Page 1

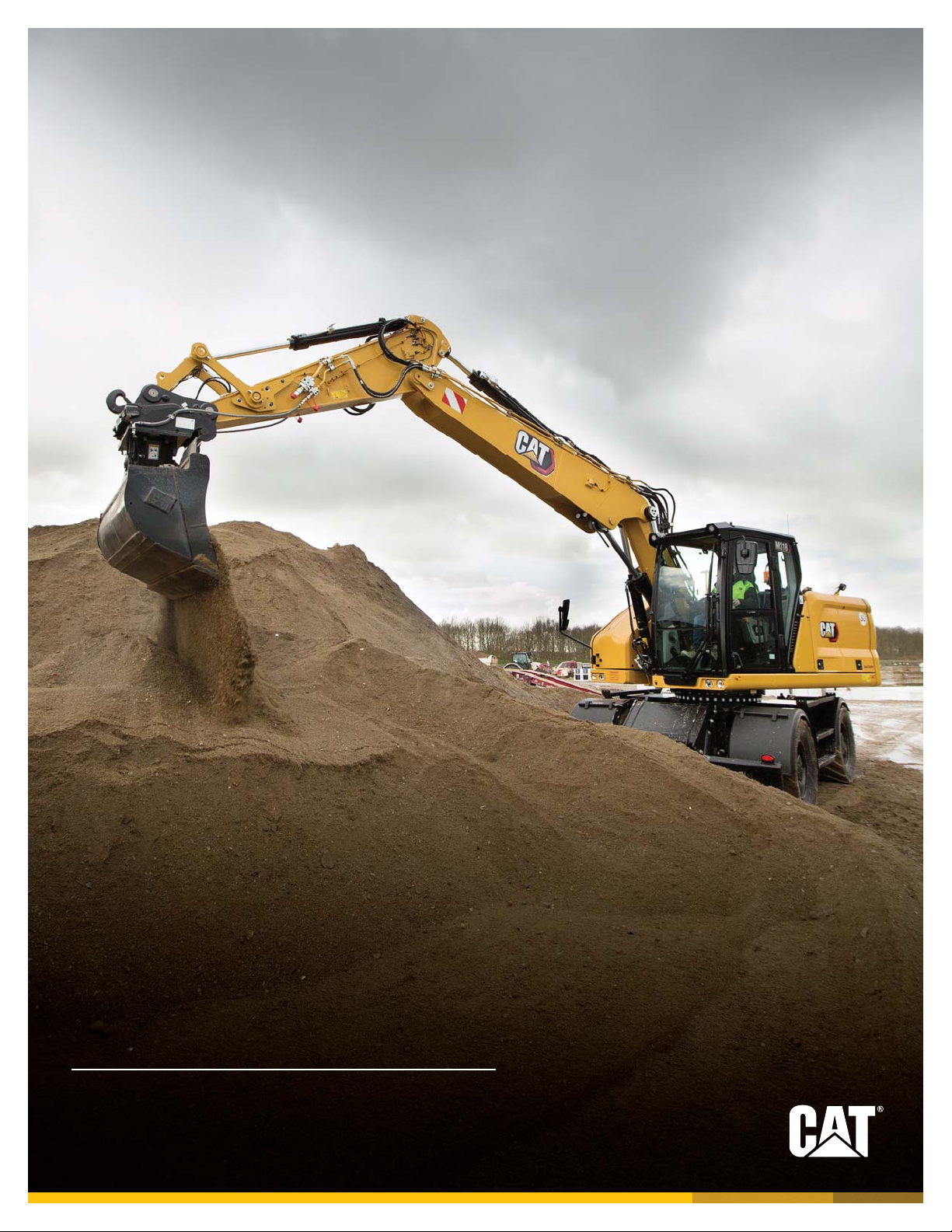

M318

WHEELED EXCAVATOR

Engine Power (ISO 14396) 129 kW (174 hp)

Operating Weight 19 950 kg (43,980 lbs)

Cat C4.4 engine meets U.S. EPA Tier 4 Final, EU Stage V, and Korea Tier 4 Final emission standards.

Page 2

CAT

BOOSTING EFFICIENCY

THE NEW

®

M318

The Cat M318 increases your

productivity with more comfort in the

cab, full tiltrotator integration, and

easy-to-use controls. Lower fuel and

maintenance costs puts money back in

your pocket.

NEXT GENERATION WHEELED EXCAVATORS

The new wheeled excavators match your performance needs to bring you:

+ LOWER OPERATING AND MAINTENANCE COSTS

+ INCREASED OPERATOR EFFICIENCY AND VISIBILITY

+ MORE IN-CAB COMFORT

2

M318 WHEELED EXCAVATOR

Page 3

DO MORE WORK WIT

H

S

M

et

ube

Boom/Stick

Link

Lube

.

200 hrs.

300

.

400

.

500

EXTENDED INTERVAL

Buck

Linkage

L

age

100 hrs

hrs

hrs. hrs

MAXIMIZE

PERFORMANCE

Work faster with up to 14% more swing torque

with lower fuel and DEF consumption. Tiltrotator

integration gives you more versatility to complete

more tasks faster with one machine.

ENHANCED

CAB COMFORT

Operate comfortably with the ergonomic control

layout and cab options. Get better visibility with rear

and side view cameras and an optional 360-degree

machine view system.

UP TO 10%

MAINTENANCE SAVINGS

1

8

318

Fewer maintenance costs, combined with 100% daily

ground-level maintenance and extended service

intervals, increase uptime and keep overall costs down.

1

Compared to the M318F

3

M318 WHEELED EXCAVATOR

Page 4

CAT LINK TECHNOLOGY

TAKES THE GUESSWORK OUT OF MANAGING YOUR EQUIPMENT

Cat Link telematics technology helps take the complexity out of managing your jobsites by gathering data generated by your

equipment, materials, and people and serving it up to you in customizable formats.

PRODUCT LINK™

Product Link collects data automatically and accurately from your

assets – any type and any brand. Information such as location,

hours, fuel usage, productivity, idle time, maintenance alerts,

diagnostic codes, and machine health can be viewed online

through web and mobile applications.

VISIONLINK

Access information anytime, anywhere with VisionLink. Use it

to make informed decisions that boost productivity, lower costs,

simplify maintenance, and improve safety and security on your

jobsite. With different subscription level options, your Cat dealer

can help you confi gure exactly what you need to connect your

fl eet and manage your business without paying for extras you

don’t want. Subscriptions are available with cellular or satellite

reporting (or both).

Remote Services is a suite of technologies that improve your

jobsite effi ciency.

Remote Troubleshoot allows your Cat dealer to perform

diagnostic testing on your connected machine remotely,

pinpointing potential issues while the machine is in operation.

Remote Troubleshoot helps ensure the technician arrives with the

correct parts and tools the fi rst time, eliminating additional trips to

save you time and money.

®

4

M318 WHEELED EXCAVATOR

Remote Flash updates on-board software without a technician

being present, potentially reducing update time by as much as

50 percent. You can initiate the update when convenient,

increasing your overall operating effi ciency.

The Cat App helps you manage your assets – at any time – right

from your smartphone. You can see your fl eet location, hours,

and other information. You will get critical alerts for required

maintenance, and you can even request service from your local

Cat dealer.

Page 5

Get in and out of the cab more

easily with the tilt-up left console.

Deluxe and Premium cab options

offer supreme comfort, from a

heated/cooled seat to automatic

temperature control.

CAB TAKES

THE HARD OUT

OF WORK

ERGONOMIC

CONTROL LAYOUT

Controls are positioned to reduce fatigue

and straining movements to help keep you

operating at your full potential.

REDUCED CAB

VIBRATIONS

Feel more comfortable in the cab while

you work with reduced cab vibrations from

advanced viscous mounts.

BLUETOOTH

®

CONNECTION

Bluetooth® integrated radio allows for

seamless mobile phone connection to

listen to music, podcasts, and hands-free

calling.

M318 WHEELED EXCAVATOR

5

Page 6

LONGER SERVICE

GROUND LEVEL

NEW FILTERS

INTERVALS

The in-cab monitor tracks fi lter life and

machine intervals, so you always know

when it’s time for regular machine service.

ACCESS

Complete your daily machine checks

entirely from the ground, minimizing the

need to access the upper platform.

Two levels of fi ltration protect your engine

from dirty diesel. The new hydraulic oil

fi lter improves fi ltration performance and

lasts up to 50 percent longer than previous

fi lter designs.

SAVE UP TO

10% IN MAINTENANCE COSTS

6

M318 WHEELED EXCAVATOR

Page 7

KEYLESS PUSH START

Start the engine with the push-to-start

button or using the unique Operator ID

function.

MACHINE SETTINGS

Access the operator manual at your

fi ngertips as well as the power mode

selector to keep productivity while

using less fuel.

JOYSTICK PREFERENCES

Program your preferred power mode

and joystick preferences with your

Operator ID. Once you enter in your

Operator ID, the excavator remembers

your settings each time.

TOUCHSCREEN MONITOR

Use the standard 254 mm (10-in)

touchscreen monitor to adjust your

heating/cooling setting for more

comfort or to view your machine

information.

M318 WHEELED EXCAVATOR

7

Page 8

LOOK OUT FOR YOUR PEOPLE AND YOUR EQUIPMENT

SAFETY FEATURES

Daily maintenance checks can be performed with 100% of

the points accessible from ground level, making maintenance

faster, easier, and safer. Standard LED lights gives you a better

view of your jobsite.

+ ENJOY BETTER VISIBILITY INTO TRENCHES, IN EACH SWING

DIRECTION, AND BEHIND YOU. THE SMALLER CAB PILLARS,

LARGER WINDOWS, AND A FLAT ENGINE HOOD DESIGN

LOWER OBSTRUCTION TO YOUR VIEW. REARVIEW AND

SIDEVIEW CAMERAS ARE STANDARD, AND THE 360 DEGREE

VIEW SYSTEM OPTION OFFERS A HIGHER VIEWING VANTAGE

POINT OF THE MACHINE. .

+ THE STANDARD SOUND SUPPRESSION ROPS CAB MEETS

ISO 12117-2:2008 REQUIREMENTS AND HELPS TO BLOCK THE

NOISE TO STAY FOCUSED ON THE JOB.

+ THE SERVICE PLATFORM DESIGN PROVIDES EASY, SAFE, AND

QUICK ACCESS TO UPPER PLATFORM. THE STEPS USE

ANTI-SKID PUNCH PLATES TO PREVENT SLIPPING.

+ THE AUTO AXLE LOCK PRESSES THE PEDAL FOR YOU TO

REDUCE YOUR OVERALL NUMBER OF ACTIONS. THE MACHINE

AUTOMATICALLY DETECTS WHEN THE SERVICE BRAKE AND

AXLE NEED TO BE LOCKED OR UNLOCKED. IT RELEASES

AUTOMATICALLY WHEN YOU PRESS THE TRAVEL PEDAL.

8

M318 WHEELED EXCAVATOR

Page 9

INCREASE PRODUCTIVITY AND VERSATILITY

WITH CAT ATTACHMENTS

You can easily expand the performance of your machine by utilizing any of the variety of Cat Attachments.

Each Cat Attachment is designed to fi t the weight and horsepower of Cat wheeled excavators for improved

performance, safety, and stability.

BUCKETS

QUICK COUPLER

GRAPPLES

SHEARS

HYDRAULIC HAMMERS

VIBRATORY PLATE

COMPACTORS

MULCHERS*

*Not all features are available in all regions. Consult your Cat dealer for specifi c confi gurations available in your region.

TILTROTATOR*

PIN GRABBER COUPLER*

M318 WHEELED EXCAVATOR

9

Page 10

TECHNICAL SPECIFICATIONS

See cat.com for complete specifi cations.

ENGINE

Engine Model

Engine Power – ISO 14396 129 kW 174 hp

Engine Power – ISO 14396 (metric) 176 hp (PS)

Bore 105 mm 4 in

Stroke 127 mm 5 in

Displacement 4.4 L 268.5 in3

• Meets U.S. EPA Tier 4 Final, EU Stage V, and Korea Tier 4 Final emission

standards and Blue Angel Certifi ed.

• Net power advert ised is the power available at the fl ywheel when engine is

equipped with fan, air cleaner, CEM exhaust gas aftertreatment, alternator,

and cooling fan running at intermediate speed.

• Recommended for use up to 30 00 m (9,84 3 ft) alti tude with engine power

derat ing above 300 0 m (9,843 f t).

• Rated speed 2 ,200 rpm.

Cat C4.4

HYDRAULIC SYSTEM

Main System – Maximum Flow 254 L/min 67 gal/min

Maximum Pressure – Equipment 37 000 kPa 5,366 psi

Maximum Pressure – Travel 35 000 kPa 5,076 psi

Maximum Pressure – Swing 35 500 kPa 5,149 psi

SWING MECHANISM

Swing Speed

Maximum Swing Torque

9.4 rpm

44kN·m 32,560 lbf-ft

WEIGHTS

Operating Weight Minimum 17 500 kg 38,580 lb

Operating Weight Maximum 19 950 kg 43,980 lb

** Operating weight includes full fuel tank, operator, bucket 610 kg (1,340 lb),

and dual pneumatic tires. Weight varies depending on confi guration.

Typical confi gurations include 2500 mm (8'2") medium stick and 3700 kg

(8,157 lb) counterweight.

SERVICE REFILL CAPACITIES

Fuel Tank 350 L 92.5 gal

Cooling System 32 L 8.5 gal

Engine Oil 11 L 2.9 gal

Diesel Exhaust Fluid (DEF) Tank 20 L 5.3 gal

Final Drive 2.5 L 0.7 gal

Hydraulic System (including tank) 260 L 68.7 gal

Hydraulic Tank 120 L 31.7 gal

DIMENSIONS

Boom Reach 5250 mm (17' 1")

Stick Reach 2500 mm (8' 2")

3

Bucket GD 0.91 m

Shipping Height (top of cab) 3360 mm 11'

Support Point 3520 mm 11' 7"

Shipping Length 8470 mm 27' 9"

Tail Swing Radius 2350 mm 7' 9"

Counterweight Clearance 1301 mm 4' 3"

Ground Clearance 325 mm 1' 1"

Undercarriage Length 4440 mm 14' 7"

Wheel Base 2700 mm 8' 10"

(1.19 yd3)

WORKING RANGES AND FORCES

Boom Type VA Boom

Stick Reach 2500 mm (8'2")

3

Bucket GD 0.91 m

Loading Height 7300 mm 23' 11"

Cutting Height 10 260 mm 33' 8"

Digging Height 5890 mm 19' 4"

Reach at Ground Level 9210 mm 30' 3"

Vertical Wall Digging Depth 4600 mm 15' 1"

Bucket Forces (ISO) 119 kN 26,752 lbf

Stick Forces (ISO) 75 kN 16,861 lbf

• Range values are with dual pneumatic tires (10.00-20 ).

• Range values are calculated with a GD bucket ( CW) and C W-30 quick

coupler wit h a tip radius of 1484 mm (4'10 ").

• Force values are calculated with heavy lif t on, a GD bucket (pin-on) , and a

tip radius of 1378 mm (4'6").

(1.19 yd3)

AIR CONDITIONING SYSTEM

• The air conditioning system on this machine contains the fl uorinated

greenhouse gas refrigerant R134a (Global Warming Potential = 1430 ).

The system contains 0.85 kg of refrigerant which has a CO2 equivalent

of 1.216 metric tonnes.

10

M318 WHEELED EXCAVATOR

Page 11

STANDARD & OPTIONAL EQUIPMENT

Standard and optional equipment may vary. Consult your Cat dealer for details.

CAB STANDARD OPTIONAL

ROPS, sound suppression

Keyless push-to-start engine control

Deluxe Cab

Premium Cab

High-Resolution 254 mm (10 in) LCD

touchscreen monitor

CAT TECHNOLOGIES STANDARD OPTIONAL

Product Link

Remote Flash/Troubleshoot Capability

ENGINE STANDARD OPTIONAL

Power mode selector

One-touch low idle with auto engine speed

control

Auto engine idle shutdown

52°C (125°F) high-ambient cooling capacity

-18°C (0°F) cold start capability

Double element air fi lter with integrated

precleaner

Biodiesel capability up to B20

On-demand electric cooling fans with autoreverse function

Electric priming pump

Ride control

Separate dedicated swing pump

HYDRAULIC SYSTEM STANDARD OPTIONAL

Auto hydraulic warmup

Automatic swing brake

Boom and stick drift reduction valve

Electronic main control valve

Slider joysticks (2 types)

Boom/stick lowering check valves

SmartBoom™

Cat TRS support

Joystick steering

Combined fl ow/high-pressure auxiliary

circuit

Quick coupler circuit

Ride control

Separate dedicated swing pump

SAFETY AND SECURITY STANDARD OPTIONAL

l

l

l

l

l

Rear and right-side-view cameras

360° visibility

Wide angle mirrors

Ground-level engine shutoff switch

Handrail and hand holds on service platform

Signaling/warning horn

l

l

l

l

l

l

BOOM AND STICKS STANDARD OPTIONAL

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

5100 mm (16’9”) One-piece boom

5250 mm (17’1”) variable adjustable boom

2200 mm (7’3”) stick

1

2500 mm (8’2”) stick

2900 mm (9’6”) stick

UNDERCARRIAGE AND STRUCTURES STANDARD OPTIONAL

10.00-20 16 PR, dual tires

315/70R22.5, no gap dual tires

1

445/70R 19.5, single tires

All-wheel drive

Automatic brake/axle lock

l

l

3700 kg (8,157 lb) counterweight

4200 kg (9,259 lb) counterweight

Fenders

ELECTRICAL SYSTEM STANDARD OPTIONAL

LED lights on boom and cab

Roading and indicator lights, front and rear

Maintenance-free batteries

Centralized electrical disconnect switch

l

l

l

l

LED chassis light, left-hand/right-hand

boom lights, cab lights

Electrical refueling pump

SERVICE AND MAINTENANCE STANDARD OPTIONAL

Sampling ports for Scheduled Oil Sampling

(S•O•SSM)

Ground-level and platform-level engine oil

dipsticks

l

l

Automatic lubrication system for implement

and swing system

Ground-level engine shutoff switch

Anti-skid plate

Signaling/warning horn

l

l

l

Rotating beacon

1

All regions except North America

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

Not all features are available in all regions. Please check with your local Cat dealer for specifi c offering availability in your area.

For additional information, refer to the Technical Specifi cations brochures for the M318 available at www.cat.com or your Cat dealer.

M318 WHEELED EXCAVATOR

11

Page 12

For more complete information on Cat products, dealer services and industry solutions, visit us on the web at www.cat.com.

VisionLink is a trademark of Trimble Navigation Limited, registered in the United States and in other countries.

Materials and specifi cations are subject to change without notice. Featured machines in photos may include additional

equipment. See your Cat dealer for available options.

© 2020 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, Product Link, S•O•S,

“Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product

identity used herein, are trademarks of Caterpillar and may not be used without permission.

www.cat.com www.caterpillar.com

AEXQ2926-02 (11-2020)

Replaced AEXQ2926-01

Build Number: 07A

(N Am, Eur, Aus-NZ)

Loading...

Loading...