Page 1

Carrier

30HH,HJ

r-

Installation and

30

(o

Maintenance Instructions

in

¡n

\r.

4111111 y I

Jiy nil|FilJ

B

■as

HERMETIC RECIPROCATING

<a

LiaUIO CHILLING PACKAGE

0

Carrier Corporation 1964

LItbo m L’«S.A.

Tab

IS

12-62

Page 2

INSTALLATION

CONTENTS

PAGE

STALLATION SECTION

Dimension Drawings

Preliminary Survey

Moving and Placing Unit

Unit Specifications

Compressor Physical Data

Condenser Physical Data

Cooler Physical Data

Refrigerant Circuits

Refrigerant Charge

Compressor Mounting

Condenser Water Piping

Cooler Water Piping

Refrigerant Piping

Leak Testing

Dehydrate the System

Start-up Procedures

Charge with Refrigerant

Oil Charge

Check the Controls

Starters and Overloads

Circuit Breakers

Water Regulating Valve

Temperature Controller Adjustment

Wiring Diagrams

Electrical Data

Capacity Controls 34-35

Sequence of Operation

Moisture and Liquid Indicator

3-5

6

6-7

7-10

7

8

9

10

10

10

11-13

14

15-16

17

17-18

18-20

20-21

21

21-23

23

23-24

24

24-26

27-32

33-34

35-36

37

Carrier

AINTENANCE SECTION

Condenser Maintenance 38-39

Trouble Diagnosis Chart

Compressor Maintenance

Cause and Prevention of Freeze-up

40-42

42

42

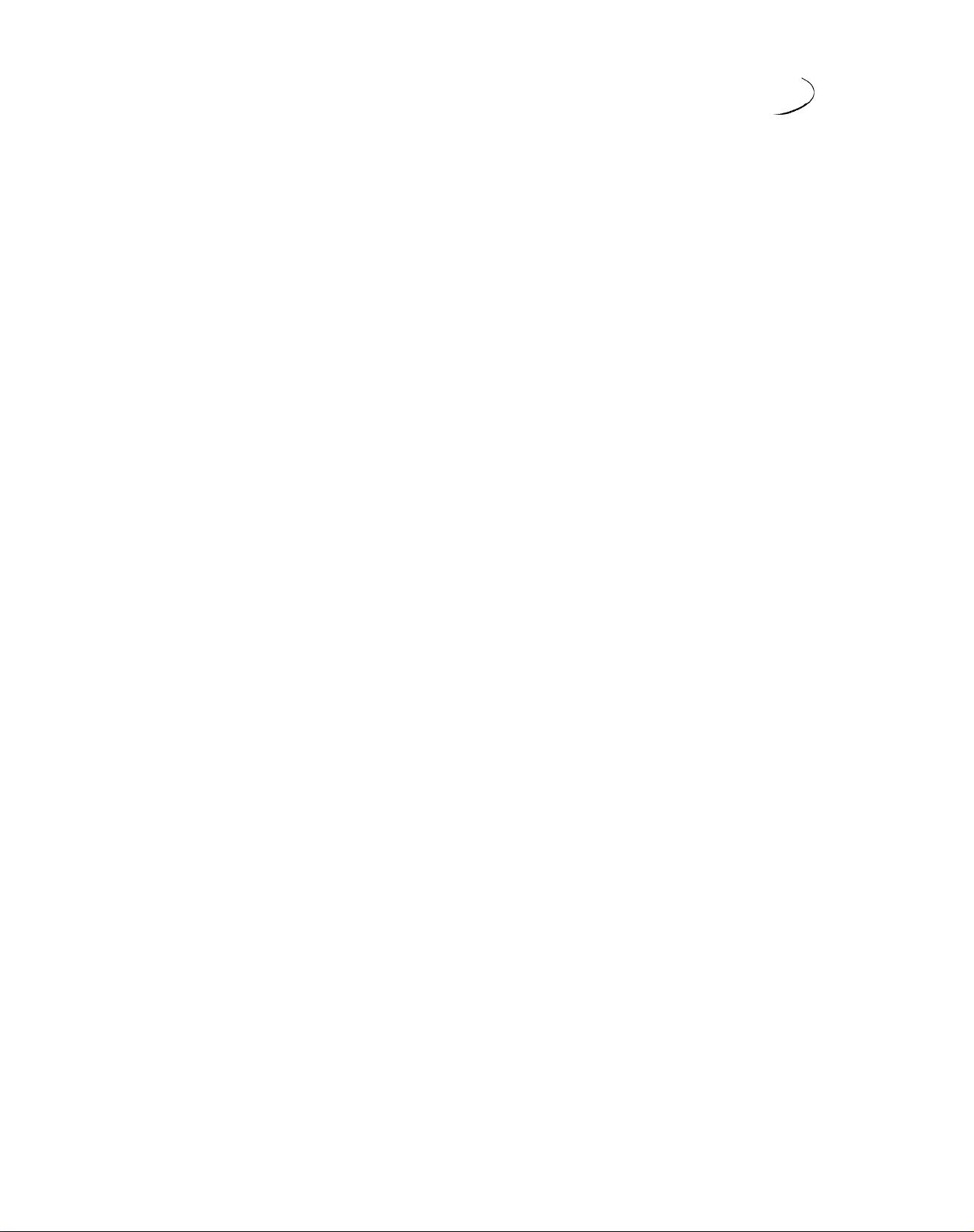

Page 3

INSTALLATION

30HH,HJ

LEFT SiDE VIEW

NOTES;

1. CONDENSER AND ATTACHED PIPING AS SHOWN ARE FOR

30HH MODEL ONLY.

2. REMOVABLE PANELS FURNISHED ON UN IT AS FOLLOWS'. ONE

PANEL EACH SIDE, PANELS FRONT AND BACK OF COOLER

SECTION, PANELS OVER FRONT OF COMPR., STEP CONT

AND CONTROL CENTER SECTIONS.

3. SIDE PANELS PROVIDED WITH HOLES FOR CHILLED

WATER PIPING.

FRONT VIEW

. TWO HOLES PROVIDED IN REAR PANEL OF CONTROL

BOX FOR CONTROL AND AUXILIARY WIRE ACCESS.

CONTROL BULB OF TEMPERATURE CONTROLLER TO

BE FIELD INSTALLED IN INLET CHILLED WATER LINE.

STANDARD CON T ROL VOLTAGE IS 230 VOLTS FOR 208,

230 aAOOVOLT UNITS FOR 460 a 575 VOLT UNITS

STANDARD CONTROL VOLTAGE IS 115 VOLTS.

Fig. 1 - 30HH,HJ015 Dimensiona! Data

NOTES;

I. CONDENSER AND ATTACHED PIPING AS SHOWN ARE FOR

30HH MODEL ONLY.

2 REMOVABLE PANELS FURN ISHED ON UNIT AS FOLLOWSlONE

PANEL EACH SI DE, PANELS FRONT AND BACK OF COOLER

. TWO HOLES PROVIDED IN REAR PANEL OF CONTROL

BOX FOR CONTROL AND AUXILIARY WIRE ACCESS.

. CONTROL BULB OF TEMPERATURE CONTROLLER TO

BE FIELD INSTALLED IN INLET CHILLED WATER LINE.

I

.

I

LEFT SIDE VIEW

FRONT VIEW

Fig. 2 - 30HH,HJ020 Dimensional Data

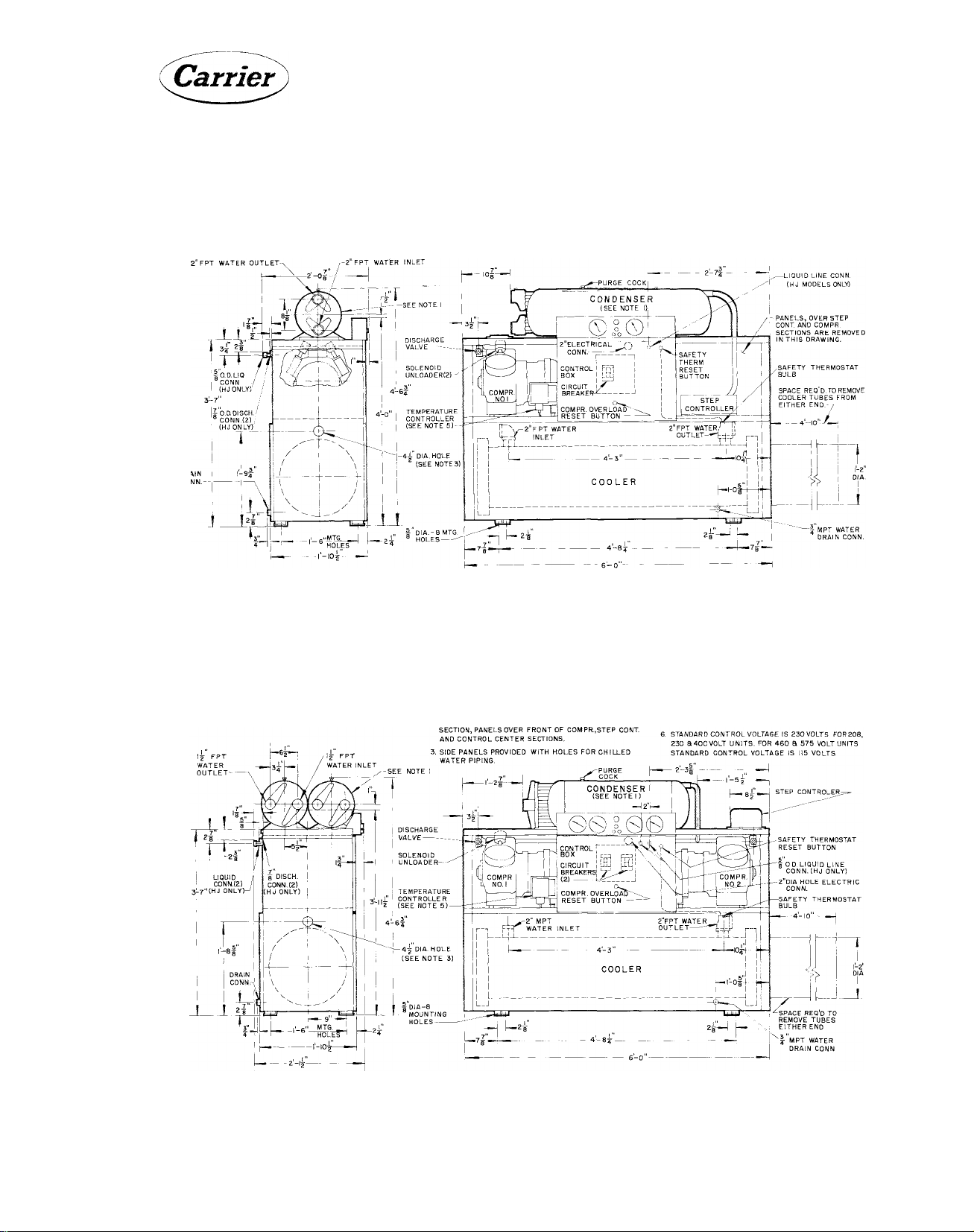

Page 4

30HH,HJ INSTALLATION

Carrier

SEE NOTE !

2”FPT water

OUTLET -

CONDENSERS FOR

30HH030

-------------------

CONDENSERS FOR

30HH025

I 2 FPT WATER

INLET—-.,

I2 FPT WATER

OUTLET—

FPT WATER

INLET

NOTES;

I CONDENSER ANDATTACHED PIPING AS SHOWN ARE FOR

30 HH MODEL ONLY.

2. REMOVABLE PANELS FURNfSHEO ON UNITAS FOLLOWS. ONE

PANEL EACHSIDE, PANELS FRONT AND BACK OF COOLER

SECTION, PANELS OVER FRONTOF COM PR., STEP CONT

AND CONTROL CENTER SECTIONS.

SIDE PANELS PROVIDED WITH HOLES FOR CHILLED

WATER PIPING.,,,

COND.

MPT WATER

INLET

CONDENSER

(SEE NOTE I )

V..y V

CONTROL

BOX

CIRCUIT

BREAKERS' y •

COMPR. OVERLOAD

RESET BUTTON -

4 TWO HOLES PROVIDED IN REAR PANEL OF CONTROL

BOX FOR CONTROL AND AUXILIARY WIRE ACCESS.

5. CONTROLSULB OF TEMPERATURE CONTROLLER TO

BE FIELD INSTALLED IN INLET CHILLEDWATER LINE.

6. STANDARD CONTROL VOLTAGE IS23OV0LTS F0R208.

230 9 400V0LT UNITS. FOR 460 S 575 VOLT UNITS

STANDARD CONTROL VOLTAGE IS 115 VOLTS.

STEP CONTROLLER

DISCH CONN.iHJ ONLY)

HJ025- I OD

HJ030- IffOD___________

SAFETY THERMOSTAT

RESET BUTTON

2 DIA. HOLE ELECTRIC

CONN.

_

IDE VIEW

NOTES:

1 CONDENSER AND ATTACHED PIPING AS SHOWN ARE FOR

30HH MODEL ONLY.

2 REMOVABLE PANELS FURNISHED ON UNIT AS FOLLOWS: ONE

PANEL EACH SIDE, PANELS FRONT AND BACKOF COOLER

SECTION, PANELS OVER FRONT OF COMPR, STEP CONT.

AND CONTROL CENTER SECTIONS.

3 SIDE PANELS PROVIDED WITH HOLES FOR CHILLED WATER

PIPING.

FRONT VIEW

Fig. 3 - 30HH,HJ025,030 Dimensional Data

TWO HOLES PROVIDED IN REAR PANEL OF CONTROL

BOX FOR CONTROL AND AUXILIARY WIRE ACCESS.

. CONTROL BULB OF TEMPERATURE CONTROLLER TO

BE FIELD INSTALLED IN INLET CHILLED WATER LINE.

STANDARD CONTROL VOLTAGE IS 230 VOLTS FOR

208,230 5 400 VOLT UNITS FOR 460 5 575 VOLT

UNITS STANDARD CONTROL VOLTAGE IS 115 VOLTS.

h 5''— 2 ^

I' o.D. LIQUID LINE

Fig, 4 - 30HH,HJ045 Dimensional Data

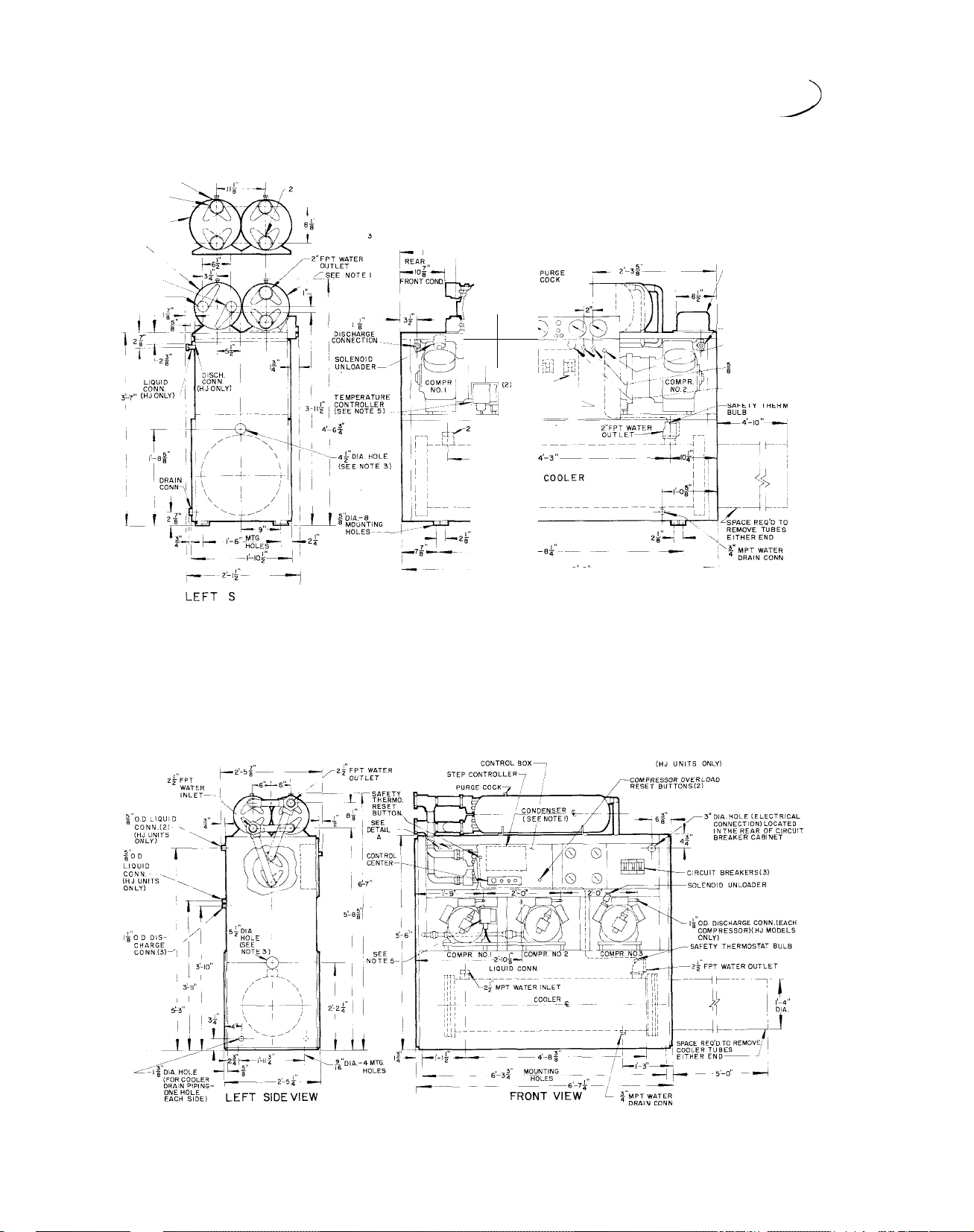

Page 5

Carrier

INSTALLATION 30HH,HJ

notes:

1. CONDENSER AND ATTACHED PIPING AS SHOWN ARE FOR

30HH MODEL ONLY.

2. REMOVABLE PANELS FURNISHED ON UNIT AS FOLLOWS. ONE

PANEL EACH SIDE, PANELS FRONT AND BACK OF COOLER

SECTION, PANELS OVER FRONT OF COMPR., STEP CONT.

AND CONTROL CENTER SECTIONS.

3. SIDE PANELS PROVIDED WITH HOLES FOR CHILLED

WATER PIPING.

Fig. 5 - 30HH055 Dimensional Data

4. TWO HOLES PROVIDED IN REAR PANEL OF CONTROL

BOX FOR CONTROL AND AUXILIARY WIRE ACCESS

5. CONTROL BULB OF TEMPERATURE CONTROLLER TO

BE FIELD INSTALLED IN INLET CHILLED WATER LINE.

6. STANDARD CONTROL VOLTAGE IS 230 VOLTS FOR

208, 230 8 400 VOLT UNITS FOR 460 8575 VOLT

UNITS STANDARD CONTROL VOLTAGE IS 115

VOLTS.

-3’’DIA.H0LE FOR

ELECTRICAL CONN

LOCATED IN REAR

OF CIRCUIT BREAKER

CABINET

Fig. 6 - 30HH,HJ055 Dimensional Data

Page 6

30HH,HJ

INSTALLATION

PRELIMINARY SURVEY

Before installation is started, a survey should

be made to establish the procedures and ma

terials required by installation personnel. See

cover picture for typical unit.

Storage

Because of the sensitive control mechanisms and

electrical devices incorporated in the 30HH,HJ

units, they should not be exposed to the weather.

Location

Always locate the unit indoors. In order to pre

vent freezing, the unit must be located in a space

where the temperature is at least 40 degrees.

Space Requirements and Clearance

Dimensions for the units are given in Table 1.

These dimensions are useful in checking door

clearances for moving the unit in and for deter

mining space requirements. A clearance of 2 to

3 feet should be left on each side and on the ends

for piping and electrical connections and also

to facilitate service operations. Clearance at

one end of the unit, equal to the length of the

unit, for servicing and removal of chiller tubes

must be provided.

Adequate Floor Strength

Approximate weights of units are given in Table

1. Make certain that the floor is strong enough

to support this weight. If necessary, add sup

porting structure to the floor for transferring

weight to the nearest beams. This can be done

with steel beams or reinforced concrete slabs.

Vibration Isolation

Rubber-in-shear vibration insulators and muf

flers are installed on, or furnished with, the

compressors of all units beginning with early

1961 production. The inter-connecting piping

must be sufficiently flexible to prevent vibra

tion transmission, if vibration still exists, vi

bration isolators may be used on the unit itself.

The field-purchased vibration mountings should

be placed under each corner of the package. The

weight distribution of all packages except the

30HH015 and 30HJ015 is such that each corner

mounting supports one fourth of the operating

weight. The weight distribution of the 30HH015

and 30HJ015 units is 55-45 side to side and sym

metrical front to back.

All phases of vibration isolation are fully de

scribed in Section 5X-1 of the Product Infor

mation book. Consult same for best results.

For additional information see "Compressor

Mounting."

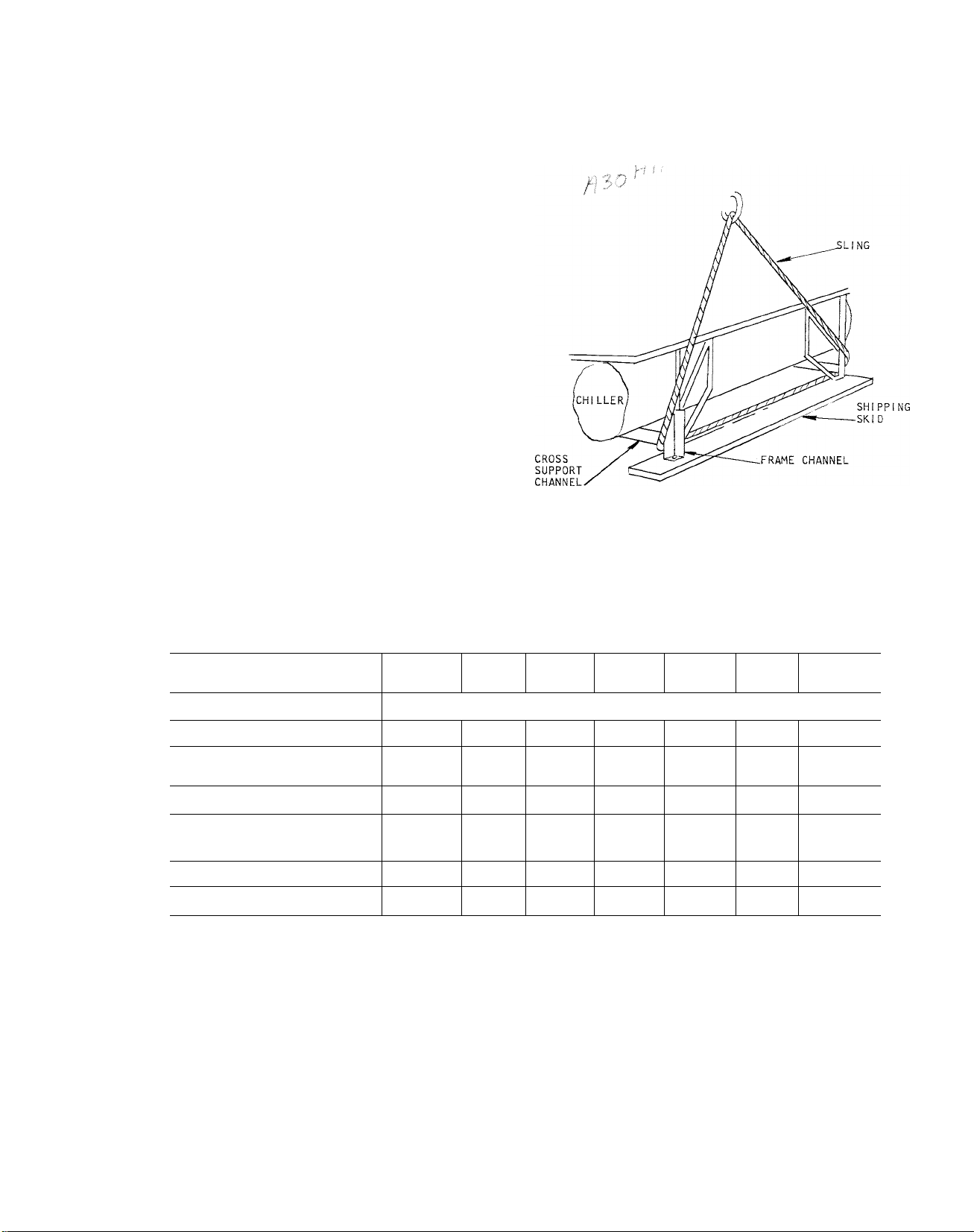

MOVING AND PLACING UNIT

Moving

The skids on which the unit is mounted should

not be removed until the unit is at the final loca

tion. When handling the unit with a chain hoist,

remove the panels so that they will not be dam

aged by the sling. Do not attach the sling to

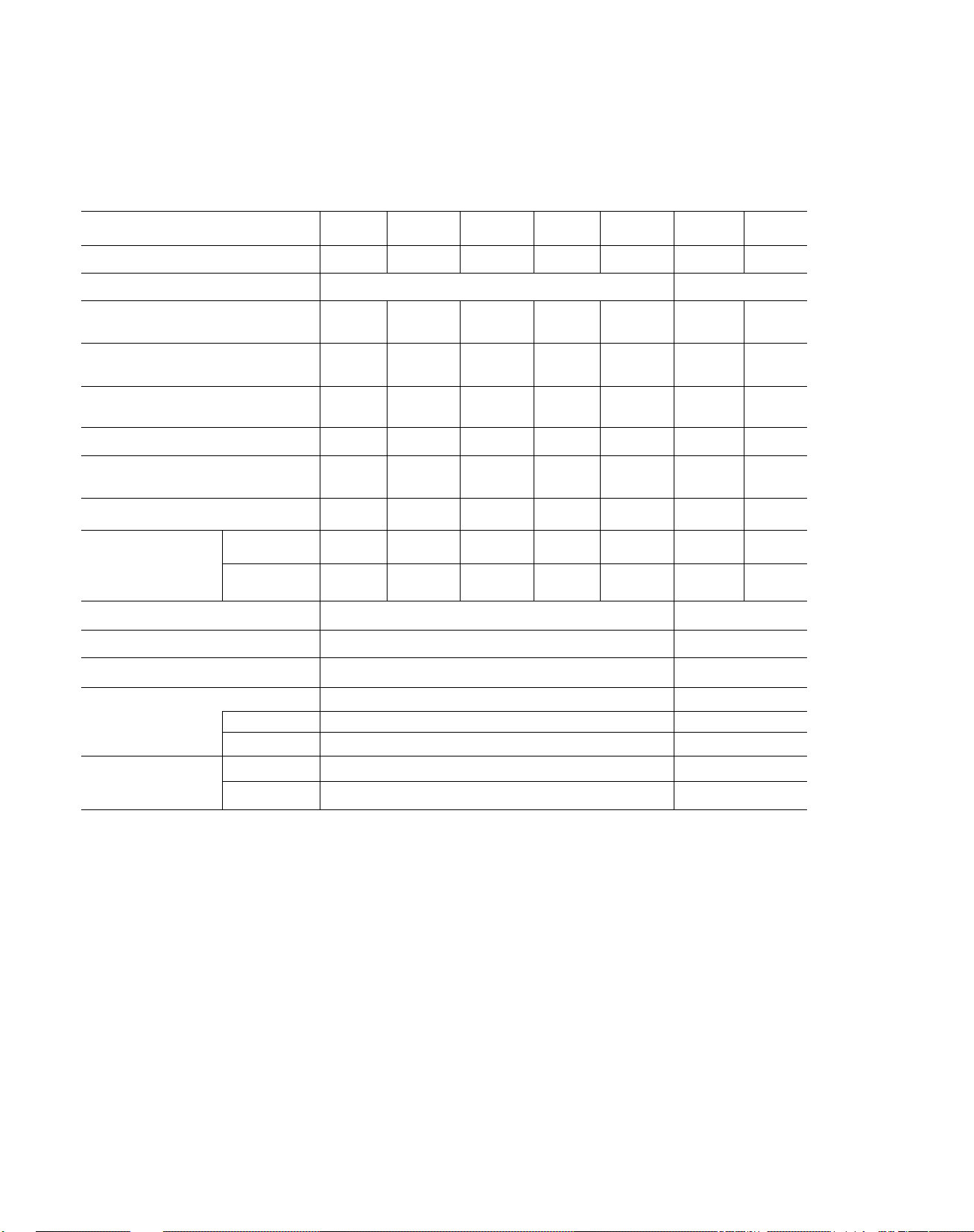

Table 1 - Weight and Overall Dimensions - 30HH.HJ Liquid Chiller Package

Shipping

Unit

30HH015

30HH020

30HJ015 1270

ЗОН] 020

30HH025 2200

30HH030 2550

30H]025

30HJ030 2150

30HH045

30HJ045 2455

30HH055 4622

30HH065 4700

30HJ065 3700

Wt. (lbs.)

1430

2200

1700

2100

3010

Operating

Wt. (lbs.)

1625

2150

1460

1800

1950

1950

1800

1850

3391 79-1/4 29-1/4

2835

5158

5236

4236

Uncrated Dimensions (Ins.)

Length

72

72

72

72

72

72 22-1/2

72

72 25-1/2

•79-1/4

105-1/4

105-1/4

105-1/4

Crated Dimensions (Ins.)

Width Height

22-1/2 54-3/4 76 30 63

22-1/2

22-1/2 47

25-1/2 47

22-1/2 54-3/4

25-1/2 47

29-1/4 66 83-1/2 33

29-1/4 80-3/8

29-1/4

29-1/4

54-3/4 76

54-3/4

47

79 83-1/2 33

80-3/8

Ó6

Length

76

76 30

76 30

76 30

76

76

109-3/4 33

109-3/4 33

109-3/4

Width Height

30 63

30

30 63

30 63

33

63

63

63

63

84-7/8

84-7/8

86-3/4

86-3/4

86-3/4

Page 7

Carrier

INSTALLATION

piping or equipment. Move the unit in an upright

position, and let it down gently from the truck

or rollers. On 30HH,HJ015-030 units the sling

can be placed under the frame channels at the

main support (Fig. 7). On 30HH,HJ045 thru 065

units, the sling can be placed under the skids.

Placing

To anchor the equipment;

1. Locate the hold down bolts as shown in the

dimension drawings. The areas where the

four corners will be located should be ap

proximately level before the unit is placed.

2. Set the unit in place and level with a spirit

level on the frame channels.

3. Bolt the unit to the floor. This is usually de

sirable for basement or ground floor instal

lations that can transmit vibration to the

ground without affecting the building struc

ture.

30HH,HJ

Fig. 7 - Rig Sling to Hoist Unit

(015-030 Shown)

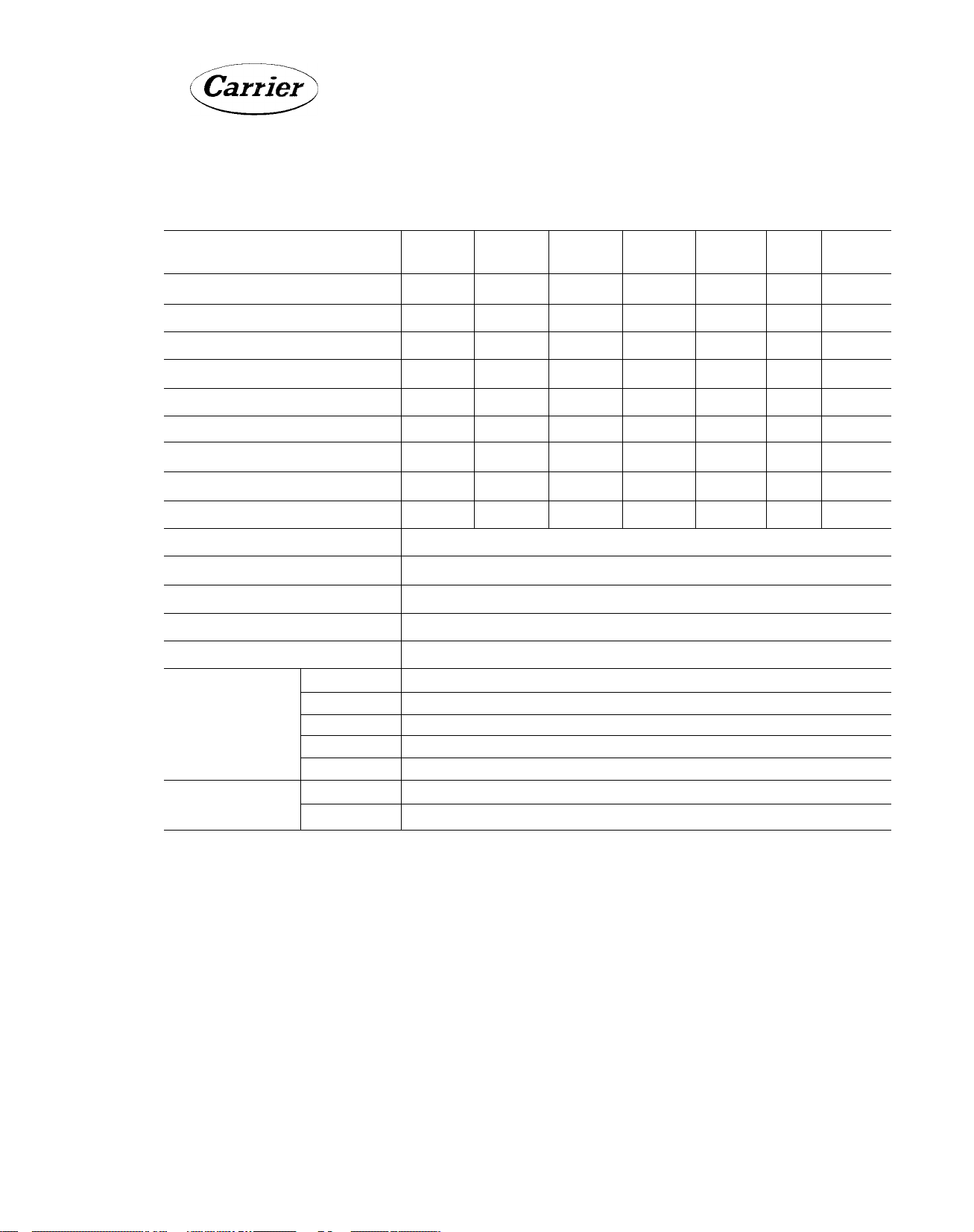

Table 2 - Compressor Motor Physical Data

Unit Size

Compressor Type

Number

Sizes

Cylinder (Total No.)

Speed - 60 Cycle (rpm) 1750 1750 1750

- 50 Cycle (rpm) 1460 1460

Oil Charge (10 pt per compr) (pr) 10 20 20 20

Cylinder Unloading Devices (No.) t 2 1 1 1

*6D7 3 Compressors are used on rhe 30HH models

only. 30HJ Models are supplied with 6D75 com

pressors.

30HH, H]

0J5

1 - 6D73» 2 - 6D68 1 - 6D68

6

30HH, H]

020

2 2 2 3 4

12 12 12 18 24

30HH, HJ

025

1 - 6D73*

1460

t Each cylinder unloading device unloads two cylinders

of the compressor when it is energized.

30HH, HJ

030

Hermetic Reciprocating

2 - 6D73* 3 - 6D73* 1 - 6D68

1750 1750

1460

30HH, HJ

1460 1460 1460

045

30 40 40

30HH

055

3 - 6D73

1750

30HH, HJ

4 - 6D73*

065

4

24

1750

1

Page 8

30HH/HJ INSTALLATION

Table 3 - Condenser Physical Data

Carrier

Unit Size

Condensers (No.)

Condenser Type

Tubes or Coils, each

Effective External Surface, each (sq ft)

Water Side Volume, each (gal)

Nominal Shell Diam (in.)

Shell Length (in.)

Water Connections (Total No.)

Water Connection

Size (each cond. )

Coil or Tube Type

Coil or Tube OD (in.)

Nominal Shell Thickness (in.)

Materials

of

Construction

Max. Design

Working Press, (psig)

Inlet

Outlet

Shell

Coil or Tubes

Tube Sheet

Water Side

Refrig. Side

30HH015

1

6

82.7

3.5

10-15/16 10-15/16 10-15/16 10-15/16

42-5/8

2 4

1 - 2"

1 - 2"

30HH020

2

4

53.9

2.5

34-5/8

2 - 1-1/2”

2 - 1-1/2"

30HH025

2 2

Shell-and-Coil

1 - 6

1 - 4

1-53.9

1 - 82.7

1 - 2.5

1 - 3.5

1 - 34-5/8

1 - 42-5/8

4 4

1 - 1-1/2”

1 - 2"

1 - 1-1/2"

1 - 2"

Trufin

7/8 3/4

.278

Steel Steel

Copper Copper

Steel Steel

100

385

30HH030

6

82.7

3.5

42-5/8 42-5/8 77 77

2 - 2"

2 - 2” 3 - 2"

30HH045 30HH055

3

6

82.7

3.5

10-15/16

2 4

3 - 2"

2

Sheil-anc -Tube

64 64

165.7 165.7

5.0

10-3/4 10-3/4

2 - 2"

2 - 1-1/2"

Trufin

.307

100

385

30HH065

2

5.0

3

1 - 3"

2 - 2”

Г'

NOTE: The 30HH065 unit is supplied with two subcooiers (one per circuit) to provide 15 F of subcooling.

Page 9

m

INSTALLATION 30HH,HJ

Tabie 4 - Cooler Physical Data

Unit Size

Refrigerant Circuits (No.)

Tubes (No.) 136

Effective External Tube Surface (sq ft)

Length Between Tube Sheets (in.)

Shell Side Water Volume (gal) 20.4

Baffles (No.)

Baffle Spacing (in.)

Nominal Shell Diam. (in.)

Water Connection Size, IPS (in.)

Cooler Type

Construction

Tube Type and Size (in.) Prime Surface, 3/4 OD

Nominal Shell Thickness (in.) 1/4

Nominal Tube Sheet Thickness (in.)

30 HH, HJ

015

1

125

60-1/4

31

1-7/16

14

2

30HH, HJ

020

2

136

126

60-1/4 60-1/4 60-1/4

20.6

25 21

1-27/32 2-7/32

14

2

30HH, HJ

025

2

136

127

20.8

14 14

2

Shell-and-Tube, Fixed Tubesheet

30HH. HJ

030

2

136

128 179

21.0

17 15

2-3/4 3-1/4

2

Direct Expansion

1-3/8 Min.

30HH. HJ

045

2

188

60-1/4

26.6

16

2

30 HH

055

186

258 258

85-7/8

38.2

4-1/2 4-1/2

30HH, HJ

2

85-7/8

17 17

16 16

3

065

2

186

38.2

3

Materials

of

Construction

Maximum Design

Working Press.(psig)

Shell

Tubes

Tube Sheet

Baffles

insulation

Water Side

Refrig. Side 150

Closed Cell Foam Plastic, Vapor Sealed

Steel

Copper

Steel

Polypropylene

250

Page 10

30HH,HJ INSTALLATION

Table 5 - Refrigerant Circuits

Carrier

Unit Size

зоны, HJ015

30HH, HJ020

зоны, HJ025 2

ЗОНЫ, HJ030 2

ЗОНН, HJ045

30НН055 2

ЗОНН, HJ065

NOTE: 6D73 Compressors arc used on ЗОНЫ models. 6D75 Compressors are used on 30HJ miodels.

Circuits

1

2

2

2

Description of Refrigerant Circuit

(i) 6D73 or 6D75 Compr, Full Cooler Surface

(1) 6D68 Compr, 1/2 Cooler Surface

(1) 6D68 Compr, 1/2 Cooler Surface

(1) 6D68 Compr, 1/2 Cooler Surface

(1) 6D73 or 6D75 Compr, 1/2 Cooler Surface

(1) 6D73 or 6D75 Compr, 1/2 Cooler Surface

(1) 6D73 or 6D75 Compr, 1/2 Cooler Surface

(1) 6D73 or 6D75 Compr, 1/3 Cooler Surface

(2) 6D73 or 6D7S Compr, 2/3 Cooler Surface

(2) 6D73 Compr, 1/2 Cooler Surface

(1) 6D73 & (1) 6D68 Compr, 1/2 Cooler Surface 45

(2) 6D73 or 6D75 Compr, 1/2 Cooler Surface

(2) 6D73 or 6D75 Comipr, 1/2 Cooler Surface

Table 6 - Refrigerant Charge

Capacity (%)

100

50

50

40

60

50

50

33

67

55

50

50

Model ЗОНН, HJ

Refrigerant 22 (lb)

NOTES: 1. The refrigerant charges listed above do

not include the additional charge required

for remote condensers and piping with

ЗОН] models.

015

35

020

46

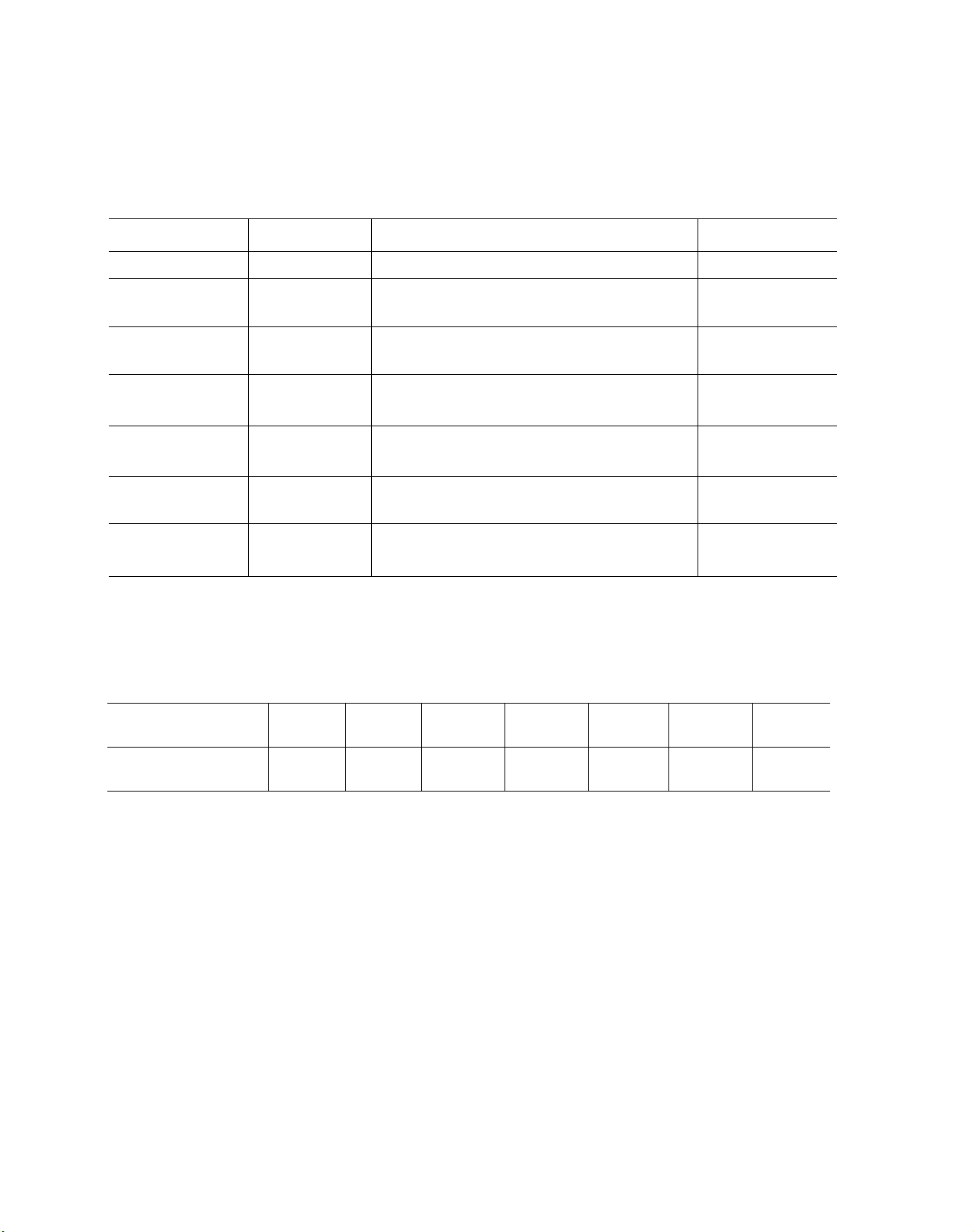

COMPRESSOR MOUNTING

All 30HH,HJ chillers, as shipped, have the com

pressor rigidly mounted to the frame with bolts

and steel pipe spacers. For proper operation,

the following procedure should be followed;

30HH,HJ020 to 030 units (Fig. 8):

1. Loosen the four (4) hold-down bolts on one

compressor.

2. Remove one hold-down bolt, lock washer

and nut on oil pump end of compressor. Lift

025 030

46 46

2. The 30HH015 and 30HH020 units are

shipped fully charged with refrigerant.

Other units are shipped with holding

charges only.

045 055

69

124

end of compressor and remove pipe spacer.

3. Tighten hold-down bolt which is diagonally

opposite spacer which was removed.

4. Install 3/8-16 X 1-1/2" bolt, supplied in bag

of fastenings, between compressor foot and

bracket. Reinstall lock washer and nut.

5. Loosen hold-down bolt tightened in step No. 3.

6. Repeat steps 2 thru 5 for other oil pump end

bolt.

065

140

10

Page 11

INSTALLATION

30HH,HJ

Fig. 8 - 30HH,HJ015-030 Compressor

Mounting

7. Remove both compressor motor end hold

down bolts, nuts, lock washers, and pipe

spacers, and replace with 3/8-16 x 1” bolts.

Reinstall lock washers and nuts to fasten

mounting brackets to resilient mounts.

FRONT

MOTOR END

REAR

PUMP END

Fig. 9 - 30HH,HJ045-065 Compressor

Mounting

6. Repeat steps 5 and 6 for the other motor end

fastenings of the compressor.

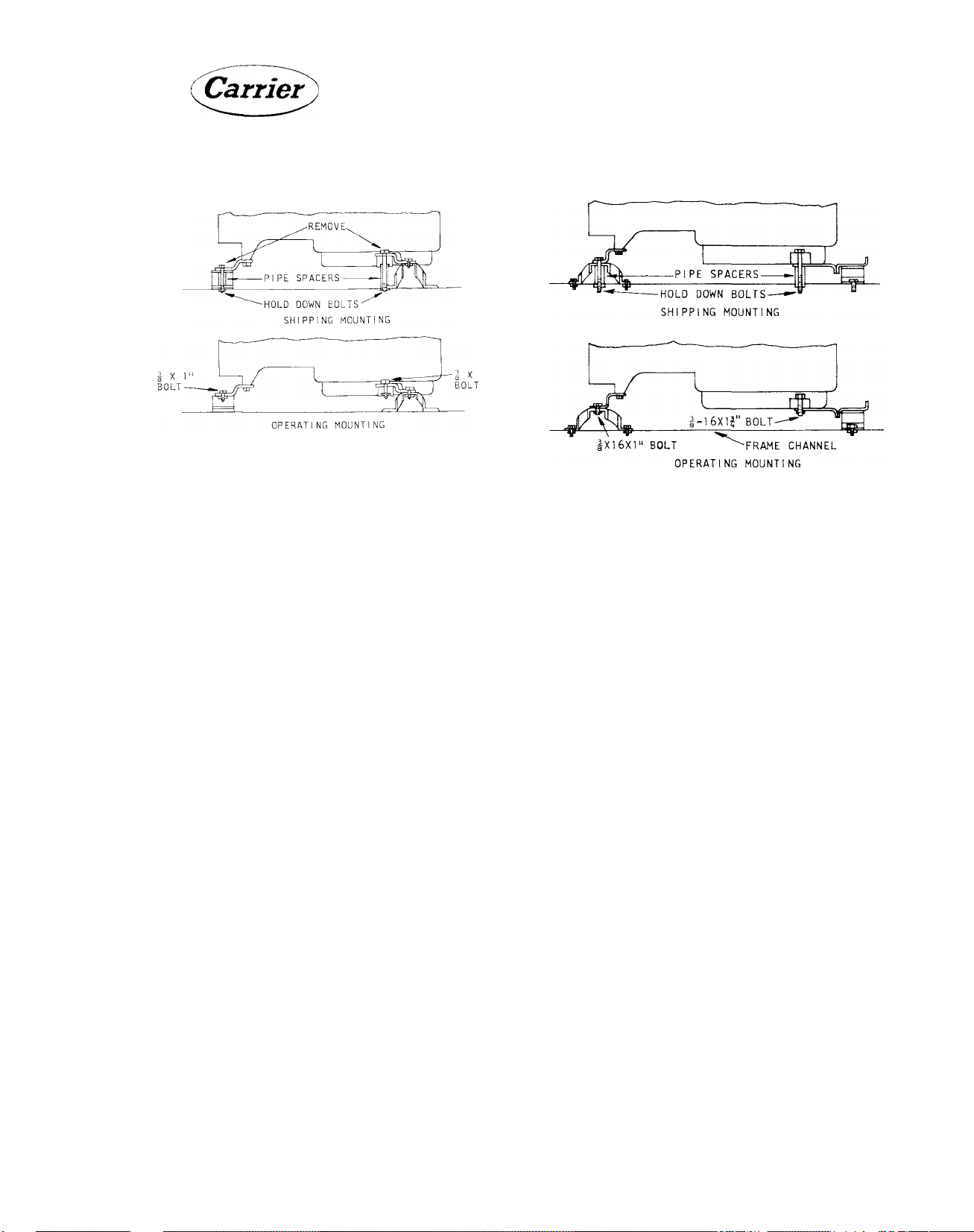

CONDENSER WATER PIPING

30HH,HJ045 to 065 units (Fig. 9):

The pairs of manifolded compressors are mount

ed on common mounting brackets. Be sure all

pipe spacers are removed for proper operation.

The mounting of the single compressor on

30HH,HJ045 units is similar.

1. Remove one 3/8-16 x 3-1/2” hold-down bolt,

nut, lock washer, and pipe spacer on the pump

end of the compressor.

2. Install a 3/8-16 x 1-3/4” bolt, supplied in

bag of fastenings, and reinstall nut and lock

washer from hold-down bolt, to fasten com

pressor to mounting bracket.

3. Repeat steps 1 and 2 for the other pump end

fastenings of the compressors.

4. Remove one 3/8-16 x 2-1/2” hold-down bolt,

nut, lock washer and pipe spacer on the motor

end of the compressor.

5. Install a 3/8-16 x 1” bolt, supplied in bag of

fastenings, and reinstall nut and lock washer

from hold-down bolt to fasten mounting

bracket to resilient mount.

Water supply lines should be as short as condi

tions will permit. The size of these lines is not

necessarily the same as those of the water valve

connections. All piping must be sized in accord

ance with tije pressure head available. This is

especially true on cooling tower applications.

See the System Design Manual, Part 3- "Piping

Design” for methods used in sizing pipe.

For installations using a waste water system, a

separate water regulating valve is required for

each refrigerant circuit. Water regulating valves

are not supplied by Carrier.

NOTE: Provide means for draining the

system in the winter and for repairs.

Figure 10 thru 16 show suggested piping

connections for each model when used

with waste water or cooling towers.

Frangible Disc Safety Union

Each condenser is provided with a frangible

disc that will relieve at 385 psig to protect the

system from excessive pressure.

Some local codes require piping from the relief

to the outdoors. The relief outlet size on both

models is 3/8” male flare.

11

1064

Page 12

зонн^ш

OUTLET

2" PIPE THD.

INLET

2" PIPE THD.

INSTALLATION

WATER REGULATING

VALUE-WASTE WATER

SYSTEMS ONLY

Carrier

Fig. 10 - 30HH015 Condenser Piping Fig. 11 - 30HH020 Condenser Piping

Fig. 12 - 30HH025 Condenser Piping

1064

Fig. 13 - 30HH030 Condenser Piping

12

Page 13

Carrier

INSTALLATION

30HH,HJ

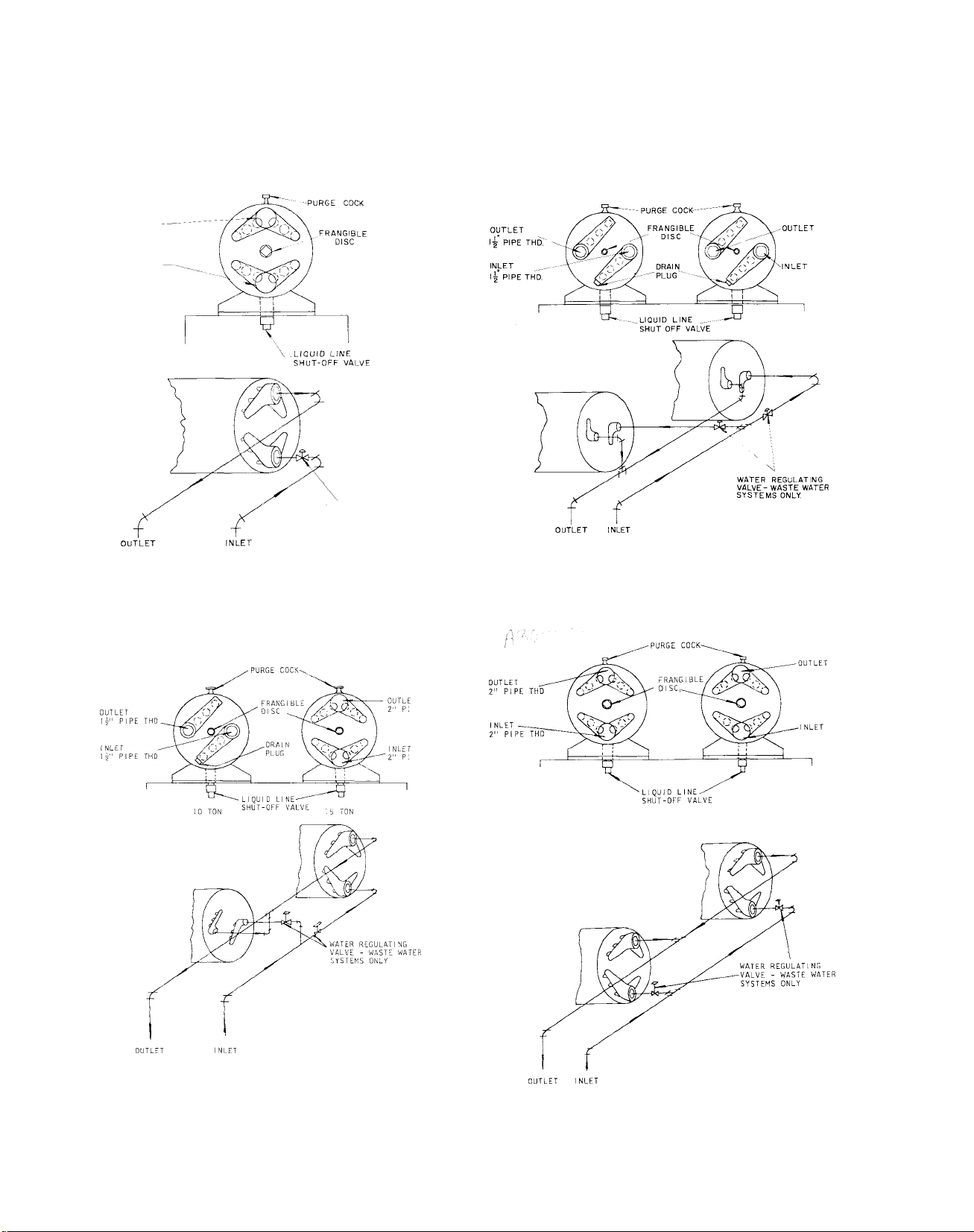

Fig. 14 - 30HH045 Condenser Piping

Fig. 15 - 30HH055 Condenser Piping

13

Fig. 16 - 30HH065 Condenser Piping

1064

Page 14

30HH,HJ

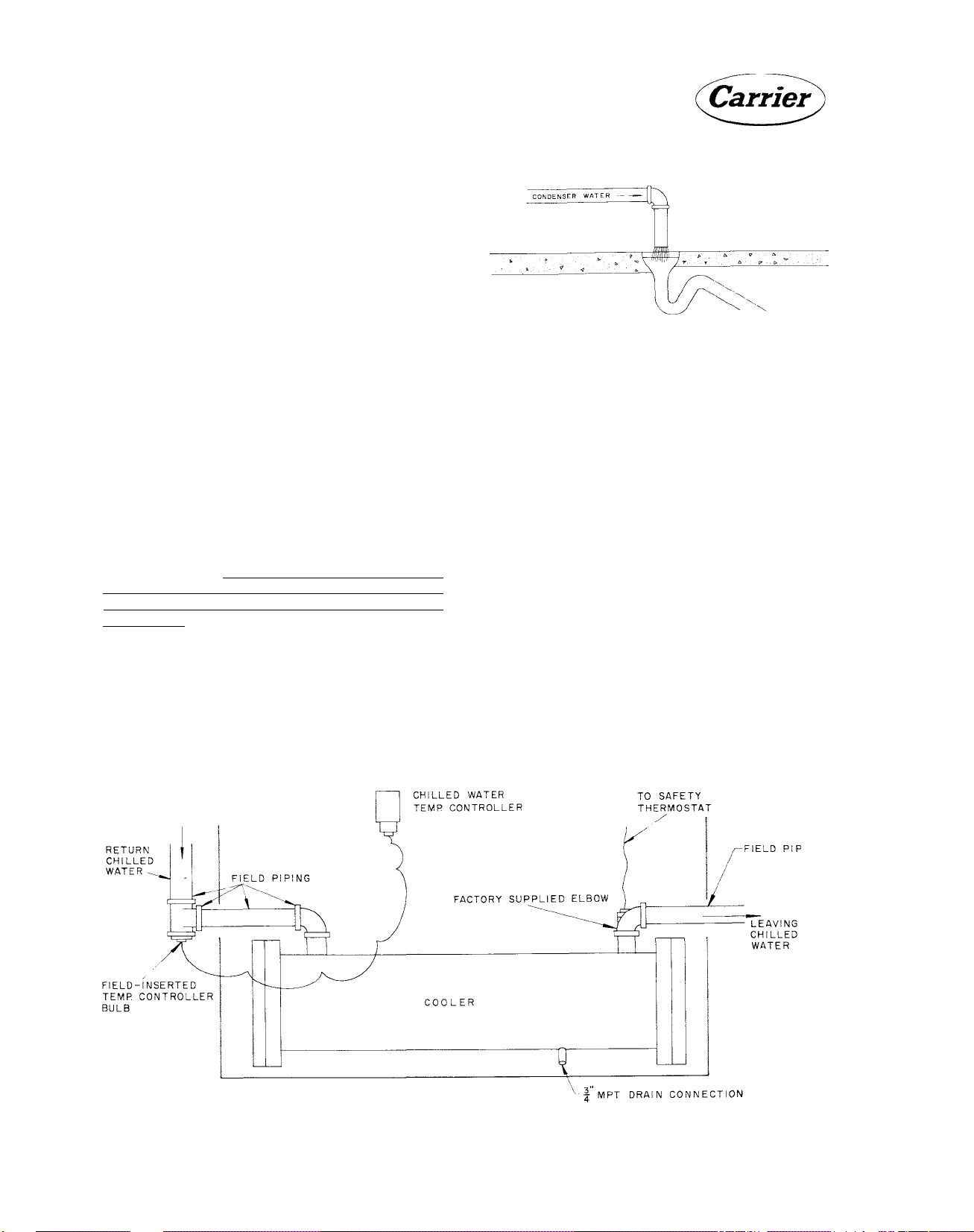

Drain Connection

Drain connections are generally governed by

local codes. Water leaving the condenser is

under pressure and should not be connected

directly into sewer lines; otherwise water may

back up into other fixtures. Local codes nor

mally require connections similar to the one

shown in Fig. 17.

INSTALLATION

COOLER WATER PIPING

The cooler of each liquid chilling package is pro

vided with stubouts for chilled water piping con

nections. The water outlet stubout is provided

with a 90 degree elbow which contains the chilled

water safety thermostat bulb. Holes are pro

vided in both of the side panels for piping to the

stubouts.

The chilled water temperature controller is

mounted on the front of the unit and has the con

trol bulb and capillary tubing wrapped and taped

before shipping. It is required that the control

bulb be field inserted in the chilled water line.

It usually is inserted in the return or inlet chilled

water piping. Figure 18 shows a typical chilled

water piping arrangement in the vicinity of the

cooler. Details of the required remote chilled

water piping are outlined in the Carrier System

Design Manual, Part 3, "Piping Design."

Plan the piping so it has a minimum number of

changes in elevation. A manual or automatic

Fig. 17 - Drain Connections

vent-valve must be installed at the high points

in the line to permit venting of air from the

chilled water circuit. Standard practice for in

stalling forced water systems must be followed.

System pressures may be maintained by using a

pressure tank or a combination relief valve and

reducing valve.

It is recommended that thermometers be in

stalled in entering and leaving chilled liquid

lines. Provide drain connections at all low points

to permit complete drainage of the system. A

chiller drain shut-off valve should be connected

to the chiller drain line before placing the unit

in operation (Fig. 18).

Insulate piping to prevent heat loss and sweating.

Cover the insulation with a moisture seal. Do

not insulate piping before all leak testing has

been completed.

Fig. 18 - Cooler Water Piping, Front View

14

Page 15

Carrier

INSTALLATION

30HH,HJ

REFRIGERANT PIPING

For refrigerant piping sizing refer to Part 3 ’’Piping Design” - of the System Design Manual.

The ЗОНЫ and HJ Packaged Liquid Chillers are

leak tested at the factory and provided with a

holding charge of Refrigerant 22.

NOTE: 30HH015,020 fully charged with

R 22 at factory.

If the holding charge is still in the system upon

arrival at the erection site, the likelihood of leaks

is slight. If the unit is not under pressure, test

for leaks as outlined under Leak Testing.

NOTE: Be sure to open all stop valves

when testing for leaks.

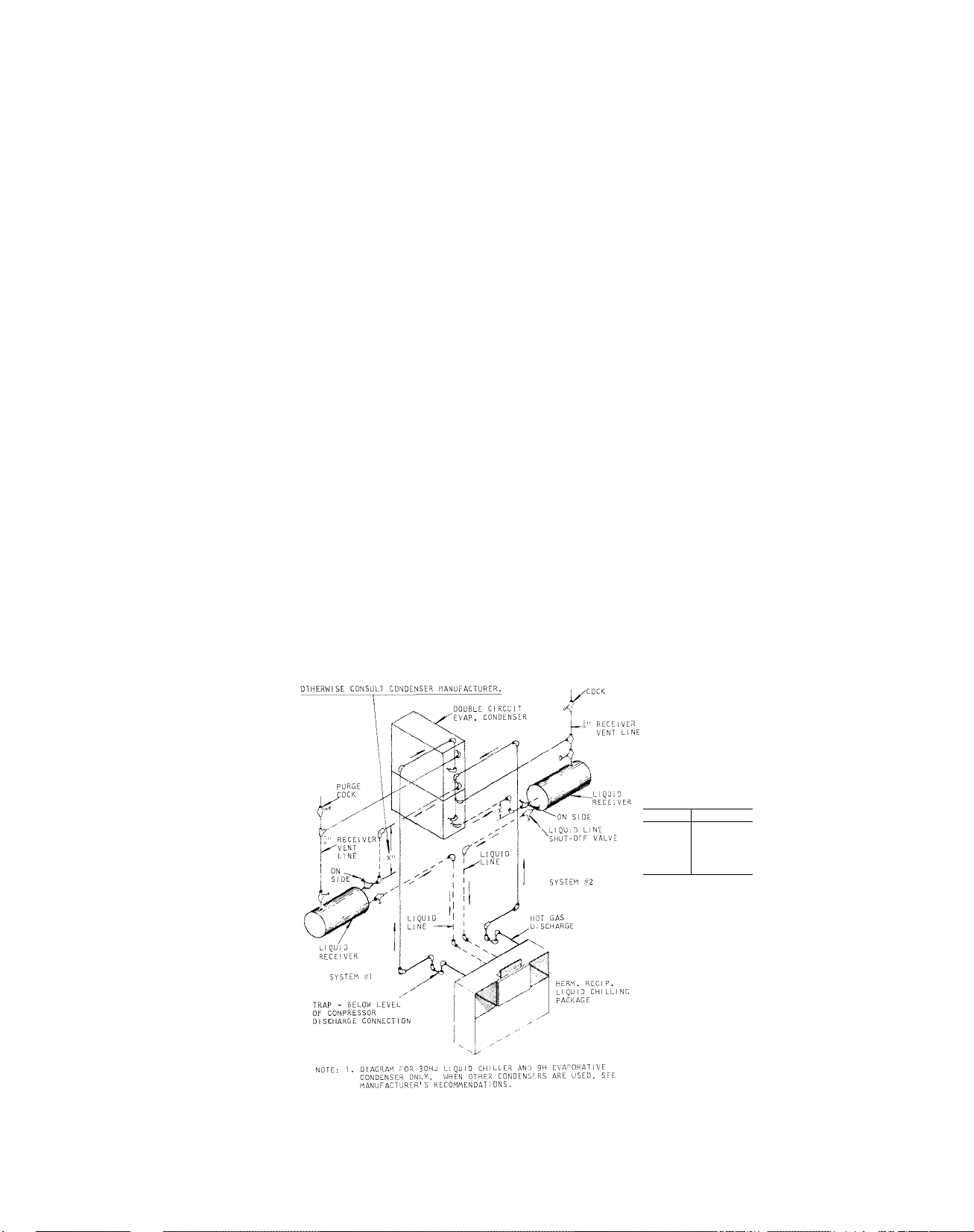

30HJ UNIT

This section also applies to the 30HJ unit which

is to be connected to a remote condenser in the

field. Figure 19 is a typical refrigerant piping

diagram showing the 30HJ020 thru 030 unit and a

9H Evaporative Condenser. Simdlar connections

may be used for the 30Ш045 and 065 unit using

manifolded compressors. Figure 20-22 illus

trate typical refrigerant piping for 30HJ020 thru

065 units and air-cooled condensers. Receivers

have been omitted, but it must be recognized

that with this arrangement the refrigerant charge

is critical. An overcharged or undercharged

system can cause a loss of capacity. If a receiver

is not Included, an accurate refrigerant charge

must be maintained to assure efficient operation.

Figure 20-22 are shown to illustrate a typical

installation using 9A or 09DC016 air-cooled con

densers. These illustrations are to be used as a

guide when designing a system and are not in

tended to be used as an actual piping layout. Con

sult the ’’System Design Manual” and condenser

literature before designing the actual system.

Each 30HJ unit (except -015) consists of two

independent refrigerant circuits. Each circuit

must be isolated from the other.

Discharge lines and liquid lines are shown mani

folded at the units on 30HJ045 and 065 units to

permit a minimum amount of piping. Individual

discharge lines may be run from each compres

sor to the condenser if desirable. Liquid lines

must be manifolded as shown to enter the 30HJ065

unit to agree with the unit refrigerant circuit. In

dividual liquid line connections are necessary on

the 30HJ045 unit.

FROM TABLE - FOR VENTING AS SHOWN

MUFFLERS SHOULD

AS POSSISLE.

INSTALLED AS CLOSE TO THE COMPRESSOч

Fig. 19 - Typical Refrigerant Piping 30HJ020-030 Units

with 9H Evaporative Condenser

UNI T

30HU015

3ÛHJ020

30HJ025 15"

30HJ030

30HU0A5

3OHJO65

“X” DIM. *

6"

15"

15"

15"

1 5"

"X" DIM. - THIS IS

THE MINIMUM, ELEVATION

REQUIRED BETWEEN A

CONDENSER COIL OUTLET

AND A RECE!VER INLET

FOR THE TOTAL LOAD

WHEN RECE;VER 1S

VENTED TO COI I. OUTLET

HEADER (BASED ON 10'

OF HORIZONTAL PIPE,

1 VALVE AND 2 ELBOWS).

APPLIES TO 9H TYPE

EVAP. CONDENSER

- REFRIG. GAS

-REFIG. LIQUID

15

Page 16

30HH,HJ

In order to prevent condensed liquid refrigerant

or oil from causing damage to the compressor,

install a trap in the vertical discharge line near

the compressor. The trap may be installed within

or adjacent to the unit base. The height of the

trap (or loop) should be 6 inches for every 10

feet of vertical discharge line. If the height of

the vertical discharge line is such as to make

a single trap impractical, the loop can be re

placed by a check valve or several traps.

To prevent the formation of copper oxide when

brazing copper tubing, bleed a small amount of

dry nitrogen gas thru the piping. The nitrogen

will displace the air containing oxygen.

Complete all field piping before removing the

seals on the unit refrigerant piping. Upon com

pletion of the field piping, add a small amount

of refrigerant and build up the required test

pressure with dry nitrogen or other inert gas.

If a test pressure is not specified, ASA-B9

Code calls for 300 psig high side and 150 psig

low side test pressures for R 22.

NOTE: 1. Install mufflers as close to compres

sor discharge valve as possible.

2. Make sure a pressure relief device is

installed in the hot gas line or con

denser used with the 30HJ models.

INSTALLATION

Fig. 21 - Rafrigerant Piping to Three Air-

Cooled Condensers 30HJ045 (without Receivers)

Fig. 20 - Refrigerant Piping to Two Air-

Cooled Condensers 30HJ020,025,030

(without Receivers)

Fig. 22 - Refrigerant Piping to Four Air-

Cooled Condensers 30HJ065 (without Receivers)

16

Page 17

Carrier

INSTALLATION 30HH,HJ

LEAK TESTING

The Halide Leak Detector

The Halide Leak Detector pictured in Fig. 23

consists of a burner, needle valve, suction tube,

and a chimney with a copper reaction plate.

Some torches use alcohol and others use pro

pane fuel.

/Ч, '

Preparation

Before dehydrating a system make the following

preparations:

1. Obtain a pump that will produce a vacuum of

.2" Hg absolute. Do not use the compressor

as a vacuum pump. It is not designed for such

use and may be seriously damaged.

2. Pressure test system to be sure it is free of

leaks.

3. Obtain a vacuum indicator similar to that

shown in Fig. 24 (available thru local Carrier

Distributor).

4. Keep the ambient temperature above 60 F to

speed the evaporation of moisture.

и

1 SAE PLUG , - . ,

l."SAE FLARE NUT--

--------------

S--------------r*

u

I »SOLATIO«-

Fig. 23 - Halide Leak Detector

To use the leak detector;

1. Adjust the flame so the top of the flame cone

is level with or slightly above the chimney.

2. Place the end of the suction tube at the point

to be tested. The tube pulls in a sample of

air to the burner where the refrigerant is de

composed by reaction with the copper plate.

3. Observe the color of the flame. Small leaks

give a greenish tint and large ones a vivid

blue. Leaks can also be detected with a soap

solution or an electronic gun.

DEHYDRATE THE SYSTEM

If there has been a leak in the 30HH unit or after

field piping the 30HJ unit, the system must be

evacuated.

Moisture in the system causes oil-sludge and

corrosion, it is likely to freeze up the expansion

valve of a low temperature system. The best

means of dehydration is evacuation with a pump

specially built for this purpose.

TME«MC«ETEft

distilled WATER

L.. J T

Fig. 24 - Vacuum Indicator

Description and Use of the Vacuum Indicator

The vacuum indicator consists of a wet bulb

thermometer in an insulated glass tube contain

ing distilled water. Part of the tube is exposed

so the thermometer can be read and the water

level checked. When the vacuum indicator is

connected to the vacuum pump suction line, the

thermometer reads the temperature of the water

in the tube. The temperature is related to the

absolute pressure in the tube. Table 7 gives

the absolute pressures corresponding to var

ious temperatures.

¿HahdlQ the vacuum indicator with care. It must

be vacuum tight to give a true reading. The top

17

Page 18

INSTALLATION

Table 7 - Vapor Pressures of Water

Temperature, degrees F

Observed on Vacuum

indicator

70

60

55

50

45

40

35

32

NOTE: To determine the vacuum in inches of

mercury subtract the absolute pressure

from the barometer reading.

seal of the indicator is not designed to support

a long run of connecting tubes. Fasten the tubes

to supports to prevent damage.

Use only distilled water in the indicator. Be

sure the wick is clean. Oil or dirt on the wick

causes erroneous readings. To prevent loss of

oil from the vacuum pump and contamination

of the indicator;

Absolute Pressure

Inches of Mercury

0.739

0.522

0.436

0.363

0.300

0.248

0.204

0.180

value corresponding to the vapor pressure of

the water in the indicator, the temperature

will start to drop. In the example shown in

Fig. 25, the ambient temperature and the

temperature of the water in the indicator is

60 F. Starting at 60 F and 0 time the temper

ature of the water in the indicator remains

at 60 F until the pressure in the system is

pulled down to the pressure corresponding to

the saturation temperature of the water (60 F).

At this point the moisture in the system will

start to boil. The temperature drops slowly

until the free moisture is removed (35 F).

Dehydration is nearly completed at this point

provided the ambient temperature remains

at 60 F or higher. If the ambient temperature

were lower than 60 F ice might form before

moisture removal is complete.

3. Continue the dehydrating operation until the

vacuum indicator shows a reading of 35 F

which corresponds to a pressure of 0.204”

Hg absolute. This may take several hours. It

may be advantageous to run the pump all

night.

4. With the pump still running, open the system

at a point furthest from the pump and admit

air thru the drier. Close system and repeat

steps 2 and 3. Vapor left in the system is

thus greatly diluted and almost completely

removed by double dehydration.

1. install a shut-off valve in the suction line at

the vacuum pump.

2. Install a shut-off valve in the suction line at

the vacuum indicator.

3. When shutting off the pump, close the indi

cator valve, the pump valve and turn off the

pump in that sequence.

Procedure for Dehydrating the System

1. Connect the pump and vacuum indicator to

the system. Put a ’’jumper" line between the

high and low side so that the pump will draw

a vacuum on all portions of the system. Open

the compressor shut-off valves. Start the

pump.

2. Open the indicator connection shut-off valve

occasionally and take a reading. Keep the

valve open at least three minutes for each

reading. (Keep the valve closed at all other

times to decrease the amount of water the

pump must handle and hasten dehydration.)

When the pressure in the system drops to a

5. After evacuation, turn off the pump suction

valve and break the vacuum by admitting

refrigerant.

START-UP PROCEDURES

initial Check

Do not attempt to start the ЗОНЫ and HJ Liquid

Chiller even momentarily until the following

steps have been completed.

1. Check all auxiliary components of the instal

lation such as chilled liquid circulating

pump, cooling tower if used, air handling

equipment, or other equipment to which the

chiller supplies liquid. Consult the manufac

turer's instructions.

2. Check safety thermostat. See "Safety Ther

mostat Adjustment" under "CHECKING

THE CONTROLS."

3. Backseat (open) the compressor suction and

discharge shut-off valves. Close the valves

18

Page 19

INSTALLATION

30HH,HJ

TIME

Fig. 25 - Dehydration Puii-Down Curve

one turn to allow pressure to reach the

gages.

4. Open the liquid line shut-off valves at the

condensers (30HH if using the vapor charg

ing method - see "Charge With Refriger

ant”) or the inlet, outlet, and vent valves on

the receivers (30HJ).

5. Open the valves to the capillaries of the

water regulating valves (when used).

6. Fill the chilled liquid circuit completely

with clean water or other non-corrosive

fluids to be cooled. Bleed all air out of the

high points of the system.

7. If the condenser is cooled by waste water,

open the water supply valve. If it is cooled

by a cooling tower, fill the tower with water.

8. Start the air handling equipment or other

equipment to which the 30HH or HJ is con

nected.

lay and remove protective paper between

contacts of the balancing relay in the step

controller.

Start Up

Upon completing the initial check, charge the

unit with refrigerant. (See "Charge with Refrig

erant.”)

IMPORTANT: 30HH015,020 units are

fully charged at factory.

The unit should only be started under the super

vision of a refrigeration mechanic who is famil

iar with the accepted operating practices for

refrigeration systems.

1. Open all compressor or system valves that

may have been closed during or after charg

ing.

2. Start the unit by pushing the "START" and

"STOP” button.

9. Set the temperature controller (page 24).

10. Check tightness of all electrical connec

tions.

11. Remove cardboard spacer from recycle re -

3. Check all controls for proper operation. (See

"Check Controls.”)

4. Adjust watfer regulating valve to the most

economical pressure for the locality. Nor

mally 200 to 230 pounds for F 22.

19

Page 20

30HH,HJ INSTALLATION

TYPE LIQUID SHUT-OFF VALVE CHARGE

USING VAPOR METHOD

Fig. 26 - 30HH Condenser Liquid Line Shut-Off Valves

5. Check chiller leaving temperature to see

that it remains well above freezing.

6. Check compressor oil level ("Oil Charge”).

CHARGE WITH REFRIGERANT

Each system in the 30HH and HJ units must be

charged individually.

IMPORTANT: 30HH015,020 units are

fully charged at factory.

Charge early models of the 30HH015 to 030 units

using the vapor charging method.

Charge later models of the 30HH units using

liquid charging method. A redesign of the con

denser liquid shut-off valve makes it possible

to charge liquid refrigerant thru the gage port

directly into the chiller, when the valve is in the

front seated position. Check Fig. 26 showing

both valves to determine the method of charging

to be used.

CAUTION: When charging the units,

circulate water thru the condenser

(30HH) and chiller (30HH and HJ) at all

times to prevent freezing. Freezing of

equipment with resulting damage is

considered abuse and not covered by

the Carrier Warranty.

Vapor Charging Method

Vapor charge the units thru compressor suction

shut-off valves as follows:

2. Connect a refrigerant cylinder loosely to the

gage connection of the suction shut-off valve.

The charging line should contain a drier.

3. Purge the charging line and tighten the con

nections.

4. Turn the stem of the suction shut-off valve

clockwise a couple of turns.

5. Stand the cylinder upright so that only gas is

charged into the system. Crack valve on the

charging cylinder and break vacuum (30HJ

units) with refrigerant vapor. Open the valve

of the charging cylinder and start the com

pressor. (See ”Start-Up Procedures.”) Al

low the compressor to cycle on the low-

pressure cut-out until the refrigerant charge

builds up sufficiently to permit continuous

compressor operation.

As the cylinder is discharged, its pressure

will eventually drop to the same level as suc

tion pressure. The remaining refrigerant can

be drawn from the cylinder by front seating

the suction shut-off valve and pulling a vac

uum on the cylinder.

6. Check the refrigerant charge frequently at

the moisture liquid-indicator. A steady flow

of liquid refrigerant will indicate a sufficient

charge.

7. When the unit is sufficiently charged, close

the cylinder valve, backseat the suction shut

off valve, and remove the charging apparatus.

1. Backseat the suction shut-off valve.

Replace the plug in the suction shut-off valve.

20

Page 21

Carrier

INSTALLATION 30HH,HJ

Liquid Charging Method

Liquid charge the units thru the condenser liquid

line shut-off valves.

1. Backseat condenser liquid line shut-off valve.

2. Connect a refrigerant cylinder loosely to the

gage connection of the condenser liquid line

shut-off valve. Purge the charging line and

tighten the connections.

3. Weigh the refrigerant cylinder (if possible).

4. Front seat the condenser liquid shut-off valve.

5. if the system has been dehydrated and is

under vacuum, break vacuum with refriger

ant (Gas charge). Build system pressure to

58 psi for R 22 (32 F). Invert refrigerant

cylinder so that liquid refrigerant will be

charged.

6. Allow the compressor to cycle on the low

pressure cut-out until sufficient pounds of

refrigerant have been added (Table 6).

7. When the unit is sufficiently charged, close

the cylinder valve, backseat the liquid line

shut-off valve, and remove the charging ap

paratus. Replace the cap in the liquid line

shut-off valve.

evaporative condenser models, it may be neces

sary to add oil at the job site. Observe the oil

level closely at startup and add oil, if required,

to bring the level in the crankcase to the middle

of the bull's-eye during steady operation.

To Add Oil

1. Close suction shut-off valve and pump down

crankcase to 2 psig. (Low pressure cut-out

must be shorted.) Wait a few minutes and

repeat as needed until pressure remains at

2 psig.

2. Remove oil fill plug to the right of the bull'seye and add oil thru plug hole.

3. Replace plug.

4. Run compressor for about 20 minutes and

check the oil level.

CAUTION: To insure trouble free oper

ation, use only Carrier approved com

pressor oil, Specification No. PP-33-2.

Do not re-use oil that has been drained

out, or oil that has been left open to the

atmosphere.

To Remove Oil

1. Pump down compressor to 2 psig gage.

NOTE: Where it is impossible to weigh

the refrigerant cylinder, the initial re

frigerant charge must be an approxi

mation. After it has been added, back

seat the liquid line shut-off valve and

allow the unit to operate. A clear flow

of liquid in the liquid-moisture indica

tor, indicates a satisfactory charge.

If the charge is not sufficient, add re

frigerant until a clear flow of liquid

show in the glass.

CAUTION: Be careful not to overcharge

the system. Overcharging results in:

(a) Higher discharge pressure with

higher cooling water consumption.

(b) Possible compressor damage.

(c) Higher power consumption.

OIL CHARGE

The 30HH,HJ units are charged with oil at the

factory (Table 2). Because of added piping with

2. Loosen the 1/4” pipe plug in compressor

base and allow the oil to seep out past the

threads of the plug.

CAUTION: The crankcase will be under

slight pressure. Be careful not to re

move the plug; the entire oil

may be lost.

charge

CHECK THE CONTROLS

Expansion Valve

The thermal expansion valves control the flow

of liquid refrigerant by maintaining constant

superheat of the vapor leaving the cooler. They

are pre-set at the factory to maintain a super

heat of 8 F. Do not attempt to adjust them unless

you are certain it is absolutely necessary.

Safety Thermostat Adjustment

The safety thermostat is of non-cycling, manual

reset type. It has an adjusting dial with a stop

set at 36 F for normal chilled water applica

tions, but can be readjusted for a lower stop if

21

Page 22

30HH,HJ INSTALLATION

glycols or brines are to be cooled. The adjust

ment tolerance is commonly j- 1 F.

DAMAGE DUE TO THE FREEZING OF A CHILL ER IS NOT COVERED BY THE WARRANTY.

The safety thermostat bulb is located in the

leaving chilled water piping stubout.

IMPORTANT: This thermostat should

be checked at the time of installation

and at least once every season. If the

bulb is damaged in handling, its cali

bration may be off.

To check the safety thermostat:

1. Place the thermal bulb in a vacuum bottle

filled with water and add crushed ice.

NOTE: This is an insert type bulb. On

earlier units, removal opens water sysexcept on 30HH,HJ045 thru 065 units

which use a sealed well. Later units

all use a sealed well.

I ‘-f

FIXED IMDICATOR

ADJUSTING SLOT

2. Stir the contents with a thermometer and

note the temperature at which safety thermo

stat cuts out.

3. Reset the safety thermostat if necessary. To

set the control, use screwdriver in slot and

rotate dial until the desired temperature at

which compressor is to stop is directly under

indicator "B”.

To recalibrate the safety thermostat;

1. Measure the temperature as close to the bulb

as possible, immediately after the compres

sor stops.

2. Break the painted seal between the dial and

the adjusting plate with a knife.

3. Carefully loosen the two dial screws. Be care

ful not to turn the brass cylinder below the

dial during this or any of the following oper

ations.

4. Turn the dial ONLY so that the fixed indica

tor points to thè temperature measured at

step 1.

5. Carefully tighten the dial screws.

Fig. 27 - Safety Thermostat

High and Low Pressure Controls

Pressure control settings are shown in Table 8.

The 30HJ high pressure control settings are suit

able for use with either air-cooled or evaporative

condensers. The control setting (Table 8) is a

fixed setting and is nonadjustable.

Check the high pressure switch setting by slowly

closing the discharge shut-off valve. The com

pressor should shut down when the discharge

pressure reaches 260 or 355 psi (as required)

and start up when the pressure drops to 210, or

255 psi (as required).

The 30HH high pressure switches are adjustable

and equipped with a stop to prevent field setting

above 280 lbs.

To check the low pressure switch, close the

suction shut-off valve and allow the compressor

to pump down. The compressor should cut out

when the suction pressure falls to 46 psig, and

automatically start up again when the suction

pressure builds up to 83 psig.

Both sides should be checked at startup and at

least once a year thereafter.

22

Page 23

Carrier

INSTALLATION 30HH,HJ

Tabie 8 - Pressure Contro! Settings

High Pressure

Cutout

Cutout

Model

30HH

30HJ

Liquid Line Solenoid Valves (30HJ models only) -

All 30HJ condenserless models are provided with

a liquid line solenoid valve in each refrigerant

circuit. These valves and the low pressure cut

out switches provide pumpdown control of idle

refrigerant circuits when the unit is in operation.

(Psig)

260 210

355

Cut-in

(Psig)

255

Low Pressure

Cutout

Cutout

(psig)

46

46

Cut-in

(psig)

83

83

Crankcase Heaters

All compressors are furnished with crankcase

heaters to prevent accumulation of liquid in the

compressors. They are inserted into blind holes

in the compressor bottom cover. Electrically,

they are wired into the control circuit by con

necting them to the normally closed auxiliary

contacts on the compressor starters. The crank

case heaters are energized at all times when

the unit is not in operation.

Electrical Characteristics: 75 watt, 230 volt,

single phase, 50/60 cycle for each crankcase

heater on 230 volt units; 75 watt, 115 volt single

phase, 50/60 cycle for 460 volt and 575 volt

units.

STARTERS AND OVERLOADS

The starters have been selected and the over

loads have been sized at the factory to give prop

er protection to the compressor motor. Do not

increase their size or bypass their connections.

If trouble is encountered, the cause should be

found and corrected before the overloads are

reset.

Compressor Thermal Protection

An internal thermostat is located in the motor

windings of each compressor. Should the tem

perature of the compressor rise too high, the

thermostat will trip and stop the compressor.

It will not restart until the temperature drops.

On the part winding compressor, the thermo

stat is located externally on the compressor

housing.

CIRCUIT BREAKERS

Circuit breakers provide separate branch cir

cuit protection, one for each compressor. They

are jumpered so that only one power lead to the

unit is required.

When branch circuit overload causes the break

ers to trip, they must be manually reset, by

throwing the switch off and on again. The cause

of the overload should be determined and rem

edied before restarting.

Control Circuit

To stop unit, push ’’STOP-START"

center of the gage panel.

button in

Table 9 - Circuit Breaker Trip Amperes

Circuit Breaker Size (Amps)

208-3-60

Compressor and Unit

6D73 (HH) 90 90 40

6D75 (HJ) 90 90 50

6D68 (HH) 50 50

6D68 (HJ) 70

230-3-60

230-3-50

50 30

23

460-3-60

400-3-50 575-3-60

40

40

25 20

30

Page 24

30HH,HJ

Carrier

INSTALLATION

Two eight ampere fuses protect the control cir

cuit against overload. The control light will be

on whenever the control circuit is energized.

Disengage the fuse caps to remove blown fuses.

Fig. 28 - Gauge Panel (30HH,HJ045)

The "X" values (Table 10) were established by

experimentation and are such that the compres

sor is prevented from cycling more than once

in a five minute period.

The throttling range is determined as follows;

Throttling Range (modulating) =

Design Rise + "X”

The throttling range setting is arrived at by

entering the graph below at the "set point” and

moving across an amount equal to the throttling

range. The setting is read from the top scale

and will fall somewhere between min. - F. To

illustrate, with a 30HH065 Chiller, a 4-compres

sor unit, at a 10 F design rise, 45 F leaving

chilled water temperature, the set point would

be 45 - 1 = 44 F. The throttling range would be

10 + 1 = F.

Entering the graph at 44 F and moving across

11 F indicates a throttling range setting of just

under "A”.

Table 10 - ”X” Values, F

WATER REGULATING VALVE

The water regulating valve should be set to

maintain the most economical head pressure as

determined by the design engineer, based on the

relative cost of water and electricity in a given

area. It should not be adjusted to compensate

for high head pressures caused by fouled con

denser tubes, excess refrigerant or the pres

ence of noncondensables. Due to changes in

water temperatures, it may be necessary to

adjust the valve seasonally. After adjusting for

the economical head pressure, the machine

should be shut down. The water regulating valve

should shut off the flow of water in a few min

utes. If it does not, it will be necessary to

raise the head pressure setting. The water reg

ulating valve is used for city water and in

some cases with multiple units on a single

cooling tower.

TEMPERATURE CONTROLLER ADJUSTMENT

The chilled water temperature controller must

be adjusted in the field before initial startup.

Two adjustments are required - Set Point (main

scale, 15 - 90 F) and Throttling Range (modu

lating, min - F).

Design Rise F

No. of Comp. 8 10 12

1

2

3

4

SET POINT

ADJUSTMENT SCREW

2.0

2.0

1.25

.75

^ADJUSTMENT SCREW

2.5

2.5

1.5

1.0

THROTTLING RANGE (MODULATING)

3.0

3.0

1.75

1.25

THROTTLING

RANGE

SCALE

The set point is determined as follows ;

Set Point = Design Leaving Chilled Water

Temperature - ”X”

Fig. 29 - Chilled Water Temperature

Controller

24

Page 25

Carrier

INSTALLATION

THROTTLING (MODULATING) RANGE SETTING

MIN. A B C DE F

.CONTACTORS

CURRENT OVERLOADS

Fig. 30 - Temperature Contro!ie‘r Graph

(HI-LOW STEP

PRESSURESTATS CONTROLLER

SAFETY HI-LOW CONTACTORS

THERMOSTAT PRESSURESTATS / \

I

TERMINAL STRIP

Fig. 31 - Control Box - 30HH.HJ055

25

CURRENT OVERLOADS

Page 26

30HH,HJ INSTALLATION

CAM

SWITCHES

BALANCif'^G

POTENTIOMETER r~ TRANSFORMER

TEMPERATURE.

BRIDGE

Carrier

I

COMPRESSOR ; «

(2 BANKS OF—i

UNLOADING) * '•

^ oH

Fig. 32 ~ Step Controller

K)

•n

Fig. 33 - 30HH015 Chiller with Front Panel

Removed

Fig. 34 - 30HH015 Control Panel

26

Page 27

INSTALL/

♦

Fig. 35 - 30HH.HJ015 Wiring Diagram

Page 28

non

30HH,HJ

f jTRANS-

nlpORMER

balancing

RELAY

Idxgxg.

TERMINALS ON MAIN TERMINAL StRiR TERMINALS ON PANEL LIGHT

□

TERMINALS ON STEP CONTROLLER f / TERMINALS ON PRESS. SWITCH

o

TERMINALS ON TEMPERATURE CONTROLLER

A

NOTES

ALL WIRING SHOWN IS FACTORY WIRING EXCEPT AS OUTLINED IN NOTE 2.

208 VOLT a 230 UNITS HAVE 208/230 VOLT CONTROL CIRCUITS. ON THESE UNITS ONLY, LEADS ARE

SUPPLIED FROM NUMBER i CONTACTOR TO TERMINALS 182 FOR TH£ PURPOSE OF ENERGIZING THE

CONTROL CIRCUIT. 460 8 575 VOLT UNITS HAVE US VOuT CONTROL CIRCUITS. AND A SEPARATE 115 VOLT

SOURCE MUST BE FIELD SUPPLIED THROUGH A FUSED DISCONNECT SWITCH TO TERMINALS 18 2.

FACTORY WIRING IS IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE. ANY FIELD MODIFICATIONS

OR ADDITIONS MUST BE IN COMPLIANCE WITH ALL APPLICABLE CODES,

CONTROL CIRCUIT FUSES MUST ALWAYS REMAIN IN THE CONTROL CU.RCUiT. THE FUSES ARE i/4" x 1 1/4"

CERAMIC TUBE RATED AT 8 AMPS FOP 220 VOLT Cl RCUS TS AND 15 AM PS FOP I! 5 VOLT CIRC U IT S.

MINIMUM SWITCH RATING FOR TERMINALS [T] , [Tj ^20 VOLTS IS VOlT-AMPERES EACH.

REMOVE JUMPERS AS REQUIRED FOR AUXILIARY fNTERL<^KS.

MAXIMUM EXTERNAL CONTINUOUS LOADS TO BE CONNECTED BETWEEN TERMINALS [TIaND / 9 /, AND

TERMINALS AND ARE 2^ VOLT-AMPERES EACH- ‘

LOAD SWITCHES ARE SHOWN WITH I

£ND)TO OPERATE LOAD SWITCHES

I5CVA TRANSFORMER REQUIRED FOR DEVICES SHOWN ON CONTROL WIRING DIAGRAM. IF ADDITIONAL CONTROLS ARE

USED. THE TRANSFORMER SIZE MUST 8E INCREASED ACCORDINGLY.

FULLY UNLOADED, CAMSHAFT MOTOR RUNS CC W. (FROM POTENTIOMETER

1 IN SEQUENCE AS CHILLED WATER TEMPERATURE INCREASES,

o

----

^ ^^

ross-the-Line and Part Winding)

27

Page 29

INS

i^SOLENOlD UNLOaOER

COMPR, MOTOR

POWER TERMINAL

\ MOTOR TERMINALS i-2-3

TH'STAT 8-9

“7^

•^CRANKCASE

HEATER

TERMINAL 7 NOT USED

TEMPERATURE CONTROLLER

HI-LOW

IHI-LOW

\[U ZjE7

SWITCH

! SWITCH

CONTACTOR

NO.

CIRCUIT

BREAKER

N0,1

|!3|i2|l0j7i6[5iA|Aj4j2| l]

TERMINAL STRIP

OilTSOL CENTER

CIRCUIT

BREAKER

N02

CHILLED

WATER SAFETY

THERMOSTAT

CONTACTOR

N0.2

0 L

OL 0 L

2 3

LOCATION OF CONTROL COMPONENTS

TEMP CONTROL BULB

Fig. 36 - 30HH.HJ020, 025

28

Page 30

ALLATION

AUX. CONTACTS POR

CRANKCASE HEATERS

CONTROL CiRCUiT POWER LEADS

220 V. ONLY (SEE NOTE 2)

CONTACTOR

POWER WIRING

CIRCUIT BREAKERS

Carrier

FIELD POWER

SUPPLY (SEE NOTE 3)

VOLTSPHASE.

CYCLE.

CAM

SHAFT

BALANCING POT-

LiMiT SWITCHES

CAM OPERATED

LOAD SWITCHES

i^STEP CONTROLLER

TOP VIEW

7^ /

TRANS

FORMER

iBALANCING

RELAY

WHEN

ENERGIZED)

LEGEND

TERMINALS ON MAIN TERMINAL STRIP

□

TERMINALS ON STEP CONTROLL

о

TERM! NALSONTEMPERATURE CONTROLLER

A

ER / / TERMINALS ON PRESS,

TERMINALS ON PANEL

NOTES

1. ALL WIRING SHOWN IS FACTORY WIRING EXCEPT AS OUTLINED IN NOTE 2.

2. 208 VOLT a 230 UNITS HAVE 208/230 VOLT CONTROL CIRCUITS. ON THESE UNITS ONLY, LEADS ARE

SUPPLIED FROM NUMBER ! CONTACTOR TO TERMINALS 132 FOR THE PURPOSE OF ENERGIZING THE

CONTROL CIRCUIT. 460 8 575 VOLT UNITS HAVE 115 VOLT CONTROL CIRCUITS. AND A SEPARATE 115 VOLT

SOURCE MUST BE FIELD SUPPLIED THROUGH A FUSED DISCONNECT SWITCH TO TERMINALS 182.

3. FACTORY WIRING IS 1N ACCOR0ANCE WITH THE NATIONAL ELECTRICAL CODE. ANY FIELD MODIFICATIONS

OR ADDITIONS MUST BE IN COMPLIANCE WITH ALL APPLiCASLE COOES.

4. CONTROL CIRCUIT FUSES MUST ALWAYS REMAIN Ш THE CONTROL CIRCUIT. THE FUSES ARE 1/4" x I 1/4"

CERAMIC TUBE RATED AT 8 AMPS FOR 220 VOLT CIRCUITS AND 15 AMPS, FOR И5 VOLT CIRCUITS.

5. MINIMUM SWITCH RATING FOR TERMINALS .[J] . LI] 220 VOLTS IS 500 VOLT-AMPERES EACH.

REMOVE JUMPERS AS REQUIRED FOR AUXILIARY INTERLOCKS.

6. MAXIMUM external ^il^TINUOUS LOADS TO 8E CONNECTED BET WEEN TERMIN ALS FÄIaNO / 9 / AND

TERMINALS РГ1 AND iTl ARC VOLT-AMPERES EACH. ' ' ^

7 load switches are shown WITH UNIT FULLY UNLOAOCD.CAMSHAFT MOTOR RUNS C.C.W.{FROM POTENTIOMETER

ENOJTO OPERATE LOAD SWITCHES 1 THRU 4 IN SEQUENCE AS CHILLED WATER TEMPERATURE INCREASES,

8 25CVA TRANSFORMER REQUIRED FOR DEVICES SHOWN ON CONTROL WIRING DiAGRAM, IF ADDITIONAL CONTROLS

ARE USED, THE TRANSFORMER SIZE MUST BE INCRCASEO ACCORDINGLY.

-----

'

nd 030 Wiring Diagram (Across-the-Line)

Page 31

INSTALL

i

TRANSFORMER WIRED AS SHOWN

FOR 208 a 230 VOLT UNITS, DASHED LINES

INDICATE CONN. FOR 4B0 a 575 VOLT UNITS

SOLENOID UNLOADER

COMPR.MOTOR

POWER TERMINAL

MOTOR WINDING

HIGH TEMP CUTOUT

SOCKET^

'T

^7 V-' V

^9cV

TEMP CONTROL BULB

CONTROL WIRING

MOTOR TERMINALS i-2-3

TH'STAT 8-9

TERM INAL 7 NOT USED

-TEMPERATURE CONTROLLE R

HI-LOW Hi- LOW

B

R

1

W

\

m m

SWITCH SWITCH

CONTACTOR

NO

O.L.O.L.O.L. O.L.

9

CONTACTOR

NO.i

I 2 3

-Control center

[

---------! T D.R.!

1

CIRCUIT CIRCUIT

BREAKER

N01

|3|l2jl0|7|6|5|^i4|4|2|l|

TERMINAL STRIP

_____

BREAKER

N02

IN CHILLED WATER LINE

c.'i

^7 0 0^3

Tg,, ,T2

o‘a

ACROSS

THE LINE

CHILLED

WATER SAFETY

THERMOSTAT

1

i

CONTACTOR

N0,2

O.L.

O.L. O.L.

1 2

COMPR.MOTOR

POWER TERMINAL

(VIEW LOOKING IN)

3

TEMP CONTROL BULB

LOCATION OF CONTROL COMPONENTS

Fig. 37 - 30HH,HJ025 Wirin

Page 32

lTION 30HH,HJ

CONTROL CIRCUIT POWER LEADS

5 CONTROLLER

OP VIEW

LEGEND

I I TERMINALS ON MAIN TERMINAL STRIP

o TERMINALS ON STEP CONTROLLER

TERMINALS ON PANEL LIGHT

TERMINALS ON PRESS, SWITCH

A TERMINALS ON TEMPERATURE CONTROLLER

NOTES

ALL WIRING SHOWN IS FACTORY WIRING EXCEPT AS OUTLINED !N NOTE 2.

2. 208 VOLT a 230 UNITS HAVE 208/230 VOLT CONTROL

SUPPLIED FROM NUMBER SCONTACTOR TO TERMINALS i 82 FOR THE PURPOSE OF ENERGIZING THE

CONTROL CIRCUIT 460 8 575 VOlT UNITS HAVE M5 VOLT CONTROL CIRCUITS. AND A SEPARATE 115 VOLT

SOURCE MUST BE FIELD SUPPLIED THROUGH A FUSED DISCONNECT SWITCH TO TERMINALS 182.

3. FACTORY WIRING IS IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE. ANY FIELD MODIFICATIONS

OR ADDITIONS MUST BE IN COMPLIANCE WITH ALL APPLICABLE COOES.

4. CONTROL CIRCUIT FUSES MUST ALWAYS REMAIN IN THE CONTROL CIRCUIT. THE FUSES ARE l/4‘'xll/4‘'

CERAMIC TUBE RATED AT 8 AMRS. FOR 220 VOLT CIRCUITS AND 15 AMPS. FOR 115 VOLT CIRCUIT.

5. MINIMUM SWITCH RATING FOR TERMINALS [Tj, AND [71 AT 220 VOLTS IS ^ VOLT-AMPERES EACH.

REMOVE JUMPERS AS REQUIRED FOR AUXILIARY INTERLOCKS.

6. MAXIMUM EXTERNAL CONTINUOUS LOADS TO 8E CONNECTED BETWEEN TERMINALS FTIaND /s /.AND

TERMINALS Q AND Q ARE VOLT-AMPERES EACH. ‘----------------’ ^'

7 LOAD SWITCHES ARE SHOWN WITH UNIT FULLY UNLOADED,CAMSHAFT MOTOR RUNS C.C.W. ( FROM POTENTIOM ETER

ENDITO OPERATE LOAD SWITCHES 1 THRU 4 IN SEQUENCE AS CHILLED WATER TEMPERATURE INCREASES.

a 250VA TRANSFORMER REQUIRED FOR DEVICES SHOWN ON CONTROL WIRING DIAGRAM. IF ADDITIONAL CONTROLS

ARE USED, THE TRANSFORMER SIZE MUST BE INCREASED ACCORDINGLY.

CIRCUITS. ON THESE UNITS ONLY.

.EADS ARE

Jiagram (Part Winding)

29

Page 33

30HH,HJ

INSTi

-SOLENOID UNLOADER

COMPR. MOTOR

POWER TERMINAL

-CRAN KCASE

HEATER

MOTOR WINDING

HIGH TEMP CUTOUT

SOCKET^

TEMP CONTROL BULB

B

A

R

A

W

A

TEMPERATURE CONTROLLER

ÌH1-LOW

1 A7

ŒJ

ISWITCH SWITCH

NO!

CONTACTOR

N0.1

^CONTROL CENTER

CONTACTOR

LOCATION OF CONTROL COMPONENTS

ITITI

lELRI

CIRCUIT

BREAKER

3[l2[l0|2

TERMINAL

D.|D.|

N0.2

CHILLED

WATER SAFETY

THERMOSTAT

CONTACTOR

N0.2

CONTACTOR

N0.2

Fig. 38 - 30HH,HJ030

w

i

I! ,

“ I

// ‘-“•

CAN

SHA

------

30

Page 34

LLATION

Carrier

C

COiV/TROL CIRCUIT POWER LEADS

BALANCING POT-

LIMIT SWITCHES^

..

лосолте!

RECYCLE

RELAY

TOP VIEW

LU U

Xi-i

CAM' OPE RATED

LOAD SWITCHES

5^

^STEP CONTROLLER

TRANS

FORMER

BALANCING

RELAY

тф Ш

^SOLE NOID

UNLOADER

(UNLOADED

WHEN

ENERGIZED)

POWER WIRING

LEGEND

I I TERMINALS ON MAIN TERMINAL STRIP

TERMINALS ON STEP CONTROLLER

/\ TERMINALS ON TEMPERATURE CONTROLLER

TERMINALS ON PANEL LIGHT

О

TERMINALS ON PRESS. SWITCH

NOTES

1. ALLWIRING SHOWN IS FACTORY WIRING EXCEPT AS OUTLINED IN NOTE 2.

2. 208 VOLT a 230 UNITS HAVE 208/230 VOLT CONTROL CIRCUITS. ON THESE UNITS ONLY, LEADS ARE

SUPPLIED FROM NUMBER ICONTACTOR TO TERMINALS 182 FOR THE PURPOSE OF ENERGIZING THE

CONTROLCIRCUiT. 460 8 575 VOLT UNITS HAVE 115 VOLT CONTROL CIRCUITS, AND A SEPARATE 115 VOLT

SOURCE MUST BE FIELD SUPPLIED THROUGH AFUSED DISCONNECT SWITCH TO TERMINALS 182,

3. FACTORY WIRING IS IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE. ANY FIELD MODIFICATIONS

OR ADDITIONS MUST BE IN COMPLIANCE WITH ALL APPLICABLE CODES.

4 CONTROL CIRCUIT FUSES MUST ALWAYS REMAIN IN THE CONTROLCIRCUIT. THE FUSES ARE l/4"x li/4"

CERAMIC TUBE RATED AT 8 AMPS. FOR 220VOLT CIRCUIT AND 15AMPS, FOR 115 VOLT CIRCUITS.

5, MINIMUM SWITCH RATING FOR TERMINALS Щ AND AT 220 VOLTS IS 5QQ VOLT-AM PERES EACH.

REMOVE JUMPERS AS REQUIRED FOR AUXILIARY INTERLOCKS.

6 MAXIMUM EXTERNAL C^TINUOUS LOADS TO BECONNECTED BETWEEN TERMINALS AND /э/, AND

TERMINALS |~^ AND|5~[ ARE 250 VOLT-AMPERES EACH, ' ^

7. LOAD SWITCHES ARE SHOWN WITH UNIT FULLY UN LOADED. CAMSHAF T MOTOR RUNS C.C.W.(FROM POTENTIOMETER

END) TO OPERATE LOAD SWITCHES 1 THRU 1 IN SEQUENCE AS CHILLED WATER TEMPERATURE I NCR EASES

8. 250VA TRANSFORMER REQUIRED FOR DEVICES SHOWN ON CONTROL WIRING DIAGRAM. IFADDITIONAL CONTROLS

ARE USED. THE TRANSFORMER SIZE MUST BE INCREASED ACCORDINGLY.

-----

'

(

'¡ring Diagram (Part Winding)

Page 35

Carrier

INSTALL/

--------OVERLO/

RELAYS

_____

COMPR. MOTOR

POWER TERMiNAL-

'-'I

7 ^-»3

9 - r

8‘-

CONTROL CENTER-

NO. 2

COMPR.

CONTACTOR

1 1

!

L_

’

OVERLO

,D

RELAYS

'MOTOR TERMINALS 1-2-3

THERMOSTAT 8-9

'-2

TERM. 7 DUMMY

i 1

1

CONTROL WIRING

LIMIT SWITCHES

MOTOR

BALANCING POT~>.^

lililí!]

*7“!—1 ! f l-i-i lJ

CAM OPERATED

TEMP. CONTROL BULB

-----------

^

TRANS

FORMER

N0.3

COMPR,

CONTACTOR

LOCATION OF CONTROL COMPONENTS

Fig. 39 - 30HH,HJ045 Wiring Die

Page 36

ION

v-SQUiD

SOLENOID

tio г coMPR.

FIELD POWER CONN.-

NO, 1 NO. 2 N0.3

CIRCUIT BREAKERS

COiLS IN

COMPR.

MOTOR

CONTACTORS

POWER WIRING

LEGEND

[ [ TERMINALS ON MAIN TERMINAL STRIP

TERMINALS ON PANEL LIGHT

О

o TERMINALS ON STEP CONTROLLER

/\ TERMINALS ON TEMPERATURE CONTROLLER

NOTES

1. ALL WIRING SHOWN IS FACTORY WIRING EXCEPTAS OUTLINED IN NOTE 2,

2. 208 VOLT a 230 UNITS HAVE 208/230 VOLT CONTROL CIRCUITS, ON THESE UNITS ONLY, LEADS ARE

SUPPLIED FROM NUMBER 3 CONTACTOR TO TERMINALS 182 FOR THE PURPOSE OF ENERGIZING THE

CONTROL CIRCUIT, 4$0 a 57S VOLT UNITS HAVE И5 VOLT CONTROL CIRCUITS. AND A SEPARATE I15V0LT

SOURCE MUST 8£ FIELD SUPPLIED THROUGH A FUSED DISCONNECT SWITCH TO TERMINALS I a 2.

3. FACTORY WIRING IS IN ACCORDANCE WITH THE NATIONAL ELECTRCAL CODE. ANY FIELD MODIFICATIONS

OR ADDITIONS MUST 8E IN COMPLIANCE WITH ALL APPLICASLE CODES,

4 CONTROL CIRCUIT FUSES MUST ALWAYS REMAIN IN THE CONTROL CIRCUIT. THE FUSES ARE l/4"x I 1/4“

CERAMIC TUBE RATED AT 8 AMPS. FOR 220 VOLT CIRCUIT AND I5AMPS. FOR П5 VOLT CIRCUITS.

5. MINIMUM SWITCH RATING FOR TERMINALS [T] . fs1 AND 220 VOL*

EACH. REMOVE JUMPERS ASREOUIRED FOR AUXILLARY INTERLOCKS.

MAXIMUM EX TERNAL CONTINUOUS LOADS TO BE CONNECTED BETWEEN TERMINALS [T] AND [~s]

AND TERMINALsQ ANdQ ARE VOLT AMPERES EACH

LOAD SWITCHES ARE SHOWN WITH UNIT FULLY UNLOADED. CAMSHAFT MOTOR RUNS C.C.W.(FROM

POTENTIOMETER END) TO OPERATE LOAD SWITCHES ITHRU^ IN SEQUENCE AS CHILLED WATER

TEMPERATURE INCREASED

300 VA TRANSFORMER REQUIRED FOR DEVICES SHOWN ON CONTROL WIRING DIAGRAM. IF ADDITIONAL

CONTROLS ARE USED. THE TRANSFORMER SIZE MUST 8E INCREASED ACCORDINGLY.

rs IS VOLT-AM PERES

am (Across-the-Line)

31

Page 37

30HH,HJ

INS

32

Fig. 40 - 30HH055 and ЗОН

Page 38

ALLATION

CAM OPERATED

LOAD SWITCHES

STEP CONTROLLER

OVERLOAD RELAYS-

N0,4 COMP

О ^ —

T,

‘ YELLOW

%

^BLU^

1_ T j ■" 1

------

r~A

-------

lYELLOW :

iBLUE

CONTROL CIRCUIT POWER LEADS

Ф

---------

o-

1 BLACK

! ‘ /

YELLOW

220V. ONLY (SEE NOTE 2)

NO 4

L

—c

FIELD POWER

SU PPLY

LO PRESS

SWITCH

1__J

AUX. CONTACTS FOR

CRANKCASE HEATERS-

CONTACTORS

CIRCUIT BREAKERS

POWER WIRING

LEGEND

ni TERMINALS ON MAIN TERMINAL STRIP

O TERMINALS ON STEP CONTROLLER

/\ TERMINALS ON TEMPERATURE CONTROLLER

TERMINALS ON PANEL LIGHT

О

NOTES

1. ALL WIRING SHOWN IS FAC TOR Y W i R I N G E XC E P T AS OUT L I N ED IN NOTE 2.

2. 208 VOLT a 230 UNITS HAVE 208/230 VOLT CONTROL CIRCUITS. ON THESE UNITS ONLY, LEADS ARE

SUPPLIED FROM NUMBER 3 CONTACTOR TO TERMINALS 182 FOR THE PURPOSE OF ENERGIZING THE

CONTROL CIRCUIT. 460 8 575 VOLT UNITS HAVE !I5 VOLT CONTROL CIRCUITS, AND A SEPARATE 115 VOLT

SOURCE MUST BE FIELD SUPPLIED THROUGH A FUSED DISCONNECT SWITCH TO TERMINALS I 8 2.

3. FACTORY WIRING IS IN ACCORDANCE W IT H THE N AT Ю NAL ELE CT RICA L CODE A NY F lELD MOD i FI CATIONS

OR ADDITIONS MUST BE IN COMPLIANCE WITH ALL APPLICABLE CODES.

4. CONTROL CIRCUIT FUSES MUST ALWAYS REMAIN IN THE CONTROL CIRCUIT. THE FUSES ARE l/4"x 1 1/4"

CERAMIC TUBE RATED AT 8 AMPS. FOR 220V0LT CIRCUIT A N D 15 A MPS. FOR 11 5 VO LT C IRC U ITS.

5. MINIMUM SWITCH RATING FOR TERMINALS [~^ , fs~[ Д N D AT 220 VOLTS IS 500 VOLT-AMPERES

EACH. REMOVE JUMPERS AS REQUIRED FOR AUXi LLARY INTERLOCKS.

6. MAXIMUM EXTERNALCONTINUOUS LOADS TO BECONNECTED В ETWE E N TERM I N ALS A N D [T] ,

AND terminals!^ ANDARE 250 VOLT AMPERES EACH,

7 LOAD SWITCH ES ARE SHOWN WITH UNIT FULLY UNLOADED, CAMSHAFT MOTOR RUNS C.C.W. (FROM

POTENTIOMETER END) TO OPERATE LO A 0 SWITCHES i THR U 6 IN S EQUEN CE AS C H ILL E D WATER

TEMPERATURE INCREASES.

8. 375 VA TRANSFORMER REQUIRED FOR DEVICES SHOWN ON CONTROL WIRING DIAGRAM. IF ADDITIONAL

CONTROLS ARE USED. THE TRANSFORMER SIZE MUST BE INCREASED ACCORDINGLY.

9. SOLENOID UNLOADER (UNLOADED WHEN ENERGIZED) NO. I COMPRESSOR.

HJ065 Wiring Diagram (Across-the-Line)

Page 39

Carrier

30HH

IMSTALLATION 30HH,HJ

Table 11 - Electrical Data

3-PHASE, 60 CYCLE, ACROSS-THE-LINE (XL) START EXCEPT AS INDICATED BY (t)

TOTAL AMPS*

Lock

3QHJ

NO. OF

COMPR 30HH, F ull

SIZE

VOLTS

30 HJ

Load

edi 0 verioad

Rotor Trip

MAX

KW

015 Ì -6D73

015

020 2-6D68

020

025

1 -6D73

Ì — 6DÓS

025

030

2-6D73

Ì -6075

2-6D68

1 -6D7S

1 -6068

208

230

460

575

208 54.4

230 50.4

460 25.4 32.4 154 154

575 20.4

208 Í

2301 71.7

460

575

2081 98.6

2301 93.0

460 46.4 51,4

575

045

055

045

3-6D75

3-6D73

i — 6D68

208 147.9

230 139.5

460 69.6

575

208 175.1

230 164.7 669

460

575

208

230

065

3 PHASE, 50 CYCLE, ACROSS-THE-LINE (XL) START EXCEPT AS INDICATED BY (t)

015

015

020

020

025

025

030

030

045

045

055

-

065

065

*6D73, 6D75 single compressor ratings os shown for 30HH,HJ-

015. For 6D68 compressor full load, locked rotor and overload

trip amps divide 30HH,HJ020 Total Amp ratings by 2.

tPariiol winding (PW) or across-the-Ii ne (XL) start.

iLocked rotor amps indicate inrush result if all compressors

were started instantaneously across-the-I ine. Step controller

provides staggered starting.

4-ÓD7S

1 -6D73 2301 38.6

1 ™ 6D7S

2-6D66 230 42.8 54.4 256

2-6068

1 -6073

1 - 6D68

1 -6D75

1 -6D68

2-6D73 2301 77.2

2-6D75 400

3-6D73 230 115.8 128.7 429

3-6D75 400 69.6 77 1

3-6D73

1 -- 6D68

-

4-6D73 230

4-6075

460

575

400

400 25.4

2301

400

230 137.2

400

400

49.31

46.5

23.2

54.31

51.St 172

2S.7

191

86

18.6 20.7 69

67.2 340

65.0

26.0

306

124 124 28.4

76.5 87,9 361

84.0

325

35.9 41.9 163 197

28.8 33.7

131 158 40.2

108.6 382

Ì03.0

344

172

37.2 41.4

138

162.9 573

154.5 516

77.1 258

55.8 62,1

207

743 245,0

82.3

66.0

197.2

-

2! 7.2

335

269

764

186.0 206.0 688

92.8

■02.8

74.4

67.S

42.9 143

23.2 25.7

32.4

344

276 384

83 115

148

60,0 71.Ì 271

35.9 41.9 157 ÌS9

85.8 286

46.4 5L4

166

249

557

82.3

154.4

92.8 102,8 332

-

171,6

323

572

NOTE: Control Circuit Voltoge is 115 volts on 460 and 575 volt

units, ail others are 230 volts.

Overload trip amps vary because,of vendor ratings. Full

load amps vary because they ore colculated from over

load trip omp ratings.

266 69.0 /6,0

240

120

96 26.0

340 76.0

65.0 7 :.Q

32.5

7-,y

94 C

306 70.6 91.0

35.4

4,5.4

36.4

436 107.0

393

123.0

100.3 117.S

50,2 .58.7

47. '

532

480- 130.0

240

192

798

"m

360

138.0

152.0

144.C

65.0

72.0

52.0

57,8

207.0 22S.C

195.0

2'6.0

97.5

1C8.0

288 78.0 86.7

230.3

115.2

-

1064

92.2

276.0

-

104.7

960 260.0 ?se.o

480 130.0

200

256 60.0

148

22B

4C0

.230

600

345

....

-

800 216.0 240.0 53,2

460

144.0

• !5.f.

104.0

54.0

60.0

32.5

36,0

76.0

35,4

45.4

84.0

98.0

CO 7

50.2

108.0

1.0.0

65.0

72.0 31.6

162.0 130 0

97.5

108 (,

145.8

115.2

130.0

144.0 63-2

—

- -

IÓ.0

19.8

32.0

48.0

57.9

____

13.3

16.6 .

21.6

26.6

39.9

48,2

19.0

Od A

38.0

57 0

76.0

________

15.8

19.2

'^5 4

47.4

33

Page 40

30HH,HJ

INSTALLATION

Carrier

ELECTRICAL DATA

The 6D73 and 6D75 compressors (30HH,HJ -

015,025,030 models) for 220 volt, 50 cycle ap

plication are supplied with six lead, part wind

ing motors and extra starters to provide part

winding start. This is available for the same

60 cycle units on special order.

Time delay relays are required for part winding

starting.

Staggered starting of multiple compressors is

insured by the step controller camshaft drive

motor and recycle relay. Time delay relays

are not required.

Normal Network

Volts - 3 Phase

60 Cycle

208 208

230 220 to 240

460

575 550 to 600

Voltage

Application

Range

440 to 480

Voltage

Limits for

Satisfactory

Operation

187 to 229

198 to 264

396 to 528

495 to 660

CAPACITY CONTROLS

Step Controller - The step controller includes

a small, low voltage motor with clockwise and

counter-clockwise rotation windings that drive

a camshaft. The factory-set cams operate load

switches which start or stop compressors and

load or unload cylinders. The motor windings

of the camshaft drive motor are energized by

a balancing relay which contains windings in

the temperature bridge circuit between the

chilled water temperature controller and the

motor balancing potentiometer located at the

end of the camshaft. When the unit is loading

or unloading (counter-clockwise or clockwise

rotation of the camshaft drive motor), one chilled

water temperature corresponds to one position

of the camshaft. Camshaft rotation is limited in

each direction by limit switches.

The step controller also includes a recycle re

lay which insures that the camshaft is fully re

cycled to the unload position at startup or after

a power interruption. After the camshaft has

recycled to the unload position, the chilled water

temperature controller takes control and starts

camshaft rotation in the load direction which

starts the compressors in sequence, insuring

staggered compressor starting in every case.

W'hile the unit is operating, the factory cam set

tings on the step controller protect the compres

sors against rapid cycling.

The 30HH,HJ units are supplied with capacity

controls which cycle compressors and load and

unload cylinders of one compressor to give

capacity control steps shown in Table 12 below.

The capacity controls supplied with each unit

consists of a step controller, a solenoid-operated

cylinder unloading device (two unloaders on