COMPACT PARTS BENDERS

MODEL NO: CCB1B & CCB2B

PART NO: 7630083 & 7630084

OPERATION

INSTRUCTIONS

ORIGINAL INSTRUCTIONS GC0221 rev -2

INTRODUCTION

Thank you for purchasing this CLARKE product. The compact metal parts

bender allows you to economically make a variety of bends in flat, square or

solid round stock. These instructions provide basic information on using the

bender, plus step-by-step examples of how to bend stock to make several

common products. We urge you to read the complete Operation section

before trying to use the bender.

Before attempting to use this product, please read this manual thoroughly and

follow the instructions carefully. In doing so you will ensure the safety of yourself

and that of others around you and you can look forward to your purchase

giving you long and satisfactory service.

GUARANTEE

This product is guaranteed against faulty manufacture for a period of 12

months from the date of purchase. Please keep your receipt which will be

required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or

tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

SAFETY PRECAUTIONS

WARNING: THE USER MUST FOLLOW ALL INSTRUCTIONS WITHIN THIS

INSTRUCTION BOOKLET

To protect against serious injury, use common sense and observe the following

precautions when using this product. Clarke International is not responsible for

misuse of the equipment.

• ALWAYS secure the metal bender to the floor or bench before use.

• ALWAYS study these instructions before operating and pay close

attention to all warnings.

• ALWAYS keep the work area free of obstructions.

2

• ALWAYS wear safety goggles when bending parts and when

grinding or sanding them.

• ALWAYS be sure that enough material extends beyond the stop

block and forming die when making bends, to be sure the material

does not come free and allow the handle to release suddenly.

• ALWAYS insert the hinge pins fully before making bends.

• NEVER try to bend material other than hot-rolled mild steel.

• NEVER try to bend flat material larger than 5 16 x 2 in or square or

solid round material larger than 5 8 in. (EXCEPTION: Rebar that is 1/2in. diameter may be bent around the 3” die only).

• NEVER bend round stock when using the sharp-angle-bend

attachment. Use only flat, hot-rolled, mild steel up to 3/16 x 2” or 1/4

x 1-1/4” with this attachment.

• NEVER try to bend material that is more than 1/ 4” thick around the

centre pin (instead, use the 1” die on the pin).

• NEVER modify the metal bender or use a handle extension arm other

than the one provided.

INDEX

Assembly 4

Basic Operations 5

Using the Stop Block 7

Using the Sharp-Angle-Bend Attachment 9

Examples

Bending Handles 10

Bending Tube Clamps 12

Bending Anchor Bolt

Bending Letters for Signs 19

Parts List & Diagram 46

s and U-Bolts 15

3

ASSEMBLY

1. To attach the ring assembly to the

stand (refer to the illustration

posite):

op

a. Attach the loop end of the ring

a

ssembly to the stand. Use the long bolt,

flat washer, thick spacer (inside the

loop), thin spacer, lock washer, and lock

nut.

b.Attach the ring end to the stand with

the two flat-head bolts, using thin

spacers, flat washer, lock washers, and

lock nuts.

2. Insert the loop end of the handle

inside the loop

and secure it by inserting one of the

two longer hitch pins.

3. Remove the 'R' clip from the handle

pin then remove the pin from the

handle. Pull out the extension arm,

install the pin in the outer hole, and

reinstall the 'R' clip.

4. Set the bender in the position where

you intend it to be used. Rotate the

handle as far as it will go in both directions, to be sure there will be no

obstructions when bending.

of the ring assembly,

5. Attach the bender’s base securely to the floor.

4

BASIC OPERATION

Most of this manual is devoted to showing you how to create basic shapes.

Other than these specific instructions, setting up the bender to form your

particular shape will involve a certain amount of trial-and-error.

You will notice some differences in operation depending on whether you are

forming the piece around a die, or whether you are making a sharp-angle

bend in the piece. However, in general you will:

1. Determine the appropriate material and size for the part(s) to be made.

2. Determine the appropriate dies to install on the centre pin and/or the pin

installed in the handle, and determine the appropriate hole for attaching

the handle to the ring assembly’s loop.

3. Install the stop block or the sharp-angle-bend attachment, as appropriate.

Install the block support. If the stop block is used, orient it properly. Refer to

pages 4 and 5 for more information on the stop block and the sharp-anglebend attachment.

4. Insert the blank stock into the bender, and position it properly for the first

bend.

5. Make the first bend. Re-check the angle and location before continuing.

6. Make any additional bends in the same way. In some cases, you may have

to remove the piece from the bender and turn it end-for-end or upsidedown.

HOLE IDENTIFICATION

In the examples shown in this manual,

the holes in the loop and those in the

handle are identified by a number.

Refer to the illustration at right.

MEASURING BEND ANGLES

When accuracy is required, you will

need a suitable device for measuring

the bend angles.

FIXED AND ADJUSTABLE STOPS

If you are making multiple parts with

the same bend angle, using the

same setup (dies and hole locations),

the operation will be speeded up by

installing either the fixed or adjustable stop in the appropriate hole in the ring

assembly.

5

After determining the handle

rotation, insert the fixed stop into the

next open hole and use as a guide

for bending additional parts.

When greater precision is required,

attach the adjustable stop as

accurately as you can at the limit of

handle rotation. Make a test part with

scrap material, and reposition the

adjustable stop as necessary. Tighten

bolt and nut securely before bending

production parts.

NOTE: If precise dimension are

required, start by making a

test part using scrap

material of the same thickness. Readjust the setup as necessary.

NOTE: Once you determine the dimensions, die size(s), holes, and

bending sequence for a part, write down the information for

future reference.

6

USING THE STOP BLOCK

IMPORTANT: Read page 4 before you proceed to this section.

THE PURPOSE OF THE STOP BLOCK

The stop block prevents the material

from rotating while a forming die in the

handle bends the material around

either the centre pin or another die that

has been installed on the centre pin.

When you are bending material, the

stop block will be located (using a hitch

pin) at one of the five large holes in the

middle of the ring assembly’s loop. (The

large hole at the open end of the loop

is for the centre pin.) You will have to

determine by trial which hole you will

use, depending on the thickness of the

material being bent, the size of the

centre-pin die, and the orientation of

the stop block.

POSITIONING THE STOP BLOCK

The stop block can be placed in several

positions by rotating it on the hinge pin

or by turning it upside down and

rotating it on the pin. However, only four

of the possible positions are used when

bending. Throughout this manual, those

four positions are identified by a

number (refer to the illustration at right).

CAUTION: ALWAYS POSITION THE STOP

BLOCK OFF-CENTRE TO THE RIGHT—NO

MATTER WHICH FACE IS USED AGAINST THE

MATERIAL. IF POSITIONED OFF-CENTRE TO

THE LEFT, THE BLOCK WILL TURN AND THE

MATERIAL WILL SLIP IN THE BENDER.

To position the stop block (that is, to

select the proper orientation and the

proper hole in the loop):

1. Connect the handle to the centre

pin of the loop, with the appropriate

die installed on the centre pin.

7

2. Install the appropriate die at the appropriate hole in the handle.

3. Inset a piece of the material to be formed. With the handle all the way

back (anticlockwise), install the stop block in the orientation that places it

as close to the centre pin as possible.

IMPORTANT: Always use the loop hole that places the stop block as close to

the centre pin or die as possible, while leaving space for the material to be

inserted.

If there is too much space between the stop block and the centre pin or die,

turn the block to a different orientation or move the block one hole closer to

the centre.

POSITIONING THE BLOCK SUPPORT

The block support must be located under the stop block as shown, to keep the

block centered vertically in the loop.

Install the support in the appropriate loop hole where it will support the stop

block but not interfere with inserting the hitch pin all the way through the

block hole and the lower hole in the loop.

CLAMPING

If the stop block is positioned

correctly, the material will normally

not have to be clamped in the

bender. However, when you are

making special bends or need

precise dimensions, it is helpful to

clamp the material against the stop

block using a vice-grip pliers as

shown at right.

8

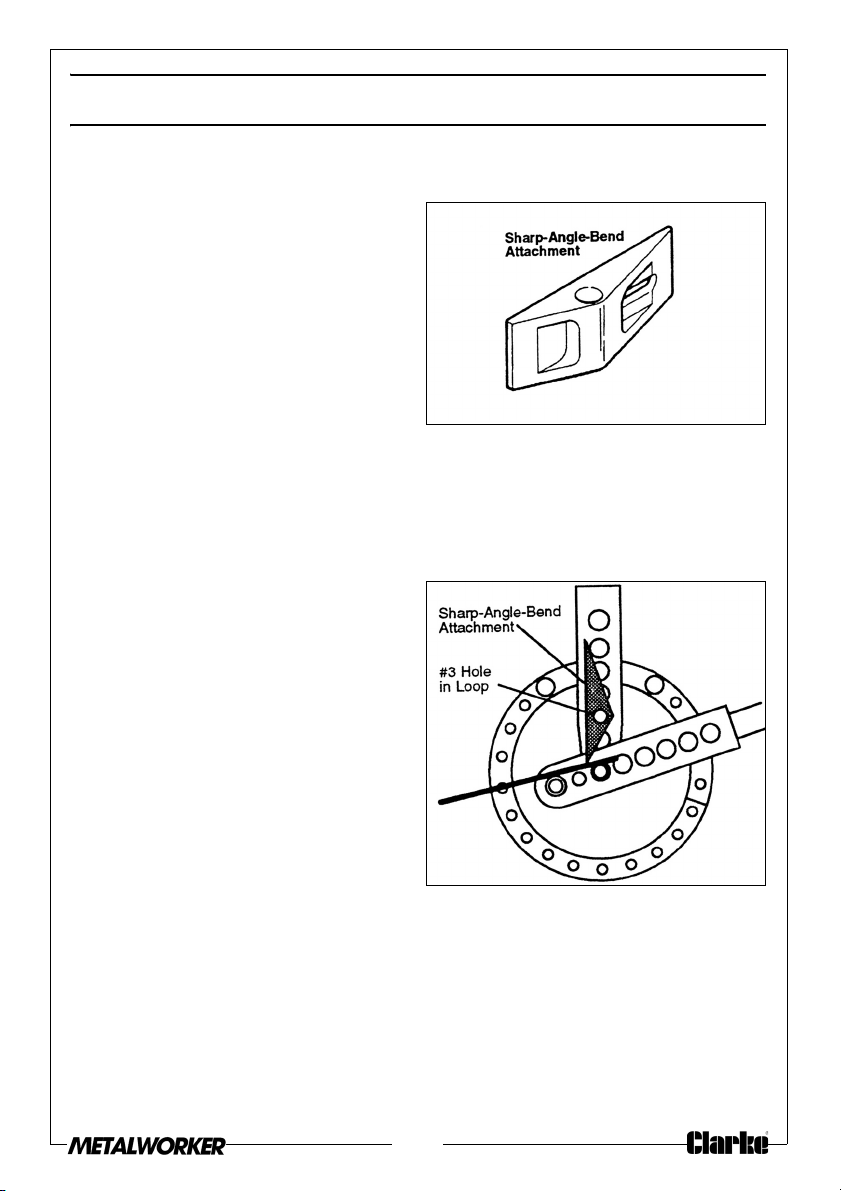

USING THE SHARP-ANGLE-BEND ATTACHMENT

PURPOSE OF THE ATTACHMENT

The sharp-angle-bend attachment is

used instead of the stop block when

you make a right-angle bend or

other sharp bend in flat material.

POSITIONING THE ATTACHMENT

In contrast to the stop block, the

sharp-angle bend attachment has

only one correct orientation—as

shown at right, and with the hinge pin

in the #2 hole in the loop.

POSITIONING THE BLOCK SUPPORT

The block support must be located under the sharp-angle-bend attachments,

to keep the attachment centered vertically in the loop. (Compare the

illustration on page 6 with the stop block.)

Install the support in the #3 loop hole,

so it will support the attachment but

not interfere with inserting the hitch

pin all the way through the

attachment’s hole and the lower

hole in the loop.

CLAMPING

The material should not need to be

clamped when using the sharpangle-bend attachment.

BENDING THE MATERIAL

Make thin chalk marks on the flat

material to show where you want to make the bends. For an example, see

page 10.

Insert the material into the bender so that half the width of the chalk mark

shows and the other half is covered by the bending edge of the attachment.

If you are making two right-angle bends on the same side of the material,

space their chalk marks about 1/8” further apart than the desired inside

dimension after the bend.

9

EXAMPLE: BENDING HANDLES

HANDLES FROM ROUND STOCK

To make a typical handle, using a 9in. length of 3/8in. round stock and two

pieces of flat stock:

NOTE: To make other sizes of handles, experiment to find the

appropriate die sizes and stop block orientation.

1. With a long hinge pin, attach the handle and ring loops at their centre-pin

holes. Install a 1in. die on the centre pin. With the short hinge pin, install a 2

in. die in the handle (#2 hole).

2. With a long hinge pin, install the stop block (oriented as in A).

3. Insert the round stock into the Bender so that it extends 2” beyond the

centre-pin die (see B), and make the first bend to 90°.

4. Turn the part end-for-end, position it as in C, and make the second 90°

bend. Remove the stock from the bender.

5. Drill 5/8”holes in the flat stock & insert the handle halfway through the holes

Always drill the holes the same size as the diameter of the handle stock.

6. Weld the flat stock pieces in place from the back side. If any weld material

extends below the surface of the flat plate, grind it flush.

10

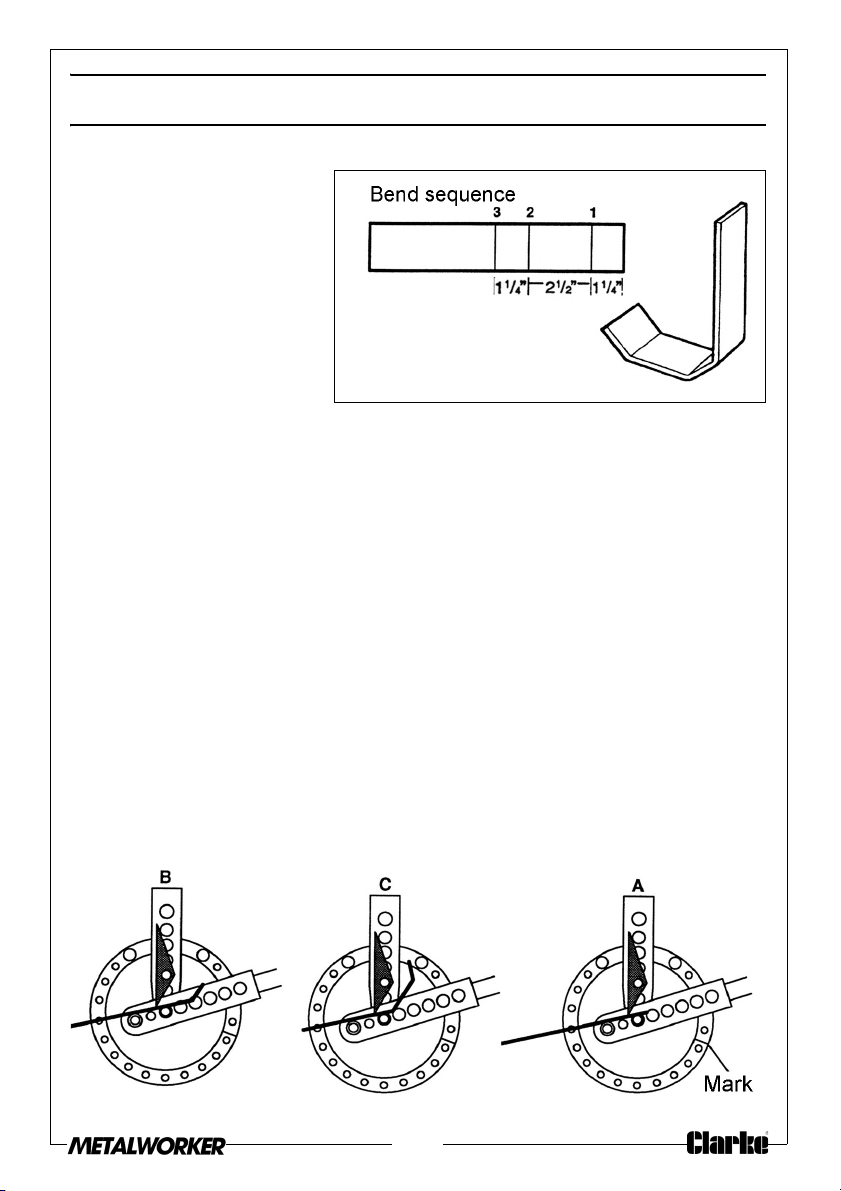

HANDLES FROM FLAT STOCK

To make a typical handle, using a 9” length of 3/16” x 1” hot-rolled flat stock:

NOTE: To make other sizes of handles, experiment to find the

appropriate bend locations.

1. Install the sharp-angle-bend

attachment.

2. Place chalk marks on the material

as shown under “Bend

Sequence.” the #1 and #2 marks

are on one face of the material

and the #3 and #4 marks are on

the opposite face.

3. Insert the flat stock into the bender to the #1 mark as in A) and make a 90°

bend. Check the angle before continuing.

4. Set the adjustable stop so each bend will be 90°.

5. Turn the stock end-for-end. Insert it to the #2 mark

bend.

6. Turn the stock over front-to-back.

a 90° bend.

7. Turn the stock end-for-end. Insert it to the #4 mark (as in

bend.

8. Grind and sand all sharp corners.

Insert it to the #3 mark (as in C) and make

(as in B) and make a 90°

D) and make a 90°

11

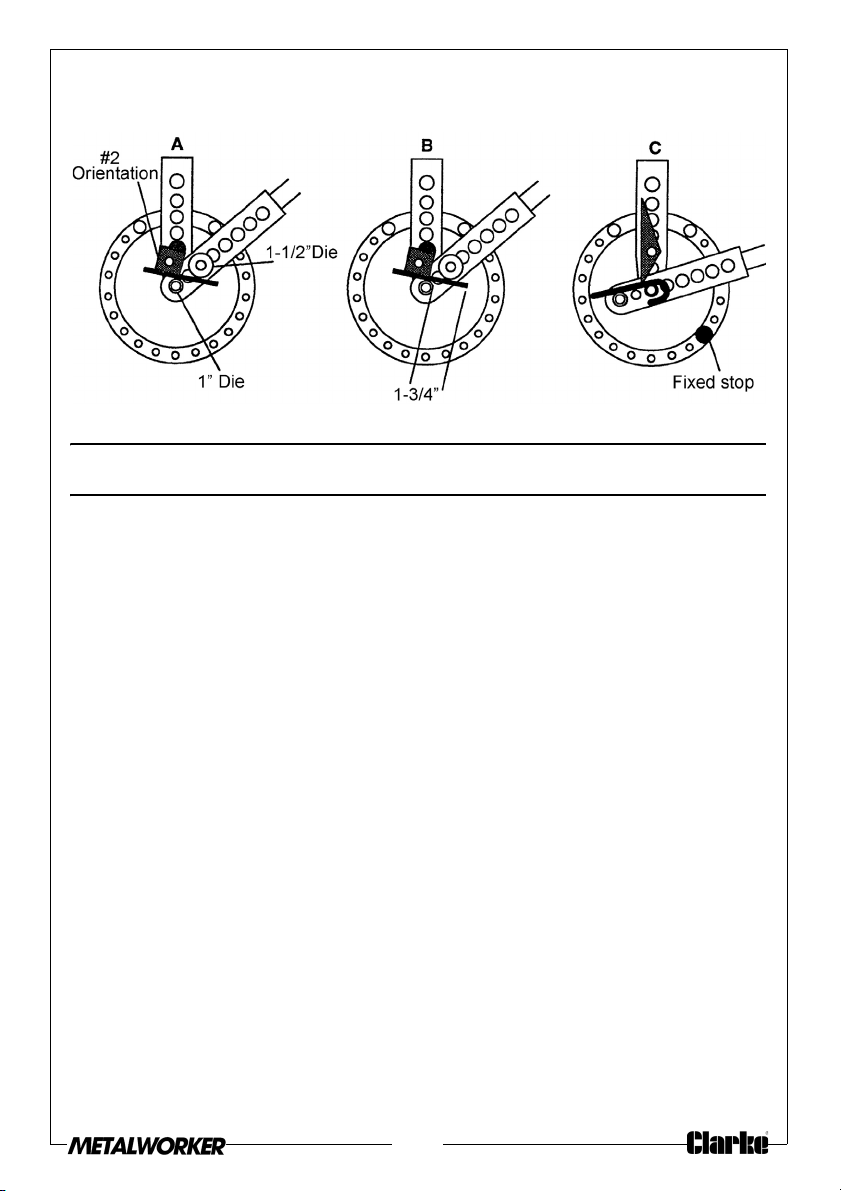

EXAMPLE: BENDING TUBE CLAMPS

SINGLE-TUBE CLAMP

To make a 1” I.D. tube clamp (for

clamping 1” O.D. tubing), using a 4½”

length of 3/16” x 1” hot-rolled flat

stock:

NOTE: To make other sizes of

clamps, experiment to find

the appropriate die sizes

and stop block orientation.

1. With a long hinge pin, attach the

handle and ring loops at their

centre-pin holes. Install a 1” die on

the centre pin.

2. With the short hinge pin, install a

1½-in. die in the handle (#2 hole).

3. With a long hinge pin, install the

stop block (oriented as in A

below).

4. Insert the flat stock into the bender so that it extends 1½-in. beyond the

centre-pin die (as in B below).

5. Clamp the stock against the stop block using a vice-grip pliers, to prevent

the stock from slipping.

6. Make the first bend by pulling the handle around until the handle die runs

off the end of the piece.

7. Remove the stop block and the two dies. Change the handle connection,

and install the sharp-angle-bend attachment (as in C below).

8. Insert the stop pin into the 6th hole of the ring (counting clockwise from the

closed end of the loop).

12

9. Make the second bend by pulling the handle until it is about 1/8” from the

stop pin.

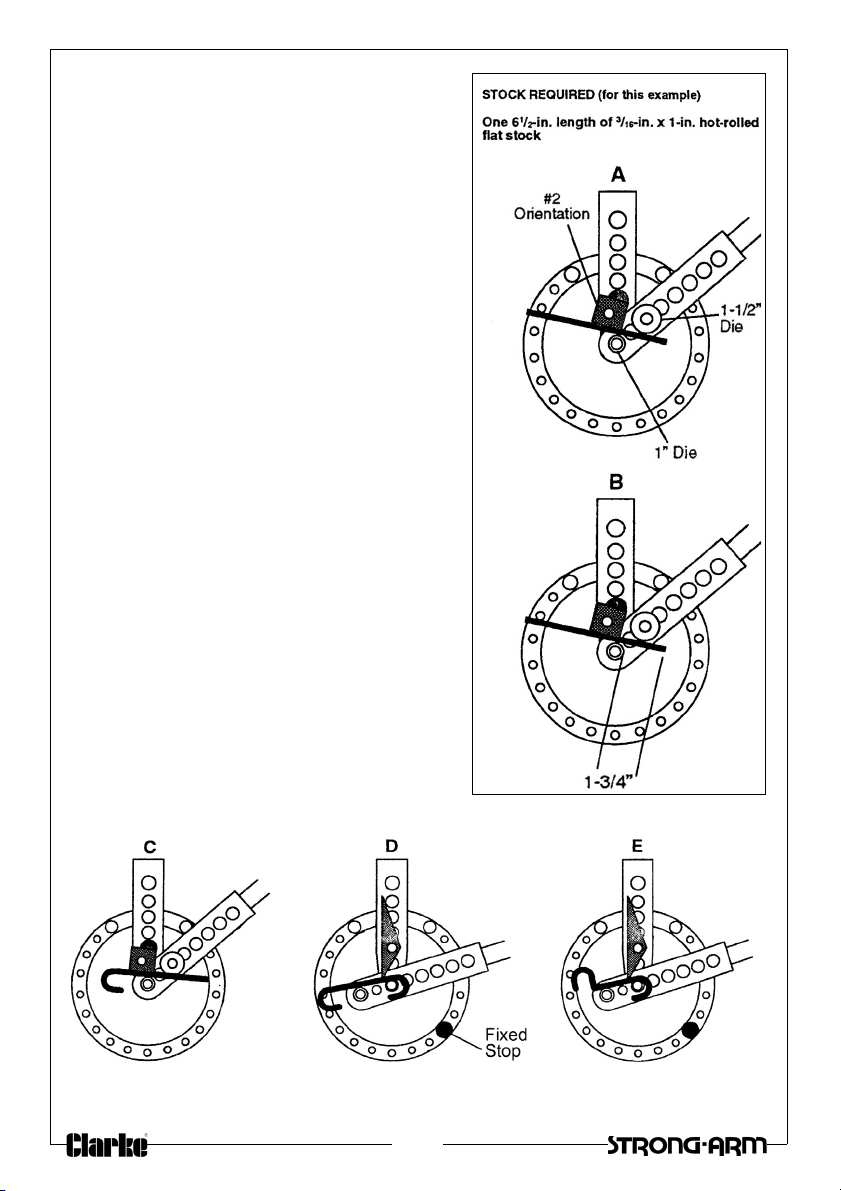

EXAMPLE: BENDING DOUBLE TUBE CLAMPS

DOUBLE-TUBE CLAMP

To make a 1” I.D. tube clamp (for clamping two lengths of 1” O.D. tubing),

using a 4½” length of 3/ 16” x 1” hot-rolled flat stock:

NOTE: To make other sizes of clamps, experiment to find the

appropriate die sizes and stop block orientation.

1. With a long hinge pin, attach the handle and ring loops at their centre-pin

hole

s. Install a 1” die on the centre pin.

2. With the short hinge pin, install a 1½” die in the handle #2 hole).

3. With a long hinge pin, install the

4. Insert the flat stock into the bender so th

centre-pin die (as in B).

stop block (oriented as in A).

at it extends 1-3/4” beyond the

13

5. Make the first bend by pulling the

handle around until the handle die runs

off the end of the piece.

6. Reverse the part end-for-end. Insert it

into the Bender so that it extends 1-3/4”

beyond the centre-pin die (as in C).

7. Make the second bend by pulling the

handle around until the handle die runs

off the end of the piece.

8. Remove the stop block,

sharp-angle-bend attachment.

9. You will have to temporarily remove the

centre pin to insert the piece into the

bender. Slide the piece as far left as

possible, against the centre pin (as in

D).

10. Make the third bend by pulling the

handle until it is about 1/8” from the

stop pin.

11. Reverse the part end-for-end. Slide the

piece as far left as possible, against the

centre pin (as in E). You will again have

to temporarily remove the centre pin to

insert the piece into the bender.

12. Make the fourth bend by pulling the

handle until it is about 1/8” from the

fixed stop.

and install the

14

BENDING ANCHOR BOLTS AND U-BOLTS

ANCHOR BOLTS

To make a 10” long anchor bolt

shown, from a 12¼” blank:

NOTE: To make another length

bolt, just use a shorter or

longer blank, or, change the

dimension given in Step 3

below (being sure that

enough material is caught

by the block).

1. With a long hinge pin, attach the

handle and ring loops at their

centre pin holes. Install a 1” die on

the centre pen.

2. With the short hinge pin, install a

2” die in the handle #2 hole).

3. With a long hinge pin, install the

stop block. Orientate the block appropriately for the diameter of the u-bolt

blank:

#2 orientation for 3/8” or ½” bolts;

#4 orientation for 5/8” bolts

4. Insert the bolt blank into the bender so that the un-threaded end extends

beyond the stop block:

• 1/2” for 3/8” bolts;

• 5/8” for ½” bolts;

• 3/4” for 5/8” bolts.

5. Pull the handle around until the bolt shaft is 90° from the anchor.

15

U-BOLTS

The tables on pages 18 and 19 show the appropriate setup for making U-bolts

in typical finished lengths and bend radiuses, from common diameters of

round stock.

The illustration below shows the setup for making a U-bolt that is 3½” long and

2” I.D., using 5/8” diameter stock. For other sizes, adjust the die sizes, stop block

orientation, etc., as shown in the tables.

LENGTH

For longer U-bolts, add twice the additional length desired to the “blank

length” indicated (for example, to make a U-bolt that is 1” longer, add 2” to

the blank length).

BEND RADIUS

Eight bend radiuses are possible—by selecting from the seven forming dies, or

by using centre pin without a die. However to avoid bending the centre pin,

always use a forming die with round stock larger than 3/8” diameter.

NOTES

• Because blank stock may vary slightly in content or size, we

recommend making a test bend using unthreaded stock before you

make a quantity of U-bolts.

• Keep a record of die sizes, die positions, and other measurements for

future reference.

16

BENDING U-BOLTS FROM 1/4” ROUND STOCK

FINISHED SIZE SETUP FOR BENDING

Length I.D. Blank

Length

2” 1” 5” 1 2 Flush 1” 2” 2

2¼” 1¼” 5¼” 1 2 ¼” 1¼” 2” 2

2½” 1½” 6⅜” 1 1 ⅜ 1½” 2” 2

3” 1¾” 7½” 2 4 ¼” 1¼” 2” 2

3½”2”8⅝” 2 4 ⅞ 2” 1¾” 2

Loop

Hole

No

Stop

Block Ori-

entation

17

Stop

Block

meas’t

Centre

Pin Die

Handle

Die

Handle

Hole No

BENDING U-BOLTS FROM 1/4” ROUND STOCK

FINISHED SIZE SETUP FOR BENDING

Length I.D. Blank

Length

2½” 1¼” 6¼” 1 1 5/16” 1¼” 2” 2

3” 1½” 7⅜” 2 4 ¼” 1½” 2” 2

3” 1¾” 7⅝” 2 4 ⅜” 1¾” 2” 2

3½” 2” 8¾” 2 4 15/16” 2” 2” 2

Loop

Hole

No

Stop

Block Ori-

entation

Stop

Block

meas’t

Centre

Pin Die

Handle

Die

BENDING U-BOLTS FROM 3/8” ROUND STOCK

FINISHED SIZE SETUP FOR BENDING

Length I.D. Blank

Length

2½” 1¼” 6-½” 1 1 ⅝” 1¼” 2” 2

3” 1½” 7-½” 2 4 7/16” 1½” 3” 2

3” 1¾” 7-¾” 2 4 9/16” 1¾” 3” 2

3” 2” 8” 2 3 ⅛” 2” 2” 2

Loop

Hole

No

Stop

Block Ori-

entation

Stop

Block

meas’t

Centre

Pin Die

Handle

Die

BENDING U-BOLTS FROM 1/2” ROUND STOCK

Handle

Hole No

Handle

Hole No

FINISHED SIZE SETUP FOR BENDING

Length I.D. Blank

Length

2¾” 1½” 7¼” 2 4 7/16” 1½” 3” 3

3” 1¾” 8” 2 4 5/16” 1¾” 2” 3

3¼”2”8¾” 2 3 ¾” 2” 2½” 3

4” 2½” 10⅛” 2 2 1” 2½” 2” 3

4½” 3” 11⅝” 3 4 1” 3” 2” 3

Loop

Hole

No

Stop

Block Ori-

entation

18

Stop

Block

meas’t

Centre

Pin Die

Handle

Die

Handle

Hole No

BENDING U-BOLTS FROM 5/8” ROUND STOCK

FINISHED SIZE SETUP FOR BENDING

Length I.D. Blank

Length

3½” 2” 9¾” 2 2 1” 2” 3” 3

2½ 2½” 11½” 2 1 1⅝” 2½” 2” 3

5” 3” 12¾” 3 4 1⅞” 3” 2” 3

Loop

Hole

No

Stop

Block Ori-

entation

Stop

Block

meas’t

Centre

Pin Die

Handle

Die

BENDING LETTERS FOR SIGNS

Handle

Hole No

The following pages show how to make all 26 letters of the alphabet in a

typical style. Using the procedure that is shown on these pages results in letters

(from 3/16” flat stock) which are:

•6” high

•2” wide (deep)

NOTES

•Use only hot-rolled mild steel for forming the letters.

• Follow the bending steps exactly, and in the sequence given. This is

especially important for the letter “S”, which is the most difficult to

form.

19

• To avoid wasting material, practice some of the letters using 316”

stock that is only 1/2” wide before you attempt the finished version.

• If you have two or more identical letters, make all of them before

proceeding to a different letter.

LETTER A

STOCK REQUIRED

• 3/16” stock; 2” max. width

• One 14” blank

• One 3-1/2” blank

SETUP

Make chalk marks on the 14” blank as shown on the “Bend Sequence.”

BEND NO. 1

Insert the stock into the Bender to the #1 chalk mark (as in A), and bend it to

76°. Re-check the angle before you go on to the second bend.

20

BEND NO. 2

Slide the stock to the #2 chalk mark (as in B), and bend it to 76°. Re-check the

angle.

To remove the part from the Bender, remove the pin that holds the sharpangle-bend attachment.

FINISHING

Tack-weld the 3-1/2”. insert piece between the legs of the “A,” parallel to the

top edge. Grind and sand all sharp corners.

LETTER B

STOCK REQUIRED

• 3/16” stock; 2” max.

Width

SETUP

Make chalk marks on the

two 8-7/8” blanks as shown

on the “Bend Sequence.”

BEND NO. 1

Insert one of the blanks into the Bender to the #1 chalk mark (as in A), and

bend it to 45°. Re-check the angle before you go on to the second bend.

Chalk-mark the ring, or set a stop, for ease of repeating the 45° bend.

BEND NO. 2

Slide the stock to the #2 chalk mark (as in B), and bend it to 45°. Re-check the

angle.

BEND NO. 3

Reverse the stock end-for-end. Slide it to the #3 chalk mark (as in C), and bend

it to 45°. Re-check the angle.

BEND NO. 4

Again reverse the stock end-for-end. Move it to the #4 chalk mark (as in D),

and bend it to 45°. Re-check the angle.

To remove the part from the Bender, remove the pin that holds the sharpangle-bend attachment.

21

FINISHING

Tack-weld the two loops together. Tack-weld the 6 in. piece to form the back

of the letter “B”. Grind and sand all sharp corners.

LETTER C

STOCK REQUIRED

• 3/16” stock; 2” max. Width (1x 14-in blank)

SETUP

Make chalk marks on the 14” blank as shown on the “Bend Sequence.”

22

BEND NO. 1

Insert the stock into the Bender to the #1 chalk mark (as in A), and bend it to

45°. Re-check the angle before you go on to the second bend.

BEND NO. 2

Slide the stock to the #2 chalk mark (as in B), and bend it to 45°. Re-check the

angle.

BEND NO. 3

Slide the stock to the #3 chalk mark (as in C), and bend it to 45°. Re-check the

angle.

FINISHING

Reverse the stock end-for-end. Slide it to the #4 chalk mark (as in D), and bend

it to 45°. Re-check the angle.

BEND NO. 4

Slide the stock to the #5 chalk mark (as in E), and bend it to 45°. Re-check the

angle.

BEND NO. 65

Slide the stock to the #6 chalk mark (as in F), and bend it to 45°. Re-check the

angle.

23

To remove the part from the bender, remove the pin that holds the sharp-

angle-bend attachment.

FINISHING

Grind and sand all sharp corners.

24

LETTER D

STOCK REQUIRED

• 3/16” stock; 2” max. width

• 1x 12-1/2in blank

• 1 x 6 in blank

SETUP

Make chalk marks on the two 12-7/8”

blank as shown on the “Bend

Sequence.”

BEND NO. 1

Insert the blank into the Bender to the

#1 chalk mark (as in A), and bend it

to 45°. Re-check the angle before

you go on to the second bend.

Chalk-mark the ring, or set a stop, for

ease of repeating the 45° bend.

BEND NO. 2

Slide the stock to the #2 chalk mark

(as in B), and bend it to 45°. Re-check

the angle.

Remove the blank from the Bender.

Re-check that the bend leg is at 90°

to the front of the “D”.

25

BEND NO. 3

Reverse the stock end-for-end. Slide it to the #3 chalk mark (as in C), and bend

it to 45°. Re-check the angle.

BEND NO. 4

Slide the stock to the #4 chalk mark (as in D), and bend it to 45°.

Re-check the angle. Re-check that the two legs are parallel.

To remove the part from the Bender, remove the pin that holds the sharpangle-bend attachment.

FINISHING

Tack-weld the 6 in. piece to form the back of the letter “D”. Grind and sand all

sharp corners.

26

LETTER E

STOCK REQUIRED

• 3/16” stock; 2” max. width

• 1x 14-9/16in blank

• 1 x 2-1/2 in blank

SETUP

Make chalk marks on the 14-9/16” blank as shown on the “Bend Sequence.”

BEND NO. 1

Insert the blank into the bender to the #1 chalk mark (as in A), and bend it to

45°. Re-check the angle before you go on to the second bend.

27

BEND NO. 2

Slide the stock to the #2 chalk mark (as in B), and bend it to 90°. Re-check the

angle.

BEND NO. 3

Reverse the stock end-for-end. Slide it to the #3 chalk mark (as in C), and bend

it to 45°. Re-check the angle.

BEND NO. 4

Slide the stock to the #4 chalk mark (as in D), and bend it to 90°. Re-check the

angle and that the top and bottom of the E are parallel.

To remove the part from the bender, remove the pin that holds the sharpangle-bend attachment.

FINISHING

Tack-weld the 3-1/2 in insert piece in piece between the legs of the “A”,

parallel to the top edge. Grind and sand all sharp corners.

LETTER F

STOCK REQUIRED

• 3/16” stock; 2” max. width

• 1x 10-3/8in blank

• 1 x 2-1/2 in blank

SETUP

Make a letter “L” as shown on page 33.

FINISHING

Position the 2-1/2” piece as shown and tack weld it.

Grind and sand all sharp corners.

28

LETTER G

STOCK REQUIRED

• 3/16” stock; 2” max. width

• 1x 14in blank

• 1 x 3 in blank

SETUP

Make a letter “C” as shown on

pages 22-25.

BEND

Insert the 3” blank into the bender to the chalk mark and bend it to 90°. Recheck the angle.

To remove the part from the bender, remove the pin that holds the sharpangle-bend attachment.

FINISHING

Position the 3” piece as shown and tack-weld it. Grind and sand all sharp

corners.

LETTER H

STOCK REQUIRED

• 3/16” stock; 2” max. width

• 2 x 6in blank

• 1 x 3-1/4 in blank

SETUP

None

FINISHING

Tack-weld the pieces together as

shown.

Re-check that the pieces are at 90° to each other. Grind and sand all sharp

corners.

29

LETTER I

STOCK REQUIRED

• 3/16” stock; 2”

max. width

• 2 x 5in blank

• 1 x 5-5/8 in blank

SETUP

Make chalk marks on

the 5” blanks as shown

on the “Bend

Sequence.”

BEND NO. 1

Insert the blank into

the Bender to the #1

chalk mark, and bend it to 45°. Re-check the angle.

Chalk mark the ring, or set a stop, for ease of repeating the 45° bend.

BEND NO. 2

Reverse the stock end-for-end. Slide it to the #2 chalk mark, and bend it to 45°.

Re-check the angle.

To remove the part from the Bender, remove the pin that holds the sharpangle-bend attachment.

FINISHING

Position the 5-5/8” piece between the bent pieces as shown and tack-weld it.

Re-check that the parts are 90°.

Grind and sand all sharp corners.

30

LETTER J

STOCK REQUIRED

• 3/16” stock; 2” max.

width

• 1 x 10in blank

SETUP

Make chalk marks on the

blanks as shown on the

“Bend Sequence.”

BEND NO. 1

Insert the blank into the bender to the #1 chalk mark, (as in A), and bend it to

45°. Re-check the angle before you go on to the second bend.

Chalk mark the ring, or set a stop, for ease of repeating the 45° bend.

BEND NO. 2

Slide the stock to the #2 chalk mark (as in B), and bend it to 45°. Re-check the

angle.

BEND NO. 3

Slide the stock to the #3 chalk mark (as in C), and bend it to 45°. Re-check the

angle.

To remove the part from the bender, remove the pin that holds the sharpangle-bend attachment.

FINISHING

Grind and sand all sharp corners.

31

LETTER K

STOCK REQUIRED

• 3/16” stock; 2” max.

width

• 1 x 7in blank

• 1 x 6in blank

• 1 x 2-1/2 in blank

SETUP

Make chalk marks on the 7”

blanks as shown on the

“Bend Sequence.”

BEND

Insert the blank into the

Bender to the chalk mark,

and bend until it measures 6

in. as shown.

FINISHING

Tack-weld the pieces together as shown.

Re-check that the outer tips of the bent piece are equal distances from the

straight piece. Grind and sand all sharp corners.

LETTER L

STOCK REQUIRED

• 3/16” stock; 2” max. width

• 1 x 10-3/8in blank

SETUP

Make chalk marks on the blanks as shown on the “Bend Sequence.”

BEND NO. 1

Insert the blank into the Bender to the #1 chalk mark, and bend it to 45°. Recheck the angle.

32

BEND NO. 2

Slide the stock to the #2 chalk mark, and bend to 90°. Re-check the angle.

To remove the part from the bender, remove the pin that holds the sharp-

angle-bend attachment.

FINISHING

Grind and sand all sharp corners.

LETTER M

STOCK REQUIRED:

• 3/16” STOCK; 2” max width

• 2 X 13-1/2”” Blanks

SETUP

Make two letter “v”s as shown on

page 42.

33

FINISHING

Turn the “V”s upside down and tack weld them together as shown. Check

that the three bottom tips are aligned.

Grind and sand all sharp corners.

LETTER N

STOCK REQUIRED:

• 3/16” STOCK; 2” max width

• 1 X 8-1/16” blank

• 2 x 6 in blanks

SETUP

Make chalk marks on the 8-1/16” blanks as shown on the “Bend Sequence.”

BEND NO. 1

Insert the blank into the Bender to the #1 chalk mark, (as in A), and bend it to

73°. Re-check the angle.

BEND NO. 2

Reverse the stock end-for-end. Slide it to the #2 chalk mark, and bend it to 73°.

Re-check the angle.

34

To remove the part from the bender, remove the pin that holds the sharpangle-bend attachment.

FINISHING

Tack-weld the pieces together. Re-check that the straight legs are parallel.

Grind and sand all sharp corners.

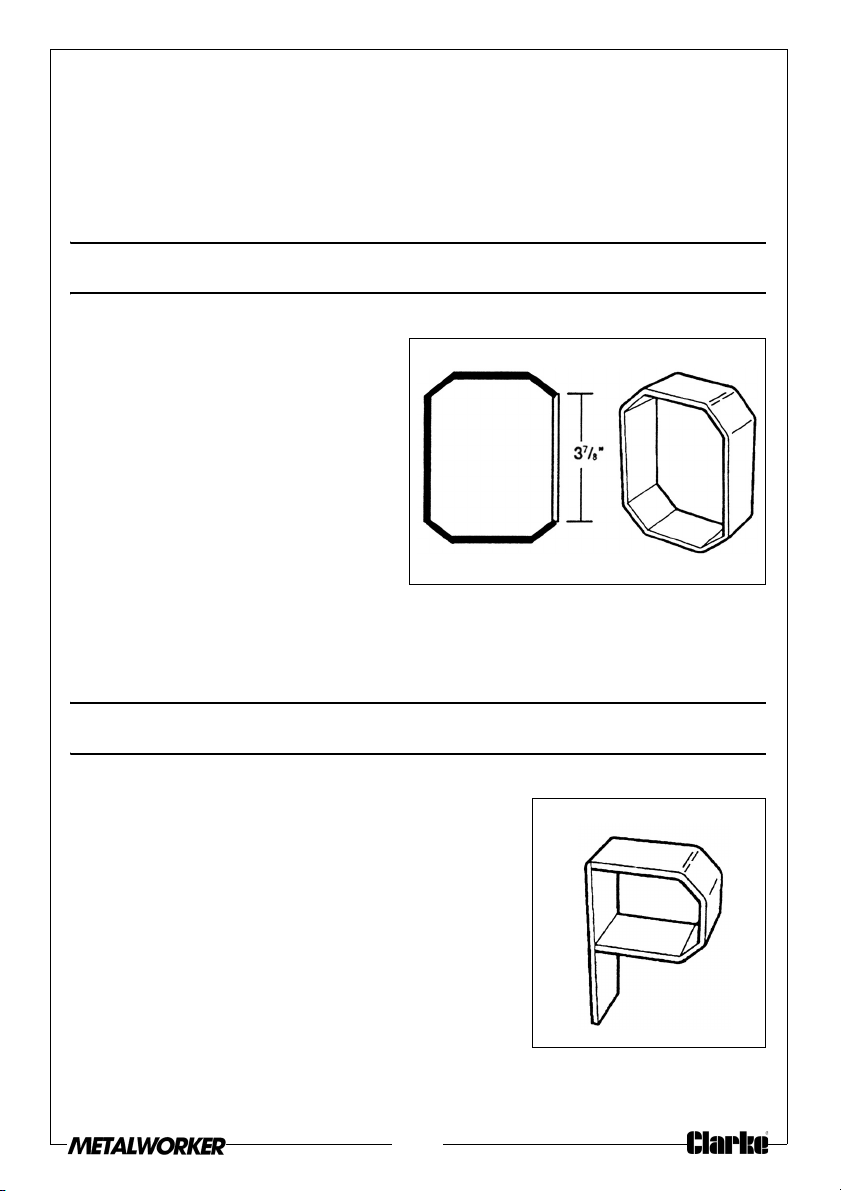

LETTER O

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 1 X 14” Blank

• 1 x 3-7/8” Blank

SETUP

Make a letter “C” from the 14”

blank as shown on page 17

FINISHING

Tack-weld the two pieces together as shown. Grind and sand all sharp

corners.

.

LETTER P

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 1 X 8-7/8” Blank

• 1 x 6” Blank

SETUP

Make part of a letter “B” (page16)—the straight

piece and one loop.

FINISHING

Tack-weld the pieces together. Grind and sand all sharp corners

35

LETTER Q

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 1 X 14” Blank

• 1 x 3-7/8” Blank

• 1 x 2” Blank

• 1 x 3/4” Blank

SETUP

Make a letter “O” (above).

FINISHING

Tack-weld the short pieces to the “O” as shown above. Grind and sand all

sharp corners.

LETTER R

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 1 X 8-7/8” Blank

• 1 x 6” Blank

• 1 x 3-1/8” Blank

SETUP

Make part of a letter “P” (page 26).

FINISHING

Tack-weld the 3-1/8” piece to the “P” as shown.

Grind and sand all sharp corners.

36

LETTER S

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 1 X 16-1/2” Blank

SETUP

Make chalk marks on the blank as shown on the “Bend Sequence.” Note that

the five chalk marks on one end of the blank must be on the opposite face

from the five marks on the other end.

BEND NO. 1

Insert the blank into the Bender to

the #1 chalk mark (as in A), and

bend it to 45°. Re-check the angle.

Chalk-mark the ring, or set a stop,

for ease of repeating the 45° bend.

(Note that Bends #3 and #7 are to

41°.)

BEND NO. 2

Slide the blank to the #2 chalk mark

(as in B), and bend it to 45°.

CAUTION: Because of the number

of bends, it is especially important

to check all bend angles carefully

when making the letter “S.”

BEND NO. 3

Slide the blank to the #3 chalk mark

(as in C), and bend it to 41°. Recheck the angle.

37

BEND NO. 4

Slide the blank back to the #4 chalk mark (as in D), and bend it to 45°.

BEND NO. 5

Reverse the stock end-for-end. Slide the blank to the #5 chalk mark (as in E),

and bend it to 45°. Re-check the angle.

BEND NO. 6

Slide the blank back to the #6 chalk mark (as in F), and bend it to 45°. Re-

check the angle.

BEND NO. 7

Slide the blank to the #7 chalk mark (as in G), and bend it to 41°. Re-check the

angle.

38

BEND NO. 8

Slide the blank back to the #8 chalk mark (as in H), and bend it to 45°. Recheck the angle.

BEND NO. 9

Reverse the stock end-for-end. Pull the pin in the sharp-angle-bend

attachment to allow space for the blank. Insert the blank, and reinstall the pin.

Slide the blank to the #9 chalk mark (as in I), and bend it to 45°. Re-check the

angle.

BEND NO. 10

Again reverse the stock end-for-end. Slide the blank to the #10 chalk mark (as

in J), and bend it to 45°. Re-check the angle, and check that the top and

bottom of the “S” are parallel.

39

LETTER T

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 1 X 6” Blank

• 1 x 5-1/16 blank

SETUP

Make chalk marks on the 5-13/16” blank as shown on the “Bend Sequence.”

BEND NO. 1

Insert the blank into the bender to the #1 chalk mark (as in A), and bend it to

45°. Re-check the angle.

Chalk mark the ring, or set a stop, for ease of repeating the 45° bend.

BEND NO. 2

Reverse the stock end-for-end. Slide it to the #2 chalk mark (as in B), and bend

it to 45°. Re-check the angle.

FINISHING

Grind and sand all sharp corners.

40

LETTER U

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 1 X 14-3/4” Blank

SETUP-U

Make chalk marks on the blank as shown on the “Bend Sequence.”

BEND NO. 1

Insert the blank into the bender to the #1 chalk mark, (as in A), and bend it to

45°. Re-check the angle.

Chalk-mark the ring, or set a stop, for ease of repeating the 45° bend.

BEND NO. 2

Slide the blank to the #2 chalk mark (as in B), and bend it to 45°. Re-check the

angle.

BEND NO. 3

Reverse the stock end-for-end. Slide it to the #3 chalk mark (as in C), and bend

it to 45°. Re-check the angle.

BEND NO. 4

Slide the stock to the #4 chalk mark (as in D), and bend it to 45. Re-check the

angle, and check that the legs of the “U” are parallel.

FINISHING

Grind and sand all sharp corners.

41

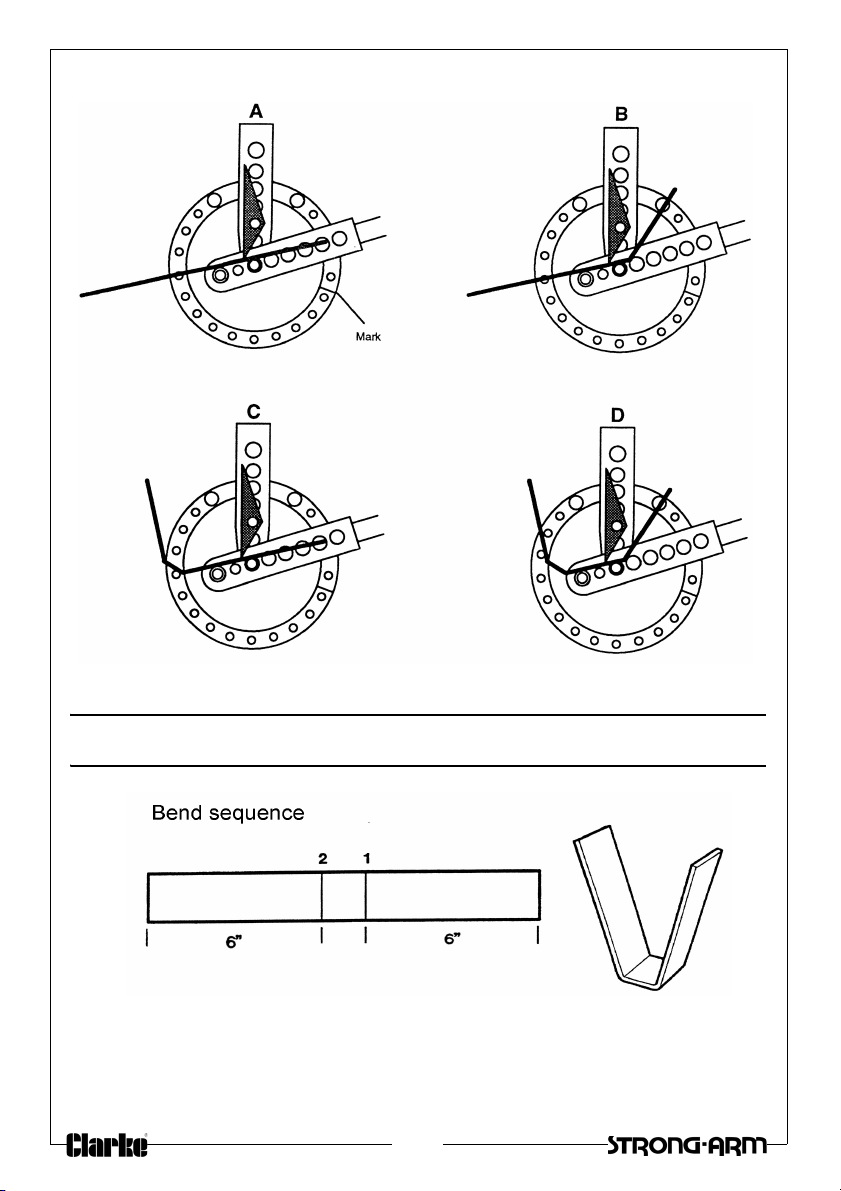

LETTER V

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 1 X 13-1/2” Blank

42

SETUP

Make chalk marks on the 5-13/16-in. blank as shown on the “Bend Sequence.”

BEND NO. 1

Insert the blank into the bender to the #1 chalk mark

(as in A), and bend it to 75°.

BEND NO. 2

Slide the blank to the #2 chalk mark (as in B), and bend it to 75°. To remove the

part, pull the pin in the sharp-angle-bend attachment.

FINISHING

Grind and sand all sharp corners.

LETTER W

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 2 x 13-1/2” Blanks

Make the letter “W” by tack-welding

together two letter “V”s (the same

as a letter “M”, page 33).

43

LETTER X

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 2 x 7-1/2” Blanks

SETUP

Make chalk marks on the blank as shown on the “Bend Sequence.”

BEND

Insert the blank into the Bender to the chalk mark, and bend it until the outside

dimension is 6 in. (as shown).

FINISHING

Tack-weld the two pieces together. Check that the parts are parallel. Grind

and sand all sharp corners.

LETTER Y

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

44

• 1 x 9-1/2” Blank

• 1 x 3-3/4” Blank

SETUP

Make chalk marks on the blank as shown on the “Bend Sequence.”

BEND NO. 1

Insert the blank into the Bender to the #1 chalk mark (as in A), and bend it to

80°. Re-check the angle.

BEND NO. 2

Slide the stock to the #2 chalk mark (as in B), and bend it to 80°. Re-check the

angle.

To remove the part, pull the pin from the sharp-angle-bend attachment.

FINISHING

Grind and sand all sharp corners.

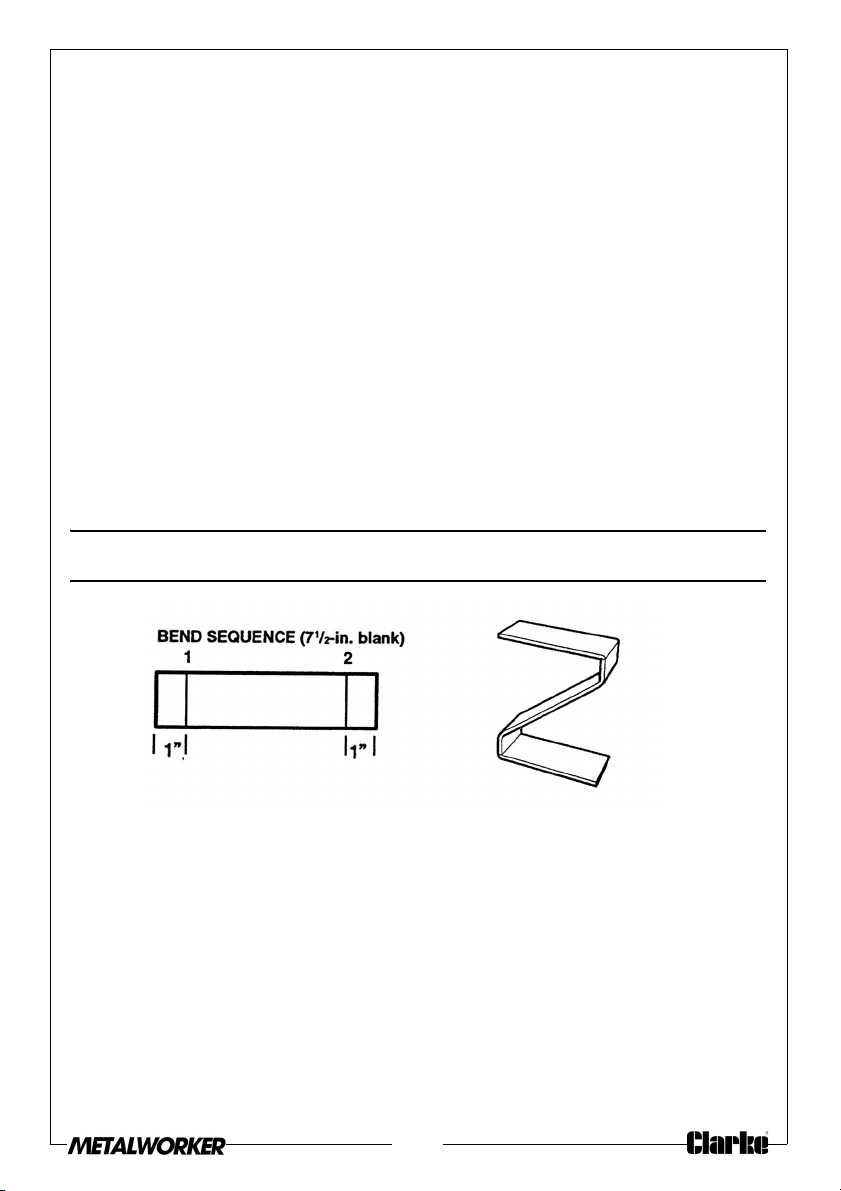

LETTER Z

STOCK REQUIRED:

• 3/16” STOCK; 2” MAX WIDTH

• 2 x 7-1/2” Blanks

SETUP

Make chalk marks on the 7-1/2” blank as shown on the “Bend Sequence.”

BEND NO. 1

Insert the blank into the Bender to the #1 chalk mark (as in A), and bend it to

50°. Re-check the angle.

45

BEND NO. 2

Reverse the part end-for-end. Slide it to the #2 chalk mark (as in B), and bend it

to 50°.

FINISHING

Tack-weld the bent piece to the two 4-1/2” pieces. The legs of the ”Z” should

be parallel, 6” apart. Grind and sand all sharp corners.

COMPONENT PARTS

46

Item Description

1 Spacer, loop

2 Bolt, ⅜ x

3 Washer, flat, ⅜

4 Ring Assembly

5 Bolt, flat-head ⅜ in

6 Spacer, ring

7 Lockwasher ⅜ i

8 Nut ⅜ in

4⅛ in

n

ITEM DESCRIPTION ITEM DESCRIPTION

9 Hich Pin - long 19 Sharp angle bend attachment

10 Stop Block 20# Stand (CCB1B)

11 Support block 20# Stand (CCB2B)

12 Bolt, ⅜ x 1⅛ in 21 Die - 1-in

13 Adjustable stop 22

14 Fixed stop 23

15 Hitch Pin-short 24

16 Handle extension 25 Die - 2-in

17 Pin with clip 26

18 Handle 27 Die - 3-in

47

¼-in

Die - 1

Die - 1

½-in

Die - 1¾-in

Die - 2½-in

Loading...

Loading...