Carrier 38MHRBQ12AA3 Specifications

38MHRB

Outdoor Unit Single Zone Ductless System

Sizes 09 to 24

Product Data

INDUSTRY LEADING

FEATURES / BENEFITS

A PERFECT BALANCE BETWEEN

BUDGET LIMITS, ENERGY SAVINGS AND

COMFORT.

The 38MHRB series ductless systems are a matched combination

of an outdoor condensing unit and an indoor fan coil unit

connected only by refrigerant tubing and wires.

The ductless system permits creative solutions to design problems

such as:

NOTE: Images are for illustration purposes only. Actual models

may differ slightly.

TABLE OF CONTENTS

PAGE

MODEL NUMBER NOMENCLATURE 3.................

STANDARD FEATURES AND ACCESSORIES 4...........

DIMENSIONS − OUTDOOR 5..........................

CLEARANCES − OUTDOOR 8.........................

SPECIFICATIONS − OUTDOOR COOLING ONLY 9........

COMPATIBILITY 9...................................

PERFORMANCE 9...................................

SPECIFICATIONS − OUTDOOR HEAT PUMP 10..........

COMPATIBILITY 10..................................

PERFORMANCE 10..................................

COOLING PERFORMANCE DATA − (COOLING ONLY) 11..

COOLING PERFORMANCE DATA − (HEAT PUMP) 12.....

HEATING PERFORMANCE DATA − (HEAT PUMP) 13......

APPLICATION DATA 14...............................

WIRING 15..........................................

AIR FLOW DATA 16..................................

SOUND DATA 16.....................................

SOUND PRESSURE IN OCTAVE BANDS 16..............

ELECTRICAL DATA 17...............................

FAN AND MOTOR SPECIFICATIONS 18.................

WIRING DIAGRAMS 19...............................

GUIDE SPECIFICATIONS 25...........................

S Add−ons to current space (an office or family room

addition)

S Special space requirements

S When changes in the load cannot be handled by the

existing system

S When adding air conditioning to spaces that are heated

by hydronic or electric heat and have no ductwork

S Historical renovations or any application where

preserving the look of the original structure is essential.

The ideal compliment to your ducted system when it is impractical

or prohibitively expensive to use ductwork.

The compact indoor fan coil units take up very little space in the

room and do not obstruct windows. The fan coils are attractively

styled to blend with most room decors. Advanced system

components incorporate innovative technology to provide reliable

cooling performance at low sound levels.

Inverter Technology

The inverter driven compressor is designed to run at various input

power frequencies (Hz) which controls the compressor’s motor

speed.

Even Temperature – The control package, including the inverter,

monitors the outdoor and indoor temperatures as they relate to the

selected indoor set point and adjusts the compressor speed to match

the load and keep the system operating continuously rather than

cycling and creating temperature swings. This translates to higher

comfort levels for the occupants.

Rapid Pull Down/Warm−Up – Comfort is increased by the

inverter system’s ability to ramp up the compressor speed enabling

the system to reach the user selected room temperature set point

quicker.

Humidity Control – Running the system for longer periods and

continuously varying the compressor speed enhances the humidity

control.

Individual Room Comfort

Maximum comfort is provided because each space can be

controlled individually based on the usage pattern.

Low Sound Levels

When noise is a concern, ductless systems are the answer. The

indoor units are whisper quiet. There are no compressors indoors,

either in the conditioned space or directly over it, and there is none

of the noise usually generated by air being forced through the

ductwork.

When sound ordinances and proximity to neighbors demand quiet

operation, this outdoor unit is the right choice. With the inverter

technology, these units run at lower speeds most of the time

resulting in reduced sound levels.

Inverter Technology – Enhanced Economical Operation

Ductless systems are inherently economical to operate. Individual

rooms are heated or cooled only when required, and since the air is

delivered directly to the space, there is no need to use additional

energy to move the air in the ductwork. This economical operation

is enhanced further when the inverter system output matches the

load resulting in a more efficient system.

Easy−To−Use Controls

The systems have microprocessor−based controls to provide the

ultimate in comfort and efficiency. The user friendly wired and

wireless remote controls provide the interface between the user and

the unit.

Secure Operation

If security is an issue, outdoor and indoor units are connected only

by refrigerant piping and wiring to prevent intruders from crawling

through ductwork or wall openings. In addition, since the outdoor

unit can be installed close to an outside wall, coils are protected

from vandals and severe weather.

Fast Installation

This compact ductless system is simple to install. Only wires and

piping need to run between the indoor and outdoor units. These

units are fast and easy to install ensuring minimal disruption to

customers in homes or the workplace. This makes these systems

the equipment of choice for retrofit applications.

Simple Servicing and Maintenance

Removing the top panel of the outdoor unit provides immediate

access to the control compartment, providing the service technician

access to the diagnostic LEDs to facilitate the troubleshooting

process. In addition, the draw−thru design of the outdoor unit

means that dirt accumulates on the outside surface of the coil. Coils

can be cleaned quickly from the inside using a pressure hose and

detergent.

On the indoor units, service and maintenance expense is reduced

due to the permanent easy to clean filters. Also, error codes are

displayed on the front panel to alert the user to certain system

malfunctions

Built−in Reliability

Ductless system indoor and outdoor units are designed to provide

years of trouble−free operation.

Both the indoor and outdoor units are well protected. Whenever

the microprocessor detects abnormal conditions, the unit stops and

an error code appears.

Inverter systems provide additional reliability due to the soft start.

This refers to the ability of the inverter to start the compressor

motor using reduced voltage and reduced current. This feature is

beneficial from an electrical standpoint (eliminates current spikes)

as well as an overall reliability standpoint due to reduced stress on

all associated system components.

Agency Listings

All systems are listed with AHRI (Air conditioning, Heating, and

Refrigeration Institute) and are ETL certified per UL 1995

standard.

2

MODEL NUMBER NOMENCLATURE

OUTDOOR UNIT

38 MH 3Q

38 = OUTDOOR UNIT

BR09

A

A

VOLTAGE

1 =115-1-60

3 = 208/230-1-60

MH = MODEL

UNIT TYPE

R = OUTDOOR UNIT

MAJOR SERIES

SYSTEM TYPE

C = COOLING ONLY

Q = HEAT PUMP

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

VARIATIONS

A = STANDARD

MAXIMUM NUMBER OF FAN COIL UNITS THAT

CAN BE CONNECTED TO THE OUTDOOR UNIT

A = 1:1

NOMINAL CAPACITY

09 - 3/4 TON

12 - 1 TON

18 - 1-1/2 TONS

24 - 2 TONS

3

STANDARD FEATURES AND ACCESSORIES

Ease Of Installation

Low Voltage Controls S

Comfort Features

Microprocessor Controls S

Auto Restart Function S

Auto Changeover S

Energy Saving Features

Inverter Driven Compressor S

46°F Heating Mode (Heating Setback)

Safety And Reliability

3 Minute Time Delay For Compressor S

High Compressor Discharge Temperature S

Low Voltage Protection S

Compressor Overload Protection S

Compressor Over Current Protection S

IPM Module Protection S

Condenser High Temp Protection in Cooling Mode S

Aluminum Golden Hydrophilic pre-coated fins S

Ease Of Service And Maintenance

Diagnostics S

Liquid Line Pressure Taps S

Application Flexibility

Crankcase Heater S

Base pan Heater on Heat Pump units Only S

Legend

S Standard

A Accessory

S

OUTDOOR UNITS

Crankcase Heater

The crankcase heater is standard on all unit sizes. Heater clamps

must be placed around the compressor oil stump.

Base pan Heater

The base pan heater is standard on all heat pump unit sizes.

ACCESSORIES

Outdoor Unit

Model Number

38MHRBC12AA1

38MHRBC18AA3

38MHRBC24AA3 25

38MHRBQ12AA1

38MHRBQ12AA3

38MHRBQ18AA3 13

38MHRBQ24AA3 25

NOTE: The basepan is constructed with multiple holes to provide

proper draining during defrost. For applications where is required

to seal these holes, and re−direct the condensate drain, rubber plugs

are available through RCD.

Basepan Base

Rubber Plugs

RCD Part Number

12600801A00077

Quantity per Unit

1238MHRBC12AA3

1238MHRBQ09AA3

4

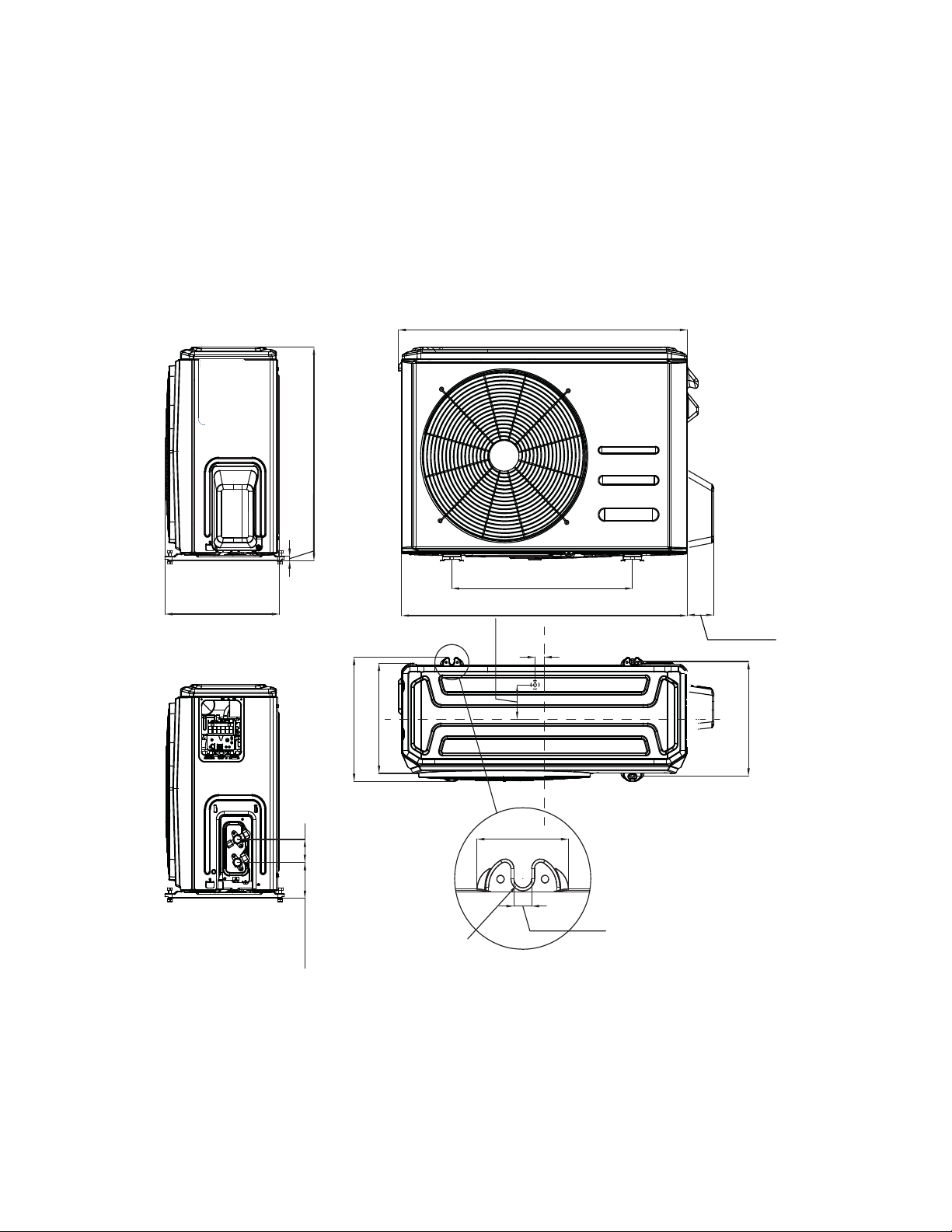

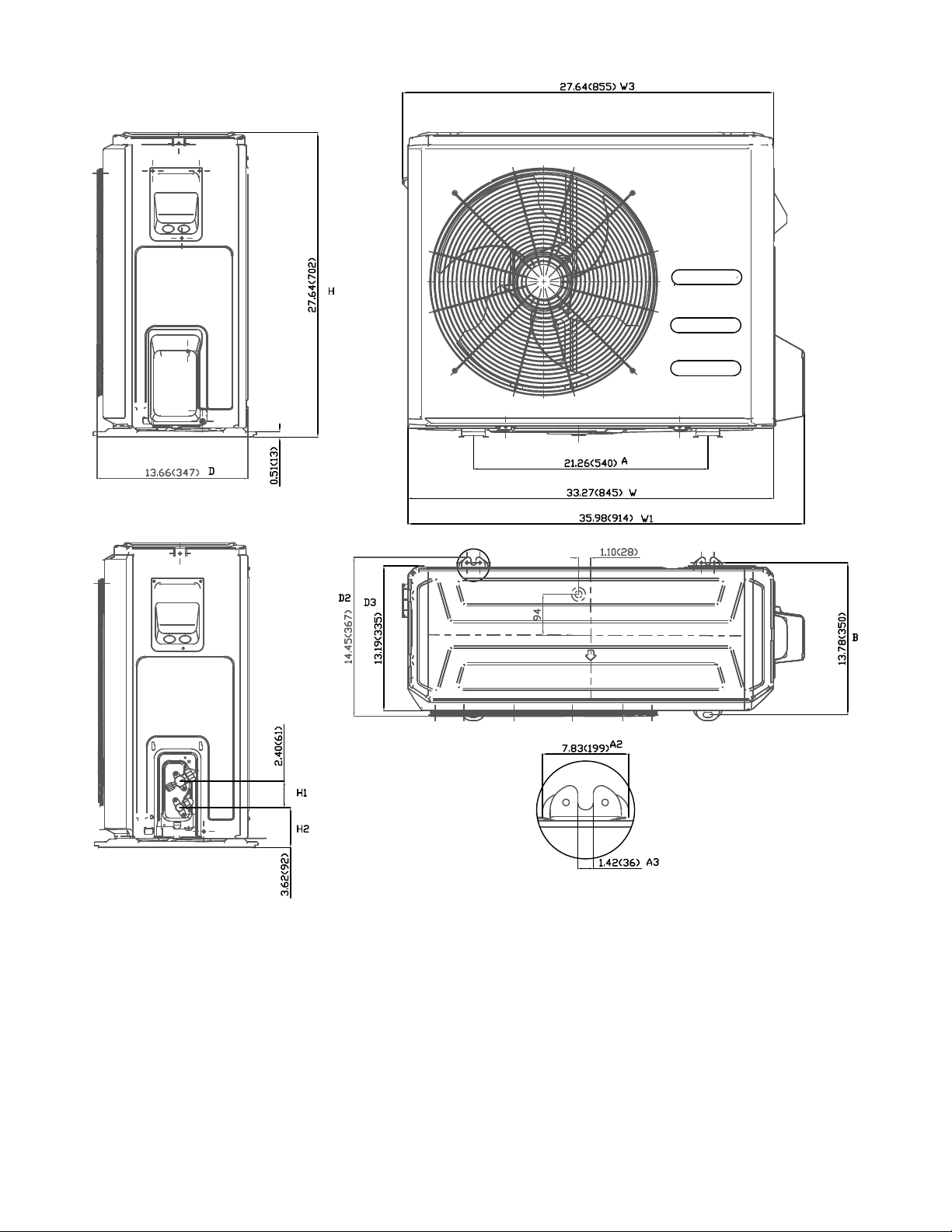

DIMENSIONS − OUTDOOR

System Size Height (H) in. (mm) Width (W) in. (mm) Depth (D) in. (mm) Weight-Net lbs. (kg)

Cooling

Only

Heat

Pump

12K (115V) 21.85(555) 30.31(770) 11.81(300) 57.8(26.2)

12K (208/230V) 21.85(555) 30.31(770) 11.81(300) 53.8(24.4)

18K (208/230V) 21.85 (555) 30.31 (770) 11.81 (300) 65.9 (29.9)

24K (208/230V) 27.64(702) 33.27(845) 14.29(363) 88.6(40.2)

System Size Height (H) in. (mm) Width (W) in. (mm) Depth (D) in. (mm) Weight-Net lbs. (kg)

12K (115V) 21.85(555) 30.31(770) 11.81(300) 69(31.3)

9K (208/230V) 21.85(555) 30.31(770) 11.81(300) 63(28.6)

12K (208/230V) 21.85(555) 30.31(770) 11.81(300) 65.5(29.7)

18K (208/230V) 21.81(554) 31.50(800) 13.11(333) 79.6(36.1)

24K (208/230V) 27.64(702) 33.27(845) 14.29(363) 114.2(51.8)

H

21.85(555)

30.66(779) W3

11.81(300) D

0.47(12)

19.17(487) W1

30.31(770) W

0.98(25) B1

D3

D2

11.26(286)

13.07(322)

2.36(60)

3.54(90) B2

2.42(61.5) A2

H1

H2

.24(6)

0

R

3.66(93)

0.47(12) A1

Unit: inch(mm)

Fig. 1 – Sizes 9K and 12K Heat Pump and Size 18K Cooling Only

2.76(70) W

D1

11.73(298)

5

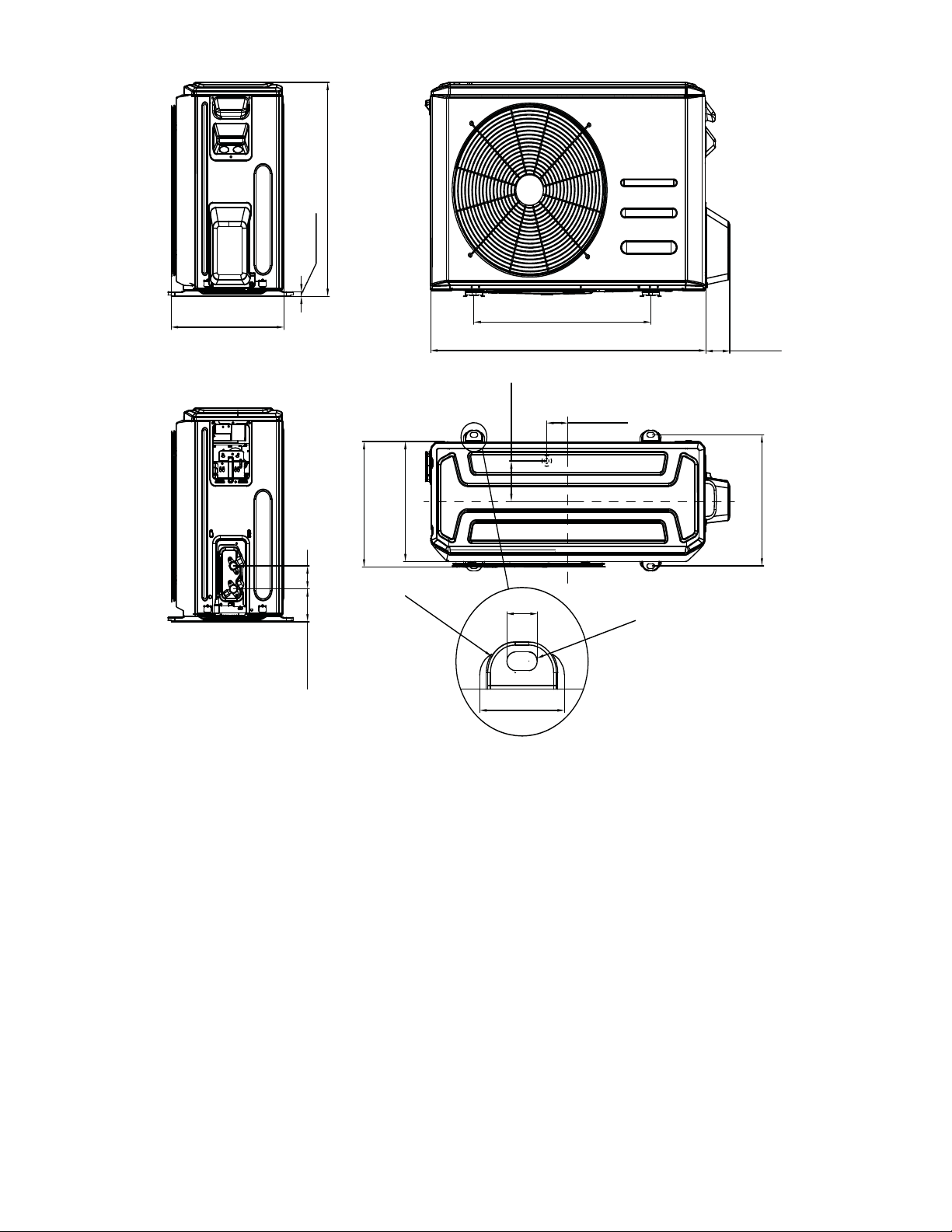

DIMENSIONS − OUTDOOR (CONT)

H

21.81 (554)

0.47 (1 2)

13.11

D

(333)

20.24 (514)

31.50 (800)

B2

4.17 (1 06)

D3

D2

12.80 (325)

H1

2.36 (6 0)

H2

3.37 (8 5.5)

12.24 (311)

R

0

.

7

9

(R

2

0

)

0.87 (2 2)

A1

2.43 (6 1.6)

A2

W

W1

2.43 (6 1.8)

B1

4

2

.

0

R

)

6

R

(

Unit: inch(mm)

2.76 (7 0)

W2

D1

13.39 (340)

Fig. 2 – Size 18K Heat Pump

6

DIMENSIONS − OUTDOOR (CONT)

Fig. 3 – Size 24K

7

Unit: inch (mm)

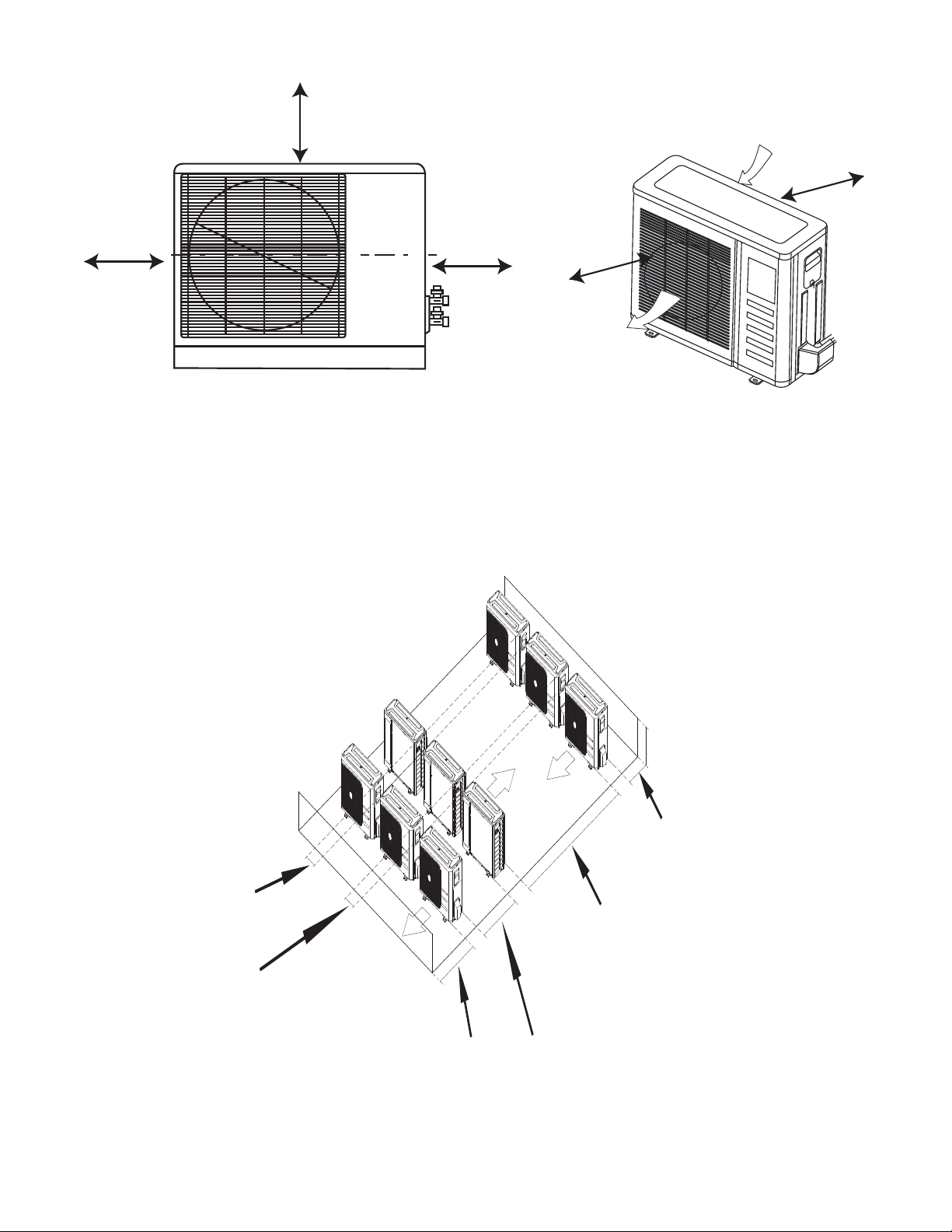

CLEARANCES − OUTDOOR

A

D

B

C

Air-outlet

Fig. 4 – Outdoor Unit Clearance

UNIT MINIMUM VALUE in. (mm)

A 24 (610)

B 24 (610)

C 24 (610)

D 4 (101)

E 4 (101)

NOTE: The outdoor unit must be mounted at least 2in. (50mm) above the maximum anticipated snow depth.

Air-inlet

E

9.8in (25cm)

or more for

proper airow

24in (61cm) or

more is

recommended

for service

9.8in (25cm)

or more for proper airow

24in (61cm)

or more is

recommended

for service

59in (150cm)

or more on a

multiple parallel

unit arrangement

24in (61cm) or more

on a single parallel

unit arrangement

24in (60cm)

or more

Fig. 5 – Clearances for multiple units

8

19in (48cm) or more

on a multiple parallel

unit arrangement

4in (10cm) or more on

a single parallel unit

arrangement

118in (300cm) or more

Loading...

Loading...