Application Data

Control Selection Guide

for Fan Coil Air Conditioners

42 Series

Fan Coil Units

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 3

Tab 7a

PC 201 Catalog No. 514-203 Printed in U.S.A. Form 42-3XC Pg 1 6-90 Replaces: 42-2XC

CONTENTS

Page

CONTROL SELECTION GUIDE ............... 3

STANDARD WIRING PACKAGES ............ 4-8

Manual Fan Control ......................... 4

Thermostatic Fan Control,

2-Pipe Systems ............................ 4

Thermostatic Fan Control,

2-Pipe System with Safety Cycle ............ 5

Thermostatic Electric Valve Control, 2-Pipe ... 5

Thermostatic 2-Pipe Auxiliary Electric Heat

with Valve Control ......................... 6

Thermostatic 2-Pipe Total Electric Heat

with Valve Control ......................... 7

Thermostatic Valve Control, 4-Pipe ........... 8

ELECTRIC HEAT ............................ 9

Application ................................. 9

Heater Construction ......................... 9

Heater Electrical Data ....................... 9

REMOTE-MOUNTED CONTROLS ............ 10

Standard 3-Speed Switch ................... 10

Combination Thermostat/3-Speed Switch .... 10

Wall Thermostat, 2-Pipe .................... 10

Wall Thermostat, 4-Pipe .................... 10

ALTERNATE WALL THERMOSTATS ......... 11

Wall Thermostat (Honeywell) with Manual

3-Speed Fan Switch and ON-OFF Switch ... 11

Wall Thermostat (Sunne) with Manual

3-Speed Fan Switch and ON-OFF Switch ... 11

Page

UNIT MOUNTED CONTROLS .............. 12,13

Standard 3-Speed Switch ................... 12

Combination Thermostat/3-Speed Switch .... 12

Combination Thermostat/ON-OFF

Toggle Switch ............................ 12

Two-Pipe Thermostat ....................... 13

Four-Pipe Thermostat ...................... 13

Automatic Changeover ..................... 13

BASIC DEFINITIONS ....................... 14

FIELD PIPING CONNECTIONS .............. 15

VALVE PACKAGES ....................... 16-19

General ................................... 16

Two-Way Motorized Control Valve ........... 18

Two-Way Motorized Control Valve

with Aquastat Bleed Bypass Line .......... 18

Three-Way Motorized Control Valve ......... 19

No Motorized Control Valve ................. 19

VALVE PACKAGE ARRANGEMENTS ....... 20-23

PIPING COMPONENTS .................... 24-27

Cv FACTOR vs WATER PRESSURE DROP ... 28

SYSTEM COMPONENT WORKING

PRESSURE ............................... 29

COPPER WATER TUBE AND JOINT MATERIAL

PRESSURE RATINGS ..................... 30

CORRECTION FACTORS FOR GLYCOL ...... 31

STANDARD ACCESSORIES AND OPTIONS .. 32

2

CONTROL SELECTION GUIDE

Use this guide to make sure that all necessary components are provided for and that the components are compatible

with the required control system.

NOTE: When thermostatic fan control is selected or when unit outside air dampers are used, unit-mounted thermostats

are not recommended as their use will result in poor room temperature sensing.

SYSTEM DESCRIPTION THERMOSTAT

CHANGEOVER

ON

SUPPLY PIPE

VALVE

FAN

SWITCH (SW)

NOTES

2-PIPE HEATING-COOLING*

Fan

Control

(2-Pipe)

Fan manually cycled None None None Standard

3-Speed SW

Not recommended

for high humidity

application

Thermostat cycles fan on-off

from speed set with

fan switch.

Wall mounted

includes heat-cool

switch.

None None Thermostat has

integral

3-Speed SW

Thermostat cycles fan on-off

from fan speed set

with switch. Mode

automatically switched

by changeover

sensing water temp.

Wall mounted.

Heating/cooling

Thermostat

Yes None Standard

3-Speed SW

Unit mounted

thermostats provide

very poor room

temperature control

Thermostat cycles fan from

high to low on cooling

and low to off on heating.

Wall or unit

mounted

Yes None No Standard

3-Speed Switch,

ON-OFF toggle SW

only

Best fan cycle

control for

high humidity

applications

Twoposition

electric

valves

(2-pipe)

Thermostat cycles valve

open or closed.

Wall mounted

includes heat-cool

switch.

None Motorized (N.C.)

3-way or 2-way,

no bypass required.

Thermostat

has integral

3-Speed SW

Valve packages

with belled end(s)

for field soldering

to coil.

Thermostat cycles valve

open or closed.

Mode automatically

switched by changeover

sensing water temp.

Wall or unit

mounted.

Heating/cooling

Thermostat

Yes Motorized (N.C.)

3-way or 2-way

Standard

3-Speed SW.

Others have

thermostats with

integral 3-Speed SW

Pneumatic

modulating

valves

(2-pipe)

Thermostat modulates

pneumatic control valve.

By others. By others. 2- and 3-way

furnished by others.

Can be equipped

with factory

assembled

valve package.

Standard

3-Speed SW

Factory assembled

in valve package

w/flare nuts.

Valve packages

with belled end(s)

for field soldering

to coil.

ELECTRIC HEAT

Twoposition

electric

valve with

Auxiliary

Electric

Heat

(2-pipe)

Thermostat cycles valve

open or closed. 2° F after

valve closes, thermostat

activates electric heater.

Heater can’t turn on

if hot water is in coil.

Wall or unit

mounted. Sequenced

heating and cooling.

Yes.

Two Required.

Motorized

3-way or 2-way

Standard

3-Speed SW

Others have

thermostats with

integral 3-Speed SW

Valve packages

with belled end(s)

for field soldering

to coil.

Thermostat cycles valve

open or closed. Manual

changeover switch

changes thermostat to

heat to activate electric

heater.

Wall mounted

includes heat-cool

switch.

None Motorized

3-way or 2-way,

no bypass required

Thermostat

has integral

3-Speed SW

Valve packages

with belled end(s)

for field soldering

to coil.

Twoposition

electric

valve with

total

electric

heat

(2-pipe)

Thermostat cycles valve

open or closed.

Manual changeover switch

changes thermostat to heat

to activate electric heater.

Wall mounted

includes heat-cool

switch.

None Motorized (N.C.)

3-way or 2-way,

no bypass required

Thermostat

has integral

3-Speed SW

Valve packages

with belled end(s)

for field soldering

to coil.

Thermostat cycles valve

open or closed.

2° F after valve closes,

thermostat activates

electric heater.

Wall or unit

mounted.

Sequenced heating

and cooling

None Motorized (N.C.)

3-way or 2-way,

no bypass required

Standard

3-Speed SW

Pneumatic

modulating

valves

(2-pipe)

Thermostat modulates

pneumatic control valve.

After changeover,

thermostat

activates electric heater.

By others. By others. 2- and 3-way

furnished by others.

Can be equipped

with factory

assembled

valve package.

Standard

3-Speed SW

Factory assembled

in valve package

w/flare nuts.

Valve packages

with belled end(s)

for field soldering

to coil.

4-PIPE

Twoposition

electric

valves

(4-pipe)

Thermostat cycles

cooling and heating

valves open or closed.

Wall mounted

includes subbase

with heat-cool

switch.

None Motorized (N.C.)

3-way or 2-way

(requires 2 valves)

Thermostat

has integral

3-Speed SW

Valve packages

with belled end(s)

for field soldering

to coil.

Thermostat cycles cooling

valve open or closed. 2° F

after valve closes,

thermostat cycles

heating valve open or closed.

Wall or unit

mounted.

Sequenced heating

and cooling.

None Motorized (N.C.)

3-way or 2-way

(requires 2 valves)

Standard

3-Speed SW.

Others have

thermostats

with integral

3-Speed SW

Pneumatic

modulating

valves

(4-pipe)

Thermostat modulates

cooling valve.

After changeover,

thermostat modulates

heating valve.

By others. By others. 2- or 3-way

furnished by others.

Can be equipped

with factory

assembled

valve package.

Standard

3-Speed SW

Factory assembled

in valve package

w/flare nuts.

Valve packages

include unions for

for field assembly

to coil.

*If system is HEATING-ONLY or COOLING-ONLY, no changeover or bypass is required.

NOTE: Unit-mounted thermostats are not recommended with either fan-cycle control or applications with outside air dampers.

3

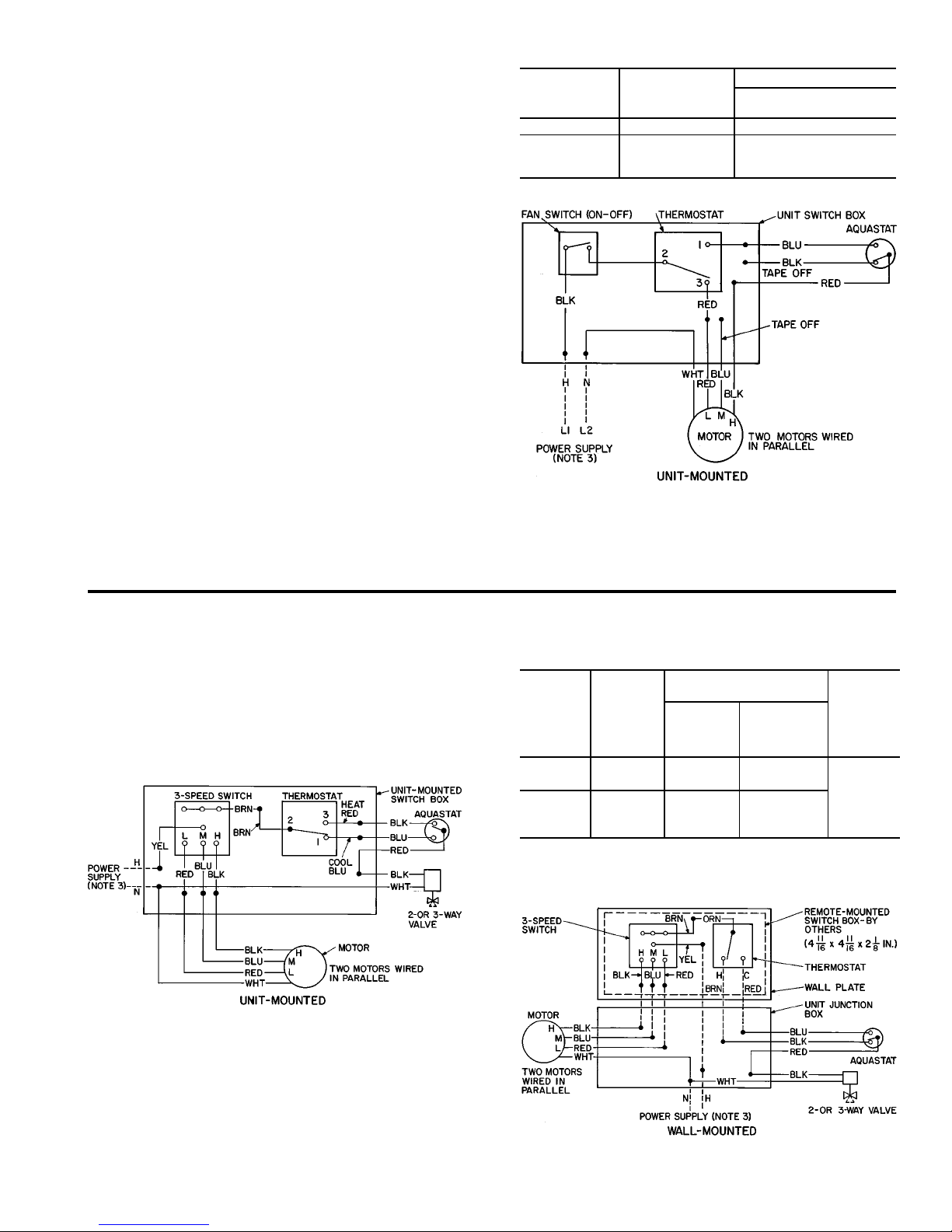

STANDARD WIRING PACKAGES

IMPORTANT: Wiring diagrams shown depict typical

control functions. Refer to unit wiring label for specific functions.

Manual Fan Control — On all Vertical Cabinet units,

the standard fan-speed switch is furnished unit-mounted and

wired. On all VerticalFurred-In units and all Horizontal units,

the switch is shipped separately on a decorative wall plate

for field mounting and wiring.

The standard switch has LOW,MEDIUM, HIGH and OFF

positions plus an auxilliary contact to energize thermostats,

valves, dampers, etc.

NOTE: Wiring diagrams are for 120-v power supply.If other

voltages for heaters or controls are specified, wiring may differ from that shown.

The standard 3-speed switches are illustrated on page 12

(unit mounted) and on page 10 (wall mounted).

For NOTES, see below.

Thermostatic Fan Control, 2-Pipe Systems —

The thermostat cycles the fan on and off from any selected

speed setting to maintain selected room temperature. Controls can be wired for heating-only,cooling-only or for heating/

cooling by the addition of an automatic changeover device

that senses water temperature and changes the action of the

thermostat as required.

For control package descriptions, see control components

sections entitled Remote-Mounted Controls and UnitMounted Controls, pages 10-13.

UNIT

TYPE

LOCATION

THERMOSTAT OR

WIRING PACKAGE*

Heating or

Cooling Only

Heating and Cooling

Plus Changeover†

Vertical Unit Mounted N/A N/A

Vertical

or

Horizontal

Wall Mounted

22-C, 22-D

22-E, 22-F

22-A, 22-B

*Packages listed on current price pages. First 2 digits are item

numbers.

†For alternate thermostat with manual changeover. Refer to current

price pages.

NOTES:

1. Motors are thermally protected.

2. Use copper conductors only.

3. See unit nameplate for power supply. Provide disconnect means

and overload protection as required.

4. Unit-mounted thermostats are not recommended for fan control

because of poor temperature sensing. Fan control not available

on 42VC,VE Loboy units.

4

Thermostatic Fan Control, 2-Pipe System with

Safety Cycle —

This control is used for high humidity

situations in which condensate problems can occur if fan is

turned off while chilled water is still running through the

coil.

The wiring provides fan cycling from HIGH to LOW on

the cooling cycle and from LOW to OFF on the heating cycle.

An ON-OFF toggle switch replaces the standard 3-speed fan

switch. The toggle switch can be concealed to ensure that

the unit runs on low speed when cooling. This action greatly

reduces the chance of condensation problems that exist with

other standard fan cycling controls.

For control package descriptions, see control components

section entitled Remote-Mounted Controls and Unit-Mounted

Controls.

UNIT

TYPE

LOCATION

PACKAGE CODE*

Heating and Cooling

Plus Changeover

Vertical Unit Mounted 24-R

Vertical

or

Horizontal

Wall Mounted 23-17

* Packages listed on current price pages.

For NOTES, see below.

Thermostatic Electric Valve Control, 2-Pipe —

A thermostatically controlled 2-position valve provides superior control to fan cycling. With this control, the fan runs

continuously unless it is manually switched to the OFF position. The fan must be on before the valve can be opened to

supply water to the coil.

This system can be used for normal 2-pipe changeover

systems and can also be furnished for cooling-only or heatingonly applications by omitting the changeover and specifying

which application is intended.

NOTES:

1. Motors are thermally protected.

2. Use copper conductors only.

3. See unit nameplate for power supply. Provide disconnect means

and overload protection as required.

For control package descriptions, see control components

sections entitled Remote-Mounted Controls and UnitMounted Controls.

UNIT

TYPE

LOCATION

THERMOSTAT OR

WIRING PACKAGE*

ELECTRIC

VALVE

Heating or

Cooling

Only

Heating and

Cooling

Plus

Changeover†

Vertical

Unit

Mounted

24-M,

24-N

24-L

Any 2- or

3-way,

2-position

valve

package.

Vertical

or

Horizontal

Wall

Mounted

22-C, 22-D,

22-E, 22-F

22-A, 22-B

*Packages listed on current price pages. First 2 digits are item

numbers.

†For alternate thermostat with manual changeover. Refer to current

price pages.

5

STANDARD WIRING PACKAGES (cont)

Thermostatic 2-Pipe Auxiliary Electric Heat

with Valve Control —

This system, also called Twilight or Intermediate Season electric heat, goes a long way

towards solving the spring and fall control problems of 2-pipe

systems.

You can run chilled water late into the fall, turn it on early

in the spring and still have heat available to all units whenever required.

In winter the system is switched over to hot water. Two

changeover devices are required for this. One device switches

the action of the thermostat and the other locks out the electric heat when hot water is in the coil.

With this system, the fan runs continuously unless manually switched to OFF position. Fan must be on before thermostat can send signal to open chilled water valve or turn on

electric heater.

Two control methods are available:

1. Use the standard automatic changeover thermostat with a

dead band between heating and cooling, or —

2. Use a manual changeover thermostat. With this method

only one changeover is required.

Be sure to include a 2-way or 3-way electric valve with

this system.

NOTE: Wiring diagrams are for 120-v power supply.If other

voltages for heaters or controls are specified,wiring may differ from that shown.

For control package descriptions, see control components

sections entitled Remote-Mounted Controls and UnitMounted Controls.

UNIT

TYPE

LOCATION

WIRING PACKAGE*

ELECTRIC

VALVE

Automatic System Manual System

Vertical

Unit

Mounted

24-Q Available on Special Order.

Any 2- or 3-way,

2-position valve

Package.

Vertical

or

Horizontal

Wall Mounted

22-J, 22-K,

23-09, 23-10

23-15, 23-16

*Packages on current price pages.

NOTES:

1. Motors are thermally protected.

2. Use copper conductors only.

3. See unit nameplate for power supply. Provide disconnect means

and overload protection as required.

6

Thermostatic 2-Pipe Total Electric Heat withValve Control —

With this system, the complete heating requirement for the space is provided by the electric heater;

the water system is never changed over for heating. It is therefore possible, just as with 4-pipe systems, to have heating or

cooling at any time of the year.

The fan runs continuously unless it is manually switched

to OFF position. Fan must be on before thermostat can send

signal to open chilled water valve or turn on electric heater.

Normally,an automatic changeover thermostat with a dead

band between heating and cooling is used, but a manual

changeover thermostat is also suitable. A 2-way or 3-way

valve must also be used so that the chilled water is off whenever the heater is on. No changeover device to sense water

temperature is necessary.

NOTE: Wiring diagrams are for 120-v power supply. If other

voltages for heaters or controls are specified, wiring may differ from that shown.

For control package descriptions, see control components

sections entitled Remote-Mounted Controls and UnitMounted Controls.

UNIT

TYPE

LOCATION

WIRING PACKAGE*

ELECTRIC

VALVE

Automatic System Manual System

Vertical

Unit

Mounted

24-Q Available on Special Order.

Any 2- or 3-way,

2-position valve

Package.

Vertical

or

Horizontal

Wall Mounted

22-J, 22-K,

23-09, 23-10

23-15, 23-16

*Packages on current price pages.

NOTES:

1. Motors thermally protected.

2. Use copper conductors only.

3. See unit nameplate for power supply. Provide disconnect means

and overload protection as required.

7

STANDARD WIRING PACKAGES (cont)

Thermostatic V alveControl, 4-Pipe —

The 4-pipe

system provides the ultimate in economy and room temperature control. Both hot water and chilled water are available at any time.

Normally an automatic changeover thermostat is used, but

a manual changeover thermostat is also suitable. Two2-way

valves, two 3-way valves, or one 2-way plus one 3-way valve

must be selected. An automatic changeover device to sense

water temperature is not required.

With this system, the fan runs continuously unless it is

manually switched to OFF position. Fan must be on before

thermostat can send signal to open the chilled water or hot

water valve.

NOTE: Wiring diagrams are for 120-v power supply.If other

voltages for heaters or controls are specified, wiring may differ from that shown.

For control package descriptions, see control components

sections entitled Remote-Mounted Controls and UnitMounted Controls.

UNIT TYPE LOCATION

WIRING PACKAGE*

ELECTRIC

VALVE

Automatic System Manual System

Vertical Unit Mounted 24-P Available on Special Order.

Any 2- or 3-way,

2-position valve

package.

Vertical

or

Horizontal

Wall Mounted

22-G, 22-H,

23-07, 23-08

23-13, 23-14

*Packages on current price pages.

NOTES:

1. Motors thermally protected.

2. Use copper conductors only.

3. See unit nameplate for power supply. Provide disconnect means

and overload protection as required.

8

ELECTRIC HEAT

Application —

Electric heaters are available for

in-stallation on Carrier fan coil units in the following

applications.

TOTAL ELECTRIC HEAT — This system provides complete heating during the heating season; no boiler is required. Heating and cooling are now available on an individual basis throughout the year with a 2-pipe system.

Chilled water is used for cooling and the electric heater is

used for heating. Room controls can be supplied for

either manual or automatic changeover.

AUXILIARYELECTRIC HEAT — This system is used for

heating between seasons or during the cooling season when

chilled water is being circulated. Individual room controls

are supplied to provide electric heat only when chilled water

is being circulated through the system. Water flow through

the unit is shut off when the heater is turned on.

During the winter heating season, heating is provided

by hot water circulated through the system. A changeover

device locks out the electric heat when the hot water is

circulated.

Heater Construction

STRIP HEATERS — Used with Model 42C ceiling units,

Model 42D ducted units and Model 42S stack units.

These heaters consist of coils of the highest grade

resistance wire, insulated by ceramic insulators in aluminized brackets.

All heaters except those used in 42S stack units are positioned on the incoming (preheat) side of the unit coil. On

42S stack units, the strip heater is located in the fan discharge on the leaving side of the coil.

SHEATHHEATERS — Used with Model 42V vertical units.

These heaters consist of the highest grade resistance wire,

centered in a

1

⁄2-in. diameter copper-plated steel sheath. The

wire is insulated from the sheath by magnesium oxide powder packed around it. To increase the heater surface exposed

to air, a 11⁄4-in. OD fin of copper-plated steel is wound around

the sheath in a continuous spiral that makes 5 turns per lineal inch. Sheath and fin are permanently bonded together by

copper brazing.

The heaters are positioned on the leaving (reheat) side of

the unit coil. On special units with high efficiency motors, a

strip heater will be installed in the fan discharge on the incoming (preheat) side of the unit coil.

Heater Electrical Data

1. Load voltage may be 120, 208, 240 or 277 volts. For unit

size and kW limitations, refer to the specific unit

catalogs.

2. All heaters are single stage and single phase.

3. Unless a single power-source option is selected, the elec-

tric heat units require 2 separate power sources. With the

single power-source option, only one line circuit need be

brought into the unit. Fuse protection is added to the motor/

control circuit to protect these components. This is separate from the field-furnished total unit overcurrent protection.

MODEL 42V VERTICAL UNIT

WITH ELECTRIC SHEATH HEATER

MODEL 42C CEILING UNIT

WITH ELECTRIC STRIP HEATER

9

REMOTE-MOUNTED CONTROLS

Standard 3-Speed Switch —

This standard switch

has 4 positions: OFF, HIGH, MEDIUM, and LOW. Switch

has auxiliary contact that is energized when switch is in HIGH,

MEDIUM or LOW position.

Some of the options common with the 3-speed switch are:

1. Unit-mounted switch on Furred-In VerticalModel. (Avail-

able as special order on Horizontal Models)

2. Switch without OFF position.

3. Key-operated switch.

Combination Thermostat/3-Speed Switch

(Packages 22-B, 22-D, 22-F, 22-H, 22-K*) — Thermostat

and standard switch are mounted on a common decorative

wall plate, suitable for installation in a 411⁄16-in. square junction box. Packages 22-A and 22-B include Model TC-126

2-pipe heating and cooling thermostat and automatic changeover switch (shipped separately for field wiring and mounting).

Packages 22-C and 22-D include Model TC-126 thermo-

stat less automatic changeover switch wired for cooling only.

Packages 22-E and 22-F include Model TC-126 thermo-

stat, less automatic changeover, wired for heating only.

Package 22-G includes Model TH-126 4-pipe thermostat

for sequenced heating and cooling, plus 3-speed switch. (For

4-pipe or total electric heat systems.)

Package 22-J is the same as 22-G except that 2 automatic

changeover switches are shipped with package. (For auxiliary electric heat systems.)

Wall Thermostat, 2-Pipe (Packages 22-A through

22-F*) — Model TC-126 thermostat for heating and cooling, operates on line voltage. Action is SPDT. Temperature

range is 50-90 F.

Packages 22-A and 22-B — Heating and cooling, includes one automatic changeover switch (shipped separately

for field wiring and mounting).

Wall Thermostat, 4-Pipe (Packages 22-G through

22-K*) — Model TH-126 thermostat is also used on 2-pipe

system with electric heat. Heating and cooling are sequenced (automatic changeover) with 6 degree separation between HEATINGON and COOLING ON. T emperaturerange

is 50 - 90 F.

Packages 22-G and 22-H — For 4-pipe and total electric

heat systems.

Packages 22-J and 22-K — For auxiliary electric heat systems, includes 2 automatic changeover switches (shipped separately for field wiring and mounting).

* Packages listed on current price pages.

50

60

70

80

90

50

60

70

80

90

Thermostat Electrical Data

(Pilot Duty — 125 VA)

VOLTS

HEATING COOLING

FLA LRA FLA LRA

120 5.8 34.8 5.8 34.8

240 4.9 29.4 4.9 29.4

277 4.1 24.6 4.1 24.6

10

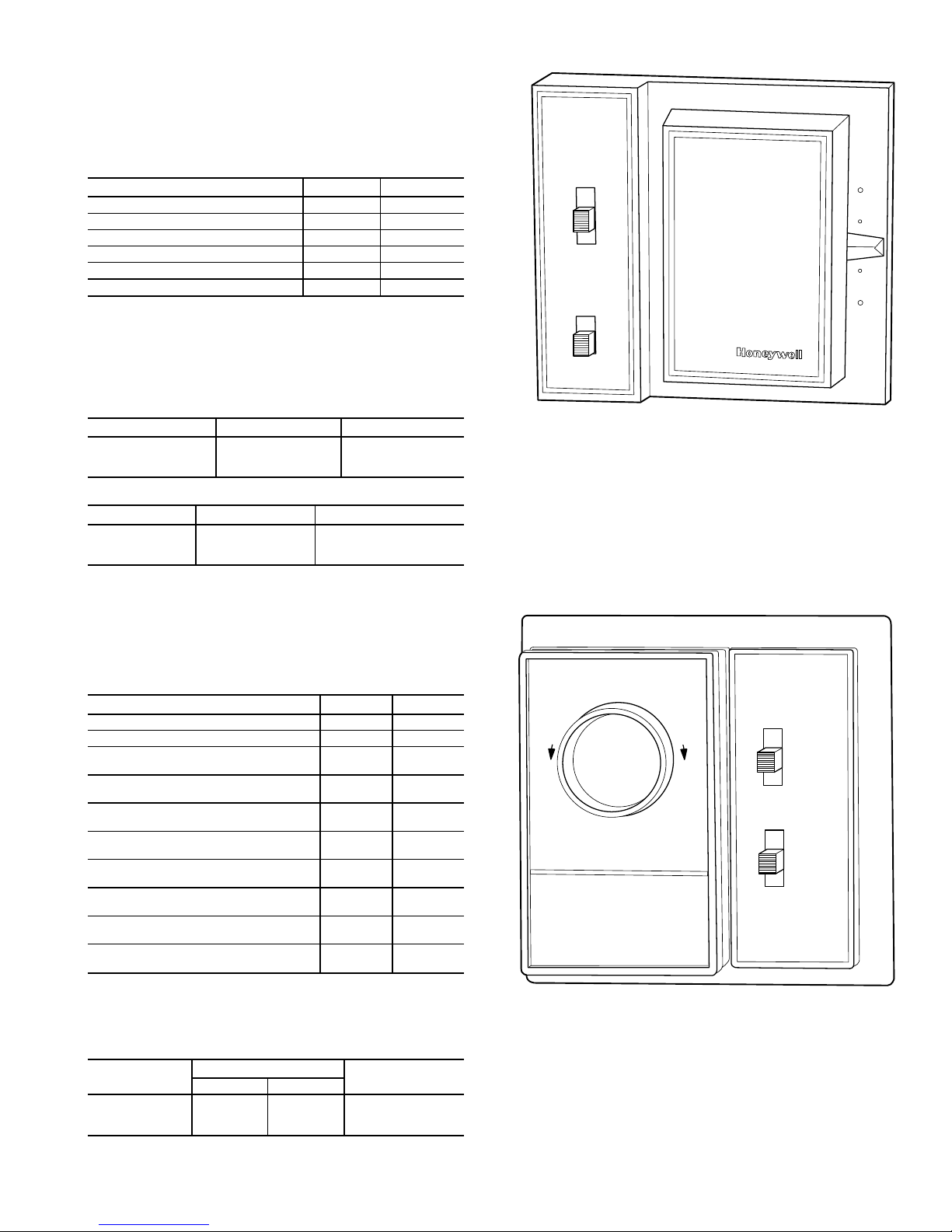

ALTERNATE WALL THERMOSTATS

WallThermostat (Honeywell Model T4039) with

Manual 3-Speed Fan Switch and ON-OFF Switch

Temperature range is approximately 55 to 95 F in 10° F

increments from 75 F midpoint. Scale is marked warmercooler. Thermostat mounts in 4-in. square junction box or

2-ganged outlet boxes.

SYSTEM MODEL PACKAGE

2-Pipe Cooling Only T4039B* 23-05

2-Pipe Heating Only T4039F* 23-03

2-Pipe Heating/Cooling† T4039F* 23-01

2-Pipe w/Total Electric Heat T4039M** 23-07

4-Pipe Heating/Cooling T4039M** 23-07

2-Pipe w/Auxiliary Electric Heat†† T4039M** 23-09

*Fan off breaks cooling circuit and fan.

†Includes one remote-mounted changeover on unit

**Fan off breaks both heating/cooling circuits and fan.

†† Includes 2 remote-mounted changeovers on unit.

NOTE: All above packages include thermostat, ON-OFF switch and HIMED-LOW switch.

Thermostat Electrical Ratings (Amperes)

Thermostat (Valve Load)

VOLTAGE NORMAL IN-RUSH

120V AC 0.32 1.00

240V AC 0.16 0.50

277V AC 0.14 0.43

Fan Switch

VOLTAGE FULL LOAD LOCKED ROTOR

120V AC 5.50 33.0

240V AC 2.75 16.5

277V AC 2.40 14.4

WallThermostat (Sunne Model154) with Manual

3-Speed Fan Switch and ON-OFF Switch

Temperature range is approximately 55 to 95 F in 10° F

increments from 75 F midpoint. Scale is marked warmercooler. Thermostat mounts in 4-in. square junction box or

2-ganged outlet boxes.

SYSTEM MODEL PACKAGE

2-Pipe, Cooling Only TC154-004 23-06

2-Pipe, Heating Only TC154-004 23-04

2-Pipe, Heating/Cooling

with Auto. Changeover*

TC154-004 23-02

2-Pipe, Heating/Cooling

with Manual Changeover

TC154-014 23-12

2-Pipe, Cooling with Total Electric

Heat and Auto. Changeover.

TC154-003 23-08

2-Pipe, Cooling with Total Electric

Heat and Manual Changeover

TC154-014 23-14

2-Pipe, Heating/Cooling with Auxiliary

Electric Heat and Auto. Changeover†

TC154-003 23-10

2-Pipe, Heating/Cooling with Auxiliary

Electric Heat and Manual Changeover

TC154-014 23-16

4-Pipe, Heating/Cooling with

Auto. Changeover

TC154-003 23-08

4-Pipe, Heating/Cooling with

Manual Changeover

TC154-014 23-14

*Includes one remote mounted changeover on unit.

†Includes 2 remote mounted changeovers on unit.

NOTE: All of the above packagesincludethermostat, ON-OFF switch and

HI-MED-LOW switch.

Thermostat and Fan Switch Electrical Ratings

VOLTAGE

INDUCTIVE

PILOT DUTY

FLA LRA

125V AC 5.8 34.8 125 VA

240V AC 4.9 29.4 125 VA

277V AC 4.1 24.6 125 VA

ON

WARM

COOL

OFF

HI

MED

LO

FAN

HONEYWELL MODEL T4039

THERMOSTAT

HEAT

OFF

COOL

HI

MED

LO

F

A

N

W

A

R

M

E

R

C

O

O

L

E

R

SUNNE MODEL 154

THERMOSTAT

11

UNIT-MOUNTED CONTROLS

OFF

HI

MED

LO

Standard3-Speed Switch — Switch has OFF, HIGH,

MED and LOW positions. Switch is also equipped with auxiliary connection energized when switch is in HIGH, MED

or LOW position.

COMBINATION THERMOSTAT AND TOGGLE SWITCH

CombinationThermostat/ON-OFF ToggleSwitch

(Package 24-R*) — Includes Model TF103 2-pipe thermostat and toggle switch. Used as special fan control for cycling fan from HIGH to LOW on cooling; from LOW to

OFF on heating.

OFF

HI

MED

LO

Combination Thermostat/3-Speed Switch (Pack-

ages 24-L, M, N, Pand Q*) — Thermostat and standard switch

are unit mounted in a common electrical junction box.

Package 24-L includes Model TF103 2-pipe thermostat

and standard 3-speed switch, plus automatic changeover for

mounting on supply pipe.

Package 24-M and 24-N include Model TF103 2-pipe thermostat and standard 3-speed switch only.

Package 24-P includes Model TH104 4-pipe thermostat

and standard 3-speed switch. May be used on 4-pipe systems with electric valves or on 2-pipe systems with total electric heat.

Package 24-Q includes Model TH104 4-pipe thermostat,

standard 3-speed switch and 2 automatic changeover switches

for 2-pipe systems with auxiliary electric heat.

* Packages listed on current price pages.

12

T wo-PipeThermostat,Model TF103 — This single-

pole, double-throw (SPDT) thermostat has snap-action contacts. The standard temperature range is 60 - 90 F.

Four-Pipe Thermostat,Model TH104 — With this

thermostat, heating and cooling are sequenced (automatic

changeover) with 6 degree separation between HEATING

ON and COOLING ON. The standard temperature range is

60-90F.

Thermostat Electrical Data

(Pilot Duty — 125 VA at 120-277 v)

ITEM VOLTS FLA LRA

TF103

and

TH104

120 16 80

240 12 60

277 10 50

Automatic Changeover (Summer-Winter Switch) —

The automatic-changeover thermostat is a single-pole doublethrow (SPDT) thermal switch in a moistureproof and dustproof enclosure. Thermostat mechanism and lead ends are

hermetically sealed in a polypropylene enclosure with epoxy resin. Device clamps on coil supply pipe with end snap-on

clip.

The set point temperatures are factory set. When water

temperature rises above 80 F (approximately), the thermostat switches to the winter cycle. When water temperature

drops below approximately 70 F, the thermostat switches to

the summer cycle. Switch reset is automatic.

STEMCO

416-79

L80 8220

AUTOMATIC CHANGEOVER (Summer-Winter) SWITCH

13

BASIC DEFINITIONS

Unit Hand — When facing the supply air outlet from the front of the unit (air blow-

ing in your face), your right hand will be the right hand side of the unit and your left

hand the left hand side of the unit.

Same End Connection (2 Pipe or 4 Pipe) — All piping connections are on the same end (side) of the unit. Controls

and electrical connection will be on the end (side) opposite the piping connection.

Standard 2-pipe units will be the same end connection.

NOTE:

Piping determines the hand of the unit.

Opposite End Connection (4-Pipe Option) — Hot water (HW) piping connections and electrical will be on the end

(side) opposite the chilled water (CW) and drain connections.

NOTE:

Chilled water piping determines the hand of the unit.

Valve Packages For 2-Pipe Systems — Valve packages for standard 2-pipe

units are piped for same end connection (L.H. or R.H.).

Valve Packages for 4-Pipe Systems - Select 2 valve packages per unit.

NOTE:

Hot water valve package requirements may not be the same as chilled water valve package!

14

Hydronic Coil Arrangement

FIELD PIPING CONNECTIONS*

VERTICALFLOOR UNITS — 42VB, VE, VF

Pipe into cabinet end compartment

(opening in bottom and back).

VERTICAL FLOOR UNITS — 42VA, VC

Pipe to external connections (no cabinet).

CEILING UNITS (EXPOSED) — 42CG, CK,

DE, DF

Pipe through knock-outs in rear of cabinetto

coil and valve package connections.

CEILING UNITS (CONCEALED) — 42CA,

CE, CF, DA, DC

Pipe to connections extending from end of

unit.

VERTICAL UNITS — 42DD

Pipeto stub connectionsextending from side

of unit.

HORIZONTAL AIR HANDLERS (BELT

DRIVE) — 42BH

Pipe to stub connections extending through

side of unit.

Valvepackages arenot factory supplied with

these units.

WALL UNITS, FURRED-IN

Pipe to stub connections at the side of unit.

or into optional piping compartment. Op-

tionalpiping compartmentis required if valves

are factory installed. Factory installed valve

packageis limited toone 2-way or3-way motorized valve and 2 hand valves.

*Locationof field pipingconnections will varydepending on number of coil rows on factory-

supplied coil or arrangement of factory-supplied valves.

15

VALVE PACKAGES

General —

Table 1 lists acceptable pneumatic valves for

installation on 42 series fan coil units. There are limitations

on physical size of pneumatic valves, quantity and type of

matching components, required control interface. See Fig. 1

for symbols and placement of valves.

Consult factory before ordering any special valve pack-

age components that are not covered in this book.

Valve packages are shipped with the units or in unit cartons. Valve packages include belled ends for field soldering

to coil connections.

All factory-furnished cooling valve packages are arranged to position as much of the package as possible over

an auxiliary drain pan or drip lip. This helps minimize field

piping insulation requirements.

Fig. 1 — Symbol And Placement Of Valves

16

LEGEND For Fig. 1

Component Sizing —

1

⁄29 nominal (for5⁄89 OD copper tubing) or3⁄49 nominal (for7⁄89 OD copper tubing).

Manual Air Vent — Standard component - Brazed into high point of hydronic cooling and/or heating coil circuit.

Automatic Air Vent — Brazed into high point of coil circuit.

Coil Connections (Positions A & B) — When isolation valve only is added to supply or return line, the isolation valve

will be factory brazed to the coil stub-out. Addition of any other component or connection to the supply or return line

will change the respective coil connection(s) to one of the following:

STANDARD: Swage fitting for field braze.

OPTION: Union(s) added by factory for field connection.

Service Fittings (PositionsC&D)—Optional fittings for attaching pressure/temperature sensing devices to obtain

pressure drop or temperature differential accross coil. Used with ball valve or balance valve where extremely accurate

water flow balancing is required.

GAGE COCK: Pressure test only - In supply and return lines.

PRESSURE TEST PORT: Pressure test only - In supply and return lines.

INSERTION TEST PORT: Pressure/Temperature test - In supply and return lines.

Water Flow Balancing (Positions E, F, & H) — Only one device per total valve package to be used for balancing

water flow through the coil. When isolation valve (ball valve or ball valve with memory stop at position H) is used for

water flow balancing, do not specify additional balancing device at position E or F. When balancing device is specified

at position E or F, isolation valve does not require balancing feature at position H (See exception, 3-way motorized

valve).

CIRCUIT SETTER: May serve as a positive shut-off valve in lieu of isolation valve at position H

(check service requirements).

BALANCING VALVE: Check specifications for service fitting requirements.

FIXED FLOW: No balancing required - When there are more devices on the supply line of the valve

package than on the return line, the factory may move this device to position E to fit valve package

within allotted space. Consult your factory representative to match the available fixed flow valve to your

job requirements.

Strainer (Position G) — Does not include blow down fitting and should not be used in lieu of main piping strainers.

Isolation Valves (PositionsH&J)—Normally requires one each on supply and return line (see exception under

circuit setter). When position H is used for balancing (ball vall or ball valve with memory stop), check specifications for

service valve requirements.

GATE VALVE: Shut-off only - Do not use for balancing.

BALL VALVE: Shut-off/balance - No memory stop.

BALL VALVE WITH MEMORY STOP: Shut-off/balance - Memory stop allows re-opening to balance point

after usage as a shut-off.

17

VALVE PACKAGES (cont)

Two-Way Motorized Control Valve

The 2-way motorized valve motor drives valve open

and a spring returns valve to normally closed position

(no water flow with unit OFF).

Supplyconnection at coil will beswage fit forfield braze

(standard) or union (option). Return connection at coil

will be factory brazed if isolation valve only. Addition of

anyother component willrequire swage fitfor field braze

or optional union connection.

Check job specifications for system pressure, pressuredrop limitations and flow rateprior to selectingvalve

package components or valve package size (

1

⁄29,3⁄49,

etc.).

2-PIPE SYSTEM (One ValvePackage) or 4-PIPE SYS-

TEM (Two Valve Packages) Application:

• 2 Pipe - Hydronic Heating Only

• 2 Pipe - Hydronic Cooling Only

• 2 Pipe - Hydronic Cooling with Total Electric Heat

• 4 Pipe - Hydronic Cooling and Heating

NOTE:A

1

⁄4-in.bypass line is included inthe piping packagewhen a 2-way valve is specified witha control package containing an automatic changeover device.

Two-Way Motorized Control Valve with

Aquastat Bleed Bypass Line

The 2-way motorized valve motor drives valve open

and a spring returns valve to normally closed position

(no water flow through coil with unit OFF).

The aquastat bleed bypass bleeds a small amount of

water from supply to return when control valve is closed

(requiredfor systemwater temperature sensing by aquastat). Aquastat (A) clips on supply line upstream from

aquastat bleed bypass (as shown at right). It senses

system water temperature to prevent cooling operation

withhot water in system piping or heatingoperation with

chilled water in system piping. Additional aquastat requiredto lock out the optionalauxiliary electricheat when

hot water in system.

Supply and return connections at coil will be swage fit

for field braze (standard) or unions (option).

Check job specifications for system pressure, pressuredrop limitations and flow rateprior to selectingvalve

package components or valve package size (

1

⁄29,3⁄49,

etc.).

2-PIPE SYSTEM (One Valve Package) Application:

• 2 Pipe - Hydronic Cooling and Heating

• 2 Pipe - Hydronic Cooling and Heating with Auxiliary

Electric Heat

NOTES: Additional aquastat required as noted above.

18

Three-Way Motorized Control Valve

On the 3-way motorized valve flow is normally closed

to coil and open to system return. Motor closes bypass

flow to system return while opening flow through coil.

Waterbypasses coil and flows directly to system return

when unit is OFF.

The aquastat (A) clips on supply line upstream from

3-way valve (as shown above). It senses system water

temperature to prevent cooling operation with hot waterin system piping or heating operation withchilled waterin system piping.Aquastat(s) requiredfor 2-pipe cooling

and heating with automatic changeover control and/or

auxiliary electric heat.

A bypass balancing valve may be specified in the bypass line to permit equal flow balancing.

Supply and return connections at coil will be swage fit

for field braze (standard) or unions (option).

Check job specifications for system pressure, pressuredrop limitations and flow rateprior to selectingvalve

package components or valve package size (

1

⁄29,3⁄49,

etc.).

2-PIPE SYSTEM (One ValvePackage) or 4-PIPE SYS-

TEM (Two Valve Packages) Application:

• 2 Pipe - Hydronic Heating Only

• 2 Pipe - Hydronic Cooling Only

• 2 Pipe - Hydronic Cooling with Total Electric Heat

• 2 Pipe - Hydronic Cooling and Heating

• 2 Pipe - Hydronic Cooling and Heating with Auxiliary

Electric Heat

• 4 Pipe - Hydronic Cooling and Heating

No Motorized Control Valve

When isolation valves only are specified, they will be

brazed to the coil stub-outs.

Check job specifications for system pressure, pressuredrop limitations and flow rate prior toselecting specific components or valve package size (

1

⁄29,3⁄49, etc.).

2-PIPE SYSTEM ONLY (One Valve Package)

Application:

• 2 Pipe - Hydronic Heating Only

• 2 Pipe - Hydronic Cooling Only

NOTES:

1. Continuous water flow, chilled water or hot water.

2. Not recommended for high humidity applications.

3. Not recommended with unit-mounted thermostat on

vertical units (except package R).

4. The addition of any other component(s) will require

swage fitting for field braze or optional union conection.

19

VALVE PACKAGE ARRANGEMENTS

20

LEGEND

— Ball Valve

— Ball Valve with Memory Stop

— Gate Shut Off Valve

— Balancing Valve

— Circuit Setter

— Motorized 2-Way Valve

— Motorized 3-Way Valve

* When aquastat is used for automatic changeover, bypass is re-

quired as indicated by dashed line.

NOTES:

1. Packages factory furnished and installed.

2. Valves are

5

⁄8-in. ODS unless otherwise specified.

3. If an automatic flow control valve is added, it will be located on

supply line between shutoff valve and coil (or motorized control

valve, if supplied).

4. Packages are listed on current price pages.

21

VALVE PACKAGE ARRANGEMENTS (cont)

LEGEND

ITEM DESCRIPTION

Pneumatic Control Valve, 2-Way

Code 18(typical) -2* (

1

⁄2-or5⁄8-in. ODF tubing conn) or

Code 18(typical) -3* (7⁄8-in. ODF tubing conn)

Pneumatic Control Valve, 3-Way

Code 18(typical) -14* (1⁄2-or5⁄8-in. ODF tubing conn) or

Code 18(typical) -5* (7⁄8-in. ODF tubing conn)

*Valve packages listed on current price pages.

NOTES:

1. Pneumatic valves are field furnished for factory installation.

2. To simplify valve installation and maintenance, cabinet units with

4-pipe coils must have opposite-end connections.

3. Alternate designations for the terms N.O., N.C. and RETURN on

3-way valves are as follows:

Manufacturer N.O. N.C. Return

Barber-Coleman B A AB

Honeywell B A AB

Johnson Service N.O. N.C. C

Powers B U C

4. All orders entered must include a job specific piping diagram OR

reference can be made to standard arrangements 18-A through

18-E as shown here.

5. Hand valves shown in Arrangements 17-A through 17-F may be

included with pneumatic valves. These arrangements should also

be shown on piping diagrams submitted.

22

Table 1 — Acceptable Field-Furnished Pneumatic Valves

MANUFACTURER VALVE NUMBER TYPE MODE

SIZE (in.)

(OD Male Flare)

CAPACITY

(CV) RATING

HONEYWELL

VP517A 3-WAY MIXING

7

⁄

8

3.0, 4.0, 6.3

VP522A&B 3-WAY SEQUENCING

5

⁄8or7⁄

8

1.6/2.5 or 2.5/3.5/4.0

VP526A 3-WAY MIXING

5

⁄

8

1.6, 2.5

VP527A 2-WAY N.O.

1

⁄

2

0.63, 1.0, 1.6

VP513A 2-WAY N.O.

5

⁄8or7⁄

8

2.5, 4.0

VP513B 2-WAY N.C.

5

⁄

8

1.0, 1.6, 2.5

VP531A 2-WAY N.O.

5

⁄8or7⁄8(ODS) 1.6, 2.6, 3.3

JOHNSON

SERVICE

V4332 3-WAY MIXING

1

⁄

2

1.2, 2.0

V4334 3-WAY MIXING

5

⁄

8

4.7

V4440 3-WAY SEQUENCING

1

⁄

2

1.4, 2.4

V4440 3-WAY SEQUENCING

5

⁄

8

4.1, 4.7

V3766 2-WAY N.O.

1

⁄

2

1.0, 1.7, 3.2

V3966 2-WAY N.C.

1

⁄

2

1.7, 3.2

BARBER-

COLEMAN

VK9312 3-WAY MIXING

5

⁄

8

2.0, 4.0

VK9332 3-WAY SEQUENCING

5

⁄

8

1.7, 2.4, 4.0

VK9212 2-WAY N.O.

5

⁄

8

0.4, 1.3, 2.2, 3.3

VK9222 2-WAY N.C.

5

⁄

8

0.4, 1.3, 2.2, 3.3

MCC

POWERS

VP656-0011, 10, 09 3-WAY MIXING

1

⁄

2

1.5, 2.5

VP658-0004, 5 3-WAY DIVERTING

1

⁄

2

2.5

VP658-0050, 51 3-WAY SEQUENCING

1

⁄

2

1.5, 2.5

VP658-0004, 5 2-WAY N.O.

1

⁄

2

1.0, 2.5

VP656-0002, 4 2-WAY N.O.

1

⁄

2

0.9, 2.1

VP656-0012 2-WAY N.C.

1

⁄

2

2.1

ROBERTSHAW

2582 (V8200) 2-WAY N.O.

1

⁄

2

0.4, 0.6, 1.0, 1.6

2583 (V8300) 3-WAY MIXING

1

⁄

2

1.6

2561 (V6101) 2-WAY N.C.

1

⁄2,5⁄

8

1.2, 2.2, 4.1

2561 (V6102) 2-WAY N.O.

1

⁄

2

1.0, 1.6

2563 (V6300) 3-WAY MIXING

1

⁄

2

1.6

2563 (V6301) 3-WAY MIXING

5

⁄

8

2.5

2569 (V6900, 01) 3-WAY SEQUENCING

1

⁄2,5⁄8,7⁄

8

.6, 1.0, 1.1, 1.6,

2.5, 3.2, 2.4, 4.0, 4.5

CV— See Note 5.

N.C. — Normally Closed

N.O. — Normally Open

OD — Outside Diameter

NOTES:

1. This reference table lists valves that are acceptable because of

capacityand piping connection type.Actualvalve selection for specific mode (N.O. or N.C.) and capacity rating (CV) to meet jobsite

conditions must be made by field personnel.

2. Valve size (

1

⁄2-,5⁄8-, and7⁄8-in. OD) designates the matching tubing size.

Use price page package 18-2 or 18-4 for selecting

1

⁄2-in. or5⁄8-in.

OD valves. Use price page package 18-3 or 18-5 for7⁄8-in. OD

valves.

3. The

1

⁄2-in. and5⁄8-in. OD valves are usedprimarily on 42C (ceiling)

and 42V (vertical) room fan coil units. The7⁄8-in. OD valves are

recommended for use on 42D (ducted) units.

4. Flare connections are 45° SAE flare with body threaded for standard flare nuts.

5. The CVcapacity rating is the gpm flow through a valve at 1.0 psi

pressure drop.

EXAMPLE: A 2.5 CVvalve has a flow of 2.5 gpm at 1.0 psi pressure drop.

As flow changes, pressure drop can be determined by the

formula:

Actual gpm

2

P=

C

V

6. Restrictions imposed by limitedpiping enclosures often require that

thevalve manufacturer’s recommendation for obstruction free service clearances be waived. Service/isolation valves normally specified will permit removal ofthe entire pneumatic valve for field service if necessary.

7. Certain combinations of pipingaccessoriesand control valves have

proven unacceptable in the past, therefore the factory must reserve the right of review for final acceptance.

8. Consult factory on all applications involving valves with thermostatic actuators or built in pneumatic thermostats.

23

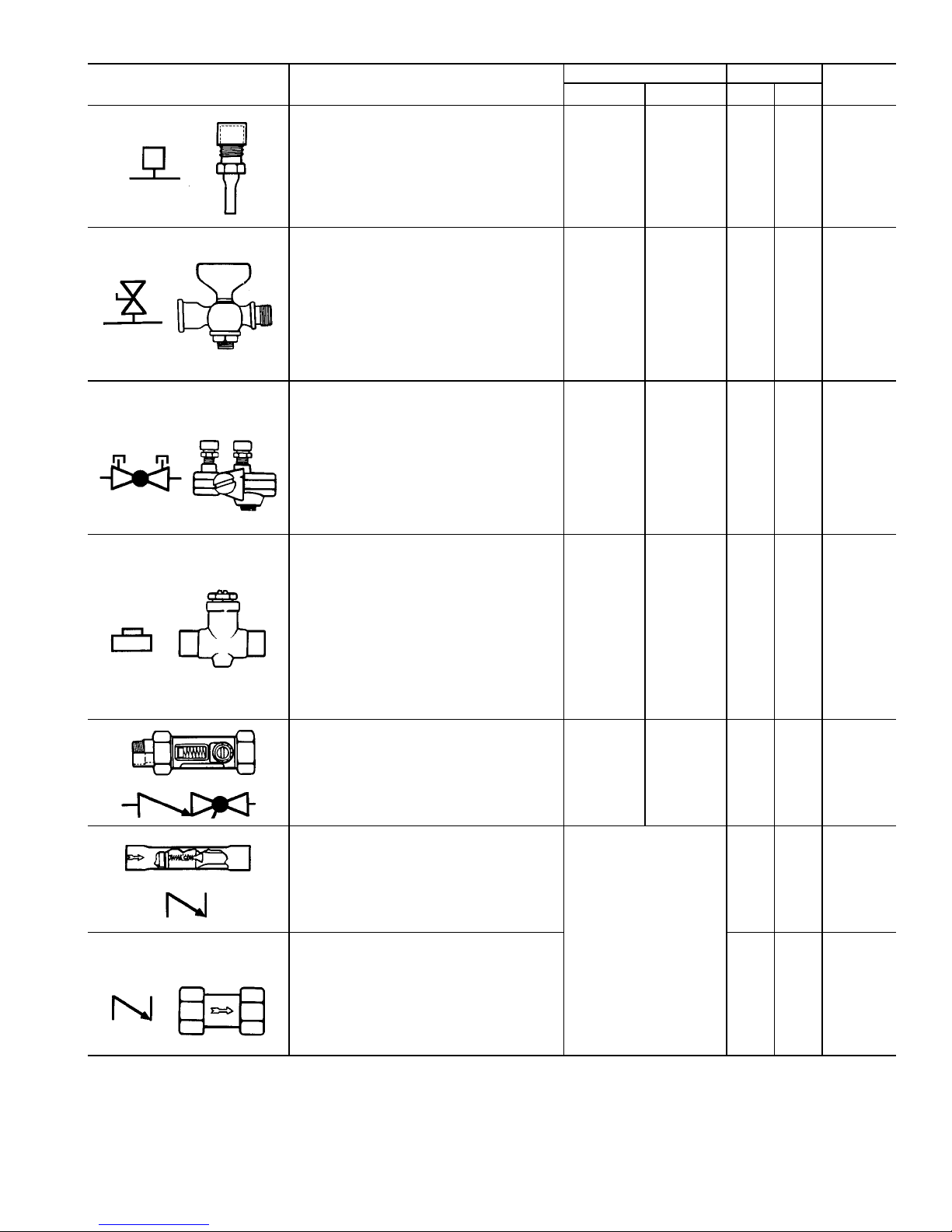

PIPING COMPONENTS

SYMBOL/SKETCH DESCRIPTION

CVFACTOR RATING

STEAM

USE

1

⁄

2

3

⁄

4

PSI F

MANUAL AIR VENT: Threaded brass

needle valve with screwdriver slot

for adjustment.

Application - Body brazed into high

point of heating and cooling coils for

bleeding air from coil. Standard item

on all hydronic coils (not used on

steam or DX coils). Should not be used

in lieu of main system air vents.

N/A N/A 400 100 NO

AUTOMATIC AIR VENT: Nickel

plated brass valve, fiber-disc type, with

positive shut-off ballcheck and quick

vent feature via knurled vent screw.

Application - Optional replacement for

manual air vent. Automatically passes

minute quantities of air through the

fiber discs which expand upon contact

with water, completely sealing the

valve. As air accumulates, the fiber

discs dry and shrink, repeating the

cycle. Not recommended for removing

large quantities of air encountered

during initial start-up or subsequent

draining and refilling. Should not be

used in lieu of main system air vents.

N/A N/A 125 240 NO

SWAGE: Copper tube end expanded

to accept a copper tube of the same

size for factory or field brazing.

Application - Used where possible for

all tubing joints for best joint integrity.

(*) See page 30 for ratings of different

joining materials and operating

temperatures.

N/A N/A

300

(*)

200

(*)

YES

UNION: Combination wrought

copper/cast brass union assembly,

solder by solder.

Application - Used for quick connect

(and disconnect) of valve package

components to minimize field labor

and facilitate servicing of unit.

(*) See page 30 for ratings of different

joining materials and operating

temperatures.

N/A N/A

300

(*)

200

(*)

YES

INSERTION TEST PORT: Brass body

valve for acceptance of test probe (up

to

1

⁄8in. diameter).

Application - Installed on one (or both)

sides of the coil to allow for temperature

or pressure sensing. Used for close

tolerance water balancing and

service analysis.

N/A N/A 250 250 NO

24

SYMBOL/SKETCH DESCRIPTION

CVFACTOR RATING

STEAM

USE

1

⁄

2

3

⁄

4

PSI F

PRESSURE TEST PORT: Brass body

1

⁄4service access fitting with

removable depressor type core.

Application - Installed on both sides of

the coil to allow for pressure sensing.

Attach pressure gages to facilitate

close tolerance water balancing.

N/A N/A 400 210 NO

GAGE COCK: Brass shut-off valve

with

1

⁄4FPT fitting for attachment of

pressure gages.

Application - Installed on both sides of

the coil to allow for pressure sensing.

Attach pressure gages to facilitate

close tolerance water balancing. May

be used in bleed bypass line to

regulate water flow.

N/A N/A 200 250 N/A

B+G

CIRCUIT SETTER: Variable water

flow balancing valve with manual

adjustment knob, pointer, percent-open

scale, memory stop and integral

pressure read-out ports.

Application - Used for close tolerance

water flow balancing. Positive shut-off

ball valve feature allows usage as combination balancing and shut-off valve.

1.95 4.15 200 250 NO

BALANCE VALVE: Variable water

flow manual balancing valve with

screwdriver slot adjustment screw.

Application - Often used in conjunction

with test port fittings for water flow

balancing. Balance by temperature

differential or coil pressure drop (check

specifications for service fittings

required if balancing by pressure drop).

May be used in 3-way valve bypass

line to permit equal flow balancing.

3.0 8.9 150 200 NO

FLOW SETTER: Variable water flow

manual balancing valve with

screwdriver slot adjustment and direct

gpm read-out sight glass.

Application - Used for water flow

balancing (8.0 gpm maximum).

2.2 5.4 125 210 NO

FIXED FLOW VALVE: Spring and

insert type (non-adjustable).

Application - Used for water flow

balancing. Valve automatically adjusts

the flow to within 10% of set point. Not

available for flow rates above 8 gpm.

Valve orifice size

determines C

V

factor. The orifice

of these fixed flow

valves changes as

flow is regulated.

As the water

pressure increases,

the orifice size

decreases, thereby

automatically

limiting the flow

rate to the

specified gpm

(+/210%).

125 240 NO

HAYES

FIXED FLOW VALVE: Flexible orifice

type (non-adjustable).

Application - Used for water flow

balancing. Valve automatically adjusts

the flow to within 10% of set point.

Requires 15 psi (35 ft) of additional

pump head for proper operation.

150 160 NO

25

PIPING COMPONENTS (cont)

SYMBOL/SKETCH DESCRIPTION

CVFACTOR RATING

STEAM

USE

1

⁄

2

3

⁄

4

PSI F

STRAINER: Y-type body with

50 mesh stainless steel screen.

Application - Used for removal of small

particles from system water during

normal system operation. Should not

be used in lieu of main system

strainers. Strainer screen may have to

be removed during initial high pressure

system flushing during start-up.

Screen should be removed and cleaned

per normal maintenance schedule

(provisions for strainer blow-down

not provided).

9.0

Clean

19.0

Clean

400 250 N/A

GATE VALVE: Manual shut-off valve.

Application - Used for unit isolation

during system flushing, servicing, etc.

Do not use for water balancing.

19.8 36.0 200 200 NO

GLOBE VALVE: Standard pattern,

manual shut-off and throttling valve.

Application - Used for unit isolation.

Not recommended for high flow rates

due to relatively high pressure drop.

1.8 3.9 200 200 NO

COMPRESSION STOP VALVE:

Manual shut-off valve.

Application - Used for unit isolation

during system flushing, servicing, etc.

Not recommended for high flow rates

due to relatively high pressure drop.

2.3 5.4 150 200 NO

BALL VALVE: Manual balance and

shut-off valve.

Application - Used for unit isolation

and water flow balancing. Without

memory stop feature water balance

point must be marked by installer (if

necessary). Check specifications for

service fittings required when used for

water balancing.

4.0 7.5 400 200 YES

BALL VALVE WITH MEMORY STOP:

Manual balance and shut-off valve.

Application - Used for unit isolation

and water flow balancing. The adjustable memory stop feature allows return

to the balance point after shut-off.

Check specifications for service

fittings required when used for

water balancing.

4.0 7.5 400 200 N/A

26

SYMBOL/SKETCH DESCRIPTION

C

V

FACTOR RATING

STEAM

USE

1

⁄

2

3

⁄

4

PSI F

2-WAY MOTORIZED VALVE: Electric

2-position flow control valve

(open/closed). Normally-closed body

with manual override lever. Installed in

supply line to unit.

Application - All standard control and

valve packages are based upon

normally-closed valves (valve

electrically powered open and closed

by spring return when electric power

removed). Manual override lever allows

valve to be placed in the open position

for secondary (unit) flushing, constant

water flow prior to start-up, etc.

Manual override is automatically

disengaged when valve is electrically

activated. Consult factory for

normally-open valve applications.

2.3 2.3 300 200

YES

15

PSI

MAX.

3-WAY MOTORIZED VALVE: Electric

2-position flow control valve (closed to

coil/open to bypass or open to coil/

closed to bypass). Normally-closed

with manual override lever. Installed in

supply line to unit.

Application - Same comments as

2-way motorized valve except with

manual override lever engaged the

valve is open to both ports and water

flow will take the path of least

resistance through the valve package

(not necessarily 100% through the coil).

5.0 5.0

300 200 N/A

SERVICE

2.8 2.8

BYPASS

2-WAY PNEUMATIC VALVE:

Pneumatic operated 2-way

control valve.

Application - Specified and supplied by

others when required as part of a

factory-assembled valve package.

See Table 1 for approved listing of

pneumatic valves suitable for

installation on various unit models.

SPECS VARY WITH SUPPLIER

3-WAY PNEUMATIC VALVE:

Pneumatically operated 3-way

control valve.

Application - Specified and supplied

by others when required as a part of a

factory-assembled valve package.

See Table 1 for approved listing of

pneumatic valves suitable for

installation on various unit models.

SPECS VARY WITH SUPPLIER

AQUASTAT: Water temperature

sensing electrical switch.

Application - Clips directly on nominal

size

1

⁄29 or3⁄49 copper tubing for

water temperature sensing. Must be

correctly located for proper control

operation.

NOTES:

1. Motorized 2-way valves have a maximum close-off differential of 25 psi.

2. Motorized 3-way valves have a maximum close-off differential of 10 psi.

27

CVFACTOR vs WATER PRESSURE DROP

CVFACTOR:

The flow rate in gallons per minute (gpm) through a piping component when the pressure drop (DP) in pounds per

square inch (psi) across the component is 1.0 (psi).

Pressure drop (ft-H

2

O) = 2.31 x psi (pressure drop)

GRAPH EXAMPLE:

DP for 2.0 gpm through a component with a C

V

of 1.0 is 4.0 psi x 2.31 = 9.24 ft-H2O

FORMULA EXAMPLE:

DP (ft-H2O) =

(gpm)

2

x 2.31 =

(2.0)

2

x 2.31 = 9.24 ft-H2O

(C

v

)

2

(1.0)

2

TOTAL PRESSURE DROP is the Sum of the pressure drop of all piping and components in the water flow path.

28

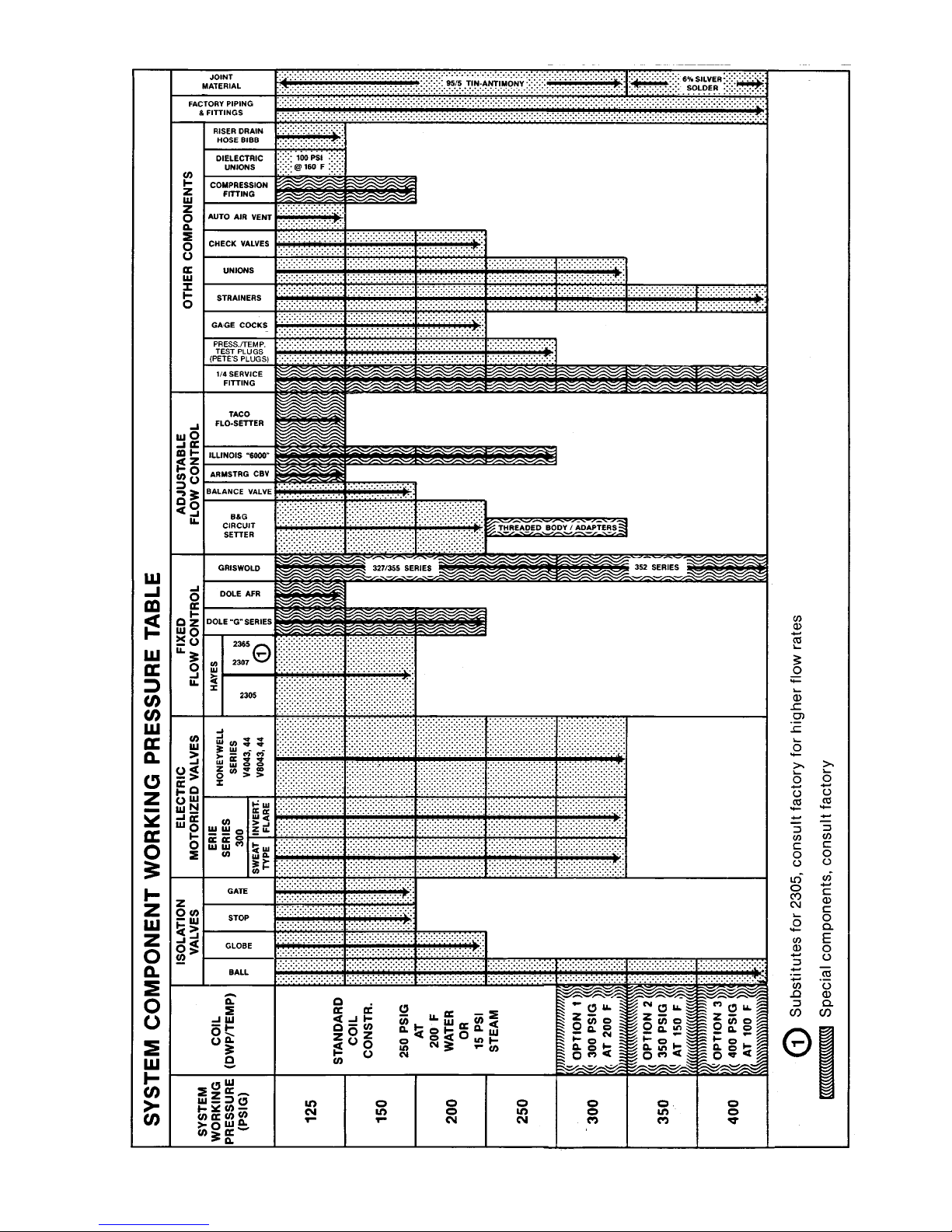

29

COPPER WATER TUBE AND JOINT MATERIAL PRESSURE RATINGS

JOINT MATERIALS

A 50-50 Lead-Tin at 200 F

Note 1

D 95-5 Tin-Antimony at 200 F

Note 2

B 50-50 Lead-Tin at 150 F E 95-5 Tin-Antimony at 150 F

C 50-50 Lead-Tin at 100 F F 95-5 Tin-Antimony at 100 F

1. Not recommended for high system water pressures.

2. Standard factory joint material.

THE ABOVE CHART IS FOR REFERENCE ONLY: Check all system component pressure ratings (coils, valves, pumps, etc.)

and any applicable local or national piping codes prior to specifying system pressure rating.

30

CORRECTION FACTORS FOR GLYCOL

(Equivalent water flow method for all 42 Series Models)

This method allows you to calculate cooling and heating performance without adjusting capacities for glycol

concentration.

After completing the standard selection procedure including water flow rates, use the correction multiplier shown below

to determine new (equivalent) flow rates required for the specified glycol concentration.

EXAMPLE:

COOLING PERFORMANCE REQUIRES 3.0 gpm of 100% WATER.

What flow rate of 30% glycol by voume will be required to match the cooling performance? Referring to the

chart above, you will note that the cooling flow rate multiplier for 30% glycol is 1.14.

100% WATER (3.0 gpm) x 1.14 = 3.42 gpm of 30% GLYCOL (EQUIVALENT FLOW RATE)

What will the new pressure drop be for 3.42 gpm of 30% glycol? Referring to the chart above, you will note

that the cooling pressure drop multiplier for 30% glycol is 1.27.

(A) Obtain pressure drop for 3.42 gpm of 100% water.

(B) Multiply (A) times 1.27 to obtain pressure drop for 3.42 gpm of 30% glycol.

31

Table 2 — Standard Accessories and Options

STANDARD ACCESSORIES

AND OPTIONS

UNIT SERIES — 42

Ceiling — Horizontal Floor — Vertical Ducted — Horizontal

Belt

Drive

Stack — Vertical

CA CE CG CK CF VA VB VF VC VE VG DA DC DE DF DD BH SG SH SJ

CABINET CHANGES

Front Panel, 16 Gage ••

Extended Cabinet when electric

heat or valves are installed

•••

Valve Compartment Extension, 10 in. •

Stamped Toe Space Return Grille ••

CLEANABLE FILTERS ••••••••• •••• • • • •

COILS

3-Row (2-row cooling, 1-row heating) ••

3-Row (high capacity) ••

4-Row (3-row cooling, 1-row heating) •••••••• • • •

4-Row (high capacity) ••••Std••• StdStdStdStdStdStd • • •

5-Row (4-row cooling, 1-row heating) •••••••• ••••• • • • •

5-Row (3-row cooling, 2-row heating) •••••••• • • •

6-Row (4-row cooling, 2-row heating) ••••• •

6-Row (high capacity) ••••• •

7-Row (6-row cooling, 1-row heating) •••• •

8-Row (6-row cooling, 2-row heating) •

DAMPERS

Manual — Adjustable through return

air opening

•••

Manual Adjustment, remote mounted •••

Manual — Rear opening with

sliding damper — not filtered

••

Outdoor Air Connection (6 in.),

with filter and with or without

damper ••••

Damper, Linkage and Motor wired to

auxiliary contact of 3-speed switch

•••

DECORATIVE COLORS

(See Carrier Fan Coil Paint

Selector Guide)

•• •• • • •

DISCHARGE GRILLES

Stamped Front Discharge • • Std

Double Deflection, installed •••• • •

Double Deflection, shipped

loose

•• ••• • • •

Reverse stamped for vertical discharge •

DRAIN PANS

Auxiliary Drip Lip — Included with

2- or 3-way motorized valves

••••• ••••

Tell-Tale, with 2nd drain connection ••••• ••••

Sleeved Steel Extension •••••

ELECTRIC HEATERS

Nichrome Wire Strip Heater ••••• ••••• • • •

Sheath Type Heater •••••

LEVELING LEGS

(maximum adjustment,

3

⁄4in.)

•••••

MOTORS

115-1-60 PSC Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std Std

208-1-60 PSC •••••••••• ••••• • • •

240-1-60 PSC •••••••••• ••••• • • •

277-1-60 PSC •••••••••• ••••• • • •

115/230-1-60 •

220/440-3-60 •

220-1-50 PSC •••• ••••• ••••• • • •

MOTOR QUICK-DISCONNECT PLUG •••••••••• ••••• • • •

OUTSIDE-AIR WALL BOX •••

RETURN AIR GRILLE, shipped loose •• • ••• •

TAMPERPROOF LOCKS (Camloc)

Access Panels •• •• • •

Access Doors •• •

VALVE PACKAGES ••••••••••Limited ••••• • • •

WALL PANELS (for recessed unit) •

WIRING PACKAGES ••••••••••Limited ••••• • • •

Copyright 1990 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 3

Tab 7a

PC 201 Catalog No. 514-203 Printed in U.S.A. Form 42-3XC Pg 32 6-90 Replaces: 42-2XC

Loading...

Loading...