Page 1

ADF-J1

REVISION 0

SEPT . 2001

COPYRIGHT© 2001 CANON INC. 2001 CANON ADF-J1 REV.0 SEPT. 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13HK-000

Page 2

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical

theory , installation, maintenance, and repair of products. This manual covers all localities

where the products are sold. For this reason, there may be information in this manual that

does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to

improvements or changes in products. When changes occur in applicable products or in

the contents of this manual, Canon will release technical information as the need arises.

In the event of major changes in the contents of this manual over a long or short period,

Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this

manual may not be copied, reproduced or translated into another language, in whole or in

part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Imprimé au Japon

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

COPYRIGHT© 2001 CANON INC. 20 CANON ADF-J1 REV.0 SEPT. 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 3

INTRODUCTION

Memo

1 Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution,

or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

REF.

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric

outlet.

Indicates an item intended to provide notes assisting the understanding of the

topic in question.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

COPYRIGHT

©

Refers to the Copier Basics Series for a better understanding of the contents.

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

i

Page 4

INTRODUCTION

2 Outline of the Manual

This Service Manual contains basic facts and figures needed to service the ADF-J1 in the

field, and it consists of the following chapters:

Chapter 1 General Description: features, specifications, methods of operation

Chapter 2 Outline of Operation: mechanical systems by function, electrical systems

in reference to principles of operation, timing of operation; construction and outline of electrical circuitry

Chapter 3 Mechanical Systems construction of mechanical systems; disassembly,

assembly, and adjustments

Chapter 4 Maintenance and Inspection:

periodically replacement parts, durables and

consumables; scheduled servicing chart

Chapter 5 Troubleshooting standards, adjustments, troubleshooting tables

Appendix: general timing chart, list of signals/abbreviations,

general circuit diagrams

For installation, refer to the Installation Procedure found in the shipping box; this manual

omits descriptions of the installation work.

ii

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

Page 5

INTRODUCTION

The descriptions in this Service Manual are based on he following rules:

1. In each chapter, the uses of the function in question and its relationship to electrical and

mechanical systems are discussed and the timing of operation of its associated parts is

explained by means of outlines and diagrams.

In the diagrams, the symbol

represents a mechanical path, while the symbol

with a name next to it indicates the flow of an electric signal.

The expression “turn on the power” means turning on the power switch, closing the

front door, and closing the delivery door so that the machine will be supplied with

power.

2. In circuit diagrams (digital), a signal whose level is High is expressed as being ‘1’,

while a single whose level is Low is expressed as being ‘0’; the level of voltage, however, varies from circuit to circuit.

The machine uses CPUs, whose internal mechanisms cannot be checked in the field,

and, therefore, are not explained. In addition, the machine’s PCBs are not intended for

repairs at the user’s and, therefore, are explained by means of block diagrams: two types

are used, i.e., between sensors and inputs of PCBs equipped with a control or drive function and between outputs equipped with a control or drive function and loads; in addition, functional block diagrams are used at times.

Changes made to the machine for product improvement are communicated in the form of

a Service Information bulletin as needed. All ser vice persons are expected to go through all

service documentation including the bulletins and be equipped to respond to the needs of the

field (as by being able to identify possible causes of problems).

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

iii

Page 6

CONTENTS

Contents

CHAPTER 1 GENERAL DESCRIPTION

1 Features............................................... 1-1

2 Specifications...................................... 1-2

2.1 Specifica tions ............................. 1-2

3 Names of Components........................1-3

3.1 External View............................. 1-3

3.2 Cross Section ............................. 1-4

4 Using the Machine .............................. 1-5

4.1 Routine Maintenance by the User 1-5

CHAPTER 2 OUTLINE OF OPERATION

1 Basic Construction.............................. 2-1

1.1 Outline of the Electrical Circuitry 2-1

1.2 Inputs to and Outputs from the

ADF Drive PCB......................... 2-2

2 Basic Operations ................................. 2-3

2.1 Outline ....................................... 2-3

2.2 Sequence of Operation...............2-4

2.2.1 Outline ................................. 2-4

2.2.2 Picking Up and Delivering

Originals (Single-sided original

→ Single-sided print) .......... 2-4

2.3 Detecting Originals .................... 2-5

2.3.1 Outline ................................. 2-5

2.3.2 Detecting the Presence/Absence

of an Original....................... 2-6

2.3.3 Detecting the Last Original . 2-6

2.3.4 Detecting the Size of an

Original ................................ 2-7

2.4 Picking Up and Separating an

Original .................................... 2-10

2.4.1 Basic Pickup Operation ..... 2-10

2.4.2 Separation/Pickup

Mechanism ........................ 2-13

2.4.3 Sequence of Pickup

Operation ........................... 2-19

2.4.4 Pickup Unit and the Stopper 2-1 9

2.4.5 Controlling the Feed Motor

(M1) ................................... 2-20

3 Jams .................................................. 2-21

3.1 Outline ..................................... 2-21

3.2 Jam/Error Report ...................... 2-21

3.2.1 Generating a Jam/Error

Report ................................ 2-21

3.2.2 List of Jam Codes .............. 2-22

4 Power Supply.................................... 2-23

iv

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

Page 7

CHAPTER 3 MECHANICAL SYSTEMS

CONTENTS

1 Basic Construction.............................. 3-1

1.1 External Covers.......................... 3-1

1.1.1 Removing the Front Cover .. 3-2

1.1.2 Removing the Rear Cover ... 3-2

1.1.3 Removing the Feeder Cover 3-2

2 Pickup System .................................... 3-3

2.1 Separation Roller Unit ............... 3-3

2.1.1 Removing the Separation

Roller Unit ........................... 3-3

2.1.2 Mounting the Separation

Roller Unit ........................... 3-4

2.2 Separation Pad ........................... 3-5

2.2.1 Removing the Pre-Separation

Pad/Separation Pad .............. 3-5

3 Drive System....................................... 3-6

3.1 Feeder Motor .............................. 3-6

3.1.1 Removing the Feeder Motor 3-6

3.2 Drive System .............................. 3-7

3.2.1 Removing the Feeder Unit...3-7

3.2.2 Removing the Clutch ........... 3-9

3.2.3 Disassembling the Feeder

Drive Assembly ................. 3-11

3.2.4 Removing the Platen

Roller ................................. 3-12

3.2.5 Removing the Feeder

Roller ................................. 3-13

3.2.6 Remove the Feeder

Roller 2 .............................. 3-15

3.2.7 Removing the Pull-Off

Roller .................................3-16

3.2.8 Adjusting the Platen

Guide L ............................. 3-17

4 Electrical Systems............................. 3-18

4.1 ADF Driver PCB...................... 3-18

4.1.1 Removing the ADF Driver

PCB.................................... 3-18

4.2 Sensors in the Feeder Unit....... 3-18

4.2.1 Removing the Sensor Unit. 3-18

4.2.2 Removing the Sensors ....... 3-19

4.3 Sensors in the Original Pickup

Tray .......................................... 3-19

4.3.1 Removing the Original Width

Sensor ................................ 3-19

4.3.2 Mounting the Slide Guide

Gear Plate .......................... 3-20

CHAPTER 4 MAINTENANCE AND INSPECTION

1 Periodically Replaced Parts ................ 4-1

2 Durables and Consumables ................ 4-1

3 Scheduled Servicing Chart ................. 4-1

4 Replacement ....................................... 4-2

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

4.1 Replacing the Feed Roller Guide

(dust-collecting tape) ................. 4-2

4.2 Replacing the Stamp .................. 4-2

v

Page 8

CONTENTS

CHAPTER 5 TROUBLESHOOTING

1 Standards and Adjustments.................5-1

1.1 Basic Adjustments...................... 5-1

1.1.1 Adjusting the Height............ 5-1

1.1.2 Adjusting the Right Angle ... 5-2

1.1.3 Adjusting the Read

Position ................................ 5-5

1.1.4 Adjusting the Ratio

Mechanism .......................... 5-6

1.1.5 Adjusting the Horizontal

Registration..........................5-7

1.1.6 Adjusting the Leading Edge

Registration........................5-10

2 Troubleshooting Malfunctions .......... 5-12

2.1 Troubleshooting Malfunctions . . 5-12

APPENDIX

2.1.1 Pickup Fault ....................... 5-12

2.1.2 The output has black lines in

sub scanning direction ....... 5-12

2.1.3 The output has blurred

images ............................... 5-14

2.1.4 The output is out of focus or

has black fogging............... 5-14

3 Arrangement of Electrical

Components ..................................... 5-15

3.1 Sensors ..................................... 5-15

3.2 Motors, Clutches, Solenoids,

PCBs, and Others ..................... 5-16

4 Self Diagnosis ................................... 5-17

4.1 Outline ..................................... 5-17

1 General Timing Charts....................... A-1

1.1 Flow-Scanning a Single-sided A4

Document .................................. A-1

2 Signal Name/Designation List ........... A-3

3 General Block Diagram ..................... A-5

4 ADF Controller Block Diagram ........ A-6

5 Jam Code List .................................... A-7

6 Special Tools List............................... A-8

7 Solvent/Grease List............................ A-8

vi

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

Page 9

CHAPTER 1

GENERAL DESCRIPTION

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

Page 10

Page 11

CHAPTER 1 GENERAL DESCRIPTION

1 Features

a.Exclusive Use for Stream Reading

The machine is designed for reading all originals in stream reading mode.

b.Control by the Host Machine

The machine is not equipped with a controller PCB, and is directly controlled by its host

machine.

c.Original Size Detection

The machine is able to identify the size of originals based on length (feed direction) and

width for communication to its host machine.

d.Extra-Length Mode

When extra length mode is selected, the machine will read an original as long as 1000

mm in length.

e.Mixed Original Sizes (of the same width)

The machine accepts 2 different sizes of originals*.

* Must not be of different configurations.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

1-1

Page 12

CHAPTER 1 GENERAL DESCRIPTION

2 Specifications

2.1 Specifications

Item

Method of original

pickup

Orientation of original

Placement of original

Method of original

separation

Type of original

Size of original

Original tray

Delivery assembly

Original handling

Identification of original size

Detection of residual

original

Originals of mixed sizes

Communication with

host machine

Power supply

Weight

Dimensions

Serial number

Operating environment

Temperature

Humidity

Specifications

Auto pickup/delivery

Original tray: Face-up

Original tray: Center reference

Top separation

Single-sided original:

Continuous feeding (52 to 105 g/m

Single feeding (38 to 128 g/m

Book Original:

40 mm/1.57 in height

AB: B6/A5/B5/A4/A5R/B5R/A4R/

B4/A3

Inch: STMT/LTR/LTRR/LGL/11"x 17"

Width: 148 mm/5.83 in (A5R) to 297 mm/11.7

in (A3)

Length:128 mm/5.04 in (STMT) to 432 mm/17

in (11" x 17")

50 sheets (small size)

25 sheets (large size)

50 sheets

Single-sided original

Yes (default size only)

Yes (in association with host machine)

Yes (if of same configuration)

Directly controlled by host machine

24 VDC, 5 VDC; from host machine

7.1 kg/15.6 lb (approx.)

592 x 484 x 22 mm/23.3 x 19.1 x 0.87 in (W x

D x H)

A-configuration: XGKxxxxx

Inch/A-configuration: XGJxxxxx

AB-configuration: XGHxxxxx

AB-configuration: XGLxxxxx

Same as host machine

Same as host machine

2

)

2

)

Remarks

If 432 mm/17.0 in or

2

2

or less.

2

or less.

2

or less.

.

longer, 60 to 90 g/m

In extra-length mode, as

long as 1000 mm/39.4 in.

Paper of 80 g/m

Paper of 80 g/m

Paper of 80 g/m

1-2

COPYRIGHT

©

T01-201-01

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 13

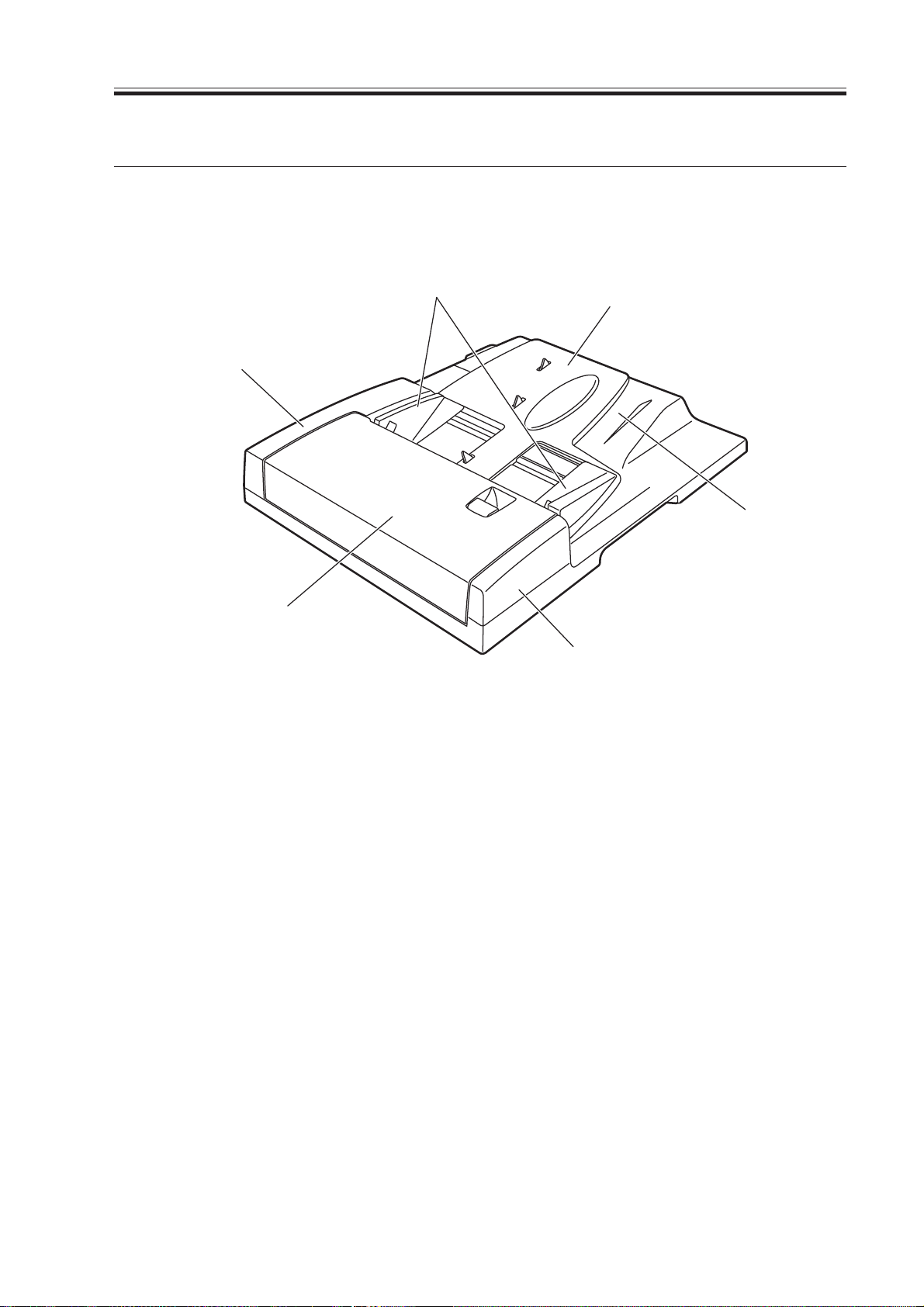

3 Names of Components

3.1 External View

CHAPTER 1 GENERAL DESCRIPTION

[2]

[1]

[3]

F01-301-01

[4]

[6]

[5]

[1] Feeder cover

[2] Rear cover

[3] Slide guide

[4] Original pickup tray

[5] Front cover

[6] Original delivery assembly

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

1-3

Page 14

CHAPTER 1 GENERAL DESCRIPTION

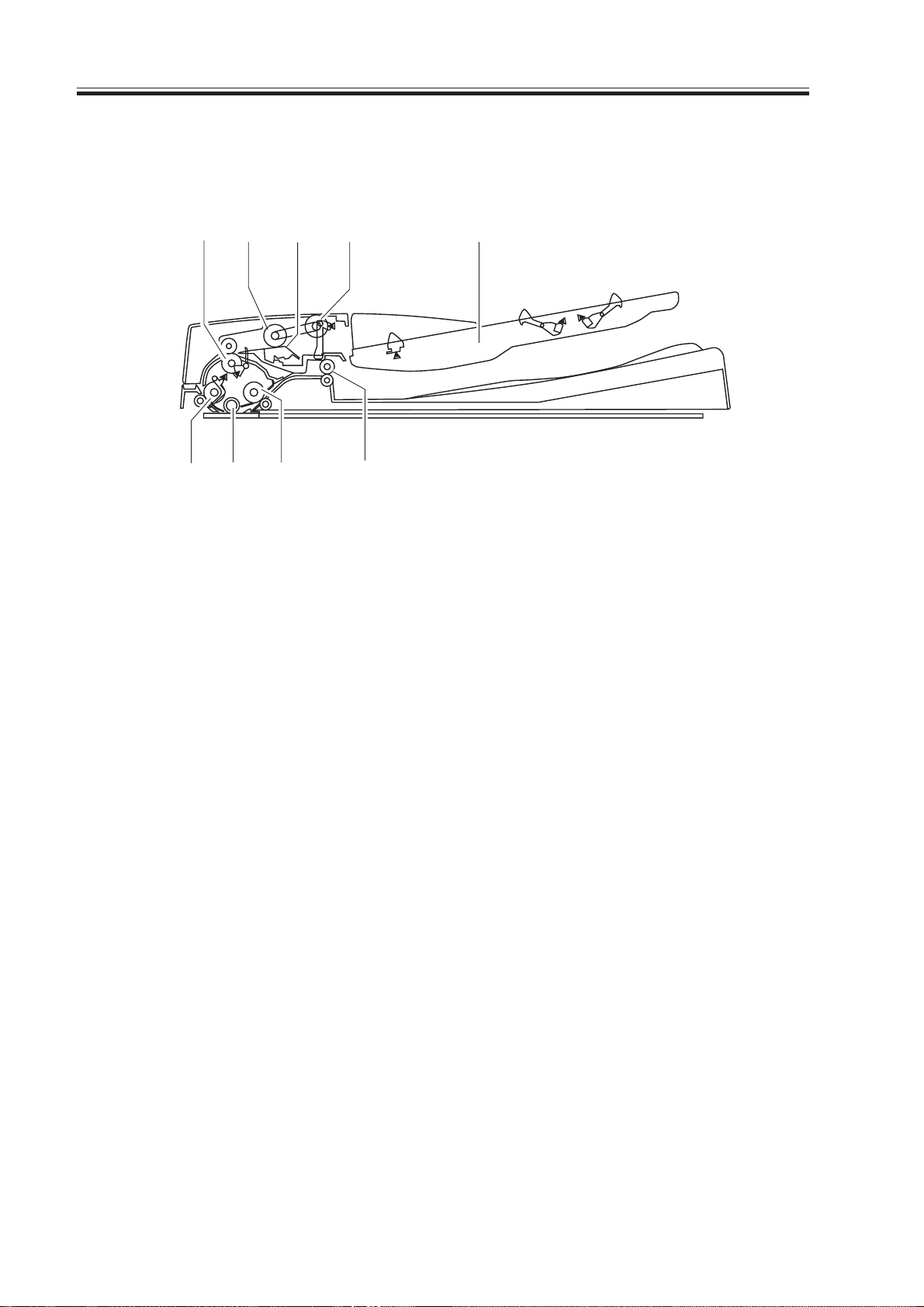

3.2 Cross Section

[1] [5]

[2]

[8] [7][9]

[3]

[4]

[6]

F01-302-01

[1] Pull-off roller

[2] Separation roller

[3] Separation pad

[4] Pickup roller

[5] Original pickup tray

[6] Delivery roller

[7] Feeding roller 2

[8] Platen roller

[9] Feeding roller 1

1-4

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 15

CHAPTER 1 GENERAL DESCRIPTION

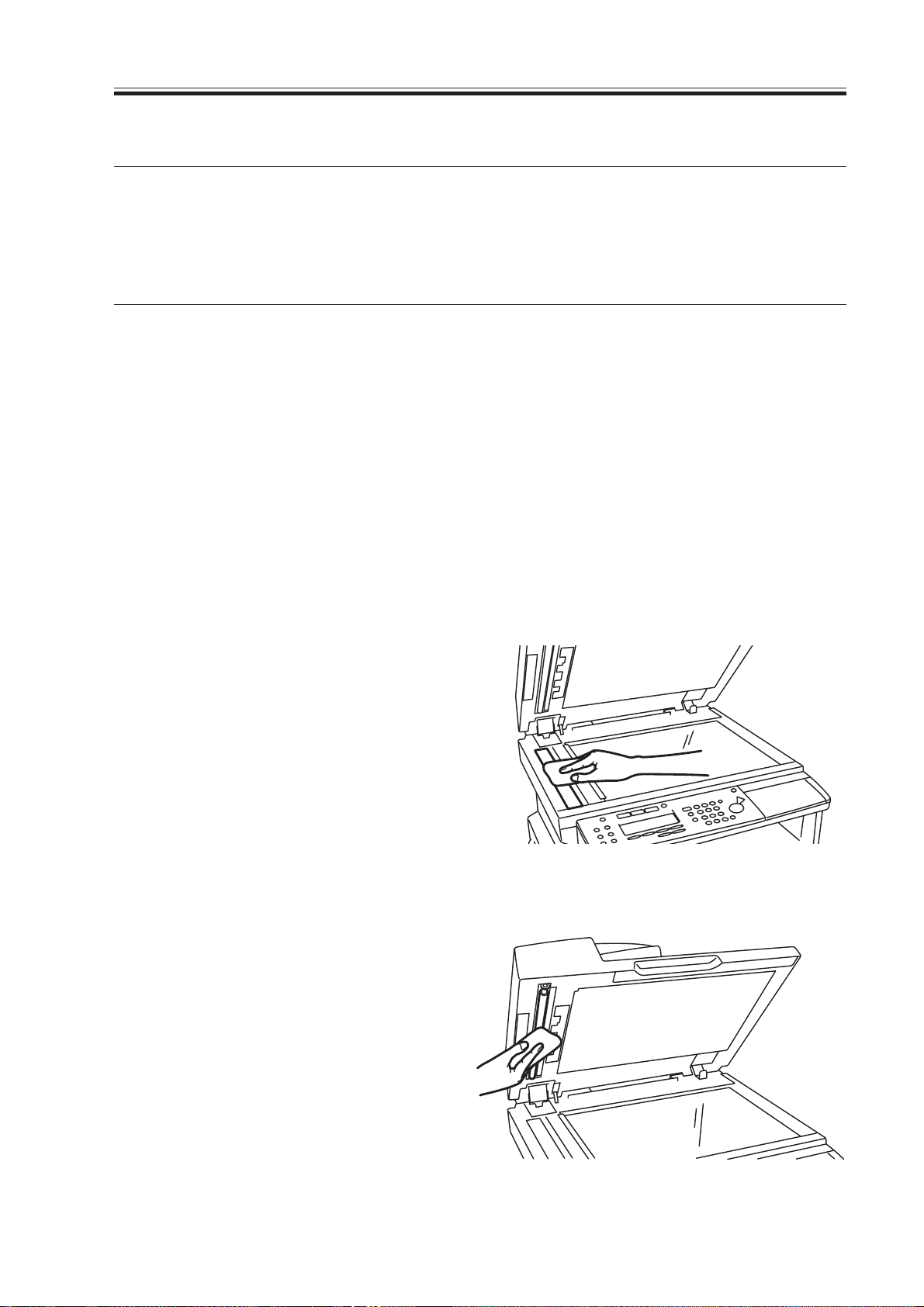

4.Using the Machine

4.1 Routine Maintenance by the User

Instruct the user to clean the following component about once a month:

Component

Copyboard glass

Copyboard glass retainer

Vertical size plate

Platen roller

White plate (copyboard

cover)

Wipe with a cloth moistened with water or alcohol; then, dry wipe.

Description

T01-401-01

To clean, go through the following:

1) Clean the copyboard glass, copyboard

glass retainer, and vertical size plate

with a cloth moistened with water; then,

dry wipe them with a dry, soft cloth.

Remarks

• Parts of the reader assembly.

• Parts of the reader assembly.

• Parts of the reader assembly.

2) Wipe the platen roller and the

copyboard cover with a cloth moistened

with water; then dry wipe them with a

dry, soft cloth.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

F01-401-01

F01-401-02

1-5

Page 16

Page 17

CHAPTER 2

OUTLINE OF OPERATION

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

Page 18

Page 19

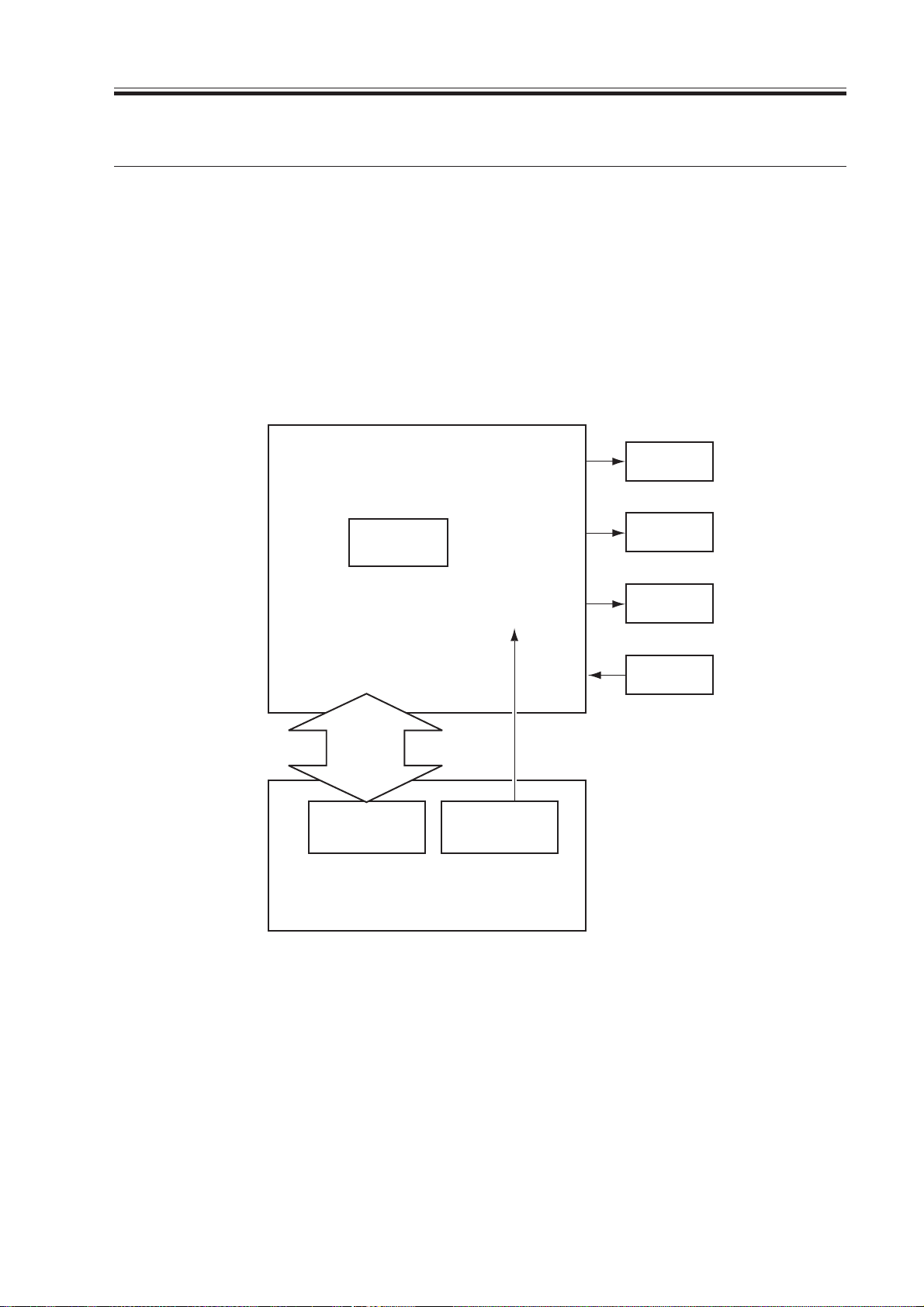

CHAPTER 2 OUTLINE OF OPERATION

1 Basic Constr uction

1.1 Outline of the Electrical Circuitry

The machine is not equipped with a controller PCB; it, however, has a driver PCB. Its

electrical mechanisms are controlled by the controller PCB of its host machine (CPU identified as IC1).

The CPU of the host machine interprets the input signals from sensors, and sends signals

to the machine’s driver PCB to drive the loads (motor, clutch, solenoid) at such times as programmed in advance.

ADF Driver PCB

Motor

J1

Sensor

drive

signal

Controller

PCB

Driver IC

(IC1)

Power supply

Host machine

Clutch

Solenoid

+24V

Sensor

J2-1,2

PCB

COPYRIGHT

©

F02-101-01

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-1

Page 20

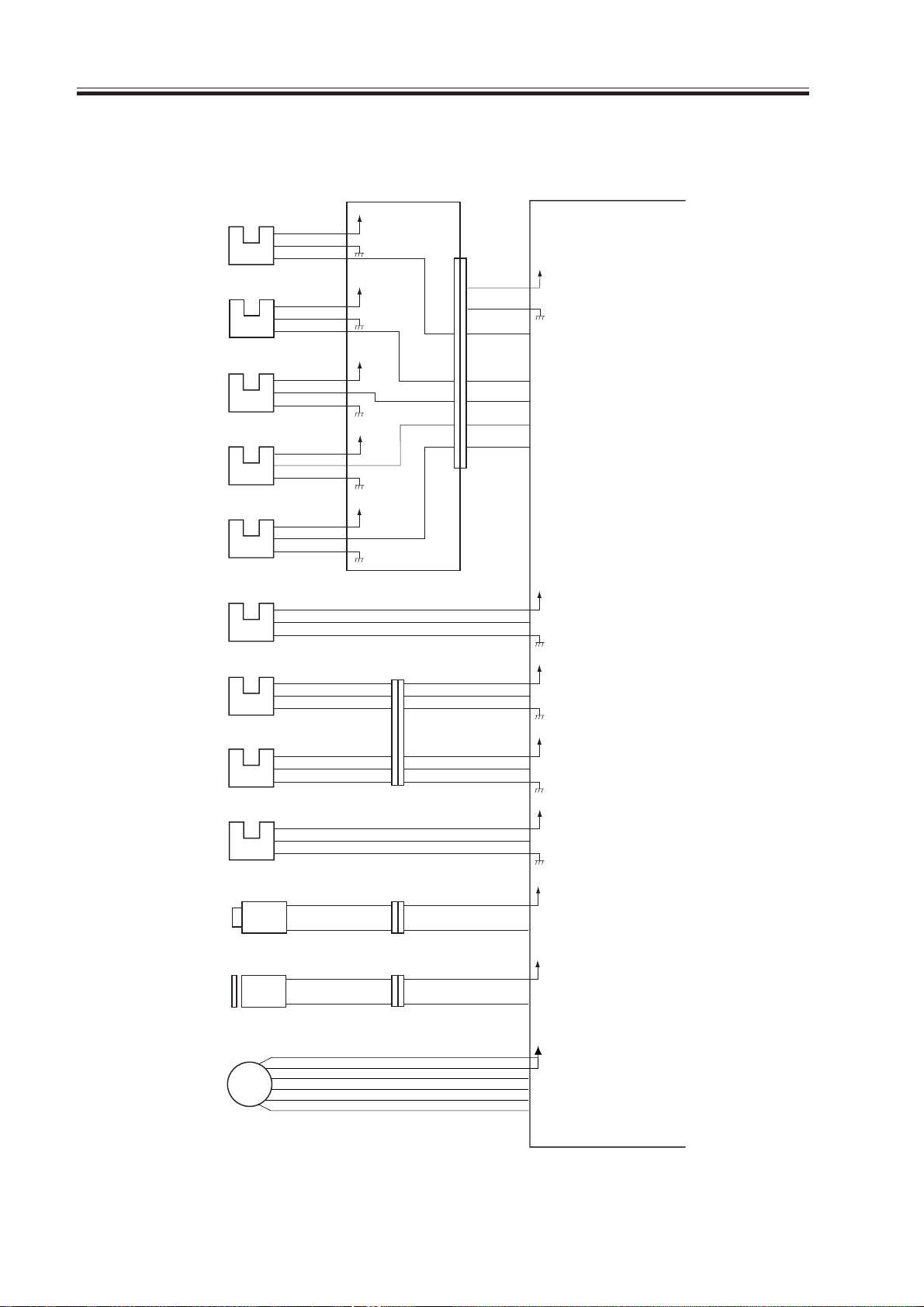

CHAPTER 2 OUTLINE OF OPERATION

1.2 Inputs to and Outputs from the ADF Drive PCB

Inputs to and Outputs from the ADF Driver

Last original

detection sensor

Length sensor 1

Length sensor 2

Original width

sensor 1

Original width

sensor 2

Original

placement sensor

PI1

PI2

PI3

PI4

PI5

PI6

J21-3

J22-3

J23-3

J24-3

J25-3

J26-3

-2

-1

-2

-1

-1

-2

-1

-2

-1

-2

-1

-2

J102-1

-10

-12

-11

-13

-15

-14

+3.3VE

+3.3VE

+3.3VE

+3.3VE

+3.3VE

Relay PCB

J101

-7

-6

-5

-4

-3

-2

-1

J3-1

J6-1

-2

-3

-4

-5

-6

-7

-9

-8

J5-1

-2

-3

-2

-3

-4

-3

-2

LENG1

LENG2

LENG3

WID1

WID2

SET

ADF driver PCB

+3.3VE

When paper is present, '1'.

When paper is present, '1'.

When paper is present, '1'.

Detects paper width.

Detects paper width.

+3.3VS

When paper is present, '0'.

Registration sensor

Read sensor

Cover open/closed

sensor

Stamp solenoid

Pickup clutch

Feeder motor

PI7

PI8

PI9

M1

SL1

CL1

J27-3

J28-3

J31-3

-10

-12

-11

J7-1

J8-1

J4-1

-4

-6

-5

-7

-9

-8

-2

-2

-2

-3

-4

-5

-6

+3.3VE

REG

+3.3VE

READ

+3.3VE

DFCVS

+24V

STAMP_SL

+24V

CL

+24V

MOTA

MOTA*

MOTB

MOTB*

When paper is present, '1'.

When paper is present, '1'.

When the ADF cover is opened, '1'.

When '0', SL1 goes ON.

When '0', CL1 goes ON.

For details, see p. 2-20.

J30

-2

-1

-2

-1

-2

-1

-2

-1

-3

-2

-4

-6

-5

-1

-2

-1

-2

-3

J13

J201

-4

-1

-3

-1

-2

-2

-1

-3

-2

-1

2-2

COPYRIGHT

©

F02-102-01

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 21

CHAPTER 2 OUTLINE OF OPERATION

2.Basic Operations

2.1 Outline

The machine is designed exclusively for stream reading.

The machine uses a single motor to pick up and move originals.

Name (Notation)

Feeder motor (M1)

Moves originals.

T02-201-01

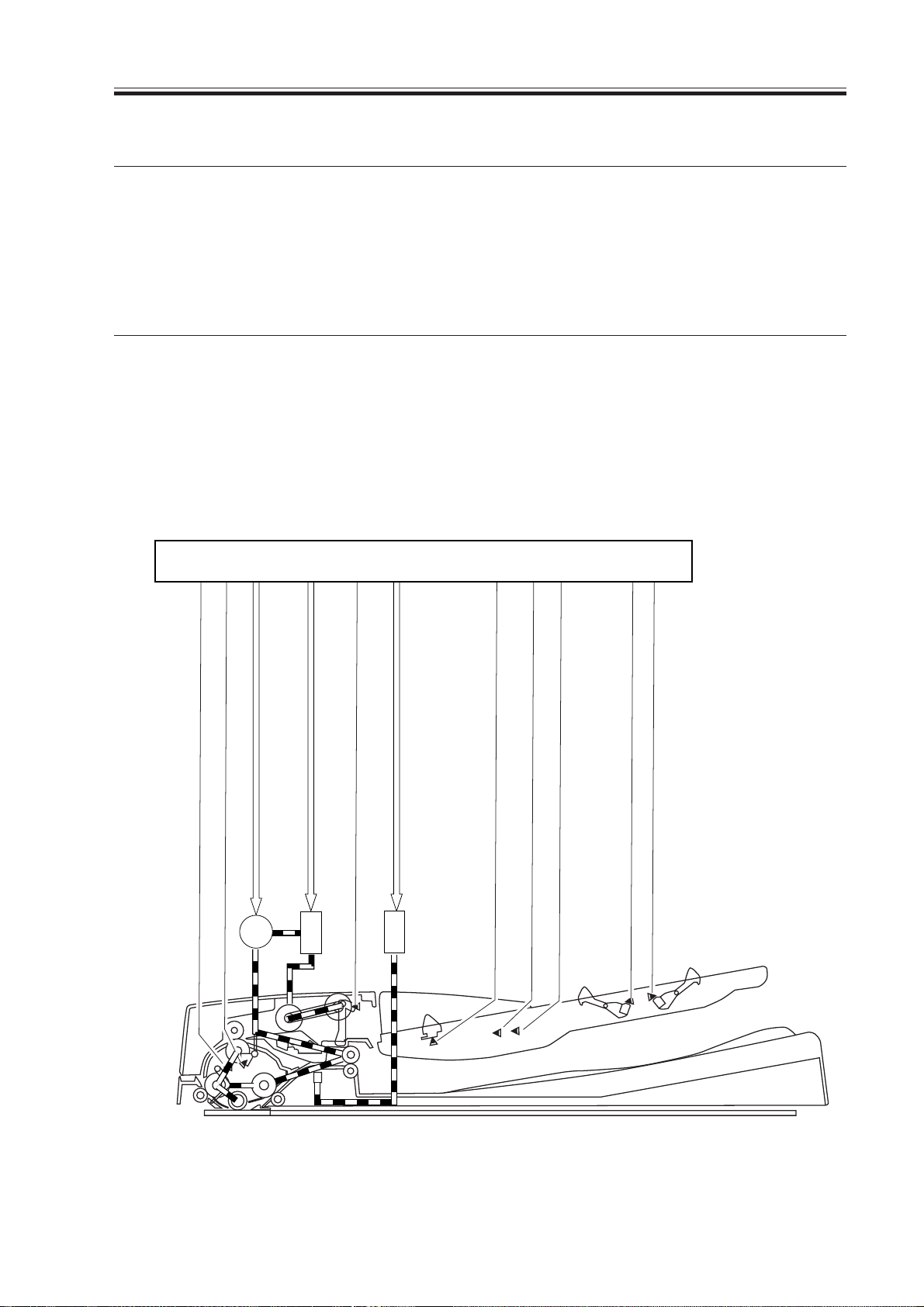

The following is a drive diagram of the machine:

ADF driver PCB

Function

PI8

COPYRIGHT

©

CL1

Original placement signal (SET) J5-3

PI6

Stamp solenoid drive signal (STP_SL) J7-2

SL1

Last original detection signal (LENG1) J3-3

PI1

Original width detection signal 2 (WID2) J6-4

PI5

Original width detection signal 1 (WID1) J6-3

PI4

Original detection signal (READ) J5-9

Original detection signal (REG) J5-6

PI7

Feed motor drive signal (FMOT) J4

M1

Pickup clutch drive signal (CL) J8-2

F02-201-01

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Original length detection signal 1 (LENG2) J6-1

PI2

Original length detection signal 2 (LENG3) J6-2

PI3

2-3

Page 22

CHAPTER 2 OUTLINE OF OPERATION

2.2 Sequence of Operation

2.2.1 Outline

The machine does not possess a reversing mechanism, and picks up and delivers originals

as they are.

2.2.2 Picking Up and Delivering Originals

(Single-sided original → Single-sided pr int)

The machine moves the original as follows:

Original

Separation

Pickup

Reading

Delivery

2-4

Read timing detection

F02-202-01

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 23

CHAPTER 2 OUTLINE OF OPERATION

2.3 Detecting Originals

2.3.1 Outline

The machine possesses the following 3 original detection mechanisms:

Item

Original detection

Last original detection

Initial original size

detection

• Feed direction

• Width direction

Description

Detects the presence/absence of an original in the original pickup tray .

Determines whether the original being

fed is a last original.

Detects the length of the original placed

in the original pickup tray .

• Identification between small size and

large size

Detects the width of the original placed

in the original pickup tray .

T02-203-01

Sensor used (Notation)

Original placement sensor (PI6)

Last original sensor (PI1)

Registration sensor (PI7)

Length sensor 1/2 (PI1/PI2)

Original width sensor 1/2 (PI4/

PI5)

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-5

Page 24

CHAPTER 2 OUTLINE OF OPERATION

2.3.2 Detecting the Presence/Absence of an Original

The presence/absence of an original in the original tray is detected by the original placement sensor (PI6). The detecting lever operates in conjunction with the light-blocking plate.

When an original is placed in the original tray, the light from the photointerrupter is

blocked, thereby causing the original placement sensor (PI6) to generate the original placement signal (SET).

ADF driver PCB

SET

PI6

Original

F02-203-01

2.3.3 Detecting the Last Original

The last original sensor (PI1) and the registration sensor (PI7) are used to find out

whether or not the original being picked is the last original.

When the last original has been picked up and its trailing edge moves past the last original

detecting lever, the detecting lever blocks the light of the photointerrupter while operating in

association with the light-blocking plate. At this time, if the leading edge of the original is as

far as the registration sensor (PI7), the last original sensor (PI1) generates the last original

detection signal (LENG1) to communicate to the host machine that the original in question

is the last from the stack in the original tray.

2-6

PI7

COPYRIGHT

©

ADF driver PCB

LENG1

PI1

F02-203-02

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 25

CHAPTER 2 OUTLINE OF OPERATION

2.3.4 Detecting the Size of an Original

a.Detecting the Length in Feed Direction

The length of an original in feed direction is detect by the length sensor 1 (PI1) and the

length sensor 2 (PI2). When an original is placed in the original tray, the detecting levers of

these 2 length sensors operate in conjunction with the light-blocking plate to block the light

of the photointerrupter.

In mixed original size mode, however the length is detected based on the number of lines

read by the scanner connected to it.

ADF driver PCB

Original

LENG3

LENG2

F02-203-03

PI2

Detecting lever

PI3

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-7

Page 26

CHAPTER 2 OUTLINE OF OPERATION

b.Detecting the Width

The width of an original is detected using the width sensor 1 (PI4) and the width sensor 2

(PI5) found in the original tray in relation to the slide guide, whose movement will block or

unblock the light of the photointerrupter.

ADF driver PCB

PI5

WID2

WID1

F02-203-04

PI4

2-8

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 27

CHAPTER 2 OUTLINE OF OPERATION

T02-203-02 shows the relationship between the length sensor signals and the sizes or

originals.

AB-Configured Paper

Width sensor 1 (PI4) Width sensor 2 (PI5) Length sensor 1 (PI2) AB-configuration

1 0 0 A5R

1 0 1 B5R

00 0A5

0 0 1 A4R

01 0B5

0 1 1 B4R

11 0A4

1 1 1 A3R

Inch-Configured Paper

Width sensor 1 (PI4) Width sensor 2 (PI5) Length sensor 2 (PI3) Inch-configuration

1 0 0 LTRR

1 0 1 LGL

00 0LTR

0 0 1 11”x17”

T02-203-02

PI5

PI4

PI3

PI2

COPYRIGHT

©

F02-203-05

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-9

Page 28

CHAPTER 2 OUTLINE OF OPERATION

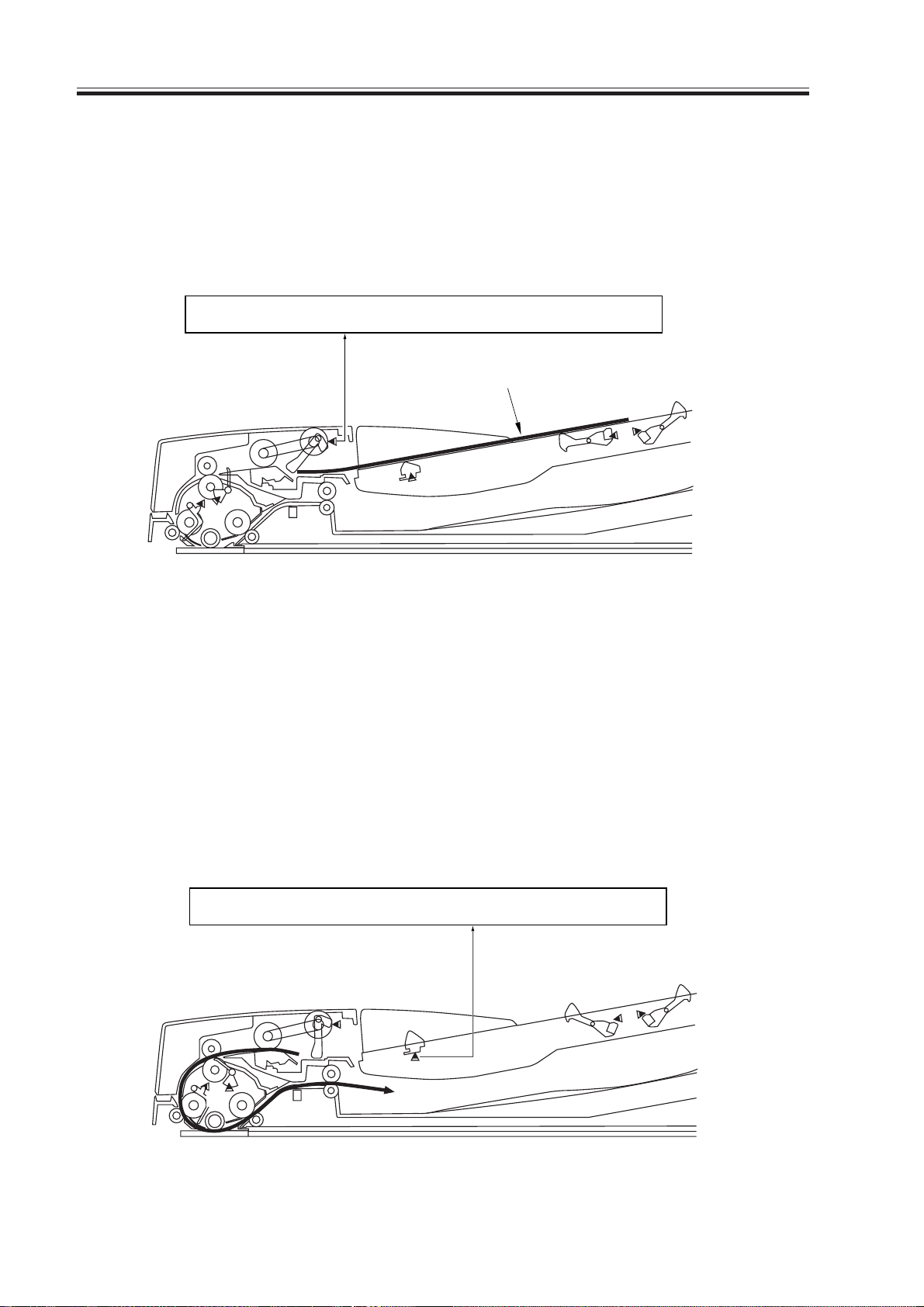

2.4 Picking Up and Separating an Original

2.4.1 Basic Pickup Operation

When an original is placed in the original tray and the Start key is pressed, the machine

will go through the following sequence:

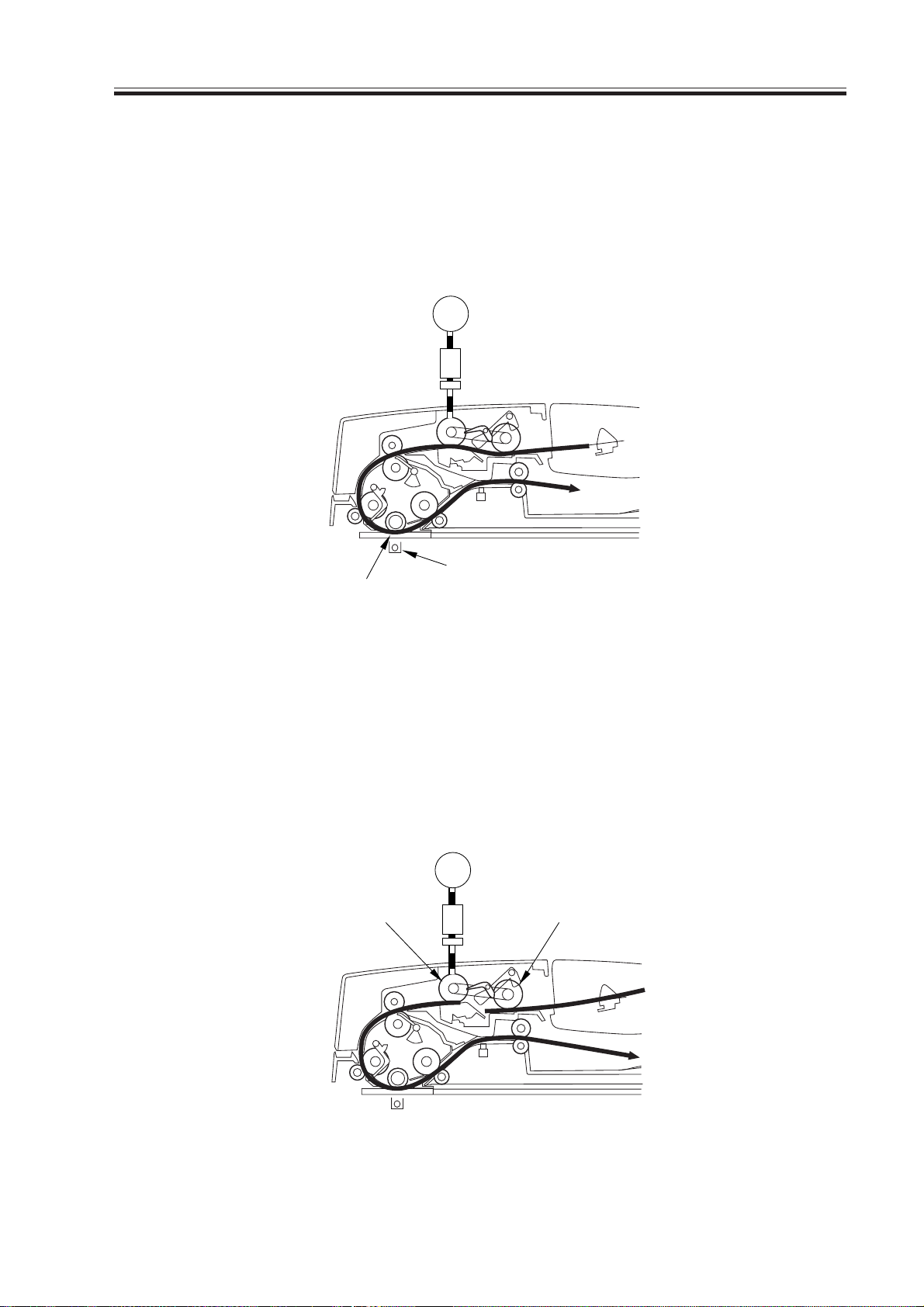

a.Pickup

When the electromagnetic clutch goes ON and the feed motor (M1) rotates clockwise, the

pickup roller moves down, and the separation roller and the pickup roller start to rotate to

pick up an original; then, the stopper moves up in conduction.

The pre-separation pad and the separation pad serve to prevent double feeding of originals.

M1

CL1

Pre-separation pad

Stopper

M1

Pickup roller

CL1

Original

Separation pad

F02-204-01

b.Feeding

The rollers found beyond the pull-off roller rotate at a speed about 50% higher than the

separation roller. When the original reaches the pull-off roller, its movement grows faster,

thereby causing the pickup roller and the separation roller to rotate in conjunction.

2-10

Pull-off roller

COPYRIGHT

©

M1

CL1

F02-204-02

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 29

CHAPTER 2 OUTLINE OF OPERATION

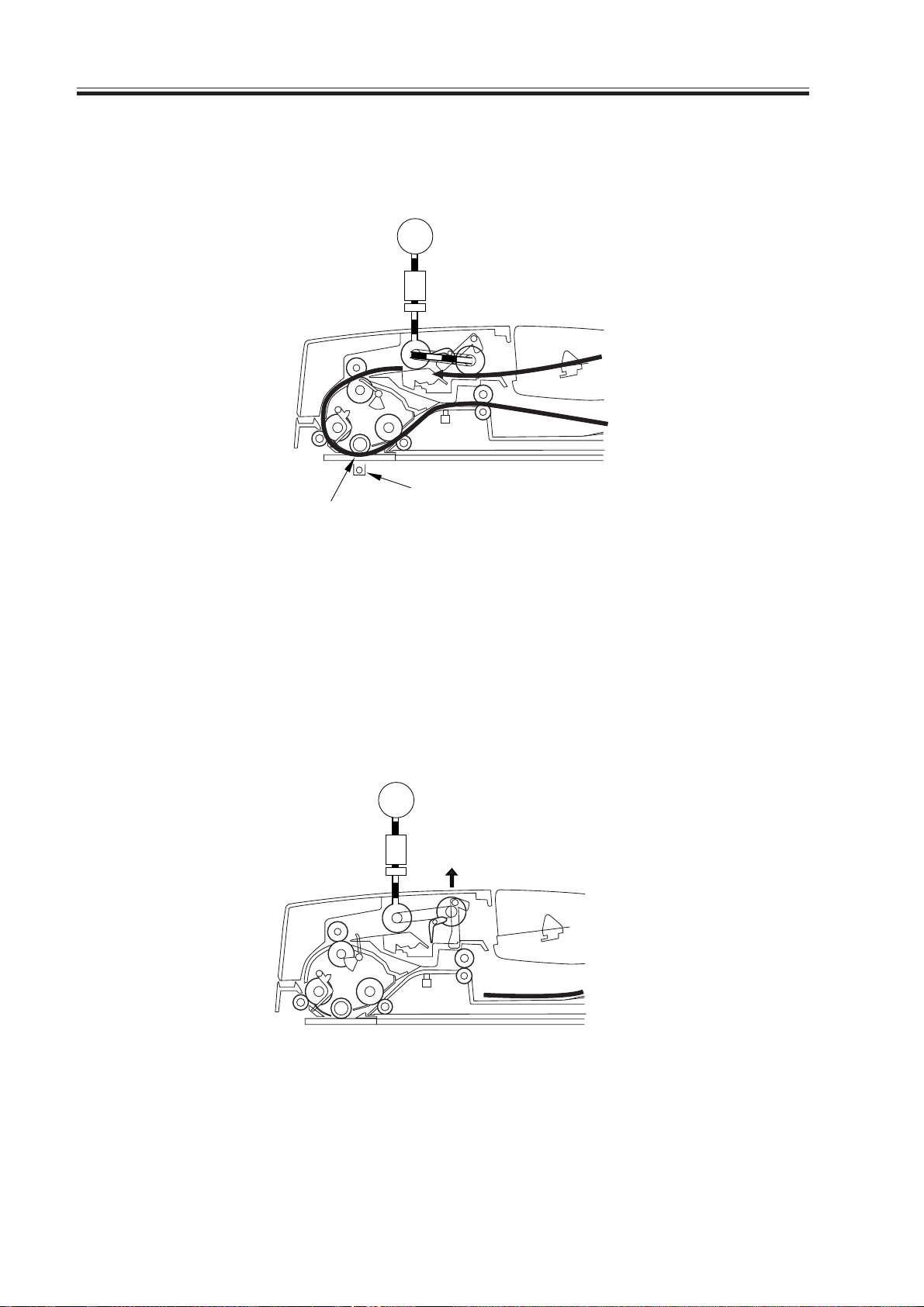

c.Stream Reading and Delivery

When the leading edge of the original reaches read wait position, the machine sends the

image leading edge signal to its host machine to start stream reading; thereafter, the delivery

roller operates to delivery the original.

In stream reading, the host machine’s scanner is fixed in place, and the original is moved

over the scanner glass for scanning.

M1

CL1

Scanning lamp

Read glass

F02-204-03

d.End of Pickup for the 1st Original

When the trailing edge of the original moves past the pickup roller, the pickup roller will

come into contact with the 2nd original. However, since the separation roller is pulled by the

1st original at a higher speed than its drive shaft, the spring clutch mounted to the shaft

slips, transmitting the drive and preventing the rotation of the pickup roller and, as a result,

not picking up the 2nd original.

M1

Rating

CL1

At reset

COPYRIGHT

©

F02-204-04

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-11

Page 30

CHAPTER 2 OUTLINE OF OPERATION

e.Picking Up the 2nd Original

When the trailing edge of the original leaves the separation roller, the spring clutch trans-

mits the drive, causing the pickup roller to rotate to pick up the 2nd original.

M1

CL1

Scanning lamp

Read glass

F02-204-05

f. Returning the Pickup Roller to Standby Position

When the last original moves past the original sensor and a specific period of time passes

thereafter, the electromagnetic clutch goes OFF and the feed motor stops.

When the electromagnetic clutch goes ON and the feed motor starts to rotate in reverse,

the pickup roller is returned to standby position, at the end of which the feeder motor and

the electromagnetic clutch goes OFF.

M1

CL1

2-12

COPYRIGHT

©

F02-204-06

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 31

CHAPTER 2 OUTLINE OF OPERATION

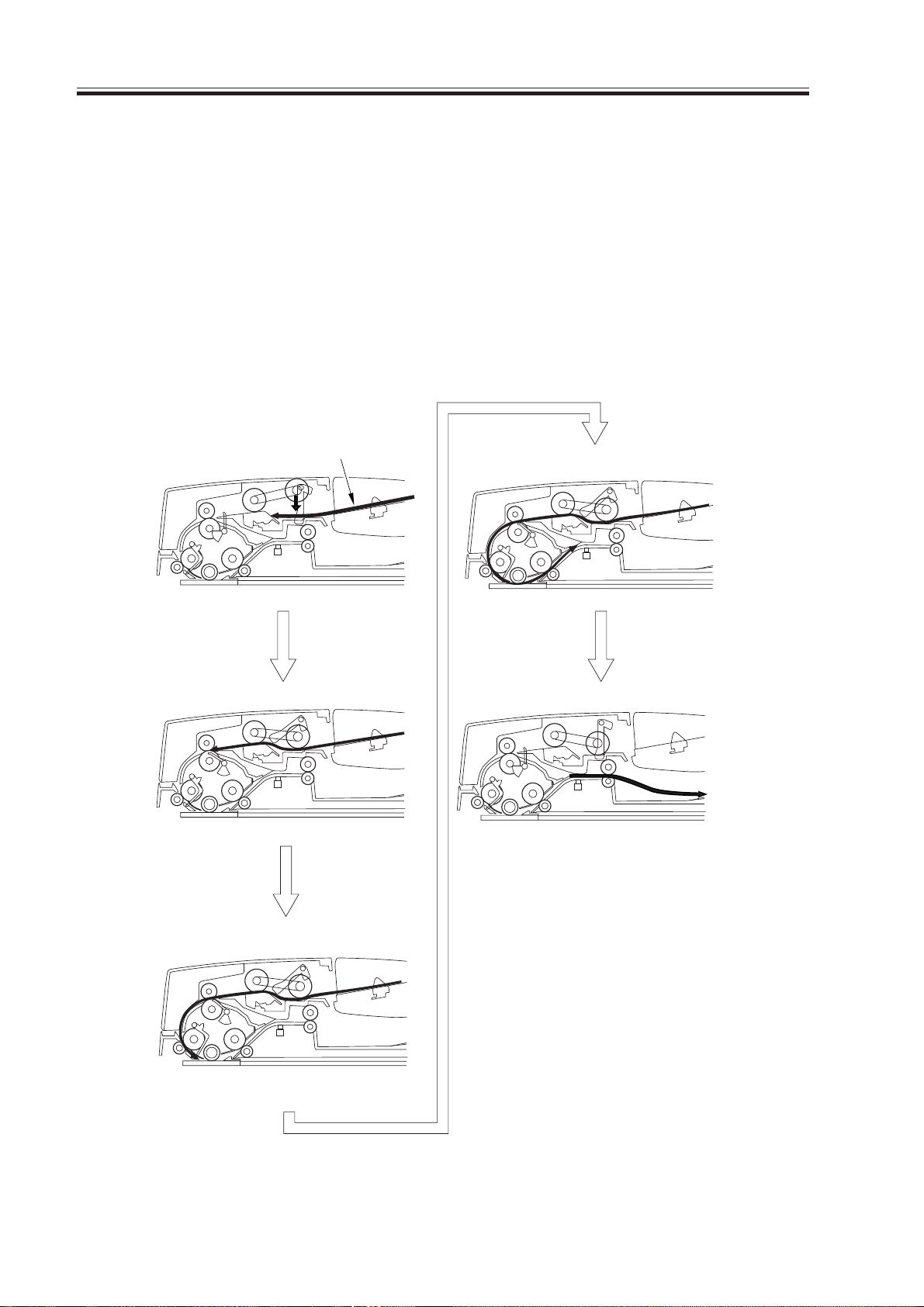

2.4.2 Separation/Pickup Mechanism

The machine uses a single stepping motor to pick up, separate, and move originals. Its

pickup assembly is equipped with 6 spring clutches which operate in various ways in relation to the direction of motor rotation as follows; the arrows in the diagrams indicates the

direction of rotation.

Down

Up

F02-204-07

a.SPCL 1 (preventing the pickup roller from moving down)

In standby, the pickup roller must be kept in up position. While the pickup roller remain

in up position, its own weight tries to force the clutch shaft to rotate clockwise; this, however, is prevented by the tightening of SPCL1, which makes a connection to the serials of

gears linked to the motor.

The drive occurring as a result of clockwise/counterclockwise rotation of the motor is

transmitted to the shaft when the clutch goes ON, and the operation of the clutch is irrelevant.

SPCL1

Pickup roller prevent down

COPYRIGHT

©

Down

Pickup roller

F02-204-08

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-13

Page 32

CHAPTER 2 OUTLINE OF OPERATION

b.CPCL2 (separation roller/pickup roller drive; ascent/decent movement and upper

limit of pickup roller)

Motor in Clockwise Rotation

As the spring clutch contracts, the pickup roller and the separation roller are driven; as a

result, the pickup roller is moved down to rotate.

Motor Rotating in Reverse

The pickup roller is moved up, and is held in “escape” position. If the pickup roller comes

into contact with the feeder cover, the spring clutch loosens to serve as a limiter, thereby

preventing damage.

SPCL2

Seperation roller/pickup roller drive,

Seperation roller

UP/DOWN, upper limiter

Pickup roller

Down

Up

F02-204-09

2-14

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 33

CHAPTER 2 OUTLINE OF OPERATION

c.Coupling

The drive from the motor is transmitted by means of a coupling, from which it may reach

the pickup roller drive shaft through SPCL3 or reach the sepapation roller and pickup roller

through SPCL4.

SPCL4

SPCL3

Pickup roller UP

Pickup roller drive shaft

Coupling

Pickup roller DOWN

seperation roller/pickup roller drive

Separation roller

Coupling

Up

Pickup roller

F02-204-10

d.SPCL3 (pickup roller ascent/movement)

Motor in Clockwise Rotation

As the spring clutch expands, the drive shaft on the separation roller shaft stops to rotate;

SPCL4 is used to drive and to move down the pickup roller.

Motor Rotating in Reverse

The spring contracts to rotate the drive shaft on the separation roller shaft, and the drive is

carried through SPCL4 to move up the pickup roller.

Down

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-15

Page 34

CHAPTER 2 OUTLINE OF OPERATION

SPCL5

Up/Down; pressure limiter (on paper)

SPCL3

Pick roller UP

Up

F02-204-11

e.SPCL4 (pickup roller descent movement, separation roller/pic kup roller drive; one way)

Motor in Clockwise Rotation

As the spring contracts, the pickup roller is moved down; at the same time, the separation

roller and the pickup roller are driven in the direction of pickup. When paper is moved by

the pull-off roller, it picks up speed, pulling and causing the separation roller to rotate in response; at this time, the spring clutch expands so that the pickup roller drive shaft stops to

rotate, ultimately stopping the pickup roller.

Motor in Reverse Rotation

The spring clutch loosens to cut the drive.

SPCL4

Pickup roller DOWN

Separation roller

seperation roller/pickup roller drive (one-way)

2-16

COPYRIGHT

©

F02-204-12

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 35

CHAPTER 2 OUTLINE OF OPERATION

f. SPCL5 (pickup roller ascent/decent; pressure limiter)

Motor in Clockwise Rotatoiin

The pickup roller is moved down (in the direction that causes the spring to loosen) and is

forced against the paper. When the pickup roller comes into contact with the paper, the

spring clutch serves as a limit to keep the pressure against the paper at a specific level.

Motor in Reverse Rotation

The pickup roller is moved up (in the direction that causes the spring to tighten).

SPCL5

Pickup roller

Pickup roller

Down

Up

F02-204-13

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-17

Page 36

CHAPTER 2 OUTLINE OF OPERATION

g.SPCL6 (pickup roller drive; one-way)

Motor in Clockwise Rotation

The drive of the belt is transmitted to the pickup roller for rotation into pickup direction

(in the direction that causes the spring to tighten). When the paper is moved by the pull-off

roller, its speed increases, and the pickup roller is pulled by the paper to rotate in conjunction. At this time, the spring clutch loosens, and the drive to the belt is cut.

Motor in Reverse Rotation

The spring clutch loosens to cut the drive.

SPCL6

Pickup roller drive (one-way)

F02-204-14

2-18

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 37

2.4.3 Sequence of Pickup Operation

Start key ONOriginal set

CHAPTER 2 OUTLINE OF OPERATION

Feed motor (M1)

Pickup clutch (CL1)

Original placement

sensor (PI6)

Registration sensor

(PI7)

Read sensor (PI8)

Pickup roller

Separation roller

Other rollers

Original separated/

moved

: motor, roller in reverse.

Note 1: The speed increases when the paper is pulled by the pull-off roller.

1st original read 2nd original read Original delivered

Note 1 Note 1

F02-204-15

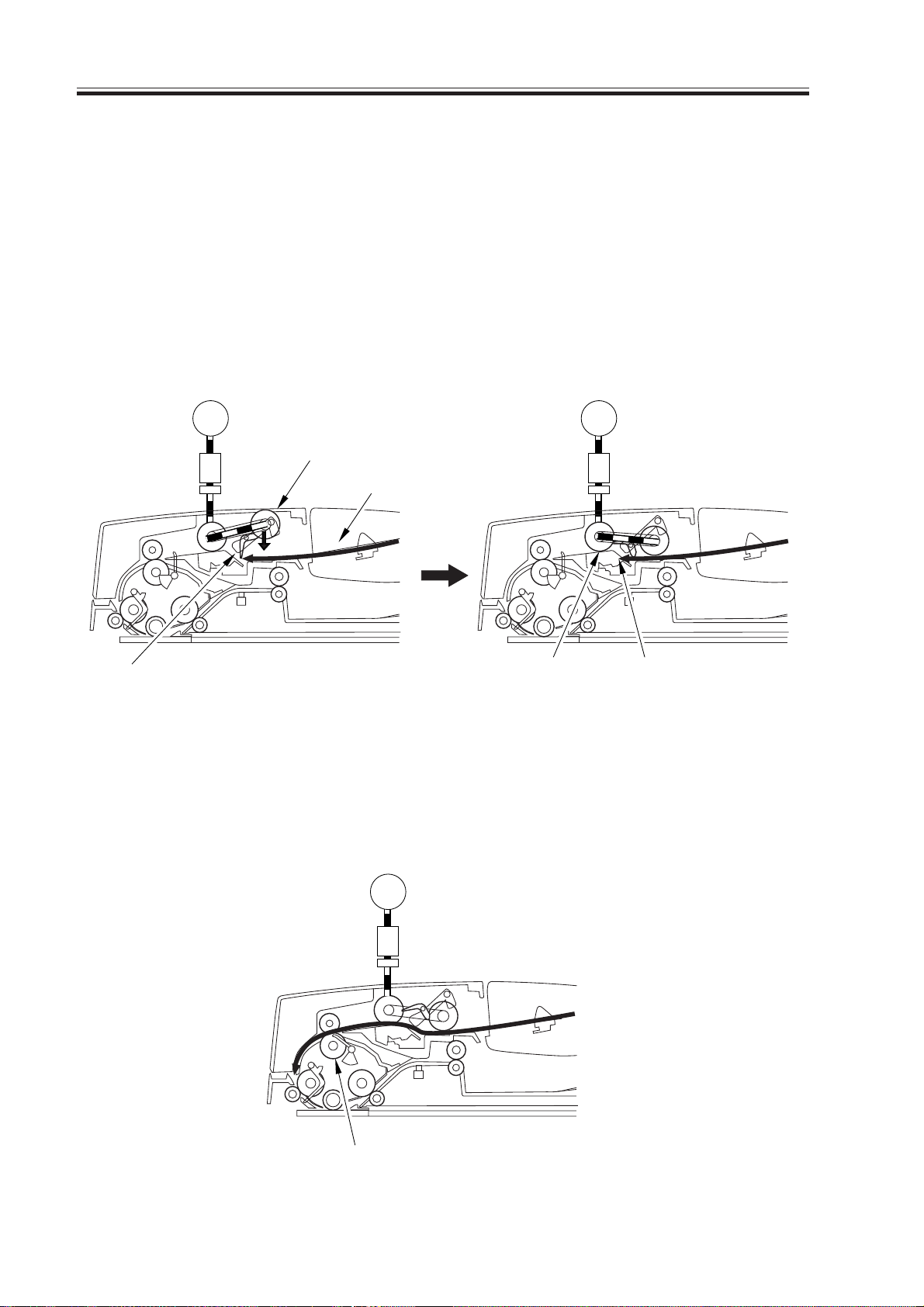

2.4.4 Pickup Unit and the Stopper

The pickup unit consists of a pickup roller and a separation roller. When the Start key is

pressed or the original pickup signal arrives, the feed motor (M1) rotates to move down the

pickup unit, and the pickup roller and the separation roller rotate to move the paper.

The stopper operates in conjunction with the pickup unit, and moves up. To prevent

double feeding at time of pickup, the separation pad and the separation plate are used to

make sure that sheets are separated.

M1

CL1

COPYRIGHT

©

F02-204-16

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-19

Page 38

CHAPTER 2 OUTLINE OF OPERATION

2.4.5 Controlling the Feed Motor (M1)

The following is a diagram of the circuit used to control the feed motor (M1). The pickup

motor is a 2-phase stepping motor, and the functions of the circuit include the following:

• turning on and off the motor.

• controlling the direction of motor operation.

• controlling the speed of motor rotation.

+24V

J4

3

1

4

5

2

6

M1

IC1

CPU

PHA

PHB

PHXA

PHXB

MAPWM

MBPWM

IC1

Motor

driver

MOT A

MOT A*

MOT B

MOT B*

Host machine

controller PCB

ADF drive PCB

F02-204-17

The motor driver (IC1) on the ADF driver PCB receives commands from the host ma-

chine, and sends drive pulses to the pick motor.

The feed motor is a stepping motor, and it controls the direction and speed of rotation by

changing the order in which the drive pulses (MOTA, MOTA*, MOTB, MOTB*) are sent

and the frequency.

Signal Description

PHA drive pulse A

PHB drive pulse B

PHXA drive pulse A (reverse phase)

PHXB drive pulse B (reverse phase)

MAPWM reference current level setting A

MBPWM reference current level setting B

2-20

COPYRIGHT

©

T02-204-1

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 39

CHAPTER 2 OUTLINE OF OPERATION

3 Jams

3.1 Outline

The machine uses the sensors shown in F02-302-01 to check for original jams at such

times as stored in the ROM on the controller PCB of the host machine. A jam is identified in

reference to the presence/absence of paper over a specific sensor.

The nature of a jam may be checked by generating a jam/error report in service mode.

3.2 Jam/Error Report

3.2.1 Generating a Jam/Error Report

1) Press the User mode key “ ” and then the “#” key in sequence in the control panel to

start service mode.

2) Select ‘REPORT’ using the Arrow key (right, bottommost) in the control panel of the

host machine, and press the OK key.

As a result, a jam/error report will be generated:

NN MM/DD HH : MM hh : mm P H JJJJ CCCCCC K SSSSS

NN Serial number

MM/DD month/day of occurrence MM for moth, DD for day

HH : MM time of occurrence HH for hour, MM for minute

hh : mm time of recovery hh for recovery hour , mm for reco very minute

P location general ‘4’ indicates ADF

(‘3’ indicates host, while ‘5’ indicates finisher)

H location detail ‘1’ indicates ADF

(‘0’ indicates host, while ‘2’ indicates finisher)

JJJJ jam code jam code by 4 digits

(see T02-302-01)

CCCCCC counter reading counter reading at occurrence

K source cassette, manual feeder

SSSSS paper size paper size

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-21

Page 40

CHAPTER 2 OUTLINE OF OPERATION

3.2.2 List of Jam Codes

The following is a list of jam codes, indicating types and related sensors.

Jam code

0001

0003

0004

0007

0009

000a

000b

0011

0012

0012

0016

Jam type

Pickup fault

Delay jam

Stationary jam

Sheet-to-sheet gap

jam

ADF open jam

Feeder cover open

jam

Stationary jam at

power-on

No paper (forced

out original)

Jam in response to

Stop key

Initialization jam

Others

Related sensor

PI7

PI7, PI8

PI7, PI8

PI8

ADF open sensor of

host machine

PI9

PI7, PI8

PI6

PI7, PI8

PI7, PI8

Condition of detection

At the start of pickup, the original does

not reach the registration sensor within a

specific period of time.

The original does not reach the sensor

within a specific period of time.

The original does not leave the sensor

within a specific period of time.

After an original is read, the next original reaches the sensor before a specific

period of time.

The ADF is opened while it is in operation.

The feeder cover is opened while the

ADF is in operation.

An original exists when the power is

tuned on.

The original set sensor is OFF at the

start of pickup.

The Stop key is pressed during operation, leaving the original inside the ADF.

The sensor detects an original at time of

initialization.

Others

2-22

PI9

PI7

PI8

COPYRIGHT

PI6

T02-302-01

F02-302-01

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 41

CHAPTER 2 OUTLINE OF OPERATION

4 Power Supply

The following is an outline diagram of the machine’s power supply system:

The machine is supplied by its host machine with 24 V, 5 V, and 3.3 V; 24 V is used for

the motor, clutches, and solenoids; 5 v is used to drive the motor driver: and 3.3 V is used

for sensor signals.

J2

24V

1

2

24V

• Clutch

• Solenoid

Host

machine

5V

3.3V

J1

J1

A4

B11

A2

B13

B14

Motor driver

IC1

ADF driver PCB

F02-401-01

24V

3.3V

• Motor

• Sensor

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

2-23

Page 42

Page 43

CHAPTER 3

MECHANICAL SYSTEMS

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

Page 44

Page 45

1 Basic Construction

CHAPTER 3 MECHANICAL SYSTEMS

1.1 External Covers

[1] Front cover

[2] Rear cover

[3] Feeder cover

[4] Original pickup tray

[5] Original delivery assembly

[6] Slide guide

Remove the covers as necessary as follows

when cleaning, checking, or repairing the

inside of the machine:

[2]

[3]

[6]

[4]

[5]

[1]

F03-101-01

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

3-1

Page 46

CHAPTER 3 MECHANICAL SYSTEMS

1.1.1 Removing the Front Cover

1) Open the feeder cover[1], and remove

the 2 screws [2]; then, detach the front

cover.

1.1.2 Removing the Rear Cover

1) Open the feeder cover, and remove the 2

screws [1]; then, detach the rear cover.

[2]

[1]

F03-101-02

[1]

1.1.3 Removing the Feeder Cover

1) Remove the front cover.

2) Remove the screw [1] and the positioning pin [2]; then, detach the feeder

cover [3].

[1]

F03-101-03

[3]

[2]

3-2

COPYRIGHT

©

[1]

F03-101-04

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 47

2 Pickup System

2.1 Separation Roller Unit

2.1.1 Removing the Separation Roller Unit

1) Remove the feeder cover.

2) Remove 4 screws [1]; then, detach the

feeder cover inside cover [2].

[1]

CHAPTER 3 MECHANICAL SYSTEMS

[1]

3) Remove the two shutter [1].

4) Remove the resin E-ring [2]; then, while

holding down the rear of the drive shaft,

detach the separation roller unit [3].

[3]

[2]

[2]

F03-201-01

[1]

F03-201-02

COPYRIGHT

©

Do not disassemble the separation roller unit any further. It

must be replaced with all components as shown; any further

assembly can deform the spring

of the spring clutch.

F03-201-03

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

3-3

Page 48

CHAPTER 3 MECHANICAL SYSTEMS

2.1.2 Mounting the Separation Roller Unit

1) Mount the separation roller unit [1].

[1]

F03-201-04

2) Mount the stopper arm [2] in the orientation indicated.

3) Mount the feeder cover inside cover.

[2]

F03-201-05

3-4

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 49

CHAPTER 3 MECHANICAL SYSTEMS

2.2 Separation Pad

2.2.1 Removing the Pre-Separation Pad/Separation Pad

1) Open the feeder cover.

2) Remove the 2 screws [1], and detach the

pre-separation pad [2] and the separation pad [3].

[1]

[3]

[2]

3) Slide the separation pad [3] to detach in

the direction indicated.

Take care not to lose the spring [4] attached to the bottom of the separation

pad.

F03-202-01

[3]

[4]

F03-202-02

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

3-5

Page 50

CHAPTER 3 MECHANICAL SYSTEMS

3 Drive System

3.1 Feeder Motor

3.1.1 Removing the Feeder Motor

1) Remove the rear cover.

2) Disconnect the connector [1].

3) Remove the tension spring [2].

4) Remove the 2 fixing screws [3], and detected feeder motor.

[1]

[2]

F03-301-01

[3]

3-6

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 51

3.2 Drive System

3.2.1 Removing the Feeder Unit

If you must replace the components of the

feeder unit, replace the feeder unit as

shown:

If you have removed the feeder

REF.

1) Remove the ADF from its host machine.

2) Remove the rear cover, front cover, and

feeder cover.

3) Disconnect the 5 connectors [1], and

remove the grounding fixing screw [2].

unit, you must adjust the gap L

of the platen guide after mounting it back .(See p. 3-17.)

CHAPTER 3 MECHANICAL SYSTEMS

4) Remove the screw [4], and detach the

original placement sensor [5]; then, detach the original pickup tray [6].

[1]

F03-302-01

[6]

F03-302-02

[2]

[4]

[5]

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

3-7

Page 52

CHAPTER 3 MECHANICAL SYSTEMS

5) Remove the 8 screws [1].

6) Remove the 2 screws [2].

[A]

[1]

F03-302-03

When you install the feeder

unit, tighten the 3 screws [A] at

first, then tighten the other

screws.

7) Remove the feeder unit.

If you try to remove the feeder

unit without detaching the ADF

from its host machine, the ADF

will shift up. Keep this in mind.

[A]

[2]

F03-302-04

3-8

COPYRIGHT

©

F03-302-05

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 53

3.2.2 Removing the Clutch

1) Remove the feeder unit.

2) Remove the 2-resin E-rings [1].

3) Shift the gear [2] toward the rear, and

detach the parallel pin [3].

CHAPTER 3 MECHANICAL SYSTEMS

[1]

[3]

[2]

F03-302-06

4) Remove the clutch together with its

shaft.

The machine’s clutch must be

replaced together with its shaft;

do not disassemble it any further.

When installing the clutch,

match the stop assembly [1]

agdinst the fixing plate [2].

[2]

[1]

F03-302-07

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

3-9

Page 54

CHAPTER 3 MECHANICAL SYSTEMS

If you have removed the clutch

from its shaft, go through the

following when mounting it

back: fit the spring [1] of the

spring clutch into the opening in

the clutch spring fixing plate

[2], and match the stop assembly [3] against the fixing plate

[4].

When securing the clutch in

place with the grip ring [1], be

sure to allow a gap of 0.2 mm

between the grip ring and the

clutch itself.

[2]

F03-302-08

[1]

[4]

[3]

0.2mm

[1]

F03-302-09

3-10

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 55

CHAPTER 3 MECHANICAL SYSTEMS

[1]

[1]

[2]

3.2.3 Disassembling the Feeder Drive Assembly

1) Remove the feeder unit.

2) Remove the harness and the harness

guide.

3) Remove the resin E-ring [1], and detach

the pulley [2].

[2]

[1]

F03-302-10

4) Remove the 3 screws [1], and detach the

feeder rear plate [2].

F03-302-11

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

3-11

Page 56

CHAPTER 3 MECHANICAL SYSTEMS

3.2.4 Removing the Platen Roller

1) Remove the feeder unit.

2) Turn over the feeder unit, and remove

the screw [1]; then, detach the platen

guide R [2].

Do not remove the platen guide

L [3].

3) Remove the resin E-ring [1] at the front;

then, detach the pulley [2], belt [3], and

bushing [4].

4) Remove the resin E-ring [5] at the rear,

and detach the bushing [6].

[2]

[2]

[3]

[1]

F03-302-12

[4]

5) Remove the platen roller [1] as shown.

[1]

[5][6]

[3]

F03-302-13

[1]

3-12

COPYRIGHT

©

F03-302-14

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 57

3.2.5 Removing the Feeder Roller

1) Remove the feeder unit.

2) Remove the platen guides L and R and

the platen roller.

3) Remove the resin E-ring [1]; then, detach the pulley [2] and the bearing [3].

CHAPTER 3 MECHANICAL SYSTEMS

[3]

[2]

[1]

F03-302-15

4) Loosen the screw [1], and detach the

spring [2] of the belt tensioner.

5) Remove the resin E-ring [1]; then, detach the pulley [2] and the bushing [3].

[1] [2]

F03-302-16

COPYRIGHT

©

F03-302-17

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

[3]

[2]

[1]

3-13

Page 58

CHAPTER 3 MECHANICAL SYSTEMS

5) Remove the resin E-ring [1], and detach

the feeder roller as shown.

[1]

F03-302-18

3-14

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 59

3.2.6 Remove the Feeder Roller 2

1) Remove the feeder unit.

2) Remove the platen guides L and R, and

remove the platen roller.

3) Remove resin E-ring [1]; then, detach

the gear [2] and the bushing [3].

CHAPTER 3 MECHANICAL SYSTEMS

[1]

[3]

[2]

F03-302-19

4) Loosen the 2 screws [1], and detach the

2 springs [2] of the belt tensioner.

5) Remove the resin E-ring [1]; then, detach the pulley [2] and the busing [3].

6) Remove the feede roller 2.

[2]

[1]

F03-302-20

COPYRIGHT

©

F03-302-21

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

[3]

[2]

[1]

3-15

Page 60

CHAPTER 3 MECHANICAL SYSTEMS

[1]

[2]

3.2.7 Removing the Pull-Off Roller

1) Remove the feeder unit.

2) Remove the feeder motor.

3) Remove the feeder drive assembly.

4) Remove the platen roller, feeding roller

1, and feeding roller 2.

5) Remove the resin E-ring [1] and the

bushing [2].

6) Remove the 2 resin E-rings [1]; then,

detach the 2 pulleys [2], bushing [3],

and parallel pin [4].

[1]

[2]

F03-302-22

7) Remove the 3 screws [1], and shift the

plate [2] to the front.

8) Shift the pull-off roller to the front, and

pull it off.

[1]

[2]

[3]

[4]

[2]

[1]

F03-302-23

3-16

COPYRIGHT

©

F03-302-24

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 61

3.2.8 Adjusting the Platen Guide L

[1]

If you have removed the pickup unit or the

platen guide L, be sure to adjust the gap between the platen guide L and the frame of

the machine after mounting it back.

1) Open the ADF, and loosen the 2 fixing

screws [1] of the platen guide.

CHAPTER 3 MECHANICAL SYSTEMS

F03-302-25

2) Fit a gap gauge (special tool; with a gap

of 1.4 mm) [4] in the gap between the

platen guide L [2] and the frame [3] of

the machine; and tighten the 2 screws

[1] while butting the gauge against the

platen guide [4] as shown in the figure.

[1]

[2]

[3]

[4]

[2]

COPYRIGHT

©

[3]

F03-302-26

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

[4]

3-17

Page 62

CHAPTER 3 MECHANICAL SYSTEMS

4 Electrical Systems

4.1 ADF Driver PCB

4.1.1 Removing the ADF Driver PCB

1) Remove the rear cover.

2) Disconnect all connectors from the ADF

driver PCB.

3) Remove the 2 screws [1], and detach the

ADF driver PCB.

[1]

4.2 Sensors in the Feeder Unit

4.2.1 Removing the Sensor Unit

1) Remove the feeder unit.

2) Remove the platen guide R.

3) Remove the platen roller.

4) Remove the 2 screws [1], and detach the

sensor unit [2].

[1]

F03-401-01

[2]

F03-402-01

[1]

3-18

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 63

4.2.2 Removing the Sensors

1) Disconnect the connector.

2) Remove the registration sensor [1] and

the read sensor [2].

CHAPTER 3 MECHANICAL SYSTEMS

4.3 Sensors in the Original Pickup Tray

4.3.1 Removing the Original Width Sensor

1) Remove the front cover.

2) Raise the original pickup tray.

3) Remove the 3 screws [1], and detach the

lower cover [2].

[2]

[2]

F03-402-02

[1]

[1]

[1]

COPYRIGHT

©

F03-403-01

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

3-19

Page 64

CHAPTER 3 MECHANICAL SYSTEMS

4) Remove the 2 screws [1], and detach the

slide guide gear plate [2].

5) Remove the original width sensor 1 [3]

and the original width sensor 2 [4].

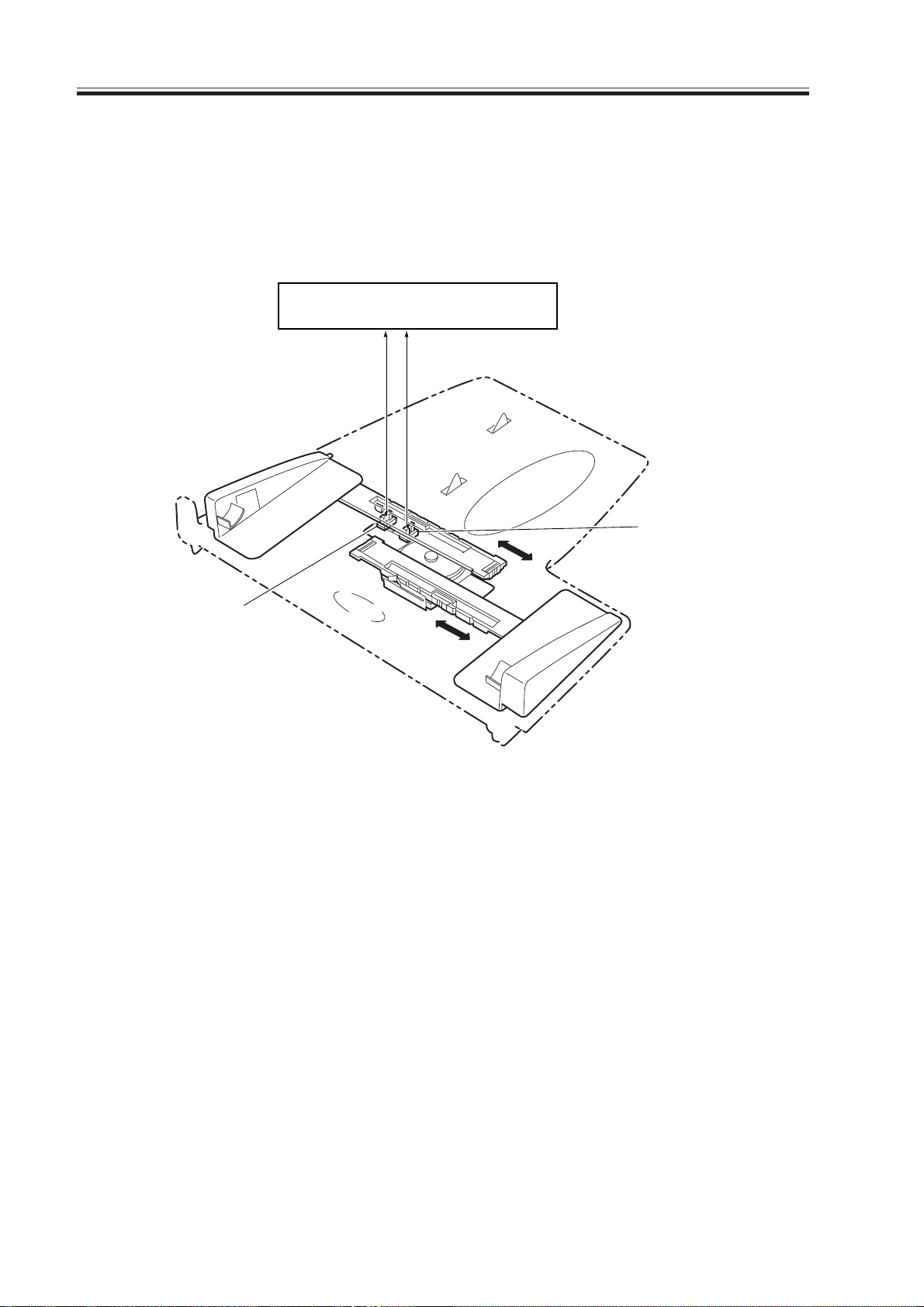

4.3.2 Mounting the Slide Guide Gear Plate

1) Spread out the slide guide [1] fully.

2) Mount the slide guide gear plate while

matching the top and bottom marking [2] of the gear and the

[3] of the front/rear slide guide.

marking

[2]

[1]

F03-403-02

[3]

[3]

[4]

[2]

3-20

COPYRIGHT

©

[1]

[3]

[2]

F03-403-03

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 65

CHAPTER 4

MAINTENANCE AND INSPECTION

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

Page 66

Page 67

CHAPTER 4 MAINTENANCE AND INSPECTION

1 Periodically Replaced Parts

The machine does not have parts that must be replaced on a periodical basis.

2 Durables and Consumables

The machine does not have parts that may require replacement because of wear or dam-

age once or more during the period of product warranty.

3 Scheduled Ser vicing Char t

The machine does not have parts that require periodical servicing.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

4-1

Page 68

CHAPTER 4 MAINTENANCE AND INSPECTION

4 Replacement

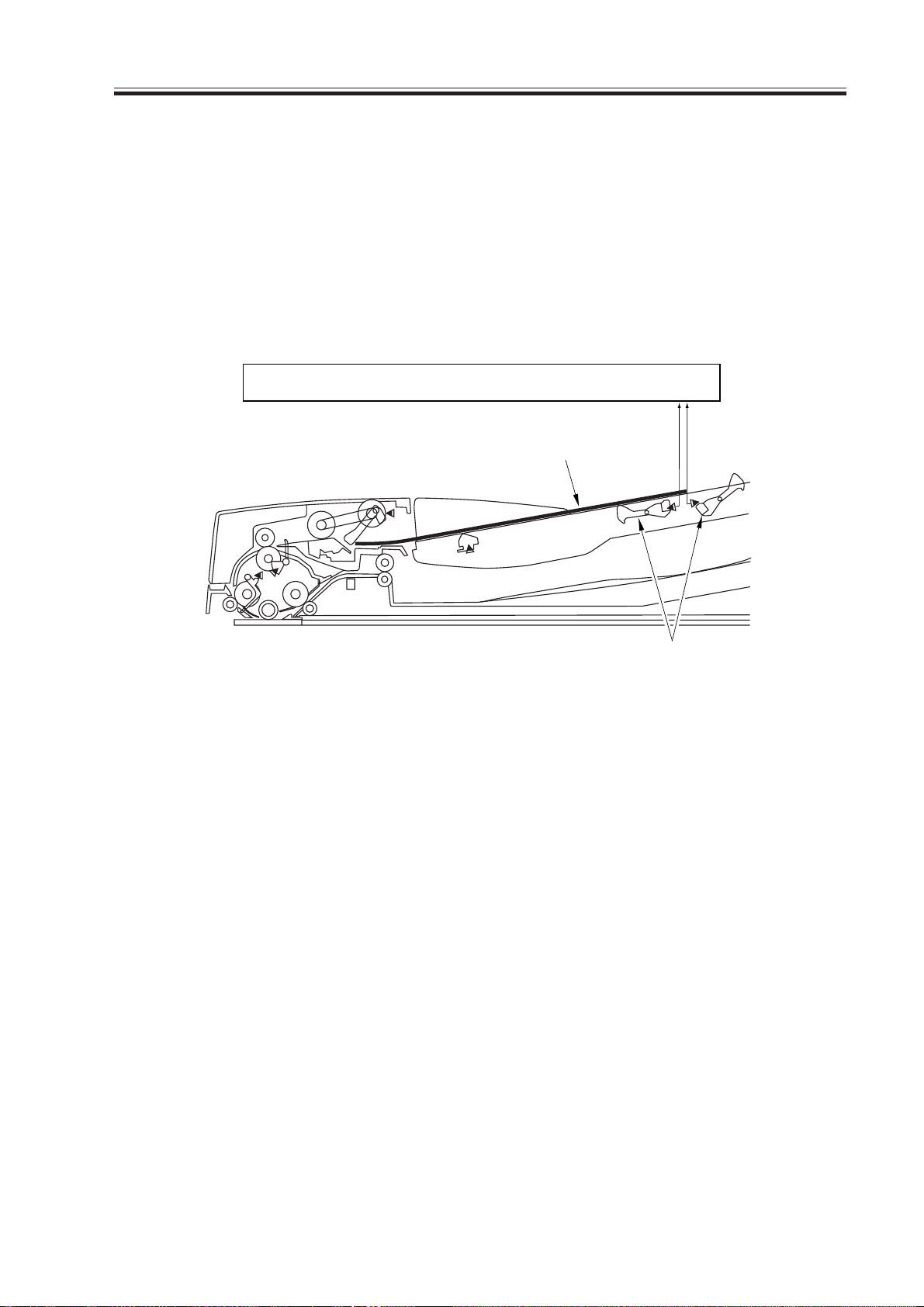

4.1 Replacing the Feed Roller Guide (dust-collecting tape)

1) Open the ADF.

2) Remove the 2 screws [1], and remove

the feed roll guide [2].

3) Mount the new feed roll guide.

[2]

[1]

4.2 Replacing the Stamp

1) Open the ADF cover and the separation

guide.

2) Using tweezes, remove the stamp.

3) Using tweezers, mount the new stamp.

Be sure that the stamp is oriented so

that the side with faces up.

F04-401-01

F04-402-01

4-2

Be sure to fit it until a click is

heard; otherwise, jams can occur.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 69

CHAPTER 5

TROUBLESHOOTING

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

Page 70

Page 71

CHAPTER 5 TROUBLESHOOTING

1 Standards and Adjustments

1.1 Basic Adjustments

Be sure to perform basic adjustments of the machine in the following order:

[1] Height

[2] Right angle

[3] Read position

[4] Ratio

[5] Horizontal registration

[6] Leading edge registration

1.1.1 Adjusting the Height

1) Check to see if the gap between the

copyboard glass of the host machine

and the copyboard stop assembly [1] on

the pickup side is 0.1 ± 0.05 mm when

the ADF is closed (approximately a

single sheet of 64 g/m

2

paper may be

inserted).

At the same time, check also that the

copyboard stop assembly [2] on the

pickup front side is in contact with the

copyboard glass. (Use a sheet of paper

to check.)

t=0.1 0.05mm

[3]

[1]

[2]

[If Not As Indicated]

1) If one side is not in contact, turn the

height adjusting bolt [3] on the left

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

F05-101-01

5-1

Page 72

CHAPTER 5 TROUBLESHOOTING

hinge to make adjustments.

2) If the front side is not in contact, give

the height adjusting plate [1] of the

right hinge a 90º turn, and then adjust

the left hinge.

[1]

• If the front is not in contact, tighten

the adjusting screw.

• If the rear is not in contact, loosen the

adjusting screw.

1.1.2 Adjusting the Right Angle

Check the angle between the scanner of the

host machine and the direction of feed of

the machine, and make adjustments as necessary.

1) Using A4 or LTR paper, prepare a test

chart as shown.

F05-101-02

10mm

10mm

Right

angle

10mm

10mm

5-2

COPYRIGHT

©

F05-101-03

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 73

2) Place the test chart in the original tray,

and make a Direct print.

3) Place the test chart over the output obtained in step 2), and check the angle of

the image.

A ≤ 1mm

B ≤ 1mm

CHAPTER 5 TROUBLESHOOTING

A

Feed direction

Separate

paper

Check the right angle by referring to the lines on the leading

edge.

Output obtained in step 2

B

Feed direction

Separate

paper

Output obtained in step 2)

F05-101-04

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

5-3

Page 74

CHAPTER 5 TROUBLESHOOTING

[If Not As Indicated]

1) Loosen the locking nut [2] on the angle

adjusting screw [1] found at the rear of

the right hinge unit.

2) Turn the angle adjusting screw [1] to

adjust the angle.

3) Tighten the locking nut [2] to secure it

in place.

4) Make a print of the test chart once again

to see that the image is as indicated.

[1]

[2]

F05-101-05

[3]

0.4 mm/interval

REF.

A marking [3] is provided on

the right hinge assembly (bottom of the ADF); a shift over a

single interval will cause a slant

of about 0.4 mm in an image.

F05-101-06

5-4

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 75

1.1.3 Adjusting the Read P osition

Adjust the stream read position of the host

machine in relation to the read position of

the ADF .

1) Turn on the host machine, and press the

User Mode key “

key in sequence in its control panel to

start service mode.

2) Press the Arrow key in the control panel

of the host machine so that “TEST

MODE” is indicated.

3) Press the OK key.

4) Press “2” on the keypad so that “2.

CCD TEST” is indicated.

5) Press ‘3’ on the keypad so that “CS POS

ADJ (ADF)” is indicated.

The scanner starts scanning operation;

in about 5 sec, auto adjustment ends. If

“OK” is indicated, end the work; if

“NG” is indicated, repeat the foregoing

steps.

” and then the “#”

CHAPTER 5 TROUBLESHOOTING

If auto adjustment fails, clean

the platen roller of the ADF and

the copyboard glass of the host

machine; then, execute auto adjustment once again. If it still

fails, suspect a fault in the host

machine.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

5-5

Page 76

CHAPTER 5 TROUBLESHOOTING

1.1.4 Adjusting the Ratio Mechanism

Adjust the feed speed used to move originals, thereby adjusting the length of images

in feed direction.

1) Using A4 or LTR paper, prepare a test

chart as shown.

2) Place the test chart in the original tray,

and make a Direct print.

3) Check to see if the distance A on the

test chart and the distance B in the image obtained in step 2 ) are as follows:

A ≤ 1mm

B ≤ 1mm

Feed direction

Output obtained in step 2)

10mm

10mm

Right

angle

10mm

F05-101-07

Test chart

Test chart

10mm

A

[If Not As Indicated]

Use service mode of the host machine to

make adjustments:

1) Press the User Mode key “

” and the

“#” key in the control panel in order to

start service mode.

Feed direction

Output obtained in step 2)

B

F05-101-08

5-6

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 77

2) Operate as follows on the Service Mode

screen:

• Using the Arrow key, select “#6 SCANNER”; then, press the OK key.

• Using the Arrow key, select “8. CCD”;

then, press the OK key.

• Using the keypad, press “#032” or select “32” on the keypad.

3) Using the keypad, find the best value,

and press the OK key.

default : 16

unit : 0.1%

• If the image is too short, decrease the

value (to slow down the movement of

the original).

• If the image is too long, increase the

value (to speed up the movement of the

original).

4) Make a print of the test chart once

again, and check to see that the image is

as indicated.

CHAPTER 5 TROUBLESHOOTING

1.1.5 Adjusting the Horizontal Registration

Adjust the feed speed used to move originals, thereby adjusting the length of images

in feed direction.

Correct the displacement in horizontal registration between original and copy paper in

any of the following 2 ways:

• using service mode of the host machine

• moving the slide guide of the ADF

pickup tray

1) Using A4 or LTR paper, prepare a test

chart.

10mm

Right

angle

10mm

10mm

10mm

COPYRIGHT

©

F05-101-09

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

5-7

Page 78

CHAPTER 5 TROUBLESHOOTING

2) Place the test chart in the original pickup

tray , and make a Direct print.

3) Place the test chart over the output obtained in step 2), and check to see that

the following is true:

A ≤ 1mm

B ≤ 1mm

Output obtained in step 2)

A

Feed direction

Test chart

Output obtained in step 2)

B

Feed direction

Test chart

[If Not As Indicated]

a.Using Service Mode of the Host Machine

1) Press the User Mode key “

” and the

“#” key in the control panel to start service mode.

2) Operate as follows on the Service Mode

screen:

• Using the Arrow key, select “#6 SCANNER”; then, press the OK key.

• Using the Arrow key, select “8. CCD”;

then, press the OK key.

• Using the keypad, press “#022”; or, using the Arrow key, select “22”.

F05-101-10

10mm

10mm

Right

angle

10mm

F05-101-11

10mm

5-8

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 79

CHAPTER 5 TROUBLESHOOTING

3) Using the keypad, select the best value;

then, press the OK key.

default : 128

unit : 0.1mm

• If the image is displaced to the front,

increase the value.

• If the image is displaced to the rear, decrease the value.

4) Make a print of the chart, and check to

see that the image is as indicated.

b. Adjusting the position of the Side Guide of the ADF Pickup Tray

1) Remove the 3 mounting screws [1], and

detach the lower cover [2].

[2]

[1]

2) Loosen the mounting screw [1], and remove the screw [2] from the positioning

hole side; then, fit it into the adjusting

angle hole [3] lightly.

3) Shift the slide guide gear holder [4] to

the front or the rear to make adjustments.

4) Tighten the screw [1] and the screw [2]

fitted to the adjusting angle holder [3].

5) Thereafter, mount the cover.

6) Make a print of the test chart once again

to see that the image is as indicated.

[1]

F05-101-12

[1]

[4]

[2]

[3]

COPYRIGHT

©

F05-101-13

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

5-9

Page 80

CHAPTER 5 TROUBLESHOOTING

1.1.6 Adjusting the Leading Edge Registration

Correct the displacement of images in feed

direction as follows:

1) Prepare a test chart using A4 or LTR paper as shown:

10mm

2) Place the test chart on the original tray,

and make a Direct print.

3) Check to make sure that the dimension

A of the test chart is indicated as follows in the output obtained in step 2):

A ≤ 1mm

B ≤ 1mm

Right

angle

F05-101-14

Feed direction

Output obtained in step 2)

10mm

10mm

10mm

Test chart

A

Test chart

B

5-10

COPYRIGHT

©

Feed direction

Output obtained in step 2)

F05-101-15

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 81

[If Not As Indicated]

Use service mode of the host machine.

1) Press the User Mode key “

” and

then the “#” key in sequence to start service mode.

2) On the Service Mode screen, operate as

follows:

• Using the Arrow keys, select “#6

SCANNER”; then, press the OK key.

• Using the Arrow keys, select “8. CCD”;

then, press the OK key.

• Using the keypad, press “024”; or, using

the Arrow keys, select “24”.

3) Vary the value on the keypad to obtain

the best value; then, press the OK key.

default : 230

unit : 0.4 mm

• If the image is displaced to the left, decrease the value.

• If the image is displaced to the right,

increase the value.

4) Make a print of the test chart once again

to see that the image is as indicated.

CHAPTER 5 TROUBLESHOOTING

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

5-11

Page 82

CHAPTER 5 TROUBLESHOOTING

2 Troubleshooting Malfunctions

2.1 Troubleshooting Malfunctions

2.1.1 Pickup Fault

Motor, Clutch

1) Does the pickup roller rotate normally at time of pickup?

NO: Repair or replace the motor, clutch, drive gear, spring clutch, or the

like.

Pickup roller unit

2) Does the pickup roller rotate normally at time of pickup?

NO: Replace the separation roller unit. (see p. 3-3.)

Separation pad

3) Is the separation pad or the pre-separation pad appreciably soiled

or worn?

YES: Clean or replace it. (see p. 3-5.)

Pickup roller unit

4) Is the pickup roller unit appreciably soiled?

YES: Clean the pickup roller unit.

NO: Replace the pickup roller unit.

2.1.2 The output has black lines in sub scanning direction.

ADF read glass

1) Is there dust on the reading glass?

YES: Clean the read glass as instructed. (see p. 1-5.)

Separation PE sheet/separation guide

2-1) Is the separation PE sheet [1] appreciably soiled?

YES: Clean the separation PE sheet [1].

2-2) Is there a buildup of paper lint or toner on the separation guide?

YES: Clean the separation guide.

[1]

5-12

COPYRIGHT

©

F05-201-01

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 83

CHAPTER 5 TROUBLESHOOTING

Feeding roll guide

3) Is there a buildup of paper on the feeding roll guide?

YES: Replace the feeding roll guide. (See p. 4-2.)

Sharpness setting

4) Does the fault still occurs on a periodical basis even after going

through the foregoing?

YES: Change the sharpness setting to the lower level.

Caution: Setting the level to ‘weak’ can lead to deteriorated output im-

ages in sheet or book read mode. Be sure to obtain the user’s

consent before changing the setting.

[Changing the Sharpness Setting in User Mode]

1) Turn on the host machine, and press the User Mode key “

2) Press [02 copy settings].

”.

3) Press the OK key.

4) Press [08 sharpness].

5) Press the OK key.

6) Press ‘weaker’ to decrease the sharpness.

* At time of shipment, the setting is in the middle of the 9-setting index.

7) Press the OK key.

8) Press the Stop key or the Reset key to return to normal mode.

9) Make a copy, and check the output. If the correction is not good enough, select a still

lower level of sharpness.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

5-13

Page 84

CHAPTER 5 TROUBLESHOOTING

2.1.3 The output has blurred images.

Platen guide L

1) Is the gap of the platen guide L correct?

NO: Correct the gap. (See p. 3-17.)

Feeding roller

2) Are the spring pressure of the feeding roller 1/2 and the pull-off

roller correct?

NO: Correct the spring pressure.

2.1.4 The output is out of focus or has black fogging.

ADF

1) Is the height of the ADF correct?

NO: Correct the height. (See p. 5-1.)

Platen roller

2) Does the platen roller correctly come into contact with the glass

surface when the ADF is closed?

NO: Make adjustments so that the roller will come correctly in contact.

5-14

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 85

CHAPTER 5 TROUBLESHOOTING

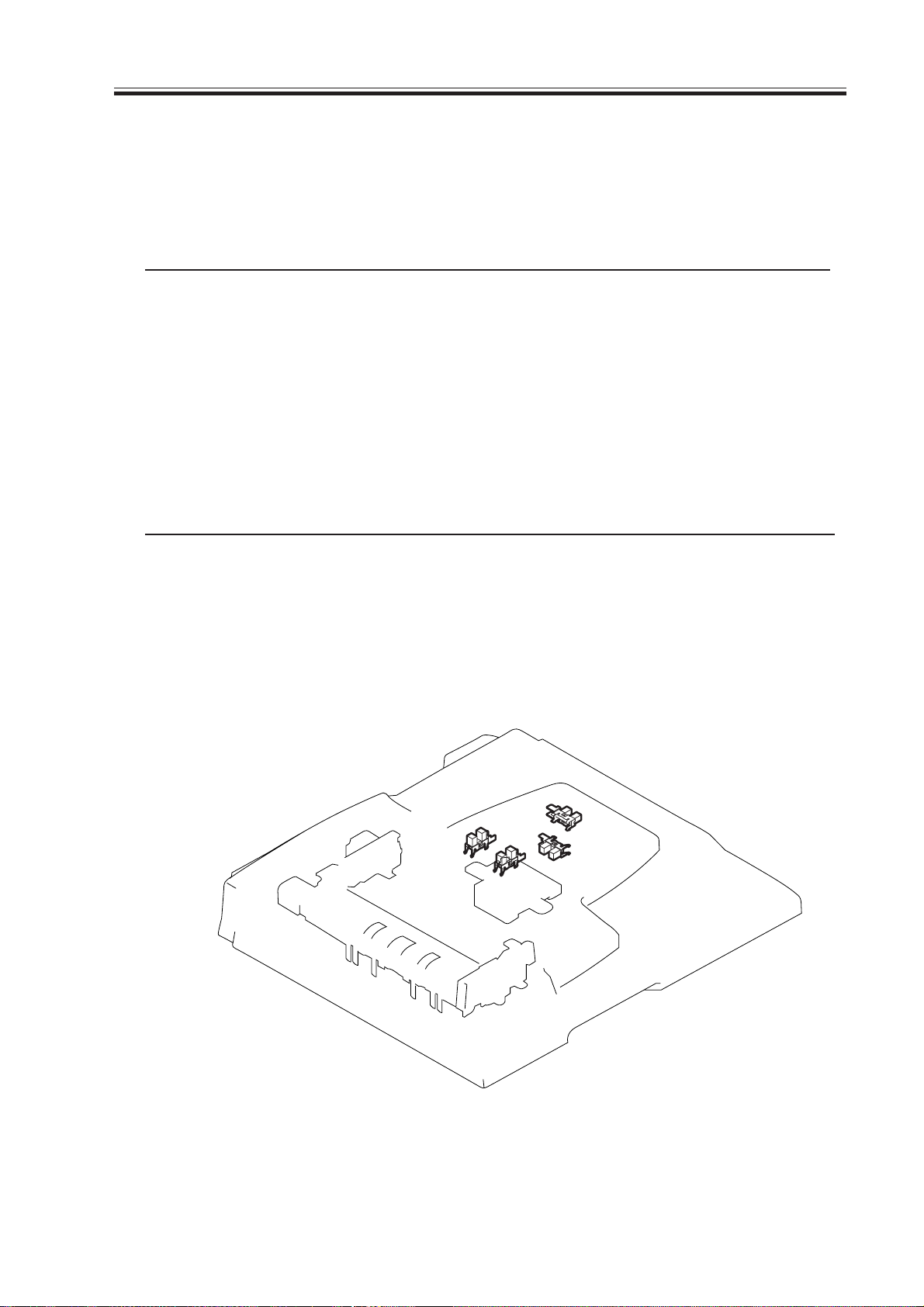

3 Arrangement of Electrical Components

3.1 Sensors

PI3

PI2

PI4

PI7

PI9

PI8

PI6

PI5

PI1

F05-301-01

Symbol Name Notation Description

Photointerrupters PI1 Last original detection sensor

PI2 Length sensor 1

PI3 Length sensor 2

PI4 Original width sensor 1

PI5 Original width sensor 2

PI6 Original placement sensor

PI7 Registration sensor

PI8 Read sensor

PI9 Feeder cover open/closed sensor

COPYRIGHT

©

T05-301-01

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

5-15

Page 86

CHAPTER 5 TROUBLESHOOTING

3.2 Motors, Clutches, Solenoids, PCBs, and Others

M1

CL1

PCB1

PCB2

SL1

F05-302-01

Symbol Name Notation Description

Motor M1 Feed motor

M

5-16

SL

CL

Solenoid SL1 Stamp solenoid

Cultch CL1 Pickup clutch

ADF drier PCB PCB1 ADF drive

Relay PCB PCB2 Relay for sensor inside original

pickup tray

T05-302-01

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

Page 87

CHAPTER 5 TROUBLESHOOTING

4 Self Diagnosis

4.1 Outline

The machine does not have a controller PCB, and depends on the controller PCB of its

host machine for diagnosis. The checks are limited to jams, and do not look for alarm or error conditions. For discussions of jams, see 3 “Jams” in Chapter 2 (p. 2-21).

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

5-17

Page 88

Page 89

APPENDIX

COPYRIGHT

©

2001 CANON INC. 2001 2001 2001 2001 CANON ADF-J1 REV.0 SEPT. 2001

Page 90

Page 91

1 General Timing Charts

1.1 Flow-Scanning a Single-sided A4 Document

Start key ONOriginal set

Feed motor (M1)

Pickup clutch (CL1)

Original placement

sensor (PI6)

Registration sensor

(PI7)

Read sensor (PI8)

Pickup roller

Separation roller

Other rollers

Original separated/

moved

: motor, roller in reverse.

Note 1: The speed increases when the paper is pulled by the pull-off roller.

1st original read 2nd original read Original delivered

Note 1 Note 1

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

A-1

Page 92

Page 93

APPENDIX

2 Signal Name/Designation List

Definitions of the signal names and other designations used in this chapter and in the

block diagrams are listed below.

Note: Designations in brackets denote an electrical signal, or an analog signal whose

state cannot be represented as a 0 or 1. Other designations denote a digital signal whose

state can be represented as a 0 or 1.

DFCVS Feeder Cover Open/Closed Detection signal

SET Document Set Detection signal

LENG1 Last original detection signal

LENG2 Document Length Detection signal 1

LENG3 Document Length Detection signal 2

MOTA Feed Motor Drive signal

MOTA* Feed Motor Drive signal

MOTB Feed Motor Drive signal

MOTB* Feed Motor Drive signal

READ Read Original Document signal

REG Separated Paper Detection signal

STAMP_SL Stamp Solenoid Drive signal

WID1 Original Width Detection signal 1

WID2 Original Width Detection signal 2

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON ADF-J1 REV.0 SEPT. 2001

A-3

Page 94

Page 95

3 General Block Diagram

Stamp solenoid

SL

SL1

Pickup clutch

CL