SPECIFICATION SHEET

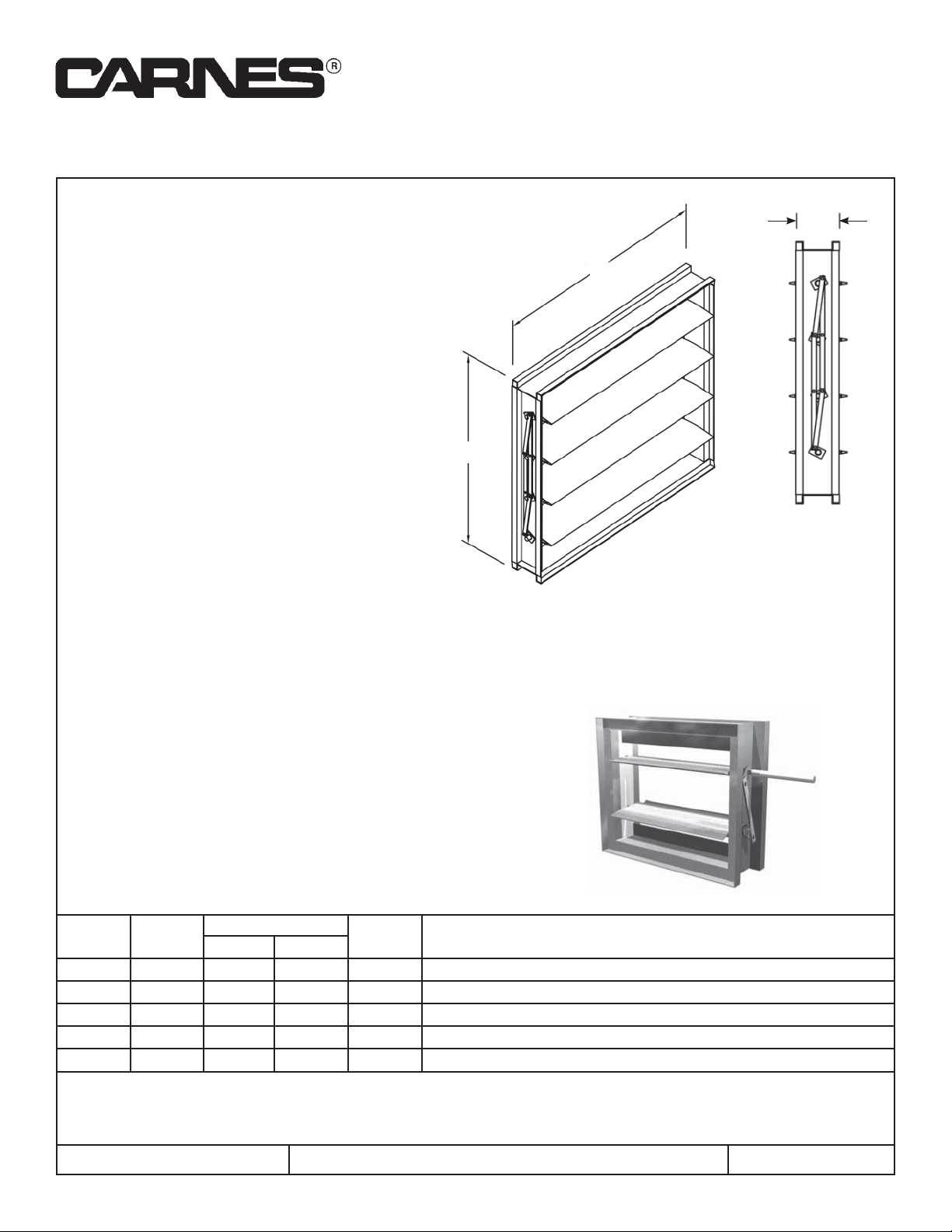

Stainless Steel Airfoil Blade Control Damper/Zone Damper

(w/Optional Insulated Blade)

Model FAQA - Opposed Blade, Model FARA - Parallel Blade

CARNES COMPANY, 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 Phone: (608)845-6411 Fax: (608)845-6504 carnes@carnes.com

Model FAQA & FARA

Standard Specifications

Frame: 304 stainless steel

Blades: 6” wide stainless steel airfoil

Extended Shaft: 1/2” diameter

Bearing: nylon

Linkage: concealed in frame

Axels: zinc plated

Blade Seals: PVC (175°F)

Jamb Seals: stainless steel (compression)

Options

- Hand Quadrant

- Chain Operated

- Factory Installed Pneumatic or Electric Actuators

- Position Switch

- Stand Off Bracket, 2”

- Side Plate (End Flange)

- Face and By-pass Damper

- Single Flange

- Double Flange

- Bolt Holes in Flange

- 6-1/2” Deep Frame

- 304L Stainless Steel Construction*

- 316L Stainless Steel Construction*

- 12 ga. Construction

- 10 ga. Construction

- Heresite Coated (Air Dry)

- Expoxy Coated (Powder Coated at 415°)

- Insulated (Foam Filled Blades)

4.5”

*W

*H

*Undersized 1/4”

Standard

Minimum Size: 8”w x 8”h

Maximum Size: 48”w x 60”h (single section)

9”h and under - single blade

Maximum Multi-Section: Unlimited

(*304 stainless steel linkage)

Tag Qty.

Size

Width Height

Frame Variations

Project Location

Arch./Engr. Contractor

Representative Date

COPYRIGHT © 2015 CARNES COMPANY

ALL RIGHTS RESERVED

SUPERSEDES 17174 17174-A

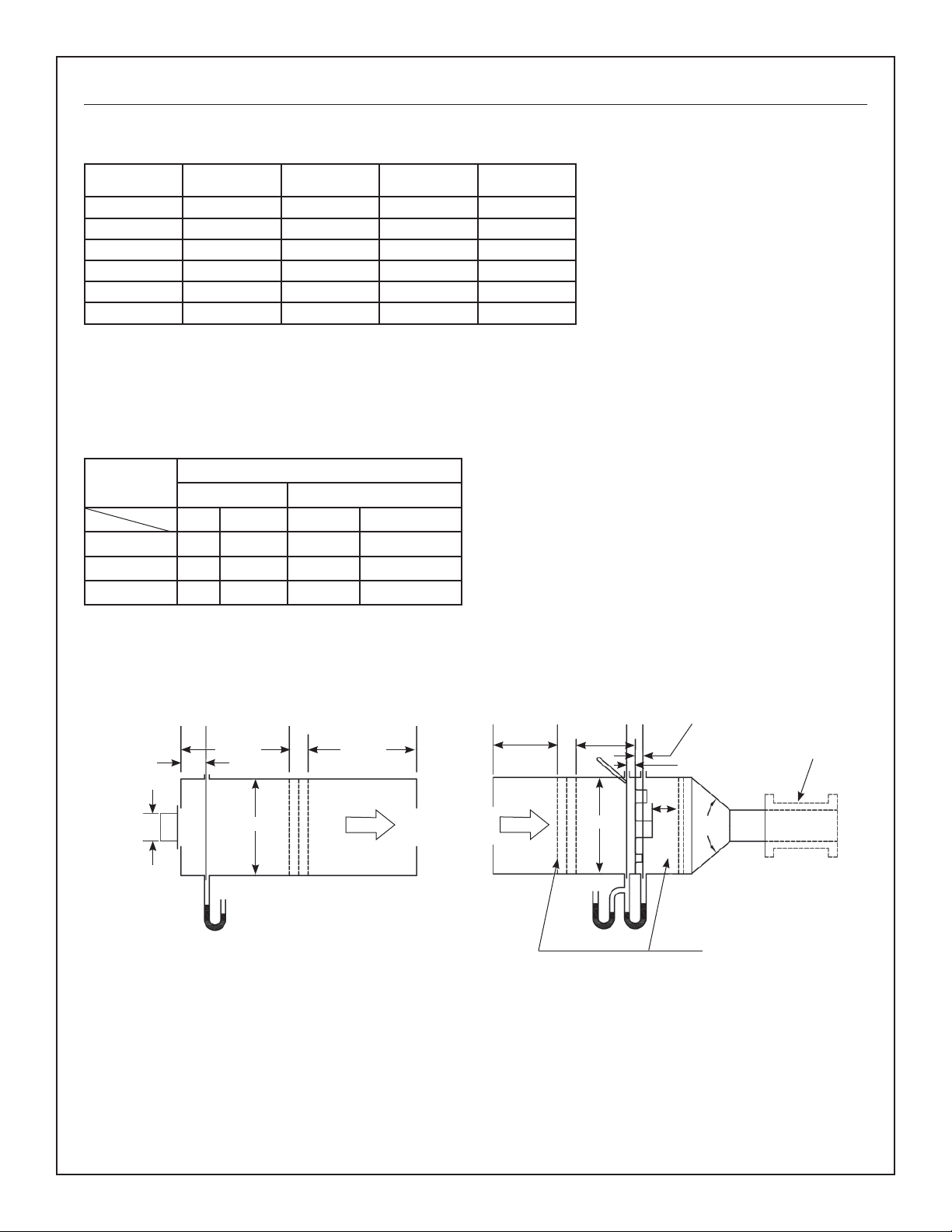

Model FAQA & FARA Performance Data

Imperial Units (Forward Flow)

Damper

Width x Height

1 in. w.g. Class 4 in. w.g. Class 8 in. w.g. Class

(per sq. ft.)

12” x 12” Class I Class II Class II 15 lbs-in

24” x 24” Class I Class I Class I 12.59 lbs-in

36” x 36” Class II Class II Class II 15.55 lbs-in

12” x 48” Class III Class III Class II 12.59 lbs-in

48” x 12” Class I Class I Class I 12.59 lbs-in

60” x 36” Class II Class II Class II 15 lbs-in

*Torque applied to hold damper in closed position.

**Only 36” x 36” size is certified by Certaire Technical Servies, LTD.

Leakage, ft.3/min/ft.

2

Required Rating Extended Ranges (optional)

Class

Pressure

1” 4” 8” 12”

I4811 14

II 10 20 28 35

III 40 80 112 140

All data corrected to represent standard air at a density of 0.075 lbs/ft.

3

*Torque

Air leakage is based on operation

between 50°F to 104°F. All data

corrected to represent air density

of 0.075 lbs/ft.

3

75mm ± 6mm

(3 in. ± .025 in.)

Device

W x H

being

tested

Figure 5.4 - Test Device Setup with Outlet Chamber

PL-1

PL-7 PL-X

M/2 min.

P

s7

PL-Y

M/2 min.

M

AIRFLOW

Note: For pressure drop testing an outlet

chamber shall have a cross sectional

area at least fifteen times the free

area of the device being tested.

PL-A

PL-B PL-5 PL-6

M/2 min.

Figure 6.3 - Airflow Rate Measurement Setup -

38mm ± 6mm

M/2 min.

t

d5

M

(1.5 in. ± .025 in.)

38mm ± 6mm

(1.5 in. ± .025 in.)

Any

2.5 D

6

angle

min.

D6 = Throat dia. of largest nozzle

P

s7Pn

Settling means

Multiple Nozzle Chamber on Fan Inlet

Variable

exhaust

system

17174-A, pg 2

Loading...

Loading...