Canon MF5900 Service Manual

MF5900/MF6100/D1300 Series

Product Overview

Technical Overview

Periodical Services

Disassembly/Assembly

Adjustment

Trouble Shooting

Error Codes

Service Mode

Appendex

Service Manual Rev.2

F-0-1

87654321

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not

apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When changes occur in applicable products or in the contents of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual

may not be copied, reproduced or

translated into another language, in whole or in part, without the written consent of Canon Inc.

(C) CANON INC. 2013

Caution

Use of this manual should be strictly supervised to avoid disclosure of condential

information.

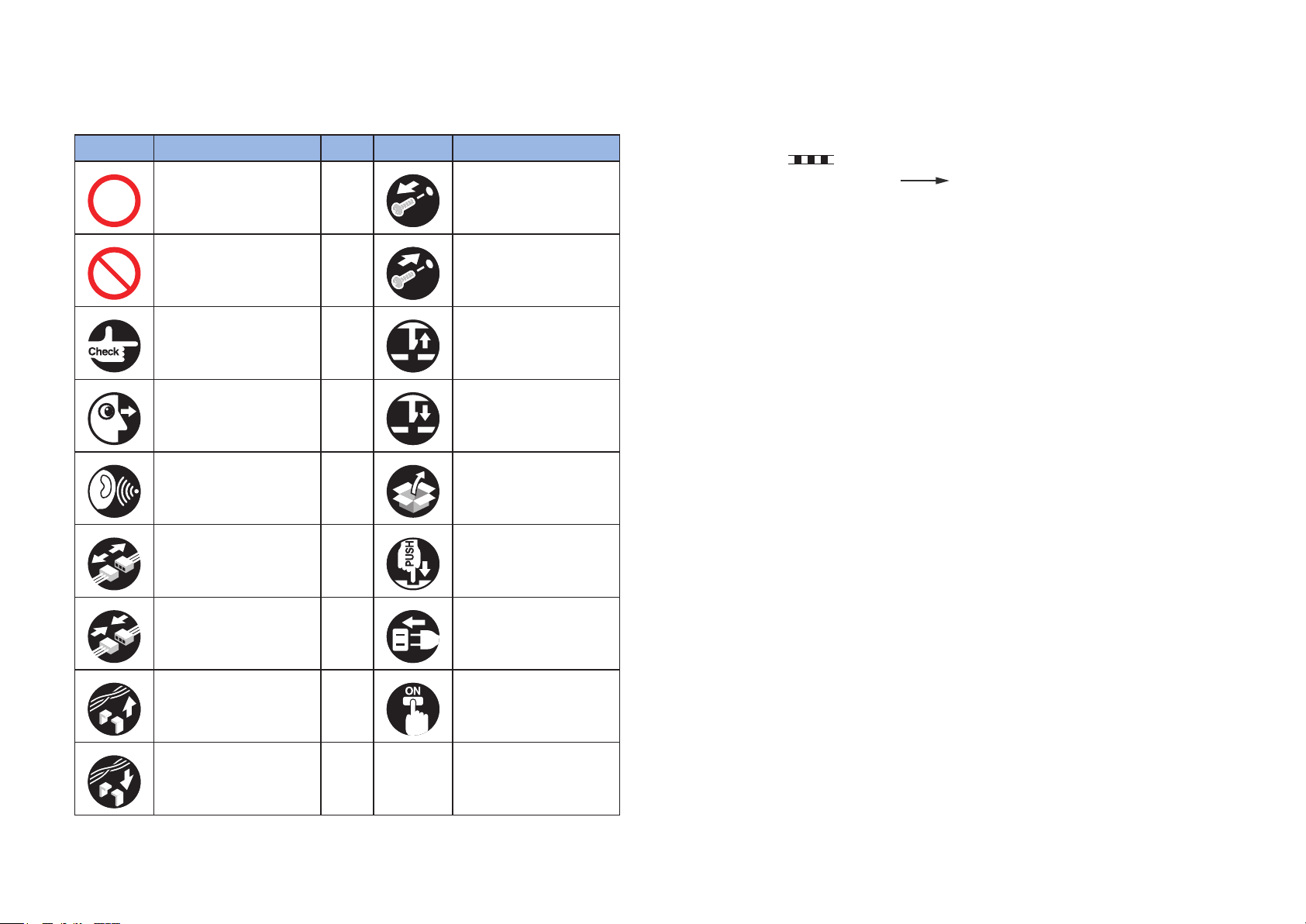

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Used to show permission. Remove the screw.

Used to show prohibition. Tighten the screw.

Check. Remove the claw.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specic functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams,

represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow indicates the direction of the electric signal.

The expression "turn on the power" means ipping on the power switch, closing the front

door, and closing the delivery unit door, which results in supplying the machine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High",

while '0' is used to indicate "Low". (The voltage value, however, dif

fers from circuit to circuit.)

In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on

when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the eld. Therefore, the operations of the microprocessors used in the machines are not

discussed: they are explained in terms of from sensors to the input of the DC controller

PCB and from the output of the DC controller PCB to the loads.

Check visually. Insert the claw.

Check the noise. Use the bundled part.

Disconnect the connector. Push the part.

Connect the connector. Plug the power cable.

Remove the cable/wire

from the cable guide or wire

saddle.

Set the cable/wire to the

cable guide or wire saddle.

Turn on the power.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

T-0-1

Contents

Safety Precautions

CDRH Provisions -------------------------------------------------------------0-2

Laser Safety

About Laser Beams --------------------------------------------------------------- 0-2

Handling Laser Scanner Unit

Toner Safety --------------------------------------------------------------------0-3

About Toner ------------------------------------------------------------------------- 0-3

Handling Adhered Toner --------------------------------------------------------- 0-3

Notes When Handling A Battery -------------------------------------------0-3

Notes On Assembly/Disassembly

Product Overview

Product Lineups ---------------------------------------------------------------1-2

Main Unit ----------------------------------------------------------------------------- 1-2

Options ------------------------------------------------------------------------------- 1-3

Product Features --------------------------------------------------------------1-4

Features ------------------------------------------------------------------------------ 1-4

Specications ------------------------------------------------------------------1-4

Main Unit Specications ---------------------------------------------------------- 1-4

ADF Specications ---------------------------------------------------------------- 1-6

FAX Specications ----------------------------------------------------------------- 1-6

Print Speed. ------------------------------------------------------------------------- 1-7

Paper types -------------------------------------------------------------------------- 1-7

Paper size --------------------------------------------------------------------------- 1-7

Name of Parts ------------------------------------------------------------------1-8

External View ----------------------------------------------------------------------- 1-8

MF5900/6100 Series----------------------------------------------------------------------- 1-8

D1300 Series

Cross Sectional View ------------------------------------------------------------1-10

MF5900/6100 Series----------------------------------------------------------------------1-10

D1300 Series

--------------------------------------------------------------------0-2

--------------------------------------------------- 0-2

-----------------------------------------0-3

-------------------------------------------------------------------------------- 1-9

-------------------------------------------------------------------------------1-11

Operation Panel -------------------------------------------------------------------1-12

Main Operation Panel --------------------------------------------------------------------1-12

FAX Operation Panel

---------------------------------------------------------------------1-13

Technical Overview

Basic Conguration -----------------------------------------------------------2-2

Conguration Function ----------------------------------------------------------- 2-2

Basic Sequence -------------------------------------------------------------------- 2-2

Basic Operational Sequence ------------------------------------------------------------ 2-2

Print Sequence

Print Mode --------------------------------------------------------------------------- 2-4

Document Exposure / Delivery System ---------------------------------2-5

Specications / Control / Function List ------------------------------------------------ 2-5

Major Components

Document Feeder System ------------------------------------------------------- 2-6

Pickup/Feed/Delivery Operation -------------------------------------------------------- 2-6

Original Detection--------------------------------------------------------------------------- 2-7

Jam Detection

Service Tasks ----------------------------------------------------------------------- 2-8

Action for Parts Replacement ----------------------------------------------------------- 2-8

Maintenance

Service Notes

Controller System -------------------------------------------------------------2-9

Outline -------------------------------------------------------------------------------- 2-9

Controls ------------------------------------------------------------------------------ 2-9

Outline ----------------------------------------------------------------------------------------- 2-9

Motor / Fan Control------------------------------------------------------------------------2-10

Failure Detection

Low-voltage Power Supply ----------------------------------------------------- 2-11

Outline ---------------------------------------------------------------------------------------- 2-11

Protective Function

Safety

-----------------------------------------------------------------------------------------2-12

Low-voltage Power Supply Unit Failure Detection

Power-Saving Mode

Service Tasks ----------------------------------------------------------------------2-13

Action for Parts Replacement ----------------------------------------------------------2-13

Maintenance

------------------------------------------------------------------------------ 2-3

------------------------------------------------------------------------- 2-5

------------------------------------------------------------------------------- 2-8

--------------------------------------------------------------------------------- 2-8

-------------------------------------------------------------------------------- 2-8

---------------------------------------------------------------------------2-11

------------------------------------------------------------------------2-12

--------------------------------2-12

----------------------------------------------------------------------2-12

--------------------------------------------------------------------------------2-13

Service Notes -------------------------------------------------------------------------------2-13

Laser Exposure System --------------------------------------------------- 2-14

Outline -------------------------------------------------------------------------------2-14

Optical Unit Failure Detection --------------------------------------------------2-14

Service Tasks ----------------------------------------------------------------------2-14

Action for Parts Replacement ----------------------------------------------------------2-14

Maintenance

Service Notes

--------------------------------------------------------------------------------2-14

-------------------------------------------------------------------------------2-14

Image Formation System ------------------------------------------------- 2-15

Outline -------------------------------------------------------------------------------2-15

Image Formation Process ------------------------------------------------------2-15

Outline ----------------------------------------------------------------------------------------2-15

Latent Image Formation Block

Developing Block

Transfer Block

Fixing Block

Drum Cleaning Block

--------------------------------------------------------------------------2-16

------------------------------------------------------------------------------2-17

---------------------------------------------------------------------------------2-17

---------------------------------------------------------------------2-17

---------------------------------------------------------2-16

High-voltage Power Supply ----------------------------------------------------2-18

Outline ----------------------------------------------------------------------------------------2-18

Service Tasks ----------------------------------------------------------------------2-18

Action for Parts Replacement ----------------------------------------------------------2-18

Maintenance

Notes on Field Service

--------------------------------------------------------------------------------2-18

-------------------------------------------------------------------2-18

Fixing System ---------------------------------------------------------------- 2-19

Outline -------------------------------------------------------------------------------2-19

Fixing Control Circuit ------------------------------------------------------------- 2-20

Throughput Reduction Control ---------------------------------------------------------2-20

Fixing Temperature Control

Protective Function

Failure Detection

------------------------------------------------------------------------2-21

---------------------------------------------------------------------------2-22

-------------------------------------------------------------2-21

Service Tasks ----------------------------------------------------------------------2-22

At Parts Replacement --------------------------------------------------------------------2-22

Maintenance

Notes On Service Works

--------------------------------------------------------------------------------2-22

-----------------------------------------------------------------2-22

Pickup / Feed System ------------------------------------------------------ 2-24

Outline -------------------------------------------------------------------------------2-24

Drive Conguration ---------------------------------------------------------------2-24

Jam Detection ---------------------------------------------------------------------2-25

Outline ----------------------------------------------------------------------------------------2-25

Pickup Delay Jam

Pickup Stationary Jam--------------------------------------------------------------------2-26

Delivery Delay Jam

Delivery Stationary Jam

Fixing Paper Wrap Jam

Reverse Delay Jam

Reverse Stationary Jam

Internal Residual Jam

Door Open Jam

-------------------------------------------------------------------------2-26

------------------------------------------------------------------------2-26

------------------------------------------------------------------2-26

-----------------------------------------------------------------2-26

-----------------------------------------------------------------------2-26

-----------------------------------------------------------------2-26

--------------------------------------------------------------------2-26

----------------------------------------------------------------------------2-26

Service Tasks ----------------------------------------------------------------------2-26

At Parts Replacement --------------------------------------------------------------------2-26

Maintenance

Notes On Service Works

--------------------------------------------------------------------------------2-26

-----------------------------------------------------------------2-26

Periodical Services

Periodically Replaced Parts ------------------------------------------------3-2

Consumable Parts

Periodical Service

Cleaning

-------------------------------------------------------------------------3-2

------------------------------------------------------------3-2

-------------------------------------------------------------3-2

Disassembly/Assembly

List of Parts ---------------------------------------------------------------------4-2

External View ----------------------------------------------------------------------- 4-2

MF5900/6100 Series----------------------------------------------------------------------- 4-2

D1300 Series

Main Unit ----------------------------------------------------------------------------- 4-4

Main Parts --------------------------------------------------------------------------- 4-5

Sensor / Switch ------------------------------------------------------------------------------ 4-5

Motor / Fan

Other

------------------------------------------------------------------------------------------- 4-6

PCB

-------------------------------------------------------------------------------------------- 4-7

Connector Layout Drawing ------------------------------------------------------ 4-8

External Cover (D1300 Series) ------------------------------------------ 4-12

Removing the Left Cover Unit -------------------------------------------------4-12

Removing the Left Rear Cover ------------------------------------------------ 4-14

-------------------------------------------------------------------------------- 4-3

----------------------------------------------------------------------------------- 4-6

Removing the Right Cover Unit -----------------------------------------------4-15

Removing the Front Cover Unit -----------------------------------------------4-17

Removing the Rear Cover Unit ------------------------------------------------ 4-18

Removing the Upper Cover ----------------------------------------------------4-19

External Cover (MF5900/MF6100) ------------------------------------- 4-20

Removing the Left Cover Unit -------------------------------------------------4-20

Removing the Left Rear Cover ------------------------------------------------ 4-21

Removing the Right Cover -----------------------------------------------------4-22

Removing the Front Cover -----------------------------------------------------4-24

Removing the Rear Cover Unit ------------------------------------------------ 4-24

Removing the Upper Cover ----------------------------------------------------4-26

Document Exposure / Delivery System ------------------------------- 4-27

Removing the ADF Unit + Reader Unit --------------------------------------4-27

Removing the ADF Roller Unit -------------------------------------------------4-29

Removing the ADF Pickup Roller --------------------------------------------- 4-30

Removing the ADF Separation Roller ---------------------------------------4-31

Removing the ADF Separation Pad ------------------------------------------ 4-33

Removing the ADF Pickup Feed Unit ----------------------------------------4-34

Removing the ADF Pickup Motor Unit --------------------------------------- 4-37

Removing the ADF Delivery Solenoid Unit ---------------------------------4-38

Removing the Reader Unit Upper Cover -----------------------------------4-38

Removing the CIS Unit ---------------------------------------------------------- 4-40

Controller System ----------------------------------------------------------- 4-42

Removing the Controller Cover -----------------------------------------------4-42

Removing the Main Controller Board ---------------------------------------- 4-42

Removing the NCU PCB (FAX Model Only) ------------------------------- 4-44

Removing the OFF Hook PCB (FAX Model Only) ------------------------ 4-44

Removing the Controller Box --------------------------------------------------4-45

Removing the Engine Controller Unit --------------------------------------- 4-46

Removing the Control Panel --------------------------------------------------- 4-49

Removing the Main Motor -----------------------------------------------------4-51

Removing the Main Fan --------------------------------------------------------- 4-52

Removing the Main Drive Unit ------------------------------------------------4-53

Removing the Duplex Drive Unit ----------------------------------------------4-55

Removing the Duplex Reverse Solenoid -----------------------------------4-56

Removing the Cassette Pickup Solenoid ----------------------------------- 4-57

Laser Scanner System ---------------------------------------------------- 4-58

Removing the Laser Scanner Unit --------------------------------------------4-58

Image Forming System ---------------------------------------------------- 4-59

Removing the Transfer Roller --------------------------------------------------4-59

Removing the Registration Unit ----------------------------------------------- 4-60

Fixing System ---------------------------------------------------------------- 4-61

Removing the Fixing Assembly ------------------------------------------------4-61

Pickup / Feed System ------------------------------------------------------ 4-63

Removing the Duplex Feed Unit ---------------------------------------------- 4-63

Removing the Cassette Pickup Roller ---------------------------------------4-65

Removing the Cassette Separation Pad ------------------------------------4-66

Removing the MP Pickup Roller ----------------------------------------------4-66

Removing the MP Separation Pad -------------------------------------------4-67

Adjustment

Overview ------------------------------------------------------------------------5-2

Actions after Replacement Parts

Document Exposure / Delivery System -------------------------------------- 5-2

After Replacing the CIS Unit ------------------------------------------------------------- 5-2

After Replacing the ADF Unit

After Replacing the Reader Unit

After Replacing the Reader Upper Cover Unit

Controller System ------------------------------------------------------------------ 5-4

After Replacing the Main Controller PCB --------------------------------------------- 5-4

------------------------------------------5-2

------------------------------------------------------------ 5-2

-------------------------------------------------------- 5-3

-------------------------------------- 5-3

Trouble Shooting

Test Print ------------------------------------------------------------------------6-2

Test Pages --------------------------------------------------------------------------- 6-2

Engine-test Page --------------------------------------------------------------------------- 6-2

Controller Test Print

Trouble Shooting Items ------------------------------------------------------6-3

Special Mode ----------------------------------------------------------------------- 6-3

Trailing edge image soiling ------------------------------------------------------ 6-4

Repetitive Image Defects Ruler ------------------------------------------------ 6-4

Nip-width Specications ---------------------------------------------------------- 6-5

Version Up ----------------------------------------------------------------------6-6

----------------------------------------------------------------------- 6-2

Overview of Upgrading ----------------------------------------------------------- 6-6

Firmware Conguration ---------------------------------------------------------- 6-6

Preparation -------------------------------------------------------------------------- 6-7

Necessary System Environment -------------------------------------------------------- 6-7

Before Downloading the System Software

------------------------------------------- 6-7

Downloading the System Software -------------------------------------------- 6-8

Procedure of Downloading --------------------------------------------------------------- 6-8

Error Codes

Overview ------------------------------------------------------------------------7-2

Outline -------------------------------------------------------------------------------- 7-2

Jam Code ------------------------------------------------------------------------------------- 7-2

Error Code ----------------------------------------------------------------------7-3

Jam Code

-----------------------------------------------------------------------7-5

Service Mode

Overview ------------------------------------------------------------------------8-2

Service Mode Menu --------------------------------------------------------------- 8-2

Backing up Service Mode -------------------------------------------------------- 8-2

Screen ow of Service Mode --------------------------------------------------- 8-3

Service mode structure-------------------------------------------------------------------- 8-3

Screen ow of Service mode

COPIER -------------------------------------------------------------------------8-4

DISPLAY ----------------------------------------------------------------------------- 8-4

VERSION ------------------------------------------------------------------------------------- 8-4

ERR

-------------------------------------------------------------------------------------------- 8-4

JAM

-------------------------------------------------------------------------------------------- 8-4

CCD

-------------------------------------------------------------------------------------------- 8-5

I/O -------------------------------------------------------------------------------------- 8-5

R-CON ----------------------------------------------------------------------------------------- 8-5

ADJUST ------------------------------------------------------------------------------ 8-6

ADJ-XY ---------------------------------------------------------------------------------------- 8-6

CCD

-------------------------------------------------------------------------------------------- 8-7

PASCAL

FEED-ADJ

FUNCTION -------------------------------------------------------------------------8-13

CCD -------------------------------------------------------------------------------------------8-13

-------------------------------------------------------------------------------------- 8-11

-----------------------------------------------------------------------------------8-12

------------------------------------------------------------ 8-3

CLEAR

MISC-R

MISC-P

SYSTEM

SPLMAN

INSTALL

---------------------------------------------------------------------------------------8-14

---------------------------------------------------------------------------------------8-14

---------------------------------------------------------------------------------------8-14

------------------------------------------------------------------------------------- 8-15

------------------------------------------------------------------------------------- 8-15

--------------------------------------------------------------------------------------8-16

OPTION -----------------------------------------------------------------------------8-17

BODY -----------------------------------------------------------------------------------------8-17

USER

----------------------------------------------------------------------------------------- 8-18

ACC

------------------------------------------------------------------------------------------- 8-18

SERIAL

---------------------------------------------------------------------------------------8-18

COUNTER --------------------------------------------------------------------------8-19

TOTAL ----------------------------------------------------------------------------------------8-19

PICK-UP

FEEDER

JAM

DRBL-2

-------------------------------------------------------------------------------------8-20

-------------------------------------------------------------------------------------8-20

-------------------------------------------------------------------------------------------8-20

---------------------------------------------------------------------------------------8-21

FEEDER ----------------------------------------------------------------------- 8-22

ADJUST -----------------------------------------------------------------------------8-22

FUNCTION -------------------------------------------------------------------------8-23

FAX ----------------------------------------------------------------------------- 8-24

List of SSSW -----------------------------------------------------------------------8-24

List of MENU -----------------------------------------------------------------------8-25

List of NUM -------------------------------------------------------------------------8-26

Setting of NCU Parameters ----------------------------------------------------8-26

TONE/PULSE ------------------------------------------------------------------------------8-26

DIAL TONE

2nd DIAL TONE

BUSY TONE 0

BUSY TONE 1

REORDER TONE

MULTI

AUTO RX

CNG DETECT

RKEY

PBX DIAL TONE 1

PBX BUSY TONE

FTSW OGM

----------------------------------------------------------------------------------8-27

----------------------------------------------------------------------------8-27

------------------------------------------------------------------------------8-28

------------------------------------------------------------------------------8-28

-------------------------------------------------------------------------8-29

-----------------------------------------------------------------------------------------8-29

------------------------------------------------------------------------------------8-29

------------------------------------------------------------------------------8-29

-----------------------------------------------------------------------------------------8-30

------------------------------------------------------------------------8-30

-------------------------------------------------------------------------8-30

---------------------------------------------------------------------------------8-30

DAM -------------------------------------------------------------------------------------------8-30

TESTMODE ------------------------------------------------------------------ 8-31

PRINT --------------------------------------------------------------------------------8-31

FAX -----------------------------------------------------------------------------------8-32

MODEM --------------------------------------------------------------------------------------8-32

FACULTY

------------------------------------------------------------------------------------8-33

Appendex

Service Tools -------------------------------------------------------------------9-2

Special Tools ------------------------------------------------------------------------ 9-2

Solvents and Oils ------------------------------------------------------------------ 9-2

General Timing Chart --------------------------------------------------------9-3

General Circuit Diagram

General Circuit Diagram (1/2) -------------------------------------------------- 9-4

General Circuit Diagram (2/2) -------------------------------------------------- 9-5

Backup Data --------------------------------------------------------------------9-6

-----------------------------------------------------9-4

Safety Precautions

CDRH Provisions

■

Laser Safety

■

Toner Safety

■

Notes When Handling A Battery

■

Notes On Assembly/Disassembly

■

0

Safety Precautions > Laser Safety > Handling Laser Scanner Unit

0-2

CDRH Provisions

Food and Drug CDRH (Center for Devices and Radiological Health) under FDA (Food and

Drug Administration) enforced provisions of the section for laser and laser products on August

2, 1976. These provisions are applicable to all laser products manufactured or assembled

after August 1, 1976 and allow only products certied their compliance with the provisions

to market in the US. Each product shall have afxed the applicable label as shown below to

follow the labeling requirements prescribed in CDRH provisions.

Note that the wording included in labels is different depending on laser product

classications.

CAUTION:

Note that the wording included in labels is different depending on laser product

classications.

Laser Safety

About Laser Beams

Laser radiation may be hazardous to human. The laser scanner unit mounted in this device is

sealed in the protective housing and the external cover to prevent laser beams from leaking

to the environment. As long as the device is operated under normal conditions, users are

safely arded from laser leaks.

Handling Laser Scanner Unit

Before providing service works for the laser scanner unit and its peripherals, ensure to turn

off the power of the device.

Any cover with potential dangers of laser beam reection has afxed the caution label at the

position shown in the gure below.

Safety Precautions > Laser Safety > Handling Laser Scanner Unit

0

[1]

F-0-2

0-2

0

Safety Precautions > Notes On Assembly/Disassembly

0-3

Toner Safety

About Toner

Toner is a nontoxic matter composed of plastic, iron and a trace of pigments.

Never throw toner in ames to avoid explosion.

CAUTION:

Never throw toner in ames to avoid explosion.

Handling Adhered Toner

• Use dry tissue paper to wipe off toner adhered to skin or clothes and wash in water.

• Never use warm water for cleaning up toner to prevent toner particles from being gelated to

soak into bers permanently.

• Toner particles are reactive with vinyl polymers. Avoid contacting these materials.

Notes When Handling A Battery

Notes On Assembly/Disassembly

Follow the items below to assemble/disassemble the device.

1. Disconnect the power plug to avoid any potential dangers during assembling/disassembling

works.

2. If not specially instructed, reverse the order of disassembly to reinstall.

3. Ensure to use the right screw type (length, diameter, etc.) at the right position when

assembling.

4. To keep electric conduction, binding screws with washers are used to attach the grounding

wire and the varistor. Ensure to use the right screw type when assembling.

5. Unless it is specially needed, do not operate the device with some parts removed.

6. Never remove the paint-locked screws when disassembling.

CAUTION

DOUBLE POLE/NEUTRAL FUSING

F-0-3

CAUTION:

Risk Of Explosion If Battery Is Replaced By An Incorrect Type.

Dispose Of Used Batteries According To The Instructions.

The following warnings are given to comply with Safety Principles (EN60950).

CAUTION:

Wenn mit dem falschen Typ ausgewechselt, besteht Explosionsgefahr.

Gebrauchte Batterien gemäß der Anleitung beseitigen.

Safety Precautions > Notes On Assembly/Disassembly

0

0-3

Product Overview

1

Product Lineups

■

Product Features

■

Specications

■

Name of Parts

■

Product Overview

1

1

Product Overview > Product Lineups > Main Unit

1-2

Product Lineups

Main Unit

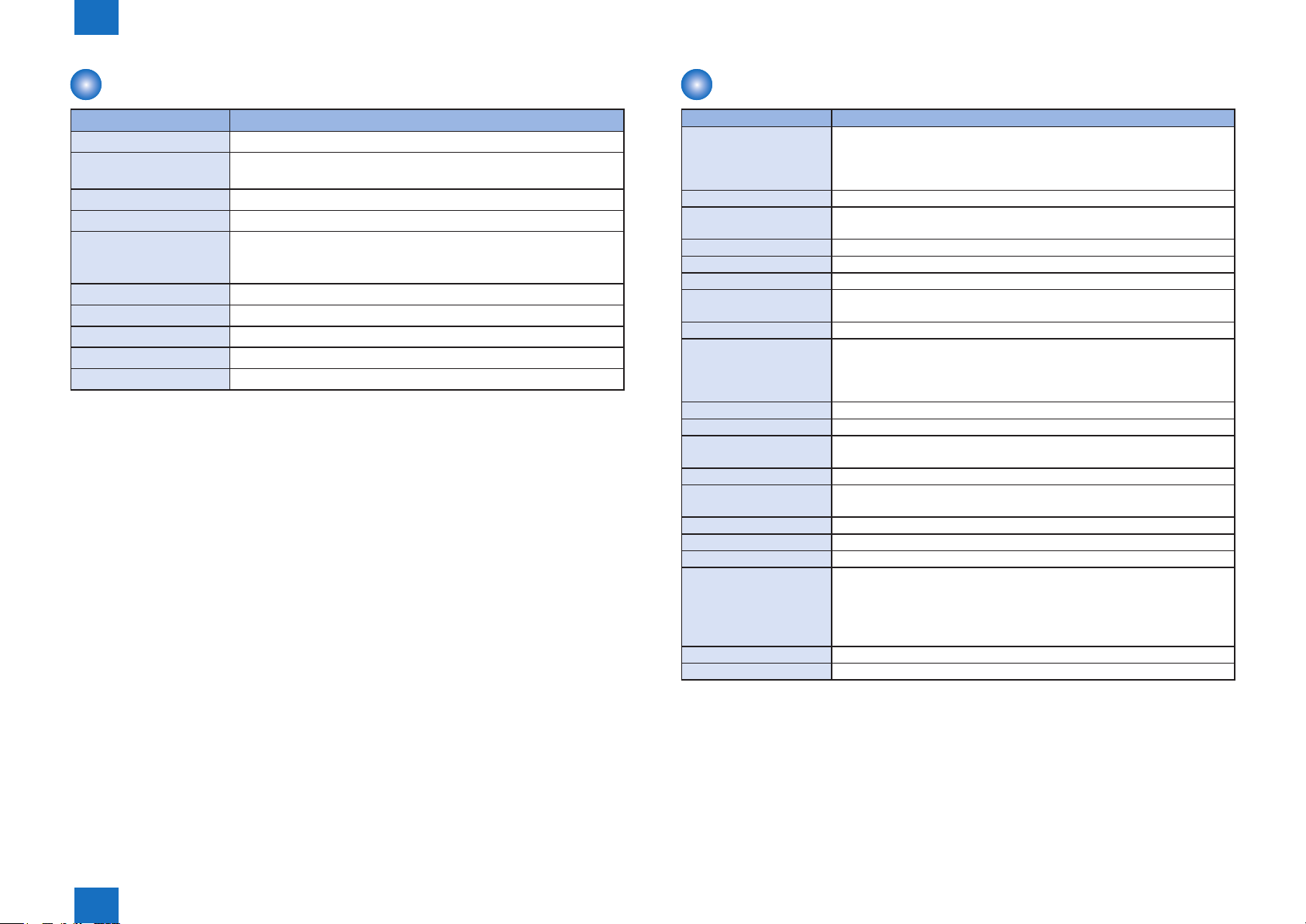

Function Canon imageCLASS/ i-SENSYS

MF5930dn MF5950dw

MF6150dw

Appearance

Copy O O O O O O

Print O O O O O O

Fax O O O O O O

SEND O O O O O O

Direct Print O O O O O O

Scan to USB O O O O O O

Secure Print O O O O O O

Remote UI O O O O O O

DADF O O O O O O

Automatic 2-sided Print

(60 to 128g / m2 paper)

Wireless LAN - O - - O O

PS - - O - O PCL - - O O O O

O O O O O O

MF5960dn MF5940dw

MF6140dn

MF5980dn

MF6180dw

MF6160dw

T-1-1

Function Canon imageCLASS Series

D1320 D1350 D1370 D1380

Appearance

Copy O O O O

Print O O O O

Fax - O O O

SEND - - O O

Direct Print O O O O

Scan

USB O O O O

to

Secure Print - - O O

Remote UI O O O O

DADF O O O O

Automatic 2-sided Print

(60 to 128g / m2 paper)

Wireless LAN - - - O

PS - - O PCL - - O O

O O O O

T-1-2

Product Overview > Product Lineups > Main Unit

1

1-2

1

Product Overview > Product Lineups > Options

1-3

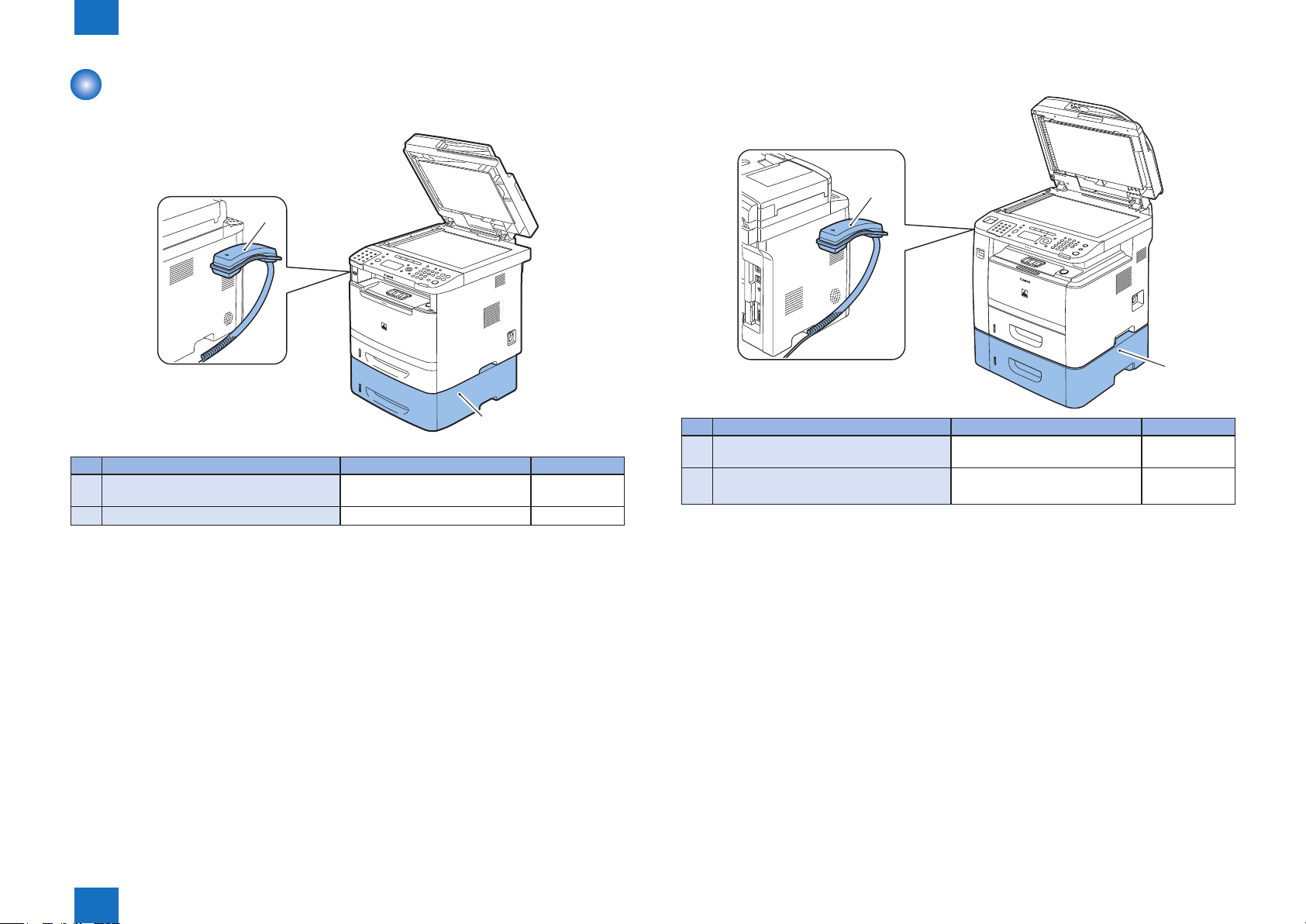

Options

MF5900/6100 Series

[2]

[1]

F-1-1

No. Name Description Remarks

[1] Paper FeederUnit PF-44 Approx. 500 Sheets (Plain paper

60 - 89g/ m2)

[2] TELEPHONE 6 KIT Long cord Cool White

-

T-1-3

D1300 Series

[2]

[1]

No. Name Description Remarks

[1] Canon Cassette Feeding Unit-U1 Approx. 500 Sheets (Plain paper

60 - 89g/ m2)

[2] TELEPHONE 6 KIT Long cord Cool White

F-1-2

-

for China /

Taiwan only

T-1-4

Product Overview > Product Lineups > Options

1

1-3

1

Product Overview > Specications > Main Unit Specications

1-4

Product Features

Features

Compact MFP

The product compactied with lower height.

431.0 mm

390.0 mm

F-1-3

High-speed MFP

This compact A4 color MFP can prints at high speeds of up to 33/35 pages per minute (A4/

LTR).

Power-saving MFP

This product employed SURF xing method with a ceramic heater and 3W sleep mode to

achieve electric power saving.

450.0 mm

464.0 mm

F-1-4

Specications

Main Unit Specications

Item

Body Desktop (DADF standard type)

Light Source Type LED

Photosensitive Medium OPC drum

Image Reading Method Contact Sensor Reading Method

Reproduction Method Indirect electrostatic copying method

Exposure Method Semiconductor laser

Charging Method Roller contact charging method

Development Method Dry system - element jumping development method

Transfer Method Roller transfer method

Separation Method

Cassette Pickup Method Pad separation method

MP Pickup Method Pad separation method

Drum Cleaning Method Rubber blade

Fixing Method On-demand

Toner Level Sensor 2 Levels (OK, Low) Unable to detect absence of toner.

Toner Type Magnetic negative toner

Toner Supply Type By drum style toner cartridge

Toner Save Mode Yes

Original Type Sheets, books, solids (up to 2 kg)

Maximum Original Size

Reproduction Ratio Zoom: 0.50 to 2.00 (specied by the percent)

Warm-up Time 11.0 seconds or less

Reading Resolution

Printing Resolution 600 x 600 dpi

First Print Time 6 seconds or less (A4/LTR)

First Copy Time

Print Speed Approximately 35/33 sheets / minute (A4/LTR)

Electrostatic separation (neutralizing needle) and curvature

separation

Fixed: 216mm x 356mm

ADF: 216mm x 356mm

<TEXT/PHOTO>: 300 dpi x 600 dpi

<TEXT>, <PHOTO>, <TEXT/PHOTO+>: 600 dpi x 600 dpi

Book: 8 seconds or less (A4/LTR)

ADF; 12 seconds or less (A4/LTR)

D1300 Series MF5900/6100 Series

Specication/function

Product Overview > Specications > Main Unit Specications

1

1-4

1

Product Overview > Specications > Main Unit Specications

1-5

Item

Cassette Paper Size

MP Feed Paper Size 76 × 127 to 216 × 356 mm

Cassette Paper Type

MP Tray Paper Type

Cassette Capacity 500 sheets (60 - 90g / m2) 250 sheets (60 - 90g / m2)

MP Tray Capacity 50 sheets (60 - 90g / m2)

Delivery Tray Stack 75 sheets (60 - 90g / m2)

Continuous Reproduction 1 to 99 sheets

Duplex Method Auto Duplexing

Interface

Hard Disk Standard:No, option:No

Memory

Energy Save Mode

Operating Environment

(Temperature Range)

Operating Environment

(Humidity Range)

Operating Environment

(Atmospheric Pressure)

Power Supply Rating

Power Consumption

(Maximum)

Power Consumption

Dimensions

LTR, LGL, A4, B5, A5, Executive, Ocio, Brazil-Ocio, MexicoOcio, FLSP, A-FLS, Government-LTR, Government-LGL

Plain Paper (60 to 89g / m2), Plain Paper (60 to 89 g/m2) recycled

paper (60 to 89 g/m2), Color (64 g/m2), Heavy Paper 1 (90 to 128

g/m2),

Plain Paper (60 to 89g / m2), Plain Paper (60 to 89 g/m2), recycled

paper (60 to 89 g/m2), Color (64 g/m2), Heavy Paper 1 (90 to 128

g/m2), Heavy Paper 2 (129 to 163 g/m2), Transparency, Labels,

Envelopes

Network (100Base-TX / 10Base-T)

USB Port Front(USB1.1)

USB Port Rear(USB1.1/2.0)

option:No

128MB: D1320, D1350

256MB: D1370, D1380

Yes. (Manual ON / OFF, automatically OFF after a set period of

time, automatically ON when receiving facsimile / print data)

10 to 30 degrees C

20 to 80 %

0.16 to 1.01 hPa (0. 6 to 1 bar)

120V-127V (60Hz)

220-240V, 50/60Hz

Maximum consumption: Less than 1090 W

During operation: approximately 550W or less (reference value)

At standby: approximately 18W (referenve velue)In sleep mode:

approximately 3W (reference value)

464 mm (H) × 472 mm (D) ×

450 mm (W)

D1300 Series MF5900/6100 Series

Specication/function

256MB

431 mm (H) × 472 mm (D) × 390

mm (W)

Item

Approximately 20.6 kg

Weight

PDL BDL-Image, PCL5 / PCLXL

(including the toner cartridge

21.4 kg)

D1300 Series MF5900/6100 Series

Specication/function

Approximately 18.3 kg (including

the toner cartridge 19.1 kg)

T-1-5

Product Overview > Specications > Main Unit Specications

1

1-5

1

Product Overview > Specications > FAX Specications

1-6

ADF Specications

Item Specication/function

Original position center reference

Original processing mode

Original reading stream reading method

Stack A4/LTR: 50 sheets, LGL: 30 sheets

Original reading speed

Mixed original sizes Yes

Original AE detection No

Original size recognition No

Stamp No

Operating environment pursuant to the host machine

1-sided to 1-sided copy, 2-sided to 2-sided copy, 1-sided to 2-sided

copy, 2-sided to 1-sided copy

A4/LTR: 300 x 300 dpi

Color: 9.3 sheets / minute

BW: 28 sheets / minute

T-1-6

FAX Specications

Item Specication/function

Suitable Line Public Switched Telephone Network (PSTN)

Up to 28.8Kbps in modem speed is currently available in PSTN. Note

that available modem speed is telephone-line dependent.

Telephone line connection: 1

Communication Protocol Super G3

Modulation Method Image modulation : V.34/V.8/V.17/V.29/V.27ter

Transmission procedure : V.21

Transmission Speed 33,600 bps

Coding Compression method: JBIG, MMR, MR, MH

Error Correction ECM

Minimum Receivable Input

Level

Modem IC CONEXANT DFX336

Scanning Line Density Normal : 8 dots/mm x 3.85 lines/mm

Half Tone 256 tones

Reproduction Resolution 600 x 600 dpi

Receivable Reduction

Setting

FAX/TEL Switching Available

Answering Machine

Transfer Setting

Remote Reception Available

Auto-dialing Available

Delayed Transmission Available

Broadcast Transmission Maximum number of destinations: 210

Dual Access Up to 70 schedules

Image Data Backup Available

V.17, V.27ter, V.29: -6 to -43 dBm

V.34: -10 to -43 dBm

Fine : 8 dots/mm x 7.7 lines/mm

Super ne : 8 dots/mm x 15.4 lines/mm

Ultra ne : 16 dots/mm x 15.4 lines/mm

Automatic reduction: 75-100% (1% increment)

Available

One-touch dial: 19 + coded dial: 181 + new destinations: 10

Priority order of destinations to be sent

New destination => one-touch destination => coded destination (sent in

this order)

T-1-7

Product Overview > Specications > FAX Specications

1

1-6

1

Product Overview > Specications > Paper size

1-7

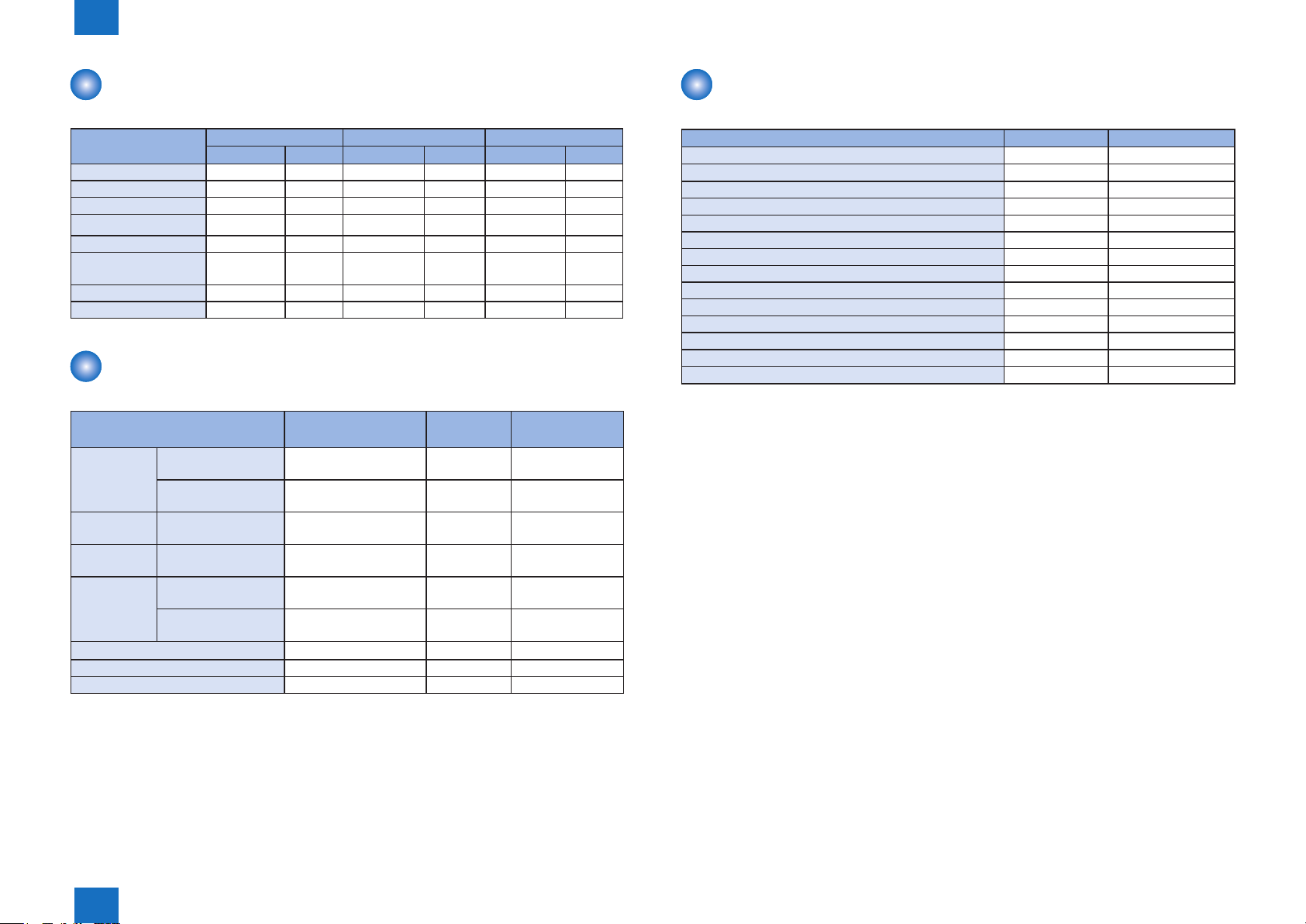

Print Speed.

(Unit: page/minute)

Paper type

A4 33 16.8 33 16.8 33 16.8

LTR 35 17 35 17 35 17

LGL 28.7 13.8 28.7 13.8 28.7 13.8

B5 13>12>8>6 - 16>12>8>6 - 10>10>8>6 -

A5 15>12>8>6 - 17>12>8>6 - 11>11>8>6 Strip of paper (90 to

297 mm)

Postcard - - 17>12>8>6 - - Envelope - - 12>8>6 - - -

Cassette MP Tray OP Cassette

1-sided 2-sided 1-sided 2-sided 1-sided 2-sided

- - 2>1 - - -

Paper types

(○: available -: not available)

Paper types Printer driver setting Cassette Multi-purpose

Tray

Plain 60 to 89 g/m2

(From 16 to 24 lb)

60 to 89 g/m2

(From 16 to 24 lb)

Color 60 to 89 g/m2

(From 16 to 24 lb)

Recycled* 60 to 89 g/m2

(From 16 to 24 lb)

Thick 90 to 128 g/m2

(From 24 to 33 lb)

129 to 163 g/m2

(From 33 to 43 lb)

Transparency Transparency *1 - ○

Label Label - ○

Envelope Envelope - ○

*1: Use only LTR or A4 transparencies made especially for this machine.

Plain Paper ○ ○

Plain Paper L ○ ○

Color ○ ○

Recycled ○ ○

Heavy Paper 1 ○ -

Heavy Paper 2 - ○

T-1-8

T-1-9

Paper size

(○: available -: not available)

Paper size Cassette Multi-purpose Tray

A4 (210.0 mm × 297.0 mm) ○ ○

B5 (182.0 mm × 257.0 mm) ○ ○

A5 (148.0 mm × 210.0 mm) ○ ○

Legal (LGL) (215.9 mm × 355.6 mm) ○ ○

Letter (LTR) (215.9 mm × 279.4 mm) ○ ○

Executive (EXEC) (184.0 mm × 266.7 mm) ○ ○

Ofcio (215.9 mm × 317.5 mm) ○ ○

Brazil Ofcio (215.9 mm × 355.6 mm) ○ ○

Mexico Ofcio (215.9 mm × 341 mm) ○ ○

Government Letter (203.2 mm × 266.7 mm) ○ ○

Government Legal (203.2 mm × 330.2 mm) ○ ○

FOOLSCAP (215.9 mm × 330.2 mm) ○ ○

A-FLS (205.7 mm × 337.82mm) ○ ○

3"×5" to Legal (76 × 127 to 216 mm× 356 mm) - ○

T-1-10

Product Overview > Specications > Paper size

1

1-7

1

Product Overview > Name of Parts > External View > MF5900/6100 Series

1-8

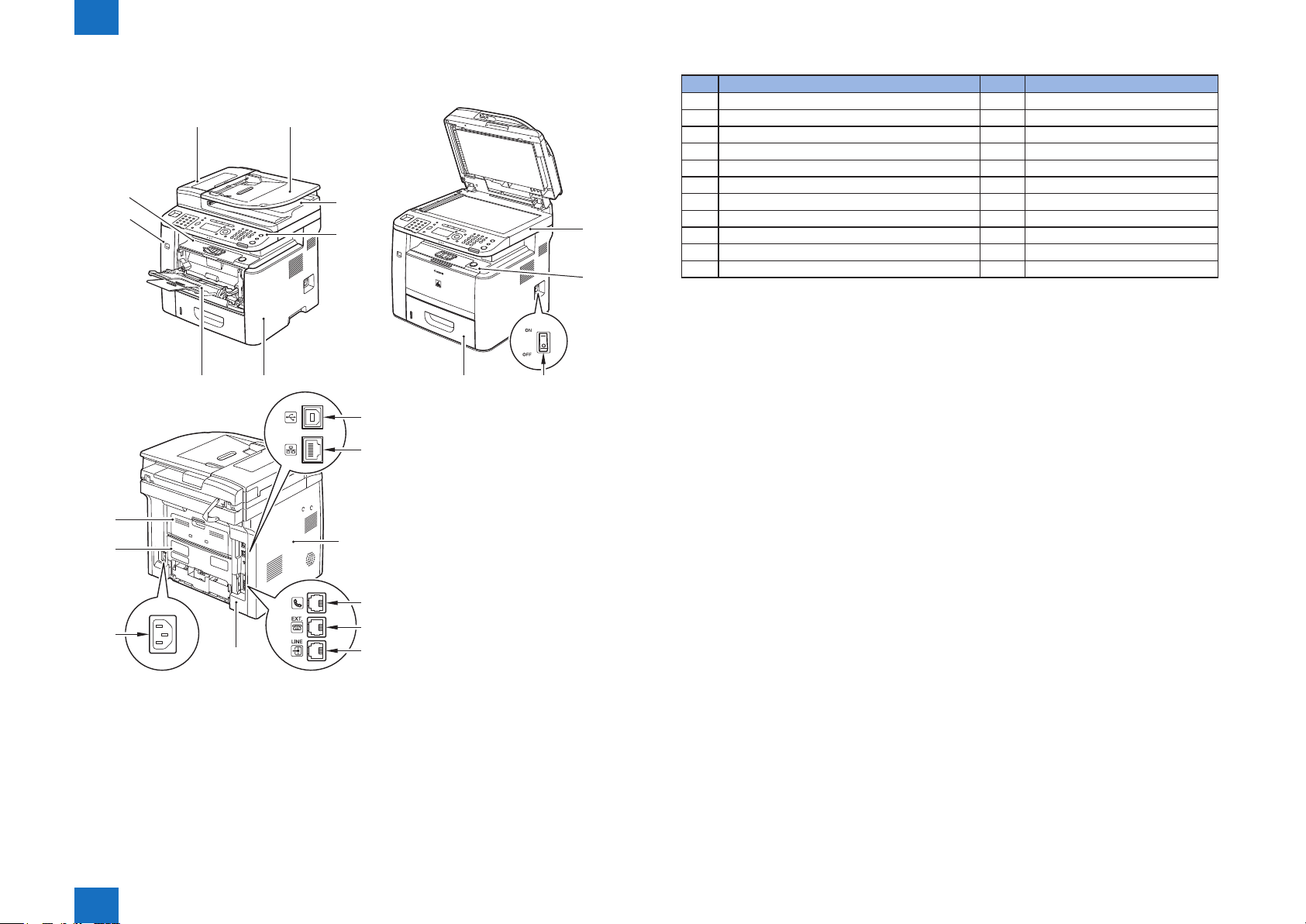

Name of Parts

External View

MF5900/6100 Series

■

[1]

[7]

[8]

Key Name Key Name

[1] DADF (Duplex Automatic Document

Feeder)

[2] Document Feeder Tray [14] Ethernet Port

[3] Document Delivery Tray [15] Left Cover Unit

[4] Control Panel [16] Handset Terminal

[5] Right Cover [17] External Telephone Terminal

[6] MP Pickup Tray [18] Telephone Line Terminal

[2]

[3]

[4]

[5][6]

[13]

[11][12]

[9]

[10]

[7] Upper Cover [19] Left Rear Cover

[8] USB Port [20] Power Socket

[9] Reader Unit [21] Rear Lower Cover

[10] Front Cover [22] Rear Upper Cover

[11] Main Power Switch

[12] Paper Cassette

[13] USB Port 2

T-1-11

[14]

[22]

[21]

HAND

SET

[20]

[19]

Product Overview > Name of Parts > External View > MF5900/6100 Series

[15]

[16]

[17]

[18]

1

F-1-5

1-8

1

Product Overview > Name of Parts > External View > D1300 Series

D1300 Series

■

[7]

[8]

[1]

[2]

[3]

[4]

[5][6] [11][12]

[13]

[14]

[9]

[10]

1-9

Key Name Key Name

[1] DADF (Duplex Automatic Document Feeder) [12] Paper Cassette

[2] Document Feeder Tray [13] USB Port 2

[3] Document Delivery Tray [14] Ethernet Port

[4] Control Panel [15] Left Cover Unit

[5] Right Cover [16] Handset Terminal

[6] MP Pickup Tray [17] External Telephone Terminal

[7] Upper Cover [18] Telephone Line Terminal

[8] USB Port [19] Left Rear Cover

[9] Reader Unit [20] Power Socket

[10] Front Cover [21] Rear Lower Cover

[11] Main Power Switch [22] Rear Upper Cover

T-1-12

[22]

[21]

HAND

SET

[20]

[19]

Product Overview > Name of Parts > External View > D1300 Series

[15]

[16]

[17]

[18]

1

F-1-6

1-9

1

[2] [3]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

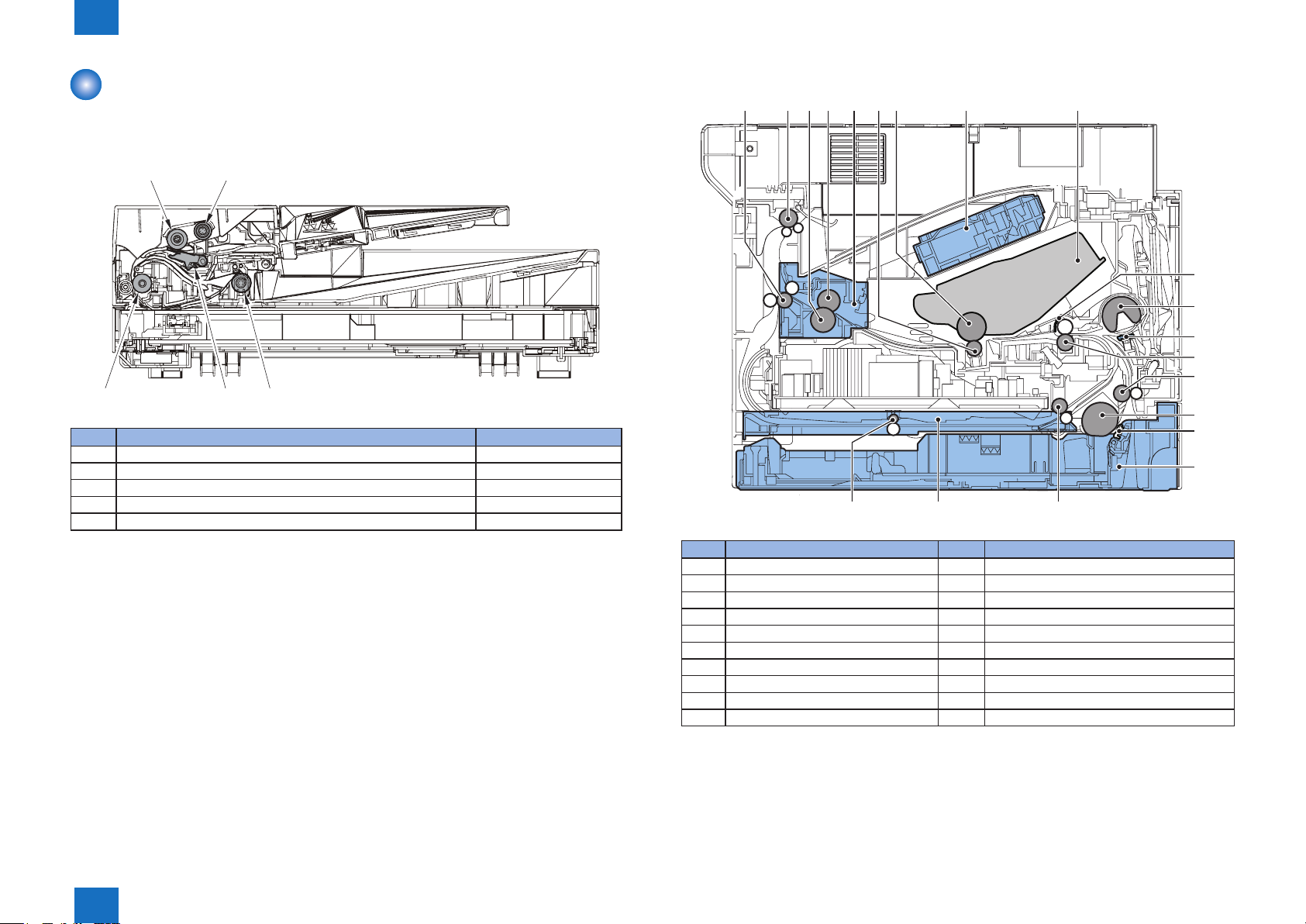

Product Overview > Name of Parts > Cross Sectional View > MF5900/6100 Series

1-10

Cross Sectional View

MF5900/6100 Series

■

ADF/Reader Unit

[4]

[5]

[1]

Key Name Reference

[1] ADF Paper Feed Roller

[2] ADF Separation Roller

[3] ADF Pickup Roller

[4] ADF Delivery roller

[5] ADF Separation Pad

F-1-7

T-1-13

Printer

[19][20]

Key Name Key Name

[1] Fixing delivery roller [11] MP tray pickup roller

[2] Face-down delivery roller [12] MP tray separation pad

[3] Pressure roller [13] Registration roller

[4] Fixing lm unit [14] Feed roller

[5] Fixing unit [15] Cassette pickup roller

[6] Transfer roller [16] Cassette separation pad

[7] Photosensitive drum [17] Cassette

[8] Laser scanner unit [18] Duplex re-pickup roller

[9] Cartridge [19] Duplex feed unitr

[10] Registration shutterroller [20] Duplex feed roller

[18]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

F-1-8

T-1-14

Product Overview > Name of Parts > Cross Sectional View > MF5900/6100 Series

1

1-10

1

Product Overview > Name of Parts > Cross Sectional View > D1300 Series

D1300 Series

■

ADF / Reader Unit

[1]

[2] [3]

1-11

Printer

[7]

[5]

Key Name Reference

[1] ADF Paper Feed Roller

[2] ADF Separation Roller

[3] ADF Pickup Roller

[4] ADF Delivery roller

[5] ADF Separation Pad

[4]

F-1-9

T-1-15

[3]

[2]

[1]

[5]

[20]

[19]

Key Name Key Name

[1] Fixing delivery roller [11] MP tray pickup roller

[2] Face-down delivery roller [12] MP tray separation pad

[3] Fixing unit [13] Feed roller

[4] Fixing lm unit [14] Cassette pickup roller

[5] Pressure roller [15] Cassette separation pad

[6] Laser scanner unit [16] Duplex re-pickup roller

[7] Copyboard glass (scanning glass) [17] Transfer roller

[8] Cartridge [18] Photosensitive drum

[9] Registration shutter [19] Duplex feed roller

[10] Registration roller [20] Duplex feed unit

[4]

[18]

[17]

[6]

[16]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

F-1-10

T-1-16

Product Overview > Name of Parts > Cross Sectional View > D1300 Series

1

1-11

1

[1] [2] [3]

[5] [6] [7]

[10] [11]

[12]

[14]

[9]

[8]

[15]

[4]

Product Overview > Name of Parts > Operation Panel > Main Operation Panel

1-12

Operation Panel

Main Operation Panel

■

MF5900 Series

[13]

Print

Error

Scan PC2Scan PC1

Copy

Start

[18][19][20][21][22][23][24][25][26][27][28][29]

Menu

2-Sideb

Select Paper/settings

COPY

FAX

Reset

Back

SCAN

DIRECT

PRINT

Status Monitor/

Cancel

OK

View

Settings

ABC DEF

1

GHI JKL MNO

4

7

Tone

Report

2

5

WXYZPQRS TUV

8 9

SYMBOLS

0

Energy

Saver

Log In/Out

ID

3

Clear

6

C

Stop

Processing/

Data

Key Name Key Name

[1] Paper Select indicator [16] [Paper Save Copy] key

[2] [2-Sided] key [17] [Secure print] key

[3] [Menu] key [18] [Start] key

[4] Display [19] Error indicator

[5] [COPY] key [20] Processing/Data indicator

[6] [FAX] key [21] [Stop] key

[7] [SCAN] key [22] [Numeric] key

[8] [DIRECT PRINT] key [23] [Tone] key

[9] Wi-Fi LED * [24] [Status Monitor/Cancel] key

[10] [Report] key [25] [View Settings] key

[11] [Energy Saver] keys [26]

[12] [Log In/Out] key (ID key) [27] [Back] key

[ ▲ ][ ▼ ][ < ][ > ] key

[13] [Clear] key [28] [Reset] key

[14] [Scan to PC1] key [29] [Select Paper/Settings] key

[15] [Scan to PC2] key

* MF5950/MF5980 only

[16]

[17]

F-1-11

T-1-17

MF6100 Series

[1] [4] [9][2] [3] [5] [6] [7] [8] [10]

Menu

Two-Sided

Paper Select

FAX

MEDIA

SCANCOPY

PRINT

Status Monitor/

Reset

Back

[27][29]

Cancel

OK

View

Settings

1

GHI JKL MNO

4

7

Tone

[24][28]

Key Name Key Name

[1] Paper Select indicator [16] [Paper Save Copy] key

[2] [2-Sided] key [17] [Secure print] key

[3] [Menu] key [18] [Start] key

[4] Display [19] Error indicator

[5] [COPY] key [20] Processing/Data indicator

[6] [FAX] key [21] [Stop] key

[7] [SCAN] key [22] [Numeric] key

[8] [DIRECT PRINT] key [23] [Tone] key

[9] Wi-Fi LED * [24] [Status Monitor/Cancel] key

[10] [Report] key [25] [View Settings] key

[11] [Energy Saver] keys [26]

[12] [Log In/Out] key (ID key) [27] [Back] key

[13] [Clear] key [28] [Reset] key

[14] [Scan to PC1] key [29] [Select Paper/Settings] key

[15] [Scan to PC2] key

* MF6150/MF6160/MF6180 only

[11] [12] [15]

Energy

Saver

ABC DEF

2

5

WXYZPQRS TUV

8 9

SYMBOLS

0

Report

3

6

Log In/Out

ID

Clear

C

Processung/

Dara

Scan PC1

Secured Print

Stop

[ ▲ ][ ▼ ][ < ][ > ] key

[13] [14]

Scan PC2

Paper Save Copy

Start

Error

[16]

[17]

[18][19][20][21][22][23][26] [25]

F-1-12

T-1-18

Product Overview > Name of Parts > Operation Panel > Main Operation Panel

1

1-12

1

[1] [2] [3] [4] [5] [6] [7] [10] [11] [12] [13] [14][9][8]

[1]

[2]

[1]

[2]

Product Overview > Name of Parts > Operation Panel > FAX Operation Panel

1-13

D1300 Series

Menu

Key Name Key Name

[1] Paper Select indicator [16] [Stop/Reset] key

[2] [2-Sided] key [17] [Start] key

[3] [Menu] key [18] Error indicator

[4] Display [19] Processing/Data indicator

[5] [COPY] key [20] [Numeric] key

[6] [FAX] key *1 [21] [Tone] key

[7] [SCAN] key [22] [Status Monitor/Cancel] key

[8] [DIRECT PRINT] key [23] [View Settings] key

[9] Wi-Fi LED *2 [24]

[10] [Counter] key [25] [Back] key

[11] [Report] key [26] [Reset] key

[12] [Energy Saver] keys [27] [Select Paper/Settings] key

[13] [Log In/Out] key (ID key)

[14] [Clear] key *3

[15] [Secure print] key

*1 D1350/D1370/D1380 only

*2 D1380 only

*3 D1370/D1380 only

COPY

FAX

SCAN

OK

DIRECT

PRINT

1

GHI JKL MNO

4

7

Tone

[ ▲ ][ ▼ ][ < ][ > ] key

Report

ABC DEF

2

5

8 9

0

FAX Operation Panel

■

MF5900/6100 Series

Energy

Saver

Log In/Out

ID

3

Clear

6

C

WXYZPQRS TUV

Processing/

Data

Error

[17][18][19][20][21][22][23][24][25] [15][26]

Print

Stop/Reset

Start

[16]

F-1-13

Panel open

Address

02

04

06

Pause

[6]

Book

Coded

Dial

Recall

Hook

[4]

08

09

10

11

12

13

14

15

16

17

18

19

[5]

01

03

05

07

[5]

Key Name Key Name

Menu

2-Sideb

Select Paper/settings

[3]

F-1-14

[1] [Address Book] key [4] [Hook] key

[2] [Coded Dial] key [5] [One touch] key

[3] [Recall] key [6] [Pause] key

T-1-20

D1300 Series

Panel open

T-1-19

08

09

10

11

12

13

14

15

16

17

18

19

Key Name Key Name

[1] [Address Book] key [4] [Hook] key

[2] [Coded Dial] key [5] [One touch] key

[3] [Redial] key [6] [Pause] key

01

02

03

04

05

06

07

[6]

[4]

[5][5]

[3]

F-1-15

T-1-21

Product Overview > Name of Parts > Operation Panel > FAX Operation Panel

1

1-13

Technical Overview

2

Basic Conguration

■

Document Exposure / Delivery

■

System

Controller System

■

Laser Exposure System

■

Image Formation System

■

Fixing System

■

Pickup / Feed System

■

Technical Overview

2

2

Technical Overview > Basic Conguration > Basic Sequence > Basic Operational Sequence

2-2

Basic Conguration

Conguration Function

This device is roughly composed of the 6 functional blocks as shown in the gure below

• Document Exposure/Delivery System • Image Formation System

• Controller System • Fixing System

• Laser Exposure System • Pickup / Feed System

Document exposure/delivery system

ADF unit

Contact Sensor

Delivery unit

Fixing System

Fixing unit

Main

Controller

Laser Exposure System

Laser scanner

Cartridge

Image Formation System

Photosensitive drum

MP Tray

Pickup / Feed System

Transfer roller

Controller system

Engine controller

Casette

Basic Sequence

Basic Operational Sequence

■

The CPU on the Engine Controller PCB controls the operational sequence. The table below

shows the operation and the purposes in each status from start-up of the device and to last

rotation after print job completion.

Status Operation

WAIT

(Wait)

STBY

(STBY)

INTR

(IINTR)

PRINT

(Print)

LSTR

(Last

rotation)

Interval from power-ON

or reactivation from sleep

mode upon shutting the

door(s) to entering the printready status

Interval from the wait time or

the last rotation to issuance

of a print command from the

main controller or powerOFF.

Interval from issuance of

a print command from the

main controller during the

stand-by status to warming

up the Fixing Unit to the

target temperature.

Interval from the initial

rotation to completion of last

page xation.

Interval from print job

completion to Motor

deactivation.

Activate the printer to be ready for printing. During WAIT

time, the following operations are done: pressure is applied

to the pressure roller of the Fixing Unit; check cartridges

and units being in place; move the developing unit to the

home position; and, clean the ITB. When needed, color

displacement is corrected and the image is stabilized.

Maintain the print-ready status. The printer enters the sleep

mode upon receiving a “sleep” command from the main

controller during the stand-by status. The printer executes

color displacement correction or image stabilization upon

receiving corresponding commands from the main controller.

To make the printer ready for print jobs, activate highvoltage bias PCBs, the Laser Scanner Unit and the Fixing

Unit.

Based on the video signals input from the main controller,

form the static latent image on the photosensitive drum to

transfer and x the toner image on paper. When a certain

pages are printed after power-ON, the device undergoes

color displacement correction and/or image stabilization.

The last page of the print job is completely delivered. In

this status, the Laser Scanner Unit and high-voltage bias

PCBs are inactive. The printer starts the initial rotation upon

receiving a print command from the main controller during

this status.

T-2-1

PC

Laser beam

Paper flow

Signal flow

F-2-1

2-2

Technical Overview > Basic Conguration > Basic Sequence > Basic Operational Sequence

2

2

Power switch ON

Technical Overview > Basic Conguration > Basic Sequence > Print Sequence

Print Sequence

■

Timing chart two consecutive prints on LTR paper

2-3

Operation

1

TOP sensor (PS204)

Fixing delivery sensor (PS915)

2

3

Print start command (EEC12)

Scanner Motor (M202)

4

Laser Diode

5

6

BD Output signal (BDO)

7

Main Motor (M201)

Primary Charging Bias (AC)

8

9

Primary Charging Bias (DC)

10

Developing Bias

Transfer Charging Bias

11

12

Fixing Heater (H201/H2010)

Cassette pickup solenoid (SL201)

13

14

Main Fan (FM201)

15

16

17

18

19

20

WAIT STBY INTR PRINT LASTR STBY

Technical Overview > Basic Conguration > Basic Sequence > Print Sequence

2

2-3

2

Technical Overview > Basic Conguration > Print Mode

Print Mode

Print modes Feeding speed Media type Print speed Remarks

Normal speed

mode

1/2 speed mode 1/2 speed Plain paper A4/LTR width

*1: Normal mode is recommended for Neenah Bond 60g/m2

1/1speed Speed for plain paper A4/LTR

width (60 to 89g)

Transparencies

(60 to 89g)

Plain paper less than A4 width (60

to 89g)

Heavy paper (90 to 163g)

Bond paper (60 to 163g)

Label paper

Postcard, Tab paper

Envelope

33/35 ppm

2-4

T-2-2

Technical Overview > Basic Conguration > Print Mode

2

2-4

2

Technical Overview > Document Exposure / Delivery System

Document Exposure / Delivery System

Specications / Control / Function List

■

item function / method

Document Exposure LED

Document Scan Book mode: scan by the shift of the contact Book mode: scan by the shift

of the contact image sensor (CIS)

ADF: document stream reading by xed contact image sensor (CIS)

Scanning Resolution 600 dpi (horizontal scanner) X 600 dpi (vertical scanner)

Number Of Gradations 256 gradations

Magnication 50% to 200%

horizontal: image processing by Main Controller PCB

vertical: change of carriage shift speed, image processing by Main

Controller PCB

Lens rod lens array

CMOS Sensor number of lines: 1 line

number of pixels: 5184 pixels as total pixels (5107 pixels as effective

pixels)

maximum document scanning width: 216 mm

CS Drive Control drive control by Reader Motor (M701)

CS HP Detection Yes

Document Size Detection None

Dirt Sensor Detection Yes

T-2-3

2-5

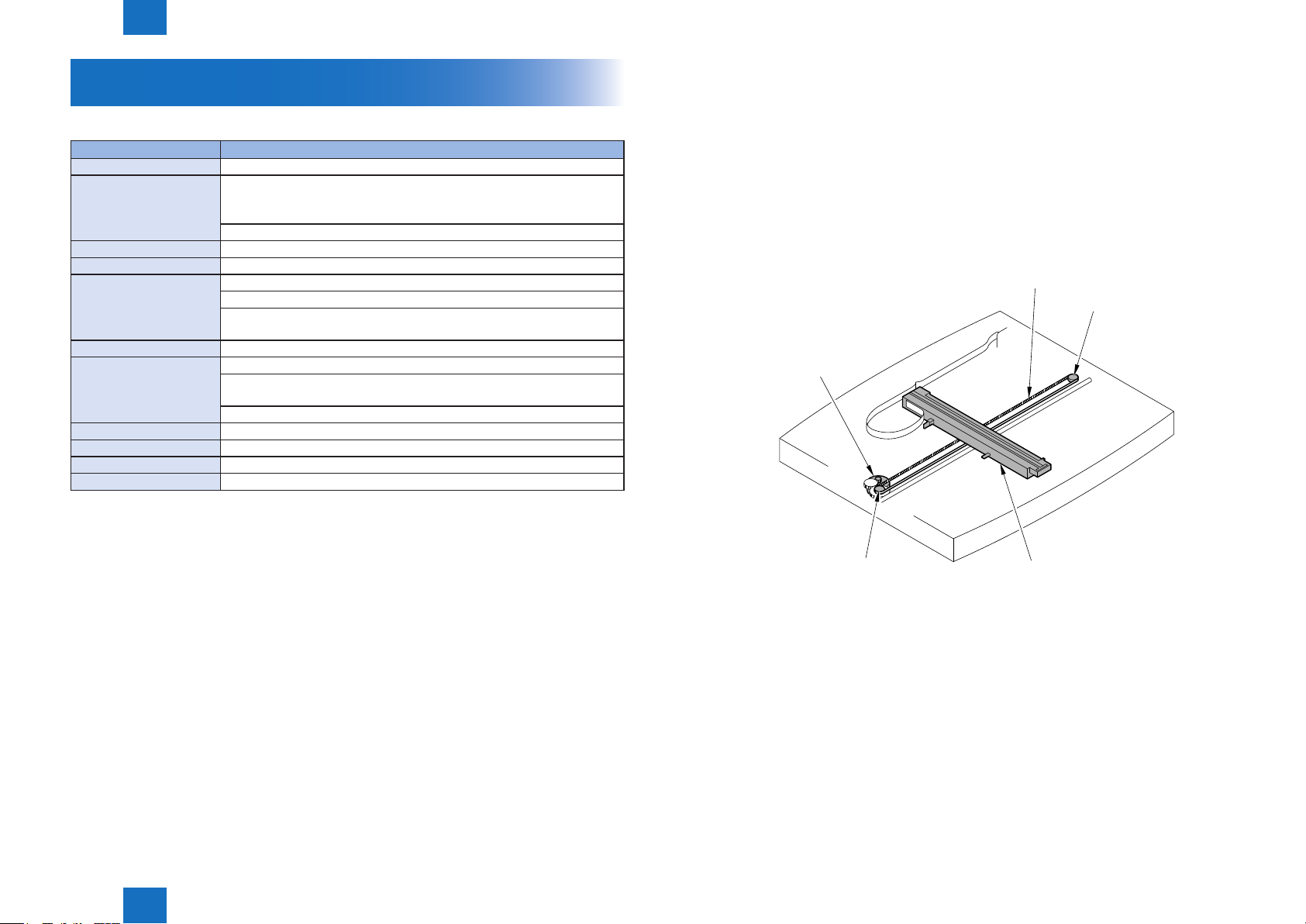

Major Components

■

Followings are the major components for Document Exposure System.

• The Contact Sensor to scan document

• The Reader Motor (M701), the Drive Pulley, the Drive Belt, to shift the Contact Sensor

In image scanning control, the Contact Image Sensor is shifted by rotating the Reader Motor

based on the drive signal from the Engine Controller PCB and scan the original on the

Copyboard Glass. When ADF is in use, image is scanned by feeding the originals by ADF

instead of shifting the Contact Image Sensor.

Drive belt

Drive pulley

Reader motor (M701)

Technical Overview > Document Exposure / Delivery System

2

Drive pulley

Contact sensor

F-2-2

2-5

2

PS703

Technical Overview > Document Exposure / Delivery System > Document Feeder System > Pickup/Feed/Delivery Operation

2-6

Document Feeder System

Pickup/Feed/Delivery Operation

■

The Auto Document Feeder (ADF) mounted onto this host machine is dedicated to stream-

reading.

1 Motor (DADF Motor: M702) is engaged in pickup/feeding/delivery.

At the start of copy/fax/scan, the DADF Motor (M702) is driven by the drive command from

the Main Controller PCB to pickup/feed the originals set face up on the original tray one by

one in order from the top. The original is scanned by the Contact Image Sensor when moving

through the Copyboard Glass, and then delivered face down to the original delivery assembly.

PS702

+3.3V

GND

DS

GND

+3.3V

J910

789101112

F-2-3

DES

MCON

Operation at Duplex Reading

- Pickup to Reading of the 1st side

F-2-4

- Reverse to Reading of the 2nd side

F-2-5

- Delivery

Technical Overview > Document Exposure / Delivery System > Document Feeder System > Pickup/Feed/Delivery Operation

2

F-2-6

2-6

Loading...

Loading...