Carnes EFVA Installation Manual

FORM 40005

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

Models EFVA and EGVA Corridor Dampers

CAUTION! DO NOT INSTALL, USE OR OPERATE THIS EQUIPMENT UNTIL THIS

MANUAL HAS BEEN READ AND UNDERSTOOD. READ AND SAVE THESE INSTRUCTIONS FOR FUTURE USE.

INSTALLATION INSTRUCTION FOR CORRIDOR DAMPERS

These installation instructions apply to tunnel corridor dampers installed in 1 hour rated

drywall fire separations. Specific requirements in these instructions are mandatory. These

instructions meet the requirements of UL 555 and UL 555S.

1. CLEARANCE REQUIRED BETWEEN DAMPER SLEEVE AND OPENINGS: Damper and

sleeve assemblies expand during periods of intense heat. Therefore it is essential that the openings be larger than the damper and sleeve assembly to allow for expansion. Clearance required between the outside of the

damper/sleeve assembly and the opening in the fire separation is a minimum clearance of 1/4”. This is a total clearance and does

not need to be equally spaced around the damper/sleeve assembly.

2. SLEEVE LENGTH: The damper must be installed in a sleeve. The sleeve must be long enough to permit proper support of the

damper and offset drive shaft and also permit appropriate securing of perimeter angles. The minimum sleeve length is 16”. (A 16”

sleeve should be appropriate for separations up to and including 6” in depth when the sleeve is flush with the underside of the fire

separation. For separation deeper, add 1” sleeve length for each additional inch, over 6”, of separation depth.) If the sleeve is mounted below the separation, the distance below the separation should be added to the sleeve length.

3. SECURING THE DAMPER TO THE SLEEVE: Dampers must be secured to the sleeve with #10 sheet metal screws, 1/4” bolts and

nuts, welding (1/2” long minimum), 3/16” diameter pop rivets, or 3/16” diameter toggle lock, 6” on center, 2” maximum from the

corners. The damper must be installed in the sleeve so that the backside (non-drive shaft side) is a minimum of 1/2” from the edge

of the sleeve. This permits clearance to allow for caulking around the edge of the damper frame should it be required.

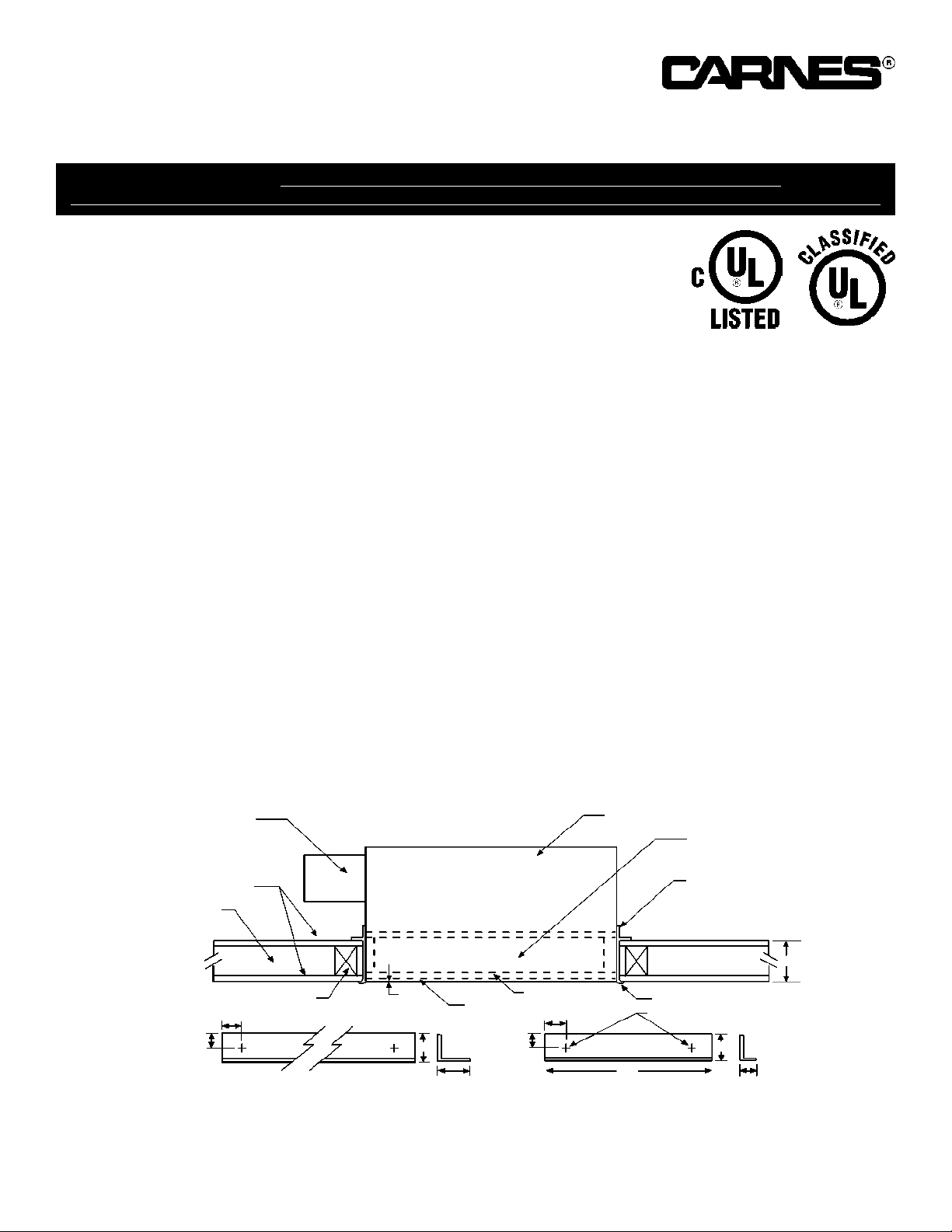

4. SECURING THE DAMPER/SLEEVE ASSEMBLY TO THE SEPARATION OPENING: The damper/sleeve assembly should be

installed in the separation opening using retaining angles on both sides of the opening. The retaining angles should be made from

a minimum of 16 gauge steel. The bottom angle should be 8” long and be 3/4” by 1-1/2” (see details on drawing below). The fasteners should be located as indicated on drawing below. The bottom angle should be located such that the center of the angles lines

up with the center of the damper sleeve on each side. The perimeter angles on the top of the assembly should be the same length

as the damper width or height and should have one leg 3/4” long and the other leg must be long enough to allow the fasteners to be

attached to the sleeve and NOT interfere or damage the damper or the internal linkage so as to interfere with the closing capabilities of the damper. To determine the height of the perimeter angle leg, dimension A on drawing below, follow the instructions below:

A. Damper/Sleeve Assembly is Mounted Flush with the Underside of the Fire Separation - Take the distance from the back

edge of the damper frame to the edge of the damper sleeve, dimension B (see drawing below), add 5-1/2” and subtract the depth

of the fire separation, dimension C. Note: the minimum height of the perimeter angle is 1-1/2”. Therefore, for a damper installed

1” from the edge of the damper sleeve and in a 4” deep fire separation, the height of the upper perimeter leg should be 2-1/2”.

B. Damper/Sleeve Assembly is Mounted Below the Underside of the Fire Separation

FORM 40005

Manufacturer’s Recommendations

All moving parts of the damper must be inspected and cycled at intervals not greater than every 12 months or in accordance with the

latest edition of NAPA 90A, 92A, local codes, and the actuator manufacturer. In addition, fuse links shall be removed and inspected for

corrosion. Dry lubricants are recommended.

Actuator

5/8” Drywall

Fire Separation

Damper/Sleeve Assembly

Tunnel Corridor Damper

Top Retaining Angle

Bottom Retaining Angle

Back Edge

of Damper

Edge of

Damper

Sleeve

2 x 4 Wood Stud Type

Metal Stud Acceptable

Top Retaining Angle

Bottom Retaining Angle

2” Max.

2” Max.

3/4” 3/4”

“A”

3/4”

8”

1-1/2”

1-1/2”

“C”

CARNES COMPANY 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 Phone: (608)845-6411 Fax: (608)845-6470 www.carnes.com

Fastener Location

Loading...

Loading...