Page 1

DADF-B1

REVISION 0

APR. 1999

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13G6-000

Page 2

IMPORTANT

THIS DOCUMENT IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE OF

REFERENCE FOR WORK IN THE FIELD .

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER

PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMA TION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPAR TMENT OF THE SALES COMPANY.

THIS DOCUMENT IS INTENDED FOR ALL SALES AREAS, AND MA Y CONTAIN INFORMATION

NOT APPLICABLE T O CERTAIN AREAS.

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly supervised to avoid disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride, Ibaraki, 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 3

INTRODUCTION

This Service Manual provides information needed to service the ADF in the field. This Service

Manual consists of the following chapters:

Chapter 1 “General Description” introduces the ADF’s features and specifications, and shows

how to operate it.

Chapter 2 “Basic Operation” introduces the ADAF’s mechanical and electrical systems; it also

explains the principles used in these systems and the timing at which they are

operated with reference to the ADAF’s electrical circuitry.

Chapter 3 “Mechanical System” explains the ADAF’s mechanical construction and how its

parts may be disassembled/assembled and adjusted.

Chapter 4 “Maintenance and Servicing” provides tables of periodically replaced parts and

consumables/durables and scheduled servicing charts.

Chapter 5 “Troubleshooting” provides tables of maintenance/inspection, standards/

adjustments, and problem identification (image fault/malfunction).

Appendix contains a general timing chart and general circuit diagrams.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of Service

Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins, and be able to identify and isolate faults in the

machine.

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

Page 4

Page 5

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES.................................1-1

II. SPECIFICATIONS ......................1-2

III. NAMES OF PARTS .................... 1-4

A. External View .........................1-4

B. Cross Section.........................1-4

IV. OPERATIONS .............................1-5

CHAPTER 2 BASIC OPERATION

I. BASIC CONSTRUCTION........... 2-1

A. Outline of Electrical Circuitry ....2-1

B. Inputs to the ADF Controller

PCB........................................2-2

C. Outputs from the ADF Controller

PCB........................................2-4

II. BASIC OPERATIONS................. 2-5

A. Outline.................................... 2-5

B. Detecting an Original .............2-6

A. Original Set Indicator .............1-5

B. Making Copies ....................... 1-5

C. Warnings and Actions ............1-5

D. Routine Maintenance by the

User........................................1-6

C. Picking Up and Separating

Originals...............................2-11

D. Moving Originals .................. 2-18

E. Turning Over an Original/

Delivery................................2-23

F. Movement of Originals .........2-32

G. Detecting an Original Jam ... 2-43

H. Alarm Detection ...................2-47

I. Power Supply ....................... 2-50

CHAPTER 3 MECHANICAL SYSTEM

I. BASIC CONSTRUCTION ...............3-1

A. External Covers .....................3-1

B. Removing the Feed Belt Unit...3-4

C. ADF Controller PCB .............. 3-5

II. DRIVE SYSTEM ............................3-6

A. Removing the Pickup Unit .....3-6

B. Removing the Separation

Motor (M1) ..............................3-6

Removing the Feed Motor (M2)

C.

D. Reversal Delivery Unit ...........3-8

E. Removing the Reversal Delivery

Motor (M3) ..............................3-9

III. FEEDING SYSTEM .................. 3-10

A. Removing the Separation Pad

Assembly .............................3-10

B. Removing the Separation

Roller ....................................3-11

C. Removing the Pickup Roller ..3-12

....3-7

Mounting the Separation Roller

D.

Unit ........................................

E. Removing the Reversing Roller

and Feed Roller ................... 3-14

F. Replacing the Feed Belt ......3-16

VI. SENSORS ..................................3-18

A. Removing the Original Set Sen-

sor PCB (U503)....................3-18

B. Removing the Original Set Indi-

cator LED PCB.....................3-18

C. Removing the Last Original

Sensor PCB (U504) .............3-19

D . Original Width Detecting Volume

(VR)......................................3-19

E. Removing the Pre-Registration

Sensor (U502)......................3-21

F. Removing the Reversal Outlet

Sensor (U505)......................3-21

3-13

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

Page 6

CHAPTER 4

MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED

PARTS ........................................ 4-1

CONSUMABLES AND

II.

DURABLES...................................

4-1

CHAPTER 5 TROUBLESHOOTING

I. STANDARDS AND ADJUST-

MENTS........................................5-1

A. Mechanical System................5-1

B. Electrical System ................... 5-4

II. TROUBLESHOOTING................5-9

A. Troubleshooting

Malfunctions......................... 5-10

III. ARRANGEMENT OF THE ELEC-

TRICAL PARTS ........................ 5-12

A. Motors, Solenoids, and

Sensors................................5-12

B. PCBs....................................5-14

III. SCHEDULED SERVICING

CHART........................................4-2

IV. VARIABLE RESISTORS (VR),

LIGHT-EMITTING DIODES, AND

CHECK PINS BY PCB ............. 5-15

A. ADF Controller PCB ............ 5-15

B. Sensor PCBs ....................... 5-16

C. Indicator PCB.......................5-18

V. SERVICE MODE AND DIP

SWITCH.................................... 5-19

A. Outline..................................5-19

B. Service Mode .......................5-20

C. Using the DIP Switch ...........5-28

VI. SELF DIAGNOSIS .................... 5-32

A. ADF Self Diagnosis ............. 5-32

APPENDIX

A. GENERAL TIMING CHART ......... A-1

B. SIGNALS AND

ABBREVIATIONS ...................... A-5

C. GENERAL CIRCUIT

DIAGRAM .................................. A-7

D. ADF CONTROLLER PCB ......... A-8

E. PRE-REGISTRATION SENSOR

PCB .......................................... A-12

F. REVERSAL OUTLET SENSOR

PCB .......................................... A-13

G. ORIGINAL SET INDICATOR LED

PC B..........................................A-15

H. ORIGINAL SET SENSOR .......A-17

I. LAST ORIGINAL SENSOR ..... A-18

J. SPECIAL TOOLS ..................... A-19

K. SOLVENTS AND OILS ............ A-20

iv

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 7

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES................................. 1-1

II. SPECIFICATIONS ...................... 1-2

III. NAMES OF PARTS .................... 1-4

A. External View .........................1-4

B. Cross Section.........................1-4

IV. OPERATIONS .............................1-5

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

A. Original Set Indicator .............1-5

B. Making Copies ....................... 1-5

C. Warnings and Actions ............1-5

D. Routine Maintenance by the

User........................................1-6

Page 8

Page 9

CHAPTER 1 GENERAL DESCRIPITON

I. FEATURES

1. Small in size, and light in weight.

It is a document feeder designed as a single-frame unit for small size and light weight.

2. Handles double-sided originals.

It is equipped with a reversing delivery unit, capable of turning over originals and returning them

to the copyboard glass.

3. Wingless design.

Its delivery tray is of an integrated construction.

4. Automatic identification of original size.

It is capable of identifying the size of an original in terms of lengthwise (feeding) and

breadthwise directions for communication to its host copier.

4. Handles mixed sizes.

It can accommodate originals of different sizes (of the same width, i.e., configuration).

5. Accommodates thick originals.

It is equipped with a book equalizing hinge, enabling the use of a thick original (50 mm thick;

e.g., book).

6. Reversal delivery flapper.

It rotates the reversal delivery motor clockwise and counterclockwise to open and close the

flapper, switching the feeding path.

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

Page 10

CHAPTER 1 GENERAL DESCRIPITON

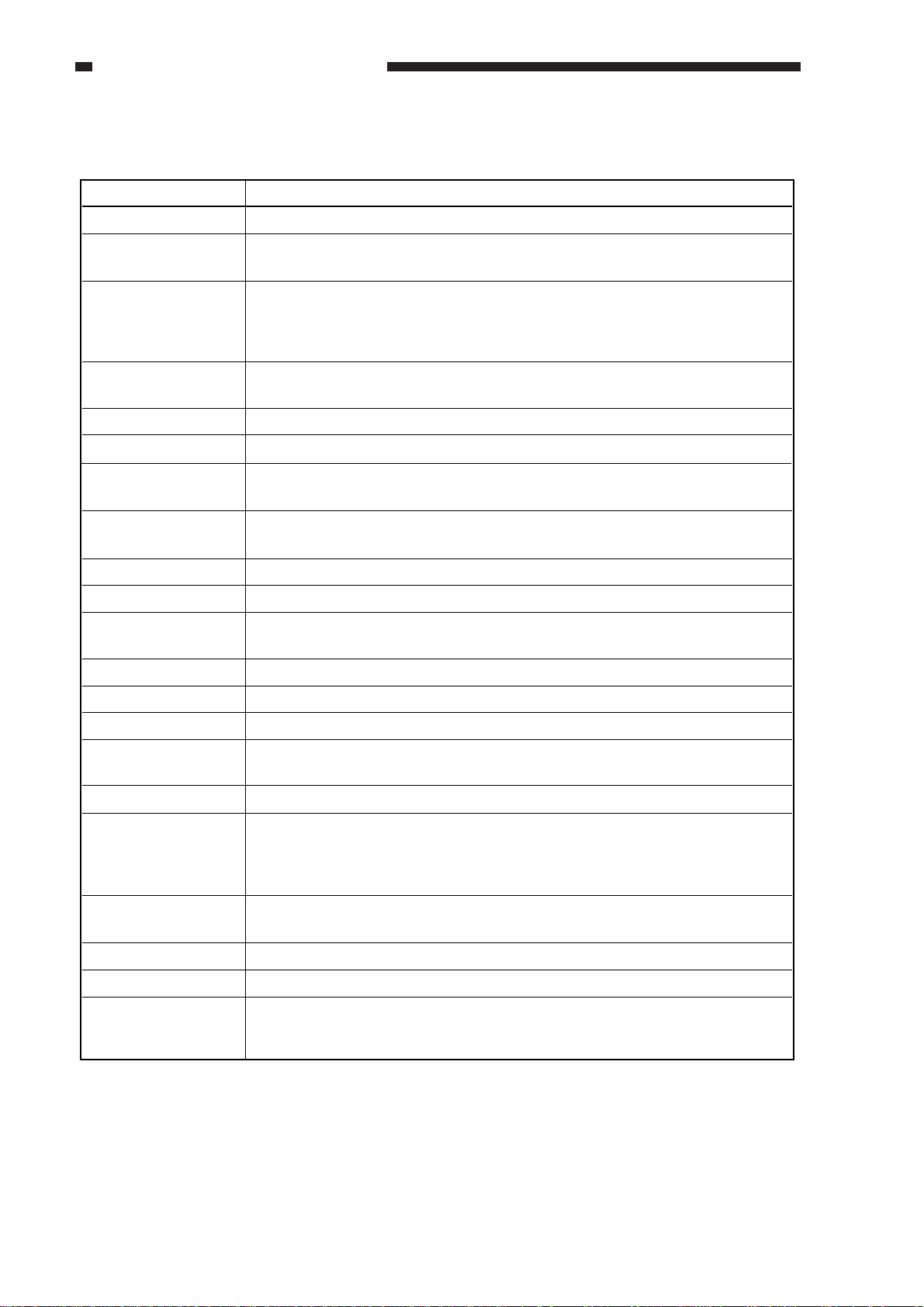

II. SPECIFICATIONS

Item Specifications

Pickup method Automatic pickup/delivery

Type of original Original tray: double-sided sheet (52 to 105 g/m

Copyboard glass: book (50 mm thick max.)

Size of original A3 (279 mm x 431.8 mm; 11"x17") to A5 (STMT)

Length: 140 to 432 mm (feeding direction)

Width: 140 to 297 (305) mm

Note: The values in parentheses indicate when the guide lock is released.

Orientation of original Face up

1st page at top

Placement of original Center reference

Original separation Separation pad (top separation)

2

); see Note 1.

Original processing

mode

Height of stack

(80 g/m

Mixing sizes Possible (of the same width)

Size identification Yes (feeding direction + default width)

Residual original

detection

2-on-1 function No (by copier's memory)

Stamp No

Last original detection 690 msec or less

Communication with

copier

Power supply 24 VDC (from copier)

Serial numbers ZSB xxxxx AB

Maximum power

supply

2

paper)

Single-sided original processing (small-size, large-size), double-sided original

processing

30 sheets (small size; A4, B5, A5, STMT, LTR)

15 sheets (large-size; A3, 279x431.8 mm/11"x17", B4, LGL)

Yes (by LED)

IPC 2

ZSC xxxxx INCH/A

ZSD xxxxx A

ZSE xxxxx AB/INCH

160 W or less at peak; 39 W in average

Weight 12.8 kg (approx.)

Dimensions 583 (W) x 506 (D) x 179 (H) mm

Operating environment

temperature/humidity

range

Same as copier

Table 1-201

1-2

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 11

CHAPTER 1 GENERAL DESCRIPITON

Time to replace originals

Point of exposure

(leading edge of image)

Note 1:

The following may not be used as an

original:

• Sheet with holes (as for filing).

• Sheet with a staple, clip, or adhesive.

• Sheet with a cut-and-paste patch.

• Sheet with a carbon back.

• Sheet with large curling, bending, or

wrinkling.

If an original has large curling, straighten

it out as much as possible, and place it so that

the curling edge is the trailing edge.

Note:

The specifications are subject to change

for product improvement.

Note 2:

Time Taken to Replace Originals

The value indicates the time passing from

when an original is moved to when its trailing

edge reaches the point of exposure. However,

it does not include separation of the original.

Figure 1-201

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

Page 12

CHAPTER 1 GENERAL DESCRIPITON

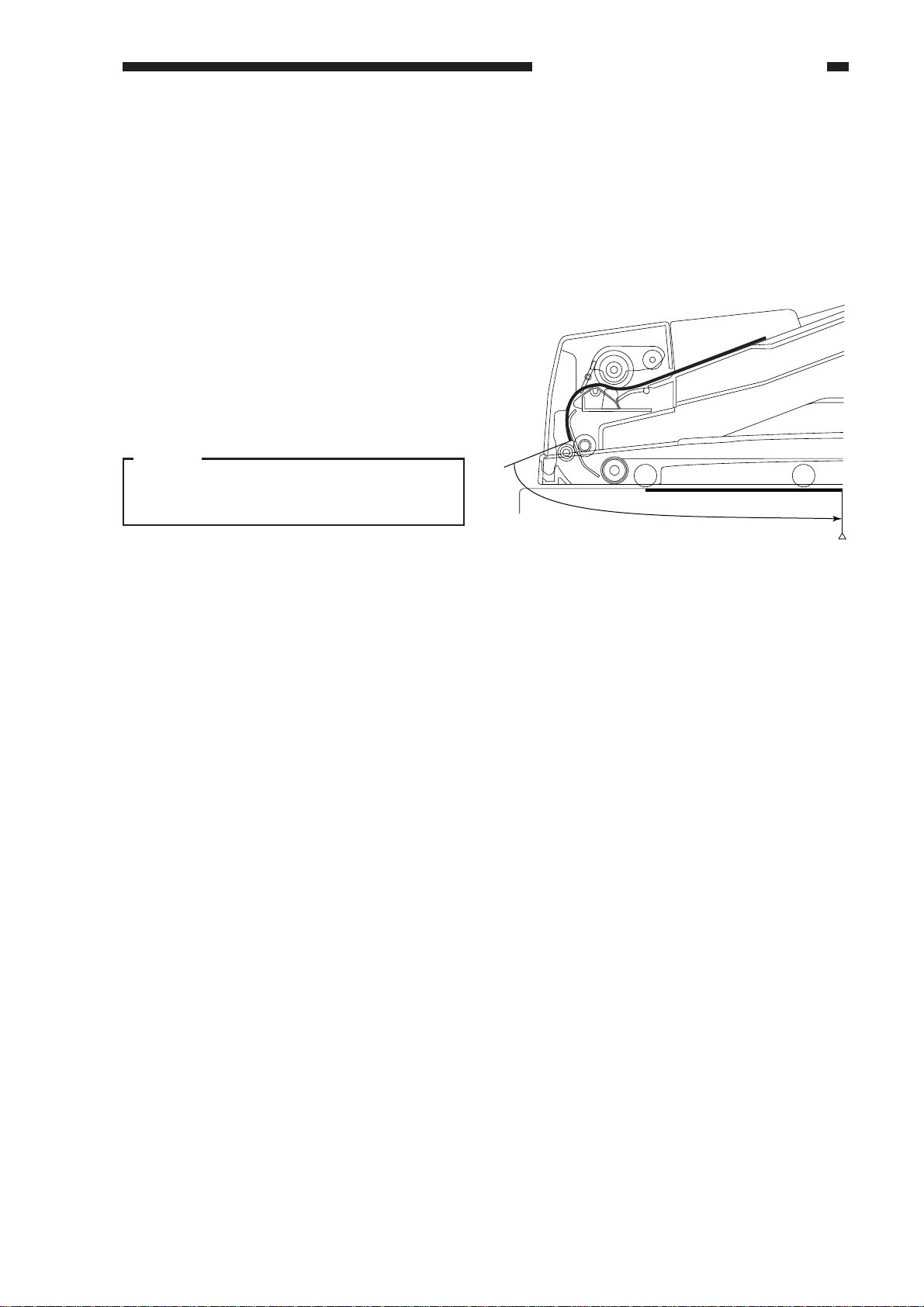

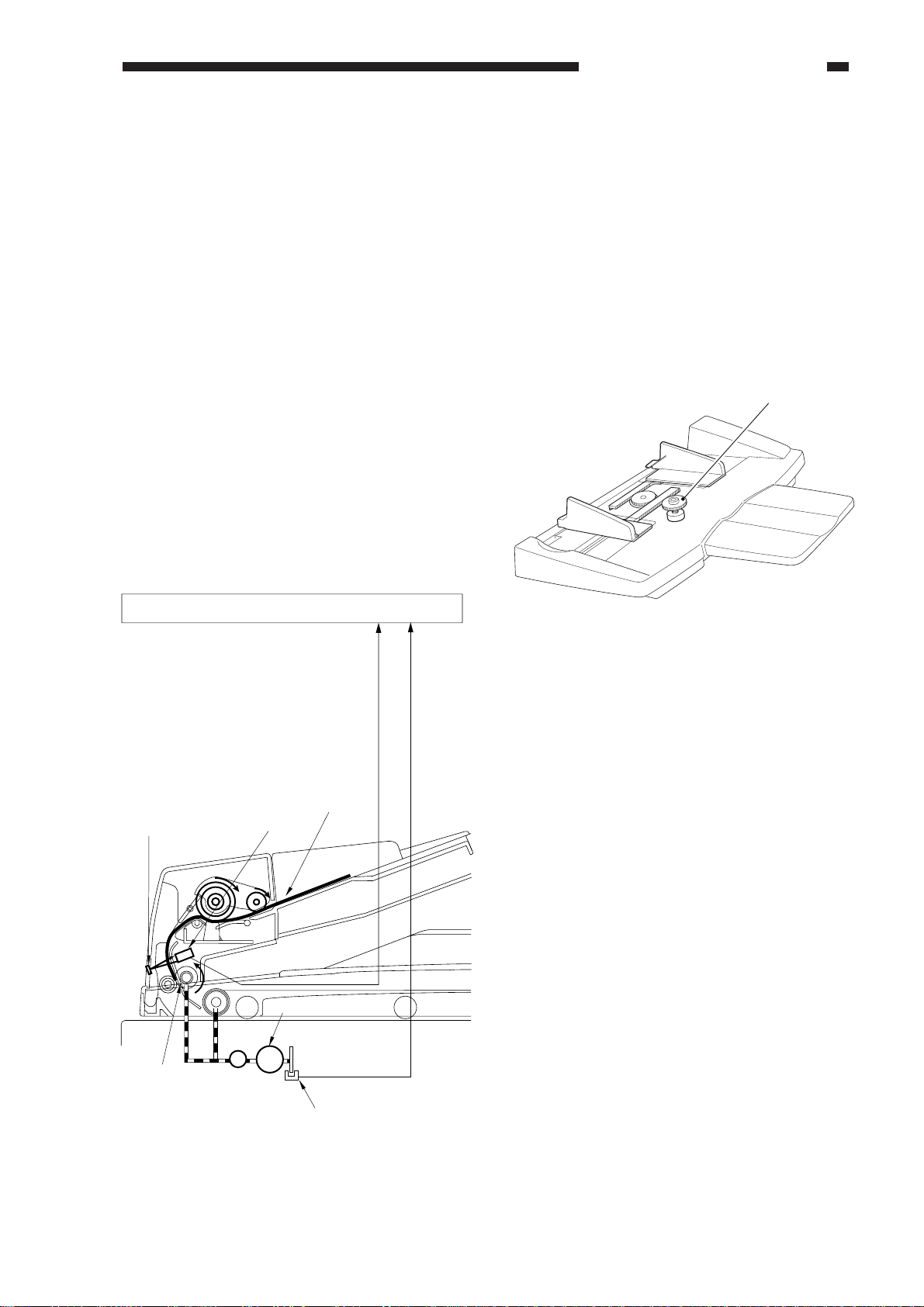

III. NAMES OF PARTS

A. External view

[2]

[1][3]

[6]

[4]

[8]

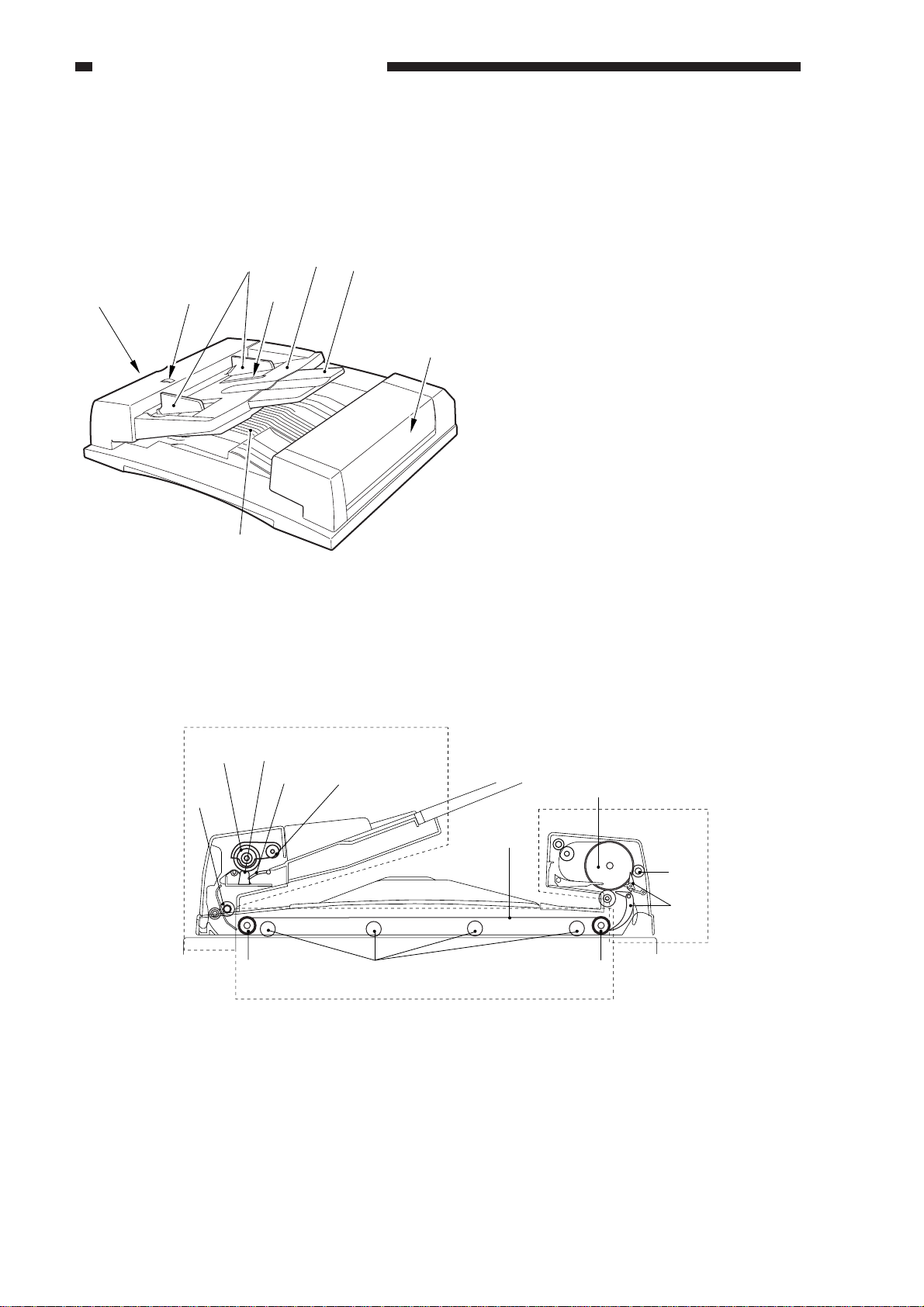

B. Cross Section

[5]

[7]

Figure 1-301

[1] Original tray

[2] Auxiliary tray

[3] Slide guides

[4] Original Set indicator

[5] Last original sensor

[6] Pickup unit cover

[7] Reversal delivery unit cover

[8] Original delivery tray

[4]

[5]

Pickup Assembly

[1] Pickup roller

[2] Lifter

[3] Separation pad

[4] Separation roller

[5] Registration roller

[3]

[2]

[7] [8] [9]

Pickup assembly

[1]

[12]

[6]

Feeding assembly

Figure 1-302

Feeding Assembly

[6] Feeding belt

[7] Feeding belt drive roller

[8] Retaining roll

[9] Feeding belt linkage roller

Reversal Delivery Assembly

[10] Reversal delivery flapper

[11] Reversal delivery

registration roller

[12] Reversing roller

Reversal

delivery

assembly

[11]

[10]

1-4

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 13

CHAPTER 1 GENERAL DESCRIPITON

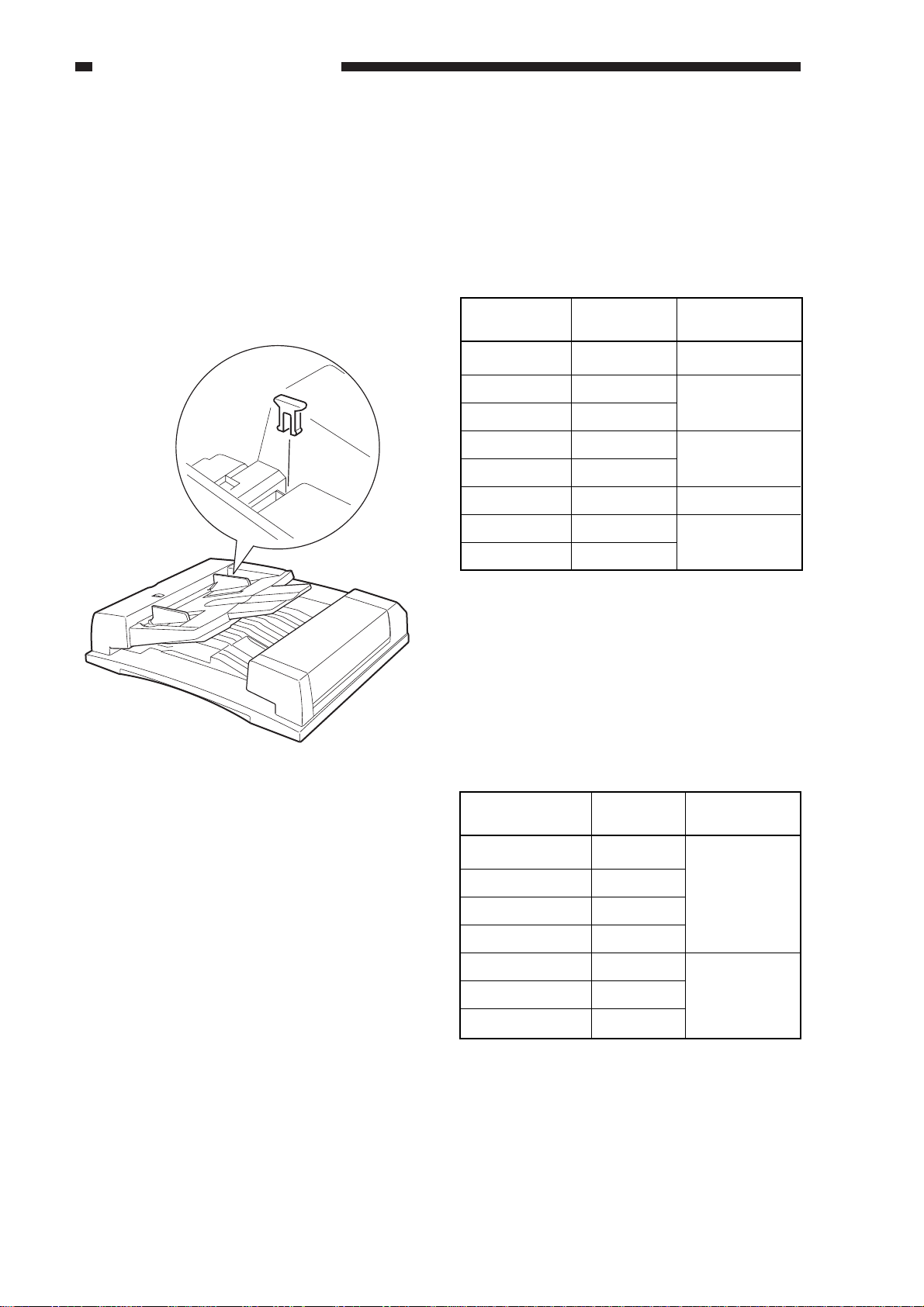

IV. OPERATIONS

A. Original Set Indicator

The Original Set indicator turns on when an original is on the original tray, and it starts to flash

when a jam occurs.

Figure 1-401

B. Making Copies

1) Adjust the slide guides to suit the size of the originals.

2) Place the stack of originals against the end plate of the original tray with the first page on top.

3) Set the copier to the appropriate copying mode.

4) Press the copier’s Copy Start key.

C. Warnings and Actions

You can suspect an original jam if the Original Set indicator has started to flash. Make the

following checks, and take the appropriate actions:

1) Open the pickup unit cover and the reversal delivery unit; then, remove any original jam.

2) Remove the originals from the original tray.

3) Open the ADF, and remove any original jam.

4) Remove any original from the copyboard glass.

5) Close the ADF.

6) Put the originals back into order, and place the stack on the original tray once again.

7) Press the copier’s Copy Start key.

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

Page 14

CHAPTER 1 GENERAL DESCRIPITON

D. Routine Inspection by the

User

Instruct the user to clean the following on a regular basis:

1. Copyboard Glass

Clean it using a cloth moistened with water or alcohol; then, dry wipe it.

2. Feeding Belt

Clean it using water or alcohol.

3. Others

If any part of the external panels of the ADF is soiled, clean it with a solution of mild detergent;

then, dry wip it.

1-6

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 15

CHAPTER 2

BASIC OPERATION

I. BASIC CONSTRUCTION........... 2-1

A. Outline of Electrical Circuitry ....2-1

B. Inputs to the ADF Controller

PCB........................................2-2

C. Outputs from the ADF Controller

PCB........................................2-4

II. BASIC OPERATIONS................. 2-5

A. Outline.................................... 2-5

B. Detecting an Original .............2-6

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

C. Picking Up and Separating

Originals...............................2-11

D. Moving Originals .................. 2-18

E. Turning Over an Original/

Delivery................................2-23

F. Movement of Originals .........2-32

G. Detecting an Original Jam ... 2-43

H. Alarm Detection ...................2-47

I. Power Supply ....................... 2-50

Page 16

Page 17

CHAPTER 2 BASIC OPERATION

I. BASIC CONSTRUCTION

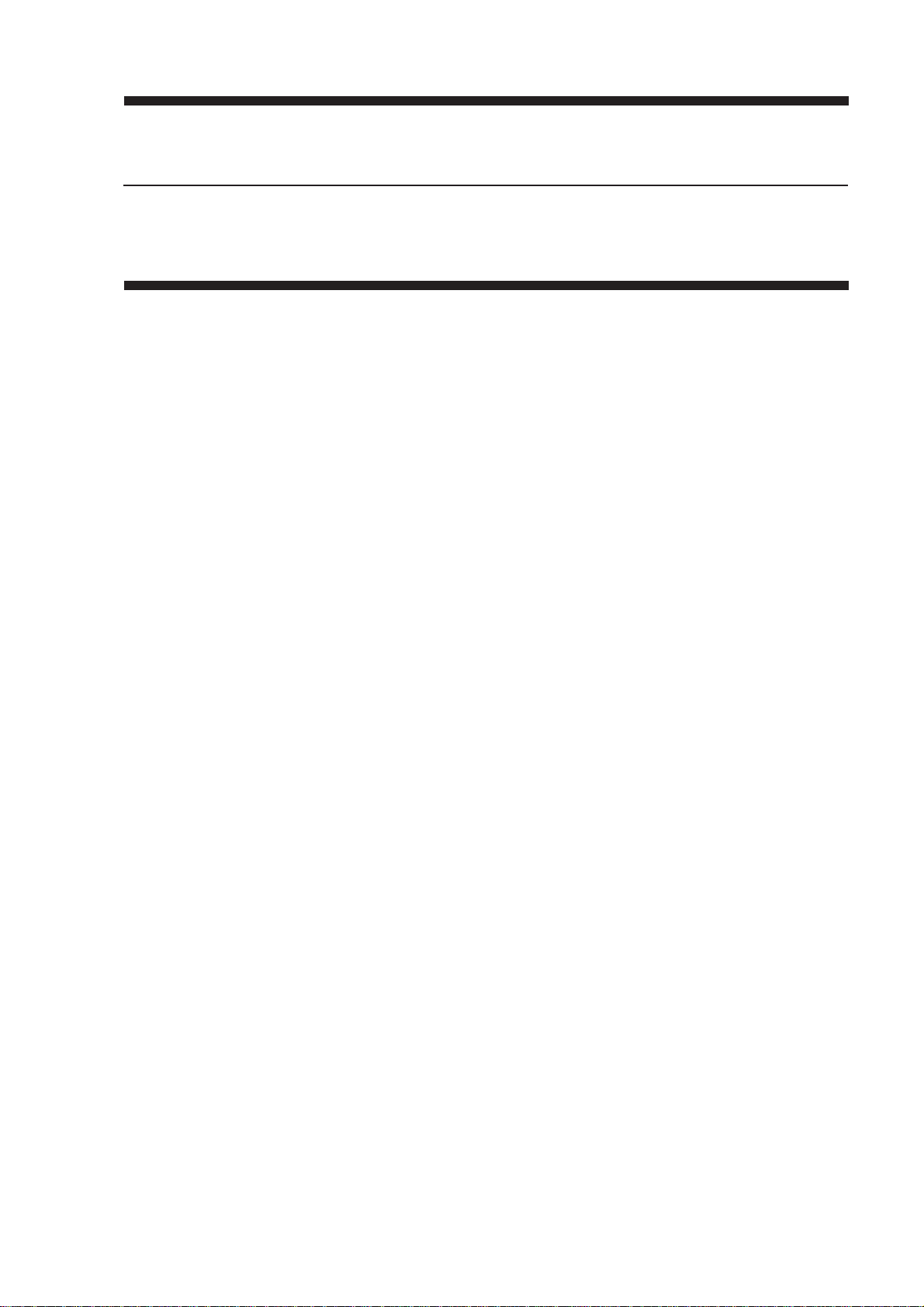

A.

Outline of Electrical Circuitry

The major electrical mechanisms of the ADF are controlled by a microprocessor (CPU) on the

ADF controller PCB.

The microprocessor is designed to read signals from sensors and its host copier to generate

signals used to drive loads (motors, brakes).

ADF controller PCB

Sensor

Variable

resistor

ROM

(Q2)

IPC

(Q3)

CPU

(Q1)

EEPROM

(Q4)

24V 5V

5 VDC

power supply

Power supply

circuit

Motor

Brake

Indicator

LED PCB

Copier

Figure 2-101

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-1

Page 18

CHAPTER 2 BASIC OPERATION

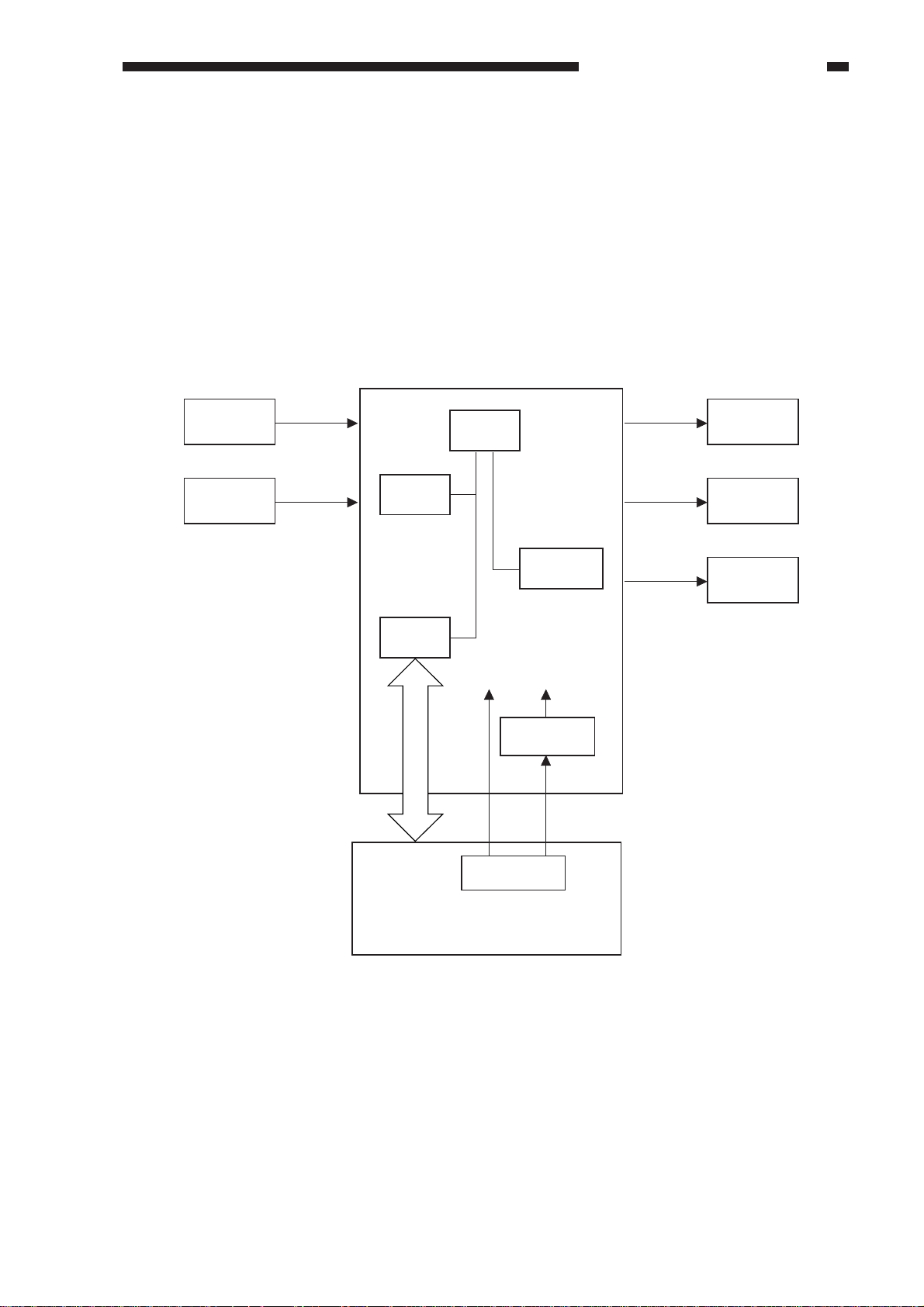

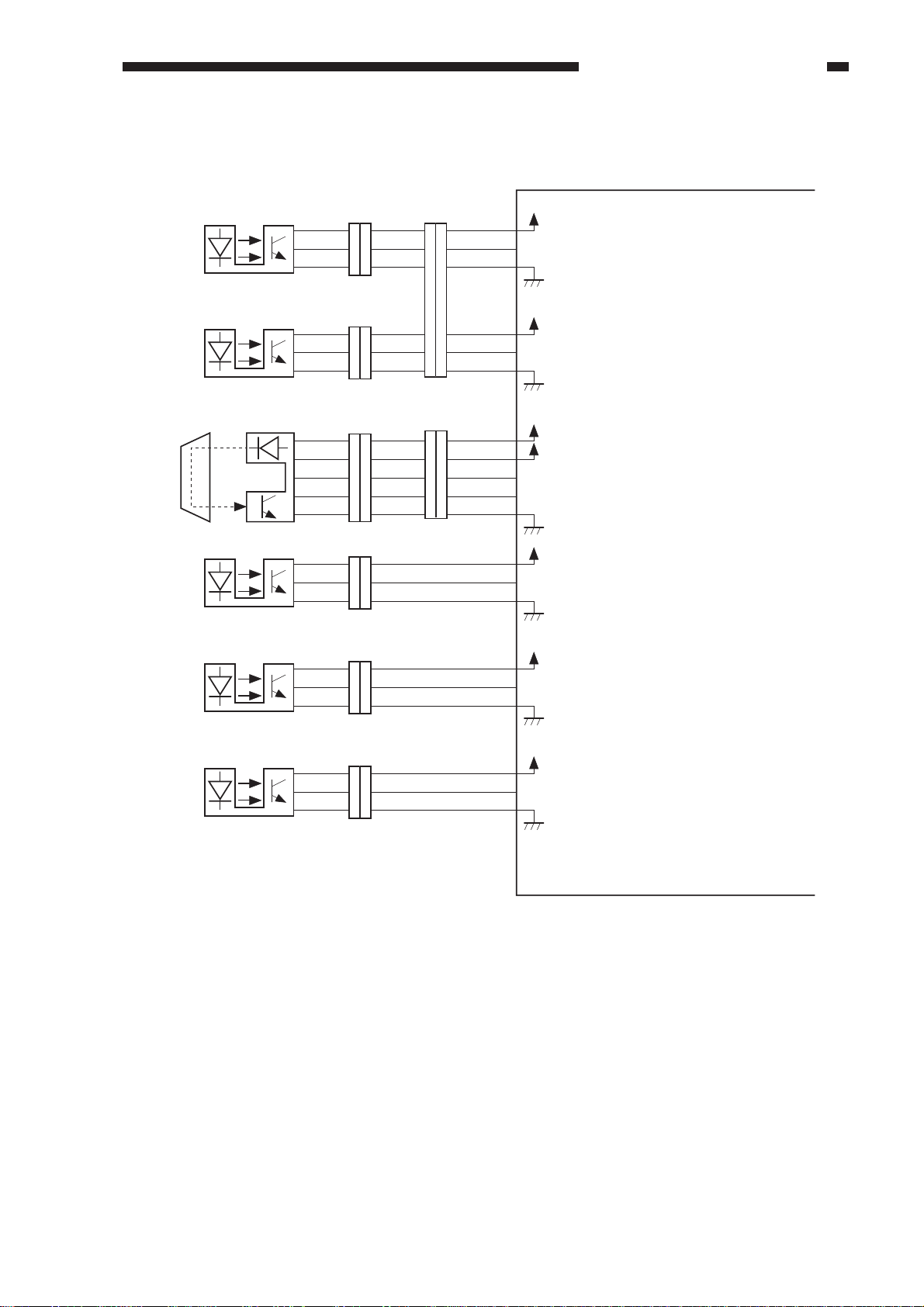

B. Inputs to the ADF Controller PCB

1. Inputs to the ADF Controller PCB (1/2)

ADF controller PCB

Feed motor clock sensor

SR1

Pickup unit cover sensor

SR2

Separation sensor

SR3

Original set sensor

U503

+

3

3

2

2

1

1

3

3

1

1

2

2

J102

3

3

1

1

2

2

J103

4

4

3

3

2

2

1

5

J301

10

1

11

5

1

2

3

J1101J101

1

3

2

4

6

5

8

9

7

J1102

3

2

1

11

9

10

8

6

7

4

3

2

1

5

J6A-3

J6FA-2

J6FA-1

J6A-4

J6FA-6

J6FA-5

J6A-7

J6FA-9

J6FA-8

J6A-11

J6FA-12

J6FA-13

J6FA-14

J6FA-10

5V

FMCK

+

5V

SCVR

+

5V

SPR

+

5V

+

24V

EMP

EPLED

While the feed motor is rotating,

alternates between ’1’ and ’0’.

When the pickup unit cover is

opened, ’0’.

(When the light-blocking plate is

not at the sensor.)

When an original is detected, ’0’.

(When the light-blocking plate is

not at the sensor.)

When an original blocks the

sensor, ’0’.

Pre-registration sensor

U502

Original width detecting

volume

U508

Last original sensor

U504

4

2

3

3

5

5

4

4

1

1

J201

1

3

1

2

2

2

3

1

3

J801

4

4

3

2

1

5

J401 J1801

5

3

6

2

7

1

8

5

4

J6B-6

J6FB-5

J6FB-3

J6FB-4

J6FB-7

J6B-8

8

J6FA-9

7

J6FA-10

6

4

J6B-12

3

J6FB-13

2

J6FB-14

J6FB-15

1

J6FB-11

5

Figure 2-102

+

5V

+

24V

ENT

ETLED

+

5V

WIDE

+

5V

+

24V

LAST

LTLED

When the original blocks the

sensor, ’0’.

Generates an analog voltage to

suit the width of the original placed

on the original tray.

When an original blocks the

sensor, ’1’.

2-2

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 19

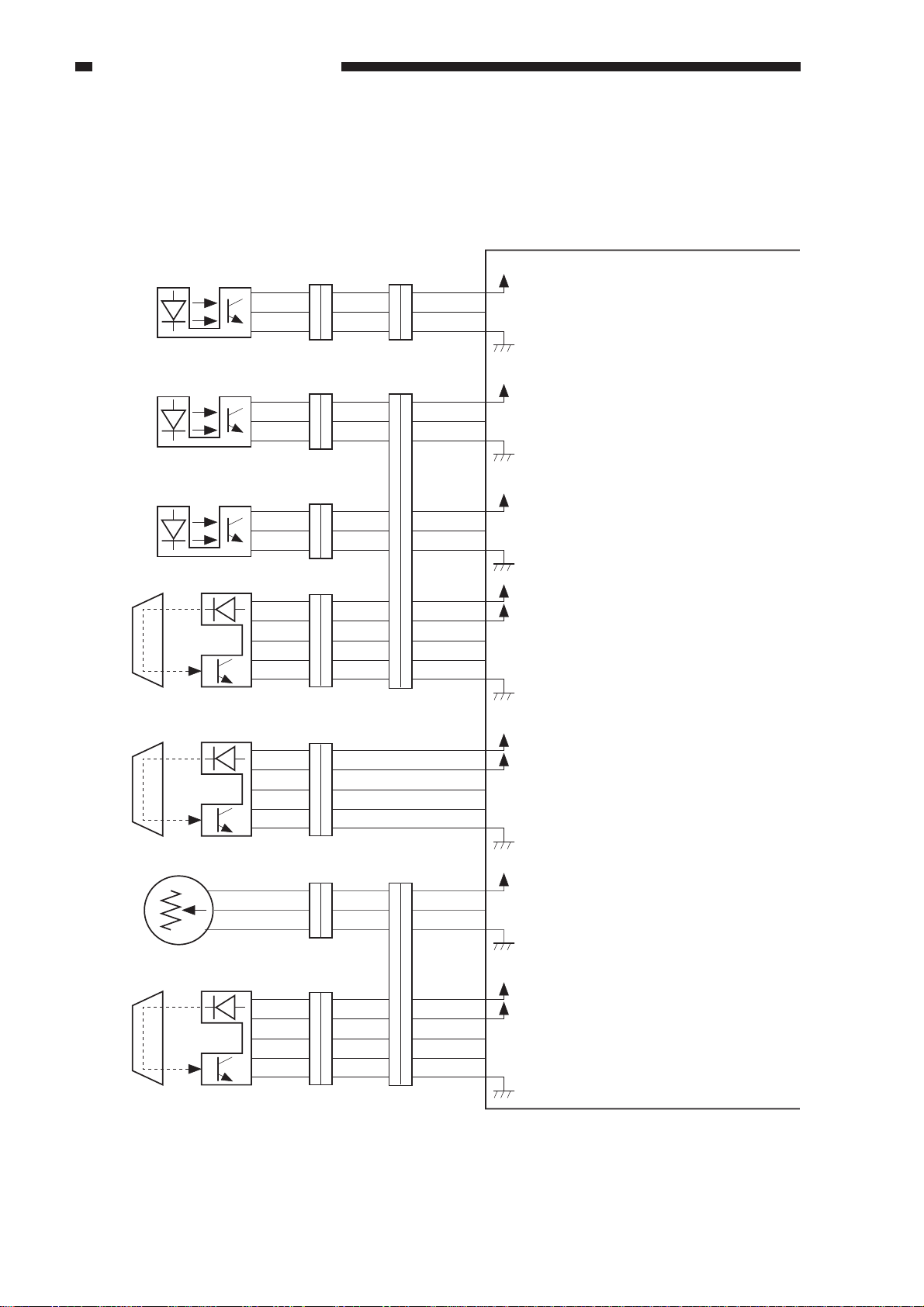

2. Inputs to the ADF Controller PCB (2/2)

Reversal delivery inlet

sensor

SR4

Reversal delivery

registration sensor/delivery sensor

SR5

Reversal outlet sensor

U505

ADF open/closed sensor

SR6

Reversal delivery motor

clock sensor

SR7

Reversal delivery

unit cover sensor

SR8

3

3

1

2

J107

3

1

2

J108

J103

2

3

5

4

1

J501 J502

3

1

2

J109

1

2

3

J110

3

1

2

J111

1

1

3

2

2

4

3

6

1

5

2

2

4

3

3

5

1

4

2

5

1

3

1

2

1

2

3

3

1

2

J1107

6

4

5

3

1

2

2

3

5

4

J6FA-11

1

J7A-1

J6FA-3

J6FA-2

J7A-4

J6FA-6

J6FA-5

J7B-10

J6FA-9

J6FA-7

J6FA-8

J7B-1

J6FA-3

J6FA-2

J7B-6

J6FA-5

J6FA-4

J7B-7

J6FA-9

J6FA-8

+

5V

EENT

+

5V

EREG

+

5V

+

24V

TURN

TULED

+

5V

OPEN*

+

5V

EMCK

+

5V

CHAPTER 2 BASIC OPERATION

ADF controller PCB

When an original is detected, ’1’.

(When the light-blocking plate is at

the sensor.)

When an original is detected, ’1’.

(When the light-blocking plate is at

the sensor.)

When an original blocks the sensor, ’0’.

When the ADF is opened, ’0’.

(When the light-blocking plate is

not at the sensor.)

While the reversing delivery motor is

rotating, alternates between ’1’ and ’0’.

When the reversal delivery unit cover

is opened, ’0’.

(When the light-blocking plate is at

the sensor.)

The asterisk (*) indicates that the signal turns on

when ’0’ (low active).

Figure 2-103

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-3

Page 20

CHAPTER 2 BASIC OPERATION

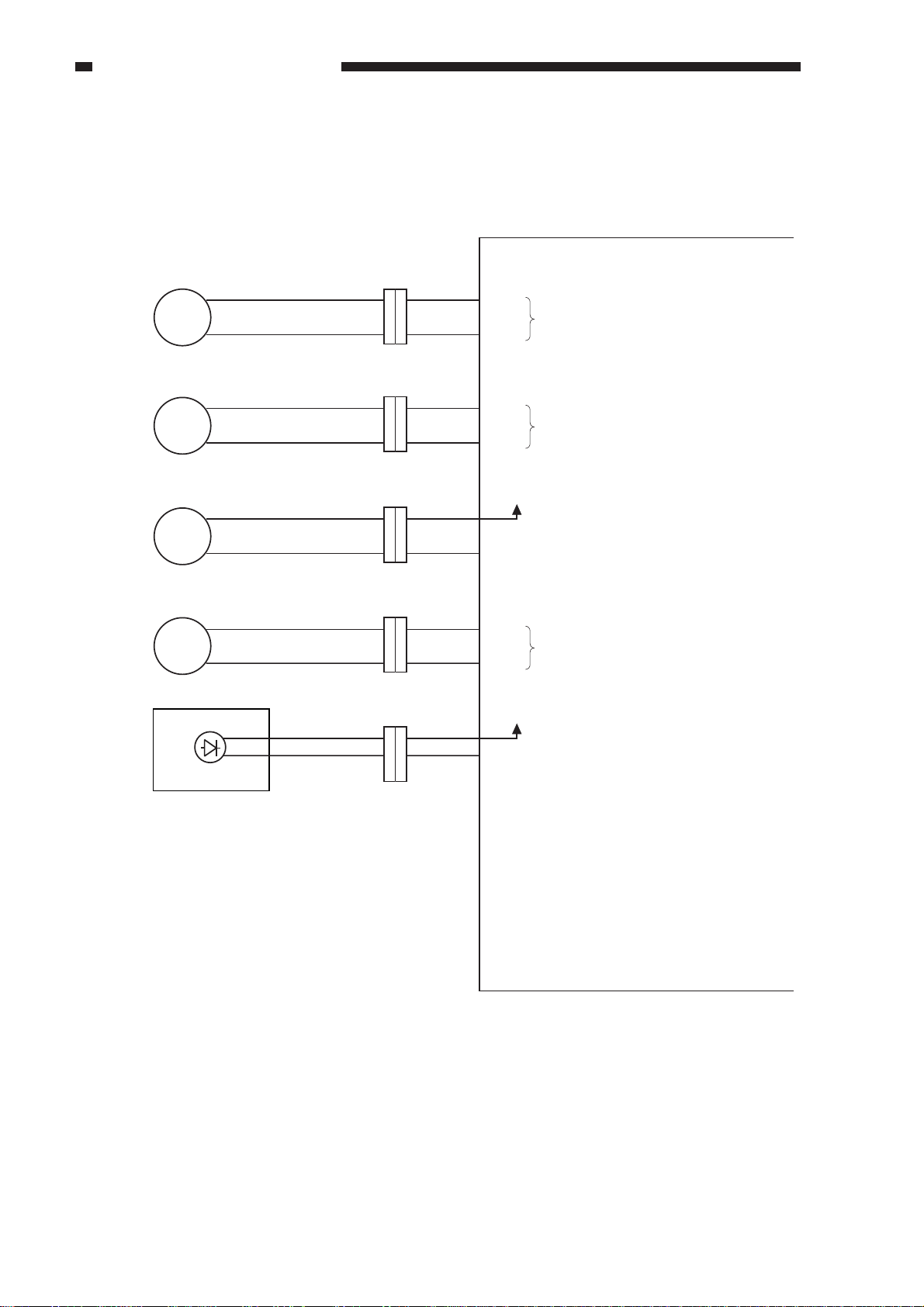

C. Outputs from the ADF Controller PCB

1. Outputs from the ADF Controller PCB (1/1)

Separation motor

J5-1

1

M1

Feed motor

M2

M

M

1

2

1

2

J104

J104

2

1

2

J6FA-2

J6FA-4

J5-3

SPM1

SPM2

FDM1

FDM2

ADF controller PCB

See "Controlling the

Separation Motor (M1)" on p. 2-16.

See "Controlling the

Feed Motor (M2)" on p. 2-21.

Feed motor brake

BK1

BK

Reversal delivery motor

M3

M

Original Set indicator (LED)

U507

1

2

1

2

2

1

J112

J112

J701

1

J6FAJ5-6

2

1

J6FA-2

2

J6B-1

2

J6FA-2

1

J5-5

J9-1

BK

EJM1

EJM2

OGLED

+

24V

When ’0’, the brake (BK1) turns on.

See "Controlling the Reversal

Delivery Motor (M3)" on p. 2-29.

+5

V

When ’0’, the Original Set indicator

turns on.

2-4

Figure 2-104

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 21

CHAPTER 2 BASIC OPERATION

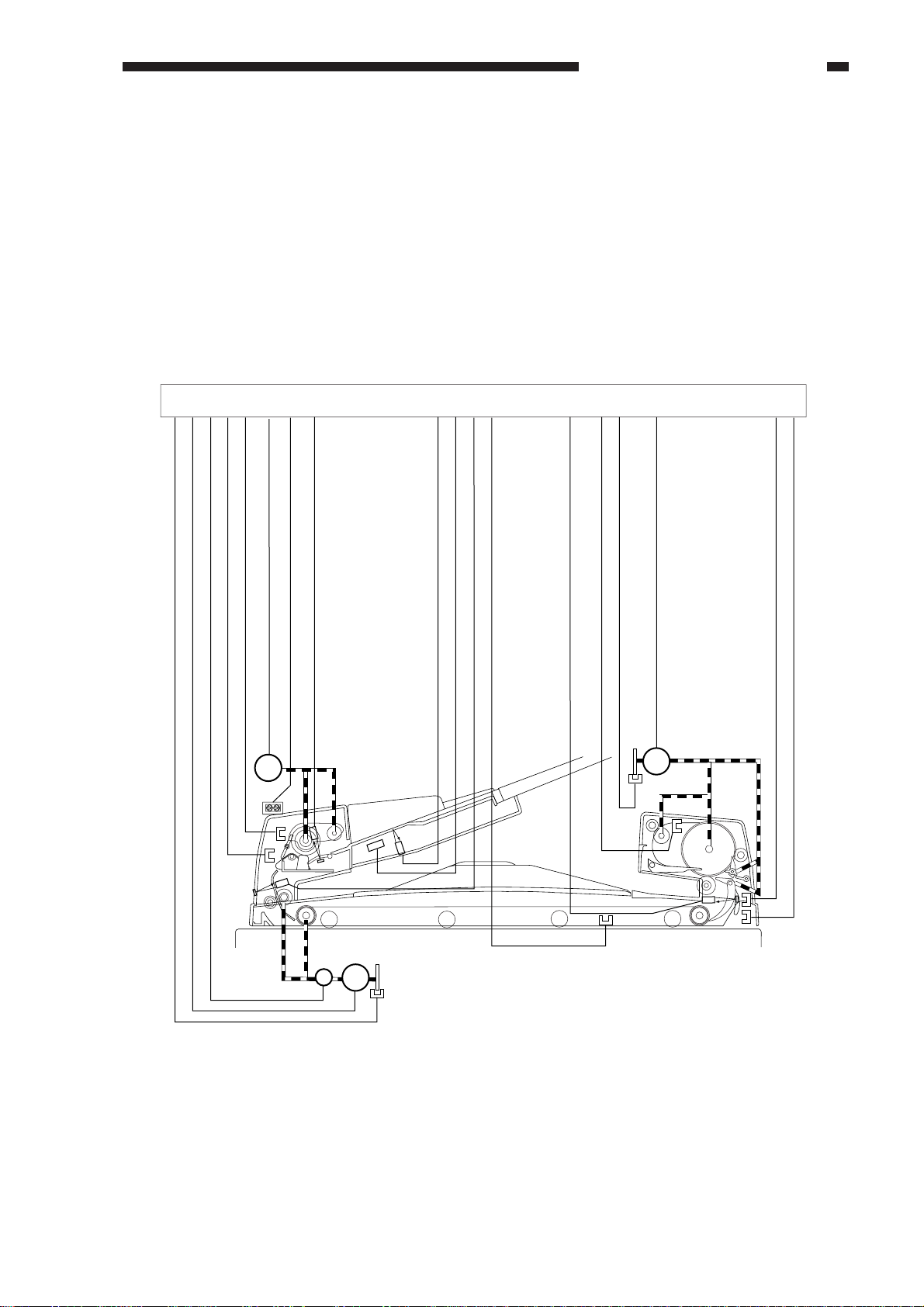

II. BASIC OPERATIONS

A. Outline

The ADF is equipped with three motors for separation, feeding, and delivery (reversal)

and one brake.

The separation motor (M1) is used to separate and pick up originals. The feed motor (M2) is used

to move originals to and stop them at the copyboard glass, while the reversal delivery motor (M3) is

deigned to deliver or reverse originals. The brake (BK) serves to stop the operation of the feed motor

(M2).

ADF controller PCB

Feed motor clock signal (FMCK)

Feed motor drive signal (FDM1, FDM2)

Pickup detection signal (SPR)

Pickup unit cover open/closed detection signal (SCVR)

Feed motor brake drive signal (Bk*)

M1

SR3

SR2

Original pickup tray paper detection signal (EMP)

Original Set indicator ON signal (OGLED)

Separation motor drive signal (SPM1, SPM2)

U507

U508

U503

BK

M2

Last original detection signal (LAST)

Original size detection signal (WIDE)

Pickup registration signal (ENT)

ADF open/closed detection signal (OPEN)

U504

Copier

SR1

Figure 2-201

Reversal/delivery outlet paper detection signal (TURN)

Reversal delivery unit cover open/

closed detection signal (ECVR)

Reversal/delivery motor clock signal (EMCK)

Reversal delivery motor drive signal (EJM1, EJM2)

M3

SR7

SR8

U505

SR6

Reversal/delivery registration signal/

delivery detection signal (EREG)

Reversal/delivery inlet paper detection signal (EENT)

SR5

SR4

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-5

Page 22

CHAPTER 2 BASIC OPERATION

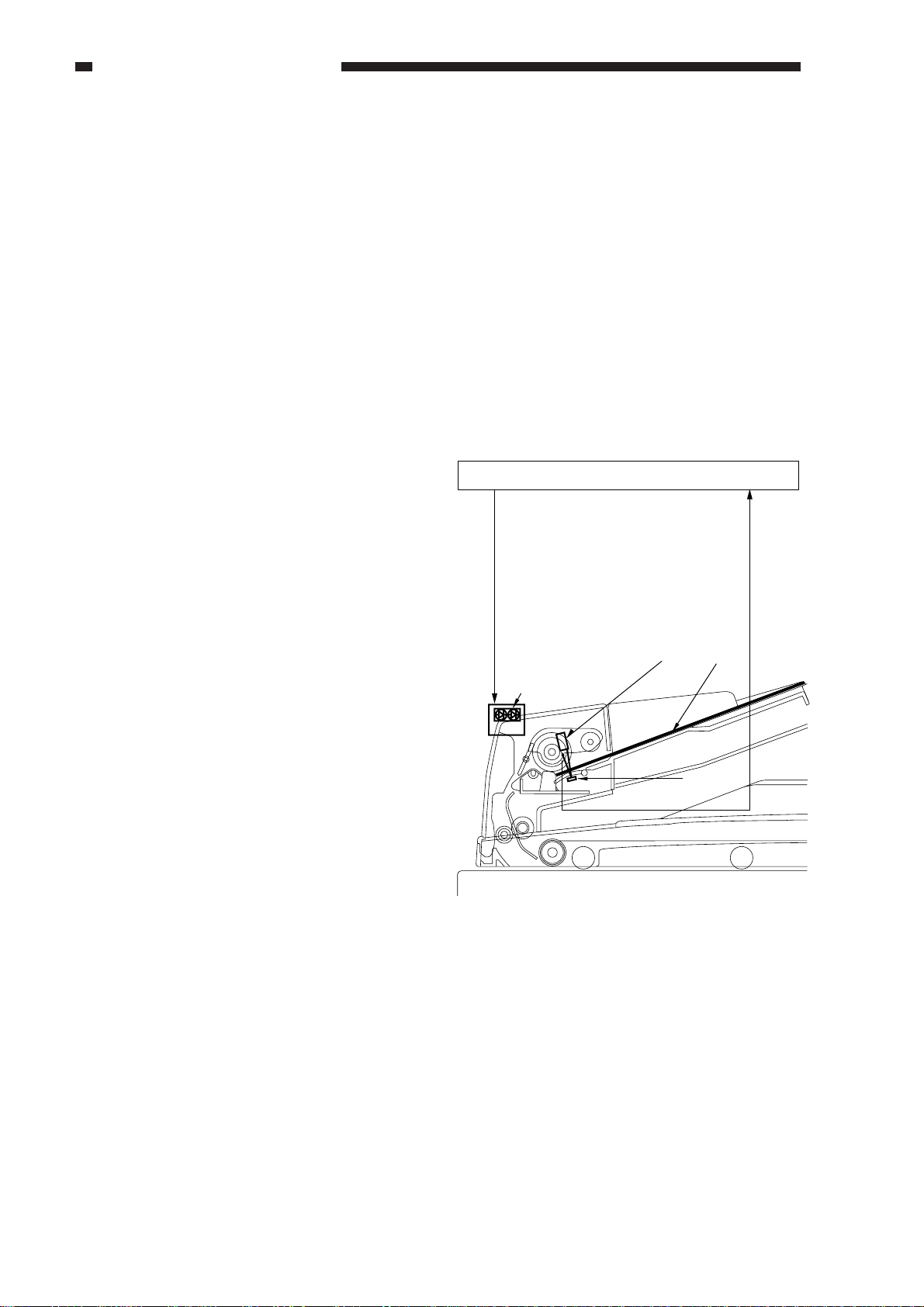

B. Detecting an Original

1. Outline

The ADF is equipped with the following

three types of original detecting mechanisms:

a. Detecting the Presence/Absence of

an Original

It detects the presence/absence of an

original on the original tray.

b. Identifying the Size of an Original

It identifies the length (feeding direction)

and width of an original.

c. Detecting the Last Original

It detects the trailing edge of the last

original.

a. Detecting the Presence/Absence of

an Original

The presence/absence of an original on the

original tray is detected by the original set

sensor. When an original is placed on the

original tray, the light from the light-emitting

side of the original set sensor is blocked, and

the light-receiving side of the original set

sensor starts to send the original detection

signal (EMP) to the ADF controller PCB.

In response, the ADF controller PCB

generates the original set indicator ON signal

(OGLED) to turn not the Original Set indicator

(U507).

ADF controller PCB

U507

Original set indicator

ON signal (OGLED)

Original Set sensor Original

Original Set indictor

LED

U503

Figure 2-202

Prism

Original tray paper

detection signal (EMP)

2-6

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 23

CHAPTER 2 BASIC OPERATION

b. Identifying the Size of an Original

The ADF identifies the size of an original

in terms of length (feeding direction) and

width.

The length is computed in reference to the

number of clock signals from the preregistration sensor (U502) and the registration

roller.

When the pre-registration sensor detects

the leading edge of an original (ON) and the

trailing edge (OFF), the ADF controller

computes the time taken by the original to

move past the pre-registration sensor with

reference to the number of clock signals from

the feed motor clock sensor (SR1) to find out

the size in the lengthwise direction (feeding

direction).

The ADF controller uses the result to

identify a default size, and communicates it to

the copier so that copy paper of the appropriate

size may be selected.

The ADF refers to the original width

detecting volume (U508) located inside the

original tray to find out the width of an original.

The original width detecting volume

operates in conjunction with the slide guides,

and the resistance of the voltage varies in

analog mode. The ADF controller uses

changes occurring in the resistance as the

original size detection signal (WIDE), and uses

them to find out the width of a specific original.

Original width detecting volume

ADF controller PCB

Prism

Registration roller

Pre-registration

sensor

U502

BK

Original

Feed motor

M2

SR4

(FMCK)

Feed motor clock signal

Original tray paper detection signal

(ENT)

Figure 2-204

Feed motor clock

sensor

Figure 2-203

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-7

Page 24

CHAPTER 2 BASIC OPERATION

Default size Length (mm) Width (mm)

B5R

A5

A4R

B5

B4

COMPUTER

A4

A3

237 to 297

128 to 188

277 to 317

162 to 222

344 to 404

361 to 421

190 to 250

400 to 460

180 to 184

208 to 212

255 to 259

277.4 to 281.4

295 to 299

Default size Length (mm) Width (mm)

STMT

LTRR

FLSC

LGL

LTR

COMPUTER

11x17

(297.4 to 431.8)

120 to 180

259 to 309

310 to 343

343 to 396

196 to 256

361 to 411

412 to 472

213.9 to 217.9

277.4 to 281.4

· Slide Guide Lock

The ADF is equipped with a slide guide

lock so that the slide guides will not move any

farther than 297 mm (A4 length or A3 width).

If an original larger than 297 mm is used,

the slide guide lock may be released (to

accommodate up to 305 mm). The length of the

original, nevertheless, must be 32 mm or less.

The copier assumes that any original is an

original of a default size based on the data on

length and width from the ADF. Tables 2-201,

-202, and -203 show the default sizes that the

copier will assume in reference to the length

and width data.

· A/B-Configured ADF

Figure 2-205

A default size is identified in reference to

±10 mm for the length of an original, and ±5

mm for the width. Any lengths or widths

falling outside these ranges will be assumed to

represent a non-default size original.

Table 2-201

· Inch-Configured ADF

2-8

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

A default size is identified in reference to

±10 mm for the length of an original, and±5

mm for the width. Any lengths or widths falling

outside these ranges will be assumed to

represent a non-default size original.

Table 2-202

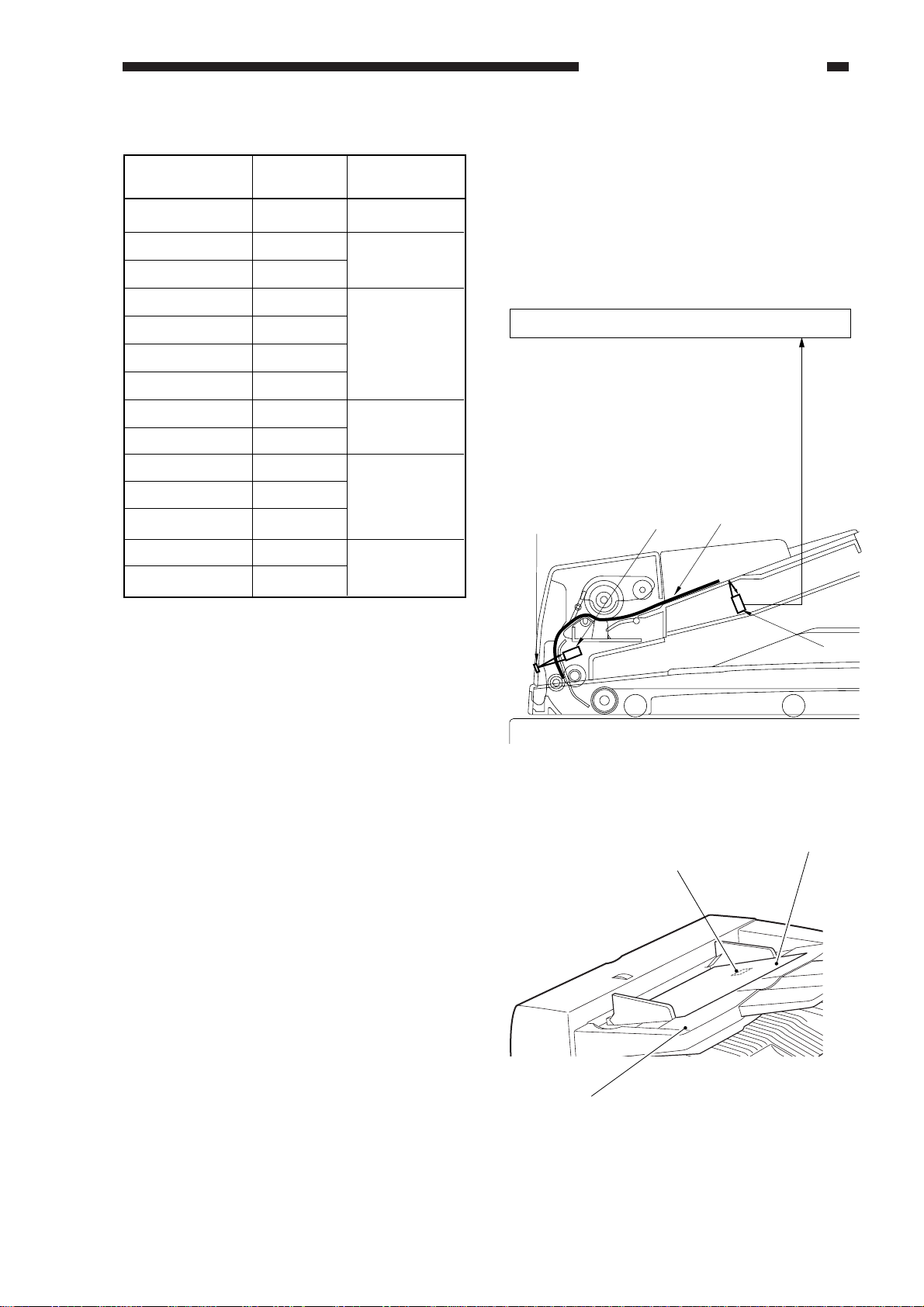

Page 25

CHAPTER 2 BASIC OPERATION

U504

U502

Last original sensor

ADF controller PCB

Prism

Original

Pre-registration

sensor

Last original detection signal

(LAST)

Last original sensor

Original

Original tray

· Inch/A/B-Configured ADF

Default size Length (mm) Width (mm)

B5R

A5

A4R

STMT

LTRR

FLSC

LGL

B5

B4

LTR

COMPUTER

11x17

(297.4 to 431.8)

A4

237 to 297

128 to 188

277 to 337

120 to 180

259 to 309

310 to 343

343 to 396

162 to 222

344 to 404

196 to 256

361 to 411

412 to 472

190 to 250

180 to 184

208 to 212

213.9 to 217.9

255 to 259

277.4 to 281.4

295 to 299

assume the original as the last original and

sends the last original detection signal (LAST)

to the copier so as to prevent pickup of copy

paper.

Last Original Detection and Original Sizes

default size: B5, A4, LTR

length: 170 to 190 mm; 205 to

226 mm

A3

400 to 460

A default size is identified in reference to

±10 mm for the length of an original, and ±5

mm for the width. Any lengths or widths

falling outside these ranges will be assumed to

represent a non-default size original.

Table 2-203

c. Identifying the last Original

A copier with a long paper path (from

cassette to drum) is designed to pick up copy

paper early to enable faster copying operation.

As such, when the ADF picks up the last

original and places it on the copyboard glass,

the copier may already have finished picking

up copy paper.

The ADF moves the second original as far

as the pre-registration sensor immediately after

it picks up the first original (advance

separation). If the last original sensor does not

detect an original, the ADF controller will

Figure 2-206

Figure 2-207

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-9

Page 26

CHAPTER 2 BASIC OPERATION

· Counting Originals

The number of times that the registration

sensor has turned on in response to the trailing

edge of an original is used as the number of

originals.

The ADF is not equipped with an original

feed mode for counting originals when making

double-sided copies of single-sided originals.

The originals are copied in order of how they

are picked up and delivered accordingly.

2-10

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 27

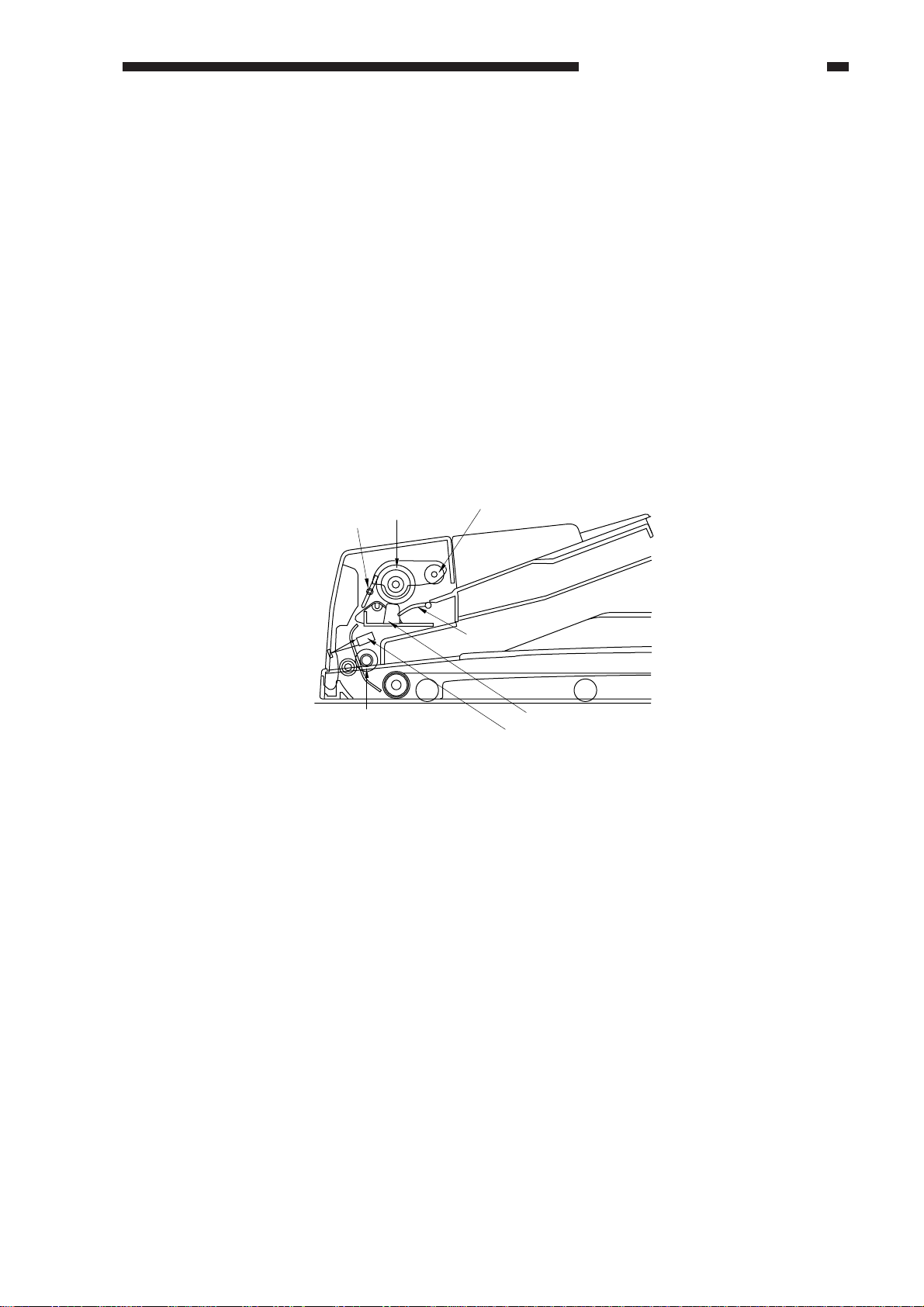

CHAPTER 2 BASIC OPERATION

C. Picking Up and Separating Originals

1. Outline

The pickup roller and the lifter are moved up so as to hold the entire stack of originals, and the

separation roller is rotated. When this takes place while the stack is butted against the separation pad,

the topmost sheet is separated from the rest of the stack.

The pickup roller is moved down and the lifter is moved up by rotating the separation motor (M1)

counterclockwise. On the other hand, the pickup roller is moved up, the lifter is moved down, and the

separation roller is turned by rotating the separation motor (M1) clockwise.

The separation assembly is equipped with a separation sensor (SR3) to monitor the movement of

originals.

When the copier’s Copy Start key is pressed while originals are placed on the original tray, the

originals are picked up and separated in the following sequence of operations:

Separation

sensor

Registration roller

Separation

roller

Pickup roller

Lifter

Separation pad

Pre-registration sensor

Figure 2-208

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-11

Page 28

CHAPTER 2 BASIC OPERATION

1. Starting Ascent (pre-separation)

When the separation motor (M1) rotates

counterclockwise, the lifter moves up to hold

up the entire stack of originals from under,

while at the same time the pickup roller moves

down onto the stack to hold it in place.

The separation motor rotates

counterclockwise for 250 msec and then stops.

Figure 2-209

3. Arching

The original is butted against the

registration roller, and is made to arch. The

separation roller stops to rotate 52 msec after

the pre-registration sensor (U502) detects the

leading edge of the original.

Figure 2-211

2. Pickup/Separation Operations

When the separation motor (M1) rotates

clockwise, its drive reaches the pickup roller

and the separation roller and, as a result, the

first (topmost) original is picked up. The

separation pad is used to make sure that only

one original is separated and moved to the

registration roller.

At the end of this operation, the lifter starts

to move down, and then the pickup roller

moves up.

2-12

Figure 2-210

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 29

CHAPTER 2 BASIC OPERATION

2. Moving Up the Pickup Roller Unit

The pickup roller and the lifter are designed to operate (move up and down) in conjunction with

the separation motor (M1).

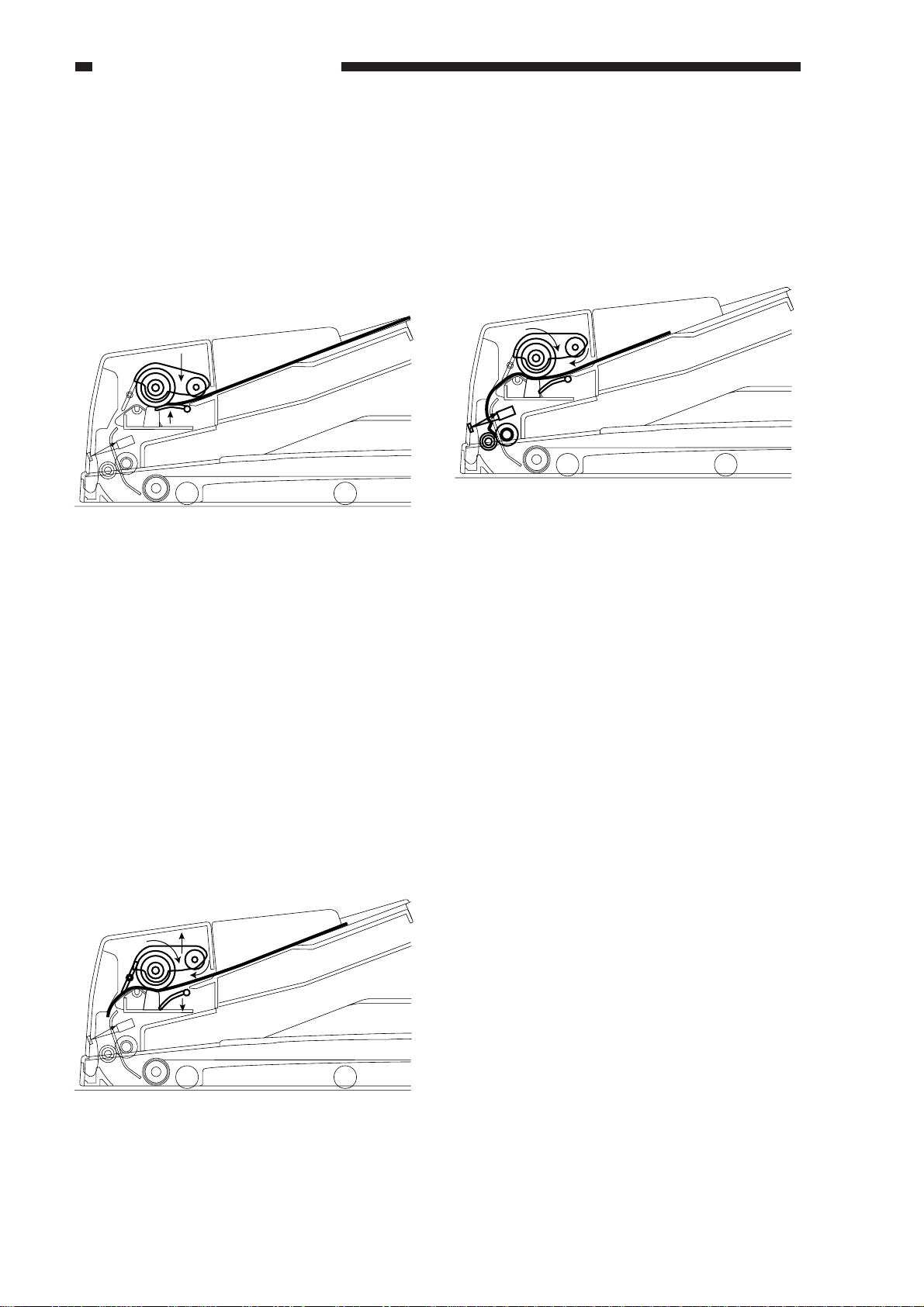

■ Separation Motor Rotating Counterclockwise

When the separation motor rotates counterclockwise, the work of a cam disengages the lock used

to keep the pickup roller in place, and the pickup roller starts to move down on its own weight.

In addition, the drive reaches the arm of the lifter, causing the lifter to move up. This operation

moves up the originals while they are held intact in preparation for pickup operation.

Separation motor

Pickup roller

Lifter

Counter clockwise

Separation roller

Figure 2-212

When the separation motor (M1) rotates clockwise, the work of the cam moves down the lifter,

and then the pickup roller returns to the ascent position. When the separation motor is rotating

clockwise, the work of the one-way clutch lets the rotation drive of the separation motor (M1) to

reach the separation roller and the pickup roller. When the separation motor rotates

counterclockwise, its rotation drive will not reach the separation roller or the pickup roller.

■ Separation Motor Rotating Clockwise

Separation motor

Clockwise

Pickup roller

Separation roller

Lifter

Figure 2-213

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-13

Page 30

CHAPTER 2 BASIC OPERATION

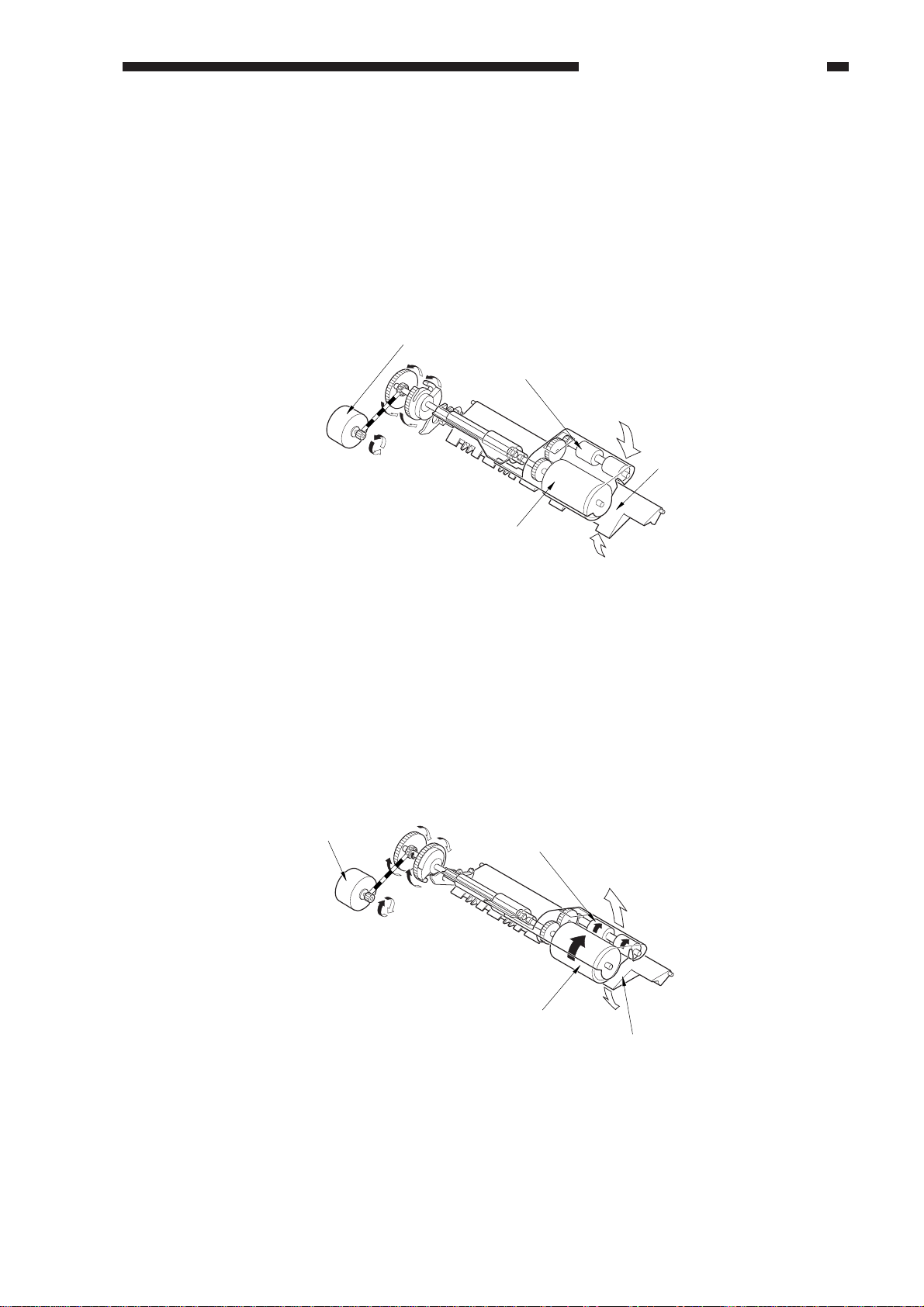

1. When the copier’s Copy Start key is

pressed, the separation motor (M1) starts to

rotate counterclockwise. In response, the

lock used to keep the pickup roller in place

becomes disengaged, and the pickup roller

falls down on the original on its own

weight.

The work of a cam, on the other hand,

moves up the lifter and, consequently, the

original.

The separation motor rotates

counterclockwise

for 250 msec and then stops to end ascent.

M1

3. A moment after the separation motor starts

to rotate clockwise, the lifter starts to move

down by the work of the cam.

Then, the pickup roller starts to move up

while rotating, returning to its initial

position.

M1

Figure 2-216

Figure 2-214

2. When the pickup roller stops moving

down and the lifter stops moving up, the

separation motor starts to rotate clockwise

so that its rotation drives the separation

roller and the pickup roller, moving the

first original to the separation assembly.

M1

4. When the pre-registration sensor (U502)

detects the trailing edge of the original

(OFF), the separation motor starts to rotate

counterclockwise once again. In response,

the lock used to keep the pickup roller in

place becomes disengaged, and the pickup

roller falls down onto the original on its

own weight.

The work of the cam, on the other hand,

moves up the lifter to hold up the original.

M1

2-14

Figure 2-217

Figure 2-215

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 31

CHAPTER 2 BASIC OPERATION

Not detected by the separation sensor

within a specific time

Separation sensor (SR3)

Detected by the separation sensor

within a specific time

Separation sensor

3. Separation Sensor (SR3)

The original feeding path is equipped with a separation sensor (SR3) to monitor the movement of

originals.

If the separation sensor does not detect an original a specific time after the separation motor has

started to rotate clockwise to move an original, the ADF controller will assume the condition as a

separation fault (delay), and will stop the machine and cause the copier to indicate the Jam message.

Figure 2-218

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-15

Page 32

CHAPTER 2 BASIC OPERATION

4. Controlling the Separation Motor (M1)

Figure 2-219 is a diagram of the control circuit used for the separtion motor (M1).

The separation motor is a DC motor, and the CPU (Q1) on the ADF controller PCB sends the

separation motor rotation speed control signal (SMPWM) and the separation motor rotation direction

signal (SMFWD, SMREV) to the drive circuit, which in response drives the separation motor.

The control circuit does no possess a circuit designed to communicate the state of the separation

motor back to the CPU (Q1). The rotation speed control signal (SMPWM) remains the same at all

times, and no correction is made even when changes occur in the rotation speed of the separation

motor because of external force.

ADF controller PCB

Separation

SMPWM J5F-1

motor

SMFWD

SMREV

Q1

CPU

Drive

circuit

M1

J5F-2

Figure 2-219

The relationship between the separation motor rotation speed control signal (SMPWM), the

separation motor rotation direction signal (SMFWD, SMREV), and the separation motor is as shown

in Table 2-204.

Separation motor rotation

speed control signal

(SMPWM)

’0’

’1’

’1’

2-16

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Separation motor rotation

direction signal

(SMFWD)

’0’

’0’

’1’

Table 2-204

Separation motor rotation

direction signal

(SMREV)

’0’

’1’

’0’

Separation motor

operation

Stops

Rotates CW

Rotates CCW

Page 33

5. Sequence of Operations (pickup assembly)

Separation sensor

(SR3)

Separation motor

Copying

started

Pre-registration

sensor ON

Pre-registration

sensor ON

Reversal inlet

sensor ON

Lifter ascent

Pickup roller ascent

CCW

CW

CCW

CW

Pickup roller rotation

Separation roller

rotation

Pre-registration

sensor (U502)

Original leading

edge detected

Original trailing

edge detected

Original leading

edge detected

Original trailing

edge detected

Down Up

Up Down

Down Up

Up Down

(separation roller)

(pickup roller holder)

CHAPTER 2 BASIC OPERATION

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Figure 2-220

2-17

Page 34

CHAPTER 2 BASIC OPERATION

D. Moving Originals

1. Outline

The drive of the feed motor (M2) is used to rotate the registration roller and the feed belt drive

roller, thereby moving originals.

Originals are moved in normal or reverse direction according to the size of the original (small,

large) and operating mode (single-sided, double-sided).

Pre-registration

sensor

Registration roller

Feed belt drive roller

BK

Feed motor brake

Feed motor

M2

Feed belt

Feed belt link roller

Retaining roll

Figure 2-221

2-18

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 35

CHAPTER 2 BASIC OPERATION

1. Starting to Move an Original

When an original has been picked up and moved to the separation assembly, the feed motor (M2)

is rotated clockwise. Its drive reaches the registration roller and the feed belt link roller, and the

original is moved to the copyboard glass.

Figure 2-222

2. Slowing Down the Movement

When the pre-registration sensor (U502) detects the trailing edge of an original (OFF), the length

(in feeding direction) of the original is computed from the time of detection by the pre-registration

sensor and the number of clocks from the feed motor.

At the same time, the movement is decelerated gradually so that the trailing edge of the original is

moved to the image leading edge position on the copyboard glass.

Figure 2-223

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-19

Page 36

CHAPTER 2 BASIC OPERATION

3. Stopping the Movement (start of copying)

When the original reaches the image leading edge position on the copyboard glass, the feed

motor brake (CL) is turned on to stop its movement.

If the original is a small-size original (continuous feeding), the next original is picked up at that

point in time, and is butted against the registration roller.

If the original is a large-size original (or mixed sizes), the next original is picked up when the

scanner ended its forward movement.

Figure 2-224

4. Starting Delivery (end of copying)

When the copier has ended its scanning operation, the feed motor (M2) is rotated clockwise once

again to rotate the registration roller and the feed belt drive roller so that the original is moved to the

reversal delivery assembly.

If the original is a small-size original (continuous feeding), the original is moved to the right half

of the copyboard glass; if it is a large-size original, on the other hand, it is moved to the reversal

delivery assembly.

2-20

Figure 2-225

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 37

CHAPTER 2 BASIC OPERATION

2. Controlling the Feed Motor (M2)

Figure 2-225 is a diagram of the control circuit used for the feed motor (M2).

The feed motor is a DC motor. The CPU (Q1) on the ADF controller PCB sends the feed motor

rotation speed control signal (FMPWM) and the feed motor rotation direction signal (FMFWD,

FMREV) to the drive circuit, which in response drives the feed motor.

When the feed motor (M1) starts to rotate, the feed motor clock sensor (SR1) turns on to send the

feed motor lock signal (FMCK) to the CPU (Q1). In response, the CPU (Q1) compares the rotation

speed that has been selected in advance and the feed motor clock signals (FMCK), and varies the

feed motor rotation speed control signal (FMPWM) to enable the selected speed.

ADF controller PCB

Feed motor

FMPWM J5F-3

FMFWD

FMREV

Q1

CPU

FMCK

Drive

circuit

M2

J5F-4

SR1

Feed motor clock

sensor

Figure 2-226

The relationship between the feed motor rotation speed control signal (FMPWM), feed motor

rotation direction signal (FMFWD, FMREV), and feed motor is as follows:

Feed motor rotation

speed control signal

(FMPWM)

’0’

’1’

’1’

Feed motor rotation

direction signal

(FMFWD)

’0’

’0’

’1’

Feed motor rotation

direction signal

(FMREV)

’0’

’1’

’0’

Feed motor operation

Stops

Rotates CW

Rotates CCW

Table 2-205

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-21

Page 38

CHAPTER 2 BASIC OPERATION

3. Sequence of Operations (feeding assembly)

Pre-registration

sensor (U502)

Feed motor (M2)

Brake (BK1)

Original leading

edge detected

Original trailing

edge detected

Registration

sensor OFF

Slow down

CW CW

(scanning)

Original leading

edge detected

Figure 2-227

Original trailing

edge detected

Registration

sensor OFF

Slow down

(scanning)

2-22

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 39

CHAPTER 2 BASIC OPERATION

E. Turning Over an Original/Delivery

1. Outline

An original is delivered by the reversal delivery roller and the reversal delivery link roller using

the drive of the reversal delivery motor (M3).

The ADF moves an original by the reversal delivery roller in feeding direction, switches the

feeding path, and rotates the reversal delivery motor counterclockwise to start delivery. In other

words, originals are delivered to the delivery tray face down, starting with the first page.

The feeding path is switched by opening and closing two flappers. The reversal delivery

registration sensor and the delivery sensor operate in conjunction with the two levers located in the

feeding path, and turn on or off according to the direction of rotation of the reversal delivery motor.

M3

Reversal delivery

roller

Reversal delivery

link roller

Reversal delivery

registration roller

Delivery roller

Reversal delivery

outlet sensor

Figure 2-228

Reversal delivery

flapper (upper)

Reversal delivery

registration sensor

Reversal delivery

flapper (down)

Reversal delivery

inlet sensor

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-23

Page 40

CHAPTER 2 BASIC OPERATION

a. Small-Size (A5, A4, B5, STMT, LTR)

If the original is a small-size original, the

reversal delivery motor (M3) is rotated

clockwise so that the original is moved to the

small-size switch-back position; then, it is

delivered to the delivery tray face down by

rotating the reversal delivery motor

counterclockwise.

1. Starting Delivery

When the copier ends scanning, the

original on the copyboard glass is moved to the

reversal delivery assembly by rotating the feed

motor (M2) clockwise once again.

2. Delivery (clockwise rotation)

When the reversal delivery registration

sensor (SR5) detects the leading edge of an

original (ON), the reversal delivery motor (M3)

rotates clockwise to move the original to the

reversal delivery assembly.

At this time, the reversal delivery motor is

rotated clockwise so that the original is moved

to the path where the flapper is closed.

Figure 2-230

Figure 2-229

3. Delivery (counterclockwise rotation)

When the reversal delivery registration

sensor (SR5) detects the leading edge of an

original (OFF), the reversal delivery motor

(M3) moves the original over a specific

distance (until the leading edge of the original

reaches the switch-back position), and stops.

Figure 2-231

2-24

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 41

CHAPTER 2 BASIC OPERATION

4. Controlling Deceleration

The reversal delivery motor (M3) starts to

move counterclockwise when the original

reaches and stops at the switch-back position.

The reversal delivery motor rotates

counterclockwise, and the original is moved to

the feeding path where the flapper is open.

The reversal delivery motor is controlled

for deceleration when an original has been

moved over a specific distance after the

delivery sensor (SR5) detects its leading edge.

b. Large-Size Originals (A4R, B5R, A3,

B4, LTRR, LGL, 11X17)

If the original is a large-size original, the

reversal delivery motor (M3) is rotated

clockwise to move the original to the large-size

reversal position; then, the reversal delivery

motor is rotated counterclockwise to move the

original to the delivery tray face down.

1. Start of Delivery

When the copier ends scanning operation,

the original on the copyboard glass is moved to

the reversal delivery assembly by rotating the

feed motor (M2) clockwise once again.

Figure 2-232

5. End of Delivery

The reversal delivery motor (M3) is

decelerated, and then is rotated

counterclockwise until the original reaches the

delivery tray (face down), at which time it is

stopped.

When the reversal delivery motor has

stopped, it is rotated clockwise once again for

an equivalent of 60 mm to close the flapper.

Figure 2-234

Figure 2-233

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-25

Page 42

CHAPTER 2 BASIC OPERATION

2. Delivery (clockwise rotation)

When the reversal delivery inlet sensor

(SR4) detects the leading edge of an original

(ON), the reversal delivery motor (M3) rotates

clockwise to move the original to the reversal

delivery assembly.

At this time, the reversal delivery motor

rotates clockwise so that the original is moved

to the paper path where the flapper is closed.

Figure 2-235

4. End of Reversal

When the reversal outlet sensor (U505)

detects the trailing edge of an original (OFF),

the feed motor (M2) moves the original over a

specific distance (until the leading edge of an

original reaches the reversal stop position, and

stops.

Figure 2-237

3. Start of Reversal

When the reversal outlet sensor (U505)

detects the leading edge of an original (ON),

the feed motor (M2) rotates to move the

original back to the original glass.

Figure 2-236

5. Switching the Feeding Path

When the original has stopped at the

reversal stop position, the reversal delivery

motor (M3) is rotated counterclockwise for an

equivalent of 60 mm to keep the flapper open.

Figure 2-238

2-26

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 43

6. Deceleration Control

When the flapper opens, the feed motor

(M2) starts to move clockwise, and the reversal

delivery motor (M3) starts to move

counterclockwise to deliver the original to the

delivery tray.

When the reversal inlet sensor (SR4)

detects the leading edge of an original (ON),

the feed motor starts counting; as soon as the

original leaves the retaining roll, the count is

incremented, and the reversal delivery motor

(M3) is subjected to deceleration control.

CHAPTER 2 BASIC OPERATION

Figure 2-239

7. End of Delivery

After deceleration control, the reversal

delivery motor (M3) rotates counterclockwise

until the original reaches the delivery tray (face

down), at which time it stops.

The reversal delivery motor stops, and then

it rotates for an equivalent of 60 mm once again

to close the flapper.

Figure 2-240

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-27

Page 44

CHAPTER 2 BASIC OPERATION

Large-size delivery

Small-size delivery

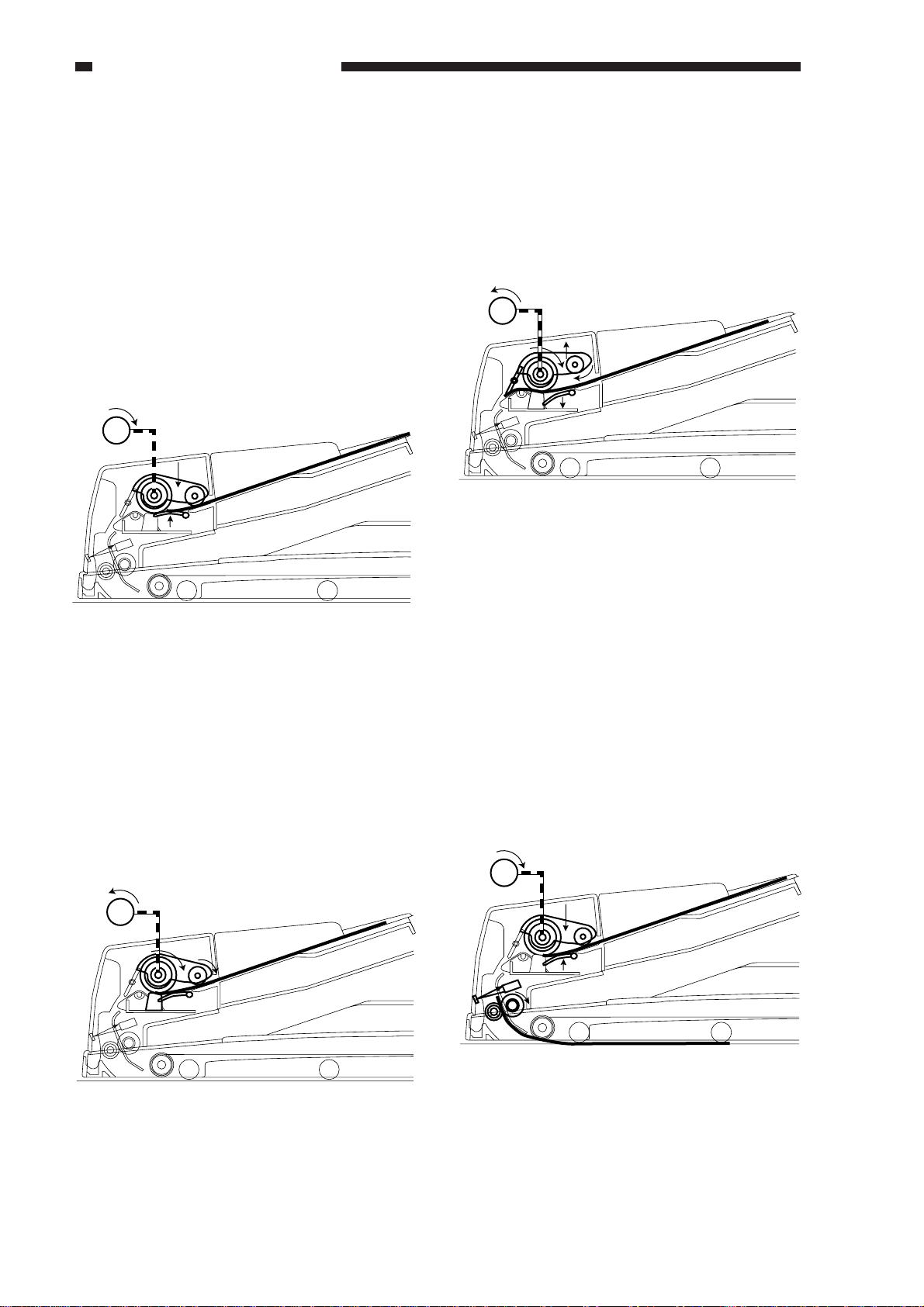

2. Operation of the Reversal Delivery Flapper

The reversal delivery flapper consists of three flappers as shown, and operates (opens and closes)

in conjunction with the reversal delivery motor (M3).

When the reversal delivery motor rotates counterclockwise, the flapper opens; when the motor

rotates clockwise, on the other hand, it closes, switching the feed path.

Delivery roller

Reversal delivery

flapper (upper)

Reversal delivery

flapper (lower)

Figure 2-241

■ Reversal Delivery Motor Clockwise

Rotation

When the reversal delivery motor (M3)

rotates clockwise, the three flappers close, and

the paper path will be as follows:

■ Reversal Delivery Motor

(counterclockwise rotation)

When the reversal delivery motor (M3)

rotates counterclockwise, the three flappers

open, and the paper path will be as follows:

Reversal delivery flapper closed

2-28

Figure 2-242 Figure 2-243

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 45

CHAPTER 2 BASIC OPERATION

3. Controlling the Reversal Delivery Motor (M3)

Figure 2-243 is a diagram of the control circuit used for the reversal delivery motor (M3).

The reversal delivery motor is a DC motor. The CPU (Q1) on the ADF controller PCB sends the

reversal delivery motor rotation speed control signal (EMPWM) and the reversal delivery motor

rotation direction signal (EMFWD, EMREV) to the drive circuit, which in response drives the

reversal delivery motor.

When the reversal delivery motor (M3) rotates, the reversal delivery motor clock sensor (SR7)

turns on to send the reversal delivery motor clock signal (EMCK) to the CPU (Q1).

The CPU (Q1) compares the rotation speed selected in advance and the reversal delivery motor

clock signal (FMCK), and varies the reversal delivery motor rotation speed control signal (EMPWM)

to suit the selected speed.

ADF controller PCB

Reversal delivery

EMPWM J9F-1

motor

EMFWD

EMREV

Q1

CPU

EMCK

Drive

circuit

M3

J9F-2

SR7

Reversal delivery

motor clock sensor

Figure 2-244

The relationship between the reversal delivery motor rotation speed control signal (EMPWM),

reversal motor rotation direction signal (EMFWD, EMREV), and reversal delivery motor is as

follows:

Reversal delivery motor

rotation speed control

signal (EMPWM)

’0’

’1’

’1’

Reversal delivery motor

rotation speed signal

(EMFWD)

’0’

’0’

’1’

Reversal delivery motor

rotation direction signal

(EMREV)

’0’

’1’

’0’

Reversal delivery motor

operation

Stops

Rotates CW

Rotates CCW

Table 2-206

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-29

Page 46

CHAPTER 2 BASIC OPERATION

4. Sequence of Operations (reversal delivery assembly)

a. Small-Size Originals

Feed motor (M2)

Brake (BK1)

Slow down

Reversal delivery

motor (M3)

Reversal delivery

flapper (open/close)

Reversal registration sensor (SR4)

Delivery sensor

Pre-registration

sensor OFF

Slow down

CW CW

Reversal registration

sensor ON OFF

CWCW CW CWCW

Closes Opens Closes Opens

(scanning) (scanning)

Delivery

sensor OFF

Slow down

CCW CCW

Reversal registration

sensor ON OFF

Pre-registration

sensor OFF

Slow down

Delivery

sensor OFF

Slow down

Reversal delivery

inlet sensor (SR4)

Figure 2-245

2-30

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 47

b. Large-Size Originals

CHAPTER 2 BASIC OPERATION

Pre-registration

sensor OFF

Feed motor (M2)

Brake (BK1)

Reversal delivery

motor (M3)

Reversal delivery

flapper (open/close)

Reversal delivery inlet

sensor (SR4)

Reversal delivery

registration sensor (SR5)

Reversal delivery outlet

sensor (U505)

Slow down

CW CCW CCWCWCW

Reversal delivery

inlet sensor ON

Slow down Slow down

Closes ClosesOpens Opens

Reversal delivery

outlet sensor ON OFF

CWCW CWCW CW CWCWCW

CCW CCW

(scanning)

Closes

Reversal delivery

inlet sensor ON

Reversal delivery

outlet sensor ON OFF

Figure 2-246

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-31

Page 48

CHAPTER 2 BASIC OPERATION

F. Movement of Originals

1. Small-Size Originals (continuous feeding, single-sided)

When making single-sided copies of small-size originals, the second original is picked up as soon

as the first original is sent to the copyboard glass.

The original sent to the copyboard glass is scanned, and then moved to the right, while the next

original is sent to the copyboard glass.

1. When the Copy Start key is pressed, the separation motor (M1) rotates counterclockwise for a

limited time, causing the pickup roller to move down and the lifter to move up (in wait for

pickup).

Figure 2-247

2. The separation motor (M1) stops once, and then starts to rotate clockwise so that the separation

roller and the pickup roller rotate to separate the first original.

The lifter starts to move down, and then the pickup roller starts to move up.

The separation motor stops when the pre-registration sensor (U502) detects the leading edge of

an original (ON).

Figure 2-248

3) The feed motor (M2) rotates clockwise, and the original is moved to the copyboard glass. When

the pre-registration sensor (U502) detects the trailing edge of an original (OFF), the ADF is in

wait for pickup of the next original.

2-32

Figure 2-249

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 49

CHAPTER 2 BASIC OPERATION

4. When the pre-registration sensor (U502) detects the trailing edge of an original (OFF), the feed

motor (M2) starts to slow down.

The feed motor stops when the trailing edge of the original reaches the image leading position,

and scanning starts when the original reaches a specific position. At this time, the next original is

put through separation operation.

Figure 2-250

5. When the first original has been scanned, the feed motor (M2) rotates clockwise to move the

original to the right. At the same time, the next original is moved to the copyboard glass.

When the pre-registration sensor (U502) detects the trailing edge of the next original (OFF), the

feed motor (M2) starts to slow down.

The feed motor stops when the trailing edge of the next original reaches the image leading edge

position, and scanning starts when the next original reaches a specific position.

Figure 2-251

6. When the reversal delivery registration sensor (SR5) detects the leading edge of an original

(ON), the reversal delivery motor (M3) starts to rotate clockwise. When the reversal delivery

motor is rotating clockwise, the reversal delivery flapper remains closed.

Figure 2-252

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-33

Page 50

CHAPTER 2 BASIC OPERATION

7. When the reversal delivery registration sensor (SR5) detects the leading edge of the original

(OFF), the reversal delivery motor (M3) moves the original over a specific distance (to the

switch-back position), stops, and starts to rotate counterclockwise.

When the reversal delivery motor rotates counterclockwise, the reversal delivery flapper opens to

switch the paper path.

Figure 2-253

8. The reversal delivery motor (M3) rotates counterclockwise so that the first original is sent to the

delivery tray. The reversal delivery motor starts to slow down when the delivery sensor (SR5)

detects the trailing edge of the original (OFF).

Figure 2-254

9. The reversal delivery motor (M3) stops when the original reaches the delivery tray. The reversal

delivery motor then stops, and then starts to rotate clockwise for a limited time so that the reversal

delivery flapper closes.

Figure 2-255

2-34

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 51

CHAPTER 2 BASIC OPERATION

2. Large-Size Originals (single-sided)

When making single-sided copies of large-size originals, the second original is sent to the

copyboard glass after the first original has been delivered. In the case of large-size originals, delivery

occurs after the original moved to the reversal delivery assembly is turned over and returned to the

copyboard glass.

1. When the Copy Start key is pressed, the separation motor (M1) rotates counterclockwise for a

limited time so that the pickup roller moves down and the lifter moves up (in wait for pickup).

Figure 2-256

2. The separation motor (M1) stops once, and then starts to rotate clockwise so that the separation

roller and the pickup roller rotate to separate the first original.

The lifter starts to move down, and then the pickup roller starts to move up.

The separation motor stops when the pre-registration sensor (U502) detects the leading edge of

the original (ON).

Figure 2-257

3. The feed motor (M2) rotates clockwise, and the original is moved to the copyboard glass. When

the pre-registration sensor (U502) detects the trailing edge of the original (OFF), the ADF will be

in wait for pickup.

Figure 2-258

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-35

Page 52

CHAPTER 2 BASIC OPERATION

4. When the pre-registration sensor (U502) detects the trailing edge of the original (OFF), the feed

motor (M2) slows down.

The feed motor stops when the trailing edge of the original reaches the image leading edge

position, and scanning starts when the original reaches and stops at a specific position.

Figure 2-259

5. When scanning ends, the 2nd original is separated; the separation motor is stopped once 100

msec after the separation sensor has turned on.

When the reversal inlet sensor (SR5) detects the leading edge of the original (ON), the reversal

delivery motor (M3) starts to rotate clockwise.

The reversal delivery flapper remains closed while the reversal delivery motor is rotating

clockwise.

Separation sensor

Figure 2-260

6. When the reversal delivery outlet sensor (U505) detects the leading edge of the original (ON),

the feed motor (M2) stops, and then starts to rotate counterclockwise, moving the original to the

copyboard glass.

Figure 2-261

2-36

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 53

CHAPTER 2 BASIC OPERATION

7. When the reversal outlet sensor (U505) detects the trailing edge of the original (FF), the feed

motor (M2) moves the original over a specific distance (until the trailing edge of the original

reaches the reversal stop position), and then stops.

The feed motor stops once, and then the reversal delivery motor rotates counterclockwise for a

limited time so that the reversal delivery flapper opens to switch the paper path.

The separation motor (M1) rotates clockwise to rotate the separation roll and the pickup roller,

thereby separating the first original.

Figure 2-262

8. When pickup ends, the feed motor (M1) starts to rotate clockwise; the reversal delivery motor

(M3), on the other hand, starts to rotate counterclockwise.

The first original is sent to the delivery tray, and at the same time the next original is moved to the

copyboard glass.

When the reversal delivery inlet sensor (SR4) detects the leading edge of the original (ON), and

the original has been moved over a specific distance, the reversal delivery motor starts to slow

down.

Figure 2-263

9. When the pre-registration sensor (U502) detects the trailing edge of the next original (OFF), the

feed motor (M2) slows down; the motor stops when the trailing edge of the next original reaches

the image leading edge position.

When the reversal delivery inlet sensor (SR4) detects the leading edge of the first original, and the

original is moved over a specific distance, the reversal delivery motor (M3) slows down and

stops when the original reaches the delivery tray.

The reversal delivery motor stops once, and then rotates clockwise so that the reversal delivery

flapper closes.

Figure 2-263

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-37

Page 54

CHAPTER 2 BASIC OPERATION

3. Duplexing Copying Mode

When making double-sided copies, the face of an original is scanned, and the original is turned

over while it is moved through the reversal delivery assembly; thereafter, the original is returned to

the pre-registration sensor (U502) once, and matched against the image leading edge position on the

copyboard glass, and its back is scanned before delivery.

1. When the Copy Start key is pressed, the separation motor (M1) rotates counterclockwise for a

limited time so that the pickup roller moves down and the lifter moves up (in wait for pickup).

Figure 2-265

2. The separation motor stops once, and then starts to rotate clockwise so that the separation roller

and the pickup roller rotate to separate the first original.

The lifter starts to move down, and then the pickup roller starts to move up.

When the pre-registration sensor (U502) detects the leading edge of the original (ON), the

separation motor stops.

Figure 2-266

3. The feed motor (M2) rotates clockwise, and the original is moved to the copyboard glass. When

the pre-registration sensor (U502) detects the trailing edge of the original (OFF), the ADF will be

in wait for pickup.

2-38

Figure 2-267

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 55

CHAPTER 2 BASIC OPERATION

4. When the pre-registration sensor (U502) detects the trailing edge of the original (OF), the feed

motor (M2) starts to slow down. The feed motor stops when the original reaches the image

leading edge position, at which time its face is scanned.

Figure 2-268

5. When scanning ends, the feed motor (M2) rotates clockwise, and the original is moved to the

reversal delivery assembly.

When the reversal inlet sensor (SR4) detects the leading edge of the original (ON), the reversal

delivery motor (M3) starts to rotate.

The reversal delivery flapper remains closed while the reversal delivery motor is rotating

clockwise.

Figure 2-269

6. When the reversal outlet sensor (U505) detects the leading edge of the original (ON), the feed

motor (M2) stops once, and starts to rotate counterclockwise, causing the original to reach the

copyboard glass face down.

Figure 2-270

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-39

Page 56

CHAPTER 2 BASIC OPERATION

7. The original is moved to the copyboard glass and then to the pickup assembly. When the preregistration sensor (U502) detects the leading edge of the original, the feed motor (M2) stops.

Figure 2-271

8. The feed motor stops once, and starts to rotate clockwise. When the pre-registration sensor

(U502) detects the leading edge of the original (OFF), the feed motor (M2) starts to slow down.

The feed motor stops when the leading edge of the original reaches the image leading edge

position.

Figure 2-272

9. When the original reaches a specific position, the reversal delivery motor (M3) rotates

counterclockwise for a limited time so that the reversal delivery flapper opens to switch the paper

path. The back of the original is then scanned.

Figure 2-273

2-40

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 57

CHAPTER 2 BASIC OPERATION

10. When scanning ends and separation of the 2nd original starts, the feed motor (M2) starts to rotate

clockwise, moving the 1st original to the right side.

Figure 2-274

11. When the feed motor stops, the separation motor (M1) rotates clockwise to separate the original.

When the pre-registration sensor (U502) detects the leading edge of the original (ON), the

separation motor stops.

Figure 2-275

12. After the separation motor stops, the feed motor (M2) starts to rotate clockwise while the reversal

delivery motor (M3) starts to rotate counterclockwise.

The first original is moved to the delivery tray, and the next original is moved to the copyboard

glass.

Figure 2-276

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-41

Page 58

CHAPTER 2 BASIC OPERATION

13. When the pre-registration sensor (U502) detects the trailing edge of the next original (OFF), the

feed motor (M2) slows down and stops as soon as the trailing edge of the original reaches the

image leading edge position.

When the reversal delivery inlet sensor (SR4) detects the leading edge of the first original (ON)

and the original is then moved over a specific distance, the reversal delivery motor (M3) slows

down and stops as soon as the original reaches the original delivery tray.

The reversal delivery motor stops once, and rotates clockwise for a limited time so that the

reversal delivery flapper closes.

Figure 2-277

4. Mixed Sizes

The ADF allows placement of originals of different sizes (but of the same configuration width).

Regardless of whether they are small- or large-size, the second original is sent to the copyboard glass

only after the first original has been delivered. The mode of operation is the same as the mode used

for large-size paper or the last of double-sided copying.

5. Jam Removal Mode

When a jam occurs, the originals that may have been copied and that remain on the copyboard

glass are moved without specific operation. The flow of originals is the same as when making singlesided copies, but scanning does not take place.

2-42

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 59

CHAPTER 2 BASIC OPERATION

G. Detecting an Original Jam

The ADF uses the following sensors to check for original jams. The timing at which checks are

made is stored in advance in the CPU (Q1) on the ADF controller PCB, and a jam is identified in

relation to the presence/absence of paper over a specific sensor.

In response to a jam, the ADF communicates to the copier in the form of a code, which may be

checked in the copier’s service mode (COPIER>DISPLAY>JAM).

Service Mode Screen (copier)

Display

< JAM >

AA BBBB CCCC DDDD E FFFF G HHHHHH IIIII

AA BBBB CCCC DDDD E FFFF G HHHHHH IIIII

AA BBBB CCCC DDDD E FFFF G HHHHHH IIIII

AA BBBB CCCC DDDD E FFFF G HHHHHH IIIII

AA BBBB CCCC DDDD E FFFF G HHHHHH IIIII

AA BBBB CCCC DDDD E FFFF G HHHHHH IIIII

AA BBBB CCCC DDDD E FFFF G HHHHHH IIIII

AA BBBB CCCC DDDD E FFFF G HHHHHH IIIII

I/O

Adjust

Function

< 1/7 > < READY >

Option Test

+/-

'1' indicates that

the jam is in the ADF.

OK

Jam code

Counter

Figure 2-278

SR3

U503

SR2

U504

SR8

U505

SR2...... pickup unit cover sensor

SR3...... separation sensor

SR4...... reversal inlet sensor

SR5...... reversal registration sensor/

delivery sensor

SR6...... ADF open/closed sensor

SR8...... reversal delivery

unit cover sensor

U502....pre-registration sensor

U503....original set sensor

U504....last original sensor

U505....reversal outlet sensor

U502

U508

SR5

SR4

U508....original detecting volume

Figure 2-279

COPYRIGHT © 1999 CANON INC. CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-43

Page 60

CHAPTER 2 BASIC OPERATION

Note:

1. Response to a Jam

The ADF is stopped immediately in response to any of the jams in Table 2-207.

2. Resetting after a Jam

For a pickup delay jam, remove the originals from the original tray to reset the ADF. For other

types of jams, remove the originals from the original tray and from inside the ADF; then, open

and close the ADF to reset.

3. An alarm indication will turn on when either of the following is executed:

· mixed size operation without selecting mixed size mode

· copying stapled originals

If the original must be removed from inside the machine, both jam and alarm indications will be

turned on.