Canon Pixma MX340, Pixma MX350 Simplified service manual

PIXMA

MX340 / MX350

SIMPLIFIED

SER VICE MANUAL

Canon

Copyright © 2010, Canon U.S.A. This technical publication is the proprietary and confidential information of Canon U.S.A. which

shall be retained for reference purposes by Authorized Service Facilities of Canon U.S.A. Its unauthorized use is prohibited.

MX340 / MX350

SIMPLIFIED SERVICE MANUAL

1. LIST OF ERROR DISPLAY

1-1. Operator Call Errors (Alarm Lamp Lit In Orange)

1-2. Service Call Errors (by Cyclic Blinking of Alarm and Power Lamps)

1-3. FAX Errors

2. MAJOR UNIT REPLACEMENT

3. ADJUSTMENT / SETTINGS

3-1. Service Mode

3-2. PTT Parameter Mode

3-3. User Mode

3-4. Special Notes on Servicing

3-5. Grease application

3-6. Notes on Transportation

4. EXTERNAL VIEW / PARTS LIST

4-1. External View

QY8-13CS-000

Rev. 00

Dec. 2009

Canon Inc.

(1/37)

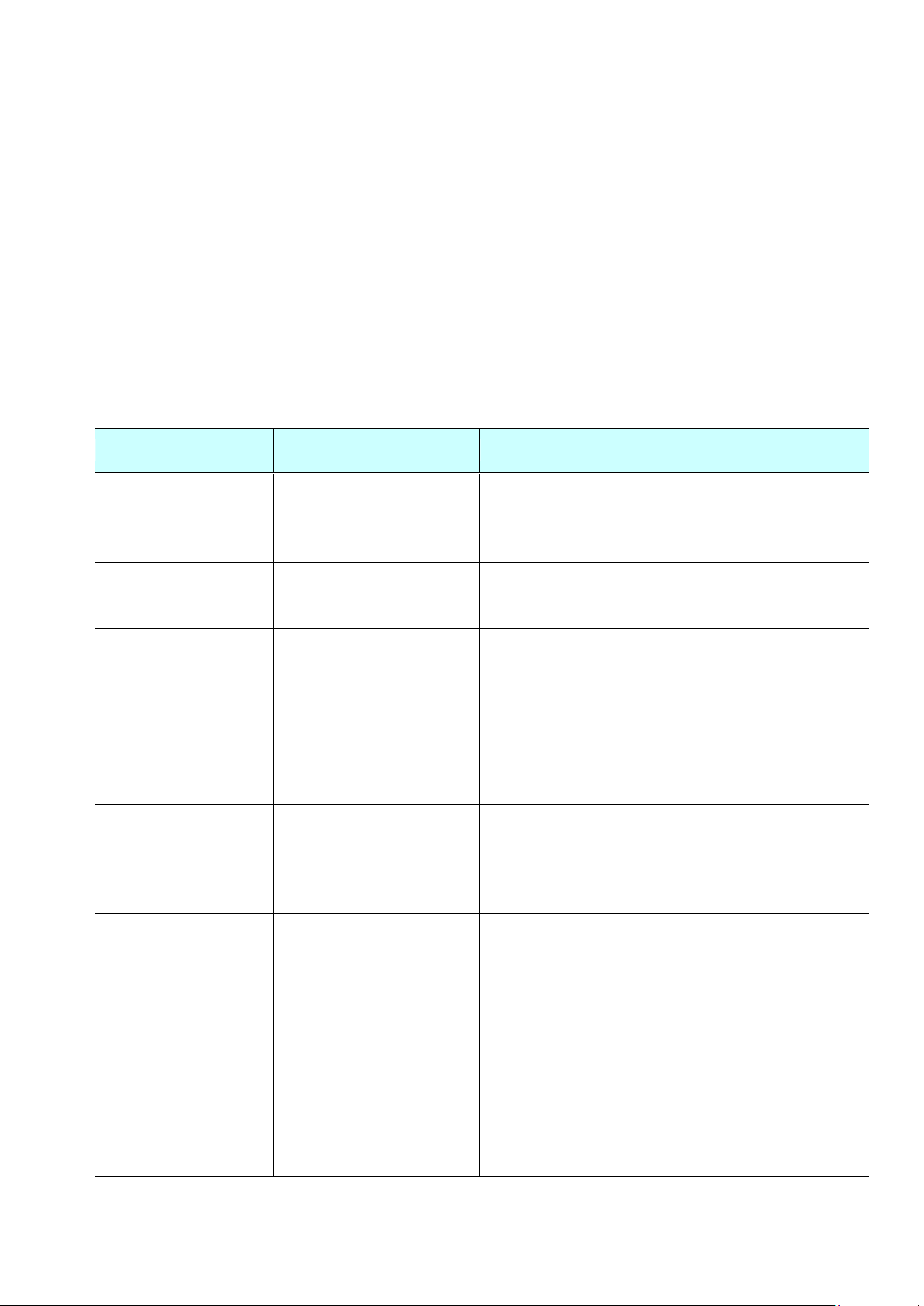

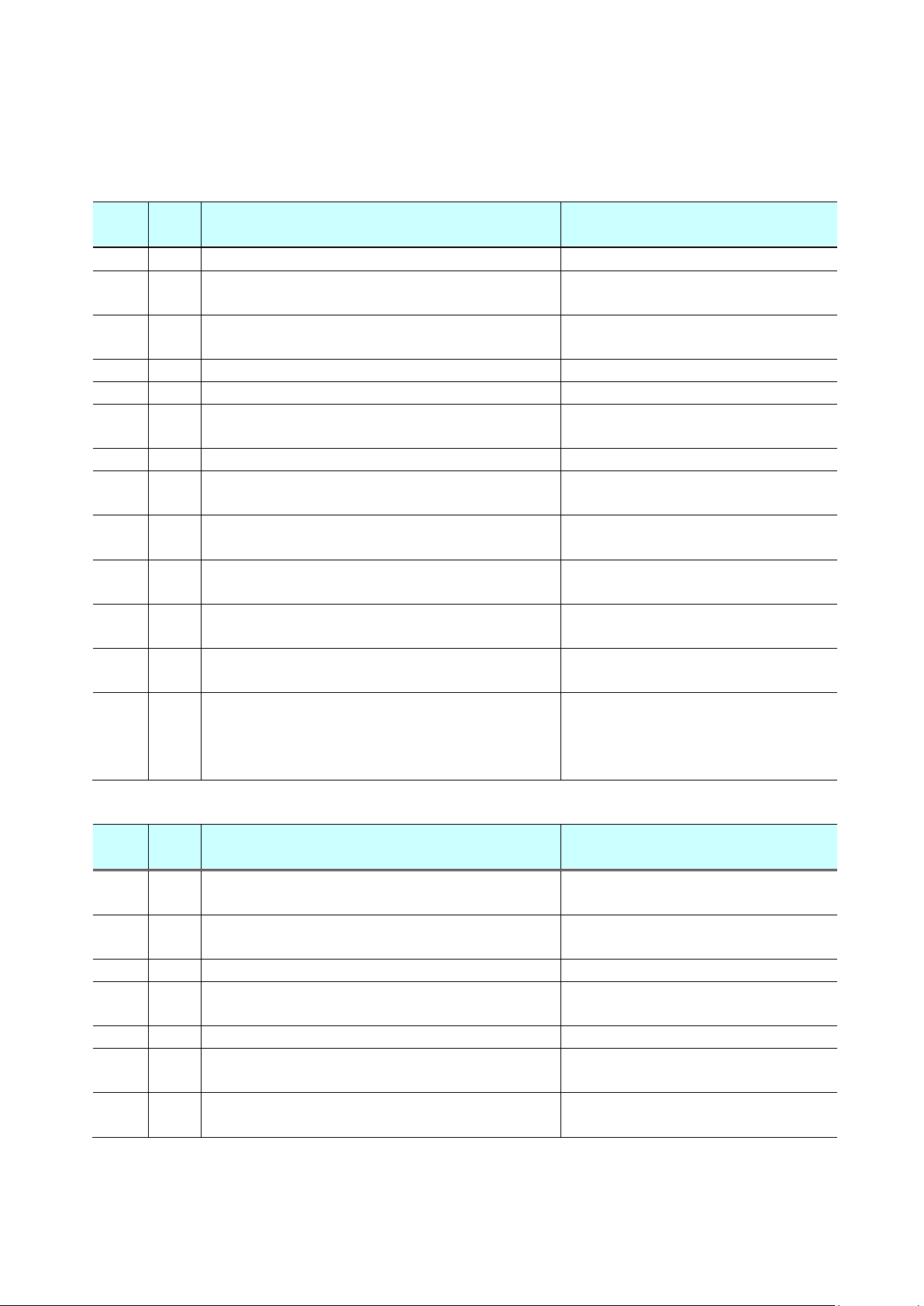

1. LIST OF ERROR DISPLAY

Error

Error

code

U No.

Message on the LCD

Solution

Parts that are likely to be

faulty

No paper in the

rear tray.

[1000]

---

There is no paper.

Load paper and press

[OK].

Set the paper in the rear

tray, and press the OK

button.

- PE PWB unit

- Pick-up roller

- Drive unit

- Logic board

The paper output

tray closed.

[1251]

---

Paper output tray is

closed. Open the paper

output tray.

Open the paper output tray,

and press the OK button.

Paper jam.

[1300]

---

The paper is jammed.

Clear the paper and

press [OK].

Remove the jammed paper,

and press the OK button.

- PE PWB unit

- Logic board

Ink cartridge not

installed, or not

properly installed.

[1401]

U051

Print head is not

installed. Install the

print head.

Install the ink cartridge

properly. If the error is not

cleared, the ink cartridge

may be defective. Replace

the ink cartridge.

- Ink cartridge

- Carriage unit

- Logic board

Ink cartridge

temperature

sensor error.

[1403]

U052

The type of print head

is incorrect. Install the

print head.

Re-set the ink cartridge. If

the error is not cleared, the

ink cartridge may be

defective. Replace the ink

cartridge.

- Ink cartridge

- Carriage unit

- Logic board

Non-supported

ink cartridge

installed.

[1485]

U059

The ink cartridge

cannot be recognized.

A non-supported ink

cartridge is installed. Install

the supported ink cartridge.

If the error is not cleared,

the ink cartridge may be

defective. Replace the ink

cartridge.

- Ink cartridge

- Carriage unit

- Logic board

Ink cartridge in a

wrong position.

[1486]

U076

Some ink cartridges

are not installed in

place.

Install the ink cartridge(s) in

the correct position. If the

error is not cleared, the ink

cartridge may be defective.

Replace the ink cartridge.

- Ink cartridge

- Carriage unit

- Logic board

Errors and warnings are displayed by the following ways:

- Operator call errors are indicated by the Alarm lamp lit in orange, and the error and its solution

are displayed on the LCD.

- Messages during printing from a computer are displayed on the printer driver Status Monitor.

- Error codes are printed in the "operator call/service call error record" area in EEPROM

information print.

1-1. Operator Call Errors (Alarm Lamp Lit In Orange)

Buttons valid when an operator call error occurs:

- ON button: To turn the printer off and on again.

- OK button: To clear and recover from an error. In some operator call errors, the error will

automatically be cleared when the cause of the error is eliminated, and pressing

the OK button may not be necessary.

- Stop button: To cancel the job at error occurrence, and to clear the error.

(2/37)

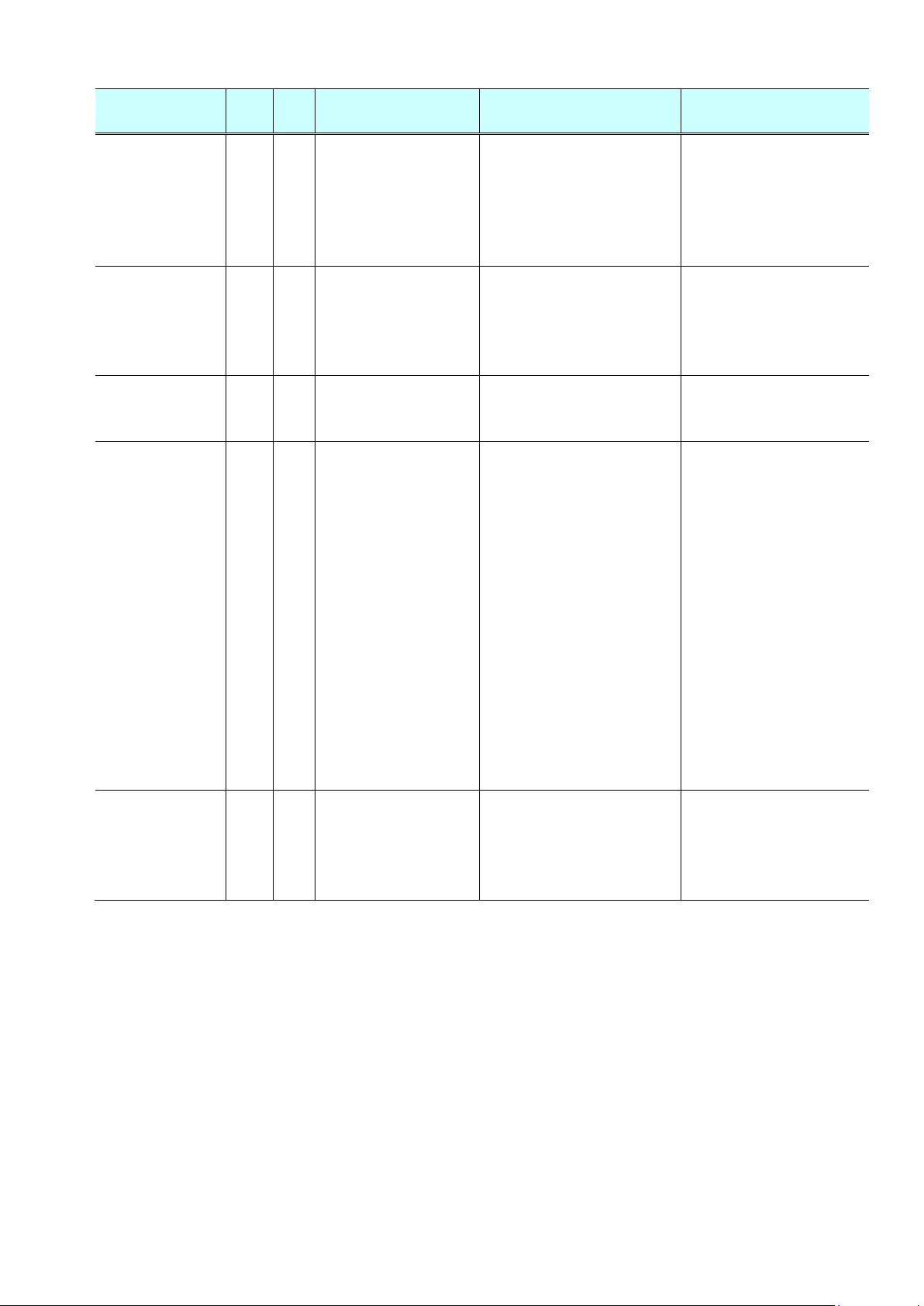

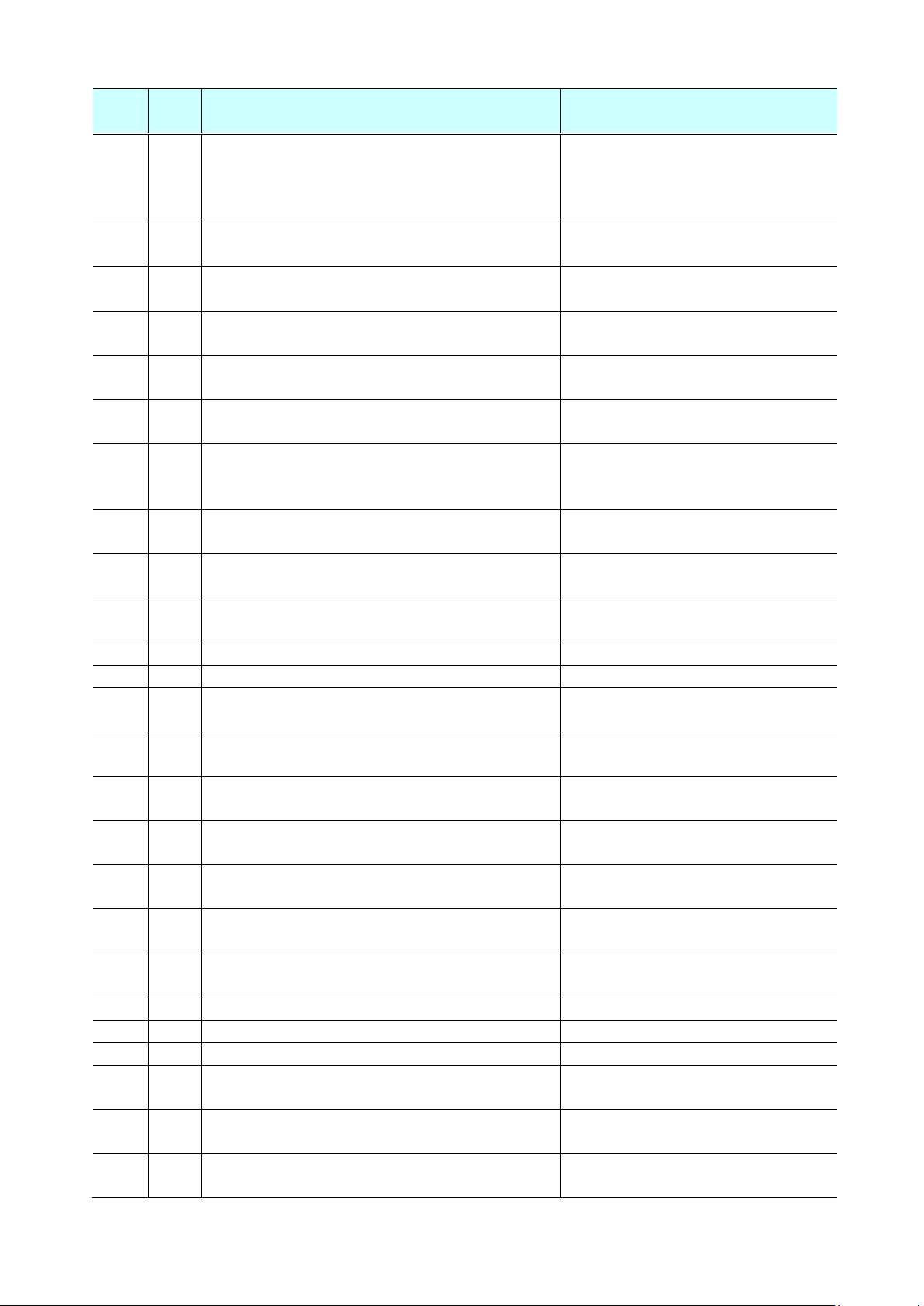

Error

Error

code

U No.

Message on the LCD

Solution

Parts that are likely to be

faulty

Multiple ink

cartridges of the

same color

installed.

[1487]

U075

Some ink cartridges

are not installed in

place.

Replace the wrong ink

cartridge(s) with the correct

one(s). If the error is not

cleared, the ink cartridge

may be defective. Replace

the ink cartridge.

- Ink cartridge

- Carriage unit

- Logic board

Ink cartridge

hardware error

[1682]

U150

The ink cartridge

cannot be recognized.

Re-set the ink cartridge(s). If

the error is not cleared, the

ink cartridge may be

defective. Replace the ink

cartridge.

- Ink cartridge

- Carriage unit

- Logic board

Ink cartridge not

recognized

[1684]

U140

The ink cartridge

cannot be recognized.

A non-supported ink

cartridge is installed. Install

the supported ink cartridge.

- Ink cartridge

- Carriage unit

- Logic board

The remaining ink

amount unknown.

[1686]

U162

Ink may have run out.

Replacing the ink

cartridge is

recommended.

Replace the applicable ink

cartridge with a new one.

Printing without replacing

the ink cartridge can

damage the printer.

To continue printing without

replacing the ink

cartridge(s), press the Stop

button for 5 sec. or longer to

disable the function to detect

the remaining ink amount.

After the operation, it is

recorded in the printer

EEPROM that the function

to detect the remaining ink

amount was disabled.

- Ink cartridge

- Logic board

Ink cartridge not

installed properly.

[1687]

U053

The ink cartridge

cannot be recognized.

Re-set the ink cartridge. If

the error is not cleared, the

ink cartridge may be

defective. Replace the ink

cartridge.

- Ink cartridge

- Carriage unit

- Logic board

(3/37)

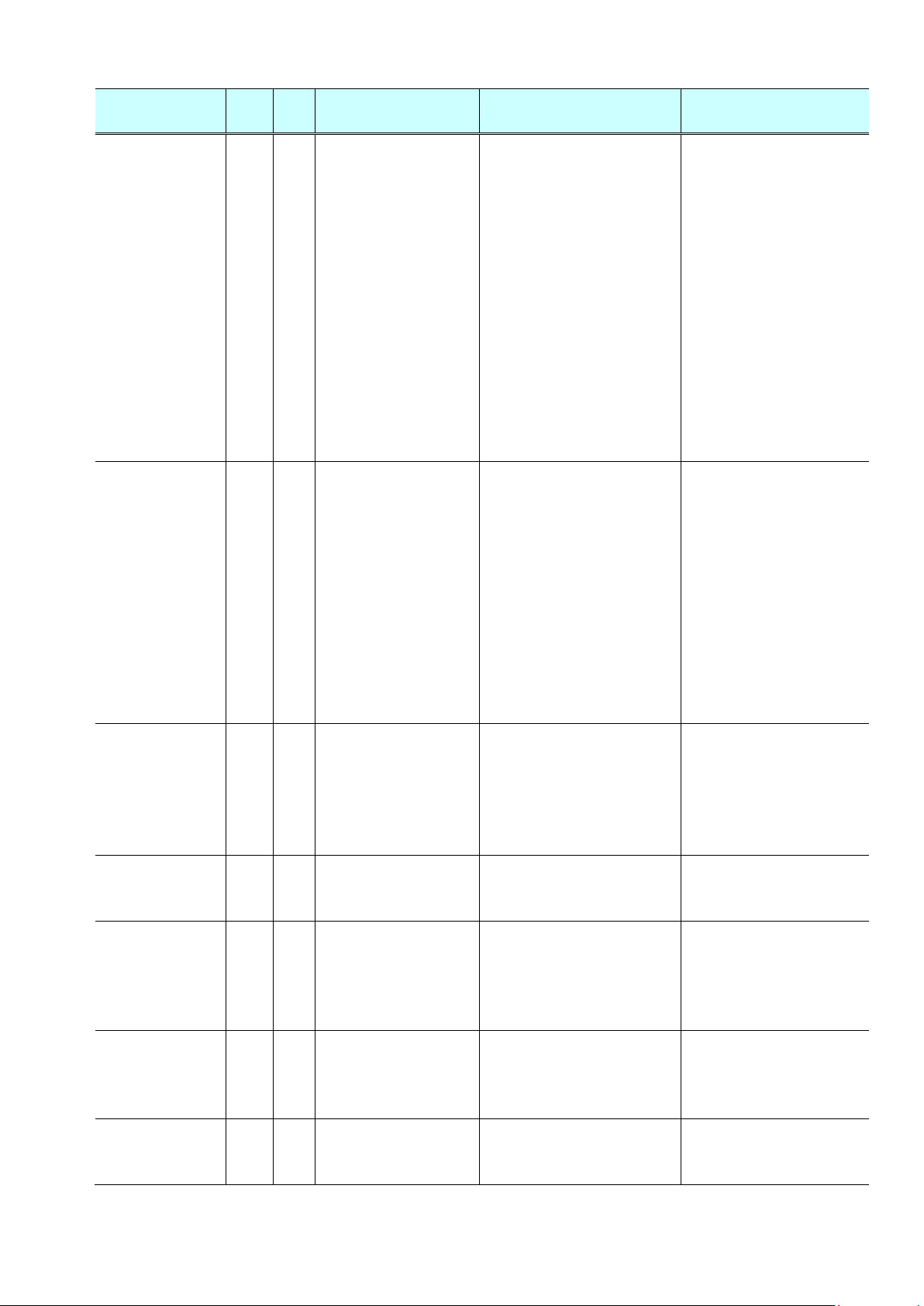

Error

Error

code

U No.

Message on the LCD

Solution

Parts that are likely to be

faulty

No ink (no raw

ink).

[1688]

U163

Ink has run out.

Replace the ink

cartridge.

Replace the empty ink

cartridge(s). Printing with an

empty ink cartridge can

damage the printer.

To continue printing without

replacing the ink

cartridge(s), press the Stop

button for 5 sec. or longer to

disable the function to detect

the remaining ink amount.

After the operation, it is

recorded in the printer that

the function to detect the

remaining ink amount was

disabled.

- Ink cartridge

- Logic board

Warning: The ink

absorber

becomes almost

full.

[1700]

---

The ink absorber is

almost full.

Replace the ink absorber,

and reset its counter. (See

2-1, Service Mode.)

Pressing the STOP button

will exit the error, and enable

printing without replacing the

ink absorber. However,

when the ink absorber

becomes full, no further

printing can be performed

unless the applicable ink

absorber is replaced.

- Ink absorber kit

The connected

digital camera or

digital video

camera does not

support Camera

Direct Printing.

[2001]

---

Incompatible device

detected.

Remove the device.

Remove the cable between

the camera and the printer.

- PictBridge harness

- Logic board

Non-supported

hub

[2002]

---

An unsupported USB

hub is connected.

Remove the hub.

Remove the applicable USB

hub from the PictBridge

(USB) connector.

- PictBridge harness

- Logic board

Paper jam in the

ADF

[2801]

---

Document in ADF.

Redo operation after

checking document in

ADF and pressing

[OK].

Remove the jammed paper

from the ADF, press the OK

button, then perform the

operation again.

- Document upper guide

unit

No paper in the

ADF

[2802]

---

No document in ADF.

Press [OK] and redo

operation after setting

document.

Press the OK button, set the

document in the ADF, and

perform the operation again.

- Document upper guide

unit

The paper in the

ADF is too long.

[2803]

---

Document is too long.

Press [OK] and redo

operation.

Press the OK button, and

perform the operation again.

- Document upper guide

unit

(4/37)

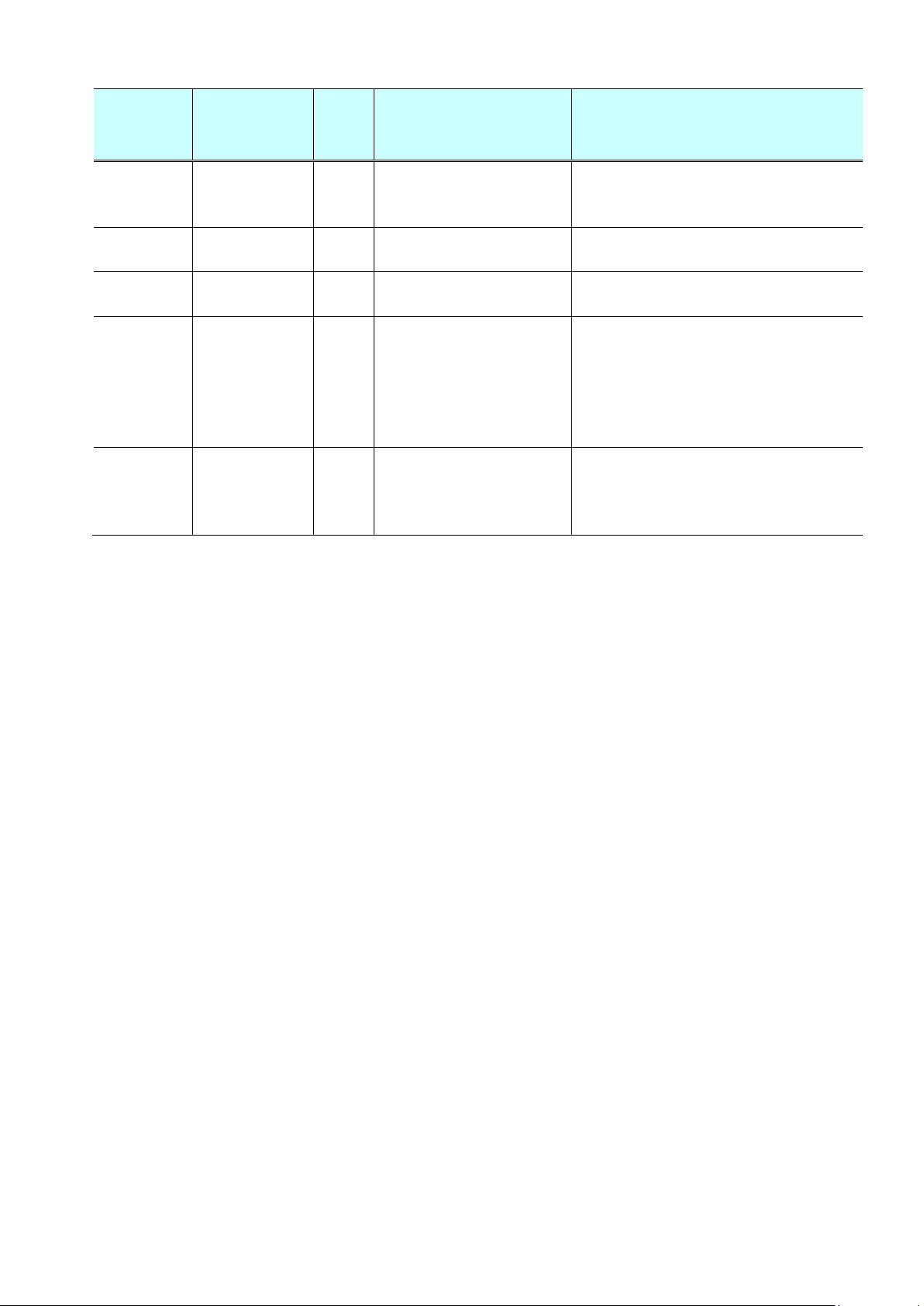

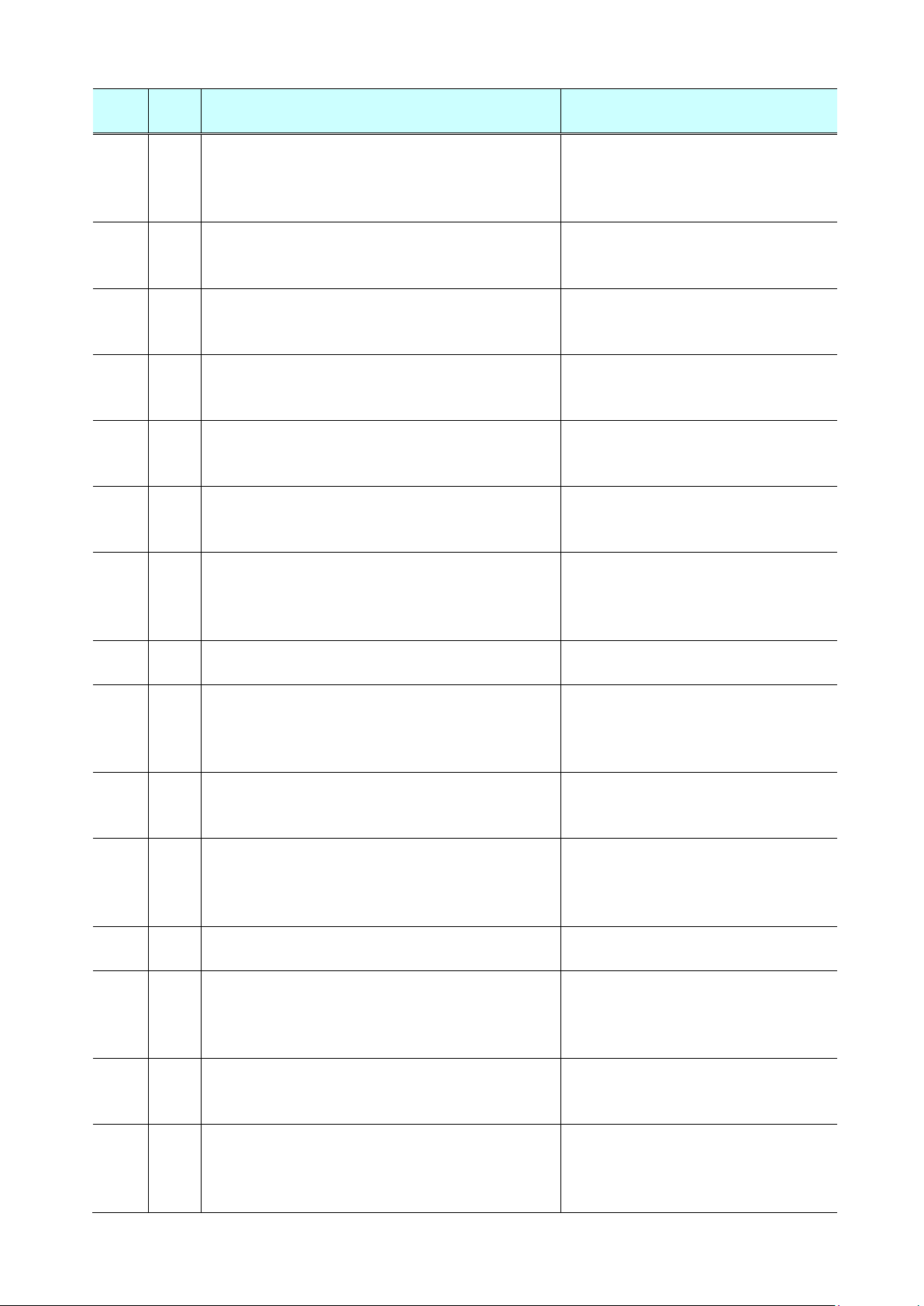

1-2. Service Call Errors (by Cyclic Blinking of Alarm and Power Lamps)

Cycles of

blinking of

Alarm and

Power LEDs

Error

Error

code

Conditions

Solution

(Check points and replacement items)

2 times

Carriage error

[5100]

An error occurred in the

carriage encoder signal.

1) Smearing or scratches on the timing

slit film;

clean the timing slit film.

2) Foreign material or paper debris that

obstructs the carriage movement;

remove foreign material.

3) Ink cartridge conditions;

reseat the ink cartridges.

4) Cable connection

5) Part replacement:

- Timing slit film

- Carriage unit

- Logic board

3 times

Line feed error

[6000]

An error occurred in the LF

encoder signal.

1) Smearing or scratches on the LF

encoder;

clean the LF encoder.

2) Foreign material or paper debris in the

LF drive;

remove foreign material.

3) Cable connection

4) Part replacement:

- LF encoder

- Logic board

5 times

ASF cam sensor

error

[5700]

An error occurred in the

ASF cam sensor (during

paper feeding from the rear

tray).

1) Cable connection

2) Part replacement:

- PE PWB unit

- Drive unit

- Logic board

6 times

Internal

temperature

error

[5400]

The internal temperature is

not normal.

1) Cable connection

2) Part replacement:

- Logic board

- Ink cartridge

7 times

Ink absorber full

[5B00]

The ink absorber is

supposed to be full.

1) Ink absorber condition

2) Part replacement:

- Ink absorber kit

3) Ink absorber counter value in the

EEPROM;

reset the ink absorber counter.

8 times

Print head

temperature rise

error

[5200]

The print head temperature

exceeded the specified

value.

1) Ink cartridge conditions

2) Cable connection

3) Part replacement:

- Ink cartridge

- Logic board

9 times

EEPROM error

[6800]

[6801]

A problem occurred in

reading from or writing to

the EEPROM.

1) Part replacement:

- Logic board

(5/37)

Cycles of

blinking of

Alarm and

Power LEDs

Error

Error

code

Conditions

Solution

(Check points and replacement items)

10 times

VH monitor error

[B200]

The print head voltage is

not normal.

1) Part replacement:

- Ink cartridge and logic board

- Power supply unit

15 times

USB VBUS

overcurrent

[9000]

The USB VBUS is

overloaded.

1) Part replacement:

- Logic board

20 times

Other errors

[6500]

1) Part replacement:

- Logic board

22 times

Scanner error

[5011]

An error occurred in the

scanner.

1) Document pressure sheet condition

2) Cable connection

3) Part replacement:

- Document pressure sheet

- Scanner unit

- Logic board

Power LED

turned off,

and Alarm

LED lit

ROM / RAM

error

---

The check sum value is

incorrect in the ROM check

or RAM check at

hard-power-on.

1) Part replacement:

- Logic board

(6/37)

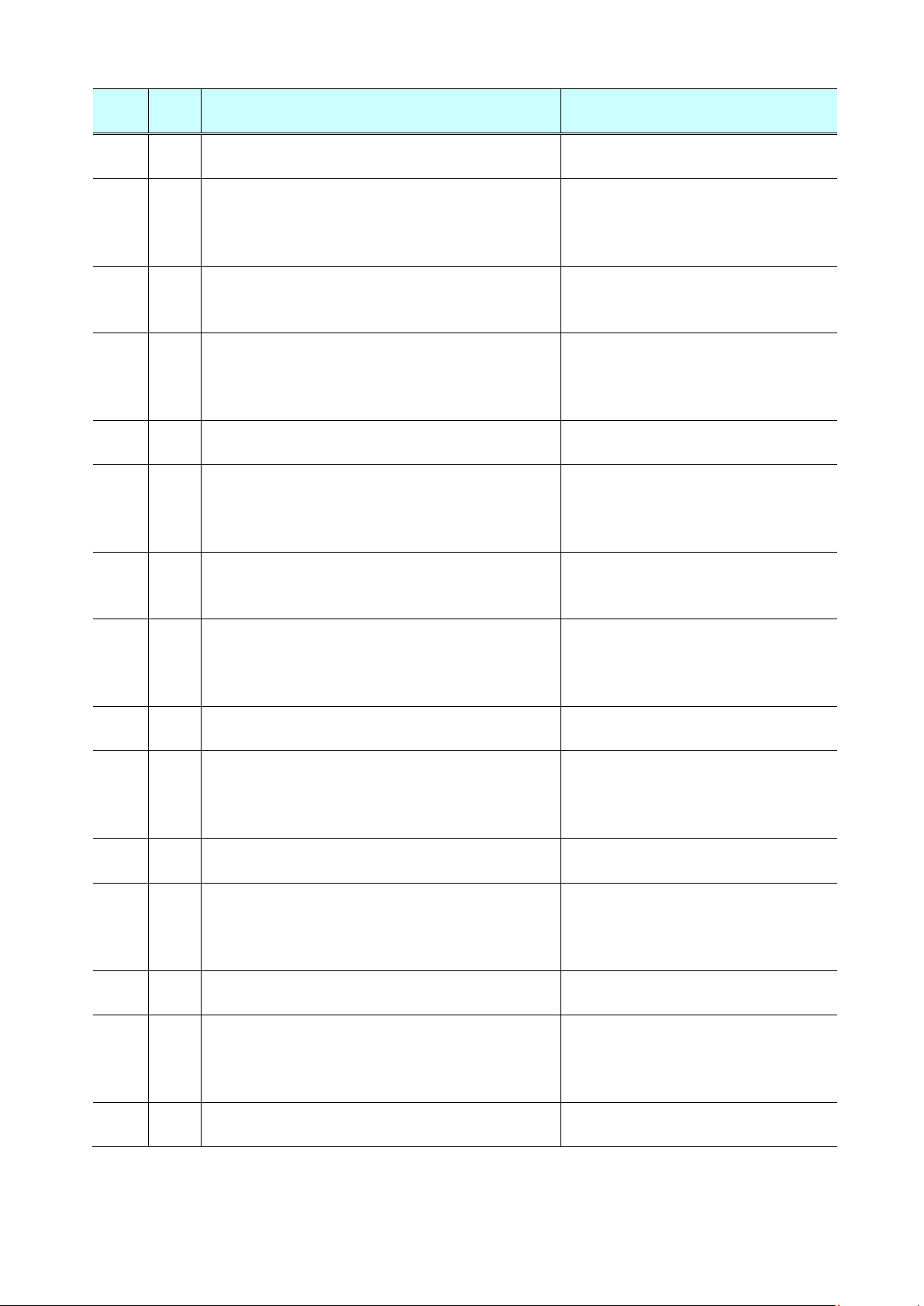

1-3. FAX Errors

Error

code

TX /

RX

Meaning

Solution

(parts that are likely to be faulty)

#001

TX

Document jam

- Document upper guide

#003

TX /

RX

Document is too long, or page time-over

- Document upper guide

#005

TX /

RX

Initial identification (T0 / T1) time-over

- Check the telephone line type settings

(rotary pulse / touch tone).

#012

TX

No recording paper at the receiving machine

#017

TX

Redial time-over, but no DT detected

#018

TX

Auto dialing transmission error, or redial time-over

- Check the telephone line type settings

(rotary pulse / touch tone).

#022

TX

Call failed (no dial registration)

- Register a dial number.

#037

RX

Memory overflow at reception of an image

- Delete unnecessary image data from

the memory.

#046

RX

Direct mail rejection (rejection of mail reception)

- Register the dial number of the calling

machine.

#059

TX

Dialed number not matches the CSI of the

connected machine

- Register the dial number (CSI)

properly on the receiving machine.

#085

TX

No color fax function supported in the receiving

machine

- Send a fax in the B&W mode.

#099

TX /

RX

Transmission terminated mid-way by pressing the

Stop button

#995

TX /

RX

During TX (sending):

Memory transmission reservation cancelled

During RX (receiving):

Image data received in the memory cleared

Error

code

TX /

RX

Meaning

Solution

(parts that are likely to be faulty)

##100

TX

Re-transmission of the procedure signal has been

attempted the specified number of times, but failed.

- Try a higher transmission level.

##101

TX /

RX

Sender's modem speed does not match the

receiving machine.

##102

TX

Fallback is not available.

- Try a higher transmission level.

##103

RX

EOL has not been detected for 5 seconds (or 15

seconds in CBT).

- Increase the transmission level of the

sending machine.

##104

TX

RTN or PIN has been received.

- Try a higher transmission level.

##106

RX

The procedure signal has been expected for 6

seconds, but not received.

- Increase the transmission level of the

sending machine.

##107

RX

Fallback is not available at the sending machine.

- Increase the transmission level of the

sending machine.

For errors other than those listed below, please refer to the "G3 / G4 Facsimile Error Code List (Rev.

2)" (HY8-23A0-020 in English).

< User error codes >

< Service error codes >

(7/37)

Error

code

TX /

RX

Meaning

Solution

(parts that are likely to be faulty)

##109

TX

After DCS transmission, a signal other than DIS,

DTC, FTT, CFR, or CRP has been received, and

re-transmission of the procedure signal has been

attempted the specified number of times but failed.

##111

TX /

RX

Memory error

- Eliminate all the data, and register

them again.

##114

RX

RTN has been received.

- Increase the transmission level of the

sending machine.

##200

RX

A carrier has not been detected for 5 seconds

during image reception.

- Increase the transmission level of the

sending machine.

##201

TX /

RX

DCN has been received in a method other than the

binary procedure.

- Set the other machine ready for

reception.

##204

TX

DTC has been received even when there is no

sending data.

##220

TX /

RX

System error (main program hang-up)

- Turn the machine off, and turn it on

again.

- NCU board

##224

TX /

RX

An error has occurred in the procedure signal in G3

transmission.

##226

TX /

RX

The stack pointer has shifted from the RAM area.

- Turn the machine off, and turn it on

again.

##229

RX

The recording area has been locked for 1 minute.

- After the area is unlocked, print the

recorded image.

##232

TX

The encoder control unit has malfunctioned.

- NCU board

##237

RX

The decoder control unit has malfunctioned.

- NCU board

##238

RX

The print control unit has malfunctioned.

- NCU board

- Logic board

##261

TX /

RX

A system error has occurred between the modem

and the system control board.

- NCU board

- Logic board

##280

TX

Re-transmission of the procedure signal has been

attempted the specified number of times, but failed.

- Try a higher transmission level.

##281

TX

Re-transmission of the procedure signal has been

attempted the specified number of times, but failed.

- Try a higher transmission level.

##282

TX

Re-transmission of the procedure signal has been

attempted the specified number of times, but failed.

- Try a higher transmission level.

##283

TX

Re-transmission of the procedure signal has been

attempted the specified number of times, but failed.

- Try a higher transmission level.

##284

TX

After TCF transmission, DCN has been received.

- Set the receiving machine ready for

reception.

##285

TX

After EOP transmission, DCN has been received.

- Re-send the fax.

##286

TX

After EOM transmission, DCN has been received.

- Re-send the fax.

##287

TX

After MPS transmission, DCN has been received.

- Re-send the fax.

##288

TX

After EOP transmission, a signal other than PIN,

PIP, MCF, RTP, RTN has been received.

##289

TX

After EOM transmission, a signal other than PIN,

PIP, MCF, RTP, RTN has been received.

##290

TX

After MPS transmission, a signal other than PIN,

PIP, MCF, RTP, RTN has been received.

(8/37)

Error

code

TX /

RX

Meaning

Solution

(parts that are likely to be faulty)

##670

TX

In V.8 late start, the DIS V.8 ability from the

receiving machine was detected, and CI was sent in

response; however, the procedure failed, causing

T1 time-over.

- In bit 0 of the service data #1 SSSW

SW28, prohibit the V.8 / V.34

procedure of the sending machine.

##671

RX

In V.8 call reception, the procedure fails to proceed

to phase 2 after CM detection, causing T1

time-over.

- In bit 0 of the service data #1 SSSW

SW28, prohibit the V.8 / V.34

procedure of the sending machine.

##672

TX

In V.34 transmission, the procedure fails to proceed

from phase 2 to phase 3 or later, causing T1

time-over

- In bit 0 of the service data #1 SSSW

SW28, prohibit the V.8 / V.34

procedure of the sending machine.

##673

RX

In V.34 reception, the procedure fails to proceed

from phase 2 to phase 3 or later, causing T1

time-over

- In bit 0 of the service data #1 SSSW

SW28, prohibit the V.8 / V.34

procedure of the sending machine.

##674

TX

In V.34 transmission, the procedure fails to proceed

from phase 3 or 4 to the control channel or later,

causing T1 time-over

- In bit 0 of the service data #1 SSSW

SW28, prohibit the V.8 / V.34

procedure of the sending machine.

##675

RX

In V.34 reception, the procedure fails to proceed

from phase 3 or 4 to the control channel or further,

causing T1 time-over

- In bit 0 of the service data #1 SSSW

SW28, prohibit the V.8 / V.34

procedure of the sending machine.

##750

TX

After transmitting PPS-NULL in ECM transmission,

no significant signal has been received, and

re-transmission of the procedure signal has been

attempted the number of specified times but failed.

- Try a higher transmission level.

##752

TX

After transmitting PPS-NULL in ECM transmission,

DCN has been received.

- Try a higher transmission level.

##753

TX

After transmitting PPS-NULL in ECM transmission,

re-transmission of the procedure signal has been

attempted the number of specified times but failed,

or T5 time-over (60 sec.) has occurred.

- Increase the period of time of the T5

time-over.

##754

TX

After transmitting PPS-NULL in ECM transmission,

re-transmission of the procedure signal has been

attempted the number of specified times but failed.

- Try a higher transmission level.

##755

TX

After transmitting PPS-MPS in ECM transmission,

no significant signal has been received, and

re-transmission of the procedure signal has been

attempted the number of specified times but failed.

- Try a higher transmission level.

##757

TX

After transmitting PPS-MPS in ECM transmission,

DCN has been received.

- Try a higher transmission level.

##758

TX

After transmitting PPS-MPS in ECM transmission,

re-transmission of the procedure signal has been

attempted the number of specified times but failed,

or T5 time-over (60 sec.) has occurred.

- Increase the period of time of the T5

time-over.

##759

TX

After transmitting PPS-MPS in ECM transmission,

re-transmission of the procedure signal has been

attempted the number of specified times but failed.

- Try a higher transmission level.

##760

TX

After transmitting PPS-EOM in ECM transmission,

no significant signal has been received, and

re-transmission of the procedure signal has been

attempted the number of specified times but failed.

- Try a higher transmission level.

(9/37)

Error

code

TX /

RX

Meaning

Solution

(parts that are likely to be faulty)

##762

TX

After transmitting PPS-EOM in ECM transmission,

DCN has been received.

- Try a higher transmission level.

##763

TX

After transmitting PPS-EOM in ECM transmission,

re-transmission of the procedure signal has been

attempted the number of specified times but failed,

or T5 time-over (60 sec.) has occurred.

- Increase the period of time of the T5

time-over.

##764

TX

After transmitting PPS-EOM in ECM transmission,

re-transmission of the procedure signal has been

attempted the number of specified times but failed.

- Try a higher transmission level.

- Increase the transmission level of the

receiving machine.

##765

TX

After transmitting PPS-EOP in ECM transmission,

no significant signal has been received, and

re-transmission of the procedure signal has been

attempted the number of specified times but failed.

- Try a higher transmission level.

- Increase the transmission level of the

receiving machine.

##767

TX

After transmitting PPS-EOP in ECM transmission,

DCN has been received.

- Try a higher transmission level.

##768

TX

After transmitting PPS-EOP in ECM transmission,

re-transmission of the procedure signal has been

attempted the number of specified times but failed,

or T5 time-over (60 sec.) has occurred.

- Increase the period of time of the T5

time-over.

##769

TX

After transmitting PPS-EOP in ECM transmission,

re-transmission of the procedure signal has been

attempted the number of specified times but failed.

- Try a higher transmission level.

- Increase the transmission level of the

receiving machine.

##770

TX

After transmitting EOR-NULL in ECM transmission,

no significant signal has been received, and

re-transmission of the procedure signal has been

attempted the number of specified times but failed.

- Try a higher transmission level.

- Increase the transmission level of the

receiving machine.

##772

TX

After transmitting EOR-NULL in ECM transmission,

DCN has been received.

- Try a higher transmission level.

##773

TX

After transmitting EOR-NULL in ECM transmission,

re-transmission of the procedure signal has been

attempted the number of specified times but failed,

or T5 time-over (60 sec.) has occurred.

- Increase the period of time of the T5

time-over.

##774

TX

After transmitting EOR-NULL in ECM transmission,

ERR has been received.

- Try a higher transmission level.

##775

TX

After transmitting EOR-MPS in ECM transmission,

no significant signal has been received, and

re-transmission of the procedure signal has been

attempted the number of specified times but failed.

- Try a higher transmission level.

##777

TX

After transmitting EOR-MPS in ECM transmission,

DCN has been received.

- Try a higher transmission level.

##778

TX

After transmitting EOR-MPS in ECM transmission,

re-transmission of the procedure signal has been

attempted the number of specified times but failed,

or T5 time-over (60 sec.) has occurred.

- Increase the period of time of the T5

time-over.

##779

TX

After transmitting EOR-MPS in ECM transmission,

ERR has been received.

- Try a higher transmission level.

(10/37)

Loading...

Loading...