Page 1

GB

F

D

E

HR

GR

CZ

H

I

NL

P

PL

www.liftmaster.com

Email: info@chamberlain.com

0678

AT/BA/BE/BG/CH/CY/CZ/DE/DK/ES/

FR/GB/GR/HR/HU/IE/IS/IT/LU/MT/NL

NO/PL/PT/RO/RU/SE/SI/SK/TR/YU

RUS

709438

i

INT

FR

GB

NL

(+49) 06838-907-172

03.87.95.39.28

0845-602-4285

020.684.79.78

DE

06838-907-172

Anleitungen und elektrische Installation CB10

Instructions et installation électrique CB10

Instructions and electrical set up CB10

Návody a elektrická instalace CB10

Instrucciones y instalación eléctrica CB10

Οδηγίες και ηλεκτρική εγκατάσταση CB10

Útmutatók és elektromos installáció CB10

Upute i električne instalacije CB10

Istruzioni e installazione elettrica CB10

Instruktie en electrische installatie CB10

Manuais e instalação eléctrica CB10

Instrukcja i instalacja elektryczna CB10

Инструкции и электромонтаж CB10

Page 2

709438

© Chamberlain GmbH 2010, all rights reserved

Page 3

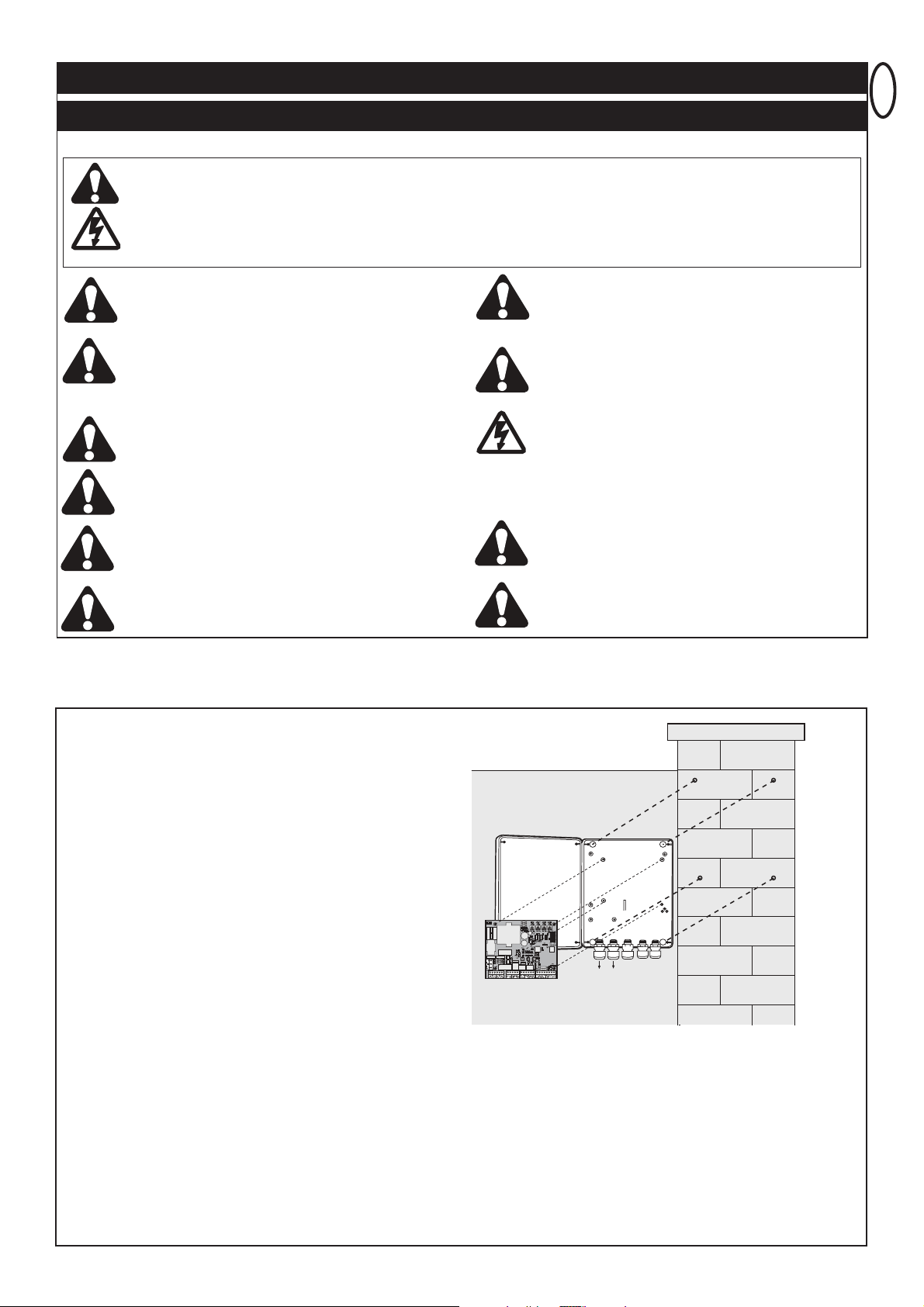

INSTALLATION OF THE CONTROL BOX

The CB11 control board was designed for installation in a special,

waterproof box (203391). Before fitting, measure the required

distances and determine the correct holes. Use a screwdriver to force

the plastic out of the holes. Insert threaded cable connections with

strain relief, hold the box against the surface on which it is to be

mounted. Insert screws through the mounting holes in the rear panel

and tighten. The motor control unit is a highly modern electronic unit

controlled by a microprocessor. It has all wiring facilities and functions

required for safe operation. Moisture and water will destroy the control

board. Make sure under all circumstances that water, moisture or storage

moisture cannot penetrate the control board. Make sure that all openings

and cable entries are sealed watertight. The control box with the motor

control unit is mounted with the cable entries facing down. It must not be

permanently exposed to direct sunlight. The electronics can be used for

the precise adjustment of the push-pull torque. The gate can be held by

hand if the fitting/setting is correct. During operation, the gate can be

stopped at all times via remote control, push-button or key-operated

switch. The gate wing requires a firm stop for the “OPEN” and

“CLOSED” positions, because the gate drives have no limit switch.

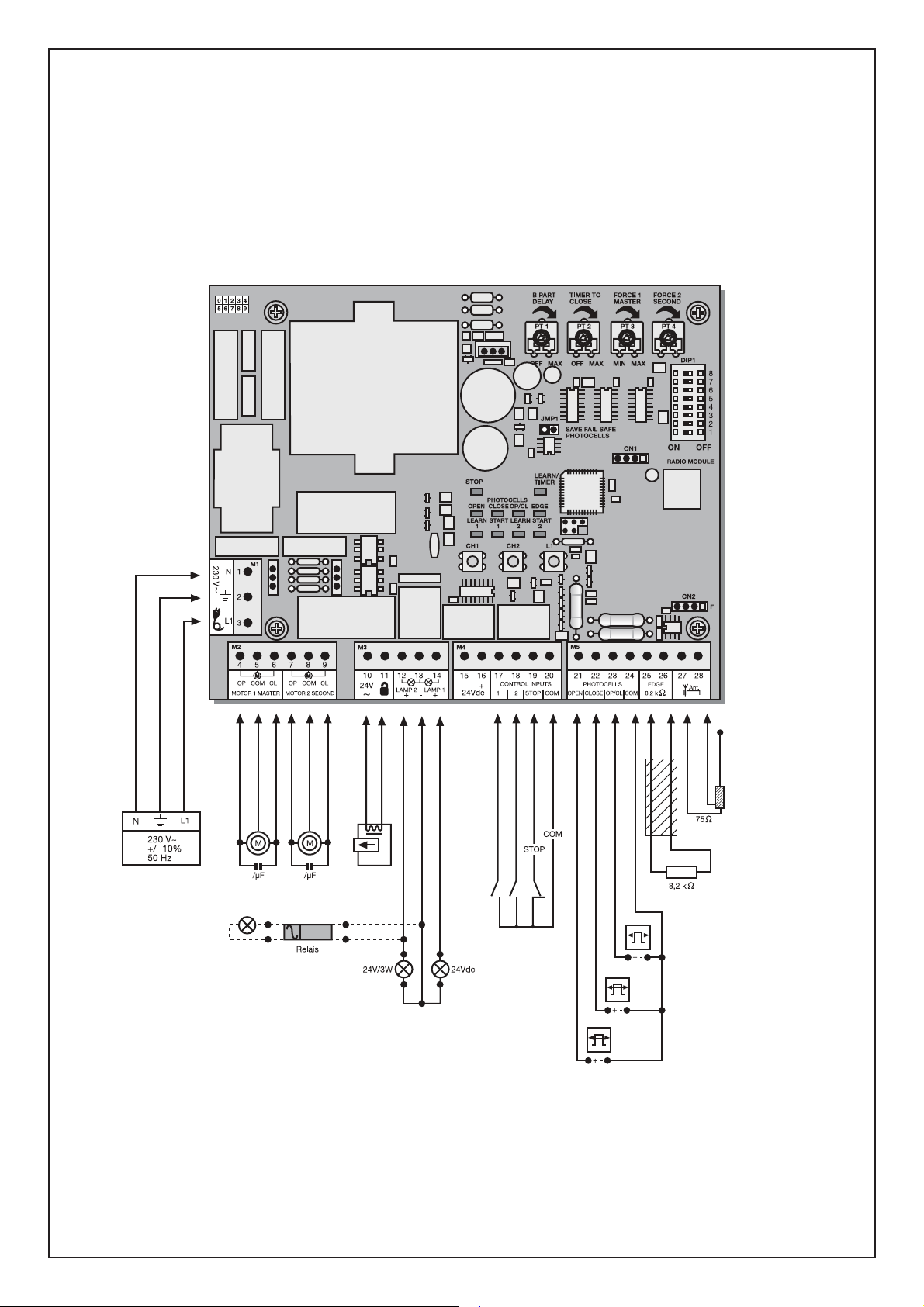

CURRENT DISTRIBUTION

The cable coming from the drive arm must be inserted into a

commercial, waterproof distribution box. A firm cable connection can

then be established from the distribution box to the control board. It is

frequently possible to lead the drive, that is fixed directly next to the

control board, directly into the box. Never lay distribution boxes under

the ground.

The following minimum cable cross-sections should be used:

• 100-230 volts 1.5 mm² or more more

• 0-24 volts 0.5 mm² or more more

Tips: Bell wires often cause problems when used, because they lose

too much voltage if lines are long. Disconnect the cables in the cable

trunkings i.e. the motor cable and the cable for the photocell, in

particular for key-operated switches and start buttons (coming from the

house), otherwise malfunctions are possible if lines are long.

TECHNCAL DATA

Voltage: 230 V~ ±10 % 50 Hz

Max. consumption: 22 mA

Drive max.: 230 V~ 50 Hz 1000 W max

Power supply for accessories: 24 Vdc / 0.5 A max

Operating temperature: -25 ºC ÷ 55 ºC

Operating modes:

Standard/ standard & no self-hold (hold to run) in closing/

Automatic with stop/ residential/ channel separation/ car park/

no self-hold (hold to run)

Max. running time: 80 sec

Rest time: 0 ÷ 150 sec

Dimensions: 124x152 mm (without box)

GB-1

PLEASE START BY READING THESE IMPORTANT SAFETY RULES • SAVE THESE INSTRUCTIONS

This safety alert symbol means "Caution" - failure to comply with such an instruction involves risk of personal injury or damage

to property. Please read these warnings carefully.

This gate drive mechanism is designed and tested to offer appropriately safe service provided it is installed and operated in

strict accordance with the following safety rules.

Incorrect installation and/or failure to comply with the following instructions may result in serious personal injury or property

damage.

Installation and wiring must be in compliance with

your local building and electrical installation codes.

Power cables must only be connected to a properly

earthed supply.

Any entrapment possibility by the moving wing between

wing & walls must be secured with safety edges or IRsensors.

.

Disconnect electric power to the system before making

repairs or removing covers.

A disconnecting device must be provided in the

permanently-wired installation to guarantee all-pole

disconnection by means of a switch (at least 3mm

contact gap) or by a separate fuse.

When using tools and small parts to install or carry

out repair work on a gate exercise caution and do not

wear rings, watches or loose clothing.

Make sure that people who install, maintain or

operate the gate drive follow these instructions. Keep

these instructions in a safe place so that you can refer to

them quickly when you need to.

Please remove any locks fitted to the gate in order to

prevent damage to the gate.

It is important to make sure that the gate always runs

smoothly. Gates which stick or jam must be repaired

immediately. Employ a qualified technician to repair the

gate, never attempt to repair it yourself.

Keep additional accessories away from children. Do not

allow children to play with pushbuttons or remote controls.

A gate can cause serious injuries as it closes.

After the installation a final test of the full function of

the system and the full function of the safety devices

must be done.

The full protection against potential squeeze or

entrappment must work direct when the drive arms

are installed.

This drive cannot be used with a gate incorporating a

wicket door unless the drive cannot be operated with

the wicket door open.

IMPORTANT FITTING AND OPERATING INSTRUCTIONS

ATTENTION

709438

Page 4

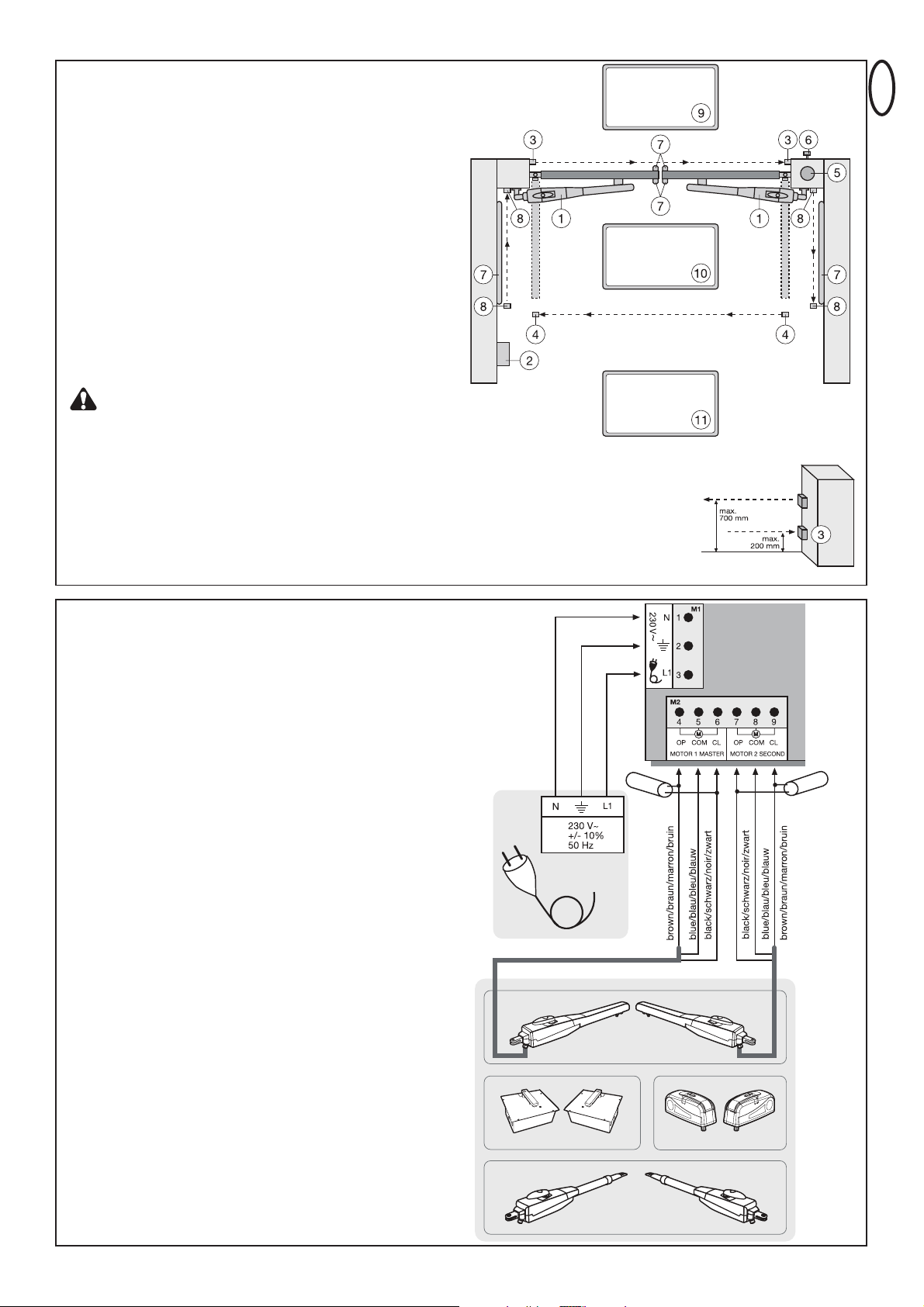

MOTORS:

The motor to open first is the “master “ motor 1, the other one is

the “second” motor 2. If only one motor is used, the connection

for motor 2 is held in reserve.

The cable for the capacitors supplied with the motors must be

inserted in terminals OP and CL together with the cables for the

direction of rotation (brown/black). For space reasons the

capacitors may also be installed in the distribution boxes. Make

sure that they are connected correctly and powered sufficiently.

The capacitors are responsible for the force that the motors will

have later on.

First connect the motors as follows:

Motor 1

4 Brown & capacitor 1

5 Blue

6 Black & capacitor 1

—————————————————————

Motor 2

7 Black & capacitor 2

8 Blue

9 Brown & capacitor 2

To start up see the section Initial operation / basic setting.

Note: During initial operation, the gate wings must OPEN for

the first run. If one or both wings close(s) instead of opening,

the brown and black cables must be swapped on this motor.

Disconnect from the power supply before doing so!

Typical configuration of a unit:

1. Motor

2. Control board

3. photocell (active for closing), max. height 200 mm

First photocell.

4. photocell (active for opening), max. height 200 mm

Second photocell.

5. Flashing light (optional)

Important visual information on the movement of the gate.

6. Key-operated switch

Is mounted on the outside. The gate is opened by key or by

entering a number.

7. Contact strip (optional)

Safeguards the gate on being touched. Contact strips can be

mounted on the gate or on the pillars. If required, contact strips

must be mounted at a height of up to 2.5m.

8. photocell (active for opening/closing), max. height 200 mm

(optional)

9. Contact loop entrance (optional)

10. Safety contact loop in the swinging range of the gate (optional)

11. Contact loop exit (optional)

The control board complies with the latest EU

guidelines. One of these guidelines specifies that the closing

forces at the gate edge must not exceed 400 N (40 kg) for the last

500 mm before the door is CLOSED. Above 500 mm, the

maximum force at the gate edge must not exceed 1400 N (140

kg). If this cannot be ensured, a contact strip must be mounted on

the gate at a height up to 2.5 m or on the pillar on the opposite

side (EN12453).

GB-2

709438

Page 5

CONTROL BOX CONFIGURATION

POINT DESCRIPTION FUNCTION

1 M1, terminals:1,2,3 Feeder cable

2 M2, terminals:4,5,6 Drive 1 (master)

Terminals:7,8,9 Drive 2 (second)

3 M3, terminals:10,11 Connection for e-lock 24 V

Terminals:12,13 Gate monitor/lighting

Terminals:13,14 Flashing lamp

4 M4, terminals:15,16 Connection for accessories 24V

Terminals:17,20 Impulse transmitter channel 1

Terminals:18,20 Impulse transmitter channel 2

Terminals:19,20 Emergency-stop push-button /

must be bridged without switch

connected

5 M5,terminals:21,24 photocell active OPEN

Terminals:22,24 photocell active CLOSED

Terminals:23,24 photocell active OPEN +

CLOSED

Terminals:25,26 Contact strip 8.2 kilo ohms

Terminals:27,28 Antenna

6 CN1/CN2, connector Radio module sockets

7 CH1, pushbutton Learn/Delete radio channel 1

8 CH2, pushbutton Learn/Delete radio channel 2

9 L1, pushbutton Learning the distance covered

10 JMP1, jumper Programming the photocell

11 DIP1 Dip switch block

12 PT4, potentiometer Force setting drive 2

13 PT3, potentiometer Force setting drive 1

14 PT2, potentiometer Automatic closing

15 PT1, potentiometer Bipart delay

GB-3

DESCRIPTION OF THE LEDs

RED LEDs should be switched off. Indication of faults to be

rectified; this does not apply to failsafe photocells not connected.

(see “JUMPER” description)

(Example: short circuit, photocells and/or contact strip)

POINT DESCRIPTION

LED A RED Learn/Delete radio channel 1

LED B RED Start impulse channel 1

LED C RED Learn/Delete radio channel 2

LED D RED Start impulse channel 2

LED E RED photocell active for OPEN

LED F RED photocell active for CLOSE

LED G RED photocell active for OPEN/CLOSE

LED H RED contact strip

LED I GREEN stop

LED J RED learn program (distance covered)

709438

Page 6

PROGRAMS

The control board has 7 operating modes (programs). The desired

program is set using the dip switch “ON” or “OFF”.

ON

DIP1

OFF

The various operating modes are assigned to the

ON

DIP2

DIP3

DIP4

DIP5

DIP6

DIP7

DIP8

drives (see separate table)

OFF

ON

OFF

E-lock

ON

As soon as an impulse is given, the drive moves the

gate in CLOSED direction and opens the relay for

activating the e-lock for one second. ( Function due to

the various commercial e-locks available.)

Function disabled

OFF

Setting for Chamberlain photocells (770E/771E),

ON

complies with EN60335-2-103.

Setting for relay-controlled photocells (100263E) or

OFF

other relay photocells.

ON

Preflash function of flashing light 2 seconds before the

drive starts.

OFF

Preflash function disabled

ON

Once the gate has fully opened, drive 1 moves the

gate with maximum force for 1 second in “OPEN”

direction.

OFF

Function disabled

ON

Once the gate has fully closed, drive 1 switches off for

2 seconds to ensure that the e-lock engages. The drive

then continues

to move the gate for 1 second in “CLOSED” direction

with maximum force.

Function disabled

OFF

GB-4

Only modify settings when control bord

is disconnected. Otherwise modifications will

not be accepted!!!

POTENTIOMETER

PT1 (TRIMMING POTENTIOMETER 1): BIPART DELAY

Controls the bipart delay if wings overlap. For OPEN = 0 or 3 sec. For

CLOSED = 0-20 sec. Motor 1 (master) is opened first and closed last.

It is necessary that the bipart delay is always set so that nobody is

caught between the wings when they close. Left stop: Bipart delay

OFF

PT2 (TRIMMING POTENTIOMETER 2): AUTOMATIC CLOSING

(TIMER TO CLOSE)

The waiting time for the gate for GATE OPEN can be defined. The

gate is closed 0-150 sec. after the set time expires. Only working

with failsafe photocell(s) 771E installed.

Left stop: Automatic closing OFF

One of these guidelines specifies that the closing forces at the gate

edge must not exceed 400 N (40 kg) for the last 500 mm before the

door is CLOSED. Above 500 mm, the maximum force at the gate

edge must not exceed 1400 N (140 kg). If this cannot be ensured, a

contact strip must be mounted on the gate at a height up to 2.5 m or

on the opposite pillar (EN12453).

PT3 (TRIMMING POTENTIOMETER 3): FORCE SETTING

1 MASTER)

Definition of the force with which motor 1 = master is to operate. The

required force depends on weight and function of the gate.

PT4 (TRIMMING POTENTIOMETER 4): FORCE SETTING (FORCE

2 SECOND)

Definition of the force with which motor 2 = second is to operate. The

required force depends on weight and function of the gate.

The control board complies with the latest EU guidelines.

(FORCE

Only modify settings when control bord

is disconnected. Otherwise modifications will

not be accepted!!!

709438

Page 7

GB-5

Separate table for setting the operating modes

Gate closed:

1. impulse opens, the next

one stops, the next one

closes, the next one stops,

the next one opens etc.

Gate closed:

1. impulse opens pedestrian

door, the next one stops, the next

one closes, the next one stops,

the next one opens etc.

Impulse during closing stops

the gate

Impulse during closing stops the

gate

Impulse during opening stops

the gate

Impulse during opening stops the

gate

Impulse during the rest

closes the gate immediately

Impulse during the rest closes the

gate immediately

Standard

Standard &

no self-hold (hold to run) for closing

Gate closed:

1. impulse opens, the next

one stops, the next one

closes, the next one stops,

the next one opens etc.

Gate open:

Permanent signal required for

closing, letting go stops

Impulse during closing stops

the gate

Radio disabled, safety equipment

disabled

Impulse during opening stops

the gate

Impulse during the rest closes

the gate immediately

Automatic with stop

Gate closed:

1. impulse opens, the next one

stops, the next one closes, the

next one opens

Gate closed:

1. impulse opens pedestrian door,

the next one stops, the next one

closes

Gate opened:

1. impulse closes, the next one

opens

Impulse while pedestrian stops,

the next one closes

Residential

Gate closed:

1. impulse opens, the next one

closes, the next one opens, the

next one closes etc.

Gate closed:

1. impulse opens pedestrian door,

the next one closes immediately

Impulse while pedestrian closes

the gate immediately

Impulse during the rest closes the

gate immediately

Impulse during automatic

closing opens the gate

immediately

Impulse during the rest closes

the gate immediately.

Channel separation Gate closed:

1. impulse opens, the next one

stops, the next one opens, the

next one stops etc.

Gate open:

1. impulse closes, the next one

stops, the next one closes etc

Impulse during closing stops the

gate

Impulse during opening stops the

gate

DIP1

ON

ON

OFF

OFF

ON

ON

OFF

DIP2

ON

OFF

OFF

ON

ON

OFF

OFF

DIP3

OFF

ON

ON

OFF

ON

OFF

OFF

Impulse transmitter/channel 1 Impulse transmitter/channel 2

Car park Gate closed:

1. impulse opens both wings

completely, further impulses are

ignored.

Gate closed:

1. impulse opens pedestrian

door completely, further

impulses are ignored

Impulse while pedestrian opens

the second wing as well

Impulse during closing opens the

gate immediately

Impulse during closing opens the

gate immediately

No self-hold (hold to run)

Gate closed:

Permanent signal

required, letting go stops

Gate open:

Permanent signal required,

letting go stops

Radio disabled, safety

equipment disabled

Radio disabled, safety equipment

disabled

709438

Page 8

ACCESSORIES

GB-6

PHOTOCELLS (OPTIONAL)

The photocells are for safeguarding the gate and must be used. The

fitting location depends on the gate’s design. EN12453 specifies that

a pair of photocells must be installed at a height of 200 mm and

activated to “Close”; a second pair must be installed at a height of

200 mm and activated to “Open”. A third pair of photocells can be

optionally installed and activated to “Close” and “Open”. The

photocells consist of a transmitter and a receiver and must be

opposite each other. The housing of the photocell (plastic) can be

opened using a screwdriver. The photocell is mounted on the wall

using small screws and wall plugs. It is possible to use two different

photocell systems (see Dip switch description). To enable the

“Automatic Closing” function, the Chamberlain failsafe photocell must

be installed. A combination of photocells is not possible. The

Chamberlain failsafe system (2-cable system) has small LEDs (light)

that can be seen from the outside on both sides to indicate the status

of the photocell. Two Chamberlain failsafe photocell models are

available. The one model is ideal for walls lying opposite. The other

model is ideal for the inside of the gate, because fittings are already

available.

Diagnosis at the Chamberlain failsafe photocell

LED constant = OK

LED flashes = photocell disables control board

LED off = no current, incorrect connection or polarity

Diagnosis on the control board

LED off = OK

LED on constantly = control board disables

LED flashes = OK no photocell connected

Cable cross-section: 0.5 mm2or more.

Voltage: 12/24 volts AC/DC.

Do not use any fixed copper lines. Do not lay any 230 volt cables in

parallel and do not lay any 2 cables in the same cable trunking.

open/öffnen/ouvrir/open

close/schliessen/fermer/sluiten

close/schliessen/

fermer/sluiten

open/öffnen/

ouvrir/open

JUMPERS

Programming of failsafe photocells model 771E/770E

1.Before the Initial Setup

2.When connecting or removing photocell(s)

- Switch off control board ( disconnect from current)

- Slip jumper on designated pins

- Dipswitch 5 to “ON”

- Connect photocell(s) according illustration

- Reconnect control board, wait short-time

- Pull jumper, wait short-time

Done! (The number of photocells connected are stored)

Programming of relay photocells such as 100263

The control board must be disconnected from the mains for a few

seconds. All terminals to which no photocell is connected must be

bridged with COM. (21-24, 22-24, 23-24). The power supply for the

relay photocell of terminals 15-16. Dip switch 5 must be at OFF. The

jumper must be unplugged.

Note: Relay photocells are no longer permitted for new installations

as per EN12978, because they cannot perform self-checks (failsafe).

Operation without photocells

DANGER: Not permitted for normal operation. In this case contact

strips must safeguard the gate.

The control board must be disconnected from the mains for a few

seconds. Terminals 21-22-23-24 must all be bridged. Dip switch 5

must be at OFF. The jumper must be unplugged.

Note: It is not possible to combine different photocell models.

709438

Page 9

GB-7

PUSHBUTTON / KEY-OPERATED SWITCH (OPTIONAL)

The control board / drive can be activated using various inputs.

This can be done using a transmitter or keyswitch (terminals 17

and 20).

Transmitter = see “Teaching the transmitter”

Switch input 1 = input control 1 normal operation

Switch input 2 = input control 2 active for special settings

(see Dip switch description)

EMERGENCY STOP (OPTIONAL) 600084

A switch can be connected to stop or disable the unit. The

movement of the wings is stopped immediately. Terminals 19 and

20 must be bridged if no switch is installed.

CONNECTION FOR CONTACT LOOP (OPTIONAL)

A contact loop evaluation unit (203292 1-channel, 203308 2channel) can be connected to the control board. A 2-channel

evaluation unit can be used to evaluate 2 channels separately or in

combination.

Note:

The description only refers to the separate evaluation of

each loop. If a 2-channel evaluation unit is used, two consecutive

loops can be laid to detect the driving direction of vehicles. Further

connection combination options are then possible.

To open the entrance or exit

Connection to terminals 17 + 20. Dip switch in car park function.

Automatic closing enabled (recommended).

For protection in the swinging range of the gate

Connection to terminals 19 + 20 (stop). Relay output of the

evaluation unit when using failsafe photocells NO (closer). If relay

photocells are used as NC (opener). Automatic closing function not

recommended.

Attention: The only safeguard that is not permitted according

to EU standard!

24 VDC - OUTPUT

For relay infrared senors or other devices (e.g. receivers)

max. 500 mA

Do not use any fixed copper lines. Do not lay any 230

volt cables in parallel and do not lay any 2 cables in the same

cable trunking.

ELECTRIC LOCK (OPTIONAL) 600022 (24V)

An electric lock can be connected to the control board using terminals

10 and 11.

Cable cross-section: 0.5 mm

2

or more.

Voltage: 24 volts AC/DC.

GATE MONITOR / LIGHTING (OPTIONAL)

A 24V/3W light bulb can be connected to monitor the status of the

gate. Alternatively, a yard lighting system can be used by adding a

relay (accessory). Cable cross-section: 0.5 mm2or more.

Voltage: 24 V

FLASHING LAMP (OPTIONAL) FLA24-2

A flashing lamp can be connected to the control board. It warns when

the gate is being moved. The flashing light should be fitted as high as

possible and in good clear view. The control board emits a constant

signal that the lamp converts to a flashing signal.

Cable cross-section: 0.5 mm2or more.

Voltage: 24 V DC

Do not use any fixed copper lines. Do not lay any 230 volt

cables in parallel and do not lay any 2 cables in the same cable

trunking.

709438

Page 10

GB-8

INITIAL OPERATION

BASIC SETTING

Proceed step by step. If you are not sure, start again at the

beginning. Take sufficient time to make these settings.

1. Are all components required for operation connected? Motors,

photocells, safety contact strip, stop switch.

2. Make sure that nobody is present in the range of the gates.

3. Check if the LEDs (lamps) are OK or whether they are blocking

any functions. Red LEDs (lamps) should not be on permanently. The

green LED must be on.

4. Set the dip switch program standard 1=”ON”, 2= “ON”, 3=”OFF”.

Later corrections can be made at all times.

5. Is an e-lock installed? If yes dip switch 4=”ON”

6. Set force potentiometer “FORCE 1” “FORCE 2” to max. 30 %.

Even lower if the gates are very light. Try before correcting! Only

increase the force in small steps.

7. If two motors are connected, the bipart delay must be set. Turn the

potentiometer to approx. 50 %. Later corrections can be made at any

time.

8. Switch off control board (cut from current)

8.1 Slip jumper on designated pins

8.2 Change Dipswitch 5 to “ON”

8.3 Connect photocell(s) according to illustration

8.4 Reconnect control board to current, wait short-time

8.5 Pull jumper, wait short-time. The LED(s) of the photocell(s)

connected stay(s) out. The LED(s) of the photocell(s) not connected

will flash. Done!

1

3

6

7

TEACHING / DELETING THE transmitterS

Press button CH1. The LED “Learn1” lights up red. Now press one

of the transmitter’s button for approx. 5 seconds. The LED “Learn 1”

flashes now. Finished. Proceed in exactly the same way for CH2.

However, now press one of the transmitter’s buttons that has not yet

been assigned. Up to 128 transmitters can be programmed in this

way.

To delete the programmed transmitter setting, simply press button

CH1 until the LED goes out. Proceed in the same way for CH2.

RADIO MODULE (OPTIONAL)

To operate the control board via radio remote control, a radio

module must first be installed in slots CN1/CN2. The following

modules are available: 801221 (433.92 MHz), 801429 (27.145

MHz), 207542 (315.15 MHz China)

CONTACT STRIP (OPTIONAL)

A contact strip working according to the 8.2 kilo ohm principle can

be connected to the control board, i.e. a 8.2 kilo ohm test resistor is

attached to the end of the contact strip. It ensures that the electric

circuit is monitored permanently. The control board is supplied with

an 8.2 kilo ohm resistor installed. Several contact strips are

connected in series.

Cable cross-section: 0.5 mm2or more.

ANTENNA (OPTIONAL) ANT4X-1LM

The control board is standard-equipped with a wire antenna.

An external antenna (accessory) can be connected to terminals 27

and 28. A larger range (radio) can thus be achieved. Mount the

antenna as high as possible.

Do not use any fixed copper lines. Do not lay any 230 volt

cables in parallel and do not lay any 2 cables in the same cable

trunking.

709438

Page 11

GB-9

Programming the time for the standard distance covered

(without soft stop, slow run)

Note: If only one drive (1-wing operation) is used, the learning

steps for wing 2 are different.

For “standard” programming: See the text for information.

For “advanced” programming omit steps 5,6,7 and 8 by pressing

button L1.

Button L1 must be pressed twice for this program.

1. The wings should be closed and locked.

2. Press button L1 briefly (1 second), both wings open.

Note: If one or both wings close instead of opening, the brown

and black cables must be swapped on this motor. Switch off the

power (restart), then start programming again from the

beginning.

3. Press L1 again when both wings have reached the limit stop (+ let

it buzz for two seconds). Only wing 2 is now running, it closes now.

When wing 2 has closed, wing 1 starts to run automatically and

closes.

Note: If only one wing is used, please wait (for about 15

seconds) without pressing any button, wing 1 starts to move

automatically.

Continue with the completion of the installation

Programming the “Advanced” distance covered (individual)

Button L1 must be pressed 9x in all for this program. Each time this is

done a position (time) is saved. This makes it possible to save the

soft stop (slow run) for the individual adaptation of the gate or

application. Very long soft stop phases or almost none are possible.

Wing 1 = “master”

Wing 2 = “second”

1. The wings should be closed and locked.

2. Press L1; for more than 5 seconds = until wing 1 starts (opens).

Let go of button!!

3. Press L1 again; soft stop OPEN for wing 1 begins at this position.

4. Press L1 again; limit stop reached (+2 seconds) Wing 2 now starts

automatically.

5. Press L1 again; soft stop OPEN for wing 2 begins at this position.

6. Press L1 again; limit stop reached (+2 seconds) Wing 2 now

restarts automatically and closes.

7. Press L1 again; soft stop CLOSED for wing 2 begins at this

position.

8. Press L1 again; limit stop CLOSED reached (+2 seconds) Wing 1

now starts automatically.

9. Press L1 again; soft stop CLOSED for wing 1 begins at this

position.

10. Press L1 again; limit stop CLOSED reached (+2 seconds)

Finished

Completion of the installation/programming:

Once the covered distance is programmed, the transmitters can

be programmed (not required for kits) or deleted.

1. Start the gate with the transmitter or a connected button and

observe the process. Close the gate again WITHOUT having made

any settings.

2. If the gate does not close completely by itself, adjust the

potentiometer to other values, adapted to fit the experience value

from the test. (e.g. increase running time, correct force. bipart delay)

Caution: The wing must run for at least one second at the stop

so that it reaches the stop in the even of wind loads (slower). It

is not possible to compensate this using increased force. The

programming of the running time must be repeated.

3. Now start a second attempt and proceed again as above. Close

the gate first before you make any settings.

4. Once all settings have been made, check the function of the

photocells, buttons, flashing lamp, transmitters, accessories etc. If

you desire automatic closing, set the potentiometer for the rest to

gate OPEN (“timer to close”).

5. Show all persons that use the gate how the gate moves, how the

safety functions work and how to operate the drive by hand.

709438

Page 12

GB-10

709438

Gate opener does not function / does not respond

when button is pressed.

1. Connection to button is loose.

2. STOP switch connection is loose; STOP

LED is off.

3. Obstacle is blocking photocell in direction

of movement.

4. Safety edge is damaged or has

encountered an obstacle.

5. Gate opener is still released.

1. Check button and COM connections.

2. Check STOP switch connections

(STOP and COM).

3. Remove obstacle.

4. Remove obstacle and check

connections and wiring.

5. Lock gate opener.

The gate opener does not open the gate fully. 1. Are the post dimensions A+B correct?

2. Has the running time of the controller been

set correctly?

3. Has the force been set correctly?

1. Check A+B dimensions.

2. Reprogram as required – plus

approx. 3 seconds.

3. Correct force setting (gate opener

runs somewhat slower in windy

conditions).

The controller doesn’t respond when I alter the

Dip-switches.

Disconnect controller from power

supply, then alter Dip-switches.

“Timer to close” doesn’t work.

1. Only works if the 2-cable photocell

770E(ML) or 771E(ML) has been

installed.

2. Then turn “timer to close”

potentiometer in a clockwise direction.

The gate opener doesn’t respond at all; no LED is

on.

Possibly power failure.

1. Check conductor and zero conductor.

2. Check house fusing.

Immediately after the gate has started moving, it

stops and reverses.

Obstacle in area of gate.

Check area of gate for objects

The gate opener hums slightly but has no force

1. Capacitor is not correctly connected to the

brown and black cable.

2. Force has not been set.

3. The gate opener has been released.

1. Check wiring of capacitor.

2. Turn force potentiometer in a clockwise

direction.

3. Lock gate opener.

The gate opener only works when I press and

hold the button on the remote control.

1. Controller in ‘hold to run’ operating mode.

2. A safety facility is not working correctly

(photocell, safety edge).

1. Disconnect controller from power supply,

then alter Dip-switches.

2. Observe LEDs; find and rectify fault.

The gate opener doesn’t respond at all, although

the controller has been connected (LEDs are on).

1. Remote control has not been programmed.

2. LEDs indicate a fault.

3. Photocell connected incorrectly.

4. Jumper between STOP and COM missing.

5. Motor terminal possibly not connected

properly.

1. Programming remote control.

2. Find and rectify fault(s) (see description

of LEDs).

3. Check photocell connection /

programming.

4. Connect simple jumper.

5. Check terminals and connections.

The gate opener stops suddenly and then restarts

only after a lengthy pause.

If the gate is operated constantly, the motor

will reach its cut-off temperature - protective

facility - as the gate opener is not designed

for permanent operation.

Allow motor sufficient time to cool (min. 15

minutes).

How long is the probable service life of a gate opener?

When used for private purposes, a correctly installed gate opener can

operate perfectly for in excess of 10 years. Both the gate and the gate

opener must be checked regularly and serviced in accordance with

their respective instructions.

What happens in case of power failure?

All Chamberlain gate openers are equipped with a release system by

means of which the gate can be operated manually in case of power

failure.

How long does it take to install a gate opener?

Depending on your specific technical skills, the installation of the

mechanical components can take approx. 3 to 8 hours. Firstly, the gate

needs to be properly prepared such that installation work can

commence. The electrical connection work takes approx. 1 to 2 hours.

Each user should be instructed for at least 30 minutes with regard to

the operation of the gate opener, whereby its functionality should be

demonstrated and safety aspects, protective facilities and procedure in

case of power failure should all be explained.

Is it possible to open just one wing of the gate (pedestrian mode)?

Yes, it is possible. This process can be operated via remote control (a

2-channel remote control is the minimum requirement here) or via

switch operation (see “Standard” operation mode setting).

Frequently asked questions

Page 13

GB-11

709438

The control board does not work any more using

the transmitter, only with the switch and even then

only as long as a button is pressed and kept

pressed.

Open with push-button (1) or CLOSE with pushbutton (2)

1.Dip switch setting not as desired

2.A safety photocell, a contact strip or the

stop disables the control board

3.Only one photocell was connected for

OPEN

1.Correction of the dip switch,

elimination of fault required. If the fault

cannot be repaired, it will be necessary

to “reset” and reprogram (see photocell)

2.At least one photocell must be

connected and activated for CLOSED

or OPEN & CLOSED.

The unit does not close automatically, it

OPENS automatically

The motor cables are not connected correctly The motor cables (brown,black) must be

swapped

Control board does not work with transmitter 1.transmitter not programmed

2.An photocell blocks

1.Program transmitter

2.Check photocells

Gate can only be opened

1.photocell blocks

2.Dip switch setting not as desired

1.Function and connection must be

checked

2.Check dip switch

The control board is not running No covered distance learned Learn covered distance.

See Initial operation

The wings do not open completely. 1.Insufficient force in the event of high

wind loads

(entire gates)

2.Gate sluggish/heavy

1.Reset force ( increase )

2.Improve ease of movement

3.Program control board again

(Remote controlled) universal receiver does not work Observe polarity (terminals 15/16)

Swap “+” and “-” cables

The gate opener is so strong that it bends the

gate and/or post.

1. A+B dimensions correct?

2. Force set too high?

3. Reinforce gate?

1. Check A+B dimensions.

2. Turn force potentiometer in an

anticlockwise direction.

3. Possibly screw gate opener to a

reinforcement plate (post).

Possibly fit reinforcement plate at point

of pull / push pressure (gate wing).

Use suitable screws and plugs

Can different A+B dimensions be used on the two

sides?

Generally speaking, yes, but the wings then open at different speeds. If the A+B dimensions

are altered significantly from the standard setting, the gate will run poorly and the fittings will

be subjected to greater stress (considerably reduced service life of installation).

The gate must follow a slope.

Not recommended! Change gate! The gate can move in an uncontrolled (dangerous) manner

if the gate opener has been released. A stronger force is needed in the upwards direction of

the slope and then, in the opposite direction, the gate opener’s force is too strong.

The force setting has been altered, but no

difference is apparent.

Disconnect the controller from the power supply for a few seconds in order to activate the

control board’s self-diagnosis functionality.

The remote control’s range is too short.

The installation of an external aerial is recommended as the controller with the short cable

aerial is located either behind the post or near ground level in most cases. The optimum

location of the aerial is as high as possible in all cases. An appropriate aerial with installation

kit can be obtained from Chamberlain as an accessory with the product ref. no. ANT4X1EML.

The gate post is so thick that I am unable to

comply with the requisite A+B dimensions.

Reduce post thickness or shift gate location.

Loading...

Loading...