Carrier 38AH044-134 User Manual

É,

COMMERCIAL

UNITARY

SYSTEMS

38AH044-134

Air-Cooled Condensing Units

50/60 Hz

Installation, Start-Up and

Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS.....................

INSTALLATION

Step 1 — Rig and Place Unit

• DOMESTIC UNITS

• EXPORT UNITS

• PLACING UNITS

Step 2 — Check Compressor Mounting

• UNITS 38AH044-084

• UNITS 38AH094-I34

Step 3 — Make Refrigerant Piping

Connections .............................................

• UNITS 38AH044-084

• UNITS 38AH094-134

Step 4 — Make Electricai Connections

• POWER SUPPLY

• FIELD POWER CONNECTIONS

• MAIN POWER

• CONTROL CIRCUIT WIRING

Step 5 — Instali Accessories

• LOW-AMBIENT OPERATION

• MISCELLANEOUS ACCESSORIES

PRE-START-UP .......................................

START-UP

SERViCE....................................................

CONTROL .................................................

TROUBLESHOOTING

START-UP CHECKLIST

Installing, starting up, and servicing this equipment can

be hazardous due to system pressures, electrical compo

nents, and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics

should install, start up, and service this equipment.

Untrained personnel can perform basic maintenance func

tions, such as cleaning coils. All other operations should be

performed by trained service personnel.

When working on the equipment, observe precautions in

the literature, and on tags, stickers, and labels attached to the

equipment and any other safety precautions that may apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging, and setting bulky

equipment.

.........................................

....................

.................

................................................

..............................

...................

SAFETY CONSIDERATIONS

... 1

. 1-37

... 1

............

..........

37

........

37-43

........

44-47

........

47-50

51,52

CL-L CL-2

13

23

37

INSTALLATION

Step 1 — Rig and Place Unit — All units are de

signed for overhead rigging, and it is important that this method

be used. Lifting holes are provided in the frame base rails,

which are marked for rigging (see rigging label on the unit

and Tables 1, 2A, and 2B for rigging weights and center of

gravity). It is recommended that field-supplied pipes, of suf

ficient length to extend at least 12-in. (305 mm) beyond the

frame, be passed through the holes.

To maintain unit stability while lifting, use 4 cables,

chains, or straps of equal length. Attach one end of

each cable to one pipe end and the other end of each

cable to the overhead rigging point.

Use spreader bars or frame to keep the cables, chains,

and straps clear of the unit sides. Leave standard coil pro

tection packaging in place during rigging to provide protec

tion to coils. Remove and discard all coil protection after

rigging cables are detached.

DOMESTIC UNITS — For units 38AH044-084, 124, and

134; standard unit packaging consists of coil protection only.

There is no standard packaging provided for units 38AH094

and 104. Skids are not provided. If overhead rigging is not

available at the jobsite, place the unit on a skid or pad before

dragging or rolling. When rolling, use a minimum of

3 rollers. When dragging, pull the pad or skid. Do not apply

force to the unit. When in final position, raise from above to

lift unit off the pad or skid.

EXPORT UNITS — All export units are mounted on skids

with vertical coil protection. Leave the unit on the skid until

it is in final position. While on the skid, the unit can be rolled

or skidded. Apply force to the skid, not to the unit. Use a

minimum of 3 rollers when rolling. When in final position,

raise from above to remove the skid.

PLACING UNITS

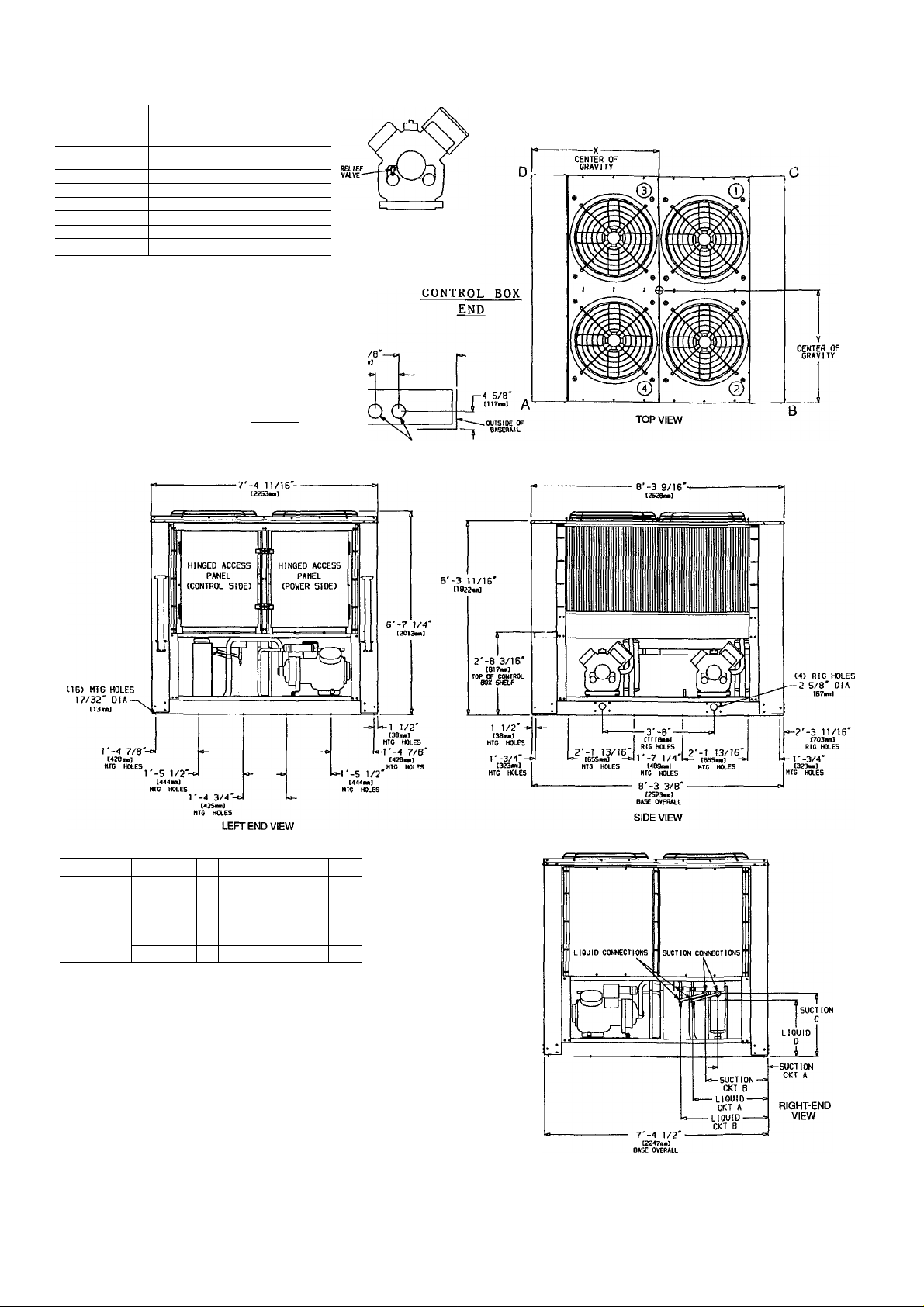

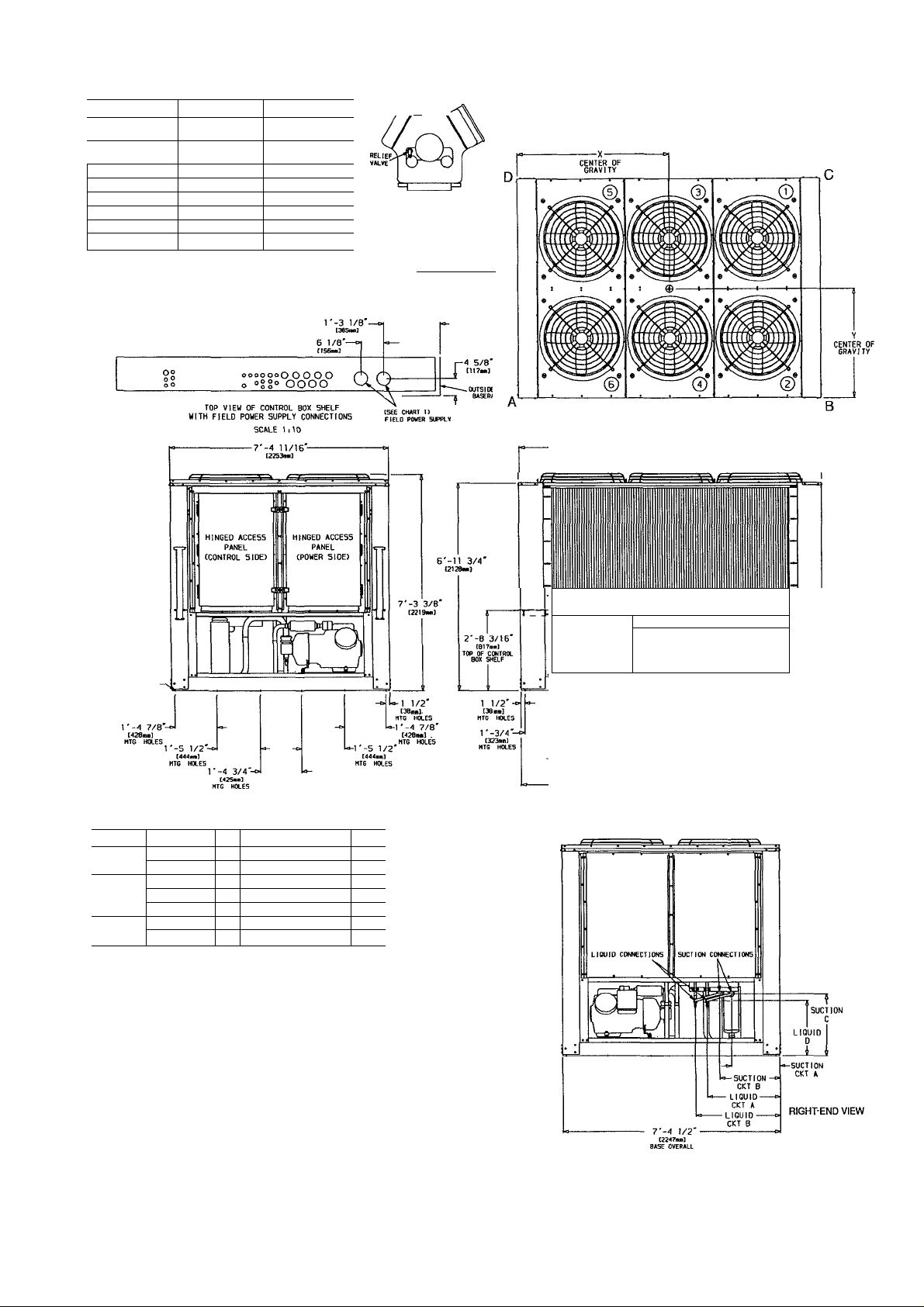

Units 38AH044-084 — Refer to Fig. 1 and 2 for airflow clear

ances. Recommended minimum clearances are 6 ft (1829 mm)

for unrestricted airflow and service on sides of unit, 5 ft

(1524 mm) on ends, and unrestricted clear air space above

the unit. Provide ample space to connect liquid and suction

lines to indoor unit. For multiple units, allow 8 ft (2440 mm)

separation between units for airflow and service.

A CAUTION

Do not forklift these units unless the unit is attached to

a skid designed for forklifting.

S till

eg

Book 11 PC 111 Catalog No 533-812 Printed in U.S A. Form 38AH-14SI Pg 1 5-96 Replaces: 38AH-13SI

Tab 3a

ELECTRIC SHOCK HAZARD.

Open all remote disconnects before servicing

this equipment.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obiigations.

The placement area must be level and strong enough to

support the operating weight of the unit (see Table 3A or

3B). When unit is in proper location, use of mounting holes

in base rails is recommended for securing unit to supporting

structure. For mounting unit on vibration isolators, a perim

eter support channel between the unit and the isolators is

recommended. Fasteners for mounting unit are field sup

plied. Be sure to mount unit level to ensure proper oil return

to compressors.

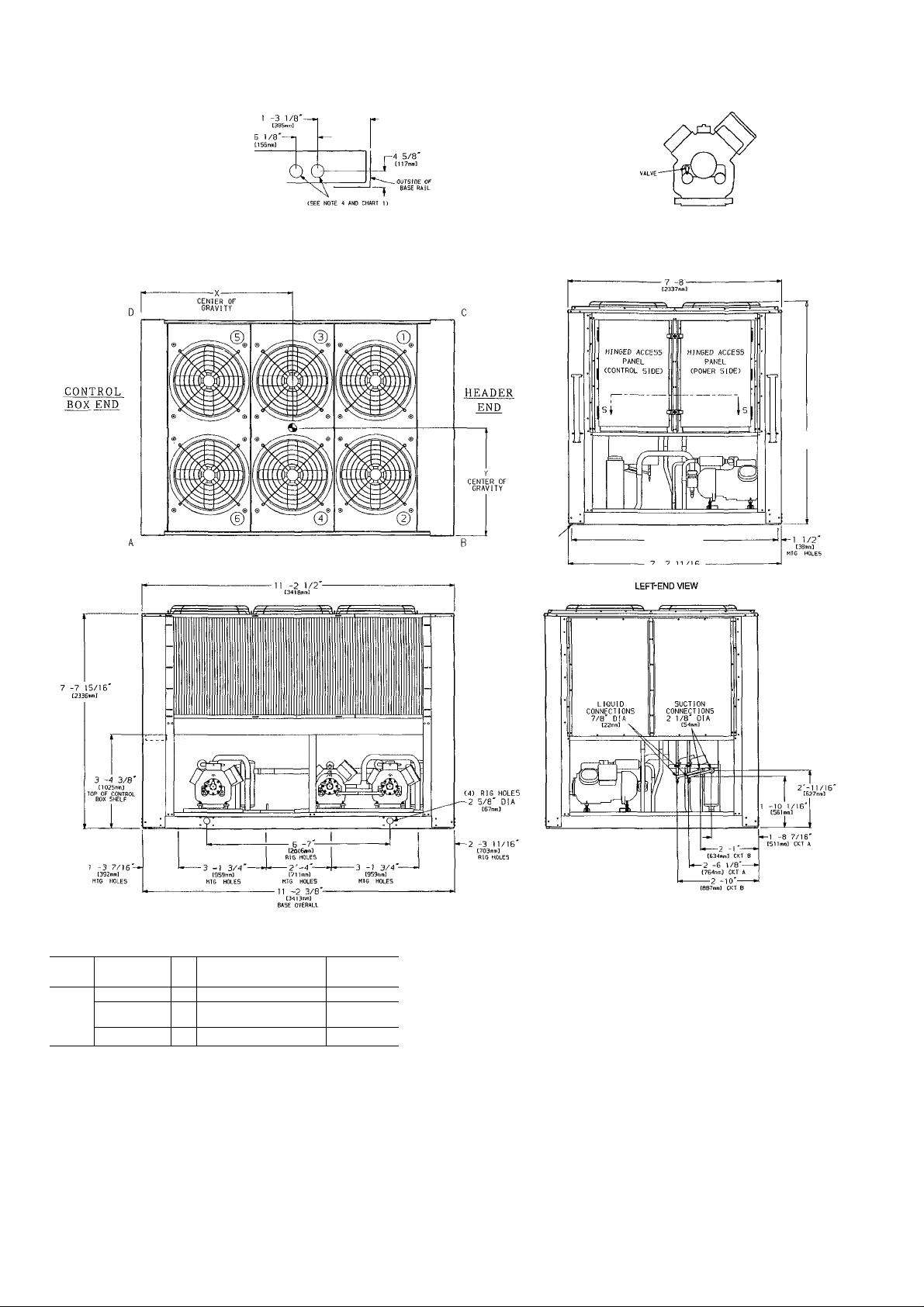

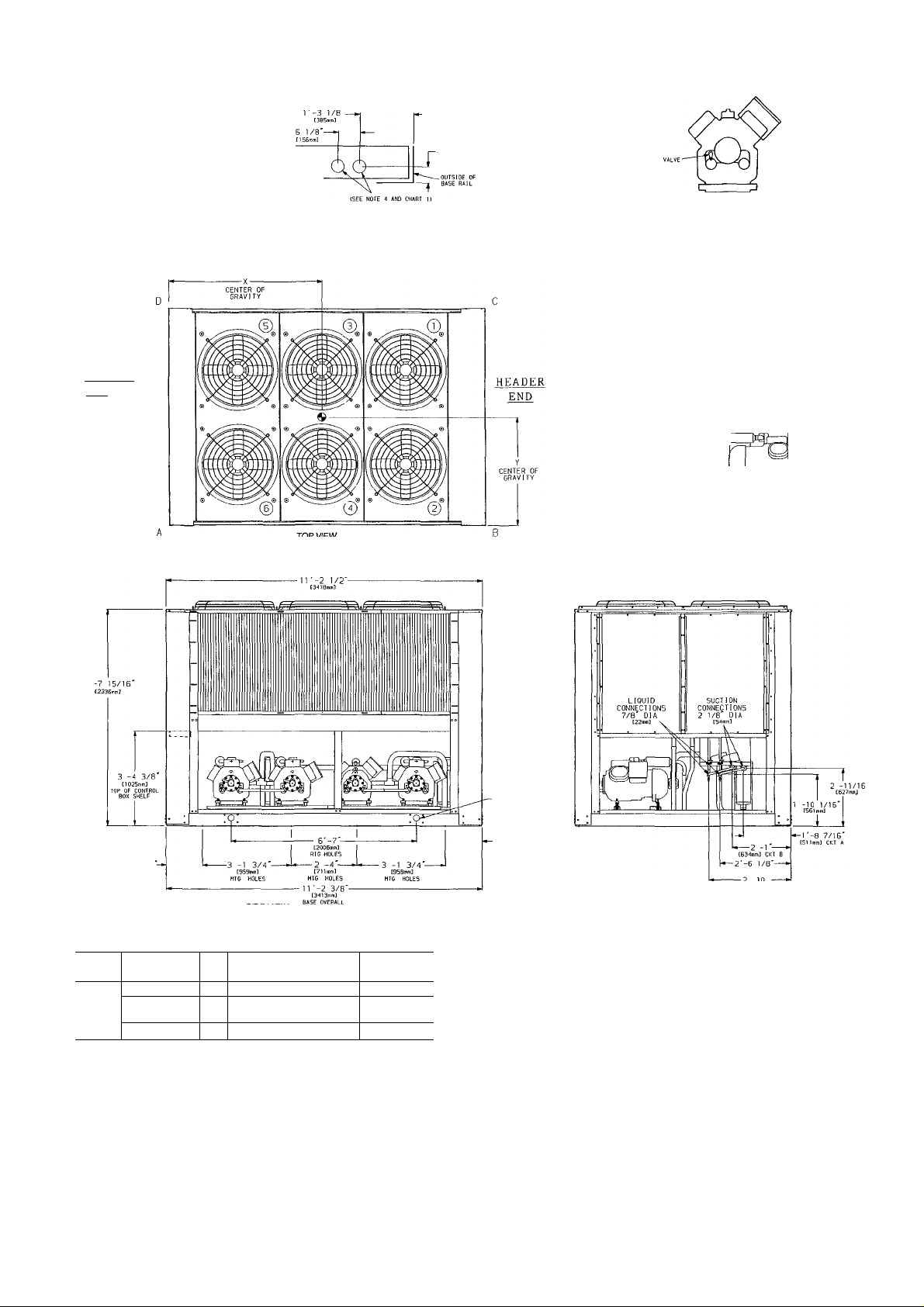

Units 38AH094-134 — Refer to Fig. 3-6 for airflow

clearances. Recommended minimum clearances are 6 ft

(1829 mm) for unrestricted airflow and service on sides of

unit, 5 ft (1524 mm) on ends, and unrestricted clear air space

above unit. Provide ample space to connect liquid and suc

tion lines to indoor unit. For multiple units, allow

8 ft (2440 mm) separation between units for airflow and

service.

A CAUTION

Do not forklift these units unless the unit is attached to

a skid designed for forklifting.

The placement area must be level and strong enough to

support the operating weight of the unit. See Table 4A

or 4B. Refer to the following paragraphs for the proper place

ment of the unit.

Units 38AH094.104 — For mounting units on vibration iso

lators, a perimeter support channel is required between the

unit and the support isolators. The perimeter support chan

nel must be sized to support the fully assembled unit. Do not

support units on individual isolation supports. Support chaiinel, hardware, and fasteners are field supplied. When unit is

in proper location, level unit and bolt into position with fieldsupplied bolts.

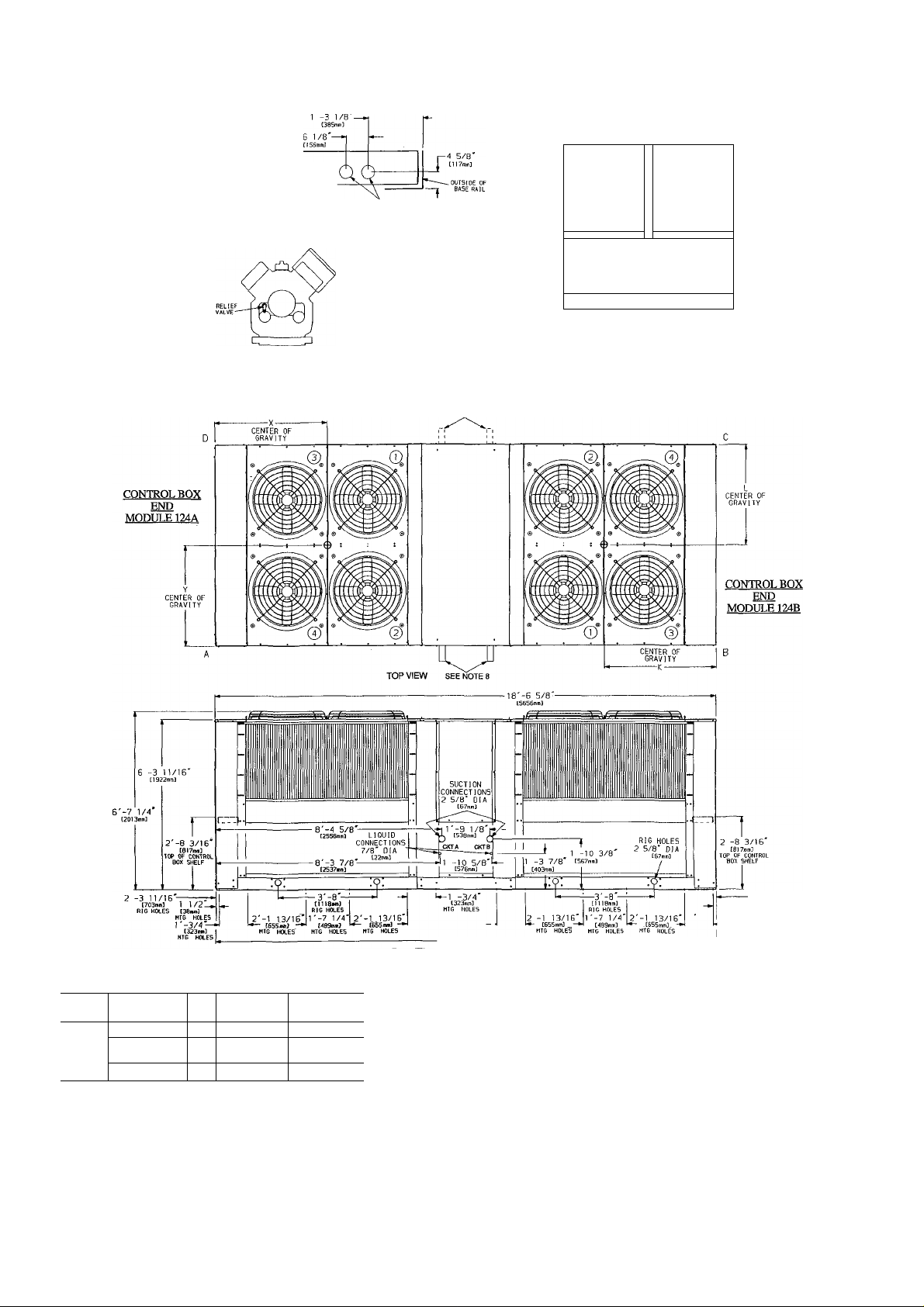

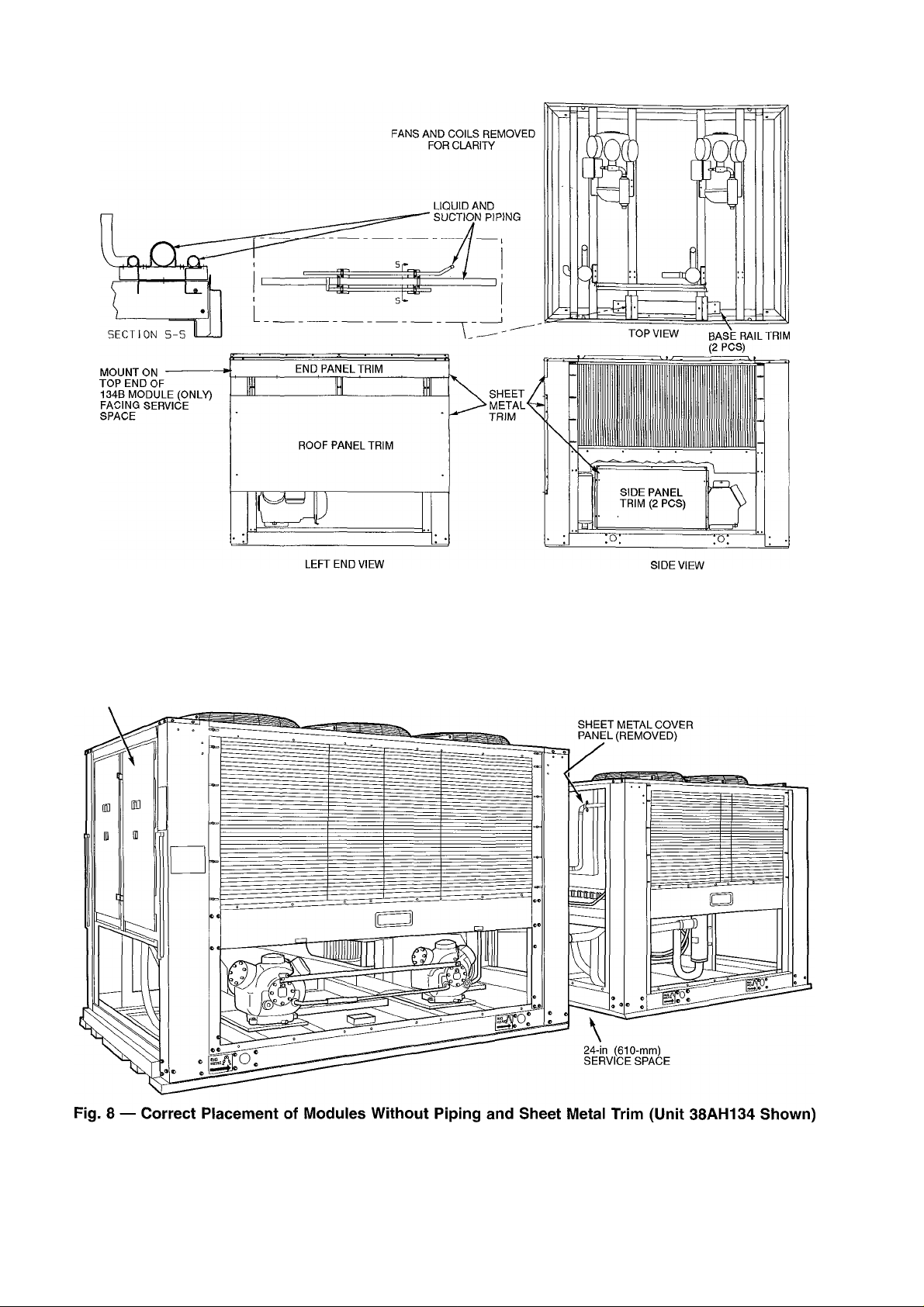

Units 38AH124.134 — For ease of shipment and handling,

unit 38AH124 is shipped as 2 modules (124A and 124B)

and unit 38AH134 is shipped as 2 modules (134A and 134B).

The modules must be connected at the final installation site

with the factory-shipped piping and sheet metal trim kit mounted

on Module 124A or 134A. See Fig. 7.

A WARNING

Do not move assembled 38AH124 or 134 units as a single

assembly. Always move modules individually during in

stallation or at any other time.

Mark installation site for placement of Modules 124 A and

124B or Modules 134A and 134B. See Table 4A or 4B for

final assembled dimensions. A service space of 24 in.

(610 mm) is required between the 2 modules for piping and

sheet metal trim installation.

Place Module 124A or 134A in position, ensuring that the

control box is at the end opposite the service space. See

Fig. 8.

Remove sheet metal and tubing from Module 124A or 134A

sheet metal trim kit (Fig, 7). Remove sheet metal cover pan

els from return-bend end of unit facing the service space.

See Fig. 8. These panels may be discarded or saved for re-

installation if module is moved from site. See Fig. 9.

UNIT

38AH

Dimension X 49 (1232)

Dimension Y

Dimension X-C 49 (1234) 48 (1229)

Dimension Y-C 39 (993) 39 (991)

Dimension K

Dimension L

Dimension K-C

Dimension L-C

LEGEND

— — Not Applicable

C — Copper Fin Coils

044 054 064

48 (1224) 50 (1260)

39 (984)

39 (978)

—

—

—

—

—

— —

— —

Y

A

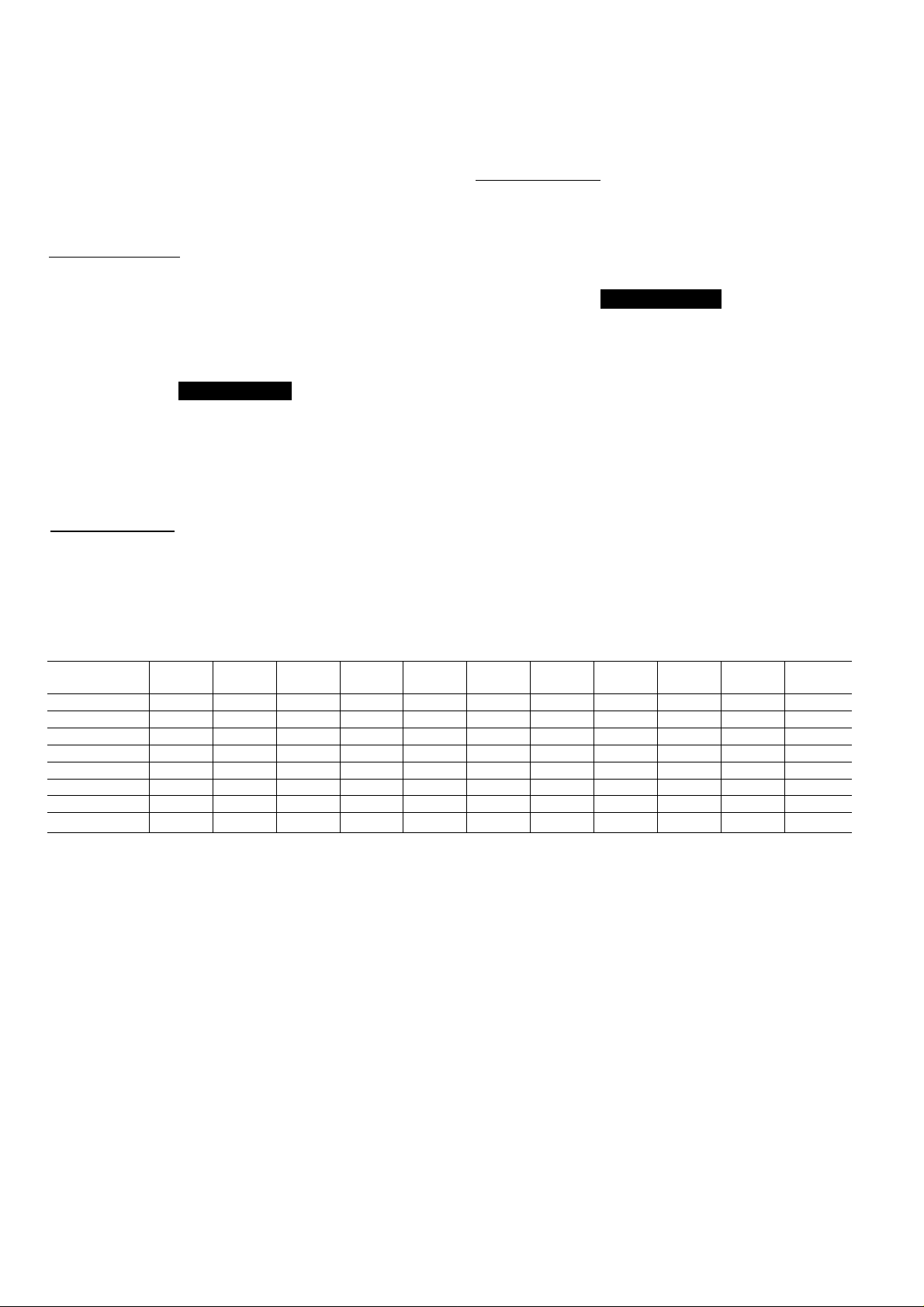

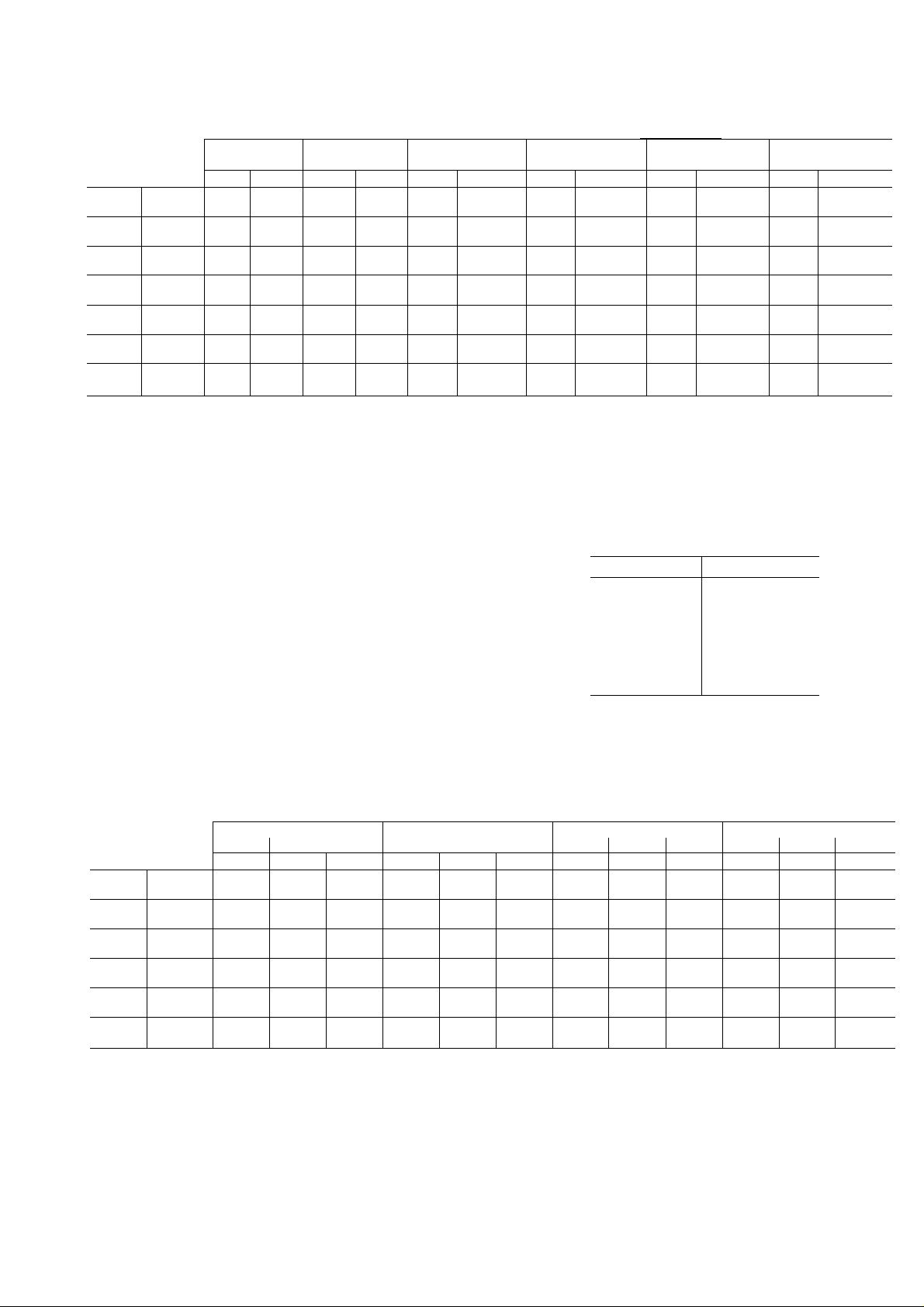

Table 1 — Rigging Center of Gravity — in. (mm)

MODULE

50 (1260)

38 (968)

50 (1260) —

39 (986) —

—

COMPR COMPR

57 (1443)

38 (968)

50 (1261)

39 (986)

CONTROL

BOX

END

39 (993) 39 (991) 31 (787) 34 (851)

56 (1425)

40 (1006)

—

_

COMPR COMPR

074

— — — — —

— — — — — 38 (968) —

— — — — —

—

084 094

57 (1448) 66 (1676)

56 (1422)

40 (1008) 31 (787)

66 (1676) 63 (1600)

— —

104

63 (1600)

34 (851)

r—"T I

TOP VIEW, TYPICAL

124, 134 ONLY

124A

—

MODULE

124B

-

—

50 (1260)

50 (1260)

39 (986)

CONTROL

BOX

END

MODULE

134A

50 (1260)

38 (968)

50 (1260)

39 (986)

—

—

—

MODULE

134B

—

—

—

—

57(1443)

39 (993)

56 (1425)

40 (1006)

Remove sheet metal cover panels from return-bend end of

Module 124B or 134B. Place Module 124B or 134B in po

sition. The exposed retnrn-bend ends of each module are now

opposite each other and facing the service space. The com

pressors of each modnle are on opposite sides of the unit.

IMPORTANT; Modules must be placed 24 in.

(610 mm) apart and sqnare relative to each other.

The modules are now in position for piping installation

and final assembly. See Fig. 8. For mounting units on vi

bration isolators, a perimeter support channel is required be

tween the assembled unit and the support isolators. The pe

rimeter support channel must be sized to support the fully

assembled unit. Do not support modules on individual iso

lation supports. Support channel, hardware, and fasteners are

field supplied.

When unit is in proper location, level unit and bolt into

position with field-supplied bolts.

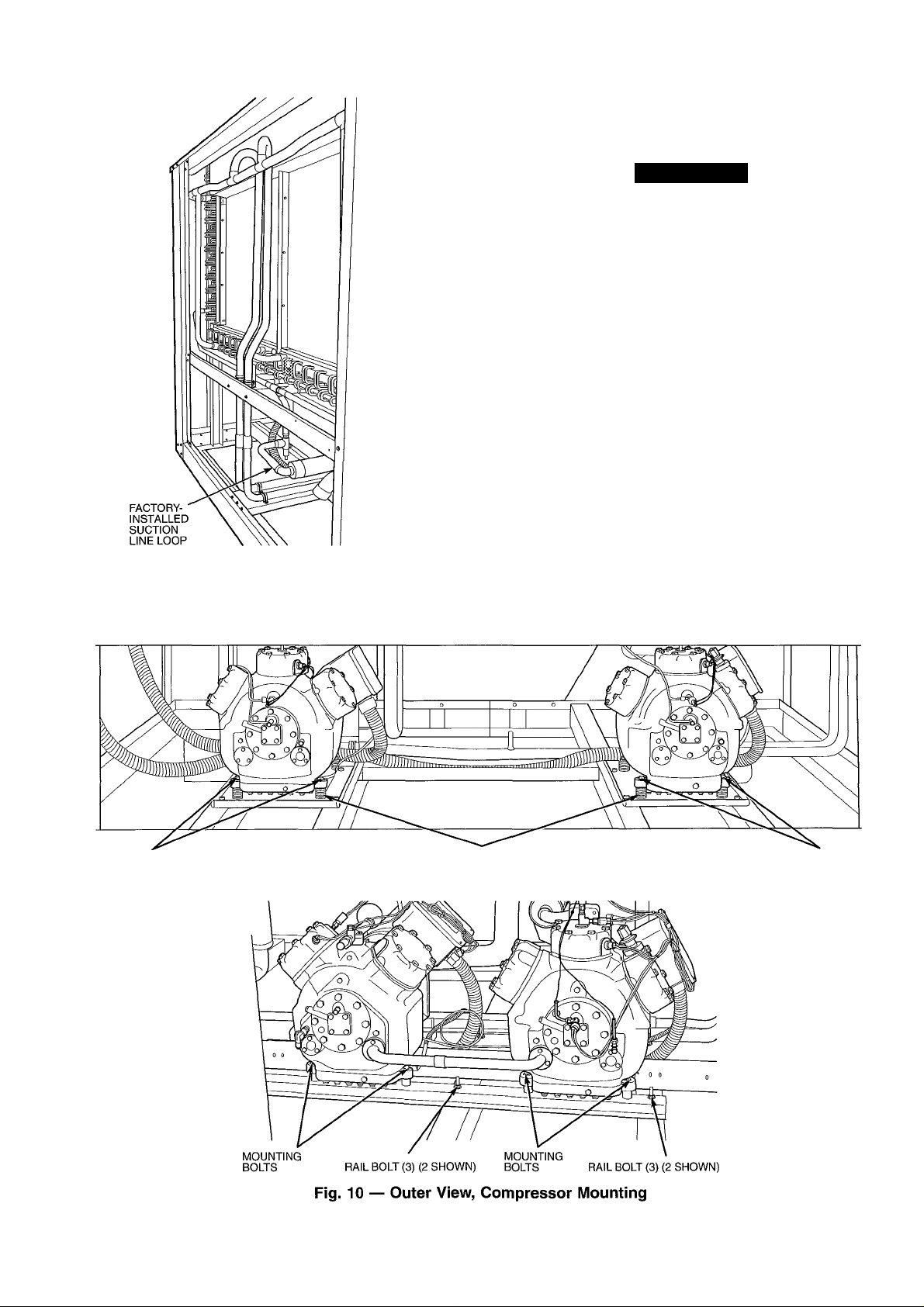

Step 2 — Check Compressor Mounting

UNITS 38AH044-084 — Compressors are mounted on pans

and are held down by 4 bolts dnring shipment. After unit is

installed, loosen each of these bolts until the snubber washer

can be moved with finger pressure. See Fig. 10.

UNITS 38AH094-134 — Units 38AH094 and 104 compres

sors are mounted on rails and held down by rail bolts during

shipment. After unit is installed, loosen the rail bolts to al

low the rails and compressors to float freely on the springs

located under the rails. See Fig. 10.

Units 38AH124 and 134 compressors are mounted on pans

and are held down by 4 bolts during shipment. After unit is

installed, loosen each of these bolts until snubber washer can

be moved with finger pressure. See Fig. 10.

Table 2A — Operational Corner Weights with

Refrigerant Charge (Approximate) — Lb

UNIT

38AH

044

044C

054

054C

064

064C

074

074C

084

084C

094

094C

104

104C

MODULE

38AH

124A

124A-C

124B 3630

124B-C 4063

134A

134A-C

134B

134B-C

C — Copper Fin Coils

NOTE: Total weight may differ from summation of corner weights due

to rounding of numerals

TOTAL

WEIGHT

3259 939 893 695

3547

3309

3597 1034 978 771 814 054C

3565

3998 1125 1117

3812 1146 986

4229

4057 1220 1049

4735 1425 1186 965 1159 084C

5088 1114 2192

5813 1273

5435 1240 2138

6160

3630 1037 1030 779 785 124A

4063 1144 1137 889

3630 1037 1030 779 785 134A

4063 1144 1137 889

3877 1167

4294

LEGEND

OPERATIONAL CORNER WEIGHT

A

1013

964

1018

1272

1405

1037

1144 1137 889 894 124B-C

1293 1080

В

967

905

1011

1059

2504 1350

2423

1030

997

C D

765

697 742 054

765 771

874

777

862

827

1182

1302

1476 856 104C

779

789 924 134B 1759

874 1047 134B-C

732 044

802 044C

879 064C

903

1035

961 084

601

686

755 104

894

785

894

Table 2B — Operational Corner Weights with

Refrigerant Charge (Approximate) — Kg

UNIT

38AH

064

074

074C

094 2308

094C

MODULE

38AH

124A-C

124B

134A-C

C — Copper Fin Coils

NOTE. Total weight may differ from summation of corner weights due

to rounding of numerals

TOTAL

WEIGHT

1478 426

1609 460 438

1501

1632

1617 462

1813 510

1729 520 447

1918 577

1840 553 476

2148 646 538

2637 577 1136

2465 562 970 591

2794 637

1647

1843

1647 470 467 353 356

1843 519 516

1647

1843

1948 587 490

LEGEND

OPERATIONAL CORNER WEIGHT

A

437 411 316 337

469

505 994 536 272

470 467

519

470 467

519

529 452 358 419

В

405

444 350 369

459

508

481 391

1099

516

516

C D

316

347 364

347

397

352

375 436

438 526

612

670

353 356

403 405

403

353 356

403 405

396

332

350

399

410

470

311

342

388

405

475

Г'

CONTROL

BOX

END

COMPR

Г'

TOP VIEW, TYPICAL

COMPR

SUCTION

CONNECTiON(S)

LIQUID

CONNECTION(S)

SUCTION C 2'-iVi6" [627mm]

LIQUID D

SUCTION {Ckt A) V-713/16'' [503mm]

SUCTION (Ckt B)

LIQUID (Ckt A)

LIQUID (Ckt B)

DUAL CKT SINGLE CKT

2Ve" Dia [54 mm]

Va" Dia [22 mm] IVa" Dia [29 mm]

1'-10Vi6" [561mm] 1'-10yi6" [567mm]

2'-%" [626mm]

2'-5%" [756mm] 2'-10%" [879mm]

2'-10%" [879mm]

25/e" Dia [67 mm]

r-10^/w" [567mm]

2'-%" [626mm]

—

—

RELIEF VALVES LOCATED ON

THE C0HPRE55OR5 ARE EQUIPPED

WITH A 3/8" 5AE FLARE FOR

FIELD CONNECTION

SCALE 1<6

6 1/8'-

CISSmi]

OO

O O

WITH FIELD POWER SUPPLY CONNECTIONS.

ooooooOOOOO

O OOOO

TOP VIEW OF CONTROL BOX SHELF

(SEE NOTE 4 ANO CHART I)

FIELD PONER SUPPLY

Chart 1, Field Power Supply Connections

UNIT VOLTAGE Hz

044

044, 054

044, 054, 064 460,575,380 60

064

LEGEND

C — Copper Fin Coils

MTG — Mounting

SAE — Society of Automotive Engineers

NOTES;

1 The approximate operating weight of the unit is:

-------------- --------------------------------- 1478 kg

38AH-044—

38AH-044-C

38AH-054— 3309 lb

38AH-054-C

38AH-064— 3565 lb

38AH-064-C

2 Unit must have clearances for airflow as fo lows:

Top — Do not restrict in any way

Ends — 5 ft [1524 mm]

Sides — 6 ft [1829 mm]

3 Mounting holes may be used to mount unit to concrete pad They are not recommended for mounting

unit to spring isolators If spring isolators are used, a perimeter support channel between the unit and

the isolators is recommended

4 One 35/s" (92 mm) diameter hole is recommended for single-entry power on size 064 (208/230-v) units

5. See Table 1 for rigging center of gravity (Dimensions X,Y) See Table 2A and 2B for A-D corner weights

6 Circled numerals in Top View refer to condenser fans by position

230

208/230 60

346, 380/415

208/230 60 2Va [63]

346, 380/415

DIAMETER — in. [mm]

50

50 2V2 [63]

50 3% [92]

3259 lb

3547 lb

3597 lb

3998 lb

3% [92]

3% [92]

2Va [63]

1609 kg

1501 kg

1632 kg

1617 kg

[1813 kg

QTY

1

1

1

1

2

1

Fig. 1 — Dimensions — Units 38AH044,054,064

f

SUCTION

CONNECTION(S)

LIQUID

CONNECTION(S)

SUCTION C

LIQUID D

SUCTION (Ckt A) 1'-7i3/i6" [503mm]

SUCTION (Ckt B)

LIQUID (Ckt A)

LIQUID (Ckt B)

DUAL CKT

2Vs'' Dia [54 mm] 2¥8" Dia [67 mm]

%" Dia [22 mm]

2'-iyi6" [627mm] 1'-10¥i6" [567mm]

r-IOVie" [561mm]

2'-¥e" [626mm]

2'-5¥4" [756mm]

2'-10¥e" [879mm]

SINGLE CKT

IVs" Dia [29 mm]

1'-10¥i6" [567mm]

2'-¥8" [626mm]

—

2'-10¥b" [879mm]

—

I I

RELIEF VALVES LOCATED ON

THE COMPRESSORS ARE EQUIPPED

WITH A 3/B' SAE FLARE FOR

FIELD CONNECTION

SCALE 1,8

CONTROL BOX

END

TOP VIEW

10'-3 1/4

[313lM]

06) MTG HOLES

17/32' DIA

nam]

LEFT-END VIEW

Chart 1, Field Power Supply Connections

UNIT

074

074, 084

084

VOLTAGE

208/230 60

460

346, 380/415

380 60

575

208/230 60

460 60 3¥a [92]

DIAMETER — in. [mm]

Hz

60

50

60

2V2 [63]

2Vs [63]

3% [92] 1

3¥s [92]

2Va [63]

3¥e [92]

QTY

2

1

1

1

2

1

LEGEND

C — Copper Fin Coils

MTG — Mounting

SAE — Society of Automotive Engineers

NOTES:

1 The approximate operating weight of the unit is:

38AH-074— 3812 lb (1729 kg)

38AH-074-C 4229 lb (1918 kg)

38AH-084— 4057 lb (1840 kg)

38AH-084-C 4735 lb (2148 kg)

2 Unit must have clearances for airflow as follows:

Top — Do not restrict in any way

Ends — 5 ft [1524 mm]

Sides — 6 ft [1829 mm]

3 Mounting holes may be used to mount unit to concrete pad They are not recommended for mount

ing unit to spring isolators If spring isolators are used, a perimeter support channel between the

unit and the isolators is recommended

4 See Table 1 for rigging center of gravity (Dimensions X,Y) See Table 2A and 2B for A-D corner

weights

5 Circled numerals in Top View refer to condenser fans by position

Fig. 2 — Dimensions — Units 38AH074,084

-r-B 3/4'

1528»] .

HTG HOLES

— J0'-3'—

(3I25IM]

BASE OVERALL

SIDE VIEW

7'-1 1/2

(2)72«nl

RIG HOLES

r-8 3/4-

t528m]

HTG HOLES

C4) RIO HOLES

-2 5/8' DIA

(67»1

-r-6 3/4

1476»]

RIG HOLES

-r-3/4

(323»1

HTG HOLES

ooooooO O O O O

o OOOO

VIEW 5-5

TOP VIEW OF CONTROL BOX SHELF

WITH FIELD POWER SUPPLY CONNECTIONS

RELIEF VALVES LOCATED ON

COMPRESSORS A2 AND B1 ARE EQUIPPED

WITH A 3/8' SAE FLARE FOR

FIELD CONNECTION

SCALE 1:8

7'-11 9/16'

[2‘128mmD

Chart 1, Field Power Supply Connections

UNIT

38AH

094

VOLTAGE

208/230 60

460, 575,

380

346, 380/415 50

Hz DIAMETER — in. (mm)

60

3% (92)

3% (92)

3 5 / 8 (92)

(8) MTG HOLES

7/32' DIA

LEGEND

QUANTITY

2

1

1

C — Copper Fin Coils

MTG — Mounting

SAE — Society of Automotive Engineers

NOTES:

1 The approximate operating weight of the unit is:

38AH-094— 5088 lb (2308 kg)

38AH-094-C 5813 lb (2637 kg)

2 Unit must have clearances for airflow as follows:

Top — Do not restrict in any way

Ends — 5 ft [1524 mm]

Sides — 6 ft [1829 mm]

3 Mounting holes may be used to mount unit to concrete pad They are not

recommended for mounting unit to spring isolators

4 Two 3%" (92-mm) dia holes are recommended for parallel conductors on

208/230 V units.

5. Circled numerals in Top View refer to condenser fans by position

6 If spring isolators are used, a perimeter support channel between the unit

and the isolators is recommended

7. See Table 1 for rigging center of gravity (Dimensions X,Y) See Table 2A

and 2B for A-D corner weights

Fig. 3 — Dimensions — Unit 38AH094

-7 -4 11/16'-

[2252m(T)

HTG HOLES

-7'-7 11/16'-

C2326n<r[i}

BASE OVERALL

RIGHT-END VIEW

ooooO O O O O

oooo

VIEW 5-5

TOP VIEW OF CONTROL BOX SHELF

WITH FIELD POWER SUPPLY CONNECTIONS

4 5/8'

ni7mml

RELIEF VALVES LOCATED ON

COMPRESSORS A2 AND B2 ARE EQUIPPED

WITH A 3/8' SAE FLARE FOR

FIELD CONNECTION

SCALE 1:8

CONTROL

BOX END

(8) MTG HOLES

17/32' DIA

C13tnmJ

HINGED ACCESS

PANEL

(CONTROL SIDE)

-7 -4 11/16

-7 -7 11/16'

LEFT-END VIEW

HINGED ACCESS

t2252mm)

MTG HOLES

[2328mm]

BASE OVERALL

PANEL

(POWER SIDE)

---------

---------

?'-ll 9/16'

(2428mm]

-1 1/2

[38mm]

MTG HOLES

-3 7/16

C392mm]

MTG HOLES

Chart 1, Field Power Supply Connections

UNIT

38AH

104

VOLTAGE Hz

208/230

460, 575,

380

346, 380/415 50

DIAMETER — in. (mm) QUANTITY

60

60

3% (92) 2

3% (92) 1

3 5 /e (92)

Fig. 4 — Dimensions — Unit 38AH104

(4) RIG HOLES

2 5/8' DIA

[67mm]

2 -3 11/16'

[703 mm]-

RIG HOLES

[764mm] CKT A

2 -10'-

[8S7mir] CKT B

RIGHT-END VIEW

LEGEND

C — Copper Fin Coils

MTG — Mounting

SAE — Society of Automotive Engineers

NOTES;

1 The approximate operating weight of the unit is:

38AH-104— 5435 lb (2465 kg)

1

38AH-104-C 6160 lb (2794 kg)

2 Unit must have clearances for airflow as follows:

Top — Do not restrict in any way

Ends — 5 ft [1524 mm]

Sides —6 ft [1829 mm]

3 Mounting holes may be used to mount unit to concrete pad They are not

recommended for mounting unit to spring isolators

4 Two 3%" (92-mm) dia holes are recommended for parallel conductors on

208/230 V units

5 Circled numerals in Top View refer to condenser fans by position

6. If spring isolators are used, a perimeter support channel between the unit

and the isolators is recommended

7 See Table 1 for rigging center of gravity (Dimensions X,Y) See Table 2A

and 2B for A-D corner weights

-7 -4 11/16'[2253mra]

ooooO о о о о

оооо

TOP VIEW OF CONTROL BOX SHELF

WITH FIELD POWER SUPPLY CONNECTIONS

VIEW 5-S

SCALE UlO

RELIEF VALVES LOCATED ON

THE COMPRESSORS ARE EQUIPPED

WITH A 3/8' SAE FLARE FOR

FIELD CONNECTION

SCALE 1:8

(32) MTG HOLES

17/32' DIA.

[13mm]

1 1/2-*

C38imn]

MTG HOLES

1'-4 7/8'—

C420n""l 1 r 1 /-)"

MTG HOLES' 1X4

I HINGED ACCESS

(CONTROL SIDE)

' s|

MTG HOLES ' -4 3/4-

[425mir)

i

I PANEL '

TYPICAL

BOTH ENDS

MTG HOLES

HINGED ACCESS

■ PANEL

(POWER SIDE)

7'-4 1/2'-

f2247ti.ml

BASE OVERALL

LEFT-END VIEW

TYPICAL

BOTH ENDS

is

1 ' c- 1 /-)' (‘>28nim]

-1 -5 1/2 MTG HOLES

[444tntnD

MTG HOLES

-1 -4 7/8

Chart 1, Field Power Supply Connections

UNIT

38AH

VOLTAGE

208/230 60

124A

124B

460, 575,

380

346, 380/415 50

LEGEND

C — Copper Fin Coils

MTG — Mounting

SAE — Society of Automotive Engineers

Hz

60

DIAMETER

(in.)

3% (92)

2V2 (63)

3% (92)

r-3/4'

[323mm] *

MTG HOLES

- 18'-6 3/8'-

SIDE VIEW

QUANTITY

1

1

1

CSGSOmm]

BASE OVERALL

NOTES;

1

The approximate operating weight of the unit is:

38AH-124— 7260 lb (3293 kg)

38AH-124-C 8126 lb (3686 kg)

Unit must have clearances for airflow as follows:

Top — Do not restrict in any way

Ends — 5 ft [1524 mm]

Sides — 6 ft [1829 mm]

Mounting holes may be used to mount unit to concrete pad They are not rec

ommended for mounting unit to spring isolators

One 3¥s" (92-mm) dia hole is recommended for single-entry power into each

module (124A and 124B) of the 208/230-v units

Circled numerals in Top View refer to condenser fans by position

If spring isolators are used, a perimeter support channel between the unit and

the isolators is recommended Do not support each module separately

Each module of the unit must be rigged into position separately The unit must

not be rigged after modules have been connected.

8.

Suction and liquid connections can exit on either side of the unit.

9.

Field power supply connections are required for each module

10

See Table 1 for rigging center of gravity (Dimensions K.L.X.Y) See Table 2A

and 2B for A-D corner weights

Fig. 5 — Dimensions — Unit 38AH124

8

t2 -3 11/16

^1 1/2 [703mmT

^ [ЗВтт] RIG HOLES

MTG HOLES

•- 1 '-3/4'

C323mroJ

MTG HOLES

J HINGED ACCESS

'Г

VIEW S-5

TOP VIEW OF CONTROL BOX SHELF

WITH FIELD POWER SUPPLY CONNECTIONS

SCALE 1:10

(32) MT6 HOLES

17/32' DIA.

[13mtn]

\ PANEL '

(CONTROL SIDE)

, 1 TYPICAL

•1 BOTH ENOS

HINGED ACCESS ,

> PANEL

(POWER SIDE)

TYPICAL

BOTH ENDS

■ Isl"

RELIEF VALVES LOCATED ON

THE COMPRESSORS ARE EQUIPPED

WITH A 3/8' 5AE FLARE FOR

FIELD CONNECTION

-1 -4 7/8'

1 c- 1 /'i' (42ВямпЗ

I -b I/2 MTG HOLES

НТО HOLES

Chart 1, Field Power Supply Connections

UNIT

38AH

VOLTAGE

208/230

134A

460, 575, 380 60

346, 380/415

208/230 60

134B

460, 575 60

380

346, 380/415

LEGEND

C — Copper Fin Coils

MTG — Mounting

SAE — Society of Automotive Engineers

Hz

60

50

60 ЗУв (92)

50

DIAMETER —

in. (mm)

ЗУ8 (92) 1

2Уг (63)

ЗУв (92) 1

2Vi (63)

2Уг (63) 1

ЗУв (92) 1

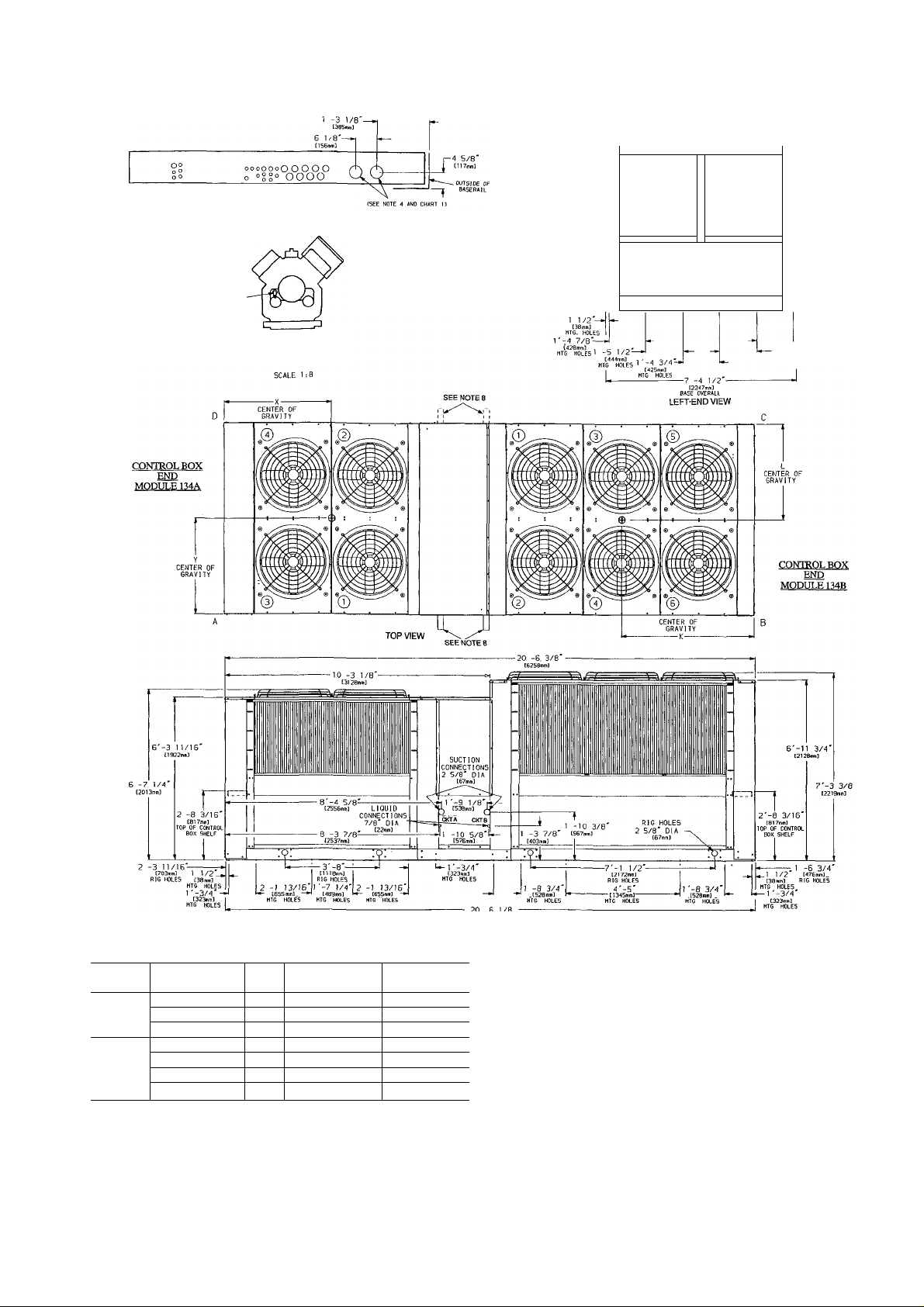

Fig. 6 — Dimensions — Unit 38AH134

QUANTITY

1

2

1

I -3/4'

СЭ23вя|]

ИТ6 HOLES

[6253inm]

BASE OVERALL

-20'-6 1/8'-

NOTES;

The approximate operating weight of the unit is;

1

38AH-134— 7507 ib (3405 kg)

38AH-134-C 8357 ib (3791 kg)

Unit must have ciearances for airfiow as foliows;

Top — Do not restrict in any way

Ends — 5 ft [1524 mm]

Sides — 6 ft [1829 mm]

Mounting hoies may be used to mount unit to concrete pad They are not

recommended for mounting unit to spring isoiators.

One ЗУа" (92-mm) dia hoie is recommended for single-entry power into

Module 134A and 208/230-v units Single entry power into Module 134B is

not recommended

Circled numerals in Top View refer to condenser fans by position

If spring isolators are used, a perimeter support channel between the as

sembled unit and the isolators is recommended Do not support each mod

ule separately

Each module of the unit must be rigged into position separately. The unit

must not be rigged after modules have been connected.

Suction and liquid connections can exit on either side of the unit

8

Field power supply connections are required for each module

9

See Table 1A or 1В for rigging center of gravity (Dimensions K,L,X,Y). See

10

Table 2A and 2B for A-D corner weights.

Table ЗА — Units 38AH044-084 Physical Data — 50/60 Hz (English)

38AH

OPERATING WEIGHT WITH Cu-AI

REFRIGERANT (Approx) — Lb Cu-Cu

SHIP WEIGHT WITH COIL PROTECTION ONLY

(Approx) — Lb Cu-AI

TYPICAL OPERATING REFRIGERANT

Charge (Approx) — Lb

Qty of Circuits Std

COMPRESSOR Type...Rpm

(Qty Cylinder) Compressor*

Model No. 06E

(Qty Cylinder) Compressor*

Model No. 06E

Oil Charge (Pt)

Capacity Control Stepsf

CONDENSER FANS (6 Blade) — 60 Hz

Qty...Dla (In.)

Ainlow (Cfm)

Speed (Rpm)

Total Power (kW)

CONDENSER FANS (6 Blade) -

Qty...Dia (in.)

Airflow (Cfm)

Speed (Rpm)

Total Power (kW)

CONDENSER COIL

Rows...Fins per in.

Face Area (sq ft)

Storage Capacity (Lb per Circuit) at 120 F

CONNECTIONS

Suction, ODF (in.)**

Liquid, ODF (in.)**

Hot Gas Bypass, ODF (in.)

■50 Hz

044

3259

3547

3250

Cu-Cu

Opt

Std

Std 250 250

Opt (4)A1 (4) A2

Opt 250 250

Std 17 17

Opt 17 17

3538

62

2

1

(4)A1

2...17 2...17 3...17

80.5

35

Reciprocating Semi-Hermetic

(4) B1

(4) A1 (6) B1 (6) A1

250

(6) A1 (4) A2

265

17

21

054

3309

3597

3290

3578

72

2

1

265 265

250 275

21

17 21 21

4. .30

35,000

1140

6.2

4. ,30

35,000

950

62

Enhanced Copper Tubes, Aluminum Lanced Fin

80.5 80.5

35 55

064

3565

3998

3530

3963

R-22

88

2

1

1750 @ 60 Hz; 1458 @ 50 Hz

(6) B1 (6) A1 (6) B1

2Va

275

(6) A2

265

21

%

¥e

(6) A1

21

275 299

(6) A1 (6) A2

299 275

21 19

19 21

074

3812

4229

3780

4197

104

2

1

52,000

52,000 I 51,000

2...19

116.7

6 .30

55

1140

93

6 .30

950

93

I

(6)A1

299

(6)A1

299

19

19

084

4057

4735

4000

4678

130

2

1

51,000

3 .17

1167

80

(6) B1

299

(6) A2

299

19

19

Table 3B — Units 38AH044-084 Physical Data — 50/60 Hz (SI)

38AH

OPERATING WEIGHT WITH

REFRIGERANT (Approx) — Kg

SHIP WEIGHT WITH COIL PROTECTION ONLY

(Approx) — Kg

TYPICAL OPERATING REFRIGERANT

CHARGE (Approx) — Kg

Qty of Circuits

COMPRESSOR Type...R/s

(Qty Cylinder) Compressor*

Model No. 06E

(Qty) Cylinder) Compressor*

Model No. 06E

Oil Charge (L)

Capacity Control Stepsf

CONDENSER FANS (6 Blade) — 50 Hz

Qty...Dia (mm)

Airflow (L/s)

Speed (R/s)

Total Power (kW)

CONDENSER FANS (6 Blade) — 60 Hz

Qty...Dia (mm)

Airflow (L/s)

Speed (R/s)

Total Power (kW)

CONDENSER COIL

Rows...Fins per m

Face Area (sq m)

Storage Capacity (Kg per Circuit) at 48.9 C

CONNECTIONS

Suction, ODF (in.)**

Liquid, ODF (in.)**

Hot Gas Bypass, ODF (in.)

Cu-AI — Copper tubes with aluminum fins

Cu-Cu — Copper tubes with copper fins

ODF — Outside Diameter, Female

Opt — Optional Single-Circuit Units

Std — Standard Dual-Circuit Units

•Compressor A1 is lead on standard and optional single-circuit units

tCapacity control steps listed are for constant-volume units with no accesso

ries Refer to Table 19A or 19B, page 46, for additional system capacity

information

LEGEND

Cu-AI

Cu-Cu

Cu-AI

Cu-Cu

Std

Opt

(4) A1 (4)B1 (4) A1

Std

250

Std

(4)A1 (4) A2 (6) A1 (4) A2 (6) A1

Opt

Opt 250 250

Std 8 0 80

Opt 80 80

044 054

1478 1501

1609

1474 1492 1601 1715

1605

28 1 32 7 39 9

2 2

250

2..

669

7.48

16 16 25 25

1632 1813

1623 1798 1904

1 1

Reciprocating Semi-Hermetic 29.2 @ 60 Hz; 24.3 @ 50 Hz

(6) B1

250 265 265 275

265 250 275 265

80

99

9 9

80

4.. 762 6 762

16 500

15.8

62 93

4..

762

16 500

19.0 19.0

62 93

Enhanced Copper Tubes, Aiuminum Lanced Fin

2.. 669 3,. 669

7.48 7.48 10 84

**For single-circuit units, suction ODF is 2% in. (66 7 mm) and liquid ODF is

IVs in (28.6 mm) Single circuits have a factory-installed manifold; no

field modification is required.

NOTES:

1 Certified dimensional drawings available on request

2 Equivalent connection values in mm are as follows;

in.

% 15.9

%

2Ув 54 0

064

1617 1729 1840

R-22

2 2 2

(6) A1

(6) B1

(6) A2 (6)A1 (6) A2 (6)A1 (6) A2

9 9 99 99

9.9 99 90

Z

;

2Va

Ve

%

mm

22 2

1918

(6) A1

275

299

24 500

24 500

2 ..782 3...669

299

299 299

762

084

2148

1814

2122

24 100

24 100

10 84

36

074

47 2 58 9

1 1

(6) B1 (6) A1 (6) B1

299

275

90 9.0 90

99 90 90

15.8

6.

299

10

Table 4A — Units 38AH094-134 Physical Data — 50/60 Hz (English)

38AH

OPERATING WEIGHT WITH Cu-AI 5088

REFRIGERANT (Approx) — Lb Cu-Cu 5813

SHIP WEIGHT WITH

COIL PROTECTION AND SKID

(Approx) — Lb

TYPICAL OPERATING

REFRIGERANT CHARGE

(Approx) — Lb

Qty of Circuits

COMPRESSOR Type...Rpm

(Qty Cylinder) Compressorf

Model No. 06E

Oil Charge (Pt)

Capacity Control Steps**

CONDENSER FANS (6 Blade) — 60 Hz

Qty...Dia (in.)

Airfiow (Cfm)

Speed (Rpm)

Totai Power (kW)

CONDENSER FANS (6 Biade) — 50 Hz

Qty...Dia (in.)

Airfiow (Cfm)

Speed (Rpm)

Totai Power (kW)

CONDENSER COIL

Rows...Fins per in.

Face Area (sq ft)

Storage Capacity

(Lb per circuit) at 120 F

CONNECTiONS

Suction, ODF (in.)

Liquid, ODF (in.) % % 1Ув

Hot Gas Bypass, ODF (in.) Ys

___________________

Cu-AI

Cu-Cu 6355

094

5630

148

2

(4)A2 (6)B1

(6)A1

-275 -250

21

-299

17 19

6. .30

52,000

1140

94

6. .30

52,000

950

94

3...17

128 3

178

2Ve 2Ve

104

5435

6160

5990

6715

R-22

135

Reciprocating Semi-Hermetic. 1750 @ 60 Hz; 1460 @ 50 Hz

(6)A1

-265

21

2

M)A2

{6)B1

-250

-265

17 21

6. .30

52,000

1140

95

6...30

52,000

950

95

Enhanced Copper Tubes, Aluminum Lanced Fin

3...17

128 3

178

Ya Ye Ya Ye

(6)B2

-265

21

(6)A1

-275

124 134

124A 124B 134A 134B

3630*

4063*

3907* 3907* 3907*

4340* 4340* 4340*

88

1

(6)A2

-265

21

21

4, .30

35,000

1140

64

4, .30

35,000

950

64

'3...17

80 5

110

2% 2Ye

(6)A1

-275

21

3630*

4063*

88

1

4. .30

35,000

1140

64

4. .30

35,000

950

64

3...17

80 5

110

V/a

(6)A2

-265

21

3630*

4063* 4294*

88

1

(6)A2

(6)A1

-265

-275

21

21

4. .30

35,000

1140

64

4. .30

35,000

950

64

3...17

80 5

110

2У8 2Ye

1У8 1Ve

(6)A1

-299

3877*

4080*

4497*

19

6. .30

52,000

6. .30

52,000

2 .19

104

1

1140

92

950

92

1167

110

Ye

(6)A2

-275

21

Table 4B — Units 38AH094-134 Physical Data — 50/60 Hz (SI)

38AH 094 104

OPERATING WEIGHT WITH

REFRIGERANT (Approx) — Kg

SHIP WEIGHT WITH Cu-AI 2554 2717 1860*

COIL PROTECTION AND SKID

(Approx) — Kg

TYPICAL OPERATING

REFRIGERANT CHARGE

(Approx) — Kg

Qty of Circuits

COMPRESSOR Type...R/s

(Qty Cyiiner) Compressorf

Modei No. 06E

Oii Charge (L)

Capacity Controi Steps**

CONDENSER FANS (6 Blade) — 60 Hz

Qty...Dia (mm)

Airflow (L/s)

Speed (R/s)

Total Power (kW)

CONDENSER FANS (6 Blade) — 50 Hz

Qty...Dia (mm)

Airflow (L/s)

Speed (R/s)

Total Power (kW)

CONDENSER COIL

Rows...Fins per m

Face Area (sq m)

Storage Capacity

(Kg per circuit) at 49 C

CONNECTIONS

Suction, ODF (in.)

Liquid, ODF (in.)

Hot Gas Bypass, ODF (in.)

LEGEND

Cu-AI — Copper Tubes with Aluminum Fins

Cu-Cu — Copper Tubes with Copper Fins

ODF — Outside Diameter, Female

'Includes piping and trim kit

fCompressors are shipped with minimum oil charge.

•'Capacity control steps listed are for constant volume units with no accesso

ries Refer to Table 20, page 46, for additional system capacity information

Cu-AI

Cu-Cu 2637 2794 1843* 1843* 1843* 1948*

Cu-Cu 2883

2308 2465

3046

67 1

2

(6)A1

-275

10

(6)B1

(4)A2

-250

8

5

6.762

24 544

19

94

6.762

24 544

158

94

3 .669 3 3. .669 3 3 669.3 3 669 3 3 .669 3

11 9 11 9

81

2Ув 2Уа

%

%

-299

(6)A1

-265

9

10

61 2

2

Reciprocating Semi-Hermetic.. 29 2 @ 60 Hz; 24 3 @ 50 Hz

(4)A2

-250

8

6.762

24 544

19

95

6.762

24 544

15.8

95

Enhanced Copper Tubes, Aluminum Lanced Ein

81

Va 1У8 V/a V/a

Ya

(6)B2

(6)B1

-265

-265

10

10

NOTES:

1 Unit 38AH124 consists of one 124A module and one 124B module Unit

38AH134 consists of one 134A module and one 134B module

2 Certified dimensional drawings available on request

3 Equivalent connection values in mm are as follows:

124A

1647*

1968*

R-22

39.9

(6)A1

-275

10

4.. 762

16 520

4.. 762

16 520

in. mm

Ya 15.9

Va

1У8

2Ув 54 0

2Ya 66 7

124 134

124B 134A 134B

1647* 1647* 1759*

1860* 1860* 1851*

1968* 1968* 1968*

1

(6)A2

-265

10

19

64

15 8

64

75

50

2% 2Ya 2Ya

Ya

22 2

28 6

39 9

1

(6)A1

(6)A2

-265

-275

10

10

4.. 762

16 520

19

64

4...762

16 520

158

64

75 75

50 50

% Ya

(6)A1

-275

10

39 9

4.. 762

16 520

4.. 762

16 520

1

19

64

158

64

(6)A2

-265

10

(6)A1

-299

9

47 2

1

(6)A2

-275

6.762

24 544

19

92

6 ..762

24 544

15.8

92

2 .781 6

10 8

50

2%

1Ve

Ye

10

11

Fig. 7 — Modules 38AH124A or 134A — Shipping Locations of Piping and Sheet Metal Trim Kit

%

CONTROL

BOX

12

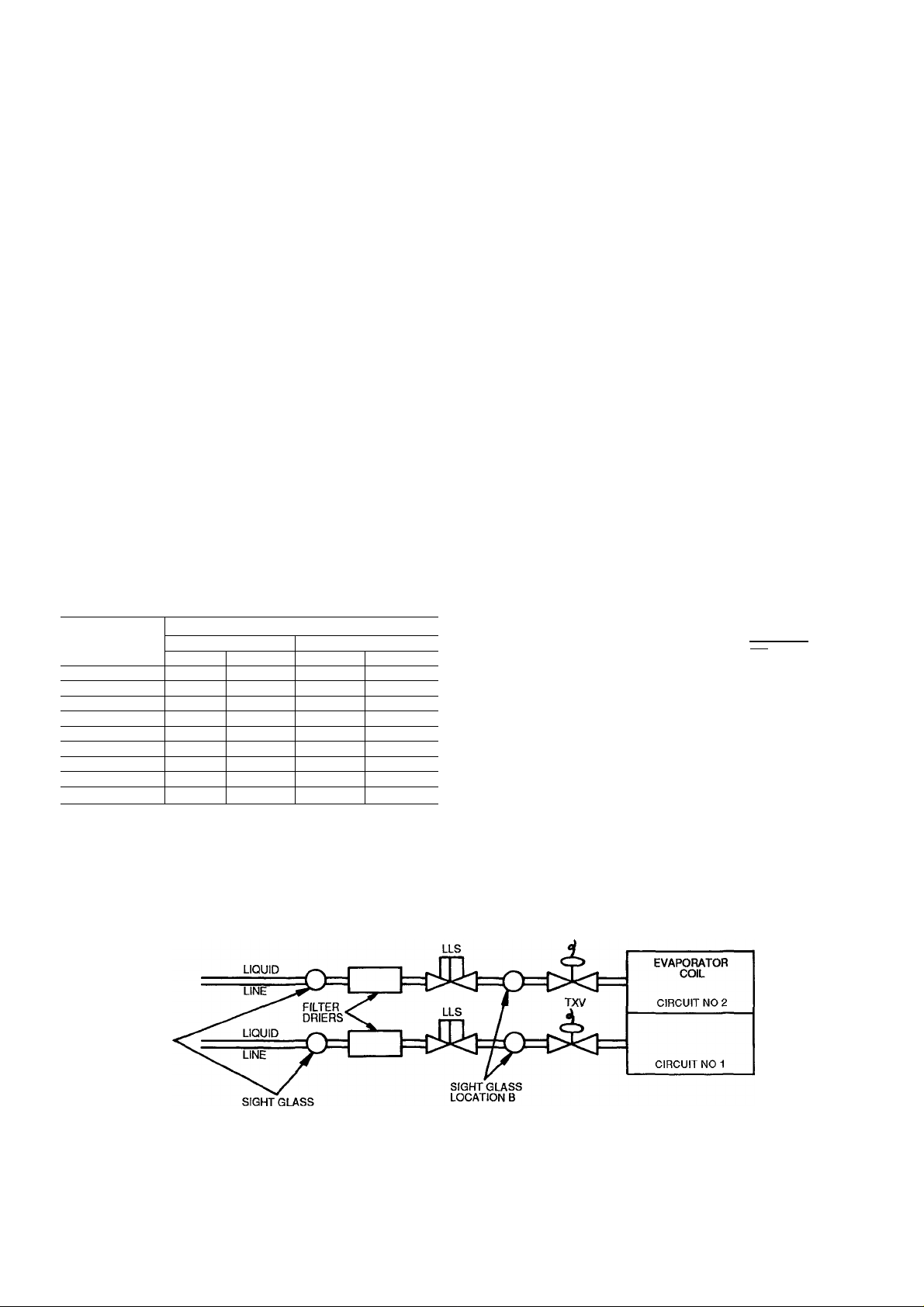

Step 3 — Make Refrigerant Piping Connections

A CAUTION

The field-supplied liquid line solenoid valve must be in

stalled at the evaporator to avoid possible compressor

damage during unit operation. See Fig. 11 (for 38AH044084 dual-circuit and 38AH094-134 units), or Fig. 12 (for

38AH044-084 optional single-circuit units).

The units have large suction lines to minimize friction losses.

The units also have the ability to operate at low capacity.

Because of these capabilities, use special care with suction

piping and suction risers to ensure proper compressor oil

return under all operating conditions. Maximum allowable

vertical separation between the condensing unit and the evapo

rator is shown in Table 5. Size suction lines in accordance

with Tables 6A or 6B through 9A or 9B and Fig. 13. Mount

liquid line solenoid valve just ahead of the TXVs (thermo

static expansion valves) which will be mounted at the

evaporator. See Fig. 11 (for 38AH044-084 dual-circuit and

38AH094-134 units) or Fig. 12 (for 38AH044-084 optional

single-circuit units).

Fig. 9 — Typical Module with Cover Panels

Removed

38AH044-084,124,134

SHIPMENT BOLTS

MOUNTING SPRINGS

38AH094,104

SHIPMENT BOLTS

13

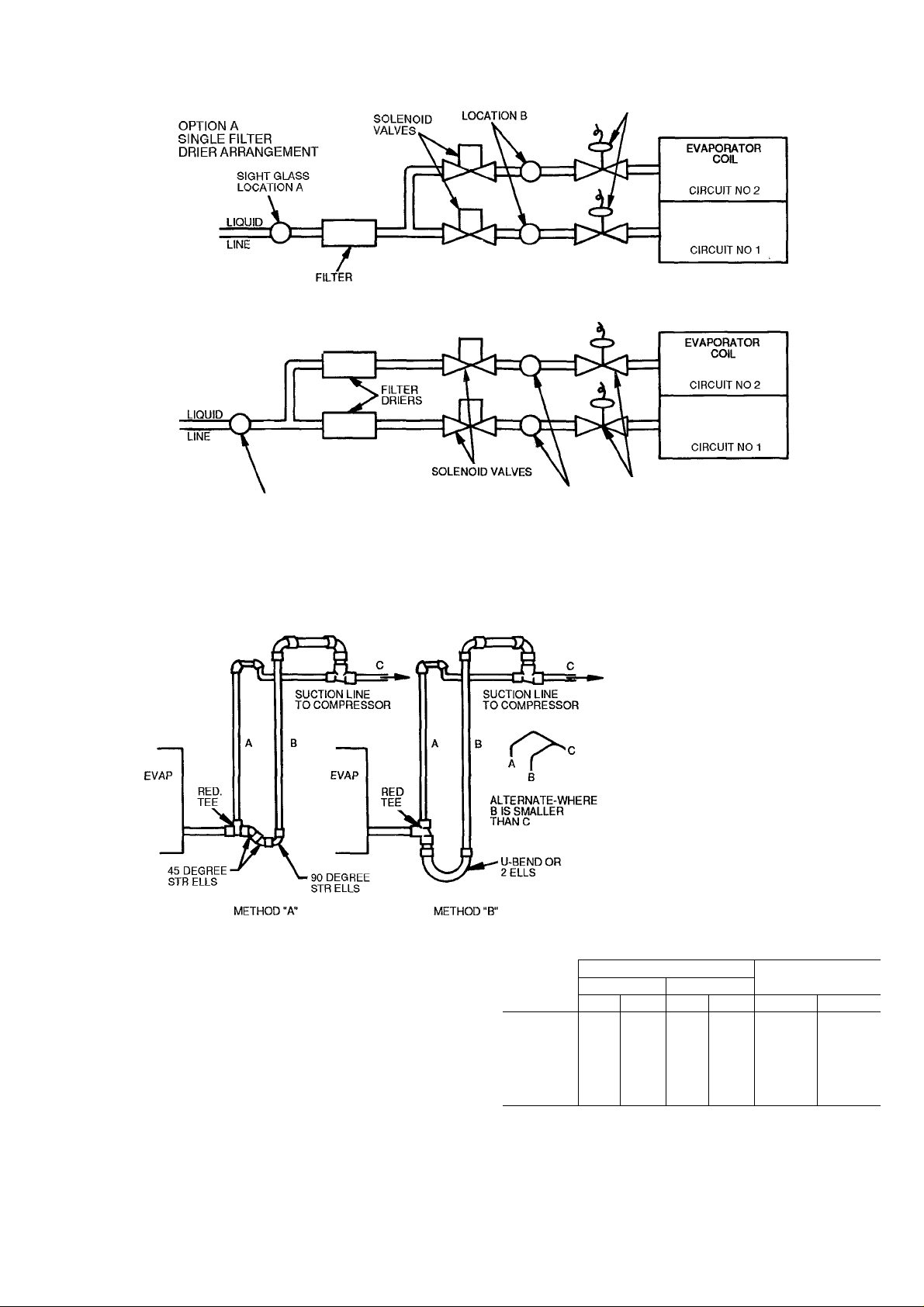

To achieve good mixing of the refrigerant leaving the evapo

rator suction header for proper sensing by the TXV bulb:

1. Install a minimum of two 90-degree elbows upstream of

the TXV bulb location. See Fig. 14 (for 38AH044-084

dual-circuit and 38AH094-134 units) or Fig. 15 (for

38AH044-084 optional single-circuit units).

2. Locate the TXV bulb on a vertical riser, where possible.

If a horizontal location is necessary, secure the bulb at

approximately the 4 o’clock position.

3. Size the suction line from the evaporator to the common

suction line to achieve high refrigerant velocity. See

Tables 6A or 6B through 9A or 9B and Fig. 13.

If an oil return connection at the bottom of the suction

header is supplied with an evaporator, tee-in this connection

ahead of first mixing elbow. See Fig. 14 (for 38AH044-084

dual-circuit and 38AH094-134 units) or Fig. 15 (for 38AH044084 optional single-circuit units). When the compressor is

below the evaporator, the riser at the evaporator should ex

tend to the top of the evaporator section. After the riser is

installed, the suction line can elbow down immediately.

Install a field-supplied filter drier and sight glasses in each

refrigerant system. Select the filter drier for maximum unit

capacity and minimum pressure drop. Figure 11 (for 38AH044084 dual-circuit and 38AH094-134 units) or Fig. 12 (for

38AH044-084 optional single-circuit units) shows required

location of solenoid valves and recommended locations for

the filter driers and sight glasses. Complete the refrigerant

piping from the evaporator to the condenser before opening

the liquid and suction lines at the condenser.

Table 5 — Liquid Lift

UNIT 38AH 60 Hz

044 69

054

064 75 23 0

074 45

084 75 23 0

094

104 50 152

124 75 23 0

134 45 137

Ft

75 23 0

55

MAXIMUM LIQUID LIFT

M

21 0

137

167

50 Hz

Ft M

57 5

75 0 23 0

65 0 19 8

37 5

75 0 23 0

46 0

42 0 128

65 0

37 5 11 4

175

11 4

140

19.8

UNITS 38AH044-084 — Relieve the pressure caused by the

holding charge into a refrigerant recovery system. Uneap the

suction line and cut the run-around tube at the liquid line

as close to the loop elbow as possible. This will leave ap

proximately 2 , in. (50 mm) of straight tube for liquid line

connection.

IMPORTANT: Protect the liquid valves from the heat

of brazing.

Leak test the entire system by using soap bubbles and

nitrogen or R-22 with an eleetronic leak detector.

Purge nitrogen or reclaim R-22 from system after comple

tion of leak-checking procedure. Repair leak if one is found.

When finished, evacuate and dehydrate system using the meth

ods described in Carrier GTACII (General Training Air Con

ditioning II), Module 4, System Dehydration.

UNITS 38AH094-I34 — Relieve the R-22 holding charge

of each circuit into a refrigerant recovery system. Remove

the liquid line to factory-installed suction line loop by cut

ting the loop at the liquid valve. (See diagram below and

Fig. 9.) Cut as close to the 90-degree bend in the loop as

possible. The remaining tube piece in the valve will be used

for brazing the liquid line. Unbraze and remove the cap from

the liquid line. For 38AH094 and 104 units, sweat-connect

the liquid and suction lines from the evaporator. For 38AH124

and 134 units, see Piping Kit Connections on page 21.

TOP VIEW

FACTORY-INSTALLED

SUCTION

LINE

SUCTION LINE LOOP

1

---

r _ r LINE

~-r . -I-

-CUT LINE

LIQUID

TXV

LOCATION A

LEGEND

LLS — Liquid Line Solenoid

TXV — Thermostatic Expansion Valve

Fig. 11 — Required Location of Soienoid Valves and Recommended Filter Drier and Sight Glass Locations for

38AH044-084 Dual-Circuit and 38AH094-134 Units.

14

OPTION B

DUAL FILTER

DRIER ARRANGEMENT

DRIER

SIGHT GLASS

THERMOSTATIC

EXPANSION VALVES

THERMOSTATIC

EXPANSION

VALVES

SIGHT GLASS

LOCATION A

SIGHT GLASS

LOCATION B

Fig. 12 — Required Location of Soienoid Vaives and Recommended Fiiter Drier and

Sight Giass Locations for 38AH044-084 Optionai Single-Circuit Units

u

■ CONDENSING

1—UNIT

3 FT MAX (914 mm)

\

-------

\

LEGEND

A — Pipe A, Suction Riser, without Trap

B — Pipe B, Suction Riser with Trap

C — Suction Line to Condensing Unit

D — Pipe D, Suction Riser Short Lift

RED. — Reducer

STR — Street

NOTES1 Short riser, pipe D, is used when routing suction iine to condens

ing unit connection See table at right

2. See Tables 7A, 7B, 9A, and 9B for values of A, B, and C.

Fig. 13 — Double Suction Riser Construction

PIPE D DIAMETER

UNIT

38AH

044

054 1%

064 1% 41 21/8 54

074

084 21/8

094, 104 21/8

124, 134 2% 67 2% 67 — —

‘Maximum iength of riser is 3 ft (914 mm).

tDouble suction riser required if accessory

instaiied

Dual Circuit*

A

mm in. mm in. mm

in.

1% 41 1% 41 21/8 54

41 1% 41 21/8 54

21/0 54 21/8 54 21/8 54

54 21/8 54

54

B

21/8 54

15

Singie Circuit*

21/a 54

2%t 67t

— —

unioader is fieid

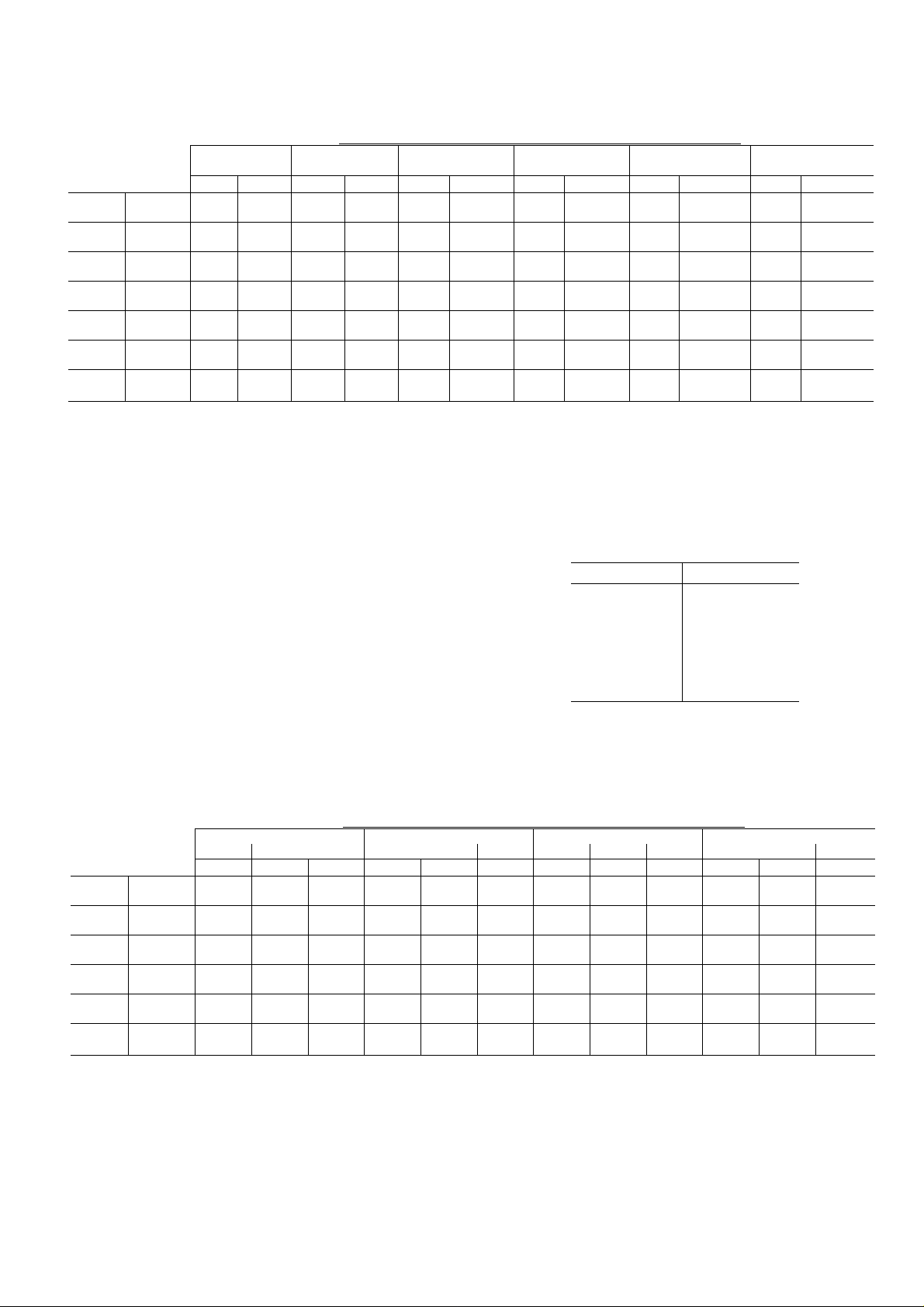

Table 6A — Refrigerant Piping Requirements — 38AH044-104 Dual-Circuit Units — 60 Hz

TOTAL LINEAR LENGTH OF INTERCONNECTING PIPE — FT (M)

UNIT 38AH

044

054

064

074

084

094

104

Ckt A

Ckt В %

Ckt A

Ckt В У8 1%

Ckt A

Ckt В % 2Ve

Ckt A

Ckt В

Ckt A

Ckt В V8 2Уа

Ckt A

Ckt В % 2Ve

Ckt A

Ckt В

LEGEND

CV — Constant Volume

L — Liquid Line

S — Suction Line

VAV — Variable Air Voiume

‘Double suction riser required on units with field installed unloader

on circuit В compressor if condensing unit is elevated above

evaporator.

tDouble suction riser required on units with field installed unloader

on circuit В compressor if condensing unit is elevated above

evaporator.

“Double suction riser required on all unit configurations if condens

ing unit is elevated above evaporator.

NOTES:

1. Addition of 2 unloaders to circuit В compressor is not

recommended

2 38AH094 and 38AH104 piping sizes apply only to factory sup

plied unit configurations They do NOT take into account any field

installed unloaders

3 Piping sizes are based on unit operation above 40 F (4 4 C) satu

rated suction temperature (SST) When operating below 40 F

(4 4 C), refer to Carrier System Design Manuai, E20-IÌ piping de

sign program, or ASHRAE Handbook to select proper line sizes

4 Pipe sizes are based on the total linear length shown for each

column, plus a 50% allowance for fittings.

15-25 25-50

(4.6-7.6) (7.6-15.2)

L s

%

%

%

%

%

%

%

%

%

1% У8 1У8 Ув

1% У8 1% Ув

1% У8 1% Ув

1% У8 2Ув Ув

2Ve У8 2Уа Ув

2V8 1У8 2У8 1У8 2Ув

2V8 1Ув 2Ув 1Уе 2Ув

2V8 1Уб 2Уа 1 Ve

2Ув 1У8 2Ув 1Ув

2Ув

L

У8 2У8 Ув 2Ув

У8 2Ув Ув 2Ув 1Ув

1У8 2Ув 1Ув 2Ув

Ув 2У8 V/a 2Ув

1Уб 2Ув 1Ув 2Уе

(15.2-22.9) (22.9-30.5)

S

L S

50-75 75-100

L S L

2Ув Уе 2Уе

2Ув Ув 2Ув

2Ув Va 2Ув

2Ув Уе 2Ув

2Ув 1Ув 2Ув

2%t

2%t

1Ув 2Ув

1Ув

1У8

1Ув

1Ув

1Ув

1Уз

1Ув

5 Suction and liquid line sizing is based on pressure drop equivalent

to 2 F (1.1 C) at nominal rating conditions. Higher pressure drop

design criteria may allow selection of smaller pipe sizes, but at a

penalty of decreased system capacity and efficiency

6. Double suction risers may be required if condensing unit is el

evated above the evaporator See footnotes and double suction

riser table below

7 Refer to Carrier System Design Manual or to E20-II design

programs for further information on selecting pipe sizes for split

systems

8. All pipe sizes are OD inches Equivalent sizes in millimeters

follow

100-150

(30.5-45.7)

Уе 2Ув

Va

Va 2Ув Va

1Ув

2Ув

2% 1Ув

2%t

2% 1У8

2%t

2%

2%t

2%

1Уе 2Ув

1У8

1Ув

1%

1%

1Уа 2%

1Ув

1% ЗУв“

in. mm

% 15.9

Уе 22.2

v/a

V/a 34 9

V/a

2Уа

2%

ЗУв

3%

S

2Уе

2Ув

2%

2%t

2%

2%

2%t

2%t

2%t

28.6

41 3

54 0

66 7

79 4

92 1

150-200

(45.7-61.0)

L

Va 2Ув

Va

1У8

1Ув

1У8

1У8

1%

1Ув

1Ув

1% ЗУв“

1Ув

1У8 ЗУв“

1У8

s

2Ув

2Ув

2%*

2%t

2%

2%t

2%

2%t

2%

2%

ЗУв“

Table 6B — Refrigerant Piping Requirements for Double Suction Risers,

38AH054-104 Duai-Circuit Units — 60 Hz

TOTAL LINEAR LENGTH OF INTERCONNECTING PIPE — FT (M)

UNIT 38АН

054

064

074

084

094

104

— — Not Required

Pipe A — Suction Riser Without Trap

Pipe B — Suction Riser With Trap

Pipe C — Suction Line to Condensing Unit

NOTES.

1 See Refrigerant Piping Requirements table at top of page to de

termine need for double suction risers.

2 Pipe sizes are based on the total linear length, shown for each

column, plus a 50% allowance for fittings.

Ckt А

Ckt В

Ckt A

Ckt В

Ckt A

Ckt В

Ckt A

Ckt В

Ckt A

Ckt В

Ckt A

Ckt В

LEGEND

1У8

1Ув

50-75 75-100 100-150

15.2-22.9) (22.9-30.5 30.5-45.7

A

_

_

_

_

—

В С

—

___

___

—

2Ув

2Ув

—

— —

—

— —

—

1Ув

2% V/a 2Ув 2% 1% 2Ув

2¥а V/a 2Ув 2% 1Ув 2Ув

—

А

—

В С

—

— —

___

2Уе

—

—

2% 1Уе 2Ув

— — —

150-200

(45.7-61.0

А В

С

А

В

С

—

___

___

1Ув 2Ув

1Ув 2%

Suction and liquid line sizing is based on pressure drop equivalent

to 2 F (1 1C) at nominal rating conditions Higher design pressure

drop criteria may allow selection of smaller pipe sizes but at a pen

alty of decreased system capacity and efficiency.

Refer to Carrier System Design Manual or to E20-II design

programs for further information on selecting pipe sizes for split

systems

All pipe sizes are OD inches. See Table 6A notes for metric

equivalents

Refer to Fig. 13 for double suction riser construction

___

—

___

2%

2%

2%

2%

ЗУв

V/a 2Ув

V/a

2Va

1Ув 2Уа

V/a 2Va

V/a

V/a 2%

V/a 2%

2%

2%

2%

2%

2%

ЗУв

ЗУв

ЗУв

16

Table 7A — Refrigerant Piping Requirements, 38AH044-104 Dual-Circuit Units — 50 Hz

TOTAL LINEAR LENGTH OF INTERCONNECTING PIPE — FT (M)

UNIT 15-25 25-50

38AH

(4.6-7.6) (7.6-15.2)

L S L S

044

054

064

074

084

094

104

CV — Constant Volume

L — Liquid Line

S — Suction Line

VAV — Variable Air Volume

’Double suction riser required on units with field installed unloader

on circuit B compressor if condensing unit is elevated above

evaporator.

TDouble suction riser required on units with field installed unloader

on circuit B compressor if condensing unit is elevated above

evaporator.

’’Double suction riser required on all unit configurations if condens

ing unit is elevated above evaporator

NOTES1 Addition of 2 unloaders to circuit B compressor is not

2. 38AH094 and 38AH104 piping sizes apply only to factory sup

i.

3 Piping sizes are based on unit operation above 40 F (4 4 C) satu

4 Pipe sizes are based on the total linear length shown for each

Ckt A % 1% % 1%

Ckt В

Ckt A %

Ckt В

Ckt A %

Ckt В

Ckt A % 1% Va

Ckt В

%

%

%

Ckt A %

Ckt В %

Ckt A

Ckt В

Ckt A

Ckt В %

LEGEND

recommended

plied unit configurations They do NOT take into account any field

installed unloaders

rated suction temperature (SST) When operating below 40 F

(4 4 C), refer to Carrier System Design Manual, E20-II piping de

sign program, or ASHRAE Handbook to select proper line sizes

column, plus a 50% allowance for fittings

1% % 1%

1%

Wa Va 1%

Wa

1% Va 2У8

Va 1%

Va

1%

2Уа

2Ув Va 2Уб 1У8

%

2Va

2Va

2Va

%

2Va % 2Уе 1У8 2У8

%

2Va Va 2Ув 1У8 2Уа

%

2Va 1У8 2Ув 1У8 2%

Va 2Ув 1У8

Va 2Ув 1Ув

IVe 2Ув ^ 1У8 2%”

50-75

(15.2-22.9)

L

%

Va

Va

Va

Va

Va

Va

s

1% %

1% Va

1%

2У8

2yst

2Ув

2Ув

2Ув

2Ув

2У8

5. Suction and liquid line sizing is based on pressure drop equivalent

6 Double suction risers may be required if condensing unit is el

7 Refer to Carrier System Design Manual or to E20-II design

8 All pipe sizes are OD inches Equivalent sizes in millimeters

75-100

(22.9-30.5)

L

Va

Va

Va

Va

Va

1У8

1У8

1Уа

1У8

1У8

1У8

1У8

to 2 F (1 1 C) at nominal rating conditions. Higher pressure drop

design criteria may allow selection of smaller pipe sizes, but at a

penalty of decreased system capacity and efficiency

evated above the evaporator See footnotes and double suction

riser table below

programs for further information on selecting pipe sizes for split

systems

follow

s

2У8

2У8

2Уб

2Уа

2Va\

2Va

2Va

2%

2%t

2%

2%”

2¥8*t

2%”

2Va

ЗУ8 79 4

ЗУ8

100-150 150-200

(30.5-45.7)

L s

Va 2Уе

Va 2Va

Va 2Va

^Va 2Va

V/a 2Va\

V/a 2%*

^Va

V/a 2% 1У8 2%

1У8

2%t

2Щ 1У8

1У8 2%

1У8

1У8

1У8 2У8**

1%

in.

Va

Va

V/a 28 6

V/a 34 9

V/a

2Va 54 0

2Va

2%” 1% ЗУв”

2%*t

2% 1% ЗУ8”

mm

159

22 2

41 3

66.7

92 1

(45.7-61.0)

L

Va 2У8

Va 2У8

Va 2У8

1У8

1У8 2%”

' 1У8

1У8

1У8

1У8

1%

s

2%*t

2%’

2%t

2%t

2%

2%’t

ЗУе”

Table 7B— Refrigerant Piping Requirements for Double Suction Risers,

38AH054-104 Dual-Circuit Units — 50 Hz

TOTAL LINEAR LENGTH OF INTERCONNECTING PIPE — FT (M)

UNIT 50-75 75-100

38AH 15.2-22.9) (22.9-30.5)

A

054

064

074

084

094

104

— — Not Required

Pipe A — Suction Riser Without Trap

Pipe B — Suction Riser With Trap

Ckt A

Ckt В

Ckt A 1%

Ckt В

Ckt A

Ckt В

Ckt A

Ckt В

Ckt A

Ckt В

Ckt A

Ckt В

LEGEND

___

— —

___ ___

___

V/a

— —

— — —

—

Pipe C — Suction Line to Condensing Unit

NOTES:

1 See Refrigerant Piping Requirements table at top of page to de

termine need for double suction risers

2 Pipe sizes are based on the total linear length, shown for each

column, plus a 50% allowance for fittings.

В

C

—

___

V/a 2У8

___

2Vs

—

—

—

—

2% V/a 2Уз

—

—

A В

___

V/a

—

___

V/a 2У8

V/a

V/a 2Уе

—

V/a

— —

___

2Ув

— —

100-150

30.5-45.7) 45.7-61.0

С

___

2Ув

___

25/8

25/8

25/8

25/8

—

3.

4.

А В С А

— —

15/8 15/8

15/8

15/8

15/8

15/s

15/8

15/8

—

Suction and liquid line sizing is based on pressure drop equivalent

to 2 F (1 1C) at nominal rating conditions. Higher design pressure

drop criteria may allow selection of smaller pipe sizes but at a pen

alty of decreased system capacity and efficiency.

Refer to Carrier System Design Manual or to E20-II design

programs for further information on selecting pipe sizes for split

systems

All pipe sizes are OD inches. See Table 7A notes for metric

equivalents

Refer to Fig. 13 for double suction riser construction

2Уа

2Уа

2Уа

2Уа

2Уа

2Уа

— —

___

2У8 V/a

25/8

25/8

25/8

25/8

25/8

25/8

150-200

В

V/a

V/a

V/a

V/a

V/a

V/a

V/a

V/a

2Уа 25/8

2Уа

2Уа 25/8

2Уа

2Уа 25/8

25/8

2У8 25/8

25/8

25/8

С

25/8

25/8

ЗУз

ЗУб

ЗУ8

17

Loading...

Loading...