Carnes HBAE Installation Manual

ELECTRONICALLY CONTROLLED STEAM HUMIDIFIER

DESIGN SERIES “E”

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

CARNES COMPANY,

448 S. Main St.,

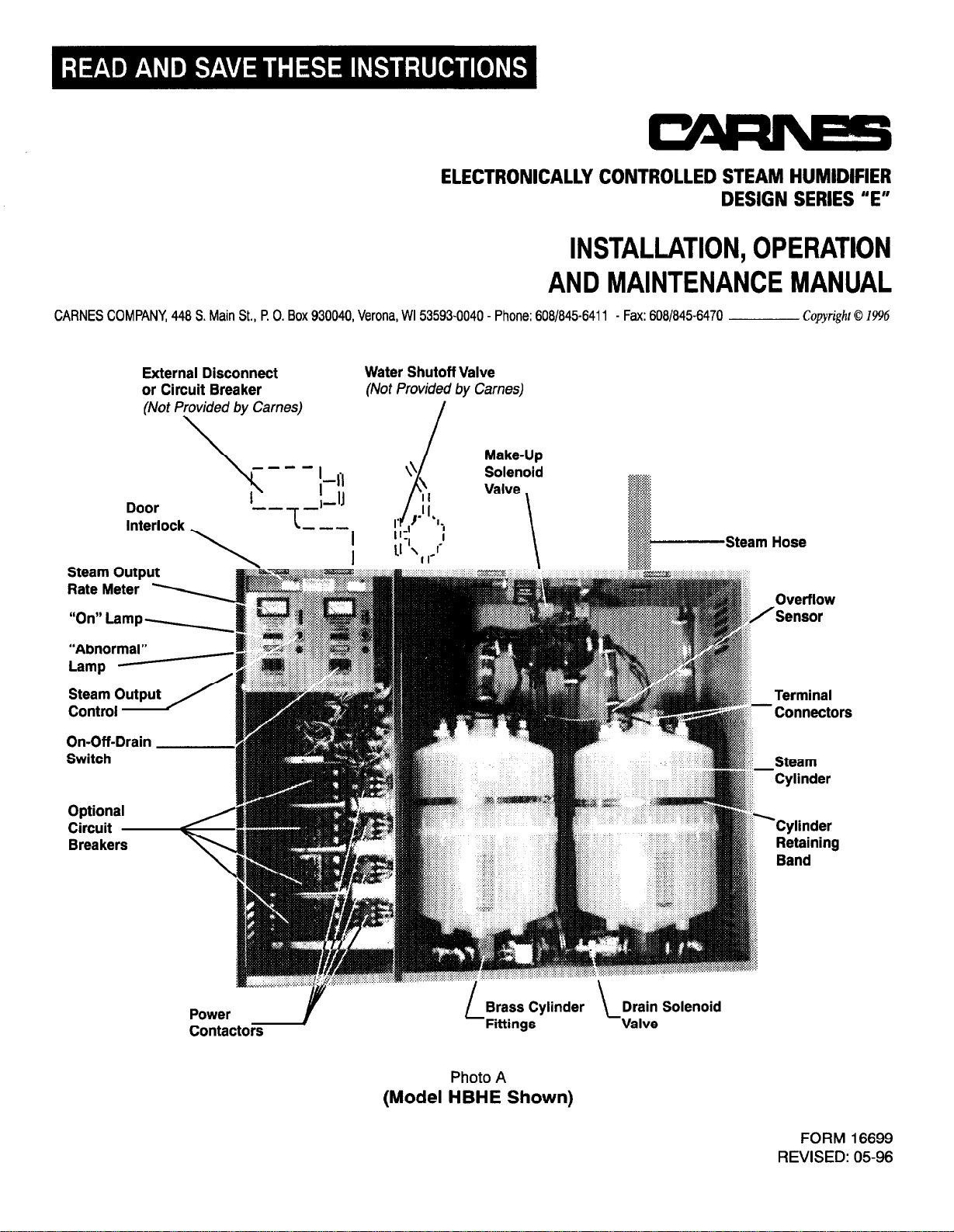

External Disconnect

or Circuit Breaker

(Not Provided by Carnes)

P. 0. Box 930040, Verona,

\

WI 53593-0040 - Phone:

Water Shutoff Valve

(Not Provided by Carnes)

I

608/845-6411 -

Fax: 608/845-6470

Copyrighl 0 1996

Overflow

‘Sensor

Terminal

‘Connectors

-Steam

Cylinder

Power

Contactors

LBrass Cylinder

Fittings

Photo A

(Model HBHE

-Cylinder

Retaining

Band

LDrain Solenoid

Valve

Shown)

FORM 16699

REVISED: 05-96

UNPACKING AND INSPECTION

1. An envelope attached to the outside of the cabinet

contains one cabinet key.

2. Open the cabinet and check for concealed shipping

damage. Report any damage immediately to the

carrier who delivered the shipment.

3. The following components are packed in a shipping

carton for connection when installing humidifier.

A. Distribution pipe.

6. Steam hose.

C. Condensate return line.

4. Optional accessories may be packed with the cabinet

or in the same shipping carton. Large accessories

may ship in separate cartons.

5. Inside the cabinet is an envelope containing the

following items:

A. Steam hose clamps.

B. Condensate return line clamps.

C. Air gap drain fitting.

D. Installation instructions.

MOUNTING THE HUMIDIFIER

Mount the humidifier cabinet securely on a level and plumb

surface near the ductwork. Allow 6” or more on each side

for proper ventilation and minimum of 16”from the bottom of

the cabinet to the floor to allow space for the drain connection. The humidifier must never be mounted outside or

where it may be exposed to freezing temperatures.

Maximum operating weights for the humidifier are shown

below.

WATER SUPPLY CONNECTION

Use ordinary tap water (20 to 120 psi) - DO NOT use hot

water, deionized water, or water that has been treated

by a water softener without consulting the factory. A

3/8” FPT fitting is provided at the top of the humidifier for

connection to tap water supply. A shutoff valve, not provided by Carnes, must be installed just ahead of this fitting.

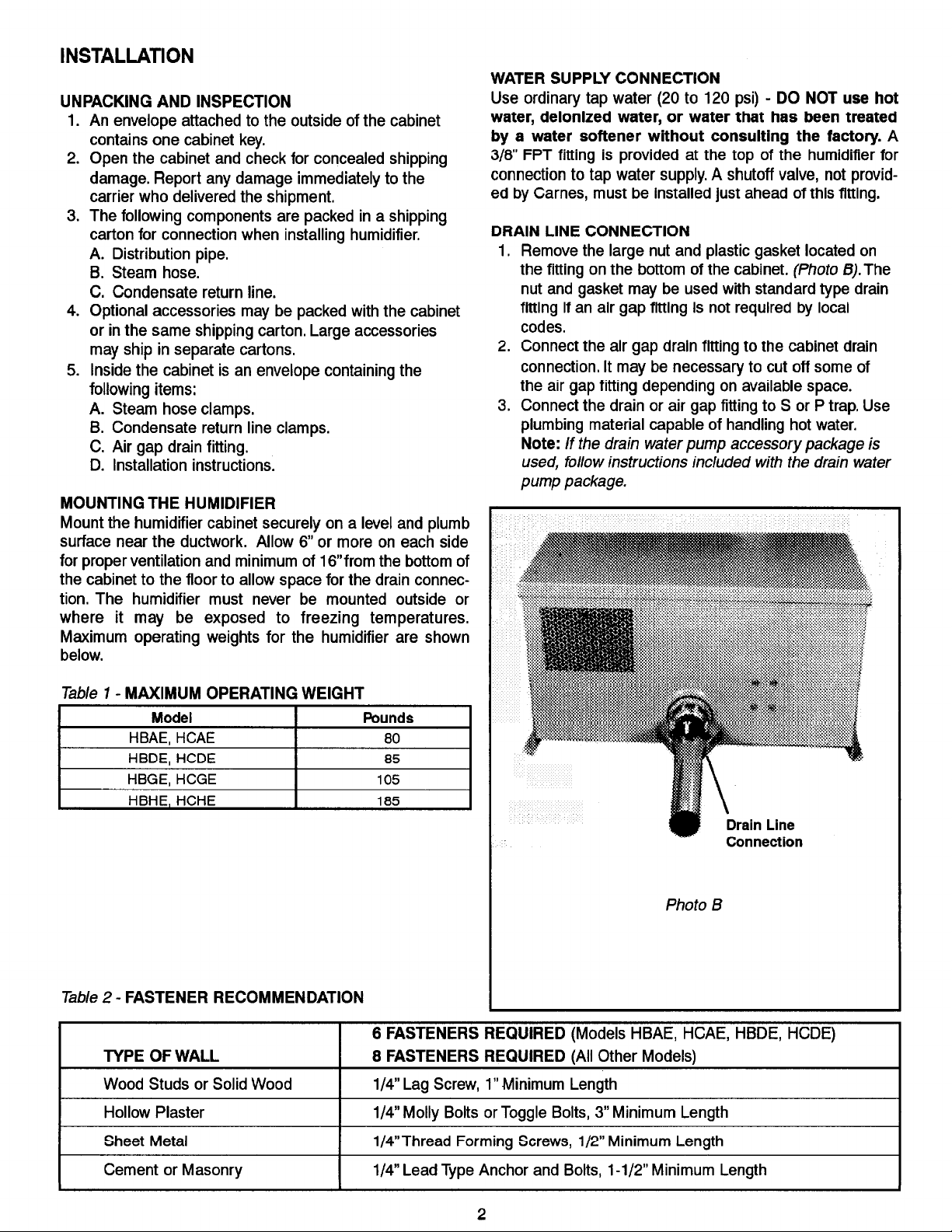

DRAIN LINE CONNECTION

I. Remove the large nut and plastic gasket located on

the fitting on the bottom of the cabinet. (phofo B).The

nut and gasket may be used with standard type drain

fiiing if an air

gap

fitting is not required by local

codes.

2. Connect the air gap drain fitting to the cabinet drain

connection. It may be necessary to cut off some of

the air gap fitting depending on available space.

3. Connect the drain or air gap fitting to S or P trap. Use

plumbing material capable of handling hot water.

Note: If the

used, follow instructions included with the drain water

pump

drain wafer pump accessory package is

package.

Table 7 - MAXIMUM OPERATING WEIGHT

Model

HBAE.

I

Tab/e

HBDE, HCDE

HBGE, HCGE

HBHE, HCHE 185

2 - FASTENER RECOMMENDATION

HCAE

I

I

I

TYPE OF WALL

Wood Studs or Solid Wood

Hollow Plaster

Sheet Metal

Pounds

80

a5

105

I

\

Drain Line

Connection

Photo B

6 FASTENERS REQUIRED (Models HBAE, HCAE, HBDE, HCDE)

6 FASTENERS REQUIRED (All Other Models)

l/4” Lag Screw, 1” Minimum Length

l/4” Molly Bolts or Toggle Bolts, 3” Minimum Length

1/4”Thread Forming Screws, l/2” Minimum Length

Cement or Masonry

l/4” Lead Type Anchor and Bolts, 1 -l/2” Minimum Length

2

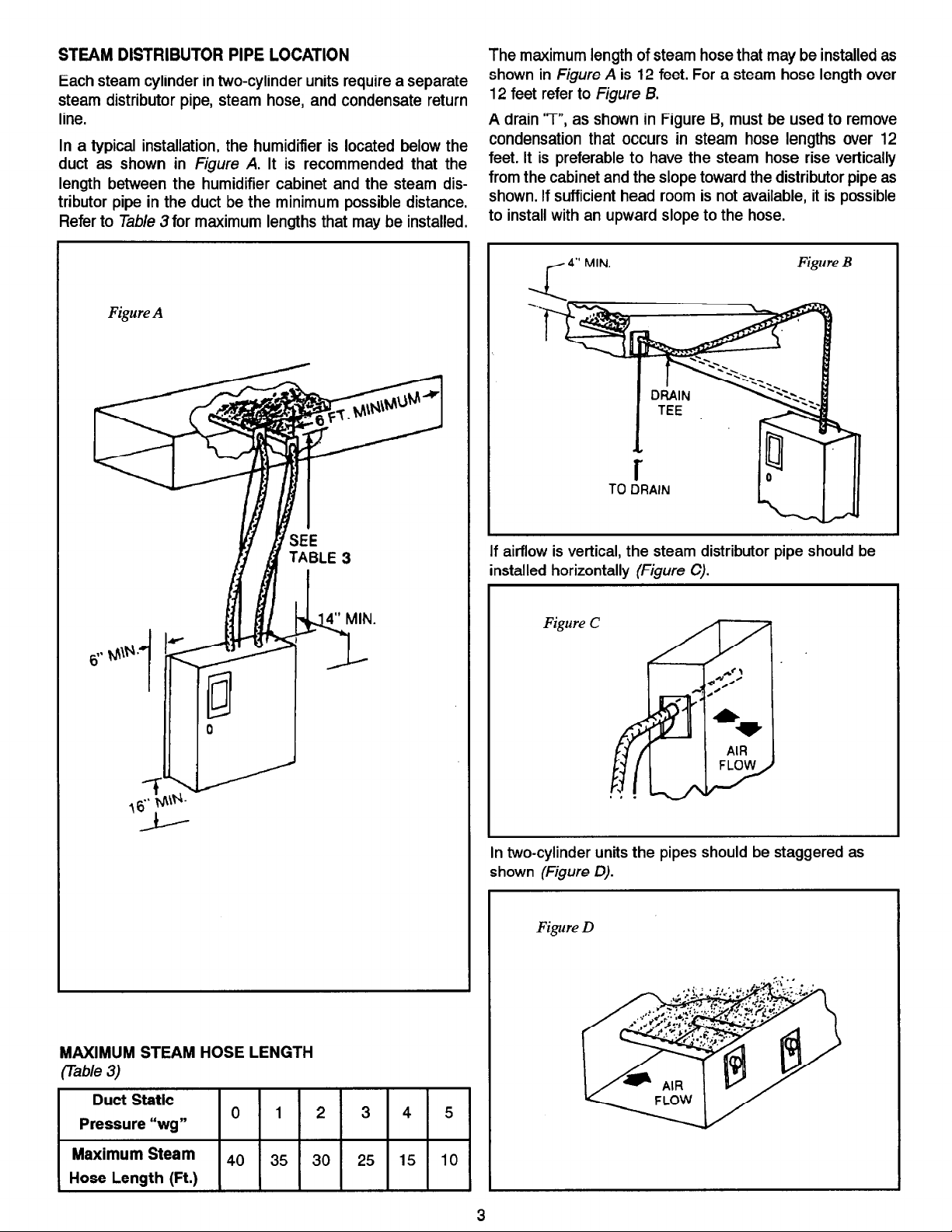

STEAM DISTRIBUTOR PIPE LOCATION

Each steam cylinder in two-cylinder units require a separate

steam distributor pipe, steam hose, and condensate return

line.

In a typical installation, the humidifier is located below the

duct as shown in Figure

length between the humidifier cabinet and the steam dis-

tributor pipe in the duct be the minimum possible distance.

Refer to Table 3for maximum lengths that may be installed.

A.

It is recommended that the

The maximum length of steam hose that may be installed as

shown in Figure A is 12 feet. For a steam hose length over

12 feet refer to Figure 8.

A drain “T”, as shown in Figure B, must be used to remove

condensation that occurs in steam hose lengths over 12

feet. It is preferable to have the steam hose rise vertically

from the cabinet and the slope toward the distributor pipe as

shown. If sufficient head room is not available, it is possible

to install with an upward slope to the hose.

Figure A

4” MIN.

Figure B

r

TO

DRAIN

If airflow is vertical, the steam distributor pipe should be

installed horizontally

Figure

c

(Figure

C).

MAXIMUM STEAM HOSE LENGTH

(Table 3)

Duct Static

Pressure “wg”

Maximum Steam

Hose Length (Ft.)

0 1 2 3 4 5

4. 35 30 25 15 10

In two-cylinder units the pipes should be staggered as

shown

3

(Figure 0).

Figure D

STEAM DISTRIBUTOR PIPE LOCATION (Continued)

Steam distributor pipes must be located on a plumb surface.

This is required so the condensate which forms in the distributor pipe will drain to the return line and back to the unit.

Steam distributor pipes should be mounted in the duct to

insure even distribution of steam across the center portion

of the duct.The condensate return line must always be kept

on the bottom. A minimum clearance of 4” must be maintained between top of the duct and distributor pipe.

The steam distributor pipe should be located in the supply

air stream, downstream of the fan. When installed in pack-

aged units (central station air handlers, multizone units,

make-up air units, etc.) the distributor pipe should be

mounted just downstream of the fan discharge in the pri-

mary air stream.

In multizone applications it is preferable to have a separate

humidifier serving each zone. However, steam can be introduced into the hot deck upstream of the zone dampers. In

this case, good distribution of steam across the entire hot

deck is very important.

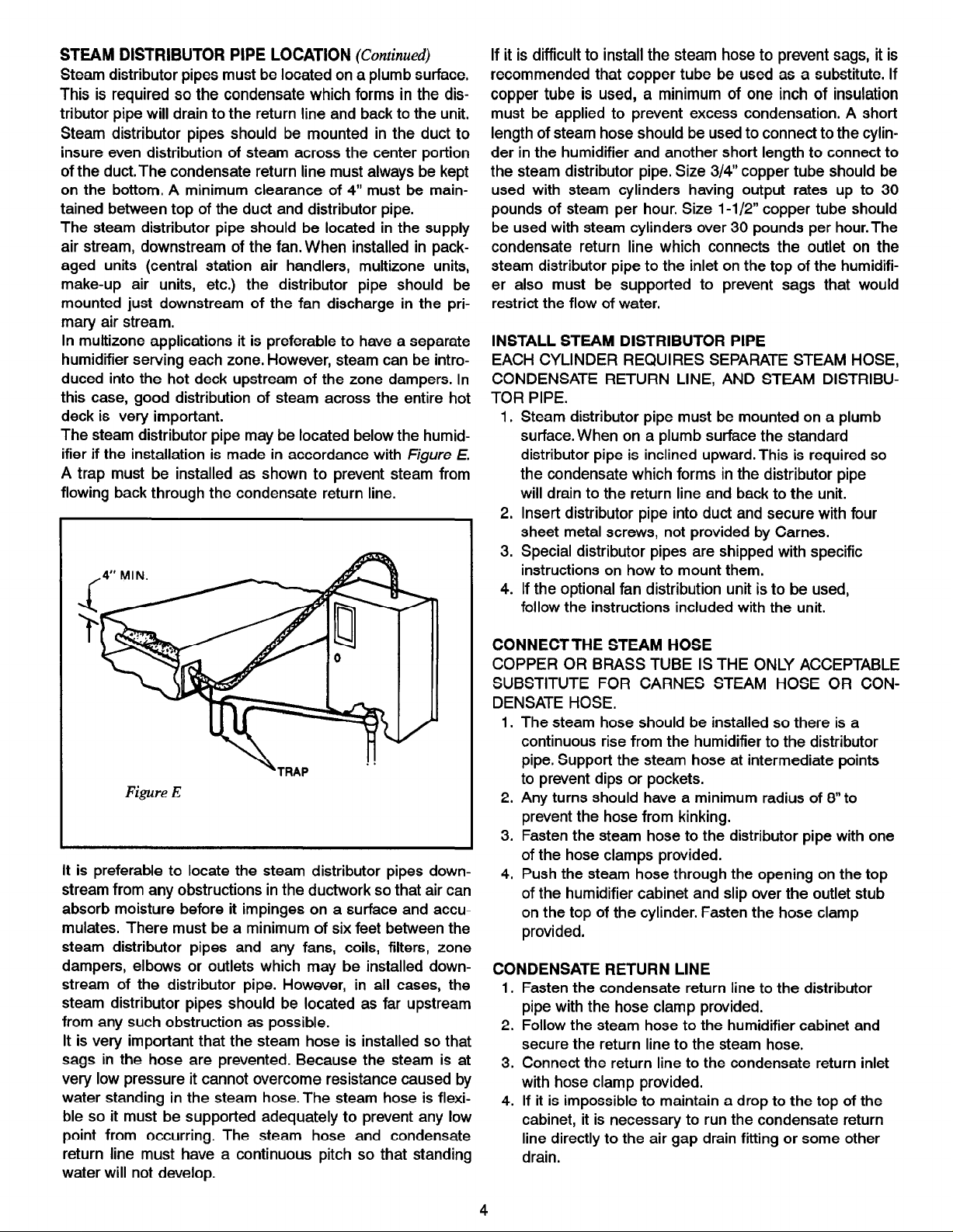

The steam distributor pipe may be located below the humid-

ifier if the installation is made in accordance with Figure

E.

A trap must be installed as shown to prevent steam from

flowing back through the condensate return line.

If it is difficult to install the steam hose to prevent sags, it is

recommended that copper tube be used as a substitute. If

copper tube is used, a minimum of one inch of insulation

must be applied to prevent excess condensation, A short

length of steam hose should be used to connect to the cylinder in the humidifier and another short length to connect to

the steam distributor pipe. Size 3/4” copper tube should be

used with steam cylinders having output rates up to 30

pounds of steam per hour. Size l-1/2” copper tube should

be used with steam cylinders over 30 pounds per hour.The

condensate return line which connects the outlet on the

steam distributor pipe to the inlet on the top of the humidifi-

er also must be supported to prevent sags that would

restrict the flow of water,

INSTALL STEAM DISTRIBUTOR PIPE

EACH CYLINDER REQUIRES SEPARATE STEAM HOSE,

CONDENSATE RETURN LINE, AND STEAM DISTRIBUTOR PIPE.

1. Steam distributor pipe must be mounted on a plumb

surface. When on a plumb surface the standard

distributor pipe is inclined upward.This is required so

the condensate which forms in the distributor pipe

will drain to the return line and back to the unit.

2. Insert distributor pipe into duct and secure with four

sheet metal screws, not provided by Carnes.

3. Special distributor pipes are shipped with specific

instructions on how to mount them.

4. If the optional fan distribution unit is to be used,

follow the instructions included with the unit.

Figure E

It is preferable to locate the steam distributor pipes downstream from any obstructions in the ductwork so that air can

absorb moisture before it impinges on a surface and accumulates. There must be a minimum of six feet between the

steam distributor pipes and any fans, coils, filters, zone

dampers, elbows or outlets which may be installed downstream of the distributor pipe. However, in all cases, the

steam distributor pipes should be located as far upstream

from any such obstruction as possible.

It is very important that the steam hose is installed so that

sags in the hose are prevented. Because the steam is at

very low pressure it cannot overcome resistance caused by

water standing in the steam hose. The steam hose is flexi-

ble so it must be supported adequately to prevent any low

point from occurring. The steam hose and condensate

return line must have a continuous pitch so that standing

water will not develop.

CONNECTTHE STEAM HOSE

COPPER OR BRASS TUBE IS THE ONLY ACCEPTABLE

SUBSTITUTE FOR CARNES STEAM HOSE OR CONDENSATE HOSE.

1. The steam hose should be installed so there is a

continuous rise from the humidifier to the distributor

pipe. Support the steam hose at intermediate points

to prevent dips or pockets.

2. Any turns should have a minimum radius of 8” to

prevent the hose from kinking.

3. Fasten the steam hose to the distributor pipe with one

of the hose clamps provided.

4. Push the steam hose through the opening on the top

of the humidifier cabinet and slip over the outlet stub

on the top of the cylinder. Fasten the hose clamp

provided.

CONDENSATE RETURN LINE

1. Fasten the condensate return line to the distributor

pipe with the hose clamp provided.

2. Follow the steam hose to the humidifier cabinet and

secure the return line to the steam hose.

3. Connect the return line to the condensate return inlet

with hose clamp provided.

4. If it is impossible to maintain a drop to the top of the

cabinet, it is necessary to run the condensate return

line directly to the air gap drain fitting or some other

drain.

4

Loading...

Loading...