Page 1

Cisco Application Services Engine Hardware Installation Guide

First Published: 2019-10-15

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Page 2

©

2019 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

CHAPTER 1

CHAPTER 2

Overview 1

Overview 1

External Features 1

Serviceable Component Locations 4

Summary of Server Features 6

Installing the Server 9

Preparing for Installation 9

Installation Warnings and Guidelines 9

Rack Requirements 11

Installing the Server in a Rack 12

Installing the Cable Management Arm (Optional) 14

Reversing the Cable Management Arm (Optional) 15

Initial Server Setup 16

Connecting to the Server Locally For Setup 17

Connecting to the Server Remotely For Setup 18

CHAPTER 3

Updating the BIOS and Cisco IMC Firmware 19

Accessing the System BIOS 19

Smart Access Serial 20

Maintaining the Server 21

Status LEDs and Buttons 21

Front-Panel LEDs 21

Rear-Panel LEDs 24

Internal Diagnostic LEDs 25

Preparing For Component Installation 26

Cisco Application Services Engine Hardware Installation Guide

iii

Page 4

Contents

Required Equipment For Service Procedures 26

Shutting Down and Removing Power From the Server 27

Shutting Down Using the Power Button 27

Shutting Down Using The Cisco IMC GUI 27

Shutting Down Using The Cisco IMC CLI 28

Removing the Server Top Cover 28

Serial Number Location 29

Hot Swap vs Hot Plug 29

Removing and Replacing Components 30

Serviceable Component Locations 30

Replacing SAS/SATA Hard Drives or Solid State Drives 32

SAS/SATA Drive Population Guidelines 32

4K Sector Format SAS/SATA Drives Considerations 33

Replacing a SAS/SATA Drive 33

Replacing a Front-Loading NVMe SSD 34

Front-Loading NVMe SSD Population Guidelines 34

Front-Loading NVME SSD Requirements and Restrictions 35

Enabling Hot-Plug Support in the System BIOS 35

Replacing a Front-Loading NVMe SSD 36

Installing a PCIe Cable For Front-Loading NVMe SSDs 37

Replacing Fan Modules 38

Replacing CPUs and Heatsinks 39

CPU Configuration Rules 39

Tools Required For CPU Replacement 39

Replacing a CPU and Heatsink 40

Moving an M5 Generation CPU 46

Replacing Memory DIMMs 51

DIMM Population Rules and Memory Performance Guidelines 51

Replacing DIMMs 53

Replacing a Mini-Storage Module 53

Replacing a Mini-Storage Module Carrier 54

Replacing an M.2 SSD in a Mini-Storage Carrier For M.2 55

Replacing an Internal USB Drive 56

Replacing a USB Drive 56

Cisco Application Services Engine Hardware Installation Guide

iv

Page 5

Enabling or Disabling the Internal USB Port 57

Replacing the RTC Battery 58

Replacing Power Supplies 59

Replacing AC Power Supplies 59

Replacing a PCIe Card 60

PCIe Slot Specifications 60

Replacing a PCIe Card 61

Cisco Virtual Interface Card (VIC) Considerations 64

Replacing an mLOM Card 65

Replacing an mRAID Riser (Riser 3) 66

Replacing a SAS Storage Controller Card (RAID or HBA) in Riser 3 68

Storage Controller Card Firmware Compatibility 68

Replacing a SAS Storage Controller Card (RAID or HBA) 69

Contents

Replacing a Boot-Optimized M.2 RAID Controller Module 70

Cisco Boot-Optimized M.2 RAID Controller Considerations 70

Replacing a Cisco Boot-Optimized M.2 RAID Controller 71

Replacing the Supercap (RAID Backup) 73

Replacing a SATA Interposer Card 75

Replacing a Chassis Intrusion Switch 76

Installing a Trusted Platform Module (TPM) 77

TPM Considerations 77

Service Headers and Jumpers 78

Using the Clear CMOS Header (J38, Pins 9 - 10) 79

Using the BIOS Recovery Header (J38, Pins 11 - 12) 80

Procedure 1: Reboot With recovery.cap File 80

Procedure 2: Use BIOS Recovery Header and bios.cap Recovery File 81

Using the Clear Password Header (J38, Pins 13 - 14) 81

Using the Boot Alternate Cisco IMC Image Header (J39, Pins 1 - 2) 82

Using the Reset Cisco IMC Password to Default Header (J39, Pins 3 - 4) 83

Using the Reset Cisco IMC to Defaults Header (J39, Pins 5 - 6) 84

APPENDIX A

Server Specifications 85

Server Specifications 85

Physical Specifications 85

Cisco Application Services Engine Hardware Installation Guide

v

Page 6

Contents

Environmental Specifications 85

Power Specifications 86

1050 W AC Power Supply 86

Power Cord Specifications 87

APPENDIX B

Storage Controller Considerations 91

Supported Storage Controllers and Cables 91

Storage Controller Card Firmware Compatibility 92

RAID Backup (Supercap) 92

Write-Cache Policy for Cisco 12G SAS Modular RAID Controller 92

Mixing Drive Types in RAID Groups 93

RAID Controller Migration 93

Storage Controller and Backplane Connectors 94

Embedded SATA RAID Controller 96

Embbeded SATA RAID Requirements 97

Embedded SATA RAID Controller Considerations 97

Embedded SATA RAID: Two SATA Controllers 98

Enabling SATA Mode For the Embedded Controllers 98

Accessing the Software RAID Configuration Utility 99

For More RAID Utility Information 99

Cisco Application Services Engine Hardware Installation Guide

vi

Page 7

Overview

CHAPTER 1

Overview

• Overview, on page 1

• External Features, on page 1

• Serviceable Component Locations, on page 4

• Summary of Server Features, on page 6

Cisco Application Services Engine provides a common platform for deploying Cisco Data Center applications.

These applications provide real time analytics, visibility and assurance for policy and infrastructure.

The Cisco Application Services Engine server is required for installing and hosting the Cisco Application

Services Engine application.

The server is orderable in the following version:

• SE-CL-L3 — Small form-factor (SFF) drives, with 10-drive backplane. Supports up to 10 2.5-inch

SAS/SATA drives. Drive bays 1 and 2 support NVMe SSDs.

Note

The Cisco Application Services Engine software is pre-installed on the server. It is detected after the server

is connected, installed and powered on. Cisco Application Services Engine app allows you to fully enable the

capabilities of the Cisco Application Services Engine.

Cisco Application Services Engine app can be downloaded from the Cisco DC App Center. See the Cisco

Application Services Engine for more information on downloading and using the app.

External Features

This topic shows the external features of the server versions.

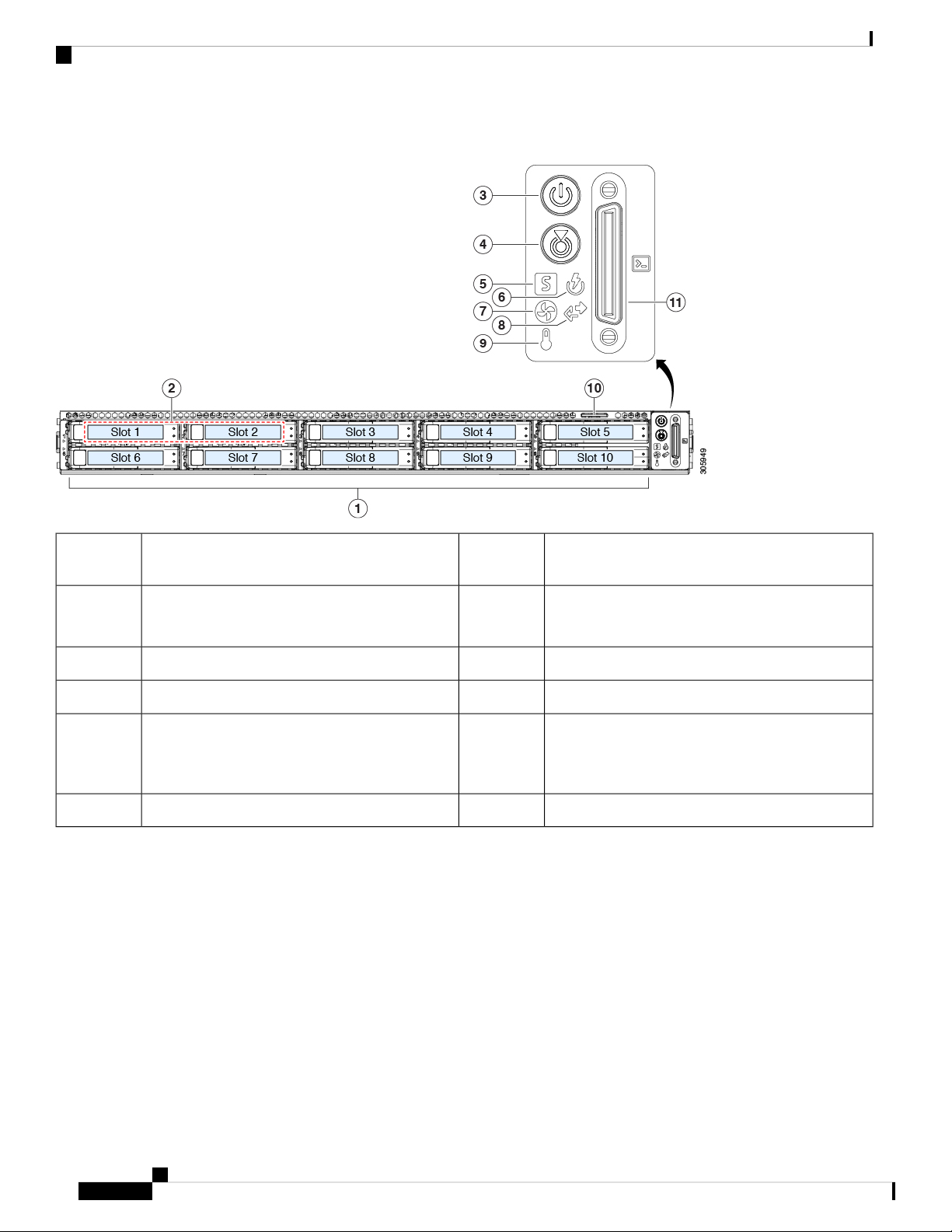

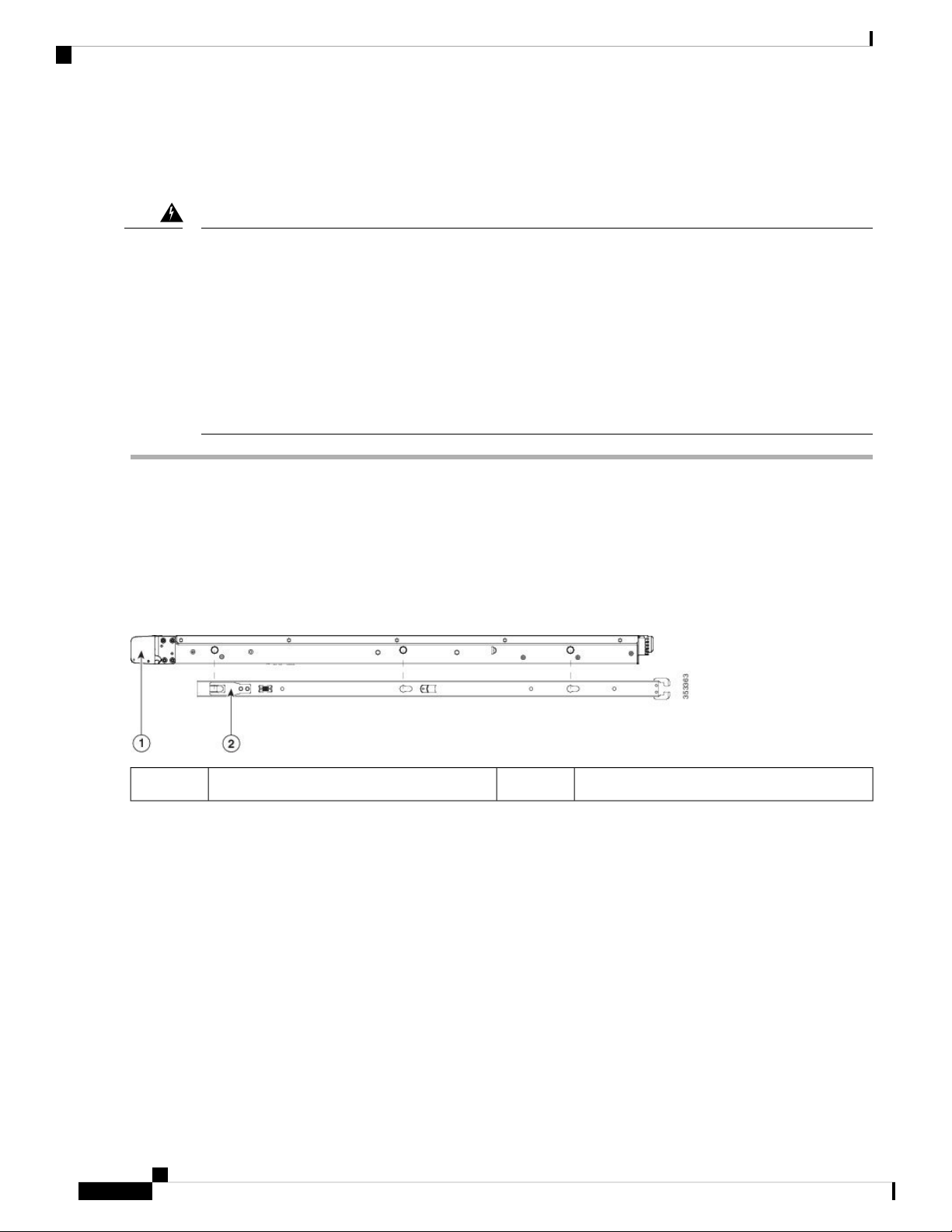

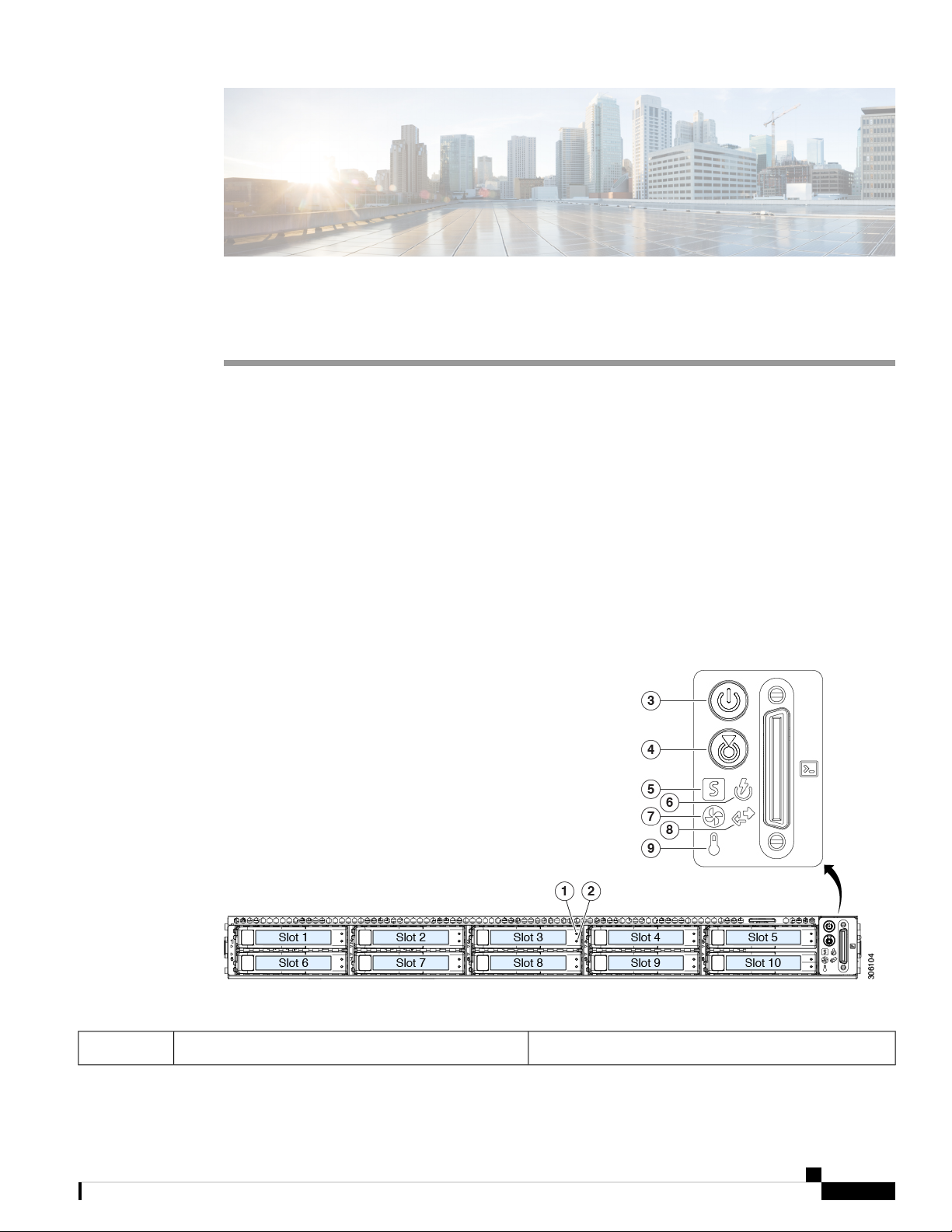

Cisco SE-CL-L3 (SFF Drives) Front Panel Features

The following figure shows the front panel features of the small form-factor drive versions of the server.

For definitions of LED states, see Front-Panel LEDs, on page 21.

Cisco Application Services Engine Hardware Installation Guide

1

Page 8

External Features

Figure 1: Cisco SE-CL-L3 (SFF Drives) Front Panel

Overview

1

Fan status LED7Drive bays 1 – 10 support SAS/SATA hard disk

drives (HDDs) and solid state drives (SSDs)

2

Network link activity LED8• SE-CL-L3 : Drive bays 1 and 2 support

NVMe PCIe SSDs.

Temperature status LED9Power button/power status LED3

Pull-out asset tag10Unit identification button/LED4

11System status LED5

KVM connector

(used with KVM cable that provides one DB-15

VGA, one DB-9 serial, and two USB connectors)

-Power supply status LED6

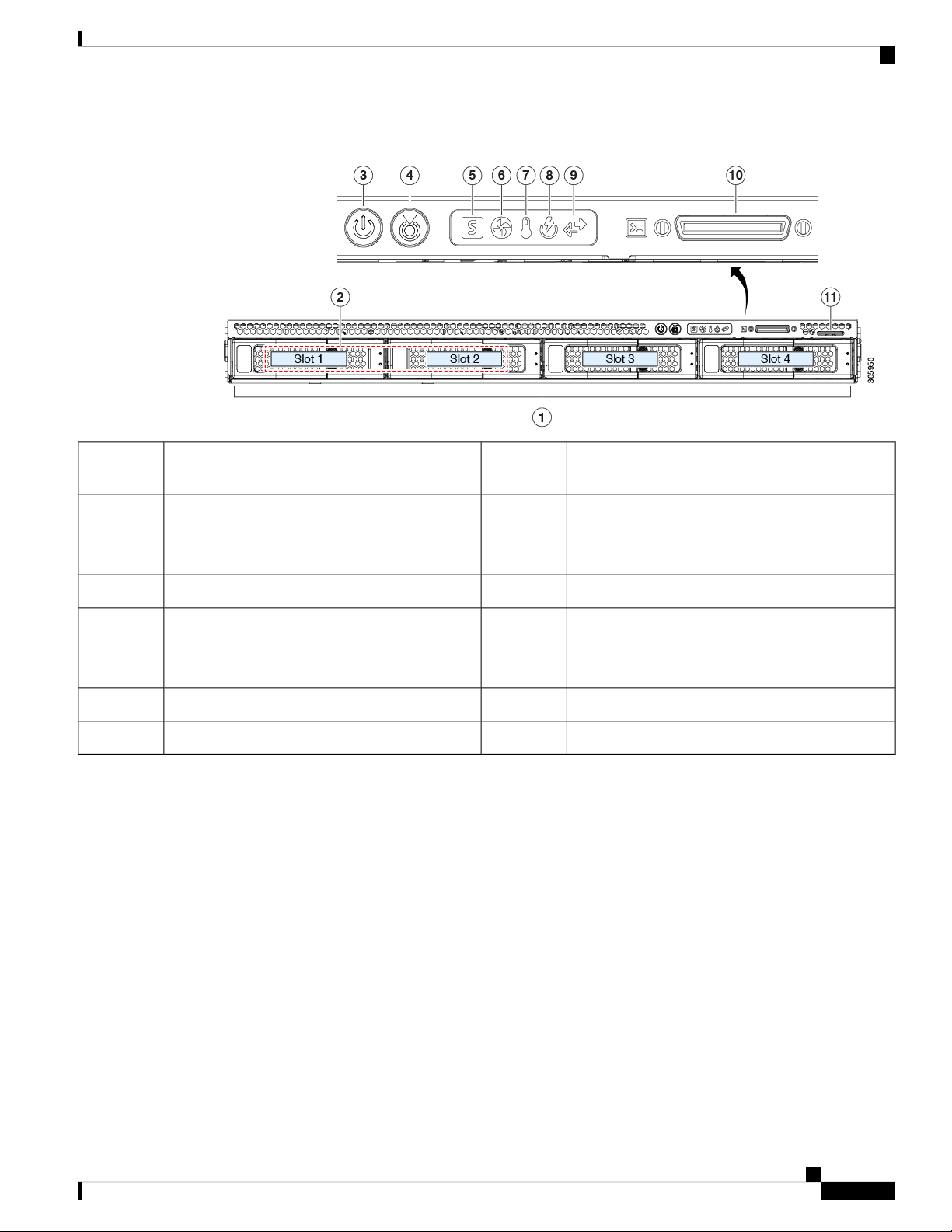

SE-CL-L3 (LFF Drives) Front Panel Features

The following figure shows the front panel features of the large form-factor drive version of the server.

For definitions of LED states, see Front-Panel LEDs, on page 21.

Cisco Application Services Engine Hardware Installation Guide

2

Page 9

Overview

External Features

Figure 2: SE-CL-L3 (LFF Drives) Front Panel

1

Temperature status LED7Drive bays 1 – 4 support SAS/SATA HDDs and

SSDs

2

Power supply status LED8Drive bays 1 and 2 support NVMe PCIe SSDs.

A size-converter drive sled is required if 2.5-inch

SSDs are used.

Network link activity LED9Power button/power status LED3

10Unit identification button/LED4

KVM connector

(used with KVM cable that provides one DB-15

VGA, one DB-9 serial, and two USB connectors)

Pull-out asset tag11System health LED5

-Fan status LED6

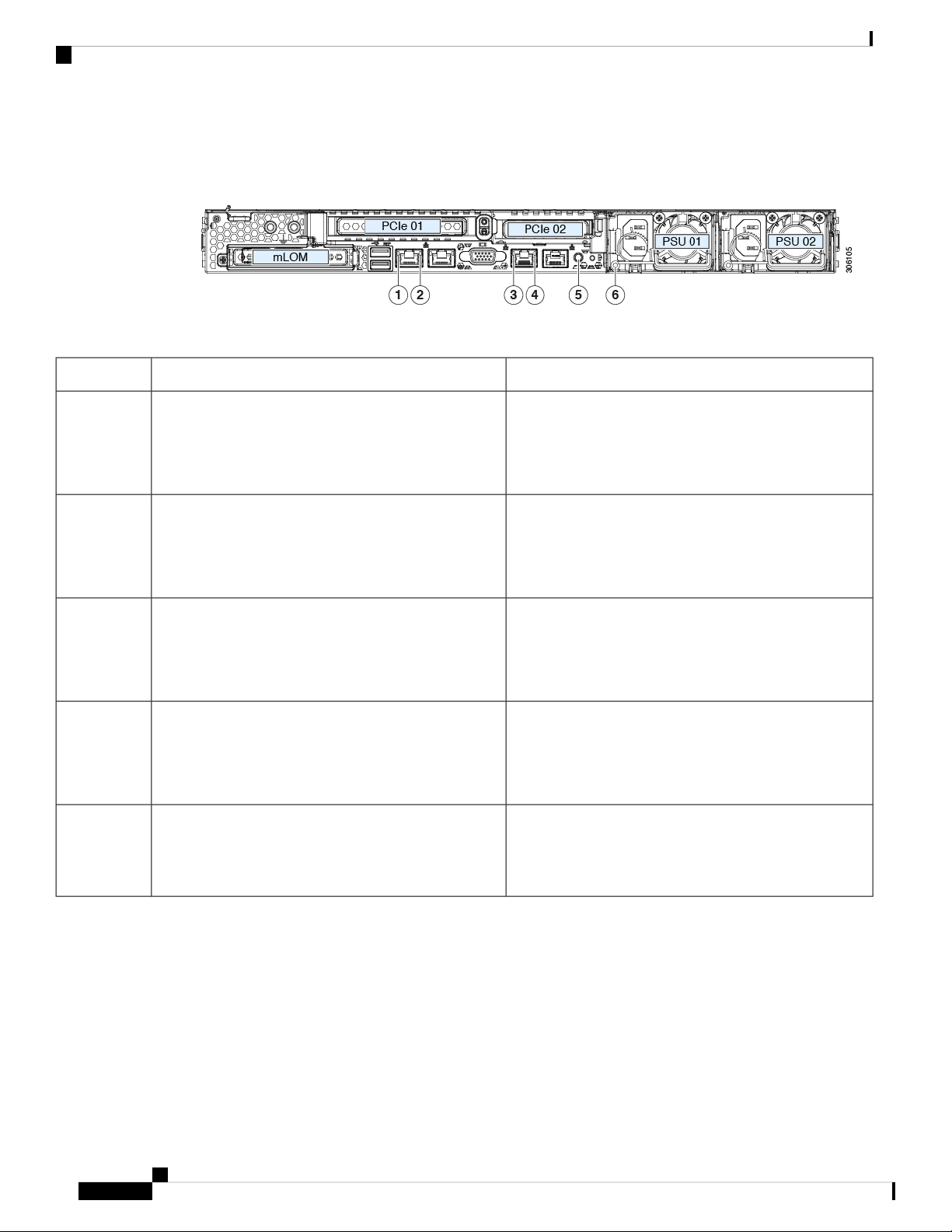

SE-CL-L3 Rear Panel Features

The rear panel features are the same for all versions of the server.

For definitions of LED states, see Rear-Panel LEDs, on page 24.

Cisco Application Services Engine Hardware Installation Guide

3

Page 10

Serviceable Component Locations

Figure 3: SE-CL-L3 Rear Panel

Overview

1

(x16 PCIe lane)

3

LAN2)

The dual LAN ports can support 1 Gbps and 10

Gbps, depending on the link partner capability.

9Dual 1-Gb/10-Gb Ethernet ports (LAN1 and

-Serial port (RJ-45 connector)6

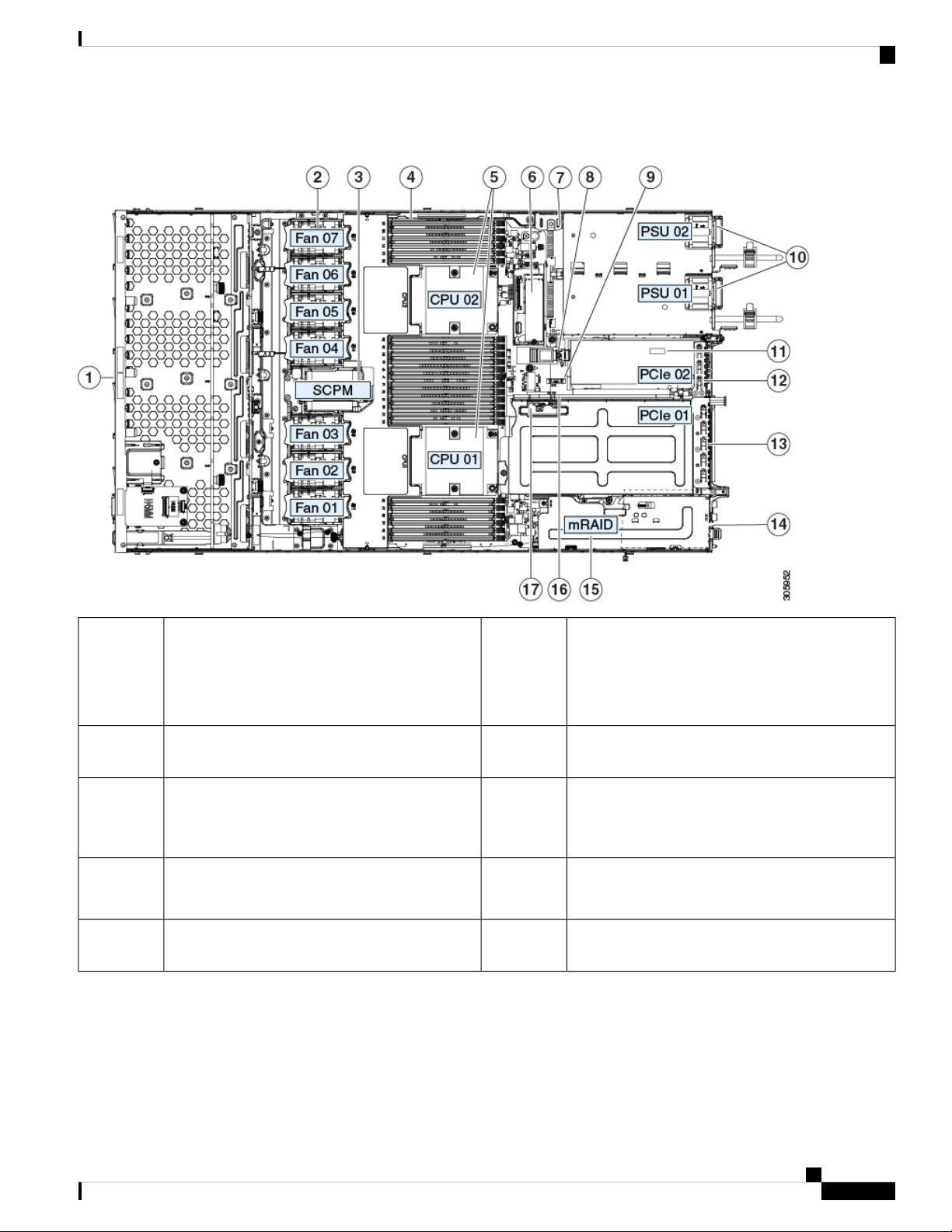

Serviceable Component Locations

This topic shows the locations of the field-replaceable components and service-related items. The view in the

following figure shows the server with the top cover removed.

Rear unit identification button/LED7Modular LAN-on-motherboard (mLOM) card bay

Power supplies (two, redundant as 1+1)8USB 3.0 ports (two)2

PCIe riser 2/slot 2 (x16 lane)

Includes PCIe cable connectors for front-loading

NVMe SSDs (x8 lane)

PCIe riser 1/slot 1 (x16 lane)10VGA video port (DB-15 connector)4

Threaded holes for dual-hole grounding lug111-Gb Ethernet dedicated management port5

Cisco Application Services Engine Hardware Installation Guide

4

Page 11

Overview

Figure 4: SE-CL-L3 , Serviceable Component Locations

Serviceable Component Locations

1

10Front-loading drive bays 1–10 support SAS/SATA

drives.

Power supplies (hot-swappable when redundant as

1+1)

• SE-CL-L3 : Drive bays 1 and 2 support

NVMe PCIe SSDs.

11Cooling fan modules (seven, hot-swappable)2

Trusted platform module (TPM) socket on

motherboard (not visible in this view)

12Supercap unit mounting bracket (RAID backup)3

PCIe riser 2/slot 2 (half-height, x16 lane)

Includes PCIe cable connectors for front-loading

NVMe SSDs (x8 lane)

13DIMM sockets on motherboard (12 per CPU)4

PCIe riser 1/slot 1 (full-height, x16 lane)

Includes socket for Micro-SD card

14CPUs and heatsinks (up to two)5

Modular LOM (mLOM) card bay on chassis floor

(x16 PCIe lane), not visible in this view

Cisco Application Services Engine Hardware Installation Guide

5

Page 12

Summary of Server Features

Overview

6

• SD card module with two SD card slots

• M.2 module with slots for either two SATA

M.2 drives or two NVMe M.2 drives

• Cisco Boot-Optimized M.2 RAID Controller

(module with two slots for SATA M.2 drives,

plus an integrated SATA RAID controller that

can control the two M.2 drives in a RAID 1

array)

Summary of Server Features

The following table lists a summary of server features.

15Mini-storage module socket. Options:

16Chassis intrusion switch (optional)7

-RTC battery, vertical socket9

Modular RAID (mRAID) riser, can optionally be a

riser that supports either:

• Hardware RAID controller card

• Interposer card for embedded SATA RAID

PCIe cable connectors for front-loading NVMe SSDs

on PCIe riser 2

Micro-SD card socket on PCIe riser 117Internal USB 3.0 port on motherboard8

Central Processor

Baseboard management

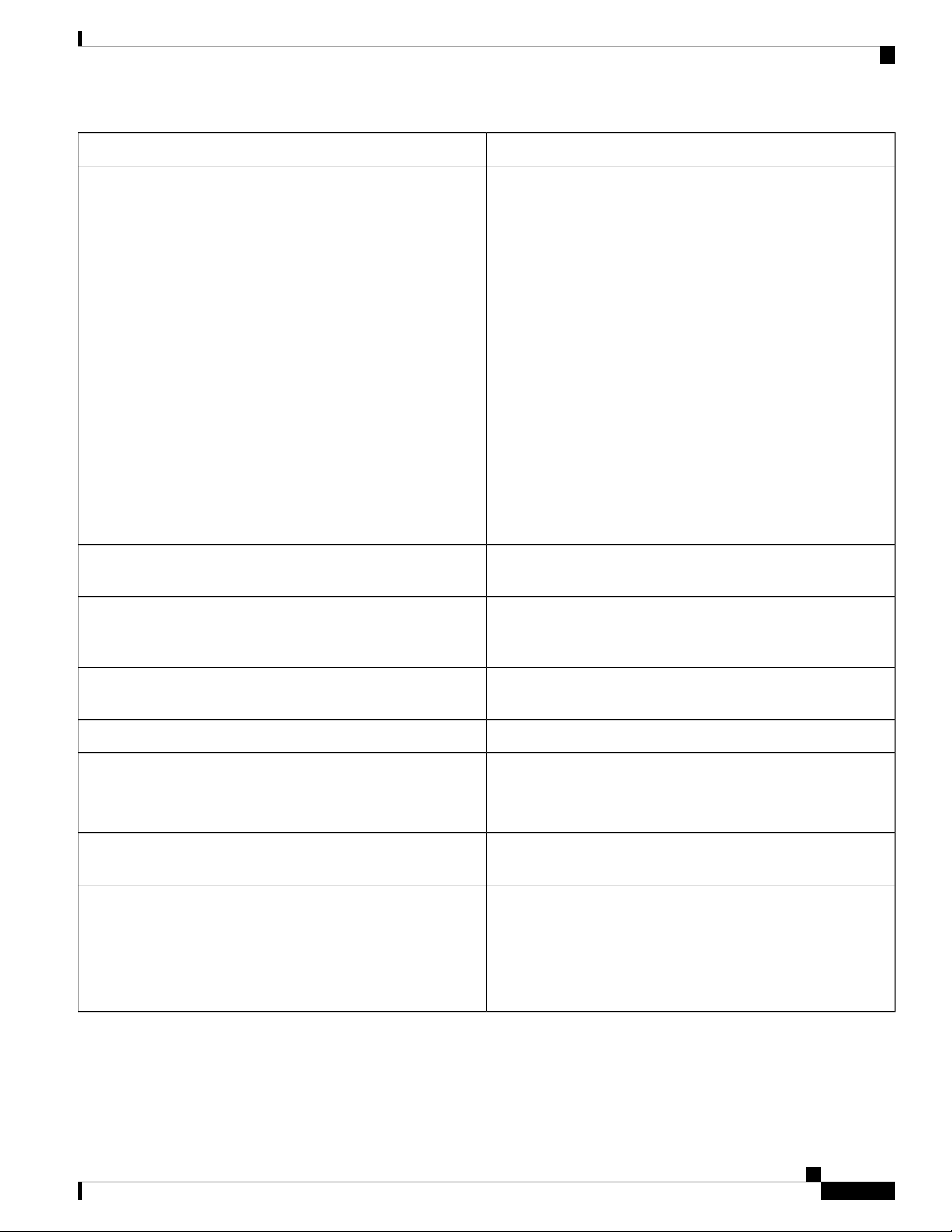

DescriptionFeature

One rack-unit (1RU) chassisChassis

Up to two CPUs from the Intel Xeon Processor Scalable Family.

This includes CPUs from the following series:

• Intel Xeon Silver 4XXX Processors

24 DDR4 DIMM sockets on the motherboard (12 each CPU)Memory

Multi-bit error protection is supportedMulti-bit error protection

BMC, running Cisco Integrated Management Controller (Cisco

IMC) firmware.

Depending on your Cisco IMC settings, Cisco IMC can be

accessed through the 1-Gb dedicated management port, the

1-Gb/10-Gb Ethernet LAN ports, or a Cisco virtual interface card.

Cisco Application Services Engine Hardware Installation Guide

6

Page 13

Overview

Summary of Server Features

DescriptionFeature

Network and management I/O

Modular LOM

Power

Rear panel:

• One 1-Gb Ethernet dedicated management port (RJ-45

connector)

• Two 1-Gb/10-Gb BASE-T Ethernet LAN ports (RJ-45

connectors)

The dual LAN ports can support 1 Gbps and 10 Gbps,

depending on the link partner capability.

• One RS-232 serial port (RJ-45 connector)

• One VGA video connector port (DB-15 connector)

• Two USB 3.0 ports

Front panel:

• One front-panel keyboard/video/mouse (KVM) connector

that is used with the KVM cable, which provides two USB

2.0, one VGA, and one DB-9 serial connector.

One dedicated socket (x16 PCIe lane) that can be used to add an

mLOM card for additional rear-panel connectivity.

One power supply:

ACPI

PCIe I/O

InfiniBand

Storage, front-panel

• AC power supplies 1050 W AC each

The advanced configuration and power interface (ACPI) 4.0

standard is supported.

Seven hot-swappable fan modules for front-to-rear cooling.Cooling

Two horizontal PCIe expansion slots on a PCIe riser assembly.

See PCIe Slot Specifications, on page 60 for specifications of the

slots.

The PCIe bus slots in this server support the InfiniBand

architecture.

The server is orderable in three different versions, each with a

different front panel/drive-backplane configuration.

• SE-CL-L3 , Small form-factor (SFF) drives, with 10-drive

backplane. Supports up to 10 2.5-inch SAS/SATA drives.

Drive bays 1 and 2 support NVMe SSDs.

Cisco Application Services Engine Hardware Installation Guide

7

Page 14

Summary of Server Features

Overview

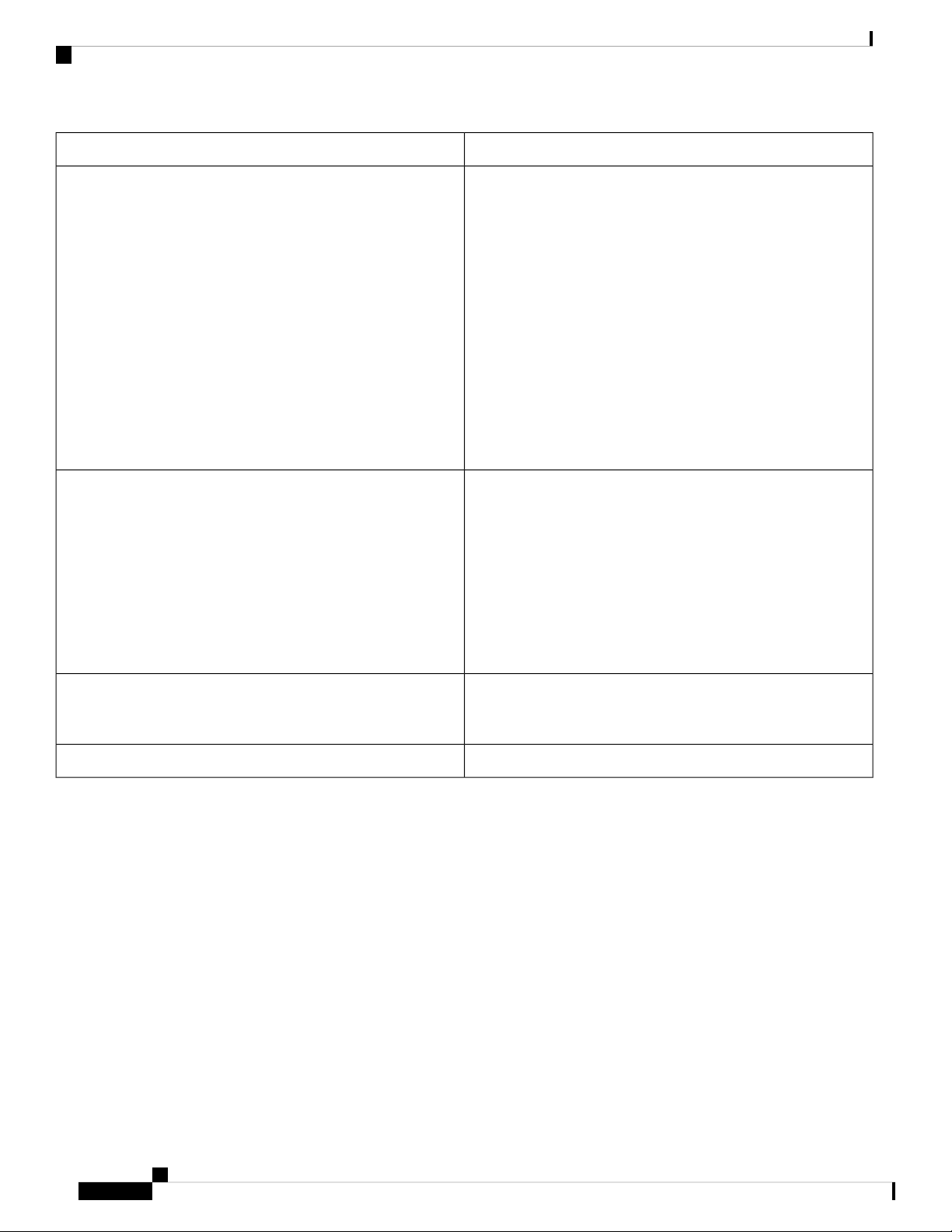

DescriptionFeature

Storage, internal

Storage management

The server has these internal storage options:

• One USB port on the motherboard.

• One micro-SD card socket on PCIe riser 1.

• Mini-storage module socket, optionally with either:

• SD card module. Supports up to two SD cards.

• M.2 SSD module. Supports either two SATA M.2 SSDs

or two NVMe M.2 SSDs.

• Cisco Boot-Optimized M.2 RAID Controller (module

with two slots for SATA M.2 drives, plus an integrated

SATA RAID controller that can control the two SATA

M.2 drives in a RAID 1 array)

The server has a dedicated internal mRAID riser that supports

one of the following storage-controller options:

• A PCIe-style Cisco modular RAID controller card

(SAS/SATA).

• A PCIe-style interposer card for the server’s embedded

SATA RAID controller.

RAID backup

For a detailed list of storage controller options, see Supported

Storage Controllers and Cables, on page 91.

The server has a mounting bracket near the cooling fans for the

supercap unit that is used with the Cisco modular RAID controller

card.

Integrated VGA video.Integrated video

Cisco Application Services Engine Hardware Installation Guide

8

Page 15

Installing the Server

• Preparing for Installation, on page 9

• Installing the Server in a Rack, on page 12

• Installing the Cable Management Arm (Optional), on page 14

• Reversing the Cable Management Arm (Optional), on page 15

• Initial Server Setup, on page 16

• Connecting to the Server Locally For Setup, on page 17

• Connecting to the Server Remotely For Setup, on page 18

• Updating the BIOS and Cisco IMC Firmware, on page 19

• Accessing the System BIOS, on page 19

• Smart Access Serial, on page 20

Preparing for Installation

This section contains the following topics:

CHAPTER 2

Installation Warnings and Guidelines

Note

Before you install, operate, or service a server, review the Regulatory Compliance and Safety Information for

important safety information.

Warning

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you work

on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard

practices for preventing accidents. Use the statement number provided at the end of each warning to locate

its translation in the translated safety warnings that accompanied this device.

Statement 1071

Cisco Application Services Engine Hardware Installation Guide

9

Page 16

Installation Warnings and Guidelines

Installing the Server

Warning

Warning

Warning

Warning

To prevent the system from overheating, do not operate it in an area that exceeds the maximum recommended

ambient temperature of: 35° C (95° F).

Statement 1047

The plug-socket combination must be accessible at all times, because it serves as the main disconnecting

device.

Statement 1019

This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that the

protective device is rated not greater than: 250 V, 15 A.

Statement 1005

Installation of the equipment must comply with local and national electrical codes.

Statement 1074

Warning

Caution

Caution

This unit is intended for installation in restricted access areas. A restricted access area can be accessed only

through the use of a special tool, lock, and key, or other means of security.

Statement 1017

To ensure proper airflow it is necessary to rack the servers using rail kits. Physically placing the units on top

of one another or “stacking” without the use of the rail kits blocks the air vents on top of the servers, which

could result in overheating, higher fan speeds, and higher power consumption. We recommend that you mount

your servers on rail kits when you are installing them into the rack because these rails provide the minimal

spacing required between the servers. No additional spacing between the servers is required when you mount

the units using rail kits.

Avoid uninterruptible power supply (UPS) types that use ferroresonant technology. These UPS types can

become unstable with systems such as the Cisco UCS, which can have substantial current draw fluctuations

from fluctuating data traffic patterns.

When you are installing a server, use the following guidelines:

• Plan your site configuration and prepare the site before installing the server.

Cisco Application Services Engine Hardware Installation Guide

10

Page 17

Installing the Server

• Ensure that there is adequate space around the server to allow for accessing the server and for adequate

airflow. The airflow in this server is from front to back.

• Ensure that the air-conditioning meets the thermal requirements listed in the Environmental Specifications,

on page 85.

• Ensure that the cabinet or rack meets the requirements listed in the Rack Requirements, on page 11.

• Ensure that the site power meets the power requirements listed in the Power Specifications, on page 86.

If available, you can use an uninterruptible power supply (UPS) to protect against power failures.

Rack Requirements

The rack must be of the following type:

• A standard 19-in. (48.3-cm) wide, four-post EIA rack, with mounting posts that conform to English

universal hole spacing, per section 1 of ANSI/EIA-310-D-1992.

• The rack-post holes can be square 0.38-inch (9.6 mm), round 0.28-inch (7.1 mm), #12-24 UNC, or #10-32

UNC when you use the Cisco-supplied slide rails.

Rack Requirements

• The minimum vertical rack space per server must be one rack unit (RU), equal to 1.75 in. (44.45 mm).

Supported Cisco Slide Rail Kits

The server supports the following rail kit:

• Cisco part UCSC-RAILB-M4= (ball-bearing slide rail kit)

Rack Installation Tools Required

The slide rails sold by Cisco Systems for this server do not require tools for installation.

Slide Rail and Cable Management Arm Dimensions

The slide rails for this server have an adjustment range of 24 to 36 inches (610 to 914 mm).

The optional cable management arm (CMA) adds additional length requirements:

• The additional distance from the rear of the server to the rear of the CMA is 5.4 inches (137.4 mm).

• The total length of the server including the CMA is 35.2 inches (894 mm).

Cisco Application Services Engine Hardware Installation Guide

11

Page 18

Installing the Server in a Rack

Installing the Server in a Rack

Installing the Server

Warning

Step 1 Attach the inner rails to the sides of the server:

a) Align an inner rail with one side of the server so that the three keyed slots in the rail align with the three pegs on the

b) Set the keyed slots over the pegs, and then slide the rail toward the front to lock it in place on the pegs. The front slot

c) Install the second inner rail to the opposite side of the server.

Figure 5: Attaching the Inner Rail to the Side of the Server

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions to

ensure that the system remains stable. The following guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest

component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in

the rack.

Statement 1006

side of the server.

has a metal clip that locks over the front peg.

Locking clip on front of inner rail2Front of server1

Step 2 Open the front securing plate on both slide-rail assemblies. The front end of the slide-rail assembly has a spring-loaded

securing plate that must be open before you can insert the mounting pegs into the rack-post holes.

On the outside of the assembly, push the green-arrow button toward the rear to open the securing plate.

Cisco Application Services Engine Hardware Installation Guide

12

Page 19

Installing the Server

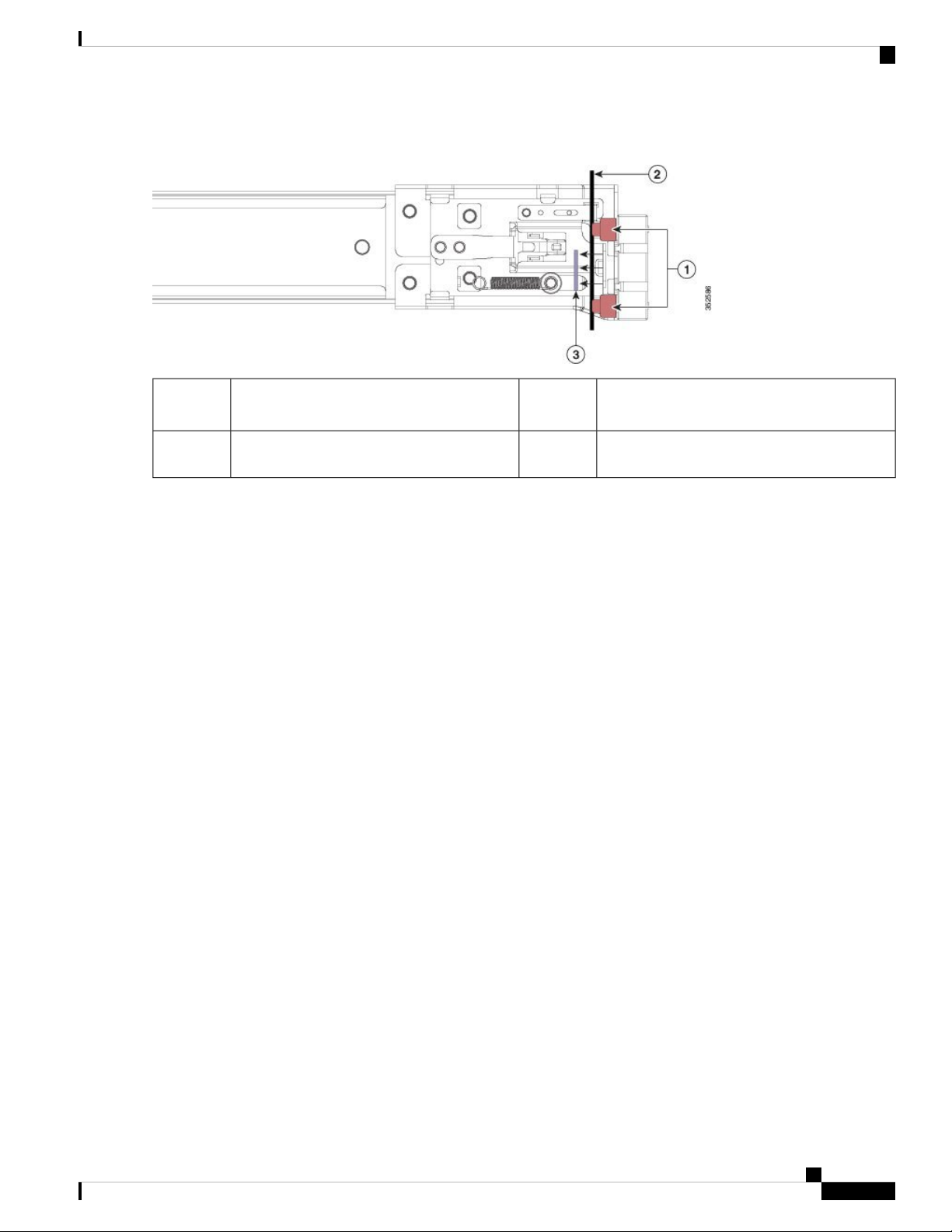

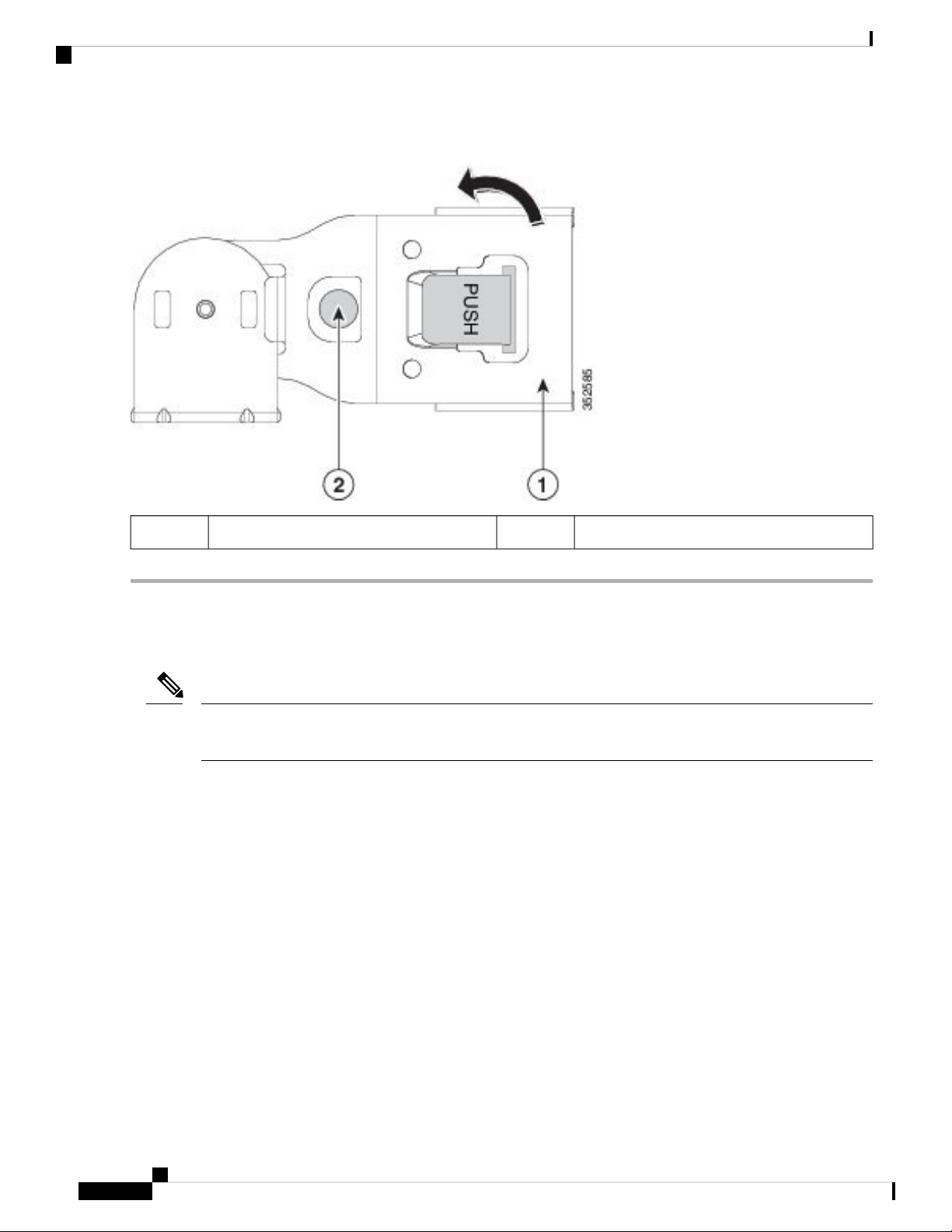

Figure 6: Front Securing Mechanism, Inside of Front End

Installing the Server in a Rack

2

securing plate

Step 3 Install the outer slide rails into the rack:

a) Align one slide-rail assembly front end with the front rack-post holes that you want to use.

The slide rail front-end wraps around the outside of the rack post and the mounting pegs enter the rack-post holes

from the outside-front.

Note

The rack post must be between the mounting pegs and the open securing plate.

b) Push the mounting pegs into the rack-post holes from the outside-front.

c) Press the securing plate release button, marked PUSH. The spring-loaded securing plate closes to lock the pegs in

place.

d) Adjust the slide-rail length, and then push the rear mounting pegs into the corresponding rear rack-post holes. The

slide rail must be level front-to-rear.

The rear mounting pegs enter the rear rack-post holes from the inside of the rack post.

e) Attach the second slide-rail assembly to the opposite side of the rack. Ensure that the two slide-rail assemblies are at

the same height and are level front-to-back.

f) Pull the inner slide rails on each assembly out toward the rack front until they hit the internal stops and lock in place.

Step 4 Insert the server into the slide rails:

3Front mounting pegs1

Securing plate shown pulled back to the open

position

-Rack post between mounting pegs and opened

Caution

This server can weigh up to 60 pounds (27 kilograms) when fully loaded with components. We recommend

that you use a minimum of two people or a mechanical lift when lifting the server. Attempting this procedure

alone could result in personal injury or equipment damage.

a) Align the rear ends of the inner rails that are attached to the server sides with the front ends of the empty slide rails

on the rack.

b) Push the inner rails into the slide rails on the rack until they stop at the internal stops.

c) Slide the inner-rail release clip toward the rear on both inner rails, and then continue pushing the server into the rack

until its front slam-latches engage with the rack posts.

Cisco Application Services Engine Hardware Installation Guide

13

Page 20

Installing the Cable Management Arm (Optional)

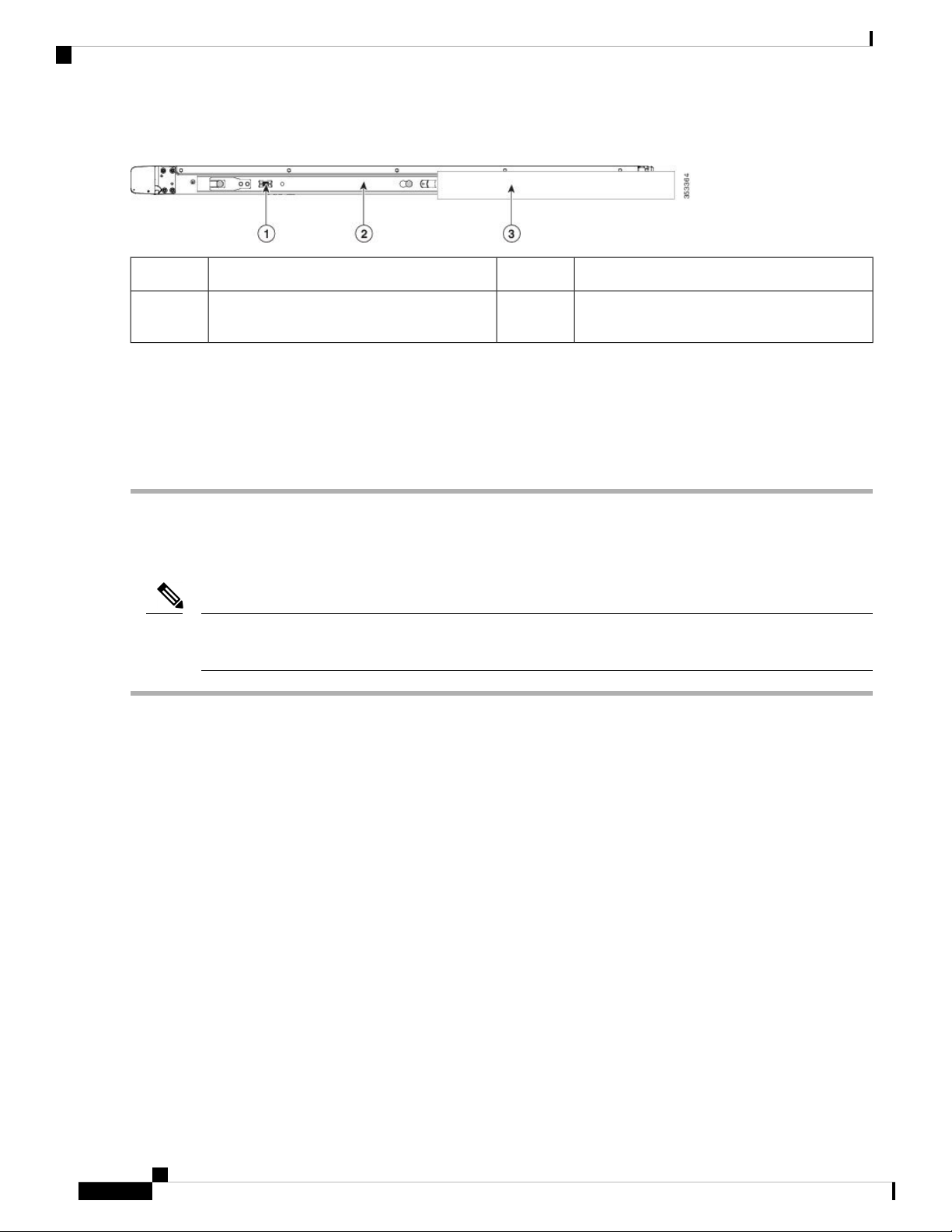

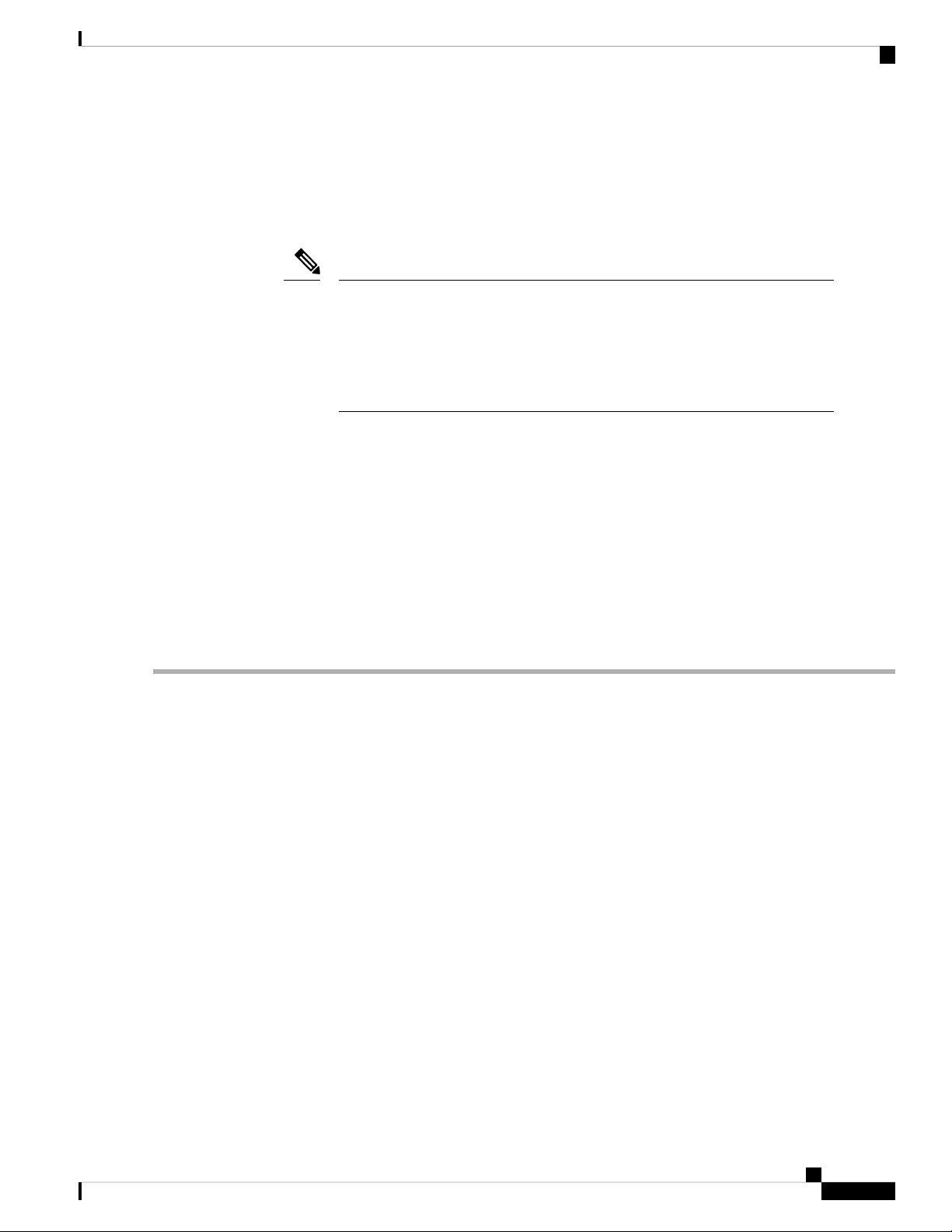

Figure 7: Inner-Rail Release Clip

Installing the Server

Outer slide rail attached to rack post3Inner-rail release clip1

2

outer slide rail

Step 5 (Optional) Secure the server in the rack more permanently by using the two screws that are provided with the slide rails.

Perform this step if you plan to move the rack with servers installed.

With the server fully pushed into the slide rails, open a hinged slam latch lever on the front of the server and insert a

screw through the hole that is under the lever. The screw threads into the static part of the rail on the rack post and prevents

the server from being pulled out. Repeat for the opposite slam latch.

-Inner rail attached to server and inserted into

Installing the Cable Management Arm (Optional)

Note

The cable management arm (CMA) is reversible left-to-right. To reverse the CMA, see Reversing the Cable

Management Arm (Optional), on page 15 before installation.

Step 1 With the server pushed fully into the rack, slide the CMA tab of the CMA arm that is farthest from the server onto the

end of the stationary slide rail that is attached to the rack post. Slide the tab over the end of the rail until it clicks and

locks.

Cisco Application Services Engine Hardware Installation Guide

14

Page 21

Installing the Server

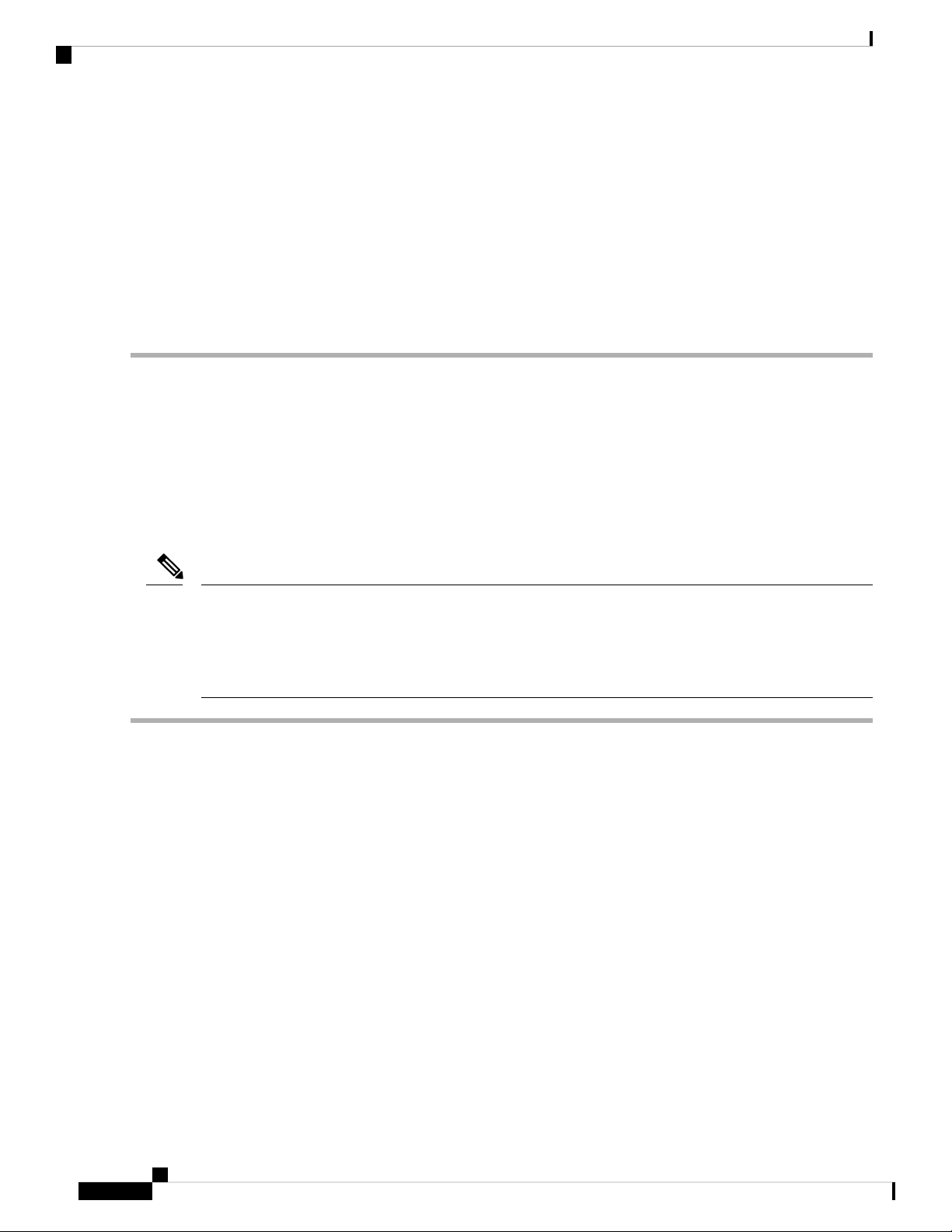

Figure 8: Attaching the CMA to the Rear Ends of the Slide Rails

Reversing the Cable Management Arm (Optional)

1

to end of stationary outer slide rail.

2

to end of inner slide rail attached to server.

Step 2 Slide the CMA tab that is closest to the server over the end of the inner rail that is attached to the server. Slide the tab

over the end of the rail until it clicks and locks

Step 3 Pull out the width-adjustment slider that is at the opposite end of the CMA assembly until it matches the width of your

rack.

Step 4 Slide the CMA tab that is at the end of the width-adjustment slider onto the end of the stationary slide rail that is attached

to the rack post. Slide the tab over the end of the rail until it clicks and locks.

Step 5 Open the hinged flap at the top of each plastic cable guide and route your cables through the cable guides as desired.

3CMA tab on arm farthest from server attaches

CMA tab on width-adjustment slider attaches

to end of stationary outer slide rail.

Rear of server4CMA tab on arm closest to the server attaches

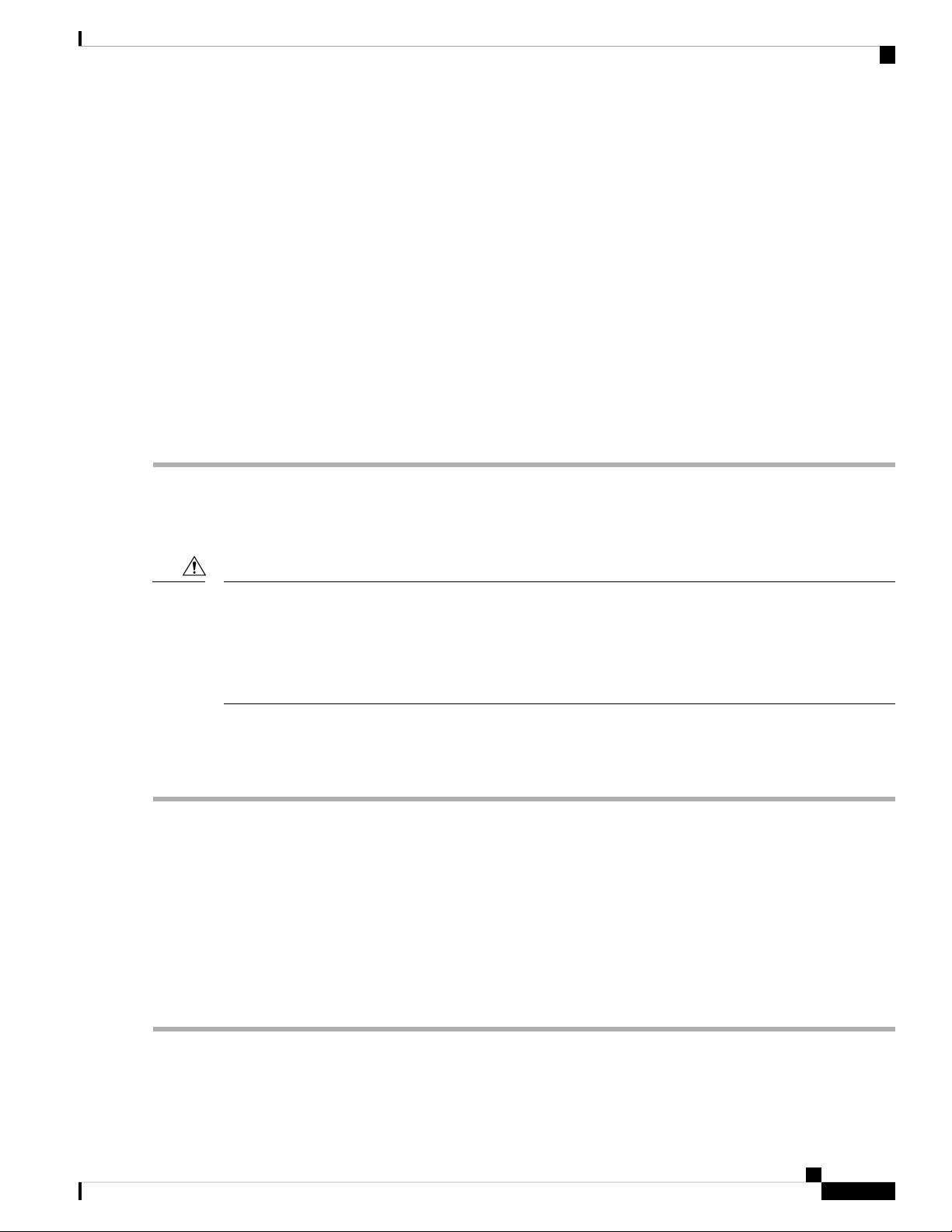

Reversing the Cable Management Arm (Optional)

Step 1 Rotate the entire CMA assembly 180 degrees, left-to-right. The plastic cable guides must remain pointing upward.

Step 2 Flip the tabs at the ends of the CMA arms so that they point toward the rear of the server.

Step 3 Pivot the tab that is at the end of the width-adjustment slider. Depress and hold the metal button on the outside of the tab

and pivot the tab 180 degrees so that it points toward the rear of the server.

Cisco Application Services Engine Hardware Installation Guide

15

Page 22

Initial Server Setup

Figure 9: Reversing the CMA

Installing the Server

Initial Server Setup

Note

This section describes how to power on the server, assign an IP address, and connect to server management

when using the server in standalone mode.

Server Default Settings

The server is shipped with these default settings:

• The NIC mode is Shared LOM EXT.

Shared LOM EXT mode enables the 1-Gb/10-Gb Ethernet ports and the ports on any installed Cisco

virtual interface card (VIC) to access the Cisco Integrated Management Interface (Cisco IMC).

• The NIC redundancy is Active-Active. All Ethernet ports are utilized simultaneously.

• DHCP is enabled.

Metal button on outside of tab2CMA tab on end of width-adjustment slider1

• IPv4 is enabled.

Connection Methods

There are two methods for connecting to the system for initial setup:

Cisco Application Services Engine Hardware Installation Guide

16

Page 23

Installing the Server

Connecting to the Server Locally For Setup

• Local setup—Use this procedure if you want to connect a keyboard and monitor directly to the system

for setup. This procedure can use a KVM cable (Cisco PID N20-BKVM) or the ports on the rear of the

server.

• Remote setup—Use this procedure if you want to perform setup through your dedicated management

LAN.

Note

To configure the system remotely, you must have a DHCP server on the same

network as the system. Your DHCP server must be preconfigured with the range

of MAC addresses for this server node. The MAC address is printed on a label

that is on the pull-out asset tag on the front panel. This server node has a range

of six MAC addresses assigned to the Cisco IMC. The MAC address printed on

the label is the beginning of the range of six contiguous MAC addresses.

This section contains the following topics:

Connecting to the Server Locally For Setup

This procedure requires the following equipment:

• VGA monitor

• USB keyboard

• Either the supported Cisco KVM cable (Cisco PID N20-BKVM); or a USB cable and VGA DB-15 cable

Step 1 Attach a power cord to each power supply in your server, and then attach each power cord to a grounded power outlet.

Wait for approximately two minutes to let the server boot to standby power during the first bootup. You can verify system

power status by looking at the system Power Status LED on the front panel. The system is in standby power mode when

the LED is amber.

Step 2 Connect a USB keyboard and VGA monitor to the server using one of the following methods:

• Connect an optional KVM cable (Cisco PID N20-BKVM) to the KVM connector on the front panel. Connect your

USB keyboard and VGA monitor to the KVM cable.

• Connect a USB keyboard and VGA monitor to the corresponding connectors on the rear panel.

Step 3 Open the Cisco IMC Configuration Utility:

a) Press and hold the front panel power button for four seconds to boot the server.

b) During bootup, press F8 when prompted to open the Cisco IMC Configuration Utility.

Note

The following are the requirements for Strong Password:

The first time that you enter the Cisco IMC Configuration Utility, you are prompted to change the default

password. The default password is password. The Strong Password feature is enabled.

• The password can have minimum 8 characters; maximum 14 characters.

Cisco Application Services Engine Hardware Installation Guide

17

Page 24

Connecting to the Server Remotely For Setup

• The password must not contain the user’s name.

• The password must contain characters from three of the following four categories:

• English uppercase letters (A through Z)

• English lowercase letters (a through z)

• Base 10 digits (0 through 9)

• Non-alphabetic characters !, @, #, $, %, ^, &, *, -, _, =, “

Connecting to the Server Remotely For Setup

This procedure requires the following equipment:

• One RJ-45 Ethernet cable that is connected to your management LAN.

Installing the Server

Before you begin

Note

To configure the system remotely, you must have a DHCP server on the same network as the system. Your

DHCP server must be preconfigured with the range of MAC addresses for this server node. The MAC address

is printed on a label that is on the pull-out asset tag on the front panel. This server node has a range of six

MAC addresses assigned to the Cisco IMC. The MAC address printed on the label is the beginning of the

range of six contiguous MAC addresses.

Step 1 Attach a power cord to each power supply in your server, and then attach each power cord to a grounded power outlet.

Wait for approximately two minutes to let the server boot to standby power during the first bootup. You can verify system

power status by looking at the system Power Status LED on the front panel. The system is in standby power mode when

the LED is amber.

Step 2 Plug your management Ethernet cable into the dedicated management port on the rear panel.

Step 3 Allow your preconfigured DHCP server to assign an IP address to the server node.

Step 4 Use the assigned IP address to access and log in to the Cisco IMC for the server node. Consult with your DHCP server

administrator to determine the IP address.

Note

Step 5 From the Cisco IMC Server Summary page, click Launch KVM Console. A separate KVM console window opens.

Step 6 From the Cisco IMC Summary page, click Power Cycle Server. The system reboots.

Step 7 Select the KVM console window.

The default user name for the server is admin. The default password is password.

Note

Step 8 When prompted, press F8 to enter the Cisco IMC Configuration Utility. This utility opens in the KVM console window.

18

The KVM console window must be the active window for the following keyboard actions to work.

Cisco Application Services Engine Hardware Installation Guide

Page 25

Installing the Server

Updating the BIOS and Cisco IMC Firmware

Note

The following are the requirements for Strong Password:

The first time that you enter the Cisco IMC Configuration Utility, you are prompted to change the default

password. The default password is password. The Strong Password feature is enabled.

• The password can have minimum 8 characters; maximum 14 characters.

• The password must not contain the user’s name.

• The password must contain characters from three of the following four categories:

• English uppercase letters (A through Z)

• English lowercase letters (a through z)

• Base 10 digits (0 through 9)

• Non-alphabetic characters !, @, #, $, %, ^, &, *, -, _, =, “

Updating the BIOS and Cisco IMC Firmware

Caution

When you upgrade the BIOS firmware, you must also upgrade the Cisco IMC firmware to the same version

or the server does not boot. Do not power off the server until the BIOS and Cisco IMC firmware are matching

or the server does not boot.

Cisco provides the Cisco Host Upgrade Utility to assist with simultaneously upgrading the BIOS, Cisco IMC,

and other firmware to compatible levels.

Accessing the System BIOS

Step 1 Enter the BIOS Setup Utility by pressing the F2 key when prompted during bootup.

Note

Step 2 Use the arrow keys to select the BIOS menu page.

Step 3 Highlight the field to be modified by using the arrow keys.

Step 4 Press Enter to select the field that you want to change, and then modify the value in the field.

Step 5 Press the right arrow key until the Exit menu screen is displayed.

Step 6 Follow the instructions on the Exit menu screen to save your changes and exit the setup utility (or press F10). You can

exit without saving changes by pressing Esc.

The version and build of the current BIOS are displayed on the Main page of the utility.

Cisco Application Services Engine Hardware Installation Guide

19

Page 26

Smart Access Serial

Smart Access Serial

This server supports the Smart Access Serial feature. This feature allows you to switch between host serial

and Cisco IMC CLI.

• This feature has the following requirements:

• A serial cable connection, which can use either the RJ-45 serial connector on the server rear panel,

or a DB-9 connection when using the KVM cable (Cisco PID N20-BKVM) on the front-panel KVM

console connector.

• Console redirection must be enabled in the server BIOS.

• Terminal type must be set to VT100+ or VTUFT8.

• Serial-over-LAN (SOL) must be disabled (SOL is disabled by default).

• To switch from host serial to Cisco IMC CLI, press Esc+9.

You must enter your Cisco IMC credentials to authenticate the connection.

Installing the Server

• To switch from Cisco IMC CLI to host serial, press Esc+8.

Note

You cannot switch to Cisco IMC CLI if the serial-over-LAN (SOL) feature is

enabled.

• After a session is created, it is shown in the CLI or web GUI by the name serial.

Cisco Application Services Engine Hardware Installation Guide

20

Page 27

Maintaining the Server

• Status LEDs and Buttons, on page 21

• Preparing For Component Installation, on page 26

• Removing and Replacing Components, on page 30

• Service Headers and Jumpers, on page 78

Status LEDs and Buttons

This section contains information for interpreting front, rear, and internal LED states.

Front-Panel LEDs

Figure 10: Front Panel LEDs

CHAPTER 3

Table 1: Front Panel LEDs, Definition of States

StatesLED Name

Cisco Application Services Engine Hardware Installation Guide

21

Page 28

Front-Panel LEDs

Maintaining the Server

1

SAS

SAS

1

NVMe

SAS/SATA drive fault

Note

NVMe solid state drive (SSD) drive tray

LEDs have different behavior than

SAS/SATA drive trays.

SAS/SATA drive activity LED2

NVMe SSD drive fault

Note

NVMe solid state drive (SSD) drive tray

LEDs have different behavior than

SAS/SATA drive trays.

• Off—The hard drive is operating properly.

• Amber—Drive fault detected.

• Amber, blinking—The device is rebuilding.

• Amber, blinking with one-second interval—Drive

locate function activated in the software.

• Off—There is no hard drive in the hard drive tray (no

access, no fault).

• Green—The hard drive is ready.

• Green, blinking—The hard drive is reading or writing

data.

• Off—The drive is not in use and can be safely

removed.

• Green—The drive is in use and functioning properly.

• Green, blinking—the driver is initializing following

insertion or the driver is unloading following an eject

command.

• Amber—The drive has failed.

NVMe

• Amber, blinking—A drive Locate command has been

issued in the software.

NVMe SSD activity2

• Off—No drive activity.

• Green, blinking—There is drive activity.

Power button/LED3

• Off—There is no AC power to the server.

• Amber—The server is in standby power mode. Power

is supplied only to the Cisco IMC and some

motherboard functions.

• Green—The server is in main power mode. Power is

supplied to all server components.

Unit identification4

• Off—The unit identification function is not in use.

• Blue, blinking—The unit identification function is

activated.

Cisco Application Services Engine Hardware Installation Guide

22

Page 29

Maintaining the Server

Front-Panel LEDs

System health5

• Green—The server is running in normal operating

condition.

• Green, blinking—The server is performing system

initialization and memory check.

• Amber, steady—The server is in a degraded

operational state (minor fault). For example:

• Power supply redundancy is lost.

• CPUs are mismatched.

• At least one CPU is faulty.

• At least one DIMM is faulty.

• At least one drive in a RAID configuration failed.

• Amber, 2 blinks—There is a major fault with the

system board.

• Amber, 3 blinks—There is a major fault with the

memory DIMMs.

• Amber, 4 blinks—There is a major fault with the

CPUs.

Power supply status6

• Green—All power supplies are operating normally.

• Amber, steady—One or more power supplies are in

a degraded operational state.

• Amber, blinking—One or more power supplies are

in a critical fault state.

Fan status7

• Green—All fan modules are operating properly.

• Amber, blinking—One or more fan modules breached

the non-recoverable threshold.

Network link activity8

• Off—The Ethernet LOM port link is idle.

• Green—One or more Ethernet LOM ports are

link-active, but there is no activity.

• Green, blinking—One or more Ethernet LOM ports

are link-active, with activity.

Temperature status9

• Green—The server is operating at normal temperature.

• Amber, steady—One or more temperature sensors

breached the critical threshold.

• Amber, blinking—One or more temperature sensors

breached the non-recoverable threshold.

Cisco Application Services Engine Hardware Installation Guide

23

Page 30

Rear-Panel LEDs

Rear-Panel LEDs

Figure 11: Rear Panel LEDs

Table 2: Rear Panel LEDs, Definition of States

Maintaining the Server

StatesLED Name

1

1-Gb/10-Gb Ethernet link speed (on both LAN1 and

LAN2)

• Amber—Link speed is 100 Mbps.

• Amber—Link speed is 1 Gbps.

• Green—Link speed is 10 Gbps.

2

1-Gb/10-Gb Ethernet link status (on both LAN1 and

LAN2)

• Off—No link is present.

• Green—Link is active.

• Green, blinking—Traffic is present on the active link.

1-Gb Ethernet dedicated management link speed3

• Off—Link speed is 10 Mbps.

• Amber—Link speed is 100 Mbps.

• Green—Link speed is 1 Gbps.

1-Gb Ethernet dedicated management link status4

• Off—No link is present.

• Green—Link is active.

• Green, blinking—Traffic is present on the active link.

Rear unit identification5

• Off—The unit identification function is not in use.

• Blue, blinking—The unit identification function is

activated.

Cisco Application Services Engine Hardware Installation Guide

24

Page 31

Maintaining the Server

Internal Diagnostic LEDs

Power supply status (one LED each power supply unit)6

AC power supplies:

• Off—No AC input (12 V main power off, 12 V

standby power off).

• Green, blinking—12 V main power off; 12 V standby

power on.

• Green, solid—12 V main power on; 12 V standby

power on.

• Amber, blinking—Warning threshold detected but 12

V main power on.

• Amber, solid—Critical error detected; 12 V main

power off (for example, over-current, over-voltage,

or over-temperature failure).

DC power supplies:

• Off—No DC input (12 V main power off, 12 V

standby power off).

• Green, blinking—12 V main power off; 12 V standby

power on.

• Green, solid—12 V main power on; 12 V standby

power on.

Internal Diagnostic LEDs

The server has internal fault LEDs for CPUs, DIMMs, and fan modules.

• Amber, blinking—Warning threshold detected but 12

V main power on.

• Amber, solid—Critical error detected; 12 V main

power off (for example, over-current, over-voltage,

or over-temperature failure).

Cisco Application Services Engine Hardware Installation Guide

25

Page 32

Preparing For Component Installation

Figure 12: Internal Diagnostic LED Locations

Maintaining the Server

1

connector on the motherboard)

• Amber—Fan has a fault or is not fully seated.

• Green—Fan is OK.

2

the motherboard).

These LEDs operate only when the server is in

standby power mode.

• Amber—CPU has a fault.

• Off—CPU is OK.

3Fan module fault LEDs (one behind each fan

-CPU fault LEDs (one behind each CPU socket on

Preparing For Component Installation

This section includes information and tasks that help prepare the server for component installation.

DIMM fault LEDs (one behind each DIMM socket

on the motherboard)

These LEDs operate only when the server is in

standby power mode.

• Amber—DIMM has a fault.

• Off—DIMM is OK.

Required Equipment For Service Procedures

The following tools and equipment are used to perform the procedures in this chapter:

Cisco Application Services Engine Hardware Installation Guide

26

Page 33

Maintaining the Server

Shutting Down and Removing Power From the Server

• T-30 Torx driver (supplied with replacement CPUs for heatsink removal)

• #1 flat-head screwdriver (supplied with replacement CPUs for heatsink removal)

• #1 Phillips-head screwdriver (for M.2 SSD and intrusion switch replacement)

• Electrostatic discharge (ESD) strap or other grounding equipment such as a grounded mat

Shutting Down and Removing Power From the Server

The server can run in either of two power modes:

• Main power mode—Power is supplied to all server components and any operating system on your drives

can run.

• Standby power mode—Power is supplied only to the service processor and certain components. It is safe

for the operating system and data to remove power cords from the server in this mode.

Caution

After a server is shut down to standby power, electric current is still present in the server. To completely

remove power as directed in some service procedures, you must disconnect all power cords from all power

supplies in the server.

You can shut down the server by using the front-panel power button or the software management interfaces.

Shutting Down Using the Power Button

Step 1 Check the color of the Power button/LED:

• Amber—The server is already in standby mode and you can safely remove power.

• Green—The server is in main power mode and must be shut down before you can safely remove power.

Step 2 Invoke either a graceful shutdown or a hard shutdown:

Caution

To avoid data loss or damage to your operating system, you should always invoke a graceful shutdown of the

operating system.

• Graceful shutdown—Press and release the Power button. The operating system performs a graceful shutdown and

the server goes to standby mode, which is indicated by an amber Power button/LED.

• Emergency shutdown—Press and hold the Power button for 4 seconds to force the main power off and immediately

enter standby mode.

Step 3 If a service procedure instructs you to completely remove power from the server, disconnect all power cords from the

power supplies in the server.

Shutting Down Using The Cisco IMC GUI

You must log in with user or admin privileges to perform this task.

Cisco Application Services Engine Hardware Installation Guide

27

Page 34

Maintaining the Server

Shutting Down Using The Cisco IMC CLI

Step 1 In the Navigation pane, click the Server tab.

Step 2 On the Server tab, click Summary.

Step 3 In the Actions area, click Power Off Server.

Step 4 Click OK.

The operating system performs a graceful shutdown and the server goes to standby mode, which is indicated by an amber

Power button/LED.

Step 5 If a service procedure instructs you to completely remove power from the server, disconnect all power cords from the

power supplies in the server.

Shutting Down Using The Cisco IMC CLI

You must log in with user or admin privileges to perform this task.

Step 1 At the server prompt, enter:

Example:

server# scope chassis

Step 2 At the chassis prompt, enter:

Example:

server/chassis# power shutdown

The operating system performs a graceful shutdown and the server goes to standby mode, which is indicated by an amber

Power button/LED.

Step 3 If a service procedure instructs you to completely remove power from the server, disconnect all power cords from the

power supplies in the server.

Removing the Server Top Cover

Step 1 Remove the top cover:

a) If the cover latch is locked, use a screwdriver to turn the lock 90-degrees counterclockwise to unlock it.

b) Lift on the end of the latch that has the green finger grip. The cover is pushed back to the open position as you lift

the latch.

c) Lift the top cover straight up from the server and set it aside.

Step 2 Replace the top cover:

a) With the latch in the fully open position, place the cover on top of the server about one-half inch (1.27 cm) behind

the lip of the front cover panel. The opening in the latch should fit over the peg that sticks up from the fan tray.

b) Press the cover latch down to the closed position. The cover is pushed forward to the closed position as you push

down the latch.

c) If desired, lock the latch by using a screwdriver to turn the lock 90-degrees clockwise.

Cisco Application Services Engine Hardware Installation Guide

28

Page 35

Maintaining the Server

Figure 13: Removing the Top Cover

Serial Number Location

Serial Number Location

The serial number for the server is printed on a label on the top of the server, near the front. See Removing

the Server Top Cover, on page 28.

Hot Swap vs Hot Plug

Some components can be removed and replaced without shutting down and removing power from the server.

This type of replacement has two varieties: hot-swap and hot-plug.

• Hot-swap replacement—You do not have to shut down the component in the software or operating

system. This applies to the following components:

Locking cover latch2Top cover1

Serial number label location3

Cisco Application Services Engine Hardware Installation Guide

29

Page 36

Removing and Replacing Components

• SAS/SATA hard drives

• SAS/SATA solid state drives

• Cooling fan modules

• Power supplies (when redundant as 1+1)

• Hot-plug replacement—You must take the component offline before removing it for the following

component:

• NVMe PCIe solid state drives

Removing and Replacing Components

Maintaining the Server

Warning

Caution

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages

and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other

equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all

cards, faceplates, front covers, and rear covers are in place.

Statement 1029

When handling server components, handle them only by carrier edges and use an electrostatic discharge (ESD)

wrist-strap or other grounding device to avoid damage.

Tip

You can press the unit identification button on the front panel or rear panel to turn on a flashing, blue unit

identification LED on both the front and rear panels of the server. This button allows you to locate the specific

server that you are servicing when you go to the opposite side of the rack. You can also activate these LEDs

remotely by using the Cisco IMC interface.

This section describes how to install and replace server components.

Serviceable Component Locations

This topic shows the locations of the field-replaceable components and service-related items. The view in the

following figure shows the server with the top cover removed.

Cisco Application Services Engine Hardware Installation Guide

30

Page 37

Maintaining the Server

Figure 14: SE-CL-L3 , Serviceable Component Locations

Serviceable Component Locations

1

10Front-loading drive bays 1–10 support SAS/SATA

drives.

Power supplies (hot-swappable when redundant as

1+1)

• SE-CL-L3 : Drive bays 1 and 2 support

NVMe PCIe SSDs.

11Cooling fan modules (seven, hot-swappable)2

Trusted platform module (TPM) socket on

motherboard (not visible in this view)

12Supercap unit mounting bracket (RAID backup)3

PCIe riser 2/slot 2 (half-height, x16 lane)

Includes PCIe cable connectors for front-loading

NVMe SSDs (x8 lane)

13DIMM sockets on motherboard (12 per CPU)4

PCIe riser 1/slot 1 (full-height, x16 lane)

Includes socket for Micro-SD card

14CPUs and heatsinks (up to two)5

Modular LOM (mLOM) card bay on chassis floor

(x16 PCIe lane), not visible in this view

Cisco Application Services Engine Hardware Installation Guide

31

Page 38

Replacing SAS/SATA Hard Drives or Solid State Drives

Maintaining the Server

6

15Mini-storage module socket. Options:

• SD card module with two SD card slots

• M.2 module with slots for either two SATA

M.2 drives or two NVMe M.2 drives

Modular RAID (mRAID) riser, can optionally be a

riser that supports either:

• Hardware RAID controller card

• Interposer card for embedded SATA RAID

• Cisco Boot-Optimized M.2 RAID Controller

(module with two slots for SATA M.2 drives,

plus an integrated SATA RAID controller that

can control the two M.2 drives in a RAID 1

array)

16Chassis intrusion switch (optional)7

PCIe cable connectors for front-loading NVMe SSDs

on PCIe riser 2

Micro-SD card socket on PCIe riser 117Internal USB 3.0 port on motherboard8

-RTC battery, vertical socket9

Replacing SAS/SATA Hard Drives or Solid State Drives

Note

You do not have to shut down the server or drive to replace SAS/SATA hard drives or SSDs because they

are hot-swappable. To replace an NVMe PCIe SSD drive, which must be shut down before removal, see

Replacing a Front-Loading NVMe SSD, on page 36.

SAS/SATA Drive Population Guidelines

The server is orderable in the following different version

• SE-CL-L3 —Small form-factor (SFF) drives, with 10-drive backplane. Supports up to 10 2.5-inch

SAS/SATA drives. Drive bays 1 and 2 support NVMe SSDs.

Drive bay numbering is shown in the following figures.

Figure 15: Small Form-Factor Drive Versions, Drive Bay Numbering

Figure 16: Large Form-Factor Drive Version, Drive Bay Numbering

Observe these drive population guidelines for optimum performance:

• When populating drives, add drives to the lowest-numbered bays first.

Cisco Application Services Engine Hardware Installation Guide

32

Page 39

Maintaining the Server

• Keep an empty drive blanking tray in any unused bays to ensure proper airflow.

• You can mix SAS/SATA hard drives and SAS/SATA SSDs in the same server. However, you cannot

configure a logical volume (virtual drive) that contains a mix of hard drives and SSDs. That is, when

you create a logical volume, it must contain all SAS/SATA hard drives or all SAS/SATA SSDs.

4K Sector Format SAS/SATA Drives Considerations

About this task

• You must boot 4K sector format drives in UEFI mode, not legacy mode. UEFI mode is the system default.

Only if the mode has been changed and must be changed back to UEFI mode, see the following procedure.

• Do not configure 4K sector format and 512-byte sector format drives as part of the same RAID volume.

• Operating system support on 4K sector drives is as follows: Windows: Win2012 and Win2012R2; Linux:

RHEL 6.5, 6.6, 6.7, 7.0, 7.2; SLES 11 SP3, and SLES 12. ESXi/Vmware is not supported.

Setting Up UEFI Mode Booting in the BIOS Setup Utility

4K Sector Format SAS/SATA Drives Considerations

UEFI mode is the system default. Use this procedure if the mode has been changed and must be set back to

UEFI mode.

Step 1 Enter the BIOS setup utility by pressing the F2 key when prompted during bootup.

Step 2 Go to the Boot Options tab.

Step 3 Set Boot Mode to UEFI Mode.

Step 4 Under Boot Option Priorities, set your OS installation media (such as a virtual DVD) as your Boot Option #1.

Step 5 Press F10 to save changes and exit the BIOS setup utility. Allow the server to reboot.

Step 6 After the OS installs, verify the installation:

a) Enter the BIOS setup utility by pressing the F2 key when prompted during bootup.

b) Go to the Boot Options tab.

c) Under Boot Option Priorities, verify that the OS you installed is listed as your Boot Option #1.

Replacing a SAS/SATA Drive

Step 1 Remove the drive that you are replacing or remove a blank drive tray from the bay:

a) Press the release button on the face of the drive tray.

b) Grasp and open the ejector lever and then pull the drive tray out of the slot.

c) If you are replacing an existing drive, remove the four drive-tray screws that secure the drive to the tray and then lift

the drive out of the tray.

Step 2 Install a new drive:

a) Place a new drive in the empty drive tray and install the four drive-tray screws.

b) With the ejector lever on the drive tray open, insert the drive tray into the empty drive bay.

c) Push the tray into the slot until it touches the backplane, and then close the ejector lever to lock the drive in place.

Cisco Application Services Engine Hardware Installation Guide

33

Page 40

Replacing a Front-Loading NVMe SSD

Figure 17: Replacing a Drive in a Drive Tray

Maintaining the Server

Replacing a Front-Loading NVMe SSD

This section is for replacing 2.5-inch or 3.5-inch form-factor NVMe solid-state drives (SSDs) in front-panel

drive bays.

Front-Loading NVMe SSD Population Guidelines

The front drive bay support for 2.5-inch NVMe SSDs:

• SE-CL-L3 —Small form-factor (SFF) drives, with 10-drive backplane. Drive bays 1 and 2 support

2.5-inch NVMe SSDs.

Cisco Application Services Engine Hardware Installation Guide

34

Drive tray screws (two on each side)3Ejector lever1

Drive removed from drive tray4Release button2

Page 41

Maintaining the Server

Front-Loading NVME SSD Requirements and Restrictions

Observe these requirements:

• The server must have two CPUs. PCIe riser 2 is not available in a single-CPU system. PCIe riser 2 has

connectors for the cable that connects to the front-panel drive backplane.

• PCIe cable CBL-NVME-C220FF. This is the cable that carries the PCIe signal from the front-panel drive

backplane to PCIe riser 2. This cable is for all versions of this server.

• Hot-plug support must be enabled in the system BIOS. If you ordered the system with NVMe drives,

hot-plug support is enabled at the factory.

Observe these restrictions:

• NVMe SFF 2.5- and 3.5-inch SSDs support booting only in UEFI mode. Legacy boot is not supported.

For instructions on setting up UEFI boot, see 4K Sector Format SAS/SATA Drives Considerations, on

page 33.

• You cannot control NVMe PCIe SSDs with a SAS RAID controller because NVMe SSDs interface with

the server via the PCIe bus.

Front-Loading NVME SSD Requirements and Restrictions

• UEFI boot is supported in all supported operating systems. Hot-insertion and hot-removal are supported

in all supported operating systems except VMWare ESXi.

Enabling Hot-Plug Support in the System BIOS

Hot-plug (OS-informed hot-insertion and hot-removal) is disabled in the system BIOS by default.

• If the system was ordered with NVMe PCIe SSDs, the setting was enabled at the factory. No action is

required.

• If you are adding NVMe PCIe SSDs after-factory, you must enable hot-plug support in the BIOS. See

the following procedures.

Enabling Hot-Plug Support Using the BIOS Setup Utility

Step 1 Enter the BIOS setup utility by pressing the F2 key when prompted during bootup.

Step 2 Navigate to Advanced > PCI Subsystem Settings > NVMe SSD Hot-Plug Support.

Step 3 Set the value to Enabled.

Step 4 Save your changes and exit the utility.

Enabling Hot-Plug Support Using the Cisco IMC GUI

Step 1 Use a browser to log in to the Cisco IMC GUI for the server.

Step 2 Navigate to Compute > BIOS > Advanced > PCI Configuration.

Step 3 Set NVME SSD Hot-Plug Support to Enabled.

Step 4 Save your changes.

Cisco Application Services Engine Hardware Installation Guide

35

Page 42

Replacing a Front-Loading NVMe SSD

Replacing a Front-Loading NVMe SSD

This topic describes how to replace 2.5- or 3.5-inch form-factor NVMe SSDs in the front-panel drive bays.

Note

OS-surprise removal is not supported. OS-informed hot-insertion and hot-removal are supported on all

supported operating systems except VMware ESXi.

Note

OS-informed hot-insertion and hot-removal must be enabled in the system BIOS. See Enabling Hot-Plug

Support in the System BIOS, on page 35

Step 1 Remove an existing front-loading NVMe SSD:

a) Shut down the NVMe SSD to initiate an OS-informed removal. Use your operating system interface to shut down

the drive, and then observe the drive-tray LED:

Maintaining the Server

• Green—The drive is in use and functioning properly. Do not remove.

• Green, blinking—the driver is unloading following a shutdown command. Do not remove.

• Off—The drive is not in use and can be safely removed.

b) Press the release button on the face of the drive tray.

c) Grasp and open the ejector lever and then pull the drive tray out of the slot.

d) Remove the four drive tray screws that secure the SSD to the tray and then lift the SSD out of the tray.

Note

If this is the first time that front-loading NVMe SSDs are being installed in the server, you must install PCIe

cable CBL-NVME-C220FF before installing the drive. See Installing a PCIe Cable For Front-Loading NVMe

SSDs, on page 37.

Step 2 Install a new front-loading NVMe SSD:

a) Place a new SSD in the empty drive tray and install the four drive-tray screws.

b) With the ejector lever on the drive tray open, insert the drive tray into the empty drive bay.

c) Push the tray into the slot until it touches the backplane, and then close the ejector lever to lock the drive in place.

Step 3 Observe the drive-tray LED and wait until it returns to solid green before accessing the drive:

• Off—The drive is not in use.

• Green, blinking—the driver is initializing following hot-plug insertion.

• Green—The drive is in use and functioning properly.

Cisco Application Services Engine Hardware Installation Guide

36

Page 43

Maintaining the Server

Figure 18: Replacing a Drive in a Drive Tray

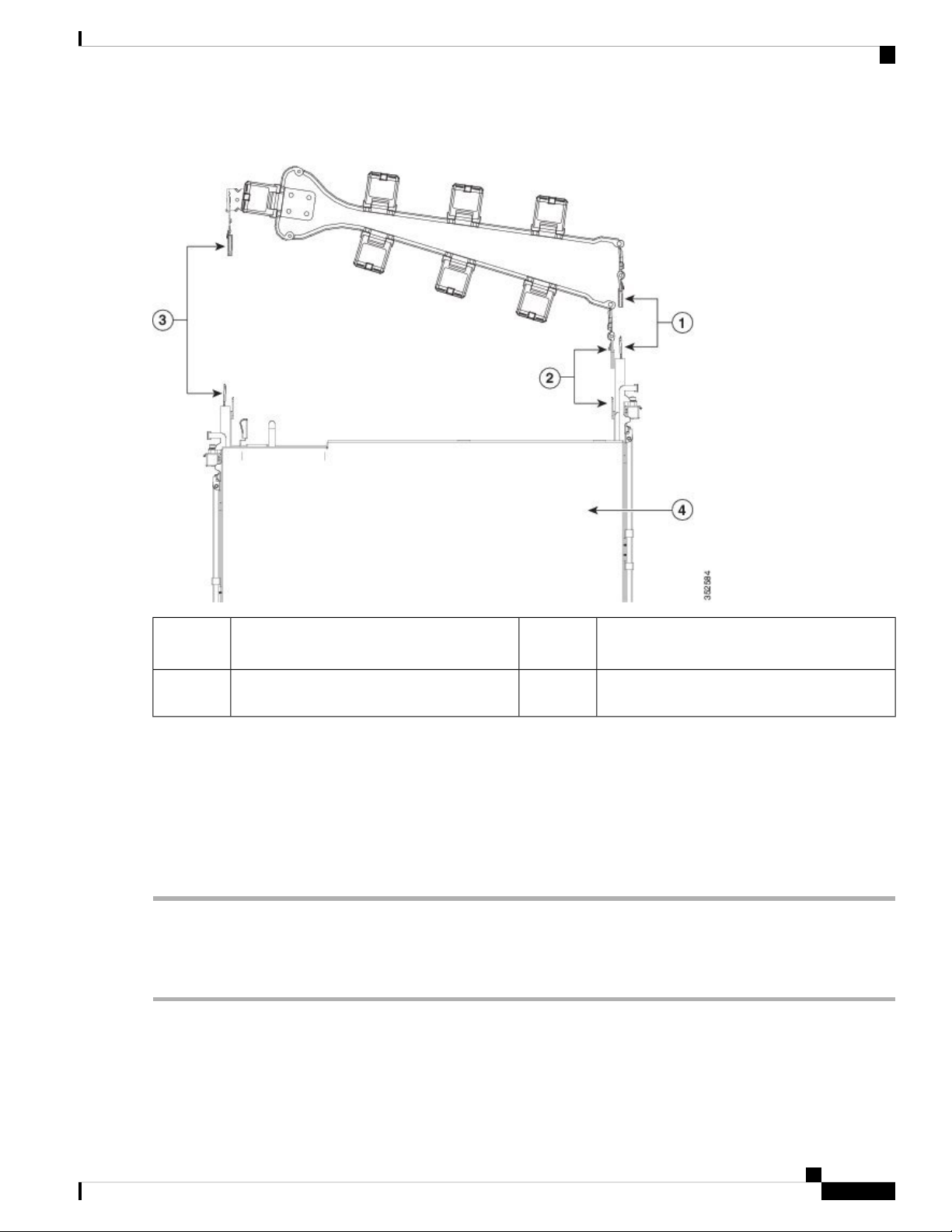

Installing a PCIe Cable For Front-Loading NVMe SSDs

Installing a PCIe Cable For Front-Loading NVMe SSDs

The front-loading NVMe SSDs interface with the server via the PCIe bus. Cable CBL-NVME-C220FF

connects the front-panel drive backplane to the PCIe riser 2 board on the PCIe riser assembly.

• If the server was ordered with 2.5- or 3.5-inch form-factor NVMe SSDs, this cable was preinstalled at

the factory. No action is required.

• If you are adding 2.5- or 3.5-inch form-factor NVMe SSDs for the first time, you must order and install

the cable as described in the following procedure.

Cisco Application Services Engine Hardware Installation Guide

Drive tray screws (two on each side)3Ejector lever1

Drive removed from drive tray4Release button2

37

Page 44

Maintaining the Server

Replacing Fan Modules

Step 1 Connect the two connectors on one end of the cable to the PCIE-A1 and PCIE-A2 connectors on the drive backplane.

Step 2 Route the cables through the chassis cable guides to the rear of the server as shown below.

Step 3 Connect the single connector on the other end of the cable to the PCIE-FRONT connector on PCIe riser 2.

Figure 19: PCIe Cabling to Drive Backplane

Replacing Fan Modules

The seven fan modules in the server are numbered as shown in the figure 1.

Tip

Each fan module has a fault LED next to the fan connector on the motherboard. This LED lights green when

the fan is correctly seated and is operating OK. The LED lights amber when the fan has a fault or is not

correctly seated.

Caution

Step 1 Remove an existing fan module:

a) Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach

You do not have to shut down or remove power from the server to replace fan modules because they are hotswappable. However, to maintain proper cooling, do not operate the server for more than one minute with

any fan module removed.

cables from the rear panel to provide clearance.

Caution

If you cannot safely view and access the component, remove the server from the rack.

Cisco Application Services Engine Hardware Installation Guide

38

Page 45

Maintaining the Server

b) Remove the top cover from the server as described in Removing the Server Top Cover, on page 28.

c) Grasp the fan module at its front and rear finger-grips. Lift straight up to disengage its connector from the motherboard.

Step 2 Install a new fan module:

a) Set the new fan module in place. The arrow printed on the top of the fan module should point toward the rear of the

server.

b) Press down gently on the fan module to fully engage it with the connector on the motherboard.

c) Replace the top cover to the server.

d) Replace the server in the rack, replace cables, and then fully power on the server by pressing the Power button.

Replacing CPUs and Heatsinks

This section contains CPU configuration rules and the procedure for replacing CPUs and heatsinks:

CPU Configuration Rules

This server has two CPU sockets on the motherboard. Each CPU supports six DIM channels (12 DIMM slots).

See DIMM Population Rules and Memory Performance Guidelines, on page 51.

Replacing CPUs and Heatsinks

• The server operates with two identical CPUs installed.

• The maximum combined memory allowed in the 12 DIMM slots controlled by any one CPU is 768 GB.

To populate the 12 DIMM slots with more than 768 GB of combined memory, you must use a

high-memory CPU that has a PID that ends with an "M", for example, UCS-CPU-6134M.

Tools Required For CPU Replacement

You need the following tools and equipment for this procedure:

• T-30 Torx driver—Supplied with replacement CPU.

• #1 flat-head screwdriver—Supplied with replacement CPU.

• CPU assembly tool—Supplied with replacement CPU. Orderable separately as Cisco PID UCS-CPUAT=.

• Heatsink cleaning kit—Supplied with replacement CPU. Orderable separately as Cisco PID

UCSX-HSCK=.

One cleaning kit can clean up to four CPUs.

• Thermal interface material (TIM)—Syringe supplied with replacement CPU. Use only if you are reusing

your existing heatsink (new heatsinks have a pre-applied pad of TIM). Orderable separately as Cisco

PID UCS-CPU-TIM=.

One TIM kit covers one CPU.

Cisco Application Services Engine Hardware Installation Guide

39

Page 46

Replacing a CPU and Heatsink

Replacing a CPU and Heatsink

Maintaining the Server

Caution

CPUs and their sockets are fragile and must be handled with extreme care to avoid damaging pins. The CPUs

must be installed with heatsinks and thermal interface material to ensure cooling. Failure to install a CPU

correctly might result in damage to the server.

Step 1 Remove the existing CPU/heatsink assembly from the server:

a) Shut down and remove power from the server as described in Shutting Down and Removing Power From the Server,

on page 27.

b) Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach

cables from the rear panel to provide clearance.

Caution

If you cannot safely view and access the component, remove the server from the rack.

c) Remove the top cover from the server as described in Removing the Server Top Cover, on page 28.

d) Use the T-30 Torx driver that is supplied with the replacement CPU to loosen the four captive nuts that secure the

assembly to the motherboard standoffs.

Note

Alternate loosening the heatsink nuts evenly so that the heatsink remains level as it is raised. Loosen the

heatsink nuts in the order shown on the heatsink label: 4, 3, 2, 1.

e) Lift straight up on the CPU/heatsink assembly and set it heatsink-down on an antistatic surface.

Cisco Application Services Engine Hardware Installation Guide

40

Page 47

Maintaining the Server

Figure 20: Removing the CPU/Heatsink Assembly

Replacing a CPU and Heatsink

CPU socket on motherboard4Heatsink1

T-30 Torx driver5Heatsink captive nuts (two on each side)2

-CPU carrier (below heatsink in this view)3

Step 2 Separate the heatsink from the CPU assembly (the CPU assembly includes the CPU and the CPU carrier):

a) Place the heatsink with CPU assembly so that it is oriented upside-down as shown below.

Note the thermal-interface material (TIM) breaker location. TIM BREAKER is stamped on the CPU carrier next to

a small slot.

Cisco Application Services Engine Hardware Installation Guide

41

Page 48

Replacing a CPU and Heatsink

Figure 21: Separating the CPU Assembly From the Heatsink

Maintaining the Server

4CPU carrier1

CPU-carrier inner-latch nearest to the TIM

breaker slot

5CPU2

#1 flat-head screwdriver inserted into TIM

breaker slot

-TIM BREAKER slot in CPU carrier3

b) Pinch inward on the CPU-carrier inner-latch that is nearest the TIM breaker slot and then push up to disengage the

clip from its slot in the heatsink corner.

c) Insert the blade of a #1 flat-head screwdriver into the slot marked TIM BREAKER.

Caution

In the following step, do not pry on the CPU surface. Use gentle rotation to lift on the plastic surface of the

CPU carrier at the TIM breaker slot. Use caution to avoid damaging the heatsink surface.

d) Gently rotate the screwdriver to lift up on the CPU until the TIM on the heatsink separates from the CPU.

Note

Do not allow the screwdriver tip to touch or damage the green CPU substrate.

e) Pinch the CPU-carrier inner-latch at the corner opposite the TIM breaker and push up to disengage the clip from its

slot in the heatsink corner.

f) On the remaining two corners of the CPU carrier, gently pry outward on the outer-latches and then lift the

CPU-assembly from the heatsink.

Note

Handle the CPU-assembly by the plastic carrier only. Do not touch the CPU surface. Do not separate the

CPU from the carrier.

Cisco Application Services Engine Hardware Installation Guide

42

Page 49

Maintaining the Server

Replacing a CPU and Heatsink

Step 3 The new CPU assembly is shipped on a CPU assembly tool. Take the new CPU assembly and CPU assembly tool out of

the carton.

If the CPU assembly and CPU assembly tool become separated, note the alignment features shown below for correct

orientation. The pin 1 triangle on the CPU carrier must be aligned with the angled corner on the CPU assembly tool.

Caution

Figure 22: CPU Assembly Tool, CPU Assembly, and Heatsink Alignment Features

CPUs and their sockets are fragile and must be handled with extreme care to avoid damaging pins.

Step 4 Apply new TIM to the heatsink:

Note

The heatsink must have new TIM on the heatsink-to-CPU surface to ensure proper cooling and performance.

4CPU assembly tool1

Angled corner on heatsink (pin 1 alignment

feature)

5CPU assembly (CPU in plastic carrier)2

Triangle cut into carrier (pin 1 alignment

feature)

6Heatsink3

Angled corner on CPU assembly tool (pin 1

alignment feature)

Cisco Application Services Engine Hardware Installation Guide

43

Page 50

Replacing a CPU and Heatsink

• If you are installing a new heatsink, it is shipped with a pre-applied pad of TIM. Go to step 5.

• If you are reusing a heatsink, you must remove the old TIM from the heatsink and then apply new TIM to the CPU

surface from the supplied syringe. Continue with step a below.

a) Apply the cleaning solution that is included with the heatsink cleaning kit (UCSX-HSCK=) to the old TIM on the

heatsink and let it soak for a least 15 seconds.

b) Wipe all of the TIM off the heatsink using the soft cloth that is included with the heatsink cleaning kit. Be careful to

avoid scratching the heatsink surface.

c) Using the syringe of TIM provided with the new CPU (UCS-CPU-TIM=), apply 4 cubic centimeters of thermal

interface material to the top of the CPU. Use the pattern shown below to ensure even coverage.

Figure 23: Thermal Interface Material Application Pattern

Maintaining the Server

Caution

Use only the correct heatsink for your CPUs to ensure proper cooling. There are two different heatsinks:

UCSC-HS-C220M5= for standard-performance CPUs 150 W and less; UCSC-HS2-C220M5= for

high-performance CPUs above 150 W. Note the wattage described on the heatsink label.

Step 5 With the CPU assembly on the CPU assembly tool, set the heatsink onto the CPU assembly. Note the pin 1 alignment

features for correct orientation. Push down gently until you hear the corner clips of the CPU carrier click onto the heatsink

corners.

Caution

In the following step, use extreme care to avoid touching or damaging the CPU contacts or the CPU socket

pins.

Step 6 Install the CPU/heatsink assembly to the server:

a) Lift the heatsink with attached CPU assembly from the CPU assembly tool.

b) Align the CPU with heatsink over the CPU socket on the motherboard, as shown below.

Note the alignment features. The pin 1 angled corner on the heatsink must align with the pin 1 angled corner on the

CPU socket. The CPU-socket posts must align with the guide-holes in the assembly.

Cisco Application Services Engine Hardware Installation Guide

44

Page 51

Maintaining the Server

Figure 24: Installing the Heatsink/CPU Assembly to the CPU Socket

Replacing a CPU and Heatsink

4Guide hole in assembly (two)1

Angled corner on heatsink (pin 1 alignment

feature)

5CPU socket alignment post (two)2

Angled corner on socket (pin 1 alignment

feature)

-CPU socket leaf spring3

c) Set the heatsink with CPU assembly down onto the CPU socket.

d) Use the T-30 Torx driver that is supplied with the replacement CPU to tighten the four captive nuts that secure the

heatsink to the motherboard standoffs.

Caution

Alternate tightening the heatsink nuts evenly so that the heatsink remains level while it is lowered. Tighten

the heatsink nuts in the order shown on the heatsink label: 1, 2, 3, 4. The captive nuts must be fully tightened

so that the leaf springs on the CPU socket lie flat.

e) Replace the top cover to the server.

f) Replace the server in the rack, replace cables, and then fully power on the server by pressing the Power button.

Cisco Application Services Engine Hardware Installation Guide

45

Page 52

Moving an M5 Generation CPU

Moving an M5 Generation CPU

Tool required for this procedure: T-30 Torx driver

Maintaining the Server

Caution

When you receive a replacement server for an RMA, it includes dust covers on all CPU sockets. These covers

protect the socket pins from damage during shipping. You must transfer these covers to the system that you

are returning, as described in this procedure.

Step 1 When moving an M5 CPU to a new server, you do not have to separate the heatsink from the CPU. Perform the following

steps:

a) Use a T-30 Torx driver to loosen the four captive nuts that secure the assembly to the board standoffs.

Note

Alternate loosening the heatsink nuts evenly so that the heatsink remains level as it is raised. Loosen the