Carrier 40KMC018-7N, 40KMC012-7N, 40KMC118-7EN, 40KMC018-3N, 40KMC024-7N Installation Manual

...

A

M

P

M

40KMC---N

INST ALLA TION MANUAL

GB - 1

40KMC---N

Split system “Global cassette” indoor unit

ENGLISH

IR Remote Control “Room Controller” “Zone Manager”

The unit can be used with infrared Remote Control, with the Carrier “Room

Controller” or “Zone Manager”.

Infrared control installation instructions are contained in the unit instruction and

maintenance manual.

Remote controls intallation instructions are contained in the relevant manuals,

supplied with the remote controls.

The operation and maintenance instructions for the indoor unit and the installation

instructions for the indoor and the outdoor unit are given in the manuals for each

unit. These are supplied with the unit.

Contents

Page

Dimensions and weight......................................................................................... 2

T echnical data....................................................................................................... 3

Technical data of electric heaters ......................................................................... 3

Material supplied .................................................................................................. 3

Operating limits..................................................................................................... 3

Components required for a complete installation................................................. 3

General information.............................................................................................. 4

Accessories .......................................................................................................... 4

Warnings: avoid .................................................................................................... 5/6

Installation ............................................................................................................ 6/8

Refrigerant connections ....................................................................................... 9

Electrical connections........................................................................................... 10/14

Fresh air renewal and conditioned air supply to adjacent room........................... 15/16

System configuration............................................................................................ 17

Operating test, address switch and address selector................................. 18

Fault code, button T: “EMERGENCY” and guide for the owner.................. 19

Indoor unit Indoor unit Indoor unit

item number item number 50Hz + item number

Sizes 50Hz electric heater 60Hz

with grille with grille with grille

12 40KMC012-7N 40KMC112-7EN 40KMC012-3N

18 40KMC018-7N 40KMC118-7EN 40KMC018-3N

24 40KMC024-7N 40KMC124-7EN 40KMC024-3N

28 40KMC028-7N 40KMC328-7EN 40KMC028-3N

36 40KMC036-7N 40KMC336-7EN 40KMC036-3N

48 40KMC048-7N 40KMC348-7EN 40KMC048-3N

60 40KMC060-7N 40KMC360-7EN 40KMC060-3N

40KMC---N

GB - 2

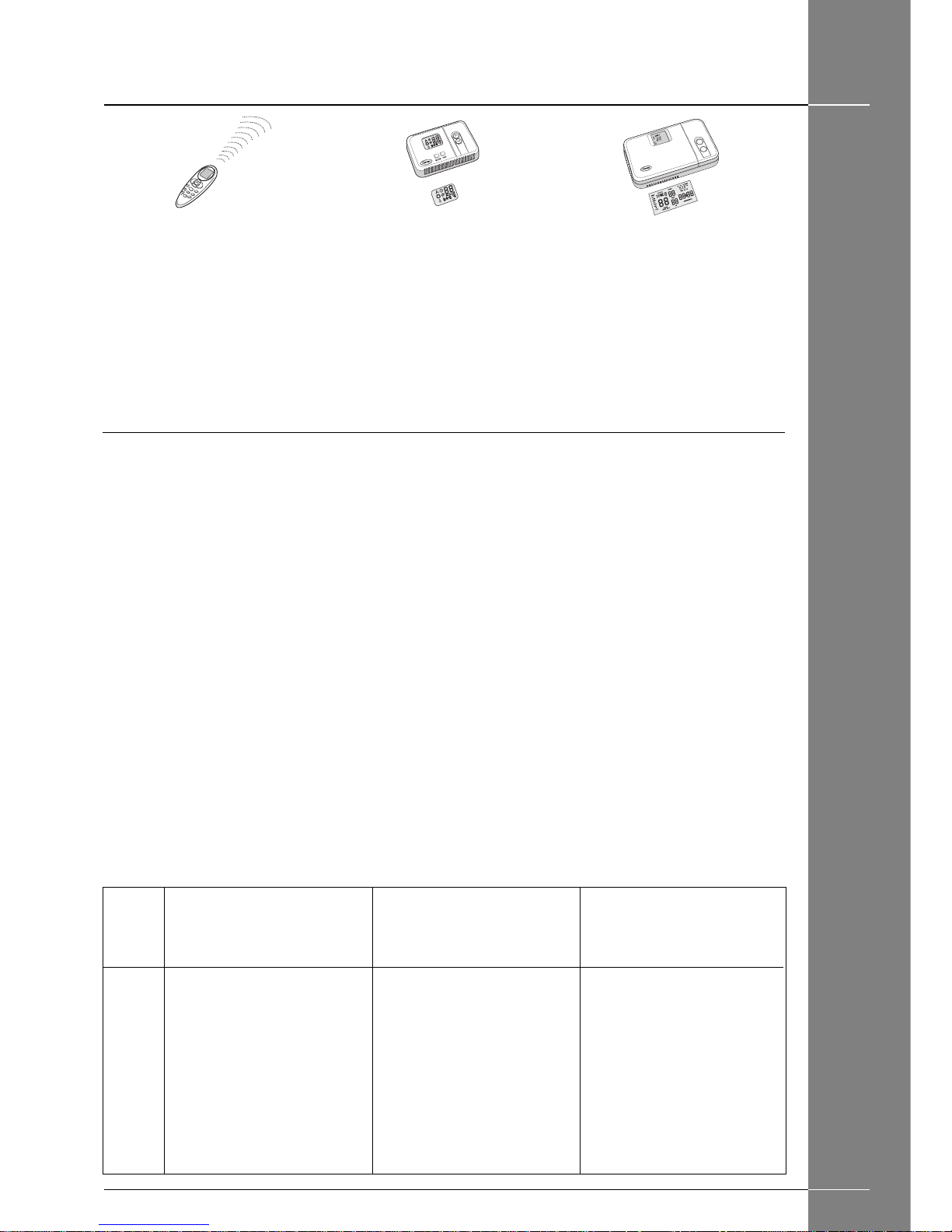

Dimensions and weight

40KMC---7N 012 018 024 028 036 048 060

Unit 17,5 19 19 36 38 38 41

Frame / Grille assembly 3335555

kg

575

298

120

225

280

56

52

91

575

158

720

550

515

Ø 150

Ø 70

50

30

Ø 25

813

595

825

120

298

168

237

960

825

Ø 150

66

48

Ø 25

Ø 100

150

40KMC 028N - 036N - 048N - 060N

40KMC 012N - 018N - 024N

40KMC---N

GB - 3

ENGLISH

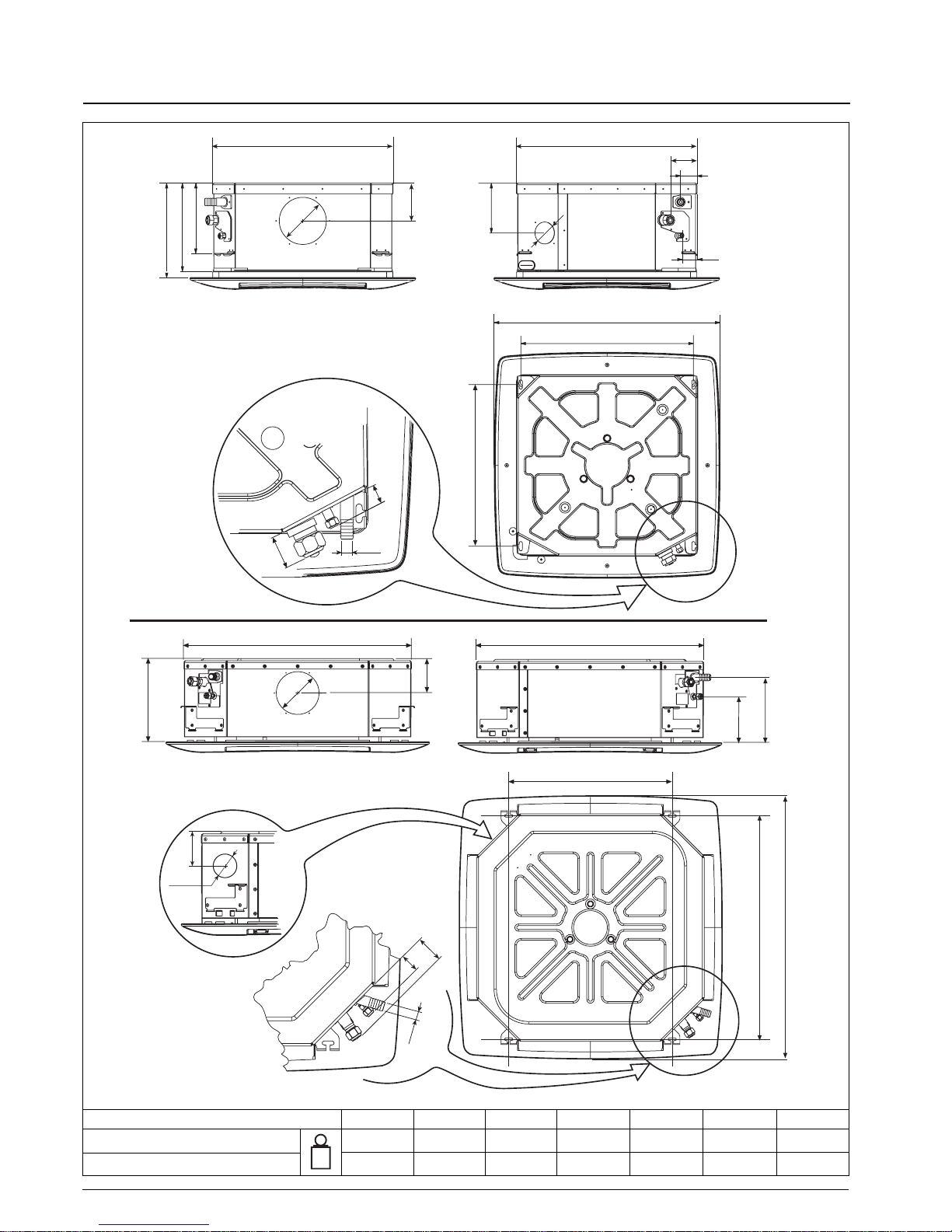

T echnical data

Note: For power supply wire size and delay type fuses, refer to the outdoor unit installation instructions.

Table I: Nominal data

POWER INPUT (WATT)

Cooling only

Sizes standard Cooling Heating

12 40KMC012-7N 75 75

18 40KMC018-7N 80 80

24 40KMC024-7N 105 105

28 40KMC028-7N 107 107

36 40KMC036-7N 131 131

48 40KMC048-7N 178 178

60 40KMC060-7N 231 231

Sizes with electric heaters Cooling Heating

12

40KMC112-7EN

75 1575

18

40KMC118-7EN

80 2580

24

40KMC124-7EN

105 2605

28

40KMC328-7EN

107 3107

36

40KMC336-7EN

131 3131

48

40KMC348-7EN

178 3178

60

40KMC360-7EN

231 3231

POWER INPUT (WATT)

Heat pump

Sizes standard Cooling Heating

12 40KMC012-7N 75 75

18 40KMC018-7N 80 80

24 40KMC024-7N 105 105

28 40KMC028-7N 107 107

36 40KMC036-7N 131 131

48 40KMC048-7N 178 178

60 40KMC060-7N 231 231

Sizes with electric heaters Cooling Heating

12

40KMC112-7EN

75 1575

18

40KMC118-7EN

80 1580

24

40KMC124-7EN

105 1605

28

40KMC328-7EN

107 2107

36

40KMC336-7EN

131 2131

48

40KMC348-7EN

178 2178

60

40KMC360-7EN

231 2231

Table II: Technical data of electric heaters (if installed)

Heat pump Cooling only

Mod. 12 18 24 28 36 48 60 12 18 24 28 36 48 60

Electric heater kW 1.5 1.5 1.5 2 x 1.0 2 x 1.0 2 x 1.0 2 x 1.0 1.5 1.5 1.5 2 x 1.0 2 x 1.0 2 x 1.0 2 x 1.0

++++++

capacity

1.0 1.0 2 x 0.5 2 x 0.5 2 x 0.5 2 x 0.5

Supply voltage V 230 230 230 230 230 230 230 230 230 230 400 400 400 400

(*) (*) (*) (*) (*) (*) 3N 3N 3N 3N

Max. current draw A 6.5 6.5 6.5 8.8 8.8 8.8 8.8 6,5 10.8 10.8 7.5 7.5 7.5 7.5

Control device GMC electronic control

Safety thermostat

N° 1

Manual reset thermostat

ST1 60°C

N° 1

Manual reset thermostat

ST2 100°C

Power supply cables mm23 G 1.5 3 G 1.5 3 G 1.5 4 G 1.5 4 G 1.5 4 G 1.5 4 G 1.5 3 G 1.5 3 G 2.5 3 G 2.5 5 G 1.5 5 G 1.5 5 G 1.5 5 G 1.5

Recommended fuse (gL type) A 88888888121210101010

*

In areas with a 2 kW limit for single-phase electric heaters it is possible to divide the power supply on two phases and neutral of a three phase supply with neutral.

Use cable type

H07 RN-F - 4G1,5 mm2 - 400V 2N ~

T able III:

Material supplied

Description Quantity Use

Installation instructions 1 Indoor unit installation

Owner's Manual 1 Correct use

Fresh air intake baffle 1 Air renewal

Table IV: Operating limits

Cooling / Heating Refer to outdoor unit installation manual.

Nominal single-phase voltage 230V ~ 50Hz 230V-240V ~ 60Hz

Main power supply Operating voltage limits min. 198V – max. 264V

Nominal three-phase voltage 400V 3N~ 50Hz

Operating voltage limits min. 342V – max. 462V

Electric heater 27

°C

T able V : Components required for a complete installation

Name Specification

Connection pipe

40KMC 012N Ø (1/2") 12.70 mm (Gas) / Ø (1/4") 6.35 mm (Liquid)

40KMC 018N, 024N, 028N, 036N, 048N and 060N Ø (1/2") 12.70 mm (Gas) / Ø (1/4") 6.35 mm (Liquid)

Wall sleeve

Wall cap

Finishing tape PVC film

Fastening tape

Tube insulation

Drain hose

I.D. 16 - 17 mm

Sealer putty

- Outdoor power supply cable H07 RN-F (60245IEC66),

cable with synthetic rubber insulation and polychloroprene sheath.

- Electrical connecting cable H07 RN-F (60245IEC66),

between indoor and outdoor unit cable with synthetic rubber insulation and polychloroprenesheath.

40KMC---N

GB - 4

Unit installation

Read this instruction manual thoroughly before starting

installation.

• This unit complies with the low-voltage (EEC/73/23) and

electromagnetic compatibility (EEC/ 89/336) directives.

• Follow all current national safety code requirements.

In particular ensure that a properly sized and connected ground

wire is in place.

• Check that the voltage and frequency of the mains power supply

are as required for the unit to be installed; the available power

source must be adequate to operate all other appliances

connected to the same line.

Also ensure that national safety code requirements have been

followed for the main supply circuit.

• Connection of the system to the mains power supply is to be

carried out in compliance with the wiring diagram shown in

the installation instructions of the external section.

• Connect indoor and outdoor units with field-supplied copper

pipes by means of flare connections. Use insulated seamless

refrigeration grade pipe only, (Cu DHP type according to

ISO1337), degreased and deoxidized, suitable for operating

pressures of at least 4200 kPa and for burst pressure of at least

20700 kPa. Under no circumstances must sanitary type copper

pipe be used.

• Where necessary, use field-supplied 25 mm I.D. PVC pipe (not

supplied) of appropriate length and with the correct thermal

insulation for the condensate drain extension.

• After installation thoroughly test system operation and explain all

system functions to the owner.

• Use this unit only for factory approved applications: the unit

cannot be used in laundry or steam pressing premises.

WARNING:

Disconnect the mains power supply switch before servicing

the system or handling any internal parts of the unit.

• Do not open the remote control to avoid possible damage. In case

of malfunctioning contact a qualified service engineer.

• This installation manual describes the installation procedures of

the indoor unit of a residential split system consisting of two

Carrier manufactured units.

Do not connect this unit to any other manufacturer's outdoor unit.

The manufacturer declines any liability for system malfunction

resulting from unauthorised system combinations.

• The manufacturer declines any liability for damage resulting

from modifications or errors in the electrical or refrigerant

connections.

Failure to observe the installation instructions, or use of the

unit under conditions other than those indicated in table

General information

“Operating limits” of the outdoor unit installation manual, will

immediately invalidate the unit warranty.

• Failure to observe electric safety codes may cause a fire hazard in

the event of short circuits.

• Inspect equipment for damage during transport. In case of

damage file an immediate claim with the shipping company.

Do not install or use damaged units.

• In case of malfunction turn the unit off, disconnect the mains

power supply and contact a qualified service engineer.

• Maintenance of the refrigerant circuit must only be carried out by

qualified personnel.

• All of the manufacturing and packaging materials used for this

appliance are biodegradable and recyclable.

• Dispose of the packaging material in accordance with local

requiremements.

• This equipment contains refrigerant that must be disposed of

correctly.

When disposing of the unit at the end of its operational life,

take the unit to an authorised waste disposal centre, or to the

original equipment dealer, for correct disposal.

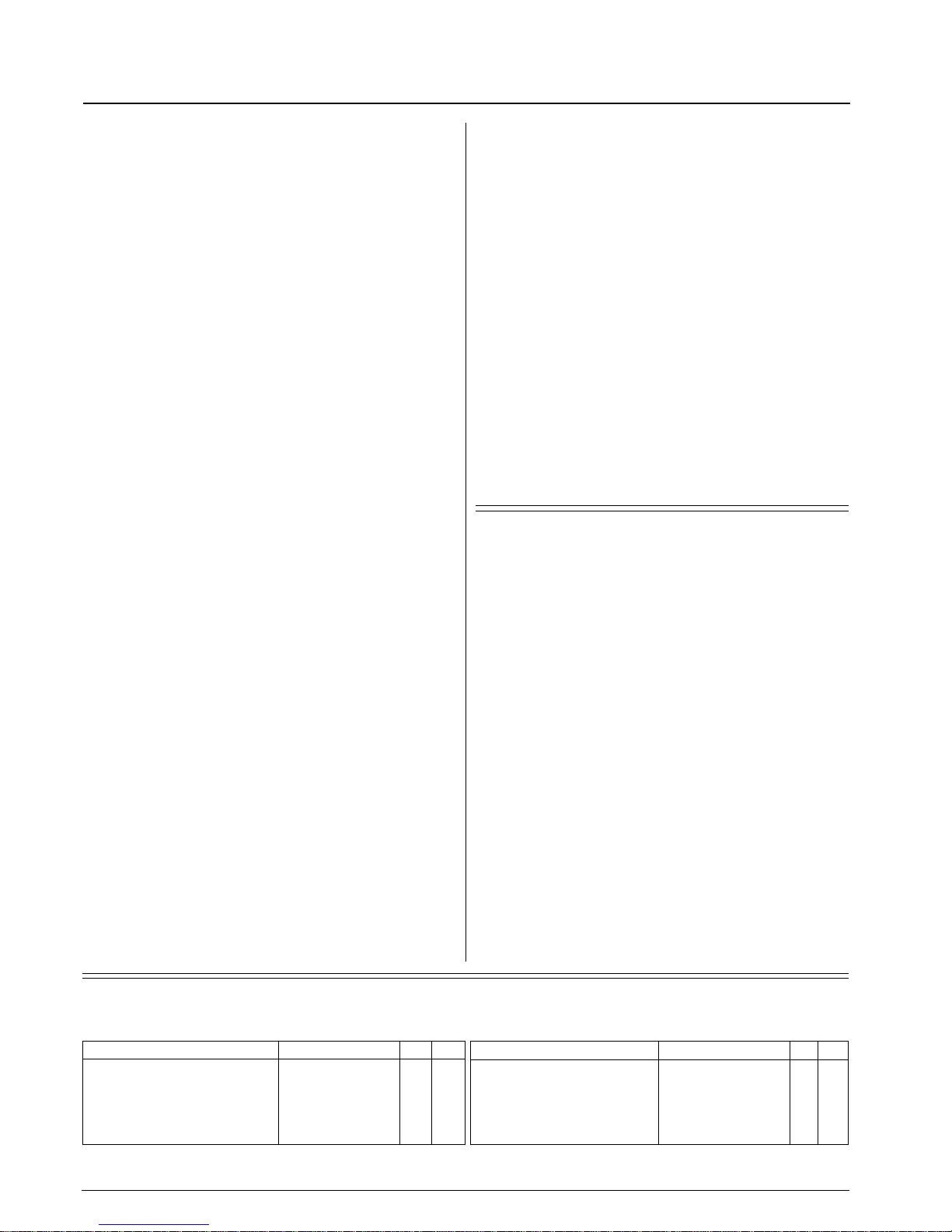

Choosing the installation site

Positions to avoid:

• Exposure to direct sunlight.

• Areas close to heat sources.

• On damp walls or in positions that may be exposed to water

hazard.

• Where curtains or furniture may obstruct free air circulation.

Recommendations:

• Choose an area free from obstructions which may cause uneven

air distribution and/or return.

• Consider using an area where installation is easy.

• Choose a position that allows for the clearances required.

• Look for a position in the room which ensures the best possible air

distribution.

• Install unit in a position where condensate can easily be piped to an

appropriate drain.

Notes:

(1)

Not to be used on units equipped with electric heater.

(2)

IMQ approved kit.

T able VI: Accessories A= mod. 012, 018, 024. B= mod. 028, 036, 048, 060.

Description Code A B

Air supply outlet obstruction kit

(1)

40GK-900---003-40 X

40GK-900---013-40 X

Room Controller kit (Grouping) 33MC9002 X X

Zone manager kit (Zoning) 33MC9001 X X

Zone manager 33MC-ZM X X

Infrared control kit

(2)

33MC-MC X X

Description Code A B

Electrostatic filter

40GK-900---001-40 X

40GK-900---011-40 X

Active carbon filter

40GK-900---002-40 X

40GK-900---012-40 X

Room Controller 33MC-RC X X

GB - 5

40KMC---N

ENGLISH

Warnings: avoid...

MAX 200 mm

... any obstruction of the unit air intake or supply grilles.

... exposure to direct sunshine, when the unit is operating in the

cooling mode; always use shutters or shades.

... positions too close to heating sources which may damage the unit.

... ascending sections of condensate drain piping.

These may only be used near the unit with a maximum height

difference of 200 mm from the top of the unit.

... flattening or kinking the refrigerant pipes or condensate pipes.

... installation in areas with high frequency waves. ... only partial insulation of the piping.

Non-level installation which will cause condensate dripping.

... exposure to oil vapours.

... connecting condensate piping to sewage system drain without

appropriate trap. Trap height must be calculated according to the

unit discharge head in order to allow sufficient and continuous

water evacuation.

... horizontal sections or curves of condensate drain piping with less

than 2% slope.

... excessive height difference between outdoor and indoor units

(see installation manual of outdoor unit).

40KMC---N

GB - 6

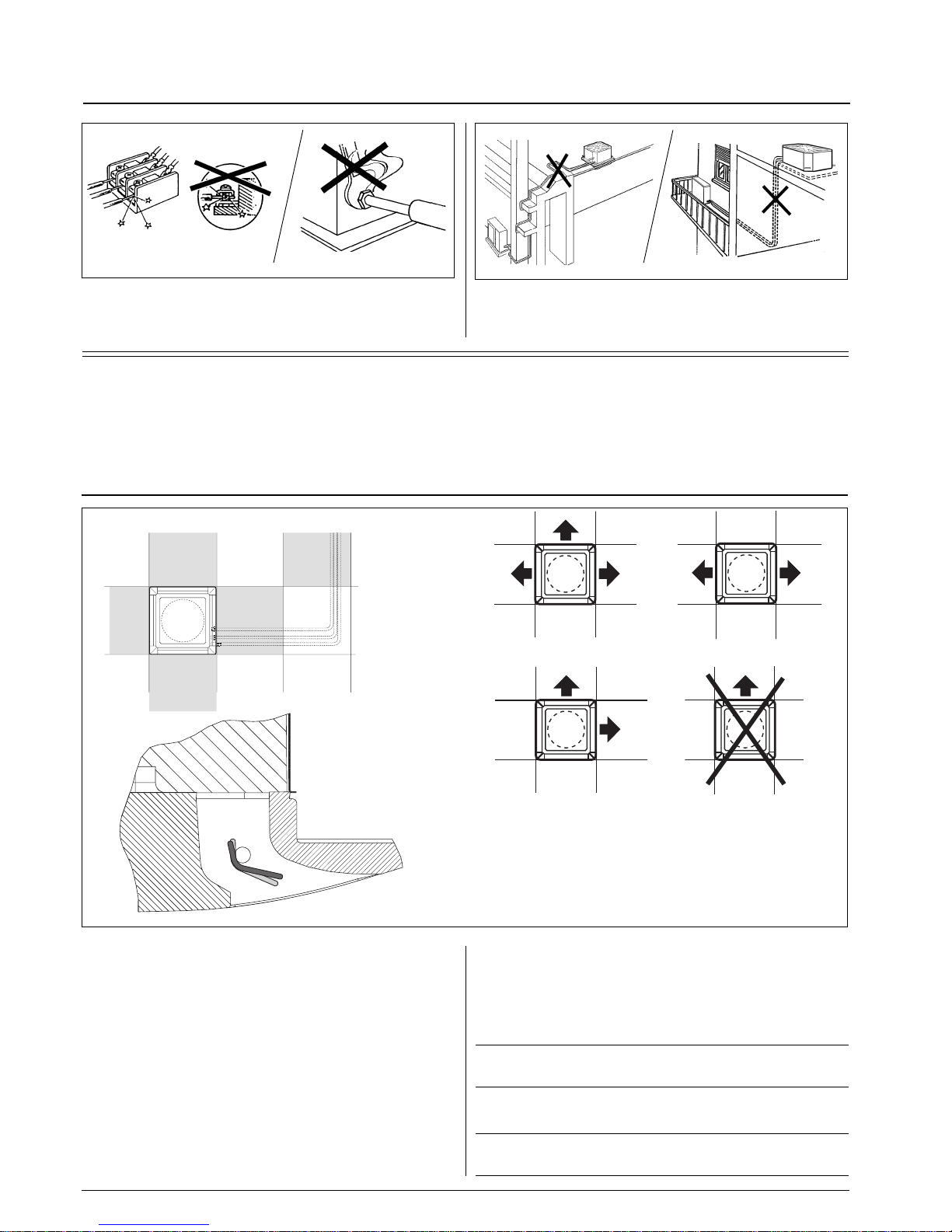

Max. 2 louvres closed

Heat pump: louvre position for correct air flow

Cooling: louvre position for correct air flow

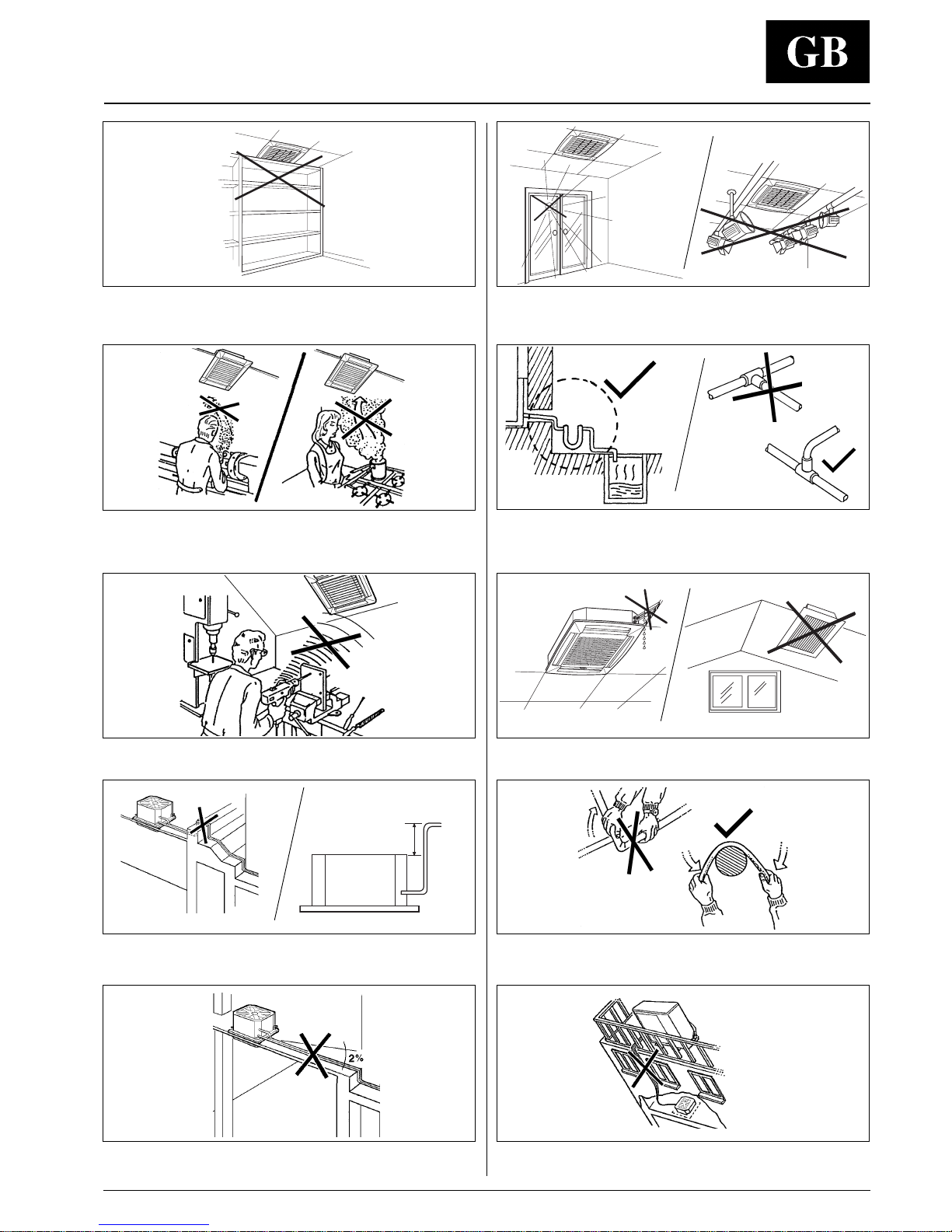

Warnings: avoid...

... unnecessary turns and bends in connection pipes (see

installation manual of outdoor unit).

Excessive connection pipe length (see installation manual of

outdoor unit).

... slack on electrical connections.

... disconnecting refrigerant connections after installation: this will

cause refrigerant leaks.

Installation

• In order to allow easy and rapid installation and maintenance,

make sure that in the selected position it is possible to remove

the ceiling panels or, if the ceiling is constructed using

masonry, that access to the unit is guaranteed.

ATTENTION:

Only restrict the air outlets as indicated in the drawing.

WARNING:

To close one or two air outlets use the special kit.

• Install the unit as centrally as possible in the room, the air flow

direction can be controlled by means of the remote control

(where used) or automatically, according to the operating mode

(cooling or heating): this will ensure optimum distribution of the

air in the room.

• During cooling mode operation the best position for the

deflecting louvres is one which allows air diffusion close to the

ceiling (Coanda effect).

In heating mode, the louvres should be positioned so that the air

is directed towards the floor, in order to prevent layers of hot air

forming in the upper part of the room (this will happen

automatically when the deflecting louvres are positioned in the

“AUTOMATIC” mode).

Alternatively the louvres can be placed in intermediate positions

(with infrared control only) or allowed to move continuously

(SWING).

Loading...

Loading...