Page 1

p

EQ90 Series

Group Delay/Amplitude Equalizer

Installation and O

eration Manual

Part Number MN/EQ900.IOM Revision 2

Page 2

EQ90 Series

Comtech EFData is an ISO 9001

Registered Company.

Group Delay/Amplitude Equalizer

Installation and Operation Manual

Part Number MN/EQ90.IOM

Revision 2

June 14, 1998

Copyright © Comtech EFData, 2000. All rights reserved. Printed in the USA.

Comtech EFData, 2114 West 7th Street, Tempe, Arizona 85281 USA, (480) 333-2200, FAX: (480) 333-2161.

Page 3

Customer Support

Contact the Comtech EFData Customer Support Department for:

• Product support or training

• Information on upgrading or returning a product

• Reporting comments or suggestions concerning manuals

A Customer Support representative may be reached at:

Comtech EFData

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

(480) 333-2200 (Main Comtech EFData Number)

(480) 333-4357 (Customer Support Desk)

(480) 333-2161 FAX

or, E-Mail can be sent to the Customer Support Department at:

service@comtechefdata.com

Contact us via the web at www.comtechefdata.com

1. To return a Comtech EFData product (in-warranty and out-of-warranty) for

repair or replacement:

2. Request a Return Material Authorization (RMA) number from the Comtech

EFData Customer Support Department.

3. Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

4. To ensure that the product is not damaged during shipping, pack the product in

its original shipping carton/packaging.

5. Ship the product back to Comtech EFData. (Shipping charges should be prepaid.)

For more information regarding the warranty policies, see Warranty Policy, p. viii.

.

ii Rev. 2

Page 4

Table of Contents

CHAPTER 1. INTRODUCTION..................................................................................1–1

1.1 Overview..................................................................................................................................................... 1–1

1.2 Description of Equipment .........................................................................................................................1–3

1.2.1 Functional Description........................................................................................................................1–3

1.2.2 Mechanical Description.......................................................................................................................1–3

1.3 Specification ............................................................................................................................................... 1–4

1.4 Dimensional Envelope ............................................................................................................................... 1–6

CHAPTER 2. INSTALLATION...................................................................................2–1

2.1 Unpacking................................................................................................................................................... 2–1

2.2 Installation.................................................................................................................................................. 2–2

2.3 External Connectors.................................................................................................................................. 2–4

2.3.1 Channel Monitor ................................................................................................................................. 2–5

2.4 Chassis Ground.......................................................................................................................................... 2–5

CHAPTER 3. OPERATION.........................................................................................3-1

3.1 Front Panel Indicators................................................................................................................................3-1

3.2 Rear Panel Control and Connectors .........................................................................................................3-3

3.3 Equalizer Adjustments...............................................................................................................................3-5

3.3.1 Power ON.............................................................................................................................................3-5

3.4 Alignment Procedures................................................................................................................................3-5

Rev. 2 iii

Page 5

Errata B

Comtech EFData Documentation Update

Subject:

Date:

Document:

Part Number:

Collating Instructions:

Comments:

The following addition is provided to revise the unit.

Change Specifics:

Add DC Input Filter Module pinouts

September 7, 2005

EQ-90 IF Group Delay Equalizer

Part Number MN/RC1160.EA1

Attach this page to 2-2

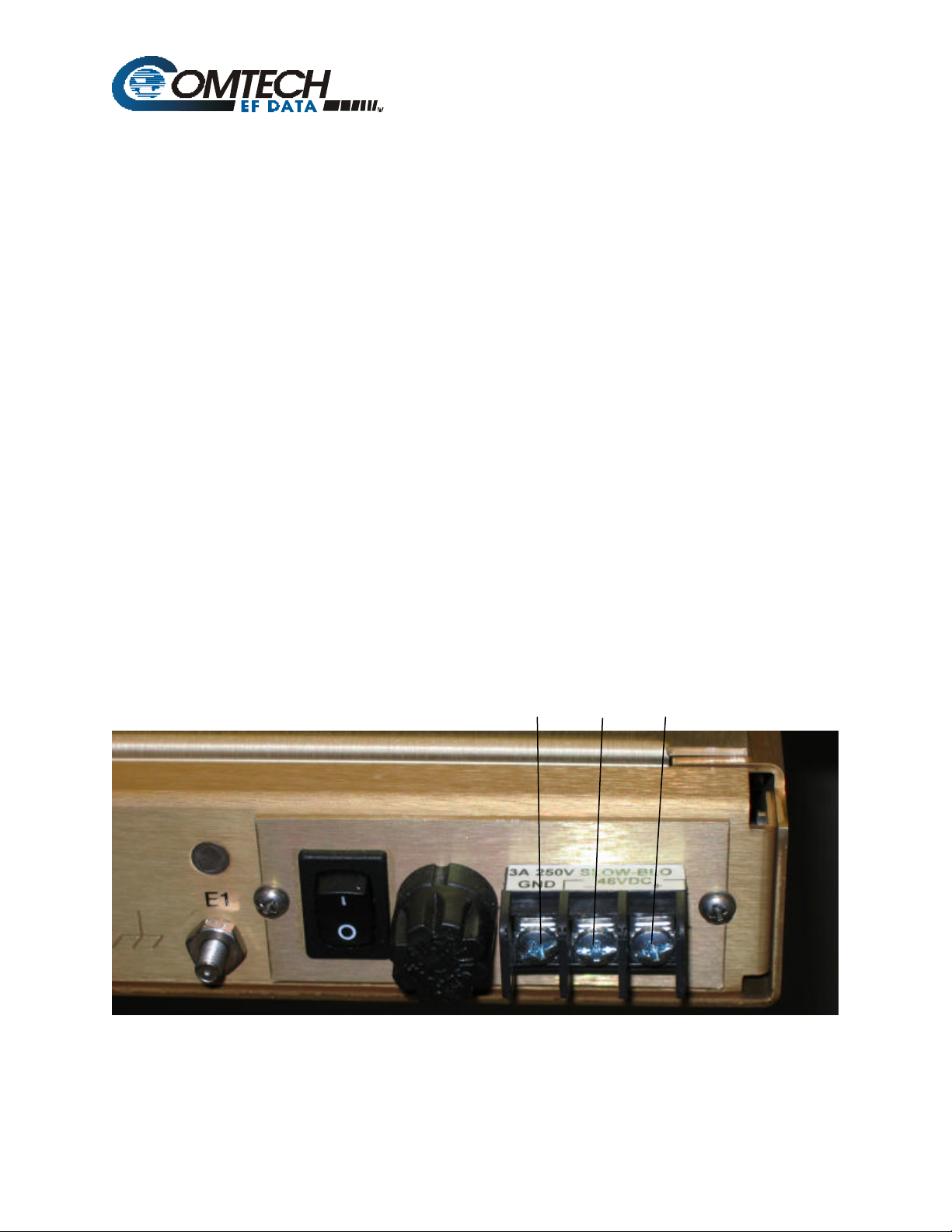

2.3.1 DC Filter Input Module

The DC Input Filter Module (shown in Figure Figure 2-1) has pinouts listed in Table 2-1. Input

voltage range: -36 to -72 VDC.

A B C

Figure 2-1. DC Input Filter Module

Filename: T_ERRATA 1

Page 6

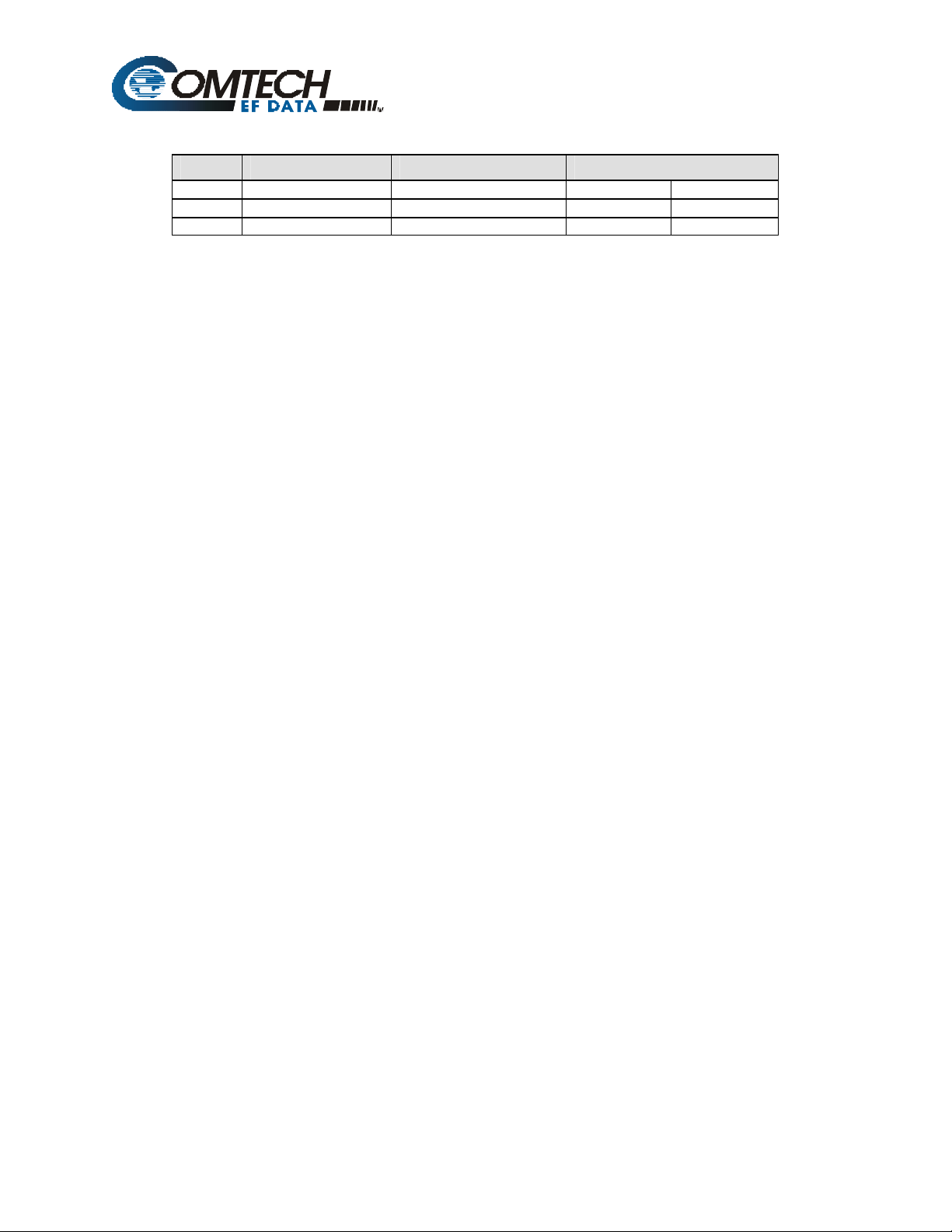

Table 2-1. DC Input Filter Module

Pin # Signal Name Wire Colors Wiring Options

A Ground Green/Yellow Earth Ground Earth Ground

B Negative Black -48 VDC 0 VDC

C Positive Red 0 VDC +48 VDC

Filename: T_ERRATA 2

Page 7

Preface EQ90 Series

3.4.1 Equalizer Adjustment...........................................................................................................................3-5

3.4.2 Alignment to a Specific Delay Requirement......................................................................................3-11

3.4.3 Slope Equalizer Adjustment...............................................................................................................3-15

3.4.4 System Integration Alignment Procedure..........................................................................................3-16

CHAPTER 4. MAINTENANCE...................................................................................4–1

4.1 Checkout..................................................................................................................................................... 4–1

4.2 Troubleshooting.........................................................................................................................................4–2

4.3 Replacement Procedures...........................................................................................................................4–3

4.3.1 Chassis Cover...................................................................................................................................... 4–3

4.3.2 Equalizer Modules .............................................................................................................................. 4–3

4.3.3 Power Supply Assembly .....................................................................................................................4–3

4.3.4 Fuse Replacement ............................................................................................................................... 4–4

4.3.5 Spare Parts........................................................................................................................................... 4–4

APPENDIX A. APPLICATION NOTE ....................................................................... A–1

A.1 Introduction..........................................................................................................................................A–1

A.2 Operational Parameters....................................................................................................................... A–2

A.3 Fault Monitor........................................................................................................................................ A–3

A.4 Monitor Interface.................................................................................................................................A–3

GLOSSARY ................................................................................................................g–1

iv Rev. 2

Page 8

EQ90 Series Preface

Figures

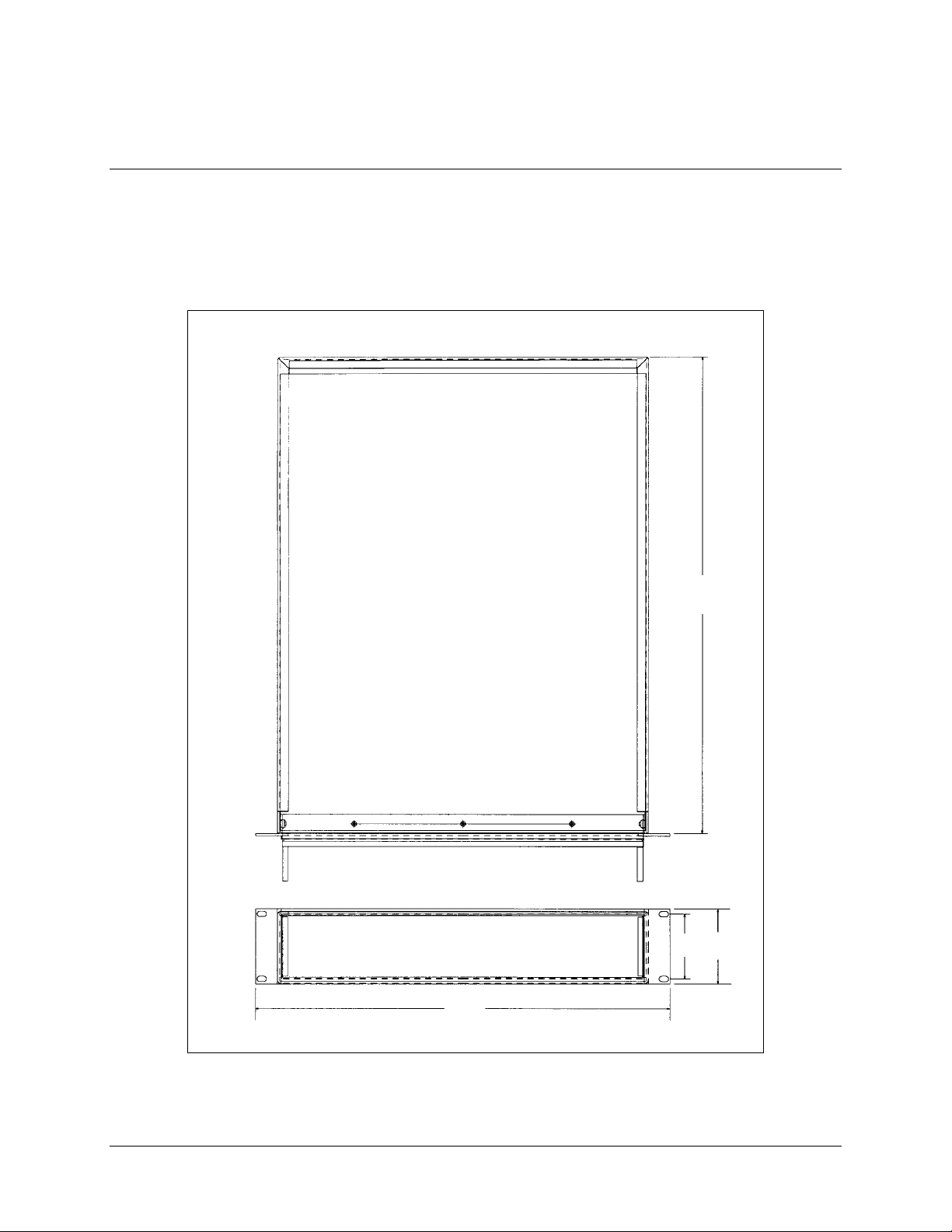

Figure 1-1. EQ90 Series Group Delay/Amplitude Equalizer Assembly..............................................1–2

Figure 1-2. Dimensional Envelope.......................................................................................................1–6

Figure 2-1. Typical Rack Installation................................................................................................... 2–3

Figure 2-2. Equalizer Power and Interface Connectors ........................................................................ 2–4

Figure 3-1. Front Panel Indicators.........................................................................................................3-2

Figure 3-2. Rear Panel Control and Connectors....................................................................................3-3

Figure 3-3. Equalizer Module...............................................................................................................3-6

Figure 3-4. Alignment Setup.................................................................................................................3-8

Figure 3-5. Effect on Delay of Varying C Switch.................................................................................3-8

Figure 3-6. Effect on Delay of Varying “L”........................................................................................3-10

Figure 3-7. Effect on Amplitude of Varying “R”................................................................................3-10

Figure 3-8. Effect on Amplitude of Varying “R”................................................................................3-11

Figure 3-9. Multi-Pole Bandpass Filter Delay Response ....................................................................3-11

Figure 3-10. Single-Section Equalizer Delay Response......................................................................3-12

Figure 3-11. Composite Delay Response............................................................................................3-12

Figure 3-12. Equalizer Composite Delay Response............................................................................3-14

Figure 3-13. All Sections Tuned 1 MHz Lower in Frequency............................................................3-14

Figure 3-14. All Sections Tuned 1 MHz Higher In Frequency...........................................................3-15

Figure 3-15. System Integration Alignment Test Setup......................................................................3-16

Figure 3-16. Typical Satellite Transponder Delay..............................................................................3-17

Figure 3-17. Required Equalizer Delay Characteristic........................................................................3-17

Figure 3-18. Ideal Composite Delay Result........................................................................................3-18

Figure 3-19. Typical Half Transponder Video Carrier Delay.............................................................3-19

Figure 3-20. Required Equalized Delay Characteristic.......................................................................3-19

Figure 3-21. Ideal Composite Delay Result........................................................................................3-20

Figure 3-22. Typical Delay Characteristic..........................................................................................3-20

Figure 3-23. Shifted Equalizer Delay Characteristic...........................................................................3-21

Figure 3-24. Resultant Composite Delay Characteristic.....................................................................3-21

Figure 3-25. Transponder Delay Characteristic ..................................................................................3-23

Figure 3-26. Equalizer Delay Characteristic.......................................................................................3-23

Figure 3-27. Resultant Composite Delay Characteristic.....................................................................3-24

Figure 3-28. Transponder Delay Characteristic ..................................................................................3-24

Figure 3-29. Equalizer Offset Delay Characteristic............................................................................3-25

Figure 3-30. Resultant Composite Delay Characteristic.....................................................................3-25

Figure 4-1. Equalizer Component Locations ....................................................................................... 4–5

Tables

Table 1-1. Electrical Specifications and Operational Characteristics.......................................... 1–4

Table 2-1. Single Channel Equalizer Rear Panel Mating Connectors......................................... 2–5

Table 2-2. Dual Channel Equalizer Rear Mating Connectors .....................................................2–5

Table 3-1. Front Panel Indicator Functions..................................................................................3-2

Table 3-2. Rear Panel Controls and Connector Functions ...........................................................3-4

Table 3-3. Equalizer Module Control Functions..........................................................................3-6

Table 3-4. Peak-to-Peak Delay Magnitude ................................................................................3-13

Table 4-1. Equalizer Troubleshooting Procedure........................................................................ 4–2

Table 4-2. Equalizer Spare Parts................................................................................................. 4–5

Rev. 2 v

Page 9

Preface EQ90 Series

Overview of Changes to Previous Edition

A summary of the changes made to Rev. 1 are as follows:

• Manual updated for styles and conventions relative to Comtech EFData format.

About this Manual

This manual provides installation and operation information for the EFData EQ-90 Series

Group Delay/Amplitude Equalizer. This is a technical document intended for earth

station engineers, technicians, and operators responsible for the operation and

maintenance of the EQ-90.

Conventions and References

Cautions and Warnings

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other

CAUTION

unsafe practices or risks of property damage.

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

WARNING

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assist the operator in cross-referencing English to Metric

conversions.

Recommended Standard Designations

Recommended Standard (RS) Designations have been superseded by the new designation

of the Electronic Industries Association (EIA). References to the old designations are

shown only when depicting actual text displayed on the screen of the unit (RS-232, RS-

vi Rev. 2

Page 10

EQ90 Series Preface

485, etc.). All other references in the manual will be shown with the EIA designations

(EIA-232, EIA-485, etc.) only.

Military Standards

“MIL-STD-188” apply to the 114A series (i.e., MIL-STD-188-114A), which provides

electrical and functional characteristics of the unbalanced and balanced voltage digital

interface circuits applicable to both long haul and tactical communications. Specifically,

these references apply to the MIL-STD-188-114A electrical characteristics for a balanced

voltage digital interface circuit, Type 1 generator, for the full range of data rates. For

more information, refer to the Department of Defense (DOD) MIL-STD-188-114A,

“Electrical Characteristics of Digital Interface Circuits.”

Trademarks

Windows is a trademark of Microsoft Corporation. Other product names mentioned in

this manual may be trademarks or registered trademarks of their respective companies

and are hereby acknowledged.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EFData Customer Support

Department.

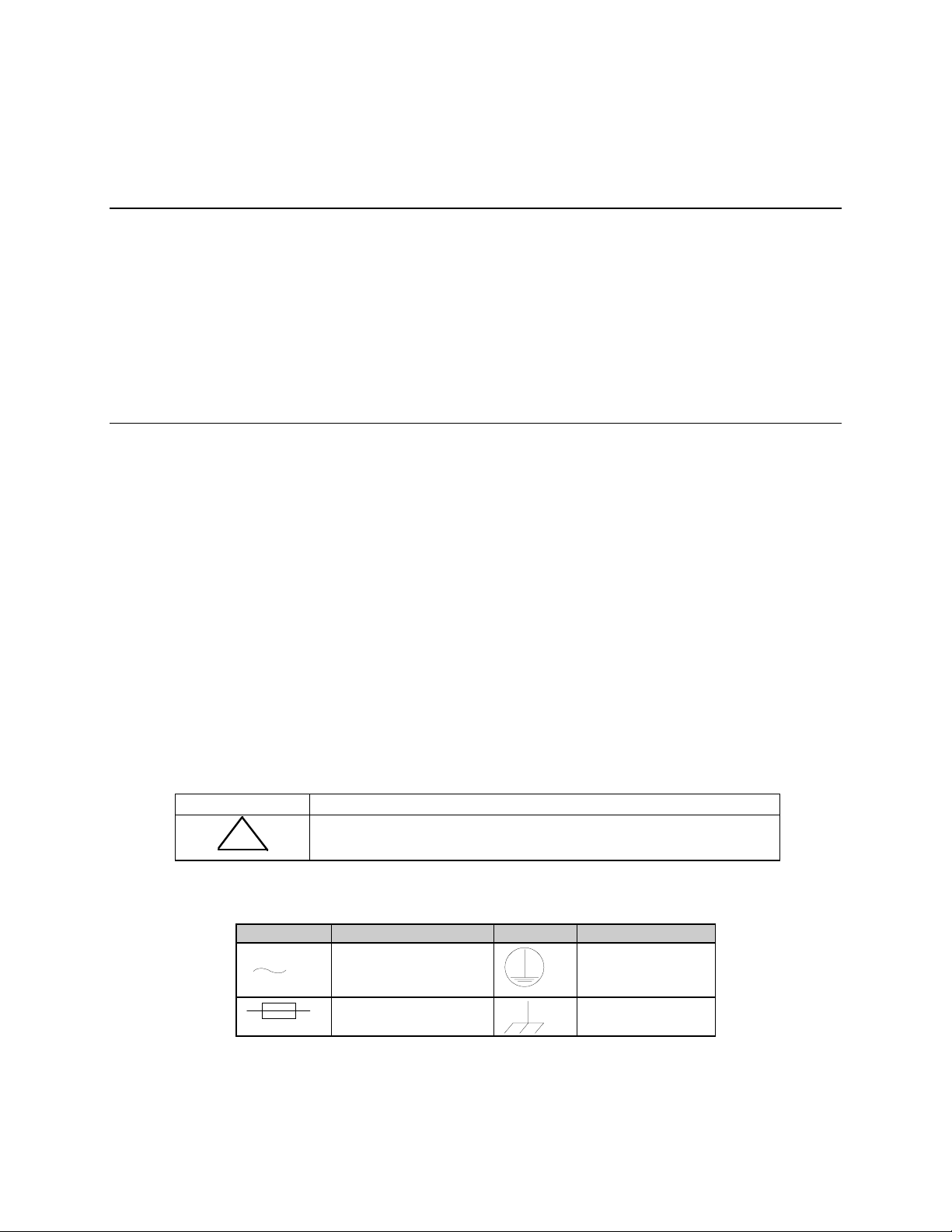

Low Voltage Directive (LVD)

The following information is applicable for the European Low Voltage Directive

(EN60950):

<HAR>

!

International Symbols:

Symbol Definition Symbol Definition.

Type of power cord required for use in the European Community.

CAUTION: Double-pole/Neutral Fusing.

ACHTUNG: Zweipolige bzw. Neutralleiter-Sicherung.

Alternating Current.

Fuse.

Safety Ground.

Chassis Ground.

Rev. 2 vii

Page 11

Preface EQ90 Series

Warranty Policy

This Comtech EFData product is warranted against defects in material and workmanship

for a period of one year from the date of shipment. During the warranty period, Comtech

EFData will, at its option, repair or replace products that prove to be defective.

For equipment under warranty, the customer is responsible for freight to Comtech

EFData and all related custom, taxes, tariffs, insurance, etc. Comtech EFData is

responsible for the freight charges

the customer. Comtech EFData will return the equipment by the same method (i.e., Air,

Express, Surface) as the equipment was sent to Comtech EFData.

only

for return of the equipment from the factory to

Limitations of Warranty

The foregoing warranty shall not apply to defects resulting from improper installation or

maintenance, abuse, unauthorized modification, or operation outside of environmental

specifications for the product, or, for damages that occur due to improper repackaging of

equipment for return to Comtech EFData.

No other warranty is expressed or implied. Comtech EFData specifically disclaims the

implied warranties of merchantability and fitness for particular purpose.

Exclusive Remedies

The remedies provided herein are the buyer's sole and exclusive remedies. Comtech

EFData shall not be liable for any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any other legal theory.

Disclaimer

Comtech EFData has reviewed this manual thoroughly in order that it will be an easy-touse guide to your equipment. All statements, technical information, and

recommendations in this manual and in any guides or related documents are believed

reliable, but the accuracy and completeness thereof are not guaranteed or warranted, and

they are not intended to be, nor should they be understood to be, representations or

warranties concerning the products described. Further, Comtech EFData reserves the

right to make chang es in the specifications of the products described in this m anual at any

time without notice and without obligation to notify any person of such changes.

If you have any questions regarding your equipment or the information in this manual,

please contact the Comtech EFData Customer Support Department.

viii Rev. 2

Page 12

Errata A

Comtech EFData Documentation Update

Subject:

Date:

Document:

Part Number:

Collating Instructions:

Comments:

The following changes provide additional Table 2-3 and updates to paragraph 2.3.1. This

information will be incorporated into the next r evision.

Changes to Table 2-2. Summar y Alarm Interface Connector J3 Pin

Assignments

October 18, 2000

EQ90 Group Delay/Amplitude Equalizer Installation and Operation

Manual, Rev. 2, dated June 14, 1998

MN/EQ90.EA2

Attach this page to page 2-5

Change Specifics:

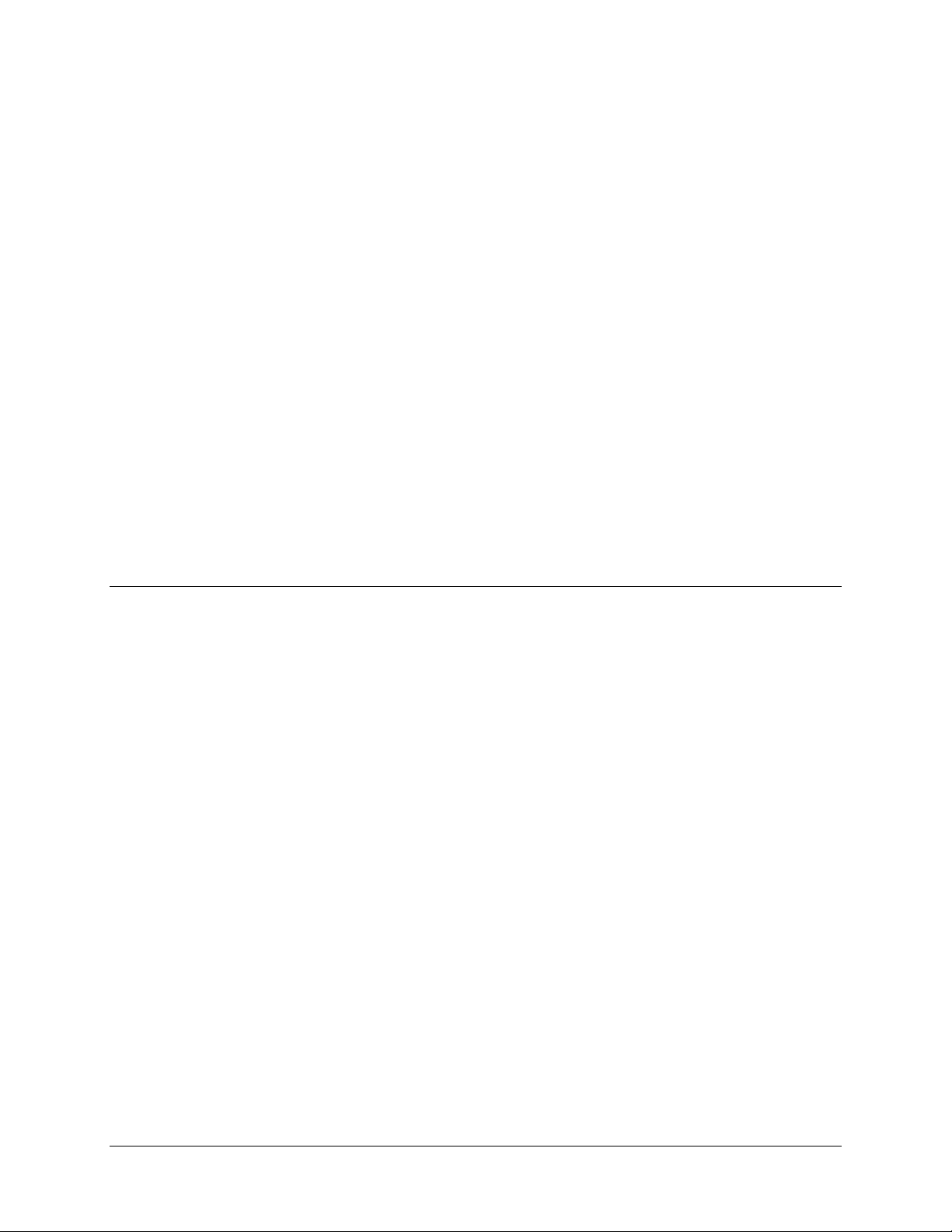

Table 2-3. Summary Alarm Interface Connector J3 Pin Assignments

Pin No. Assignment

1,2

3 Normally Open (Equalizer Operational). Referenced to pin 4.

4 Common

5,6 Not Used

7 Alarm Out (Open, Equalizer Operational). Referenced to pin 8.

8 Alarm Common

9 Normally Closed (Equalizer Operational). Referenced to pin 4.

Not Used

2.3.1 Channel Monitor

The alarm monitor output connector (J3) provides a summary fault status out put to a summary

alarm panel, or annunciator type device, or redundancy switching equipm ent . Refer to Table 2-3

for pin assignments.

EQ90 REV 2 ERRATA A.DOC

1

Page 13

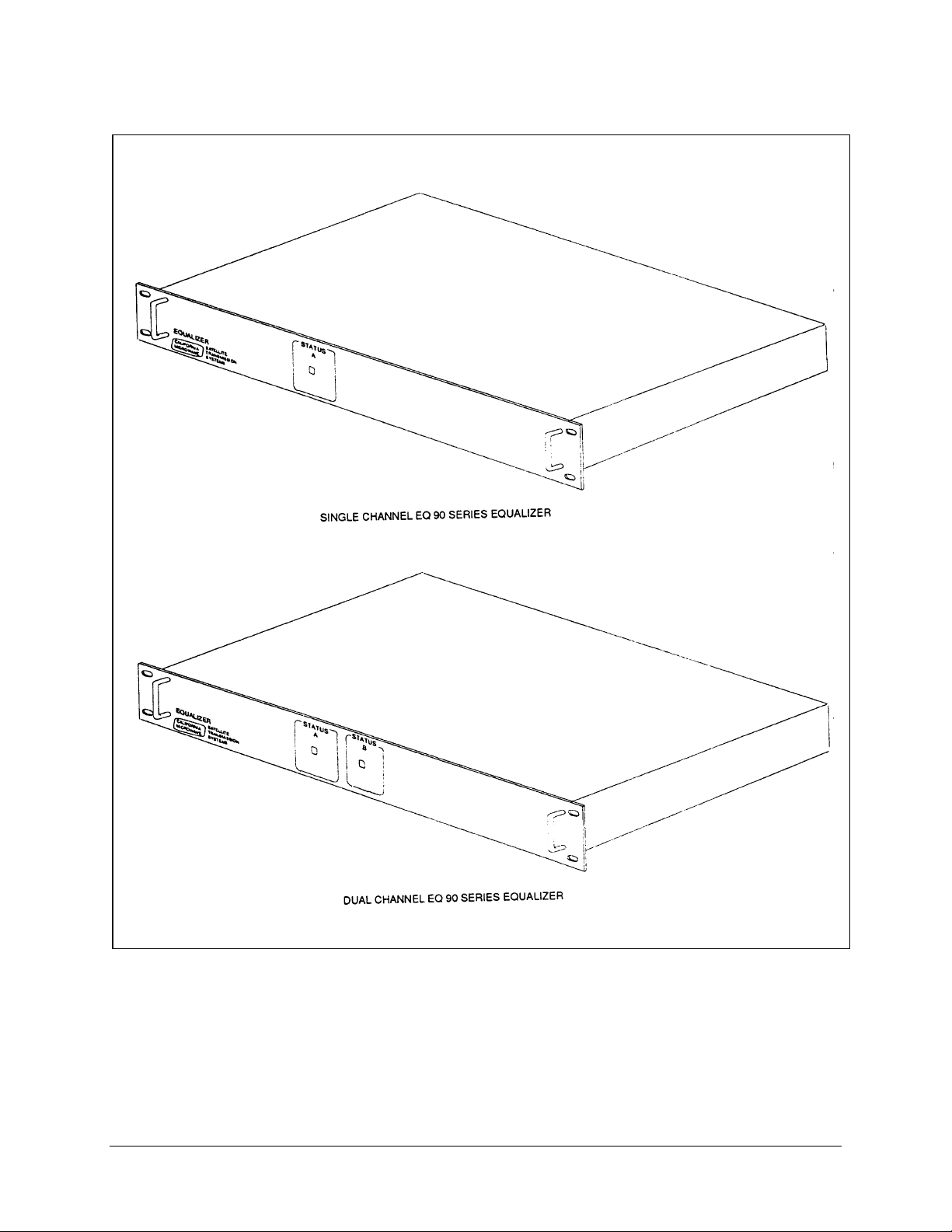

This chapter contains an introduction, a description of the equipment, its purpose and

capabilities, and major characteristics and specifications.

1.1 Overview

This chapter provides instructions for the EQ90 Series Group Delay/Amplitude

Equalizer Assembly (Figure 1-1), herein after referred to as, “the equalizer.” Two

versions of the equalizer are manufactured:

Single channel unit

•

Dual channel unit

•

The single channel unit (D68563) and dual channel unit (D68564) can be equipped for a

70 or 140 MHz input/output signal.

The 10-section 70 MHz delay equalization PCB is contained in the internal equalizer

assembly A1 and A2. The PCB contains a switch which enables or disables the alarm

output from the equalizer due to a low IF output signal level. The switch is accessed by

removing the equalizer top cover. The cover on the internal assembly A1 or A2 is labeled

BYPASS or LVL MON.

In the LVL MON position, the IF output signal level is monitored. In the event,

•

the IF signals level falls below

-20 dBm nominal, an alarm indicated on the front panel of the equalizer and

reported to external monitor and control equipment.

In the BYPASS position, an alarm will result only if the internal power supply

•

fails.

Chapter 1.

INTRODUCTION

1

Rev. 2 1–1

Page 14

Introduction EQ90 Amplitude Equalizer

Figure 1-1. EQ90 Series Group Delay/Amplitude Equalizer Assembly

1–2 Rev. 2

Page 15

EQ90 Amplitude Equalizer Introduction

1.2 Description of Equipment

1.2.1 Functional Description

The equalizer is intended to be used in ground-based satellite transmit (TX) and receive

(RX) communications systems. It provides delay equalization to compensate for nonlinear delay distortions by:

Up and Down Converters

•

High Power Amplifiers

•

High Power Multiplex Combiners

•

Satellite Filters

•

Waveguide

•

The equalizer is designed as a stand-alone device that can be installed in a 70 or

140 MHz signal path to provide delay equalization of the uplink or downlink.

1.2.2 Mechanical Description

The equalizer is contained in a 1.75 inch (4.4 cm) tall, slide-mounted drawer designed to

mount directly in a standard Electronics Industries Association (EIA) equipment rack or

cabinet. The drawer, when fully extended on its slides, permits rear panel connector

access.

A removable top cover, secured to the chassis with two screws, provides access to the

internal modules.

Rev. 2 1–3

Page 16

Introduction EQ90 Amplitude Equalizer

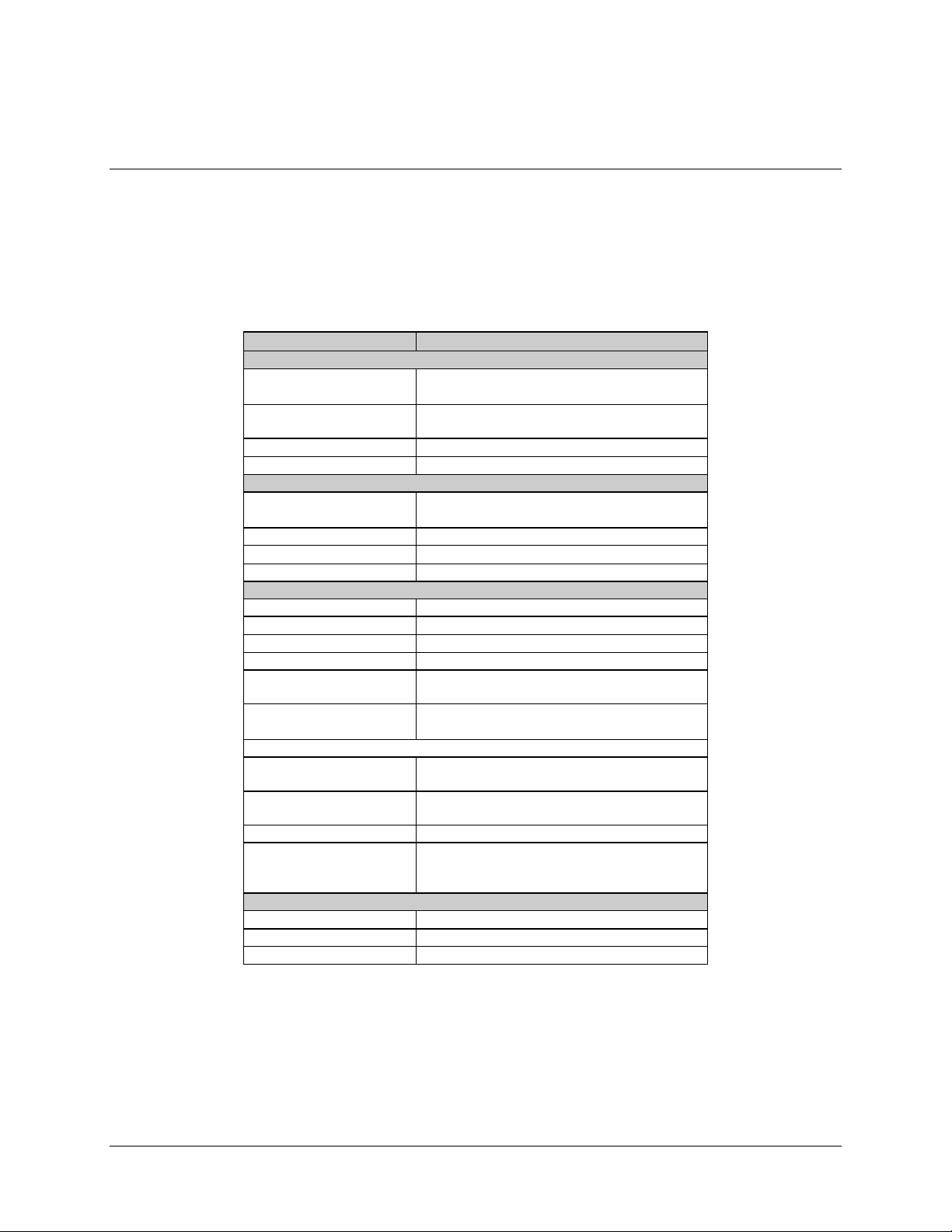

1.3 Specification

Refer to Table Chapter 1-1 for the electrical and operational characteristics of the

equalizer.

Table Chapter 1-1. Electrical Specifications and Operational

Characteristics

Characteristic Specification

IF Input

Frequency

Level -15 dBm maximum (single carrier)

Impedance

Return Loss 20 dB

Frequency

Level 0 dB nominal

Impedance

Return Loss 20 dB

Gain 15 dB nominal

Amplitude Response

1 dB Compression +8 dBm

Third Order Intercept Point +18 dBm

Group Delay

(All Sections Off)

Amplitude Equalization

Adjustment Range

Delay Equalization Adjustment Range/per section

70 MHz < 15 ns/36 MHz

140 MHz < 10 ns/72 MHz

IF Fail Trip Point Approx. -20 dBm

Fault/Status Type Relay contact output

Voltage

Frequency 47 to 63 Hz

Power Consumption 10 VA/Nominal

70 MHz ± 18 MHz

140 MHz ± 36 MHz

-18 dBm maximum. (multi-carrier composite)

75 Ω, unbalanced

IF Output

70 MHz ± 18 MHz

140 MHz ± 36 MHz

75Ω, unbalanced

Input to Output

Adjustable to ± 0.15 dB

< 2 ns

3 dB/36 MHz minimum (70 MHz)

±

3 dB/72 MHz minimum (140 MHz)

±

>40 ns/36 MHz

> 30 ns/72 MHz

1 Form ‘C’

1 Form ‘A’

Primary Power Requirements

84 to 265 VAC ± 10%

1–4 Rev. 2

Page 17

EQ90 Amplitude Equalizer Introduction

Table 1-1. Electrical Specifications and Operational Characteristics (Continued)

Temperature

Operating

Storage

Operating 0 to 95%, non-condensing

Storage 0 to 100%

Operating to 10,000 feet (3.048 km) ASL

Storage to 50,000 feet (15.24 km) ASL

Shock and Vibration As encountered in normal commercial

Front Panel Indicators Power/Status

0° to +50°C (32° to 122°F)

-30° to +75°C (-22° to +167°F)

Humidity

Altitude

shipping, handling, and operation.

Rev. 2 1–5

Page 18

Introduction EQ90 Amplitude Equalizer

1.4 Dimensional Envelope

Refer to Figure 1-2 for the dimensional envelope of the equalizer.

Note:

All dimensions are in inches, centimeters are in parenthesis.

19.00

(48.26)

1.00

(2.54)

20.00

(50.8)

(4.45)

1.75

Figure 1-2. Dimensional Envelope

1–6 Rev. 2

Page 19

Chapter 2.

INSTALLATION

2

This chapter provides unpacking and installation instructions, and a description of

external connections and backward alarm information.

The equipment contains parts and assemblies sensitive to damage by

Electrostatic Discharge (ESD). Use ESD precautionary procedures when

CAUTION

touching, removing, or inserting PCBs.

2.1 Unpacking

The modem and manual are packaged in pre-formed, reusable, cardboard cartons

containing foam spacing for maximum shipping protection.

Do not use any cutting tool that will extend more than 1 inch into the

container. This can cause damage to the modem.

CAUTION

Unpack the equalizer as follows:

Rev. 2 2–1

1. Cut the tape at the top of the carton indicated by OPEN THIS END.

2. Remove the cardboard/foam space covering the equalizer.

3. Remove the equalizer, manual, and power cord from the carton.

4. Save the packing material for storage or reshipment purposes.

5. Inspect the equipment for any possible damage incurred during shipment.

6. Check the equipment against the packing list to ensure the shipment is correct.

7. Refer to Section 2.2 for installation instructions.

Page 20

Installation EQ90 Series Group Delay/Amplitude Equalizer

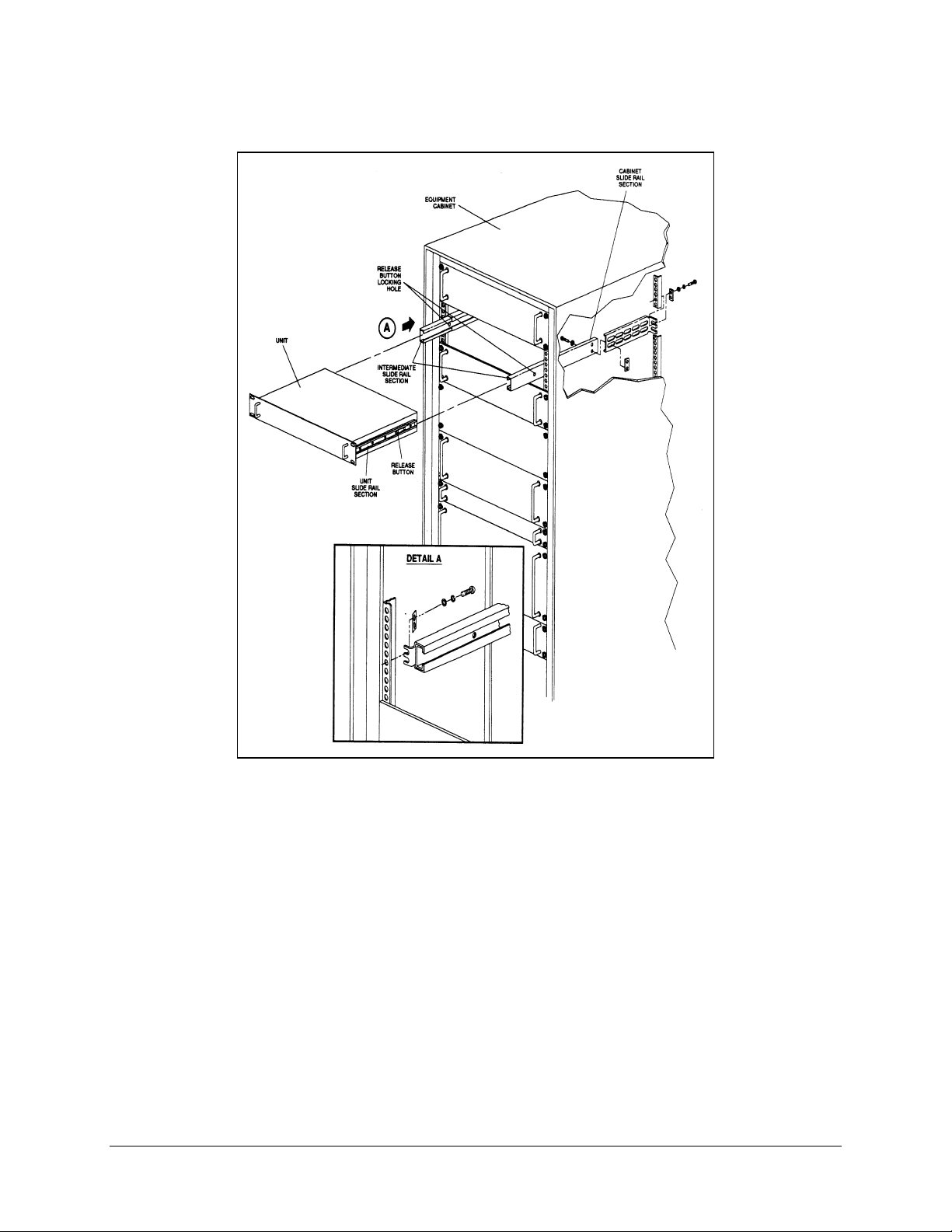

2.2 Installation

Note:

Omit Steps 1, 2, and 3 if the cabinet slide sections with extenders are already

installed within the equipment rack at the proper elevation, and the chassis slide sections

are mounted on the equalizer chassis.

1. Attach chassis slide sections (Figure 2-1) to equalizer with four number 8-32

screws and lockwashers on each side of chassis.

2. Attach mounting bracket to rear of each cabinet slide section with two number

10-32 screws and flatwashers and nut plates. Before tightening hardware, adjust

mounting brackets so that mounting surfaces of brackets butt up against

mounting surfaces of equipment rack.

3. At the proper elevation within the equipment rack, mount slides with mounting

bracket to equipment rack as follows:

a. Mount each mounting bracket to rear cabinet mounting surface with

modified nut plates (optional) and two number 10-32 screws, lockwashers,

and flatwashers.

b. Mount each slide to front cabinet mounting surface with modified nut plates

and two number 10-32 screws, lockwashers, and flatwashers.

4. Slide cabinet slide extenders out to fully extended and locked positions.

5. Lift equalizer into position so that chassis slide sections are aligned with cabinet

slide extenders and slide chassis slide sections into cabinet slide extenders. Slide

equalizer back until slide release buttons on chassis slide sections snap into holes

in cabinet slide sections.

6. Connect all cables to associated rear panel connectors.

7. Press in slide release buttons, push equalizer fully into rack, and install

appropriate hardware for front panel mounting flanges to secure equalizer to

rack.

2–2 Rev. 2

Page 21

EQ90 Series Group Delay/Amplitude Equalizer Installation

Figure 2-1. Typical Rack Installation

Rev. 2 2–3

Page 22

Installation EQ90 Series Group Delay/Amplitude Equalizer

123

456

9

Q

2.3 External Connectors

The rear panel provides all the necessary external connections between the equalizer and

other equipment. Refer to Figure 2-2 connector locations, and Table 2-1and Table 2-2

for connector descriptions.

CHAN B

MONITOR

B

OUT

B

IN

DUAL CHANNEL EQUALIZER

SINGLE CHANNEL E

CHAN A

MONITOR

CHAN A

MONITOR

13

13

UALIZER

7

A

OUT

7891011

A

OUTAIN

8

A

IN

E1

12

E1

12

10 11

Figure 2-2. Equalizer Power and Interface Connectors

2–4 Rev. 2

Page 23

EQ90 Series Group Delay/Amplitude Equalizer Installation

Table 2-1

Nomenclature and Item No. Ref Des Connector Type Mating Conne c tor

Primary Power Input

(11, Figure 2-2)

IF Input (8) A IN Type BNC, female

IF Output (7) A OUT Type BNC, female

Channel A Monitor (13) 9-pin D, female

Ground (12) E1

. Single Channel

IEC-320 Socket with Belden 17250-C North American

Equalizer Rear Panel Mating Connectors

18 AWG and NEMA UL Listed plug, or Belden Type 17820

with Harmonized Cordage.

Table 2-2. Dual Channel Equalizer Rear Mating Connectors

Nomenclature and Item No. Ref Des Connector Type Mating Conne c tor

Primary Power Input

(1, 11, Figure 2-2)

IF Output (8) A IN Type BNC, female

IF Output (7) A OUT Type BNC, female

IF Output (6) B IN

IF Output (5) B OUT

Channel A Monitor (13) Plug

Channel B Monitor (4) Screw

Ground (12) E1

AC1

AC2

IEC-320 Socket with Belden 17250-C North American

18 AWG and NEMA UL Listed plug, or Belden Type 17820

with Harmonized Cordage.

2.3.1 Channel Monitor

The alarm monitor output connector (J3) provides a summary fault status output to a

summary alarm panel, or annuciator type device, or redundancy switching equipment.

2.4 Chassis Ground

A number 10-32 threaded ground stud (E1) is provided on the rear panel of the

equalizer. This ground stud is connected to the chassis and should be connected, via a

1/2 inch or 1 inch ground braid, to the cabinet ground to form the ground reference point

of the system installation.

This ground should be connected at all times for the safety of equipment service

personnel.

Rev. 2 2–5

Page 24

Installation EQ90 Series Group Delay/Amplitude Equalizer

This page is intentionally left blank.

2–6 Rev. 2

Page 25

This chapter contains operating instructions for the equalizer. Included in this section are

descriptions of the operating modes, configurations, functions, and indicators.

3.1 Front Panel Indicators

Refer to Figure Chapter 3-1 for an illustration of the equalizer front panel indicators, and

Table Chapter 3-1 for descriptions of the indicator functions.

Note:

The functions for the single channel equalizer indicators are identical to those of

the dual channel model.

Chapter 3.

OPERATION

3

Rev. 2 3-1

Page 26

Operation EQ90 Amplitude Equalizer

EQUALIZER

EQUALIZER

STATUS

A

1

EQ90

SINGLE CHANNEL EQUALIZER

2

STATUS STATUS

AB

3

EQ90

DUAL CHANNEL EQUALIZER

Figure Chapter 3-1. Front Panel Indicators

Table Chapter 3-1. Front Panel Indicator Functions

Item Nomenclature Function

1 or 2 STATUS A Indicator Dual color (Red/Green) indicator. Lights

green when prime power is applied to the

equalizer, and the rear panel on/off

switch is set to ON. Also lights green to

indicate that no faults exist within the

equalizer. Lights red to indicate loss of

the IF input signal or IF output signal

level is falling below the alarm threshold

setting (-20 dBm nominal) when the

equalizer module switch is set to LVL

MON position.

3 STATUS B Indicator Dual color (Red/Green) indicat or. Lights

green when prime power is applied to the

equalizer, and the rear panel on/off

switch is set to ON. Also lights green to

indicate that no faults exist within the

equalizer. Lights red to indicate loss of

the IF input signal or IF output signal

level is falling below the alarm threshold

setting (-20 dBm nominal) when the

equalizer module switch is set to LVL

MON position.

3-2 Rev. 2

Page 27

EQ90 Amplitude Equalizer Operation

123

456

9

Q

3.2 Rear Panel Control and Connectors

Refer to Figure Chapter 3-2 for an illustration of the equalizer rear panel control and

connectors, and Table Chapter 3-2 for descriptions of the function of each control and

connector.

Note:

The functions for the single channel equalizer controls and indicators are identical.

CHAN B

MONITOR

B

OUT

B

IN

DUAL CHANNEL EQUALIZER

SINGLE CHANNEL E

CHAN A

MONITOR

13

CHAN A

MONITOR

13

UALIZER

Figure Chapter 3-2. Rear Panel Control and Connectors

7

A

OUT

7891011

A

OUTAIN

8

A

IN

E1

12

E1

12

10 11

Rev. 2 3-3

Page 28

Operation EQ90 Amplitude Equalizer

Table Chapter 3-2. Rear Panel Controls and Connector Functions

Item Nomenclature Function

1 AC Power Receptacle AC voltage input assembly, which

provides AC input power filtering for

channel “B” power supply.

2 On/Off Switch Applies primary AC input voltage to the

internal power supply.

3 Fuse Receptacle Contains two 2A fuses to protect the

equalizer from excessive current draw.

4 CHAN B Monitor

Connector

5 B OUT Connector BNC type, female connector that routes

6 B IN Connector BNC type, female connector that routes

7 A OUT Connector BNC type, female connector that routes

8 A IN Connector BNC type, female connector that routes

9 Fuse Receptacle Contains two 2A fuses to protect the

10 On/Off Switch Applies primary AC input voltage to the

11 AC P ower Receptacle AC voltage input assembly that provides

12 Connector E1 Provides equalizer ground connection to

13 CHAN A MONITOR

Connector

9-pin, D-type female connector provides

summary alarm to an annunciator device,

summary alarm panel, or redundancy

switching equipment.

the IF signal output from the equalizer to

external equipment.

the IF signal input from external

equipment to the equalizer.

the IF signal output from the equalizer to

external equipment.

the IF signal input from external

equipment to the equalizer.

equalizer from excessive current draw.

internal power supply.

AC input power filtering for the channel

“A” power supply.

cabinet or earth station ground system.

9-pin, D-type female connector provides

summary alarm to an annunciator device,

summary alarm panel, or redundancy

switching equipment.

3-4 Rev. 2

Page 29

EQ90 Amplitude Equalizer Operation

3.3 Equalizer Adjustments

3.3.1 Power ON

To turn the equalizer on, proceed as follows:

1. Set rear panel power switch to (1, Figure Chapter 3-1) to the ON position and

verify that front panel STATUS indicator light(s) is green.

2. Gain access to the level monitor switch as follows:

a. Remove the equalizer cover. Remove the cover on the 10-section 70 MHz

(6-section 70 MHz option) delay equalizer assembly labeled A1 or A2

(BYPASS or LVL MON).

b. In the LVL MON position, the IF output signal level is monitored. In the

event the IF signal falls below –20 dB nominal, an alarm indicated on the

front panel will be ON.

c. In the BYPASS position, an alarm will be ON indicating; INTERNAL

POWER SUPPLY failure.

3. Set the level monitor switch LVL MON position and verify front panel STATUS

indicator light(s) red.

4. Set the level monitor switch to BYPASS position and verify front panel

STATUS indicator light(s) green.

3.4 Alignment Procedures

This section describes the procedures required to adjust and align the equalizer.

3.4.1 Equalizer Adjustment

The equalizer module, illustrated in Figure Chapter 3-3, shows the relationship of

adjustment and switches to function. Table Chapter 3-3 provides the function for the

switches on the equalizer module.

Rev. 2 3-5

Page 30

Operation EQ90 Amplitude Equalizer

234

6

1

C

R

L

DELAY

EQ6

RREQ7

DELAY

OUT

IN

OUT

L

C

IN

R

R

EQ5

OUT

C

L

OUT

DELAY

RREQ8

DELAY

L

C

IN

IN

R

R

EQ4

OUT

C

L

OUT

DELAY

RREQ9

DELAY

L

C

IN

IN

R

R

DELAY

OUT

IN

R

EQ3

C

C

L

EQ10

L

OUT

DELAY

R

IN

R

R

EQ2

C

L

OUT

DELAY

BYPASS

LVL MON

IN

R

R

EQ1

SLP

ADJ

C

L

DELAY

IN

OUT

R

GAIN

ADJ

8

5

7

Figure Chapter 3-3. Equalizer Module

Table Chapter 3-3. Equalizer Module Control Functions

Item Nomenclature Function

1 R Switch Used to adjust the amplitude response.

(Refer to Figure Chapter

for the signal pattern.)

3-7

2 L Switch Used to adjust the delay peak magnitude.

(Refer to Figure Chapter

3 C Switch Used to adjust the del ay peak cent er freq uency. (Refer to Figure Chapter

f or the signal pattern.)

3-6

3-5

for the signal pattern.)

4 IN/OUT Switch Used to insert an equalizer delay section to, or remove from, the signal path.

5 R Switch Used to adjust the amplitude response. (Refer to Figure Chapter

3-8

for the

signal pattern.)

6 GAIN ADJ Potentiometer Used to set the IF output signal gain level (nominally 15 dB).

7 SLP ADJ Potentiometer

Used to provide ± 3 dB amplitude slope equalization.

8 BYPASS/LVL MON Switch Used to activate the IF output signal level monitoring function. The minimum

signal level required to avoid an alarm condition is -20 dB. In the BYPASS

position, the signal level is not monitored. However, a power supply failure

will result in an alarm condition.

3-6 Rev. 2

Page 31

EQ90 Amplitude Equalizer Operation

The 10-section 70 MHz (140 MHz option) delay equalization PCB is contained in the

internal equalizer assembly A1 and A2. The PCB contains a switch which enables or

disables the alarm output from the equalizer due to a low IF output signal level.

Removing the equalizer top cover accesses the BYPASS/LVL MON switch (8,

•

Figure 3-3).

The cover on the internal assembly A1 or A2 is labeled BYPASS or LVL

•

MON.

In the LVL MON position, the IF output signal is monitored. In the event the

•

IF signal level falls below -20 dBm nominal, an alarm is indicated on the

front panel of the equalizer and reported to external monitor and control

equipment.

In the BYPASS position, an alarm will result only if the internal power

•

supply fails.

The equalizer is made up of 6 or 10 equalizer sections with four adjustments and one

IN/OUT switch (4, Figure 3-3) for each section.

The R switches (1, 5) affect the amplitude characteristic of each section in the

•

equalizer.

Adjustment of the L switch (2) will affect the frequency of peak delay as well as

•

the magnitude of the delay peak. The variable capacitors are used to return the

delay peak to its initial center frequency.

The C switch (3) control the center frequency of the delay peak. As the

•

frequency of the delay peak is varied from 52 to 88 MHz, the magnitude of delay

over a

36 MHz bandwidth centered on the delay peak frequency will remain essentially

constant.

The IN/OUT switch (4) inserts or removes the equalizer section from the signal

•

path.

Each section of a module is initially adjusted separately with all other sections bypassed

by setting the associated IN/OUT switch (4) to out.

The test setup for measurement of the group delay and amplitude response is shown in

Figure Chapter 3-4. The following procedure describes the four adjustments made to one

equalizer section:

Equalizer Adjustment

•

Alignment to a Specific Delay Requirement

•

Slope Equalizer Adjustment

•

System Integration Alignment Procedure

•

Rev. 2 3-7

Page 32

Operation EQ90 Amplitude Equalizer

3-8 Rev. 2

Page 33

EQ90 Amplitude Equalizer Operation

DELAY

(NS)

CENTER

IF

MLA

TX

MLA

TX

70 TO 140 MHz

-15 dBm

IN

IF

OUT

EQUALIZER

MODULE

EQUALIZER

Figure Chapter 3-4. Alignment Setup

Figure Chapter 3-5 through Figure Chapter 3-20 depict oscilloscope patterns as displayed

on a Microwave Link Analyzer (MLA).

Refer to Figure Chapter 3-5 for a typical MLA display.

C MAX

FREQUENCY

IF FREQUENCY (MHz)

C MIN

Figure Chapter 3-5. Effect on Delay of Varying C Switch

Rev. 2 3-9

Page 34

Operation EQ90 Amplitude Equalizer

Adjustment of the variable inductors, L switch (2, Figure 3-3) will affect the frequency

of peak delay as well as the magnitude of the delay peak. The variable capacitors are

used to return the delay peak to its initial center frequency (Figure Chapter 3-6).

When the capacitors and inductors are varied, the flatness of the amplitude

characteristics changes. The effect of varying the R switch (1, Figure Chapter 3-3) upon

amplitude response is shown in Figure Chapter 3-7. This adjustment affects the

amplitude tilt rather than peaking. An amplitude slope appears near the frequency of the

delay peak.

The effect of varying the R switch (5, Figure Chapter 3-3) upon amplitude is shown in

Figure Chapter 3-8. This control adjusts the degree of peaking or amplitude depth near

the vicinity of the delay peak.

The variable capacitors can vary the delay peak frequency beyond the 52 to 88 MHz

(104 to 176 MHz) frequencies for all values of inductance. The inductance can vary the

peak delay over 36 MHz bandwidth from <15 to> 40 ns peak-to-peak. The amplitude

adjustments can always return the amplitude response for the equalizer to ≤ 0.15 dB

peak-to- peak.

After changing the frequency of peak delay for any section, the amplitude may require

readjustment for maximum flatness before proceeding to adjust another section. When

properly adjusted for amplitude flatness, bypassing the equalizer section will generally

effect the overall gain by ≤ 0.3 dB.

When two or more adjacent sections are inserted into the signal path there will be an

interaction between sections. This interaction is reflected only in the overall amplitude

response characteristic and is at its worst when all sections are tuned to the same

frequency. Thus, the frequencies between sections are staggered as much as possible to

minimize the interaction.

Complete the module adjustment by adjusting the GAIN ADJ potentiometer

(6, Figure Chapter 3-3) control to provide an overall gain of 15 dB and SLP ADJ

potentiometer (7) control to minimize overall amplitude slope. Record the delay shapes,

frequencies, and amplitude responses of each section separately to provide a future

reference point in the event a module fails and must be replaced.

3-10 Rev. 2

Page 35

EQ90 Amplitude Equalizer Operation

L MAX

DELAY

(NS)

AMPLITUDE

DELAY

(NS)

IF FREQUEN CY ( MHz)

L MIN

Figure Chapter 3-6. Effect on Delay of Varying “L”

IF FREQUENCY (MHz)

Figure Chapter 3-7. Effect on Amplitude of Varying “R”

Rev. 2 3-11

Page 36

Operation EQ90 Amplitude Equalizer

AMPLITUDE

DELAY

(NS)

DELAY

(NS)

IF FREQUENCY (MHz)

DELAY

Figure Chapter 3-8. Effect on Amplitude of Varying “R”

3.4.2 Alignment to a Specific Delay Requirement

The following principles shall be understood before attempting this

alignment procedure. Damage to the equipment may be the result.

CAUTION

Multi-pole bandpass filters having a nearly maximally flat response will exhibit a group

delay characteristic as shown in Figure Chapter 3-9. This shape is largely parabolic and

may be slightly flat about its center frequency and slightly tilted at its edges.

IIF FREQUENCY (MHz)

Figure Chapter 3-9. Multi-Pole Bandpass Filter Delay Response

3-12 Rev. 2

Page 37

EQ90 Amplitude Equalizer Operation

DELAY

(NS)

DELAY

(SN)

A single group delay equalizer exhibiting the same peak-to-peak delay, as the filter may

appear as shown in Figure Chapter 3-10. Combining the filter and equalizer response will

produce a delay response as shown in Figure Chapter 3-11. A substantial delay ripple

may be the result (which is not desirable in most cases). This ripple response occurs

because the equalizer delay response is not parabolic in shape. The equalizer response is

actually parabolic only over a narrow frequency range near its delay peak.

IF FREQUENCY (MHz)

Figure Chapter 3-10. Single-Section Equalizer Delay Response

IF FREQUENCY (MHz)

Figure Chapter 3-11. Composite Delay Response

Rev. 2 3-13

Page 38

Operation EQ90 Amplitude Equalizer

The parabolic bandwidth of the equalizer can be increased in one of two ways.

• The first involves using two equalizers, each with half the required peak delay,

and tuning them both to the same center frequency. This increases the parabolic

bandwidth by a factor of two.

The second method requires two equalizers of the same delay but stagger-tuned

•

about the center frequency of the filter. This method can increase the parabolic

bandwidth between two and four times depending upon the delay ripple

requirements.

The second method of equalization requires fewer sections to achieve an equalized

response, and in addition, permits adjustment for non-symmetrical filter delay responses.

As additional delay equalizers are added to the system, their frequencies will be set

further and further away from the transponder center frequency.

Equalizer parameters for the satellite equalizer, which will provide a nearly ideal

parabolic group delay response over a 36 MHz bandwidth with a peak-to-peak (P-P)

delay magnitude of 40 ns are as shown in Figure Chapter 3-4.

Table Chapter 3-4. Peak-to-Peak Delay Magnitude

Section

Number

1 56.5 14

2 67.8 14

3 77.5 14

4 62.5 14

5 72.0 14

6 83.5 14

Center Frequency

(MHz)

P-P Delay Over

36 MHz (ns)

Note:

The adjacent equalizer sections are frequency staggered to minimize interactions.

The peak-to-peak delay is measured about the center frequency of the equalizer delay

peak after its amplitude response was for maximum flatness, over the 52 to 88 MHz IF

bandwidth. The above parameters will produce an equalizer group delay characteristic as

shown in Figure Chapter 3-12.

3-14 Rev. 2

Page 39

EQ90 Amplitude Equalizer Operation

AMPLIUDE

DELA Y

(NS)

EQUALIZER

Y

fo

40

NS

fo = 70 Mhz

0.1 dB/CM

36 MHz

DELA Y

Figure Chapter 3-12. Equalizer Composite Delay Response

By adjusting all sections 1 MHz above or below the given frequencies, a 17 ns linear

positive or negative slope is achieved (refer to Figure Chapter 3-13 and Figure Chapter

3-14). Thus, small frequency offsets achieve large linear delay components. A frequency

offset of only 4 MHz will produce linear delay components of about 70 to 80 ns.

Smaller IF bandwidths require fewer sections, which can be, spaced closer together in

frequency to achieve the desired delay response.

DELAY COMPONENT

LINEAR DELA

COMPONENT

IF FREQUENCY (MHz)

Figure Chapter 3-13. All Sections Tuned 1 MHz Lower in Frequency

Rev. 2 3-15

Page 40

Operation EQ90 Amplitude Equalizer

DELA Y

(NS)

EQUALIZER

Y

DELAY COMPONENT

IF FREQUENCY (MHz)

LINEAR DELA

COMPONENT

Figure Chapter 3-14. All Sections Tuned 1 MHz Higher In Frequency

The overall amplitude response can be adjusted to less than 0.15 dB peak-to-peak for the

entire equalizer. The procedure for amplitude response adjustment is as follows:

1. Center the MLA frequency to the desired frequency of the equalizer. The sweep

bandwidth of the MLA should be 36 MHz.

2. Adjust the delay inductors and the delay capacitors until the specific peak-topeak delay response is achieved.

3. Adjust the amplitude adjustments for maximum flatness.

3.4.3 Slope Equalizer Adjustment

The SLP ADJ potentiometer (7, Figure 3-3) corrects for any residual amplitude slope in

the system. Adjustments within the slope equalizer range from 3.00 dB negative slope to

3.00 dB positive slope. The residual amplitude slope in a satellite system can be due to

any component in the system or their aggregates, including runs of cables, Waveguide,

etc. The slope compensation is usually accomplished as part of the system integration

procedure.

3-16 Rev. 2

Page 41

EQ90 Amplitude Equalizer Operation

3.4.4 System Integration Alignment Procedure

Note:

The following description assumes that the equalizer has been tuned to the inverse

of the satellite transponder group delay characteristic.

The last stage of the adjustment procedure involves matching the delay characteristic of

the satellite transponder and that of the equalizer. Final adjustments of the equalizer may

be required to remove residual linear, parabolic and/or delay ripple components.

A typical test setup block diagram required for this process is shown in Figure Chapter 3-

15.

Figure Chapter 3-16 shows a typical ideal full transponder delay characteristic. The

equalizer must have an inverse delay characteristic as shown in Figure Chapter 3-17. The

two delay characteristics when combined would ideally provide the composite delay

result shown in Figure Chapter 3-18.

In actual practice, the transponder delay characteristic is rarely symmetrical or smooth as

shown in Figure Chapter 3-16 and it is rare for any two-satellite transponder to have the

same delay shape and magnitude. If the RF carrier remains at the transponder center

frequency, as the IF bandwidths of the carrier in use narrows, the transponder group

delay will be progressively reduced. However, it is typical that narrow bandwidth RF

carriers will be shifted towards one of the two transponder band edges.

70

MHz

U/C, IPA

IFL, HPA

RF, MUX

140

OR

MHz

LNA, IFL

D/C

ANT

MLA

TX

MLA

TX

UUT

Figure Chapter 3-15. System Integration Alignment Test Setup

Rev. 2 3-17

Page 42

Operation EQ90 Amplitude Equalizer

DELAY

(NS)

DELAY

(NS)

IF FREQUENCY (MHz)

Figure Chapter 3-16. Typical Satellite Transponder Delay

IF FREQUENCY (MHz)

Figure Chapter 3-17. Required Equalizer Delay Characteristic

3-18 Rev. 2

Page 43

EQ90 Amplitude Equalizer Operation

DELAY

(NS)

IF FREQUENCY (MHz)

Figure Chapter 3-18. Ideal Composite Delay Result

Figure Chapter 3-19 shows the typical group delay response of a 17.5 MHz bandwidth

carrier such as half transponder video. In this case, the RF carrier is shifted lower in

frequency (relative to transponder center frequency) by about 8 to 9 MHz. The resultant

transponder delay contains a mixture of linear and parabolic delay coefficients. The

required equalizer delay must be the inverse of the transponder delay as shown in Figure

Chapter 3-20 resulting in an ideal composite delay result as shown in Figure Chapter 3-

21.

Once the equalizer has been pre-aligned to a required inverse delay characteristic, it is

advisable to perform a station loopback delay test through the assigned transponder with

the equipment which will be used to transmit the actual carrier. Adjustments may be

required depending upon the resultant measured delay characteristic.

Figure Chapter 3-22 through Figure Chapter 3-24 illustrates how the composite delay

would appear if the transponder or equalizer frequency were shifted slightly with respect

to one another. The resultant composite delay appears as a linear slope. The direction of

this slope is dependent upon the direction of frequency offset. In this case, a negative

slope signals that a positive frequency shift is required of the equalizer characteristic to

achieve a flat composite result. Frequency offsets of as little as 0.5 MHz can result in

substantial delay slopes. In this case, a very slight increase in every equalizer section

frequency is required to preserve the delay characteristics while altering the composite

slope.

Rev. 2 3-19

Page 44

Operation EQ90 Amplitude Equalizer

DELAY

(NS)

DELAY

(NS)

IF FREQUENCY (MHz)

Figure Chapter 3-19. Typical Half Transponder Video Carrier Delay

IF FREQUENCY (MHz)

Figure Chapter 3-20. Required Equalized Delay Characteristic

3-20 Rev. 2

Page 45

EQ90 Amplitude Equalizer Operation

DELA

(

S)

DELAY

(NS)

N

Y

IF FREQUENCY (MHz)

Figure Chapter 3-21. Ideal Composite Delay Result

IF FREQUENCY (MHz)

Figure Chapter 3-22. Typical Delay Characteristic

Rev. 2 3-21

Page 46

Operation EQ90 Amplitude Equalizer

DELAY

(NS)

)

DELAY

(NS)

IF FREQUENCY (MHz

Figure Chapter 3-23. Shifted Equalizer Delay Characteristic

IF FREQUENCY (MHz)

Figure Chapter 3-24. Resultant Composite Delay Characteristic

Figure Chapter 3-25 through Figure Chapter 3-27 illustrates what would happen to the

composite delay shape if the equalizer had more delay than the satellite transponder. The

inverse composite delay characteristics would result if the equalizer had less delay than

the satellite transponder. The direction of the curve determines how the equalizer is to be

adjusted. In this instance, equalizer sections tuned to frequencies above 70 MHz must be

adjusted to even higher frequencies.

3-22 Rev. 2

Page 47

EQ90 Amplitude Equalizer Operation

The amount of frequency shift is directly proportional to the amount of frequency offset.

For example:

A section tuned to 80 MHz would have to be offset twice as much as one tuned

•

to 70 MHz.

Sections tuned to 70 MHz require no frequency adjustment.

•

Sections below 70 MHz require the same treatment as those tuned above 70

•

MHz, except in the opposite frequency direction.

These adjustments affect the magnitude of delay without greatly affecting the

•

delay shape.

The same effect can be achieved by reducing or increasing each equalizer section delay,

depending upon its particular frequency location. Although the overall effect is the same,

adjusting delay magnitude also has the effect of changing frequency of the delay section,

which complicates the adjustment process. The order of adjustment should be:

1. Eliminate linear delay.

2. Eliminate parabolic delay.

3. Reduce delay ripple.

Reduction of the magnitude of delay ripple will require adjustments of the delay

magnitude and frequency of equalizer sections, which are centered near the frequency of

the delay ripple. This process is slow and tedious, and will require many trial and error

attempts before the ripple magnitude is below acceptable levels. It is advisable during the

adjustment process to maintain a record of adjustments made so that backtracking is

possible if a series of adjustments yields poor results.

The delay characteristics discussed to this point have been largely parabolic in shape,

which is ideal for equalization. Actual transponder delays may appear more trapezoidal,

as shown in Figure Chapter 3-28, with straight-line segments. Figure Chapter 3-29 and

Figure Chapter 3-30 demonstrates the effect of an equalizer frequency offset. By using

straight line approximations of the actual characteristics, one can determine the cause of

the composite response shape and thus arrive at a correct course of action to obtain a

delay equalized composite response.

After the satellite delay characteristic has been properly equalized, it will be necessary to

adjust the equalizer for a flat amplitude characteristic. This is best accomplished on the

equalizer itself using an MLA.

Once the equalization and amplitude adjustments have been completed it is advisable to

record the amplitude and delay characteristic of each section of each equalizer module by

itself so that a backup or replacement equalizer module can be properly set without

resorting to removing traffic from the satellite transmission path.

Rev. 2 3-23

Page 48

Operation EQ90 Amplitude Equalizer

DELAY

(NS)

)

DELAY

(NS)

)

Be sure to reset the gain of the equalizer section before proceeding with other

measurements.

IF FREQUENCY (MHz

Figure Chapter 3-25. Transponder Delay Characteristic

IF FREQUENCY (MHz

Figure Chapter 3-26. Equalizer Delay Characteristic

3-24 Rev. 2

Page 49

EQ90 Amplitude Equalizer Operation

DELAY

(NS)

DELAY

(NS)

)

IF FREQUENCY (MHz)

Figure Chapter 3-27. Resultant Composite Delay Characteristic

IF FREQUENCY (MHz

Figure Chapter 3-28. Transponder Delay Characteristic

Rev. 2 3-25

Page 50

Operation EQ90 Amplitude Equalizer

DELAY

(NS)

DELAY

(NS)

IF FREQUENCY (MHz)

Figure Chapter 3-29. Equalizer Offset Delay Characteristic

IF FREQUENCY (MHz)

Figure Chapter 3-30. Resultant Composite Delay Characteristic

3-26 Rev. 2

Page 51

EQ90 Amplitude Equalizer Operation

At this point, the SLP ADJ (7, Figure 3-3) potentiometer of the slope equalizer can be

readjusted to minimize the amplitude variations in the system as follows:

1. Connect a -20 dB IF output of a MLA transmitter to the equalizer IF input

connector.

2. Adjust GAIN ADJ potentiometer (6, Figure Chapter 3-3) for +15 dB of gain.

3. Adjust the SLP ADJ potentiometer (7, Figure Chapter 3-3) so the output of the

module as measured on the MLA receiver presents a flat response.

Note:

The slope adjusts resistor provides for up to ± 3.0 dB of positive or

negative amplitude slope adjustment range.

Rev. 2 3-27

Page 52

This chapter describes the following:

System Checkout

•

Troubleshooting

•

Replacement Procedures

•

4.1 Checkout

This equipment contains parts and assemblies sensitive to damage by ESD.

Use ESD precautionary procedures when touching, removing, or inserting

CAUTION

Note:

operation and should be performed after initial installation or whenever the equalizer is

suspected of being inoperative. If a discrepancy is detected during the checkout

procedure, refer to the troubleshooting to locate the cause of the fault. After the fault is

located and the repair effected, perform a final checkout procedure before returning the

unit to service.

To perform the equalizer checkout, proceed as follows:

PCBs.

The checkout procedure in this section provides an indication of overall equalizer

1. Set rear panel power switch (10, Figure 3-2) to 1 (on) position and verify that

front panel indicator status lights.

2. Tag and disconnect system cables attached to the equalizer assembly.

3. Connect a -20 dBm, 75Ω, 70 MHz (140 MHz option) signal source to rear panel

connector A IN and terminate A OUT into 75Ω BNC termination cable.

Chapter 4.

MAINTENANCE

4

Rev. 2 4–1

Page 53

Maintenance EQ90 Amplitude Equalizer

4. Set the BYPASS/LVL MON switch (8, Figure 3-3) to the LVL MON position

and verify that the front panel STATUS indicator lights green.

5. Remove the A IN signal input to the equalizer and observe that STATUS

indicator lights (red).

6. Disconnect the signal source and termination cables.

7. Reconnect the system cables to the equalizer assembly.

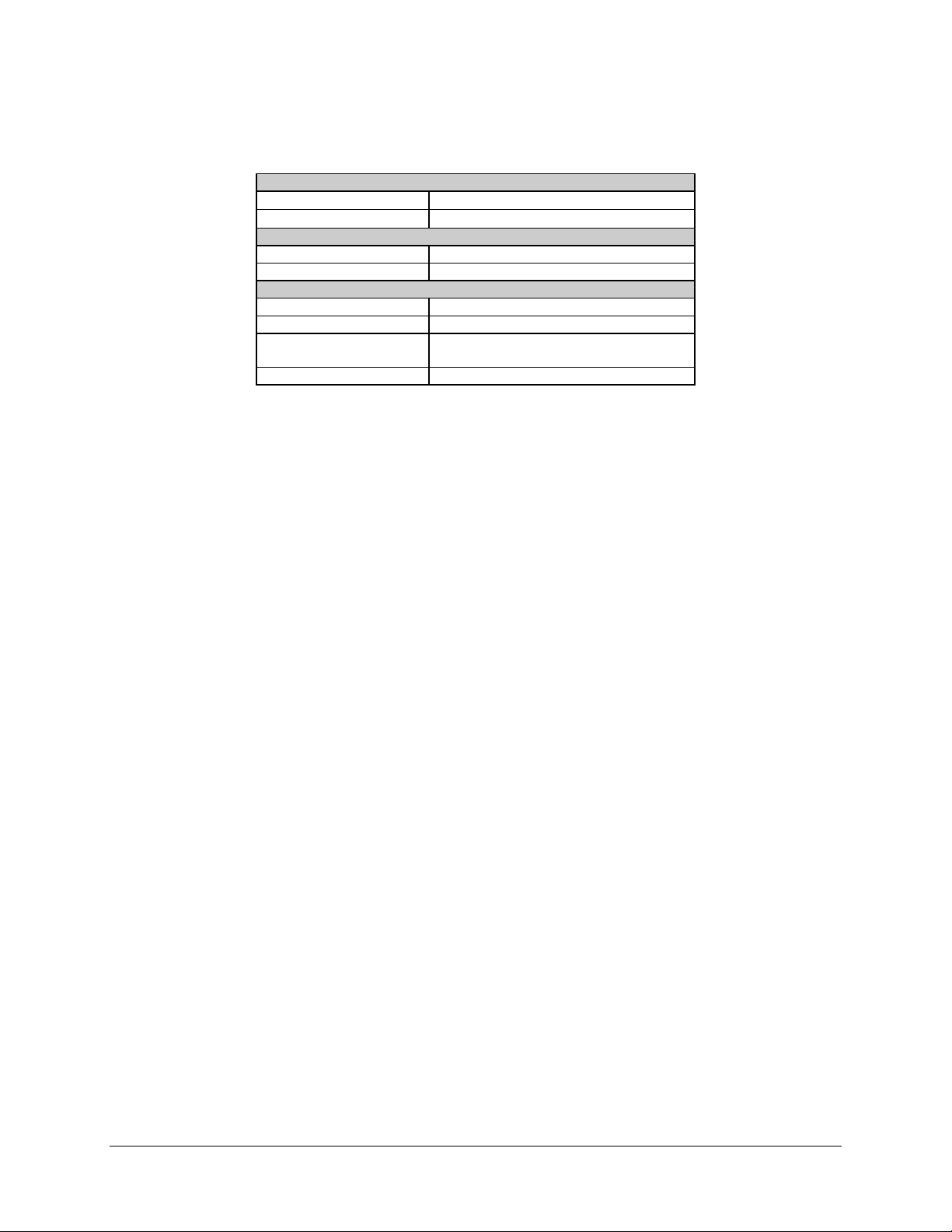

4.2 Troubleshooting

The troubleshooting procedures listed in Table 4-1 is designed to aid service personnel in

locating faulty assemblies and components in the equalizer. The troubleshooting

procedure lists the symptoms that could be detected during the checkout procedure and

operation and the probable causes for each symptom. The last column of the procedure

gives the corrective action required to isolate and correct the malfunction. When it is

necessary to replace and assembly or component, refer to the replacement procedures of

Paragraph 4.6.

Table 4-1. Equalizer Troubleshooting Procedure

Symptom Probable cause Corrective Action

Front panel STATUS indicator out 1. No power applied to unit. 1. Check that primary AC power is applied to rear

panel power receptacle.

2. Fuse. 2. Check fuse. Rep lace if open.

3. Power Supply 3 Check for +12 VDC at the output of the power

supply. If +12 VDC is not present, replace

power supply.

STATUS LED lights red 1. Power Supply 1a Refer to DC interconnect diagram and ensure

+5 and -5 VDC is present at connectors J4, pin

3 and 5.

1b If voltage is no t present, replace power supply

assembly.

2. Equalizer 2a Measure the output power level of the

equalizer; the peak or continuous wave output

power level shall be above -20 dBm.

2b If the po wer levels are correct and below

-20 dBm, set the LVL MON switch on the

equalizer module to the BYPASS position.

4–2 Rev. 2

Page 54

EQ90 Amplitude Equalizer Maintenance

4.3 Replacement Procedures

The following paragraphs describe the procedures for replacing assemblies and

components in the equalizer. The following procedures assume that power has been

disconnected and the unit has been removed from it's mounting and set in a safe work

area. For parts location and spare parts information, refer to Paragraph 4.3.5.

4.3.1 Chassis Cover

Remove the chassis cover as follows:

1. Remove and retain the two screws that secure the cover to the chassis.

2. Remove the cover.

4.3.2 Equalizer Modules

Replace an equalizer module, proceed as follows:

1. Remove chassis cover (Para. 4.3.1).

2. Disconnect cable assemblies at module connectors A IN and AN OUT.

3. Remove the six screws securing the equalizer cover to the equalizer PCB.

4. Remove standoffs and replace PCB by reversing above Steps 1, 2, and 3.

4.3.3 Power Supply Assembly

Replace the power supply assembly proceed as follows:

1. Remove chassis cover (Para. 4.3.1).

2. Disconnect cable assembly from power supply connector J1 and J2.

3. Turn equalizer over and remove the four screws securing power supply assembly

to the chassis.

4. Install replacement power supply assembly by reversing above Steps 1, 2, and 3.

Rev. 2 4–3

Page 55

Maintenance EQ90 Amplitude Equalizer

4.3.4 Fuse Replacement

Replace fuse in the power supply rear panel AC power receptacle, proceed as follows:

1. Remove power cord from primary power receptacle.

2. Using small screwdriver, pry locking tab of fuse holder to release fuse holder

from rear panel power receptacle and remove fuse holder from receptacle.

3. Remove fuse from fuse holder and install replacement fuse in fuse holder.

4. Insert fuses holder into power receptacle and press inward until fuse holder

locking tab snaps into place.

4.3.5 Spare Parts

Figure 4-1 illustrates the location of the equalizer module and components and Table 4-2

lists the spare parts for the equalizer.

4–4 Rev. 2

Page 56

EQ90 Amplitude Equalizer Maintenance

Figure 4-1. Equalizer Component Locations

Table 4-2. Equalizer Spare Parts

Item Manufacturer Part Number

10 Section 70 MHz Delay Equalizer Printed Circuit Board EFData D68302-1

6 Section 70 MHz Delay Equalizer PCB EFData D68302-2

6 Section 140 MHz Delay Equalizer PCB EFData D69978-2

Triple Output Power Supply (30 Watt) EFData A68466-1

LED Assembly EFData PL68557-1

Rev. 2 4–5

Page 57

Maintenance EQ90 Amplitude Equalizer

This page is intentionally left blank.

4–6 Rev. 2

Page 58

A

This appendix describes the application note for EQ90 Series Group Delay/Amplitude

Equalizer.

A.1 Introduction

The following application note is provided for the new product line of equalizers.

The purpose of this application note is to ensure that the EQ90 series of equalizer

specifications are understood for successful integration of this product into a system

environment.

The EQ90-70X-XX series of equalizers are designed to replace the DEQ-701, 702, 703,

and 723 series of 70 MHz equalizers.

The EQ90-14X-XX series of equalizers are designed to replace the DEQ-713, 714, 732,

and 733 series of 140 MHz equalizers.

Appendix A.

APPLICATION NOTE

Rev. 2 A–1

Page 59

Application Note EQ90 Amplitude Equalizer

A.2 Operational Parameters

Attention must be paid to IF levels and how external parameters are adjusted to achieve

optimum results from the equalizer.

The equalizer is specified for a nominal +15 dB gain. The gain will vary slightly,

approximately ± 1.5 dB over the 0° to 50°C (32 to 132°F) operating temperature range.

Composite IF input levels should not exceed -15 dBm, however:

If attenuation at the input of the equalizer is required, use the minimum amount

•

of attenuation necessary to achieve the equalizers specified input level. The

equalizer has a high noise figure, the same as the DEQ-7XX series of equalizers,

which is typically 34 dB.

Use the highest IF input signal level possible that will increase the equalizers

•

overall signal-to-noise ratio.

If the gain of the equalizer needs to be reduced, it should be done at the IF output

•

using fixed attenuators. Attenuating the IF output of the equalizer will reduce the

output noise power of the equalizer which is typically -125 dBm/Hz.

A–2 Rev. 2

Page 60

EQ90 Amplitude Equalizer Application Note

A.3 Fault Monitor

The equalizer monitors the IF output signal level and power supplies for fault conditions.

These alarms are summed and reported to the rear panel monitor connector and front

panel status indicator(s).

Normally the equalizer is set to monitor the IF output signal level.

If no signal is present at the output of the unit, a sum fault will be generated.

•

The alarm detection circuitry will not detect the loss of a single carrier in a

multi-carrier environment.

If the equalizers composite output level falls below a factory preset threshold,

•

(-20 dBm), the equalizer will generate a sum fault condition.

If level monitoring is not desired because output signal levels are too low, a

•

switch located on the equalizer module can bypass the output detection feature.

When level detection is bypassed, the equalizer fault circuitry will only monitor

•

the equalizers internal power supply.

A.4 Monitor Interface

The monitor interface of the equalizer is designed to facilitate 1:1 and 1:N redundancy

implementations when using an equalizer.

The equalizer will interface directly to V90 and V901 frequency converters via a 9-pin

female, female D ribbon cable. The channel monitor port of the equalizer is connected to

the J6 rear panel connection on these converters.

This connection places the sum fail relay contacts of the equalizer in parallel with the

fault relay contacts of the converter. V90 and V901 converters can report the fault status

of an equalizer, connected to J6, to remote M&C facilities.

The equalizer also will directly interface to the Automatic Redundancy Controller (ARC)

via a 9-pin male, female D ribbon cable. The channel monitor port of the equalizer is

connected to one of the rear panel input connections, J2, or J3, of the ARC.

Rev. 2 A–3

Page 61

Application Note EQ90 Amplitude Equalizer

This page is intentionally left blank.

A–4 Rev. 2

Page 62

G

Glossary

The following is a list of acronyms and abbreviations that may be found in this manual.

Acronym/

Abbreviation

Ω

A Ampere

AC Alternating Current

ADJ Adjust

AGC Automatic Gain Control

AIS Alarm Indication Signal

ASK Amplitude Shift Keying

ASYNC Asynchronous

AUPC Automatic Uplink Power Control

AUX 1 Auxiliary 1

BB Baseband

BCD Binary Coded Decimal

BER Bit Error Rate

BER CONT BIT Error Rate Continuous

bit/s bits per second

C Celsius

CCITT International Telephone and Telegraph Consultative Committee

CDMA Code Division Multiple Access

CH Channel

CHNL Channel

CIC Common Interface Circuit

CL Carrier Loss

CLK Clock

CLR Clear

Coax Coaxial

Codec Coder/Decoder

COM Common

CPU Central Processing Unit

cr Carriage Return

CRC Cyclic Redundancy Check

CRT Cathode Ray Tube

Ohms

Definition

Rev. 2 g–1

Page 63

Glossary EQ90 Amplitude Equalizerl

CS Clear to Send

CSC Comstream Compatible

CSMA Carrier Sense Multiple Access

CTS Clear to Send

CU Channel Unit

CW Continuous Wave

D/C Down Converter

DAC Digital-to-Analog Converter

DAMA Demand Assignment Multiple Access

dB Decibels

dB/Hz Decibels/Hertz (unit of carrier-to-noise density ratio)

dBc Decibels referred to carrier

dBm Decibels referred to 1.0 milliwatt

dBm0 The signal magnitude in dBm referenced to the nominal level at that

point

dBW Decibels referred to 1.0 watt

DC Direct Current

DDS Direct Digital Synthesis

Demod Demodulator

DET Detector

DM Data Mode

DPCM Differential Pulse Code Modulation

DPSK Differential Phase Shift Keying

DSP Digital Signal Processing

DSR Data Signal Rate

DTE Data Terminal Equipment

Eb/N0

Bit Energy-to-Noise Ratio

EFD EFData Compatible

EIA Electronic Industries Association

ESC Engineering Service Circuit or Engineering Service Channel

ESD Electrostatic Discharge

EXC External Clock

EXT External Reference Clock

FIFO First in/First Out

FW Firmware

GHz

Gigahertz (10

9

hertz)

GND Ground

HI STAB High Stability

HPA High Power Amplifier

Hz Hertz (cycle per second)

I&Q In-Phase and Quadrature

I/O Input/Output

k

kilo (10

3

)

KΩ kilo-ohms

kbit/s

kHz

Kilobits per second (10

Kilohertz (10

3

Hertz)

3

bits per second)

ks/s Kilosymbols Per Second (103 symbols per second)

kW

Kilowatt (10

3

Watts)

LAN Local Area Network

LCD Liquid Crystal Display

LED Light-Emitting Diode

lf Line Feed

mA Milliamperes

Max Maximum

Mbit/s Megabits per second

MHz

Megahertz (10

6

Hertz)

g–2 Rev. 2

Page 64

EQ90 Amplitude Equalizer Glossary

Min Minimum or Minute

Mod Modulator

ms

n

Millisecond (10

nano (10

-3

-9

second)

)

N/A Not Applicable

NACK Negative Acknowledgment

ns

Nanosecond (10

-9

second)

P-P Peak-to-Peak

PCB Printed Circuit Board

PK Peak

PPM Parts Per Million

PS Power Supply

PWR Power

REF Reference

s Second

SCPC Single Channel Per Carrier

SCR Serial Clock Recei ve

SCT Serial Clock Transmit

SCTE Serial Clock Transmit External

SD Send Data

SFS Subframe Sync

SMS Satellite Multiservice System

SN Signal-to-Noise Ratio

SSB Single-sideband

SSPA Solid State Power Amplifier

ST Send Timing

SW Switch

SYNC Synchronize

TX Transmit (Transmitter)

U/C Up converter

V Volts

VAC Volts, Alternating Current

VCO Voltage-Controlled Oscillator

VCXO Voltage-Controlled Crystal Oscillator

VDC Volts, Direct Current

VSWR Voltage Standing Wave Ratio

W Watt

WG Waveguide

Rev. 0 g–3

Page 65

Glossary EQ90 Amplitude Equalizerl

This page is intentionally left blank.

g–4 Rev. 2

Page 66

METRIC CONVERSIONS

Units of Length

Unit

1 centimeter — 0.3937 0.03281 0.01094

1 inch 2.540 — 0.08333 0.2778

1 foot 30.480 12.0 — 0.3333

1 yard 91.44 36.0 3.0 —

Centimeter

Inch

Foot

Yard

Mile

6.214 x 10

1.578 x 10

1.893 x 10

5.679 x 10

Meter

-6

-5

-4

-4

0.01 — —

0.254 — 25.4

0.3048 — —

0.9144 — —

Kilometer Millimeter

1 meter 100.0 39.37 3.281 1.094

1 mile

1 mm — 0.03937 — — — — — —

1 kilometer — — — — 0.621 — — —

1.609 x 10

5

6.336 x 104 5.280 x 103 1.760 x 103

6.214 x 10

-4

—

— — —

1.609 x 103

1.609 —

Temperature Conversions

Ounce

Troy

Formulas

C = (F - 32) * 0.555

F = (C * 1.8) + 32

Pound

Avoir.

Pound

Troy

Kilogram

Unit

32° Fahrenheit

212° Fahrenheit

-459.6° Fahrenheit

°°°°

Fahrenheit

—

—

—

°°°°

Centigrade

0

(water freezes)

100

(water boils)

273.1

(absolute 0)

Units of Weight

Unit

1 gram — 0.03527 0.03215 0.002205 0.002679 0.001

Gram

Ounce