COPYRIGHT © 2011 CARNES COMPANY

ALL RIGHTS RESERVED

17165, pg 1

SPECIFICATION SHEET

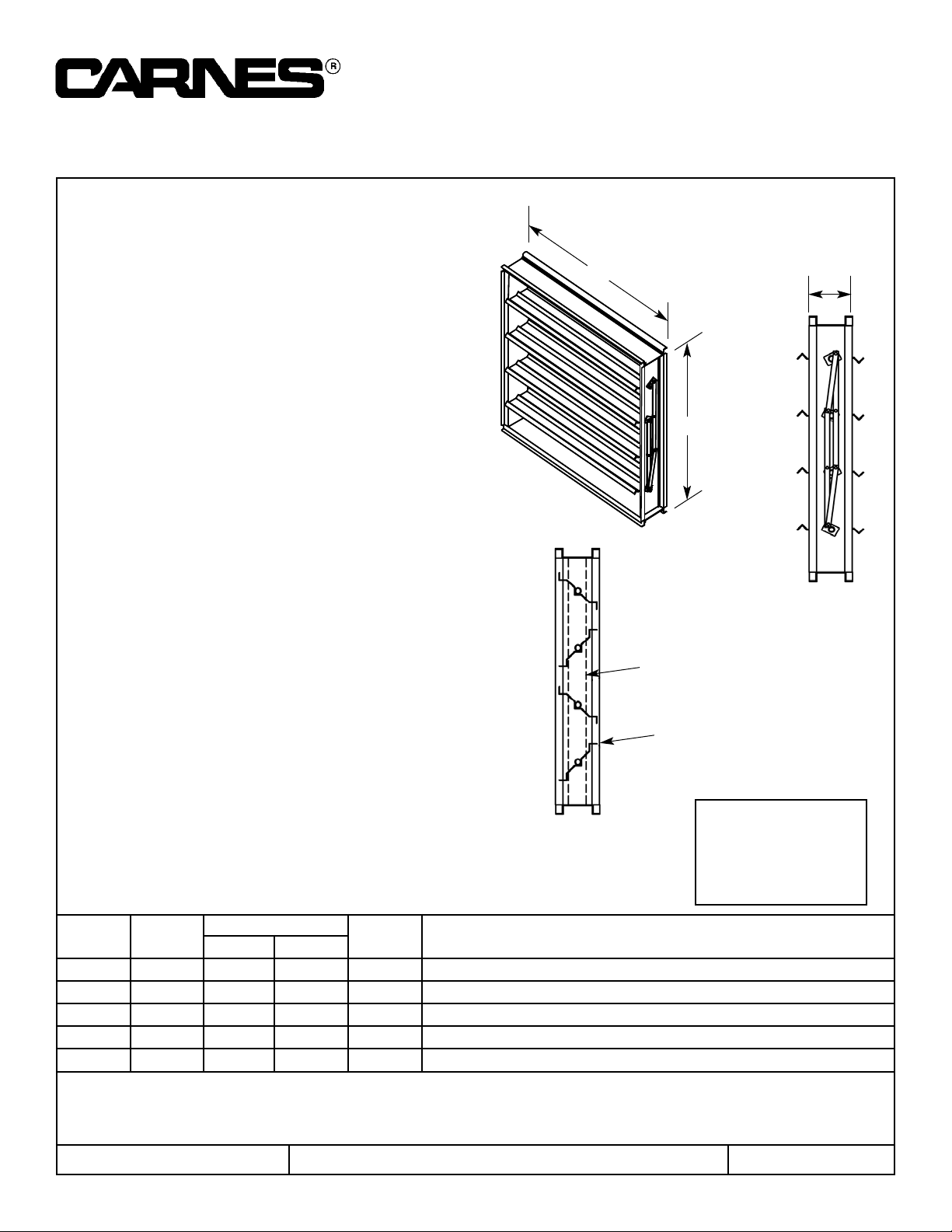

Galvanized 3V Blade Control Damper

Model FNDB - Opposed Blade, Model FDQB - Parallel Blade

CARNES COMPANY, 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 Phone: (608)845-6411 Fax: (608)845-6504 carnes@carnes.com

Model FDNB & FDQB

Standard Specifications

Frame: roll formed galvanized steel

Blades: 4” - 7” wide, 16 gauge galvanized steel

Bearings: nylon

Linkage: concealed in frame

Axles: 3/8” square plated steel

Control Shaft: Ø1/2” x 4-1/2” long shaft supplied with

all single section dampers for field mounted actuators.

Factory-installed jackshaft supplied with all multiple

section dampers.

Maximum Panel Size: 48”w x 60”h (single section)

Maximum multi-section: unlimited

Minimum Panel Size: 6”w x 6”h

9”h and under - single blade

Options

- Vinyl Blade Seals

- Compression Jamb Seals (stainless steel)

- Header Plates (end flange)

- Hand Quadrant

- Factory Installed Actuators

- Position Switch

- Face and By-pass Damper

- Chain Operator

- Single Flange

- Double Flange

- Bolt Holes in Flange

- Stainless Steel Bushings

- Heresite Coated (air dry)

- Epoxy Coated (powder coated)

- Stand Off Bracket, 2”

Tag Qty.

Size

Frame Variations

Width Height

Project Location

Arch./Engr. Contractor

Representative Date

W

H

5”

Optional

Stainless steel

jamb seals

Vinyl blade seals

12” wide -3500 FPM

24” -2800

36” -2300

48” -2100

FPM Table

17165, pg 2

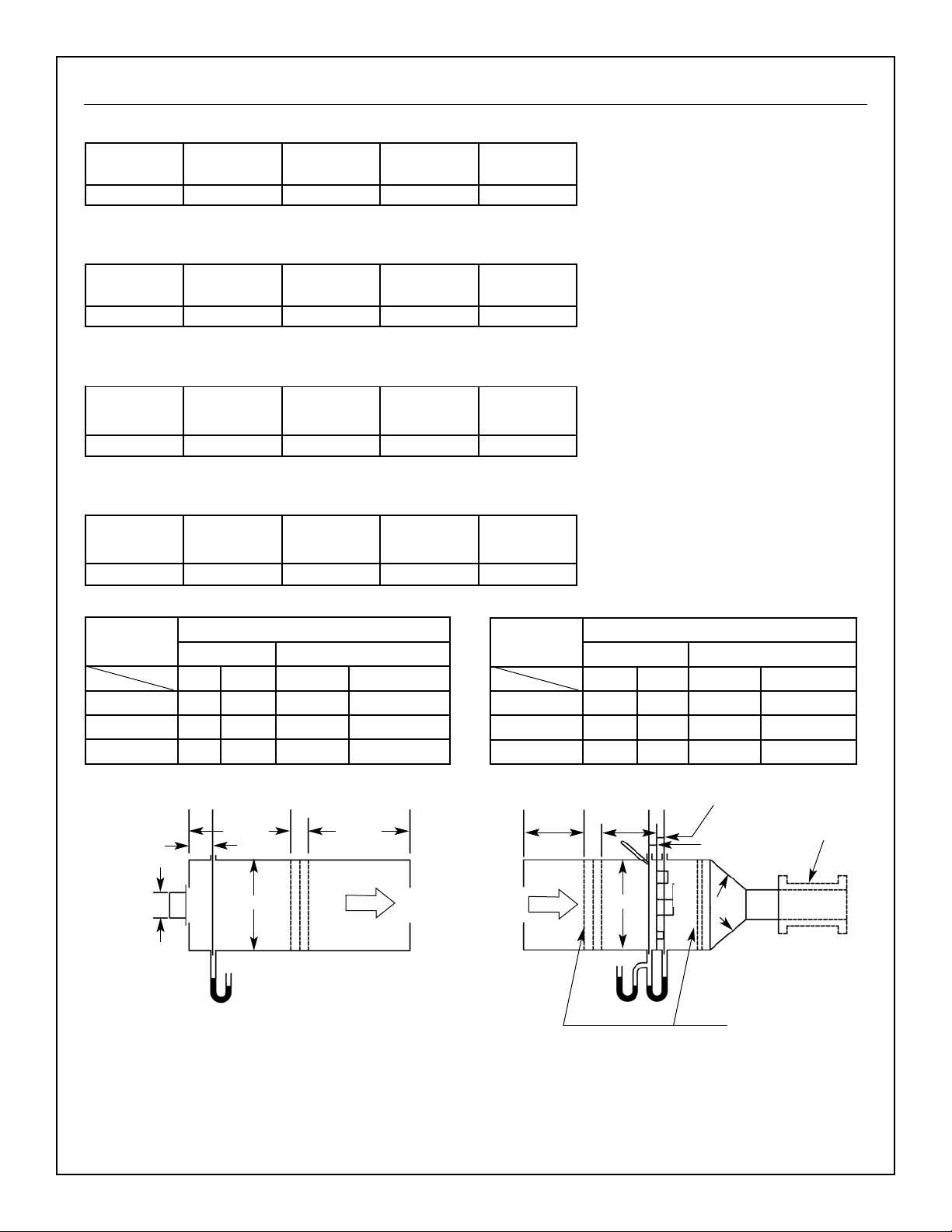

Model FDNB & FDQB Performance Data

Ratings shown are based on tests made in accordance with AMCA standard 500.

Damper

Width x Height

1 in. w.g. Class 4 in. w.g. Class 8 in. w.g. Class

*Torque

(per sq. ft.)

36” x 36” Class III Class III Class III 5.55 lbs-in

Imperial Units (Forward Flow)

*Torque applied to hold damper in closed position.

Damper

Width x Height

1 in. w.g. Class 4 in. w.g. Class 8 in. w.g. Class

*Torque

(per sq. ft.)

36” x 36” Class III Class III Class III 5.55 lbs-in

Imperial Units (Back Flow)

*Torque applied to hold damper in closed position.

Damper

Width x Height

(mm)

250 Pa Class 1 kPa Class 2 kPa Class *Torque

915 x 915 Class III Class III Class III 6,394 grams-cm

Standard International Units (Forward Flow)

*Torque applied to hold damper in closed position.

Damper

Width x Height

(mm)

250 Pa Class 1 kPa Class 2 kPa Class *Torque

915 x 915 Class III Class III Class III 6,394 grams-cm

Standard International Units (Back Flow)

*Torque applied to hold damper in closed position.

Air leakage is based on operation

between 50°F to 104°F. All data

corrected to represent air density

of 0.075 lbs/ft.

3

Air leakage is based on operation

between 10°C to 40°C. All data

corrected to represent air density

of 1.201 kg/m.

3

PL-1

PL-7 PL-X

PL-Y

M

AIRFLOW

AIRFLOW

Figure 5.4 - Test Device Setup with Outlet Chamber

Note: For pressure drop testing an outlet

chamber shall have a cross sectional

area at least fifteen times the free

area of the device being tested.

P

s7

W + H

75mm ± 6mm

(3 in. ± .025 in.)

Device

being

tested

M/2 min.

M/2 min.

Figure 6.3 - Airflow Rate Measurement Setup -

Multiple Nozzle Chamber on Fan Inlet

M

M/2 min.

P

s7ΔPn

PL-A

PL-B PL-5 PL-6

Any

angle

Variable

exhaust

system

Settling means

M/2 min.

38mm ± 6mm

(1.5 in. ± .025 in.)

38mm ± 6mm

(1.5 in. ± .025 in.)

t

d5

Leakage, ft.3/min/ft.

2

Required Rating Extended Ranges (optional)

Class

Pressure

1” 4” 8” 12”

I 4 8 11 14

II 10 20 28 35

III 40 80 112 140

All data corrected to represent standard air at a density of 0.075 lbs/ft.

3

Leakage, L/s/m.

3

Required Rating Extended Ranges (optional)

Class

Pressure

0.25 kPa 1.0 kPa 2.0 kPa 3.0 kPa

I 20.3 40.6 55.9 71.1

II 50.8 102 142 178

III 203 406 569 711

D6= Throat dia. of largest nozzle

2.5 D

6

min.

Loading...

Loading...