Page 1

ASR 5500 Installation Guide

Last updated December 19, 2014

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL

STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED

WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED

WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public domain

version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS” WITH ALL

FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE

PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING,

WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR

ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Cisco and the Cisco Logo are trademarks of Cisco Systems, Inc. and/or its affiliates in the U.S. and other countries. A listing of Cisco's trademarks can be found at

www.cisco.com/go/trademarks. Third party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership relationship

between Cisco and any other company.

Any I nternet P rotocol (IP) addresses and pho ne numbers used in this docume nt ar e not intende d to be actua l add resses a nd phone numbe rs. Any examples, command display

output, ne twork top ology dia grams, a nd other figures included in the document are shown for illust rative purposes only. Any use of actual IP addresses or phone numbers in

illustrative content is unintent ional and coincide ntal.

ASR 5500 Installation Guide

© 2014 Cisco Systems, Inc. All rights reserved.

Page 3

ASR 5500 Installation Guide ▄

iii

CONTENTS

About this Guide ................................................................................................ ix

Conventions Used .................................................................................................................................... x

Dimensions ............................................................................................................................................... x

Supported Documents and Resources ....................................................................................................xi

Related Documentation ....................................................................................................................... xi

Obtaining Documentation .................................................................................................................... xi

Contacting Customer Support ..................................................................................................................xi

ASR 5500 Hardware Platform Overview ......................................................... 13

Chassis ................................................................................................................................................... 14

Power ................................................................................................................................................. 14

Cooling ............................................................................................................................................... 15

Slot Numbering ................................................................................................................................... 15

Power Filter Units (PFUs) .................................................................................................................. 16

Cable Management System ............................................................................................................... 16

Midplane ................................................................................................................................................. 17

Card Types ............................................................................................................................................. 18

Rear Cards ......................................................................................................................................... 20

Management I/O ............................................................................................................................ 20

Data Processing Card .................................................................................................................... 21

Front Cards ........................................................................................................................................ 21

Fabric and Storage Card (FSC) ..................................................................................................... 21

System Status Card (SSC) ............................................................................................................ 22

LED Indicators ........................................................................................................................................ 23

LED Indicators Common to All Cards ................................................................................................ 23

LED Indicators on Specific Cards ...................................................................................................... 23

Technical Specifications .................................................................................. 25

Physical Dimensions .............................................................................................................................. 26

Environmental Specifications ................................................................................................................. 27

Environmental Parameters ................................................................................................................. 27

Environmental Standards ................................................................................................................... 28

Chassis Air Flow ................................................................................................................................. 29

Clearance ........................................................................................................................................... 30

Mounting Requirements ......................................................................................................................... 31

Power Requirements .............................................................................................................................. 32

Central Office Alarm Interface ................................................................................................................ 33

Chassis Grounding ................................................................................................................................. 33

Installation Procedure Overview ..................................................................... 35

Installation Sequence ............................................................................................................................. 36

Required Tools and Equipment .............................................................................................................. 37

Hand Tools ......................................................................................................................................... 37

Equipment .......................................................................................................................................... 37

Site Prerequisites ................................................................................................................................... 38

Power and Grounding ........................................................................................................................ 38

Environment ....................................................................................................................................... 38

Clearance ........................................................................................................................................... 38

Page 4

▀ Contents

▄ ASR 5500 Installation Guide

iv

ESD Precautions .................................................................................................................................... 39

Standards Compliance ........................................................................................................................... 40

FCC Warning ...................................................................................................................................... 40

ICS Notice .......................................................................................................................................... 40

Laser Notice ....................................................................................................................................... 40

Chassis Installation .......................................................................................... 41

Mounting Options .................................................................................................................................... 42

Weight Considerations ............................................................................................................................ 42

Unpacking the Chassis ........................................................................................................................... 43

Move the Container to the Installation Site......................................................................................... 43

Unpack the Chassis ............................................................................................................................ 44

Reducing the Weight of the Chassis Prior to Installation ....................................................................... 46

Removing the Fan Trays .................................................................................................................... 47

Remove the Upper Front Fan Tray ................................................................................................ 47

Remove the Lower Front Fan Tray ................................................................................................ 48

Remove the Upper Rear Fan Tray ................................................................................................. 48

Remove the Lower Rear Fan Tray ................................................................................................. 49

Removing the PFUs ........................................................................................................................... 50

Installing the Chassis .............................................................................................................................. 51

Mounting the Chassis ......................................................................................................................... 52

Flush Mount ................................................................................................................................... 52

Mid Mount....................................................................................................................................... 53

Grounding the Chassis ........................................................................................................................... 54

Ground Cabling .................................................................................................................................. 54

Grounding Procedure ......................................................................................................................... 55

Re-Installing Chassis Components ........................................................................................................ 57

Re-install the PFUs ............................................................................................................................. 57

Re-install the Front Fan Trays ............................................................................................................ 57

Lower Front Fan Tray ..................................................................................................................... 57

Upper Front Fan Tray ..................................................................................................................... 57

Re-install the Rear Fan Trays ............................................................................................................ 58

Lower Rear Fan Tray ..................................................................................................................... 58

Upper Rear Fan Tray ..................................................................................................................... 58

Re-install the Chassis Cover Panels .................................................................................................. 58

Front of Chassis ............................................................................................................................. 58

Rear of Chassis .............................................................................................................................. 58

Cable Management System ................................................................................................................... 59

Card Installation ................................................................................................ 61

Card Slot Assignments ........................................................................................................................... 62

Installing Cards ....................................................................................................................................... 63

Card Interlock Switch .......................................................................................................................... 63

Card Installation Procedure ................................................................................................................ 64

Baffle Cards ............................................................................................................................................ 67

Installing a Front Baffle Card .............................................................................................................. 68

Installing a Rear Baffle Card .............................................................................................................. 68

Save Shipping Cartons ........................................................................................................................... 68

MIO Port Cabling ............................................................................................... 69

Interface Ports ........................................................................................................................................ 70

Card Ports .......................................................................................................................................... 70

Daughter Card Ports ........................................................................................................................... 70

Cable Management System ................................................................................................................... 70

Console Port ........................................................................................................................................... 72

Page 5

Contents ▀

ASR 5500 Installation Guide ▄

v

RJ45 Port Pinouts .............................................................................................................................. 72

RJ45 to DB9 Adapter ......................................................................................................................... 73

Connect Console Port to Workstation ................................................................................................ 73

Connect Console Port to Terminal Server ......................................................................................... 74

Ethernet Management Ports .................................................................................................................. 75

RJ45 Port Pinouts .............................................................................................................................. 75

Port Status LEDs ................................................................................................................................ 76

Connect 1000Base-T Interface to Network Device ............................................................................ 76

10 GbE Optical Daughter Card Ports ..................................................................................................... 77

Fiber Optical Connections ...................................................................................................................... 78

Removing Dust Plugs ......................................................................................................................... 78

Connecting Fiber Optic Cables .......................................................................................................... 78

SSC Alarm Cabling ........................................................................................... 79

CO Alarm Interface ................................................................................................................................. 80

Alarm Cutoff (ACO) ................................................................................................................................ 81

Alarm Connector Pinout ......................................................................................................................... 82

Electrical Characteristics ........................................................................................................................ 82

CO Alarm Wiring Example ...................................................................................................................... 83

Power Cabling ................................................................................................... 85

Power Considerations ............................................................................................................................ 86

Internal Power Planes ............................................................................................................................ 87

Chassis Power Card Slot Allocations ................................................................................................. 87

Power Feed Connections ................................................................................................................... 89

Power Cable Requirements.................................................................................................................... 90

Sizing Power Cables .......................................................................................................................... 90

Terminating Power Cables ................................................................................................................. 90

Cable Routing ................................................................................................................................ 90

Method of Connection .................................................................................................................... 90

Insulate Lugs .................................................................................................................................. 90

Crimp Lugs on Cables ................................................................................................................... 90

Label All Cable ............................................................................................................................... 90

Connect Power Feeds to the PFUs ........................................................................................................ 91

System Power-up .............................................................................................. 95

System Boot Process ............................................................................................................................. 96

Applying Power to the Chassis ............................................................................................................... 97

Verifying System Startup ........................................................................................................................ 98

Checking PFU Status ......................................................................................................................... 98

Checking Status LEDs on MIOs ......................................................................................................... 98

Checking Status LEDs on DPCs or UDPCs .................................................................................... 101

Checking Status LEDs on FSCs ...................................................................................................... 102

Checking Status LEDs on SSC ........................................................................................................ 103

show leds Command ........................................................................................................................ 104

Initial System Configuration .......................................................................... 105

Basic Configuration .............................................................................................................................. 106

Context-level Security Administrator and Hostname ............................................................................ 107

MIO/UMIO Port Numbering .................................................................................................................. 109

Configure the Ethernet Management Interface .................................................................................... 110

IP Address Notation ......................................................................................................................... 110

IPv4 Dotted-Decimal Notation ..................................................................................................... 110

IPv6 Colon-Separated-Hexadecimal Notation ............................................................................. 110

Configuring the Ethernet Management Interface ............................................................................. 111

Configuring the Management Interface with a Second IP Address ................................................. 113

Page 6

▀ Contents

▄ ASR 5500 Installation Guide

vi

Configure the System for Remote Access ............................................................................................ 115

Set System Timing ................................................................................................................................ 117

Setting the System Clock and Time Zone ........................................................................................ 117

Configuring Network Time Protocol Support .................................................................................... 117

Overview of NTP Support ............................................................................................................ 117

Basic NTP Configuration .............................................................................................................. 118

Configuring NTP Servers with Local Sources .............................................................................. 118

Using a Load Balancer ................................................................................................................. 119

Verifying the NTP Configuration .................................................................................................. 119

Enable CLI Timestamping .................................................................................................................... 120

Save the Basic Configuration ............................................................................................................... 120

Additional Configuration Tasks ............................................................................................................. 120

Replaceable Components .............................................................................. 121

Air Filters ............................................................................................................................................... 122

Determining When an Air Filter Needs Replacing ............................................................................ 122

High Operating Temperatures and Fan Speeds .......................................................................... 122

Temperature and Fan Alarm Commands .................................................................................... 122

Replacing an Air Filter ...................................................................................................................... 124

Front Air Filter .............................................................................................................................. 124

Rear Air Filter ............................................................................................................................... 126

Fan Tray Units ...................................................................................................................................... 128

Determining Whether a Fan Tray Unit Needs Replacing ................................................................. 128

Replacing Front Fan Trays ............................................................................................................... 128

Replace the Upper Fan Tray ........................................................................................................ 128

Replace the Lower Fan Tray ........................................................................................................ 130

Replacing Rear Fan Trays ............................................................................................................... 130

Replace the Upper Fan Tray ........................................................................................................ 130

Replace the Lower Fan Tray ........................................................................................................ 131

PFU ....................................................................................................................................................... 133

Determining that a PFU has Failed .................................................................................................. 133

Replacing a PFU .............................................................................................................................. 133

Circuit Cards ......................................................................................................................................... 136

Determining Whether a Card has Failed .......................................................................................... 136

show card diag Command ........................................................................................................... 136

SNMP Traps ................................................................................................................................. 138

Replacement UMIOs and UDPCs .................................................................................................... 138

Backing Up the System Configuration .............................................................................................. 138

Synchronize File System .................................................................................................................. 138

Replacing a Failed Card ................................................................................................................... 139

Remove I/O Connections (MIO/UMIO and SSC) ......................................................................... 139

Remove and Replace the Circuit Card ........................................................................................ 140

Swapping the SDHC Memory Card between MIO/UMIO Cards .................................................. 142

Returning Failed Components .............................................................................................................. 143

Spare Component Recommendations.......................................................... 145

Chassis, UMIO and UDPC License Requirements ...................................... 147

License Types ....................................................................................................................................... 148

StarOS License Support Matrices ........................................................................................................ 149

Cable Management System Installation ....................................................... 151

Introduction ........................................................................................................................................... 152

Installing the Cable Management Tray ................................................................................................. 152

Removing Cable Guides ....................................................................................................................... 155

Installing the Cable Management Bracket on an MIO or UMIO Card .................................................. 156

Page 7

Contents ▀

ASR 5500 Installation Guide ▄

vii

Routing and Securing Network Cables ................................................................................................ 158

CMS Procedure for Replacing ASR 5500 Circuit Cards ...................................................................... 161

Lowering the Cable Management Tray ............................................................................................ 161

Detaching Network Cables from an MIO or UMIO Bracket.............................................................. 161

Reconnecting Network Cables to an MIO or UMIO Bracket ............................................................ 161

Raising the Cable Management Tray ............................................................................................... 162

Console Port to Cisco Server Cabling .......................................................... 163

Introduction ........................................................................................................................................... 164

Cabling.................................................................................................................................................. 165

Configuration ........................................................................................................................................ 167

RMA Shipping Procedures............................................................................. 169

RMA Overview ...................................................................................................................................... 170

Re-packaging Your RMA ................................................................................................................. 170

Shipping Multiple Components ........................................................................................................ 170

Sealing the Shipment ....................................................................................................................... 171

Labeling the Shipment...................................................................................................................... 171

Cisco Return Locations .................................................................................................................... 171

Packaging ASR 5500 Cards ................................................................................................................. 172

Front Cards ...................................................................................................................................... 172

Rear Cards ....................................................................................................................................... 173

Page 8

Page 9

ASR 5500 Installation Guide ▄

ix

About this Guide

This Installation Guide pertains to the features and functionality that run on and/or that are associated with the Cisco®

ASR 5500 platform.

It describes how to unpack, install and initially configure the system. This guide also includes technical specifications

and guidelines for monitoring system operation.

Page 10

About this Guide

▀ Conventions Used

▄ ASR 5500 Installation Guide

x

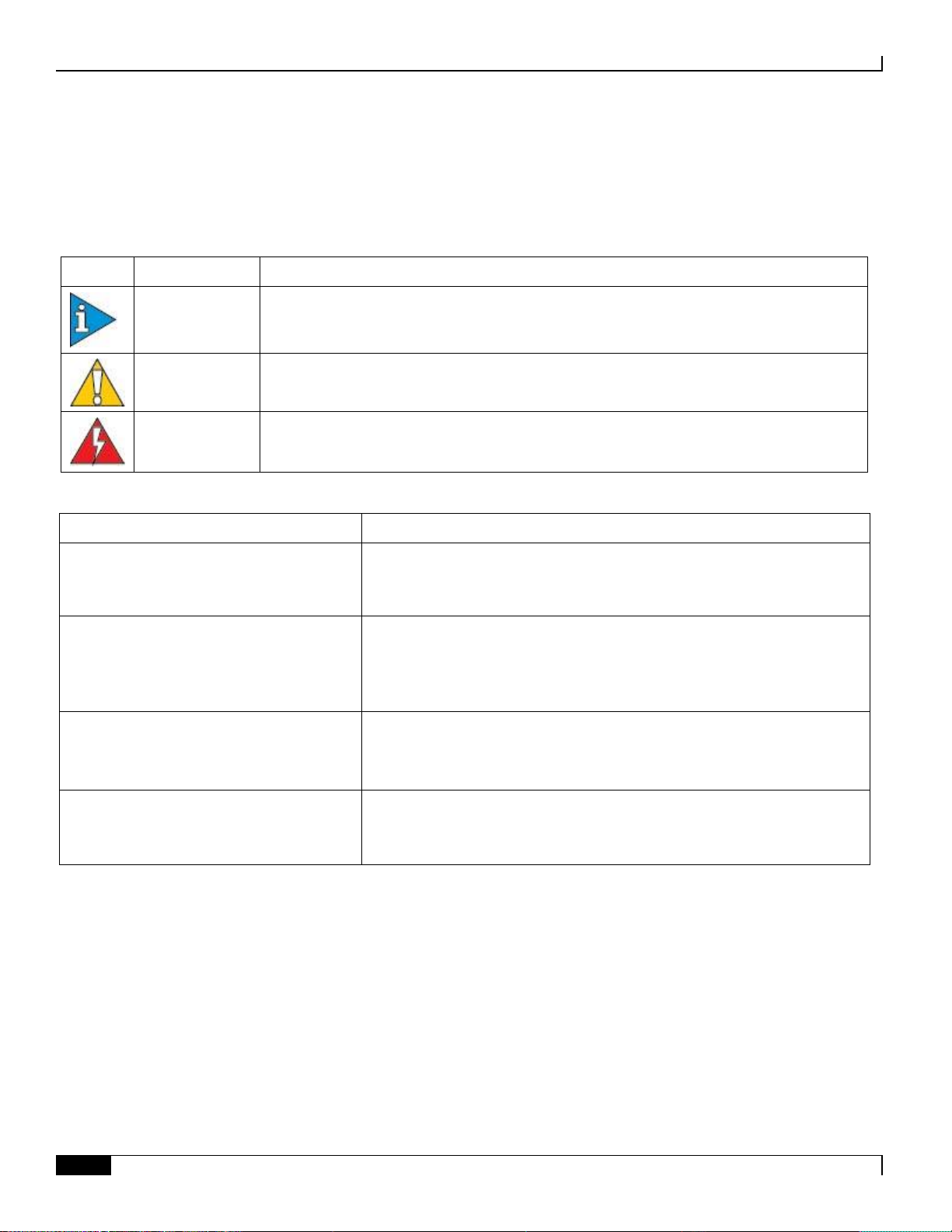

Conventions Used

Icon

Notice Type

Description

Information Note

Provides information about important features or instructions.

Caution

Alerts you of potential damage to a program, device, or system.

Warning

Alerts you of potential personal injury or fatality. May also alert you of potential electrical

hazards.

Typeface Conventions

Description

Text represented as a screen display

This typeface represents displays that appear on your terminal screen, for

example:

Login:

Text represented as commands

This typeface represents commands that you enter, for example:

show ip access-list

This document always gives the full form of a command in lowercase letters.

Commands are not case sensitive.

Text represented as a command variable

This typeface represents a variable that is part of a command, for example:

show card slot_number

slot_number is a variable representing the desired chassis slot number.

Text represented as menu or sub-menu names

This typeface represents menus and sub-menus that you access within a

software application, for example:

Click the File menu, then click New

The following tables describe the conventions used throughout this documentation.

Dimensions

Dimensions such as size, weight and temperature are first presented in their primary measurements (imperial or metric)

followed by the converted measurement (metric or imperial) in parentheses.

Page 11

About this Guide

Supported Documents and Resources ▀

ASR 5500 Installation Guide ▄

xi

Supported Documents and Resources

Related Documentation

The most up-to-date information for this product is available in the product Release Notes provided with each product

release.

The following documents are available:

ASR 5500 Installation Guide

Command Line Interface Reference

SNMP MIB Reference

Statistics and Counters Reference

Thresholding Configuration Guide

WEM Installation and Administration Guide

Product-specific and feature-specific Administration guides

Obtaining Documentation

The most current Cisco documentation is available on the following website:

http://www.cisco.com/cisco/web/psa/default.html

Use the following path selections to access the ASR 5000 documentation:

Products > Wireless > Mobile Internet> Network Functions

Contacting Customer Support

Use the information in this section to contact customer support.

Refer to the support area of http://www.cisco.com for up-to-date product documentation or to submit a service request.

A valid username and password are required to access this site. Please contact your Cisco sales or service representative

for additional information.

Page 12

Page 13

ASR 5500 Installation Guide ▄

13

Chapter 1

ASR 5500 Hardware Platform Overview

This chapter describes the hardware components that comprise the ASR 5500 chassis. The ASR 5500 is designed to

provide subscriber management services for high-capacity 4G wireless networks.

This chapter includes the following sections:

Chassis

Midplane

Card Types

LED Indicators

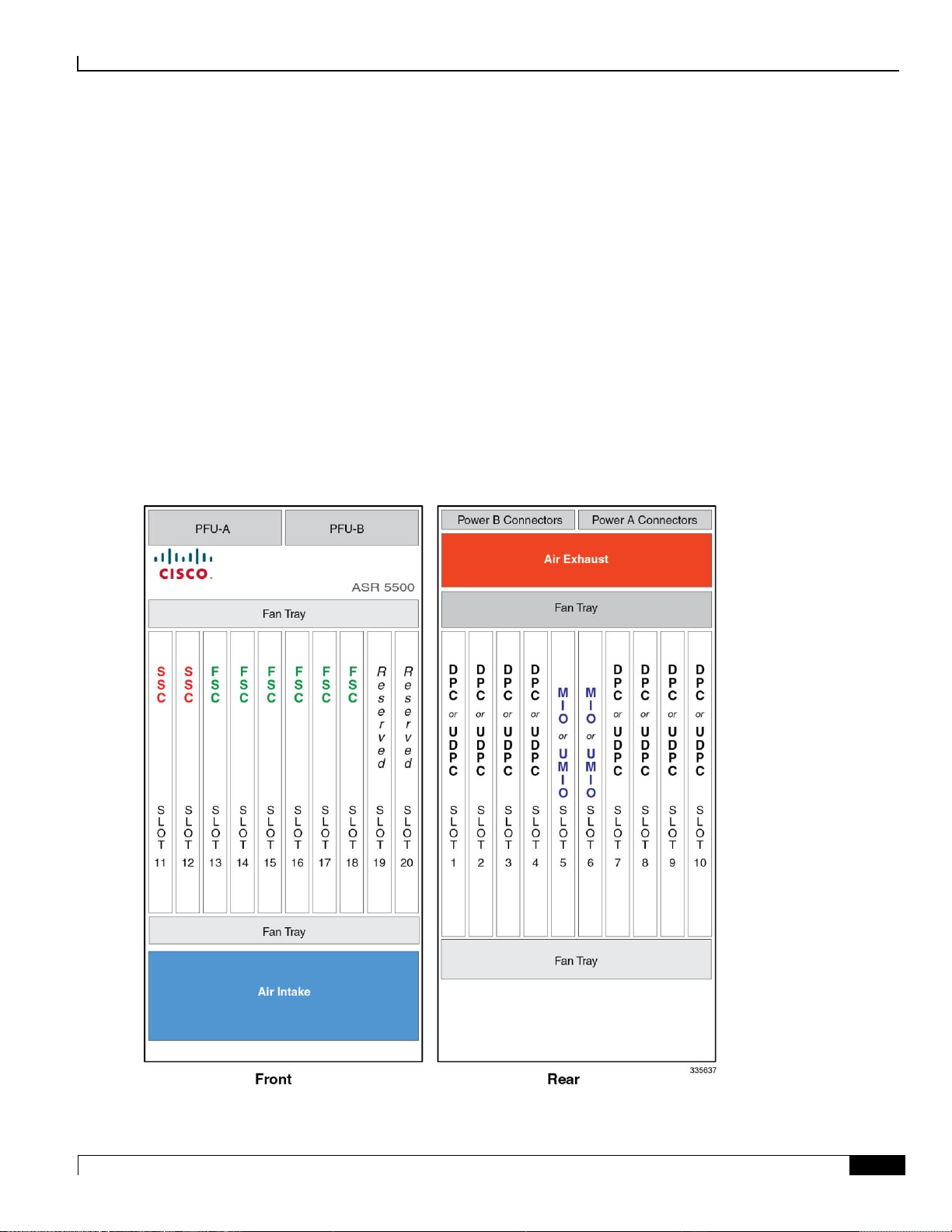

Figure 1. The ASR5500

Page 14

ASR 5500 Hardware Platform Overview

▀ Chassis

▄ ASR 5500 Installation Guide

14

Chassis

The ASR 5500 is a 21RU, 19" rack-mount midplane-based chassis with input/output (I/O) and processing cards in the

rear, and fabric cards in the front. Two ASR 5500 chassis fit into 42RU of rack space. However, the typical deployment

will be a single chassis per rack with other equipment in the same rack.

The rear cards are larger and used for chassis management, I/O and session processing. The smaller front cards are used

for fabric crossbars and persistent storage. There are 10 slots at the front and rear of the chassis.

The rear slots have a common midplane connector that is shared between the supported cards. This allows for different

mixes of I/O and processing capacity depending on the customer's intended use.

The chassis can be flush-mounted or mid-mounted in a rack or equipment cabinet.

Figure 2. Front and Rear Views of the ASR 5500 Chassis

Power

The chassis accepts up to eight 80-amp, -48 VDC power feeds across redundant power filter units (PFUs). The

connections are made at the top-rear of the chassis. The front-mounted PFUs incorporate separate circuit breakers for

each power feed.

Page 15

ASR 5500 Hardware Platform Overview

Chassis ▀

ASR 5500 Installation Guide ▄

15

Cooling

The ASR 5500 uses two types of fan tray units and a total of four fan trays per chassis – two front fan trays and two rear

fan trays. Air is drawn from the front and sides of the chassis and exhausted out the top rear and sides. Two fan trays are

mounted at the bottom of the chassis with another two at the top. The bottom fan trays incorporate replaceable

particulate air filters.

Slot Numbering

The rear slots are numbered 1 through 10 with slots 5 and 6 used for the chassis management cards. The front slots are

numbered 11 through 20. Lower slot numbers begin at the left side. There are no direct relationships between front and

rear cards.

The figure below shows the slot numbering sequence and the general layout of other components in the ASR 5500

chassis.

Figure 3. ASR 5500 Slot Numbering

Page 16

ASR 5500 Hardware Platform Overview

▀ Chassis

▄ ASR 5500 Installation Guide

16

Power Filter Units (PFUs)

Two PFUs mount at the top front of the chassis. Each PFU supports four power planes.

A total of eight -48 VDC, 80-amp power feeds are required for a full chassis. The eight feeds operate in a 4+4 redundant

configuration. In lab environments where power redundancy is not required, four 80 A lines can be used.

Cable Management System

The ASR 5500 cable management system consists of two components. The first is a tray that mounts at the rea r of the

chassis immediately below the card cage. The second is a cable management bracket that mounts to the front panel of

each Management Input/Output (MIO) or Management Input/Output Universal (UMIO) card.

Network cables are fed from either side or both sides of the tray and are then routed to the MIO/UMIO ports. The cables

are secured to the cable management brackets on the MIO/UMIOs via cable ties or hook-and-loop straps, and within the

cable management tray via hook-and-loop straps.

Page 17

ASR 5500 Hardware Platform Overview

Midplane ▀

ASR 5500 Installation Guide ▄

17

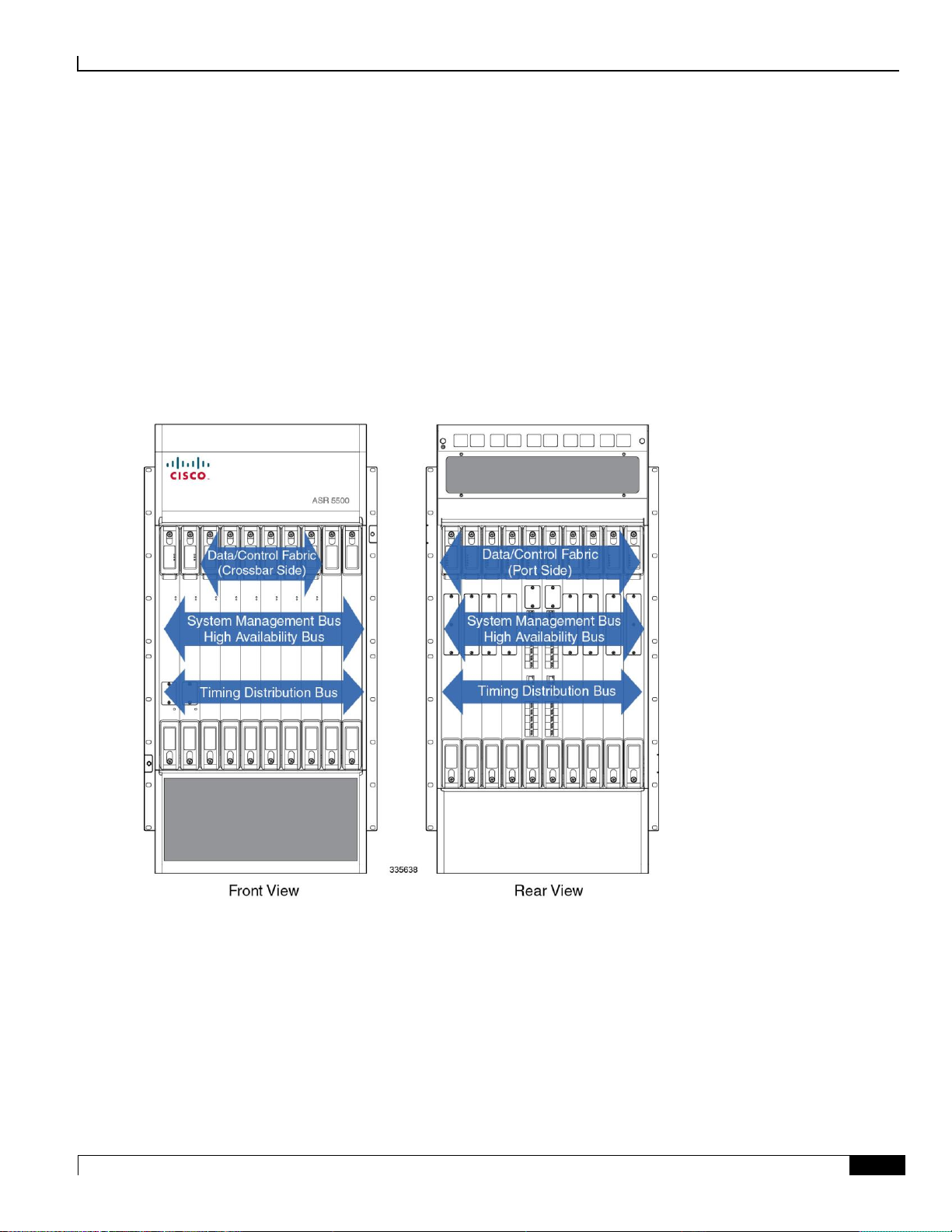

Midplane

The midplane within the ASR 5500 chassis interconnects rear input/output ports and processing cards with front fabric

cards. The larger rear cards support chassis management, input/output, and session processing. The smaller front cards

provide fabric crossbars, persistent storage and system status monitoring.

The rear slots have a common midplane connector that is shared between the supported cards. This allows for different

mixes of input/output and processing capacity depending on the customer's intended use. The two MIO or UMIO slots

(5 and 6) have additional midplane connections to perform chassis control operations, including support for a serial

Console port and dual remote management ports.

Figure 4. ASR 5500 Midplane Buses

Page 18

ASR 5500 Hardware Platform Overview

▀ Card Types

▄ ASR 5500 Installation Guide

18

Card Types

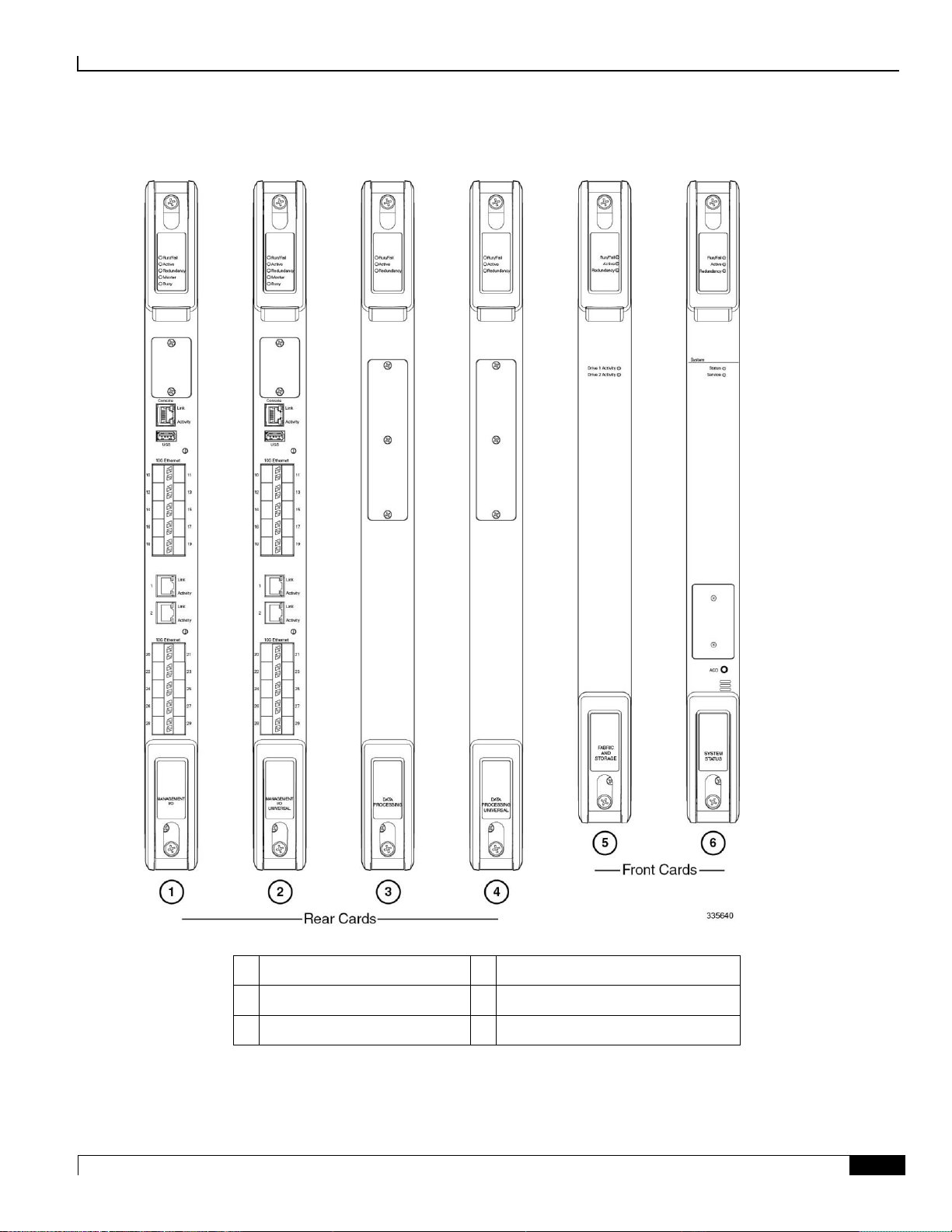

The ASR 5500 supports rear cards and front cards. Rear cards are larger and perform node management, packet

processing and I/O functions (traffic sources). Front cards determine the amount of bandwidth for the switching fabric

(crossbars), and indicate the operating and alarm status of the ASR 5500. The figure below is a simplified block diagram

showing the ASR 5500 card architecture.

Figure 5. Block Diagram of Card Architecture

Page 19

ASR 5500 Hardware Platform Overview

Card Types ▀

ASR 5500 Installation Guide ▄

19

Figure 6. ASR 5500 Circuit Cards

1

Management I/O (MIO)

2

Management I/O Universal (UMIO)

3

Data Processing Card (DPC)

4

Data Processing Universal (UDPC)

5

Fabric and Storage Card (FSC)

6

System Status Card (SSC)

Page 20

ASR 5500 Hardware Platform Overview

▀ Card Types

▄ ASR 5500 Installation Guide

20

Rear Cards

The ASR 5500 supports four types of rear-mounted cards:

Management I/O Card (MIO) or Management I/O Universal Card (UMIO) [two per system]

Data Processing Card (DPC) or Data Processing Universal Card (UDPC) [up to eight per system]

The ARS 5500 supports ten rear cards, a mix of MIOs, UMIOs, DPCs and/or UDPCs. Each card is interconnected with

the others via the switching fabric.

Important: UMIO cards and UDPCs are direct replacements for MIO cards and DPCs. However, a special

Universal PID license must be purchased and installed on the chassis for each installed UMIO and UDPC. Contact your

Cisco account representative for additional information.

Management I/O

The ASR 5500 chassis supports two MIO and/or UMIO cards placed in the rear facing slots of the chassis. These cards

perform chassis management, as well as local context and non-local context external I/O operations.

Important: The MIO/UMIO cards automatically implement 1:1 port redundancy (active/standby). Ports are 1:1

redundant across slots 5 and 6. For example, port 10 on the MIO in slot 5 is redundant with port 10 on the MIO in slot 6.

Each MIO/UMIO has:

One CPU subsystem with 96 GB of RAM

Four NPU subsystems

The two 1000Base-T (1GbE) ports on MIO/UMIO cards can only be used for local context (OAM). An MIO/UMIO

includes support for:

Midplane connections for chassis control operations

SAS storage controller for FSC solid state drives (SSDs)

RS-232 serial console (RJ45) for CLI management

USB port for an external flash device

32 GB SDHC internal flash device

MIO/UMIO cards support two daughter card (DCs) for external I/O interfaces (100 Gbps aggregate per DC). The

optical ports on the daughter cards can only be used for non-local context. The currently available DC supports ten 10

GbE interfaces. The interface ports accept SFP+ SR and LR transceivers.

Important: MIO/UMIO daughter cards are not user installable or replaceable.

Important: MIO/UMIO cards are shipped with SFP+ SR or LR transceivers installed.

Page 21

ASR 5500 Hardware Platform Overview

Card Types ▀

ASR 5500 Installation Guide ▄

21

Data Processing Card

The ASR 5500 chassis supports multiple DPCs and/or UDPCs in the rear facing slots of the chassis.

The DPC/UDPC has two identical CPU subsystems with each containing:

96 GB of RAM

NPU for session data flow offload

Crypto offload engines located on a daughter card

DPC/UDPCs manage subscriber sessions and control traffic.

Front Cards

The ASR 5500 supports two types of front-mounted cards:

Fabric and Storage Card (FSC)

System Status Card (SSC)

The crossbars that comprise the switching fabric are on the FSCs. The ASR 5500 supports multiple FSCs. Each FSC

provides six physical fabric planes. When fully populated, there are 24 fabric planes in the system. A physical fabric

plane provides full-mesh connectivity between all traffic sources.

Fabric and Storage Card (FSC)

The ASR 5500 chassis supports multiple FSCs in front facing slots of the chassis.

The FSC features:

Fabric cross-bars providing in aggregate:

120 Gbps full-duplex fabric connection to each MIO/UMIO

60 Gbps full-duplex fabric connection to each DPC/UDPC

Two 2.5" serial attached SCSI (SAS), 200GB solid state drives (SSDs) with a 6 Gbps SAS connection to each

MIO/UMIO.

Every FSC adds to the available fabric bandwidth to each card. Each FSC connects to all MIO/UMIOs or DPC/UDPCs,

with a varying number of links depending on the MIO/UMIO or DPC/UDPC slot. Three FSCs provide sufficient

bandwidth while the fourth FSC supports redundancy.

Important: Although four FSCs are required for redundancy, the system can operate with three FSCs in the

presence of a fourth failed FSC. Four FSCs must be installed for normal operation.

Important: The SSDs are not field replaceable units (FRUs). If an SSD fails the FSC must be replaced.

The ASR 5500 uses an array of solid state drives (SSDs) for short-term persistent storage. The RAID 05 configuration

has each pair of drives on an FSC striped into a RAID 0 array; all the arrays are then grouped into a RAID 5 array. Each

FSC provides the storage for one quarter of the RAID 5 array. Data is striped across all four FSCs with each FSC

providing parity data for the other three FSCs. The array is managed by the master MIO/UMIO.

Page 22

ASR 5500 Hardware Platform Overview

▀ Card Types

▄ ASR 5500 Installation Guide

22

Important: A minimum of three FSCs must be online at all times for the array to operate. When an FSC is

removed, one RAID 0 array is lost with the RAID 5 array providing redundancy.

Important: Removal of an FSC while the array is degraded or rebuilding may result in data loss.

The array appears under /hd-raid and is available to all DPC/UDPCs and MIO/UMIOs.

System Status Card (SSC)

The ASR 5500 chassis supports two SSCs in front facing slots of the chassis. SSCs use dedicated slots in the left most

slots of the front side of the chassis.

The SSC card features:

Three alarm relays (Form C contacts)

Audible alarm with front panel Alarm Cutoff (ACO)

System status LEDs

Page 23

ASR 5500 Hardware Platform Overview

LED Indicators ▀

ASR 5500 Installation Guide ▄

23

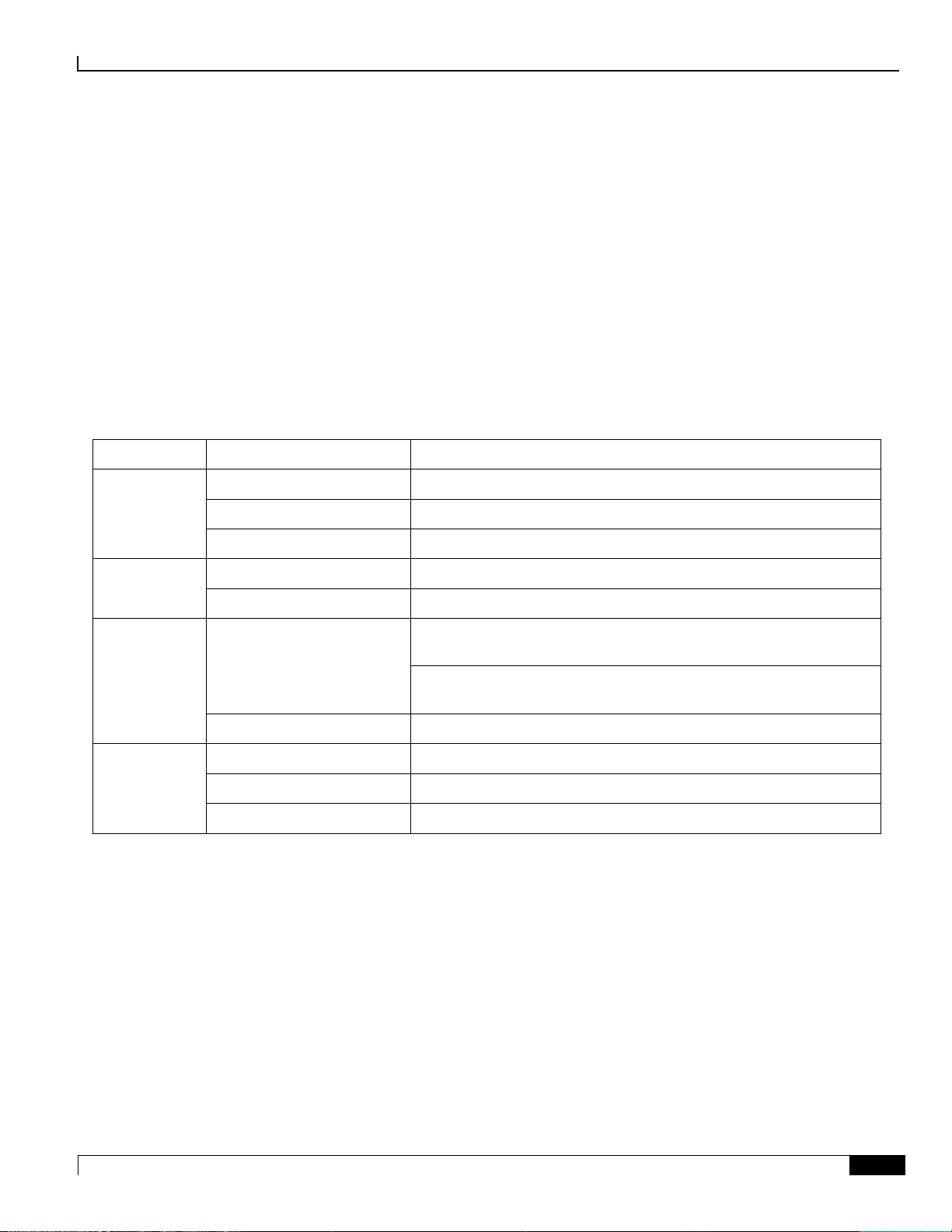

LED Indicators

Label

State

Meaning

Run/Fail

Off

Offline

Green – Blink

Transitioning

Green – Solid

Online

Red

Failure

Active

Off

Not applicable

Green – Blink

Transitioning

Green – Solid

Active

Redundancy

Off

Not applicable

Amber – Solid

Non-redundant

Amber – Blink

Transitioning

Green

Redundant

Label

State

Meaning

MIO or UMIO

Master

Off

Not applicable

Green – Blink

Transitioning

Green – Solid

Master

Busy

Off

No activity

Green

Storage activity

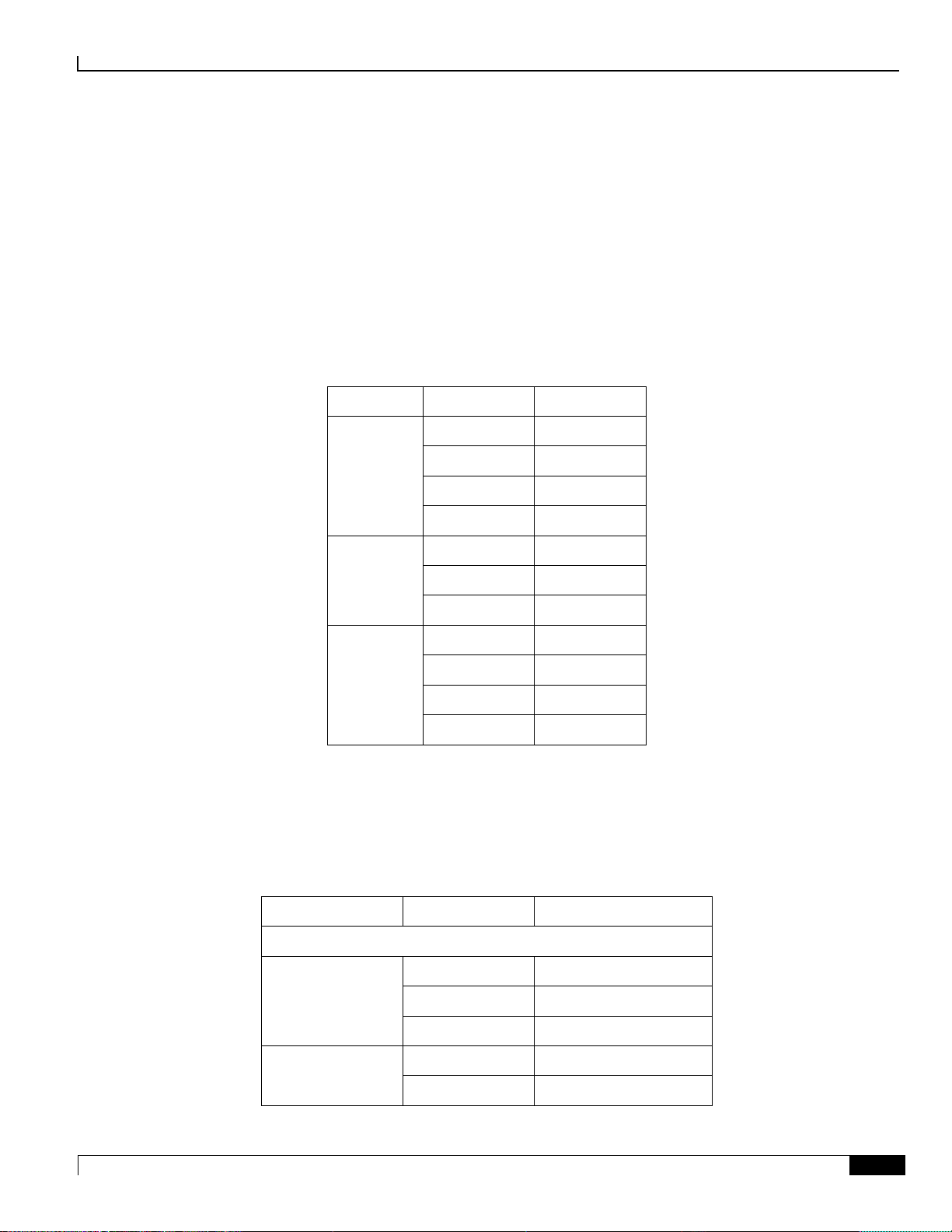

All ASR 5500 circuit cards incorporate light emitting diode (LED) status indicators. A base group appears on all cards.

Card-specific indicators show the status of ancillary functions.

LED Indicators Common to All Cards

Table 1. Base LED Group

LED Indicators on Specific Cards

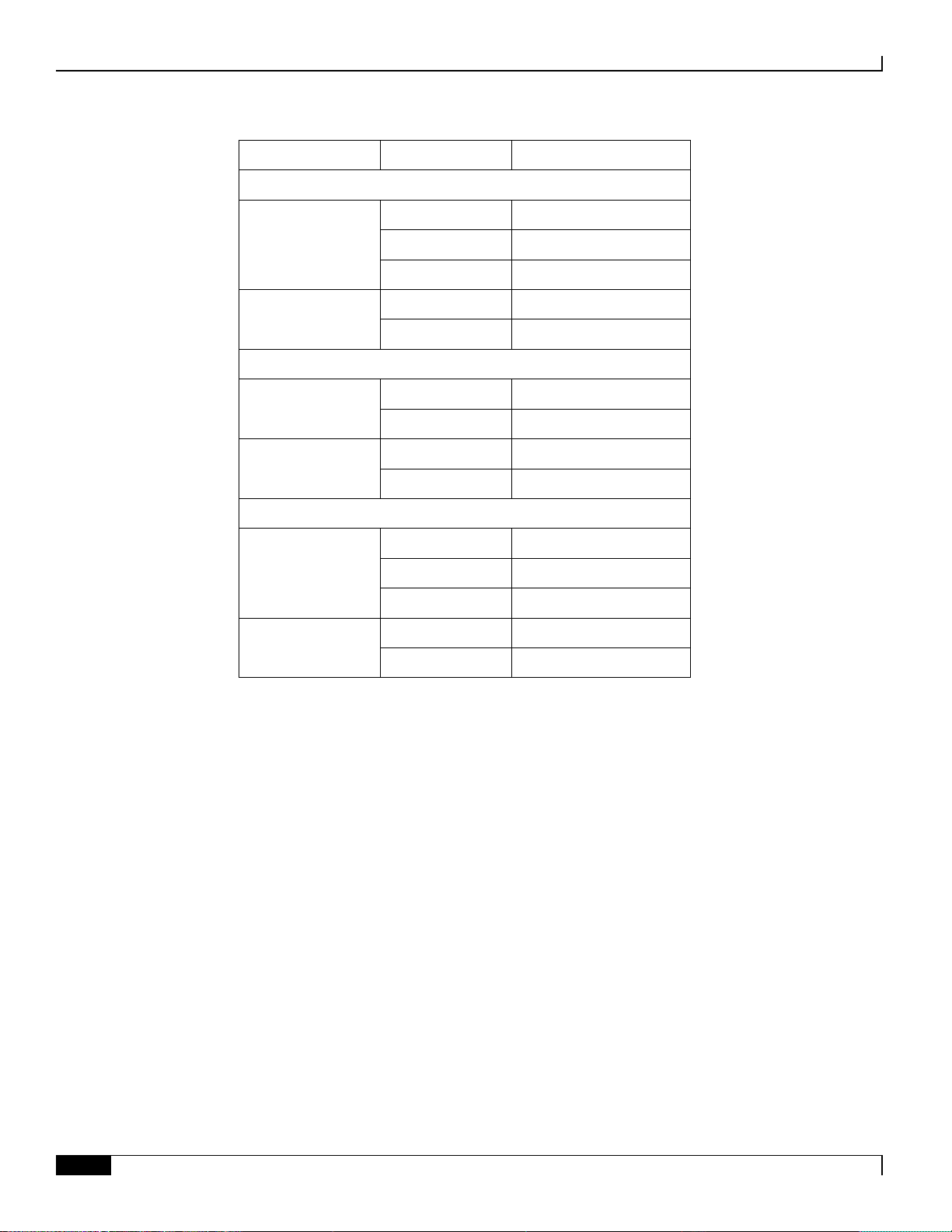

Table 2. Card-specific LED Group

Page 24

ASR 5500 Hardware Platform Overview

▀ LED Indicators

▄ ASR 5500 Installation Guide

24

Label

State

Meaning

Interface Ports

Link

Off

No link with network

Amber – Blink

Transitioning

Green – Solid

Linked with network

Activity

Off

No activity

Green – Blink

Data exchange

FSC

Drive 1 Activity

Off

No activity

Green

Activity

Drive 2 Activity

Off

No activity

Green

Activity

SSC

System Status

Off

System offline

Green

System online

Red

Service loss

System Service

Off

System OK

Amber

Failed component

Page 25

ASR 5500 Installation Guide ▄

25

Chapter 2

Technical Specifications

This chapter defines the technical specifications related to the installation of an ASR 5500 system.

It includes the following sections:

Physical Dimensions

Environmental Specifications

Mounting Requirements

Power Requirements

Central Office Alarm Interface

Chassis Grounding

Page 26

Technical Specifications

▀ Physical Dimensions

▄ ASR 5500 Installation Guide

26

Physical Dimensions

Component

Notes

Height

Width

Depth

Weight

Chassis (empty)

1

36.75 in. (93.3 cm)

17.25 in. (43.8 cm)

27.5 in. (69.8 cm)

131 lbs (51.25 kg)

Chassis as shipped

2

226 lbs (102.5 kg)

Chassis (maximum)

3

36.75 in. (93.3 cm)

17.25 in. (43.8 cm)

32.0 in. (81.3 cm)

450 lbs (204.1 kg)

Chassis (shipping)

4, 5

50 in. (127 cm)

24 in. (61 cm)

32 in. (81.3 cm)

265 bs (120.2 kg)

Fan Tray – Front

—

1.625 in. (4.13 cm)

16.37 in. (41.6 cm)

5.625 in. (14.3 cm)

5.5 lbs (2.5 kg)

Fan Tray – Rear

—

2.125 in. (5.4 cm)

16.87 in. (42.9 cm)

18.5 in. (47 cm)

24.5 lbs (11.1 kg)

Power Filter Unit

—

3.5 in. (8.9 cm)

8.5in. (21.6 cm)

21.5 in. (54.6 cm)

15 lbs (6.8 kg)

FSC

—

19.75 in. (50.2 cm)

1.75 in. (4.44cm)

6.75in. (17.1 cm)

6 lbs (2.7 kg)

SSC

—

4.5 lbs (2 kg)

MIO or UMIO

6

21.75 in. (55.24 cm)

1.75 in. (4.44 cm)

19.5 in. (49.5 cm)

18 lbs (8.16 kg)

DPC or UDPC

—

18.5 lbs (8.4 kg)

Baffle panel – front

—

19.75 in. (50.2 cm)

1.75 in. (4.44 cm)

6.25 in. (7 cm)

1 lb (0.45 kg)

Baffle panel – rear

—

21.75in. (55.2 cm

18.625 in. 47.3 cm)

2.5 lbs (1.13 kg)

The ASR 5500 can be mounted in any standard (EIA-310-D, IEC 60297) 19-inch (482.6 mm) equipment cabinet or

telecommunications rack. The table below lists the dimensions for the chassis and each component that can be placed

within the chassis.

Table 3. ASR 5500 Physical Dimensions and Weights

Notes:

1. No PFUs or fan trays.

2. Includes four Fan Tray Units and two PFUs.

3. Depth and weight with cable management tray installed and closed, and all card slots filled.

4. Includes shipping container, accessory box, and chassis with four Fan Tray Units and two PFUs

5. Width on the pallet forks.

6. Without cable management bracket.

Page 27

Technical Specifications

Environmental Specifications ▀

ASR 5500 Installation Guide ▄

27

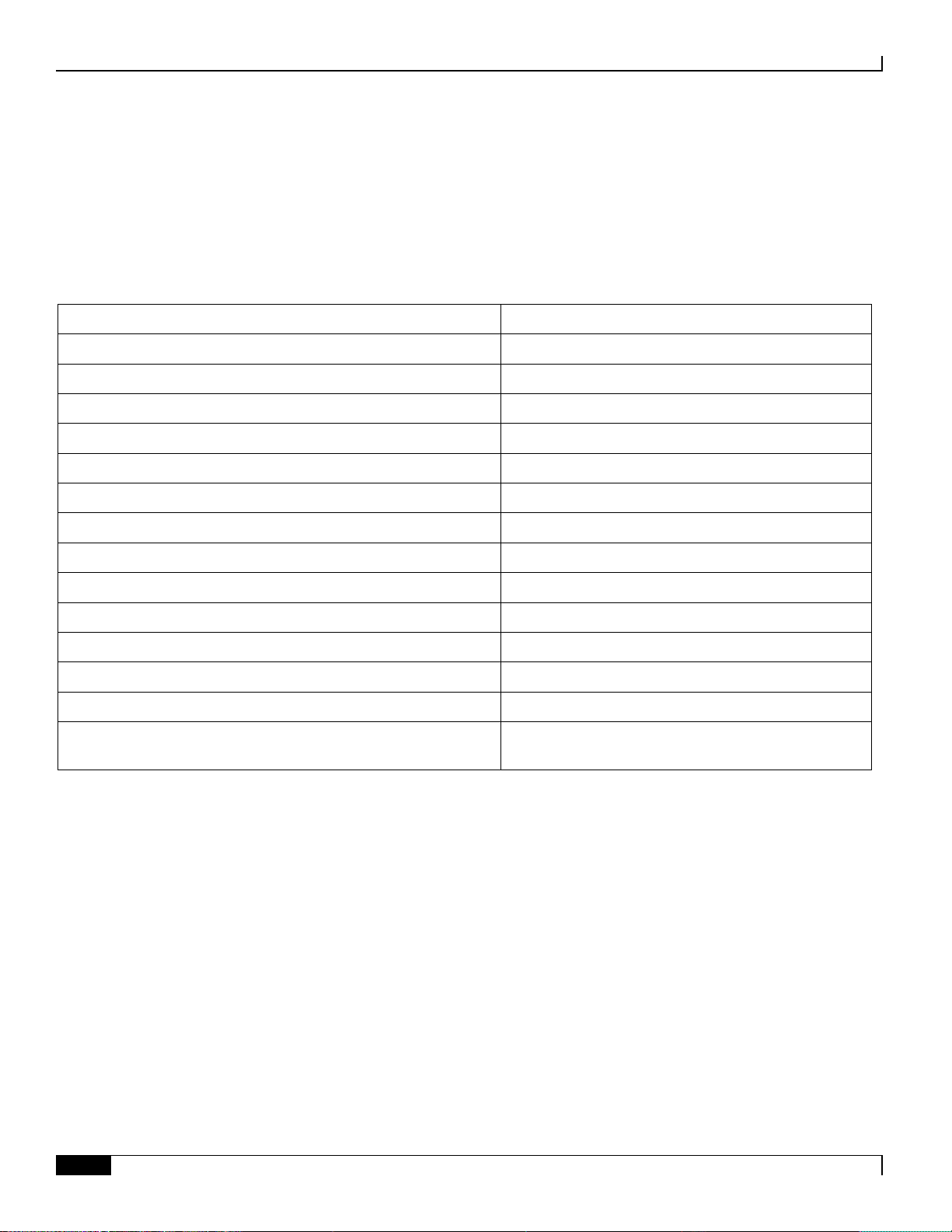

Environmental Specifications

Parameter

Subparameter

Range

Temperature

Operating

0 degrees C to +40 degrees C (32 degrees F to 104 degrees F)

Short Term

-5 degrees C to +50 degrees C (23 degrees F to 122 degrees F)

Storage

-40 degrees C to +70 degrees C (-40 degrees F to 158 degrees F)

Humidity

Operating

20 to 80 percent non-condensing

Storage

10 to 95 percent non-condensing

Altitude

Operating

197 ft. (60m) below to 5,905 ft. (1,800m) above sea level, maximum

40 degrees C (104 degrees F)

5,905 ft. (1,800m) to 13,123 ft. (4000m) above sea level, maximum

30 degrees C (86 degrees F)

Non-operating

197 ft. (60m) below to 49,212 ft. (15,000m) above sea level

Acoustic Noise

23 degrees C (73.4 degrees F)

81 dB (within GR-63 limits for unattended operation)

27 degrees C (80.6 degrees F)

81 dB (within GR-63 limits for unattended operation)

Max. Fan Speed

96 dB (as measured during GR-63 R4-97 testing)

The ASR 5500 is designed for deployment in unattended sites equipped with redundant power systems, redundant data

communications connections, environmental controls (air conditioning, fire suppression), security devices and

controlled access.

Environmental Parameters

The table below lists the environmental parameters (operating and storage) for the ASR 5500 chassis.

Table 4. Environmental Parameters

Notes:

1. Short-term refers to a period of not more than 96 consecutive hours and a total of not more than 15 days in 1

year. (This refers to a total of 360 hours in any given year, but no more than 15 occurrences during that 1-year

period.)

Page 28

Technical Specifications

▀ Environmental Specifications

▄ ASR 5500 Installation Guide

28

Environmental Standards

Type

Standard

Acoustic Noise

Telcordia GR-63 Criterion [128]

Airborne Contaminants, Indoor Levels

Telcordia GR-63 Criterion [125]

Airborne Contaminants, Outdoor Levels

Telcordia GR-63 Criteria [126, 127]

Altitude

Telcordia GR-63 Criteria [74, 76]

Earthquake Zone 4

Telcordia GR-63 Criteria [110-112, 114, 115, 117, 119]

Electromagnetic Compatibility and Electrical Safety

Telcordia Technologies GR-1089-CORE

Operational Thermal, Operating Conditions

Telcordia GR-63 Criteria [72, 73]

Operational Thermal, Short-term Conditions

Telcordia GR-63 Criteria [72, 73]

Storage Environments, and Transportation and Handling

Telcordia GR-63 Criteria [69-71, 107-109, 124]

Thermal Heat Dissipation

Telcordia GR-63 Criteria [77, 79]

Electromagnetic Compatibility and Electrical Safety

Telcordia Technologies GR-1089-CORE

Radiated Emissions (Electric Field)

FCC 47 CFR, PART 15, CLASS A

Electromagnetic Compatibility

ETSI EN 300 386 v1.4.1

Environmental Conditions and Environmental Tests for

Telecommunications Equipment

ESTI EN 300 019, ETSI EN 300 753

The ASR 5500 has been successfully tested for compliance with the environmental standards listed in table below.

Table 5. Environmental Compliance Standards

Page 29

Technical Specifications

Environmental Specifications ▀

ASR 5500 Installation Guide ▄

29

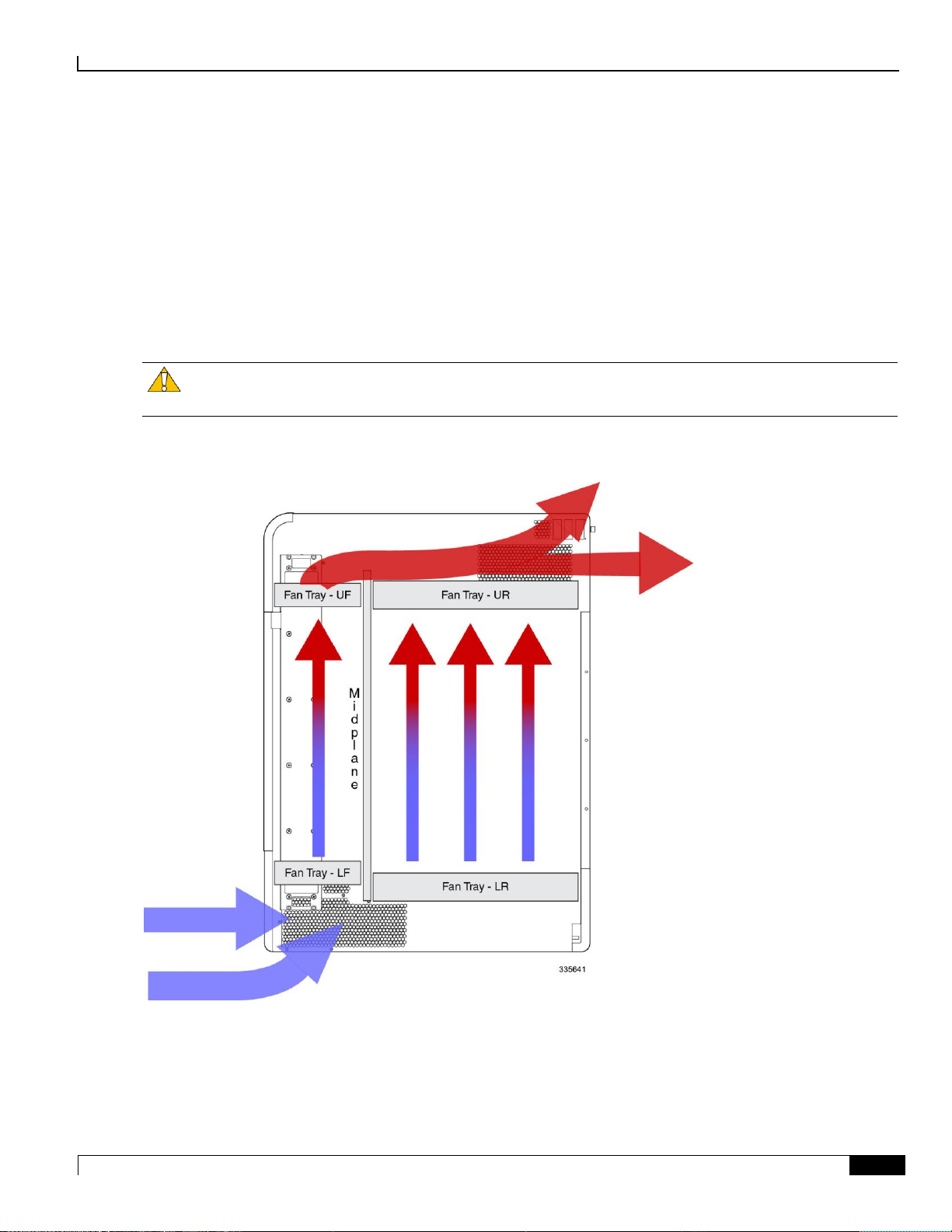

Chassis Air Flow

Air flow within the ASR 5500 complies with Telcordia recommendations to ensure vertical convection cooling of the

system.

As shown in the figure below, the lower fan trays pull ambient air inward from the front and side intake vents located

near the bottom of the chassis. The air absorbs heat from system components as it passes over them.

The upper fan trays pull heated air up through the chassis and exhaust it through the side and rear exhaust vents located

near the top rear of the chassis.

Caution: The environmental control system within the installation site must be able to maintain the ambient

environment within the limits for operating temperature and humidity.

Figure 7. Air Flow

Page 30

Technical Specifications

▀ Environmental Specifications

▄ ASR 5500 Installation Guide

30

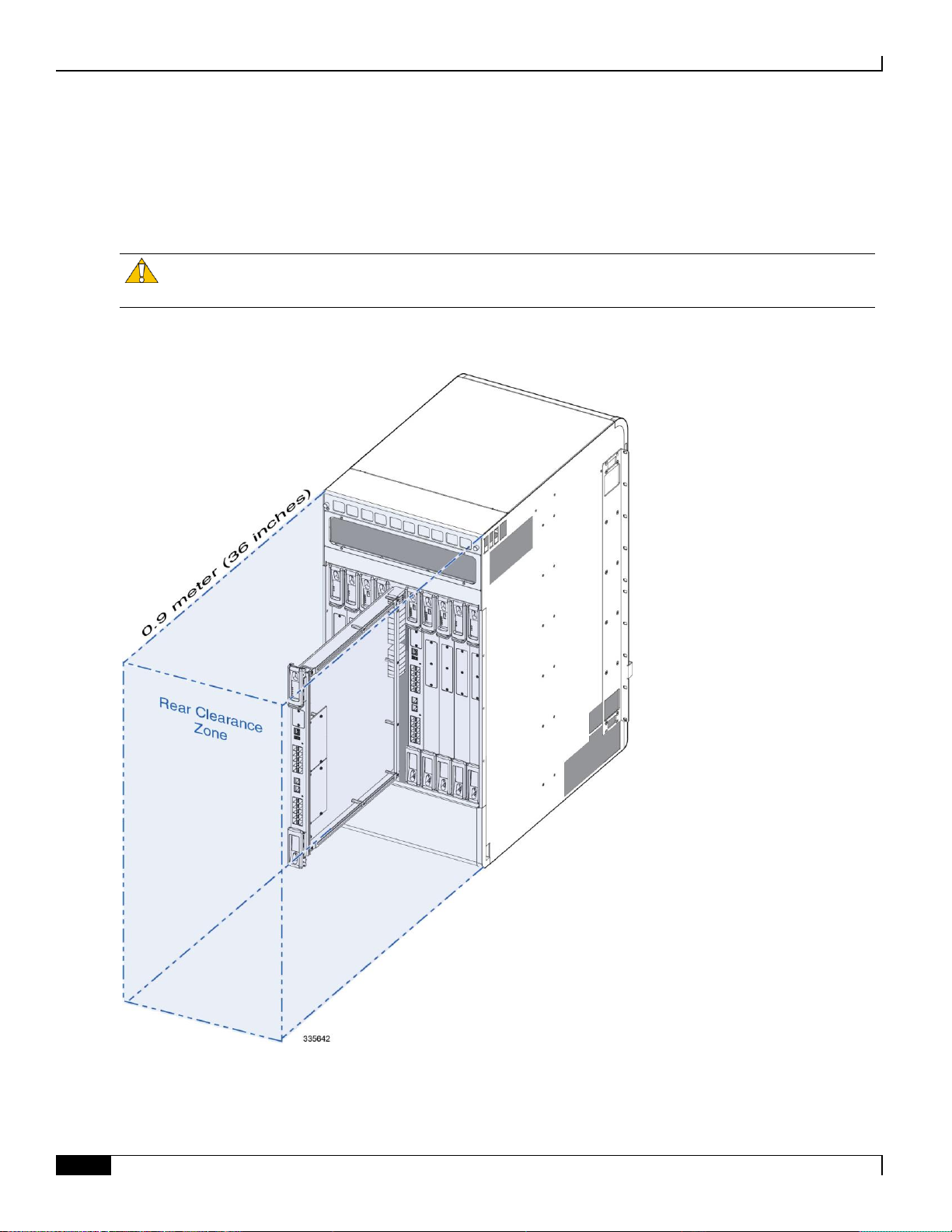

Clearance

Ensure that the equipment rack or cabinet hardware does not hinder air flow at any of the intake or exhaust vents. Allow

approximately 0.9 meter (36 inches) at the front and rear of the chassis for air flow and maintenance access.

figure below). These units are very large and require additional clearance from cable management bars, PDUs, etc.

Figure 8. Rear Clearance Zone

Caution: The rear clearance is also necessary for removing and replacing the rear cards and fan trays (see the

Page 31

Technical Specifications

Mounting Requirements ▀

ASR 5500 Installation Guide ▄

31

Mounting Requirements

Each ASR 5500 chassis occupies 21 RU (rack units) within any standard (EIA-310-D, IEC 60297) 19-inch (482.6 mm)

equipment rack or cabinet using the mounting brackets supplied with the chassis. Extension brackets (not supplied) may

be used in conjunction with the chassis mounting brackets to install the chassis in a standard 23-inch (584.2 mm)

cabinet or rack. The chassis mounting brackets may be repositioned to support flush and mid-mount installations.

The chassis footprint is approximately 19-inch (48.26 cm) wide by 26.75 in. (67.9 cm) long.

Important: This footprint does not include the rear-mounted cable management tray.

Two ASR 5500 chassis fit in 42 RU (73.5 in.) of space within an equipment rack or cabinet.

Important: Rack mounting requires the use of industry-standard equipment racks or cabinets with supplier-

recommended fasteners. The rack should be rated to accommodate the weight of one or two chassis and any auxiliary

equipment.

Page 32

Technical Specifications

▀ Power Requirements

▄ ASR 5500 Installation Guide

32

Power Requirements

Component

Parameter

Values

Chassis

Input voltage per feed circuit (nominal)

-48VDC

Input voltage per feed circuit (maximum)

-40VDC to -60VDC

Power feed circuits per PFU

4

TUV rated peak current load per feed

80 amps @ -40 VDC

Maximum power load per chassis

12,800 watts

Cards

FSC

Maximum power

100 watts

SSC

Maximum power

10 watts

MIO or UMIO

Maximum power

900 watts

DPC or UDPC

Maximum power

1,000 watts

Fan Tray Unit

Front

Maximum power

60 watts each (2 per chassis

Rear

Maximum power

840 watts each (2 per chassis)

The table below lists the power requirements for individual components of the ASR 5500 chassis.

Table 6. ASR 5500 Power Requirements

Important: The power source must be a UL/CSA listed device with a regulated output no greater that -60VDC.

Important: The DC power Battery Return (BR) or positive terminal, must be grounded at the source end (power

feed or mains power end).

Important: The DC power BR input terminal of the ASR 5500 is not connected to the equipment frame (chassis)

and is configured as DC-I in compliance with GR-1089-CORE (sec.9.8.3).

Page 33

Technical Specifications

Central Office Alarm Interface ▀

ASR 5500 Installation Guide ▄

33

Central Office Alarm Interface

The Central Office (CO) alarm interface on the SSC is a DB15 connector that supports three dry-contact relay switches.

Each of the Form C relays is rated to support a maximum switching current of 1A@30VDC.

Caution: The alarm relay contacts should never be connected to high current draw devices, such as sirens or

flashing incandescent lamps.

The three relays support both normally-open (NO) and normally-closed (NC) devices. For additional information, refer

to the SSC Alarm Cabling chapter for details.

Chassis Grounding

The ASR 5500 is suitable for installation as part of the Common Bonding Network (CBN) within a network

telecommunications facility. It is not intended for installation in an Isolated Bonding Network (IBN).

Page 34

Page 35

ASR 5500 Installation Guide ▄

35

Chapter 3

Installation Procedure Overview

This chapter briefly describes the steps and tools that are required to install the ASR 5500 chassis.

It includes the following sections:

Installation Sequence

Required Tools and Equipment

Site Prerequisites

ESD Precautions

Standards Compliance

Caution: The copper serial Console port, 1000Base-T management ports, and CO alarm interface of the

ASR 5500 are suitable for connection to intra-building or unexposed wiring or cabling only. These ports MUST NOT be

metallically connected to interfaces that connect to the outside plant (OSP) or its wiring. These interfaces are designed

for use as intra-building interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE, Issue 5) and require

isolation from the exposed OSP cabling. The addition of Primary Protectors is not sufficient protection in order to

connect these interfaces metallically to OSP wiring.

Page 36

Installation Procedure Overview

▀ Installation Sequence

▄ ASR 5500 Installation Guide

36

Installation Sequence

Installation of the ASR 5500 requires the completion of the following procedures:

1. Unpack the chassis and cards.

2. Determine which chassis mounting option to use: flush or mid-mount. Reposition the mounting brackets if

necessary.

3. Install the chassis into a standard 19-inch equipment rack or telecommunications cabinet.

4. Connect the chassis ground point to site ground.

5. Optional: Install the Chassis Management System.

6. Install SSC and FSC cards into the front of the chassis.

7. Install MIO or UMIO cards and DPCs or UDPCs into the rear of the chassis.

8. Connect data cables to the local and external ports.

9. Connect power cables to the PFU terminals at the top rear of the chassis.

10. Apply power to the chassis.

11. Verify that the system powers up successfully.

The actual sequence for completing some of the above procedures may be adapted to suit local requirements and the

availability of resources. For example, power cabling may be completed before circuit cards are installed in the chassis.

However, the chassis must always be grounded immediately after being mounted in the rack or cabinet.

Caution: For personal safety and to minimize the risk of equipment damage, power must not be applied to the

chassis until all other procedures have been completed.

Page 37

Installation Procedure Overview

Required Tools and Equipment ▀

ASR 5500 Installation Guide ▄

37

Required Tools and Equipment

This section lists the tools and equipment needed for installation.

Hand Tools

The following hand tools are required for installation of the chassis circuit cards and PFUs:

Cable/wire stripping tool – used to prepare the ends of power and ground cables for attachment to two-hole lugs.

Knife, scissors or tin snips to cut shipping straps on the chassis container.

Panduit crimping tool with 4 AWG die – used to crimp two-hole lugs on the ends of power feed cables.

Phillips #2 and #1 screwdrivers – used to tighten thumb-screws on cards, fan trays, PFUs, and mounting

brackets.

7/16-inch nut driver or ratchet and socket set – used to connect power and return, as well as chassis grounding

cable lugs to PFU terminals.

Torque wrench (rated 50 in-lb [5.65 N-m]) with 7/16-inch socket for tightening lugs to power terminals.

Grounding wrist and/or heel straps for prevention of Electro-Static Discharge (ESD).

Caution: The inappropriate use of electric or pneumatic torque drivers, or power drill/impact drivers to loosen

or tighten fasteners may result in damage to system components.

Caution: During installation, maintenance, and/or removal, wear a grounding wrist strap connected to the

ASR 5500 chassis to avoid ESD damage to the components. Failure to do so could result in damage to sensitive

electronic components and potentially void your warranty.

Equipment

The following equipment is necessary to install the chassis and verify that it is ready for configuration:

Standard 19-inch (48.26 cm) equipment rack (4-post or 2-post) or telecommunications cabinet with mounting

Multiple -48 VDC power feeds terminated at the rack/cabinet.

Voltmeter to measure input voltages at the PFU terminals.

Heat gun for installing shrink wrap tubing over power cable lugs.

Computer with a DB9 RS-232C serial port or a terminal server port that will connect to the RJ45 Console port

Pallet jack and/or chassis lift to move and position the ASR 5500 chassis. Without such mechanical assistance,

hardware. The rack/cabinet must be installed in accordance with OEM recommendations and local

practices for electrical/grounding and seismic conditions.

on the chassis management MIO or UMIO cards for accessing the Command Line Interface (CLI).

moving and positioning the chassis will require multiple craftpersons trained to safely handle heavy rackmounted units.

Page 38

Installation Procedure Overview

▀ Site Prerequisites

▄ ASR 5500 Installation Guide

38

Site Prerequisites

This section summarizes power, grounding, environment, and clearance requirements that must be met prior to

installing and operating the ASR 5500. For detailed information, refer to the Technical Specifications chapter.

Power and Grounding

Each PFU requires eight power feeds of 80A @ -48VDC (nominal). The feeds should be routed to the installation rack

from the site power supply using adequately sized conductors and circuit breakers in accordance with local electrical

codes.

The chassis must be grounded to a site ground point using the recommended conductors and lugs. The ground point

should be in close proximity to the ASR 5500 chassis to assure adequate conductivity.

Environment

The site’s heating ventilation and air conditioning (HVAC) systems must be sized to maintain the operating

temperatures and relative humidity specified in the Technical Specifications chapter. HVAC capacity requirements will

vary based on the system configuration and associated power draw, as well as the operational characteristics of other

equipment installed at the site.

Clearance

Adequate clearance must be maintained at the front and rear of the ASR 5500 chassis to assure proper air flow and

allow maintenance access for the installation, removal and replacement of components. The recommended clearance is

36 inches (92 centimeters) at the front and rear of the chassis.

Page 39

Installation Procedure Overview

ESD Precautions ▀

ASR 5500 Installation Guide ▄

39

ESD Precautions

1

Front ESD jack

2

Rear ESD jack

Electro-Static Discharge (ESD) can cause serious damage to the chassis, its sub-components and/or the cards installed in

the chassis. To prevent damage from ESD, you must take proper grounding precautions before handling the chassis or

any of its components.

The chassis and its mounting brackets are equipped with ESD jacks (see the figure below). Use the jacks in conjunction

with grounding wrist straps when handling the chassis and/or its components. The following figure shows the location

of the jacks.

Before the you can use the ESD jacks on the ASR 5500 chassis and its mounting brackets, you must first connect the

chassis to ground according to the instructions in the Chassis Installation chapter of this document.

Figure 9. Locations of ESD Jacks on the ASR 5500 Chassis

Page 40

Installation Procedure Overview

▀ Standards Compliance

▄ ASR 5500 Installation Guide

40

Standards Compliance

FCC Warning

This device complies with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules and Regulations.

Operation is subject to the following two conditions:

This device may not cause harmful interference.

This device must withstand any interference received, including interference that may cause undesired operation.

The system platform has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15

of the FCC Rules and Regulations. These limits are designed to provide reasonable protection against harmful

interference when this equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio and television communications. Operation of this equipment in a residential area is likely

to cause interference in which case the user will be required to correct the interference at his or her own expense.

Modifications to this product not authorized by Cisco could void the FCC approval and negate your authority to operate

the product.

Shielded cables must be used with this unit to ensure compliance with the FCC Class A limits.

ICS Notice

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Laser Notice

The laser devices in this equipment are Class 1 devices. Class 1 laser devices are not considered to be hazardous.

Page 41

ASR 5500 Installation Guide ▄

41

Chapter 4

Chassis Installation

This chapter describes how to install the ASR 5500 chassis and its components.

Important: The ASR 5500 is suitable for installation in Network Telecommunication Facilities designed for

unattended equipment operation.

This chapter includes the following sections:

Mounting Options

Weight Considerations

Unpacking the Chassis

Reducing the Weight of the Chassis Prior to Installation

Installing the Chassis

Grounding the Chassis

Re-Installing Chassis Components

Cable Management System

Page 42

Chassis Installation

▀ Mounting Options

▄ ASR 5500 Installation Guide

42

Mounting Options

There are two options for mounting the chassis in a standard 19-inch equipment rack or telecommunications cabinet:

Flush mount: In this configuration, the flanges of the mounting brackets are flush with the front of the chassis.

This is the default configuration as shipped. This method is typically used to mount the chassis in a 4-post rack

or equipment cabinet. Refer to Flush Mount.

Mid-mount: In this configuration, the flanges of the mounting brackets are recessed from the front of the

chassis. To do this, the mounting brackets must be removed and reinstalled toward the middle of the chassis.

This method is typically used to mount the chassis in a two-post rack. Refer to Mid Mount.

Weight Considerations

The shipping weight of the chassis is approximately 226 lbs (102.5 kg). Please consider the following recommendations

before proceeding:

If available, use an equipment lift to move the chassis and position it into the rack/cabinet.

If a lift is not available, reduce the weight of the chassis by following the instructions in Reducing the Weight of

the Chassis Prior to Installation.

Remove all obstructions in the path from the delivery location to the rack/cabinet.

At least two people should perform the installation. These individuals should be physically able to lift and

control the weight of the chassis.

When lifting any heavy object, remember to bend at the knees and lift with your legs. Bending at the waist and

lifting with your back could cause personal injury.

Important: The ASR 5500 chassis is shipped with no circuit cards installed. Only the PFUs, fan trays and air

filters are installed. The circuit cards are shipped in separate cartons.

Caution: If you are mounting two chassis in a single rack, verify that the rack is rated to handle the combined,

fully loaded weight of both chassis and any ancillary equipment.

Page 43

Chassis Installation

Unpacking the Chassis ▀

ASR 5500 Installation Guide ▄

43

Unpacking the Chassis

The ASR 5500 chassis is shipped on a palletized container.

Important: The front and rear circuit cards are packaged and shipped in separate cartons.

Important: Locate the packing list for the shipment and verify that all components have been received.

Important: Safely store the shipping container and its components in case the chassis must be shipped to another

site or returned for repair.

Move the Container to the Installation Site

Before unpacking the chassis, use a pallet jack to move the container as close to the final installation site as possible.

The cardboard cap and sleeve will protect the chassis from damage when moving the container.

The chassis container measures:

Height = 50 in. (127 cm)

Width = 24 in. (61 cm)

Depth = 32 in. (81.3 cm) [width on the pallet forks]

Weight = 265 lbs (120.2 kg)

Page 44

Chassis Installation

▀ Unpacking the Chassis

▄ ASR 5500 Installation Guide

44

1

Container sleeve

2

Pallet

3

Strap

Unpack the Chassis

Caution: You should wear protective gloves and safety glasses when handling the shipping crate banding

while unpacking the system. The straps that connect the packaging material are capable of inflicting damage to your

skin or eyes if not handled properly.

Step 1 Cut the straps that secure the cap and card board sleeve to the pallet. Remove the straps from the pallet and discard.

Page 45

Chassis Installation

Unpacking the Chassis ▀

ASR 5500 Installation Guide ▄

45

1

Cardboard top

2

Outer sleeve

3

Inner Sleeve

4

Accessory box

5

Foam Cap

6

End cap

7

Pallet

8

Plastic bag (not shown)

Step 2 Remove the cardboard cap from the top of the container.

Page 46

Chassis Installation

▀ Reducing the Weight of the Chassis Prior to Installation

▄ ASR 5500 Installation Guide

46

Step 3 Lift the outer cardboard sleeve up and over the top of the chassis.

Step 4 Lift the inner cardboard sleeve up and over the top of the chassis.

Step 5 Remove the accessory box. This box contains miscellaneous hardware items and spare air filters.

Step 6 Remove the foam cap from the top of the chassis.

Step 7 Remove the bottom front and rear end caps from the base of the chassis.

Step 8 Remove the plastic bag that covers the chassis.

Step 9 If you will be removing chassis components to reduce the weight of the chassis, leave the chassis on the pallet and

proceed to Reducing the Weight of the Chassis Prior to Installation.

Step 10 Use a chassis lift or multiple craftpersons to lift or slide the chassis off the shipping pallet. Proceed to Installing the

Chassis.

Reducing the Weight of the Chassis Prior to Installation

You can reduce the weight of the chassis prior to installation by removing the upper and lower fan trays, and the PFUs.

Follow the instructions below to safely remove these components prior to installation.