Canon NP6330 Service Handbook

SERVICE

HANDBOOK

REVISION 0

FY8-23AQ-000

MAY 1997

COPYRIGHT © 1997 CANON INC. CANON NP6330 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE OF

REFERENCE FOR WORK IN THE FIELD.

SPECIFICA TIONS AND OTHER INFORMATION CONTAINED HEREIN MA Y VARY SLIGHTLY FROM

ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER PRINTED

MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED TO

THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENTATION IS INTENDED FOR ALL SALES AREAS, AND MAY CONTAIN

INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1997 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPT. 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIV.

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302, Japan

COPYRIGHT © 1997 CANON INC. CANON NP6330 REV.0 MAY 1997 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

CONTENTS

CHAPTER 1 MAINTENANCE AND INSPECTION

A. Image Adjustment Basic

Procedure....................................1-1

B. Points to Note for

Scheduled Servicing ....................1-3

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Adjusting the Images....................2-1

1. Adjusting the Image

Leading Edge

Margin [3] No.305 ...................2-1

2. Adjusting the Leading

Edge Non-Image Width

[3] No.306................................2-2

3. Adjusting the Trailing Edge

Non-Image width [3] No.307...2-3

4. Adjusting the Left/Right

Registration ............................2-4

5. Adjusting the Image

Left/Right Margin [3] No.308...2-6

6. AE Adjustment ........................2-8

7. Adjusting the Developing

Bias DC Component [3]

No.302...................................2-12

8. Adjusting the Horizontal

Registration Paper Edge

Sensor postion [3] No.324 ....2-13

9. Adjusting the Trailing Edge

Margin for Pick-Up from the

Multifeeder [3] No.327...........2-14

10.Adjusting the Book Erasing

Width [3] No.326 ...................2-15

B. Exposure System.......................2-16

1. Routing the Scanner Drive

Cable.....................................2-16

2. Adjusting the Position of the

Mirror (optical path length

between No.1 mirror and

No.2/No.3 mirror) ..................2-17

3. Adjusting the Tension of

the Scanner Cable ................2-19

4.

Adjusting the Tension of the

Lens Drive Belt

.......................2-20

5. Cleaning the No.4 Mirror ......2-20

6.

Cleaning the No.5/No.6 Mirror

.....2-21

C.

Image Formation System

.............2-23

1. Orientation of the Scanning

Lamp .....................................2-23

2. Position of the Blank Shutter

Solenoid ................................2-23

3. Routing the Blank Shutter

Cable.....................................2-24

4. Routing the Charging Wire ..2-25

5. Stringing the Guide Wire ......2-26

6. Adjusting the Height of

the Charging Wire.................2-26

7. Position of the Developing

Assembly Magnetic Seal.......2-27

8. After Replacing the Drum

unit ........................................2-27

D. Pick-Up/Feeding System............2-28

1. Orientation of the Pick-Up

Roller ....................................2-28

2. Orientation of the Separation

Roller ....................................2-28

3. Orientation of the Feeding

Roller.....................................2-28

4. Adjusting the Pressure of the

Separation Roller

(cassette/deck)......................2-29

5. Position of the Pick-Up Roller

Solenoid (pick-up assembly;

SL1,SL2) ...............................2-30

6. Orientation of the Multifeeder

Pick-Up Roller ......................2-30

1

2

3

4

5

7. Position of the Pick-Up Guide

Plate Cam

(multifeeder assembly) ..........2-31

8. Routing the Timing Belt

(multifeeder assembly) ..........2-31

9. Adjusting the Pressure of the

Separation Pad

(multifeeder assembly) ..........2-32

10.Routing the Drive Belt...........2-32

11.Adjusting the Position of the

Horizontal Registration

Solenoid ................................2-33

E. Fixing System.............................2-34

1. Points to Note When Installing

the Fixing Heater...................2-34

2. Adjusting the Nip (tightening

the pressure adjusting nut) ..2-35

3. Position of the Fixing

Assembly Paper Guide .........2-36

4. Position of the Cleaning Belt

Solenoid ................................2-36

F. Electrical System........................2-37

1. Registering the Cassette/

Multifeeder Paper Width

Basic Setting [4]....................2-37

2. Adjusting the Original Stop

Position with the DF in Use

[3] No.325..............................2-40

3. Checking the

Photointerrupters...................2-41

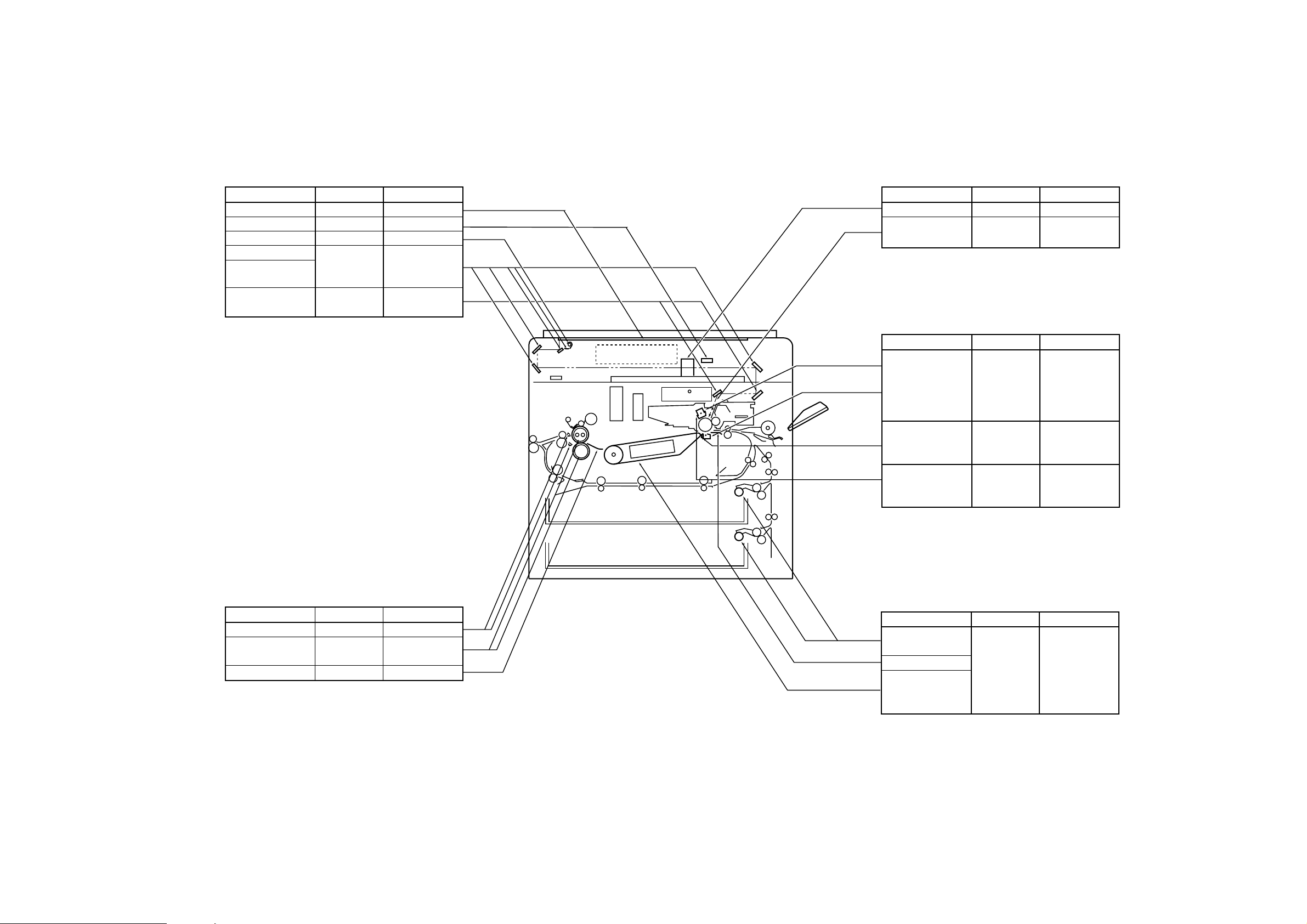

CHAPTER 3 ARRANGEMENT/FUNCTIONS OF

THE ELECTRICAL PARTS

A. Sensors........................................3-2

B. Switches clutches, and

solenoids......................................3-4

C. Heaters, lamps, and motors.........3-6

D. PCBs............................................3-8

E. Paper deck pedestal-M1............3-10

F. Variable Resistors, Light-

Emitting Diodes, and Check

Pins by PCB...............................3-12

CHAPTER 4 SERVICE MODE

A. Outline..........................................4-1

B. Using Service Mode.....................4-1

1. Starting Service Mode.............4-2

C. Using Adjustment Mode and

Optional Setting Mode..................4-3

D. Control/Display Mode [1]..............4-4

1. DC Controls PCB..................3-13

2. HVT.......................................3-14

3. Lamp Regulator PCB............3-14

4. Motor driver 1 PCB ...............3-15

5. Motor driver 2 PCB ...............3-15

6. Pedestal controller PCB

(Paper deck pedestal)...........3-16

E. I/O Display Mode [2] ..................4-19

F. Adjustment Mode [3]..................4-43

G. Function Mode [4] ......................4-45

H. Optional Settings [5]...................4-47

I. Counter Mode [6] .......................4-49

ii

CHAPTER 5 SELF DIAGNOSIS

A. Copier...........................................5-1

B. Pedestal Self Diagnosis...............5-5

APPENDIX

A. GENERAL TIMING CHART.........A-1

B.

SIGNALS AND ABBREVIATIONS

C. GENERAL CIRCUIT DIAGRAM ..A-5

(not available in electronic format)

D. PEDESTAL CONTROLLER.........A-7

(not available in electronic format)

....A-2

C. RDF/ADF Self Diagnosis ..............5-6

D. Sorter Self Diagnosis ...................5-7

E. SPECIFICATIONS .......................A-9

1. Copier .....................................A-9

2. Paper Deck Pedestal-M1......A-15

iii

CHAPTER 1 MAINTENANCE AND INSPECTION

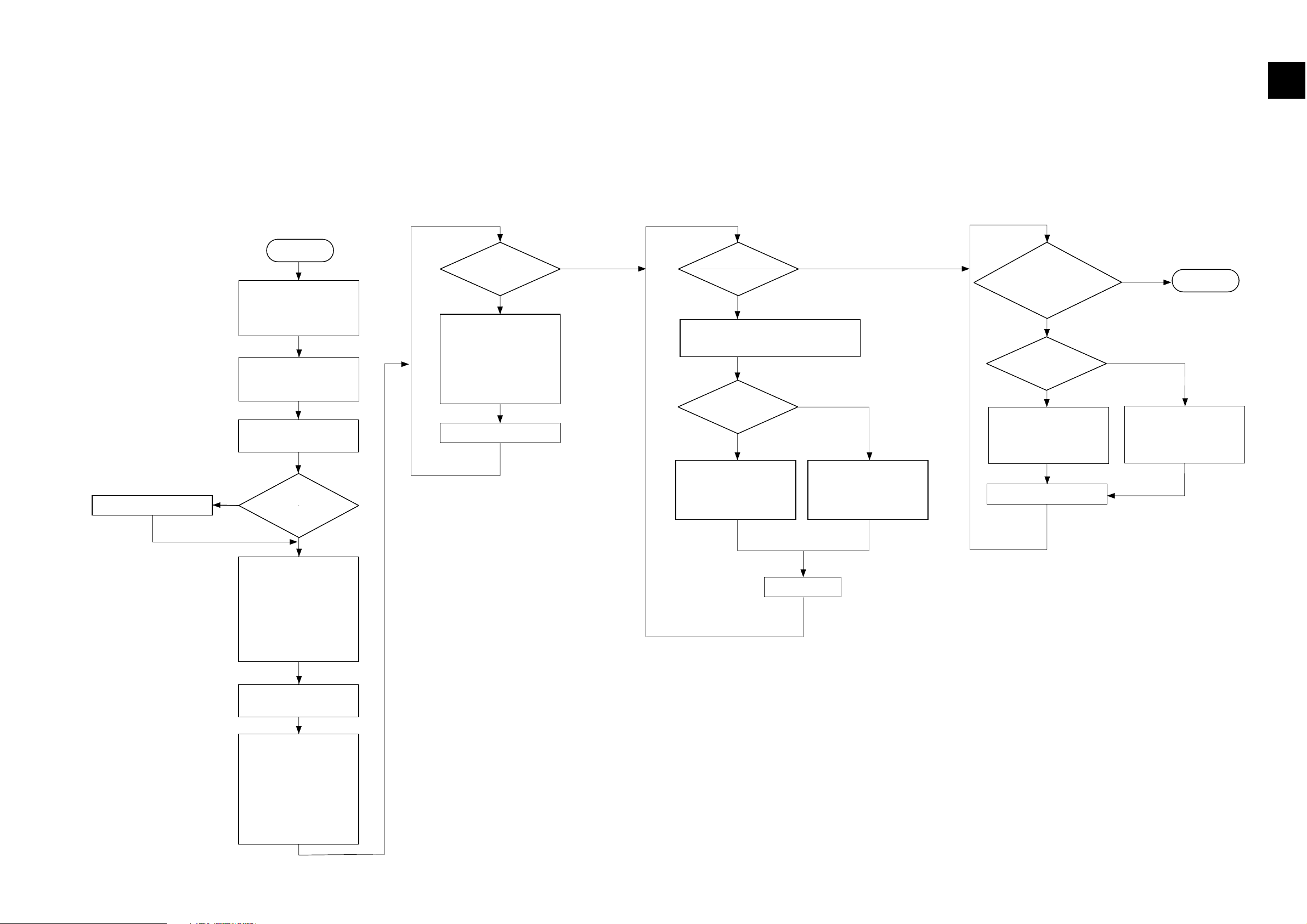

A. Image Adjustment Basic Procedure

non-AE, copy density at 5

1-1

Is the density of

gray scale No. 1

too light?

Is there a

difference in density between

front and rear?

Clean the primary

charging wire and the

static eliminator.

Execute 'U25' in user

mode (wire cleaning) to

clean the transfer

charging wire.

Make a copy.

Is it higher at front

Turn the adjusting screw

at the front of the primary

corona assembly

counterclockwise.

Turn the adjusting screw

at the front of the primary

corona assembly

clockwise.

Decrease the setting of

‘302’ in service mode [3]

so that the density of No.

9 decreases (Note 1)

Increase the setting of

‘302’ in service mode [3]

so that the density of No.

9 increases (Note 1)

Is the density

of gray scale No. 9

identical to the density of No. 8

through No. 9 of

the chart?

Is the density

of gray scale No. 9 too

high (dark)?

Pre-Check

Checks on Solid Black Density Adjustment on Density Slope

Optimum Density Adjustment

YES

NO NO

YES

NO

Make a copy.

YES

NO

YES

NO

YES

Start

Make a copy.

Adjust the slit according to the slit plate

adjustment procedure (next page)

Turn the adjusting screws

in the front and at the rear

of the primary corona

assembly counterclockwise

to move the primary corona

wire closer to the drum.

Check the height of the

corona wires.

Is the setting of ‘U21’

(density correction) in user

mode the middle

value?

Set it to the middle value.

Check to make sure that the

settings of ‘301’ and ‘302’ in

service mode [3] are as

indicated on the service

label attached to the front

door; otherwise, correct the

settings.

non-AE, copy density at 5,

2 to 3 copies (NA-3)

Check the following:

1. difference in density

between front and rear

2. density of gray scale

No. 9

3. presence/absence of

fogging in white

background

YES

NO

Note1: A shift is mode in the

control table for the

intensity of scanning

lamp.

End

1

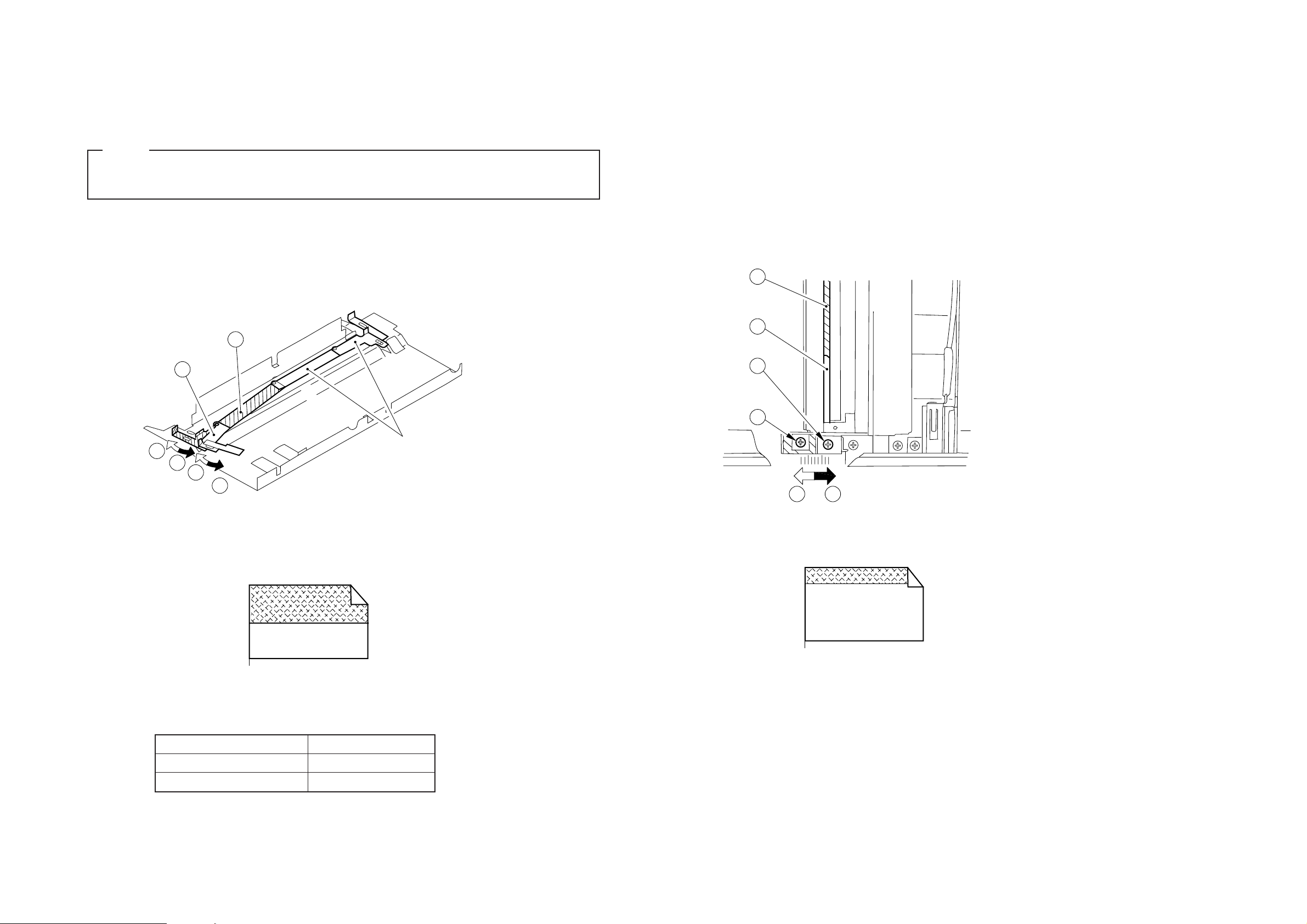

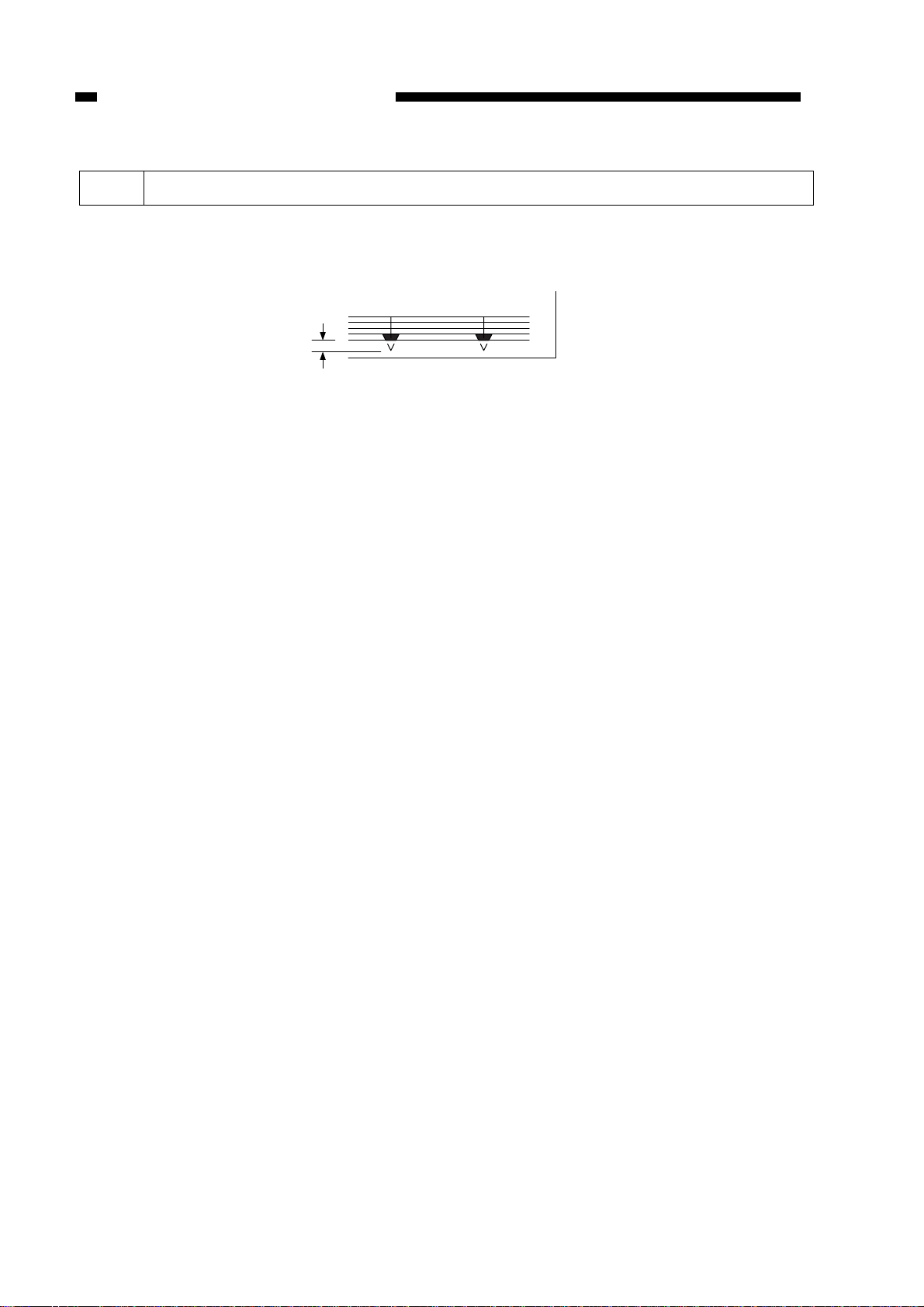

Adjusting the Slit Plate

q by loosening the screw r, the change will affect

the area from the center to the rear end.,

Note:

A

A

B

B

1

2

Rear slit plates

(These plates cannot be adjusted.)

1

2

3

4

BA

If you adjusted the slit w by loosening the screw e, the change will affect

the image end (up to a point about 30 mm from the rear).

A 3

Leading edge

A 3

{

30 mm (approx.)

Leading edge

Slit adjustment direction

A

B

Image density

Lighter

Darker

• Use only the slit plate at the front.

• If you must replace the drum unit, be sure to put the slit plate back to the white marking.

1) Turn off the power switch, and disconnect the power plug from the power outlet.

2) Remove the copyboard glass, and move the No.1 mirror mount to the center, where work is facilitated.

3) Adjust the slit plate at the front by referring to the table below.

If you adjusted the slit

1-2

B. Points to Note for Scheduled Servicing

Copyboard/Scanning system

Part tool/solvent work/remarks

Copyboard glass Alchol Cleaning

Original size sensor Blower blush Cleaning

Scanning lamp Lint-free paper Dry-wiping

Reflecting plate Blower blush.

No.1 to No.4

mirrors

No.5 to No.6 Mirror cleaning Cleaning

mirrors tool

Fixing assembly

Part tool/solvent work/remarks

Separation claw Solvent Cleaning

Upper roller/ Cleaning oil Cleaning

Lower roller (TKN-0464)

Inlet guide Solvent Cleaning

Pick-up/feeding assembly

Part tool/solvent work/remarks

Pick-up Moist cloth* Cleaning

roller

Transfer guide

Feeding belt

Feeding

assembly mount

Corona units

Part tool/solvent work/remarks

Optical path

Part tool/solvent work/remarks

Lens Brower brush Cleaning

Dust-proofing Brower brush Cleaning

glass

*Make sure the parts are completely dry.

Primary

corona unit

Transfer

corona unit

Static

eliminator

Primary

corona unit

grid

Alchol

lint-free paper

Brush

Blower brush

Dry wipe it,

there after,

clean it using

lint-free paper

with alchol

Use a cleaning

brush

Cleaning

If dirt cannot be

removed, use

lint -free paper.

1-3

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Adjusting the Images

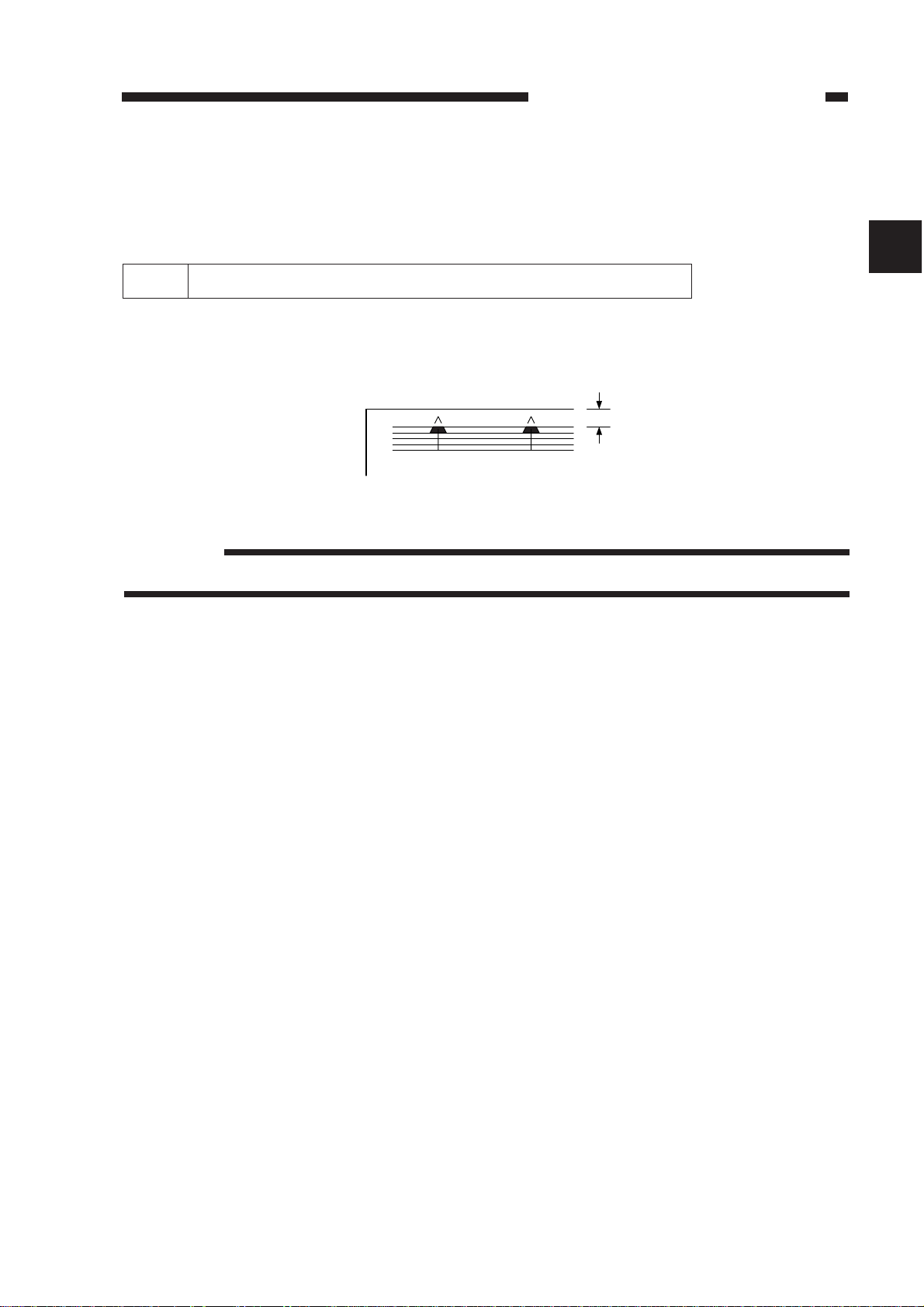

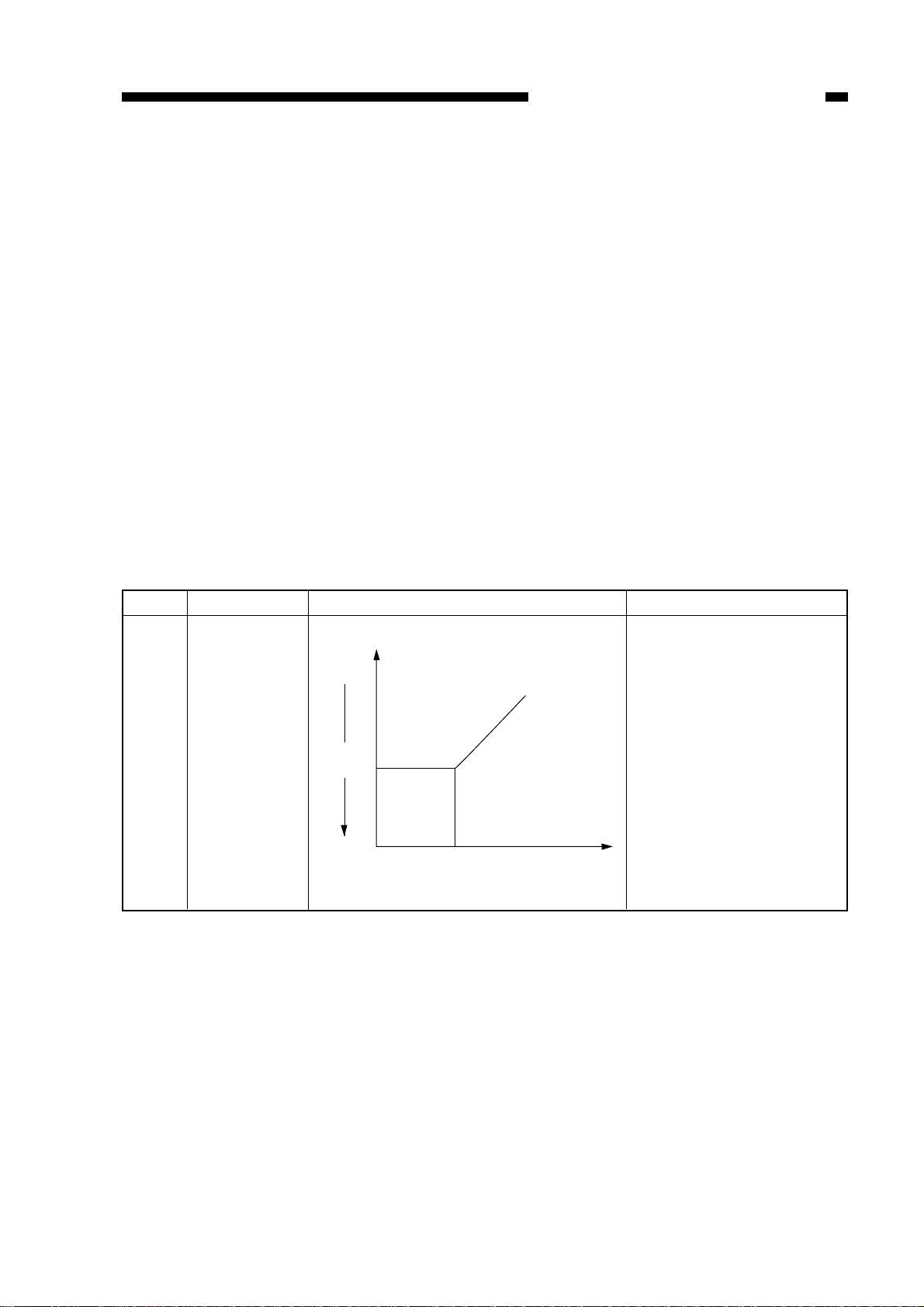

1 Adjusting the Image Leading Edge Margin [3] No. 305

Select [3] No. 305 (leading edge margin adjustment) in service mode, and make

adjustments so that the image leading edge margin is 2.5 ±1.5 mm when the Test Sheet

is copied in Direct.

Figure 2-1

Reference:

2nd side of 2-sided copy: 2.5 ±2.0 mm

Making Adjustments

1) Start [3] in service mode, and select No. 305 using the keypad.

• The display indicates ‘305’.

2) Press the OK key.

• The indicator indicates the stored setting.

3) Using the keypad or the Zoom keys, change the setting.

• The indicator flashes the setting.

• To enter a negative setting, press the % key.

4) Press the OK key.

• The new setting is stored.

• The indicator stops flashing and remains on.

• A press on the Copy Start key starts copying.

5) To change the settings in succession, repeat steps 3) and 4).

6) Press the Clear key to return to item selection.

The settings and the image positions have the following relationships:

• For each ‘1’ in the setting, the margin width changes about 0.4 mm.

• A higher setting decreases the margin width.

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-1

2

2.5 ±1.5 mm

CHAPTER 2 STANDARDS AND ADJUSTMENTS

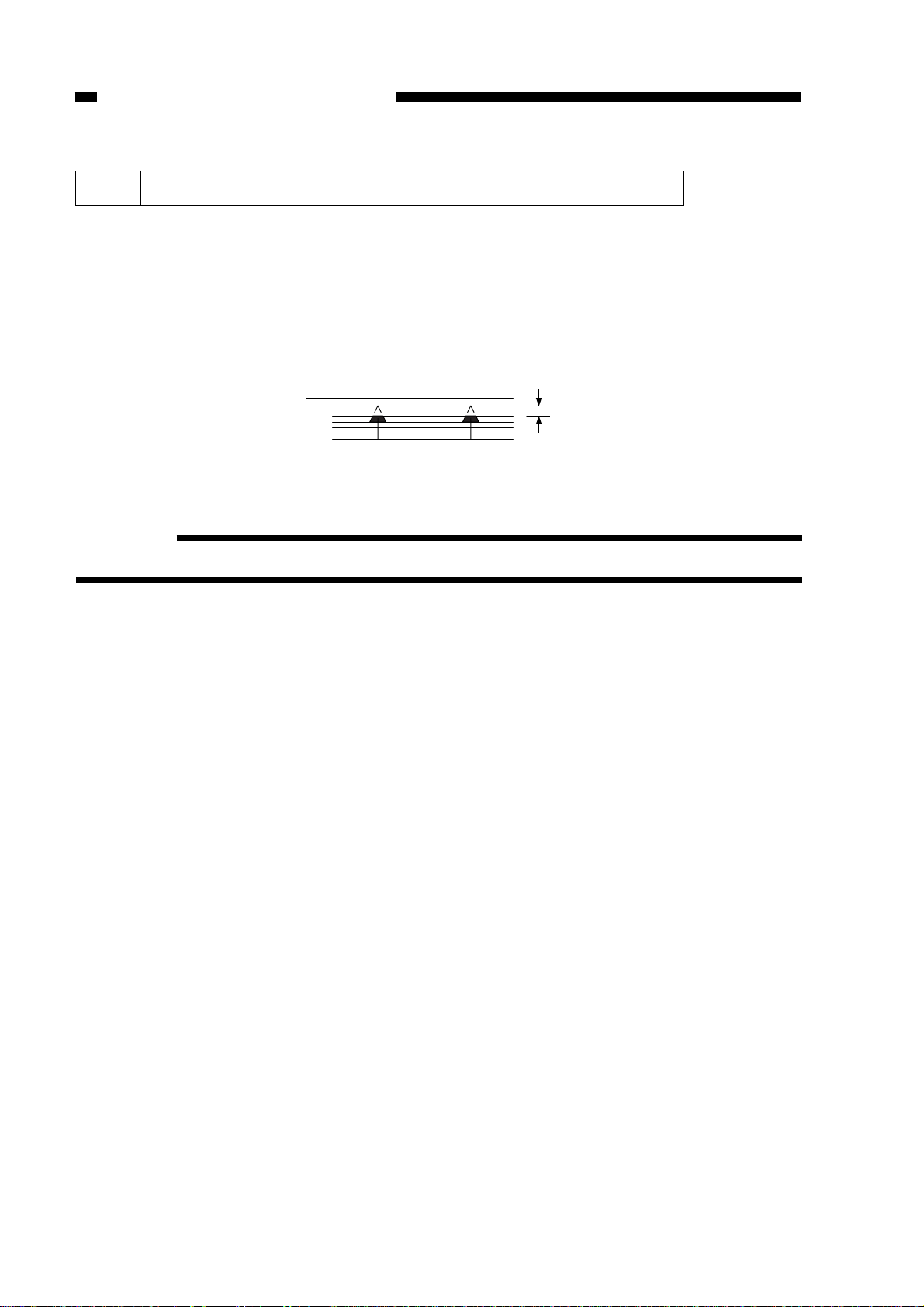

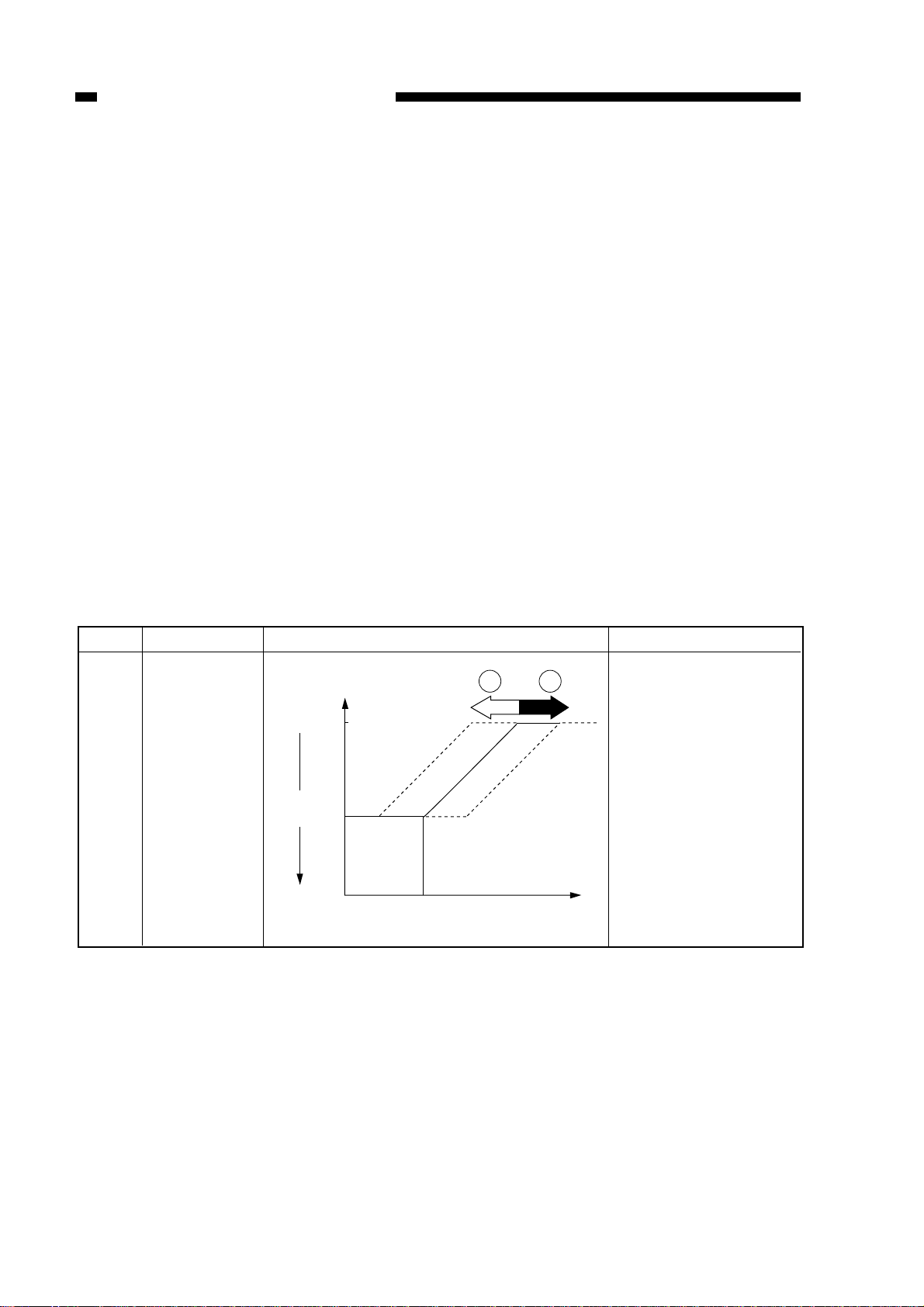

2 Adjusting the Leading Edge Non-Image Width [3] No. 306

Select [3] No. 306 in service mode (leading edge non-image width adjustment), and

make adjustments so that the leading edge non-image width is 2.0 ±1.0 mm when the

Test Sheet is copied in Direct.

The copier adjusts the leading edge non-image width in relation to the timing at

which the blank shutter is closed.

Be sure to perform the following steps whenever you have replaced the blank shutter

solenoid or the blank exposure assembly.

2.0 ±1.0 mm

Figure 2-2

Reference:

6 mm or less in Reduce or Enlarge mode (however, 8 mm or less at 50%)

Making Adjustments

1) Start [3] in service mode, and select No. 306 using the keypad.

• The indicator indicates ‘306’.

2) Press the OK key.

• The indicator indicates the stored setting.

3) Using the keypad or the Zoom keys, change the setting.

• The indicator flashes the setting.

• To enter a negative setting, press the % key.

4) Press the OK key.

• The new setting is stored.

• The indicator stops flashing and remains on.

• A press on the Copy Start key starts copying.

5) To change the settings in succession, repeat steps 3) and 4).

6) Press the Clear key to return to item selection.

The settings and the image positions have the following relationships:

• For each ‘1’ in the setting, the margin width changes about 0.4 mm.

• A higher setting increases the margin width.

2-2

CHAPTER 2 STANDARDS AND ADJUSTMENTS

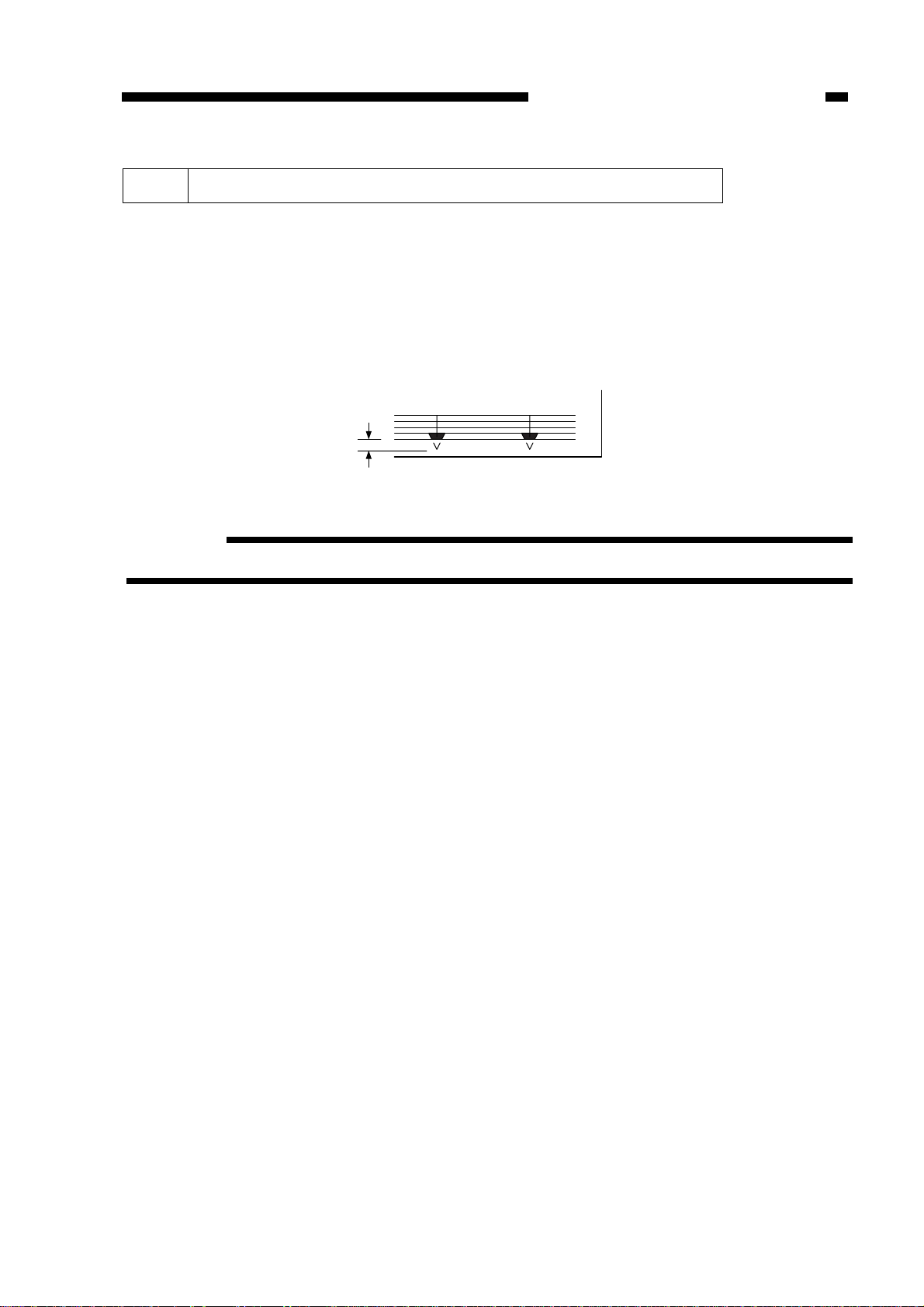

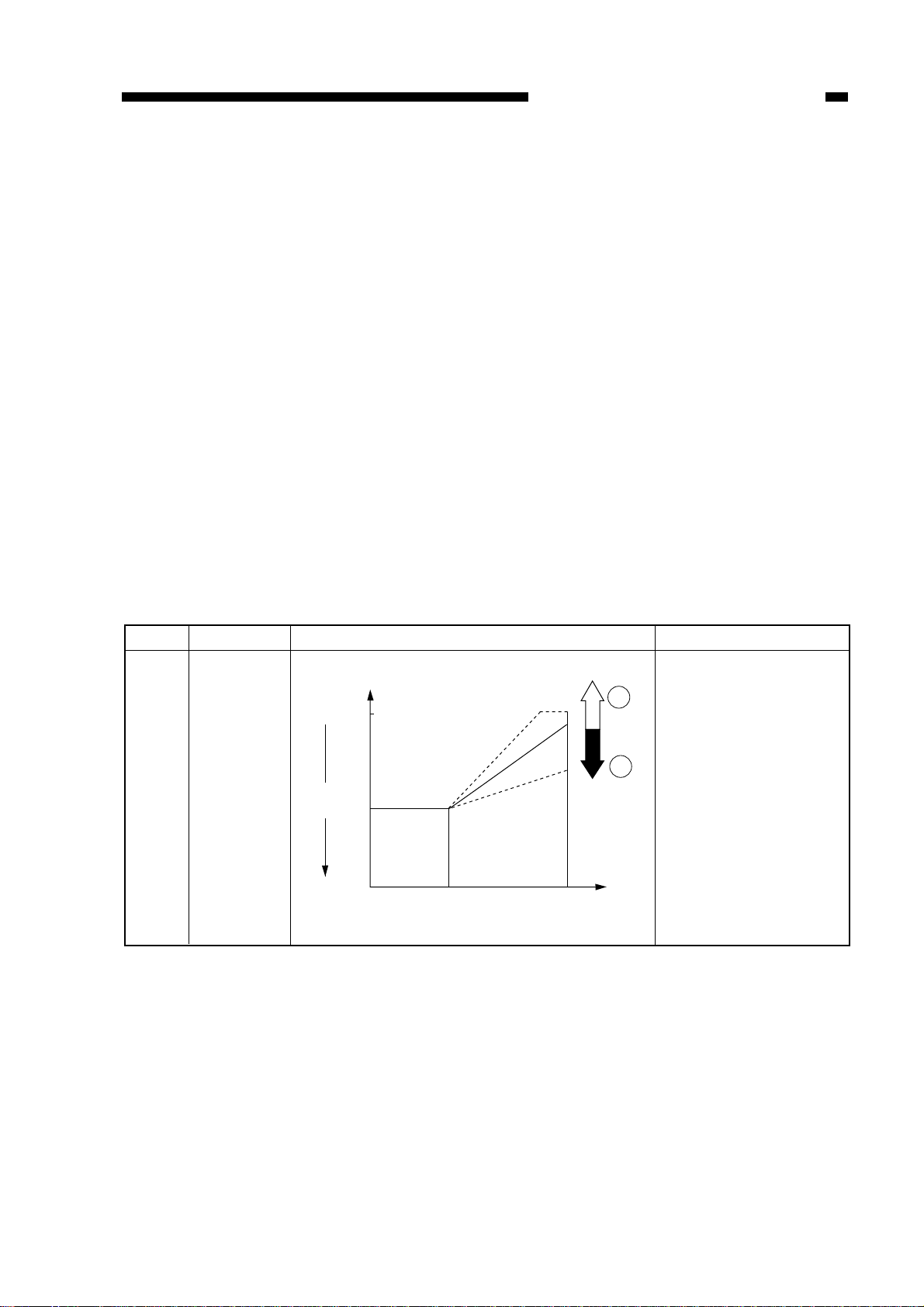

3 Adjusting the Trailing Edge Non-Image Width [3] No. 307

Select [3] No. 307 in service mode (trailing edge non-image width adjustment), and

make adjustments so that the trailing edge non-image width is 2.5 ±1.5 mm when the

Test Sheet is copied in Direct.

The copier adjusts the trailing edge non-image width in relation to the timing at which

the blank shutter is closed.

Be sure to perform the following steps whenever you have replaced the blank shutter

solenoid or the blank exposure assembly.

2.5 ±

1.5 mm

Figure 2-3

Reference:

8 mm or less in Reduce or Enlarge mode

Making Adjustments

1) Select [3] in service mode, and select No. 307 using the keypad.

• The indicator indicates ‘307’.

2) Press the OK key.

• The indicator indicates the stored setting.

3) Change the setting using the keypad or the Zoom keys.

• The indicator flashes the setting.

• To enter a negative setting, press the % key.

4) Press the OK key.

• The new setting is stored.

• The indicator stops flashing and remains on.

• A press on the Copy Start key starts copying.

5) To change the settings in succession, repeat steps 3) and 4).

6) Press the Clear key to return to item selection.

The settings and the image positions have the following relationships:

• For each ‘1’ in the setting, the margin width changes about 0.4 mm.

• A higher setting decreases the margin width.

2-3

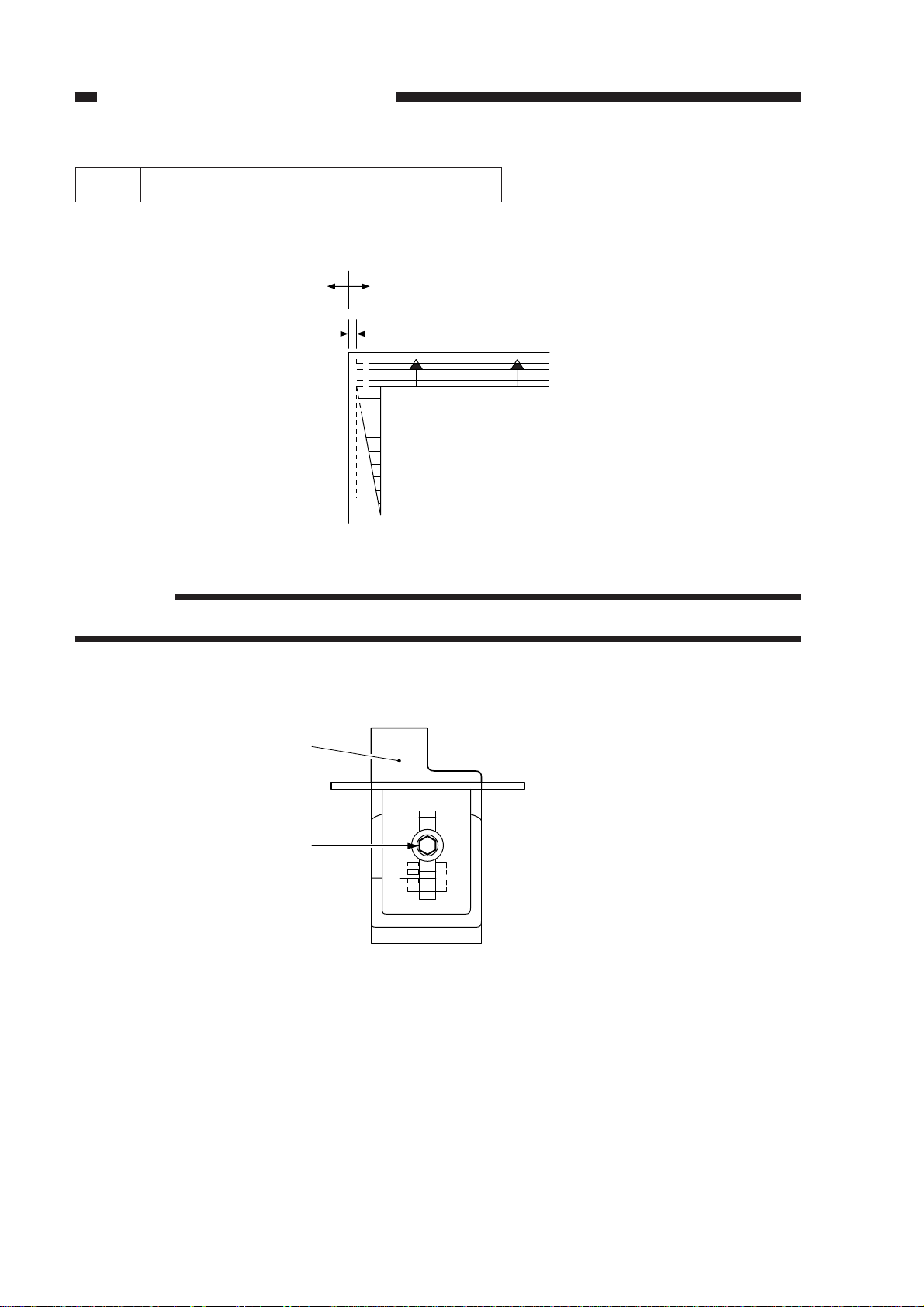

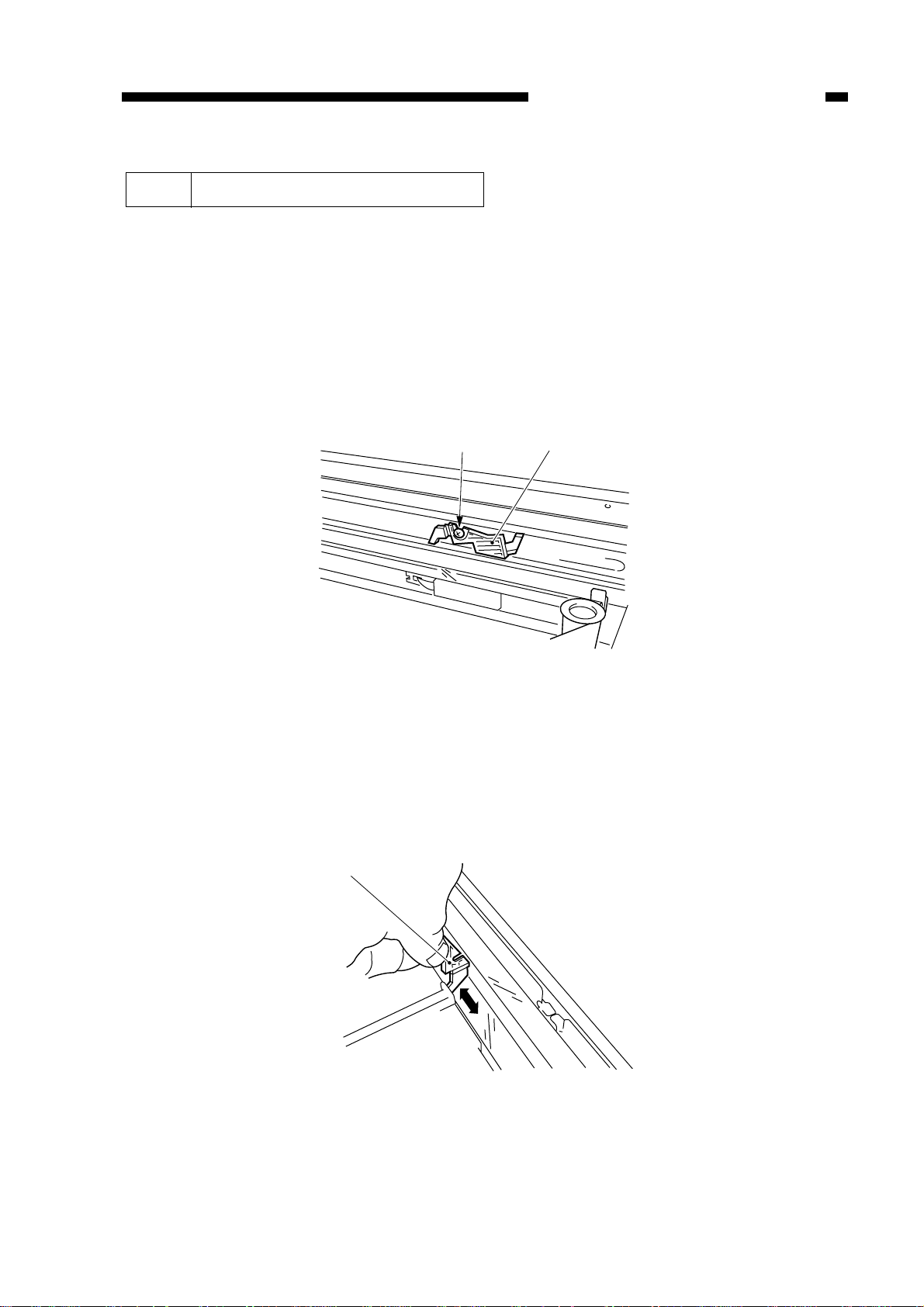

q, and adjust the position of the cassette hook plate w.

Figure 2-5

2-4

CHAPTER 2 STANDARDS AND ADJUSTMENTS

4 Adjusting the Left-Right Registration

Make adjustments so that the edges of the copy image and the copy are 0±1.5 mm

from each other.

(–) (+)

0 ±1.5 mm

0

2

4

6

8

10

Reference:

2nd side of 2-sided copy: 0 ±2.0 mm

a. Pick-Up from the Cassette

Loosen the screw

w

q

Figure 2-4

CHAPTER 2 STANDARDS AND ADJUSTMENTS

q

q

q

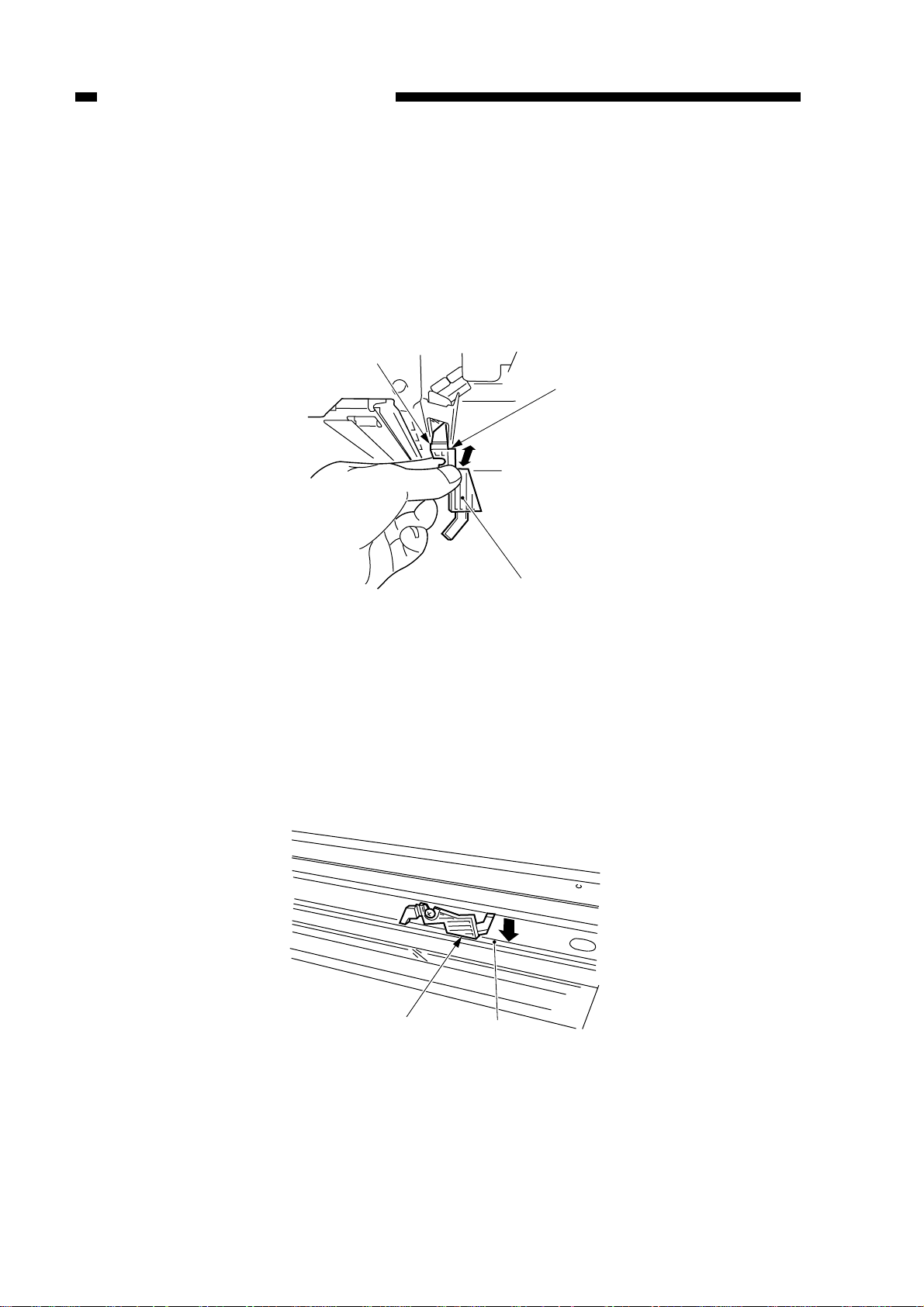

b. Pick-Up from the Multifeeder

Loosen the screw q, and adjust the position of the tray.

Figure 2-6

c. Pick-Up from the Paper Deck

Remove the deck front cover, and loosen the screw q (deck left/right); then, adjust

the position of the latch assembly in front/rear direction.

Figure 2-7

Figure 2-8

2-5

CHAPTER 2 STANDARDS AND ADJUSTMENTS

5 Adjusting the Image Left-Right Margin [3] No. 308

Select [3] No. 308 in service mode (left/right margin adjustment), and make

adjustments so that the image left/right margin is 2.5 ±1.5 mm when the Test Sheet is

copied in Direct.

Be sure you have adjusted the left/right registration before performing the following

steps.

Reference:

2nd side of 2-sided copies: 2.5 ±2.0 mm

Making Adjustments

a. Margin Width

1) Select [3] in service mode, and select No. 308 using the keypad.

• The indicator indicates ‘308’.

2) Press the OK key.

• The indicator indicates the stored setting.

3) Using the keypad or the Zoom keys, change the setting.

• The indicator flashes the new setting.

4) Press the OK key.

• The new setting is stored.

• The indicator stops flashing and remains on.

5) To change the settings in succession, repeat steps 3) and 4).

6) Press the Clear key to return to item selection.

The settings and the image positions have the following relationships:

• For each ‘1’ in the setting, the margin width changes about 0.37 mm.

• A higher setting increases the margin width.

Shutter

Adjusts the distance

between the two shutters

2-6

(+)

(-)

Figure 2-9

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Adjusting screw

Shutter

Shifts the entire

shutter

b. Adjusting the Position of the Left/Right Margin

Turn the screw, and make adjustments to suit the standards.

• A clockwise turn moves the margin toward the front.

• A counterclockwise turn moves the margin to the rear.

• A full turn of the screw moves the image by about 1 mm.

Figure 2-10

Figure 2-11

Note:

For both a. and b., be sure to try different reproduction ratios after adjustments so

that a blank shutter home position search will be executed.

2-7

∆ as

necessary.

First, execute [4] No. 402 in service mode (AE auto adjustment) for automatic

adjustments.

If the appropriate adjustments cannot be made after several tries (density indicator

LED F5 and F9 flash), or if copies of the Test Sheet made in AE mode are too dark or

too light, execute [3] No. 304 in service mode (AE mode scanning lamp activation

voltage auto adjustment).

Be sure to follow the numerical sequence of the table.

Table 2-1

• In No. 402, auto adjustment is not executed for the AE slope, and the standard slope

is used. To adjust the slope, execute No. 303.

2-8

CHAPTER 2 STANDARDS AND ADJUSTMENTS

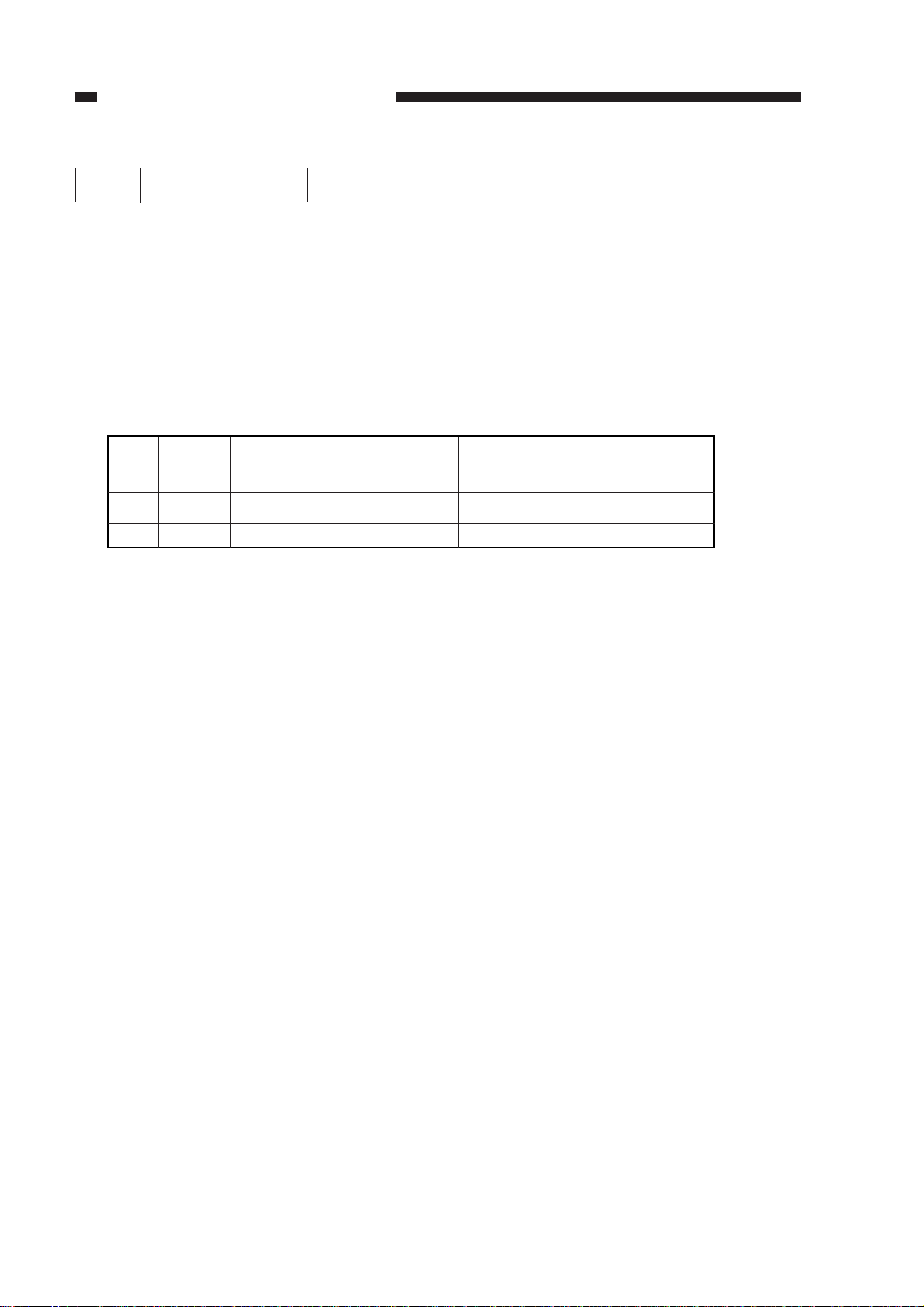

No.

1

2

3

Item

402

304

303

After replacing AE sensor

O

∆

∆

After replacing controller PCB

O

∆

∆

6 AE Adjustments

If you have replaced the scanning lamp, AE sensor, or DC controller PCB, you must

make the adjustments indicated by O; make the adjustments indicated by

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Lighter

Copy

density 5

Darker

Test Chart Original

density

• AE Auto Adjustment [4] No. 402

In AE auto adjustment, adjustments are made so that the intensity of the lamp in AE

mode matches the AE sensor output of manual copy density 5 in reference to copies of

an original (Test Sheet) on the copyboard glass.

Making Adjustments

1) Place the Test sheet (NA-3) on the Copyboard, and close the copyboard cover.

2) Start [4] in service mode, and select No. 402 using the keypad.

• The indicator indicates ‘402’.

3) Press the OK key.

• The scanning lamp turns on, and the scanner moves to the AE position.

• AE scanning is executed, and the intensity for AE scanning is automatically set.

• Thereafter , the scanner returns to home position, and the scanning lamp turns of f.

4) Press the Reset key.

• Mode selection mode starts, indicating [4].

• If necessary, execute No. 304.

Item

402

Function

AE scanning

intensity

automatic

adjustment

Description

Table 2-2

Remarks

Automatic adjustment

occurs so that the

original is copied at copy

density 5 when ‘402’ is

executed.

Note: If AE adjustment

fails, the density

indicator LED on

the control panel

F5 and F9 flash.

If such occurs,

make the adjustment once again.

2-9

Lighter

7.5

Copy

density 5

Darker

Test Chart Original

density

1

2

CHAPTER 2 STANDARDS AND ADJUSTMENTS

• Scanning Lamp Activation Voltage Auto Adjustment in AE Mode [3] No. 304

Making Adjustment

1) Start [3] in service mode, and select No. 304 using the keypad.

• The indicator indicates ‘304’.

2) Press the OK key.

• The indicator flashes the stored setting.

3) Using the keypad or the Zoom keys, change the settings according to the table

below.

• The indicator flashes the setting.

4) Press the OK key.

• The new setting is stored.

• The indicator stops flashing and remains on.

• A press on the Copy Start key starts copying.

5) Press the key.

• Item selection mode starts, indicating ‘304’.

• If necessary, execute No. 303.

Item

304

Function

AE scanning

intensity

adjustment

Description

Table 2-3

Remarks

q When the setting

is decreased in

service mode, the

AE copies will be

darker.

w If the setting is

increased in

service mode, the

AE copies will be

lighter.

2-10

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Lighter

7.5

Copy

density 5

Darker

Test Chart

Newspaper

Original

density

1

2

• Newspaper Original DC Bias Adjustment in AE Mode [3] No. 303

After executing No. 402 and No. 304, make a copy of a newspaper . If the copy is too

dark or too light, make the following adjustments:

Making Adjustments

1) Start [3] in service mode, and select No. 303 using the keypad.

• The indicator indicates ‘303’.

2) Press the OK key.

• The indicator flashes the stored setting.

3) Using the keypad or the Zoom keys, change the setting according to the table below.

• The indicator flashes the setting.

4) Press the OK key.

• The new setting is stored.

• The indicator stops flashing, and remains on.

• Press the Copy Start key to start copying.

5) Press the Reset key twice.

• These presses end service mode.

Item

303

Function

AE slope

Description

Table 2-4

Remarks

q If the setting is

decreased in

service mode, the

newspaper copies

will be lighter.

w If the setting is

increased in

service mode, the

newspaper copies

will be darker.

2-11

CHAPTER 2 STANDARDS AND ADJUSTMENTS

7 Adjusting the Developing Bias DC Component [3] No. 302

Make adjustments according to the Image Adjustment Basic Procedure.

Making Adjustments

1) Start [3] in service mode, and select No. 302 using the keypad.

• The indicator indicates ‘302’.

2) Press the OK key.

• The indicator flashes the stored setting.

3) Using the keypad or the Zoom keys, change the setting.

• The indicator flashes the setting.

• To enter a negative setting, press the % key.

4) Press the OK key.

• The setting is stored.

• The indicator stops flashing and remains on.

5) Press the Clear key to start copying.

The settings and the developing bias have the following relationships:

• For each ‘1’ of the setting, the output of the developing bias DC component

changes by about 5 V.

• A higher setting decreases the developing bias DC component, making the

copies darker.

• A lower setting increases the developing bias DC component, making the copies

lighter.

2-12

CHAPTER 2 STANDARDS AND ADJUSTMENTS

8 Adjusting the Horizontal Registration Paper Edge Sensor Position [3] No. 324

If a discrepancy is noted between front and rear margins on the second side of a two-

sided copy, make the following adjustments:

Making Adjustments

1) Start [3] in service mode, and select No. 324 using the keypad.

The indicator indicates ‘324’.

2) Press the OK key.

• The indicator indicates the stored setting.

3) Using the keypad or the Zoom keys, change the setting.

• The indicator flashes the setting.

• To enter a negative setting, press the % key.

4) Press the OK key.

• The new setting is stored.

• The indicator stops flashing and remains on.

• A press on the Copy Start key starts copying.

5) Press the Reset key twice.

• These presses end service mode.

The settings and the margin have the following relationships:

• For each ‘1’, the non-image width changes by about 0.5 mm.

• A higher setting increases the margin at the front.

• A lower setting decreases the margin at the rear.

Note:

After making adjustments, turn off and then on the power switch to move the

horizontal paper end sensor to home position.

2-13

CHAPTER 2 STANDARDS AND ADJUSTMENTS

9 Adjusting the Trailing Edge Margin for Pick-Up from the Multifeeder [3] No. 327

Make adjustments so that the trailing edge margin is 2.5 ±1.5 mm when free-size

copying is executed using the multifeeder.

2.5 ±

1.5 mm

Figure 2-12

Making Adjustments

1) Start [3] in service mode, and select No. 327 using keypad.

• The indicator indicates ‘327’.

2) Press the OK key.

• The indicator indicates the stored setting.

3) Using the keypad or the Zoom keys, change the setting.

• The indicator flashes the setting.

• To enter a negative setting, press the % key.

4) Press the OK key.

• The new setting is stored.

• The indicator stops flashing and remains on.

• A press on the Copy Start key starts copying.

5) To change the settings in succession, repeat steps 3) and 4).

6) Press the Clear key to return to item selection.

The settings and the image position have the following relationship:

• For each ‘1’, the margin width changes about 0.4 mm.

• A higher setting decreases the margin width.

2-14

CHAPTER 2 STANDARDS AND ADJUSTMENTS

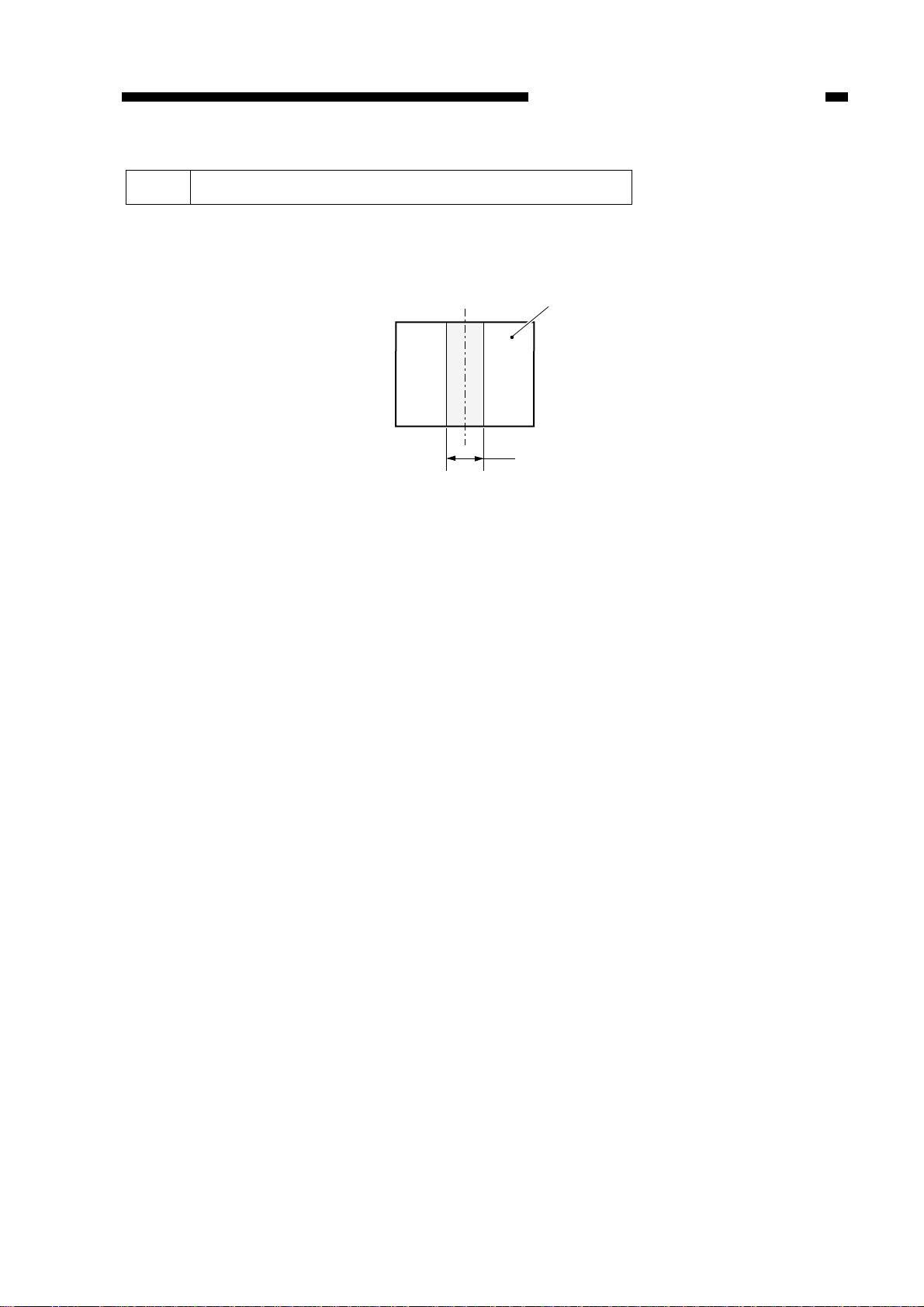

10 Adjusting the Book Erasing Width [3] No. 326

Adjust the width that runs in the middle of an original in book erase mode.

The Length of χin Figure 2-13 may be changed.

This mode does not allow changing the left/right edge of a book original.

Book original

χ

Figure 2-13

Making adjustment

1) Start [3] in service mode, and select No. 326 using the keypad.

• The indicator indicates ‘326’.

2) Press the OK key.

• The indicator indicates the stored setting.

3) Using the keypad or the Zoom keys, change the setting.

• The indicator flashes the setting.

• To enter a negative setting, press the % key.

4) Press the OK key.

• The new setting is stored.

• The indicator stops flashing and remains on.

• A press on the Copy Start key starts copying.

5) To change settings in succession, repeat steps 3) and 4).

6) Press the Clear key to return to item selection.

The settings and the book erasing width have the following relationship.

• For each ‘1’, the frame erasing width changes by about 1 mm.

• A higher setting increases the frame erasing width.

2-15

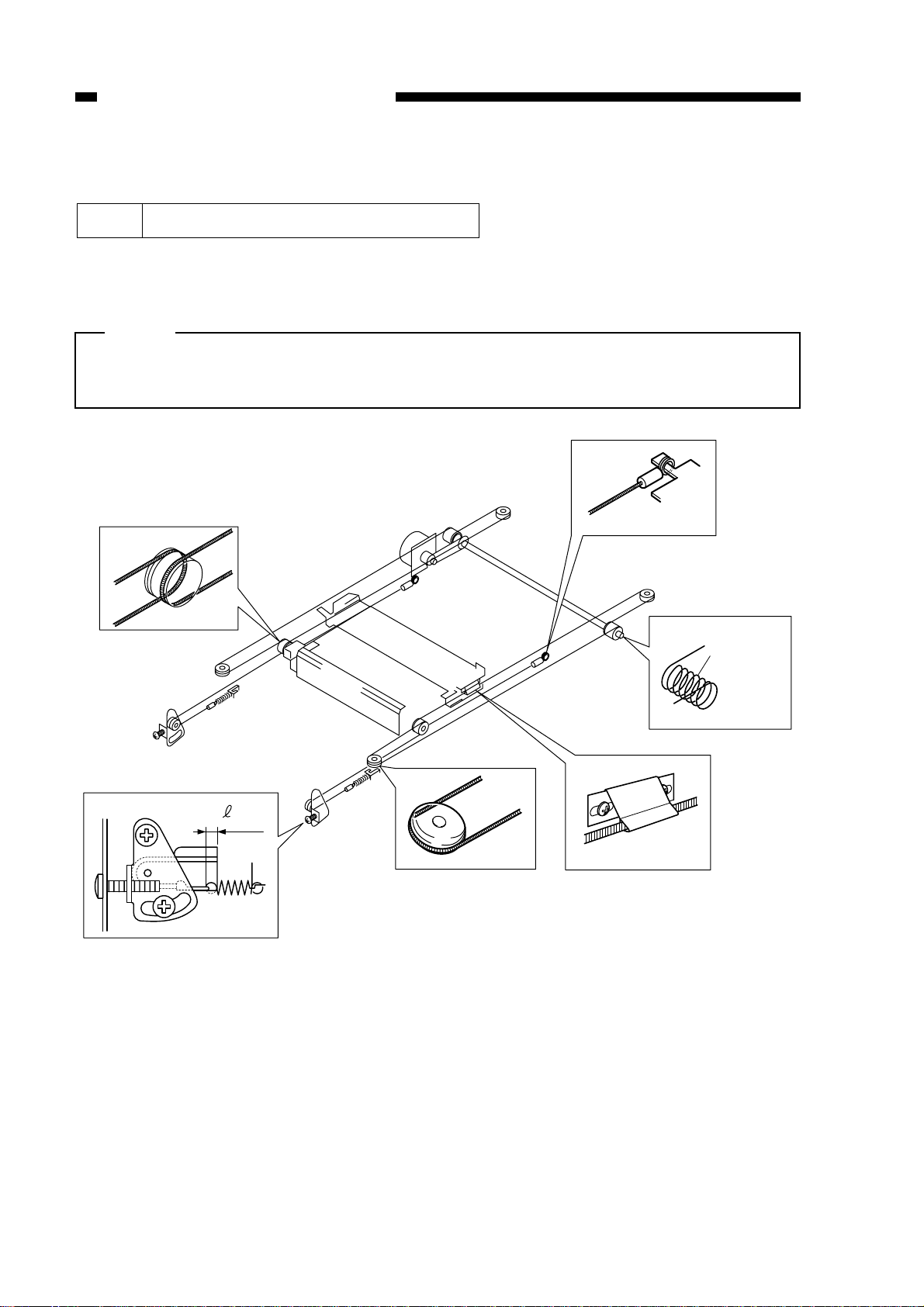

CHAPTER 2 STANDARDS AND ADJUSTMENTS

B. Exposure System

1 Routing the Scanner Drive Cable

Route the cable in the order indicated; then, adjust the tension of the cable and the

position of the mirror.

Note:

Before starting the work, be sure to fix the No. 2 mirror mount temporarily in place

to the front and rear side plates.

y

u

w

=0 –

3mm

i

Figure 2-14

t

o

q

e

Put the steel ball

r

Fix in place

temporarily.

into the hole

of the pully.

Wind

eight times.

2-16

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2 Adjusting the Position of the Mirror (optical path length between No. 1

mirror and No. 2/No. 3 mirror)

1) Remove the screw used to temporarily fix the No.2 mirror mount in position (both

front, rear).

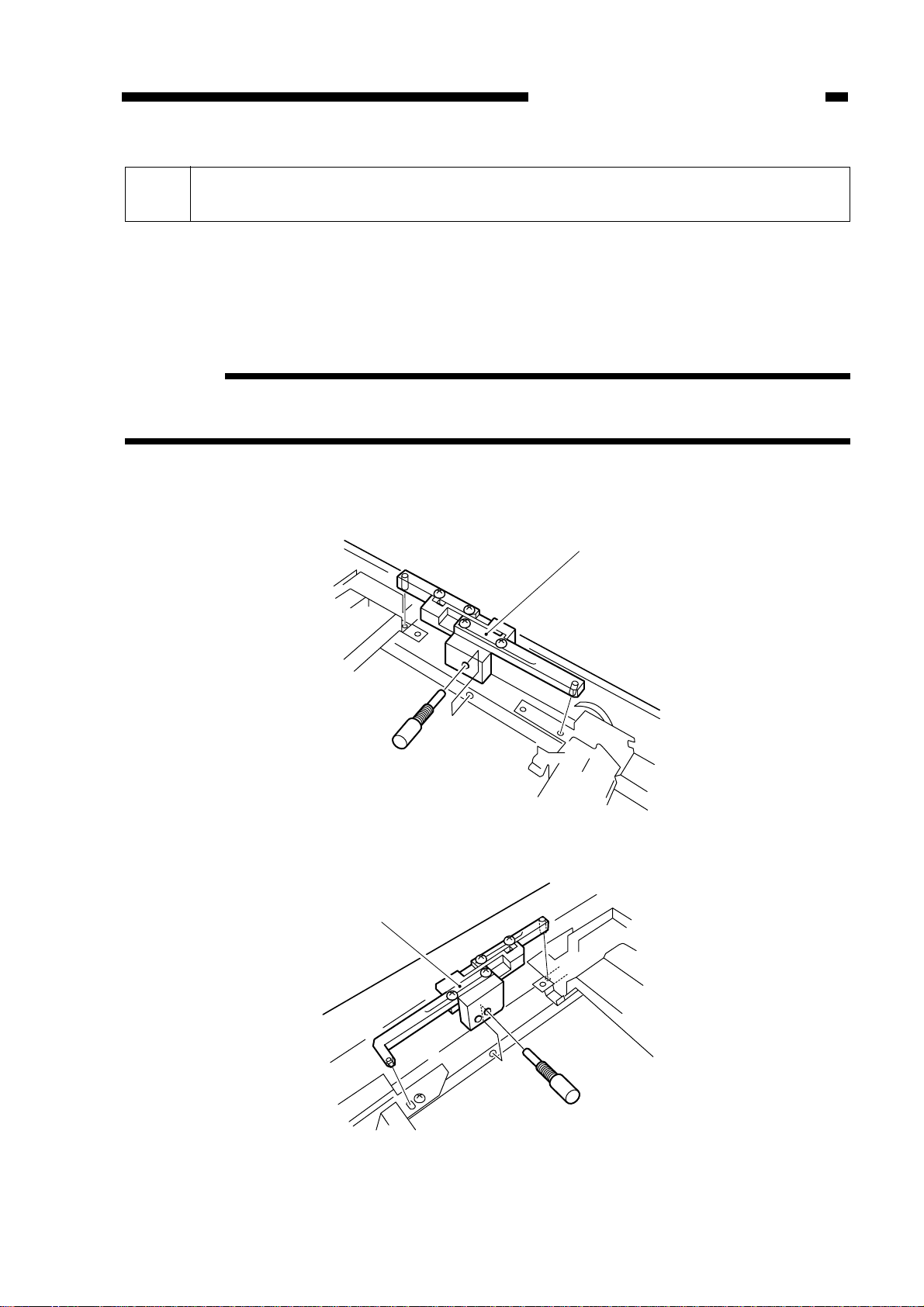

2) Loosen the four screws on the mirror positioning tool (FY9-3002-000), and extend

the two arms fully; then, tighten the screws (both front and rear).

Reference:

The mirror positioning tool is used in common with other models. Adjust the length

of the arms to suit the copier in advance.

3) Remove the pin from the mirror positioning tool (front and rear).

4) Mount the mirror positioning tool q to the No.1 mirror mount and the No.2 mirror

mount.

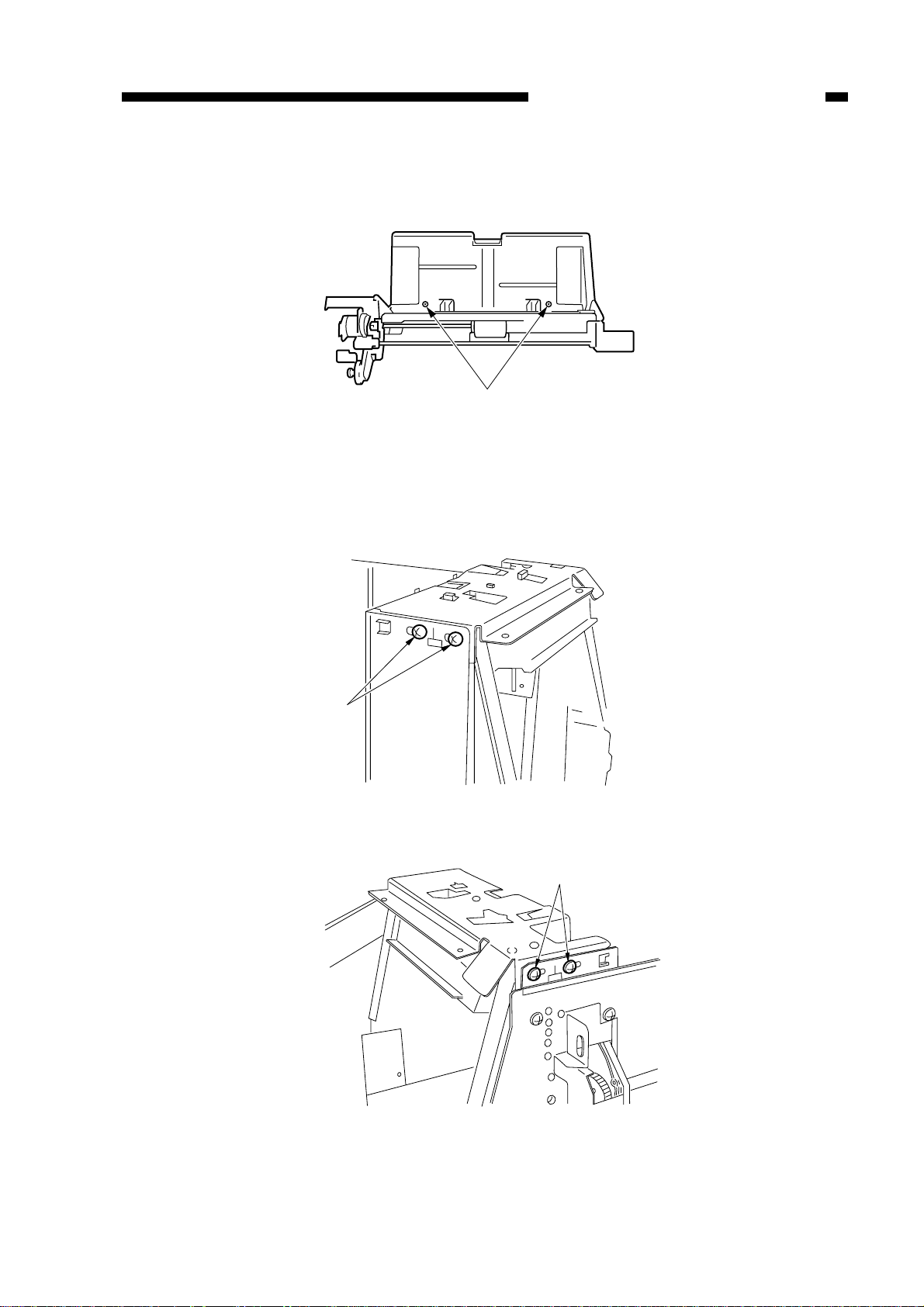

q

q

(front)

Figure 2-15

(rear)

Figure 2-16

2-17

CHAPTER 2 STANDARDS AND ADJUSTMENTS

(rear)

w

w

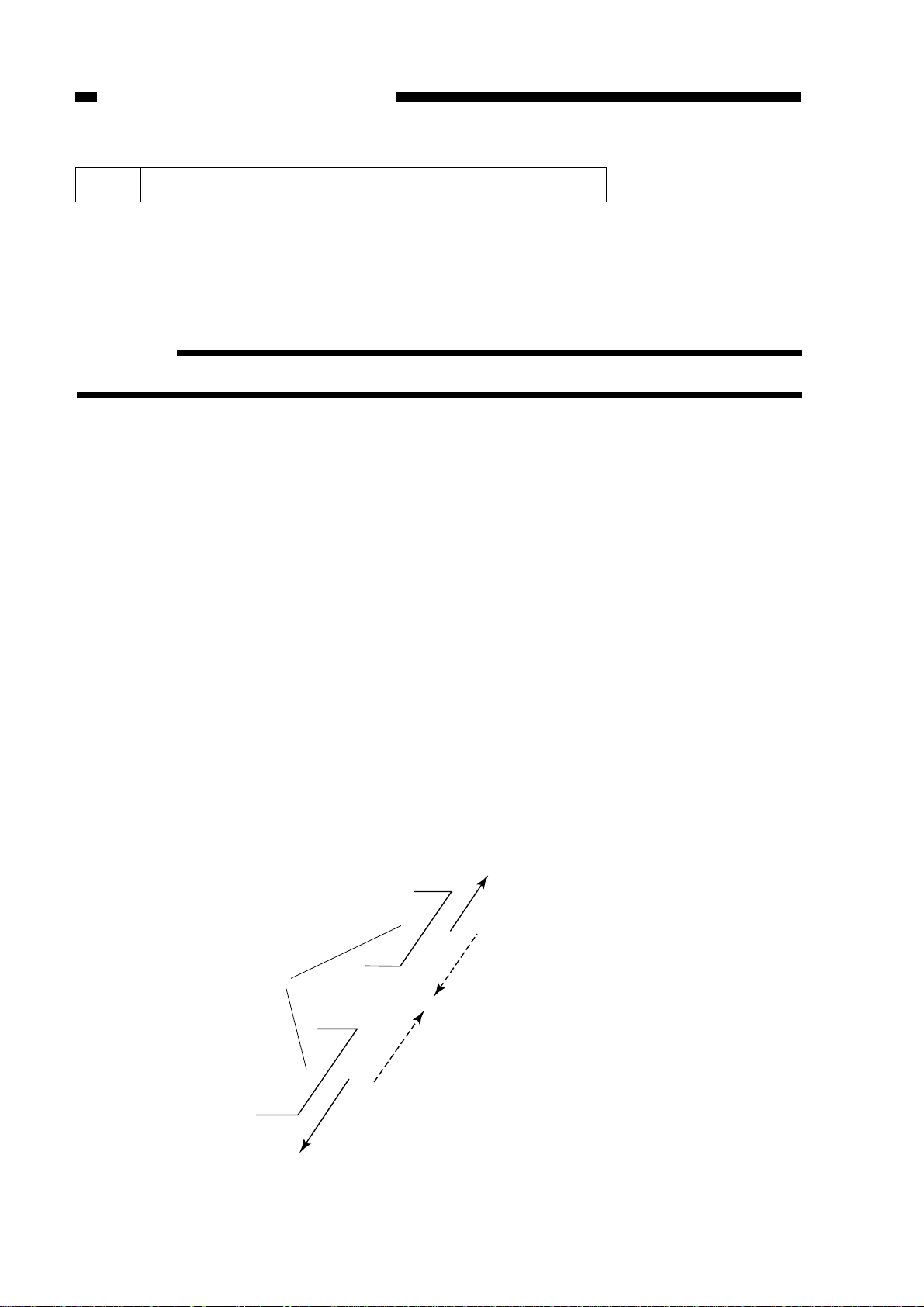

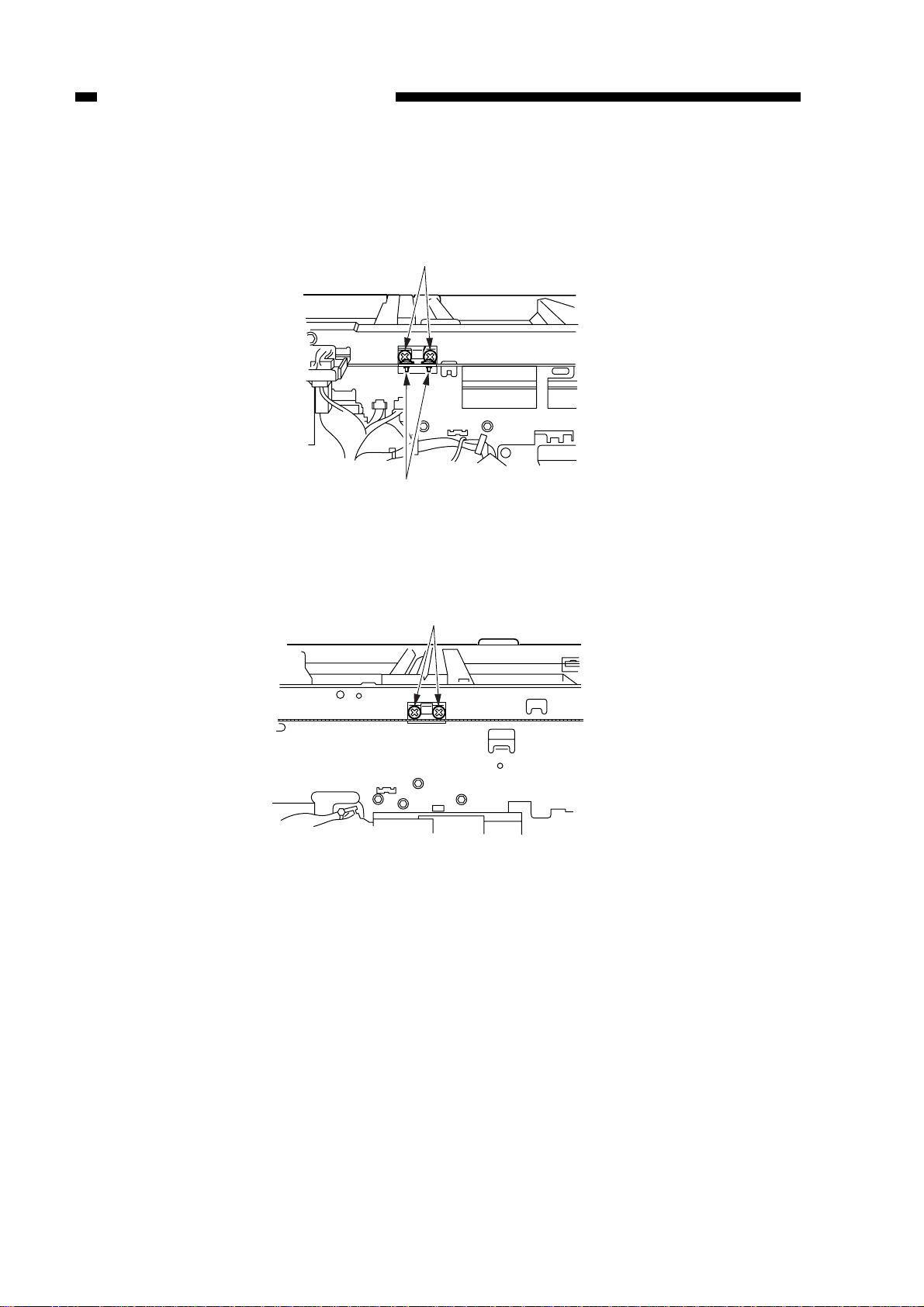

5) Mount the fixing of the scanner cable to the No.1 mirror mount (both front and rear)

with screws w.

Figure 2-17

w

(front)

Figure 2-18

2-18

CHAPTER 2 STANDARDS AND ADJUSTMENTS

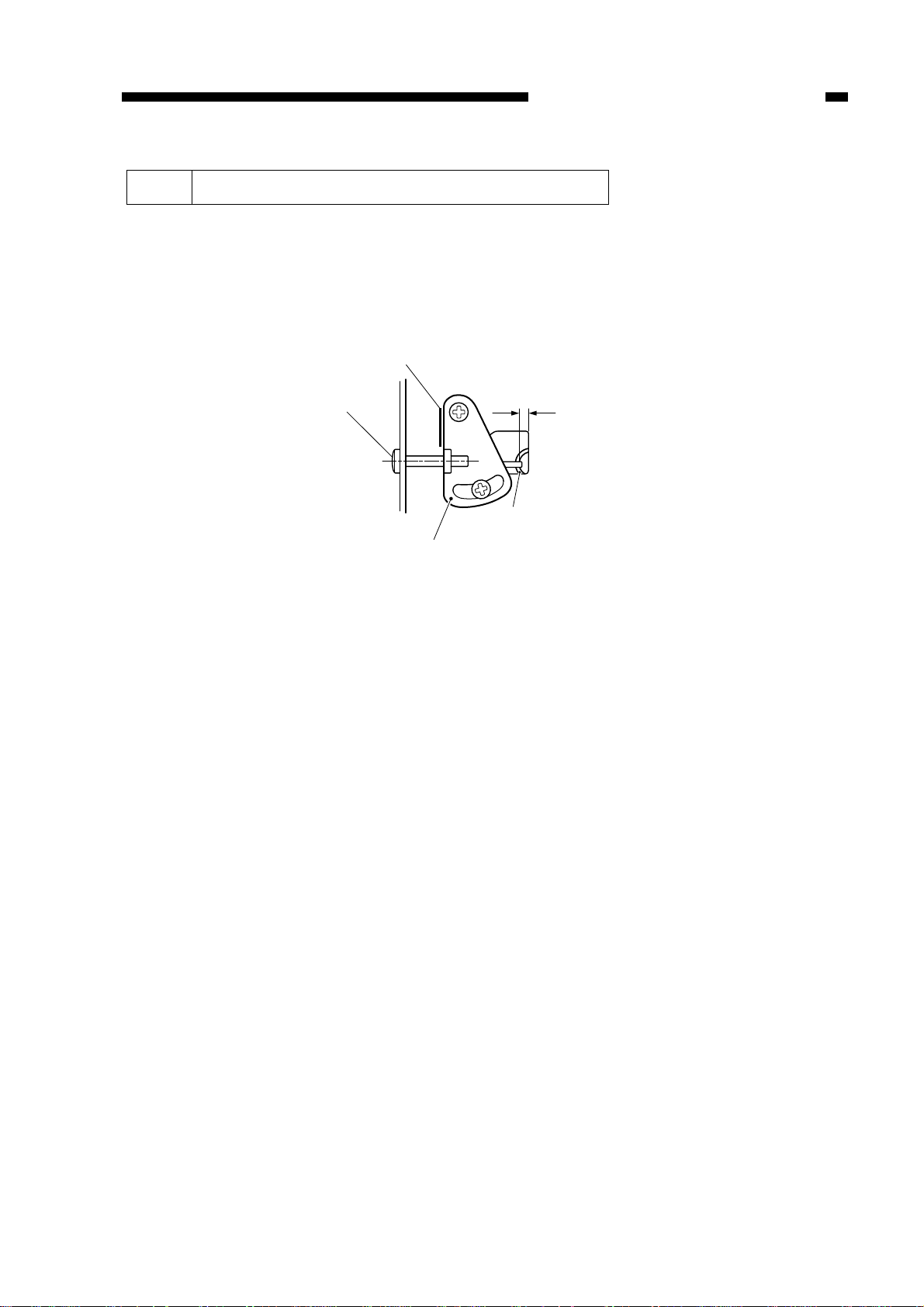

Line drawn with a scribe

Binding screw

r=0 – 3mm

Wire spring

Tensioner plate

3 Adjusting the Tension of the Scanner Cable

Loosen the binding screw, and align the tensioner plate to the line marked with a

scribe in advance.

Or, tighten the binding screw so that the wire spring and the hole in the side plate

shown in Figure 2-19 is 0 to 3 mm when viewed from the front.

Figure 2-19

2-19

CHAPTER 2 STANDARDS AND ADJUSTMENTS

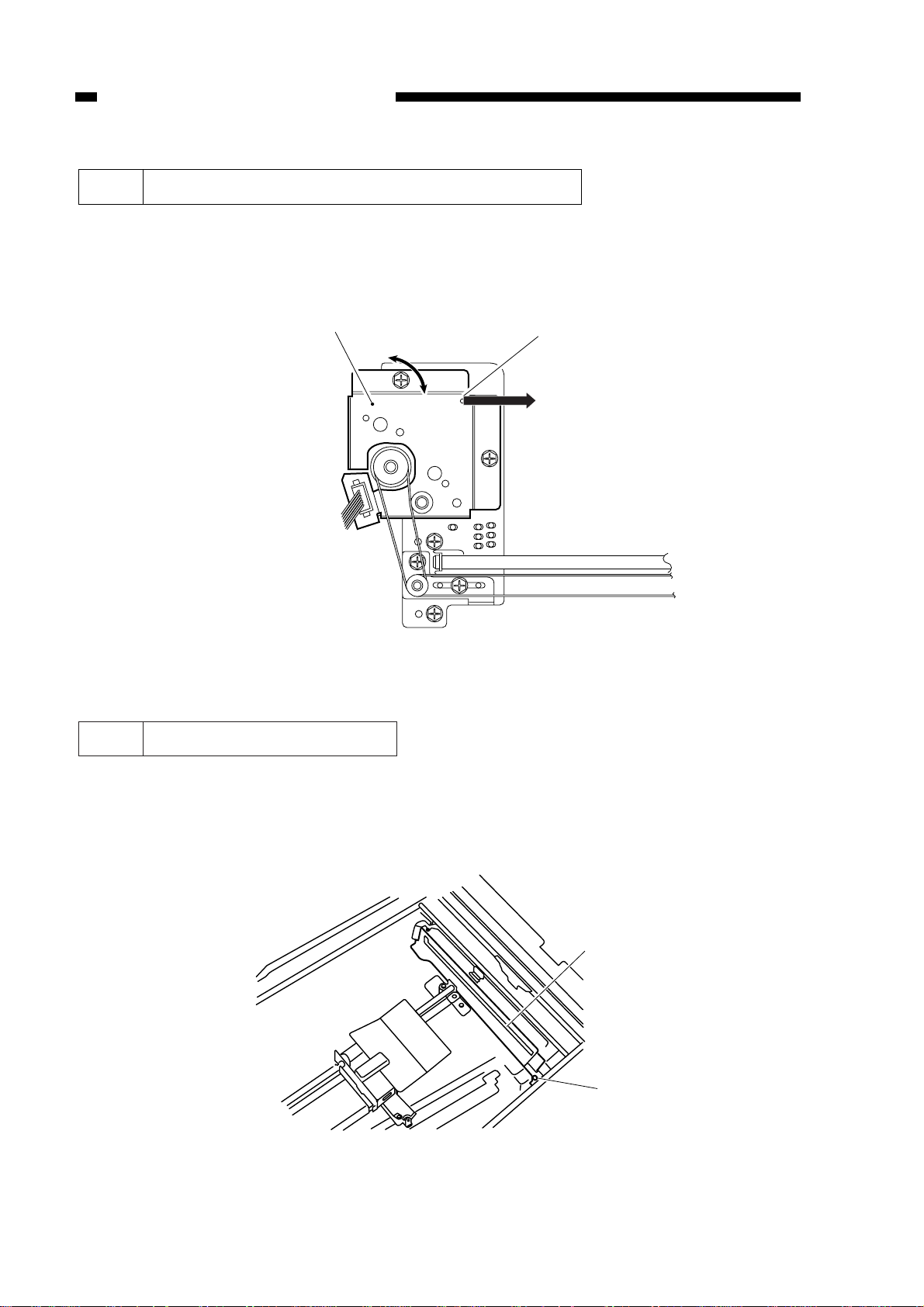

A indicated in Figure 2-20.

Figure 2-20

5 Cleaning the No.4 Mirror

1) Remove the copyboard glass and the lens hood.

2) Remove the screw q and the mirror guide plate w; then, clean the No.4 mirror.

Figure 2-21

q

A

4 Adjusting the Tension of the Lens Drive Belt

Move the lens motor support q and fit it in place so that the reading of the spring

gauge is 1000 ± 50g when motor support q is pulled with a spring gauge in the direction

of the arrow at the point

w

q

2-20

CHAPTER 2 STANDARDS AND ADJUSTMENTS

q

w

q

6 Cleaning the No.5/No.6 Mirror

a. Removing the Mirror Cleaning Tool

1) Remove the copyboard glass.

2) Remove the lens hood.

3) Remove the mirror guide plate.

4) Move the lens stage in enlargement direction.

5) Remove the screw q, and remove the mirror cleaning tool w.

Use the tool for cleaning the No.5/No.6 mirror.

Figure 2-22

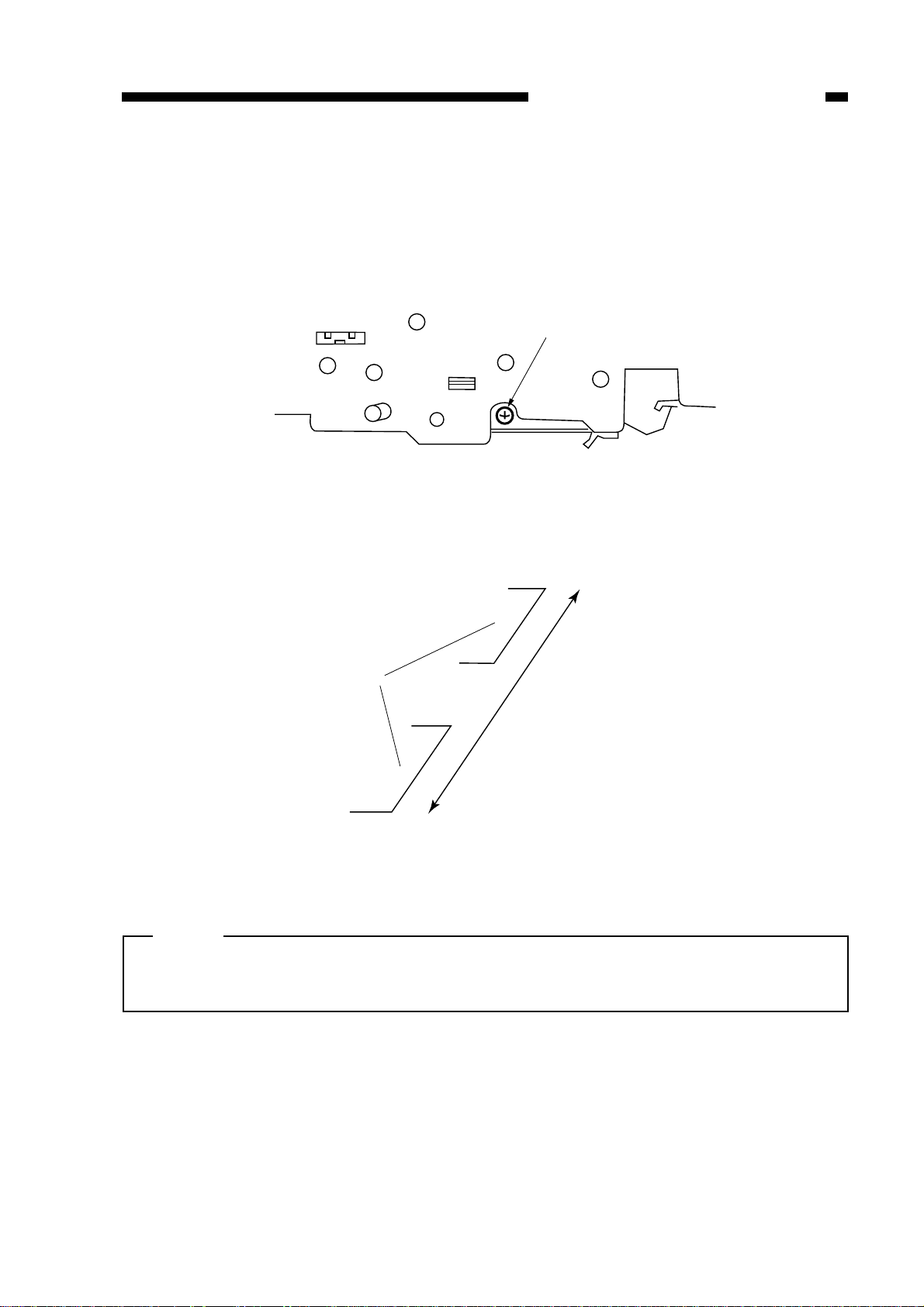

b. Cleaning the No.5 Mirror

1) Remove the mirror cleaning tool.

2) As shown, put the mirror cleaning tool q against the No.5 mirror, and move the tool

in the direction of the arrow to clean. (At this time, take care so that the cleaning tool

or your fingers will not touch the No.4 mirror.)

Figure 2-23

2-21

CHAPTER 2 STANDARDS AND ADJUSTMENTS

q

Side B

Side A

Side C

q

c. Cleaning the No.6 Mirror

1) Remove the mirror cleaning tool.

2) Open the front door, and remove the developing assembly and the drum unit.

3) Remove the dust-proofing glass.

4) While keeping the mirror cleaning tool q (sides A and B) against the lens mount,

move it in the direction of the arrow to clean.

Figure 2-24

d. Installing the Mirror Cleaning Tool

When installing the mirror cleaning tool to the right stay, butt the side C of the tool

against the right stay q and then fix it in place with a screw.

Thereafter, check to make sure that the cleaning tool and the No.1 mirror mount are

not interfering with each other.

Figure 2-25

2-22

Loading...

Loading...