Carrier 51CM User Manual

51

HEATING & COOLING

Start-Up and Service Instructions

International Series

51CM,GM,ZM.CV,GY

CONTENTS

Page

START-UP ................................................................ 1

SERVICE . . 1

General Notes .. .1

Compressor Replacement 1

SAFETY REMINDERS............................................ 2-5

Preventive Maintenance 2

System Cleaning ... .2

System Flushing .... .2

Physical and Electrical Data

Compressors ... 4

Run Capacitors. .

Thermistors ... 4

Casing Dimensions .. .4

Capillary Data . 5

Capillary Insertion 5

DISASSEMBLY INFORMATION .... 6-17

Model 104's Casing .... 6

Models 304's/404's Casing ... 13

TROUBLESHOOTING GUIDE ... 18

START-UP

Refer to operating instructions in Owner’s Handbook

provided with room air conditioner

General Notes — These Start-Up and Service Instiac

tions are provided to assist the trained and qualified

service technician in repaii ing or replacing components of

Carrier room aii conditioner models produced in 1988,

specifically International Series models (51CM,GM,ZM

Cooling Only, 51CV,GY Cooling and Electiic Heat)

Other Carriei models for prior yeais have separate StartUp and Service publications

IMPORTANT Repairing and servicing ah condi

tioners can be hazardous for untiained individuals

The insti actions printed in this publication are for

properly ttained and qualified Carrier service tech

nicians only

A WARNING

Befoi e working on any air conditioner, be sure to first

disconnect all electric power to the unit to avoid the

possibility of electiical shock and personal injury

...................................

.....................

SERVICE

3

4

1988 Room Air Conditioners

Discharge capacitors beiore disconnecting, by shorting

acioss terminals

Shield coils with cardboard to protect hands against

injury from sharp metal edges when removing compressoi and other components

When disassembling wiring, use numbered stickers to

identify wiie leads and terminals This aids in quick,

accurate reassembly

Check clearances around scroll and housing before

installing fans Before securing fan setscrews, rotate fan

by hand to ensure ample clearance

Refer to Carriei Standard Service Techniques,

Chapters 1 and 2, for information on checking motors,

removing refrigerant, adding oil, evacuating, dehydrating

and charging system Pay particular attention to all saiety

warnings for these procedures

Compressor Replacement — Stand clem ofcom-

ptessoi tetminals when wotking on comptessors With

system imdef piesswe, terminals mar blow Observe

the same safety procedures for rotary compressors as

for reciprocating compressors

When changing compressors

1 Follow all safety codes Reminder use protective

goggles, work gloves and water-soaked quenching

cloth

Shut off electric power and remove wiring irom

compressor

Purge or remove all refrigerant and pressure from

system

Cut suction and discharge lines Use tubing cutter at

convenient location on tubing, near compressor, to

ease reassembly using copper slip couplings

Remove compressor from unit Protect compressor

irom heat and carefully unbraze piping stubs

A CAUTION

Oil vapor in piping stubs can ignite irom torch

flame and cause serious injury Exercise extreme

care when brazing, and keep brazingcloth and fire

extinguisher handy for emergency use

Install oil piping stubs on new compressor and care

fully braze into place

Clean system add or replace liquid line filter drier

Reiei to System Cleaning, and System Flushing

Install new compressor and braze into place with

field-supplied copper slip couplings

9

Connect wiring, replace wire terminals if necessary

Proceed with evacuation, charging and start-up

10

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Book 1 4

8a

Tab

10a

PC131 Catalog No 535-134 PrintedinUSA Form51-20SS Pgl 7-88 Replaces:New

For replacement Items use Carrier Specified Parts

It is much easiei to unsweat a short piece of tubing from

the compressor afte) you have removed the compressoi

irom the unit It follows that you can soldei the oil piping

stub into the new compressor fittings more easily befoie

the eompiessor is put back into the unit

If you choose a good tubing location for cutting the

refrigerant lines initially, the loeation is easily accessible

when making the final joints

SAFETY REMINDERS

1 Cany a file extinguishei in youi tiuck Keep it within

reach when using a torch Check fiie extinguisher

peiiodically to be suie it is fully loaded and iunctional.

2 Know how to handle oxyacetylene equipment safely

Lock the equipment in an upright position in the

truck and at the job site

3 Use dry nitrogen oi carbon dioxide to pressuiize the

system for leak checking Always use a good regulatoi

Be careful not to exceed 150 psig test pressure in the

heimetic eompiessor

4 Weal your safety goggles and gloves when lemoving

refiigeiant from a system

5 Attend your shop safety meetings

Preventive Maintenance

CLEANING — Clean cooling coil and condensei coil

Hold flashlight behind coil to see if all spaces are clear

Use a hooked wire to lemove dirt Dust accumulation

obstructs or reduces airflow and results in loss of capacity Coils may be vacuumed when diy Outdoois, unit can

be brushed with a stiff brush and fins blown out with

compressed aii

Thoroughly clean basepan, motors, fan wheels, other

components and all drain passages Vacuum insulation

Clean all inside painted surfaces with mineral spirits to

remove grease

Clean cabinet and grille Mild detergents reduce elec

trostatic charges on plastic sections of the grille and are

good cleaners Do no! use carbon tetrachloride, solvents

or waxes containing solvents to clean plastic sections

PAINTING — Paint any parts that show evidence of

rust with a good rust-resistant paint

WIRING — Check all wiring for deterioration and all

electrical contacts for tightness and lack of corrosion

LEAKS — Check any connections that show evidence of

oil or leaks When unit is property installed, centered and

leveled (see MOUNTING), check gaskets and wing

panels for possible air leakage

MOUNTING — Make sure unit is secure in window,

level from left to right, and from front to rear according

to installation instructions provided

If used, check compressor mounting springs and re

place if necessary Spt ings tend to lose their tension with

use This could lead to noisy operation

Check fans to ensure they are correctly positioned,

centered in orifice and tight on shaft

CONTROLS — Check unit to ensure all controls ate

functioning correctly and unit operation is normal

Vibrations can cause unwanted noise Check to be sure

no piping is vibrating against any side of unit

System Cleaning — A motor burnout is recognized

by the burnt odor of the refrigerant system When the

motor of a hermetically sealed compressor but ns out, the

insulation of the stator winding forms carbon, water and

acid After burnout, clean refrigerant circuit before a new

motor-compressor is installed installation of a new

capillary and strainer is also recommended when re

placing a compressor after burnout

The system is partially cleaned by back flushing with

relrigerant vapor blown into the suction line and out the

discharge just before connecting the new compressor If

this method is chosen, install a Sporlan C052S (Carrier

No KH41EZ246) lilter drier or equal in the liquid

line, using a capillary tube adapter (Carrier Part No

DEC3680001) An alternate and equally satisfactory

method follows under System Flushing

NOTE Damage to a new compressor caused by failure

to clean the system as recommended is not covered by

the product warranty

System Flushing — Flush with liquid R-22 refrig

erant before the suction line is connected to the new

compressor

1 Clean, flux and solder discharge line to new compressor

NOTE Compressor valves keep relrigerant from

backing out through compressor

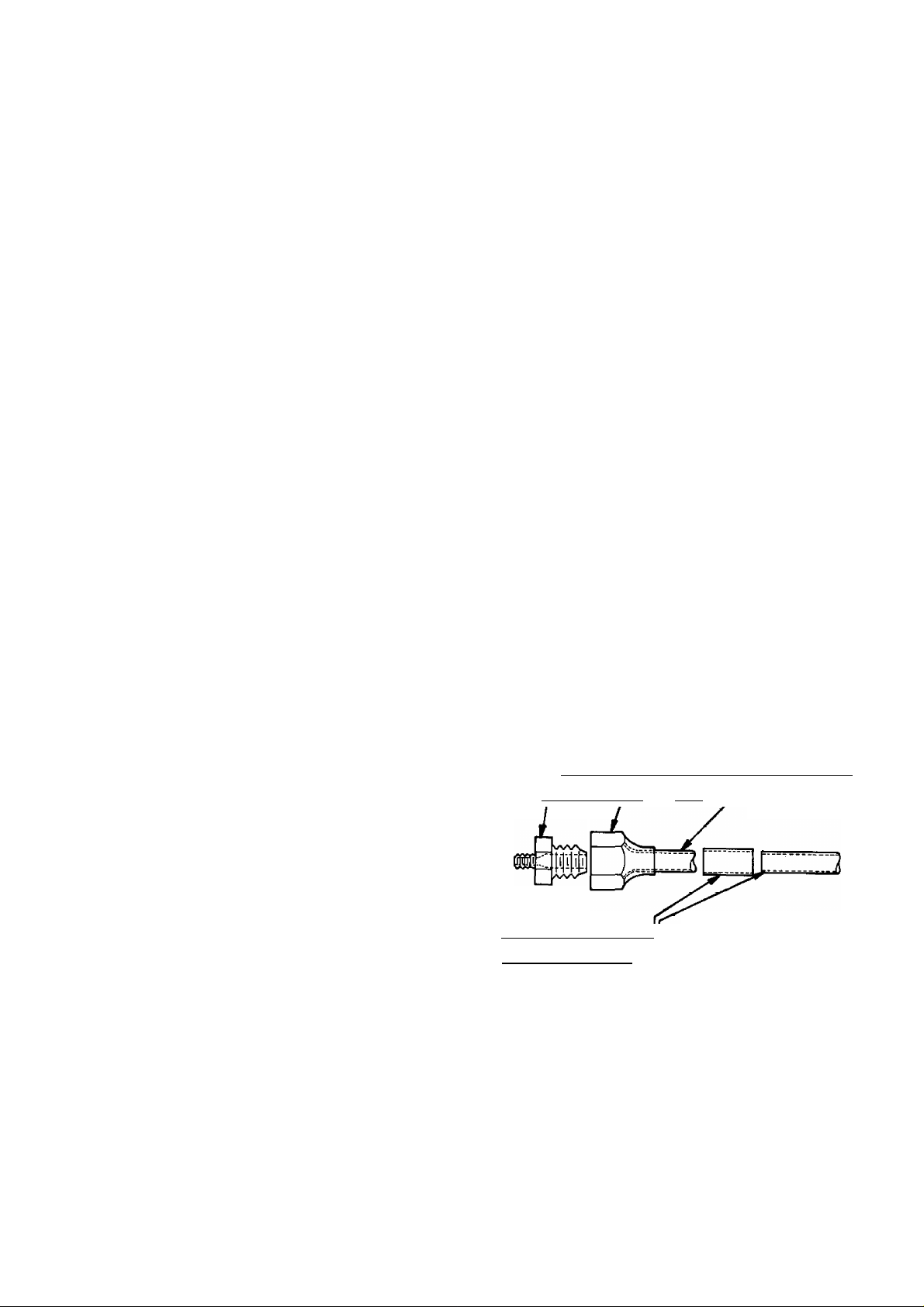

2 Makeal/4-in connection to suction line Forexample

Use a 1/2-in x 1/4-in flare reducing coupling

and a/1/2-in. flare nut and tube (flared) and a

1/2-in sweat coupling||that connects to the system

1 /2-in. suction line. For other size suction lines use

proper size fittings to make the connection Connect

1 /4-in fitting to a refrigerant di urn by using chaiging

hose 01 1 /4-in tubing

Cut off the end of the pigtail on the discharge line

Flaie and install a I /4-in stop valve or (preferably) a

charging manifold

Invert drum and charge liquid refrigerant

Open discharge valve and allow to purge slowly until

liquid Freon comes, then close valve

6 Close valve on refrigerant drum and allow refrigerant

to remain in piping at least 15 minutes

7 Open valve on discharge stub and allow refrigerant to

blow out quickly Be careful not to stand in front of

valve when purging Protect hands from refrigerant

burns with cloth

8 Disconnect refrigerant drum and unsolder connection

to suction line

9 Proceed with remainder of installation

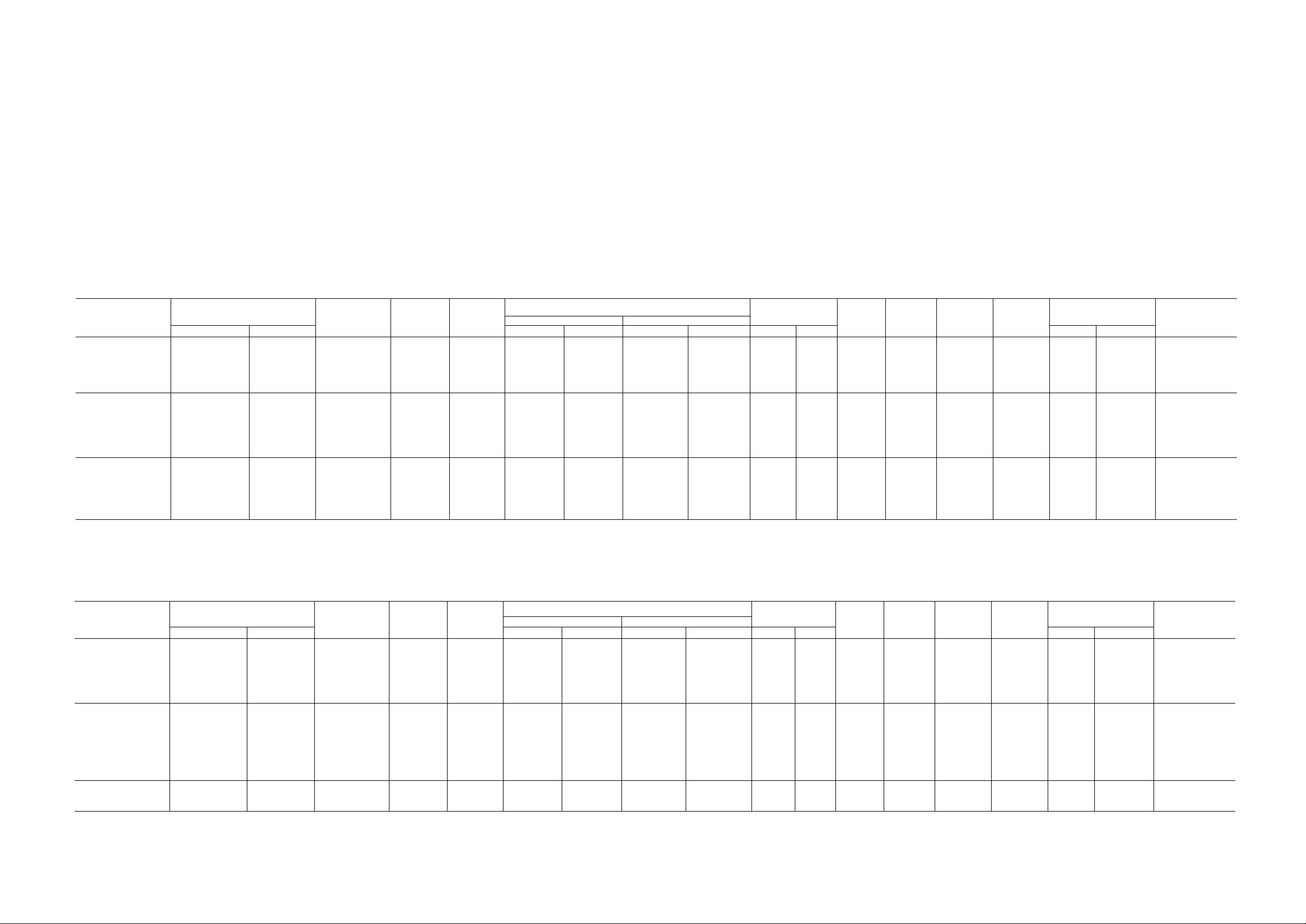

Table 2 — Physical and Electrical Data (Single Phase, 60 Hz) — 1988

MODEL 51

ZMA705101

ZMA705111

ZMA706101

ZMA706103

ZGA706103

ZMA007913

ZGAa07903

ZMA007703

ZMA008101

ZMA008103

ZGA008103

ZMA008703

ZMA009913

ZGA009903

ZMA009703

ZMA009303

ZMB009703

Table 1 — Unit Model Numbers (104, 304, 404)

CASING

104

MODEL 51

CMA109101

CMB112111

CMB112103

CMC012311

CMB012313

CMA012903

CMB012913

CGA012903

CMA012703

CVA212703

CMA115301

CMB115303

CMA118903

CGA118903

CMB118313

CMA118703

CMA115703

CASING

304

MODEL 51

GMA009101

G MA114101

GMA118301

GMA121301

GMA121311

GMA124301

GMA228301

G MA118703

GYA318703

GMA224703

CASING

404

Cool

5,200

7,600

8 800

12,000

12,000

9,000

Cool

12 000

18 000

18,000

CAPACITY

(Btuh)

‘Based on AHAM Standard RAC-1 and ANSI Z234 1

A t — Entering wet-bulb temperature minus leaving wet-bulb temperature based on 67 F room wet-bulb temperature and95F dry-bulb outside air temperature

CAPACITY

(Btuh)

MODEL

51

ZMA705101 5,200

ZMA705111

2MA706101 6,100

ZM,ZGA706103 6,100

ZMA008101 7,600

ZM,ZGA008103

ZMA009303

CMAiogioi

CMB112111

CMB,CGA112103

CMC012311

CMB012313

CMA115301

CGA.CMB115303 15,000/14,800

CMB118313

GMA009101

GMA114101 13,500

GMA118301 18 000/17 700 —

GMA121301 20,500/20 000 —

GMA121311 20,500/20,000 —

GMA124301 23,500/23,000 —

GMA228301 27,500/27,000

DOE — Department of Energy

EER — Energy Efficiency Ratio

FLA — Full Load Amps

Hp — Horsepower

PF — Power Factor

MODEL

51

ZMA007913 7,000

ZGA007903 7,000

ZMA007703 7,000/ 6,800

ZMA009913 9,000

ZGA009903 9,000

ZMA009703 9,000/ 8 750

ZMA008703

ZMB009703

CMA012903 12,000

CMA012703 12,000/11,900

CVA212703 12,000/11,900

CMA115703 15,000/14,800

CMA118703 18,000/17.800

CMA118903 18 000

CMB012913 12,000

CGA012903

CMB118913

CGA118903

G MA118703

GYA318703

GMA224703 24 000/23,500

9,000/ 8,900

11,800/11,700

11,800/11 700

15,000/14,800

18,000/17,800

8,000/ 7,775

8,500/ 8,250 --

18,000/17,500

18,000/17,500

R-22

CHG

Heat

—

—

—

—

—

----

-

—

—

—

—

—

—

—

—

—

—

If conditions vary, wet-bulb At will vary

•Heat

_

—

—

—

—

—

—

_

—

—

—

—

—

—

—

—

—

_

11,300/9,500

—

(oz ± 5 - 0)

155

15 5

15 0 12 1

150 12 1

18 0

18 0

20,0

23 0

30 0

30 0

32 0

32 0

38 0

38 0

32 0

27 0

27 0

40 0 12 1

44 0

39 0

39 0 15 8

40 0

R-22

CHG

{oz ± 5 - 0)

18 5

18 5

160 149

170

170

18 0

18 0

180

29 0 123

32 0 10 6

32 0

29 0

34 0

34 0

22 0 107

22 0 10 7

29 0

29.0 11.1

28 0

28 0 125

36 0 150

WET

BULB

(AtF)

98

98

15 5

155

16.5/16.4 230/208

96

11 2

11 2

109

109

13 1

13 1

14.0

65

86

14 5

14 5

187

VOLTS

115

115

115

115

115

115

115

115

115

230/208

230/208

230/208

230/208

230/208

115

115

230/208

230/208

230/208

230/208

230/208

Table 3 — Physical and Electrical Data (Single Phase, 50 Hz) — 1988

WET

BULB

(AtF)

159

159

21 0

21 0

20 2/20 0

20 2/20 0

20 2/20,0

10 6

10 8

12 9

13 2

11 1

12 5

VOLTS

200

200

240/220

200

200

240/220

240/220

240/220

200

240/220

240/220

240/220

240/220

200

200

200

200

200

240/220

240/220

240/220

Cool

56

56

63

63

81

8 1

4.2/ 4.6

86

120

120

5 9/62

5 9/62

7 5/79

7 5/79

9.2/10.2

7 2

120

8 7/95

10 3/11 0

10 3/11 0

11 3/12 0

15 2/16 0

Cool

44

44

3 8/40

56

56

4 5/47

4 5/47

4 5/47

62

5 6/60

5 6/60

7 8/82

9 5/99

11 9

70

70

11 0

11.0

10 4/110

10 4/11 0

13 7/14 7

NAMEPLATE*

Amps

Heat Cool

_

_

_

_

_

_

_

_

_

_

--

_

_

_

—

_

—

Amps

NAMEPLATE*

Heat Cool

_

_

—

_

_

—

—

-

_

_

_

_

_

_

_

_

15 1/14 0 2250/2190

—

580

580

665

665

845

845

900/ 890

930

1335

1335

1285

1285

1630/1610

1630/1610

2140/2120

750

1320

1950/1920

2220/2165

2220/2165

2550/2500

3350/3290

780

780

780/ 755

1000

1000

950/ 920

995/ 965

995/ 965

1265

1265/1250

1265/1250

1750/1730

2220/2200

2195

1275

1275

2115

2115

2250/2190

3000/2940

Watts

Watts

Heat

_

_

_

_

_

_

_

_

_

_

_

___

_

_

_

—

_

_

_

—

Heat

_

—

—

_

—

_

—

_

_

_

_

_

_

_

_

_

3590/3050

—

FAN

OH

MO

FLA

93

93

93

93

93

93 91

.61

1 40

1 40

1 40

70

70

90

90

.90

1 11

3 10 98

1 00

1 11

1 11

1 60

1 60 Vi 96

FLA

44

44

41

44 89

44

41 'A ,

41

.41 'Ad

60

60

60 Vi;

1 00

1 00

1 60

60

60

1 60

1.60

1 10

1 10

1 50 Va

MO

FAN

TOR

Hp

'/l5

Vts

Vl5

Vl3

V,. 93

Vl2

Vl2

’/.2

V,2

’/l2

%

%

'A 98

V,0

’/6

'A

'A

%

Hp

V20

V20

V20

V.2

y,2

'A

%

'A

'/t2

'A

'A

'A

'A

PF

(%)

90

90

92

92

91

98

93

93

98

98

97

97

93

97

94

94

98

PF

(%)

89

89

86

89

88/89

92/93

92/93

92

96

96

95

97

97

82

82

96

96

90

90

91

EER

(DOE)

90

90

92

9 2

90

90

10.0

9 5 304

90 304

90

9 2/9 1

9 2/9 1 304 T-9

9 2/9 2

9 2/9 2 304 T-12

8.4/8.4 304 T-14

120

102

92

92

9 2

9 2

82

EER

(DOE)

90 Ml-1

90 Mt-1

90 T-4

90

90

80

80

8.0

95 T'11

95 T-10

96 T-10

80 T-13

8 1 304 T-15

82

94

94

85

8.5

80 T-5

80

80 T-9

CASING COMPR

104

104

104

104

104

104

104

304

304

304

404

CASING COMPR

104

404 T-5

___

T-1

T-1

T-2

T-2

T-3

T-3

T-5

T-7

T-8

T-8

T-9

T-12

T-17

H-1

MA-1

T-14

MA-2

T-22

T-23

MI-2

MI-2

T-6

T-6

T-6

T-16

MI-3

Ml-3

MI-4

MI-4

CAPILLARY

Data

C-1

C-1

C-2

C-2 CM

C-3

C-3

C--4

__

C-8

C-9

C-9

C-19

C-19

C-7

C-7

C-11

C-10

C-13

C-14

C-15

C-15

C-20

C-16

Data Insertion

C-5

C-5

C-4

C-6

C-6

C-6

C-6

____

______

C-9

C-10

C-10

C-7

C-11

C-11

C-12

e-12

c-11

c-11

c-17

c-17 CI-3

c-18

Insertion

CI-2

CI-3

CI-1

CI-2

START

THERMISTOR

Z-1

Z-1

START

THERMISTOR

Z-1

Z-1

z-1

DOE ~ Department of Energy

EER — Energy Efficiency Ratio

FLA — Full Load Amps

Hp — Horsepower

PF — Power Factor

‘Based on AHAM Standard RAC-1 and ANSI Z234 1

A t — Entering wet-bulb temperature minus leaving wet-bulb temperature based on 67 F room wet-bulb temperature and95 Fdry-bulboutsideairtemperature

If conditions vary, wet-bulb At will vary

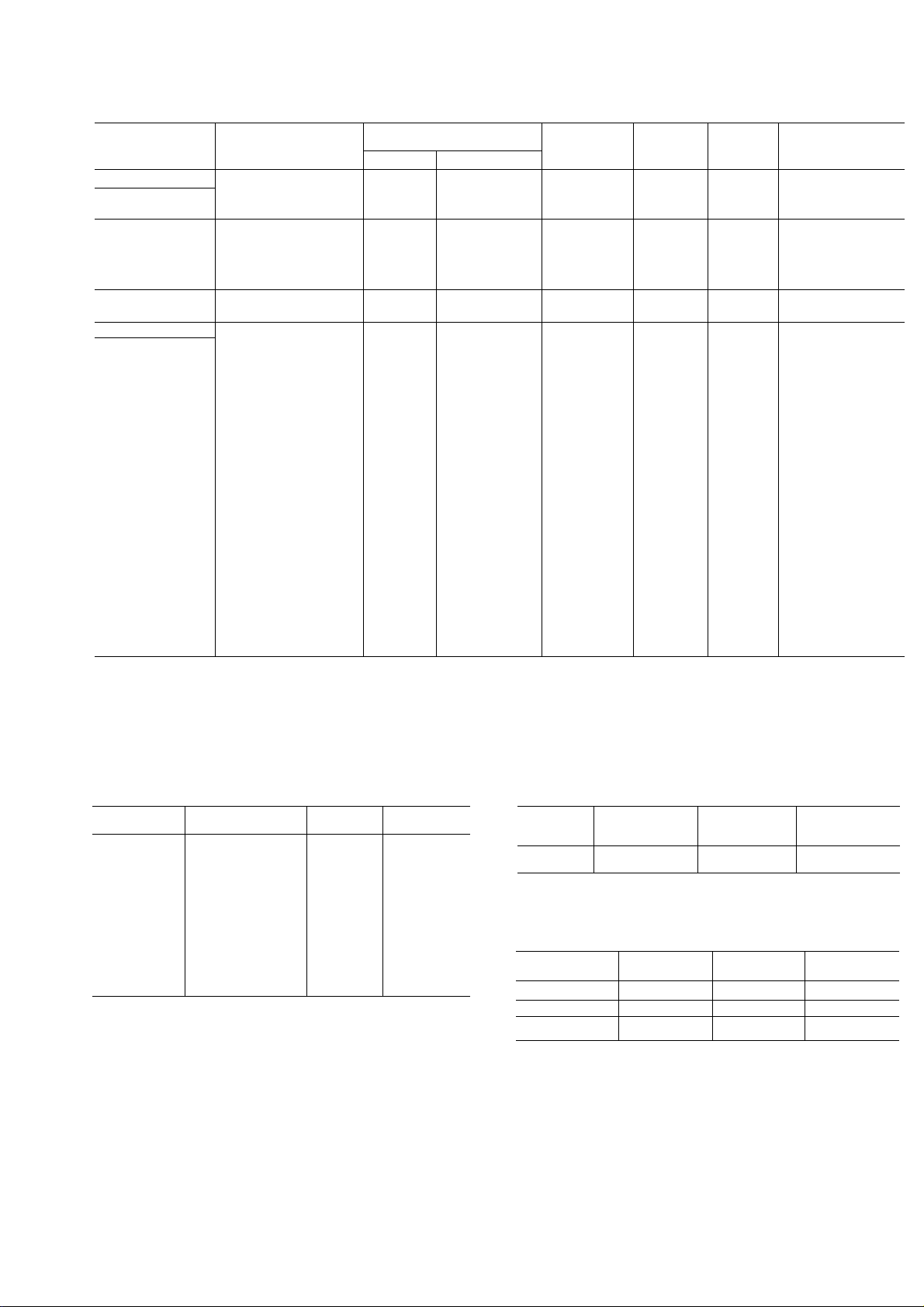

Table 4 — Compressors

KEY NO

Matsushita

MA-1

MA-2

Mitsubishi

MI-1

MI-2

MI-3

MI-4

Tecumseh

H-1

Toshiba

T-1

T-2

T-3

T-4

T-5

T-6

T-7

T-8

T-9

T-10

T-11

T-12

T-13

T-14

T-15

T-16

T-17

T-18

T-19

T-20

T-21

T-22

T-23

T-24

T-25

VENDOR MODEL

NO

2K25S3R236A-6A

2K32S3R236A-6A

RH421SS

RH427SS

RH434SS

NH455NB

RK5513E

ERH62XA3-1K

ERH68XA3-1K

EH88X1-1CU1

PRH94XA4-4K

PRH88XA4-3K

PH112X2-4KU

ERH88XA4-1K

EH120X2-1KU

PH120X2-3KU

PH142X2-4KU

PH142X2-9LU

PH160X2-3LU1

PH180X2-4LU

PH210X3-3LU

PH250X3-4LU

PH250X3-9LU

EH80X1-1CUI

PH200X33-3LTU

PH230X3J-3LTU

PH230X3J-4LTU

PH230X3-4LU

PH250X3-3LU

PH310X3-3MU

PH310X3J-4MTU

PH310X3-4MU

OiL CHARGE (02 ± 1)

Dry

14 5

14 5

10 1

19 2

180

28 7

Recharge

17 3

16 2

25 8

11 8

7 4

7 4

7 4

74

7 4

11 0

7 4

10 6

106

11 0

11 0

14 0

140

20 3

20 3

20 3

74

20 3

20 3

20 3

20 3

20 3

23 7

23 7

23 7

18 3

18 3

18 3

18 3

18 3

21 3

21 3

21 3

\ir\\ TC

125

125

9 1

9 1

67

67

67

6 7

67

9 9 240/220

67

95

95

99

99

126

126

67

183

18 3

183

230/208

230/208

200

200

200

200

115 11 4

115

115

115

240/220

230/208

115 7 7

115

230/208

240/220

200

230/208

240/220

230/208

240/220

200

115

230/208

230/208

240/220

240/220

230/208

230/208

240/220

240/220

RLA LRA

74 42 0

96 52 0

FLA

4 5

56 30 0

73 38 0

97

26 0

47 0

67 0

52 35 0

59 35 0

75

34 20 0

39 25 0

40 23 0

11 6

54

45 26 0

52 27 0

68 38 0

69 36 0

9 1

88

10 2 51 0

—

—

20 0 79 0

—

—

—

—

-

—

41 0

43 0

63 0

33 0

49 0

46 0

41 0

65 0

58 0

46 0

63 0

79 0

83 0

72 0

RUN

CAPACITOR

RC-4

RC-6

RC-12

RC-8

RC-8

RC-7

RC-9

RC-3

RC-3

RC-3

RC-1

RC-1

RC-2

RC-2

RC-5

RC-2

RC-2

RC-2

RC-4

RC-4

RC-6

RC-6

RC-6

RC-9

RC-6

RC-6

RC-6

RC-6

RC-6

RC-6

RC-10

RC-11

FLA “ Full Load Amps

LRA — Locked Rotor Amps

RLA — Rated Load Amps

Table 5 — Run Capacitors

KEY NO

RC-1

RC-2

RC-3

RC-4

RC-5

RC-6

RC-7

RC-8

RC-9

RC-10

RC-11

RC-12

MFD — Microfarad

CARRIER NO

HC98CA016

HC98CA026

HC98CA027

HC98CA036

HC98CA031

HC98CA046

HC98CA050

HC98DA031

HC98CA028

HC98CA062

HC98CA047

HC98DA026

MFD

15/5

25/5

25/7 5 370

35/5

30/5

45/5

50/5

30/5

25/10

60/7 5

45/7 5

25/5

VOLTS

370

370

370

370;

370

370

440

370

370

370

440

Table 6 — Thermistor

KEY NO

Z-1

CARRIER NO

HC95XX006 3M305C20C

VENDOR NO

Table 7 — Casing Dimensions (in.)

CASING

104

304

404

HEIGHT

UVe 20 Vm 17'/e

15S/t6 24Vm

173/i6

WIDTH

26

RESISTANCE

(Ohms)

25

DEPTH

27¥^6

28Vi6

Table 8 — Capillary Data

Table 9 — Capillary Insertion

KEY NO

C-1

C-2 106 055

C-3 106 055

C-4

C-5

C-6(2)

C-7 125 070

C-8

C-9 125 064

C-10 125

C-11

C-12 125

C-13

C-14

C-15(2)

C-16

C-16(2) 106 054

C-16

C-17 (2)

(Injection)

C-18 (2)

(injection)

C-19

C-20 (2)

OD

(± 002)

106 049

106 054

106

106

125 054

125 070

125

125 070

125 054

106 054

106 054

125

080 031

125 070

080 031

125 064

125 064

DIMENSIONS (in.

ID

(± 0003)

049

049

064

064

070

070

Length

(± 25)

30

39

38

42

26

66

34

25

25

35

22

26

26

24

16

46

34

56

36

36

31

18

30

25

NOTE Capillary number follows key number Numbercapillaries

from left to right, facing evaporator inlet, when more than one is

used

KEY NO

CI-1

C1-2

CI-3

DEPTH (In.)

Cond Coil Evap Coil

Conn Tube

(Max) (Min)

Conn Tube

Va

1

Va

1

1

DISASSEMBLY INFORMATION

Model 104's Casing

Model 51ZM — The Model 5IZM Room Air Condi-

tioner is leieiied to as the 104 size casing International

Series unit See Fig 1

Fig. 1 — Model 51ZM

1 Grille — Decorative iiont grille insert is removed by

giipping top of insert and pulling outward while lift

ing insert from grille frame See Fig 2

Fig. 3 — Removing Filter

Fig. 2 — Removing Grille Insert

Filter — Filter can be removed without having to

remove grille insert Grasp bottom edge of filter

(located behind grille insert) and gently pull filter

down and slightly toward you See Fig 3 Filter may

be vacuumed, or washed in warm water Shake filter

to remove excess water, dry thoroughly and replace

by sliding filter upward behind front grille until filter

snaps in place

Grille Frame — Grille frame is removed by first

removing 4 screws holding frame to chassis See

Fig 4 Pull top of grille frame outward and lift frame

away from chassis

Fig 4 — Removing Grille Frame Screws

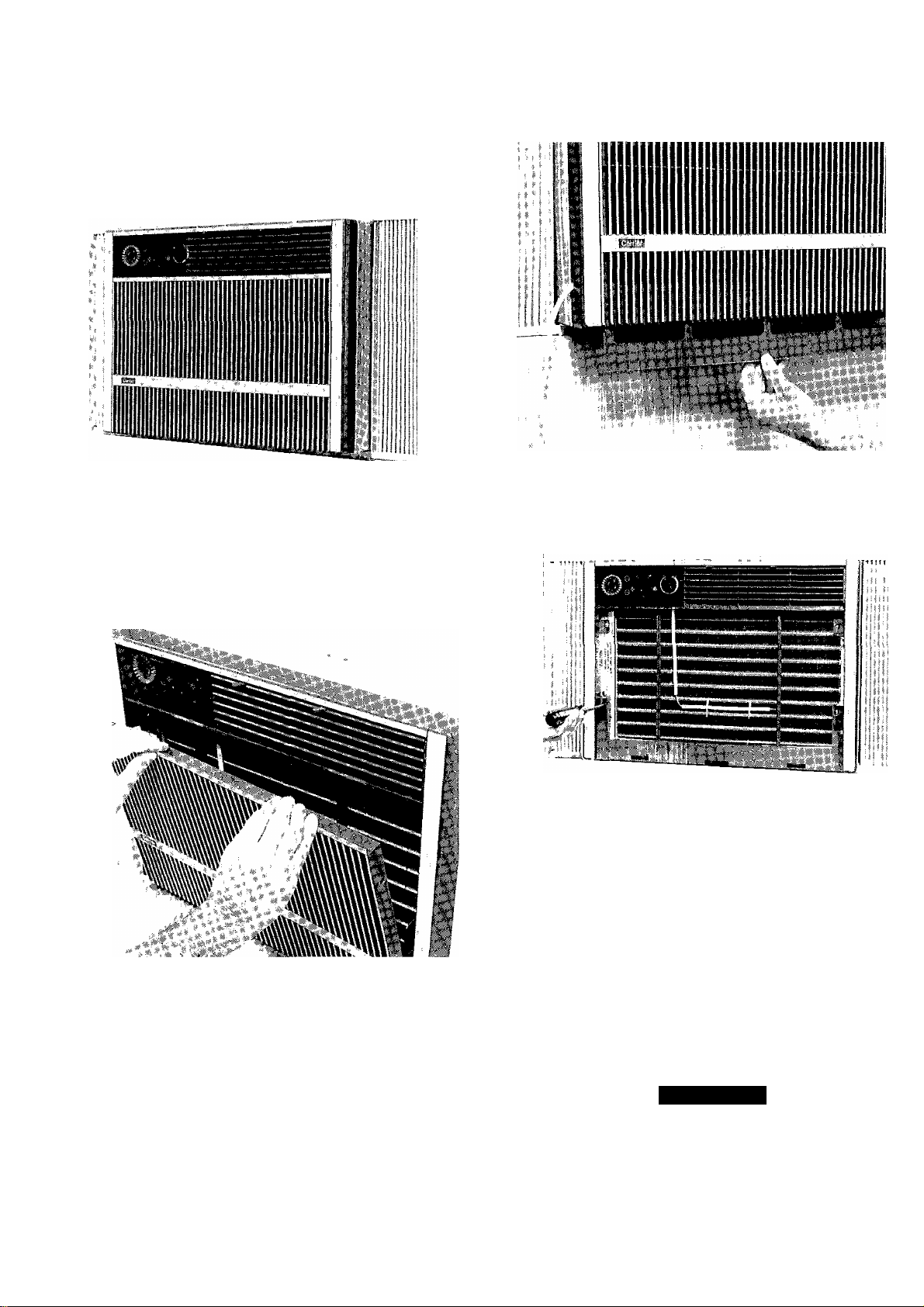

Chassis Security Lock Screw — To slide

chassis out of casing, security screw must first be

loosened Loosen screw and slide screw to unlock

position (forward) When reinstalling chassis in

casing, reverse procedure and tighten screw in lock

position See Fig 5

Chassis — The International Series models have

a slide-out chassis Servicing the chassis is possible

without having to remove rrnit casing from window

See Fig 6 Use the offset in the basepan as a fingergrip handle to slide chassis out of casing

A CAUTION

Coil fins are sharp Use care when removing

chassis from casing to avoid personal injury Do

not use plastic parts for lilting or pulling They

are not structural members of the chassis Lift

using basepan only Chassis is heavy Obtain

assistance for lifting

EVAPORATOR

COVER SCREWS (5)

Fig 5 — Unlocking Chassis Security Lock Screw

Fig 6 — Sliding Chassis Out of Casing

Fig. 7 — Evaporator Cover Screws

6 Evaporator Cover — Remove evaporator by

removing 5 sciews as shown in Fig 7

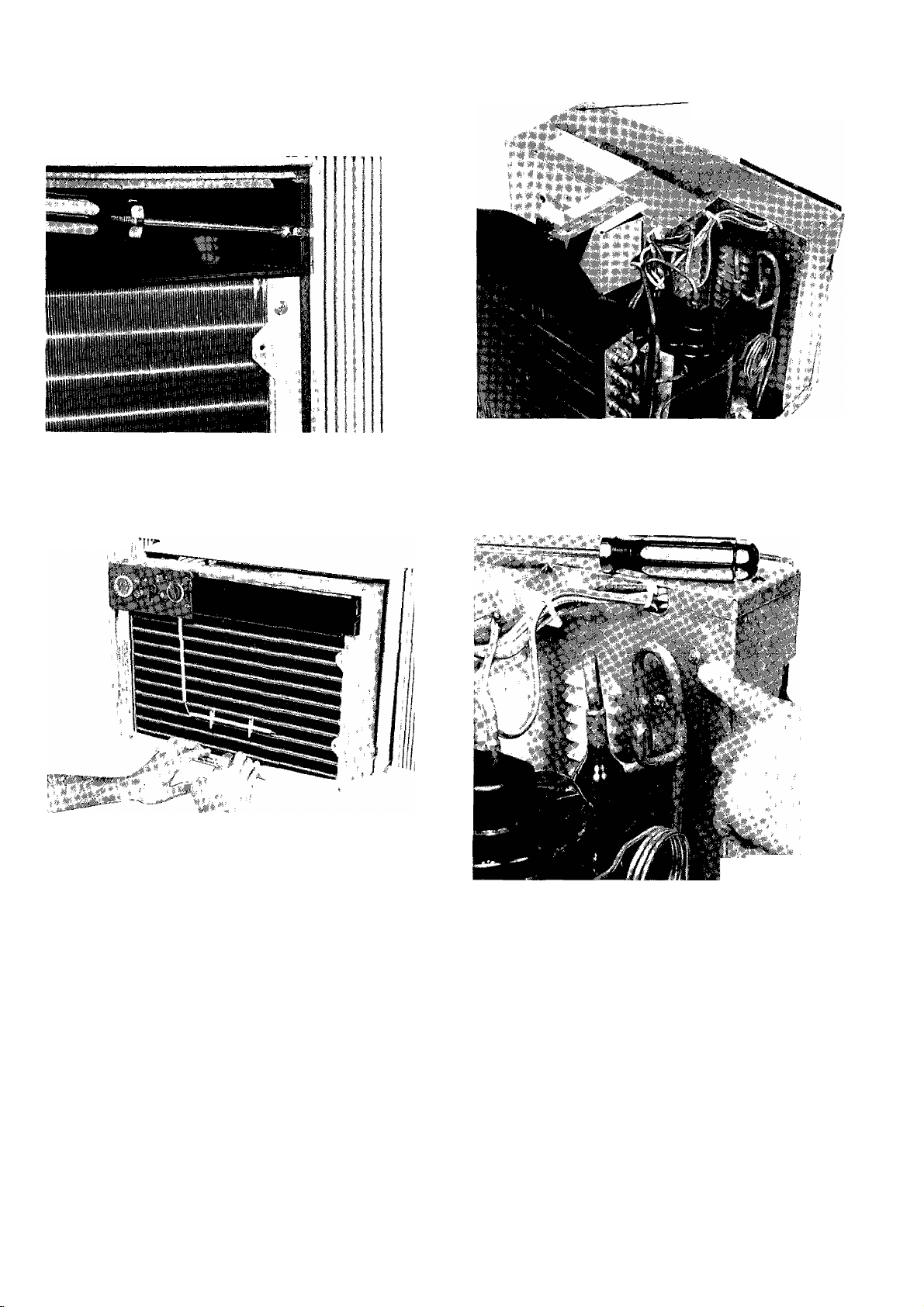

7 Control Box — Conti ol Box is secured with 2

sciews See Fig 8

a Remove sensing bulb from coil See Fig 9

b Remove service cord screw See Fig 9

c Remove control knobs by pulling off See Fig 10

d Remove escutcheon plate

8 Timer — See location of timer in Fig 11

a Remove 2 screws holding timer to control box

b Caiefully pull wires fiom timer terminals being

sure to label or mark each wire for accurate wire

replacement on timer

c To reinstall timei. reverse above procedure

Fig 8 — Control Box Screws

9 Cool-Heat Control — See Cool-Heat Control

location in Fig 11

a Remove 2 sciews holding Cool-Heat Control to

control box

b Carefully pull wires from Cool-Heat Control ter

minals being sure to label or mark each wire for

accurate wire replacement

c Reverse above procedure to reinstall Cool-Heat

Control

10 Fan Cycle Switch — See Fan Cycle Switch loca

tion in Fig 11

a Remove fan cycle switch using screwdriver as

shown in Fig 11

Loading...

Loading...