Service Bulletin

Issued by Canon Europa N.V.

COPIER

Model :

Location :

Subject :

Reason :

Details :

Finisher-C1

No.:

Saddle Finisher-C2

DATE:

FEEDER ASSEMBL Y

PREVENTING GUIDE STOPPER BREAKAGE

To communicate that the shape of the guide stopper has been changed to prevent it from breaking.

Also, to communicate field measures to take if the stopper breaks in the field.

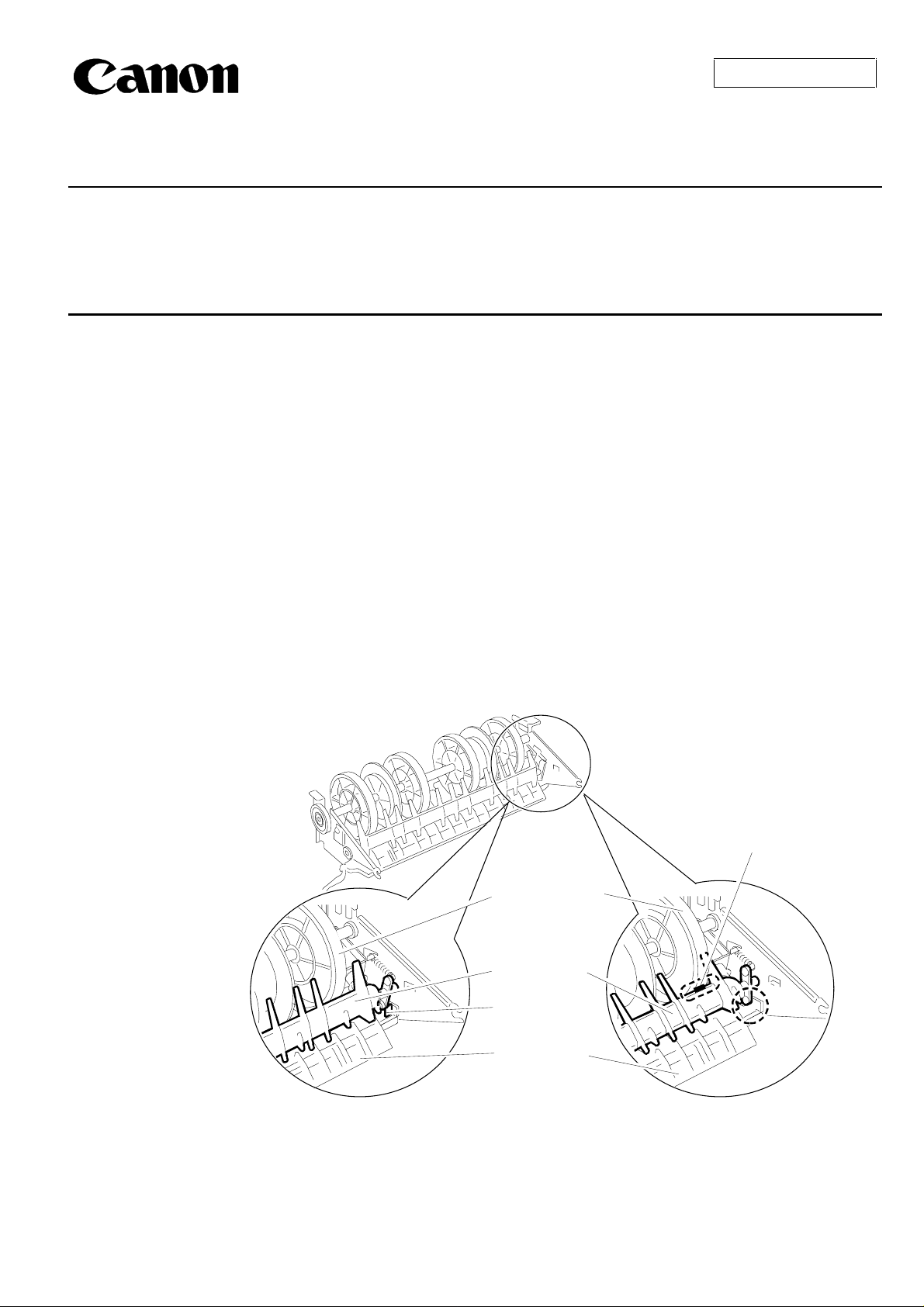

<Symptom>

If the guide stopper breaks, there are cases where the buffer roller stops the copy paper, and a

stationary jam o ccurs.

<Cause>

The guide stopper determines the stop position of the flapper, but this stopper breaks as a result of the

repeated opening and closing operation of the flapper. If the stopper breaks, the flapper makes

contact with the buffer roller, and a load is placed on the rotation of the buffer roller. In the worst

case, the rotation of the buffer roller is halted, and a stationary jam occurs. (Fig. 1)

Acc-177

(FF-T01-W-000075-01)

08.10.99

[When ther e is a stopper]

The flapper makes

contact with the buffer

roller.

Buffer roller

Flapper

Stopper

Guide

[When the stopper has broken]

Fig. 1 Feeder assembly

- 1 / 5 -

Acc-177

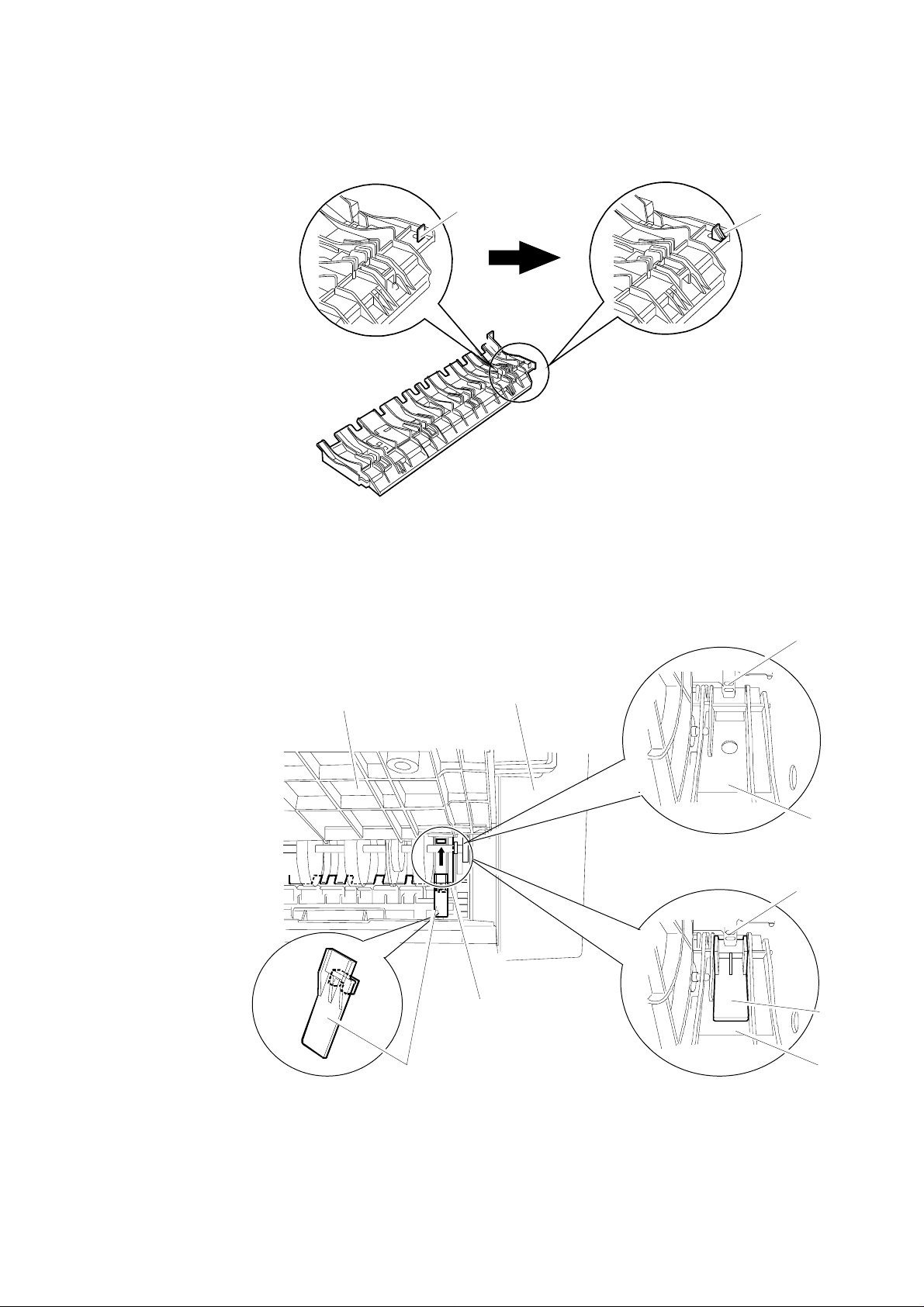

<Factory measure>

Durability of the guide stopper was improved by strengthening it with the addition of a rib (Fig. 2).

[New guide][Old guide]

Stopper strengthen ed by

Stopper

the addition of a rib

Fig. 2

Servicing :

Perform the measures below to deal with the previously-mentioned symptoms in the field.

Attach the field measure part STOP, GUIDE (FB4-9693-000), following the procedure shown below,

as a field measure (Fig. 3).

Flapper

Upper cover

(Front

cover

side)

Rear cover

Guide

[Before at taching]

Flapper

Guide

Guide stopper

Fig. 3 Section to stick the guide stopper

Guide

stopper

Guide

[Aft er at taching]

- 2 / 5 -

Loading...

Loading...