CHD850 Hammer Drill rev 4.fm Page 1 Monday, February 9, 2015 10:47 AM

850W HAMMER DRILL

MODEL NO: CHD850

PART NO: 6479500

OPERATION & MAINTENANCE

INSTRUCTIONS

GC0215

CHD850 Hammer Drill rev 4.fm Page 2 Monday, February 9, 2015 10:47 AM

INTRODUCTION

Thank you for purchasing this CLARKE Hammer Drill.

Before attempting to use this product, please read this manual thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you, and you can look forward to your purchase

giving you long and satisfactory service.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

ENVIRONMENTAL PROTECTION

Recycle unwanted materials instead of disposing of them as waste.

All tools, accessories and packaging should be sorted, taken to a

recycling centre and disposed of in a manner which is compatible

with the environment.

2

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 3 Monday, February 9, 2015 10:47 AM

SAFETY PRECAUTIONS

WARNING: READ ALL INSTRUCTIONS. FAILURE TO FOLLOW ALL

INSTRUCTIONS LISTED BELOW MAY RESULT IN ELECTRIC SHOCK, FIRE AND/

OR SERIOUS INJURY. THE TERM “POWER TOOL” IN ALL WARNINGS LISTED

BELOW REFERS TO YOUR 850W HAMMER DRILL.

WORK AREA

1. Keep work area clean and well lit. Cluttered and dark areas invite

accidents.

2. Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2. ELECTRICAL SAFETY

1. Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges or refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

2. Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

3. When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in personal injury.

2. Use safety equipment. Always wear eye protection. Safety equipment such

as dust mask, non-skid safety shoes, or hearing protection used for

appropriate conditions will reduce personal injuries.

3. Avoid accidental starting. Ensure the switch is in the off position before

connecting to the power supply.

4. Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 4 Monday, February 9, 2015 10:47 AM

5. Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

POWER TOOL USE AND CARE

1. Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at the

rate which it was designed.

2. Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and

must be repaired.

3. Disconnect the battery before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

4. Store idle tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of untrained users.

5. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

6. Keep cutting tools sharp and clean. Poorly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

7. Use the power tool and accessories in accordance with these instructions

and in the manner intended for the particular type of power tool, taking

into account the working conditions and the work to be performed. Use of

the power tool for operations different from intended could result in a

hazardous situation.

HAMMER DRILL SAFETY INSTRUCTIONS

1. Only use the drill in the manner and for the functions described.

2. Using the correct bit. Use the appropriate drill bit for the material being

drilled. Different bits are available from your Clarke dealer.

3. Use of the mains cable. Keep the mains cable well away from the drill and

ensure an adequate electrical supply is close at hand so that the

operation is not restricted by the length of the cable.

4. Working on the bench. Allow sufficient clearance beneath the work to

ensure the drill bit does not come into contact with the floor, table etc.

5. Switching off. Never place the drill on a table or bench if it has not

completely stopped. The drill bit will continue to rotate for a short time after

the trigger has been released to stop the drill.

4

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 5 Monday, February 9, 2015 10:47 AM

6. Drilling into walls. Do not drill into walls or cavities before checking for

hidden electrical wires or water pipes etc.

7. Finishing drilling. Do not touch the drill bit immediately after use, allow time

for it to cool.

8. Use outdoor extension leads. If working outdoors, always use an approved

cable extension suitable for the power rating of this tool (see

specifications), the conductor size should also be at least the same size as

that on the machine, or larger. When using a cable reel, always unwind the

cable completely. We strongly recommend that this machine is

connected to the mains supply via a Residual Current Device (RCD).

9. Cooling agents. When drilling metals, always use a cooling agent i.e.

cutting/soluble oil.

SERVICE

1. Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

Additionally, please keep these instructions in a safe place for future reference

SPECIFICATIONS

Item Specification

Operating Modes Drill or Drill & Hammer Action/Reverse

Chuck Capacity 1.5 mm -13 mm

Rated No-load Speed 0-2900 rpm

Weight 3.35 kg

Dimensions (L x W x H) 298 x 70 x 204 mm

Operating voltage & Frequency 230V~50Hz

Fuse rating 13 A

Motor Power 850 W

Sound Pressure Level 92.0 dB LpA

Sound Power Level 103 dB L

Vibration Level 8.59 m/s

5

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

WA

2

Plug must be BS1363/A approved.

Always fit a 5 Amp fuse.

Ensure that the outer sheath of the cable is firmly held by the clamp

Neutral

(Blue)

Live

(Brown)

CHD850 Hammer Drill rev 4.fm Page 6 Monday, February 9, 2015 10:47 AM

ELECTRICAL CONNECTIONS

WARNING! Read these electrical safety instructions thoroughly

before connecting the product to the mains supply.

This product battery charger is provided with a standard 13 amp, 230 volt

(50Hz), BS 1363 plug, for connection to a standard, domestic electrical supply.

Should the plug need changing at any time, ensure that a plug of identical

specification is used.

WARNING! The wires in the power cable of this product are

coloured in accordance with the following code:

Blue = Neutral Brown = Live

If the colours of the wires in the power cable of this product do not correspond

with the markings on the terminals of your plug, proceed as follows.

• The wire which is coloured Blue must be connected to the terminal

which is marked N or coloured Black.

• The wire which is coloured Brown must be connected to the terminal

which is marked L or coloured Red.

We strongly recommend that this machine is connected to the mains supply

via a Residual Current Device (RCD)

If in any doubt, consult a qualified electrician. DO NOT attempt any repairs

yourself.

This symbol indicates that this is a Class II product, and does not require

an earth connection.

6

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 7 Monday, February 9, 2015 10:47 AM

OVERVIEW

The CLARKE CHD850 is a variable-speed drill for DIY use. It is equipped with a

variable speed controller and hammer operation and has a lock-on button for

continuous operation. The drill is supplied with a depth stop rod and auxiliary

handle.

When unpacking, check for damage or shortages etc. Any found should be

reported to your CLARKE dealer where the drill was originally purchased. This

CHD850 Drill is supplied with the following components:

• 1 x Impact Drill

• 1 x Chuck Key

• 1 x Depth Stop Rod

• 1 x Auxiliary (Side) Handle

7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 8 Monday, February 9, 2015 10:47 AM

OPERATION

IMPORTANT: To avoid accidental starting, ensure the drill is switched OFF

before plugging in to the mains. To do this, briefly pull the switch, and

release to ensure the trigger lock is not set in the ‘lock’ position.

INSERTING A DRILL BIT

1. Open the chuck by rotating the

chuck sleeve anticlockwise until

the jaws are open sufficiently to

take the drill bit.

2. Place the drill bit in the jaws of the

chuck as far as it will go.

3. Insert the chuck key in one of the

three holes in the chuck and

tighten in a clockwise direction.

• Make sure that the head of the

chuck key is located on the cog barrel of the chuck when

tightening.

WARNING: REMOVE THE CHUCK KEY BEFORE OPERATING THE DRILL.

• To remove the bit, release the jaws by inserting the chuck key in one

of the holes and turning in an anticlockwise direction.

SWITCHING ON & CONTINUOUS OPERATION

1. Plug into a 13amp socket and squeeze the trigger to start the drill.

2. During use, press the trigger lock-on button and the drill will run

continuously. Squeeze the trigger again briefly to release the trigger lock &

stop the drill.

8

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 9 Monday, February 9, 2015 10:47 AM

HAMMER DRILL SELECTION

Rotate the drill/hammer drill mode

selection switch so that the ‘Hammer’

symbol is aligned with the arrow on

the drill body.

NORMAL DRILL SELECTION

Rotate the drill/hammer drill mode

selection switch so that the ‘Drill’

symbol is aligned with the arrow on

the drill body.

NOTE: Both these operations should only be performed when the drill is at a

complete stop.

FORWARD / REVERSE SELECTION

1. Set the forward/reverse selector

switch to the position marked ‘R’

for normal ‘Right Hand’ rotation

for drilling holes.

2. Set the forward/reverse selector

switch to the position marked ‘L’

for ‘Left Hand’ rotation to reverse

the drill out of the workpiece.

NOTE: This operation should only be

performed when the drill is at a

complete stop.

SPEED SELECTION

1. Turn the selector knob until the

number is aligned with the arrow

on the drill body).

NOTE: This operation should only be

performed when the drill is at a

complete stop.

• The maximum speed may be

selected by turning the

variable speed control in the

centre of the trigger.

9

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 10 Monday, February 9, 2015 10:47 AM

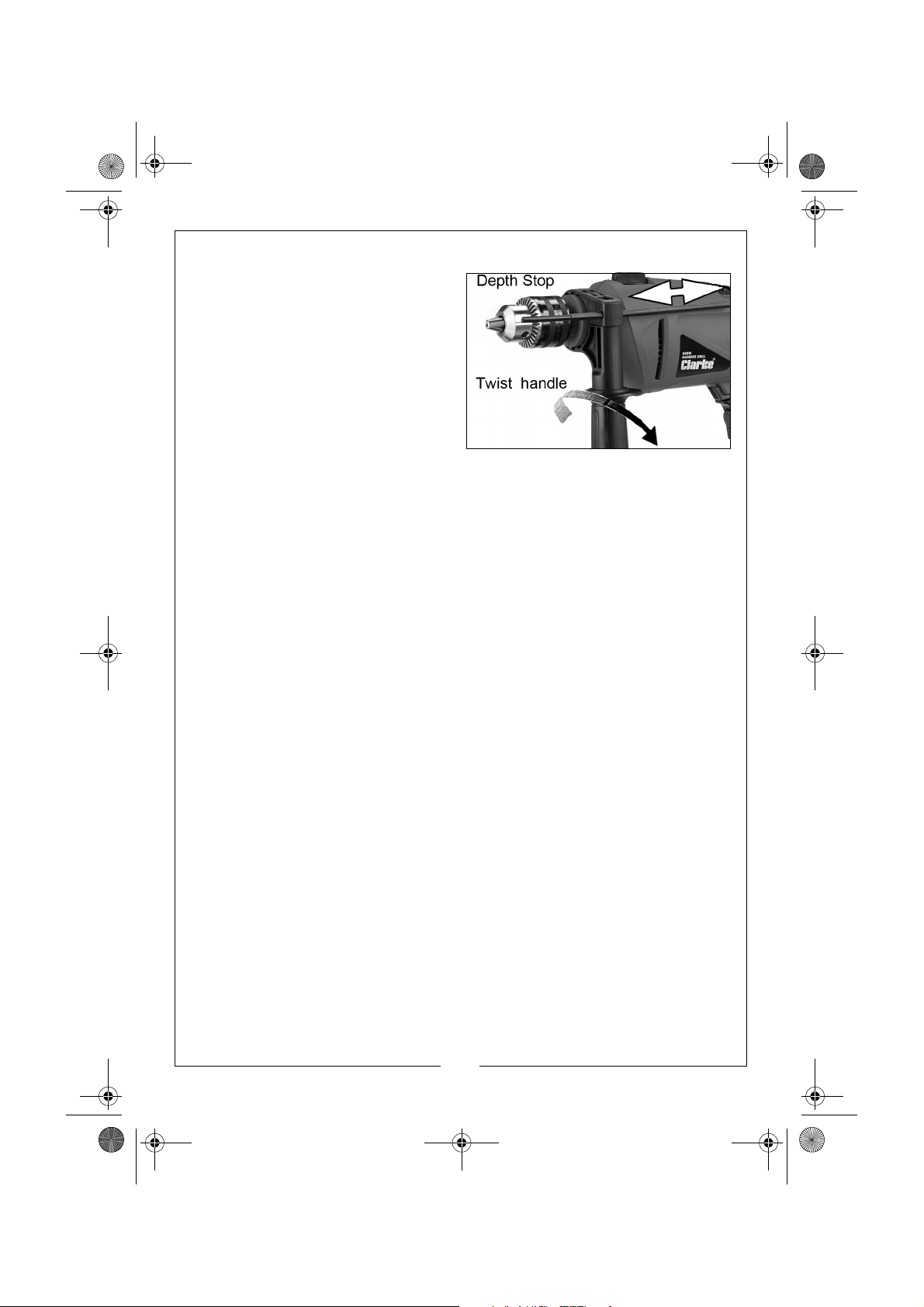

AUXILIARY HANDLE AND DEPTH STOP

The depth stop is fitted within the

auxiliary handle and can only be

used if this handle is installed.

1. Slide the handle assembly over

the chuck and onto the body of

the drill.

2. Rotate the handle to the desired

position and secure in position by

twisting clockwise.

3. Insert the depth stop rod through

the holder in the handle assembly.

• To set the depth stop, slide the rod in and out to the required position

and lock in place by turning the thumbscrew clockwise.

GENERAL DRILLING TECHNIQUE

• After drilling material to the full depth, maintain chuck rotation to

ease drill withdrawal.

• Always drill directly in line with the bit. Do not use sideways

movement as this may damage the drill or cause the bit to break.

• If the drill is not cutting the metal then sharpen the drill bits, ensuring

the various cutting angles are correct.

• Always use sharp, good quality drill bits. The performance of your drill

is dependant on the quality of the bits used.

• Reduce the pressure on the drill bit when it is about to break through.

This will prevent the drill from jamming.

• If drilling a large hole, first drill a pilot hole using a smaller drill bit.

• Always apply pressure to your drill bit in a straight line and, where

possible, at right angles to the workpiece.

• When drilling holes or driving screws into walls, floors etc., always

make sure that there are no live electrical wires in the path of the bit.

• When drilling in metal, the materials being drilled can become hot.

To reduce overheating use a suitable cooling lubricant. No cooling

lubricant is necessary when drilling cast iron or brass as they should

be drilled dry.

• When drilling metal, the harder the metal the slower the drill speed.

Similarly, the bigger the drill bit the slower the speed.

• Always start drilling at a slow speed to prevent the drill from slipping

out of the pop mark or indent, gradually increasing speed until the

10

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 11 Monday, February 9, 2015 10:47 AM

optimum cutting speed is achieved whilst maintaining a MODERATE

pressure ONLY. NEVER force the drill bit into the work. This will

overheat the tip and cause it to dull very quickly.

• To prevent the drill bit from slipping when starting to drill a hole in

metal, use a centre punch to make an indentation at the start point.

• When drilling in wood, clamp a piece of scrap wood to the

underside of the material to avoid splintering.

• Always drill directly in line with the bit. Do not use sideways

movement as this may damage the drill or cause the bit to break.

• Large holes should be drilled with wood augers, flat wood bits or

hole saws.

MAINTENANCE

Before commencing any maintenance procedures, always ensure the drill is

isolated from the electrical supply by switching off and removing the plug

from the socket.

BEFORE USE

1. Ensure all fixing screws remain tight to ensure the drill is in safe working

condition.

2. Inspect the power cable to ensure it is sound and free from cracks, bare

wires etc.

CLEANING

1. Ensure all air ventilation slots are clear of blockages, (use compressed air to

clean the machine if possible).

2. After use, clean all dust and swarf from the drill.

3. Clean the exterior of the drill with a soft cleaning cloth. Never use any

chemicals or harsh abrasives to clean the tool.

• Avoid using solvents when cleaning plastic parts, most plastics are

susceptible to damage from the various types of commercial

solvents.

GENERAL MAINTENANCE

• All bearings etc, in this tool are lubricated with a sufficient amount of

high grade lubricant for the tools lifetime under normal operating

conditions, therefore no further lubrication is necessary.

• Refer to your CLARKE dealer if internal maintenance is required.

11

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 12 Monday, February 9, 2015 10:47 AM

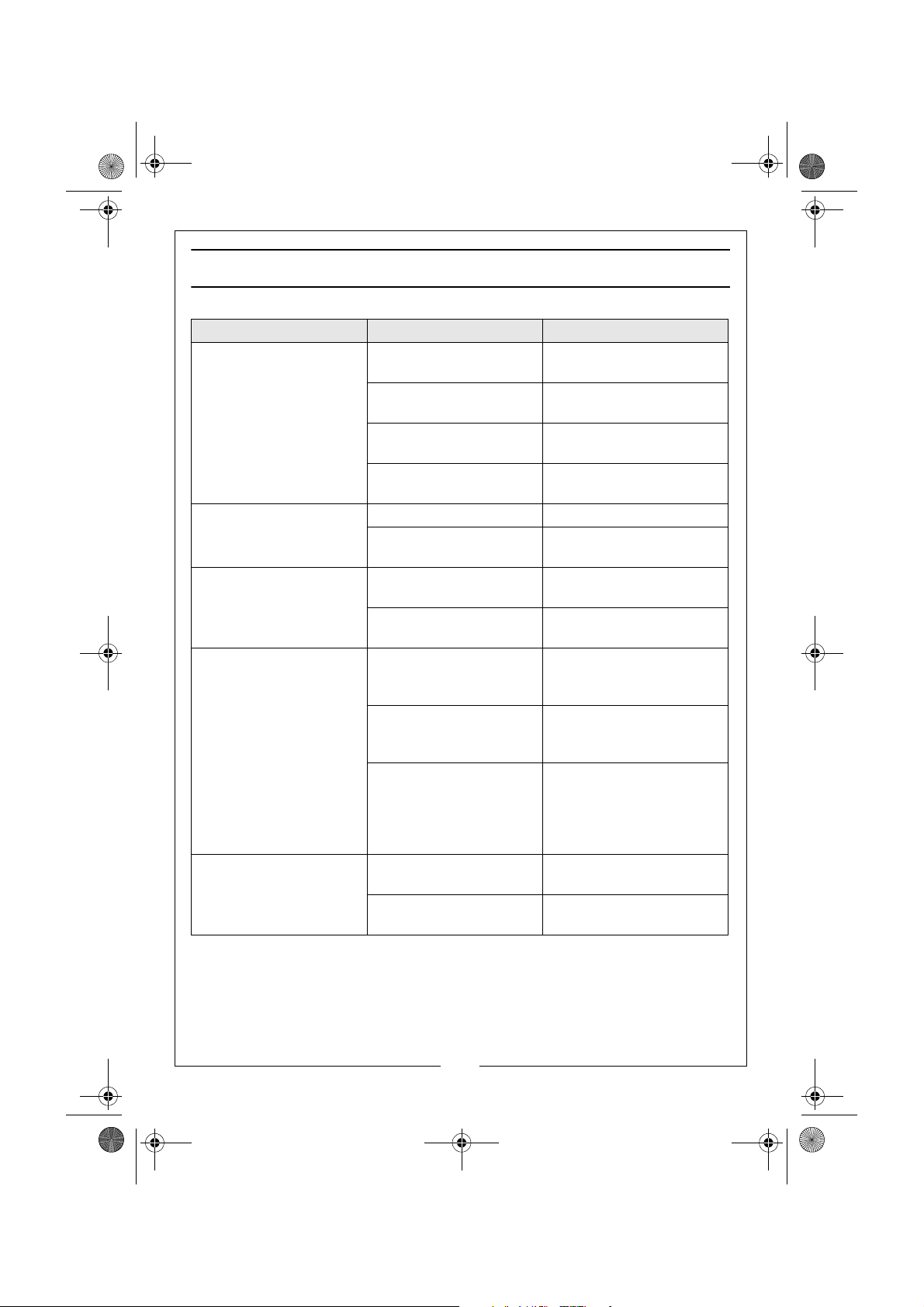

FAULTFINDING

Problem Possible Cause Remedy

Tool will not operate No power supply Check supply & rectify as

necessary

Switch is faulty Consult your Clarke

dealer

Fuse blown Check & replace if neces-

sary

Motor is faulty Consult your Clarke

dealer

Motor runs but drill bit

does not move.

Heavy internal sparking Faulty motor Consult your Clarke

Motor becomes hot Unduly heavy use Reduce the force applied

Excessive vibration. Drill bit bent or not

Drill fastening not tight. Secure drill bit.

Drive gear broken Consult your Clarke

dealer

dealer

Warn brushes Consult your Clarke

dealer

to the tool. Let the tool do

the work.

Air vent have become

blocked.

Low supply voltage Ensure supply voltage is

mounted correctly.

Machine bearings worn. Consult your Clarke

Clean out the air vents

using compressed air or

clean with a dry cloth.

correct. If an extension

cable is used, ensure it is

the correct rating and is

fully unwound.

Check and rectify.

dealer

12

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 13 Monday, February 9, 2015 10:47 AM

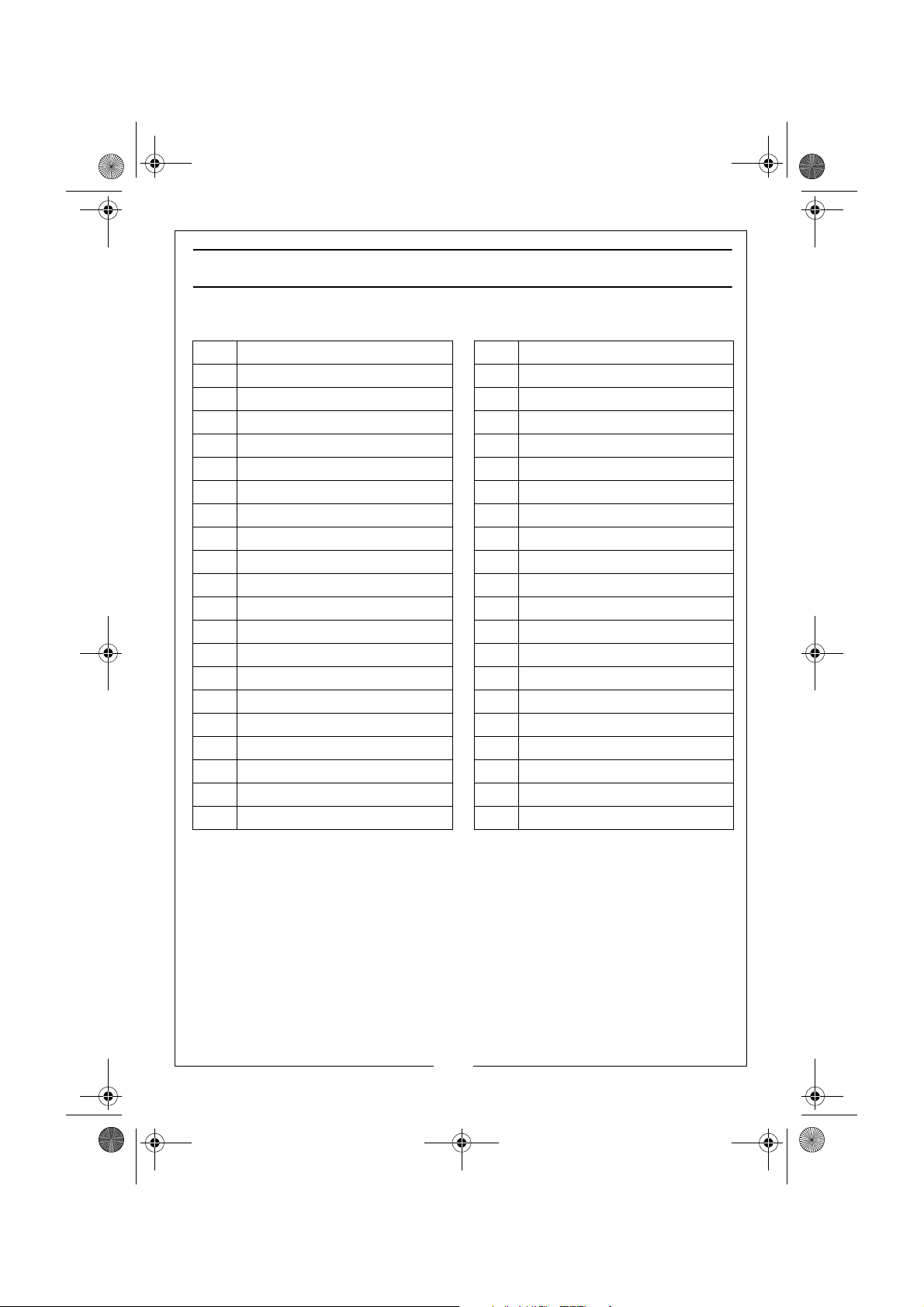

COMPONENT PARTS LIST

No Description No Description

1 Power Cable 21 Loose Rib 12mm

2 Cable Sleeve 22 Bearing

3 X-head Screw 23 Impact Spring

4 Cable Clamp 24 Drive Spindle

5 Capacitor 25 Woodruff Key

6 Trigger Assembly 26 Key Holder

7 Carbon Brush Holder 27 Spring

8 Spring 28 Impact Selector

9 Carbon Brush 29 Casing (LH)

10 Inductor 30 Air Vent

11 X-head Screw 31 Casing (RH)

12 Motor Stator 32 Casing Screw (top)

13 Motor Bearing 33 Casing Screw (rear)

14 Motor Armature 34 Casing Screw (front)

15 Motor Drive Bearing 35 Chuck

16 Drive Support Block 36 Chuck Retaining Screw

17 Oilite Bush 37 Auxiliary Handle

18 Steel Ball 38 Depth Stop Rod

19 Loose Rib 9mm 39 n/a

20 Spur Gear 40 Chuck Key

When ordering spare parts please quote the reference WG/CHD850 followed

by the number above.

13

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 14 Monday, February 9, 2015 10:47 AM

COMPONENT PARTS

14

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 15 Monday, February 9, 2015 10:47 AM

DECLARATION OF CONFORMITY

15

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

CHD850 Hammer Drill rev 4.fm Page 16 Monday, February 9, 2015 10:47 AM

Loading...

Loading...