Canon LBP351 Series, LP352 Series Service Manual

LBP351/352 Series

Service Manual

Revision 4.0

1x

1x

Introduction

Introduction

Important Notices

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products.

This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does

not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the

need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

The copyright of this document belongs to Canon Inc. This document may not be copied, reproduced or translated into another

language, in whole or in part, without the prior consent of Canon Inc.

Copyright CANON INC. 2017

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

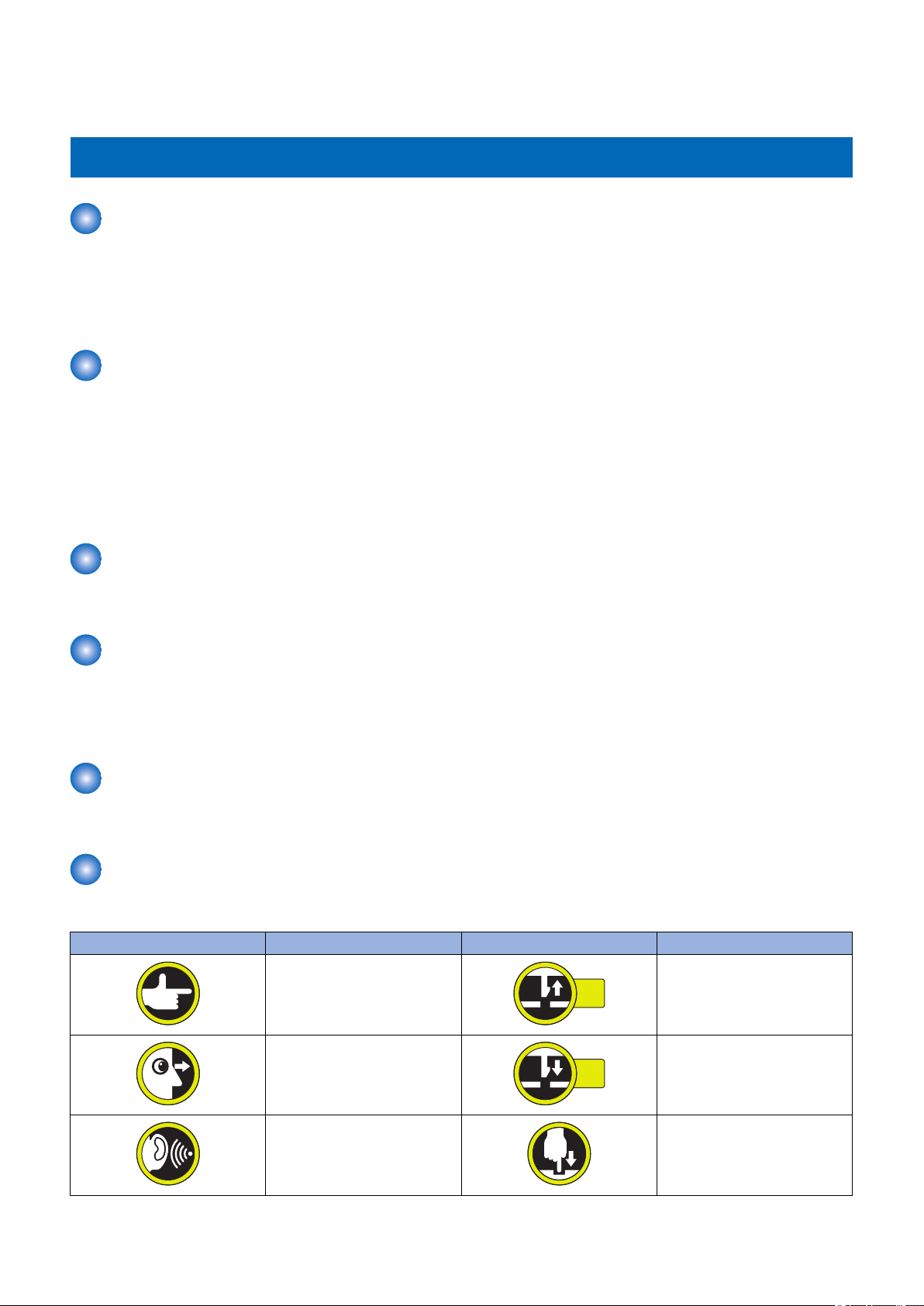

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check.

Remove the claw.

Check visually.

Check a sound. Push the part.

Insert the claw.

1x

1x

1x

1x

1x

1x

1x

1x

Introduction

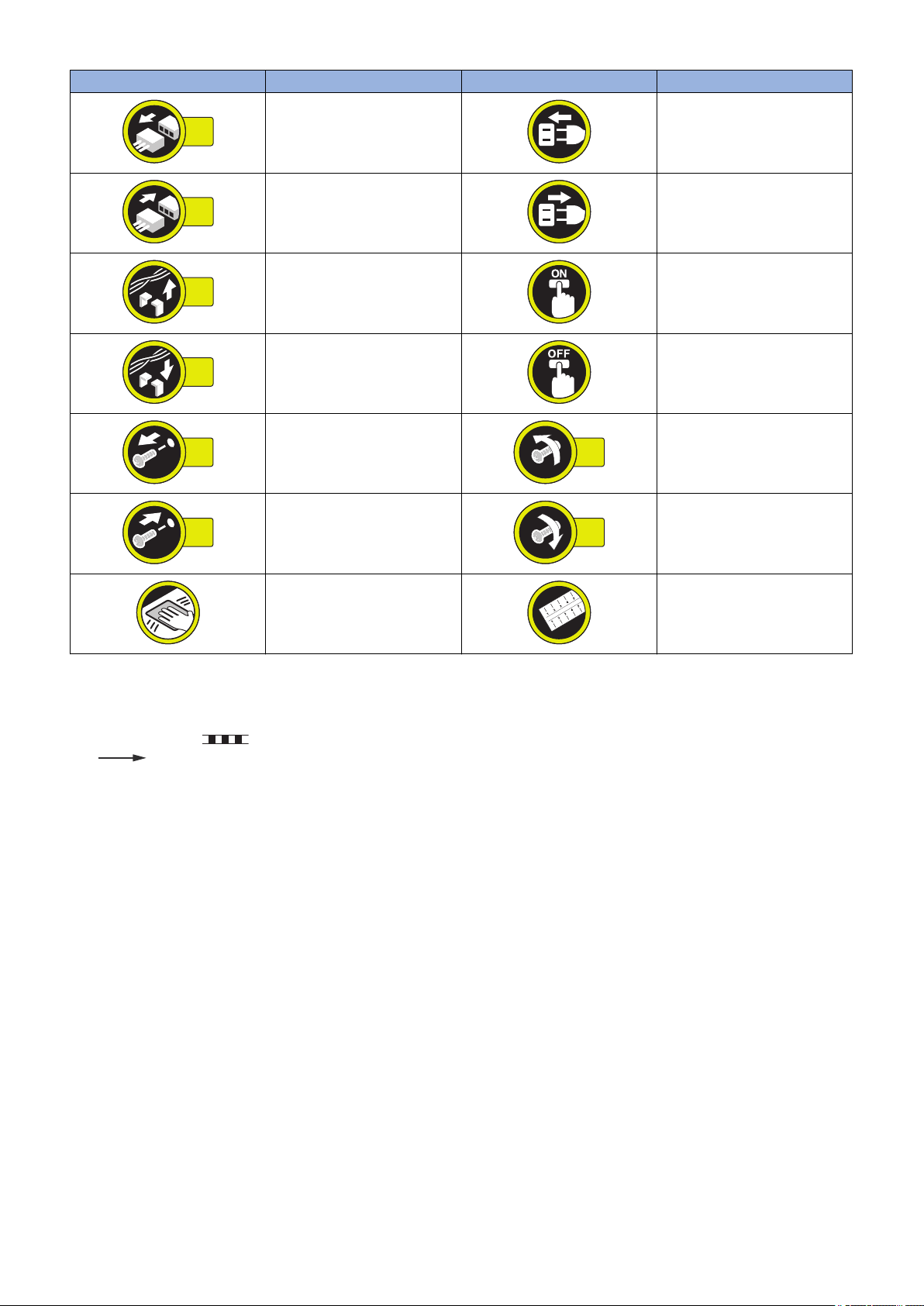

Symbols Explanation Symbols Explanation

Disconnect the connector. Connect the power cable.

Connect the connector. Disconnect the power cable.

Remove the cable/wire from the

cable guide or wire saddle.

Install the cable/wire to the cable

guide or wire saddle.

Remove the screw.

Install the screw.

Cleaning is needed. Measurement is needed.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and

mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow

indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit

door, which results in supplying the machine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".

(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations

of the microprocessors used in the machines are not discussed: they are explained in terms of from sensors to the input of

the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and

major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service

Information bulletins and be able to identify and isolate faults in the machine.

Turn on the power.

Turn off the power.

Loosen the screw.

Tighten the screw.

Contents

Contents

Safety Precautions...............................................................................................1

Laser Safety........................................................................................................................................ 2

How to Handle the Laser Scanner Unit...............................................................................................2

Power Supply...................................................................................................................................... 2

Toner Safety........................................................................................................................................3

About Toner..........................................................................................................................................3

Handling Adhered Toner........................................................................................................................3

Notes When Handling a Lithium Battery............................................................................................. 3

Notes Before it Works Serving............................................................................................................ 3

Points to Note at Cleaning...................................................................................................................4

Notes on Assembly/Disassembly........................................................................................................4

1. Product Overview.............................................................................................5

Product Lineups.................................................................................................................................. 6

Host machine........................................................................................................................................6

Options................................................................................................................................................ 6

Features...............................................................................................................................................6

Specification........................................................................................................................................7

Product Specifications...........................................................................................................................7

Print Speed.......................................................................................................................................... 9

Paper type............................................................................................................................................9

Paper size............................................................................................................................................ 9

List of Parts....................................................................................................................................... 11

External..............................................................................................................................................11

Cross Sectional View...........................................................................................................................12

2. Technical Explanation (Device).................................................................... 13

Laser Exposure System.................................................................................................................... 14

Overview............................................................................................................................................ 14

Laser Scanner Motor Control............................................................................................................... 14

Image Formation System.................................................................................................................. 16

Image Formation Process....................................................................................................................16

Cartridge............................................................................................................................................ 19

Pickup Feeding System.....................................................................................................................21

Overview............................................................................................................................................ 21

Various Control Mechanisms............................................................................................................... 23

Fixing System....................................................................................................................................32

Overview/Configuration....................................................................................................................... 32

Various Control Mechanisms............................................................................................................... 32

Controller System..............................................................................................................................36

Main Controller................................................................................................................................... 36

DC Controller......................................................................................................................................37

Power Supply..................................................................................................................................... 38

Quick Startup......................................................................................................................................39

i

Contents

Energy Saving Function.......................................................................................................................40

3. Technical Explanation (System)................................................................... 41

Version Upgrade............................................................................................................................... 42

Overview............................................................................................................................................ 42

Version Upgrade Using UST................................................................................................................43

Update Using Updater......................................................................................................................... 43

Backup/Restoration...........................................................................................................................72

Backup/Restoration Using the DCM Function........................................................................................72

Backup/Restoration Using a Function Other Than the DCM Function..................................................... 80

Monitoring Function (e-Maintenance/imageWARE Remote)............................................................ 88

Overview of System............................................................................................................................ 88

Cautions when Using E-RDS............................................................................................................... 89

Setting Procedure............................................................................................................................... 89

Maintenance.......................................................................................................................................91

MEAP Application Management........................................................................................................92

About MEAP.......................................................................................................................................92

About SMS......................................................................................................................................... 92

Setting Procedure............................................................................................................................... 97

Maintenance..................................................................................................................................... 105

4. Periodical Service........................................................................................ 108

Periodically Replaced Parts............................................................................................................ 109

Consumable parts........................................................................................................................... 110

Periodical Service............................................................................................................................111

5. Parts Replacement and Cleaning............................................................... 112

List of Parts..................................................................................................................................... 113

Main Unit.......................................................................................................................................... 113

Motor/Fan.........................................................................................................................................114

Sensor..............................................................................................................................................114

PCB................................................................................................................................................. 115

External Cover/Interior System....................................................................................................... 116

Removing the Left Cover................................................................................................................... 116

Removing the Right Cover................................................................................................................. 117

Removing the Rear Cover..................................................................................................................117

Removing the Front Cover Unit.......................................................................................................... 118

Removing the Right Front Cover........................................................................................................ 118

Removing the Upper Cover Unit.........................................................................................................119

Removing the Control Panel...............................................................................................................120

Removing the Fan1........................................................................................................................... 120

Removing the Fan2........................................................................................................................... 121

Removing the Fan3........................................................................................................................... 121

Removing the Fan4........................................................................................................................... 121

Controller System............................................................................................................................123

Removing the Controller Cover.......................................................................................................... 123

Removing the Main Controller PCB.................................................................................................... 123

Removing the Controller Box..............................................................................................................124

Removing the Power Supply Box....................................................................................................... 124

ii

Contents

Removing the DC Controller PCB.......................................................................................................125

Removing the AC Relay PCB.............................................................................................................126

Removing the Power Supply PCB...................................................................................................... 126

Removing the All-Night Power Supply PCB.........................................................................................129

Removing the Sleep Interface PCB.....................................................................................................129

Laser Exposure System.................................................................................................................. 130

Removing the Laser Scanenr Unit...................................................................................................... 130

Image Formation System................................................................................................................ 131

Removing the Transfer Roller.............................................................................................................131

Removing the Main Motor..................................................................................................................131

Removing the Main Drive Unit............................................................................................................132

Fixing System..................................................................................................................................134

Removing the Fixing Assembly.......................................................................................................... 134

Removint the Fixing Moter................................................................................................................. 134

Pickup/Feed System....................................................................................................................... 135

Removing the Duplex Unit................................................................................................................. 135

Removing the Pickup/Feeding/Separation Roller................................................................................. 135

Removing the MP-Tray Pickup/Feeding/Separation Roller................................................................... 135

Removing the Verticalpass Roller.......................................................................................................136

Removing the Lifter Motor..................................................................................................................136

Removing the Pickup Motor............................................................................................................... 136

Removing the MP-Tray Pickup Unit.................................................................................................... 137

Removing the Registration Roller Unit................................................................................................ 138

Removing the Pickup Drive Unit......................................................................................................... 138

6. Adjustment................................................................................................... 140

Actions after Replacement.............................................................................................................. 141

Before Replacing the Main Controller PCB..........................................................................................141

After Replacing the Main Controller PCB.............................................................................................141

7. Troubleshooting...........................................................................................142

Test Print.........................................................................................................................................143

Overview.......................................................................................................................................... 143

Device Log List................................................................................................................................. 146

Troubleshooting...............................................................................................................................147

Remedy for Image Failure..................................................................................................................147

Repetitive Image Defects Ruler.......................................................................................................... 147

Checking the Amount of Fixing Nip.....................................................................................................147

Obtaining Debug Log...................................................................................................................... 149

Function Overview.............................................................................................................................149

Sublog..............................................................................................................................................149

Conditions for collecting logs..............................................................................................................149

Sublog Collection Procedure..............................................................................................................150

8. Error/Jam/Alarm........................................................................................... 153

Overview......................................................................................................................................... 154

Error Code Details...........................................................................................................................155

Jam Code........................................................................................................................................160

iii

Contents

Alarm Code..................................................................................................................................... 163

9. Service Mode................................................................................................ 164

Overview......................................................................................................................................... 165

Entering Service Mode...................................................................................................................... 165

Remote UI Service Mode...................................................................................................................165

Service Report.................................................................................................................................. 166

Service Mode.................................................................................................................................. 169

COUNTER GR..................................................................................................................................169

ADJUST GR..................................................................................................................................... 169

OPTION GR......................................................................................................................................169

FUNCTION GR................................................................................................................................. 170

LOG GR........................................................................................................................................... 172

PANEL.GR....................................................................................................................................... 173

F/W UPDATE GR..............................................................................................................................173

NETWORK GR................................................................................................................................. 173

SP.ADMIN.MODE............................................................................................................................. 175

APPENDICES....................................................................................................176

Service Tools...................................................................................................................................177

Solvents and Oil List..........................................................................................................................177

General Circuit Diagram..................................................................................................................178

General Circuit Diagram (1/3).............................................................................................................178

General Circuit Diagram (2/3).............................................................................................................179

General Circuit Diagram (3/3).............................................................................................................180

Backup Data List............................................................................................................................. 181

Backup Data..................................................................................................................................... 181

List of Items Which Can Be Imported..............................................................................................182

Service Mode....................................................................................................................................182

Soft counter specifications.............................................................................................................. 184

iv

Safety Precautions

Laser Safety..........................................2

How to Handle the Laser Scanner Unit

...........................................................2

Power Supply........................................2

Toner Safety..........................................3

Notes When Handling a Lithium

Battery............................................... 3

Notes Before it Works Serving..............3

Points to Note at Cleaning.................... 4

Notes on Assembly/Disassembly..........4

Safety Precautions

Laser Safety

Since radiation emitted inside this machine is completely confined with protective housings and external covers, the laser beam

cannot escape from the machine during any phase of normal use by users.

Therefore, this machine is classified as a Class 1 laser product under the international standard IEC60825-1 that is regarded as

safe during normal use.

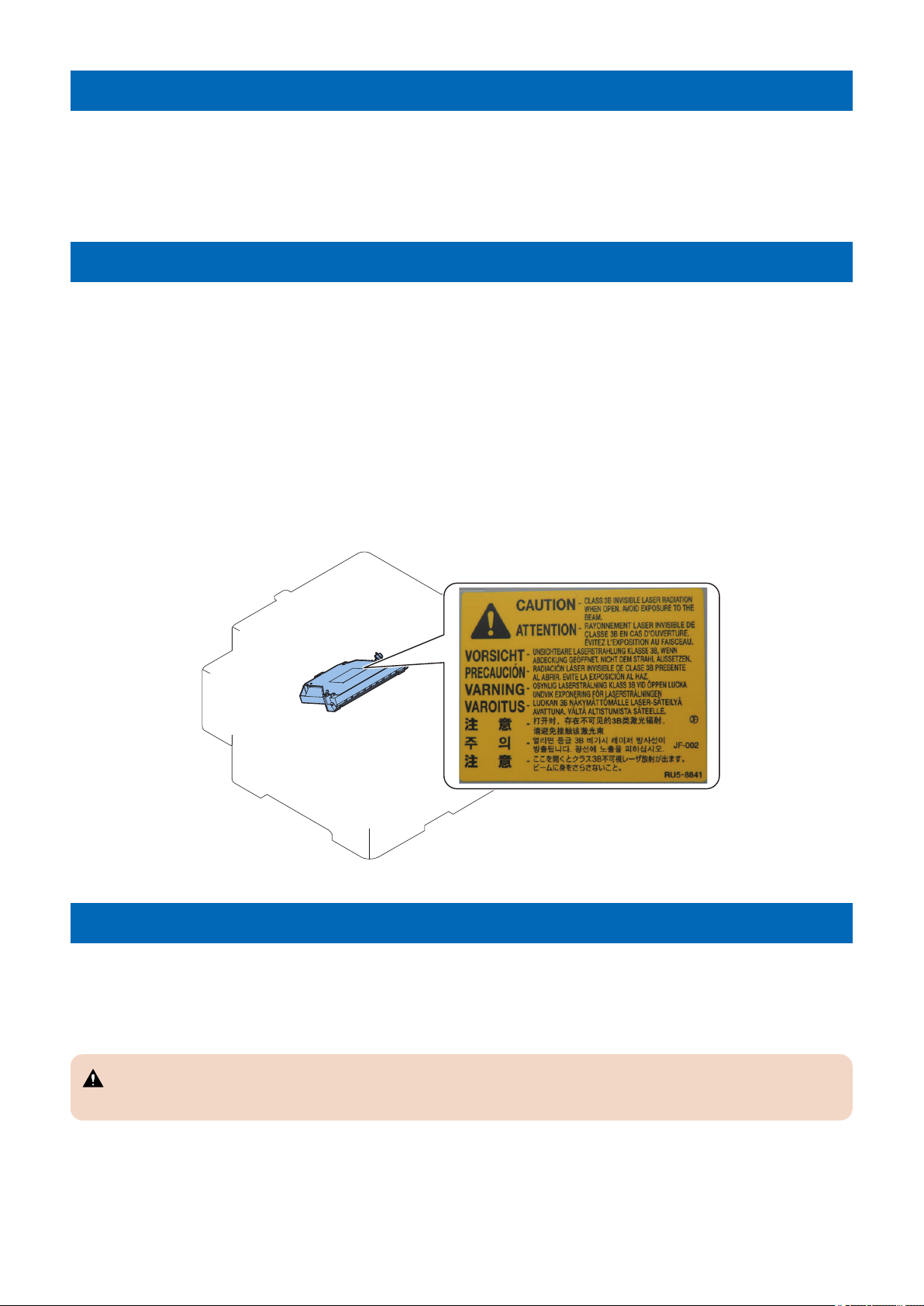

How to Handle the Laser Scanner Unit

This machine is classified as a Class 1 laser product.

However, the laser scanner unit contains source of Class 3B laser beam and exposure to the beam may cause eye injuries.

Therefore, be sure not to disassemble the laser scanner unit. No adjustment can be made to the laser scanner unit in the machine

in the field.

The label shown in the following figure is affixed on the laser scanner unit.

Dieses Gerät ist der Klasse 1 der Laserprodukte zugeordnet.

Allerdings enthält die Laserscannereinheit eine Laserstrahlquelle der Klasse 3B, die Augenschäden verursachen kann, wenn

man in diesen Strahl blickt.

Deshalb darf die Laserscannereinheit nicht zerlegt werden. An der Laserscannereinheit kann keine Justage vor Ort vorgenommen

werden.

Der in folgendem Bild dargestellte Aufkleber ist auf der Laserscannereinheit angebracht.

Power Supply

• As a general rule, do not use extension cords.

If an extension cord must be used, however, use one for local rated voltage and over, untie the cord binding, and insert the

power plug completely into the extension cord outlet to ensure a firm connection between the power cord and the extension

cord.

CAUTION:

Do not plug multiple cords together to an extension cord. It may cause a fire or electrical shock.

• The socket-outlet shall be installed near the equipment and shall be easily accessible.

2

Safety Precautions

Toner Safety

About Toner

Toner is a nontoxic matter composed of plastic, iron and a trace of pigments.

CAUTION:

Never throw toner in flames to avoid explosion.

Handling Adhered Toner

• Use dry tissue paper to wipe off toner adhered to skin or clothes and wash in water.

• Never use warm water for cleaning up toner to prevent toner particles from being gelated to soak into fibers permanently.

• Toner particles are reactive with vinyl polymers. Avoid contacting these materials.

Notes When Handling a Lithium Battery

Dispose of used batteries according to the instructions.

CAUTION:

Risk of explosion if battery is replaced by an incorrect type.

The following warnings are given to comply with Safety Principles (EN60950-1).

CAUTION:

Wenn mit dem falschen Typ ausgewechselt, besteht Explosionsgefahr.

Gebrauchte Batterien gemäß der Anleitung beseitigen.

Notes Before it Works Serving

• At servicing, be sure to turn OFF the power source according to the specified steps and disconnect the power plug.

• Be sure to disconnect the power plug on a regular basis and remove dust and dirt accumulated around the outlet with dry

cloth.

CAUTION:

Leaving the power plug connected for a long time in an environment having a lot of dust, moisture, or oily smoke will

cause a fire. (Because dust accumulated in the surrounding area will absorb moisture and cause an insulation failure)

3

ACHTUNG

Zweipolige bzw. Neutralleiter-Sicherung

Safety Precautions

Points to Note at Cleaning

When performing cleaning using organic solvent such as alcohol, be sure to check that the component of solvent is vaporized

completely before assembling.

Notes on Assembly/Disassembly

Follow the items below to assemble/disassemble the device.

1. Disconnect the power plug to avoid any potential dangers during assembling/disassembling works.

2. If not specially instructed, reverse the order of disassembly to reinstall.

3. Ensure to use the right screw type (length, diameter, etc.) at the right position when assembling.

4. To keep electric conduction, binding screws with washers are used to attach the grounding wire and the varistor. Ensure to

use the right screw type when assembling.

5. Unless it is specially needed, do not operate the device with some parts removed.

6. Never remove the paint-locked screws when disassembling.

CAUTION:

Double pole/neutral fusing

4

1

Product Overview

Product Lineups.................................... 6

Specification..........................................7

List of Parts......................................... 11

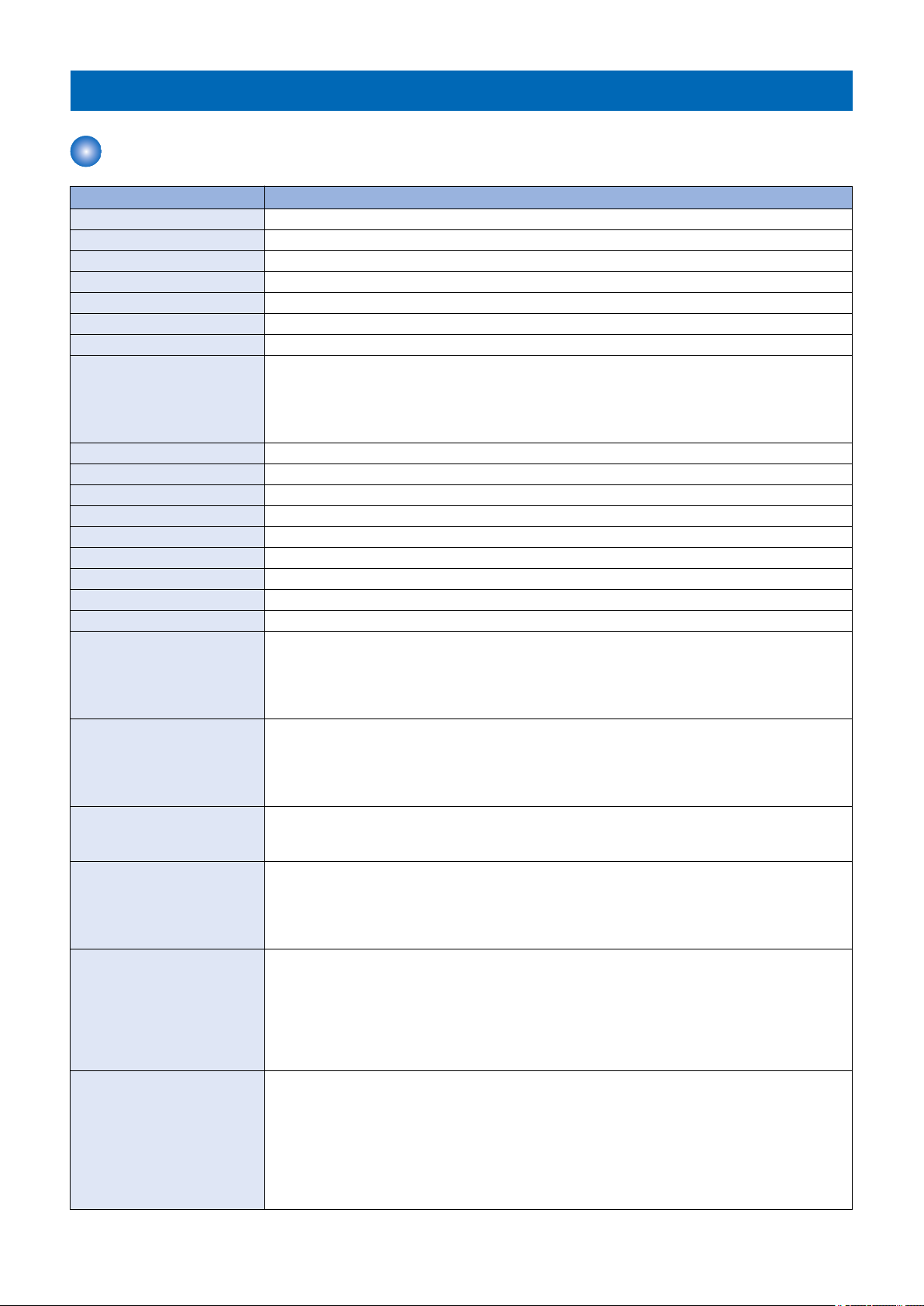

Product Lineups

Host machine

Function LBP351dn/ LBP351x

LBP352dn/ LBP352x

External

1. Product Overview

Copy -

Print Yes

Fax -

Remote UI Yes

2-sided printing Yes

MEAP Yes

Network Yes

Wireless LAN -

Options

Name Detail

Paper Feeder PF-B1 A Paper Feeder with up to 3 decks can be installed.

Paper Deck Unit PD-G1 High pickup capacity of 1500 sheets

A5 Cassette C-A1 Cassette where A5R size can be loaded

Custom Media Cassette CM-A1 Cassette where A5, A6, and custom size paper can be loaded

Envelope Feeder EF-A1 A large volume of envelopes/postcards can be printed.

Features

High-end A4/LTR B&W SFP of high speed, high durability and high capacity pickup

1. High speed and high durability

This machine is a high-speed printer that realizes a print speed of 62/65 ppm (A4/LTR) in 1-sided printing.

Superior durability, suitable for large volume printing

2. High capacity pickup

In addition to the Multi-purpose Tray and Standard Drawer, up to 3 Paper Feeders (500 sheets) and a Paper Deck Unit (1500

sheets) can be installed as options.

Up to 3,600 sheets (in the case of 80 g/m2) can be continuously and automatically picked up.

3. Improved maintainability

The maintenance kit is commercialized to promote self maintenance by end users.

6

Specification

Product Specifications

Item Specification/Function

Machine installation method Desktop page printer

Photosensitive medium OPC Drum (30 mm dia.)

Exposure method Laser beam

Charging method AC Roller charging

Developing method Dry, 1-component toner projection

Transfer method Roller transfer

Separation method Curvature separation + Static Eliminator

Pickup method Cassette

Pad separation method

Multi-purpose Tray

Pad separation method

Fixing method On-demand fixing method

Delivery method Face down (Delivery Tray) / Face up (Sub Delivery Tray)

Drum cleaning method Cleaning Blade

Toner type One-component magnetic toner

Toner supplying method All-in-one cartridge with drum

Toner level detection function Yes

Toner save mode Yes

Print method Semiconductor laser + Dry-type electrophotographic method

Print resolution 600 dpi x 600 dpi

Print speed*1

(Plain paper (60 to 89 g/m2), At

continuous A4/LTR print)

Warm-up time*2

(Duration from power-on to

standby of the machine)

Recovery time*3

(Time for recovery from deep

sleep to standby)

First print time*3

(At 1-sided A4/LTR print, using

the Delivery Tray)

Paper type Cassette

Paper size Cassette

LBP352dn/ LBP352x

62 sheets/min (A4), 65 sheets/min (LTR)

LBP351dn/ LBP351x

55 sheets/min (A4), 58 sheets/min (LTR)

At normal startup

29 sec. or less

At quick startup

12 sec. or less

10 sec. or less

LBP352dn/ LBP352x

7.0 sec.

LBP351dn/ LBP351x

7.2 sec.

Plain paper (60 to 89 g/m2), Recycled paper (60 to 89 g/m2), Heavy paper (90 to 120 g/m2),

Bond paper (60 to 90 g/m2)

Multi-purpose Tray

Plain paper (60 to 89 g/m2), Recycled paper (60 to 89 g/m2), Heavy paper (90 to 135 g/m2),

Bond paper (60 to 90 g/m2), Label paper, Envelope

A4, B5, A5, LGL, LTR, EXEC, FLS, K16, Custom paper (Width: 148.0 to 216.0 mm, Length: 210.0

to 356.0 mm)

Multi-purpose Tray

A4, B5, A5, A6, LGL, LTR, EXEC, STMT, FLS, K16, Index Card (3" x 5"), Envelope (No.10

(COM10), Monarch, C5, DL), Custom paper (Width: 76.0 to 216.0 mm, Length: 127.0 to 356.0

mm)

1. Product Overview

7

1. Product Overview

Item Specification/Function

Maximum stacking capacity Cassette

500 sheets (80 g/m2), 550 sheets (64 g/m2)

Multi-purpose Tray

100 sheets

Delivery stacking capacity*4 Delivery Tray

Approx. 500 sheets

Sub Delivery Tray

Approx. 100 sheets

2-sided printing A4, B5, A5, LGL, LTR, EXEC, FLS, 16K, Custom paper (Width: 148.0 to 215.9 mm, Length: 210.0 to

355.6 mm)

Host Interface USB Interface

Hi-Speed USB x 4 (1 on the front, 3 on the rear)

Network Interface

Common to 10BASE-T, 100BASE-TX, and 1000BASE-T (RJ-45), Full/Half Duplex

Memory capacity 1 GB

Usage environment temperature

range

Environment humidity range 20 to 80 % RH (Relative humidity; without dew condensation)

Operating noise

(Measured based on ISO7779,

Declared noise emission value

based on ISO9296)

Rated power supply AC 120 to 127 V, 60 Hz

Power consumption

(Reference value)

10 to 30 deg C

LwAd (declared A-weighted sound power level (1 B = 10 dB))

At standby: 4.0 B or less

At printing (1-sided): 7.1 B or less

At printing (2-sided): 7.1 B or less

LpAm (mean A-weighted emission sound-pressure level (bystander position))

At standby: 26 dB

LBP352dn/ LBP352x

At printing (1-sided): 57 dB

At printing (2-sided): 57 dB

LBP351dn/ LBP351x

At printing (1-sided): 56 dB

At printing (2-sided): 56 dB

AC 220 to 240 V, 50/60 Hz

Maximum

1,700 W or less (120 V), 1,650 W or less (230 V)

In operation

LBP352dn/ LBP352x

Approx. 880 W (120 V), approx. 850 W (230 V)

LBP351dn/ LBP351x

Approx. 820 W (120 V), approx. 800 W (230 V)

At standby

Approx. 20 W (120 V), approx. 19 W (230 V)

During sleep mode

Wired LAN connection: Approx. 1.0 W (120 V), approx. 1.1 W (230 V)

USB connection: Approx. 2.0 W (120 V / 230 V)

At power OFF

• At shutdown

0.12 W or less (120 V)

0.17 W or less (230 V)

• In quick off mode

0.66 W or less (120 V)

0.75 W or less (230 V)

Dimensions

(W x D x H)

Weight *5 Approx. 24.5 kg

415 x 529 x 438 mm

*1: The print speed may become lower depending on the settings such as output resolution, paper size, type, orientation, and

number of sheets printed.

8

1. Product Overview

*2: This may vary depending on the usage conditions of this machine (presence/absence of installed options, installation

environment, etc.).

*3: This may vary depending on the print environment.

*4: This may vary depending on the site environment and the type of paper used.

*5: Excluding the Toner Cartridge

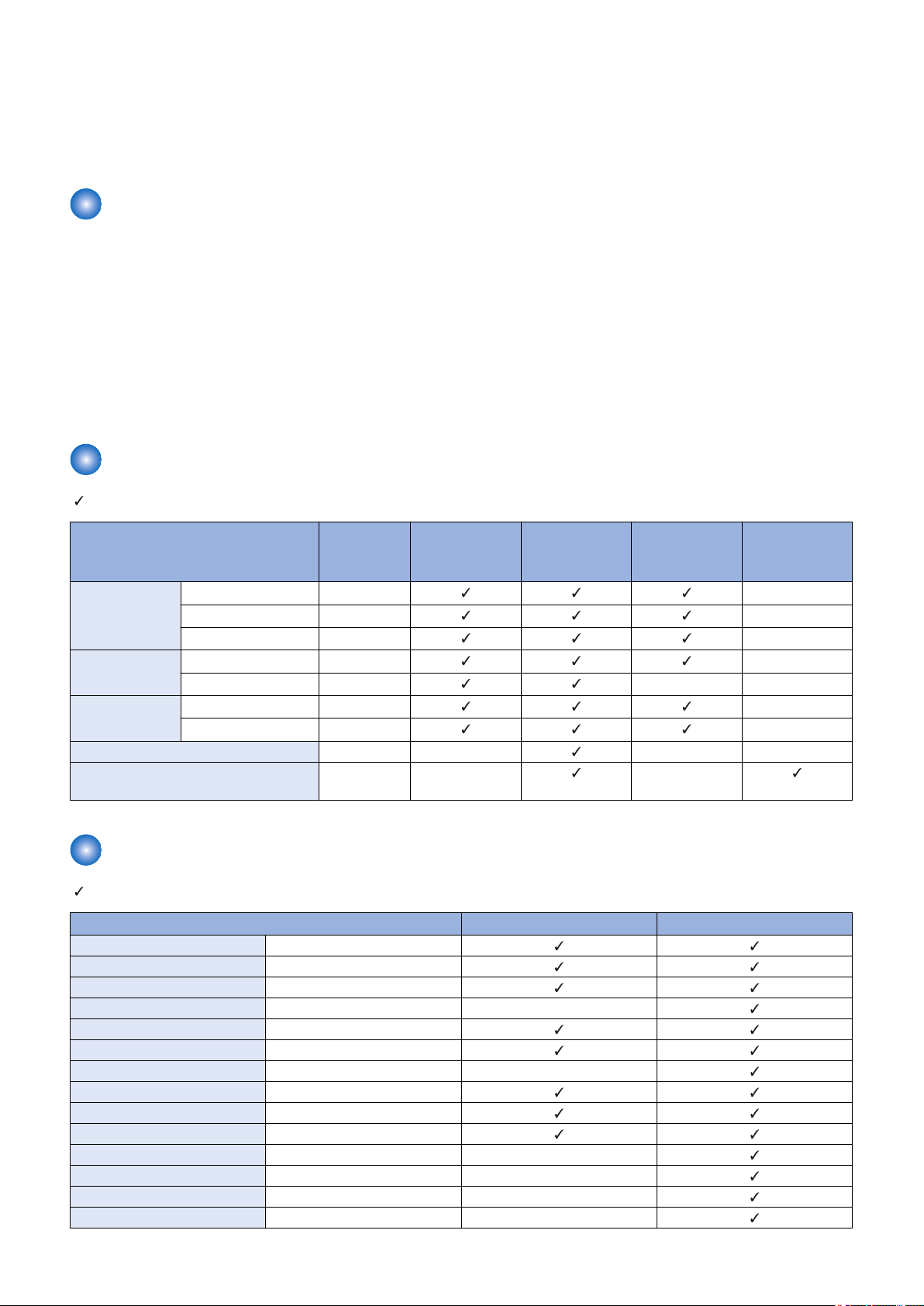

Print Speed

LBP352dn/ LBP352x

• At 1-sided printing: 62 sheets/min (A4), 65 sheets/min (LTR)

• At 2-sided printing: 41.4 pages/min (A4), 43.5 pages/min (LTR)

LBP351dn/ LBP351x

• At 1-sided printing: 55 sheets/min (A4), 58 sheets/min (LTR)

• At 2-sided printing: 36.5 pages/min (A4), 38.5 pages/min (LTR)

* The print speed may become lower depending on the settings such as output resolution, paper size, type, orientation, and

number of sheets printed. In the case of 2-sided printing, 1 page on the front side and 1 page on the back side are output as 1

sheet.

Paper type

: Pickup possible -: Pickup not possible)

(

Type of paper Paper set-

tings in this

machine

Plain paper,

recycled paper

Heavy paper

Bond paper

Label paper Labels - - -

Envelope Envelope, En-

2

60 g/m

61 to 70 g/m

71 to 89 g/m

90 to 120 g/m

121 to 135 g/m

60 to 75 g/m

76 to 90 g/m

2

2

2

2

Plain L2 -

Plain paper L -

Plain paper -

2

2

Heavy paper 1 -

Heavy paper 2 - -

Heavy paper 1 -

Heavy paper 2 -

velope H

Cassette Multi-purpose

Tray

- -

Paper Deck

(Option)

Envelope Feed-

(Option)

Paper size

( : Pickup possible -: Pickup not possible)

Paper size Cassette Multi-purpose Tray

A4 210.0 mm x 297.0 mm

B5 182.0 mm x 257.0 mm

A5 148.0 mm x 210.0 mm

A6 105.0 mm x 148.0 mm -

LGL 215.9 mm x 355.6 mm

LTR 215.9 mm x 279.4 mm

STMT 139.7 mm x 215.9 mm -

EXEC 184.1 mm x 266.7 mm

FLS 215.9 mm x 330.2 mm

16K 195.0 mm x 270.0 mm

Index Card (3" x 5") 76.2 mm x 127.0 mm -

Envelope No.10 (COM10) 104.7 mm x 241.3 mm -

Envelope Monarch 98.4 mm x 190.5 mm -

Envelope C5 162.0 mm x 229.0 mm -

er

9

1. Product Overview

Paper size Cassette Multi-purpose Tray

Envelope DL 110.0 mm x 220.0 mm -

Custom paper - *1 *2

*1:

Portrait: Width: 148.0 to 215.9 mm, Length: 210.0 to 355.6 mm

Landscape (Only when using the UFR II printer driver): Width 148.0 to 215.9 mm, Length 148.0 to 215.9 mm

*2:

Portrait: Width 76.2 to 215.9 mm, Length 127.0 to 355.6 mm

Landscape (Only when using the UFR II printer driver): Width 127.0 to 215.9 mm, Length 127.0 to 215.9 mm

10

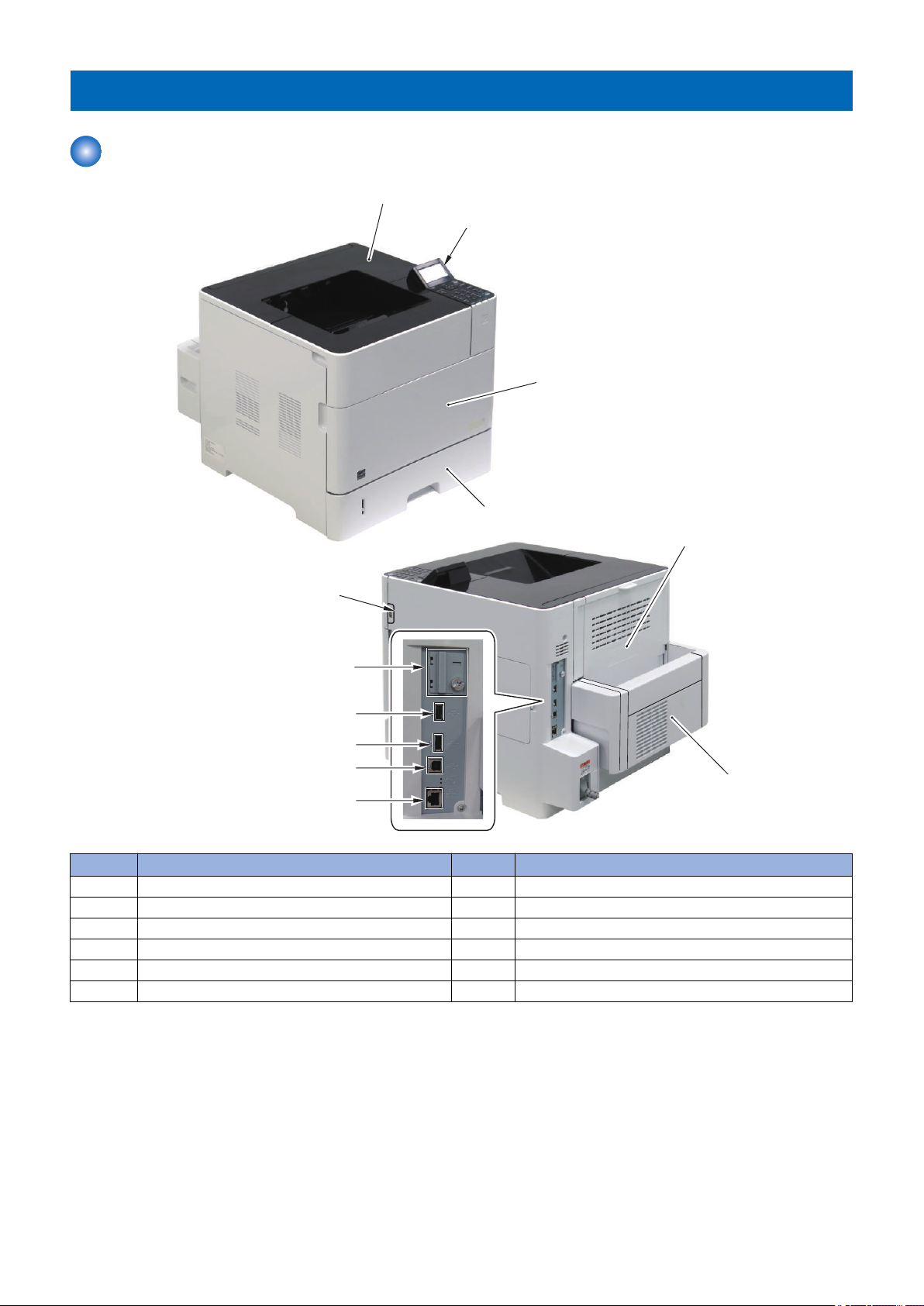

List of Parts

[9]

[8]

[10]

[11]

[12]

[1]

[3]

[4]

[5]

[2]

[6]

[7]

External

1. Product Overview

No. Name 9 Name

1 Upper Cover Unit 7 USB-H (Front)

2 Control Panel 8 Upper Cover

3 Front Cover 9 USB-H (Rear 1)

4 Cassette 10 USB-H (Rear 2)

5 Rear Cover (Sub Delivery Tray) 11 USB-D

6 Duplex Unit 12 LAN Port

11

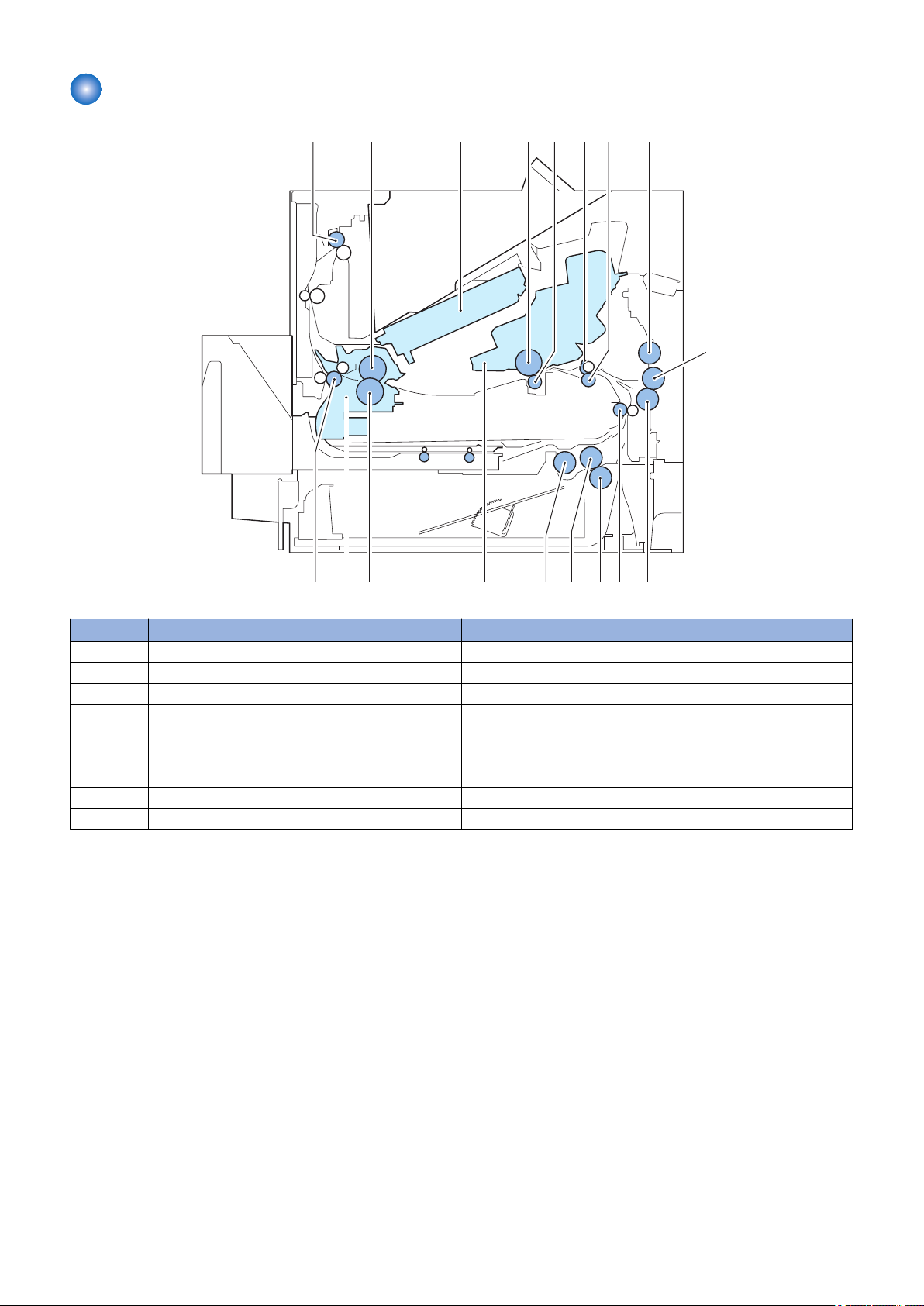

Cross Sectional View

[10]

[1]

[11]

[2]

[12]

[3]

[13]

[4]

[14]

[5]

[15]

[6]

[16]

[7]

[17]

[8]

[18]

[9]

1. Product Overview

No. Name No. Name

[1] Delivery Roller [10] Multi-purpose Tray Separation Roller

[2] Fixing Film [11] Vertical Path Roller

[3] Laser Scanner Unit [12] Cassette Separation Roller

[4] Photosensitive Drum [13] Cassette Feed Roller

[5] Transfer Roller [14] Cassette Pickup Roller

[6] Registration Shutter [15] Cartridge

[7] Registration Roller [16] Pressure Roller

[8] Multi-purpose Tray Pickup Roller [17] Fixing Assembly

[9] Multi-purpose Tray Feed Roller [18] Fixing Delivery Roller

12

Technical

2

Explanation

(Device)

Laser Exposure System......................14

Image Formation System....................16

Pickup Feeding System...................... 21

Fixing System......................................32

Controller System................................36

BD PCB

Scanner mirror

Scanner motor unit

Photosensitive drum

Laser driver

Main Controller

DC controller

LASER CONTROL signal

VIDEO signal

SCANNER MOTOR

SPEED CONTROL signal

BD INPUT signal

2. Technical Explanation (Device)

Laser Exposure System

Overview

The Laser Scanner system forms a latent image on the Photosensitive Drum according to the video signal sent from the Main

Controller.

The Laser Scanner Unit consists of the Laser Unit and the Scanner Motor Unit, and is controlled by the signal input from the DC

Controller.

The following shows an outline drawing of the Laser Scanner Unit.

Laser Scanner Motor Control

Rotates the Polygon Mirror at a specified speed.

14

2. Technical Explanation (Device)

<Execution Timing>

At startup of the Laser Scanner Motor

<Control Description>

1. The DC Controller PCB forcefully rotates the Laser Scanner Motor.

2. Sends acceleration signals (ACC) and deceleration signals (DEC) to the Laser Scanner Motor to control the speed to the

specified speed.

<Related Error Code>

E110-0000: Failure of the Laser Scanner Unit

E110-0001: Error in the initial operation of the Scanner Motor

15

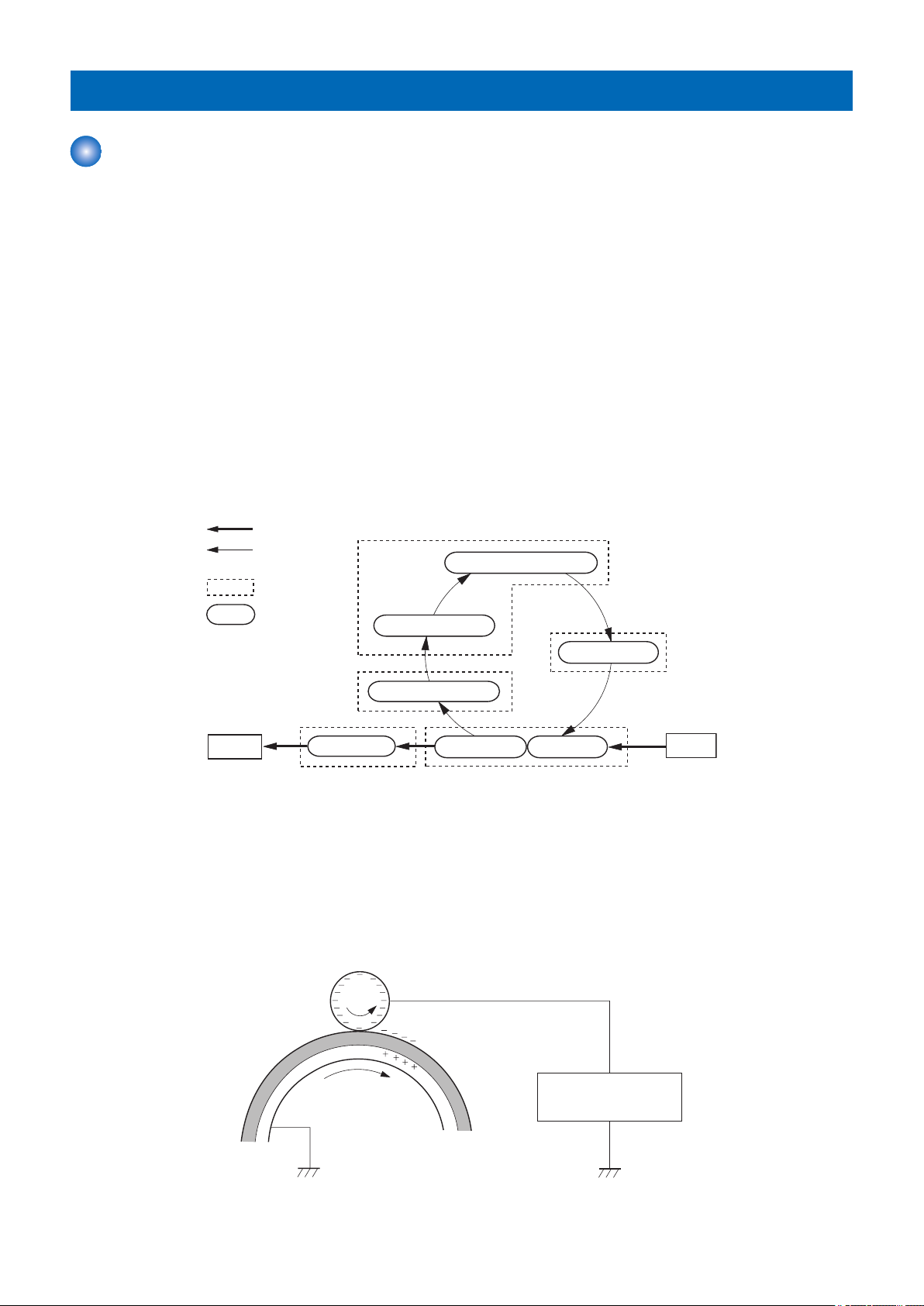

2. Laser-beam exposure

Fixing

6. Fixing

Delivery

7. Drum cleaning

3. Developing

1. Primary charging

Pickup

4.Transfer5. Separation

Transfer

Latent image formation

Media path

Direction of

the drum rotation

Block

Step

Drum cleaning

Developing

Primary charging bias

Photosensitive drum

Primary charging roller

2. Technical Explanation (Device)

Image Formation System

Image Formation Process

■ Outline

The image formation process consists of the following seven steps divided among five functional blocks:

Latent image formation block

• Step 1: Primary charging

• Step 2: Laser-beam exposure

Developing block

• Step 3: Developing

Transfer block

• Step 4: Transfer

• Step 5: Separation

Fixing block

• Step 6: Fixing

Drum cleaning block

• Step 7: Drum cleaning

■ Latent image formation block

During the two steps that comprise this block, an invisible latent image is formed on the photosensitivedrum.

Step 1: Primary charging

To prepare for latent image formation, the surface of the photosensitive drum is charged with a uniform negative potential. The

primary charging bias is applied to the primary charging roller and the roller charges the drum directly.

16

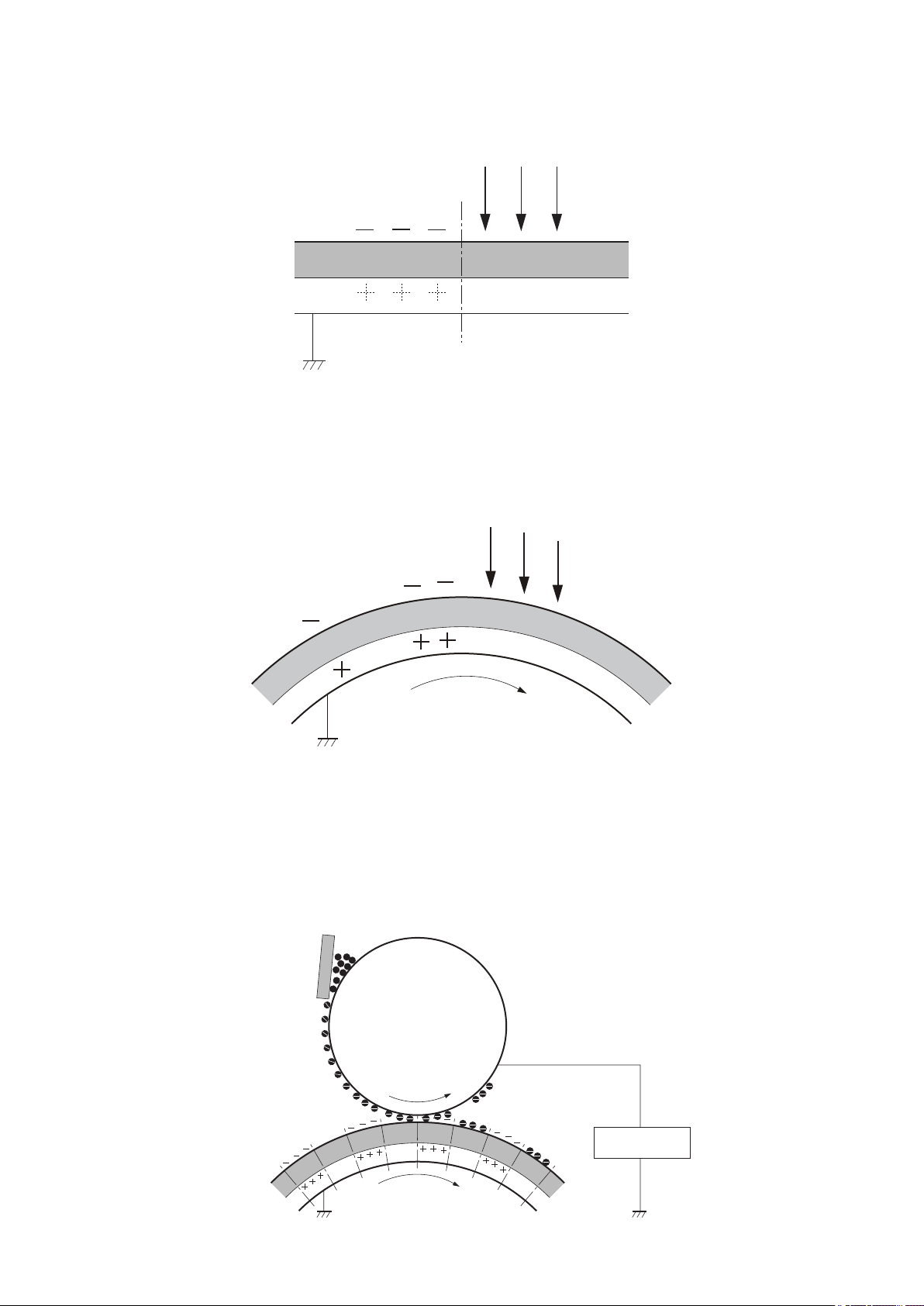

Laser beam

Unexposed area Exposed area

3KRWRVHQVLWLYH'UXP

/DVHU%HDP

Developing bias

Blade

Developing roller

Photosensitive drum

Unexposed

area

Exposed

area

Exposed

area

Unexposed

area

2. Technical Explanation (Device)

Step 2: Laser-beam exposure

The laser beam scans the photosensitive drum to neutralize the negative charge on portions of the drum surface. An electrostatic

latent image forms where the negative charge was neutralized.

● Drum discharge

The drum discharge is a feature to remove residual charge on the Photosensitive Drum surface for preventing the uneven image

density.

The Laser Beam strikes the surface of the Photosensitive Drum to remove the residual charge.

The drum discharge is performed during LSTR period.

■ Developing block

Toner adheres to the electrostatic latent image on the photosensitive drum, which becomes visible.

Step 3: Developing

Toner acquires a negative charge from the friction that occurs when the developing roller rotates against the developing blade.

The negatively charged toner is attracted to the latent image on the photosensitive drum surface because the drum surface has

a higher potential. The developing bias is applied to the developing roller.

17

Transfer bias

Media

Transfer roller

Photosensitive

drum

Media

Transfer roller

Photosensitive

drum

Static charge

eliminator

Fixing bias

Fixing film

Toner

Pressure roller

Fixing heater

Media

2. Technical Explanation (Device)

■ Transfer block

During the two steps that comprise this block, a toner image on the photosensitive drum is transferred to the print media.

Step 4: Transfer

The transfer bias is applied to the transfer roller to charge the print media positive. The positively charged media attracts the

negatively charged toner from the photosensitive drum surface.

Step 5: Separation

The elasticity of the print media and the curvature of the photosensitive drum cause the media to separate from the drum surface.

The static charge eliminator reduces back side static discharge of the media for stable media feed and image quality.

■ Fixing block

The toner image is fixed onto the print media.

Step 6: Fixing

The printer uses an on-demand fixing method. The toner image is permanently affixed to the print media by heat and pressure.

The fixing bias is applied to the fixing film to improve image quality.

18

Toner

collection box

Photosensitive

drum

Cleaning blade

M102

PCB

2. Technical Explanation (Device)

■ Drum cleaning block

The residual toner is cleared from the photosensitive drum surface.

Step 7: Drum cleaning

The cleaning blade scrapes the residual toner off the surface of the photosensitive drum. The residual toner is deposited in the

toner collection box.

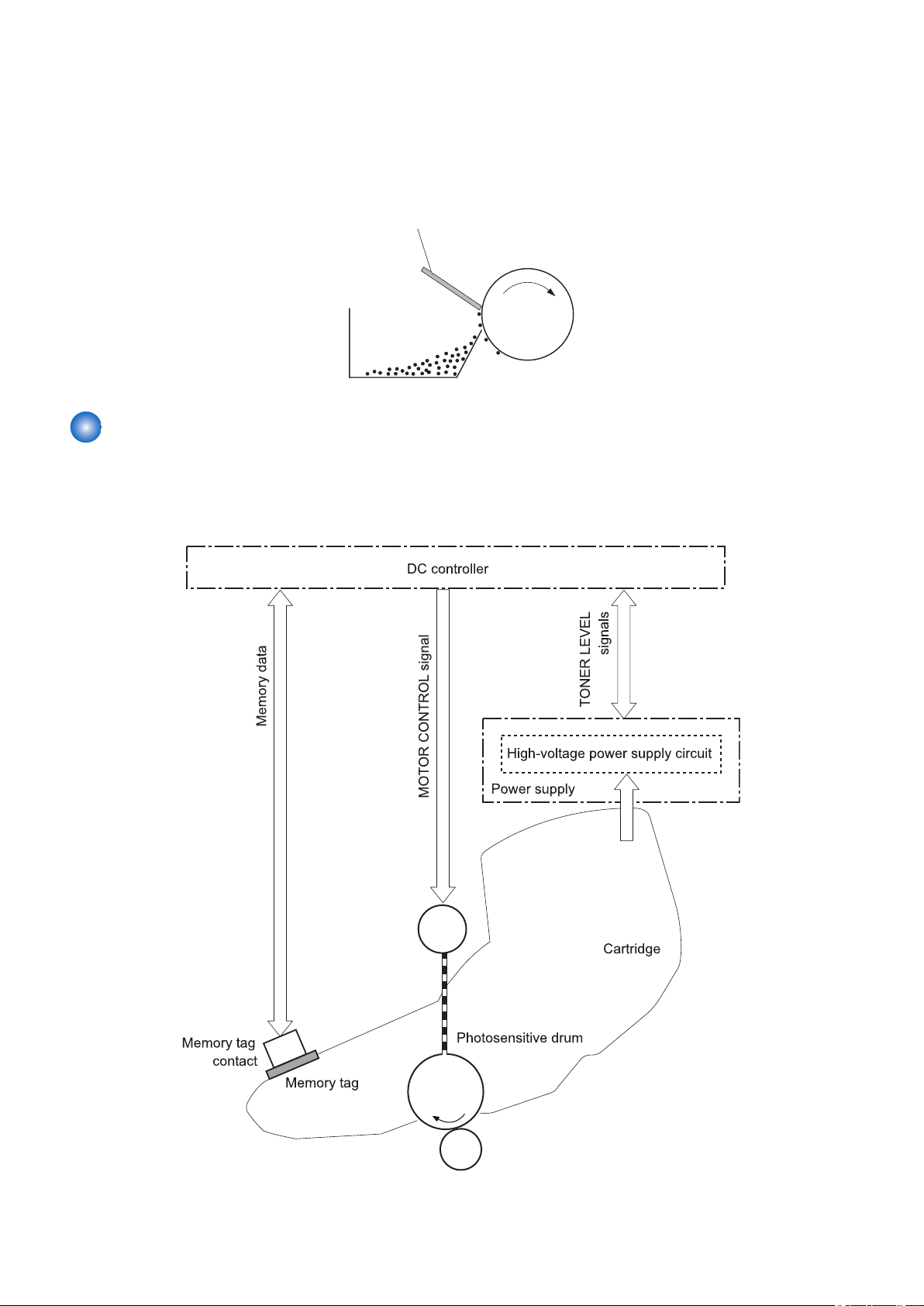

Cartridge

■ Overview

The cartridge of this machine has the function to form a visible image on the Photosensitive Drum with toner.

The following shows an outline drawing of the cartridge of this machine.

The cartridge of this machine consists of the Photosensitive Drum, Primary Charging Roller, Developing Sleeve, Stirring Plate,

Waste Toner Feed Plate, etc.

19

2. Technical Explanation (Device)

The parts other than the Primary Charging Roller are rotated by the drive of the Main Motor, and the Primary Charging Roller

rotates by engaging with the Photosensitive Drum.

The DC Controller detects the toner level by monitoring the toner level detection signal.

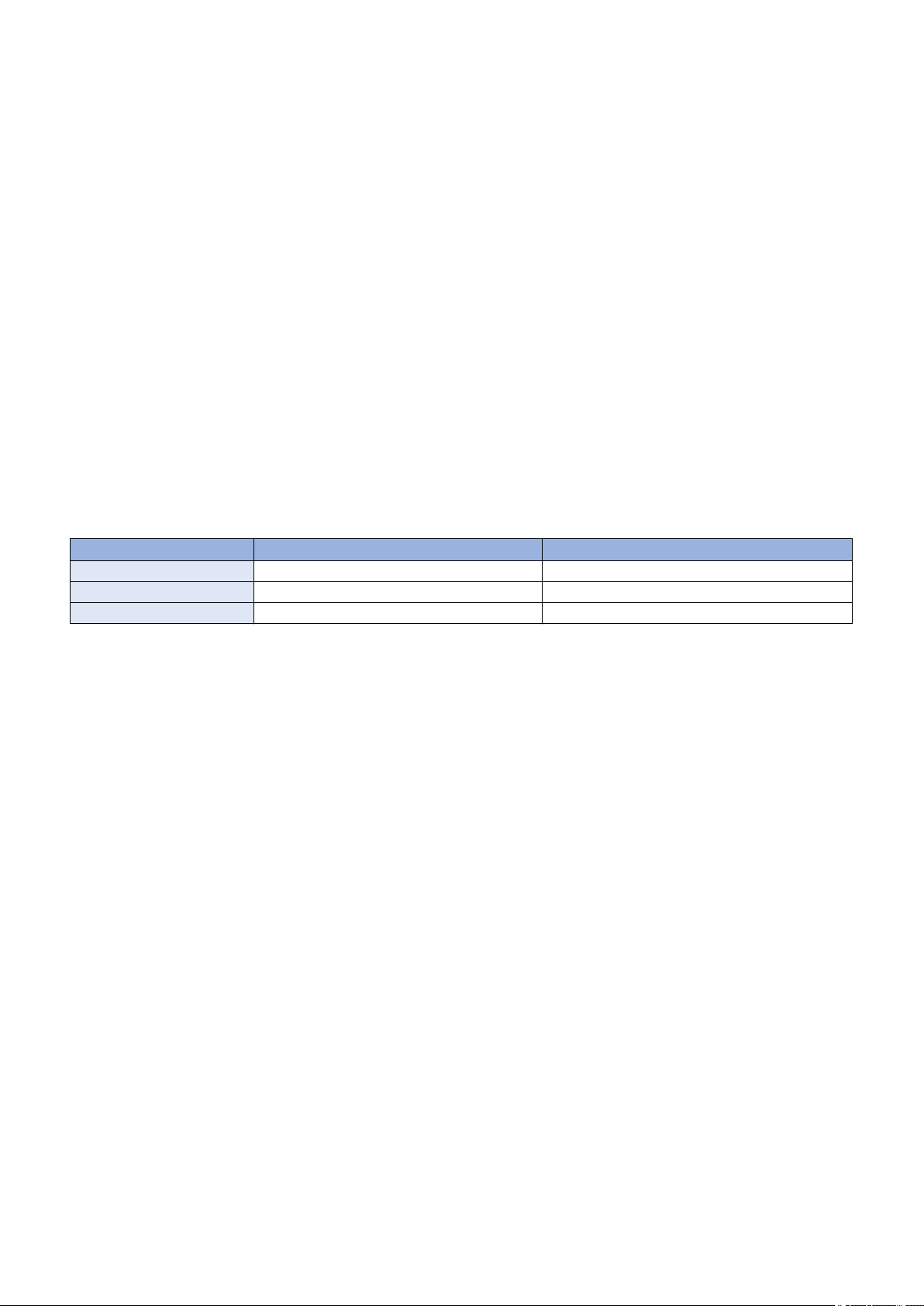

■ Memory Tag

This machine can detect and store the cartridge usage conditions and other information when the DC Controller PCB reads and

writes the data stored in the memory tag.

If the memory tag cannot be detected, "Error. Non-Canon cart. not covered by warranty" is displayed.

■ Cartridge Detection

The DC Controller detects whether a cartridge is installed according to the change in primary charging current. The DC Controller

notifies the Main Controller of the absence of a cartridge if it judges there is no cartridge.

Detection timing:

• At power-on

• When the Upper Cover is closed

Display on the Control Panel:

• Insert toner cartridge.

■ Cartridge Life Detection

The DC Controller notifies the Main Controller when cartridge consumption reaches the specified value.

Upon reception of the notification the Main Controller displays a warning or a message that the cartridge has reached the end of

its life.

Warning display*2 End of life display*4, *5

Toner level*1 Differs depending on the setting*3 0%

Detected to (location) Memory tag Memory tag

Message (machine operation) 16 Tnr cart. will soon reach end of lifetime. 1G Change toner cartridge recommended.

*1: Can be checked in [Utility Menu > Consumables > Remaining Toner > Remaining Toner].

*2: Display/Hide can be switched in [Control Menu > Warning Step > Toner Cart. Warning].

*3: Value set in [Setup > User Maintenance > Toner Check Timing/Specify Check Timing].

*4: The operation to perform when the cartridge has reached the end of life can be set in [SERVICE MODE > OPTION GR. >

CRG LIFE STEP].

*5: The cartridge life value can be changed in [SERVICE MODE > OPTION GR. > CRG LIFE STOP].

20

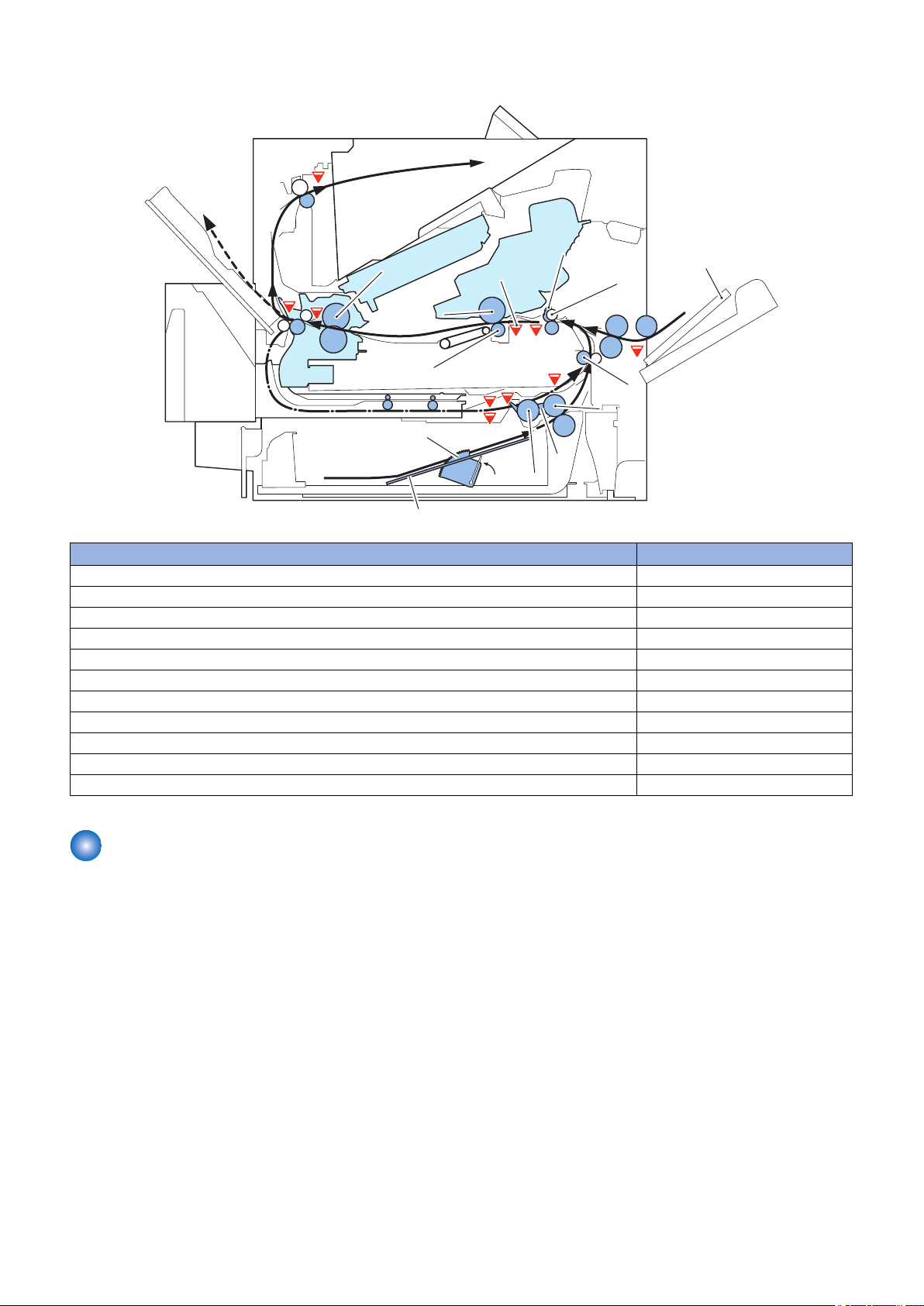

Face-downdelivery

Face-updelivery

Duplexdelivery

2. Technical Explanation (Device)

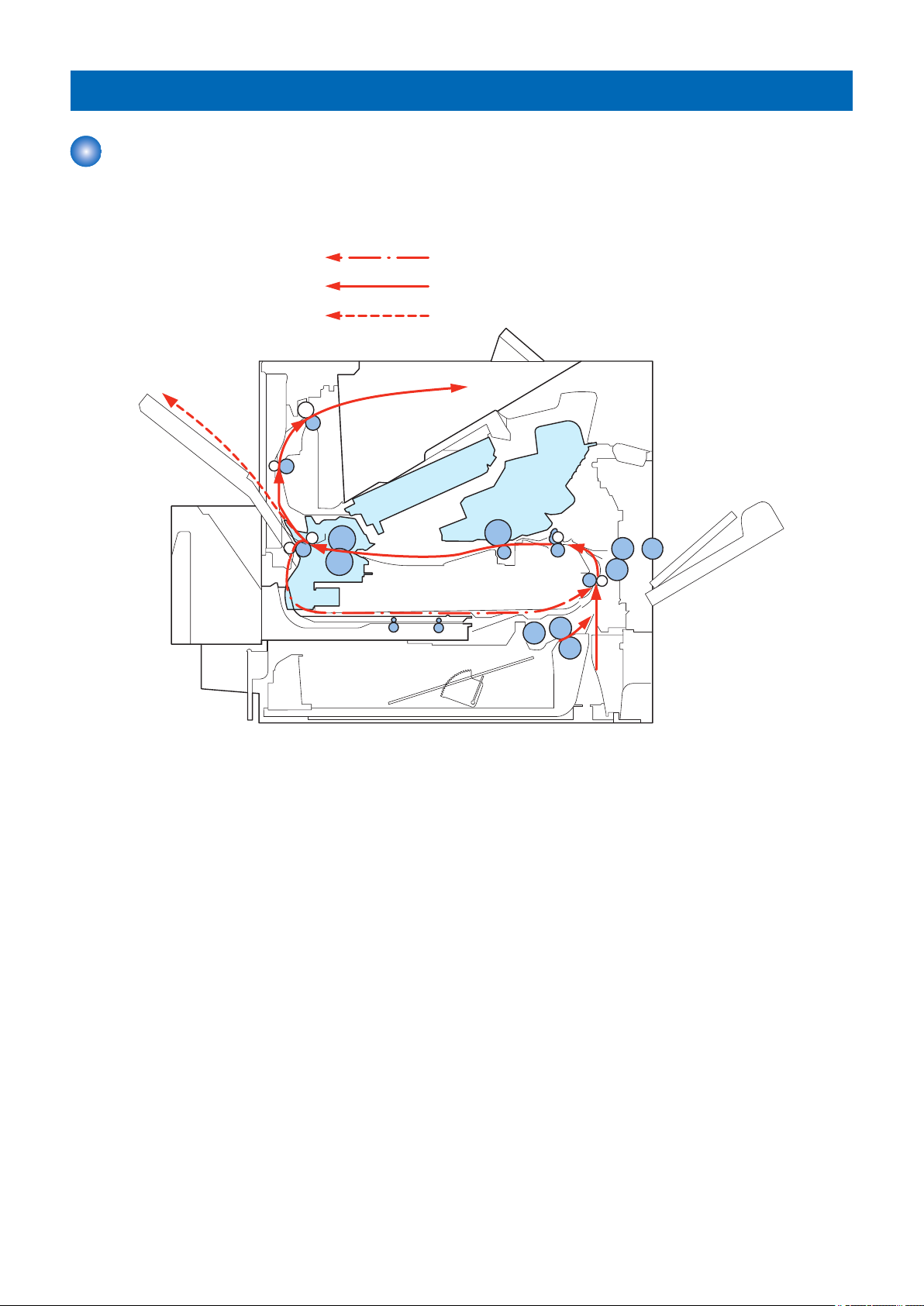

Pickup Feeding System

Overview

The Pickup Feed System performs pickup, feed, and delivery of print paper, and consists of various rollers.

Print paper flow

21

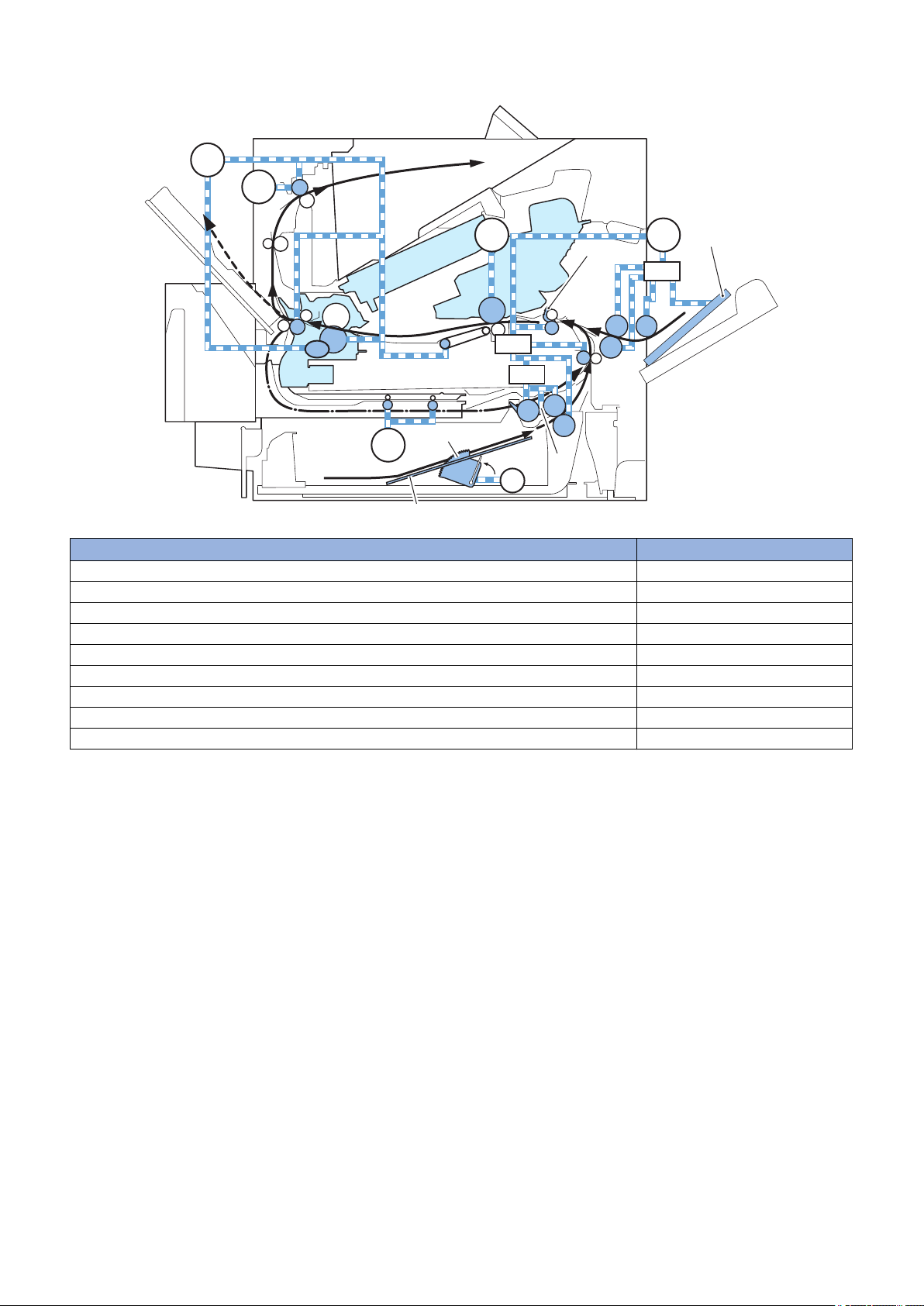

Load drives of electrical components

Cam

CW

CCW

Pickup arm

Lifter

M1501

M299

M102

SL101

Lifting plate

M103

M101

Registration shutter

SL102

Lifting plate

M1502

CL101

2. Technical Explanation (Device)

Name Electric code

Pickup Motor M101

Main Motor M102

Lifter Motor M103

Fixing Motor M299

Duplex Reverse Motor M1501

Duplex Re-pickup Motor M1502

Pickup Clutch CL101

Pickup Solenoid SL101

Multi-purpose Tray Pickup Solenoid SL102

22

Outline drawing of sensors and rollers

PS101

PS107

PS700

PS104

PS907

PS102

PS103

Pressure roller

Face-down delivery roller

Lifter

Lifting plate

Pickup roller

Pickup arm

Registration shutter

Lifting plate

Photosensitive drum

Fiking sleeve

PS699

Transfer roller

Separation roller

Feed roller

Pre-transfer roller

PS105

Feed roller

PS106

PS108

2. Technical Explanation (Device)

Name Electric code

Paper Sensor PS101

Pre-registration Sensor PS102

Registration Sensor PS103

Delivery Full Sensor PS104

Multi-purpose Tray Sensor PS105

Paper Width Sensor 1 PS106

Media Stack Surface Sensor 1 PS107

Paper Width Sensor 2 PS108

Fixing pressure release sensor PS699

Fixing Outlet Sensor PS700

Media Stack Surface Sensor 2 PS907

Various Control Mechanisms

■ Lifter control

Paper inside a cassette is lifted up by the Lifting Plate.

The Lifting Plate is lifted up by rotating the Cassette Lifter Motor (M103).

The paper surface is detected by the Paper Surface Detection Sensors 1 and 2 (PS107 and PS907).

When the Lifting Plate is rising, the Lifter Motor (M103) is controlled to keep the paper surface steady so that pickup can be

performed stably.

23

Loading...

Loading...