Carpigiani 193 BAR USA-AV-G Installation Manual

INSTRUCTION HANDBOOK

193 BAR AV

193 BAR AV

We wish to thank you for the preference granted to us by purchasing one of

CARPIGIANI machines.

To the best guarantee, since 1993 CARPIGIANI has submitted its own Quality

System to the certifi cation according to the international Standard ISO 9001,

nowadays its production has got UNI-EN-ISO 9001:2008 Certifi ed Quality

System.

Moreover, CARPIGIANI machines comply with following European Directives:

- “Machinery” Directive 2006/42/EC,

- “Low Voltage” Directive 2006/95/EC,

- “EMC” Directive 2004/108/EC,

- “PED” Directive 97/23/EC,

- Regulation 2004/1935/EC relating to “Materials and articles in contact with foodstuffs”

CARPIGIANI

Via Emilia, 45 - 40011 Anzola dell'Emilia (Bologna) - Italy

Tel. +39 051 6505111 - Fax +39 051 732178

This manual contains a TRANSLATION OF THE ORIGINAL INSTRUCTIONS and may not

be reproduced, transmitted, transcribed, fi led in a data retrieval system or translated into other

languages, without the prior written permission of CARPIGIANI.

The purchaser has the wright to reprint it for his own offi ce use.

CARPIGIANI policy pursues a steady reasearch and development, thus it reserves the right to

make changes and revisions whenever deemed necessary and without being bound to previous

statements to the purchaser.

Edition: 03 Date: 2012/12

Editor: AM Verifi ed: IM Approved: RV

193 BAR AV_EN - 2012/12 - Ed. 03

Modifi cations:

- 2 -

GENERAL INDEX

SEC. FOREWORD

INSTRUCTION HANDBOOK .....................................................................................5

PURPOSE ......................................................................................................................5

HANDBOOK STRUCTURE ........................................................................................5

ADDITIONAL DOCUMENTATION ...........................................................................5

CONVENTIONAL SYMBOLS ....................................................................................6

SYMBOLOGY QUALIFICATION OF THE STAFF ...................................................6

SAFETY ........................................................................................................................7

W ARNINGS ..................................................................................................................7

SEC. 1 - GENERAL INFORMATION

1.1 GENERAL INFORMATION .....................................................................................9

1.1.1 MANUFACTURER IDENTIFICATION DATA ...............................................9

1.1.2 INFORMATION ON MAINTENANCE SERVICE ..........................................9

1.1.3 INFORMATION FOR USERS ..........................................................................9

1.2 INFORMATION ABOUT THE MACHINE .............................................................9

1.2.1 GENERAL INFORMATION .............................................................................9

1.2.2 MACHINE LAYOUT ........................................................................................10

1.2.3 TECHNICAL FEATURES ................................................................................10

1.2.4 MACHINE UNIT LOCATION .........................................................................11

1.3 INTENDED USE .........................................................................................................11

1.4 NOISE ...........................................................................................................................11

1.5 MACHINE STORAGE ...............................................................................................11

1.6 DISPOSAL OF PACKAGE MATERIALS ...............................................................11

1.7 WEEE (Waste Electrical and Electronic Equipment) .............................................11

193 BAR AV

SEC. 2 - INSTALLATION

2.1 ROOM NECESSARY FOR MACHINE USE ..........................................................13

2.2 MACHINE WITH AIR-COOLED CONDENSER ..................................................13

2.2.1 AIR FLOW .........................................................................................................13

2.3 MACHINES WITH WA TER-COOLED CONDENSER .........................................14

2.3.1 WATER VALVE ADJUSTMENT ......................................................................14

2.4 ELECTRIC CONNECTION ......................................................................................14

2.4.1 REPLACING THE POWER CABLE ................................................................14

2.5 TOP-UPS ......................................................................................................................14

2.6 MACHINE TESTING .................................................................................................14

SEC. 3 - INSTRUCTIONS FOR USE

3.1 MACHINE CONFIGURATION ................................................................................15

3.2 ELECTRONIC CONTROL KEYBOARD AND BUTTON FUNCTIONS ...........16

3.3 SPIGOT HANDLE ......................................................................................................18

3.4 PUMP FEED MACHINE - “R” PUMP .....................................................................19

3.5 GRAVITY FED MACHINE - FEEDING NEEDLE ................................................19

3.6 PRELIMINARY OPERATIONS, WASHING AND SANITISING ........................20

3.7 STARTING THE MACHINE .....................................................................................20

3.7.1 STARTING PUMP-FED MACHINES ..............................................................20

3.7.2 STARTING GRAVITY-FED MACHINES ........................................................20

3.8 PRODUCTION ............................................................................................................21

3.9 ALARMS ......................................................................................................................22

3.9.1 BLACKOUT ......................................................................................................23

3.10 USER PROGRAMMING ...........................................................................................24

- 3 -

193 BAR AV_EN - 2012/12 - Ed. 03

193 BAR AV

SEC. 4 - SAFETY DEVICES

4.1 MACHINE SAFETY DEVICES ................................................................................25

SEC.5 - CLEANING, DISASSEMBLY AND REASSEMBLY OF

PARTS IN CONTACT WITH THE PRODUCT

5.1 GENERAL INFORMATION .....................................................................................27

5.2 WASHING CONDITIONS .........................................................................................27

5.3 TIPS ..............................................................................................................................27

5.4 HOW TO USE CLEANING/SANITISING SOLUTION ........................................28

5.5 PROGRAMMED CLEANING TIME .......................................................................28

5.6 DRAINING AND CLEANING...................................................................................28

5.7 PUMP-FED MACHINES - DISASSEMBLING PUMP AND COMPRESSION

PIPE ..............................................................................................................................29

5.8 GRAVITY-FED MACHINES - DISASSEMBLING FEEDING NEEDLE ...........29

5.9 DISASSEMBLING HOPPER BEATER ...................................................................29

5.10 DISASSEMBLING FRONT LID ...............................................................................30

5.11 PUMP-FED MACHINES - DISASSEMBLING BEATER .....................................34

5.12 GRAVITY-FED MACHINES - DISASSEMBLING BEATER ...............................31

5.13 WASHING AND SANITISING COMPONENTS ....................................................31

5.14 REASSEMBLING THE HOPPER BEATER ...........................................................30

5.15 PUMP-FED MACHINES - REASSEMBLING THE PUMP AND COMPRESSION

PIPE ..............................................................................................................................32

5.16 GRAVITY-FED MACHINES - REASSEMBLING FEEDING NEEDLE .............32

5.17 PUMP-FED MACHINES - REASSEMBLING THE BEATER .............................33

5.18 GRAVITY-FED MACHINES - REASSEMBLING THE BEATER .......................33

5.19 REASSEMBLING THE FRONT LID .......................................................................33

5.20 SANITISING THE WHOLE MACHINE ................................................................34

5.21 PRIMING THE MIX PUMP ......................................................................................34

SEC. 6 - MAINTENANCE

6.1 SERVICE TYPE ..........................................................................................................35

6.2 WATER COOLING ....................................................................................................36

6.3 AIR COOLING............................................................................................................36

6.4 ORDERING SPARE PARTS ......................................................................................37

SEC. 7 - TROUBLESHOOTING GUIDE

7.1 TROUBLESHOOTING GUIDE ................................................................................39

193 BAR AV_EN - 2012/12 - Ed. 03

- 4 -

FOREWORD

INSTRUCTION HANDBOOK

This handbook takes into due account European Community directives for the harmonisation of

safety standards and for the free circulation of industrial products within the E.C.

PURPOSE

This handbook was conceived taking machine users' needs into due account.

Topics relevant to a correct use of the machine have been analysed in order to keep unchanged

in the long run the quality features characterising CARPIGIANI machines all over the world.

A signifi cant part of this handbook refers to the conditions necessary for machine use, during

cleaning operations and ordinary and extraordinary maintenance.

Nevertheless, this handbook cannot meet all demands in detail. In case of doubts or missing

information, please contact:

CARPIGIANI Via Emilia, 45 - 4001 1 Anzola dell'Emilia (Bologna) - Italy

Tel. +39 051 6505111 - Fax +39 051 732178

HANDBOOK STRUCTURE

This handbook is divided in sections, chapters and subchapters in order to be consulted more easily.

193 BAR AV

Section

A section is the part of the handbook identifying a specifi c topic related to a machine part.

Chapter

A chapter is that part of a section describing an assembly or concept relevant to a machine part.

Sub-chapter

It is that part of a chapter detailing the specifi c component of a machine part.

Each person involved in the machine operation must read and clearly understand those parts of

the handbook of his/her own concern, and particularly:

• The Operator must read the chapters concerning machine start-up and operation of machine

components;

• A skilled technician involved in the installation, maintenance, repair, etc., of the machine must

read all parts of this handbook.

ADDITIONAL DOCUMENTATION

Along with an instruction manual, each machine is supplied also with additional documentation:

• Supplied spare parts: a list of spare parts which is delivered together with the machine for

its maintenance.

• Wiring diagram: a diagram of wiring connections is placed in the machine.

Before operating on the machine, read the instruction manual carefully.

Read the safety instructions.

- 5 -

193 BAR AV_EN - 2012/12 - Ed. 03

193 BAR AV

CONVENTIONAL SYMBOLS

WARNING: ELECTRIC SHOCK DANGER

The staff involved is warned that the non-observance of safety rules in carrying out the operation

described may cause an electric shock.

WARNING: DANGER FROM HIGH TEMPERATURES

This warns the staff involved that failure to abide by safety rules in carrying out the operation

described involves the risk of burns and scalds.

WARNING: MOVING PARTS HAZARD

This points out to the staff concerned that there are moving parts and there is a risk of suffering

physical injury in the event of failure to abide by safety regulations.

WARNING: CRUSHING HAZARD

This warns the staff involved that failure to abide by safety rules in carrying out the operation

described involves the risk of suffering crushed fi ngers or hands.

WARNING: GENERAL HAZARD

The staff involved is warned that the operation described may cause injury if not performed

following safety rules.

NOTE

It points out signifi cant information for the staff involved.

WARNINGS

The staff involved is warned that the non-observance of warning may cause loss of data and

damage to the machine.

PERSONAL PROTECTIONS

This symbol on the side means that the operator must use personal protections against an implicit

risk of accident.

SYMBOLOGY QUALIFICATION OF THE STAFF

The staff allowed to operate the machine can be differentiated by the level of preparation and

responsibility in:

MACHINE OPERATOR

Unqualifi ed personnel, without any specifi c technical abilities, capable of carrying out simple

jobs, such as: operating the machine using the commands available on the keypad, the loading

and unloading of products used during production, the loading of any consumable materials, basic

maintenance operations, (cleaning, simple blockages, inspections of the instrumentation, etc.).

QUALIFIED ENGINEER

He/she is a skilled engineer for the installation and operation of the machine under normal

conditions; he/she is able to carry out interventions on mechanical parts and all adjustments, as

well as maintenance and repairs. He/she is qualifi ed for interventions on electrical and refrigeration

components.

CARPIGIANI ENGINEER

He/she is a skilled engineer assigned by the manufacturer to interventions for complex jobs under

particular conditions or in accordance with agreements made with the machine's owner.

193 BAR AV_EN - 2012/12 - Ed. 03

- 6 -

SAFETY

When using the machine, one must be aware of the fact that drive mechanisms (rotary motion),

high voltage components, as well as parts subject to high temperatures may cause serious damage

to persons and things.

Persons in charge of plant safety must make sure that:

• any incorrect use or handling is avoided;

safety devices are not removed or tampered with;

•

• the machine is regularly serviced;

• only original spare parts are used especially as far as those components with safety functions

are concerned (ex.: protection microswitches, thermostats);

suitable personal protective equipment is worn;

•

•

attention is paid during hot product cycling.

To achieve the above, the following is necessary:

• at the work station an instruction manual relevant to the machine should be available;

• such documentation must be carefully read and requirements must consequently be met;

only adequately skilled personnel should be assigned to electrical equipment.

•

WARNING!

Make sure that the staff does not carry out any operation outside their own sphere of knowledge

and responsibility (refer to “Symbology qualifi cation of the staff”).

193 BAR AV

NOTE:

According to the standard in force, a QUALIFIED ENGINEER is a person who, thanks to:

- training, experience and education,

- knowledge of rules, prescriptions and interventions on accident prevention,

- knowledge of machine operating conditions,

is able to recognise and avoid any danger and who has also been allowed by the person in

charge of plant safety to carry out all kinds of interventions.

WARNINGS

When installing the machine, insert a differential magnetothermal protection switch on all poles

of the line, adequately sized to the absorption power shown on machine identifi cation plate and

with contact opening of 3 mm at least.

• Never put your hand into the machine during production and cleaning operations. Before

carrying out any maintenance operation, make sure that the machine is in “STOP” position

and main switch has been cut out.

• It is forbidden to wash the machine by means of a jet of pressurised water.

• It is forbidden to remove panels in order to reach the machine internal parts before disconnecting

the machine from the power supply.

• CARPIGIANI is not responsible for any accident that might happen during operation, cleaning

and/or servicing of its units, if the safety guidelines provided has not been fully complied

with..

- 7 -

193 BAR AV_EN - 2012/12 - Ed. 03

193 BAR AV

193 BAR AV_EN - 2012/12 - Ed. 03

- 8 -

1. GENERAL INFORMATION

1.1 GENERAL INFORMATION

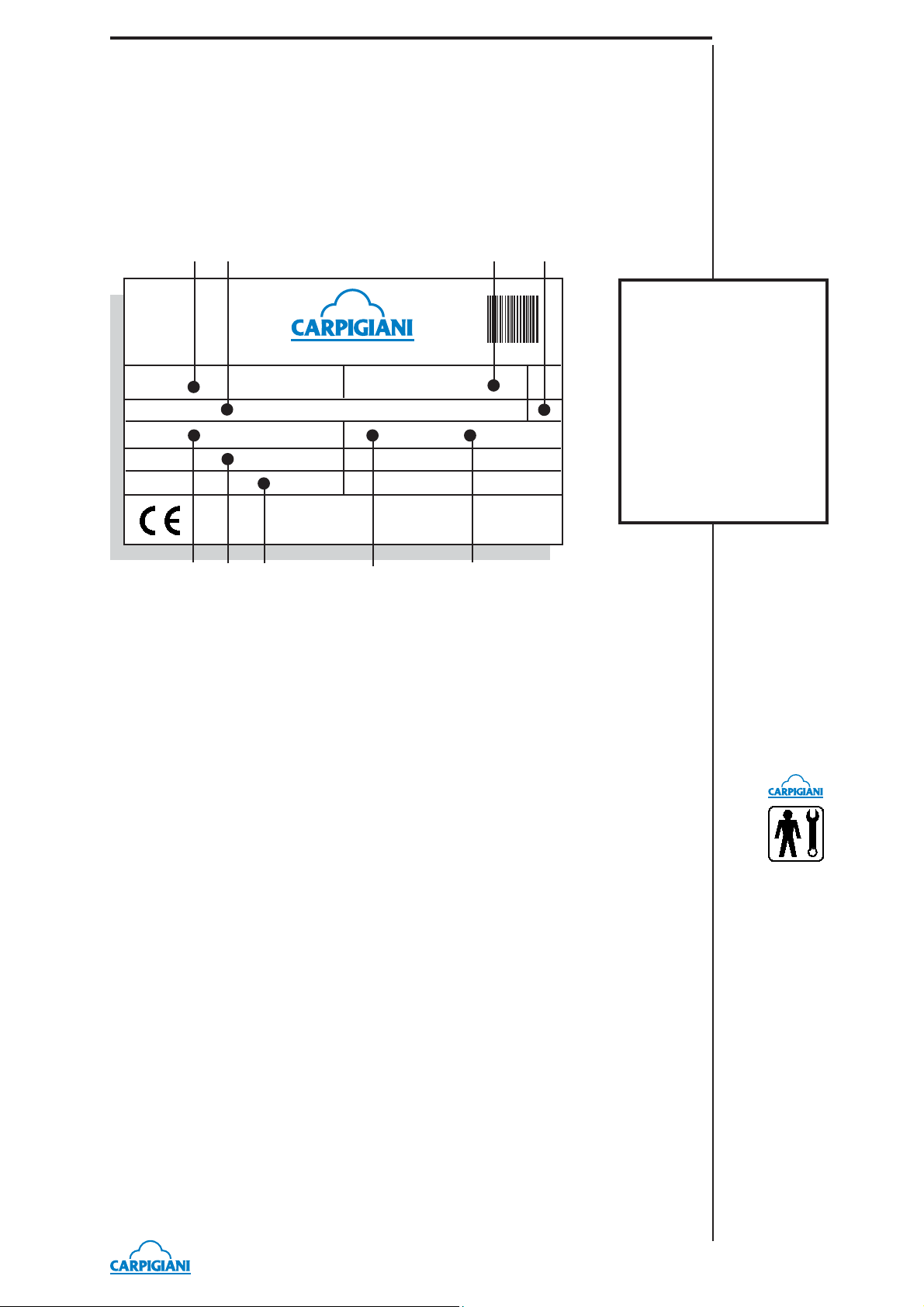

1.1.1 Manufacturer identifi cation data

The machine has an identifi cation plate carrying manufacturer data, machine type and serial

number assigned when it is manufactured.

A copy of the machine identifi cation plate is found on fi rst page of this handbook.

AB F G

KEY:

193 BAR AV

100089654588-4

Matr.

ANZOLA EMILIA - BOLOGNA - ITALY

Cod.

V Hz kW

A

Gas kg

CDE H

I

A= Serial number

B= Machine type

C= Supply voltage

D= Main switch

amperometric value

E= Gas type and weight

F= Machine code

G= Condensation

H= Frequency

I= Power

1.1.2 Information on maintenance service

All ordinary maintenance operations are described in section "Maintenance" of this manual; any

additional operation requiring technical intervention on the machine must be agreed upon with

the manufacturer, who will also examine the possibility of sending one of its own engineers for

the intervention.

1.1.3 Information for users

• The machine manufacturer can be contacted for any explanation and information about the

machine operation or any modifications aimed at improving the machine's efficiency.

• In case of need, please call the local distributor, or the manufacturer if no distributor is available.

• The manufacturer’s service department is available for any information about operation, and

requests of spare parts and service.

1.2 INFORMATION ABOUT THE MACHINE

1.2.1 General information

Counter-top machine to immediately produce and distribute soft express ice cream in two fl avours

+ mixed, available with pump to ensure a higher overrun.

CARPIGIANI recommends to always use high quality mix for ice cream production in order

to please even the most demanding customers. Any saving made to the detriment of quality will

surely turn into a much bigger loss than the saving itself.

- 9 -

193 BAR AV_EN - 2012/12 - Ed. 03

193 BAR AV

Bearing in mind the above statements, please take into consideration the following suggestions:

- Make your mixes yourselves from high quality natural ingredients or buy them from reliable

companies.

- Follow closely instructions given by your mix supplier for the preparation of the mixes.

- Do not alter your supplier’s recipes, by adding, for instance, more water or sugar than recommended.

- Taste ice cream before serving it and start selling only if entirely satisfactory.

- Make sure your staff always keeps the machine clean.

- Have your machine serviced always by companies authorised by CARPIGIANI.

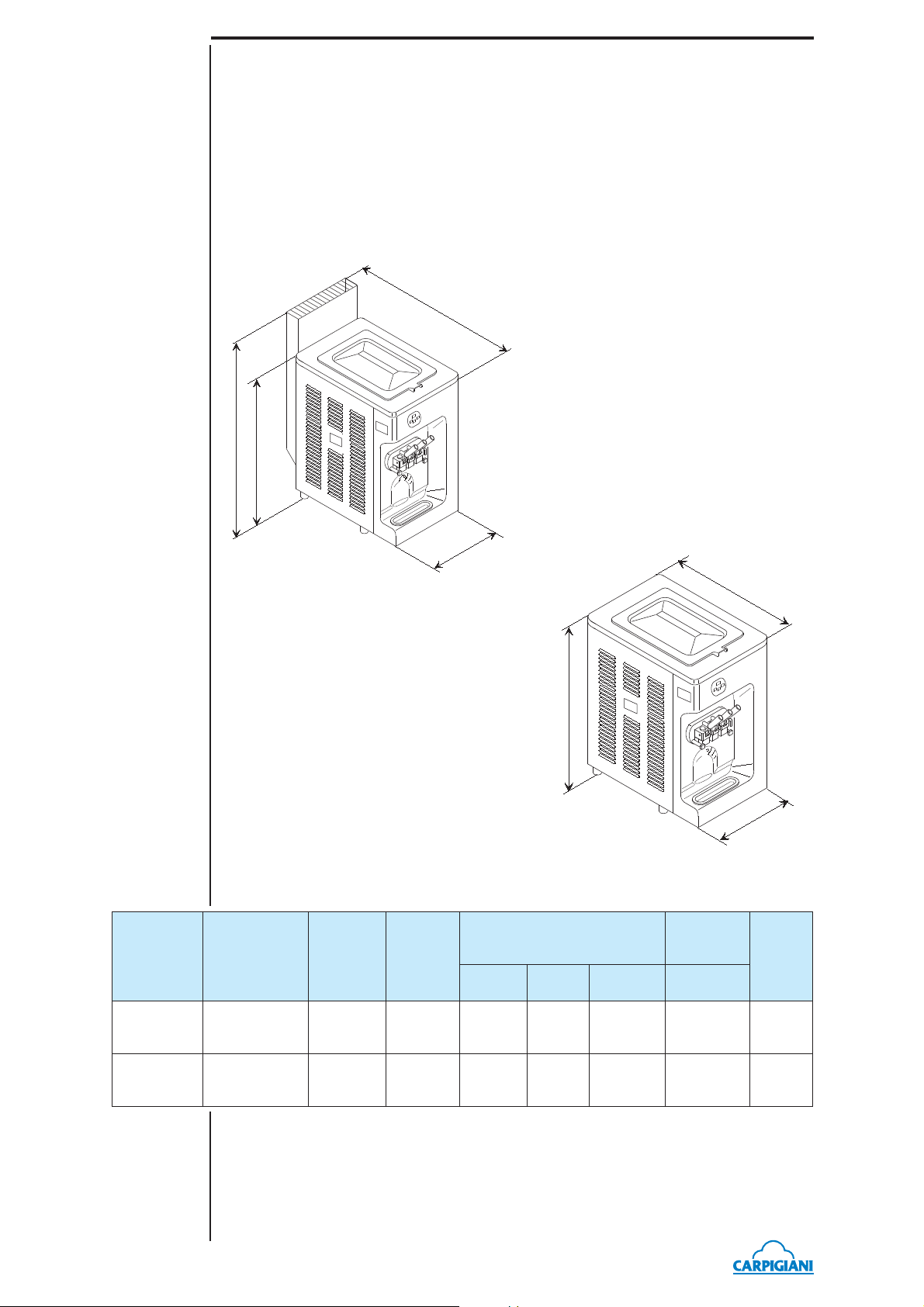

1.2.2 Machine layout

880

890

800

MODEL

Air-cooled unit

1.2.3 Technical features

Hopper

Hourly

production *

capacity

liters

Flavors

550

800

Water-cooled unit

Electrical supply **

Volt Ph. Cycles kW

Installed

power

880

550

Net

weight

kg

193 G/AV 30 Kg 18 + 18

193 P/AV 35 Kg 12 + 12

* The hourly production and the mix quantity for each ice cream can vary, according to the temperature and the type

of mix used and the increase in volume (overrun) desired.

** Other power supplies are available.

193 BAR AV_EN - 2012/12 - Ed. 03

2 +

mixed

2 +

mixed

400 3 50 4.24 190

400 3 50 4.75 212

- 10 -

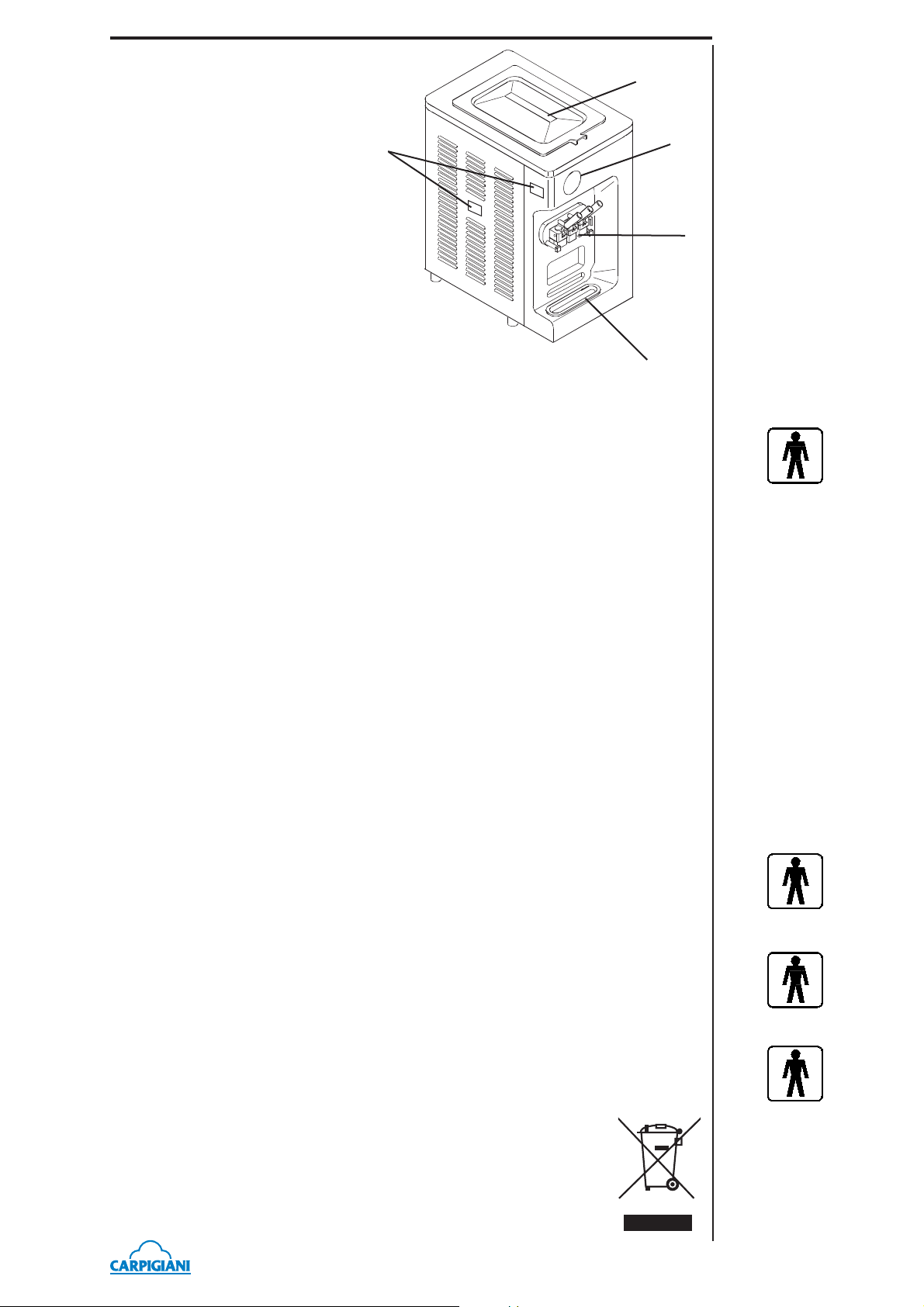

1.2.4 Machine unit location

4

Key:

1. Control panel

2. Freezing cylinder front lid

3. Shelf

4. Mix hopper cover

5. Drip drawers

5

1

2

3

1.3 INTENDED USE

The machine must be used solely for the purpose described in chapter 1.2.1, “General information”

within the functional limits decribed below.

193 BAR AV

Voltage ±10%

Min air temperature 10°C

Max air temperature 43°C

Min water temperature 10°C

Max water temperature 30°C

Min. water pressure 0.1 MPa (1 bar)

Max water pressure 0.8 MPa (8 bar)

Max relative humidity 85%

The machine must not be used for any purpose other than the one it has been originally designed for.

1.4 NOISE

The equivalent continuous A-weighted sound pressure level in a workplace for water-cooled as

well as air-cooled machines is less than 70 dB(A).

1.5 MACHINE STORAGE

The machine must be stored in a dry and damp-free place.

Before storing the machine, wrap it in a cloth in order to protect it against dust and other substances.

1.6 DISPOSAL OF PACKAGE MATERIALS

When opening the crate, divide packaging materials by type and dispose of them according to

laws in force in machine installation country.

1.7 WEEE (Waste Electrical and Electronic Equipment)

In conformity with the European Directives 2006/66/EC, on batteries and accumulators and waste

batteries and accumulators, and 2002/96/EC, also known as WEEE, the presence of the symbol

on the side of the product or packaging means that the product must not be disposed of with

normal urban waste. Instead, it is the user’s responsibility to dispose of this product by returning

it to a collection point designated for the recycling of electrical and electronic

equipment waste. Separate collection of this waste helps to optimise the recovery

and recycling of any reclaimable materials and also reduces the impact on human

health and the environment.

For more information concerning the correct disposal of this product, please contact

your local authority or the retailer where this product was purchased.

- 11 -

193 BAR AV_EN - 2012/12 - Ed. 03

193 BAR AV

193 BAR AV_EN - 2012/12 - Ed. 03

- 12 -

Loading...

Loading...