Page 1

®

AS C- 2E

WI TH

Mobile Stand Option 5004687

C o n v e c t i o n O v e n

E l e c t r i c

Model:

ASC-2E

ASC-4E

AS C- 4E

WI TH

Stand Option 5003489

Manual

Control

• I N STALLATI O N

• OP E RAT ION

• MAI NT ENAN C E

W 1 6 4 N 9 2 2 1 W a t e r S t r e e t • P. O . B o x 45 0 • M e n o m o n e e F a l l s , W i s c o n s i n 5 3 0 5 2 - 0 4 5 0 U S A

PHONE: 262.251.3800 • 800.558.8744

P RI N TE D I N U . S .A .

USA/CANADA FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY

WEBSITE: www.alto-shaam.com

#87 01/ 2 • 11 /07

Page 2

D E L I V E R Y

®

®

U N PA C K I N G

his Alto-Shaam appliance has been

T

horoughly tested and inspected to insure only the

t

ighest quality unit is provided. Upon receipt,

h

heck for any possible shipping damage and

c

report it at once to the delivering carrier. Se e

Transportation Dam ag e and Claim s section located

in this manu al.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

NO TE: All claims for warranty must include the

full model number and serial number of

the unit.

1. Carefully remove the

appliance from the

carton or crate.

OTE: Do not discard the

N

carton and other

packaging material

until you have

inspected the unit for

hidden damage and

tested it for proper

operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS M ANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner

or manager of the business or to the person

responsible for training operators. A d d itional

manuals are available from the Alto-Shaam

service dep artmen t.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

#8701/2 Electric Convection Oven - Manual Control • 1

Page 3

SAF ETY PROCEDURES

A N D P R E C A U T I O N S

nowledge of proper procedures is essential to the

K

afe operation of electrically energized equipment.

s

n accordance with generally accepted product

I

afety labeling guidelines for potential hazards,

s

he following signal words and symbols may be

t

sed throughout this manual.

u

Used to indicate the

presence of a hazard that

cause severe personal

will

injury, death, or substantial

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can cause personal injury,

possible death, or major

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can or will cause minor or

moderate personal injury

or property damage if the

warning included with this

symbol is ignored.

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this

appliance is authorized or recommended.

2. This appliance is intended for use in

commercial establishments where all

operators are familiar with the purpose,

limitations, and associated hazards of this

appliance. Operating instructions and

warnings must be read and understood by

all operators and users.

3. Any troubleshooting guides, component

views, and parts lists included in this manual

are for general reference only and are intended

for use by qualified technical personnel.

4. This manual should be considered a

permanent part of this appliance. This

manual and all supplied instructions,

diagrams, schematics, parts lists, notices, and

labels must remain with the appliance if the

item is sold or moved to another location.

NOTE:

Used to indicate the

presence of a hazard that

can or will cause minor

personal injury, property

damage, or a potential

unsafe practice if the

warning included with this

symbol is ignored.

Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

#8701/2 Electric Convection Oven - Manual Control • 2

Page 4

I N S T A L L AT I O N S A F E T Y W A R N I N G

®

METAL PARTS OFTHIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

O

PERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

DO NOT store or use any

flammable liquids or allow

flammable vapors in the vicinity of

any appliance.

DO NOT LIFT OR MOVE THE

OVEN BY USING THE DOORS

OR THE DOOR HANDLES.

S I T E I N S T A L L A T I O N

This appliance must be

installed in a location that will

permit the oven to function

for its intended purpose and

to allow adequate clearance

for ventilation, proper

cleaning, and maintenance

access.

1. Hood installation is recommended. (

LO CAL CODE S

).

CH ECK

2. The oven must be installed on a stable and

level surface.

3. DO NOT install this oven in any area where it may

be affected by any adverse conditions such as steam,

grease, dripping water, high temperatures, etc.

4. DO NOT store or use any flammable liquids or

allow flammable vapors in the vicinity of this

oven or any other appliance.

5. This appliance must be kept free and clear of any

combustible materials.

6. This appliance must be kept free and clear of

any obstructions blocking access for maintenance

or service.

A S C - 2 E • W E I G H T

NET: 250 lb (113 kg) EST. SHIP: 325 lb ( 147 kg) EST.

CRATE 44" H X 42" W X 42" D

D I M E NSI O N S: (1118mm x 1067mm x 1067mm)

MINIMUM ENTRY CLEA RANCE 31" (787mm) UNCRATE D

A S C - 2 E • D I M E N S I O N S : H x W x D

EXTERIOR: 32-1/8" x 30" x 30-1/8" (815mm x 762mm x 815mm)

INTE RIOR: 20" x 15" x 21" (508mm x 381mm x 533mm)

A S C - 4 E • W E I G H T

NET: 393 lb (178 kg) EST. SHIP: 438 lb ( 199 kg)

CRATE 40" H X 44" W X 53" D

D I M E NSI O N S: (1016mm x 1118mm x 1346mm)

MIN. ENTRY CLE ARANCE 31-1/2" (800mm) UNCRATED

W/O L EGS

A S C - 4 E • D I M E N S I O N S : H x W x D

EXTERIOR: 57-1/2" x 38" x 44-1/2" (1461mm x 965mm x 1130mm)

INTE RIOR: 24" x 29-1/8" x 25" (610mm x 740mm x 635mm)

Where automatically operated appliances are vented

through a ventilating hood or exhaust system

equipped with a damper or with a power means of

exhaust, provisions shall be made to allow the

equipment to operate only when the damper is open

to a position to properly vent the appliance and

when the power means of exhaust is in operation.

A CCORD ANCE WI TH NF PA 5 4 CO MM ON WEAL T H O F

M ASSAC HUSE TTS ONLY

.

#8701/2 Electric Convection Oven - Manual Control • 3

M I N I M U M C L E A R A N C E R E Q U I R E M E N T S

BA CK 0" (0mm)

LE FT SI DE 2" (51mm)

RI GH T SID E 2" (51mm)

FROM GREASE PRODUCING EQUIPMENT 6" (152mm)

RE CO MM EN DE D SER VI CE ACC ES S: 20" (508mm) RI GHT SI DE

Page 5

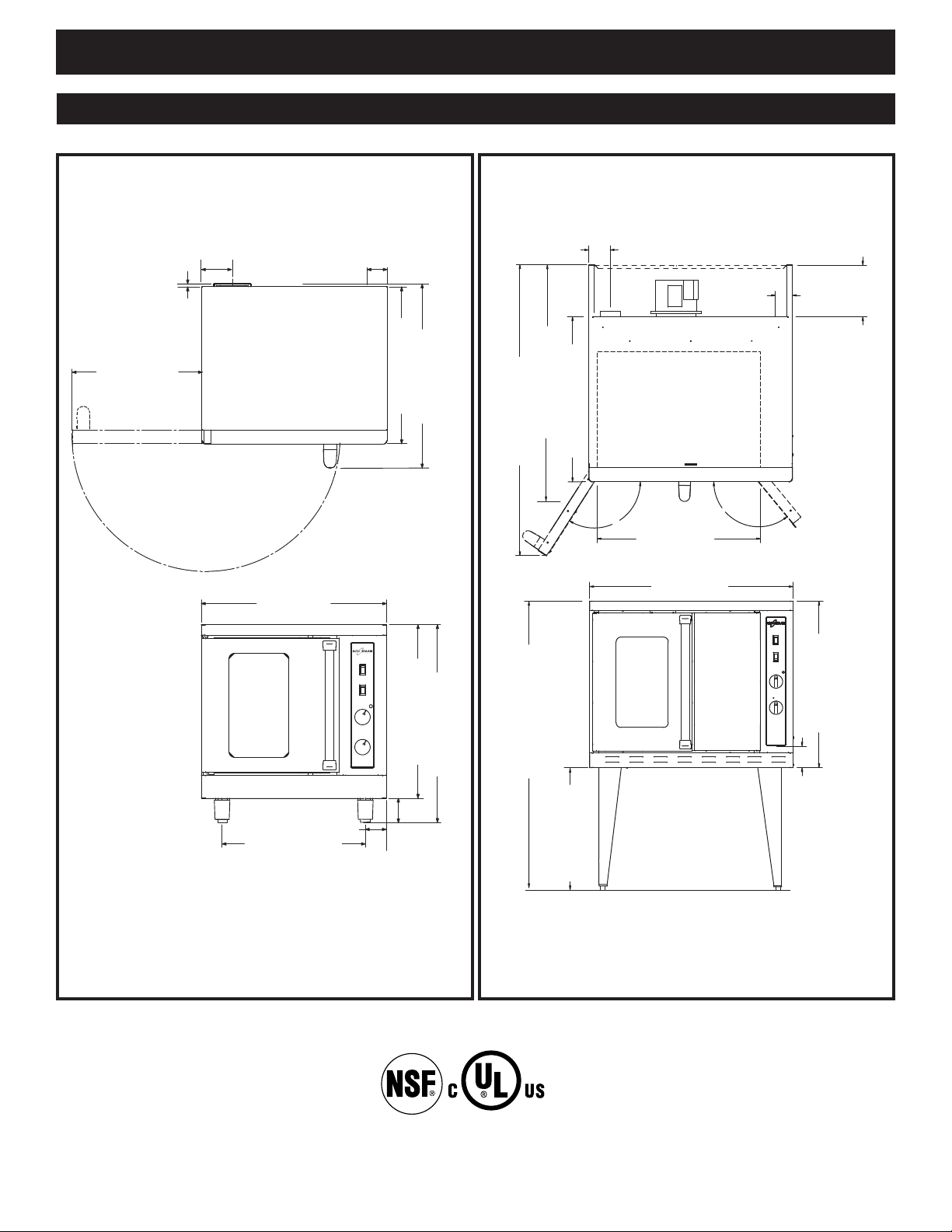

30-5/8" (778mm)

8" (203mm)

CAVITY VENT

ELECTRICAL

I

NLET

3-5/32"

(80,1mm)

9-15/16" (252mm)

ELECTRICAL ENTRANCE

1

23?

129?

29" (737mm)

CAVITY WIDTH

38" (965mm)

31-1/16" (789mm)

4" (102mm)

ELECTRICAL INLET

54-5/8" (1387mm)

44-1/2" (1130mm)

26-

1/

2"

(

673mm)

57-1/2" (1461mm)

30" (762mm)

28-3/16" (715mm)

3-15/16" (100mm)

32-1/8" (815mm)

3-3/8" (86mm)

23-1/4" (590mm)

4-11/16"

(

119mm)

1"

(25mm)

21-1/8 (536mm)

3-1/4"

(

83mm)

25-7/16 (646mm)

30-1/8" (815mm)

Exhaust

E

lectrical

2

" (51mm)

from bottom

I N S TA L L A T I O N

E X T E R I O R D I M E N S I O N S

A S C - 2 E A S C - 4 E

LISTED

#8701/2 Electric Convection Oven - Manual Control • 4

COOKING APPLIANCE

49ZA

Page 6

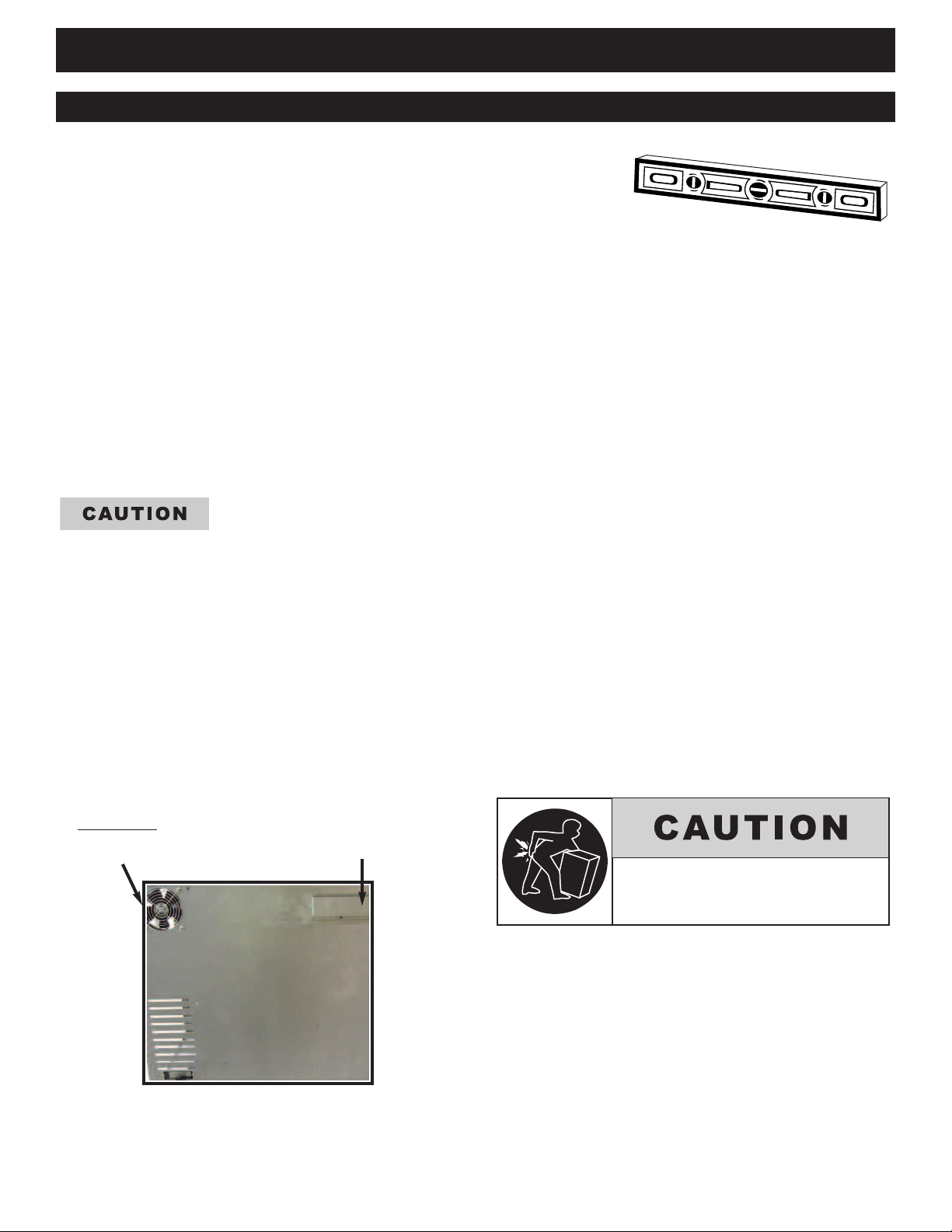

I N S T A L L A T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

I N S T A L L AT I O N R E Q U I R E M E N T S

A number of adjustments are associated with

initial installation and start-up. It is important

that these adjustments be conducted by a qualified

service technician. Installation and start-up

adjustments are the responsibility of the dealer or

user. These adjustments include but are not

limited to thermostat calibration, door adjustment,

leveling, and moisture vent installation.

All clearances for proper ventilation air supply

must be maintained to minimize fire hazard. Do

not locate the oven immediately adjacent to any

other heat generating appliance.

Inadequate ventilation may

result in a high ambient

temperature at the rear of the oven. An excessive

ambient temperature can cause the thermaloverload protection device on the blower motor to

trip resulting in severe damage to the blower

motor.

LEV ELING

Level this appliance from sideto-side and front-to-back with the use of a spirit

level. For ovens installed on a mobile stand, it is

important that the installation surface be level due

to the probability of frequent oven repositioning.

We recommend checking the level of the appliance

periodically to make certain the floor has not

shifted nor the appliance moved.

NOTE: Failure to properly level this oven can

cause improper function and will result

in the uneven baking of products

consisting of semi-liquid batter.

CO OL ING FAN

FA-3568

FAN GUA RD

GD-2396

MOISTUR E

VENT

ON BACK OF

OVEN

#8701/2 Electric Convection Oven - Manual Control Pg. 5.

Page 7

I N S TA L L A T I O N

I N S T A L L AT I O N R E Q U I R E M E N T S

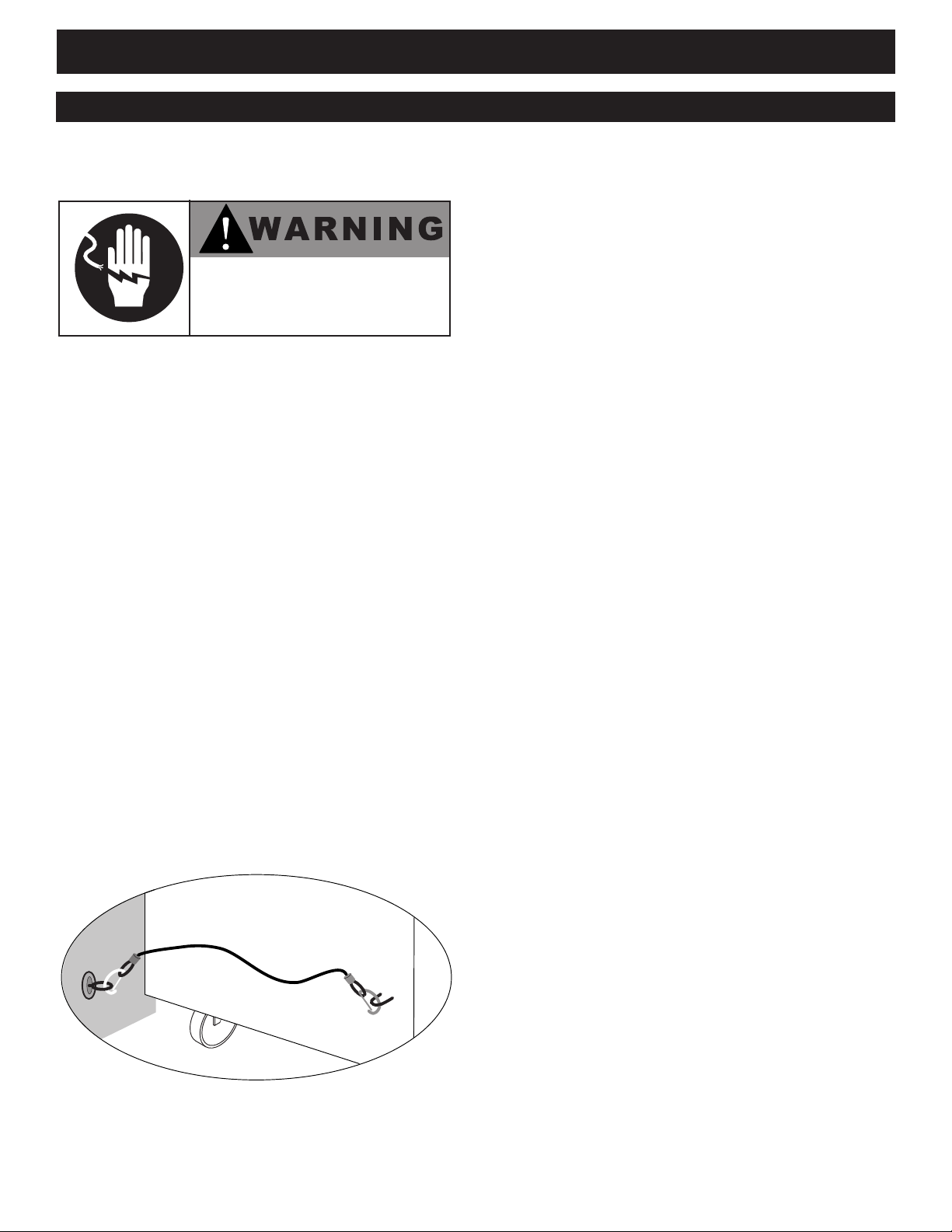

RESTRAINT REQUIREMENTS

—MOBILE EQUIPMENT

RISK OF ELECTRIC SHOCK.

Appl iance must be secured

to build ing structure.

Any appliance that is not furnished with a power

supply cord but includes a set of casters must be

provided with a tether. Adequate means must be

provided to limit the movement of this appliance

without depending on or transmitting stress to the

electrical conduit. The following requirements

apply:

1. Casters must be a maximum height of

6" (152mm).

2. Two of the casters must of be the

locking type.

3. Such mobile appliances or appliances on

mobile stands must be installed with the

use of a flexible connector secured to the

building structure.

A mounting connector for a restraining device is

located on the lower back flange of the appliance

chassis or on an oven stand, approximately 18"

(457mm) from the floor. A flexible connector is

not supplied or available from the factory.

#8701/2 Electric Convection Oven - Manual Control • 6

Page 8

I N S TA L L A T I O N

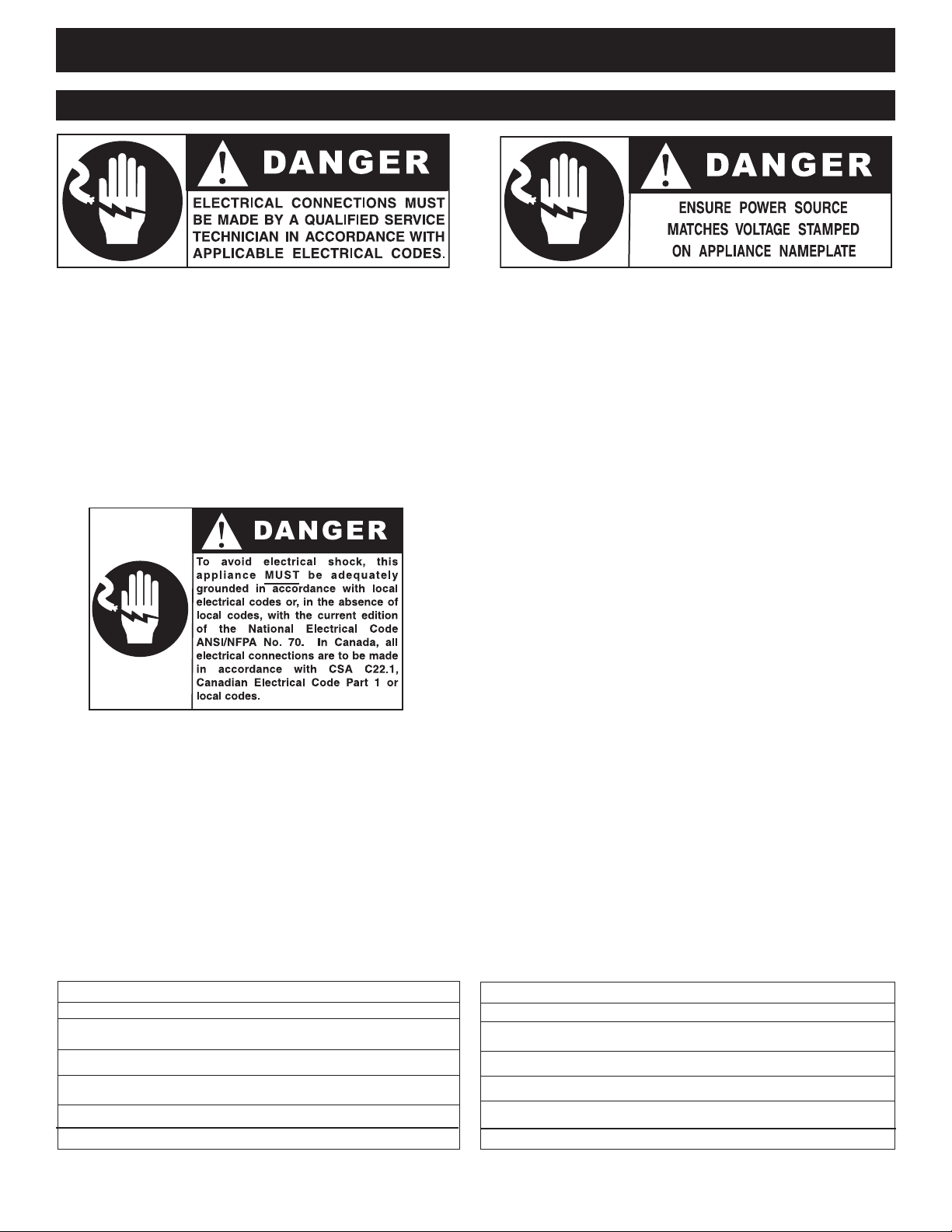

E L E C T R I C A L C O N N E C T I O N

The oven must be installed by a qualified

electrician. This appliance must be branch circuit

protected with proper ampacities, in accordance

with the wiring diagram located in this manual or

in the electrical compartment of the oven. The

oven must be properly grounded in accordance

with the National Electrical Code and applicable

local codes.

Plug the unit into a properly grounded receptacle

ONLY, positioning the unit so that the plug is

easily accessible in case of an emergency. Arcing

will occur when connecting or disconnecting the

unit unless all controls are in the “off” position.

Proper receptacle or outlet configuration or

permanent wiring for this unit must be installed

by a licensed electrician in accordance with

applicable local electrical codes.

Wire size for the main incoming power to the

unit must match the minimum size listed in the

specifications applicable to the specific oven

model. For supply connections, locate the wire

size posted on the label located near the electric

terminal block behind the service panel or

elsewhere listed in this manual. Before

attempting the electrical connection, the rating

plate should be checked to ensure that the

electrical characteristics of the appliance and the

electrical supply characteristics agree.

Installation of the wiring must be made in

accordance with U.L. 197 Commercial Electric

Cooking Appliance Standards, Local and/or

National Electrical Code, ANSI /NFPA 70-1990.

Service line entry is made through the rear of the

oven for connection to the terminal block.

Remove the service panel on the right side of the

oven for access to the terminal block.

The oven is wired at the factory for either single

phase or three phase service as indicated on the

original purchase order. Input voltage and phase

must match the voltage and phase of the oven.

Visually check all electrical connections.

E L E C T R I C A L • A C S - 2 E

VOLTAGE PHASE CYCLE/ HZ AWG AMPS kW

208 1 50/60 10 25.5 5.3

240 1 50/60 10 22.0 5.3

208 3 50/60 12 14.7 5.3

240 3 50/60 12 12.8 5.3

N O CO RD A N D P L U G

#8701/2 Electric Convection Oven - Manual Control Pg. 7.

E L E C T R I C A L • A S C - 4 E

VOLTAGE PHASE CYCLE/ HZ AWG AMPS kW

208 1 50/60 6 50.0 10.4

240 1 50/60 6 43.3 10.4

208 3 50/60 8 25.0 10.4

240 3 50/60 8 25.0 10.4

N O CO RD A N D P L U G

Page 9

I N S TA L L A T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

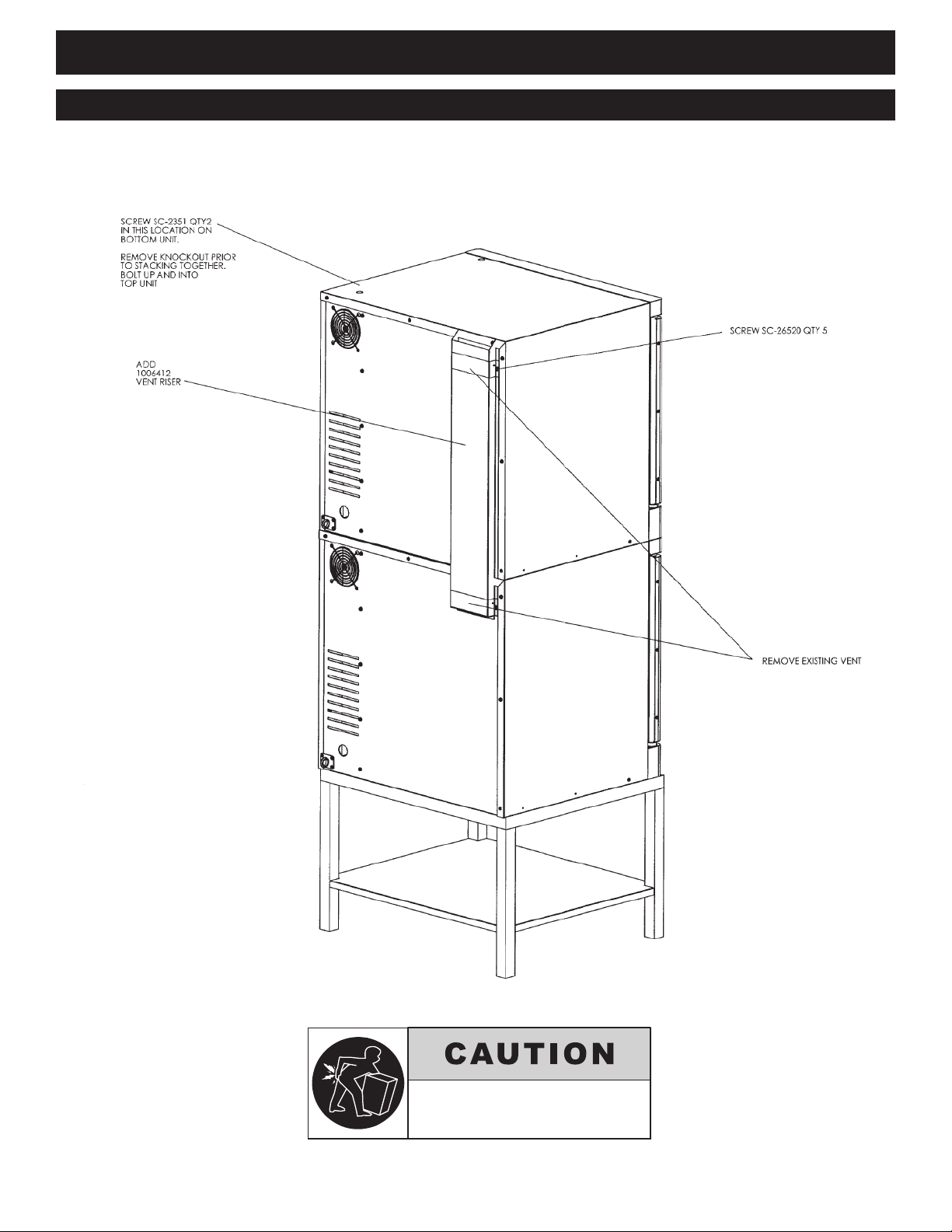

S T A C K I N G & V E N T I N G A S S E M B L Y f o r 2 - A S C - 2 E / S T K

#8701/2 Electric Convection Oven - Manual Control • 8

Stand

#5004672

2 - A S C - 2 E / S T K

Page 10

I N S TA L L A T I O N

2

3

Remove top elbow

vent prior to

installing riser.

Assemble venting

components

2 and 3 as shown.

2 1004984 RISER, FLUE ELECTRIC 1

3 SC-26520 SCREW, #10 SMS .5LG 5

Item No. Part No. Description Qty.

After legs or casters have been installed

on the bottom oven, place the upper oven

on top of lower unit. Align.

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

S T A C K I N G & V E N T I N G A S S E M B L Y f o r 2 - A S C - 4 E / S T K

2 - A S C - 4 E / S T K

#8701/2 Electric Convection Oven - Manual Control • 9

Page 11

I N S TA L L A T I O N

d

a

b

i

b

c

g

a

f

b

e

h

a

34-5/16" (872mm)

38" (965mm)

44-3/16" (1122mm)

O V E N S T A N D A S S E M B L Y - A S C - 4 E

A S C - 4 E

ITEM NO PART NUMBER DESCRIPTION QTY.

1 5003488 Leg Support Assembly 2

2 1004459 Channel, Support 2

3 LG-22185 Leg 4

CS-25474 Casters, rigid 2

CS-25674 Casters, swivel w/brake 2

4 1004461 Bracket, Stand 1

5 1004369 Bracket, Attachment 2

6 1004460 Channel, Back 1

7 1004466 Shelf, Stand 1

8 SR-26551 Rack, Oven Support 2

9 SH-26395 Oven Rack 6

10 SC-22729 Screws, 1/4-20 x 1/2 Hex Head 27

11 NU-23984 Net, 1/4-20 Nylon Insert, 18-8 S/S 27

12 WS-2294 Washer 27

#8701/2 Electric Convection Oven - Manual Control • 10

Page 12

O P E R A T I N G I N S T R U C T I O N S

U S E R S A F E T Y I N F O R M AT I O N

S T A R T- U P O P E R A T I O N

This appliance is intended for use in commercial

stablishments by qualified operating personnel

e

where all operators are familiar with the

purpose, limitations, and associated hazards of

this appliance. Operating instructions and

warnings must be read and understood by all

operators and users.

BEFOR E INITIAL USE:

Interior oven surfaces must be heated to remove

surface oils and the accompanying odor

produced during the first use of the oven.

1. Wipe all wire shelves, side racks and the full

oven interior with a clean, damp cloth.

O P T I O N S & A C C E S S O R I E S • A S C - 2 E

LEG KIT, 4" (102mm)

Seismic feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5004688

■■

LEG KIT

■■

with Bullet feet, 19-1/2" (495mm) HEIGHT . . . . . . . . .5005169

with Seismic feet, 19-1/2" (495mm) HEIGHT . . . . . . .5005168

■■

with Casters, 23" (584mm) HEIGHT . . . . . . . . . . . . . . .5005181

■■

■■

SHELF, OVEN RACK . . . . . . . . . . . . . . . . . . . . . . . .SH-26894

STACKING HARDWARE

SEE INDIVIDUAL STACKING COMBINATION SPECIFICATION SHEETS

STAND, SINGLE OVEN

with Bullet feet, 26-1/2" (673mm) HEIGHT . . . . . . . . .5004672

■■

with Seismic feet, 26-1/2" (673mm) HEIGHT . . . . . . .5005172

■■

■■

with Casters, 30" (762mm) HEIGHT . . . . . . . . . . . . . . .5004687

O P T I O N S & A C C E S S O R I E S • A S C - 4 E

■■

CASTER SET, 6" (152mm) 5003790

COOLING RACK FOR OVEN STAND 5003791

■■

LEG SET (4)

6" (152mm) with Bullet Feet 5003794

■■

■■

6" (6152mm) with Seismic Feet 5003795

■■

25" (635mm) with Seismic Feet 5003785

■■

PANEL FOR BACK, Stainless Steel 5005876

SHELF, OVEN RACK

INTERCHANGEABLE WITH COOLING RACK SH-26795

■■

STACKING HARDWARE

SEE INDIVIDUAL STACKING COMBINATION SPECIFICATION SHEETS

STAND, STAINLESS STEEL

■■

Mobile, with Cooling Racks & Casters, 38" H (965mm)5003786

Stationary, with Cooling Racks & Bullet Feet 5003489

■■

Stationary, with Cooling Racks & Seismic Feet 5003787

■■

34-1/4" (870mm) min. • 35-1/2" (902mm) max. H

#8701/2 Electric Convection Oven - Manual Control Pg. 11.

(FEET ARE ADJUSTABLE)

2. Close the oven doors, press the power

N

O

switch to the

position, and set the

thermostat to 300°F (149°C).

3. Allow the oven to cycle for approximately

2 hours or until no odor is detected.

PR EHE ATIN G:

Always preheat a cold oven for a minimum of

20 minutes before cooking product. Follow

the operating instructions indicated on the next

few pages of this manual.

IN THE EVE NT O F A POWER FAILURE:

• TURN ALL SWITCHES OFF.

• WAIT UNTIL POWER IS RESTORED BEFORE

ATTEMPTING TO OPERATE THE OVEN.

NOTE: If su ch an event has occurred, it is strong ly

recomme nded that you ensure the food in the ov en

is safe for consump tion according to local health

regulations.

A S C - 2 E • P R O D U C T \ PAN C A PA C I T Y

27 lb (12 kg) MAXIMU M — 17 qts (15 liters)

Nine (9): 18" x 13" x 1" HAL F-SIZ E SHEET PANS

5 chrome plated wire shelves with 2 removable side

racks and 9 shelf positions spaced

at 1-5/8" (41mm) ea.

A S C - 4 E • P R O D U C T \ PAN C A PA C I T Y

72 lb (33 kg) MAXIMU M — 45 qts (43 liters)

Twelve (12): 18" x 26" x 1" FUL L-SIZE S HEET PANS

6 chrome plated wire shelves with 2 removable side

racks and 12 shelf positions spaced

at 1-3/4" (43mm) ea.

Page 13

O P E R A T I N G I N S T R U C T I O N S

METAL PARTS OF THI S EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVO ID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

U S E R I N F O R M A T I O N

PAN /SH ELF POSITIONS FO R AS C-2 E:

The oven includes 5 chrome plated wire

shelves with two removable side racks and

shelf positions spaced at 1

9

-

5/8

"

(41mm).

POSITION

. The best arrangement for broiling, baking

1

2

cookies and for other baked goods under

4

-1/

" (65mm) in height. This arrangement can

2

6

8

POSITION

2. General baking with the use of sheet pans for

1

4

7

POSITION

3. Ideal positions for baking bread, meringue, or

1

5

4. Arrangement necessary for roasting whole

POSITION

1

2

also be used as the maximum capacity for

reconstituting frozen entrées.

products under 3-

1

/

" (89mm) in height.

2

Products include cakes, pies, muffins, or

extended dishes in 12" x 20" x 2-

(530mm x 325mm x 65mm GN

1

/

" deep pans

2

1

).

/

1

extended dishes and roasts in pans not to

1

exceed 5-

/

" (140mm) in height.

2

turkey or roasts up to 7" (178mm) in height.

6

PAN /SH ELF POSITIONS FO R AS C-4 E:

The oven includes 6 chrome plated wire

shelves with two removable side racks and

12 shelf positions spaced at 1-

3

/

" (43mm).

4

POSITION

1. The best arrangement for broiling,

2

4

6

8

10

12

POSITION

2. General baking with the use of sheet

1

4

7

10

POSITION

3. Ideal positions for baking bread,

1

5

9

POSITION

4. Arrangement necessary for roasting

1

6

baking cookies and for other baked

1

" (65mm) in height.

goods under 2-

/

2

This arrangement can also be used as

the maximum capacity for

reconstituting frozen entrées.

1

/

pans for products under 3-

"

2

(89mm) in height. Products include

cakes, pies, muffins, or extended

1

/

dishes in 12" x 20" x 2(530mm x 325mm x 65mm GN

" deep pans

2

1

/

).

1

meringue, or extended dishes and

1

/

roasts in pans not to exceed 5-

"

2

(140mm) in height.

whole turkey or roasts up to 7"

(178mm) in height.

#8701/2 Electric Convection Oven - Manual Control • 12

Page 14

O P E R A T I N G I N S T R U C T I O N S

MANUAL CONTROL OPERATION

1. Press POWER SWITCH to the ON position.

2. Press FAN SWITCH to high or low fan speed.

3. Set COOK TEMPERATURE THERMOSTAT

to the temperature desired.

When this temperature is reached,

LIGHT OFF\OVEN READY indicator light

will go out.

ALLOW A MINIMUM OF 20 MINUTES

TO PREHEAT A COLD OVEN.

4. Load product into the oven.

For best results, always load the oven from the

bottom to the top position and load as quickly as

possible to retain maximum oven compartment heat.

5. Set COOK TIMER by rotating the knob

clockwise past the time required and then back to

the desired time.

The timer will begin to count down. When the

timer reaches zero, the oven will produce an audible

alert signal that will continue for three minutes or

until the timer knob is turned counterclockwise to

the OFF position.

COOL-DOWN MODE

1. Press POWER SWITCH to

the COOL DOWN position.

2. Open the oven doors.

SHUT-DOWN PROCEDURE

1. Press POWER SWITCH

to the OFF position.

#8701/2 Electric Convection Oven - Manual Control • 13

Page 15

C H E F O P E R AT I N G T I P S

he Alto-Shaam convection oven will provide the best results and longest possible

T

service with the utilization of the following suggestions and guidelines.

NOTE: Moisture will escape around the doors when baking products with a heavy

moisture content such as chicken, potatoes, etc. This is a normal operating

ondition.

c

1. Preheat a cold oven for a minimum of 20 minutes

before use.

2. As a general rule, the cooking temperature can be

set lower than the temperature used in a

conventional oven. Cooking time may also be

shorter. It is suggested the first batch of each

product prepared be monitored closely to check for

variances.

3. Maintain a record of the temperatures, times, and

load capacities established for products cooked on

a regular basis since they will be the same or

similar for succeeding loads.

4. When practical, start cooking the lowest

temperature products first and gradually work up

to products with a higher cooking temperature.

5. If the cooking temperature setting for the previous

product is more than 10°F (5°C to 6°C) higher than

the temperature needed for the next load, use the

COOL-DOWN feature to decrease the oven

temperature before setting the oven to a lower

temperature.

6. Work as quickly as possible when loading the oven

to prevent heat loss.

7. When the audible signal indicates the time has

expired, remove the product from the oven as

quickly as possible to avoid over-cooking.

8. Pan s sh ould be centered b etween side rac ks a nd

each shelf should be l oad ed evenly to allow

prope r ai r circu lation within the oven

compartme nt.

9. To assure even cooking when baking, weigh or

measure the product in each pan.

10 . ASC-2E:

When cooking five pans of product, start from the

bottom of the oven and use side rack positions 1, 3,

5, 7, and 9.

AS C-4 E:

When cooking six pans of product, start

from the bottom of the oven and use side rack

positions 2, 4, 6, 8, 10, and 12.

11 . Do not overload the oven. Refer to product/pan

capacities indicated in this manual.

12 . To obtain the most evenly baked product, muffin

pans should be placed in the oven with the short

side of each pan facing the front of

the oven.

13 . When rethermalizing frozen casseroles, preheat

the oven 100°F (38°C) over the suggested

temperature to compensate for the introduction of

a large quantity of frozen product into the oven

compartment. Reset the thermostat to the correct

cooking temperature after the oven is loaded.

14. Use a pan extender or two inch (51mm) deep,

18” x 26” pans for batter-type products that weigh

more than 8 pounds (3 to 4 kg), i.e.; pineapple

upside-down cake.

15. To avoid obstructing airflow that would result in

uneven cooking results, never place anything

directly on the bottom of the oven cavity.

AT T H E E N D O F T H E DAY, U T I L I Z E T H E

C O O L - D O W N M O D E . S H U T O F F

P O W E R O N T H E CO O L E D O V E N

B E F O R E L E A V I N G .

Cooking Guidelines

F° Minutes

Food Temperature /Time

Cakes, Sheet 325° 25

Chicken pieces 400° 25

30 breasts & thighs, 25 legs & wings

Chicken halves 400° 40

Beef patties 400° 8

Bacon 350° 16

Fish, frozen (5 oz.) 350° 15

Macaroni & Cheese, frozen, 1 pan 350° 50

Macaroni & Cheese, frozen, full oven 350° 90

Macaroni & Cheese, refrigerated 350° 30

Muffins 325° 13-15

Pies, Frozen 325° 40

Pizzas, Individual 325° 15

Potatoes, Baked 350° 50

Sandwiches, Grilled Cheese 400° 4-6

Tater tots 450° 10

Do not place anything directly

on the bottom of the oven cavity.

#8701/2 Electric Convection Oven - Manual Control • 14

Page 16

C L E A N I N G A N D P R E V EN T I V E M A IN T E N A N C E

PROTECTING STAINLESS STEEL SURFACES

It is important to guard against

corrosion in the care of stainless

steel surfaces. Harsh,

corrosive, or inappropriate

chemicals can completely

destroy the protective surface

layer of stainless steel. Abrasive pads, steel wool,

or metal implements will abrade surfaces causing

damage to this protective coating and will

eventually result in areas of corrosion. Even water,

particularly hard water that contains high to

moderate concentrations of chloride, will cause

oxidation and pitting that result in rust and

corrosion. In addition, many acidic foods spilled

and left to remain on metal surfaces are

contributing factors that will corrode surfaces.

Proper cleaning agents, materials, and

methods are vital to maintaining the appearance

and life of this appliance. Spilled foods should be

removed and the area wiped as soon as possible

but at the very least, a minimum of once a day.

Always thoroughly rinse surfaces after using a

cleaning agent and wipe standing water as quickly

as possible after rinsing.

CLEANING AGENTS

Use non-abrasive cleaning products designed for use

on stainless steel surfaces. Cleaning agents must be

chloride-free compounds and must not contain

quaternary salts. Never use hydrochloric acid

(muriatic acid) on stainless steel surfaces. Always

use the proper cleaning agent at the manufacturer's

recommended strength. Contact your local cleaning

supplier for product recommendations.

CLEANING MATERIALS

The cleaning function can

usually be accomplished

with the proper cleaning

agent and a soft, clean

cloth. When more

aggressive methods must be

employed, use a non-abrasive

scouring pad on difficult areas

and make certain to scrub with the

visible grain of surface metal to avoid surface

scratches. Never use wire brushes, metal scouring

pads, or scrapers to remove food residue.

#8701/2 Electric Convection Oven - Manual Control • 15

Page 17

C L E A N I N G A N D P R E V EN T I V E M A IN T E N A N C E

The oven is fabricated with an easy to clean

porcelain enamel interior or an optional stainless

steel interior.

NOTE: Always allow the oven to cool before

cleaning. If the oven is hot, allow the

interior surfaces to become cool to the

touch by using the cool-down mode and

opening the oven door(s).

C L E A N T H E O V E N O N A D A I LY B A S I S .

AT NO TIME SHO ULD THE OVEN INTERIOR OR

XTE RIOR BE S TEAM CLE A NED, HOS E D

E

DOWN, OR F LOODED WITH ANY TYP E O F

IQUI D. DO NOT U SE A WATER JE T TO CL EAN.

L

S E V E R E D A M A G E O R E L E C T R I C A L

HAZARD C O U L D R E S U LT. SUCH METHODS

WILL ALSO VOID ANY WARRANTY CLAIMS.

NOTE: DO NO T USE ABR ASIVE CL EANIN G

CO MPOUN DS.

Completely avoid the use of

abrasive cleaning compounds, chloride-based

cleaners, or cleaners containing quaternary salts.

To protect metal finish on stainless steel, never use

hydrochloric acid (muriatic acid).

1. After the oven has cooled, remove all detachable

items such as wire shelves, side racks, and any drip

pan. Clean these items separately.

2. Remove any food scraps from shelves, shelf

supports, and blower fan wheel. Convection

baffle openings must be kept clear of food scraps

and grease.

3. Wipe the interior metal surfaces of the oven

with a paper towel to remove any remaining

food debris.

4. Clean interior with a damp cloth or sponge and

any good commercial detergent at the

recommended strength.

5. For baked-on food deposits, use a non-caustic and

non-toxic commercial oven cleaner appropriate for

the interior oven surface of the oven. Follow the

product manufacturer's instructions carefully for

the use of this product. Any commercial oven

cleaner must be approved for use on food contact

areas. Remove soil with the use of a plastic

scouring pad.

6. Wipe door gaskets, control

panel, door vents, and door

handle thoroughly since these

areas harbor food debris

and grease.

7. Rinse surfaces by wiping with a clean cloth or

sponge and clean warm water.

8. Remove excess water with a sponge and wipe dry

with a clean cloth or air dry. Leave doors open

until interior is completely dry. Replace side racks

and shelves.

Always follow appropriate state or local health

(hygiene) regulations regarding all applicable cleaning

and sanitation requirements for food service

equipment.

6. Wipe door gaskets, control panel, door vents, and

door handle thoroughly since these areas harbor

food debris and grease.

7. Rinse surfaces by wiping with a clean cloth or

sponge and clean warm water.

#8701/2 Electric Convection Oven - Manual Control • 16

AT T H E E N D O F T H E DAY, U T I L I Z E T H E

C O O L - D O W N M O D E . S H U T O F F

P O W E R O N T H E CO O L E D O V E N

B E F O R E L E A V I N G .

Page 18

C L E A N I N G A N D P R E V EN T I V E M A IN T E N A N C E

E X T E R I O R :

To help maintain the protective film coating on

polished stainless steel, clean the exterior of the

cabinet with a cleaner recommended for stainless

steel surfaces. Spray the cleaning agent on a clean

loth and wipe with the grain of the stainless steel.

c

Wipe control panel, door vents and door handles,

thoroughly since these areas harbor food debris.

Clean exterior glass surfaces with a commercial

window cleaner.

D O N O T U S E A B R A S I V E C L E A N I N G

C O M P O U N D S .

M O T O R C A R E

The convection oven motor contains selflubricating, sealed ball bearings and is generally

aintenance-free. During operation, the interior

m

of the motor is cooled by air flowing into the rear

of the motor case. This is a general operating

feature when proper clearances have been

allowed.

AT T H E E N D O F T H E DAY, U T I L I Z E T H E

C O O L - D O W N M O D E . S H U T O F F

P O W E R O N T H E CO O L E D O V E N

B E F O R E L E A V I N G .

T R O U B L E S H O O T IN G G U I D E

Oven has no power. Check to ensure oven is connected to proper power source.

Check that breaker is turned on.

Fuses are blown.

Oven has power but will not turn ON . Ensure power switch is turned on.

Ensure hi limit is not tripped.

Ensure doors are closed.

Ensure timer is turned on.

Ensure fan switch is turned on.

Door switch is bad or out of adjustment.

Oven fan turns ON , but there is no heat. Ensure thermostat is turned on.

Ensure hi-limit is not tripped.

Oven heats, fan runs, but doesn’t

shut OFF when door is opened. Door switch is bad or out of adjustment.

#8701/2 Electric Convection Oven - Manual Control • 17

Page 19

S E R V I C E - A S C- 2 E

ervice must be in accordance with all

S

local codes and must be performed by

a qualified service technician.

DOOR ASSEMB LY

5004352

SIDE RACK (2 PCS)

SR-2689 3

OVEN SHELF (5 PCS )

SH-2689 4

DOOR ROLLER

ASSEMBLY

DOOR ROLLER

ASSEMBLY

KNOB, CONTR OL ( 2 PCS)

KN-3410 3

PANEL OVER LAY

PE-2697 8

SWITCH,

ON/OFF COOL -DOWN

SW-3411 2

SWITCH,

FAN, HI/LO

SW-3410 1

INDICATOR LIGHT

LI-3951

THERMOS TAT

TT-3409 2

TIMER

TR-3417 4

GASKET

TOP & BOTTOM 1005 316

SIDES 10053 11

STAND, MOB ILE

(O PT ION AL) 5004 68 7

ASC-2E

#8701/2 Electric Convection Oven - Manual Control • 18

Page 20

S E R V I C E - A S C - 2 E

I N T E R I O R O V E N C O M P A R T M E N T

MO TO R

MO-3420 8

SI DE RAC K

SR-2689 3

SH EL F

SH-2689 4

NO T SHOW N

ASC-2E

oven interior

BA FF LE

5005074

GASKET

TOP & BOTTOM 1005 316

SIDES 10053 11

#8701/2 Electric Convection Oven - Manual Control • 19

Page 21

R I G H T S I D E S E R V I C E PA N E L - R E M O V E D

UL B/REC EP TACL E

B

LP-3686

RP-3986

N/OFF SWI TC H

O

SW-3411 2

FAN SWI TC H

SW-3410 1

S E R V I C E - A S C - 2 E

EAT ELE ME NTS

IG H LIMI T

H

SW-3415 0

H

EL-3421 1

EL-3421 2

, 20 8V

IN DI CATO R LIGHT

LI-3951

TH ER MOS TAT

TT-3409 2

TR-3417 4

TE RM INA L BLOCK

BK-3597

TI ME R

HI GH LIM IT

SW-3350 0

MO TO R

MO-3420 8

LO W LIMI T

SW-3337 8

MO TO R PR OTECTI ON

SW IT CHE S

ASC-2E

#8701/2 Electric Convection Oven - Manual Control • 20

FAN HOU SI NG

FA-3568

Page 22

S E R V I C E - A S C- 4 E

ervice must be in accordance with all

S

local codes and must be performed b y a

q u a l i f i e d s e r v i c e t e c h n i c i a n .

DOOR ASSEMB LY, L H

5005407

SIDE RACK (2 PCS)

SR-2639 6

OVEN RACK (6 PCS)

SH-2639 5

TOP & BOTTOM 6606

SIDES 6605

PANEL OVER LAY

PE-2672 9

SWITCH,

ON/OFF COOL -DOWN

SW-3411 2

SWITCH,

FAN, HI/LO

SW-3410 1

INDICATOR LIGHT

LI-3951

THERMOS TAT

TT-3409 2

KNOB, THERM OSTAT

KN-3429 7

TIMER

TR-3417 4

KNOB, TIMER C ON TROL

KN-3410 3

DOOR ASSEMB LY, R H

5005409

GASKETS

STAND, STATIONA RY

(O PT ION AL) 5003 48 9

SIDE RACK

SUPPORT ( 2 PC S)

SR-2655 1

ASC-4E

#8701/2 Electric Convection Oven - Manual Control • 21

Page 23

S E R V I C E - A S C - 4 E

I N T E R I O R O V E N C O M P A R T M E N T

LE ME NT

E

RE AR EL-341 26

MI DD LE E L-34127

RO NT

F

, 20 8V

EL-3412 8

LI GH T RE CEPTACL E

LP-3416 1

SI DE RAC K

SR-2639 6

ASC-4E

oven interior

BL OW ER W HEEL

WH-2640 5

#8701/2 Electric Convection Oven - Manual Control • 22

TH ER MOS TAT

GU AR D

1004611

Page 24

N/OFF SWI TC H

O

SW-3411 2

S E R V I C E - A S C - 4 E

R I G H T S I D E S E R V I C E PA N E L - R E M O V E D

OT OR PRO TEC TION

BU LB /RE CEP TACL E

LP-3686

RP-3986

HIGH SW-335 00 LOW SW-333 78

M

SW IT CHE S

FAN SWI TC H

SW-3410 1

TH ER MOS TAT

TT-3409 2

TI ME R

TR-3417 4

HI GH LIM IT

SW-3415 0

TE RM INA L BLOCK

BK-3597

ASC-4E

#8701/2 Electric Convection Oven - Manual Control • 23

Page 25

UX IL IAR Y

A

AN

F

S E R V I C E - A S C - 4 E

R E A R P A N E L - R E M O V E D

OI ST URE

M

EAT

H

LE ME NTS

E

VE NT

EL EC TRI CAL

CO NN ECT ION

MO TO R

MO-3421 5

ASC-4E

#8701/2 Electric Convection Oven - Manual Control • 24

Page 26

S E R V I C E PA RT S L I S T

Description ASC-2E ASC-4E

Part No.Part No. Qty.

Cosmetic/Exterior Components

Panel, Top and Side 1005455 1006623 1

Gasket, LH/RH 1005311 1006605 2

Gasket, Top/Bottom 1005316 1006606 2

Panel, Service, louvered 1006602 1006672 1

Cover, Bottom 1005458 1006678 1

Cover, Top 1005459 1006679 1

Interior

Rack, Side SR-26893 SR-26396 2

Shelf SH-26894 SH-26795 5 / 6

Lamp, *CT, snap-in, oven light -- LP-34161 2

Gasket, oven lamp -- GS-26630 2

Glass, *CT, oven lamp -- GL-26608 2

Cover for oven light -- CV-26607 2

Receptacle, Lamp -- RP-3986 1

Oven Elements

Element, Outer, 208V EL-34211 -- 1

Element, Inner, 208V EL-34212 -- 1

Element, Rear, 208V -- EL-34126 1

Element, Center, 208V -- EL-34127 1

Element, Front, 208V -- EL-34128 1

Element, Inner, 240V EL-34209 1

Element, Outer, 240V EL-34210 1

Element, Rear, 240V -- EL-34129 1

Element, Center, 240V -- EL-34146 1

Element, Front, 240V -- EL-34125 1

Motor/Blower Wheel

Motor, 208/240V MO-34208 MO-34215 1

Wheel, Blower WH-26895 WH-26405 1

Door Assembly

Assembly, Complete 5004352 1

Assembly, Complete, RH -- 5005407 1

Assembly, Complete, LH -- 5005409 1

Switches/Thermostats/Timers

Block, Terminal BK-3597 BK-3597 1

Block, Modular BK-25567 BK-25567 1

Buzzer BZ-34113 BZ-34113 1

Contactors, *CT, 240V, 50A CN-3731 CN-3731 1 / 2

Fan, Box, 70CFM, 230V, 50-60HZ FA-3568 FA-3568 1

Fuse Holder, Dual, 15A, Class G FU-3772 FU-3772 1

Fuses, *CT, 15A, Class G FU-3775 FU-3775 2

Guard, Fan GD-2396 GD-2396 1

Knob, Control, Indicating KN-34103 KN-34103 1

Knob, Thermostat KN-34297 KN-34297

Light Indicator LI-3025 LI-3025 1

Panel Overlay PE-26978 PE-26729 1

Switch, Rocker, Fan, High/Low SW-34101 SW-34101 1

Switch, On/Off/Cool-down SW-34112 SW-34112 1

Switch, High Limit TT-3750 SW-34150 1

Switch, Door, Roller SW-34164 SW-34164 1

Switch, Motor Protect SW-33500 SW-33550 1

Switch, Motor Protect SW-33378 SW-33378 1

Timer, 250V, 1 hr TR-34174 TR-34174 1

Thermostat, 140-500 Deg. F TT-34092 TT-34092 1

#8701/2 Electric Convection Oven - Manual Control • 25

Page 27

#8701/2 Electric Convection Oven - Manual Control • 26

Page 28

#8701/2 Electric Convection Oven - Manual Control Pg. 27

Page 29

#8701/2 Electric Convection Oven - Manual Control • 28

Page 30

All Alto-Shaam equipment

is sold F.O.B. shipping

p

oint, and when accepted

by the carrier, such

shipments become the

property of the consignee.

Should damage occur in shipment, it is a matter

between the carrier and the consignee. In such cases, the

carrier is assumed to be responsible for the safe delivery

o

f the merchandise, unless negligence can be established

on the part of the shipper.

1. Make an immediate inspection while the equipment

is still in the truck or immediately after it is moved to

the receiving area. Do not wait until after the

material is moved to a storage area.

2. Do not sign a delivery receipt or a freight bill until

you have made a proper count and inspection of all

merchandise received.

3. Note all damage to packages directly on the carrier’s

delivery receipt.

4. Make certain the driver signs this receipt. If he

refuses to sign, make a notation of this refusal on

the receipt.

5. If the driver refuses to allow inspection, write the

following on the delivery receipt:

Driver refuses to allow inspection of

containers for visible dam age.

6. Telephone the carrier’s office immediately upon

finding damage, and request an inspection. Mail a

written confirmation of the time, date, and the

person called.

7. Save any packages and packing material for further

inspection by the carrier.

8. Promptly file a written claim with the carrier and

attach copies of all supporting paperwork.

We will continue our policy of assisting our

customers in collecting claims which have been properly

filed and actively pursued. We cannot, however, file any

damage claims for you, assume the responsibility of any

claims, or accept deductions in payment for such claims.

Alto-Shaam, Inc. warrants to the original purchaser that any

original part that is found to be defective in material or workmanship

will, at Alto-Shaam's option, subject to provisions hereinafter stated,

be replaced with a new or rebuilt part.

The labor warranty remains in effect one (1) year from installation

or fifteen (15) months from the shipping date, whichever occurs first.

Alto-Shaam will bear normal labor charges performed during standard

business hours, and excluding overtime, holiday rates or any

additional fees.

The parts warranty remains in effect for one (1) year from

installation or fifteen (15) months from the shipping date, whichever

occurs first.

H

owever, the heating element on Halo Heat

®

c

ook/hold ovens

and the refrigeration compressor on Alto-Shaam Quickchillers

™

are

warranted for a period of five (5) years from installation. The labor

warranty is the same as stated above; namely, for one (1) year from

installation or fifteen (15) months from the shipping date, whichever

occurs first.

THIS WARRAN TY DOES NOT APP LY TO:

1. Calibration.

2. Replacement of light bulbs and/or the replacement of display

case glass due to damage of any kind.

3. Equipment damage caused by accident, shipping, improper

installation or alteration.

4. Equipment used under conditions of abuse, misuse, carelessness

or abnormal conditions including, but not limited to, equipment

subjected to harsh or inappropriate chemicals including, but not

limited to, compounds containing chloride or quaternary salts, poor

water quality, or equipment with missing or altered serial numbers.

5. Damage incurred as a direct result of poor water quality,

inadequate maintenance of steam generators and/or surfaces

affected by water quality. Water quality and required maintenance

of steam generating equipment is the responsibility of the

owner/operator.

6. Damage caused by use of any cleaning agent other than

Alto-Shaam's Combitherm

®

Cleaner including, but not limited to,

damage due to chlorine or other harmful chemicals. Use of

Alto-Shaam's Combitherm®Cleaner on Combitherm®ovens is

highly recommended.

7. Any losses or damage resulting from malfunction, including loss

of product or consequential or incidental damages of any kind.

8. Equipment modified in any manner from original model,

substitution of parts other than factory authorized parts,

removal of any parts including legs, or addition of any parts.

This warranty is exclusive and is in lieu of all other warranties,

expressed or implied, including the implied warranties of

merchantability and fitness for a particular purpose. In no event

shall Alto-Shaam be liable for loss of use, loss of revenue or profit,

or loss of product, or for any indirect or consequential damages.

No person except an officer of Alto-Shaam, Inc. is authorized to

modify this warranty or to incur on behalf of Alto-Shaam any other

obligation or liability in connection with Alto-Shaam equipment.

ALTO-SHAAM, INC.

TRANSPORTATION

DAMAGE and CLAIMS

®

RECORD THE MODEL AND SERIAL NUMBER OF THE APPLIANCE FOR EASY REFERENCE.

ALWAYS REFER TO BOTH MODEL AND SERIAL NUMBER IN ANY CONTACT WITH ALTO-SHAAM REGARDING THIS APPLIANCE.

Model: _______________________________________________Date Installed: __________________________________________________________

Voltage: ______________________________________________ Purchased From: _______________________________________________

Serial Number: _______________________________________ _______________________________________________________________________

W164 N9221 Water Street●P.O. Box 450●Menomonee Falls, Wisconsin 53052-0450●U.S.A.

PHONE: 262.251.3800 • 800.558-8744 USA/CANADA FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY

WEBSITE: www.alto-shaam.com

PRINTED IN U. S . A .

LIMITED

WARRANTY

Loading...

Loading...