Page 1

62MB,MC,MD,ME040-950

Energy Recovery

Installation, Start-Up and

Service Instructions

Ventilators

CONTENTS

Page

SAFETY CONSIDERATIONS

INTRODUCTION...................................1

INSTALLATION ................................ 1-58

Step 1 — Inspection...............................1

Step 2 — Install Roof Curb ........................ 1

• STAND-ALONE APPLICATIONS

• COUPLED APPLICATIONS

Step 3 — Rigging and Handling .................45

• MOUNTING THE UNIT INDOORS

Step 4 — Installing ERV Transitions............... 47

• ERV UNIT COUPLED WITH A 3 TO 121/2TON

HVAC UNIT

Step 5 — Make Electrical Connections ............ 47

• POWER SUPPLY

• ELECTRICAL CONNECTIONS

START-UP .................................... 59-75

Unit Preparation ................................. 59

Internal Wiring ..................................59

Rain Hoods ..................................... 59

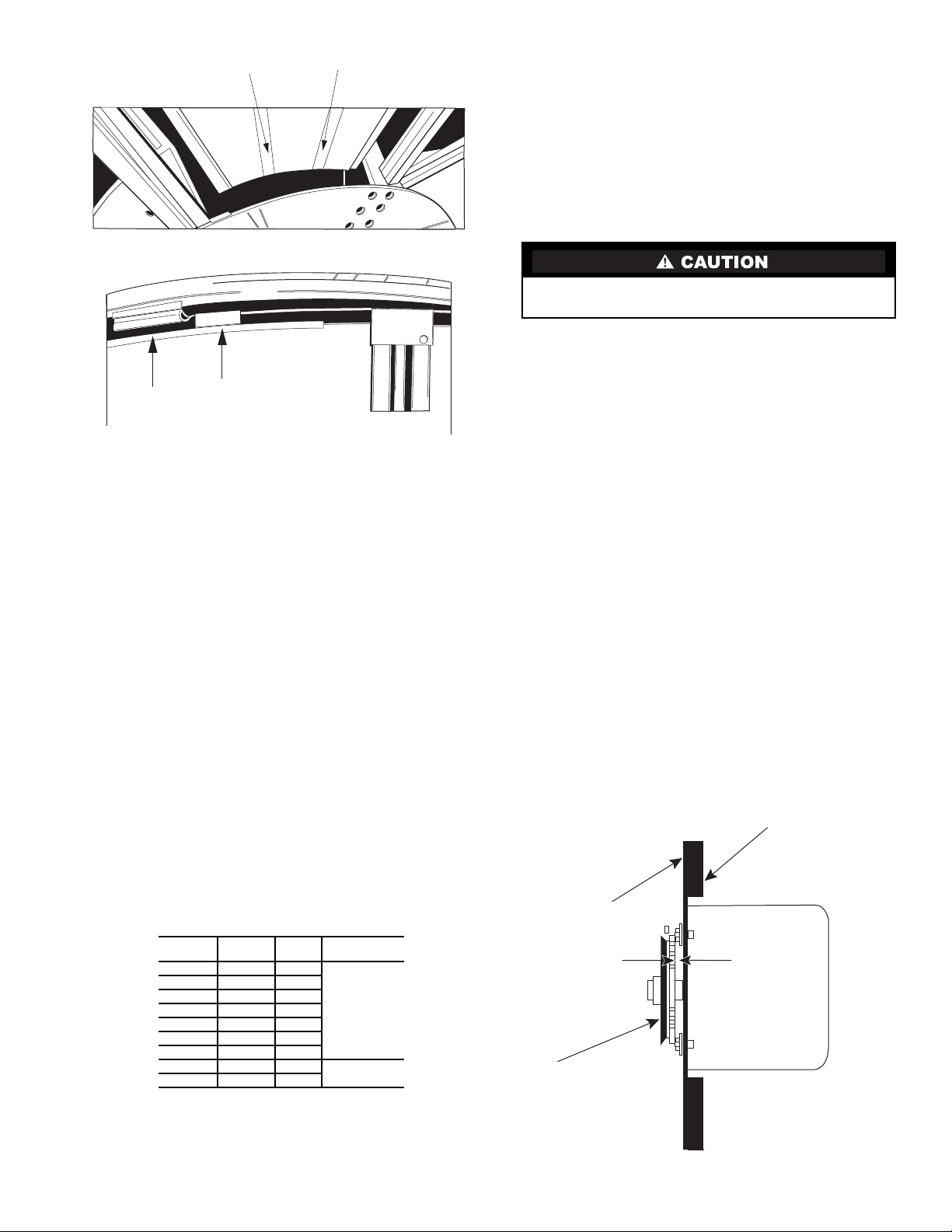

Energy Recovery Wheel .........................59

•DRIVEBELT

•AIRSEALS

Blower Rotation.................................59

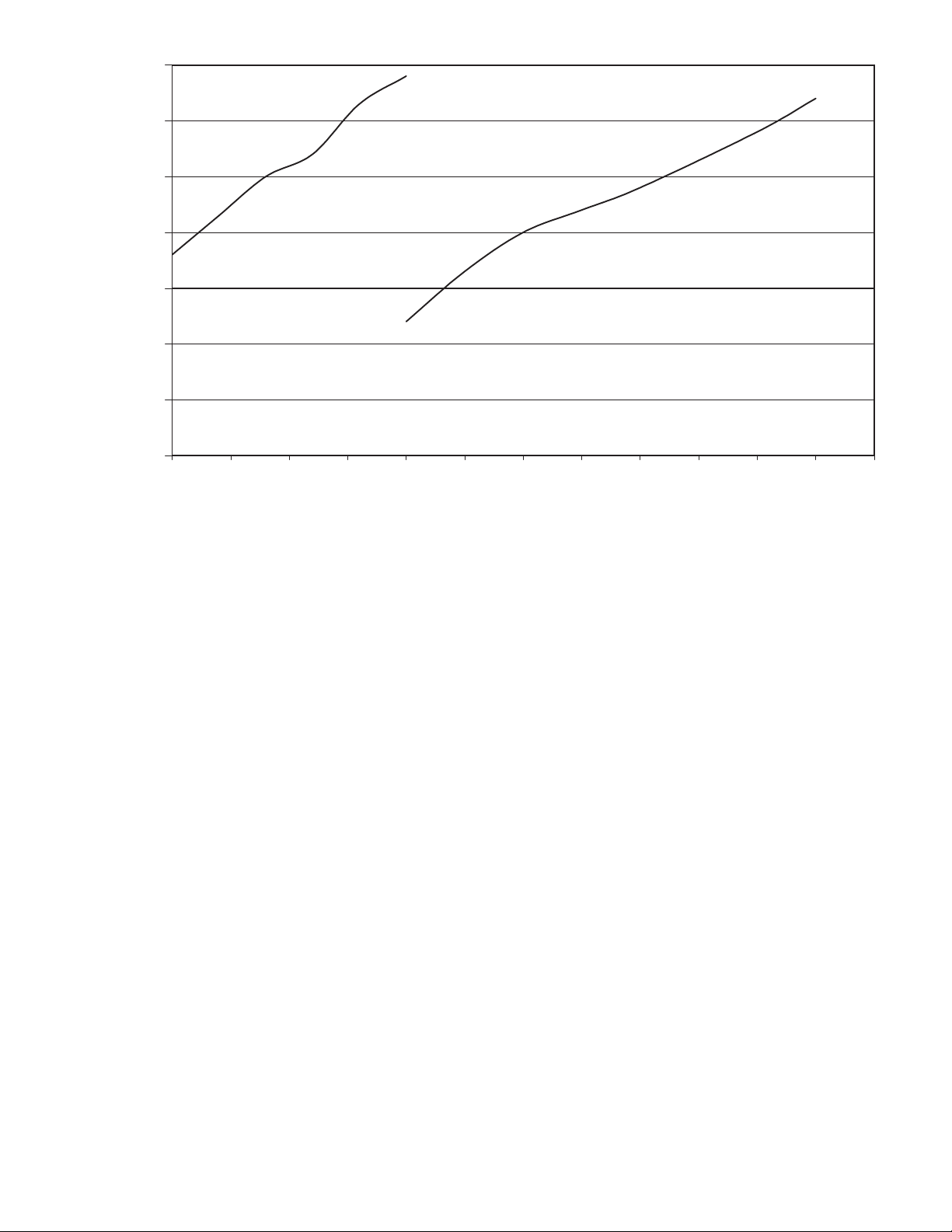

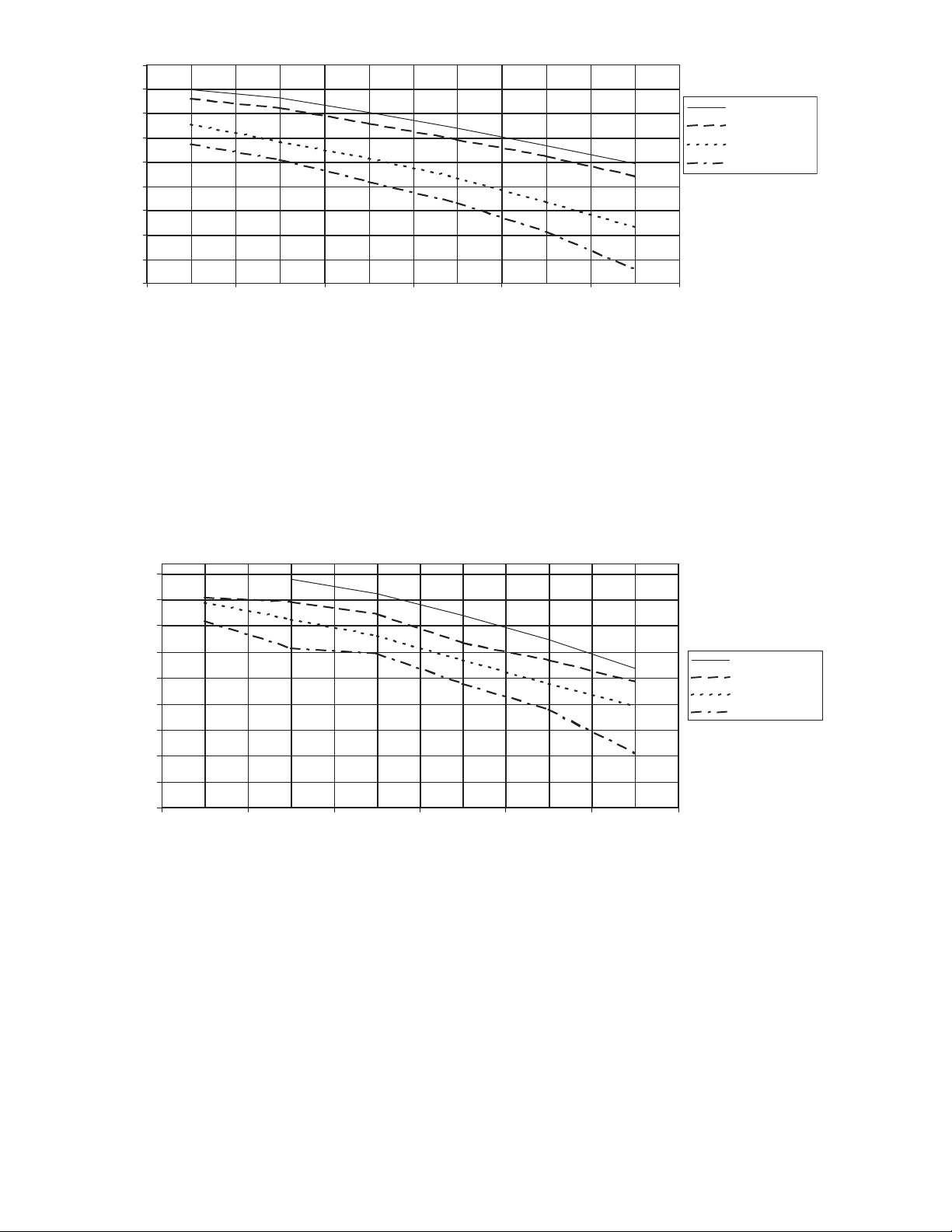

Airflow Settings and Adjustments............... 59

• FACTORY SETTING

• CURVE SELECTION

• ADJUST THE ERV BLOWER SPEED

• MEASURE MOTOR VOLTAGE, AMPERAGE

AND FAN RPM

• BELT MAINTENANCE

Variable Air Volume Option...................... 74

Operating Sequence ............................74

• OCCUPIED MODE

• UNOCCUPIED MODE

SERVICE ..................................... 75-78

Removing Wheel Segments for Cleaning

(62M170-950 Units)............................ 75

Removing and Installing Non-Segmented

Wheel for Cleaning (62M040 Units) ............75

Removing and Installing Non-Segmented

Wheel for Cleaning (62M075,120 Units) ....... 76

Installing Wheel Segments (62M170-950 Units)... 76

Wheel Drive Motor and Pulley Replacement .....77

Belt Replacement ............................... 77

MAINTENANCE ...............................78,79

START UP CHECKLIST ........................CL-1

.......................1

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance

functions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service

personnel. When working on air-conditioning equipment,

observe precautions in the literature, tags and labels attached to

the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. These instructions describe how to install, start up, and

service 62M energy recovery ventilator units.

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation. There

may be more than one disconnect switch. Tag all disconnect locations to alert others not to restore power until work

is completed.

INTRODUCTION

The 62M energy recovery ventilator (ERV) units recover

energy from building exhaust air and pre-condition ventilation

air. All ERV units are available in either vertical discharge

(through the bottom) or horizontal discharge configuration.

The 62MB and MC vertical discharge units are used when a

stand-alone ERV unit is required.

The 62MD and ME horizontal discharge unit can be used as

a stand-alone unit, or can also be coupled with a Carrier rooftop

unit.

INSTALLATION

Step 1 — Inspection —

with the shipping company if the unit is damaged. Check the

packing list to ensure that the correct items have been received

and notify your Carrier representative of any discrepancy.

Inspect the unit; file a claim

Step 2 — Install Roof Curb

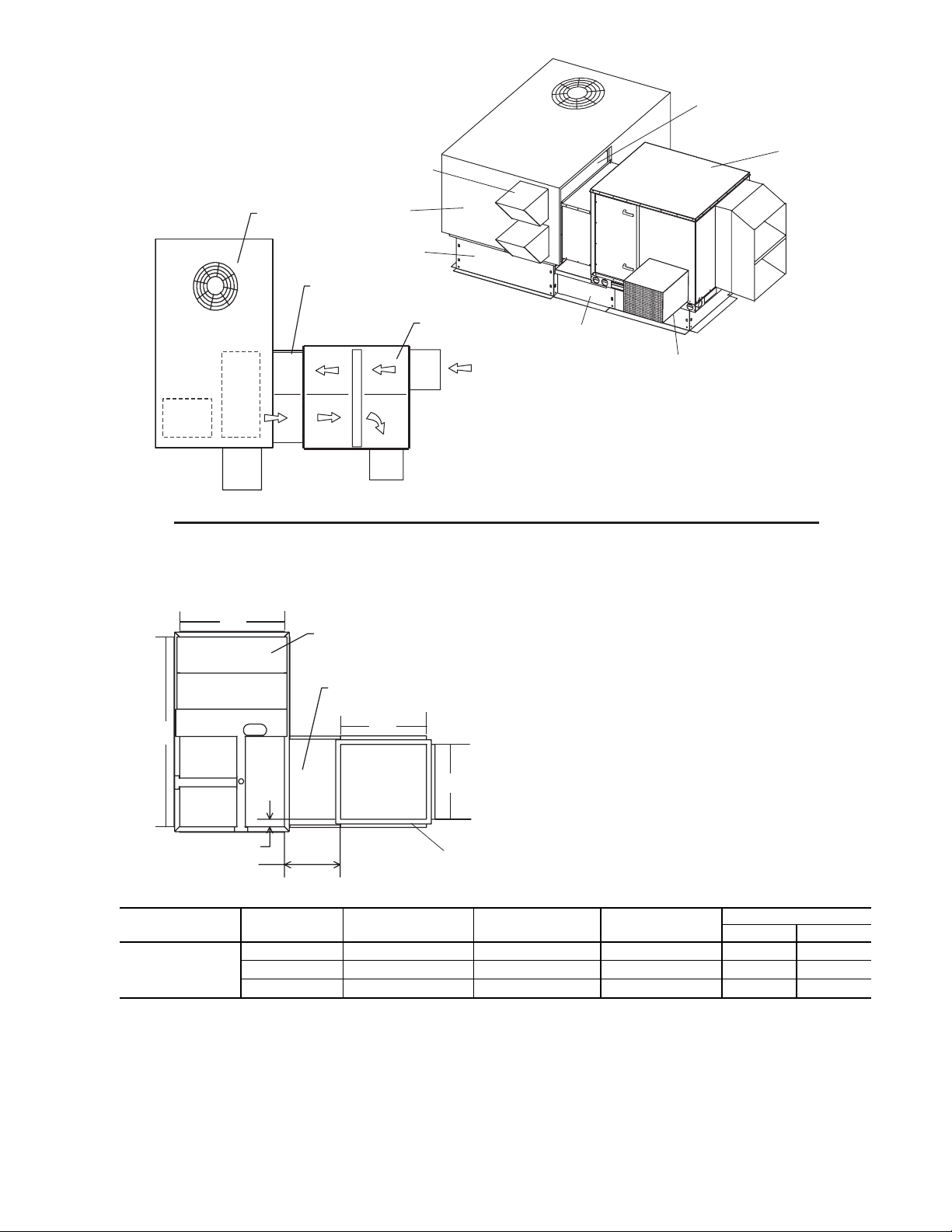

STAND-ALONE APPLICATIONS — The ERV unit can be

installed without being coupled with a Carrier rooftop unit. The

ERV units can be installed in one of three stand-alone applications: down discharge, horizontal discharge, or a combination

of both down discharge and horizontal discharge.

When installing a stand-alone ERV unit refer to Fig. 1-45

and, complete the following:

Locate the Roof Curb

sider the structural support required for the rooftop system and,

the duct drop location in relation to the joists. Allow sufficient

space for service, clearance, and locations of vents or other

sources of air.

— Prior to locating the roof curb con-

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 10a 12a

Catalog No. 536-220 Printed in U.S.A. Form 62M-1SI Pg 1 1-06 Replaces: New

Page 2

Cover roof opening if installation of the ERV unit will not

be immediate. Failure to cover roof opening could result in

water damage and/or serious personal injury.

END

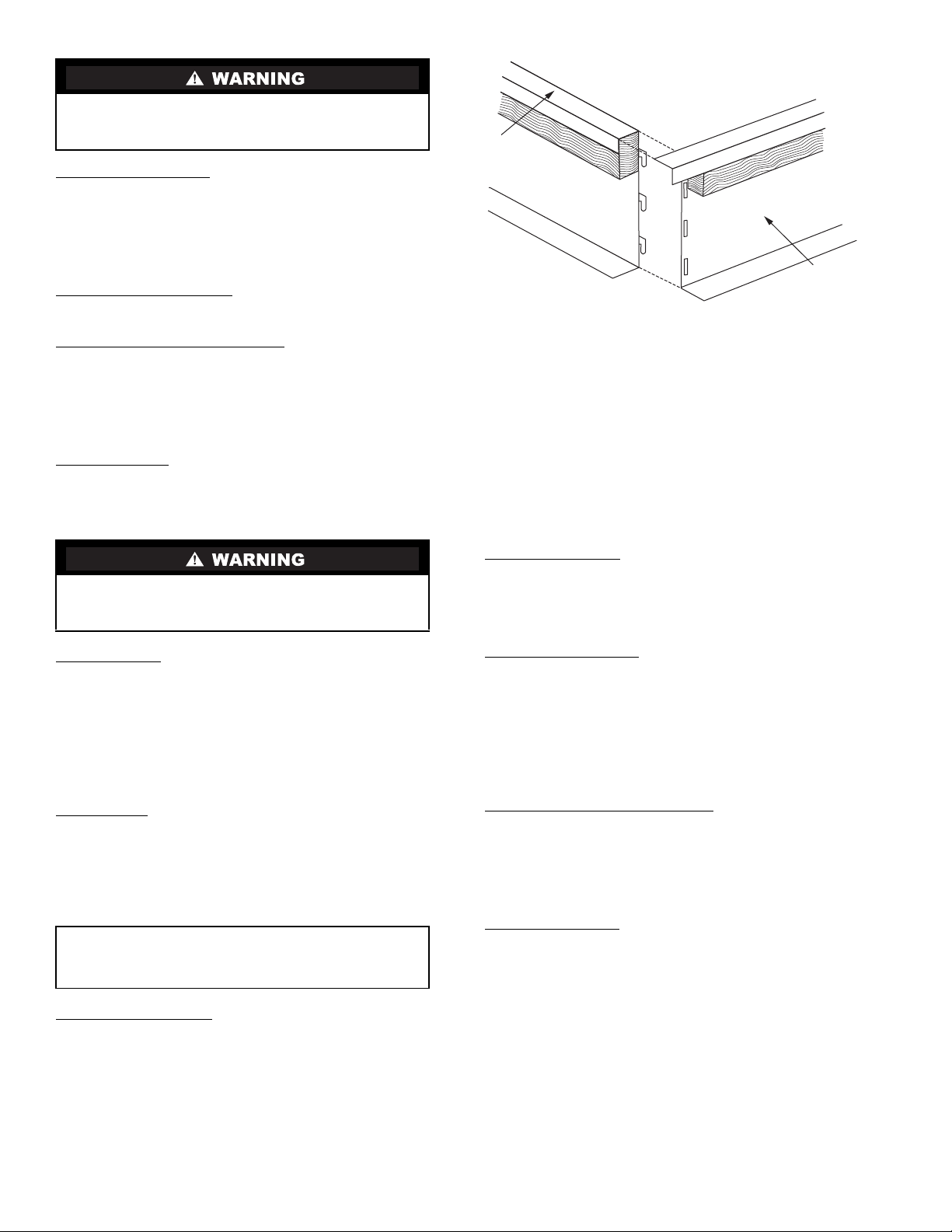

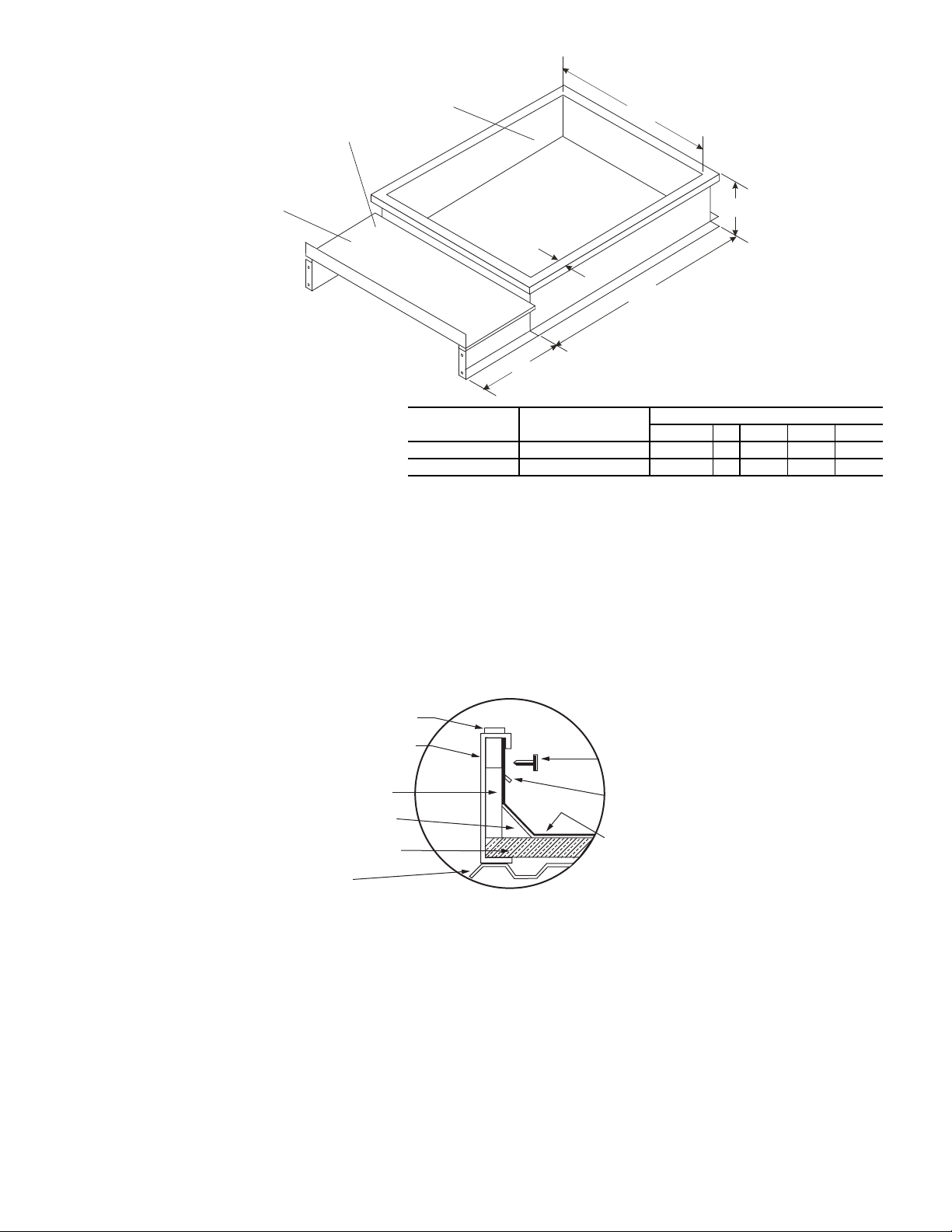

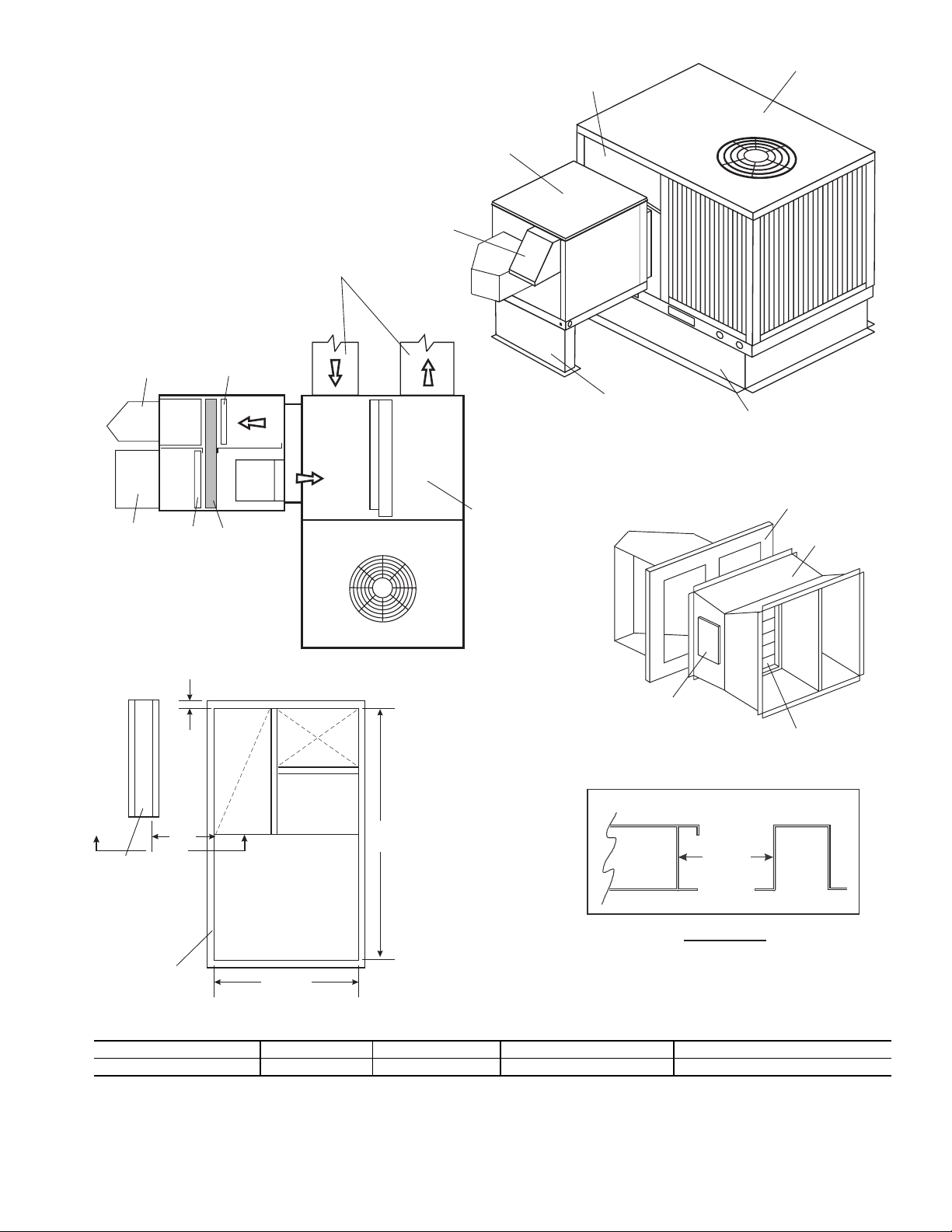

Assemble the Roof Curb

— Connect the curb side and the

curb end. See Fig. 1. Insert the tabs on the curb end into the

slots on the curb sides. Press firmly until the pieces lock into

place. It may be necessary to exert additional force to the top of

the curb to lock the pieces in place. Ensure the curb pieces are

locked together prior to proceeding.

Repeat for all corners of the roof curb.

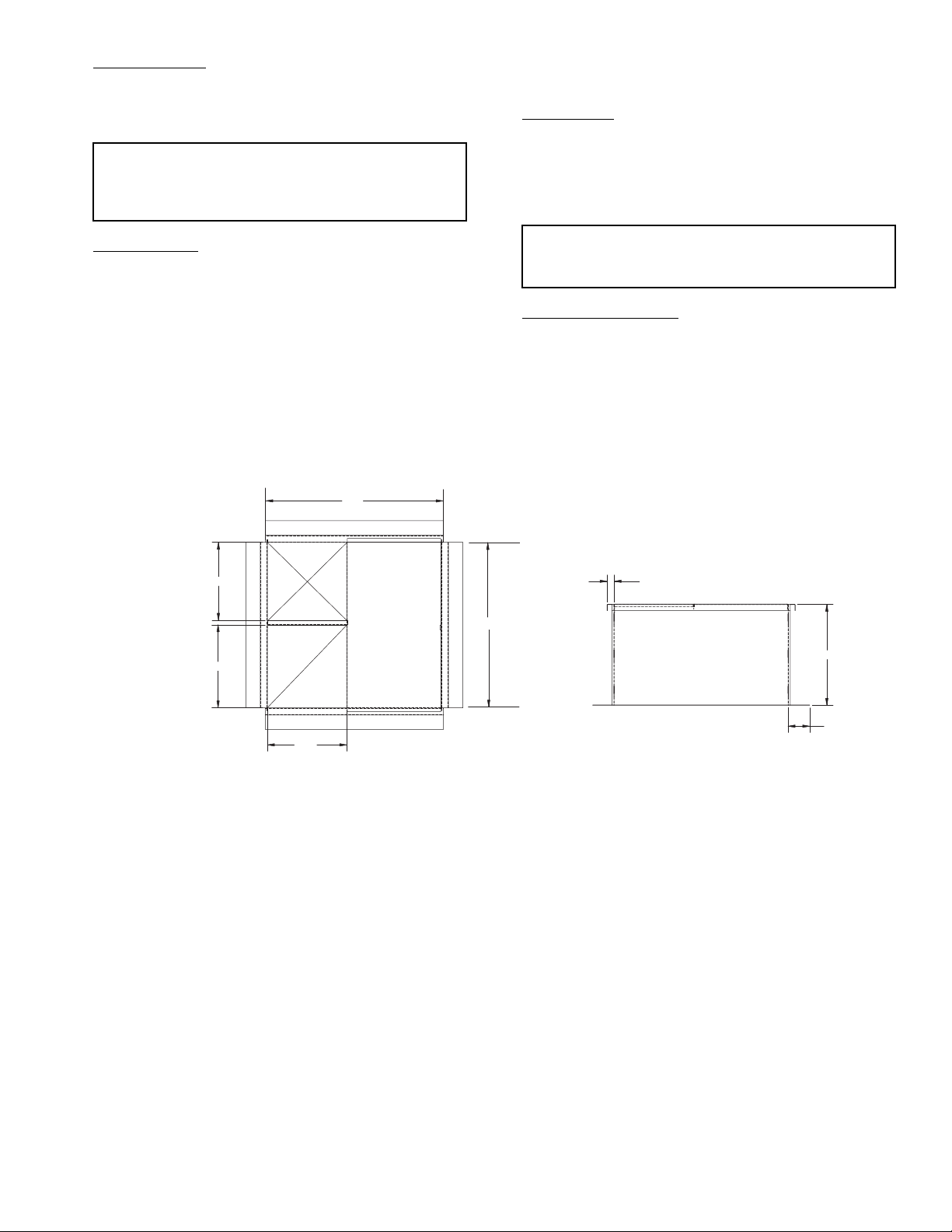

Prepare Roof Curb Location

— Cut a hole in the roof for duct

openings. See Fig. 2-5 for duct opening dimensions. Frame the

opening to provide adequate structural support.

Install Deck Pans and Duct Supports

— The roof curb may

have a duct support and deck pans, depending on the model

and application. Determine which end of the roof curb will be

the duct end.

Install the deck pans on the roof curb with the insulation

side facing up toward the ERV base. Install the duct support

between the supply and return openings.

Set the Roof Curb

— Fit the roof curb assembly by measuring

across the corners of the curb to ensure a square fit. Set the roof

curb over the roof opening. Level the curb by placing shims

under the bottom flange of the curb. Secure the curb in place by

welding or fastening the curb to the roof.

Cover the roof curb if installation of the ERV unit will not

be immediate. Failure to cover the roof curb could result in

water damage and/or serious personal injury.

Install Ductwork

— Ductwork will be installed in the roof

curb for vertical discharge and stand-alone applications. The

duct will hang from the top of the curb. See Fig. 45 for standalone application airflow.

NOTE: Ductwork must be installed before the ERV unit is set

in place.

Refer to Fig. 2-5 to determine the duct size required.

Provide field manufactured duct and place into the supply and

return openings in the curb.

Install Gaskets

— The ERV roof curbs come with a gasketing

package to provide a seal between the ERV unit and the top

perimeter of the roof curb. Install the gasket around the top

perimeter of the curb and around the supply and return opening.

NOTE: Some stand-alone curbs will not have duct openings).

Gasket strips must fit tightly together, leaving no gaps for

leakage.

IMPORTANT: Gasket installation is critical for water

integrity. Improperly installed gaskets can result in air

or water leaks, leading to poor unit performance.

Install Roofing Materials

— Insulate and add a cant strip to

the roof curb. Follow suggested and acceptable roofing practices

SIDE

Fig. 1 — Assembling the Roof Curb

for applying roofing materials. The roofing material should

extend up to the wood nailer and be secured under the counterflashing. Follow all local, national, and industry roofing

standards. Refer to Fig. 6 for roofing recommendations.

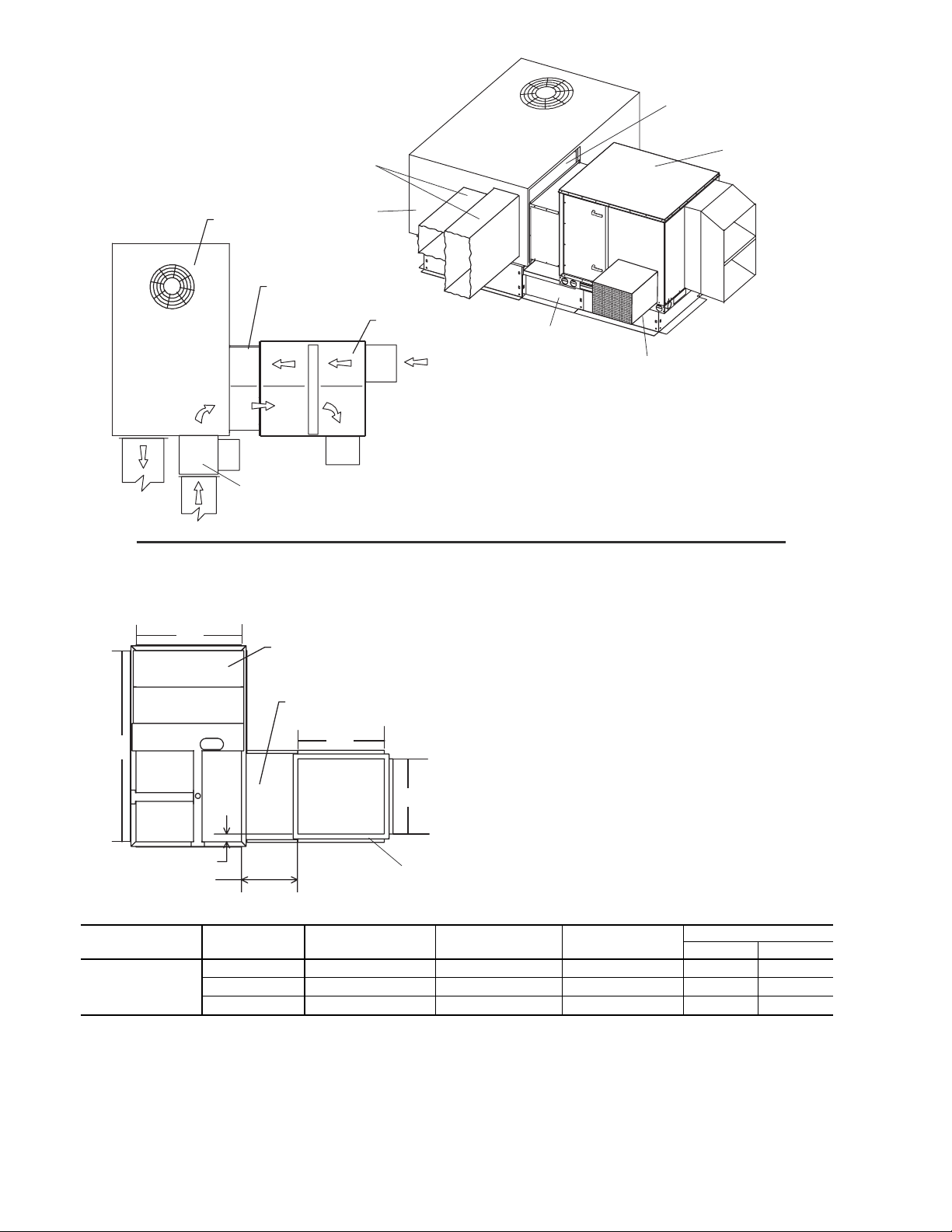

COUPLED APPLICATIONS — The ERV unit can be installed directly coupled to a Carrier rooftop unit. The connection between the ERV and HVAC (Heating, Ventilation, and

Air Conditioning) unit is made with the use of a transition. In a

coupled rooftop application there is a separate roof curb for the

HVAC curb and a separate roof curb for the ERV unit. See

Fig. 4 and 5 for roof curb dimensions.

Locate the Roof Curb

— Prior to locating the roof curb consider the structural support required for the rooftop system and,

the duct drop location in relation to the joists. Allow sufficient

space for service, clearance, and locations of vents or other

sources of air. Refer to the rooftop installation instructions for

more information regarding location considerations.

Assemble the Roof Curb

— Connect the curb side and the

curb end. Insert the tabs on the curb end into the slots on the

curb sides. Press firmly until the pieces lock in to place. It may

be necessary to exert additional force to the top of the curb to

lock the pieces in place. Ensure the curb pieces are locked together prior to proceeding.

Repeat for other corners of the roof curb.

NOTE: If lifting or moving the roof curb assembly hammer

the tabs over 90 degrees.

Install Deck Pans and Duct Supports

— The roof curb may

have a duct support and deck pans, depending on the model

and application. Refer to Fig. 2-5. Determine which end of the

roof curb will be the duct end.

Install the deck pans on the roof curb with the insulation

side facing up toward the ERV base. Install the duct support

between the supply and return openings.

Install Locator Pieces

— Some ERV roof curbs (62MA-CRB14MC and 62MB-CRB-14MC) will include locator pieces,

which are to be attached to the ERV roof curb section. The

locator pieces will help the installer ensure that the ERV and

HVAC unit roof curbs are positioned properly. Attach the

2 side locator pieces to the ERV roof curb. Install the cover

panel over the 2 sides and fasten in place.

2

Page 3

Set the Roof Curb

— Fit the roof curb assembly by measuring

across the corners of the curb to ensure a square fit. Set the roof

curb over the roof opening. Level the curb by placing shims

under the bottom flange of the curb. Secure the curb in place by

welding or fastening the curb to the roof.

IMPORTANT: The ERV roof curb must be set in

precisely the correct location relative to the rooftop

roof curb for the transitions to connect properly. See

Fig. 7-44 for location dimensions.

Refer to Fig. 2 and 3 to determine the duct size required.

Provide field manufactured duct and place into the supply and

return openings in the curb.

Install Gaskets

— The ERV roof curbs come with a gasketing

package to provide a seal between the ERV unit and the top

perimeter of the roof curb. Install the gasket around the top

perimeter of the curb and around the supply and return

opening. (Some stand-alone curbs will not have duct openings.) Gasket strips must fit tightly together, leaving no gaps for

leakage.

Install Ductwork

— Ductwork will be installed in the roof

curb for vertical, coupled applications. The duct will hang from

the top of the curb.

NOTE: Ductwork must be installed before the rooftop unit is

set in place.

NOTE: Ductwork must be installed before the ERV unit is set

in place.

24.09

SUPPLY

10.81

RETURN

11.50

IMPORTANT: Gasket installation is critical for water

integrity. Improperly installed gaskets can result in air

or water leaks, leading to poor unit performance.

Install Roofing Materials

— Insulate and add a cant strip to

the roof curb. Follow suggested and acceptable roofing procedures for applying roofing materials. The roofing material

should extend up to the wood nailer and be secured under the

counter flashing. Follow all local, national, and industry roofing standards. Refer to Fig. 5 for roofing recommendations.

1.00

TYP. 4X

22.94

14.00

11.00

NOTES:

1. All dimensions are in inches.

2. Roof curb shipped unassembled.

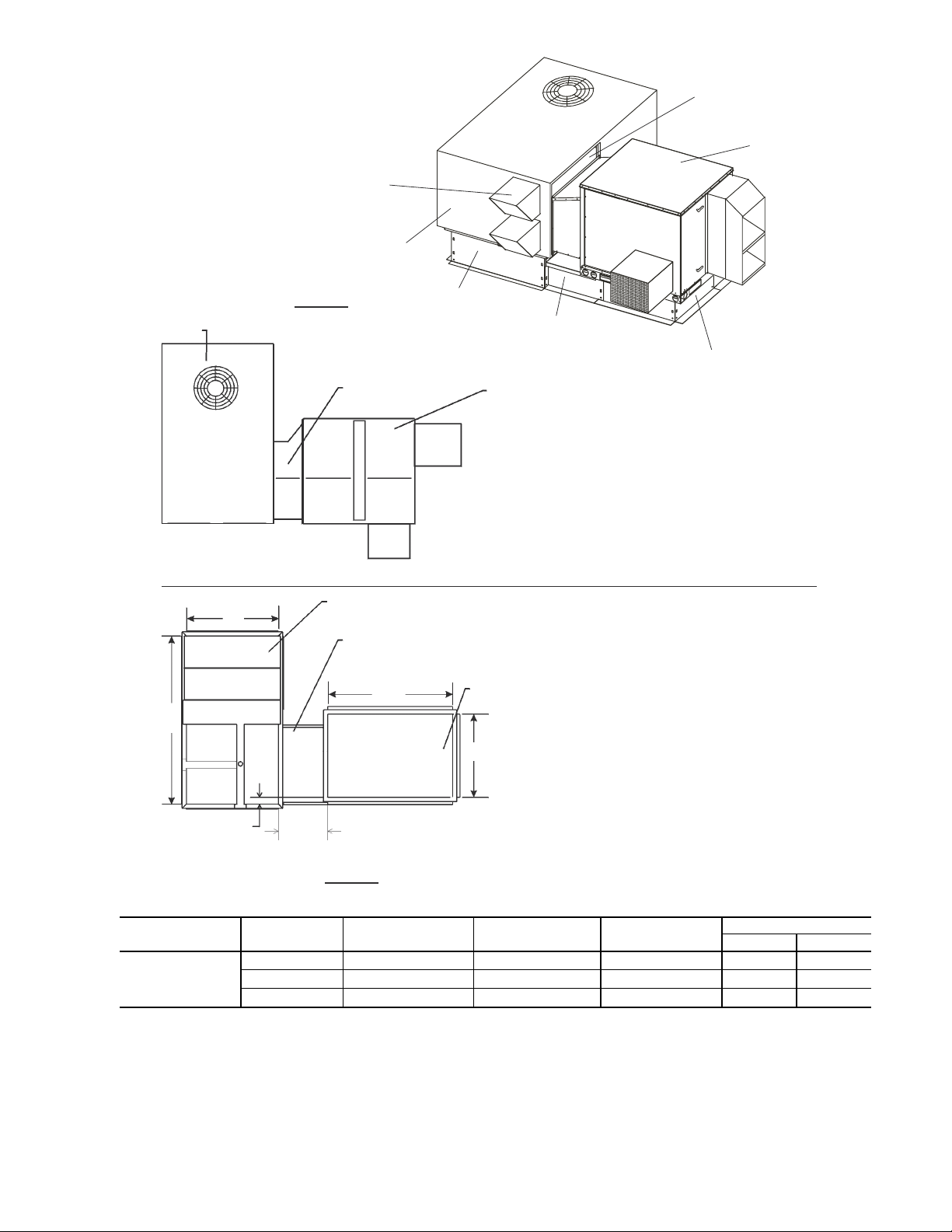

Fig. 2 — Roof Curb — 62M040 for Stand-Alone Applications

3.00

TYP. 4X

3

Page 4

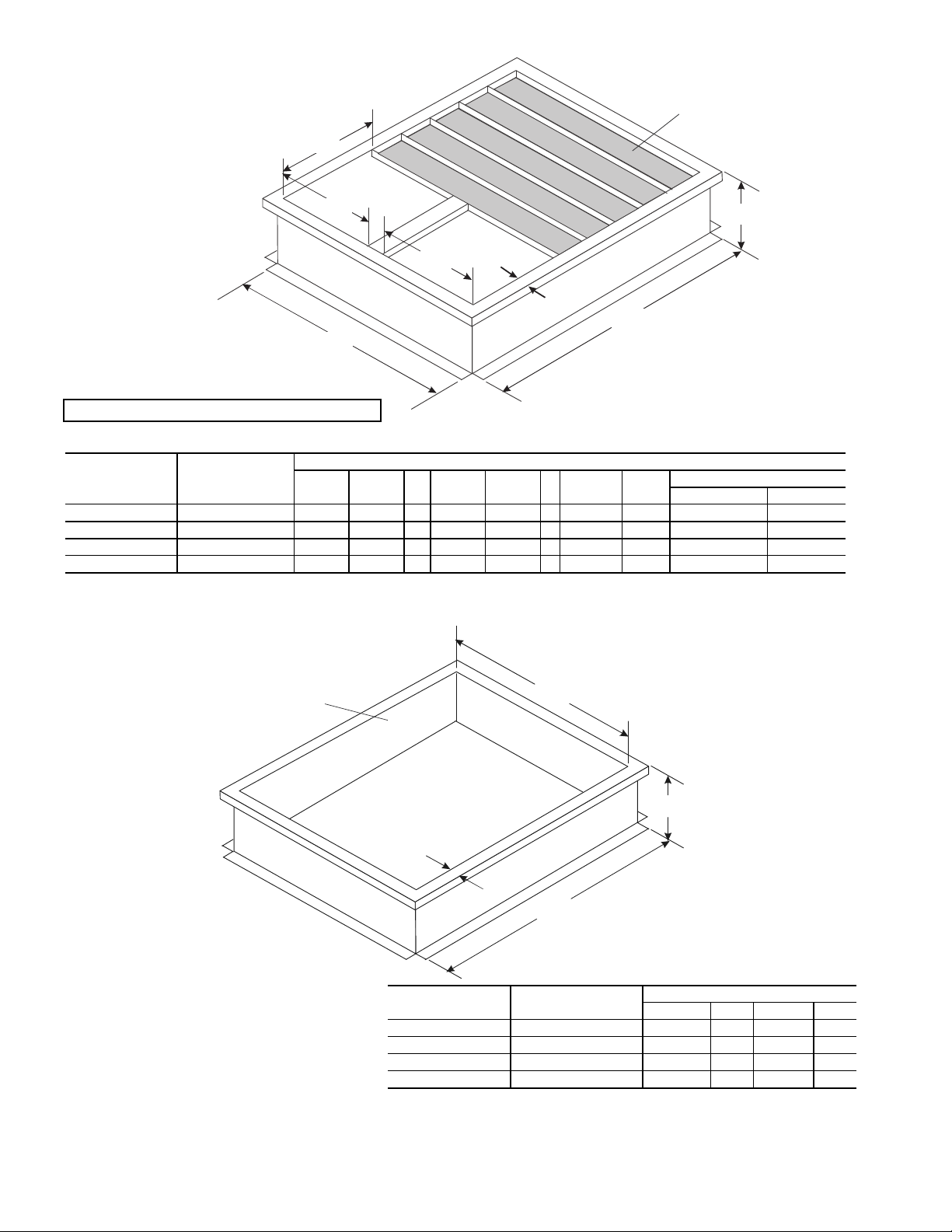

Typical Insulated deck pans.

(Insulation face up) *

D

S/A

E

F

R/A

G

H

C

LEGEND

R/A — Return Air

S/A — Supply Air

*IMPORTANT: Insulation on deck pans must face up.

NOTE: Roof curb shipped unassembled.

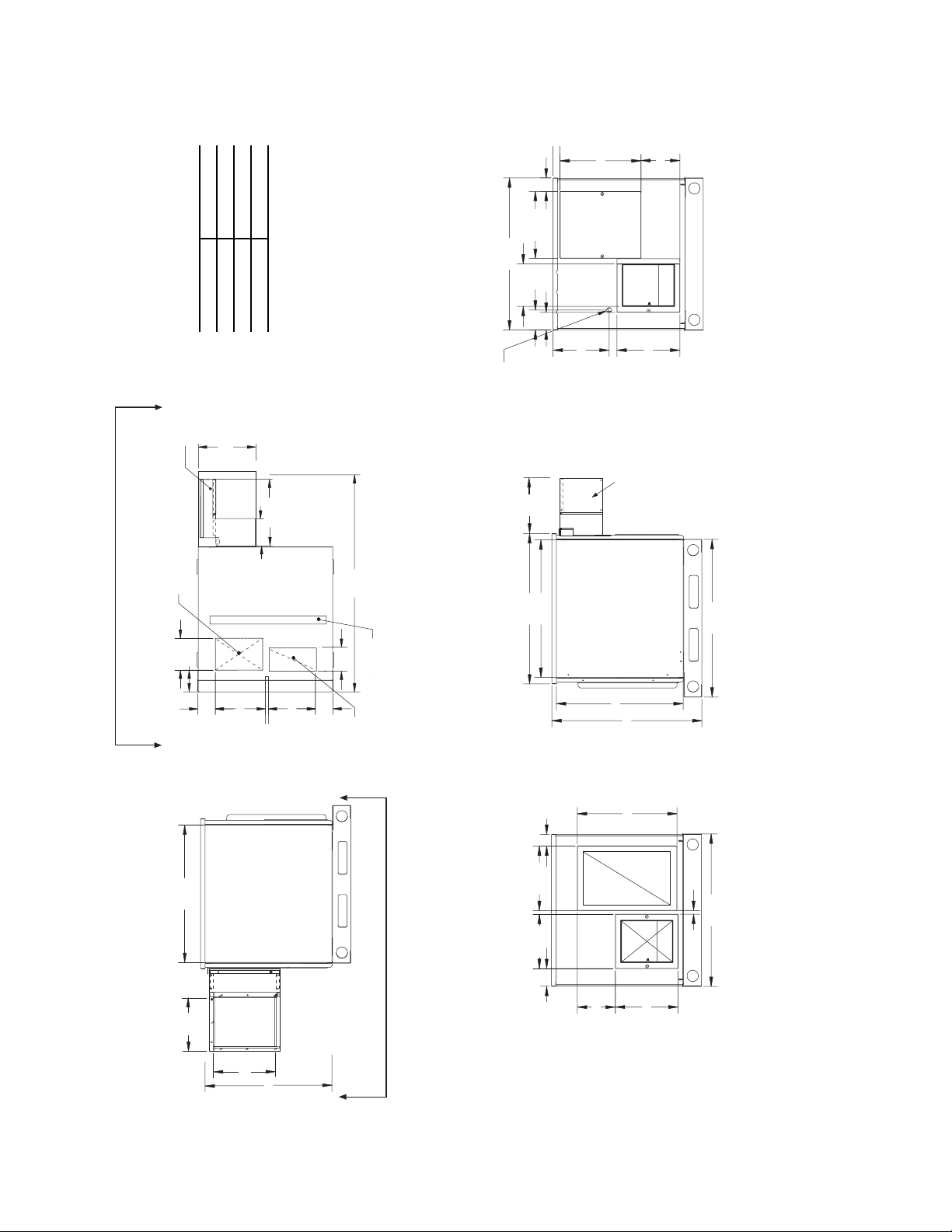

62M UNIT SIZE

075,120 62M-A-CRB-14S 27 30.5 14 14 11.3 1 14.7 1.5 13.75 x 14.38 13.75 x 11

170-285 62M-B-CRB-14S 45.5 49.63 14 17.5 19.5 2 24 1.75 17 x 23.5 17 x 19

330-640 62M-C-CRB-14S 55.41 60.34 14 24.84 23.41 2 30 — 24.5 x 29.5 24.5 x 23

750,950 62M-D-CRB-14S 86.25 95.7 14 32.5 42.13 2 42.13 — 32 x 41.75 32 x 41.75

CURB

PART N O.

A

DIMENSIONS (in.)

ABCDEFGH

B

Duct Sizes

Return Supply

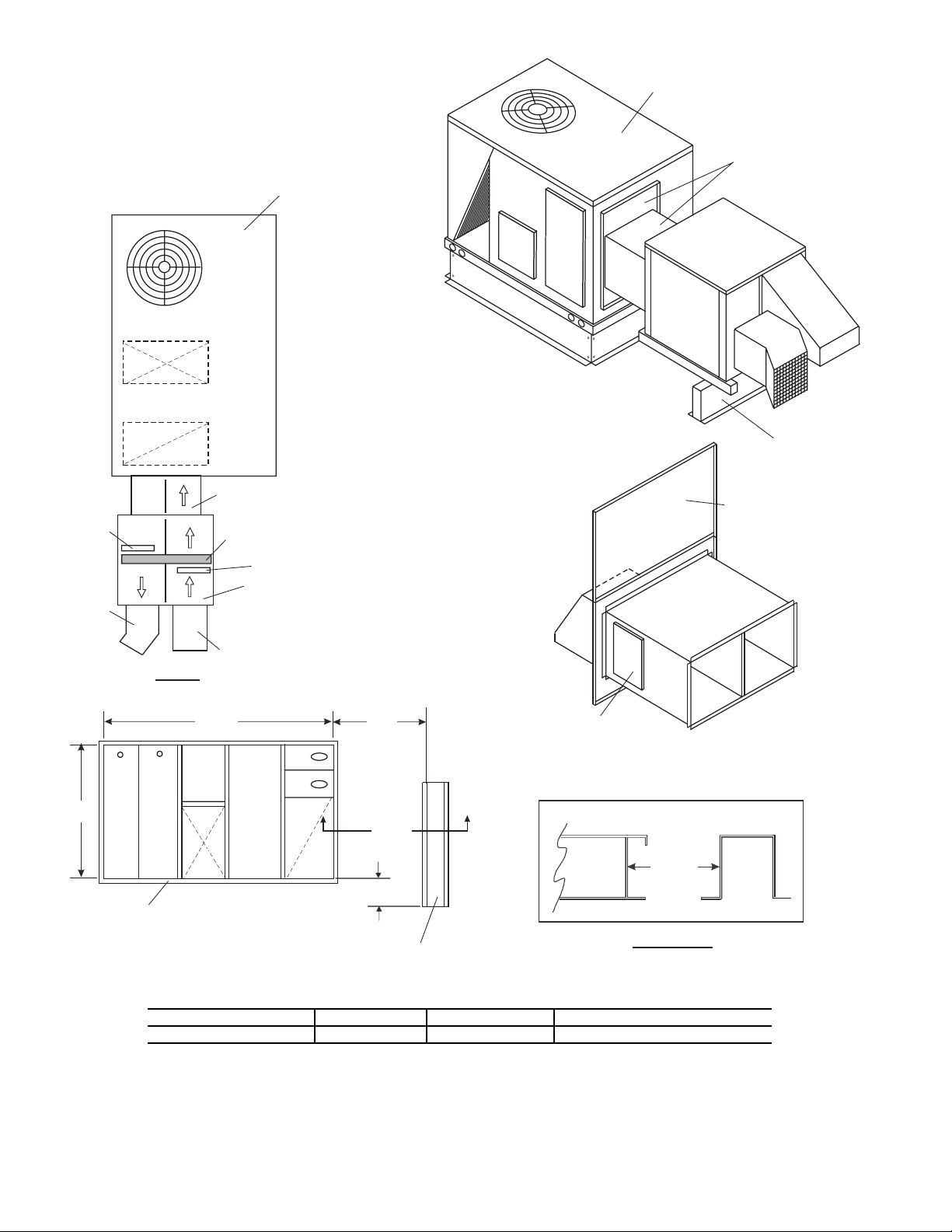

Fig. 3 — Roof Curb — 62M075-950 for Vertical Stand-Alone Applications

ERV Curb

C

LEGEND

ERV — Energy Recovery Ventilator

NOTE: Roof curb shipped unassembled.

Fig. 4 — Roof Curb — 62M075-950 for Horizontal Stand-Alone Applications

or Units Coupled with Rooftop Units 15 Tons and Above

B

D

A

62M UNIT SIZE

075,120* 62M-A-CRB-14S 27 30.5 14 1.5

170-285† 62M-B-CRB-14S 49.63 14 45.5 1.75

330-640 62M-C-CRB-14M 60.34 14 55.41 1.75

750,950 62M-D-CRB-14M 95.7 14 86.25 1.75

*62M075,120 curb is shipped with deckpans insulation and duct supports which may

be discarded.

†62M170-285 curb is shipped with deck pans and insulation.

CURB

PART N O.

DIMENSIONS (in.)

A BCD

4

Page 5

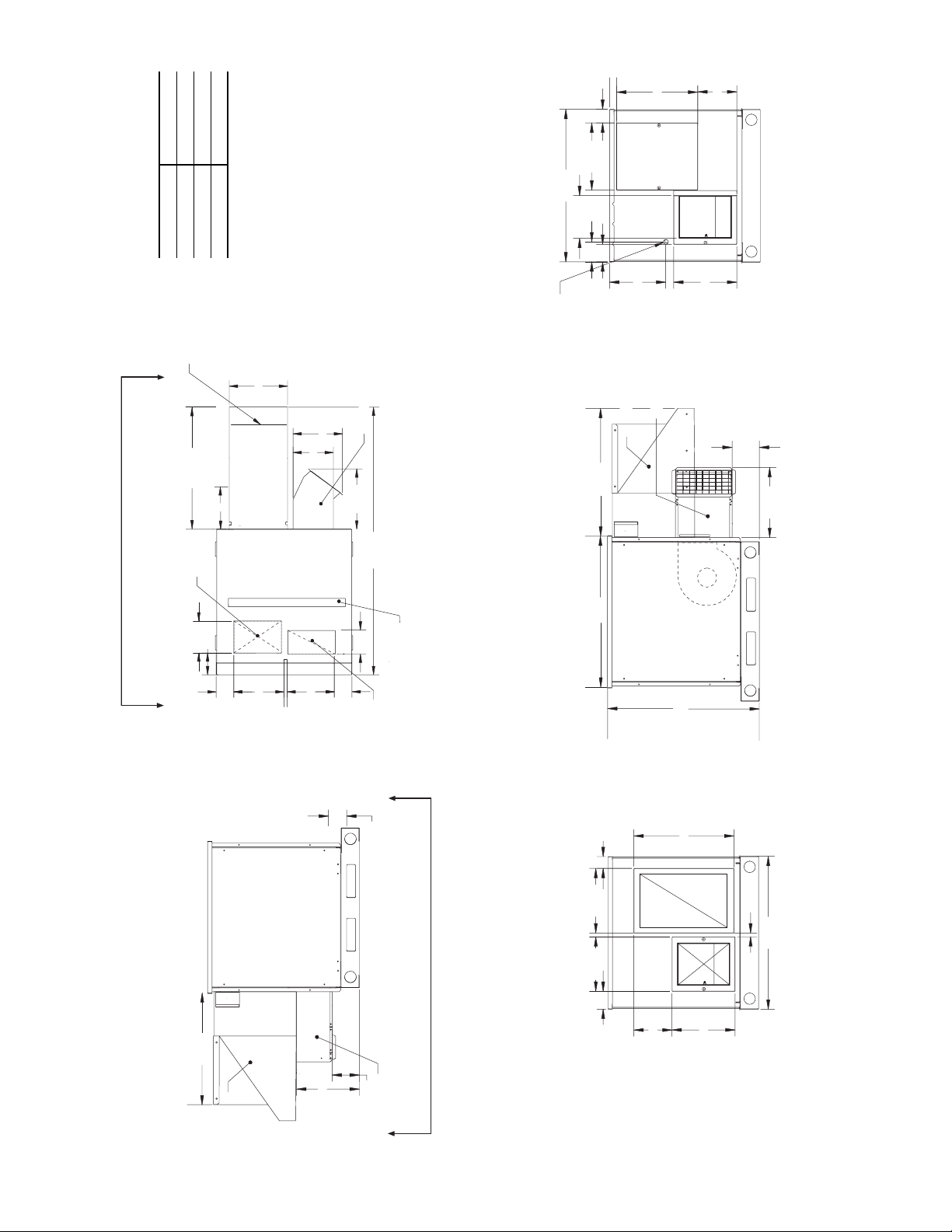

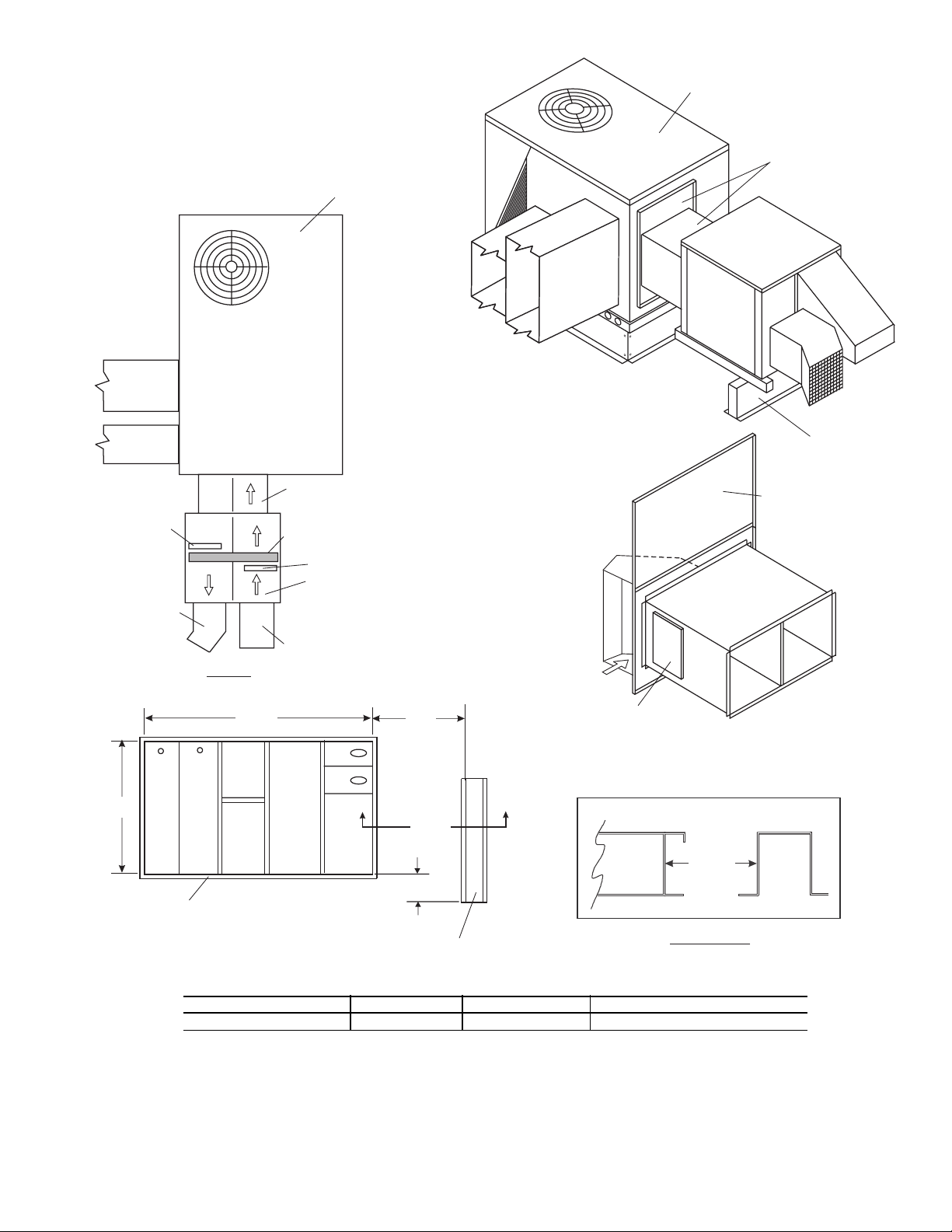

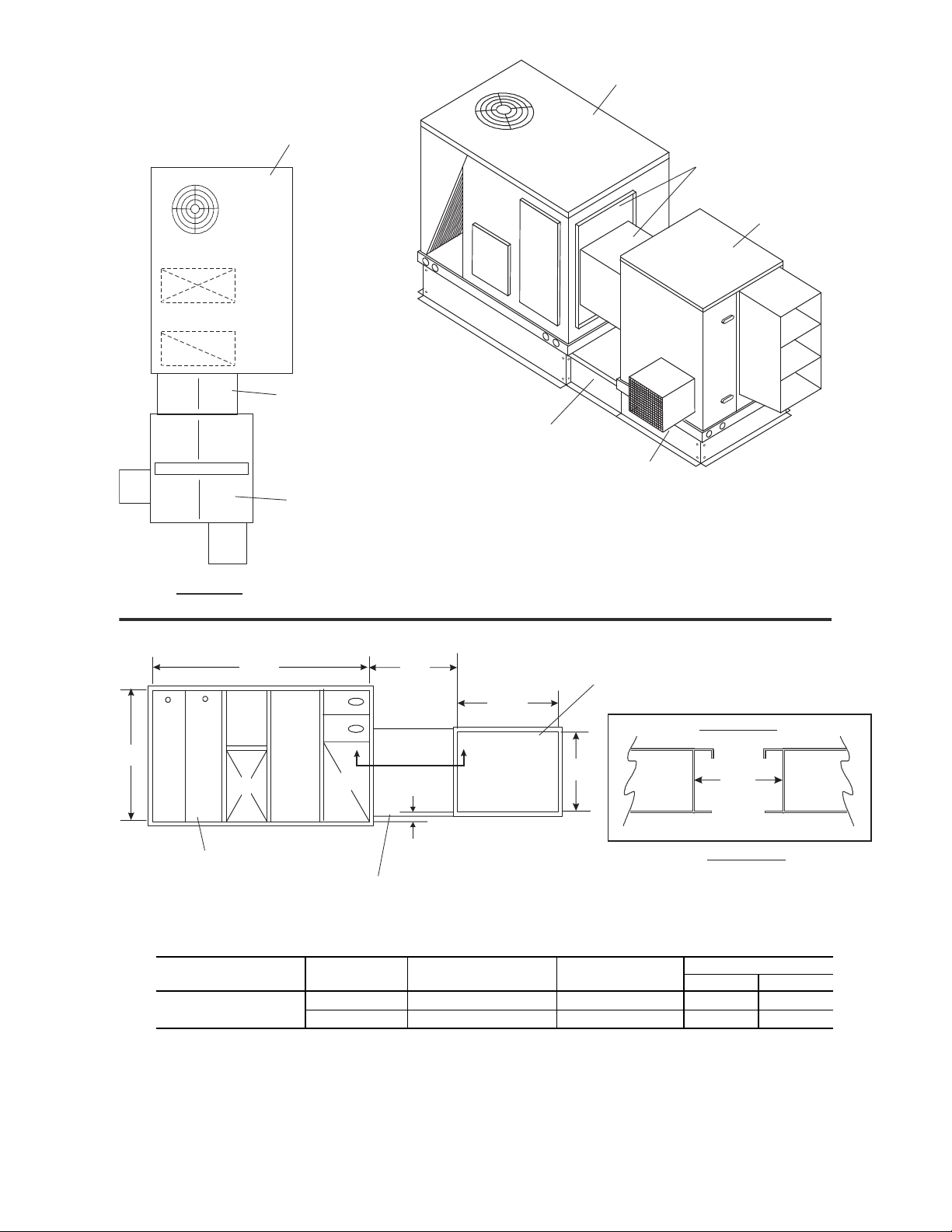

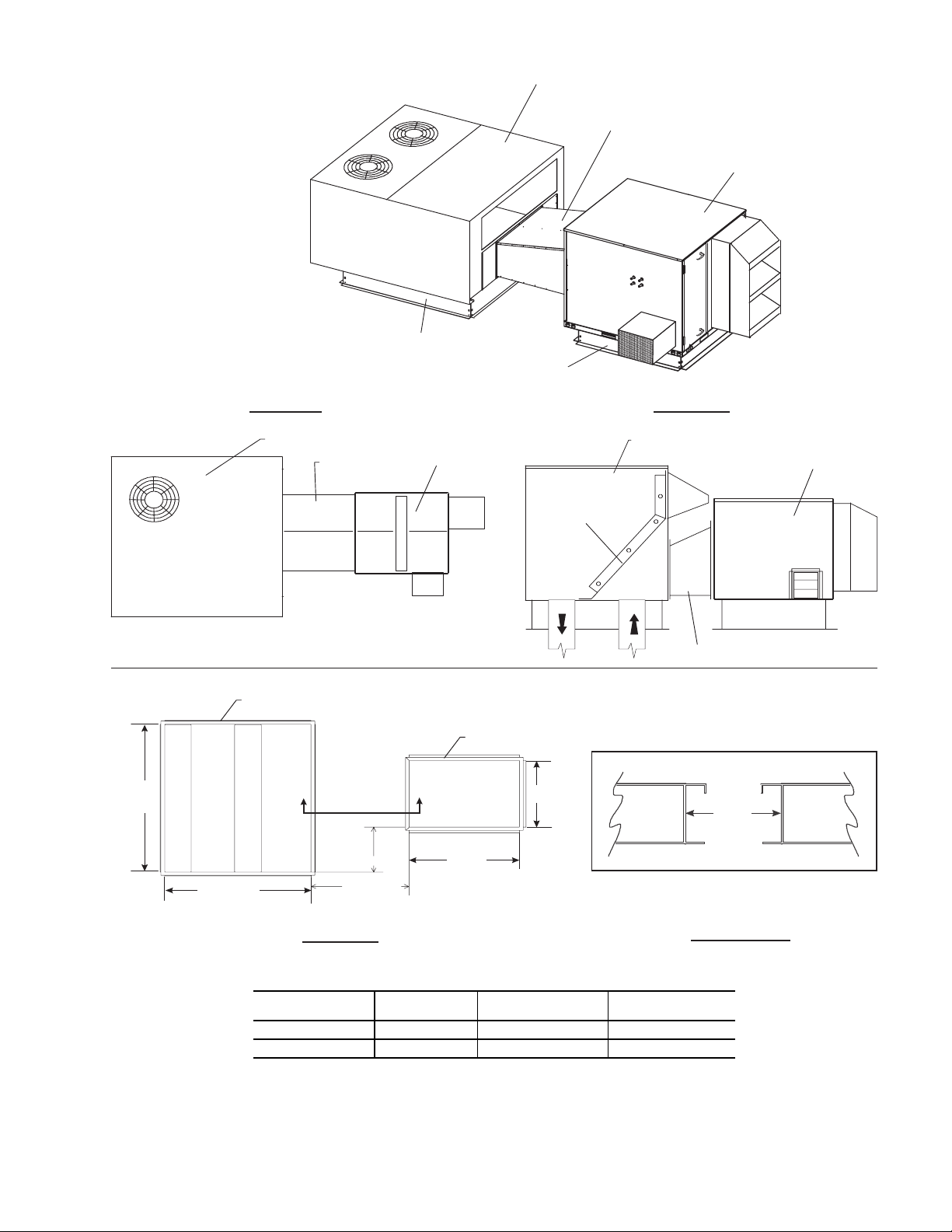

Must be Watertight

Locator pieces to connect

ERV curb to rooftop unit curb

LEGEND

ERV — Energy Recovery Ventilator

NOTE: Roof curb shipped unassembled.

Fig. 5 — Roof Curb — 62M075-285 Units 3 to 121/2Ton Rooftop Units

ERV Curb

62M UNIT SIZE

D

E

CURB

PART N O.

C

B

A

DIMENSIONS (in.)

ABC D E

075,120 62M-A-CRB-14MC 30.5 14 27 1.5 19.81

170-285 62M-B-CRB-14MC 49.63 14 45.5 1.75 37.81

GASKETING

ROOF CURB

RIGID

INSULATION*

CANT STRIP*

ROOF DECK*

ROOF*

NAIL*

FLASHING*

ROOF FELT*

*Field provided.

Fig. 6 — Roofing Materials — Recommendation

5

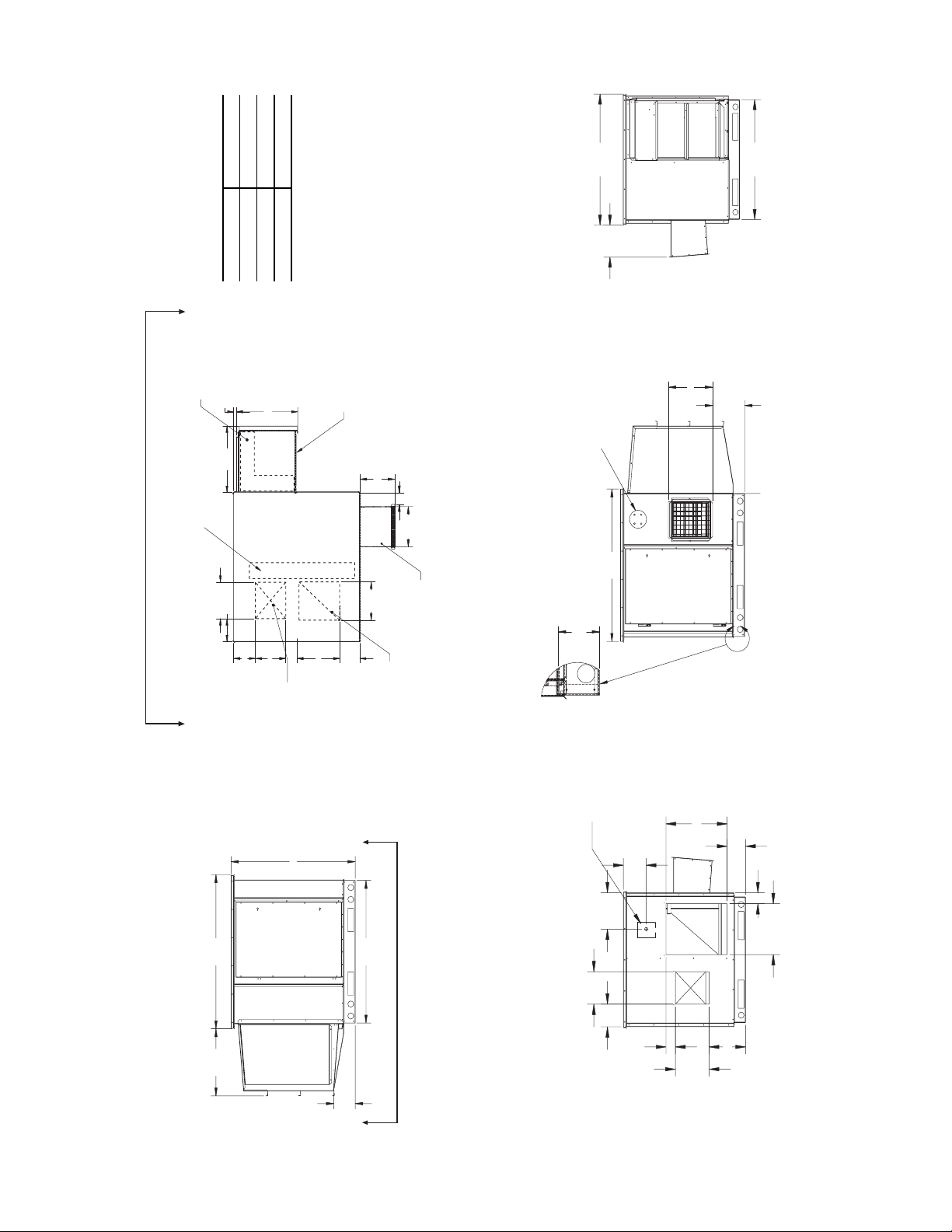

Page 6

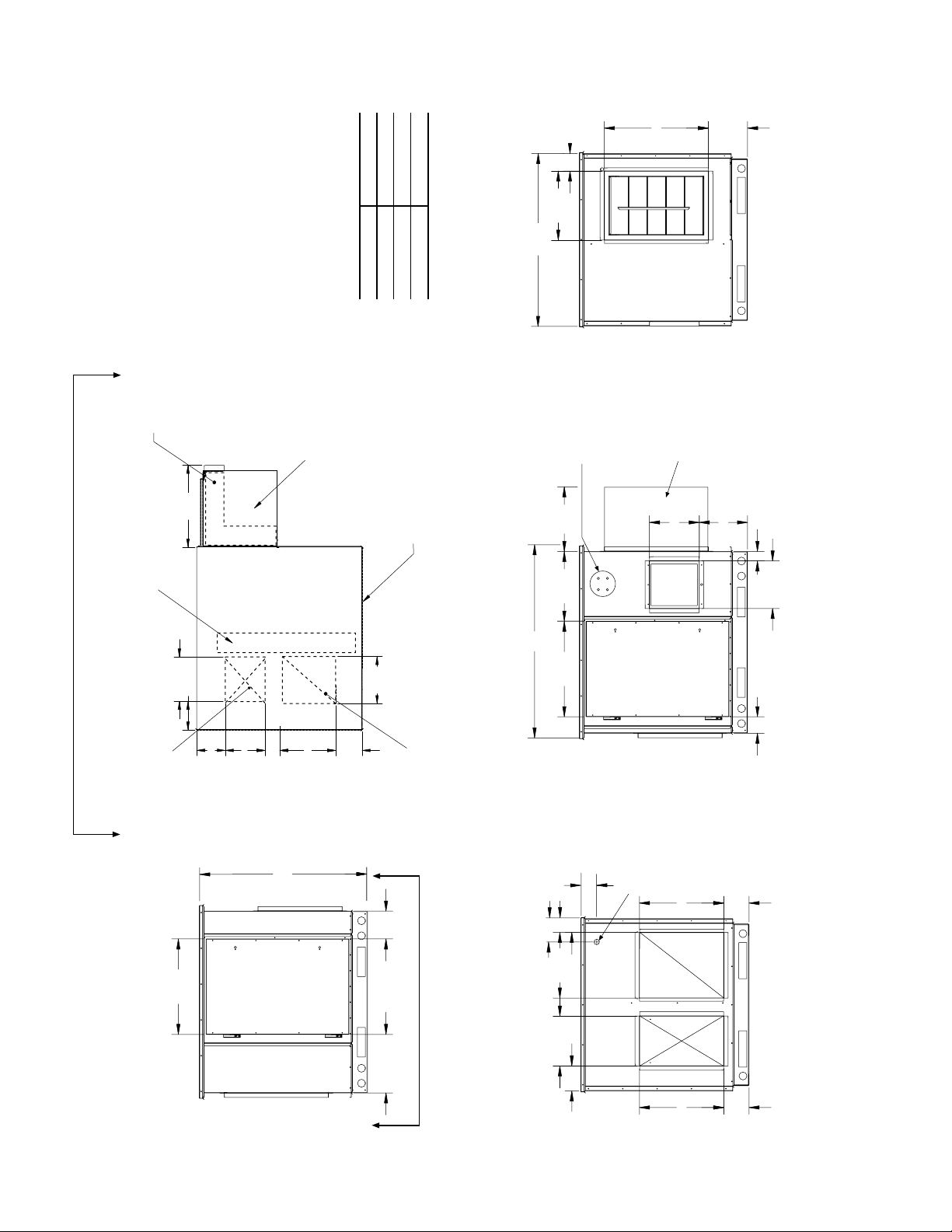

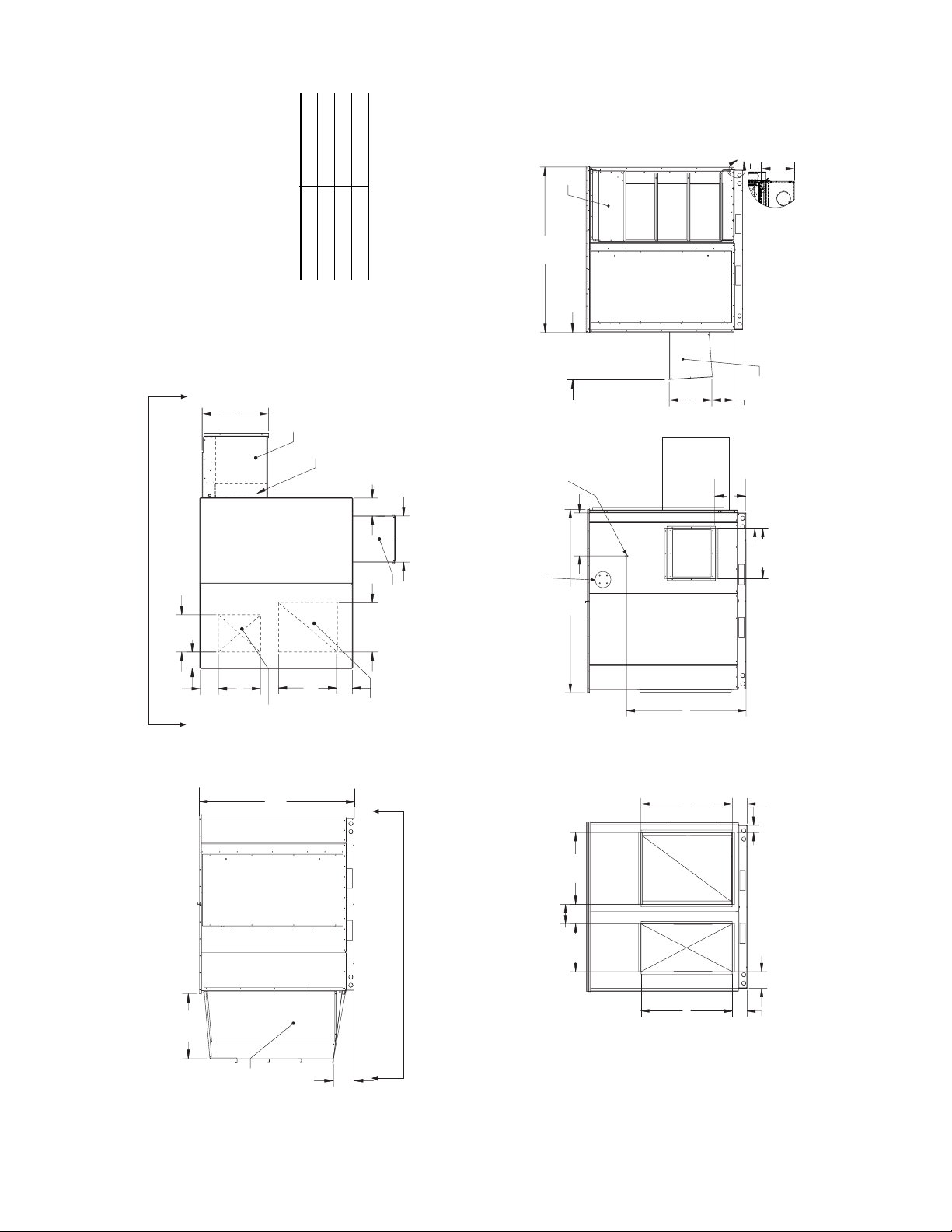

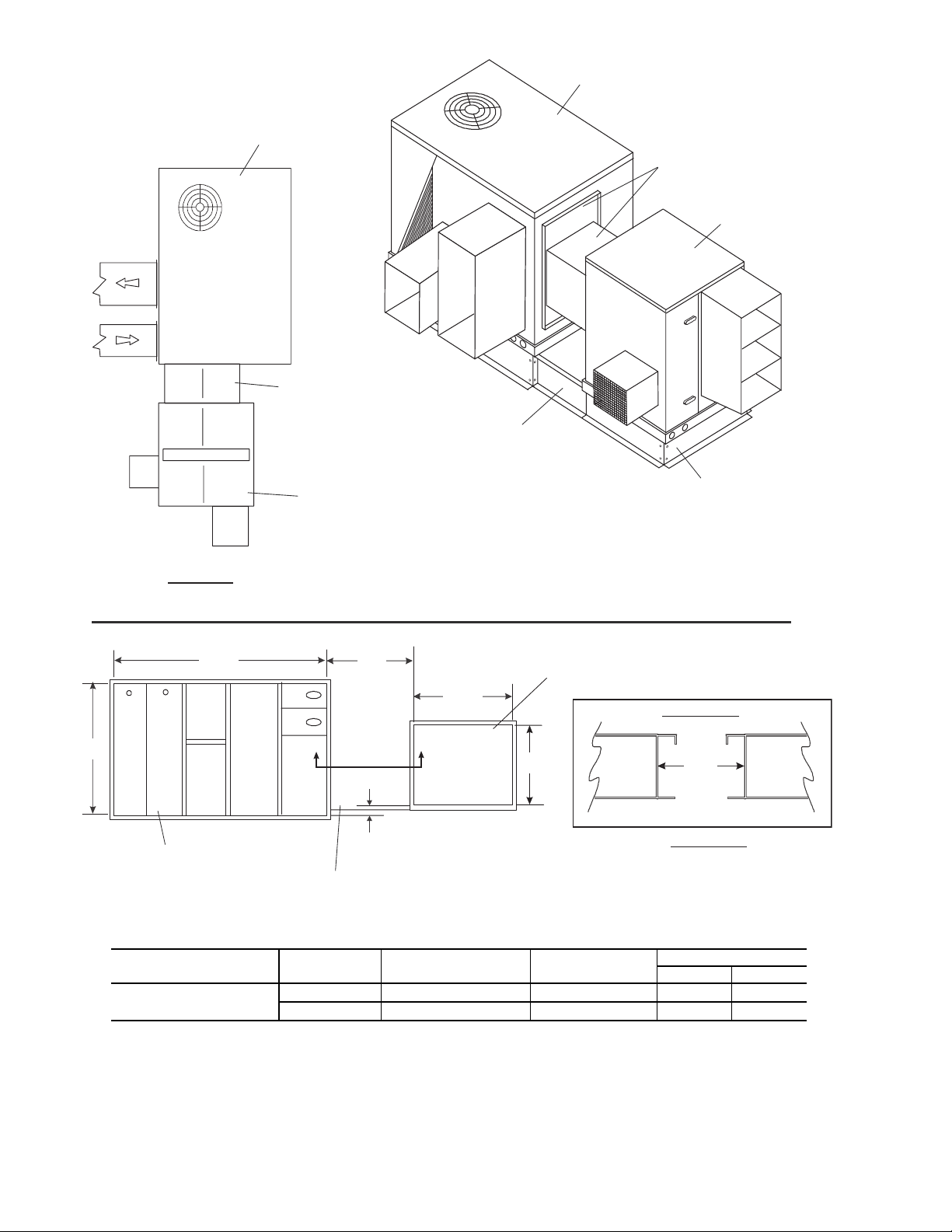

CLEARANCES

REQUIRED SERVICE

Front 16 in.

A

OPTIONAL

INDOOR PREHEATER

Rear 0in.

19.25

Left* 18 in.

Right* 18 in.

0

1

22.90

AIR

EXHAUST

12.45

OPTIONAL

(INDOOR) PREHEATER

7.69

16.02

2.67

AIR

13.26

OUTSIDE

29.88

8.43

on either Left or Right side for

ERV wheel removal.

*30 in. service clearance required

NOTE: All dimensions are in

inches.

11.09

3.48

3.95

ENTRY

POWER

16.00

SUPPLY AIR

4.83

A

(OPTIONAL)

7.13

3.91

27.19

5

2

3.

1

11.15

10.50

3.95

45.75

5.34

RETURN AIR

(OPTIONAL)

ERV

WHEEL

TOP SIDE

RIGHT SIDE

VIEW A-A

29.75

12.75

27.19

2.33

10.75

3.52

25.12

UNITS ONLY*

HORIZONTAL

AIR*

RETURN

7.53

29.75

19.75

AIR

SUPPLY

12.45

.75

31.24

LEFT SIDE FRONT SIDE

Fig. 7 — 62MB,MC040 Indoor Unit Dimensions

29.98

REAR SIDE

16

25.12

6

Page 7

CLEARANCES

REQUIRED SERVICE

16.02

2.67

AIR

13.26

OUTSIDE

29.88

Front 27.5 in.

Rear 10 in.

Left* 20 in.

Right* 20 in.

on either Left or Right side for

ERV wheel removal.

*30 in. service clearance required

NOTE: All dimensions are in

inches.

8.43

7.69

AIR

EXHAUST

FRONT SIDE

OUTSIDE AIR HOOD AND

OPTIONAL PREHEATER

A

16.00

10

SUPPLY AIR

(OPTIONAL)

4.83

7.13

3.91

A

12.96

11.15

8.97

10.50

12.45

ENTRY

POWER

3.95

3.48

11.09

EXHAUST AIR HOOD

EXHAUST AIR HOOD

11. 00

OUTSIDE AIR HOOD

5.31

16.00

3.95

13.38

5.34

45.75

ERV

TOP SIDE

29.75

WHEEL

13.5

LEFT SIDE

29.75

RETURN AIR

(OPTIONAL)

13.72

OUTSIDE AIR HOOD

12.29

3.55

TOP OF CURB

5.35

EXHAUST AIR HOOD

VIEW A-A

RIGHT SIDE

Fig. 8 — 62MD,ME040 Outdoor Unit Dimensions

UNITS ONLY*

HORIZONTAL

2.33

12.75

10.75

3.52

AIR*

RETURN

7.53

19.75

AIR

SUPPLY

12.45

29.98

.75

REAR SIDE

7

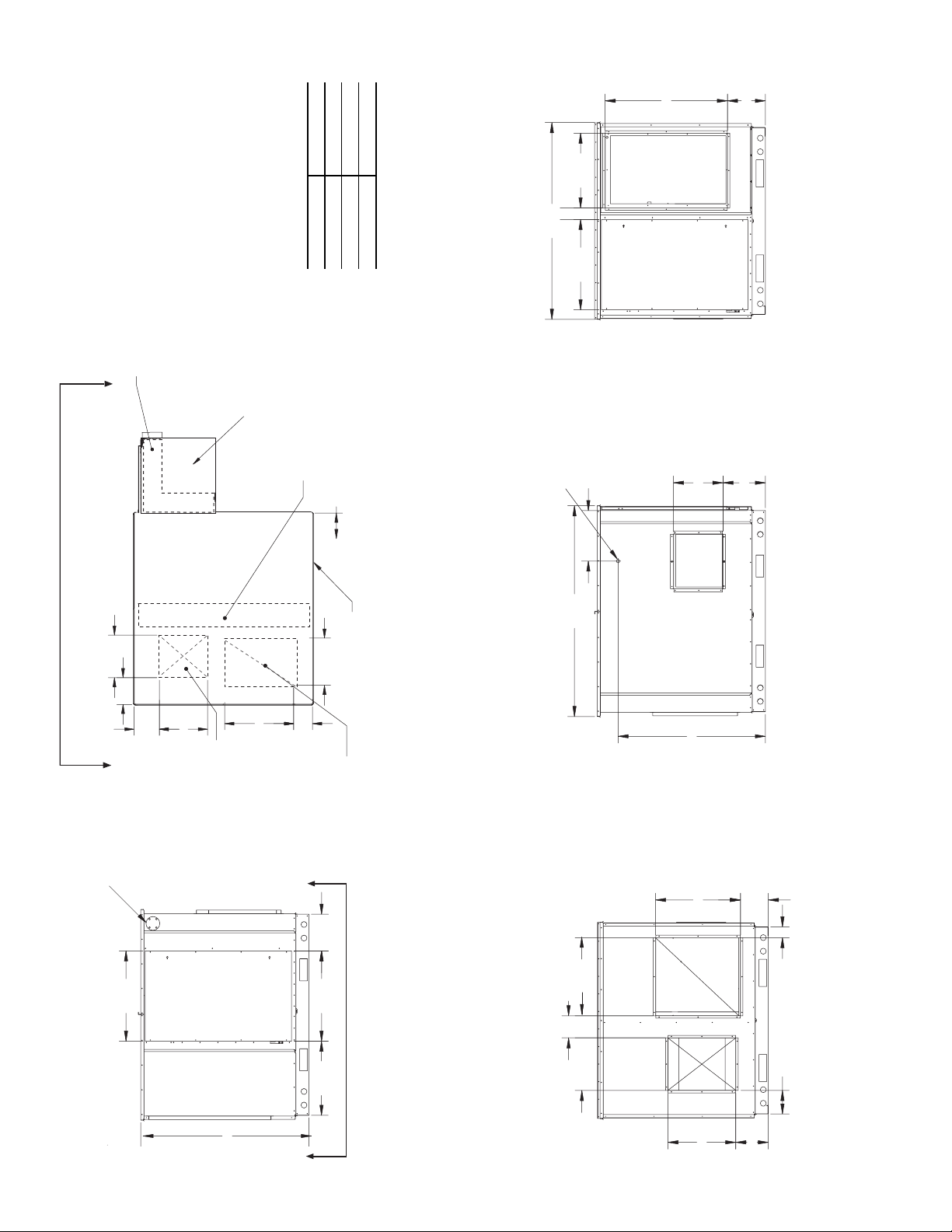

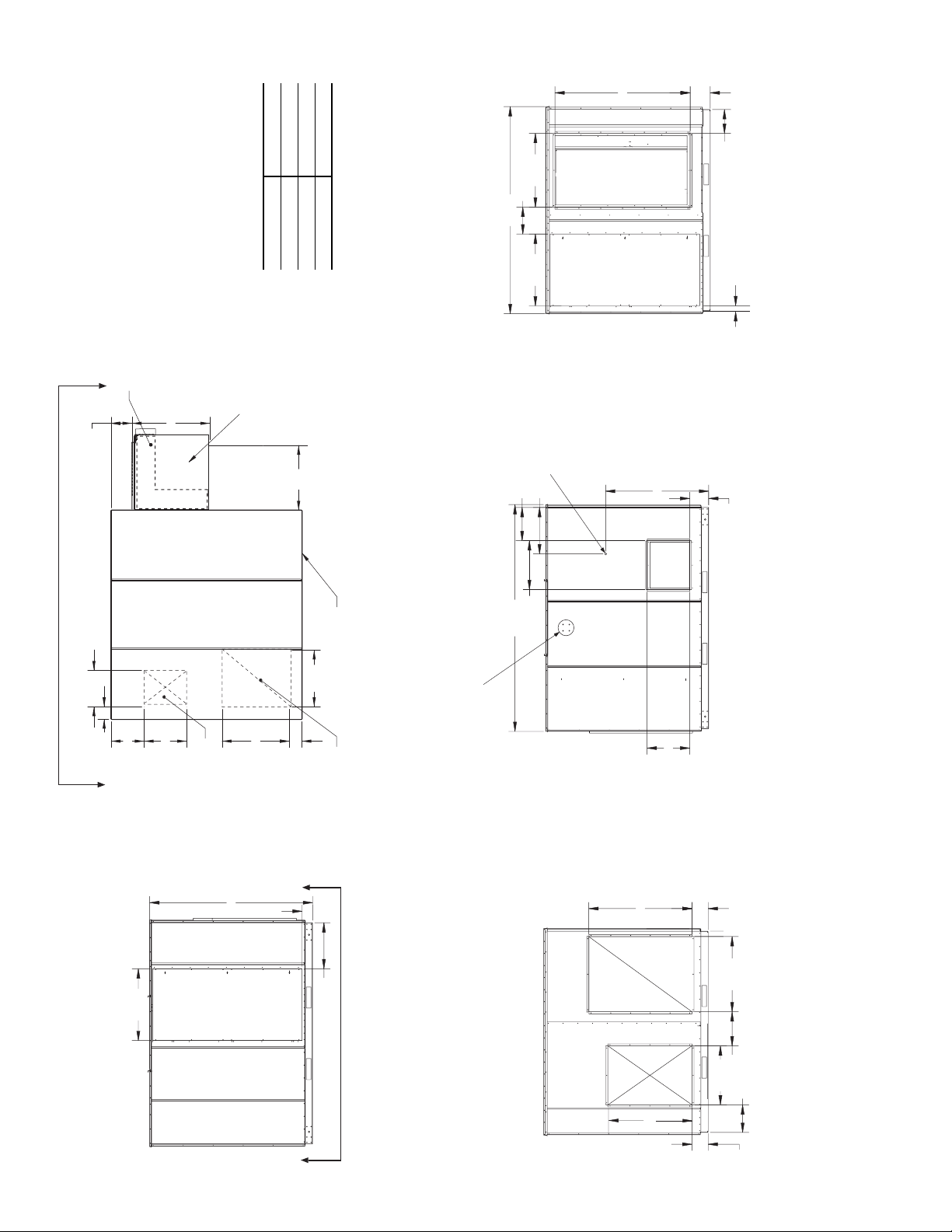

Page 8

8.63

OUTSIDE AIR

FRONT SIDE

CLEARANCES

REQUIRED SERVICE

Front 31 in.

3.88

15.25

39.03

Rear 0in.

Left 24 in.

Right* 39 in.

for ERV wheel removal.

*39 in. service clearance required

NOTE: All dimensions are in inches.

23.00

A

OPTIONAL PREHEATER

PREHEATER CABINET

PORTS

(OPTIONAL)

AIRFLOW TEST

(INDOOR)

OPTIONAL

PREHEATER

6.60

19.04

10.39

6.65

9.25

3.46

12.98

EXHAUST AIR OUTLET

TOP SIDE

10.93

6.18

42.6

18.88

15.40

21.10

EXHAUST AIR

ACCESS DOOR

11.00

10.66

2.10

3.63

10.50

LEFT SIDE

Fig. 9 — 62MB,MC075,120 Indoor Unit Dimensions

A

SUPPLY AIR

(BOTTOM SUPPLY ONLY)

37.14

OPTIONAL RETURN AIR

6.13

(BOTTOM RETURN ONLY)

POWER ENTRY / OPTIONAL

6.97

DISCONNECT LOCATION

18.63

5.58

3.34

10.32

21.10

12.90

VIEW A-A

RIGHT SIDE

14.50

RETURN

REAR SIDE

11.00

5.53

SUPPLY

18.63

5.58

8

Page 9

39.03

35.711

FRONT SIDE

CLEARANCES

REQUIRED SERVICE

Front 31 in.

Rear 0in.

OUTDOOR AIR HOOD

.87

19.04

ERV WHEEL

6.60

10.39

6.65

Left 24 in.

18.69

9.25

Right* 39 in.

3.46

for ERV wheel removal.

*39 in. service clearance required

12.98

NOTE: All dimensions are in inches.

OPTIONAL PREHEATER

6.18

9.60

10.93

2.87

10.35

TOP SIDE

EXHAUST AIR HOOD

9.60

13.24

9.59

AIRFLOW

TEST PORTS

(OPTIONAL)

42.60

4.11

ACCESS DOOR

TOP OF CURB

DETAIL A

A

A

SEE DETAIL

LEFT SIDE

AA

OPTIONAL RETURN AIR

(BOTTOM RETURN ONLY)

*NOTE*

DISCONNECT

POWER ENTRY/

OPTIONAL DISCONNECT

LOCATION IS APPROXIMATE

10.32

9.19

6.43

6.97

RETURN

SUPPLY

2.86

18.55

10.25

11.06

5.62

3.10

Fig. 10 — 62MD,ME075,120 Outdoor Unit Dimensions

14.45

REAR SIDE

43.10

18.74

SUPPLY AIR

(BOTTOM SUPPLY ONLY)

37.14

ACCESS DOOR

6.39

39.8

VIEW A-A

RIGHT SIDE

9

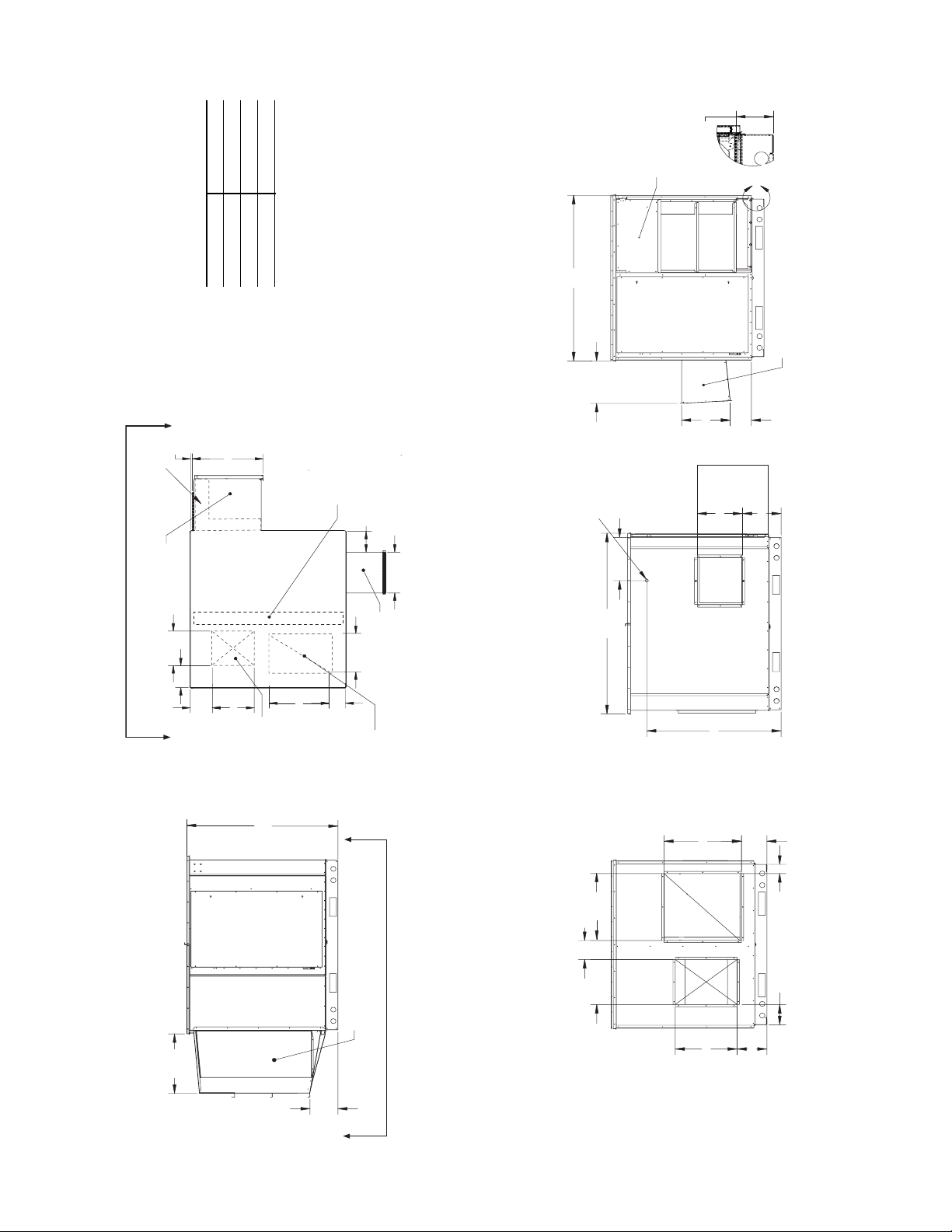

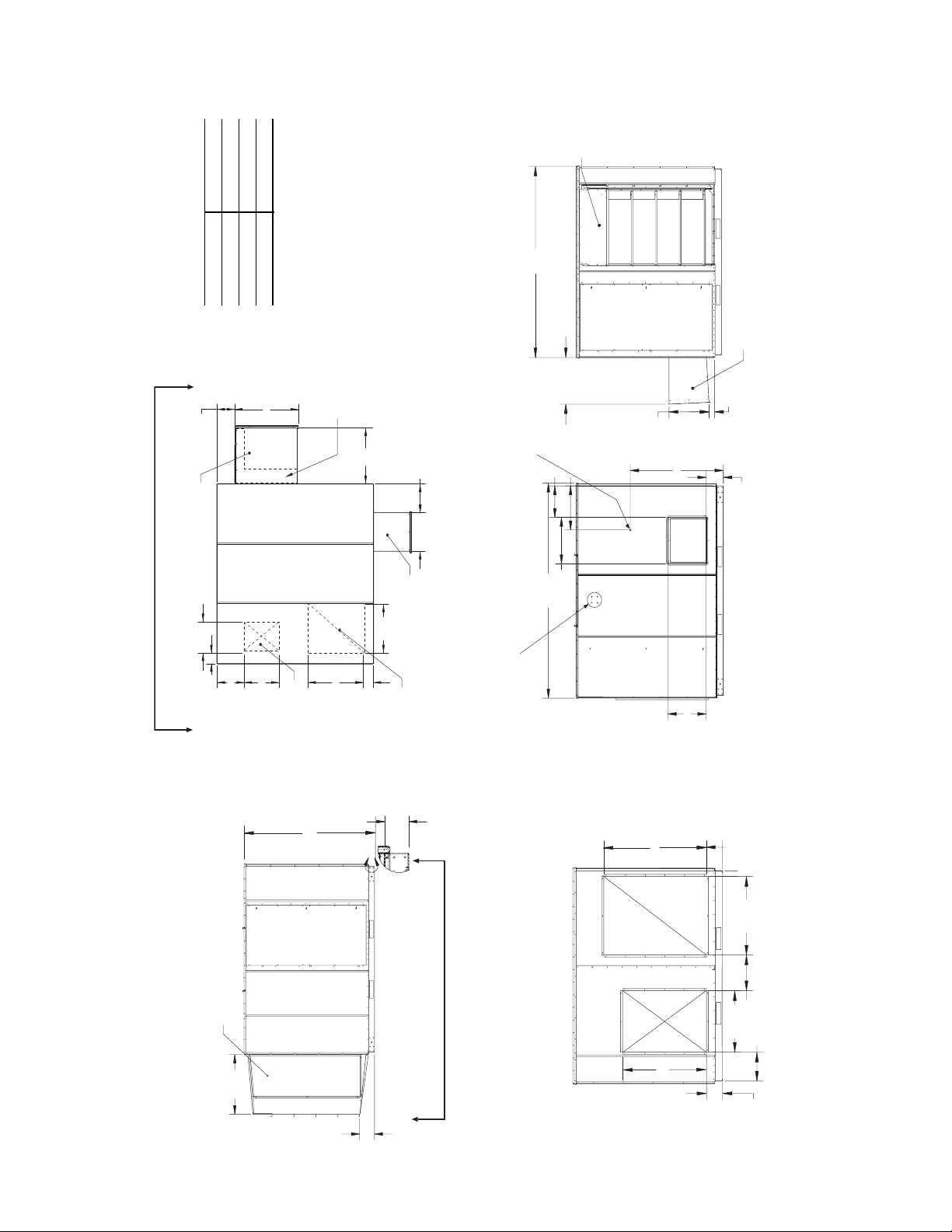

Page 10

22.00

36.00

OUTSIDE AIR

11.18

13.75

8.68

OPTIONAL PREHEATER

CLEARANCES

REQUIRED SERVICE

PREHEATER CABINET

ERV WHEEL

Front 39 in.

15.28

Rear 0in.

Left 32 in.

8.21

EXHAUST AIR OUTLET

Right* 55 in.

57.91

ERV wheel removal.

*55 in. ser vice clearance required for

NOTE: All dimensions are in inches.

TOP SIDE

26.60

POWER ENTRY

(OPTIONAL DISCONNECT)

14.86

62.03

ACCESS DOOR

EXHAUST AIR

14.57

12.50

FRONT SIDE

LEFT SIDE

22.33

8.20

15.63

6.10

43.38

AA

Fig. 11 — 62MB,MC170-285 Indoor Unit Dimensions

SUPPLY AIR OPENING

RETURN AIR OPENING

AIRFLOW TEST

PORTS (OPTIONAL)

26.60

ACCESS DOOR

49.55

10.76

26.60

21.84

VIEW A-A

RIGHT SIDE

6.48

23.00

15.50

AIR

RETURN

AIR

SUPPLY

25.00

20.00

8.20

3.16

REAR SIDE

6.92

9.62

10

Page 11

CLEARANCES

REQUIRED SERVICE

Front 39 in.

.64

Rear 0in.

26.45

Left 32 in.

Right* 55 in.

4.61

OUTSIDE AIR HOOD

ERV wheel removal.

*55 in. service clearance required for

NOTE: All dimensions are in inches.

57.91

14.84

TOP OF CURB

15.96

A

FRONT SIDE

EXHAUST AIR HOOD

6.94

22.33

ERV WHEEL

8.21

15.28

EXHAUST AIR HOOD

6.10

RETURN AIR OPENING

16.19

14.57

12.50

POWER ENTRY

(OPTIONAL DISCONNECT)

14.86

EXHAUST AIR

TOP SIDE

6.48

23.00

62.03

AIR

RETURN

25.00

LEFT SIDE

43.38

8.20

3.16

OPTIONAL PREHEATER

OUTSIDE AIR HOOD

13.75

8.68

8.20

15.63

AA

SUPPLY AIR OPENING

49.55

Fig. 12 — 62MD,ME170-285 Outdoor Unit Dimensions

20.78

OUTSIDE AIR HOOD

9.16

VIEW A-A

RIGHT SIDE

11

15.50

REAR SIDE

AIR

SUPPLY

20.00

6.92

9.62

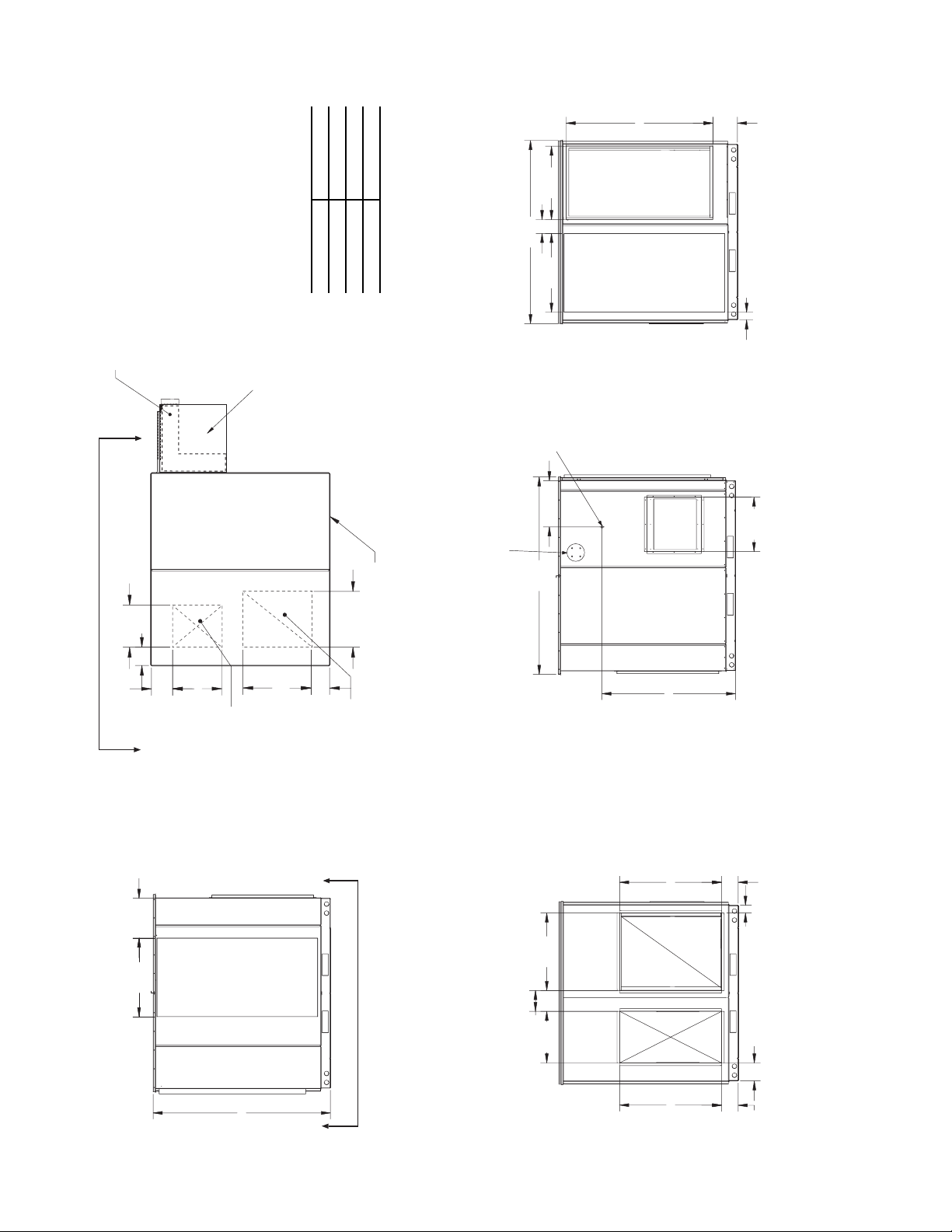

Page 12

54.00

AIR

27.00

OUTSIDE

5.11

9.03

OPTIONAL PREHEATER

15.94

6.88

CLEARANCES

REQUIRED SERVICE

PREHEATER CABINET

Front 50 in.

Rear 0in.

Left 40 in.

21.11

Right* 62 in.

for ERV wheel removal.

*62 in. service clearance required

EXHAUST AIR OUTLET

NOTE: All dimensions are in inches.

TOP SIDE

TEST PORTS

OPTIONAL AIRFLOW

67.39

29.00

POWER ENTRY

17.00

72.63

DOOR

ACCESS

(OPTIONAL DISCONNECT)

AIR

EXHAUST

FRONT SIDE

2.78

20.00

LEFT SIDE

8.01

18.62

25.76

6.93

49.1

AA

RETURN AIR OPENING

(BOTTOM RETURN ONLY)

VIEW A-A

RIGHT SIDE

7.66

28.50

19.00

AIR

RETURN

AIR

SUPPLY

37.50

37.50

6.11

2.87

6.61

6.11

14.63

29.00

ACCESS DOOR

SUPPLY AIR OPENING

(BOTTOM SUPPLY ONLY)

65.21

Fig. 13 — 62MB,MC330-640 Indoor Unit Dimensions

REAR SIDE

12

Page 13

CLEARANCES

REQUIRED SERVICE

Front 50 in.

4.21

A

CURB

TOP OF

OUTSIDE AIR HOOD

Rear 0in.

Left 40 in.

Right* 62 in.

for ERV wheel removal.

*62 in. service clearance required

NOTE: All dimensions are in inches.

67.39

FRONT SIDE

18.81

15.94

A A

6.88

8.01

29.44

18.62

OUTSIDE AIR HOOD

OPTIONAL PREHEATER

25.76

SUPPLY AIR OPENING

(BOTTOM SUPPLY ONLY)

65.21

7.63

19.69

21.11

EXHAUST AIR HOOD

6.93

RETURN AIR OPENING

(BOTTOM RETURN ONLY)

TOP SIDE

POWER ENTRY

(OPTIONAL DISCONNECT)

TEST PORTS

OPTIONAL AIRFLOW

17.00

72.63

28.50

AIR

RETURN

17.96

AIR

EXHAUST

49.1

37.50

12.52

9.22

6.11

EXHAUST AIR HOOD

20.00

LEFT SIDE

Fig. 14 — 62MD,ME330-640 Outdoor Unit Dimensions

2.87

26.41

OUTSIDE AIR HOOD

8.68

VIEW A-A

RIGHT SIDE

13

7.66

19.00

REAR SIDE

AIR

SUPPLY

37.50

6.61

6.11

Page 14

9.52

11.31

FRONT SIDE

2.37

CLEARANCES

REQUIRED SERVICE

Front 65 in.

64.25

35.08

12.77

OUTSIDE AIR

98.37

Rear 0in.

Left 50 in.

Right* 72 in.

for ERV wheel removal.

*72 in. service clearance required

NOTE: All dimensions are in inches.

34.10

ACCESS DOOR

OPTIONAL PREHEATER

PREHEATER CABINET

40.12

11.02

34 7/8

LOCATION

POWER ENTRY/

OPTIONAL DISCONNECT

48.98

9.01

EXHAUST AIR

23.25

TOP SIDE

107.75

LEFT SIDE

EXHAUST AIR OUTLET

18.75

6.42

17.07

21.88

34.73

AA

SUPPLY AIR OPENING

77.41

34.10

ACCESS DOOR

31.67

6.43

RETURN AIR OPENING

21.86

VIEW A-A

RIGHT SIDE

AIRFLOW TEST

PORTS (OPTIONAL)

49.01

RETURN AIR

AIR

SUPPLY

20.25

Fig. 15 — 62MB,MC750,950 Indoor Unit Dimensions

7.69

35.75

REAR SIDE

16.19

28.00

13.11

40

14

7.69

Page 15

OUTSIDE AIR HOOD

CLEARANCES

REQUIRED SERVICE

11.02

OUTSIDE AIR HOOD

18.75

6.42

Front 65 in.

Rear 0in.

17.07

Left 50 in.

Right* 72 in.

40.12

21.88

98.37

for ERV wheel removal.

*72 in. service clearance required

NOTE: All dimensions are in inches.

23.81

OPTIONAL PREHEATER

21.58

34.73

34 7/8

6.43

31.67

17.16

23.22

TOP SIDE

EXHAUST AIR HOOD

LOCATION

POWER ENTRY/

OPTIONAL DISCONNECT

107.75

AIRFLOW TEST

PORTS (OPTIONAL)

48.98

EXHAUST AIR

23.25

FRONT SIDE

EXHUAST AIR HOOD

2.89

9.01

LEFT SIDE

A A

OUTSIDE AIR HOOD

33.71

SUPPLY AIR OPENING

77.41

4.40

B

8.83

RETURN AIR OPENING

RIGHT SIDE

VIEW A-A

49.01

RETURN AIR

AIR

SUPPLY

20.25

Fig. 16 — 62MD,ME750,950 Outdoor Unit Dimensions

7.69

35.75

REAR SIDE

16.19

28.00

13.11

40

7.69

15

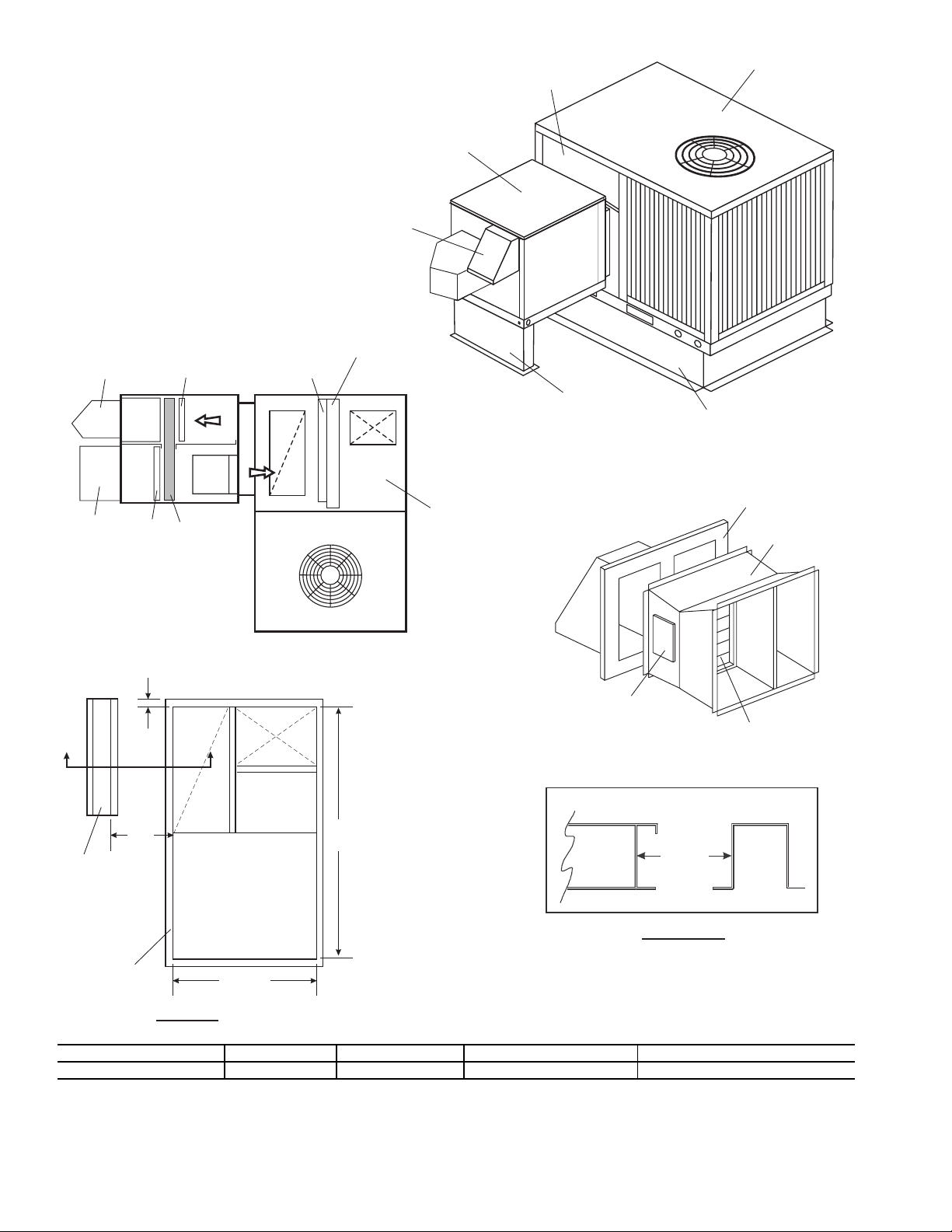

Page 16

Outside air hood

with aluminum

water entrainment filter.

Includes barometric intake

damper.

62M040 Unit

Filter access door

shipped with Rooftop

Unit

Rooftop Unit

Exhaust

hood

Outside

air hood

EXH

Filter

Filter

ERV

wheel

Supply

Blower

Filters

Evaporation

Coil

ROOF CURB LOCATION DETAIL

3”

AA

Return

Supply

3 to 6 Ton Rooftop Unit

Accessory ERV

Equipment support

TRANSITION DETAIL

Access door to

adjust balancing

damper

Standard Rooftop

Unit roof curb

Panel covering

return chamber

Balancing damper

Accessory Transition

To 62M040 Unit

Accessory ERV

Equipment support

35”

67 3/8”

Rooftop

Unit

Curb

35"

ERV

Unit

Support

Side View A-A

Rooftop Curb

37”

LEGEND

ERV — Energy Recovery Ventilator

Top View

ROOFTOP UNIT MODEL ROOFTOP SIZE TRANSITION P/N ROOFTOP ECONOMIZER ERV EQUIPMENT SUPPORT P/N

48/50HJ,TJ,TM 004-007 62M-AATR-HJ36-D 62MA-900---004 62MA-900---001

Fig. 17 — 62MD,ME040 Coupled with Carrier 48/50HJ,TJ,TM004-007 Vertical Discharge Rooftop Unit

16

Page 17

Field-Supplied

Duct

Outside air hood

with aluminum

water entrainment filter.

Includes barometric intake

damper.

62M040 Unit

Filter access door

shipped with Rooftop

Unit

Rooftop Unit

Outside

air hood

Exhaust

hood

Filter

EXH

Supply

Blower

Filter

ERV

wheel

ROOF CURB LOCATION DETAIL

3”

Supply

Return

3 to 6 Ton Rooftop Unit

Accessory ERV

Equipment support

TRANSITION DETAIL

Access door to

adjust balancing

damper

Standard Rooftop

Unit roof curb

Panel covering

return chamber

Balancing damper

Accessory Transition

To 62M040 Unit

AA

Accessory ERV

Equipment support

35”

67 3/8”

Rooftop

Unit

Curb

35"

ERV

Unit

Support

Side View A-A

Rooftop Curb

37”

ERV — Energy Recovery Ventilator

LEGEND

ROOFTOP UNIT MODEL ROOFTOP SIZE TRANSITION P/N ROOFTOP ECONOMIZER ERV EQUIPMENT SUPPORT P/N

48/50HJ,TJ,TM 004-007 62M-AATR-HJ36-D 62MA-900---008 62MA-900---001

Fig. 18 — 62MD,ME040 Coupled with Carrier 48/50HJ,TJ,TM004-007 Horizontal Discharge Rooftop Unit

17

Page 18

Supply

Rooftop Unit

Rooftop Unit

Accessory Transition

(Includes front panel)

Exhaust

hood

44 11/16”

Filter

Return

Accessory Transition

ERV

wheel

Filter

62M040 Unit

Outside air hood

Top Vi ew

ROOF CURB LOCATION DETAIL

80 5/16”

Supply

Rooftop Curb

TRANSITION DETAIL

35”

AA

Return

4 3/8”

Access door to

adjust balancing

damper

Rooftop

Unit

Curb

35"

Accessory ERV

Equipment support

2 Piece front

panel covers

return chamber

To 62M040 Unit

ERV

Unit

Support

LEGEND

ERV — Energy Recovery Ventilator

ROOFTOP UNIT MODEL ROOFTOP SIZE TRANSITION P/N ERV EQUIPMENT SUPPORT P/N

48/50PG 03-07 62M-AATR-HJ36-D 62MA-900---001

Fig. 19 — 62MD,ME040 Coupled with Carrier 48/50PG03-07 Vertical Discharge Rooftop Unit

Accessory ERV

Equipment support

18

Side View A-A

Page 19

Rooftop Unit

Rooftop Unit

TRANSITION DETAIL

Accessory Transition

(Includes front panel)

Accessory ERV

Equipment support

44 11/16”

Accessory Transition

Filter

Exhaust

hood

Top View

ERV

wheel

Filter

62M040 Unit

Outside air hood

ROOF CURB LOCATION DETAIL

80 5/16”

Rooftop Curb

LEGEND

ERV — Energy Recovery Ventilator

35”

Access door to

adjust balancing

damper

AA

Rooftop

Unit

4 3/8”

Accessory ERV

Equipment support

Curb

35"

Side View A-A

2 Piece front

panel covers

return chamber

To 62M040 Unit

ERV

Unit

Support

ROOFTOP UNIT MODEL ROOFTOP SIZE TRANSITION P/N ERV EQUIPMENT SUPPORT P/N

48/50PG 03-07 62M-AATR-HJ36-D 62MA-900---001

Fig. 20 — 62MD,ME040 Coupled with Carrier 48/50PG03-07 Horizontal Discharge Rooftop Unit

19

Page 20

r

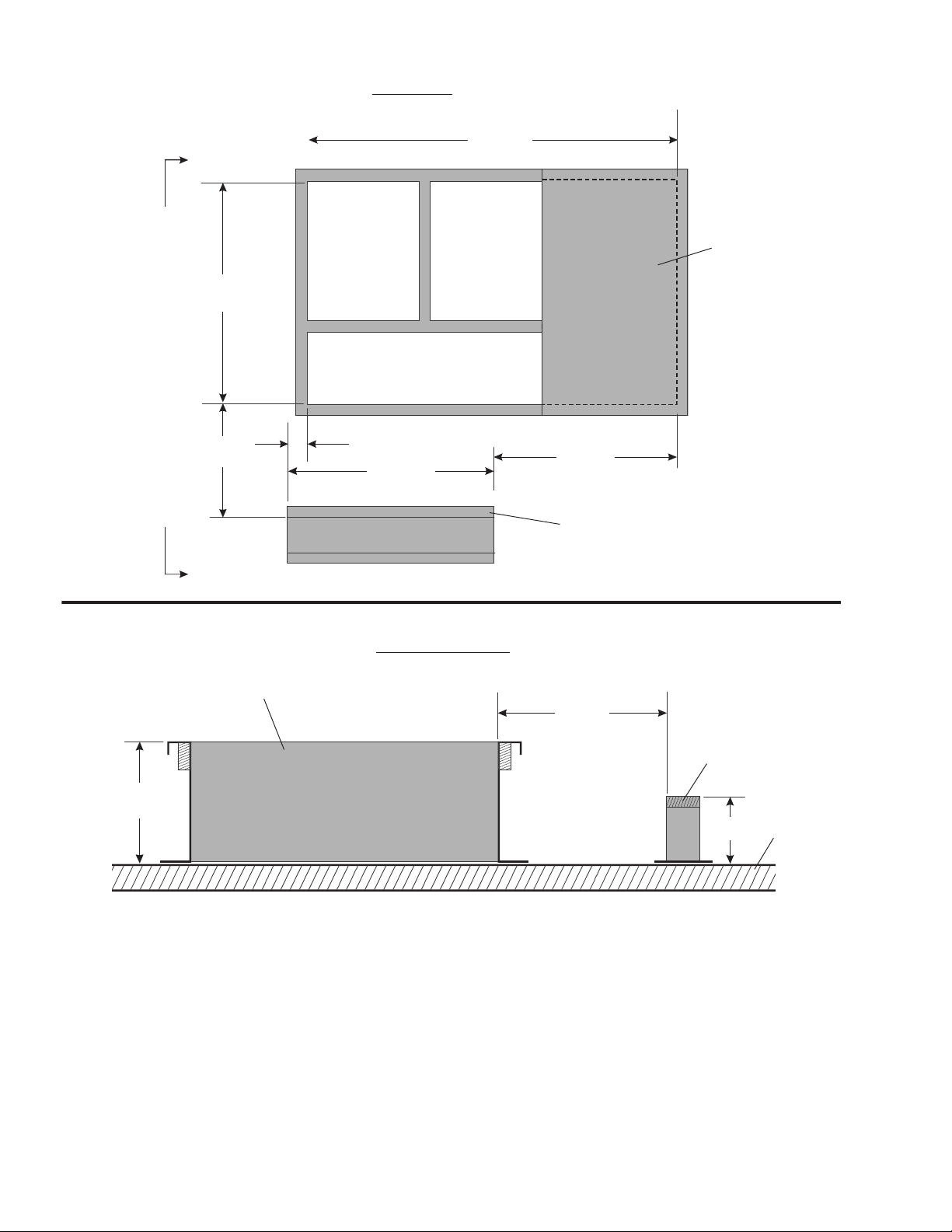

ROOF CURB LAYOUT

TOP VIEW

67 3/8"

A

Supply

Air

37 3/16"

Return

Air

Standard roof curb fo

3 to 6 ton rooftop unit

35

"

A

Standard Roof curb

for 3 to 6 ton roof top unit

14"

3"

36"

"A-A" SIDE VIEW

34 3/8"

62MA-900---001

Equipment Support

35

"

62MA-900---001

Equipment Support

Roof

10.4"

Fig. 21 — 62MD,ME040 Coupled with Carrier 48/50HJ,TJ,TM004-007 Rooftop Unit

20

Page 21

Filter door shipped

with Rooftop unit.

SUPPLY

Rooftop unit

RETURN

Rainhoods for

optional economizer

Rooftop unit

Unit curb

Accessory Transition

ERV Wheel

62M075,120 ERV Unit

Locator

pieces

(included with

ERV curb,

must be watertight)

ROOF CURB LOCATION DETAIL

62M ERV Unit

ERV curb

B

A

Rooftop

Unit curb

Locator Pieces ( included with ERV Curb)

Cover panel provided

30.5”

LEGEND

ERV — Energy Recovery Ventilator

NOTE: When using a 62M ERV unit coupled with a Carrier

rooftop unit, the rooftop factory or field-installed economizer

cannot be used. Use the 62M economizer instead.

2 3/4"

27”

ERV curb

20"

ROOFTOP UNIT

MODEL

48/50HJ,TF,TJ,TM

ROOFTOP SIZE TRANSITION P/N ERV CURB P/N

ROOFTOP

ECONOMIZER

004-007 62M-ATR-HJ36-D 62M-A-CRB-14MC 62MA-900---004 67

008,009 62M-ATR-HJ78-D 62M-A-CRB-14MC 62MA-900---005 781/

012,014 62M-ATR-HJ1012-D 62M-A-CRB-14MC 62MA-900---006 78

DIMENSIONS (in.)

AB

3

/

8

4

1

/

4

373/

50

50

16

Fig. 22 — 62MD,ME075,120 Coupled with Carrier 48/50HJ,TF,TJ,TM004-014 Vertical Discharge Rooftop Unit

21

Page 22

Filter door shipped

with Rooftop unit.

Horizontal supply and

return duct (field supplied)

Rooftop Unit

Accessory Transition

Optional Horizontal

Economizer

Rooftop unit

62M075,120

ERV Unit

ERV Wheel

ROOF CURB LOCATION DETAIL

Locator

pieces

(included with

ERV curb,

must be watertight)

62M ERV Unit

ERV curb

B

A

Rooftop

Unit curb

Locator Pieces ( included with ERV curb)

Cover panel provided

30.5"

LEGEND

ERV — Energy Recovery Ventilator

NOTE: When using a 62M ERV unit coupled with a Carrier

rooftop unit, the rooftop factory or field-installed economizer

cannot be used. Use the 62M economizer instead.

2 3/4"

27"

ERV curb

20"

ROOFTOP UNIT

MODEL

48/50HJ,TF,TJ,TM

ROOFTOP SIZE TRANSITION P/N ERV CURB P/N

ROOFTOP

ECONOMIZER

004-007 62M-ATR-HJ36-H 62M-A-CRB-14MC 62MA-900---008 67

008,009 62M-ATR-HJ78-H 62M-A-CRB-14MC 62MA-900---009 781/

012,014 62M-ATR-HJ1012-H 62M-A-CRB-14MC 62MA-900---010 78

DIMENSIONS (in.)

AB

3

/

8

4

1

/

4

373/

50

50

16

Fig. 23 — 62MD,ME075,120 Coupled with Carrier 48/50HJ,TF,TJ,TM004-014 Horizontal Discharge Rooftop Unit

22

Page 23

Supply

Return

ERV Wheel

TOP VIEW

Rooftop Unit

Accessory

Transition

62M075,120 ERV Unit

Rooftop Unit

Accessory Transition

(Includes front panel)

62M ERV Unit

Locator

pieces

(included with

ERV curb,

ERV Curb

must be watertight)

LEGEND

ERV — Energy Recovery Ventilator

NOTE: When using a 62M ERV unit coupled with a Carrier

rooftop unit, the rooftop factory or field-installed economizer cannot be used.

ROOF CURB LOCATION DETAIL

20"

2 3/4"

30 1/12"

27"

ERV Curb

Rooftop

Unit

Curb

Curb Detail

20"

Side View A-A

DIMENSIONS (in.)

AB

5

/

16

4

4411/

5315/

B

Rooftop Unit Curb

ROOFTOP MODEL ROOFTOP SIZE 62M TRANSITION ERV CURB

Supply

48/50PG

A

AA

Return

Locator pieces

(included with

ERV Curb)

03-07 62M-ATR-PG26-D 62M-A-CRB-14MC 80

08-14 62M-ATR-PG712-D 62M-A-CRB-14MC 923/

Fig. 24 — 62MD,ME075,120 Coupled with Carrier 48/50PG03-14 Vertical Discharge Rooftop Unit

ERV

Unit

Curb

16

16

23

Page 24

ERV Wheel

TOP VIEW

Rooftop Unit

Accessory

Transition

62M075-120 ERV Unit

Rooftop Unit

Locator

pieces

(included with

ERV curb,

must be watertight)

ERV — Energy Recovery Ventilator

NOTE: When using a 62M ERV unit coupled with

a Carrier rooftop unit, the rooftop factory or fieldinstalled economizer cannot be used.

Accessory Transition

(Includes front panel)

62M Unit

ERV Curb

LEGEND

ROOF CURB LOCATION DETAIL

20"

2 3/4"

30 1/12"

27"

ERV Curb

Rooftop

Unit

Curb

Curb Detail

ERV

20"

Unit

Curb

Side View A-A

DIMENSIONS (in.)

AB

5

/

16

4

4411/

5315/

16

16

B

Rooftop Unit Curb

ROOFTOP MODEL ROOFTOP SIZE 62M TRANSITION ERV CURB

48/50PG

A

AA

Locator pieces

(included with

ERV Curb)

03-07 62M-ATR-PG26-H 62M-A-CRB-14MC 80

08-14 62M-ATR-PG712-H 62M-A-CRB-14MC 923/

Fig. 25 — 62MD,ME075,120 Coupled with Carrier 48/50PG03-14 Horizontal Discharge Rooftop Unit

24

Page 25

Rainhoods for

optional economizer

Rooftop unit

Filter door shipped with

Rooftop unit

62M ERV Unit

Rooftop

Unit

SUPPLY

A

B

RETURN

Top Vie w

30”

Rooftop curb

Accessory Transition

ERV Wheel

Rooftop

Unit curb

ROOF CURB LOCATION DETAIL

Locator Pieces ( included with ERV curb)

Cover panel provided

49 5/8"

62M170-285 ERV Unit

ERV curb

Locator Pieces

(included with ERV curb,

must be watertight)

ERV Curb

45 1/2"

LEGEND

2 3/4"

38"

ERV — Energy Recovery Ventilator

NOTE: When using a 62M ERV unit coupled with a Carrier

rooftop unit, the rooftop factory or field-installed economizer

cannot be used. Use the 62M economizer instead.

ROOFTOP

ECONOMIZER

DIMENSIONS (in.)

AB

3

/

8

4

1

/

4

373/

50

50

16

ROOFTOP UNIT

MODEL

48/50HJ,TF,TJ,TM

Top View

ROOFTOP SIZE TRANSITION P/N ERV CURB P/N

004-007 62M-BTR-HJ36-D 62M-B-CRB-14MC 62MA-900---004 67

008,009 62M-BTR-HJ78-D 62M-B-CRB-14MC 62MA-900---005 781/

012,014 62M-BTR-HJ1012-D 62M-B-CRB-14MC 62MA-900---006 78

Fig. 26 — 62MD,ME170-285 Coupled with Carrier 48/50HJ,TF,TJ,TM004-014 Vertical Discharge Rooftop Unit

25

Page 26

Optional

Horizontal

Economizer

Rooftop Unit

Filter door shipped

with Rooftop unit.

62M ERV Unit

A

Rooftop

Unit

Top Vie w

Horizontal

Return duct

(field supplied)

Accessory Transition

30"

ERV Wheel

Rooftop

B

Unit curb

ROOF CURB LOCATION DETAIL

Locator Pieces ( included with ERV Curb)

Cover Panel provided

49 5/8"

62M170-285 ERV Unit

ERV curb

Locator

pieces

(included with

ERV curb,

must be watertight)

ERV Curb

45 1/2"

LEGEND

ERV — Energy Recovery Ventilator

NOTE: When using a 62M ERV unit coupled with a Carrier

rooftop unit, the rooftop factory or field-installed economizer

cannot be used. Use the 62M economizer instead.

ROOFTOP

ECONOMIZER

DIMENSIONS (in.)

AB

3

/

8

4

1

/

4

373/

50

50

16

ROOFTOP UNIT

MODEL

48/50HJ,TF,TJ,TM

2 3/4"

38"

Top Vie w

ROOFTOP SIZE TRANSITION P/N ERV CURB P/N

004-007 62M-BTR-HJ36-H 62M-B-CRB-14MC 62MA-900---008 67

008,009 62M-BTR-HJ78-H 62M-B-CRB-14MC 62MA-900---009 781/

012,014 62M-BTR-HJ1012-H 62M-B-CRB-14MC 62MA-900---010 78

Fig. 27 — 62MD,ME170-285 Coupled with Carrier 48/50HJ,TF,TJ,TM004-014 Horizontal Discharge Rooftop Unit

26

Page 27

LEGEND

ERV — Energy Recovery Ventilator

NOTES:

1. The 62M ERV unit cannot be coupled with

horizontal return 48/50TJ,TM016-028 and

48/50HJ015,017 units.

2. The ERV unit can be used with a factoryinstalled economizer, if desired.

Rooftop Unit

Accessory Transition

62M ERV unit

Unit curb

ERV curb

SIDE VIEWTOP VIEW

74 1/4"

SUPPLY

67 1/16"*

Rooftop Unit

Accessory

Transition

Rooftop Unit Curb

AA

RETURN

18 11/16"

44 3/4"

62M170-285

ERV Unit

*Optional

Economizer

ERV Wheel

ROOF CURB LOCATION DETAIL

ERV Curb

45 1/2"

49 5/8"

15 to 25 Ton RooftopUnit

Transition

Rooftop

Unit

Curb

44 3/4"

62M170-285

ERV Unit

ERV

Unit

Curb

*Length is 89

1

/16″ for 48/50TM028 units.

ROOFTOP UNIT

MODEL

48/50TJ,TM 016-028 62M-BTR-HJ1525-D 62M-B-CRB-14S

48/50HJ 015,017 62M-BTR-HJ1525-D 62M-B-CRB-14S

Fig. 28 — 62MD,ME170-285 Coupled with Carrier 48/50TJ,TM016-028

and 48/50HJ015,017 Vertical Discharge Rooftop Unit

TOP VIEW

SIDE VIEW A-A

ROOFTOP SIZE TRANSITION P/N ERV CURB P/N

27

Page 28

Supply

Return

ERV Wheel

TOP VIEW

Rooftop Unit

Accessory

Transition

62M170-285 ERV Unit

Rooftop Unit

Accessory Transition

(Includes front panel)

62M ERV Unit

Locator

pieces

(included with

ERV curb,

must be watertight)

ERV Curb

LEGEND

ERV — Energy Recovery Ventilator

NOTE: When using a 62M ERV unit coupled with a Carrier rooftop unit, the rooftop factory or field-installed economizer cannot

be used.

ROOF CURB LOCATION DETAIL

A

B

Supply

Return

Rooftop Unit Curb

Locator pieces

(included with

ERV Curb)

ROOFTOP MODEL ROOFTOP SIZE 62M TRANSITION ERV CURB

48/50PG

03-07 62M-BTR-PG26-D 62M-A-CRB-14MC 80

08-14 62M-BTR-PG712-D 62M-A-CRB-14MC 923/

38 3/4"

49 5/8"

AA

45 1/2"

0"

ERV Curb

Rooftop

Unit

Curb

Curb Detail

ERV

38 3/4"

Unit

Curb

Side View A-A

DIMENSIONS (in.)

AB

5

/

16

4

4411/

5315/

16

16

Fig. 29 — 62MD,ME170-285 Coupled with Carrier 48/50PG03-14 Vertical Discharge Rooftop Unit

28

Page 29

ERV Wheel

TOP VIEW

Rooftop Unit

Accessory Transition

62M170-285 ERV Unit

Rooftop Unit

Accessory Transition

(Includes front panel)

62M ERV Unit

Locator

pieces

(included with

ERV curb,

ERV Curb

must be watertight)

LEGEND

ERV — Energy Recovery Ventilator

NOTE: When using a 62M ERV unit coupled with a Carrier

rooftop unit, the rooftop factory or field-installed economizer

cannot be used.

ROOF CURB LOCATION DETAIL

A

B

Rooftop Unit Curb

Locator pieces

(included with

ERV Curb)

ROOFTOP MODEL ROOFTOP SIZE 62M TRANSITION ERV CURB

48/50PG

03-07 62M-BTR-PG26-H 62M-B-CRB-14MC 80

08-14 62M-BTR-PG712-H 62M-B-CRB-14MC 923/

38 3/4"

49 5/8"

AA

0"

ERV Curb

45 1/2"

Rooftop

Unit

Curb

Curb Detail

ERV

38 3/4"

Unit

Curb

Side View A-A

DIMENSIONS (in.)

AB

5

/

16

4411/

16

5315/

4

16

Fig. 30 — 62MD,ME170-285 Coupled with Carrier 48/50PG03-14 Horizontal Discharge Rooftop Unit

29

Page 30

Rooftop Unit

Curb

Horizontal / Return Duct

(field supplied)

Rooftop Unit

Outside Air Hood (See Note 2)

62M ERV Unit

Top View

A

Rooftop Unit

Accessory

Transition

leeh

W

V

RE

Relief Hood

ROOF CURB LOCATION DETAIL

Rooftop Unit Curb

44 3/4”

49 5/8”

Accessory

Transition

62M170-285 ERV Unit

ERV — Energy Recovery Ventilator

O/A Hood

O/A — Outdoor Air

NOTES:

1. The ERV unit can be used with a factoryinstalled economizer, if desired.

2. Transition includes a new outside air hood,

which allows air intake through the front of the

hood rather than the bottom. The new hood will

use the filters from the original rooftop unit

hood.

ERV Curb

ERV Curb

LEGEND

Curb Detail

B

AA

45 1/2”

Rooftop

Unit

Curb

44 3/4"

Side View A-A

ERV

Unit

Curb

Top View

ROOFTOP MODEL ROOFTOP SIZE 62M TRANSITION ERV CURB

48/50PG 20-28 62M-BTR-HG1525-H 62M-B-CRB-14MC 114.4 78.6

48/50HJ 020-028 62M-BTR-HG1525-H 62M-B-CRB-14MC 114.4 78.6

DIMENSIONS (in.)

AB

Fig. 31 — 62MD,ME170-285 Coupled with Carrier 48/50PG20-28

and 48/50HJ020-028 Horizontal Discharge Rooftop Unit

30

Page 31

Rooftop Unit

YLPPUS

Rooftop Unit

Outside Air Hood (See

Note 2)

62M ERV Unit

Standard HVAC Unit

Roofcurb

Accessory

Transition

Accessory

Transition

NRUTER

62M170-285 ERV Unit

le

ehW VRE

O/A Hood

ERV Curb

LEGEND

ERV — Energy Recovery Ventilator

O/A — Outdoor Air

NOTES:

1. The ERV unit can be used with a factoryinstalled economizer, if desired.

2. Transition includes a new outside air hood,

which allows air intake through the front of

the hood rather than the bottom. The new

hood will use the filters from the original

rooftop unit hood.

Top View

Relief Hood

ROOF CURB LOCATION DETAIL

Rooftop Unit Curb

A

B

YLP

P

U

S

NRUT

E

R

44 3/4”

49 5/8”

AA

45 1/2”

ERV Curb

Top View

ROOFTOP MODEL ROOFTOP SIZE 62M TRANSITION ERV CURB

48/50PG 20-28 62M-BTR-HG1525-D 62M-B-CRB-14MC 114.4 78.6

48/50HJ 020-028 62M-BTR-HG1525-D 62M-B-CRB-14MC 114.4 78.6

Fig. 32 — 62MD,ME170-285 Coupled with Carrier 48/50PG20-28

and 48/50HJ020-028 Vertical Discharge Rooftop Unit

Rooftop

Unit

Curb

Curb Detail

ERV

44 3/4"

Side View A-A

DIMENSIONS (in.)

AB

Unit

Curb

31

Page 32

Rooftop Unit

p

Outside air hood

for optional

economizer

Filter access door

shipped with

transition

62M ERV Unit

Supply

Rooftop Unit

Return

Outside air hood

for optional

economizer

Rooftop Unit curb

Top Vie w

Accessory

Transition

Accessory

Transition

62M330-640 ERV Unit

ERV — Energy Recovery Ventilator

O/A — Outdoor Air

NOTE: When using a 62M ERV unit coupled with a

ERV Wheel

O/A hood

Exhaust hood

Carrier rooftop unit, the rooftop factory or fieldinstalled economizer cannot be used. Use the 62M

economizer instead.

ROOF CURB LOCATION DETAIL

ERV curb

ERV Curb

LEGEND

78 1/4"

AA

Supply

ROOFTOP UNIT MODEL ROOFTOP SIZE TRANSITION P/N ERV CURB P/N ROOFTOP ECONOMIZER

48/50HJ,TF,TJ,TM 012,014 62M-CTR-HJ1012-D 62M-C-CRB-14M 62MA-900---006

50"

Return

9"

33 1/2"

View

To

60 11/32"

55 13/32"

Rooftop

Unit

Curb

33 1/2"

Side View A-A

ERV

Unit

Curb

Fig. 33 — 62MD,ME330-640 Coupled with Carrier 48/50HJ,TF,TJ,TM012,014 Vertical Discharge Rooftop Unit

32

Page 33

LEGEND

ERV — Energy Recovery Ventilator

O/A — Outdoor Air

R/A — Return Air

S/A — Supply Air

NOTE: When using a 62M ERV unit coupled with a Carrier rooftop unit, the rooftop

factory or field-installed economizer cannot

be used. Use the 62M economizer instead.

Rooftop Unit

Top Vie w

Accessory

Transitions

Rooftop Unit

Horizontal

supply duct

(field supplied)

Horizontal

return (field

supplied)

62M330-640

ERV Unit

Accessory

Transition

10 to 12 1/2 Ton

Rooftop Unit

Accessory

Transitions

Filter access door

shipped with

transition

62M ERV Unit

ERV Curb

Top Vie w

with Economizer

62M 330-640 ERV Unit

S/A

78 1/4"

ERV Wheel

R/A

Rooftop Unit curb

AA

9"

50"

33 1/2"

Top Vie w

ROOF CURB LOCATION DETAIL

O/A hood

Exhaust hood

ERV Curb

60 11/32"

S/A

Duct

55 13/32"

R/A

Duct

Rooftop

Unit

Curb

Optional

Horizontal

Economizer

33 1/2"

Side View A-A

Exhaust hood

ERV

Unit

Curb

ROOFTOP UNIT MODEL ROOFTOP SIZE TRANSITION P/N ERV CURB P/N ROOFTOP ECONOMIZER

48/50HJ,TF,TJ,TM Without Economizer 012,014 62M-CTR-HJ1012-H 62M-C-CRB-14M —

48/50HJ,TF,TJ,TM With Economizer 012,014 62M-CTR-HJ1012-HEC 62M-C-CRB-14M 62MA-900---010

Fig. 34 — 62MD,ME330-640 Coupled with Carrier 48/50HJ,TF,TJ,TM012,014 Horizontal Discharge Rooftop Unit

33

Page 34

Rooftop Unit

LEGEND

ERV — Energy Recovery Ventilator

O/A — Outdoor Air

NOTES:

1. The ERV unit can be used with a factoryinstalled economizer, if desired.

2. The ERV cannot be coupled with a horizontal return 48/50TJ,TM or HJ 15 to

25 ton rooftop unit.

Rooftop Unit

SUPPLY

RETURN

Accessory

Transition

Rooftop Unit Curb

ERV Wheel

Exhaust hood

Accessory

Transition

62M330-640

ERV Unit

O/A hood

ERV curb

TJ/HJ 15 to 25 Ton

Rooftop Unit

Optional

Economizer

Accessory

Transition

62M ERV Unit

62M ERV Unit

74 1/4"

*Length is 89

Top View

Rooftop Unit Curb

SUPPLY AIR

67 1/16"*

1

/16″ for 48/50TM028 units.

RETURN AIR

AA

11 1/2"

Top Vie w

ROOFTOP UNIT

MODEL

48/50TJ,TM 016-028 62M-BTR-HJ1525-D 62M-B-CRB-14S

48/50HJ 015,017 62M-BTR-HJ1525-D 62M-B-CRB-14S

ROOF CURB LOCATION DETAIL

ERV curb

55 13/32"

53 3/4"

ROOFTOP SIZE TRANSITION P/N ERV CURB P/N

60 11/32"

Side View

Rooftop

Unit

Curb

53 3/4"

Side View A-A

ERV

Unit

Curb

Fig. 35 — 62MD,ME330-640 Coupled with Carrier 48/50TJ,TM016-028 and 48/50HJ015,017

Vertical Discharge Rooftop Unit

34

Page 35

Supply

Return

Rooftop Unit

Rooftop 48/50PG Unit

Accessory Transition

(Includes front panel)

62M ERV Unit

Accessory Transition

ERV Wheel

62M330-640 ERV Unit

LEGEND

ERV — Energy Recovery Ventilator

NOTE: When using a 62M ERV unit coupled with a Carrier

rooftop unit, the rooftop factory or field-installed economizer

TOP VIEW

cannot be used.

ROOF CURB LOCATION DETAIL

A

B

Rooftop Unit Curb

ROOFTOP UNIT

MODEL

Supply

ROOFTOP SIZE 62M TRANSITION ERV CURB

AA

Return

48/50PG 08-14 62M-CTR-PG712-D 62M-C-CRB-14M 92

38 3/4

C

"

ERV Curb

60 11/32"

55 13/32"

ERV Curb

Curb Detail

Rooftop

Unit

Curb

38 3/4"

Side View A-A

ERV

Unit

Curb

DIMENSIONS (in.)

ABC

3

/

4

5315/

16

10

Fig. 36 — 62MD,ME330-640 Coupled with Carrier 48/50PG08-14 Vertical Discharge Rooftop Unit

35

Page 36

ERV Wheel

Rooftop Unit

Rooftop Unit

Accessory Transition

(Includes front panel)

62M ERV Unit

Accessory Transition

62M330-640 ERV Unit

ERV — Energy Recovery Ventilator

NOTE: When using a 62M ERV unit coupled with a Carrier

TOP VIEW

rooftop unit, the rooftop factory or field-installed economizer

cannot be used.

ROOF CURB LOCATION DETAIL

A

B

Rooftop Unit Curb

ROOFTOP UNIT

MODEL

48/50PG 08-14 62M-CTR-PG712-H 62M-C-CRB-14M 92

ROOFTOP SIZE 62M TRANSITION ERV CURB

38 3/4"

ERV Curb

60 11/32"

AA

55 13/32"

C

LEGEND

ERV Curb

Curb Detail

Rooftop

Unit

Curb

38 3/4"

ERV

Unit

Curb

Side View A-A

DIMENSIONS (in.)

ABC

3

/

4

5315/

16

10

Fig. 37 — 62MD,ME330-640 Coupled with Carrier 48/50PG08-14 Horizontal Discharge Rooftop Unit

36

Page 37

Horizontal Return Duct

(Field Supplied)

Rooftop Unit

Accessory

Transition

Rooftop Unit

Accessory

Transition

Rooftop Unit Curb

62M330-640 ERV Unit

Outside Air Hood (See

Note 2)

62M ERV Unit

ERV Curb

leehW VRE

Relief Hood

O/A Hood

ERV — Energy Recovery Ventilator

O/A — Outdoor Air

NOTES:

1. The ERV unit can be used with a factory-

2. Transition includes a new outside air hood,

LEGEND

installed economizer, if desired.

which allows air intake through the front of

the hood rather than the bottom. The new

hood will use the filters from the original

rooftop unit hood.

Top View

ROOF CURB LOCATION DETAIL

Rooftop Unit Curb

A

B

44 3/4"

60 11/32"

AA

55 13/32"

Rooftop

Unit

Curb

Curb Detail

44 3/4"

Side View A-A

ERV

Unit

Curb

ERV Curb

Top View

ROOFTOP MODEL ROOFTOP SIZE 62M TRANSITION ERV CURB

48/50PG 20-28 62M-CTR-HG1525-H 62M-C-CRB-14M 114.4 78.6

48/50HJ 020-028 62M-CTR-HG1525-H 62M-B-CRB-14M 114.4 78.6

DIMENSIONS (in.)

AB

Fig. 38 — 62MD,ME330-640 Coupled with Carrier 48/50PG20-28

and 48/50HJ020-028 Horizontal Discharge Rooftop Unit

37

Page 38

Rooftop Unit

Rooftop Unit Curb

Accessory

Transition

Rooftop Unit

Accessory

Transition

ERV Curb

62M330-640 ERV Unit

Outside Air Hood (See

Note 2)

62M ERV Unit

YL

N

R

P

U

PUS

T

E

R

leehW

ERV — Energy Recovery Ventilator

V

RE

O/A Hood

O/A — Outdoor Air

NOTES:

1. The ERV unit can be used with a factory-

2. Transition includes a new outside air hood,

LEGEND

installed economizer, if desired.

which allows air intake through the front of

the hood rather than the bottom. The new

Top View

Relief Hood

hood will use the filters from the original

rooftop unit hood.

ROOF CURB LOCATION DETAIL

Rooftop Unit Curb

A

Y

B

LPPUS

NRUTER

44 3/4"

60 11/32"

AA

ERV Curb

55 13/32"

Rooftop

Unit

Curb

Curb Detail

44 3/4"

Side View A-A

ERV

Unit

Curb

Top View

ROOFTOP MODEL ROOFTOP SIZE 62M TRANSITION ERV CURB

48/50PG 20-28 62M-CTR-HG1525-D 62M-C-CRB-14M 114.4 78.6

48/50HJ 020-028 62M-CTR-HG1525-D 62M-B-CRB-14M 114.4 78.6

DIMENSIONS (in.)

AB

Fig. 39 — 62MD,ME330-640 Coupled with Carrier 48/50PG20-28

and 48/50HJ020-028 Vertical Discharge Rooftop Unit

38

Page 39

TOP VIEW

Accessory

Transition

62M ERV Unit

Supply

Return

Rooftop Unit

LEGEND

ERV — Energy Recovery Ventilator

O/A — Outdoor Air

NOTES:

1. The ERV unit can be used with a factoryinstalled economizer, if desired.

2. ERV cannot be coupled to a horizontal return

rooftop unit.

Outside air

hood

62M Unit

ERV Wheel

SIDE VIEW

Supply

77 3/4"

O/A hood

Exhaust hood

ROOF CURB LA YOUT

Return

0"

58 3/4"

Rooftop Unit Curb

Rooftop Unit

60.34"

55.4"

ERV Curb

Economizer

See Note 1

ERV Wheel

ERV Curb

ROOFTOP UNIT MODEL ROOFTOP SIZE TRANSITION P/N ERV CURB P/N

48/50A 020-060 62M-CTR-AJ2060-D 62M-C-CRB-14M

Accessory

Transition

Standard

Rooftop Unit Curb

Fig. 40 — 62MD,ME330-640 Coupled with Carrier 48/50A020-060 Vertical Discharge Rooftop Unit

39

Page 40

Rooftop Unit

62M ERV Unit

Top Vie w

Rooftop Unit

SUPPLY

RETURN

Rooftop Unit Curb

Rooftop

Unit Curb

Accessory

Transition

ERV Wheel

Exhaust Hood

ROOF CURB LOCATION DETAIL

Accessory

Transition

62M750,950 ERV Unit

O/A Hood

ERV — Energy Recovery Ventilator

O/A — Outdoor Air

NOTES:

1. The standard factory economizer cannot be

used when coupled with 62M750,950 units.

Contact factory for transition with economizer.

2. 62M750,950 units cannot be used with

48/50TJ and TM016-028 horizontal discharge

rooftop units.

ERV Curb

ERV Curb

LEGEND

SUPPLY AIR

74 1/4"

67.1"*

*Length is 891/16″ for

48/50TM028 units.

ROOFTOP UNIT MODEL ROOFTOP SIZE TRANSITION P/N ERV CURB P/N ROOFTOP ECONOMIZER

48/50TJ,TM 016-028 62M-DTR-HJ1525-D 62M-D-CRB-14M 62MA-900---007

48/50HJ 015,017 62M-DTR-HJ1525-D 62M-D-CRB-14M 62MA-900---007

RETURN AIR

AA

0"

31 9/16"

Top Vie w

95.7"

86.25"

Rooftop

Unit

Curb

31 9/16"

Side View A-A

Fig. 41 — 62MD,ME750,950 Coupled with Carrier 48/50TJ,TM016-028

and 48/50HJ015,017 Vertical Discharge Rooftop Unit

ERV

Unit

Curb

40

Page 41

Rooftop Unit

Accessory

Transition

Rooftop Unit

62M ERV Unit

Accessory

Transition

62M750,950 ERV

Top View

le

e

hW

V

RE

O/A Hood

Relief Hood

ERV — Energy Recovery Ventilator

O/A — Outdoor Air

NOTE: The ERV unit can be used with a factoryinstalled economizer, if desired.

ERV Curb

LEGEND

ROOF CURB LOCATION DETAIL

ERV Curb

Curb Detail

AA

B

86 1/4"

Rooftop

Unit

Curb

44 3/4"

ERV

Unit

Curb

A

44 3/4”

95 3/4"

Side View A-A

Top View

ROOFTOP MODEL ROOFTOP SIZE 62M TRANSITION ERV CURB

48/50PG 20-28 62M-DTR-HG1525-H 62M-D-CRB-14M 114.4 78.6

48/50HJ 020-028 62M-DTR-HG1525-H 62M-D-CRB-14M 114.4 78.6

DIMENSIONS (in.)

AB

Fig. 42 — 62MD,ME750,950 Coupled with Carrier 48/50PG20-28

and 48/50HJ020-028 Vertical Discharge Rooftop Unit

41

Page 42

YLPPUS

Rooftop Unit

N

R

UTER

Top View

Rooftop Unit Curb

Accessory

Transition

Rooftop Unit

62M ERV Unit

Accessory

Transition

62M750,950 ERV

ERV Curb

le

e

hW

VR

E

O/A Hood

ERV — Energy Recovery Ventilator

O/A — Outdoor Air

NOTE: The ERV unit can be used with a

factory-installed economizer, if desired.

LEGEND

Relief Hood

ROOF CURB LOCATION DETAIL

Rooftop Unit Curb

ERV Curb

NR

B

YLPPUS

A

AA

UTE

R

44 3/4”

95 3/4"

86 1/4"

Top View

ROOFTOP MODEL ROOFTOP SIZE 62M TRANSITION ERV CURB

48/50PG 20-28 62M-DTR-HG1525-D 62M-D-CRB-14M 114.4 78.6

48/50HJ 020-028 62M-DTR-HG1525-D 62M-D-CRB-14M 114.4 78.6

Fig. 43 — 62MD,ME750,950 Coupled with Carrier 48/50PG20-28

and 48/50HJ020-028 Vertical Discharge Rooftop Unit

Rooftop

Unit

Curb

Curb Detail

ERV

44 3/4"

Side View A-A

DIMENSIONS (in.)

AB

Unit

Curb

42

Page 43

Rooftop Unit

62M ERV Unit

Rooftop Unit Curb

SUPPLY AIR

Rooftop Unit

RETURN AIR

SUPPLY AIR

RETURN AIR

Unit curb

Accessory

Transition

ERV Wheel

Accessory

Transition

62M750,950 ERV Unit

O/A Hood

Exhaust Hood

ERV Curb

LEGEND

ERV — Energy Recovery Ventilator

O/A — Outdoor Air

NOTES:

1. The standard factory economizercanbeusedin

conjunction with 62M750,950 units.

2. 62M750,950 units cannot be used with horizontal

discharge rooftop units.

ROOF CURB LOCATION DETAIL

0"

ERV Curb

CURB DETAIL

AA

57 9/16"

(See curb

detail)

77 3/4"

ROOFTOP UNIT MODEL ROOFTOP SIZE TRANSITION P/N ERV CURB P/N

Top Vie w

48/50A 020-060 62M-DTR-AJ2060-D 62M-D-CRB-14M

95.7"

86.25"

Rooftop

Unit

Curb

57 9/16"

Side View A-A

Fig. 44 — 62MD,ME750,950 Coupled with Carrier 48/50A020-060 Rooftop Unit

43

ERV

Unit

Curb

Page 44

Top Vi ew

Horizontal Discharge -

Stand-Alone Unit

Exhaust hood

(outdoor units only)

2 in. pre-filters for

exhaust

Exhaust

Blower

Outside air hood

(outdoor units only)

Optional

Pre-heater

Optional

Pre-heater

Outside air

rainhood

Top Vi ew

Down Discharge -

Stand-Alone Unit

2 in. pre-filters

outside air

Exhaust hood

(outdoor units only)

Exhaust

blower

Optional

Pre-heater

Outside air intake hood

(outside units only)

ERV wheel

2 in. pre-filters for

outside air

ERV Wheel

2 in. pre-filters

outside air

Hinged and latched

access door (both sides)

Supply air

blower

ERV wheel

2 in. pre-filters

exhaust

Supply air

blower

Return/exhaust

opening in base

Outside air blower,

mounted over supply

opening in base

Optional ERV

roof curb

Side View

Down Discharge -

Stand-Alone Unit

Supply duct for

outside air (field

provided)

Fig. 45 — 62M Airflow in Stand-Alone Applications

44

Page 45

Step 3 — Rigging and Handling — To transfer the

unit from the shipping platform to the storage or installation

site, refer to the rigging label on the unit and these instructions.

All panels must be in place when rigging. Unit is not

designed for handling by fork truck. Damage to unit may

result.

Refer to Table 1 for ERV unit weights. Check lifting devices

for capacity constraints.

Hook rigging shackles through the holes or lifting eyes in

the ERV unit.

NOTE: Some 62M units have lifting eyes, some 62M units

have holes in the ERV base rail. See Fig. 46.

Connect lifting straps and spreader bars. See Fig. 46.

Spreader bars must be positioned to prevent cables from

rubbing against the ERV unit.

Carefully lift the ERV unit and set on ERV roof curb. Do

not drop the ERV unit onto the roof curb, as damage may

occur. Avoid twisting or uneven lifting of the unit. Never lift

the unit by the hoods or any means other than the provided

lifting holes or eyes.

MOUNTING THE ERV UNIT INDOORS — The ERV unit

can be mounted indoors. Follow all local and other applicable

building codes.

All panels must be secured in place prior to lifting the ERV

unit in to place. Follow all local and other applicable codes

when lifting, locating and mounting the ERV unit. Damage

to unit may result.

Locate the ERV Unit

— Prior to locating the indoor ERV unit

consider the intake and exhaust duct accessibility to outside

walls or roof vents. When locating the ERV unit consider

required service clearances.

See Table 1 for unit weights to determine if building struc-

ture reinforcements are required.

Determine a Method for Mounting

— The method for mounting and securing the ERV unit to the building structure must be

field designed and installed. Mounting methods will vary

depending upon specific jobsite conditions.

NOTE: Hardware and pieces to secure ERV unit to the building structure must not interfere with the service clearances or

duct requirements for the unit.

Lift the ERV Unit in Place

— Secure the ERV unit to the

building structure following all applicable local building codes.

Do not use the ERV duct system to support the ERV unit in

any way. Follow all local and applicable building codes

and manufacture and install the ductwork to the ERV unit

per the duct opening connections. Equipment damage or

personal injury may result.

RIGGING HOLES ERV BASE RAIL

Spreader Bars

RIGGING FOR ERV INSTALLATION

RIGGING LIFTING EYES

Fig. 46 — Rigging Details

45

Page 46

Table 1 — Physical Data

UNIT 62M 040 075 120 170 225 285

NOMINAL CAPACITY (cfm) 400 750 1200 1700 2250 2850

CAPACITY RANGE (cfm) 100-550 500-1000 1000-1400 1400-2000 2000-2500 2500-3200

MAXIMUM SHIPPING WEIGHT (lb)

Single-Wall Models 255 440 462 850 900 1000

Double-Wall Models 367 635 657 1135 1185 1285

MAXIMUM OPERATING WEIGHT (lb)

Single-Wall Models 235 400 422 790 840 940

Double-Wall Models 347 595 617 1075 1125 1225

62MB,MC INDOOR UNIT DIMENSIONS (in.)

Length* 29.75 43.25 43.25 62.63 62.63 62.63

Width 29.88 39.13 39.13 58.38 58.38 58.38

Height 29.75 37.88 37.88 48.88 48.88 48.88

62MD,ME OUTDOOR UNIT DIMENSIONS (in.)†

Length* 48.43 60.75 60.75 87.13 87.13 87.13

Width 31.24 50.13 55.13 69.38 69.38 69.38

Height 29.72 37.88 37.88 48.88 48.88 48.88

ROTARY ENERGY EXCHANGER

Typ e Enthalpy Lightweight Polymer with Silica Gel Desiccant Coating

Size (Diam. x Depth) (in.) 22.5 x 2 29.0 x 2 29.0 x 3 40.0 x 1.5 40.0 x 1.5 40.0 x 3

Nominal Drive Motor Hp N/AN/AN/A

SUPPLY/EXHAUST AIR FAN

Qty…Type 2….Forward Curved Centrifugal

Drive Type Direct Adjustable Belt Drive

Fan Isolation Neoprene Pads

Wheel Dimensions (Diam. x Width) 5.5 x 5.5 9 x 7 9 x 7 12 x 12 12 x 12 12 x 12

Nominal Motor Hp

FILTERS (optional)

Typ e 2-in. Pleated — 30% Efficiency

Exhaust Air...Qty...Size (L x W x D) (in.) 1….12 x 20 x 2 1….18 x 25 x 2 1….18 x 25 x 2 2….20 x 25 x 2 2….20 x 25 x 2 2….20 x 25 x 2

Outside Air...Qty...Size (L x W x D) (in.) 1….12 x 20 x 2 1….18 x 25 x 2 1….18 x 25 x 2 2….20 x 25 x 2 2….20 x 25 x 2 2….20 x 25 x 2

1

/

4

1

/

2

1122

UNIT 62M 330 430 550 640 750 950

NOMINAL CAPACITY (cfm) 3300 4300 5500 6400 7500 9500

CAPACITY RANGE (cfm) 3000-3600 3600-5000 5000-6000 6000-6800 6500-8500 8500-10,500

MAXIMUM SHIPPING WEIGHT (lb)

Single-Wall Models 1300 1350 1440 1590 2650 2750

Double-Wall Models 1710 1760 1850 2000 3270 3370

MAXIMUM OPERATING WEIGHT (lb)

Single-Wall Models 1220 1270 1360 1510 2550 2650

Double-Wall Models 1630 1680 1770 1920 3170 3270

62MB,MC INDOOR UNIT DIMENSIONS (in.)

Length 73.13 73.13 73.13 73.13 108.3 108.3

Width 67.89 67.89 67.89 67.89 97.87 97.87

Height 65.21 65.21 65.21 65.21 77.4 77.4

62MD,ME OUTDOOR UNIT DIMENSIONS (in.)†

Length 100.88 100.88 100.88 100.88 143.45 143.45

Width 87.89 87.89 87.89 87.89 121.87 121.87

Height 65.21 65.21 65.21 65.21 77.4 77.4

ROTARY ENERGY EXCHANGER

Typ e Enthalpy Lightweight Polymer with Silica Gel Desiccant Coating

Size (Diam. x Depth) (in.) 56.2 x 1.5 56.2 x 1.5 56.2 x 3 56.2 x 3 68.0 x 3 68.0 x 3

Nominal Drive Motor Hp

SUPPLY/EXHAUST AIR FAN

Qty…Type 2...Forward Curved Centrifugal

Drive Type Adjustable Belt Drive

Fan Isolation Neoprene Pads

Wheel Dimensions (Diam. x Width) 15 x 15 15 x 15 15 x 15 15 x 15 18 x 18 18 x 18

Nominal Motor Hp 2357

FILTERS (optional)

Typ e 2-in. Pleated — 30% Efficiency

Exhaust Air...Qty...Size (L x W x D) (in.) 6….16 x 20 x 2 6….16 x 20 x 2 6….16 x 20 x 2 6….16 x 20 x 2 6….20 x 24 x 2 6….20 x 24 x 2

Outside Air...Qty...Size (L x W x D) (in.) 6….16 x 20 x 2 6….16 x 20 x 2 6….16 x 20 x 2 6….16 x 20 x 2 6….20 x 24 x 2 6….20 x 24 x 2

1

/

2

1

/

2

1

/

2

LEGEND

N/A — Not Applicable

*Add 10 in. to 62M040 units equipped with a preheater.

†Dimensions include outdoor air hoods.

**575-v motors are

1

/3hp.

1

/

6

1

/

2

1

/

2

1

71/

1

/4**

/

6

2

1

/

6

1

/4**

10

46

Page 47

Step 4 — Installing ERV Transitions — When cou-

pling ERV units with Carrier rooftop units an ERV transition is

required to link the ERV unit and the Carrier rooftop unit

together.

ERV UNIT COUPLED WITH A 3 to 12

UNIT — Complete the following steps to install a transition to

a3to12

1

/2ton rooftop unit.

1

/2TON HVAC

1. Remove the HVAC unit filter door and set aside for later

use.

2. Remove the panel shipped on the HVAC unit covering

the return air chamber. This panel can be discarded.

3. The 62M ERV transition for 3 to 12

1

/2ton rooftop units

includes a replacement panel to cover the return opening.

Install the replacement panel, with hood scoop attached,

onto the HVAC unit, over the return air chamber. Screw

in place. The return/exhaust scoop will cover part of the

return air opening in the HVAC unit.

NOTE: The standard transition does not seal tight around the

return air opening on the HVAC unit. This allows for some air

to flow back to the HVAC unit and some to be drawn back

through the ERV unit.

4. Slide the transition between the ERV unit and the HVAC

unit. Refer to Fig. 17-44 to orient the transition. Line up

the transition so that it covers the openings in the HVAC

unit and the ERV unit. The divider in the transition must

separate the supply and return openings in the ERV unit.

Screw the mating flanges of the transition to the ERV unit

through pre-punched holes. Caulk the seams watertight.

Screw the mating flanges on the other side of the transition to the new return air cover panel on the HVAC unit.

Caulk seams watertight.

5. On most models the filter access door shipped with the

HVAC unit will be reinstalled above the transition.

6. The transition includes a balancing damper to allow for

the desired separation of the return/exhaust air between

the ERV and HVAC units. This damper has a manual

adjustment. During balancing, this damper will be

adjusted to achieve desired exhaust cfm. The balancing

damper can be accessed through a separate door in the

transition or through the HVAC unit’s filter access door.

See Fig. 17-44.

Step 5 — Make Electrical Connections

Prior to performing service or maintenance operations on

the ERV unit, turn off and disconnect all power switches to

the unit. Be aware that there may be more than one disconnect switch. Electrical shock could cause serious personal

injury or death.

IMPORTANT: Only trained, qualified installers and

service technicians should install, wire, start-up and

service equipment.

POWER SUPPLY — The electrical characteristics of the

available power supply must agree with the unit nameplate

rating. Supply voltage must be within the limits shown. See

Tables 2 and 3 for electrical and configuration data.

ELECTRICAL CONNECTIONS — The ERV unit must

have its own electrical disconnect box. If the disconnect option

has not been ordered from the factory, it must be field supplied

and installed per local codes. See Tables 2 and 3.

If the ERV unit has an electric pre-heater factory installed, it

will be wired through the ERV unit disconnect.

NOTE: Most ERV units have electrical interlock safety

switches on the access doors, which will not allow the ERV

unit to operate if either of the access doors are opened.

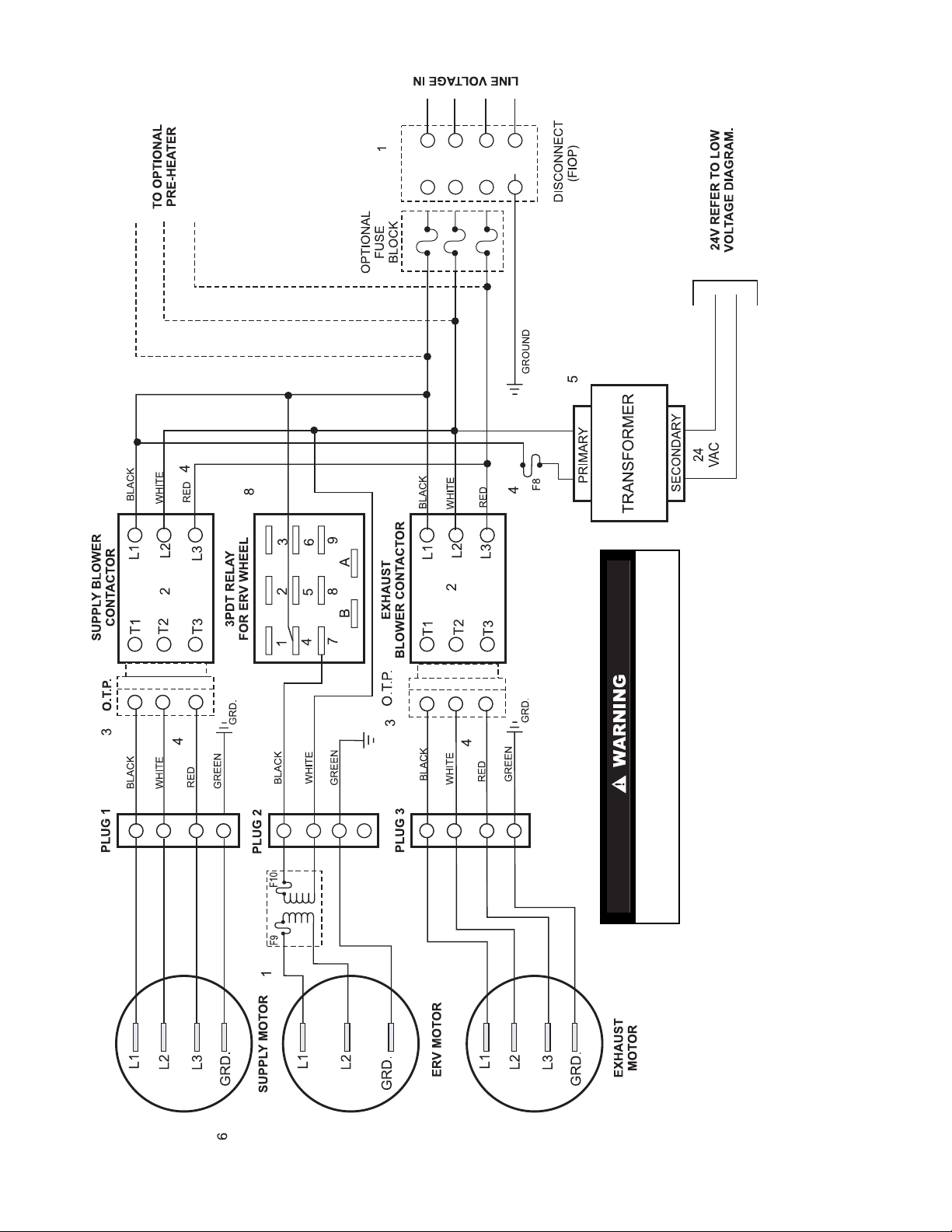

Low Voltage Wiring

— Wire low voltage per diagrams. For

coupled applications, there will be a brown and black wire in

the exhaust chamber, which must be tied into the HVAC unit’s

indoor fan so that when the indoor fan is activated, the ERV

unit will be activated.

48/50TJ, HJ 3 to 12

1

/2Ton Rooftop Units with Economizers

— The brown and black wires can be plugged into the economizer jumper plug on the HVAC unit’s economizer harness.

Insert the brown wire from the ERV unit into terminal 4 in the

jumper plug and insert the black wire from the ERV unit into

terminal 3 in the jumper plug. See Fig. 47.

1

If the 3 to 12

/2ton rooftop unit has an economizer installed, the economizer will have an end switch attached to the

economizer actuator. The end switch must be wired into the

ERV unit as shown in Fig. 48.

For ERV units coupled with units with factory-installed

economizers, (48/50TM, HJ 15 to 25 ton units 48/50HG, PG 15

to 25 ton units) the ERV transitions to these rooftop units include an economizer end switch. This switch mounts to the hub

of the economizer damper gear as shown in Fig. 49. Set the end

switch so that the ERV unit’s outside air blower is deactivated

during economizer mode.

For stand-alone units, the ERV unit is jumpered from terminals 6 and 8 and 7 and 9, providing for continuous operation.

The ERV unit should be connected to an on-off device such as

aCO

sensor.

2

High Voltage Wiring (Fig. 50-53)

— Connect high voltage

wiring to the disconnect per Fig. 50, 52 and 53. Check blower

rotation direction and adjust if necessary.

47

Page 48

UNIT SIZE

62M

040

075

120

170

ERV — Energy Recovery Ventilator

FLA — Full Load Amps

Hp — Horsepower

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electric Code

N/A — Not Applicable

*Fused disconnect only.

†Exhaust and supply fan motors are 230-1-60.

VO LTAG E

(V-Ph-Hz)

115-1-60 0.7 3.96

230-1-60

208/230-3-60

460-3-60

575-3-60

115-1-60 0.7 9.8

230-1-60

208/230-3-60 2.2

460-3-60 1.1

575-3-60 0.9

115-1-60 0.7 16

230-1-60

208/230-3-60 4.2

460-3-60 2.1

575-3-60 1.7

230-1-60

208/230-3-60 4.2

460-3-60 2.1

575-3-60 1.7

LEGEND

ERV WHEEL

FLA

0.3 1.74†

0.3

0.3

0.6

Table 2 — Electrical Data Without VAV Option

EXHAUST AND SUPPLY MOTOR

NEC - FLA Hp FLA MCA MOCP Amps

4.9

8

8

.6

0.5

HEATER

SIZE

(kW)

— 9.27 9.90 12.87 — 30 12

— 4.44 4.35 5.66 —

— 4.11 4.35 5.66 — 5

— 2.34 2.72 4.89 — 3

— 1.87 2.17 3.91 — 2

— 20.69 24.5 31.85 — 40 30

— 10.46 12.25 15.93 —

— 5.03 5.50 7.15 —

— 2.53 2.75 3.58 — 4

— 2.10 2.25 2.93 — 3

— 33.09 40.00 52.00 — 60 50

— 16.66 20.00 26.00 — 30 25

1

1

— 9.03 10.50 13.65 — 30 12

— 4.53 5.25 6.83 —

— 3.70 4.25 5.53 — 5

— 16.93 20.00 26.00 — 30 25

10 60.41 74.35 74.35 43.48 100 70

— 9.33 10.50 13.65 — 30 12

10 34.46 41.91 41.91 25.13 60 40

— 4.69 5.25 6.83 — 30 6

10 17.26 20.96 20.96 12.57 30 20

— 3.88 4.25 5.53 — 30 5

10 13.93 16.82 16.82 10.05 30 15

POWER SUPPLY

2 26.64 31.64 31.64 17.39 40 30

2 13.76 16.37 16.37 8.7 15

2 9.66 11.30 11.30 5.03 10