Page 1

CNGE3FE7MS2 Series

Managed Industrial Switch

User Manual

V1.2

August – 2009

Page 2

FCC Warning

This Equipment has been tested and found to comply with the limits for a

Class-A digital device, pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy. It may cause harmful interference to radio

communications if the equipment is not installed and used in accordance

with the instructions. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

CE Mark Warning

This is a Class-A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

Page 3

Content

Chapter 1 Introduction ............................................ 1

1.1 Hardware Features ........................................ 1

1.2 Software Features.......................................... 4

1.3 Package Contents.......................................... 7

Chapter 2 Hardware Description............................ 8

2.1 Physical Dimension........................................ 8

2.2 Front Panel..................................................... 8

2.3 Top View........................................................ 9

2.4 LED Indicators.............................................. 10

Chapter 3 Hardware Installation........................... 12

3.1 Installation Steps.......................................... 12

3.2 DIN-Rail Mounting........................................ 13

3.3 Wall Mount Plate Mounting.......................... 15

3.4 Wiring the Power Inputs............................... 16

3.5 Wiring the Fault Alarm Contact.................... 17

3.6 Wiring the Digital Inputs/ Outputs................. 18

3.7 Cabling......................................................... 19

Chapter 4 Network Application ............................ 23

4.1 X-Ring Application........................................ 24

4.2 Coupling Ring Application............................ 25

4.3

Dual Homing Application.............................. 26

Chapter 5 Console Management.......................... 27

5.1

5.2

Connecting to the Console Port................... 27

Pin Assignment............................................ 27

Page 4

5.3 Login in the Console Interface ..................... 28

5.4 CLI Management.......................................... 30

5.5 Commands Level......................................... 30

Chapter 6 Web-Based Management..................... 32

6.1 About Web-based Management .................. 32

6.2 Preparing for Web Management.................. 32

6.3 System Login ............................................... 33

6.4 System Information...................................... 34

6.5 IP Configuration ........................................... 35

6.6 DHCP Server ............................................... 37

6.6.1 System configuration...................................... 38

6.6.2 Client Entries .................................................. 39

6.6.3 Port and IP Bindings....................................... 40

6.7 TFTP............................................................ 41

6.7.1 Update Firmware............................................ 41

6.7.2 Restore Configuration..................................... 42

6.7.3 Backup Configuration ..................................... 43

6.8 System Event Log........................................ 44

6.8.1 Syslog Configuration....................................... 44

6.8.2 System Event Log—SMTP Configuration....... 46

6.8.3 System Event Log—Event Configuration ....... 48

6.9 Fault Relay Alarm......................................... 50

6.10 SNTP Configuration..................................... 51

6.11 IP Security.................................................... 55

6.12 Digital Input/Output ...................................... 57

6.13 User Authentication...................................... 60

Page 5

6.14 Port Statistics ...............................................61

6.15 Port Control..................................................63

6.16 Port Trunk ....................................................65

6.16.1 Aggregator setting ........................................ 65

6.16.2 Aggregator Information................................. 67

6.16.3 State Activity................................................. 73

6.17 Port M irroring ............................................... 75

6.18 Rate Lim iting ................................................76

6.19 VLAN configuration ...................................... 78

6.19.1 Port-based VLAN.......................................... 79

6.19.2 802.1Q VLAN................................................ 82

6.20 Rapid Spanning Tree ................................... 88

6.20.1 RSTP System Configuration......................... 88

6.20.2 Port Configuration......................................... 90

6.21 SNM P Configuration .................................... 92

6.21.1 System Configuration ................................... 92

6.21.2 Trap Configuration........................................ 94

6.21.3 SNMPV3 Configuration................................. 95

6.22 QoS Configuration........................................98

6.22.1 QoS Policy and Priority Type........................ 98

6.22.2 Port-based Priority........................................ 99

6.22.3 COS Configuration...................................... 100

6.22.4 TOS Configuration...................................... 100

6.23 IGMP Configuration.................................... 101

6.24 X-Ring........................................................ 103

6.25 Security—802.1X/Radius Configuration..... 105

6.25.1

System Configuration ................................. 105

Page 6

6.25.2 Port Configuration....................................... 107

6.25.3 Misc Configuration...................................... 108

6.26 MA C Address Table................................... 109

6.26.1 Static MAC Address.................................... 109

6.26.2 MAC Filtering.............................................. 111

6.26.3 All MAC Addresses..................................... 112

6.27 Factory Default........................................... 115

6.28 Save Configuration.................................... 115

6.29

System Reboot........................................... 115

Troubleshooting .................................................... 116

Appendix A—RJ-45 Pin Assignment................... 117

RJ-45 Pin Assignments........................................ 117

Appendix B—Command Sets............................... 121

System Commands Set....................................... 121

Port Commands Set............................................. 124

Trunk Commands Set.......................................... 126

VLAN Commands Set.......................................... 128

Spanning Tree Commands Set............................ 130

QOS Commands Set........................................... 133

IGMP Commands Set.......................................... 133

Mac / Filter Table Commands Set ....................... 134

SNMP Commands Set......................................... 135

Port Mirroring Commands Set ............................. 138

802.1x Commands Set ........................................ 138

TFTP Commands Set.......................................... 141

SystemLog, SMTP and Event Commands Set.... 141

Page 7

SNTP Commands Set.......................................... 143

X-ring Commands Set.......................................... 145

Page 8

Chapter 1 Introduction

The CNGE3FE7MS2 Managed Industrial Switch is a cost-effective solution and meets

the high reliability requirements demanded by industrial applications. The

CNGE3FE7MS2 Managed Industrial Switch can be easily managed through the Web

GUI and NS-View. Using the fiber ports can extend the connection distance that

increases the network elasticity and performance. It also provides the X-Ring function

that can prevent a network connection failure.

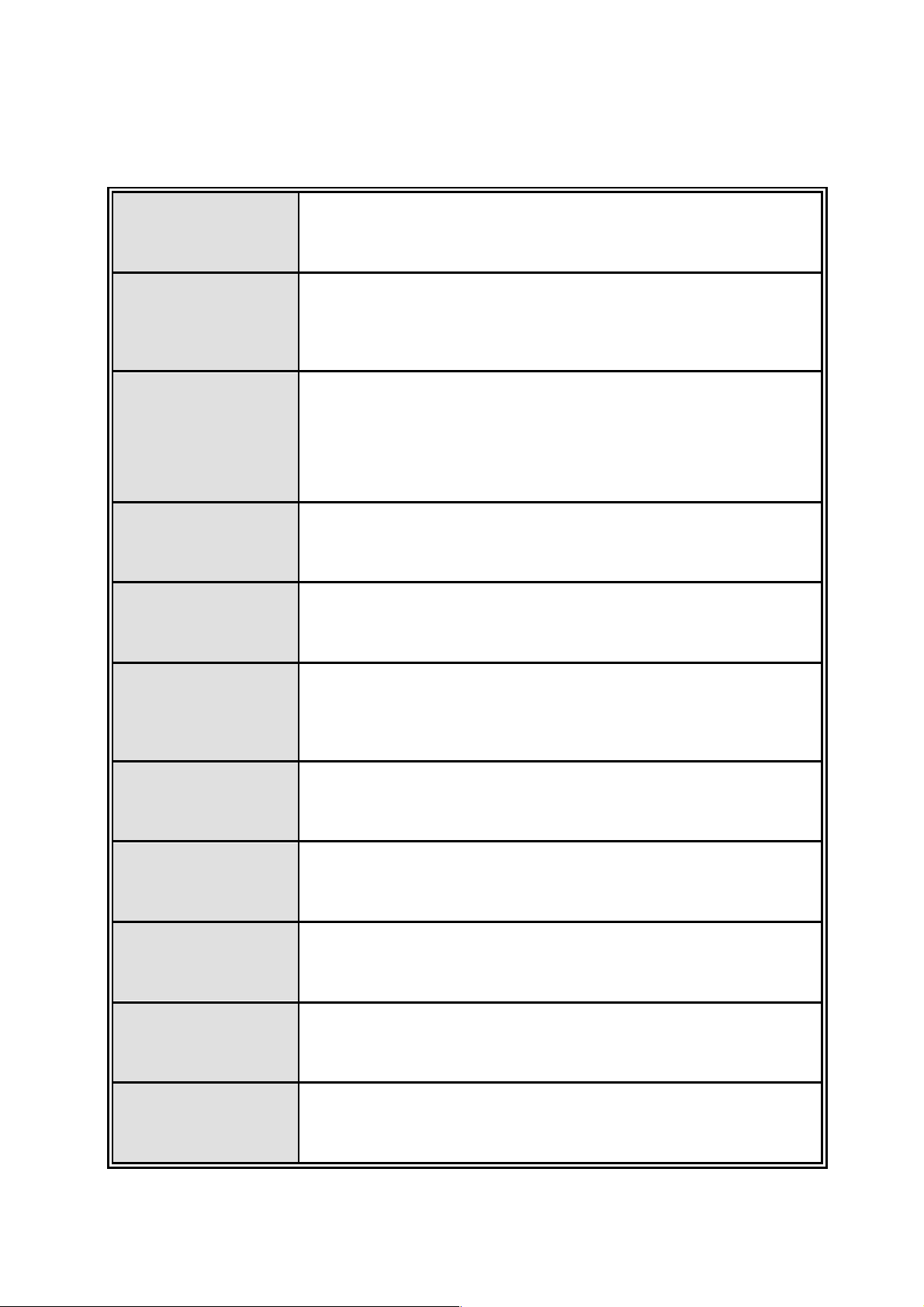

1.1 Hardware Features

Standard

Switch

Architecture

IEEE 802.3 10Base-T Ethernet

IEEE 802.3u 100Base-TX

IEEE802.3ab 1000Base-T

IEEE802.3z Gigabit fiber

IEEE802.3x Flow Control and Back Pressure

IEEE802.3ad Port trunk with LACP

IEEE802.1d Spanning Tree

IEEE802.1w Rapid Spanning Tree

IEEE802.1p Class of Service

IEEE802.1Q VLAN Tag

IEEE 802.1x User Authentication (Radius)

Back-plane (Switching Fabric): 7.4Gbps

Packet throughput ability(Full-Duplex): 11Mpps @64bytes

14,880pps for Ethernet port

Transfer Rate

Packet Buffer 1Mbits

MAC Address 8K MAC address table

148,800pps for Fast Ethernet port

1,488,000pps for Gigabit Fiber Ethernet port

1

Page 9

Flash ROM 4M bytes

DRAM 32M bytes

10/100TX: 7 x RJ-45

10/100/1000T Mini-GBIC Combo: 3 x RJ-45 + 3 x

Connector

100/1000 SFP sockets

RS-232 connector: RJ-45 type

2 Digital Input (DI): Level 0 : -30~2V

Level 1 : 10~30V

DI/DO

Max. input current:8mA

2 Digital Output(DO): Open collector to 40VDC, 200mA

10Base-T: 2-pair UTP/STP Cat. 3, 4, 5/ 5E cable

EIA/TIA-568 100-ohm (100m)

100Base-T: 2-pair UTP/STP Cat. 5/ 5E cable

Network Cable

EIA/TIA-568 100-ohm (100m)

1000Base-T: 2-pair UTP/STP Cat. 5/ 5E cable

EIA/TIA-568 100-ohm (100m)

Multimode: 50/125um~62.5/125um

Single mode: 9/125um

Optical Fiber

Available distance: SFP Dependant

Wavelength: SFP Dependant

Protocol CSMA/CD

Per unit: Power (Green), Power 1 (Green), Power 2

(Green), Fault (Red), Master (Green)

10/100TX : Link/Activity (Green), Full duplex/Collision

LED

(Amber)

Power Supply

Gigabit Copper: Link/Activity (Green), Speed (1000Mbps

Green)

SFP: Link/Activity (Green)

DC 12 ~ 48V (Source Input should be lower than 240W),

Redundant power with polarity reverse protect function and

2

Page 10

removable terminal block

Power

10.2Watts

Consumption

Operating

5% to 95% (Non-condensing)

Humidity

Operating

-40oC ~ 75oC

Temperature

Storage

-40oC ~ 85oC

Temperature

Case Dimension IP-30, 72mm (W) x 105mm (D) x 152mm (H)

Fan Number 0

Installation DIN rail and wall mount ear

FCC Class A, CE EN61000-4-2 (ESD), CE EN61000-4-3

(RS), CE EN-61000-4-4 (EFT), CE EN61000-4-5 (Surge),

EMI

CE EN61000-4-6 (CS), CE EN61000-4-8,

CE EN61000-4-12, CE EN61000-6-2, CE EN61000-6-4,

C-Tick

Safety UL, cUL, CE/EN60950-1

IEC60068-2-32 (Free fall), IEC60068-2-27 (Shock),

Stability Testing

IEC60068-2-6 (Vibration)

3

Page 11

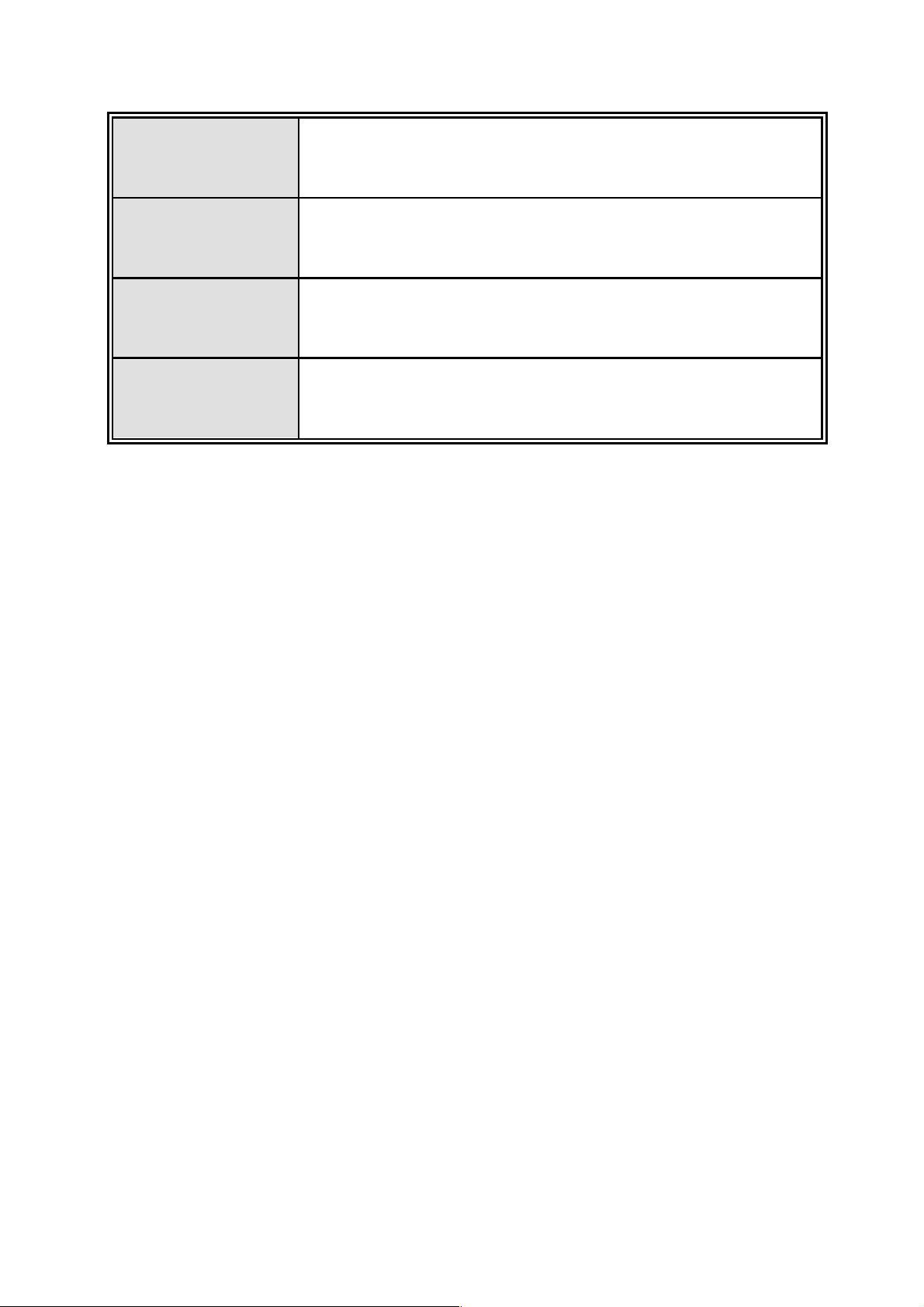

1.2 Software Features

Management SNMP v1 v2c, v3/ Web/Telnet/CLI/NS-View

RFC 1215 Trap, RFC1213 MIBII, RFC 1157 SNMP MIB,

SNMP MIB

VLAN

Port Trunk with

LACP

Spanning tree IEEE802.1w rapid spanning tree.

X-Ring

RFC 1493 Bridge MIB, RFC 2674 VLAN MIB, RFC 1643 ,

RFC 1757, RSTP MIB, Private MIB

Port Based VLAN

IEEE 802.1Q Tag VLAN (256 entries)/ VLAN ID (Up to 4K,

VLAN ID can be assigned from 1 to 4096.)

GVRP (256 Groups)

LACP Port Trunk: 4 Trunk groups/Maximum 4 trunk

members

Supports X-ring, Dual Homing, Couple Ring Topology

Provides redundant backup feature and the recovery time

below 20ms

The quality of service determined by port, Tag and IPv4

Quality of Service

Type of service, IPv4/IPv6 Different Service

Supports IEEE802.1p class of service, per port provides 4

Class of Service

priority queues

Supports 100 entries of MAC address for static MAC and

Port Security

another 100 for MAC filter

Port Mirror Supports 3 mirroring types: “RX, TX and Both packet”.

Supports IGMP snooping v1,v2

IGMP

256 multicast groups and IGMP query

4

Page 12

Supports 10 IP addresses that have permission to access

IP Security

the switch management and to prevent unauthorized

intruder.

Login Security Supports IEEE802.1X Authentication/RADIUS

Supports ingress packet filter and egress packet limit

The egress rate control supports all of packet type and the

limit rates are 100K~250Mbps

Bandwidth

Control

Ingress filter packet type combination rules are

Broadcast/Multicast/Unknown Unicast packet,

Broadcast/Multicast packet, Broadcast packet only and all

of packet. The packet filter rate can be set from 100k to

250Mbps

Supports Flow Control for Full-duplex and Back Pressure

Flow Control

for Half-duplex

System Log Supports System log record and remote system log server

Supports SMTP Server and 6 e-mail accounts for receiving

SMTP

event alert

Provides one relay output for port breakdown, power fail

Relay Alarm

Alarm Relay current carry ability: 1A @ DC24V

Up to 3 Trap stations

Cold start, Port link up, Port link down, Authentication

SNMP Trap

Failure, Private Trap for power status, Port Alarm

configuration, Fault alarm, X-Ring topology change

Provides DHCP Client, DHCP Server and IP Relay

DHCP

functions

Provides DNS client feature and supports Primary and

DNS

Secondary DNS server

5

Page 13

SNTP Supports SNTP to synchronize system clock in Internet

Firmware Update Supports TFTP firmware update, TFTP backup and restore.

Configuration

Upload/Download

ifAlias

Supports binary format file for configuration backup and

restore

Each port allows importing 128-bit of alphabetic string of

word on SNMP and CLI interface

6

Page 14

1.3 Package Contents

Please refer to the package content list below to verify them against the checklist.

CNGE3FE7MS2 Managed Industrial Switch x 1

User manual x 1

Pluggable Terminal Block x 2

Mounting plate x 2

RJ-45 to DB9-Female cable x 1

Wall mount power supply

Compare the contents of the industrial switch with the standard checklist above. If any

item is damaged or missing, please contact your local representative for service.

7

Page 15

Chapter 2 Hardware Description

In this paragraph, it will describe the Industrial switch’s hardware spec, port, cabling

information, and wiring installation.

2.1 Physical Dimension

CNGE3FE7MS2 Managed Industrial Switch dimensions (W x D x H) are 72mm x

105mm x 152mm.

2.2 Front Panel

The Front Panel of the CNGE3FE7MS2 Managed Industrial Switch is shown below:

Front Panel of the industrial switch

8

Page 16

2.3 Top View

The Top panel of the CNGE3FE7MS2 Managed Industrial Switch has two terminal block

connectors—power connector and DI/DO connector. The power connector consists of

two DC power inputs and one fault alarm. As for DI/DO connector, it comprises two

digital inputs—DI0 and DI1and two digital outputs—DO0 and DO1.

Top Panel of the industrial switch

9

Page 17

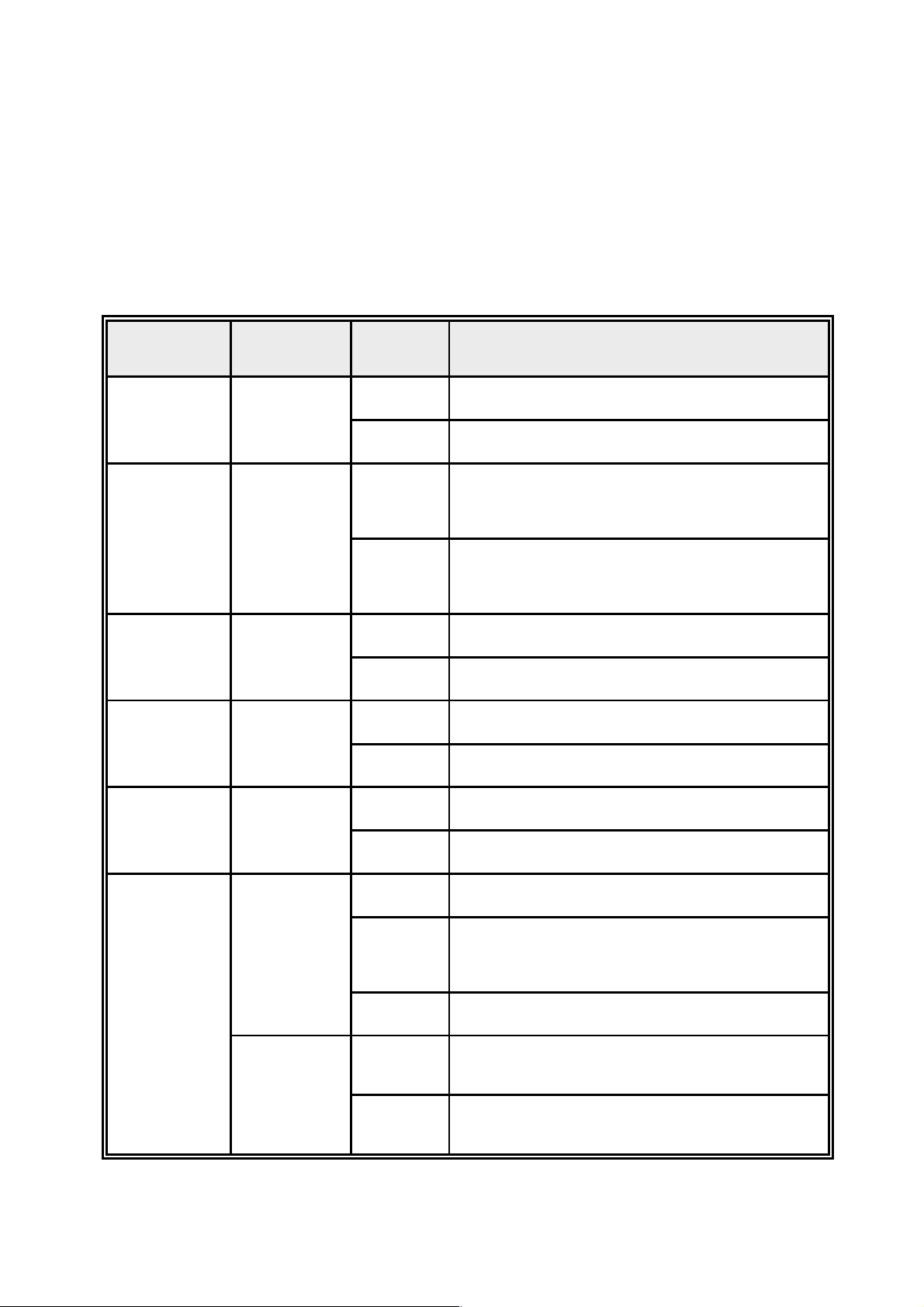

2.4 LED Indicators

The diagnostic LEDs that provide real-time information on system and operational status

are located on the front panel of the industrial switch. The following table provides the

description of the LED status and their meaning for the switch.

LED Color Status Meaning

On The switch is powered on

PWR Green

Off No power

The industrial switch is the master of X-Ring

On

R.M. Green

Off

group

The industrial switch is not a ring master in

X-Ring group

PWR1 Green

PWR2 Green

FAULT Red

Green

(Upper LED)

P7, P9, P10

(RJ-45)

Green

On Power 1 is active

Off Power 1 is inactive

On Power 2 is active

Off Power 2 is inactive

On Power or port failure

Off No failure

On A network device is detected.

The port is transmitting or receiving packets

Blinking

from the TX device.

Off No device attached

On 1000Mb

(Lower LED)

Off 10/100Mb

10

Page 18

Link/Active

(P7, P9, P10

SFP)

Green

On The SFP port is linking

The port is transmitting or receiving packets

Blinks

from the TX device.

Off No device attached

On A network device is detected.

P1 ~ P6 &

P8

Green

Amber

The port is transmitting or receiving packets

Blinking

from the TX device.

Off No device attached

On

The port is operating in full-duplex mode.

Blinking Collision of Packets occurs.

The port is operating in half-duplex mode or

Off

no device is attached.

11

Page 19

Chapter 3 Hardware Installation

In this paragraph, we will describe how to install the CNGE3FE7MS2 Managed Industrial

Switch.

3.1 Installation Steps

1. Unpack the Industrial switch

2. Check if the DIN-Rail is screwed on the Industrial switch or not. If the DIN-Rail is not

screwed on the Industrial switch, please refer to DIN-Rail Mounting section for DINRail installation. If users want to wall mount the Industrial switch, please refer to Wall

Mount Plate Mounting section for wall mount plate installation.

3. To hang the Industrial switch on the DIN-Rail track or wall.

4. Power on the Industrial switch. Please refer to the Wiring the Power Inputs section

for information about how to wire the power. The power LED on the Industrial switch

will light up. Please refer to the LED Indicators section for indication of LED lights.

5. Prepare the twisted-pair, straight through Category 5 cable for Ethernet connection.

6. Insert one side of RJ-45 cable (category 5) into the Industrial switch Ethernet port

(RJ-45 port) and another side of RJ-45 cable (category 5) to the network device’s

Ethernet port (RJ-45 port), ex: Switch, PC or Server. The UTP port (RJ-45) LED on

the Industrial switch will light up when the cable is connected with the network device.

Please refer to the LED Indicators section for LED light indication.

[NOTE] Make sure that the connected network devices support MDI/MDI-X. If it does not

support, use a crossover category-5 cable.

7. When all connections are set and LED lights all show normal, the installation is

complete.

12

Page 20

3.2 DIN-Rail Mounting

The DIN-Rail is screwed on the industrial switch when shipped from the factory. If the

DIN-Rail is not screwed on the industrial switch, please see the following pictures to

screw the DIN-Rail on the switch. Follow the steps below to hang the industrial switch.

Back Side

13

Page 21

1. First, insert the top of DIN-Rail into the track.

2. Then, lightly push the DIN-Rail into the track.

3. Check if the DIN-Rail is correctly mounted on the track or not.

4. To remove the industrial switch from the track, reverse above steps.

14

Page 22

3.3 Wall Mount Plate Mounting

Follow the steps below to mount the industrial switch with wall mount plate.

1. Remove the DIN-Rail from the industrial switch; loosen the screws to remove the

DIN-Rail.

2. Place the wall mount plate on the rear panel of the industrial switch.

3. Use the screws to screw the wall mount plate on the industrial switch.

4. Use the hook holes at the corners of the wall mount plate to hang the industrial

switch on the wall.

5. To remove the wall mount plate, reverse the above steps.

15

Page 23

3.4 Wiring the Power Inputs

Please follow the steps below to insert the power wires.

1. Insert DC power wires into the contacts 1 and 2 for power 1, or 5 and 6 for power 2.

Power inputs can support either polarity.

2. Tighten the wire-clamp screws to prevent the wires from becoming loose.

[NOTE] The wire gauge for the terminal block should be in the range between 12 ~ 24

AWG.

16

Page 24

3.5 Wiring the Fault Alarm Contact

The fault alarm contacts are in the middle of the terminal block connector as the picture

shows below. Insert the wires, the switch will detect the fault status of the power failure,

or port link failure and then forms an open circuit. The following illustration shows an

application example for wiring the fault alarm contacts.

Insert the wires into the fault alarm contacts

[NOTE] The wire gauge for the terminal block should be in the range between 12 ~ 24

AWG.

17

Page 25

3.6 Wiring the Digital inputs/ Outputs

There is another terminal block comprising two sets of digital input/output contacts on

the top side of this switch. Please refer to page 57 for how to configure Digital

Input/Output. The following illustration shows the pin assignment of the DIDO

connector. Please note do not connect DO0/DO1 to an external device using power

higher than 40V/200mA.

18

Page 26

3.7 Cabling

10/100Tx RJ-45 port:

Use four twisted-pair, Category 5e or above cabling for RJ-45 port connection. The

cable between the switch and the link partner (switch, hub, workstation, etc.) must be

less than 100 meters (328 ft.) long.

Gigabit Copper/SFP (mini-GBIC) combo port:

The Industrial switch has auto-detection Gigabit ports—Gigabit Copper/SFP combo

ports. The Gigabit Copper (10/100/1000) ports should use Category 5e or above

UTP/STP cable for the connection up to 1000Mbps. The small form-factor pluggable

(SFP) is a compact optical transceiver used in optical communications for both

telecommunication and data communications. The SFP slots support dual mode and

can switch the connection speed between 100 and 1000Mbps. They are used for

connecting to the network segment with single or multi-mode fiber. You can choose

the appropriate SFP transceiver to plug into the slots. Then use the correct multimode or single-mode fiber according to the transceiver. With fiber optic, it transmits at

speeds up to 1000 Mbps and you can prevent noise interference from the system.

Note The SFP/Copper Combo port can’t both work at the same time. The

SFP port has the higher priority than copper port; if you insert the

1000Mb SFP transceiver (which has connected to the remote device

via fiber cable) into the SFP port, the connection of the accompanying

copper port will link down.

If you insert the 100Mb SFP transceiver into the SFP port even without

a fiber connection to the remote, the connection of the accompanying

copper port will link down immediately.

Please note that you must use class I optical transceivers which

conform to U.S. code of federal regulation, 21 CFR 1040.

19

Page 27

To connect the transceiver and LC cable, please follow the steps shown as below:

First, insert the transceiver into the SFP slot. Notice that the triangle mark is on the

bottom of the module.

Transceiver to the SFP module

Make sure the module is aligned correctly and then slide the module into the SFP slot

until a click is heard.

Transceiver Inserted

Second, insert the fiber cable of LC connector into the transceiver.

20

Page 28

LC connector to the transceiver

21

Page 29

To remove the LC connector from the transceiver, please follow the steps shown below:

First, press the upper side of the LC connector from the transceiver and pull it out to

release.

Remove LC connector

Second, push down the metal loop and pull the transceiver out by the plastic part.

Pull out from the SFP module

22

Page 30

Chapter 4 Network Application

This chapter provides some sample applications to help the user understand the

industrial switch function application. A sample application of the industrial switch is

shown below:

23

Page 31

4.1 X-Ring Application

The industrial switch supports the X-Ring protocol that can help the network system to

recover from a network connection failure within 20ms or less, and make the network

system more reliable. The X-Ring algorithm is similar to spanning tree protocol (STP)

algorithm but its recovery time is faster than STP. The following figure is a sample XRing application.

24

Page 32

4.2 Coupling Ring Application

In the network, it may have more than one X-Ring group. By using the coupling ring

function, it can connect each X-Ring for redundant backup. It can ensure the

transmissions between two ring groups do not fail. The following figure is a sample of

coupling ring application. The couple ring consists of four switches—switch 1 to switch

4—which are connected to each other via the paths in orange. Please note that the

Coupling Ring Backup Path between switch 1 and switch 3 is blocked; it will work only

when the path between switch 2 and switch 4 is broken or disconnected.

25

Page 33

4.3 Dual Homing Application

Dual Homing function is to prevent a connection loss between X-Ring groups and upper

level/core switches. Assign two ports to be the Dual Homing port that is the backup port

in the X-Ring group. The Dual Homing function only works when the X-Ring function is

active. Each X-Ring group only has one Dual Homing port.

[NOTE] In Dual Homing application architecture, the upper level switches need to

enable the Rapid Spanning Tree protocol.

26

Page 34

Chapter 5 Console Management

5.1 Connecting to the Console Port

The supplied cable which one end is RS-232 connector and the other end is RJ-45

connector. Attach the end of RS-232 connector to PC or terminal and the other end of

RJ-45 connector to the console port of the switch. The connected terminal or PC must

support a terminal emulation program.

5.2 Pin Assignment

DB9 Connector RJ-45 Connector

NC 1 Orange/White

2 2 Orange

3 3 Green/White

NC 4 Blue

5 5 Blue/White

NC 6 Green

NC 7 Brown/White

NC 8 Brown

27

Page 35

5.3 Login in the Console Interface

When the connection between Switch and PC is ready, turn on the PC and run a

terminal emulation program or Hyper Terminal and configure its communication

parameters to match the following default characteristics of the console port:

Baud Rate: 9600 bps

Data Bits: 8

Parity: none

Stop Bit: 1

Flow control: None

The settings of comm unication parameters

Having finished the parameter settings, click ‘OK’. When the blank screen shows up,

press Enter key to have the login prompt appear. Key in ‘admin’ (default value) for both

User name and Password (use Enter key to switch), then press Enter and the Main

Menu of console management appears. Please see below figure for login screen.

28

Page 36

Console login interface

29

Page 37

5.4 CLI Management

The system supports the console management—CLI command. After you log in on to

the system, you will see a command prompt. To enter CLI management interface, type

in “enable” command.

CLI command interface

The following table lists the CLI commands and description.

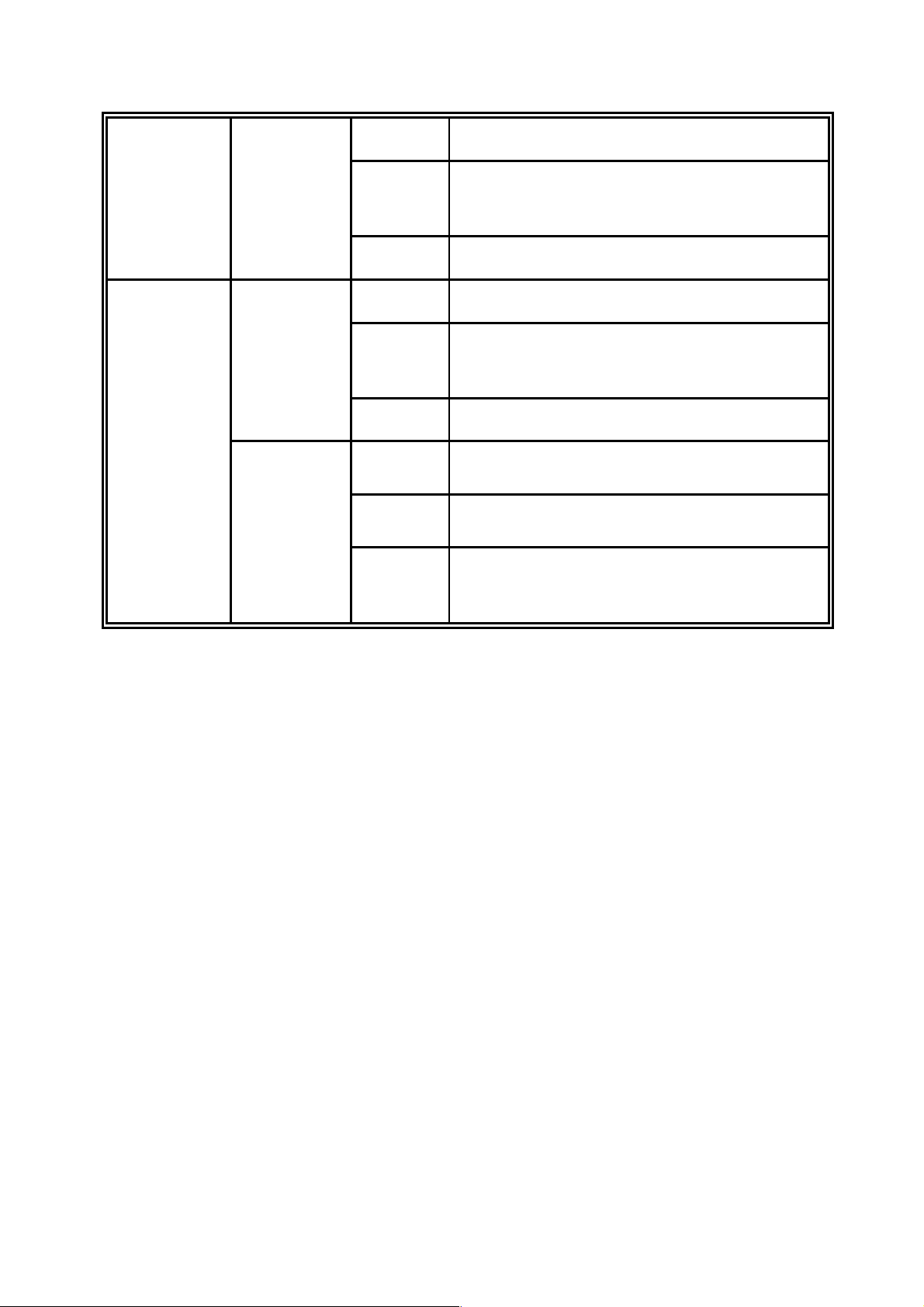

5.5 Commands Level

Access

Modes

Method

Begin a

User EXEC

Privileged

EXEC

session with

your switch.

Enter the

enable

command

while in User

EXEC mode.

Prompt

switch>

switch#

Exit

Method

Enter

logout or

quit.

Enter

disable to

exit.

About This Mode1

The user commands

available at the user

level are a subset of

those available at the

privileged level.

Use this mode to

• Perform basic tests.

• Display system

information.

The privileged

command is the

advanced mode.

Use this mode to

• Display advanced

function status

30

Page 38

Global

Configuration

VLAN

database

Enter the

configure

command

while in

privileged

EXEC mode.

Enter the

vlan

database

command

while in

privileged

switch

(config)#

switch

(vlan)#

To exit to

privileged

EXEC

mode, enter

exit or end.

To exit to

user EXEC

mode, enter

exit.

• Save configuration

Use this mode to

configure those

parameters that are

going to be applied to

your switch.

Use this mode to

configure VLANspecific parameters.

Interface

configuration

EXEC mode.

Enter the

interface of

fast Ethernet

command

(with a

specific

interface)

while in global

configuration

mode.

switch

(config-if)#

To exit to

global

configuratio

n mode,

enter exit.

To exit to

privileged

EXEC

mode, enter

exit or end.

Use this mode to

configure parameters

for the switch and

Ethernet ports.

31

Page 39

Chapter 6 Web-Based Management

This section introduces the configuration and functions of the Web-Based management.

6.1 About Web-based Management

There is an embedded HTML web site residing in flash memory on CPU board of the

switch, which offers advanced management features and allows users to manage the

switch from anywhere on the network through a standard browser such as Microsoft

Internet Explorer.

The Web-Based Management supports Internet Explorer 6.0 or later version. And, it is

applied for Java Applets for reducing network bandwidth consumption, enhance access

speed and present an easy viewing screen.

6.2 Preparing for Web Management

Before using the web management, install the industrial switch on the network and make

sure that any one of the PCs on the network can connect with the industrial switch

through the web browser. The industrial switch default value of IP, subnet mask,

username and password are listed as below:

IP Address: 192.168.10.1

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.10.254

User Name: admin

Password: admin

32

Page 40

6.3 System Login

1. Launch the Internet Explorer on the PC

2. Key in “http:// “+” the IP address of the switch”, as shown below, and then Press

“Enter”.

3. The login screen will appear right after

4. Key in the user name and password. The default user name and password are the

same as ‘admin’.

5. Press Enter or click the OK button, and then the home screen of the Web-based

management appears.

Login screen

33

Page 41

6.4 System Information

User can assign the system name, description, location and contact personnel to identify

the switch. The version table below is a read-only field to show the basic information of

the switch.

System Name: Assign the system name of the switch (The maximum length is 64

bytes)

System Description: Describes the switch.

System Location: Assign the switch physical location (The maximum length is 64

bytes).

System Contact: Enter the name of contact person or organization.

Firmware Version: Displays the switch’s firmware version

Kernel Version: Displays the kernel software version

MAC Address: Displays the unique hardware address assigned by manufacturer

(default)

And then, click

.

Switch settings interface

34

Page 42

6.5 IP Configuration

The switch is a network device which needs to be assigned an IP address for being

identified on the network. Users have to decide a means of assigning IP address to the

switch.

DHCP Client: Enable or disable the DHCP client function. When DHCP client

function is enabled, the switch will be assigned an IP address from the network

DHCP server. The default IP address will be replaced by the assigned IP address

on DHCP server. After the user clicks Apply, a popup dialog shows up to inform the

user that when the DHCP client is enabled, the current IP address will be lost and

user should find the new IP address on the DHCP server.

IP Address: Assign the IP address that the network is using. If DHCP client function

is enabled, this switch is configured as a DHCP client. The network DHCP server

will assign the IP address to the switch and display it in this column. The default IP

address is 192.168.10.1 or the user has to assign an IP address manually when

DHCP Client is disabled.

Subnet Mask: Assign the subnet mask to the IP address. If DHCP client function is

disabled, the user has to assign the subnet mask in this column field.

Gateway: Assign the network gateway for the switch. If DHCP client function is

disabled, the user has to assign the gateway in this column field. The default

gateway is 192.168.10.254.

DNS1: Assign the primary DNS IP address.

DNS2: Assign the secondary DNS IP address.

And then, click

.

35

Page 43

IP configuration interface

36

Page 44

6.6 DHCP Server

DHCP is the abbreviation of Dynamic Host Configuration Protocol that is a protocol for

assigning dynamic IP addresses to devices on a network. With dynamic addressing, a

device can have a different IP address every time it connects to the network. In some

systems, the device's IP address can even change while it is still connected. DHCP

also supports a mix of static and dynamic IP addresses. Dynamic addressing

simplifies network administration because the software keeps track of IP addresses

rather than requiring an administrator to manage the task. This means that a new

computer can be added to a network without the hassle of manually assigning it a

unique IP address.

The system provides the DHCP server function. Having enabled the DHCP server

function, the switch system will be configured as a DHCP server.

37

Page 45

6.6.1 System configuration

DHCP Server: Enable or Disable the DHCP Server function. Enable—the switch

will be the DHCP server on your local network.

Low IP Address: Type in an IP address. Low IP address is the beginning of the

dynamic IP range. For example, dynamic IP is in the range between

192.168.10.100 ~ 192.168.10.200. In contrast, 192.168.10.100 is the Low IP

address.

High IP Address: Type in an IP address. High IP address is the end of the

dynamic IP range. For example, dynamic IP is in the range between

192.168.10.100 ~ 192.168.10.200. In contrast, 192.168.10.200 is the High IP

address.

Subnet Mask: Type in the subnet mask of the IP configuration.

Gateway: Type in the IP address of the gateway in your network.

DNS: Type in the Domain Name Server IP Address in your network.

Lease Time (sec): It is the time period that system will reset the dynamic IP

assignment to ensure the dynamic IP will not been occupied for a long time or the

server doesn’t know that the dynamic IP is idle.

And then, click .

DHCP Server Configuration interface

38

Page 46

6.6.2 Client Entries

When the DHCP server function is enabled, the system will collect the DHCP client

information including the assigned IP address, the MAC address of the client device,

the IP assigning type, status and lease time.

DHCP Client Entries interface

39

Page 47

6.6.3 Port and IP Bindings

Assign the dynamic IP address bound with the port to the connected client. The user is

allowed to fill each port column with one particular IP address. When the device is

connecting to the port and asks for IP assigning, the system will assign the IP address

bound with the port.

Port and IP Bindings interface

40

Page 48

6.7 TFTP

It provides the functions allowing the user to update the switch firmware via the Trivial

File Transfer Protocol (TFTP) server. Before updating, make sure the TFTP server is

ready and the firmware image is located on the TFTP server.

6.7.1 Update Firmware

TFTP Server IP Address: Type in your TFTP server IP.

Firmware File Name: Type in the name of the firmware image file to be updated.

Click .

Update Firmware interface

41

Page 49

6.7.2 Restore Configuration

You can restore a previous backup configuration from the TFTP server to recover the

settings. Before doing that, you must locate the image file on the TFTP server first and

the switch will download the flash image.

TFTP Server IP Address: Type in the TFTP server IP.

Restore File Name: Type in the correct file name for restoring.

Click .

Restore Configuration interface

42

Page 50

6.7.3 Backup Configuration

You can back up the current configuration from flash ROM to the TFTP server for the

purpose of recovering the configuration later. It helps you to avoid wasting time on

configuring the settings by backing up the configuration.

TFTP Server IP Address: Type in the TFTP server IP.

Backup File Name: Type in the file name.

Click .

Backup Configuration interface

43

Page 51

6.8 System Event Log

This page allows the user to decide whether to send the system event log, and select the

mode which the system event log will be sent to client only, server only, or both client

and server. What kind of event log will be issued to the client/server depends on the

selection on the Event Configuration tab. There are five types of event—Device Cold

Start, Device Warm Start, Authentication Failure, X-Ring Topology Change, and Port

Event—available to be issued as the event log.

6.8.1 Syslog Configuration

Syslog Client Mode: Select the system log mode—Client Only, Server Only, or

Both. ‘Client Only’ means the system event log will only be sent to this interface of the

switch, but on the other hand ‘Server Only’ means the system log will only be sent to

the remote system log server with its IP assigned. If the mode is set in ‘Both’, the

system event log will be sent to the remote server and this interface.

System Log Server IP Address: When the ‘Syslog Mode’ item is set as Server

Only/Both, the user has to assign the system log server IP address to which the log

will be sent.

Click to refresh the event log displaying area.

Click to clear all the current event logs.

Make sure the selected mode is correct, and click to have the

setting take effect.

44

Page 52

Syslog Configuration interface

45

Page 53

6.8.2 System Event Log—SMTP Configuration

Simple Mail Transfer Protocol (SMTP) is the standard for email transmissions across

the network. You can configure the SMTP server IP, mail subject, sender, mail

account, password, and the recipient email addresses which the e-mail alert will send

to. There are also five types of event—Device Cold Start, Device Warm Start,

Authentication Failure, X-Ring Topology Change, and Port Event—available to be

issued as the e-mail alert. Besides, this function provides the authentication

mechanism including an authentication step through which the client effectively logs in

to the SMTP server during the process of sending e-mail alert.

Email Alert: With this function being enabled, the user is allowed to configure the

detail settings for sending the e-mail alert to the SMTP server when the events

occur.

SMTP Server IP: Assign the mail server IP address (when Email Alert is

enabled, this function will then be available).

Sender: Type in an alias of the switch in complete email address format, e.g.

switch101@123.com, to identify where the e-mail alert comes from.

Authentication: Having ticked this checkbox, the mail account, password and

confirm password column fields will then show up. Configure the email account

and password for authentication when this switch logs in to the SMTP server.

Mail Account: Set up the email account, e.g. johnadmin, to receive the email

alert. It must be an existing email account on the mail server.

Password: Type in the password for the email account.

Confirm Password: Reconfirm the password.

Rcpt e-mail Address 1 ~ 6: You can also fill each of the column fields with up to

6 e-mail accounts to receive the email alert.

Click to have the configuration take effect.

46

Page 54

SMTP Configuration interface

47

Page 55

6.8.3 System Event Log—Event Configuration

Having ticked the Syslog/SMTP checkboxes, the event log/email alert will be sent to the

system log server and the SMTP server respectively. Also, Port event log/alert (link up,

link down, and both) can be sent to the system log server/SMTP server respectively by

setting the trigger condition.

System event selection: There are 4 event types—Device Cold Start, Device

Warm Start, Authentication Failure, and X-ring Topology Change. The checkboxes

are not available for ticking unless the Syslog Client Mode on the Syslog

Configuration tab and the E-mail Alert on the SMTP Configuration tab are enabled

first.

Device cold start: When the device executes cold start action, the system will

issue the event log/email alert to the system log/SMTP server respectively.

Device warm start: When the device executes warm start, the system will

issue the event log/email alert to the system log/SMTP server respectively.

Authentication Failure: When the SNMP authentication fails, the system will

issue the event log/email alert to the system log/SMTP server respectively.

X-ring topology change: When the X-ring topology has changed, the system

will issue the event log/email alert to the system log/SMTP server respectively.

Port event selection: Also, before the drop-down menu items are available, the

Syslog Client Mode selection item on the Syslog Configuration tab and the E-mail

Alert selection item on the SMTP Configuration tab must be enabled first. Those

drop-down menu items have 3 selections—Link UP, Link Down, and Link UP &

Link Down. Disable means no event will be sent to the system log/SMTP server.

Link UP: The system will only issue a log message when the link-up event of

the port occurs.

Link Down: The system will only issue a log message when the link-down

event of port occurs.

Link UP & Link Down: The system will issue a log message at the time when

port connection is link-up and link-down.

48

Page 56

Event Configuration interface

49

Page 57

6.9 Fault Relay Alarm

The Fault Relay Alarm function provides Power Failure and Port Link Down/Broken

detection. With both power input 1 and power input 2 installed and the check boxes of

power 1/power 2 ticked, the FAULT LED indicator will then be possible to light up when

any one of the power failures occurs. As for the Port Link Down/Broken detection, the

FAULT LED indicator will light up when the port failure occurs; the check box beside the

port must be ticked first. Please refer to the segment of ‘Wiring the Fault Alarm

Contact’ for the failure detection.

Power Failure: Tick the check box to enable the FAULT LED on the panel when

power fails.

Port Link Down/Broken: Tick the check box to enable the FAULT LED on the

panel when Ports’ states are link down or broken.

Fault Relay Alarm interface

50

Page 58

6.10 SNTP Configuration

SNTP (Simple Network Time Protocol) is a simplified version of NTP which is an Internet

protocol used to synchronize the clocks of computers to some time reference. Because

time usually just advances, the time on different node stations will be different. With the

communicating programs running on those devices, it would cause time to jump forward

and back, a non-desirable effect. Therefore, the switch provides comprehensive

mechanisms to access national time and frequency dissemination services, organize the

time-synchronization subnet and the local clock in each participating subnet peer.

Daylight saving time (DST) is the convention of advancing clocks so that afternoons

have more daylight and mornings have less. Typically clocks are adjusted forward one

hour near the start of spring and are adjusted backward in autumn.

SNTP Client: Enable/disable SNTP function to get the time from the SNTP server.

Daylight Saving Time: This is used as a control switch to enable/disable daylight

saving period and daylight saving offset. Users can configure Daylight Saving

Period and Daylight Saving Offset in a certain period time and offset time while

there is no need to enable daylight saving function. Afterwards, users can just set

this item as enable without assign Daylight Saving Period and Daylight Saving

Offset again.

UTC Timezone: Universal Time, Coordinated. Set the switch location time zone.

The following table lists the different location time zone for your reference.

Local Time Zone

Conversion from UTC Time at 12:00 UTC

November Time Zone - 1 hour 11am

Oscar Time Zone - 2 hours 10 am

ADT - Atlantic Daylight - 3 hours 9 am

AST - Atlantic Standard

- 4 hours

EDT - Eastern Daylight

51

8 am

Page 59

EST - Eastern Standard

CDT - Central Daylight

- 5 hours 7 am

CST - Central Standard

- 6 hours 6 am

MDT - Mountain Daylight

MST - Mountain

Standard

- 7 hours 5 am

PDT - Pacific Daylight

PST - Pacific Standard

- 8 hours 4 am

ADT - Alaskan Daylight

ALA - Alaskan Standard - 9 hours 3 am

HAW - Hawaiian

- 10 hours 2 am

Standard

Nome, Alaska - 11 hours 1 am

CET - Central European

FWT - French Winter

MET - Middle European

MEWT - Middle

+ 1 hour 1 pm

European Winter

SWT - Swedish Winter

EET - Eastern

+ 2 hours 2 pm

European, USSR Zone 1

BT - Baghdad, USSR

+ 3 hours 3 pm

Zone 2

ZP4 - USSR Zone 3 + 4 hours 4 pm

ZP5 - USSR Zone 4 + 5 hours 5 pm

ZP6 - USSR Zone 5

+ 6 hours

WAST - West Australian

+ 7 hours

Standard

6 pm

7 pm

52

Page 60

CCT - China Coast,

+ 8 hours 8 pm

USSR Zone 7

JST - Japan Standard,

+ 9 hours 9 pm

USSR Zone 8

EAST - East Australian

Standard GST

+ 10 hours 10 pm

Guam Standard, USSR

Zone 9

IDLE - International Date

Line

NZST - New Zealand

+ 12 hours Midnight

Standard

NZT - New Zealand

SNTP Sever URL: Set the SNTP server IP address. You can assign a local network

time server IP address or an internet time server IP address.

Switch Timer: When the switch has successfully connected to the SNTP server

whose IP address was assigned in the column field of SNTP Server URL, the

current coordinated time is displayed here.

Daylight Saving Period: Set up the Daylight Saving beginning date/time and

Daylight Saving ending date/time. Please key in the value in the format of

‘YYYYMMDD’ and ‘HH:MM’ (leave a space between ‘YYYYMMDD’ and ‘HH:MM’).

YYYYMMDD: an eight-digit year/month/day specification.

HH:MM: a five-digit (including a colon mark) hour/minute specification.

For example, key in ‘20070701 02:00’ and ‘20071104 02:04’ in the two column

fields respectively to represent that DST begins at 2:00 a.m. on March 11, 2007

and ends at 2:00 a.m. on November 4, 2007.

Daylight Saving Offset (mins): For non-US and European countries, specify the

amount of time for day light savings. Please key in the valid figure in the range of

minute between 0 and 720, which means you can set the offset up to 12 hours.

Click to have the configuration take effect.

53

Page 61

SNTP Configuration interface

54

Page 62

6.11 IP Security

IP security function allows the user to assign 10 specific IP addresses that have

permission to manage the switch through the http and telnet services for securing switch

management. The purpose of giving the limited IP addresses permission is to allow only

the authorized personnel/device to perform the management tasks on the switch.

IP Security Mode: Having set this selection item in the Enable mode, the Enable

HTTP Server, Enable Telnet Server checkboxes and the ten security IP column

fields will then be available. If not, those items will appear in grey.

Enable HTTP Server: Having ticked this checkbox, the devices whose IP

addresses match any one of the ten IP addresses in the Security IP1 ~ IP10 table

will be given the permission to access this switch via HTTP service.

Enable Telnet Server: Having ticked this checkbox, the devices whose IP

addresses match any one of the ten IP addresses in the Security IP1 ~ IP10 table

will be given the permission to access this switch via telnet service.

Security IP 1 ~ 10: The system allows the user to assign up to 10 specific IP

addresses for access security. Only these 10 IP addresses can access and manage

the switch through the HTTP/Telnet service once IP Security Mode is enabled.

And then, click

to have the configuration take effect.

[NOTE] Remember to execute the “Save Configuration” action, otherwise the new

configuration will be lost when the switch powers off.

55

Page 63

IP Security interface

56

Page 64

6.12 Digital Input/Output

The CNGE3FE7MS2 Managed Industrial Switch contains two digital inputs and two

digital outputs. The digital inputs may be used to receive the voltage-changing signal of

remote equipment to sense the state of the remote equipment like heater, pump, and

other electrical equipment. Therefore the switch can be configured to send system log,

SMTP and SNMP traps to syslog server, SMTP server and SNMP trap station

respectively (please refer to System Event Log and SNMP configuration section).

Outputs are open-collector transistor switches used to connect to the external device like

alarm buzzer or LED to inform the user of the port/power status.

Digital Input

When First/Second Digital Input function is enabled, First Digital Input/Second

Digital Input will then be available respectively.

Digital Input: Choose the transition type to trigger DI0/DI1.

LowHigh: Having focused this radio button, DI0/DI1 will only report the

status when the external device’s voltage changes from low to high.

HighLow: Having focused this radio button, DI0/DI1 will only report the

status when the external device’s voltage changes from high to low.

Event description: Please fill in the description for the event.

Action: Tick the check boxes to decide whether or not to send the events via

Syslog, SMTP, or SNMP Trap.

57

Page 65

Digital Input interface

Digital Output

When First/Second Digital Output function is enabled, First Digital Output/Second

Digital Output will then be available respectively.

Condition: The system will send an electrical Low-to-High or High-to-Low signal to

First Digital Output (DO0)/Second Digital Output (DO1) when the condition of ticked

checkbox is met.

Port Fail: Having ticked this checkbox, DO0/DO1 will output an electrical Low-

to-High or High-to-Low signal when port failure occurs.

Power Fail: Having ticked this checkbox, DO0/DO1 will output an electrical

Low-to-High or High-to-Low signal when power failure occurs.

Action: Choose the output type of electrical signal.

LowHigh: Having focused this radio button, DO0/DO1 will output an

electrical signal of Low-to-High when the condition of the ticked checkbox is

met (port/power failure occurs).

HighLow: Having focused this radio button, DO0/DO1 will output an

electrical signal of Low-to-High when the condition of the ticked checkbox is

met (port/power failure occurs).

58

Page 66

Note: Besides ticking the checkboxes in the Condition column field, the power/port failure

checkboxes of Fault Relay Alarm have to be ticked as the pre-condition. Please refer to

Fault Relay Alarm section. Also, please note that the digital output can’t connect to the

external device using power higher than 40V/200mA.

Digital Output interface

59

Page 67

6.13 User Authentication

Change web management login user name and password.

User name: Type in the new user name (The default is ‘root’)

Password: Type in the new password (The default is ‘root’)

Confirm password: Re-type the new password

And then, click

.

User Authentication interface

60

Page 68

6.14 Port Statistics

The following chart provides the current statistic information which displays the real-time

packet transfer status for each port. The user might use the information to plan and

implement the network, or check and find the problem when a collision or heavy traffic

occurs.

Port: The port number.

Type: Displays the current speed of connection to the port.

Link: The status of linking—‘Up’ or ‘Down’.

State: It’s set by Port Control. When the state is disabled, the port will not transmit

or receive any packet.

Tx Good Packet: The counts of transmitting good packets via this port.

Tx Bad Packet: The counts of transmitting bad packets (including undersize [less

than 64 octets], oversize, CRC Align errors, fragments and jabbers packets) via this

port.

Rx Good Packet: The counts of receiving good packets via this port.

Rx Bad Packet: The counts of receiving good packets (including undersize [less

than 64 octets], oversize, CRC error, fragments and jabbers) via this port.

Tx Abort Packet: The aborted packet while transmitting.

Packet Collision: The counts of collision packet.

Packet Dropped: The counts of dropped packet.

Rx Bcast Packet: The counts of broadcast packet.

Rx Mcast Packet: The counts of multicast packet.

Click

button to clean all counts.

61

Page 69

Port Statistics interface

62

Page 70

6.15 Port Control

In Port control you can configure the settings of each port to control the connection

parameters, and the status of each port is listed beneath.

Port: Use the scroll bar and click on the port number to choose the port to be

configured.

State: Current port state. The port can be set to disable or enable mode. If the port

state is set as ‘Disable’, it will not receive or transmit any packet.

Negotiation: Auto and Force. Being set as Auto, the speed and duplex mode are

negotiated automatically. When you set it as Force, you have to set the speed and

duplex mode manually.

Speed: It is available for selecting when the Negotiation column is set as Force.

When the Negotiation column is set as Auto, this column is read-only.

Duplex: It is available for selecting when the Negotiation column is set as Force.

When the Negotiation column is set as Auto, this column is read-only.

Flow Control: Whether or not the receiving node sends feedback to the sending

node is determined by this item. When enabled, once the device exceeds the input

data rate of another device, the receiving device will send a PAUSE frame which

halts the transmission of the sender for a specified period of time. When disabled,

the receiving device will drop the packet if too much to process.

Security: When the Security selection is set as ‘On’, any access from the device

which connects to this port will be blocked unless the MAC address of the device is

included in the static MAC address table. See the segment of MAC Address

Table—Static MAC Addresses.

Click

to have the configuration take effect.

63

Page 71

Port Control interface

64

Page 72

6.16 Port Trunk

Port trunking is the combination of several ports or network cables to expand the

connection speed beyond the limits of any one single port or network cable. Link

Aggregation Control Protocol (LACP), which is a protocol running on layer 2, provides

a standardized means in accordance with IEEE 802.3ad to bundle several physical

ports together to form a single logical channel. All the ports within the logical channel

or so-called logical aggregator work at the same connection speed and LACP

operation requires full-duplex mode.

6.16.1 Aggregator setting

System Priority: A value which is used to identify the active LACP. The switch

with the lowest value has the highest priority and is selected as the active LACP

peer of the trunk group.

Group ID: There are 13 trunk groups to be selected. Assign the "Group ID" to

the trunk group.

LACP: When enabled, the trunk group is using LACP. A port which joins an

LACP trunk group has to make an agreement with its member ports first. Please

note that a trunk group, including member ports split between two switches, has

to enable the LACP function of the two switches. When disabled, the trunk group

is a static trunk group. The advantage of having the LACP disabled is that a port

joins the trunk group without any handshaking with its member ports; but member

ports won’t know that they should be aggregated together to form a logic trunk

group.

Work ports: This column field allows the user to type in the total number of

active ports up to four. With LACP static trunk group, e.g. you assign four ports

to be the members of a trunk group whose work ports column field is set as two;

the exceed ports are standby/redundant ports and can be aggregated if working

ports fail. If it is a static trunk group (non-LACP), the number of work ports must

equal the total number of group member ports.

Select the ports to join the trunk group. The system allows a maximum of four

65

Page 73

ports to be aggregated in a trunk group. Click and the ports focused

in the right side will be shifted to the left side. To remove unwanted ports, select

the ports and click .

When LACP enabled, you can configure LACP Active/Passive status for each

port on the State Activity tab.

Click .

Use to delete Trunk Group. Select the Group ID and click .

Port Trunk—Aggregator Setting interface (four ports are added to the left field with LACP enabled)

66

Page 74

6.16.2 Aggregator Information

LACP disabled

Having set up the aggregator setting with LACP disabled, you will see the local static

trunk group information on the tab of Aggregator Information.

Assigning 2 ports to a trunk group with LACP disabled

Static Trunking Group information

67

Page 75

Group Key: This is a read-only column field that displays the trunk group ID.

Port Member: This is a read-only column field that displays the members of this

static trunk group.

68

Page 76

LACP enabled

Having set up the aggregator setting with LACP enabled, you will see the trunking

group information between two switches on the tab of Aggregator Information.

Switch 1 configuration

1. Set System Priority of the trunk group. The default is 1.

2. Select a trunk group ID by pull down the drop-down menu bar.

3. Enable LACP.

4. Include the member ports by clicking the Add button after selecting the port

number and the column field of Work Ports changes automatically.

Switch 1 configuration interface

69

Page 77

Aggregation Information of Switch 1

5. Click on the tab of Aggregator Information to check the trunked group

information as the illustration shown above after the two switches configured.

70

Page 78

Switch 2 configuration

Switch 2 configuration interface

1. Set System Priority of the trunk group. The default is 1.

2. Select a trunk group ID by pull down the drop-down menu bar.

3. Enable LACP.

4. Include the member ports by clicking the Add button after selecting the port

number and the column field of Work Ports changes automatically.

71

Page 79

Aggregation Information of Switch 2

5. Click on the tab of Aggregator Information to check the trunked group

information as the illustration shown above after the two switches configured.

72

Page 80

6.16.3 State Activity

Having set up the LACP aggregator on the tab of Aggregator Setting, you can configure

the state activity for the members of the LACP trunk group. You can tick or cancel the

checkbox beside the state label. When you remove the tick mark of the port and click

, the port state activity will change to Passive.

Active: The port automatically sends LACP protocol packets.

Passive: The port does not automatically send LACP protocol packets, and

responds only if it receives LACP protocol packets from the opposite device.

[NOTE] A link having two passive LACP nodes will not perform dynamic LACP

trunk because both ports are waiting for an LACP protocol packet from

the opposite device.

State Activity of Switch 1

73

Page 81

State Activity of Switch 2

74

Page 82

6.17 Port Mirroring

Port mirroring is a method for monitoring traffic in switched networks. Traffic through

ports can be monitored by one specific port, which means traffic going in or out of

monitored (source) ports will be duplicated into mirror (destination) port.

Destination Port: Only one port can be selected to be destination (mirror) port for

monitoring both RX and TX traffic which come from source port(s). Or, use one of

two ports for monitoring RX traffic only and the other one for TX traffic only. User

can connect mirror port to LAN analyzer or Netxray.

Source Port: The ports that user wants to monitor. All monitored port traffic will be

copied to mirror (destination) port. User can select multiple source ports by checking

the RX or TX check boxes to be monitored.

And then, click

button.

Port Trunk – Port Mirroring interface

75

Page 83

6.18 Rate Limiting

You can set up every port’s bandwidth rate and frame limitation type.

Ingress Limit Frame type: select the frame type that you want to filter. There are

four frame types for selecting:

All

Broadcast/Multicast/Flooded Unicast

Broadcast/Multicast

Broadcast only

Broadcast/Multicast/Flooded Unicast, Broadcast/Multicast and Bbroadcast

only types are only for ingress frames. The egress rate only supports All type.

Rate Limiting interface

All the ports support port ingress and egress rate control. For example, assume port

1 is 10Mbps, users can set it’s effective egress rate to 1Mbps, and ingress rate to

500Kbps. The switch performs the ingress rate by packet counter to meet the

76

Page 84

specified rate

Ingress: Enter the port effective ingress rate (The default value is “0”).

Egress: Enter the port effective egress rate (The default value is “0”).

And then, click to apply the settings

77

Page 85

6.19 VLAN configuration

A Virtual LAN (VLAN) is a logical network grouping that limits the broadcast domain,

which would allow you to isolate network traffic, so only the members of the same

VLAN will receive traffic from the ones of the same VLAN. Basically, creating a VLAN

on a switch is logically equivalent of reconnecting a group of network devices to

another Layer 2 switch. However, all the network devices are still plugged into the

same switch physically.

This switch supports Port-based and 802.1Q (tagged-based) VLAN. The default

configuration of VLAN operation mode is “Disable”.

VLAN Configuration interface

78

Page 86

6.19.1 Port-based VLAN

A port-based VLAN basically consists of its members—ports, which means the VLAN

is created by grouping the selected ports. This method provides the convenience for

users to configure a simple VLAN easily without complicated steps. Packets can go

among only members of the same VLAN group. Note all unselected ports are treated

as belonging to another single VLAN. If the port-based VLAN is enabled, the VLANtagging is ignored. The port-based VLAN function allows the user to create separate

VLANs to limit unnecessary packet flooding; however, for the purpose of sharing

resources, a single port called a common port can belong to different VLANs, which

all the member devices (ports) in different VLANs have the permission to access the

common port while they still cannot communicate with each other in different VLANs.

VLAN – Port Based interface

79

Page 87

Pull down the selection item and focus on Port Based then press to set

the VLAN Operation Mode in Port Based mode.

Click to add a new VLAN group (The maximum VLAN groups are up to

64).

VLAN—Port Based Add interface

Enter the group name and VLAN ID. Add the selected port number into the right

field to group these members to be a VLAN group, or remove any of them listed

in the right field from the VLAN.

80

Page 88

And then, click to have the configuration take effect.

You will see the VLAN list displayed.

VLAN—Port Based Edit/Delete interface

Use to delete the VLAN.

Use to modify group name, VLAN ID, or add/remove the members of

the existing VLAN group.

[NOTE] Remember to execute the “Save Configuration” action, otherwise the new

configuration will be lost when the switch powers off.

81

Page 89

6.19.2 802.1Q VLAN

Virtual Local Area Network (VLAN) can be implemented on the switch to logically

create different broadcast domains.

When the 802.1Q VLAN function is enabled, all ports on the switch belong to default

VLAN of VID 1, which means they logically are regarded as members of the same

broadcast domain. The valid VLAN ID is in the range of numbers between 1 and 4094.

The amount of VLAN groups is up to 256 including default VLAN that cannot be

deleted.

Each member port of 802.1Q is on either an Access Link (VLAN-tagged) or a Trunk

Link (no VLAN-tagged). All frames on an Access Link carry no VLAN identification.

Conversely, all frames on a Trunk Link are VLAN-tagged. Besides, there is the third

mode—Hybrid. A Hybrid Link can carry both VLAN-tagged frames and untagged

frames. A single port is supposed to belong to one VLAN group, except it is on a

Trunk/Hybrid Link.

The technique of 802.1Q tagging inserts a 4-byte tag, including VLAN ID of the

destination port—PVID, in the frame. With the combination of Access/Trunk/Hybrid

Links, the communication across switches can also make the packet be sent through

tagged and untagged ports.

82

Page 90

802.1Q Configuration

Pull down the selection item and focus on 802.1Q then press to set the

VLAN Operation Mode in 802.1Q mode.

Enable GVRP Protocol: GVRP (GARP VLAN Registration Protocol) is a protocol

that facilitates control of virtual local area networks (VLANs) within a larger network.

GVRP conforms to the IEEE 802.1Q specification, which defines a method of

tagging frames with VLAN configuration data. This allows network devices to

dynamically exchange VLAN configuration information with other devices. For

example, having enabled GVRP on two switches, they are able to automatically

exchange the information of their VLAN database. Therefore, the user doesn’t need

to manually configure whether the link is trunk or hybrid, the packets belonging to

the same VLAN can communicate across switches. Tick this checkbox to enable

GVRP protocol. This checkbox is available while the VLAN Operation Mode is in

802.1Q mode.

Management VLAN ID: Only when the VLAN members, whose Untagged VID

(PVID) equals to the value in this column, will have the permission to access the

switch. The default value is ‘0’ that means this limit is not enabled (all members in

different VLANs can access this switch).

Select the port you want to configure.

Link Type: There are 3 types of link type.

Access Link: A segment which provides the link path for one or more stations

to the VLAN-aware device. An Access Port (untagged port), connected to the

access link, has an untagged VID (also called PVID). After an untagged frame

gets into the access port, the switch will insert a four-byte tag in the frame. The

contents of the last 12-bit of the tag is untagged VID. When this frame is sent

out through any of the access port of the same PVID, the switch will remove the

Note:

tag from the frame to recover it to what it was. Those ports of the same

untagged VID are regarded as the same VLAN group members.

Because the access port doesn’t have an understanding of tagged frame, the

column field of Tagged VID is not available.

83

Page 91

Trunk Link: A segment which provides the link path for one or more VLAN-

aware devices (switches). A Trunk Port, connected to the trunk link, has an

understanding of tagged frame, which is used for the communication among

VLANs across switches. Which frames of the specified VIDs will be forwarded

depends on the values filled in the Tagged VID column field. Please insert a

comma between two VIDs.

Note:

1. A trunk port doesn’t insert tag into an untagged frame, and therefore the

untagged VID column field is not available.

2. It’s not necessary to type ‘1’ in the tagged VID. The trunk port will forward

the frames of VLAN 1.

3. The trunk port has to be connected to a trunk/hybrid port of the other switch.

Both the tagged VID of the two ports have to be the same.

Hybrid Link: A segment which consists of Access and Trunk links. The hybrid

port has both the features of access and trunk ports. A hybrid port has a PVID

belonging to a particular VLAN, and it also forwards the specified taggedframes for the purpose of VLAN communication across switches.

Note:

1. It’s not necessary to type ‘1’ in the tagged VID. The hybrid port will forward

the frames of VLAN 1.

2. The trunk port has to be connected to a trunk/hybrid port of the other

switch. Both the tagged VID of the two ports have to be the same.

Untagged VID: This column field is available when Link Type is set as Access Link

and Hybrid Link. Assign a number in the range between 1 an 4094.

Tagged VID: This column field is available when Link Type is set as Trunk Link and

Hybrid Link. Assign a number in the range between 1 an 4094.

Click to have the configuration take effect.

You can see the link type, untagged VID, and tagged VID information of each port in

the table below on the screen.

84

Page 92

802.1Q VLAN interface

Group Configuration

Edit the existing VLAN Group.

Select the VLAN group in the table list.

Click .

85

Page 93

Group Configuration interface

You can modify the VLAN group name and VLAN ID.

86

Page 94

Group Configuration interface

87

Page 95

6.20 Rapid Spanning Tree

The Rapid Spanning Tree Protocol (RSTP) is an evolution of the Spanning Tree Protocol

and provides for faster spanning tree convergence after a topology change. The system

also supports STP and the system will auto-detect the connected device that is running

STP or RSTP protocol.

6.20.1 RSTP System Configuration

The user can view spanning tree information of Root Bridge.

The user can modify RSTP state. After modification, click .

RSTP mode: The user must enable the RSTP function first before configuring

the related parameters.

Priority (0-61440): The switch with the lowest value has the highest priority

and is selected as the root. If the value is changed, the user must reboot the

switch. The value must be a multiple of 4096 according to the protocol standard

rule.

Max Age (6-40): The number of seconds a switch waits without receiving

Spanning-tree Protocol configuration messages before attempting a

reconfiguration. Enter a value between 6 through 40.

Hello Time (1-10): The time that controls the switch to send out the BPDU

packet to check RSTP current status. Enter a value between 1 through 10.

Forward Delay Time (4-30): The number of seconds a port waits before

changing from its Rapid Spanning-Tree Protocol learning and listening states to

the forwarding state. Enter a value between 4 through 30.

[NOTE] Follow the rule as below to configure the MAX Age, Hello Time, and Forward

Delay Time.

2 x (Forward Delay Time value –1) > = Max Age value >= 2 x (Hello Time

value +1)

88

Page 96

RSTP System Configuration interface

89

Page 97

6.20.2 Port Configuration

This web page provides the port configuration interface for RSTP. You can assign higher

or lower priority to each port. Rapid spanning tree will have the port with the higher

priority in forwarding state and block other ports to make certain that there is no loop in

the LAN.

Select the port in the port column field.

Path Cost: The cost of the path to the other bridge from this transmitting bridge at

the specified port. Enter a number 1 through 200,000,000.

Priority: Decide which port should be blocked by setting its priority as the lowest.

Enter a number between 0 and 240. The value of priority must be the multiple of 16.

Admin P2P: The rapid state transitions possible within RSTP are dependent upon

whether the port concerned can only be connected to exactly another bridge (i.e. it

is served by a point-to-point LAN segment), or can be connected to two or more

bridges (i.e. it is served by a shared medium LAN segment). This function allows the

P2P status of the link to be manipulated administratively. True means the port is

regarded as a point-to-point link. False means the port is regarded as a shared link.

Auto means the link type is determined by the auto-negotiation between the two

peers.

Admin Edge: The port directly connected to end stations won’t create bridging loop

in the network. To configure the port as an edge port, set the port to “True” status.

Admin Non Stp: The port includes the STP mathematic calculation. True is not

including STP mathematic calculation. False is including the STP mathematic

calculation.

Click .

90

Page 98

RSTP Port Configuration interface

91

Page 99

6.21 SNMP Configuration

Simple Network Management Protocol (SNMP) is the protocol developed to manage

nodes (servers, workstations, routers, switches and hubs etc.) on an IP network. SNMP