Page 1

Quick Reference Guide

QPSK D9494 Demodulator

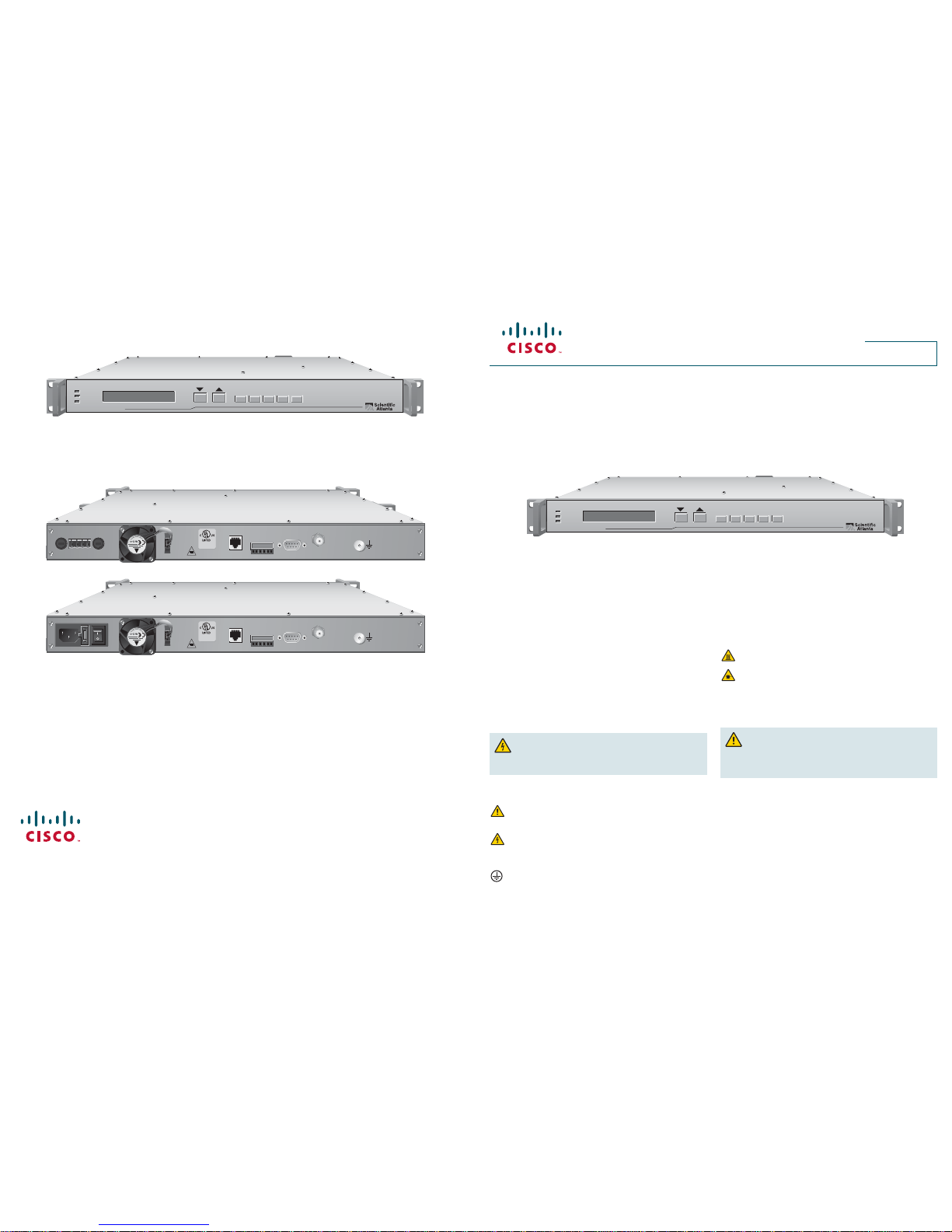

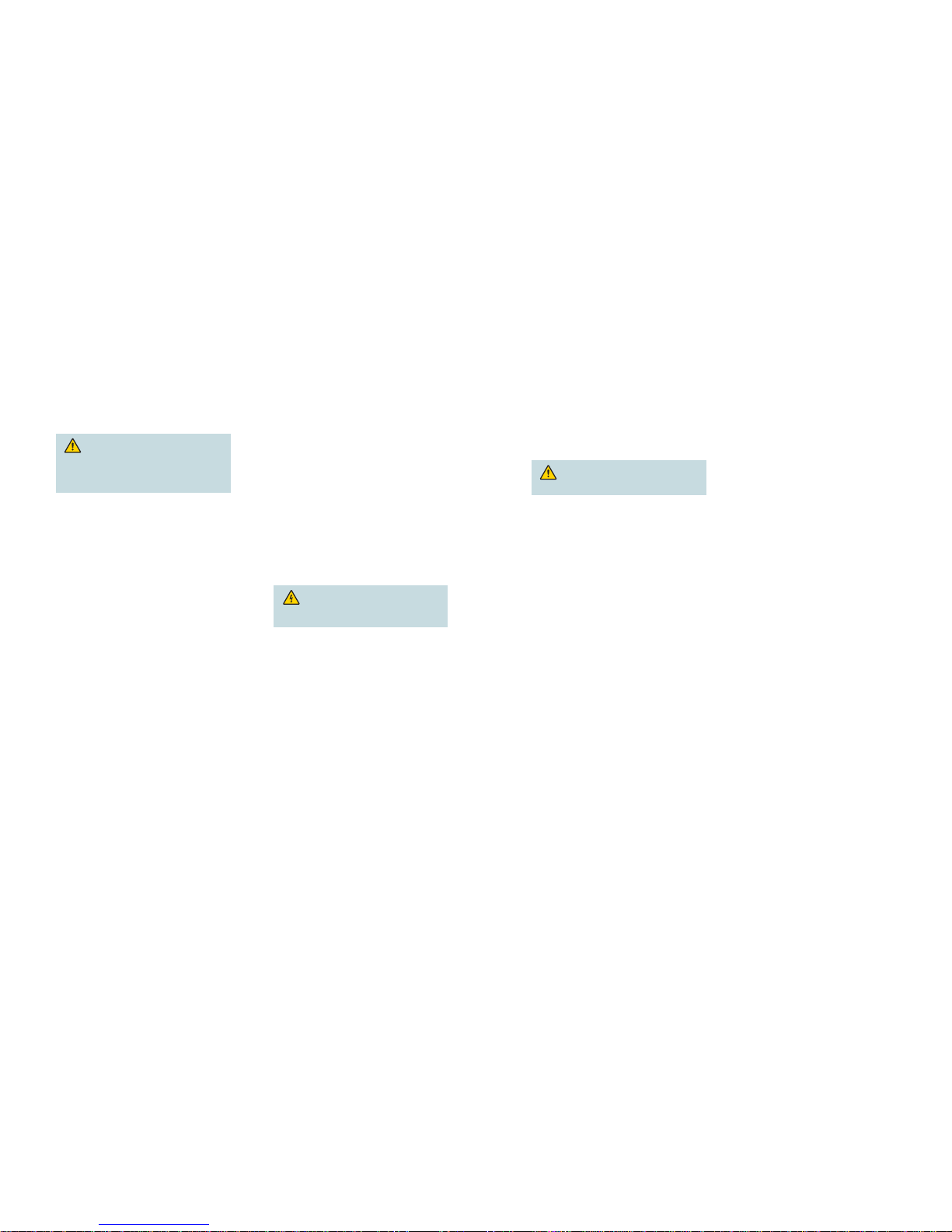

QPSK D9494 Demodulator Front Panel

Use the following diagram to assist you with the installation of the demodulator.

QPSK D9494 Demodulator Back Panels

Use the following diagrams to assist you with the installation of the demodulator, as well as the location of the connection ports.

ALARM

BURST DATA

MAC SYNC

TEST OPTIONSFREQ STATUS ENTER

QPSK Demodulator Model D9494-1

T13607

ALARM

BURST DATA

MAC SYNC

TEST OPTIONSFREQ STATUS ENTER

QPSK Demodulator Model D9494-1

T13608

QPSK D9494 Demodulator (48 VDC Model)

QPSK D9494 Demodulator (100-240 VAC Model)

POWER 120/130V 60/50Hz 2.5A

RF OUT 1 RF OUT 2 RF OUT 3 RF OUT 4

ASI IN 1 ASI IN 2 ASI IN 3 ASI IN 4

DATA 1

CRAFT

PORT

GND

10/100 BASE T

LINK ACTIVE

GIGABIT

ETHERNET

LINKACT

LINKACT

DATA 2

DATA 3

DATA 4

T4H, 250V

T

-A -V

BACKUP MAIN

T2H, 250V

A

FUSE

B

++--

RF INPUT

GND

DIAGNOSTICS

NETWORK

DATA

FUSE

FUSE

FUSE

MAJOR MINOR

NC

CNONC

C

NO

POWER - 48 VDC 24W

FAN

T

-A -V

T2H, 250V

29F9

PROFESSIONAL

VIDEO EQUIPMENT

RF INPUT

GND

DIAGNOSTICS

NETWORK

DATA

MAJOR MINOR

NC

CNONC

C

NO

100-240V ~ 60/50Hz 0.5A POWER

FAN

T

-A -V

T2H, 250V

29F9

PROFESSIONAL

VIDEO EQUIPMENT

Introduction

This quick reference guide is intended for individuals who are responsible

for installing the QPSK D9494 Demodulator into a rack unit.

For more detailed descriptions of the installation process and safety

information for this demodulator, refer to the Model D9494 DAVIC QPSK

Demodulator Installation and Operation Guide (part number 4022032).

Warning and Caution Icons

WARNING: Avoid personal injury and product damage! Do

not proceed beyond any icon until you fully understand the

indicated conditions.

The following icons alert you to important information about the safe

operation of this product.

You will fi nd this icon in the literature that accompanies this product.

This icon indicates important operating or maintenance

instructions.

You may fi nd this icon affi xed to this product and in this document

to alert you of electrical safety hazards. On this product, this icon

indicates a live terminal; the arrowhead points to the terminal

device.

You may fi nd this icon affi xed to this product. This icon indicates a

protective earth terminal.

You may fi nd this icon affi xed to this product. This icon indicates

excessive or dangerous heat.

You may fi nd this symbol affi xed to this product and in this document.

This symbol indicates an infrared laser that transmits intensitymodulated light and emits invisible laser radiation and an LED that

transmits intensity-modulated light.

Controlling the Operating Temperature

CAUTION: The operating temperature for this equipment is

32 to 122°F (0 to 50°C). Avoid damage to this product! Your warranty

is void if you operate this product above or below the maximum

specifi ed operating temperatures.

Measuring the Inlet Air Temperature

If you are concerned about inlet air temperature at the air inlet of any

demodulator, you can measure the inlet air temperature in the rack. When

measuring the temperature, ensure that all cabling is complete and that

all adjacent QPSK demodulators are installed and running.

Important: Opening the door on the back panel of the rack may have an

adverse effect on the managed airfl ow. If access to the door is not controlled,

measure the inlet air temperature with the back panel door open because

this typically redirects the airfl ow in an adverse manner.

Cisco Systems, Inc. 678 277-1120

5030 Sugarloaf Parkway, Box 465447

Lawrenceville, GA 30042 www.FLVFRcom

Cisco and the Cisco logo are registered trademarks or trademarks of Cisco and/or its aff liates in the U.S. and certain other

countries. To view a list of Cisco trademarks, go to this URL: www.cisco.com/go/trademarks

Third party trademarks mentioned are the property of their respective owners.The use of the word partner does not imply a

partnership relationship between Cisco and any other company. (1110R)

Product and service availability subject to change without notice.

© 2008,2012 Cisco Systems, Inc. All rights reserved. Printed in United States of America

September 2012 Part Number 78-4022033-01 Rev B

FINAL

Page 2

Installation and Connections

Complete steps 1 through 10 to install and connect the demodulator

into the rack unit.

Important: See the back page of this guide to view the front and

back panels of the QPSK demodulator.

1 Install the QPSK Demodulator

into a Rack

CAUTION:

• Do not to tangle or strain interconnecting cables.

• Be sure to install additional support.

• Do not stack more than eight demodulators

consecutively in the rack.

A. Unpack and inspect the demodulator.

B. Install the angle support brackets (part numbers

734845 and 734846) supplied with the demodulator.

C. Place the demodulator into the rack.

D. Insert a mounting screw through each of the four bezel

mounting holes on the front panel of the demodulator

and then into the rack.

E. Firmly tighten each mounting screw.

Important: When you use the supplied angle support

brackets, you can install the QPSK demodulators above

or below each other in the rack. These brackets provide

additional support and allow correct air circulation through

the unit.

2 Connect the Network Data Port

The Network Data port provides two-way data fl ow with

the QPSK modulator. The two-way data includes status

monitoring and control (SMC) responses, application data,

MAC Status, and SMC provisioning requests.

Use a shielded, CAT-5 Ethernet interconnect cable to

connect the Network Data ATM-25 port on the demodulator

to the modulator.

Note: The demodulator interface on the QPSK modulator

is designed to connect to up to eight QPSK demodulators.

3 Connect the Diagnostics Port

The diagnostic port connects the demodulator to a

diagnostic PC. This port is not designed to be connected

for normal operation.

A. Connect the male end of a DB-9 data cable to the

Diagnostics (craft) port on the back of the demodulator.

B. Connect the other end of a DB-9 data cable to an

available serial port on the diagnostic PC.

Note: To maintain signal clarity and strength, use a

ribbon cable no longer than 50 ft.

C. Power on the PC and activate a ProComm or

HyperTerminal window using the following modem

connection settings:

• 19200 baud

• 1 stop bit

• No parity

• 8 data bits

• No fl ow control

4 Connect the Alarm Relays

(Optional)

A. If connected, disconnect the power wires from the

power supply, or power off the unit.

WARNING: Avoid electric shock when

disconnecting the power supply. Only a qualifi ed

electrician should disconnect the power supply.

B. Determine whether the indicator trips (activates) on an

open or closed circuit (usually the external alarm has

this information).

• A simple indicator (for example, an alarm based on

a battery and beeper) would trip on a closed circuit

(use the NO and COM terminals)

• A more complex indicator (for example, a

commercial alarm system) would trip on an open

circuit (use the NC and COM terminals)

Notes:

• The alarm connections power base ratio is 2 A

at 50 V.

• The alarm connector uses a screw-cage clamp

plug with mating jack on the demodulator. The plug

accepts wire from 16 to 28 AWG.

C. Insert an indicator wire into the NO, the NC, or the

COM plug screw-cage clamp (see step B in this

section for determining which terminals to use).

Note: Make sure the screw-cage clamp closes on the

bare wire, not on the insulation.

D. Use a small slotted screwdriver to tighten the screw-

cage clamp screw.

E. Repeat steps C and D of this section for additional

connections, as needed.

F. Connect the power to the power supply.

5 Connect the RF Input Port

The RF Input port connects the demodulator to the HFC

network and to set-tops.

A. Connect one end of a 75 Ω RG-59 coaxial cable to the

RF Input port.

B. Connect the other end of the 75 Ω RG-59 coaxial

cable to an RF signal splitter in the distribution plant

(headend).

6 Connect an Earth Ground

CAUTION: The 48 VDC devices must be

connected to an earth ground.

A. Place a ground wire onto the ground lug (marked GND)

on the back of the demodulator; then, use your fi ngers

to tighten the ground lug to secure the ground wire.

B. Connect the other end of the ground wire to the rack or

earth ground.

7 Connect the Power Source

48 VDC Model

A. Verify that the DC power source to the 48 VDC model

is set to the Off position.

B. Insert the wires from the DC power source into the

screw-cage clamp. Use a small fl at-blade screwdriver

to tighten the screws at the top of the screw-cage

clamp to secure the wires.

C. Insert the plug into the mating jack on the back panel

of the demodulator.

D. Keep the DC power source set to the Off position until

you are ready to power on the demodulator.

100-240 VAC Model

A. Verify that the power switch on the back panel of the

100-240 VAC model is set to the Off position.

B. Connect the power cord to the AC power inlet on the

back panel of the demodulator.

C. Connect the other end of the power cord to an AC

electrical outlet.

D. Keep the power switch set to the Off position until you

are ready to power on the demodulator.

8 Install the Demodulator Software

For detailed information about installing the software, refer

to the QPSK Demodulator Software Installation Instructions

(part number 4022031).

9 Provision the QPSK Demodulator

on the DNCS

After you have installed and connected the QPSK

demodulator, you must provision the QPSK demodulator

on the DNCS. For detailed instructions on how to

provision the QPSK demodulator on the DNCS, refer

to the DNCS Online Help for your system release.

10 Power On the Demodulator

After you have installed, connected, and provisioned the

QPSK demodulator, power on the demodulator. The

QPSK modulator manages the QPSK demodulator, and

provides the provisioning information from the DNCS to

the demodulator after the demodulator is powered on.

FINAL

Loading...

Loading...