Page 1

INSTALLATION & OPERATION

MANUAL

SuperVisor-MC™ - 2011 CHEVY CAPRICE

With Multi Color Torus™ Technology

Interior Lighting System

CONTENTS:

Introduction ............................................................................. .2

Unpacking & Pre-Installation ...................................................2

Installation & Mounting ......................................................3-6

Wiring Instructions .............................................................6-8

LED Flash Rate / Sequence Selection ....................................8

Cruise, Take Down Steady ......................................................9

Exploded Views - Parts & Hardware List........... ..............9-10

Troubleshooting, Notes...........................................................11

Warranty .............................................................................12

For future reference record your product's serial no. here __________________________________________

IMPORTANT:

Read all instructions and warnings before installing and using.

This manual must be delivered to the end user of this equipment.

INSTALLER:

Page 2

Introduction

The Multi Color SuperVisor-MC™ (hereafter called "Unit") is an interior lighting system that ts in the visor area near the top of the

windshield. The SuperVisor-MC has room for up to (6) Torus Multi Color Light Heads.

Product Features

Torus Multi Color Light Head Options: Red/White, Blue/White, Amber/White, Red/Blue, Red/Amber, Blue/Amber

Size: 44.29" long x 1.50" tall x 6.94" deep-----------------------------------------Weight: 7.5 lbs

The use of this or any warning device does not ensure that all drivers can or will observe or react to an

emergency warning signal. Never take the right-of-way for granted. It is your responsibility to be sure you can

proceed safely before entering an intersection, driving against trafc, responding at a high rate of speed, or

walking on or around trafc lanes. The effectiveness of this warning device is highly dependent upon correct

mounting and wiring. Read and follow the manufacturer’s instructions before installing or using this device. The

vehicle operator should insure daily that all features of the device operate correctly. In use, the vehicle operator

should insure the projection of the warning signal is not blocked by vehicle components (i.e.: open trunks or

compartment doors), people, vehicles, or other obstructions. This equipment is intended for use by authorized

personnel only. It is the user’s responsibility to understand and obey all laws regarding emergency warning

devices. The user should check all applicable city, state and federal laws and regulations. Code 3, Inc., assumes

no liability for any loss resulting from the use of this warning device. Proper installation is vital to the performance

of this warning device and the safe operation of the emergency vehicle. It is important to recognize that the

operator of the emergency vehicle is under psychological and physiological stress caused by the emergency

situation. The warning device should be installed in such a manner as to: A) Not reduce the output performance

of the system, B) Place the controls within convenient reach of the operator so that he can operate the system

without losing eye contact with the roadway. Emergency warning devices often require high electrical voltages

and/or currents. Properly protect and use caution around live electrical connections. Grounding or shorting of

electrical connections can cause high current arcing, which can cause personal injury and/or severe vehicle

WARNING!

damage, including re. Any electronic device may create or be affected by electromagnetic interference. After

installation of any electronic device operate all equipment simultaneously to insure that operation is free of

interference. Never power emergency warning equipment from the same circuit or share the same grounding

circuit with radio communication equipment. All devices should be mounted in accordance with the manufacturer's

instructions and securely fastened to vehicle elements of sufcient strength to withstand the forces applied to the

device. Driver and/or passenger air bags (SRS) will affect the way equipment should be mounted. This device

should be mounted by permanent installation and within the zones specied by the vehicle manufacturer, if any.

Any device mounted in the deployment area of an air bag will damage or reduce the effectiveness of the air

bag and may damage or dislodge the device. Installer must be sure that this device, its mounting hardware and

electrical supply wiring does not interfere with the air bag or the SRS wiring or sensors. Mounting the unit inside

the vehicle by a method other than permanent installation is not recommended as unit may become dislodged

during swerving, sudden braking or collision. Failure to follow instructions can result in personal injury. PROPER

INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE OF EMERGENCY WARNING

DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF EMERGENCY PERSONNEL AND THE PUBLIC.

Unpacking & Pre-installation

Carefully remove the Unit and place it on a at surface, taking care not to scratch the lenses or damage the cable coming out of the

Housing. Examine the unit for transit damage, broken optics, LED's, etc. Report any damage to the carrier and keep the shipping carton.

The Multi Color SuperVisor-MC light bar is built to operate on 12 volt D.C. negative ground (earth). The Unit will not operate properly if

you have an electrical system other than 12 volt D.C. negative ground (earth).

Test the unit before installation. To test, touch the black wire to the ground (earth) and the other wires to +12 volts D.C., in accordance

with the instructions attached to the cable and as shown in the Multi Color SuperVisor Internal Wiring Diagram at the top of page 8 of this

manual (an automotive battery is preferable for this test). A battery charger may be used, but note that some electronic options may not

operate normally when powered by a battery charger. If problems occur at this point, contact the factory.

WARNING!

Mounting Hardware - All mounting hardware is packed in a small bag inside the main carton. There are four brackets used to mount

the SuperVisor to the vehicle. These are discussed in detail later.

Utilizing non-factory supplied screws and/or mounting brackets and/or the improper

number of screws may result in loss of warranty coverage on the equipment.

2

Page 3

Installation Instructions-All Figures are shown on Pages 4, 5 & 6

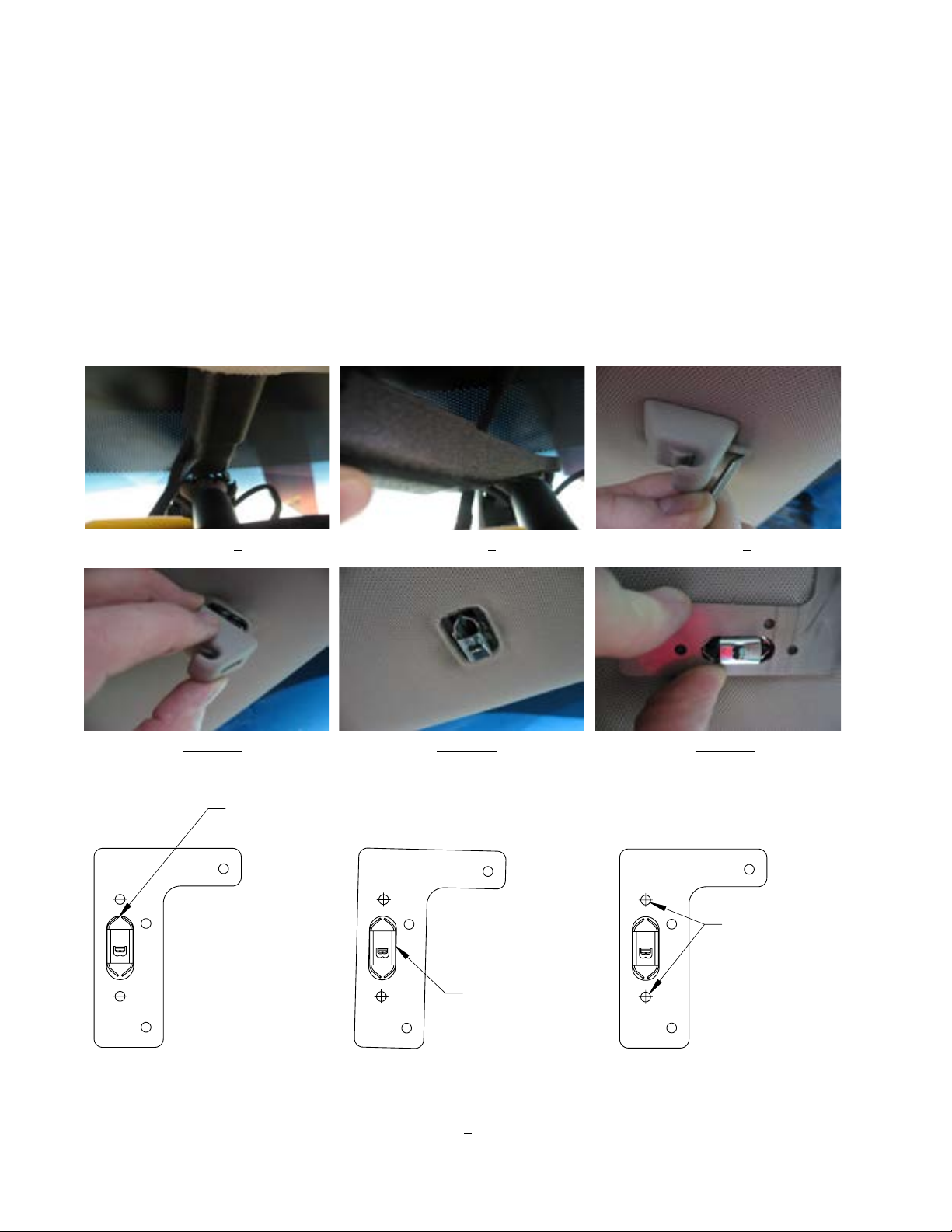

Step-1 Remove the vehicle's plastic rear view mirror wiring cover by sliding the upper sleeve portion down and forward to disengage

it from the vehicle's headliner (see Figure 1), then pull the cover off of the rear view mirror mounting bracket (see Figure 2). Discard or

store away the vehicle's plastic rear view mirror wiring cover as desired as it will not be reused for mounting the SuperVisor.

Step-2 With a small thin screw driver, remove the plastic fastening wedges that retain the vehicles's plastic inner visor clips, as

shown in Figure 3, then remove the plastic visor clips, plastic visor clip detent, and the detent spring from the vehicle's sheet metal

bracket (see Figure 4). The two inner visor clip areas of the vehicle should now look as shown in Figure 5.

Step-3 Position the supplied Sheet Metal Drilling Template over the vehicle's sheet metal visor clip bracket as shown in Figure 6.

Caution: Make absolutely certain that the Sheet Metal Drilling Template is centered over the vehicle's

sheet metal visor clip bracket in both directions and that it is held parallel to the bracket (See Figure

7 for correct and incorrect positioning). It is very important that the Drilling Template does not move

while drilling the holes! It is highly recommended that you have an assistant hold the template so that it

doesn't move while you drill the holes and to keep the holes from being drilled crooked or out of location.

While holding the Drilling Template so that it does not move, drill (2) 9/64" diameter holes one at each end of the slot in the

Drilling Template through the headliner material and through the rst layer of the Caprice's headliner sheet metal. (see Figure 7 again,

also see Figures 8 and 9). Caution: Only drill through the rst layer of the vehicle's sheet metal. Be very care-

ful not to drill all the way through the vehicle's roof!

Step-4 Loop a piece of wire through the vehicle's sheet metal visor clip bracket to prevent it from accidentally popping up into the

hole in the headliner and using a pair of plyers compress the (4) side retention tabs of the vehicles sheet metal visor clip bracket and

pull the bracket down out of the hole in the headliner (see Figure 10). Repeat this step for both of the brackets. Discard or store away

the vehicle's inner visor clip assembly as desired as it will not be reused for mounting the SuperVisor.

Step-5 Position the supplied Sheet Metal Drilling Template against the vehicle's plastic outer visor pivot brackets as shown in Figure

11-Driver Side and Figure 12-Passenger Side. Caution: Make absolutely certain that the Sheet Metal Drilling Tem-

plate is held tight against the vehicle's plastic outer visor pivot brackets in both directions as shown

and noted in Figures 11 and 12. Again as stated in Step-3, it is very important that the Drilling Template

does not move while drilling the holes. Again, it is highly recommended that you have an assistant hold

the template so that it doesn't move while you drill the holes and to keep the holes from being drilled

crooked or out of location! While holding the SuperVisor's Drilling Template so that it does not move, drill (3) 9/64" diameter

holes at each of the (3) hole locations indicated in Figures 11 and 12 (see Figures 13,14, and 15-Drivers Side Shown).

Step-6 Position the supplied Plastic Inner Visor Clips into the rectangular hole in the supplied Inner Mounting Brackets as shown

in Figure 16, then position the Inner Mounting Brackets with the Plastic Inner Visor Clips over the rectangular hole in the vehicle's

headliner, align the slotted holes in the Inner Mounting Brackets and the holes in the Plastic Inner Visor Clips with the holes drilled in

Step-3 and thread (2) supplied Black Oxided #8 X 1" Phillips Truss Head Sheet Metal Screws as shown in Figures 17 and 18. Only

thread the screws in about half way to get them started so that they will screw in and out easily for adjustment later, do not tighten the

screws at this time.

Step-7 Position the supplied Driver and Passenger Side Outer Mounting Brackets as shown in Figure 19 (Driver Side Shown), align

the slotted holes in the Mounting Brackets with the holes drilled in Step-5, and thread the (3) supplied Black Oxided #8 X 1" Phillips

Truss Head Sheet Metal Screws through the (3) slotted holes in each of the Outer Mounting Brackets and into the holes that were

drilled in the vehicle in Step 5. Only thread the screws in about half way to get them started so that they will screw in and out easily for

adjustment later. Do not tighten the screws at this time (again see Figure 19).

Step-8 Route the SuperVisor's cable to the desired side of the vehicle and through the cable slot at the end of the Outer Panel.

Make sure the cable will not interfere with the vehicle's headliner and windshield as you position the SuperVisor up to the headliner

and in front of the Inner Mounting Brackets (see Figure 20). Thread the supplied 1/4"-20 screws and internal tooth lock washers

through the slots in the Inner Mounting Brackets and into the Outer Panel (see Figure-21). Thread the supplied 1/4"-20 screws and

internal tooth lock washers through the slots in the Outer Mounting Brackets and into the Outer Panel (see Figure-22-Drivers Side

Shown). Thread all (4) of the 1/4"-20 screws up to minimize the slack between the Mounting Brackets and the SuperVisor but do not

fully tighten the screws at this time. A small amount of slack is needed for adjustment later.

3

Page 4

Installation Instructions Cont.

NOT CENTERED

WRONG WRONG

CORRECT

Step-9 While making sure the SuperVisor is centered in the vehicle tighten all of the Black Oxided #8 X 1" Phillips Truss Head Sheet

Metal Screws (see Figures 17, 18, and 19). Tighten each of the screws a little at a time so that they are all tightened somewhat simultaneously, this will help keep the SuperVisor centered.

Step-10 While pushing the SuperVisor very tightly up against the headliner, tighten the (2) 1/4"-20 Inner Mounting Bracket screws as

shown in Figure 23 then tighten the (2) 1/4"-20 Outer Mounting Bracket screws as shown in Figure 24. The idea is to slightly crush the

SuperVisor's Sheet Metal Headliner Flange into the vehicle's headliner fabric to prevent light from ashing through into the Driver's eyes.

Note: It is best to have an assistant push up on the SuperVisor while you tighten each of the the screws to assure that it is tight

against the vehicle's headliner.

Step-11 Tighten the Vehicle's Driver and Passenger Side #8 Torx outer pivot bracket mounting screws as shown in Figures 25 and 26.

Step-12 Route the SuperVisor's Cable as desired.

FIGURE 1 FIGURE 2 FIGURE 3

FIGURE 4 FIGURE 5 FIGURE 6

IN THE SLOT

DRILL HOLES

AT THESE

LOCATIONS

ANGLED

IN THE SLOT

FIGURE 7

4

Page 5

Installation Instructions Cont.

FIGURE 8 FIGURE 9 FIGURE 10

THE SUPERVISOR'S

DRILLING TEMPLATE

MUST BE HELD TIGHT

AGAINST THE EDGES

OF THE VEHICLE'S

PLASTIC VISOR PIVOT

BRACKET

DRIVERS SIDE

FRONT

OF VEHICLE

DRILL HOLES AT

THESE LOCATIONS

DRILL HOLES AT

THESE LOCATIONS

PASSENGER

FRONT

OF VEHICLE

SIDE

THE SUPERVISOR'S

DRILLING TEMPLATE

MUST BE HELD TIGHT

AGAINST THE EDGES

OF THE VEHICLE'S

PLASTIC VISOR PIVOT

BRACKET

FIGURE 11 FIGURE 12

FIGURE 13-DRIVER SIDE SHOWN FIGURE 14-DRIVER SIDE SHOWN FIGURE 15-DRIVER SIDE SHOWN

FIGURE 16 FIGURE 17 FIGURE 18

FIGURE 19-DRIVER SIDE SHOWN FIGURE 20 FIGURE 21

5

Page 6

Installation Instructions Cont.

FIGURE 22 FIGURE 23 FIGURE 24

FIGURE 25-DRIVER SIDE FIGURE 26-PASSENGER SIDE

Caution: Drilling into the housing of the light bar could damage wiring or other internal

components.

Wiring Instructions

Finish routing the cable as desired. It is advisable to leave an extra loop of cable when installing the light bar to allow for

future changes or reinstallations. For wiring of the Multi Color SuperVisor, see pages 7 & 8.

LED Fusing Considerations

NOTE: The Components of the Multi Color SuperVisor System are circuit protected by the Multi Color SuperVisor System CC

Board so the individual wires in the System do not require fusing.

DO NOT APPLY 12 VOLTS DIRECTLY TO THE SUPERVISOR WIRES AFTER IT IS CONNECTED TO THE

SUPERVISOR MULTI COLOR CC BOX. THE MULTI COLOR SUPERVISOR CC BOARD OR THE LIGHT

WARNING!

WARNING!

HEADS COULD BE DAMAGED BY APPLYING 12 VOLTS TO THE CC OUTPUTS!.

Larger wires and tight connections will provide longer service life for components. For high current wires it

is highly recommended that terminal blocks or soldered connections be used with shrink tubing to protect

the connections. Do not use insulation displacement connectors (e.g. 3M® Scotchlock type connectors).

Route wiring using grommets and sealant when passing through compartment walls. Minimize the

number of splices to reduce voltage drop. High ambient temperatures (e.g. under hood) will signicantly

reduce the current carrying capacity of wires, fuses, and circuit breakers. Use "SXL" type wire in engine

compartment. All wiring should conform to the minimum wire size and other recommendations of the

manufacturer and be protected from moving parts and hot surfaces. Looms, grommets, cable ties, and

similar installation hardware should be used to anchor and protect all wiring. Fuses or circuit breakers

should be located as close to the power takeoff points as possible and properly sized to protect the wiring

and devices. Particular attention should be paid to the location and method of making electrical connections

and splices to protect these points from corrosion and loss of conductivity. Ground terminations should

only be made to substantial chassis components, preferably directly to the vehicle battery. The user should

install a fuse sized to approximately 125% of the maximum Amp capacity in the supply line to protect

against short circuits. For example, a 30 Amp fuse should carry a maximum of 24 Amps. DO NOT USE

1/4" DIAMETER GLASS FUSES AS THEY ARE NOT SUITABLE FOR CONTINUOUS DUTY IN SIZES

ABOVE 15 AMPS. Circuit breakers are very sensitive to high temperatures and will "false trip" when

mounted in hot environments or operated close to their capacity.

6

Page 7

MULTI COLOR SUPERVISOR & CC WIRING DIAGRAM

BROWN / WHITE BROWN / WHITE

GREEN / WHITE GREEN / WHITE

ORANGE ORANGE

LIGHT BLUE LIGHT BLUE

WHITE WHITE

PINK PINK

GREEN GREEN

RED / WHITE RED / WHITE

RED RED

LIGHT BLUE / WHITE LIGHT BLUE / WHITE

PURPLE PURPLE

BROWN BROWN

MULTI COLOR

SUPERVISOR

CABLE

CONTROL INPUT

WIRES CONNECT TO

DESIRED SIREN

CONTROLLER OR

EXTERNAL

SWITCHES

MULTI COLOR SUPERVISOR

OUTPUT WIRES - CONNECT

ALL OUTPUT WIRES TO THE

MATCHING COLOR WIRES IN

THE SUPERVISOR CABLE

NOTE: COLOR SHADES MAY

VARY SLIGHTLY

AFTER CUTTING CABLE TO DESIRED LENGTH

STRIP WIRES, CRIMP SUPPLIED FEMALE QUICK

GREEN / BLACK-------LEVEL-1

WHITE / BLACK--------LEVEL-2

RED / BLACK------------LEVEL-3

BLUE / WHITE-----------DIMMING MODE

BLACK / WHITE---------CRUISE MODE

RED / WHITE-------------FLASH SEQUENCE SELECT

BLACK / RED------------FLASH RATE SELECT

BLACK---------------------TAKE DOWN STEADY

ORANGE / BLACK-----SCENE STEADY

SLIDES, AND COMPLETE THE CONNECTIONS 12X

CUSTOMER

SUPPLIED

WIRES RUN TO

Z3 SIREN OR

OTHER

SWITCHING

SYSTEM

CUSTOMER SUPPLIED

22 AMP BUTT SPLICE

TYPICAL

NOTE: FOR CALIFORNIA TITLE-13

STEADY RED TIE THE

RED / WHITE "FLASH

SEQUENCE WIRE" &

THE BLACK / RED

"FLASH RATE WIRE"

TO 12 VDC OR

TO A SWITCH THAT IS

TIED TO 12 VDC

VEHICLE BATTERY

7

POWER & GROUND WIRES

WILL REQUIRE CUSTOMER

SUPPLIED 12 GAGE WIRE,

12 GAGE BUTT SPLICES, &

20 AMP FUSE

Page 8

LIGHT BLUE/WHITE

PRIMARY

PURPLE

PRIMARY

RED

PRIMARY

PASSENGER SIDE 2011 CAPRICE DRIVER SIDE

RED/WHITE

PRIMARY

BROWN

PRIMARY

GREEN

PRIMARY

LIGHT BLUE

SECONDARY

WHITE

SECONDARY

ORANGE

SECONDARY

BROWN/WHITE

SECONDARY

PINK

SECONDARY

GREEN/WHITE

SECONDARY

MULTI COLOR SUPERVISOR INTERNAL WIRING DIAGRAM

NOTE: THIS IS THE LOCATION

FOR THE CALIFORNIA

STEADY BURN RED

LIGHT HEAD

WARNING!

This Product contains high intensity LED devices. To prevent eye

damage, DO NOT stare into light beam at close range.

Changing Flash Rates and Lighting Sequences

To change Multi Color SuperVisor Light Head ash rates, momentarily touch the Black Wire with Red Stripe (Flash Rate Control Wire) to 12

VDC Power (+ Positive). By holding the wire to + Positive for (1) second it will advance the ash rate by one, by holding the wire to + Positive for (3) seconds it will move the ash rate back by one. Holding the wire to + Positive for (5) seconds will set the ash rate back to the

factory default setting. See Flash Rate Chart Below! Changing the ash Sequence works the same way except you use the Red Wire with

White Stripe (Flash Sequence Control Wire). See Sequence Chart below!

Light Head Flash Sequences

LEFT / RIGHT PRIMARY & SECONDARY

(DEFAULT) PRIMARY ONLY - LEVEL - 1 DEFAULT

SECONDARY ONLY

PRIMARY W / WHITE POPS - LEVEL - 3 DEFAULT

PRIMARY W / WHITE RANDOM

EVEN / ODD PRIMARY & SECONDARY

PRIMARY ONLY - LEVEL - 2 DEFAULT

SECONDARY ONLY

PRIMARY W / WHITE POPS

PRIMARY W / WHITE RANDOM

IN / OUT PRIMARY & SECONDARY

PRIMARY ONLY

SECONDARY ONLY

PRIMARY W / WHITE POPS

PRIMARY W / WHITE RANDOM

RANDOM PRIMARY & SECONDARY

PRIMARY ONLY

SECONDARY ONLY

PRIMARY W / WHITE POPS

PRIMARY W / WHITE RANDOM

CYCLE SEQUENCE PRIMARY & SECONDARY

RANDOM PRIMARY ONLY

SECONDARY ONLY

PRIMARY W / WHITE POPS

PRIMARY W / WHITE RANDOM

ALL ON PRIMARY & SECONDARY

RANDOM

Light Head Flash Rates

Double Flash-75 - LEVEL - 2 DEFAULT

Triple Flash-75

Quad Flash-75

Quint Flash-75

Double Flash-150 - LEVEL - 3 DEFAULT

Triple Flash-150 - LEVEL - 1 DEFAULT

Quad Flash-150

Quint Flash-150

Triple Pop Flash-150

Quad Pop Flash-150

Single Flash-375

Cycle Rates

INSTALLER NOTE:

FLASH RATE + FLASH SEQUENCE = FLASH PATTERN

SWEEP PRIMARY & SECONDARY

LEFT / RIGHT PRIMARY ONLY

SECONDARY ONLY

PRIMARY W / WHITE POPS

PRIMARY W / WHITE RANDOM

8

Page 9

Cruise is congurable to any symetric setting.

TD Steady is congurable to any symetric setting.

Cruise TD Steady Scene Steady

2 Outter Secondary Steady 2 Inner Secondary All 6 Secondary

2 Outter Secondary Flicker 2 Middle Secondary

4 Outter Secondary Steady 2 Outer Secondary

4 Outter Secondary Flicker 4 Inner/Middle Secondary

6 Outter Secondary Steady 4 Outer/Middle Secondary

6 Outter Secondary Flicker 4 Inner/Outer Secondary

Cruise is lowest priority and will not work when any other feature is enabled. Different combinations of

lights can be used as Cruise by tapping the Sequence wire to +12V while only the Cruise is turned on.

TD Steady will work with or without Level 1, 2, or 3 lights engaged. Different combinations of lights can be

used as the TD by tapping the Sequence wire to +12V while only the TD Steady is turned on.

Scene Steady overrides all other functions.

Parts List - Multi Color SuperVisor-MC

4

5

Reference Number Part Description Part Number Quantity

1 Outer Mtg. Brkt. Drivr Side T15269 1

2 Chassis T17170 1

3 Inner Mtg. Brkt. T15267 2

6 7 8

3

9

1

2

4 Outer Mtg. Brkt. Pass Side T15270 1

5 Outer Panel T15271 1

6 Torus Multi Color Forward Facing Lt Head Module Contact Code 3, Inc for P/N 4

7 Torus Multi Color Passenger Intersection Lt Head Module Contact Code 3, Inc for P/N 1

8 Torus Multi Color Driver Intersection Lt Head Module Contact Code 3, Inc for P/N 1

9 Plastic Molded Inner Visor Clip T15276 2

10 Black Oxided #8 X 1" Phil Truss Hd SMS - NOT SHOWN T15280 10

9

Page 10

Parts List - CC Box - SuperVisor-MC - Multi Color

16

17

15

14

13

18

19

20

11

12

Reference Number Part Description Part Number Quantity

11 E-Tray - Multi Color SuperVisor T17164 1

12 Power Ground Cable--Mass State Police Slick Top System T56637 1

13 PCB Central Controller-Midrange T57137 1

14 #6-32 X.375 Phil Rd M/S, Stl, Zinc T04250 4

15 Cover-CC Housing-Multi Color SuperVisor T17165 1

16 Label-CC Box-Multi Color SuperVisor T17168 1

17 Input Harness-Multi Color SuperVisor CC Box T17166 1

18 Output Harness-Multi Color SuperVisor CC Box T17167 1

19 #8 X .25 SMS Phillips Truss Head Screw-Black Oxided T89905 1

20 Label-CC Box-Multi Color SuperVisor-INPUT/OUTPUT T17168 Part of Item 16 Above

10

Page 11

This unit must be mounted within the interior passenger compartment of the vehicle only. It is not intended for

use in exterior applications. All devices should be mounted in accordance with the manufacturer’s instructions

and securely fastened to vehicle elements of sufcient strength to withstand the forces applied to the device.

Driver and/or passenger air bags (SRS) will affect the way equipment should be mounted. This device should

be mounted by permanent installation and within the zones specied by the vehicle manufacturer, if any. Any

WARNING:

device mounted in the deployment area of an air bag will damage or reduce the effectiveness of the air bag and

may damage or dislodge the device. Installer must be sure that this device, its mounting hardware and electrical supply wiring does not interfere with the air bag or the SRS wiring or sensors. Mounting the unit inside

the vehicle by a method other than permanent installation is not recommended as unit may become dislodged

during swerving, sudden braking or collision. Failure to follow instructions can result in personal injury.

Troubleshooting

All SuperVisor-MCs are thoroughly tested prior to shipment. However, should you encounter a problem during installation or during

the life of the product, follow the guide below for information on repair and troubleshooting. Additional information may be obtained

from the factory technical help line at 314-996-2800. Follow the guide below for information on repair and troubleshooting.

TROUBLESHOOTING GUIDE

Note: LED modules must be replaced as a module. There are no user serviceable parts.

PROBLEM

LED module not

operating when

powered.

QUESTIONS POSSIBLE CAUSE

N/A

A. Bad power/ground

connection.

B. Defective module.

Notes:

SOLUTION

A. Fix connection.

B. Replace module

11

Page 12

WARRANTY

Code 3®, Inc.’s emergency devices are tested and found to be operational at the time of manufacture. Provided

they are installed and operated in accordance with manufacturer’s recommendations, Code 3®, Inc. guarantees all parts

and components except the lamps to a period of 1 year, LED Lighthead modules to a period of 5 years (unless otherwise

expressed) from the date of purchase or delivery, whichever is later. Units demonstrated to be defective within the warranty

period will be repaired or replaced at the factory service center at no cost.

Use of lamp or other electrical load of a wattage higher than installed or recommended by the factory, or use of

inappropriate or inadequate wiring or circuit protection causes this warranty to become void. Failure or destruction of the

product resulting from abuse or unusual use and/or accidents is not covered by this warranty. Code 3®, Inc. shall in no way

be liable for other damages including consequential, indirect or special damages whether loss is due to negligence or breach

of warranty.

CODE 3®, INC. MAKES NO OTHER EXPRESS OR IMPLIED WARRANTY INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF FITNESS OR MERCHANTABILITY, WITH RESPECT TO THIS PRODUCT.

NEED HELP? Call our Technical Assistance HOT LINE - (314) 996-2800

PRODUCT RETURNS

If a product must be returned for repair or replacement*, please contact our factory to obtain a Return

Goods Authorization Number (RGA number) before you ship the product to Code 3, Inc. Write the RGA number

clearly on the package near the mailing label. Be sure you use sufcient packing materials to avoid damage to

the product being returned while in transit.

*Code 3, Inc. reserves the right to repair or replace at its discretion. Code 3, Inc. assumes no responsibility or liability for expenses incurred for the removal and /or

reinstallation of products requiring service and/or repair.; nor for the packaging, handling, and shipping: nor for the handling of products returned to sender after the service has been

rendered.

St. Louis, Missouri 63114-2029—USA

Ph. (314) 426-2700 Fax (314) 426-1337

10986 N. Warson Road

www.code3pse.com

Code 3®, Inc.

Code 3 is a registered trademark of Code 3, Inc.

12

Revision 0, 10/14 - Instruction Book Part No. T17172

©2011 Printed in USA

Loading...

Loading...