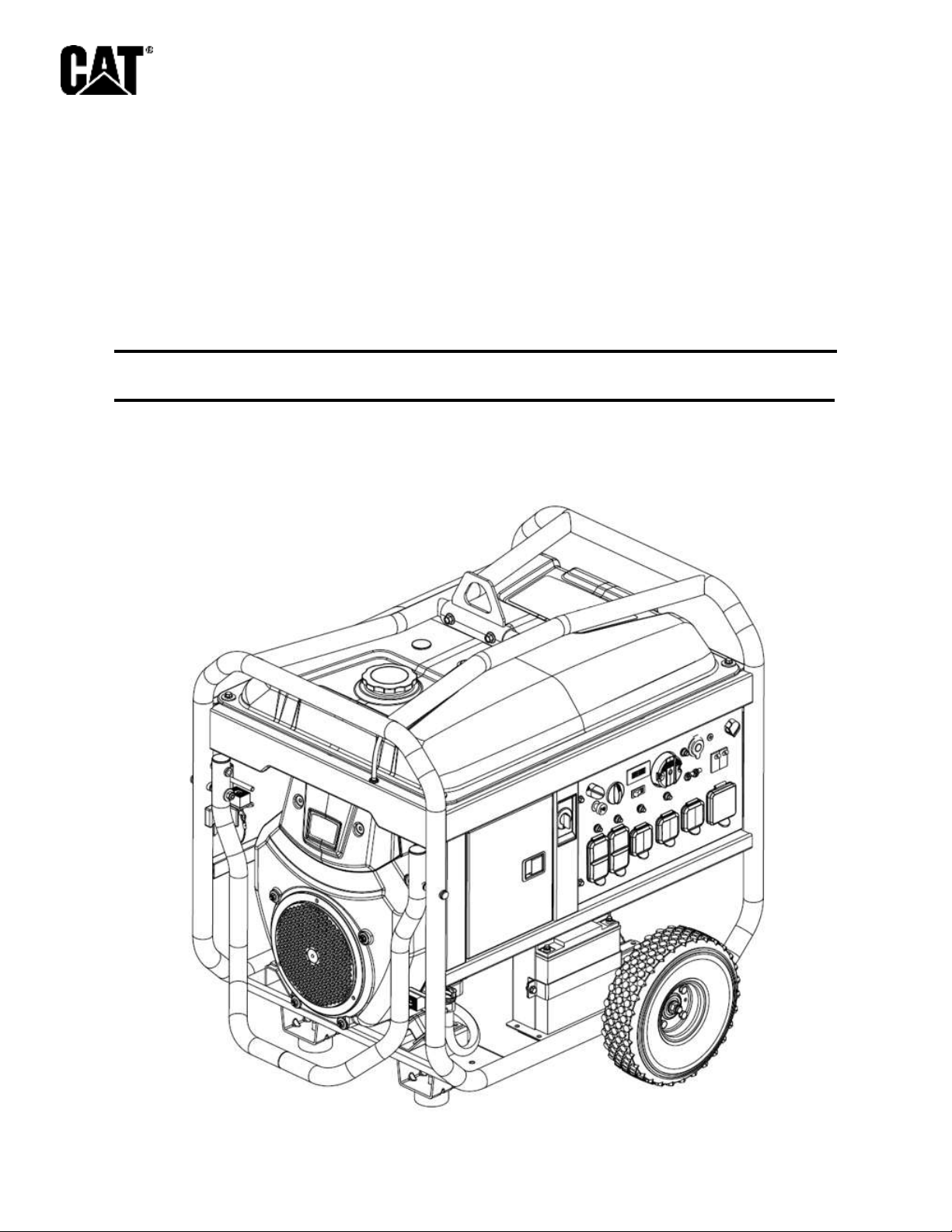

Page 1

501–5289-02

Owner's Manual

RP12000 E Portable Generator

Page 2

2

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to observe

basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous

situations before an accident occurs. A person must be alert to potential hazards, including human factors

that can affect safety. This person should also have the necessary training, skills and tools to perform

these functions properly.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons. The hazards are

identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as “DANGER”,

“WARNING” or “CAUTION”.

Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. You must not use this

product in any manner different from that considered by this manual without first satisfying yourself that

you have considered all safety rules and precautions applicable to the operation of the product in the

location of use, including site-specific rules and precautions applicable to the worksite. If a tool,

procedure, work method or operating technique that is not specifically recommended by Caterpillar is

used, you must satisfy yourself that it is safe for you and for others. You should also ensure that you are

authorized to perform this work, and that the product will not be damaged or become unsafe by the

operation, lubrication, maintenance or repair procedures that you intend to use.

The information, specifications, and illustrations in this publication are on the basis of information that was

available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job.

In the United States, the maintenance, replacement, or repair of the emission control devices and systems

may be performed by any repair establishment or individual of the owner's choosing.

This manual contains safety, operation, and maintenance information. This manual should be stored near

the product. Read, study and keep it with the literature and product information.

Consumer Arbitration Clause

The Limited Warranty included in this User Guide contains important legal terms including, but not limited

to, a Consumer Arbitration Clause calling for mandatory individual arbitration and waiving the ability to

bring a case as a class action. Please review this carefully.

California Proposition 65 Warning

Page 3

3

Table of Contents

Consumer Arbitration Clause .................................................................................................................... 2

California Proposition 65 Warning ............................................................................................................... 2

SAFETY MESSAGES ................................................................................................................................... 5

Additional Messages ................................................................................................................................. 6

Special Requirements ............................................................................................................................... 6

ASSEMBLY ................................................................................................................................................... 7

Unpackaging ............................................................................................................................................. 7

Feet Assembly .......................................................................................................................................... 7

Wheel Assembly ....................................................................................................................................... 7

Lifting Eye Assembly ................................................................................................................................. 8

Handle Assembly ...................................................................................................................................... 8

Battery Connection .................................................................................................................................... 8

Oil .............................................................................................................................................................. 8

COMPONENT IDENTIFICATION ................................................................................................................. 9

Engine Type & Serial Number ................................................................................................................. 10

CONTROLS ................................................................................................................................................ 11

Display ..................................................................................................................................................... 11

Engine Idle Control Switch ...................................................................................................................... 11

Generator Switch .................................................................................................................................... 11

Choke (if equipped) ................................................................................................................................. 11

Electronic governor and choke (if equipped) .......................................................................................... 11

Fuel Switch .............................................................................................................................................. 11

AC Circuit Breaker .................................................................................................................................. 12

120/240 VAC Circuit Breaker .................................................................................................................. 12

Low Oil Level Shutdown .......................................................................................................................... 12

CO DEFENSETM & Shut Off System (If equipped) ................................................................................. 12

120 VAC, 20 Amp, Duplex ...................................................................................................................... 13

120 VAC, 120/240 VAC, 30 Amp, Locking ............................................................................................. 13

120/240 VAC, 50 Amp ............................................................................................................................ 13

GENERATOR OPERATION........................................................................................................................ 13

Optimal Generator Operating Conditions ................................................................................................ 13

Connection to Household Power Supply ................................................................................................. 13

Generator Grounding .............................................................................................................................. 13

AC Usage ................................................................................................................................................ 14

High Altitude Kits ..................................................................................................................................... 14

BEFORE STARTING ENGINE ................................................................................................................... 14

Engine Oil ................................................................................................................................................ 14

Fuel ......................................................................................................................................................... 14

Walk-Around Inspection .......................................................................................................................... 14

STARTING THE ENGINE ........................................................................................................................... 15

Page 4

4

Electric Start ............................................................................................................................................ 15

STOPPING THE ENGINE ........................................................................................................................... 15

MAINTENANCE .......................................................................................................................................... 15

Air Filter – Check ..................................................................................................................................... 16

Cylinder Head - Clean ............................................................................................................................. 16

Engine Oil Level – Check ........................................................................................................................ 16

Engine Oil and Oil Filter – Change .......................................................................................................... 17

Engine Valve Lash – Inspect/Adjust ....................................................................................................... 17

Fuel Line – Replace ................................................................................................................................ 17

Fuel Tank Cap and Strainer – Clean ...................................................................................................... 17

Spark Arrestor - Inspect/Clean/Replace.................................................................................................. 17

Spark Plug – Inspect/Adjust/Replace ...................................................................................................... 18

Battery– Inspect/Replace ........................................................................................................................ 18

Generator - Inspect ................................................................................................................................. 18

Walk-Around Inspection .......................................................................................................................... 18

STORAGE ................................................................................................................................................... 19

Storage for 1 to 3 months ........................................................................................................................ 19

Storage for more than 3 months ............................................................................................................. 19

TROUBLESHOOTING ................................................................................................................................ 20

SPECIFICATIONS ...................................................................................................................................... 21

COMBINED EXHAUST AND EVAPORATIVE EMISSIONS CONTROLS WARRANTY STATEMENT ..... 22

Your Warranty Rights and Obligations .................................................................................................... 22

Manufacturer’s Warranty Coverage ........................................................................................................ 22

Owner’s Warranty Responsibilities ......................................................................................................... 22

Defects Warranty Requirements: ............................................................................................................ 22

WARRANTY ................................................................................................................................................ 24

CONSUMER ARBITRATION CLAUSE: MANDATORY BINDING INDIVIDUAL ARBITRATION

INSTEAD OF COURT; CLASS ACTION WAIVER ................................................................................. 24

Page 5

5

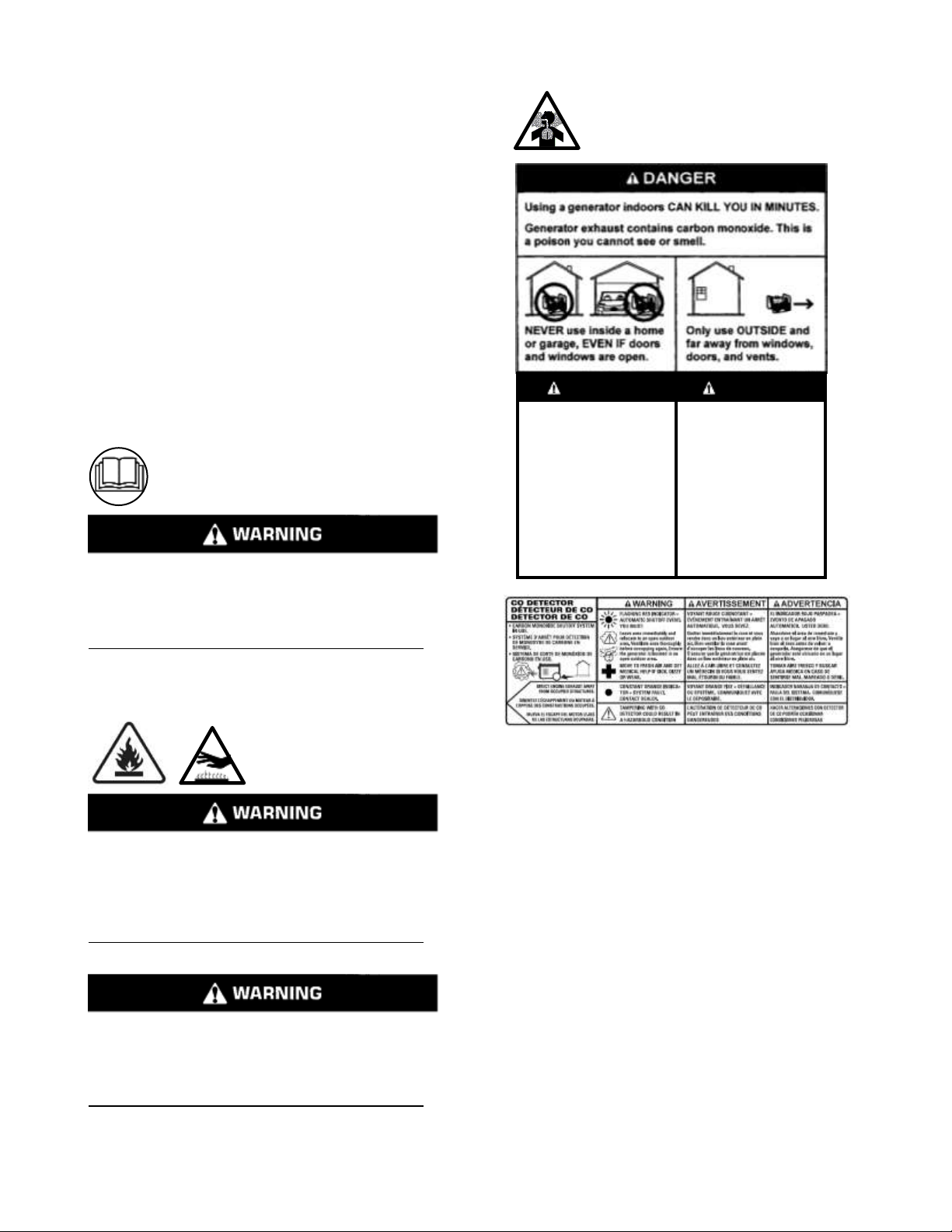

SAFETY MESSAGES

There may be several specific safety messages on

your generator. Please become familiar with all

safety messages.

Ensure that all of the safety messages are legible.

Clean the safety messages or replace the safety

messages if the words cannot be read or if the

illustrations are not visible. Use a cloth, water, and

soap to clean the safety messages. Do not use

solvents, gasoline, or other harsh chemicals.

Solvents, gasoline, or harsh chemicals could loosen

the adhesive that secures the safety messages.

Replace any safety message that is damaged or

missing. If a safety message is attached to a part of

the generator that is replaced, install a new safety

message on the replacement part.

Read the Manual

Do not operate or work on this generator unless you

have read and understand the instructions and

warnings in the Owner’s Manual. Failure to follow the

instructions or heed the warnings could result in

injury or death. Proper care is your responsibility.

Hot Surface / Do Not Touch / Flammable

Material

Hot parts or hot components can cause burns or

personal injury. Do not allow hot parts or components

to contact your skin. Use protective clothing or

protective equipment to protect your skin. Hot exhaust

presents a potential fire hazard. Be sure that nothing

flammable is within 1.5 meters of the exhaust.

Operation of this equipment may create sparks that

can start fires around dry vegetation. A spark arrestor

may be required. The operator should contact local

fire agencies for laws or regulations relating to fire

prevention requirements.

Carbon Monoxide

Operating a generator indoors can kill you in

minutes. Generator exhaust contains carbon

monoxide. Carbon monoxide is a poison that you

cannot see or smell. Never operate a generator

inside a home or garage, even if doors and windows

are open. Only operate a generator outdoors and

away from windows, doors, and vents. Always direct

engine exhaust away from occupied structures. If

anyone experiences dizziness, headaches, nausea,

or tiredness get to fresh air immediately and seek

medical attention. Ventilate the area thoroughly

before occupying again.

The carbon monoxide shutoff system is not a

substitute for safe generator operation. Do Not

adjust or modify the carbon monoxide shutoff

system. Failure to follow instructions can cause the

system to malfunction which can result in hazardous

conditions.

DANGER

PELIGRO

Utiliser un générateur à

l’intérieur PEUT VOUS TUER EN

QUELQUES MINUTES. Les gaz

d’échappement du générateur

contiennent du monoxyde de

carbone. C’est un gaz toxique

invisible et inodore.

NE JAMAIS utiliser à l’intérieur

d’une maison ou d’un garage,

MÊME SI les portes et les

fenêtres sont ouvertes.

Utiliser UNIQUEMENT à

l’EXTÉRIEUR et loin des

fenêtres, portes et ventilations.

Si usa un generador en

interiores, MORIRA EN POCOS

MINUTOS. El escape del

generador contiene monóxido

de carbono. Es un veneno que

no tiene olor ni se puede ver.

NUNCA lo use dentro de una

casa o garaje. AUN si las

puertas y vantanas están

abiertas.

Sólo úselo en EXTERIORES

y lejos de ventanas, puertas y

ductos de ventilación.

Page 6

6

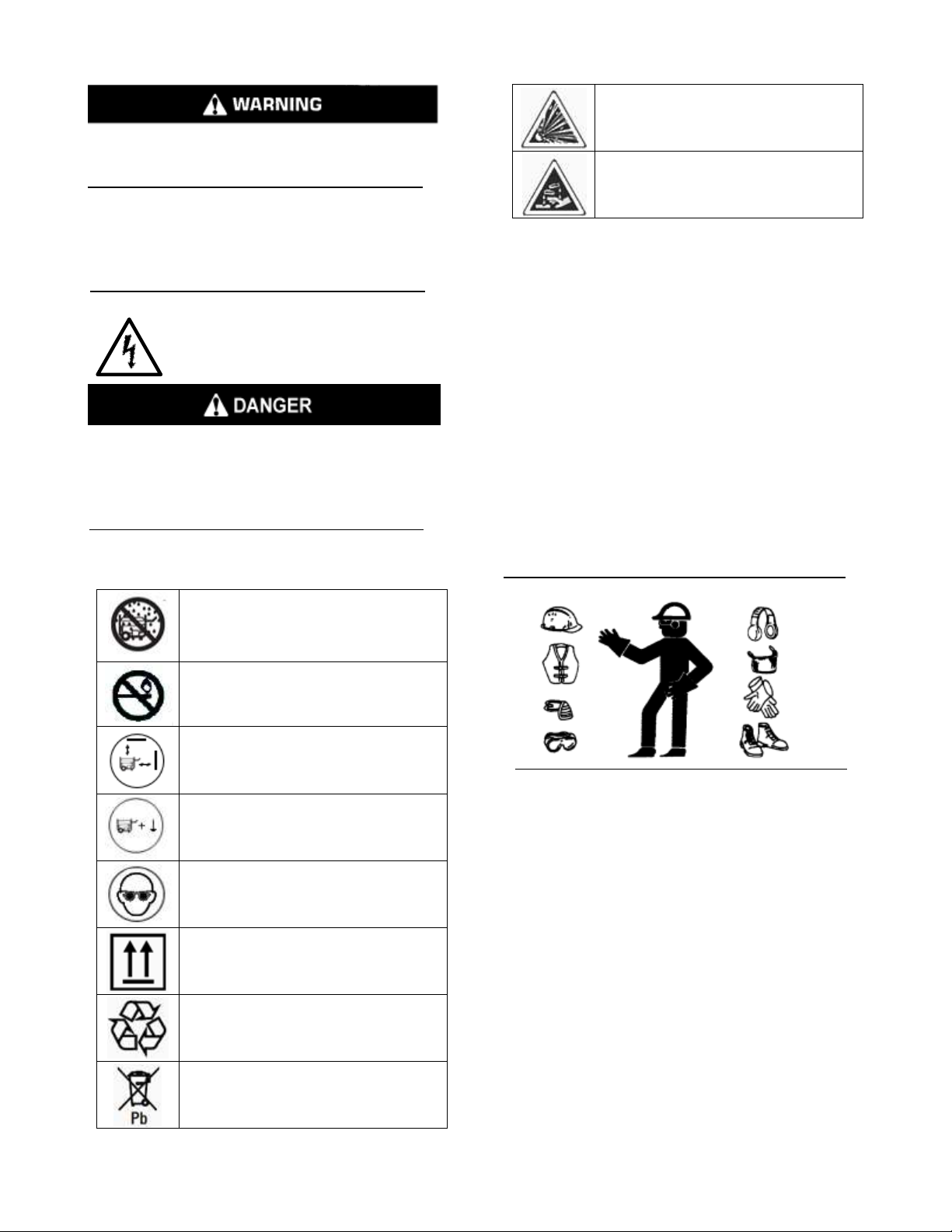

Electrical backfeed into a utility’s distribution

system can cause property damage, severe injury,

or death.

Electrical backfeed warning. Do not connect

generator to a building’s electrical system unless

using an isolation (transfer) switch installed by a

certified, licensed electrician. CA H&S Code 119075

& 119080.

Electrocution

Shock/Electrocution Hazard: Do not operate this

equipment or work on this equipment unless you

have read and understand the instructions and

warnings in the Owner’s Manual. Failure to follow

the instructions or heed the warnings will result in

serious injury or death.

Additional Messages

Do not operate in wet conditions

No smoking, no exposed flames,

no sparks.

Maintain a minimum distance of 5

feet (1.5 meters) from other

objects.

Ensure that the unit is properly

grounded.

Eye protection must be worn at

all times.

This way up. Always keep

upright.

Recyclable – Follow local

recycling & reclaiming

procedures.

Never dispose of battery. Take to

designated waste reclamation

site.

Danger: Explosive Gases.

Danger: Battery Acid – Corrosive

and poisonous.

Special Requirements

Electrical equipment, including lines and plug

connections should be covered and protected from

moisture.

In any generator set installation, the frame of the

generator must be connected to an earth ground. A

ground terminal is provided.

The RP12000 E has a permanent neutral conductor

between the stator winding and the frame.

For 120VAC duplex receptacles, use extension

cords rated for 125V at 20A or greater, and 30A or

greater for locking receptacles. For 240VAC, use

extension cords rated for 250V at 30A or greater.

Use the shortest extension cord that meets these

requirements.

•

Wear a hard hat, protective glasses, and other

protective equipment, as required.

•

When work is performed around an engine that is

operating, wear protective devices for ears in

order to help prevent damage to hearing.

•

Do not wear loose clothing or jewelry that can

snag on controls or on other parts of the engine.

•

Ensure that all protective guards and all covers

are secured in place on the engine.

•

Never put maintenance fluids into glass

containers. Glass containers can break.

•

Use all cleaning solutions with care.

The circuit breakers should match the generator

specifications. If the circuit breakers require

replacement, they must be replaced with a circuit

breaker of the same rating and performance

characteristics.

Page 7

7

ASSEMBLY

NOTE: Only assemble unit with the included

hardware to avoid the risk of personal and

property damage.

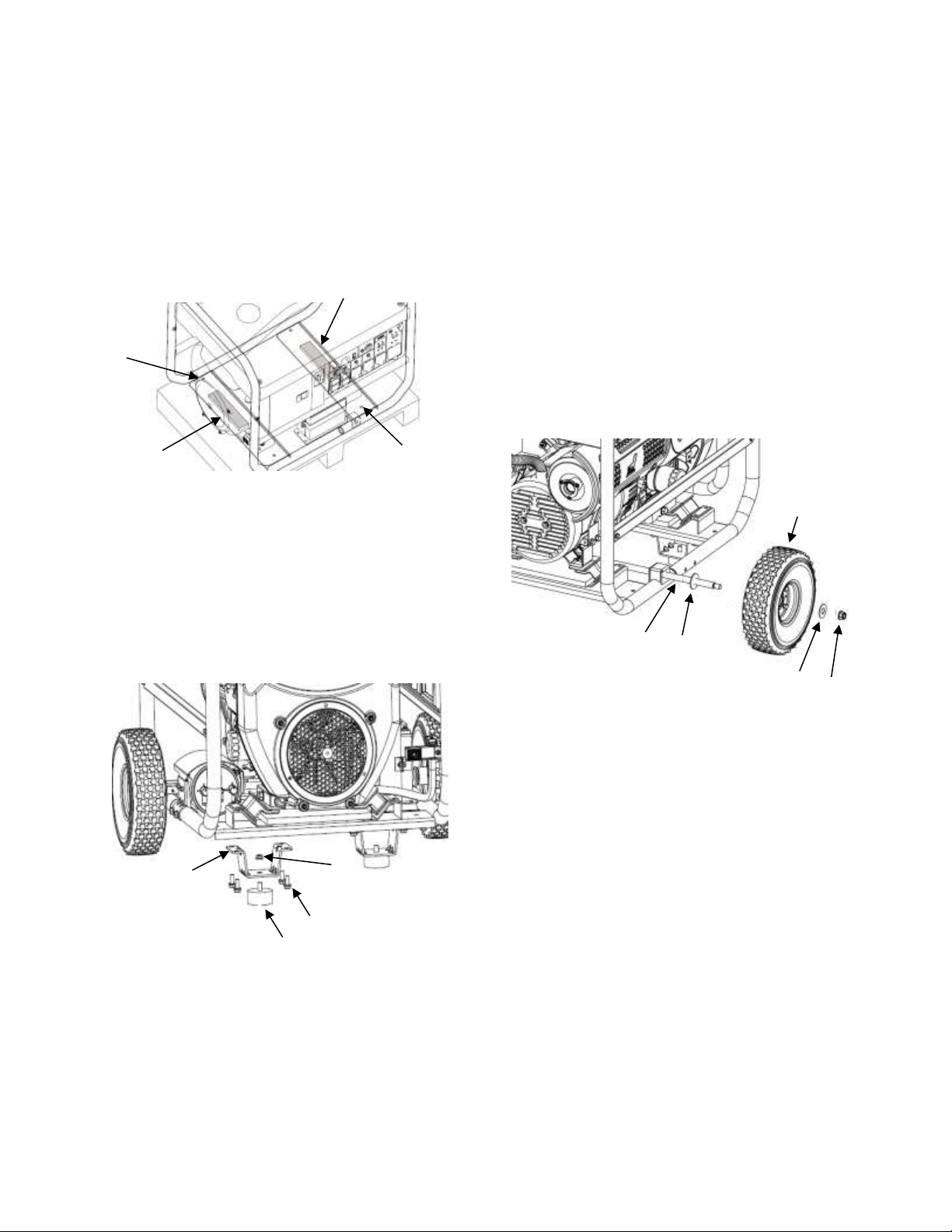

Unpackaging

1. Remove both 8 mm bolts (1) from the

pallet and frame.

2. Remove both wood blocks (2) from

below the engine and alternator.

Feet Assembly

1. Set the frame of the unit on blocks to

provide sufficient clearance to install the

feet and wheels.

2. Align the foot (4) with the mounting hole

in the foot bracket (1).

3. Install and hand tighten one 8 mm nut

(2) onto the foot.

4. Tighten the nut securely.

5. Align the mounting holes of the foot

bracket (1) with the mounting holes in

the frame.

6. Insert one 8 mm bolt (3) through each

set of mounting holes and hand tighten.

7. Repeat steps 2 – 6 for the other foot.

8. Tighten all eight bolts securely.

Wheel Assembly

1. Insert long end of axle (5) into the

mounting bracket on the frame and run

through to insert into the other mounting

bracket on opposite side of frame.

2. Place the wheel stop (4) onto the long

end of the axle.

3. Place one wheel (1) onto the axle (5)

with the bolt design facing out.

4. Install one washer (3) onto the axle.

5. Install one 12 mm locking nut (2) onto

the axle and tighten securely.

6. Repeat steps 3 – 5 for the other wheel.

7. Remove the blocking.

1

4

3

2 5 3 4 2

1

1

2

2

1

Page 8

8

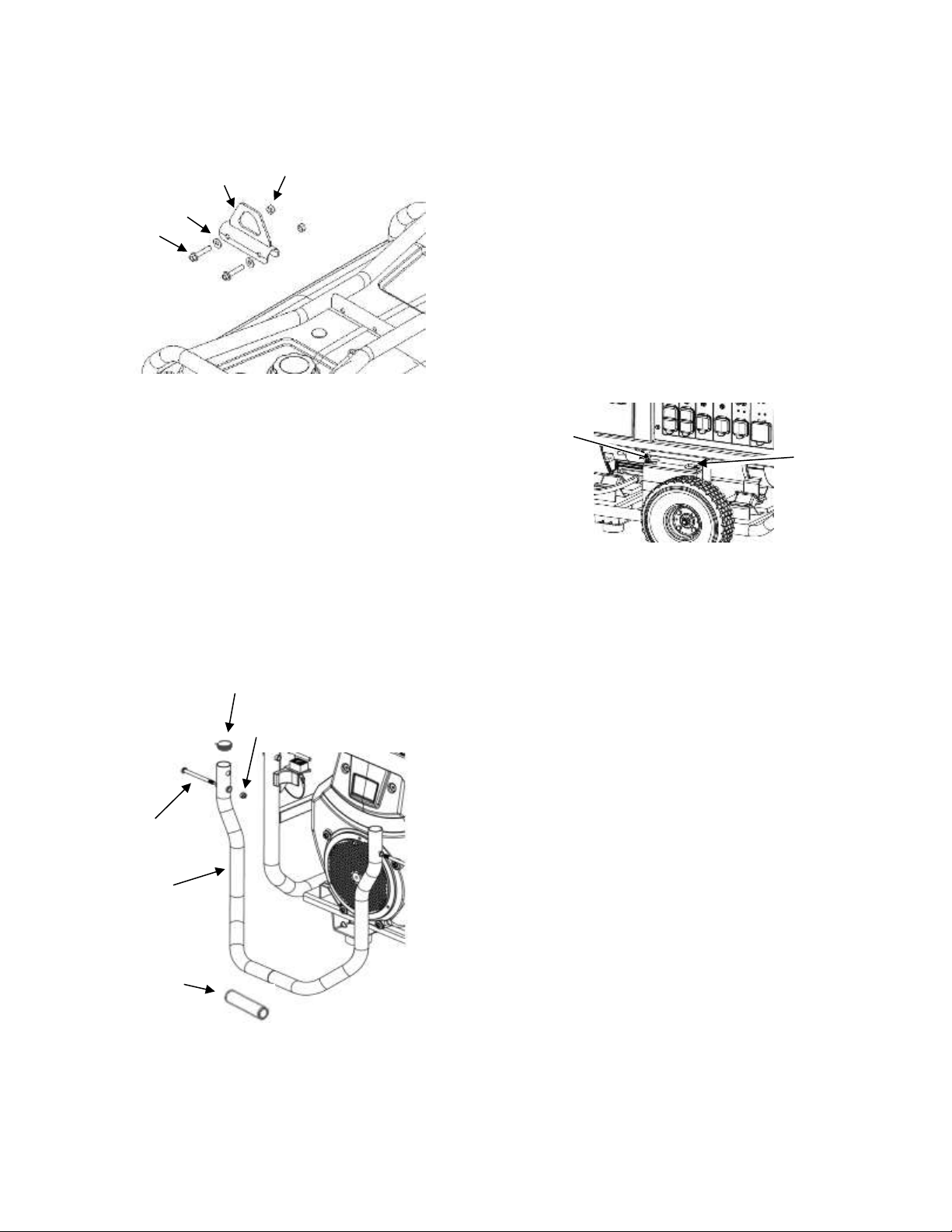

Lifting Eye Assembly

1. Align the mounting holes of the lifting

eye (3) with the mounting holes in the

frame.

2. Place one washer (2) on each 10 mm

bolt (1) and insert through each

mounting hole.

3. Install and hand tighten one 10 mm nut

(4) on each bolt.

4. Tighten both nuts to 26 ± 2 lb ft

(35 ± 3Nm).

Handle Assembly

1. Install the foam grip (3) onto the handle

(4).

2. Insert one plug (1) into each end of the

handle (4).

3. Align the mounting holes of the handle

(4) to the mounting holes of the frame.

4. Insert one 8 mm bolt (5) through each

mounting hole.

5. Install and hand tighten one 8 mm nut

(2) on each bolt.

6. Tighten the nuts securely.

Battery Connection

The generator is packaged with a valve

regulated and maintenance free lead acid

battery. The generator is packaged with the

battery mounted in the battery holder. To

connect the battery:

1. The unit ships with the positive battery

cable (1) already connected.

2. Attach the cable with the black cap (2)

to the negative battery terminal.

NOTE: Replace battery only with the same part

number. Use of a non-conforming battery can

create a fire hazard.

Oil

Follow the Engine Oil Level-Check procedure to

add the proper amount of oil for the unit as

described in the Specifications chart.

2

1

4

3

2 1 5

4

2 3 1

Page 9

9

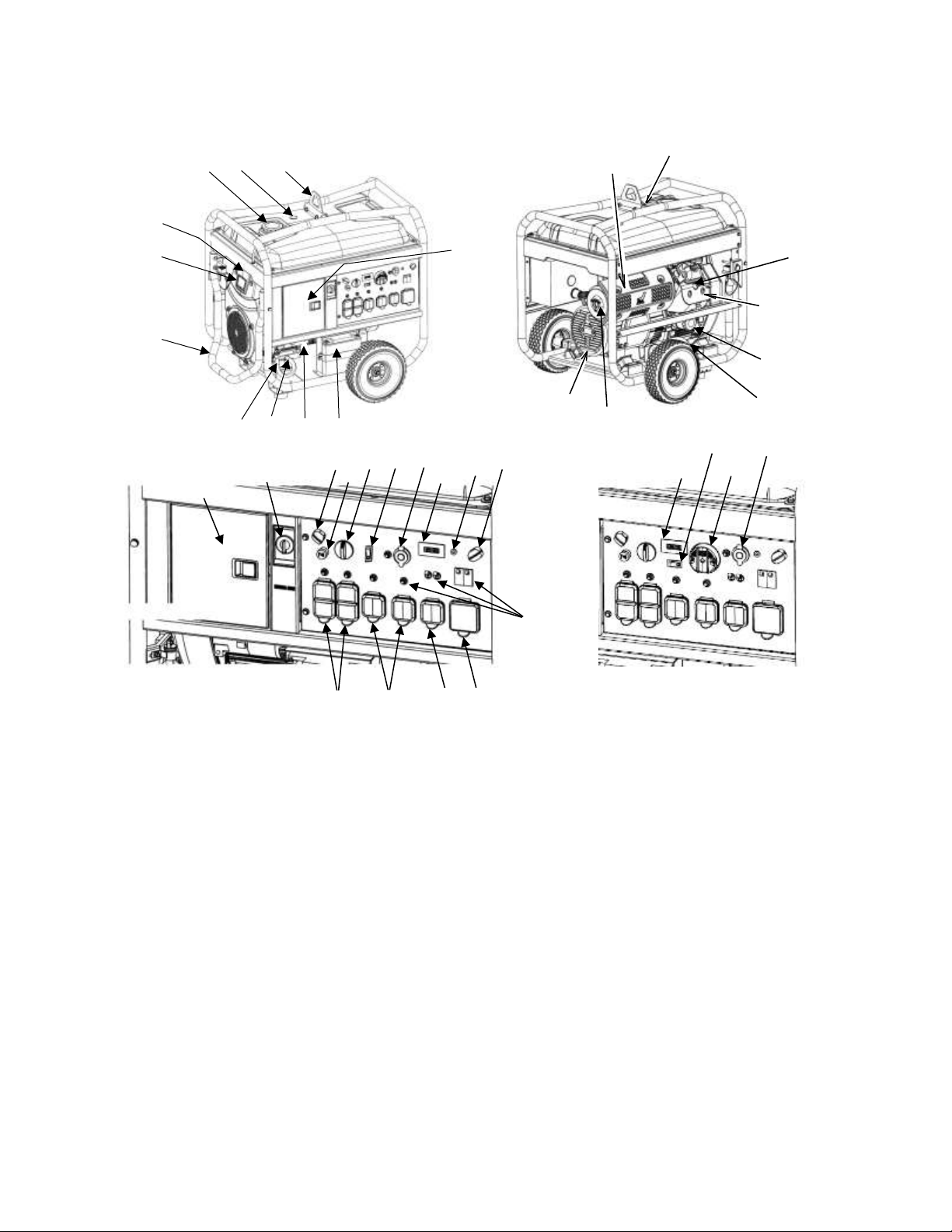

COMPONENT IDENTIFICATION

1) Fuel Cap

2) Fuel Gauge

3) Lifting Eye

4) Oil Gauge / Oil Fill*

5) Spark Plug*

6) Battery

7) Starter

8) Oil Drain Valve

9) Oil Drain

10) Handle Assembly

11) Cover Panel

12) Air Filter Assembly

13) Air Filter

14) Muffler

15) Fuel Tank Vent Pipe

16) Engine

17) Oil Filter

18) CARB Canister (If equipped)

19) Spark Arrestor

20) Alternator

21) Engine Access Door

22) Fuel Valve

23) Panel Light

24) Choke Knob (if equipped)

25) Generator Switch

26) Display

27) Idle Control Switch

28) CO Detector (If equipped)

29) Receptacle – DC 12V 8.3A

30) Trickle Charger Port

31) Circuit Breaker

32) Receptacle – 120/240 VAC 50A

33) Receptacle – 120/240 VAC 30A

34) Receptacle – 120 VAC 30A

35) Receptacle – 120 VAC GFCI double

*behind engine access door

15

16

17

14

19

20

18

5

4, 5

1

2

3

9

10

11

12, 13

6

7

8

Panel without CO Detector

Panel with CO Detector

21

22

23

23

24

26

29

25

31

35

34

32

33

30

27

29

28

26

27

Page 10

10

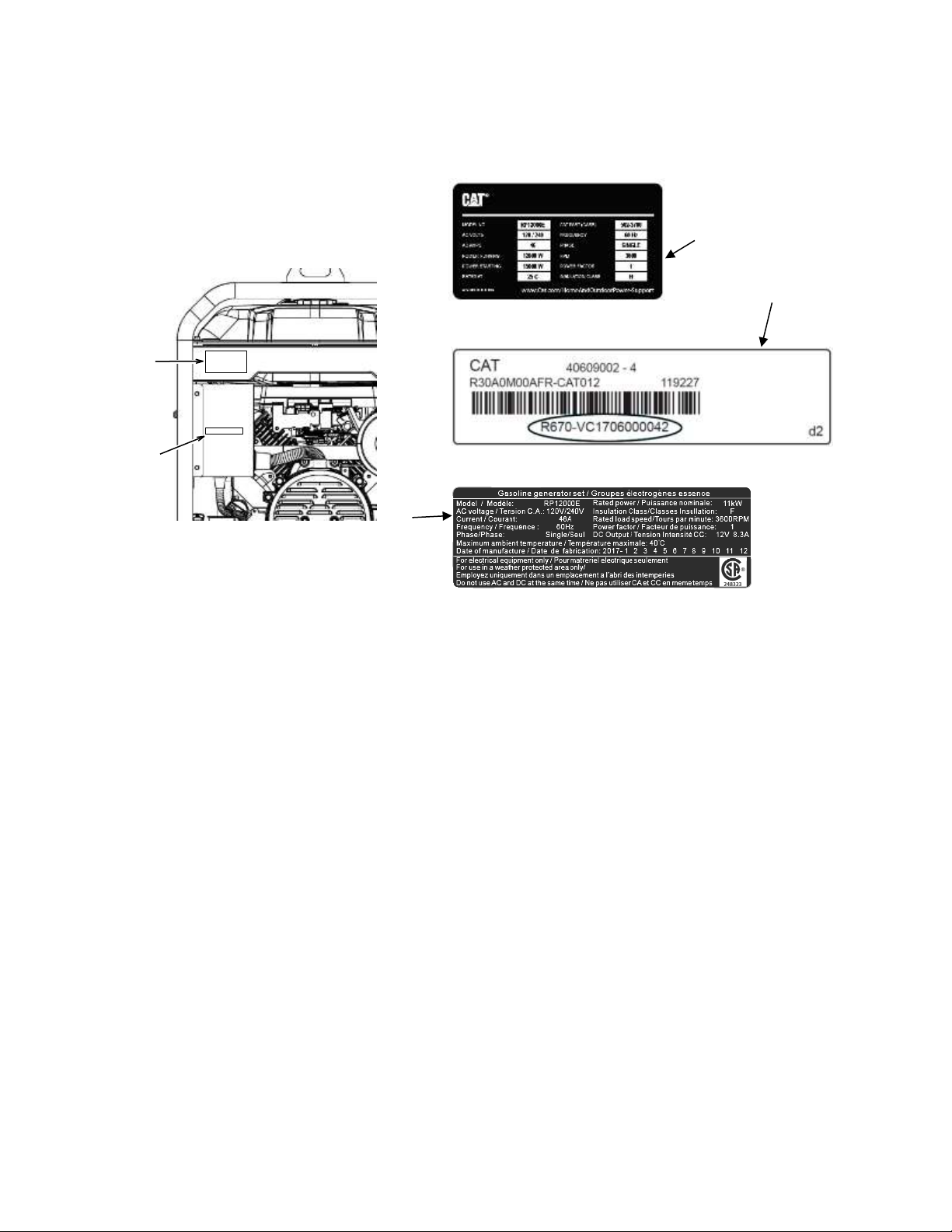

Engine Type & Serial Number

Cat® portable generators are identified with model numbers, serial numbers, and with performance

specification numbers. The model number and performance specifications are located on the ratings

plate (1) or the CSA ratings plate (3). The serial number is located on the serial number plate (2).

1

2

1/3

2

3

Page 11

11

CONTROLS

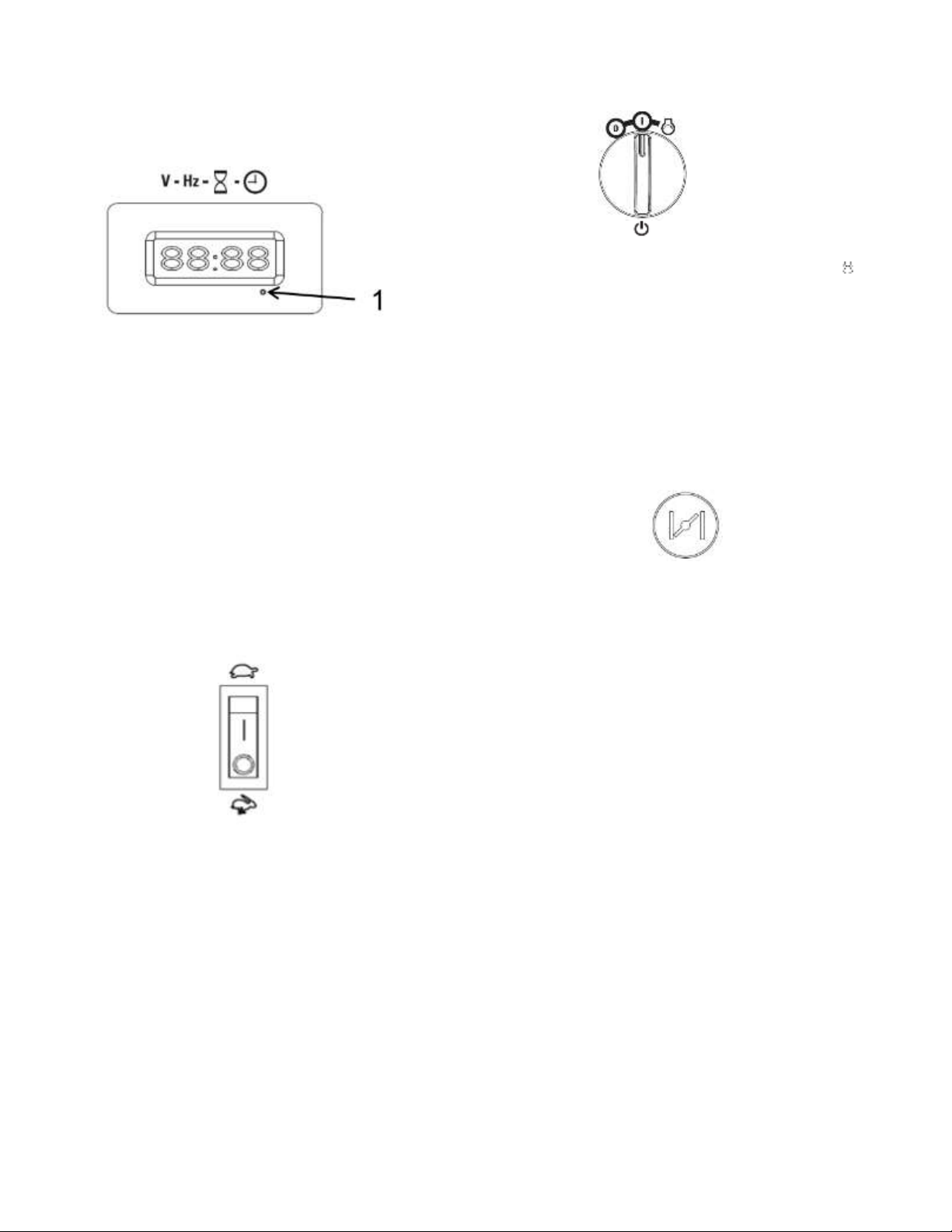

Display

This generator is equipped with a display that can

show the Voltage, frequency, total accumulated

hours of operation, and current hours. Use toggle

switch (1) to change the readout of the display to the

desired setting.

The display will show 3 maintenance messages

when running: P-25 displays after the first 25 hours

running to remind the user to change engine oil and

oil filter. P-50 displays after every 50 hours of use to

remind user to check the air filter and spark arrestor.

P-100 displays after every 100 hours of use to

remind user to change engine oil and oil filter and

check spark plug. These codes fade away after 6

minutes of use.

Engine Idle Control Switch

This generator is equipped with an engine idle

control switch. When in the on position “I” the engine

will reduce speed when power is not required to

conserve fuel and reduce wear and noise.

When power for a connected device is required the

speed will automatically increase to rated speed.

Note: If loads requiring intermittent power, or

multiple large loads are connected, turn the idle

control switch off “O” to avoid possible engine stall.

To avoid extended warm-up time, keep the idle

control off until normal operating temperatures have

been reached.

Generator Switch

Turn the generator switch to the start position “ ”

and hold until the engine starts (no more than 5

seconds). Releasing the switch automatically

returns it to the on “I” position. To turn off the

generator, turn the generator switch to the off “0”

position.

NOTE: Turn the generator switch to the off “0”

position when not in use to avoid battery drain.

Choke (if equipped)

The choke is used to provide more fuel when starting

a cold engine. If the engine is cold, pull the choke

knob out before starting the engine. Once the engine

is warm, slowly push the choke knob in.

Electronic engines are fitted with an electronic

governor and automatic choke (temperature

compensating) that do not require any user

Electronic governor and choke (if

equipped)

The electronic governor maintains a steady engine

speed regardless of operating conditions and load.

The electronic choke does not require any user input

and automatically adjusts the choke position by

monitoring the engine temperature.

Fuel Switch

The fuel switch controls the flow of the fuel from the

fuel tank to the carburetor. Turn the fuel switch to the

on “I” position before starting the engine. Turn the

fuel switch to the off "O" position after stopping the

engine.

Page 12

12

AC Circuit Breaker

The generator comes equipped with circuit breakers

that protect the unit and the load from short circuit or

overload conditions. If the circuit breaker opens,

determine why the circuit breaker tripped before

closing the circuit breaker.

120/240 VAC Circuit Breaker

The 120/240 V receptacles come with an additional

circuit breaker that will isolate these outlets on the

panel. This breaker must be in the “On” position for

the unit to provide power.

Low Oil Level Shutdown

The generator is equipped with a low oil level

shutdown that is designed to protect the engine

from damage caused by an insufficient amount of

oil in the crankcase. When the oil level in the

crankcase falls below the safe operating limit, the

low oil level shutdown will automatically shut off the

engine.

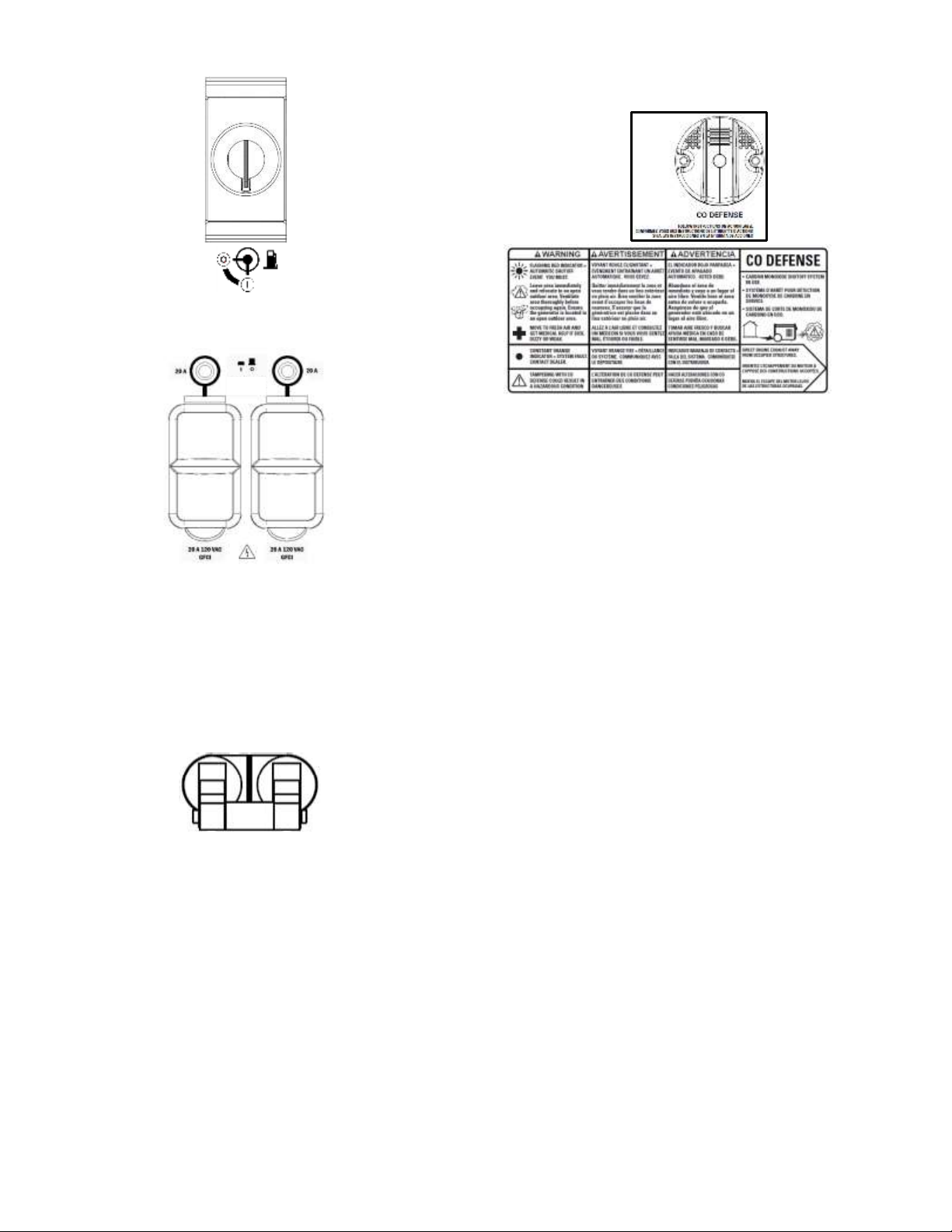

CO DEFENSETM & Shut Off System (If

equipped)

The (carbon monoxide) CO DEFENSE system

monitors the accumulation of carbon monoxide gas

while the generator is running and will shut off the

engine if the levels become dangerously high. The

CO DEFENSETM on this generator is not a substitute

for an indoor CO alarm.

Whenever the CO DEFENSE has shut off the engine

there will be a light on the control panel that

indicates the reason. Read the CO Action Label

(shown above) for the next steps to take.

If the CO DEFENSE light is flashing “red” you must

leave the area immediately and relocate to an open

outdoor area. Ventilate the area thoroughly before

again occupying it. Ensure the generator is located

in an open outdoor area with the exhaust pointed

away from occupied structures. If anyone

experiences dizziness, headaches, nausea, or

fatigue get to fresh air immediately and seek medical

attention.

If the CO DEFENSE light is a constant “orange” then

a system fault has occurred, or it is indicating that it

has reached the end of its life. This fault can only be

diagnosed and repaired by an Authorized Service

Provider.

The CO DEFENSE monitors the accumulation of CO

gas from all sources in the area around the

generator. If the CO DEFENSE light is flashing “red”

this is not an error and safety measures must be

taken immediately.

Note: Tampering with the CO DEFENSE could result in

hazardous conditions and must be avoided.

Note The generator must not be operated in

ambient temperatures greater than 131oF (55oC) as

this can damage the CO DEFENSE

Page 13

13

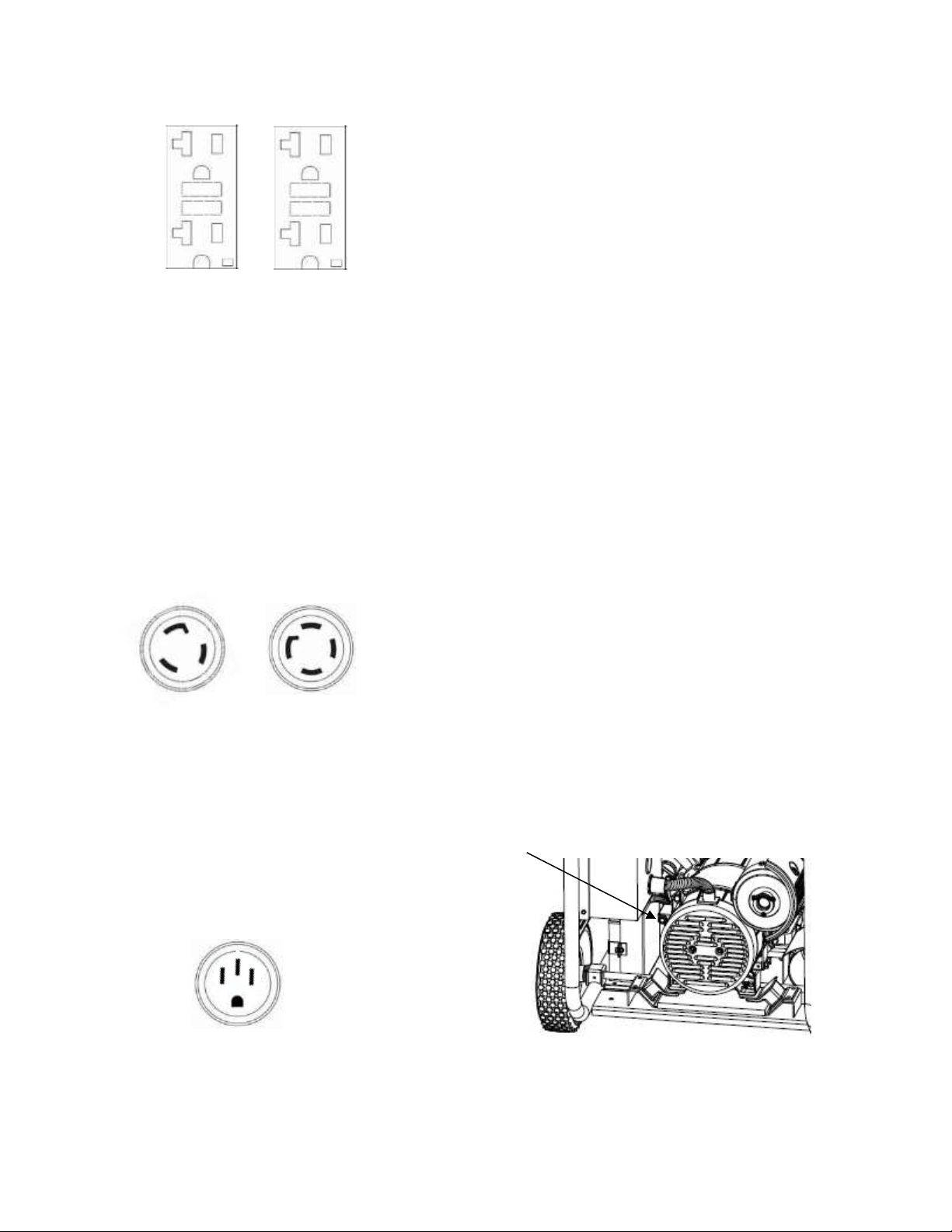

120 VAC, 20 Amp, Duplex

The 120 VAC duplex receptacle is protected

against overload by a 20 Amp push to reset

circuit breaker. It also provides protection via a

Ground Fault Circuit Interruptor (GFCI) with press

to Test and Reset buttons. Use the receptacle to

power a NEMA 5-20, 120 VAC, single phase, 60

Hz electrical load requiring 20 Amps of current.

Use only high quality, well insulated, 3-wire

grounded cords rated for 125 V at 20 Amps (or

greater). Keep extension cords as short as

possible (less than 15 feet) to prevent voltage

drop and overheating of wires.

120 VAC, 120/240 VAC, 30 Amp,

Locking

The 120 VAC locking outlet is protected against

overload by a 30 Amp push to reset circuit

breaker. The 120/240 VAC locking outlet is

protected against overload by a 30 Amp double

pole circuit breaker. Use a NEMA L5-30 (120

VAC outlets) or NEMA L14-30 (120/240 VAC

outlets) plug with this receptacle (rotate to lock

or unlock). Use the receptacle to power a 120

VAC, single phase, 60 Hz, or a 240 VAC, single

phase, 60 Hz electrical load.

120/240 VAC, 50 Amp

The 120/240 VAC outlet is protected against

overload by a 46 Amp double pole circit breaker.

Use a NEMA L14-50 plug with this receptacle.

Use the receptacle to power a 120 VAC or a 240

VAC, single phase, 60 Hz electrical load.

GENERATOR OPERATION

Optimal Generator Operating

Conditions

• Temperature: 23oF to 104 oF

(-5oC to 40oC)

• Humidity below 95%

• Height above sea level: < 3000 feet (900

m). If the height of the operating area is

over 900 m high, output power will be

reduced.

Standard operating conditions are 77oF (25oC)

and 40% humidity. Generator power may be

reduced due to different ambient conditions and

other factors such as fuel quality.

Connection to Household Power

Supply

This generator must be installed in accordance

with all applicable local laws and electrical

codes. The generator must be isolated from the

utility and the connection must be verified by a

qualified electrician.

Generator Grounding

The National Electrical Code requires generators

to be grounded to an approved earth ground.

Correct grounding for the generator is necessary

for optimum engine performance and reduces

the risk of electric shock. Use the ground

terminal (1) to properly ground the generator.

Before using the ground terminal, consult a

qualified electrician, electrical inspector, or local

authority having jurisdiction for local codes or

ordinances that apply for the intended use of the

generator.

1

Page 14

14

AC Usage

Do NOT overload the generator. Exceeding the

rated power of the generator can damage the

generator and the electrical devices connected

to it.

Motor-driven devices require a large starting

current. Make sure that the total power

requirement of these types of loads does not

exceed the rated power of the generator.

When the generator is used to power multiple

loads or electric appliances, start by connecting

the appliance with the highest starting power

requirements, followed by the second highest

and ending with the lowest.

High Altitude Kits

At higher altitudes, the standard air-fuel mixture

is too rich and will cause decreased

performance and increased fuel consumption. A

rich mixture will also foul the spark plug and

make starting difficult. Operation at higher

altitudes for extended periods of time may

increase emissions.

Proper operation can be ensured by installing an

altitude kit when required. High altitude kits

should be installed by a qualified technician.

Contact an authorized service provider if the

portable generator will be operated at altitudes

greater than 3000 feet (0.9 km) above sea level.

Note: At elevations greater than 8000 feet

above sea level, the engine may experience

decreased performance even with the high

altitude kit installed.

BEFORE STARTING ENGINE

Engine Oil

Check the oil level before each use. Refer to the

Engine Oil Level - Check procedure in this

manual.

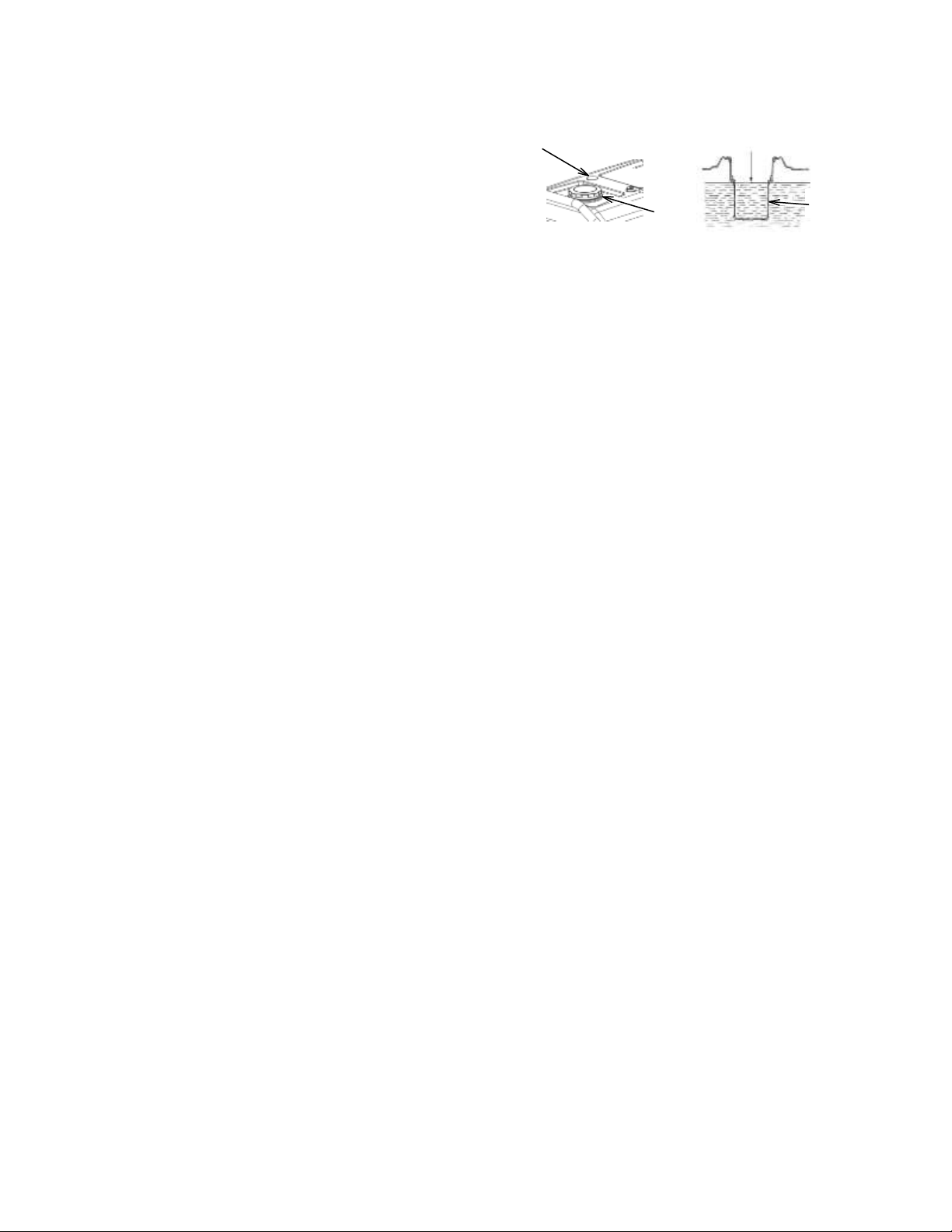

Fuel

1. Check the fuel level gauge (1).

2. If the fuel level is low, remove fuel cap

(2).

3. Check the strainer. If the strainer is

dirty, clean the strainer. Refer to Fuel

Tank Cap and Strainer – Clean for

instructions.

4. Add fuel. The use of a fuel stabilizer is

highly recommended as the unit may

sit for long periods of time before

needed.

5. Install the fuel cap after fueling.

To avoid personal injury always use caution

when you are adding fuel:

• Fuel the generator in a well-ventilated

area.

• Always stop the engine before fueling.

• Allow the engine to cool before fueling.

• Do not smoke while you are fueling the

generator.

• Do not fuel the generator near open

flames or sparks.

• Do not fill the fuel tank above the full line

(3).

• Avoid repeated or prolonged contact with

skin.

• Avoid prolonged breathing of fuel vapor.

To avoid damaging the generator:

• Use unleaded gasoline with an octane

rating greater than or equal to 86.

• Do not mix oil with the gasoline.

• Do not use gasoline with greater than

10% ethanol content.

• Do not use old gasoline.

• Avoid getting dirt or water into the fuel

tank.

Walk-Around Inspection

Perform the Walk-Around Inspection before

each use as described later in this manual.

1 2 3

4

Page 15

15

STARTING THE ENGINE

Electric Start

1. Isolate the generator from the utility.

2. Unplug any electrical devices from the

receptacles.

3. Turn the fuel switch to the on “I”

position.

4. Turn the AC circuit breakers to the off

“0” position.

5. If the engine is cold, pull out the choke

knob (not required if electronic governor

and choke is fitted)

6. Turn the generator switch to the start

position “ ” and hold it there until the

engine starts.

NOTE: Do not hold the generator switch in the

start position “ ” for more than 5 seconds.

Holding the generator switch in the start position

“ ” for more than 5 seconds will damage the

starter. If the engine fails to start, wait 10

seconds before trying again.

7. After starting the engine, immediately

release the generator switch so the

switch can automatically return to the

on “I” position.

8. After the engine has warmed, push the

choke knob in (not required if electronic

governor and choke is fitted)

9. Turn the AC circuit breaker to the on "I"

position.

STOPPING THE ENGINE

1. Disconnect the generator / unplug all

electrical devices.

2. Turn the AC circuit breaker to the off “0”

position.

3. Turn the generator switch to the off “0”

position.

4. Turn the fuel switch to the off “0”

position.

NOTE: To stop the engine in an emergency, turn

the generator switch to the off “0” position.

NOTE: Turn the generator switch to the off “0”

position when not in use to avoid battery drain.

MAINTENANCE

Ensure that all safety information, warnings, and

instructions are read and understood before any

maintenance procedures are performed.

Use service hours or calendar time, WHICH

EVER OCCURS FIRST, to determine the

correct maintenance intervals.

Stop the engine before servicing. Put the engine

in horizontal position and remove the spark plug

cap to prevent the engine from starting. Do not

operate the engine in an unventilated room or

other enclosed area.

When Required:

Fuel Tank Cap and Strainer – Clean

Every Use:

Engine Oil Level – Check

Walk-Around Inspection

First 25 Service Hours or 1 Month:

Engine Oil and Oil Filter– Change

Every Month:

Generator – Inspect

Every 50 Service Hours or 3 Months:

Air Filter – Check

Spark Arrester – Inspect/Clean/Replace

Every 100 Service Hours or 6 Months:

Engine Oil and Oil Filter – Change

Spark Plug – Inspect/Adjust/Replace

Every 300 Service Hours or 1 Year:

Carbon Brush – Inspect/Repair/Replace

Cylinder Head – Clean

Engine Valve Lash – Check

Every 2 Years:

Fuel Line – Replace

NOTE: Use only genuine Caterpillar parts.

Page 16

16

3

2

1 1 4

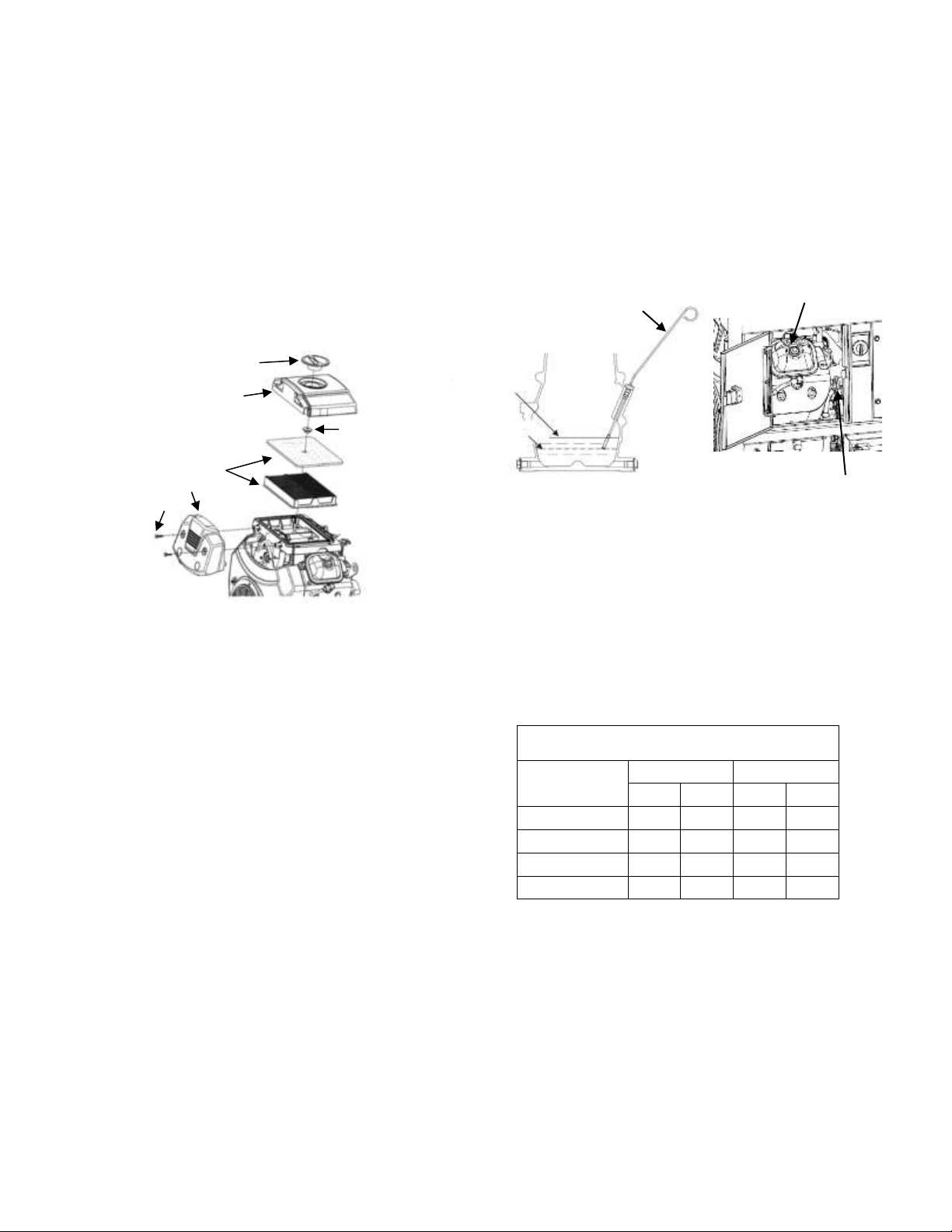

Air Filter – Check

A dirty air filter will restrict air flow into the

carburetor, will cause poor fuel economy, and

may damage the engine. To keep the generator

in good operating condition, service the air filter

regularly. Service more frequently when

operating the generator in extremely dusty areas.

Note: Never operate the generator without the

air filter in place. Operating the generator without

the air filter in place will result in rapid engine

wear.

Remove the fan cover panel (5) by removing the

screws (6) and lifting out. Unscrew and remove

the air filter lock (1) and cover case (2). Remove

the clip (3) and air filter (4). Make sure both the

paper and foam elements of the air filter (4) are

clean and not damaged. If the foam element is

dirty, wash it. If the paper element is dirty, knock

the dirt off. If either element is damaged, replace

the air filter.

Use a nonflammable solvent or a mixture of

household detergent and warm water to wash

the foam element. Rinse the filter thoroughly to

remove all of the cleaning solution. Never let the

foam element contact engine oil.

Note: Do not wring out the filter. Wringing out the

filter may damage the filter.

Use a damp rag to wipe dirt from the case and

cover. Install the filter into the housing. Place the

clip over the filter. Place the cover case over the

filter and clip. Reinstall the lock and screw in the

cover panel.

Cylinder Head - Clean

Only qualified service personnel should perform

this maintenance procedure. Contact your local

service center to schedule this maintenance.

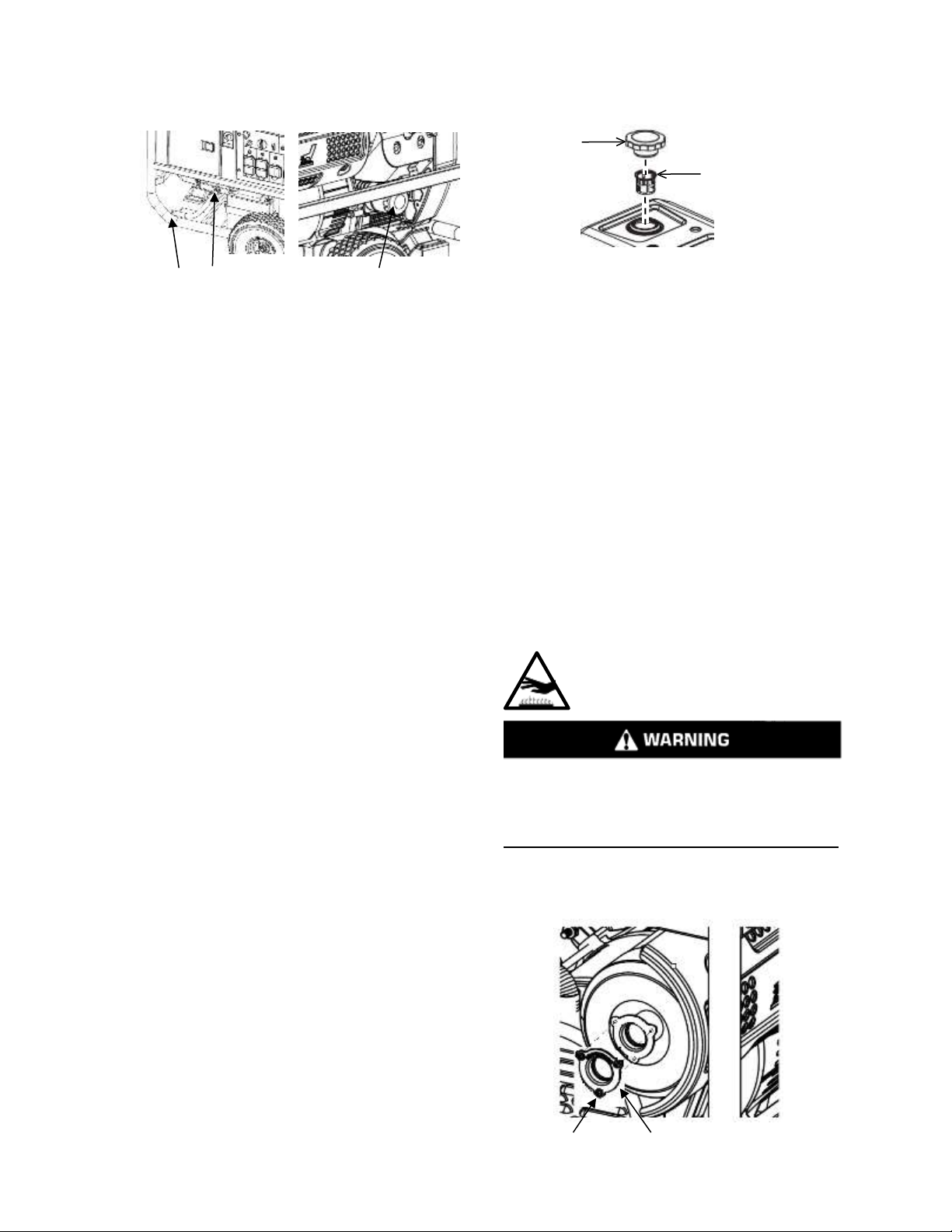

Engine Oil Level – Check

Always check the engine oil with the generator

on a level surface and with the engine stopped.

1.

Open engine access door. Remove the

oil level gauge (1) and wipe clean.

2.

Check the oil level by re-inserting the oil

level gauge.

3.

If the oil level is low (2), remove the oil

filler cap (4) and add the recommended

engine oil, using the articulated funnel

supplied, until the oil level reaches the

upper mark (3) on the oil level gauge.

Use the chart below to determine which

viscosity oil to use.

4.

After adding oil, install and tighten the oil

filler cap (4) and oil level gauge (1), and

close the engine access door.

Note: Non-detergent and 2-stroke engine oils will

damage the engine and must not be used.

Recommended Lubricant Viscosities for

Ambient Temperature

Oil Viscosities

oC o

F

Min

Max

Min

Max

SAE 0W-40

-40

40

-40

104

SAE 5W-40

-30

50

-22

122

SAE 10W-30

-18

40 0 104

SAE 15W-40

-10

50

14

122

1

2 3 4

5

6

Page 17

17

Engine Oil and Oil Filter – Change

1. Operate the engine until it reaches

normal operating temperature. Stop the

engine and use a suitable container to

collect the used oil.

2. Remove the oil filler cap and open the

oil drain valve (1). Remove the oil

drain hose from the cap (2) to drain the

oil.

3. Use an oil filter socket to remove the oil

filter (3). Discard the used oil filter

according to local regulations.

4. Apply clean oil to the seal of the new oil

filter. Install the new oil filter. Tighten the

oil filter to 10 ± 1.5 lb ft (14 ± 2Nm).

5. Close the oil drain valve (1) and

reattach the oil drain to the cap (2).

6. Refill the oil, using the articulated

funnel supplied, and check the oil level.

Refer to Engine Oil Level – Check.

7. Install and tighten the oil filler cap.

8. Dispose of the used oil properly.

9. Start the engine for a brief period and

check for leaks.

10. Stop the engine and check the oil level.

Refer to Engine Oil Level – Check.

Engine Valve Lash – Inspect/Adjust

Only qualified service personnel should perform

this maintenance procedure. Contact your local

service center to schedule this maintenance.

Fuel Line – Replace

Only qualified service personnel should perform

this maintenance procedure. Contact your local

service center to schedule this maintenance.

Fuel Tank Cap and Strainer – Clean

Wipe off the fuel cap (1) and surrounding area

before removing the fuel cap. Wiping off the fuel

cap and surrounding area before removing the

fuel cap helps to reduce the amount of

contaminants allowed into the fuel system.

If there is a build-up of debris in the fuel strainer

(2), remove the strainer and rinse out the

strainer. Allow the strainer to dry before

installing the strainer.

Spark Arrestor Inspect/Clean/Replace

This unit has a spark arrestor fitted to the

exhaust outlet of the muffler. The spark arrestor

should be cleaned with a soft wire brush after

every 50 hours or 3 months of use. The spark

arrestor should be replaced after every 100

hours of operation or if it becomes damaged.

Hot Surface

Hot parts or hot components can cause burns or

personal injury. Do not allow hot parts or

components to contact your skin. Use protective

clothing or protective equipment to protect your

skin.

DO NOT perform this maintenance procedure

until the muffler has cooled.

1

2

1

2

1 2 3

Page 18

18

1

2

3

4

Remove screws (2). Remove spark arrestor (1)

Check the spark arrestor. Carefully clean the

spark arrestor with a soft wire brush. If the spark

arrestor is damaged, replace the spark arrestor.

To install the spark arrestor, align the mounting

holes in the spark arrestor with the mounting

holes on the muffler. Insert screws (2) and

tighten securely.

Spark Plug – Inspect/Adjust/Replace

Refer to the Specifications section of this

manual to determine the proper spark plug part

number and spark plug gap for your product.

1. DO NOT perform this maintenance

procedure with the engine running.

2. Turn the generator switch to the off “O”

position.

3. Open the engine access door.

4. Remove the spark plug cap (3).

5. Use the plug wrench (1) or a spark plug

socket to remove the spark plug (2).

6. Visually check the spark plug to see if it is

damaged. If the insulator is cracked, replace

the spark plug. If the electrode is damaged,

replace the spark plug.

7. Measure the plug gap (4) with a feeler

gauge. Adjust the gap as necessary by

carefully bending the side electrode. Refer

to Specifications for the correct gap for your

product.

8. Check the spark plug washer to ensure

proper working condition. If the washer is

damaged, replace the washer.

9. Install spark plug and tighten to 16 ± 2 lb ft

(22 ± 2 Nm). DO NOT overtighten as this

may damage the engine.

10. Re-attach the spark plug cap.

11. Repeat steps 4-10 for the other spark plug

on the other side of the engine.

Battery– Inspect/Replace

If the battery voltage is below 12 volts, charge

the battery. Recommended maximum

continuous charge voltage is 15 volts.

If the battery is unable to turn over the engine,

even after charging, check the battery terminals

are secure and free from corrosion.

If the battery requires replacement:

1. Disconnect the negative (-) cable first.

2. Disconnect the positive (+) cable

second.

To install the new battery:

1. Connect the positive (+) cable first.

2. Connect the negative (-) cable second.

NOTE: Use only genuine Caterpillar parts.

CAUTION - DANGER OF EXPLOSION IF

BATTERY IS INCORRECTLY REPLACED,

REPLACE ONLY WITH THE SAME OR

EQUIVALENT TYPE.

The used battery should be recycled in

accordance with local laws.

Generator - Inspect

Once a month start the engine and run the

engine until it reaches normal operating

temperature (about 20 minutes). Plug in a

corded device and turn on the device to ensure

that the generator is providing power. Once you

have verified that the generator is providing

power, turn off the device and unplug it. Then

turn the generator off.

Walk-Around Inspection

Before starting the engine perform a visual

inspection of the unit. Look for:

• Proper oil level

• Proper fuel level

• Good quality fuel

• Fluid leaks

• Loose clamps

• Loose bolts

• Cracked fuel line

• Loose or frayed wiring

• Built up debris

In addition, make sure that:

• The ground terminal is properly connected

• The circuit breakers are in OFF “ 0 ”

position

Page 19

19

STORAGE

When a generator is in storage, air may

condense and moisture may appear on the

windings. In order to minimize condensation,

always store the generator in a dry area. Cover

the generator with a protective cover that

extends to the ground. The cover should remain

loose around the generator in order to allow

proper ventilation.

The generator must not be stored in ambient

temperatures greater than 131oF (55oC) as this

can damage the CO Detector (if equipped).

Storage for 1 to 3 months

Remove any dirt, rust, grease, and oil from the

generator. DO NOT use a pressure washer to

clean the generator. Inspect the exterior. Make

any necessary repairs.

Add fuel stabilizer to the fuel tank to prevent the

gasoline from going bad. Start and run the

engine for 10 minutes to ensure that the fuel

stabilizer has been pulled in to the carburetor.

Shut off the engine and allow the engine to cool.

Turn the fuel valve to the off “O“ position.

Move the generator to the storage place.

Attach the trickle charger to the port in the

control panel and to standard AC power to keep

the generator battery fully powered for easy start

after storage. Disconnect the battery charger

once the battery is fully charged (indicated by a

green light on the charger).

Cover the generator.

Storage for more than 3 months

Remove any dirt, rust, grease, and oil from the

generator. DO NOT use a pressure washer to

clean the generator. Inspect the exterior. Make

any necessary repairs.

Gasoline is extremely flammable and is

explosive under certain conditions. Drain the fuel

in a well-ventilated area with the engine stopped

and cool. Never smoke or allow flames or sparks

in the area during this procedure.

Drain the fuel from the fuel tank into a suitable

container using a manual siphon pump. DO

NOT save the fuel for future use in the

generator. Turn the fuel valve to the on “I“

position. Start and run the engine until the

engine stops, to allow the fuel to drain from the

fuel lines and engine system. Turn the fuel valve

to the off “O” position. Apply a small amount of

oil to the threads on the fuel tank filler neck and

install the cap.

Change the engine oil. Refer to Engine Oil and

Oil Filter – Change.

Remove both spark plugs and pour a small

amount of oil into both cylinders. Install the

spark plug but do not install the spark plug cap.

Move the generator to the storage place.

Attach the trickle charger to the port in the

control panel and to standard AC power to keep

the generator battery fully powered for easy start

after storage. Disconnect the battery charger

once the battery is fully charged (indicated by a

green light on the charger)

Cover the generator.

Page 20

20

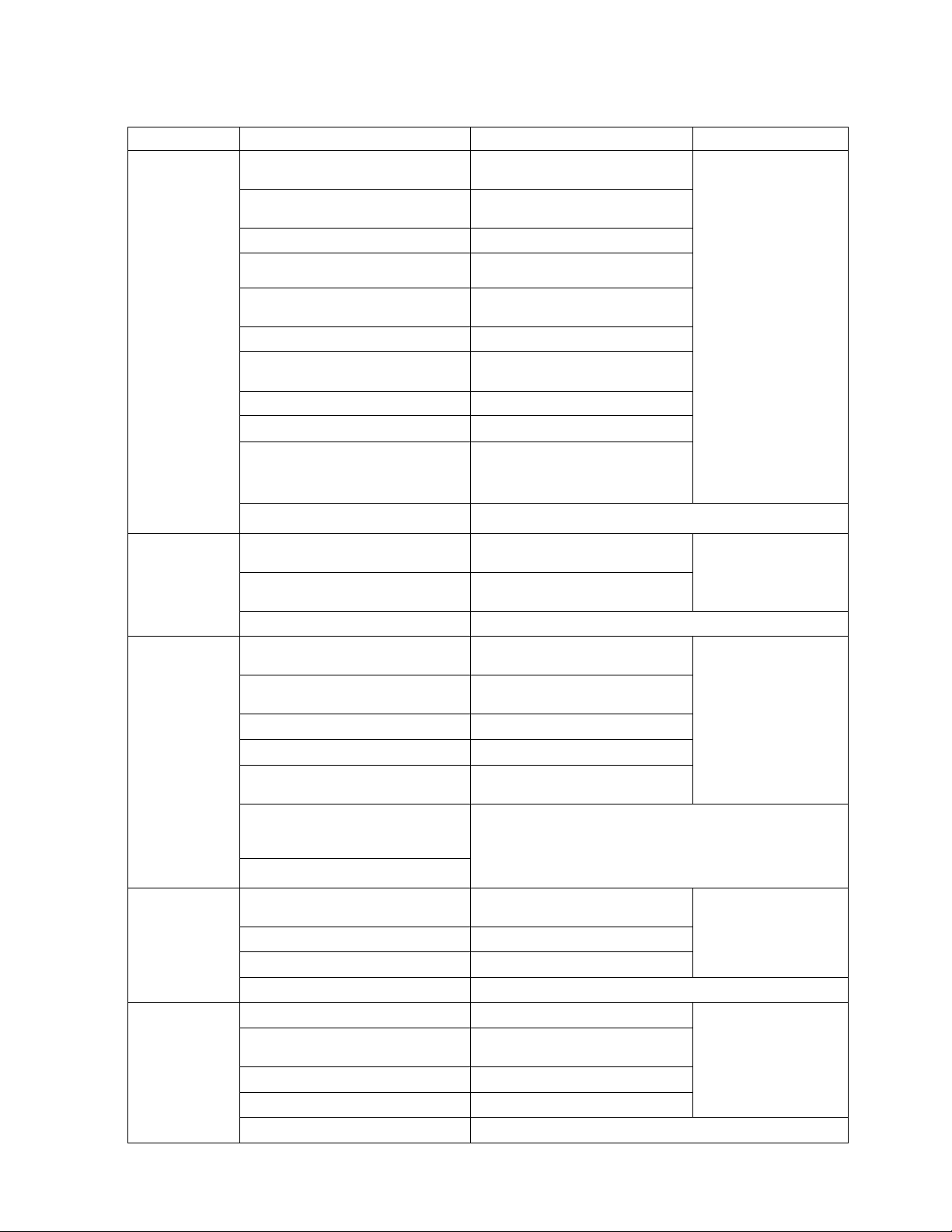

TROUBLESHOOTING

Issue:

Possible Cause:

Solution:

Check:

Engine Will

Not Start

Generator switch in the off “ 0 ”

position

Turn the generator switch to the

correct position.

Start the engine.

Choke knob in the wrong position

Place the choke knob in the

correct position.

No fuel

Fill the fuel tank.

Bad or contaminated fuel

Check the fuel.

Not enough oil in the engine

Check the oil level. If low, add

the recommended oil.

Dirty air filter

Clean the air filter.

No fuel at the carburetor

Make sure the fuel switch is in

the on "I" position.

Engine flooded

Wait 5 minutes.

No spark

Replace the spark plug.

For electric start, start the engine

using the recoil starter.

If the generator starts, check the

battery. If the battery is providing

less than 12.4 volts, replace.

If the engine still will not start:

Take the unit to an authorized service provider.

Engine Runs

Rough (no

load)

Dirty air filter

Stop the engine and check the

air filter. Clean if needed.

Start the engine /

check if it runs rough.

Choke knob in the wrong position

Place the choke knob in the

correct position.

If the engine still runs rough:

Take the unit to an authorized service provider.

Engine Shuts

Down

Out of fuel

Check the fuel. Fill the tank if

necessary.

Start the engine /

check if it shuts down.

Not enough oil in the engine

Check the oil level. If low, add

the recommended oil.

Dirty air filter

Clean the air filter.

Generator overloaded

Unplug some of the devices.

Shut off due to CO accumulation

& flashing red indicator

Follow all safety instructions on

CO Action Label

Shut off due to CO detector

system fault & constant orange

indicator

System fault or end of life indication. Take the unit to an

authorized service provider.

If the engine still shuts down:

Engine Runs

Rough (with

load)

Dirty air filter

Stop the engine and check the

air filter. Clean if needed.

Start the engine /

check if it runs rough.

Generator overloaded

Unplug some of the devices.

Defective device plugged in

Unplug defective device.

If the engine still runs rough:

Take the unit to an authorized service provider.

Engine Runs,

But Generator

Does Not

Provide

Power

Circuit breaker is open

Close the circuit breaker.

Start the engine /

check for power.

Bad connection

Stop the engine and check the

connections.

Defective power cord

Replace the cord.

Defective device plugged in

Unplug defective device.

If there is still no power:

Take the unit to an authorized service provider.

Page 21

21

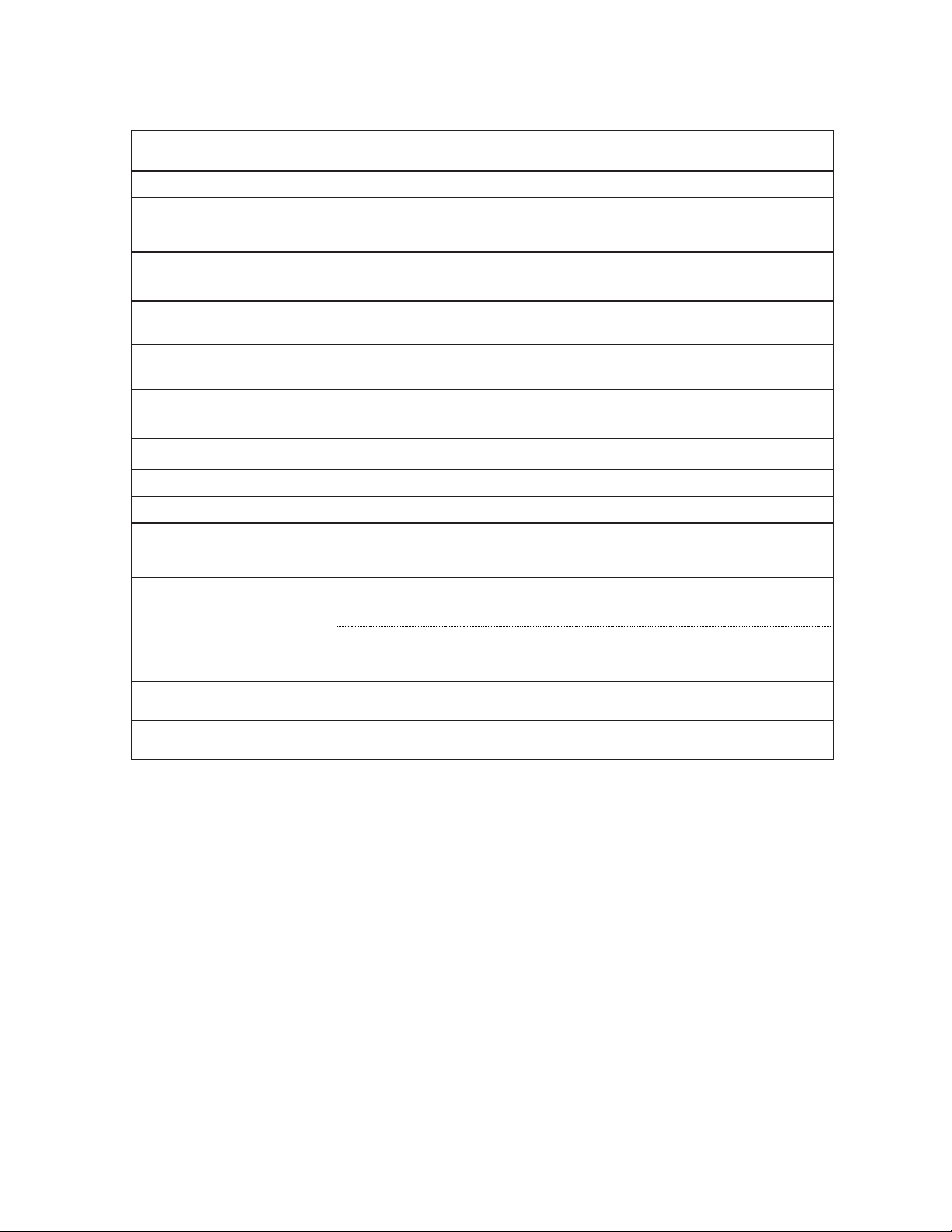

SPECIFICATIONS

Engine Type

Two Cylinder, 4-Stroke, Forced Air Cooling

Displacement (cc)

670

Ignition System

Transistorized Magneto

Spark Plug Gap

.028 - .032 inches (0.7 – 0.8mm)

Fuel Volume

11 U.S. gallons (42L)

Fuel Consumption

(g/(kW·h)

≤ 374

100% load continuous

5.1

running time (hr)

50% load continuous

9.7

running time (hr)

Oil Capacity

1.5 quart (1.6L)

Charging Voltage (VDC)

12-14.5

Charging Current (A)

0-4.5

Rated Frequency (Hz)

60

Rated Voltage (V)

120/240

Rated Output Power (kW)

US @ 77oF (25oC)

12

Canada @ 104oF (40oC)

11

Surge Output Power (kW)

15

Phase

Single

Total Harmonic Distortion

< 5%

Page 22

22

COMBINED EXHAUST AND

EVAPORATIVE EMISSIONS

CONTROLS WARRANTY

STATEMENT

Your Warranty Rights and

Obligations

The California Air Resources Board (CARB), the

United States Environmental Protection Agency

(EPA), and Caterpillar Inc. are pleased to

explain the exhaust and evaporative emissions

control system warranty on your 2020 model

year small off-road engine/equipment. In the

United States and California, new equipment

that use small off-road engines must be

designed, built, and equipped to meet stringent

emissions standards. Caterpillar must warrant

the emission control system on your small offroad engine/equipment for the periods of time

listed below provided there has been no abuse,

neglect, or improper maintenance of your small

off-road engine/equipment leading to the failure

of the emissions control system.

Your emissions control system may include

parts such as the carburetor or fuel injection

system, the ignition system, catalytic converter,

fuel tanks, fuel lines (for liquid fuel and fuel

vapors), fuel caps, valves, canisters, filters,

clamps, and other associated components. Also

included may be hoses, belts, connectors, and

other emission-related assemblies.

Where a warrantable condition exists, Caterpillar

will repair your small off-road engine/equipment

at no cost to you including diagnosis, parts, and

labor.

Manufacturer’s Warranty Coverage

The exhaust and evaporative emissions control

system on your small off-road engine/equipment

is warranted for three years. If any emissionrelated part on your small off-road

engine/equipment is defective, the part will be

repaired or replaced by Caterpillar.

Owner’s Warranty Responsibilities

As the small off-road engine/equipment owner,

you are responsible for the performance of the

required maintenance listed in your owner's

manual. Caterpillar recommends that you retain

all receipts covering maintenance on your small

off-road engine/equipment, but Caterpillar

cannot deny warranty coverage solely for the

lack of receipts or for your failure to ensure the

performance of all scheduled maintenance.

As the small off-road engine/equipment owner,

you should however be aware that Caterpillar

may deny you warranty coverage if your small

off-road engine/equipment or a part has failed

due to abuse, neglect, improper maintenance or

unapproved modifications.

You are responsible for presenting your small

off-road engine/equipment to a Caterpillar

distribution center or service center as soon as a

problem exists. The warranty repairs shall be

completed in a reasonable amount of time, not

to exceed 30 days.

If you have any questions regarding your

warranty rights and responsibilities, you should

contact Caterpillar at 1-844-797-6387 or E-mail:

homeandoutdoorpower@cat.com.

Defects Warranty Requirements:

(a) The warranty period begins on the date the

engine/equipment is delivered to an ultimate

purchaser.

(b) General Emissions Warranty Coverage.

Caterpillar warrants to the ultimate purchaser

and each subsequent owner that the engine or

equipment is:

(1) Designed, built, and equipped so as to

conform with all applicable regulations adopted

by the Air Resources Board; and

(2) Free from defects in materials and workmanship

that causes the failure of a warranted part for a

period of three years

(c) The warranty on emission-related parts will be

interpreted as follows:

(1) Any warranted part that is not scheduled for

replacement as required maintenance in the

written instructions must be warranted for the

warranty period defined in Subsection (b)(2). If

any such part fails during the period of

warranty coverage, it must be repaired or

replaced by Caterpillar according to

Subsection (4) below. Any such part repaired

or replaced under the warranty must be

warranted for the remaining warranty period.

(2) Any warranted part that is scheduled only for

regular inspection in the written instructions

must be warranted for the warranty period

defined in Subsection (b)(2). A statement in

such written instructions to the effect of “repair

or replace as necessary” shall advise owners

of the warranty coverage for emissions related

parts. Replacement within the warranty period

Page 23

23

is covered by the warranty and will not reduce

the period of warranty coverage. Any such part

repaired or replaced under warranty must be

warranted for the remaining warranty period.

(3) Any warranted part that is scheduled for

replacement as required maintenance in the

written instructions must be warranted for the

period of time prior to the first scheduled

replacement point for that part. If the part fails

prior to the first scheduled replacement, the

part must be repaired or replaced by

Caterpillar according to Subsection (4) below.

Any such part repaired or replaced under

warranty must be warranted for the remainder

of the period prior to the first scheduled

replacement point for the part.

(4) Repair or replacement of any warranted part

under the warranty provisions must be

performed at no charge to the owner at a

warranty station.

(5) Notwithstanding the provisions of Subsection

(4) above, warranty services or repairs must

be provided at distribution centers that are

franchised to service the subject

engine/equipment.

(6) The owner must not be charged for diagnostic

labor that leads to the determination that a

warranted part is in fact defective, provided

that such diagnostic work is performed at a

warranty station.

(7) Caterpillar is liable for damages to other

engine/equipment components proximately

caused by a failure under warranty of any

warranted part.

(8) Throughout the emissions control system's

warranty period set out in subsection (b)(2),

Caterpillar must maintain a supply of

warranted parts sufficient to meet the expected

demand for such parts and must obtain

additional parts if that supply is exhausted.

(9) Manufacturer-approved replacement parts that

do not increase the exhaust or evaporative

emissions of the engine or emissions control

system must be used in the performance of

any warranty maintenance or repairs and must

be provided without charge to the owner. Such

use will not reduce the warranty obligations of

Caterpillar.

(10) Add-on or modified parts that are not

exempted by the Air Resources Board may not

be used. The use of any non-exempted add-on

or modified parts will be grounds for

disallowing a warranty claim. Caterpillar will

not be liable to warrant failures of warranted

parts caused by the use of a non-exempted

add-on or modified part.

(11) Caterpillar issuing the warranty shall provide

any documents that describe that warranty

procedures or policies within five working days

of request by the Executive Officer.

(d) Emission Warranty Parts List for exhaust

(1) Fuel Metering System

(i) Carburetor and internal parts (and/or

pressure regulator or fuel injection system)

(ii) Air/fuel ratio feedback and control system

(iii) Cold start enrichment system

(2) Air Induction System

(i) Controlled hot air intake system

(ii) Intake manifold

(iii) Air filter

(3) Ignition System

(i) Spark plugs

(ii) Magneto or electronic ignition system

(iii) Spark advance/retard system

(4) Exhaust Gas Recirculation (EGR) System

(i) EGR valve body, and carburetor spacer if

applicable

(ii) EGR rate feedback and control system

(5) Air Injection System

(i) Air pump or pulse valve

(ii) Valves affecting distribution of flow

(iii) Distribution manifold

(6) Catalyst or Thermal Reactor System

(i) Catalytic converter

(ii) Thermal reactor

(iii) Exhaust manifold

(7) Particulate Controls

(i) Traps, filters, precipitators, and any other

device used to capture particulate emissions

(8) Miscellaneous Items Used in Above Systems

(i) Electronic controls

(ii) Vacuum, temperature, and time sensitive

valves and switches

(iii) Hoses, belts, connectors, and assemblies.

(e) Emissions Warranty Parts List for

Evaporative Emissions

(1) Fuel Tank

(2) Fuel Cap

(3) Fuel Lines (for liquid fuel and fuel vapors)

(4) Fuel Line Fittings

(5) Clamps*

(6) Pressure Relief Valves*

(7) Control Valves*

(8) Control Solenoids*

(9) Electronic Controls*

(10) Vacuum Control Diaphragms*

(11) Control Cables*

(12) Control Linkages*

(13) Purge Valves*

(14) Gaskets*

(15) Liquid/Vapor Separator

(16) Cabon Canister

(17) Canister Mounting Brackets

(18) Carburetor Purge Port Connector

*Note: As they relate to the evaporative

emission control system

Page 24

24

WARRANTY

CATERPILLAR LIMITED WARRANTY

FOR PORTABLE GENERATOR MODELS:

RP3600, RP5500, RP6500, RP6500 E, RP7500 E, RP8000 E, RP12000 E

Purchased in the United States and Canada

Caterpillar (Newberry) LLC. (Caterpillar) warrants to the original purchaser that any new Cat®branded portable generator products purchased in the

United States and Canada are free from defects in materials and workmanship for the warranty period set forth below, provided that the product is

operated and maintained in accordance with Caterpillar's instructions and manuals. Caterpillar will, at its option, repair or replace any part which, upon

inspection by Caterpillar or a Caterpillar authorized service representative, is found to be defective during the warranty period as set forth below. Any

product that the purchaser claims to be defective must be returned to and examined by the nearest Caterpillar authorized service representative

located in the United States or Canada. Transportation and associated costs and risk of loss are the responsibility of the purchaser.

Warranty Period:

All new portable generator products are warranted under normal use for a period of two (2) years from the date of original purchase or 1000 operating

hours, whichever occurs first. If proof of original purchase is not presented, the manufacturer's shipping date will be used to determine the start of

the warranty period. To help with any warranty claims, the original purchaser should register the product on www.cat.com/homeandoutdoorpowersupport immediately following the purchase.

By means of registering the product on www.cat.com/homeandoutdoorpower-support within thirty (30) days from the date of purchase, original

purchasers have the option to extend the Warranty Period by one additional year for a total of three (3) years calculated from the date of original

purchase of the product subject to the limitation of 1000 operating hours in total for the duration of the Warranty Period.

This Warranty shall NOT apply to the following:

1. Damage or deterioration caused by normal wear and tear.

2. Failures caused by any external cause or act of God, such as

accident, collision, theft, vandalism, riots, wars, fire, freezing,

lightning, earth-quakes, windstorms, hail, volcanic eruptions,

floods, tornados or hurricanes.

3. Failures due to alterations, adjustments, unauthorized fuel setting

changes, neglect or improper storage, repair and/or maintenance.

4. Failures due to abuse or application of the product for uses other

than for which it is designed or intended to by the manufacturer,

including but not limited to, improper installation or location in a

contaminated, harsh, corrosive or saltwater environment.

5. Failures resulting from attachments, accessory items, and parts

not sold, issued or approved by Caterpillar.

6. Failures caused by contaminated or improper fuels, fuels, oils or

other operating media or improper fluid levels.

7. Failures resulting from user’s delay in making the product

available after being notified of a potential product problem.

8. Cosmetic damage, discolorations, rusting, corrosion or scratches

to applied paint.

9. Replacement of consumables such as, but not limited to, fuses,

lamps, filters, etc.

10. Repair by any party other than a Caterpillar authorized service

representative.

11. Additional expenses for repair after normal business hours, i.e.

overtime or holiday labor rates.

12. Expenses for rental of equipment during downtime and/or

performance of warranty repairs.

13. Expenses related to investigating performance complaints and/or

troubleshooting where no manufacturing defect is found.

14. Starting batteries are NOT covered under this warranty but will be

covered under the portable generator parts warranty.

To obtain warranty service or if you have questions concerning this warranty or its applications, please call 1-844-797-6387 or visit

www.cat.com/homeandoutdoorpower-support, where you can also search for your nearest authorized Cat service representative.

CONSUMER ARBITRATION CLAUSE: MANDATORY BINDING INDIVIDUAL ARBITRATION INSTEAD OF COURT; CLASS ACTION WAIVER

a. You and Caterpillar both agree that, to the extent permitted by

applicable law, any and all disputes or claims arising out of or

relating in any way to Cat Branded portable generator products or

services related thereto, or from any advertising for any such

products or services, including any question regarding the

existence, validity, or termination of this Caterpillar Limited

Warranty, as well as any issue regarding the interpretation of the

terms and conditions of this Consumer Arbitration Clause will be

resolved by binding arbitration before a sole arbitrator, rather than

in court, except that you may assert claims in small claims court if

your claims qualify. This also includes any claims that arose before

you accepted this Caterpillar Limited Warranty, regardless of

whether prior versions of the Limited Warranty required arbitration.

In the US, The Federal Arbitration Act (9 U.S.C. § 1 et seq.) and

federal arbitration law apply to the Caterpillar Limited Warranty and

the terms and conditions of this Consumer Arbitration Clause.

b. Arbitration uses a neutral arbitrator instead of a judge and jury. An

arbitrator can award on an individual basis the same damages and

relief as a court (including injunctive and declaratory relief or

statutory damages) and must follow theterms of this Limited

Warranty (including the terms and conditions of this Consumer

Arbitration Clause) as a court would. Arbitration procedures allow

for more limited discovery, and court review of an arbitration award

is limited.

c. If you have a dispute and elect to seek arbitration or file a claim in

small claims court, you must first send to Caterpillar, by certified

mail, a written notice of your claim that (a) describes the nature

and basis of the claim or dispute; (b) sets forth the specific relief

sought and (c) includes a physical address and email address

where you may be reached ("Notice"). The Notice must be

addressed to: General Counsel, Caterpillar Inc., 100 N.E. Adams

St. Peoria Illinois 61629 (“Notice Address”) and reference a

“Notice of Claim under Caterpillar Limited Warranty.” If Caterpillar

and you do not reach an agreement to resolve the claim within 60

days after the Notice is received, you or Caterpillar may

commence an arbitration proceeding or file a claim in small claims

court.

d. You may download or copy a form to initiate arbitration at

www.adr.org. If you are required to pay a filing fee, after

Caterpillar receives notice at the Notice Address that you have

commenced arbitration, Caterpillar will reimburse you for your

payment of the filing fee, unless your claim is for greater than

US$25,000, in which case you will be responsible for filing fees.

e. The arbitration will be governed by the AAA’s then current

Consumer Arbitration Rules, as modified by the terms set forth in

this Limited Warranty (including the terms and conditions of this

Consumer Arbitration Clause), and will be administered by the

Page 25

25

AAA. The AAA Rules and Forms are available online at

www.adr.org or by calling the AAA at 1-800-778-7879. In the event

of any conflict between the terms set forth herein and the AAA

Consumer Arbitration Rules, these terms will apply.

f. If your claim totals less than US$25,000, Caterpillar will pay for all

administrative and arbitration fees, including the arbitrator’s

compensation, and will reimburse you for any administrative and

arbitration fees that you incur. If your claim exceeds US$25,000,

the parties will pay equal shares of any administrative and

arbitration fees, including the arbitrator’s compensation, except for

such fees that the AAA Consumer Arbitration Rules require

Caterpillar to pay in full. Each party will bear the expense of its own

counsel, experts, witnesses, and preparation and presentation of

evidence at any arbitration hearing.

g. If your claim is for US$25,000 or less, you and Caterpillar agree that

you may choose whether the arbitration will be conducted solely on

the basis of documents or through a telephonic hearing. You may

also request an in-person hearing, which the arbitrator may grant at

his or her discretion. If the arbitrator grants an in-person hearing,

such hearing will be conducted either at a mutually agreed location

or a location determined by the AAA or the arbitrator. In such an inperson hearing, the parties, or any of their witnesses, have the right

to participate remotely by way of videoconference or some similar

means. If your claim exceeds US$25,000, the right to a hearing will

be determined by the arbitrator.

h. You and Caterpillar agree that, to the extent permitted by applicable

law, any dispute resolution proceedings, whether in court or before

an arbitrator, will be conducted only on an individual basis and not

in a class, representative, consolidated, or mass action. Neither you

nor Caterpillar may join or consolidate claims by or against a third

party, or arbitrate or otherwise participate in any claim as a class

representative, class member or in a private attorney general

capacity. If this provision is found to be unenforceable, then the

entirety of the terms and conditions of these Dispute Resolution and

Arbitration paragraphs (other than paragraph (k)) shall be null and

void.

i. Any arbitration will be confidential. Neither you, Caterpillar, the AAA,

nor the arbitrator may disclose the existence, content (including any

oral or written submissions), or results of any arbitration, except as

may be required by law or for purposes of enforcing or challenging

of the arbitration award.

j. You may opt out of this dispute resolution procedure by providing

written notice to Caterpillar at the Notice Address no later than 30

calendar days from the date of your purchase of Caterpillar products

or services (or date of first use, in the case of free products or

services) covered by this Limited Warranty. Opting out of this

dispute resolution procedure will not otherwise affect the coverage

or applicability of the Limited Warranty, or your ability to purchase

or use Cat branded portable generator products or services, in any

way.

k. If for any reason a claim proceeds in court rather than in arbitration

or small claims court, including if you opt out under paragraph (j), to

the extent permitted by applicable law, we each waive any right to

a jury trial and agree that any such proceeding shall be conducted

only on an individual basis and not in a class, representative,

consolidated, or mass action. Under such circumstances, you and

Caterpillar agree that, to the extent any dispute arises out of a Cat

branded portable generator sold in the US, the federal and state

courts of the State of Illinois have exclusive jurisdiction to hear and

determine any such claim, consent to the personal jurisdiction of

any federal or state court in the State of Illinois, and acknowledge

that venue is proper in any judicial district within the State of Illinois.

If any part of these Dispute Resolution and Arbitration provisions or

this paragraph (k) is found to be unenforceable, the remainder of

these Dispute Resolution and Arbitration Provisions and this

paragraph (k) shall still be given full force and effect.

l. In the event that any provision of this agreement is found to be

invalid or unenforceable in a particular case or jurisdiction, that

provision will be severable in that case or jurisdiction, as the case

may be, without affecting the validity and enforceability of the

remaining provisions of the agreement, and shall not affect the

validity and enforceability of the agreement in other cases and

jurisdictions.

Applicable Law

m. By purchasing or using any Cat branded portable generator

product or service related thereto, you agree that, to the degree

permitted by applicable law, the Federal Arbitration Act, applicable

federal law, and laws of the State of Illinois, without regard to its

conflict of laws rules, will govern the terms of this Limited

Warranty, as well as any dispute of any sort that might arise

between you and Caterpillar relating to such products or services.

n. If a dispute arises out of a Cat branded portable generator sold in

Canada the foregoing dispute resolution and arbitration terms will

apply to the extent permitted by applicable law. If the foregoing

terms are not binding upon you under the applicable law of your