Canon LBP3310 Service Manual

Service Manual

LBP3310/3370 Series

Jan 25 2008

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, insta llati on, ma intenance, and repair

of products. This manual covers all localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When

changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need

arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition

of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Memo

Introduction

REF.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol , the arrow indicates the

direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in

supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the fi eld. Ther efore, the operations of the microprocessors

used in the machines are not discussed: they are explained in terms of fro m sensors to the input of the DC controller PCB and from the output of the

DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be

able to identify and isolate faults in the machine."

Contents

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Features .....................................................................................................................................................1- 1

1.1.1 Feature....................................................................................................................................................................1- 1

1.2 System Construction ..................................................................................................................................1- 1

1.2.1 System Construction ......................................................... ......................................................................................1- 1

1.2.2 System Construction ......................................................... ......................................................................................1- 1

1.3 Product Specifications................................................................................................................................1- 1

1.3.1 Product Specifications.............................................................................................................................................1- 1

1.3.2 Product Specifications.............................................................................................................................................1- 2

1.4 Name of Parts.............................................................................................................................................1- 3

1.4.1 External View............................................ ................................................... ....................................... .....................1- 3

1.4.2 External View............................................ ................................................... ....................................... .....................1- 4

1.4.3 Cross Sectional Views.............................................................................................................................................1- 5

1.5 Using the Machine......................................................................................................................................1- 6

1.5.1 Control Panel........................................................................................................................... .. ..............................1- 6

1.5.2 Control Panel........................................................................................................................... .. ..............................1- 6

Chapter 2 TECHNICAL REFERENCE

2.1 Functional Configuration........ .......................................... ... ... .......................................... .... .......................2- 1

2.1.1 Outline.....................................................................................................................................................................2- 1

2.2 Basic Sequense..........................................................................................................................................2- 1

2.2.1 Basic Operation Sequence............................................................................................................................... .......2- 1

2.2.2 Power-on sequence.................................................................................................................................... .............2- 1

2.3 LASER EXPOSURE SYSTEM...................................................................................................................2- 2

2.3.1 Overview/Configuration................................................................................................................ ...........................2- 2

2.3.1.1 Outline...................................................................................................................................................................................... 2- 2

2.3.1.2 Laser Control Circuit ................................................................................................................................................................ 2- 3

2.3.2 Controlling the Laser Activation Timing............................................................................................................ ... ....2- 5

2.3.2.1 Laser emission control.............................................................................................................................................................2- 5

2.3.2.2 Horizontal synchronous control................................................................................................................................................ 2- 5

2.3.3 Laser Control...........................................................................................................................................................2- 5

2.3.3.1 Automatic power control (APC)................................................................................................................................................2- 5

2.3.3.2 Image masking control............................................................................................................................................................. 2- 5

2.3.4 Laser Scanner Motor Control ..................................................................................................................................2- 6

2.3.4.1 Outline...................................................................................................................................................................................... 2- 6

2.3.4.2 Scanner motor speed control................................................................................................................................................... 2- 7

2.3.4.3 Scanner motor failure detection...............................................................................................................................................2- 7

2.4 IMAGE FORMATION SYSTEM..................................................................................................................2- 7

2.4.1 Overview/Configuration................................................................................................................ ...........................2- 7

2.4.1.1 Outline...................................................................................................................................................................................... 2- 7

2.4.1.2 Print Process............................................................................................................................................................................ 2- 8

2.4.1.3 Electrostatic latent image formation block ............................................................................................................................... 2- 9

2.4.1.4 Development block ...................... ..................... ..................... ..................... ............................................................................. 2- 9

2.4.1.5 Transfer block ........................................................................................................................................................................ 2- 10

2.4.1.6 Fixing block............................................................................................................................................................................2- 11

2.4.1.7 Photosensitive drum cleaning block ....................................................................................................................................... 2- 11

2.4.2 High-Voltage Control.............................................................................................................................................2- 12

2.4.2.1 Outline.................................................................................................................................................................................... 2- 12

2.4.2.2 Primary charging bias generation .......................................................................................................................................... 2- 12

2.4.2.3 Developing bias generation ................................................................................................................................................... 2- 12

2.4.2.4 Transfer charging bias generation ......................................................................................................................................... 2- 13

Contents

2.4.2.5 Fixing bias generation............................................................................................................................................................ 2- 13

2.4.2.6 Cartridge presence detection.................................................................................................................................................2- 13

2.5 PICKUP AND FEEDING SYSTEM...........................................................................................................2- 13

2.5.1 Overview/Configuration..........................................................................................................................................2- 13

2.5.1.1 Outline.................................................................................................................................................................................... 2- 13

2.5.2 Detecting Jams......................................................................................................................................................2- 14

2.5.2.1 Jam Detection Outline............................................................................................................................................................ 2- 14

2.5.2.2 Delay Jams ............................................................................................................................................................................ 2- 15

2.5.2.3 Stationary Jams ..................................................................................................................................................................... 2- 15

2.5.2.4 Other Jams ............................................................................................................................................................................ 2- 15

2.5.3 Cassette Pickup.....................................................................................................................................................2- 15

2.5.3.1 Cassette pick-up .................................................................................................................................................................... 2- 15

2.5.4 Multi-purpose Pickup .............................................................................................................................................2- 16

2.5.4.1 Manual Fees pick-ip...............................................................................................................................................................2- 16

2.5.5 Duplex Feeding ......................................................................................................................................................2- 16

2.5.5.1 Outline.................................................................................................................................................................................... 2- 16

2.5.5.2 Operation ............................................................................................................................................................................... 2- 16

2.6 EXTERNAL AND CONTROLS SYSTEM .................................................................................................2- 17

2.6.1 Fan.........................................................................................................................................................................2- 17

2.6.1.1 Fan motor control...................................................................................................................................................................2- 17

2.6.2 Power Supply............................................................................................................ ... ..........................................2- 17

2.6.2.1 Power Supply......................................................................................................................................................................... 2- 17

2.6.2.2 Protective Functions .............................................................................................................................................................. 2- 18

2.7 ENGINE CONTROL SYSTEM ....................................................... ... ... ... .... ... ... ... ... .................................2- 19

2.7.1 Video Controller.....................................................................................................................................................2- 19

2.7.1.1 Outline.................................................................................................................................................................................... 2- 19

2.7.1.2 Outline of Operation by Block ................................................................................................................................................ 2- 19

2.7.1.3 Overview................................................................................................................................................................................2- 20

2.7.1.4 Outline of Operation by Block ................................................................................................................................................ 2- 20

2.7.2 Engine Controller.................................................................... ...............................................................................2- 21

2.7.2.1 Outline.................................................................................................................................................................................... 2- 21

2.8 FIXING UNIT/DELIVERY SYSTEM..........................................................................................................2- 23

2.8.1 Overview/Configuration..........................................................................................................................................2- 23

2.8.1.1 Outline.................................................................................................................................................................................... 2- 23

2.8.2 Various Control Mechanisms.................................................................................................................................2- 24

2.8.2.1 Fixing Temperature Control ................................................................................................................................................... 2- 24

2.8.2.2 Protective Functions .............................................................................................................................................................. 2- 25

Chapter 3 DISASSEMBLY AND ASSEMBLY

3.1 EXTERNAL AND CONTROLS SYSTEM ...................................................................................................3- 1

3.1.1 Rear Cover...............................................................................................................................................................3- 1

3.1.1.1 Preparation for removing the rear cover unit ........................................................................................................................... 3- 1

3.1.1.2 Removing the rear cover unit................................................................................................................................................... 3- 1

3.1.2 Right Cover..................................................................................................................................... .........................3- 1

3.1.2.1 Detaching the right cover......................................................................................................................................................... 3- 1

3.1.3 Left Cover ................................................................................................................................................................3- 2

3.1.3.1 Detaching the left cover ........................................................................................................................................................... 3- 2

3.1.4 Upper Cover......................................................................................................................... ....................................3- 3

3.1.4.1 Preparation for detaching the upper cover unit........................................................................................................................ 3- 3

3.1.4.2 Detaching the upper cover.......................................................................................................................................................3- 3

3.1.4.3 Detaching the upper cover.......................................................................................................................................................3- 3

3.1.5 Front Cover..................................................................................................................................... .........................3- 4

3.1.5.1 Preparation for detaching the front cover unit.......................................................................................................................... 3- 4

3.1.5.2 Detaching the front cover unit.................................................................................................................................................. 3- 4

3.1.6 Main Drive Unit ........................................................................................................................................... .............3- 5

3.1.6.1 Preparation for removing the main drive assembly..................................................................................................................3- 5

3.1.6.2 Removing the main drive assembly.........................................................................................................................................3- 5

3.1.7 Duplexing Drive Unit................................................................................................................................................3- 6

Contents

3.1.7.1 Removing the duplexing drive assembly .................................................................................................................................3- 6

3.1.8 Operation Panel Unit ....................................................................................................................... ........................3- 7

3.1.8.1 Preparation for detaching the control panel.............................................................................................................................3- 7

3.1.8.2 Detaching the control panel ..................................................................................................................................................... 3- 7

3.1.8.3 Detaching the control panel ..................................................................................................................................................... 3- 7

3.1.9 Engine controller board ........................................................... ................................................................................3- 8

3.1.9.1 Preparation for removing the engine controller PCB ...............................................................................................................3- 8

3.1.9.2 Removing the engine controller PCB.......................................................................................................................................3- 8

3.1.10 Duplexing Driver Board...................................................................................................................................... ....3- 9

3.1.10.1 Preparation for removing the duplexing driver PCB...............................................................................................................3- 9

3.1.10.2 Removing the duplexing driver PCB .................................................................................................................................... 3- 10

3.1.11 Video Controller Board ........................................................................................................................................3- 10

3.1.11.1 Removing the video controller PCB ..................................................................................................................................... 3- 10

3.1.11.2 Removing the video controller PCB ..................................................................................................................................... 3- 10

3.1.12 USB Board...........................................................................................................................................................3- 11

3.1.12.1 Removing the USB PCB ...................................................................................................................................................... 3- 11

3.1.13 Door Switch ....................................................... ... ................................................... ............................................3- 12

3.1.13.1 Removing the door switch.................................................................................................................................................... 3- 12

3.1.14 Main Body Fan............................................................................................. ... .....................................................3- 12

3.1.14.1 Preparation for removing the fan.......................................................................................................................................... 3- 12

3.1.14.2 Removing the fan.................................................................................................................................................................3- 12

3.2 LASER EXPOSURE SYSTEM.................................................................................................................3- 13

3.2.1 Laser Scanner Unit................................................................................................................................................3- 13

3.2.1.1 Preparation for removing the laser scanner unit....................................................................................................................3- 13

3.2.1.2 Removing the laser scanner unit ...........................................................................................................................................3- 13

3.3 IMAGE FORMATION SYSTEM................................................................................................................3- 13

3.3.1 Transfer Charging Roller.......................................................................................................................................3- 13

3.3.1.1 Removing the transfer charging roller....................................................................................................................................3- 13

3.4 PICKUP AND FEEDING SYSTEM...........................................................................................................3- 13

3.4.1 Cassette Pickup Roller..........................................................................................................................................3- 13

3.4.1.1 Removing the cassette pickup roller......................................................................................................................................3- 13

3.4.2 Cassette Pickup solenoid......................................................................................................................................3- 14

3.4.2.1 Preparation for removing the cassette pickup solenoid ......................................................................................................... 3- 14

3.4.2.2 Removing the cassette pickup solenoid................................................................................................................................. 3- 14

3.4.3 Cassette Separation Pad.......................................................................................................................................3- 14

3.4.3.1 Removing the cassette separation pad.................................................................................................................................. 3- 14

3.4.4 Manual Pickup Roller.............................................................................................. ... ............................................3- 14

3.4.4.1 Removing the manual pickup roller........................................................................................................................................ 3- 14

3.4.5 Manual Separation Pad.........................................................................................................................................3- 15

3.4.5.1 Preparation for removing the manual separation pad............................................................................................................3- 15

3.4.5.2 Removing the manual separation pad ................................................................................................................................... 3- 15

3.4.6 Registration Roller.................................................................................................................................................3- 15

3.4.6.1 Preparation for removing the registration roller...................................................................................................................... 3- 15

3.4.6.2 Removing the registration roller.............................................................................................................................................3- 15

3.4.7 Main Motor.............................................................................................................................................................3- 16

3.4.7.1 Preparation for removing the main motor .............................................................................................................................. 3- 16

3.4.7.2 Removing the main motor......................................................................................................................................................3- 16

3.4.8 Reversal Solenoid .................................................................................................................................................3- 16

3.4.8.1 Preparation for removing the reverse solenoid......................................................................................................................3- 16

3.4.8.2 Removing the reverse solenoid .............................................................................................................................................3- 16

3.4.9 Duplexing Unit.......................................................................................................................................................3- 16

3.4.9.1 Preparation for removing the duplexing unit .......................................................................................................................... 3- 16

3.4.9.2 Removing the duplexing unit.................................................................................................................................................. 3- 16

3.5 FIXING SYSTEM......................................................................................................................................3- 17

3.5.1 Fixing Unit.............................................................................................. ................................................................3- 17

3.5.1.1 Preparation for removing the fixing assembly........................................................................................................................ 3- 17

3.5.1.2 Removing the fixing assembly ............................................................................................................................................... 3- 17

3.5.1.3 Removing the fixing assembly ............................................................................................................................................... 3- 18

3.5.2 Fixing Film Unit......................................................................................................................................................3- 19

Contents

3.5.2.1 Preparation for removing the fixing film unit........................................................................................................................... 3- 19

3.5.2.2 Removing the fixing film unit..................................................................................................................................................3- 19

3.5.3 Fixing Pressure Roller................................................................................. ... ... .....................................................3- 20

3.5.3.1 Preparation for removing the fixing pressure roller................................................................................................................3- 20

3.5.3.2 Removing the fixing pressure roller .......................................................................................................................................3- 20

Chapter 4 MAINTENANCE AND INSPECTION

4.1 Periodically Replaced Parts ....................................... ... .... ... ... ... .... ... ... ... ...................................................4- 1

4.1.1 Periodically Replaced Parts.....................................................................................................................................4- 1

4.2 Consumables .............................................................................................................................................4- 1

4.2.1 Life Expectancy of Consumable Parts.....................................................................................................................4- 1

4.3 Periodical Service.......................................................................................................................................4- 1

4.3.1 Periodic Service.......................................................................................................................................................4- 1

4.4 Cleaning .....................................................................................................................................................4- 1

4.4.1 Cleaning During Service Visit ..................................................................................................................................4- 1

Chapter 5 TROUBLESHOOTING

5.1 MEASUREMENT AND ADJUSTMENT......................... .... .........................................................................5- 1

5.1.1 Test Print..................................................................................................................................................................5- 1

5.1.1.1 Test Print.................................................................................................................................................................................. 5- 1

5.1.1.2 Test Print.................................................................................................................................................................................. 5- 1

5.1.2 Mechanical Adjustment............................................................................................................................................5- 1

5.1.2.1 Checking the Nip Width (fixing pressure roller)........................................................................................................................ 5- 1

5.2 SERVICE TOOLS ......................................................................................................................................5- 2

5.2.1 Standard Tools........................................................................................................................ .................................5- 2

5.2.2 Special Tools ..................................................................................................................................... ... ...................5- 2

5.3 ERROR CODE TABLE .. ... ... .... ... ... ... .... ...................................... .... ... ... ... .... ... ... ... ......................................5- 2

5.3.1 Error Code ......................................................................................................................................... ......................5- 2

5.3.2 Error Code ......................................................................................................................................... ......................5- 3

5.3.3 A4-XX_ERROR........................................................................................................................................................5- 4

5.3.4 A5-XX_ERROR........................................................................................................................................................5- 4

5.3.5 A7-XX_ERROR........................................................................................................................................................5- 4

5.3.6 D7-XX_ERROR .......................................................................................................................................................5- 4

5.3.7 D8-XX_ERROR .......................................................................................................................................................5- 4

5.4 Version Up..... ... ... .... ... ... ... ... ....................................... ... .... ... ... ... ................................................................5- 5

5.4.1 Overview of Upgrading Work...................................................................................................................................5- 5

5.4.2 Construction of Firmware.........................................................................................................................................5- 5

5.4.3 Outline of the Service Support Tool.........................................................................................................................5- 5

5.4.4 Registering the Firmware........................................................................................................................................5- 7

5.4.5 Making Connections ........................................................................................................................................ ........5- 9

5.4.6 The down load procedure of the system................................................................................................................5- 10

5.5 Service Mode ...........................................................................................................................................5- 13

5.5.1 PCL........................................................................................................................................................................5- 13

5.5.1.1 Overview................................................................................................................................................................................5- 13

5.5.1.2 Service Mode.........................................................................................................................................................................5- 13

Chapter 6 APPENDIX

6.1 OUTLINE OF ELECTRICAL COMPONENTS............................................................................................6- 1

6.1.1 Clutch/Solenoid........................................................................................................................................................6- 1

6.1.1.1 Solenoid...................................................................................................................................................................................6- 1

6.1.2 Motor........................................................................................................................................................................6- 1

6.1.2.1 Motor........................................................................................................................................................................................ 6- 1

6.1.3 Fan.......................................................................................................................................... ... ..............................6- 2

6.1.3.1 Fan........................................................................................................................................................................................... 6- 2

Contents

6.1.4 Sensor.....................................................................................................................................................................6- 2

6.1.4.1 Sensor...................................................................................................................................................................................... 6- 2

6.1.5 PCBs ............................................................................................................................................... ........................6- 3

6.1.5.1 PCB.......................................................................................................................................................................................... 6- 3

Chapter 1 PRODUCT DESCRIPTION

Contents

Contents

1.1 Features..........................................................................................................................................................................1-1

1.1.1 Feature.......................................................................................................................................................................................... 1-1

1.2 System Construction......................................................................................................................................................1-1

1.2.1 System Construction .................................................................................................................................................................... 1-1

1.2.2 System Construction .................................................................................................................................................................... 1-1

1.3 Product Specifications....................................................................................................................................................1-1

1.3.1 Product Specifications ................................................................................................................................................................. 1-1

1.3.2 Product Specifications ................................................................................................................................................................. 1-2

1.4 Name of Parts.................................................................................................................................................................1-3

1.4.1 External View .............................................................................................................................................................................. 1-3

1.4.2 External View .............................................................................................................................................................................. 1-4

1.4.3 Cross Sectional Views ................................................................................................................................................................. 1-5

1.5 Using the Machine.........................................................................................................................................................1-6

1.5.1 Control Panel ............................................................................................................................................................................... 1-6

1.5.2 Control Panel ............................................................................................................................................................................... 1-6

1.1 Features

Chapter 1

1.1.1 Feature

LBP3370 / LBP3310

1. Compact, high-speed and high-resolution printer

Regardless of its compact size that enables an installation on side of desks, this printer realizes the printing speed of 21 pages per minute in letter-size paper with

the resolution of 600 dpi.

2. Short wait time and low power consumption

The printer utilizes the on-demand fixing method that turns on the heater only during print operations. This shortens wait time, and enables low power

consumption during stand by period.

3. Automatic duplex printing

The printer enables an automatic duplex printing by installing the duplexing unit as a standard equipment in the printer.

1.2 System Construction

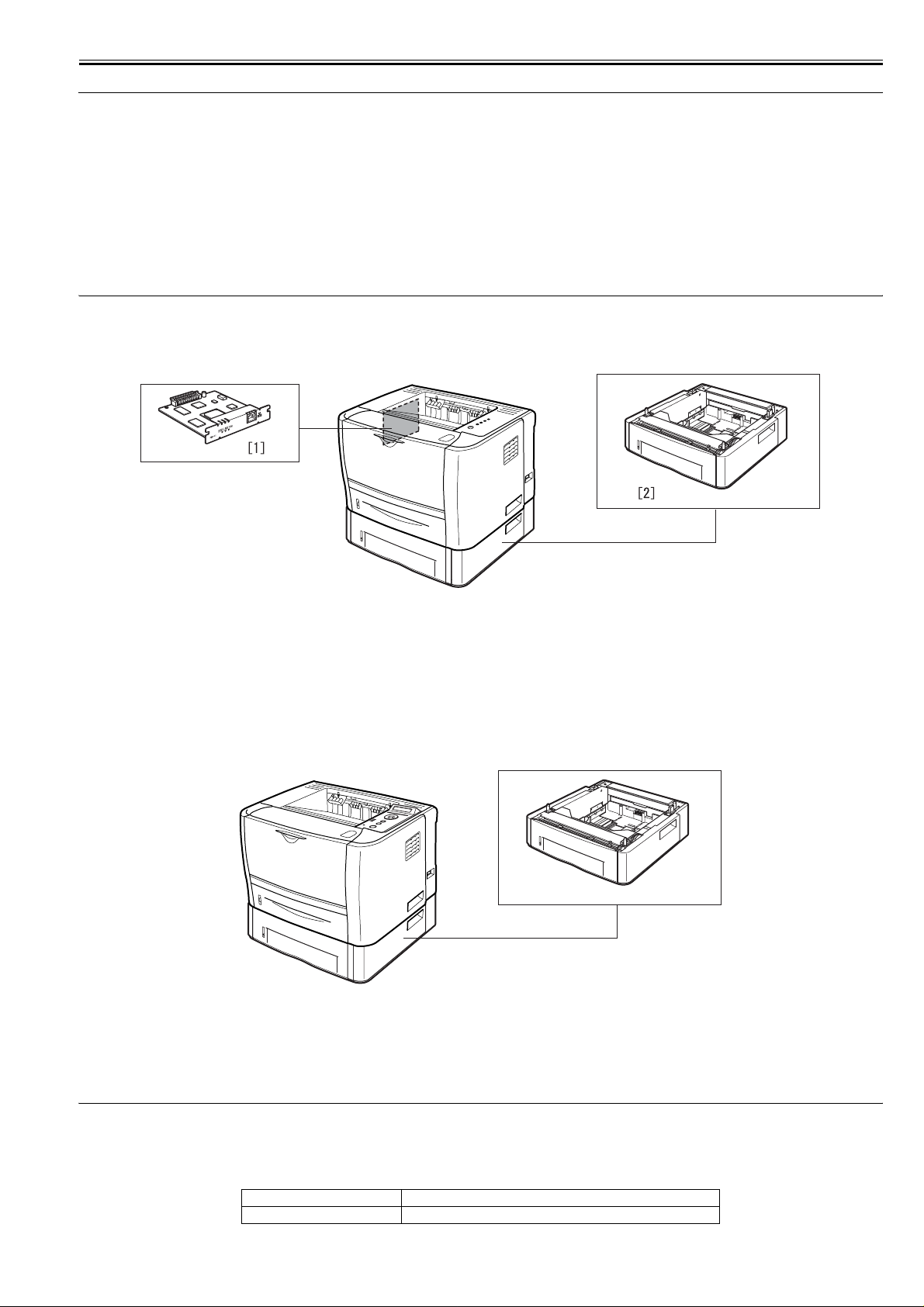

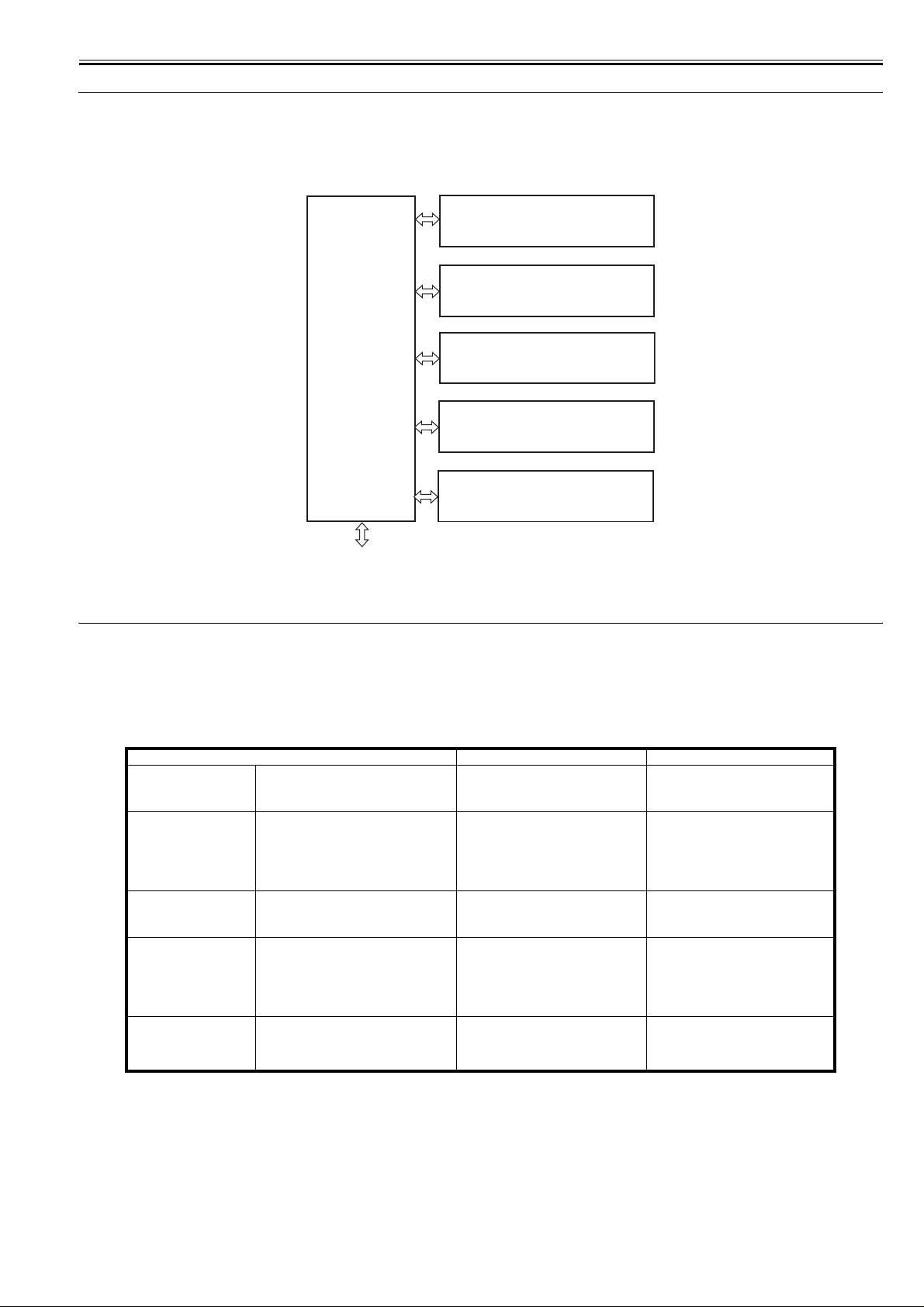

1.2.1 System Construction

LBP3310

0018-3077

0018-3078

1.2.2 System Construction

LBP3370

F-1-1

T-1-1

[1] Network Board NB-C2

[2] Paper Feeder PF-35P

0018-3079

[1]

F-1-2

T-1-2

[1] Paper Feeder PF-35P

1.3 Product Specifications

1.3.1 Product Specifications

LBP3310

Body installation method desktop page printer

Photosensitive medium OPC drum

0018-3080

1-1

Chapter 1

Exposure method semiconductor laser

Development method Toner projection development

Transfer method by roller

Separation method by curvature

Cassette pickup method by pad

Multifeeder pickup method by pad

Drum cleaning method by blade

Fixing method on-demand

Delivery method face-down/face-up

Toner supply type by toner cartridge

Warm-up time in standby: 0 sec (at power-on: 8 sec or less)

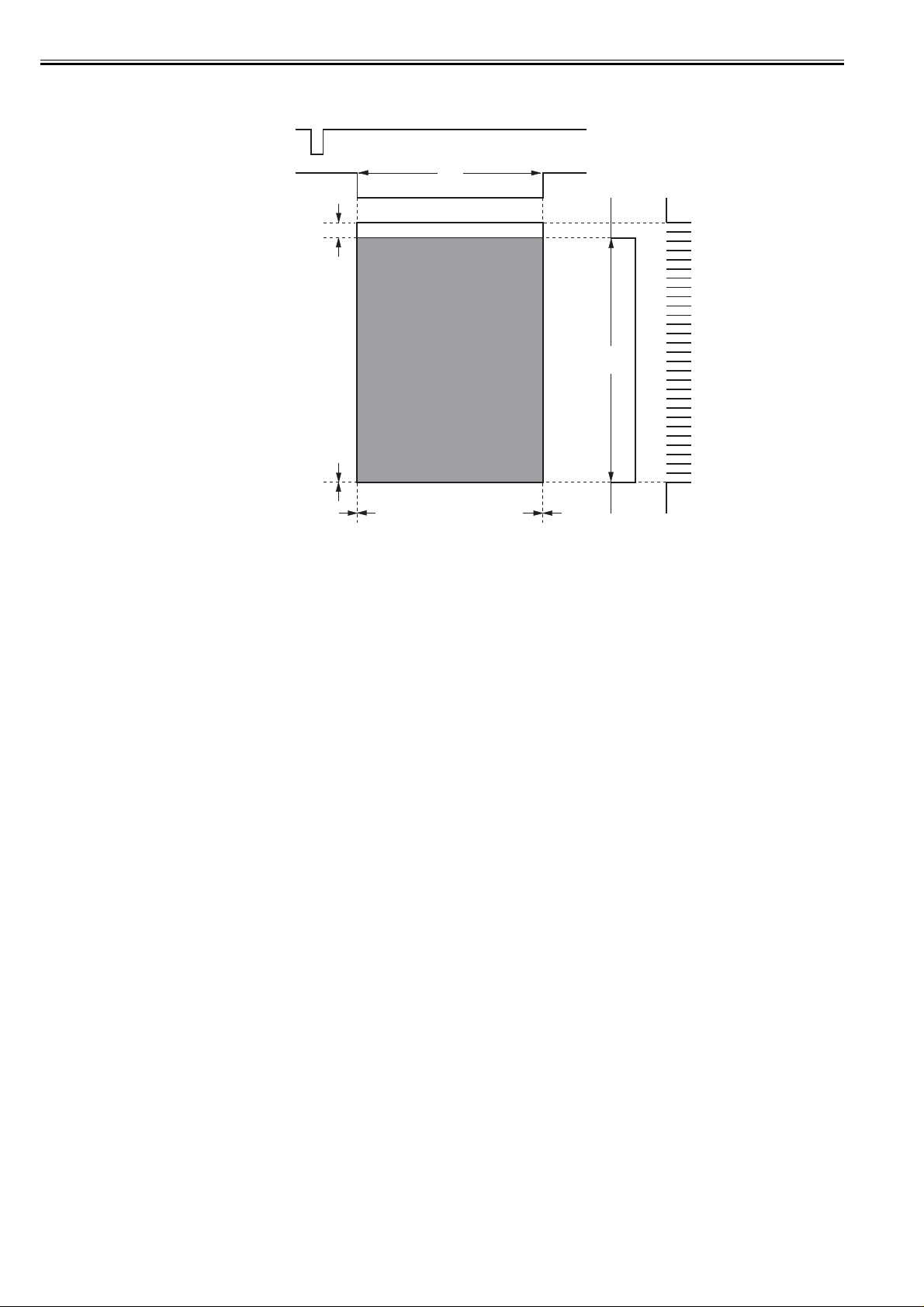

Print area top: 5 mm; bottom: 5 mm; left/right: 5 mm (if envelope, top, bottom, left,

Printing resolution 600dpi

First print time 6.5 sec or less (approx.; A4)

Print speed (A4) 26 pages/min (approx.)

Cassette paper size Standard sizes

3k cartridge: about 3000 prints

7k cartridge: about 7000 prints

(A4, single-sided; at 5% image ratio)

right: 10 mm)

A4, B5, A5, Legal, Letter, Executive

Custom sizes

Width 148.0 to 215.9 mm; Length 210.0 to 355.6 mm

Multi-purpose paper size A4, B5, A5, Legal, Letter, Executive, Envelope DL, Envelope COM10,

Cassette paper type plain paper (64 to 90 g/m2), heavy paper (91 to 120 g/m2), recycled

Multi-purpose paper type plain paper (64 to 90 g/m2), heavy paper (91 to 163 g/m2), recycled

Cassette capacity 250 sheets (approx.; plain paper, 64 g/m2)

Multi-purpose capacity 50 sheets (approx.; plain paper, 64 g/m2)

Delivery tray stack Face-down output tray: approx. 125 sheets (64 g/m2)

Duplex method Auto duplexing

Interface Standard : USB2.0, Option : 10Base-T/100Base-TX

Memory 8 MB (internal; no optional memory available)

Hard disk standard : none, option : none

Operating environment

(Temperature range)

Operating environment

(Humidity range)

Noise 55 dB or less (during printing; based on ISO9296; announced noise

Power supply rating AC120V±10% (50/60Hz ±2Hz)

Power consumption (Maximum) 120V: 845W or less

Power consumption 120V

Dimensions 399.7 (W) x 378.6 (D) x 258 (H)mm

Weight printer: Approx;11.2kg (excluding the toner cartridge); toner cartridge:

Envelope C5, Envelope Monarch, Index Card, Custom Paper Size (width

76.2 to 215.9 mm, length 127.0 to 355.6 mm)

paper,

paper, transparency, label paper, envelop (DL, COM10, C5, Monarch,

B5)

Face-up output slot: 1 sheet

10 to 32.5 deg C

20% to 80% RH

emission)

AC230V±10% (50/60Hz ±2Hz)

230V: 909W or less

(approx.; 20 deg C; for input of rated power supply; including peak value

lasting 1 sec or more)

Average suring operation: approx. 386W

Average suring standby: approx. 4W

230V

Average suring operation: approx. 382W

Average suring standby: approx. 4W

Approx,0.8kg(3K cartridge), Approx,1.0kg(7K cartridge)

Option paper feeder

1.3.2 Product Specifications

LBP3370

Body installation method desktop page printer

Photosensitive medium OPC drum

Exposure method semiconductor laser

Development method Toner projection development

1-2

0018-3219

Transfer method by roller

Separation method by curvature

Cassette pickup method by pad

Multifeeder pickup method by pad

Drum cleaning method by blade

Fixing method on-demand

Delivery method face-down/face-up

Toner supply type by toner cartridge

Warm-up time in standby: 0 sec (at power-on: 9 sec or less)

Print area top: 5 mm; bottom: 5 mm; left/right: 5 mm (if envelope, top, bottom, left,

Printing resolution 600dpi

First print time 6.5 sec or less (approx.; A4)

Print speed (A4) 26 pages/min (approx.)

Cassette paper size Standard sizes

Multi-purpose paper size Standard sizes

Cassette paper type plain paper (64 to 90 g/m2), heavy paper (91 to 120 g/m2), recycled

Multi-purpose paper type plain paper (64 to 90 g/m2), heavy paper (91 to 163 g/m2), recycled

Cassette capacity 250 sheets (approx.; plain paper, 64 g/m2)

Multi-purpose capacity 50 sheets (approx.; plain paper, 64 g/m2)

Delivery tray stack Face-down output tray: approx. 125 sheets (64 g/m2)

3k cartridge: about 3000 prints

7k cartridge: about 7000 prints

(A4, single-sided; at 5% image ratio)

right: 10 mm)

A4, B5, A5, Legal, Letter, Executive

Custom sizes

Width 148.0 to 215.9 mm; Length 210.0 to 355.6 mm

A4, B5, A5, Legal, Letter, Executive, Envelope DL, Envelope COM10,

Envelope C5, Envelope Monarch, Envelope B5, Index Card, Statement,

16K

Custom sizes

Width 76.2 to 215.9 mm; Length 127.0 to 355.6 mm

paper

paper, transparency, label paper, envelop (DL, COM10, C5, Monarch,

B5)

Face-up output slot: 1 sheet

Chapter 1

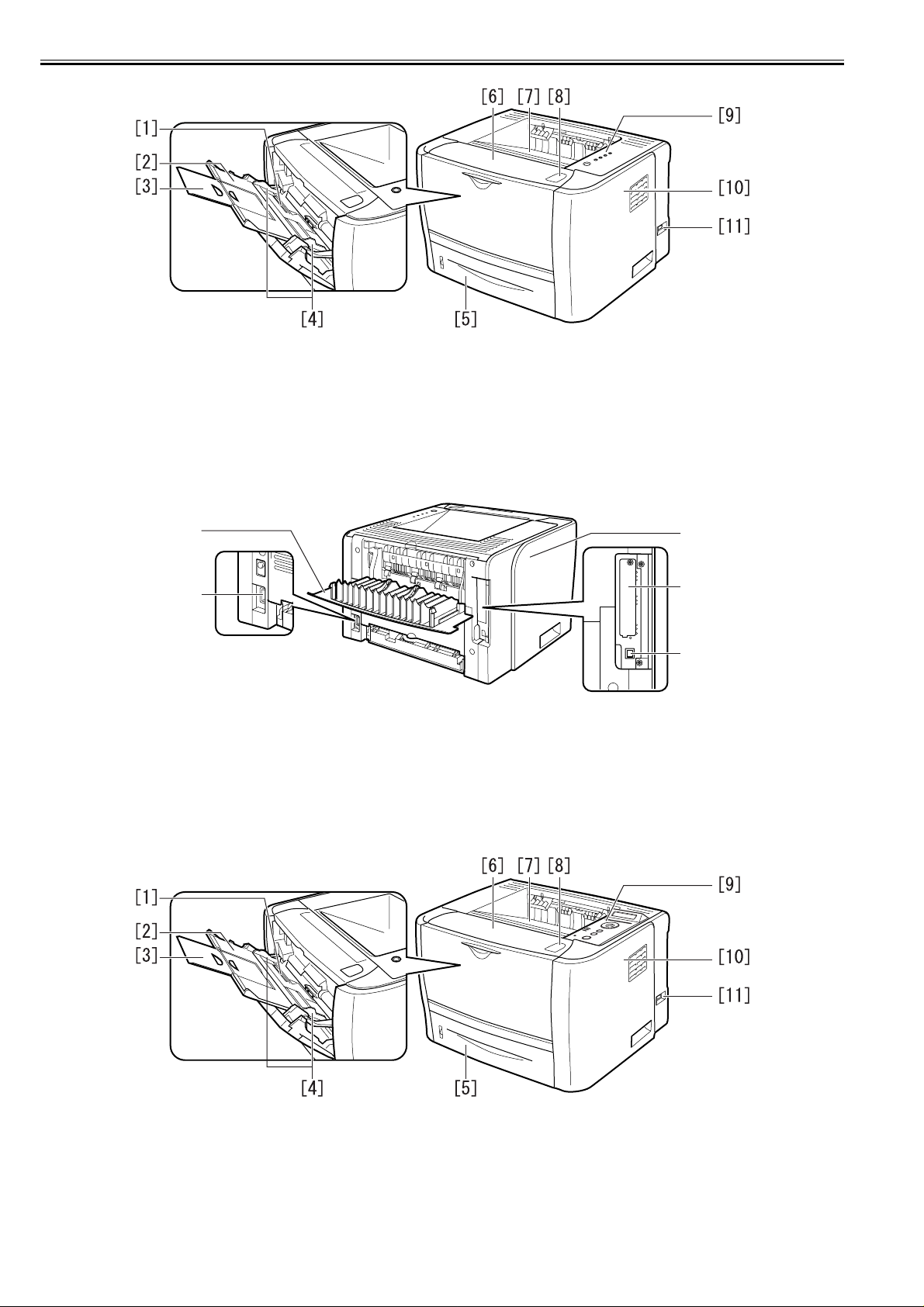

1.4 Name of Parts

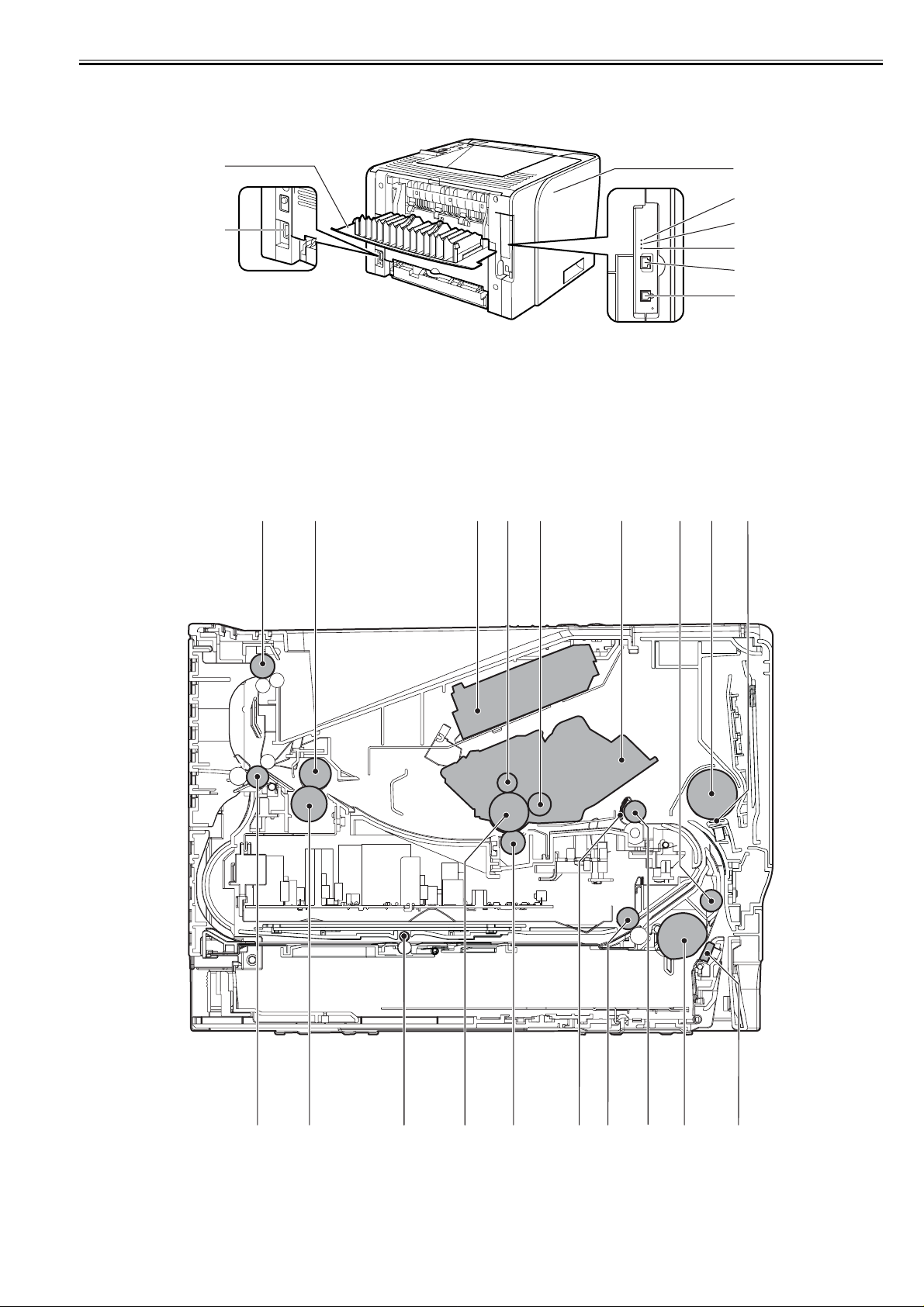

1.4.1 External View

LBP3310

Duplex method Auto duplexing

Interface Standard : USB2.0, 10Base-T/100Base-TX

Memory 8 MB (internal; no optional memory available)

Hard disk standard : none, option : none

Operating environment

(Temperature range)

Operating environment

(Humidity range)

Noise 55 dB or less (during printing; based on ISO9296; announced noise

Power supply rating AC230V±10% (50/60Hz ±2Hz)

Power consumption (Maximum) 950W or less

Power consumption Average suring operation: approx. 403W

Dimensions 399.7 x 378.6 x 267 mm

Weight printer: Approx;11.4kg (excluding the toner cartridge); toner cartridge:

Option paper feeder

10 to 32.5 deg C

20% to 80% RH

emission)

(approx.; 20 deg C)

Average suring standby: approx. 9W

Approx,0.8kg(3K cartridge), Approx,1.0kg(7K cartridge)

0018-3082

1-3

Chapter 1

F-1-3

[1] Manual feeder tray [7] Face-down Output Tray

[2] Sub tray [8] Open Button

[3] Extension tray [9] Control Panel

[4] Paper guide [10] Right cover

[5] Paper Cassette [11] Power Switch

[6] Front Cover

1.4.2 External View

LBP3370

[1]

[2]

F-1-4

[1] Face-up Output Tray [4] Expansion Slot

[2] Power Socket [5] USB Connector

[3] Left cover

[3]

[4]

[5]

0018-3084

1-4

F-1-5

[1] Manual feeder tray [7] Face-down Output Tray

[2] Sub tray [8] Open Button

[3] Extension tray [9] Control Panel

[4] Paper guide [10] Right cover

[5] Paper Cassette [11] Power Switch

[6] Front Cover

Chapter 1

[1]

[2]

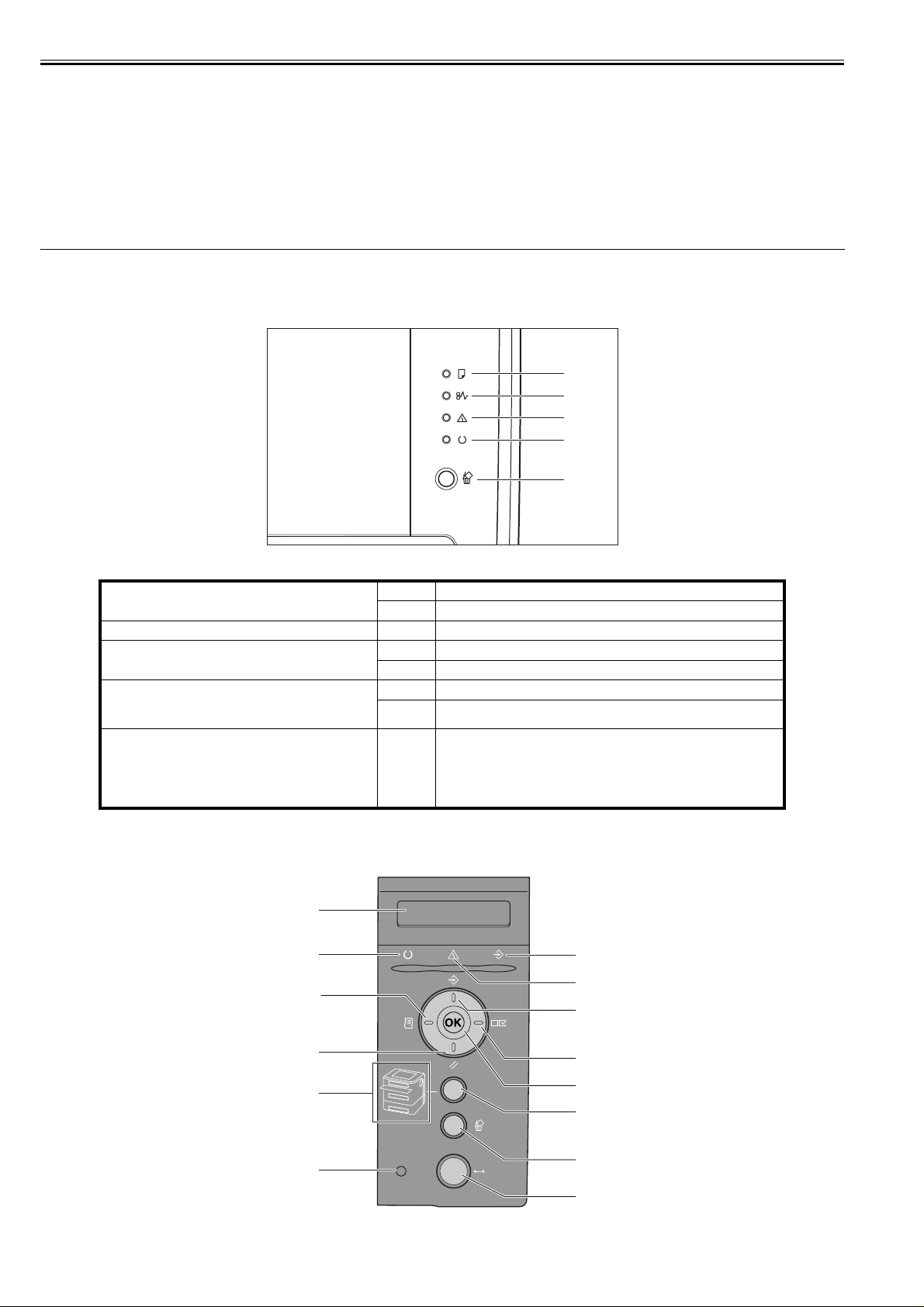

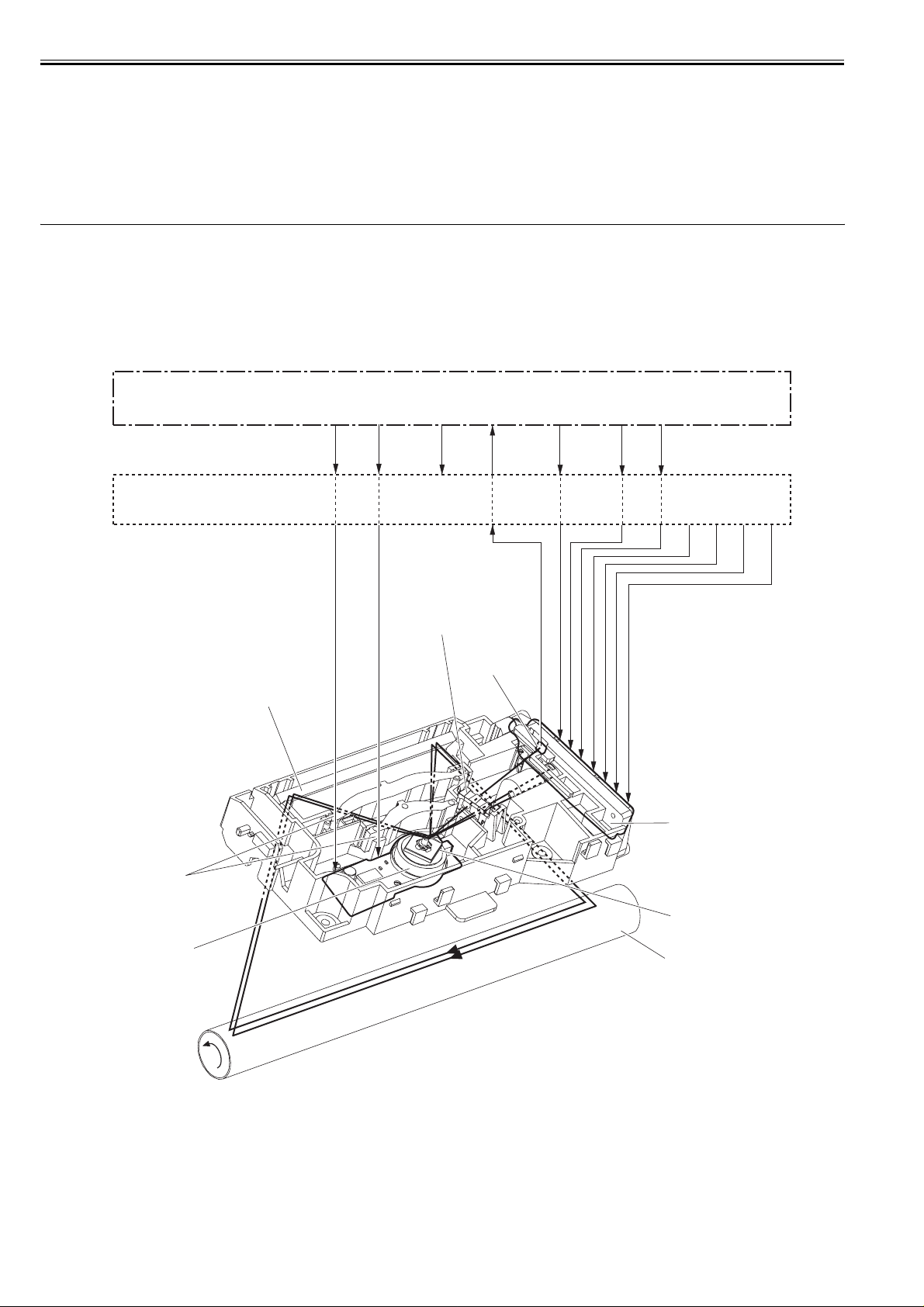

1.4.3 Cross Sectional Views

LBP3370 / LBP3310

F-1-6

[1] Face-up Output Tray [5] 10 Indicatotor

[2] Power Socket [6] TX/RX Indicatotor

[3] Left Cover [7] LAN Connector

[4] 100 Indicatotor [8] USB Connector

[1] [2] [3] [4] [5] [6] [8][7]

[3]

[4]

[5]

[6]

[7]

[8]

0018-3085

[9]

[18][19]

[1] Face-down delivery roller [11] Pick-up roller

[2] Fixing film unit [12] Registration roller

[17] [16] [15] [14] [13] [12] [11] [10]

F-1-7

1-5

Chapter 1

[3] Laser/scanner unit [13] Duplex pick-up roller

[4] Primary charging roller [14] Registration shutter

[5] Developing cylinder [15] Transfer charging roller

[6] Toner cartridge [16] Photosensitive drum

[7] Feed roller [17] Duplex feed roller

[8] Manual pickup roller [18] Pressure roller

[9] Manual separation pad [19] Face-up delivery roller

[10] Separation pad

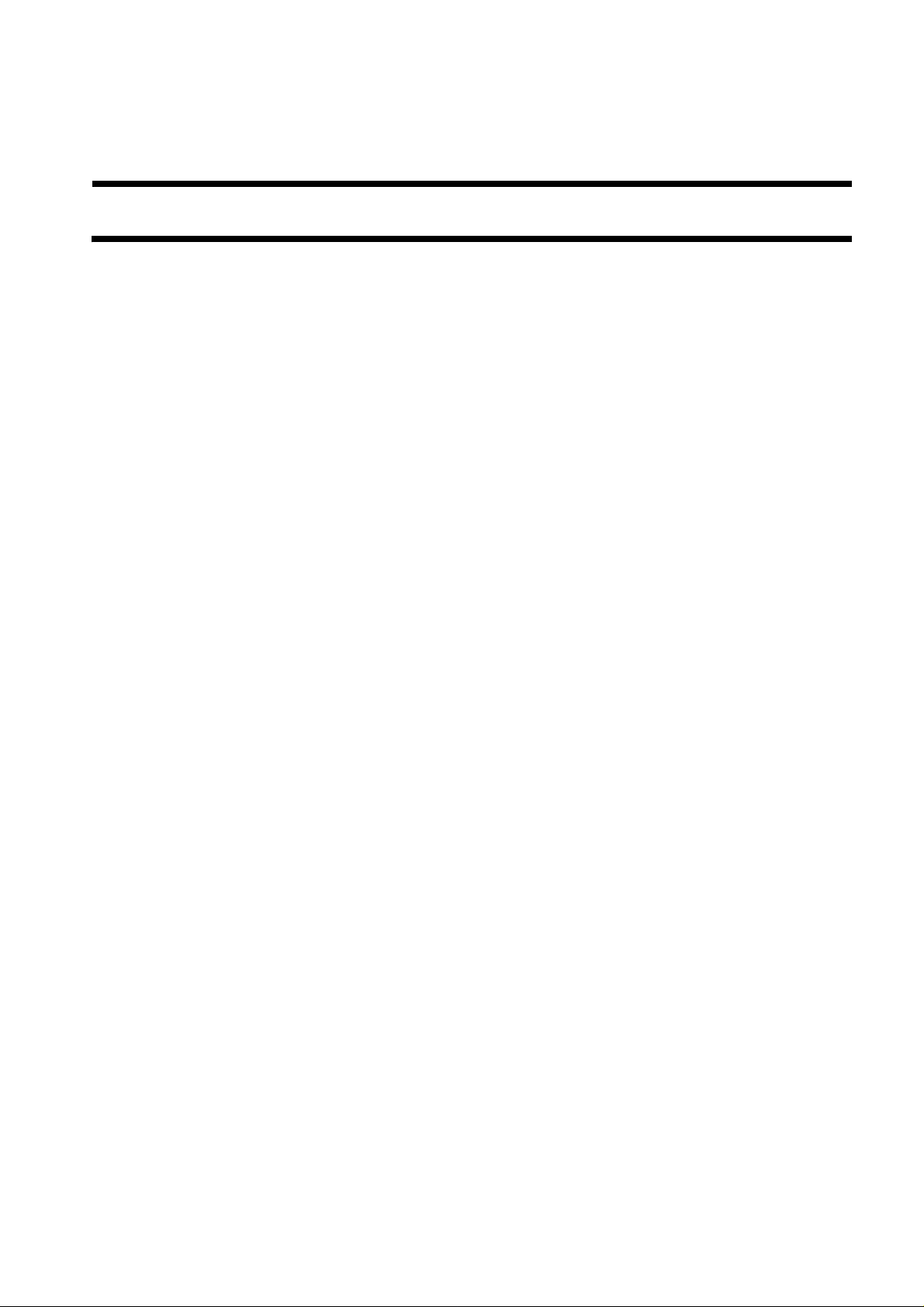

1.5 Using the Machine

1.5.1 Control Panel

LBP3310

[1] Load Paper Indicator

[2] Paper Jam Indicator

[3] Alarm Indicator

[4]Ready Indicator

[5] Cancel Job Key/Cancel Job Indicator Pressing this key enables the cancellation of the jobs in which an error is

On

Blinking:

Blinking

On

Blinking

On

Blinking

[1]

[2]

[3]

[4]

[5]

F-1-8

There is no paper in any paper source.

No paper or paper of an inappropriate size s loaded

A paper jam is occurring, disabling printing.

Service call is occurring.

An error is occurring, disabling printing.

The printer is ready to print.

The printer is busy performing some kind of processing or operation, such as

printing, warming up, cleaning, or pausing a job.

occurring and those in progress. The indicator comes on while pressing the ke y.

The indicator blinks while a job is in the cancellation process.

0018-3086

1.5.2 Control Panel

LBP3370

1-6

[1]

[14]

[13]

[12]

[11]

[10]

0018-3087

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

F-1-9

Chapter 1

[1] Display

Displays the printer status, messages, the items and setting values of the menu functions.

[2] Job Indicator (Green)

On:

The printer is receiving print data, or any print data remains in the printer memory.

Blinking:

The printer is processing print data.

Off:

There is no print data in the printer memory.

[3] Message Indicator (Orange)

On:

The printer cannot print because a problem has occurred in the printer.

(If the printer has entered Power Save Mode 1 when it is offline, only the Message indicator (orange) and Power indicator (green) are on.)

Off:

The printer is in a normal state.

[4] Job Key

On offline:

Does not function when the printer is offline.

On online:

Displays the JOB menu.

On menu operation:

Goes back to the previous menu (Goes back up the hierarchy).

[5] Settings Key

On offline:

Displays the SETUP menu.

On online:

Displays the SETUP menu. However, the USER MAIN. options cannot be specified when the printer is online.

On menu operation:

(green) are on.)

Displays the next right item in the menu. Increases the setting value.

[6] OK Key

On offline:

Does not function when the printer is offline.

On online:

Does not function when the printer is online.

On menu operation:

Goes to the next menu (Goes down the hierarchy). In a lowest menu level (When a setting value is displayed), determines the setting value.

[7] Feeder Selection Key

On offline:

Displays the SELECT FEEDER menu.

On online:

Displays the SELECT FEEDER menu.

On menu operation:

Does not function.

[8] Cancel Job Key

On offline:

Cancels the job when the Job indicator is on or blinking. Does not function when the Job indicator is off.

On online:

Cancels the job when the Job indicator is on or blinking. Does not function when the Job indicator is off.

[9] Online Key/Online Indicator (Green)

Turns on (online)/off (offline) the connection to the computer.

This key also has the function that, when an error has occurred, releases the printer from the error temporarily and continue s the paused job. However, depending

on the error, you may not be able to cancel it out.

The Online indicator under the Online key indicates the following printer status with its status.

On:

Online (The printer can receive print data from the computer.)

Off:

Offline (The printer cannot receive print data from the computer.)

However, if the printer has entered Power Save Mode, the (Online) indicator is off even when the printer is online.

[10] Power Indicator (Green)

On:

The printer is ON.

Off:

The printer is OFF.

[11]Paper Source Indicators (Green)

On:

The indicator for the currently selected paper source comes on.

Blinking:

There is no paper in the currently selected paper source, or the paper cassette is not set.

Off:

No paper source is selected. No paper cassette including the optional one or paper feeder is set.

[12] Reset Key

On offline:

Displays the RESET menu.

On online:

Displays the RESET menu.

On menu operation:

Goes to the next menu (Goes down the hierarchy).

In a lowest menu level (When a setting value is

displayed), determines the setting value.

[13] Utility Key

On offline:

Does not function when the printer is offline.

On online:

Displays the UTILITY menu.

On menu operation:

Displays the next left item in the menu. Decreases the setting value.

[14] Ready Indicator (Green)

On:

The printer is ready to print. (If the printer has entered Power Save Mode 1 when it is online, only the Ready indicator (green) and Power indicator (green) are on.)

Blinking:

The printer is performing a self-diagnostic test. The printer is in a warm-up state.

1-7

Chapter 1

Off:

The printer cannot print.

1-8

Chapter 2 TECHNICAL REFERENCE

Contents

Contents

2.1 Functional Configuration............................................................................................................................................... 2-1

2.1.1 Outline.......................................................................................................................................................................................... 2-1

2.2 Basic Sequense...............................................................................................................................................................2-1

2.2.1 Basic Operation Sequence ........................................................................................................................................................... 2-1

2.2.2 Power-on sequence ...................................................................................................................................................................... 2-1

2.3 LASER EXPOSURE SYSTEM.....................................................................................................................................2-2

2.3.1 Overview/Configuration .............................................................................................................................................................. 2-2

2.3.1.1 Outline.............................................................................................................................................................................................................2-2

2.3.1.2 Laser Control Circuit.......................................................................................................................................................................................2-3

2.3.2 Controlling the Laser Activation Timing..................................................................................................................................... 2-5

2.3.2.1 Laser emission control ....................................................................................................................................................................................2-5

2.3.2.2 Horizontal synchronous control ................................................................ ... ...................................................................................................2-5

2.3.3 Laser Control ............................................................................................................................................................................... 2-5

2.3.3.1 Automatic power control (APC) .....................................................................................................................................................................2-5

2.3.3.2 Image masking control.. ......................................................................... .........................................................................................................2-5

2.3.4 Laser Scanner Motor Control....................................................................................................................................................... 2-6

2.3.4.1 Outline.............................................................................................................................................................................................................2-6

2.3.4.2 Scanner motor speed control...........................................................................................................................................................................2-7

2.3.4.3 Scanner motor failure detection ......................................................................................................................................................................2-7

2.4 IMAGE FORMATION SYSTEM.................................................................................................................................2-7

2.4.1 Overview/Configuration .............................................................................................................................................................. 2-7

2.4.1.1 Outline.............................................................................................................................................................................................................2-7

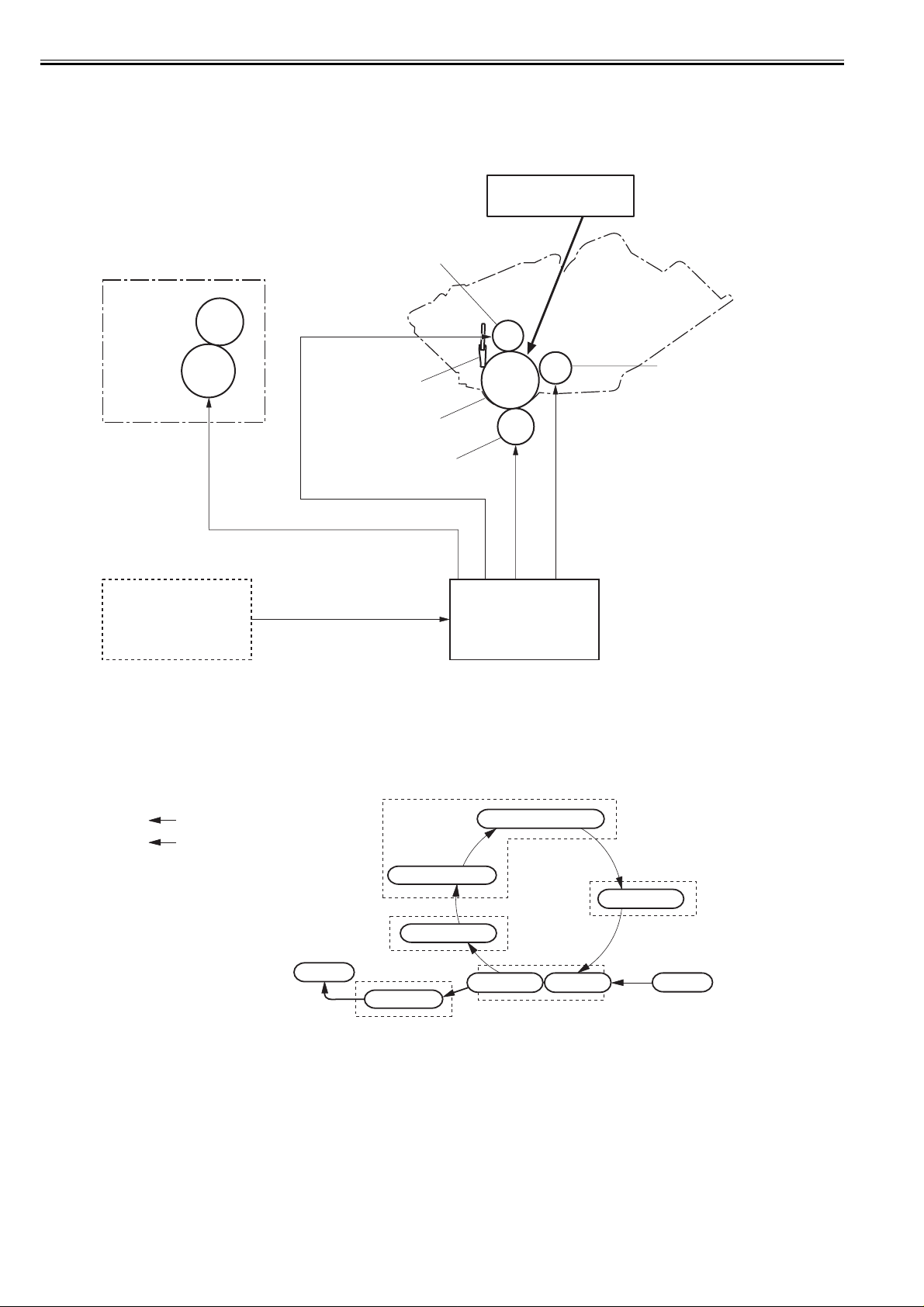

2.4.1.2 Print Process....................................................................................................................................................................................................2-8

2.4.1.3 Electrostatic latent image formation block .....................................................................................................................................................2-9

2.4.1.4 Development block .........................................................................................................................................................................................2-9

2.4.1.5 Transfer block ...............................................................................................................................................................................................2-10

2.4.1.6 Fixing block ..................................................................................................................................................................................................2-11

2.4.1.7 Photosensitive drum cleaning block................. ...................................... ... ....................................................................................................2-11

2.4.2 High-Voltage Control ................................................................................................................................................................ 2-12

2.4.2.1 Outline...........................................................................................................................................................................................................2-12

2.4.2.2 Primary charging bias generation..................................................................................................................................................................2-12

2.4.2.3 Developing bias generation........... ... ...................................... ...................................... .................................................................................2-12

2.4.2.4 Transfer charging bias generation.................................................................................................................................................................2-13

2.4.2.5 Fixing bias generation ...................................................................................................................................................................................2-13

2.4.2.6 Cartridge presence detection .........................................................................................................................................................................2-13

2.5 PICKUP AND FEEDING SYSTEM...........................................................................................................................2-13

2.5.1 Overview/Configuration ............................................................................................................................................................ 2-13

2.5.1.1 Outline...........................................................................................................................................................................................................2-13

2.5.2 Detecting Jams........................................................................................................................................................................... 2-14

2.5.2.1 Jam Detection Outline...................................................................................................................................................................................2-14

2.5.2.1.1 Outline................................... ... ...................................... ... .... ................................................................................................................2-14

2.5.2.2 Delay Jams ....................................................................................................................................................................................................2-15

2.5.2.2.1 Pick-up delay jam............................ ... ...................................... ... ..........................................................................................................2-15

2.5.2.2.2 Delivery delay jam ................................................................................................................................................................................2-15

2.5.2.2.3 Reversing delay jam..............................................................................................................................................................................2-15

2.5.2.3 Stationary Jams .............................................................................................................................................................................................2-15

2.5.2.3.1 Pick-up stationary jam .. ...................................... ...................................... ... ..........................................................................................2-15

2.5.2.3.2 Delivery stationary jam .........................................................................................................................................................................2-15

2.5.2.3.3 Reversing stationary jam.......................................................................................................................................................................2-15

2.5.2.4 Other Jams.....................................................................................................................................................................................................2-15

2.5.2.4.1 Wrapping jam.................. ...................................... ... ...................................... .......................................................................................2-15

2.5.2.4.2 Start-up residual jam .......................... ... ...................................... ... ... ....................................................................................................2-15

2.5.2.4.3 Door open jam.......................................................................................................................................................................................2-15

Contents

2.5.3 Cassette Pickup .......................................................................................................................................................................... 2-15

2.5.3.1 Cassette pick-up............................................................................................................................................................................................2-15

2.5.4 Multi-purpose Pickup................................................................................................................................................................. 2-16

2.5.4.1 Manual Fees pick-ip......................................................................................................................................................................................2-16

2.5.5 Duplex Feeding.......................................................................................................................................................................... 2-16

2.5.5.1 Outline ..........................................................................................................................................................................................................2-16

2.5.5.2 Operation ......................................................................................................................................................................................................2-16

2.6 EXTERNAL AND CONTROLS SYSTEM ............................................................................................................... 2-17

2.6.1 Fan.............................................................................................................................................................................................. 2-17

2.6.1.1 Fan motor control..........................................................................................................................................................................................2-17

2.6.2 Power Supply............................................................................................................................................................................. 2-17

2.6.2.1 Power Supply................................................................................................................................................................................................2-17

2.6.2.1.1 Low-voltage Power Supply Circuit ....... ... ...................................... ... ... ................................................................................................ 2-17

2.6.2.2 Protective Functions ..................................................................................................................................................................................... 2-18

2.6.2.2.1 Protective function....................................... ... ...................................... ... ............................................................................................. 2-18

2.7 ENGINE CONTROL SYSTEM .............. ................................................... ................................................................ 2-19

2.7.1 Video Controller ........................................................................................................................................................................ 2-19

2.7.1.1 Outline ..........................................................................................................................................................................................................2-19

2.7.1.2 Outline of Operation by Block......................................................................................................................................................................2-19

2.7.1.3 Overview....................................................................................................................................................................................................... 2-20

2.7.1.4 Outline of Operation by Block......................................................................................................................................................................2-20

2.7.2 Engine Controller....................................................................................................................................................................... 2-21

2.7.2.1 Outline ..........................................................................................................................................................................................................2-21

2.8 FIXING UNIT/DELIVERY SYSTEM....................................................................................................................... 2-23

2.8.1 Overview/Configuration ............................................................................................................................................................ 2-23

2.8.1.1 Outline ..........................................................................................................................................................................................................2-23

2.8.2 Various Control Mechanisms .................................................................................................................................................... 2-24

2.8.2.1 Fixing Temperature Control ......................................................................................................................................................................... 2-24

2.8.2.1.1 Fixing temperature control....................................................................................................................................................................2-24

2.8.2.2 Protective Functions ..................................................................................................................................................................................... 2-25

2.8.2.2.1 Protective function....................................... ... ...................................... ... ............................................................................................. 2-25

2.8.2.2.2 failure detection ........... .... ..................................... .... ...................................... ......................................................................................2-25

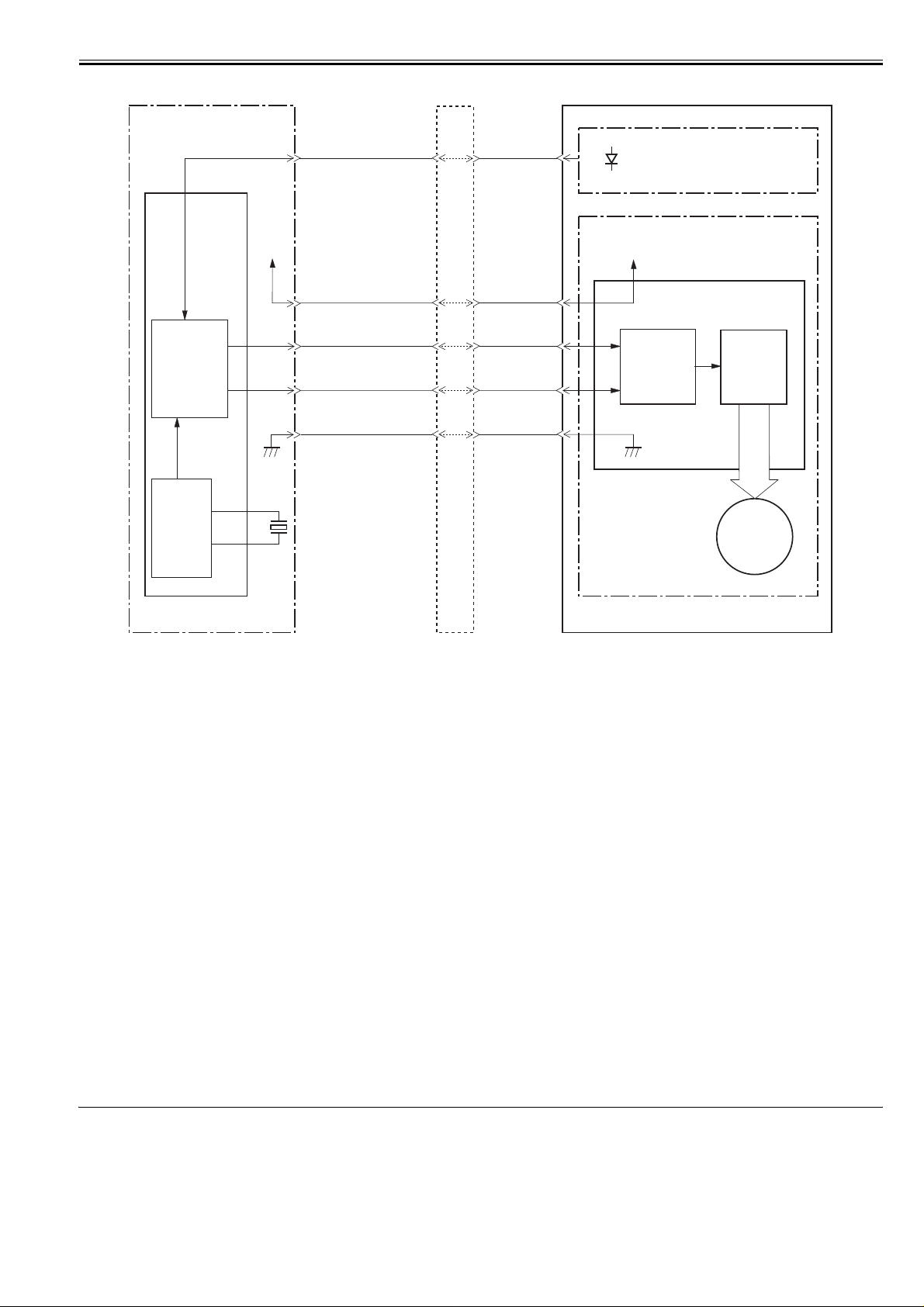

2.1 Functional Configuration

Chapter 2

2.1.1 Outline

LBP3370 / LBP3310

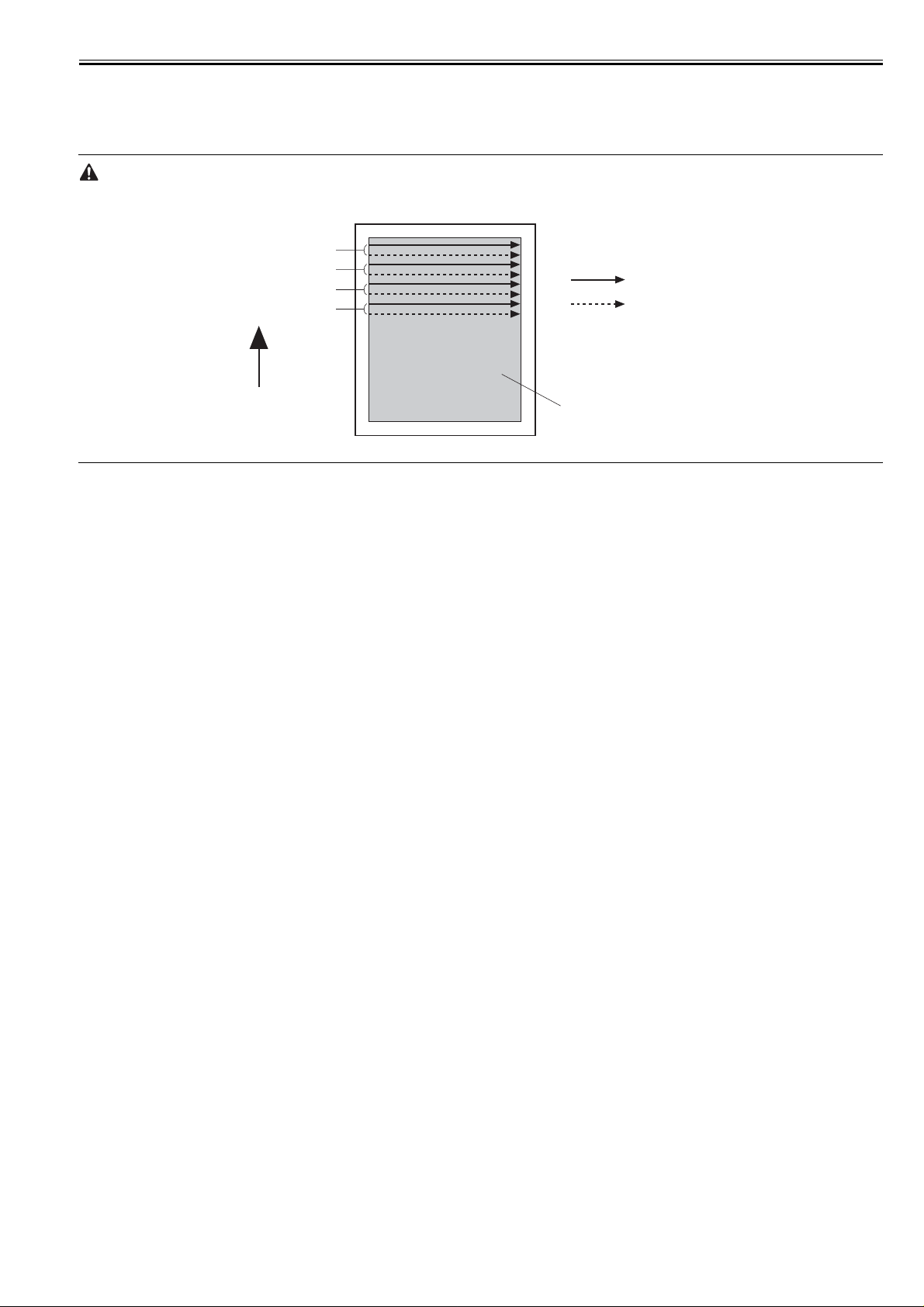

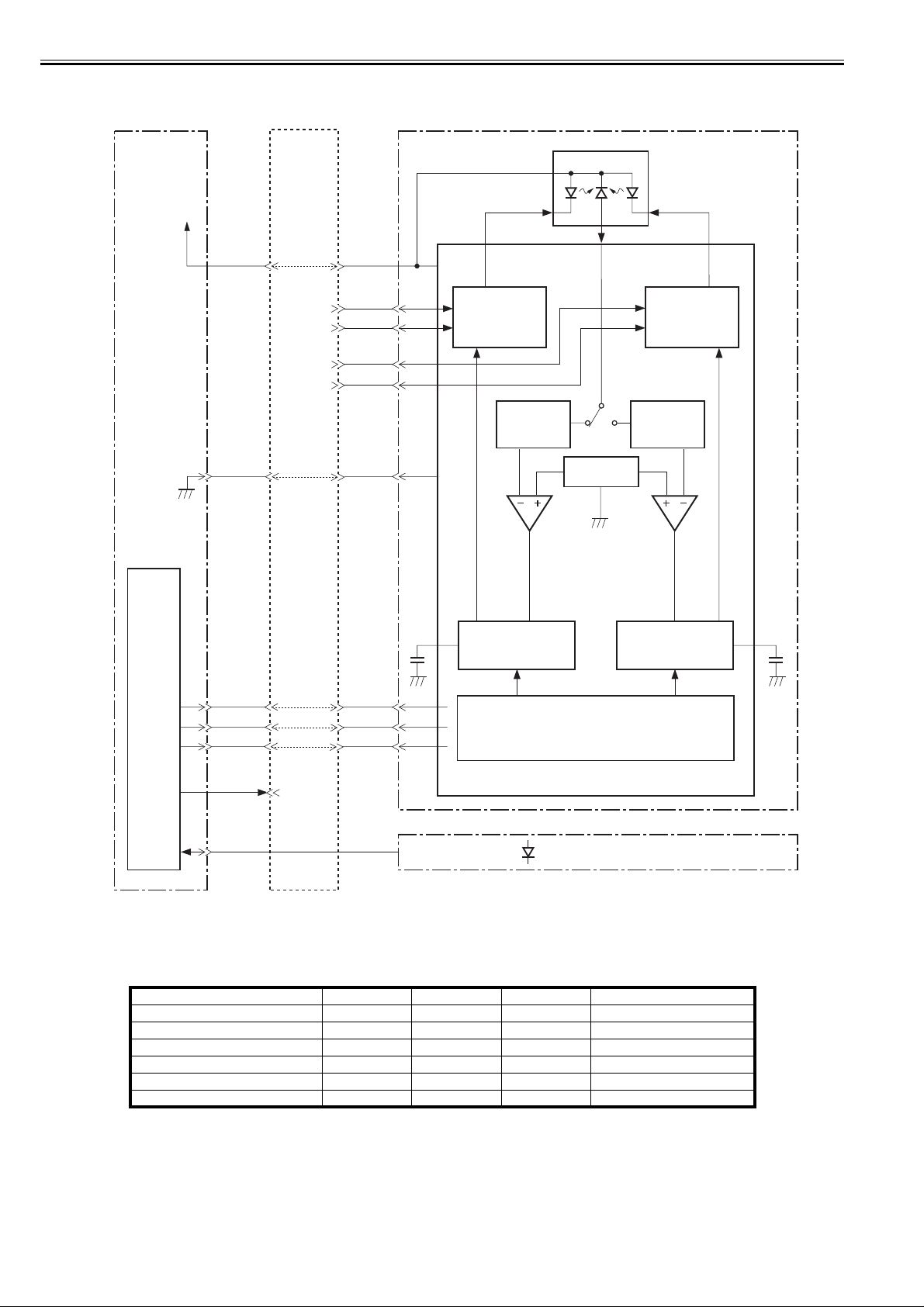

0018-3088