Page 1

Carrier

«>

30HR,HS040, 050,060

Hermetic Reciprocating Compressors 40 thru 160 Tons

зон R160

30HR,HS070thru 160

DESCRIPTION

These modern multiple-compressor liquid chilling pack

ages offer all the conveniences and economy of packaged

design, for use in chilled water air-conditioning systems and

various types of process cooling applications. Every

machine is completely factory engineered and assembled to

ensure a perfectly balanced refrigeration system. All com

ponents are matched to perform with high efficiency and

low power consumption. Only external water and electrical

connections must be completed to make the water-cooled

unit operational. Condenserless models require, in addition,

only refrigerant line connections to the remote condenser.

The water-cooled model (30HR) is a complete onepackage system with two condensers having built-in sub

coolers, and a direct expansion cooler with two refrigerant*,

circuits, one for each condenser.

FEATURES

• Low Inrush and Running Current because of sequential

starting and stopping Multiple Compressors*.

• Easy to Service bolted-hermetic compressors.

• Wide Range of Distribution Voltages (208 v to 600 v)

allowed by Carrier Voltage Standards*.

• Protection against Single-Phasing of compressor motors,

assured by manual reset, magnetic-trip circuit breakers.

• Internal Motor Protection against overheating, provided

by quick-sensing elements embedded in motor windings.

• Optimum Control of Chilled Water Temperature for

closer Capacity Control provided by Multiple-Step

Controller.

Model 30HS is a condenserless 30HR, designed for use

with remote water-cooled, air-cooled or evaporative type

condensers Includes all features of the 30HR.

Multiple serviceable compressors are mounted on spring

vibration isolators to minimize sound and vibration trans

mission to the unit frame and the building structure.

Hot-gas mufflers dampen compressor gas pulsations, giving

smooth, quiet operation.

Each refrigerant circuit includes a thermal expansion

valve, a liquid line solenoid valve, a filter-drier and

combination liquid line sight glass and moisture indicator.

Compact construction allows passage thru 36-inch door

way. Little floor space required for installation.

• Balanced Wear on Compressors assured by manual

transfer switch, which changes the lead compressor in the

starting sequence.

• Increased System Capacity, without raising horsepower

requirements, afforded by refrigerant subcooling.

• Protection against Refrigerant Migration and Oil Dilution

provided by compressor crankcase heaters, which are on

during compressor off cycle.

• Reduced Power Costs because of partial load operation

at higher suction temperatures made possible by two

separate refrigerant circuits.

©Carrier Corporation 1969

^Single feature sheet available

Form 30HR,HS-5P

Page 2

>

ACCESSORIES

• Oil Pressure Safety Switch Package available for water-cooled

units (standard on air-cooled units)

• Condenser Manifold Package, available for all 30HR units except

30HR160, provides common inlet and outlet water connections

Package contains two steel manifolds, each in two sections Field

welding required

• Control Circuit Transformer, field-installed, provides 115-volt

secondary ciicuit if separate source is not available

• Chilled Water Flow Switch prevents compressors from operating

unless water is flowing

• Unit Enclosure Panels, with fiber glass insulation, completely

enclose compressor and condenser section.

PHYSICAL DATA

UNIT PHYSICAL DATA

UNIT 30HR,HS

APPROX OPER HR

WT (lb)* HS

REFRIG CHG HR

(R-22)t HS 44 55 64 78 88 98

COMPRESSOR 06Et

% Cap.^ Ckt 1

Ckt 2

No. Control Steps

Total Cylinders

Total Oil Chg (pt)

CONDENSER 09RP 30HR Units Only

Ckt 1

Ckt 2

REFRIG CONN, (in.) N

Liquid

Discharge

040 050

2747 3186

1820 2210

79 94 5 99

55 60 50 57

45

4

8

28

022 027

022

2 % 2 Vs 2 y

2 ly» 2..iy

40 50

4

10

33 38 47 52 57

022 027 033 033

060 070 080 090 100 no

3313

2280

4

12

027

2 ly

4940

3470 3525 3585 4470

1 16 131 141 164 174

Reciprocating Semihermet

43

14 16

043

1 iy¡

5125

62 5

37 5

7

1

1. ly

7

054

iVs; 1

o. Size

y

5350

67 50 55 50

33 50

7 8 8

18

070 054

033

1 2y

1 ly

6400 6525 6655

1 13 122 132 148

c - 1750

20 22

66 71

054 054

2 ly

4530

rpm

45 50 50

070

2 ly

1 2 y

1 ly

120

7580

4590 5290

183 198

8

24

76 76

070

070 070

2 2 y

140

8000

5400

50 50

4

24 24

070

2

y

2. 2Vs

160

220

168

50

4

76

084

084

*lncludes refrigerant operating charge.

tSOHR shipped with full oper charge, 30HS shipped with holding

charge (charge for remote condenser and interconnecting piping

added in field).

COOLER PHYSICAL DATA

UNIT 30HR.HS

SHELL, Net Vol

(gal.)

OD (ft-in.)

Length (ft-in.)

TUBES

Number

Length (ft-in.)

Outside Area

(sq ft)

REFRIG CIRCUITS

REFRIG PASSES

MAX DESIGN WKG

PRESS, (psig)

050,060

040

23 6 36 5

0-1 oy 0-12y

6- 0V4

7- 6

200 294

6-2V2 7-8 y

158 284

070,080,

Prime Surface

6-ll’/i6

Refrigerant Side - 235

Water Side - 250

100,110,

090

1-4 1-6 1-6

6-9 7-6

Copper

488

7-87.6

440 645 762

140,160

120

50 0 52 7

646 646

9-2%

2

2

WATER CONN. (In.)

Inlet and Outlet*

Drain

*ASA flat-face flange

3

1

4

1

5

1

9-0

ifSee Electrical Data table for sizes and usage.

CONDENSER PHYSICAL DATA

(^DENSER 09RP

00

Length

TUBES

Number

• Length (ft-in.)

022 1 027 033 043 1 054

i-oy

3-1 oy0-1 oy

5-10 5-10 5-10 5-10 7-2

45

5-lOy.

0-1 oy

Integral Fi

56 64 84 84

5-1073 2

1-oy 1-oy

n, 19 Fins/in.

070 084

1-2

7-2 7-2

124

105

7-27«

Area

Inside (sq ft)

Outside (sq ft)

44 8 51 2 66 8 82.8

36

145 166 217 268

117

103.5 121.5

336 394

SUBCOOLERTUBES

Number

Length (ft-in.)

5 5 5 9

5

5-10732

5-10732

7-2 y

Area

Inside (sq ft)

Outside (sq ft)

6

1

WATER CONN. (in.F

Inlet

Outlet

4 C 4 0 4 9 8 8

4,0

13 0 13 0

13 0

272 3 3

272

2V2

272

272

272

3

15.9

3 4

28 5

2721

WATER PASSES

MAX DESIGN WKG

PRESS, (psig)

Refrigerant Side — 385

Water Side — 250

*ASA flat-face flanges (or weld neck flange).

fTwo inlets on 30HR160.

Page 3

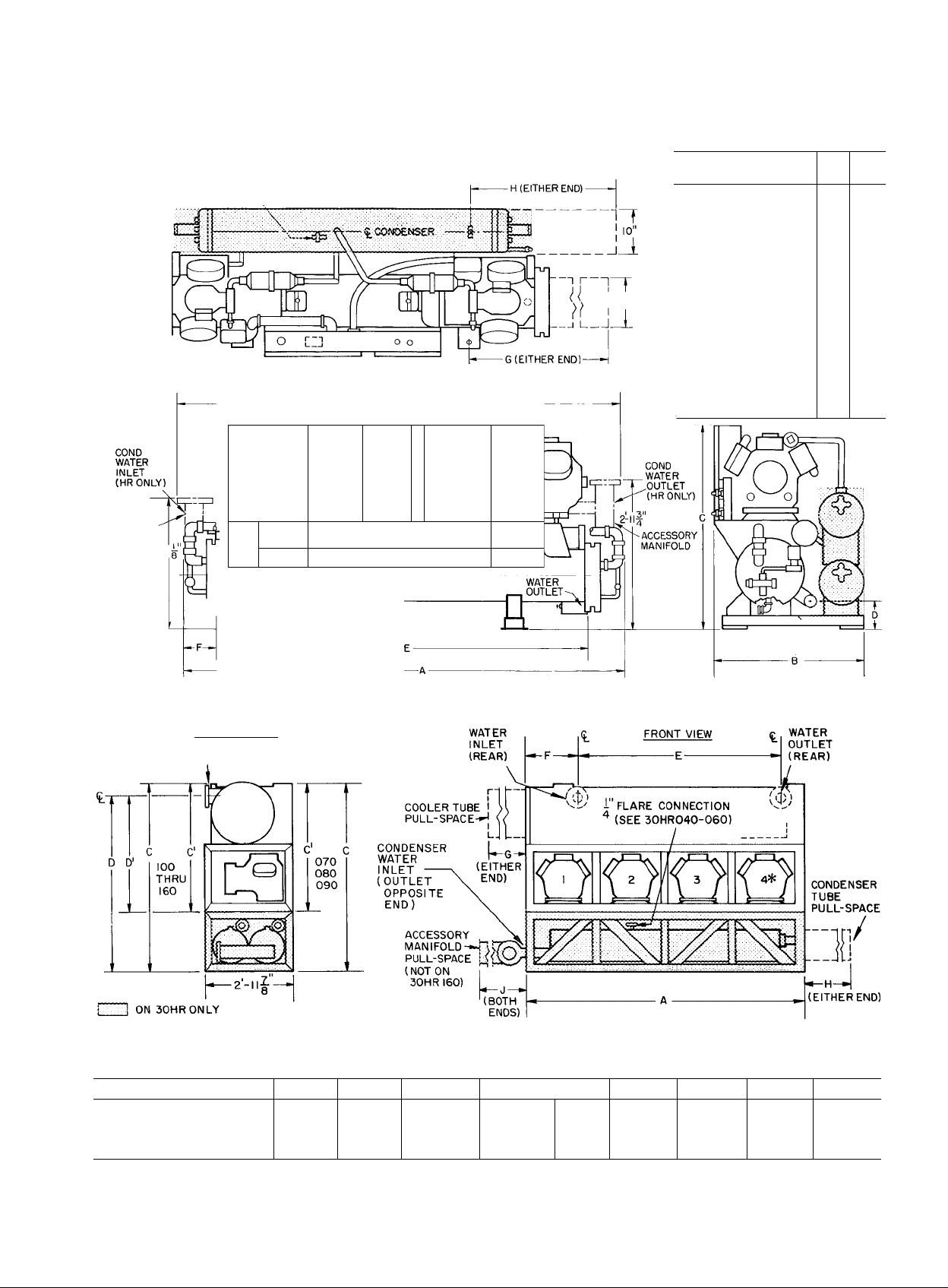

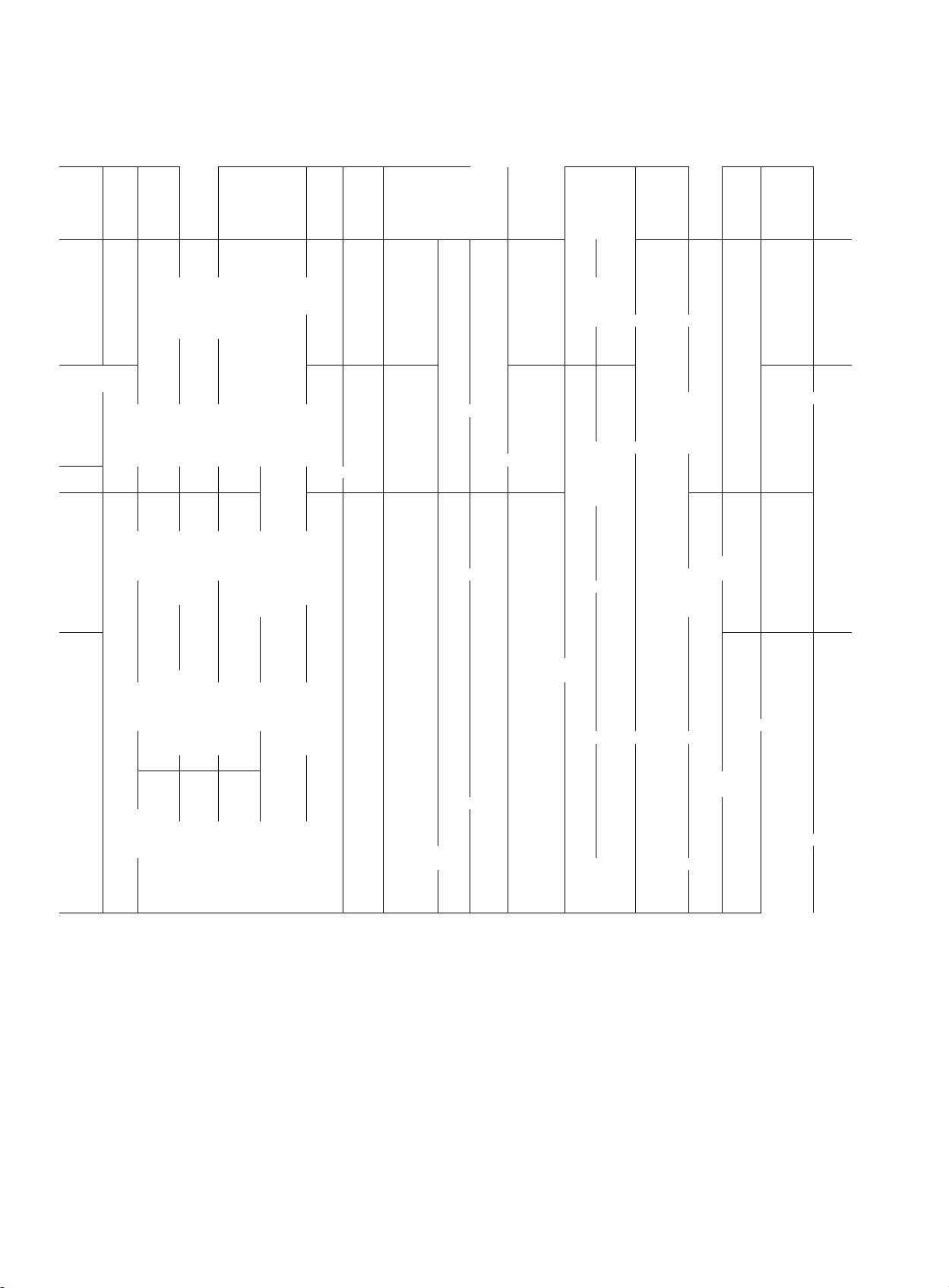

DIMENSIONS

30HR,HS040,050,060

ACCESSORYMANIFOLD

2-7

1" FLARE CONNECTION

FOR WATER REGULATING VALVE,

EACH CONDiSAMEON UNITS 30HR070-I60)

“I

_!

CONTROL

PANEL

D D

a

WATER

INLET

- i. COOLER

-9-0

3"_

0

0

0

”[

MTG HOLE

<L

n

V

! i-o|"diam

UNIT 30HR,HS

DIMENSIONS (ft-in.)

DIAM

Height to chilled

Distance between

chi 1 led water

outlets E

Distance from either

end of unit to

water outlet F

Pull Space

Cooler Tubes G

Condenser Tubes HI

Length A

Wiilth iuc? ^

" (HS) B

Height C

water outlets D

050,

040

060

7-6 9-0 */4

3-0

3-0

2-]%

2-1%

4-1%

4-1 %

0-6V s0-6 V4

6-2% 7-7

0-7%

0-8%

9-3%

7-0%

6-5%

6-5%

a

LEFT SIDE VIEW

WATER INLET AND OUTLET

NOTE: ALLOW 2-0 SERVICE SPACE AT REAR OF UNIT.

30HR,HS070thru 160

^SIZES 070-090 HAVE 3 COMPRESSORS; 100 THRU 160 HAVE 4.

DIMENSIONS (ft - in.)

1

UNIT 30HR,HS

070,080,090

100,110,120

140,160

*Overall length for 070 thru 120. Overall for 140,160 is 10-6-1/8, measured at cooler.

t30HR140 only (manifold not used on 30HR160).

A* C

; 8-6 6-3% 4-2% 5- 9%

i 9-4 6-5%

j

9-4 6-5 % 4-4%

C

4-4% 5-11%

D

5-11%6

D E F G H

3- 8% 6-1

3-10% 6-8

3-10%6

8-1

2-0%

1 -9% 7- 3%

0-7%

6- 1%

8-10%

J

7-4% 1-4

6-1

6-1 l-4%4t

1-4%4

Page 4

SELECTION PROCEDURE (With Example)

I Determine the unit size and operating conditions required to

meet the given capacity at the given conditions.

GIVEN;

Capacity ........................................................................................SOTons

Leaving Chilled Water Temp (LCWT)

Chilled Water Rise...............................................................................10 F

Entering Condenser Water Temp .....................................................85 F

Fouling Factor (Cooler and Condenser)

FOR 30HR (WATER-COOLED CONDENSER):

Enter the Ratings table marked 44 F Leaving Chilled Water

Temperature. Read down the left column (CAP ) to 80 tons

Note that either a 080 or 090 unit may be selected. Final unit

selection should be based on present and future job requirements

and the economics of the job. For this example, data from the

table is shown below for a 080 unit.

..............................................

............................................

PERFORMANCE DATA

44 F

0005

II Determine from Ratings table operating data for selected unit.

Unit...............................................................................................30HR080

Saturated Discharge Temp (SDT)

Compressor Motor Power input (KW)

Total Heat Rejection (THR) ....................................................101.5 Tons

Cooler Water Flow ..................................................................192.0 Gpm

Cooler Water Pressure Drop (PD)

Condenser Water Flow

Leaving Condenser Water Temp (Lwt)...........................................95.6 F

Condenser Water Pressure Drop (PD)

For fouling factors other than .0005 refer to the Correction For

Fouling Factors table to: adjust the required capacity, correct

the compressor power input, and correct the actual condenser

water quantity required. ForA t (SDT — entering cond water

temp) other than 30 F, refer to curve.

FOR 30HS (CONDENSERLESS):

Use the same method, with the exception that the condenser

water data do not apply. For the remote condenser data, refer to

appropriate Carrier condenser data publication.

...........................................................

.......................................................

..........................................

..................................................

...........................................

75.9 Kw

229.4 Gpm

107.0 F

10.7 Ft

12.0 Ft

CORRECTIONS FOR FOULING FACTORS

Ratings are based on .0005 fouling factor in the cooler and

condenser. Correction factors for other fouling factors are given in

the following table:

CORR FACTOR

FOULING

FOR CAPACITY

FACTOR AND COND WATER

Condenser

1 02

1.00

Clean

.0005

Cooler

1.01

1 00

.001 .98

.002

To correct capacity, adjust as follows:

a Adjusted required capacity (use to enter table)

_______

cooler factor x condenser factor

b. Actual compressor power input

= compressor kw (from table) x correction factor for

power input

c. Actual condenser water quantity

= gpm (from table) x cooler factor x condenser factor

-

required capacity

.94

________

CORR FACTOR

FOR

POWER INPUT

Condenser

98

1.00

1 03

1.10

Ratings based on: 10 F chilled water rise (suitable for 5 F to

15 F rise without adjustment), .0005 fouling factor in cooler (and

condenser on model 30HR), 15 F subcooling, and R-22.

Ratings in boldface type (44 F chilled water page) are in

accordance with the latest ARI Standard 590. Conditions:

30HR — 44 F leaving chilled water temperature with 10 F rise,

95 F leaving condenser water temp with 10 F rise and .0005 fouling

factor in cooler and condenser.

30HS — 44 F leaving chilled water temperature with 10 F rise,

.0005 fouling factor in cooler, 105 F condensing temperature for

remote water-cooled or evaporative condenser, 120 F condensing

temperature for air-cooled condenser.

Ratings based on 15 F subcooling. On 30HR units this occurs at

30 F A t (SDT — entering condenser water temperature.) When a

30HR (water-cooled condenser) unit is selected at conditions other

than 30 F A t use the curve below to correct the ratings table

capacity.

RATINGS

The following ratings tables are for both 30HR (water-cooled

condenser) and 30HS (condenserless) models. Condenser water data

apply to model 30HR only. Ratings beyond limits shown and/or

brine ratings are available in Carrier Application Data publications.

Ratings shown for Saturated Discharge Temperature (SDT) over

120 F do not apply to model 30HR.

Correction = Ratings table capacity x percent capacity correction

(from above curve).

Above 30 F At add the correction to rating table capacity.

Below 30 F At subtract the correction from rating table capacity.

30HS units matched with remote condensers which have greater

than (less than) the 15 F subcooling in the ratings, increases

(decreases) system capacity. To adjust capacity, multiply capacity

ratings by 0,94, then adjust this result upward by 0 4 percent for

each degree F of available subcooling

Page 5

PERFORMANCE DATA

30HR,HS RATINGS

Leaving Chilled

Water Temperature

42 F

COOLER

FLOW DATA

lOF RISE

(tons) (F)

34 0 j 131 4

36.G : ! 24 C

38 G

. ..“'V'.v,,

■ 40,7 Î

42 C i

44 C i 94 6 41 2

38 CÎ

40 0 j 127 4 52 6

4? C 1

.:.42.2. 0:12Q,0:: .50.2

46.0

46.4

46.9 1 5.05.0 .45.5. ...59.8

48 0

50 0

44.0

46 C

48.0

.:::49.7. i.:î2Û.O .l.S9:6T..66,.6.; .:U9.2

50.C

52 C

54,0

...55.3:

56.0

. ..56.3. Î ’.Q5.Q

58 C

60 0 96.8

62 0 92 2 50 4

54 0

56.C

58 C 126 2 74 0

60 0

.....6L2

62 C ^

64.0

66.0

68.0

68..5

. ,69.3.

70 C

72 0 100 2

60 C

62 C 132.3 86 8 86 6

64 0

66 C

68.0 121 8

, 69.0,

70. C

72 C

74.0

76.0

V 77.5

78.0

.78.,!,

80. G

82,0

65 0

70 0

75 C 122.2

: 76 .4, i: J2S.0 .90,5

80 0

85 C

S6.0

, ,:S6.3.

90.0

95 0

! .120.0 . 49..G .50.9Î .89.0. 7.4

I 1 16 7 48 0

109 4 45.7

040

107.0 44.9 53.4

- J05.0..

102 1

134 2

120.8

Ì08 n

050

ÎÔ6.8 46.2

101 6 44 6 60 7 115.2 5 3

95 1

133 9 64 4 ^62 3 105 6

128 9 62 7 63.8

124 ]

i 1 19 4 59 4

1 14 8

060

.1..1.C..3..

U07..4 ..5.5.4.

1C5.S.

101 3

134 2 77 4

130 2 75 7

122,4

; 120.0

118 6 70 8 82 1 148 8

070 114 9

111.2 67 7 85 2 158 4 7 3

107.6

; 306.6 :

;..ÌQ5.0,:

103 9

136 0

128 7

125 2

! 123.0 80.9 92 C

i ¡8 4 80,1

080 115 0

111 7

108.5 75.5

.Ì06..1..

105.2

, 5.05.0

101 9 72 5 100 6

98,6 71.0

138 6

130 1

114 5

090

107.0

Ì05.5

,5.05.0.

99 5

91 8 75 9 1 16 5

(tons)

48 8

52 2

.50.2 .50.2 86 4

51 6 91.2 7 8

53.0

.53 ..8 .. 98-9 .. 9.2 78.5 91 4

44.3.

43 4

54.3

55.7 105.6

54 8 53 6 91 2 3 3

54 9 96 0

SO s

56 3 100.8

,55.4 ; 1GÎ.4 4, ;

46 F

42.7

61 0 65.3

57 8

-jr\ rv

..56...3,

. .«’.y V.

.7Î..C. .132.6

.,71.6.

..54.S.

.54.5 ..7.LS.

53 3 73 1

51 9

72,4

80..5

.7,1.3

.81.5.

69.2 83 7 153 6 6 9 1 15 5 92 4 2 6

66.2 86 8

6.5.8

.0,5.2.

64 8

63 3

88 6

85 0

83 4 89 7

81 7 91.2 163 2

78 5

77 C

.-74.4, 93.6

74.0

:..99.ü

.73.9

102.2 196.8 11.3 [202.1 87 1 9 5 329 2 87 4 23 7

100 2 93 5

95 6

91 4

,100.9

104 '8

87 3

83.4 ,108.7 204,0 1 ? 1 151.0 92 6 4 5

82.7 Î09.S

:82..4

l'D9.7 ,207.2 .32,5. 151.1

1 12 6

79.6

Gpm

81 61 6 3

100.8 9.6

1 10 4 4.9

5v.2

59.5 !!f.2

'll 2.6 5.0

62 1 120,0

1 10.4 4 9

1 15.2

120 0

66 9

124 8 6 2

68 4

: 79.6 6 7

,,!.3.4..4.

,135,2.

139 2 7 8

144 0 8 3

74 7

148 8

76 3

129 6 4 9

76 C

77 5

134 4 5 3

79 0 139 2 5 6

3 A_A r\

. i:47_o . .6-2 1 15.5 92 0 2 5 1 15 5

163.2 7.S

n64',5

.87.2

87.9; :.:166.5. 8.0

88,4 168.0

172 8 8 7

90.0

144 0 6 0

85 2

148 8 6 4

88.2 153 6

158.4 7 3

„:T65;6 .8.0.

Î 68.0 8 2

92 S

94 3 172 8

95.9 177 6

97.4

182 4

: TS5.9: lO.'.l

187 2

99 G

137.4 .10.2

192.0 10.7

156 0

97.2 168 0 8 2

180.0

:l.83..3i 9.7 151 0 91 5 4 5 151 0 96 5

Î02.0

192 0

2'D6.4

216 0 13 6

228.0 15 1

75 80

PD

Gpm Lwt (F) PD

-

_ _

7 0

72 0

96 0

97.6 .9.0 73 3 92 5 2 2

:..7.0;.

....7,2.

72 0 92 2 2 1

8 7 72 0 92 7 2 1 78 4

90 4 89 4 3 2

10 5

174.3 82 7 11 1

3 7

4.1

78 0

78 0 93 1 2.1 90 6

5.0 78 2

83 4 92 1 2 3 1116

102 1

5.8

183 3

4 5

S 7

. S.7. , 84 0

5 8

84 0 94.1

84 0 94 6 2 1 84 0

84 0 95 0 2.1

87 1 94 6 2 3 1 15 6 94 7

95 9 92 9

7,3

101 2

131 8 88 3 5 4 201 3

200 1 84.0

8 9

6.0

6 4

115 5 92 1 2 6 115 5 97 1 2 6

1 15 5

1 15 5 93 1 2 6

7.9 1 15 5 93 2 2 6 142 2 94 8

120 1 92 6

8 2

127 2

163 6 88 2 5 0 256 3 88 5 11 5

6.9

7 8

127 5 92 3 4 0

127 5 92 5

8.7

127 5 92 8

9 2

127 5

9,7

127.5 93 4

127 5 93 6 4.0 158 8 94 9

iC 2

128 1

129.4

155 5

7 1

9 4

10.7

151 0 92 0

Î2.4

151 0 92,7

200 2 88.8

92.0 2.1 72 0 97.0

__ _

_ _ _ _

_

92.2

93 2

89 2

83.1 11,2

_ _

-

_

_ _

_

94 0 2.1

92 1 3 1

~ - - - - - - - - _ _

_

— _

_ — —

— _ —

—

92 8 2 6 1 15 5

91 7

_ _ _

— — —

— _ —

_ _

—

— _

93.1 4.0

93 5 4 0 169 9

93 3

90.5

_ _ _

_

— — _ - —

— —

92 7 4 5 185 5 94 4 6 7

_

2 4

_

2.1 78 0

2 1

3.6 151 2

_

_ _

2 1 84 0 99 1

2 8 I3I 6

12 6

_

2 7

3 : 175 7 92 1 5 7 288 1 92.4 14 4

—

4 0 127 5

4.0

4 0

4 0 172 8 93 8 7 0

5 8 227 5

_

4 5

4 5 178.1 95 0

7 7 316 7 88,8 17 9

-

CONJJENSER WATER

Entering Water Temperature (F)

85 90

Gpm

Lwt(F) PD

_ _ _

-

_ _

72.0

97 2

96 2

89 3

103 2

129 2

141 6

115 5

133.2

160 7

127.5 97 3

127 5 97 8 4.0

127 5

135.1 97.3 4.5

151 0 97.0 4.5

160 7

94 3 3,1

92 6 4 1 162 0 93 2 9 9

90 1

- - - - - - - -

_

_

_

_ _ _ __ __

97 2 2 1

95 6

97 3 94 6

92.8

89.6 7 7

- - - - - - -

_

_

__ _

—

84 0

99,0

95 1 97 7 2 8 131.2 97 8

99 6 2 1

93 1

92 3 6 3

88 7

_

_

_ _ _ _ _

_ _

_ _

— _ — — _ —

97 0

97 4

97 8 2,6

95.7 3.4

93 2 4 8 253 0 93 4 11 4

_

_

_ _

_

_

—

_

97 5 4 0

98 1

94 0 6 8

90 6 11 8

_

— —

96 4 5.2 230.0 96.6 10.0

-

- -

Gpm

Lwt (F) PD

_ _ _ _

_

72 0

2.1

72.0

2.1

2.5 103.5

i:28.T

227 3

6 3

78 0

IT? 9

2.8

3 3

]42„3 .95.0 Ó.8.:

4.2 174 2

__

_ _ _

84 0

2 1

84 0 104 1

2 1

94.2

4 1

5.7£),:6 .9.T

5 4 203 0

224 6

12 7

_ _ _ _

_ —

_ — _ _ — _

2 5 115 5

115 5

115 5

2 6

140 3 99 6

190.3 ^6 0

3 8 SiÓ.2

__

_ — _ — —

_ _ _

_

_ — —

4.0 127 5

127 5

127.5

145.5

4.0

1.88

6.0 Ì236.3 . : .95:,C.:.

260 7 94.1 IS 3

267.3 93.9

_

_

4.5 151 C 101 5

151 0

6.2 '263.:7

286.0

_

102 0

102 2 2 ;

97.3

;95.;,Q’

90 7 18 0

_ _

_ _

102 2 2 1 80,7 106.7 2 2

96.1 5.6

93 2 10 2

—

_ _ _

— _ __ _

104 0 2.1

102 4 2.7 130 6 102 6

9 3 .5

92 8 16 2

_

102 0 2 5 1 15 8

102 1

102 4

. 95 0

- - - - - -

_ _ _

_ _ — — —

102.3

102 5

102 8

100.8 5 1 211 2

97.4

—

-

- - - - -

_

—

-

— —

__

— — -

102 0

T::'95.1QV: T3;3.

94.5 15.C

-

-

-

Gpm

Lwt(F)

_ _ _ _

74 2 106 5

2 1

87 2 104.3

4,1

164.4 97 8 9 9

; 6.'2

215 7

_

—

— —

_ _

_ _

_

_ _

_

_

96 6 15 5

_

_ _

90 6

2 1 93.0 107 3

204 6 98 2 13.2

5,3

13,0

_

_

2 6

2 6

208 1 99 9

3 7

6.6 328 9

7.9

_ _

4 0

4.0 128 2

4.0 158 2

305.0 97 7 20 6

8 3

:52.7,

16.0

_

4.5

4 5 177 3 104.3

— -

-

107 7

—

— — _

—

—

_ _

—

_

— _

—

_

106.9

1 17 0 106 9

148 5 103.6

96 4

_

— __

—

—

_

_

_ _

-

— —

-

-

- -

—

_

-

-

-

107 3

104 3

100 9

- -

- —

- -

— —

- —

—

106 5 4 5

- _

-

- —

127 5 107 3

151.0

-

PD

2 2

3,0

_

_

_

_

_

_

_

2 4

2 6

5 3

_

_

_

_

_

2 5

2 6

4.1

7 8

18 4

_

—

—

_

_

4.0

4 0

6 0

10.3

—

—

6.2

—

CAP. — Capacity

KW — Compressor Motor Power Input at Rated Voltage

r ~1 Shaded areas show ratings for 105 F and 1 20 F condensing temp and ratings with 95 F leaving condenser water temp with 10 F rise

* Ratings for SDT above 120 F do not apply to 30H R

Lwt — Leaving Water Temp (F)

PD — Pressure Drop (ft)

SDT - Saturated Discharge Temp (F)

THR — Total Fleat Rejection (tons)

Page 6

^2 P Leaving Chilled

Water Temperature

CAP.

SIZE

SDT*

(tons)

75.0

80 0

85.C

87.6 '

90 0

95.0

98.7

99.5

100 .0

105.0

85 C 1

90 0 1

95.0

.95,5:

100 0

105.0

107:71

iOS,2.

1 10 c

1 15.0

90.0

95.0

100 .0

■f03;3

105 0

1 10 C

1 15.0

116.6

)57.0

Ì20.C

125 0

102 .0 Ì34.5

106 0

1 10. 0

1 14.0

1)5.7

1 18.0

122. 0

126.0

129.0

.13G..5,

134 0

1 17.0

121.0

125.0

129.0

.;3U

135 0

139.0

;45;0

546,4

1 50 0

154 0

(F)

137.4 112 4

130.3 108.0 1 10.7

1 23.6

;t2o;q' 501.8: .Ì5Ó.6

117 0 100 1

inn

1 10.7 96.4

l'Oó.Oi

:5.Q5.,0.

104.4 92.8 126.3 240.0 11 3 166.1

98 :

133 ;

126.8 115 8

120 6

!.12a.O:' i 11.415:27.5::

114 7

1 in

' ' 108.8 n04 2

105.7 ¡102.3

505.0

103 0 10 0 6

97 1

135 6 132.1 127.5

129 6

123.8 123 6 135 1 240.0 11.3

1 T20.0?120.'9.

1 1 18 2 119 7 139.0 252 0

520

1 12 7 1 15 8 142.9 264 0 13 6 158 0

' 107.2 11 2. 1 146.8

105.5

505.0

101 8 108 4 150.8

96 3

130 1 151 4 149 0 254 0 7.0

125.8 148 5 152 1

121 7

1120 .0

140

Ì ‘¡7.5

113 5

' 109.4

106.4

5,05.0

101.4 127 3

134 : 179 6 feo 0 28Î.C 8 4

130 1

126 C 172.8 174 1 300.0

122 Q 169.0 177.C 310 .0

; 120.0,

160

1 16 1 162.91181 3

1 12 2

106.3 1,52.3

1Q5..0

101.4

97.51143 1 194.6 370.0 13 7

PERFORMANCE DATA

-‘■"T ' "

j COOL

,ER

THR

KW

(tons)j Gpm

106 9 180 0

1 14 5

104.0

1 18.4

] 90 4

935/

T2S.3 236.9

93.5:1.125.9 238.S

89.2 130.3

119.1 204 0

120 .0

122.9 216.0 9.1

111.8

126.8 228.0 10. 2

108.0 130.7 240.0 Ì Ì 3 145.0

134.6

5 3c. 7

,505.8 137.2

138 6 264.0 13 6 194 2 92 2 5.1

97 C 142 5 276 0 14.9 312 5 86 0

127 8

131.3

,137.6

14S:T

no. 9

148.4

5 50.6

104.8 154.8

154.6 145 9 245.0

144.7

155 1

'¡43:3'

156.3

Ì 4 2

158.1 283'C ‘

137 7 161 1 293.0

164.1

134. 2

566.4

5.3 5.6

167.5 353-0 ;0.2

130.3

170 2

DATA

LISE

PD

Gpm

Lwt(F)

_ _ _ _ _

6 3

192.0 7 2

204.0 8.1

,8.6. 126 0 97.2

210,4.

216.0

228.0 10. 2 126 0 98.3

n.G 151.1 94 9

n.i. 160.1 93.9

252.0 12.4

_

— _ _ _ _

9.1

126.0

268.6 86 .6 10.7 - - - ~

8.1

_ _ _ _

_

229.2. .50:3..

252.0

258.5 53.1

259.6

216.0 9 1

228 0 10 .2

:24S„0.:

2.76.0

279:.B 55 3 177.2

280.6

288.0 16 2 222 8

300 0

264 0

274.0

278.0 8 .2

302.0

3I0V0

322.0 10.7

145 0 96 1 2 9

145.0

12 4

164.9

171 3 94 3 4 0

13.1

_

— — _ _

—

158.0

12.0

12 4 158 0 96 1 2 7

14 9

162 3

15.4 181 5 94 6

17 6 355.5 85 4 12 6

■‘8.5 160 0 99.0 2.9

10.0

_

6 5

_

—

7 5

_

8.0

160 C

9.0 160.0 99.0 2 9

169 0

9.6

197 0 95 0

215 0 94 0

275 0 90.0

_ _ _ _

176 4 171 1 290.0 8 9

10.G

.566.9 578,5.1 3.15.0. T0.3

158 71184.1

150,8 189.3

147 1

324 0

334 0

188-3 34S.0 12.3

351.,0:

191 8

360.0 13 1 308 0 90 0 6 7

10 8 180 0 99 0

11 4

12.5

_ — — _ _ _

-,

9.4

_

180 0 99 0

180 0

225 C 95 0

100 0

244. C

429 0

30HR,HS RATINGS

ENSER WA

COND

8 0

102 .2

102 6

94 9

93 9

93 2

101. 1

98.3

95.0

94.3

92.1

100.9

101.7

96.9

95 1

104.0

98.0

95.0

94 0

104 0

104.0

95.0

90 0

ater Temper

PD ; Gpm

_

2 6 126 0

132 9

2.6

197.8

3.5

6.2 300.9-

335.2

7 2

358 5

7.9

_

145.0

2.9

162 5

2 9

245.1 98 2

4.3

6 4

33.1.0 ,:9S.O. .

7 Ì ¡356 4

9 8

-

_

_

158.0

2.7

158.0

2 7

2 7 194 9

4 6 298,5.

5 8 I35.5-.6

372 9 94 6

6.2

10 6

- - - - - - -

_ _

_

_ — —

160.0

2.9

2.9 174 0

219.0

3 3

4.9

298 0 98.0

7 21400.0

8.9 474 0 94.0

16 3

_

181.0 109.0

2 3

215.0

2 3

274,0

3 1

6.4

447 .0

517 C 94 0

7 9

14.6

E

itering W

7 5

_

97.6 2 6

93 3 4 3

_

-

Gpm

_

2.6

126.0

126 0

2.6

148.1 99 8

3 6

201.7

4.C

218.1

229 2

_

Lwt(F)

__ _ _

145.0

96.8

97 4 2 9

95 0 3 8

_ _

—

95 9 2 7

96 7 2 7

96 7

95.1 3 4

91 2

_

—

_ _ _

98 0

98.0

— _

__ _ _

94.0

86 0 12 ^

2.9

12.4

_

2.9

3.5

5 2

_

_

2 9

3.3

4.3

5.C

7 7

2 3

2.3

2 3

3.6

4.2

145 0 101 8

177.3

220 .0

231.8

275 7

158 0

158 0 1 01 .1

158 0

208.2

235 7

243 8 94 6

325.1 91 1

160.0 103 0

160 0

172 0 103 0

214.0

264 0

298.0

419 0 90 0

180.0

180 0

209 0 101 0

301 c

335 0 94 0

458.0

TER

ature (F'

"^Ts

Lwt (?) pd" Gpm

_ _

_ _

_

107 2

106.4 2.9

99.8

:, 951.0 . , M3.2

94.1

93.5 18 3

_

_

_ _

_

_ _

106.1

104 3 3 7

94.3 15.9

— — — _ _

_

_ _

2 6 142 9

172.0

6.0 296.3 99.9 12 .8

16 2

_

2.9 154.0 109 8

218.7

7.9

389,8

1:3.,8

- -

__

_

— — _ _ _

__

— _ _ _

105 9

106.1

102 .6 4.1 274.2 102 5 7 7

.. 96.8,.

.55.0 12 .6

_ - _

_

—

_ —

108.0 2.9

107.0

103.0

,..95.0. :15*Q.

__

164 8

2 7

182 2

2.7

503 1

..9.0,

13 7

_

_ __

_ _ _

_

194.0 109.0 4 1

3.4

225 0 107 0 5 4

312.0 102.0 9 7

5.2

8.9

480 0 98 0 20 7

20 3

90^ -

Lwt (F)'

_

_ _

109 6

106.5 4 6

_

_

_

_ _

_

_ _

_

_

_

_

104 4

98 4 18.8

— _

_

— _

--

- -

__

_ _

110. 1

108.3 3.6

24 1

97 0

_

_

_ _

_

_

_ _

_

_

_

—

_

_ _ —

- - - - - -

_

...95.0

-

_

—

—

105.0 3 3

101.0 5.3

— — _

-

_ _

_ _ _

_ _ _

223.0 109.0

2.3

286.0

396 0 101.0 11.0

13.9

18 7

_

_

— —

_

_ _

105.0 5.8

—

_ —

- - - -

PD

3.2

3 3

6 4

2 9

3.5

_

_

__

_

_

_

_

_

_

_

_

„

_

_

—

_

—

44 F

CAP. ¡SIZE

(tons)

5

36 0 :

38.0 i

40.C

040

42.0

42.6

44.0

46.0

Leaving Chilled

Water Temperature

SDT’

(F)

128 9

121.7!

Î2C*Q.^

114.6:

107.Sr

105.0;

100 3

92.9

THR

KW

(tons)

52.4 50.9

50.2 52.3

49.6; 52.61

48.01 53 6 I

45.7; 55.0 [

44.9; 55.41

43.4' 56 3 !

41.21 57.71

COOLER

FLOW DATA

lOF RISE

G pm

PD

86.4

7 0

91 2

7.8

92^3 ) 7.9

96.0 I 8.7

Î00.3 1 9,6

Ì02.4 i 9.8

105 6 no.5

110.4J11.5 Ì218.0

Gpm

72.0

72.0

73 7

81.6

107.0

75

Lwt (F)| po’

92.5

92.9

92 9

91.3

87.6

¡16 7

81 4

Gpm

2 C : 72.0

2 1 i 72.0

2 2 90 3

2.6

108.3

4 4

165.4 I

CONDENSER WATER

Entering Water Temperature (F)

80 _

PD

2.0

2 1

3 2

4 5

10 0

Gpm85Lwt(F)

72 0

102.5 2 0

79 3

m.7i

171 4

95.0 6.2

93.0 I 10.8

Lwt [F)

97.5

97 9

94 6

92 4

88 2

PD

2 5

Gpm

77 6

105.3

217.0

90

Lwt(F)

106 3

102 3

96 1

PD

2.4

4.3

16.7

Page 7

PERFORMANCE DATA

30HR,HS RATINGS

Leaving Chilled

Water Temperature

44 F

CAP.

(tons)

40 G

42 C

44,0

44.4

46

48 C

42,5 n07.2

49.2 Î05.0

50 0

52 C 96 2 43 7

46 G

48 C

SO 0

51.9

52 C i

54 C

56 C

57.4 307.8 56.3 73.40 T37.S

58.0 106 5

5S.6 305.O1 ' 55 .3

60 c

62 C

64 C

56 C

58 C

60 0

62. C

63.8

64 C

66 0

68 C 112,6

70,0

n.z

77.C

72.2

74.0

76 C

62 C

64 C 133 6

66 c 130.1

68 C 126 6

70 C

72.0 320.0 82.3

74 0 1 16 7

76 C

78 C

80.0

80.4

83.2 305.0

82 0 103 8

84 C 100 6

86 C .97 3 71 4 106 3 206 4

70 C 135 0

7^ 0

79.6

80 C

85,C

89.2

89.7

90 0 104 6

95 C 97 2

SDT*

SIZE

T20.0, .5303.

050

T20.0

060 1 10 9

070

080

090

KW THR

(F)

134 4

56 :

127 8

53 8 57 3

12! .4

51 6 58 7 105.6 4.5

Ì Ì5 :

49 6 6Ü i Ì iO 4

108.8 47 .6 61.5

47.3

.4.6.8 62.3

102 5

45 6 63 0

133 9 65 6 64 6

129 0

63.8

62.1

124.3

60,5 69,3 124.5

Ì19 8

60 5

58 9

115 3

57 4

5^ 8

i02 1

54 3

97 6 52 8 77 C

51 4 78 6

93 2

135 1

79 2

77 4 80 0

131 1

127 3 75 7 81 5

3 90 c;

74.0

320.0

72.4

1 19 8 72 4

70 8

116.2

69 3 87 7

67.7 89.2 168 0

109.C

306.9 66.9

105 4

ÓÓ.3

305.0 66.3

101 8 64 8

98 2

63 3

137 21 90 8 87 8 148 8 6 4

89 C 89 3 153 6

87 2 90 8 158 4

85 4 92 3 163 2

123,3 83,8 93 8 168.0

80 5 96 9 177 6

1 13 4

78 9

1 10 2 77 4 100 0 187 2

107 0

75,9

306.4

75.61303.9

74.91 102.5

74 3 103 ' 196 8

72 S

100 0 98 4 168

1.27.0 95.5 1Q2 ^ 180.0

320.0Ì 93.6 30S.6

119 4 9i 3 105 9

87 3

112 0

83.9

305.7

305.0 83.5

83 4 1 13 7 216 G 13 6 151 3

79 5

FLOW

lOF

(tons)

101.5 1 9? 0

Gpm

55 9 96 0

100 8 4 1

59.0

3Q6.6:

1 1 5 ?

336.4 5.4

63;9

.338.3. S.S

¡20 0

124 8

64 4

1 10 4

115 2 5 3

66 1

^7 6

120.0

124 8

69 2

129 6

70 7

134 4

72.3

139,2

73 9

74.3] 340.3 7,9 107 4 91 7

144 0

75 4

148 8 8 9 195 9

153 6 9 4

134 4 5 3

78 5

139 2

144 0

148 8

83.0

353.3] 6.8

84.5

84 6 153 6 6 9 115 5 92 6 2 6 115 5

158 4

86 1

163 2 7 8 115 5 93 3 2 6 1 15.5

370.8 8.5 115 5 93 8 2 6 146 7

90.3

90.8

172 8

373.3 8.7 125.7

90.9

92 4 177 6 9 2 153 6

182 4 9 7

94 C

95.3 372.8

98 4 182 4

392.9

395.0

104 7 201 6

393.0

192.0

204 0

109,8

133.1 234.2 T3.3 151.0

133.4

235.3

1 17 6 228 0

COOLER

DATA

RISE

PD

3 7

'.■;4.5'.

4 9

5.3

5 8 101 9

6 2 175 6 83 8

4.9

5.8

6.3

Ô 2 84 0

6 7 84 0 95 2

7 ?

V..7.6

7 8

8 3 132 0 88 7 5 4 198 6

5 6

6 C

6 ^

7.3

8 ?

87 122 8

6 9

7 3

7 8

8,2

8.7 127,5

9 2 127 5

9 7

10 2 127 5

10 7 127 5 94 1

30.8 127.5 94 2

U.O 134 5

1 1 3 144 4 92 1

1 1 8 181 7 88 8

12.4

8.2

9 4

30.6

10 7

12,1 151 0 92 8

33.4 151 5

15 1 260 6 86 2

CONDENSER WATER

Tiering Vl

7 5 ”

Lwt(F)

Gpm

_

_ _

_ _

78 0 93 0

78 0

78 0 93 8

79 2

88 4

84 0 94 7

84 0 95 7

90 1

97 3 93 2

115 5

115 5 93 0

115 5 93 6

208 6

127 5 93 5

242.3 85.5^

151 0

151 0 92 1

93.4

93 7 2.2 101 2

91 8

_

—

- - - _ _

_

—

—

_

_ _

— — _ _ _ _ _

93 0

_ —

_ _ _ _ _ _ _ _ _ _

PDEGpm

.

89 7

—

— _ _ — — —

-

94 8

94.5

84 4

-

— _

92 5 2 6

92 8

92 4

89,5 4.4 230 0

85 8

_

_

_

93 2 4 0

93 8

93 3 4 4

_ _

_ _ _ _

_

2 1

2 1 78 0

2 ;

2 7 120 7 92 4

148 2

3 6

10 3

— —

— _ — — — — — -

2 1

2 1

2 1 84 0

2 1

2 5 119 8

2 9 132 6

3 5 151 4

12 0

_

- — -

- —

115 5 97 5

1 15 5 98 0

2 6

128 5 96 7

2 6

164 5 93 3

2 9

170 6 92 9

3 G

357 5 86 3 21 e

7 8

_

__

_

_

4.0 127 5

127 5

4 C

127 5 98 5

128 7

4 C

4 0 156 8 95 5

4 0

164 2 94 9

183 3 93 4

5 1 202 5

7 7 279 0 89 0

13.3

_

92 0

93.3 4,5 184 4 94 9

93 2 4 5

93 2 4 6

151 0

4.5

4.5

151 0 97 1 4 5 151 0

4 5 151 0 97 8

195 0 94 2

201 1 93 8

12 5

8 0

Lwt (F)

_ _ _

_

78 0 98 0

91.5 96 0

84 0 99.7

84,0

97 1 97 9 2,9 133.3 98.0 5 5 205.6

98 4

94.6

90 1

- - - - - - -

99 8

100.2 2 .1 96 7

94 7

93 4 5,4 202 0 93 8 12.8

91 9

89 1

—

-

_ __

- -

_ - - —

97.6

98 3

94 8 4 C .'2T7.21 9S.0.

89 7

_ _

_

_

_

_

98 0

98 2

98 6

92 2 9 5

- -

_ _ _ _

____

97 0 4 5 151 0

- -

emperature (F

ater

"T „ 1 ^ ^

PD

Gpm 1 Lwt (F)

_

21 78 0

21 83 2 102.3

2 9 127.7 96.5 5.5

3.5 148. Î

185 0 93.1

5.0

7 4

—

21

2.1

4 4 57615

241.6

71

12 4

- —

— -

-

115 5

2 6

115 5 102.6 2 6

2 6

115 5 103 0 2 6 143 0

2 6

2.61135 2 100 6

177.8

3 1

257 1 93 5 11 6

5.C

271 5 93 1 12 9

5 3

9 4

4 0 127 5 103 0

4.0 127 5 103 2

4 c 137 3 102 2

4 ; 172 3 98 9

229 4

5 9

6 4 ^244.7 95.0

285 9 93 6

7 9

328 5 92 5

17 3

103.0

—

_

84 0

104.7 2.1

84 0 104.8

102 6

-

-

-

102 5

-

_

____

PD Gpm90Lwt(F)

_ _

_ _

_

2, 1 83 7

2 4 1116

95.0

—

95.0

92.5 18 7

- - - - -

— -

— -

95.6

7.4

■| Ì .9

_

- -

-

- -

97 1

- -

_

- -

- —

_

2.1

2 9 133 7

9.7

- - —

_ —

_

2 6

3 5

5.8

8.4

4 0 127 5 108 0 4 0

4 C 148 4 105 6 5 3

4 6

7.0

12.0

53.6

13 2

23 6

- - _ - - _ - -

102.0

4 5

163 1 101.3

278.9 95.0

6 6

7 3 303 2 94.3 16 6

7 8 317 2

102 1

93.9

-

14.2

18 C

- -

4 5 151 0

4.5

5.3

-

- -

-

- -

- -

-

-

_

97.4

-

_

_

13.3

14 7

...

10.4

PD

2 4

4.3

2 7

2.6

6.8

4.5

_

__

_

_ __

106,8

210 1 97.0 14,7

291.7

264 7 99 1 15 7

102 9

_ _

— —

— —

-

95,0 107 5

96 1 107.3 2.8

102 7 5.5

98.4

-

—

-

- - -

_

115 5

115 5 107 6 2.6

193 9

191 7 102 3 8 6

107,5

104.5 3.8

100 9

- — -

—

- - -

— — -

-

_ _ _

„ _

_ _ _

_

_ _ _

107.0 4 5

151.0 107 1

234 2

101 5

_

_

_

_ _ _

- -

_

—

—

-

-

-

-

-

-

-

-

-

—

-

_

_

_

_

_

-

CAP. — Capacity

KW — Compressor Motor Power Input at Rated Voltage

Lwt — Leaving Water Temp (F)

Shaded areas show ratings for 105 F and 120 F condensing temp and ratings with 95 F leaving condenser water temp with 10 F rise

•Ratings for SDT above 120 F do not apply to 30FIR

Boldface values in shaded areas are ARI rating points: standard 590

PD — Pressure Drop (ft)

SDT — Saturated Discharge Temp (F)

THR — Total Fteat Rejection (tons)

Page 8

P Leaving Chilled

Water Temperature

PERFORMANCE DATA

30HR,HS RATINGS

. - -

CAP.

(tons)

100 0 109 4

ÎÔ2.6

103.5 105.0

105 C

1 lO.C

100 c

105 0

1 10.C 108 1 105 2

111,8 106.0 103.9

112.6

1 15 C 102 3 101 6

Ì 10 C 120

125 C

140.C

size! SDT*

80.6

85 G

90. C

9Ì.5

95 C

100

85 C 138 1

90 C

95.0

99.6 120.0

no 113 8

120 0

95 0 134 5

100 0 128 6 129 3 136 7

105 0

t07.7 120.0

115 0

120.0

121.0

121.8 105.0

130 0

107 0

Ilio

115 0 125 6

'^9 0

120.6

i 23 0

140

127.0

.0 109

134.0

135.9

139.0

143 0

121 0 135 0

125 0

129 0

133 0

136.4

160

144 0

148.0

151.0

152.2 105.0

156 0 101 4 149 3

160 0

KW

THR

(F) (tons)

135 2

113 0 1 12 1

128 4 108 7 1 15 9

104,7

121 9

120.0

115 6 100 8 123 6 228 d

106.3 95.2 129.6 246.1 11.8 156 3 94 9 3 9 208 9

103 3 93 4

97.1 89 8 135.5 264.0

131 6 121.1 124.4 216 0 9 1

125 5

119.6 112 9 132 1

105.0

96 6

123.0 125.1 140 5 252 0

117 6 Ì2Ì 1 Ì44 4

1 12 2 117 2 148 3

106 9 113 4 152 2

105.S 112.7

lOl 6 109 7

96.2

134.0 157.2 151 7 257 0

129.81 154 0 154 7

121 6

120.0 145.7

117 6 143.7 163.8 295 0 9 2

113 6 140 1

106.8; 134.0

105.0 132.3 173.5; 326.0

101 9 129 7 175 8 334 0

98 0 126.3 178,9 343 0

131 0 180 6

127 1 177 0 179 3 310 0 10 C

123.2

120.0; 169.S

116 5

112 7 161.9

108 9

106.1

97 6 145.4

1 19.7

103.4 120.4

97 C 127 6

94.3 130.3 248.5

131 5 252 0

125 6 120 7

116 9

128 2 228.0 10.2

113.1 131.8

109.0 136 C

139.9

141.3

103.2 142.0

143 8

97 9

147 8

133 7

133 Ò

122.9

142.6

153.0 290.4 16.5 182 4 95 1 3 6 242 9

153.6 292.3

112.1

Ì 56 2

160 ’

106 1

150 6 157 3 276 0 8 ;

147 2

160.8 286 0 8.6

162.0

166 8

169 8

136 6

172.0 322.0

183 8 173 2

176 3

173. 2

182 2

1S4.6 327.0

166 1 187 2 336 0

190 C

157 7

192 8

194.9

154.5

153.2 195.7

198 4

201 3 384.0

COOLER

FLOW DATA

lOF F

?ISE

p b ’

Gpm

192 0 7 2

204 0

216 0

219.6

240 0

204 0 8 1

239.2 11.2 145 0 96 9

240 0 11.3

252 0 12 4 145.0

264.0

268.4 14.1 170 5 95 0

270.4 14.3 180 2

276 0

288 0

228 0 10 2

240 0 1 1 3

258.5

264 0

276 0

288 0

300 0 17.6

312 0

266 0 7 6

289.0 8.9 160 0 99.0 2 9 160 0 104.0

305 0

31^* 0

290 0 8 9

300 0

319 0

346 0 12 2

355 0

362.0 13.3

365.0

374 0 14 0

8 1

9 1

9.4

126 0

10 2

126 0 98 5 2 6 126.0

11 3

132.8 98 1

12.0

168 6

12 4

188.5 91 7 5 5

13.6

313.9

145.0 97 0 2 9

152 8

13.6

14 9 214 2 91 2

16 2 350 5 85 2

12 4

13.0

157 9

i3 Ó 158.0 96 9

14 9 158.0

16 2

172 5

16.7 191 4 94 3 3 9

239 0 90 7 5 9 353 6

19 C 382 9 85 0

7 r

9 7 160 0 100 0 2 9 179.0 102 0 3 6

1 Q 3

10.7

203 0

11.0 227 0 93 0 5 5 318 0 93 0 10 0 508 0

11.4 281 0 90.0 8 C 425.0

397 0

12 C

9 4

10 6

11.0

11 6

12 8

207 0 97 0 3 c 265 0 97.0 5 C

240.0 95,0 4 ^ 324.0

13.4

257.0 93.0 4.7 355 0 93 0

328 0 98 0

14 7

452. G 86 0

75

Gpm

Lwt(F)

- — — —

- - -

98 0

93.5

85.4

—

— - -

-

97 6

97 0

94 0 4 4

- -

- - - - - - - - -

- - -

96.6 2 7

97 5 2 7 164 4

96 2

_

-

_

-

160 0 100 0

175 0 98 0

—

— - — — — -

_ _

— _

180 0 100.0 2 3 180 0

180 0 100 0

180 0 100 0

PD Gpm

_ _

2 6

2 9 168.1 98 2

4.4

14.3

—

— — - - - - - -

-

-

2.9 145 0

2 9

3 3

4 C

6 1 31 1 4

15 4

- -

2 7 158 0

3 2

14 4

_ _ _ _ __ _ _ _

_

- - — -

_

— —

2 9

95.0 4 5

86 0 14 8

3 5 222 0

— — _

_ a

_

2.3

2 3

7 5

14 2

Entering Water Temperature (F)

80

lwt (F)“

__

- - - - - - - _

- - - -

126.0

231 3

268 4 91 8 10 7

145 0 102 0 2 9 145 0

145.7 102 5

196 2

227 8

246 0 94 0

224 7 96 3

259 9

103 0 2 6 126 0 108 0 2 6

103 5 2 6

94 9 6 7 311,2

93 5

- - - - - - - ~ -

—

- 101,9

97 2 5 2

95 0 6 9

91 2 12 3

- - - - -

- - - - - -

- - - - - - - -

157 9 101 6 2 7

160 0 105 0 2 9

273 0

214 0

490 0

101 9 2 7

101 7 2 9 211 5

95 1 6 ;

94 2

90 6

- -

— —

_

98 0 5 3

95 0

90 0 16 7

- - - - - - - - -

— — — _

105 0

180 0 105 0 2 3 221 0

101,0

94 0 7 <

90 0 16 71 -

-

CONDENSER WATER

85

Gpm

PD

4 4

8 C

- -

- - - - 2 9

3,0 180 2

7 9

5 3 1327 8

6 9

12 4 - - -

-

_

— 2 9

7 6

_

_ —

2 3

3 2

8 8

Lwt (fT

_ —

150 6

232 0

145 0

278.5

342,3

380 8 94 0 18 0

365.4 95.0

401 6

104 7

J~/ 0

- - - -

106 9 2 9 162 2 109.5

107 0 2.9

103 2 4 4 249 3 103 1 8.2

-

157.9

158 0

230 0 102 0 5 6

31 ! 0 98 0 9.6

413.0 95.0 15.9

279 0 101 0 5 5 401 0 101 0 11 3

373.0 97.0

486.01 95.0

551 0

106 6

106 9 2 7 198 7 107 4

101 8 4 7 303 9

-

-

- - - - -

164 0 109 0

182 0 107 0

-

- - ~

-

187 0

109 0 2 5 235 0 109.0 3 9

105 0

-

PD Gpm

_

- 150 9

201 8 104 7

3 6

98.2

95.0

93 0 18.2

97.’

95.0 14.7

-

96 1

94 2 15 8

_

- - - -

-

93.0

-

— —

— —

94 0

_

362 9 98 4 18 7

8 1

- -

14.1

-

-

-

165 7 109 2

1 n Q

-

-

-

- - - -

- “ -

172 0 109 9 3 2

2 7

- - -

10.8

13.2

- - -

- - -

-

_

-

204 0

3 1

238 0

3 7

329 0

499 2

-

- -

22 9

- - - -

- - - -

_

-

3 5 294 0 105 0 6 1

9. 7 595 0

16.5

21 2

- -

_

90.

Lwt(F)

- —

- -

109 2 3 6

- -

-

„

- -

101 7 9 3

-

- 109 0

107 0

102.0 10 6

98 0 22 2

- -

-

— —

98 0

— -

-

p5'

6 2

-

-_

3 6

3.8

__

4 2

-

_

-

4 5

6.0

_

24.5

_

-

CAP. — Capacity

KW — Compressor Motor Power Input at Rated Voltage

Lwt — Leaving Water Temp (F)

__31 Shaded areas show ratings for 105 F and 120 F condensing temp and ratings with 95 F leaving condenser water temp with 10 F rise

* Ratings for SDT above 120 F do not apply to 30HR

Boldface values in shaded areas are ARI rating points: standard 590

PD — Pressure Drop (ft)

SDT — Saturated Discharge Temp (F)

THR — Total Pleat Rejection (tons)

Page 9

PERFORMANCE DATA

30HR,HS RATINGS

Leaving Chilled p

Water Temperature

m

!

CAP. SIZE SDT*

(tons)j

36 (Ti

38.0 ! 124.2

39. T :12Q'.0"

40 0 ÌÌ7 1

42.0

42.3 ;

43.4 i

44 0 i 103 0

46 0 j 95 8 42 3

" 42 C

44 C =

45.5.

46 C

48,0

49 .é.

oO.O

50,3

52 C 100 0

040

1 118.6 51.1

050

. :C6.2

m:o:5.:0..

131 4

1 10 1

•i '2:

105.0

131 2

124 8

1 12 4

1C7.4.

54.0

48 C 131 5 65.3

50 C 126 8

52 0 122.2

53.0 : 52o:o' 61. •

54 0 1 117 s 6o:3‘

56 0

060

58.0

58.5

59. S

60 0 1Û4 6

62 0 100 3

64.C

66.C

109.0

Ì07.9

105.0 .55 .7 75.6 143.5 8.2

56 0 137 6

58 0

60 G 129.7 77 4

62 C 126 C 75 7

64 0

,:,65.2

66 c 1 18 6

070

68 C

70 0

72.C

72.5

. 73..Ó

74.0 104 4 66 3

76 0

78.0

64 C 91 0

66.0

68.0

70 0

72.0

73'.4

74 C

76 0

78.0

80.0 1Q9.5 77.6 102.C

:'8T.9

82.0

S2.S

84.0 103 Ì 7 4 5 105.2

107.1 67.4

^ 97.^

'l36 1

080

1 106.3 76. :

;■ 10510

86.0

70.0 137 5

75 0 129 5

80 C

. 81.2

85 0

90.0

■90;9

91.4

95 0

090

' 107.1

1 105.0 84.1,

KW

(F)

53 5

51.4

50; u 53.4..

49 2

46.9

46 0 55.8 1G2.7

■ V- / .0

45.2 56.3 1.04,2. 10.2

44.6

55 5 57 8 100.8 4 î

53 3

il 20.0 STS

49 1

47.5 63.1.

47 ;

46.7 63.6

45 2 64 8 124 8

93.6

43.3

63.6 68 C 120 0 5 8

61.9

113 4 58 7 72 7

.57.1

56.7

55 6 75 8 144 0 8 3 1 12 4 91 2

541 77 4 148 8 8 9 157 6

52 6 78 9

95 9

91.5 51.1

81.C

79 1

133 6

74.0 8,5 0 1.53.6

122.3

73.C

n2c:o’

72 4 86 6 158 4 7 3 1 15 5

70.8 88 1 163 2 7.8 1 15 5

115 0

69 3 89 7 168 0 8 2 1 15 5

1115

107.9 67.8

105.0. 66.5

100 8 64 8

89 2 91 3 158.4 7 3

132 5

129 1 87 4

125.7 85 6

122.4 84 0

82.7

T20.0

119 1 82 3

80 7

115 9

1 12 7 79 1

:TCó,.5176..ì 103.5

75:4

100.c

73.c

102 .4 99 1 168 0 8 2

97 7

93.3 106.5

121.8

; I20...0 : 92,3 .10 7.4

89.2

1 14 4

85.3

8416

r!05.?'

81 4

1 99 8

COOLER

FLOW DATA

THR

(tons) Gpm

100 5 187 2 10 2 127.5 93 9 4.0

ÌG3.Ó 196.8

104.2 ' 198,7

106.7

102.7

110.3

114.2

144.9

115.3

118. ; 228,0 1 15 1 211 1 88 7

10 F RISE

PD Gpm

51 2

52.6

54.0 96.0 S 7

55,3 100 8

56 7 105.6 10 5

58.0 110.4 11 5

59.1

60.1

60 5

61 9 1 15.2

63.4

66.3

66 5

69 6

70.3

71,1 129 Ó

74.2

74 6 140.4

86 4 7 0

01 2

.. 94. 0

lOS 6

.o59.3 4-3-

1 10 4

. 15.9 ,Q.

120.0 5 8

120.9

129.6 6 .7

1 15 2 5 3

124.8 6.2

127.2

134.4

139 .2

7 8

8.2

9 6

9.9

166.0

4 5

4 9

5.3 78.0 94 0

.5,7

5.8 91.3

128 9

6 2

6,5

Ó 7

7 2 84 0

7.8 86 4 95 6 2 3

7.9 91 6

109.7 91 6 3.7

9.4

153.6

80.5 158.4 10.0 - - - - - - - -

79. G 134 4 5 3

139 2 5 6

80.5

82 C 144 C 6 0

83.5 148.8 6 4

85.9 156.5

172 8 8 7

91.2

91,6 174.0 8.8 115.6

92.5

, 1.76,8,.

92 8

177 Ó

94 4 182 4

96. C 187.2 10. 2 237.1 84.7

89 8

153 6

92 8 163.2

94 3

168 0

95.8 172.8 8.7

96,9

. .i.76,3'

97.4

177.6

98 9 182 4 9 7 127 5

192.0

..19.6 .,5

201.6 11 S 154.5 91 3

206.4 12.4

180 0

192 .0

•94.91 11.0 151 0

204 0 12 1 151 0

216.0 13.6

218.1 13.8

219,5

243 7 82 8 18 8

6.9

7.1

I 15 5

1 15 5

, ..9,1 128 9

9 2

133 0 91 8

9.7 170 3

6 9

7 8

8 2

.9.0

127.5 93.2 4 0

9 2 127 5

127 5 94.2 4.0

10,7

11.2 128 C 94 4 4 0

■ ’ 3

128 4 94 3 4 1

il.4

137.5 93 1

196.5 88.1

9 4

10 7

151.0

151 0

14.C

153.2

75

Lwt (F) PD

Gpm Lwt(F) PD

_ __

- _ _

72 0

92 8

72 0

93 0 2 1 72,0

72 0

93 4 2 1 80 3 96 5

74 6

92 9 2 2

83 1

91 3

89 9

91.3

83 4 10 2

_

2.C

72.0

92.9 94 4 3 4

2 8 111 5 92.2 4 8

3 3

128 8

_ _

— _ _ _ _ _ _ _ _

77.9

93 4 2 0 77 9 98.4 2.0

78 0

93 5 2 1

80 1

93 8 2 2

84.8 92.9 2.5

91 7 2.9

87 0 5 7

- - - - -

78 0 98 5 2.1 78.0 103 5

2 1 79 2

103 2

1 12 9

126.2

207 4 87 6

_ _

- — _ _ _

- — _

95 1

84 0

84 0 95.3

95 8 2 1

94 5 2 6 121 9 94 7 4 6

86.8 7 7 249 5

_

-

—

—

—

92 9

93 1

93 4

93,7

94 0 2.6

94 1 2.6

2 1

84 0

2 1 84.0 100 3 2 1 85.9

86 2 100 2

1 12 9 95 8 3 9 161.9

154 7

3 9 159 6 91 4 7 9 256 7 92 1

_ _

—

_

_ _

— _

_ _ _

2 6

115.5 97 9 2 6 1 15 5 102 9 2 6

2 Ó

115 5 98 1 2.6

2.6

1 15 5 98 4 2 6

2.6

115 5 98 7 2 6

140 6

149 1 94 8

92.3 3 2 176 2 92 7

3 4 184 6 92 1 6 2

265 2 88 6

10.0 - - - - - - -

__ — _ _

— —

_

- — _ _ — — — — — - — _

127 5

4 C

127 5 98 3 4 0 127 5 103 3

4.0

127 5 98 6

127 5 98 9

136 6 97 9

166 9

169 2 94.7 6 8

4 5

187 7

5 7

221 2 91 4

308.6 88.3

9.0

_ _

—

—

_ _

4 5

151 0 97 4

4 S

151 0 97 8

4.5 171 3

4 5

187 4

4 6

200 9 94.1

8 5

333 9

—

- _

_

-

_

_ _

_

— _

88 3 5 4

93 3

93 6

92 4

92 8

93 5

93 6

93 3

CONDENSER WATER

Entering Water Temperature (F)

80

Gpm Lwt(F)

__

__

__

_

_

85

_ _

PD j Gpm Lwt(F)

_

_

_ _

97 8 2 0 72.1 102 8 2 0 78 3 106 4 2.4

98 0 2 1 72.7 102 8 21 90 7

1C6 C

2.6

.133.9

90.5

-

-

178 0 92 9 11 7

219 8 91 2 16 9

6 2

97 5

,. 95.0,.

- - -

4 3

166.5 98 1

6.7.

230 0 93 8 18.0

_

-

_ „ _ _

77 9 103 4

98 7

94 6

93 4

92,2 5 5 196.0 92.8 13 4

2 2

3 7

4 4

14 4

__

100,5

15 T2

172.4 93 8

99.7

95.0

_

_

_

_ _

100 1

84 0 105 1 2 1 97 4 107 3 2 9

2 1

2 3

104 9 2 2 113 4

100 4 3 9

113 3

96.0

_ _

_

_

_

_ _

__

103 1

—

_

— —

95.0 !.0,..l

92 4

92 4 15 6

91 8 7 4 >246 5

87 4

_ __ _

_ _

_

__

_ _

_

_

95.6

_

— — —

.179.4

19.7

_

_ _ _ _

_

_

115 5

120 0 102 7 2 8

149 6 99 4 4 2

3 7 202 3 95 9 7.4

4 2;22'C.S ...95.Ü

5 7

282 0 92 9 13 8

301.3

12 3

_

— — —

- —

98.2 4 0 127 5 103 2

4.0

127 5 103.6

4 0 147 7

20.9

_ —

11 2

19 7

4 6

243.6

253 4

8.2

293 2

_ _

4 5 151 0 102 4

4.5

6 8 283.5

7 7

94 9 6 Ó

93.4

_ _ _ — — - —

96.2 5 8

94.9

88.8

101 3

187.8

151 0

248.1 96.3

314.5

98.0

■..95,0.

94.8 14 5

93 5

—

- - - -

_

102 8 4 5 193 5 103 9

95.0

94 1 17 8

2.0

85 0

90.6 105 9 2 8

21

146 6

3 5

.

7.7

_

10 0

_ _ _

_

_

- -

_

__

_ . _

_

_

— _

164 1

8.2 264.8

_ _ —

— — -

19 4

_ — -

20 9

_

__ __ _ _

__ _

__

_ _ _

_

_

_

_ _

_

—

1 17.7

2 6

125 4 106 6

160 3 103 2

224 2

348 4 96 3

—

8.7

- - -

—

_

_

_

_

— _

— — -

— - — -

4.0

128 7

4 0

130 2 107 9

4 0

161 4

5 3 211 5

296 5 98 3

8 2

19 1

- —

_

_

— - -

■. 14.0

_

_

4 5

11.5

14.7

—

151.0

—

— -

-

— —

9Ò

104 3 3 2

_

_ _

- -

106 9 2 4

100 1 7 3

_ —

_

_

_

_

105 0 4 0

100 6

96 7 22 3

__

_

_ —

107 6 2 6

99 6 9 0

—

— _

—

_

—

108.0

104,7 6 2

101,4 10 3

-

- -

- —

_ _

- -

107.4 4.5

_

-

PD

_

10,1

__

_

_

-

_

_

—

8.4

__

_

_

_

_

3 0

4 8

20 5

-

—

_

—

—

—

—

4.0

4 2

19 5

-

7.3

—

—

__

Page 10

45 F

Leaving Chilled

Water Temperature

PERFORMANCE DATA

30HR,HS RATINGS

CAP.

(tons)

80 Ü

85 C

90/’

à \

v5 C

1 (^r\ n

:04 :

;

1 10 G_J 99 7J 91 9

90 0 134 1

95 0 127 9

1 r

\ *! 7

i 05 C no

1 '0 c

: 14.9

■ : f>.C

120 C

95 f

100 c

1 fV-s P

: :0.vn 5 C

120 C 109 4

‘ 23.3 \0:> 9

"i 2-'- "> 105 C

i 25 L 104 1

1 30 C 98 9 108 f 160 8

109 C ' 134 3

1 1J (J

1 17 C

121,0

■ '23 '

125 0

129 C 114 2

133 C

'36.6 :C6-9 V .66. ’

1 *.o

‘ 0

14 i L

145 0

124 C 134 5 185 1

128 C

132 C 126.7

136.C

:39.0 120.C

143 (3

147 C 112 6 163 0

'51 0

153.0 : J 07.

155.2 : 105.Ü

Ì 69 C 1 101 4 lì50 5

163 c

SDT*

SIZE

420. C.

100

120

140

160

KW

THR

(F)

137 7

130 9

1 04 A

118 1 'i 03 Ì 124 3 228 0

1119

106.4 v6 9

105,8 9 6..6

' 06,0

122.C

1 jO . V

116 2 111 5

1 Ì Q _ A

106.0

; C'

99 3

Î3 7 0 136 ;

131 1

126.'^

s

' ^ V * . V

1 14 7 1 19 9

130 2 155 7

126 1 152 3 160 3 281 0 8 4

122 1 148 9

> ¿sJ ‘M14 7. 0

118 1

no 4

'

.‘.vD v/'

102 7

98 9 127 9

130 6 181 8 179 6

122 9 174.3 185.5 326 C

116 3

108 8

97 7 1146 5 1204 6

1 12 8 192 0

115 6

1 16 6

111 2

1 ny r

190..4;

93.0’

P4.2

1 TQ 9

99 2

139 .1

95 0

136 1

123 9 125 2 216 0

119 6

129 C

115./,

132.8

1,54.1

114.C

136 7

140 6 264.0

IQF 6

■ 34.6

Vs/. “

100 2

Ì 4o 9 ./88 0

1 33 g~

132 2 137 5

197 .0

'23.0

:.*'à9.2

149 0

153.C

1 16 C

1.55 c 276.0

1Î3 5

V; 2. B : 56.2

112 3 1 56 9

159 r 154 ■ 262 0

145

141 8 169 ; 310 0

138 3

1 72 3

131 3

178.2 182 6

i187.7 334 .0

171.3

167 2 lì90 5

•196 '

158 8

4.56.7

1154 .4

i2G) 7

COOLER

FLOW DATA

10 F RISE

Gpm PD

(tons)

204 0 8 1

2'6 0

.224,3

240.0

131. 7

250,8

?52 C

;3?.6 253.5

264 0 13 6 254 2 87 8

228 0 10 2

2 /in\ r\

"^44 9

252 Ü

.7

273 6

'4/^.6 2”6,0

228 0

240 0 1 1 3

Ml 3

^^62.0

264,0

276 0

•288 .0

298.0 ' / 4

500 0

312 0

157 2 271 0

163.3 290 0

164 ?

396.0

300 0 9 4 160 0 100 0 2 9 160 0

166 ;

319 0

174,9

328.C

176.5 333.0

338 0

Ì78 3

348 0 1 2 3

181 3

298 0

176 6

307 0 9 9

317 0

343 0

353 0

193 3

36? 0

197.5

i 367.0 !3,6

199.0 ; 372.0

i 382 0

i 391 0| 15 2 462 0 86 0

Gpm Lwt (F)

7 2

9 J

9.«

126 0 98 4

10 2

126 0

1 -1

126 0

■ A

1

159 0 94 9 4 0 212 6

12 4

164 6 94 3

173 1 93 4

12.6

9 1

1 1 O

145 0

n.6

145 0

Ì2 4

145 0 98 4 2 9

13.6

14.6 173 9 94 9 4 1

: 4.9 185 8 93 7 4 7

16 2

281 4

10 2“

12.4

158 0

■3..0

14 9

158 0

158 0 98 2 2 7 195 8

16 2

1 / 1 185 8 95 1 3 7

195 8

) 7 0

206 2 93 3

19 0

305 9

7 4

7 9

8 9

9.2 160 0 100 0

10 0

160 0

10 6 174 0

207 0 95 0

MA

233 0 93 0

i Ì 7

273 0 91 0 7 6 406 0

378.0

9 3

10 4

1 1 n

11 4

180 0 100 0 2*3 180 0

12 0 180 0

12 6 180 0 101 0 2 3

13 3

213 0

234 0

13.9

264 0 93 0

14 5

336 0

75

_

— — — - - -

— — —

98 7 2 6

99 4 2 6 149 1 100 6 3 5

_

— — _

- - - - — - - - - - -

-- - 97 3 2 9 145 0

97 8 2 9

87 8 10 2

_ — — — — - -

- - - - - - - - - - -

_ — — — — - —

97 1 2 7 158 0

97 6 2 7

94 2 4 0

87 6 9 5

_

_ _ _ _ — -

- — — — - - - - - - - — — — — - - — — - - -

100 0 2 9 178 0 103 0

99 0

87 0 13 6

_

- - - - - - - - - - -

-

—

100 0

97 0 3 2 275 0

95 0 3 9

89 0 7 9

CONDENSER WATER

Entering Water Temperature (F)

8 0 I 85 90

PD

Gpm Lwt(F)

_ _ _

_ _

2 6

126 0

126 0 103 7 2 6

4 3

222 7

4 7

238 2

9 6

398 2

145 0

172 5

233 0

254 9 93 7

248 1

266 8

4 5

286 5 93 1

493 7

2.9

3 4

219 0

4 6

278 0

5 8 328 0 93 0

- - - - - - - - - - -

- - - - - - - - - - -

- - - - - -

2 3

4 9

14 9

103 4 2 6 126 8

_

102 3

102 8 2 9 160 3

- - - - - - - - -

102 1 2 7 158 0

102 6 2 7

158 0

160 0

185 0 105 0

221 0

312 0

366 0

505 0 90 0

105 0 2 9 167 0

105 0

- - - - - - - - -

105 0

101 0

- - - -

PD G pm

- — - - _ — -

94 9 6.9 .3:6.4

94 2

7 5 336 7

93 4 8 5

88 2 22 3

_

_

2 9 145 0

99 6 4 1 232.C 99.6

94 9 7 2

98 8 4 1

95 0

94 0 7 3 413 3

87 8

8 5 396 7

6 4

8 4

23 3

2 9

3 6

99 0

95 0 7 9

91 0

97 0

95 0 6 8

93 0

5 2

10 6

15 4

2 3

2.4

3 4 290 0

5 3

9 4 565 0

17 7

Lwt (F) PD

_

108 3 2 6

135 5

196 5

369 0 93,6

350.4 95.0 '0.4

268 8

373.5

456 1 93 3

227 0 103 0

303 0

>^20. Q

:4óO.Qj, , 95,0.

107 0

100 .7

95.0

94 4

- - - - - -

- -

- - 107 3

105 5

93 8 19.4

_

107 1 2 7

185 9

525 0

230 0

104 2 3.7

98.7 7 4

95.0 13 .8

94 1 16 7 - - -

- -

_

_

109 0

107 0

182 0

99 0 9 2

95.0.

94 0 24 5

- - - - -

109 0

190 0

105 0 3 7

101 0 5 9 420 0

97 0

93 0 22 ?

- - - ~ - -

Gpm iLwt (F) PD

_ — — _

_

154 6

3 0 174 1 107 1 4 7

5 9 287 3

— _

Ì4.5

— —

16 3

- - -

19 4

_

_

166 0 109.4 3 8

2 9

211 3

3 6

7 1

352.1

_

- - - 176 2

251.9

422 2 98 7

20 1

- - - -

_

- - - -

- - 3 2 209 0 109 0

3 7 236 0

5 5

321 0 103 0 10 2

478 0

16.4

„

240 0 109 0

2 6

308 0 105.0

10.5

14.7

- -

- -

109 1

100 7

_

- -

105 6 6 0

99 7 15 5

- -

- -

- - -

109 8 3 4

104 2 6 6

- - -

- - -

— -

107 0 5 9

99 0

- - -

- - -

— , -

101.0 12 3

- - -

- -

-

3 8

12.1

_

_

-

17 3

_

_

4 8

20 6

4 1

6 7

. _

-

CAP. -

- Capacity

KW

• Compressor Motor Power Input at Rated Voltage

Lwt

■ Leaving Water Temp (F)

__

Î Shaded areas show ratings for 1 05 F and 1 20 F condensing temp and ratings with 95 F leaving condenser water temp with 10 F rise

‘Ratings for SDT above 120 F do not apply to 30HR

PD

— Pressure Drop (ft)

SDT — Saturated Discharge Temp (F)

THR — Total Heat Rejection (tons)

10

Page 11

i

i

SIZE

CAP.

(tons)

“36“cT 133 8 54 6* 51 5

38.C

39.S

40 0

42 0

43.5 Ï07.5 46.3'

44 C

44.2 i

46 C i 98 7

48 0

42 0 . 134.8

44 C ! 128 3

46,0

46.6 120.0 52.0

48 0

50 0

50.7

ST5 •C5.C

52 0 103.7

54 C

48 (H 134 0

50.0 129.3

52 0

54,0

54,1

56 0 1 Ì15 9

58 0

59.6

Ó0.0

61.0 105.1

62 C

64 0

66 C 94 2

60.0 132.2

62.0 128 4

64 0 124.7

66 C 121 1

66.6

68 0

70 0

7? 0

73.3.

74.0 ' 106 9

75.1

76 C

78 0

68 0

70 0 128.1

72.0

74,0

75.0

76 C

78.0

80 0

82 0

83-4 1106.7 : 76.7

84 0 i 1Q5.7

84.4 Ì. .105.-0,

86 0

88.0

75XT

80 0

32.0 i IX'.0

85 C

90 0

92.5

93.2 i ■ 105.0

95 0

lOO.C 1

SDT* KW

(F)

126,6

■20.0

1 i19.6 50 3 54 3

1 12 7

040

i 105.7 45.8 57.0

: 105 0 45.51 .57.1 106.0,

^ 91 4

122.1 52 8

1 ÌS.9 50 7

050

109 8 48 7 73 8 120.0 5,8

1C7.6

97.5

124 7

120 3

120.0 61,4

060

111 5

508.1 57.2

107.2

102 9 55.4

98.6 53,9

i i2c;o

070

117.5 72.4 88 6

1 114 0 70 9

1 110.4

n07.2

i 10.5.0

103,4

99 9 64 8 96 4 187 2 10.2

131.5 89.4 93 4 f63.2

124 8 85.9

121.6

: 120.0

1 18.4 82.5 99 4

115 2

080

112.0 79 3

108.9

! 102 6

99 4

131.9'

1 124 3

1 i 16 9

090

1 109.7

106.0 ! 85.2

. 102 4

j 95 2

THR

(tons) Gpm

52 9

52.5

50.4 i .54.2

48.11

55 Ó

56 7 T04.4^

58 3

43.5

59 7 115 2 12 5 - - - - - - -

41 3

57 4*

58.3 100 8

55 C 59 6 105 6 4 5

61,0

61.4

62 4 115 2

48.0 64.3

47.1

64.9

46 7 65 3 Ì24.8

66.7 129.6

44.8

66 8 67 C 1 15 2 5 3

65 0

68 5 120 0

70 0 124 8

63 3

71 5

61 Ó

71.6

60 C

73 C

58.4

74.6 139.2

75.8

56.9 76.2 144.0 8 3

.56.1

76.9

77.7 148 8

79 3

80.9

52 4

79.1

82 5

77 4 84.0 148 8

85 5

75.7

74 0 87.0

S7.4

73.5

90 1

91.7

69.3

6.7.9 93.1

67.8 93 3

66.9

94.0

94.8 182.4 9 7 144 9 90.8 3 9 208 2 91 0 7 8

66 3

87 6 94 9 168 0

96 4 172 8

97 9 177.6 9 2

84,2

; 83.4

! 76 3

; 7.5.9

Ì 93.0 ! 109.2

1 91 2

I 87.2

; S4.7

! 83 3

! 79 5

98.7

80 9 101.0 187 2 10.2

102 5

104. 1

77.8

105.2

105 7

; 106.0

107 2 206 4 124

74 7

108.8

73 2

99 9 103 4

95 4

107.1

1110 9

1 1 14 8 216 01 13.6 151 0

il 16.71 222.1

i 117.2 .i .223.7

1Ì18 7 i 228 0

! 122 6 1 240.0| 16 8 348 1 83 8

PERFORMANCE DATA

30HR,HS RATINGS

COOLER

FLOW DATA

lOF RISE

PD

Gpm 1

86 4 7 0

7 8

91,2

95.7 i 3.6

8.7

96.0

100.8

■05 Ó 0.5 81 C 91 8

i 10.4 1 ] 5 128 7

110 4

112.0 5.0 78 C 93 8 2. ;

121.7

123.7

129.6

'■29,9 6.7 84.0

Ì34.4 7 2 84 0

■43.0 8.2 93.2 94 5

14Ó.4

153 6

158.4 10.0

144.0 6 C

153.6 6 9

158.4

159.8

163.2

168 0

172.8 8,7

177.2

177 6

180.2

180.G

182 4

192 0

196.8 11.3

i 200.1 11.7

( 201 6

: 202.6 11.9.

9 6

T0.2

10.6

4 1

4 9

5 3

' 5.9 81 3

6.1

101.0

6 2

6.7

166.8 84.5

5.8

6 2

6 7

7 8 84 0

112 5 91 4

8.6

8 9

131 3 89.2 5 3 194.5 89.6 11 9

9.4

190.4

6 4

7 3

7.4

115 5

7 8

115 5

8.2 1 15.5

115 5 94.1

9.1

1 17 1 94 1 2 6 151 5 94.8

118.8 93 9 2 7

9.2

9.4

131 7

189.7

7.8

8 2

8 7

127 5

9.4

9 7

127 5

127.5 94,0 4 0

10 7 127 5

127.5 94,6

128.7 94 6

1 ! 8 135 2

141 1

165 3

7 5

Lwt(F)

__

— _ _ _

_

—

72 0

72 0

72 0

75.2 93 0

84 4

78 C

78.0

93 9

84.0 95 4 2 1

98 1 93.6 2 9

93 0 2 1 72 0 98 0

93 1 2.1 72 0 98 1

93 5

91.2