Page 1

Number One

Airconditioning

Maker

Carrier Parkwav • Syracuse NY 13221

Reciprocating Liquid Chillers (60 Hz)

All 208/230-volt units have extended-voltage

compressor motors.

All units have suction-cutoff unloading

system.

CONTENTS

Page

SAFETY CONSIDERATIONS

INSTALLATION..................................................................1-6

Step 1 — Inspect Shipment.................................................... 1

Step 2 — Rig and Place Unit

• RIGGING

• PLACEMENT

Step 3 — Check Compressor Mounting

and Connections.................................................................. 3

• SERVICE ACCESS

Step 4 — Make Piping Connections

• CONDENSER DESCRIPTION

• CONDENSER PIPING

• COOLER DESCRIPTION

• COOLER PIPING

Step 5 — Make Electrical Connections ..................................4

• ELECTRICAL BOX, CONTROL SECTION

• UNBALANCED 3-PHASE SUPPLY

VOLTAGE

• ELECTRICAL BOX, POWER SECTION

START-UP AND SERVICE.................................................. 6

Initial Check............................................................................ 6

Check Refrigerant Charge..................................................... 6

• LIQUID CHARGING METHOD

Check Oil Charge

• TO ADD OIL

• TO REMOVE OIL

START-UP............................................................................7-10

Check Refrigerant Feed Components................................... 7

• THERMOSTATIC EXPANSION VALVE

• FILTER DRIER

• MOISTURE-LIQUID INDICATOR

• LIQUID-LINE SERVICE VALVE

• LIQUID-LINE SOLENOID VALVE

• PRESSURE RELIEF DEVICES

• CHECK VALVE

Check Compressor Protection Devices

• CIRCUIT BREAKER

• MOTOR OVERTEMPERATURE

THERMOSTAT

• CRANKCASE HEATER

• TIME GUARD® CONTROL

• FOUR-FUNCTION TIMER

• OIL PRESSURE SAFETY

SWITCH (OPS)

Check Unit Safety Devices

• SAFETY THERMOSTAT

• HIGH-PRESSURE SWITCH

• LOW-PRESSURE SWITCH

Check Capacity Control System............... 10

DESCRIPTION

3-STEP TEMPERATURE

CONTROLLER

DESIGN SET POINT ADJUSTMENT

CYLINDER UNLOADING SYSTEM

...................................................................

.............................................

.................................................

......................................

_

........................

I

1

3

7

Page

UNIT OPERATION...........................................................10-11

Control Power

Control Sequence.................................................................. 11

Unit Stoppage and Restart

SERVICING COOLER

Tube Plugging ....................................................................... 12

Retubing ................................................................................ 12

Tightening Cooler Head Bolts

• GASKET PREPARATION

• BOLT TORQUES

• BOLT TIGHTENING SEQUENCE

TROUBLESHOOTING GUIDE

.......................................................................

..................................................

.....................................................

.............................................

.......................................

10

11

11-13

12

14,15

SAFETY CONSIDERATIONS

Installation, start-up and servicing of this

equipment can be hazardous due to system pres

sures, electrical components and equipment

location (roofs, elevated structures, etc.).

Only trained, qualified installers and service

mechanics should install, start-up and service

this equipment.

When working on the equipment, observe pre

cautions in the literature, tags, stickers and labels

attached to the equipment and any other safety

precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging and setting bulky

equipment.

INSTALLATION

Step 1 — Inspect Shipment

Inspect unit for damage or missing parts. If dam

age is detected, or if shipment is incomplete, file a

claim immediately with the shipping company.

Step 2 — Rig and Place Unit

RIGGING

On each end of cooler, a steel loop is provided for

the preferred method of lifting unit. Use spreader

bars to keep cables away from compressor enclo*sure and control box. If unit is to be moved by fork

truck, use the following methods:

1. From front or rear, lift under the cooler rails.

Unit can be either on or off skid.

2. When moving from ends, leave unit on skid. Lift

from under skid.

© Carrier Corporation 1983

Form 30HK.HL-10SI

Page 2

Table 1 — Weight Distribution (ib)

UM!T

30( )--

015

020

025

030

Location of mounting holes:

APPROX

OPERWT

HK HL A I B C

1637

1016

1787

1136

1980

1310 3031 205

1334

1985

HK

142j 201 755

182| 240

3031 205

HL

D A B

539

790 575 296 296 272

592 880

592 885 377

266 266

367

C

242

285 373

285

290 290

242

272

377

SClF-IlOCKINö

0OLT

D

—

J

_

SNOb&ER Ft.ANo>--0

WASHER

NEOPHENE

SNUSSKR

'COMPRESSOR FOOT

i

WATER

INLET

END

1

PLAN VIEW

FRONT

i

To ensure safe moving, unit should remain on

shipping skid until final placement. If unit is moved

on rollers, use minimum of 3. Unit can also be

dragged into final position (must be on skid).

When rolling or dragging, apply force to the skid,

not the unit. Use care to avoid damage to piping and

control box.

PLACEMENT

When unit is in final position, remove skid, level

unit with a spirit level and bolt to floor or pad.

1090

ISfL A'lON S-RING

Fig. 2 — Compressor Mounting

These units are not suitable for unprotected

outdoor use.

Carrier recommends that these units be located

in the basement or on the ground floor. However,

if it is necessary to locate unit on an upper floor,

be sure the structure has been designed to support

the weight. If necessary, add structural support to

floor. Also, be sure surface for installation is level.

Refer to Fig. I for space requirements and Table 1

for weight distribution.

Page 3

Table 2 — Physical Data

UNIT AND COMPRESSOR

UNIT 30HK.HL

APPROXIMATE

OPERATING WT (lb)

REFRIGERANT(R-22)

CHARGE (lb)

COMPRESSOR 06*

No. Cylinders

Oil Charge (pt)t

No. of Unioaders

Cap. Control Steps

CONDENSER. 09RP (HK) 022

MAX DESIGN WORKING

PRESSURE (psig)

_ , ( Water Side

Cooler i „ , - .

„ . f Water Side

Condenser Side

COOLER10HA400

UNIT 30HK.HL 015,020

SHELL, Net Vol. (Gal.)t 6.8 9.9

TUBES (Copper) Internal Fins,

Number 81

Length (in.)

Eff. Outside Surface (sq ft)

REFRIGERANT CIRCUITS

CONNECTIONS (in.)

Water 1

^ ( Drain (MPT)

Refrig

WEIGHTS (lb)

Cooler (Net)

Water

Refrigerant 8 12

Total

09RP 022

TUBES Copper, Integral Fins

OD (in.) 3/4

Wall Thickness (in.)

Length (in.)

Fins/in.

Number"

Surface Area (sq ft) i .

NO. WATER PASSES

CONNECTIONS (in.)

^ f Out (IPS)

Relief Valve Outlet (SAE)

Water Regulating Valve /4

Liquid Outlet (ODF) /в

Hot Gas (ODF)

'Prefix; 2 = 1 electric unloader; C, 7 = 2 electric unloaders.

tSee Check Oil Charge for Carrier-approved oil.

+ lncludes nozzles.

"Includes 5 subcooler tubes.

< Refrig Side

< Suction

Plain End

Finned Section

... , ( In (IPS)

015

1637

HK

1016

HL

HK

HL

HK DC537

HL DC537 E2250 E7265 E7275

COOLER

CONDENSER

! Outside

020 025 030

1787

1136 1310

34

Holding Charge

E2150 E7265 E7175

6

8.5 14

2 1 2 2

3

774 784

5/8-in. OD X 0.020 wall

62.5 85.5

66.3 91.7

1 1

2 2

3/4

I 1.125 1.125

1.625 ODM

354

75

437 558

1980 1985

38 40

4

3 3

133.6

6

19 19

150

235

250

385

2.125 ODM

0.043

0.028

10^7

40

36 44

32.9

2/2 Sched 40

2/2 Sched 40

Ув

13/в

1334

027

025,030

81

3/4

446

100

027

40 2

163.4

Only electrical power connections and water con

nections for condenser and cooler are required for

HK installation. Installation of HL units varies only

in field piping required for the remote condenser.

Step 3 — Check Compressor Mounting and

45

Connections

As shipped, compressor is held down by special

self-locking bolts and plain lock washers. After unit

is installed, remove self-locking bolts one at a time

6

and reassemble with flanged washers and neoprene

snubbers as shown in Fig. 2. Special flanged washers

3

and neoprene snubbers are shipped in a cloth bag

tied to one of the compressor feet. Tighten all 4

bolts. Then loosen each until flanged washer can be

moved sideways with finger pressure.

t’.-M "! ION: iie sure mierconnecting piping and

electrical condu■'.^ aic suspended Irec oi contact

with any adjacent wails, and be sure unit capilk;:;cs are nol rur'-.nmg aguinst ;i::>thing.

SERVICE ACCESS

Remove combination top and back cover over

compressor. Servicing can be performed from either

top or back. For rear access, allow approximately

3 ft of clear space behind unit.

Step 4 — Make Piping Connections

CONDENSER DESCRIPTION

The condenser is a sheli-and-tube type with

removable heads for easy tube servicing. Condenser

has an internal subcooler designed for 12- 15 F total

liquid subcooling at average tower water conditions.

For further condenser data refer to Table 2, Physi

cal Data.

CONDENSER PIPING

Provide a means for draining system in winter

and for maintenance.

1MP(.)R 1 ,-\N i ; L -.mdeu.sc: v>a*.cr ntust enter at

ho:tom I;.;- proper operation ot the intcrual .sub-

cooler in condenser bottom (Fig. I).

Keep water supply lines as short as possible. Si/e

lines according to available head pressure, rather

than by connection size, especially on cooling

tower applications. Use flexible connections to

reduce vibration transmission. Refer to Carrier

System Design Manual, Part 3, Piping Design.

The 30HL units using air-cooled or evaporative

condenser should have adequate means for head

pressure control when operating below 60 F outdoor

ambient temperature.

A water regulating valve must be installed on

cooling tower application when any of the following

conditions exists:

1. Low outdoor ambient temperatures affect head

pressure.

2. Entering chilled water temperature is below 70 F.

1090

Page 4

3. A specific head pressure must be maintained.

Set water regulating valve to maintain design

head pressure. Do not adjust to compensate for

high head pressures caused by fouled condenser

tubes, excess refrigerant or the presence of non-con

densables. Due to changes in water temperature, it

may be necessary to adjust valve seasonally. After

adjusting for design head pressure, shut unit down.

Water regulating valve should shut off flow of water

in a few minutes. If it does not, raise head pressure

setting. Make sure that capillary tube from water

regulating valve is connected to condenser purge

valve.

Instead of water regulating valve(s), a bypass

arrangement may be used. This permits leaving

condenser water to mix with condenser supply

water, in order to maintain entering chilled water

temperature above 70 F or an appropriate tem

perature necessary to maintain a specific head

pressure.

CAl ;'a;\; keliglr.e:: ali condenser ixuui bolts

before filling system with water. Torque bolts to

a maximum of 45 ft-lb.

Water leaving condenser is under pressure and

should not be connected directly into sewer lines.

Check local codes. A 3/ 8-in. drain plug is located in

the head at each condenser end.

Refer to PRESSURE RELIEF DEVICES and

CHECK VALVE, page 8, concerning piping con

nections for these components.

COOLER DESCRIPTION

The cooler is a direct-expansion type with

removable heads and is partitioned for multi-pass

refrigerant flow. Water flow across the tube bundle

is directed by baffles designed for minimum waterpressure drop. The tubes have integral internal fins

for maximum heat transfer efficiency.

Viewed from unit front, the return chilled water

enters at left end of cooler and leaves at right end.

The sensing bulb for the water temperature con

troller is in the return-water nozzle, the returnwater temperature being the control point. The

sensor for the low water-temperature cutout is

located in the leaving-water nozzle.

The cooler is insulated with a flexible, closed

cell plastic foam insulation of suitable thickness.

Water vapor cannot penetrate the cellular structure

to condense either within cells or on the cooler

shell. Thus, the insulation itself is a vapor barrier.

Because of the toughness of insulation, a protective

sheet metal covering is not necessary.

The standard cooler can be used for all glycol

brines down to -20 F. However, for calcium or

sodium chloride brines, it is improtant that the

proper inhibitors be carefully selected for protection

of the copper tubes. Refer to publications of the

Calcium Institute or the Mutual Chemical Division

of Allied Chemical Corporation for information on

corrosion control in calcium or sodium chloride

systems.

COOLER PIPING

Plan piping for minimum number of changes in

elevation. Install manual or automatic vent valve at

high points in line. Maintain system pressure by

using a pressure tank or combination relief and

reducing valve.

See Carrier System Design Manual, Part 3,

Piping Design, for chilled-water piping details.

Install thermometers in entering and leaving

water lines. Provide drain connections at all low

points to permit complete drainage of system.

Connect shutoff valve to drain line before oper

ating unit. Install shutoff valves near entering and

leaving water connections. Use flexible connections

to reduce vibration transmission.

Insulate piping after leak testing to prevent heat

transfer and sweating. Cover insulation with

moisture seal.

A chilled water flow switch is factory installed in

the line entering the cooler. Sec Table 3 for min

imum recommended cooler and condenser flow

rates and loop volume.

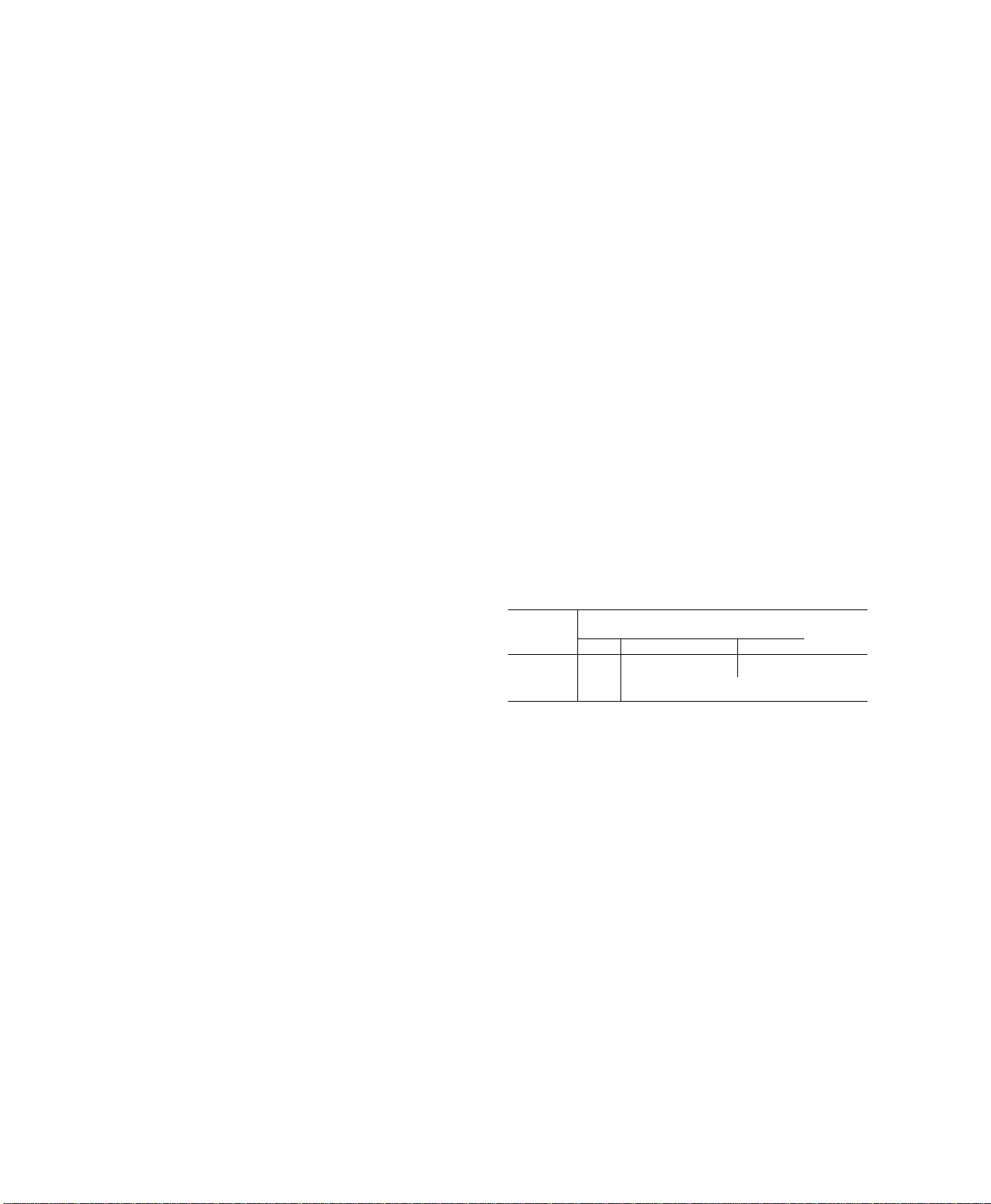

^ Table 3 — Minimum Cooler and Condenser

Water Flow Rates and Minimum Loop Volume

MINIMUM FLOW

UNIT

30HK,HL015 '~25~

020

025 38

030

'Applicable to 30HK units only.

tMlnimum system water volumes:

Gallons = V X ARi Capacity in Tons

NOTE: Minimum condenser water flow based on 3 ft/sec to minimize

condenser fouling. Flow rates below 3 ft/sec may require more frequent

tube cleaning.

(GPM)

34

32

38

34

41

41

PRESSURE DROP

T

(ftwg)

Condenser

3,2

5.1

5,5

5.5

I,

APPLICATION

Normal Air Conditioning

Process Type Cooling'

Low Ambient Operation

MINIMUM

VOLUME!

2,1 47

2,1 60

2,1

2.1 88

(Gal)Cooler ContSenser*ICooler

81

Step 5 — Make Electrical Connections

All field wiring must conform with local code

requirements. Control circuit is 115 volts on all

60-Hertz units. Control power is supplied from a

separate source, thru a !5-amp fused disconnect.

Inside the control box, provisions are made to

connect the ground wires which must be installed

with each field power supply.

The 30HK,HL015 units are factory supplied with

across-the-line start at all voltages and cannot

be converted to part-winding start. The 30HK,

HL020,025,030 units are factory supplied with part

winding start at 208/230 volts and across-the-line

start at 460,575 volts.

1090

Page 5

Refer to Tables 4 and 5 for electrical data on indi

vidual compressors and complete units. Compressor

usage is given in Tables 2 and 5.

ELECTRICAL BOX, CONTROL SECTION

Inside this section are relays, high- and lowpressure cutouts, low water-temperature cutout,

timer, terminal strips and a 3-step temperature

controller. On the outside (control panel) are con

trol circuit ON-OEF switch, partial load switch

(DLS), compressor run light, safety trip lights and

control circuit fuse. The control panel is hinged to

provide easy access to the controls inside.

^ Table 4 — Unit Voltage and Model Number*

VOLTS

208/230

460

575

'Compiete number has 10 digits.

Example: 30HK020530.

UNIT 30HK.HL

015,020,025,030

5-6-1--

UNBALANCED 3-PHASE SUPPLY VOLTAGE

Never operate a motor where a phase imbalance

in supply voltage is greater than 2%. Use the follow

ing formula to determine the % voltage imbalance:

% Voltage Imbalance =

100 X-

max voltage deviation from average voltage

average voltage

* *

Maximum deviation is 4 volts.

Determine % voltage imbalance:

% Voltage Imbalance = 100 x

A

239

= 1.7%

This amount of phase imbalance is satisfactory

as it is below the maximum allowable 2%.

IMPOR 1 .-XN'l : li the ■'UppU \oliagc phase im

balance is more than 2((', contact \our h>cal

electric uulits cornpain immcdiateU.

LQUIP GND

Control circuit power is from separate source, Incoming wires are

connected directly to terminals and on TB2.

EQUIPGMD — Equipment Ground

Fig. 3 — Wiring Schematic — Unit and

Control Power Supply

Example: Supply voltage is 240-3-60.

* ^ AB = 243 volts

BC = 236 volts

AC = 238 volts

Average Voltage

243 + 236 + 238

717

= 239 volts

3

Determine maximum deviation from average

voltage:

(AB) 243 - 239 = 4 volts

(BC) 239

(AC) 239

236

238

3 volts

1 volt

ELECTRICAL BOX, POWER SECTION

The main electrical power supply is brought in

thru the top of the electrical box, on the left-hand

side (see Fig. 1). The hole accommodates up to a

3-in. conduit. Pressure-lug connections on terminal

block are suitable for copper, copper-clad alumi

num or aluminum wire, unless otherwise noted on a

label near the terminal block.

The power section contains: main power terminal

block, compressor circuit breaker with calibrated

magnetic trip (for compressor motor overload and

locked rotor protection), and compressor motor

contactors. The panel over this section is secured

with screws as a safety measure against casual entry

for purposes other than service.

1090

Page 6

VOLTS

UNIT 30

HK

HL

Table 5 — Electrical Data; 3-Phase, 60-Hertz

COMPLETE UNIT

Nameplate 208/230*

Supply Ränget 187-253

MKW

015

020 21.8

025 29.0 103 175

030

015 19.1

020

025 31.8 115 200

030

015 0537**

020 2150 21.8 63 283 88

025

030

015 0537** 19.1

020 2250

025

030

7265

7175

7265

7275

16.4

31.0 115 200

25.2 90 150

35.9 140 250

COMPRESSOR

06t

MCA

69

79

80 125

Kw

16.4

29.0

31.0

25.2 72

31.8 92 446

35.9

RLA LRA

55 266 77

82 446 114

92 446

64

112 506

Max

Fuse

Amps

110 34

125 36

INDIVIDUAL COMPRESSORS

208/230V*

MTA

128 40 223 56

266 89

345 100

128 40 223 56 36 164 50

156

460

414-508

MCA

50

50

38 60 30

42

50

62 110

Max

Fuse

Amps

60

60 34

90 45

90 49

70 38

90 45

460 V 575 V

RLA LRA MTA

27 120 37

29

40 223 56

30 120

33 173

49 253 68 42 176 58

142

575

518 632

MCA

29 50

53

Max

Fuse

Amps

60

80

80

50

60

80

90

RLA LRA

40 27 98

41

45 30 120

COMPRESSOR

06E USAGES

0537**

2150

7265

7175

C537**

2250

7265

7275

MTA

23

36

39

24

96 31

164 50

164

96

37

54

33

42

KW — Maxi mum Power Input (compressor)

LRA — Locked Rotor Am.ps

MCA -- Mm imum Circuit Amps (for wire sizing). Complies with

National Electrical Code (NEC) Section 430-24.

MKW — Unit power input at operating conditions of 50 F Leaving

Chilled Water Temperature (44 F Saturated Suction

Temperature) and 120F (FIK) or 145F (HL) Saturated

Discharge Temperature.

MTA — Must Trip Amps (factory-installed circuit breaker)

RLA — Rated Load Amps

START-UP AND SERVICE

WAk\lN(j; Shut oil all powur to unit hdorc

proceeding with any ^cr\!ce woik.

Initial Check

Do not attempt to start the liquid chiller even

momentarily until the following steps have been

completed.

1. Check all auxiliary components such as chilled

liquid circulating pump, cooling tower if used,

air handling equipment, or other equipment to

which chiller supplies liquid. Consult manu

facturer’s instructions.

2. Checksafety thermostat. See Safety Thermostat.

3. Determine if there is a refrigerant charge in the

system. Refer to Check Refrigerant Charge.

4. Backseat (open) compressor suction and dis

charge shutoff valves.

5. Open liquid line shutoff valves.

6. Open valves to capillaries of water-regulating

valve (when used).

’Compressors in ail models have extended voltage motor.

tUnits are suitable for use on electrical systems where voltage

supplied to the unit terminals is not below or above the range

limits shown.

fPrefix: 2 = 1 electric unloader; C, 7 = 2 electric unloaders.

”30FIK,HL015 models use 06D compressor instead

of 06E compressors.

7. Fill chilled liquid circuit with clean water or

other noncorrosive fluid to be cooled. Bleed

all air out of high points of system.

8. Open supply valve (or fill cooling tower if used)

for condenser cooling water.

9. Set temperature controller.

Check tightness of all electrical connections.

10.

Be sure compressor is floating freely on the

11.

isolation springs. See installation. Step 3.

Check compressor oil (should be visible in

12.

bull’s-eye). Refer to Check Oil Charge.

Be sure crankcase of each compressor is warm

13.

(heaters should be on for 24 hours before start

ing compressors).

Check Refrigerant Charge

IMPORI AN'l; Do not open liquid \al\e or

compressor discharge \al\e until there is a

charge in remainder ol system. .A positive pres

sure will indicate a eharue in svstem.

1090

Page 7

The ЗОН К units are shipped with a full refrigerant

charge (see Table 2). However, if it is necessary to

add refrigerant, operate the unit for some time at

full capacity and then add charge until the sight glass

is clear of bubbles. For maximum liquid subcooling,

liquid level should be up to condenser liquid level

test cock located on shell, near condenser end. This

usually requires additional refrigerant charge

beyond amount to clear sight glass.

30HL units (condenserless) are shipped with a

holding charge only. After chiller assembly is com

pleted in the field, system must be fully charged.

While unit is running at full capacity, add refrigerant

until sight glass is clear.

If there is no refrigerant vapor pressure in the

system, the entire system must be leak tested. After

repair of leaks, evacuate system before recharging.

See Carrier Standard Service Techniques Manual,

Chapter 1, Refrigerants, for leak testing, evacuation

and charging procedures.

6. To ensure maximum subcooler performance on

30HK units, check liquid level in condenser by

means of test cock located on condenser shell

near right end tube sheet. Liquid discharge from

test cock indicates fully charged subcooler.

Check on Charge — All units are factory charged

with oil. If oil is visible in sight glass, check unit for

operating readiness as described in the section,

Initial Check; then start compressor. Observe level

and add oil, if required, to bring level in crankcase

1/8 to 3/8 of bull’s-eye during steady operation. To

add or remove oil, see Carrier Standard Service

Techniques Manual, Chapter 1, Refrigerants.

Use only Carrier-approved compressor oil:

Witco Chemical Co

lexaco, Inc

........................................

................................

Capella WF-32

Suniso 3GS

Do not reuse oil that has been drained and do

not use oil that has been exposed to atmosphere.

CAU TION; When adjusting relrigcrant charge,

circulate water thru the condenser and cooler at

all times to prevent free/ing. Freezing damage is

considered abuse and may affect the Carrier

The liquid charging method is recommended for

complete charging or when additional charge is

required.

LIQUID CHARGING METHOD

C.'M 1 ION; Be careful nut to overcharge sys

tem. (.)\ercharging results in higher dischaige

pres.sure wiih higher cooling water consump

tion. possible compressor damage, and higher

power cemsumption.

Charge thru 1/4-in. flare connection on liquid

line shutoff valve. Never charge liquid into low-

pressure side of system.

1. Frontseat (close) liquid line shutoff valve.

2. Connect a refrigerant cylinder loosely to charg

ing valve connection. Purge charging line and

tighten connections.

3. Open liquid line shutoff valve.

4. If system has been dehydrated and is under

vacuum, break vacuum with refrigerant (gas

charge). Build up system pressure to 58psi for

R-22 (32 F). Invert refrigerant cylinder so that

liquid refrigerant will be charged.

5. a. For complete charge, see Charging in Carrier

Standard Service Techniques Manual, Chap

ter 1, Refrigerants. Follow Charging By

Weight procedure. (When charge is nearly

full, complete process by observing sight glass

for clear liquid flow.)

b. For complete charge where refrigerant cyl

inder cannot be weighed, or for adding refrig

erant, follow the procedure Charging By Sight

Glass in manual.

TO ADD OIL

Close suction shutoff valve and pump down

crankcase to 2 psig (low-pressure cutout must be

bypassed with a jumper). Wait a few minutes and

repeat as needed until pressure remains at 2 psig.

Close discharge shutoff valve. Remove oil fill plug

above bull’s-eye, add oil thru plug hole and replace

plug. Reopen suction and discharge valves. Run

compressor for about 20 minutes and check oil level.

TO REMOVE OIL

Pump down compressor to 2 psig. Close suction

and discharge valves. Loosen the 1/4-in. pipe plug

in compressor base and allow oil to seep out past

plug threads. The crankcase will be under slight

pressure. Be careful not to remove plug; the entire

oil charge may he lost. Small amounts of oil can be

removed thru oil pump discharge connection while

compressor is running.

START-UP

Start-up should be performed only under super

vision of experienced refrigeration mechanic. Be

sure crankcase heaters have been energized for

24 hours.

!. Open all system valves that may have been

closed during or after charging.

2. Check air handling equipment, chilled water and

condenser water pumps, and any other equip

ment connected to chiller.

3. Start unit by firmly pushing ON button.

4. Check all controls for proper operation. Refer to

Check Unit Safety Devices.

5. Adjust water-regulating valve (if used) to most

economical head pressure (based on relative cost

of water and electricity). Head pressure is nor

mally 200 to 230 psi for R-22.

1090

Page 8

6. Check leaving chilled water temperature to see

that it remains well above freezing.

7. Recheck compressor oil level. See Check Oil

Charge.

Check Refrigerant Feed Components

THERMOSTATIC EXPANSION VALVE (TXV)

This valve controls refrigerant flow. Valve is

activated by a temperature sensing bulb clamped to

suction line. The valve is factory set to maintain a

superheat of 8 F to 10 F. Do not change setting

unless absolutely necessary.

FILTER DRIER

The 30HK,HL015 thru 030 units (single com

pressor) have sealed-type driers. When a drier must

be changed, the entire drier must be replaced. The

function of the filter drier is to maintain a clean,

dry system. The moisture indicator (below) can indi

cate any need to change filter drier.

MOISTURE-LIQUID INDICATOR

The indicator is located immediately ahead of

the TXV to provide a constant indication of refrig

erant moisture content. It also provides a sight

glass for refrigerant liquid. Clear flow of liquid

refrigerant indicates sufficient charge in system.

Bubbles indicate under-charged system or presence

of noncondensables. Moisture in the system,

measured in parts per million (ppm), will change

color of indicator.

Unit must be in operation at least 12 hours

before moisture indicator will give an accurate

reading. With unit running, indicating element must

be in contact with liquid refrigerant to give true

moisture indication.

At first sign of moisture in the system, change

the filter drier. The tables below indicate when the

change is required.

30HK,HL01 5,020

COLOR

Green

Chartreuse

Yellow

COLOR CONDITION

Blue

Light violet

Pink

Dry; moisture is below 45 ppm

Caution: 45 ppm

Wet; above 130 ppm

30HK,HL025,030

Safe, dry

First sign of moisture

Dangerous moisture level

CONDITION

PRESSURE RELIEF DEVICES

On HK units, a high-side pressure-relief valve is

factory installed on the condenser. The valve is set

to open at a maximum pressure of 385 psig (maxi

mum design working pressure of the condenser).

For ЗОНЕ units, pressure relief device, designed

to relieve at 450 psig, is field supplied and installed

in the discharge line after the muffler according to

ANSI.B9.1 code requirements.

Additional pressure relief valves, properly se

lected, must be field installed to protect field-

installed high-side equipment as may be required by

applicable codes.

A fusible plug is factory installed on the suction

line for low-side protection. This plug will relieve

on temperature rise to 170 F.

Most local codes require that a relief valve be

vented directly to outdoors. The vent line must not

he smaller than the relief valve outlet (518-in. SAE).

CHECK VALVE

A discharge-line check valve is supplied with each

condenseriess (HL) unit as standard equipment.

This valve should be located downstream from, but

close to, the hot gas muffler. The valve can be

mounted in either horizontal or vertical position.

The valve prevents migration of refrigerant from

condenser to compressor and cooler during offcycle of compressor.

Check Compressor Protection Devices

CIRCUIT BREAKER

The compressor is protected against an over

current condition by a manual-reset calibrated-trip

circuit breaker.

IMPOR LAN I l'>o not bypass connections or

increase brcakci si/c ti> correct trouble. Deter

mine the cause and correct before resetting

breaker.

MOTOR OVERTEMPERATURE

THERMOSTAT

On size 015 units, a sensor embedded in motor

windings protects against overtemperature.

On all other sizes, a sensor in the discharge side

of the compressor reacts to excessively high dis

charge gas temperature and shuts off the com

pressor. A high discharge gas temperature indicates

an overtemperature condition in motor windings.

LIQUID-LINE SERVICE VALVE

This valve provides a refrigerant charging port

and, in combination with the compressor discharge

service valve, allows the refrigerant to be pumped

into the high side.

LIQUID-LINE SOLENOID VALVE (HL only)

The solenoid valve closes when its circuit is in

operative, either from capacity control or from any

safety trip.

1090

CRANKCASE HEATER

The heater prevents absorption of liquid refrig

erant by oil when compressor is not operating.

On size 015 units, the heater is secured by a clip;

on all other sizes, it is held in place by a bracket.

t. AU l ION; The hcatci must be light to prevent

il from backing out ot the crankcase. I he heater

will burn out if exposed to aii for an extended

Page 9

The electric heater is wired into the 115-volt

control circuit thru normally closed contacts of

control relay in such a way that it is energized only

when compressor is not operating.

All heaters are 125 watts.

C .\L 1 ION: Never open an\ >witeh or discon

nect that will de-encrgi/e crankcase healer un

less unit IS being serviced or will be shut down

tor a prolonged period. .Alter such service or

prrdonged shutdown, energize crankcase heater

lor 24 hours before starting compressor.

TIME GUARD® CONTROL

This control protects compressor against short

cycling (Switch A on four-function timer).

FOUR-FUNCTION TIMER

Refer to Fig. 4 — Timer Cycle. The functions are

as follows:

Switch A (Contacts A-Al, A-A2) runs timer motor.

This provides a minimum of 5-1/2 minutes after

compressor stops before it can restart, to prevent

short cycling (Time Guard control).

Switch B (Contacts B-Bl, B-B2) provides 1-second

time delay for part-winding start and also provides

a lock-out function.

Switch D (Contacts D-D 1) provides a 2-1 / 2 minute

bypass of the low-pressure switch at start-up to

prevent nuisance trips under cold-start conditions.

Switch E (Contacts E-El) provides a 35-second by

pass of the oil safety switch (OPS) at compressor

start-up (when OPS is used), if sufficient oil pressure

does not build up in this time, compressor stops.

SWITCH POSITION

Close on rise 9 - 12 psi diff

Open on fall

PRESSURE SETTING

4 - 6 psi diff

The oil pressure safety switch is wired in parallel

with Switch E of the 4-function timer. This arrange

ment allows approximately 35 seconds for oil pres

sure to reach normal operating level after com

pressor starts. If the oil safety switch does not close

within 35 seconds, the compressor shuts down.

To restart the compressor, the control circuit

ON-OFF switch must be pressed to OFF and then to

ON. The timer will start and after approximately

5-1/2 minutes compressor will start. If normal oil

pressure is established within the next 35 seconds,

the compressor continues to run. If, however, the oil

pressure does not reach a safe level, the compressor

stops at the end of the 35 seconds and locks out.

(’.ли I ION; Di' not attempt to restart the com

pressor tor a second time until the problem has

been determined and corrected.

REMOVE ORANGE Wl RE

0 OR 8 MiN.

1 BBi

____Щ_______

7 SEC±4 —И h

S DDI

NOTE: BLACK DENOTES CLOSED CONTACTS

POSITION DURING UNIT OPERATION-

1 1

I . ............................................. 1

COMPRESSOR STARTS

H 1—-1 SEC±05

H^SSECiZ

■«

............^----------

40SEC15

1--------------------------1

Fig. 4 — Timer Cycle

OIL PRESSURE SAFETY SWITCH (OPS)

This control is standard on ЗОНЕ (condenserless)

units (020-030) and is available as an accessory for

30HK units (020-030). Refer to Fig. 5 for field

wiring connections. It is not available for the 015

unit.

The pressure switch is factory set at the following

pressures and should not be adjusted in the field.

OPS — Oil Pressure Safety Switch

TB — Terminal Board

Fig. 5 — Oil Pressure Safety Switch to

Control Box Wiring Connections

(020-030 Only)

LOW LIMIT STOP TAB

5

Fig. 6 — Safety Thermostat

(No. HH22CC050 Shown)

1090

Page 10

Check Unit Safety Devices

SAFETY THERMOSTAT (Fig. 6)

The low water temperature cutout (LWTC) pro

tects the unit against freeze-up due to operating mal

function. The sensing bulb is inserted into a well

located in the leaving water nozzle. As installed, the

standard control is factory set to open at 36 ± 2 F,

breaking the control circuit and locking out unit.

The contacts remake at 5 ± 2 F above cutout point,

but the control circuit switch must be pressed to

OFF and then to ON for unit restart. This action re

energizes the control circuit and starts the timer

under Time Guard® control.

The thermostat cuts out in a range down to -30 F,

but to obtain this range, the low-limit stop tab on the

underside of dial must be either cut or bent. Make

this adjustment only if necessary (when cooling

glycols or brines).

HIGH-PRESSURE SWITCH (HPS)

The HPS settings are nonadjuslable. Table 6

shows factory settings for this switch.

If HPS cuts out while unit is in normal operation

(2-1/2 minutes or more after compressor start-up),

compressor will stop and lock out. To restart com

pressor, the ON-OFF control circuit switch must

be manually pressed to OFF and then to ON. The

timer will start, and after approximately 5-1/2 min

utes, the compressor will start under Time Guard

control. If the pressure has not dropped to the HPS

cut-in point (see Table 6), the compressor will stop

again immediately and again lock out. Do not

attempt to restart until trouble is found and

corrected. Unless control circuit swdtch is pressed to

OFF at this time, timer will continue to run.

Table 6 — Pressure Switch Specifications

UNIT 30 HK HL

PRESSURE

RANGE (psig)

DIFFERENTIAL

SETTING (psi)

FACTORY

SETTING (psig)

High

Low

High

Low

High

Low

Fixed

10 to 90

96 ± 17 (Fixed) | 1 03 ± 19 (Fixed)

1 3 to 50 Adjustable

Cutout

260 ± 10

Cut-in

29 ± 4 44 ± 4

Adjustable

Cutout

335+10

29 ± 4

Fixed

Cut-in

44 ± 4

LOW-PRESSURE SWEICH (EPS)

The EPS is bypas.sed for 2-1/2 minule.s after

compressor start on all start-ups. The EPS has an

adjustable range from 10 to 90 psig and a differential

of 13 to 50 psi. See Fig. 7. Table 6 shows factory

settings for this switch.

If EPS cuts out while unit is in normal operation

(any time after 2-1/2 minutes from compressor

start-up) timer starts and runs for approximately

5-1/2 minutes. The compressor then starts, by

passing the EPS for 2-1/2 minutes under Time

Guard control. If the EPS cut-in pressure is reached

within 2-1/2 minutes, compressor continues to run;

if, on the other hand, the required pressure has not

built up, compressor stops at end of 2-1 /2 minutes

and locks out.

Do not attempt to restart unit until trouble has

been found and corrected. The LPS contacts must

be closed before compressor can be restarted after

lockout.

, RANGE ADJ SCREW

/ TURN CLOCKWISE TO RAISE

J BOTH CUT-IN AND CUTOUT

7

/

(RIGHT SIDE OF CONTROL BOX, VIEWED FROM TOP)

^^G7PSI PER TURN)

aiWFFERENTIAL ADJ SCREW

TURN CLOCKWISE TO DECREASE

(8 PSI PER TURN). ONLY CUTOUT

CHANGES

Fig. 7 — Low-Pressure Switch (LPS)

Adjustment

Check Capacity Control System

DESCRIPTION

Capacity control is a system which loads and

unloads compressor cylinders and starts and stops

compressor to maintain load requirements. System

includes a 3-step temperature controller and cyl

inder unloaders (see Table 2). Table 7 shows ca

pacity control steps.

Table 7 — Capacity Control Steps

UNIT

30HK,

30HL

015

020

025,

030

'Uses hot gas bypass.

CONTROL

STEPS

1

2 67

3 100

1 35

2 50

3 100 4

1

2

3

%

CAP.

33

33

67

100

OPER

CYL

2

4

6

2*

2

2

4

6

3-STEP TEMPERATURE CONTROLLER

This controller consists of 3 load switches actu

ated by pressures developed in a temperature

sensing bulb located in return water line of chilled

water system. The controller is factory set to control

from return water temperature thru a cooling range

of 10 F. Sequence switches are factory calibrated

and sealed and should not require any field changes.

IMPOR 1 .\N 1. It a dilferent reiurn-waler cool

ing range or leaving-water control is specified,

or if brine below 10 L' is to be used, controller

must be changed. Consult local Carrier repre

sentative for proper control device.

10

Page 11

The return water temperature at which the last

step of capacity unloads is indicated by the leaving

water temperature design set point on the adjustable

dial (Fig. 8).

Example:

Design set point is at 44 F. On a reduction in load,

the capacity of the unit will be reduced to zero when

return water temperature drops to 44 F, and unit

will cycle off.

W.ARNlNCj; .Anj, alteration ol factory settings,

except design set point, without t. arrier authori

zation, mav \oid the (.'arricr Warianix

DESIGN SET POINT ADJUSTMENT

When unit IS ready for operation, insert small

screwdriver in adjusting slot (Fig. 8) and rotate to

turn dial (dial may also be turned by hand). Rotate

until design set point for installation appears direct

ly under pointer. Insert a thermometer in the return

chilled water connection and allow unit to run thru a

cycle. .At instant the last step of capacity unloads

(switch no. 1 opens), read temperature. If it is not

same as dial reading, variation can be compensated

by shifting control point slightly.

UNIT OPERATION

Control Power (115 volts) can be from a separate

source, thru a 15-amp fused disconnect or can be

taken from the main unit power source, thru a

field-supplied transformer shown on wiring label.

Control Sequence — At initial start-up, assume

all safety devices are satisfied and the chilled water

temperature controller switches are all in position

for maximum cooling capacity.

Close compressor circuit breaker and press con

trol circuit ON-OFF switch to ON. The timer starts

and, depending on position of timer the compressor

starts in approximately 12 seconds to 8 minutes. At

compressor start-up, D-Dl contacts (see Four-

Function Timer and Fig. 4) are closed, bypassing

low-pressure switch for 2-1/2minutes. In addition,

the E-El contacts are closed, bypassing the oil safety

switch (if used) for approximately 35 seconds. Both

these bypass functions protect against compressor

continuing to run under conditions that could cause

damage to the compressor. Barring any malfunc

tion, when timer contacts A-A2 dose, approxi

mately 2-1/2 minutes after start-up, unit is in normal

operation. The timer stops when A-A2 contacts

close and holds in this position while the tempera

ture controller regulates the cooling capacity by

loading and unloading compressor cylinders, and by

stopping and starting the compressor, under Time

Guard® control, in response to load requirements.

t \i I loN. Di' :.o: ^■..p. 1

c.iu ^au'c .1,"^ .1- pi'.m ami dama.---

Fig. 8 — Set Point Adjustment

CYLINDER UNLOADING SYSTEM

Each unloading device is the cylinder head suction

cutoff type, which unloads 2 cylinders (one bank)

when the control solenoid is energized. Load

switches in the temperature controller energize and

de-energize the cylinder unloaders.

Unit Stoppage and Restart — After each descrip

tion of a possible cause for unit stoppage is a short

description of the normal method of restart.

1. CONTROL POWER INTERRUPTION (IN

CLUDES BLOWN FUSE).

After power is restored, or fuse replaced, restart

is automatic thru normal timer cycle.

2. CONTROL CIRCUIT ON-OFF SWITCH IS

OPENED.

The timer motor starts automatically, runs for

approximately 5-1/2 minutes, and then stops.

To restart, press ON-OFF switch to ON. Com

pressor will start in approximately 12 seconds.

3. CONTACTS OF ANY AUXILIARY INTER

LOCK ARE OPEN.

After trouble has been corrected, restart is

automatic thru the normal timer cycle.

4. LOW WATER TEMPERATURE CUTOUT

CONTACTS ARE OPEN.

Allow time for water temperature to rise 5 F;

then press the control circuit ON-OFF switch to

OFF, and back to ON. This restarts timer. Unit

restarts automatically on the normal timer cycle.

5. CONTROL CIRCUIT FUSE BLOWS.

Refer to Stoppage Cause No. ! above for normal

restart description.

Page 12

6. ANY SAFETY DEVICE TRIPS.

If device is low-pressure switch, reset is automatic

and unit restart is thru normal timer cycle. In the

case of low, or lost, refrigerant charge, charge

must be increased to normal level before restart.

If device is one of the following, high-pressure

switch, overtemperature switch or oil pressure

safety switch, press control circuit ON-OFF

switch to OFF, then to ON. Restart occurs thru

normal timer cycle.

If chilled water flow has stopped, locate and

correct cause, restart water flow. Unit will restart

automatically thru normal timer cycle.

IMi’Oxl .ANl; И sU;ppage b\ ;; •.aic;;. deuce

rcpca.s -..nee. do attempt am/ti'cr restart

unt.. IS ds

titted and cotijcted

Refer also to Troubleshooting section for addi

tional information on unit malfunctions.

SERVICING COOLER

When cooler heads and partition plates are

removed, tube sheets are exposed showing tube

ends shown in Fig. 9.

C.-M I'lON; Four lubes m the bun-.iie .ue 'Ci,tired

inside cooler at baffles and cannot he removed.

These are identified on the tube sheets by a drill

mark horizontally adjacent to each of the 4

lubes. !; iruku^te o; ^ oi ou\ - V4 m!>< s.

Jc.M r:;>eJ i:ihler Inhe

Tube Plugging — Leaky tube(s) can be plugged

until retubing can be done. The number of plugged

tubes determines how soon cooler must be retubed.

If several tubes require plugging, check with your

local Carrier representative to find out how number

and location will affect unit capacity.

Figure 10 shows an Elliott tube plug and a crosssectional view of a plug in place. Table 8 lists the

components for plugging.

C.Ai'ilON; Use e.vtreme caie when mslalling

plugs to prevent damaging the lube sheet sec

tions between holes.

Clean parts with Loequie "N" and apply a few

drops of Loctite #75 to obtain a tight seal without

using too much force to set pin.

Usually plugs can be removed by heating pro

jecting end of pin to approximately 1000 F and

chilling quickly with water. Apply heating flame to

side of the pin to prevent overheating tube sheet.

Table 8 — Plugs and Tubes

UNIT 30HK.HL j

COMPONENTS FOR i

PLUGGING i

For Tubes i

Brass Pin

Brass Ring

For Holes without Tubes |

Brass Pin '

Brass Ring i 853002 631 '

Loctite i

Loequie i

‘Order directly from Elliott Tube Co.

Dayton, Ohio.

tCan be obtained locally.

015.020 025,030

PART NUMBER

853103-500‘

853002-570*

853103-1*

No. 75t

-N"t

c

‘Four fixed tubes (cannot be removed) identified by adjacent drill

points.

Fig. 9 — Typical Tube Sheet

1090

Retubing (See Table 8) — When retubing is to be

done, obtain service of qualified personnel exper

ienced in boiler maintenance and repair. Most

standard procedures can be followed when retubing

the lOHA coolers. A (i% crush is recommended

when rolling replacement tubes into the tube sheet.

A 6% crush can be achieved by setting the torque on

the gun at 48 to 50 in. lbs.

The following Elliott Co. tube rolling tools are

required:

В3400 Expander Assembly

B3401 Cage

В 3405 Mandrel

B3408 Rolls

Place one drop of Loctite No. 67541, or

equivalent, on top of tube prior to rolling.

12

Page 13

Tube information:

(mm)

(16.03)

(15.87)

(14.76 to

14.94)

Tube sheet hole diameter

Tube OD

...............................

......

Tube ID after rolling.............

(includes expansion due

to clearance)

in.

.... 0.631

.... 0.625

.... 0.581

to

0.588

NOTE: Tubes next to gasket webs must be flush

with tube sheet (both ends).

Tightening Cooler Head Bolts

GASKET PREPARATION

When reassembling, use new gaskets. Com

pressed asbestos neoprene gaskets. Carrier Material

Specification ZAOO-24, are to be momentarily

dipped in compressor break-in oil prior to assembly.

Do nut soak gaskets in oil as gasket deterioration

results. Use dipped gaskets within 30 minutes to

prevent deterioration.

BOLT TIGHTENING SEQUENCE (Fig. 11)

The following is a recommended bolt tightening

sequence:

Step 1 — Tighten moderately (without torquing)

all the flange bolts in sequence shown.

Step 2 — Repeat Step 1, tightening bolts to speci

fied torque.

BOLT TORQUES

Apply the following torques during bolt tighten

ing sequence described below:

1/2-in. diameter flange bolts

..............

70 - 90 lb ft

Fig. 10 — Elliott Tube Plug

Fig. 11 — Tightening Sequence,

Cooler Head Bolts

Tuet SHEET

13

1090

Page 14

TROUBLESHOOTING GUIDE

SYMPTOMS

Compressor does not run !

Compressor cycles on low-

pressure control

Compressor loses oil

Frosted suction line

Compressor cycles on highpressure control

Unit operates long or

continuously

PROBABLE CAUSE

1

Power line open

Control circuit breaker tripped

!

s

j Safety tripped

1

Tripped power breaker

REMEDY

Reset circuit breaker.

Check control circuit for ground or

short.

Reset breaker.

Reset.

Check the controls. Find cause of

trip and reset breaker.

Condenser circulating pump not Power off — restart.

1

j

running

Pump binding — free pump.

Incorrect wiring — rewire.

Pump motor burned out — replace.

Loose terminal connection

Check connections.

Improperly wired controls Check wiring and rewire.

Low line voltage

1

Check line voltage — determine

location of voltage drop and

remedy deficiency.

Compressor motor defective

Check motor winding for open or

short. Replace compressor, if

j

;

Seized compressor Replace compressor.

i

Low-pressure control erratic in Raise differential setting.

i

action

1

necessary.

Check capillary for pinches.

Replace control.

Compressor suction valve leaking Replace valve plate.

Compressor suction shutoff valve

Open valve.

partially closed

Low refrigerant charge

Plugged compressor suction

Add refrigerant.

Clean strainer or replace.

strainer

Leak in system

Mechanical damage (blown piston

or broken discharge valve)

Oil trapped in line

Crankcase heaters not energized

during shutdown

Repair leak.

Repair damage or replace

compressor.

Check piping for oil traps.

Check wiring and crankcase

heater relay. Replace heater if

necessary.

Expansion valve admitting excess

refrigerant

High-pressure control erratic in

action

Compressor discharge valve

Adjust expansion valve. Replace

valve if defective.

Check capillary tube for pinches.

Set control as required.

Open valve, or replace if defective.

partially closed

Air in system Purge.

Condenser scaled

Condenser water pump or fans not

operating

Low refrigerant charge

Control contacts fused

Air in system

Partially plugged or plugged

Clean condenser.

Start pump — repair or replace if

defective.

Add refrigerant.

Replace control.

Purge.

Clean or replace.

expansion valve or strainer

Defective insulation

Service load too high

Inefficient compressor

Replace or repair.

Keep doors and windows closed.

Check valves, replace if necessary.

!4

Page 15

TROUBLESHOOTING GUIDE (cont)

SYMPTOM 1 PROBABLE CAUSE

System noises | Piping vibration

Freeze-up

Hot liquid line

Frosted liquid line

Compressor will not unload

Compressor will not load

REMEDY

Support piping as required.

Check for loose pipe connectors.

Expansion valve hissing

Compressor noisy

improper charging Make sure that a full quantity of

Improperly set safety thermostat

Operating with safety thermostat

bypassed

Improper circulation of chilled

water

System not drained for winter

shutdown

Shortage of refrigerant due to leak Repair leak and recharge.

Restricted filter drier

Burned-out coil

Defective capacity control valve Replace valve.

Miswired solenoid

Weak, broken or wrong valve body

spring

Miswired solenoid

Defective capacity control valve Replace valve.

Plugged strainer (high side)

Stuck or damaged unloader piston

or piston rings.

Add refrigerant.

Check for plugged liquid line

strainer.

Check valve plates for valve noise.

Replace compressor (worn

bearings).

Check for loose compressor

holddown bolts.

water is flowing thru the cooler

while charging and that suction

pressure in cooler is equal to or

greater than that corresponding to

32 F (58 psig for Refrigerant 22).

Check safety thermostat for proper

setting at beginning of each

season.

If thermostat was bypassed

for checking, be sure it is back in

the circuit before starting the unit.

Use ample size cleanable strainer

in the chilled water circuit. Make

sure strainer is clean. It may some

times be necessary to chemically

treat the water to prevent forma

tion of deposits.

Remove drain plugs at end of

cooling season. Blow out any

residual water. Instead of drain

ing, a suitable antifreeze may be

added to the water. Damage to the

chiller due to freezing is considered

abuse and may affect the warranty.

Remove restriction or replace

filter drier core.

Replace coil.

Rewire correctly.

Replace spring.

Rewire correctly.

Clean or replace strainer.

Clean or replace necessary parts.

15

Page 16

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book |2 Form 30HK.HL-1 OSI Supersedes 30HK,HL-8SI Printed in U.S.A. 1090 3-83 PC 1 11 Catalog No. 533-064

Tab|5c

Loading...

Loading...