Carnes HBAD Installation Manual

ELECTRONICALLY CONTROLLED STEAM HUMlDlFlERS

DESIGN SERIES “C” & “D”

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

CARNES COMPANY, P.O. Box 930040,446 S. Main St., Verona, WI. 53593-1499 - Phone: 608/845-6411 Fax: 608/845-6470

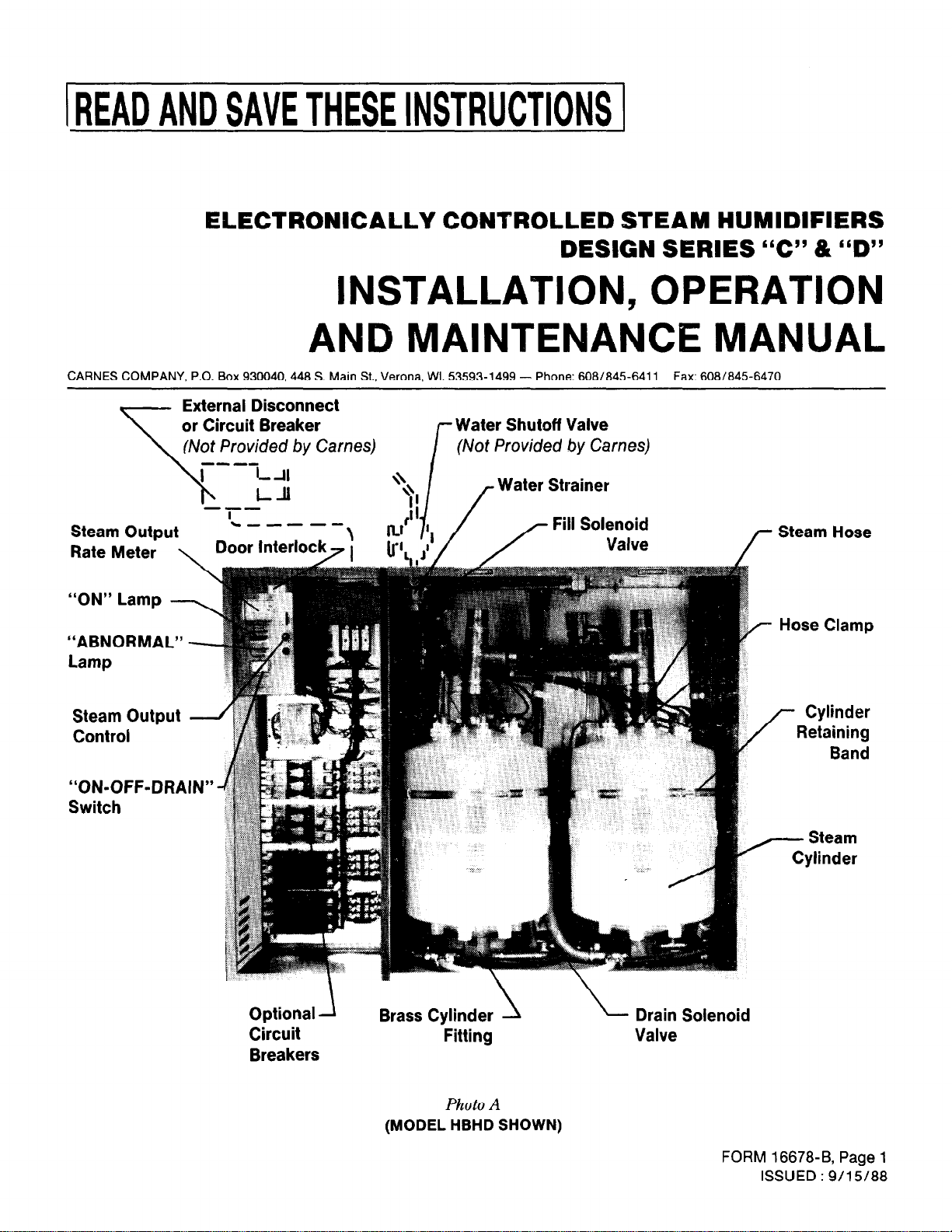

“ON” Lamp -

“ABNORMAL”

Lamp

Steam Output

Control

“ON-OFF-DRA

Switch

k---v-

Steam Hose

Hose Clamp

r Cylinder

Retaining

Band

- Steam

Cylinder

Optional 1

Circuit

Breakers

Brass Cylinder

Fitting

Photo A

(MODEL HBHD SHOWN)

Drain Solenoid

Valve

FORM 16678-8, Page 1

ISSUED : 9/l 5/88

INSTALLATION

UNPACKING AND INSPECTION

1. An envelope attached to the outside of the cabinet

contains one cabinet key.

2. Open the cabinet and check for concealed shipping damage. Report any damage immediately to

the carrier who delivered shipment.

3. The following components are packed in a shipping carton for connection when installing

humidifier:

A. Distributor pipe.

6. Steam hose.

C. Condensate return line.

4. Optional accessories may be packed with the

cabinet or in the same shipping carton. Large

accessories may ship in separate cartons,

5. Inside the cabinet is an envelope containing the

following items:

A. Steam hose clamps.

B. Condensate return line clamps.

C. Air gap drain fitting.

D. Installation instructions.

MOUNTING THE HUMIDIFIER

Mount the humidifier cabinet securely on a level and

plumb surface near the ductwork. Allow 6” or more

on each side for proper ventilation and a minimum of

16”from the bottom of the cabinet to the floor to allow

space for the drain connection. The humidifier must

never be mounted outside or where it may be

exposed to freezing temperatures. Maximum

operating weights for the humidifiers are shown

below.

WATER SUPPLY CONNECTION

Use ordinary tap water (20 to 120 psi)

hot water, deionized water, or water that has been

treated by a water softener without consulting the

factory. A 3/8” FPTfitting is provided at the top of the 4

humidifier for connection to tap water supp1y.A shutoff valve, not provided by Carnes, must be installed

just ahead of this fitting.

-DO NOT use

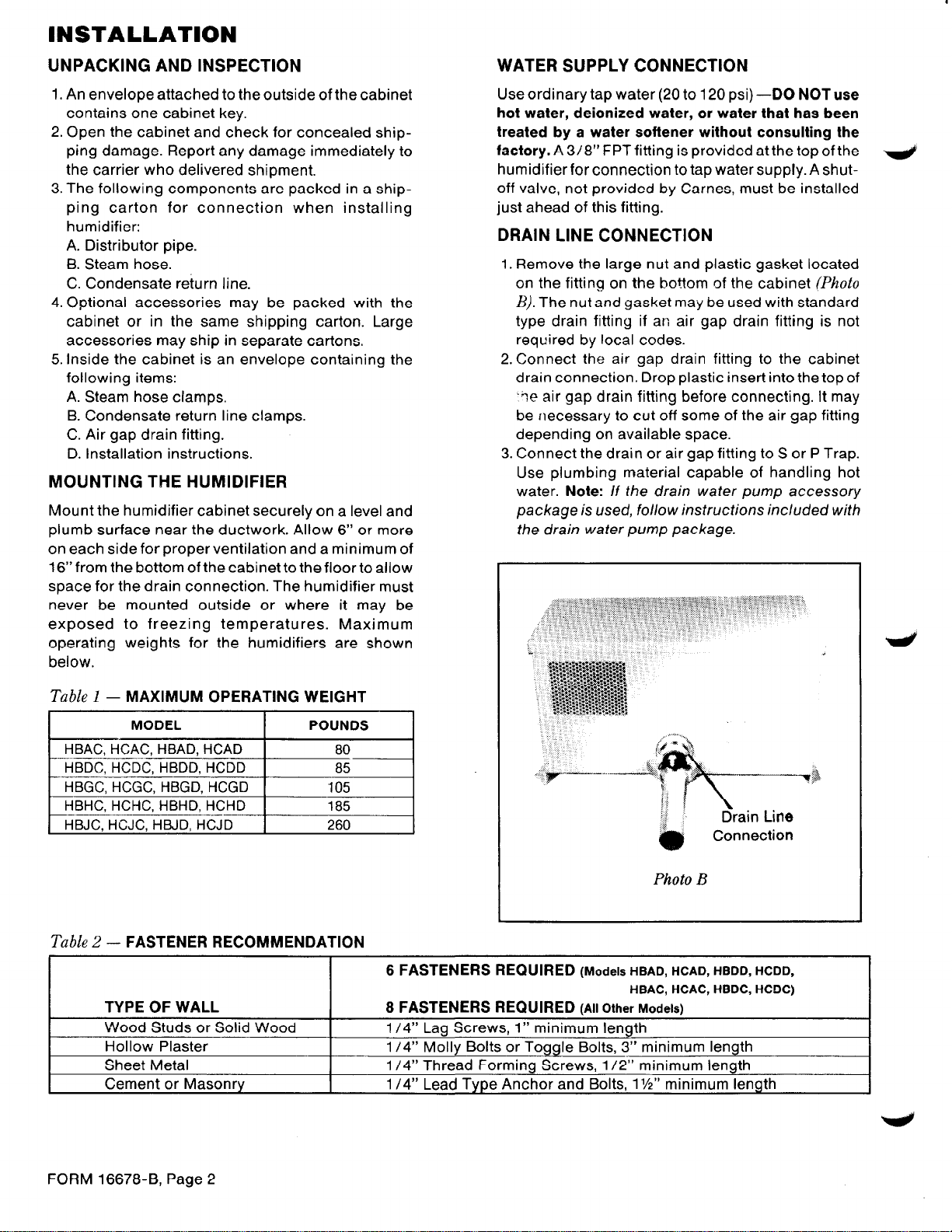

DRAIN LINE CONNECTION

1.

Remove the large nut and plastic gasket located

on the fitting on the bottom of the cabinet

B). The nut and gasket may be used with standard

type drain fitting if an air gap drain fitting is not

required by local codes.

2. Connect the air gap drain fitting to the cabinet

drain connection. Drop plastic insert into the top of

‘ie air gap drain fitting before connecting. It may

be necessary to cut off some of the air gap fitting

depending on available space.

3. Connect the drain or air gap fitting to S or P Trap.

Use plumbing material capable of handling hot

water.

package is used, follow instructions included with

the drain water pump package.

Note:

If the drain water pump accessory

(Photo

Table

I - MAXIMUM OPERATING WEIGHT

MODEL

Table

2 - FASTENER RECOMMENDATION

TYPE OF WALL

Wood Studs or Solid Wood

Hollow Plaster

Sheet Metal

Cement or Masonry

POUNDS

D\rain Line

Connection

Photo B

6 FASTENERS REQUIRED

8 FASTENERS REQUIRED

l/4” Lag Screws, 1” minimum length

l/4” Molly Bolts or Toggle Bolts, 3” minimum length

l/4” Thread Forming Screws, l/2” minimum length

l/4” Lead Type Anchor and Bolts, 1 l/2” minimum length

(Models HBAD, HCAD, HBDD, HCDD,

HBAC, HCAC, HBDC, HCDC)

(All Other Models)

FORM 16678-B, Page 2

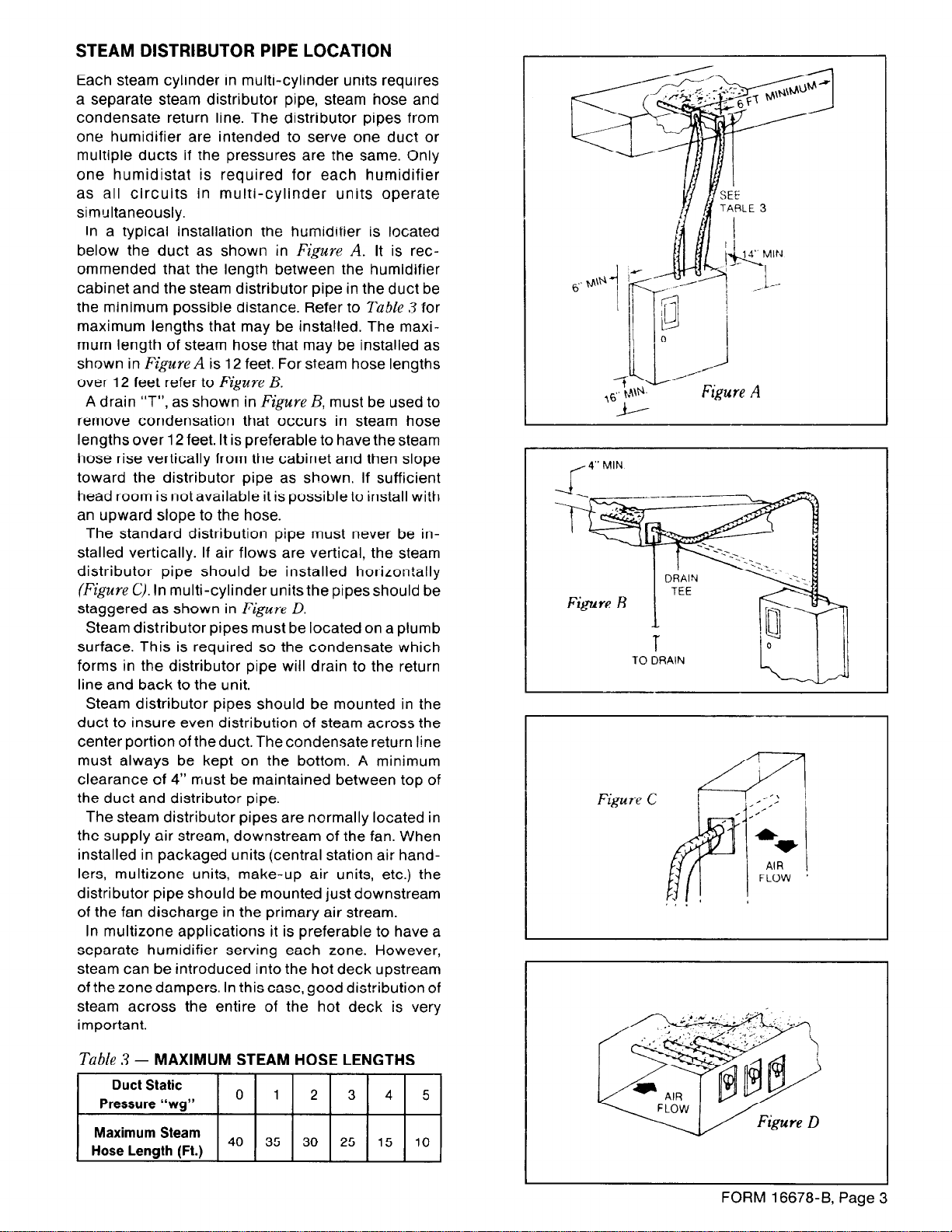

STEAM DISTRIBUTOR PIPE LOCATION

Each steam cylinder in multi-cylinder units requires

a separate steam distributor pipe, steam hose and

condensate return line. The distributor pipes from

one humidifier are intended to serve one duct or

multiple ducts if the pressures are the same. Only

one humidistat is required for each humidifier

as all circuits in multi-cylinder units operate

simultaneously.

In a typical installation the humiditier is located

below the duct as shown in

ommended that the length between the humidifier

cabinet and the steam distributor pipe in the duct be

the minimum possible distance. Refer to

maximum lengths that may be insta!led. The maximum length of steam hose that may be installed as

shown in

over 12 feet refer to

A drain “T”, as shown in

remove condensation that occurs in steam hose

lengths over 12 feet. It is preferable to have the steam

hose rise vertically from the cabinet and then slope

toward the distributor pipe as shown. If sufficient

head room is not available it is possible to install with

an upward slope to the hose.

The standard distribution pipe must never be installed vertically. If air flows are vertical, the steam

distributor pipe should be installed horizon?ally

(Figure

staggered as shown in

Steam distributor pipes must be located on a plumb

surface. This is required so the condensate which

forms in the distributor pipe will drain to the return

line and back to the unit.

Steam distributor pipes should be mounted in the

duct to insure even distribution of steam across the

center portion of the duct. The condensate return line

must always be kept on the bottom. A minimum

clearance of 4” must be maintained between top of

the duct and distributor pipe.

The steam distributor pipes are normally located in

the supply air stream, downstream of the fan. When

installed in packaged units (central station air handlers, multizone units, make-up air units, etc.) the

distributor pipe should be mounted just downstream

of the fan discharge in the primary air stream.

In multizone applications it is preferable to have a

separate humidifier serving each zone. However,

steam can be introduced into the hot deck upstream

of the zone dampers. In this case, good distribution of

steam across the entire of the hot deck is very

important.

Figure A

is 12 feet. For steam hose lengths

Figure B.

C). In multi-cylinder units the pipes should be

Figure D.

Figure A.

Figure B,

It is rec-

Table 3

must be used to

for

Figu w

Table 3

(

- MAXIMUM STEAM HOSE LENGTHS

FORM 16678-B, Page 3

Loading...

Loading...