splitter, and a block converter are

available.

For more information on the LNA assemblies, refer to the following manuals:

• CST-5000 C-Band Satellite Terminal Installation and Operation Manual

• CST-7000 C-Band Satellite Terminal (Insat) Installation and Operation Manual

• KST-12000 Ku-Band Satellite Terminal Installation and Operation Manual

1.2.2 Radio Frequency Terminal (RFT)

The RFT is a weatherproof enclosure which houses:

• Up and down converters

• Frequency synthesizer

• IF and RF interface

• M&C system

• Power supply

• Cables

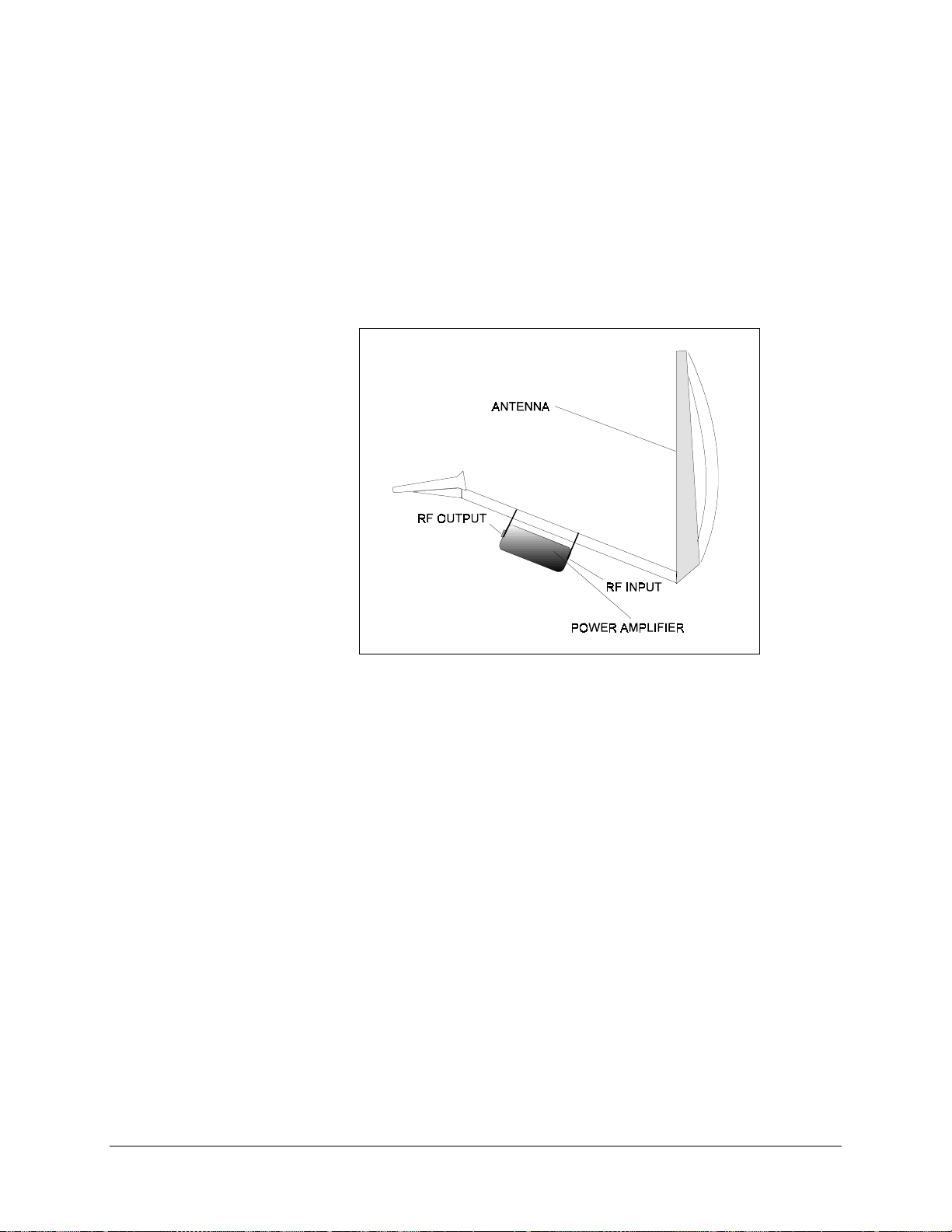

In the transmit (uplink) direction, the terminal accepts a 70 MHz IF signal and transmits

it in the uplink transmit frequency band. This output is coupled through a type N

connector to the external TWTA assembly. This system provides the high-power output

to the antenna through a waveguide switch. A 40 dB coupler is included at the output of

the waveguide switch to meet INTELSAT specifications.

A high-power termination is included on the offline channel port of the waveguide

switch for testing. Each redundant thread has been factory-compensated for TX gain

stability over temperature. EFData recommends that when replacing a faulted unit, the

RFT, TWTA, and associated coax link must be replaced as a set. Otherwise, gain

stability can not be guaranteed.

In the receive (downlink) direction, the terminal accepts an RF signal in the downlink

frequency band, and down-converts it to a 70 MHz IF output. The LNA assembly has an

RF RX type N coax output to each RFT receive input.

1–6 Rev. 1

Page 23

High-Power TWTA Satellite Terminals Introduction

The RFT power level at 1 dB compression to drive the external TWTA is +8 dBm. The

up and down converters are dual conversion, and are configured with individual

synthesizers for independent transmit and receive transponder selection.

For more information on RFTs, refer to the following manuals:

• CST-5000 C-Band Satellite Terminal Installation and Operation Manual

• CST-7000 C-Band Satellite Terminal (INSAT) Installation and Operation

Manual

• KST-12000 Ku-Band Satellite Terminal Installation and Operation Manual

1.2.3 TWTA Models

The TWTA is an all-weather, high-power system specifically designed for compact

outdoor installation for earth station satellite communication. Because of the

compactness, the unit can be mounted on the antenna, thus reducing transmission losses

to the antenna feed. This outdoor unit contains:

• RF filters

• Self-contained forced air cooling system

• Control inputs

• Monitor output signals

EFData offers six TWTA models that operate in the satellite earth station uplink bands.

Specific models and options are identified by the EFData part number in Table 1-3.

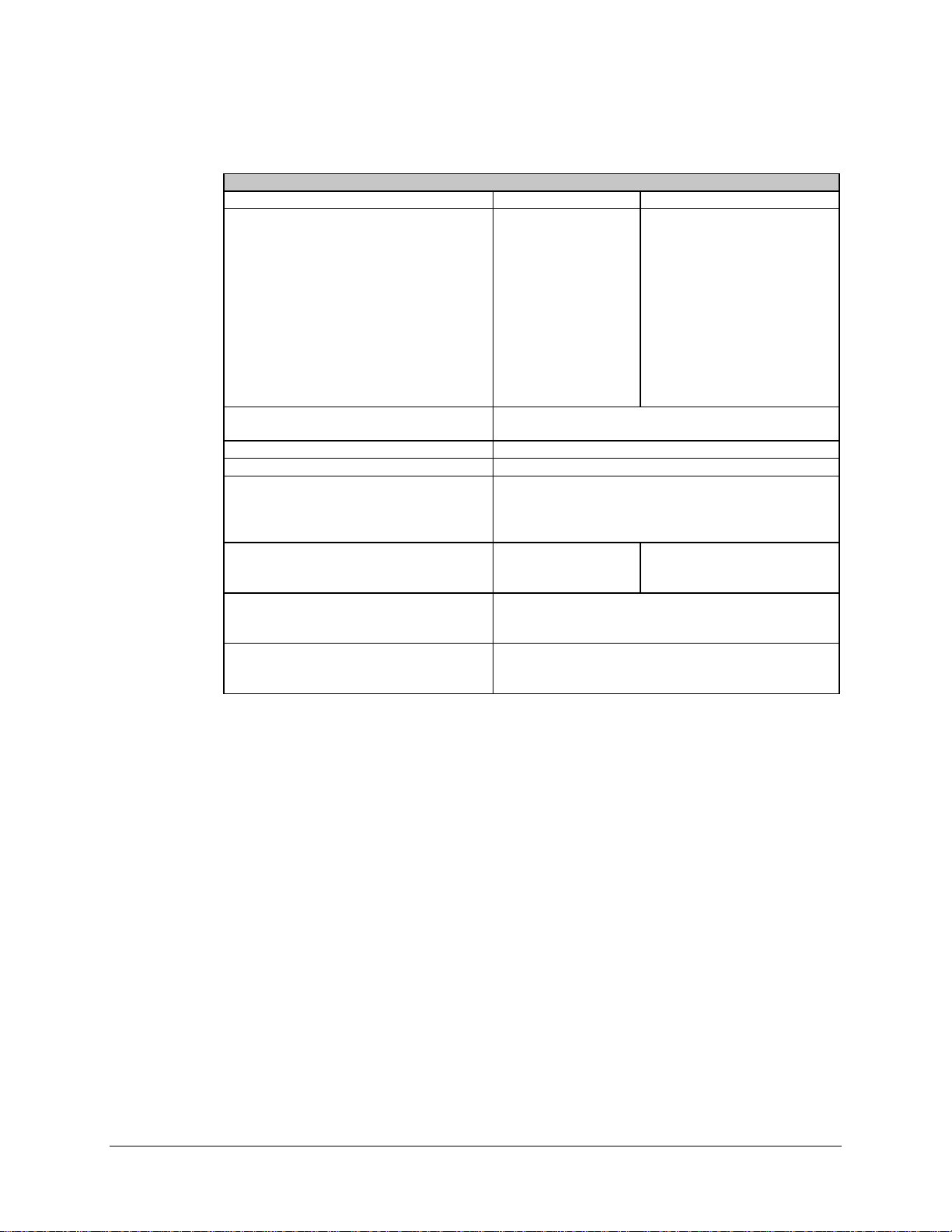

Table Chapter 1-3. TWTA Models

Band Model # EFData

Part #

C-Band HPA-500

HPA-500

HPA-700

HPA-700

Ku-Band HPA-1200

HPA-1200

Note:

Manufacturing changes which do not impact component interchangability are

RF/XT-100C

RF/XT-400C

RF/XT-100CI

RF/XT-400CI

RF/XT-100K

RF/XT-400K

Frequency Rated RF

5.845 to 6.425 GHz

5.845 to 6.425 GHz

7.9 to 8.4 GHz

7.9 to 8.4 GHz

14.0 to 14.5 GHz

14.0 to 14.5 GHz

Power (Min.)

140W

350W

140W

350W

100W

300W

reflected in the revision level of the power amplifier part number. EFData maintains a

configuration log by serial number to track the applicable revision level for each power

amplifier. Please include the amplifier serial number when ordering parts or discussing

the amplifier with EFData representatives.

Prime input power to the unit is AC, as follows:

• 115 or 230VAC for the 100W unit

Rev. 1 1–7

Page 24

Introduction High-Power TWTA Satellite Terminals

• 100 to 260VAC for the 350W unit.

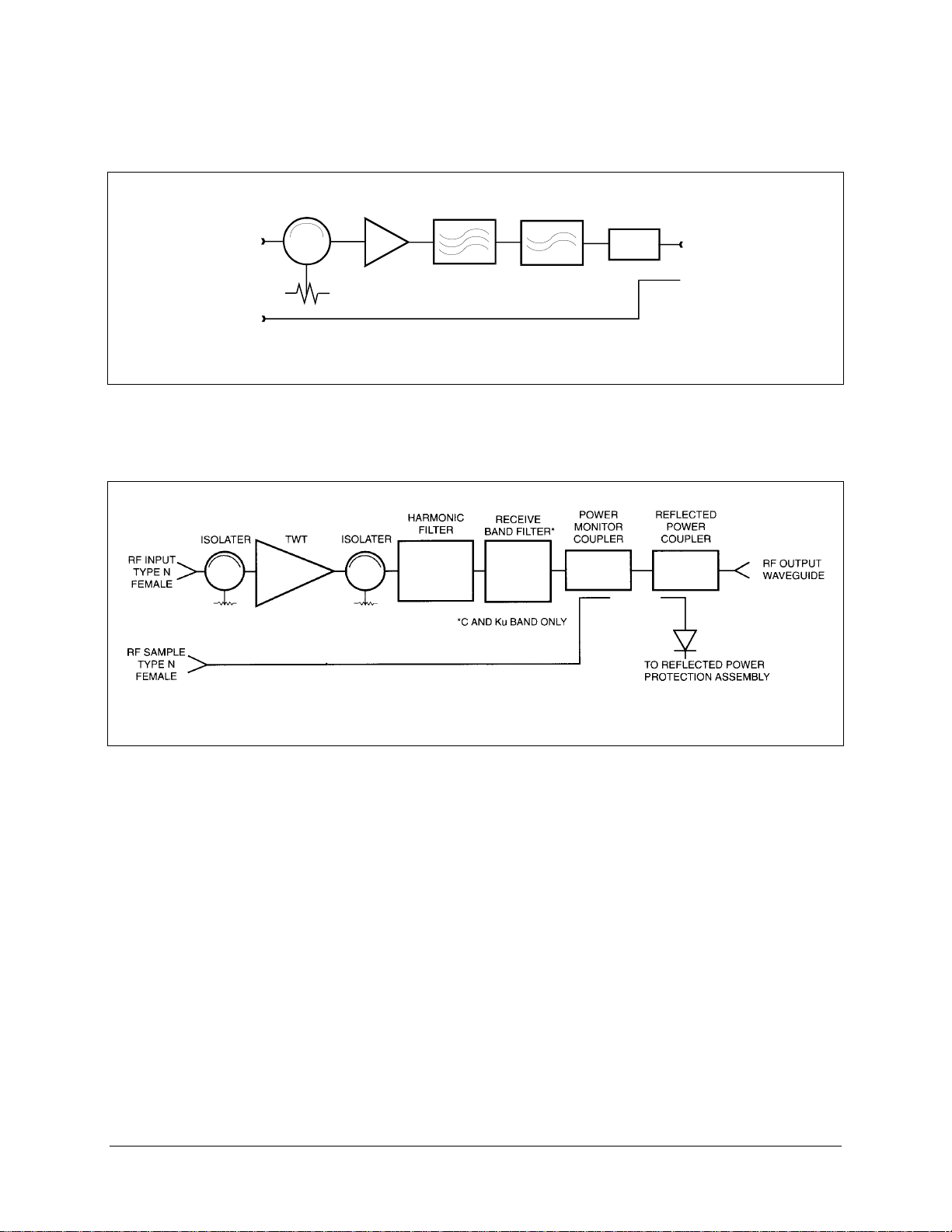

• Refer to Figures 1-5 and 1-6 for block diagrams.

1–8 Rev. 1

Page 25

High-Power TWTA Satellite Terminals Introduction

RECEIVE

POWER

RF INPUT

TYPE N

FEMA LE

RF SAMPLE

TYPE N

FEMALE

ISOLAT E R

TW T

HARMONIC

FILTER

BAND

FILTER*

MONITOR

COUPLER

*C AND Ku BAND O NLY

Figure Chapter 1-5. 100W and 140W Unit Block Diagram

RF OUTPUT

WAVEGUIDE

Figure Chapter 1-6. 300W and 350W Unit Block Diagram

Rev. 1 1–9

Page 26

Introduction High-Power TWTA Satellite Terminals

1.2.4 High-Power Controller (HPC)

The optional HPCs are indoor rack-mounted units used to monitor and control the status

of the TWTA units in the HPCST–5000/–7000, and HPKST–12000 high-power satellite

terminal systems.

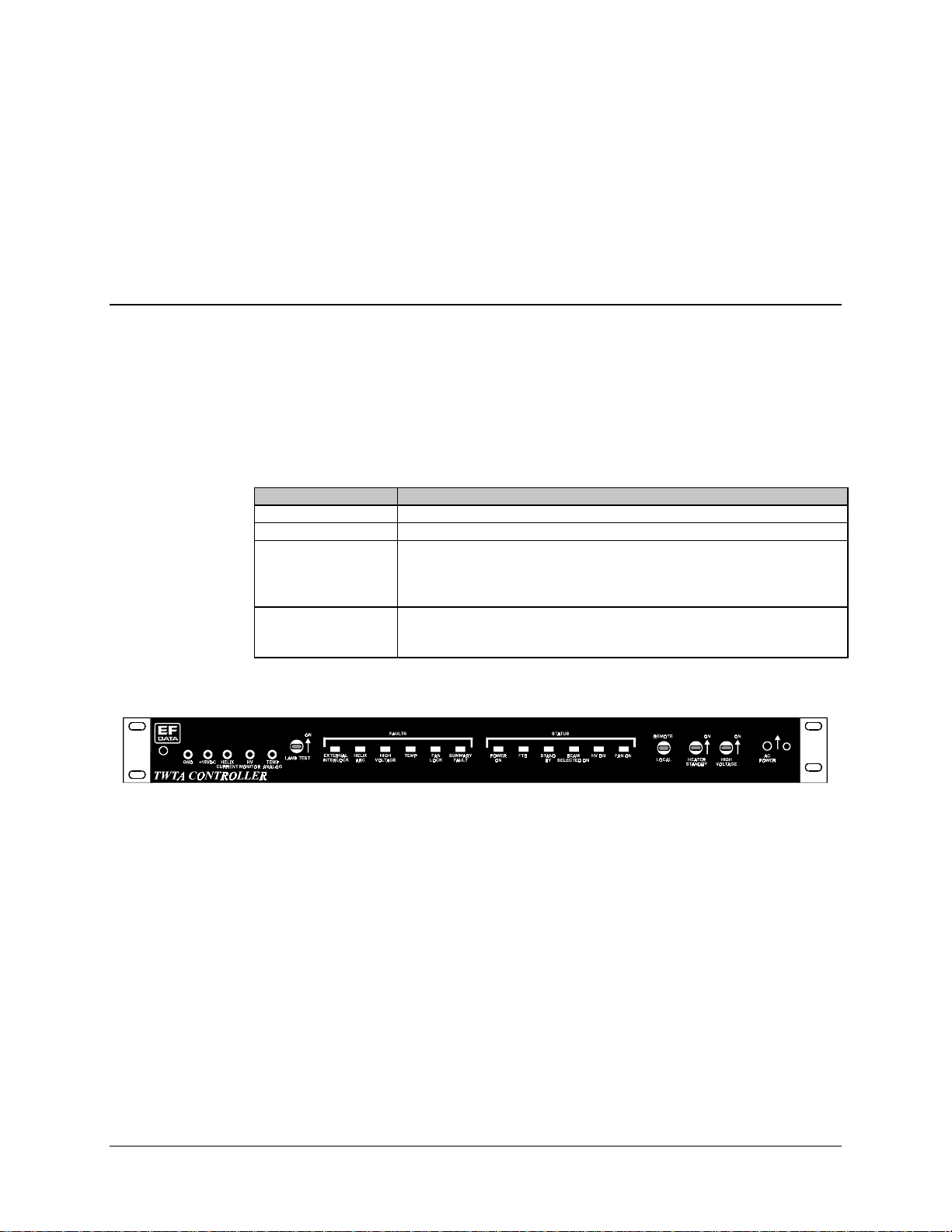

1.2.4.1 HPC-1200

The HPC-1200 (Figure 1-7) is specifically designed to monitor and control a TWTA in a

single thread configuration. Refer to Figure Chapter 1-4 for a description of the HPC-

1200.

Table Chapter 1-4. Description of the HPC-1200

Component Description

EFData Part No. RF/XCT-100

Connector 25-Pin D output connector for integ ra tion with other M&C eleme nts.

Local Control Can provide local control at the HPC site, or control f rom a remote site through

a remote interface to the HPC.

This is a manual selection at the HPC site.

Front Panel The front panel prov ide s c ontrol s witches and indicators, a r ea r pa ne l of

discrete interface connections for the TWTA, and a remote interface control

connector.

Figure Chapter 1-7. HPC-1200 Single Thread Controller

1–10 Rev. 1

Page 27

High-Power TWTA Satellite Terminals Introduction

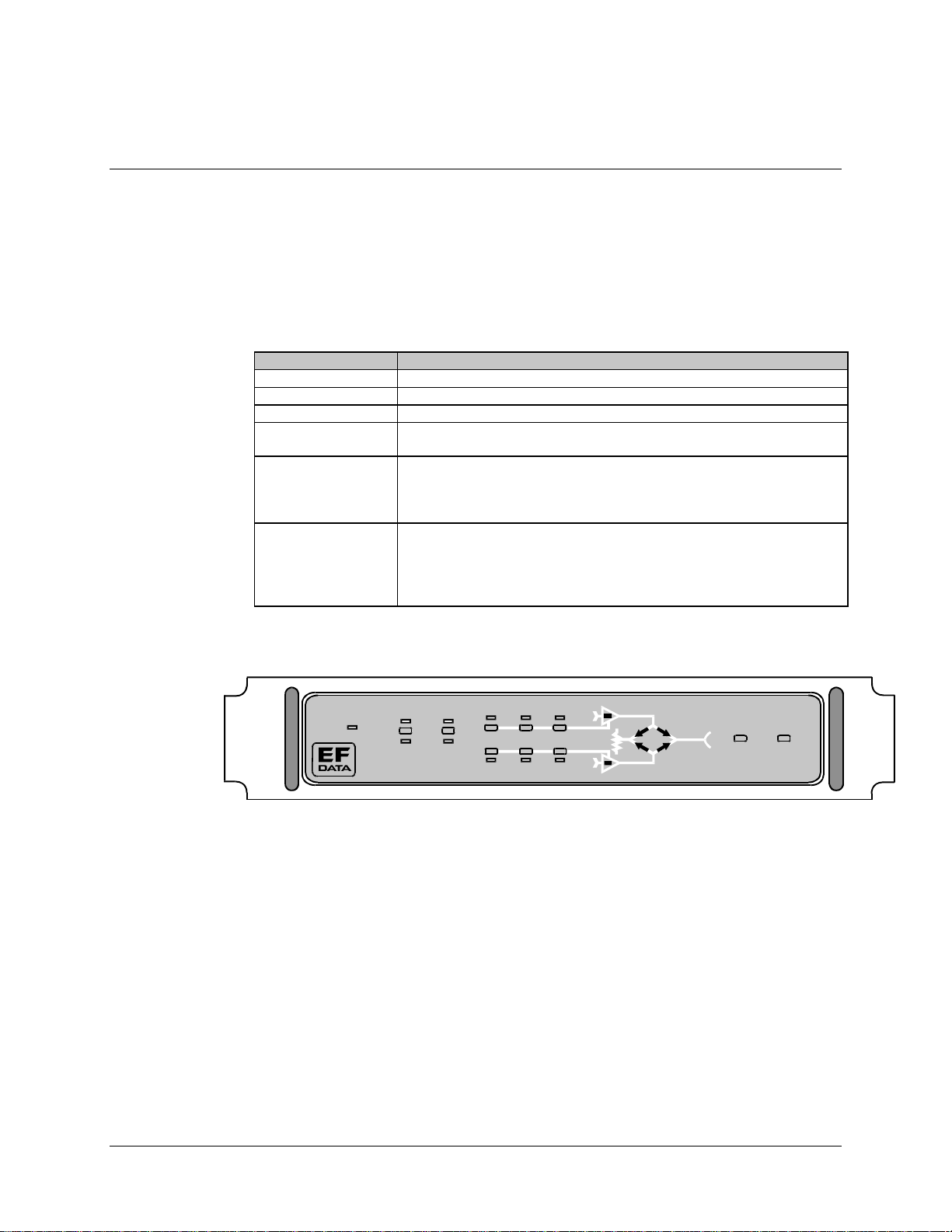

1.2.4.2 HPC-1110

The HPC-1110 (Figure 1-8) is specifically designed to monitor and control a TWTA

in a 1:1 redundant configuration. Refer to Table 1-5 for a description of the

HPC-1110. Refer to Appendix A for programming guidelines.

Table Chapter 1-5. Description of the HPC-1110

Feature Description

EFData Part No. RF/XTC-111D

Auto Mode For automatic operation when switched from offline to online system.

Power Supply TWTA is power from an A C input.

Control Interface The control interface from the TWTA to the HPC is parallel (discrete) signal

lines.

Local Control Provides local control at the H PC site , or c ontrol from a remote site throug h a

remote control interface.

This is a manual selection at the HPC site.

Panels The front panel prov ide s c ontrol s witches and indicators. A re a r pa ne l of

discrete interface connections for the TWT A, an interlock connector input, a nd

a remote interface control connector. Also, an input is provided for the

waveguide switch position indicators. A f a ult indica tor a nd f a ult r es e t is

provided for each channel.

Remote

Power

1:1 CO NTROLLER

Auto matic

Local Manual

TWTA

Power

Heater

Standby

HV O N

A

Fault R eset Lamp Test

B

Figure Chapter 1-8. HPC-1110 1:1 Redundant Controller

Rev. 1 1–11

Page 28

Introduction High-Power TWTA Satellite Terminals

1.2.5 Redundant Switch Unit (RSU)

The RSU-503L (Figure 1-9) is an all-weather unit that provides for primary and backup

operation as a communications terminal.

The RSU is designed for mounting on either the antenna or support pole.

The RSU controls the switching from primary to backup service in a 1:1 redundant

configuration.

For information on the RSU-503L, refer to the RSU-503 Redundancy Switch Unit

Installation and Operation Manual.

Figure 1-9. RSU-503L

1–12 Rev. 1

Page 29

High-Power TWTA Satellite Terminals Introduction

1.3 Equipment List

Refer to Table 1-6 through Table 1-10 for an equipment list for single thread and

redundant systems.

Notes:

1. These lists are subject to change without notice.

2. Indented part numbers are subsets of higher level part numbers, and are shown

for reference only.

Table 1-6. HPCST-5000/-7000 Single Thread Systems Equipment List (Typical)

Description EFData Part Number Notes

Single CST-5000 System:

RFT-500 (No TWTA)

RFT-700 (No TWTA)

Std Cable, AC

Std Cable, DC

Univ Mounting Kit

Single C-band LNA System

LNA Assy, EFD Std CST

Single HPCST-5000/7000 System

Single HPCST-5000 System

Single System Cable Harn ess

Waveguide ABS 1:2 Ku-b and

HPA-500/700 TWT Amplifier

C-Band HPA TWTA 140W

C-Band HPA TWTA 350W

Mounting Kit, HPA (C/KST)

.CST500....../.CST700.......

.RFT500/.......

.RFT700/.......

KT/3272-1

KT/3272-2

KT/3576

.CA.......

.HPCST500..../.HPCST700.....

PL/5129

CA/5124

KT/5115

.HPA500..../.HPA700.....

RF/XT-100C

RF/XT-400C

KT/5032

option

option

option

option

option

option

HPC-1200

RF/XTC-100

option

Rev. 1 1-13

Page 30

Introduction High-Power TWTA Satellite Terminals

Table 1-7. HPCST-5000 and -7000 Redundant Systems Equipment List (Typical)

Description EFData Part Number Notes

1:1 CST-5000/7000 System:

RFT-500 (No TWTA)

RFT-700 (No TWTA)

Univ Mounting Kit

RSU-503L

.REDCST500...../.REDCST700.........

.RFT500/A 00 1 2D 0

.RFT700/A 00 1 1A 0

KT/3577

.RSU503L (AS/3000-1)

option

option

1:1 LNA System:

Plate Assy, RCST LNA

LNA Assy

1:1 HPCST-5000/7000 Cable/Hardware Kit:

CBL/Hdw, R_CST, AC, 9m Ant

CBL/Hdw, R_CST, AC, Uplk, 4.6m Ant

1:1 HPCST-5000/7000:

1:1 High Power CSAT

Waveguide Assembly

Waveguide ABS 1:2 C-band

Mounting, 1:1 HPWR C/KSAT

HPA-500/700 TWT Amplifier

C-band HPA-500/140W

xtd_C-band HPA-700/140W

C-band HPA-500/350W

xtd_C-band HPA-700/350W

CBL/Hdw, RHPA, 115V, Uplink Only

Cable Harness, Uplnk, 4.6 Ant

Pwr Cable, 115 VAC

CBL/Hdw, RHPA, 230V

1:1 Cable Harness, 9m Ant

Pwr Cable, 230 VAC

CBL/Hdw, RHPA, 230V

1:1 Cable Harness, Sys

Pwr Cable, 230 VAC

.CSRED..........

AS/3220

.CA......

(no dot code)

KT/3107-7

KT/tbd

.HPCST5000RED......./.HPCST7000RED......

AS/5127

PL/5089

KT/5115

KT/5125

.HPA500..../HPA700......

RF/XT-100C

RF/XT-100CI

RF/XT-400C

RF/XT-400CI

KT/5249 -1

CA/5248

PL/5240-1

KT/5249 -2

CA/5122

PL/5240

KT/5249 -3

CA/5122-1

PL/5240

option

option

option

option

option

option

option

option

option

option

option

CBL/Hdw, RHPA, 230V, Uplnk Only

1:1 Cable Harness, 4.6m Ant

Pwr Cable, 230 VAC

HPC-1110 RF/XTC-111D option

KT/5249-4

CA/5248

PL/5240

option

1-14

Rev. 1

Page 31

High-Power TWTA Satellite Terminals Introduction

Table 1-8. HPKST-12000 Single Thread System Equipment List (Typical)

Description EFData Part Number Notes

Single Thread KST-12000 System:

RFT-1200 (No TWTA)

Std Cable/Hdw Ki t, AC

Std Cable/Hdw Kit, DC

Univ Mounting Kit

LNA System

LNA Assy, EFD Std KST

Single HPKST-12000 System

HPWR KST Assembly

Waveguide ABS 1:2 Ku-b and

Mounting Kit, TWTA (C/KST)

HPA-1200 TWT Amplifier

Ku-band HPA-1200/125W

Ku-band HPA-1200/300W

.KST12000.......

.RFT1200.......

KT/3954-1

KT/3954-2

KT/3576

.KA............

.HPKST1200....

PL/5130

KT/2820

KT/5032

.HPA1200......

RF/XT-100K

RF/XT-400K

option

option

option

option

option

option

CBL/Hdw, Single HPKST

Cable Harness, System

Pwr Cable, 115 VAC

CBL/Hdw, Single HPKST

Cable Harness, ? Ant

Pwr Cable, 230V

HPC-1200

KT/_ _ _ _ - tbd

CA/5124 - tbd

PL//5240-1

KT/_ _ _ _ - tbd

CA/5124 -tbd

PL//5240

RF/XTC-100

option

option

option

Rev. 1 1-15

Page 32

Introduction High-Power TWTA Satellite Terminals

Table 1-9. HPKST-12000 Redundant System Equipment List (Typical)

Description EFData Part Number Notes

1:1 KST-12000 System: .REDKST12000.......

RFT-1200 (No TWTA) RFT1200/A 00 1 2D 1 option

Univ Mounting Kit KT/3577

RSU-503L .RSU503L (PL/3000-1)

1:1 LNA System: .K1RED..........

Plate Assy, Std. LNA AS/4386 option

LNA Assy. KA....

Plate Assy, C03 LNA AS/3957 option

LNA Assy KA....

Plate Assy, C11 LNA AS/5223 option

LNA Assy. KA....

1:1 HPKST-12000 Cable/Hardware Kits (no dot code)

CBL/Hdw, R_C/KST, AC, 9mAnt KT/3950-5 option

CBL/Hdw, R_C/KST, AC, Uplk, 4.6m Ant KT/3950-6 option

CBL/Hdw, R_C/KST, AC, Uplk, 4.6m Ant KT/3950-8 option

1:1 High Power (HPKST-12000 System): .HPKST12000RED....

1:1 High Power KST PL/5033

Waveguide Assembly PL/5088

Waveguide ABS 1:2 Ku-band KT/2820

Mounting, 1:1 HPWR C/KSAT KT/5125

HPA-1200 TWT Amplifier .HPA1200.......

Ku-band HPA-1200/125W RF/XT-100K option

Ku-band HPA-1200/300W RF/XT-400K option

CBL/Hdw, RHPA, 115V, Uplink Only KT/5249 -1 option

1:1 Cbl Harness, Uplnk, 4.6 Ant CA/5248

Pwr Cable, 115 VAC PL/5240-1

CBL/Hdw, RHPA, 230V KT/5249 -2 option

1:1 Cable Harness, 9m Ant CA/5122

Pwr Cable, 230 VAC PL/5240-1

CBL/Hdw, RHPA, 230V KT/5249 -3 option

1:1 Cable Harness, Sys CA/5122-1

Pwr Cable, 230 VAC PL/5240

CBL/Hdw, RHPA, 230V, Uplnk Only KT/5249-4 option

1:1 Cable Harness, 4.6m Ant CA/5248

Pwr Cable, 230 VAC PL/5240

HPC-1110 RF/XTC-111D option

1-16

Rev. 1

Page 33

High-Power TWTA Satellite Terminals Introduction

1.4 Specifications

1.4.1 System Interface

Table 1-10 lists the types of interface required for each system component.

Table 1-10. System Interfaces for System Components

Description Type

RFT-500, -700:

TX IF Input (J1)

RX IF Output (J3)

RX RF Input (J4, C-band)

TX RF Output (J2, C-band)

M&C Control (J6)

RFT-1200:

TX IF Input (J1)

RX IF Output (J3)

RX RF Input (J4, Ku-band)

TX RF Output (J2, Ku-band)

M&C Control (J6)

HPA-500, -700:

RF TX Output (W/G Port)

RF RX Input (J3, C-band)

RF TX Sample (J4, C-ba nd)

M&C Control (J2)

HPA-1200:

RF TX Output (W/G Port)

RF RX Input (J3, Ku band)

RF TX Sample (J4, Ku-band)

M&C Control (J2)

Redundant TWTA Assembly

Customer Interface (P1) Circular type, PTO6E-20-41S

LNA Assy.:

RF RX Input (W/G)

RF RX Output (2x)

Block Converter Output

1:1 Switch Control

HPC-1110:

ODU #1 M&C (J1)

ODU #2 M&C (J2)

Remote M&C (J3)

W/G Switch #1

External Interlock

1:1 TWTA W / G Switch Control Circular, MS3116E-14-12P

TNC female , 50Ω, VSWR 1.25:1 max.

TNC female , 50Ω, VSWR 1.25:1 max.

N, female , VSW R 1.25:1 max.

N, female , VSW R 1.25:1 max.

Circular, PT06E-16-26S

TNC female, 50Ω, VSWR 1.25:1 max

TNC female, 50Ω, VSWR 1.25:1 max

N, female , VSW R 1.25:1 max

N, female , VSW R 1.25:1 max

Circular type, PT06E- 16-26S

CPR-137G, VSWR:

2.2:1 max. (for 140W ) , or 1.3:1 (for 350W)

N, female, VSWR: 1.3:1

N, female, VSWR: 1.3:1; typical 42 dB coupler

Circular, PT06E-18-32S

WR-75 G, VSWR:

2.2:1 max. (for 100W ) or 1.3:1 ( for 300W)

N, female, VSWR: 1.3:1

N, female, VSWR: 1.3:1; typical 42 dB coupler

Circular type, PT06E- 18-32S

CPR-229G, VSWR 1.25:1 ma x. (C-band)

WR-75 G, VSWR 1.25:1 max (Ku-band)

N, VSWR 1.25:1 max., female

N, VSWR 1.3:1 max., female

Circular, PT06E-14-19P

D-type, 37 pin, female

D-type, 37 pin, female

D-type, 9 pin, female

D-type, 15 pin, male

D-type, 15 pin, male

Rev. 1 1-17

Page 34

Introduction High-Power TWTA Satellite Terminals

Table 1-10. System Interfaces for System Components (Continued)

Description Type

RSU-503L:

M&C for RFT #A (J4)

IF RX Input (J2)

IF TX Output (J1)

M&C for RFT #B (J8)

IF RX Input (J6)

IF TX Output (J5)

Remote M&C (J16)

IF RX Output (J15)

IF TX Input (J14)

Waveguide Sw itch (J10)

Circular, PT06E-16-26S

TNC, female

TNC, female

Circular, PT06E-16-26S

TNC, female

TNC, female

Circular, PT06E-16-26S

TNC, female

TNC, female

Circular, PT06E-14-19S

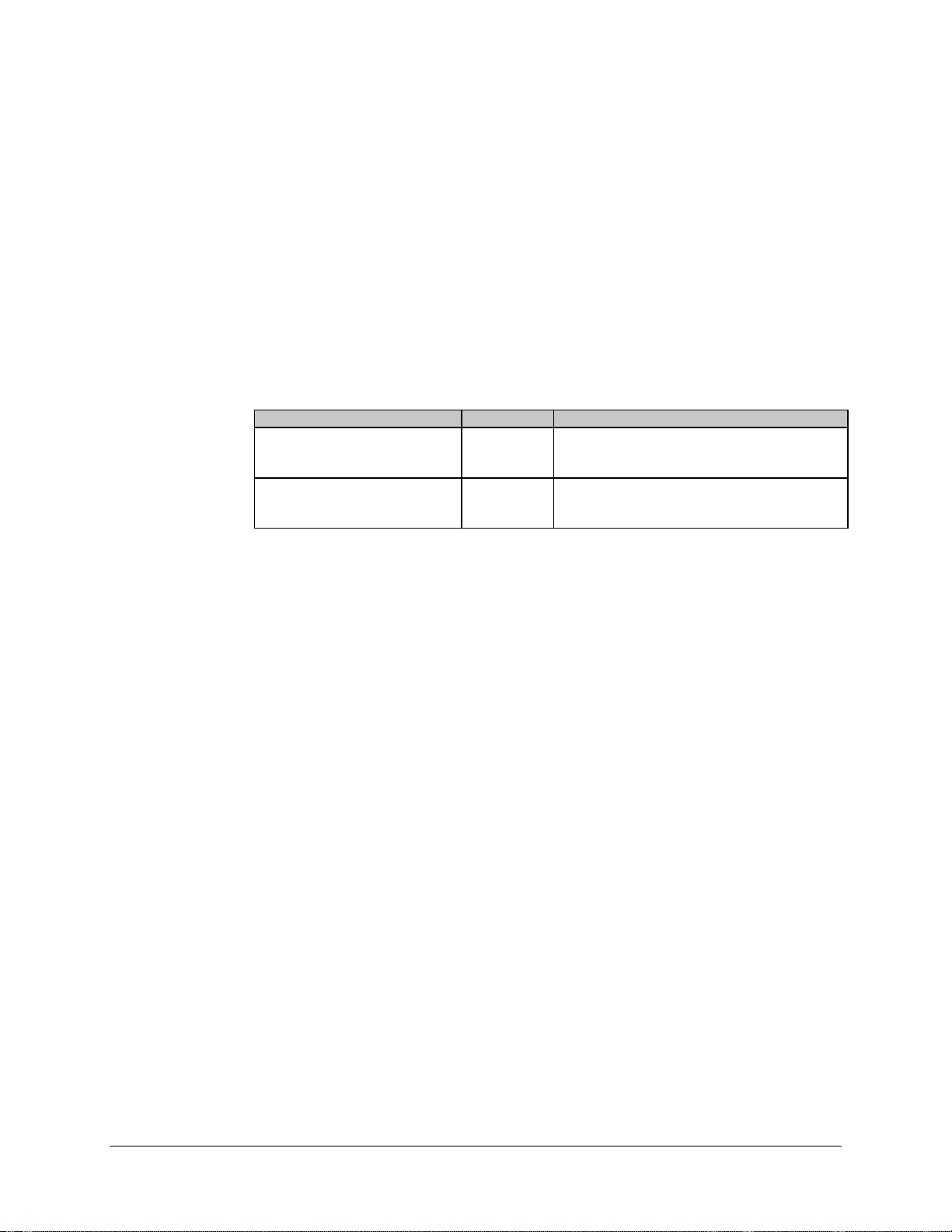

1.3.2 Prime Power

Table 1-11 specifies the prime power specifications for each system component.

Table 1-11. Prime Power

Assembly Options Prime Power

RFT-500, -700 (J5) AC 90 to 230 VAC, 47 to 63 Hz, 1.0A

RFT-1200 (J5) AC 90 to 230 VAC, 47 to 63 Hz, 1.0A

HPA-500, -700 (J1):

140W

350W

HPA-1200 (J1):

100 W

300 W

HPC-1110 AC 90 to 230 VAC, 47 to 63 Hz

RSU-503L (J4, J8) DC +10.8 VDC from either RFT

LNA DC +10.8 ± 0.2 VDC as provided f r om RSU

AC

AC

AC

AC

Prime Power/Power C o n sumpti on

115 or 230 VAC,

100 to 230 VAC, 47 to 63 Hz, 1550 VA

Prime Power/Power C o n sumpti on

115 or 230 VAC,

100 to 230 VAC, 47 to 63 Hz, 1550 VA

20%, 47 to 63 Hz, 950 VA

±

20%, 47 to 63 Hz, 950 VA

±

1-18

Rev. 1

Page 35

High-Power TWTA Satellite Terminals Introduction

1.4.3 Performance

1.4.3.1 Receive

The receiver performance is defined for the LNA input to the 70 MHz output of the RFT

units.

Note: Intervening cable losses due to installation variables must be considered when

comparing the performance data listed in Table 1-12.

Table 1-12. HPCST-5000/-7000 Receive Characteristics

Receive Characteristics

Input Frequency Ra ng e , R FT-500 3.625 to 4.200 GHz, in 2.5 MHz steps

Input Frequency Ra ng e , R FT-700 4.50 to 4.80 GHz, in 2.5 MHz steps

Frequency Sens e No inversion

Input Level -127 to -80 dBm

RX Gain

Adj. (1 dB max. steps)

RX Freq. Stability

Life RX Freq. Drift

Gain Flatness

RX IF Output Bandwidth 70 ± 18 MHz at 1 dB

Noise Figure

Transmit Freq. Reject 60 dB

Receive Image Rejection -45 dBc

Linearity (Third Order Intercept) -30 dBc for 2 tones at -88 dBm (w ith LNA)

Group Delay (a ny 36 MHz)

Linear

Parabolic

Ripple

Synthesizer Lock Time < 1 second

Phase Noise(SSB) at:

10 Hz

100 Hz

1 kHz

10 kHz

100 kHz

Spurious (signal related) a t 0 dBm RX IF

output

Inband Overdrive No damage to 0 dBm

Third Order Interce pt +24 dBm minimum

RX IF Output at 1 dB Compres s ion +17 dBm minimum

95 dB min.

0 to 15 dB min. (remote ly controlled)

1 x 10-8 at 23°C

±

1 x 10-7 at 23°C

±

1.0 dB/36 MHz

±

+0.5 dB/4 MHz

65°K (other options available)

IESS-309, Figure 3, < 10 ns

0.28 ns/MHz

0.025 ns/MHz

< 5 ns P-P

(Maximum)

-30 dBc/Hz

-60 dBc/Hz

-70 dBc/Hz

-75 dBc/Hz

-80 dBc/Hz

-40 dBc

2

Rev. 1 1-19

Page 36

Introduction High-Power TWTA Satellite Terminals

Table 1-12. HPKST-12000 Receive Characteristics (Continued)

Receive Characteristics

Input Frequency Ra ng e 10.95 to 12.75 GHz

(2.5 MHz step size, 1.0 MHz option)

Frequency Sens e No inversion

Input Level -127 to -80 dBm

RX Gain

Adj (1 dB max steps)

RX Frequency Stability

Life RX Frequency Drift

Gain Flatness

RX IF Output Bandwidth 70 ± 18 MHz at 1 dB

Noise Figure 120°K (options to 90°K)

Transmit Freque nc y Reject 60 dB

Receive Image Rejection -45 dBc

Linearity

(Third Order Interc e pt) -35 dBc for 2 tones at - 86 dBm pin (with LNA)

Group Delay (a ny 36 MHz):

Linear

Parabolic

Ripple

Synthesizer Lock Time

Phase Noise (SSB) at:

10 Hz

100 Hz

1 kHz

10 kHz

100 kHz

Spurious (signal related):

at 0 dBm RX IF output -40 dBc

Inband Overdrive No damage to 0 dB m

Third Order Intercept

RX IF Output:

at 1 dB Compress ion

95 dB min

0 to 15 dB min (remote ly controlled)

1 x 10-8 at 23°C

±

1 x 10-7 at 23°C

±

1.0 dB/36 MHz

±

0.5 dB/4 MHz

±

IESS-309, Figure 3, < 10 ns

0.28 ns/MHz

0.025 ns/MHz

5 ns P-P

<

1 second

<

Maximum

-30 dBc/Hz

-60 dBc/Hz

-70 dBc/Hz

-75 dBc/Hz

-90 dBc/Hz

24 dBm min

+

17 dBm min

+

1-20

Rev. 1

Page 37

High-Power TWTA Satellite Terminals Introduction

1.4.3.2 Transmit

The transmit performance is the summation of the effects of the RFT and TWTA units.

Note: Intervening cable losses due to installation variables must be considered when

comparing the performance data listed in Table 1-13 through Table 1-16.

Table 1-13. HPCST-5000/-7000 Transmit Characteristics

Transmit Characteristics

Frequency Ra ng e :

RFT-500

RFT-700

System G a in:

140W System:

at 6 dB backoff, small signal

at saturated pwr, large signa l

350W System:

at 6 dB backoff, small signal

at saturated pwr, large signa l

TX IF Input Level Ra ng e -35 to -25 dBm typical

Output Power at saturation:

170W TWT

400W TWT

TX IF Input Bandwidth at -1 dB 70 ± 18 MHz

Gain: Stability (over temp.)

Flatness

Variation

Group Delay (a ny 36 MHz):

Linear

Parabolic

Ripple

TX Freq. Stability ± 1 x 10

TX Synthesizer L oc k - up time < 1 second

Spurious (not inter-mods):

at 6 dB backoff

with carrier off

5.845 to 6.425 GHz, in 2.5 MHz ste ps

6.725 to 7.025 GHz, in 2.5 MHz ste ps

73 dB min.

78 dB min.

77 dB min.

83 dB min.

140W

350W

+1.5 dB (matched RFT with TWTA)

±

1.5 dB/36 MHz

+2.0 dB max.

IESS-309, Figure 3, < 10ns

0.28 ns/MHz

0.15 ns/MHz

< 5 ns P-P

IESS-309, Paragraph 3.2.1

-40 dBc min. (

-50 dBc min. (> 2.048 MHz inform. rate)

-24 dBm/4 kHz ma x . (a nywhere in satellite band)

2

-8

2.048 MHz inform. rate )

≤

Intermod Spurious with two equal carriers

Harmonic (out of ba nd)

TX Phase Noise(SSB) at:

10 Hz

100 Hz

1 kHz

10 kHz

100 kHz

Rev. 1 1-21

-22 dBc at 6 dB back off

-60 dBc at 6 dB back off

(Maximum)

-30 dBc/Hz

-60 dBc/Hz

-70 dBc/Hz

-75 dBc/Hz

-80 dBc/Hz

Page 38

Introduction High-Power TWTA Satellite Terminals

Table 1-14. HPA-500, -700 Transmit Characteristics

Transmit Characteristics

TWT Rate d Pow e r 170W 400W

Rated Output Power at Flange:

140W

Gain (minimum):

Large signal (LSG)

Small signal (SSG)

42 dB min.

46 dB min.

Maximum SSG Variation:

Any 40 MHz ba nd

IF full Band

Slope

Stability (24 hr)

Stability, Temp

Inter-modulation:

(with two equal signals)

1.0 dB max.

2.5 dB max.

0.04 dB/MHz max.

0.25 dB max.

±

1.0 dB max.

±

-18 dBc max. w ith two equal carriers at 4 dB tota l output

backoff

Harmonic Output 60 dBc min.

AM to PM Conversion 2.5°/dB a t 6 dB be low rated power

Group Delay :

Linear (LDD)

Parabolic (PDD)

Ripple

(any 40 MHz)

0.01 ns/MHz

0.005 ns/MHz

0.5 ns p-p

≤

2

Noise Power:

Transmit band

Receive band

-80 dBW/4 kHz

-160 dBW/4 kHz

Residual AM Noise -50 dBc to 10 kHz

-20 (1.5 + logf) dBc to 500 k H z

-85 dBc above 500 kH z

Phase Noise 10 dB below IESS pha s e nois e profile

AC fundam e nta l - 50 dBc

Sum of all spurs - 47 dBc

350W

47 dB min.

52 dB min.

1.0 dB max.

2.5 dB max.

0.04 dB/MHz max.