Page 1

Clarion Co., Ltd.

TEXT

5-35-2, Hakusan, Bunkyouku, Tokyo, 112-8608 Japan

Service Dept.- 50 kamitoda,Toda-shi,Saitama,335-8511 Japan Tel: 048-443-1111 FAX:048-433-6996

Service Manual

Published by Service Dept.

298-5960-00

Printed in Japan

Dec.2001 P

6 - D I S C CD CH A NG E R

OP TI CA L D I G I T AL OU TP UT

■SPECIFICATIONS

Frequency response: 5Hz to 20kHz(±1dB)

Signal to noise ratio: 105dB(1kHz)IHF-A

Wow and flutter: Below measurement limits

Power supply voltage: 14.4V DC

(10.8 to 15.6V allowable)

Ground: Negative

Current consumption: 1A

Dimensions(mm): 225(W)

Weight: 1.65kg

×63(H)×167(D)

■NOTES

※ Use a CeNET extension cable that is less than 20m in

length.

※ CD singles cannot be used.

※ This unit is compatible with CD text.When it is connected

to a center unit suitable for CD text display, CD text can

be displayed.(When it is connected to a center unit without CD text function,CD text cannot be displayed.)

※ The following magazines cannot be used for this

unit.Using them will result in a damage to hte mechanism and cause the magazine not to eject.

1.Magazine(CAA-122) for the 12-disc CD chnager

2.Magazine(CAA-355) for the 6-disc CD changer

※ Do not play heart-shaped, octagonal, or other specially

shaped CDs.

※ We cannot supply PWB with component parts in prin-

ciple. When a circuit on PWB has failure , please repair

it by component parts base. Parts which are not mentioned in service manual are not supplied.

※ Specifications and design are subject to change without

notice for further improvement.

6 Disc CD Changer with CD text

Model

(PE-2433B/for U.S.A.)

(PE-2433K/for Other Countries)

Model

(PE-2433E/for Europe)

■COMPONENTS

PE-2433B-A/K-A/E-A

Main unit −−−−− 1

CD magazine CAA-397-900 1

Mounting bracket 300-9873-20 2

Mounting bracket(with bolt) 300-9874-20 2

Lock pin 335-0594-20 3

Extension lead(13P) 855-3416-50 1

Parts bag

Cushion rubber 345-8653-00 2

Parts bag

Cord clamp 335-0833-01 2

Wing nut 722-0545-00 4

Hex-bolt 734-5008-37 4

−−−−−

−−−−−

■To engineers in charge of repair or

inspection of our products.

Before repair or inspection, make sure to follow

the instructions so that customers and Engineers

in charge of repair or inspection can avoid suffering any risk or injury.

1. Use specified parts.

The system uses parts with special safety features against

fire and voltage. Use only parts with equivalent characteristics when replacing them.

The use of unspecified parts shall be regarded as remodeling for which we shall not be liable. The onus of

product liability (PL) shall not be our responsibility in cases

where an accident or failure is as a result of unspecified

parts being used.

2. Place the parts and wiring back in their original positions

after replacement or re-wiring.

For proper circuit construction, use of insulation tubes,

bonding, gaps to PWB, etc, is involved. The wiring con-

- 1 -

DCZ625

DCZ628

Page 2

nection and routing to the PWB are specially planned

using clamps to keep away from heated and high voltage

parts. Ensure that they are placed back in their original

positions after repair or inspection.

If extended damage is caused due to negligence during

repair, the legal responsibility shall be with the repairing

company.

3. Check for safety after repair.

Check that the screws, parts and wires are put back securely in their original position after repair. Ensure for

safety reasons there is no possibility of secondary

ploblems around the repaired spots.

If extended damage is caused due to negligence of repair, the legal responsibility shall be with the repairing

company.

4. Caution in removal and making wiring connection to the

parts for the automobile.

Disconnect the battery terminal after turning the ignition

key off. If wrong wiring connections are made with the

battery connected, a short circuit and/or fire may occur.

If extensive damage is caused due to negligence of repair, the legal responsibility shall be with the repairing

company.

5. Cautions regarding chips.

Do not reuse removed chips even when no abnormality

is observed in their appearance. Always replace them

with new ones. (The chip parts include resistors, capacitors, diodes, transistors, etc). The negative pole of tantalum capacitors is highly susceptible to heat, so use special care when replacing them and check the operation

afterwards.

6. Cautions in handling flexible PWB

Before working with a soldering iron, make sure that the

iron tip temperature is around 270

℃. Take care not to

apply the iron tip repeatedly(more than three times)to the

same patterns. Also take care not to apply the tip with

force.

7. Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the

unit.

8. Cautions in checking that the optical pickup lights up.

The laser is focused on the disc reflection surface through

the lens of the optical pickup. When checking that the

laser optical diode lights up, keep your eyes more than

30cms away from the lens. Prolonged viewing of the laser within 30cms may damage your eyesight.

9. Cautions in handling the optical pickup

The laser diode of the optical pickup can be damaged by

electrostatic charge caused by your clothes and body.

Make sure to avoid electrostatic charges on your clothes

or body, or discharge static electricity before handling the

optical pickup.

9-1. Laser diode

The laser diode terminals are shorted for transportation in order to prevent electrostatic damage.

After replacement, open the shorted circuit. When

removing the pickup from the mechanism, short

the terminals by soldering them to prevent this

damage.

9-2. Actuator

The actuator has a powerful magnetic circuit. If a

magnetic material is put close to it. Its characteristics will change. Ensure that no foreign substances

enter through the ventilation slots in the cover.

9-3. Cleaning the lens

Dust on the optical lens affects performance. To

clean the lens, apply a small amount of

isopropyl alcohol to lens paper and wipe the lens

gently.

■CAUTIONS

Use of controls,adjustment or performance of procedures

other than those specified herein,may result in hazardous

radiation exposure.

The COMPACT DISC player and MINI DISC player should

not be adjusted or repaired by anyone except properly qualified service personnel.

This appliance contains a laser system and is classified as

a "CLASS 1 LASER PRODUCT".To use this model

properly,read this Owner's Manual carefully and kep this

manual for your future reference.In case of any trouble with

this player,please contact your nearest"AUTHORIZED service station".To prevent direct exposure to the laser beam,do

not to open the enclosure.

X

DCZ625

DCZ628

- 2 -

Page 3

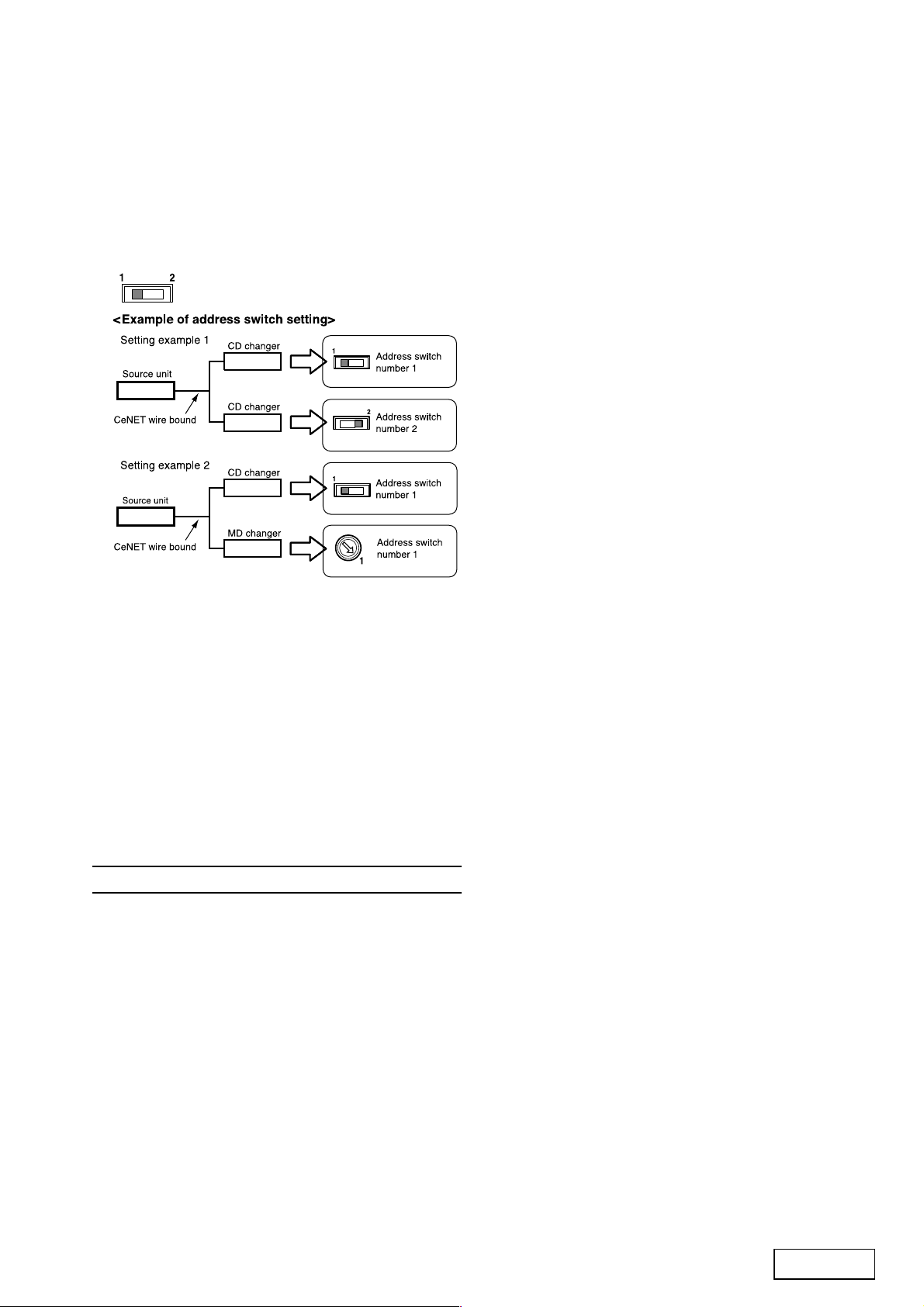

■HOW TO CHANGE THE ADDRESS

SWITCH

When connecting an CD changer and MD changer by CeNET,no more than 2 units can be connected.When both of

them are CD,the address switch needs to be reset so that

the address switch number is not the same for each.

How to change the address switch

Switch the address by using a plastic stick with a sharp

tip or equivalent.

Caution

・ The unit may not operate when both CD changers are

set to the same address switch number.

・ Never change the address switch during operation.Doing

sp can cause malfunction or breakdown.Do not change

the address switch forcibly,because this may also cause

malfunction.

・ The Ce-NET cable wiring must be less than

20m(65.62ft)in length.

・ Be sure that the CD changer numbers are not the same.

・ Do not use the address switch numbers "3" and "4" for

the MD changer.

■EXPLANATION OF IC

052-5046-01 M30621M8A-F27GP CD Auto Changer Control

1.Terminal Description

pin 1: POWER ON 1 : O : The power ON signal output to the power

pin 2: SB SYNC : IN : Sub code data sync.

pin 3: A MUTE : O : Audio mute signal output.

pin 4: CD AC FLAG : O : The CD auto changer active flag output.

pin 5: NU : - : Not in use.

pin 6: CN VSS : IN : Inputting "L" at single mode operation.

pin 7: NU : - : Not in use.

pin 8: NU : - : Not in use.

pin 9: RESET : IN : Reset signal input.

pin 10: X OUT : O : Crystal connection.

pin 11: VSS : - : Negative supply voltage.

pin 12: X IN :IN : Crystal connection.

pin 13: VDD : - : Positive supply voltage.

pin 14: NMI : IN : Connect to VDD.

pin 15: B/U DET : IN : Backup voltage ON signal input.

pin 16: SYS ACC : IN : ACC detect signal input.

pin 17: MAG SW :IN : The inserted flag input for the magazine.

pin 18: CONNECT : IN : IE-BUS input.

pin 19: NU : - : Not in use.

supply section.

pin 20: ADDRESS : IN : The address input for the CD auto chang-

pin 21: WRITE :IN : The write command input.

pin 22: RX : IN : Serial data input of IE BUS.

pin 23: TX : O : Serial data output of IE BUS.

pin 24: NU : - : Not in use.

pin 25: NU : - : Not in use.

pin 26: NU : - : Not in use.

pin 27: NU : - : Not in use.

pin 28: NU : - : Not in use.

pin 29: NU : - : Not in use.

pin 30: NU : - : Not in use.

pin 31: NU : - : Not in use.

pin 32: NU : - : Not in use.

pin 33: NU : - : Not in use.

pin 34: NU : - : Not in use.

pin 35: NU : - : Not in use.

pin 36: DATUM : IN : The datum point signal input for counting

pin 37: D No TR :IN : Disk number detect pulse input.

pin 38: NU : - : Not in use.

pin 39: CE :IN : Chip enable signal input.

pin 40: NU : - : Not in use.

pin 41: PW ON INV : O : The inverted signal of "POWER ON 1(pin

pin 42: POWER ON 2 : O : The power ON signal output to the power

pin 43: NU : - : Not in use.

pin 44: LIMIT : IN : Limiting switch signal input.

pin 45: HOLD IN : IN : "L"= The magazine is charged.

pin 46: LOAD END : O : The loading end signal output.

pin 47: 8cm/12cm : IN : 8cm/12cm

pin 48: UD CW : O : Up/down motor control signal output.

pin 49: UD CCW : O : Up/down motor control signal output.

pin 50: LD CW : O : Loading motor control signal output.

pin 51: LD CCW : O : Loading motor control signal output.

pin 52: NU : - : Not in use.

pin 53: T CLK : O : "Test mode display" clock output.

pin 54: T DATA : O : The serial data output for the test mode

pin 55: T CLR : O : The clear signal output for the test mode

pin 56: NU : - : Not in use.

pin 57: NU : - : Not in use.

pin 58: NU : - : Not in use.

pin 59: DR MUTE : O : The muting pulse output to the CD driver.

pin 60: GV SW : O : The reset pulse output to the digital servo

pin 61: RST : IN : Reset signal input.

pin 62: CCE : O : Chip enable signal output to CD IC.

pin 63: BUC CLOCK : O : CD IC clock pulse output.

pin 64: BUS 3 :I/O: CD IC Data input / output.

pin 65: BUS 2 :I/O: CD IC Data input / output.

pin 66: BUS 1 :I/O: CD IC Data input / output.

pin 67: BUS 0 :I/O: CD IC Data input / output.

pin 68: NU : - : Not in use.

pin 69: NU : - : Not in use.

pin 70: NU : - : Not in use.

pin 71: EJECT : IN : Eject signal input.

pin 72: TEST 4 :IN : For the test.

pin 73: TEST 3 :IN : For the test.

pin 74: TEST 2 :IN : For the test.

pin 75: A VSS : - : Analog ground.

pin 76: TEST 1 :IN : For the test.

pin 77: Vref : - : Reference voltage

pin 78 : A VCC : - : Positive supply voltage for the internal an-

pin 79: NU : - : Not in use.

pin 80: D STOP : O : Digital output control. Outputs "H" at Play.

er.

the disk number.

1)".

supply section.

indication.

indication.

IC.

alog section.

- 3 -

DCZ625

DCZ628

Page 4

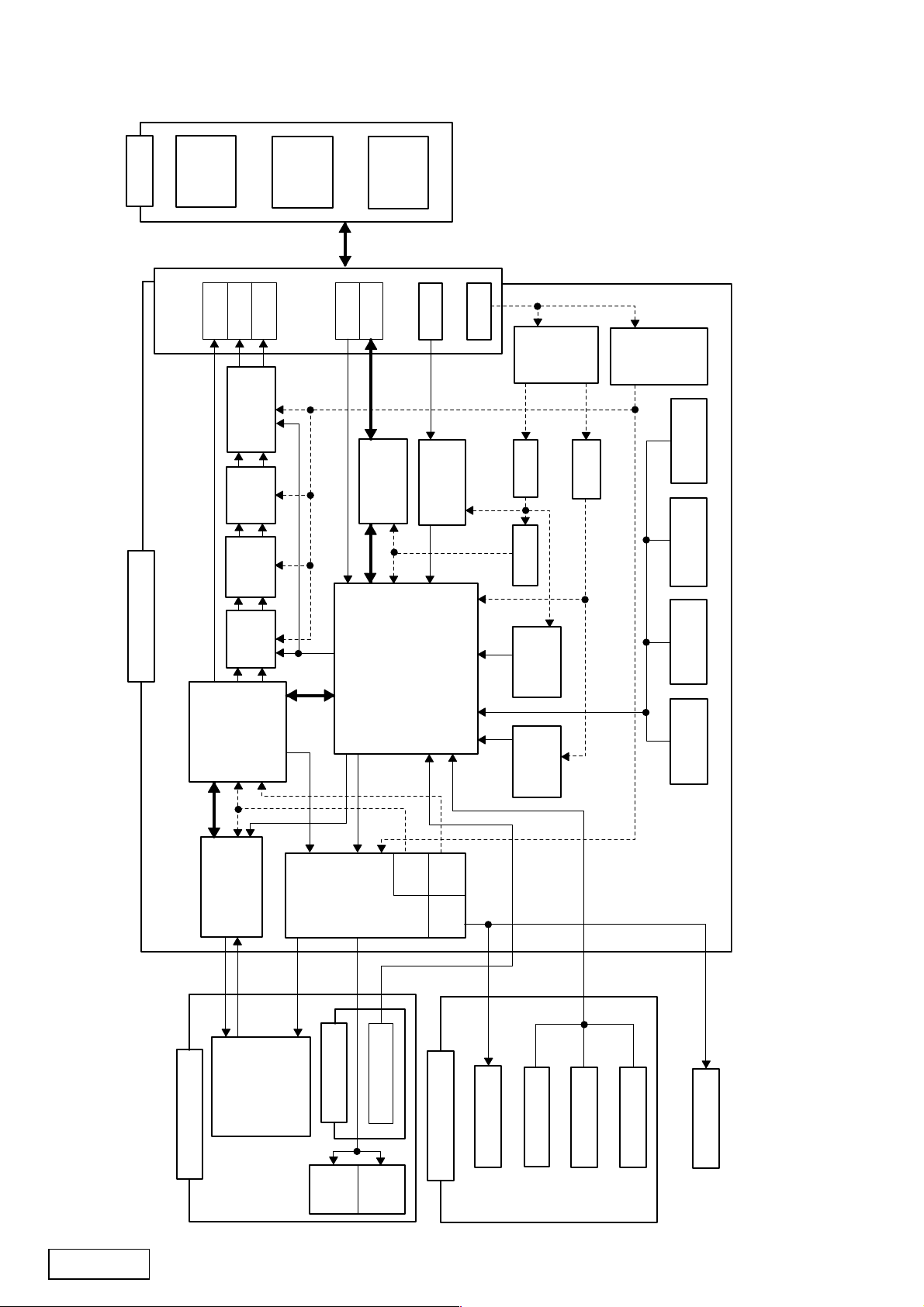

■BLOCK DIAGRAM

D-OUT

CONNECTOR

FPC

14P CONNECTOR

P301

D-OUT

J4

L +/-

R +/-

ANALOG SW

IC12

74VHC4066

B.T.L.

IC11

NJM4558

13P DIN

J301

ADRS

ADDRESS SW

S301

BUS+/BUS-

BUS DRIVER

IC6

CA0008

SYS-ACC

ACC-DET

B/U 12V

VDD 5V

POWER 5V

MEMO-VDD

CD 9V

IC4

BA09ST

DISC NO. TR

IC3

GP1S94

MAIN PWB

LPF

MUTE

DSP & DAC

IC5

RF AMP

IC1

TA2157F

IC9

NJM4558

Q4,5

2SD1306

TC94A14FA

SERVO DRIVER

IC2

BD7961

MAIN CONTROLLER

IC7

M30621M8A

3.3V

REG5VREG

MOTOR

DRIVER

VDD REF

5V

B/U DET

IC10

S-80843

RESET

IC8

S-80721

POSITION SW

S1

MAGAZINE SW

S3

EJECT SW

S2

DCZ625

DCZ628

DRIVE UNIT

PICK UP

DRIVE FPC

SPINDLE

MOTOR

LIMIT SW

SLED

MOTOR

LOADING FPC

- 4 -

LOADING MOTOR

LOAD-END SW

HOLDER-IN SW

12/8 DISC SENSOR

UP/DOWN MOTOR

Page 5

■EXPLODED VIEW・PARTS LIST

Main section

B6

17

6

14

B4

B2

5

3

B5

4

13

12

8

B4

B3

B1

21

B5

10

B6

12

19

15

16

B3

1

A3

A4

12

11

A4

12

20

A2

18

A3

2-1

12

A1

B2

B1

14

2

Note)Some parts depend on each model.The model name is specified in the description.

1 −−−−− CHANGER MECHANISM 1

2 940-7965-63 ESCUTCHEON ASSY(DCZ625) 1

940-7965-60 ESCUTCHEON ASSY(DCZ628) 1

(025020)

2-1 716-0872-00 PAD SCREW 1

3 013-3968-00 SWITCH 1

4 039-1948-20 CONNECTOR PWB 1

(WITHOUT COMPONENT)

5 074-1194-00 OUTLET SOCKET 1

6 075-0305-00 JACK 1

7 286-9860-00 SETPLATE(DCZ625/U.S.A) 1

286-9858-00 SETPLATE(DCZ628)

286-9861-00 SETPLATE(DCZ625/OTHER)

8 310-1742-21 UPPER CASE 1

9 311-1838-20 LOWER CASE 1

10 750-3460-21 FL-SPRING L 1

- 5 -

22

9

7

A1

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

11 750-3459-21 FL-SPRING R 1

12 716-1716-00 SCREW 11

13 716-0484-00 SPECIAL SCREW 1

14 629-0080-00 DAMPER GS-6 4

15 371-5693-22 TRIM PLATE 1

16 382-6254-20 BUTTON 1

17 620-1088-20 CE-NET HOLDER 1

18 620-0996-21 DAMPER PLATE R 1

19 620-0997-20 DAMPER PLATE F 1

20 622-1545-20 FL PIN R 1

21 622-1546-20 FL PIN L 1

22 348-0331-00 TAPE 1

12

DCZ625

DCZ628

A2

Page 6

Changer mechanism section

5

A

55

A7

55

10

B3

55

B3

36

B2

A4

B2

62

B10

6

51

65

55

A8

45

12

62

B1

B8

B9

B8

5

A14

44

55

A2

N1

A12

32

12

B1

B6

B7

C1

33

C2

C3

D2

A11

E

A4

A9

62

B7

55

B10

B6

A5

55

B4

B5

B5

67

B4

30

34

D1

A10

1

2

3

4

5

6

67

A10

31

B9

E1

9

A5

55

A2

4

5

6

A1

8

A9

A13

A6

A3

71

19

A13

A1

A14

A3

E

1

2

3

A7

57

65

69

N1

68

A8

12

54

57

A12

11

C1

57

59

A11

16

63

D2

1 966-0582-22 DRIVE-P-ASSY 1

2 966-0583-20 DISC HOLD ASSY 1

3 966-0584-23 CLAMP-P-ASSY F 1

4 966-0585-22 CAM GEAR ASSY 1

5 966-0586-22 MOTOR-P-ASSY 1

6 966-0588-21 HOLDER-L-ASSY 1

7 966-0589-23 L-UPPER-P-ASSY 1

8 966-0590-20 MG-LO-P-ASSY 1

9 966-0591-21 REAR PANEL ASSY 1

10 966-0592-20 UP-PLATE ASSY 1

11 966-0593-20 UD-GEAR-P-ASSY 1

DCZ625

DCZ628

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

12 966-0594-24 V-CHASSIS ASSY 1

13 966-0454-00 SH-RACK-ASSY 1

14 966-0623-23 L-LOWER-P-ASSY 1

15 969-0061-30 PICK UP-ASSY 1

16 039-1947-20 MAIN PWB 1

(WITHOUT COMPONENT)

17 001-0563-00 LED 1

18 013-7413-50 DETECTOR SWITCH 3

19 SMA-180-100 MOTOR ASSY(UP/DOWN) 1

20 SMA-181-100 MOTOR ASSY(SLED) 1

21 SMA-179-100 MOTOR ASSY(SPINDLE) 1

- 6 -

Page 7

1

57

35

O1

65

66

G1

2

I1

26

I1

N2

G1

65

F1

G2

4

O1

70

C2

7

F2

M1

47

52

24

18

F4

G2

D1

F5

3

E1

L1

65

65

49

J1

55

7

48

72

N1

N2N1J4

23

F4

J4

J2

L1

K1

64

55

63

55

J2

J1

J3

F5

5

55

J3

27

55

14

55

29

F2

F1

H1

K2

28

C3

M2

H2

46

55

6

H1

41

60

60

K2

57

1

65

21

61

37

61

P1

57

43

20

50

38

58

13

15

P1

53

K3

K1

42

H2

M2

M1

55

K3

56

Q1

Q1

57

25

57

39

40

22

57

18

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

22 039-1949-20 DRIVE PWB 1

23 039-1950-20 LOADING PWB 1

(WITHOUT COMPONENT)

(WITHOUT COMPONENT)

24 060-0252-01 PHOTO-TR 1

25 620-0999-21 LS-SPRING 1

26 620-1575-21 SWITCH PLATE 1

27 620-1007-22 CLAMP PLATE M 1

28 620-1008-24 CLAMP PLATE R 1

29 620-1009-21 CLAMPER PLATE 1

30 620-1016-20 GAP PLATE R 1

31 620-1017-20 GAP PLATE F 1

32 620-1018-20 MG EJECT PLATE 1

33 620-1019-20 SLIDE PLATE R 1

34 620-1020-20 SLIDE PLATE F 1

35 620-1031-21 LOADING ARM 1

36 620-1034-23 SIDE PANEL 1

37 621-0587-21 SCREW HOLD BASE 1

- 7 -

38 801-4912-60 VINYL-COAT-WIRE(BRN) 1

39 621-0589-20 SECOND GEAR 1

40 621-0590-20 LS GEAR 1

41 621-0591-20 PICK UP GUIDE 1

42 621-0592-21 LS-HOLDER 1

43 621-0593-20 LS GUIDE 1

44 802-4906-60 VINYL-COAT-WIRE(RED) 1

45 621-0597-20 V-GEAR A 1

46 621-0630-22 HOLDER-G-RAIL R 1

47 621-0631-21 HOLDER-G-RAIL L 1

48 621-0703-20 L-GEAR A 1

49 621-0633-20 L-GEAR B 1

50 805-4912-60 VINYL-COAT-WIRE(GRN) 1

51 621-0635-20 V-HELICAL GEAR 1

52 621-0636-21 CLAMPER RING 1

53 624-3022-00 LEAD SCREW 1

54 629-0061-00 GEAR DAMPER 1

DCZ625

DCZ628

Page 8

55 716-0484-00 SCREW(M2×2.5) 23

56 716-0675-00 SCREW(M2×5.5) 1

57 716-1716-00 SCREW(M2×3) 10

58 716-3469-00 SCREW 2

59 735-2006-11 D-SEMS-SCREW(M2×6) 1

60 739-1722-17 SCREW(M1.7×2.2) 2

61 739-2022-17 SCREW(M2×2.2) 2

62 743-1500-10 E-RING 3

63 743-2000-10 E-RING 2

NO. PART NO. DESCRIPTION Q'TYNO. PART NO. DESCRIPTION Q'TY

64 745-0789-01 DRIVE WASHER 1

65 746-0761-00 WASHER 7

66 750-3461-21 DISC-H-SPRING 1

67 750-3462-20 GAP SPRING 2

68 750-3463-20 MG LOCK SPRING 1

69 750-3464-20 MG EJECT SPRING 1

70 750-3492-22 CLAMPER SPRING 1

71 800-4906-60 VINYL-COAT-WIRE(BLK) 1

72 SMA-188-100 MOTOR ASSY(LOADING) 1

■ELECTRICAL PARTS LIST

Main PWB(B1) section

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

C1 178-1052-78 16V1uF

C2 043-0533-50 0.047uF

C3 042-0426-31 6.3V100uF

C4 183-1073-17 6.3V100uF

C5 046-6822-58 6800pF

C6 178-1052-78 16V1uF

C7 168-1042-78 16V0.1uF

C8 183-3363-27 10V33uF

C9 183-3363-27 10V33uF

C10 168-1042-78 16V0.1uF

C11 168-1042-78 16V0.1uF

C12 045-5096-50 5pF

C13 183-3363-27 10V33uF

C14 178-1052-78 16V1uF

C16 168-1032-55 0.01uF

C17 045-5601-50 56pF

C18 045-1011-50 100pF

C19 168-1032-55 0.01uF

C20 043-0533-50 0.047uF

C21 046-1532-78 0.015uF

C22 045-4701-50 47pF

C23 043-0533-50 0.047uF

C24 046-1522-58 1500pF

C25 046-4722-58 4700pF

C26 046-1032-78 0.01uF

C27 043-0533-50 0.047uF

C28 046-3332-78 0.033uF

C29 046-3332-78 0.033uF

C30 046-4712-58 470pF

C31 045-4701-50 47pF

C33 043-0533-50 0.047uF

C34 043-0533-50 0.047uF

C36 042-0452-81 10V220uF

C37 168-1042-78 16V0.1uF

C38 168-1042-78 16V0.1uF

C39 166-1801-50 18pF

C40 166-1801-50 18pF

C41 168-1032-55 0.01uF

C42 168-1042-78 16V0.1uF

C43 183-3363-27 10V33uF

C44 168-1032-55 0.01uF

C45 168-1032-55 0.01uF

C47 166-1011-50 100pF

C48 183-3363-27 10V33uF

C49 183-1063-37 16V10uF

C50 183-1063-37 16V10uF

C51 042-0576-00 5.5V0.1F

C52 183-1063-37 16V10uF

C53 183-1063-37 16V10uF

C54 183-1063-37 16V10uF

C55 043-0533-50 0.047uF

C56 046-1032-78 0.01uF

C58 046-1032-78 0.01uF

C59 183-1063-37 16V10uF

C60 045-6801-50 68pF

C61 045-6801-50 68pF

DCZ625

DCZ628

C62 183-1073-17 6.3V100uF

C64 046-1032-78 0.01uF

C65 045-2201-50 22pF

C66 045-2201-50 22pF

C67 183-2263-37 16V22uF

C69 183-2263-37 16V22uF

C70 184-4773-31 16V470uF

C71 046-1032-78 0.01uF

C74 183-1073-17 6.3V100uF

C75 183-2263-37 16V22uF

C76 183-2263-37 16V22uF

C77 183-2263-37 16V22uF

C78 183-2263-37 16V22uF

C79 183-2263-37 16V22uF

C80 183-2263-37 16V22uF

C81 178-3342-78 0.33uF

D1 001-0516-90 MA111

D2 001-1305-90 DAN217U

D3 001-1304-90 DAN202U

D4 001-0466-90 S5688B

D5 001-0466-90 S5688B

D6 001-0516-90 MA111

D7 001-0504-35 HZS6C2L

D8 001-0516-90 MA111

IC1 051-5710-90 TA2157F

IC2 051-6060-08 BD7961FM

IC3 051-5806-00 GP1S94

IC4 051-3289-00 BA09ST

IC5 051-6376-00 TC94A14FA

IC6 051-6600-38 CA0008AM

IC7 052-5046-01 M30621M8A-F27GP

IC8 051-5407-08 S-80721AN

IC9 051-0350-93 NJM4558M

IC10 051-5434-08 S-80843ALNP-EA7

IC11 051-0350-93 NJM4558M

IC12 051-7232-08 74VHC4066M

J1 074-1138-65 15P

J2 074-1158-56 6P

J3 074-1158-58 8P

J4 074-1158-64 14P

L1 010-3050-93 10uH

L2 010-2285-57 BLM21B102

L3 010-2285-57 BLM21B102

L4 010-2285-57 BLM21B102

L5 010-2285-57 BLM21B102

Q1 191-1237-50 2SB1237

Q2 191-1237-50 2SB1237

Q3 191-1237-50 2SB1237

Q4 193-1306-00 2SD1306

Q5 193-1306-00 2SD1306

Q6 125-2004-92 RN1402

Q7 190-1048-50 2SA1048

Q8 125-2004-92 RN1402

Q9 125-0014-92 DTA114

Q10 190-1162-00 2SA1162

Q11 193-1858-50 2SD1858

Note) Several different parts of the same reference number are alternative parts.

One of those parts is used in the set.

Q12 125-2004-92 RN1402

R1 033-1041-15 1/16W 100kΩ

R2 033-1041-15 1/16W 100kΩ

R3 033-1041-15 1/16W 100kΩ

R4 033-1041-15 1/16W 100kΩ

R5 033-1041-15 1/16W 100kΩ

R6 033-1041-15 1/16W 100kΩ

R7 033-2211-15 1/16W 220Ω

R8 111-2711-98 1/16W 270Ω

R9 033-6831-15 1/16W 68kΩ

R10 111-2201-98 1/4WS 22Ω

R11 111-2201-98 1/4WS 22Ω

R12 119-1031-15 1/16W 10kΩ

R13 119-2231-15 1/16W 22kΩ

R14 033-8211-15 1/16W 820Ω

R15 111-1001-98 1/4WS 10Ω

R16 119-1031-15 1/16W 10kΩ

R17 119-1531-15 1/16W 15kΩ

R18 033-6831-15 1/16W 68kΩ

R19 033-2721-15 1/16W 2.7kΩ

R20 033-1011-15 1/16W 100Ω

R21 033-1021-15 1/16W 1kΩ

R22 033-1031-15 1/16W 10kΩ

R23 033-1831-15 1/16W 18kΩ

R24 033-1531-15 1/16W 15kΩ

R25 033-1031-15 1/16W 10kΩ

R26 033-4731-15 1/16W 47kΩ

R27 033-1041-15 1/16W 100kΩ

R28 033-5621-15 1/16W 5.6kΩ

R29 033-1041-15 1/16W 100kΩ

R31 111-2711-98 1/16W 270Ω

R32 033-1041-15 1/16W 100kΩ

R33 033-3331-15 1/16W 33kΩ

R34 033-1051-15 1/16W 1MΩ

R35 033-4711-15 1/16W 470Ω

R36 119-2211-15 1/16W 220Ω

R37 033-3321-15 1/16W 3.3kΩ

R38 119-4731-15 1/16W 47kΩ

R39 033-4731-15 1/16W 47kΩ

R40 033-1041-15 1/16W 100kΩ

R41 033-4731-15 1/16W 47kΩ

R42 033-4731-15 1/16W 47kΩ

R43 033-1011-15 1/16W 100Ω

R44 033-1011-15 1/16W 100Ω

R45 033-1031-15 1/16W 10kΩ

R46 033-1031-15 1/16W 10kΩ

R47 033-5621-15 1/16W 5.6kΩ

R48 033-1031-15 1/16W 10kΩ

R49 033-4731-15 1/16W 47kΩ

R50 033-4711-15 1/16W 470Ω

R51 033-1041-15 1/16W 100kΩ

R52 119-1041-15 1/16W 100kΩ

R53 033-1531-15 1/16W 15kΩ

R54 033-1531-15 1/16W 15kΩ

R55 033-2231-15 1/16W 22kΩ

R56 033-1021-15 1/16W 1kΩ

- 8 -

Page 9

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

R57 033-4731-15 1/16W 47kΩ

R58 033-2731-15 1/16W 27kΩ

R59 033-2731-15 1/16W 27kΩ

R60 033-1031-15 1/16W 10kΩ

R61 033-1031-15 1/16W 10kΩ

R62 033-1031-15 1/16W 10kΩ

R63 033-1031-15 1/16W 10kΩ

R64 033-1021-15 1/16W 1kΩ

R65 033-1531-15 1/16W 15kΩ

R66 033-4731-15 1/16W 47kΩ

R67 033-1031-15 1/16W 10kΩ

R68 033-1031-15 1/16W 10kΩ

R69 033-8221-15 1/16W 8.2kΩ

R70 119-1041-15 1/16W 100kΩ

R71 119-1041-15 1/16W 100kΩ

R72 119-1041-15 1/16W 100kΩ

R73 119-1041-15 1/16W 100kΩ

R74 033-1031-15 1/16W 10kΩ

R75 119-1011-15 1/16W 100Ω

R76 119-1011-15 1/16W 100Ω

R77 119-1011-15 1/16W 100Ω

R78 119-1011-15 1/16W 100Ω

R79 033-4721-15 1/16W 4.7kΩ

R80 033-2211-15 1/16W 220Ω

S1 013-7404-50 00110676

S2 013-6100-10 SKHLLD

S3 013-7404-50 00110676

T1 009-0679-00 E1-19

X1 061-3038-00 16.9344MHz

X2 060-1505-50 CSTCC10MG

Connector PWB(B2) section

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

J301 074-1194-00 13P

P301 075-0305-00 DIGITAL OUT

S301 013-3968-00 SSSS2

Loading PWB(B3) section

REF No. PART No. DESCRIPTION REF No. PART No. DESCRIPTION

D501 001-0563-00 GL380

Q501 060-0252-01 PT4850F

S501 013-7413-50 SPVG12

S502 013-7413-50 SPVG12

Drive PWB(B4) section

REF No. PART No. DESCRIPTION

S503 013-7413-50 SPVG12

- 9 -

DCZ625

DCZ628

Page 10

CIRCUIT DIAGRAM /

Main PWB(B1)/Connector PWB(B2)/Loading PWB(B3)/Drive PWB(B4) section

- 10 -

1 G N D

2 B A C K UP

3 L -C H(+)

4 NC

5 NC

6 B U S (+)

7 R -C H(+)

8 R -C H(-)

9 S YS AC C

10 BUS ( -)

11 L-C H (-)

12 NC

13 NC

DCZ625

DCZ628

Page 11

■

PRINTED WIRING BOARD /

プリント基板図

Main PWB(B1)/Connector PWB(B2)/Loading PWB(B3)/Drive PWB(B4) section

BLK

RED

BRN

GRN

SLED MOTOR

SPINDLE MOTOR

S 503

1 GND

2 BACK UP

3 L-CH(+)

4 NC

5 NC

6 BUS(+)

7 R-CH(+)

8 R-CH(-)

9 SYS ACC

10 BUS(-)

11 L-CH(-)

12 NC

13 NC

S 502

Q5 01

D501

S 501

LOADING MOTOR

- 11 -

DCZ625

DCZ628

Loading...

Loading...